Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

292results about How to "Contact resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

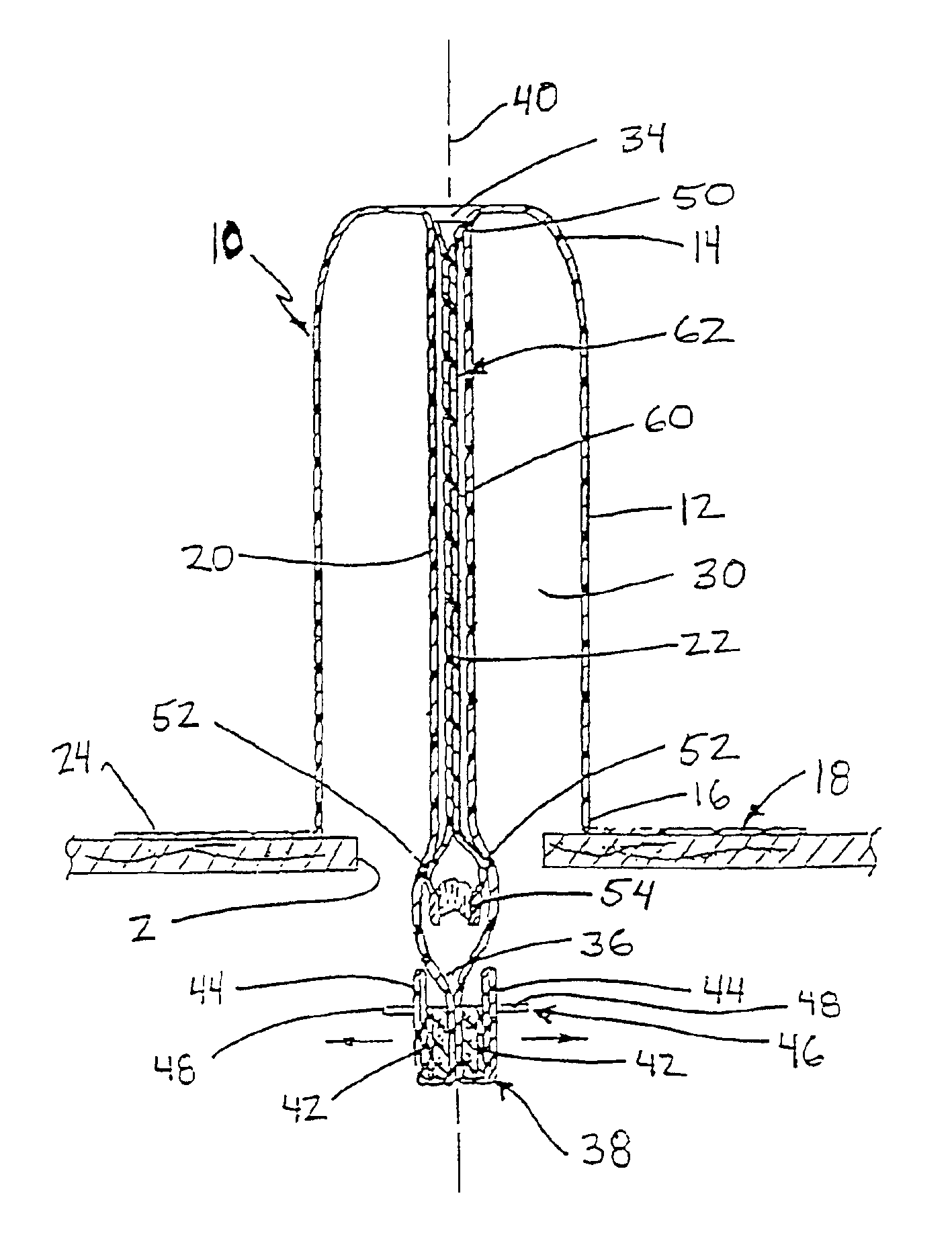

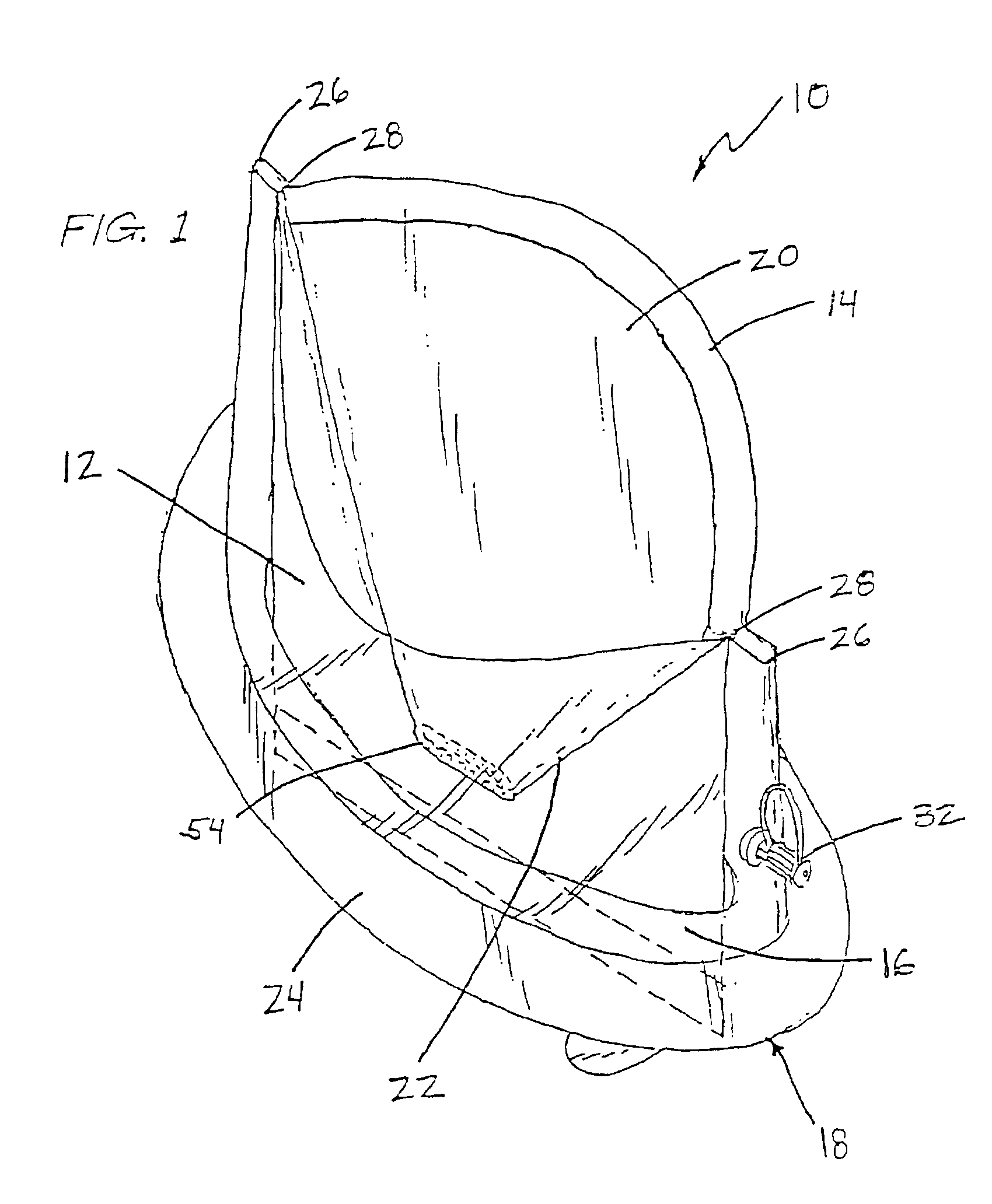

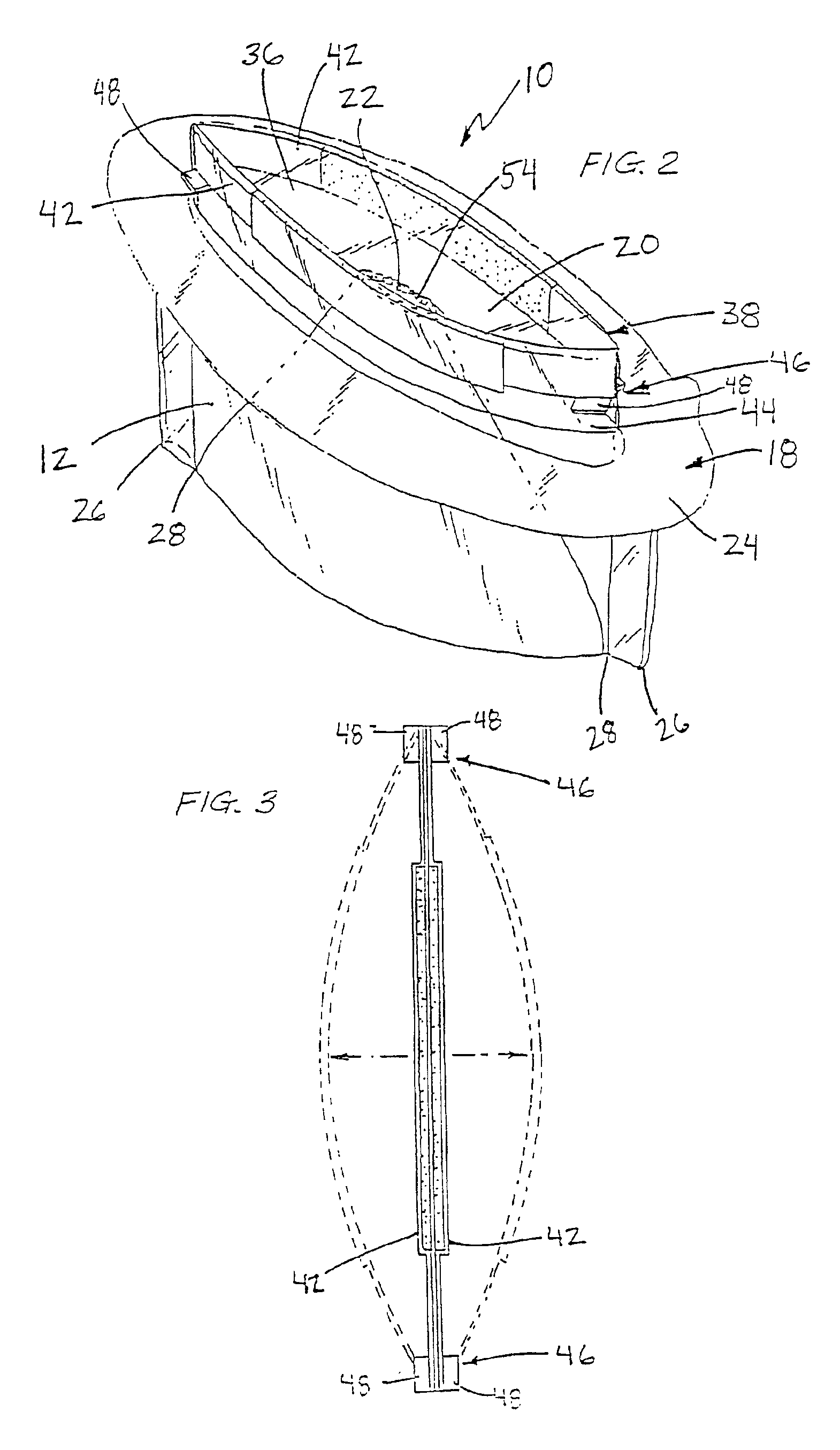

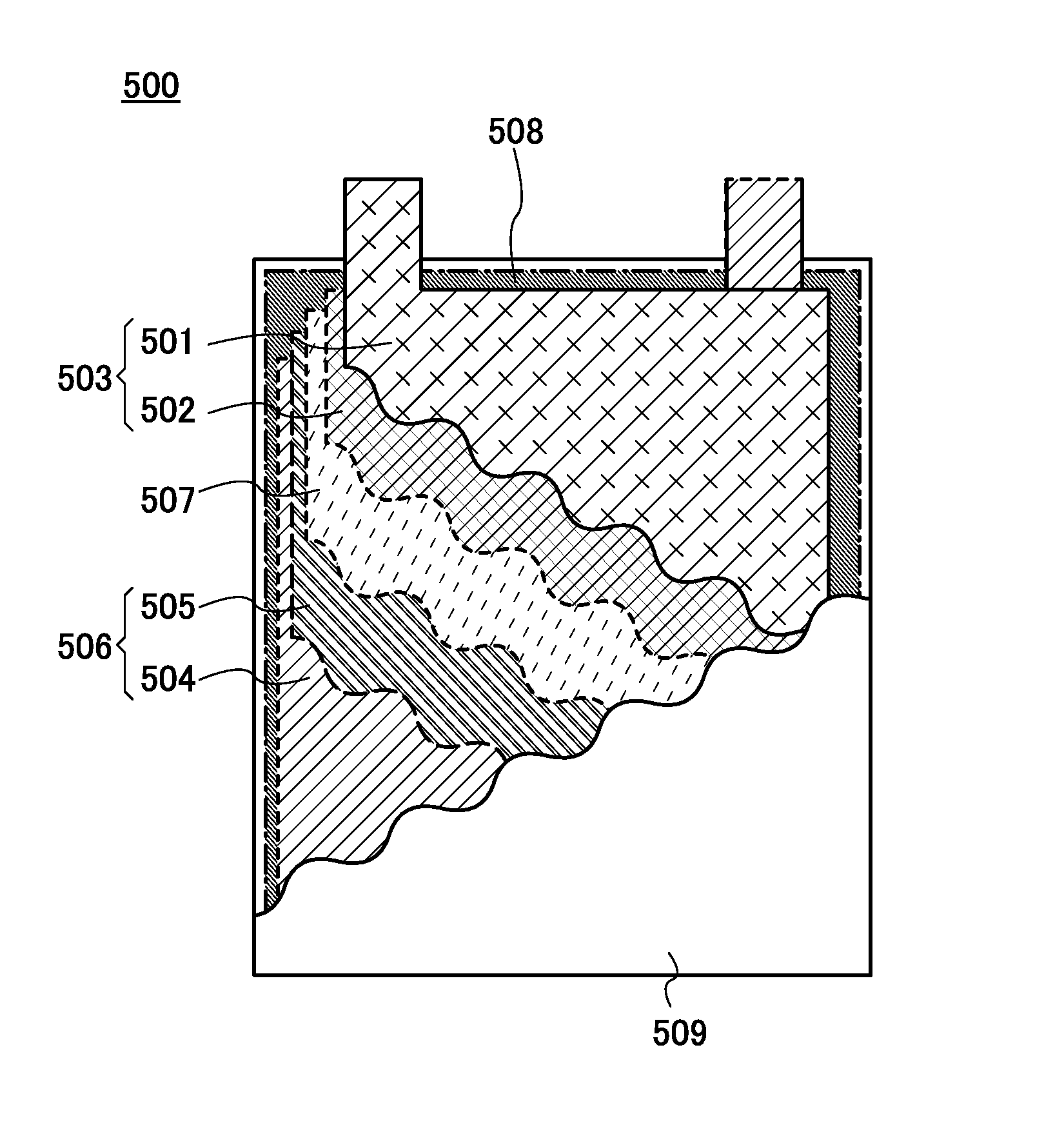

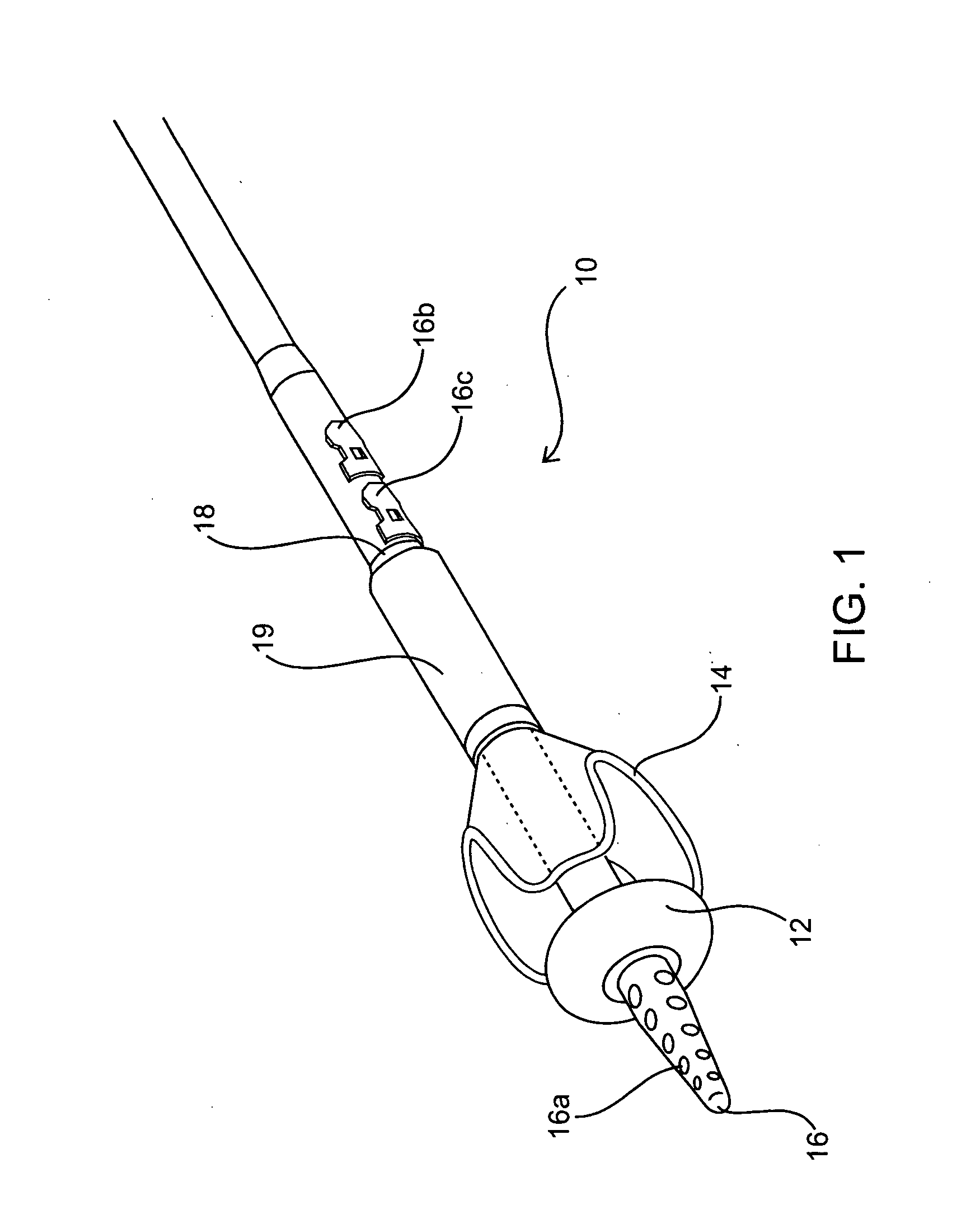

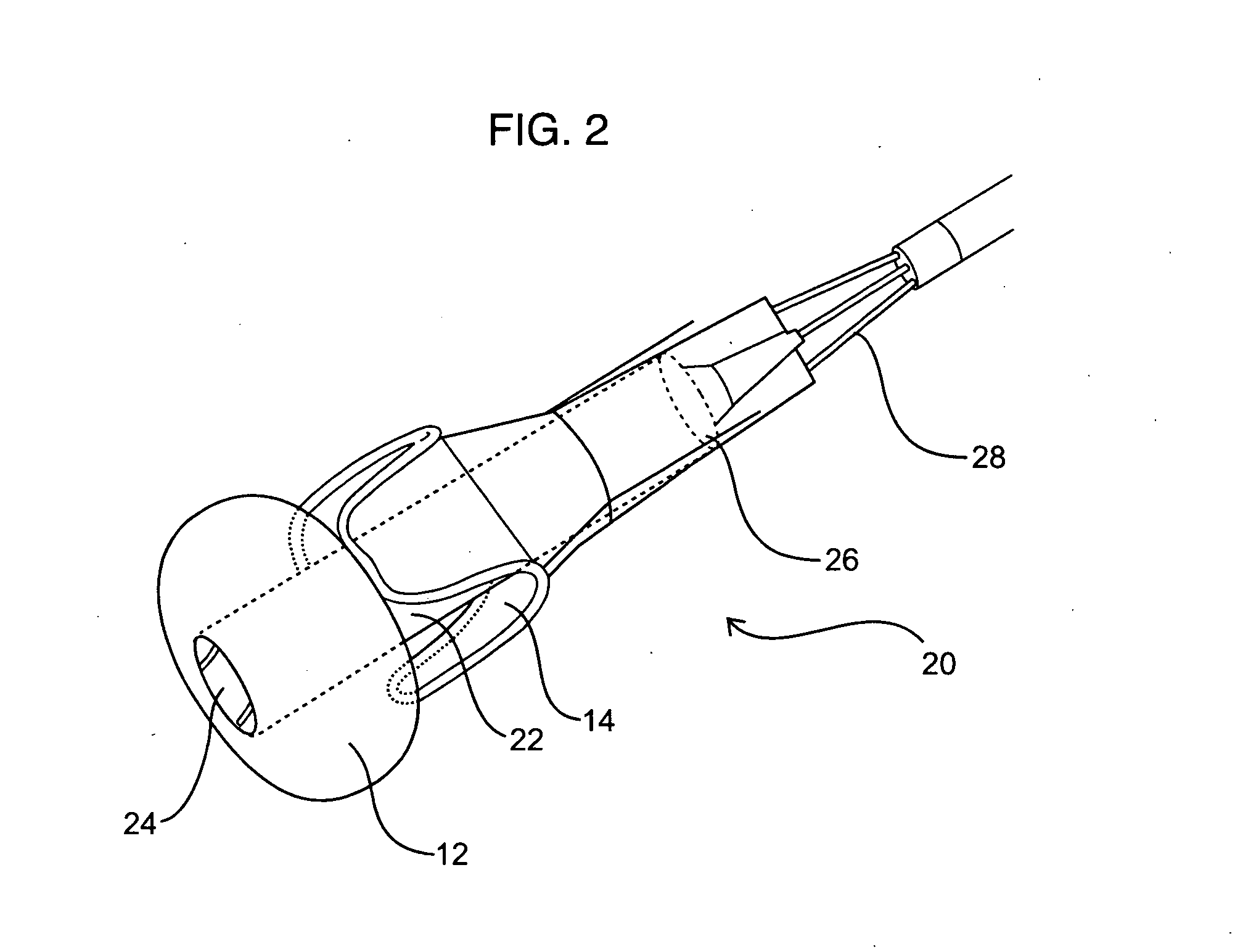

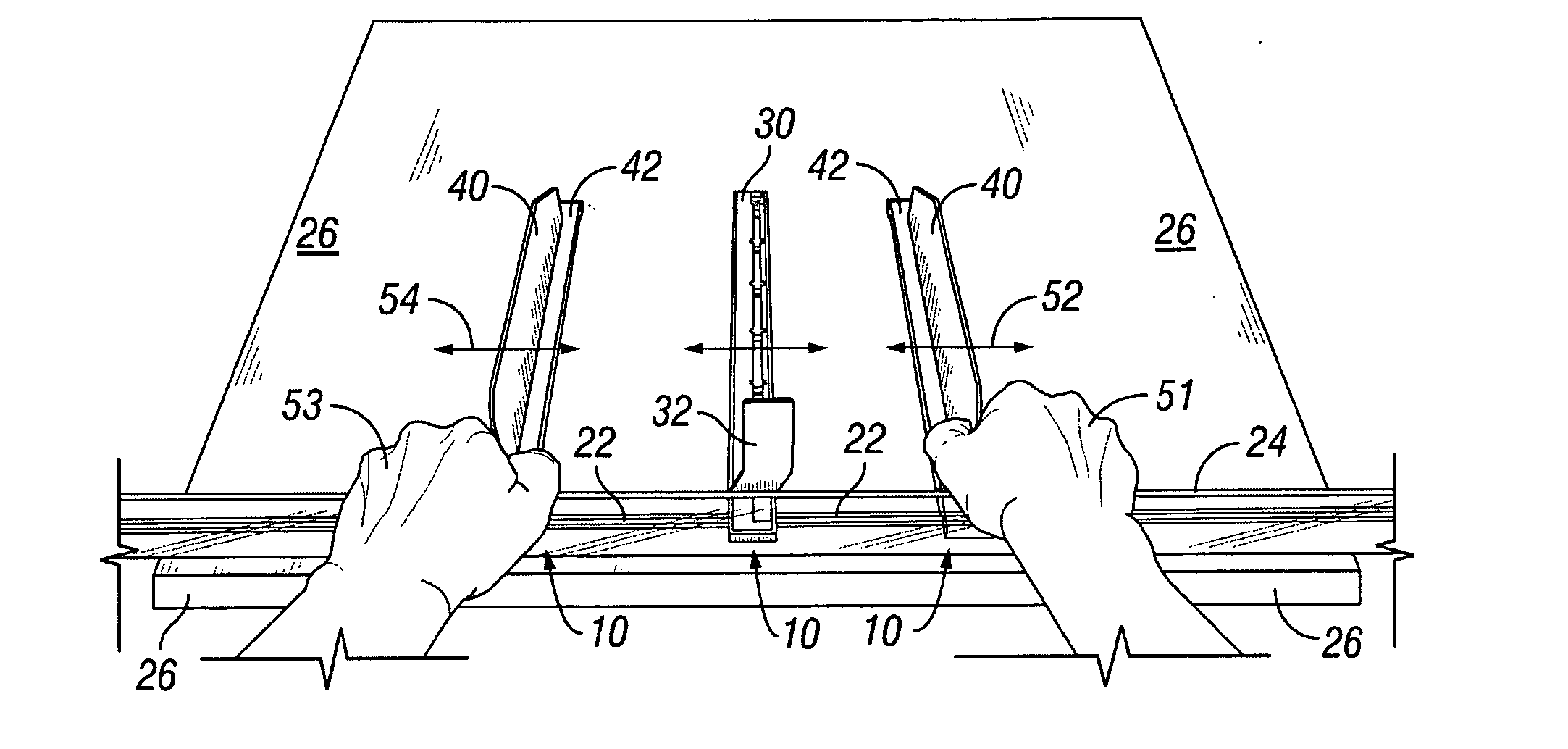

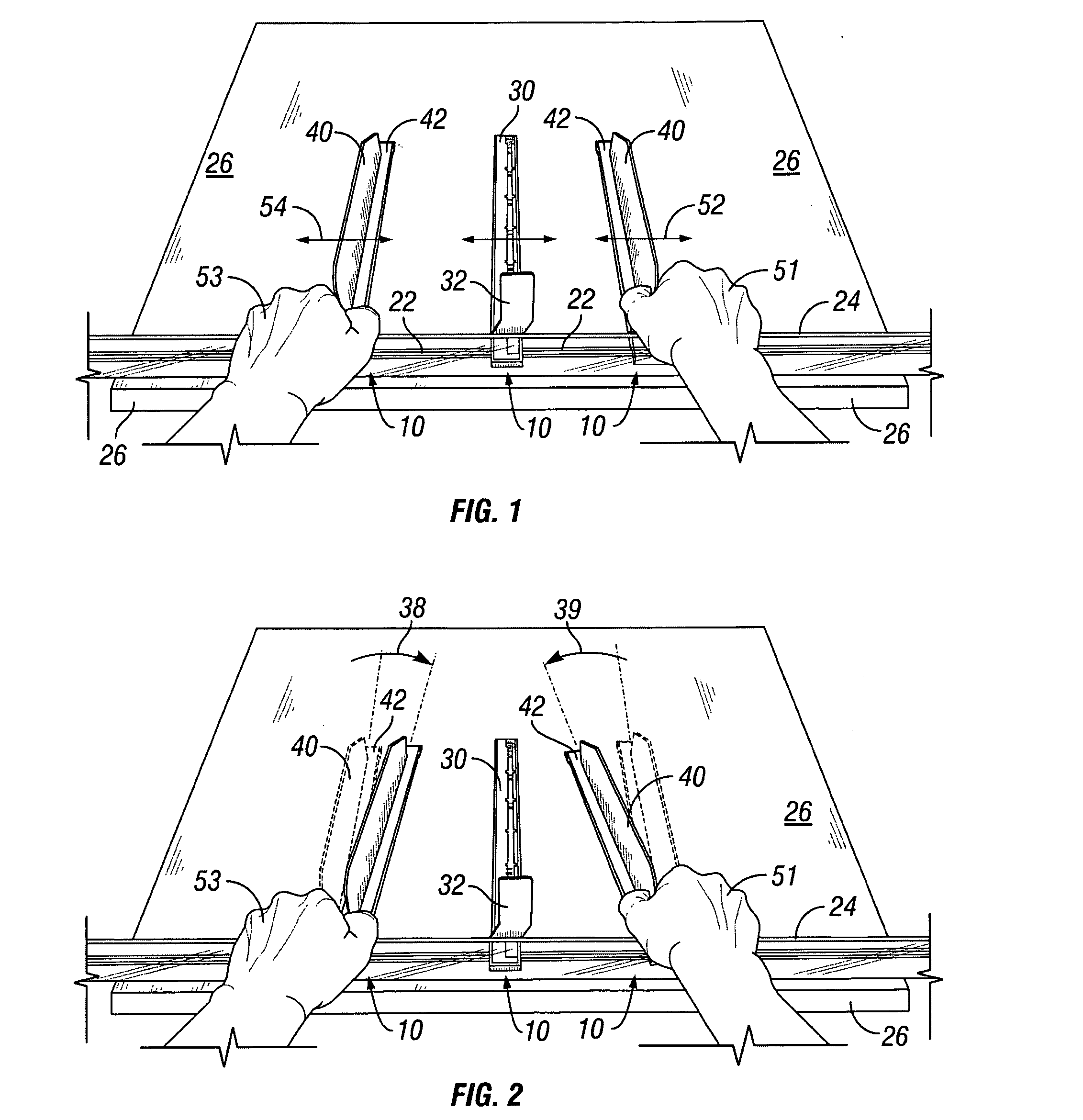

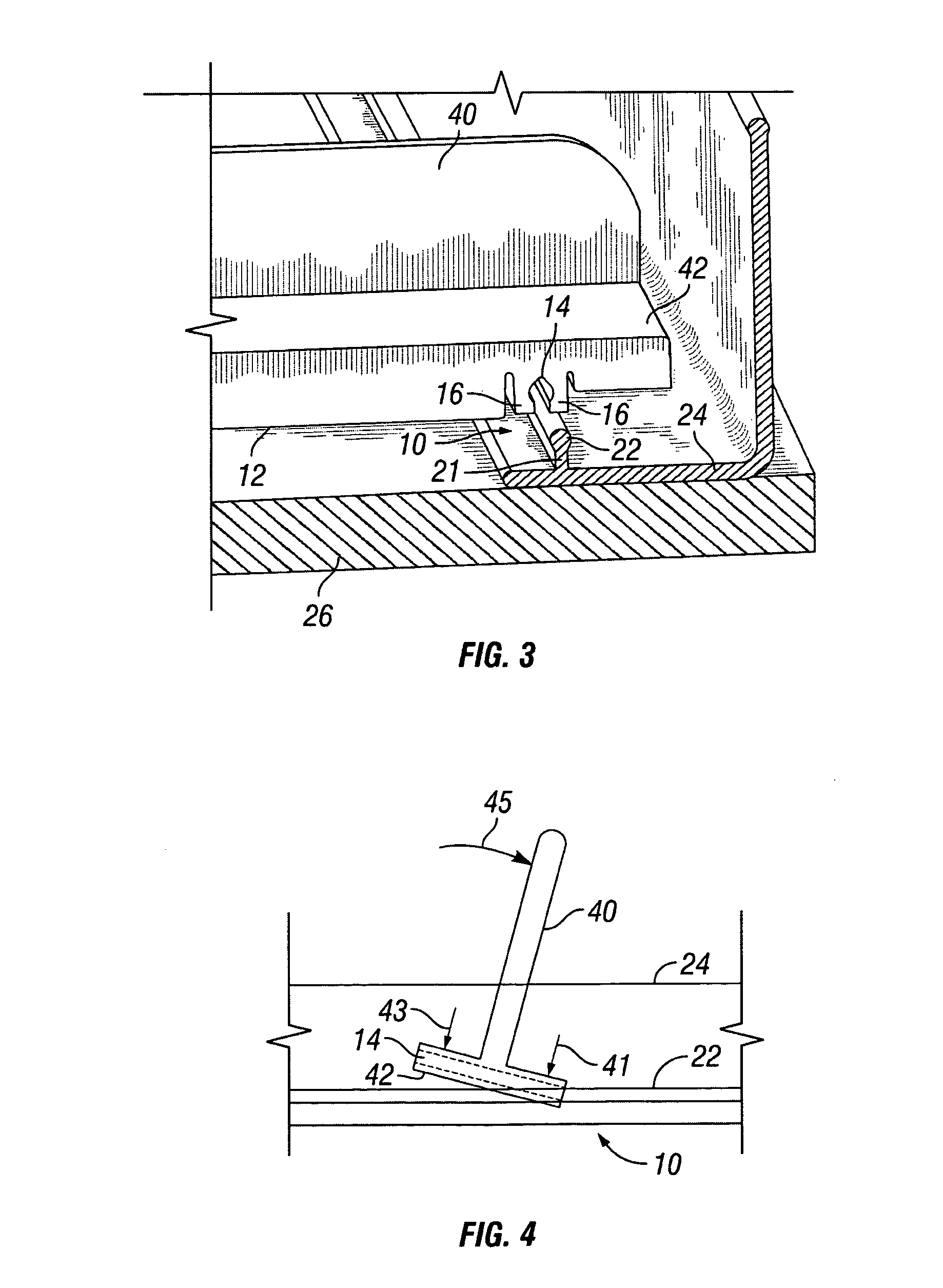

Hand access port device

InactiveUS6908430B2Reduce leakagePrevent substantial leakage of gasEar treatmentCannulasEngineeringGas chamber

An access port device is provided which enables hand access to a patient's body cavity while retaining pneumoperitoneum by minimizing gas leakage through the access port device. In one embodiment, the access port device includes first and second sleeves forming an inflatable chamber and a third sleeve mounted within the second sleeve including an elastic band for sealingly engaging a hand or wrist. The access port device may also include an exit opening seal for positioning within the patient's body cavity and a second sleeve retraction prevention device for preventing inadvertent movement of the second sleeve outwardly from the patient's body cavity through the incision. In another embodiment, an access port device provided which includes an inner annular sealing device and a non-adhesive outer annular sealing device for creating a non-adhesive seal against the outer surface of a patient. An access component forming an inflatable chamber and including an integral sleeved glove may also be provided. In another embodiment, a sealing force applying feature includes a biasing surface formed on a generally flat annular extension and exposed to gas pressure in an adjacent gas chamber positioned to receive leakage gas leakage between the access port device an the patient to create sealing forces which tend to enhance the seal between the flexible annular extension and patient's skin.

Owner:APPL MEDICAL RESOURCES CORP

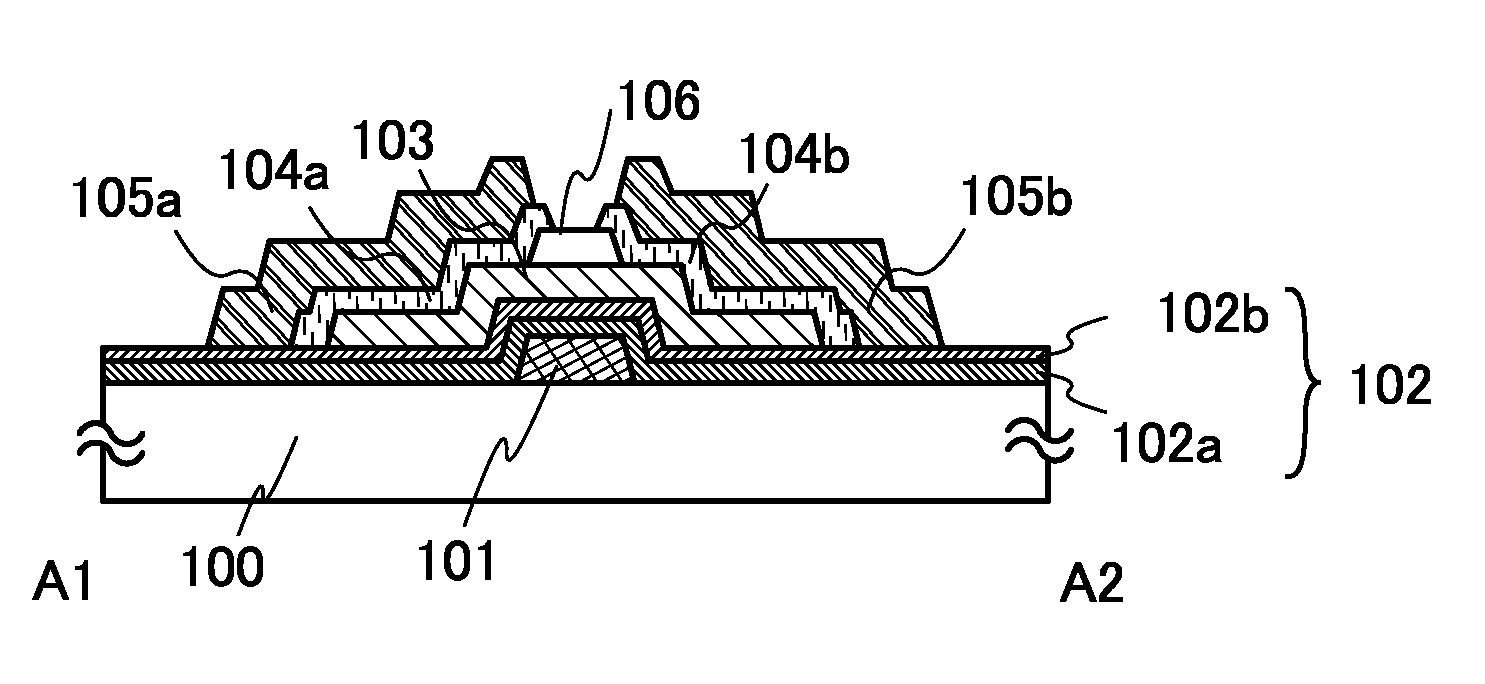

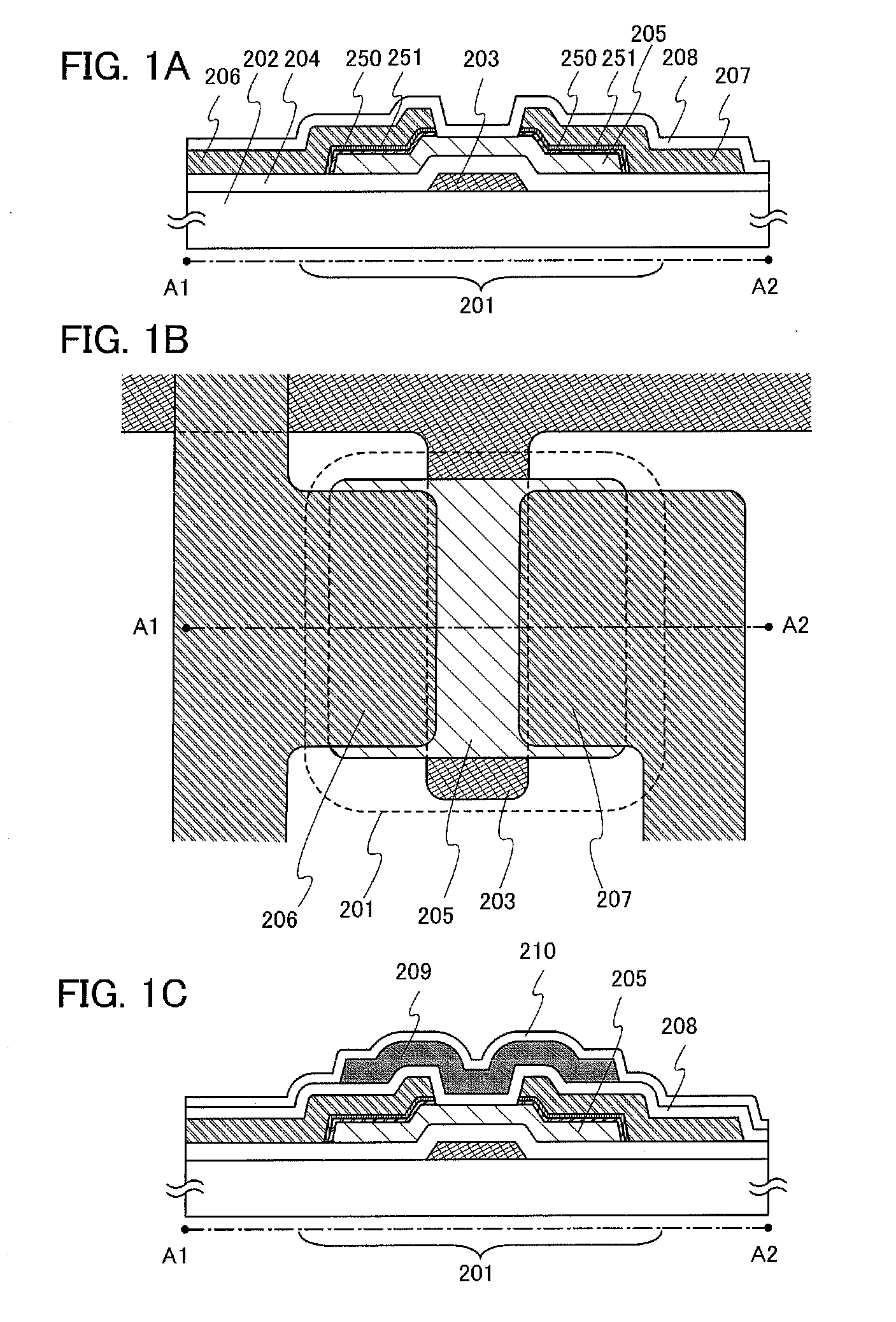

Semiconductor device and manufacturing method thereof

ActiveUS20100025676A1Small amount of photocurrentReduce parasitic capacitanceTransistorSolid-state devicesCharge carrierOhmic contact

To offer a semiconductor device including a thin film transistor having excellent characteristics and high reliability and a method for manufacturing the semiconductor device without variation. The summary is to include an inverted-staggered (bottom-gate structure) thin film transistor in which an oxide semiconductor film containing In, Ga, and Zn is used for a semiconductor layer and a buffer layer is provided between the semiconductor layer and source and drain electrode layers. An ohmic contact is formed by intentionally providing a buffer layer containing In, Ga, and Zn and having a higher carrier concentration than the semiconductor layer between the semiconductor layer and the source and drain electrode layers.

