Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

184results about How to "Reduce electricity demand" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

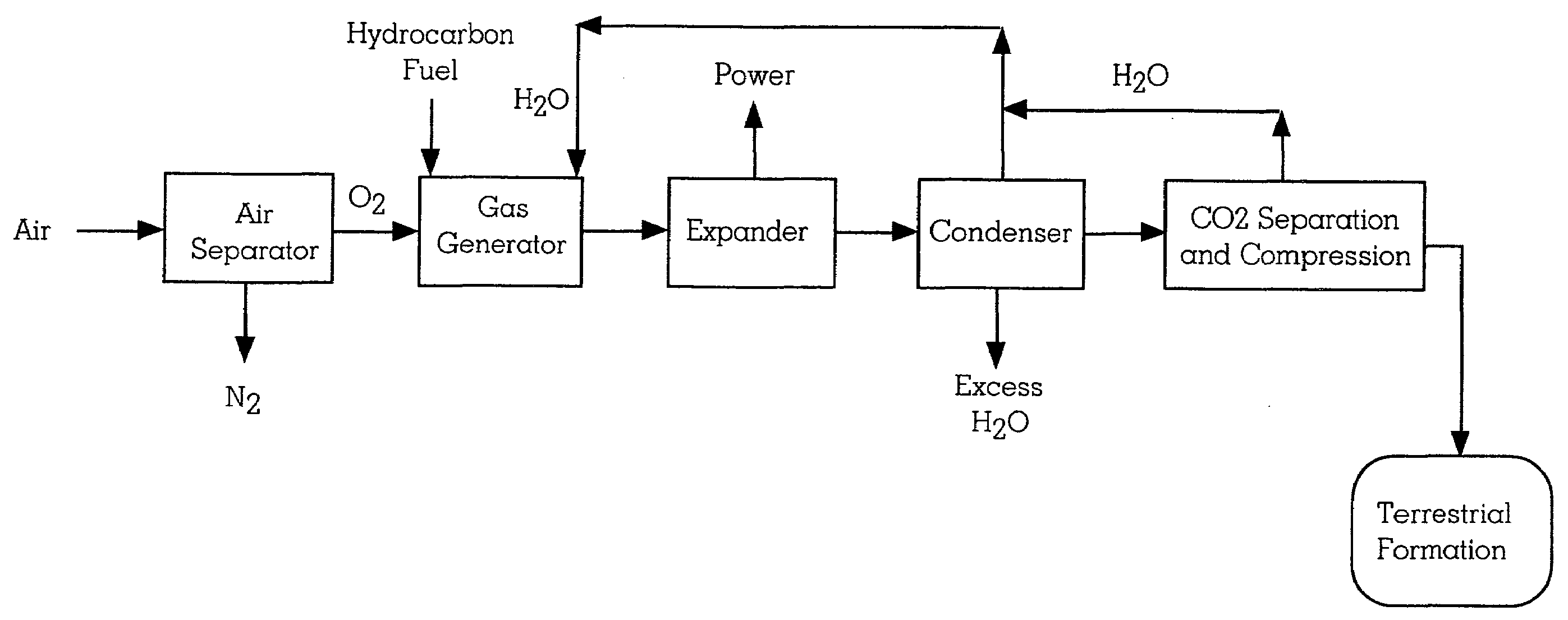

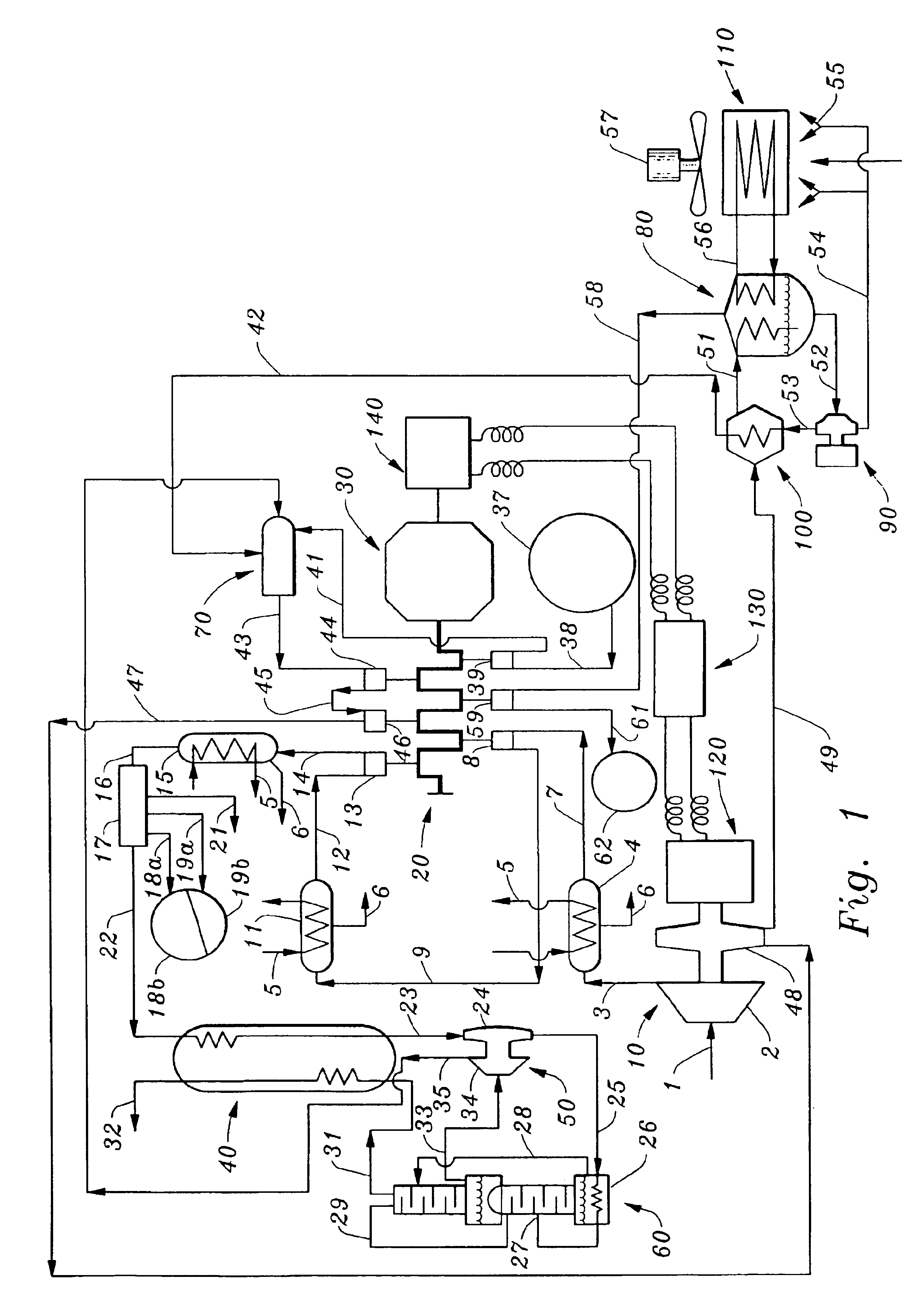

Hydrocarbon combustion power generation system with CO2 sequestration

InactiveUS7043920B2Eliminate needReduce electricity demandReciprocating combination enginesSolidificationAtmospheric airOxygen

A low or no pollution engine is provided for delivering power for vehicles or other power applications. The engine has an air inlet which collects air from a surrounding environment. At least a portion of the nitrogen in the air is removed. The remaining gas is primarily oxygen, which is then routed to a gas generator. The gas generator has inputs for the oxygen and a hydrocarbon fuel. The fuel and oxygen are combusted within the gas generator, forming water and carbon dioxide. The combustion products are then expanded through a power generating device, such as a turbine or piston expander to deliver output power for operation of a vehicle or other power uses. The combustion products are then passed through a condenser where the steam is condensed and the carbon dioxide is collected or discharged. A portion of the water is routed back to the gas generator. The carbon dioxide is compressed and delivered to a terrestrial formation from which return of the CO2 into the atmosphere is inhibited.

Owner:CLEAN ENERGY SYST

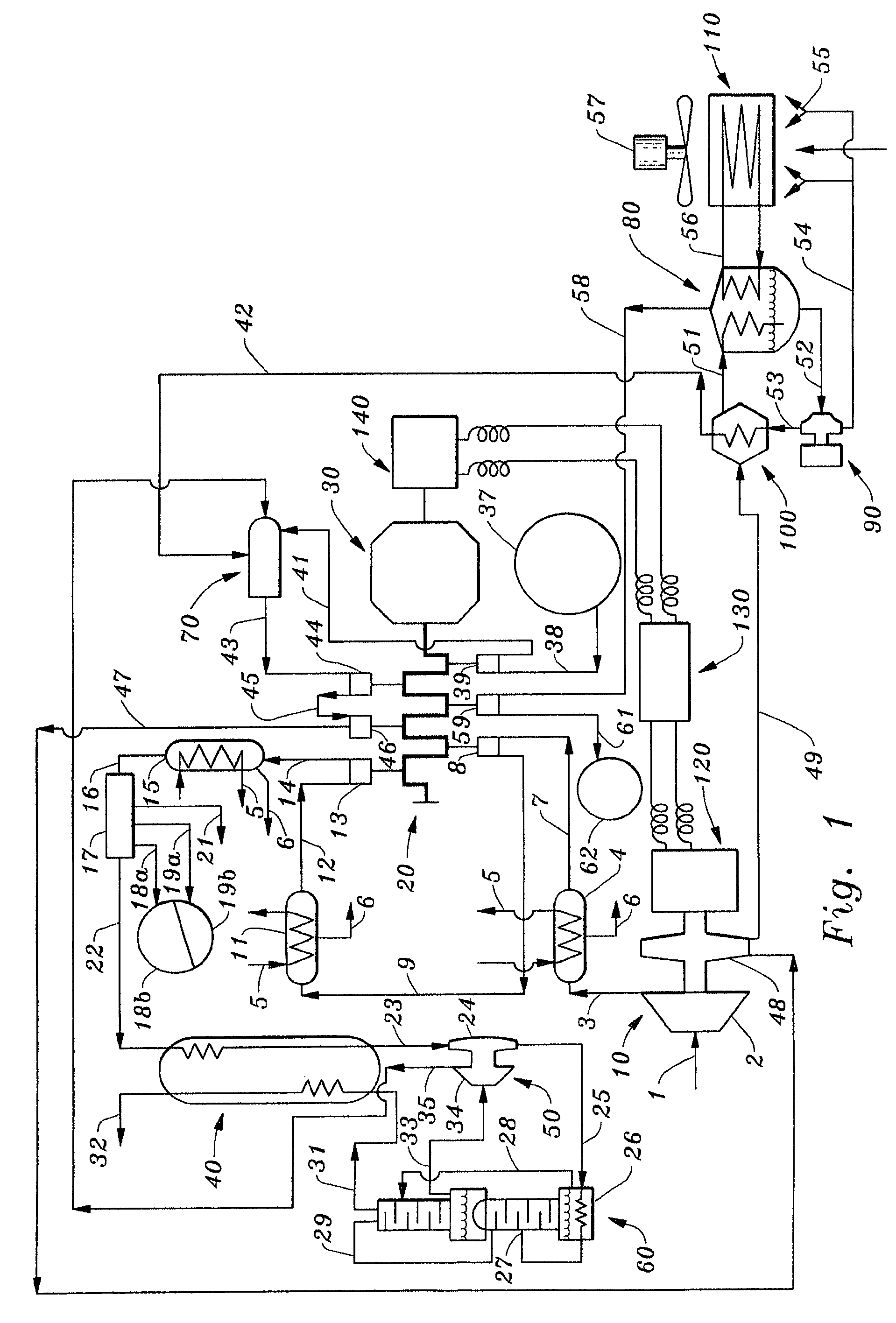

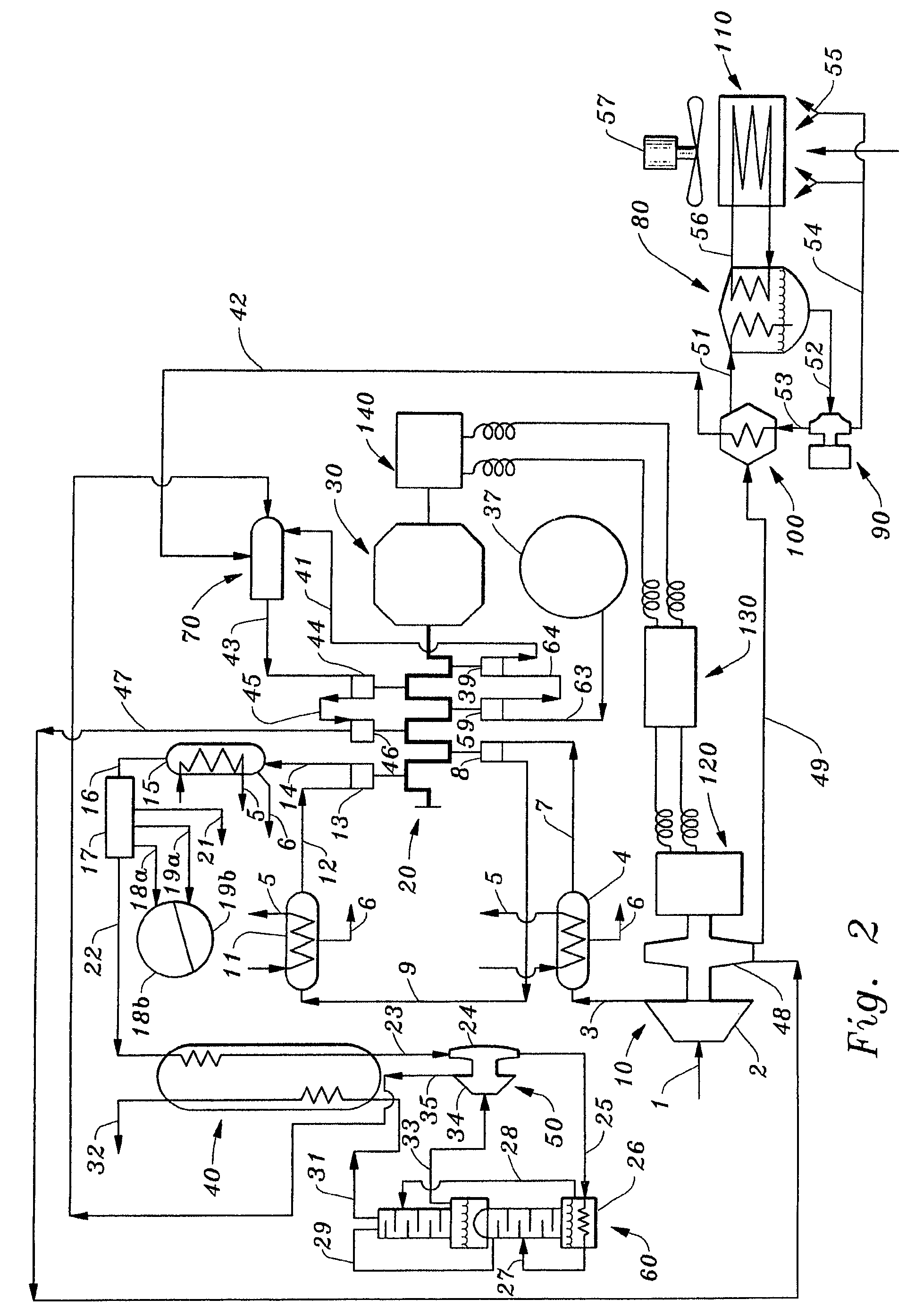

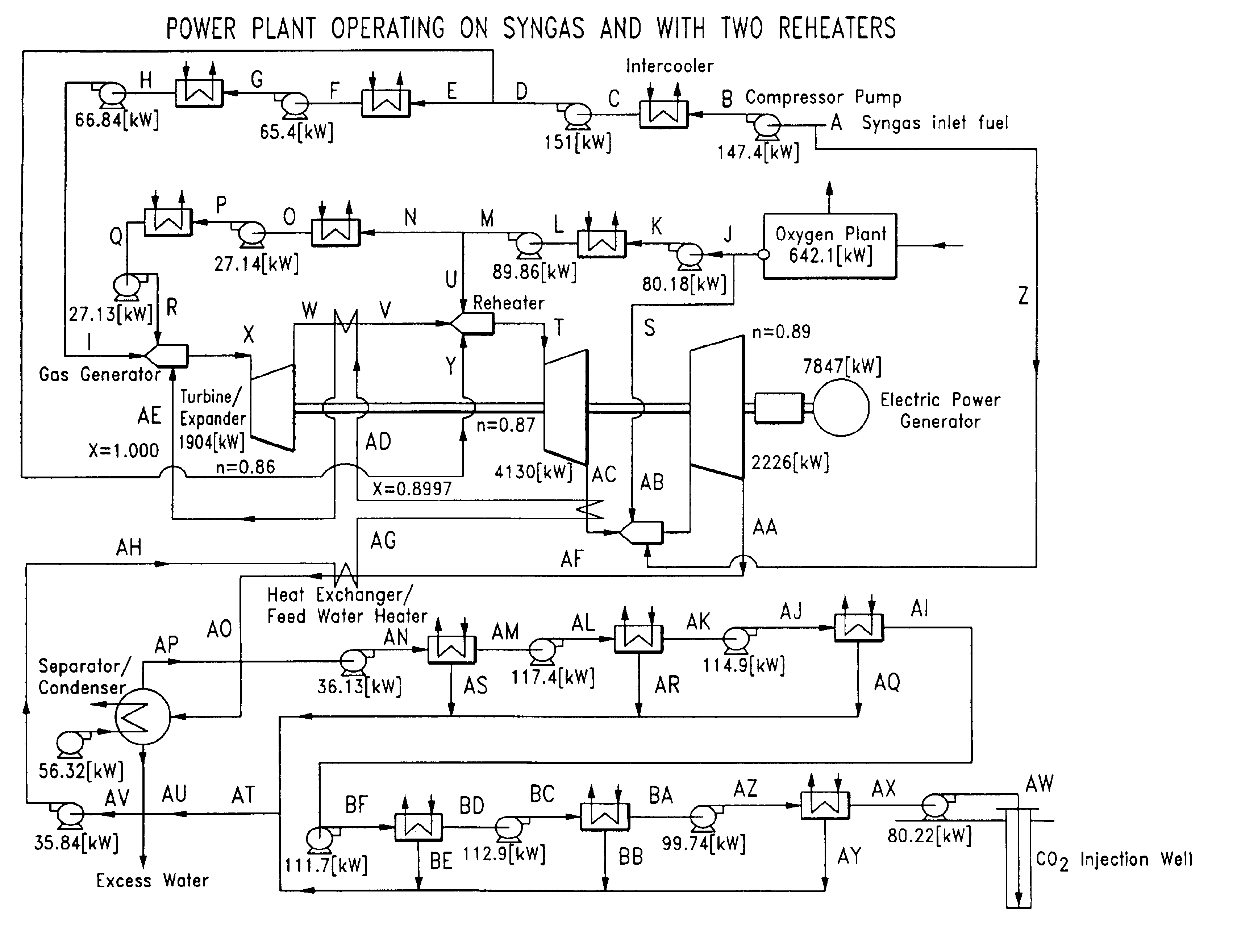

Low pollution power generation system with ion transfer membrane air separation

InactiveUS6945029B2Nitrogen oxideReduce electricity demandSolidificationLiquefactionPollutionCombustion products

A low or no pollution power generation system is provided. The system has an air separator to collect oxygen. A gas generator is provided with inputs for the oxygen and a hydrocarbon fuel. The fuel and oxygen are combusted within the gas generator, forming water and carbon dioxide. Water or other diluents are also delivered into the gas generator to control temperature of the combustion products. The combustion products are then expanded through at least one turbine or other expander to deliver output power. The combustion products are then passed through a separator where the steam is condensed. A portion of the water is discharged and the remainder is routed back to the gas generator as diluent. The carbon dioxide can be conditioned for sequestration. The system can be optimized by adding multiple expanders, reheaters and water diluent preheaters, and by preheating air for an ion transfer membrane oxygen separation.

Owner:CLEAN ENERGY SYST

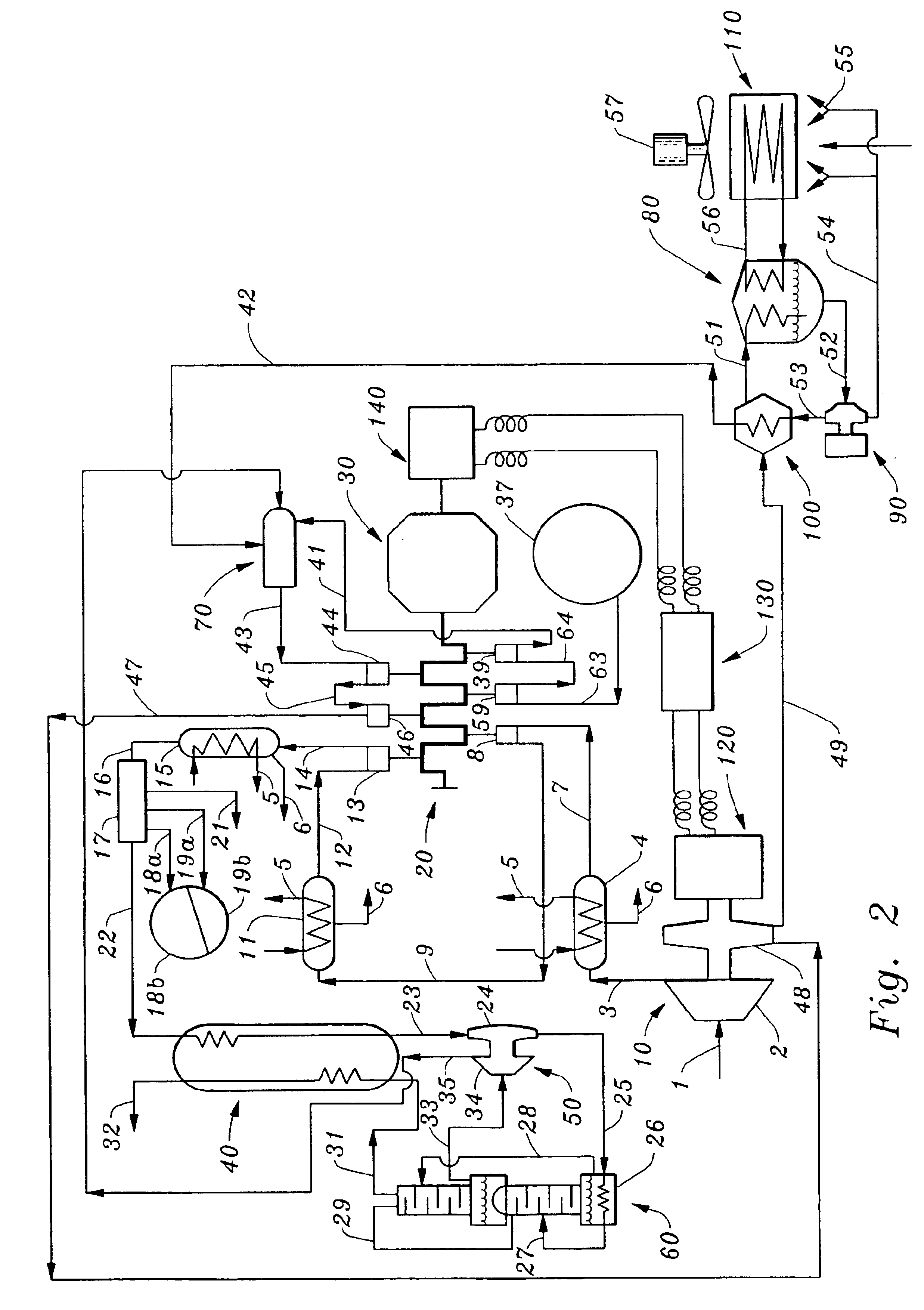

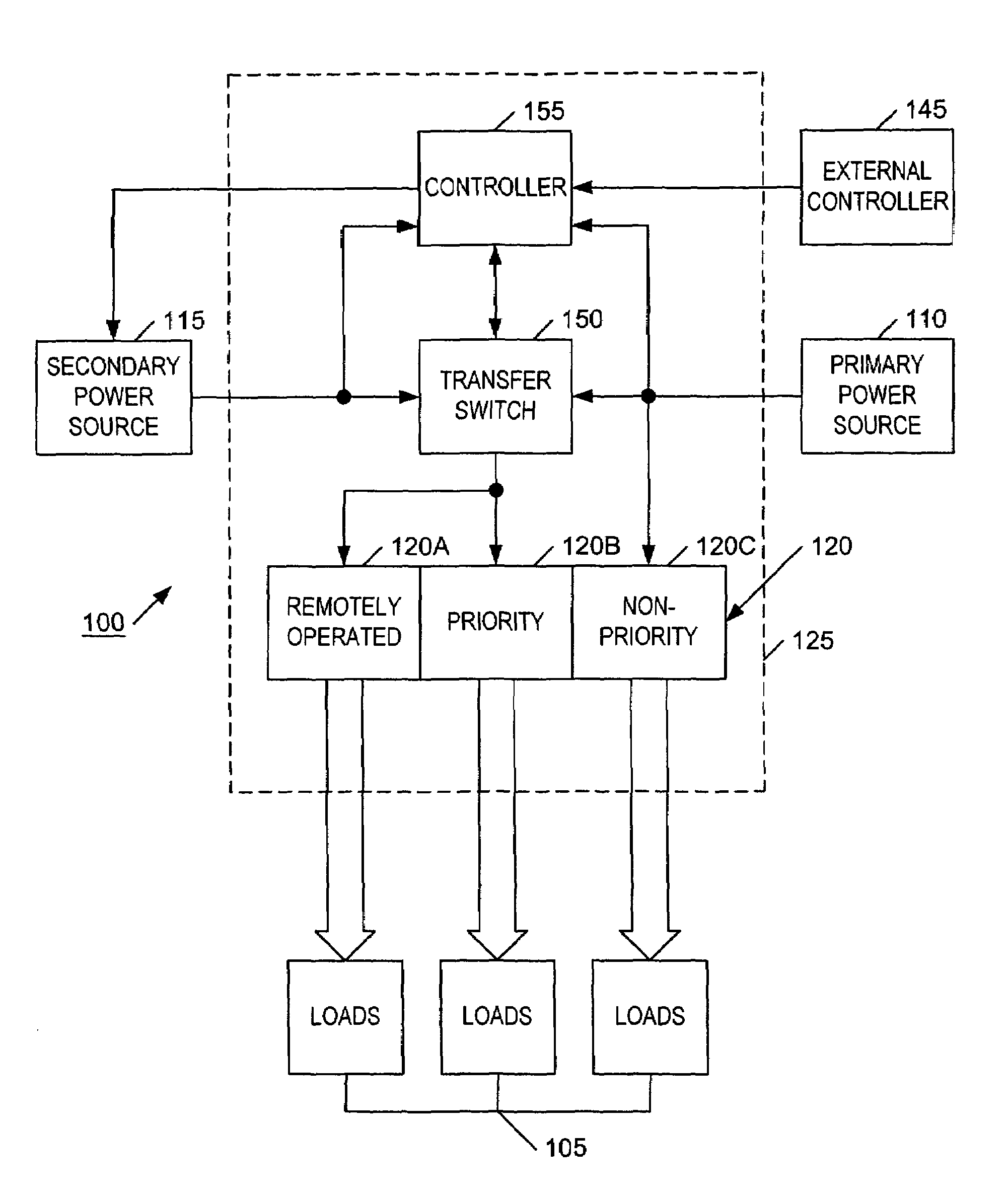

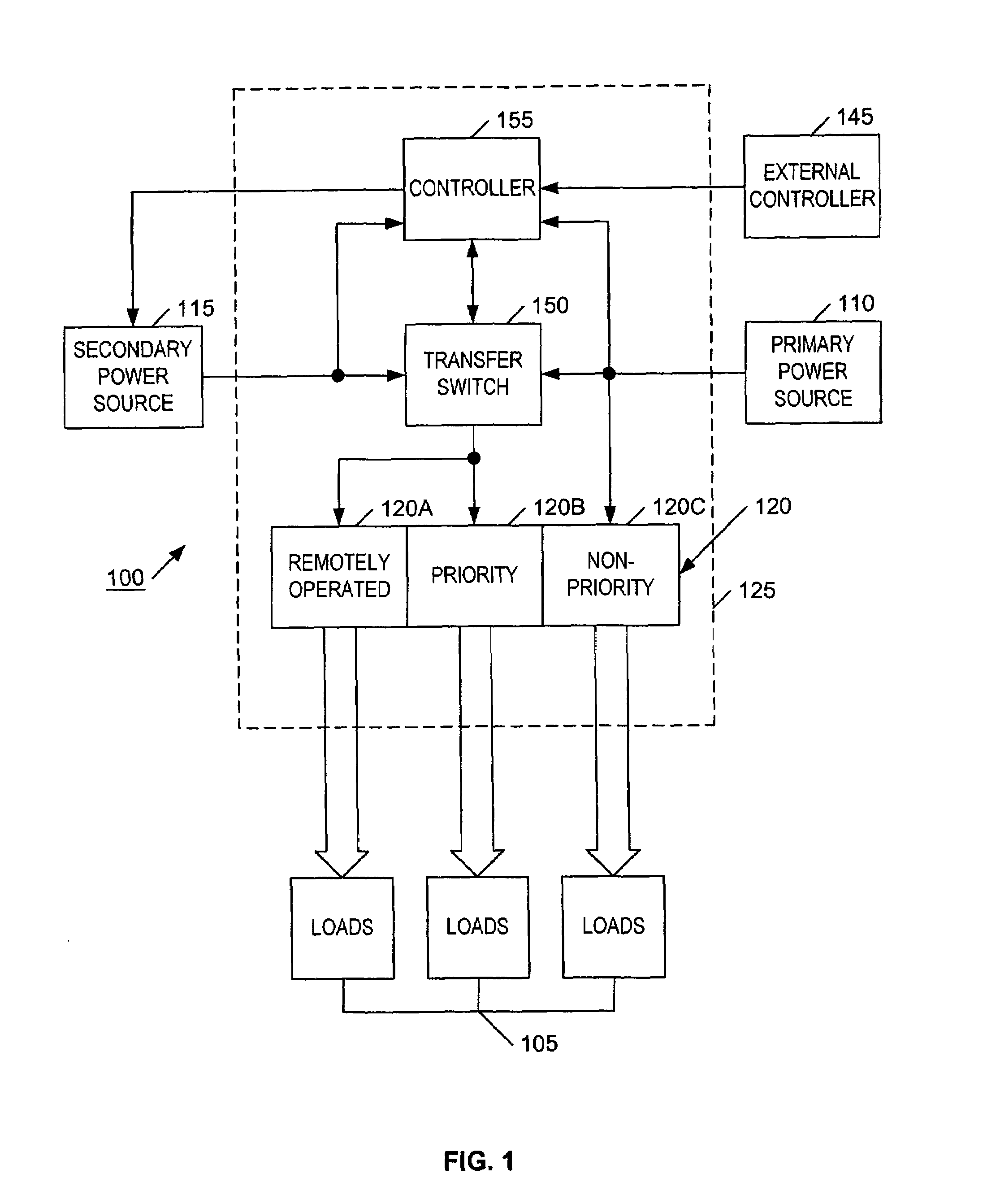

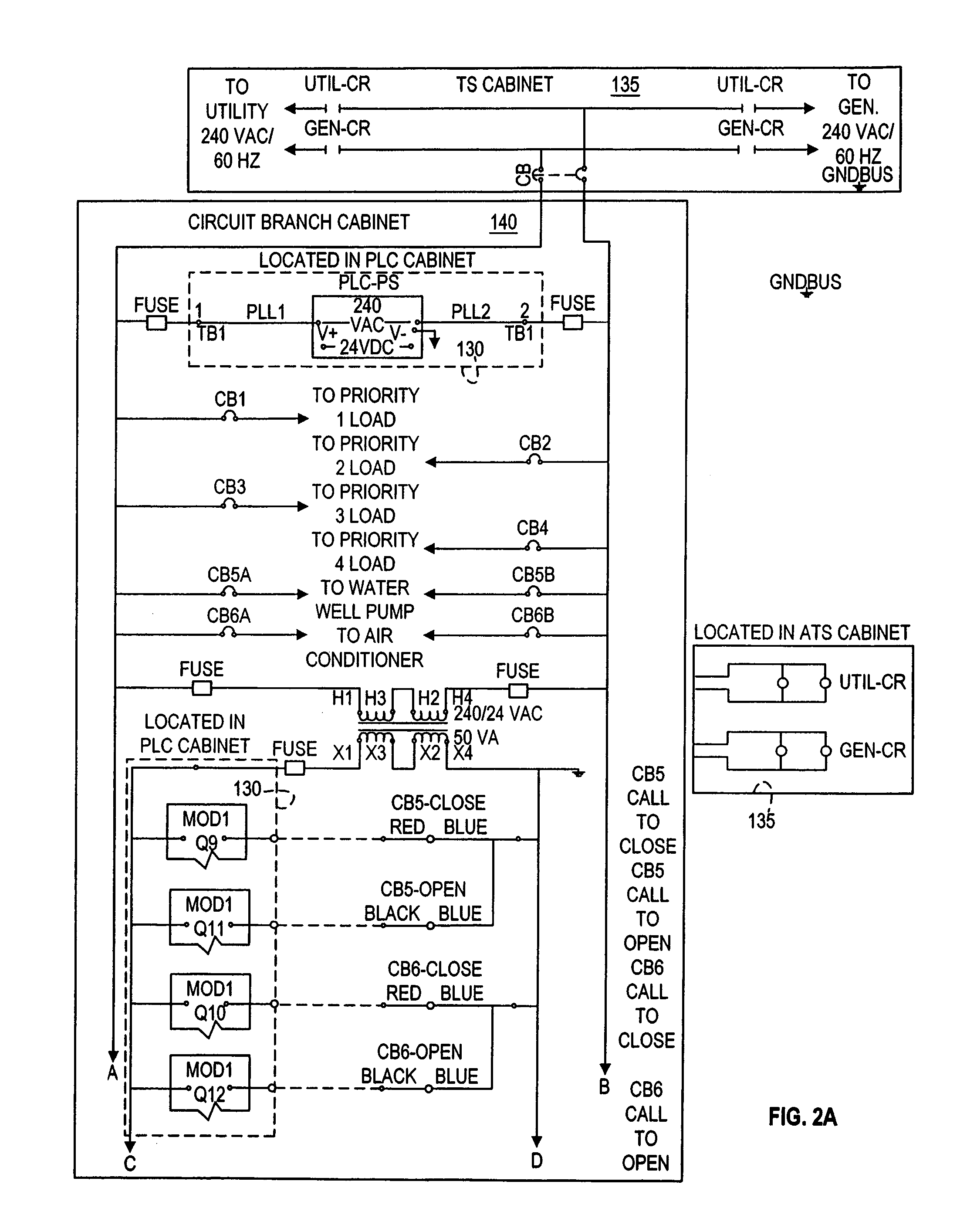

Backup power management system and method of operating the same

ActiveUS7015599B2Reduce electricity demandLess expenseMechanical power/torque controlDc network circuit arrangementsStandby powerTransfer switch

A backup power management system connectable to a primary power source and a secondary power source, and a method of operating the same. The system includes a transfer switch connectable to the primary and secondary power sources, and a plurality of circuit branches connected to the transfer switch. The circuit branches include first and second remotely operated branches having first and second managed circuit breakers, respectively. The system further includes a controller connected to the first and second managed circuit breakers. The controller controls the managed circuit breakers, thereby controlling the current through the first and second managed circuit branches.

