Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4628 results about "Air heater" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

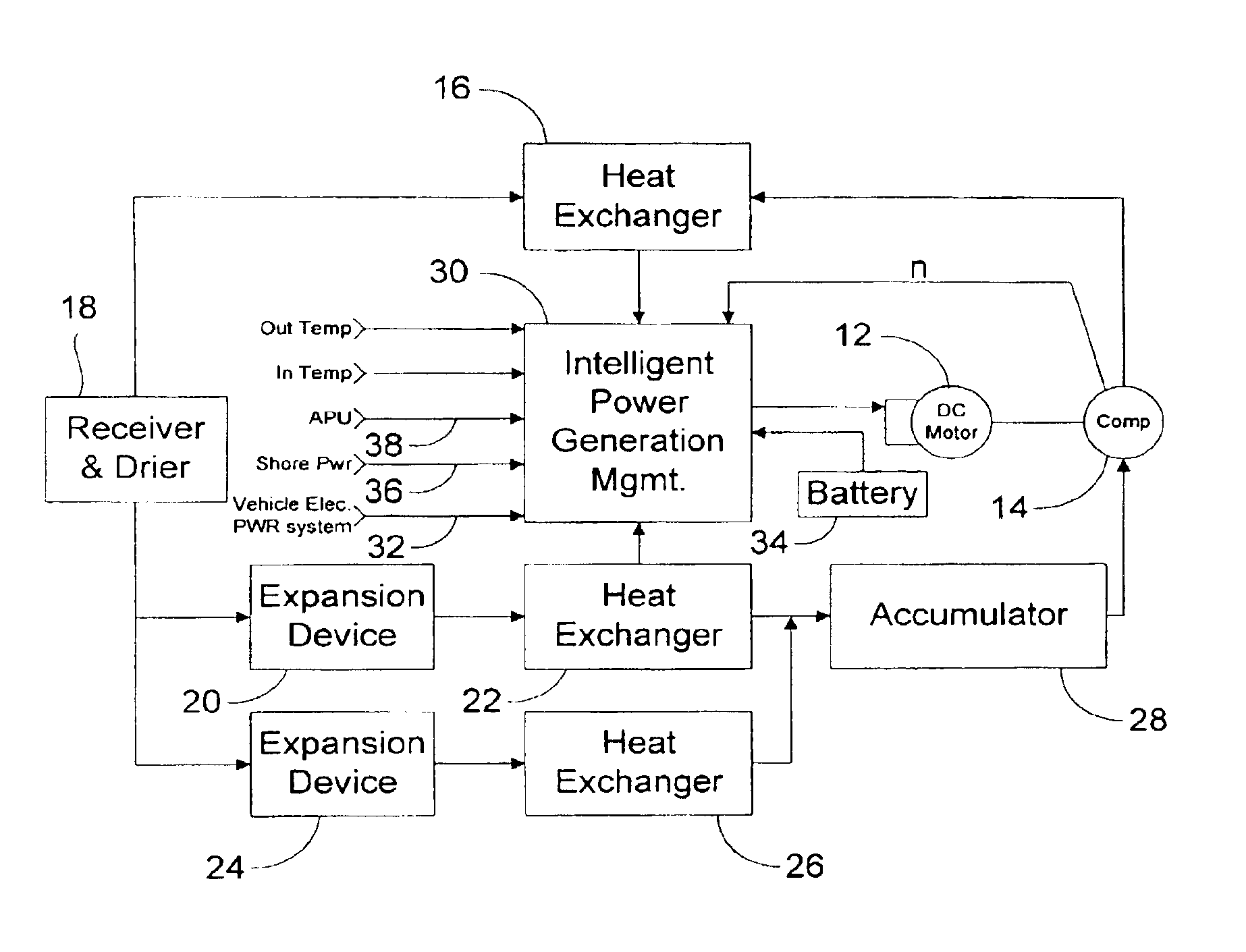

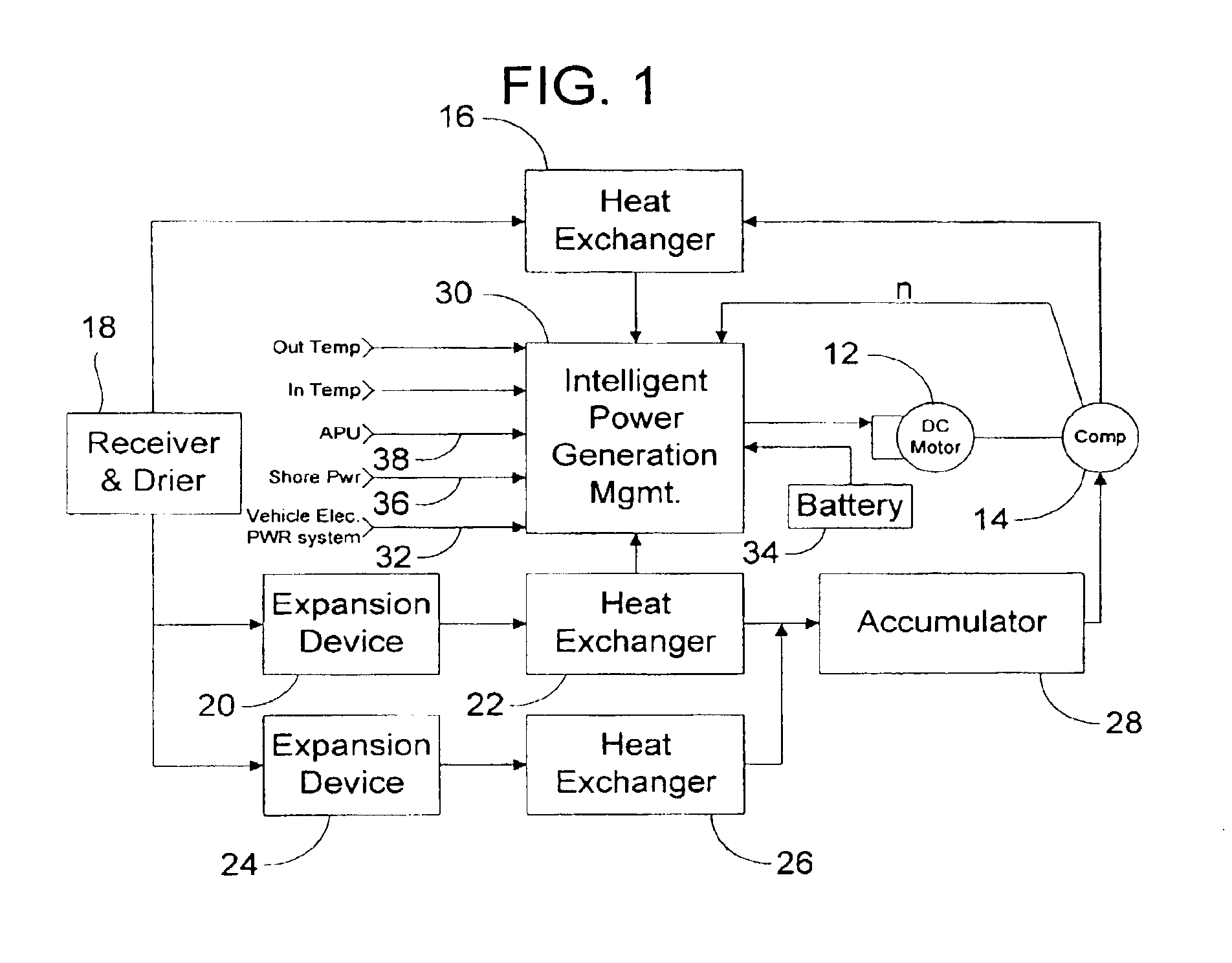

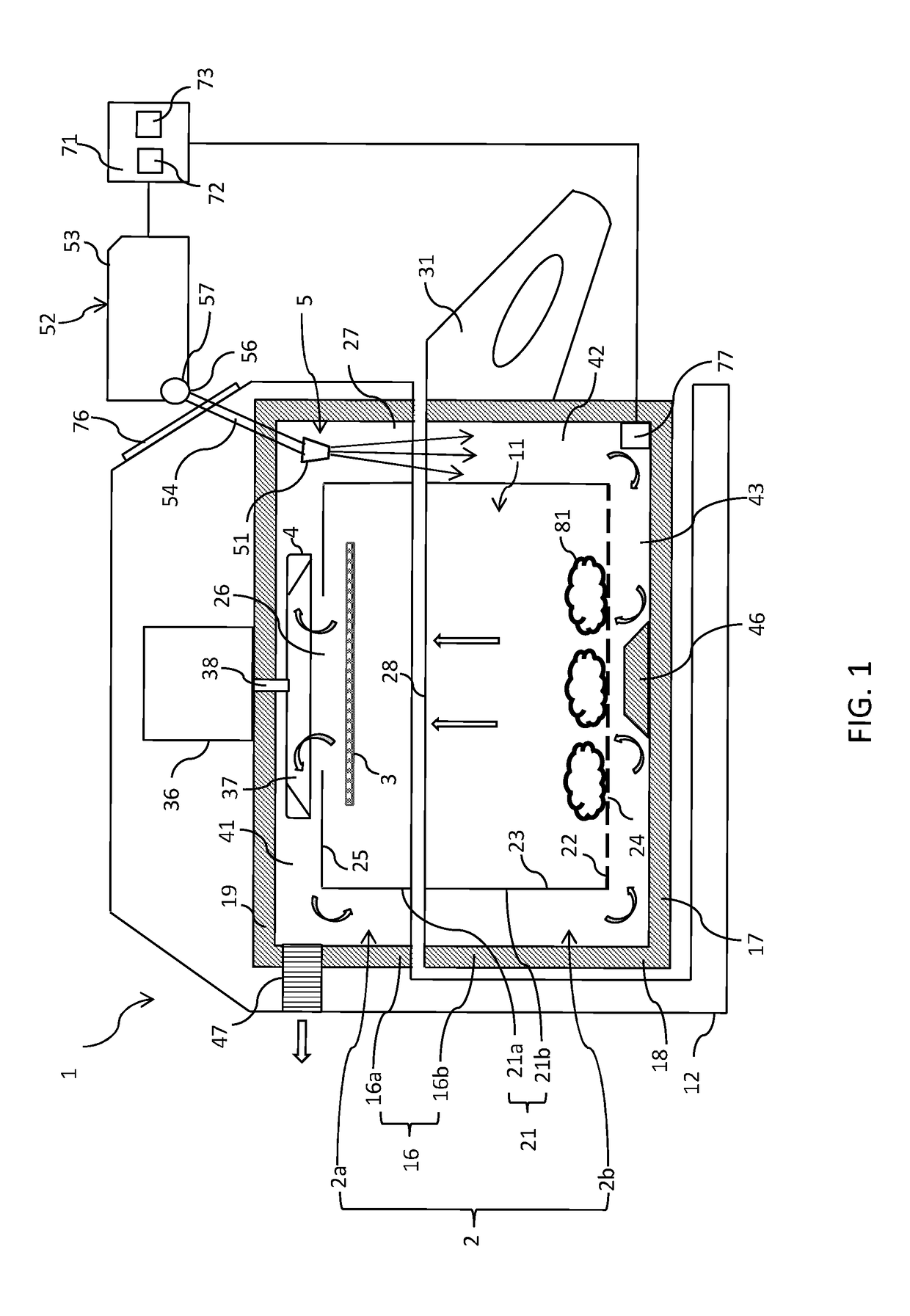

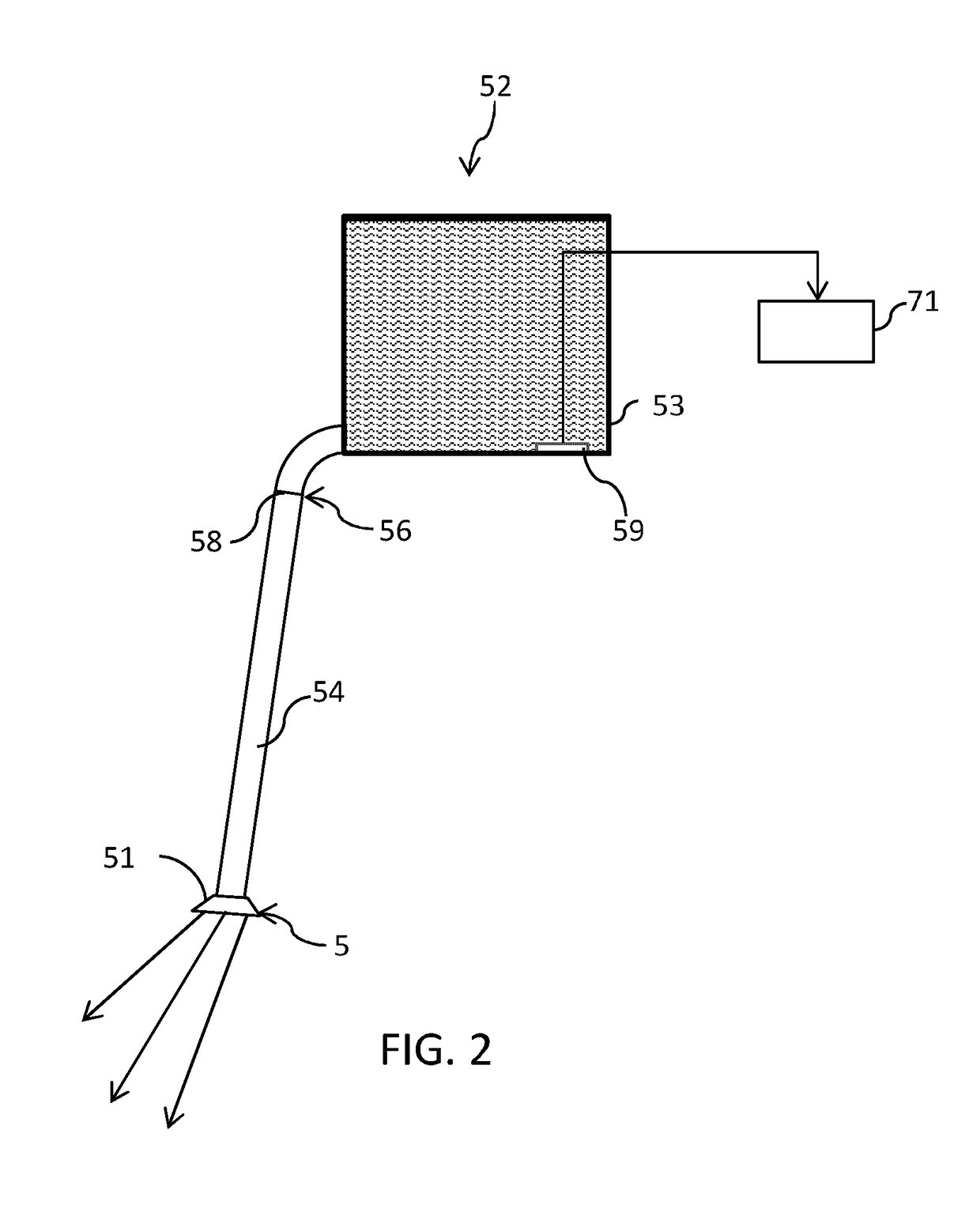

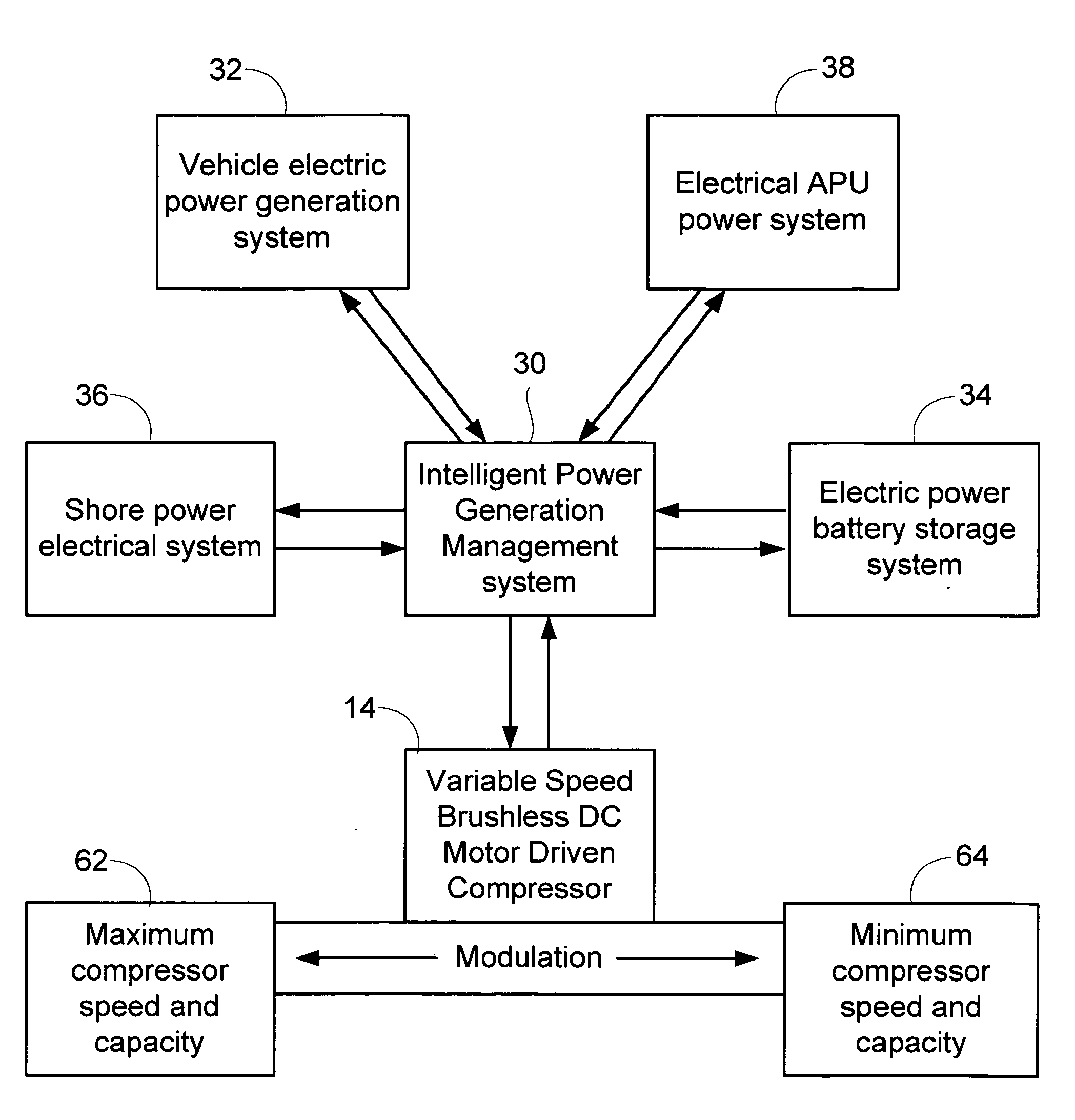

Vehicle air conditioning and heating system providing engine on and engine off operation

InactiveUS6889762B2Easy to operateSolve insufficient capacityAir-treating devicesVehicle heating/cooling devicesMotor driveAir conditioning

An air conditioning system for use in an over-the-road or off road vehicle is provided that allows operation during both engine on and engine off conditions. The system utilizes a variable speed, motor driven compressor controlled by an intelligent power generation management controller. This controller selects from one of the available sources of power on the vehicle to drive the compressor, and modulates the compressor speed and capacity based on operational parameters and source availability and depletion. The controller may also operate a coolant or air heater to provide heating to the interior compartments.

Owner:BERGSTROM INC

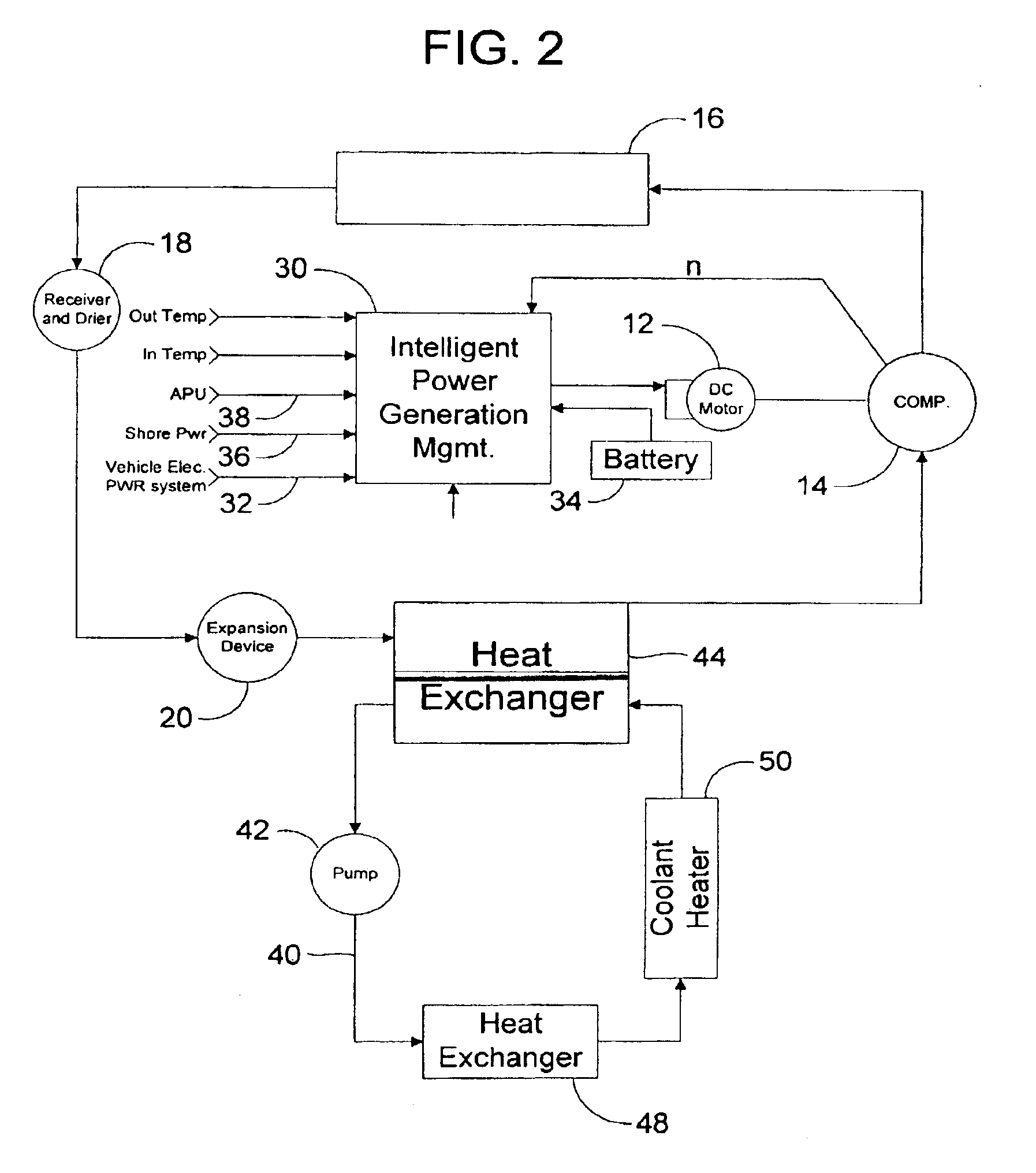

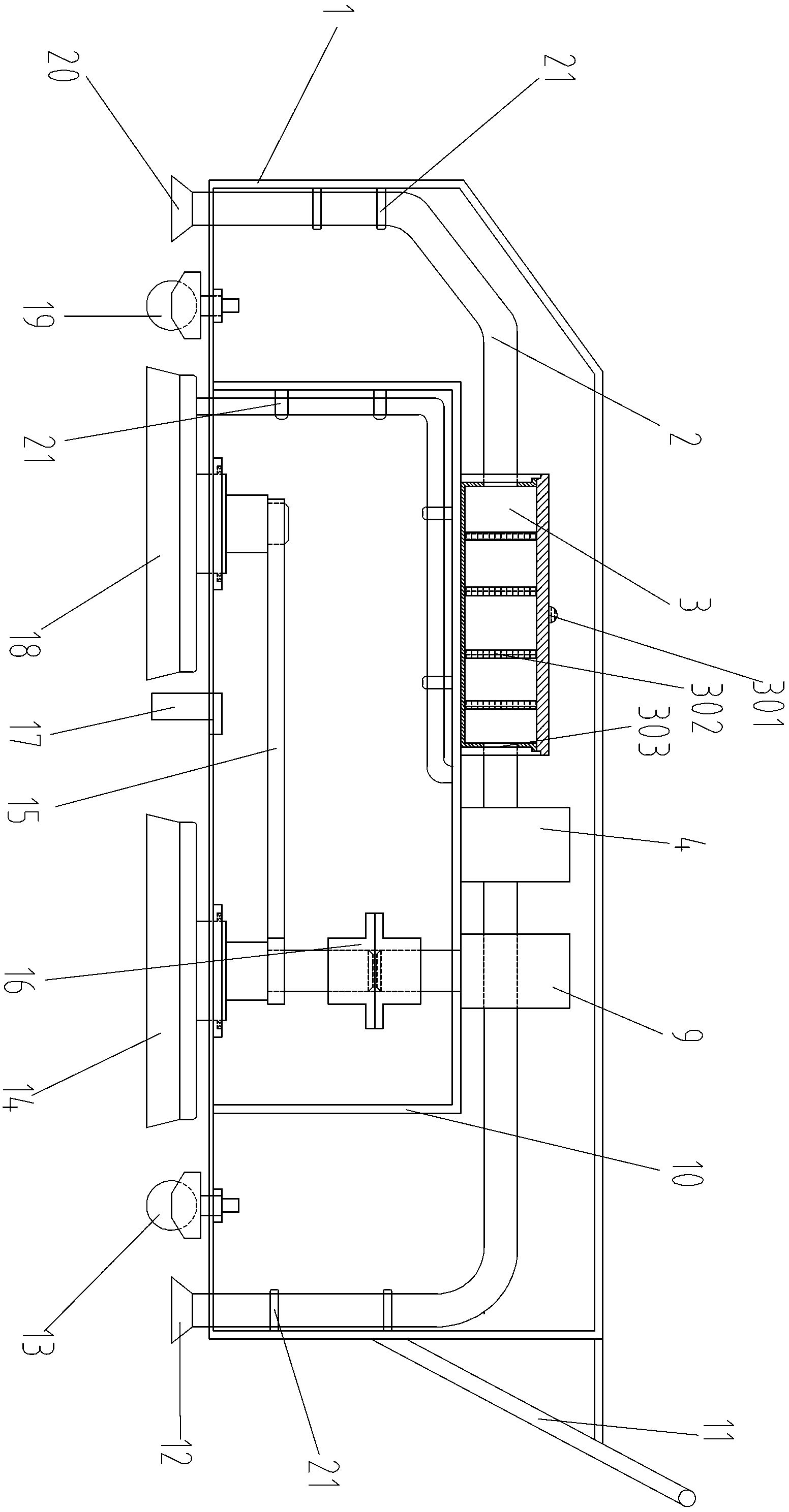

Integrated thermal cycling system of electric vehicle

ActiveCN102941791AAchieve mutual integrationMeet the high requirements of the service temperatureAir-treating devicesCell temperature controlAir conditioningElectric vehicle

The invention relates to the field of heat management of electric vehicles, and in particular to an integrated thermal cycling system of an electric vehicle. The integrated thermal cycling system of the electric vehicle comprises a motor system heat dissipation device, a motor, a motor controller, an air-conditioning system, a first water pump, an air heater, a water cooling jacket, a battery pack, a heater, a battery pack heat dissipation device, a second water pump, a heat exchanger and an evaporator; and a refrigerant pipeline and a water pipeline are connected onto the heat exchanger, the water cooling jacket is installed on the battery pack, and the motor system heat dissipation device, the first water pump, the motor controller and a motor are sequentially and circularly connected with each other according to the circulating water flowing direction, so that a motor cooling cycling circuit is formed. When the environment temperature is low, the battery pack is preheated and heated and an air conditioner in the vehicle is warmed up before the electric vehicle is started, when the environment temperature is high, the battery pack is cooled, a cab is refrigerated and the motor and the motor controller are cooled, accordingly, high requirements on the self operating temperatures of the motor system and a battery are satisfied, so that the service lives and efficiency of the motor system and the battery are increased.