Owner:SEMICON ENERGY LAB CO LTD

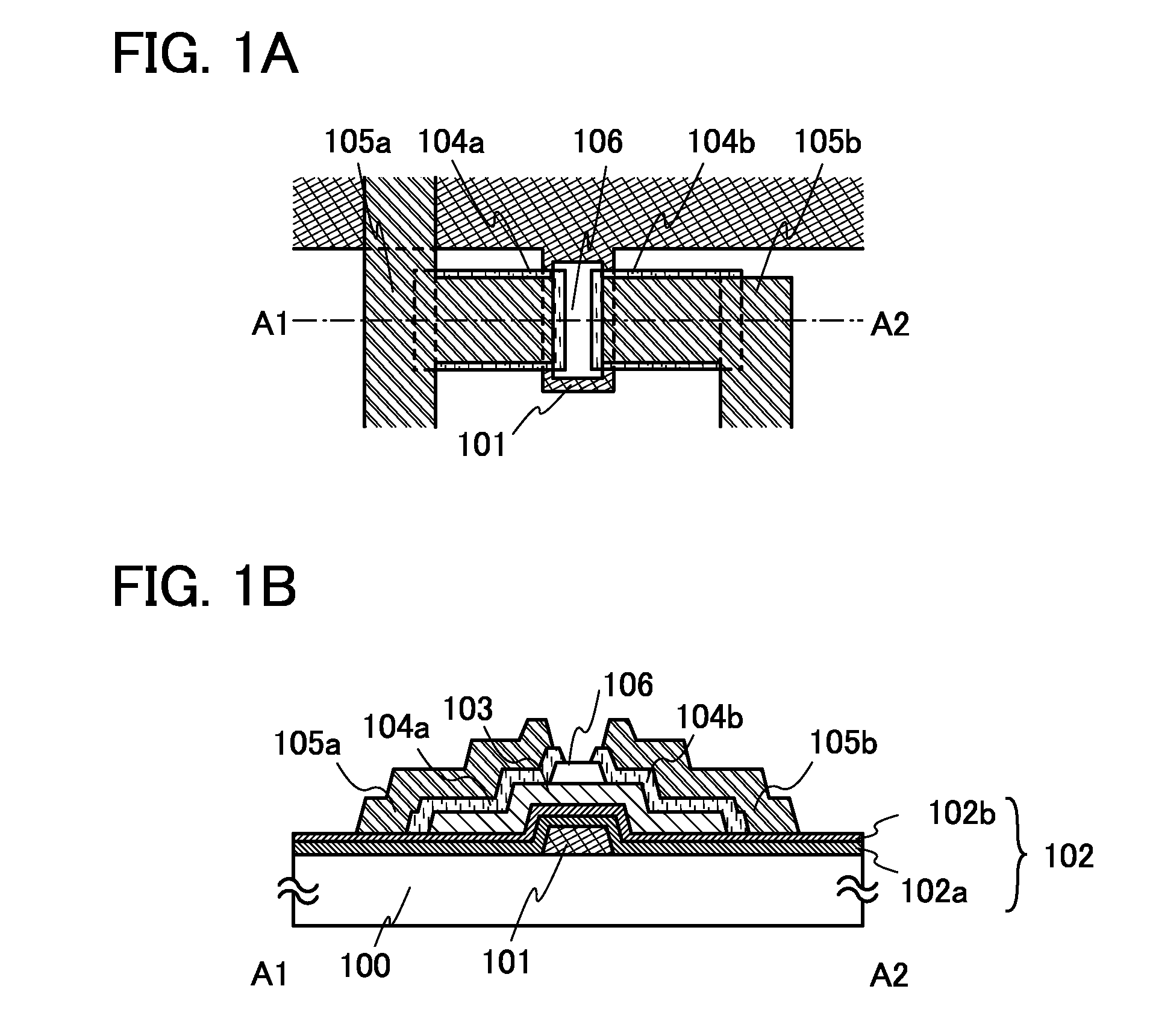

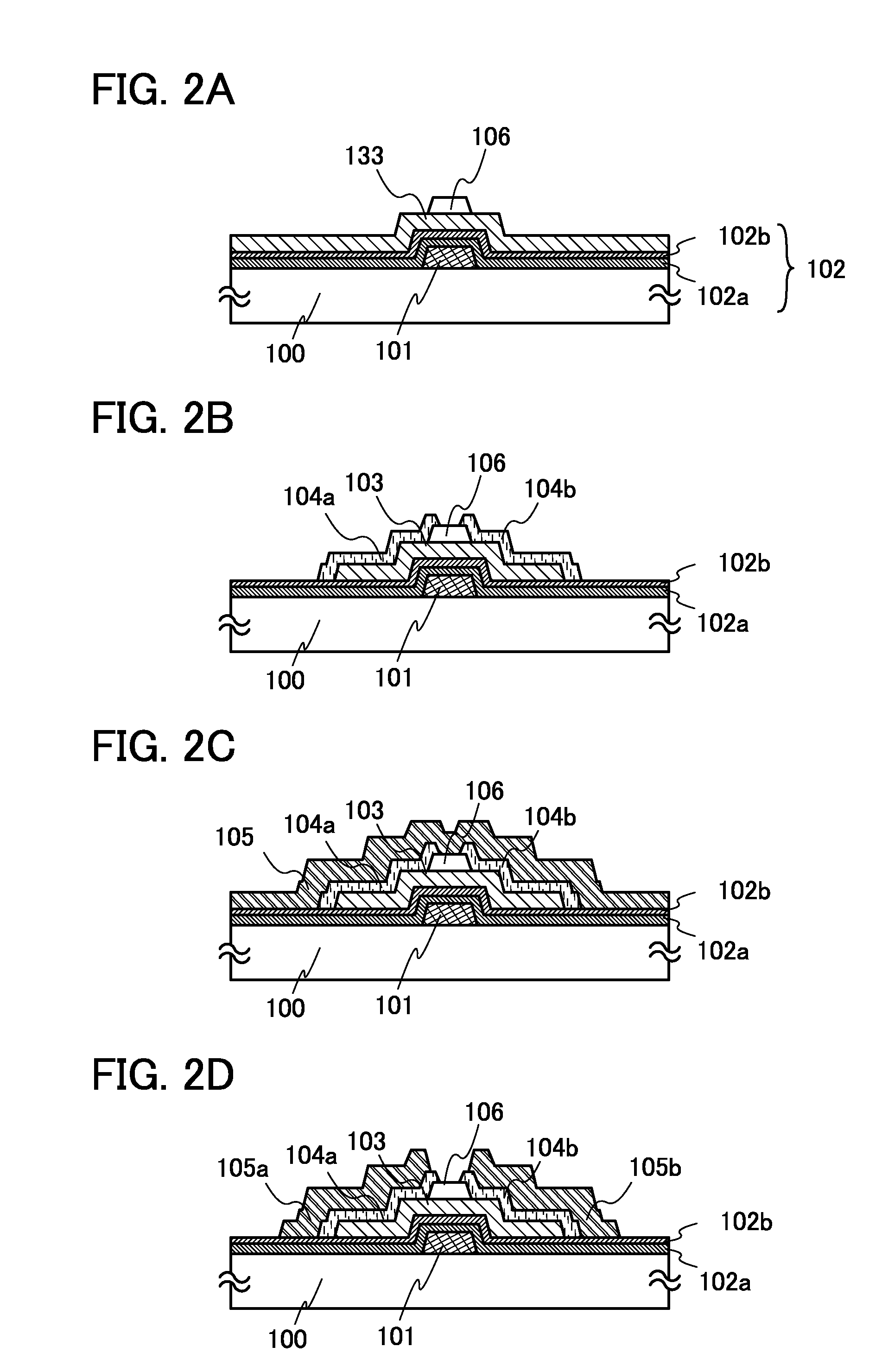

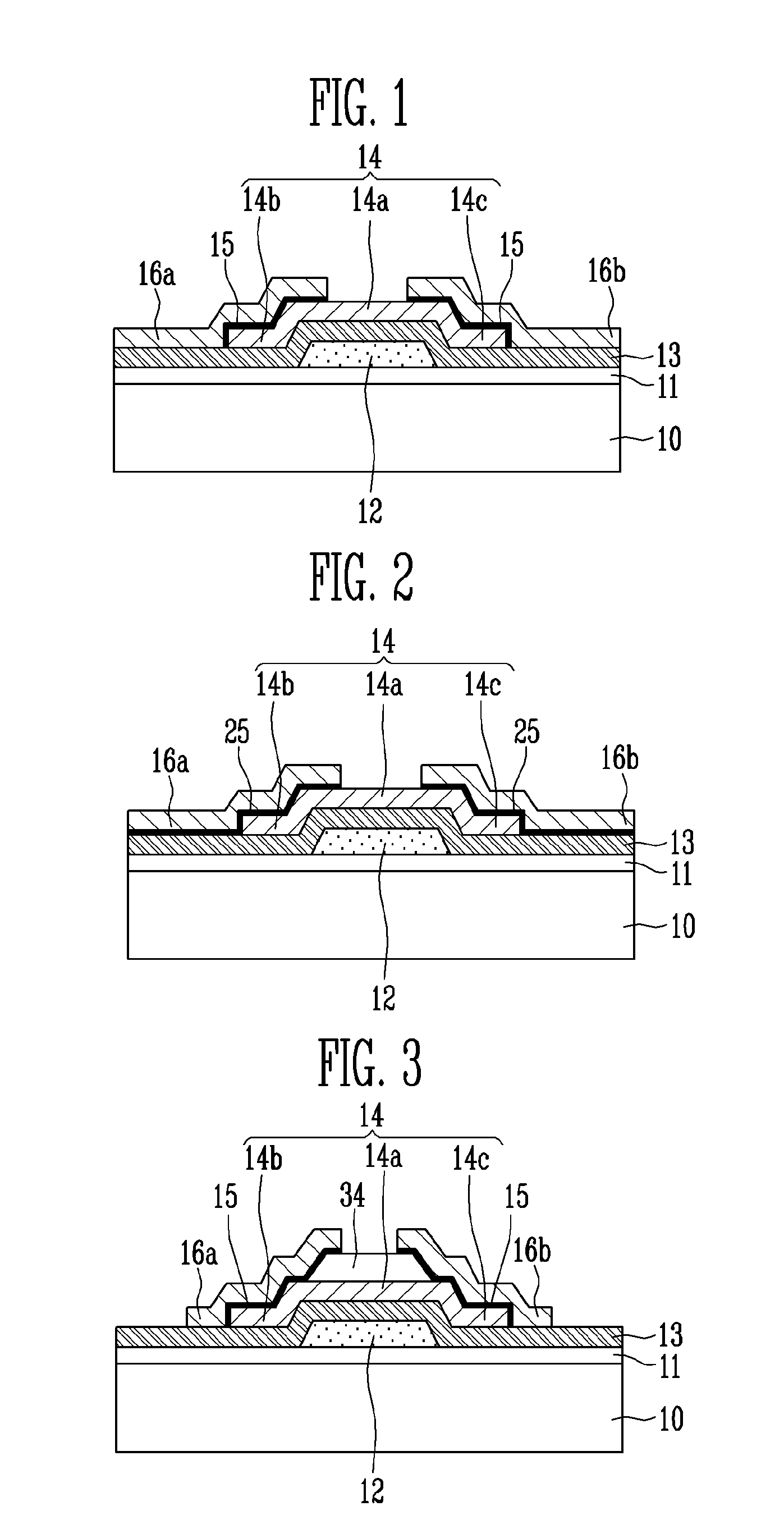

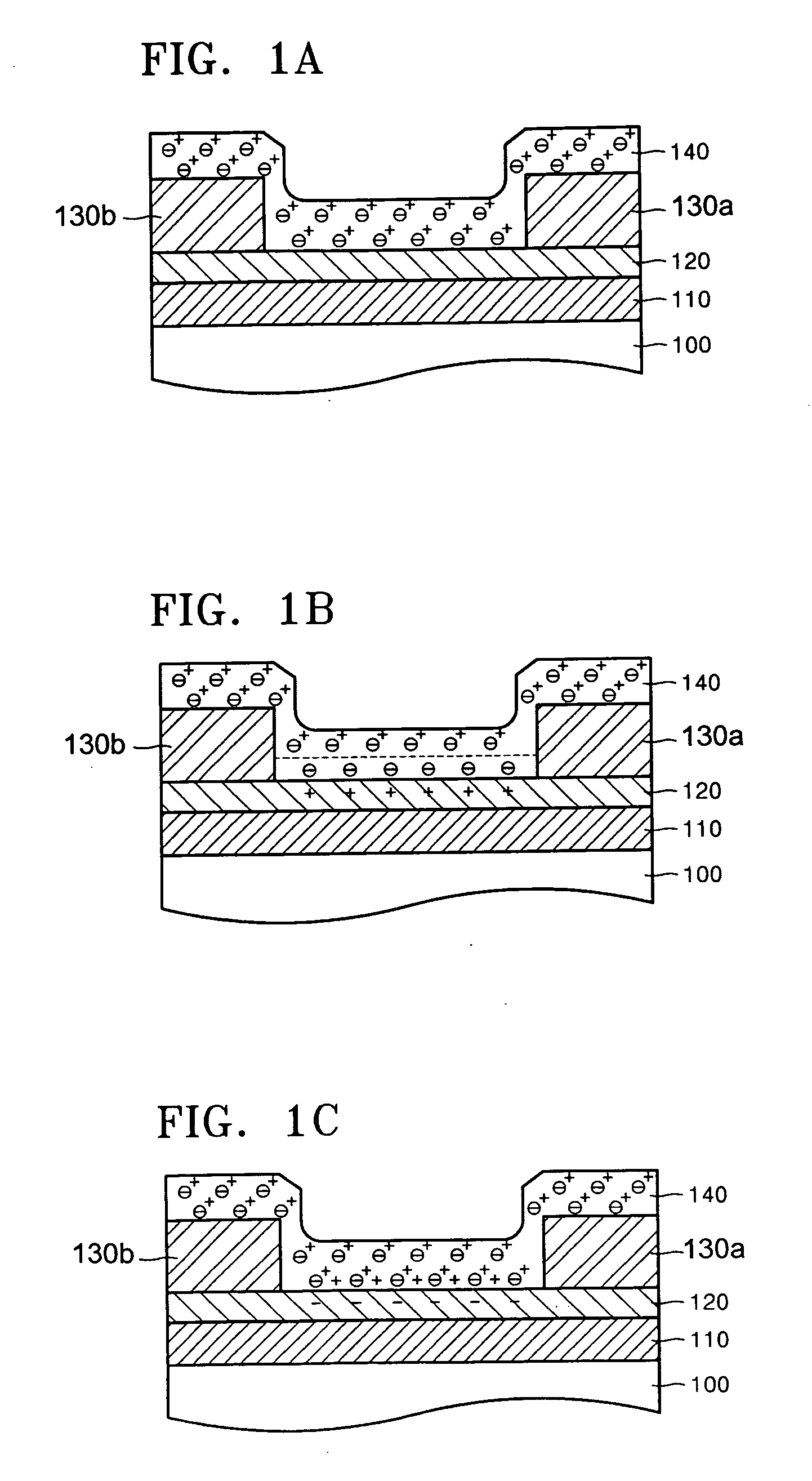

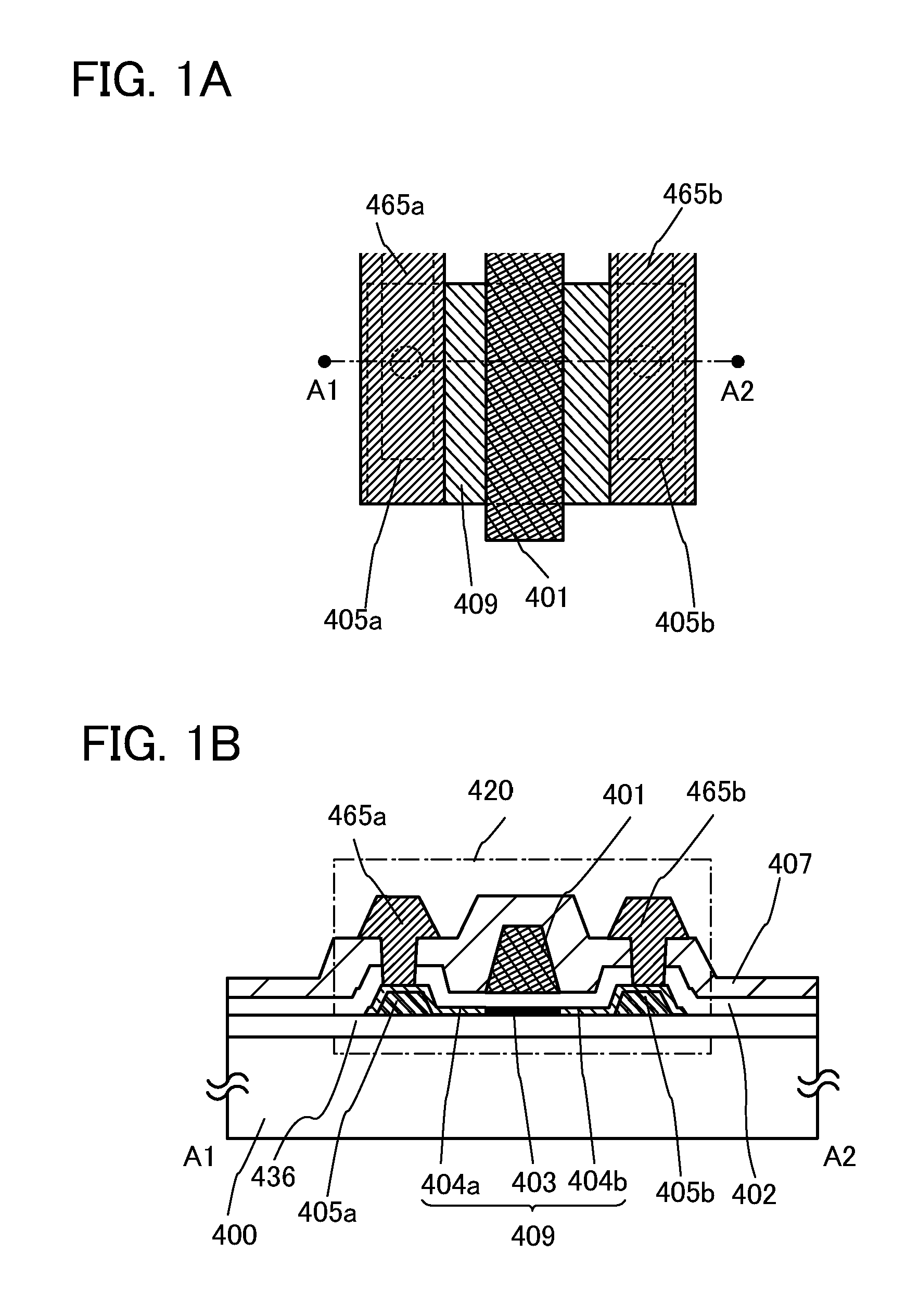

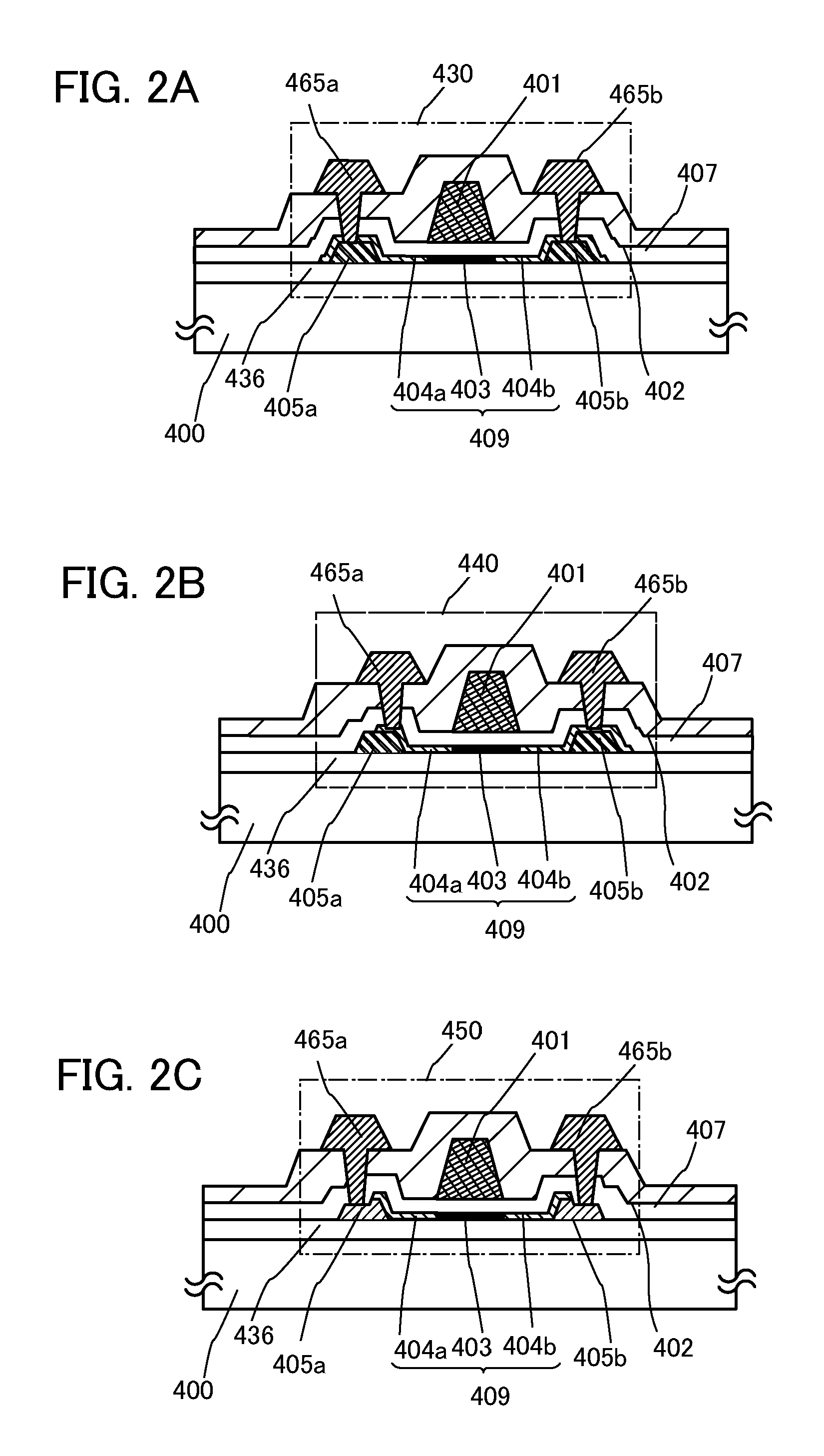

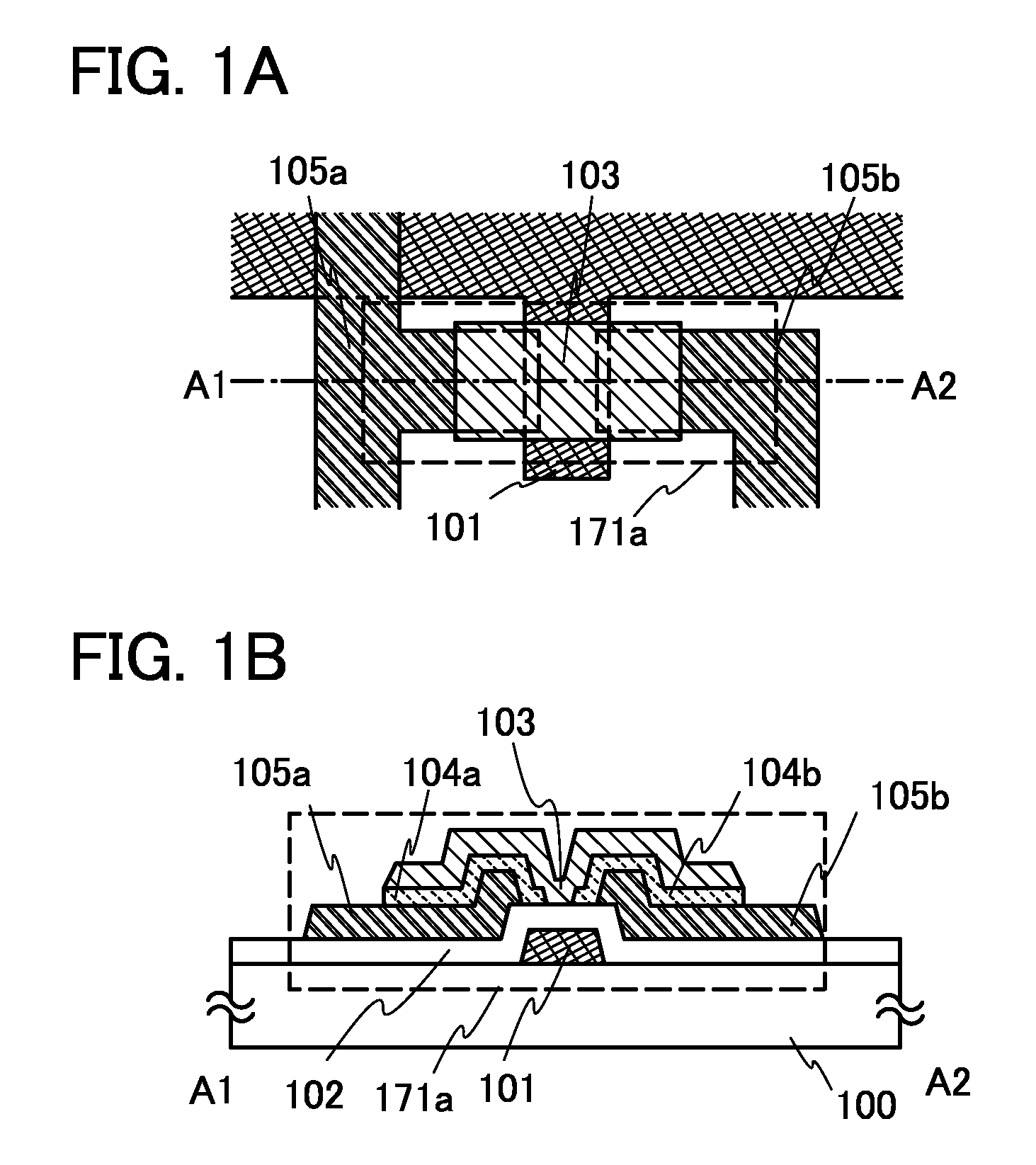

Transistor and method for manufacturing the transistor

ActiveUS20100193782A1Reduce variationContact resistanceTransistorSolid-state devicesCrystal structureSemiconductor

It is an object to reduce characteristic variation among transistors and reduce contact resistance between an oxide semiconductor layer and a source electrode layer and a drain electrode layer, in a transistor where the oxide semiconductor layer is used as a channel layer. In a transistor where an oxide semiconductor is used as a channel layer, at least an amorphous structure is included in a region of an oxide semiconductor layer between a source electrode layer and a drain electrode layer, where a channel is to be formed, and a crystal structure is included in a region of the oxide semiconductor layer which is electrically connected to an external portion such as the source electrode layer and the drain electrode layer.

Owner:SEMICON ENERGY LAB CO LTD

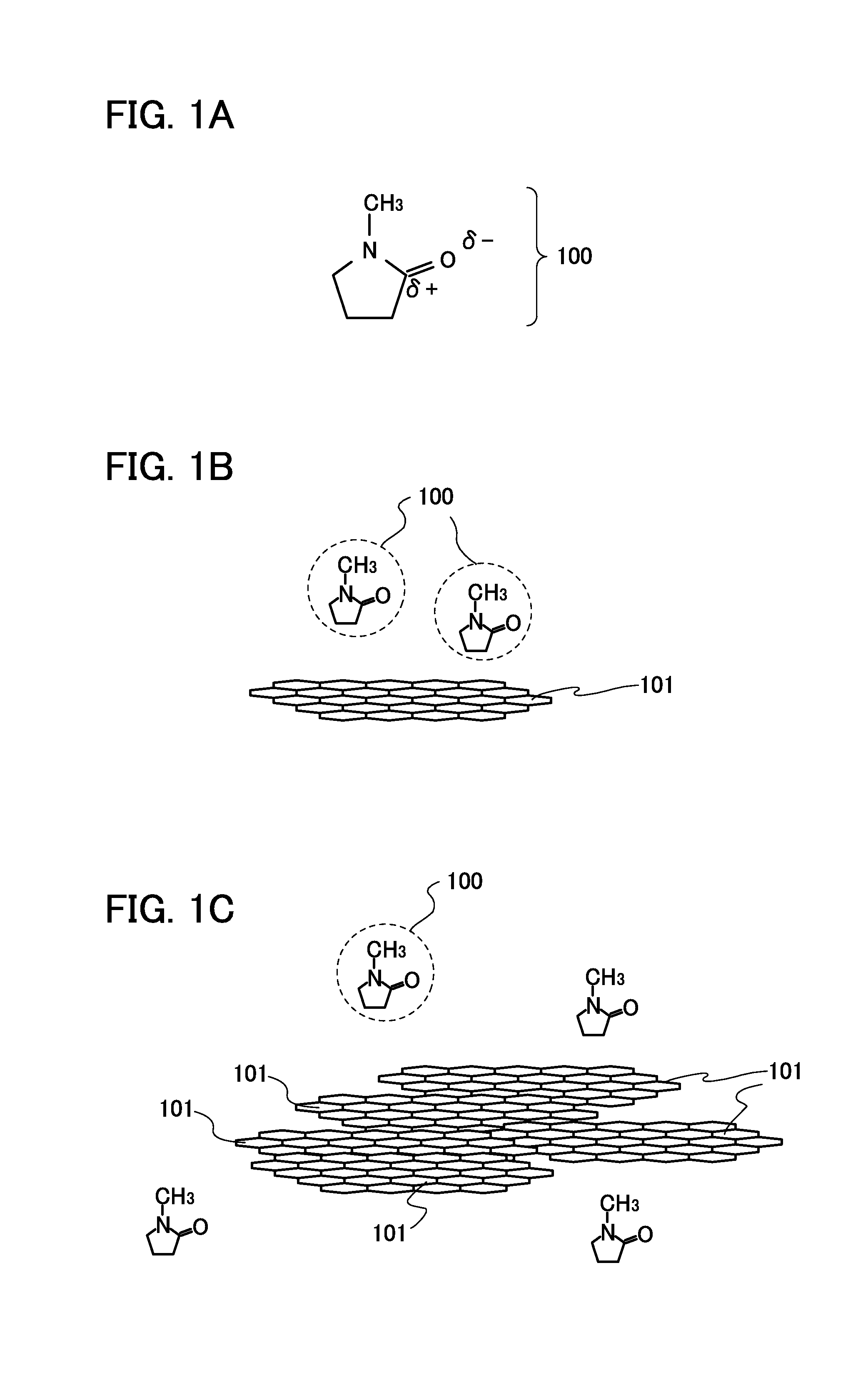

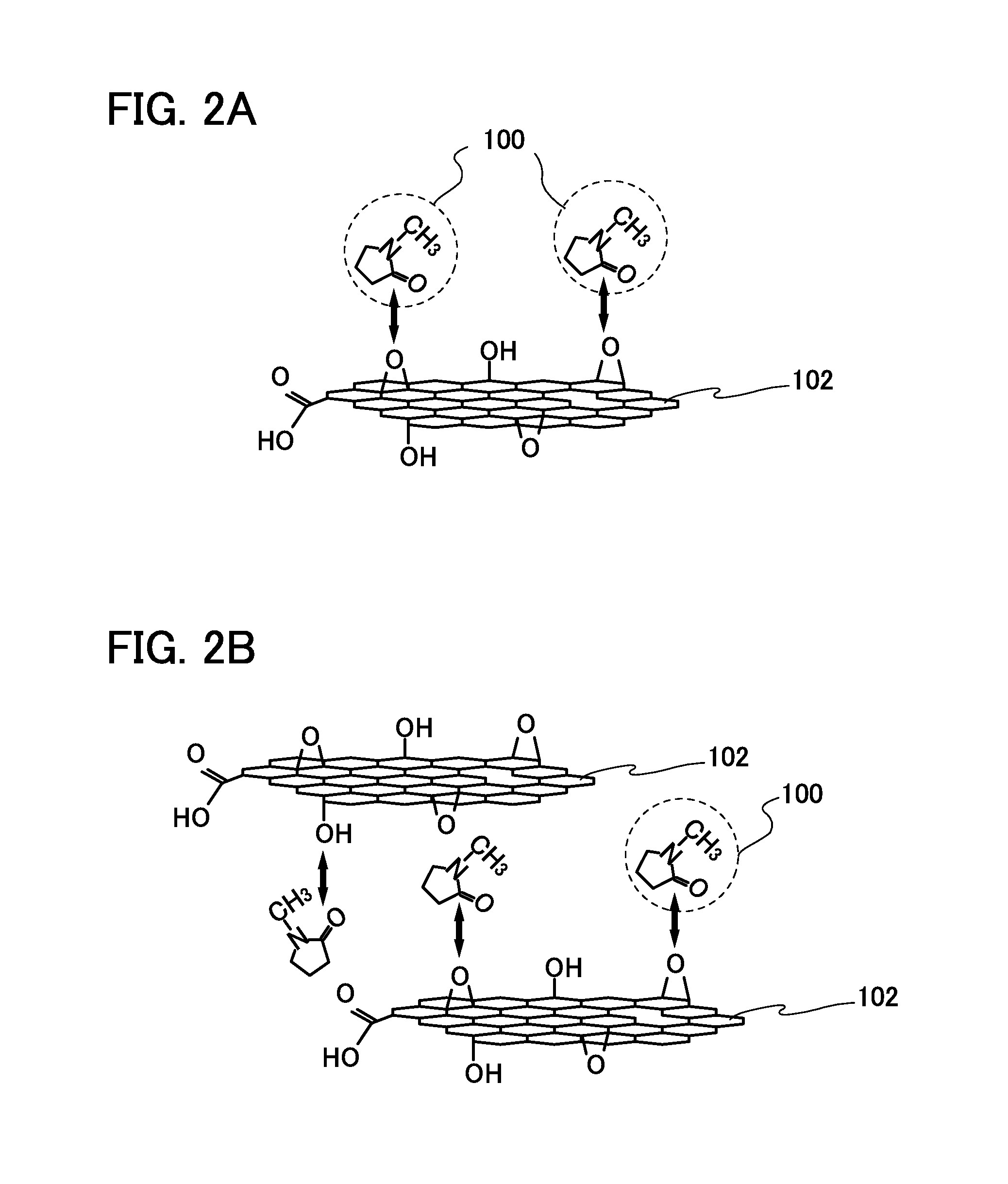

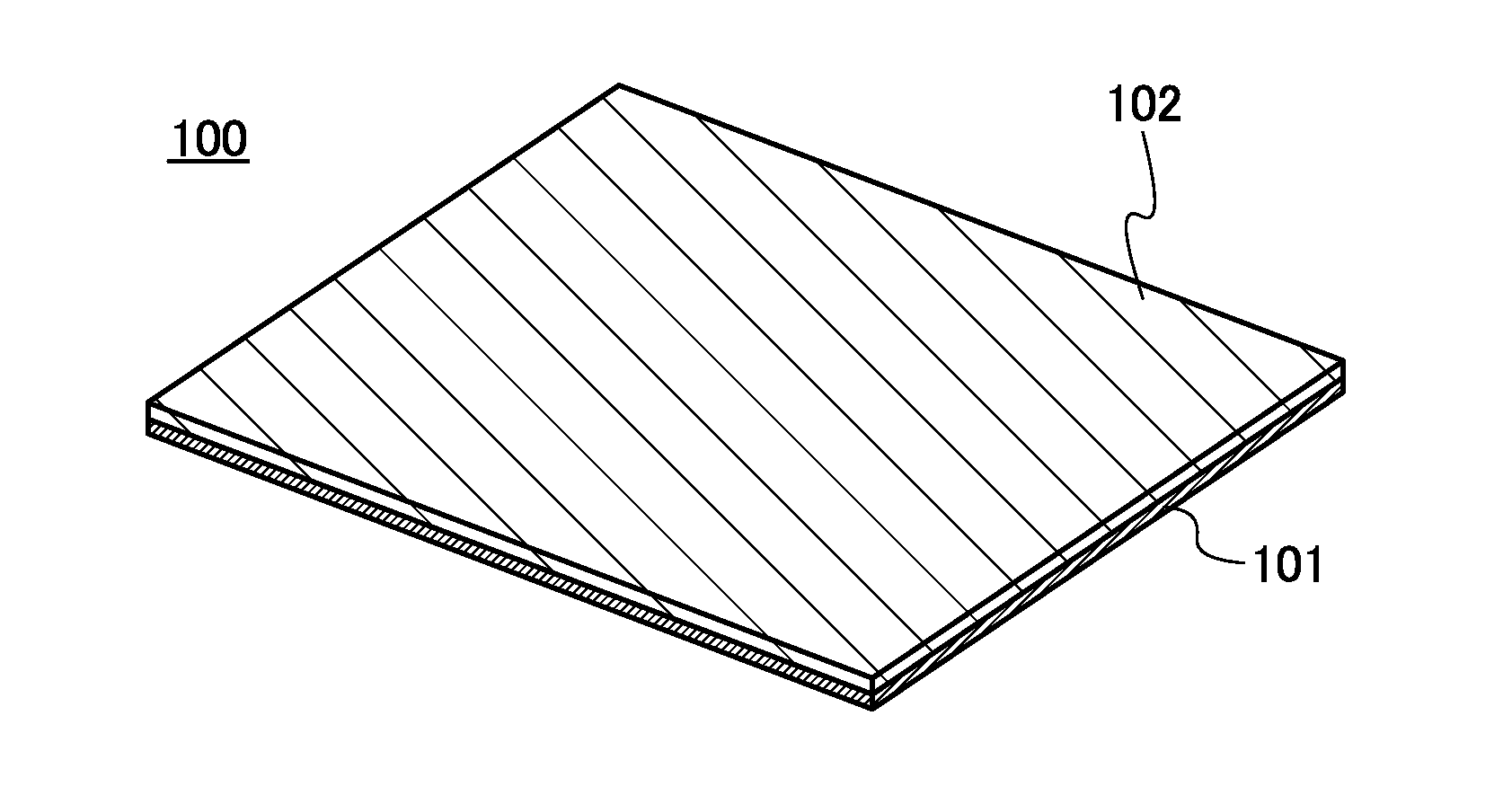

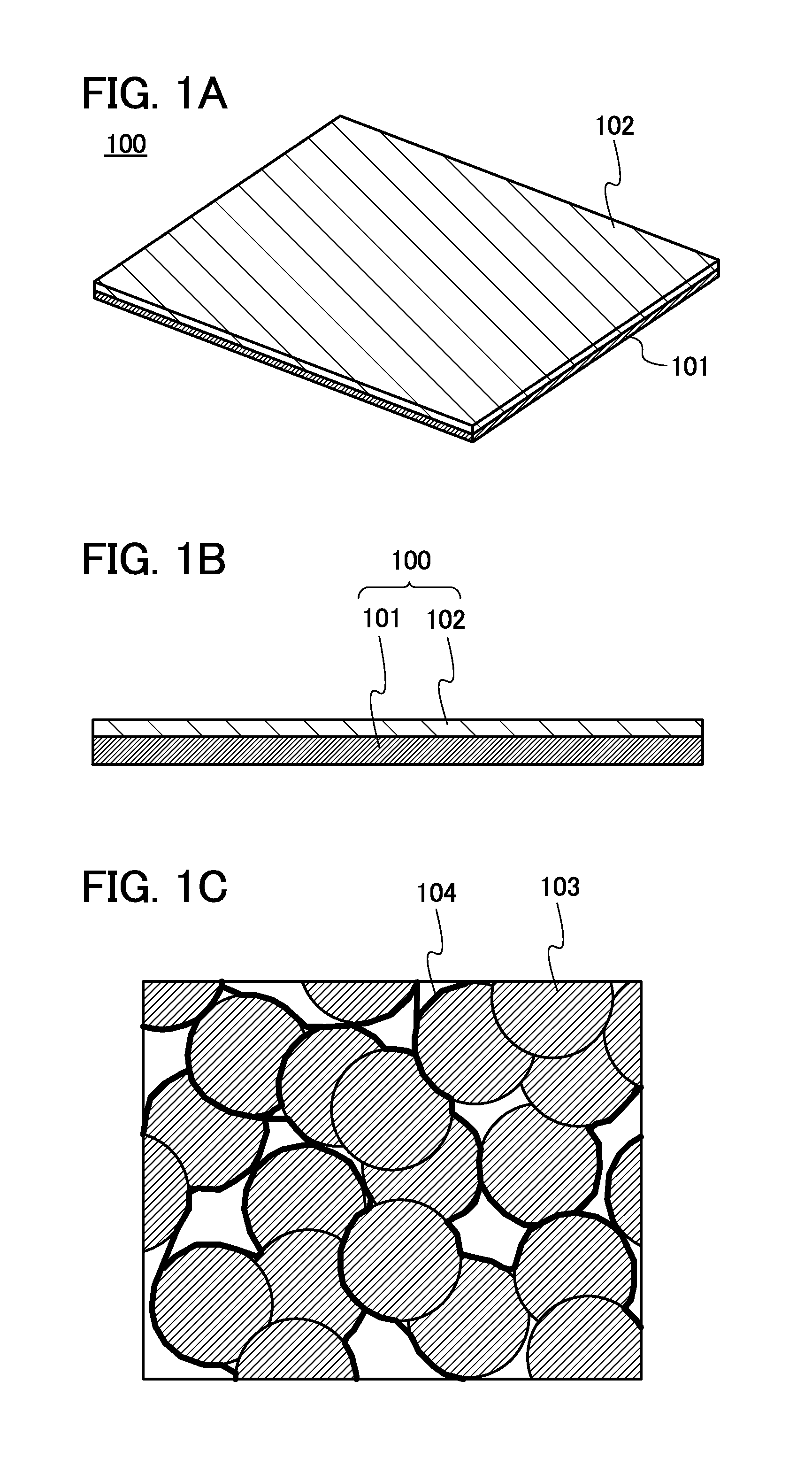

Graphene oxide, positive electrode for nonaqueous secondary battery using graphene oxide, method of manufacturing positive electrode for nonaqueous secondary battery, nonaqueous secondary battery, and electronic device

ActiveUS20130266859A1High capacityReduce capacityOrganic chemistryGraphiteGraphite oxideGraphene oxide paper

A graphene oxide used as a raw material of a conductive additive for forming an active material layer with high electron conductivity with a small amount of a conductive additive is provided. A positive electrode for a nonaqueous secondary battery using the graphene oxide as a conductive additive is provided. The graphene oxide is used as a raw material of a conductive additive in a positive electrode for a nonaqueous secondary battery and, in the graphene oxide, the weight ratio of oxygen to carbon is greater than or equal to 0.405.

