Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

255results about How to "Low volatile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite material of polypropylene in low smell and volatile matter

A polypropene composition with low odor and low volatile components is proportionally prepared from polypropene, talc powder, fine-porous silica gel, toughening agent poe, thermal stabilizer DSTP, thermal stabilizer 3114 and thermal stabilizer 618 through mixing, dual-screw extruding out and granulating.

Owner:上海天原集团胜德塑料有限公司

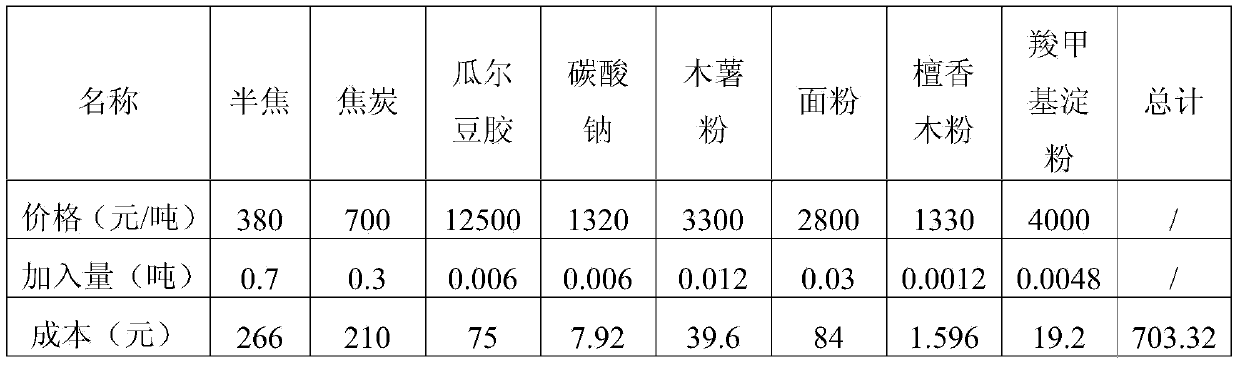

Columnar activated carbon based on coal pitch binders and preparation method of columnar activated carbon

InactiveCN102674341AImprove initial strengthEquivalent mechanical strengthCarbon compoundsActivated carbonUltimate tensile strength

The invention discloses columnar activated carbon based on coal pitch binders. The columnar activated carbon with grain size range of 1.0-10mm is prepared through a preparation method which comprises the steps of: using 100 parts by weight of carbonaceous materials as basic raw materials and 6-30 parts by weight of coal pitch as binders, respectively pulverizing the carbonaceous materials and the coal pitch, mixing the pulverized carbonaceous materials with the pulverized coal pitch, adding 20-50 parts by weight of temporary binders, kneading, molding, drying, carbonizing in a rotary carbonizing furnace and activating in a Slapple activating furnace. Since the temporary binders are used for endowing the molded materials with primary strength and the coal pitch and the pulverized carbon are co-carbonized and solidified and endow the carbonized materials with final mechanical strength, the traditional long-lasting mode of columnar activated carbon coal tar molding production is broken through and the goal of preparing columnar activated carbon by using coal pitch as binders to replace coal tar is realized.

Owner:李钱胜

Heat-conducting silica gel and preparation method thereof

The invention discloses a heat-conducting silica gel and a preparation method thereof, wherein the heat-conducting silica gel comprises the following components in parts by weight: 100 parts of a basic polymer, 0.1-10 parts of a crosslinking agent, 500-1800 parts of a filler, and 0.1-15 parts of a silane coupling agent. The technical scheme of the invention can obtain a heat-conducting interface material which has higher heat-conducting stability compared with silicone grease, silicone cream and heat-conducting mud which are generally used on market at present, and solves the problem that the silicone grease, the silicone cream and the heat-conducting mud which are generally used on market at present will become dry when used at a high temperature for a long time, thereby ensuring the heat-conducting efficiency of long-term use of the heat-conducting interface material.

Owner:厦门安耐伟业新材料有限公司

Coal blending and coking method for metallurgical coke

The present invention relates to coal blending and coking method for metallurgical coke, and especially the coal blending and coking method with thermal coal and weakly caking coal. The present invention adopts conventional coking process and the coal consists of weakly caking coal 0-15 wt%, thermal coal 0-10 wt%, gas coal 13-45 wt%, fatty coal 9-20 wt% and coking coal 40-45 wt%. The produced coke has dropping strength M40 of 77-78.5 %, abrasion resistance strength M10 <8.6 %, reactivity of 35-37 %, thermal state strength of 45-55 %, and granularity of 25-40 mm and 40-80 mm, and meets the requirement for iron smelting in blast furnace of 1000 cubic meter or larger. The present invention has expanded coal variety range for coking, and lowered coking cost.

Owner:武钢集团有限公司

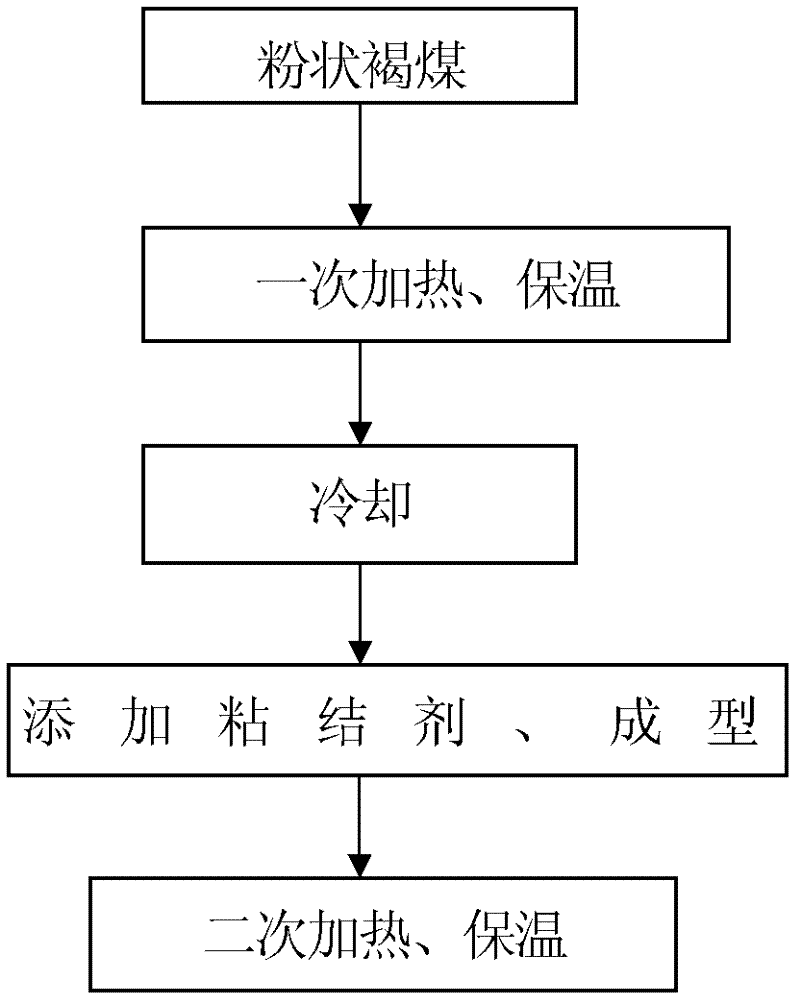

Technology for processing pulverized lignite

The invention discloses a technology for processing pulverized lignite. The technology comprises the followings steps of: firstly, heating pulverized lignite to 100-1000 DEG C, and then heat-preserving for 1-5h; secondly, cooling the lignite processed and obtained in the first step below 100; thirdly, then adding a binding agent, and uniformly stirring to form; fourthly, heating the formed lignite to 100-1000 DEG C and heat-preserving for 1-5h. According to the technology for processing the pulverized lignite disclosed by the invention, the lower calorific value of finally obtained products is greatly increased compared with that of the raw coal and is increased by more than 2 times compared with that of the raw coal before modification; all water is nearly completely removed, volatile components are greatly reduced, the content of solid carbon is greatly improved, and yield of condensed water is greater; and compared with the prior art, the technology for processing the pulverized lignite disclosed by the invention has lower cost, and the obtained products can be convenient to transport and has high calorific value.

Owner:QIANQIU ENERGY SHANGHAI

Chemical processing method for preparing high quality inflatable graphite

The invention discloses a chemical treatment method for preparing high-quality expandable graphite. The method adopts concentrated sulfuric acid as an intercalator and hydrogen peroxide as a catalyst to prepare the high-quality expandable graphite under the vacuum condition. Because water has constant boiling point under the condition of constant vacuum degree, the reaction temperature can be well controlled and simultaneously stable reaction temperature can be maintained by utilizing vacuum to bring away heat exhausted during reaction in time. The method can obtain the high-quality expandable graphite of which the volatile component is less than 12 percent and the sulfur content is less than 1.5 percent, and the sulfur content can be less than 800 ppm after the high-quality expandable graphite is treated for 30 seconds at a high temperature of between 900 and 1,000 DEG C.

Owner:晟茂(青岛)先进材料有限公司

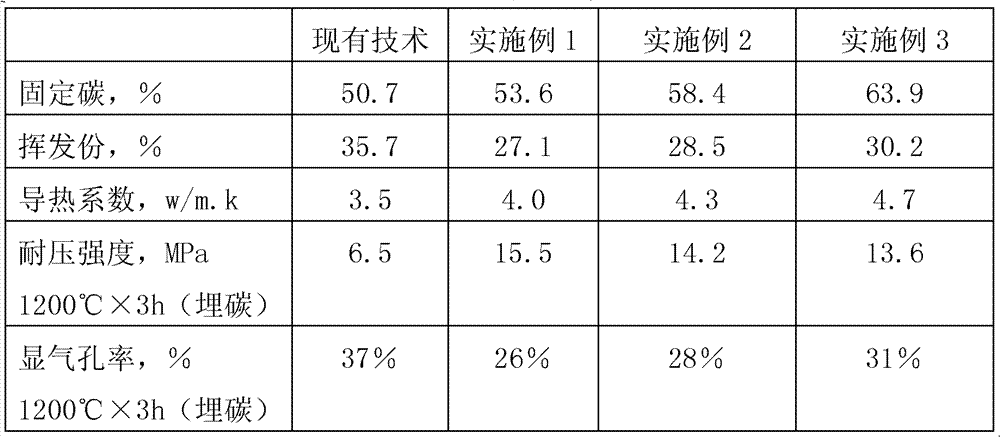

Method for preparing graphite crucible with recycled graphite

The invention relates to the technical field of waste graphite recycling, in particular to a method for preparing a graphite crucible with recycled graphite. The method comprises the steps of: 1) putting pitch in a pitch melting tank at 160-180 DEG C for dehydration and settling for 72h to form moderate temperature modified pitch, 2) crushing and screening the recycled graphite and calcined coke respectively to form recycled graphite powder and calcined coke powder for future use, 3) uniformly mixing the standby recycled graphite powder and the calcined coke powder to form a mixed dry material, 4) putting the obtained mixed dry material into a mixing-kneading pot for dry mixing for 35-45min, then adding the moderate temperature modified pitch for wet mixing for 35-45min, 5) cooling mixed and kneaded paste to the room temperature, 6) grinding the aired paste into powder, 7) pressing the ground powder for forming to form a crucible blank, 8) putting the obtained crucible blank in a roasting furnace for roasting, and 9) machining the qualified roasted crucible blank. The method is simple and improves product quality.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