Owner:SAIC MOTOR

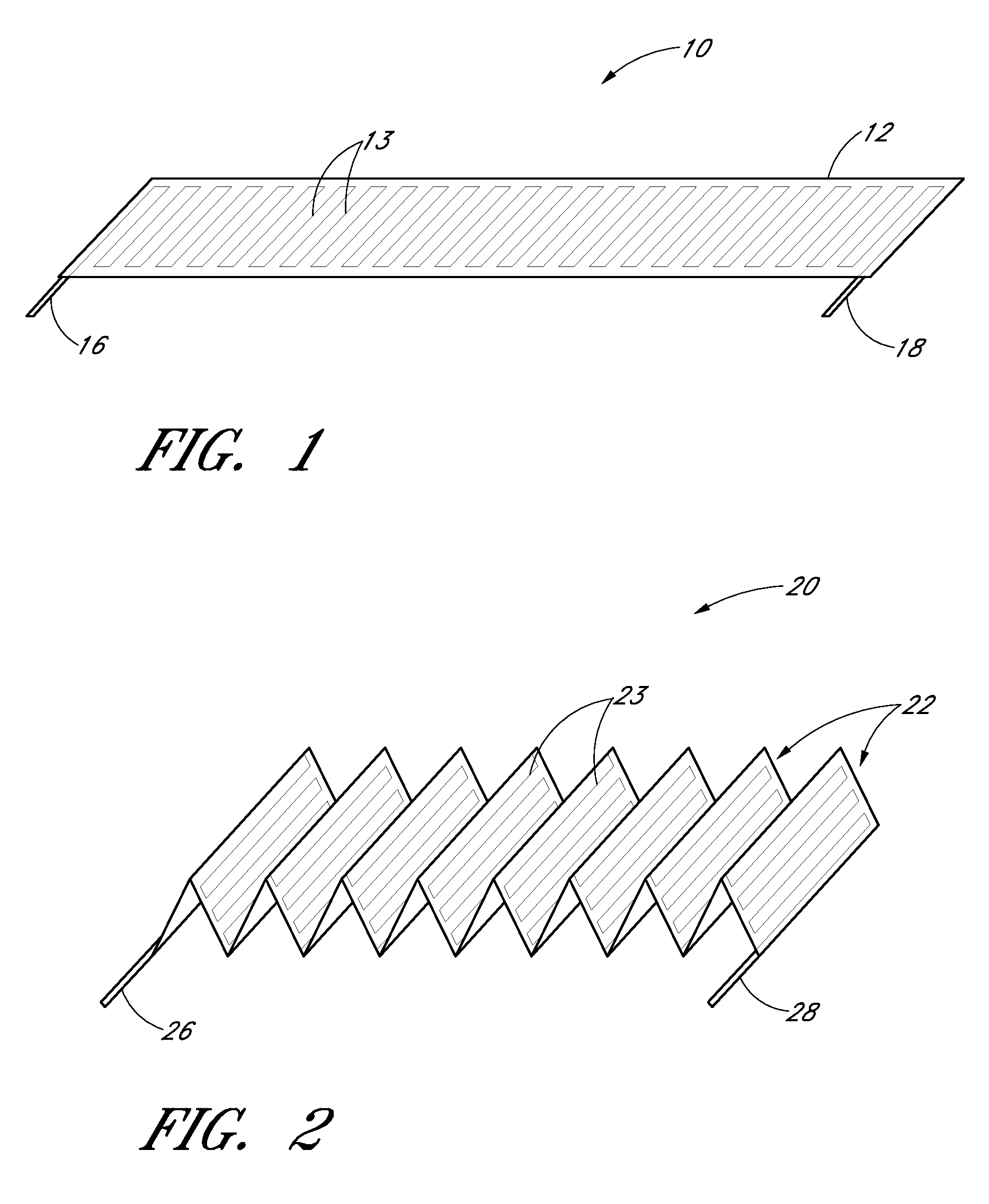

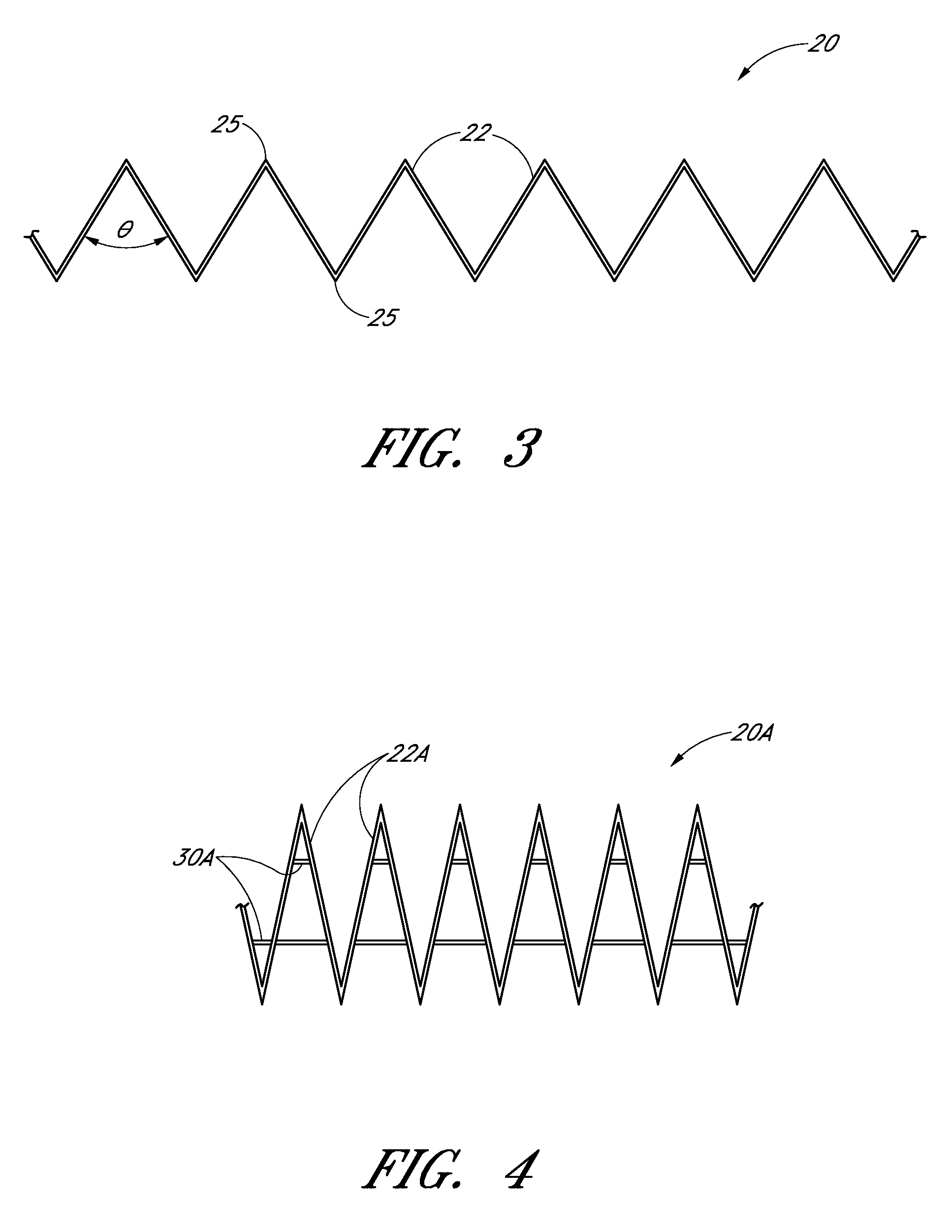

Air warmer

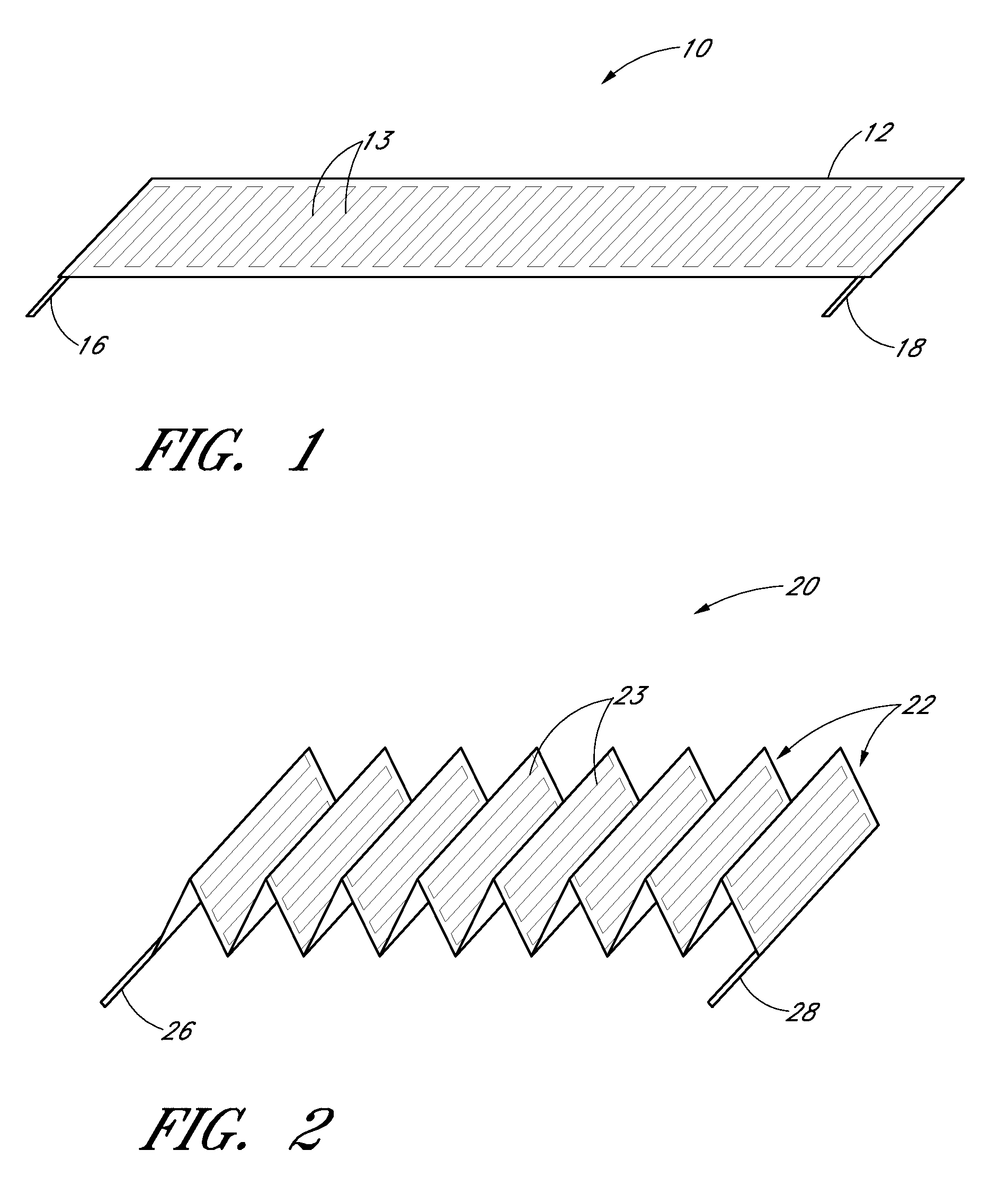

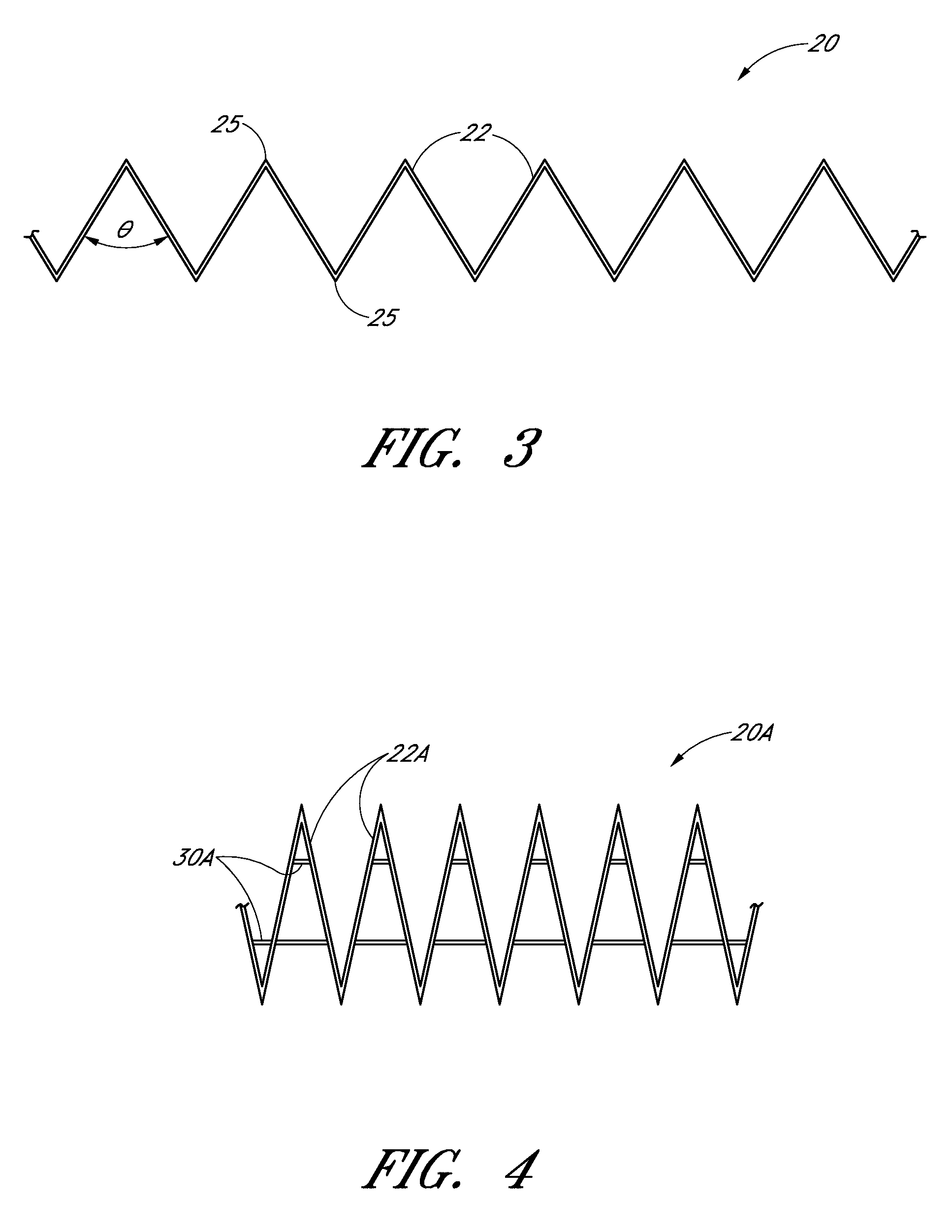

InactiveUS20080223841A1Vehicle seatsOhmic-resistance heating detailsElectrical resistance and conductanceEngineering

A heating element includes a plurality of folded surfaces which can be resistively heating using electrical current. The heating element can advantageously function both as a heating source and a heat transfer device, as the need for separate fins or other heat dissipation members is eliminated. In some embodiments, the heating element can be included in a fluid heating system. The fluid heating system can include a fluid transfer device configured to deliver a volume or ambient air or other fluid through the heating element. As air moves past the heated folded surface of the heating element, it is heated. Heated air can then be discharged to one or more desired locations.

Owner:GENTHERM INC

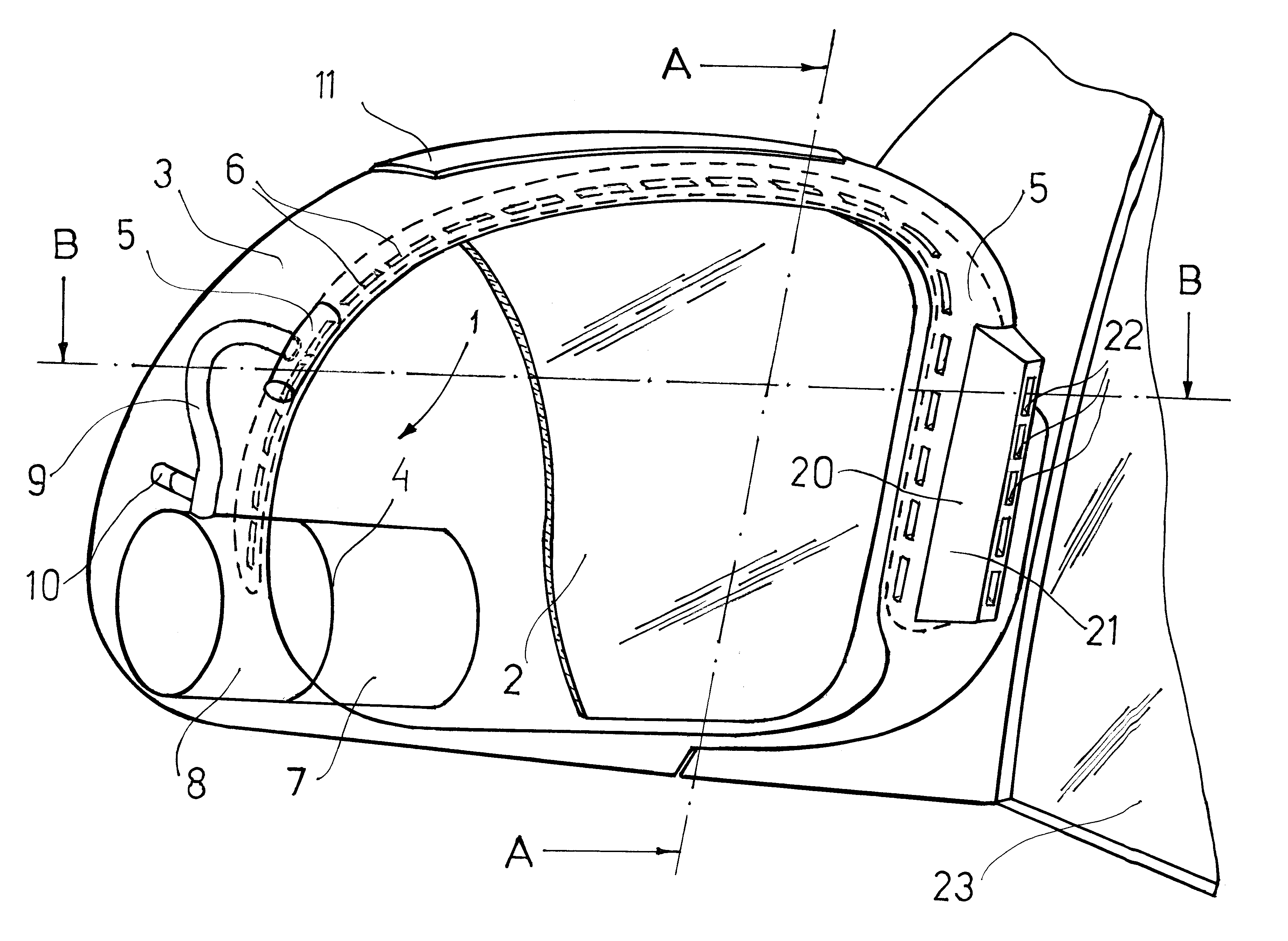

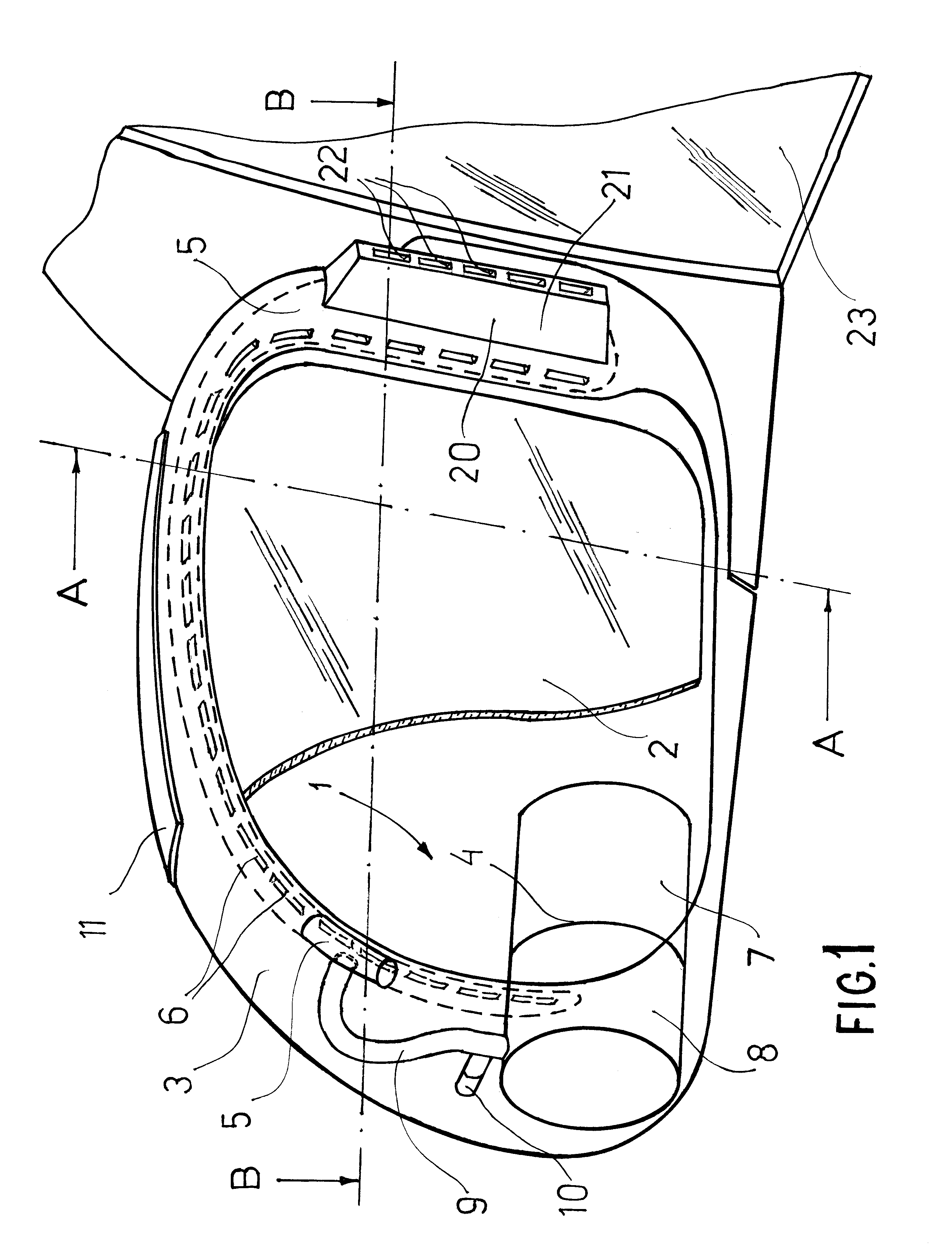

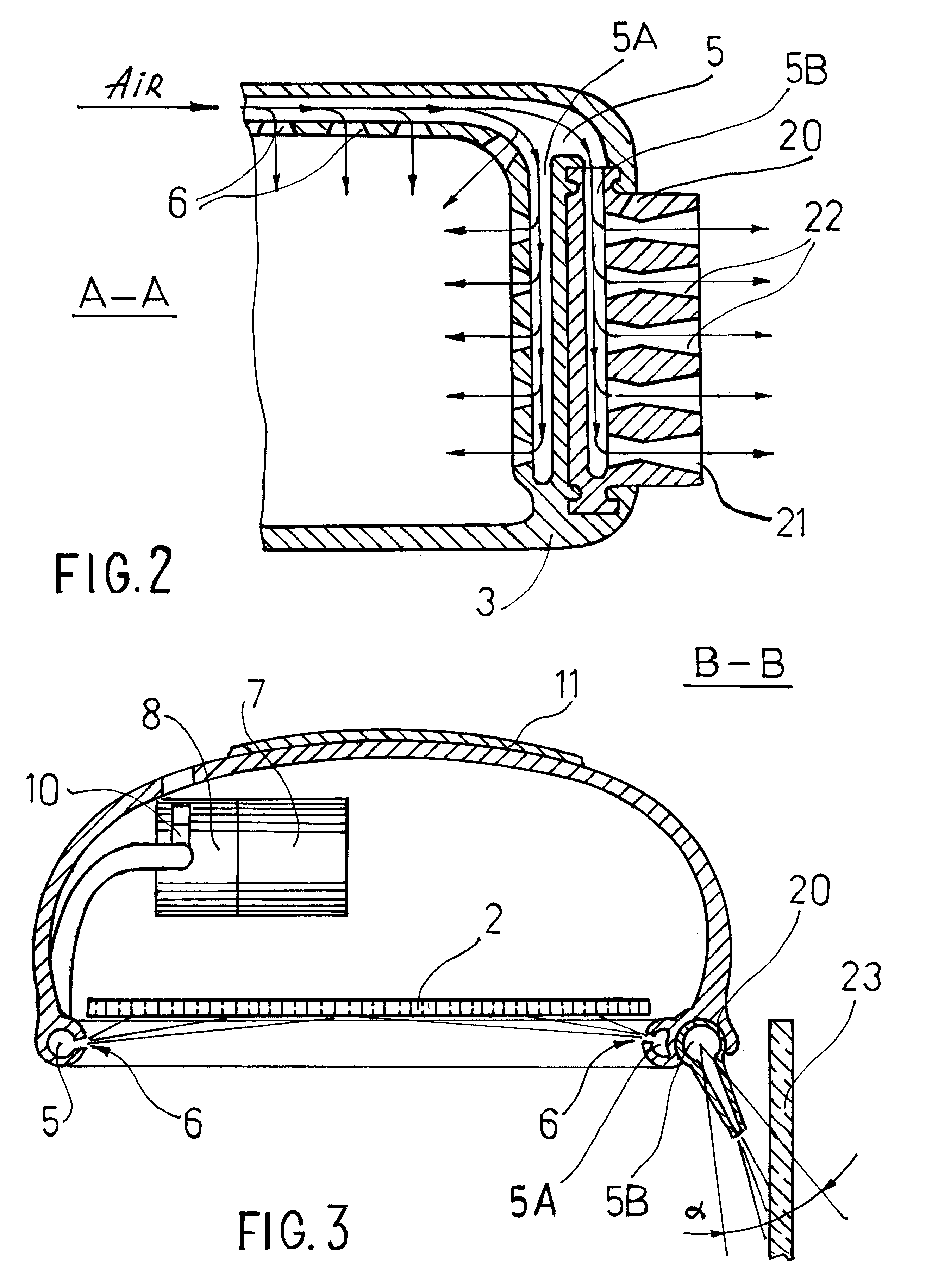

Universal clearing air system for windows and external mirrors of a vehicle

A clearing system for external mirrors and side windows of a vehicle provides a flow of compressed warm air to an air distribution unit equipped with a number of openings to direct the flow of air towards the surface of the mirror or a side window. In one embodiment, the air compressor, the air heater and an optional air filter are located in the housing of the external mirror. In another embodiment, a supplemental air distribution unit is provided to be mounted along the door of the vehicle to increase the coverage area of the side window. In a further embodiment of the invention, the system is made adjustable for allowing the most appropriate angle for the air openings towards the mirror and the side window. Provisions are also made to use the system for newly designed vehicles and incorporate the elements of the system into the design of the vehicle door. Alternately, an add-on elements are described to allow existing vehicles to benefit from the system. Additional supplemental air disbribution units may be attached to the main system to improve visibility throughout the vehicle.