Owner:SEMICON ENERGY LAB CO LTD

Display device

InactiveUS20060275618A1Low electrical connection resistivityImprove display qualitySolid-state devicesNatural mineral layered productsLiquid-crystal displayDisplay device

A display device in which interconnection—electrode comprising a Cu alloy film having a lower electrical resistivity than Al alloy and a transparent conductive film are directly connected not by way of a refractory metal thin film, wherein the Cu alloy film contains Zn and / or Mg in a total amount from 0.1 to 3.0 at %, or Ni and / or Mn in a total amount from 0.1 to 5 at %, thereby enabling the direct connection at low resistivity between the Cu alloy film and the transparent electrode without using a barrier metal, and giving high display quality in a case of application, for example, to a liquid crystal display.

Owner:KOBE STEEL LTD

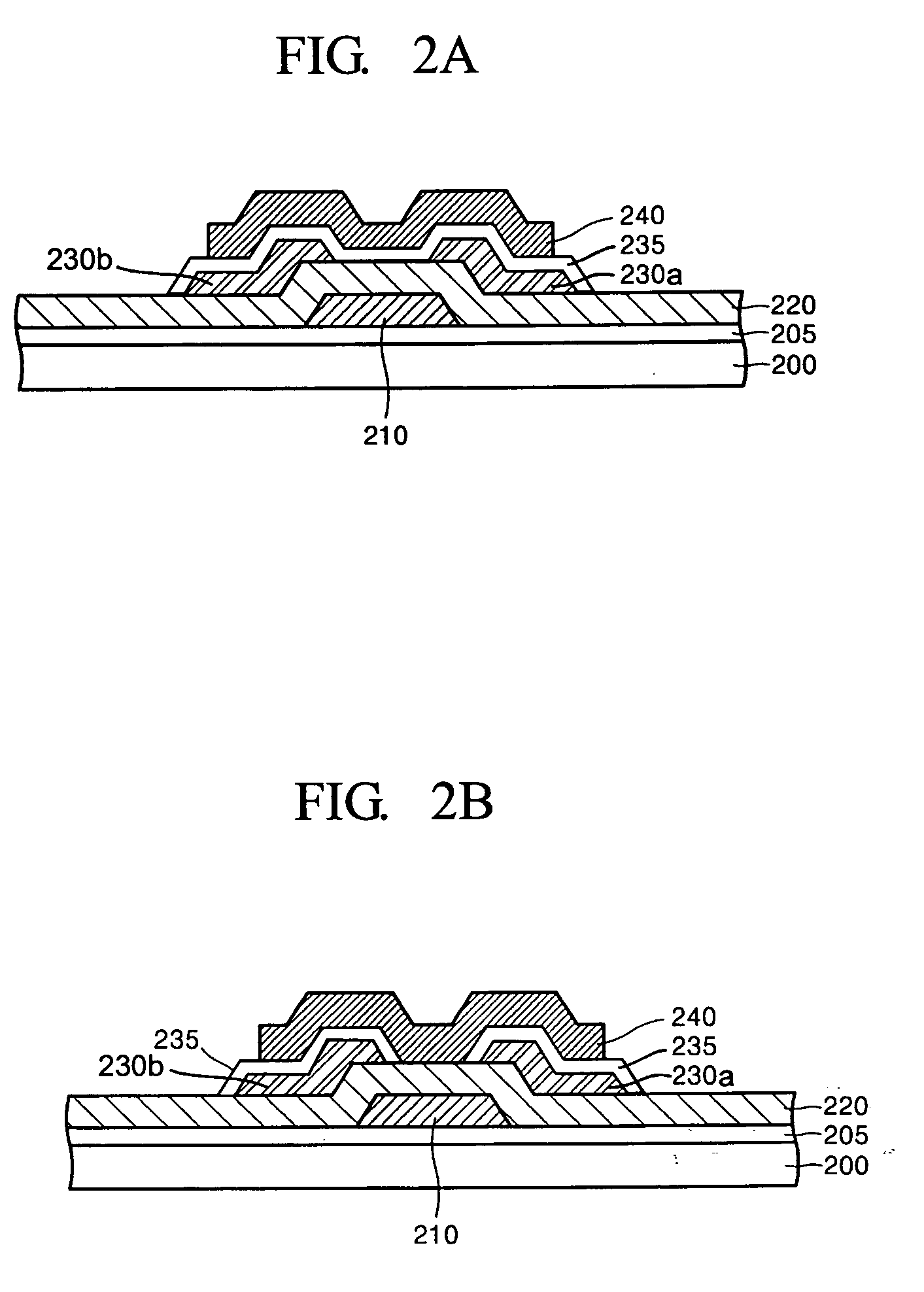

Thin film transistor, method of manufacturing the same, and flat panel display device haviing the same

InactiveUS20090315026A1Good ohmic contactLower Schottky Barrier HeightTransistorNon-linear opticsOhmic contactEngineering

A thin film transistor, a method of manufacturing the same, and a flat panel display device having the same use an oxide semiconductor as an active layer, wherein the thin film transistor includes: an oxide semiconductor layer formed on a substrate and having a channel region, a source region, and a drain region; a gate electrode insulated from the oxide semiconductor layer by a gate insulating layer; an ohmic contact layer formed on the source region and the drain region of the oxide semiconductor layer; and a source electrode and a drain electrode coupled to the source region and the drain region through the ohmic contact layer, the ohmic contact layer being formed of a metal having a lower work function lower than work functions of the source electrode and the drain electrode.

Owner:SAMSUNG DISPLAY CO LTD

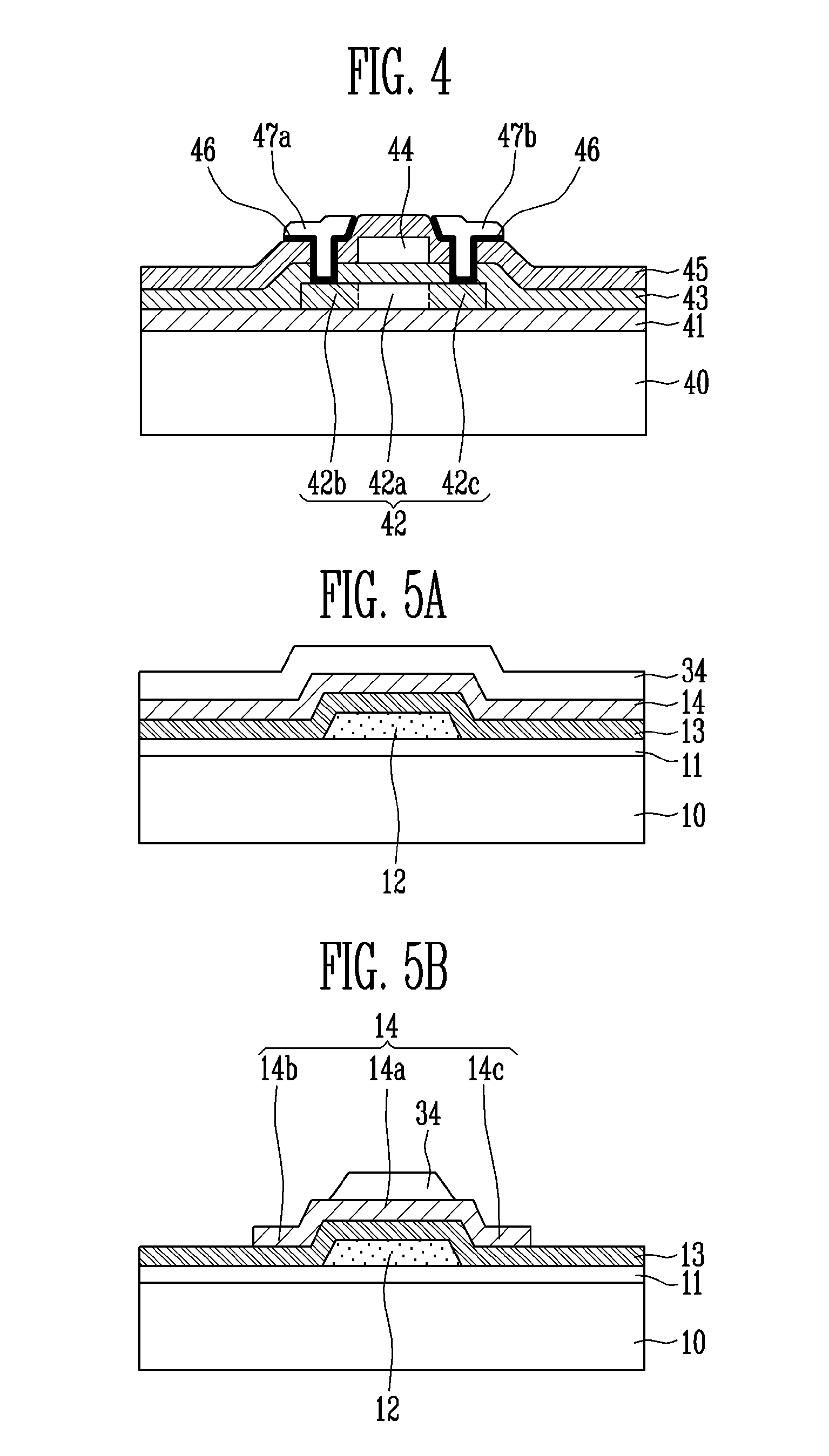

Semiconductor device and method for manufacturing the same

ActiveUS20110084272A1Excellent electrical propertiesLower resistanceElectroluminescent light sourcesSolid-state devicesPower semiconductor deviceSemiconductor

An object is to provide a thin film transistor having favorable electric characteristics and a semiconductor device including the thin film transistor as a switching element. The thin film transistor includes a gate electrode formed over an insulating surface, a gate insulating film over the gate electrode, an oxide semiconductor film which overlaps with the gate electrode over the gate insulating film and which includes a layer where the concentration of one or a plurality of metals contained in the oxide semiconductor is higher than that in other regions, a pair of metal oxide films formed over the oxide semiconductor film and in contact with the layer, and a source electrode and a drain electrode in contact with the metal oxide films. The metal oxide films are formed by oxidation of a metal contained in the source electrode and the drain electrode.

Owner:SEMICON ENERGY LAB CO LTD

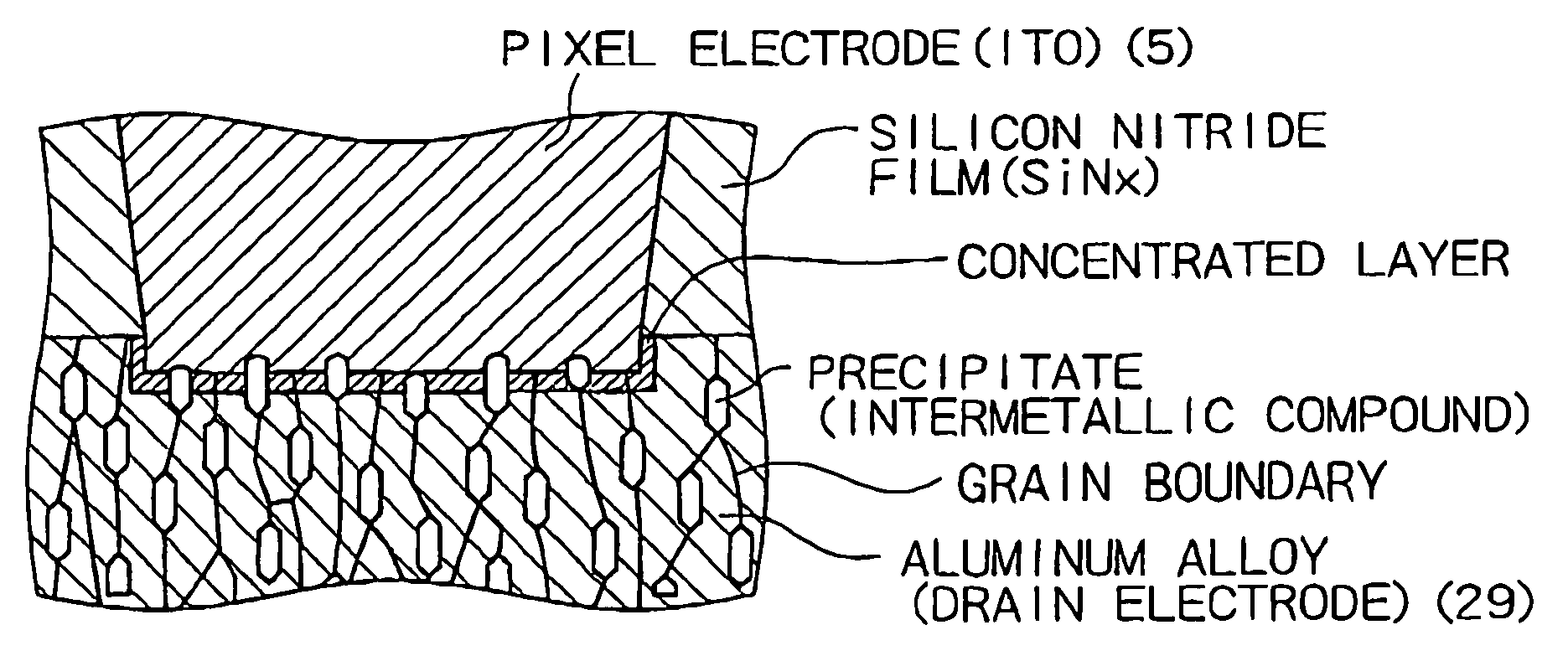

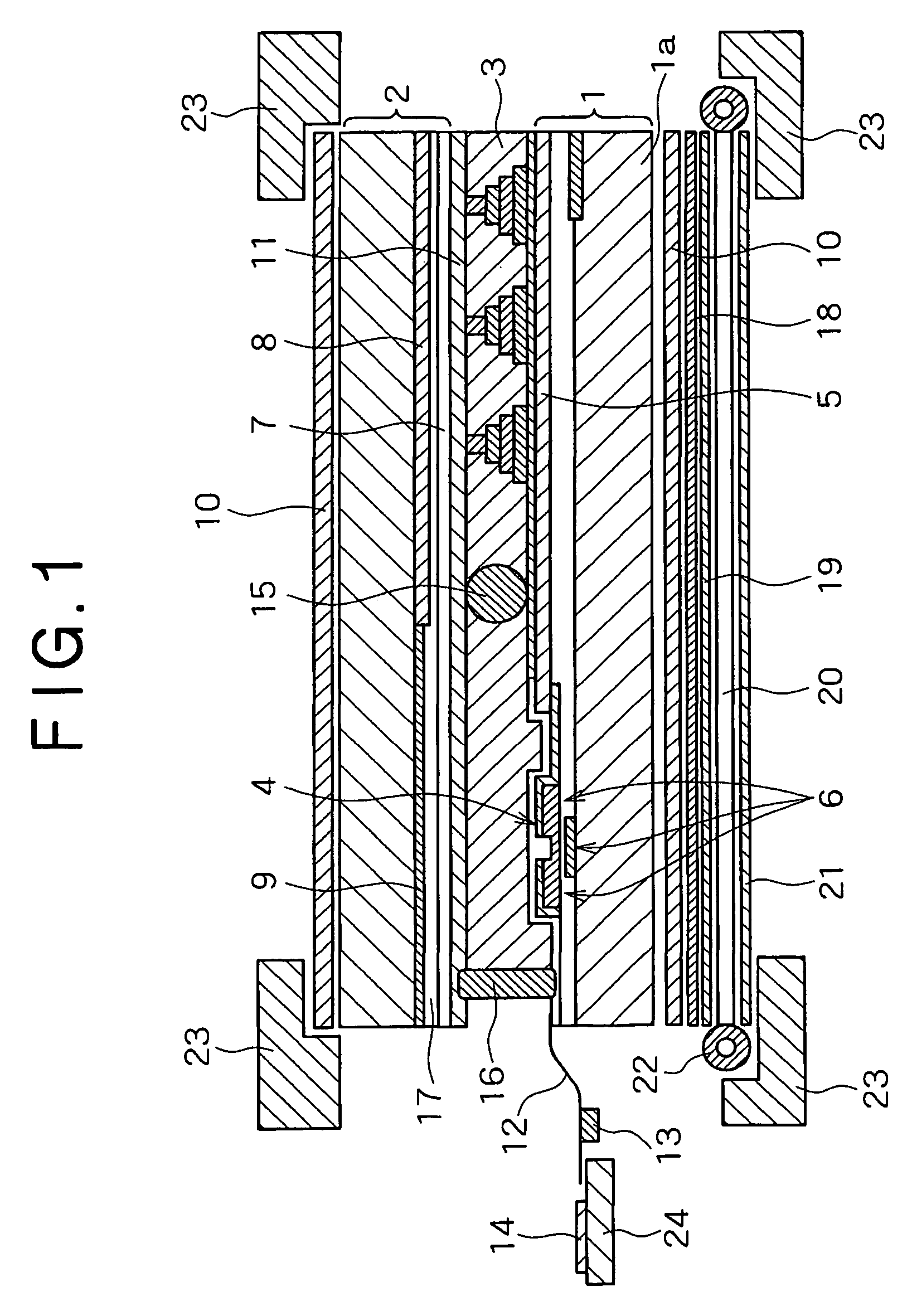

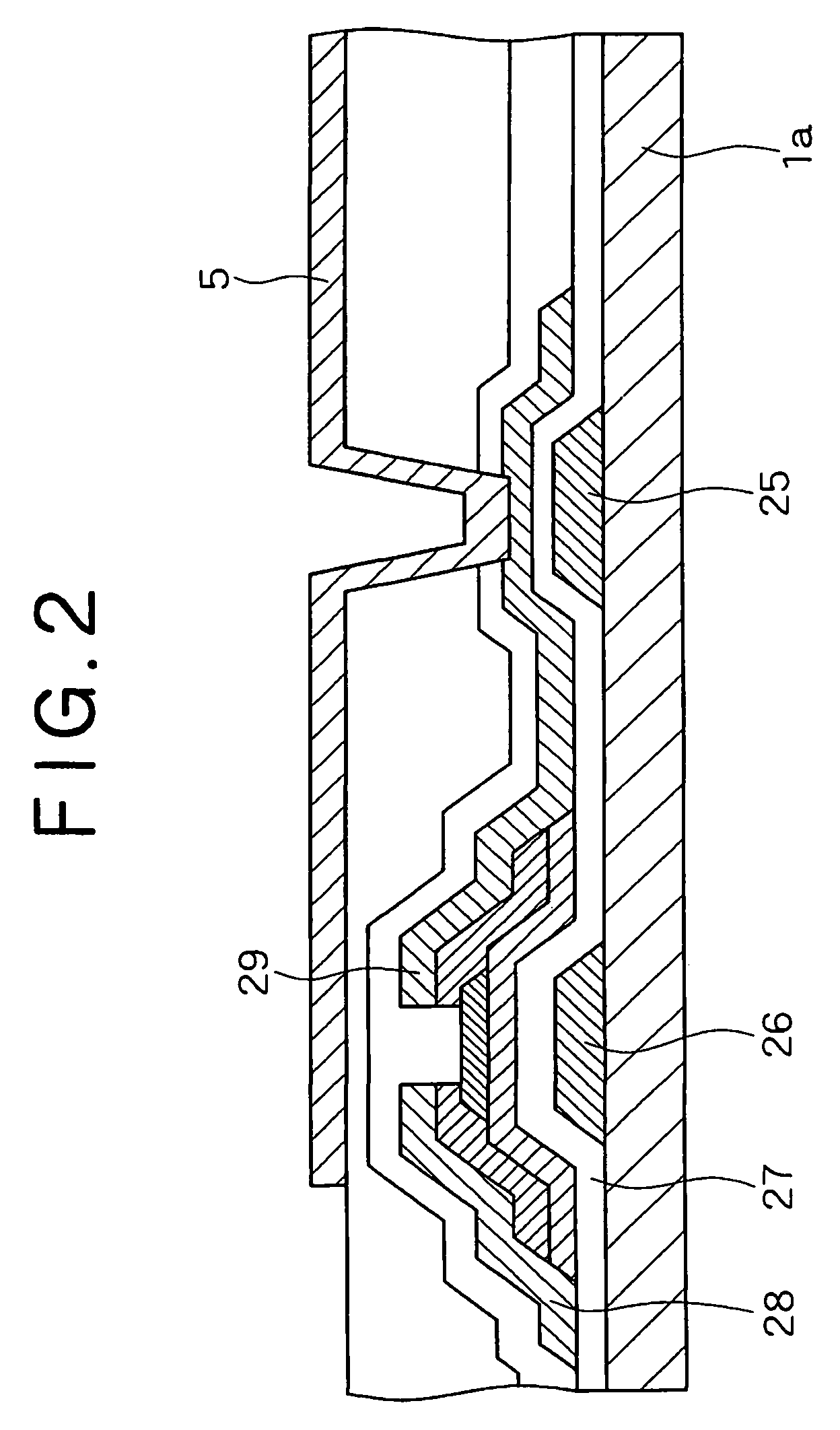

Electronic device, method of manufacture of the same, and sputtering target

InactiveUS7098539B2Simplification of processImprove electrical performancePig casting plantsSemiconductor/solid-state device detailsManufacturing technologyMetal

In an electronic device comprising a first electrodes consisting of a metal oxide and a second electrode consisting of an aluminum alloy film directly contacted and electrically connected to the first electrode, the contact interface between the aluminum alloy film and the first electrode is constructed so that at least a part of alloy components constituting the aluminum alloy film exist as a precipitate or concentrated layer. This construction enables direct contact between the aluminum alloy film and the electrode consisting of a metallic oxide and allows elimination of a barrier metal in such an electronic device, and manufacturing technology therefor.

Owner:KOBE STEEL LTD

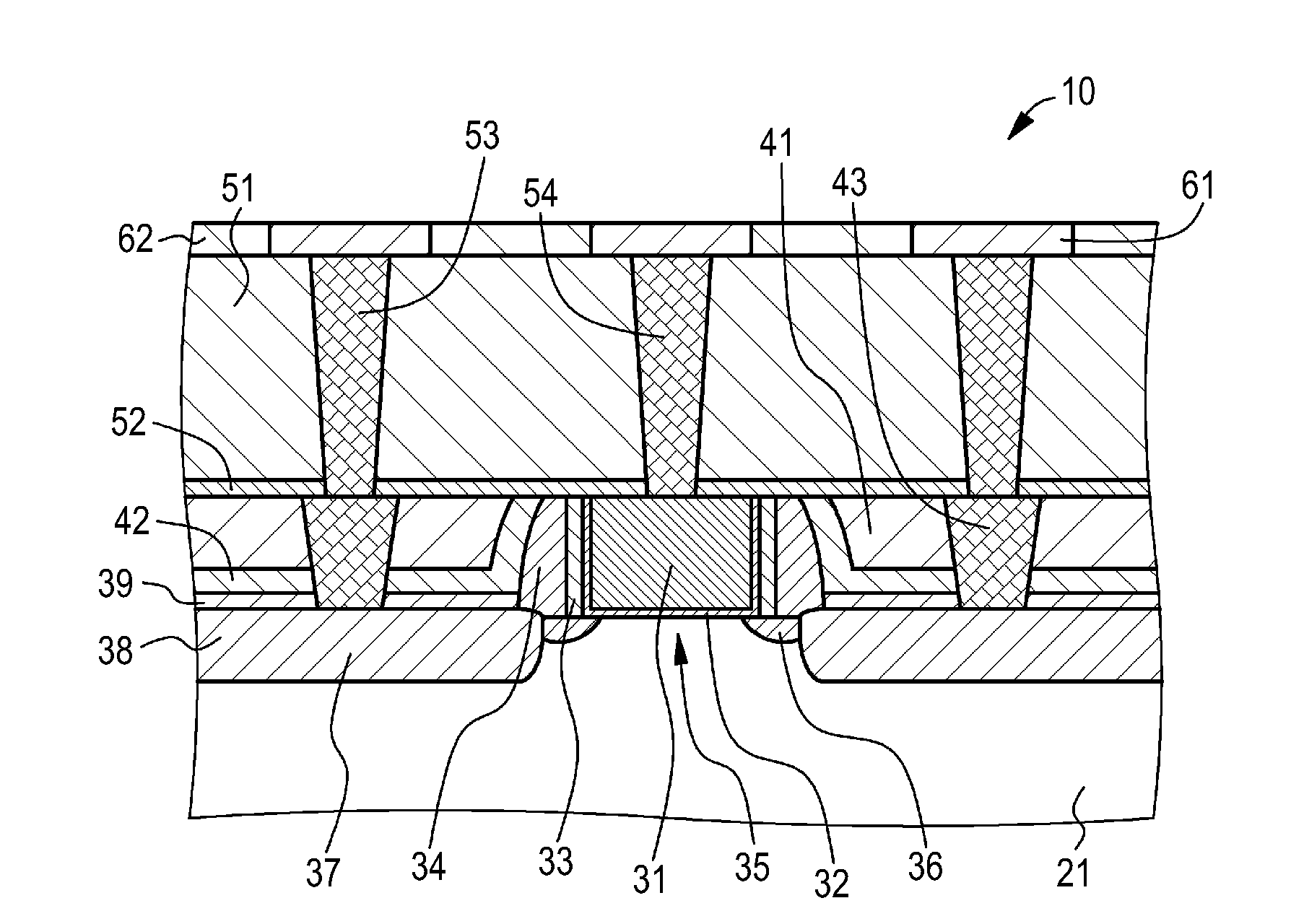

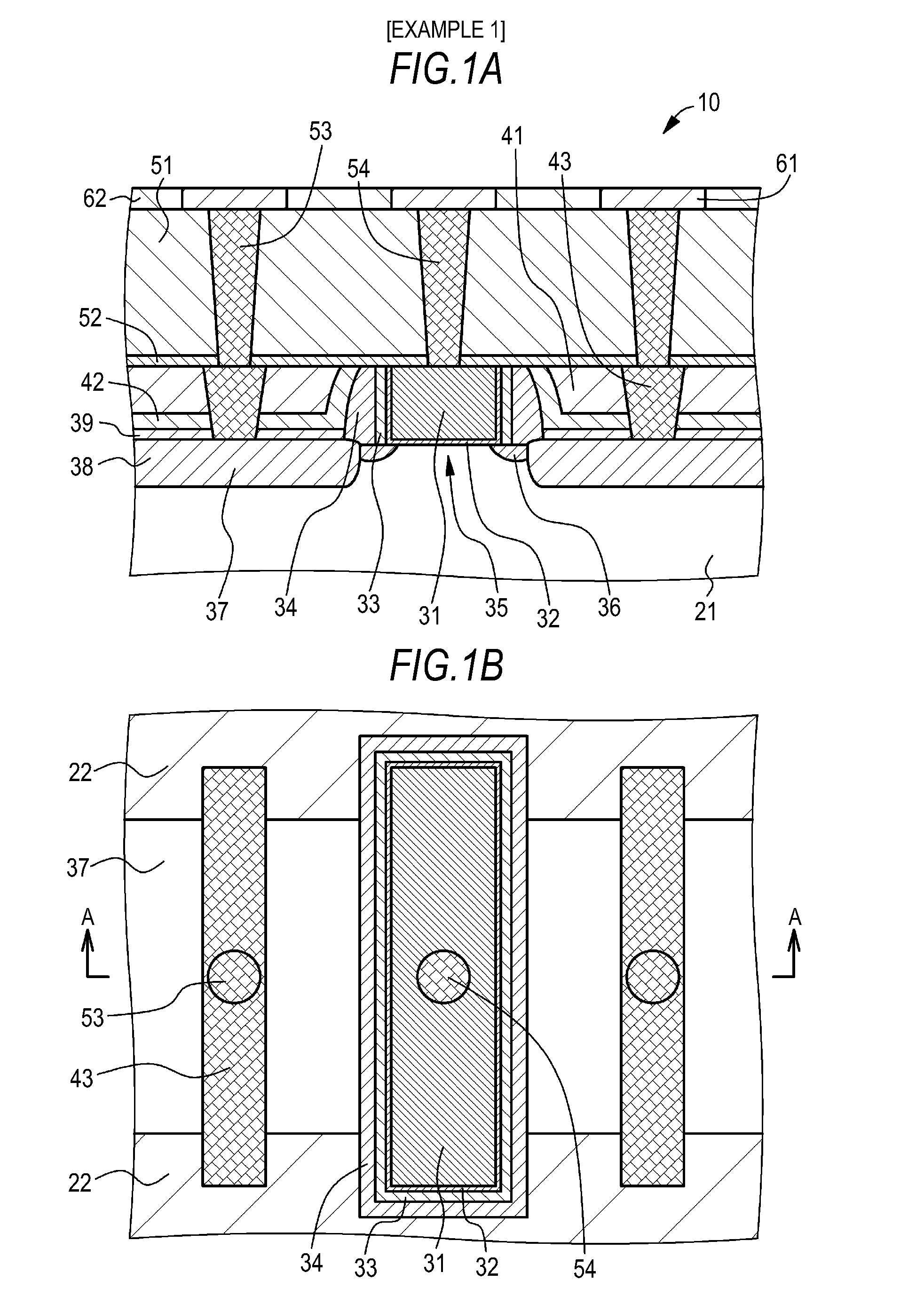

Semiconductor device and method for manufacturing the same

ActiveUS20110042752A1Reduce contact resistanceExtend long distanceTransistorSemiconductor/solid-state device detailsSemiconductor device modelingSemiconductor

A method for manufacturing a semiconductor device includes the steps of: (a) forming a gate electrode on a substrate, forming source / drain regions and a channel forming region in the substrate, and forming on the source / drain regions a first interlayer insulating layer equal in height to the gate electrode; (b) forming in the first interlayer insulating layer groove-shaped first contact portions connected to the source / drain regions; (c) forming a second interlayer insulating layer on a whole surface; (d) forming hole-shaped second contact portions in portions of the second interlayer insulating layer on the first contact portion; and (e) forming on the second interlayer insulating layer wires connected to the second contact portions.

Owner:SONY CORP

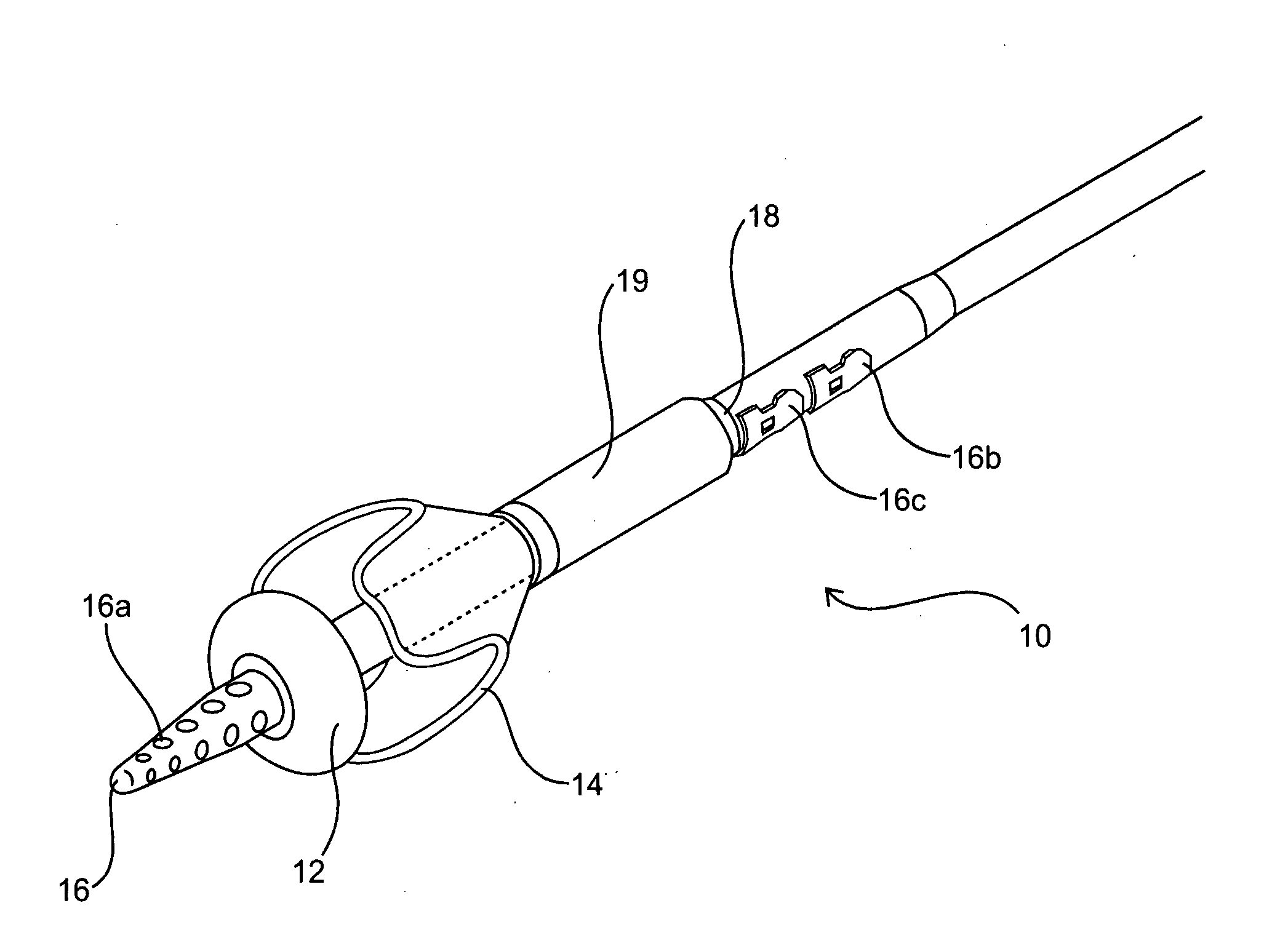

Devices and methods for percutaneously treating aortic valve stenosis

InactiveUS20050054977A1Increasing aortic valve flowContact resistanceStentsBalloon catheterAortic valve flowBiomedical engineering

Devices and methods for their use in percutaneously increasing the aortic valve flow of a stenotic aortic valve are provided. The subject devices include an aortic valve isolation element, a shunt element and an aortic valve flushing element. Also provided are systems and kits that include the subject devices and can be employed in practicing the subject methods. The subject devices, methods, systems and kits find use in treating conditions associated with the presence of stenotic aortic valves.

Owner:CORDIS CORP

Organic thin film transistor including organic acceptor film

InactiveUS20050242342A1Increase charge mobilityContact resistanceTransistorSolid-state devicesOrganic filmOrganic semiconductor

An organic thin film transistor (TFT) includes: an organic semiconductor film; source and drain electrodes electrically connected to the organic semiconductor film; a gate electrode electrically insulated from the source and drain electrodes and the organic semiconductor film; and an organic acceptor film interposed between the source and drain electrodes and the organic semiconductor film.

Owner:SAMSUNG DISPLAY CO LTD

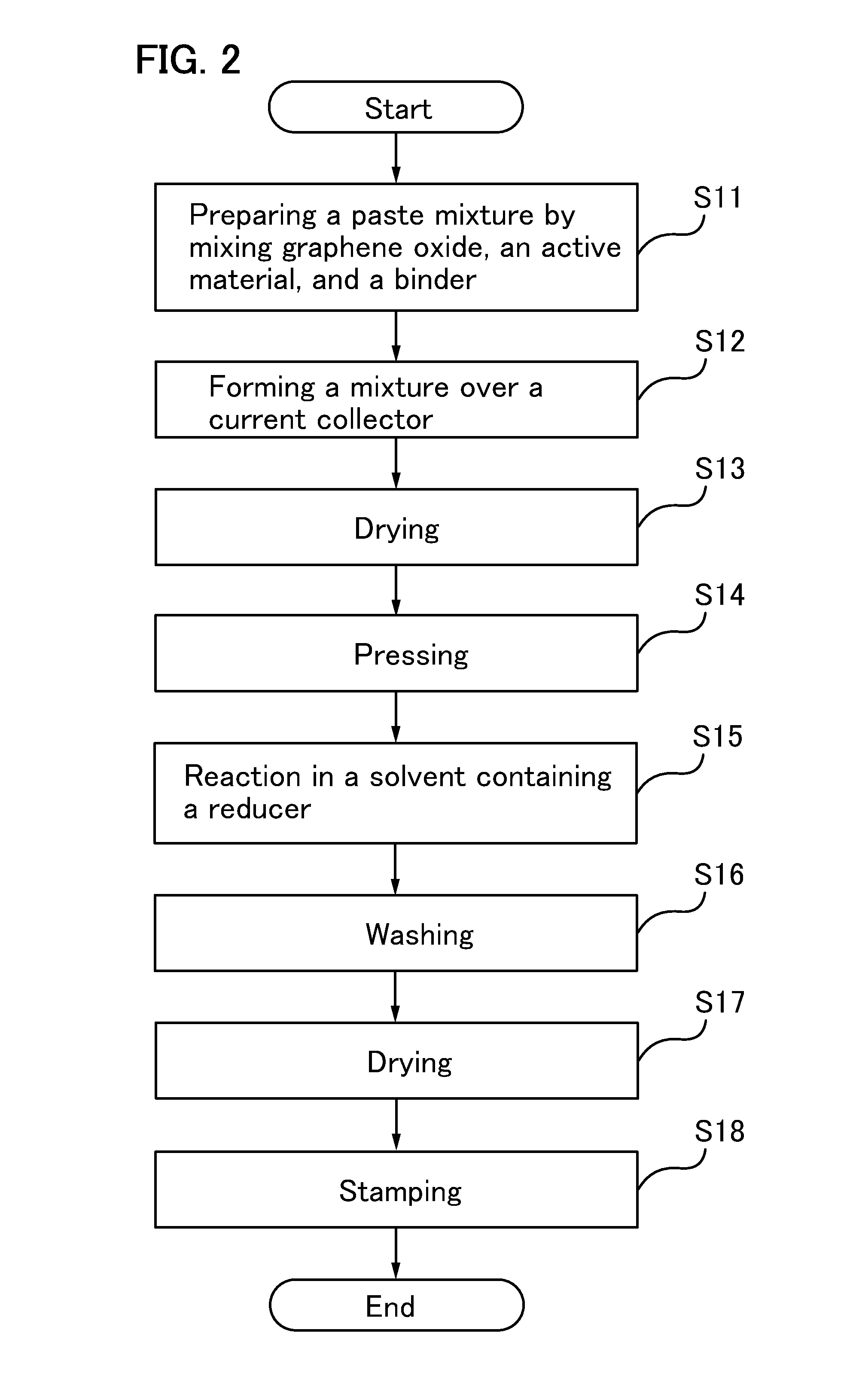

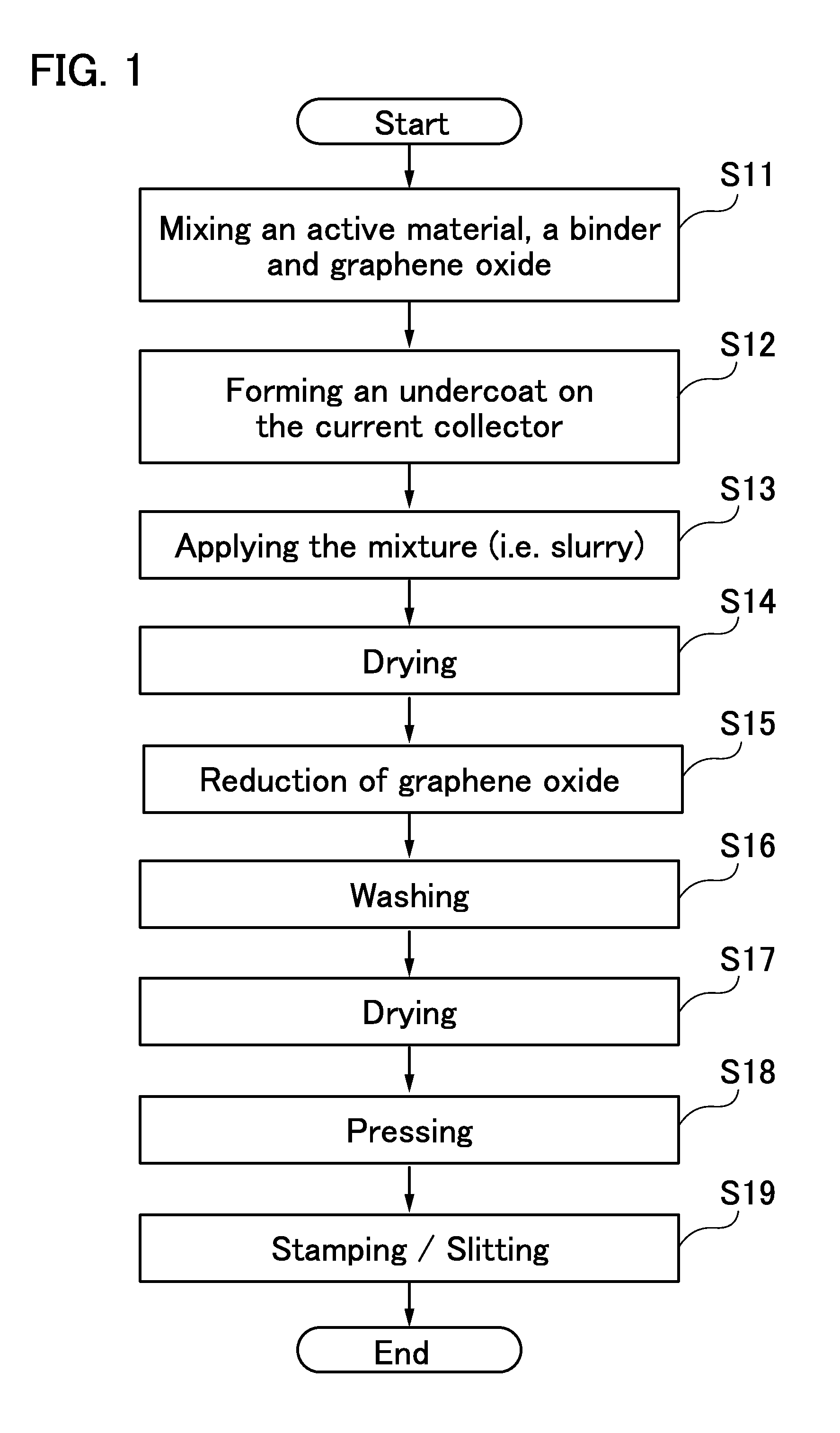

Method for manufacturing storage battery electrode, storage battery electrode, storage battery, and electronic device

ActiveUS20130337320A1High densityReduce electrical conductivityElectrode rolling/calenderingElectrode thermal treatmentSolventElectron

To provide a method for forming a storage battery electrode including an active material layer with high density in which the proportion of conductive additive is low and the proportion of the active material is high. To provide a storage battery having a higher capacity per unit volume of an electrode with the use of a storage battery electrode formed by the formation method. A method for forming a storage battery electrode includes the steps of forming a mixture including an active material, graphene oxide, and a binder; providing a mixture over a current collector; and immersing the mixture provided over the current collector in a polar solvent containing a reducer, so that the graphene oxide is reduced.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device and method for manufacturing the semiconductor device

ActiveUS20100117086A1Contact resistanceImprove featuresTransistorSolid-state devicesSemiconductorSemiconductor device

An object is to suppress deterioration of element characteristics even when an oxide semiconductor is formed after a gate insulating layer, a source electrode layer, and a drain electrode layer are formed. A gate electrode layer is formed over a substrate. A gate insulating layer is formed over the gate electrode layer. A source electrode layer and a drain electrode layer are formed over the gate insulating layer. Surface treatment is performed on surfaces of the gate insulating layer, the source electrode layer, and the drain electrode layer which are formed over the substrate. After the surface treatment is performed, an oxide semiconductor layer is formed over the gate insulating layer, the source electrode layer, and the drain electrode layer.

