Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56 results about "Blue carbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blue carbon is the carbon captured by the world's coastal ocean ecosystems, mostly mangroves, salt marshes, seagrasses and potentially macroalgae. Historically the ocean and terrestrial forest ecosystems have been the major natural carbon (C) sinks. New research on the role of vegetated coastal ecosystems has highlighted their potential as highly efficient C sinks, and led to the scientific recognition of the term "Blue Carbon". "Blue Carbon" designates carbon that is fixed via coastal ocean ecosystems, rather than traditional land ecosystems, like forests. Although the ocean’s vegetated habitats cover less than 0.5% of the seabed, they are responsible for more than 50%, and potentially up to 70%, of all carbon storage in ocean sediments. Mangroves, Salt marshes and seagrasses make up the majority of the ocean’s vegetated habitats but only equal 0.05% of the plant biomass on land. Despite their small footprint, they can store a comparable amount of carbon per year and are highly efficient carbon sinks. Seagrasses, mangroves and salt marshes can capture carbon dioxide (CO2) from the atmosphere by sequestering the C in their underlying sediments, in underground and below-ground biomass, and in dead biomass.

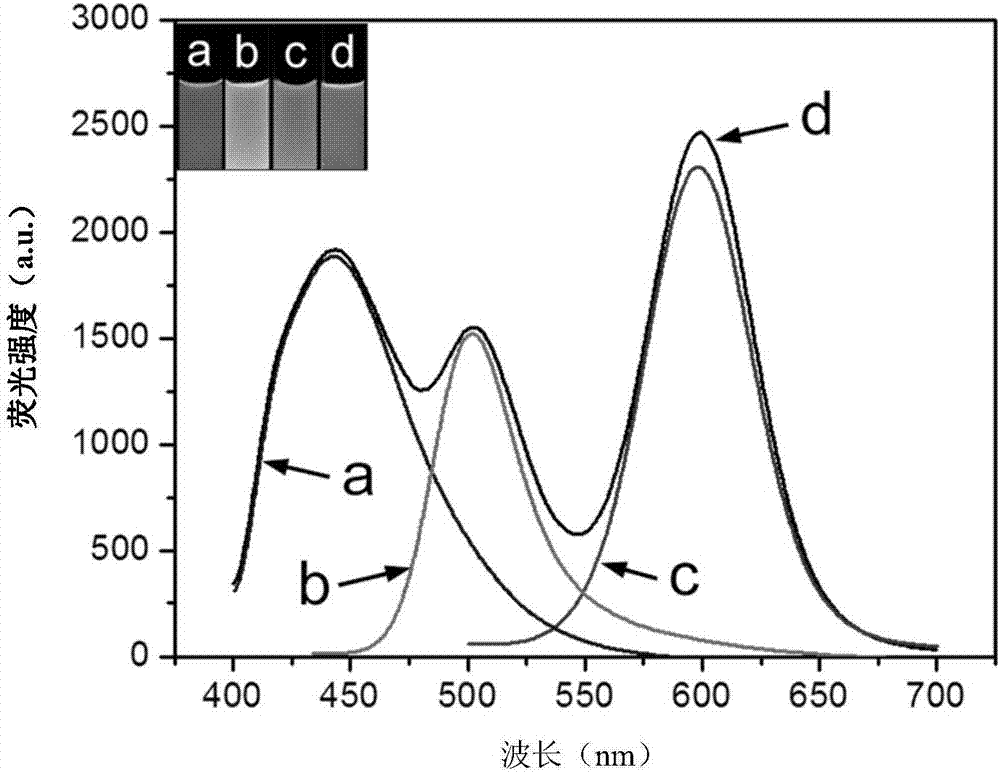

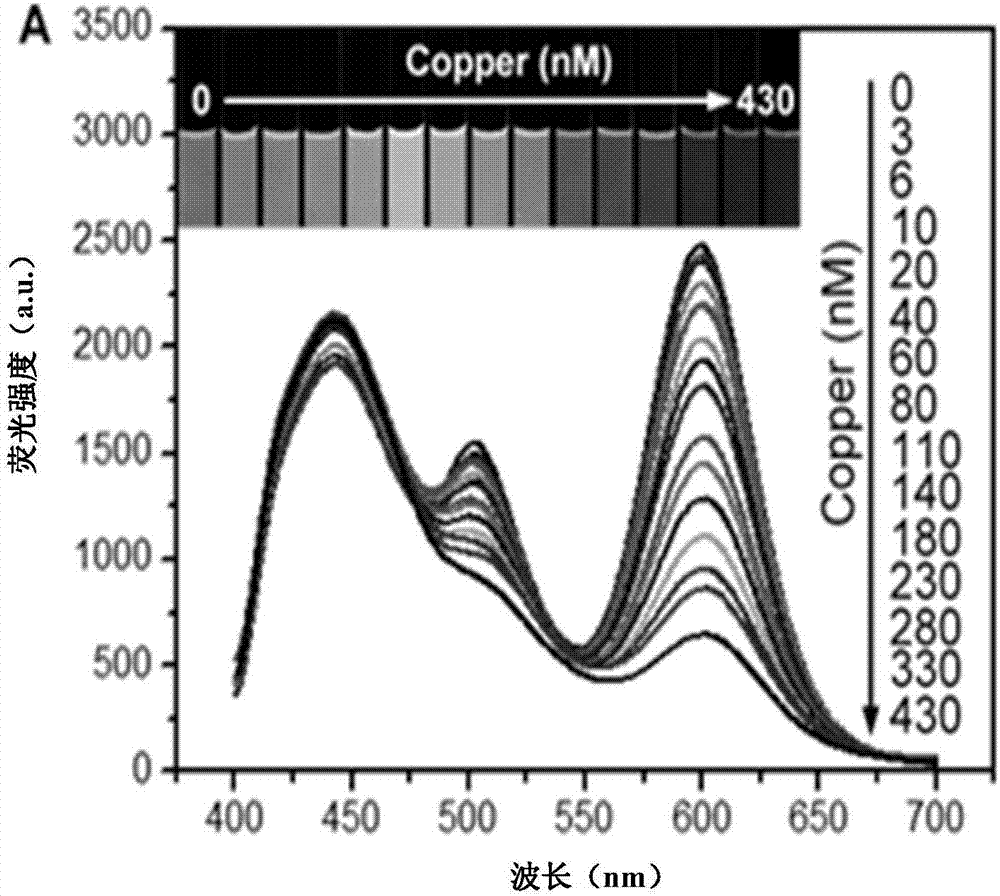

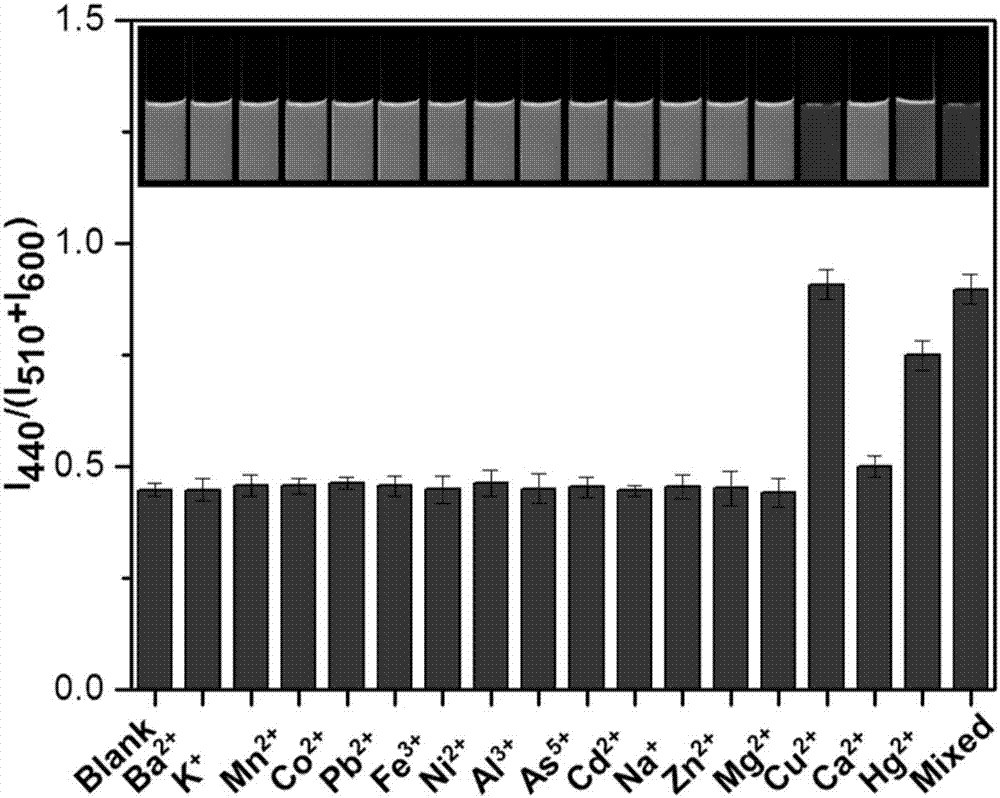

Fluorescent wide chroma test paper for visually detecting copper ions as well as preparation method and application of test paper

ActiveCN107345910AAvoid interferenceWide range of discolorationFluorescence/phosphorescenceFluorescenceColor changes

