Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1412 results about "Ferroalloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ferroalloy refers to various alloys of iron with a high proportion of one or more other elements such as manganese (Mn), aluminium (Al), or silicon (Si). They are used in the production of steels and alloys. The alloys impart distinctive qualities to steel and cast iron or serve important functions during production and are, therefore, closely associated with the iron and steel industry, the leading consumer of ferroalloys. The leading ferroalloy-producing countries in 2008 were Ukraine, China, South Africa and Russia, which accounted for 77% of the world production. World production of bulk chromium, manganese and silicon ferroalloys was estimated as 29.1 million tonnes (Mt) in 2008, a 3% decrease compared with 2007.

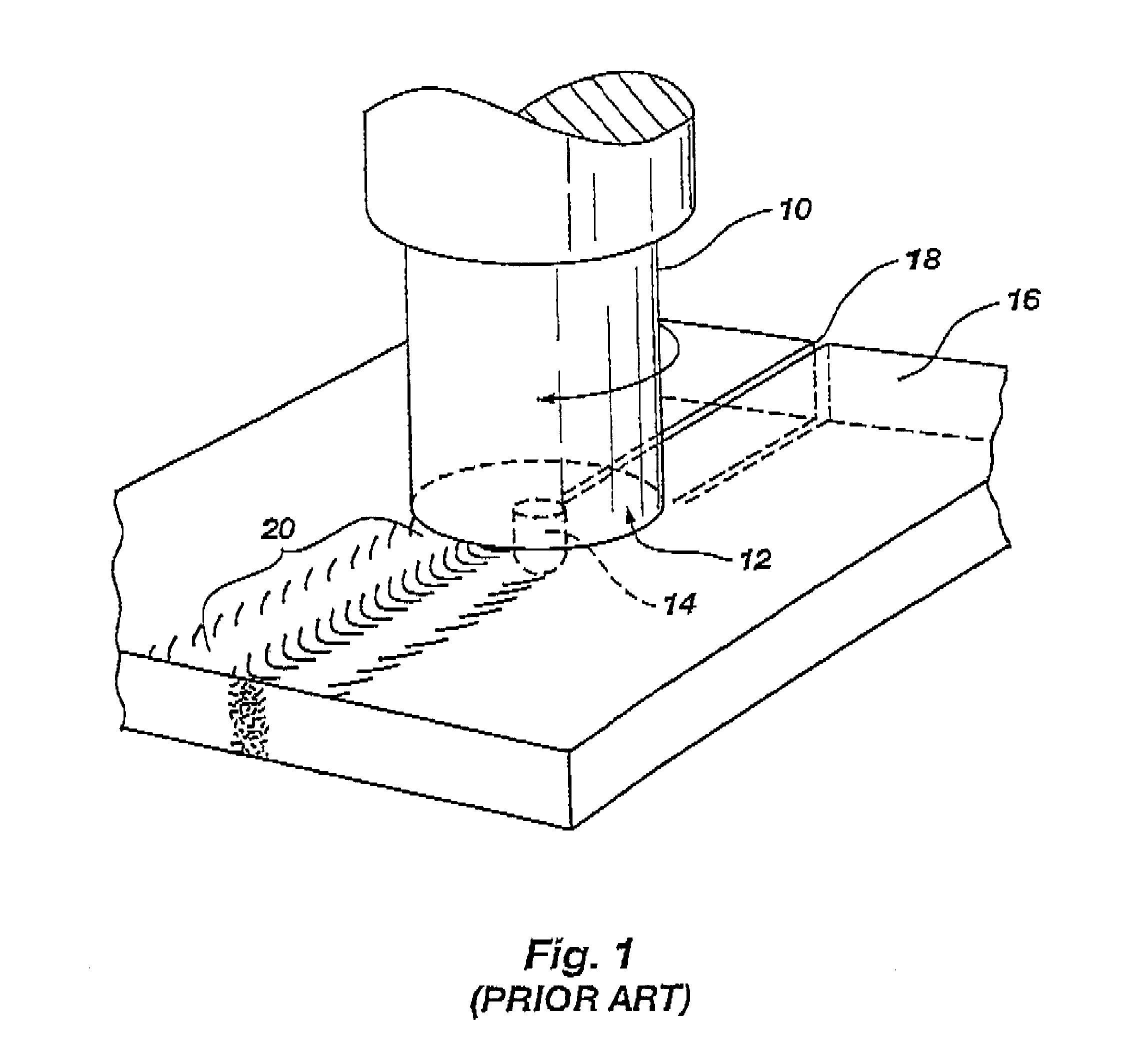

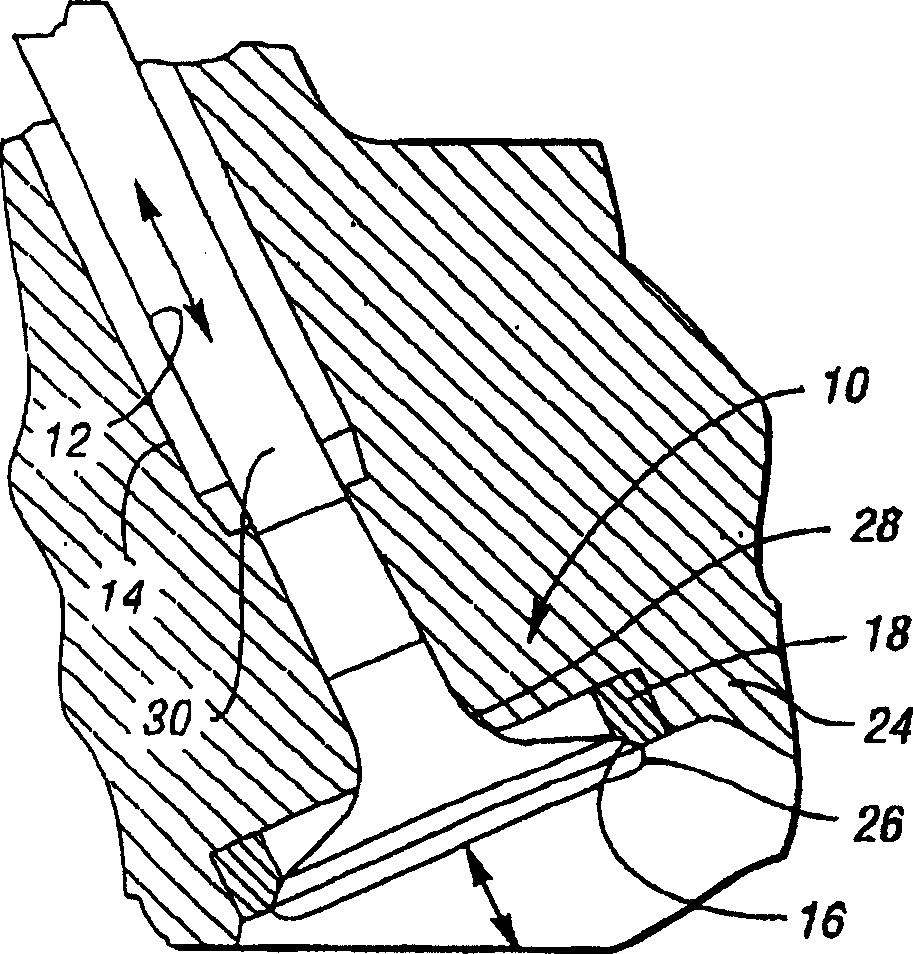

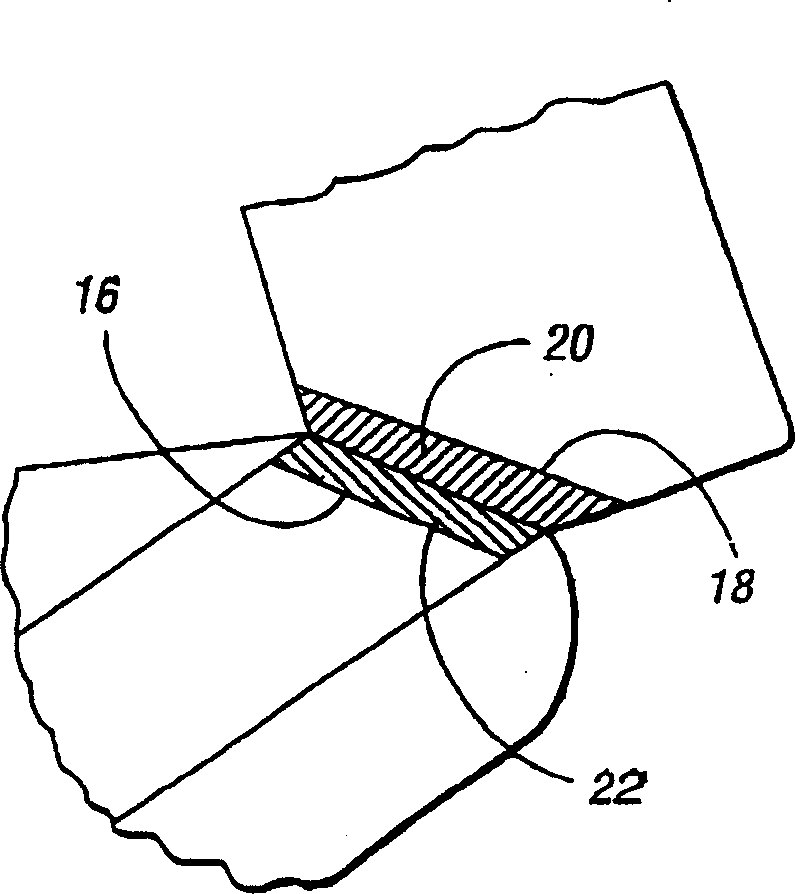

Friction stir welding using a superabrasive tool

InactiveUS6648206B2Improve wear characteristicsReduced tool wearWelding/cutting auxillary devicesVacuum evaporation coatingHeat flowEngineering

A probe for friction stir welding MMCs, ferrous alloys, non-ferrous alloys, and superalloys, as well as non-ferrous alloys, the probe including a shank, a shoulder, and a pin disposed through the shoulder and into the shank, wherein the pin and the shoulder at least include a coating comprised of a superabrasive material, the pin and shoulder being designed to reduce stress risers, disposing a collar around a portion of the shoulder and the shank to thereby prevent movement of the shoulder relative to the shank, and incorporating thermal management by providing a thermal flow barrier between the shoulder and the shank, and between the collar and the tool.

Owner:BRIGHAM YOUNG UNIV +1

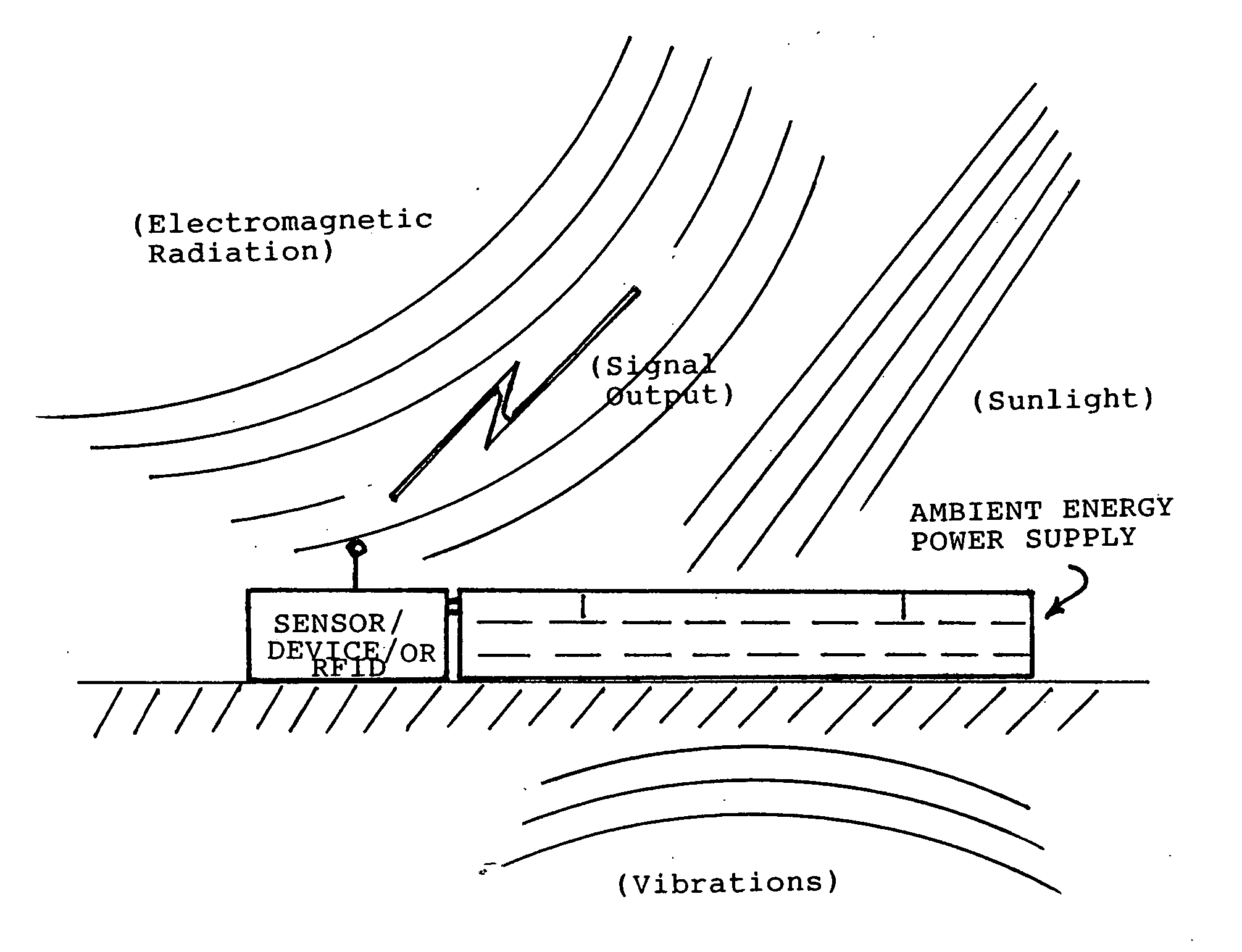

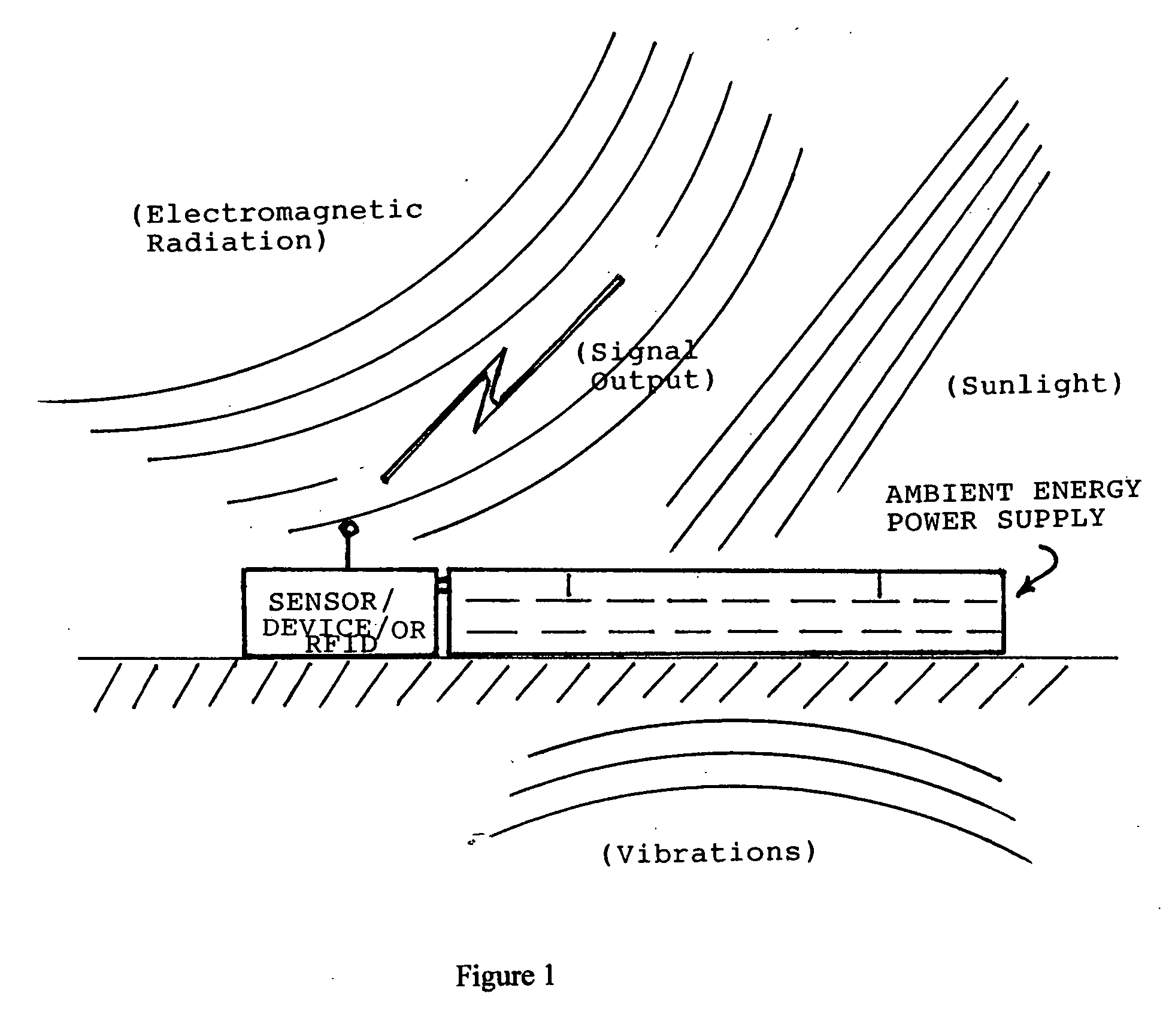

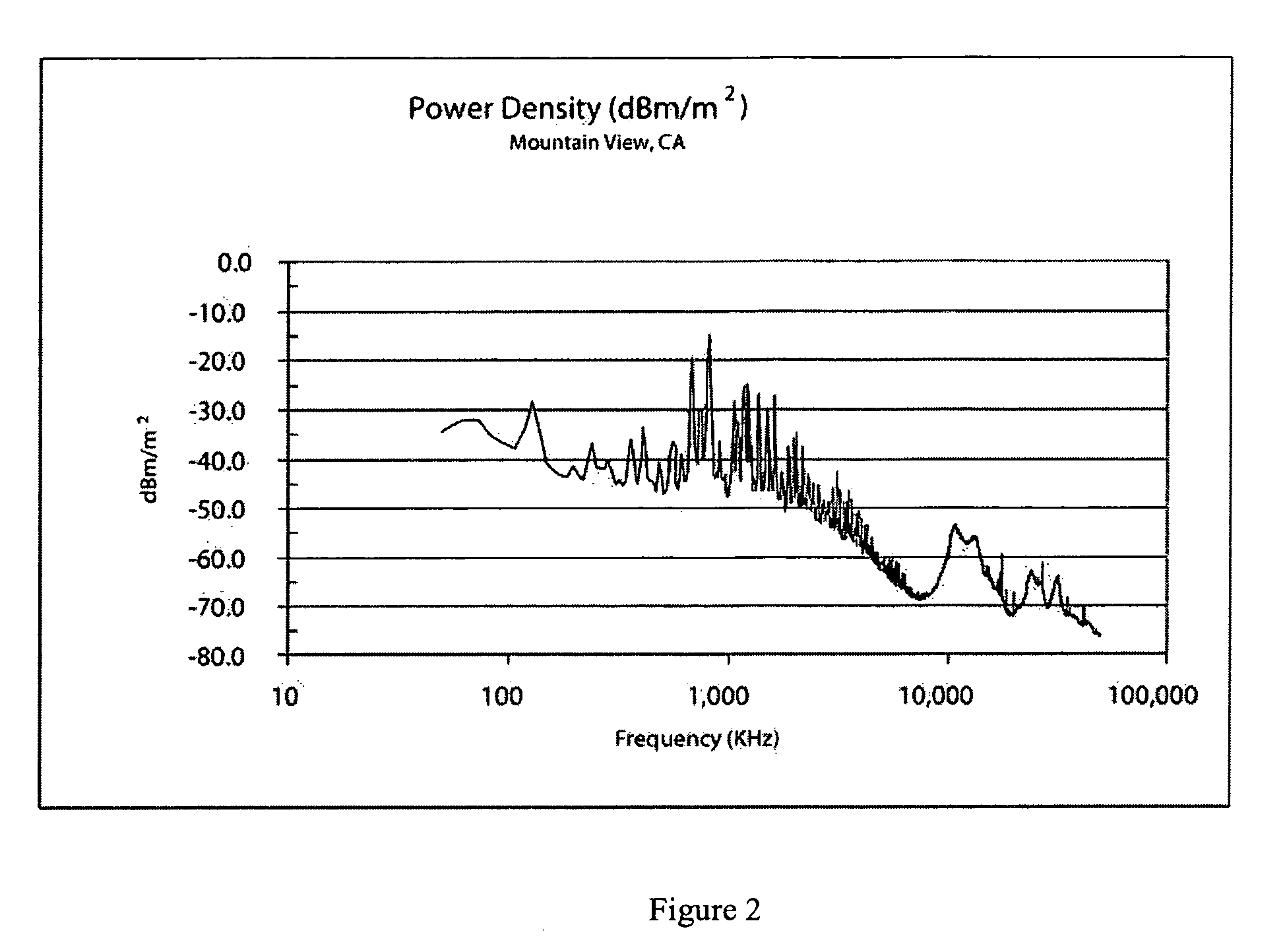

Multi-source ambient energy power supply for embedded devices or remote sensor or RFID networks

InactiveUS20070107766A1Prevent tamperingSmall sizeBatteries circuit arrangementsElectromagnetic wave systemCollector deviceMagnetic core

An ambient electromagnetic energy collector has a magnetic core of high permeability ferromagnetic material wrapped in an inductor coil for coupling primarily to a magnetic field component of a propagating transverse electromagnetic (TEM) wave. For coupling to electromagnetic waves of a wide range of frequencies and magnitudes, the collector is coupled to a multi-phase transformer connected to a multi-phase diode voltage multiplier to provide a current source output to an associated energy storage device. An output controller supplies output power as needed to the associated energy-using device. Preferred types of ferromagnetic materials include nickel-iron alloys with a small percentage of silicon, molybdenum, or copper. It may be combined with other types of ambient energy collectors, such as acoustic / vibration, thermoelectric, and photovoltaic collectors, in a multi-source device provided with a collector interface for converting the different outputs for storage in a common energy storage device. The multi-source ambient energy collector device can be used to supply power to embedded devices, remotely deployed wireless sensors or RFID tags, and other types of monitoring devices distributed over large areas or in industrial environments.