Owner:BRIGGS & STRATTON LLC

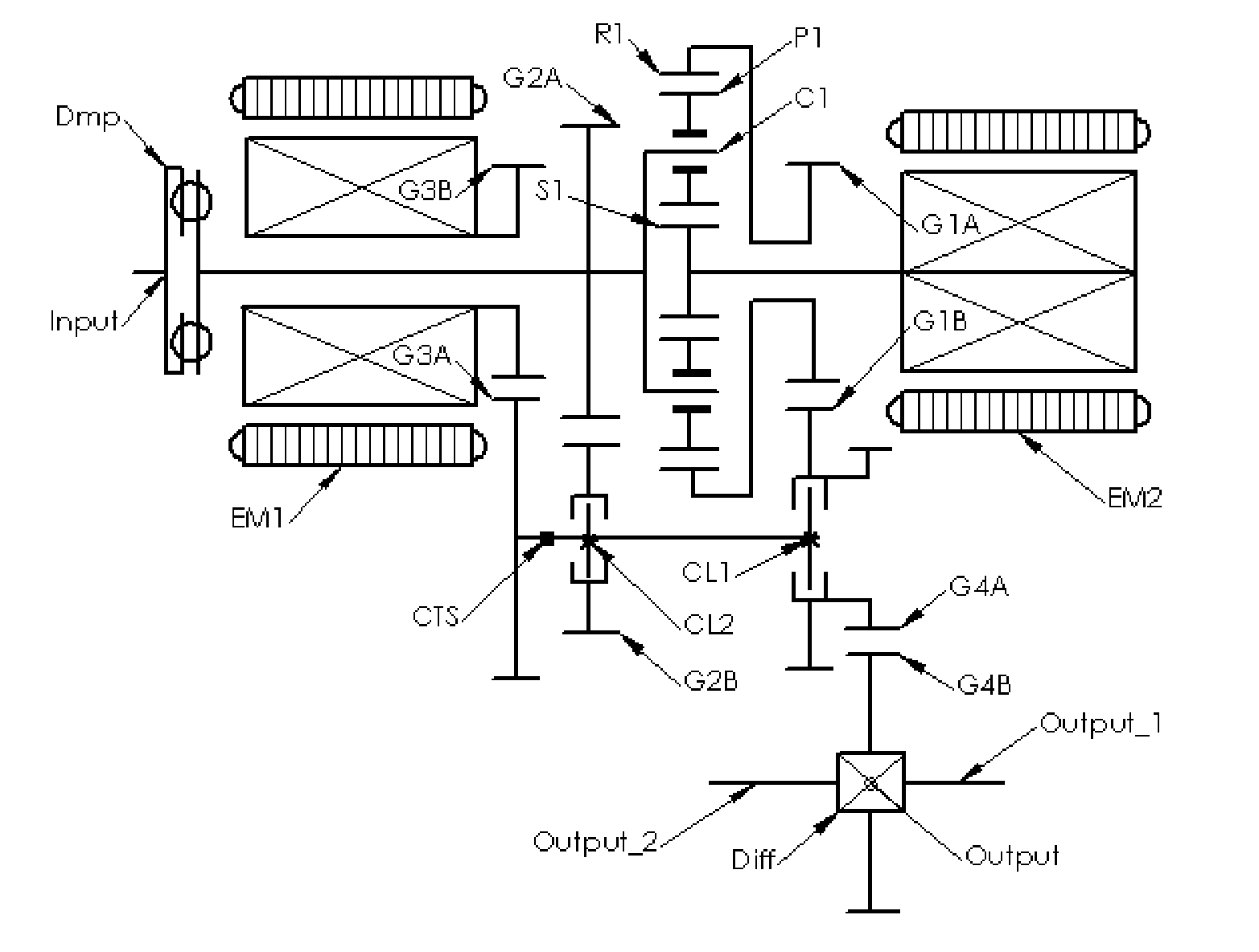

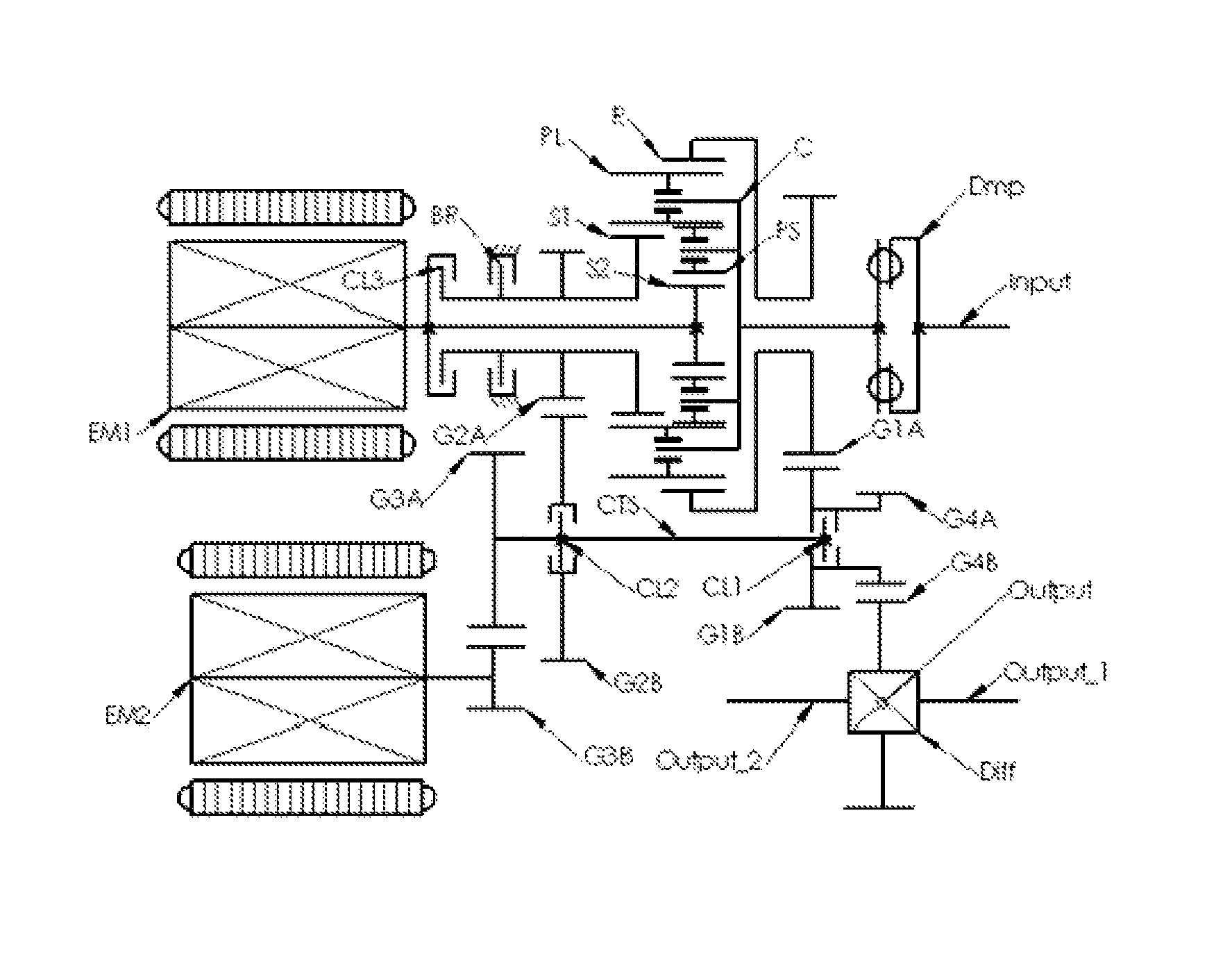

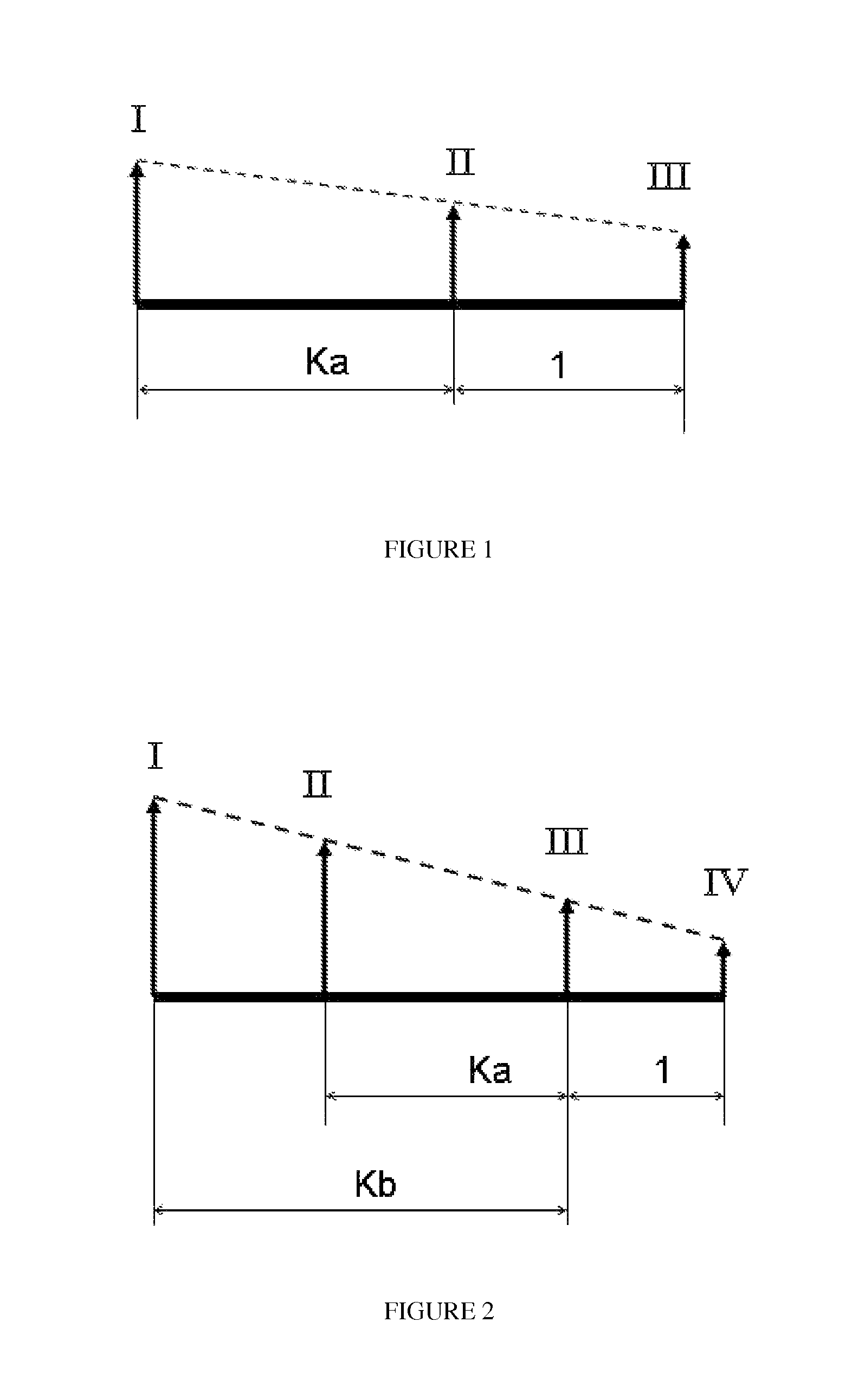

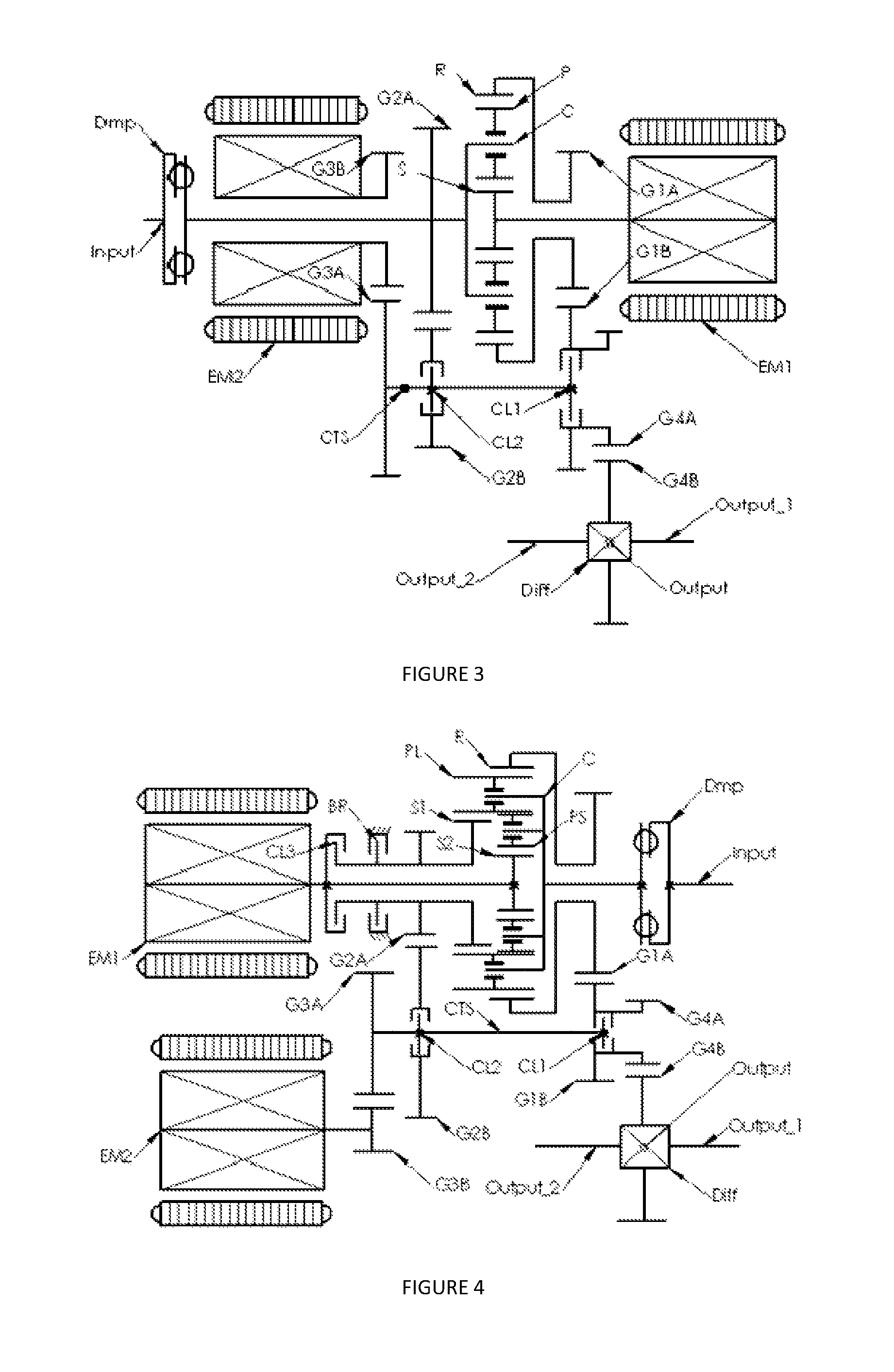

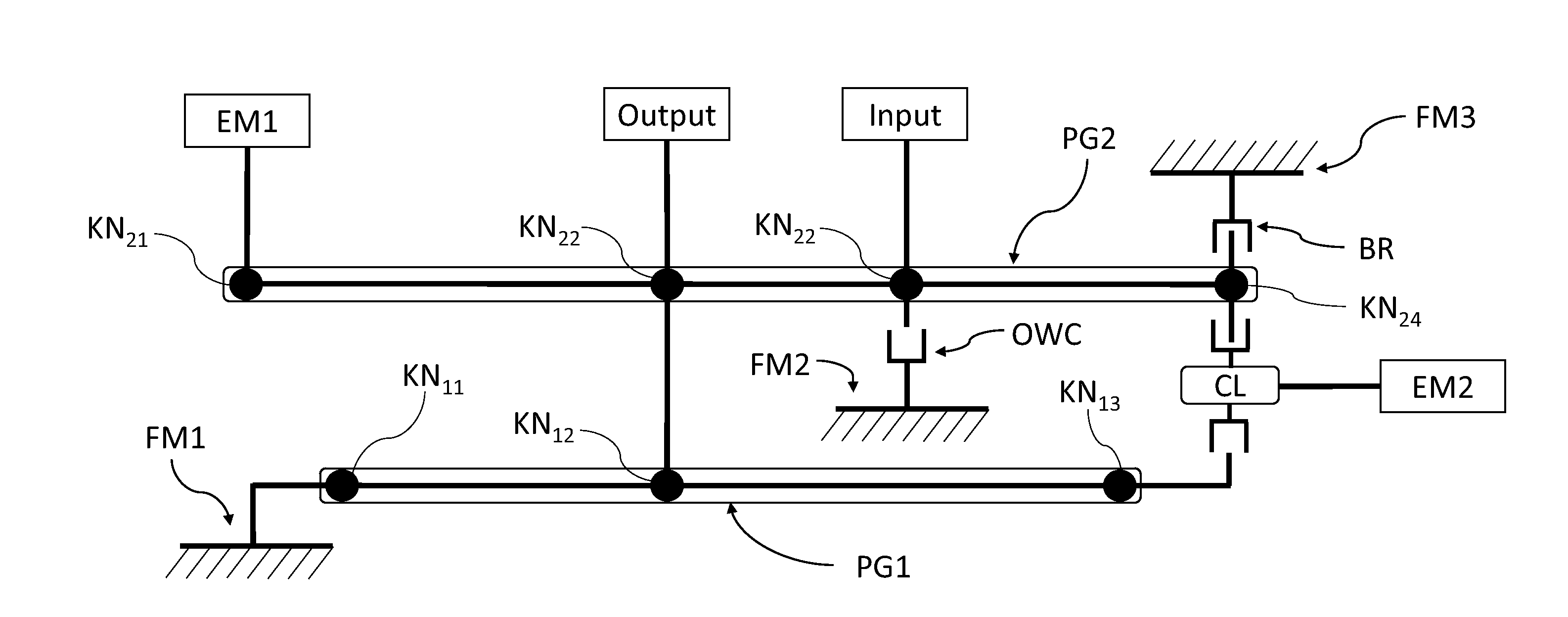

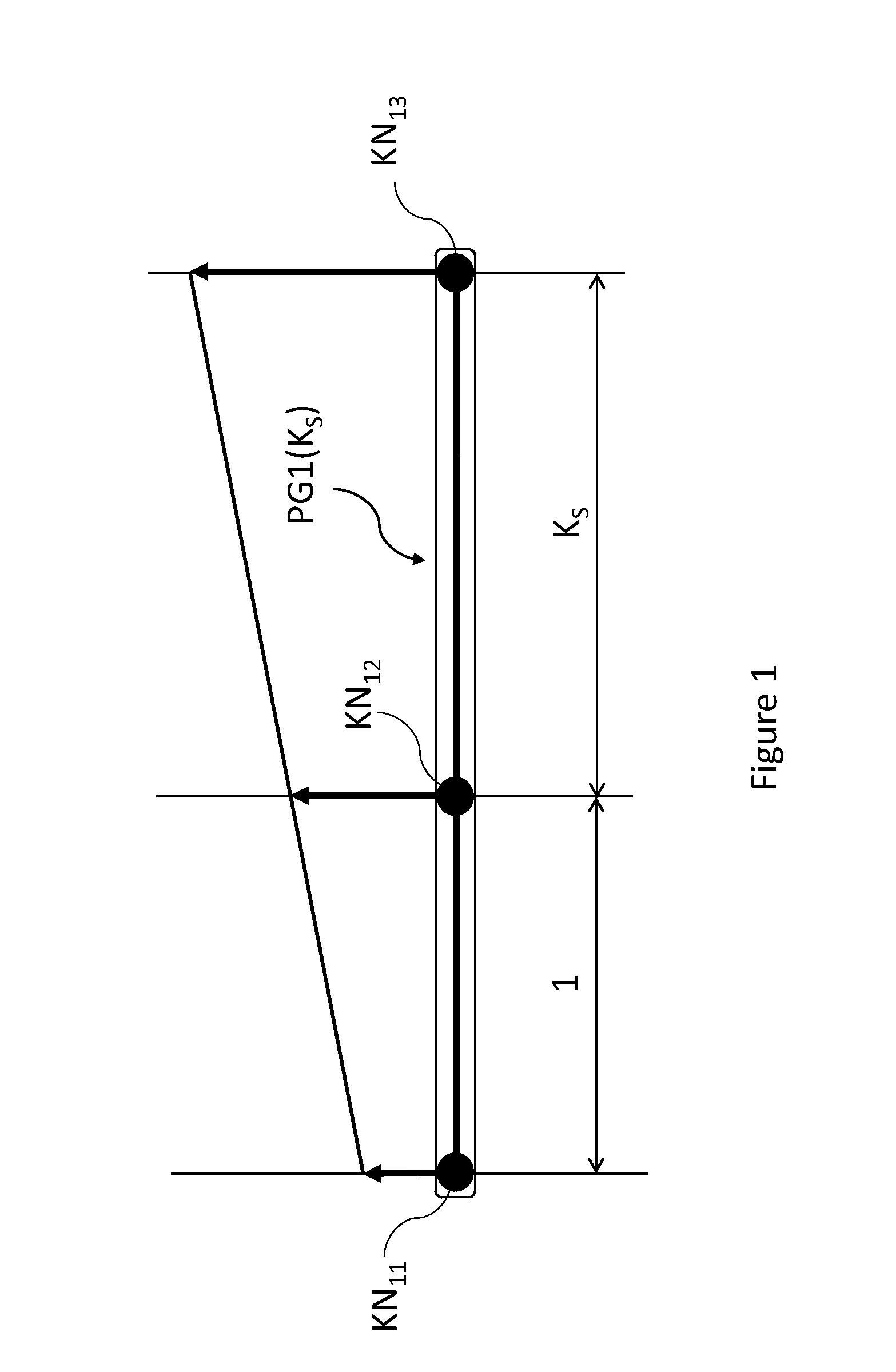

Dual-mode electromechanical variable speed transmission apparatus and method of control

InactiveUS20100261565A1Improve transmission efficiencyAvoid powerHybrid vehiclesElectric propulsion mountingDual modeElectric machine

The current invention discloses a dual-mode electro-mechanical variable speed transmission. Said transmission includes an input shaft, an output shaft system, a planetary gear system having at least three co-axial rotating members, two electric machines along with the associated controllers for the electric machines, and at least a clutch. Said planetary gear system has at least three branches; each branch corresponds to a co-axial rotating member. The first branch couples to the first electric machine with a fixed speed ratio; another branch couples to the input shaft with a fixed speed ratio; and yet anther branch couples to the output shaft system with a fixed speed ratio; the second electric machine couples selectively to two of the branches in the planetary gear system with different speed ratios. Said two branches are not the first branch and one of the said two branches is connected to the output shaft system. Said dual-mode electro-mechanical variable speed transmission is capable of providing at least two power splitting operation modes, including an output power splitting mode. Different operation modes cover different speed ratio regimes. At the mode switching point, the corresponding clutch or clutches is automatically synchronized. Thus the speeds of the rotation members of the transmission are continuous, and the transmission is free from shock loads at the operating mode switching point. In addition, said transmission is capable of providing operations with at least a fixed input-to-output speed ratio.

Owner:SHANDONG LIANCHENG GREENMAX TECH

Dual-mode electromechanical variable speed transmission apparatus and method of control

InactiveUS8734281B2Improve transmission efficiencyAvoid powerHybrid vehiclesElectric propulsion mountingElectric machineDual mode

A dual-mode electro-mechanical variable speed transmission includes an input shaft, an output shaft system, a gear system having at least three branches, two electric machines, and at least a clutch. The first electric machine couples to a branch of the gear system, the output shaft system couples to another branch of the gear system, the input shaft couples to the remaining branch or one of the remaining branches of the gear system, and the second electric machine selectively couples either to the same branch that is coupled to the output shaft system with a speed ratio or to one of the remaining branches that that is not coupled to the first electric machine with a different speed ratio. The transmission provides at least two power splitting modes to cover different speed ratio regimes. The transmission can also provide at least a fixed output shaft to input shaft speed ratio.

Owner:SHANDONG LIANCHENG GREENMAX TECH

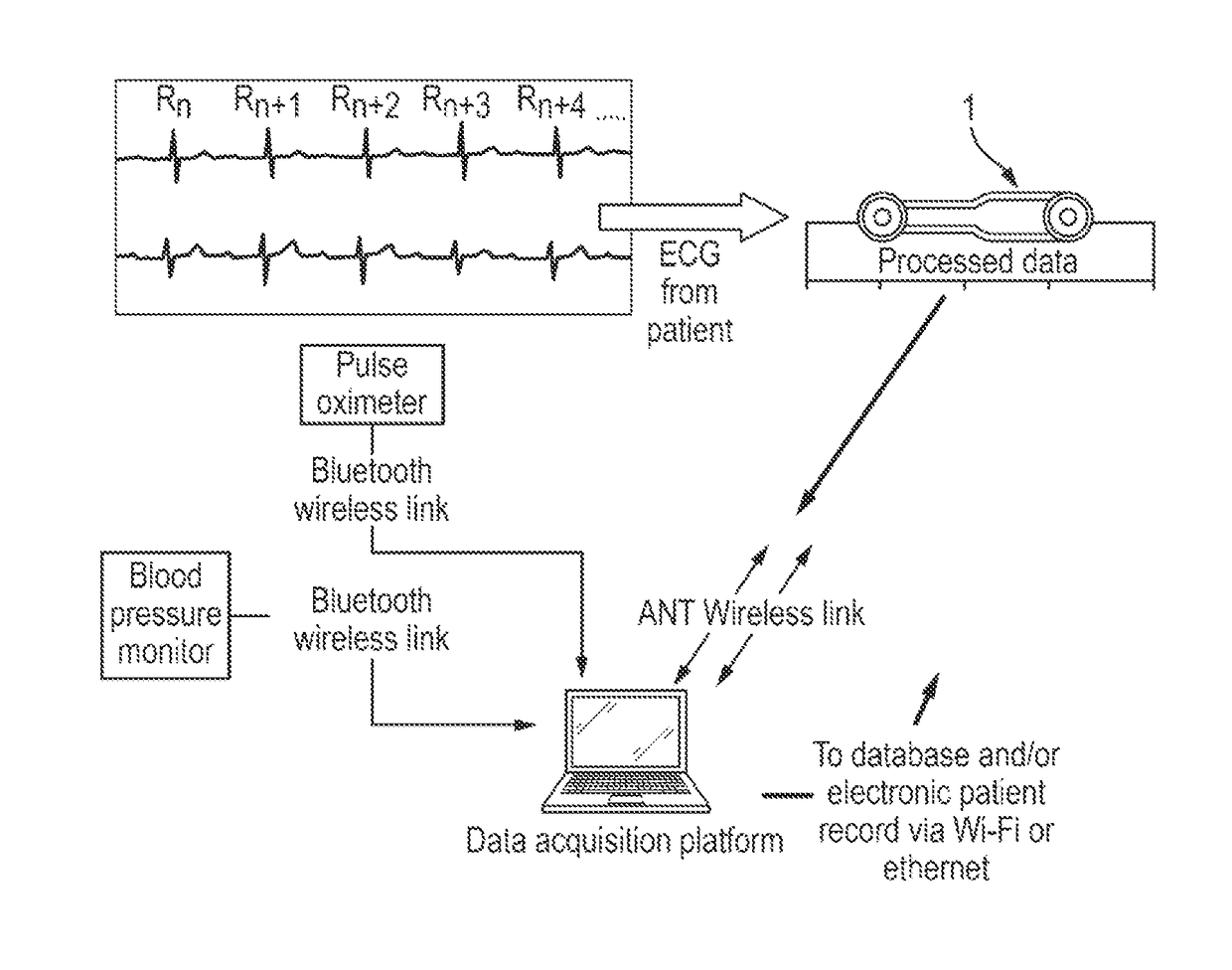

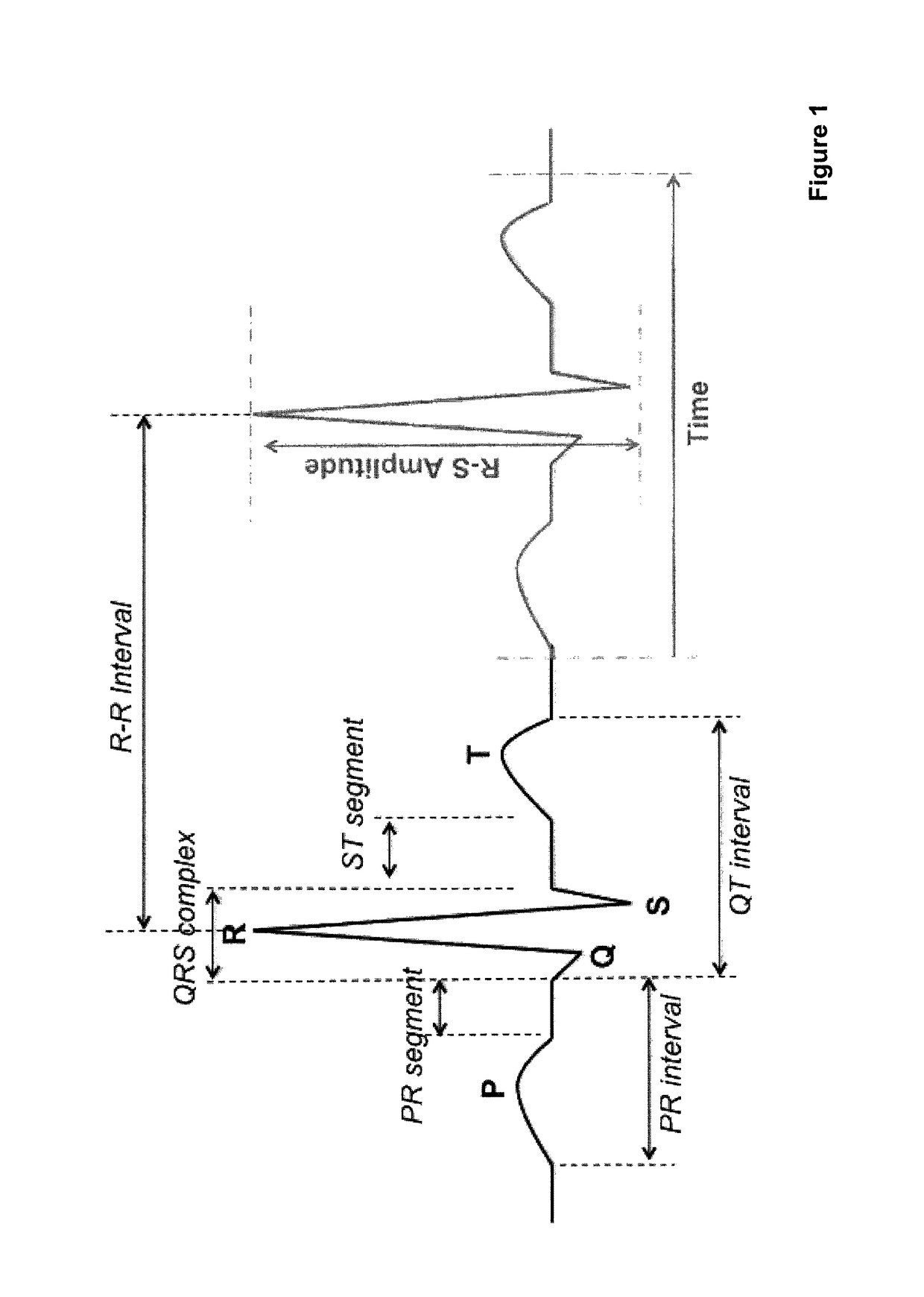

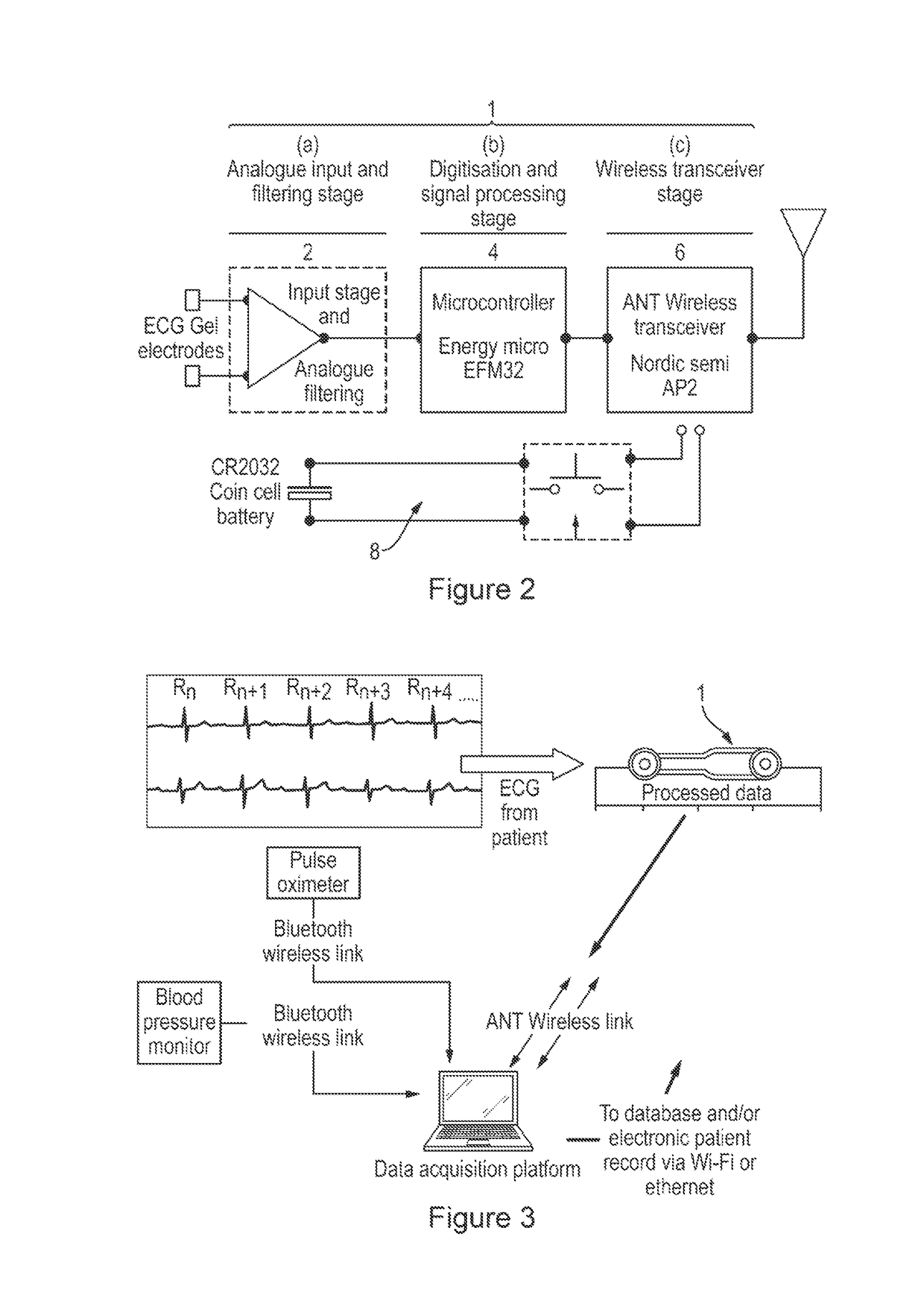

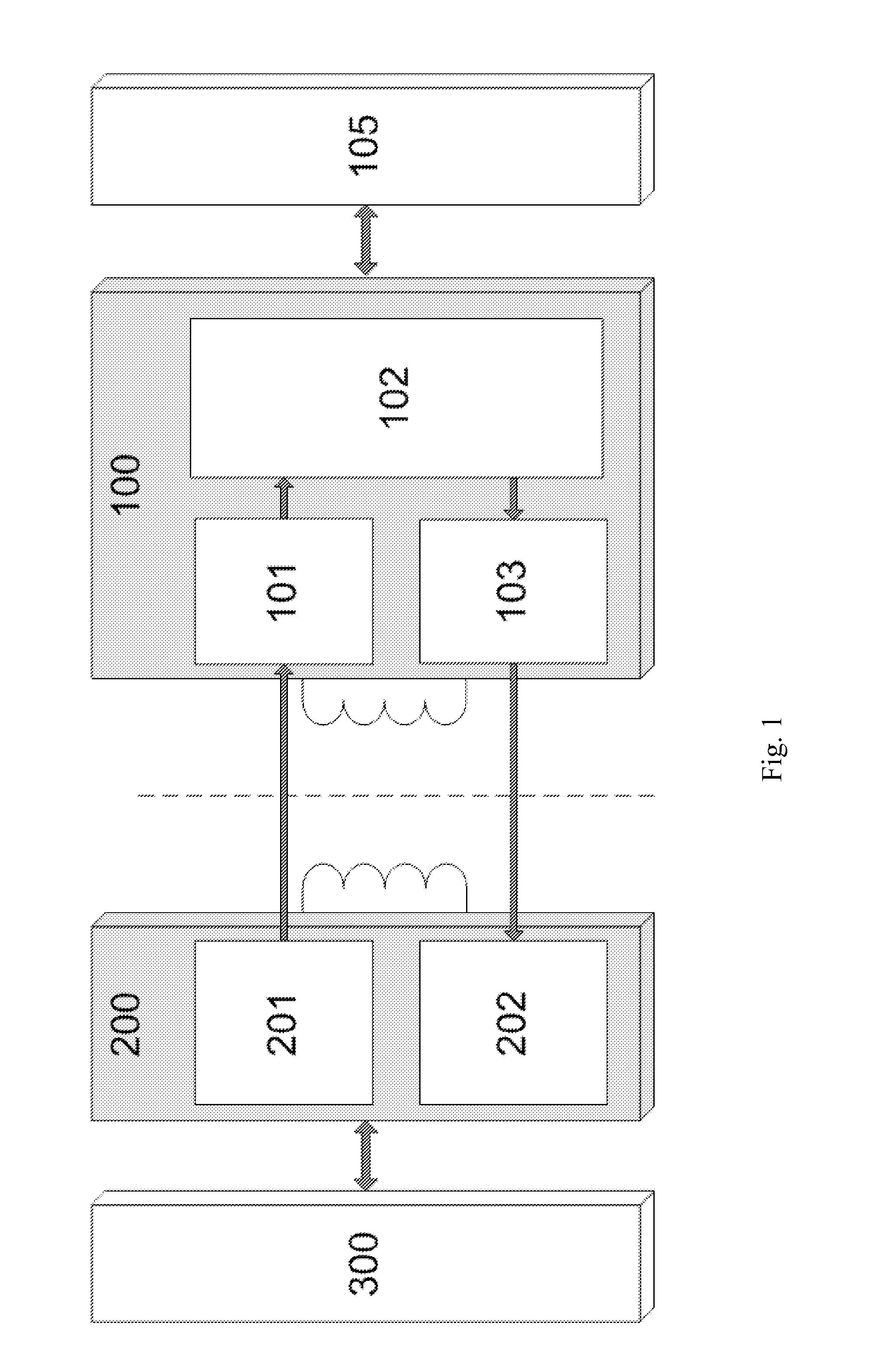

Health monitoring

ActiveUS10049182B2Reduce local power demandMinimiseElectrocardiographySensorsEcg signalCardiac monitoring

Health monitoring devices allow for monitoring of the vital signs of a subject. Wireless devices can enable a subject's cardiac and / or respiratory functions to be monitored remotely, e.g. without the subject being attached to bedside equipment. A cardiac monitoring device may include a substrate, electrodes for measuring ECG signals, and an electronics module including a data processor and a wireless transmitter. The electronics module is sealed within the substrate and arranged to receive the measured ECG signals. Each ECG signal associated with a heartbeat is processed in the data processor to provide key data relating to that heartbeat. The key data may include the temporal position of a characteristic feature in the ECG signal. The key data is provided to the wireless transmitter for transmission.

