Rare-earth ferroalloy and preparation process thereof

A ferroalloy and rare earth technology, applied in the field of rare earth pyrometallurgy, can solve the problems of low current efficiency and rare earth metal yield, unsuitable for large-scale industrial production, increased cost of fluorine-containing harmful gases, etc., and achieves current efficiency and rare earth metal yield. High metal yield, improve metal yield, current efficiency and product quality, and reduce anode current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

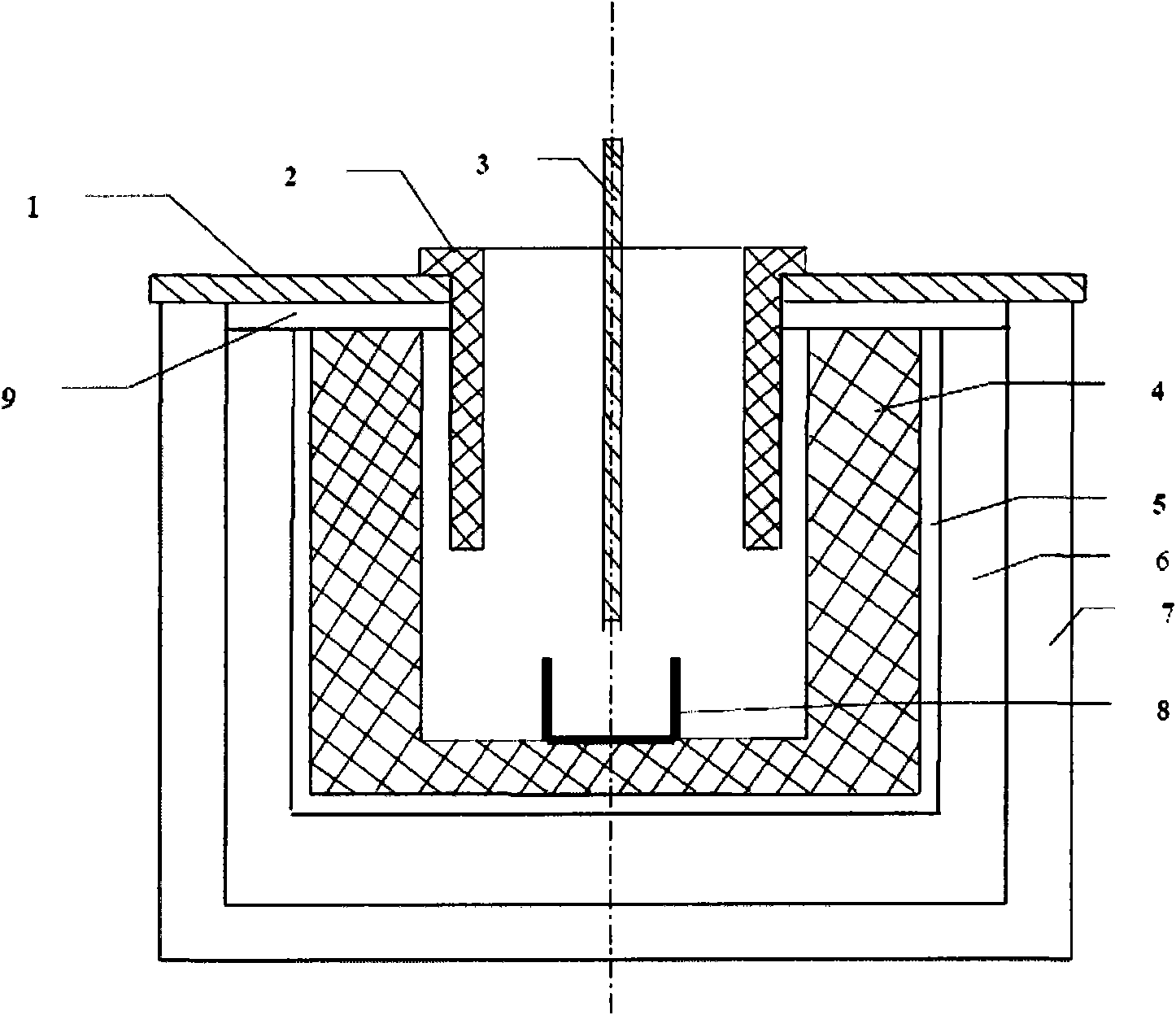

Method used

Image

Examples

Embodiment 1

[0046] Φ600mm circular graphite electrolytic cell is used, the anode is composed of 4 graphite plates, and NdF in the electrolyte 3 The content is 65wt%, LiF is 35wt%, the iron cathode is Φ55mm pure iron rod, the average current intensity is 2400A, and the anode current density is 0.5~0.8A / cm 2 , the cathode current density is 5~6A / cm 2 , The electrolysis temperature is maintained at 900-980°C. Each furnace was electrolyzed for 1 hour, adding 3.3kg of neodymium oxide, continuous electrolysis for 130 hours, 425kg of neodymium oxide and 46kg of neodymium fluoride were consumed, and 421kg of NdFe alloy was obtained. The ratio is 95.3%. The alloy analysis results are shown in Table 1-1.

[0047] The alloy prepared in this example is added to the main component of NdFeB, and the sintered NdFeB magnets are prepared by melting belt→hydrogen crushing and jet milling→magnetic field forming→vacuum sintering process, and the standard deviation is used to represent the uniformity of the...

Embodiment 2

[0056] Φ600mm circular graphite electrolytic cell is used, the anode is composed of 4 graphite plates, and NdF in the electrolyte 3 The content is 75wt%, LiF is 25wt%, the iron cathode is Φ55mm pure iron rod, the average current intensity is 2600A, and the anode current density is 0.6~0.9A / cm 2 , the cathode current density is 5~8A / cm 2 , The electrolysis temperature is maintained at 940-1020°C. Each furnace is electrolyzed for about 1 hour, adding about 3.6kg of neodymium oxide, continuous electrolysis for 160 hours, 622kg of neodymium oxide and 55kg of neodymium fluoride are consumed, and 641kg of NdFe alloy is obtained, with an average neodymium content of 79.6% and a current efficiency of 76%. The yield of neodymium was 95.8%. The alloy analysis results are shown in Table 2-1.

[0057] The alloy prepared in this example is added to the main component of NdFeB, and the sintered NdFeB magnets are prepared by melting belt→hydrogen crushing and jet milling→magnetic field for...

Embodiment 3

[0065] Φ600mm circular graphite electrolytic cell is used, the anode is composed of 4 graphite plates, and NdF in the electrolyte 3 The content is 85wt%, LiF is 15wt%, the iron cathode is Φ50mm pure iron rod, the average current intensity is 2800A, and the anode current density is 0.8~1.2A / cm 2 , the cathode current density is 7~11A / cm 2 , The electrolysis temperature is maintained at 980-1060°C. Each furnace was electrolyzed for about 1 hour, adding about 3.9kg of neodymium oxide, continuous electrolysis for 150 hours, 584kg of neodymium oxide and 53kg of neodymium fluoride were consumed, and 726kg of NdFe alloy was obtained, with an average neodymium content of 71.2% and a current efficiency of 76.2%. The yield of neodymium was 95.7%. The alloy analysis results are shown in Table 3-1.

[0066] The alloy prepared in this example is added to the main component of NdFeB, and the sintered NdFeB magnets are prepared by melting belt→hydrogen crushing and jet milling→magnetic fie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com