Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

69results about How to "Stable atomization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

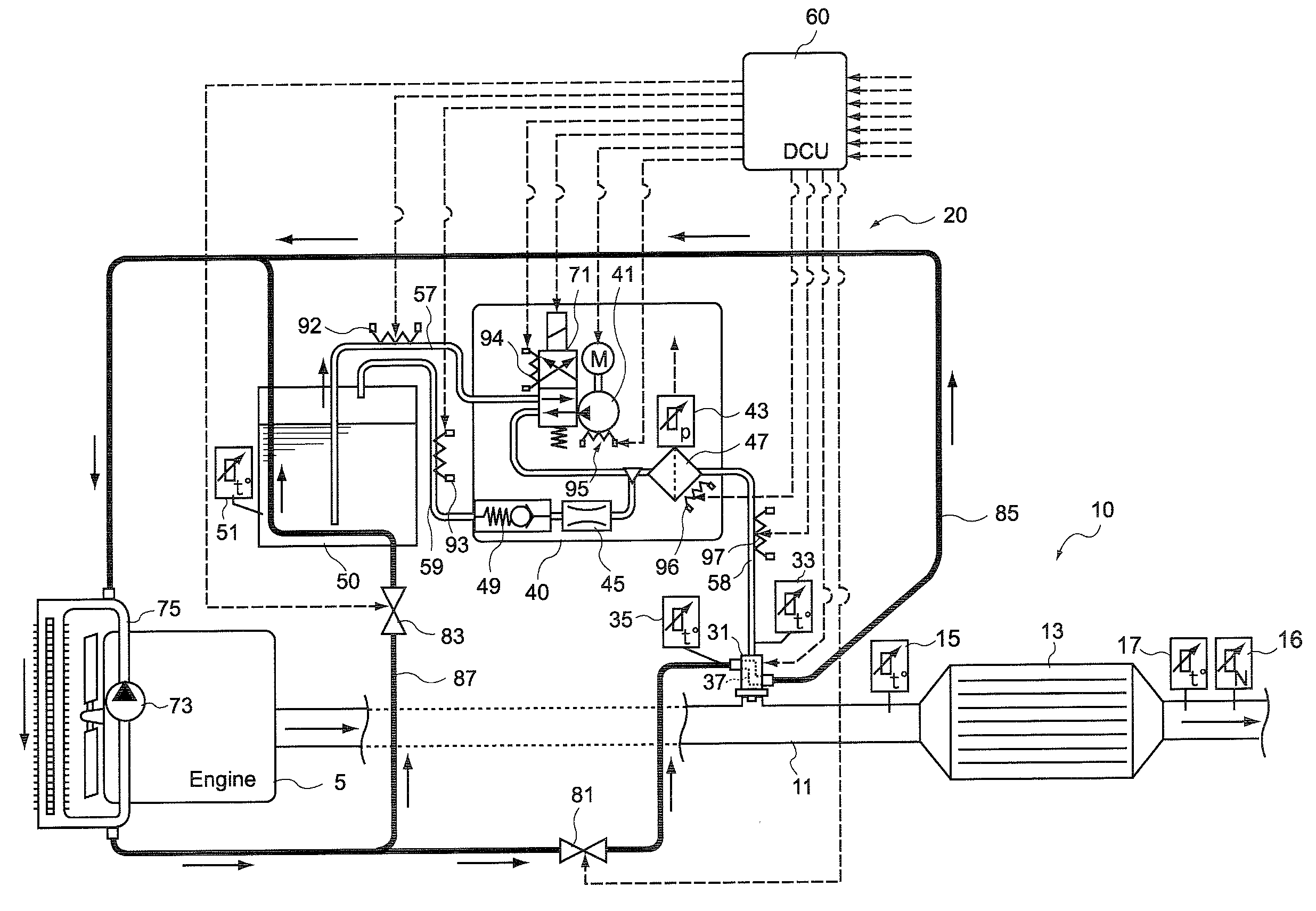

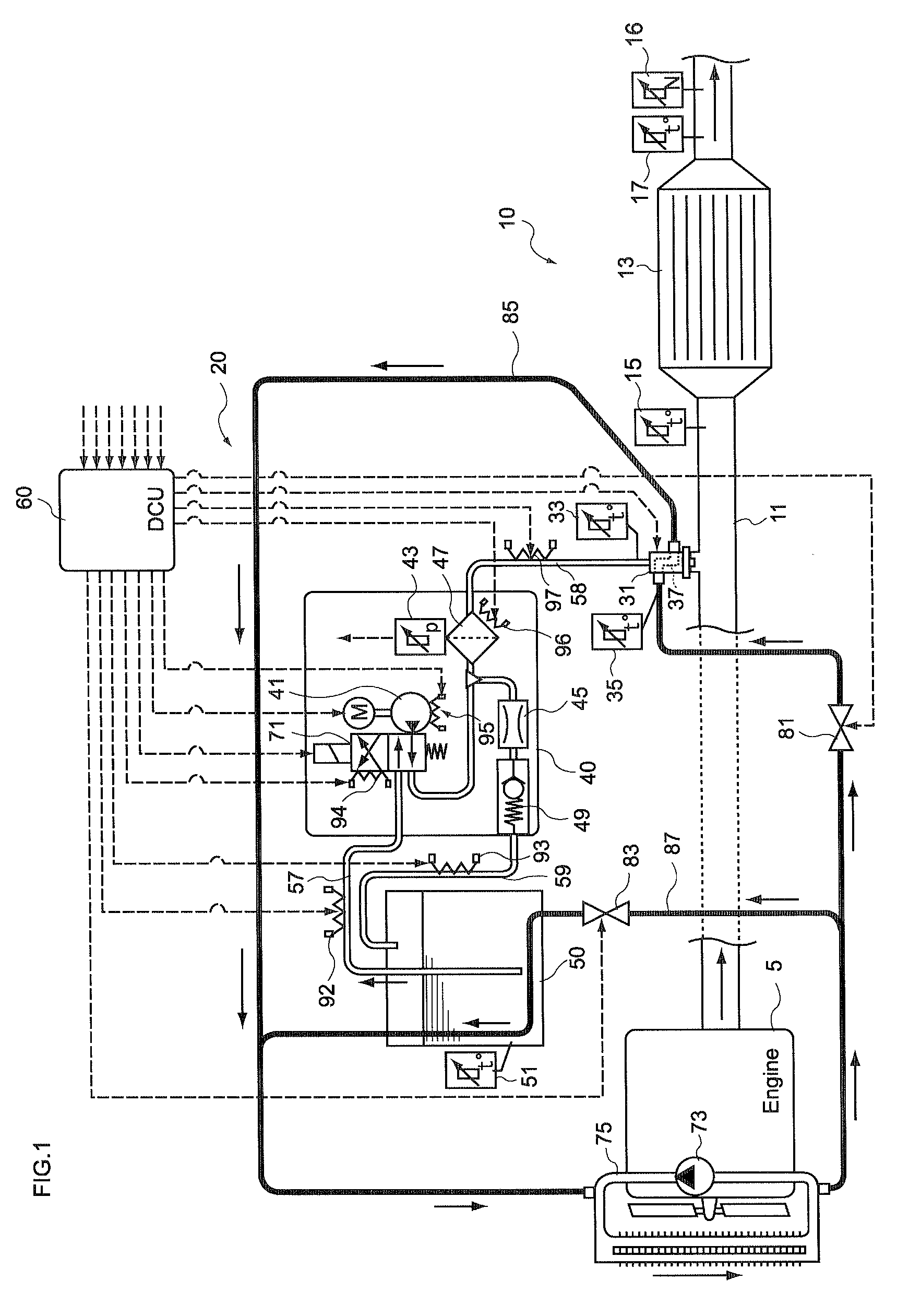

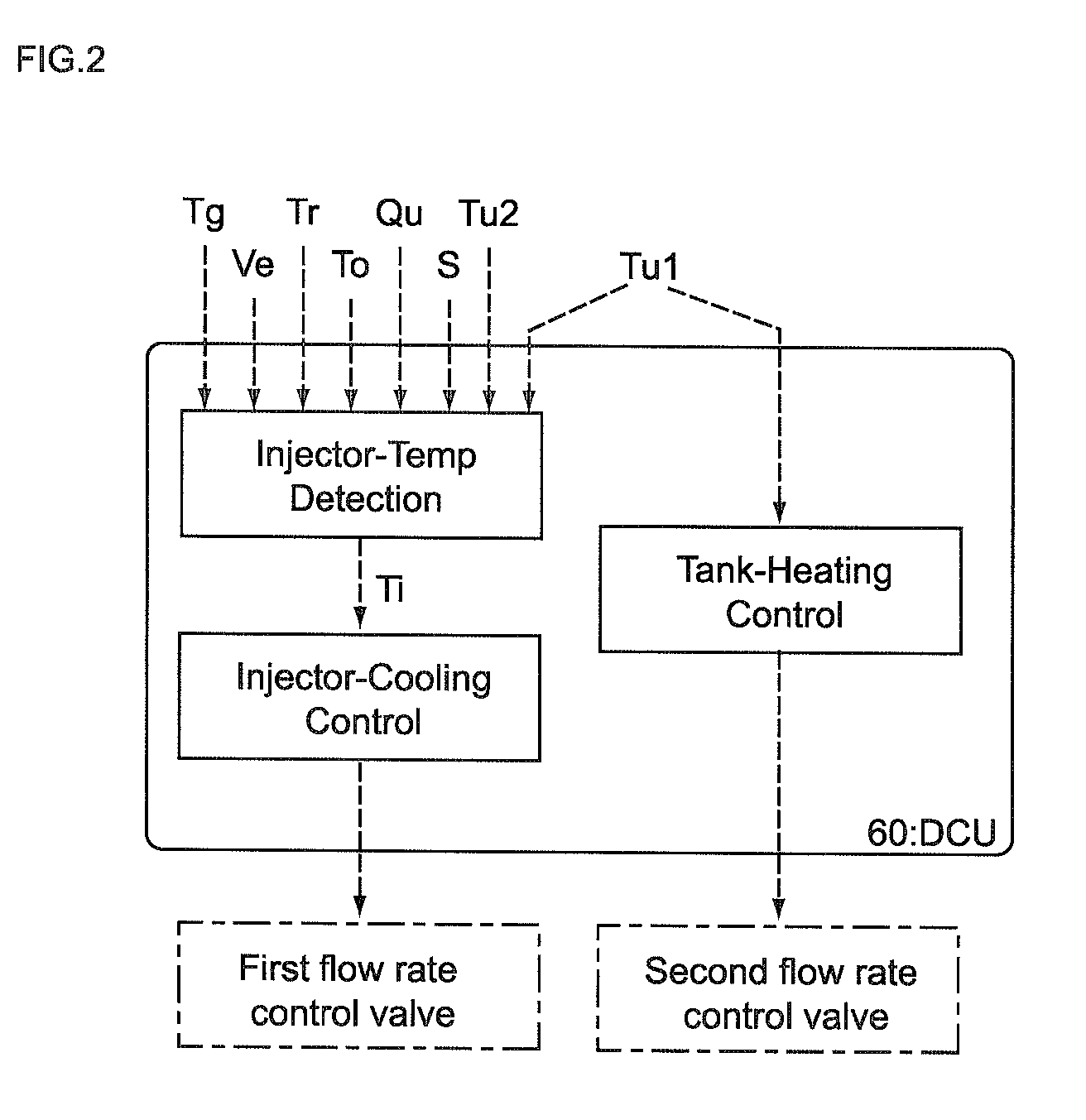

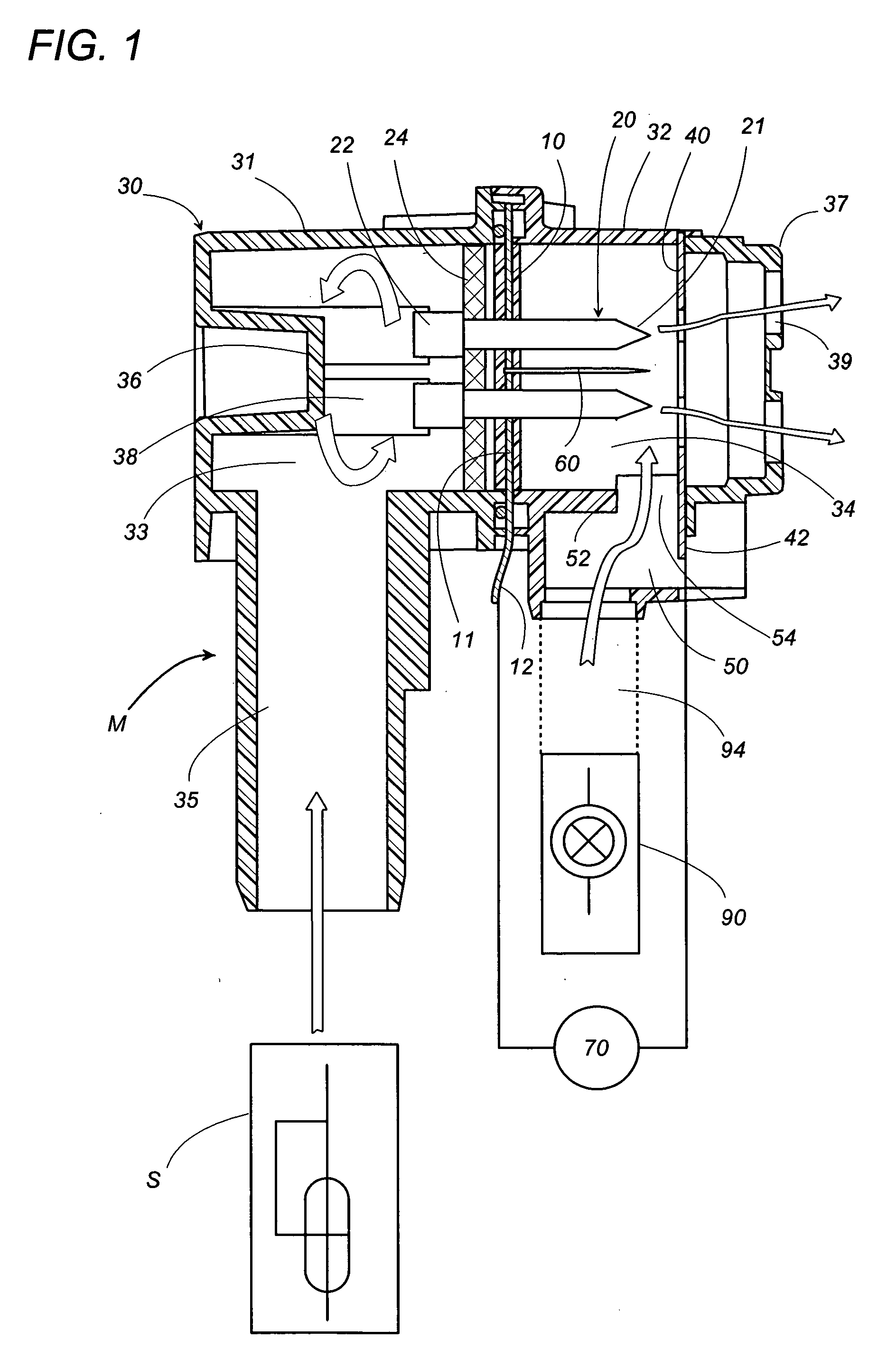

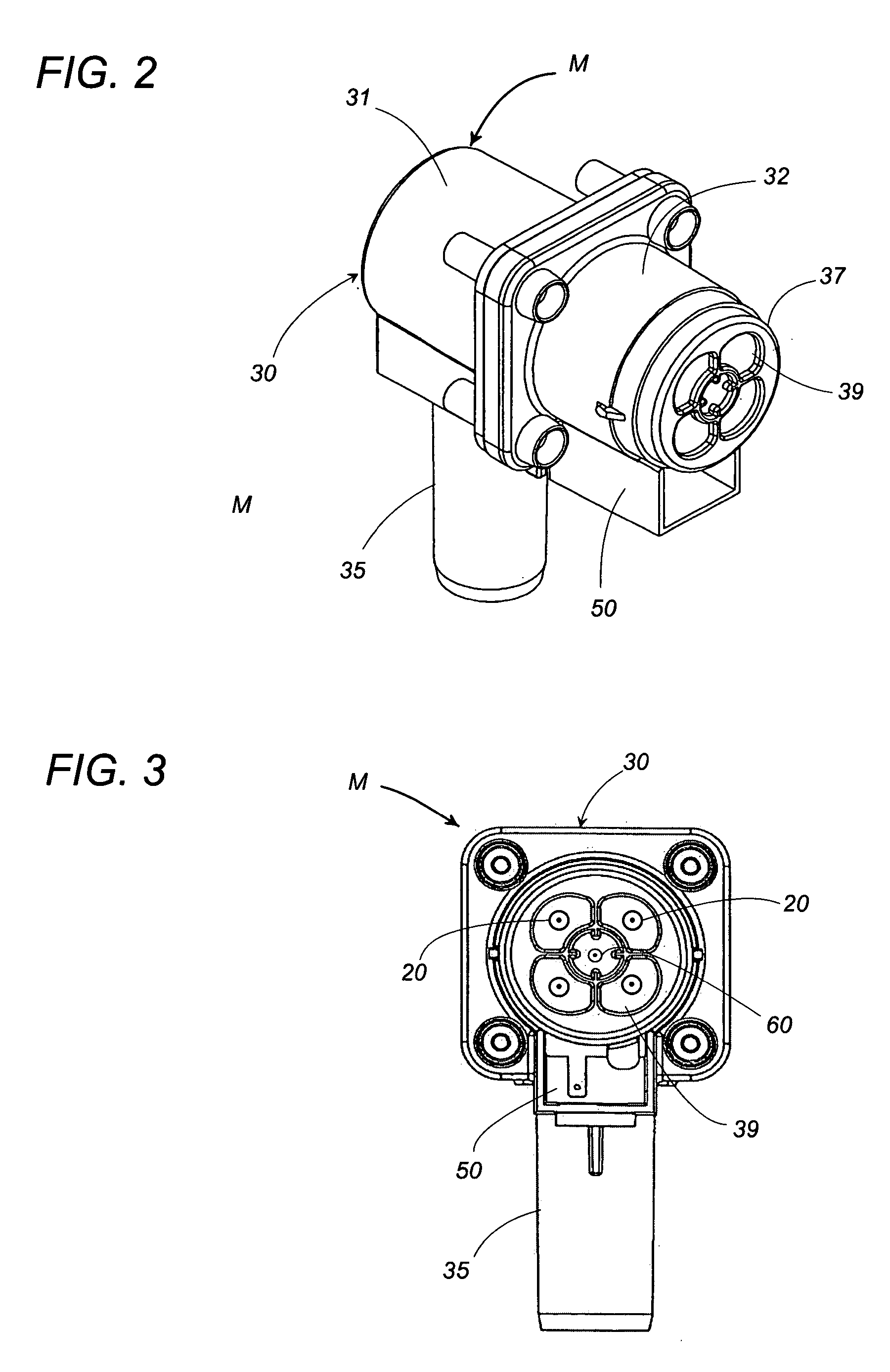

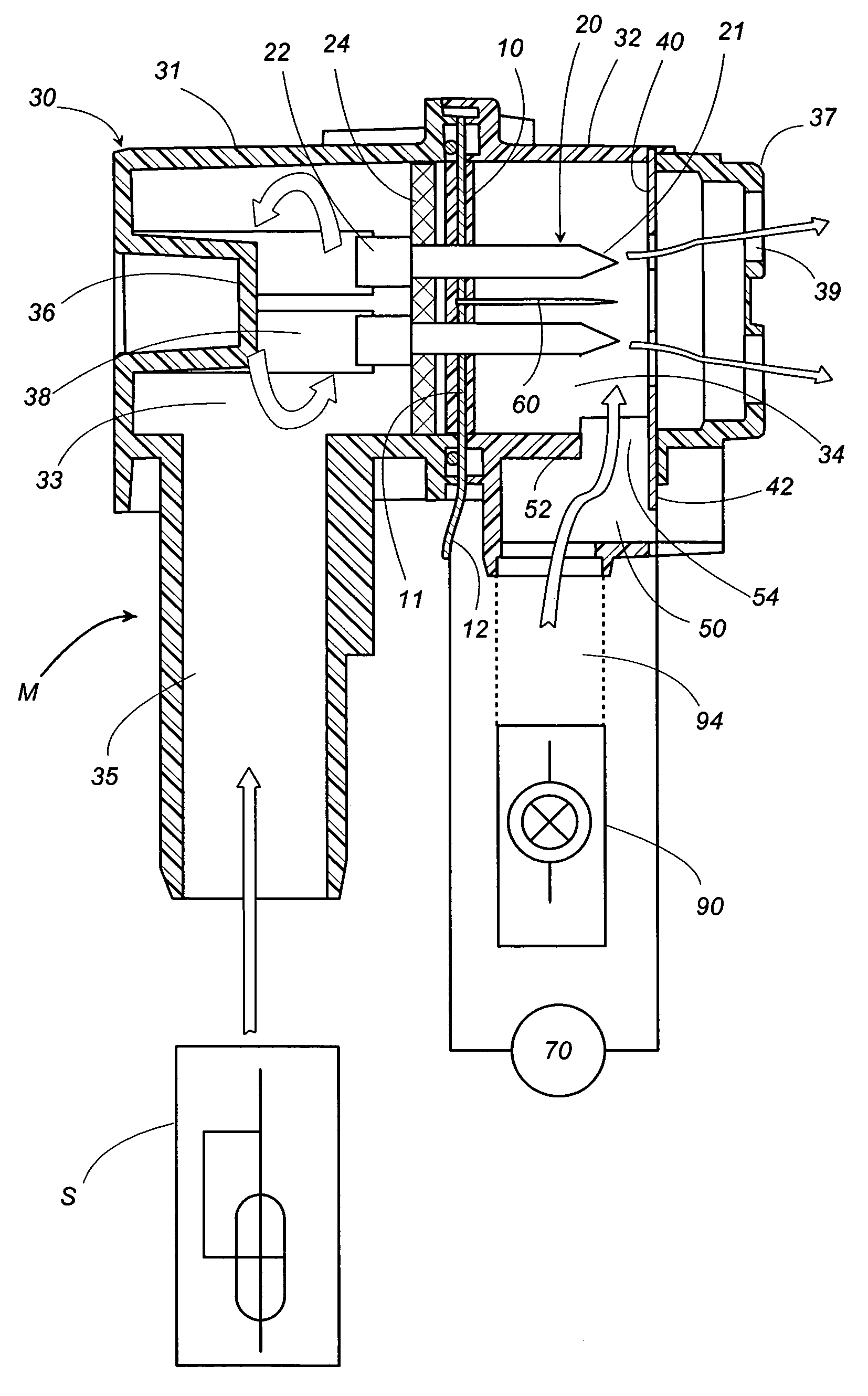

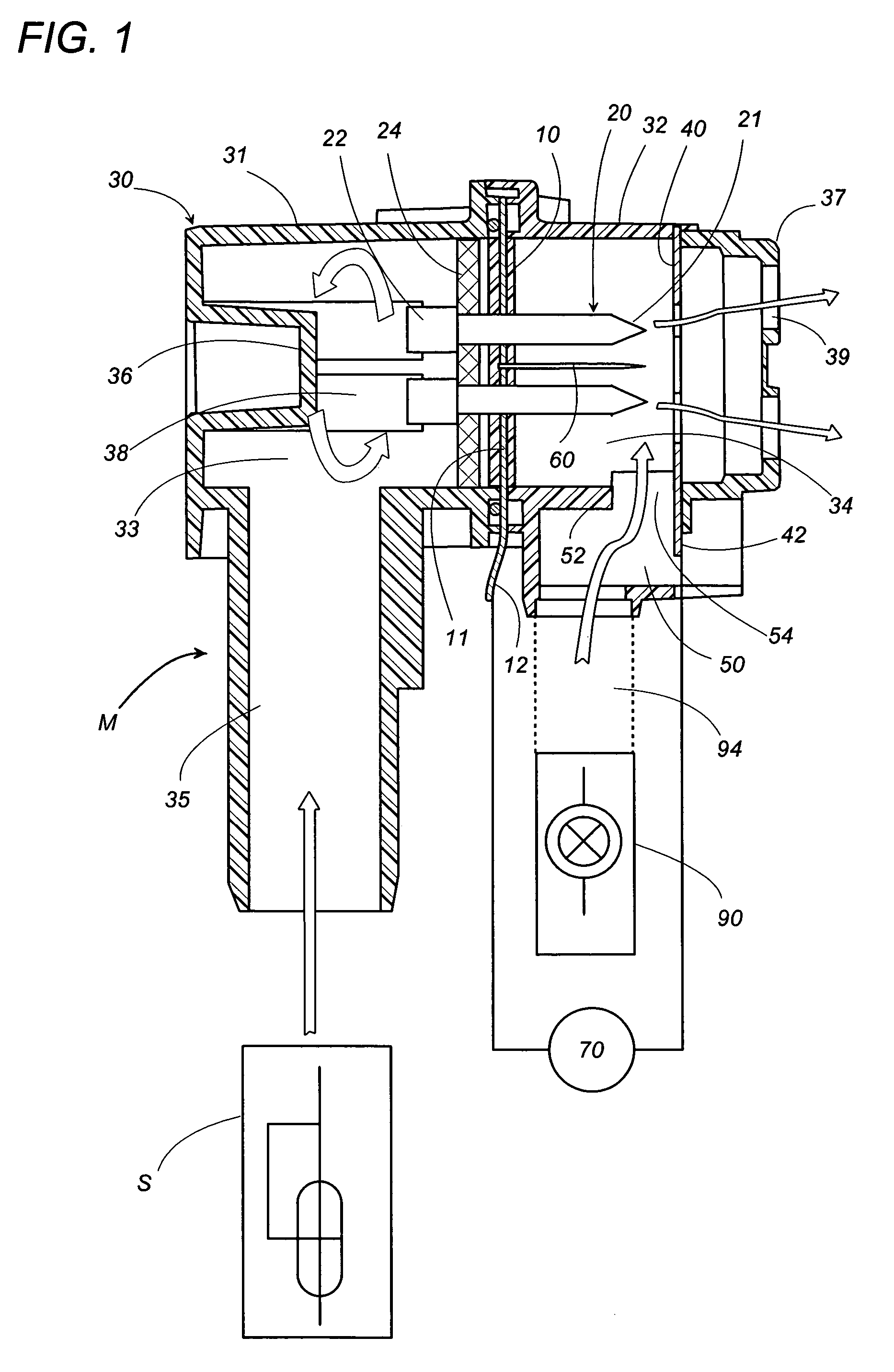

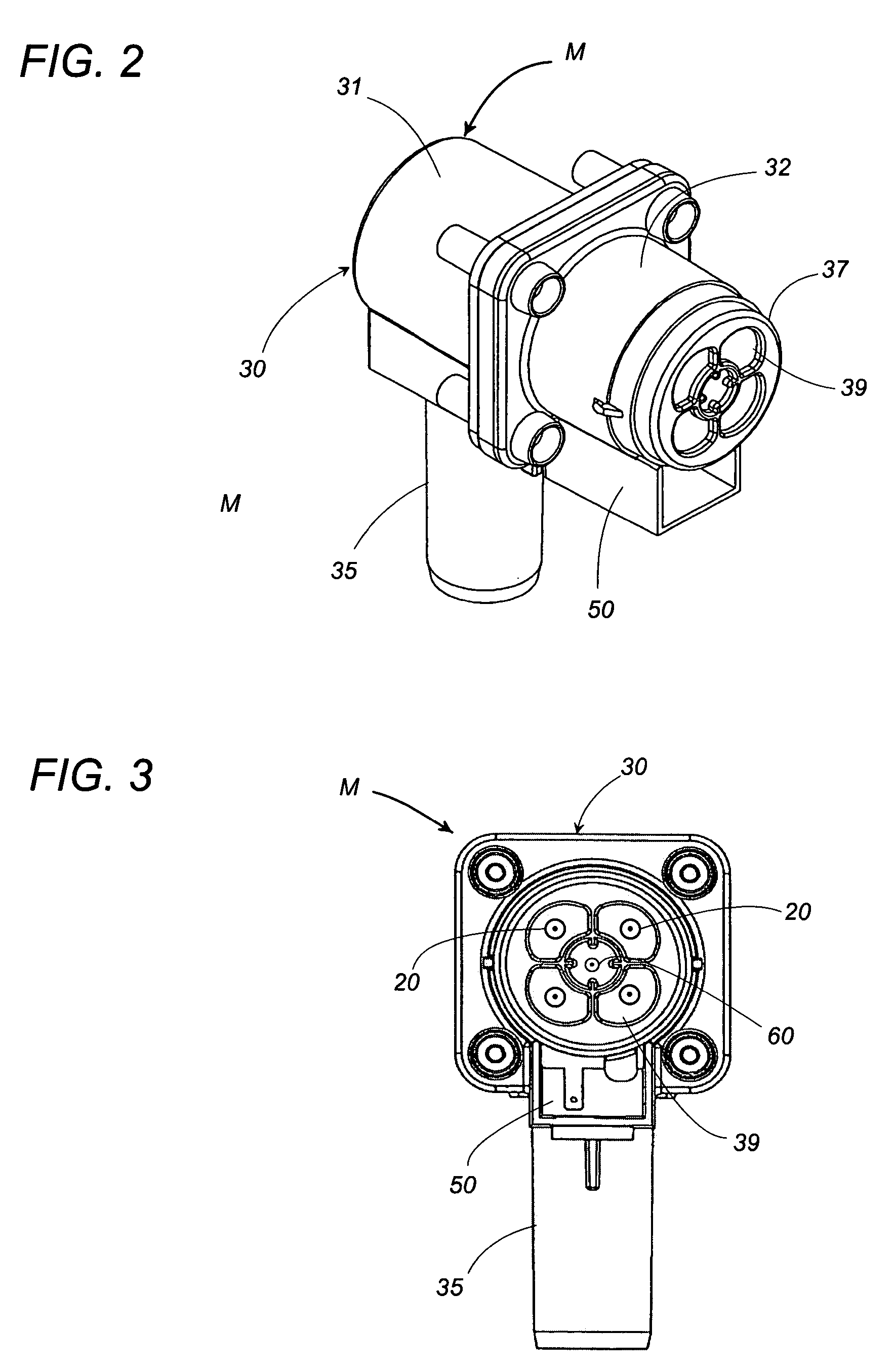

Control unit and control method for reductant supply device

InactiveUS20100242439A1Prevent overcoolingImprove cooling effectLiquid coolingInternal combustion piston enginesEngineeringWater circulation

There are provided a reductant supply device and a control method for the reductant supply device, which can prevent heat damage of a reductant injection valve, and also prevent crystallization of urea solution due to excessive cooling of the solution reductant.The reductant supply device which is used in an exhaust gas purification device that injects and supplies, as a reductant, a urea solution to an exhaust gas upstream side of a reduction catalyst disposed in an exhaust gas passage of an internal combustion engine, and that reduces and purifies nitrogen oxides contained in exhaust gas using the reduction catalyst, the reductant supply device having a reductant injection valve that is fixed to an exhaust pipe on the exhaust gas upstream side of the reduction catalyst, includes: a cooling water circulation passage that circulates at least part of cooling water of the internal combustion engine to cool the reductant injection valve; flow rate control means for adjusting a flow rate of cooling water flowing through the cooling water circulation passage; temperature detection means for detecting a temperature of the reductant injection valve; and control means for controlling the flow rate control means based on the temperature of the reductant injection valve.