Owner:ISANSYS LIFECARE

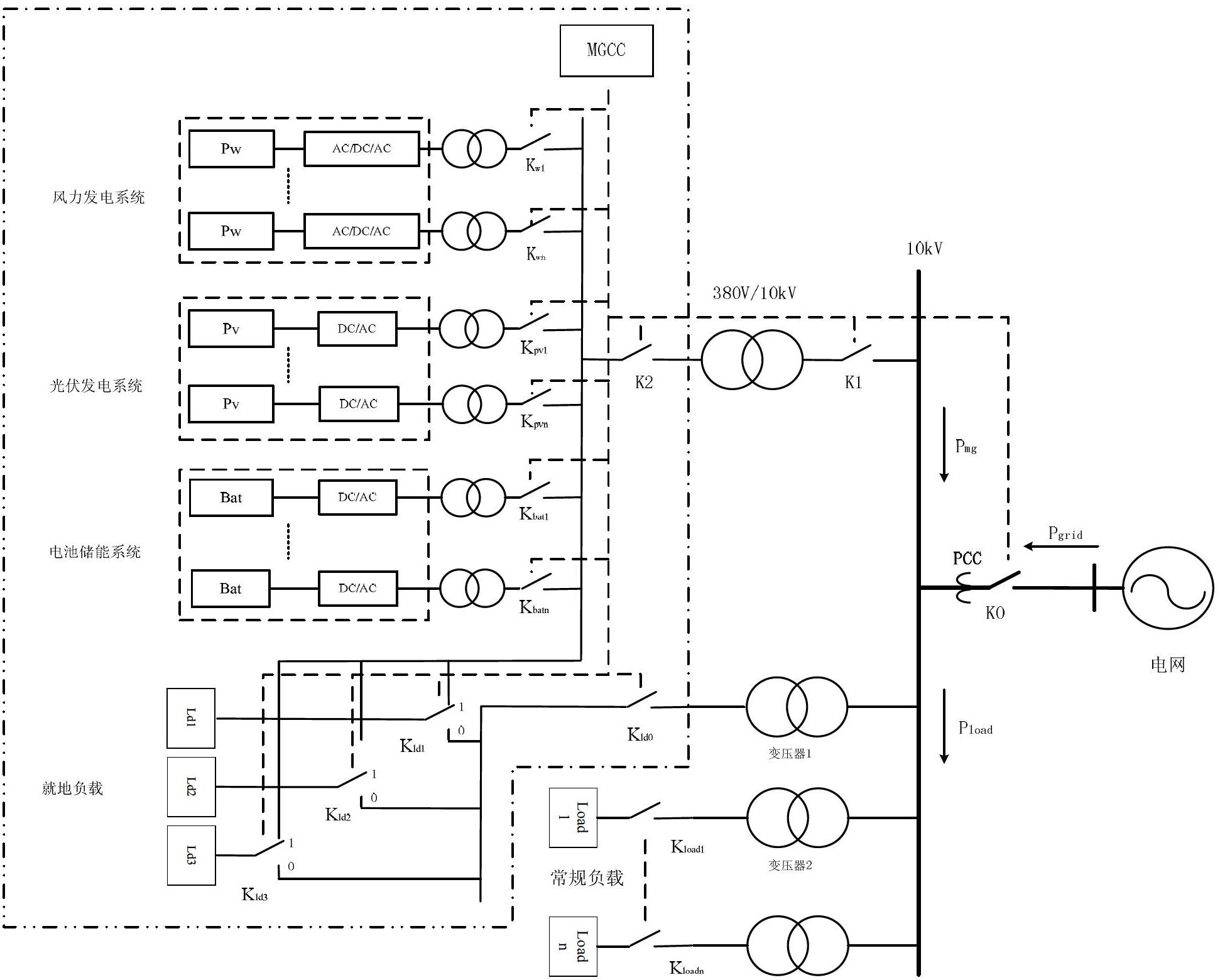

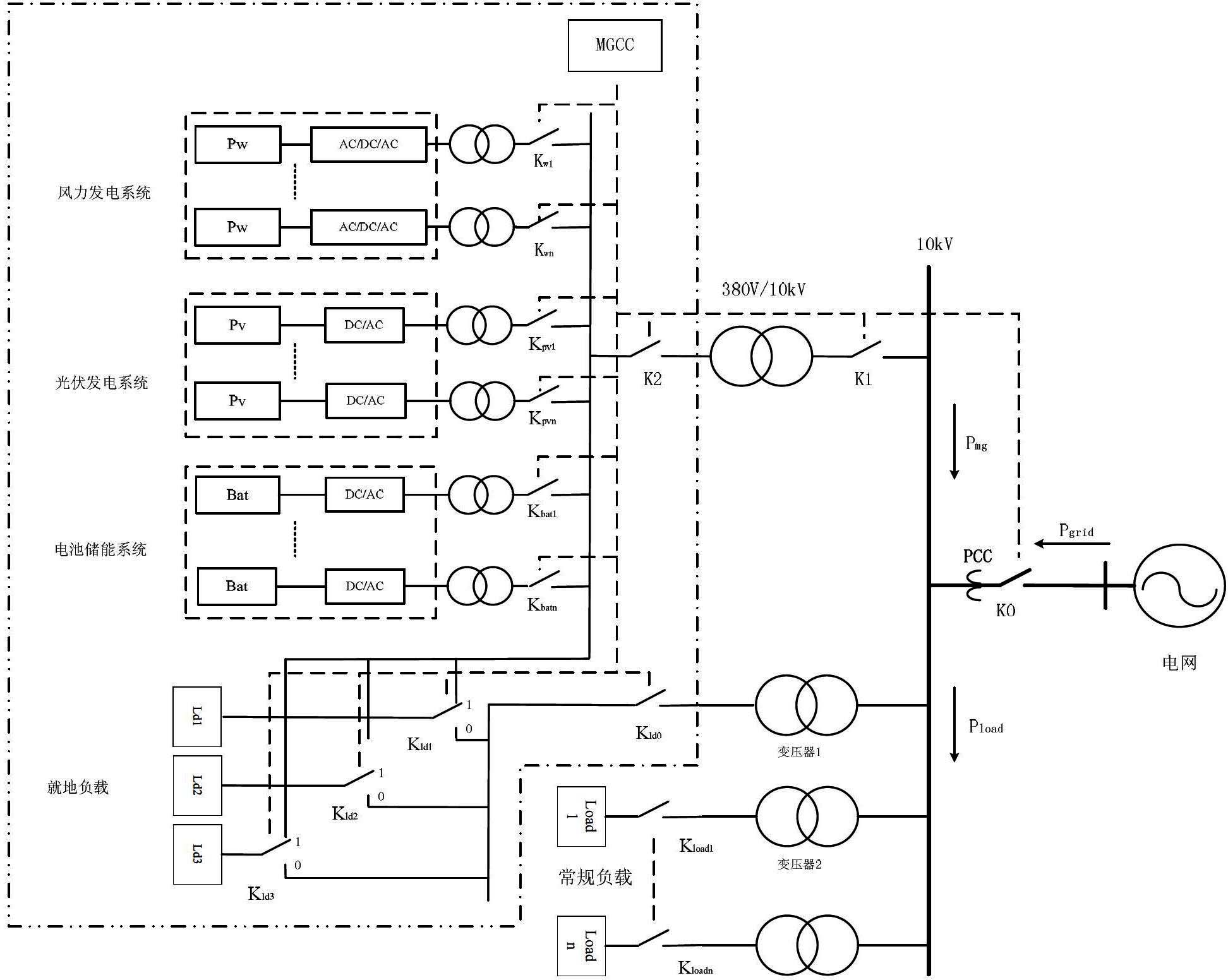

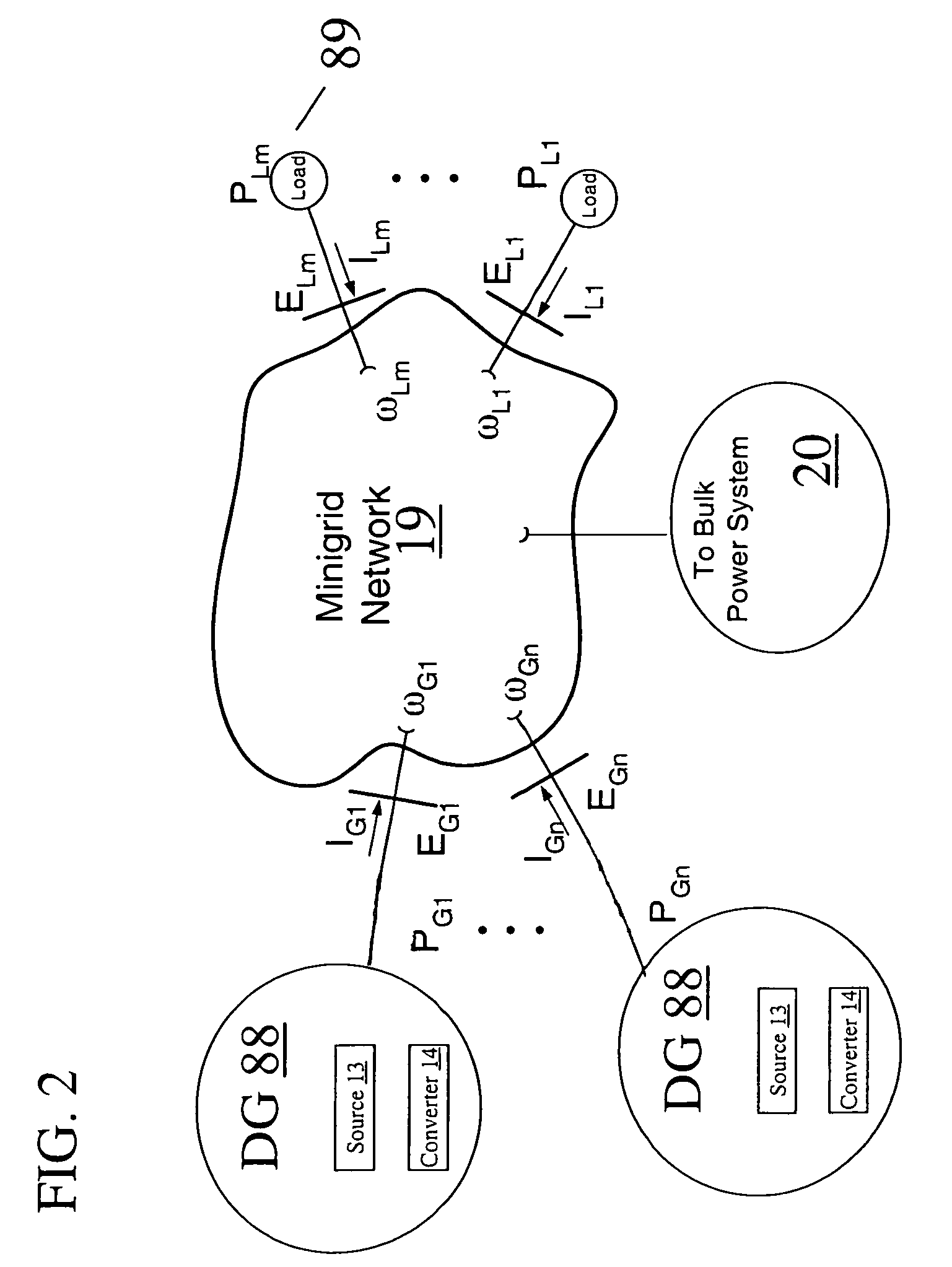

Grid-connected non-networking micro-grid system and control protection method thereof

ActiveCN102664429AReduce electricity demandAvoid shockSingle network parallel feeding arrangementsAc network load balancingTransmitted powerNew energy

The invention discloses a grid-connected non-networking micro-grid system and a control protection method thereof. On the premise of basically not changing the structure of the original power distribution system, multiple types of distributed power sources, such as wind power generation system, photovoltaic power generation system, cell accumulation system and the like, are connected into a common power grid along with user loads through AC buses, and reasonable load layout and active energy management are utilized to implement grid-connected non-networking of the micro-grid system. By using the structural design and the active energy management of the micro-grid central control unit, the new energy power generation system can be completely self-sufficient, and does not reversely transmit power to the common power grid, thereby avoiding impacting the normal power supply of the common power grid; and meanwhile, by the aid of the common power grid, the user loads have higher power supply reliability and electric power quality.

Owner:GUODIAN UNITED POWER TECH

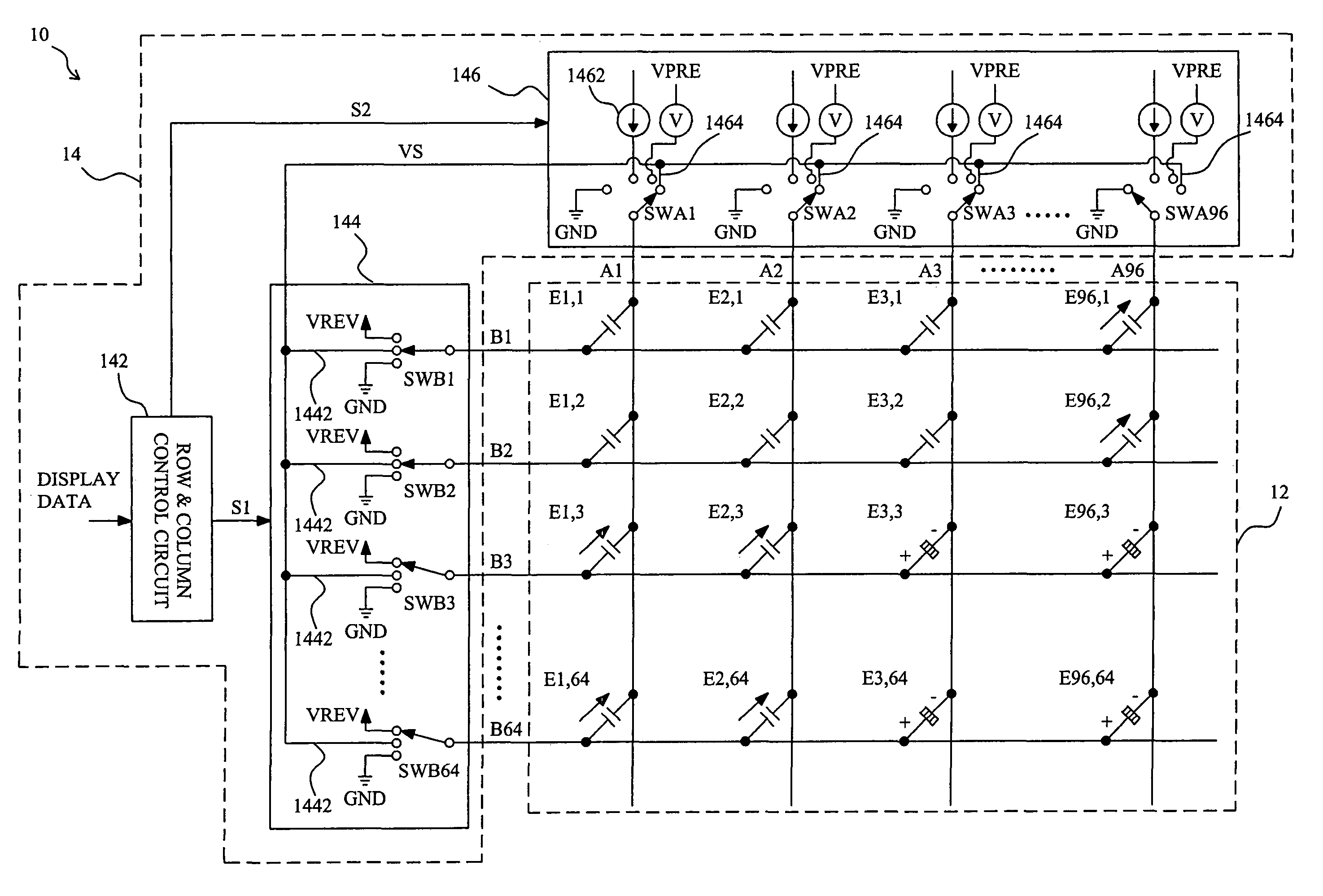

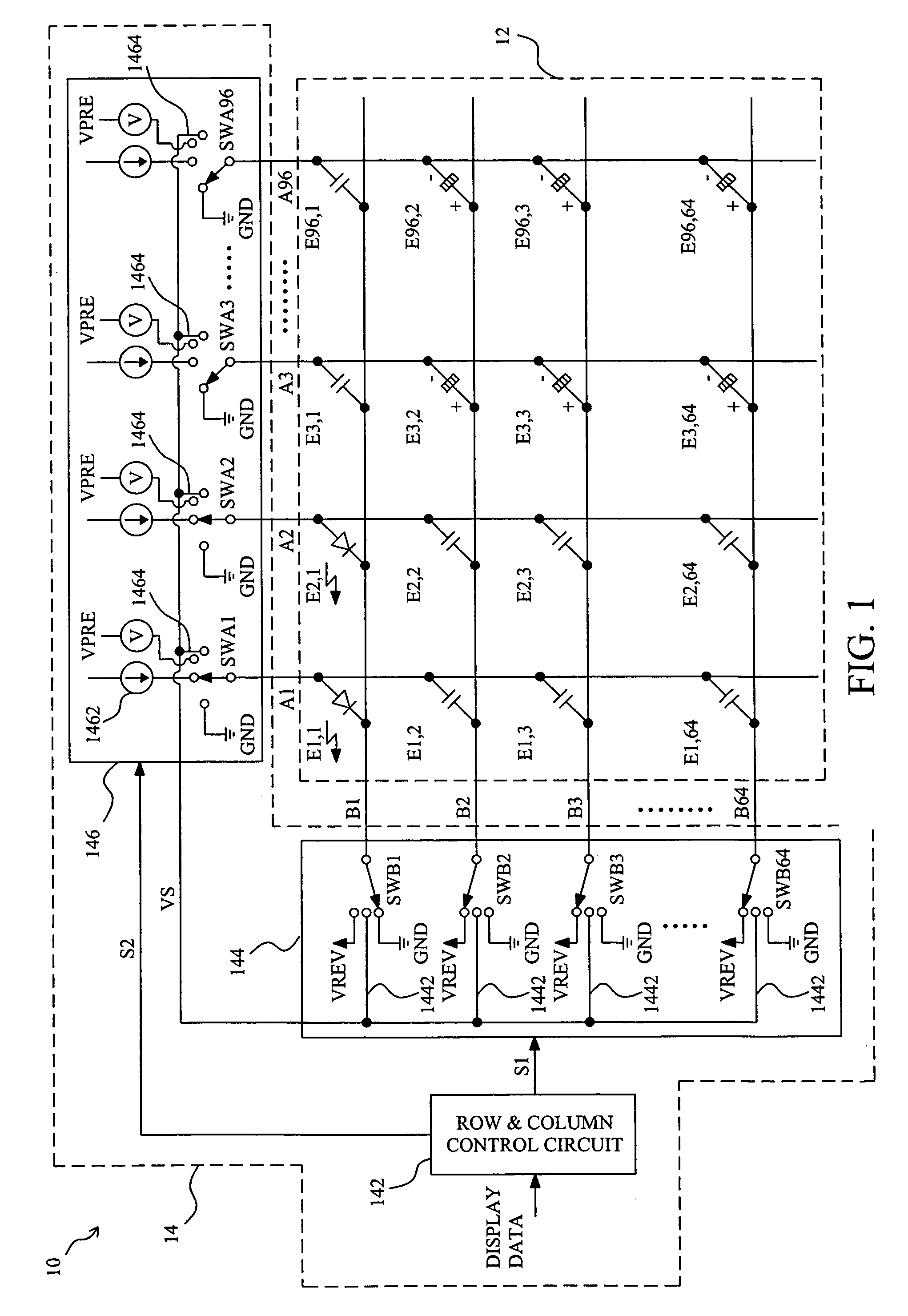

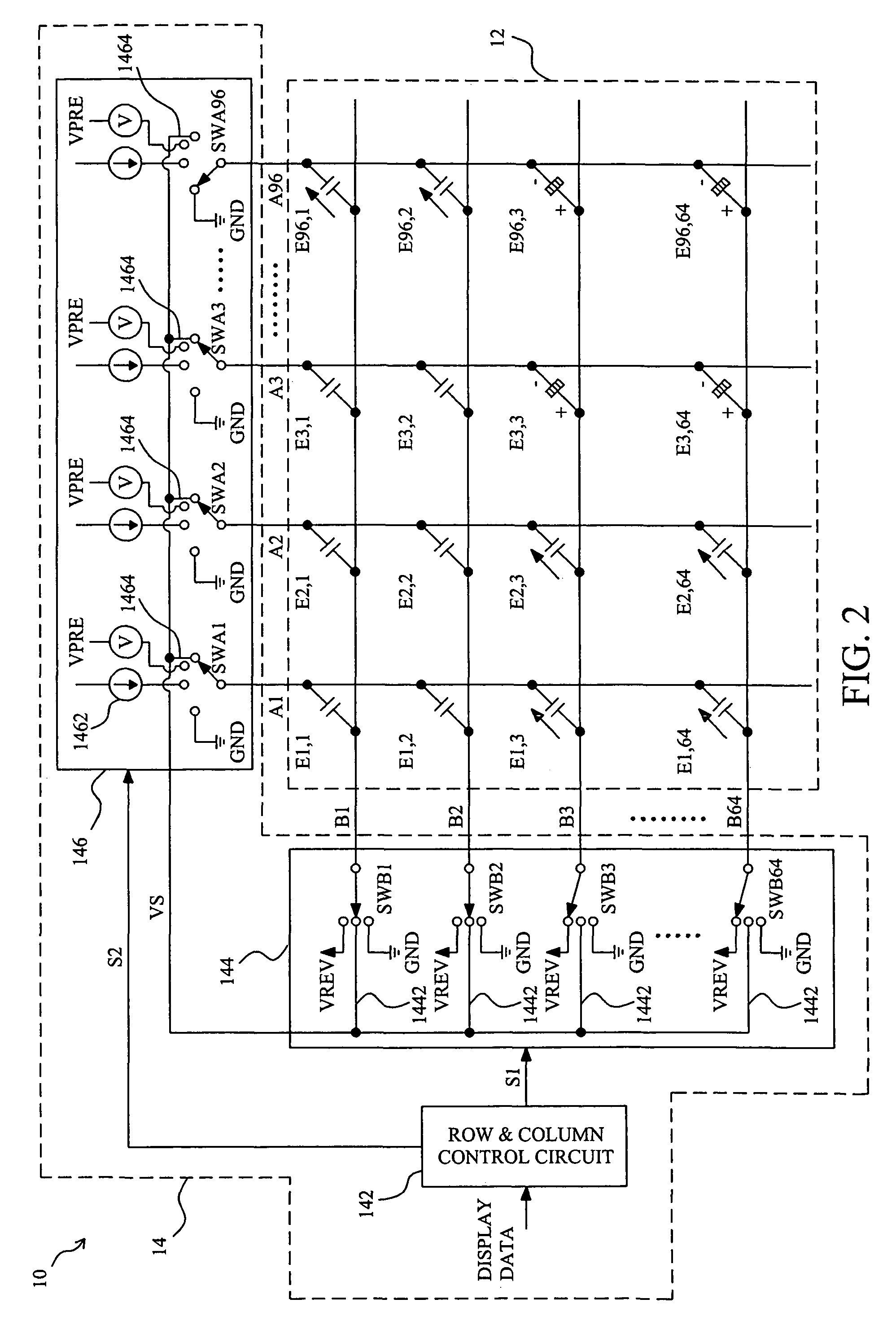

Driving system and method for an electroluminescent display

A driving system and method for electroluminescent displays which by connecting the electroluminescent elements that have been lighted up to the electroluminescent elements that are to be lighted up causes charge to be shared among the elements, so as to increase the voltage level at the anodes of the electroluminescent elements which are to be lighted up, thereby reducing the power consumption and increasing the response speed.