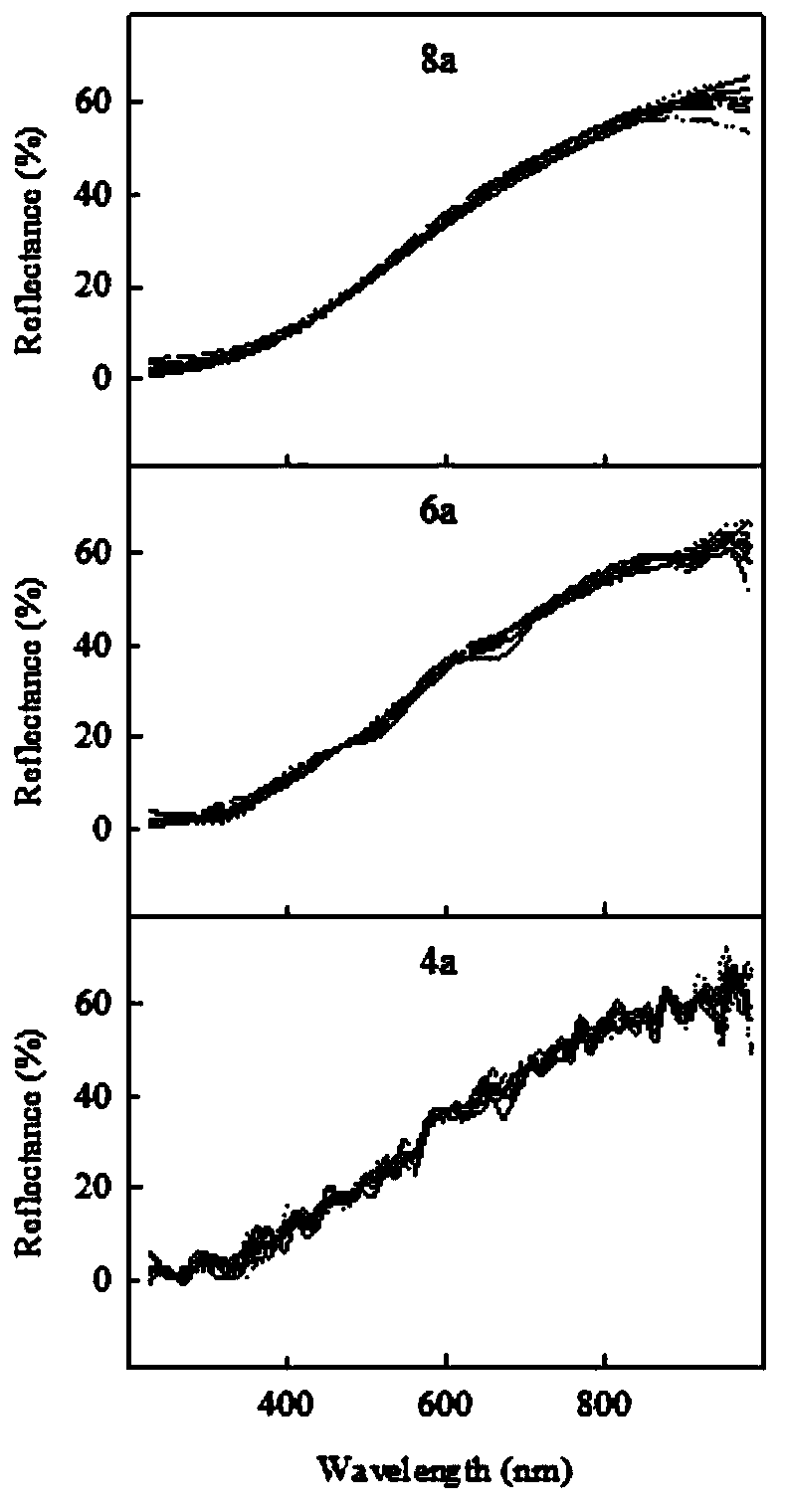

The invention discloses fluorescent wide chroma test paper for visually detecting copper ions as well as a preparation method and application of the test paper. The preparation method comprises the following steps: by taking a three-color ratio fluorescence probe as ink and taking filter paper as a solid-phase carrier through an inkjet printer, uniformly printing, thereby obtaining the test paper capable of visually detecting the copper ions, wherein the three-color ratio fluorescence probe refers to blue carbon dots, green quantum dots and red quantum dots, and the quantum dots are all modified by 3-mercaptopropionic acid. The three-color ratio fluorescence test paper is constructed to be used for visually detecting the copper ions by utilizing double-quenching principle first, the prepared detection test paper has the advantage that the color change range is wide compared with the conventional double-ratio fluorescence test paper, and along with addition of the detection object, test paper colors can be obviously identified by naked eyes from light scarlet, light flesh color, deep orange, grass green, dark olive green, slate blue, royalblue to cyanic color (Figure 4).

Owner:NANJING MEDICAL UNIV

Method for forming suitable lands for mangrove forests on gravel beaches

ActiveCN107810823AExtended Recovery AreaImprove ecological conditionsClimate change adaptationAfforestationBedrockBiology

Owner:GUANGXI MANGROVE RES CENT

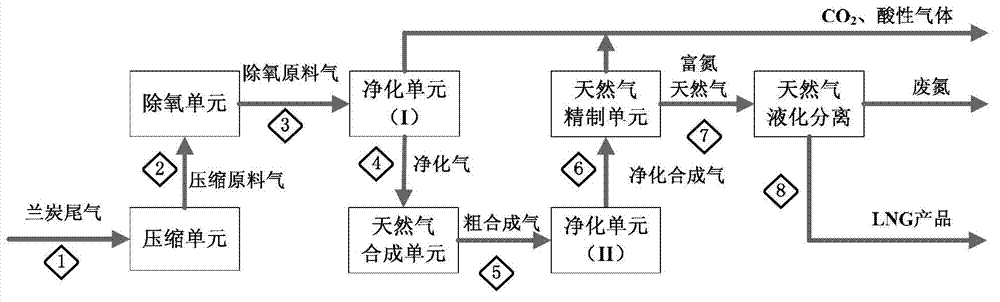

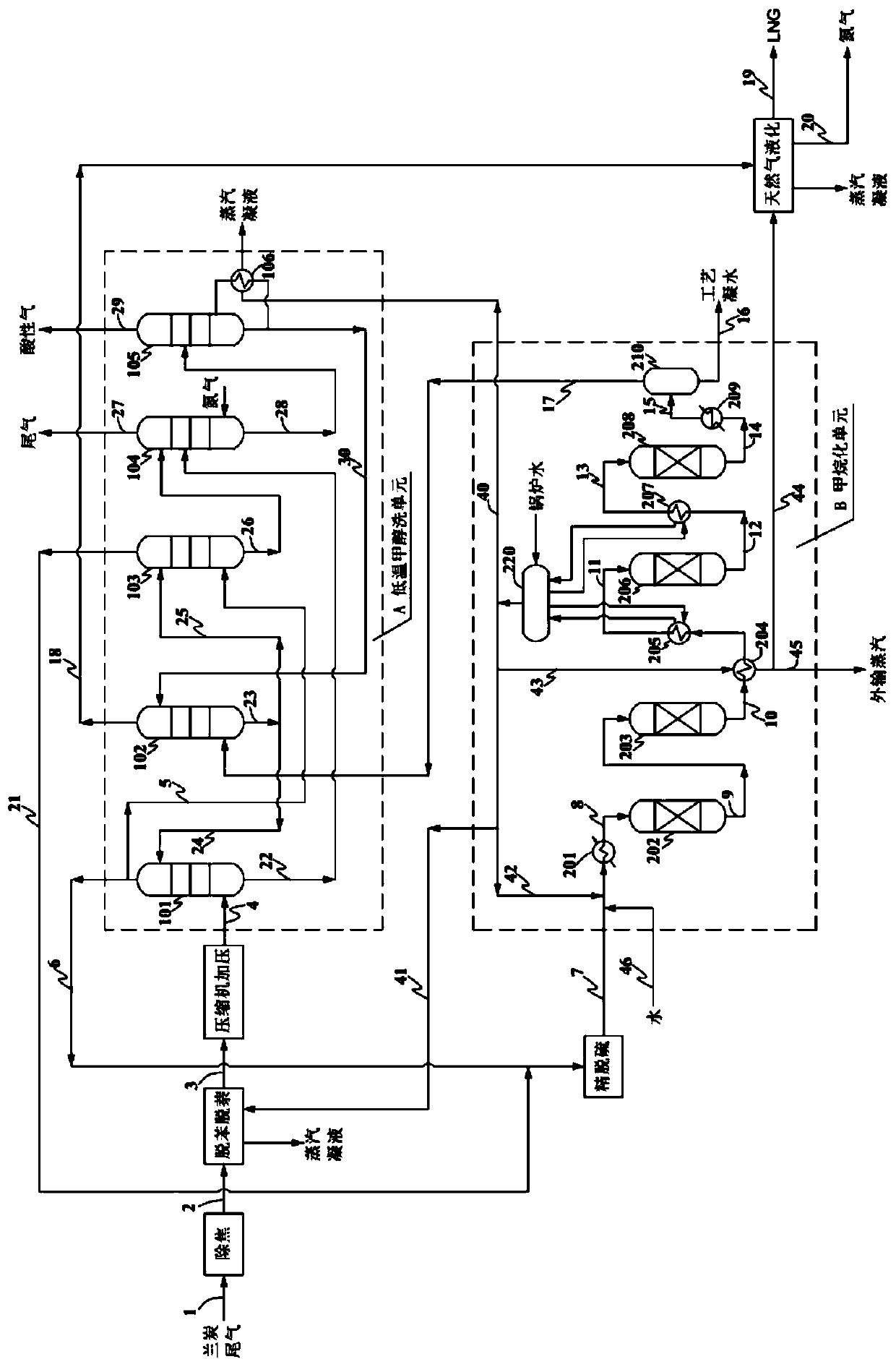

Method for producing liquefied natural gas

InactiveCN102732349AStrong industrial reliabilitySolve complexitySolidificationLiquefactionMethanationEconomic benefits

The invention discloses a method for producing liquefied natural gas. The method comprises the following steps of: (1) compressing and preheating virgin gas, and then deoxidizing to obtain deoxidized virgin gas; (2) introducing the deoxidized virgin gas into a purifying unit I to remove acid gas to obtain purified gas; (3) introducing the purified gas into a natural synthesis unit to react with methane to obtain crude synthesis gas; (4) introducing the crude synthesis gas into a purifying unit II for decarbonizing to obtain purified synthesis gas; (5) introducing the purified synthesis gas into a natural gas refining unit to remove H2O and CO2 to obtain nitrogen-rich natural gas; and (6) introducing the nitrogen-rich natural gas into a natural gas liquefying and separating unit for cooling and separating to obtain the liquefied natural gas. In the invention, low-heat-value blue carbon gas is converted into high-added-value clean fuel LNG (Liquefied Natural Gas) by adopting an advanced and reliable process technology, so the method has active effects on saving energy, reducing emission and protecting environment, conforms to the requirements of national industrial policies and environmental protection policies, enables enterprises to obtain considerable economic benefit and opens a new approach for the reasonable utilization of the blue carbon gas.