Owner:LANGLEY JOHN B II +2

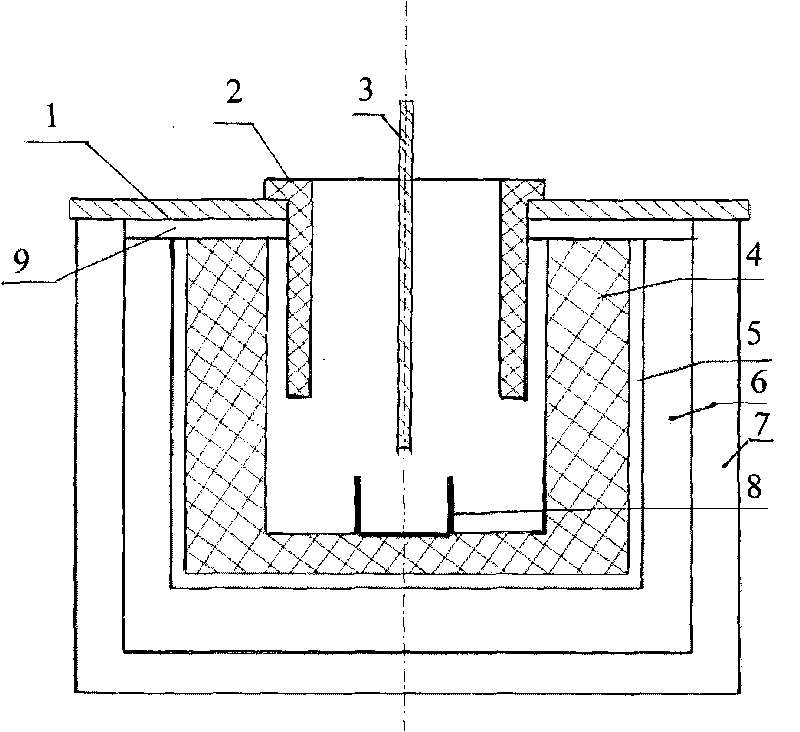

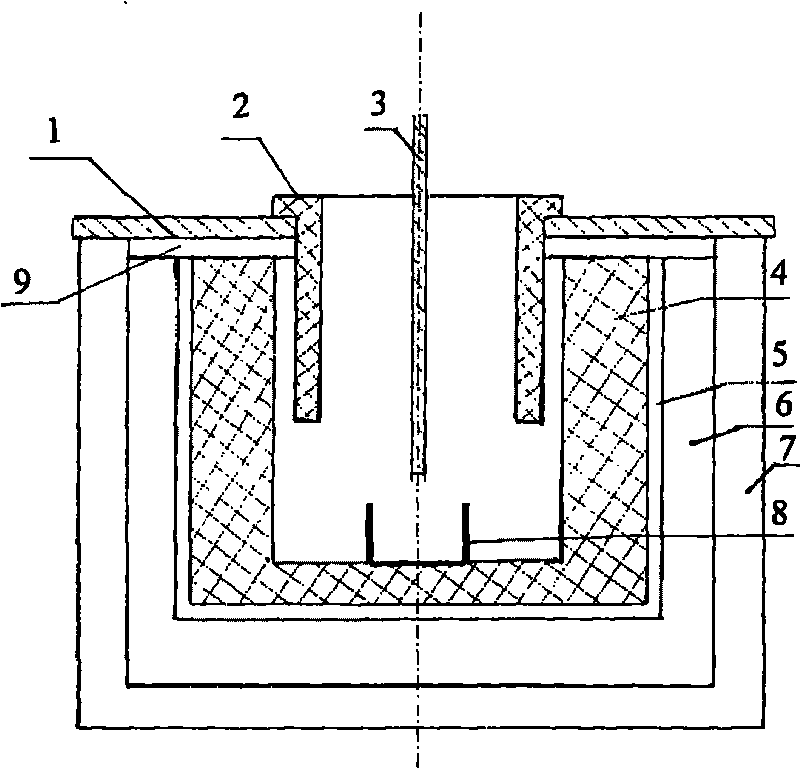

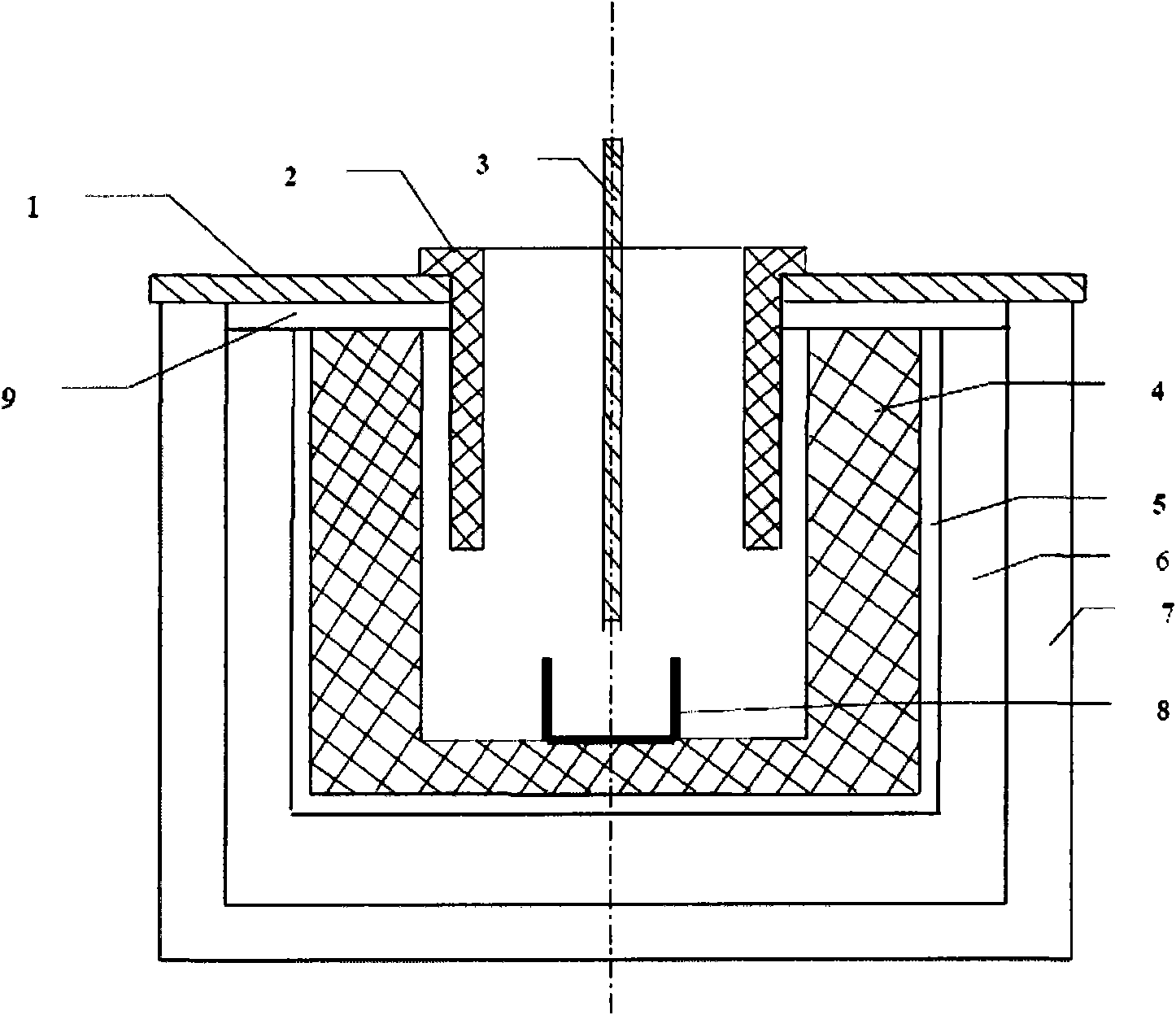

Rare earth aluminum alloy, and method and device for preparing same

The invention discloses a rare earth aluminum alloy, and a method and a device for preparing the same. The alloy contains at least one rare earth metal of lanthanum, cerium, praseodymium, neodymium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, lutetium, scandium and yttrium, the content of raw earth is 5 to 98 weight percent, and the balance is aluminum and inevitable impurities. The device for preparing the rare earth aluminum alloy is characterized in that: a) graphite serves as an electrolysis bath, a graphite plate is an anode, a tungsten bar is a cathode and a molybdenum crucible serves as a rare earth aluminum alloy receiver; b) the diameter of the tungsten bar is 30 to 55 mm; and c) the anode of the graphite consists of a plurality of graphite plates. The rare earth aluminum alloy, and the method and the device for preparing the same have the advantages that: the alloy has uniform components, little segregation and low impurity content; technology for preparing the rare earth aluminum alloy through fusion electrolysis can maximally replace a process for preparing single medium-heavy metal through metallothermic reduction, greatly reduce energy consumption and the emission of fluorine-containing tail gas and solid waste residue, improve current efficiency and metal yield and reduce the consumption of auxiliary materials and the energy consumption; and the rare earth aluminum alloys with different rare earth contents can be obtained by controlling different electrolytic temperatures and different cathode current densities.

Owner:GRIREM ADVANCED MATERIALS CO LTD

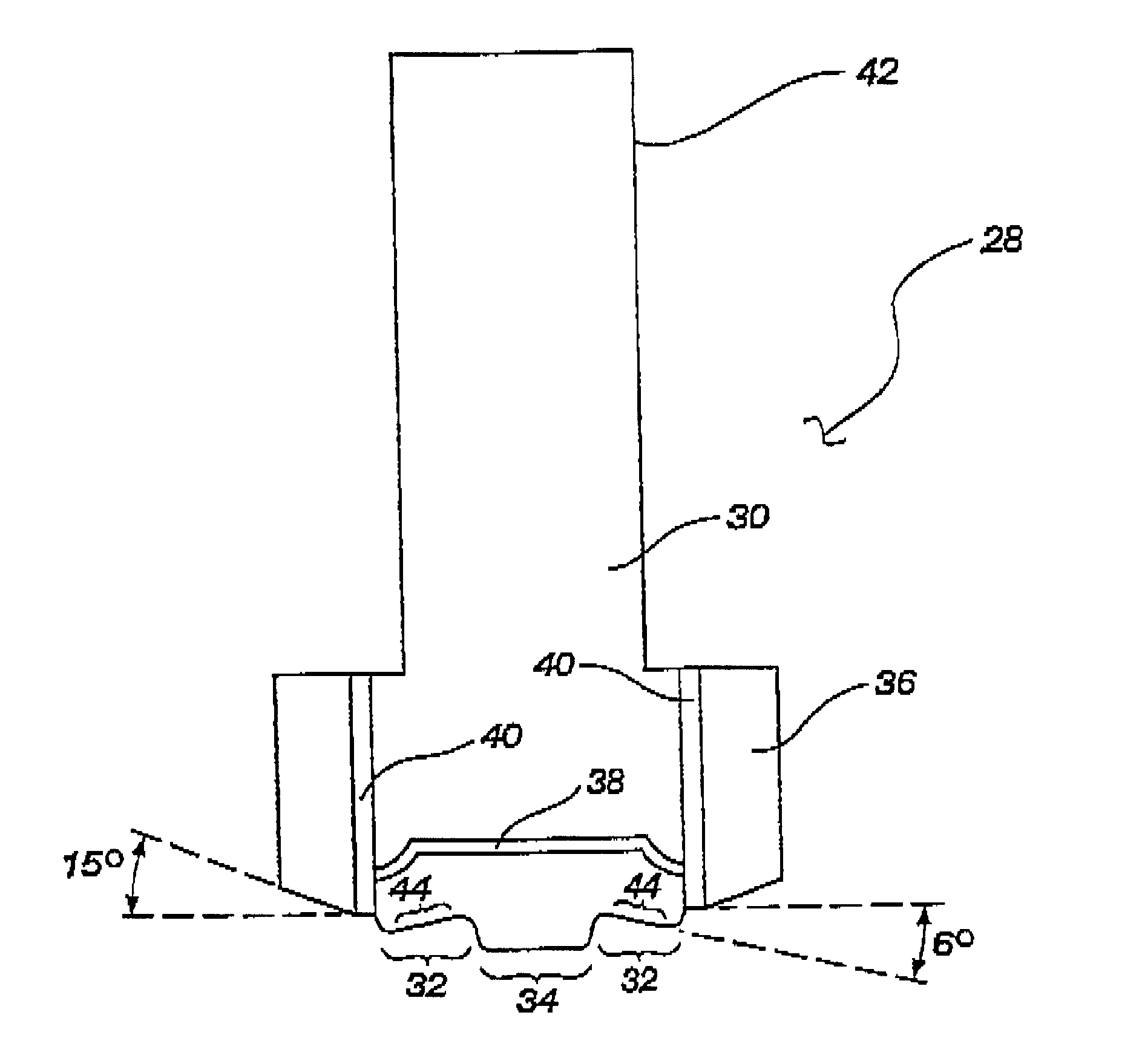

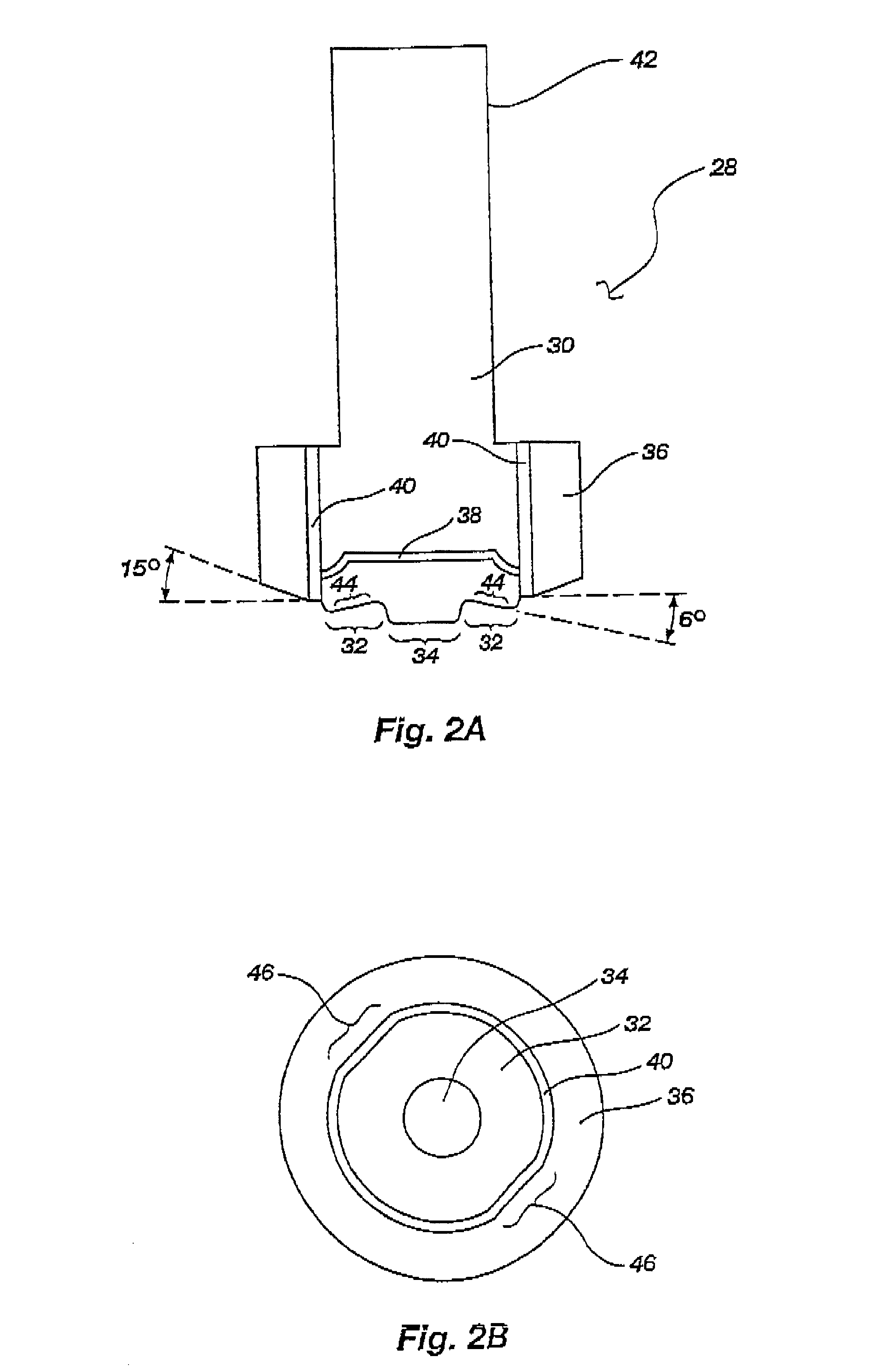

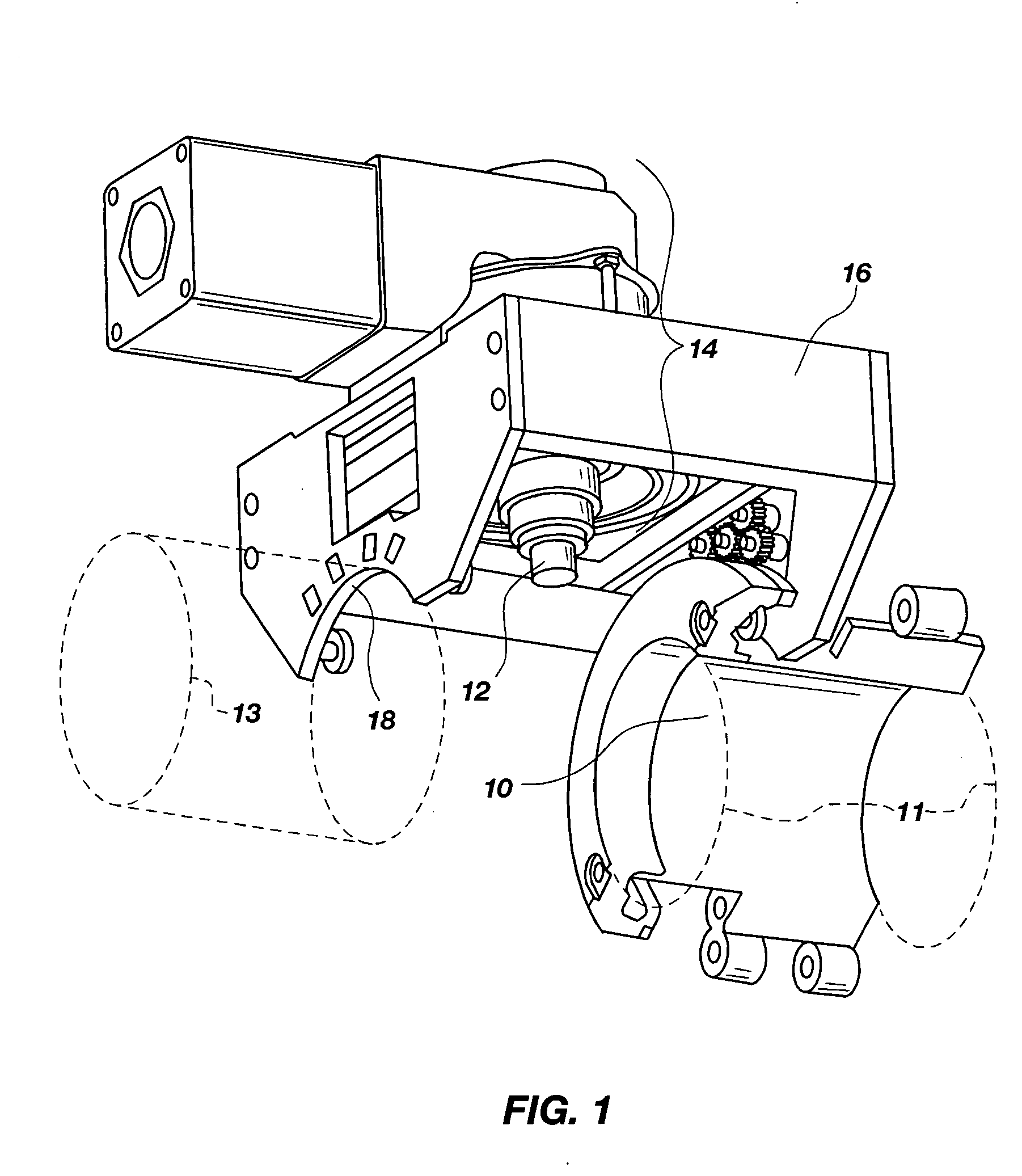

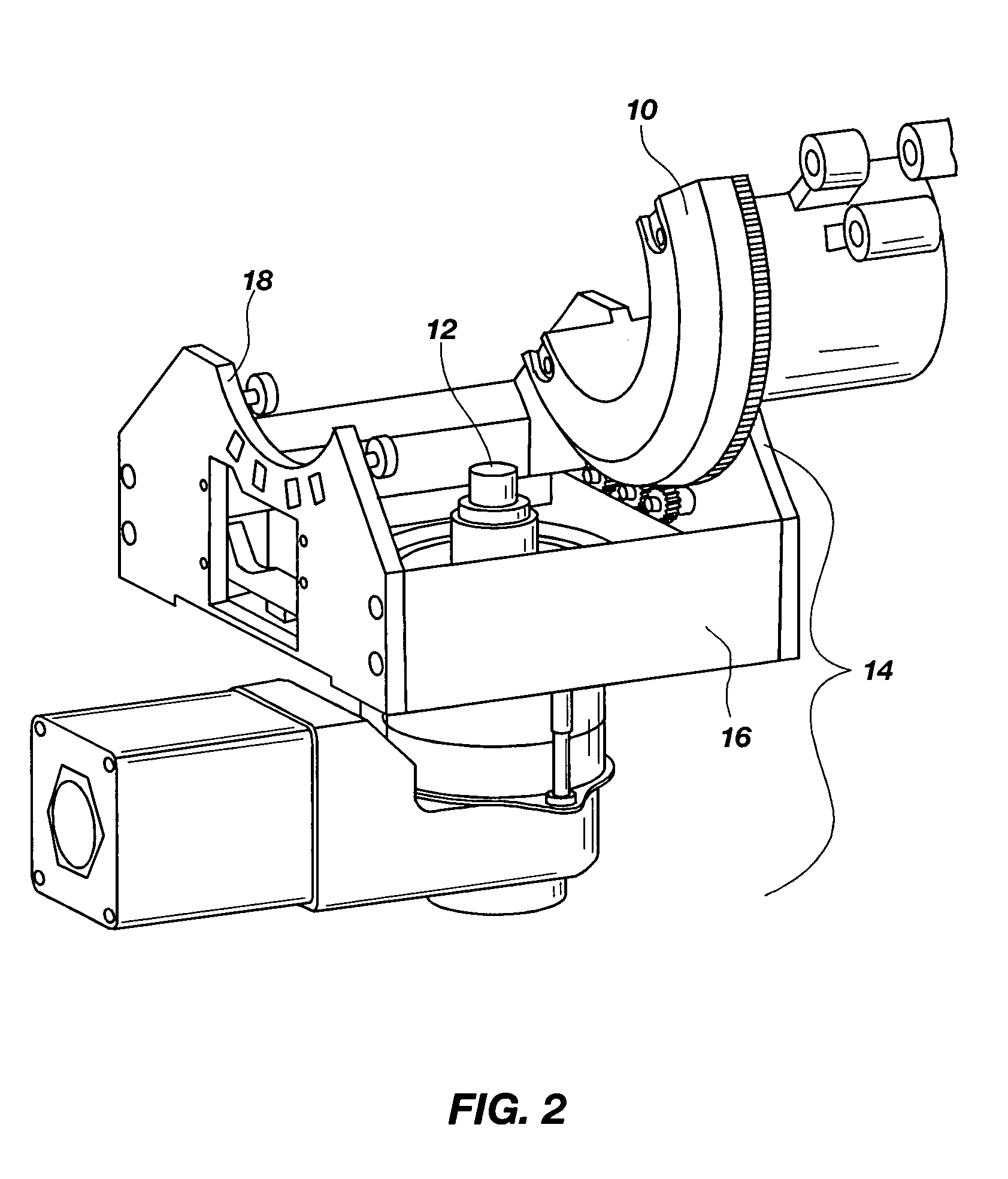

Friction stir welding improvements for metal matrix composites, ferrous alloys, non-ferrous alloys, and superalloys using a superabrasive tool

InactiveUS20050082342A1Improves friction stir weldingImprove featuresWelding/cutting auxillary devicesPipe elementsMetal alloyEngineering

A friction stir welding system that enables clamping of a pipe to enable friction stir welding around the pipe OD, a movable mandrel that provides a counter-force to the pressure exerted on the outside of a pipe by a tool, and a system for providing friction stir welding and repair inside a nuclear vessel in an underwater environment.