Owner:RICHTEK TECH

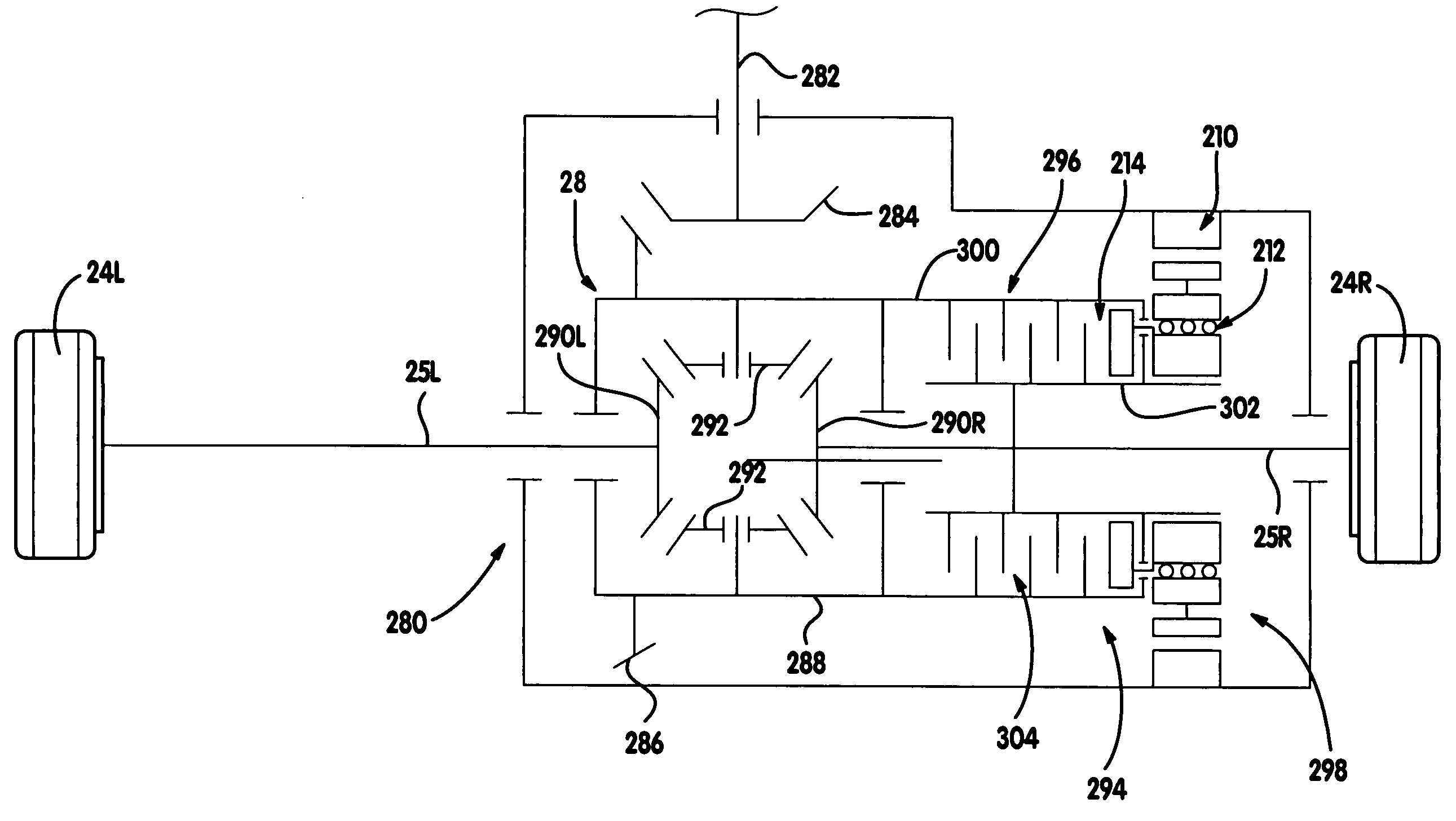

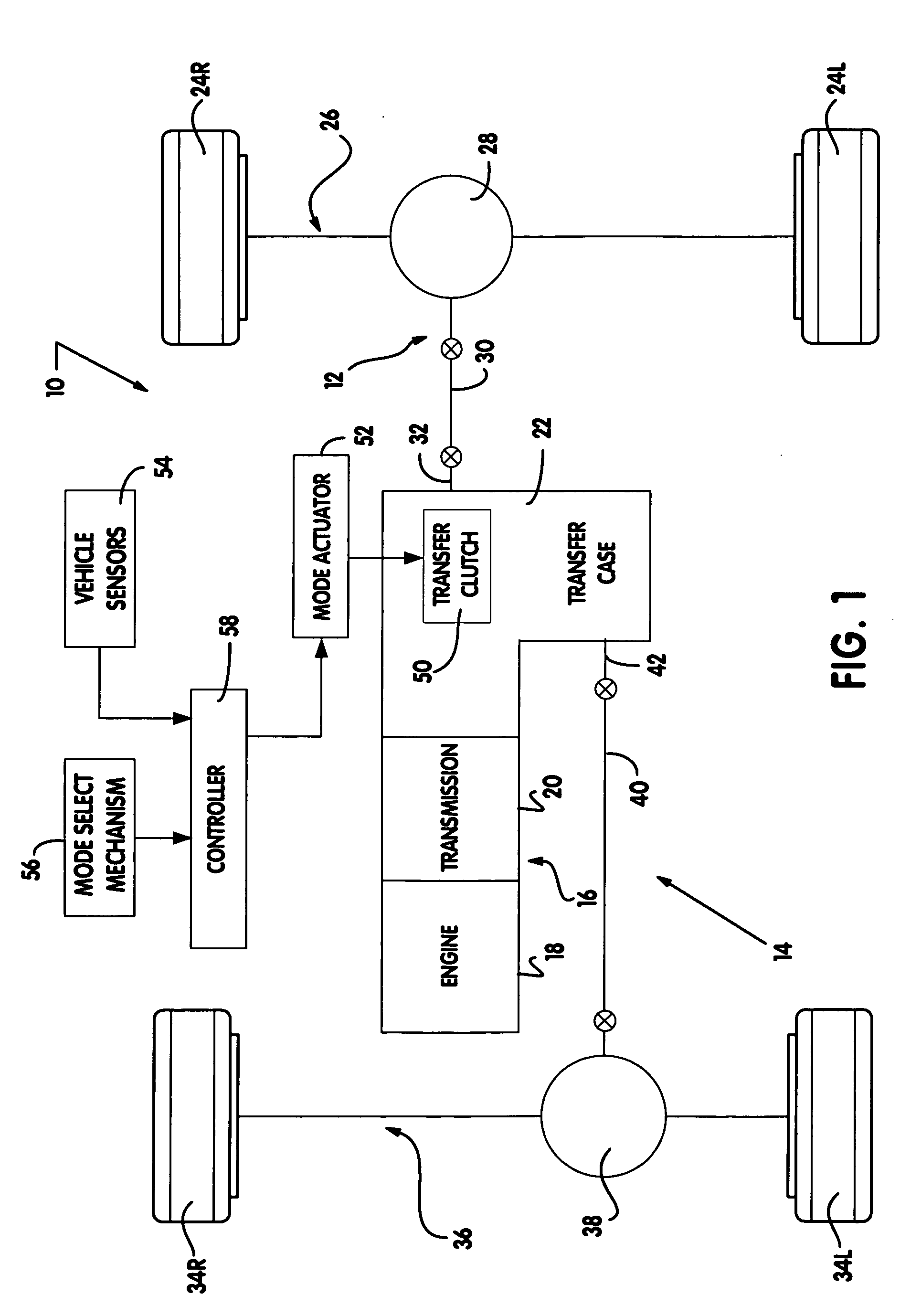

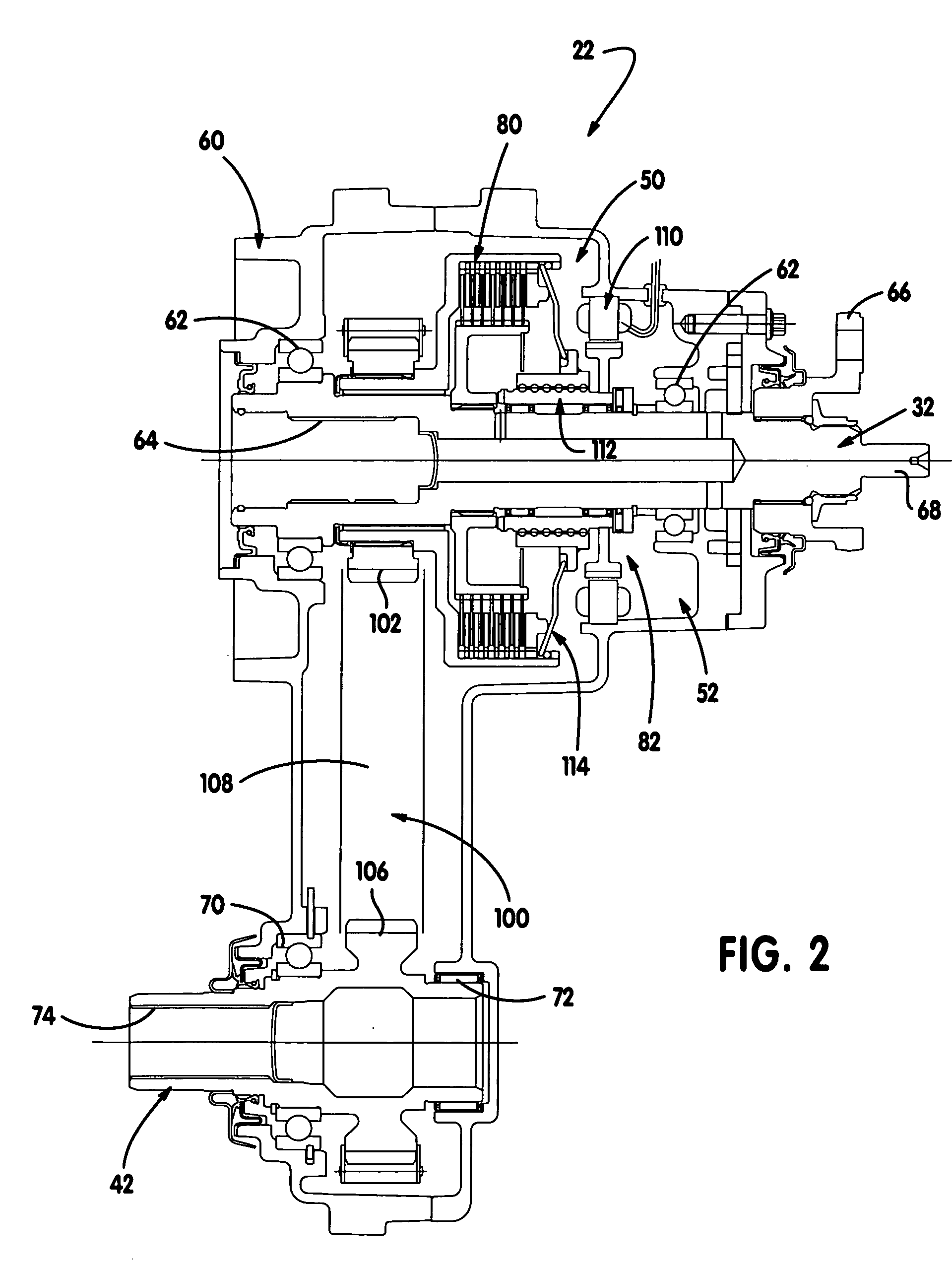

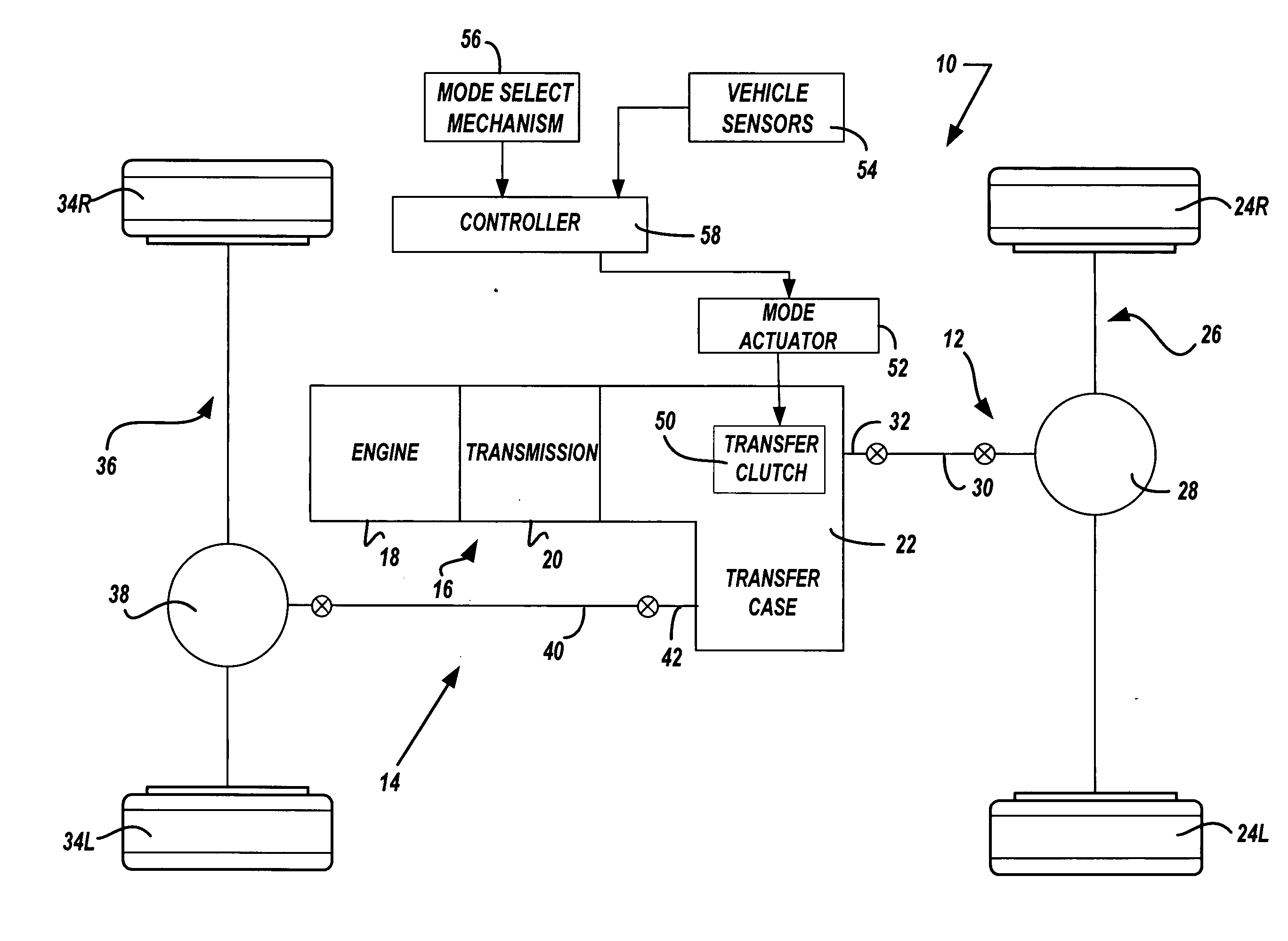

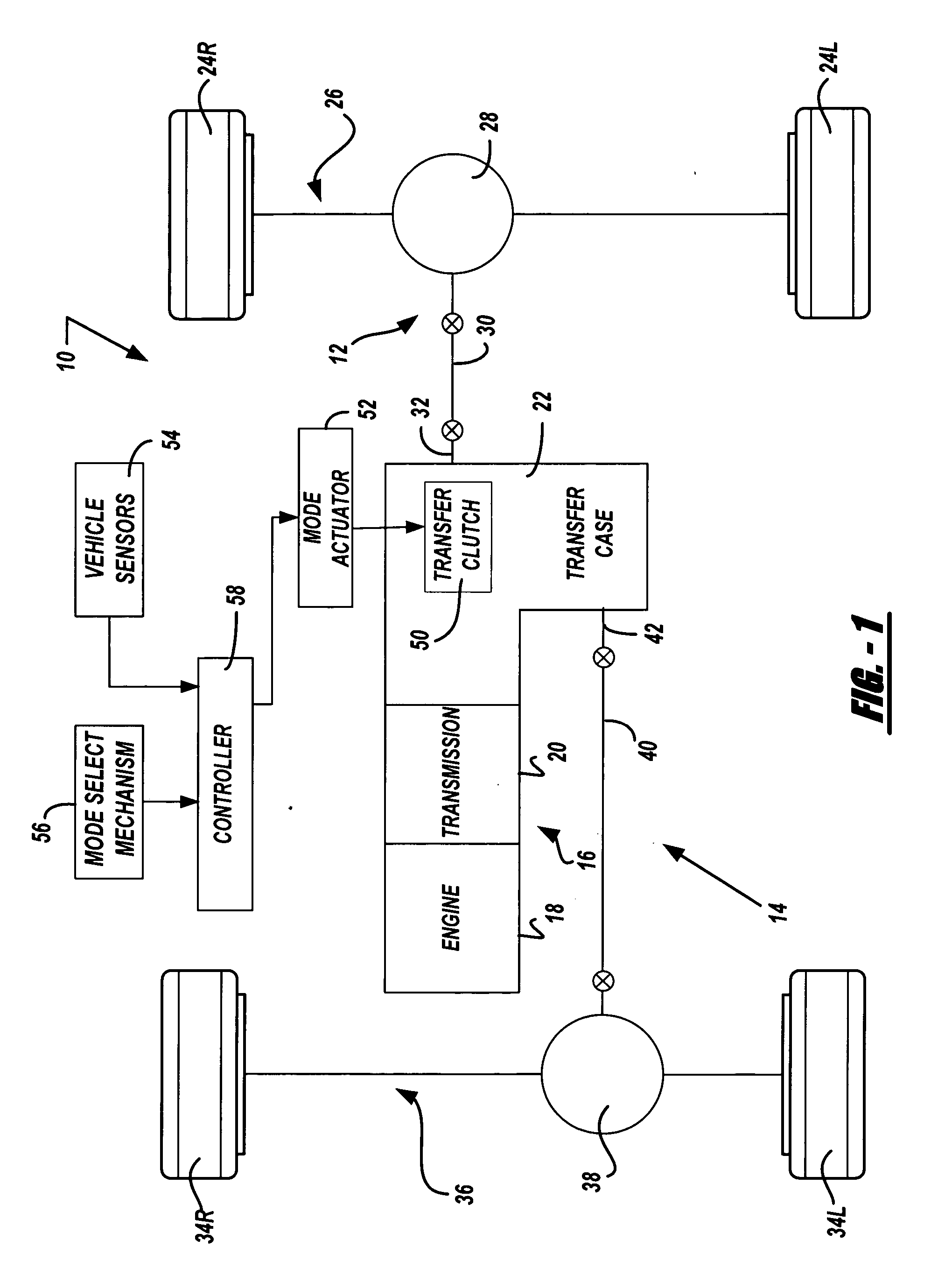

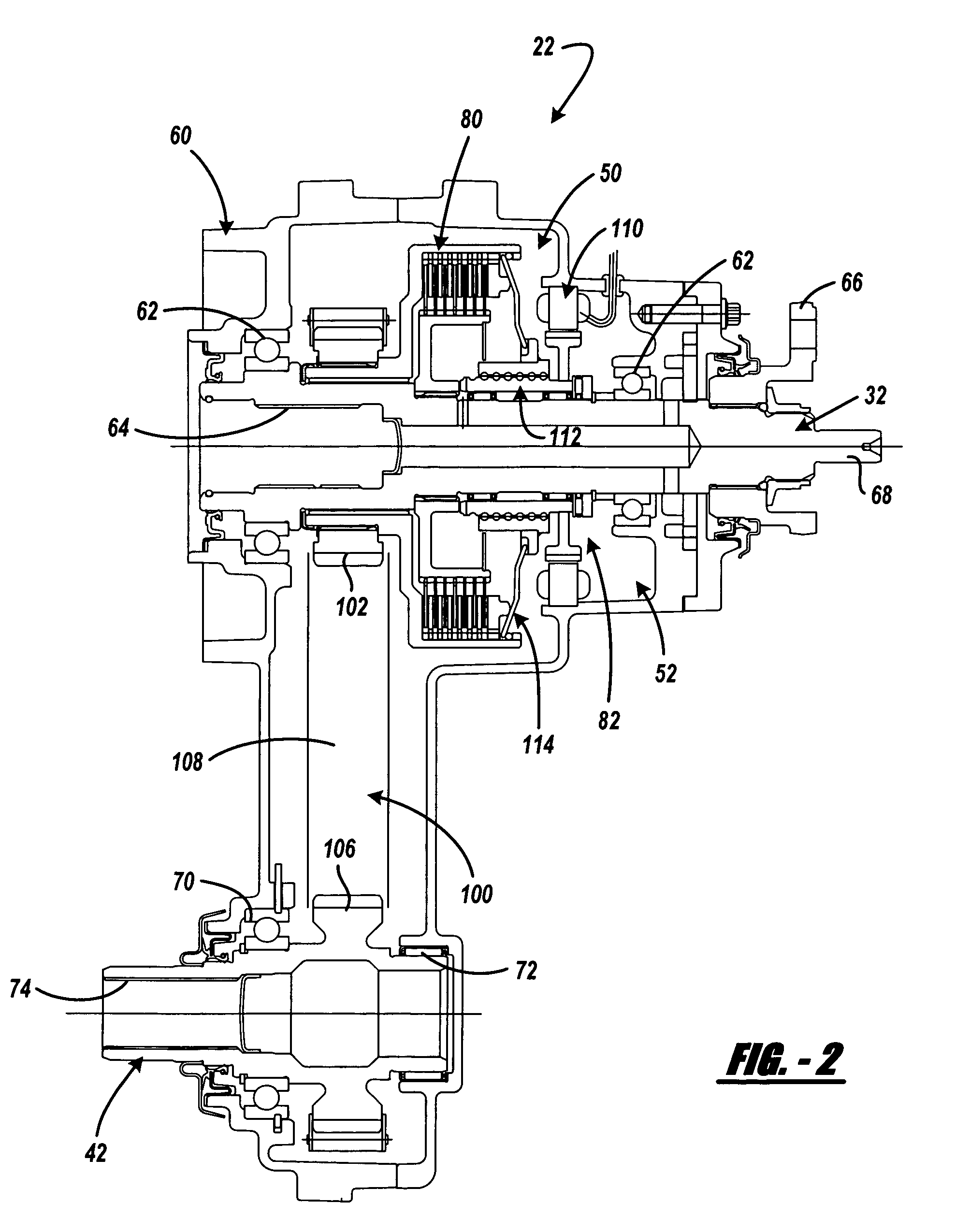

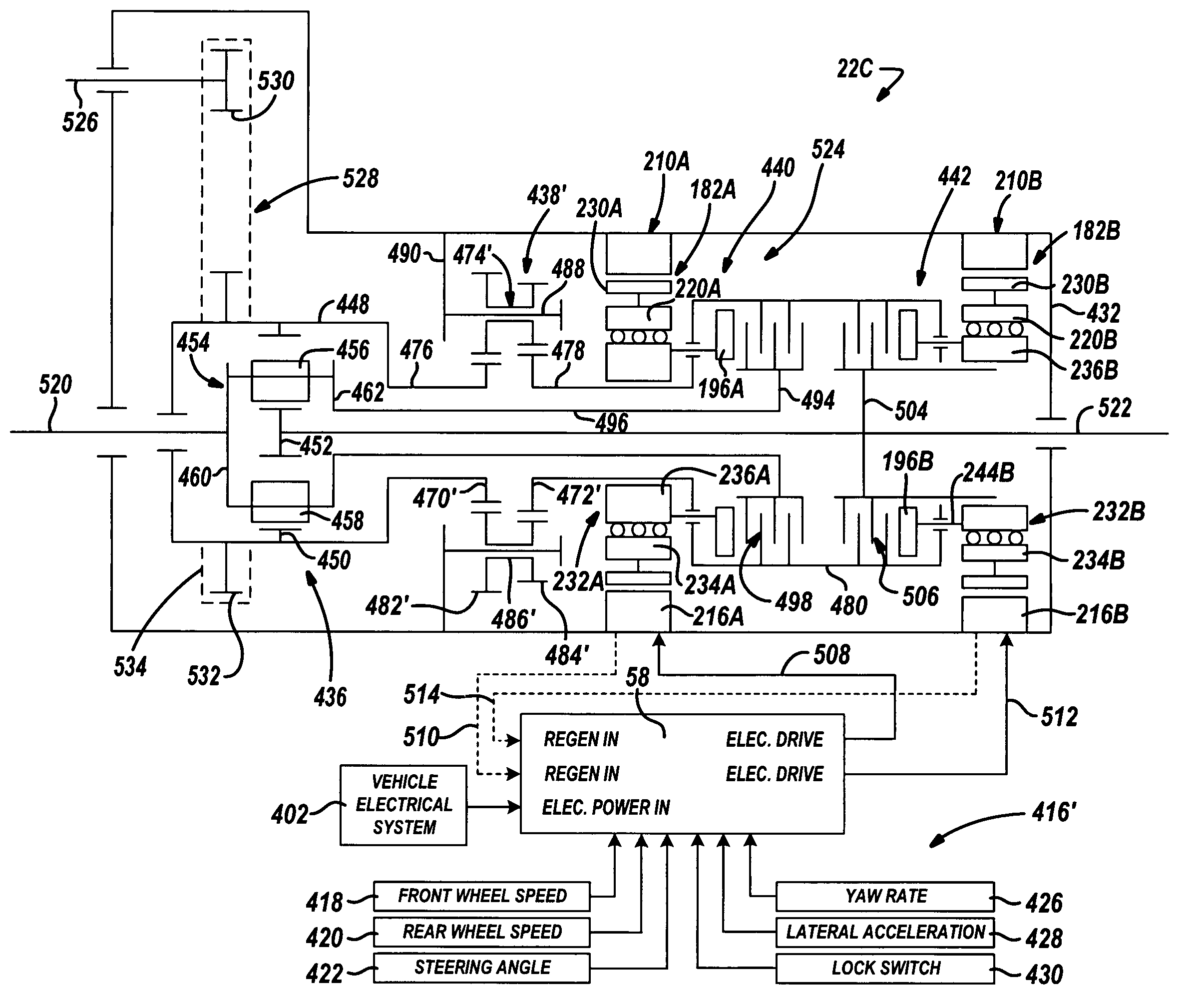

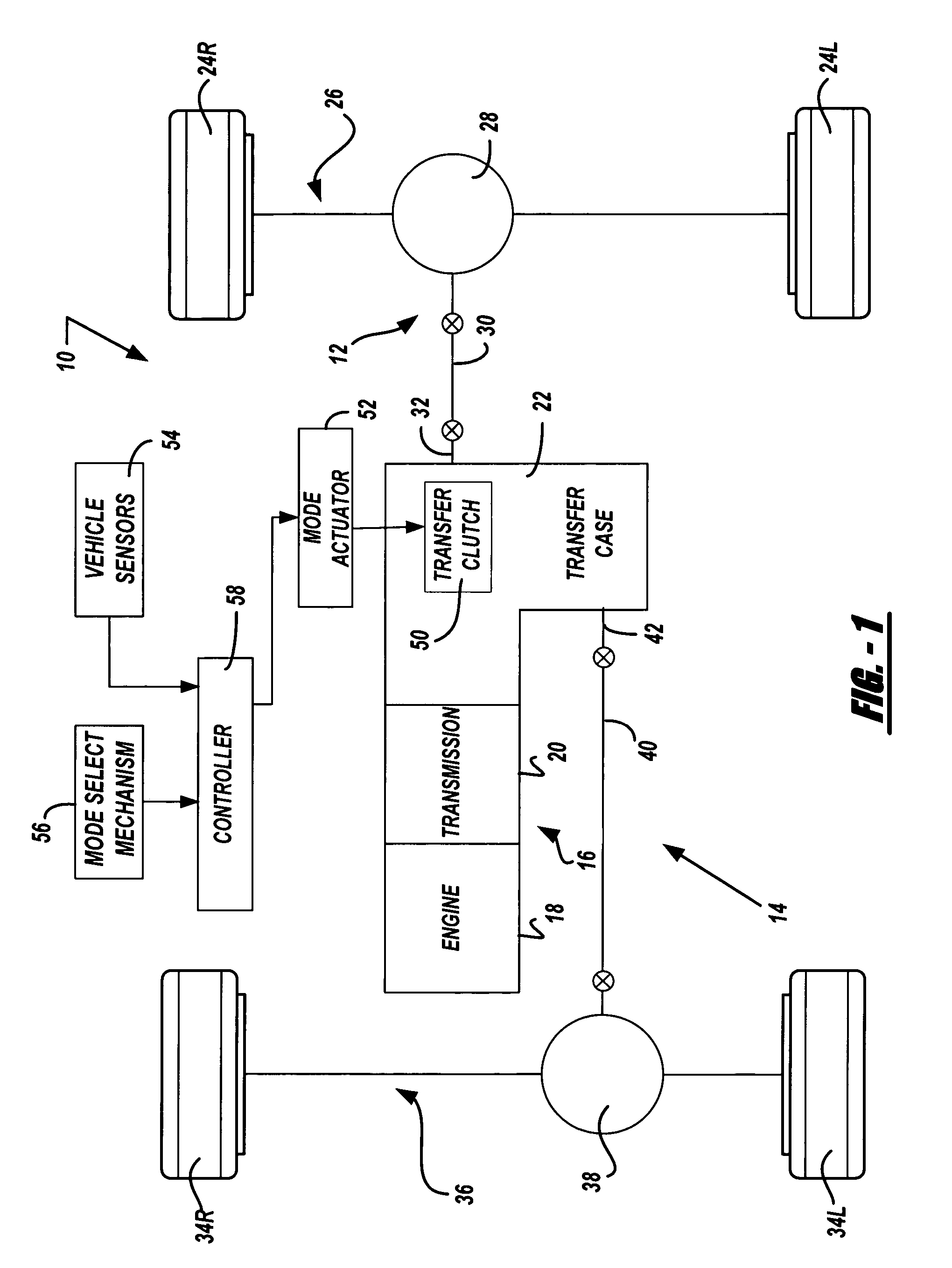

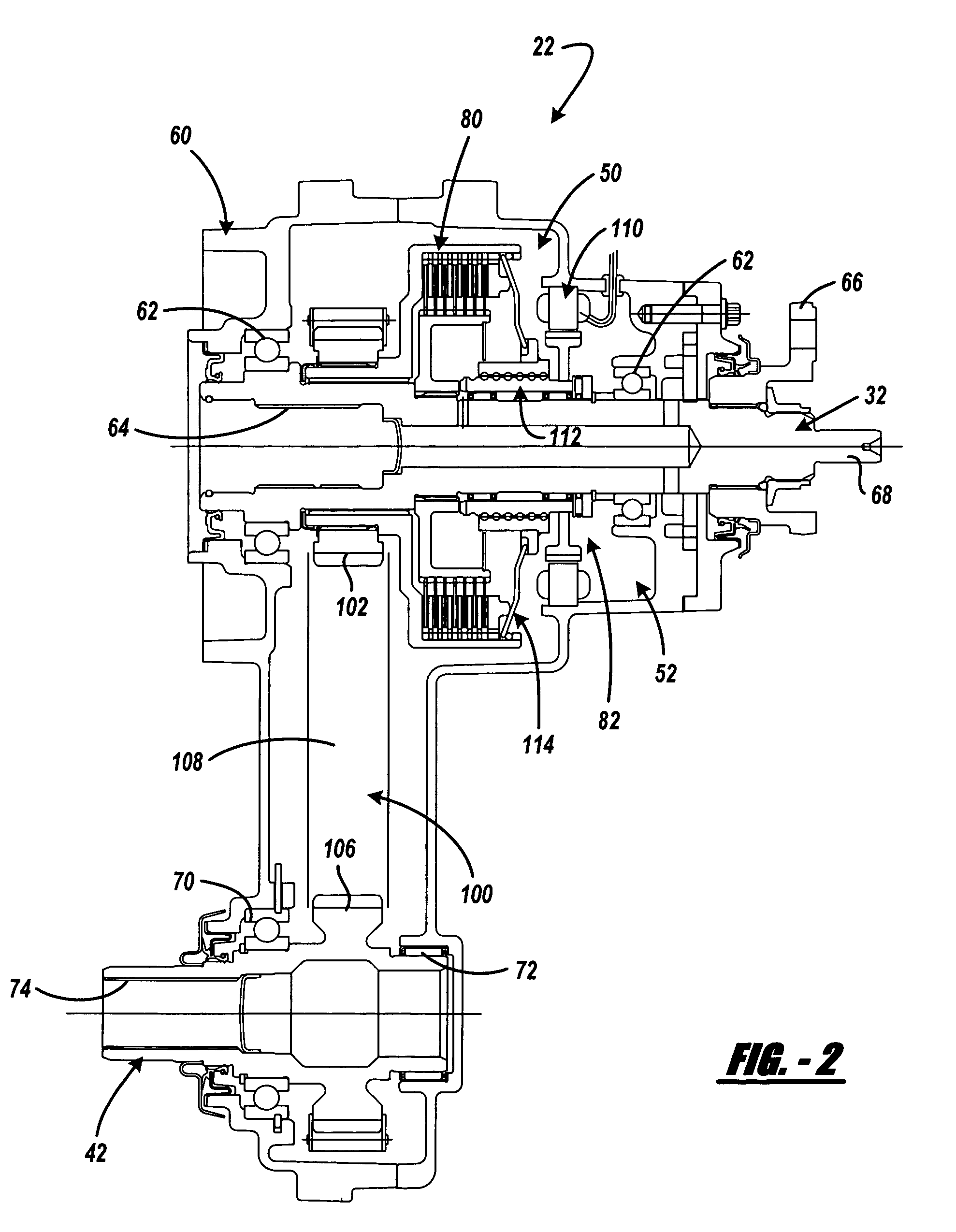

Torque vectoring drive mechanism having a power sharing control system

InactiveUS20050176543A1Reduced Power RequirementsReduce electricity demandMechanical actuated clutchesToothed gearingsLinear motionControl system

A torque transfer mechanism is provided for controlling the magnitude of a clutch engagement force exerted on a multi-plate clutch assembly that is operably disposed between a first rotary and a second rotary member. The torque transfer mechanism includes a clutch actuator assembly for generating and applying a clutch engagement force on the clutch assembly. The clutch actuator assembly includes an electric motor / brake unit and a torque / force conversion mechanism. The motor / brake unit can be operated in either of a motor mode or a brake mode to cause bi-directional linear movement of an output member of the torque / force conversion mechanism. The thrust force generated by the torque / force conversion mechanism is applied to the clutch assembly. The dual mode feature of the electric motor / brake unit significantly reduces the power requirements. A torque vectoring drive axle is equipped with a pair of such torque transfer mechanisms.

Owner:MAGNA DRIVETRAIN OF AMERICA

Torque vectoring device having an electric motor/brake actuator and friction clutch

InactiveUS20060199697A1Reduce electricity demandReduced Power RequirementsMagnetically actuated clutchesEngine controllersClutchTransfer mechanism

A torque transfer mechanism is provided for controlling the magnitude of a clutch engagement force exerted on a multi-plate clutch assembly that is operably disposed between a first rotary and a second rotary member. The torque transfer mechanism includes a clutch actuator assembly for generating and applying a clutch engagement force on the clutch assembly. The clutch actuator assembly includes an electric motor / brake unit and a torque / force conversion mechanism. The motor / brake unit can be operated in either of a motor mode or a brake mode to cause bi-directional linear movement of an output member of the torque / force conversion mechanism. The thrust force generated by the torque / force conversion mechanism is applied to the clutch assembly. The dual mode feature of the electric motor / brake unit significantly reduces the power requirements. A torque vectoring drive axle is equipped with a pair of such torque transfer mechanisms.

Owner:MAGNA POWERTRAIN USA

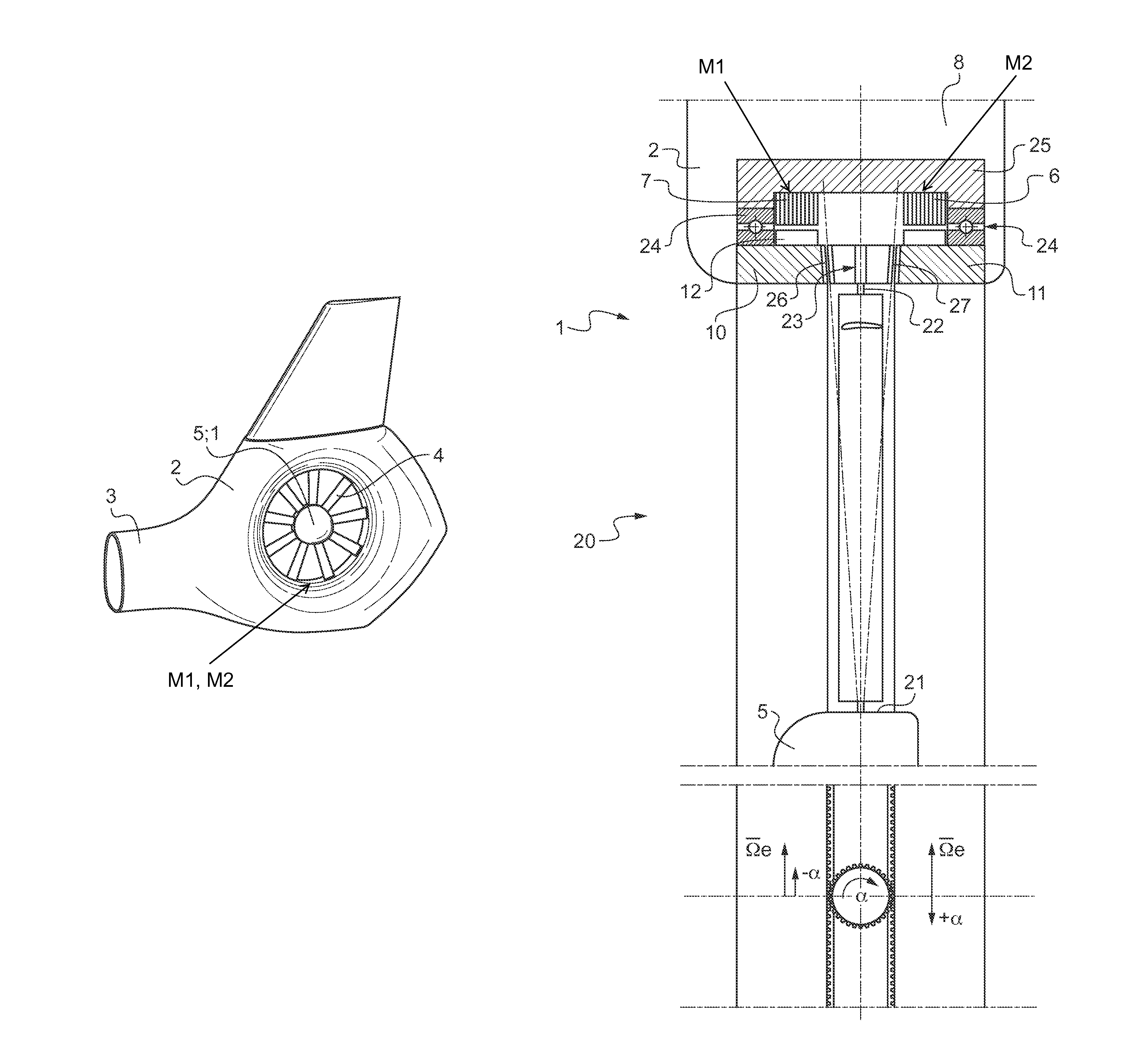

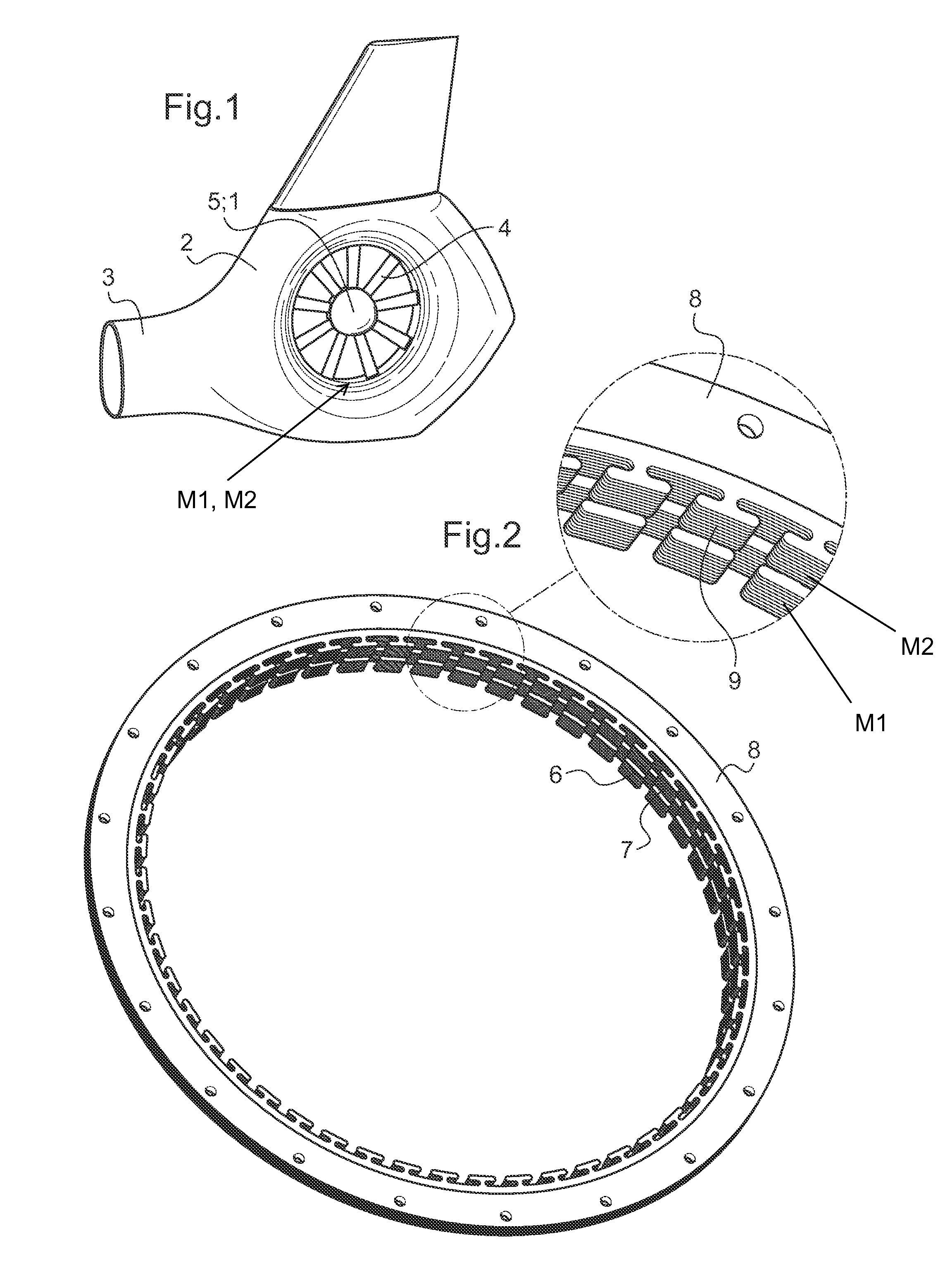

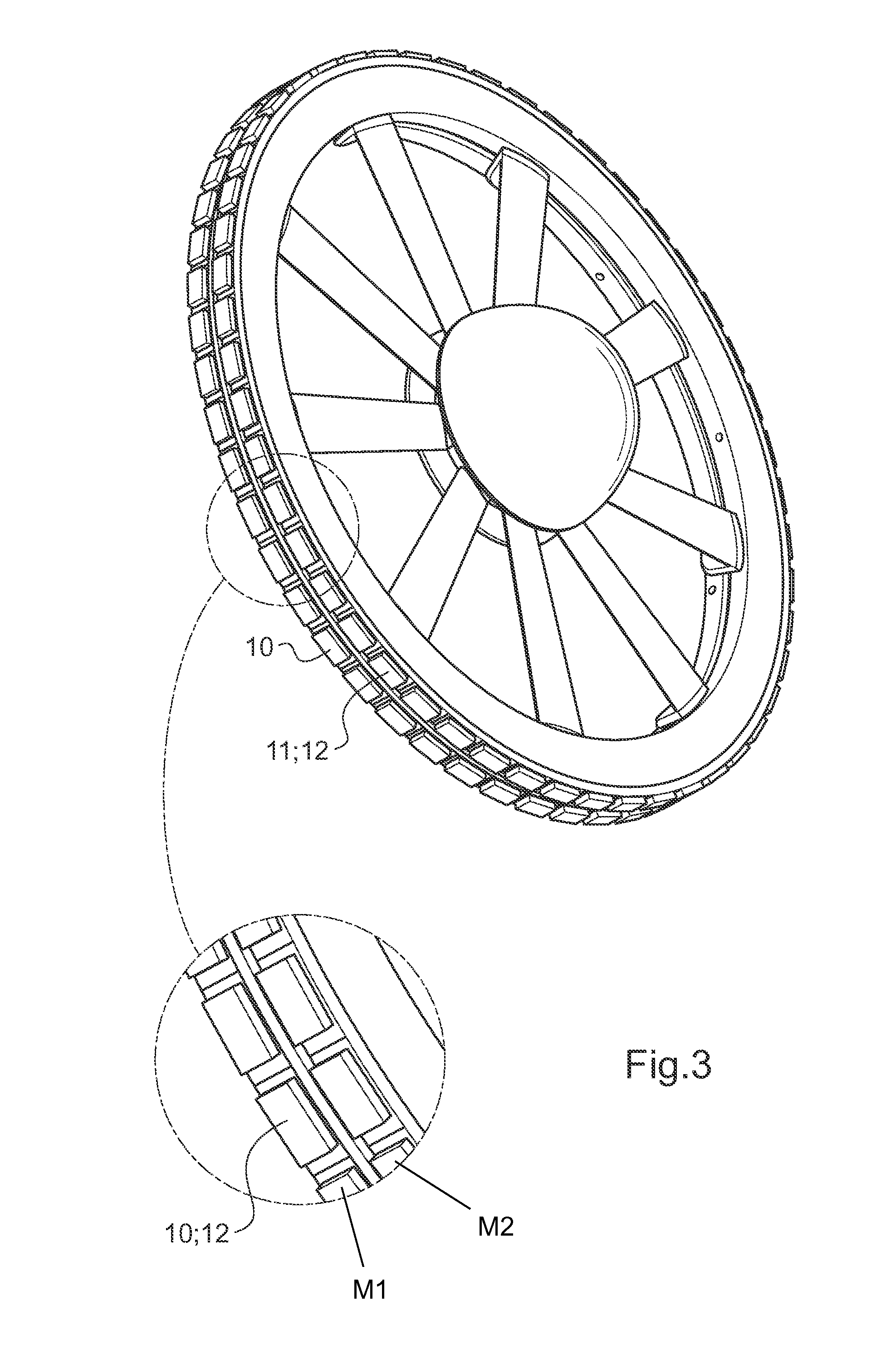

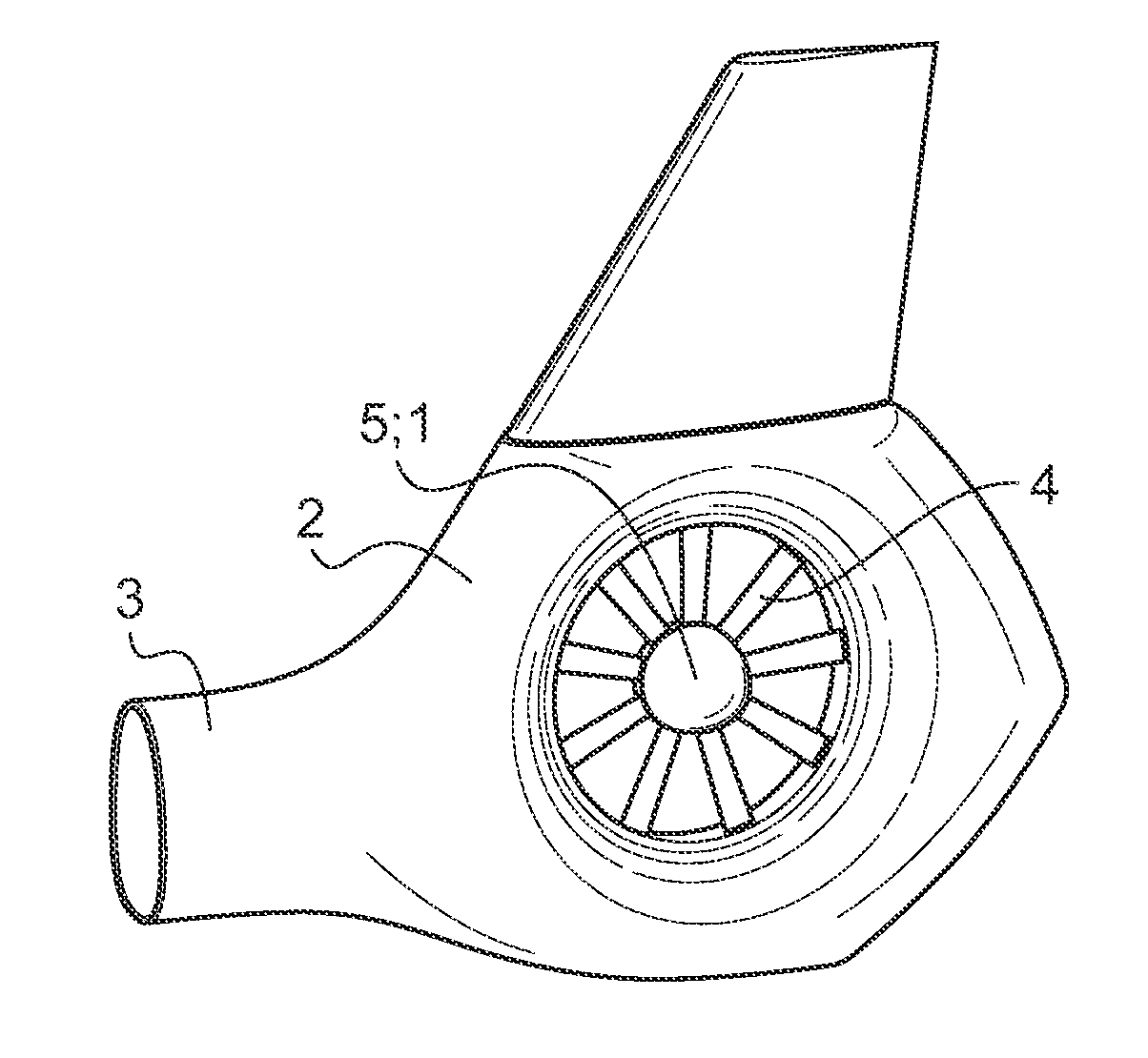

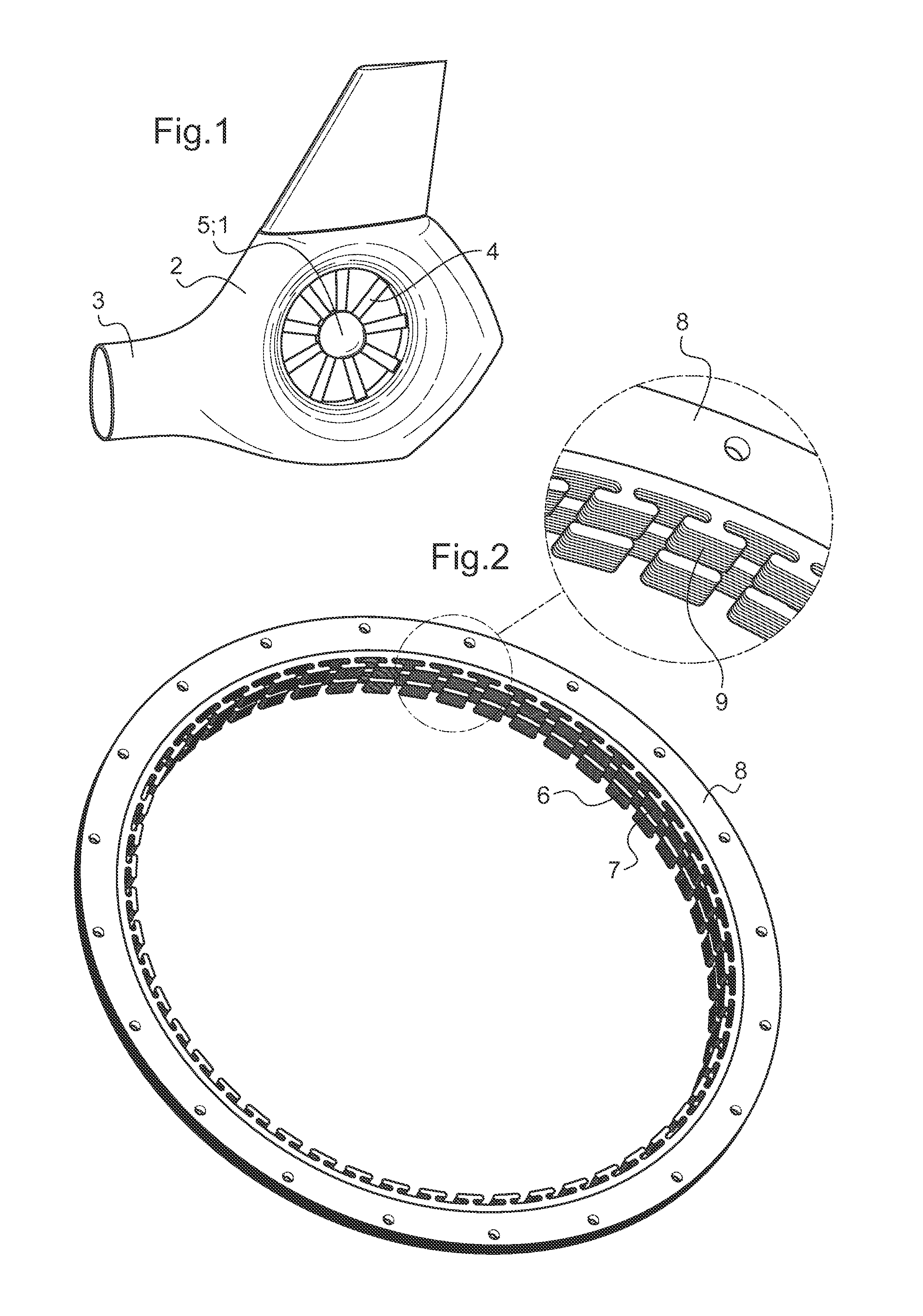

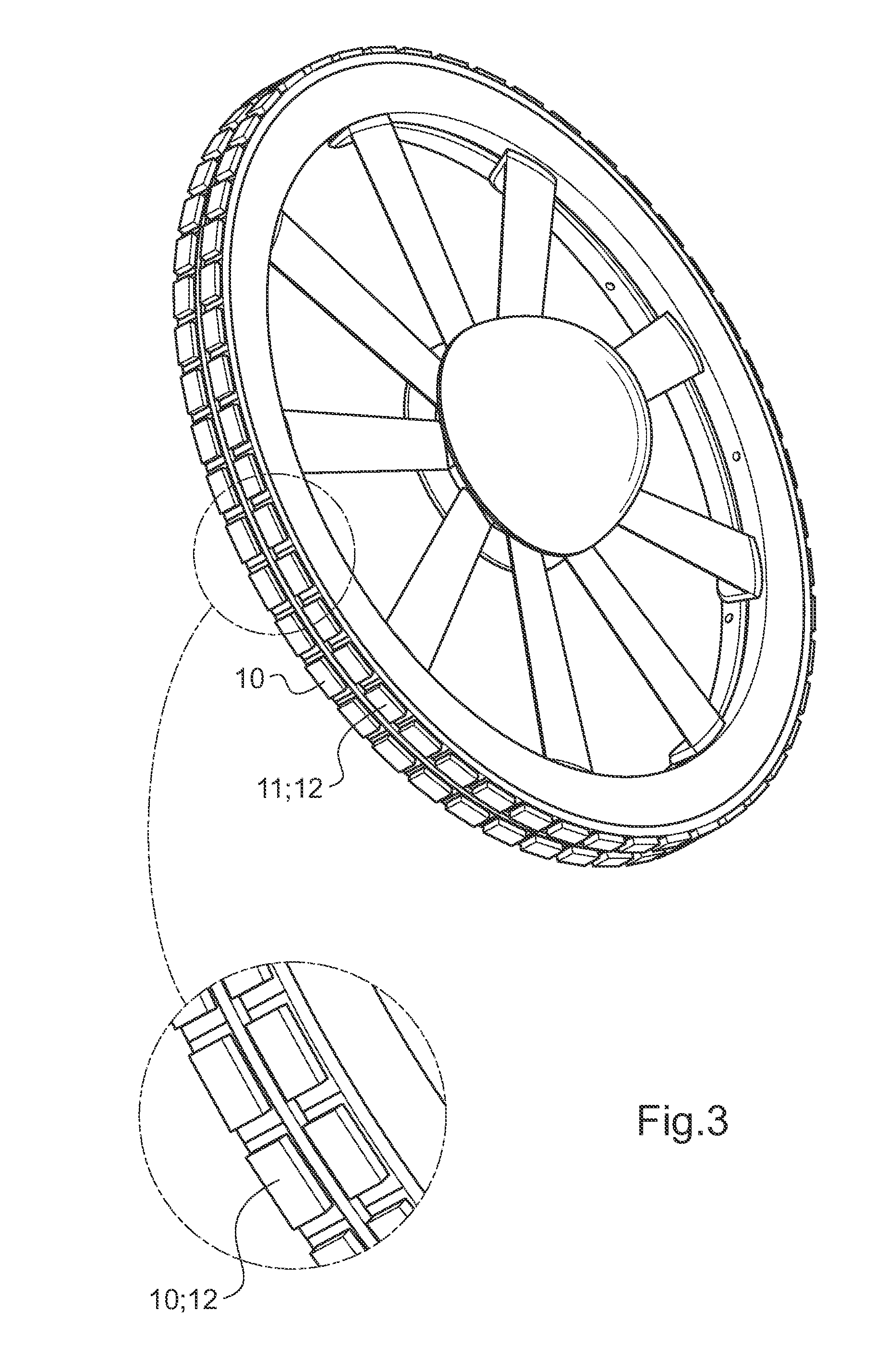

Electrical powered tail rotor of a helicopter

ActiveUS9174728B2Improve efficiencyIncrease the number of polesMagnetic circuit stationary partsMachines/enginesSynchronous motorEngineering

The invention is related to an electrical powered tail rotor (1) of a helicopter comprising a housing (2) around the tail rotor (1), and at least one permanent magnet energized synchronous motor with a stator (6, 7) with an increased number of poles (9). Said at least one synchronous motor is integrated as a torus (8) around an opening of the housing (2) encompassing the tail rotor (1). Blades (4) of the tail rotor (1) are fixed to at least one rotating component (10, 11) of said at least one synchronous motor. Supply means provide for electric energy to said at least one synchronous motor. Blade pitch control means are provided at the torus (8).