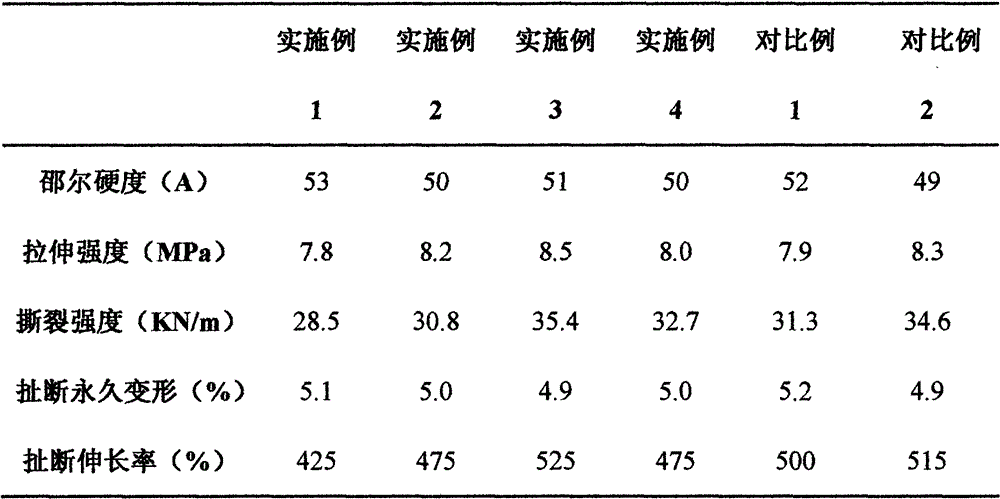

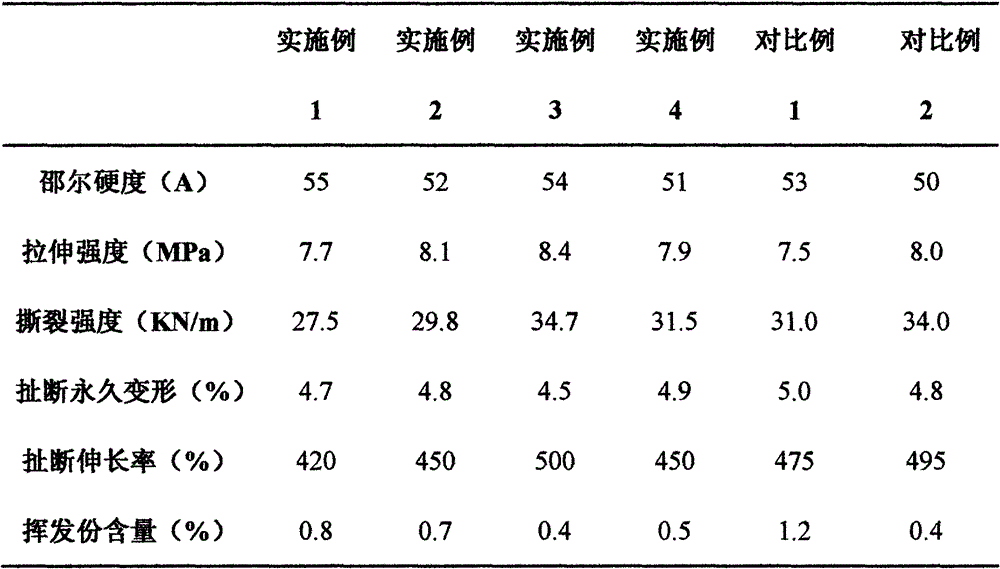

Low-volatile silicone rubber compound and preparation method thereof

The invention discloses a low-volatile silicone rubber compound. The low-volatile silicone rubber compound is characterized by comprising the following raw materials in part by weight: 100 parts of raw silicone rubber, 20-70 parts of white carbon black, 1-12 parts of hydroxy silicone oil, 1-10 parts of ethylhydroxy silicone oil, 0.5-8 parts of hydrogen-containing silicone oil and 0.1-1.5 parts of release agent. The invention also discloses a preparation method of the low-volatile silicone rubber compound. The invention has the advantages that: the hydroxy silicone oil and the ethylhydroxy silicone oil are mixed as a structure control agent, so that after vulcanization of the rubber compound, the content of volatiles is low and physical properties are fundamentally changed; and the prepared silicone rubber compound is low in volatile content, good in processing performance and environment-friendly, has better tearing strength on the premise of ensuring good other physical and mechanical properties, and meets requirements of some special products.

Owner:阳江市万丰实业有限公司 +1

Solvent-free one-component polyurethane waterproof coating

ActiveCN105315878AReduce performanceInhibit migrationPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxySolvent free

The invention relates to a solvent-free one-component polyurethane waterproof coating in the field of waterproof materials. A formula of the solvent-free one-component polyurethane waterproof coating comprises the following components in weight percent: 5-10% of polyether EP-330N, 30-40% of polyether DL-2000D, 20-25% of diphenylmethane diisocyanate, 10-15% of self-made epoxy resin, 0.1-0.2% of an anti-aging agent, 0.1-0.5% of an ultraviolet absorber, 0.01-0.15% of a defoaming agent, 0.1-0.5% of an anti-settling agent, 0.1-0.5% of a dispersing agent, 0.1-0.15% of a catalyst, 0.5-3% of pigment, 10-15% of kaolin and 5-10% of talcum powder. The solvent-free one-component polyurethane waterproof coating provided by the invention overcomes the defects that the existing one-component polyurethane waterproof coating contains a plasticizer and a solvent, does harm to a human body and pollutes the environment and mechanical properties of a film are reduced after long-term use; and the provided solvent-free one-component polyurethane waterproof coating is anti-aging, long in service life and environment-friendly, the adhesion and water resistance of the coating are good, and mechanical properties of the film are good.

Owner:SICHUAN SHUYANG WATERPROOF MATERIAL

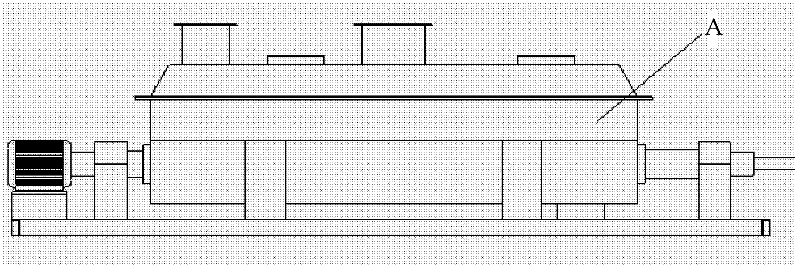

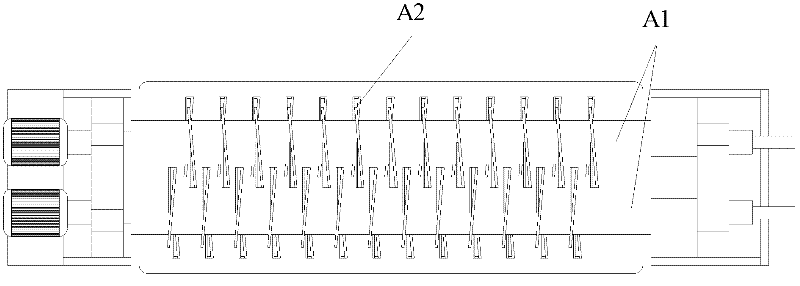

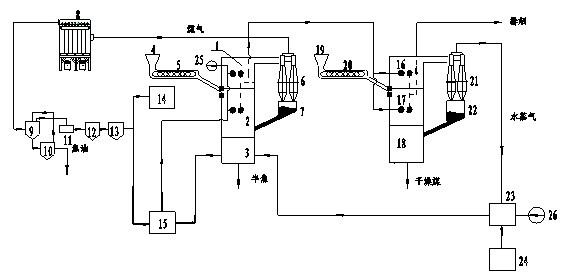

Large-size low-temperature destructive distillation system for low-order lignite

InactiveCN102329628AHeating evenlyAvoid secondary pyrolysisCoke quenchingSpecial form destructive distillationTarHeat carrier

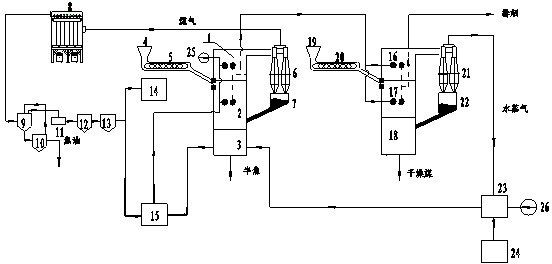

The invention provides a large-size low-temperature destructive distillation system for low-order lignite, solving the problem of industrial destructive distillation of low-order lignite. The system consists of a lignite preparation part, a drying part, a destructive distillation part, a heat source part, a semicoke cooling and transporting part and a gas and tar treatment part, wherein in the lignite preparation part, raw lignite is smashed and then fed into the drying part for drying; dried lignite particles are fed to the destructive distillation part for destructive distillation; the gas obtained after destructive distillation is dedusted and then enters into the gas and tar treatment part to be treated and then stored; air cooling is carried out on the semicoke subjected to destructive distillation and then the semicoke is discharged; the destructive distillation heat source is supplied by high-temperature smoke produced by combusting partial destructive distillation self-produced gas in a combustion furnace; low-temperature waste smoke extracted from the destructive distillation part is used as the heat carrier of the drying part; and cold air for cooling the semicoke is introduced into the combustion furnace after absorbing the heat of the semicoke for combusting the gas. The large-size low-temperature destructive distillation system is suitable for large-scale industrial continuous production, has simple equipment and is easy to implement, thereby providing an effective way for the utilization of the low-order lignite.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

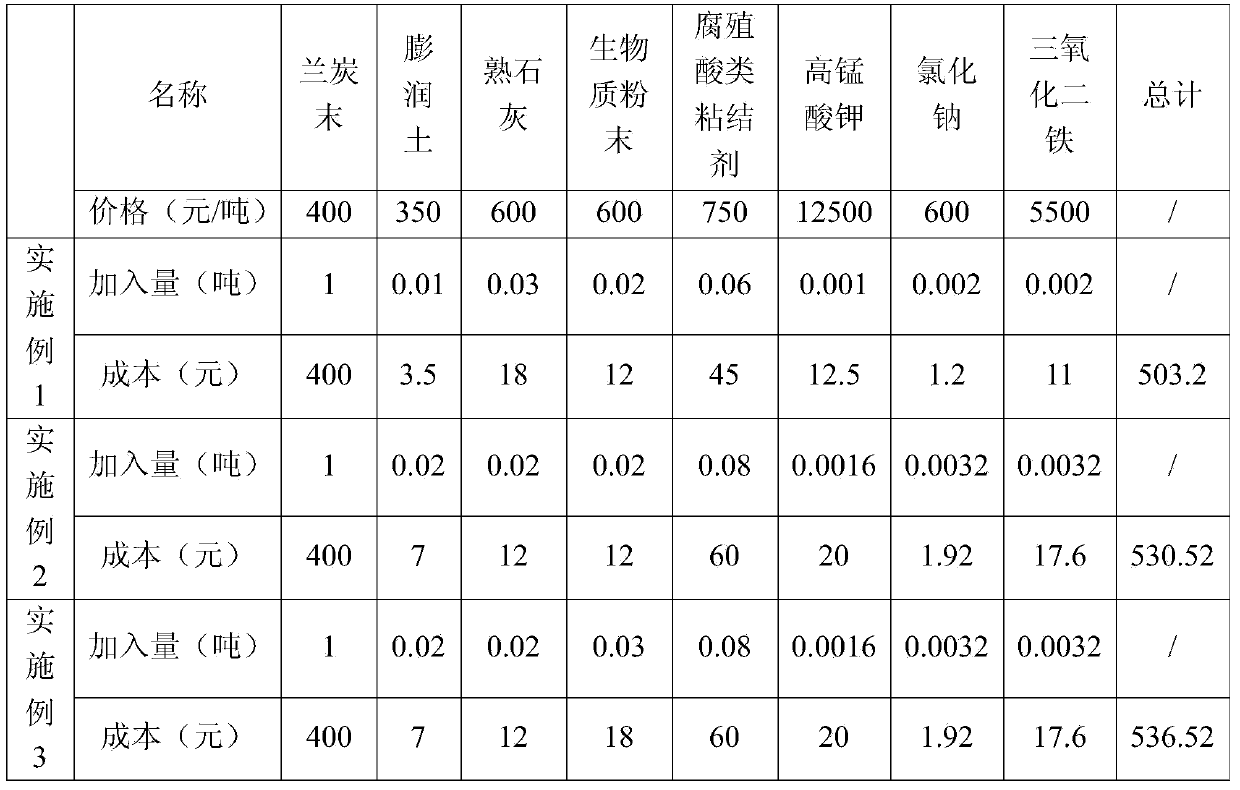

Biomass moulded coal and preparation method thereof

InactiveCN101985575ALow calorific valueLow volatileBiofuelsSolid fuelsFixation agentSodium hydroxide

The invention provides a method for preparing biomass moulded coal by using biomass and inferior smokeless pulverized coal as raw materials. The biomass moulded coal is prepared by uniformly mixing the biomass, the inferior smokeless pulverized coal and additives (a sulfur fixation agent, a biomass binder, an oxidant and a waterproofing agent), and performing low-pressure compression moulding by a wet method, wherein the sulfur fixation agent is calcined lime CaO; the biomass binder is light yellow dope prepared by treating bagasse by using 1 to 2 percent sodium hydroxide solution; the oxidant is potassium permanganate; and the waterproofing agent is tar or a binder. The biomass moulded coal comprises following raw materials in part by mass: 40 to 65 parts of inferior smokeless pulverized coal, 25 to 55 parts of biomass and 5 to 10 parts of additive. The biomass moulded coal has the advantages of low cost, low ignition point, high burn-off rate and integrative desulfurization and water proofing performance, and has great significance of energy conservation and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

Nitrile rubber production process

The invention relates to the technical field of rubber production, aiming to provide an improved nitrile rubber production process, which comprises polymerization, degassing and condensation. Raw materials including acrylonitrile, butadiene, desalinated and deoxidized water, condensed water and molecular weight regulators are fed into a polymerization position, convergence is carried out in a header pipe at the polymerization position, the converged mixture is pre-emulsified sequentially through a pipe pump and a pipe mixer, heat exchange is carried out through an ammonia-cooling heat exchanger for cooling, the cooled mixture, initiator emulsion and activator solution are sequentially fed into a plurality of reactors for polymerization to produce latex, the latex taken out of the reactorsand terminating defoamer solution are fed into a maturing reactor and are fully mixed when the rate of polymerization and conversion reaches 70 plus or minus 5 percent, and the mixture is then fed into a degassing tower to be degassed and into a condensation reactor for condensation. The problem of blockage of the heat exchanger can be avoided, the process is simple, the production process is stable and economical, the Mooney of rubber can be controlled easily, and the produced nitrile rubber has high quality.