Owner:SEMICON ENERGY LAB CO LTD

Slidable coupling components for shelf management systems

InactiveUS20070080126A1Enhanced couplingContact resistanceShow shelvesShow hangersCouplingFront edge

Self-fronting merchandise pusher systems. Numerous products in a store are merchandised on shelves and spring-biased pushers are used to urge products toward the front edge of the shelf on which the products are displayed and stored. Each pusher is generally mounted on a track, and each pusher track is generally positioned between two divider walls or between a divider wall and an end wall. Each pusher is independently biased towards the front of the shelf. The system provides an improved apparatus for coupling any of the longitudinal members, such as the pusher tracks, divider walls or integrated divider / pusher tracks, to the shelf-mounting member. The shelf-mounting member forms an alignment track for selective and slidable coupling with the longitudinal members. The coupling is designed to resist sliding when the coupling is under torque.

Owner:SEMASYS

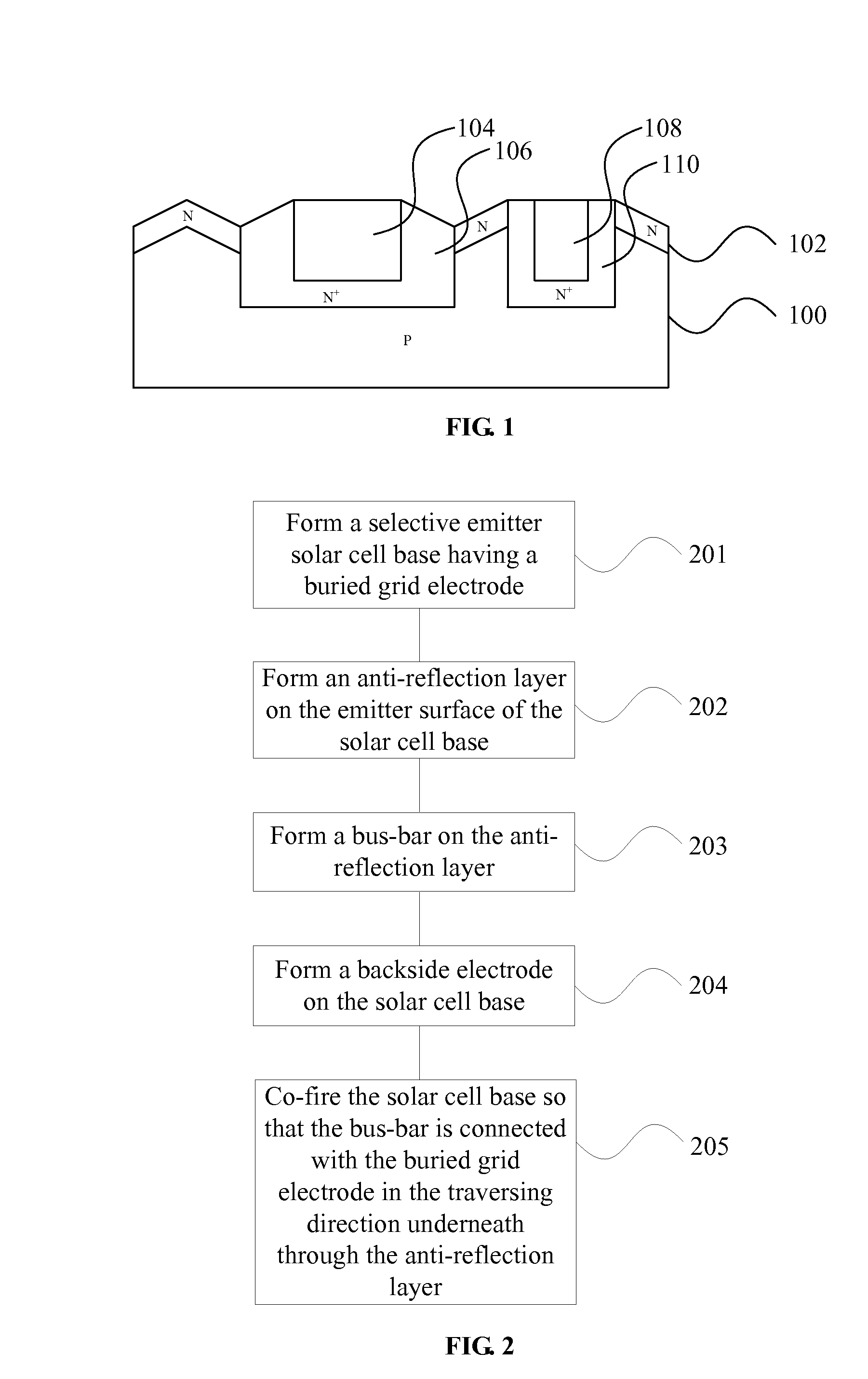

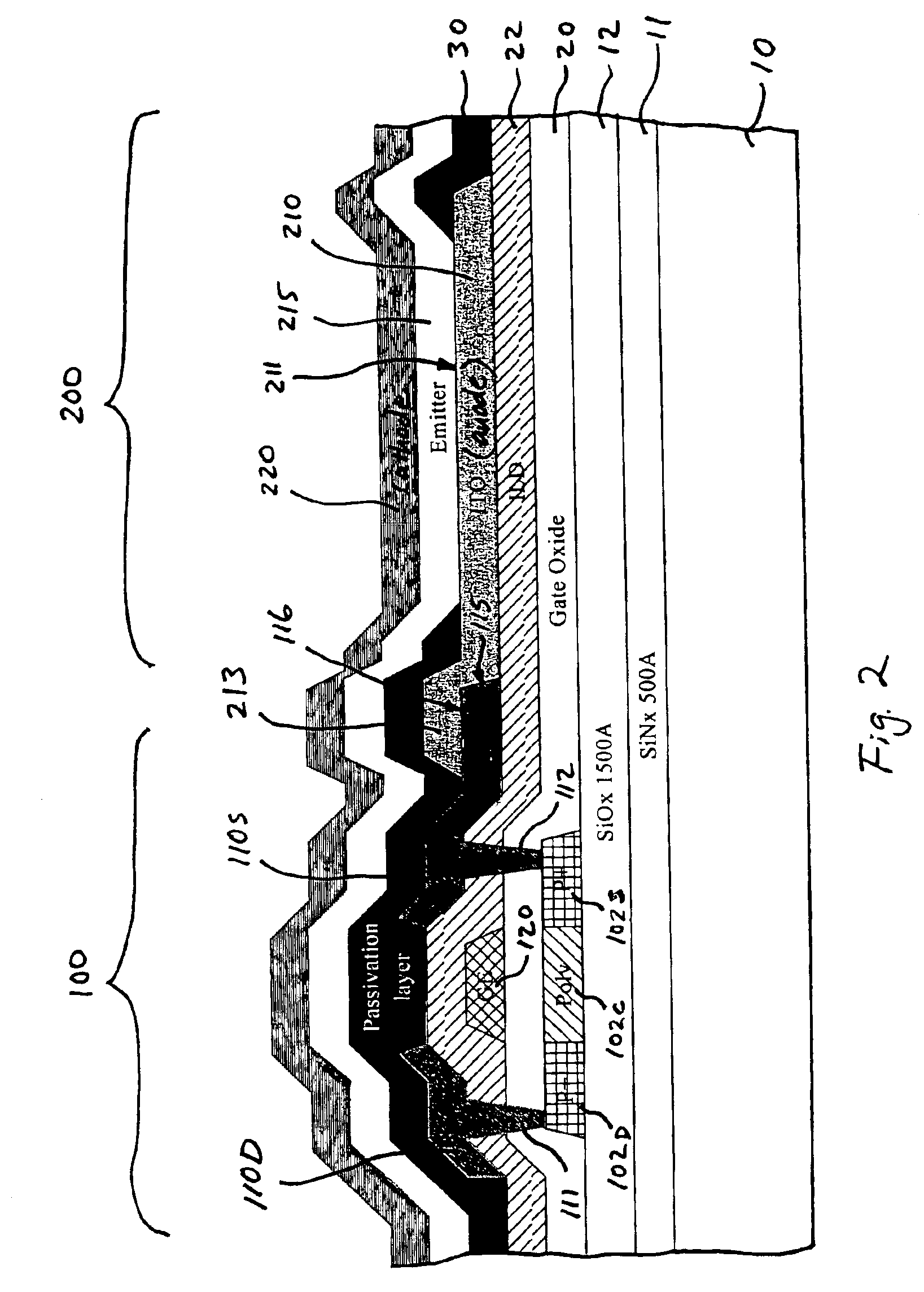

Selective Emitter Solar Cell and Fabrication Method Thereof

InactiveUS20100037952A1Improve conversion efficiencyReduce widthFinal product manufactureSemiconductor/solid-state device manufacturingTO-18Solar cell

A fabrication method of a selective emitter solar cell, including: forming a selective emitter solar cell base having a buried grid electrode; forming an anti-reflection layer on the emitter surface of the solar cell base; forming a bus-bar on the anti-reflection layer; and connecting the buried grid electrode with the bus-bar in the traversing direction underneath through the anti-reflection layer. Accordingly, the invention provides a selective emitter solar cell. With the method of the invention, emitters and bus-bars are made separately, the width of the emitters can be reduced according to actual needs, the area that is unnecessarily taken may be reduced, the effective area for a solar cell panel to receive sunlight may be increased. The invention improves conversion efficiency of a selective emitter solar cell panel from 16.5% to 18% or more.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