Owner:AIRBUS HELICOPTERS DEUT GMBH

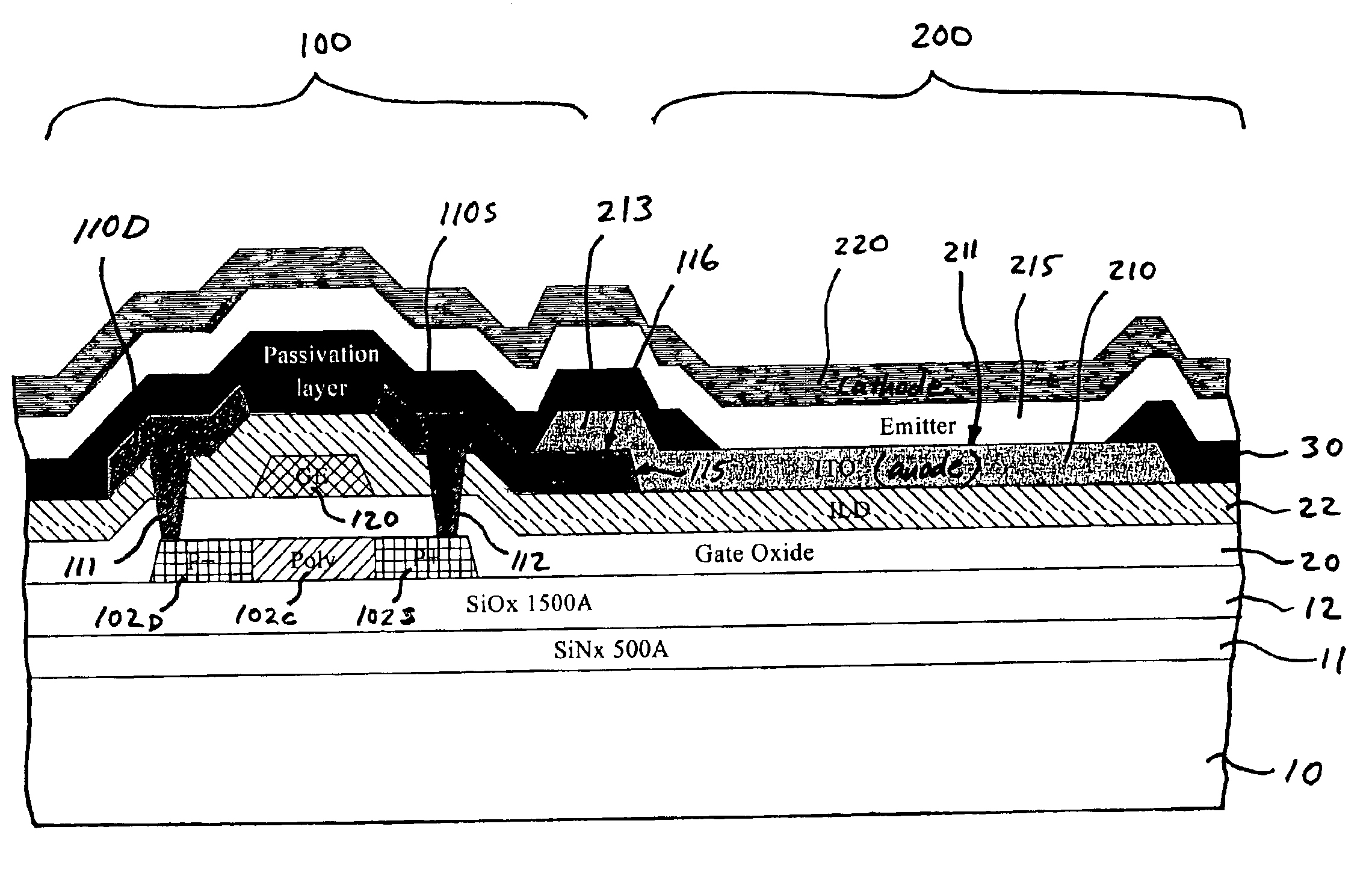

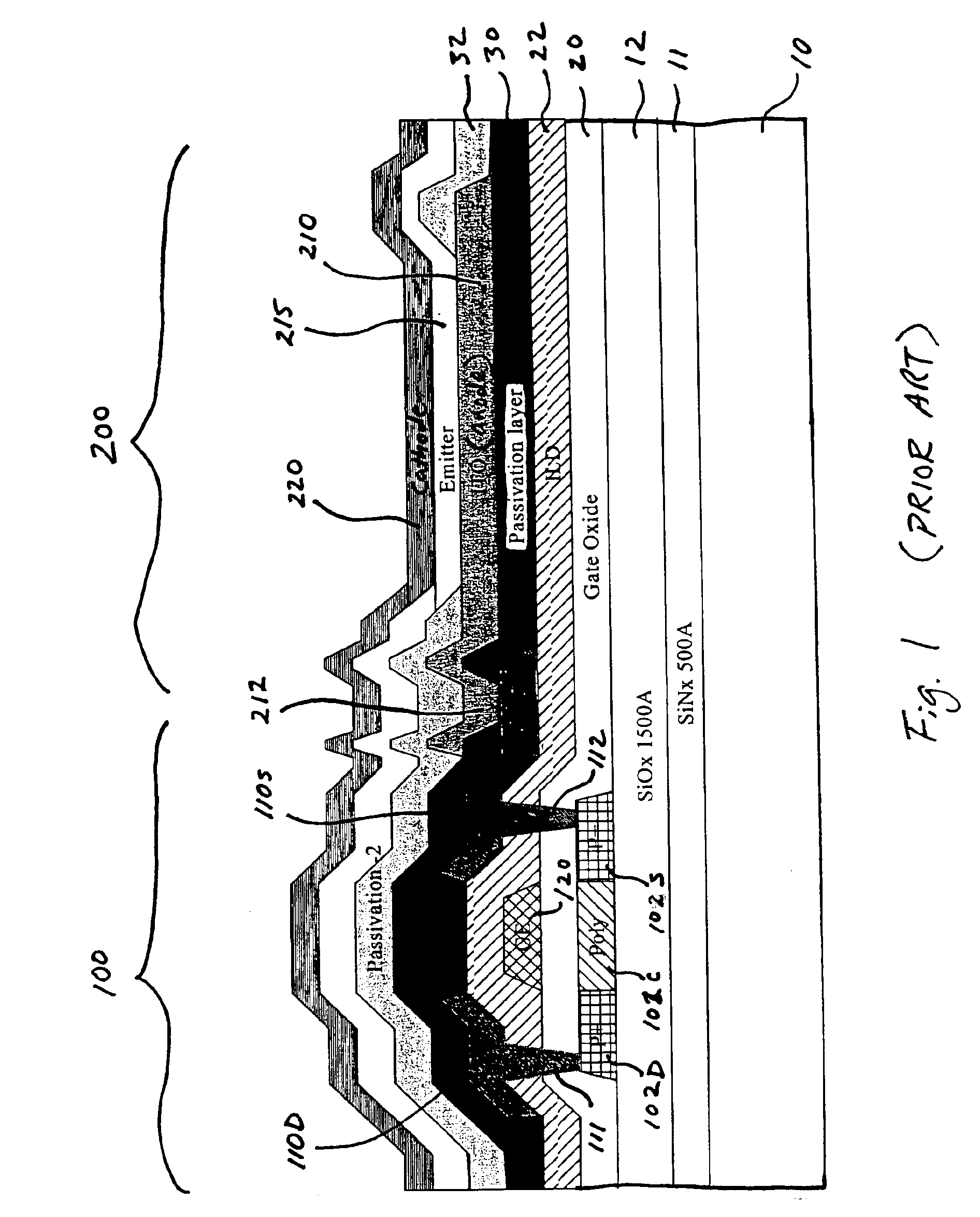

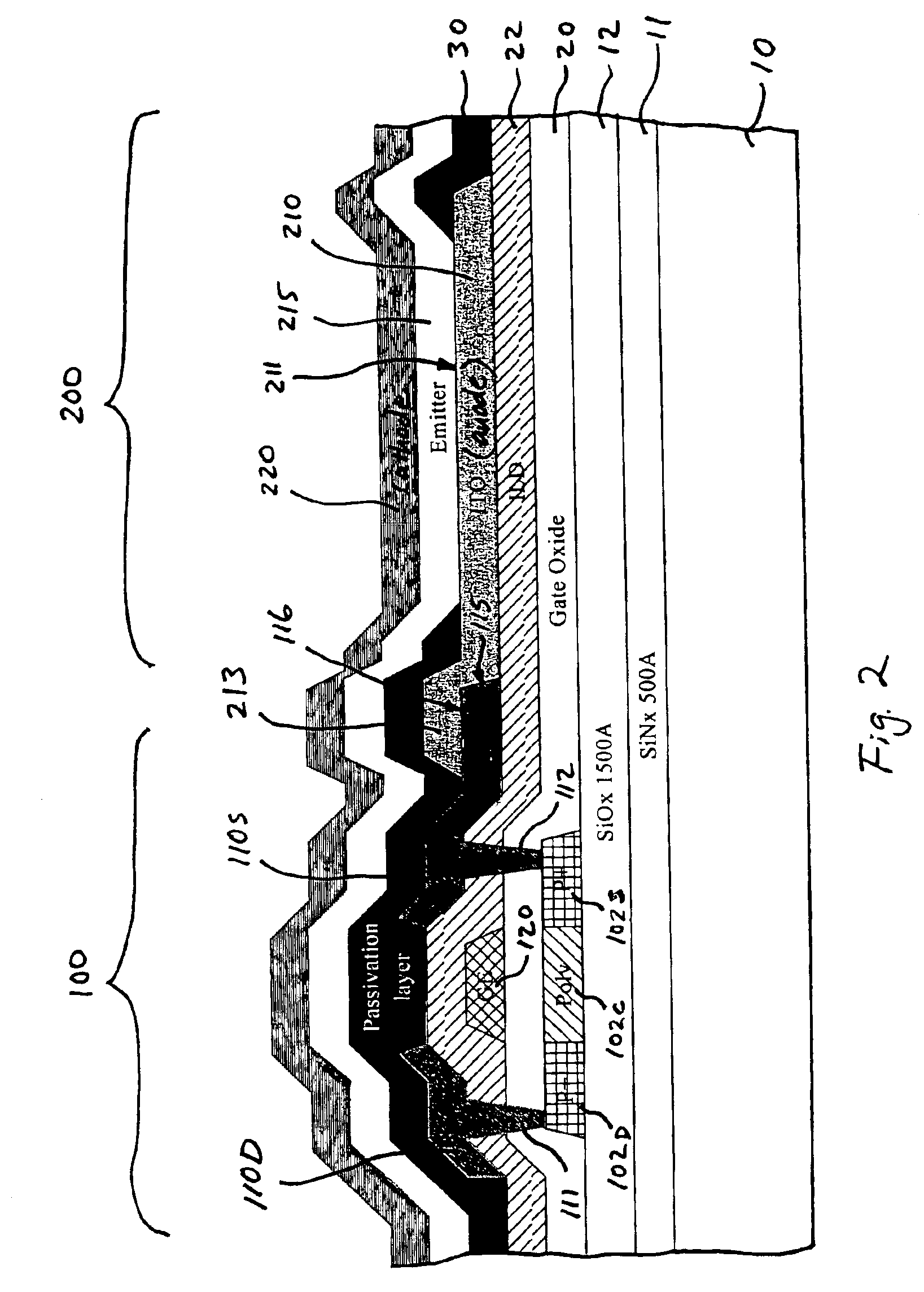

Thin film transistor organic light emitting diode structure

InactiveUS6850000B1Reduce electricity demandContact resistanceDischarge tube luminescnet screensStatic indicating devicesDisplay deviceLight-emitting diode

An electroluminescence display device comprising a thin film transistor and an electroluminescence element wherein the electroluminescence element's anode and a portion of the thin film transistor's source / drain electrode are deposited on to a same surface and the electroluminescence element's anode and the portion of the thin film transistor's source / drain electrode overlap and make an electrical contact with improved contact resistance.

Owner:AU OPTRONICS CORP

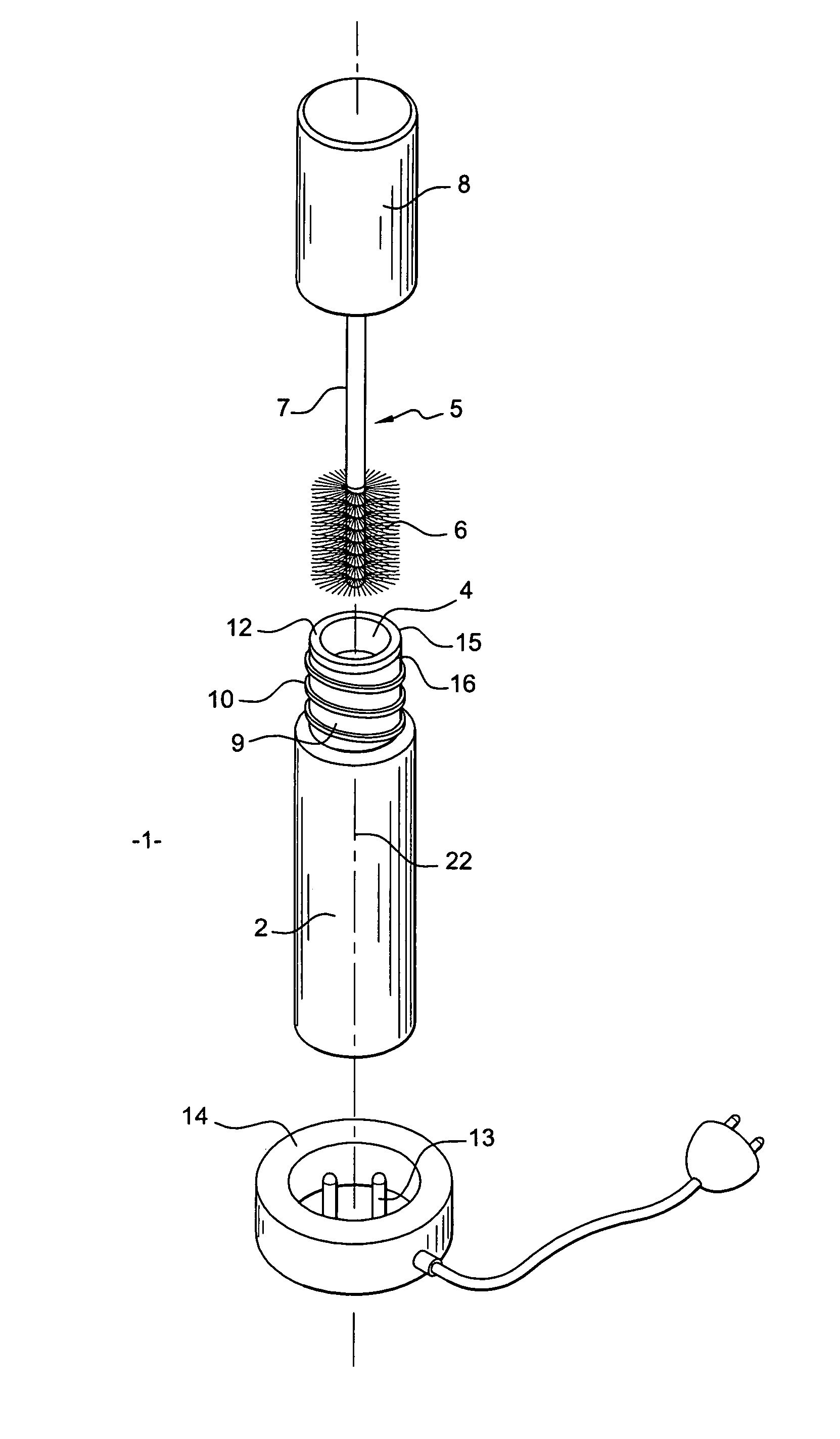

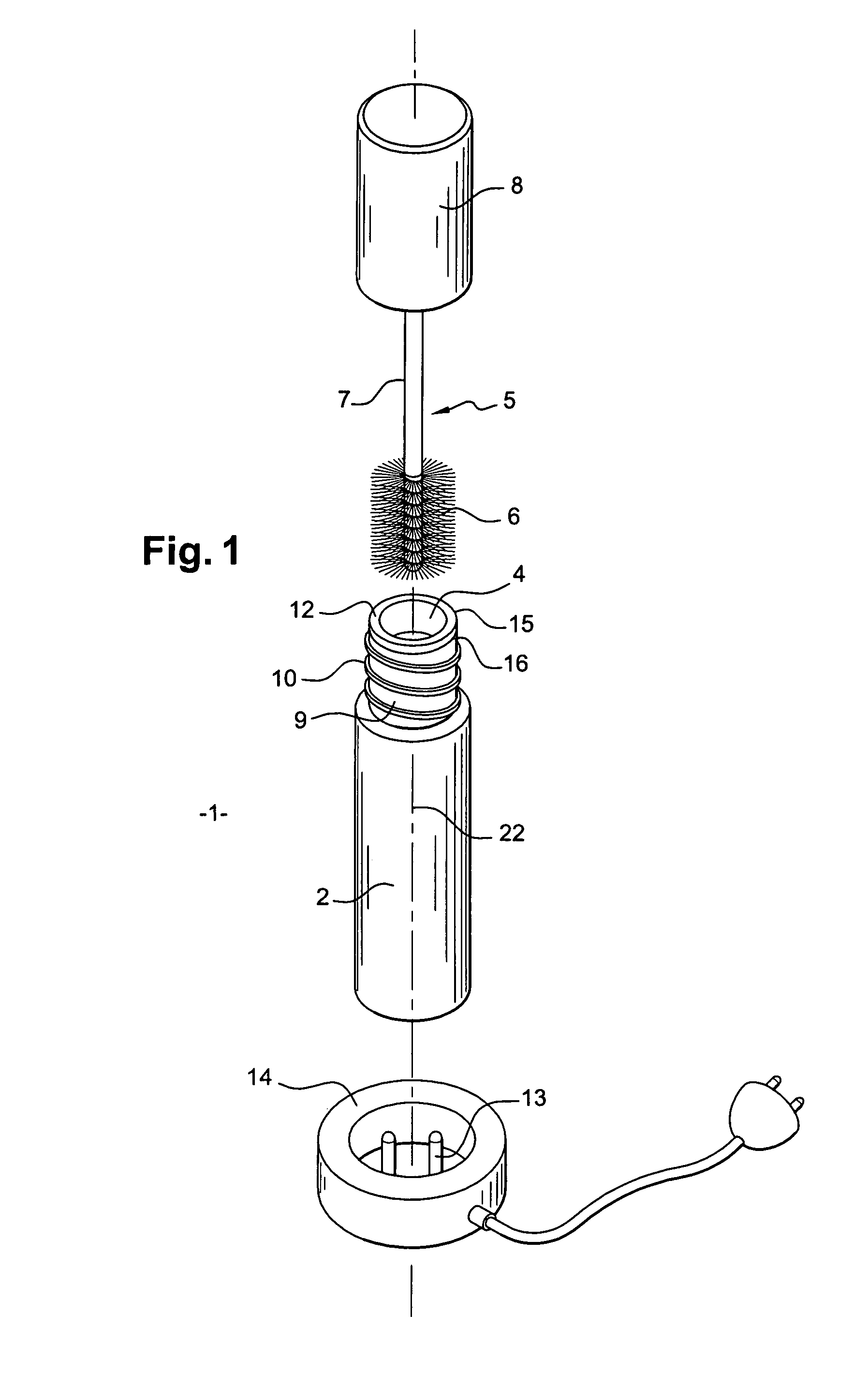

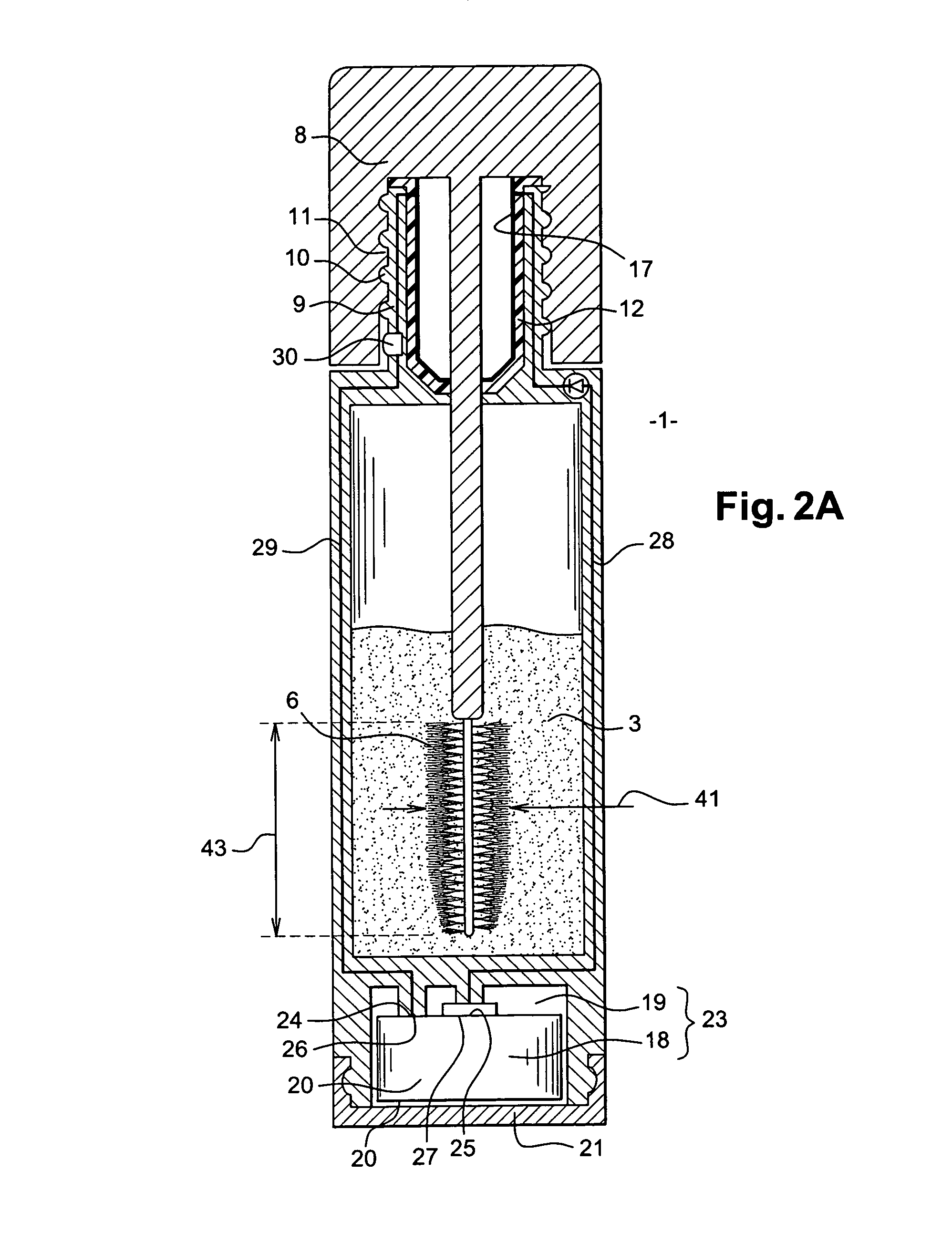

Packaging and applicator device for a cosmetic product and/or a beauty care product incorporating a means of heating

InactiveUS7108438B2Simple actionLimiting and reducing aging and potential deteriorationDispensing apparatusBristleFiberBiomedical engineering

Owner:LOREAL SA

Torque vectoring device having an electric motor/brake actuator and friction clutch

InactiveUS7175557B2Reduced Power RequirementsReduce electricity demandMagnetically actuated clutchesEngine controllersLinear motionDual mode

Owner:MAGNA POWERTRAIN USA

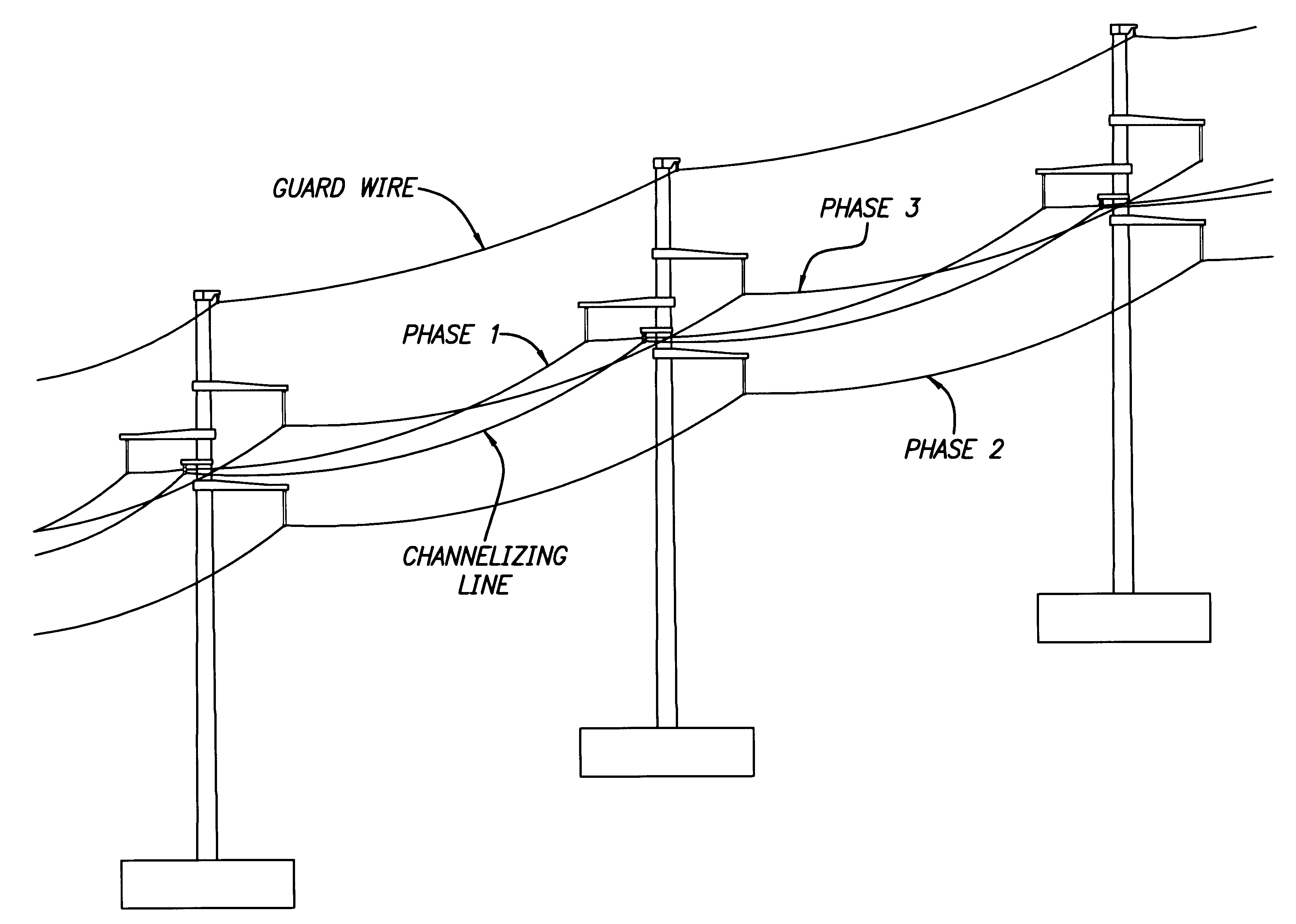

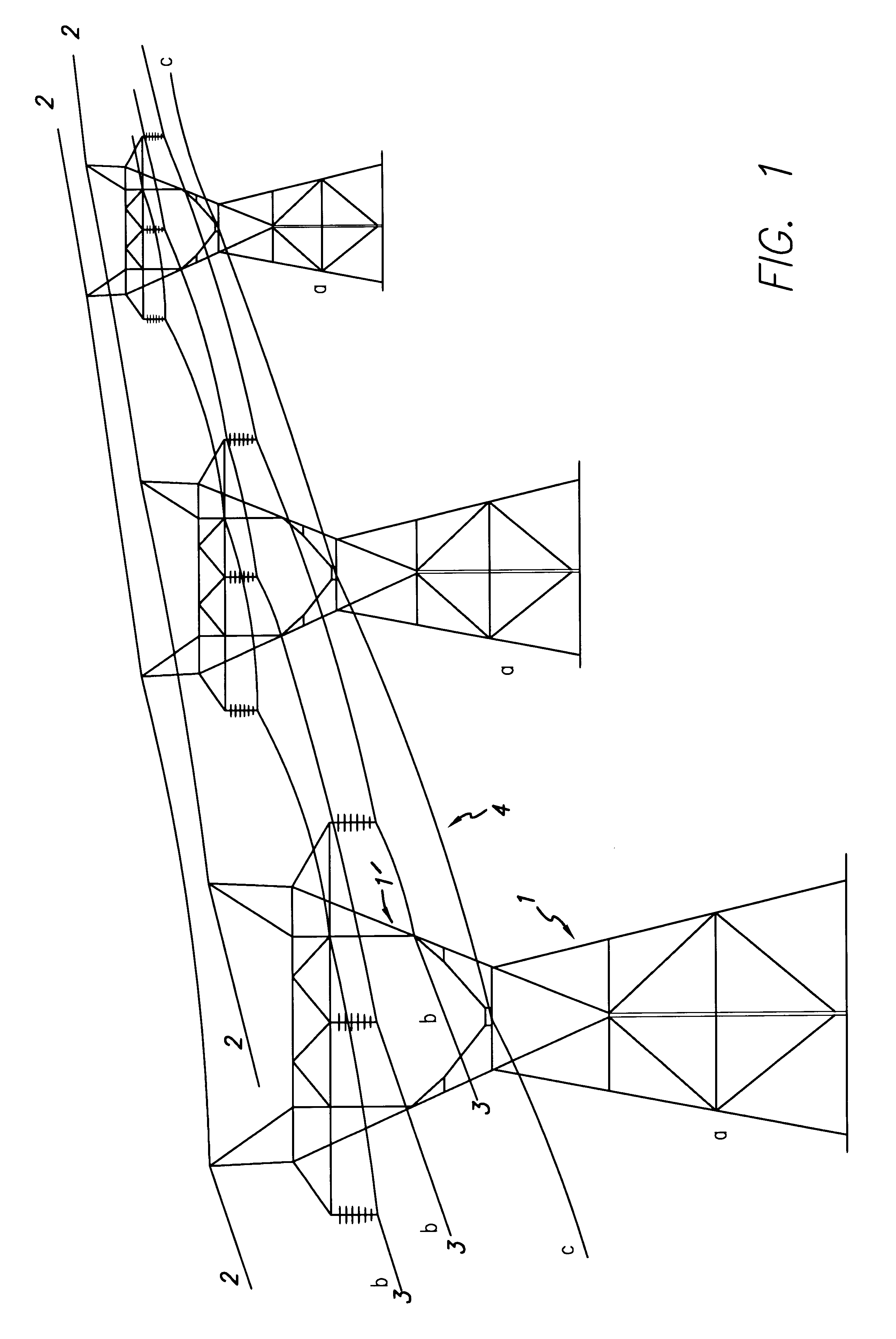

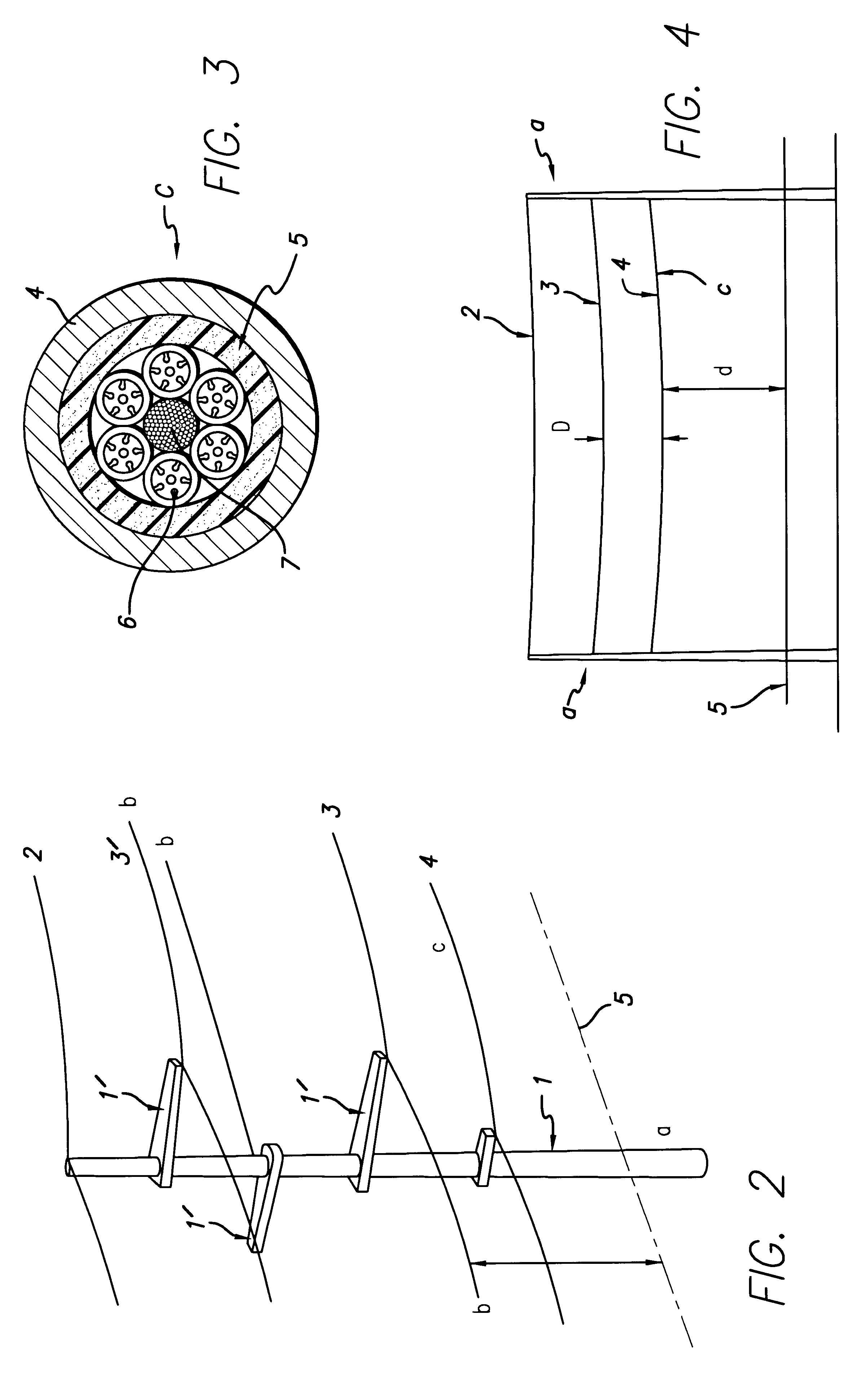

Transmission conduit and method of installation

InactiveUS6191354B1Simplifies installationMinimize necessityMaintaining distance between parallel conductorsSuspension arrangements for electric cablesEngineeringHigh pressure

A tubular channeling unit including a grounded external metal or conductive polymer sheathing and an internal longitudinal cavity, and method for laying such a tubular channeling unit by suspension on a high voltage aerial power line system including at least two towers supporting a set of high voltage electrical conductors suspended from the towers at a specified height above the ground and at a minimum predetermined safety level.