Owner:BERZIN LEONID

Air warmer

A heating element includes a plurality of folded surfaces which can be resistively heating using electrical current. The heating element can advantageously function both as a heating source and a heat transfer device, as the need for separate fins or other heat dissipation members is eliminated. In some embodiments, the heating element can be included in a fluid heating system. The fluid heating system can include a fluid transfer device configured to deliver a volume or ambient air or other fluid through the heating element. As air moves past the heated folded surface of the heating element, it is heated. Heated air can then be discharged to one or more desired locations.

Owner:GENTHERM INC

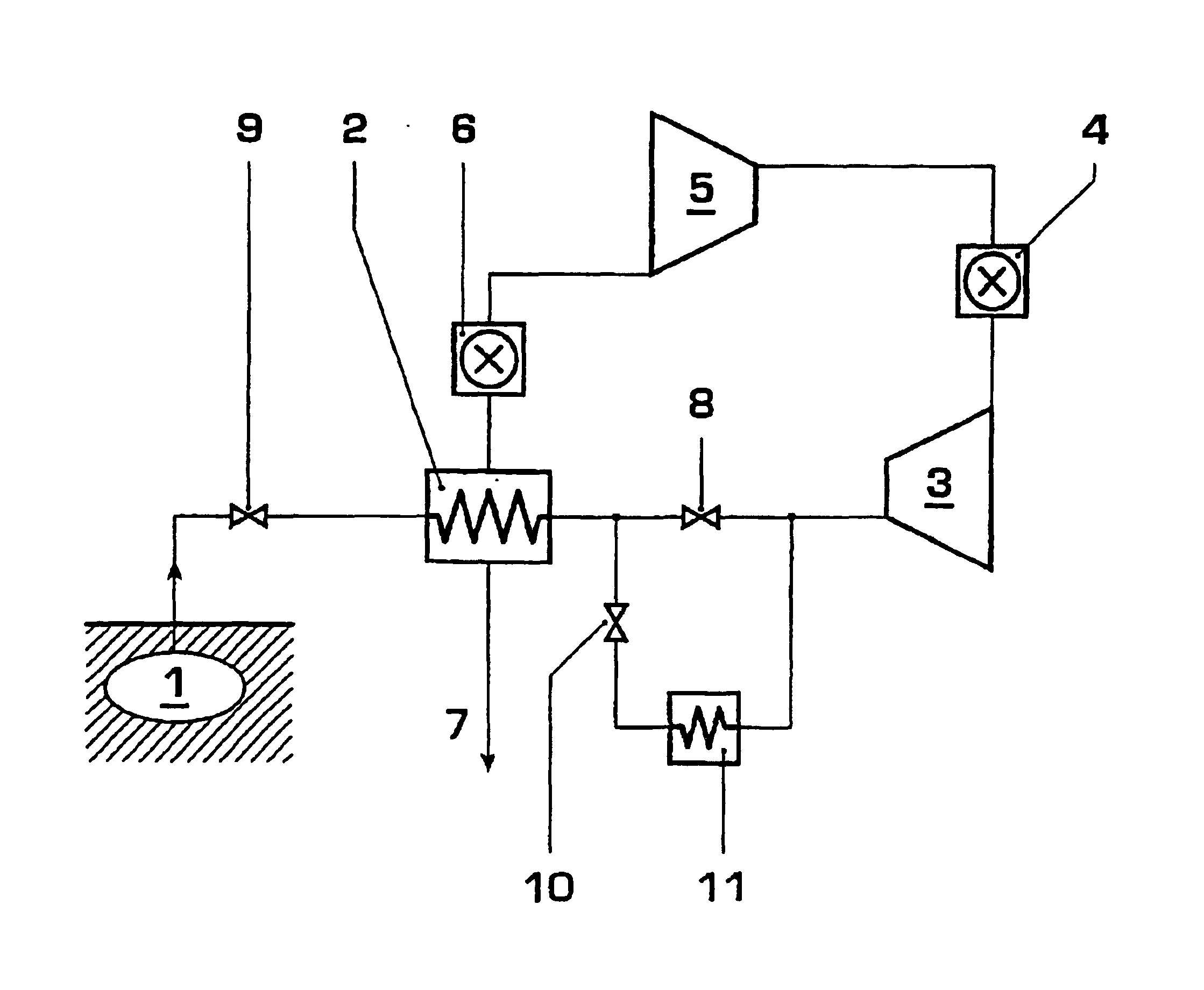

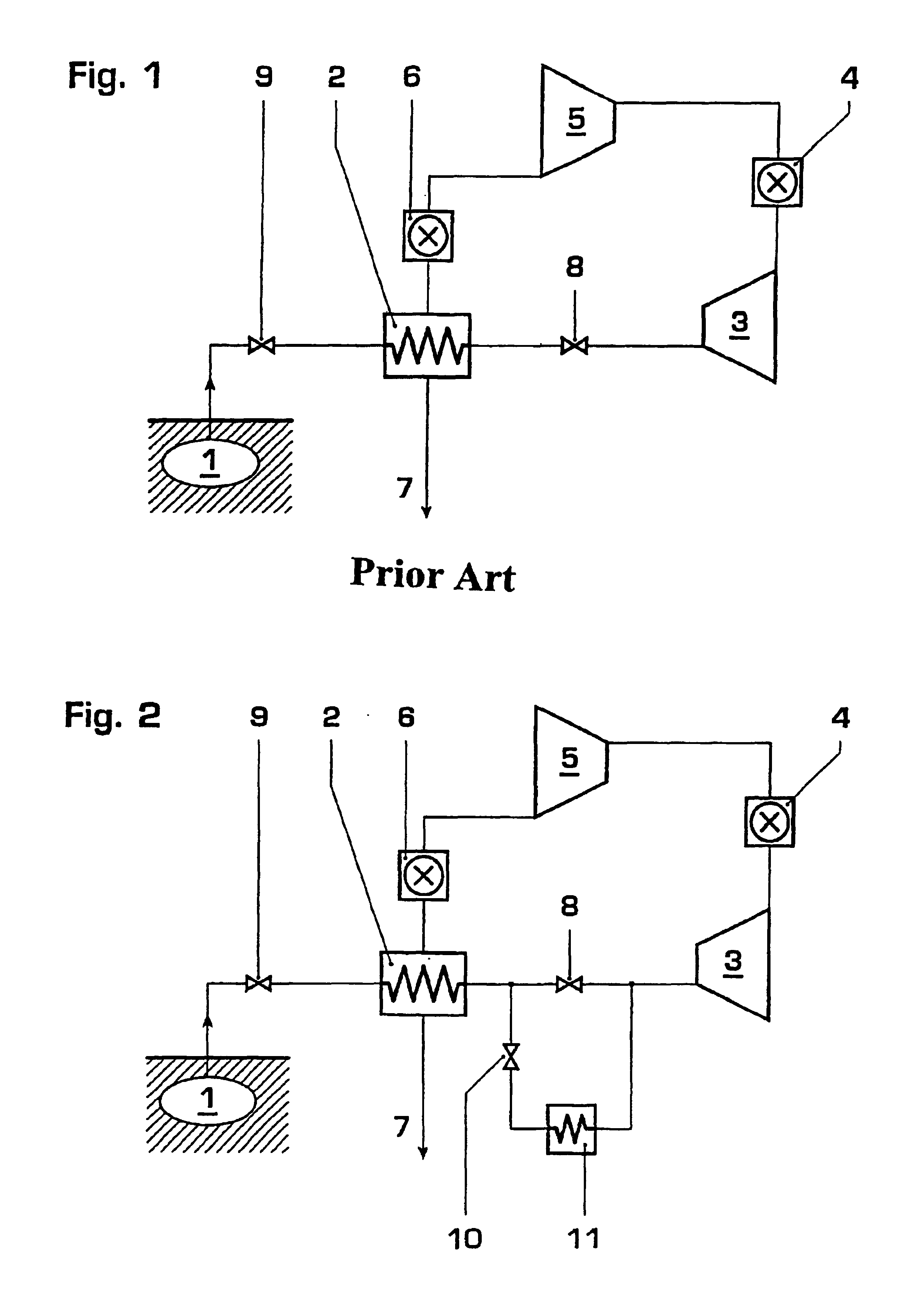

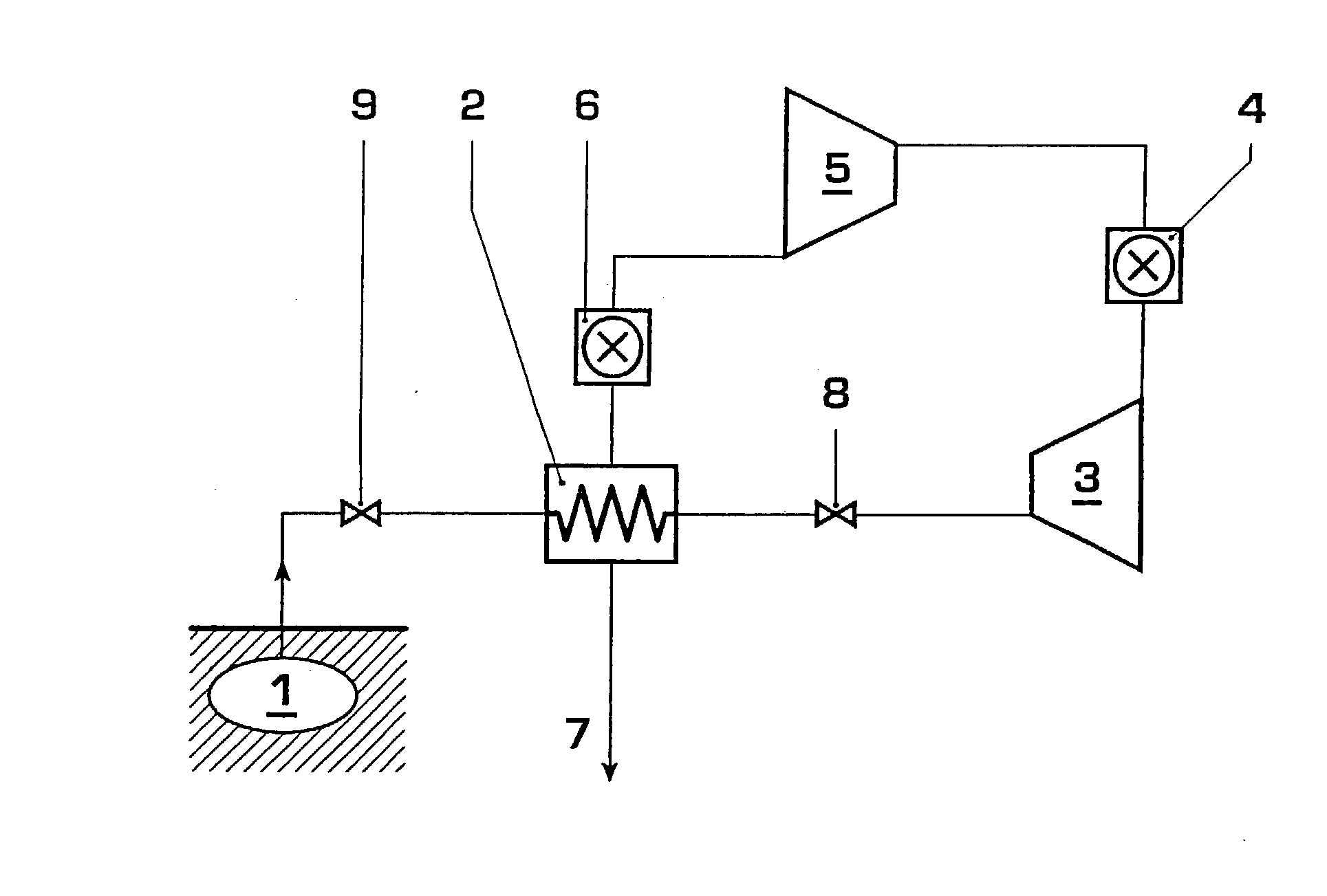

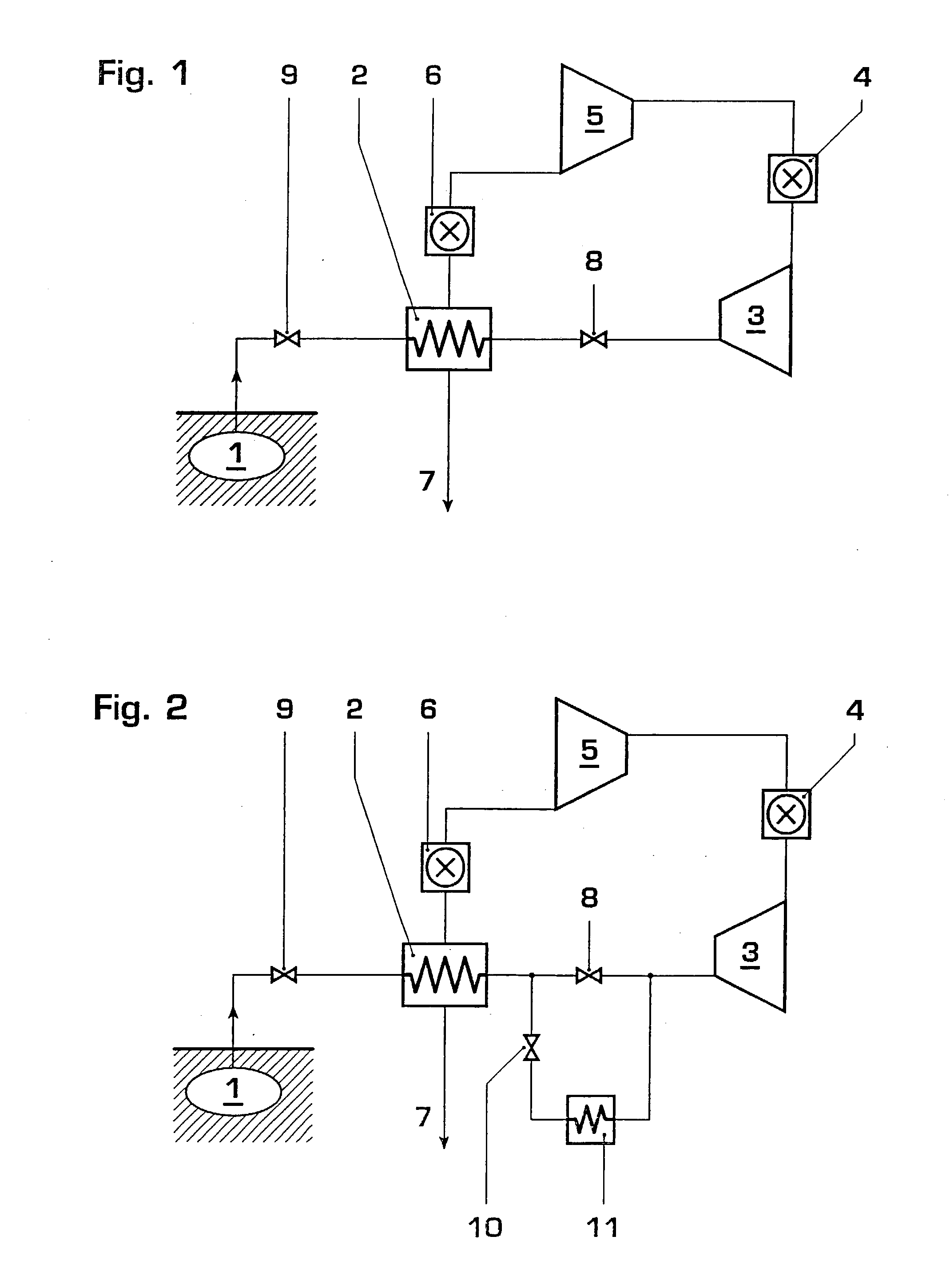

Compressed air energy storage system having a standby warm keeping system including an electric air heater

InactiveUS6848259B2Reduce thermal stressEasy temperature controlGas turbine plantsJet propulsion plantsTemperature controlCombustor

A compressed air energy storage system comprises a cavern (1) for stored compressed air and a system for providing the compressed air to a power train (3, 5), this system including a recuperator (7) and a first valve arrangement (8) that controls the flow of the compressed air from the recuperator and to the power train (3, 5). A system for warm-keeping of the power train (3, 5) during stand-by operation of the compressed air energy storage system comprises the recuperator (2) and / or an auxiliary electrical air heater (11) and a second valve arrangement (10, 13) for controlling the airflow for warm-keeping. The system for warm-keeping of the power train allows improved temperature control and avoids disadvantages associated with a warm-keeping system having a combustor.