Owner:SYNEFUELS CHINA +1

Carbon dot with continuous golgi apparatus target imaging capability and preparation method thereof

InactiveCN104987862AHigh blue fluorescence intensityHigh Absolute Quantum YieldNanoopticsFluorescence/phosphorescenceDiseaseQuantum yield

The invention discloses a photobleaching-resisting carbon dot with the continuous golgi apparatus target imaging capability and a preparation method thereof. The preparation method comprises the steps that a small carbon dot skeleton is prepared from citric acid through pyrolysis and condensation at high temperature at first, and then the carbon dot skeleton and L-cysteine are in condensation to form a carbon dot. The surface of the carbon dot has a large number of cysteine residues. According to the carbon dot with the high blue-fluorescence intensity and the continuous golgi apparatus target imaging capability, tedious follow-up modification steps needed by conventional methods are avoided. The absolute quantum yield of the blue carbon dot obtained through the preparation method reaches up to 68%. The blue carbon dot has the good photobleaching resistance and biocompatibility, and brings more accurate help to cell process detection, disease diagnosis and the like.

Owner:SOUTHWEST UNIV

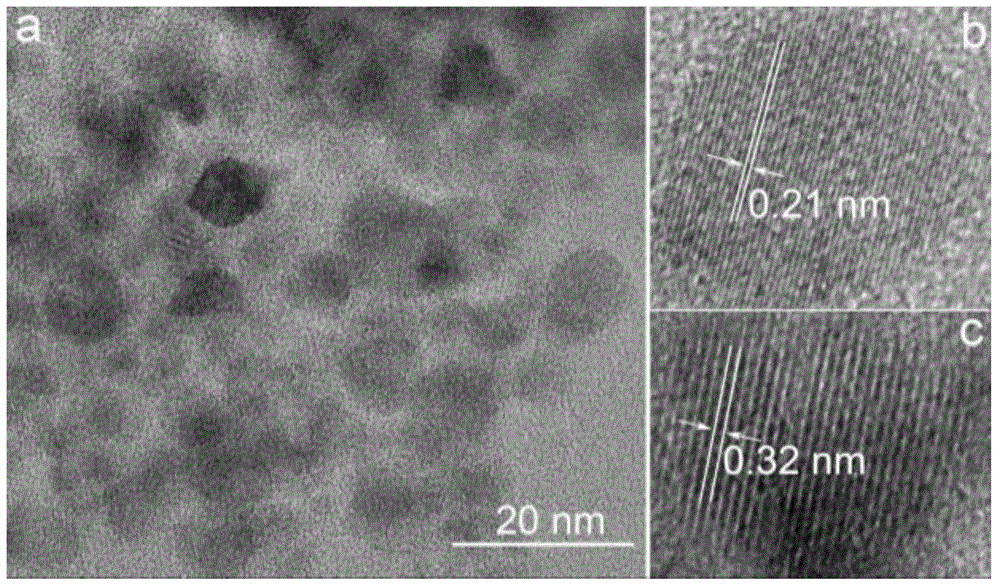

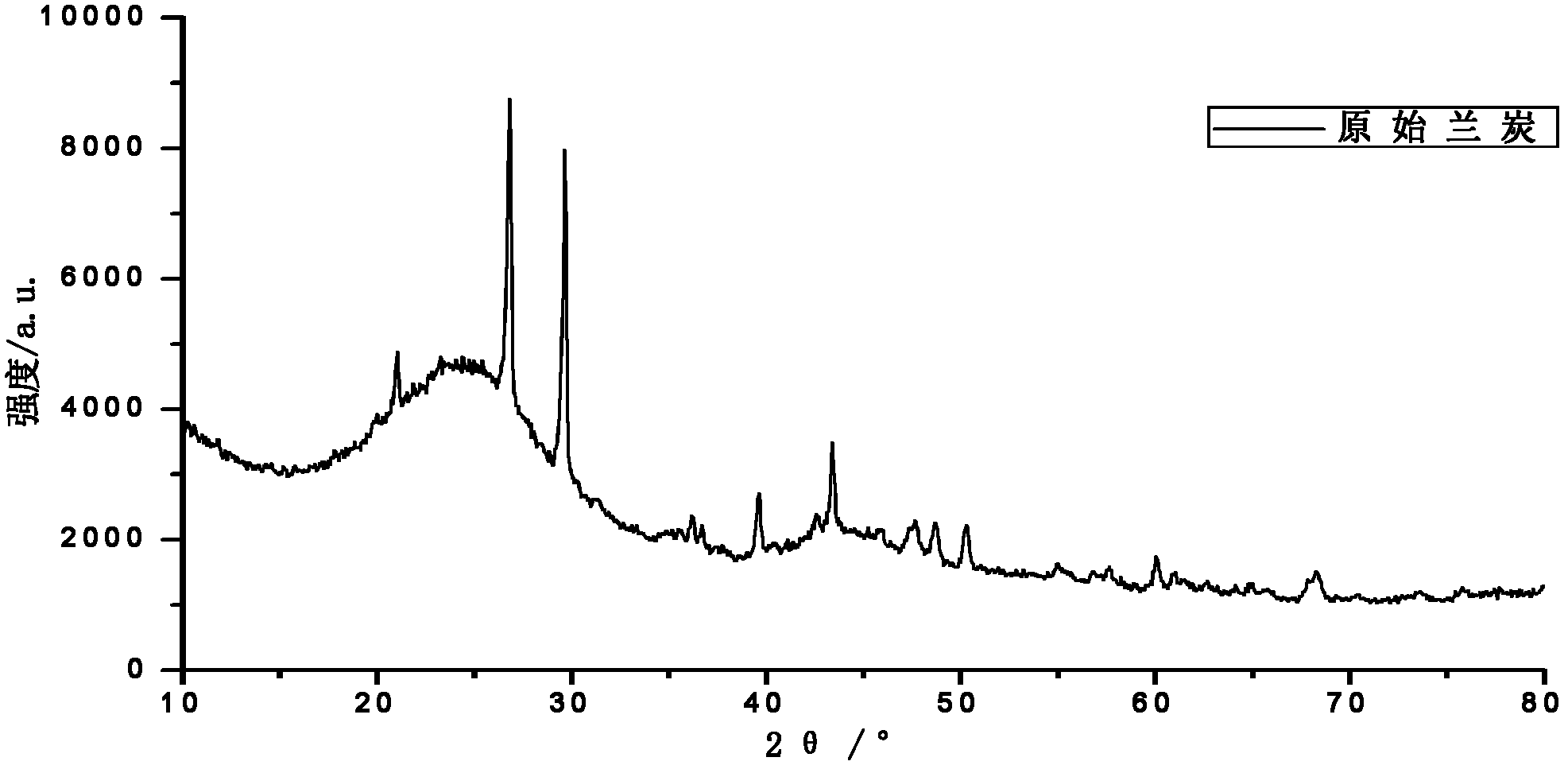

Lithium ion battery cathode material prepared by blue carbon solid waste, and preparation method of lithium ion battery cathode material

InactiveCN102633251ALow costPromote circulationElectrode manufacturing processesCarbon preparation/purificationPhysical chemistryLithium electrode

The invention relates to a preparation technology of a lithium ion battery cathode material, and in particular relates to a lithium ion battery cathode material prepared by blue carbon solid waste through a certain treatment technology. The preparation process mainly comprises pretreatment of raw materials, catalyst doping treatment, high-temperature graphitization treatment and the like. After being treated by the preparation method provided by the invention, the maximum discharge capacity of blue carbon reaches 346mAh.g<-1>, and the coulomb efficiency is 80%; and after circulation is carried out for 320 times, the capacity is maintained to be 316mAh.g<-1>, and the capacity maintenance rate is 91%.