Owner:MAZAK CORP +1

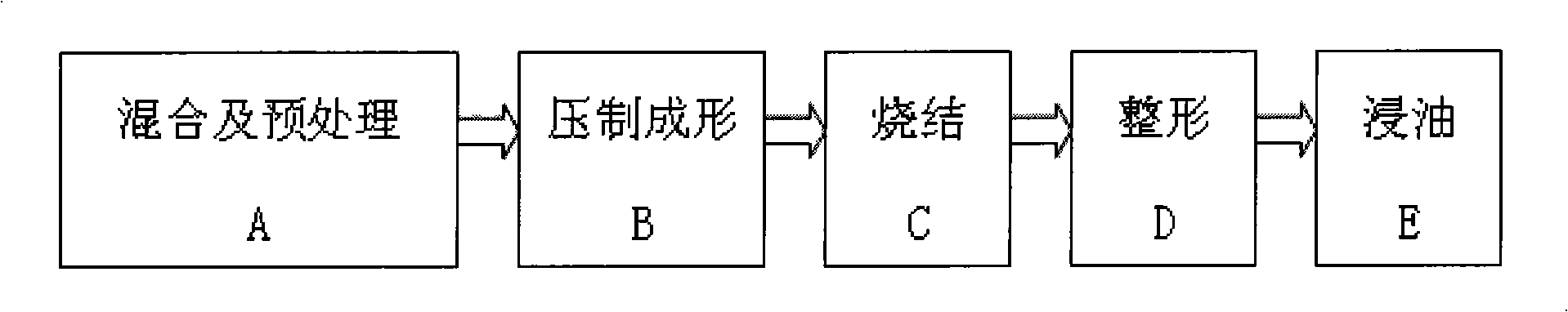

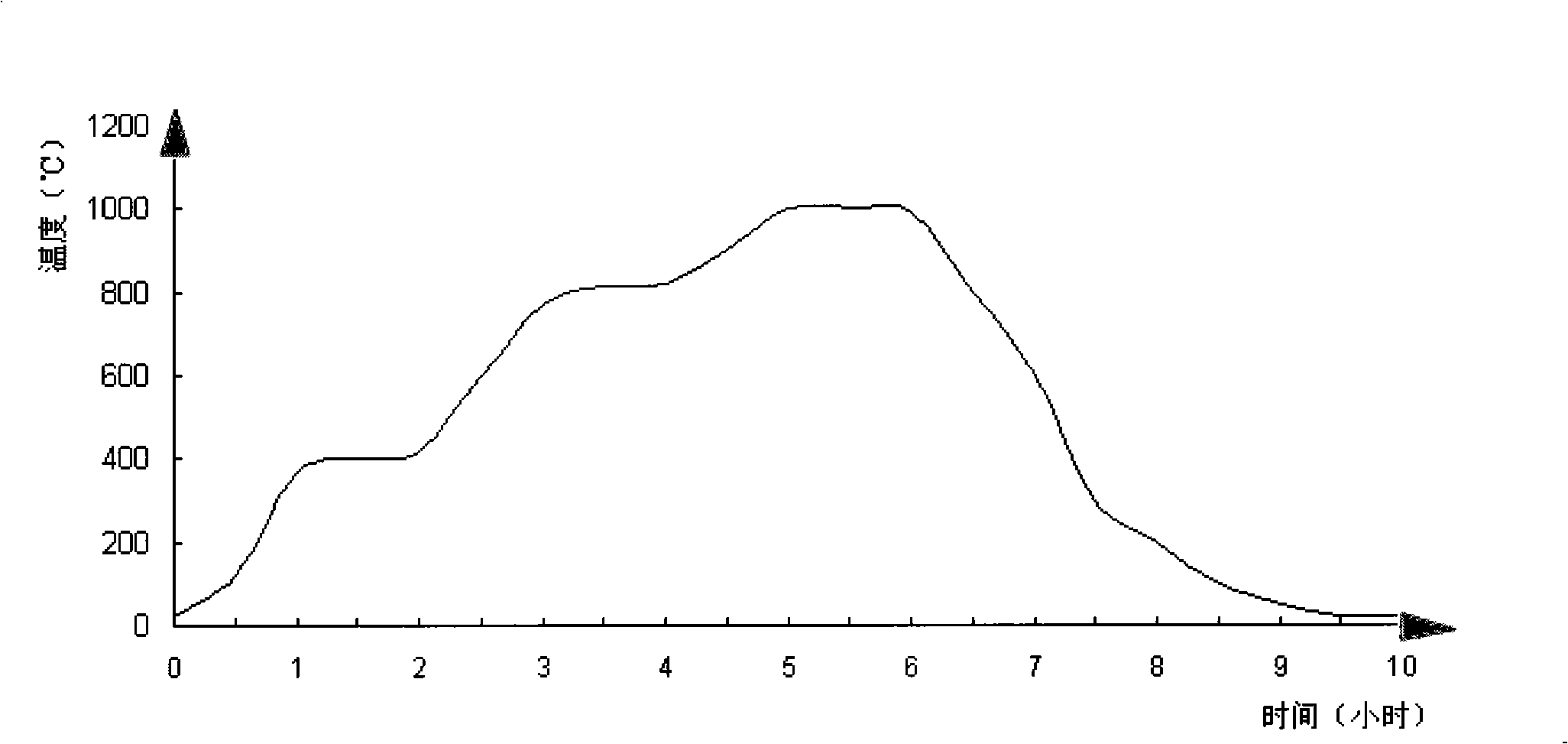

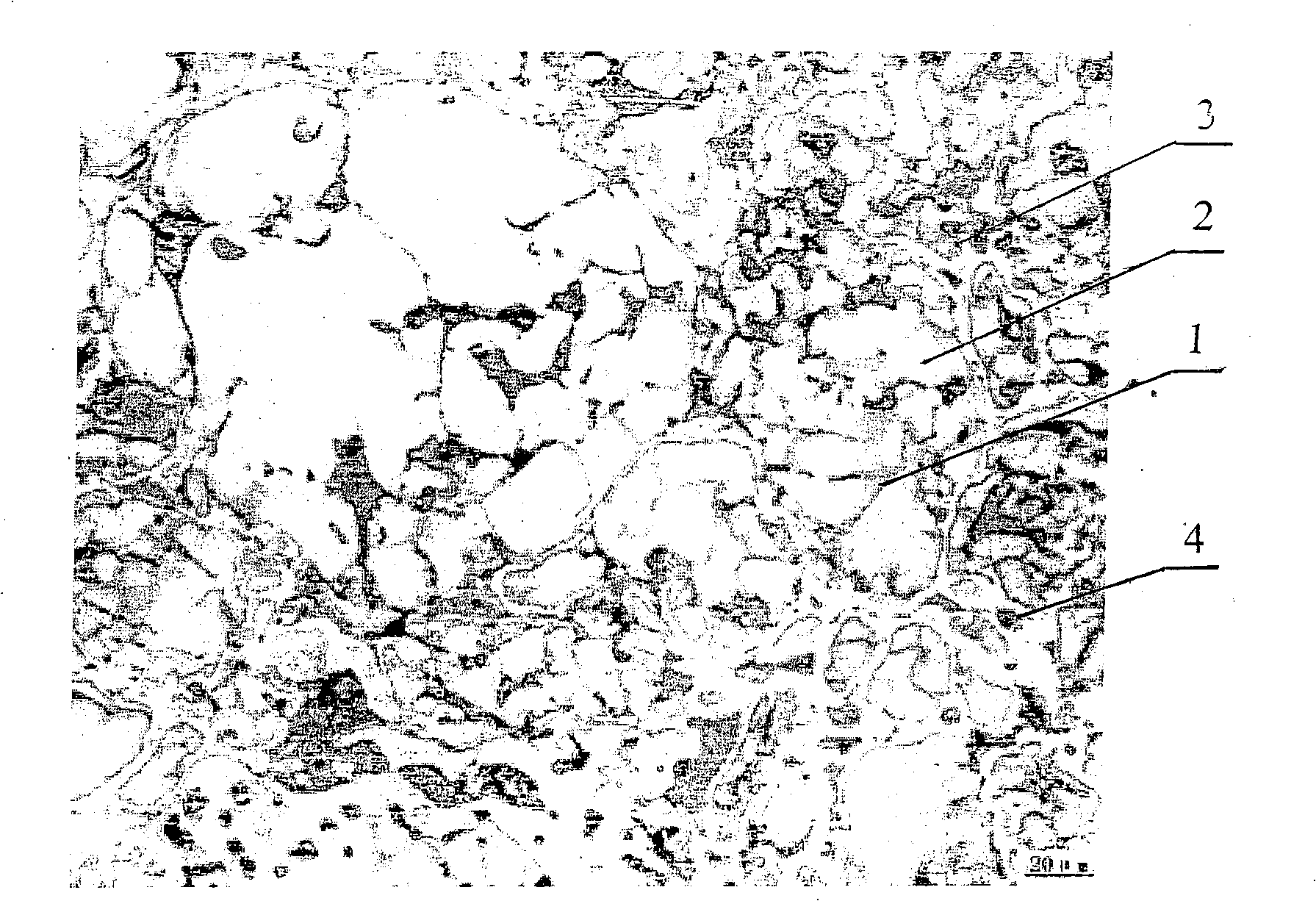

Powder metallurgy rare earth copper coated ferroalloy oil-retaining bearing and manufacturing method thereof

InactiveCN101407889AMeet environmental protection requirementsExtended service lifeTurbinesOther manufacturing equipments/toolsManufacturing cost reductionRare earth

The invention discloses a powder metallurgy rare-earth copper-clad iron alloy oil-impregnated bearing and a manufacturing method thereof. Accounted by percentage, the bearing consists of the following compositions by percentage: 18 to 22 percent of Cu, 0.2 to 1.0 percent of graphite, 0.3 to 0.8 percent of La or Ce and the residual quantity of Fe and unavoidable impurities. The bearing is made by the procedures of mixing, low temperature diffusion treatment, pressing, sintering and the like of a mixture formed by copper-clad iron powder, powder of the element La or Ce and the residual quantity of Fe and unavoidable impurities according to certain mixture ratios. The bearing uses the iron powder for substituting most of the copper powder to reduce the manufacturing cost; lead is not contained in the bearing, which meets the requirement of environmental protection; the rare earth is adopted as a catalyst for causing the copper-clad iron powder to be easily combined with other powder, and the alloy is uniformly distributed, which is beneficial for the refinement of alloy grains and leads thin through holes to be formed in the sintering body with hole connection efficiency being more than 95 percent. The mechanical property of the bearing is better than technical standards of oil-impregnated bearings sintered by copper-clad iron powder and 6-6-3 bronze powder.

Owner:JIANGSU YINGQIU GRP CO LTD

Production technology of preparing manganeisen from low grade manganese mine

InactiveCN102382977ANo pollution in the processLow costProcess efficiency improvementTunnel kilnManganese

A production technology of preparing manganeisen from low grade manganese mine. Low grade manganese mine with a metal manganese content of 15-30% is dried, added with reducing agent, catalyst, solvent and bonding agent and mixed well to prepare a composite material; the low grade manganese mine composite raw material is placed in a rotary kiln or a tunnel kiln, heated to 400+ / -80 DEG C by energy of gas or natural gas with an air excess coefficient controlled at 0.9-1.0, with a heating speed of 1-4 DEG C / min at a normal temperature, wherein the furnace is kept in a weak reducing atmosphere, and insulated for 0.5-5 h; then the low grade manganese mine composite raw material is heated to 750+ / -80 DEG C with a heating speed of 2-5 DEG C / min and insulated for 0.5-5h; finally the low grade manganese mine composite raw material is heated to 1100+ / -150 DEG C and insulated for 0.5-6h; gas pressure in the furnace is kept at 0.12-0.15 MPa during heating and insulation; after the reaction, the material is cooled and treated with magnetic separation to obtain the manganeisen and tailings. The manganeisen comprises 15-20% of metal Fe, 65-75% of metal Mn, less than 5% of gangue, 1.0-6.5% of carbon, less than 0.15% of phosphor and less than 0.15% of sulfur, can be used as a raw material for smelting of high-quality manganeisen by a converter or an electric furnace and has low cost and wide application prospect.

Owner:CENT SOUTH UNIV

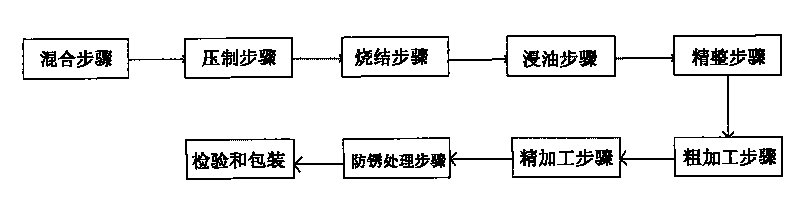

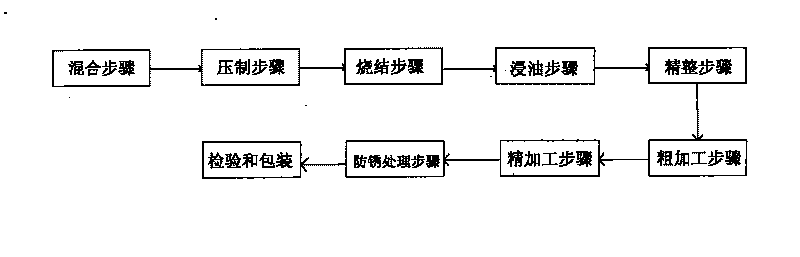

Powder metallurgy technical formula and technical process thereof

The invention discloses a powder metallurgy technical formula and a technical process thereof. The formula is iron-base powder formed by uniformly mixing graphite powder, copper powder, zinc stearate and iron powder. The forumula is characterized in that ferrophosphorus alloy and manganese sulfate are added to the iron-base powder; and the iron-base powder comprises the following components in percentage by weight: 0.4-1.5% of graphite powder, 1-3% of copper powder, 1-2.5% of manganese sulfide, 1-2.5% ferrophosphorus alloy, 0.5-1% of zinc stearate and 70-98% of iron powder. The technical process comprises the following steps: (1) mixing; (2) compacting; (3) sintering; (4) oil immersing; (5) finishing; (6) rough processing; (7) fine processing; and (8) rust-proofing treatment. The invention replaces electrolytic copper with ferrophosphorus alloy, thereby enhancing the performance and the strength of the product, reducing the manufacturing cost, enhancing the production efficiency and having the advantages of strong wear resistance, short sintering time and stable quality.