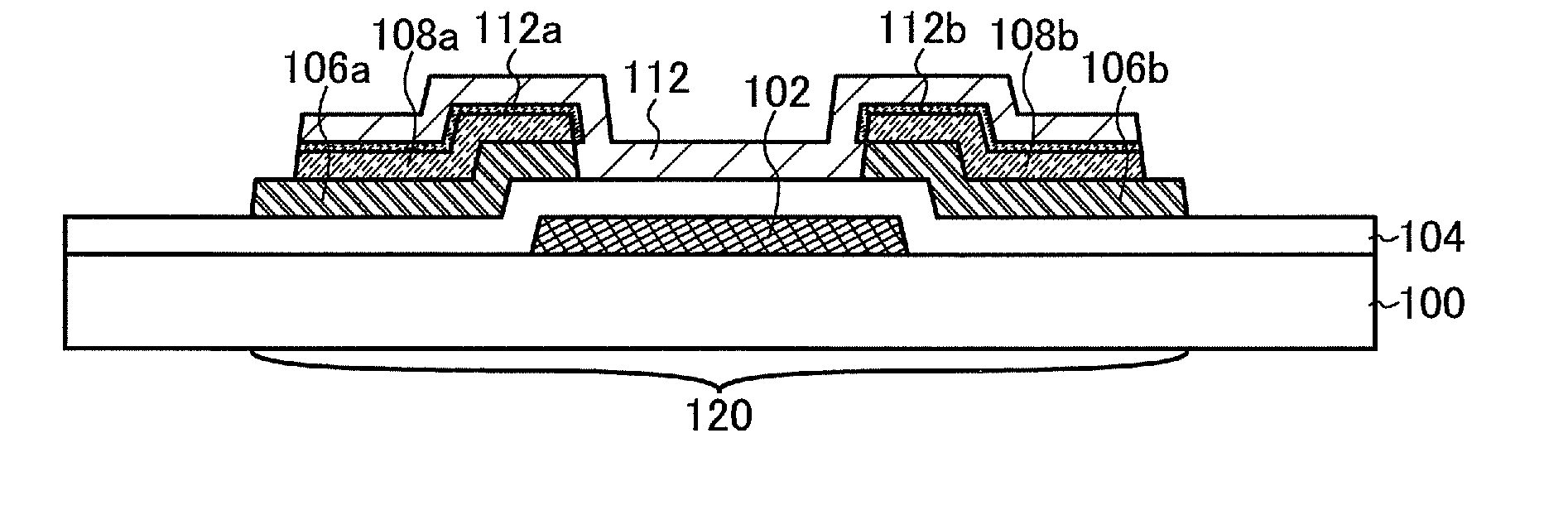

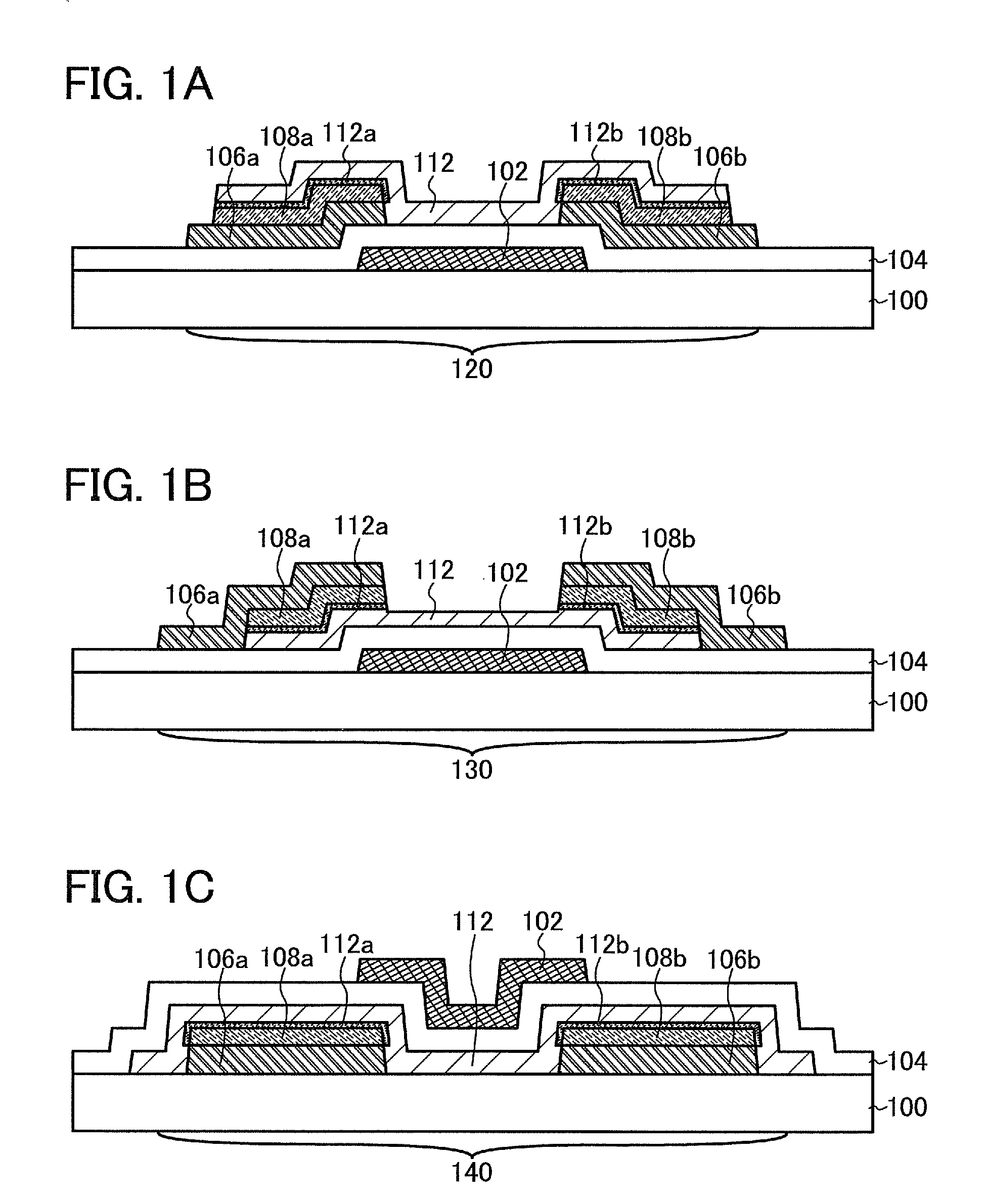

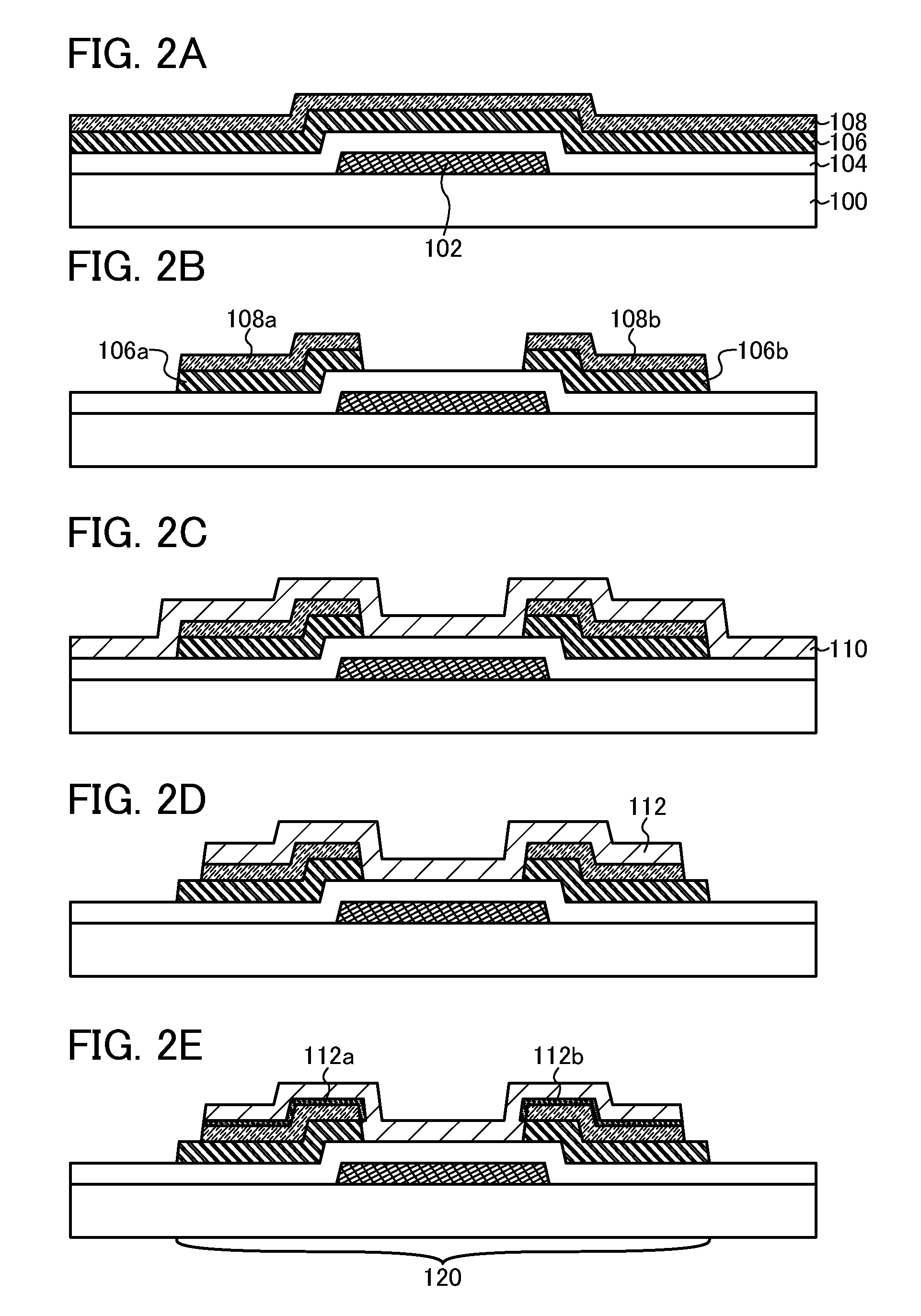

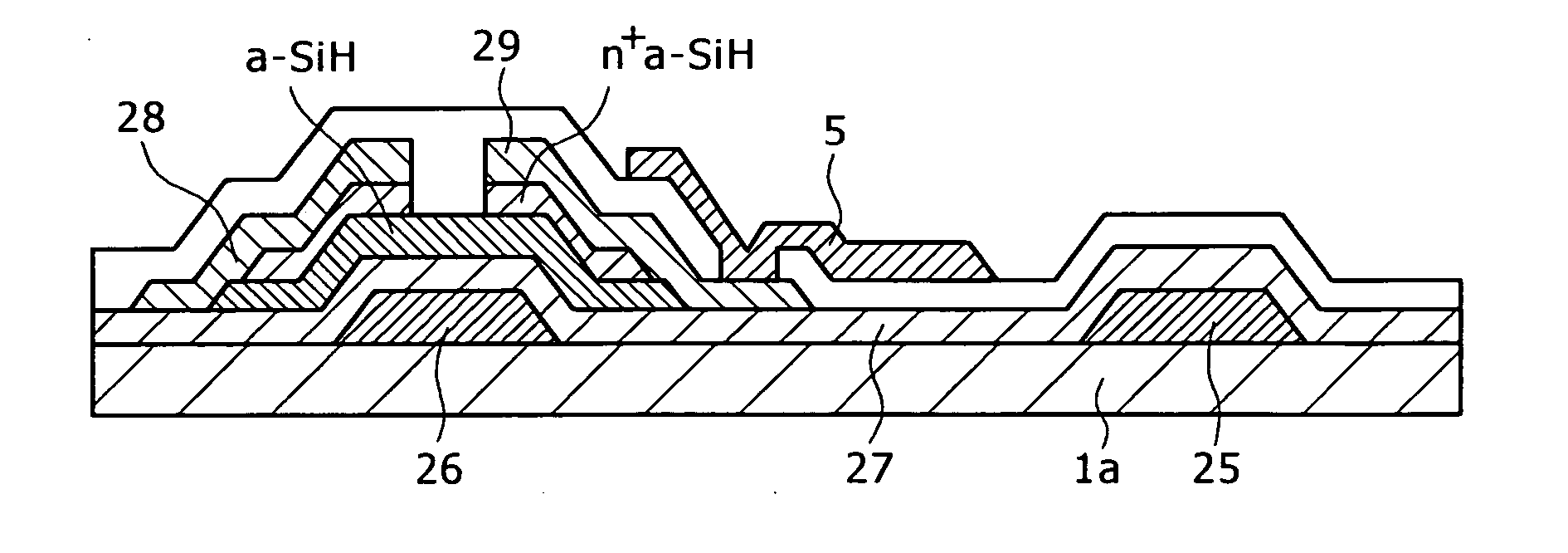

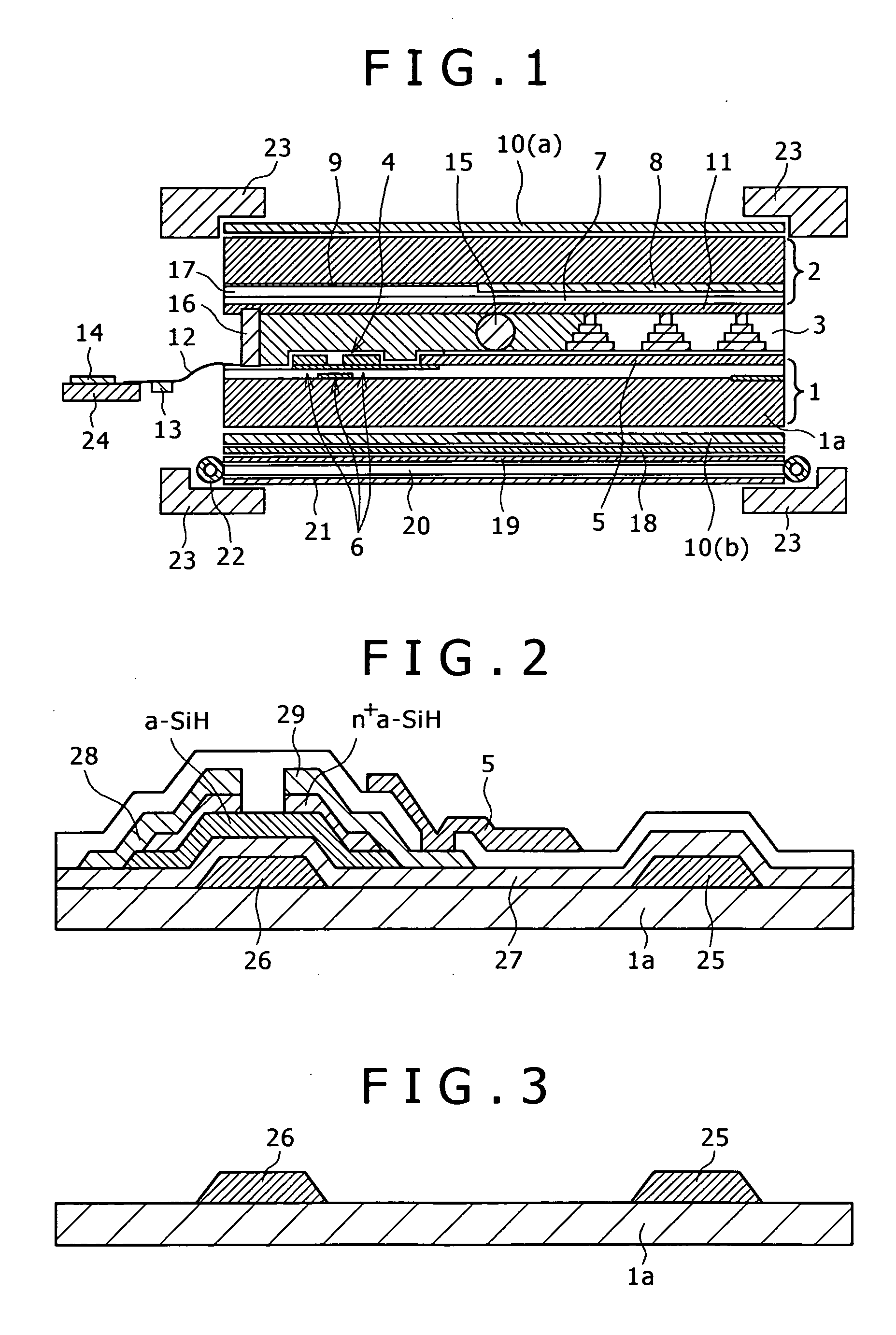

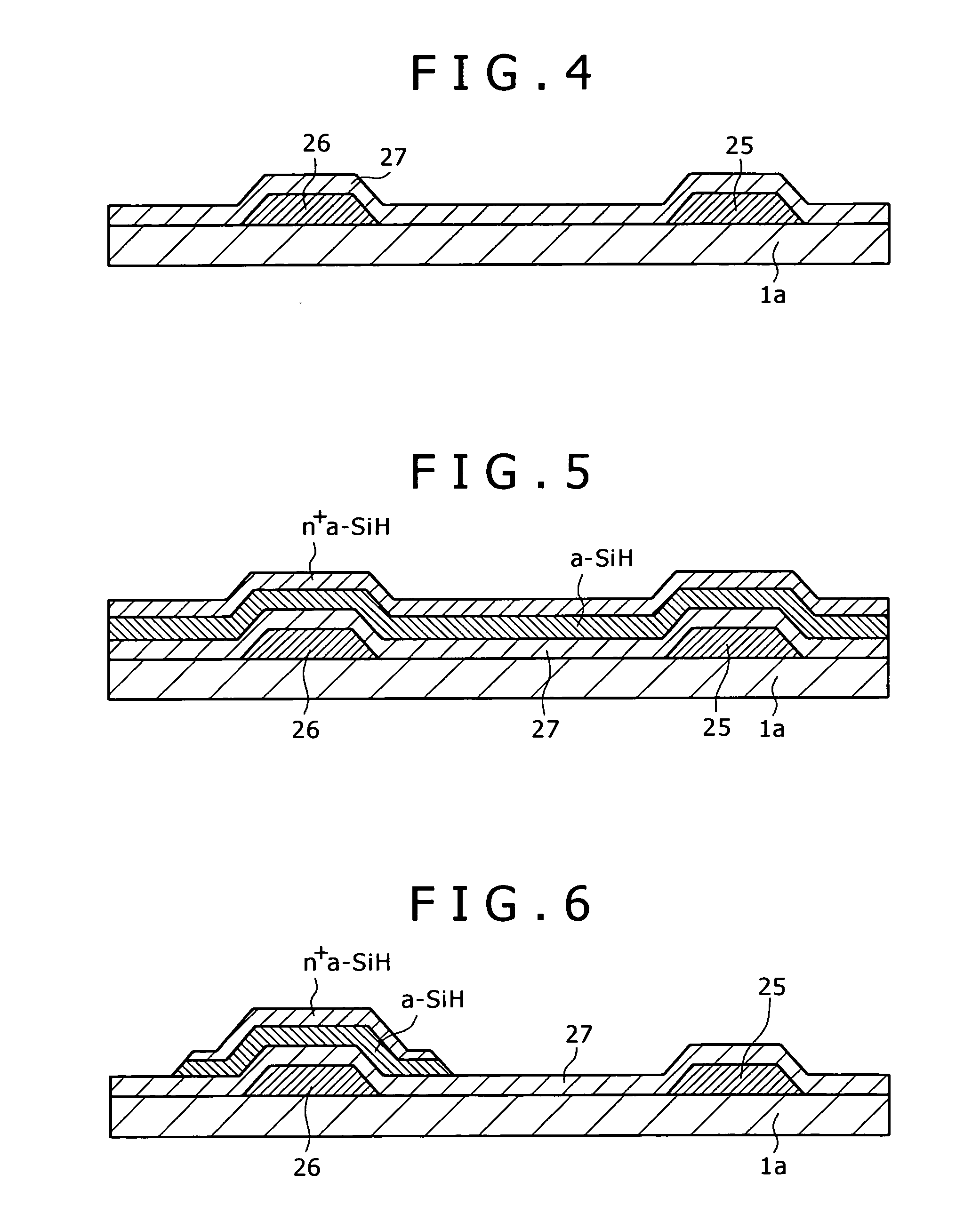

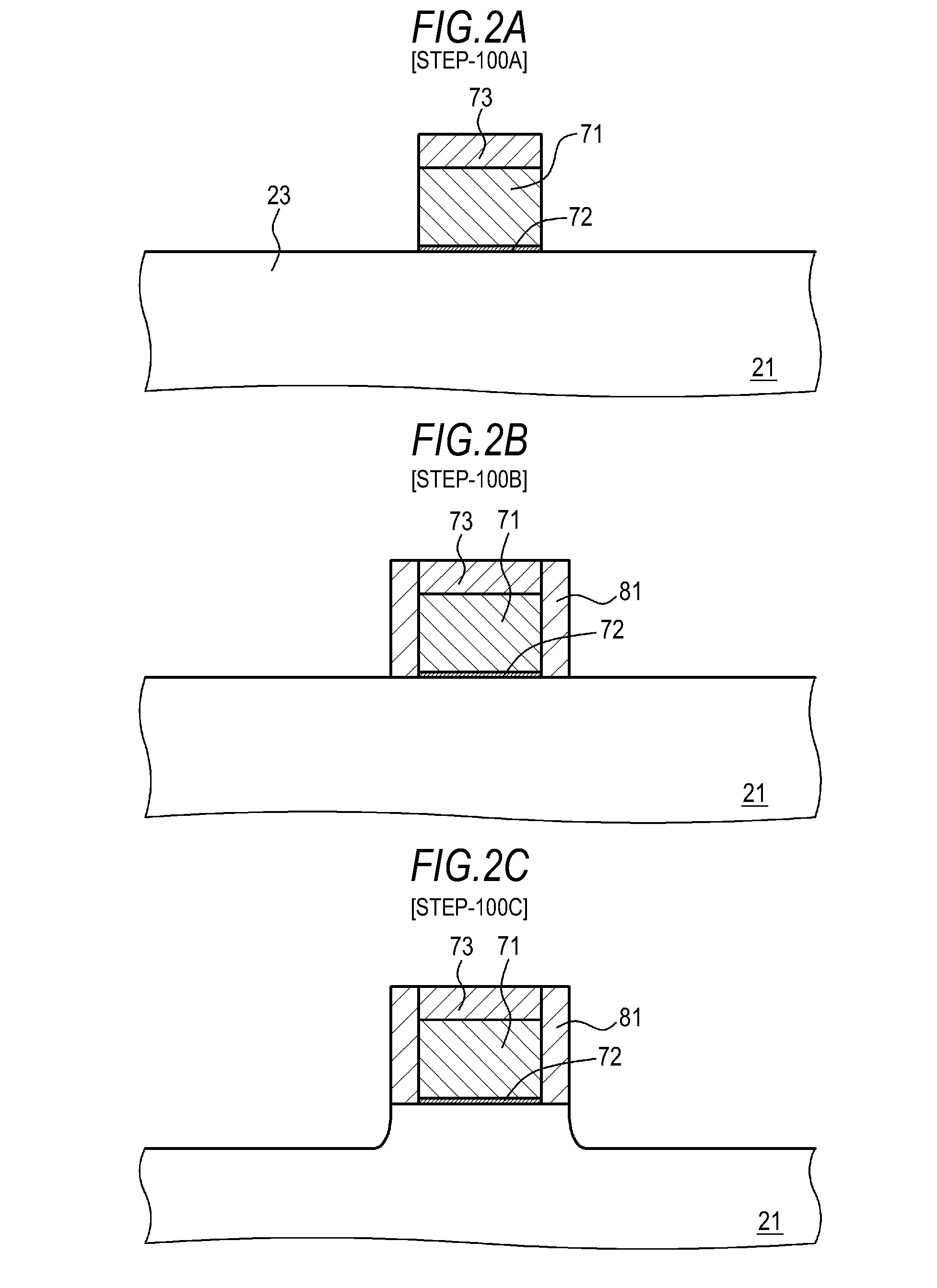

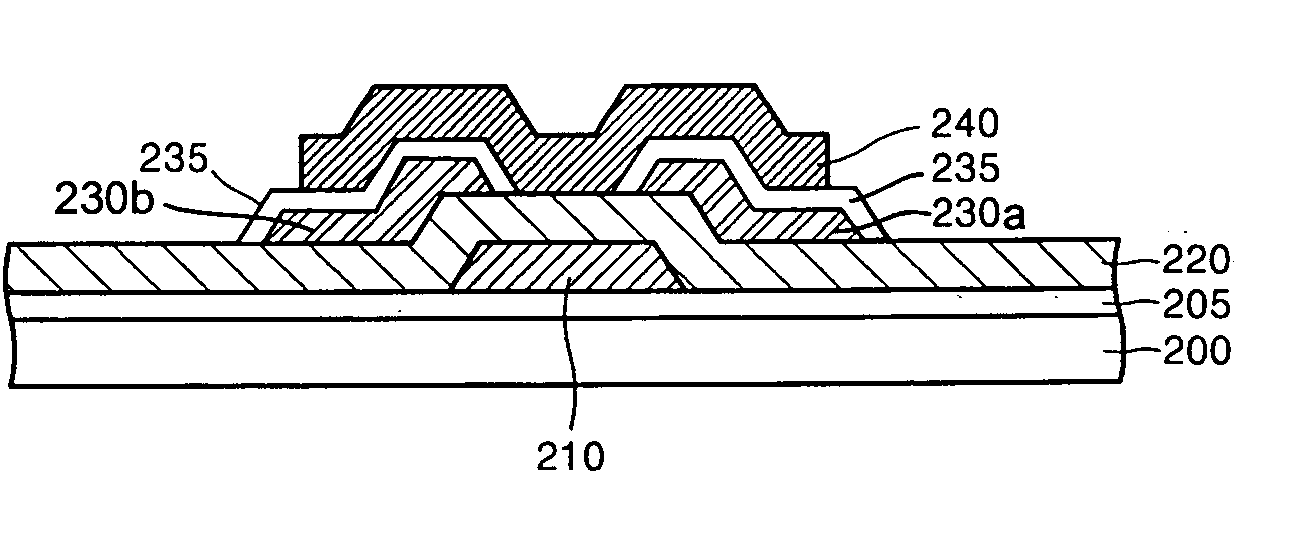

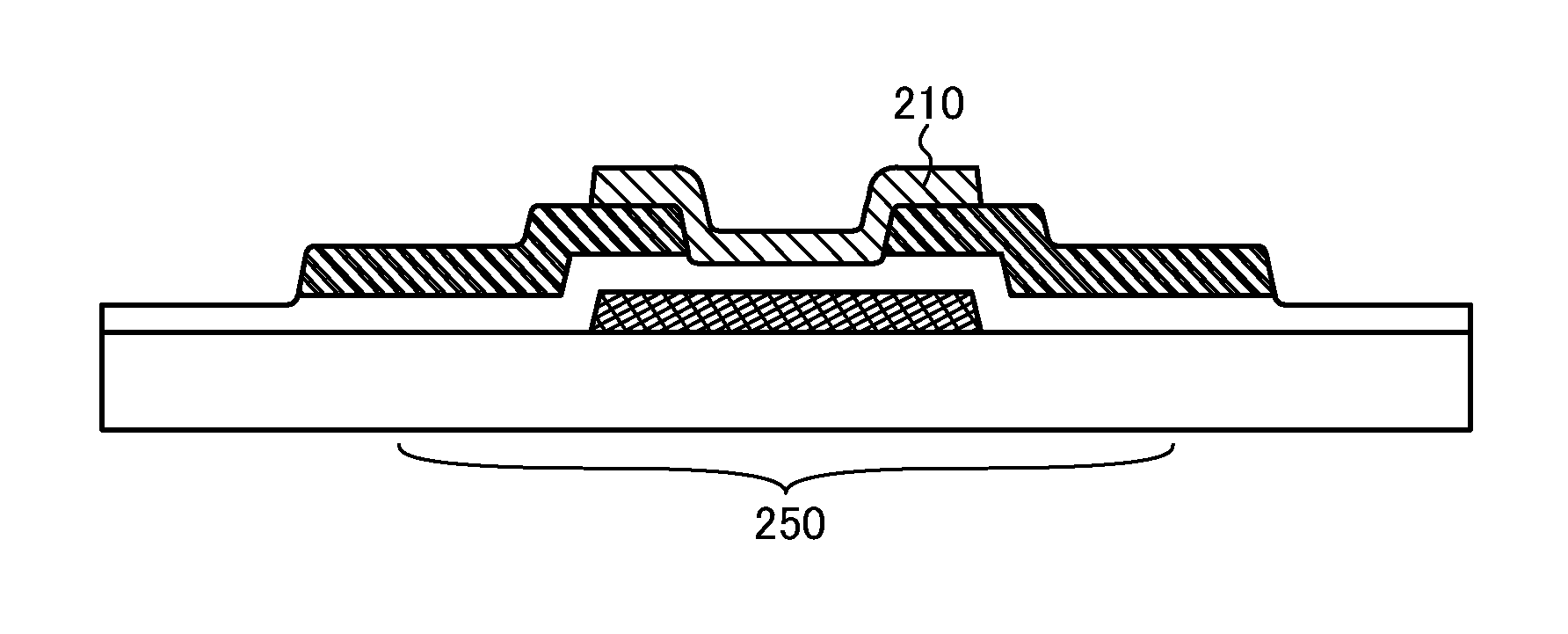

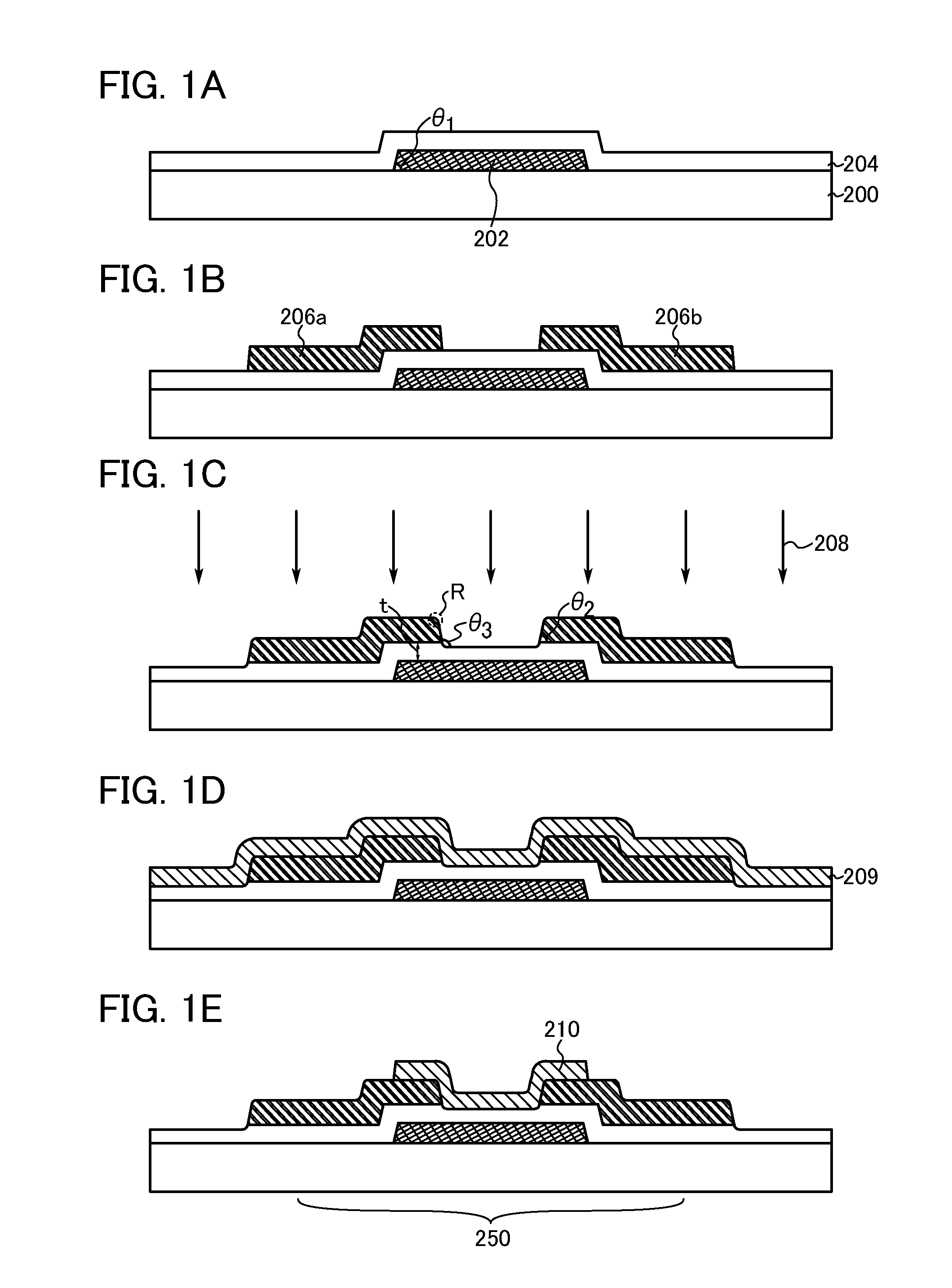

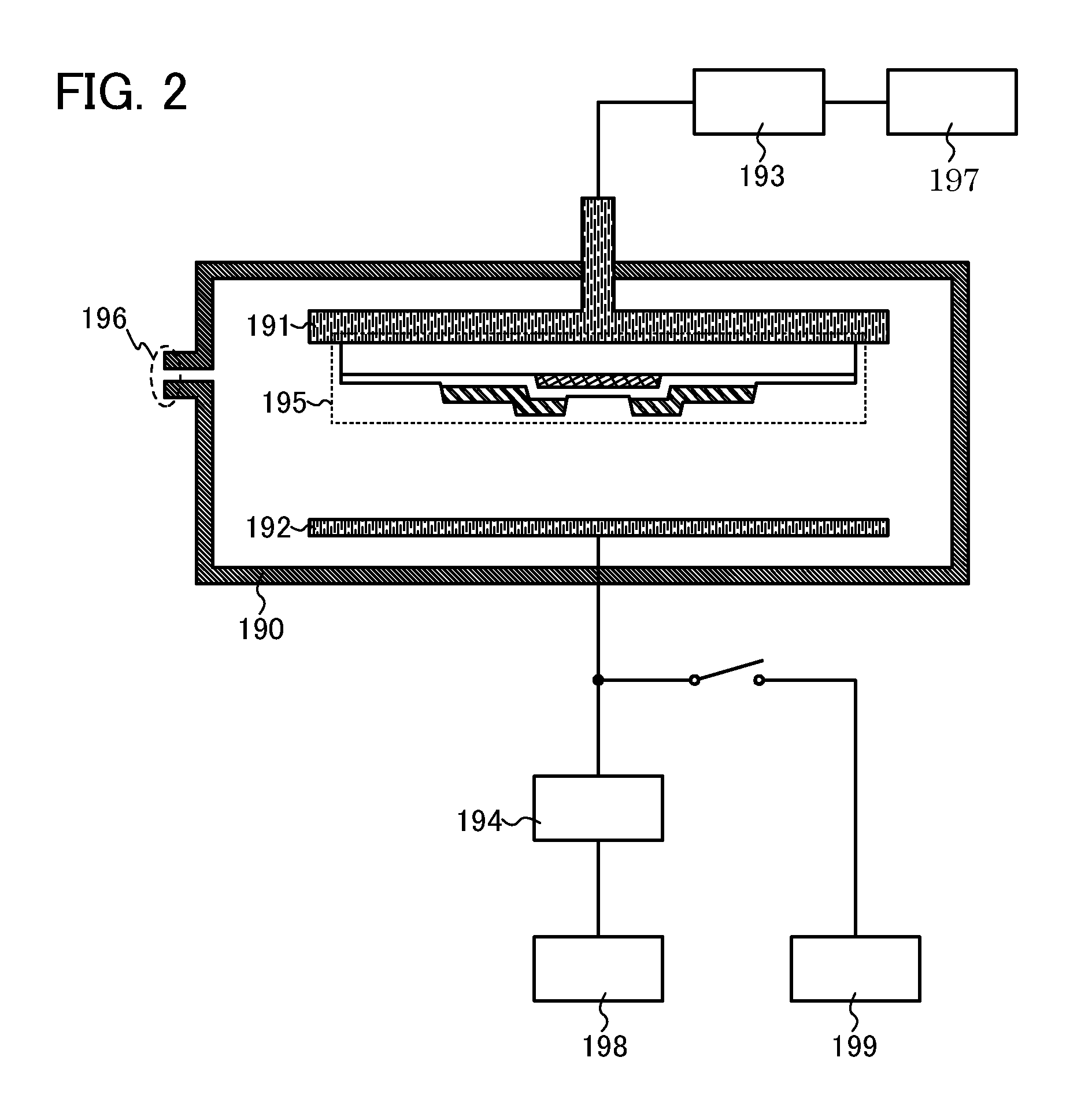

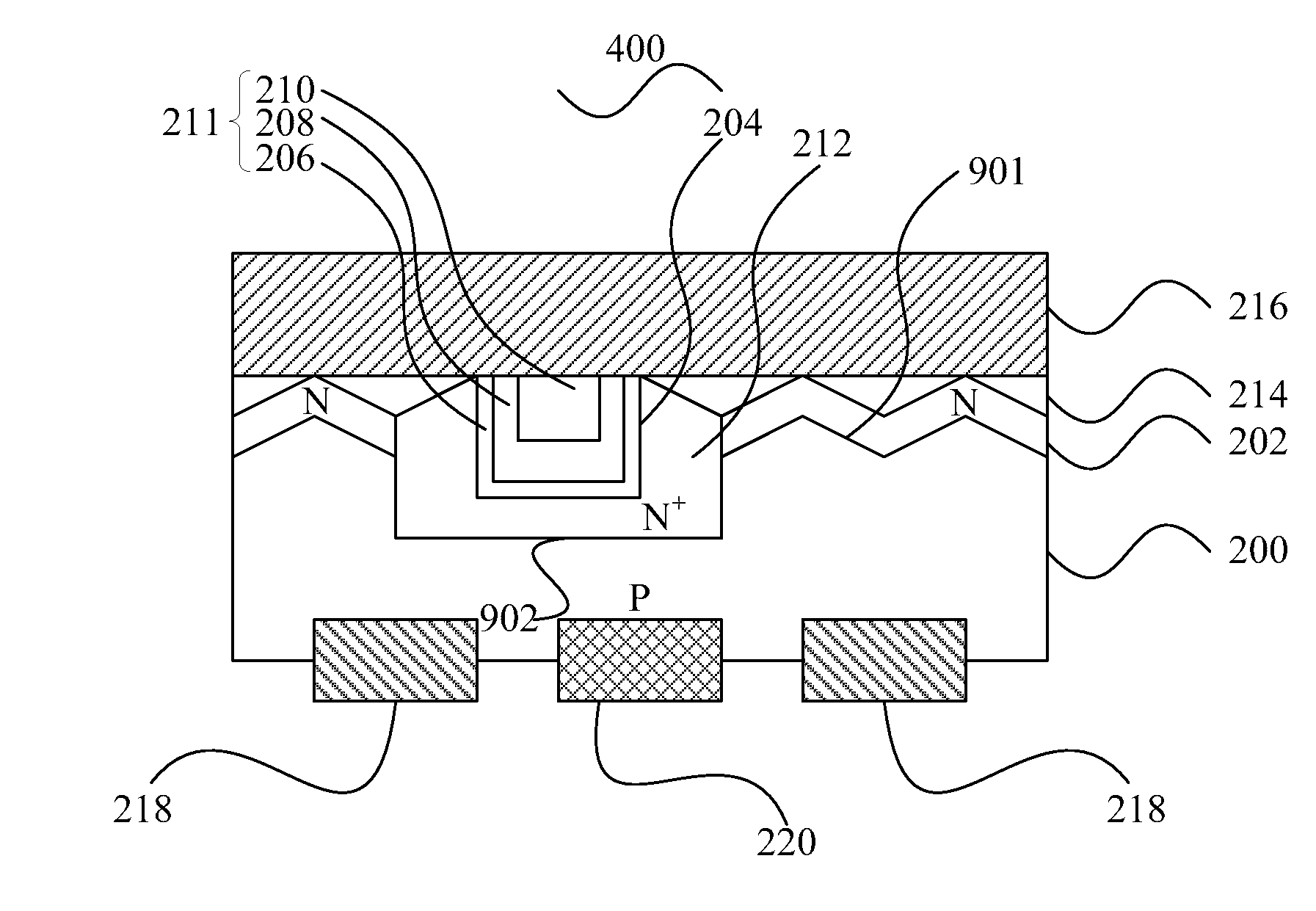

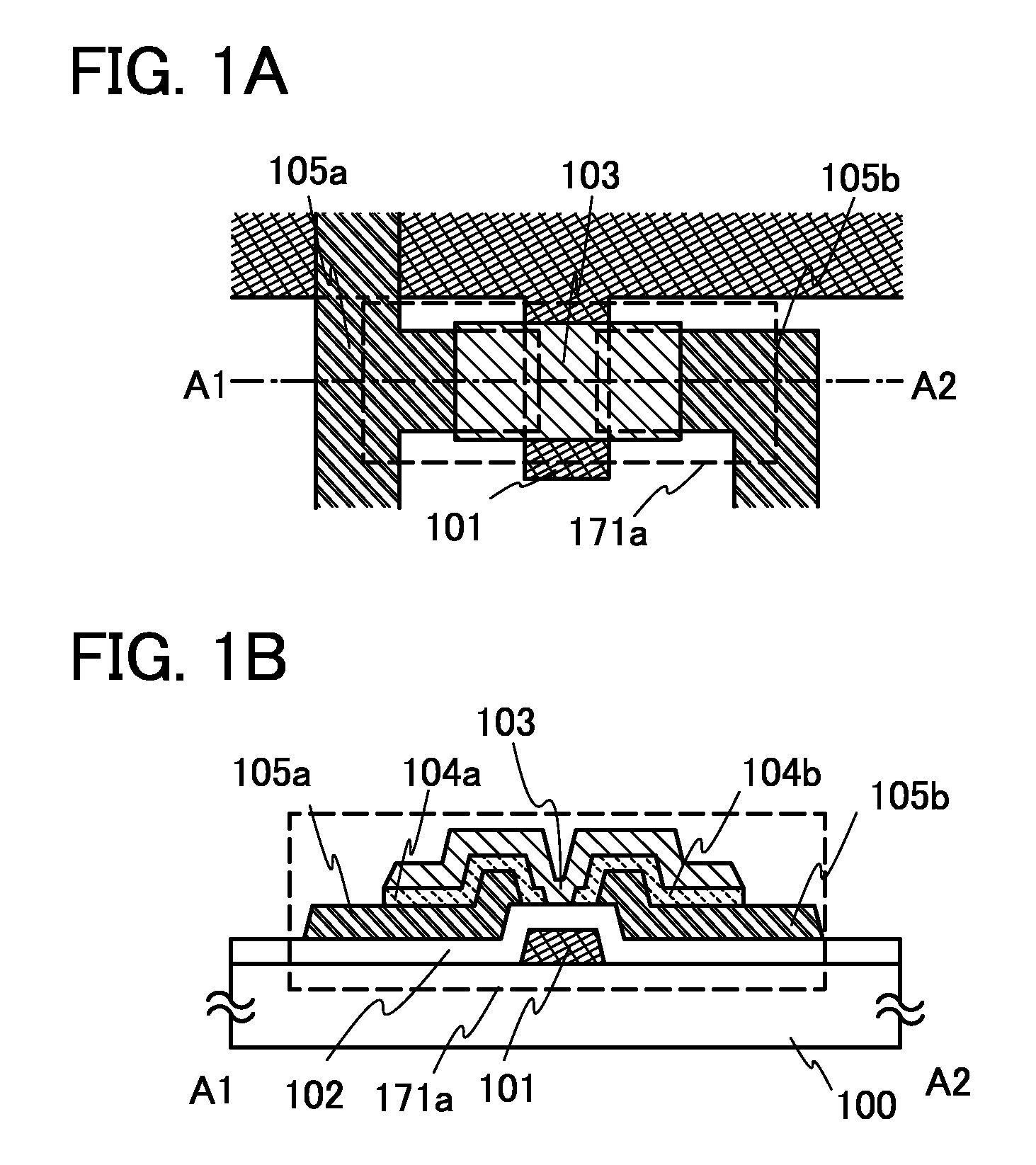

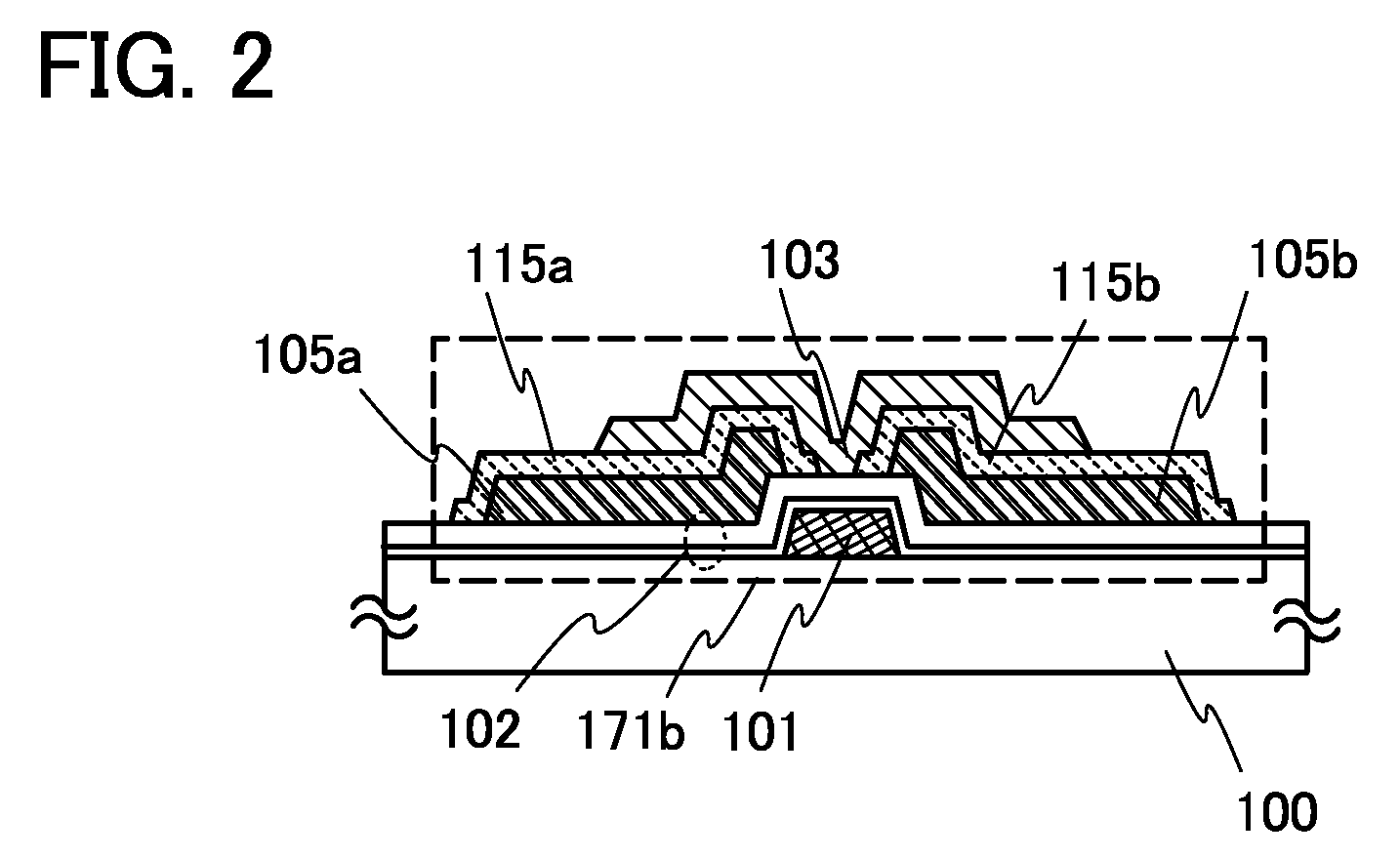

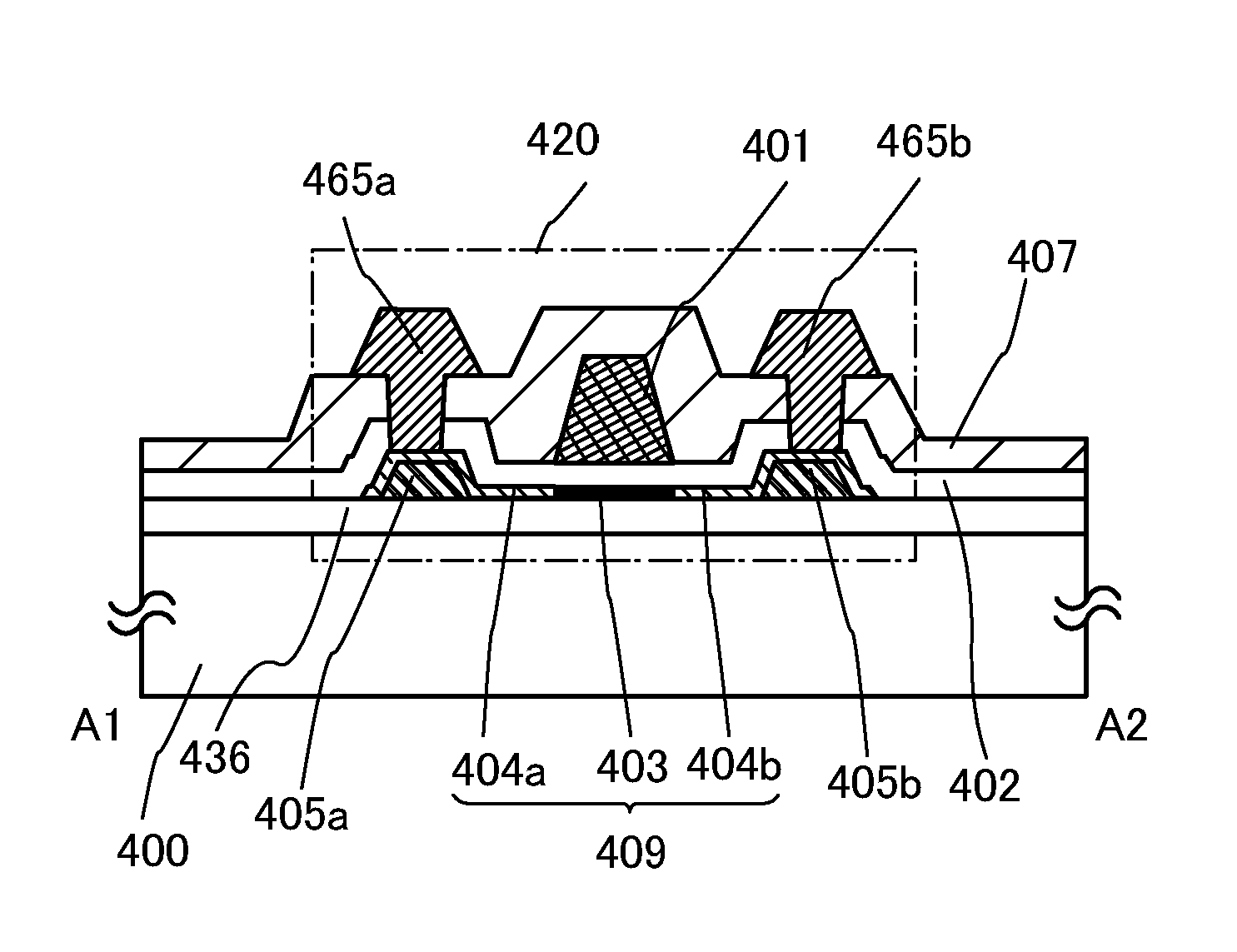

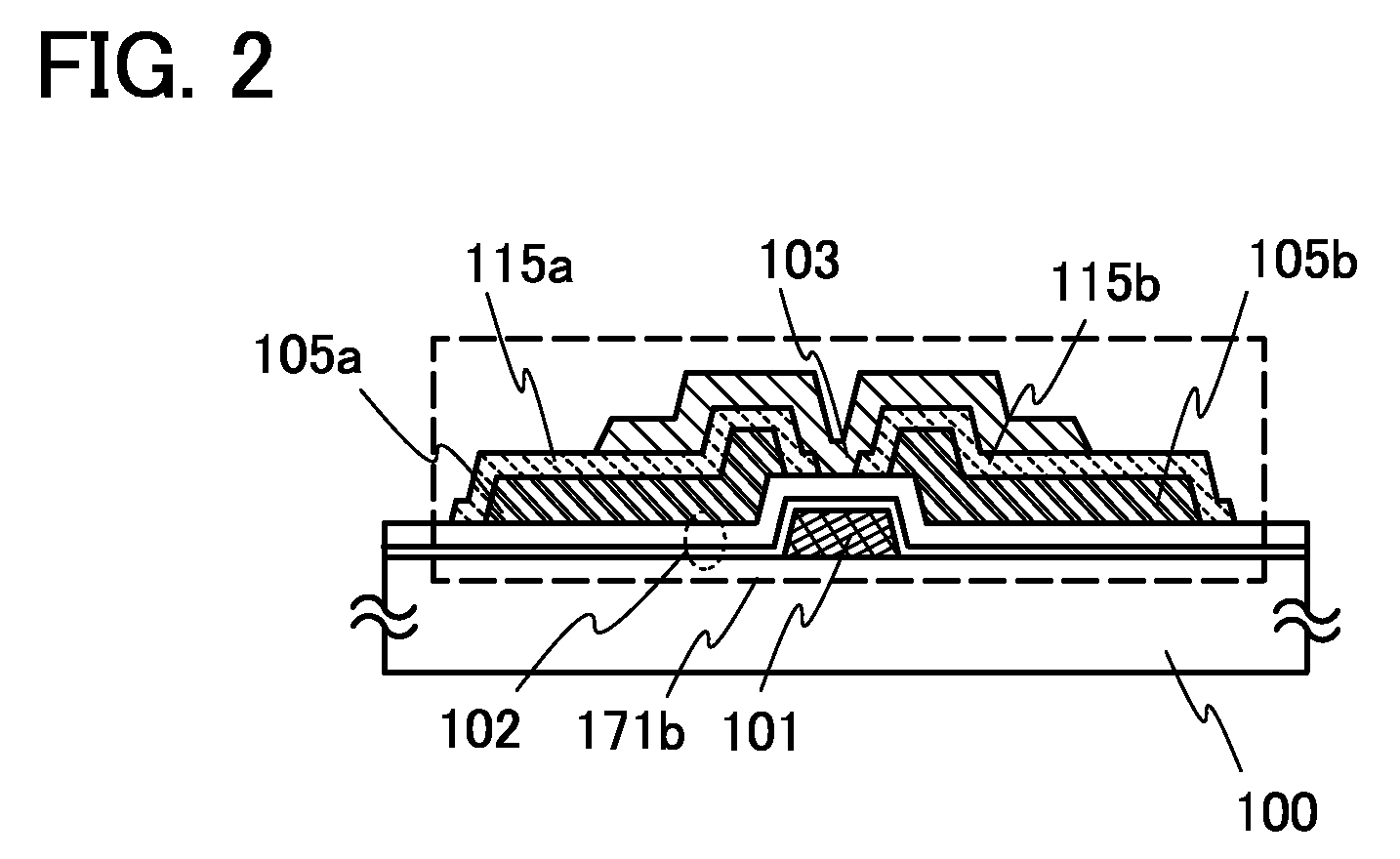

Semiconductor device and manufacturing method thereof

InactiveUS8030663B2Contact resistanceReduce contact resistanceSolid-state devicesSemiconductor/solid-state device manufacturingIndiumN type conductivity

A semiconductor device including thin film transistors having high electrical properties and reliability is proposed. Further, a method for manufacturing the semiconductor devices with mass productivity is proposed. The semiconductor device includes a thin film transistor which includes a gate electrode layer, a gate insulating layer over the gate electrode layer, a source electrode layer and a drain electrode layer over the gate insulating layer, a buffer layer over the source electrode layer and the drain electrode layer, and a semiconductor layer over the buffer layer. A part of the semiconductor layer overlapping with the gate electrode layer is over and in contact with the gate insulating layer and is provided between the source electrode layer and the drain electrode layer. The semiconductor layer is an oxide semiconductor layer containing indium, gallium, and zinc. The buffer layer contains a metal oxide having n-type conductivity. The semiconductor layer and the source and drain electrode layers are electrically connected to each other through the buffer layer.

Owner:SEMICON ENERGY LAB CO LTD

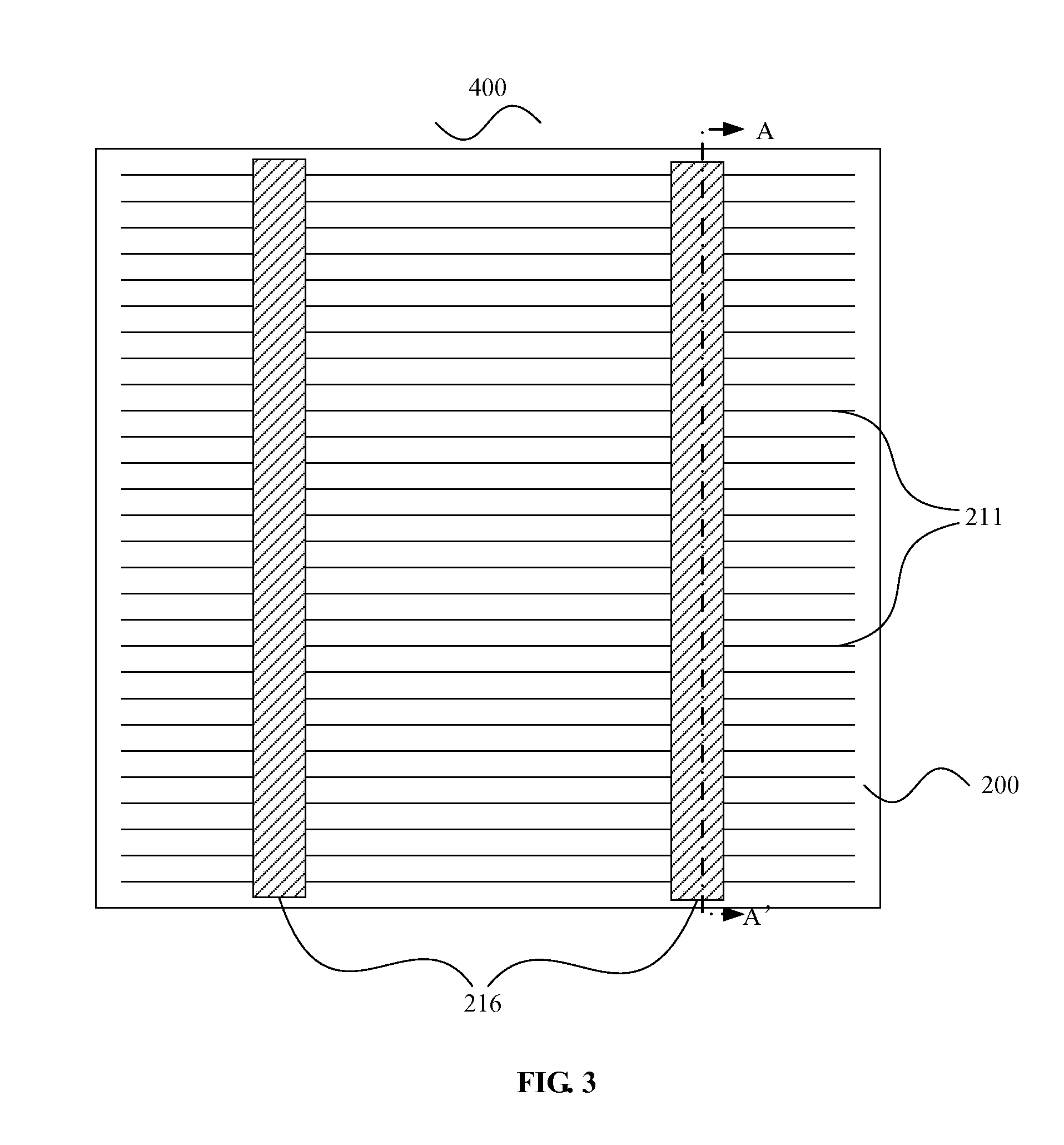

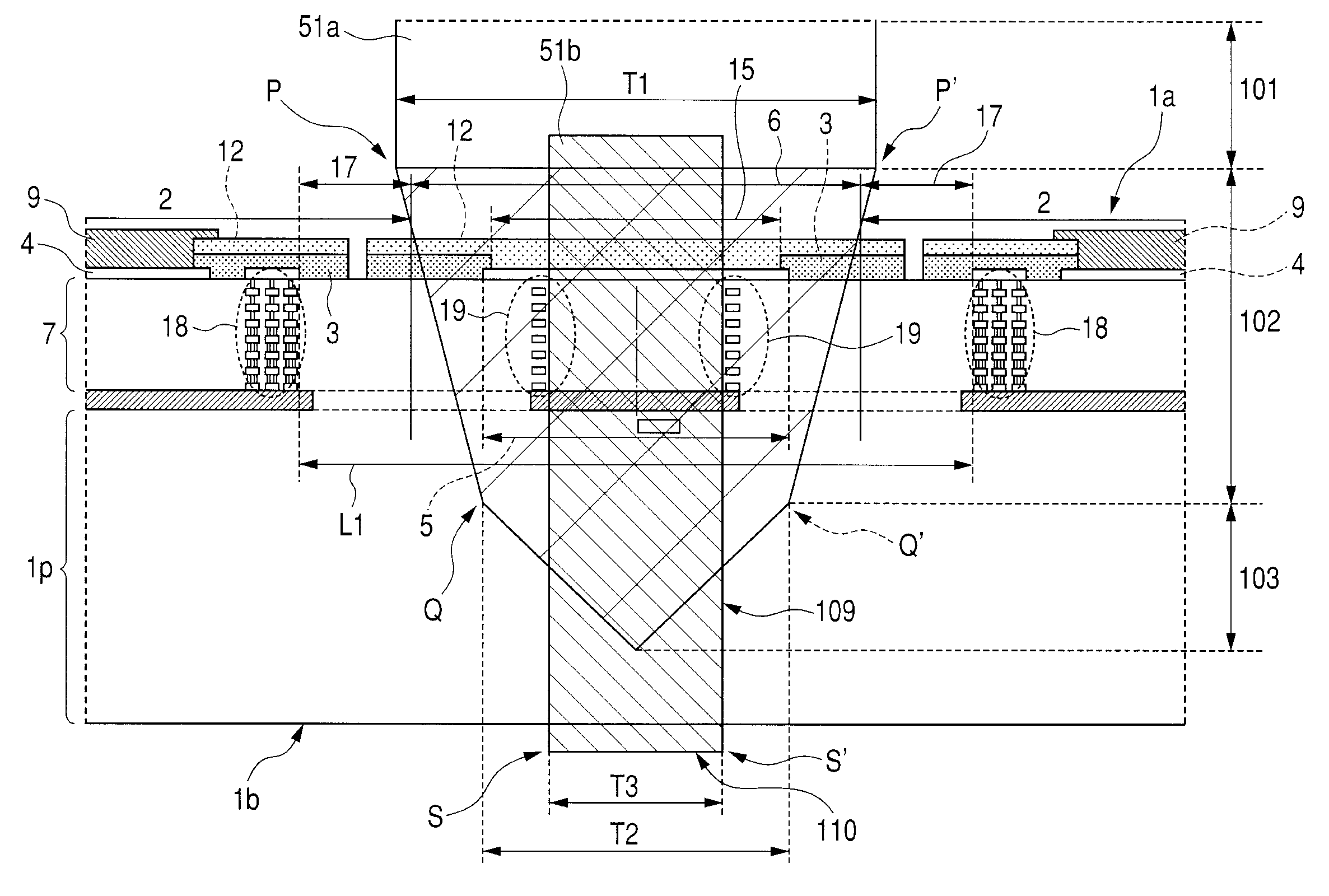

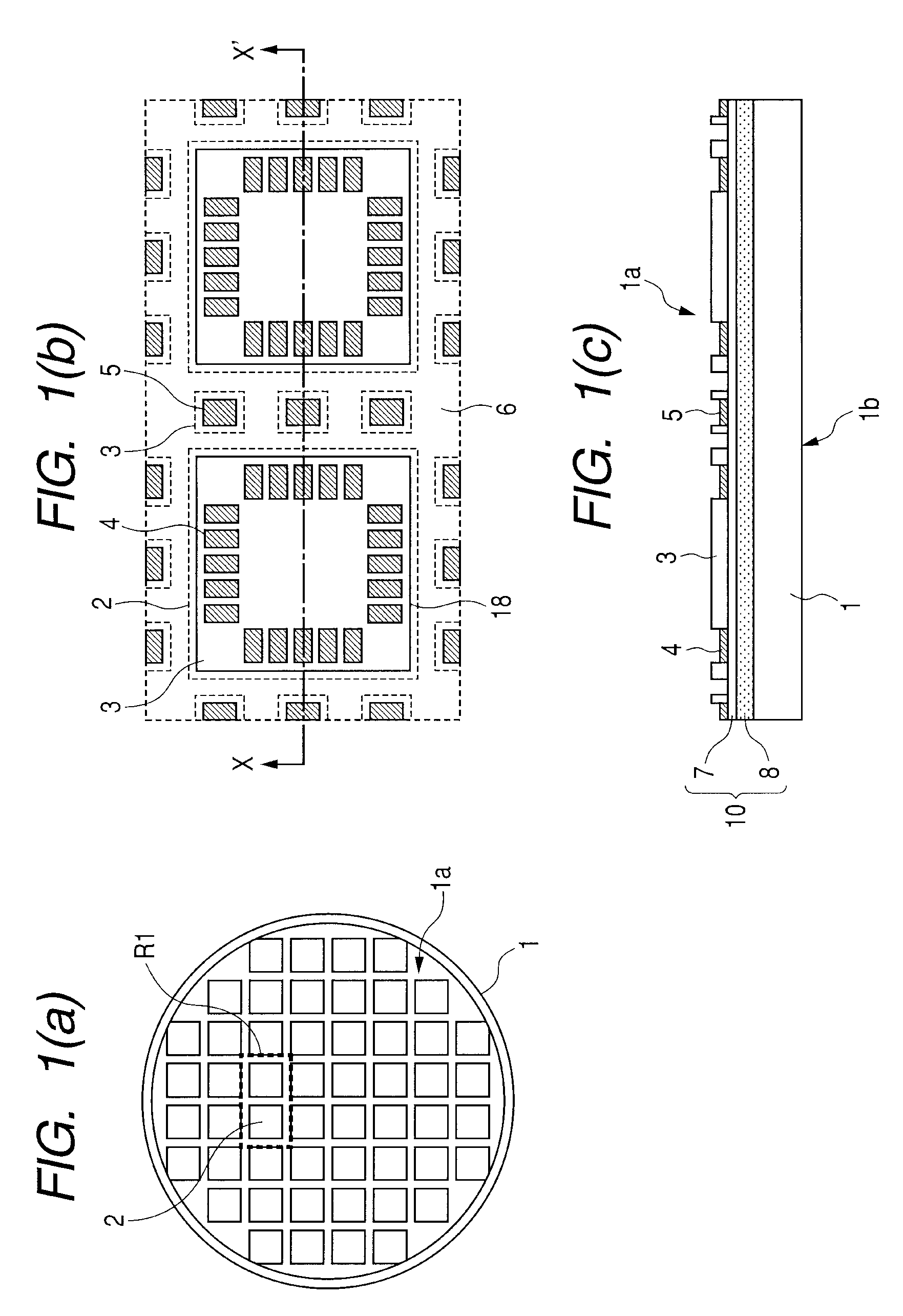

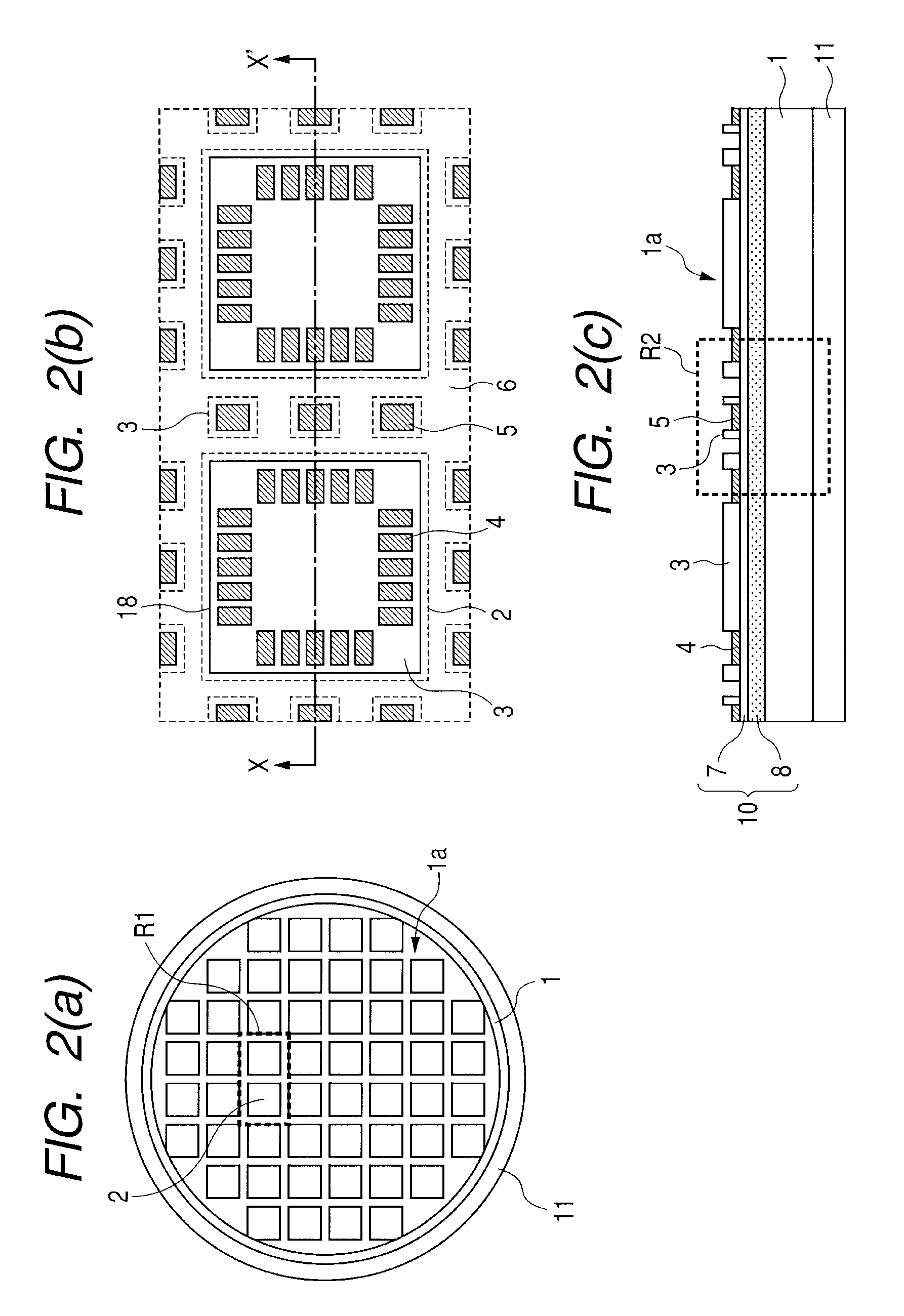

Semiconductor device and manufacturing method of the same

InactiveUS20100181681A1Easy to crackReliability is deterioratedSemiconductor/solid-state device detailsSolid-state devicesParasitic capacitorWafering

With a recent shrinking semiconductor process, insulating layers formed between interconnect layers are becoming thin. To avoid parasitic capacitance between them, materials of a low dielectric constant have been used for an insulating layer in a multilevel interconnect. Low-k materials, however, have low strength compared with the conventional insulating layers. Porous low-k materials are structurally fragile. The invention therefore provides a manufacturing method of a semiconductor device having a multilevel interconnect layer including a low-k layer. According to the method, in a two-step cutting system dicing in which after formation of a groove in a semiconductor water with a tapered blade, the groove is divided with a straight blade thinner than the groove width, the multilevel interconnect layer portion is cut while being covered with a tapered face and then the wafer is separated with a thin blade which is not brought into contact with the multilevel interconnect layer portion. The wafer can be diced without damaging a relatively fragile low-k layer.