Owner:XI AN JIAOTONG UNIV

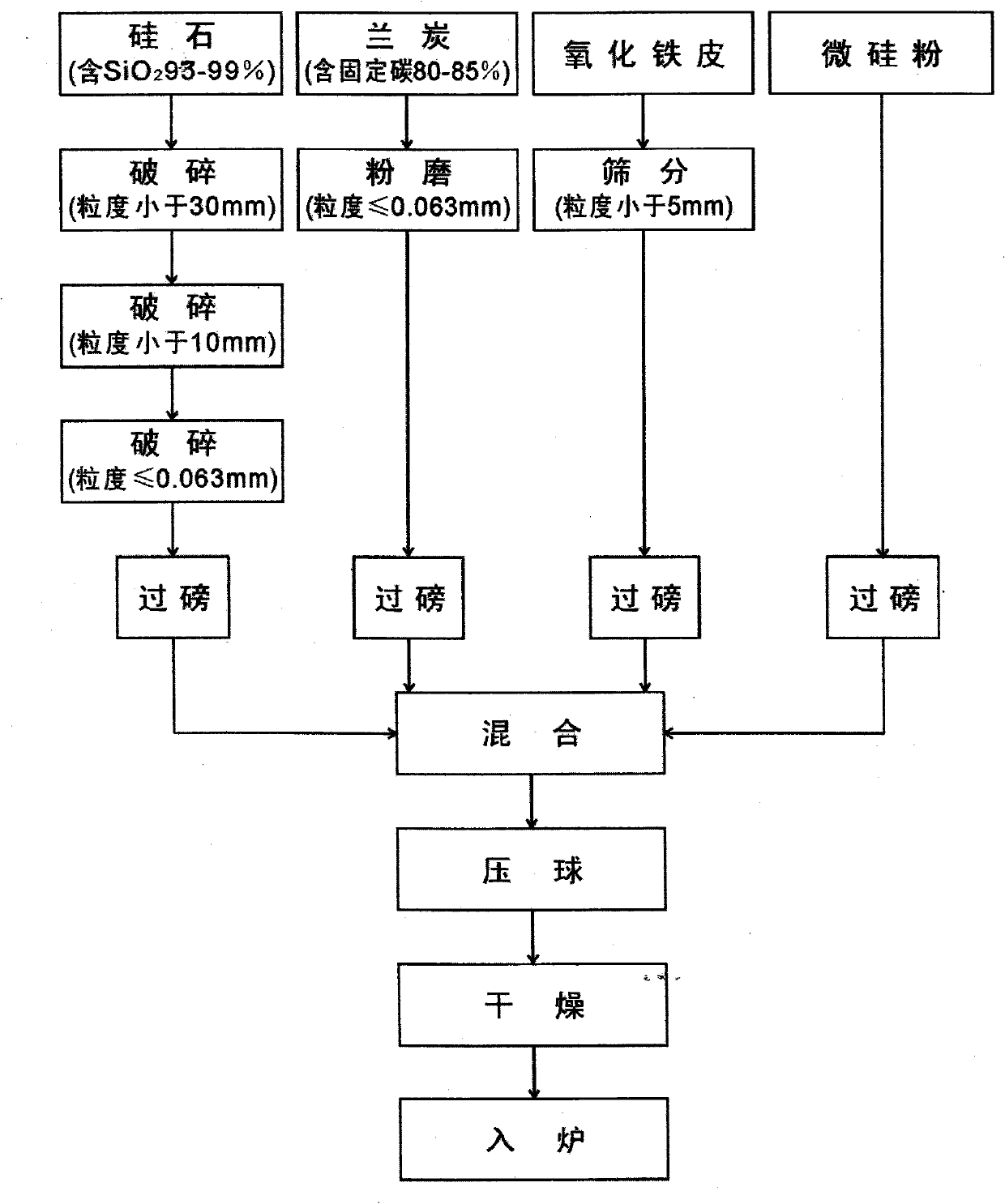

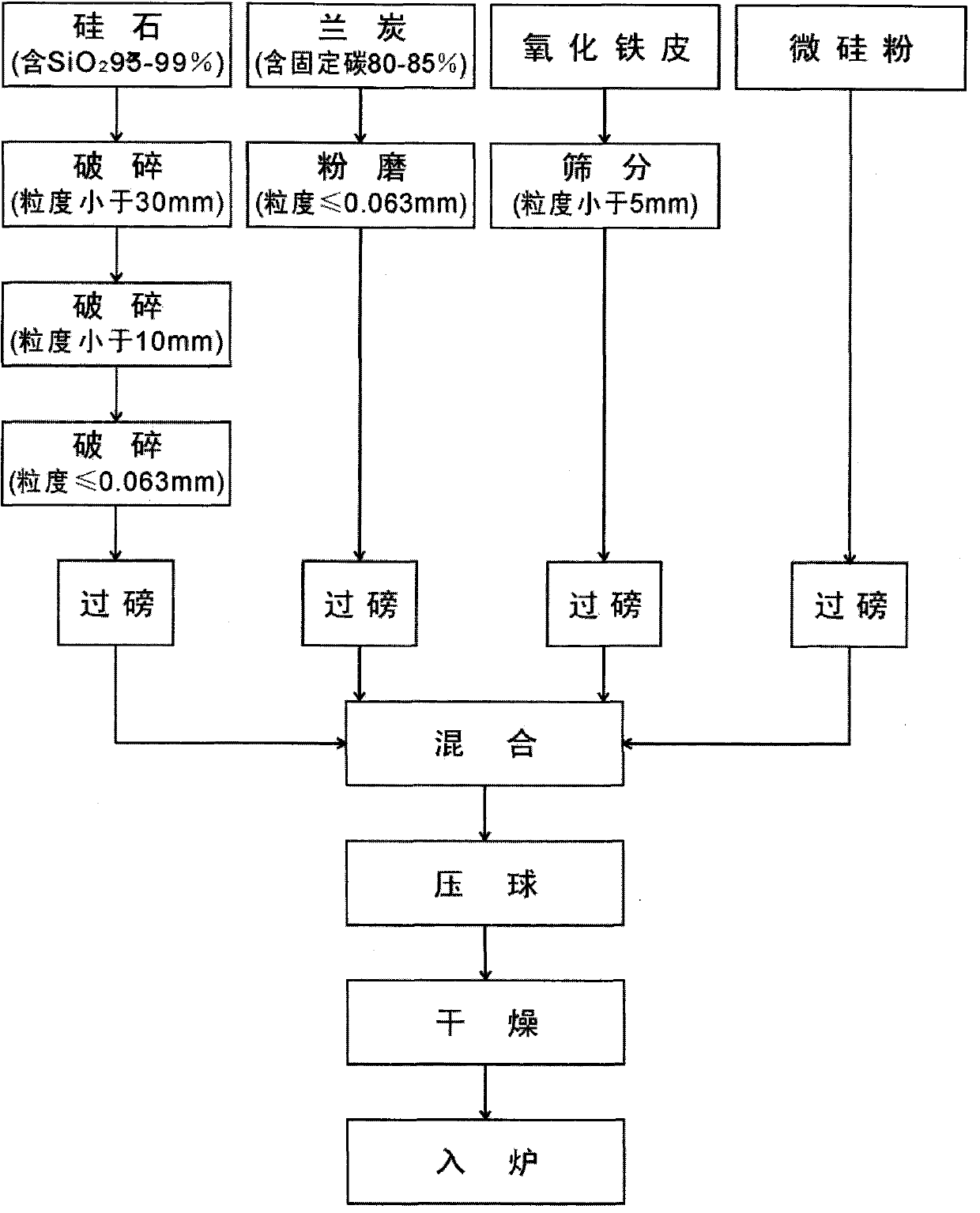

Raw material processing technology for smelting ferrosilicon in submerged arc furnace

The invention relates to a raw material processing technology for smelting ferrosilicon in a submerged arc furnace, which belongs to the technical field of ferroalloy production, raw materials mainly comprise silica containing 93-99% of silicon dioxide, blue carbon containing 80-84% of fixed carbon and iron oxide scale containing more than 70% of ferric oxide, the raw materials are respectively ground into flour with the particle size of not more than 0.063mm and mixed with silicon micro-powder containing more than 70% of silicon dioxide according to the following weight percentage: the silica powder accounts for 45-55%, the blue carbon powder accounts for 25-35%, the iron oxide scale powder accounts for 10-20% and the silicon micro-powder accounts for 3-5%, the mixture is weighed, then stirred and pressed into a blank, the forming pressure of the blank is 1.2-2.0Mp / cm2, the size can be decided according to the furnace type, the blank needs to be dried before entering into the furnace, the water content is less than 3%, and the use of the raw material processing technology can save the electricity for smelting by 20-30%, and save the blue carbon by 15%-25%. The raw material processing technology has the characteristics of simple technology, significantly shortened smelting time, high efficiency, small pollution, significant energy-saving effect and good economic benefits and social benefits.

Owner:张先明

Colorful magnetic laser printer toner and preparation method thereof

The invention discloses a colorful magnetic laser printer toner. The colorful magnetic laser printer toner is prepared from the following components in parts by weight: 50-60 parts of resin, 20-30 parts of ferromagnetic powder, 10-20 parts of a charge control agent, 1-3 parts of a flowable agent, 2-5 parts of colorful masterbatch and 5-15 parts of a surface modifier. The components are subjected to mixing, dispersing, blending, crushing, grading and surface modification to obtain the finished product. The colorful magnetic laser printer toner has the beneficial effects that the colorful masterbatch is taken as a color tone, prepared blue carbon powder can be directly applied to printing of construction drawings, and traditional printing modes with a vegetable parchment, blueprinting and the like are not adopted, so that when the colorful magnetic laser printer toner is used for printing colorful drawings such as the construction drawings, a great amount of printing time, the cost and the manpower can be saved, and the low-carbon drawing can be realized truly.

Owner:刘同波

Method for determining accumulation rate of shellfish cultured blue carbon in sediment

ActiveCN109959619AEasy to lockSolving the Difficulties of Increasing Sinks and Quantifying Emission ReductionsColor/spectral properties measurementsEcological environmentObservation point

The invention relates to the field of ecological environment monitoring and analysis, and in particular relates to a method for detecting the accumulation rate of shellfish cultured blue carbon in a sediment. The method for determining the accumulation rate of shellfish cultured blue carbon in the sediment comprises the steps that (1) m and n observation points are set in a shellfish culture zoneand an adjacent non-shellfish culture zone respectively; (2) sediment samples from the observation points are collected to construct a spectral model of the carbon content in the sediment; (3) the spectral data of the observation points are measured and substituted into the spectral model to calculate the carbon content of the sediment profile of the observation points; (4) the carbon content of the sediment profile of the observation points is converted into the carbon reserve of the observation points through a conversion coefficient t; and (5) the accumulation rate of cultured blue carbon in the sediment in a certain period of time is calculated through a formula. The method for determining the accumulation rate of shellfish cultured blue carbon in the sediment solves the difficulty ofemission reduction quantifying of culture sink, and facilitates scientific evaluation of the contribution of the culture carbon sink.