Owner:NINGBO SHUNZE RUBBER

Re-molten spherical alumina casting sand and its prepn

InactiveCN1468673AImprove temperature resistanceStrong collapsibilityFoundry mouldsFoundry coresMolten stateElectric arc furnace

The present invention relates to the formation technology of thermosetting material, and the re-molten spherical alumina casting sand is produced with alumyte or incinerated alumyte tail ore as material. The casting sand has the components including alumina 70-80 wt%, silica 10-20 wt%, ferric oxide less than 5 wt%, and titanium oxide less than 5 wt%. Its production process includes incineration of alumyte under 1000-1400 deg.c for 1-2 hr; blowing incinerated alumyte in molten state inside an electric arc furnace to make spheres; and sieving to take 0.1-2.9 mm grains as the casting sand product. The casting sand product has good heat resistance, high collapsibility, good demolding performance, low powdered and volatile component content, high mechanical strength, and other advantages and may be used in high precision casting mold.

Owner:阳泉中创陶粒股份有限公司

Chromium corundum material and production method thereof

The invention relates to a chromium corundum material and a production method thereof. The chromium corundum material consists of 90wt%-94.5wt% of aluminum oxide, 3wt%-8wt% of chromic oxide and less than and equal to 2.5wt% of total impurities. The production method comprises the steps of uniformly mixing aluminum-chromium slag having a particle size less than and equal to 20mm, aluminum oxide having a particle size less than and equal to 1mm, petroleum coke having a particle size less than and equal to 20mm and aluminum fluoride, heating bitumen and spraying to the mixture, pressing into ball materials, drying, and adding the dried ball materials to an electric-arc furnace; smelting, pouring smelted liquid in a slag pot, removing the calcium fluoride floating on the upper part of the liquid material and standing; and separating from the slag pot, crushing, selecting chromium metal reduced by carbon and finishing to obtain the chromium corundum material. The chromium corundum material has the advantages that the problem of aluminum chromium slag solid waste is solved by taking aluminum chromium slag as raw materials, environmental friendliness is achieved, the raw material cost is lowered, the contents of Al2O3 and Cr2O3 are improved and the high-temperature performance, slag resistance and corrosion resistance of the chromium corundum material are ensured.

Owner:锦州集信高温材料有限公司

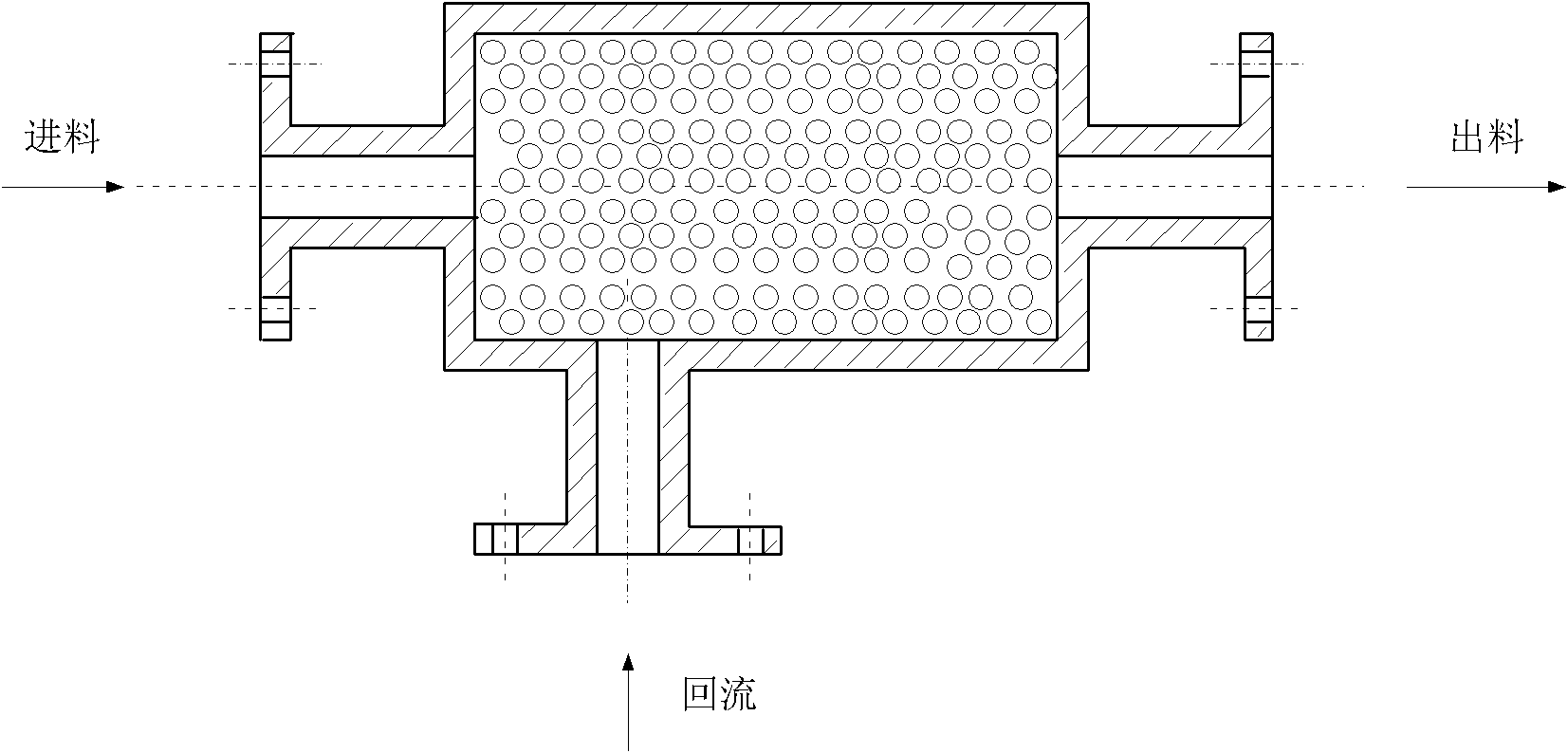

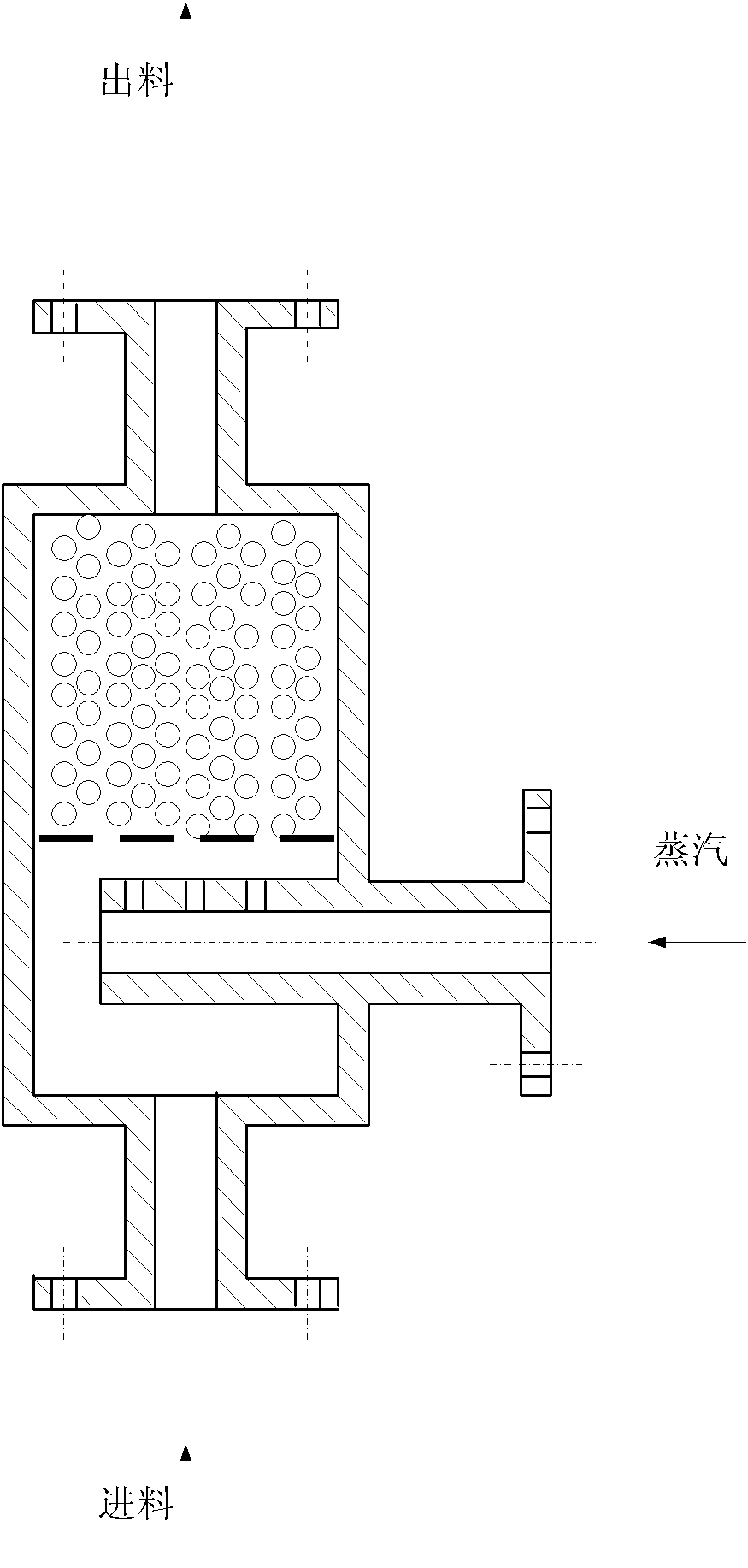

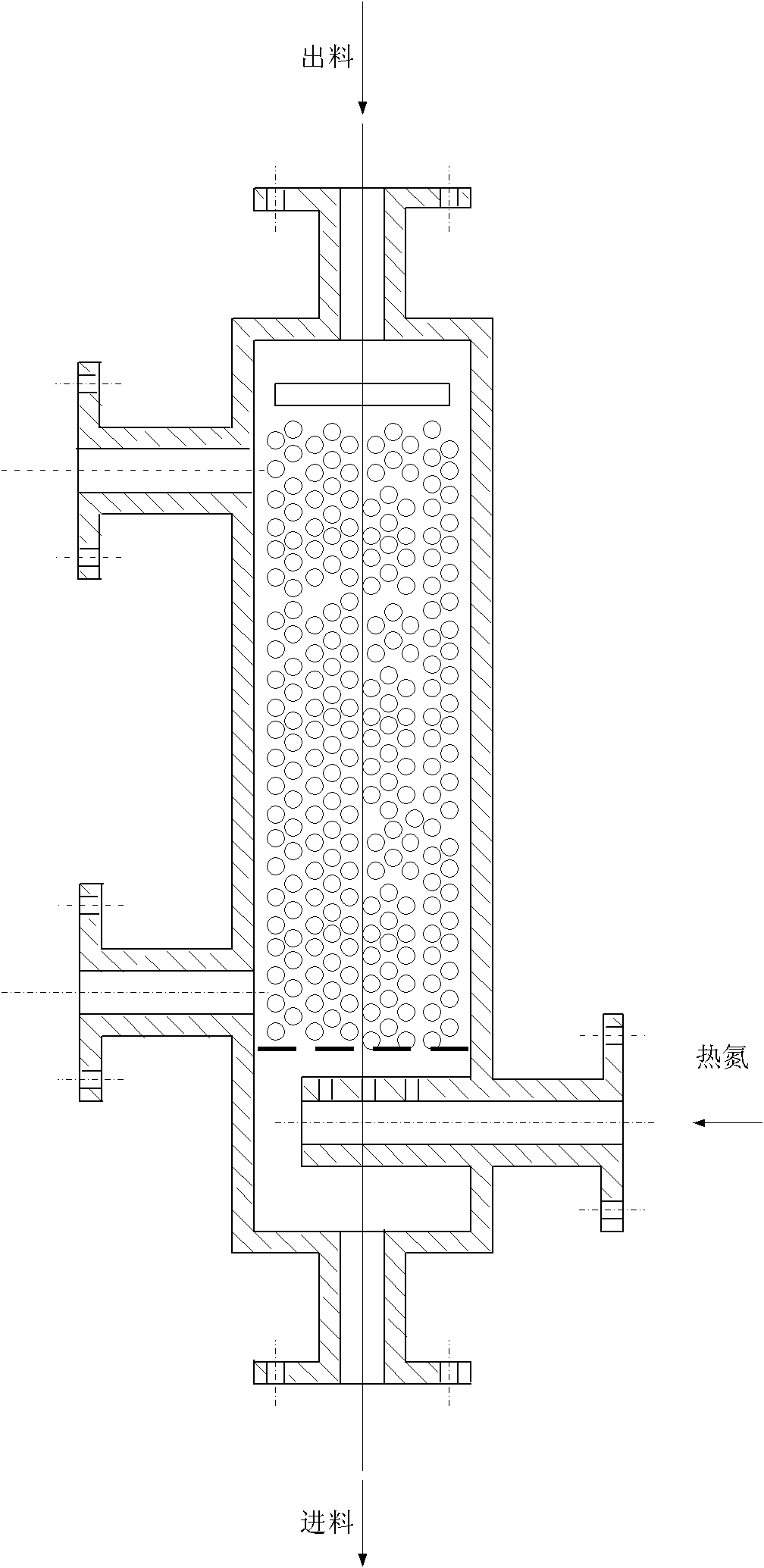

Method and device for reducing volatile matters of o-cresol-formaldehyde epoxy resin