Owner:安徽省芜湖市信达粉末冶金零部件有限公司

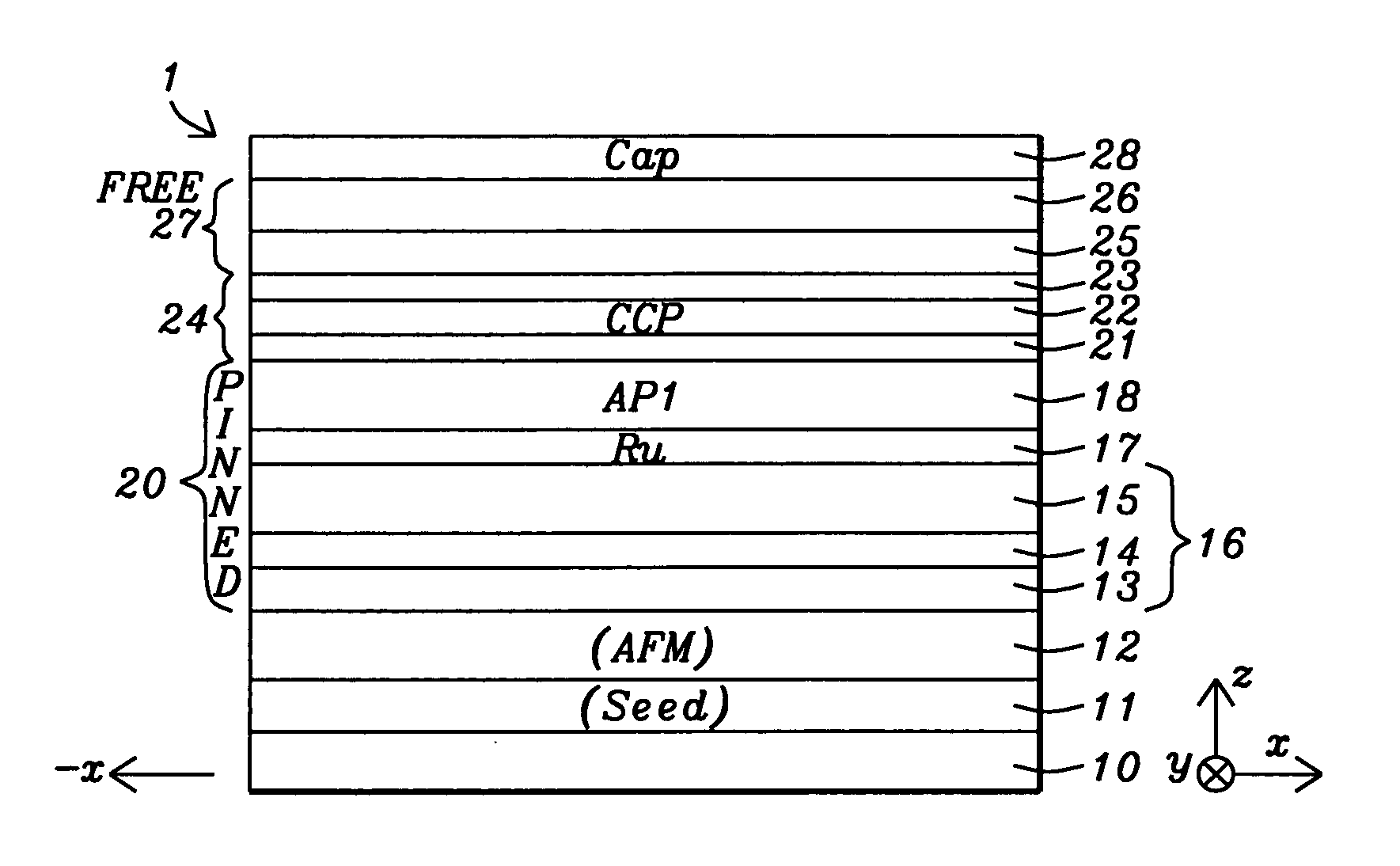

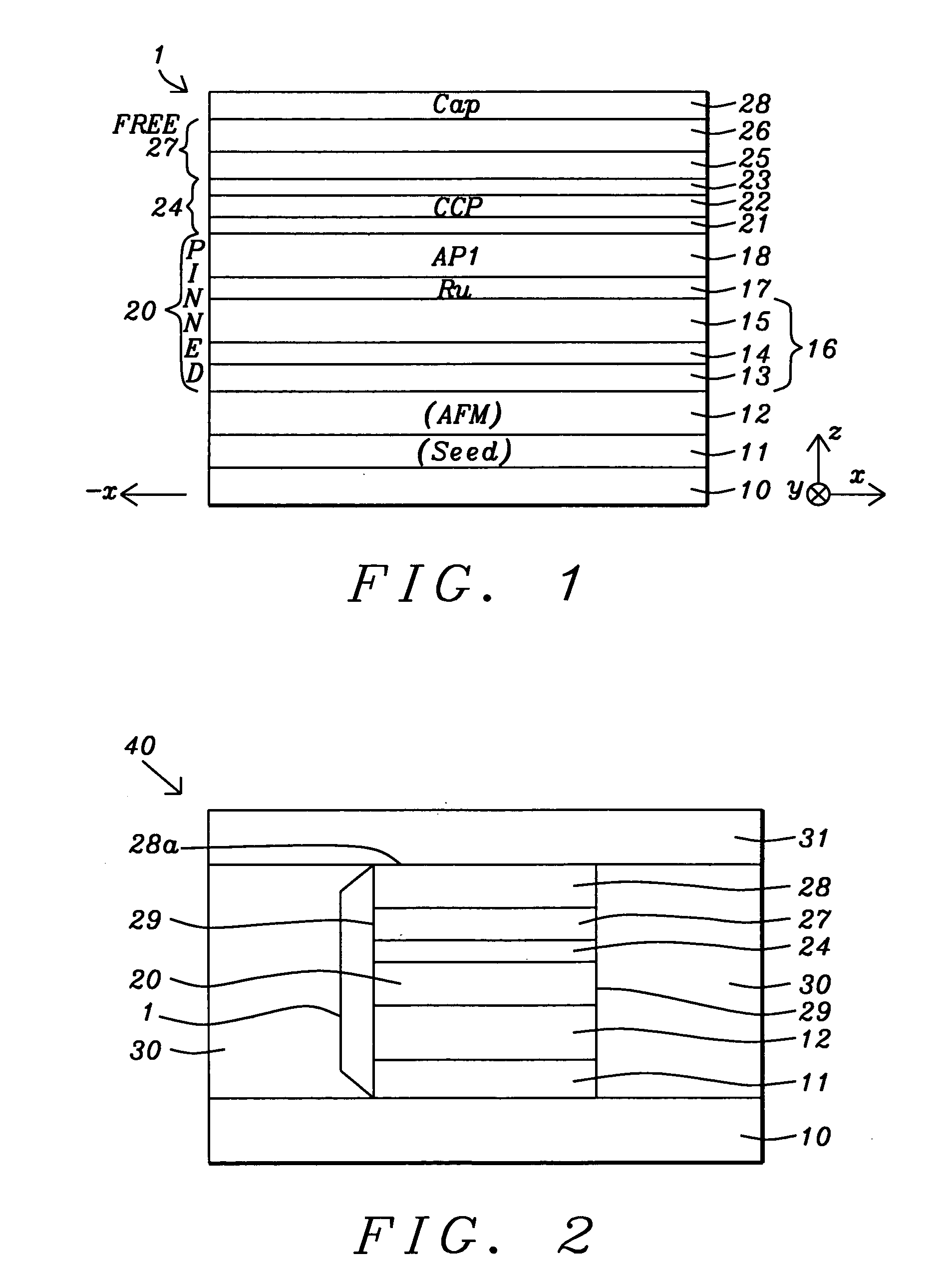

FCC-like trilayer AP2 structure for CPP GMR EM improvement

ActiveUS20070070556A1Improved EM performanceMaintains and increases MR ratioNanomagnetismNanoinformaticsMetallurgySpin valve

A CPP-GMR spin valve having a pinned layer with an AP2 / coupling / AP1 configuration is disclosed wherein the AP2 portion is a FCC-like trilayer having a composition represented by CoZFe(100-Z) / Fe(100-X)TaX / CoZFe(100-Z) or CoZFe(100-Z) / FeYCo(100-Y) / CoZFe(100-Z) where x is 3 to 30 atomic %, y is 40 to 100 atomic %, and z is 75 to 100 atomic %. Preferably, z is 90 to provide a face centered cubic structure that minimizes electromigration. Optionally, the middle layer is comprised of an Fe rich alloy such as FeCr, FeV, FeW, FeZr, FeNb, FeHf, or FeMo. EM performance is improved significantly compared to a spin valve with a conventional AP2 Co50Fe5 or Co75Fe25 single layer. The MR ratio of the spin valve is also increased and the RA is maintained at an acceptable level. The coupling layer is preferably Ru and the AP1 layer may be comprised of a lamination of CoFe and Cu layers as in [CoFe / Cu]2 / CoFe.

Owner:HEADWAY TECH INC

Industrial waste slag-doped composite silicate cement and production method thereof

InactiveCN102101757ABlending amount increasedImprove early strengthCement productionMetallurgical slagAlloy

The invention discloses industrial waste slag-doped composite silicate cement and a production method thereof. The industrial waste slag-doped composite silicate cement comprises the following material components: 45-58 percent of silicate cement clinker, 3-5 percent of desulfurization gypsum, 1.5-4 percent of lime stone, 0.2-0.3 percent of cement grinding additive, 10-29 percent of granulated blast furnace slag, 2-10 percent of coal slag, 4-10 percent of pulverized fuel ash, 2-10 percent of ferroalloy slag, 2-10 percent of zinc metallurgical slag and 0.2-0.25 percent of waste slag grinding aid active excitant. The production method comprises the following steps of: taking and mixing the first four materials according to the proportion and grinding into 300-350m<2> / kg of powder; taking and mixing the rest six materials according to the proportion and grinding into 420-450m<2> / kg of superfine powder; and then combining the two kinds of powder, stirring and homogenizing. By adopting respective grinding of clinker and waste slag, the waste slag fineness reaches an optical value for stimulating the activity, the hydration progress and the cement clinker reach synchronization, and the doping amount and doping category of waste slag are also improved.

Owner:王明贵

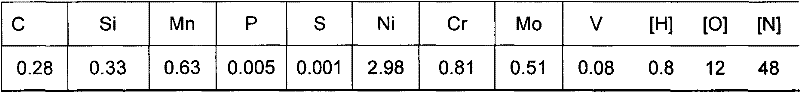

Smelting method of axle steel for high-speed motor car

The invention relates to a smelting method of axle steel for a high-speed motor car, which comprises the following steps of: I. smelting in an electric furnace, firstly adding steel scraps into the electric furnace and adding pretreated molten iron, wherein the weight proportion of the pretreated molten iron is 80% to 95%, and in the steel scraps, P is less than or equal to 0.015% and S is less than or equal to 0.010%; blowing oxygen and adding lime, and tapping from the electric furnace after P is less than or equal to 0.008%; adding slagging materials, iron alloys and metals into steel ladles according to the types of steel; II. adopting slag systems with high alkalinity and high Al2O3 content for ladle furnace refining, controlling the alkalinity R of molten slag, wherein R is equal to 4.0 to 6.0; the molten steel comprises following components in percent by weight: 0.26 to 0.31% of C, 0.20 to 0.35% of Si, 0.55 to 0.70% of Mn, less than or equal to 0.005% of S, less than or equal to 0.015% of P, 0.75 to 0.90% of Cr, 2.90 to 3.30% of Ni, 0.45 to 0.55% of Mo and 0.08 to 0.13% of V; and III. feeding Si and Ca into the molten steel and blowing argon from the bottom after carrying out VD (Vacuum Distillation) and the vacuum refining. Inclusions of the steel rolled axle smelted by the smelting method of axle steel for the high-speed motor car meet the using requirements on the high-speed axle.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

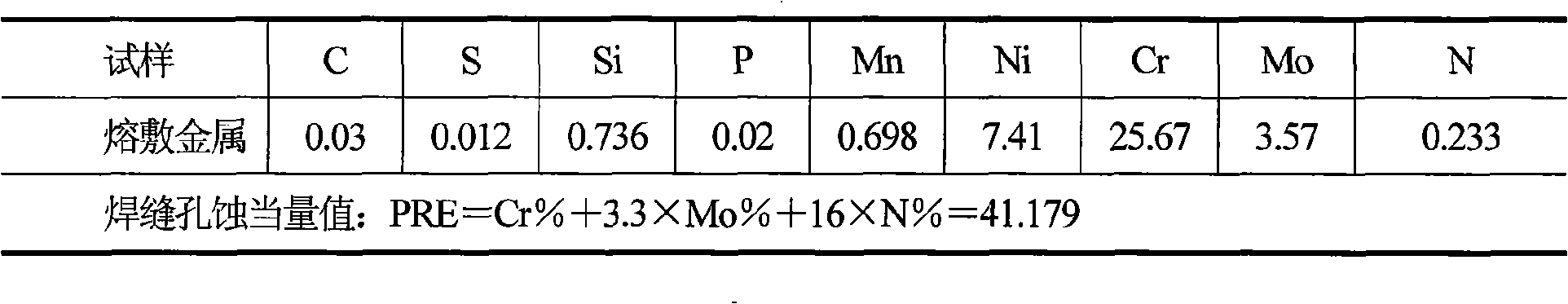

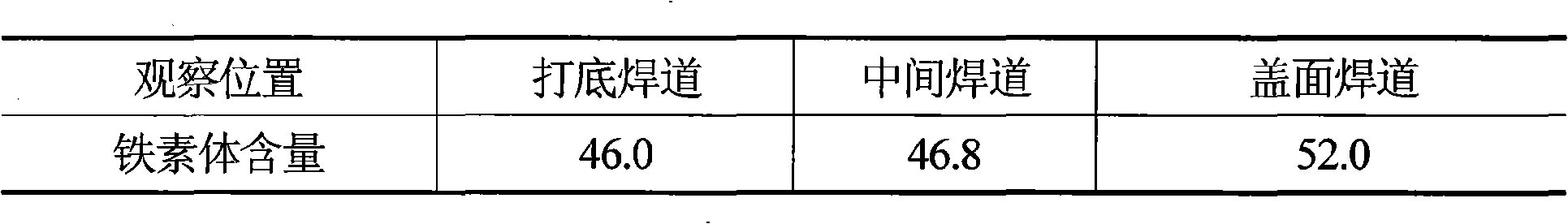

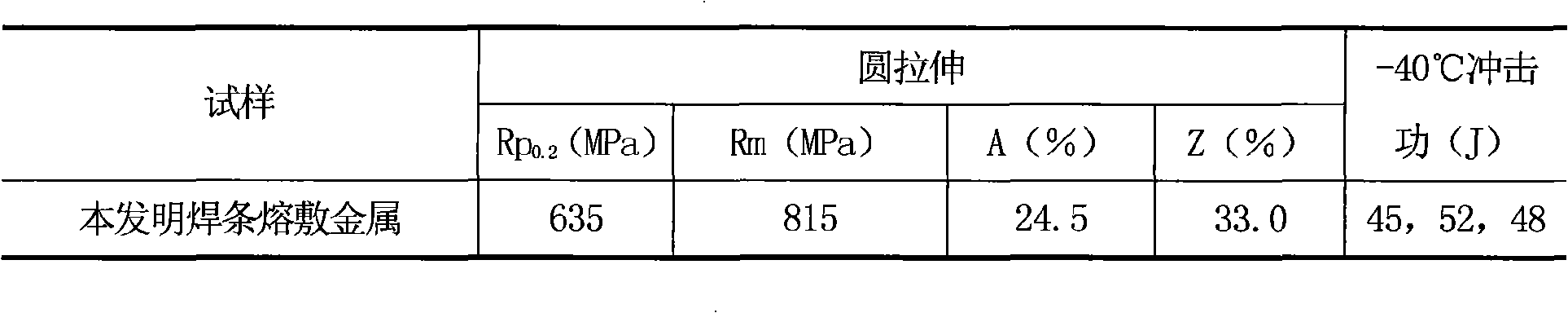

Acidic coating super two-phase stainless steel electrode

InactiveCN101323058ASimple welding processArc stabilizationWelding/cutting media/materialsSoldering mediaPhase ratioRare earth

The invention relates to an acidic coating super duplex stainless steel welding rod and belongs to welding material technology. The invention adopts 2507 duplex stainless steel wires as the welding core; the components and the weight percentages of the components of the welding rod coating are as follows: 30-40 of rutile, 3-7 of titanium dioxide, 15-20 of potash feldspar, 1-3 of phlogopite, 5-10 of marble, 16-20 of metal powder, 0.5-1.5 of rare earth fluoride, 2-3 of cryolite, 5-8 of chrome green, 0.5-1.0 of soda, and 1.5-3.5 of ferroalloy. The welding rod of the invention has the advantages, showed by the test results of manufacturability, metallographic observation, mechanical property and corrosion resistance, that the welding rod has extremely good welding technical property; electric arc is stable during welding, and spattering does not basically exist; the formation of weld joints is good; slag detachability is good; the manipulability of the welding rod is excellent; through metallographic observation, the content of ferrite in the structure of welding joints ranges from 40 percent to 60 percent, and the phase ratio can meet engineering application requirement; the welded welding joint has excellent mechanical property, and tensile strength can be more than 800 MPa; low temperature toughness is good; the stress corrosion resistance and pitting corrosion resistance of the welding joint are excellent.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

Aluminum-calcium-magnesium-cerium composite alloy used for strong desulfurization, final desoxidation, and quenching and tempering of liquid steel

InactiveCN101705334AStrong deep desulfurization abilityWith deep desulfurization abilitySteelmakingAlkaline earth metal

The invention provides an aluminum-calcium-magnesium-cerium composite alloy used for strong desulfurization, final desoxidation, and microalloying quenching and tempering of liquid steel, belonging to the technical field of ferroalloy used for steelmaking. Based on aluminum deoxidization, the aluminum-calcium-magnesium-cerium composite alloy is added with alkaline-earth metal calcium and magnesium to conduct the strong desulphurization and the final desoxidation on the liquid steel so as to reduce inclusions in steel, and adopts rare earth-cerium and alloy elements such as titanium, niobium, vanadium and the like to conduct quenching and tempering, and microalloying on the liquid steel so as to change the morphology of the inclusions, lead the steel to be solidified, crystallized and refined, and optimize the steel performance. The aluminum-calcium-magnesium-cerium composite alloy contains the following chemical compositions (mass percent): 10-60% of aluminum, 10-30% of calcium, 10-30% of magnesium, 0.5-10% of cerium, less than or equal to 1% of impurities (carbon + silicon + phosphorus + sulphur), and the balance of ferrum; and for the purpose of achieving different microalloying, the composite alloy also can contain one or more microalloying elements of titanium, niobium, molybdenum, vanadium, tungsten and boron, and the weight percentage content of the microalloying elements is 0.1-10%. In the invention, the final desoxidation, the strong desulfurization, the microalloying and the quenching and tempering of the liquid steel is completed in one step, thus improving the refining efficiency and effect, and greatly improving the steel quality.

Owner:JIANGSU UNIV

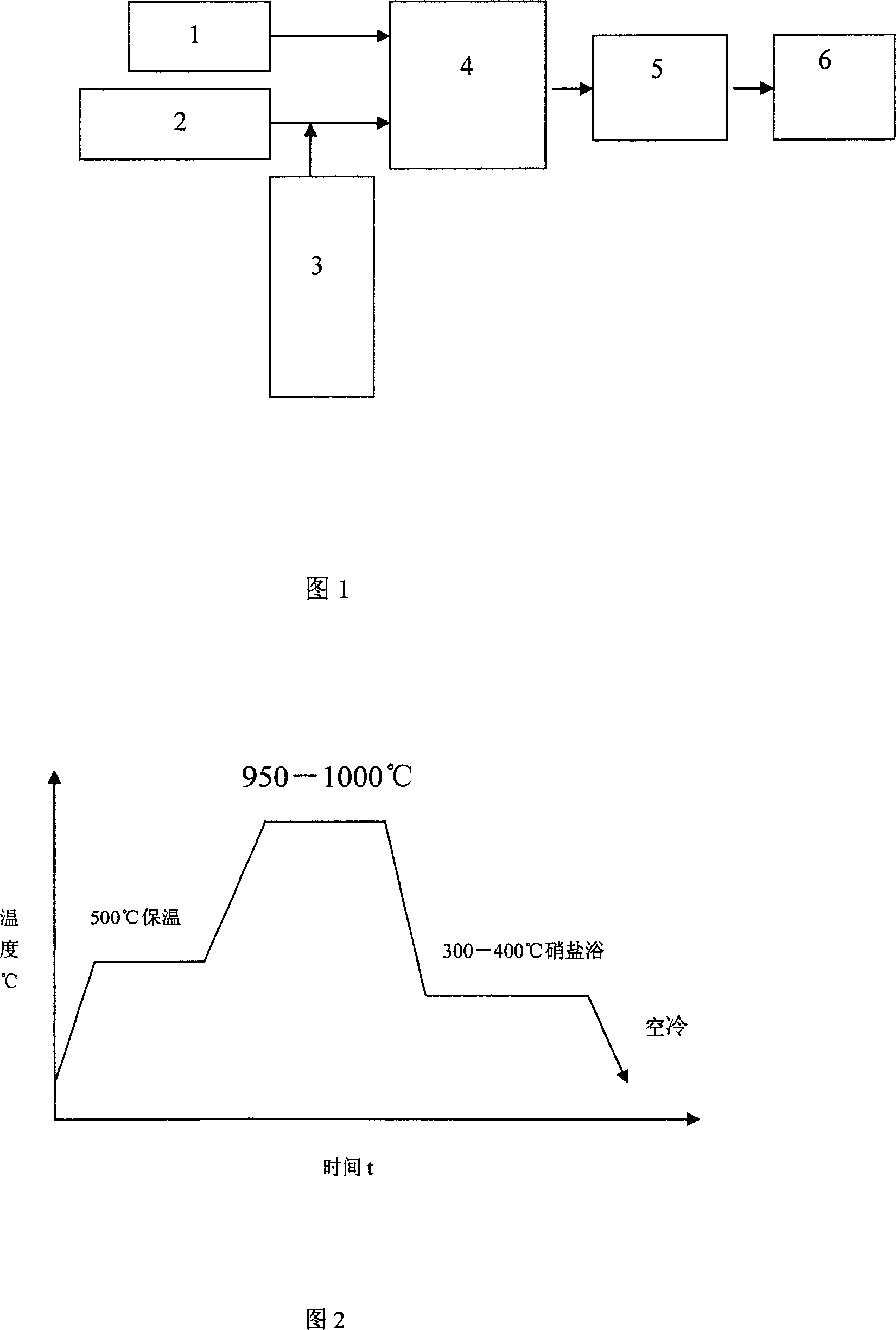

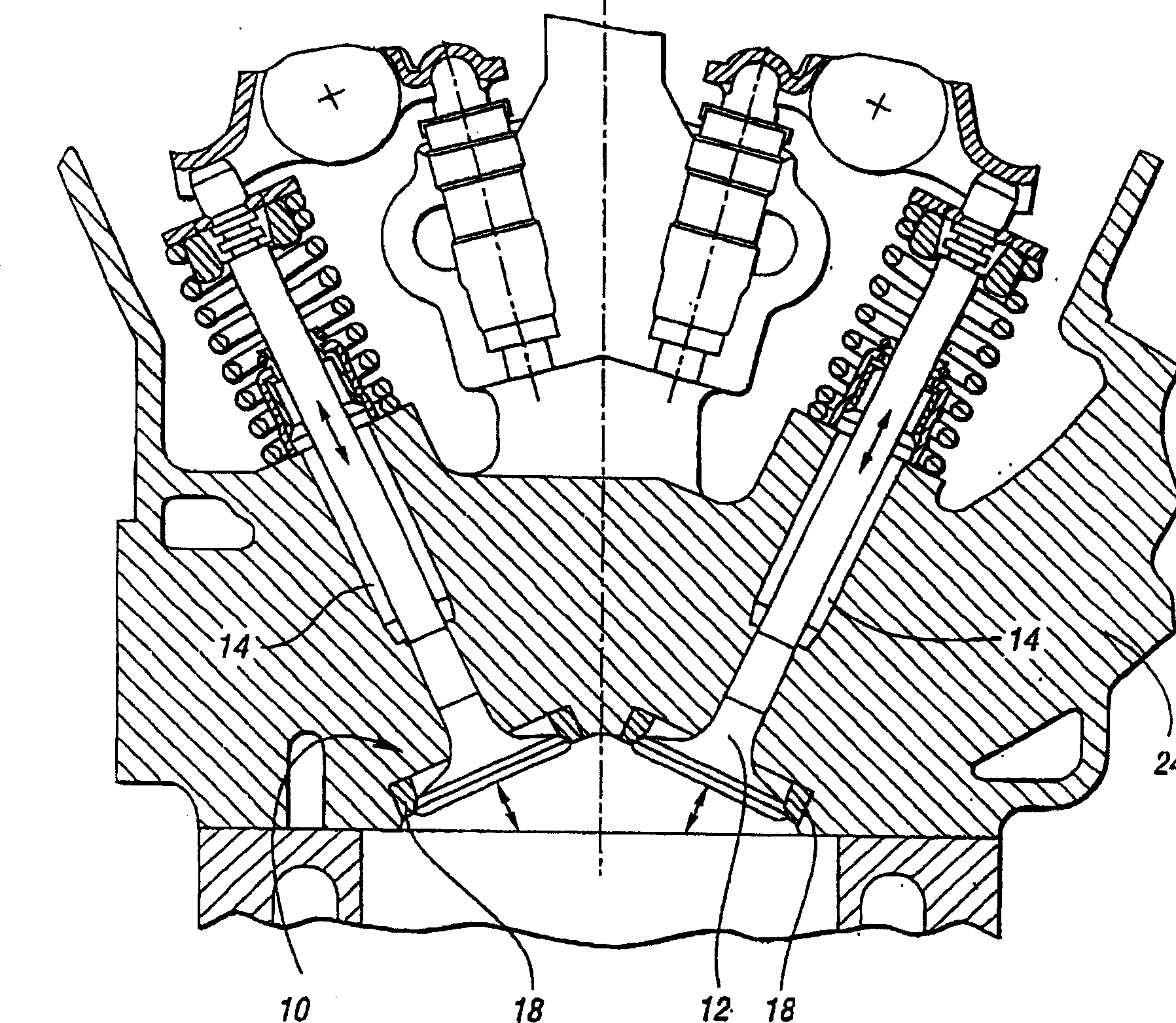

Method for manufacturing high chromium white wear-resistant cast iron

InactiveCN101104196AHigh hardnessImprove impact toughnessHeat treatment bathsIntermediate frequencyWear resistant

The invention discloses a manufacturing method of high chromium white mouth wear resistance cast iron, which adopts a wet casting; pig iron, scrap steel and partial ferroalloy are added in an intermediate frequency induction electric furnace in proportion to smelt qualified liquid iron; and then re modification is carried out; the modified processed liquid iron is cast into a sand mould to be cast and molded; finally isothermal salt bathing heat treatment is carried out. The stiffness, the impacting toughness and the wear resistance of the cast iron manufactured by the method are obviously improved with lower cost , and thus the invention is convenient for the industrial production.