Owner:OCEANOGRAPHIC INSTR RES INST SHANDONG ACAD OF SCI

Method for synthesizing raw materials for calcium carbide smelting with semi-coke, calcined coal and lime powder

The invention relates to a method for synthesizing raw materials for calcium carbide smelting by using semi-coke, calcined coal and lime powder. The process steps are: combining semi-coke powder, calcined coal powder, lime powder and medium-temperature coal tar pitch according to 28-30%: 28-30 %: 28-30%: 10-16% by weight and mix evenly, then stir for 10-15 minutes at a constant temperature of 200°C-220°C, and finally roll out and cool naturally to form pellets. The method of the invention can fully utilize semi-coke, calcined coal and lime in calcium carbide smelting under the condition of low cost and low technical requirements, so as to achieve the purposes of reducing cost, saving resources and protecting the environment.

Owner:宁夏兴平精细化工股份有限公司

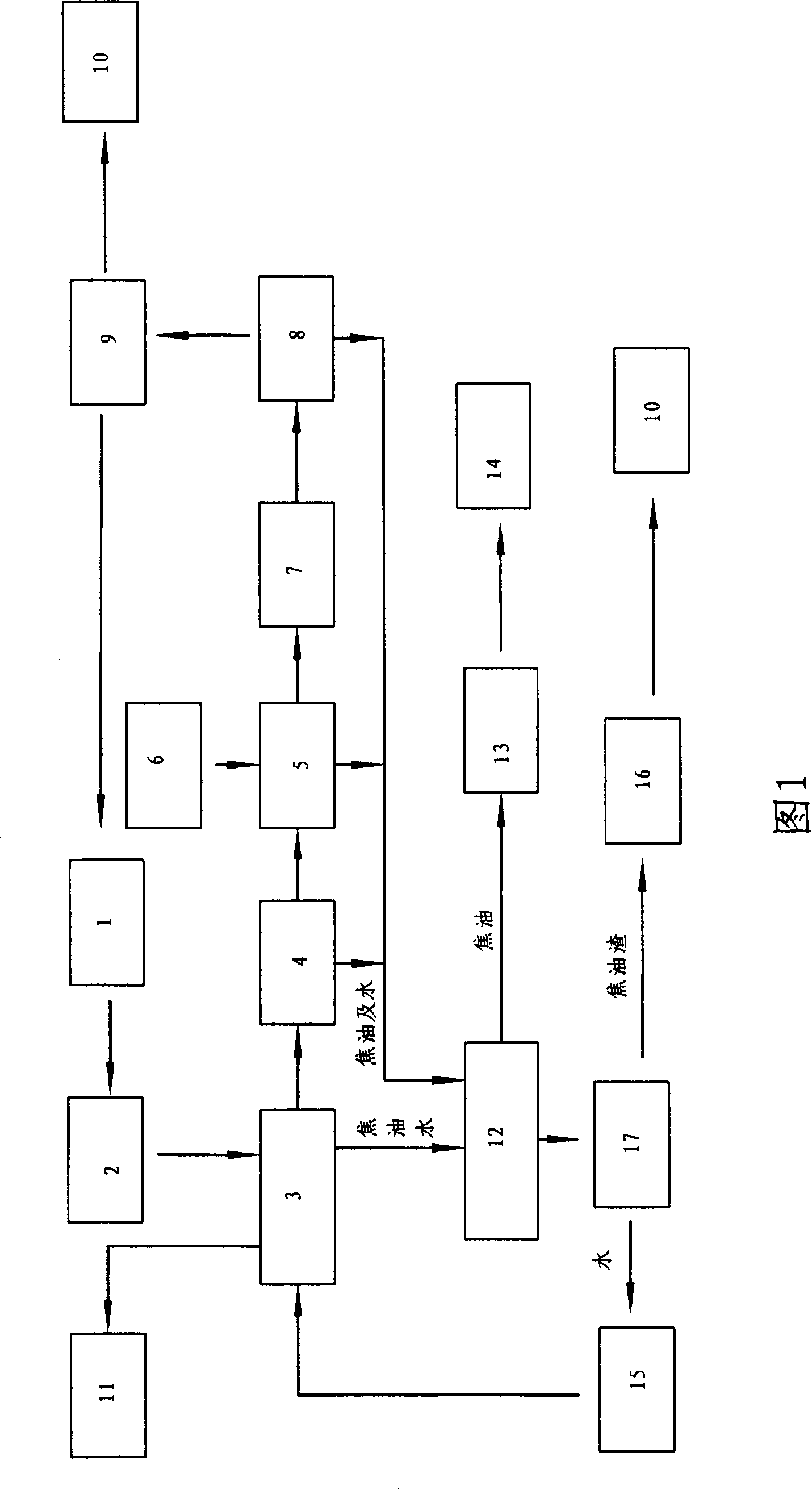

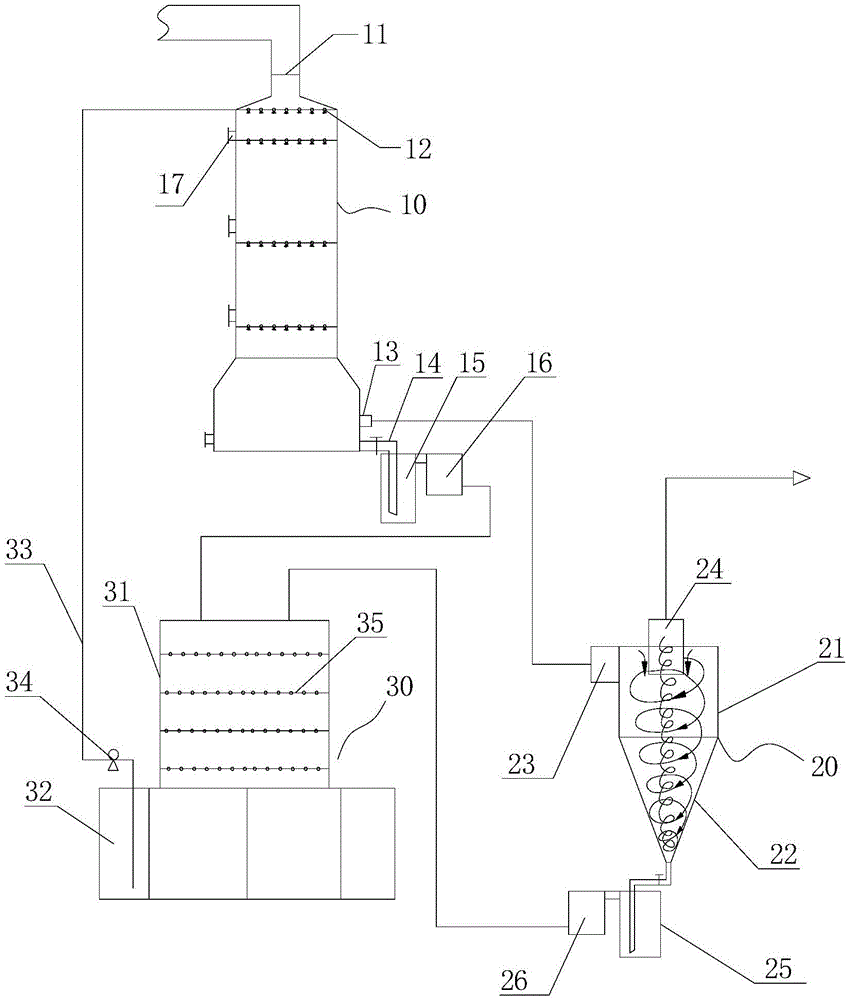

A process method and device for resource utilization of semi-coke production wastewater

ActiveCN104445815BImprove biodegradabilityImprove economic competitivenessOrganic chemistryOrganic compound preparationResource utilizationCoking wastewater

The invention discloses a technological method and device for semi-coke production wastewater resource utilization. The technological method comprises three steps, namely deep oil-water separation, high-efficiency complexing extraction dephenolization and ammonia stilling, to be specific, firstly, separating and recycling a part of coal tar from wastewater when the wastewater passes through an oil partitioning tank, recycling coal tar in a precision filter and an oil-water separator in sequence after discharged water passes through a coarse filter; feeding the oil-removed semi-coke wastewater and an extraction agent into an extraction tower for extraction and dephenolization, feeding the extract phase and a sodium hydroxide solution into a reverse extraction tower for countercurrent contact reverse extraction, feeding an obtained sodium phenolate solution into an acidification kettle, and adding sulfuric acid for acidification to obtain crude phenol; feeding dephenolized wastewater discharged from the bottom of the extraction tower into a wastewater heater, feeding into an ammonia cyanogen separator to be mixed with hot air from an air heater to remove ammonia after being heated by fume from the air heater, and feeding an ammonia-containing mixed gas discharged from the top of the ammonia-cyanogen separator into an ammonia water cooler for cooling to obtain ammonia water. By adopting the method and the device, precious resources such as coal tar, phenol and ammonia can be recycled from the semi-coke production wastewater resource, and the biodegradability of the semi-coke wastewater is improved.

Owner:陕西华祥能源科技集团有限公司

A method for recovering waste gas during regenerative process of filtering adsorption material

InactiveCN101161334AFatty/oily/floating substances removal devicesGeneral water supply conservationSlagComponents of crude oil

A method for recovering the exhaust gas in the regenerative process of the filtering and absorbing material comprises the following steps: A) doing dust removing treating to the exhaust gas; B) doing gas-liquid separating treating for the gas which is treated by the process A; C) using the gas treated by the step B as the fuel; D) reclaiming the tar water generated in the step A and B to do oil-water separation treating, the generated clear water is reused and the generated tar oil is reclaimed, and the generated tar slag is used as the boiler fuel; wherein, the filtering absorbing material is prepared using the anthracite, lean coal, black-jack, charred coal, fat coal, gas coal, candle coal, brown coal, coke, blue carbon and breeze as raw material. In the course of using the filtering adsorbing material to regenerate, the organic matter in the filtering and adsorbing holes volatilizes and decomposes at the high temperature condition, forms the mixed gas which is composed of methyl hydride, ethane, ethane, tar oil steam, carbon dioxide and carbon monoxide, etc., the mixed gas is reclaimed as the boiler fuel, not only can avoid the air pollution caused by the discharging of the harmful gas but also can save the energy.