ActiveCN102464792AUniform film formationGuaranteed removal rateMultiple-effect evaporationEpoxyVapor–liquid separator

The invention discloses a method and device for reducing volatile matters of an o-cresol-formaldehyde epoxy resin. The method comprises the following step of: performing a two-stage desolventizing step, including a coarse desolventizing step and a fine desolventizing step to remove a solvent and a high-boiling residue component from an o-cresol-formaldehyde epoxy resin. The device comprises a feed pump, a first pipeline mixer, a falling film evaporator, a gas-liquid separator, a primary removal extraction pump, a second pipeline mixer, a thin-film evaporator, a packing tower and a secondary removal extraction pump which are connected in sequence, wherein a part of an o-cresol-formaldehyde epoxy resin solution output by the gas-liquid separator returns to the first pipeline mixer through areflux pump; a steam inlet / outlet is formed in the second pipeline mixer; and both the gas-liquid separator and a film evaporator are provided with a volatile matter gas-phase outlet. According to the method and the device for reducing the volatile matters of the o-cresol-formaldehyde epoxy resin, volatile matters of a product can be reduced to be below 0.05 percent, and the performance of the product applied to an electronic molding compound can be improved remarkably.

Owner:CHINA PETROCHEMICAL CORP

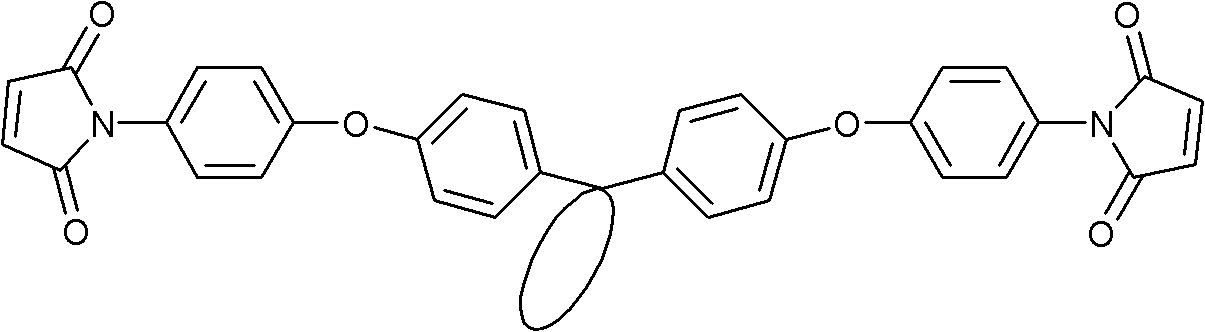

Modified bismaleimide resin prepolymer and preparation method thereof

The invention provides a modified bismaleimide resin prepolymer. Bismaleimide is subjected to copolymerization, chain extension and toughening modification by a melting polymerization process and by using an allyl compound, aminophenylacetylene and benzoxazine; the obtained modified bismaleimide resin prepolymer has excellent processing property while maintaining high heat resistance of the bismaleimide, and can greatly improve the mechanical property; furthermore, the prepolymer is moderate in melt viscosity, low in volatile component, high in paving and covering property, long in storage period and low in cost, and is an ideal adhesive film material for prepreg; and the modified bismaleimide resin prepolymer can serve as matrix resin of a composite material, a high-temperature-resistant adhesive, an electronic appliance copper-clad plate insulating material and the like, and is applicable in the technical fields of aerospace, electronic appliances, traffic and transportation and the like.

Owner:WUHAN UNIV OF TECH

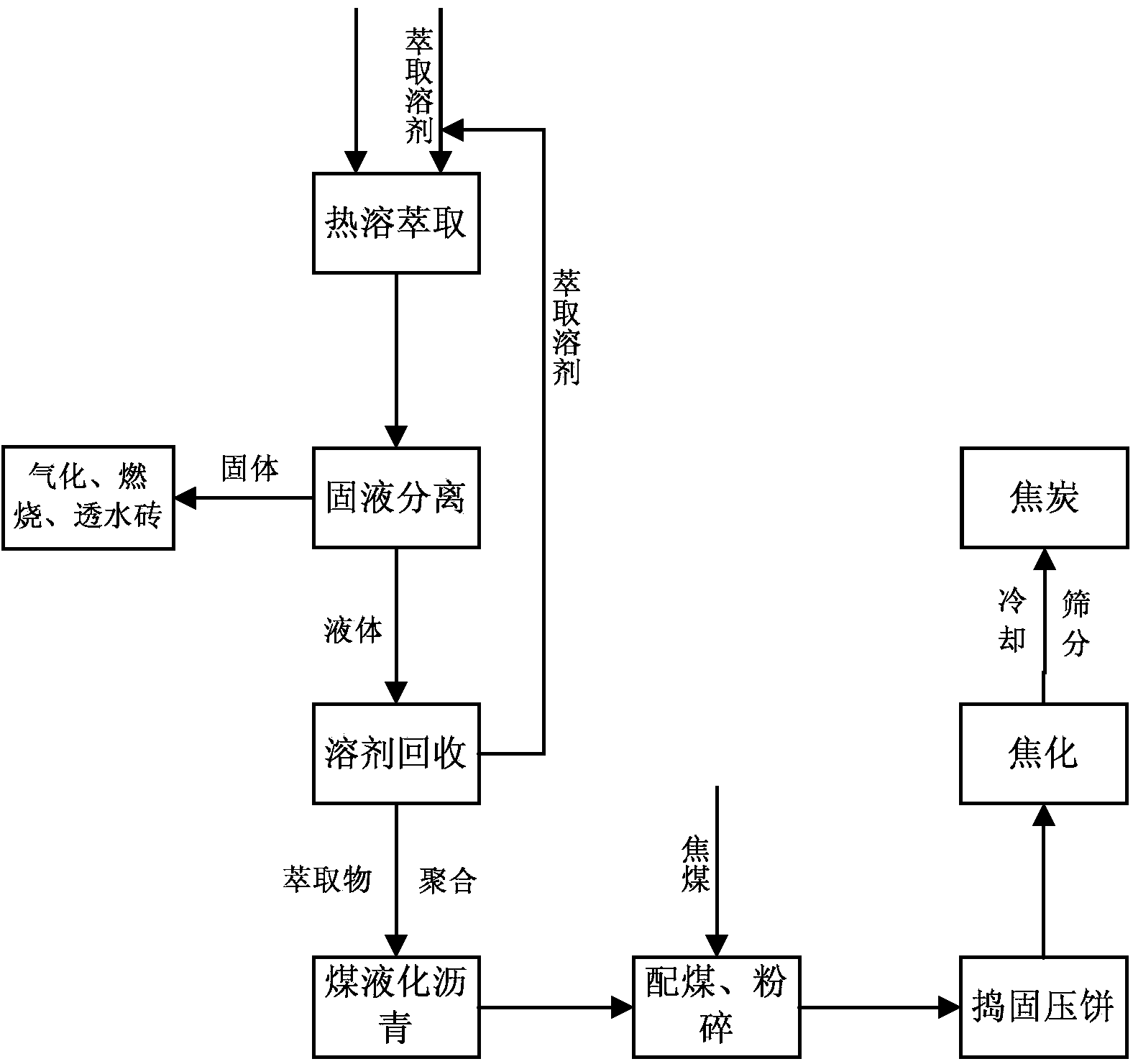

Method for preparing coke by using direct coal-liquefied residue

ActiveCN103436280AHigh beta-resin contentHigh softening pointWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by chemical meansCoal briquetteCoke burner

The invention discloses a method for preparing coke by using direct coal-liquefied residue. The method comprises the following steps: S1, orderly carrying out primary hot melt-extraction, primary solid-liquid separation and polymeric modification on the direct coal-liquefied residue, so as to obtain coal-liquefied modified asphalt; S2, mixing the coal-liquefied modified asphalt with cleaned coal for coking, crushing, tamping and pressing into a cake, so as to obtain a coal briquette; and S3, conveying the coal cake to a coke burner to heat and insulate heat in isolated air, and then cooling and screening to obtain the coke. The coal-liquefied modified asphalt which is obtained from the direct coal-liquefied residue in manners of hot melt-extraction, solid-liquid separation and polymeric modification is applied to a tamping coking process, so that the coke of which all indexes achieve the first national metallurgical coke standard is obtained; the yield of qualified products can be up to over 82%.

Owner:CHNA ENERGY INVESTMENT CORP LTD +3

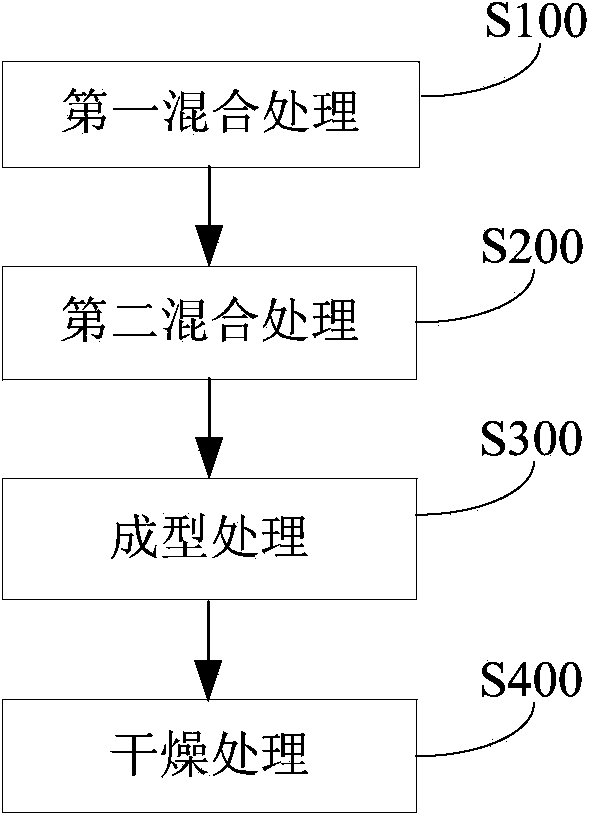

Fuel rod and preparation method thereof

The invention discloses a fuel rod and a preparation method thereof. The preparation method comprises the following steps: carrying primary mixing treatment on semi-coke powder, biomass powder, a combustion improver, a sulfur-fixing agent and bentonite to obtain a first mixed material; carrying out secondary mixing treatment on the first mixed material and a binder to obtain a second mixed material; molding the second mixed material by virtue of a looping-model molding machine to obtain a molded material and drying the molded material to obtain the fuel rod. The fuel rod prepared by the method has the characteristics of low volatile components, low content of sulfur and high calorific value and is cheap, and thus the fuel rod can replace the blind coal to be applied in suburban villages or rural areas in winter for heating and cooking so that fog and haze can be significantly reduced and the air quality is effectively improved.

Owner:SHENWU TECH GRP CO LTD

High temperature calcination method of electrolytic aluminum cathode scrap residue

The invention discloses a high temperature calcination method of electrolytic aluminum cathode scrap residue. The method is characterized by comprising the following steps of: crushing and ball milling the electrolytic aluminum cathode scrap residue; separating powdered carbon through floatation; then removing iron-containing impurities from the powdered carbon through magnetic separation; and calcining the powdered carbon by a calcining furnace to remove fluoride salt and sulfur from the powdered carbon, thus obtaining high-purity powdered carbon. According to the invention, through direct high temperature calcination of the powdered carbon recovered from the electrolytic aluminum cathode scrap residue, the processes of asphalt blending, tar kneading and profiling are reduced, so that the method is simpler; and compared with calcined carbon blocks, the powdered carbon grains are small and quick in temperature rise, and can rapidly reach a high temperature over 1700 DEG C in the calcining furnace, so that sulfur and fluoride salt are gasified and released. Therefore, the calcination time is greatly reduced, and the calcination can be finished in 10-20 minutes, thus saving a large amount of heating time and electric energy. The calcined powdered carbon has the advantages of low volatile component, low sulfur, high purity and more balanced quality, and can be used as a high-quality carbon raw material.