Owner:PROFESSIONAL COMM

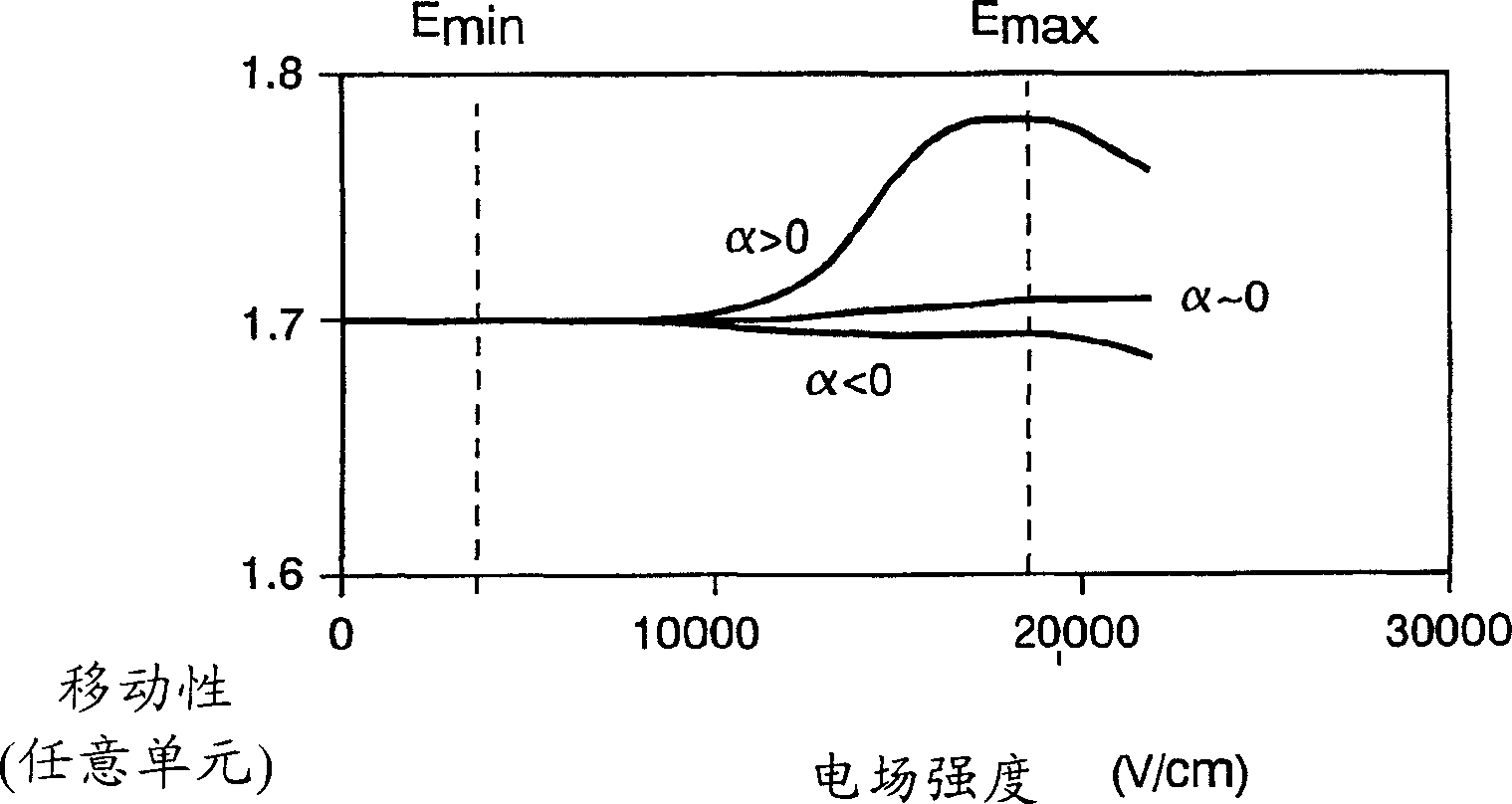

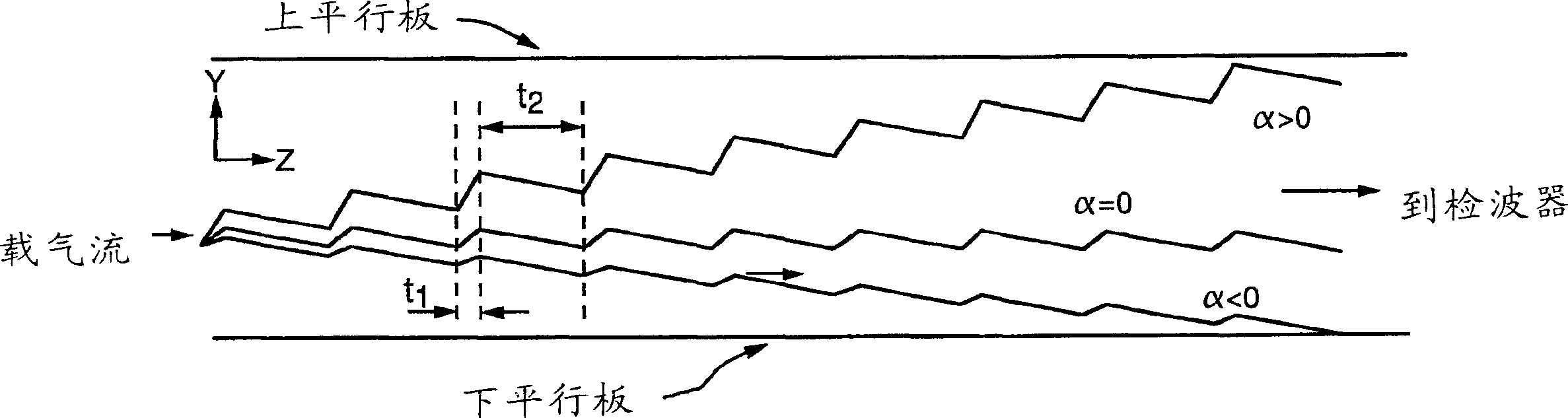

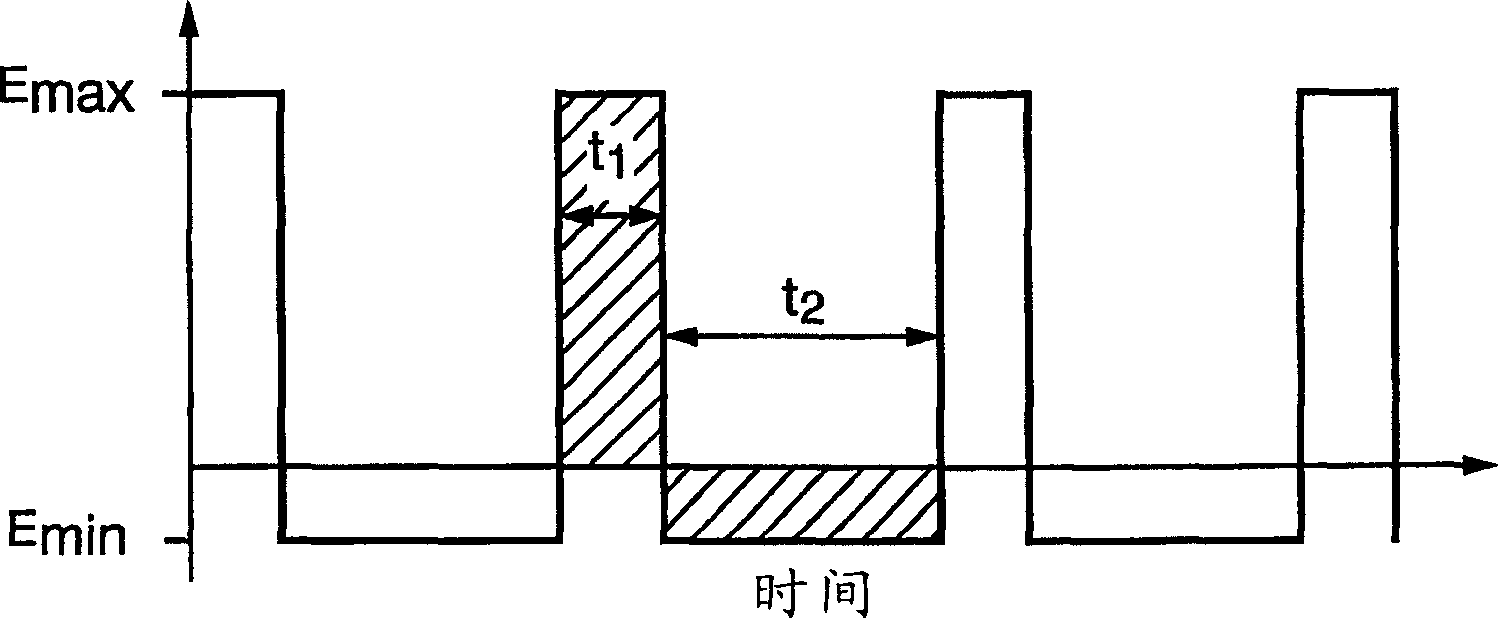

Methods and apparatus for electrospray-augmented high field asymmetric ion mobility spectrometry

InactiveCN1585666AInevitable separationEasy to identifyStability-of-path spectrometersTime-of-flight spectrometersIon-mobility spectrometryComputational chemistry

Method and apparatus for the analysis of compounds using electrospray in hihg field asymmetric ion mobility spectrometry.

Owner:CHARLES STARK DRAPER LABORATORY

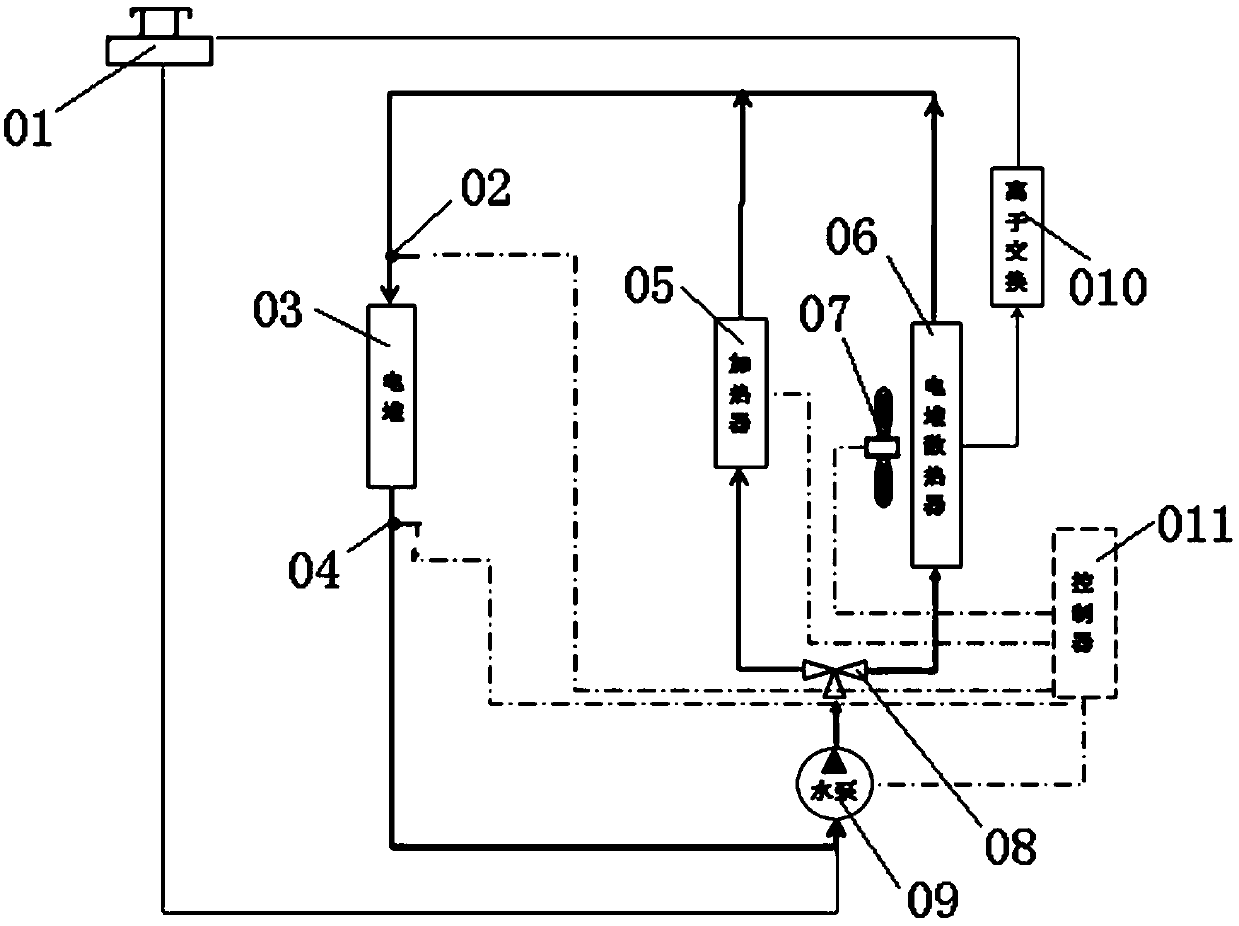

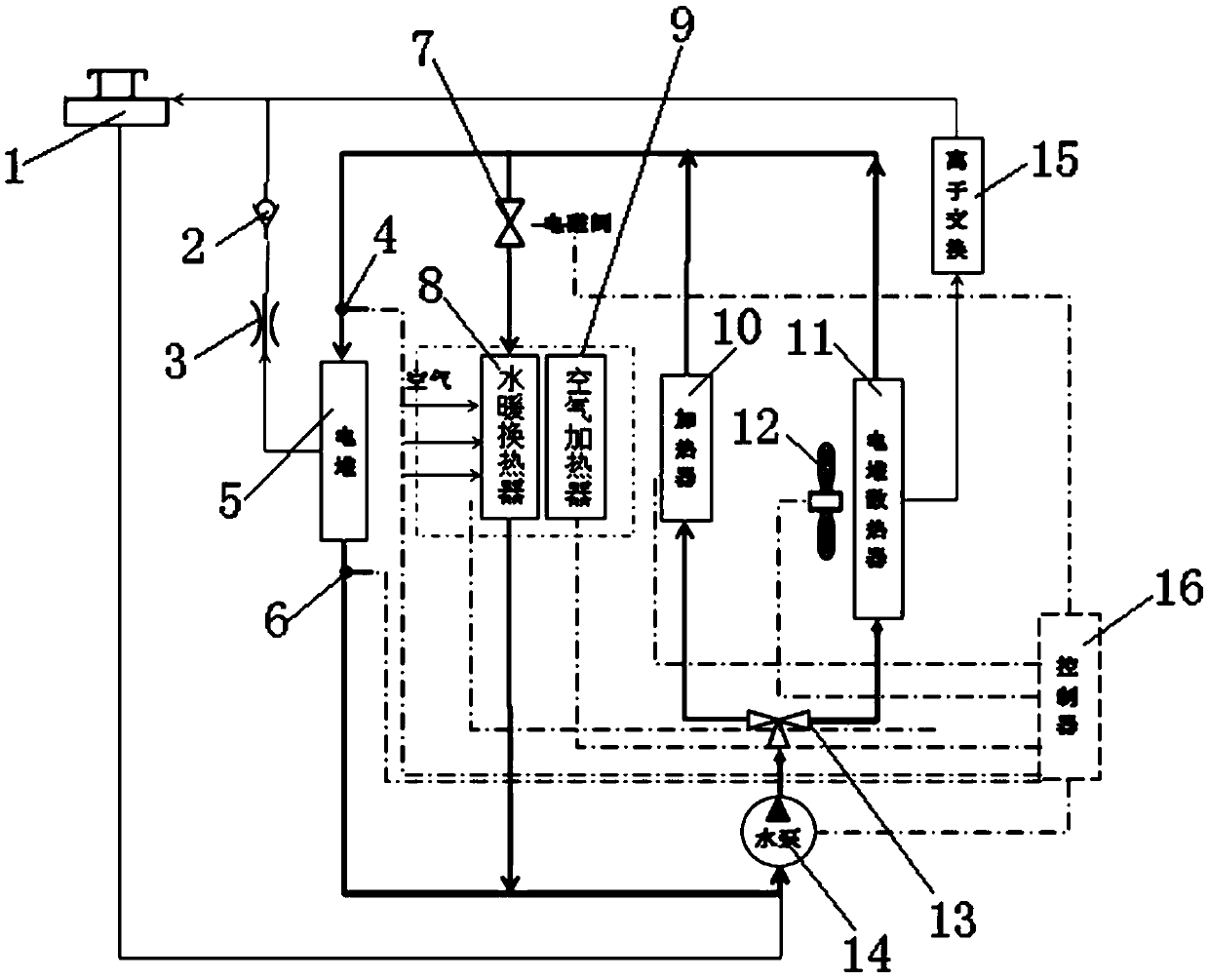

Thermal management system and control method for hydrogen fuel cell vehicle

ActiveCN109532565AStart fastImprove adaptabilityAir-treating devicesVehicle heating/cooling devicesSolenoid valveHydrogen fuel cell

The invention relates to a thermal management system and control method for a hydrogen fuel cell vehicle. The method includes an expansion kettle, a water pump, an electronic thermostat, a fuel cell radiator, a solenoid valve, a fuel cell stack and an ion exchanger. In order to overcome the restriction that an existing fuel cell stack can not be started under the condition of too low ambient temperature, an auxiliary water heating scheme is designed in a small circulation branch to achieve the fast start-up of the fuel cell stack at low temperature and improve the adaptability of the fuel cellstack to the low temperature environment. The waste heat recovery and utilization of the fuel cell stack can be achieved by adding an auxiliary air-conditioning water heating and heat exchange systemin a water system. The electricity demand of an air heater is reduced, the electric energy of the whole vehicle is saved, and the endurance range of vehicles in winter is increased. Through the design improvement of a degassing device for the fuel cell stack, the degassing problem of the fuel cell stack water system in the process of filling and operation is solved, and the reliability of the fuel cell heat management system is improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

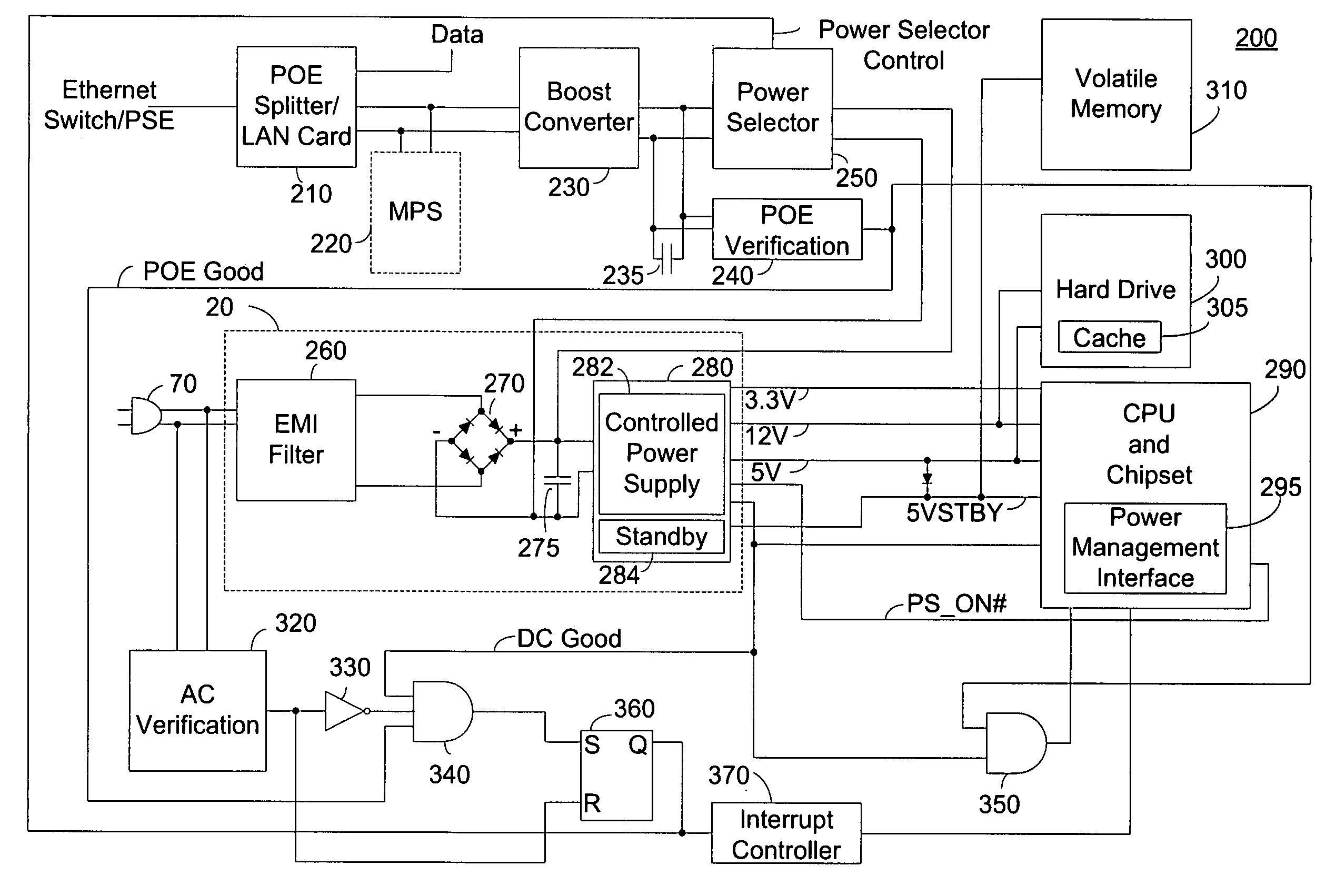

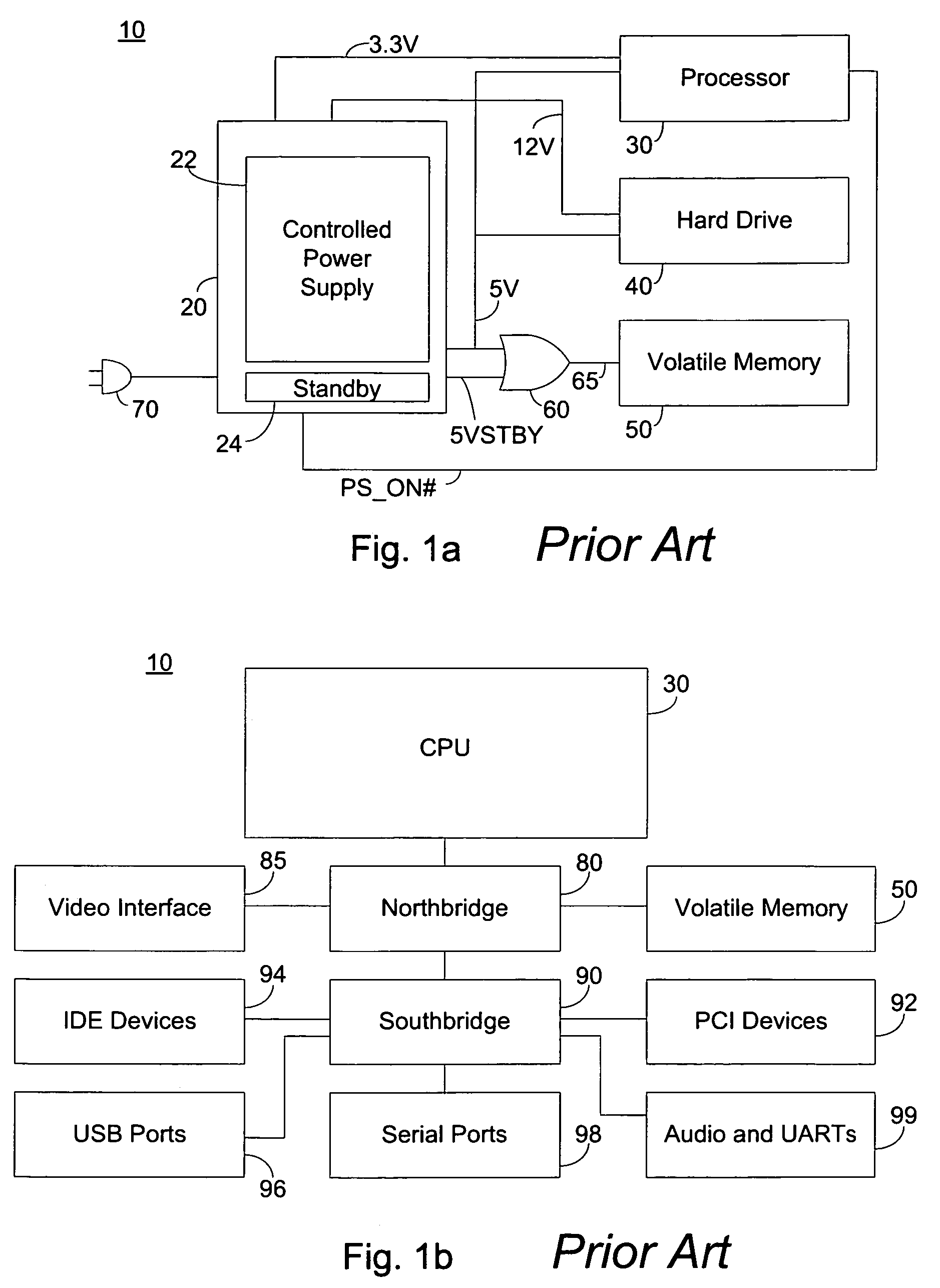

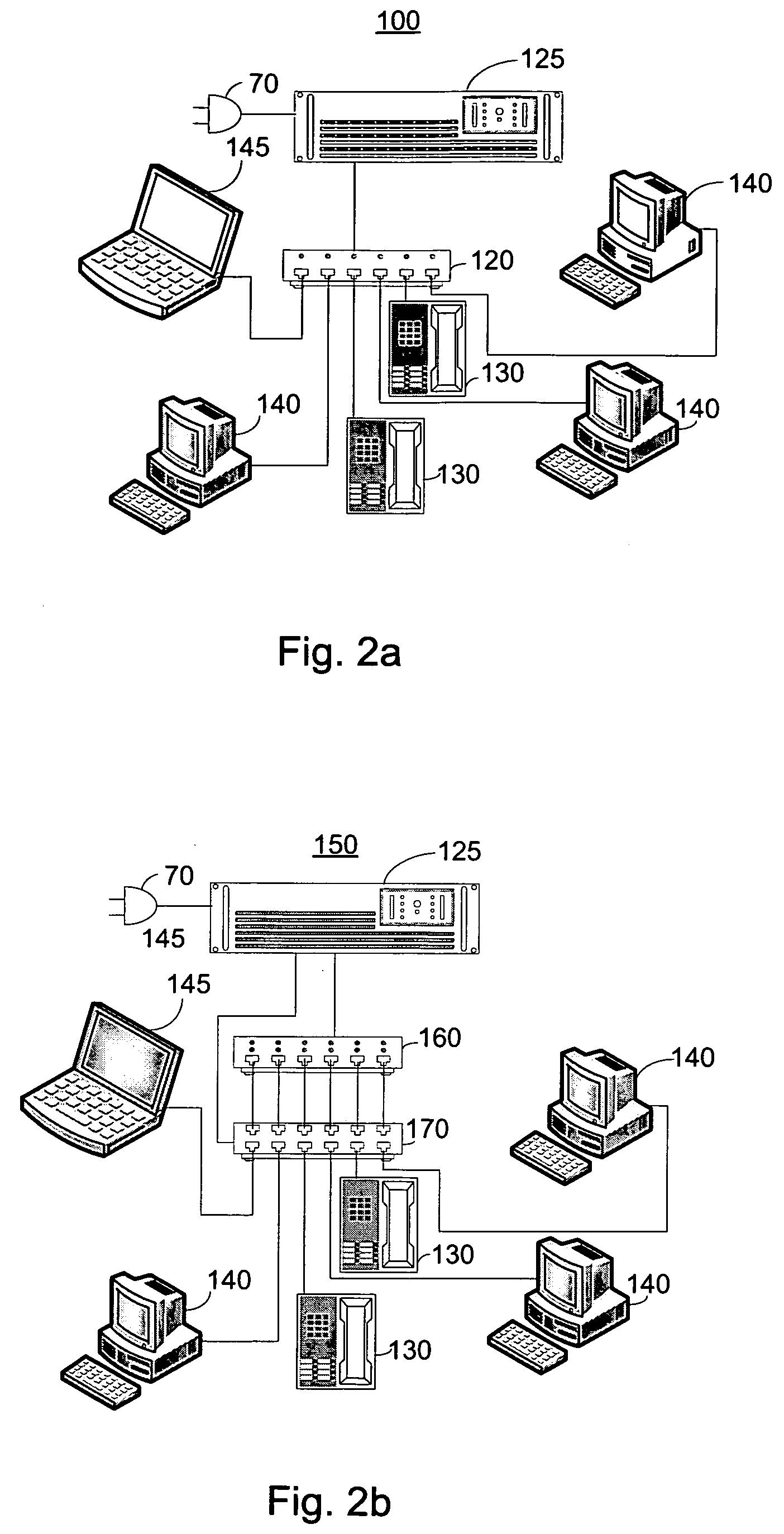

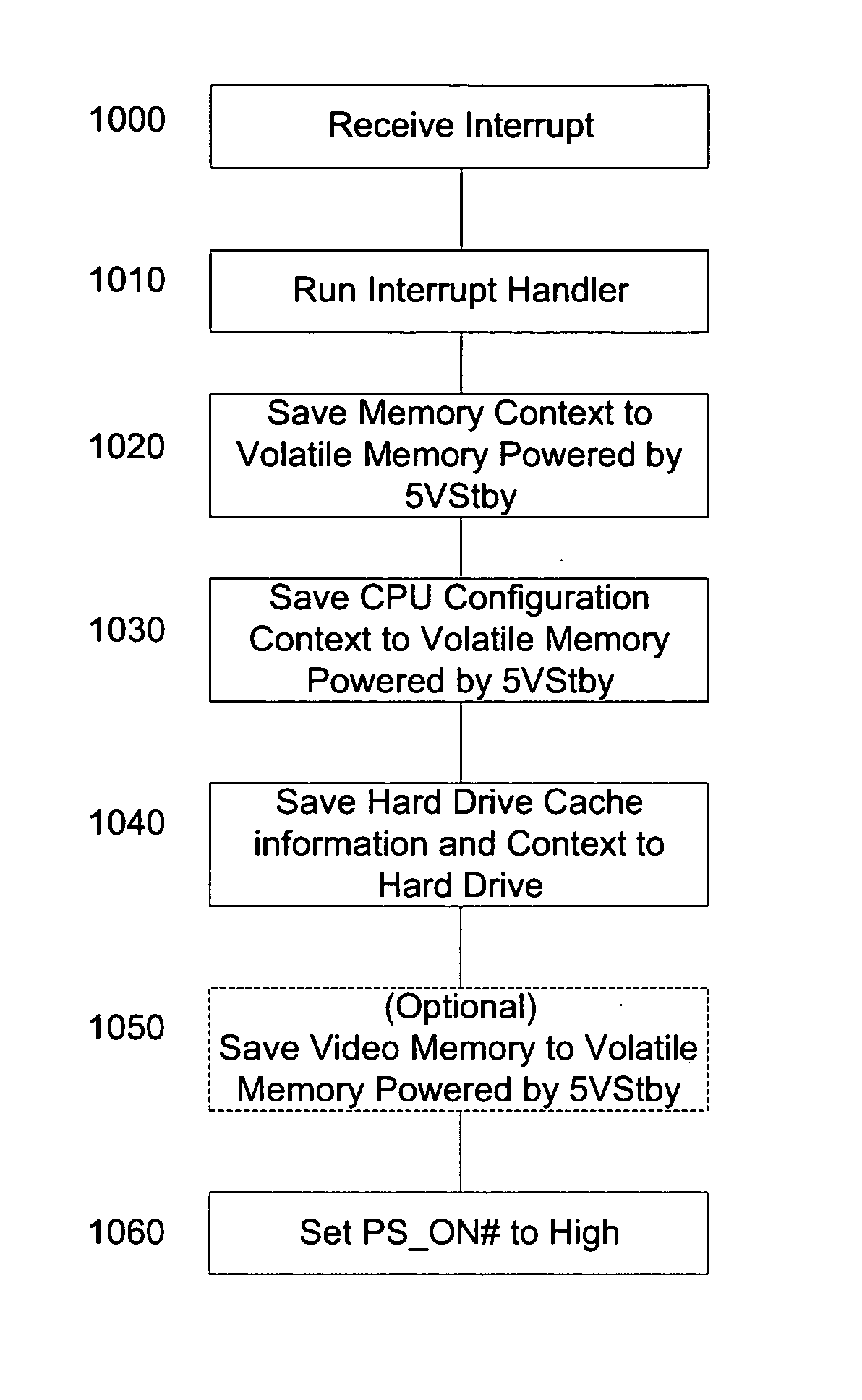

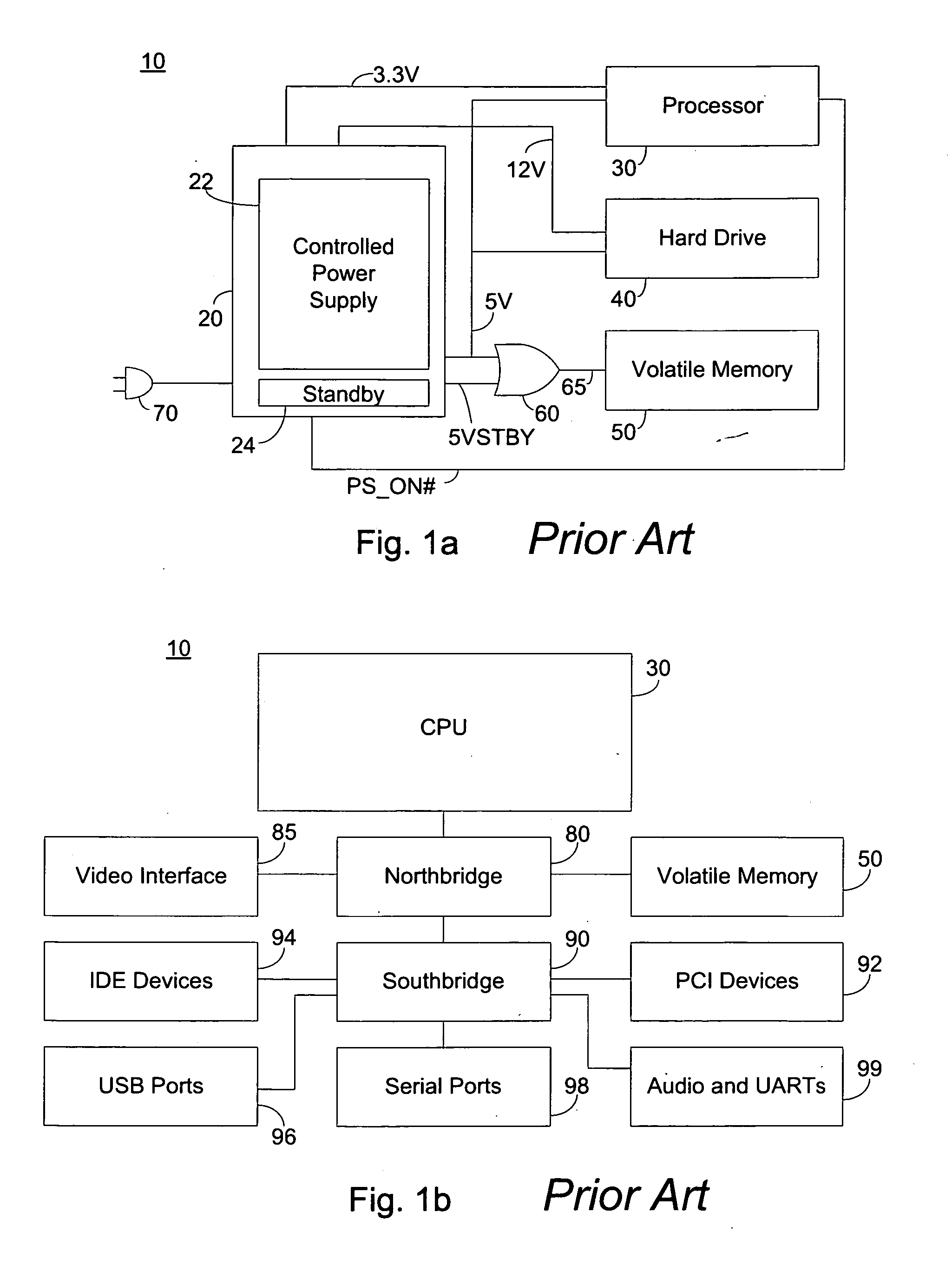

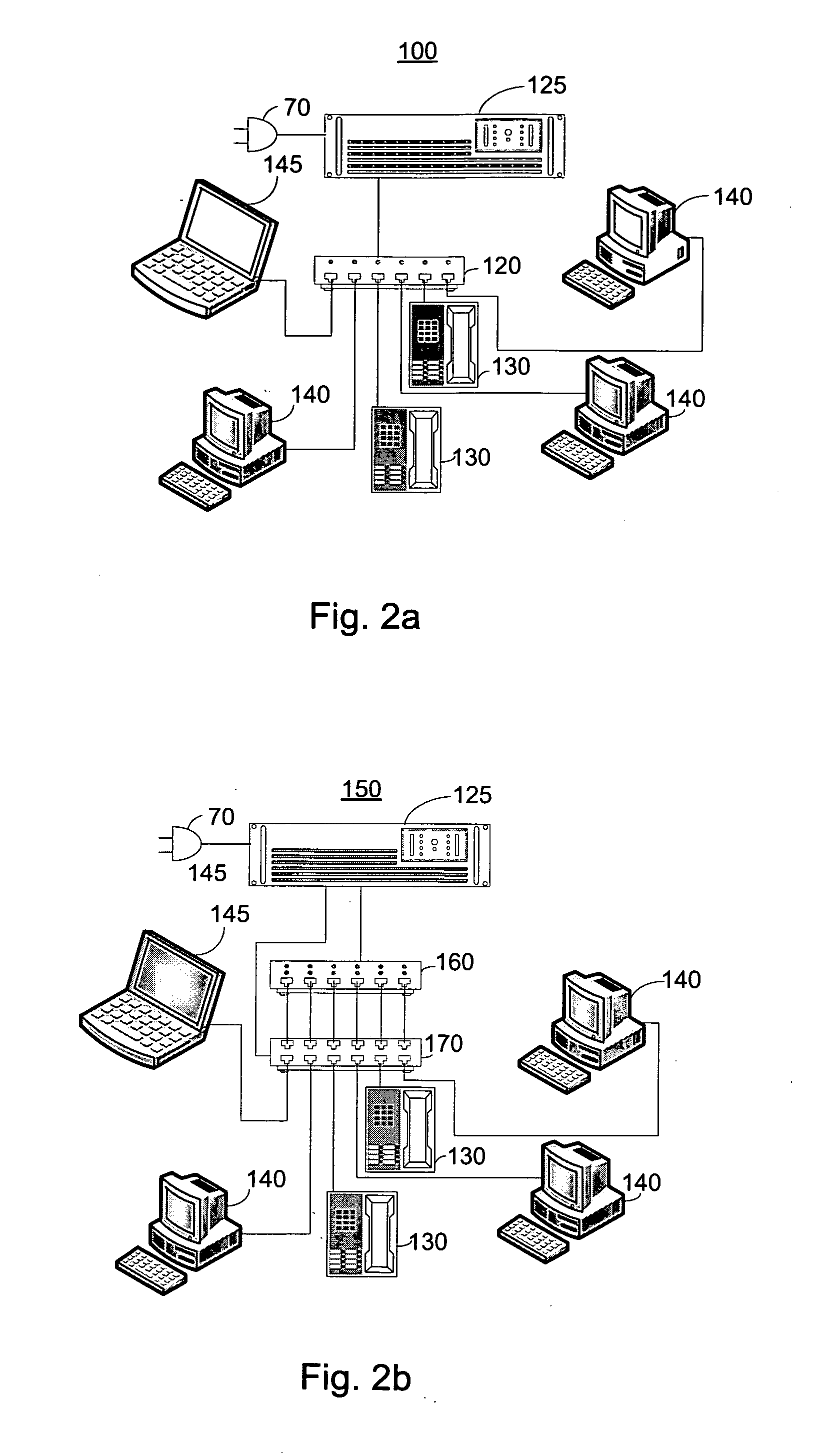

Computer volatile memory power backup system

ActiveUS7484109B2Reduce electricity demandVolume/mass flow measurementPower supply for data processingStandby powerEngineering

A system for placing and maintaining a computer in a standby mode during power failure, utilizing one of: a powered device controller exhibiting a maintain power signature functionality and arranged to receive power over communication cabling; and a MEMS flywheel energy system to provide a standby power. The standby power is less than the power required for full operation. In one embodiment the system additionally exhibits: a mains power failure sensor; a volatile memory arranged to be powered from the source of standby power in the event of a failure of mains power; and a processor operative responsive to the mains power failure sensor to store status information on the volatile memory and reduce power demand of the processor and associated devices to no more than that available from the source of standby power.

Owner:MICROSEMI CORP ANALOG MIXED SIGNAL GRP LTD

Electrical powered tail rotor of a helicopter

ActiveUS20130170985A1Improve efficiencyIncrease the number of polesMagnetic circuit stationary partsMachines/enginesSynchronous motorEngineering

The invention is related to an electrical powered tail rotor (1) of a helicopter comprising a housing (2) around the tail rotor (1), and at least one permanent magnet energized synchronous motor with a stator (6, 7) with an increased number of poles (9). Said at least one synchronous motor is integrated as a torus (8) around an opening of the housing (2) encompassing the tail rotor (1). Blades (4) of the tail rotor (1) are fixed to at least one rotating component (10, 11) of said at least one synchronous motor. Supply means provide for electric energy to said at least one synchronous motor. Blade pitch control means are provided at the torus (8).