Owner:张大伟

Technology for preparing rareearth cerium silicon and rareearth lanthanum silicon alloy by rareearth enriching material and products thereof

The technological process for preparing rare-earth-cerium silicon and rare-earth-lanthanum-silicon alloy by using rare earth enriched material is characterized by that the carbon-added quantity is 2.8-3.5 times carbon quantity required for converting all the rare earth oxides being in wet rare earth enriched material into carbide, the carbonaceous adhesive can be uniformly mixed, extruded and formed, and self-baked and coked in the uniformly mixed, extruded and formed, and self-baked and coked in the ore-smelting furnace to obtain coked briquette, then the silica, gas coal coke and blue carbon are added. The ratio of rate earth metal in the briquette and silicon total quantity in the silica is 1:0.50-1.0; the coke is used as reducing agent, the above-mentioned three materials are uniformly added into ore-smelting furnace for smelting, its potential gradient is 0.90-1.20 V / cm.

Owner:PINGLUO FENGHUA METALLURGICAL CO LTD

Method for producing silicon iron smelting carbonaceous reducing agent by using industrial waste residues

The invention relates to a method for producing silicon iron smelting carbonaceous reducing agent by using industrial waste residues. The method is characterized in that blue carbon powder, calcined coal powder, coke powder and medium temperature coal pitch are uniformly mixed according to the weight ratio of 28 to 30 percent : 28 to 30 percent : 28 to 30 percent : 10 to 16 percent; then stirring is performed for 10 to 15 min in a constant temperature condition at the temperature of 200 to 220 DEG C; finally extrusion forming is performed; and carbonaceous reducing agent is obtained after natural cooling. The method adopts industrial waste residues including the blue carbon powder, the calcined coal powder, the coke powder and the medium temperature coal pitch to produce the silicon iron smelting carbonaceous reducing agent, and the carbonaceous reducing agent can also be involved in smelting reaction, so that the industrial waste residue including blue carbon powder, calcined coal powder, the coke powder and the like can be sufficiently utilized during silicon iron smelting in conditions of low cost and low technical requirements, and the purposes of waste resource recycling, cost reducing, resource saving and environment protection are achieved. The pellet carbonaceous reducing agent manufactured according to the ratio of the method can be directly applied to silicon iron smelting, and totally meets smelting principle and actual operation, and the cost of the carbonaceous reducing agent is one half of that of coke or blue carbon, so that the economic benefit is obvious.

Owner:宁夏兴平精细化工股份有限公司

Adsorption-type permeable reaction barrier composite material and preparation method and application thereof

InactiveCN110237815AImprove structural strengthAchieve modificationOther chemical processesWater contaminantsPorosityIon content

The invention discloses an adsorption-type permeable reaction barrier composite material and a preparation method and application thereof. The composite material is prepared by press molding and high temperature physical activation treatment by using blue carbon powder with high specific surface area and porosity as a main material, using coal liquefaction residue with high adhesion as a binder, and using an oxygen releasing agent. Compared with an activated carbon material, the composite material has the advantages of high structural strength, low economic cost, high chemical stability and the like, and can be applied to treat contaminated groundwater with high organic matter content and high heavy metal ion content caused by occasions such as garbage disposal sites, mine yards, and solid waste landfills.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Multifunctional environmentally-friendly BSK sintering technology shaft kiln and use method thereof

ActiveCN108168292AShaft kiln structure is simpleSimple structureHandling discharged materialControl devices for furnacesEnvironmental resistanceSeparation technology

The invention relates to the field of non-metallic ore sintering shaft kilns, in particular to a multifunctional environmentally-friendly BSK sintering technology shaft kiln and a use method of the shaft kiln. The shaft kiln comprises an inner sleeve ring cooler, an inner sleeve ring tray, an inner sleeve ring, an outer sleeve ring, a kiln shell, a cooling wind feeding fire bridge, a hot air discharging fire bridge, combustion product feeding fire bridges, combustors with combustion channels and a ring type gravity gas-powder separator. New sintering kiln design thoughts includes that a combustion and heat transfer process analysis separation technology is adopted; a heating bridge technology is adopted for sintering in the kiln; a ring type material channel technology is adopted for all segments in the kiln; and a boiling fluidization technology is adopted for the cooling segment in the kiln. According to the multifunctional environmentally-friendly BSK sintering technology shaft kiln, the particle size application range of a non-metallic ore sintering material is wide, product quality is good, the yield is high, and energy conservation and environment protection are achieved; andthe problems of the product output, quality, energy consumption and environment protection of products produced by the sintering industry of non-metal ores such as limestone, magnesite, light calciumcarbonate, dolomite, kaolin and blue carbon can be solved.

Owner:方国庆 +3

Semi-carbon wastewater treatment method

ActiveCN105060628BSimple processLow construction costMultistage water/sewage treatmentFiltrationEmission standard

Owner:CHONGQING JIERUN TECH

Manufacturing process of cryptical code

InactiveCN106739602AImprove confidentialityTo prevent cross-sellingPattern printingConfidentialityUltraviolet lights

The invention discloses a manufacturing process of a cryptical code. The manufacturing process comprises the following steps: generating the cryptical code: generating a dot identified cryptical anti-counterfeiting identification code array from anti-counterfeiting information needing to be spray-printed through computer software; printing a bottom layer of the cryptical code: coating and printing a layer of carbon-free printing ink on a printed material, wherein the carbon-free printing ink is prepared by mixing a red carbon-free printing ink, a blue carbon-free printing ink and a yellow carbon-free printing ink at the ratio of 1:1:1; spray-printing the cryptical code: using cryptical code spraying equipment to spray-printing nearly white carbon-free printing ink on the generated identification code array against a printed surface printed with the carbon-free printing ink; coating a gloss paint: coating a layer of gloss paint on the printed surface spray-printed with the identification code array to cover the identification code array; curing UV: illuminating the printed surface with ultraviolet light of 4200 W to 4600 W to cure the gloss print. The manufacturing process of the cryptical code leads to higher confidentiality of the cryptical code.

Owner:豪门印刷(上海)有限公司

Blue carbon powder and method for preparing same

The invention relates to a blue carbon powder and its manufacturing method. It is made by mixing 75-98 parts resin, 1-10 parts polyacrylic wax or polyethylene wax, 1-1. 5 yellow pigment, 0.5-10 electric charge regulator, 0.1-1 part earth silicon, through extruding, coarse crushing and fine crushing. Matching blue carbon powders with black, red and blue ones, it can simplify printing process, improve working efficiency, and reduce printing cost, applicable for long time preservation of archives.

Owner:王建新

Environment-friendly and energy-saving multifunctional platform for coastal zone blue carbon observation and protection

ActiveCN114228910ANo pollution in the processAvoid excessive turning distanceBatteries circuit arrangementsWaterborne vesselsWireless transmissionGas cylinder

The invention discloses an environment-friendly and energy-saving multifunctional platform for coastal zone blue carbon observation and protection, which relates to the technical field of marine environment monitoring and comprises a shell, an anti-collision ring, a bottom plate, a power device, a sample bin, an observation bin, a partition plate, a support rod, a gas cylinder bin, a gas cylinder, a PLC (programmable logic controller), a wireless transmission device, a flexible solar panel and a water bin. The anti-collision ring is fixedly connected to the outer side of the shell, the bottom plate is fixedly connected to the bottom of the shell, a steering motor bin is fixedly connected to the upper portion of the center of the bottom plate, a steering motor is fixedly connected into the steering motor bin, and an output shaft of the steering motor penetrates through the bottom plate to be rotationally connected with the power device. Power is supplied through the flexible solar cell panel, and the device can be used outdoors for a long time, is energy-saving and environment-friendly, and does not pollute the ocean.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

Durable antifake blue carbon powder for laser printer use and producing method thereof

This invention discloses a kind of durability guard against false blue carbon dust used for laser printer and its preparation method. It is produced by mixing, 80-90 portion polyester resin, 5-10 portion polypropylene wax, 3-9 portion electric charge conditioning agent , 7-10 portion iron blue , 10-20 portion ultraviolet fluorescent powder, 2-4 dimethyl two chlorine silane and 7-10 portion six methyl two silicons nitrogen alkane, and doing the following steps such as molding, smashing and sifting. Use this laser printer durability guard against false blue carbon dust print color picture culture and blue print, not only the color's durability is good, be able to satisfy the request that the file reporters, need to save for a long time, it can also differentiate out true-false, has the function of guards against the false, makes the false maker has no loophole to exploit. Especially be applied to print reporters such as signature, and file.

Owner:周学良

Blue carbon environment-friendly moulded coals and preparation method thereof

InactiveCN101906341ATake advantage ofIncrease added valueSolid fuelsSodium BentoniteAdditional values

The invention discloses blue carbon environment-friendly moulded coals, which contain the following components in percentage by weight: 95 to 96 percent of blue carbon powder and 4 to 5 percent of sodium bentonite. The invention also discloses a preparation method of the blue carbon environment-friendly moulded coals. Coal carbon resources are fully utilized to effectively promote the additional value of the coals; the heat productivity of the moulded coals is high and reaches 7,000 to 8, 000 kilocalories / kilogram, the moulded coals are completely burned for a long time, and the burning time is about two times of raw coals. By using the blue carbon powder as the main raw material, the blue carbon environment-friendly moulded coals solve the problem that the pollution on the environment is caused by using the blue carbon powder as a waste, and simultaneously the prepared moulded coals have no smoke during burning and good environment protection property. The preparation method overcomes the technical difficulties that the main raw material has no caking property and has a loosened structure.