Owner:周俊和 +1

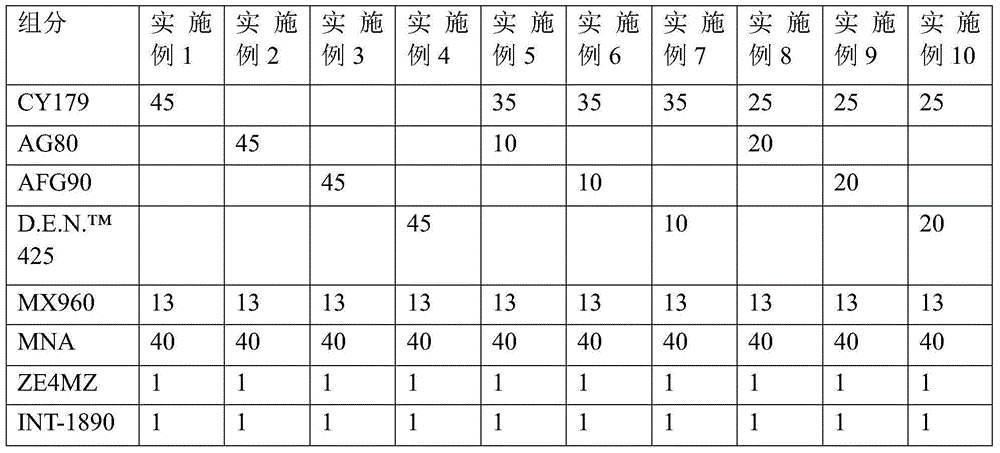

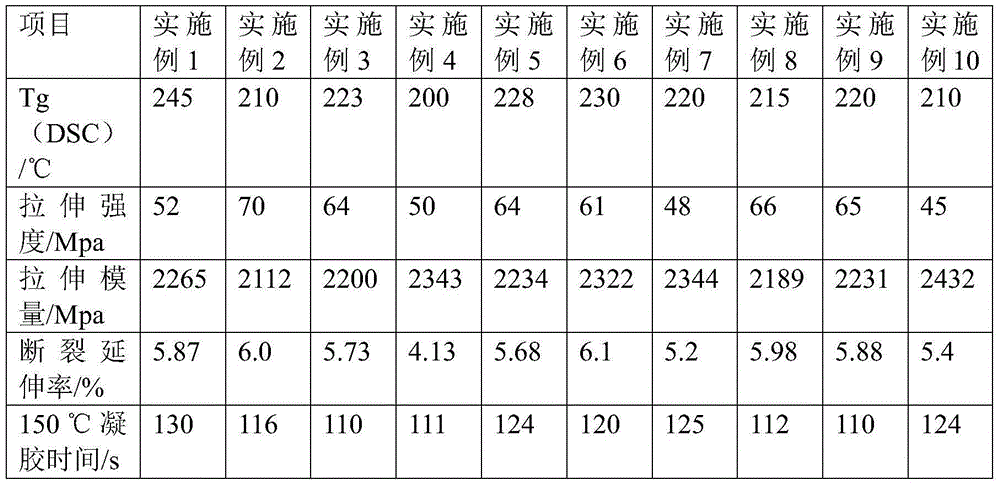

Thermosetting resin and preparation method thereof

The invention discloses thermosetting resin used for pultrusion and a preparation method of the thermosetting resin. The thermosetting resin is composed of the following components by weight percentage: 35-60% of an epoxy resin mixture, 5-15% of a flexibilizer, 35-60% of a curing agent, 0-10% of a catalyst and 0-3% of an internal releasing agent. The preparation method of the thermosetting resin comprises the following steps: uniformly dispersing the epoxy resin mixture and the flexibilizer to be used as a component A by a high-speed dispersing agent at 60 DEG C, stirring the curing agent, an accelerant and the internal releasing agent at a high speed to uniformly disperse to be used as a component B, uniformly mixing the component A and the component B at normal temperature, and finally defoaming the mixture resin in a vacuum oven to prepare a resin casting body. Compared with unsaturated polyester resin, the thermosetting resin is low in volatile component, low in pollution, good in heat resistance, strong in adhesive force, excellent in mechanical property of a cured material and wide in designable range in terms of temperature tolerance.