Owner:安徽省安工机械制造有限公司

V2O5 direct alloying steelmaking technology

The present invention discloses process of alloying V2O5 directly to smelting V-containing steel, and features that in the later oxidizing period during smelting steel and after the oxidation sludge is eliminated, the crushed mixture of V2O5, reductant, flux and additive is loaded, so that V2O5 is reduced with the reductant, flux and additive, and the reduced V is alloyed with molten steel directly to form V-containing steel. The present invention can reach V yield over 95 %, and has the advantages of lowered V-containing steel smelting cost, low power consumption and reduced environmental pollution.

Owner:CENT IRON & STEEL RES INST

Power-matallurgy valve seat inserts

InactiveCN1438350AHigh temperature resistanceExcellent machinabilityTransportation and packagingMetal-working apparatusVALVE PORTValve seat

A powdered metal blend mixture for making a powdered metal part especially a valve seat insert. The mixture includes 15 to 30 wt.% of a valve steel powder, 0 to 10 wt.% nickel, 0 to 5 wt.% copper, 5 to 15 wt.% of a ferro-alloy powder, 0 to 15 wt.% of a tool steel powder, 0.5 to 5 wt.% of a solid lubricant, 0.5 to 2 wt.% graphite, 0.3 to 1.0% of a temporary lubricant, and the balance being substantially a low alloy steel powder containing 0.6 to 2.0 wt.% molybdenum, 0 to 5 wt.% nickel, and 0 to 3.0 wt.% copper. The present invention provides improved high temperature wear and corrosion resistance over prior art materials as well as improved machinability. The blend of the present invention provides a relatively high density material that allows for a single press and sinter technique.

Owner:EATON CORP

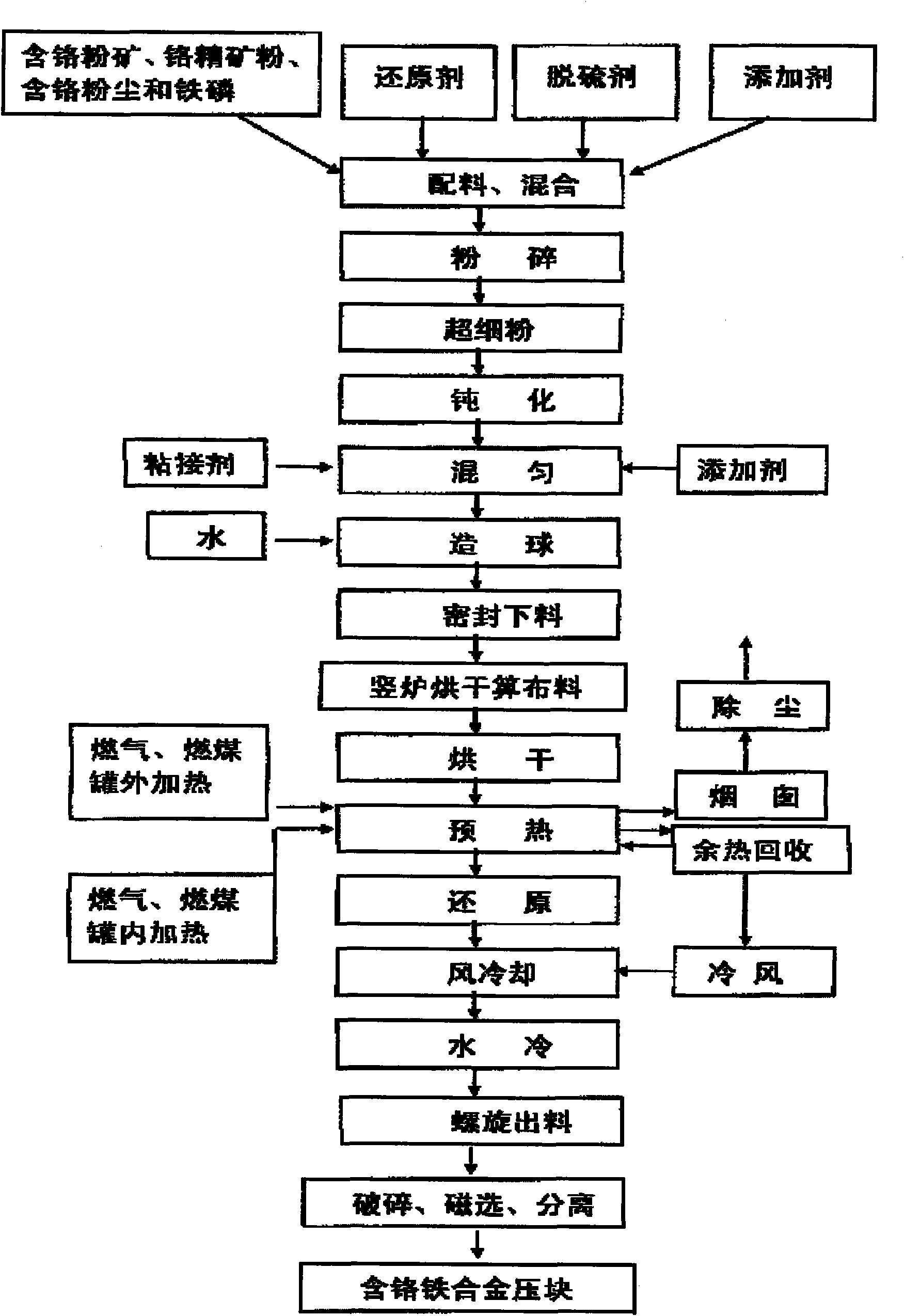

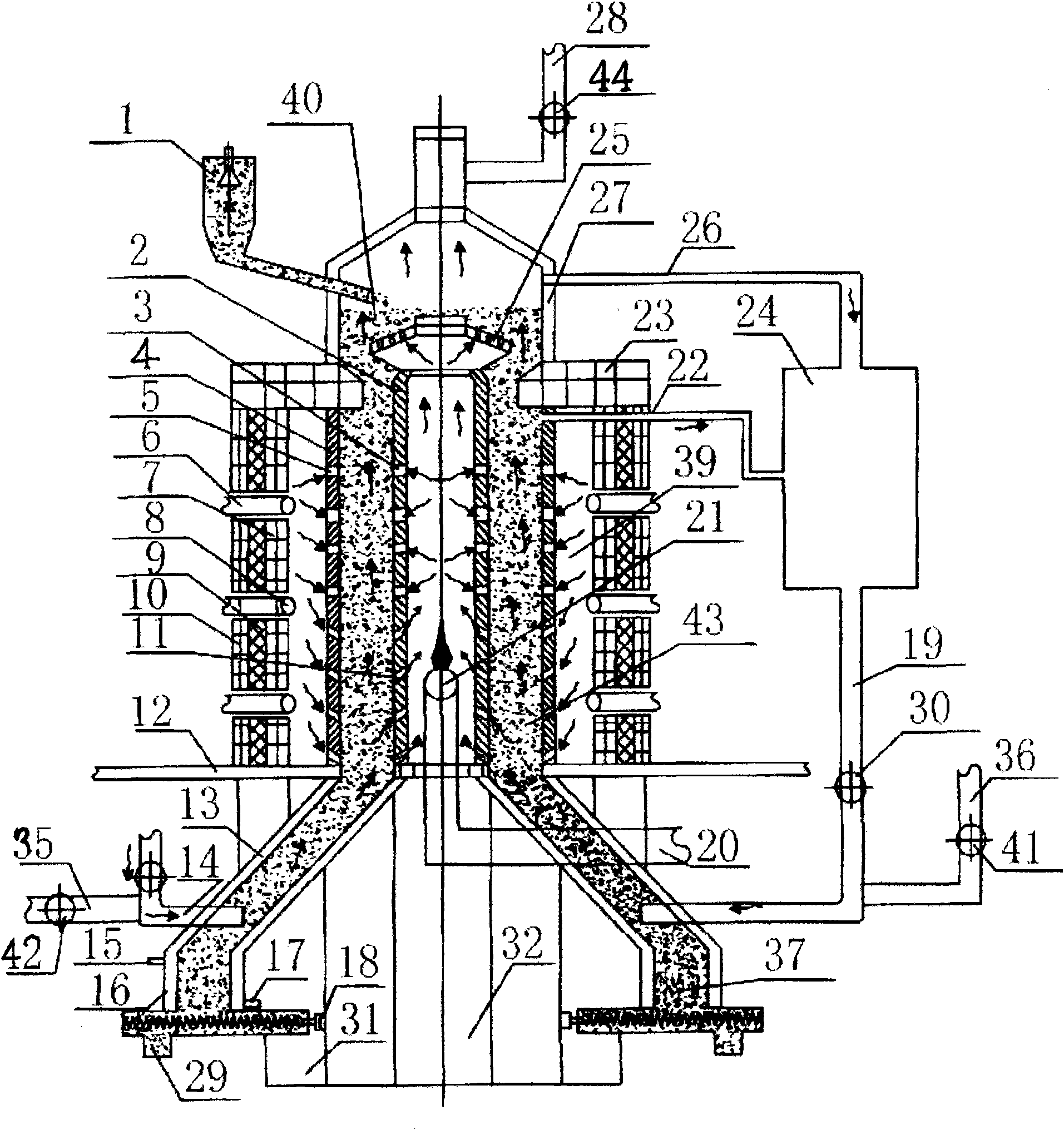

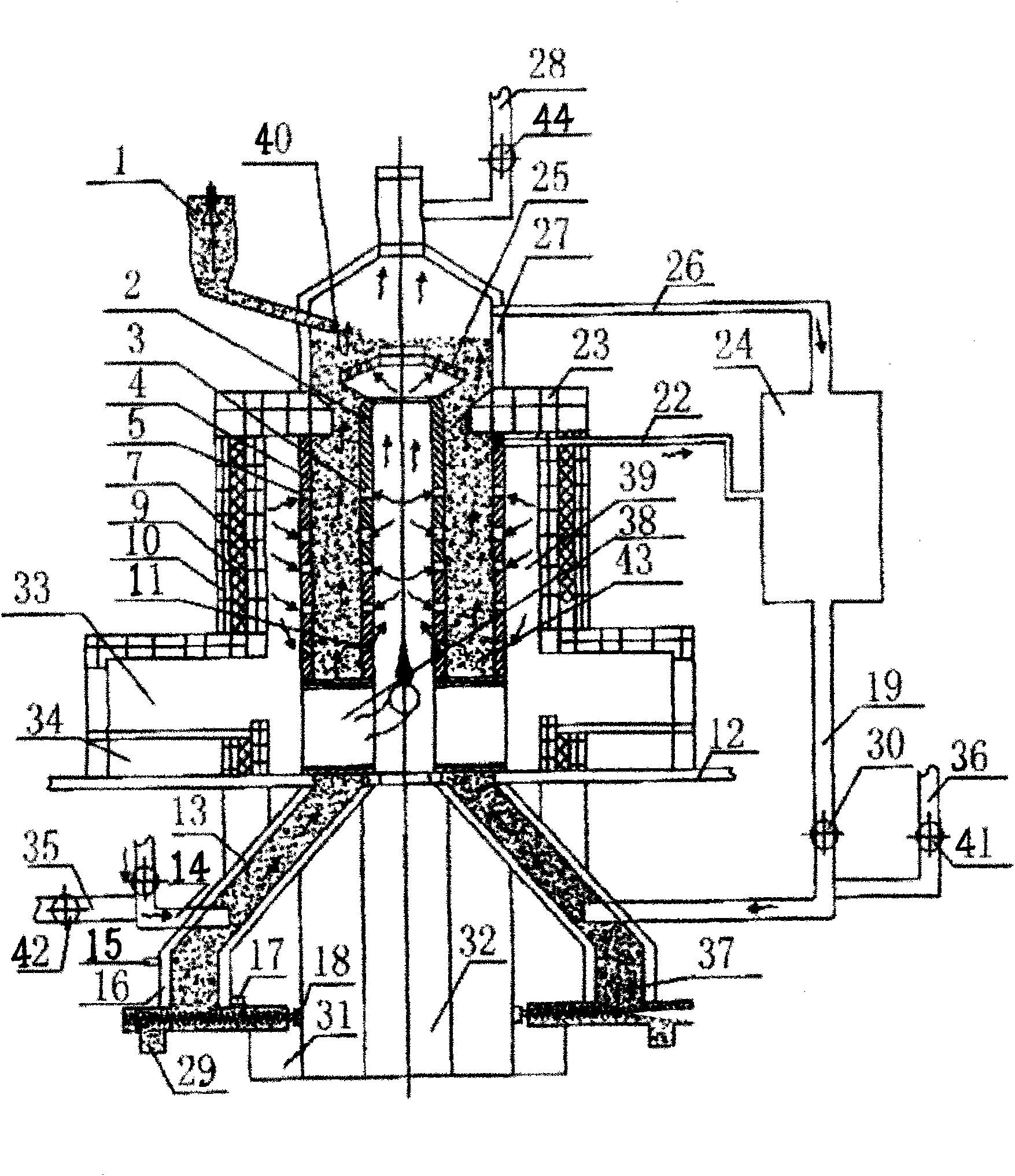

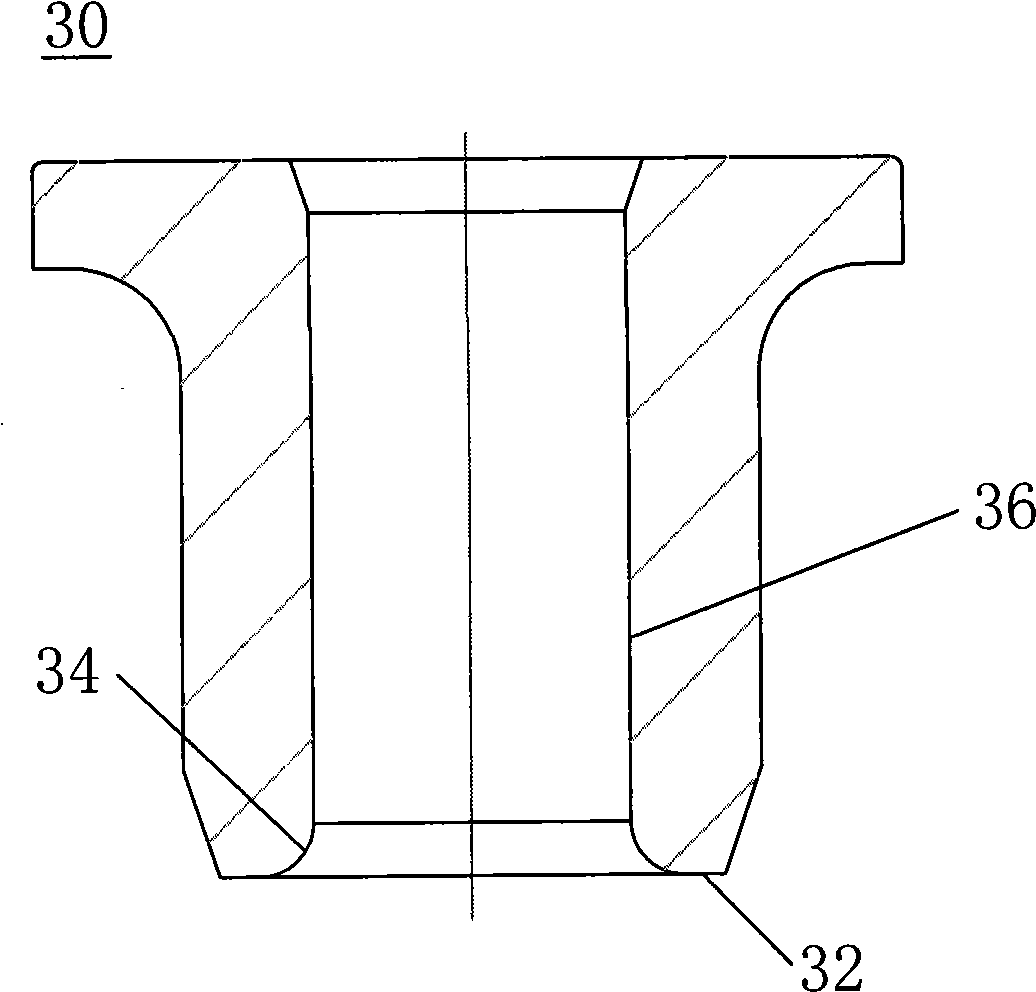

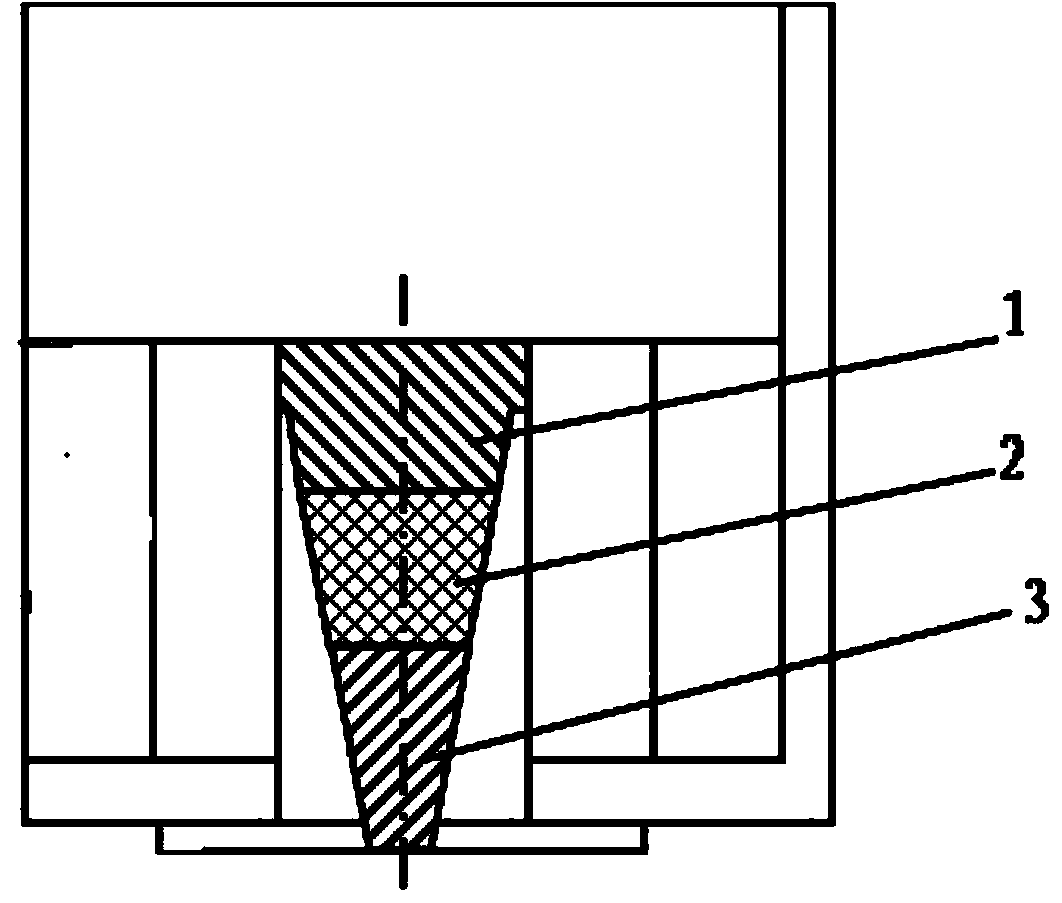

Process and device for preparing chromium iron by using chromium ore powder

InactiveCN101538630AHigh recovery rateGuaranteed uniformityProcess efficiency improvementShaft furnaceResource consumptionSolvent

The invention relates to a process and a device for preparing chromium iron by using chromium ore powder, which belongs to metallurgical industry steel-making raw material. The process comprises the following steps: mixing chromium iron containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the pelletizing materials into a reducing furnace, drying and roasting, and obtaining chromium irons after the reduction reaction. The reducing device is connected with an upper furnace above a furnace base, a lower furnace body is connected to the downside of the furnace base, the upper end of the upper furnace body is connected with an upper furnace mantle, a drying bed grate is positioned at the upper end in the upper furnace body, a purifying device is connected with the upper furnace body and the lower furnace body through pipelines, and a residual heat circulating device is connected with the lower furnace body. The invention has the advantages that: firstly, the reduction temperature is low, the reduction speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is ensured; secondly, the device is simple with less investment, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the cost is low because the chromium ore powder and chromium-containing waste are adopted as raw materials; and fifthly, the waste resource can be recycled so as to save the resource consumption.