Owner:AIRBUS HELICOPTERS DEUT GMBH

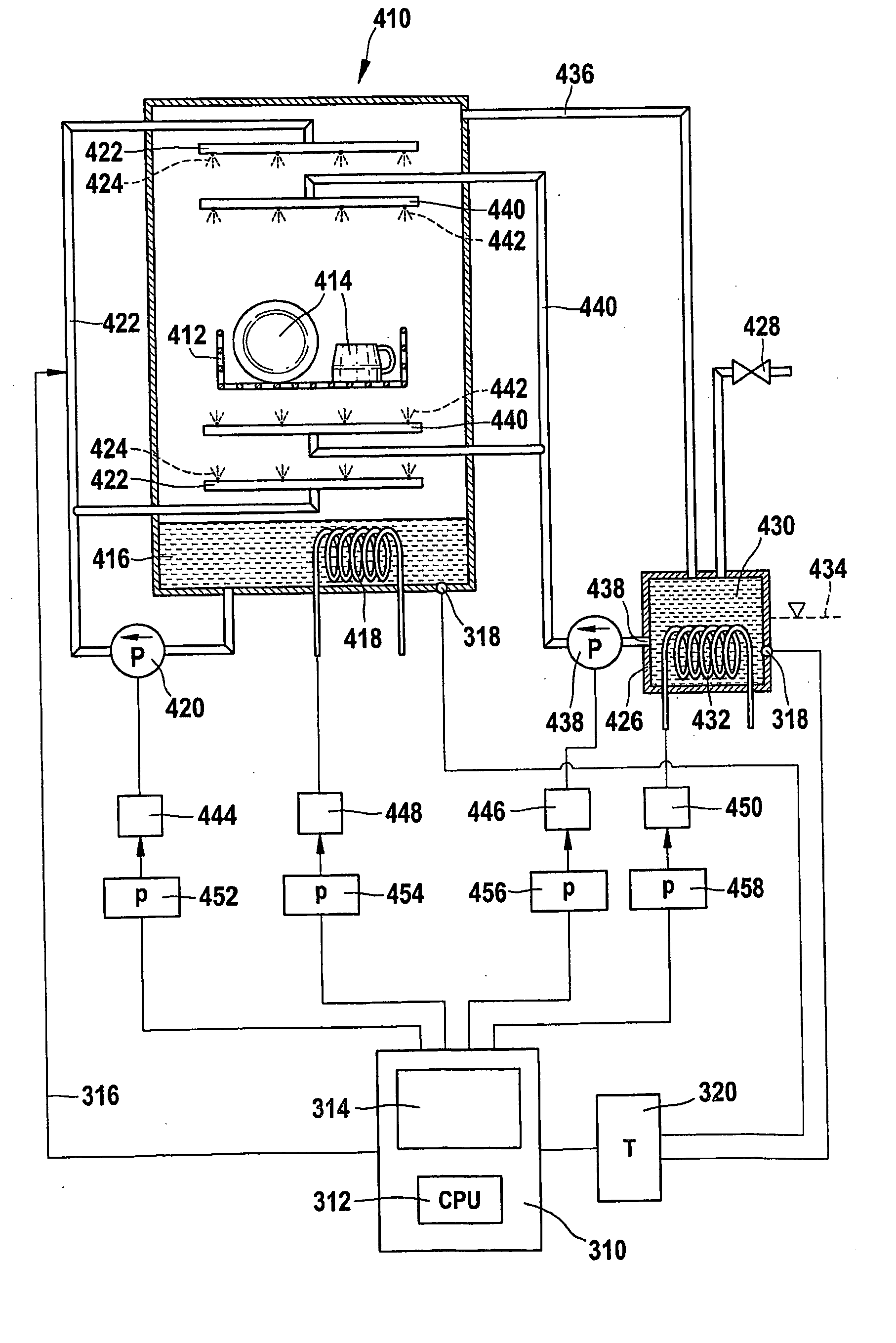

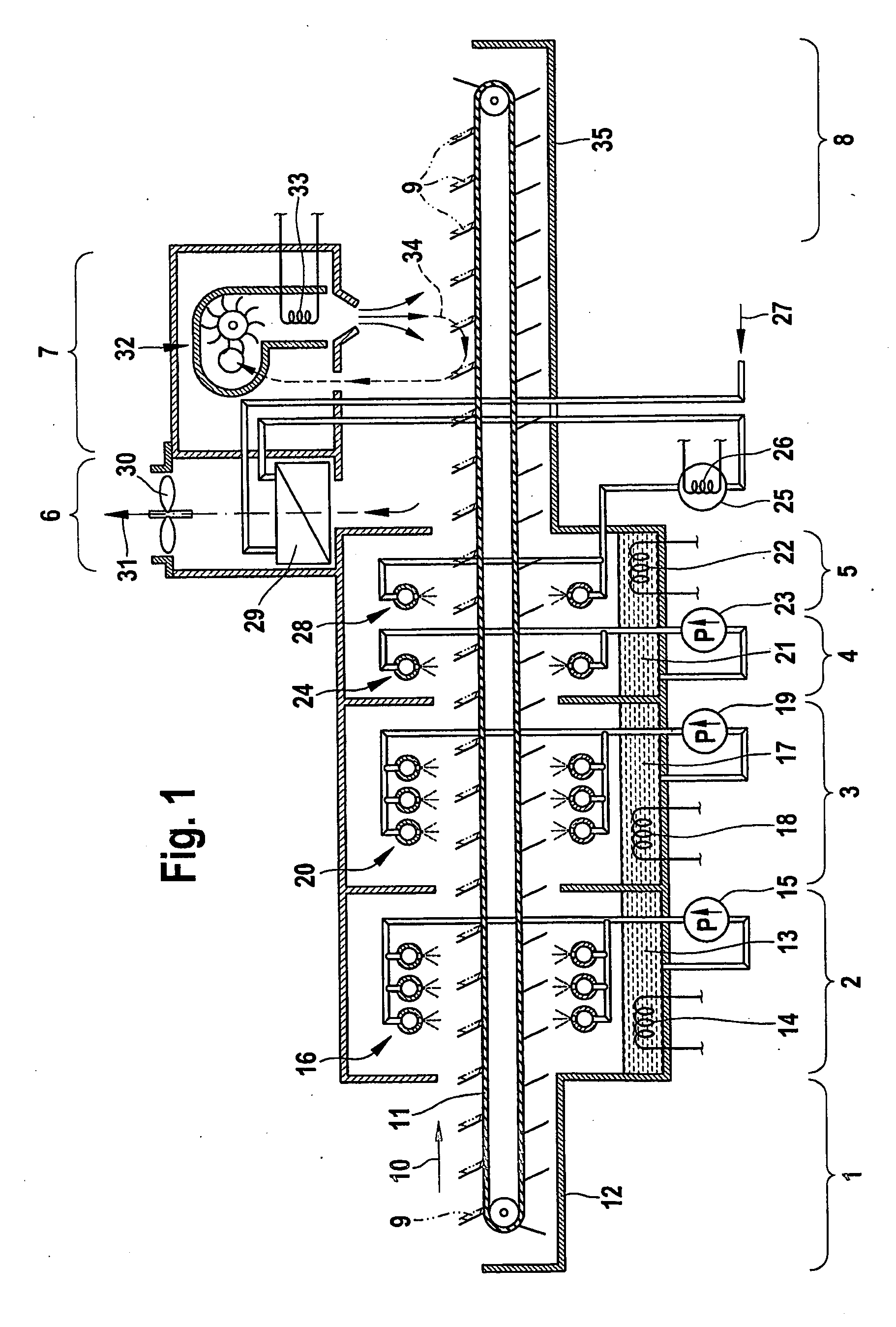

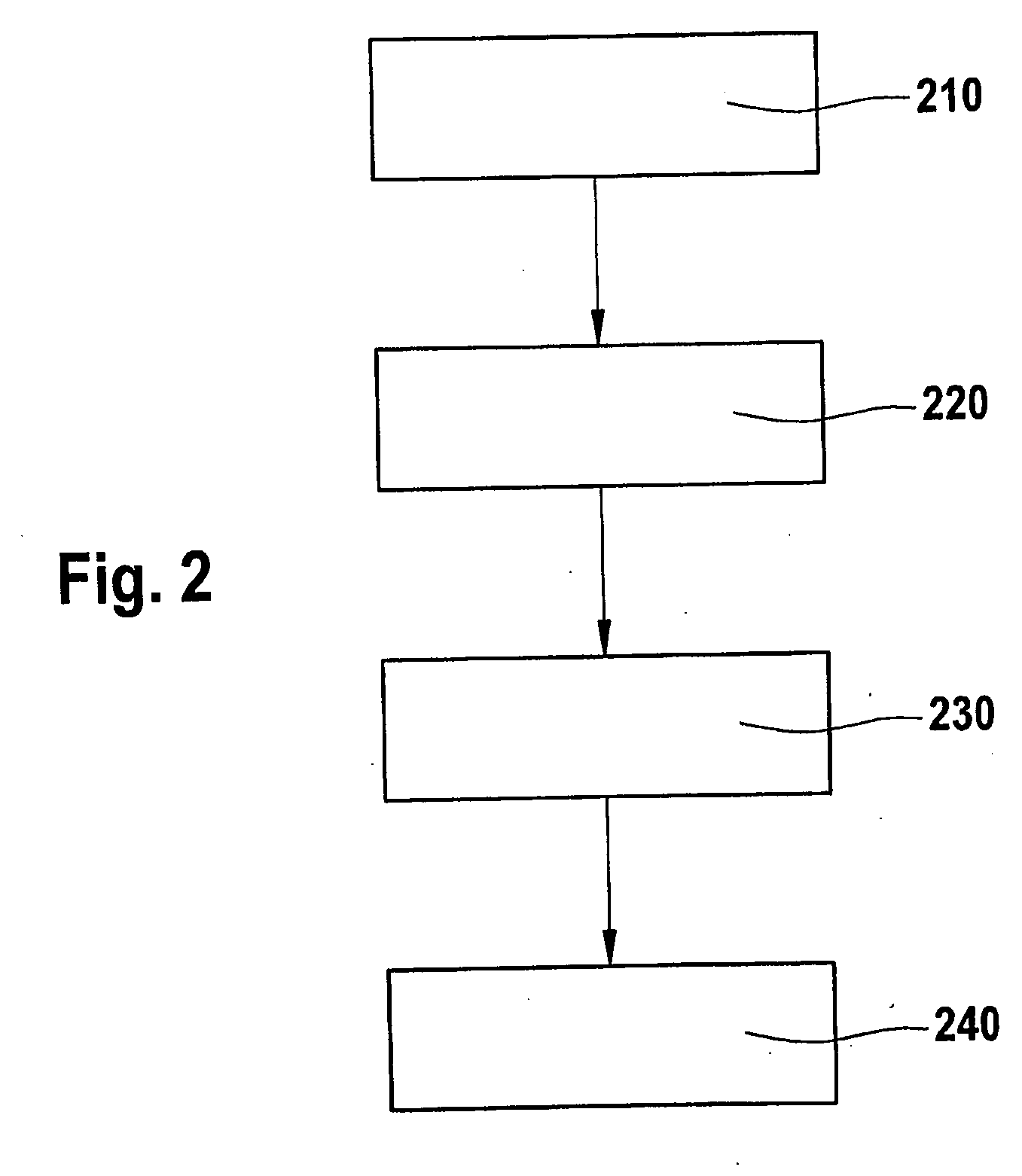

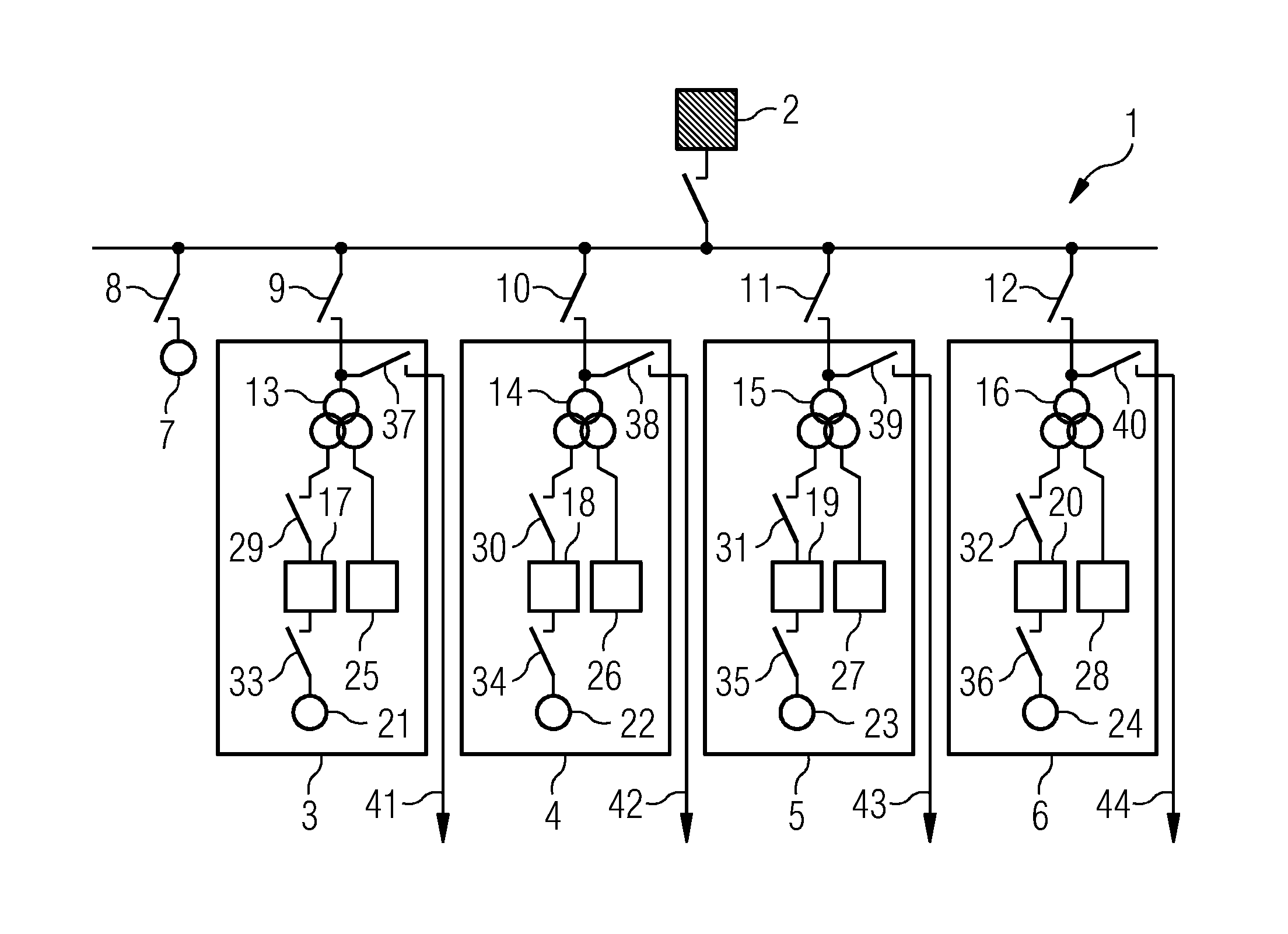

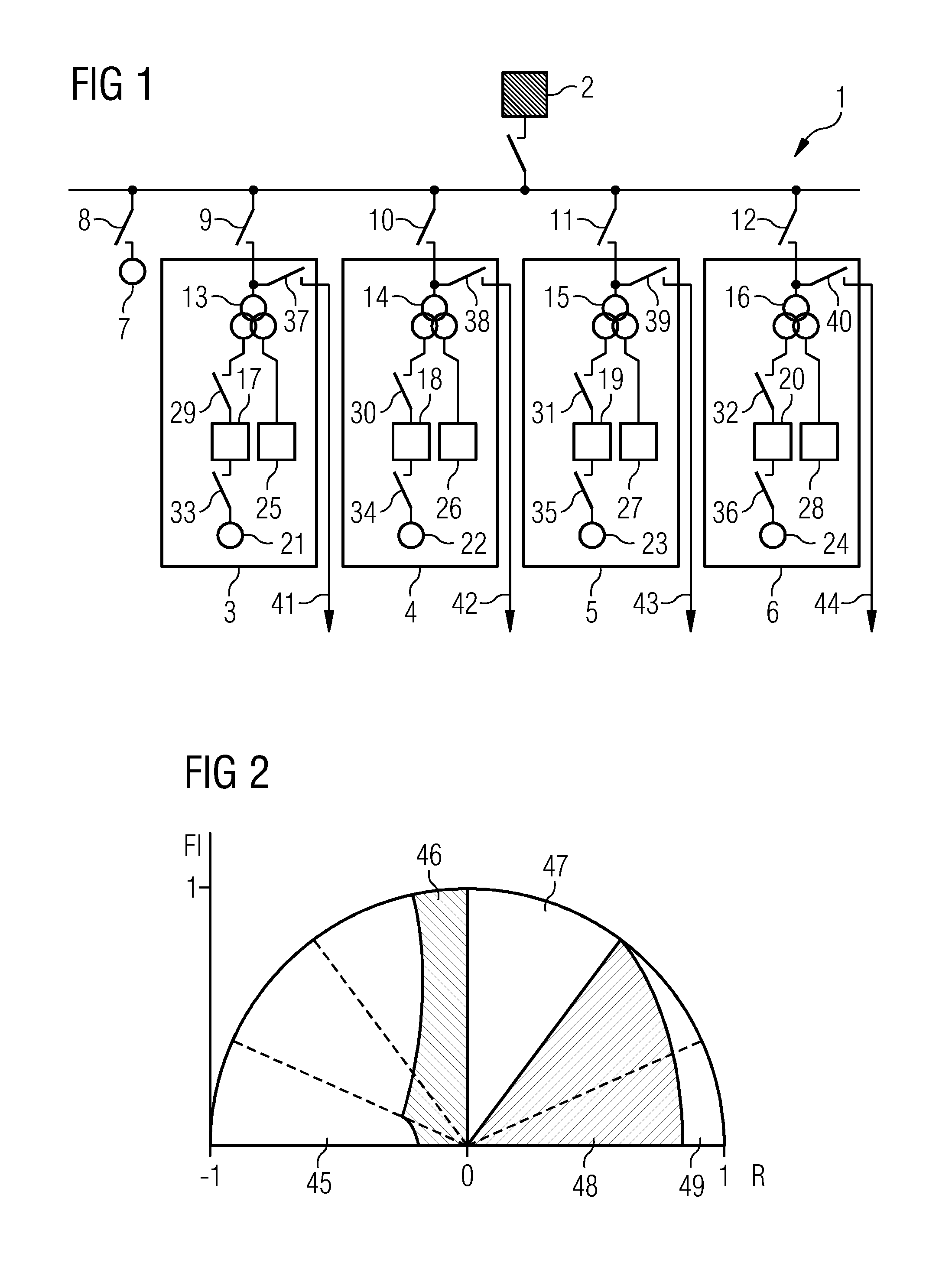

Method and arrangement for the energy-saving operation of dishwashers

ActiveUS20090151750A1Save energyMore flexibleTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionElectricityEngineering

The energy-saving operation of dishwashers (110; 410) plays an important role, in particular for larger enterprises, e.g. for the canteens of hospitals or large enterprises, and in the medical disinfection field. The invention thus discloses a method and a device, in which a total maximum electric output is assigned to a group of electric consumer elements (14, 15, 18, 19, 22, 23, 26, 33; 418, 420, 432, 438) of a dishwasher (110; 410). In addition, at least two output levels are assigned to each electric consumer element (14, 15, 18, 19, 22, 23, 26, 33; 418, 420, 432, 438) of said group. An optimum combination of output levels is then selected in a requirement determination step, based on an operational state B of the dishwasher (119), whereby for each consumer element (14, 15, 18, 19, 22, 23, 26, 33; 418, 420, 432, 438) the selected output level is adapted to the output requirement of the consumer element (14, 15, 18, 19, 22, 23, 26, 33; 418, 420, 432, 438) in operational state B and the total output of all consumer elements (14, 15, 18, 19, 22, 23, 26, 33; 418, 420, 432, 438) does not exceed the maximum electric total output. The operation of the dishwasher (110; 410) can also be divided into three phases, a start phase, an activation phase and a load control phase. The output levels of the individual consumer elements (14, 15, 18, 19, 22, 23, 26, 33; 418, 420, 432, 438) are optimally adapted in accordance with the requirements in said operating phases, thus allowing a response to be made to any fluctuations in the operational state. The inventive method permits significant energy savings to be made in comparison to conventional methods for controlling dishwashers (110; 410) and leads to a more rapid attainment of a ready status of the dishwasher (110; 410) upon activation.

Owner:MEIKO MASCHENBAU

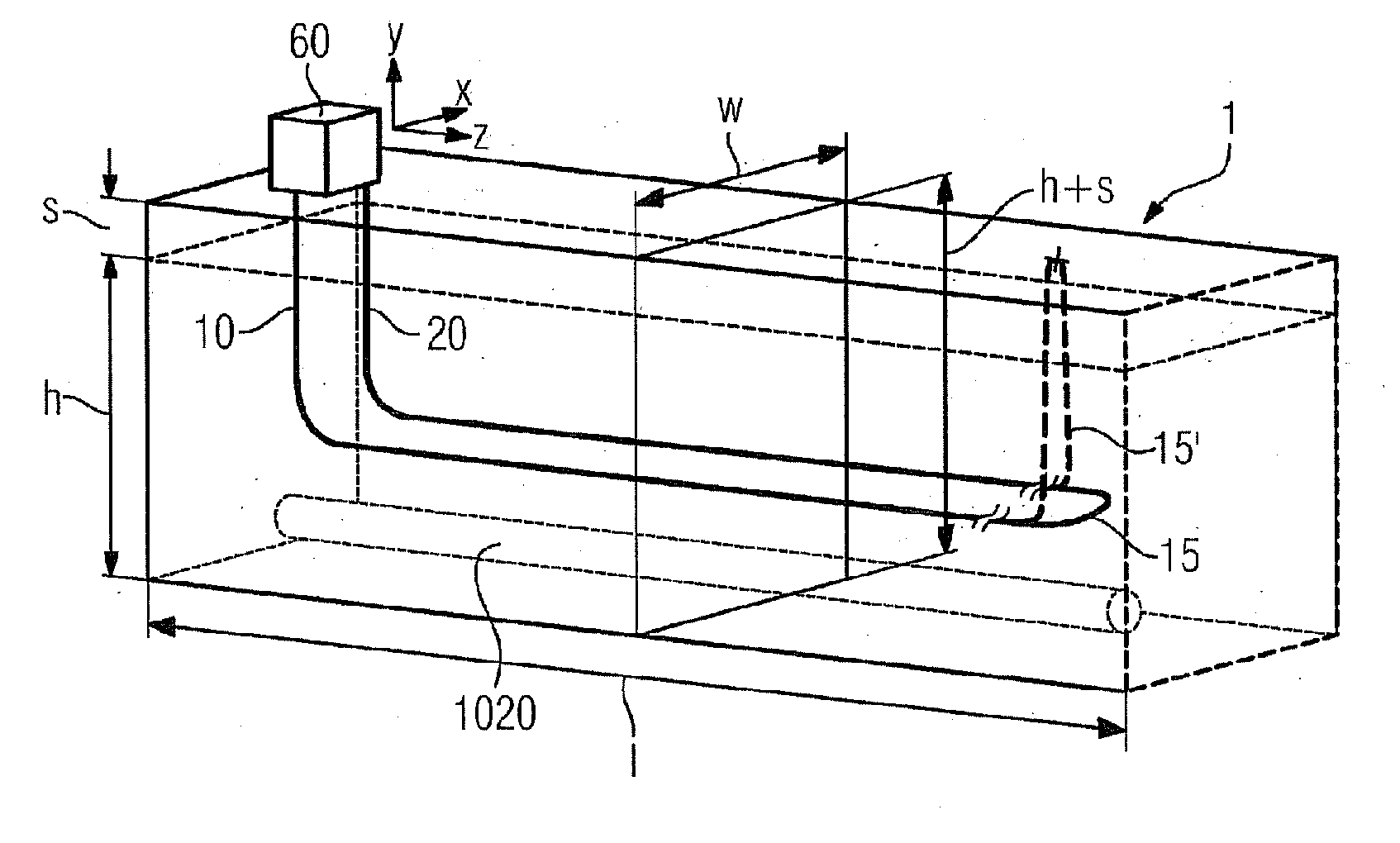

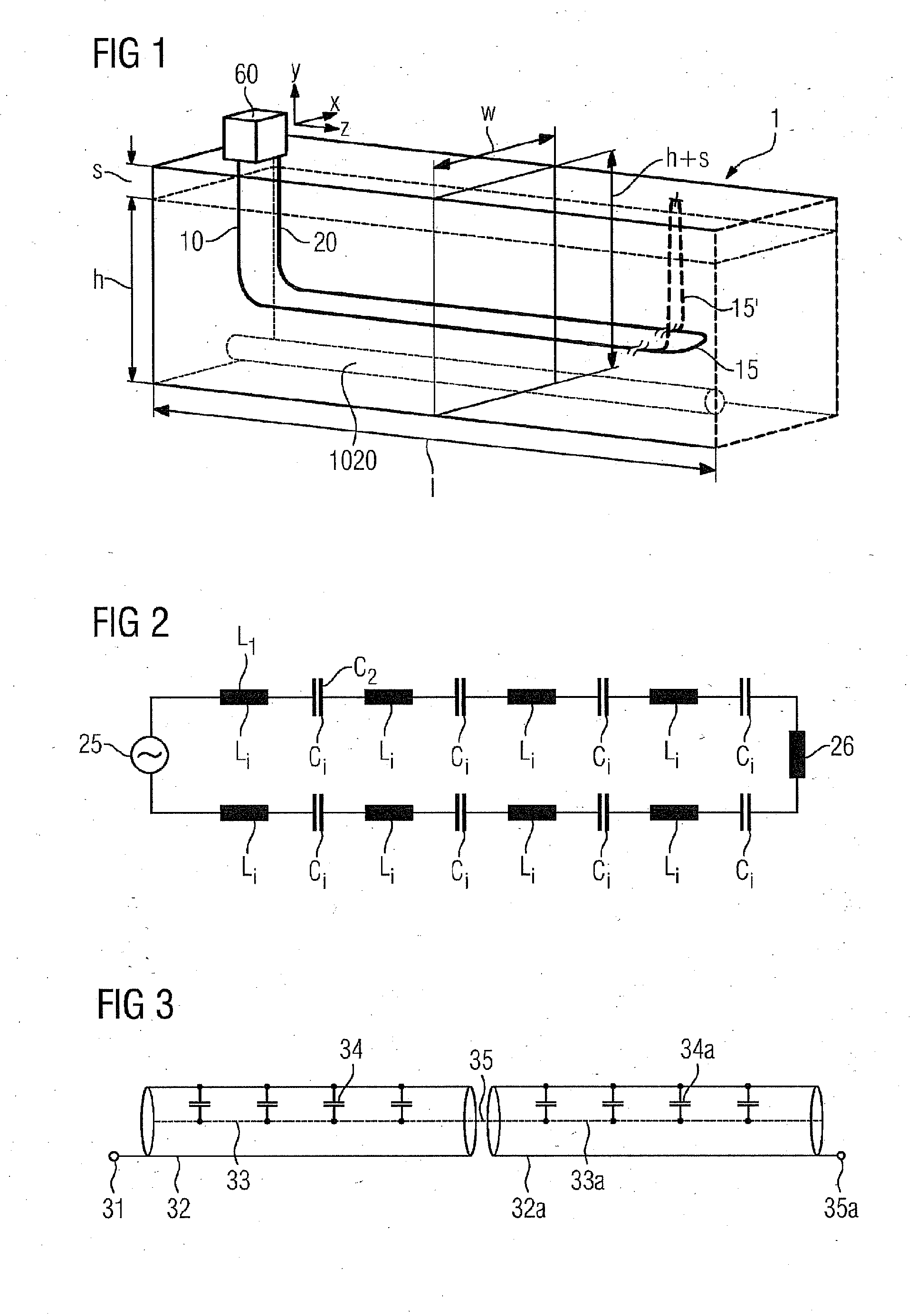

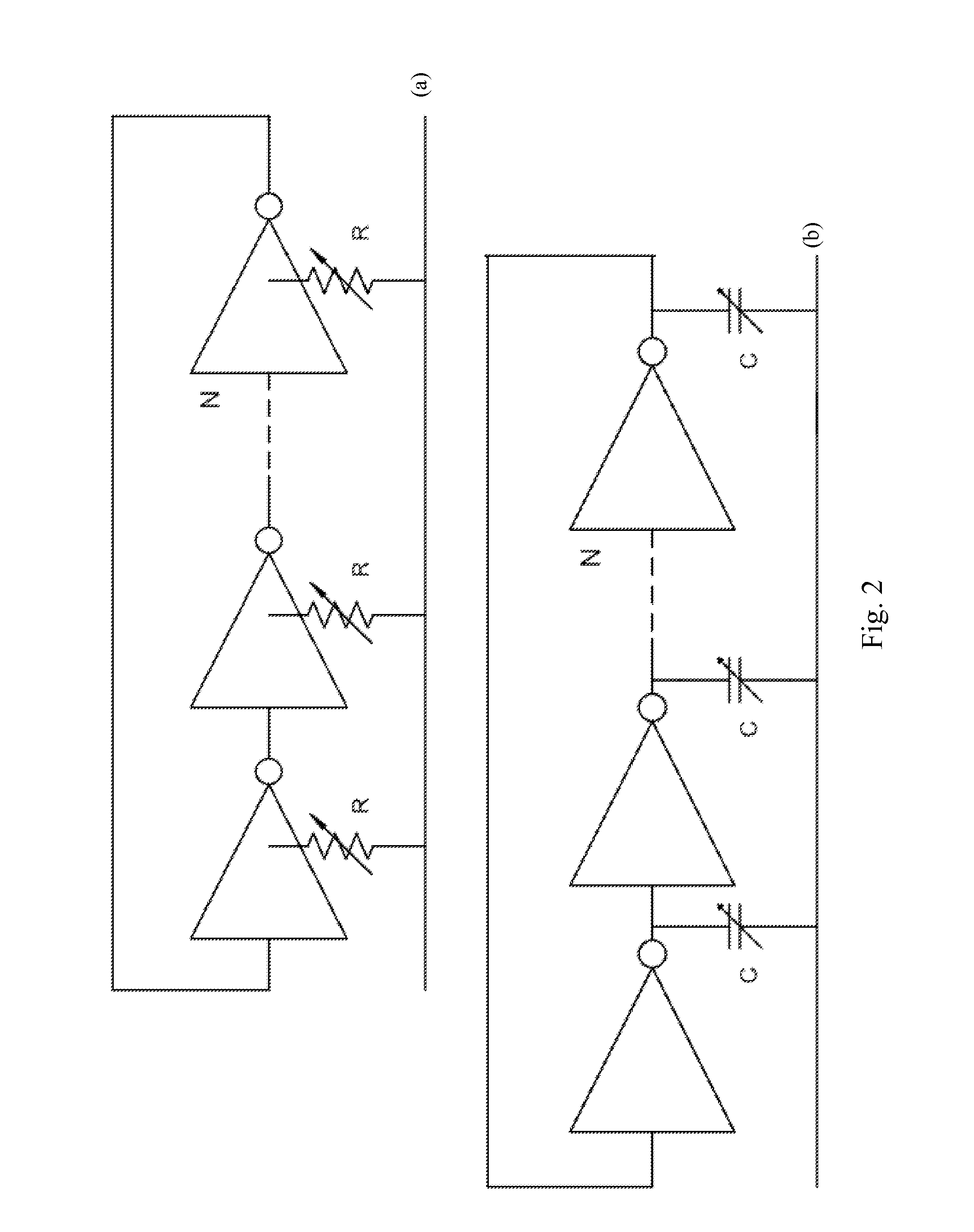

Apparatus for the Inductive Heating of Oil Sand and Heavy Oil Deposits by way of Current-Carrying Conductors

InactiveUS20110006055A1Reduces and avoids additional ohmic lossReduce electricity demandInduction heatingInsulationCapacitanceElectrical conductor

An apparatus for the inductive heating of oil sand and heavy oil deposits by way of current-carrying conductors is provided. The conductors include individual conductor groups, wherein the conductor groups are designed in periodically repeating sections of defined length defining a resonance length, and wherein two or more of the conductor groups are capacitively coupled. In this way, each conductor can be advantageously insulated and may include a single wire.

Owner:SIEMENS AG

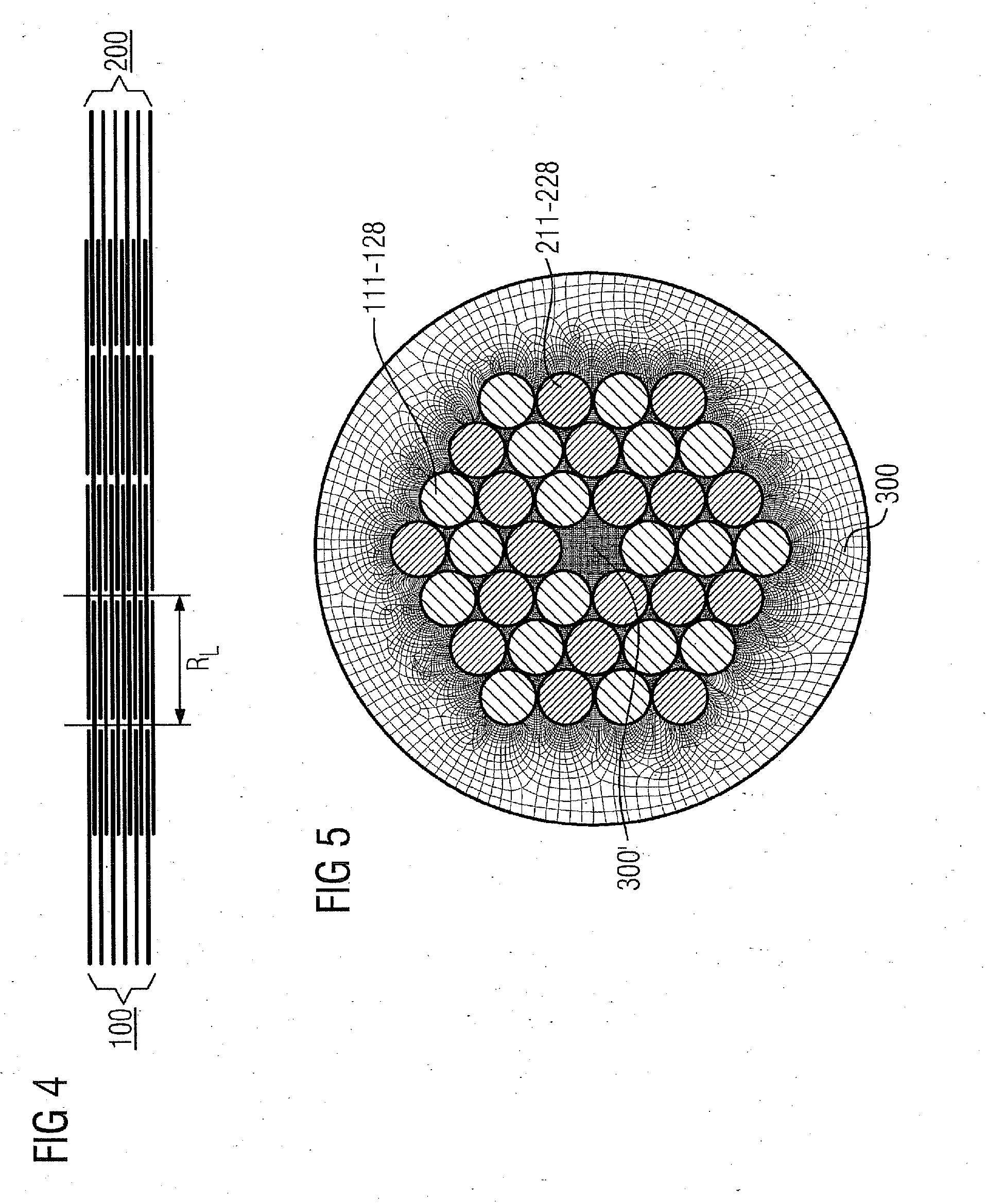

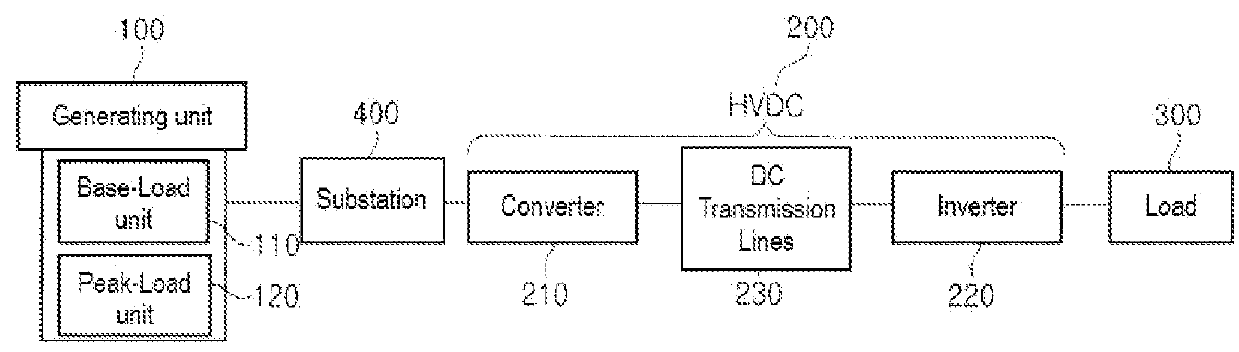

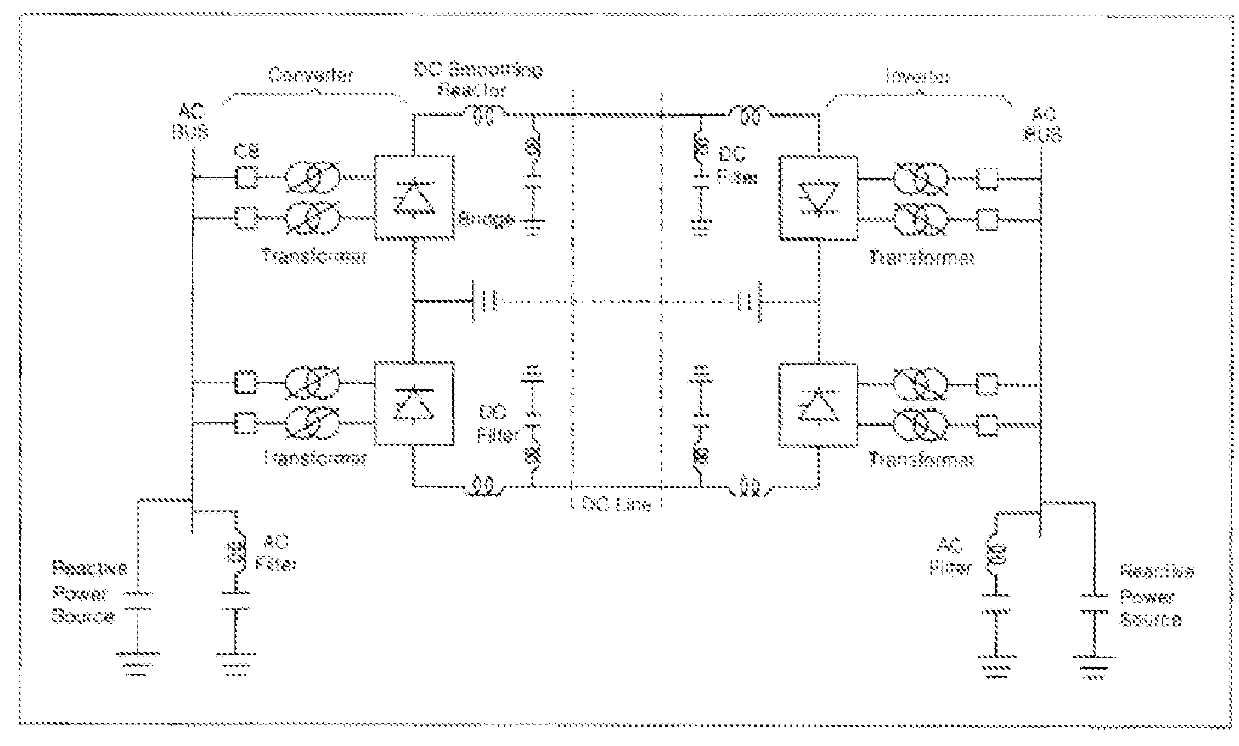

Power grid frequency flexible operation system and method using the same

ActiveUS20160036341A1Maintenance savingReduce electricity demandConversion with intermediate conversion to dcElectric power transfer ac networkOperational systemAs Directed

A power grid frequency flexible operation system is provided. The system comprises a generating unit, which includes a base-load unit and a peak-load unit; a high voltage direct-current (HVDC) transmission unit, which transmits the power generated in the generating unit as direct current (DC) power; and a load, which is supplied with the power generated by the generating unit; wherein the high-voltage direct current (HVDC) transmission unit comprises a converter, which transforms to direct current (DC) power, alternating current (AC) power generated in the generating unit and having a first frequency variation allowance range; an inverter, which is connected to the converter and transforms the direct current (DC) power to alternating current (AC) power having a second frequency variation allowance range, wherein the first frequency variation allowance range is larger than the second frequency variation allowance range.