Owner:HENGSHEN

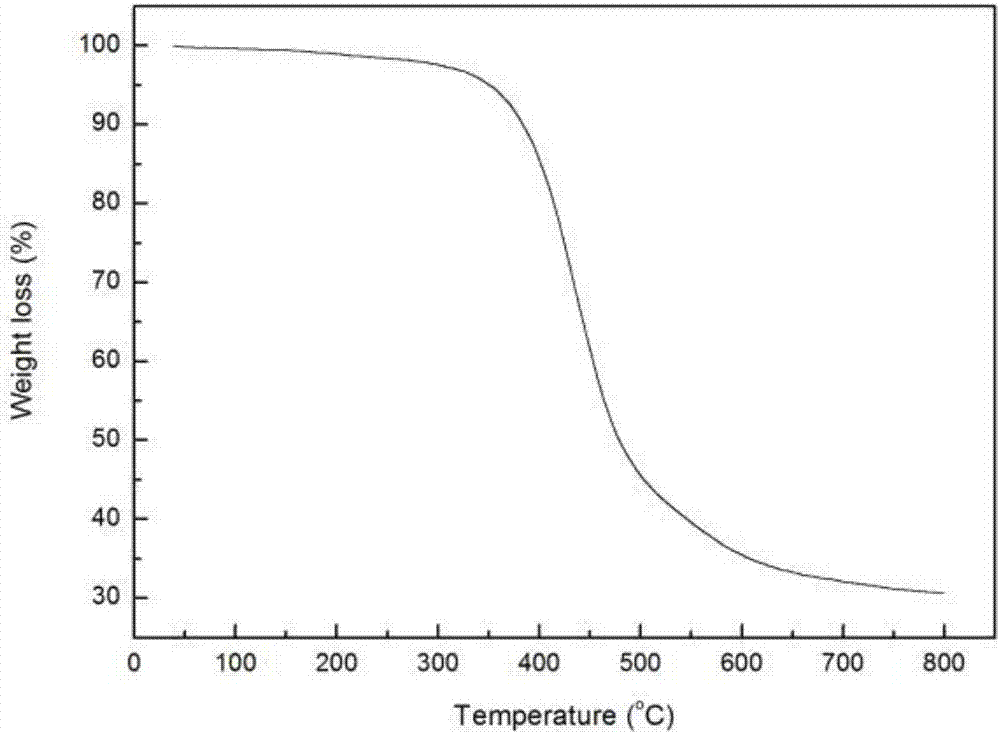

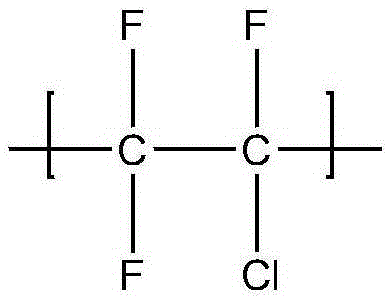

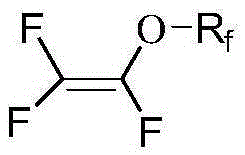

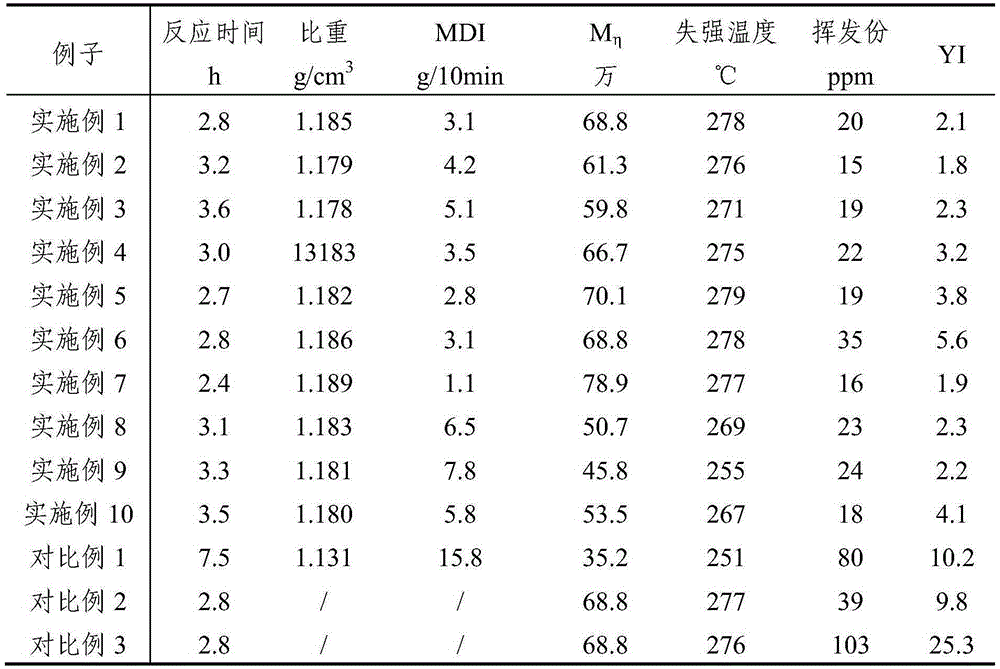

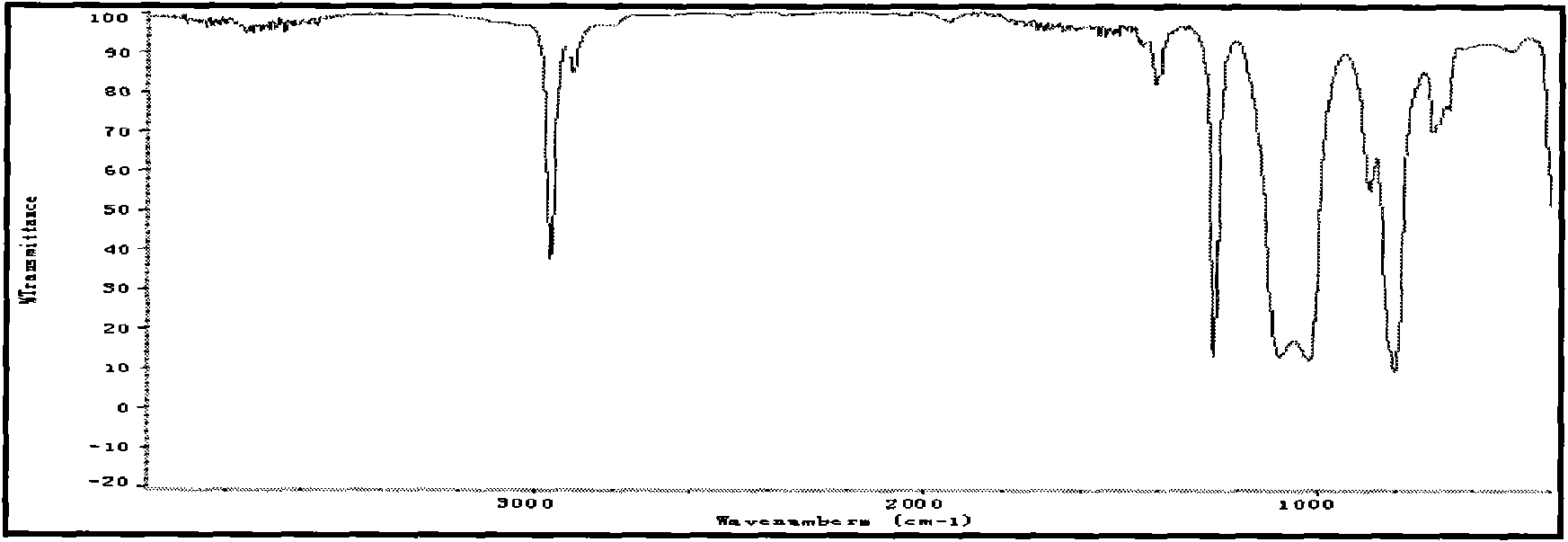

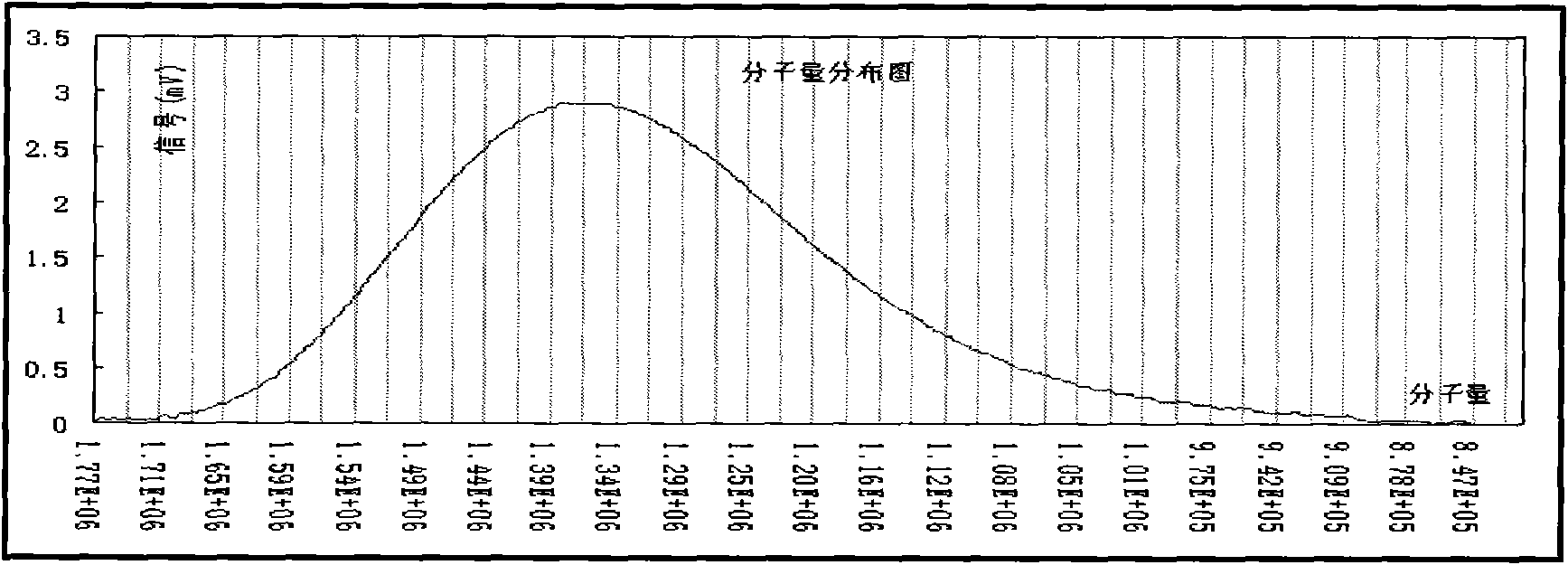

Polychlorotrifluoroethylene resin and preparation method thereof

ActiveCN106832072ALarge mass transfer areaQuick responseAnti-corrosive paintsPolymer scienceEmulsion

The invention relates to a preparation method of polychlorotrifluoroethylene resin, which adopts a horizontal reactor with an aspect ratio ≥ 1.0 as polymerization equipment; uses chlorotrifluoroethylene monomer or chlorotrifluoroethylene monomer and other comonomers The polymerization reaction occurs under constant pressure conditions, which improves the reaction speed and polymerization efficiency; the semi-mechanical and semi-chemical coagulation method is used to effectively separate the impurities in the emulsion, and the residual unstable groups are removed through wet heat treatment, effectively reducing the volatilization of the product parts, greatly improving the appearance of the product. M can be obtained by the method of the present invention η PCTFE and its copolymerization products exceeding 500,000, volatile matter less than 0.01%, strength loss temperature higher than 260°C, yellowness index (YI) less than 10.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

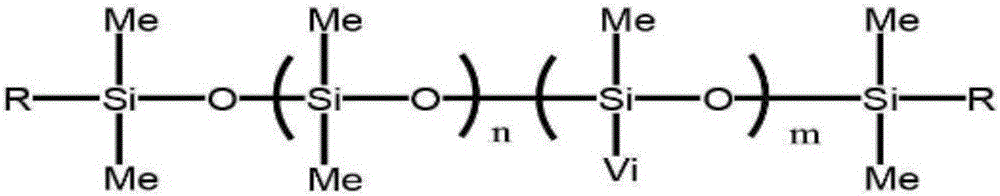

Preparation method for polysiloxane with extra high molecular weight

The invention discloses a preparation method for polysiloxane with extra high molecular weight, comprising the steps of (1) adding dimethyl siloxane or alpha, omega-dihydroxy polydimethylsiloxane intoa reactor, stirring, controlling the rotating speed being 30 to 60 revolutions per minute, heating up to 90-160 DEG C., adding catalyzer which occupies 0.001% to 0.1% by weight of raw materials and reacting for 2.0 to 6.0 hours at constant temperature, (2) at constant temperature, vacuum-pumping for 1.0 to 4.0 hours, and controlling the vacuum degree being -0.080 to -0.10 MPa, and (3) adding neutralizing agent which occupies 0 to 0.1% by weight of raw materials, heating up to 170-180 DEG C., introducing nitrogen, vacuum-pumping for 2.0 to 6.0 hours, stopping heating, stirring, discharging after cooling to room temperature to obtain the blocky or granular hydroxyl silicone oil products with extra high molecular weight. The invention can prepare the polysiloxane with molecular weight more than 1000000.

Owner:GUANGZHOU TINCI MATERIALS TECH

Coking coal blending method of wide carbonization chamber coke oven

The invention discloses a coking coal blending method of a wide carbonization chamber coke oven. The method comprises a step of blending various single coking coals, wherein each single coking coal comprises the following components in percentage by weight: 16-25% of lean coal and meager lean coal, 10-20% of fat coal 1#, 17-29% of 1 / 3 coking coal, 15-20% of coking coal 1#, 6-20% of coking coal 2#, 5-10% of coking coal 3#, 6-10% of gas-fat coal and fat coal 2# and the balance of other random available coking coal of which the volatile component content Vdaf is less than or equal to 35%; the maximum Gieseler fluidity of the compound coal is 600-1,400ddpm; and the volatile components account for 24-27%. The method disclosed by the invention effectively reduces the coal preparation cost, overcomes adverse impact on the high-temperature flowing property of the coking coal caused by the heating speed reduction in a coking process of the wide carbonization chamber coke oven, effectively reduces the graphite accumulation speed on the oven top and improves the coke quality and the coke output.

Owner:武汉钢铁有限公司

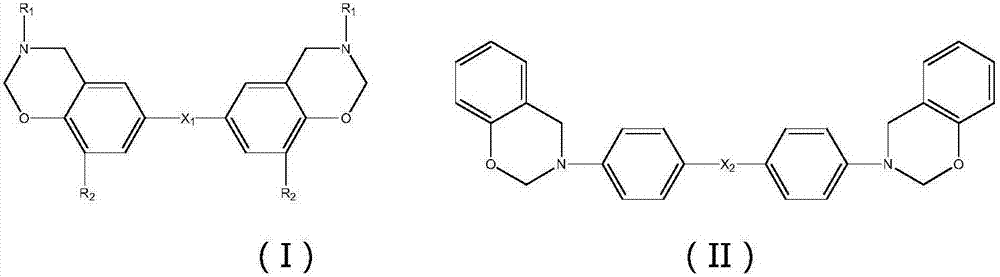

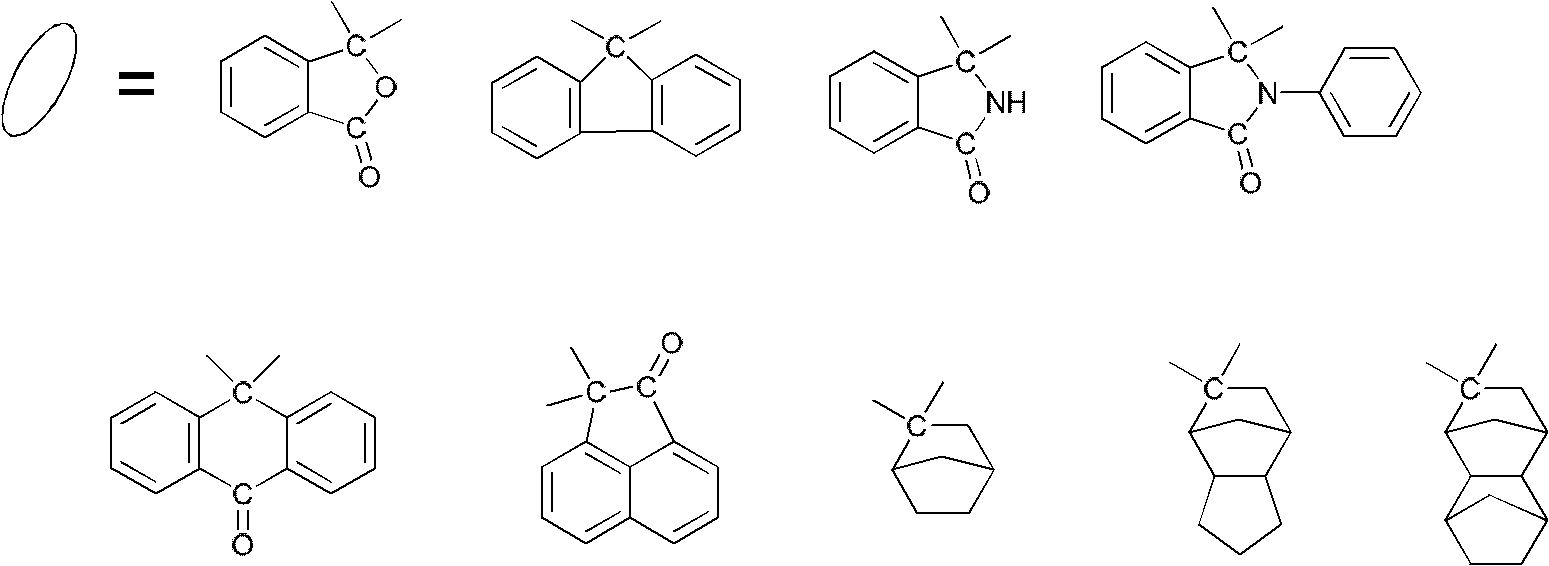

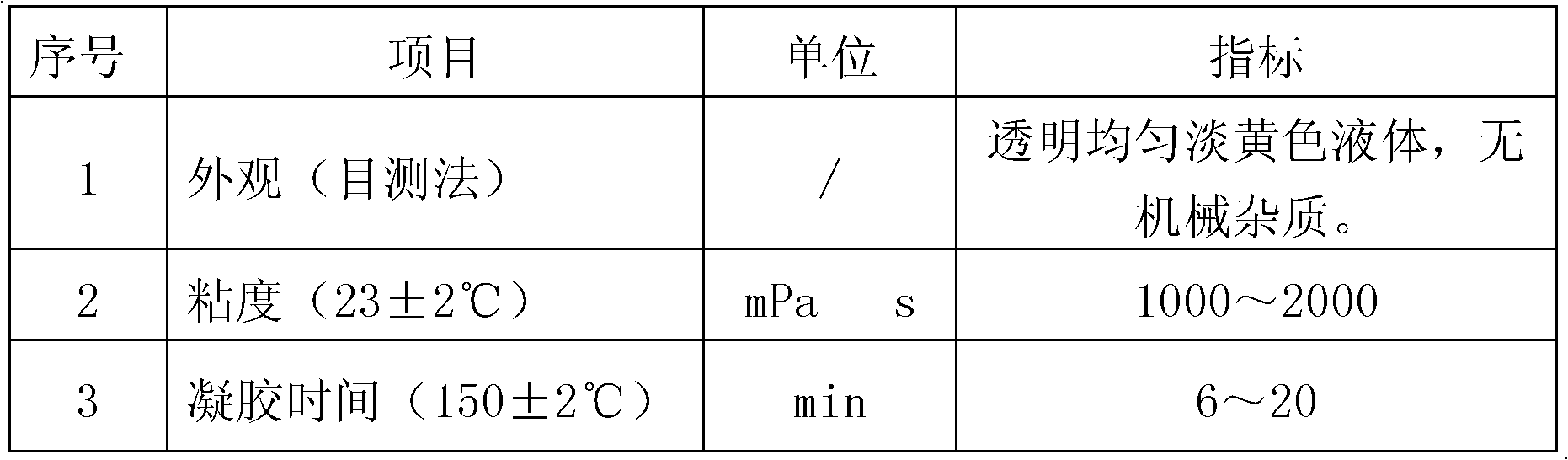

Double-component imine modified epoxy solvent-free impregnated resin and preparation and use methods

The invention discloses double-component imine modified epoxy solvent-free impregnated resin and preparation and use methods. The double-component imine modified epoxy solvent-free impregnated resin is formed by mixing 100 parts by weight of component A and 40-80 parts by weight of component B, wherein the component A comprises the following materials in parts by weight: 100 parts of epoxy resin,10-60 parts of Cardo type bismaleimide and 0-20 parts of diluting agent; the component B comprises the following materials in parts by weight: 80-100 parts of liquid acid anhydride, 0.3-2.0 parts of initiator and 0.5-2.0 parts of microcapsule accelerator; the impregnated resin is applied to a vacuum pressure impregnation (VPI) process of a traction motor; the temperature of the impregnated resin is 40-60 DEG C; the curing and baking temperature is 140-200 DEG C; and the time is 10-20 hours. The impregnated resin has the advantages of simplicity in synthesis, cheap raw materials, low cost and superior toughness of a curing system; the synthesized resin is convenient to transport and store and has longer working life during use; the production of toxic and harmful gases is reduced during production; and the impregnated resin belongs to an environmentally-friendly product.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

