Fuel rod and preparation method thereof

A technology of fuel rods and mixed materials, which is applied to fuels, waste fuels, solid fuels, etc., can solve the problems of high cost, low conversion rate of achievements, and difficulty in promotion, and achieves low cost, low volatile content, and easy promotion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

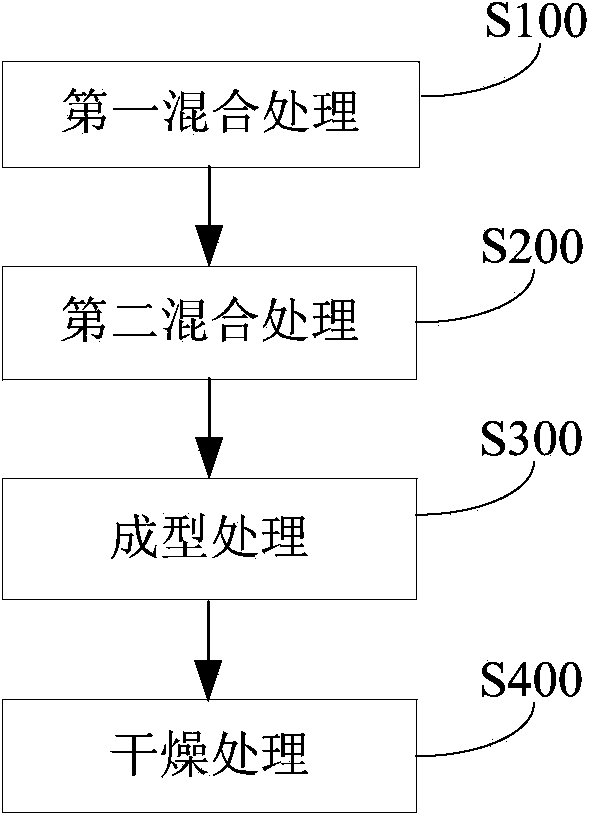

Method used

Image

Examples

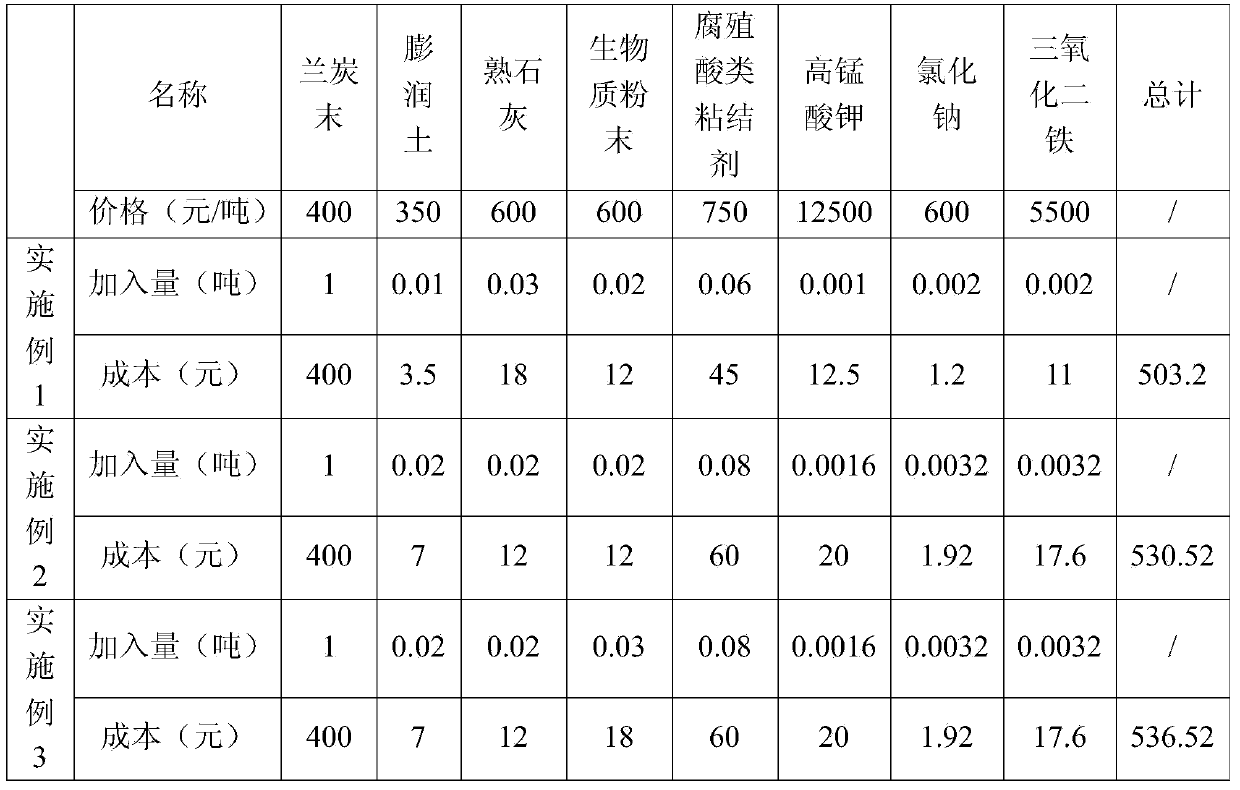

Embodiment 1

[0063] Raw material formula: 1 part by weight of bentonite, 3 parts by weight of slaked lime, 2 parts by weight of biomass powder, 0.5 part by weight of combustion-supporting agent, 6 parts by weight of humic acid binder, 100 parts by weight of blue carbon powder;

[0064] Preparation method: firstly mix blue charcoal powder with biomass powder, bentonite, slaked lime and combustion accelerant to obtain a first mixture material, then add humic acid binder to the first mixture material and continue stirring to obtain a second mixture Then, the second mixed material is extruded by a ring mode molding machine to obtain a molding material, and then the obtained molding material is dried to obtain a fuel rod.

[0065] The obtained fuel rods have a drop strength of 92.8%, compressive strength of 712N / piece, dry ashless volatile matter of 7.4%, moisture content of 3.46%, calorific value of 26.12MJ / kg, and density of 1.16g / cm 3 , and test the fuel rods, the continuous burning time can...

Embodiment 2