Owner:BOSCH CORP

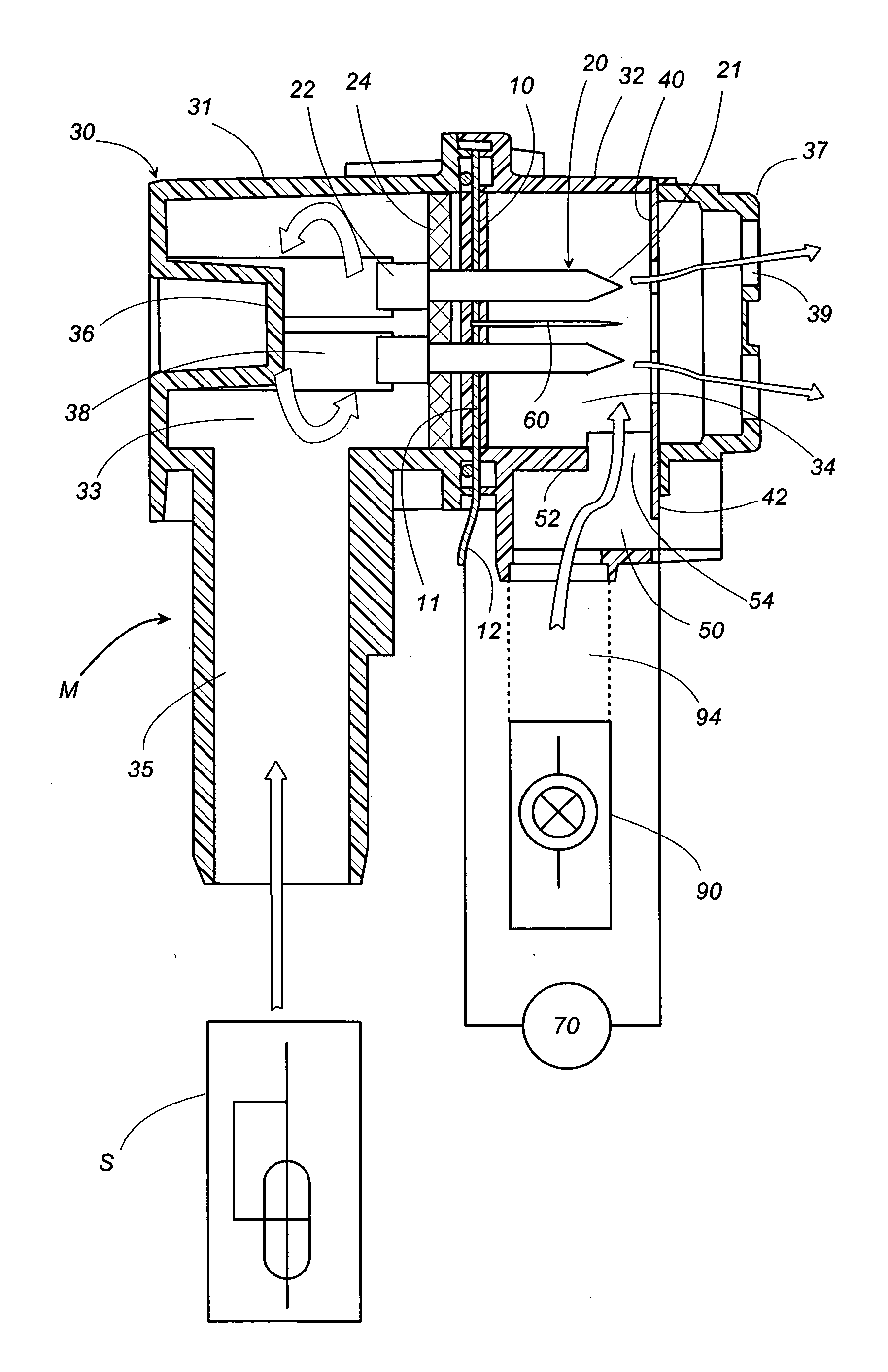

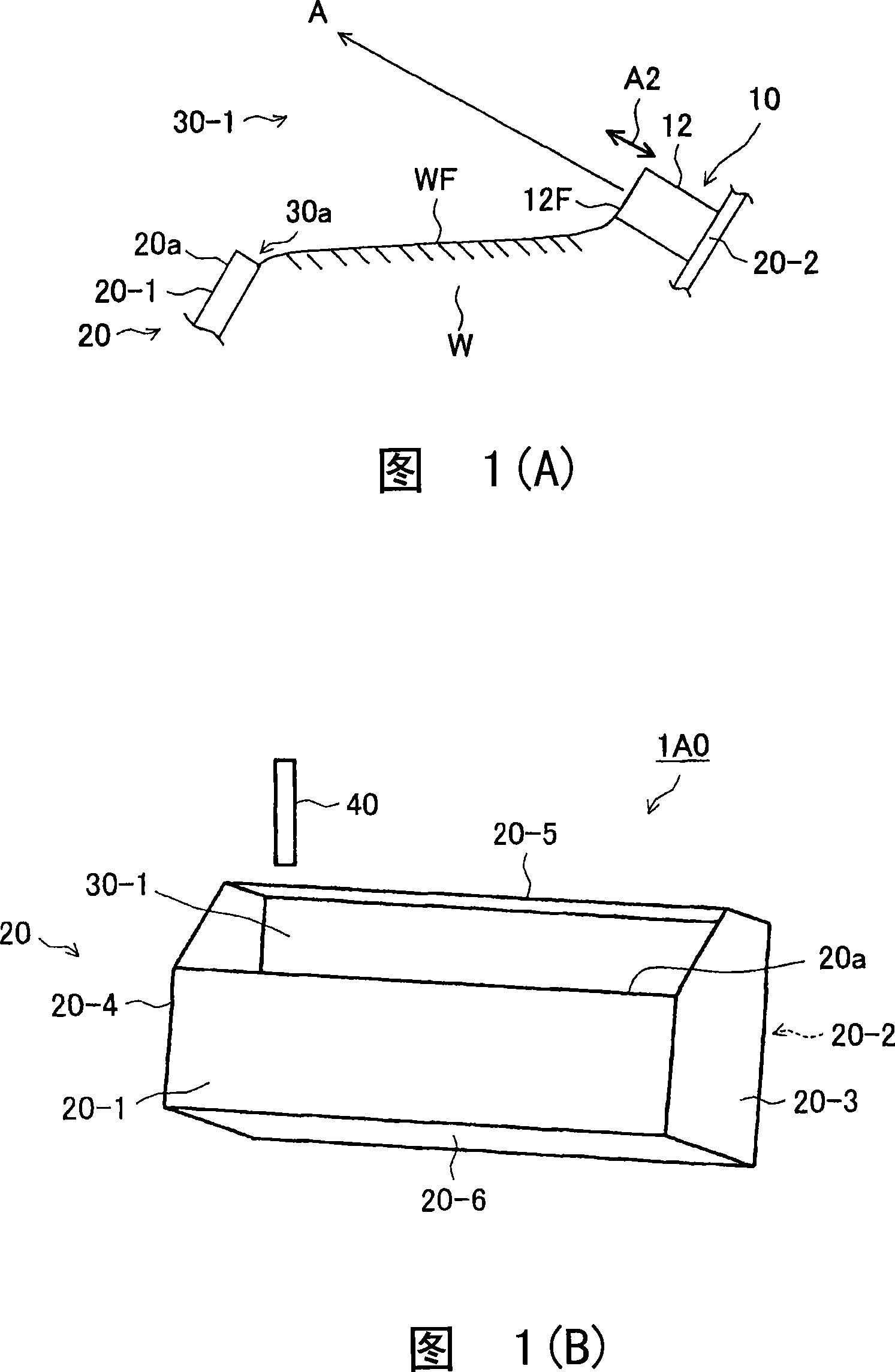

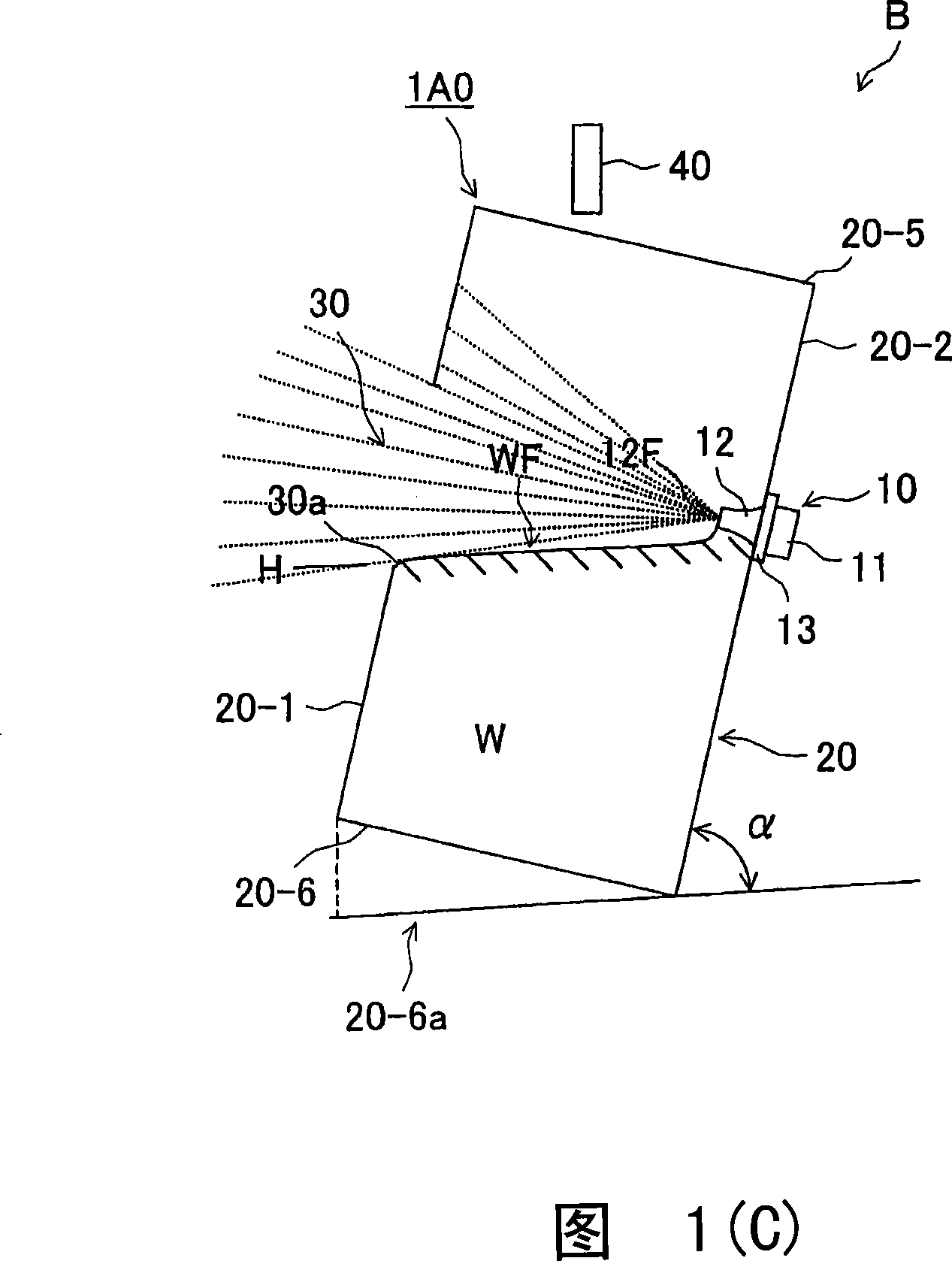

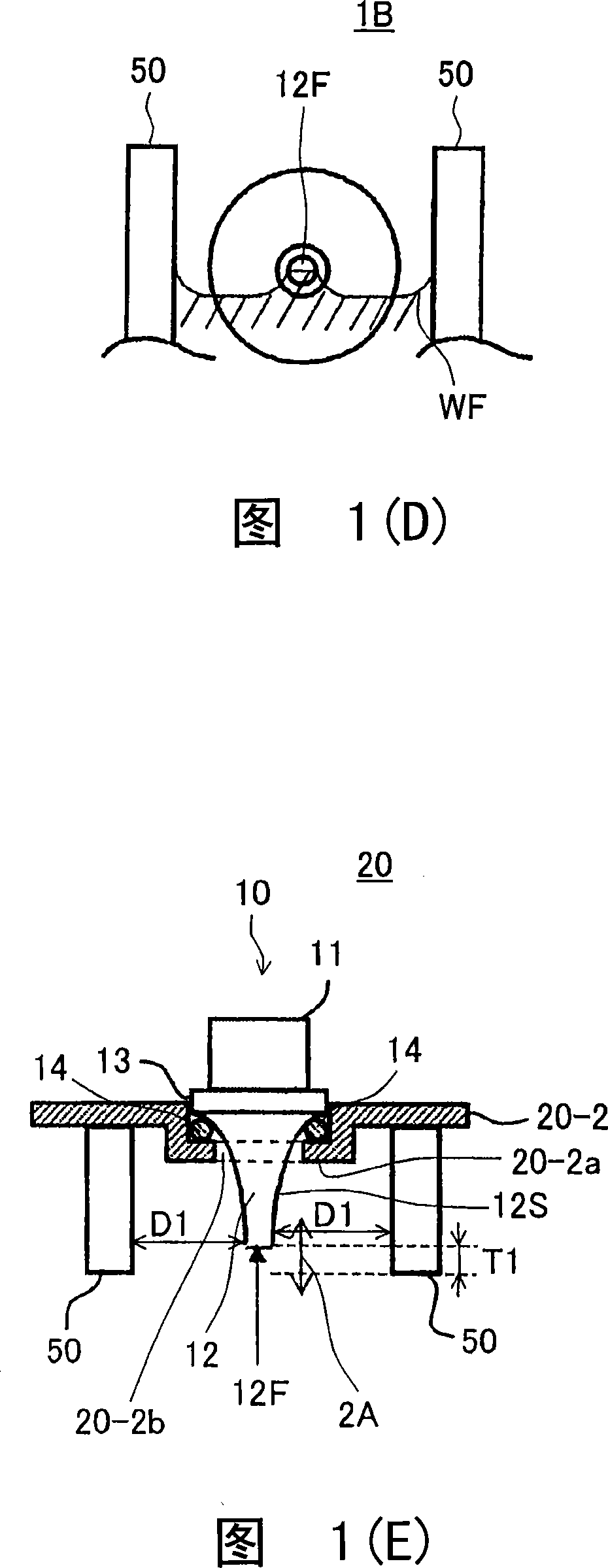

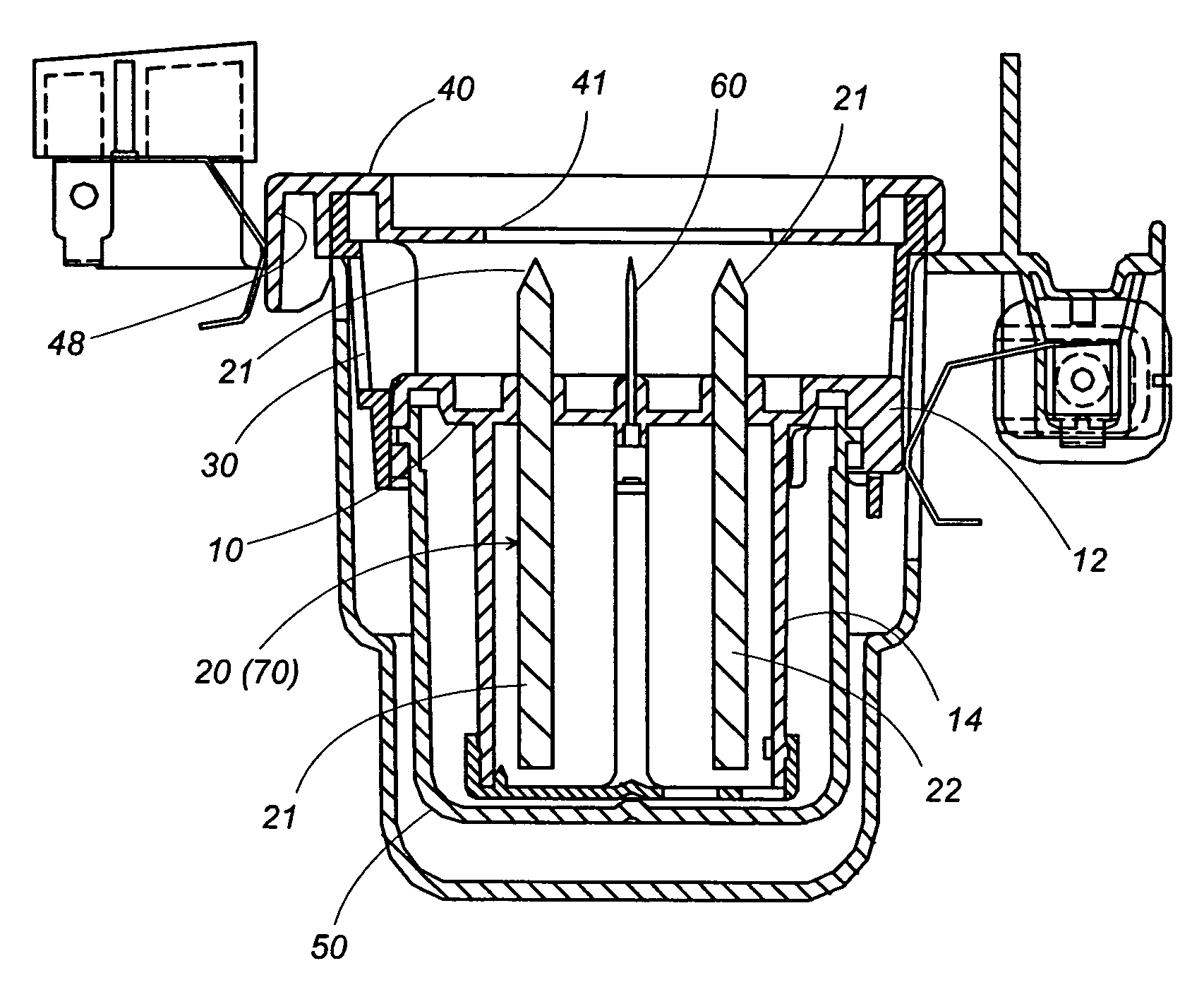