Owner:GENERAL ELECTRIC TECH GMBH

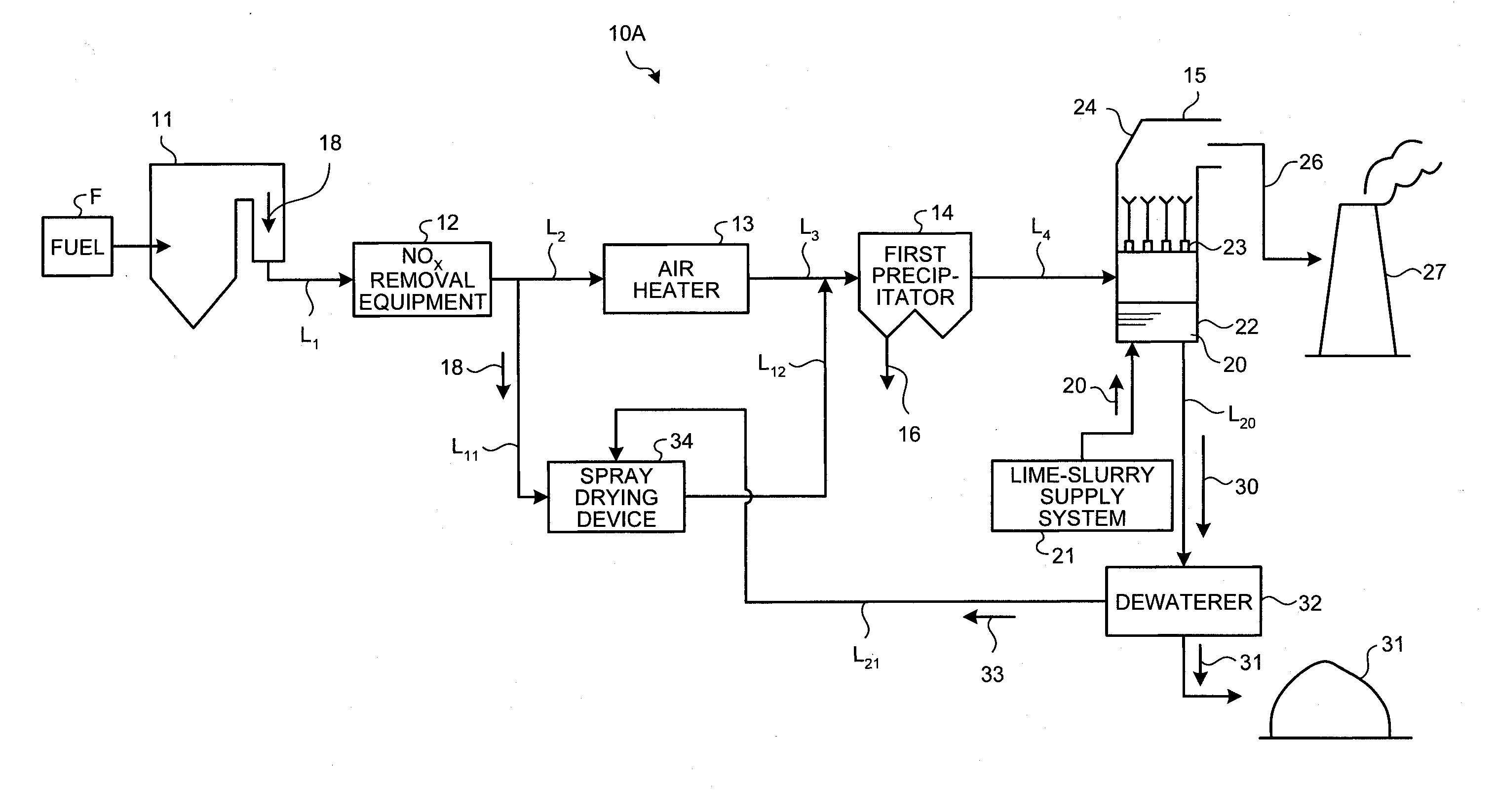

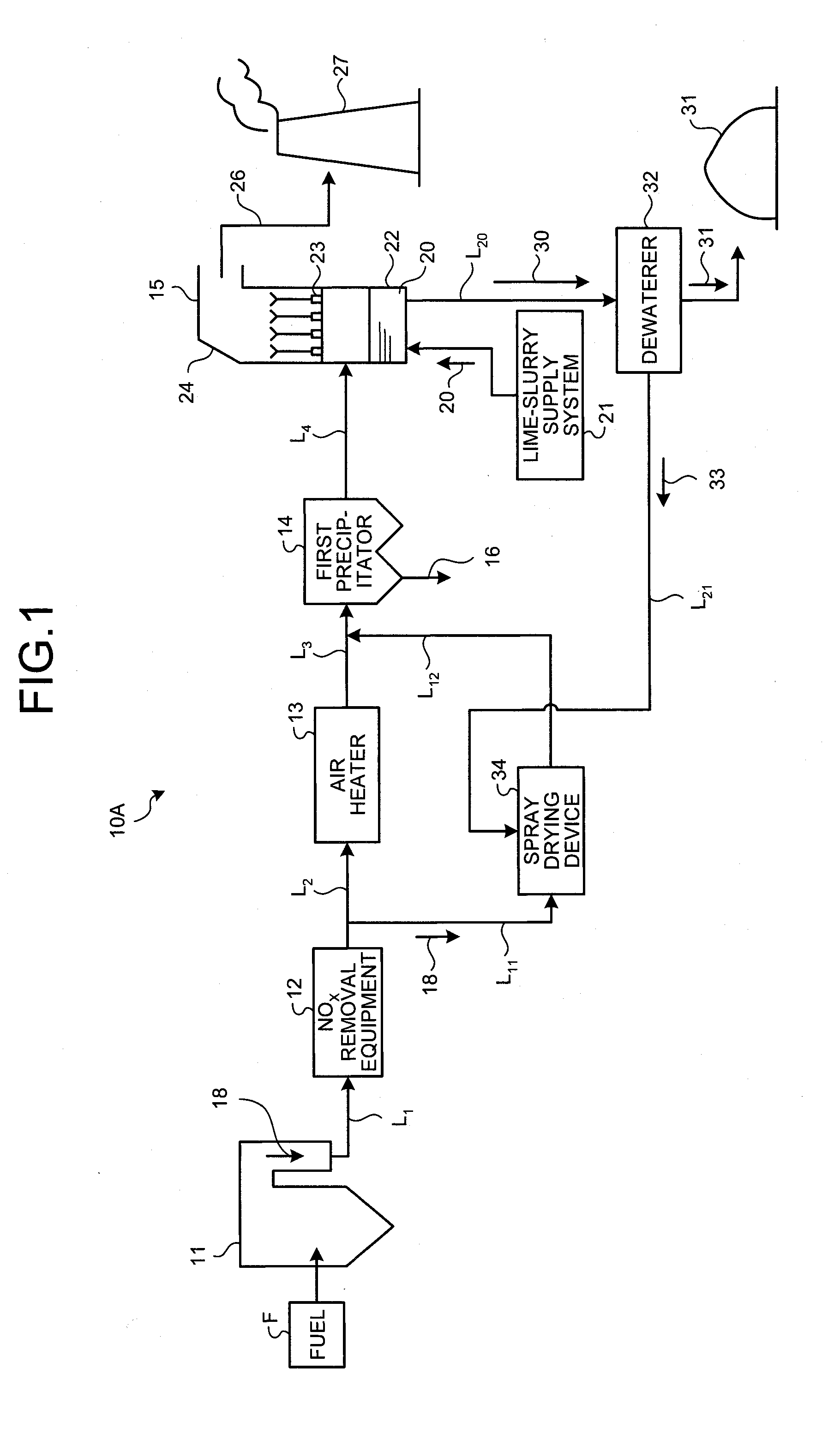

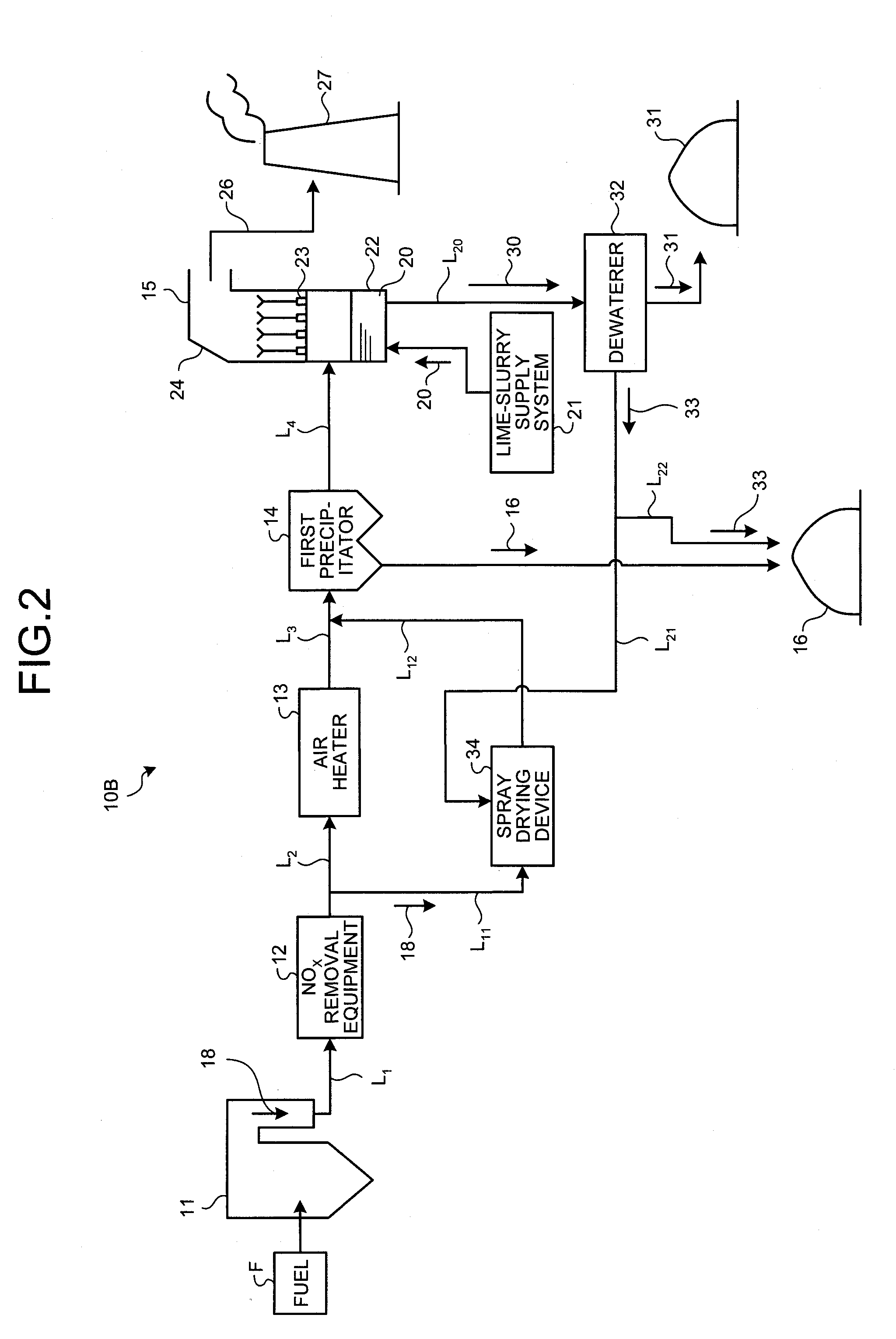

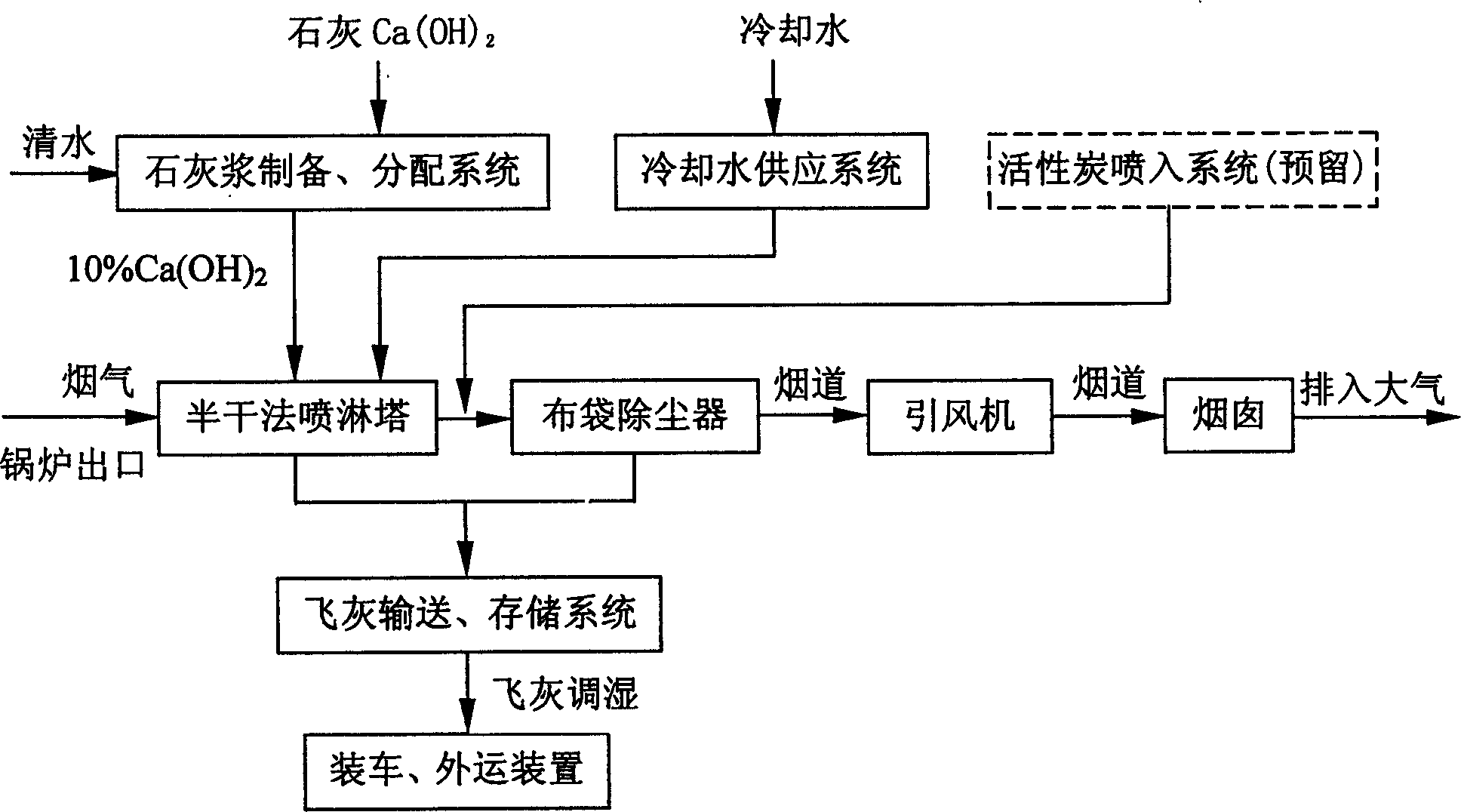

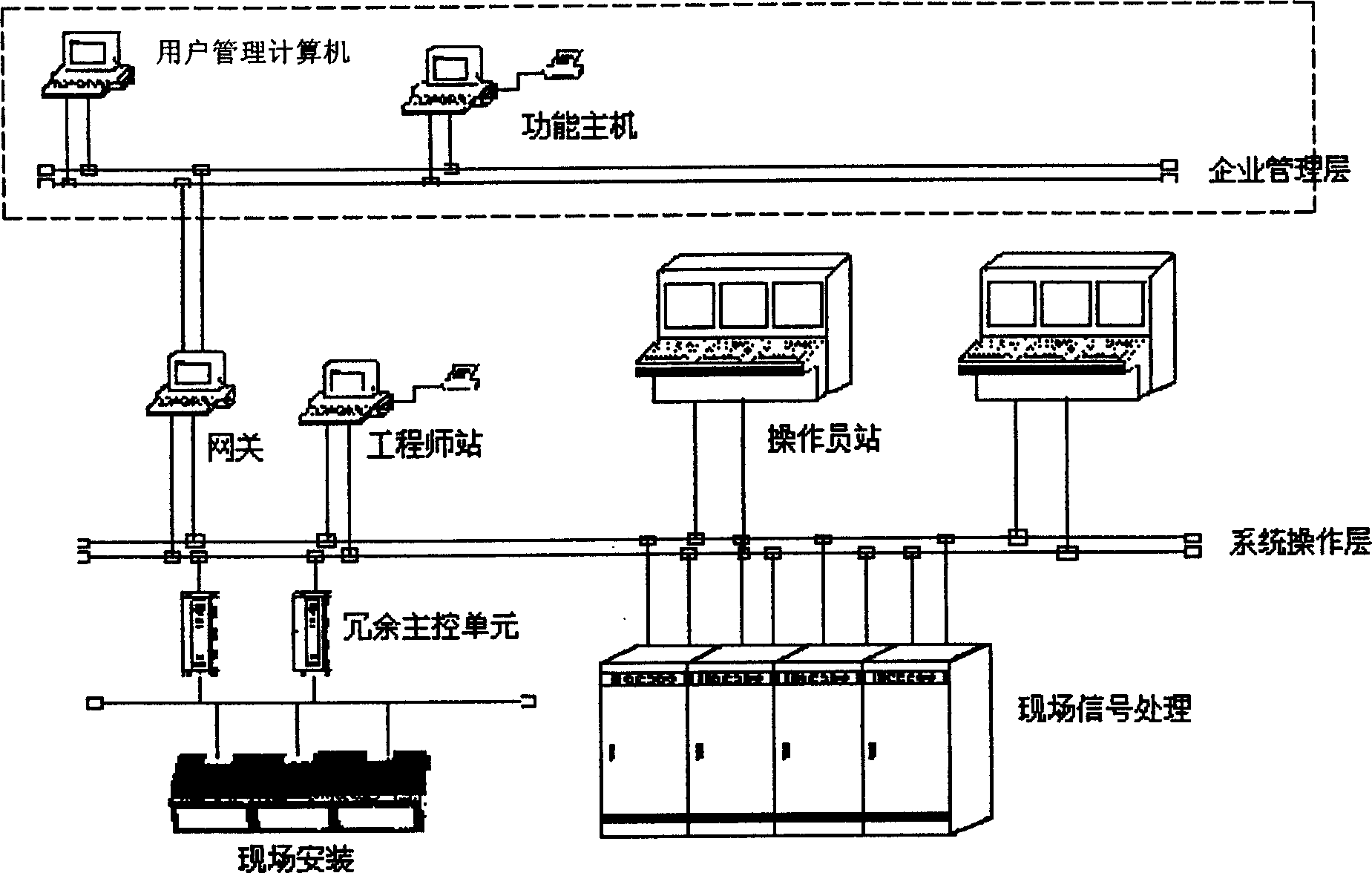

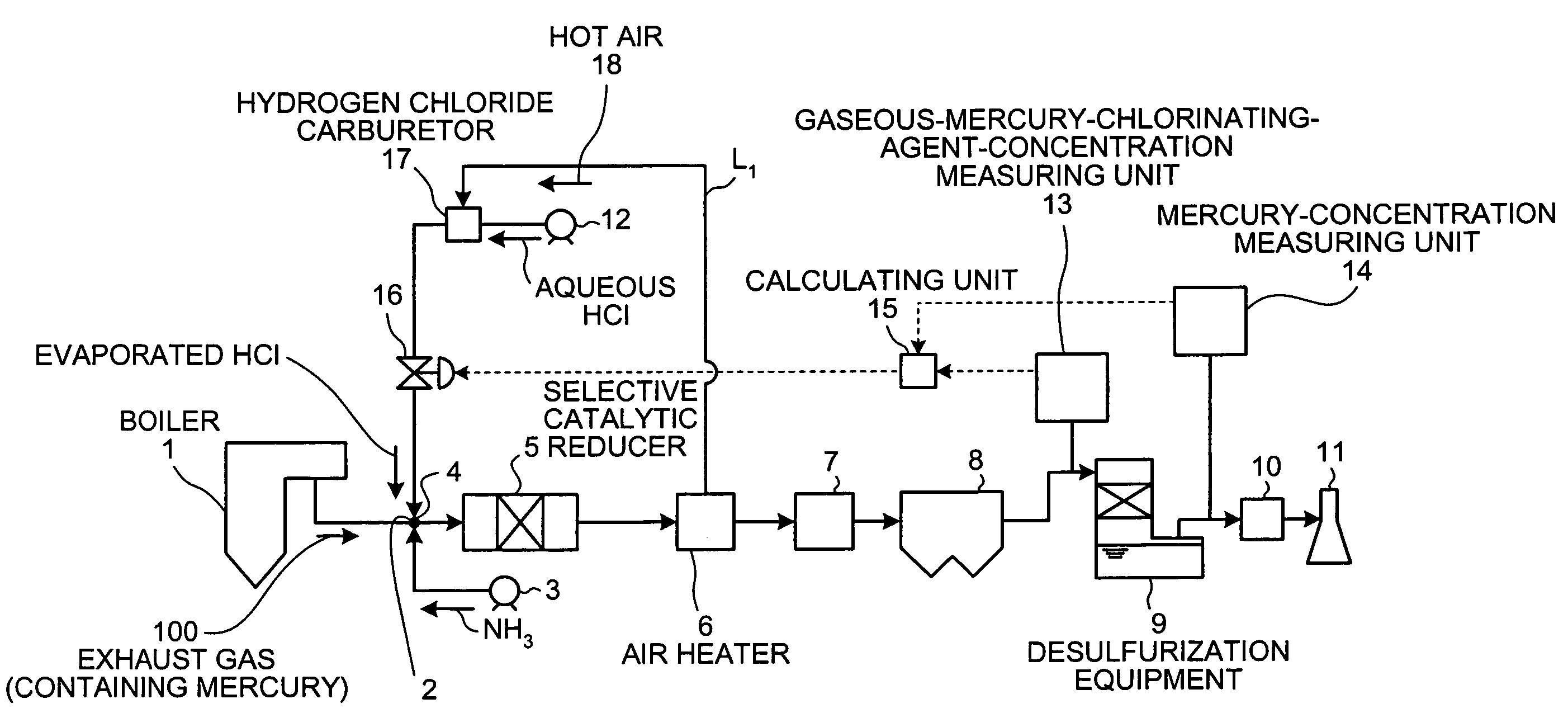

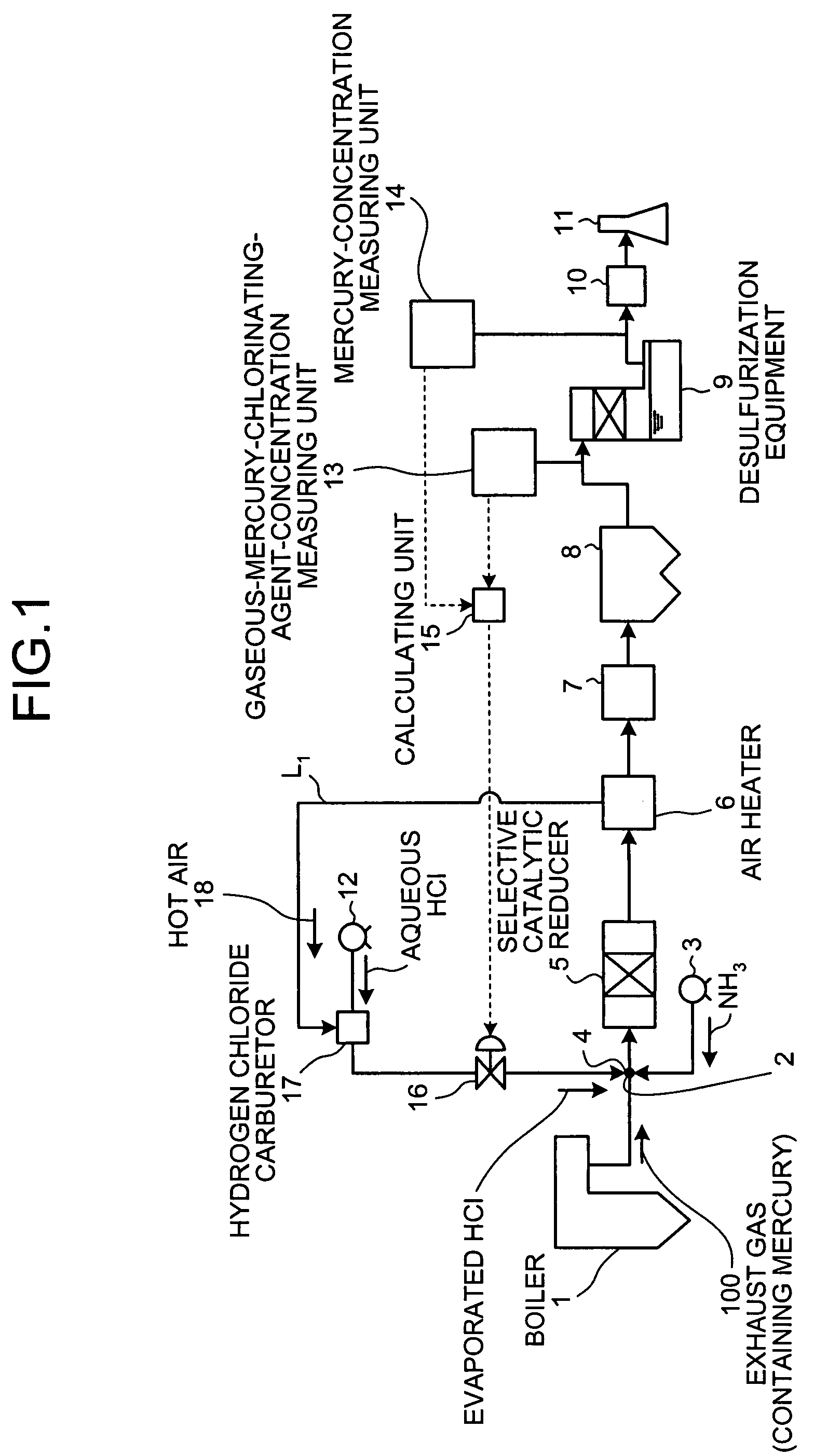

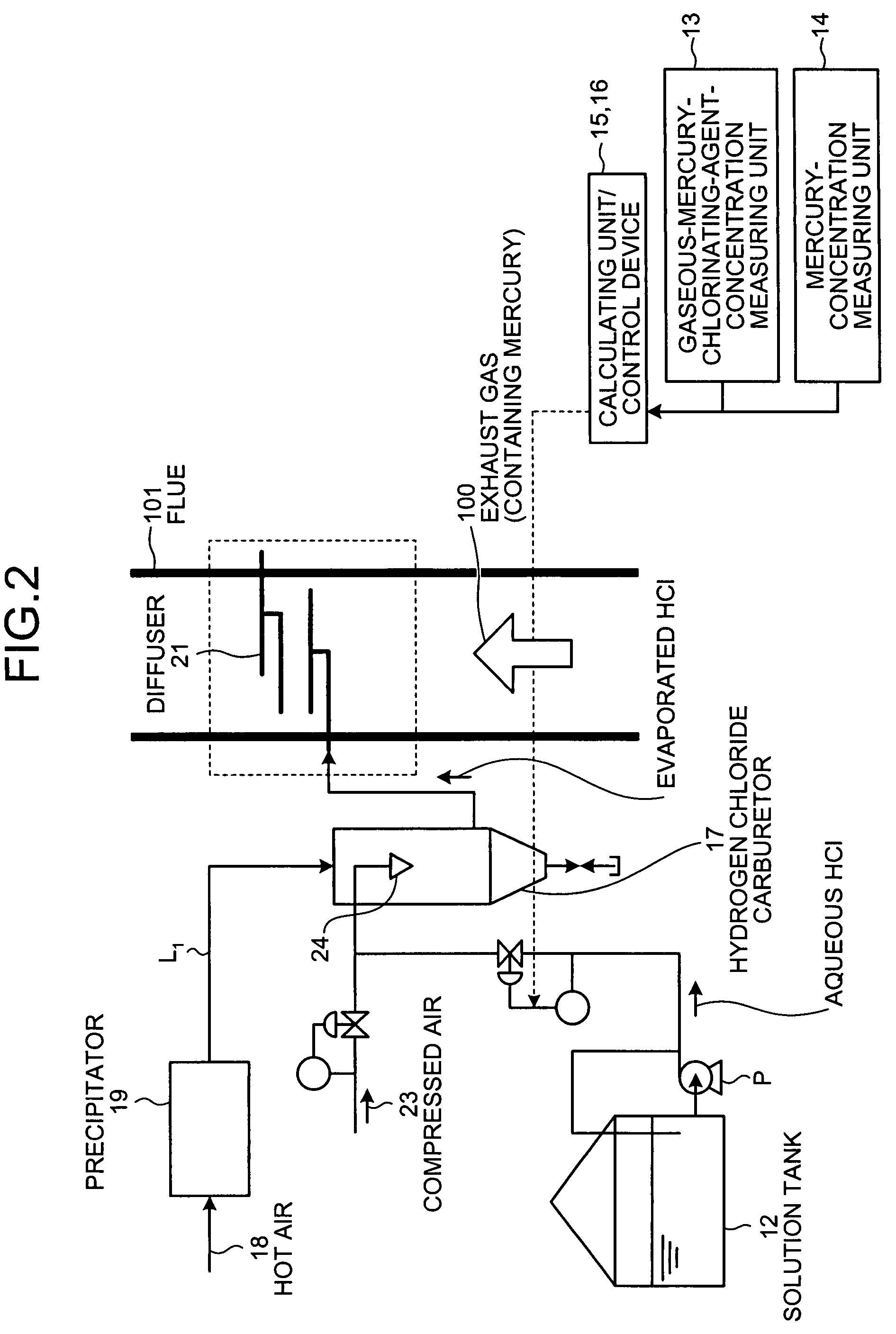

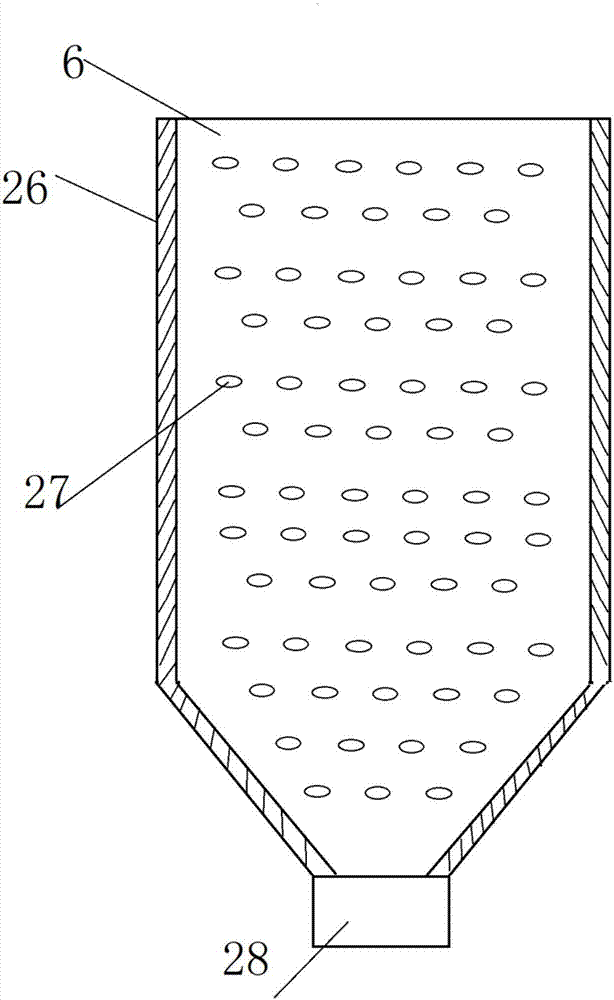

Air pollution control system and air pollution control method, spray drying device of dewatering filtration fluid from desulfurization discharged water, and method thereof

ActiveUS20120240761A1Improve performanceStable atomizationGas treatmentLiquid degasificationControl systemFlue gas

Owner:MITSUBISHI POWER LTD

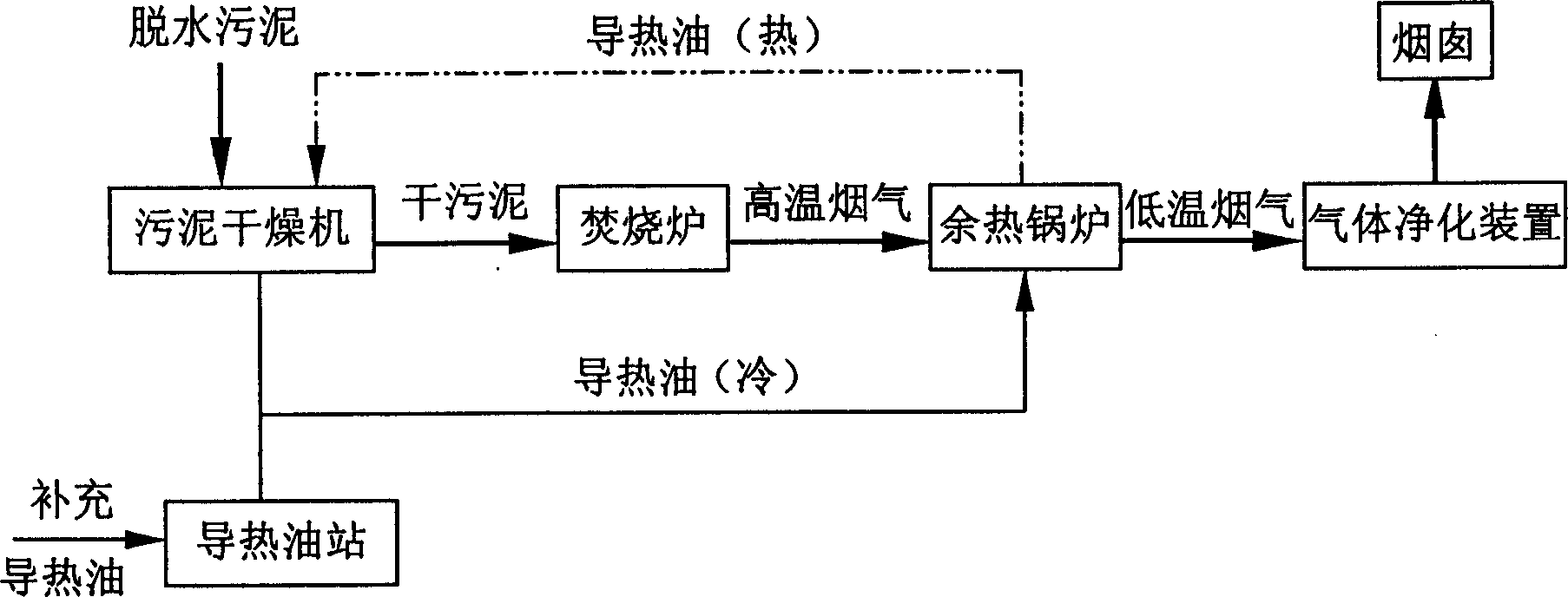

Sludge anhydration and burning process, and its systematic device

ActiveCN1800062ALow investment costLow running costSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationAir preheaterHeat conducting

The invention relates to a sludge drying and burning technique and its system devices, applying to the handling of active sludge in urban sewage treatment plants, its process flows through: wet sludge stock house, measuring bin, sludge mixer, sludge dryer, granular splitter, cooler, drying products storage bin, incinerator, smoke gas cleaning devices, which is characterized by: said incinerator is bubbling fluid bed incinerator with coal economizer, air heater fixed in its end part, high-heat smoke gas generated by burning is used to heat heat-conducting oil and cool air individually, and heat-conducting oil after being heated is transferred to sludge dryer through the circulating pump to dry wet-sludge. The invention is characterized by: take heat-conducting oil as heating medium, use the heat generated by burning dry sludge to heat heat-conducting oil and then dry wet-sludge to make full use of resources; the volume-reducing quantity after drying and burning could reach over 90%; the percentage of desulphurization in incinerator could reach 75% as a result of adopting two stage technology of sulfur removal, and the gross percentage of desulphurization meets national environmental legislation requirements. The invention accomplishes the resources, volume reduction, and innocence of sludge.