Owner:RENESAS ELECTRONICS CORP

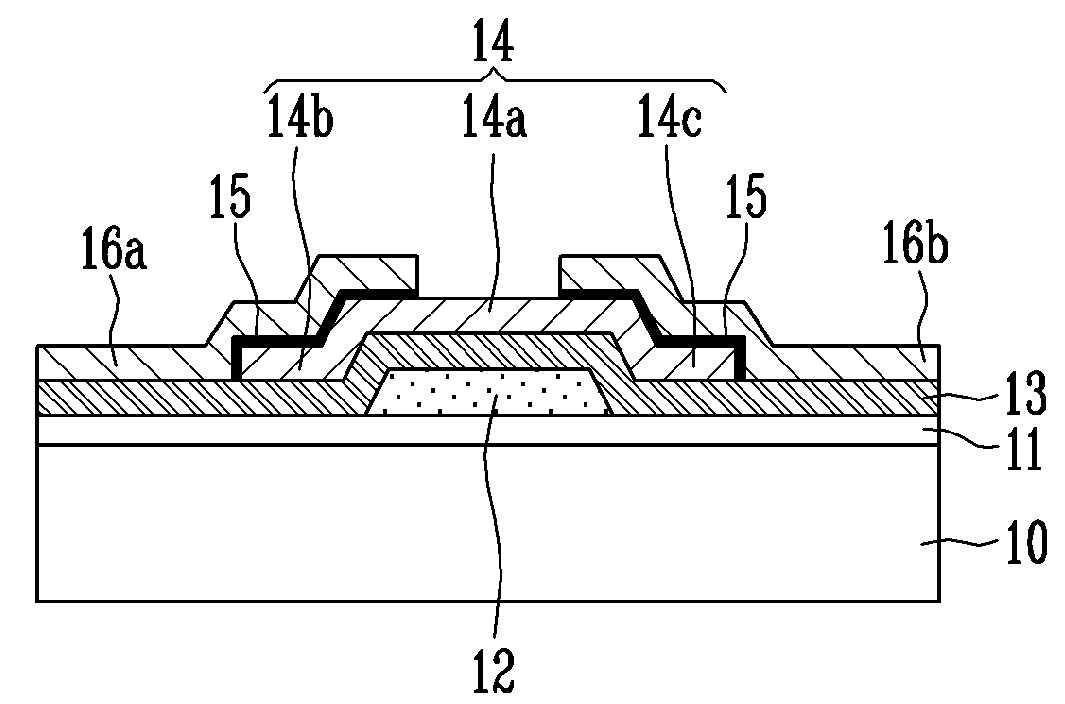

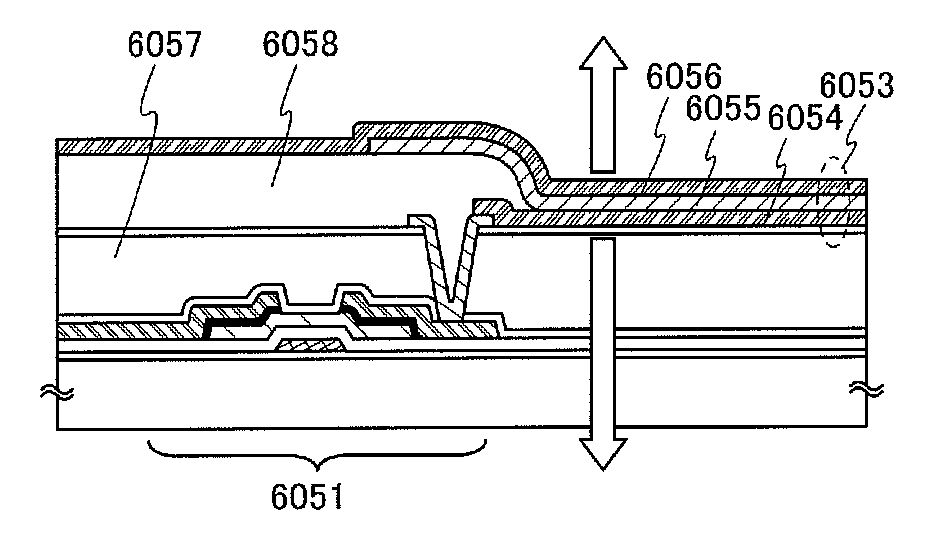

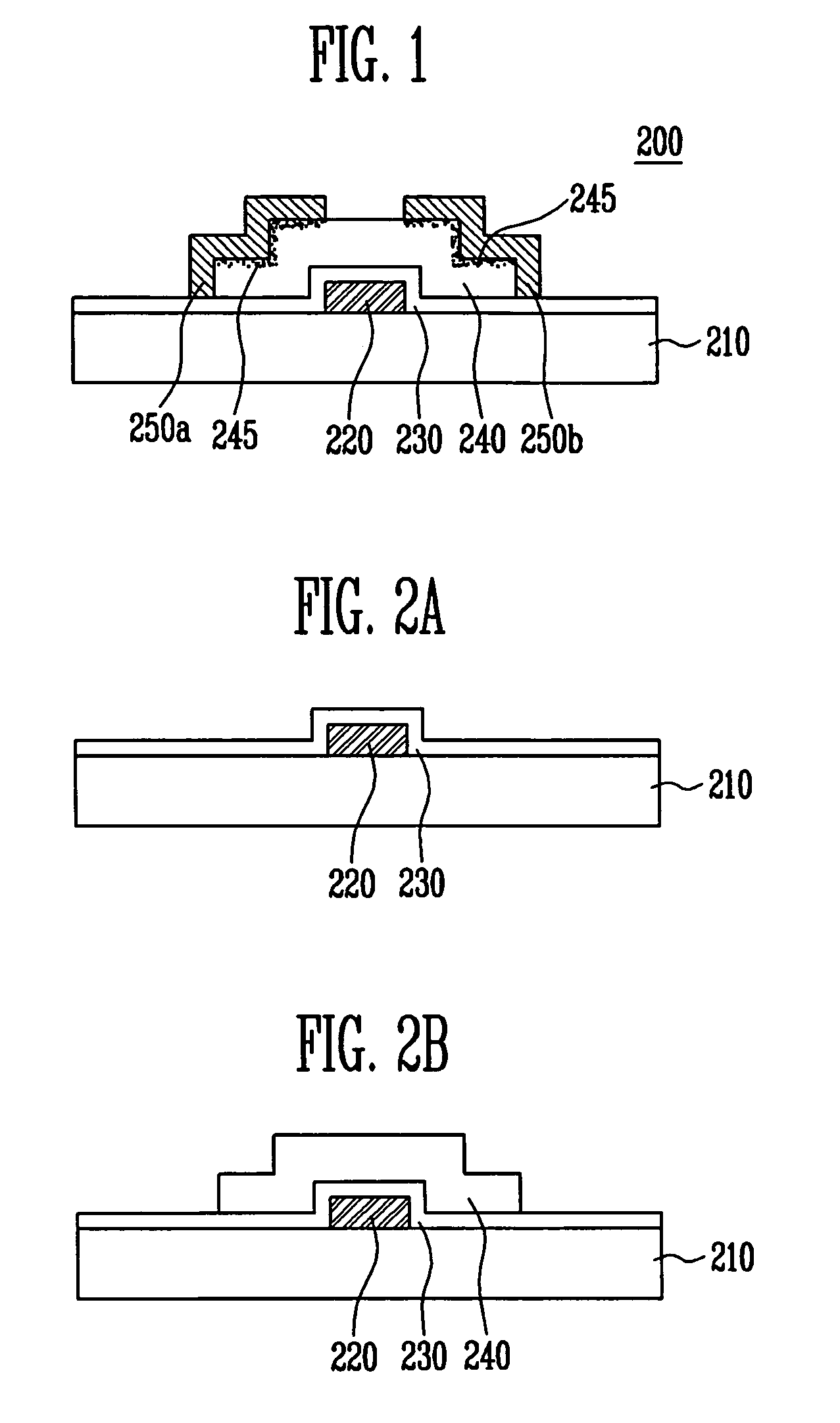

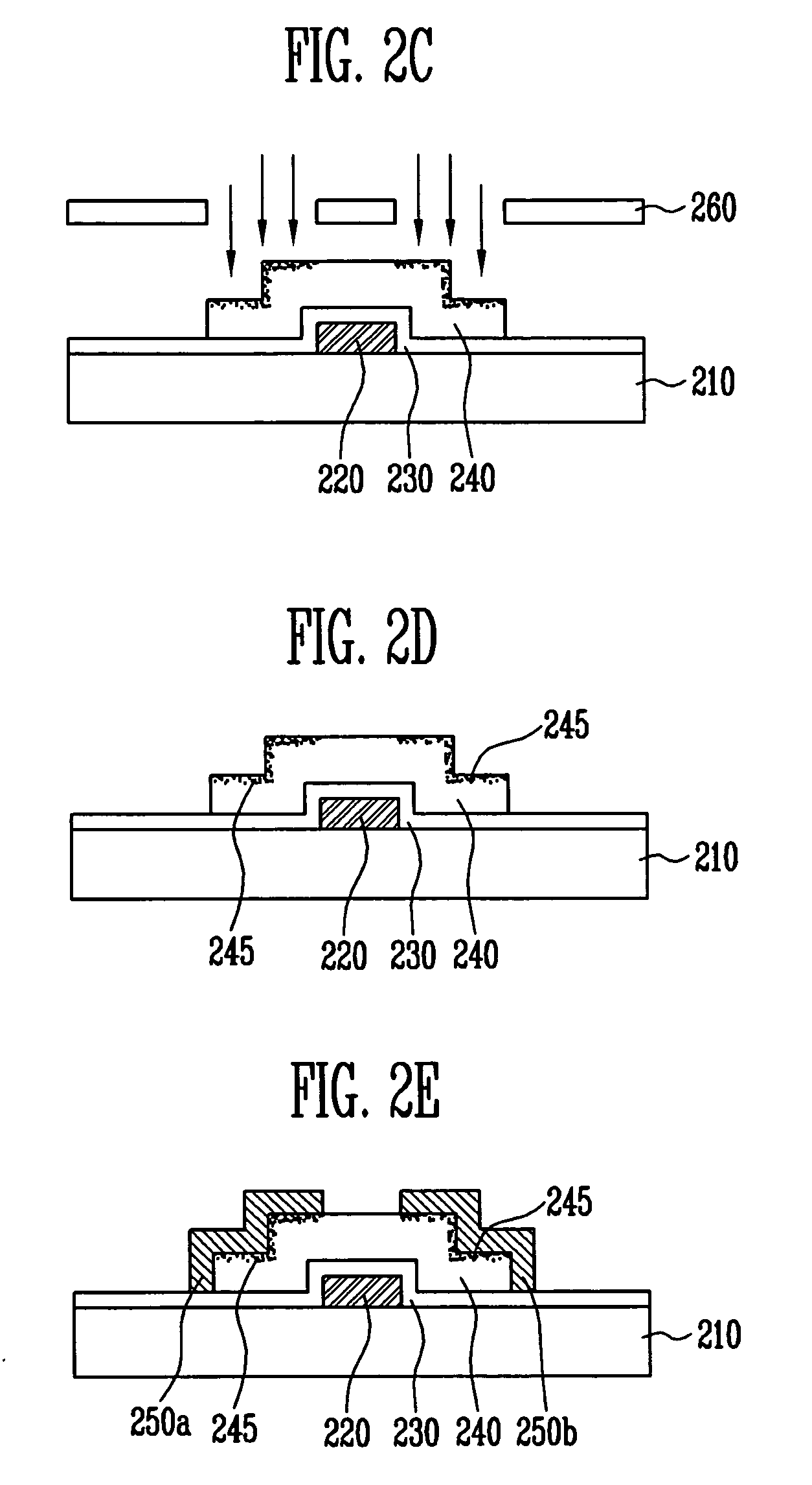

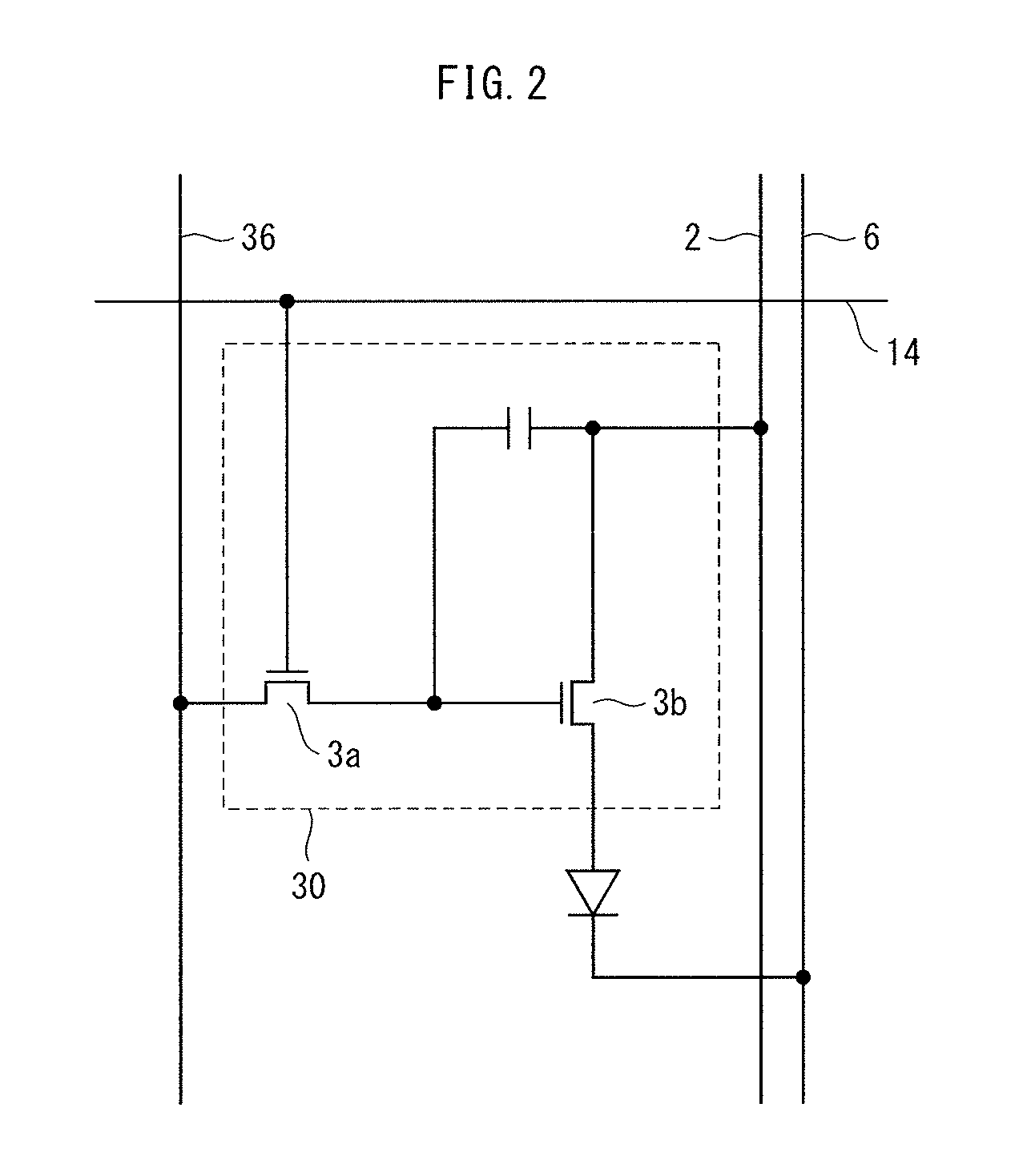

Thin film transistor, light-emitting display device having the same and associated methods

ActiveUS20090057674A1Contact resistanceReduce contact resistanceSolid-state devicesSemiconductor/solid-state device manufacturingGate dielectricDisplay device

A thin film transistor (TFT) includes an N-type oxide semiconductor layer on a substrate, a gate electrode spaced apart from the N-type oxide semiconductor layer by a gate dielectric layer, a source electrode contacting a first portion of the N-type oxide semiconductor layer, and a drain electrode contacting a second portion of the N-type oxide semiconductor layer. The first and second portions each have a doped region containing ions of at least one Group 1 element, and the ions of the at least one Group 1 element in the doped region may have a work function that is less than that of an N-type oxide semiconductor material included in the semiconductor layer.

Owner:SAMSUNG DISPLAY CO LTD

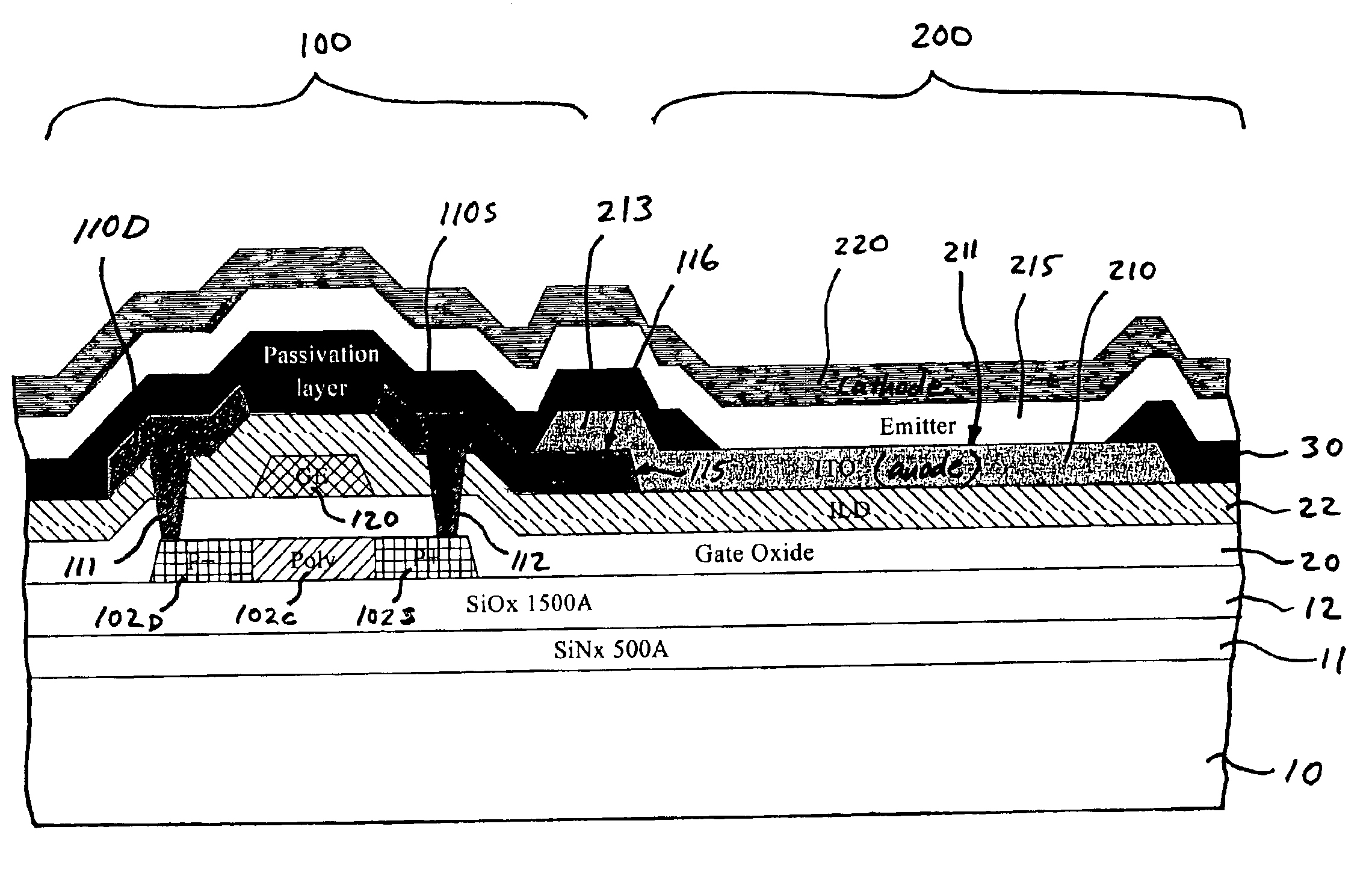

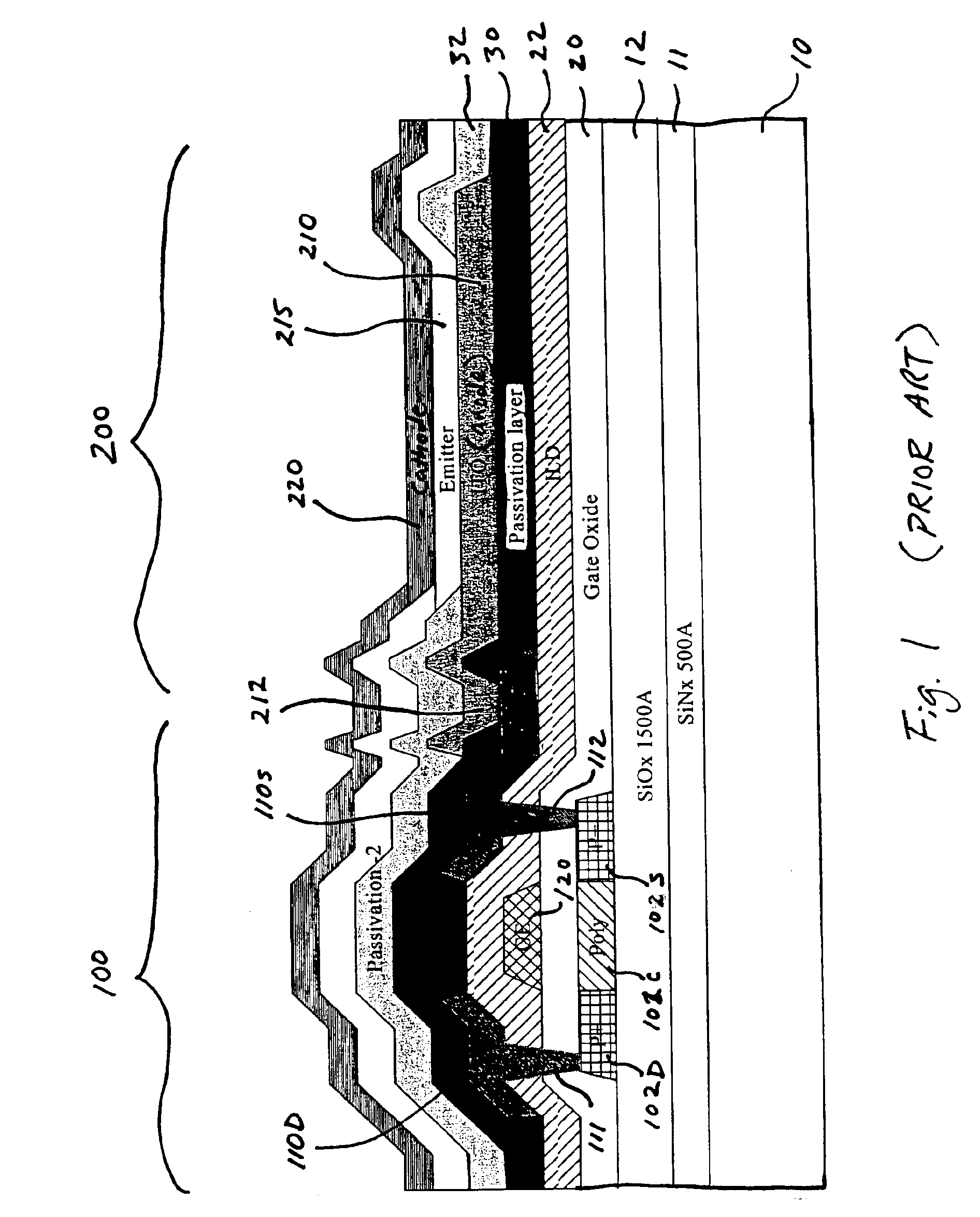

Thin film transistor organic light emitting diode structure

InactiveUS6850000B1Reduce electricity demandContact resistanceDischarge tube luminescnet screensStatic indicating devicesDisplay deviceLight-emitting diode

An electroluminescence display device comprising a thin film transistor and an electroluminescence element wherein the electroluminescence element's anode and a portion of the thin film transistor's source / drain electrode are deposited on to a same surface and the electroluminescence element's anode and the portion of the thin film transistor's source / drain electrode overlap and make an electrical contact with improved contact resistance.

Owner:AU OPTRONICS CORP

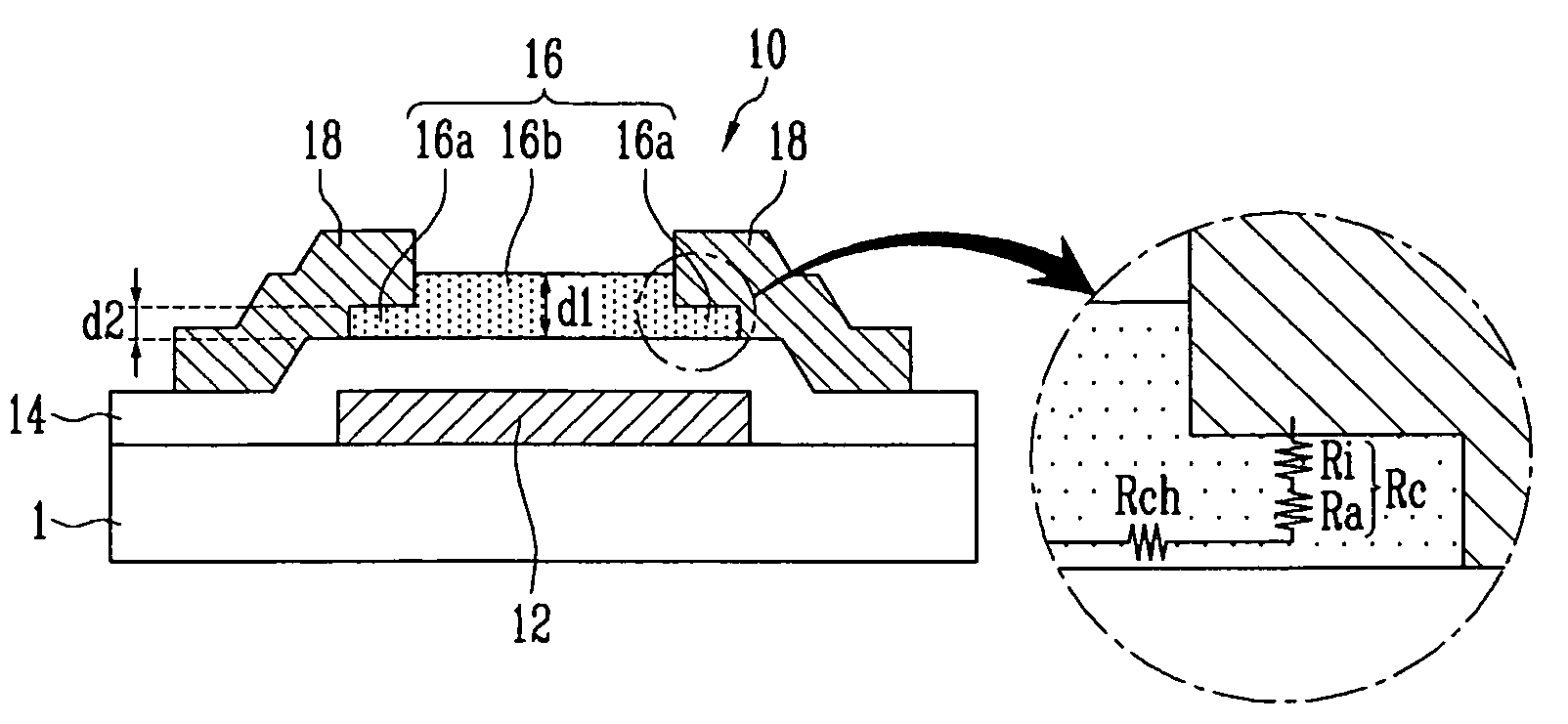

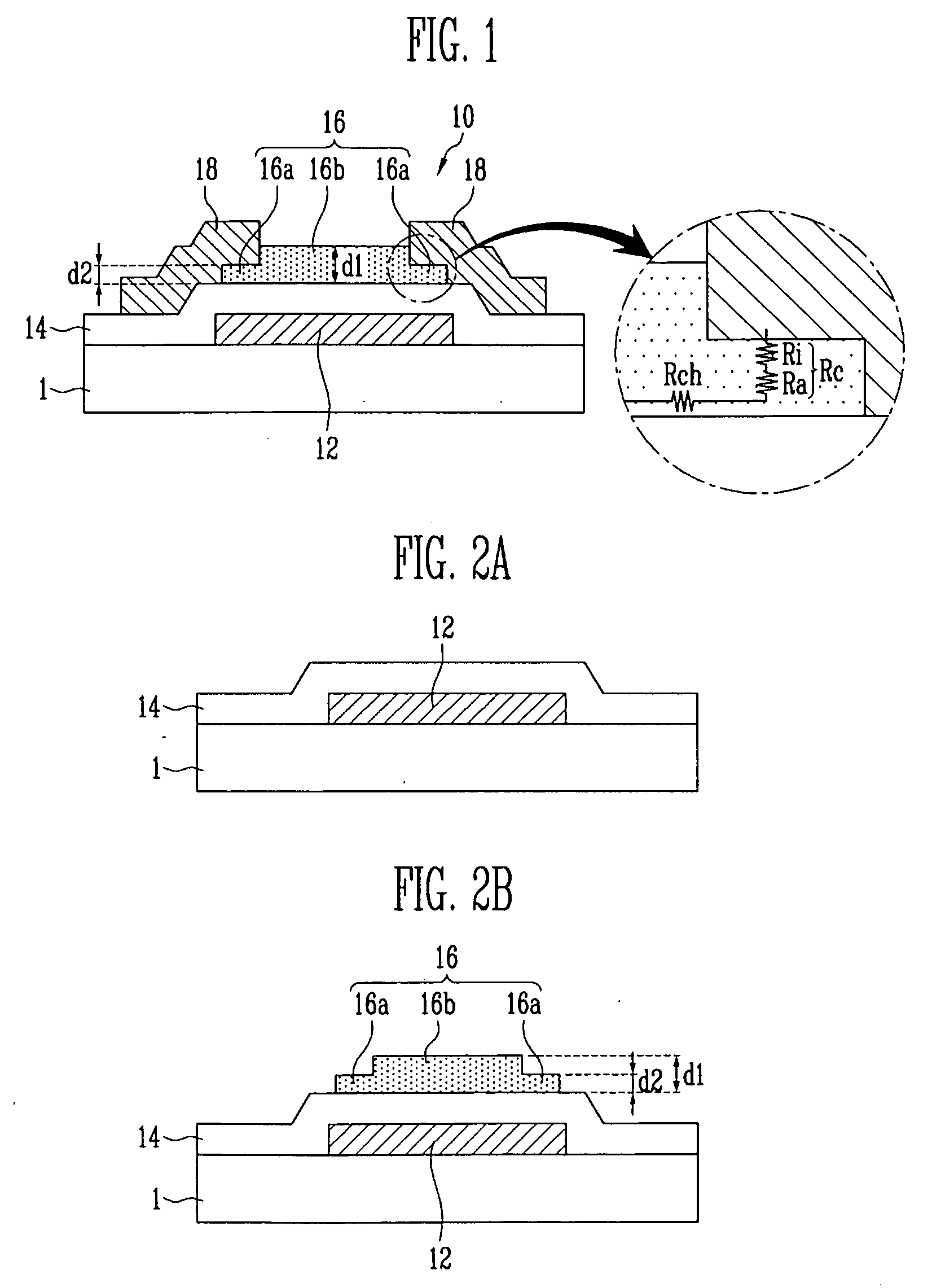

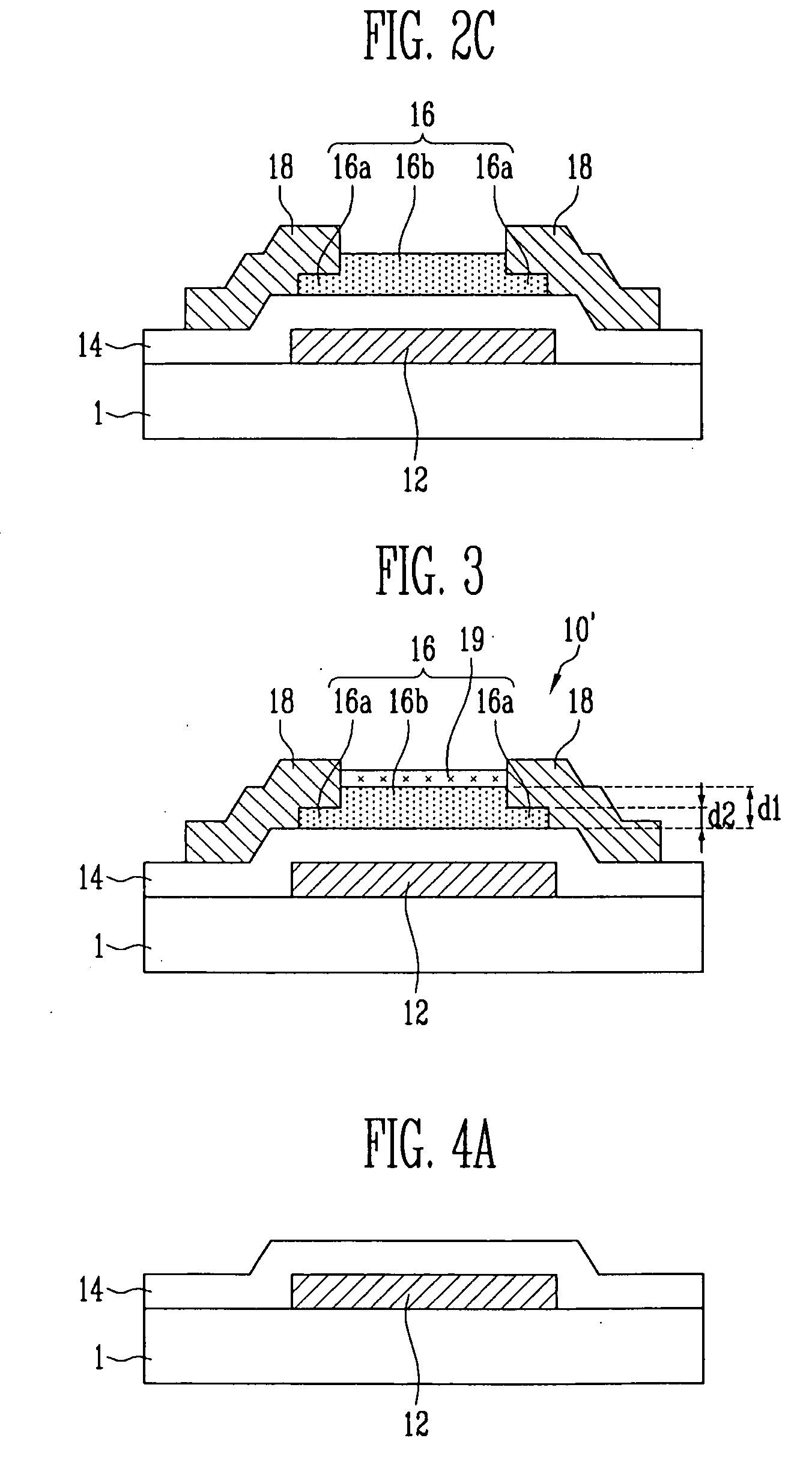

Thin film transistor and method of fabricating the same

ActiveUS20100044699A1Reduce contact resistanceSmall thicknessSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringActive layer

A thin film transistor (TFT) including a gate electrode, an active layer, and source and drain electrodes. The active layer includes contact regions that contact the source and drain electrodes, which are thinner than a remaining region of the active layer. The contact regions reduce the contact resistance between the active material layer and the source and drain electrodes.

Owner:SAMSUNG DISPLAY CO LTD

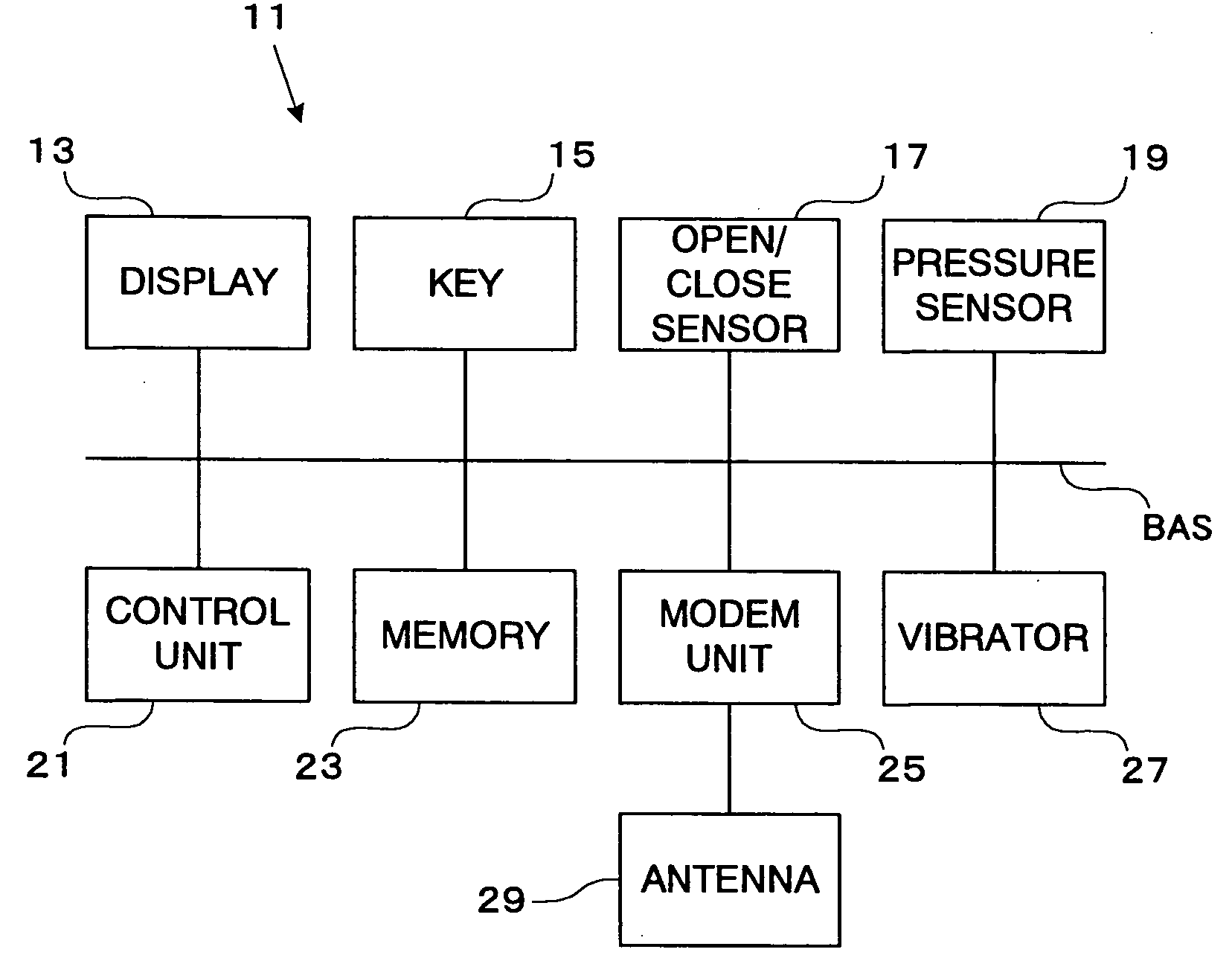

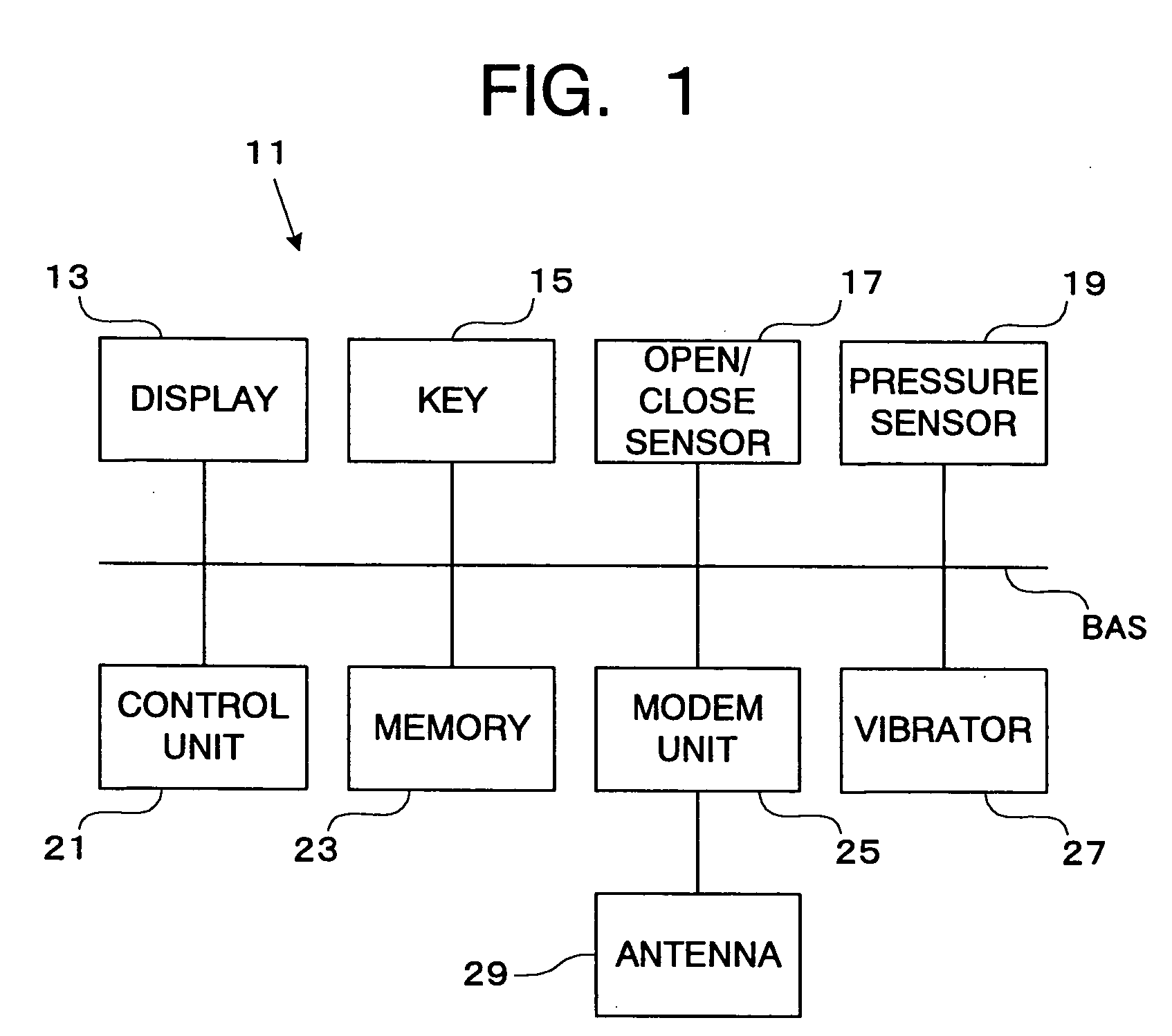

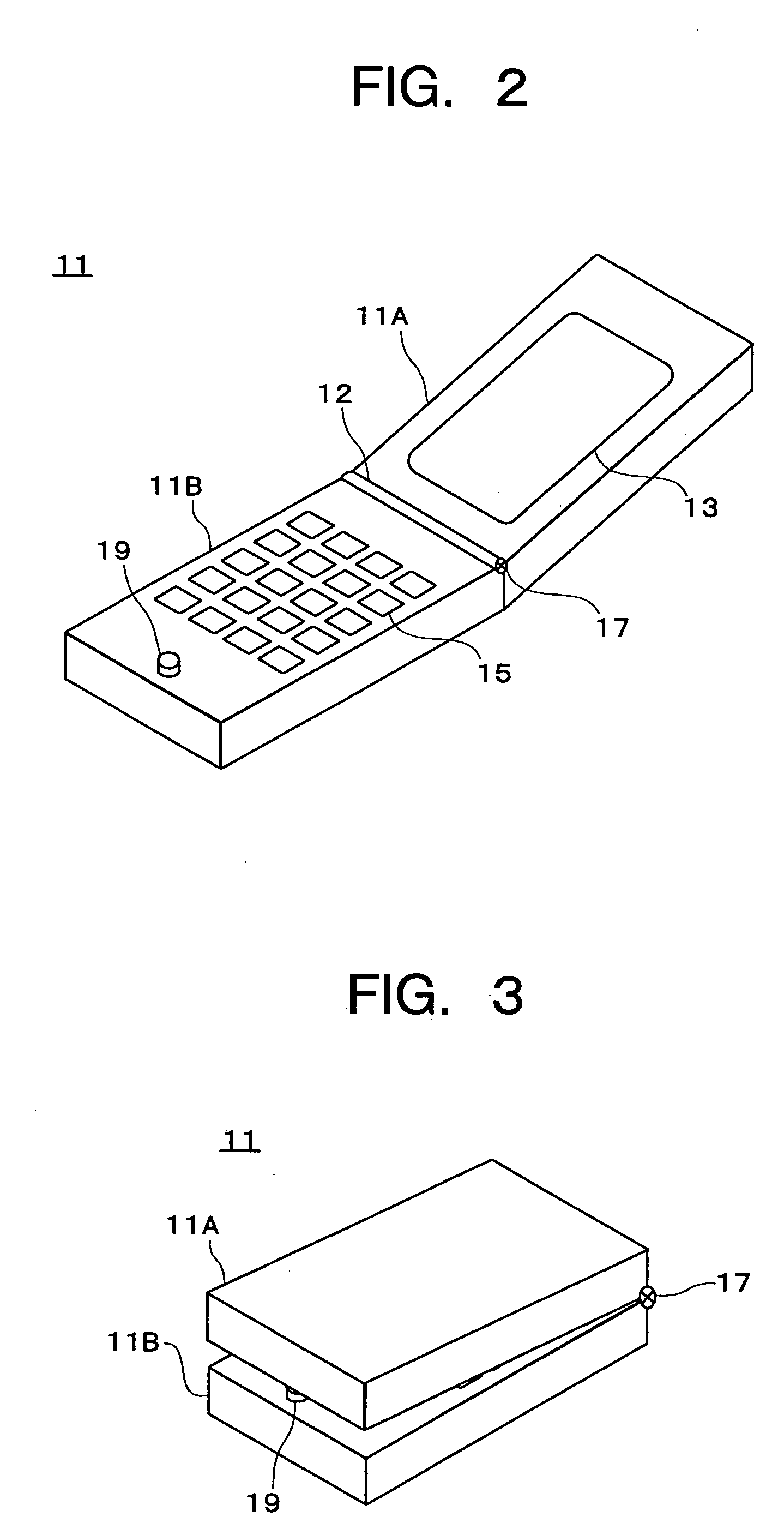

Mobile phone and vibration control method of mobile phone

InactiveUS20050208903A1Contact resistanceDevices with sensorCurrent supply arrangementsVibration controlEngineering

Pressure applied to a mobile phone main body is detected at the time of call / mail arrival, and in compliance therewith vibration of a vibrator of a mobile phone is controlled. As a result, vibration is controlled in compliance with a degree of contact between the mobile phone and a body of a user, so that notification of an incoming call / mail by vibration can be conducted more surely.