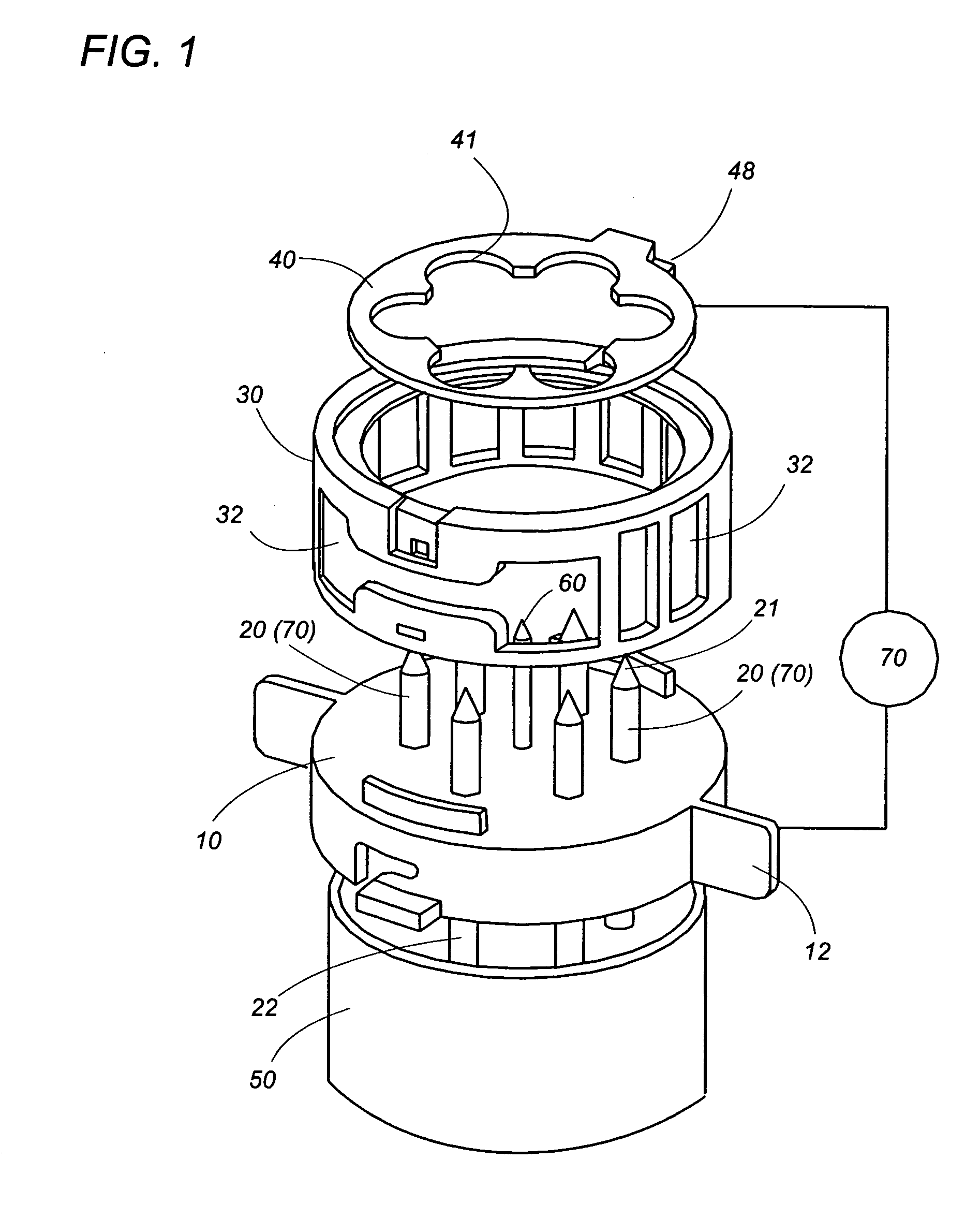

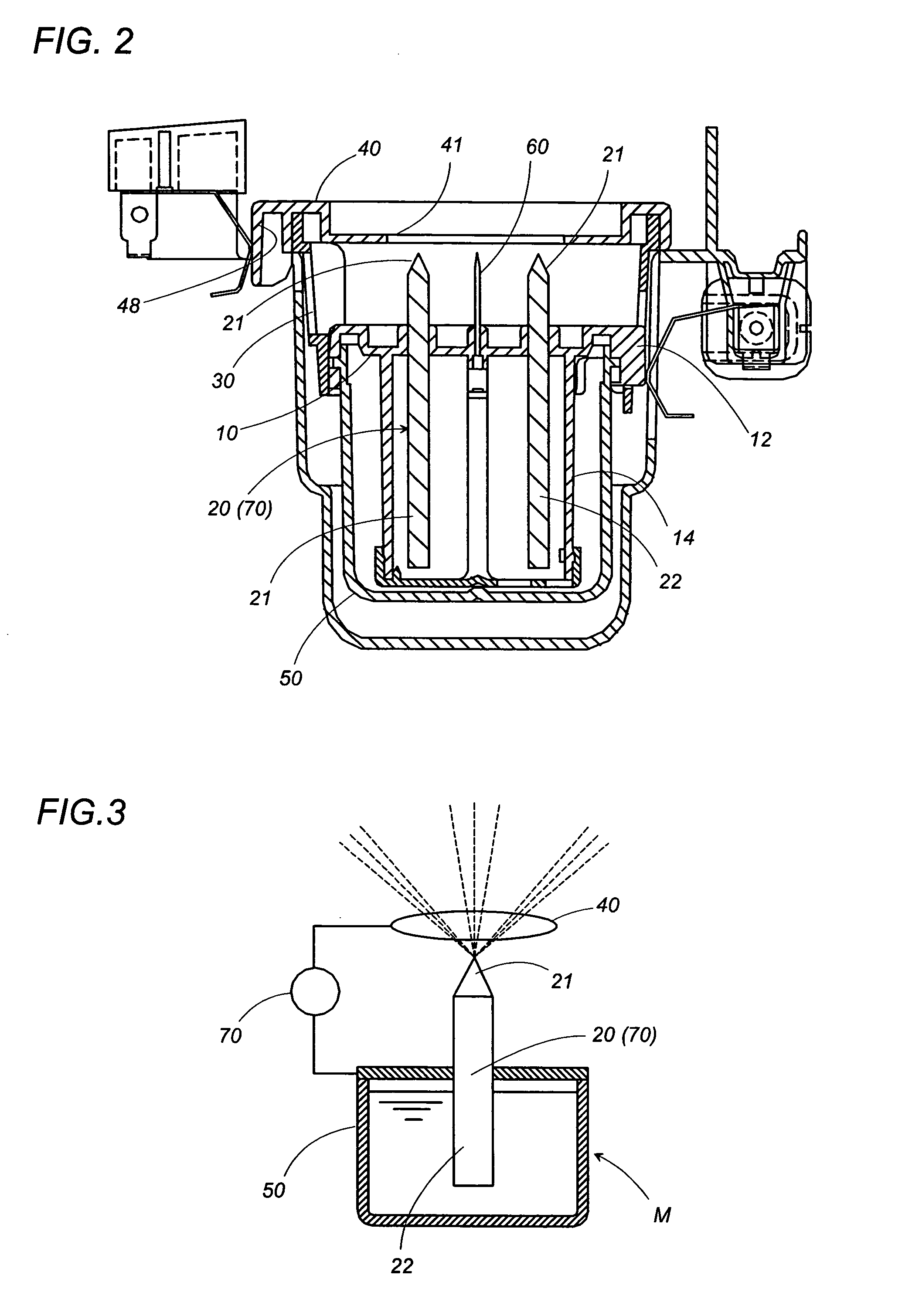

Electrostatic atomizing device and humidifier using this

InactiveUS20060131449A1Stable atomizationPrevent precipitationBurnersLiquid supply arrangementsEngineeringHigh pressure