Owner:贵州筑信水务环境产业有限公司

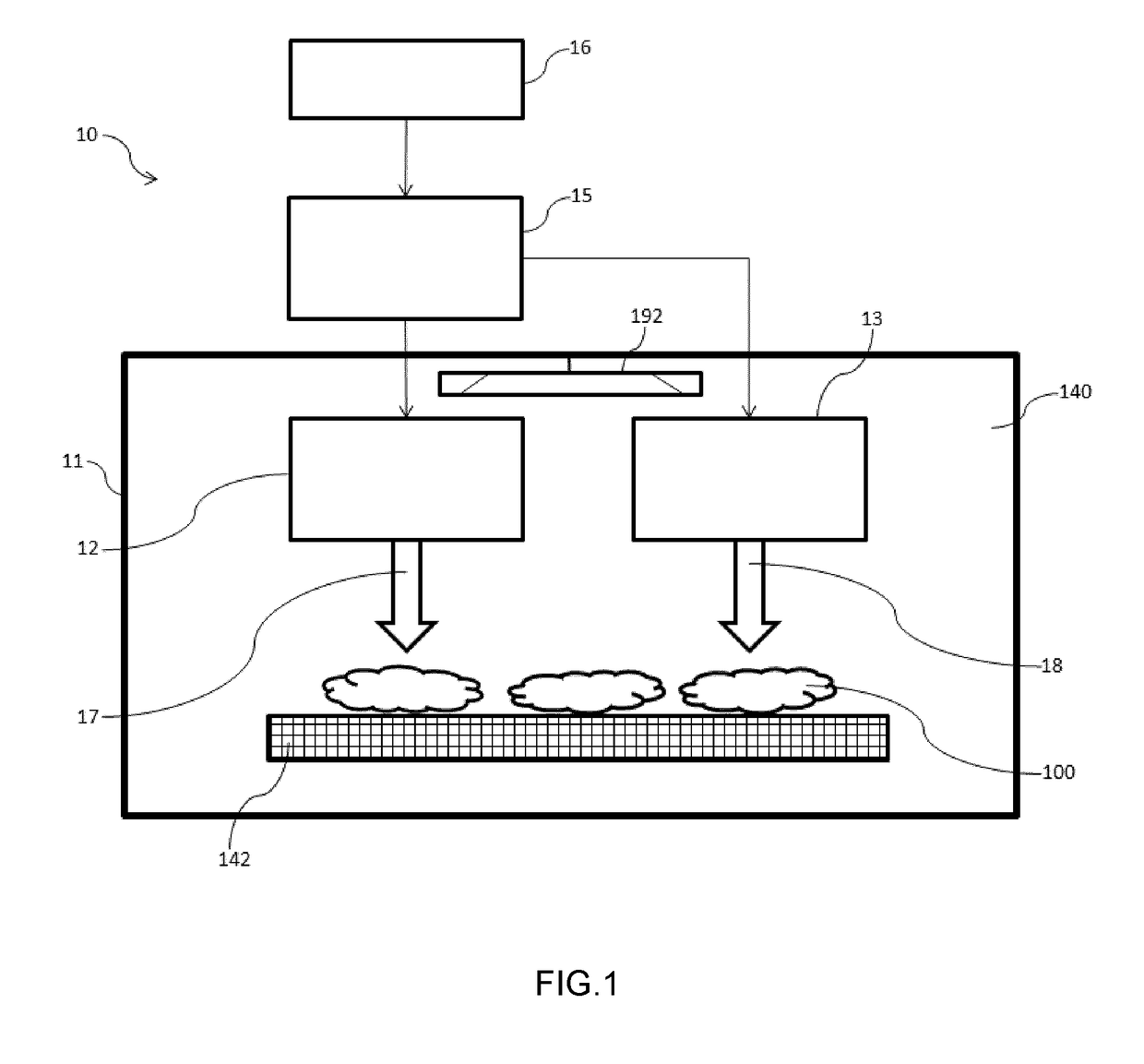

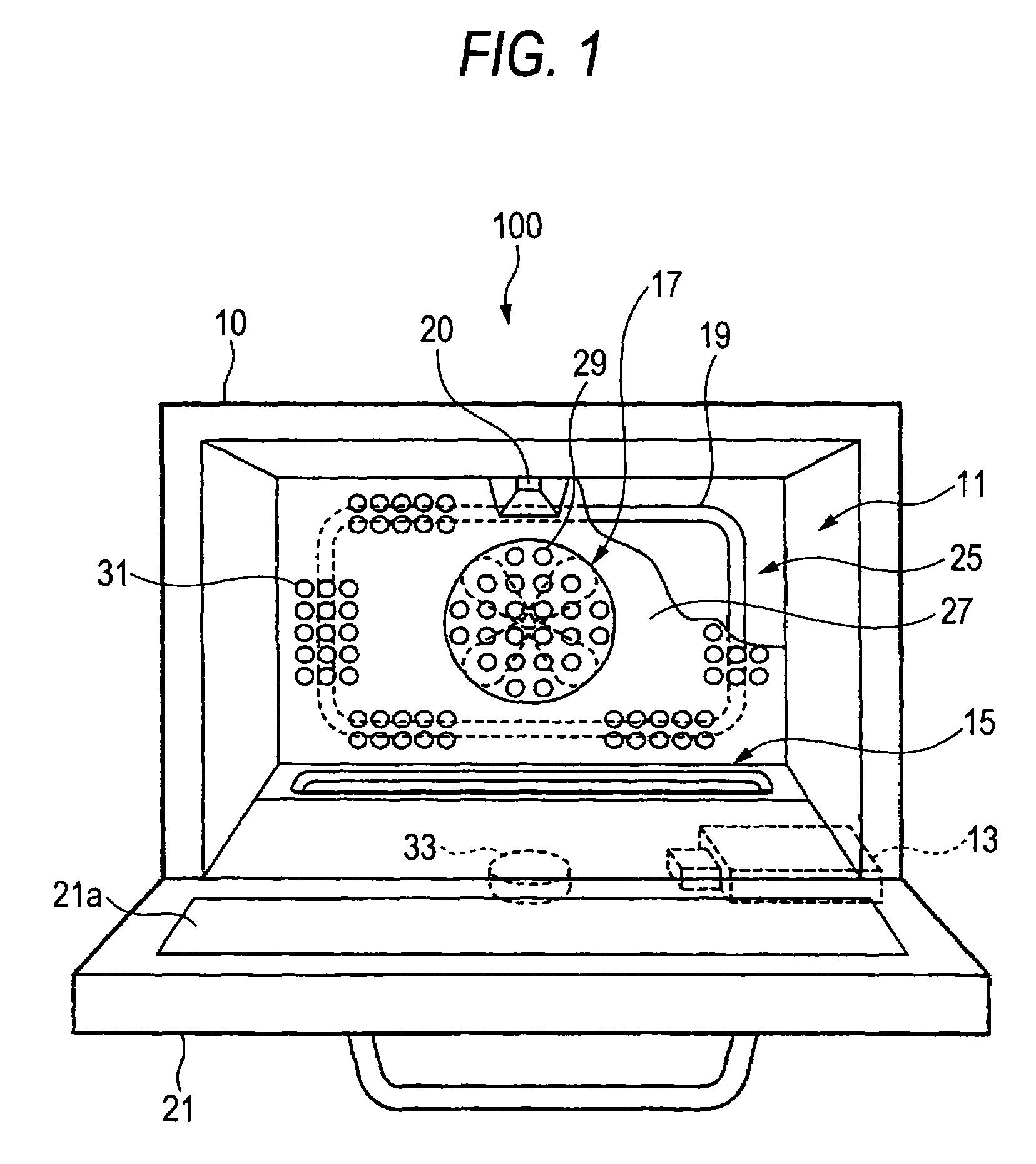

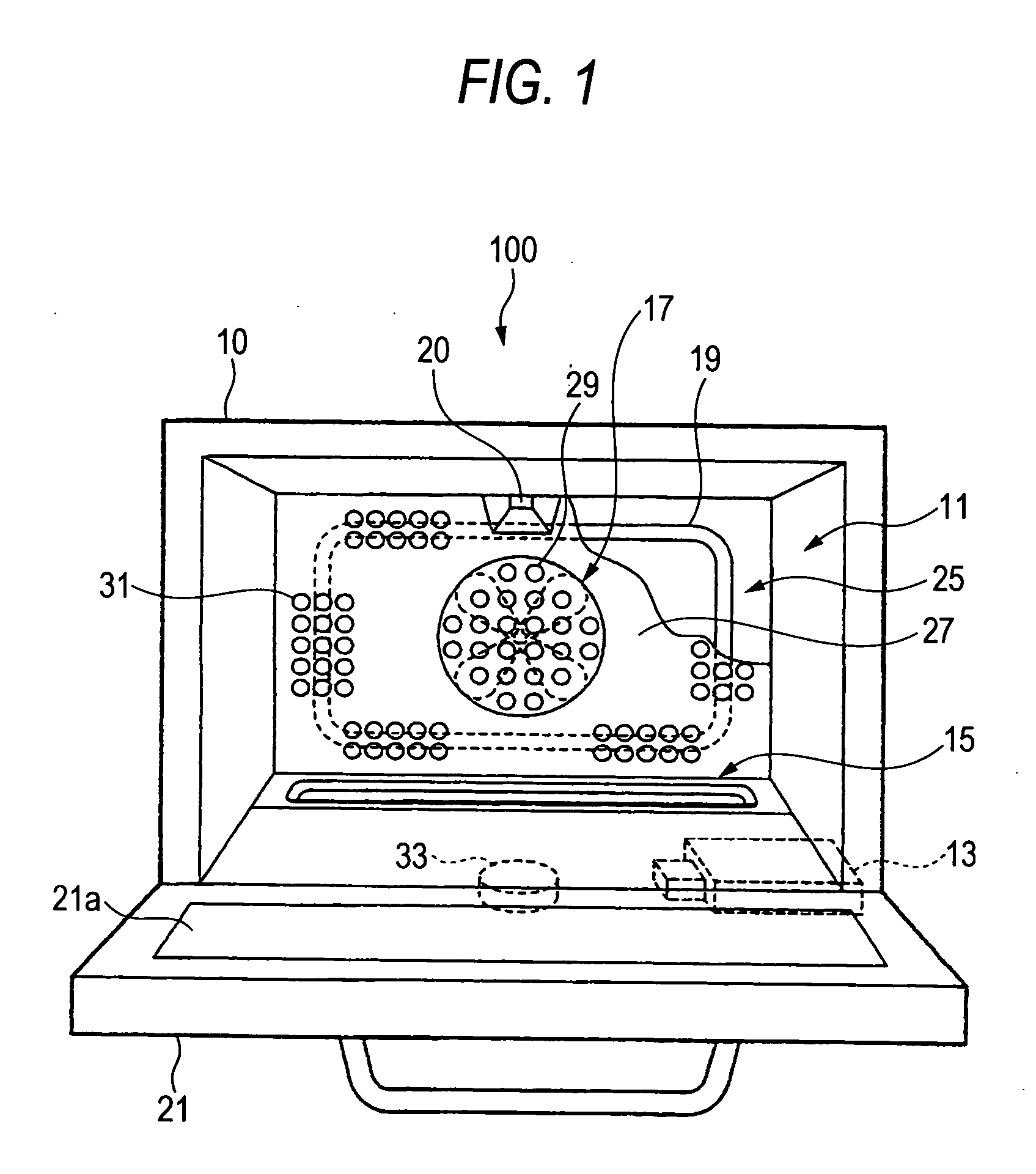

Apparatus and method for preparing food

ActiveUS20170245683A1Reduce surface moisture contentImprove propertiesDomestic stoves or rangesOven air-treatment devicesAir heaterEngineering

The present invention relates to an air-based flyer (10) apparatus comprising a food preparation chamber (140) comprising an outer wall (11), an inner wall (14) defining a food receiving space (141) with an air inlet (142) and an air discharge opening (145), and a circulation channel (113) defined between the outer wall (11) and the inner wall (14). The apparatus also comprises an air heater (13) for heating air in the food preparation chamber (140), a fan (192) for moving a flow of hot air successively through the air inlet (142), the food receiving space (141), the discharge opening (145), and the channel (113). The apparatus also comprises a steam generator (12) comprising at least one nozzle (127) extending into the food receiving space (141) for spraying temperature-controlled steam (18) onto the food; and a controller (15) adapted to control the steam generator to spray steam to food placed in the food receiving space (141) for a first predetermined period, and to control the air heater (13) and the fan (192) to circulate hot air to the food for a subsequent second predetermined period. This apparatus allows keeping the tenderness or crunchiness of the food during subsequent hot air cooking.

Owner:KONINKLJIJKE PHILIPS NV

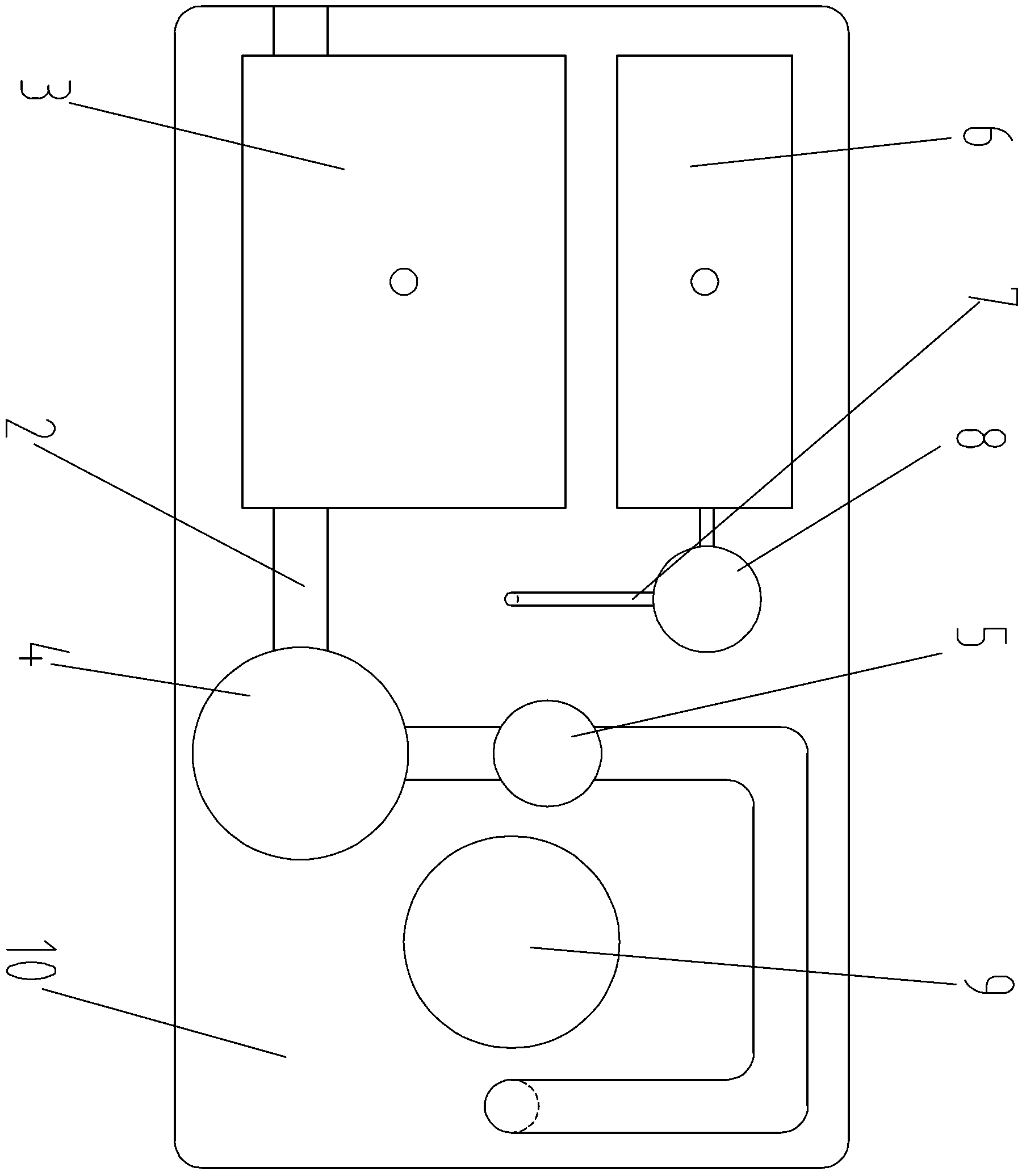

Apparatus and method for preparing food ingredients with hot air and fluid introduced thereinto

ActiveUS20180289212A1Easy to cleanQuality improvementDomestic stoves or rangesLighting and heating apparatusFood ComponentAdditive ingredient

The present application relates to an air based fryer (1) for preparing food ingredients. The air based fryer comprises a food preparation chamber (2), an air heater (3) for heating air in the food preparation chamber (2) and a fan (4) for circulating a flow of hot air in the food preparation chamber (2). The air-based fryer (1) further comprises a fluid inlet (5) for the introduction of a fluid directly into the circulating flow of hot air. This solution allows increasing the humidity of the flow of hot air results in superior quality food in terms of taste, texture, and aesthetics and increases the versatility of the air-based flyer.

Owner:VERSUNI HLDG BV

Vehicle air conditioning and heating system providing engine on and engine off operation

InactiveUS20050161211A1Solve insufficient capacityAccurate lifeAir-treating devicesCompression machines with non-reversible cycleMotor driveAir conditioning

An air conditioning system for use in an over-the-road or off road vehicle is provided that allows operation during both engine on and engine off conditions. The system utilizes a variable speed, motor driven compressor controlled by an intelligent power generation management controller. This controller selects from one of the available sources of power on the vehicle to drive the compressor, and modulates the compressor speed and capacity based on operational parameters and source availability and depletion. The controller may also operate a coolant or air heater to provide heating to the interior compartments.

Owner:BERGSTROM INC

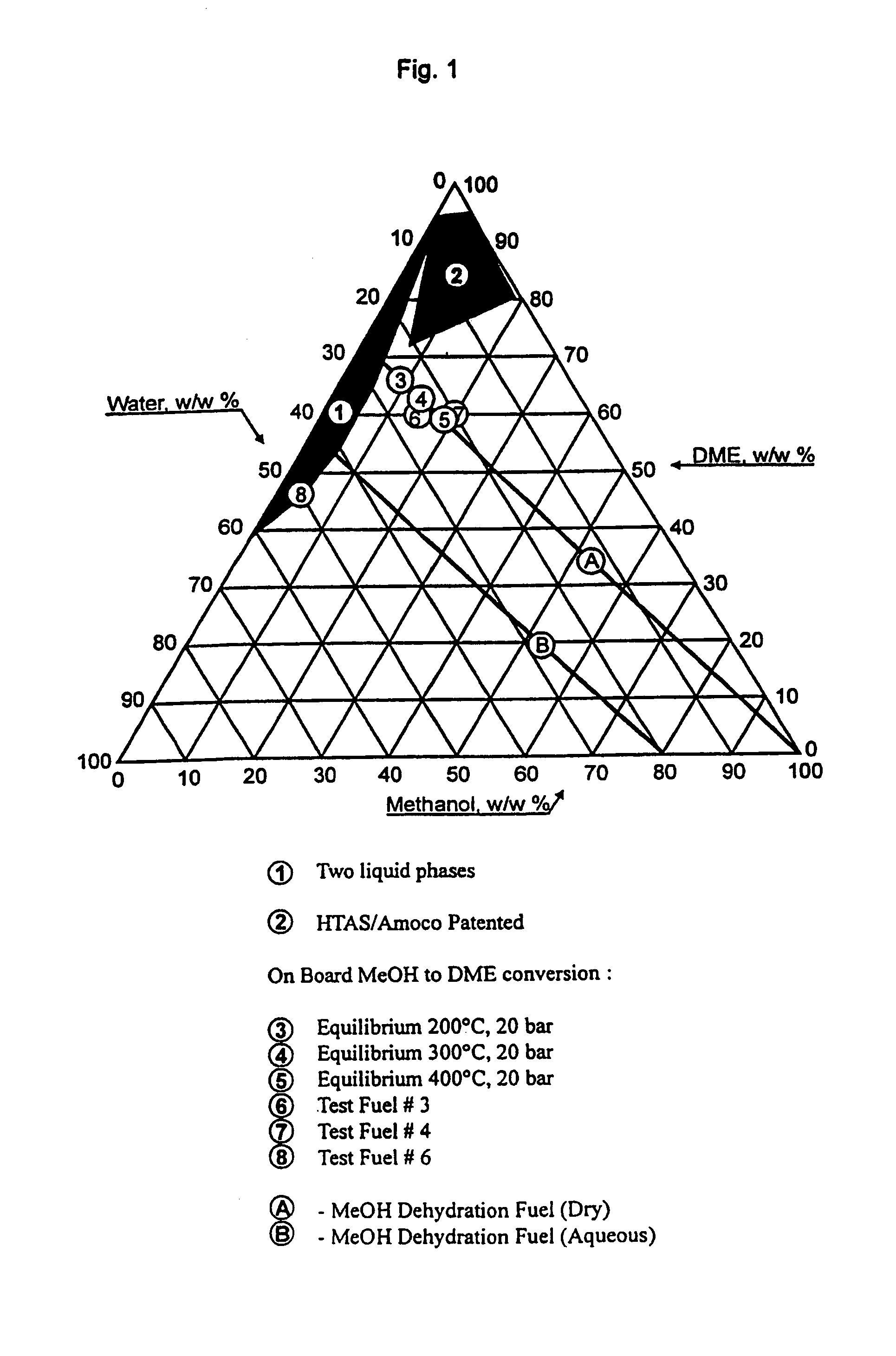

Continuous dehydration of alcohol to ether and water used as fuel for diesel engines

InactiveUS7449034B1Improve fuel efficiencyEmission reductionDomestic stoves or rangesExhaust apparatusWater useCombustion

The present invention relates to an oxygenated fuel composition suitable for use in compression ignition internal combustion engines, equipped with inlet air heater and catalytic alcohol dehydration equipment suitable for chemical equilibrium conversion of methanol and higher alcohol to their associated ether plus water.

Owner:HALDOR TOPSOE AS

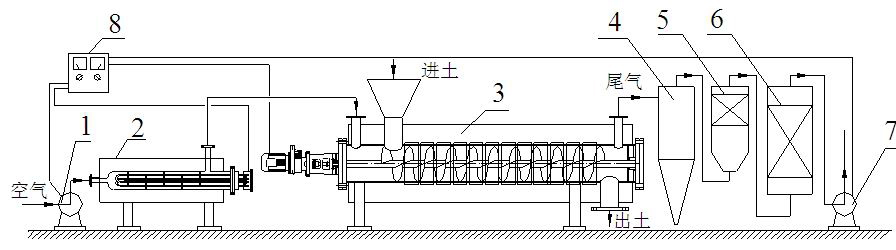

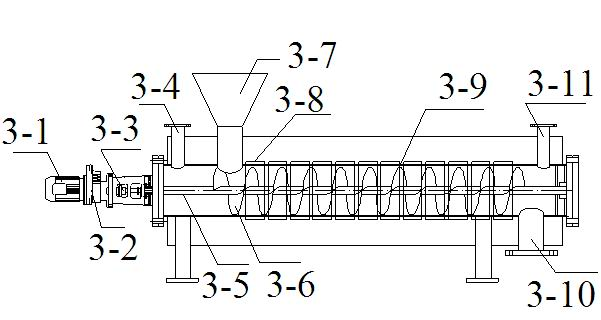

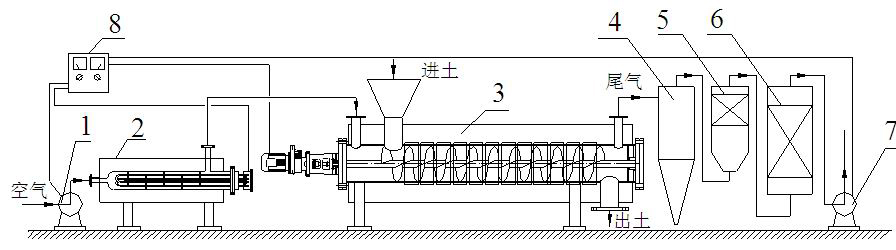

System for restoring organic contaminated soil by forced ventilation and spiral stirring thermal desorption

ActiveCN101972773AEfficient repairRemediation of organic pollution is effectiveContaminated soil reclamationAgricultural engineeringCyclonic spray scrubber

The invention provides a system for restoring organic contaminated soil by forced ventilation and spiral stirring thermal desorption, which comprises an air preheating system, a spiral stirring thermal desorption system, a tail gas treatment system and a control system, wherein the air preheating system consists of a blower and an air heater, the spiral stirring thermal desorption system consists of a spiral stirring thermal desorption device and a draft fan, the tail gas treatment system consists of a cyclone dust collector, a dehumidifier and an absorption tower, and the control system can realize the effective control of the rotation speed of a spiral stirrer, the air preheating temperature and the soil heating temperature. The system can be used for restoring soil contaminated by volatile / semi-volatile organic matters.