Owner:丁家伟

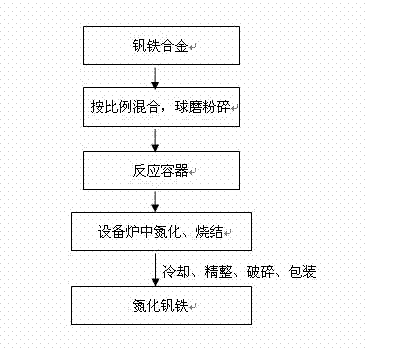

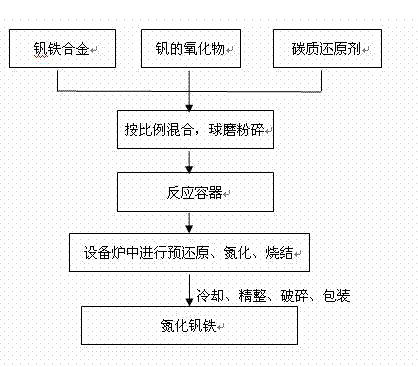

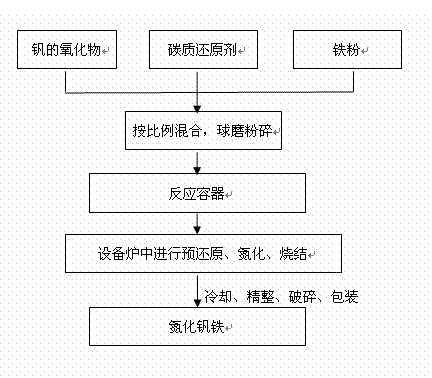

Production method for vanadium nitride ferroalloy

InactiveCN102644015AQuick responseReduce consumptionSolid state diffusion coatingVanadium nitrideReaction temperature

The invention relates to a production method for a vanadium nitride ferroalloy and belongs to the technical field of chemical metallurgy. The technical scheme provided by the invention is that the production method comprises the following steps of: 1-, performing crushing and fine grinding on a raw material after entering a ball mill; 2-, putting the powdery material after being finely ground in a reaction vessel coated with an anti-sticking agent, and then, delivering the reaction vessel filled with the powdery material into a preparation furnace; 3-, introducing reaction gas into the furnace; heating the preparation furnace, and performing a nitriding reaction and a sintering reaction on the powdery material in the preparation furnace; and 4-, discharging under the nitrogen protection for cooling to obtain the vanadium nitride ferroalloy. According to the production method for the vanadium nitride ferroalloy, a pre-reduction reaction, a carbonization reaction and the nitriding reaction are performed on the raw material in the preparation furnace in the manner of powder, and the three reactions are realized in the same equipment furnace, thereby, the production efficiency is high. Briquetting is not needed, and thus, the speed of the nitriding reaction is accelerated; the required reaction temperature is low; the energy consumption is low; and the equipment operating rate and the labor productivity are high. The production method for the vanadium nitride ferroalloy is more suitable for large-scale industrial production. Vacuum equipment is not needed; the raw material completely reacts in the manner of powder; the product quality is stable; and the vanadium yield is high.

Owner:HEBEI IRON AND STEEL

Hard surfacing sintered flux and manufacturing method thereof

InactiveCN101564804AMeet different requirements of hardnessImprove performanceWelding/cutting media/materialsSoldering mediaMaterials preparationThermal fatigue

The invention relates to a hard surfacing sintered flux and a manufacturing method thereof. The sintered flux comprises MgO of 30 percent to 50 precent, CaO of 2 percent to 10 percent, Al2O3 of 10 percent to 20 percent, CaF2 of 18 percent to 28 percent, SiO2 of 10 percent to 20 percent, SiC of 0 percent to 1.5 percent and other components of 0 percent to 5 percent such as ferroalloy mainly playing a role of desoxidation and the like. Material preparation, dry mixing and wet mixing by adding soluble glass into a blender are conducted until granules which have the required sizes are formed, then the granules are dried in a rotary drying way at the low temperature of 200 DEG C to 250 DEG C, and then finished products are obtained by high-temperature sintering in a rotary drying oven at the high temperature of 700 DEG C to 750 DEG C, sieving and packaging. The invention has low flux cost so as to meet the requirements of different hardness, excellent technique and good high-temperature slag detachability; the deposited metal has no gas hole, no crackle but adjustable hardness; and the high-temperature wear-resistance, oxide etch resistance and cold and thermal fatigue resistance of a hot roll are greatly improved.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

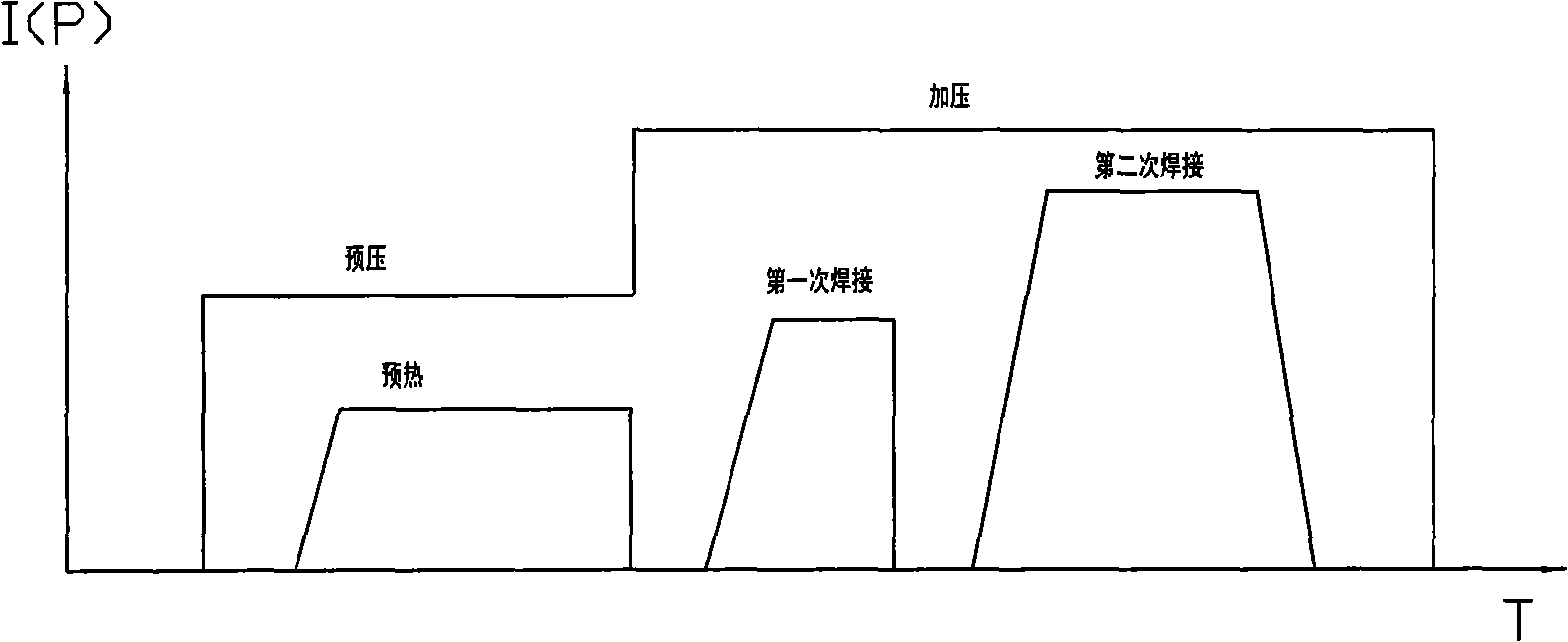

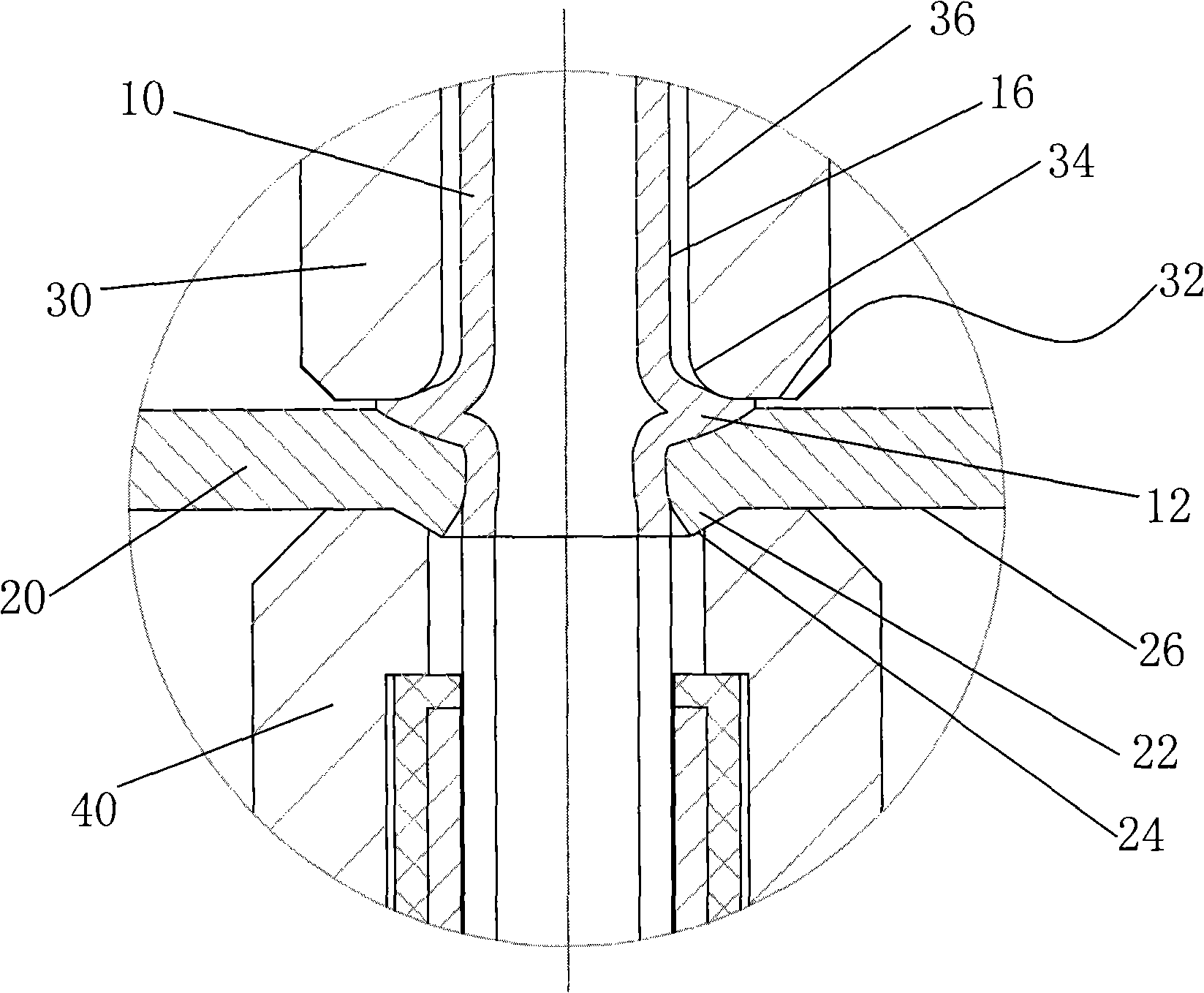

Electric resistance welding method

ActiveCN101318256APromote interpenetrationTightly boundWelding/soldering/cutting articlesResistance welding apparatusElectrical resistance and conductanceWelding power supply

The invention discloses a resistance welding method for welding the copper or copper alloy and the steel or steel alloy, which adopts general principles of the resistance welding to carry out the spot welding or the loop projection welding of the copper or the copper alloy and the steel or the steel alloy to obtain complete liquid phase nuggets by using the technique of applying pulse currents and pressures by sections on special electrode tips of the resistance welding and a special welding power, and the real welding can be realized, wherein, the welding power provides direct current for welding and the discharging time is 110ms to 280ms, the maximum current is 36KA to 280KA, the current frequency before the rectification is 1000Hz, 1200Hz or 1500Hz, the welding current between work pieces and the electrode tips is the direct current, and the pressure is 1 to 5.9Kgf / cm<2>.

Owner:HERON INTELLIGENT EQUIP CO LTD

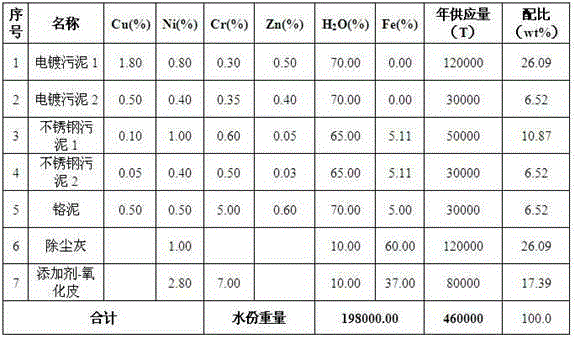

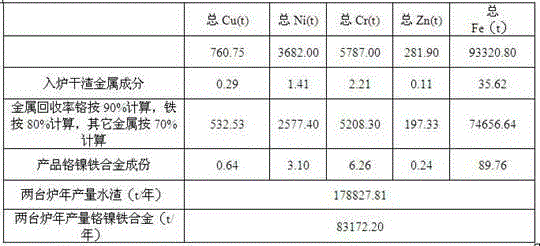

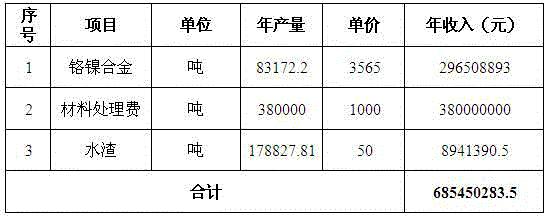

Heavy metal sludge recycling and comprehensive utilization method

InactiveCN104561525AAvoid secondary pollutionSave resourcesProcess efficiency improvementSludgeDust control

The invention belongs to the field of reutilization of heavy metal sludge, and particularly relates to a heavy metal sludge recycling and comprehensive utilization method. The method comprises the following steps: mixing stainless steel sludge, electroplating sludge, chromium sludge, dedusting ash generated in the chromium-nickel-iron alloy production process, and additive scales, predrying, carrying out reduction roasting, smelting to obtain a chromium-nickel-iron alloy, and using the byproduct smelting slag in preparing the cement additive. The dedusting ash and smelting slag generated in the whole technical process can be recycled, and thus, the method does not generate secondary pollution, maximally saves the resources and energy, lowers the production cost, and has obvious economic benefits.

Owner:FUJIAN NONNON RENEWABLE RESOURCES TECH

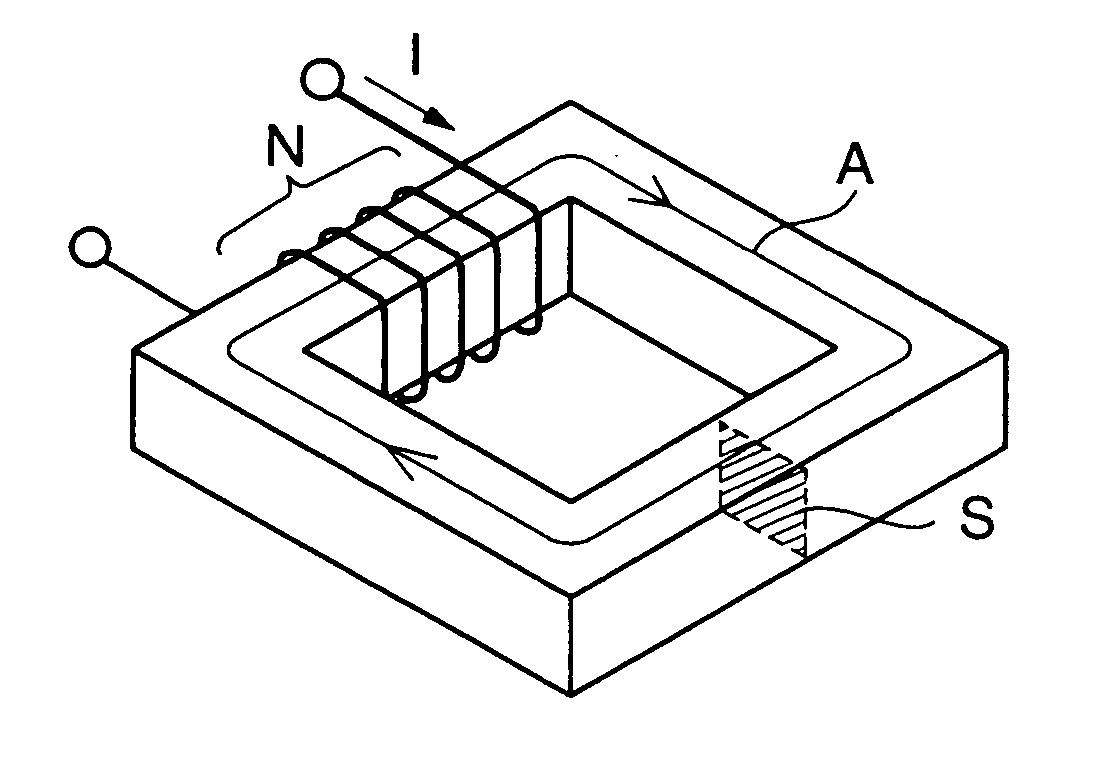

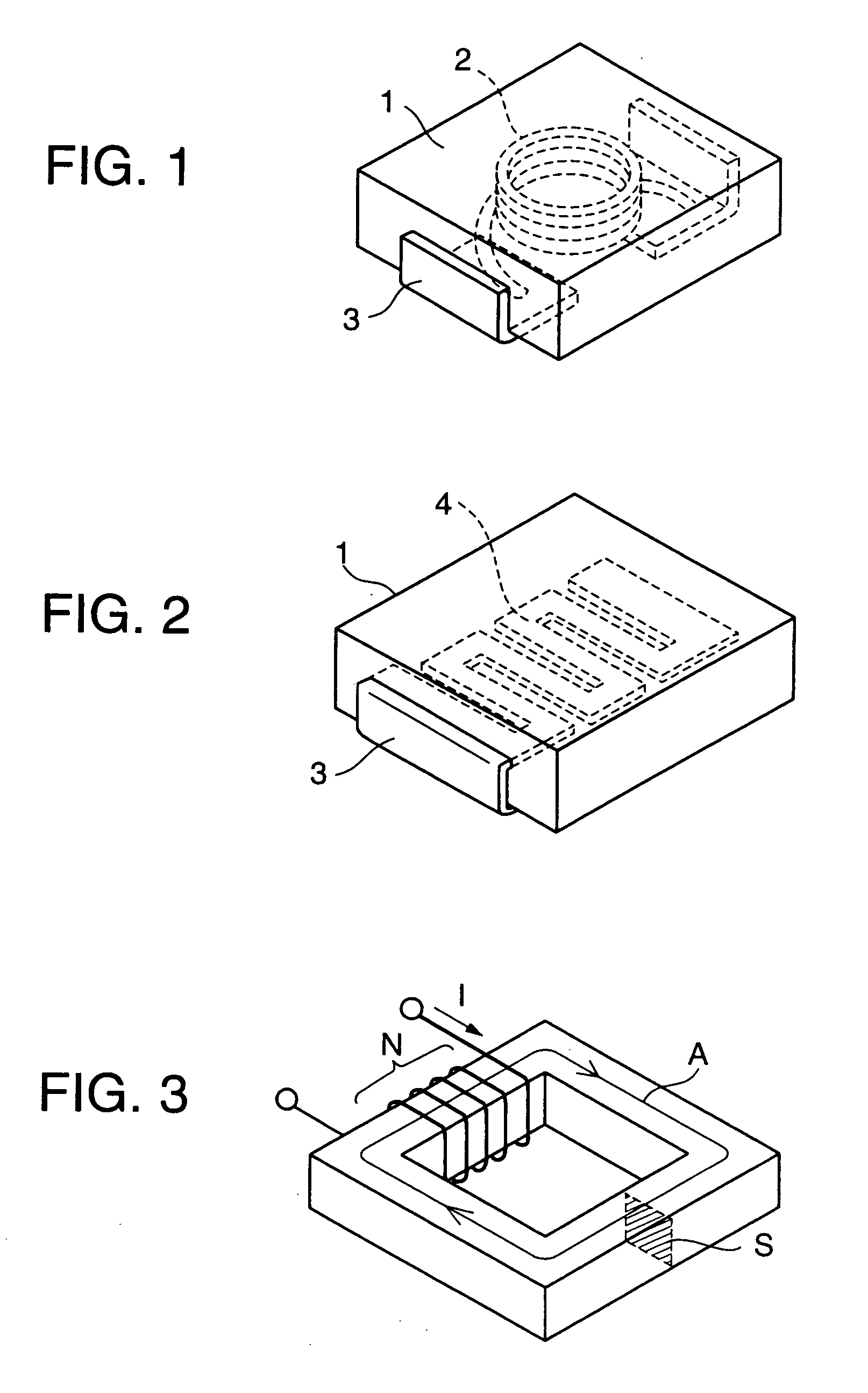

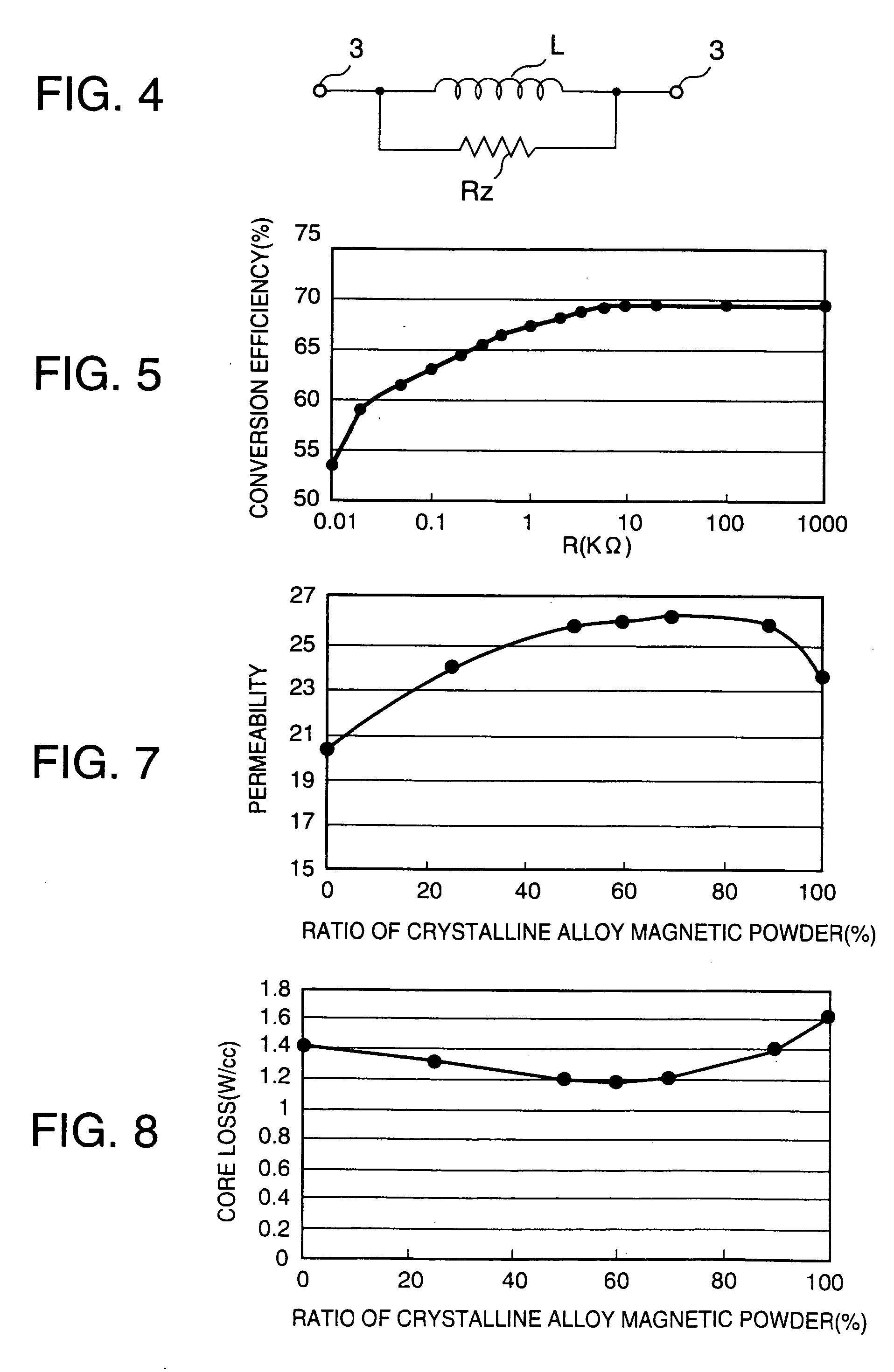

Complex magnetic material, and core and magnetic element using the complex magnetic material

Conventional single-piece molded-type inductors are made by pressure-molding magnetic particles of ferroalloy, and have a problem that their insulation resistance drops sharply when placed in a high-temperature environment. Complex magnetic powder is obtained by mixing ferrous crystalline alloy magnetic powder with ferrous amorphous alloy magnetic powder, a connecting agent of 1 wt % to 10 wt % of the mixed magnetic powder being additionally mixed therein, producing a complex magnetic material for use in electronic components. Furthermore, a core is pressure-molded from the complex magnetic material, and a coil is buried in the core to obtain a magnetic element, such as an inductor.