Owner:KOREA UNIV RES & BUSINESS FOUND

Method for controlling a wind farm, wind farm controller, wind farm, computer-readable medium and program element

ActiveUS20130257050A1Easy to implementReduce electricity demandElectric motor controlWind motor combinationsTransformerPower grid

A method is provided for controlling a wind farm connected to a grid. The wind farm includes a wind farm emergency generator and at least a first wind turbine. The first wind turbine includes a wind turbine transformer, a wind turbine converter and auxiliary equipment. The method includes detecting a lost grid connection, providing active power to the auxiliary equipment via the wind farm emergency generator, providing reactive power via the wind turbine converter.

Owner:SIEMENS GAMESA RENEWABLE ENERGY AS

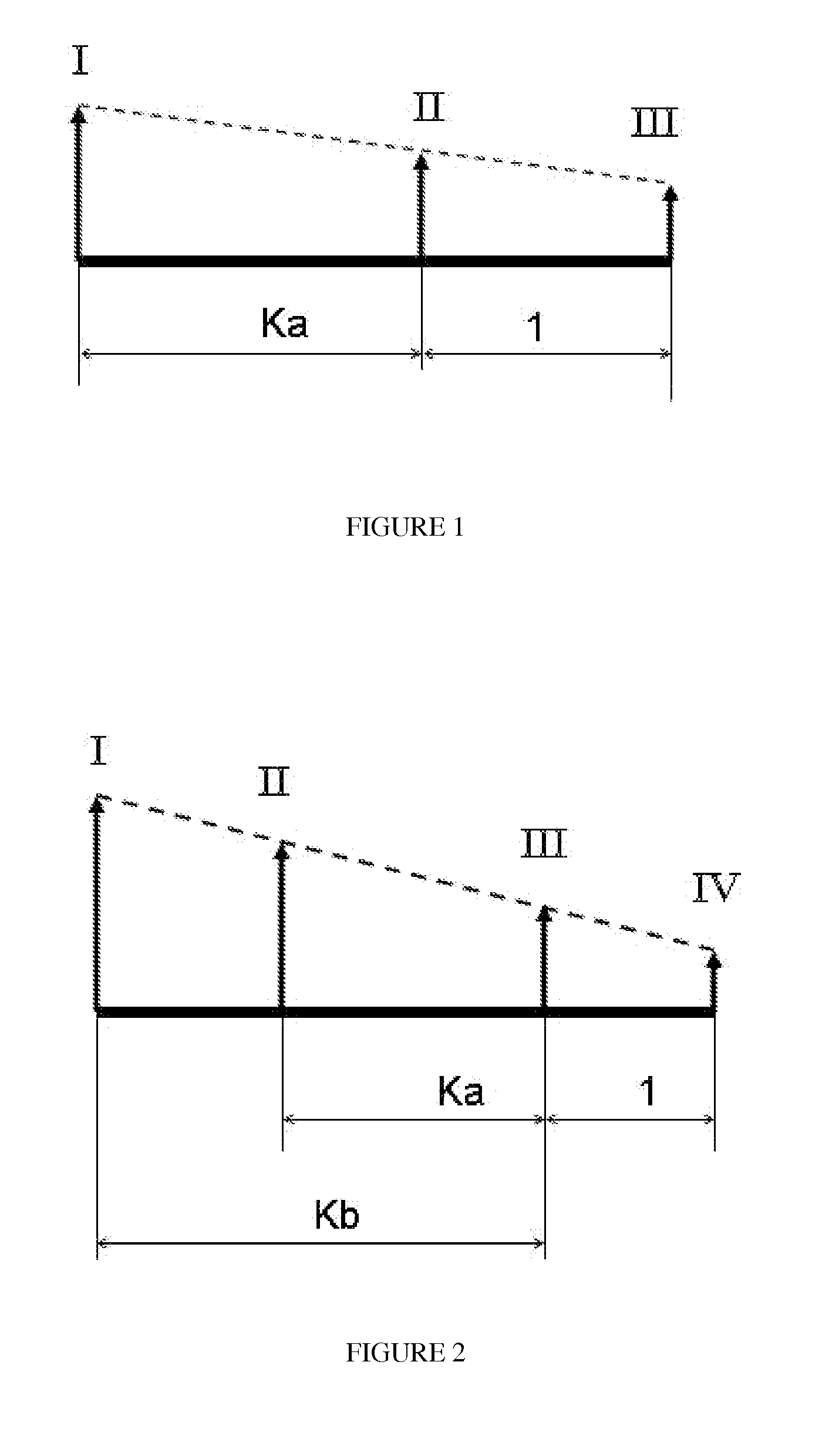

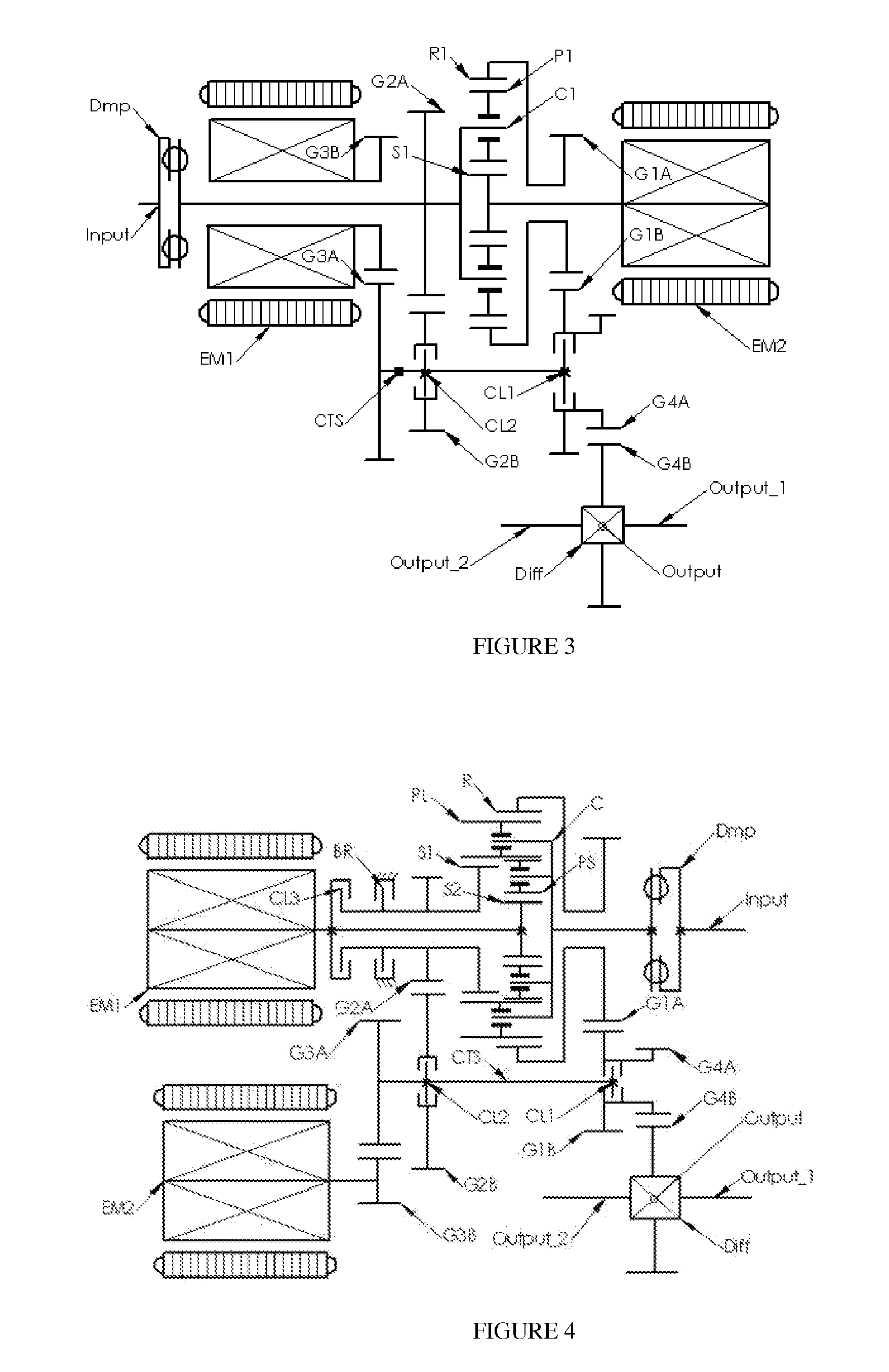

Multimode electromechanical variable speed transmission apparatus and method of control

InactiveUS20150292600A1Improve fuel efficiencyImproved performance characteristicHybrid vehiclesTransmission elementsElectricityPower split

The current invention discloses a multi-mode electro-mechanical variable speed transmission. The transmission includes an input shaft, an output system, at least one planetary gear set having at least three branches each represents a co-axial rotating member, two electric machines along with the associated controllers for the electric machines, and at least a clutch. The first branch couples to the first electric machine with a constant speed ratio; the second branch couples to the output system with a constant speed ratio; and the third branch couples to the input shaft with a constant speed ratio; the second electric machine selectively couples to two different the branches of the planetary gear set with two different constant speed ratios, respectively. Said multi-mode electro-mechanical variable speed transmission is capable of providing multiple operation modes including two electric drive modes and two power split operation modes. Different operation modes cover different speed ratio regimes and are suitable for different power requirements. At the mode switching point, the corresponding clutch or clutches is automatically synchronized. This avoids shock loads during operation mode switching. The transmission is capable of providing operations with at least a fixed output to input speed ratio.

Owner:AI XIAOLIN +3

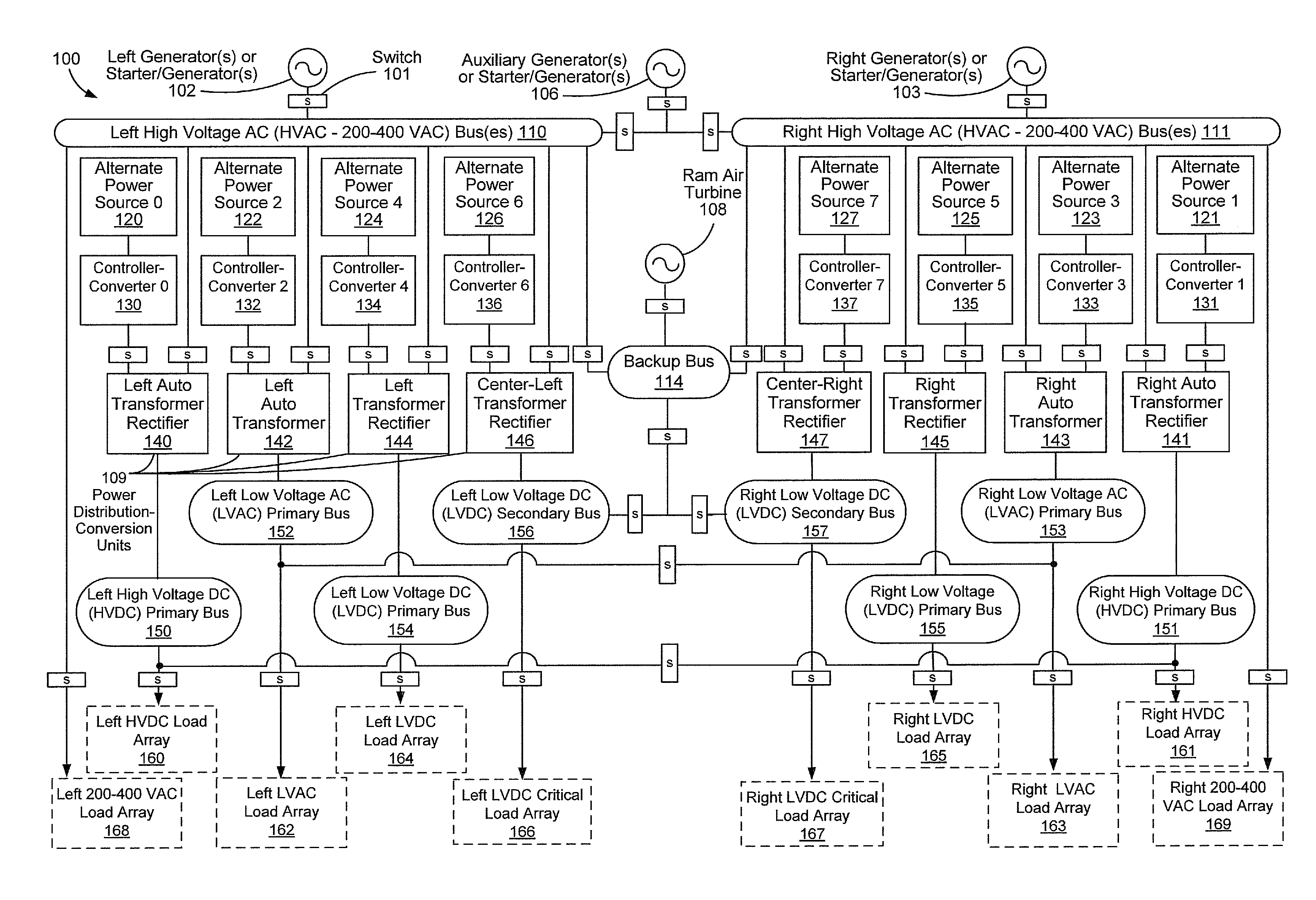

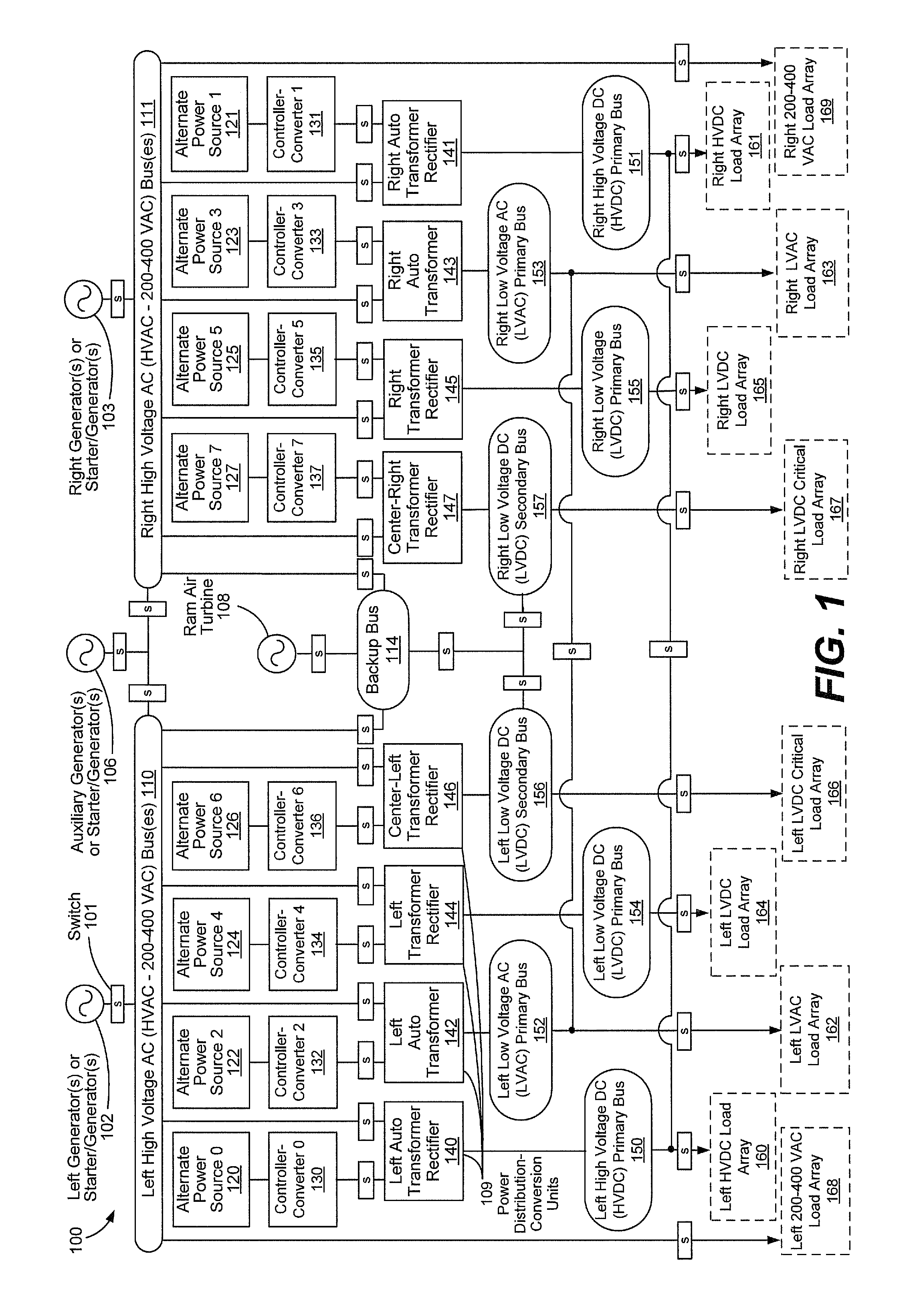

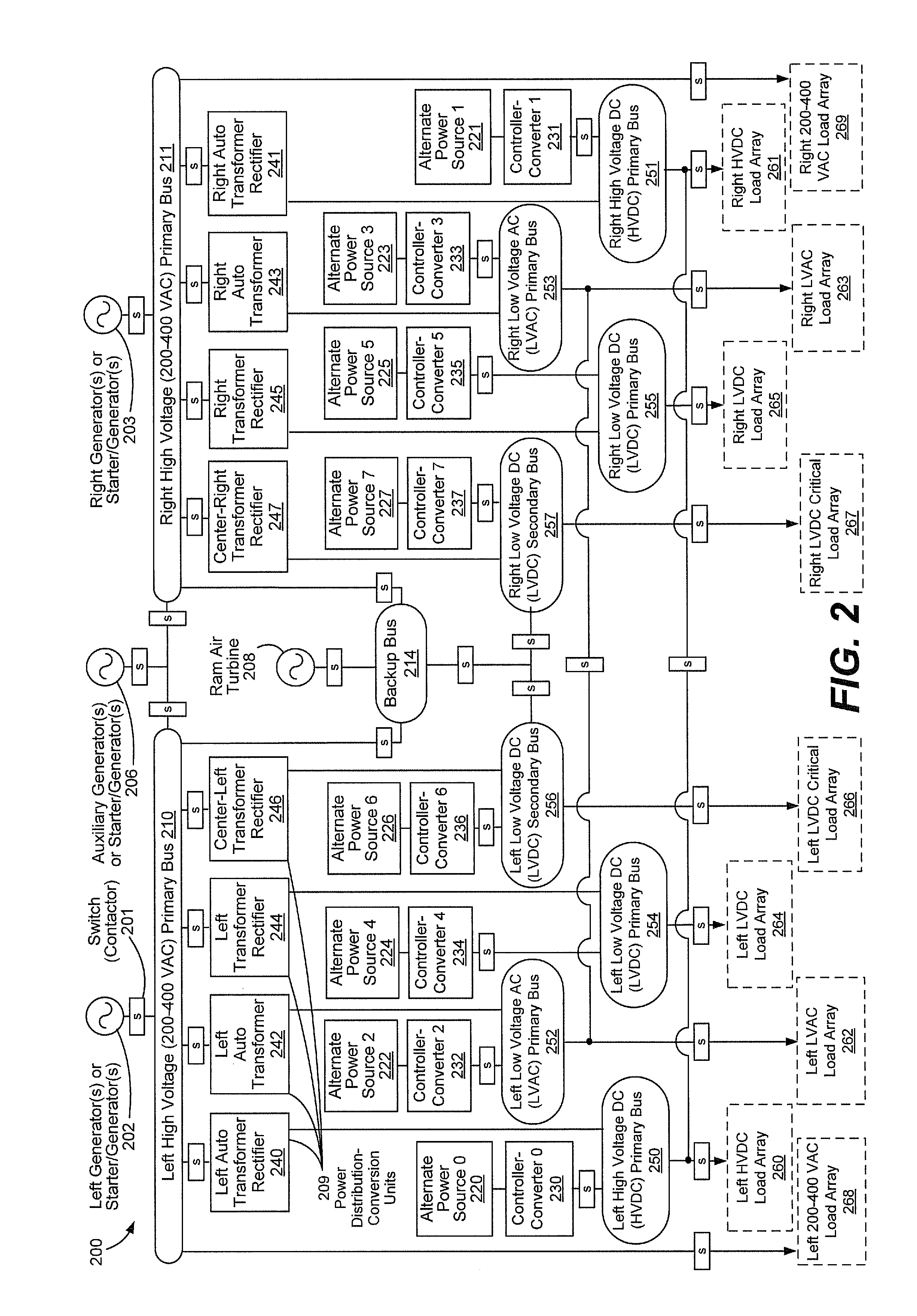

Vehicle electrical power management and distribution

ActiveUS8738268B2Reduce electricity demandReduce consumptionLevel controlPower plant arrangements/mountingControl signalStandby power

Vehicles, systems, and methods are disclosed for providing and directing first power, such as vehicle generator power, and alternate sources of power. In a particular embodiment, a vehicle includes a power distribution grid that includes a plurality of power sources and a plurality of distributions buses configured to distribute power from the plurality of power sources. The plurality of power sources include an engine-driven power source is configured to provide first power where the first power has first power characteristics. The plurality of power sources also includes a plurality of engine-independent power sources including a first alternate power source configured to provide first alternate power. The first alternate power has first alternate power characteristics that are different than the first power characteristics. The plurality of engine-independent power sources also includes a second alternate power source configured to provide second alternate power. The second alternate power has second alternate power characteristics that are different from the first power characteristics and different from the first alternate power characteristics. The vehicle also includes a global controller that sends control signals to control generation of power by the engine-driven power source, the first alternate power source and the second alternate power source via the plurality of distribution buses responsive to power demand of the power distribution grid.

Owner:THE BOEING CO

Computer volatile memory power backup system

ActiveUS20060224907A1Reduce electricity demandReduced Power RequirementsVolume/mass flow measurementPower supply for data processingStored energyElectrical battery

A system for placing and maintaining a computer in a standby mode during power failure, the system comprising: a mains power failure sensor; a source of standby power, the source of standby power being less than the power available for full operation; a volatile memory arranged to be powered from the source of standby power in the event of a failure of mains power; and a processor operative responsive to the mains power failure sensor to store status information on the volatile memory and reduce power demand of the processor and associated devices to no more than that available from the source of standby power. In an exemplary embodiment the source of standby power is one of a battery, a capacitor, a flywheel energy storage system and a power over Ethernet connection.

Owner:MICROSEMI

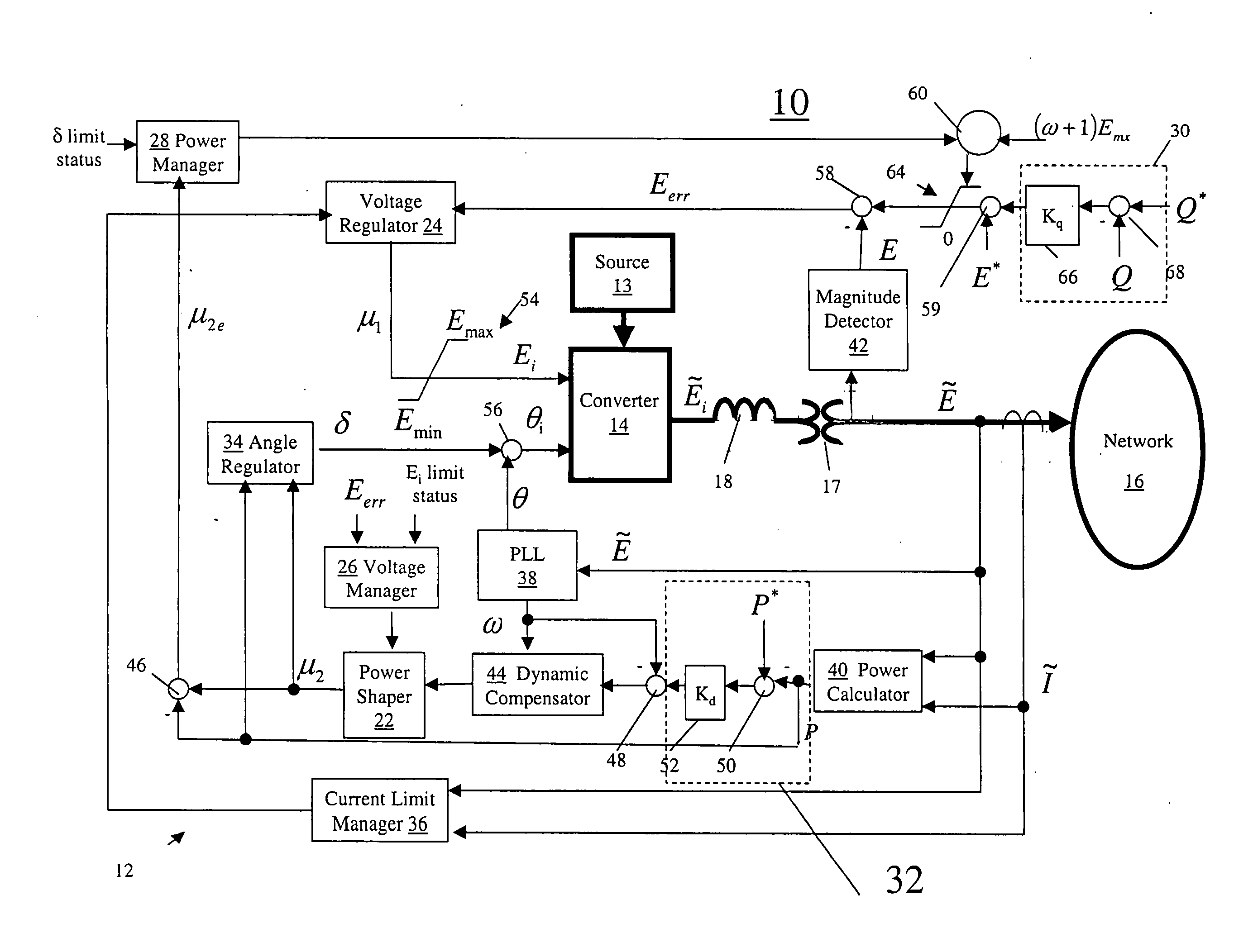

Power generation system

InactiveUS20070055408A1Minimal costReduce loadMechanical power/torque controlLevel controlDemand loadPower grid

A power generation system includes a converter configured for supplying power from a constrained power or energy source to a power network and a control system configured for balancing instantaneously available power from the constrained source against demanded load from the power network by dynamically adjusting power network voltage, power network frequency, or a combination of power network voltage and power network frequency.

Owner:GENERAL ELECTRIC CO

Power generation system

InactiveUS7680562B2Reduce load demandReduce electricity demandMechanical power/torque controlLevel controlControl systemEngineering

A power generation system includes a converter configured for supplying power from a constrained power or energy source to a power network and a control system configured for balancing instantaneously available power from the constrained source against demanded load from the power network by dynamically adjusting power network voltage, power network frequency, or a combination of power network voltage and power network frequency.

Owner:GENERAL ELECTRIC CO

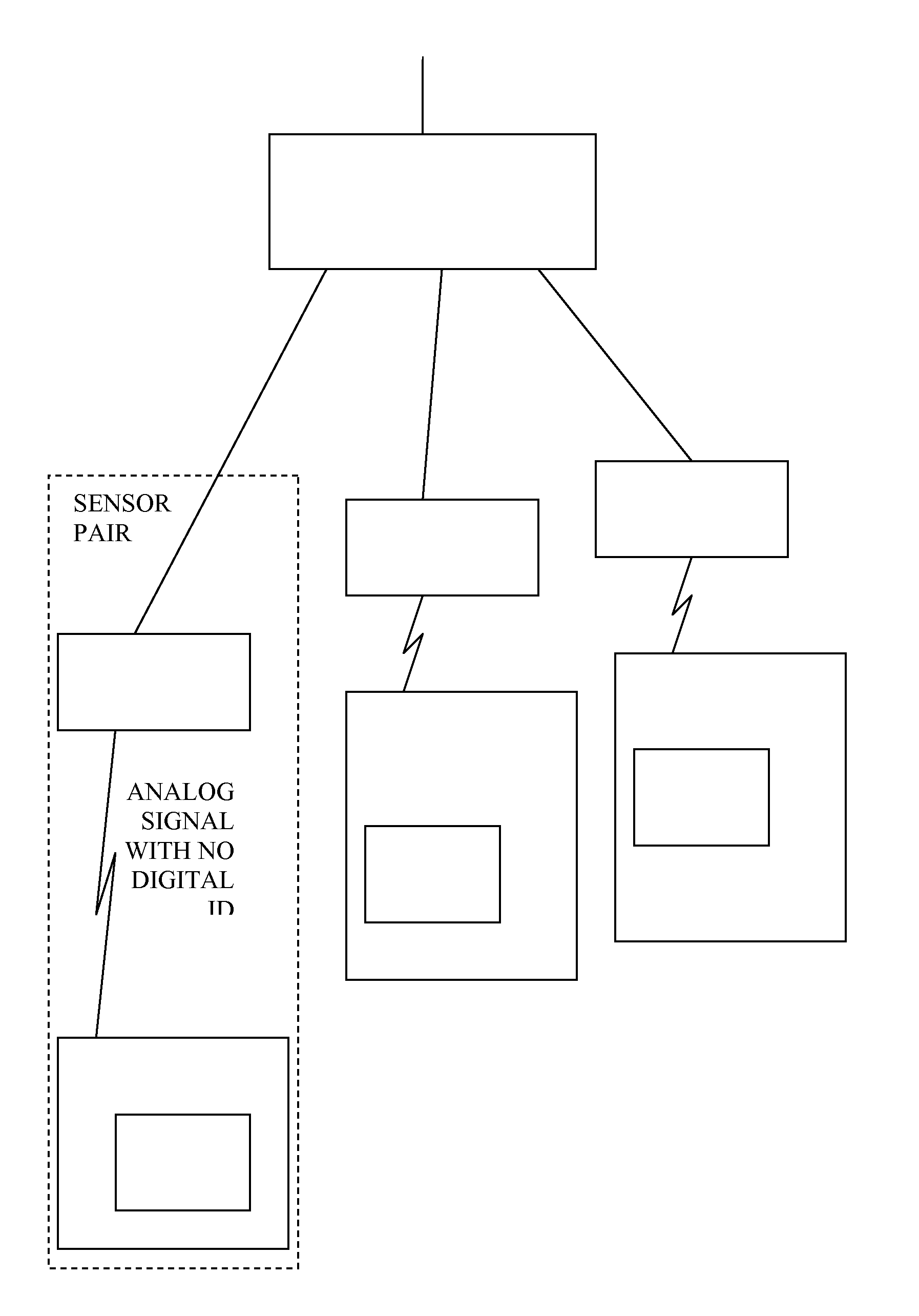

Network architecture for wirelessly interfacing sensors at ultra low power

InactiveUS20100308980A1Limiting and reducing power consumptionReduce Design ComplexityElectric signal transmission systemsMobile data collection deviceResistive sensorsShortest distance

A sensing network is described, consisting of a multiplexing reader and one or more sensor pairs, each sensor pair comprising a transponder and a dedicated reader, dedicated to that transponder, each transponder having a sensor. Each sensor pair is able to wirelessly interface and power both capacitive and resistive sensors at a short distance with high efficiency. By providing a dedicated reader for each transponder, each link can be optimized and there is no need for the dedicated reader to distinguish between signals from other transponders. The transponder generates an analog signal directly using a sensor or analog memory value and sends it by modulation to the dedicated reader. So, the dedicated readers do not need to have circuitry to demodulate a digital signal or ID code. The transponder includes the sensors and their electronic circuits and can be optionally remotely powered by the dedicated reader through the wireless link. The expected consumption of the dedicated reader can be lower than 200 μW.

Owner:UNIVERSITE CATHOLIQUE DE LOUVAIN

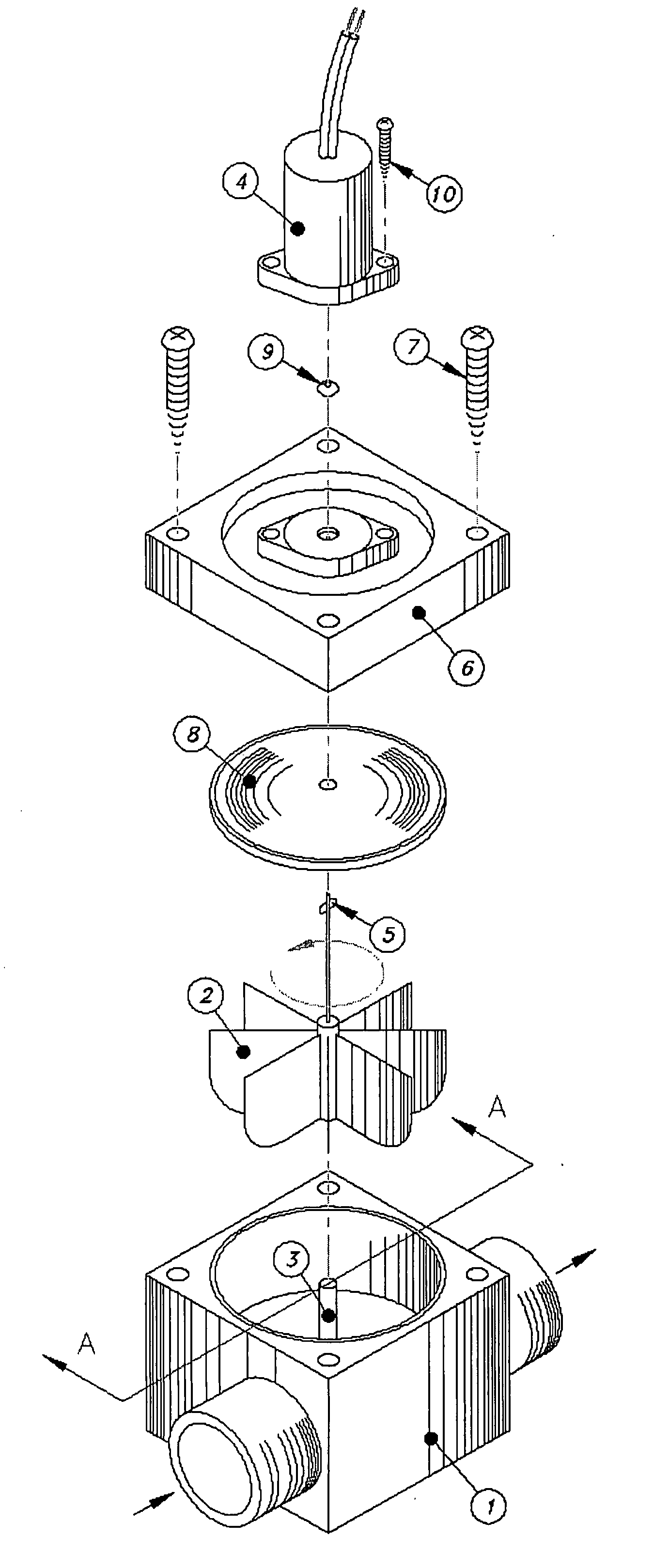

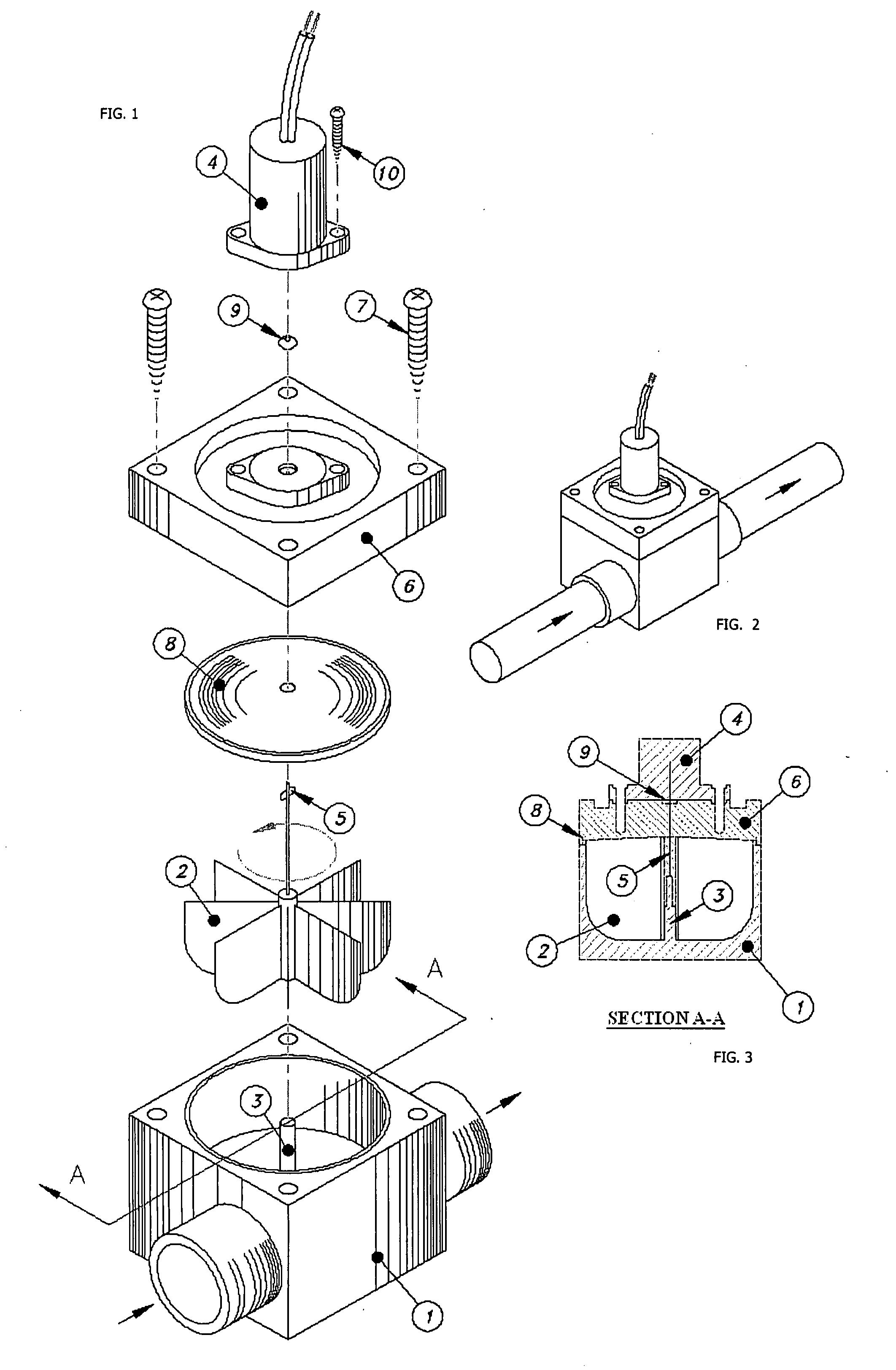

System and method for generating residential hydropower

InactiveUS20080246282A1Easy to installSmall designMachines/enginesEngine componentsGear driveWater source

A system and method are disclosed for generating small-scale hydropower from a home water supply. As contemplated herein, a hydro-powered system battery charger may produce electric power from the flow of water from a domestic water service. Power is generated as water from a domestic water source passes through a system housing. The water drives a Pelton wheel located within a cavity in the housing. As the Pelton wheel rotates, it drives a gear driven generator. A battery may store the energy generated thereby to satisfy concurrent or later demand.

Owner:HATHAWAY PHILIP JOHN +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com