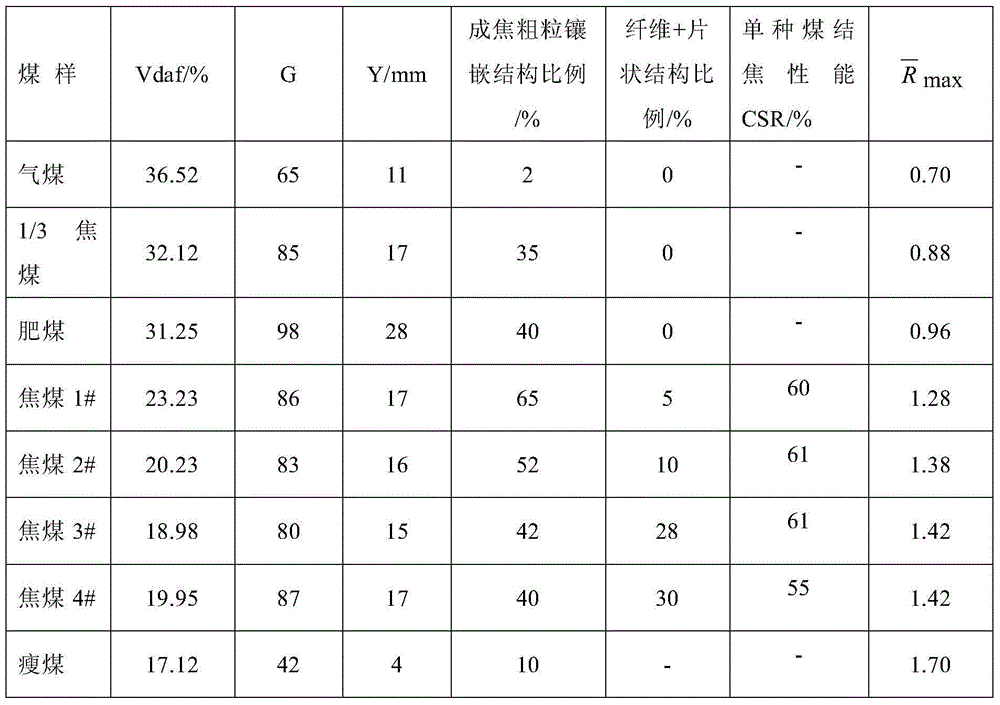

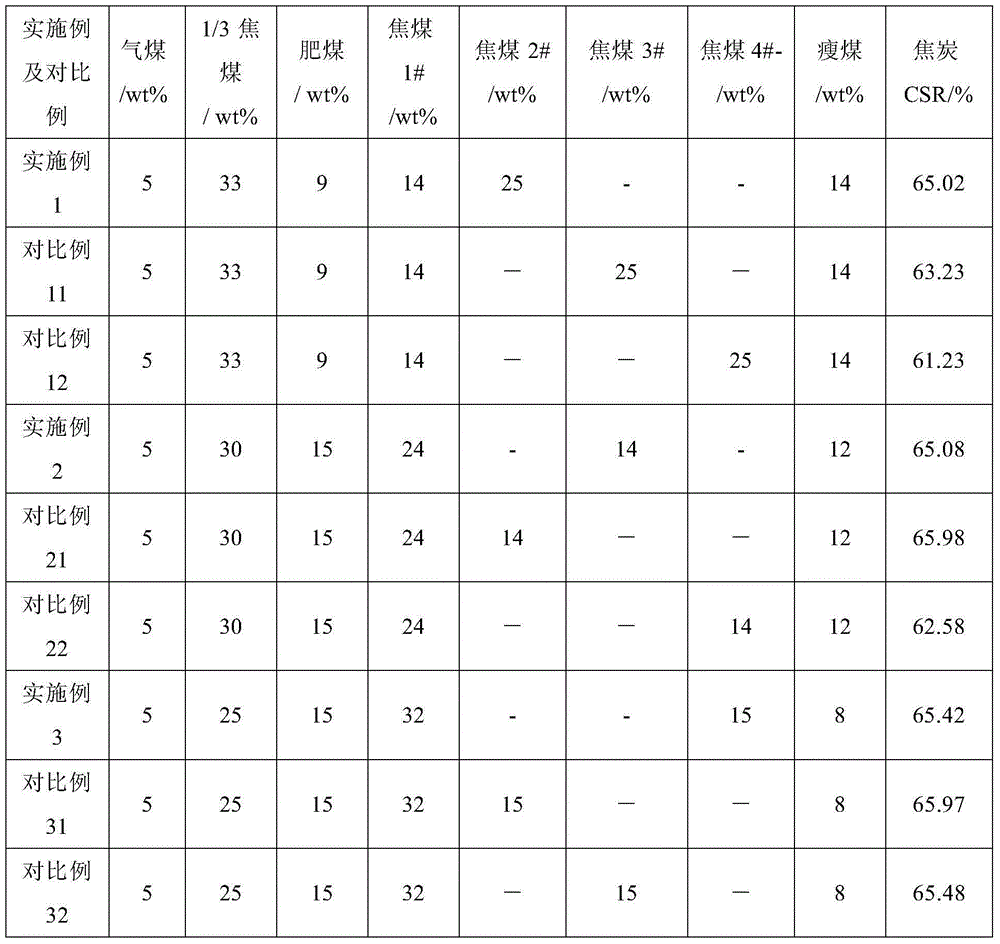

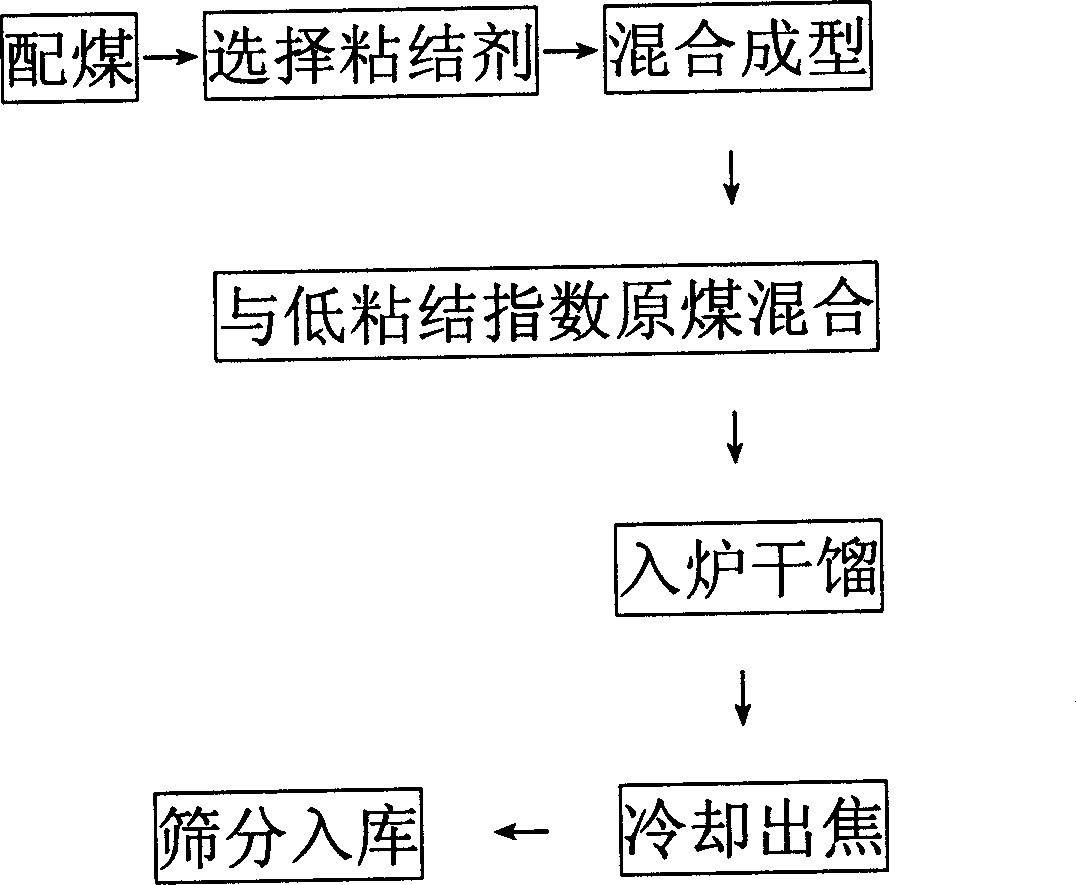

Coke making method by using low-volatile coking coal in coal blending

The invention discloses a coke making method by using low-volatile coking coal in coal blending, which comprises the following steps: 1) coke microstructure testing: carrying out single-coal coking on the low-volatile coking coal, and carrying out microstructure testing on the obtained coke; 2) single-coal coking thermal performance testing: respectively obtaining the strengths of the reference coking coal (of which the volatile content is 21-24%, the single-coal coking coarse grain mosaic structure is greater than or equal to 65%, the G value is greater than 85 and the solid softening temperature range is up to 85 DEG C above) and low-volatile coking coal subjected to coke thermal reaction, and comparing; and 3) carrying out classified blending on the low-volatile coking coal according to the coke microstructure characteristics and the single-coal coking thermal properties. The low-volatile coking coal is reasonably divided and subjected to classified blending according to the coke microstructure characteristics and the single-coal coking thermal properties; and thus, the method can effectively utilize the low-volatile coking coal resources under the technological conditions of no graded crushing, briquette technique or tamping coking, the coke quality does not deteriorate, and the CSR of the coke made by the 6m-above coke oven is greater than 65%.