[0067] Raw material formula: 2 parts by weight of bentonite, 2 parts by weight of slaked lime, 2 parts by weight of biomass powder, 0.8 parts by weight of combustion-supporting agent, 8 parts by weight of humic acid binder, 100 parts by weight of blue carbon powder;

[0068] Preparation method: same as Example 1.

[0069] The obtained fuel rod has a drop strength of 93.5%, a compressive strength of 720N / piece, a dry ashless volatile matter of 8.7%, a moisture content of 2.86%, a calorific value of 27.86MJ / kg, and a density of 1.17g / cm 3 , and the fuel rods are tested for burning, the continuous burning time can reach 9 hours, and the SO2 emitted in the flue gas 2 The concentration is 16.5mg / m 3 , NO x Concentration is 42mg / m 3, obviously lower than the standard of "Beijing Boiler Air Pollutant Emission Standard" DB 11 / 139-2007.

Embodiment 3

[0071] Raw material formula: 2 parts by weight of bentonite, 2 parts by weight of slaked lime, 3 parts by weight of biomass powder, 0.8 parts by weight of combustion-supporting agent, 8 parts by weight of humic acid binder, 100 parts by weight of blue carbon powder;

[0072] Preparation method: same as Example 1.

[0073] The obtained fuel rod has a drop strength of 90.2%, a compressive strength of 703N / piece, a dry ashless base volatile matter of 9.5%, a moisture content of 3.67%, a calorific value of 28.65MJ / kg, and a density of 1.15g / cm 3 , and the fuel rods are tested for burning, the continuous burning time can reach 8.5 hours, and the SO2 emitted in the flue gas 2 Concentration is 16mg / m 3 , NO x Concentration is 44mg / m 3 , obviously lower than the standard of "Beijing Boiler Air Pollutant Emission Standard" DB 11 / 139-2007.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com