Owner:LIAONING HUAFU ENVIRONMENTAL ENG

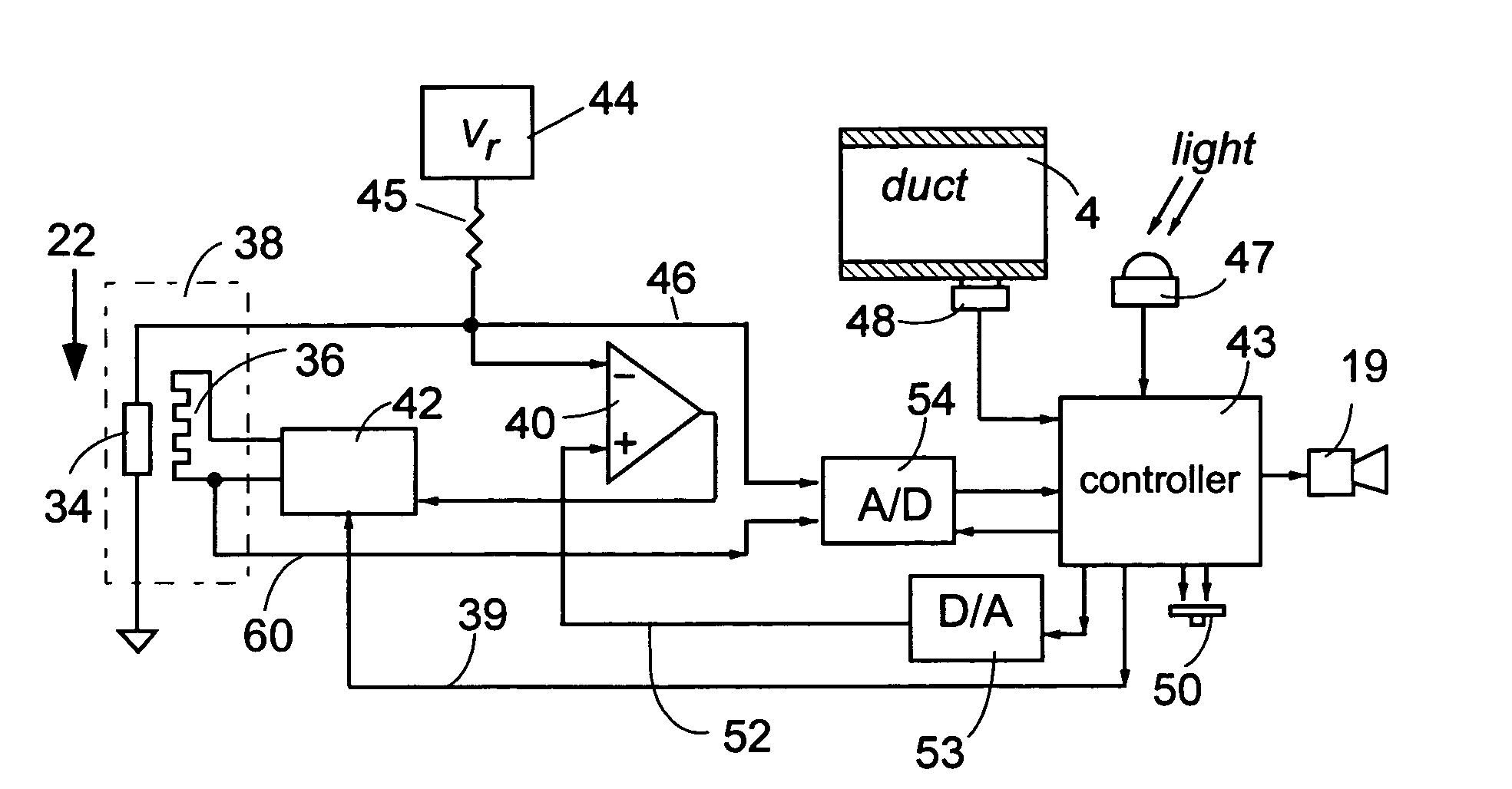

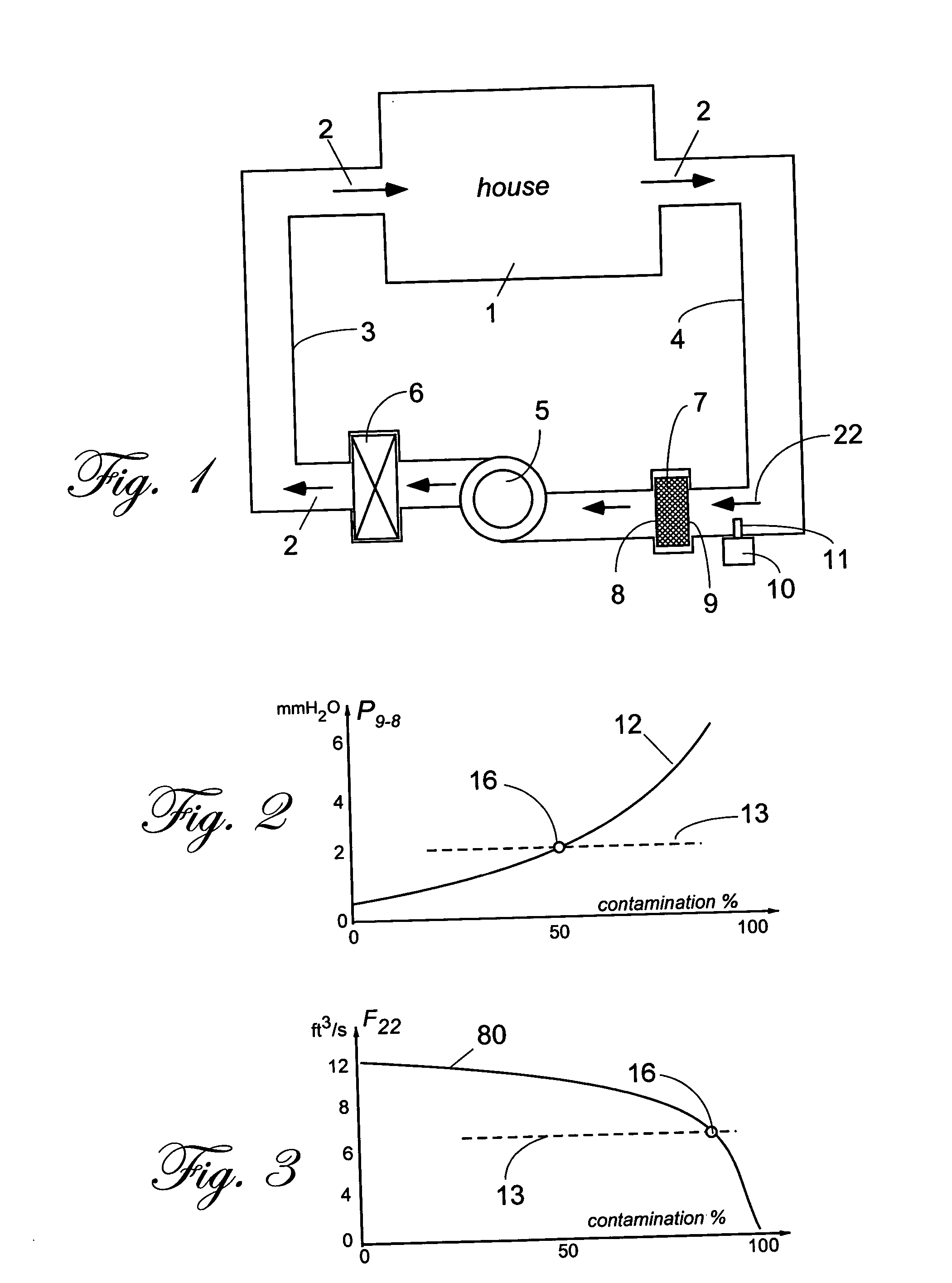

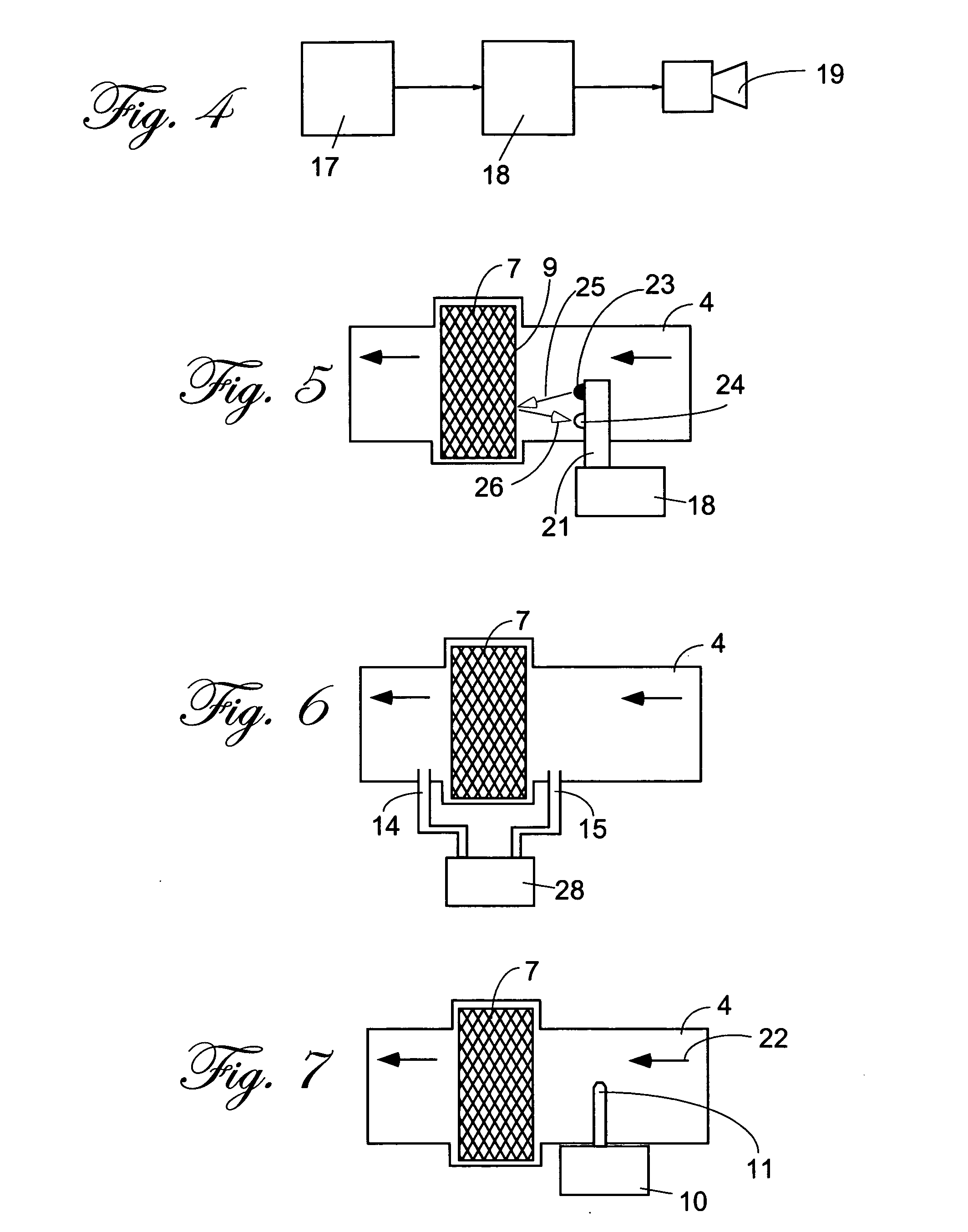

Clogging detector for air filter

The detector for monitoring decrease in air flow rate due to air filter clogging. It is based on combination of three essential components: the air flow sensor, a threshold detector and an indicator. The air flow sensor is built in form of a novel thermo-anemometer which contains a thermistor, a heating element, and a thermal insulator. Temperature of the sensor is maintained above the air temperature by a constant value by means of an electronic servo circuit. The threshold detector is implemented either in a hardware or software. A novel design of a thermo-anemometer (closely related to a hot wire anemometer) automatically compensates for variations in the air temperatures. The thermo-anemometer triggers the threshold circuit when air flow rate drops below a preset level. For reduction of power consumption, the detector may employ two additional sensors: one is for detection of the blower operation and the other is a presence detector to enable the alarm in presence of people to perceive the alarm. The device automatically calibrates itself upon installation of a new or cleaned air filter. The applications include residential and commercial air conditioners, air heaters, internal combustion engines, vacuum cleaners and other systems where air filters are employed.

Owner:CLEAN ALERT

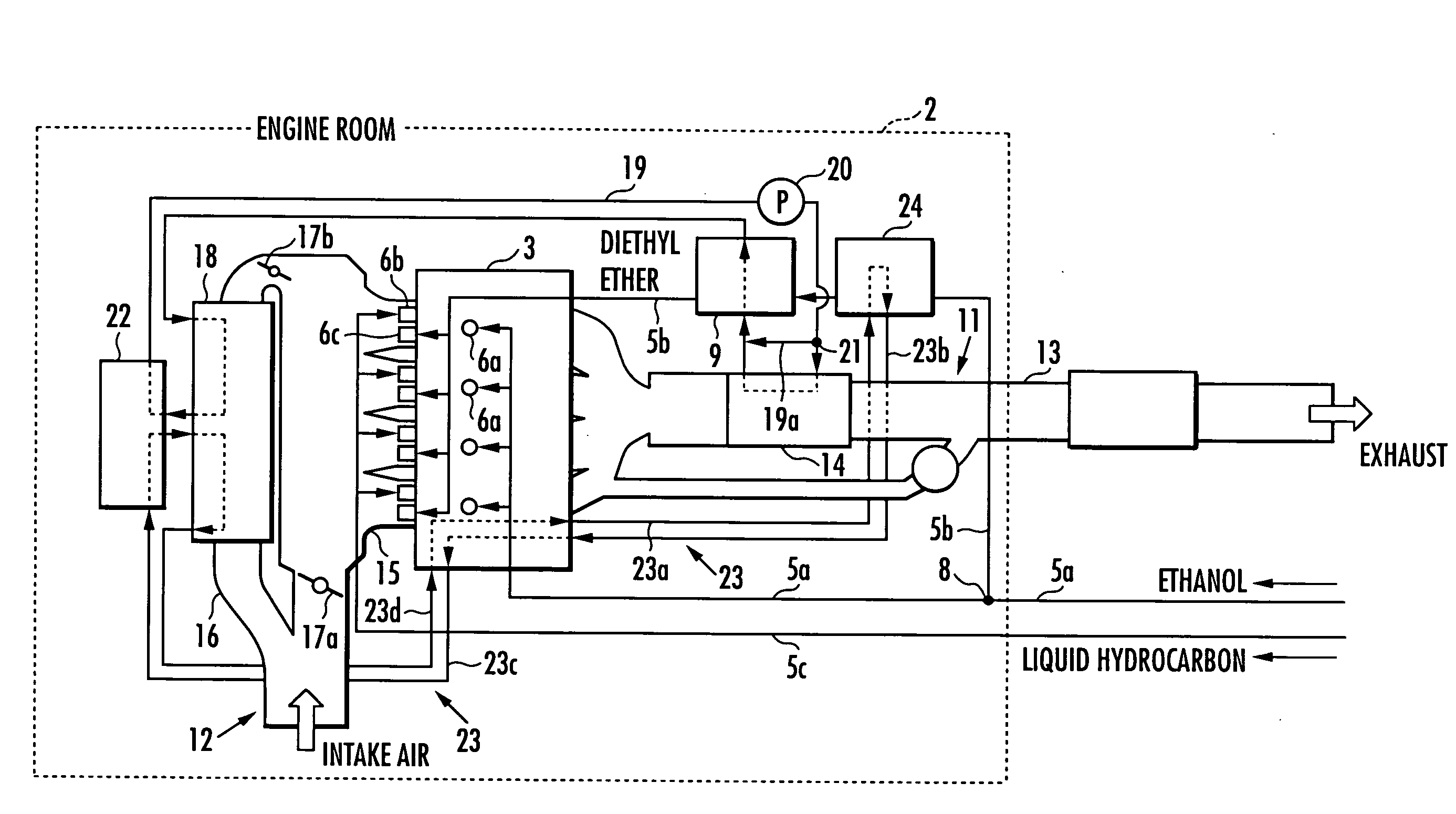

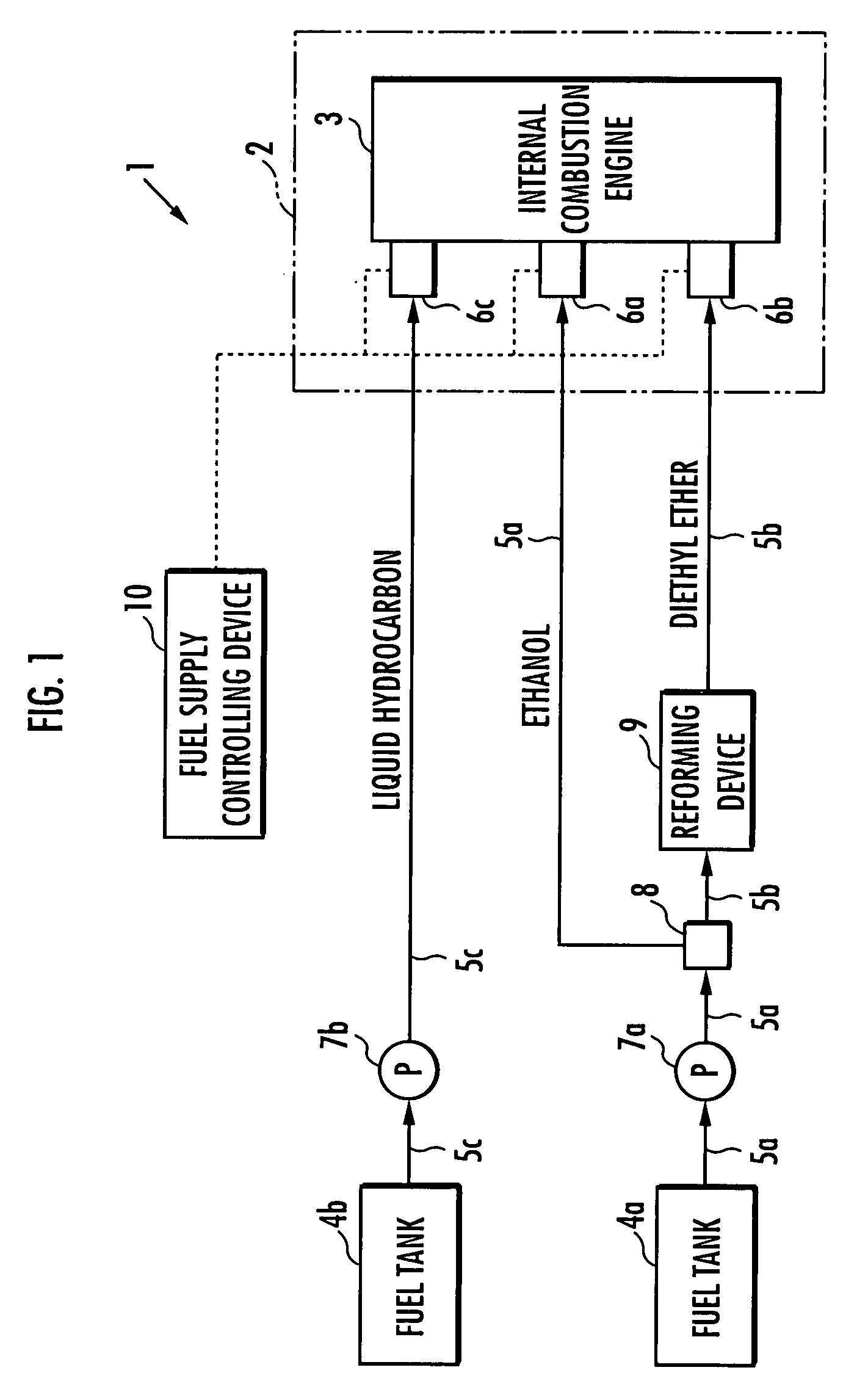

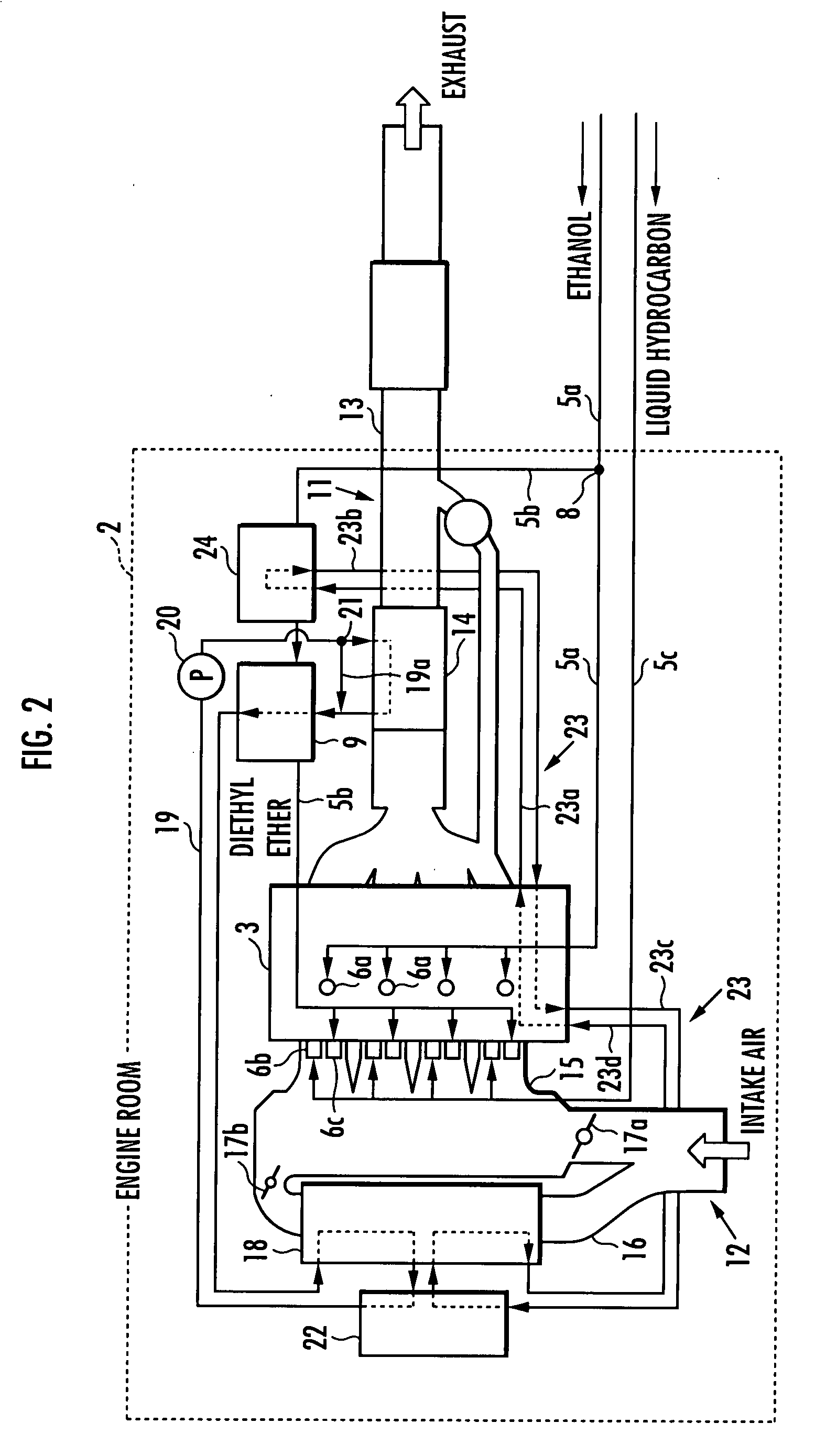

Internal combustion engine system

InactiveUS20080098985A1Accurate timingElectrical controlNon-fuel substance addition to fuelHomogeneous charge compression ignitionNaphtha

The present invention provides an internal combustion engine system that can precisely control ignition timing on homogeneous charge compression ignition. The internal combustion engine system includes a fuel tank 4a containing ethanol, a fuel tank 4b containing at least one of gasoline and GTL naphtha, a reforming device 9 for reforming ethanol to obtain diethyl ether, a heat exchange device 14 for heating a heating medium, an ethanol heater 9b for heating ethanol with the heating medium, and a fuel supply controlling device 10 for controlling a mixture ratio of the fuel. The internal combustion engine system further includes an intake air heater 18 for heating intake air with the heating medium. The internal combustion engine system further comprises an adiabatic storage container 29 for storing the heating medium during a halt of an internal combustion engine 3. The internal combustion engine system further comprises a flow controlling device 27 for flowing the heating medium to the adiabatic storage container 29 only when a temperature detected by a thermal detector 30a is higher than a temperature detected by a thermal detector 30b during an operation of the internal combustion engine 3. The internal combustion engine system further comprises a fuel tank 42 containing a mixed fuel, and a separating device 43 for separating the mixed fuel into an ethanol-water mixture, gasoline and GTL naphtha by adding water to the mixed fuel.