Owner:KK TOSHIBA

Semiconductor device

InactiveUS20130069055A1Excellent electrical propertiesImprove reliabilitySolid-state devicesSemiconductor devicesElectrical resistance and conductanceEngineering

Provided is a semiconductor device in which an oxide semiconductor layer is provided; a pair of wiring layers which are provided with the gate electrode layer interposed therebetween are electrically connected to the low-resistance regions; and electrode layers are provided to be in contact with the low-resistance regions, below regions where the wiring layers are formed.

Owner:SEMICON ENERGY LAB CO LTD

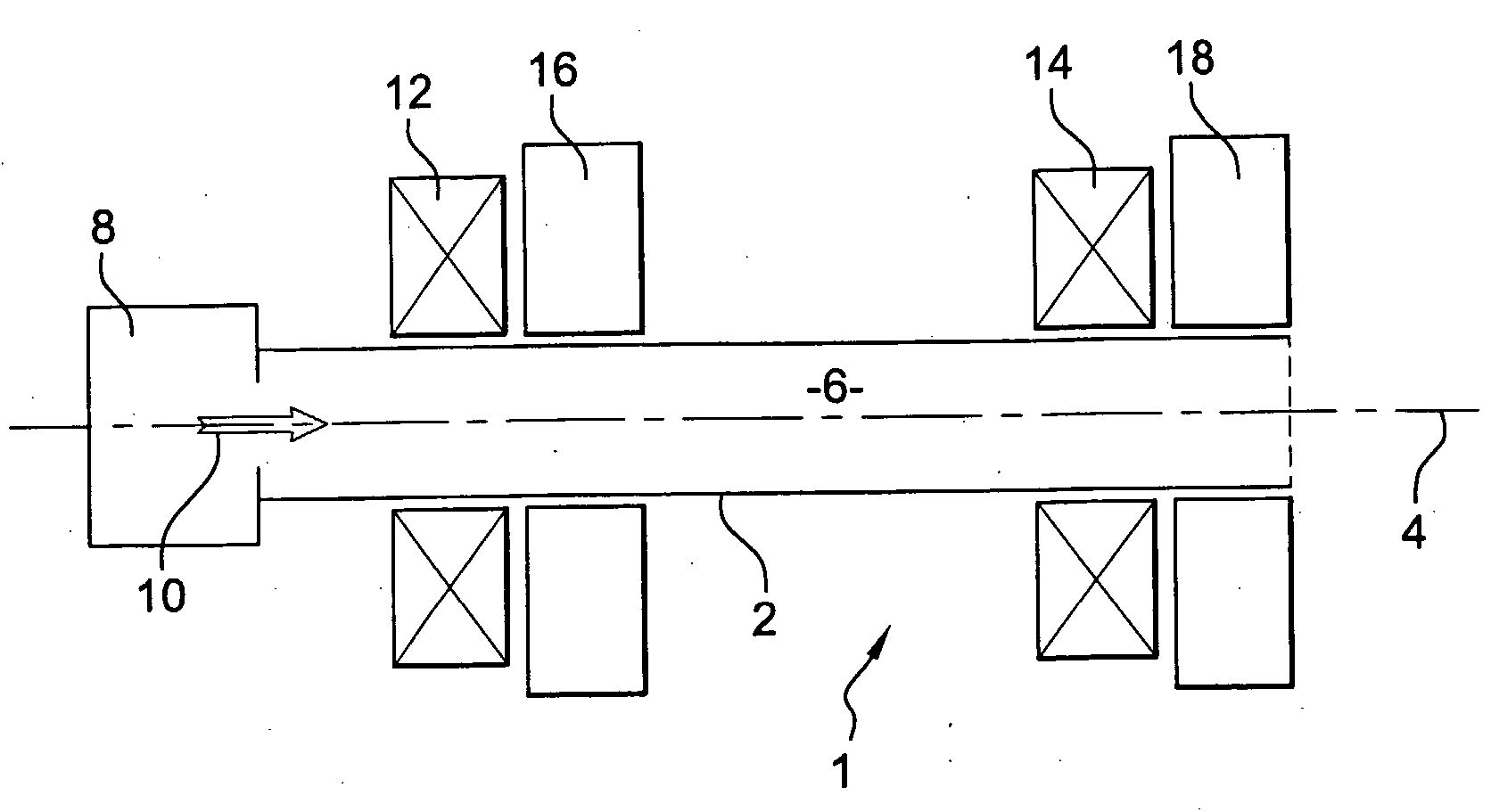

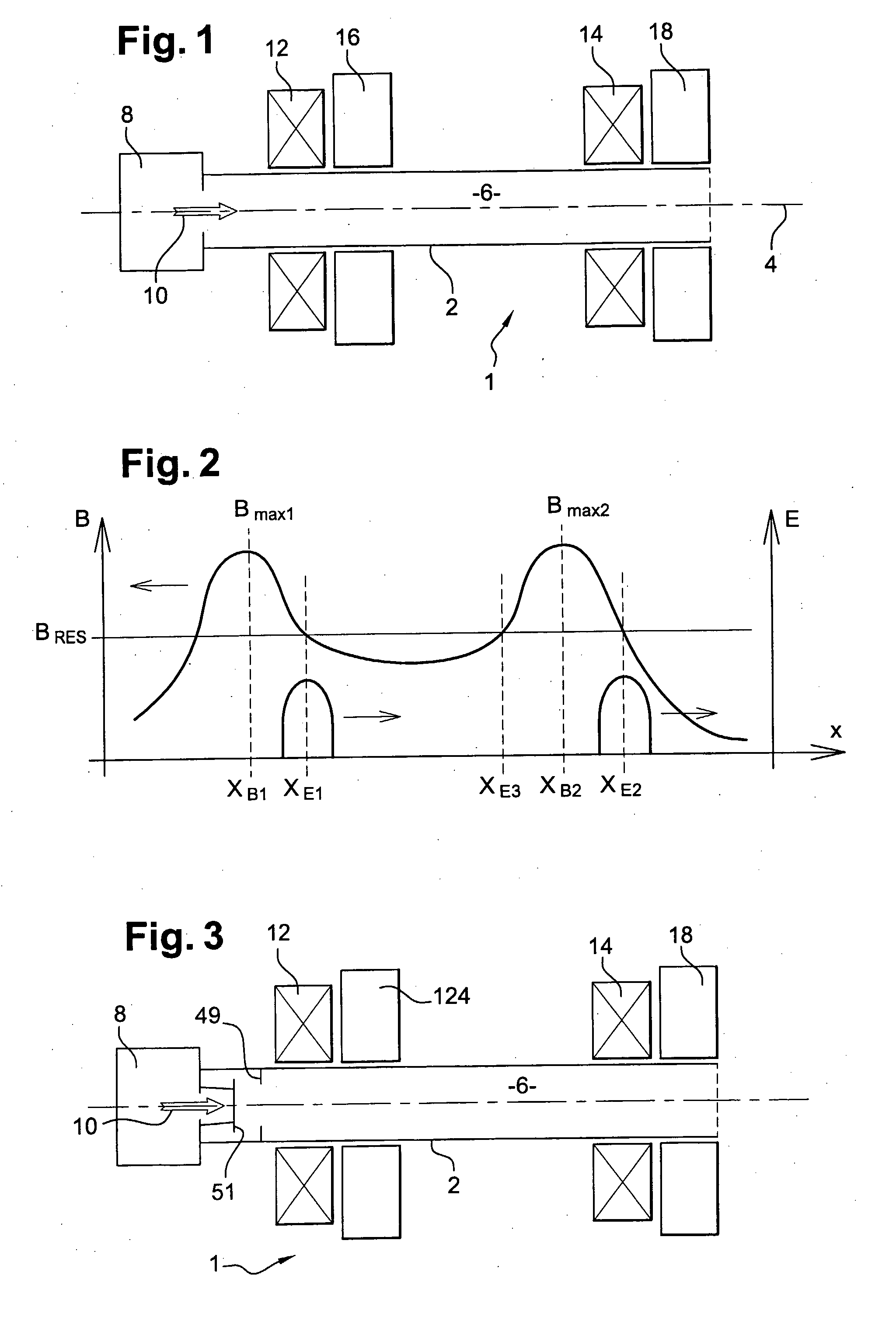

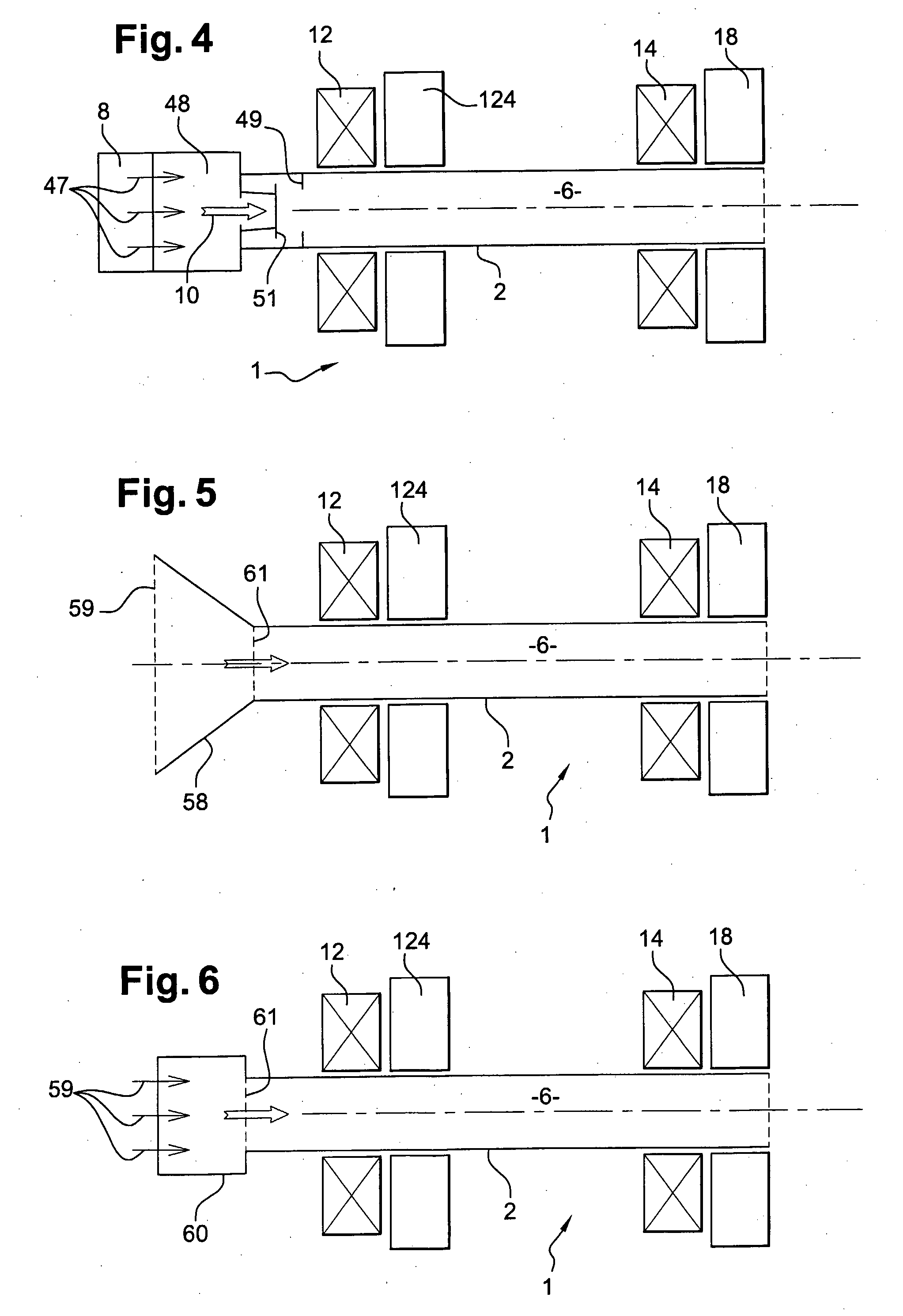

Spacecraft Thruster

InactiveUS20080093506A1Facilitated ionizationImprove confinementCosmonautic vehiclesRocket engine plantsSpacecraft propulsionEngineering

A thruster (1) has a main chamber (6) defined within a tube (2). The tube has a longitudinal axis which defines an axis (4) of thrust; an injector (8) injects ionizable gas within the tube, at one end of the main chamber. An ionizer (124) is adapted to ionize the injected gas within the main chamber (6). A first magnetic field generator (12, 14) and an electromagnetic field generator (18) are adapted to generate a magnetized ponderomotive accelerating field downstream of said ionizer (124) along the direction of thrust on said axis (4), The thruster (1) ionizes the gas, and subsequently accelerates both electrons and ions by the magnetized ponderomotive force.

Owner:ELWING LLC

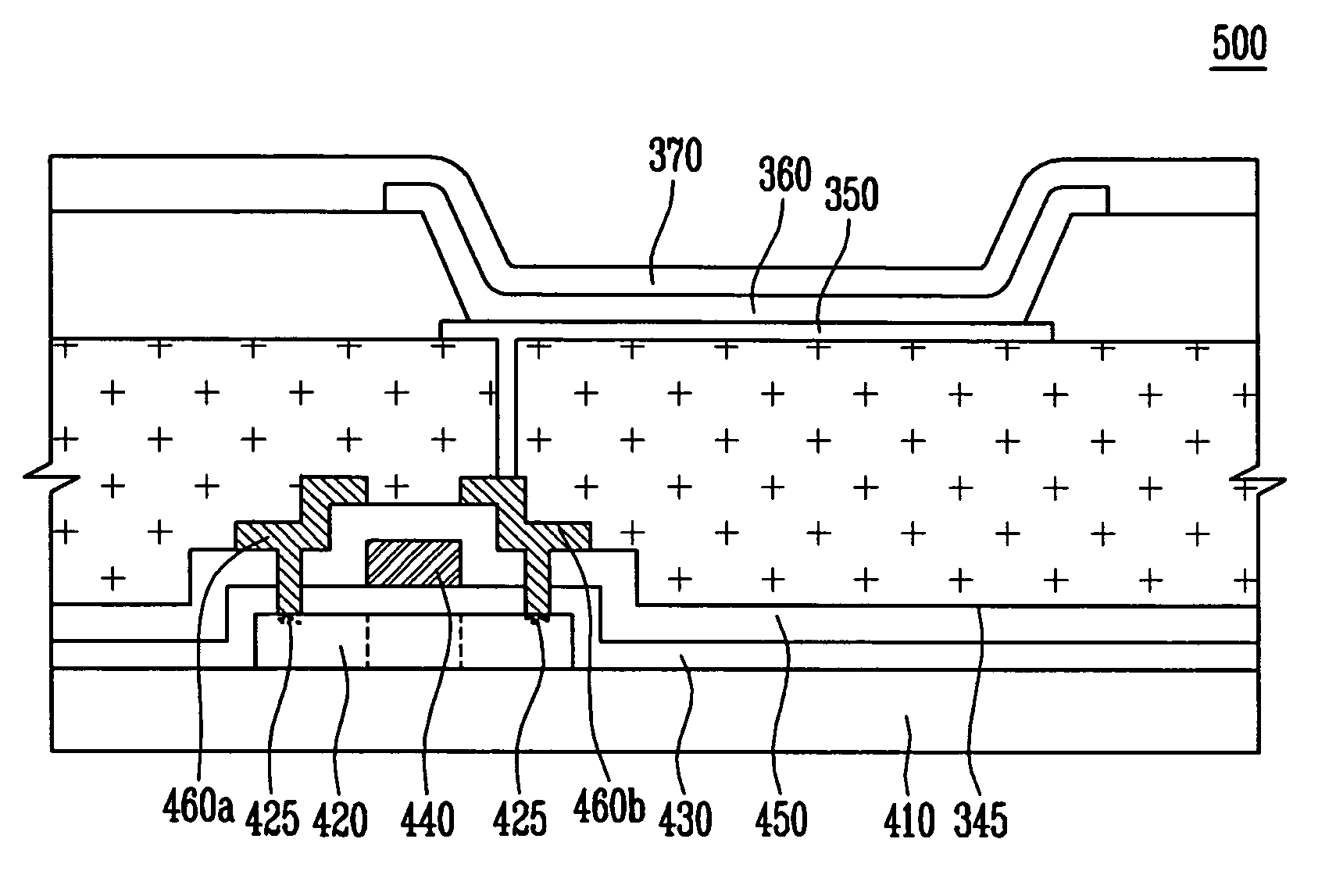

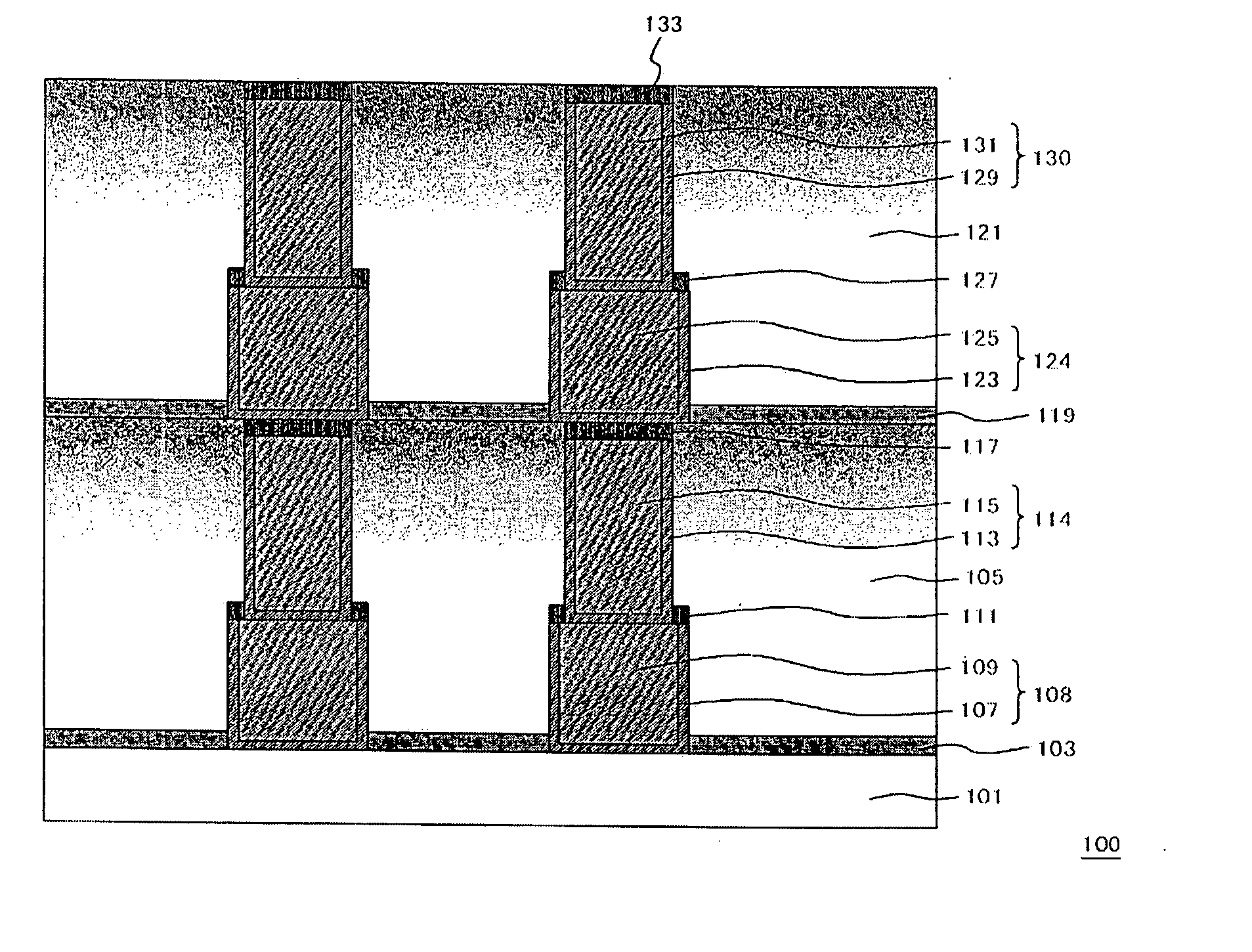

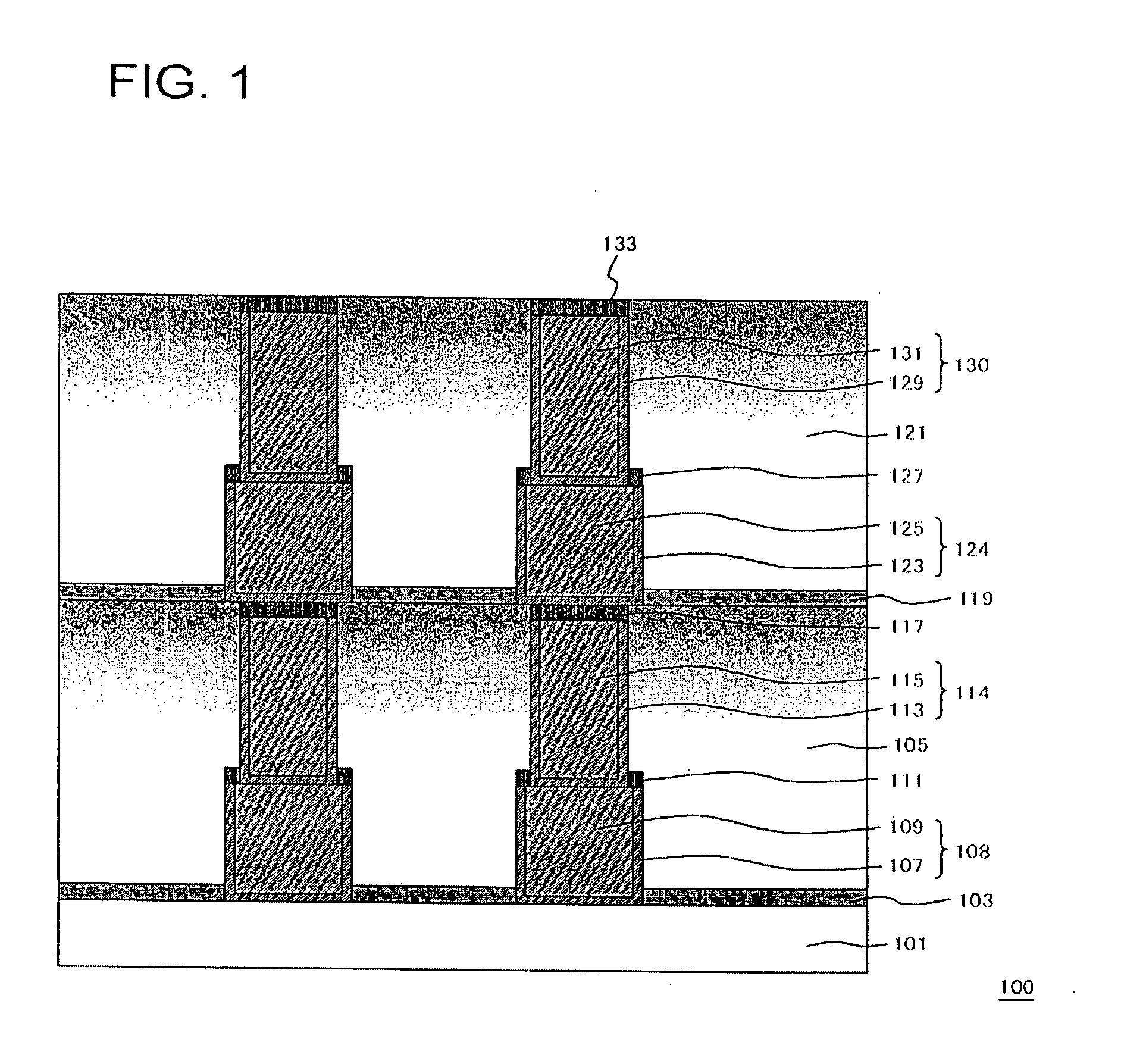

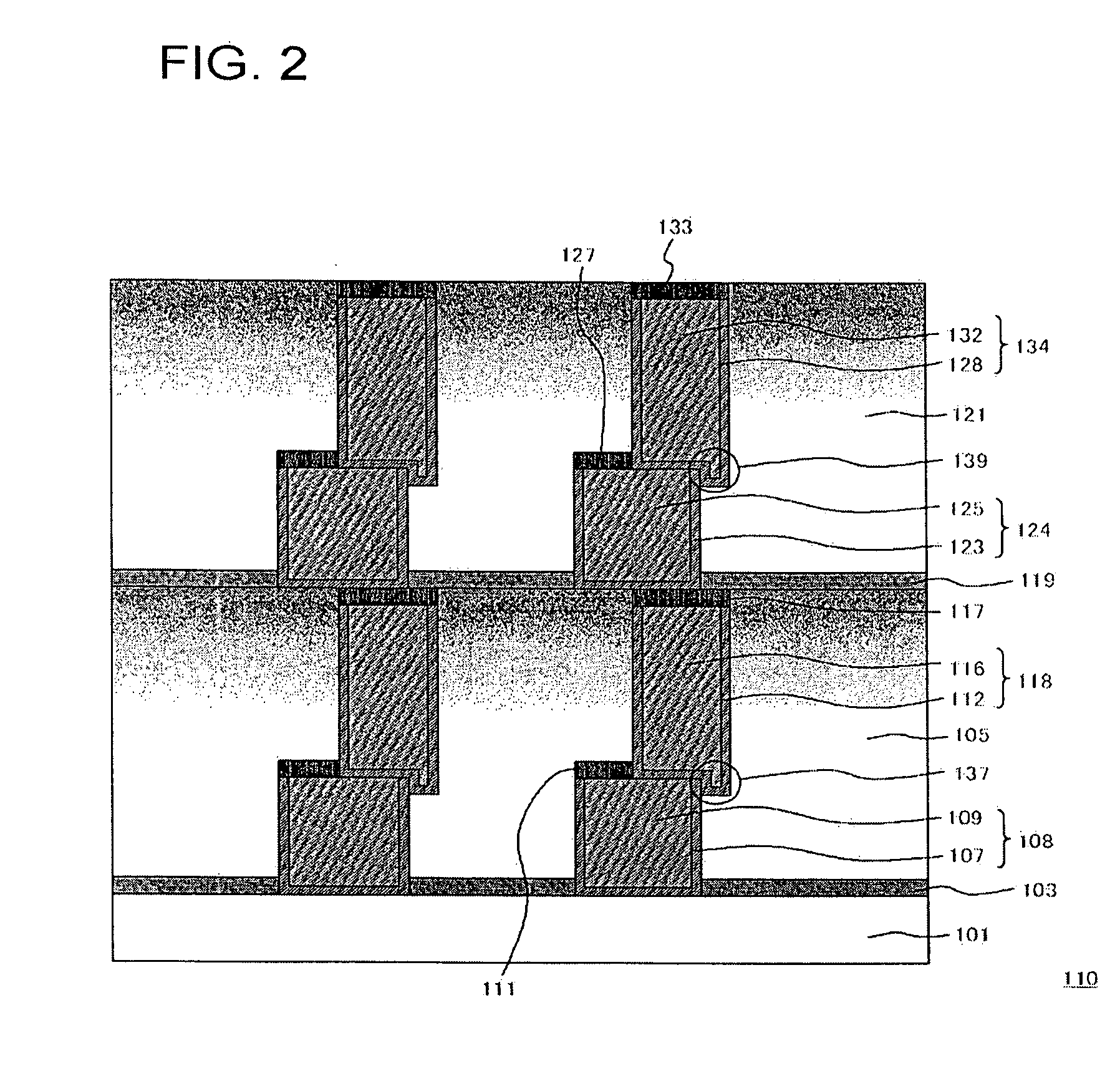

Semiconductor device and manufacturing process therefor

ActiveUS20060211235A1Low dielectric constantContact resistanceSemiconductor/solid-state device detailsSolid-state devicesEngineeringCopper

An object of this invention is to effectively reduce a connection resistance between a plug and an interconnect, and a dielectric constant of an insulating film. A semiconductor device 100 has a semiconductor substrate (not shown); a first interconnect 108 made of a copper-containing metal which is formed over the semiconductor substrate; a conductive first plug 114 formed over the first interconnect 108 and connected to the first interconnect 108; a Cu silicide layer 111 over the first interconnect 108 in an area other than the area where the first plug 114 is formed; a Cu silicide layer 117 over the first plug 114; and a first porous MSQ film 105 formed over an area from the side surface of the first interconnect 108 to the side surface of the first plug 114 and covering the side surface of the first interconnect 108, the upper portion of the first interconnect 108 and the side surface of the first plug 114.

Owner:RENESAS ELECTRONICS CORP

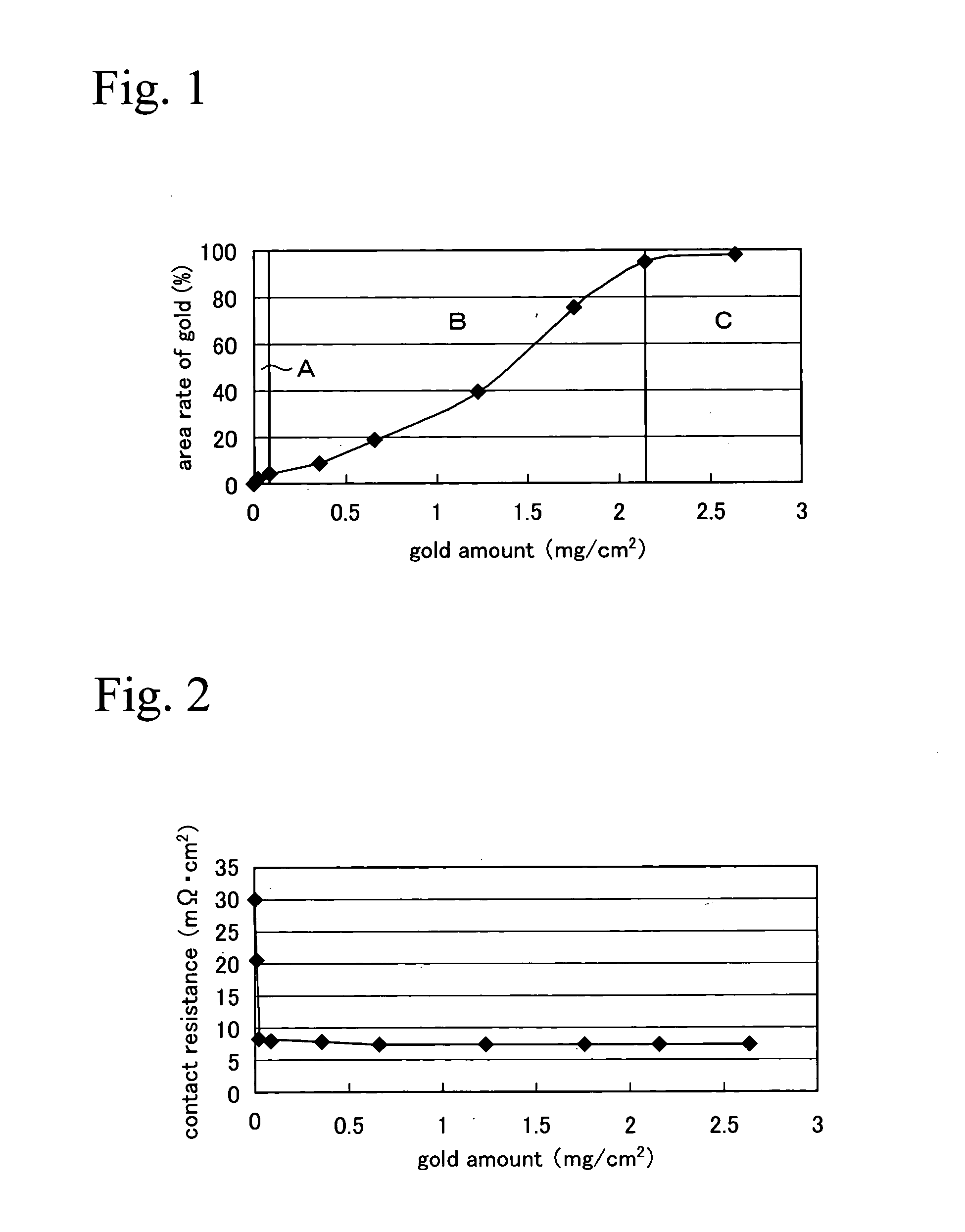

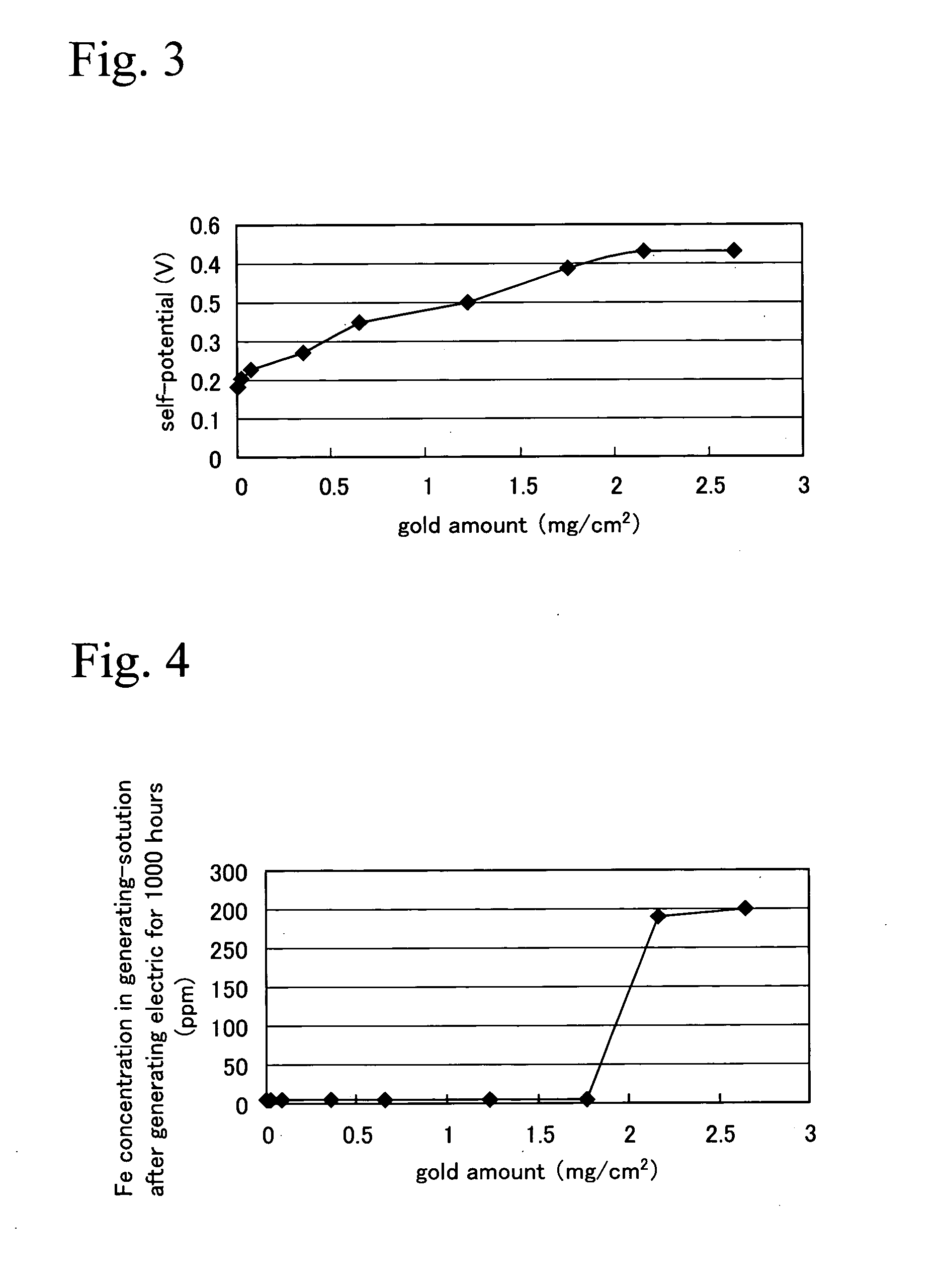

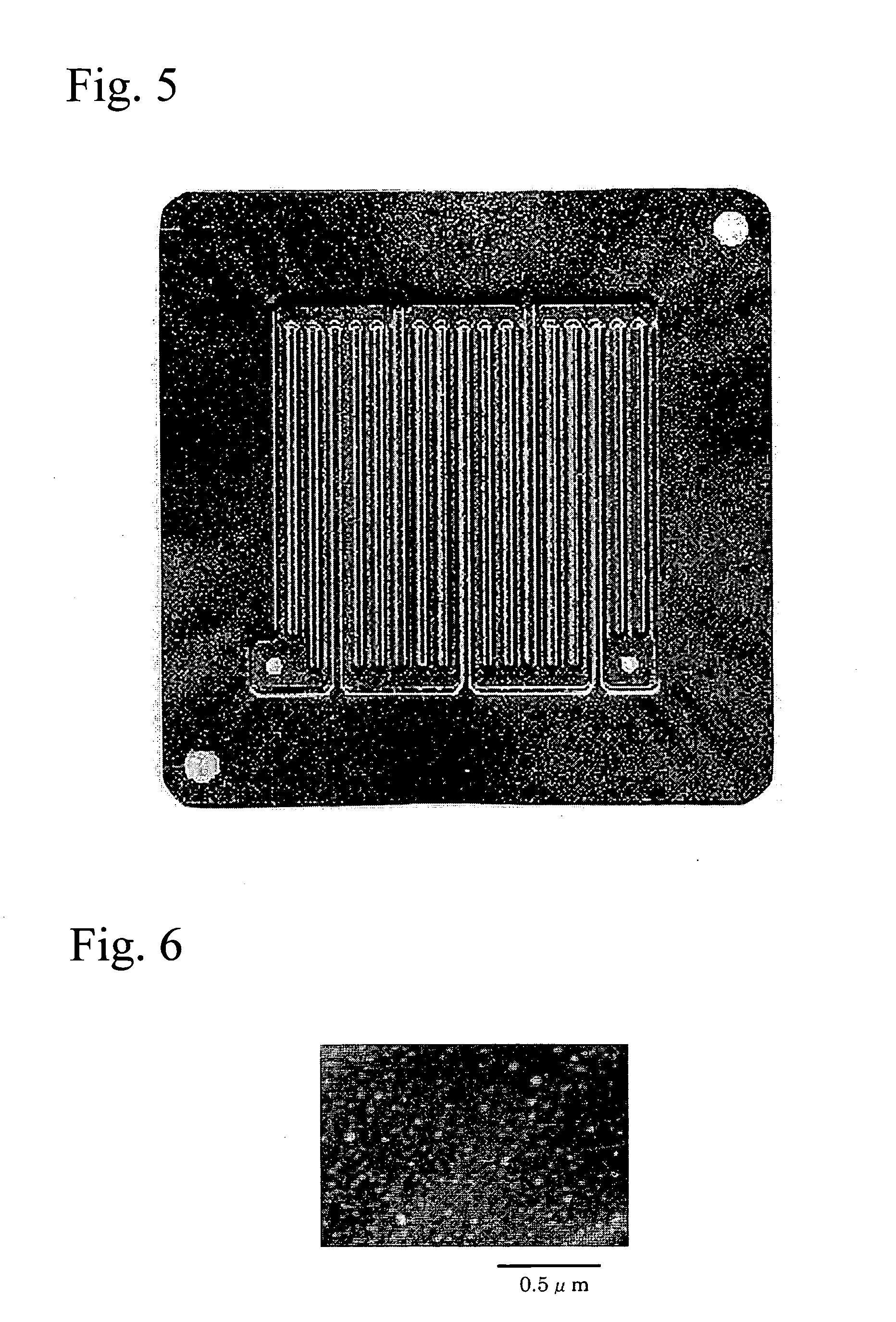

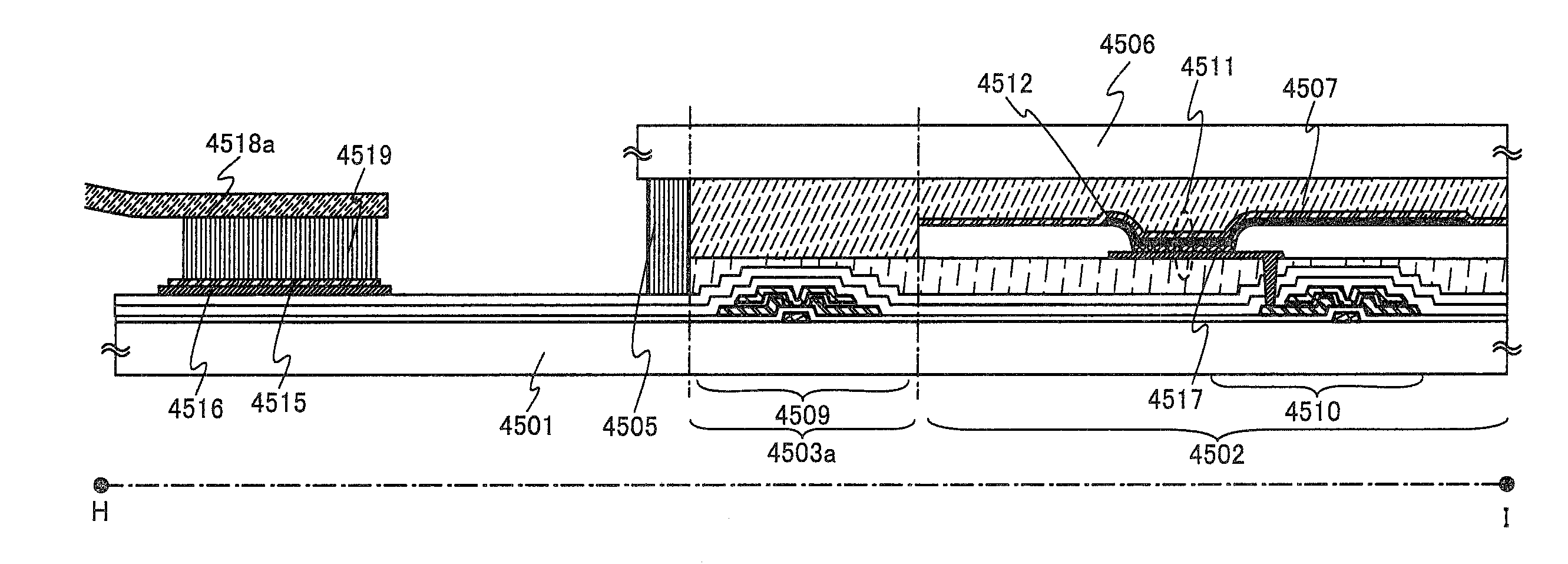

Metallic separtor for fuel cell and production method for the same

ActiveUS20040197661A1Contact resistanceDifficult to separateAnodisationFinal product manufactureFuel cellsContact resistance

A metallic separator for a fuel cell has excellent corrosion resistance and contact resistance, even when a gold coating is applied directly without a surface treatment by a nickel coating. The metallic separator for a fuel cell, comprising stainless steel having a surface, can be obtained by coating at 2.3 to 94 % of area rate on the surface without a surface treatment.