Owner:武汉钢铁有限公司

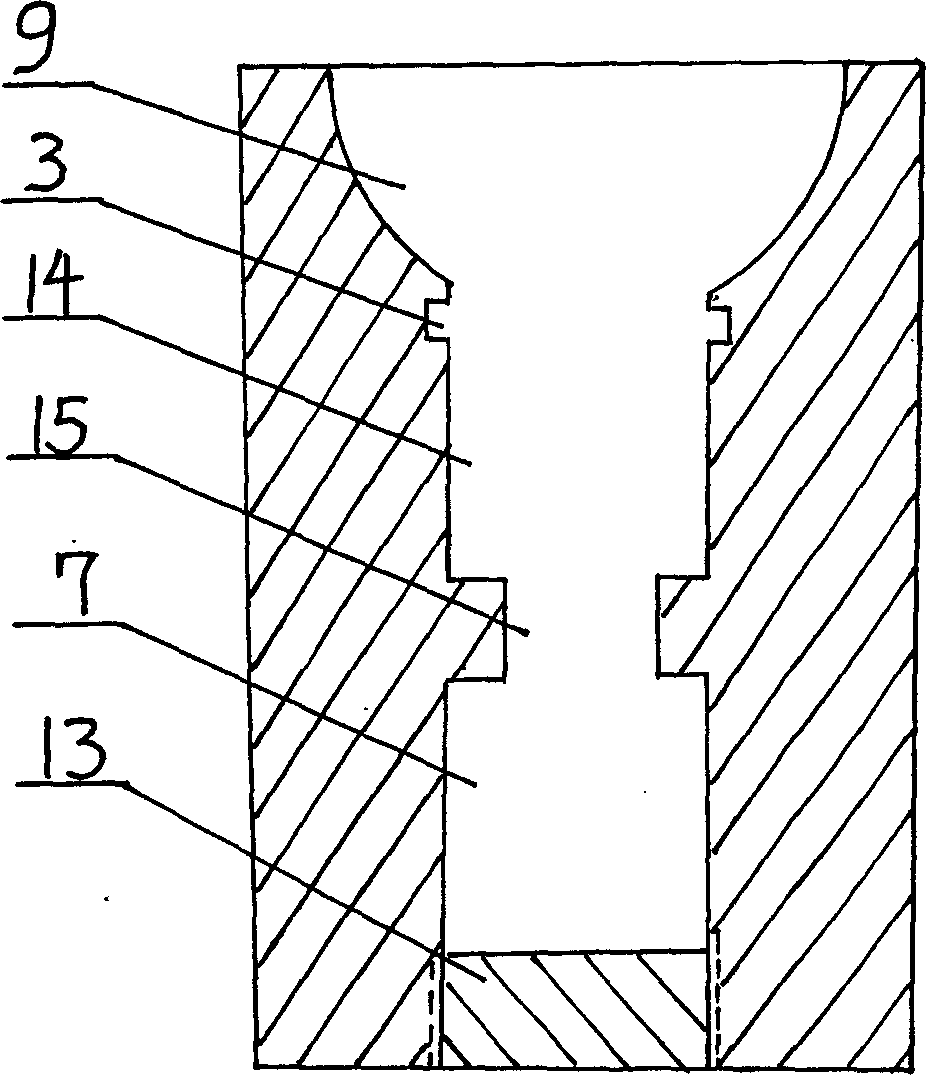

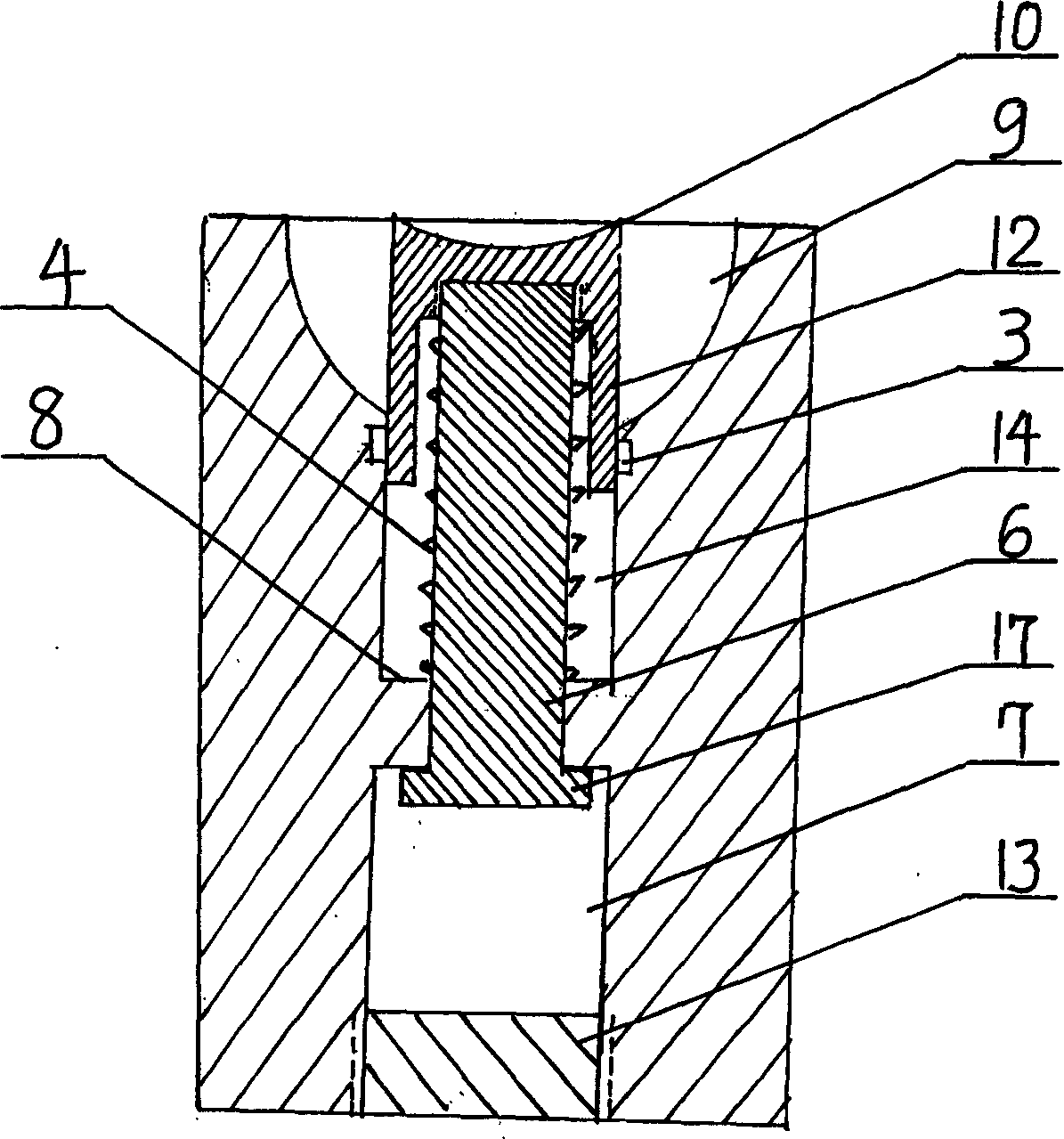

Sectional coke and its production method and pressure forming equipment

InactiveCN1488709ARaise the combustion temperatureIncrease temperatureCoke ovensAdhesiveCarbonization

The present invention relates to a formed coke, it is made up by using raw coal and / or semi-coke and / or coke powder and organic adhesive through the processes of mixing, press-forming and carbonization, and in which the described formed cake is made into the form of spheroid, its diameter is 30-300 mm, and its density is 1.25-1.5 g / cu.cm. Said invention also provides the pressure forming equipment for producing the above-mentioned spheriod formed coke and its production method.

Owner:刘英旺 +1

Method for making biological coal by reaction of fly ash and municipal sludge

The invention discloses a method for making biological coal by the reaction of fly ash and municipal sludge, comprising the following steps of: firstly determining water content of the municipal sludge in pipelines by utilizing a computer system, and adding the fly ash to municipal sludge pipelines through fly ash pipelines according to the determined water content to make the fly ash mix with the municipal sludge to react and absorb water, wherein the water content of the mixture after the reaction at the discharge opening is 1-5%; and then adding a liquid deodorizer to the mixture and mixing in an agitator tank, wherein the water content of the mixed municipal sludge is 8-10%; finally making grains with different gradations by a pelletizer. The weight percentage of calcium oxide to the fly ash is 15-35%, and the weight percentage of free calcium to the fly ash is 0.2-0.4%. By utilizing the method of the invention, the floor area stacking the fly ash of a power plant is also reduced while the municipal sludge is treated, the volatile matter of the produced biological coal as received basis ranges 27-35%, the low calorific value of the as received basis is 3000-4000 kcal / kg totally similar to that of the coal, and the sustained combustion of the biological coal can be completely realized.

Owner:SHANXIN KETAO TECH BEIJING +1

Environment-friendly type carbonaceous press material for maintaining blast furnace hearth

The invention provides an environment-friendly type carbonaceous press material for a maintaining blast furnace hearth. The environment-friendly type carbonaceous press material comprises the following components by weight: 15-35% of electrode graphite, 20-32% of crystalline flake graphite, 4-11% of silicon carbide, 5-15% of quartz sand, 1.0-3.0% of boron carbide, and 24-35% of environmental protection modified tar, wherein the sum of the components is 100%. The various said dry raw materials, in the proportions, can be used in a production field after weighted, burdened, uniformly mixed, uniformly stirred with a liquid binder and sealedly packaged. The carbonaceous press material of the invention has advantages of good fluidity and fallibility, high density and intensity, high thermal conductivity, good anti-aggressivity to melt molten iron and slag, high temperature air-flow flushing resistance, and good anti oxidizability, and is especially in favor of raising a blast furnace life and in favor of safety production. The carbonaceous press material contains less poisonous and harmful substances like benzopyrene, and is in favor of environmental protection.

Owner:BAOSHAN IRON & STEEL CO LTD

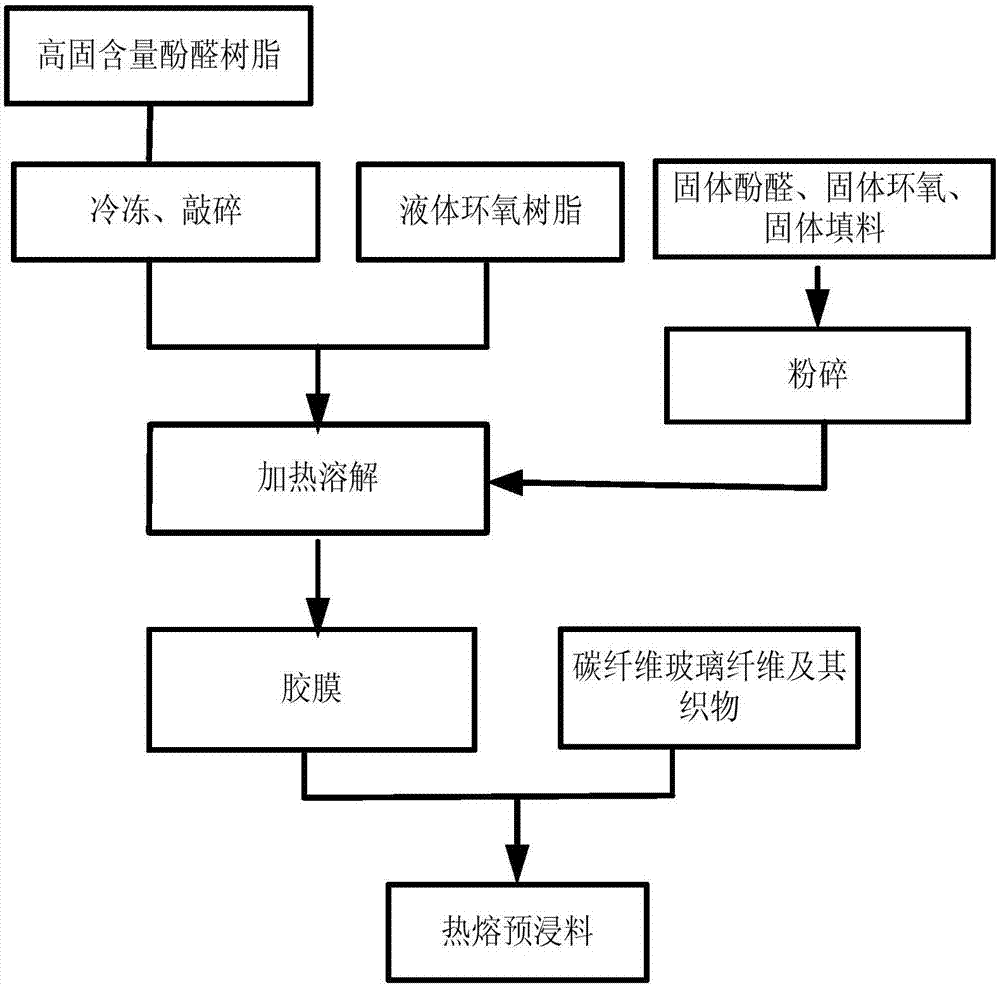

Preparation method of halogen-free, flame-retardant, low-smoke and low-toxin hot melt phenolic prepreg

The invention relates to a preparation method of halogen-free, flame-retardant, low-smoke and low-toxin hot melt phenolic prepreg. The solid content and the viscosity-temperature flow characteristic of phenolic resin are controlled with a reasonable synthesis process; solid phenolic resin and liquid epoxy resin are mixed uniformly according to formula design, and a resin system suitable for preparation of prepreg with a hot melt process is obtained; the gelation time of the resin is controlled to range from 140 s to 250 s, a hot melt resin adhesive film is prepared from the hot melt phenolic resin system, the coating temperature is controlled to range from 40 DEG C to 65 DEG C, the hot melt phenolic resin adhesive film and unidirectional fiber or fiber fabric are composited under heating and pressurizing conditions, and the hot melt prepreg is prepared. The hot prepreg with uniform texture and stable resin content can be obtained through resin synthesis, formula design and process design, and the hot melt prepreg and the composite have the characteristics of low smoke, no halogen, low smog toxin and flame retardancy and can meet requirements for use performance of interior trimming and structural composites for high-seed railways, aircrafts, steamships and other transportation tools.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

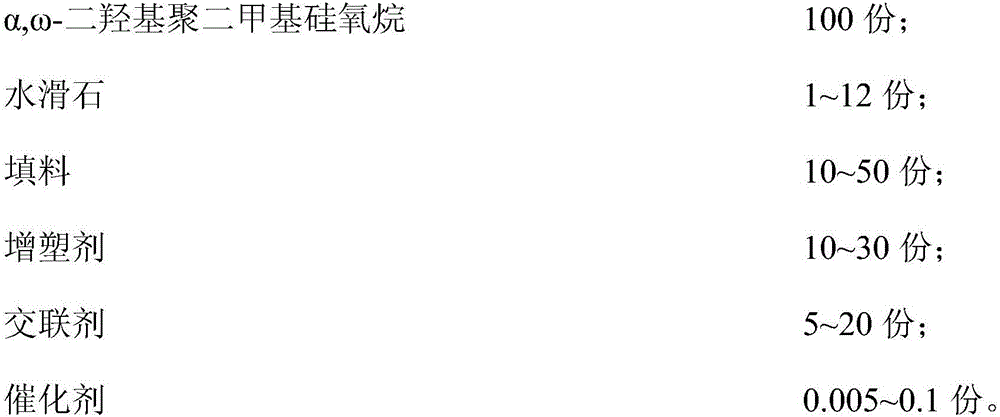

Deacidification type organic silicone adhesive and preparation method thereof

ActiveCN106753203AReduce concentrationBarrier and flame retardantNon-macromolecular adhesive additivesPlasticizerHydrotalcite

The invention relates to a deacidification type organic silicone adhesive and a preparation method thereof. The raw materials of the deacidification type organic silicone adhesive comprise alpha, omega-dihydroxydimethylpolysiloxane, hydrotalcite, filler, a plasticizer, a crosslinking agent and a catalyst, the deacidification type organic silicone adhesive has excellent adhesion and low corrosion to adhered materials, the volatile matters of the used raw materials are few, and meanwhile the deacidification type organic silicone adhesive also has efficient, environmental-friendly, nontoxic and halogen-free flame retardant properties..

Owner:GUANGZHOU BAIYUN CHEM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com