A carrier is used to carry a liquid, and a high voltage is applied between a discharge end of the carrier and an opposed electrode to emit ionized liquid particles. The carrier has a liquid collecting end opposite to the discharge end to feed the steam of the liquid from a steam generator, condensing the liquid therearound, and feeding the condensed liquid to the discharge end. Accordingly, even when the liquid contains cations such as those of Ca and Mg, the steam of the liquid can extremely reduce the content of these impurities, avoiding the precipitation of the impurities at the discharge end of the carrier to assure stable electrostatic atomization.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Electrostatic atomizing device and humidifier using the same

InactiveUS7494532B2Stable atomizationPrevent precipitationBurnersLiquid supply arrangementsImpurityPrecipitation

A carrier is used to carry a liquid, and a high voltage is applied between a discharge end of the carrier and an opposed electrode to emit ionized liquid particles. The carrier has a liquid collecting end opposite to the discharge end to feed the steam of the liquid from a steam generator, condensing the liquid therearound, and feeding the condensed liquid to the discharge end. Accordingly, even when the liquid contains cations such as those of Ca and Mg, the steam of the liquid can extremely reduce the content of these impurities, avoiding the precipitation of the impurities at the discharge end of the carrier to assure stable electrostatic atomization.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Control unit and control method for reductant supply device

InactiveUS20130118155A1Prevent excessive coolingAvoid heatingLiquid coolingInternal combustion piston enginesBoiling pointEngineering

A reductant supply device having a reductant injection valve with an injection tip that is fixed to an exhaust pipe on the exhaust gas upstream side of a reduction catalyst, the device directly injecting and supplying an urea aqueous solution which is pressure-fed to the reductant injection valve in a state of a liquid fluid, by controlling opening and closing of the reductant injection valve. The device includes a cooling water circulation passage; a flow rate control valve; a temperature sensor for detecting a temperature at the tip of the reductant injection valve; and a controller for controlling the flow rate control valve based on the temperature at the tip such that the temperature at the tip of the reductant injection valve is maintained at a temperature between equal to or higher than a boiling point of the urea aqueous solution and equal to or lower than 130° C.

Owner:BOSCH CORP

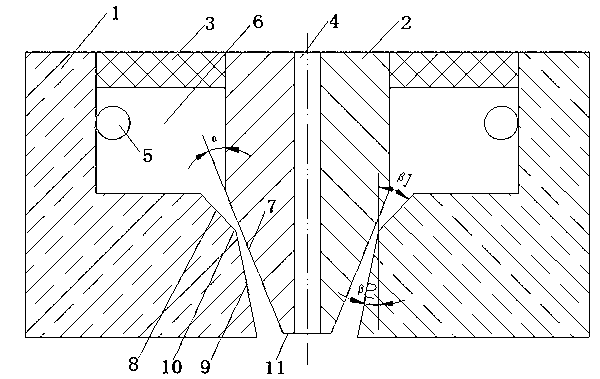

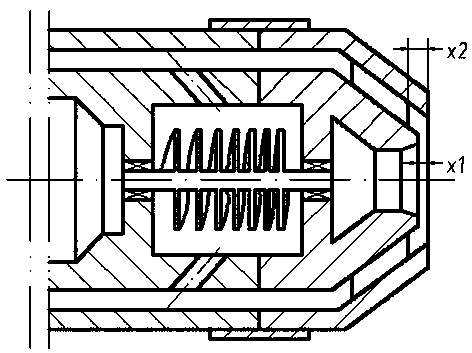

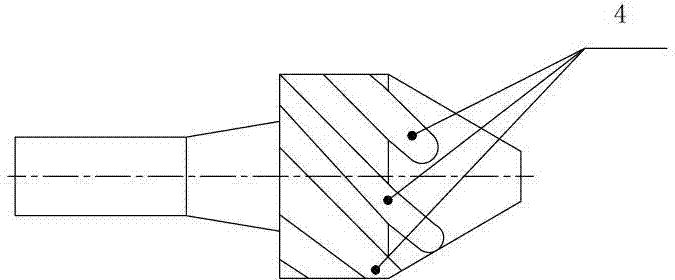

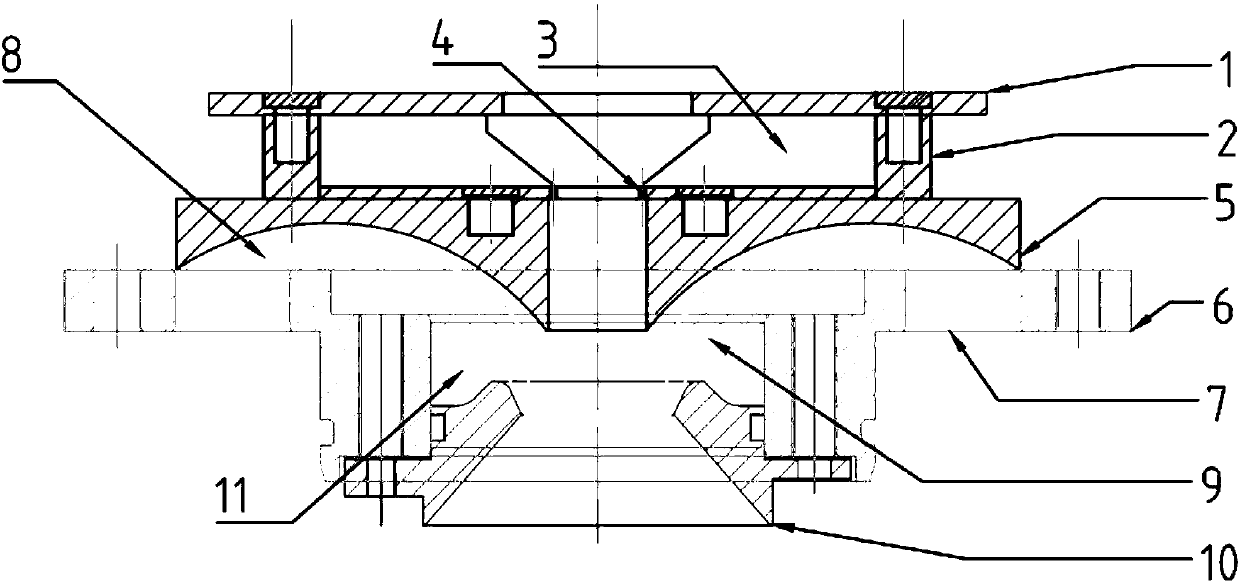

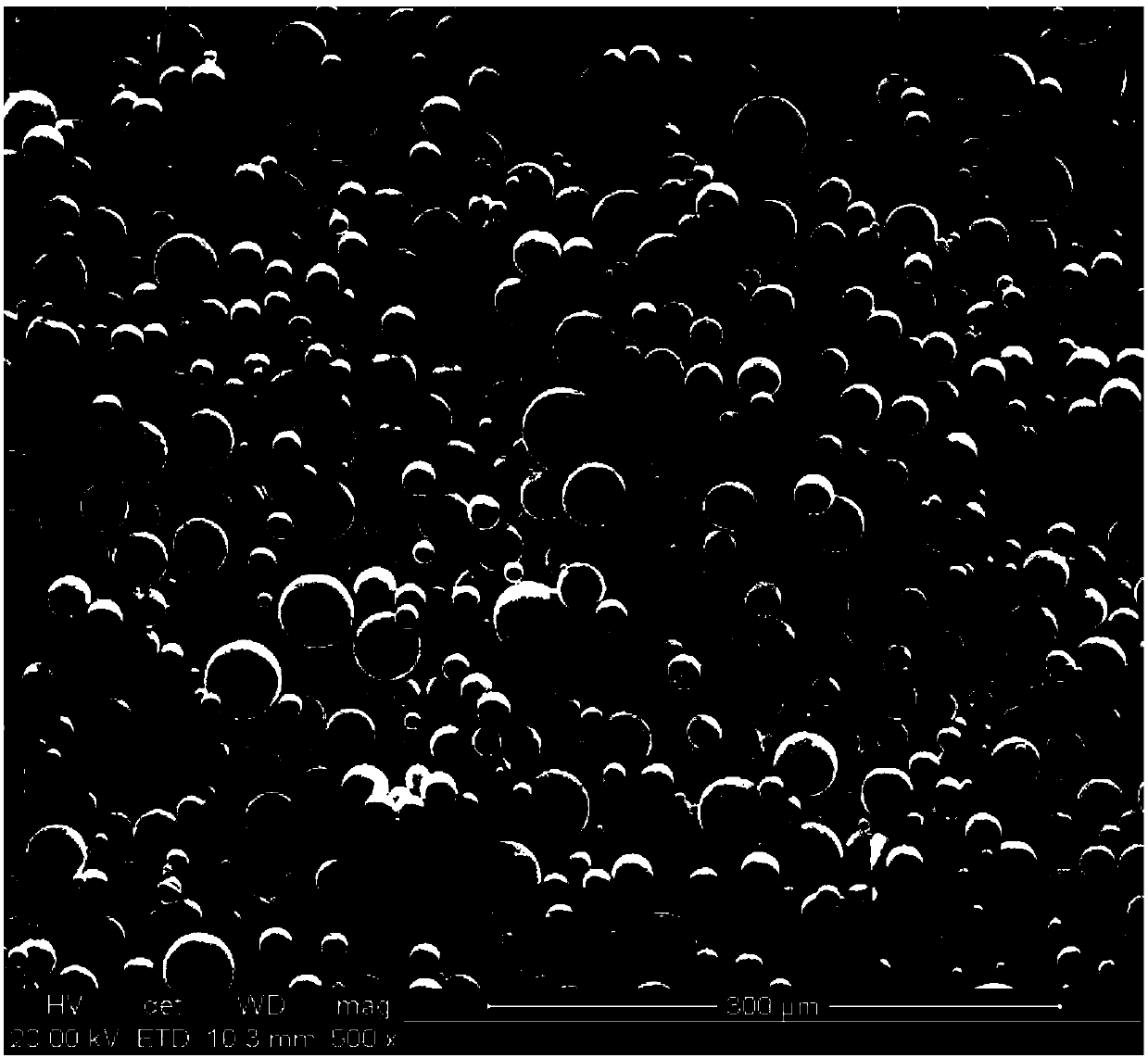

Adjustable ultra-fine atomizing nozzle for titanium and titanium alloy melt

The invention discloses an adjustable ultra-fine atomizing nozzle for titanium and titanium alloy melt. A titanium melt passage penetrates a titanium melt flow guide pipe along the axis, a nozzle sleeve is fixed at one end of the titanium melt flow guide pipe through positioning bolts, high-pressure gas source chambers provided with high-pressure gas source inlets are formed among the outer wall of the titanium melt flow guide pipe and the inner walls of the nozzle sleeve which are partitioned by the positioning bolts, the other end of the titanium melt flow guide pipe is contracted gradually, the inner walls of the nozzle sleeve, opposite to corresponding gradually contracted surfaces, respectively comprise two slope surfaces so that a Laval nozzle is formed among the slope surfaces and the gradually contracted outer wall of the titanium melt flow guide pipe, and the positioning bolts adjust the section size of the Laval nozzle. The size of a throat of the Laval nozzle can be adjusted by the nozzle sleeve, Mach number sprayed by high-pressure gas flow is determined by the throat size, and accordingly, the size of round powder particles formed after atomization of titanium and titanium alloy is determined. By the aid of the adjustable ultra-fine atomizing nozzle for the titanium and titanium alloy melt, powder in different particle sizes can be obtained according to needs, so that equipment flexibility is improved, and an atomizing process is stable and easy to control.