Owner:HONDA MOTOR CO LTD

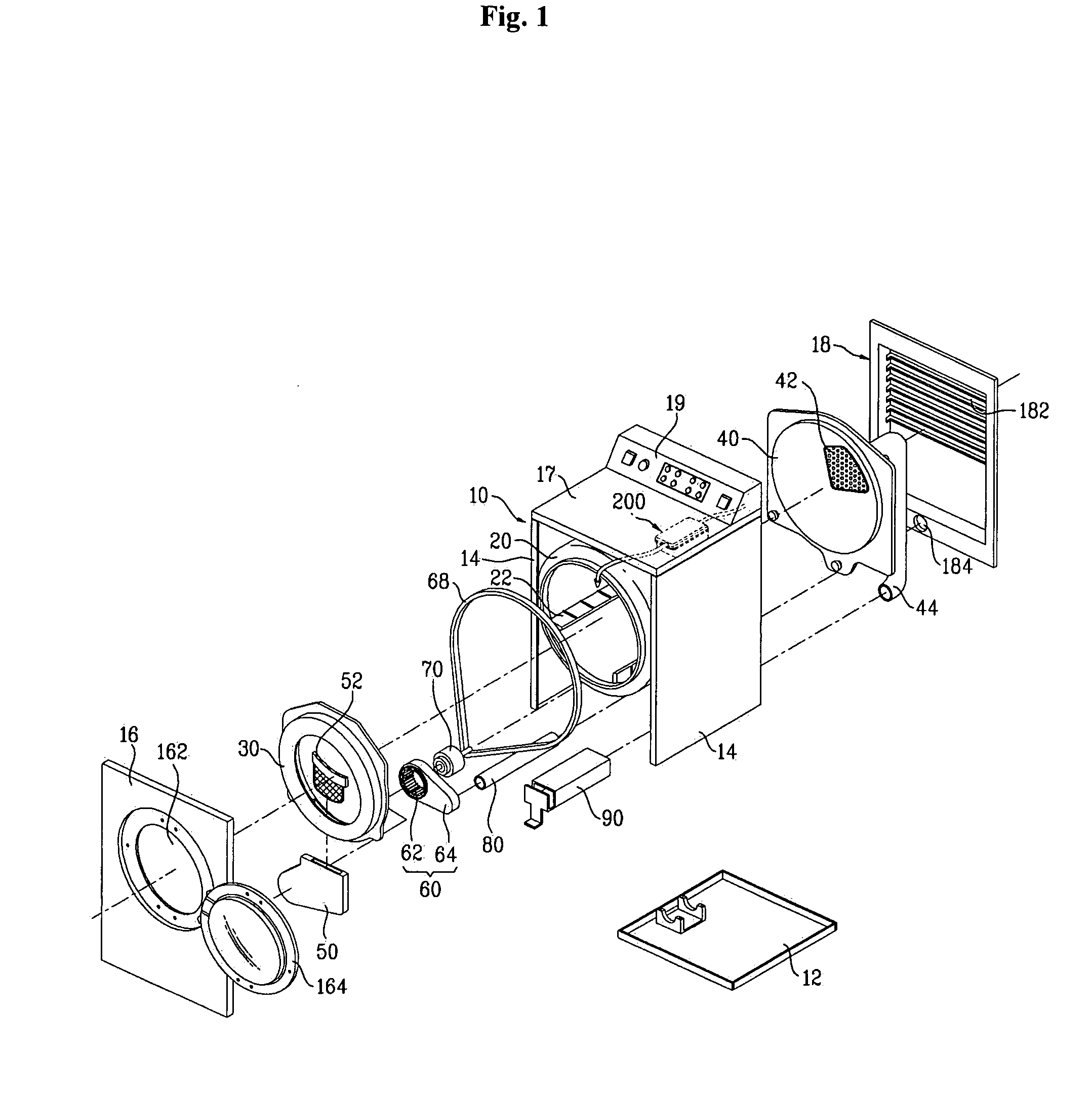

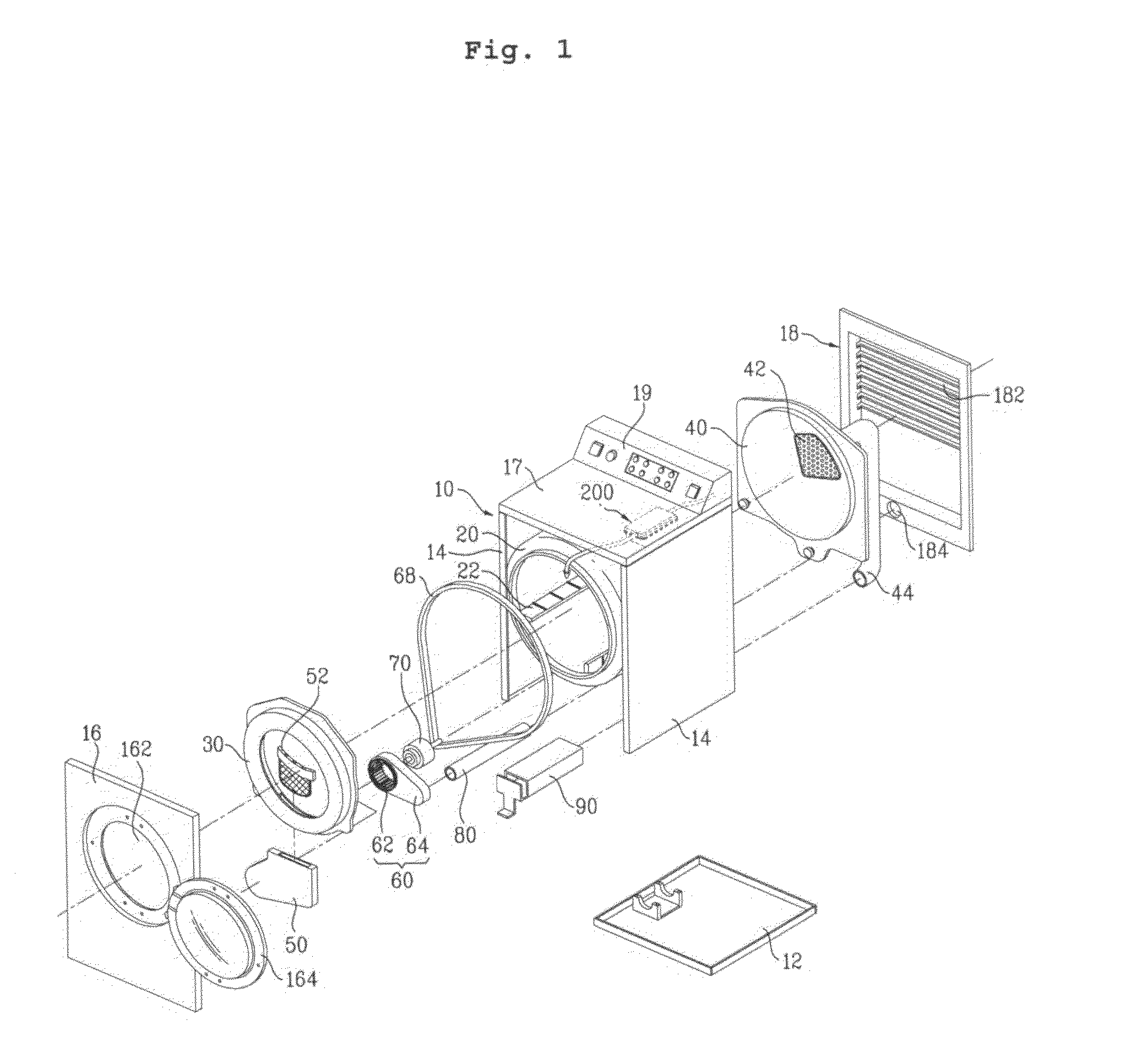

Laundry machine

ActiveUS20080141558A1Prevent and remove wrinkleFacilitate demountingDrying machines with non-progressive movementsTextiles and paperEngineeringLaundry

A steam laundry dryer is disclosed. The steam laundry dryer includes a drum rotatably mounted in a cabinet, a hot air heater to heat air to supply hot air into the drum, a steam generator to supply steam into the drum, a water supply source to supply water into the steam generator, and a container drawably mounted in a portion of the cabinet. The water supply source is detachably mounted in the container.

Owner:LG ELECTRONICS INC

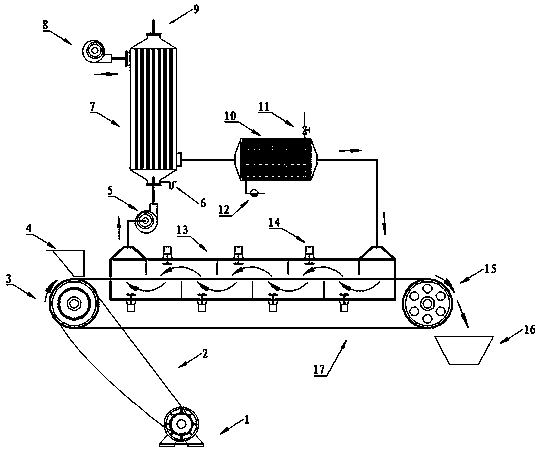

Penetrating type reverse-flow drying device

InactiveCN103471373AStrong penetrating powerLow running costDrying gas arrangementsDrying machines with progressive movementsTransport systemPulp and paper industry

The invention discloses a penetrating type reverse-flow drying device. The penetrating type reverse-flow drying device comprises a heat exchanger, an air heater, a driving drum, a driven drum, a sieve plate type conveying steel belt and a dryer body, wherein an air blower is connected with one side of the upper end of the heat exchanger, the air heater is connected with one side of the lower end of the heat exchanger, the driving drum is connected with a double-stage cycloidal-pin wheel speed reducer through a transmission chain, a material conveying system is formed by the driving drum and the driven drum through the sieve plate type conveying steel belt, a feeding hopper is arranged at one end of the material conveying system, a discharging hopper is arranged at the other end of the material conveying system, the sieve plate type conveying steel belt penetrates through the dryer body, the dryer body is of a sealed structure, a plurality of axial fans are reasonably distributed on the top face and the bottom face of the dryer body, one side of the dryer body is connected with an outlet of the air heater, the other side of the dryer body is connected with an suction fan, and an air outlet of the suction fan is connected with an inlet pipe arranged at the bottom of the heat exchanger. The penetrating type reverse-flow drying device is simple in structure and good in practicability, can achieve rapid and efficient drying of materials, is low in energy consumption and has broad prospects.

Owner:东莞市胜源纸品有限公司

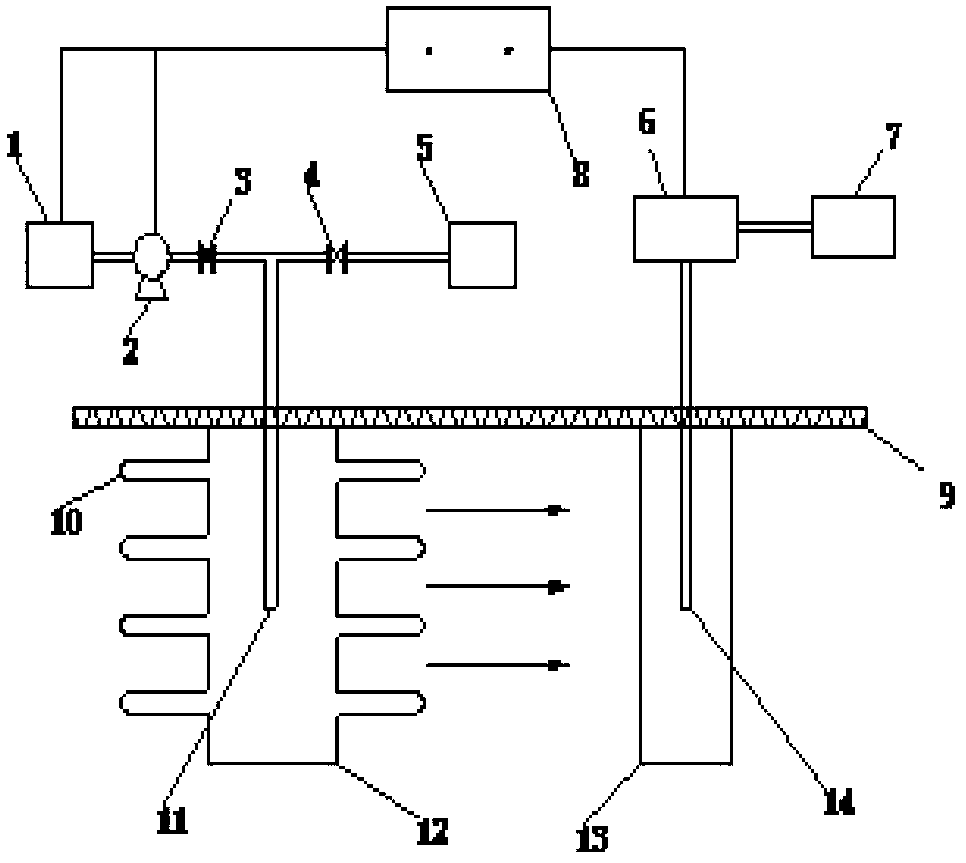

A device for remediation of organic contaminated soil by using thermal desorption combined with an oxidant and a remediation method

ActiveCN103230933AReduce moistureIncrease temperatureContaminated soil reclamationSoil propertiesInsulation layer

The invention belongs to the technical field of environmental protection, and in particular relates to a device for remediation of organic contaminated soil by using thermal desorption combined with an oxidant and a remediation method. The device of the invention is composed of an air heater, an air compressor, an air valve, a dosing valve, a dosing tank, a vacuum suction pump, a delivery pump, an electric power control unit, an insulation layer, lateral pipes, injection syringes, injection wells, a gas collection well and vacuum suction pipelines. According to the invention, through a treatment method of in situ thermal desorption and adding the oxidant, volatile organic compound contaminated soil is effectively treated. The technique of the invention is applicable to a relatively broad scope, can be used to perform in situ pollution remediation of volatile organic compounds under different climatic conditions, geological conditions, soil properties, and earth surface conditions. The heater of the present invention can infuse more produced heat into the soil, thus saving fuel and combustion time.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

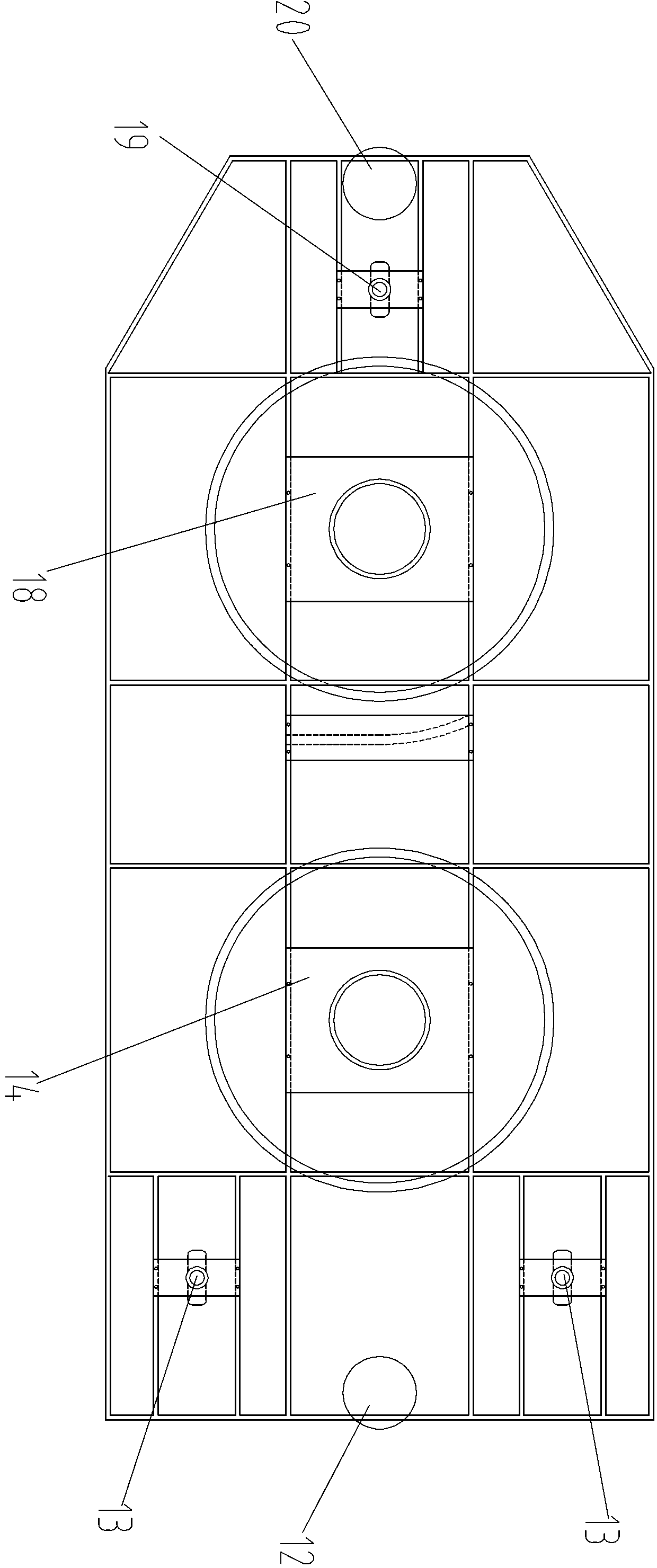

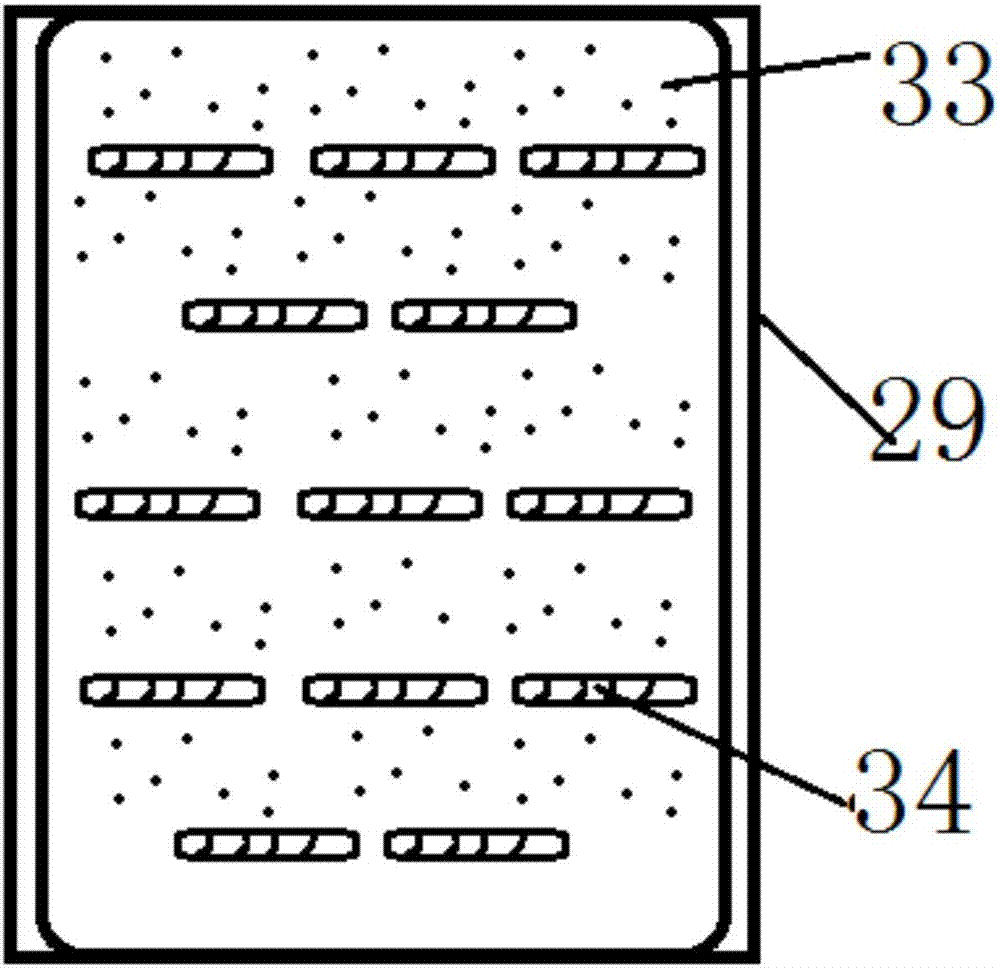

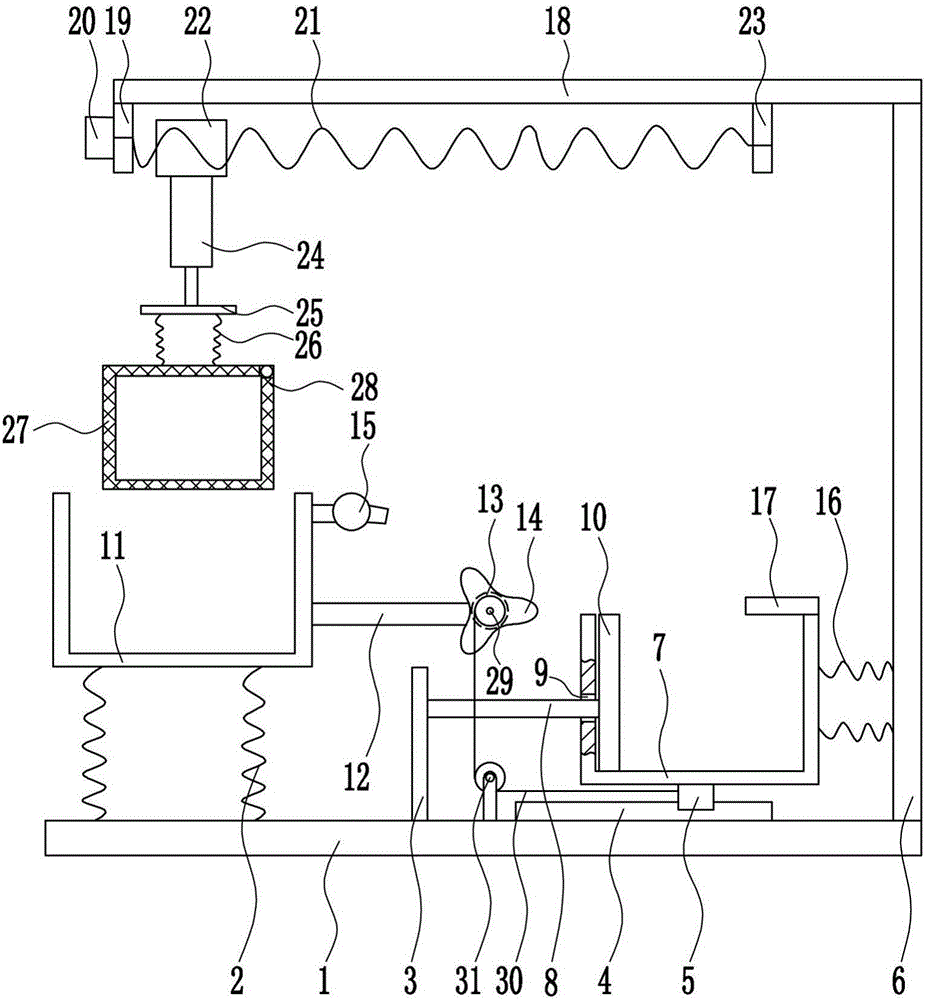

Dust collecting, mopping and drying integrated cleaning cart

InactiveCN103054523AEasy to cleanImprove cleaning efficiencyCarpet cleanersFloor cleanersEngineeringAir heater

The invention provides a dust collecting, mopping and drying integrated cleaning cart and solves the problem that an existing dust collector is single in function of dust collecting and cleaning and is time and labor wasting when cannot realize multiple cleaning tasks simultaneously. The dust collecting, mopping and drying integrated cleaning cart comprises a closed cart housing, a pushing handle is fixedly arranged at the tail end of the cart housing, wheels are arranged on a chassis of the cart housing, a dust collecting and drying pipeline is arranged in the cart housing and provided with a front dust collecting port and a rear air outlet and is sequentially serially connected with a dust collecting barrel, a fan and an air heater from front to back, a wet rotating mop and a dry rotating mop extent out of the chassis of the cart housing, the wet rotating mop is connected with a water supply device, the dry rotating mop is connected with a driving device, and the dry rotating mop and the wet rotating mp are in transmission connection. The dust collecting, mopping and drying integrated cleaning cart is capable of orderly completing serial cleaning steps of dust collecting, wet wiping, dry wiping and air drying, can guarantee good cleaning effect and doubly improve cleaning efficiency, and is timesaving and laborsaving.

Owner:SHANDONG UNIV OF SCI & TECH

High-moisture-content lignite predrying method and system integrated with thermal power plant

InactiveCN102353237AWith drying capacityKeep dryDrying solid materials with heatFeed water supplyThermal energyFluidized bed drying

The invention discloses a high-moisture-content lignite predrying method and system integrated with a thermal power plant. In the method, lignite is dried by using hot air as a fluidizing agent and a drying medium in a fluidized bed dryer; and a heater is built in the fluidized bed dryer to supply partial heat for drying. The lignite predrying system integrated with the thermal power plant comprises the fluidized bed dryer, the heater built in the dryer, a deduster, a gas-gas heat exchanger, a gas-water heat exchanger, an air heater and a fan. According to the system, waste heat in the system and low-grade heat energy in the power plant are fully utilized to dry the lignite. By applying the method and the system disclosed by the invention, the moisture content of the lignite fed into a furnace can be reduced, the heat loss of a boiler due to exhaust gas can be reduced, and the efficiency of the lignite boiler is increased; the low-grade heat energy and waste heat resources in the thermal power plant are fully utilized, so that the consumption of high-grade energy sources in a drying process is reduced, and the power generation efficiency of a lignite power plant is increased.

Owner:XI AN JIAOTONG UNIV

Clogging detector for air filter

The detector for monitoring decrease in air flow rate due to air filter clogging. It is based on combination of three essential components: the air flow sensor, a threshold detector and an indicator. The air flow sensor is built in form of a novel thermo-anemometer which contains a thermistor, a heating element, and a thermal insulator. Temperature of the sensor is maintained above the air temperature by a constant value by means of an electronic servo circuit. The threshold detector is implemented either in a hardware or software. A novel design of a thermo-anemometer (closely related to a hot wire anemometer) automatically compensates for variations in the air temperatures. The thermo-anemometer triggers the threshold circuit when air flow rate drops below a preset level. For reduction of power consumption, the detector may employ two additional sensors: one is for detection of the blower operation and the other is a presence detector to enable the alarm in presence of people to perceive the alarm. The device automatically calibrates itself upon installation of a new or cleaned air filter. The applications include residential and commercial air conditioners, air heaters, internal combustion engines, vacuum cleaners and other systems where air filters are employed.