Owner:HONDA MOTOR CO LTD

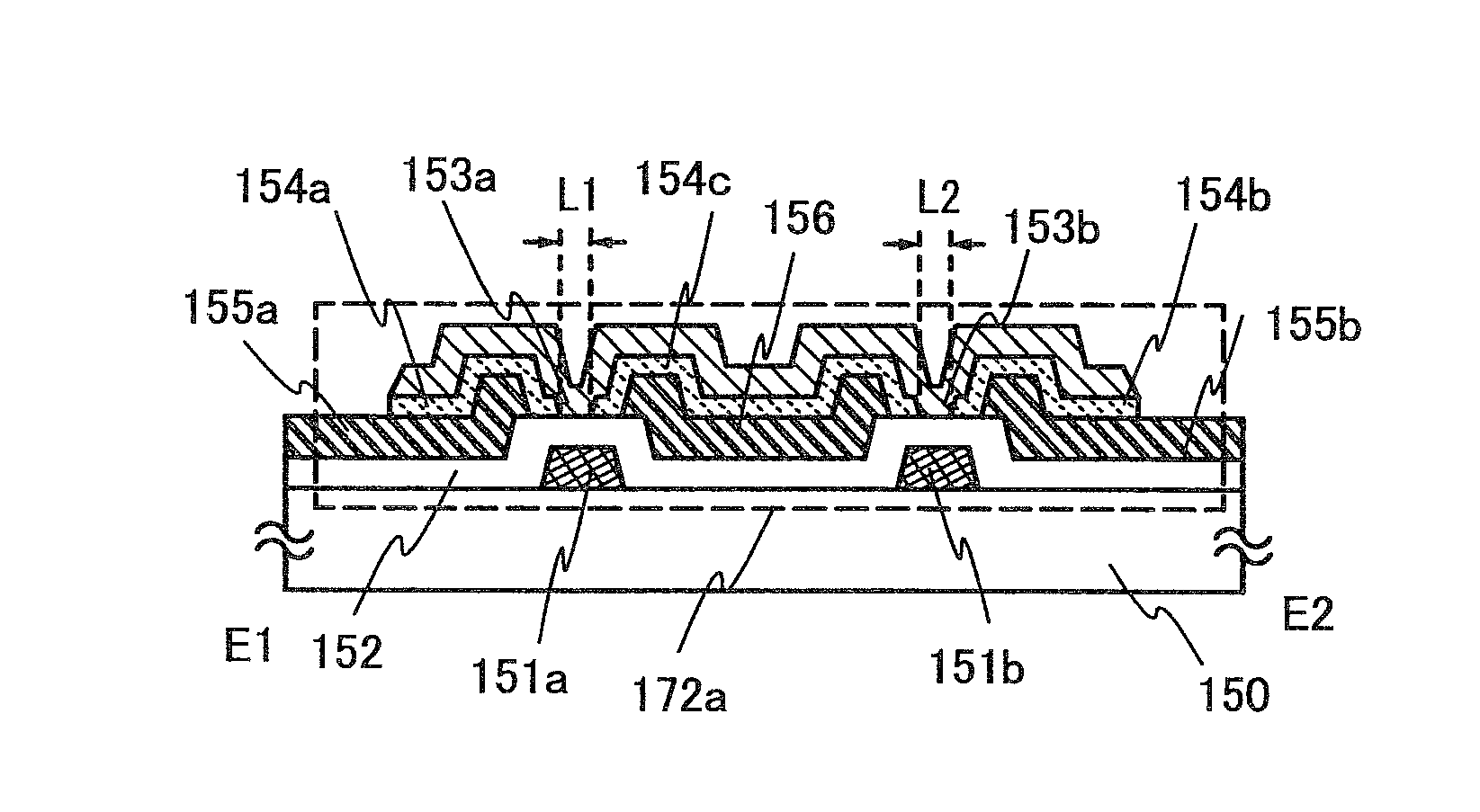

Semiconductor device and manufacturing method thereof

ActiveUS20100032666A1Small amount of photocurrentReduce parasitic capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingProduction rateIndium

A semiconductor device including thin film transistors having high electrical properties and reliability is proposed. Further, a method for manufacturing the semiconductor devices with mass productivity is proposed. The semiconductor device includes a thin film transistor which includes a gate electrode layer, a gate insulating layer over the gate electrode layer, a source electrode layer and a drain electrode layer over the gate insulating layer, a buffer layer over the source electrode layer and the drain electrode layer, and a semiconductor layer over the buffer layer. A part of the semiconductor layer overlapping with the gate electrode layer is over and in contact with the gate insulating layer and is provided between the source electrode layer and the drain electrode layer. The semiconductor layer is an oxide semiconductor layer containing indium, gallium, and zinc. The buffer layer contains a metal oxide having n-type conductivity. The semiconductor layer and the source and drain electrode layers are electrically connected to each other through the buffer layer.

Owner:SEMICON ENERGY LAB CO LTD

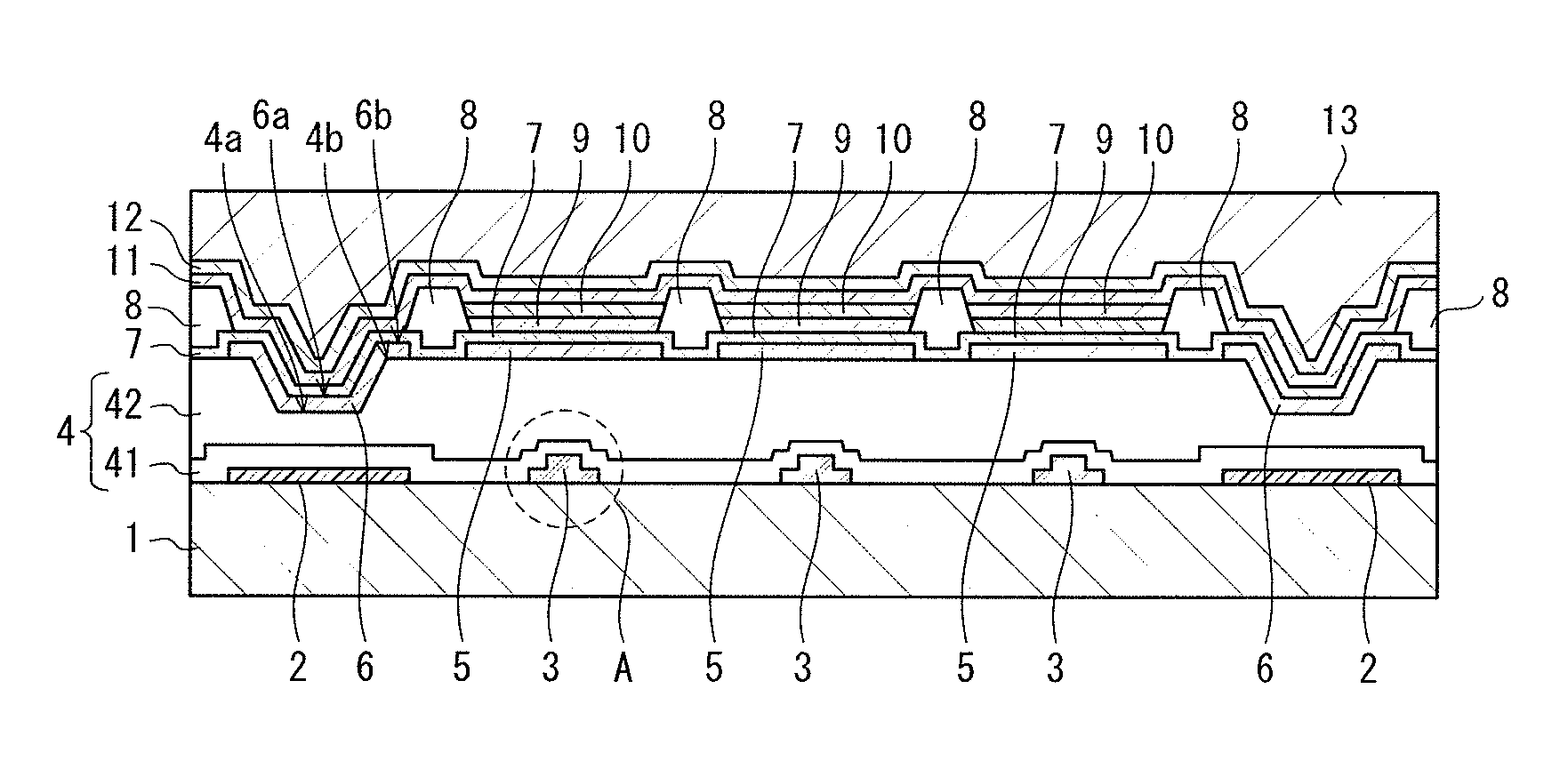

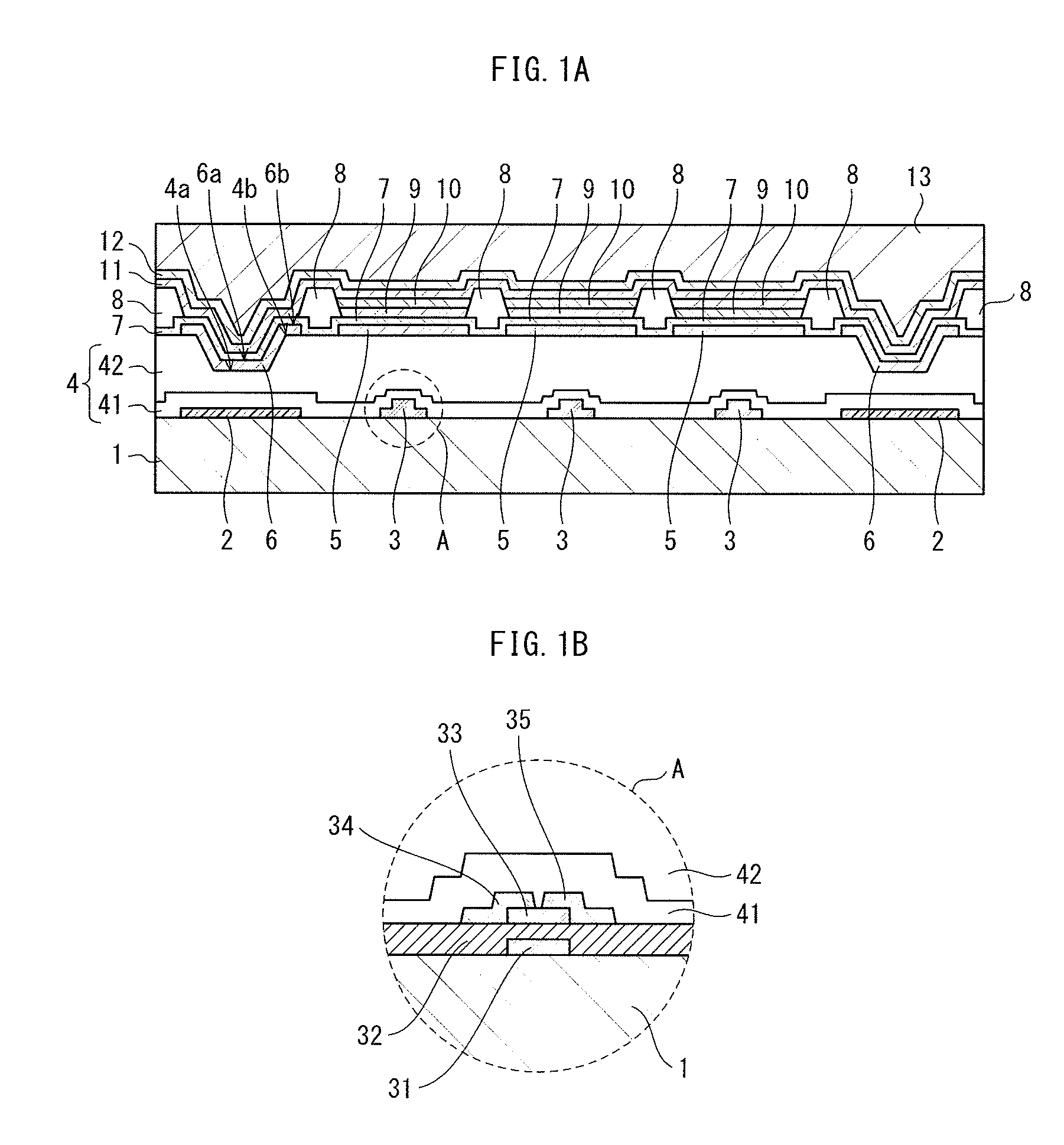

Organic electroluminescence display panel and method of manufacturing same

ActiveUS20140346484A1Reduce voltage dropContact resistanceSolid-state devicesSemiconductor/solid-state device manufacturingInter layerEngineering

A organic EL display panel includes an inter-layer insulation film, a pixel electrode, auxiliary wiring, a partition layer, an organic light-emitting layer, and a common electrode. The inter-layer insulation film has at least one paired concave portion and non-concave portion disposed in a region over the auxiliary wiring, a top face of the concave portion being concave with respect to a top face of the non-concave portion, and the auxiliary wiring includes a part over the concave portion and a part over the non-concave portion, a top face of the part over the concave portion being concave with respect to a top face of the part over the non-concave portion.

Owner:JOLED INC

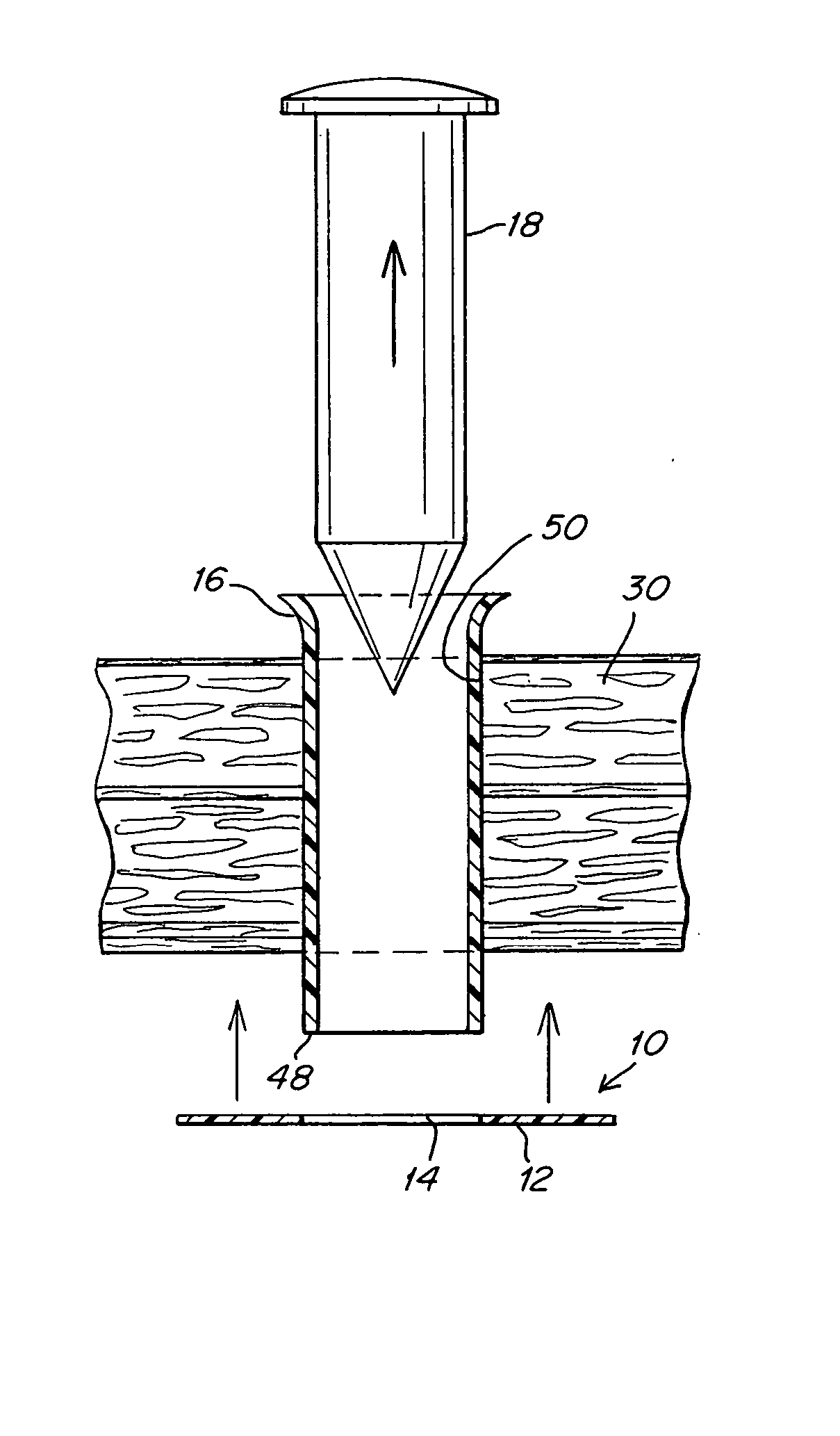

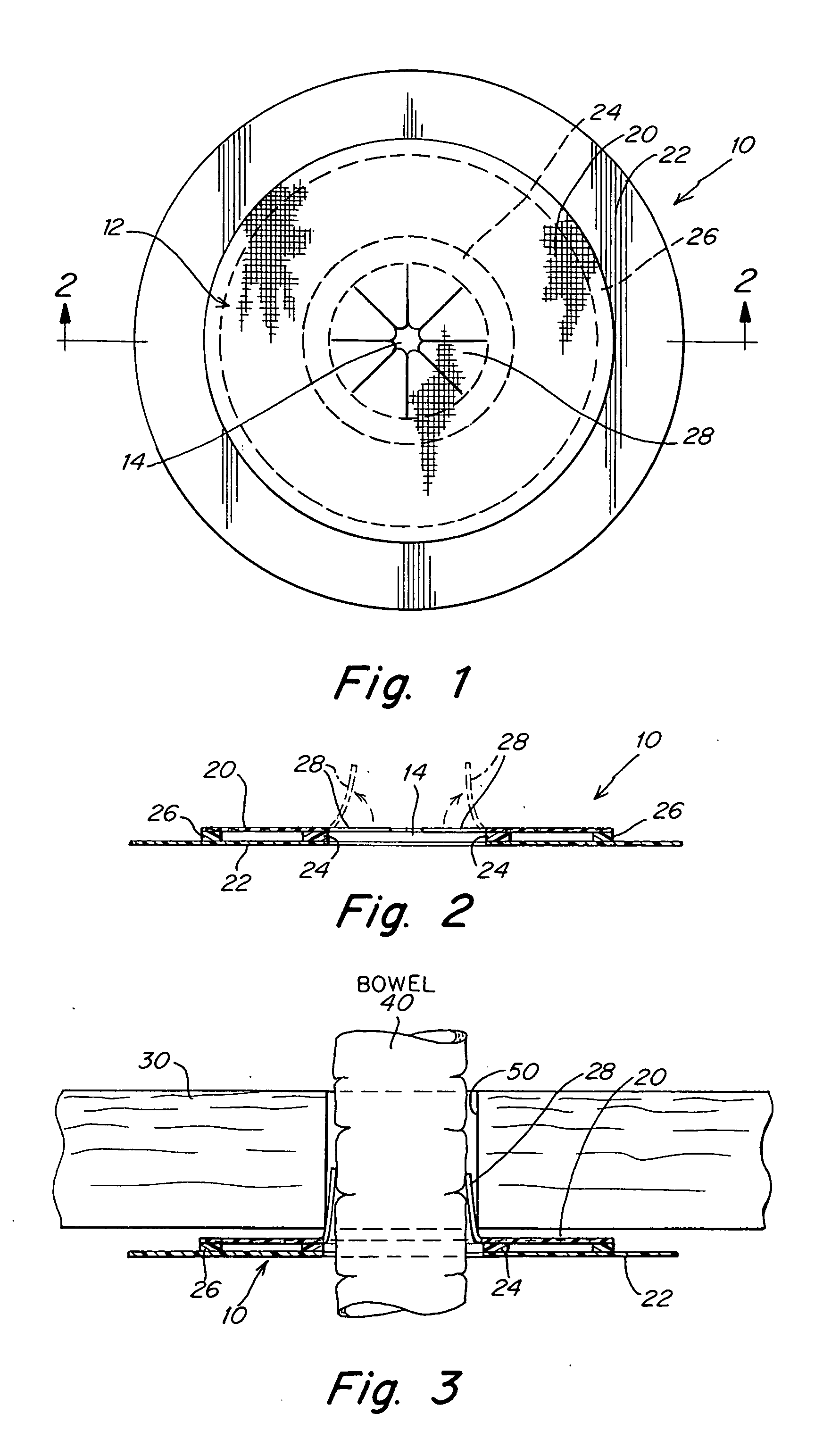

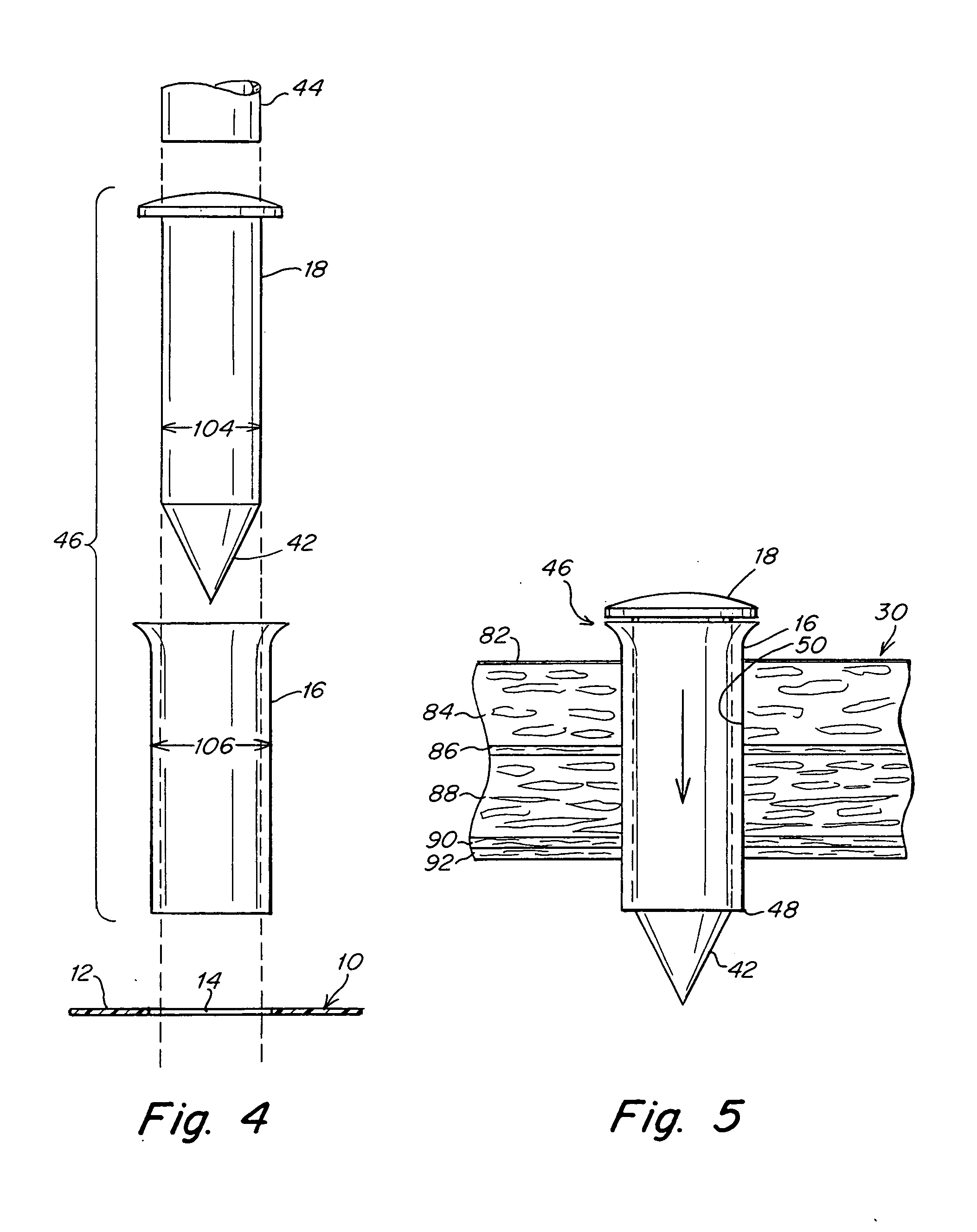

Implantable prosthesis and method of use

An implantable prosthesis and a system and method for repairing, or resisting the formation of, a hernia at an opening or stoma through an anatomical structure such as the abdominal wall. The implantable prosthesis includes a body portion and an opening therethrough, that is adapted to receive an element, such as a section of bowel, that is being externalized through the anatomical structure. The system includes the implantable prosthesis and a cannula having an outer dimension sized to fit within the opening in said implantable prosthesis, and an inner dimension sized to pass through the element. The implantable prosthesis may include a reinforcement member, and it may also include flaps that extend into the opening of the implantable prosthesis. The method includes inserting the cannula into and beyond the opening or stoma, and locating the opening of the prosthesis about the end of the cannula. A portion of the element to be externalized, such as a section of bowel in an enterostomy, is drawn through the end of the cannula such that the bowel section does not contact the implantable prosthesis. The cannula is then removed.

Owner:MICHAEL FRIMER M D

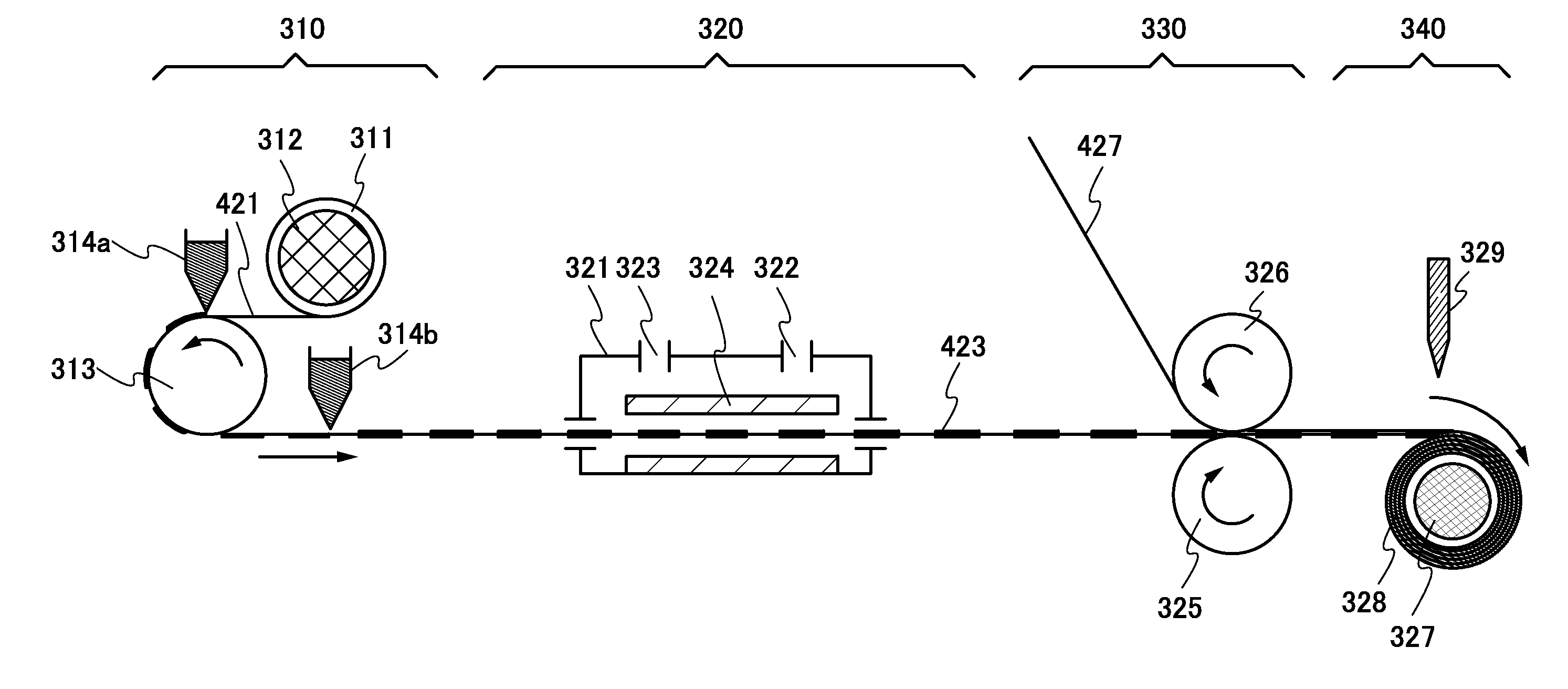

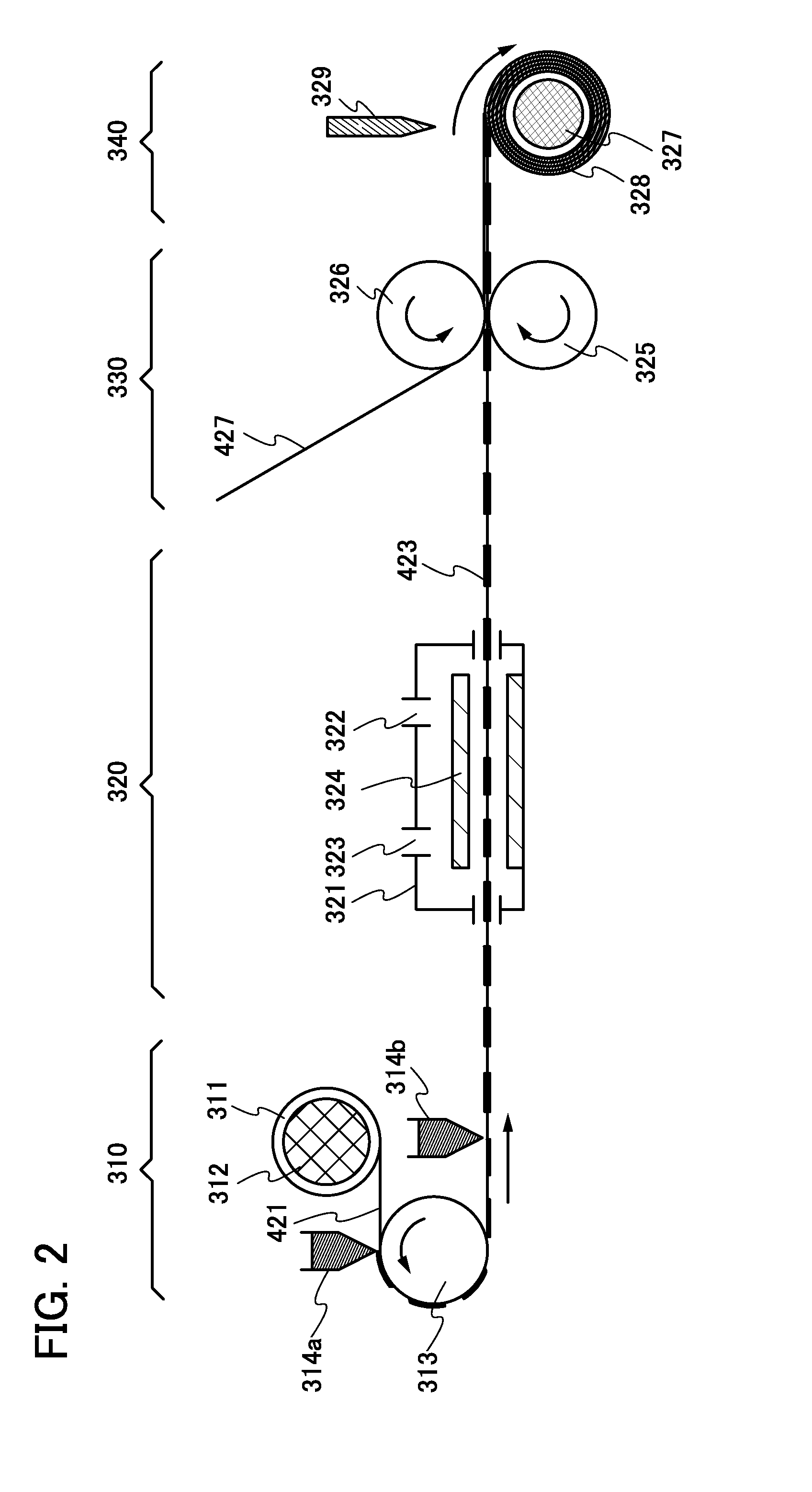

Method for manufacturing electrode for storage battery

ActiveUS20140295068A1High densityLarge capacityElectrode rolling/calenderingElectrode thermal treatmentHigh densitySlurry

To provide a storage battery electrode including an active material layer with high density that contains a smaller percentage of conductive additive. To provide a storage battery having a higher capacity per unit volume of an electrode with the use of the electrode for a storage battery. A slurry that contains an active material and graphene oxide is applied to a current collector and dried to form an active material layer over the current collector, the active material layer over the current collector is rolled up together with a spacer, and a rolled electrode which includes the spacer are immersed in a reducing solution so that graphene oxide is reduced.

Owner:SEMICON ENERGY LAB CO LTD

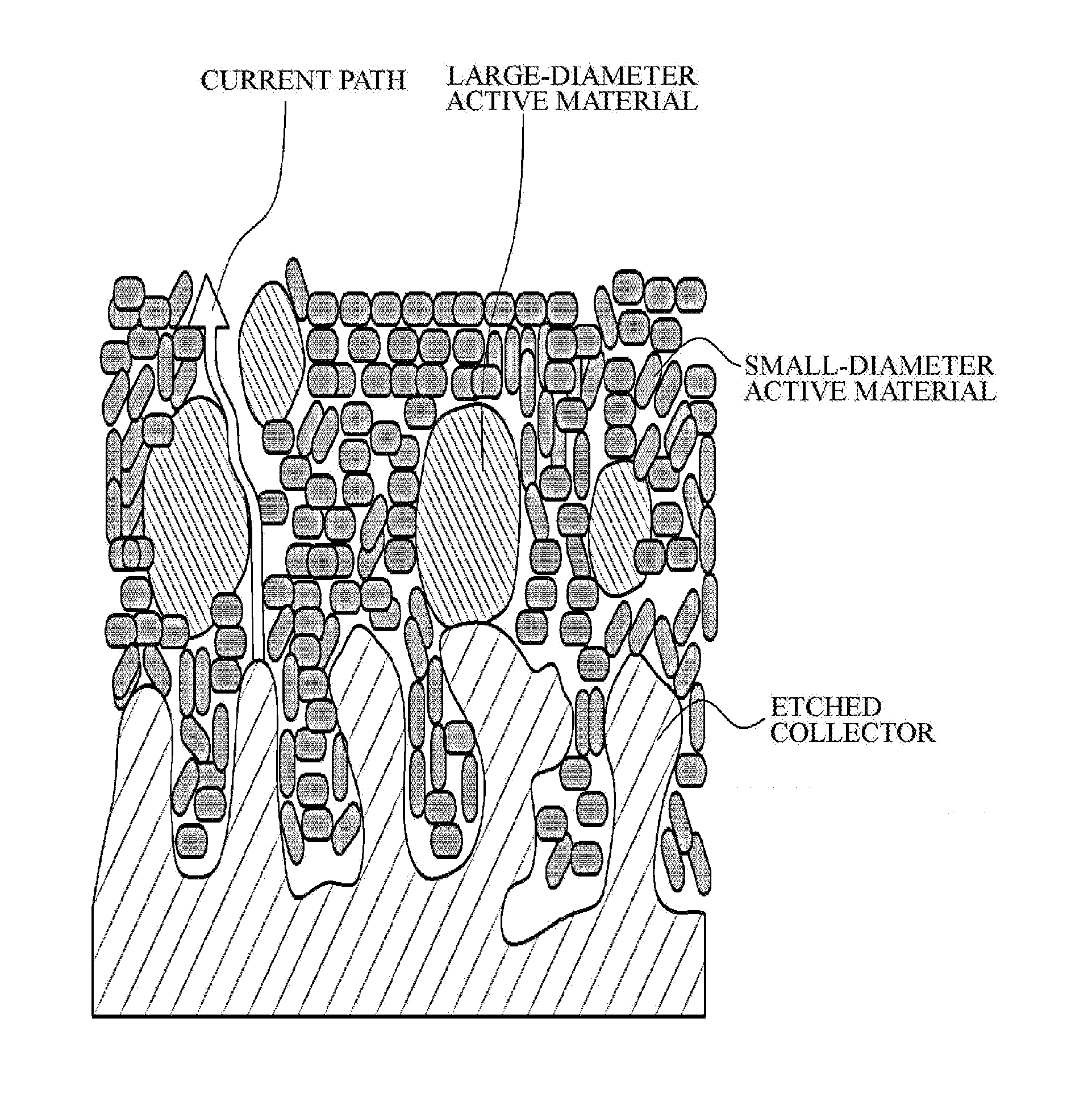

Positive electrode active material, and positive electrode and lithium secondary battery including the same

ActiveUS20120156560A1Increase battery capacityDensely packedElectrode carriers/collectorsSecondary cellsLithiumMaterials science

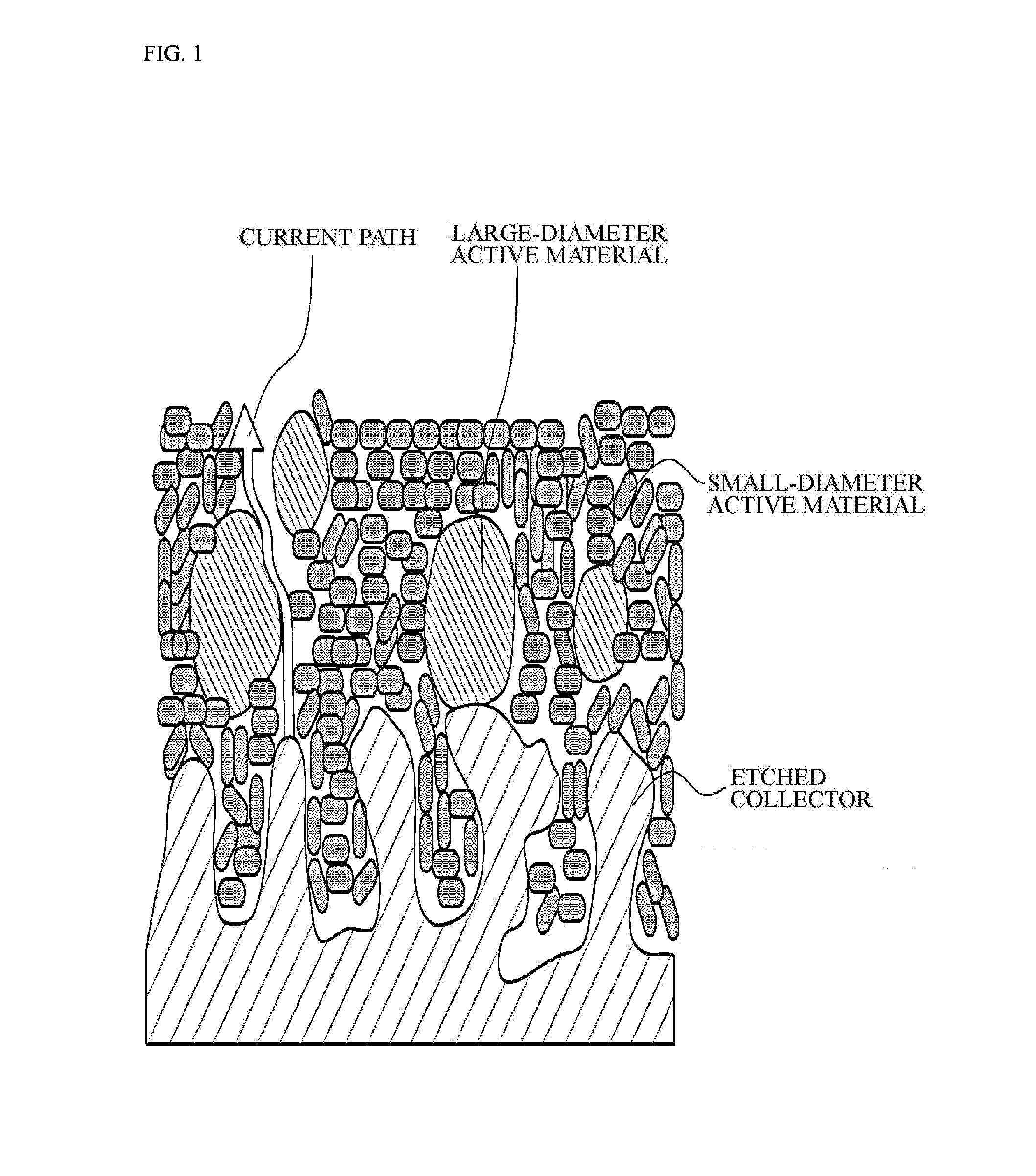

Provided is a positive electrode active material. The positive electrode active material includes: a small-diameter active material having an average particle diameter of about 0.5 μm and a maximum particle diameter of less than about 1 μm; and a large-diameter active material having an average particle diameter of about 5 μm to about 20 μm and a maximum particle diameter of less than about 100 μm.

Owner:LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com