A kind of semi-coke wastewater treatment system and process

A treatment system, a technology for charcoal wastewater, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as high implementation costs, impact on human life, damage to human health, etc. , to achieve the effect of water temperature adaptability without secondary pollution, low cost of process implementation, and effluent quality up to standard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

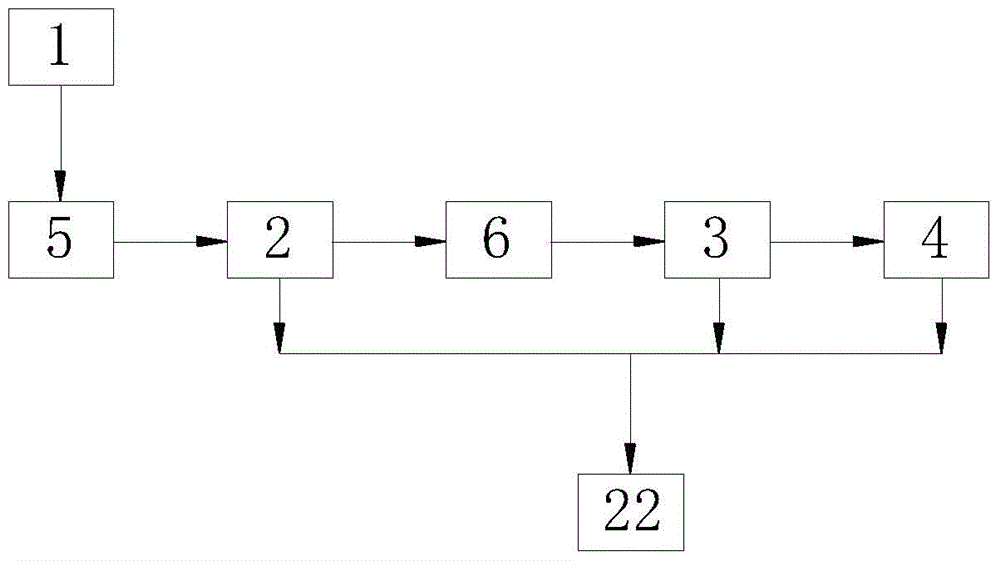

[0048] Embodiment 1 of the present invention: a kind of semi-coke wastewater treatment system, comprises accident pool 1, physicochemical treatment system 2, biochemical treatment system 3 and advanced treatment system 4 that are connected successively, between accident pool 1 and physicochemical treatment system 2 through adjustment The pool 5 is connected, the physical and chemical treatment system 2 is connected with the biochemical treatment system 3 through the water storage tank 6, and the biochemical treatment system 3 is connected with the advanced treatment system 4. After being treated by the biochemical treatment system 3, the wastewater enters the advanced treatment system 4 to remove the refractory biodegradable substances and chroma.

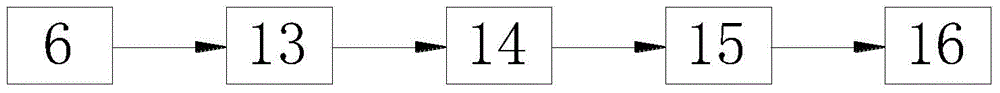

[0049] Further, the physicochemical treatment system 2 includes a grease trap 7 , a coagulation sedimentation tank 8 , an aeration Fe / C tank 9 , a first Fenton oxidation tank 10 , a stripping tank 11 and a flocculation sedimentation...

Embodiment 2

[0082] Embodiment 2 of the present invention: a blue carbon wastewater treatment system, including accident pool 1, physical and chemical treatment system 2, biochemical treatment system 3 and advanced treatment system 4 connected in sequence, between accident pool 1 and physical and chemical treatment system 2 through adjustment The pool 5 is connected, the physical and chemical treatment system 2 is connected with the biochemical treatment system 3 through the water storage tank 6, and the biochemical treatment system 3 is connected with the advanced treatment system 4. After being treated by the biochemical treatment system 3, the wastewater enters the advanced treatment system 4 to remove the refractory biodegradable substances and chroma.

[0083]Further, the physicochemical treatment system 2 includes a grease trap 7 , a coagulation sedimentation tank 8 , an aeration Fe / C tank 9 , a first Fenton oxidation tank 10 , a stripping tank 11 and a flocculation sedimentation tank...

Embodiment 3

[0116] Embodiment 3 of the present invention: a blue carbon wastewater treatment system, including accident pool 1, physicochemical treatment system 2, biochemical treatment system 3 and advanced treatment system 4 connected in sequence, accident pool 1 and physicochemical treatment system 2 are adjusted The pool 5 is connected, the physical and chemical treatment system 2 is connected with the biochemical treatment system 3 through the water storage tank 6, and the biochemical treatment system 3 is connected with the advanced treatment system 4. After being treated by the biochemical treatment system 3, the wastewater enters the advanced treatment system 4 to remove the refractory biodegradable substances and chroma.

[0117] Further, the physicochemical treatment system 2 includes a grease trap 7 , a coagulation sedimentation tank 8 , an aeration Fe / C tank 9 , a first Fenton oxidation tank 10 , a stripping tank 11 and a flocculation sedimentation tank 12 which are connected i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com