Owner:NANJING LEIRUI NEW MATERIAL SCI & TECH

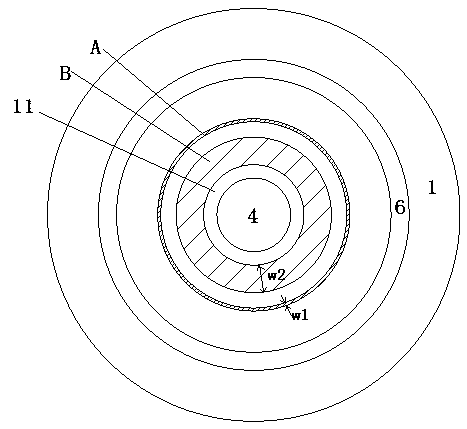

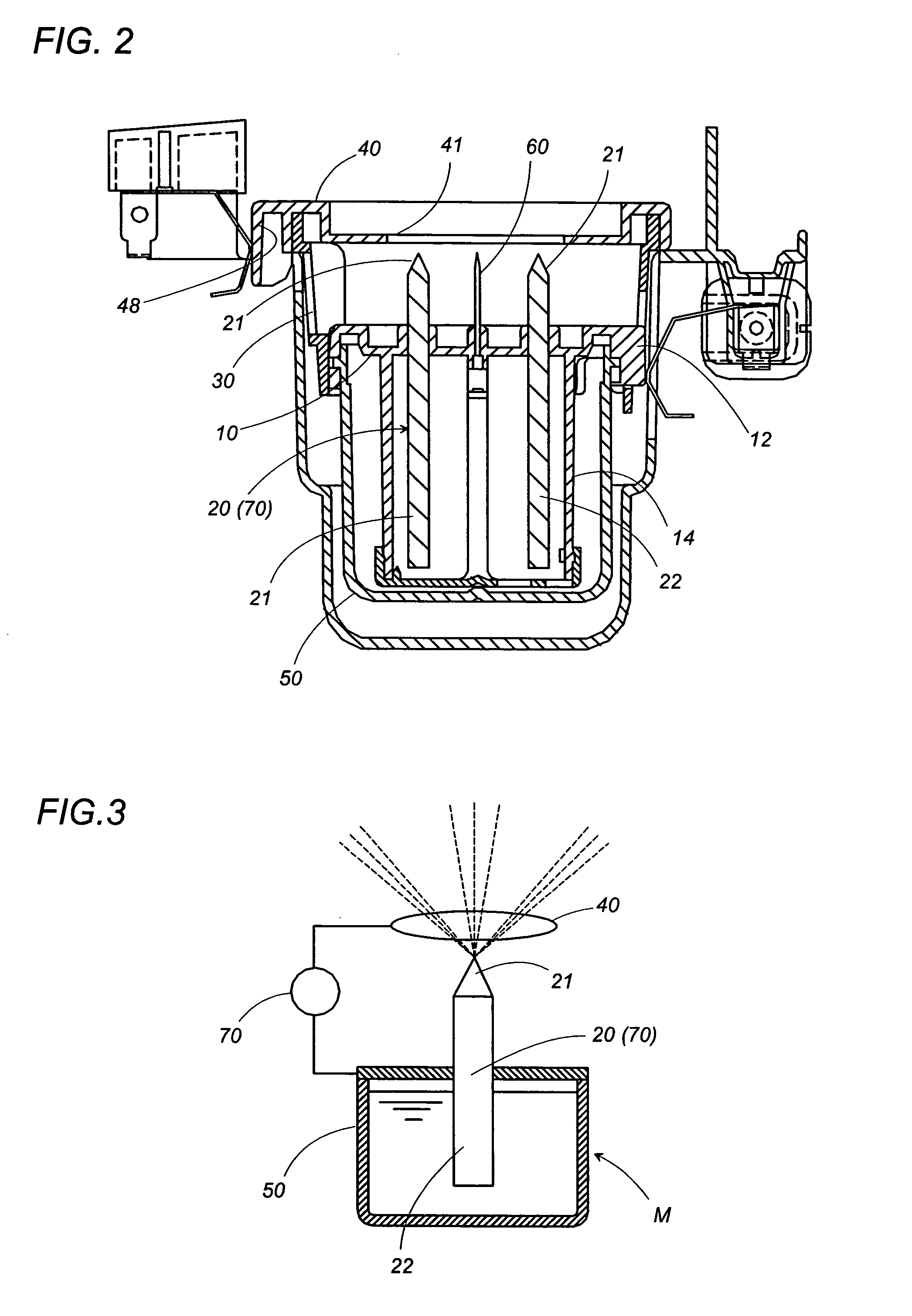

Air pollution control system and air pollution control method, spray drying device of dewatering filtration fluid from desulfurization discharged water, and method thereof

ActiveUS8715402B2Improve performanceStable atomizationGas treatmentLiquid degasificationControl systemSulfur

To include a boiler 11 that burns fuel F, an air heater 13 that recovers heat of flue gas 18 from the boiler 11, a first precipitator 14 that reduces dust in the flue gas 18 after heat recovery, a desulfurizer 15 that reduces sulfur oxides in the flue gas 18 after dust reduction by an absorbent, a dewaterer 32 that reduces gypsum 31 from desulfurization discharged water 30 discharged from the desulfurizer 15, a spray drying device 34 including an atomizer that atomizes a dewatering filtration fluid 33 discharged from the dewaterer 32, and a flue-gas introducing line L11 that introduces a part of the flue gas 18 into the spray drying device 34.

Owner:MITSUBISHI POWER LTD

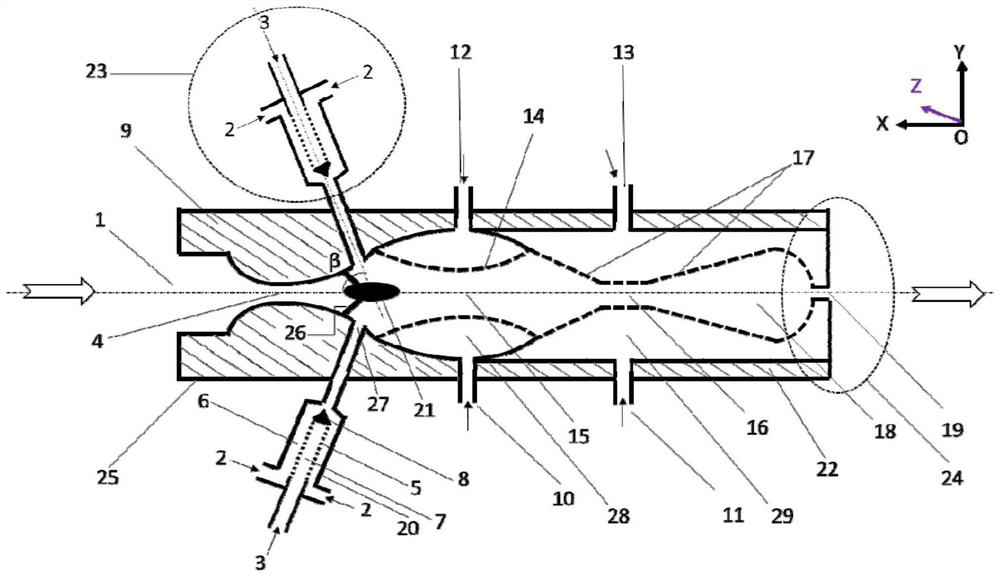

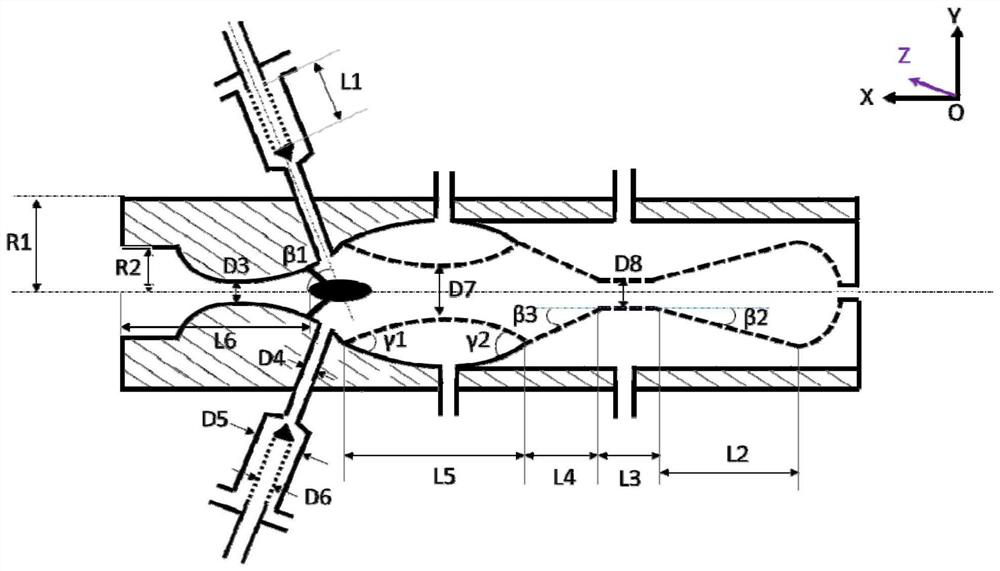

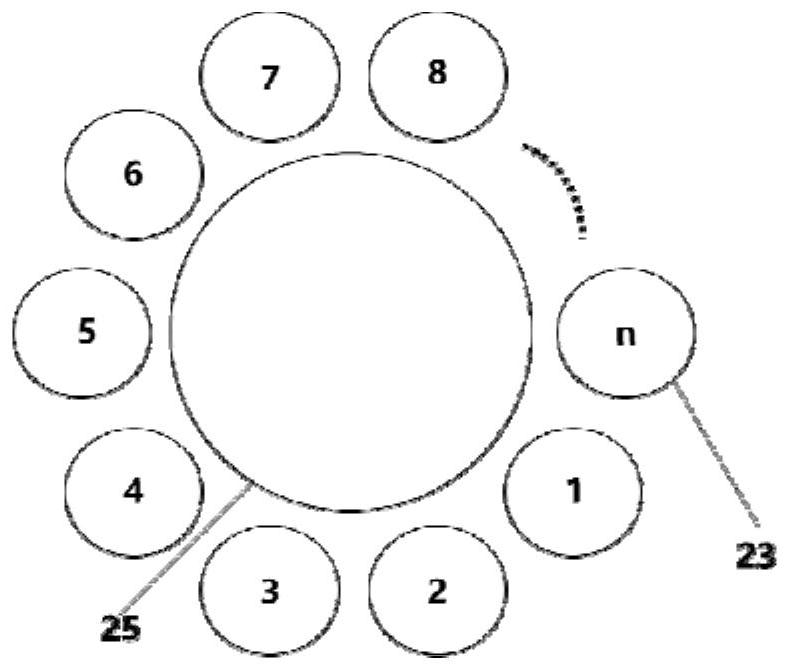

Bubble breaking and target type impact combined reinforced throat pipe type nozzle