Owner:刘子建

Oxygen functional group-enriched carbon adsorbing material and preparation method and application thereof

InactiveCN107930585ARaw materials are cheap and easy to getThe process is simple and easy to controlGas treatmentOther chemical processesWater vaporAdhesive

The invention discloses an oxygen functional group-enriched carbon adsorbing material and a preparation method and application thereof. The preparation method is characterized by comprising the following steps: with blue carbon particles as subjects, and an adhesive and deionized water as objects, sequentially mixing, moulding, carbonizing and performing water vapor activation to obtain a porous carbon material; finally, oxidizing by using strong acid to form the oxygen functional group-enriched carbon adsorbing material, wherein the carbon adsorbing material comprises the following raw materials in parts by weight: 60-80 parts of the blue carbon particles, 15-30 parts of the adhesive and 10-20 parts of the deionized water; the ratio of the used strong acid to the used carbon material is as follows: each 10-100g of the carbon material uses 50-100mL of strong acid. According to the oxygen functional group-enriched carbon adsorbing material provided by the invention, the raw materials are cheap and easy to access, the process is simple and controllable, the operating condition is mild, and the mercury removing rates of the obtained oxygen-enriched carbon adsorbing material are higherthan 70% at different temperatures.

Owner:TAIYUAN UNIV OF TECH

Blue carbon powder and method for preparing same

The invention relates to a blue carbon powder and its manufacturing method. It is made by mixing 75-98 parts resin, 1-10 parts polyacrylic wax or polyethylene wax, 1-1. 5 yellow pigment, 0.5-10 electric charge regulator, 0.1-1 part earth silicon, through extruding, coarse crushing and fine crushing. Matching blue carbon powders with black, red and blue ones, it can simplify printing process, improve working efficiency, and reduce printing cost, applicable for long time preservation of archives.

Owner:王建新

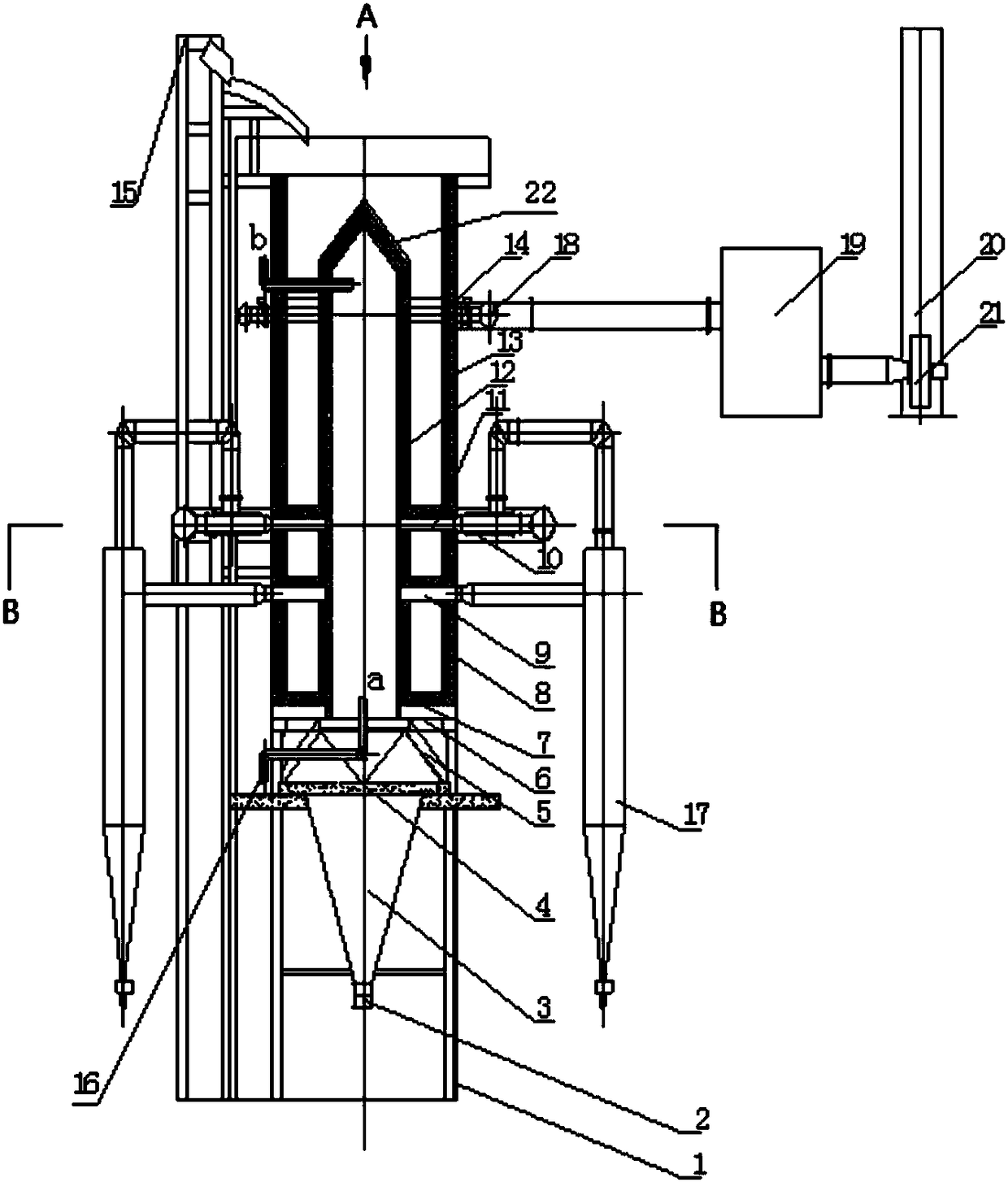

A cooling and purification system for semi-coke tail gas

ActiveCN104147886BPlay a role in desulfurizationPlay a washing roleCombination devicesComing outCooling effect

Owner:宁夏科豪陶瓷科技有限公司

Blue carbon ecosystem habitat restoration structure and use method thereof

PendingCN114352121AFree from destructionGeneral water supply conservationFencingWind drivenFan blade

The invention discloses a blue carbon ecological system habitat restoration structure and a use method thereof, and belongs to the technical field of environment restoration structures, L-shaped clamping pieces are clamped through clamping springs, the positions of fixing screws in arc-shaped notches are adjusted, then fixing nuts are used for fixing, rotatable adjusting legs are unfolded, and the environment restoration structure is formed. A second adjusting ground-inserting positioning rod is adjusted to be inserted into the ground to form a lateral supporting structure, wind power blows power generation fan blades to drive a rotating shaft to move, the rotating shaft drives a wind driven generator to generate power, when the wind power blows an elastic protection belt, a rotating rod is driven to rotate, and the generator of the wind driven generator generates power through rotation of the rotating rod; the generated power can be used for in-situ experiments such as real-time monitoring of a blue carbon ecological system, rainwater is stored through the water storage disc, and the stored fresh water can be suitable for coastal vegetation with low salinity.

Owner:SECOND INST OF OCEANOGRAPHY MNR

A kind of semi-coke flotation separation processing method for quality improvement