Owner:TOKO KABUSHIKI KAISHA

Rare earth alloy iron pan and production method thereof

InactiveCN103239139AImprove mechanical propertiesHigh burst resistanceCooking-vessel materialsSocial benefitsVegetable oil

A rare earth alloy iron pan production method includes: (1) smelting cast iron by an intermediate frequency furnace, and heating the iron molten iron till the temperature is higher than 1400 DEG C; (2) smashing rare earth ferrosilicon alloy till the size ranges from 2mm to 6mm, and preheating till the temperature reaches 60 DEG C; (3) placing the rare earth ferrosilicon alloy block with a quantity of weight ratio ranging from 0.3% to 1.8% in a ladle and then pouring the molten iron, and mixing and drossing; (4) casting after the molten iron is cleared, preheating a casting mold and injecting the molten iron to the mold, and pressing an upper pan mold down to form an iron pan; (5) taking out the iron pan after the iron pan is chilled in the mold, and clearing in a mechanical fine grinding and buffing manner; (6) feeding the iron pan into an electric furnace, heating till temperature ranges from 270 DEG C to 330 DEG C, painting edible vegetable oil on the pan body to form an oil film, and allowing oil molecules to penetrate in the pan body; and (7) taking out the iron pan and detecting. The rare earth alloy iron pan production method has good social benefit and economic benefit, and is adaptable to the field of iron pans.

Owner:SANSUI HONGLI KITCHEN UTENSILS CO LTD

Rare-earth ferroalloy and preparation process thereof

The invention relates to a rare-earth ferroalloy for producing a rare-earth permanent magnetism material with high performance and a preparation process thereof. The ferroalloy comprises the contents according to the weight percentage: 30-90 of neodymium or didymium rare earth, and the balance ferrum and less than 1 of unavoidable impurities, wherein the O content is less than or equal to 0.1, the C content is less than or equal to 0.1 and the N content is less than or equal to 0.05. The alloy is prepared by an electrolytic method of fluoride molten salt system oxide, and an electrolyte of the alloy comprises rare-earth fluoride and lithium fluoride.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

Method for adding nitrogen element into smelting molten steel of vacuum induction furnace

The invention relates to a method for adding a nitrogen element into smelting molten steel of a vacuum induction furnace. The method comprises the following steps of: when a steel grade into which the nitrogen element is needed to be added is smelted in the vacuum induction furnace, adding nitrogen-containing iron alloy which does not damage the quality of molten steel into a hopper; and after the molten steel is subjected to high vacuum refining and deoxidized fully, introducing argon into the furnace and an ingot mold, adding the nitrogen-containing iron alloy for deoxidizing finally, tapping and pouring. The method is simple and reliable; and after furnace charges are molten completely, refined and deoxidized, and the nitrogen-containing iron alloy is added under the protective atmosphere of the argon and is deoxidized finally, the molten steel is tapped and poured, so the aim of adding the nitrogen element accurately at low cost is fulfilled, the content of the nitrogen element can be controlled accurately, and the recovery rate is stabilized to be over 65 percent.

Owner:LUOYANG SHUANGRUI SPECIAL ALLOY MATERIALS

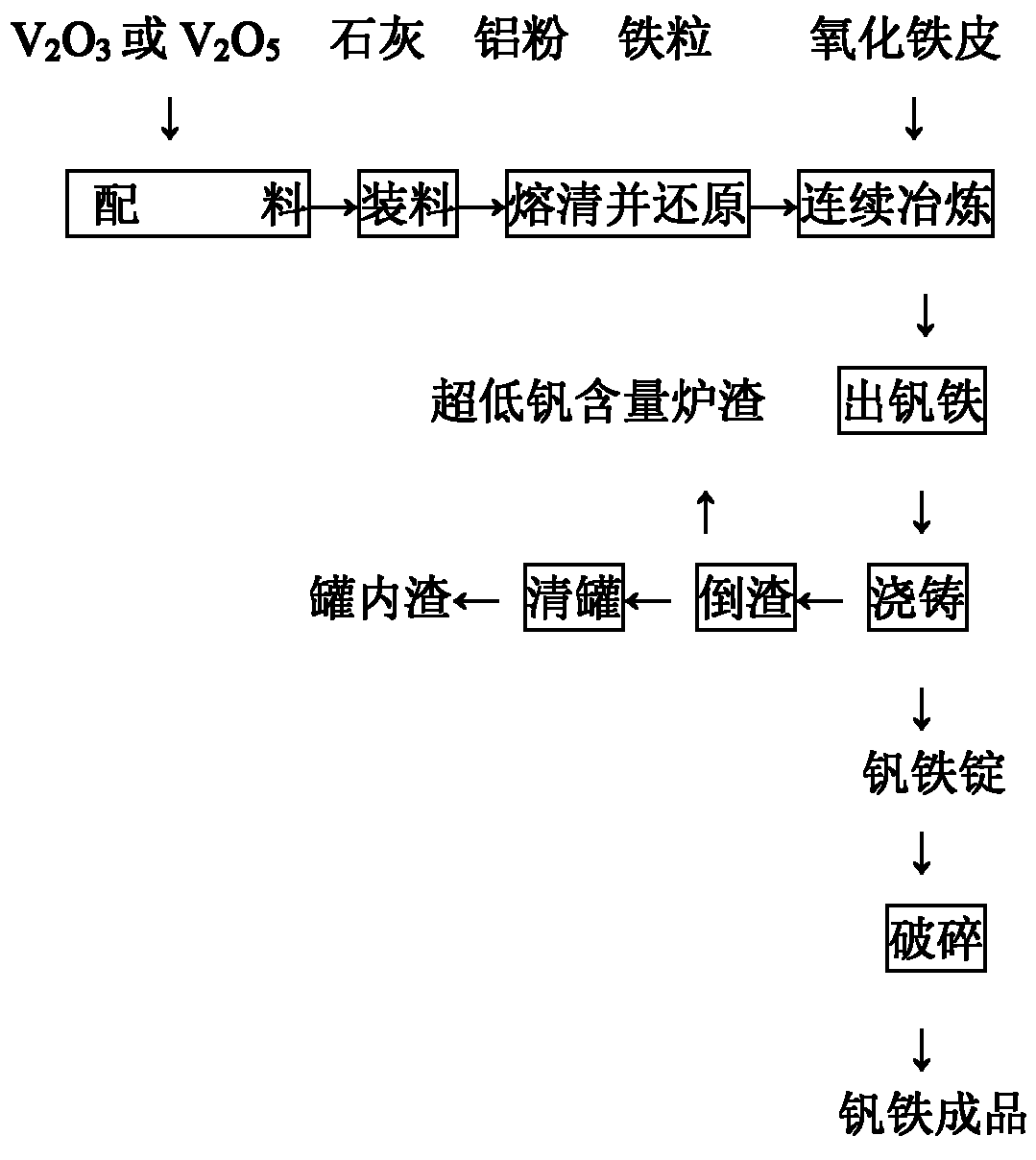

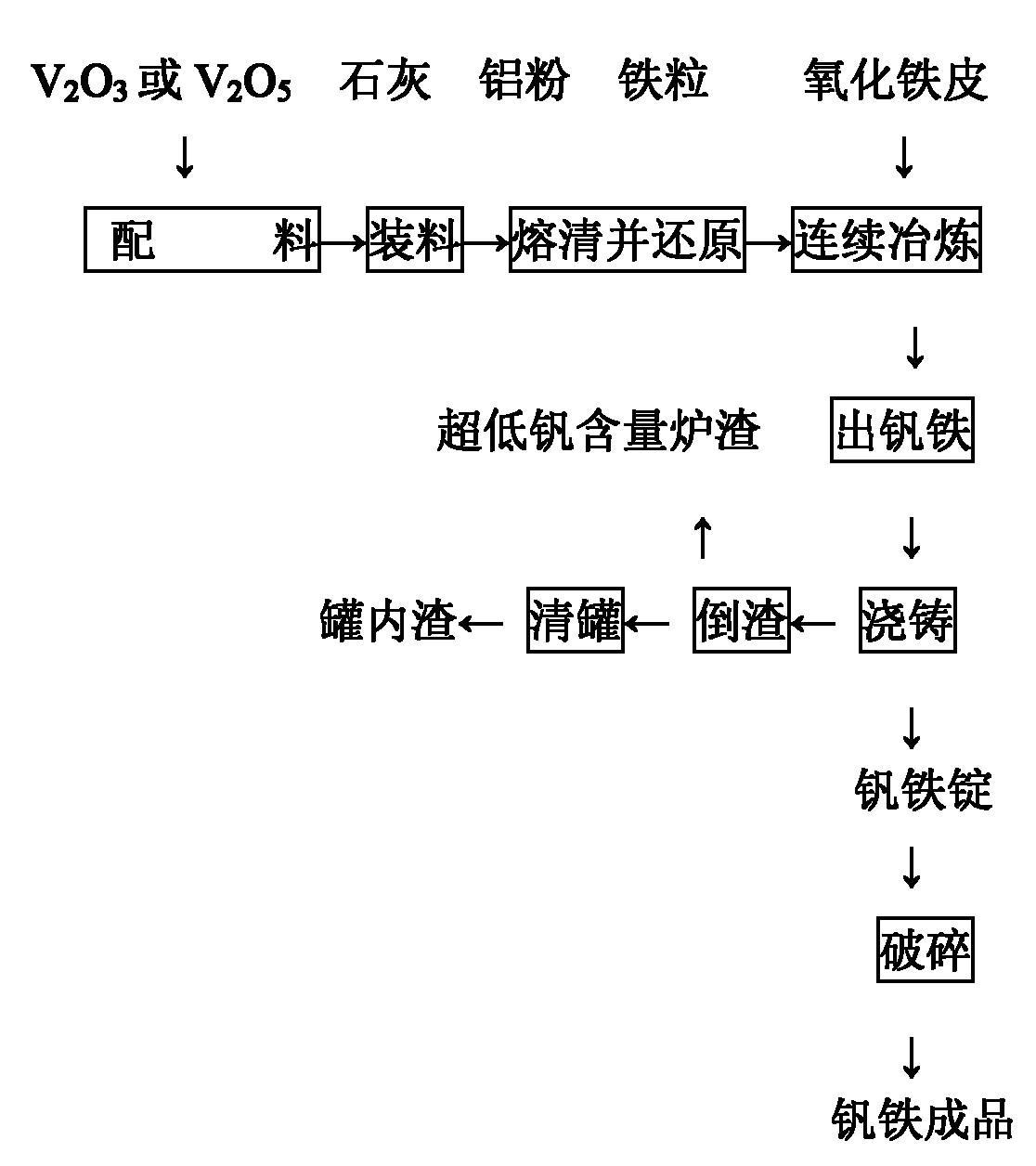

Production process for smelting vanadium ferro-alloy by electro-aluminothermic process

InactiveCN102094097AFully extractedFull recoveryProcess efficiency improvementFurnace temperatureResource utilization

The invention belongs to the technical field of iron alloy smelting, and in particular relates to a production process for smelting vanadium ferro-alloy by an electro-aluminothermic process. The important improvement is to provide a low-cost and easily controlled slag modification step in which a furnace liner is not corroded. The production process comprises the following steps of: A, mixing materials; B, performing reductive smelting; C, modifying slag; and D, casting and crushing for forming according to a conventional method. The improvement is that: iron oxide is added into the step C for modifying the slag, and the adding amount of the iron oxide is 15 to 20 percent of the weight of aluminum; and after the iron oxide is smelted, when the vanadium ferro-alloy is smelted to the furnace temperature of between 1,600 and 1,900DEG C and the aluminum in the vanadium ferro-alloy melt is less than 0.5 percent, the vanadium ferro-alloy melt and the slag are discharged together from the furnace. The added iron oxide facilitates removal of residual aluminum, and the aluminum in the alloy is reduced to be 0.2-0.5 percent; meanwhile, the slag property can be adjusted, the smelting point of the furnace slag is reduced, the smelting is smoothly performed and the metals in the slag are settled to the alloy melt; moreover, the yield of vanadium is 97 to 99 percent, so that the vanadium ferro-alloy smelting cost is reduced, the product quality is improved, and the enterprise benefit and resource utilization rate are improved.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +3

Method for smelting chromium-nickel-iron alloy from stainless steel dust-removing ash

InactiveCN101126138AEasy to recycleReduce pollutionProcess efficiency improvementChromium nickelFerrosilicon

The invention is a stainless steel ash removing method for smelting inconel. The method comprises the steps as follow; 1 make ash removing block, comprising the following three steps; 1) selective mixing; 2) extrusion molding; 3) natural drying; 2 make the master liquid by melting the normal recycled waste steel or stainless slag steel, pre-treated the molten iron, the ash removing block and the chromate nickel sponge iron inside the electric furnace; 3 batch-by- batch restoring, which comprises the following three steps: 1) add the block and the extra coke or coke breeze to smelt after the raw material used as master liquid is fully melted; 2) supply power with 15 to 20 minutes, then stop for conducting the operations of temperature measuring, exampling and analyzing, and add ferrosilicon breeze and lime; 3) the molten iron is remained between 1550 to 1600 DEG C in the smelting process; 4 finally restoring, and the main components of the metal solution after being finally restored are as follow: C percent is more than or equal to 2.50, Si percent is more than or equal to 0.20, P percent is less than or equal to 0.045, Cr percent is more than or equal to 5.0, and Ni percent is more than or equal to 1.5. The invention has the advantages of reducing environment pollution and increasing the metal yield of the ash removing.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

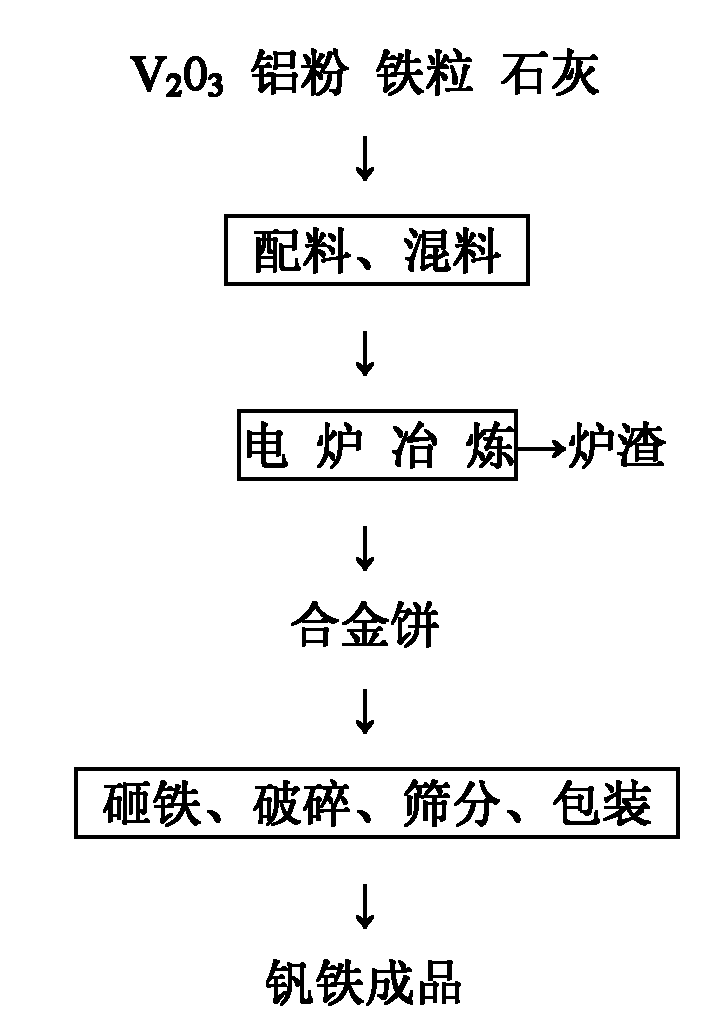

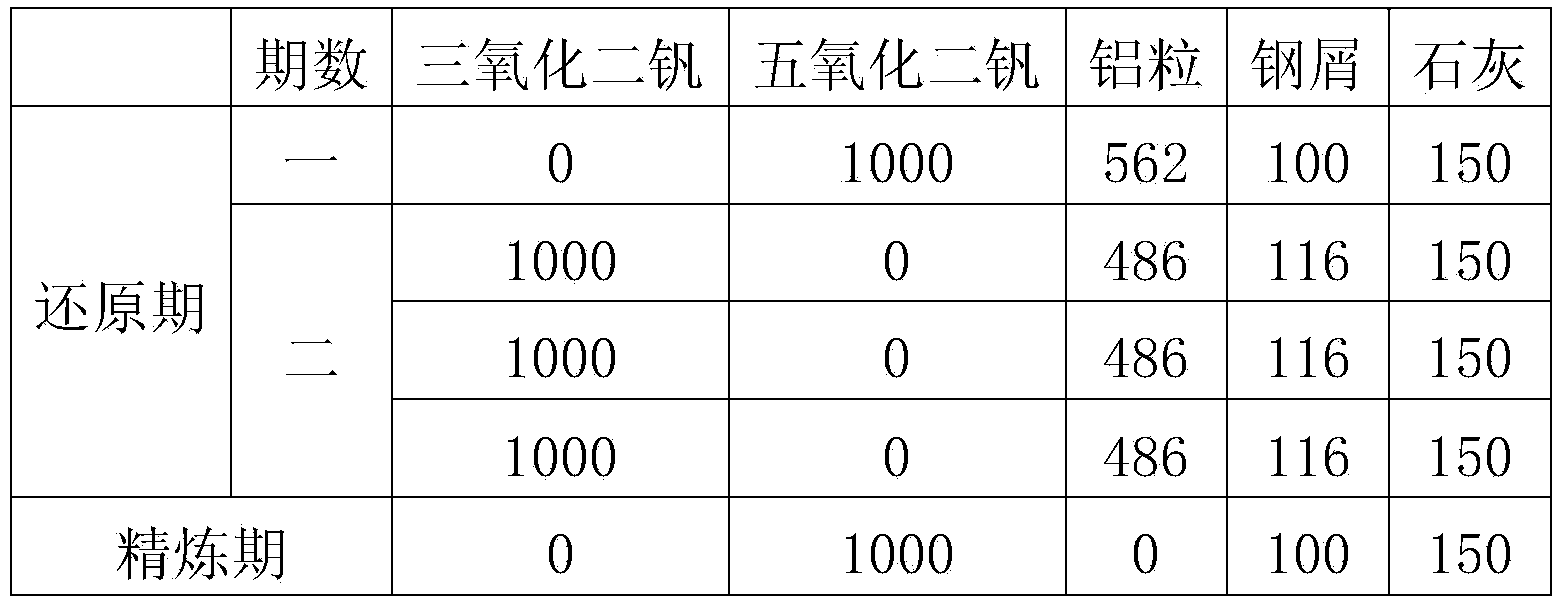

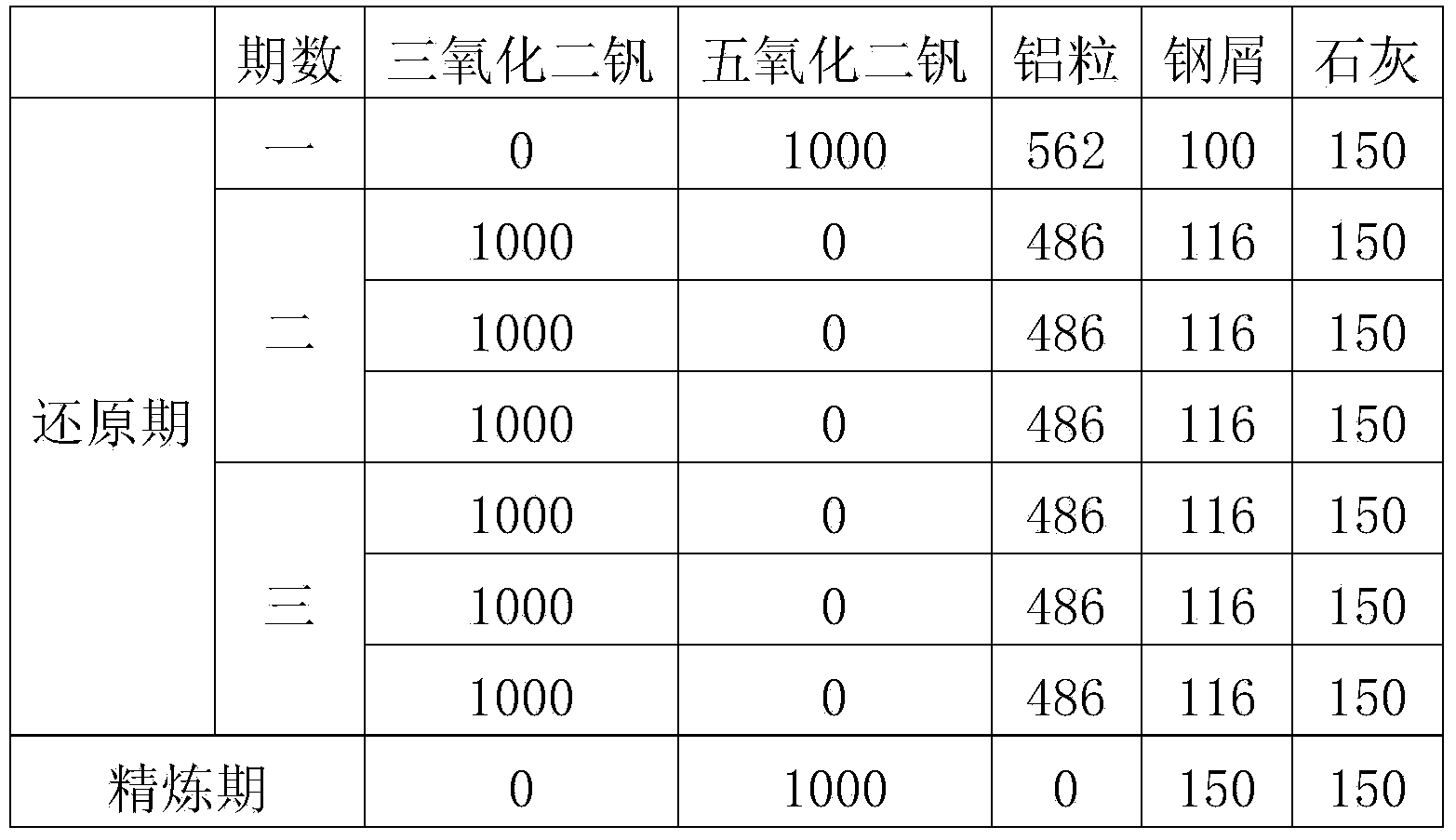

High vanadium ferroalloy smelting method and ingot mould for smelting high vanadium ferroalloy