Owner:CLEAN ALERT

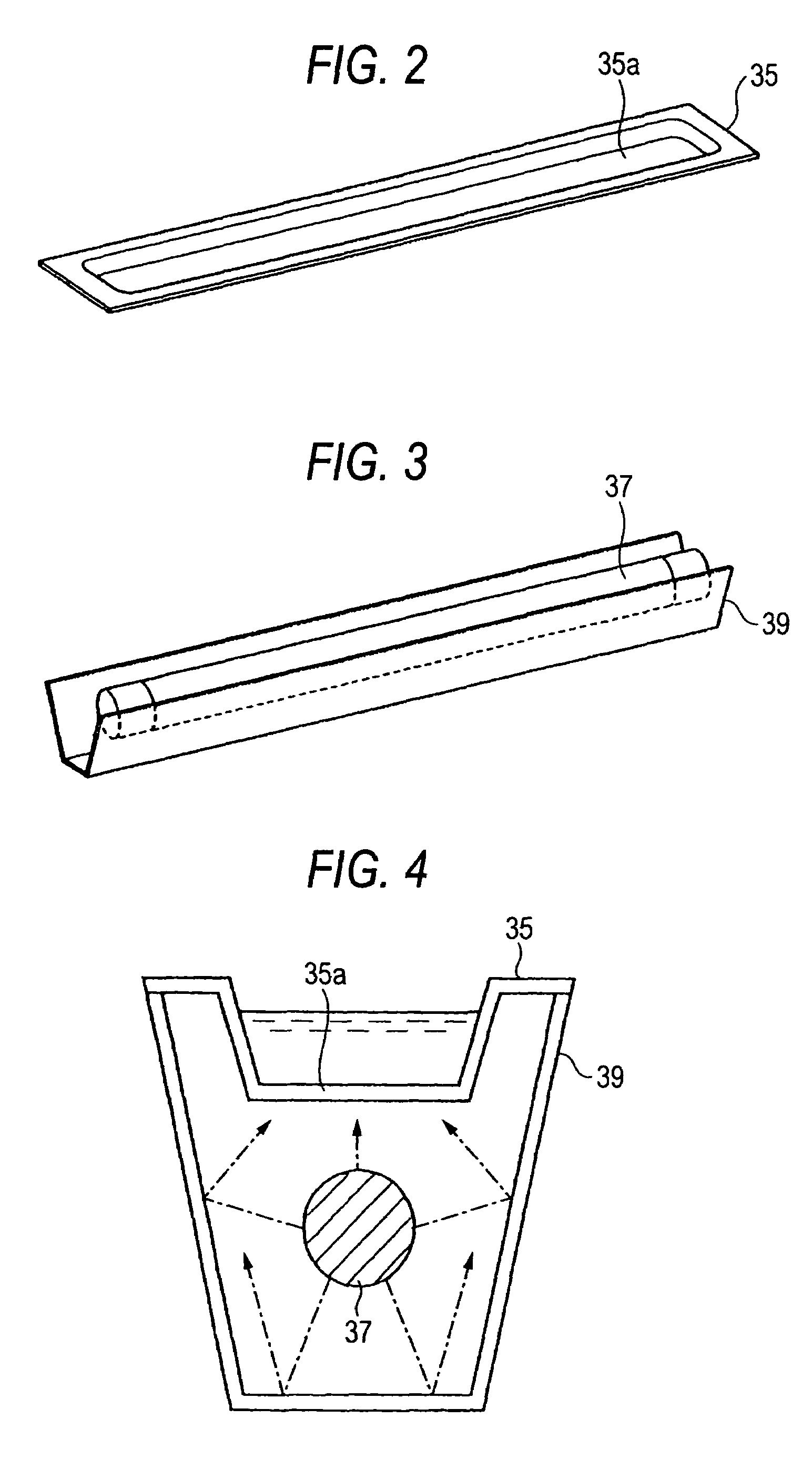

High frequency heating apparatus with steam generating function

InactiveUS7087873B2Easy to cleanAccurate measurementMilk preservationDomestic stoves or rangesEvaporating dishEngineering

Owner:PANASONIC CORP

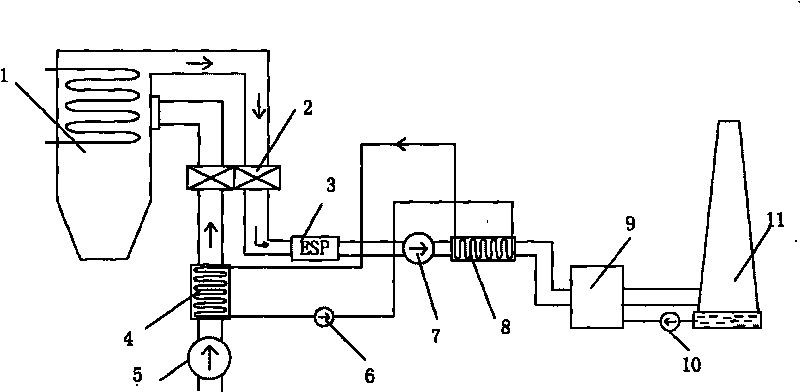

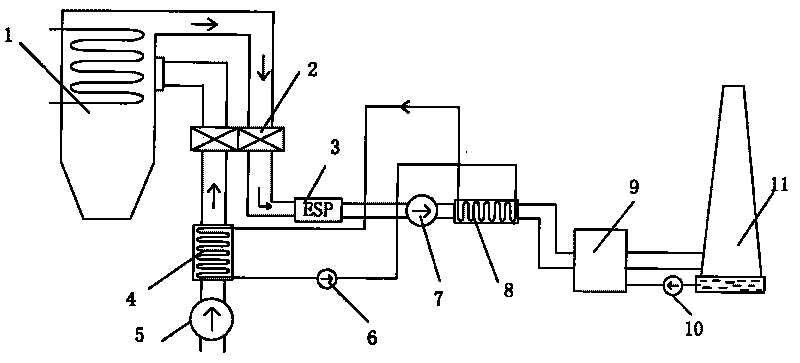

System for deep cooling and waste heat recovery of smoke gas in boiler

ActiveCN101709879AGreat effortDoes not affect normal operationCombustion processIndirect carbon-dioxide mitigationEngineeringWater circulation

The invention relates to a system for deep cooling and waste heat recovery of smoke gas in a boiler with an independent operating system, which comprises a smoke gas deep cooler, an air heater and an independent water circulation system comprising the smoke gas deep cooler and the air heater. The smoke gas of which the dust is removed by an electrostatic dust remover is used for heating the cold water in the smoke gas deep cooler to recover the waste heat of the exhausted smoke, and the hot water at the outlet of the smoke gas deep cooler is transferred to the air heater for preheating the air, thereby increasing the temperature of the combustion-supporting air in the boiler; after the smoke gas passes through the smoke gas deep cooler, the smoke gas is directly introduced into a desulfurizing tower for desulfurization and recovery processing; and finally, the smoke gas is exhausted through a wet chimney. The system of the invention does not need to change the traditional thermodynamic system of the machine unit, and the long-period safe operation of the system can not be influenced in the process of recovering the waste heat of the smoke gas, thereby lowering the temperature of the exhausted smoke, saving the desulfurization water consumption, improving the machine unit efficiency and increasing the machine unit output.

Owner:XI AN JIAOTONG UNIV +1

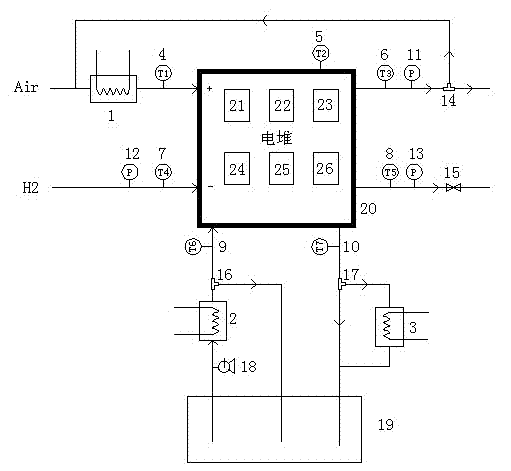

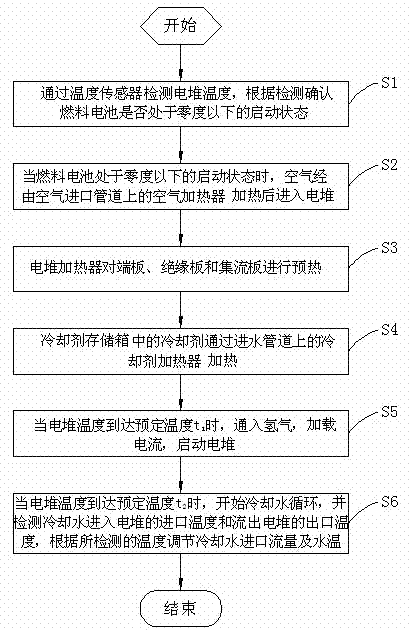

Fuel cell low-temperature quick-starting system and method adopting staged temperature control

ActiveCN103682403AStart fastWarm up fastFuel cell auxillariesBattery/fuel cell control arrangementTemperature controlProton exchange membrane fuel cell

The invention discloses a fuel cell low-temperature quick-starting system and method adopting staged temperature control. The system comprises an electric pile of a PEMFC (Proton Exchange Membrane Fuel Cell) and a coolant storage tank, wherein an air heater is mounted on an air inlet pipeline of the electric pile; a coolant heater is mounted on a water inlet pipeline between the electric pile and the coolant storage tank; an electric pile heater is further arranged on the electric pile and used for pre-heating an end plate, an insulating plate and a current collector of the PEMFC; a temperature sensor used for measuring the temperature of the electric pile is further arranged in the system. According to the invention, the temperature of a fuel cell pile can be detected, and different parts of the fuel cell pile can be pre-heated for temperature rising according to the different working medium heat capacities and the different temperature requirements for starting of different parts of a fuel cell system, so that the fuel cell can be pre-heated quickly, the phenomenon that the fuel cell pile is damaged due to the excessively high temperature gradient is avoided, and the fuel cell system can be quickly started in the environment below zero.

Owner:WUHAN UNIV OF TECH

Washing machine

ActiveUS20090120140A1Inhibition formationRemoving formedTextile treatment machine partsSpray nozzlesEngineeringAir heater

The present invention relates to a washing machine, and the washing machine includes a drum rotatably installed in a cabinet, an air heater for heating air, to supply hot air to the drum, a steam generator for generating steam, and supply the steam to the drum, and a water supply unit including a nozzle for spraying the steam generated by the steam generator to an interior of the drum, and a nozzle holder having a coupler at a rear surface of the nozzle holder, to separably mount the nozzle at a position adjacent to the drum.

Owner:LG ELECTRONICS INC

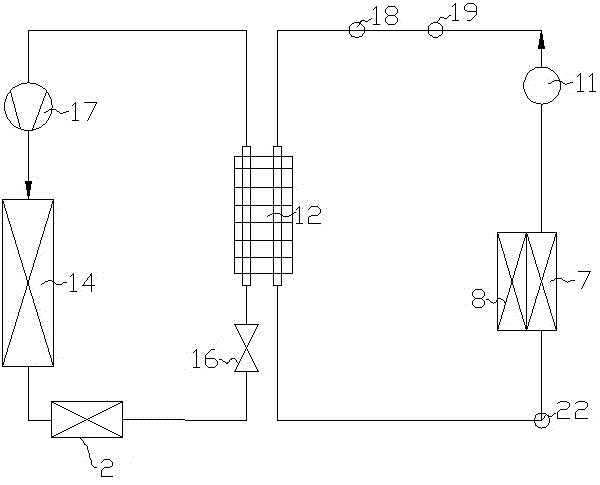

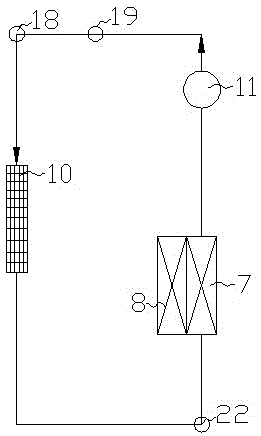

Compressed air energy storage system

InactiveUS20030177767A1Reduce thermal stressEasy temperature controlGas turbine plantsJet propulsion plantsTemperature controlCombustor

A compressed air energy storage system comprises a cavern (1) for stored compressed air and a system for providing the compressed air to a power train (3,5), this system including a recuperator (7) and a first valve arrangement (8) that controls the flow of the compressed air from the recuperator and to the power train (3,5). A system for warm-keeping of the power train (3,5) during stand-by operation of the compressed air energy storage system comprises the recuperator (2) and / or an auxiliary electrical air heater (11) and a second valve arrangement (10, 13) for controlling the airflow for warm-keeping. The system for warm-keeping of the power train allows improved temperature control and avoids disadvantages associated with a warm-keeping system having a combustor.

Owner:GENERAL ELECTRIC TECH GMBH

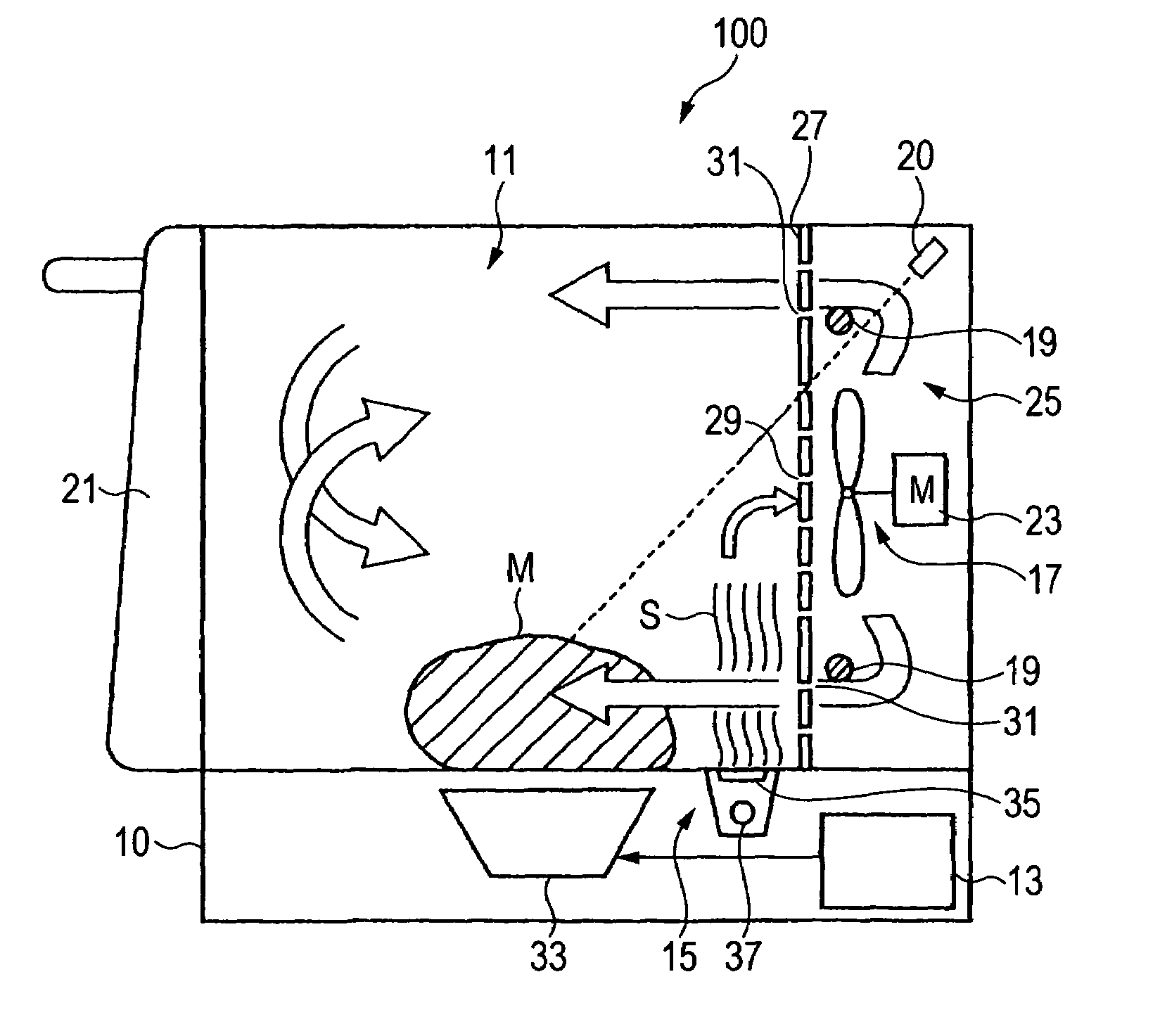

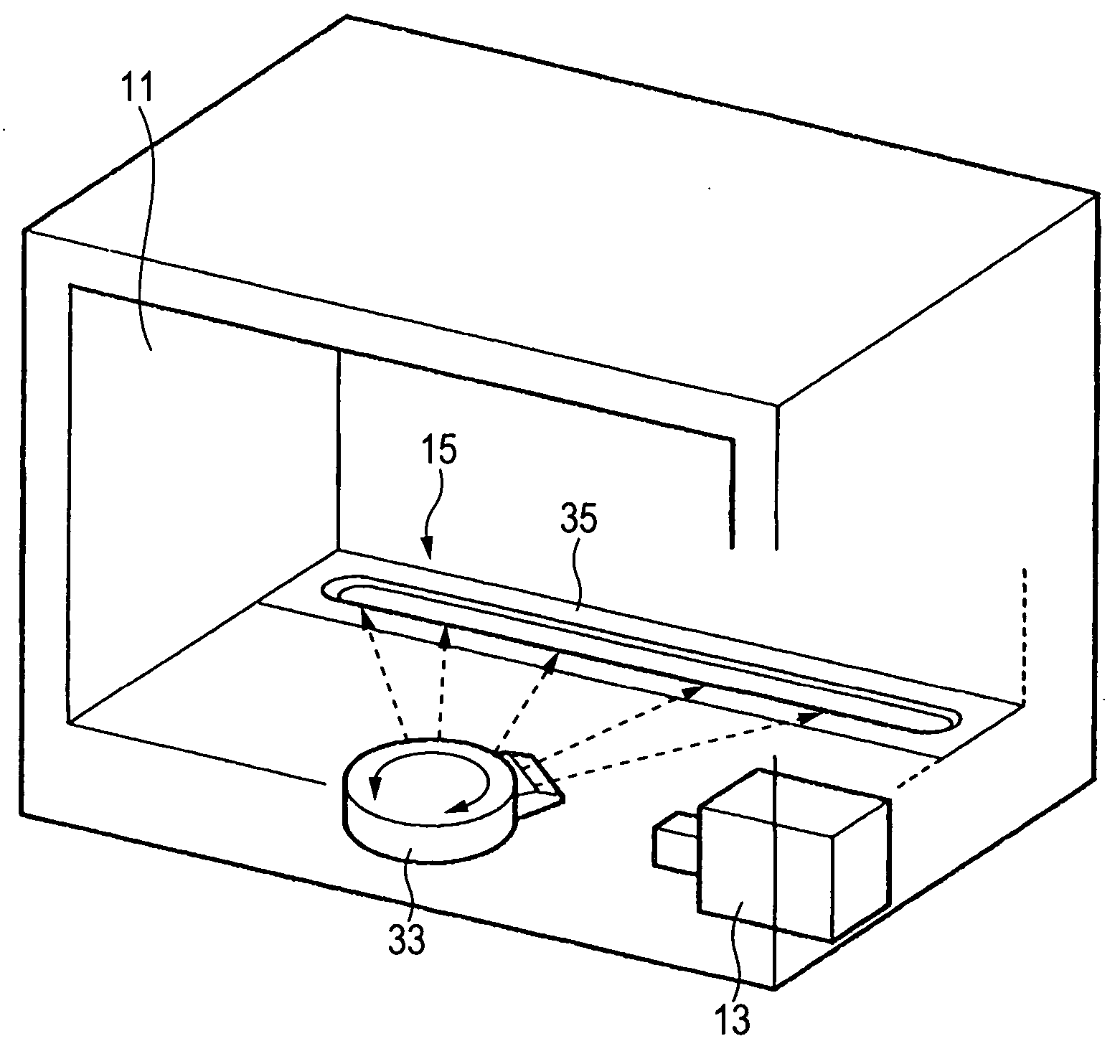

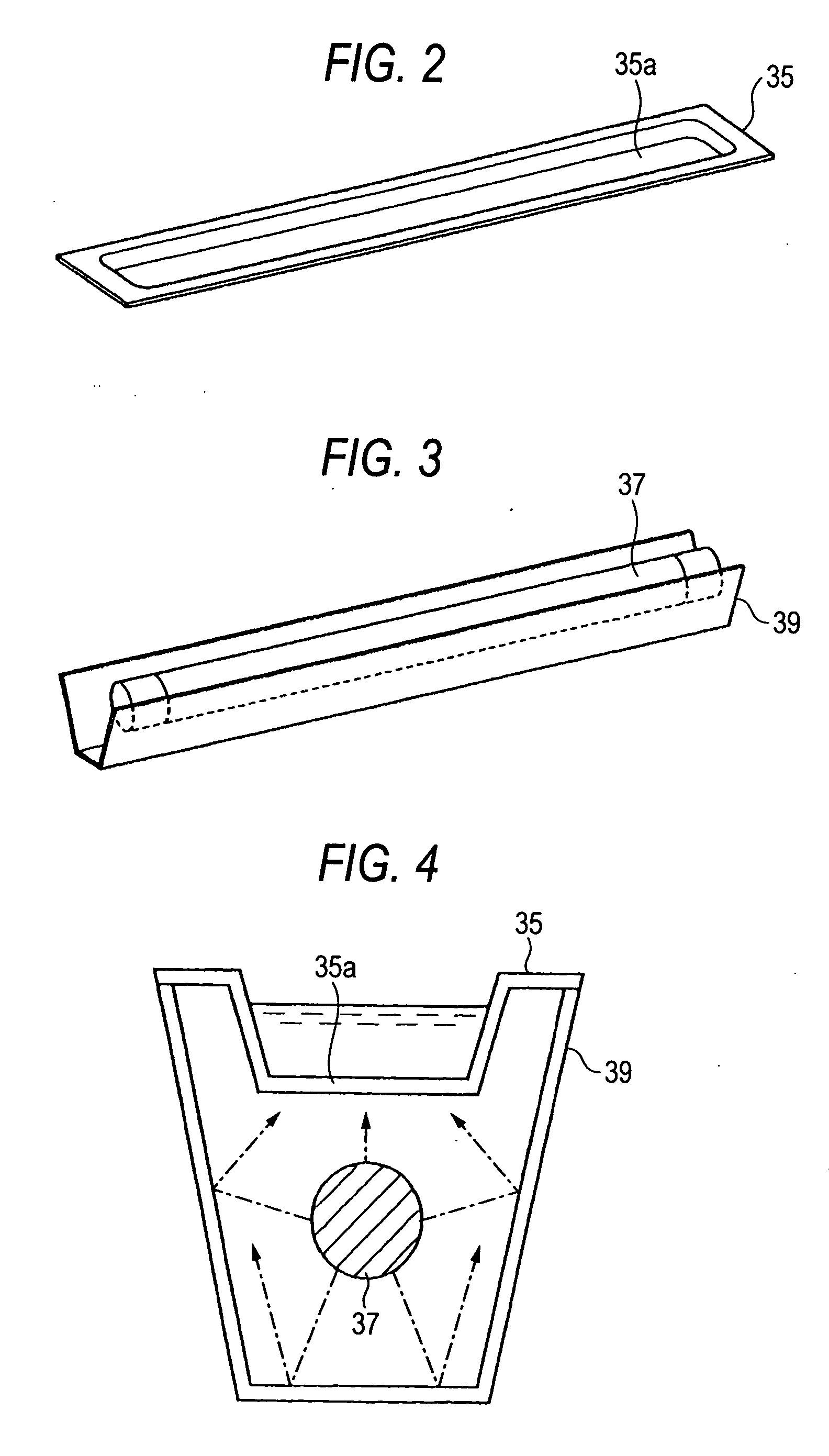

High frequency heating apparatus with steam generating function

InactiveUS20050006382A1Efficiently and gushingly exhaustedEasy to cleanDomestic stoves or rangesMilk preservationEvaporating dishEngineering

A high-frequency heating apparatus with a steam generating function, which heat-treats a to-be-heated object by supplying at least high-frequency waves or steam to a heating chamber 11 that accommodates the object. This high-frequency heating apparatus has a high frequency wave generating portion 13, a steam generating portion 15 for generating steam in the heating chamber 11, and a circulating fan 17 for agitating air in the heating chamber 11. Moreover, the high-frequency heating apparatus has a chamber air heater 19 for heating air circulating in the heating chamber 11. The steam generating portion 15 generates steam by heating an evaporating dish 35 that has a water storing recess.

Owner:PANASONIC CORP

Method and device for removing mercury

Owner:MITSUBISHI POWER LTD

High-efficiency excellent bean screening equipment

InactiveCN107159572AShorten speedDecrease the tilt angleSievingGas current separationEngineeringAir separation

Owner:黄海

Quick cleaning and briquetting device for recycling scrap iron

InactiveCN106079533AHigh degree of automationEasy to operateDrying gas arrangementsCleaning using liquidsCamAir heater

The invention relates to a briquetting device for recycling scrap iron, and particularly relates to a quick cleaning and briquetting device for recycling the scrap iron. The invention aims to solve the technical problem of providing the quick cleaning and briquetting device for recycling the scrap iron, which has the advantages of multiple functions, good briquetting effect and high working efficiency. In order to solve the technical problem, the invention provides the quick cleaning and briquetting device for recycling the scrap iron. The quick cleaning and briquetting device comprises a bottom plate, first springs, a first baffle, a sliding rail, a sliding block, a right rack, a collection frame, a fixed rod, a first pressing plate, a cleaning tank, a connecting rod, a first motor, a disk cam and an air heater, wherein the first springs are arranged on the left side of the top of the bottom plate in a bilaterally symmetrical mode. The device has the effects of multiple functions, good briquetting effect, high working efficiency and simplicity in operation, and ordinary people can use the device as long as some simple instructions are given.

Owner:周栋

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com