Owner:XIAN UNIV OF SCI & TECH

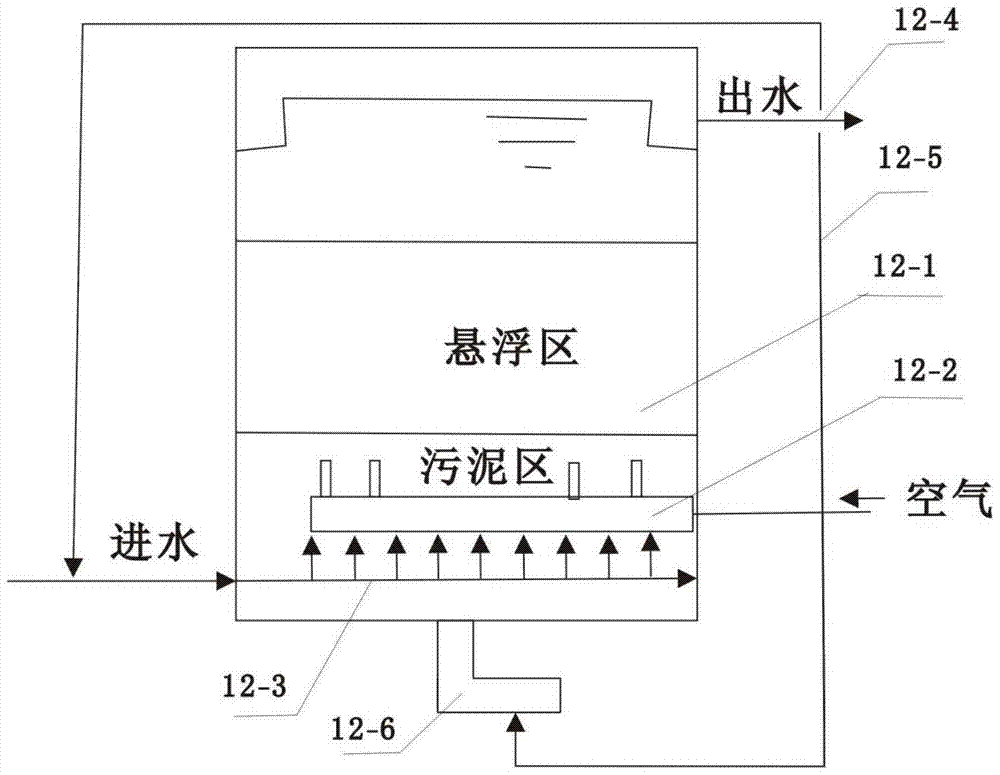

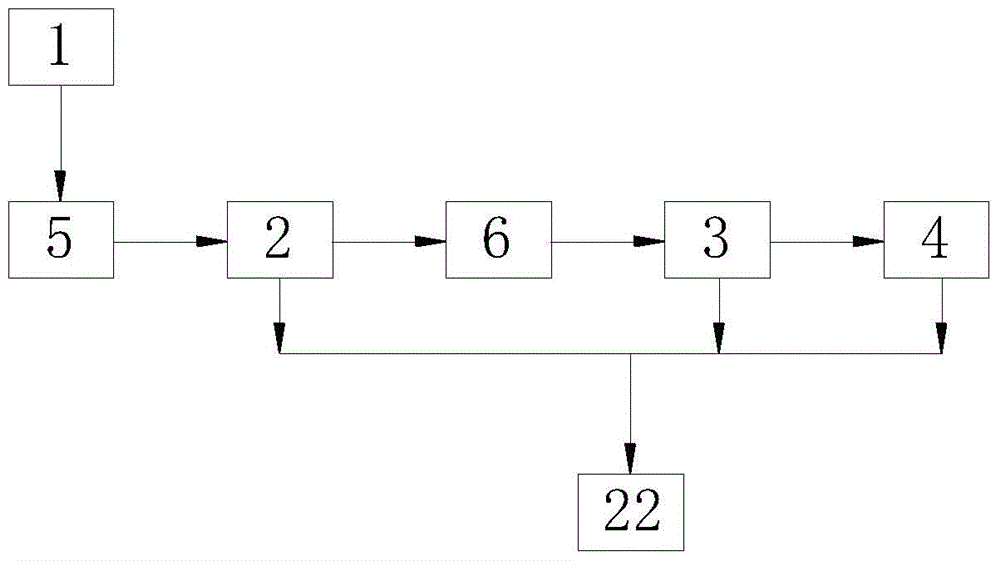

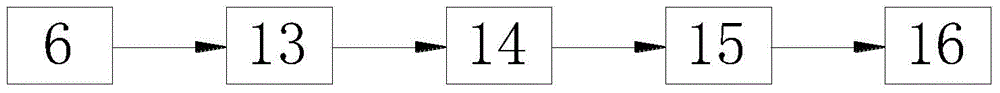

A kind of semi-coke wastewater treatment system and process

ActiveCN104773930BEasy to handleRapid responseMultistage water/sewage treatmentWater storageChemical treatment

The invention discloses a semi-coke waste water treatment system and technology. The system comprises an accident pool (1), a physical and chemical treatment system (2), a biological treatment system (3) and a deep treatment system (4) which are communicated in sequence. The accident pool (1) is connected with the physical and chemical treatment system (2) through a regulating pool (5), the physical and chemical treatment system (2) and the biological treatment system (3) are connected through a water storage pool (6), and the biological treatment system (3) is connected with the deep treatment system (4). The technology comprises the steps of physical and chemical treatment, biological treatment and deep treatment. The treatment effect is obvious, effluent meets the standard, and the whole system and the technology process are high in controllability, low in implementation cost and suitable for application and popularization.

Owner:华电水务(天津)有限公司

A kind of semi-coke dehydration device and dehydration method

ActiveCN104315823BOvercome the problem that the minimum temperature must not be lower than 700°CTake advantage ofDrying gas arrangementsRelative displacementDewatering

The invention relates to a semi coke dewatering device and method. The semi coke dewatering device comprises a fan. The outlet of the fan is connected with an air inlet in the bottom of a vertical cylindrical dryer through a pipeline. A feed inlet is formed in the top of the cylindrical dryer. A discharge outlet is formed in the bottom of the cylindrical dryer. A plurality of air inlets are further formed in the lateral wall of the cylindrical dryer. An air outlet pipe is arranged at the top of the cylindrical dryer. Due to the fact that the cylindrical dryer is vertical, feeding is performed from the upper end, discharging is performed from the lower end, semi coke materials in the cylindrical dryer has no relative displacement, no friction and collision exist among semi coke particles, the semi coke particles do not collide with the dryer body, powder is not generated, and loss caused by the fact that a large amount of powder is generated during semi coke drying is avoided. The semi coke materials in the cylindrical dryer can stay for a long time, the staying time can be controlled optionally, and semi coke contained water can be dried by using low-temperature hot air at the temperature above 150 DEG C.

Owner:府谷县奥维加能焦电化工有限公司

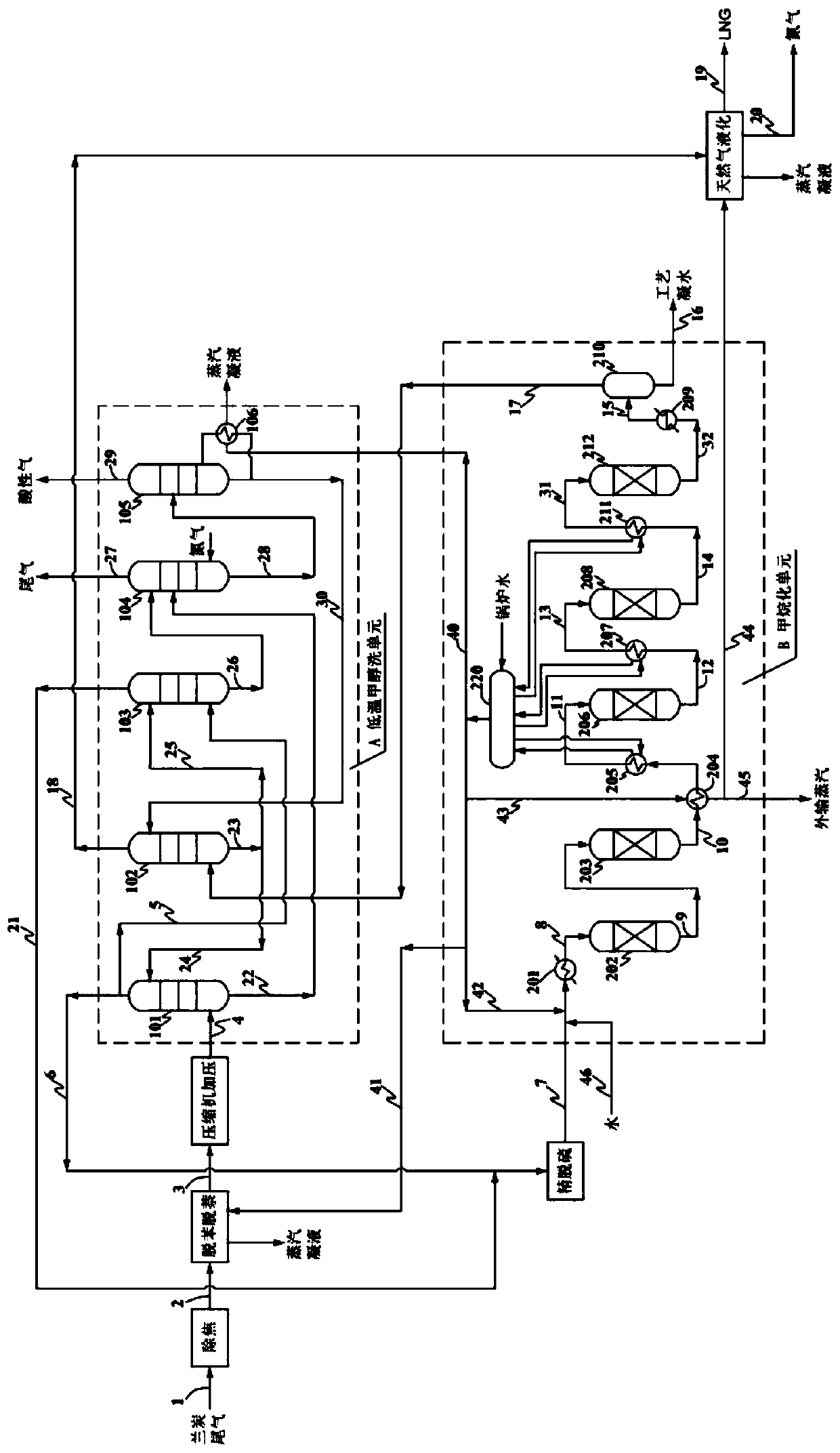

A kind of method for producing liquefied natural gas from blue carbon tail gas

The invention relates to a method for preparing liquefied natural gas from semi-coke tail gas. The method includes: firstly, after decoking and benzene and naphthalene removal of semi-coke tail gas, and sending to a rectisol unit for purification and desulfurization; then, mixing the desulfurized semi-coke tail gas with high-methane gas, jointly sending into a methanation unit for methanation to obtain a crude methane gas product, sending into the rectisol unit for purification and decarbonization; finally, performing cryogenic separation to remove nitrogen to obtain liquefied natural gas. Compared with the prior art, the method has advantages that by semi-coke tail gas treatment through the rectisol unit and the methanation unit, circulation absorbing agent consumption is sharply reduced,and energy consumption and system CH4 loss in a decarbonization process are reduced; in addition, by adoption of recovered CH4-rich gas and injection of water and / or system self-produced water vaporinto the methanation unit, methanation reaction temperature rise can be controlled so as to guarantee a methanation process against temperature runaway; moreover, heat balance of a whole system can beeffectively realized in the whole process, and economy in preparation of LNG (liquefied natural gas) from the semi-coke tail gas is improved.

Owner:WISON ENG

A kind of blue carbon wastewater treatment process

ActiveCN105016554BFull recoveryShort production processMultistage water/sewage treatmentOil phasePhenol

A process method for treating semi-coke wastewater, the process method comprising the following steps: 1) deamination, using a deammonization tower to remove ammonia nitrogen in the raw material semi-coke wastewater to obtain deammonia wastewater; 2) extraction, using an extractant to process Step 2) The deamination wastewater obtained from the treatment is subjected to countercurrent extraction in the extraction tower, and the extraction phase and the raffinate phase are respectively obtained after the extraction is completed; 3) The phenol oil is recovered, and the extraction phase obtained in step 2) is carried out in the phenol oil recovery tower. Negative pressure rectification, the extractant extracted from the top of the tower is condensed and separated to obtain the recovered extractant, the product phenol oil is extracted from the tower reactor, 4) the extractant is recovered, and the raffinate phase obtained in step 2) is carried out in the solvent recovery tower Rectification, the top fraction is condensed and phase-separated, and the organic phase is used as the recovered extraction agent, the water phase is refluxed, and the liquid in the bottom of the tower is taken out as treated purified water and sent to the subsequent process.

Owner:TIANJIN CHUANGJU TECHNOLGOY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com