ActiveCN103757171AReduce coolingOvercoming difficult follow-up problemsProcess efficiency improvementReduction treatmentElectric arc furnace

The invention discloses a high vanadium ferroalloy smelting method. The method comprises the steps of adding cold-state vanadium-rich slag and limestone to the bottom of an electric arc furnace, adding a phase-I mixture consisting of vanadium pentoxide, aluminum particles, limestone and steel cuttings and smelting; returning heat-state vanadium-enriched slag of last batch into the electric arc furnace and discharging slag when vanadium content in smelting slag is less than 0.5%; adding a phase-II mixture consisting of vanadium trioxide, aluminum particles, limestone and steel cuttings, smelting, discharging slag when vanadium content in smelting slag is less than 0.5%, and before discharging the slag, adding aluminum or aluminum-magnesium alloy for reduction treatment; adding a refining mixture consisting of vanadium pentoxide and limestone or iron scale and limestone, smelting, controlling temperature of vanadium-iron alloy liquid in the furnace to be above 1900 DEG C, discharging the vanadium-iron alloy liquid and the vanadium-enriched slag when vanadium content is 78-82% and aluminum content is less than 1.5% in the vanadium-iron alloy liquid, pouring the vanadium-iron alloy liquid into an ingot mould which is preheated to be above 500 DEG C, and cooling, demoulding and breaking to obtain high vanadium ferroalloy which contains more than 80% of vanadium.

Owner:攀钢集团西昌钒制品科技有限公司

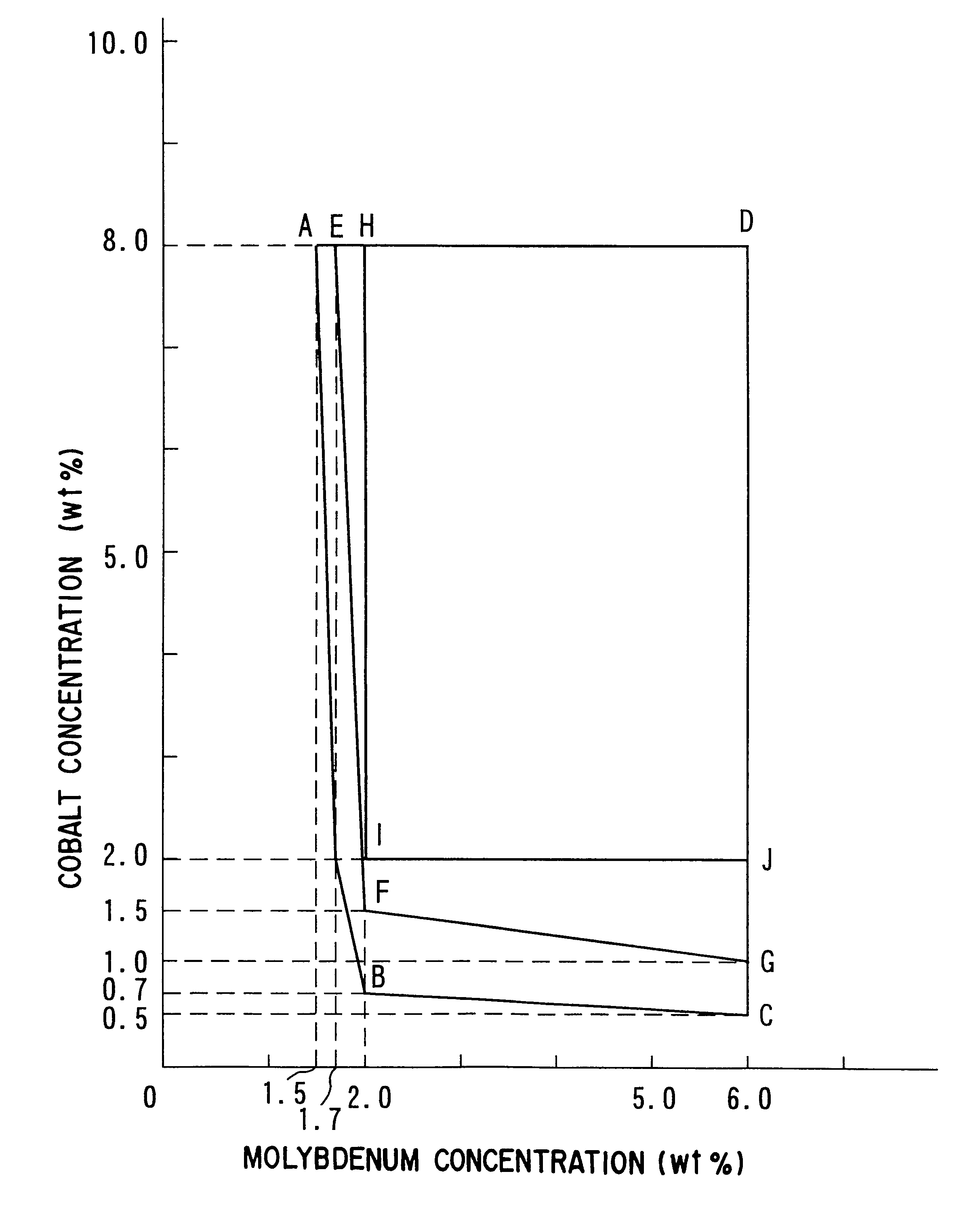

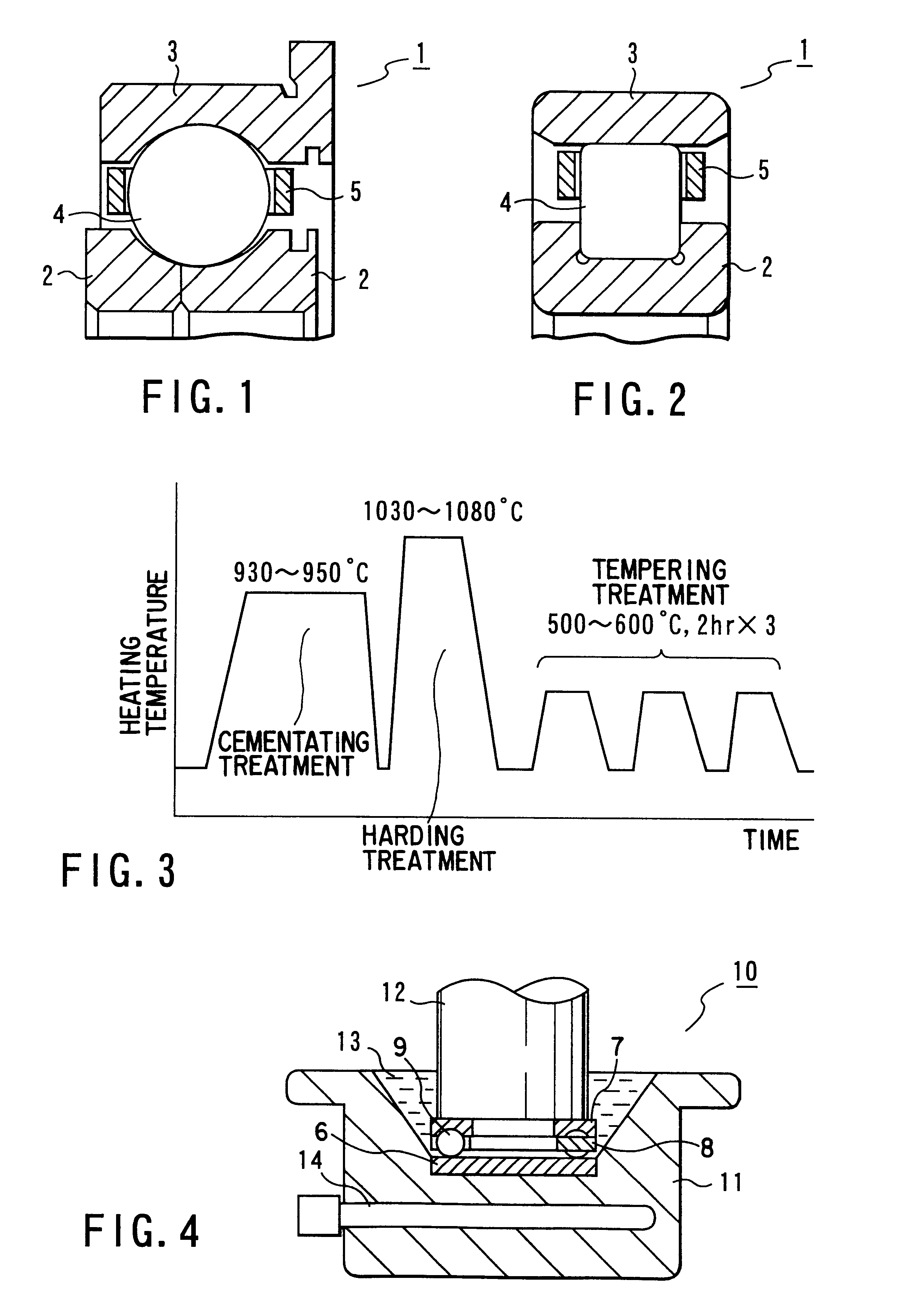

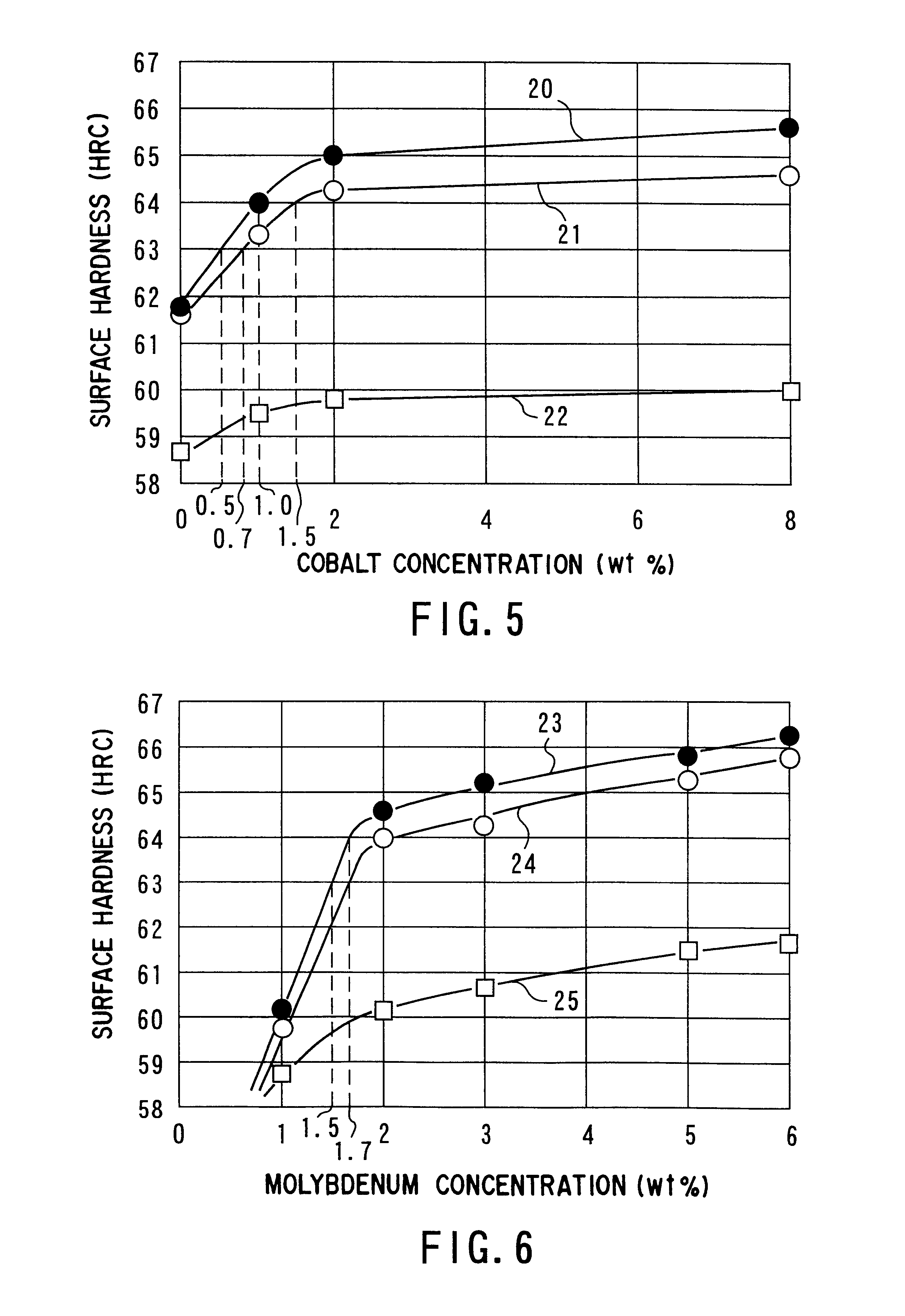

Ball-and-roller bearing and method of manufacturing the same

InactiveUS6248186B1Excellent in mechanical characteristic and corrosion resistanceBearing componentsSolid state diffusion coatingSurface layerBall bearing

A ball-and-roller bearing is disclosed having an inner ring, an outer ring arranged on the axis of the inner ring and rotating around the co-axis relative to the inner ring, and a rolling body interposed between the inner ring and the outer ring and rolling with rotation of the outer ring relative to the inner ring. One of the inner ring, the outer ring, and the rolling body has a core member made from an alloy containing iron, at least one of 0.2 to 1.0% by weight of silicon and 0.2 to 1.5% by weight of manganese, 7.0 to 11.0% by weight of chromium, 1.5 to 6.0% by weight of molybdenum, and 0.5 to 8.0% by weight of cobalt, and a case hardened surface layer. Also disclosed is the method of manufacturing the bearing by forming a core member of the alloy, forming a case hardened layer containing 0.9 to 1.5% by weight of carbon in a surface region of the core member by applying to the core member a carbonizing or carbonitriding treatment, a hardening treatment, and a tempering treatment under high temperatures, and assembling the inner ring, the outer ring and the rolling body such that the inner ring and the outer ring are positioned on the same axis and the rolling body is between the inner ring and the outer ring.

Owner:NSK LTD

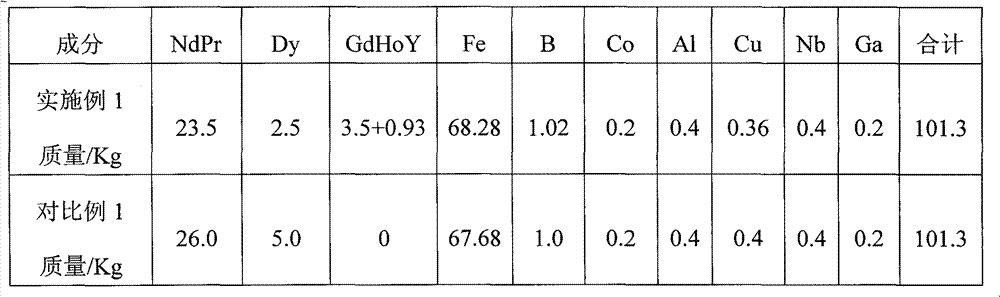

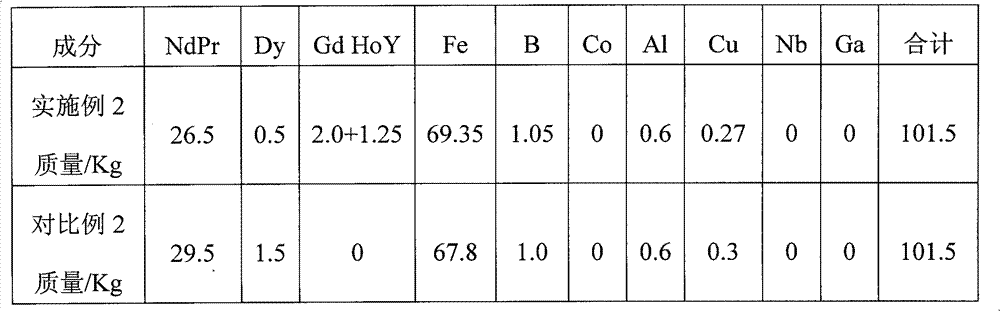

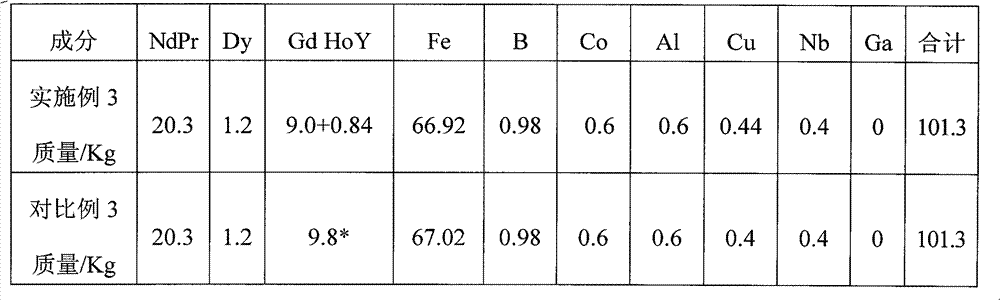

Method for preparing composite sintered neodymium-iron-boron permanent magnet material added with gadolinium, holmium and yttrium

ActiveCN102956336AImprove remanenceIncrease the maximum energy productInorganic material magnetismRare-earth elementCurie temperature

The invention provides a method for preparing a composite sintered neodymium-iron-boron permanent magnet material added with gadolinium, holmium and yttrium. The method includes the steps of primary batching, fusion casting, milling, secondary batching, powder mixing, forming, sintering and heat treatment, wherein in the primary batching step, iron alloy added with three rare earth elements of the gadolinium, the holmium and the yttrium is composited, and in the secondary batching step, oxide added with the three rare earth elements of ultrafine gadolinium, holmium and yttrium and cuprous oxide powder are composited. By the method, the relative surplus and cheap gadolinium, holmium and yttrium can be used for partially substituting for rare earth elements of neodymium, praseodymium or dysprosium, and accordingly neodymium, praseodymium or dysprosium consumption can be decreased by 10-30wt.%. Besides, Curie temperature and coercivity force of the prepared neodymium-iron-boron permanent magnet material are increased, corrosion resistance is enhanced, operating temperature and toughness are increased, and processability is improved.

Owner:GANZHOU JIATON ADVANCED MATERIALS

Method for increasing self-pouring rate of ladle and purity degree of molten steel

ActiveCN104338926AImprove high temperature performanceStable supportMelt-holding vesselsMetallic foreign materialNon-metallic inclusions

The invention relates to a method for increasing the self-pouring rate of a ladle and the purity degree of molten steel. The method comprises the following steps: filling an upper nozzle with upper plugging layer material and lower plugging layer material, wherein the upper plugging layer material is chrome ladle filler sand, and the lower plugging layer material is spherical particle ferroalloy; filling the space between the upper plugging layer material and the lower plugging layer material with mixed layer material, wherein the mixed layer material is a mixture of spherical ferroalloy and ladle filler sand, and the fineness ratio of the spherical ferroalloy to the ladle filler sand ranges from 2 to 5. The method provided by the invention is simple and easy to operate, can improve the high-temperature property of a sintered layer, increases the self-pouring rate of the ladle, remarkably reduces the addition of conventional ladle filler sand, reduces non-metallic foreign materials which are brought in by ladle filler sand during pouring of the ladle, and increases the purity degree of molten steel.

Owner:NANJING IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com