ActiveCN112452577AExit speed adjustableImproved nebulizationCatalytic crackingLiquid spraying apparatusParticle flowPtru catalyst

The invention relates to the field of catalytic cracking productive chemicals, in particular to an efficient atomizing nozzle technology for crude oil. Provided is a bubble breaking and target type impact combined reinforced throat pipe type nozzle. According to the nozzle, first-stage bubble breaking, second-stage impact breaking, third-stage throat pipe type breaking and fourth-stage throat pipetype re-breaking are included. Finally, crude oil enters a spray head (24) through an expansion buffer chamber (18) and is sprayed out from a nozzle spout (19). Due to the fact that the nozzle spoutis inclined, thin fan-shaped spraying mist flow is finally formed, and the mist flow can be fully mixed with catalyst particle flow from the pre-lifting section. According to the novel nozzle, the principle of instant bubble blasting is fully utilized, the advantages and characteristics of a target type nozzle and a throat pipe type nozzle are integrated, the atomization performance of high-viscosity crude oil is greatly improved, fog drops with small particle sizes and narrow particle size distribution are effectively generated, and the nozzle has the characteristics of adjustable droplet ejection speed, low gas-liquid ratio, stable atomization process, high operation elasticity, simple structure, impact wear resistance, reduction of coking in the cracking process and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Automizing device

ActiveCN101204688AQuality improvementFirmly attachedMechanical vibrations separationLiquid spraying apparatusEngineeringWater level

The present invention provides a atomizer excluding service wear and / or expendable component and atomizing fluid maintainably-free. The opening for fog drain and water level maintenance keeps the water level. Fog of the water atomizing on the front end surface introducing surface tension to the vibration part from the utilising the vibration of the vibration part, selectively placed in the hierarchical container using opening part of the exclude fog and the water level maintenance. Preferably, the surface tension auxiliary member is collaboration with the vibration part, improving the supplementary water of the front end surface of the vibration part.

Owner:TAMURA KK +1

Electrostatically atomizing device

InactiveUS20070119993A1Stable atomizationPrevent precipitationBurnersLiquid spraying plantsEngineeringWater particle

Water is fed from a tank to a capillary carrier having an emitter end from which an ionized water particle is emitted by a voltage being applied across the emitter end and an opposed electrode. A cation exchanger is provided to remove minerals such as Ca2+ and Mg2+ from the water being fed through the capillary carrier or from the water to be fed to the carrier from the tank, thereby avoiding the ions from precipitating at the emitter end as CaCO3 or MgO in reaction with C02 in the surrounding air, and therefore assure reliable electrostatic atomization over a long period of time.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Glazing device for tile production equipment

ActiveCN109940746ACollision uniformCollision stabilizationCeramic shaping apparatusSpray nozzleEngineering

The invention discloses a glazing device for tile production equipment. The glazing device for tile production equipment comprises a spray gun, wherein the spray gun is provided with a nozzle; the nozzle comprises a first body (1), a second body (2), a connecting element (3), a fluid channel (4), a mixing oscillation cavity (5), an outlet part (6), a spiral rotor (7), a gas channel, wherein the fluid channel, the mixing oscillation cavity and the outlet part are sequentially arranged in the fluid flow direction, the glazing device is characterized in that the mixing oscillation cavity (5) is internally provided with the spiral rotor (7), the spiral rotor comprises spiral blades (71) and a rotating shaft, the spiral blades are arranged on the periphery of the rotating shaft, the two ends ofthe rotating shaft are connected with guide frames (10) through bearings (72), the two guide frames are positioned on the first body and the second body respectively. Through the design of the spiralrotor and air inlet holes, the glaze liquid / the liquid is atomized into smaller atomized spray in the mixed oscillation cavity, the atomization refinement degree is high, the atomization is uniform and stable, the glaze spraying yield is improved, and the raw material utilization rate is improved.

Owner:JIANGXI CIMIC CERAMICS +1

Silicon-titanium alloy film coat of air preheater tube and electrostatic spraying process thereof

InactiveCN101792262AHigh densityUniform coatingLiquid spraying plantsSteel tubeTemperature resistance

The invention relates to a silicon-titanium alloy film coat of an air preheater tube and an electrostatic spraying process thereof, and belongs to the electrostatic spraying technology of an environment-friendly, energy-saving and efficient silicon-titanium alloy film air preheater tube. Main components of the coat comprise SiO2, NiO, B2O3, TiO2, Pb2O3, NaO2 and K2O. A preparation method for the coat comprises the following steps: mixing and crushing common silicon-titanium alloy power and K2O to charge the powder, spraying the mixture to an air preheater steel tube under the high pressure of 30 to 120KV by using a positioning gun, heating and cooling the steel tube, and cushioning a high-temperature pad to obtain the coat. The process can realize automatic powder spraying, does not need manpower, obtains workpieces with unlimited lengths, and has the characteristics of environmental protection, energy conservation and high efficiency; due to the addition of K2O, the atomization is stable, the film is coated uniformly, the mass density is high and the thickness is controllable; the manpower and spraying cost are saved, and the service life is prolonged; and the prepared coat is superior to that in a common enamel process and a plastic powder electrostatic spraying process on the aspects of mechanical strength, adhesive force, high temperature resistance, abrasion resistance, acid and alkali corrosion resistance, ageing resistance and the like.

Owner:济南屹林科技有限公司

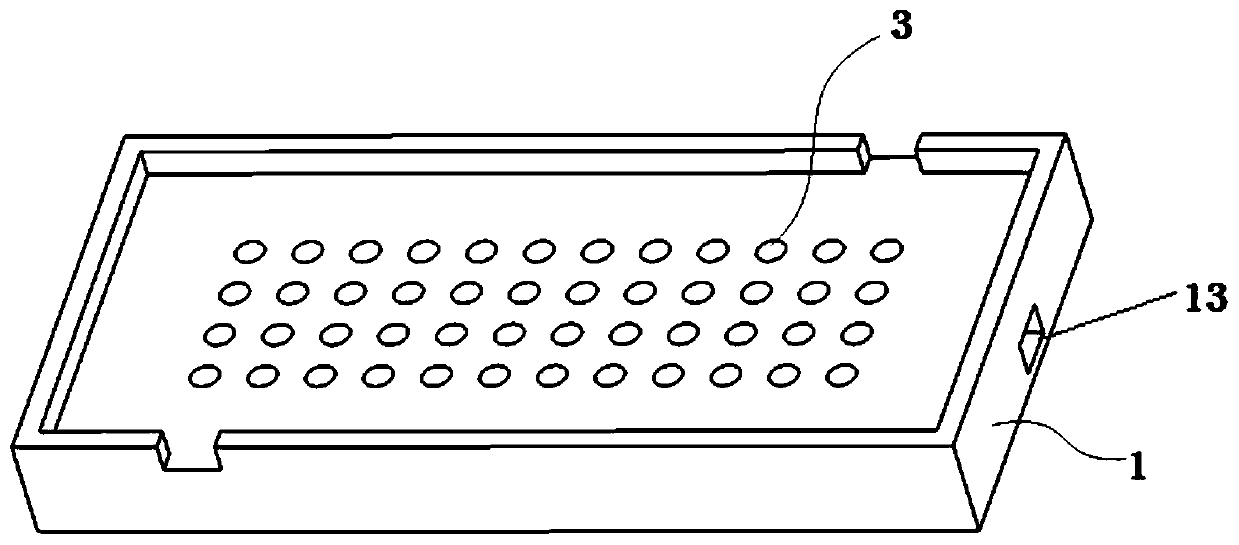

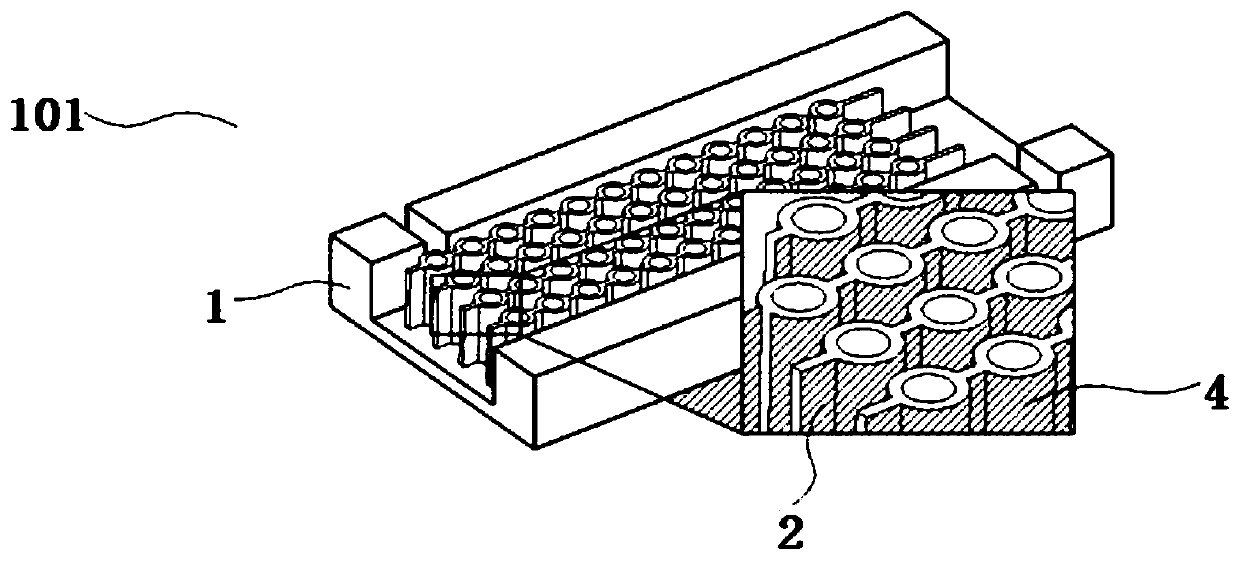

Coated silicon-based electronic cigarette atomization chip and making method thereof

ActiveCN109770438AFully atomizedEvenly dispersedFinal product manufactureOhmic-resistance waterproof/air-tight sealsGlass coverEngineering

The invention discloses a coated silicon-based electronic cigarette atomization chip and a making method thereof. The chip comprises a silicon substrate (1) and a glass cover (5); the silicon substrate (1) is provided with a microcolumn (2) array or a microhole (3) array, an inlet end (13) and an outlet end (14), the outer side wall of a microcolumn (2) is a coated side wall, the inner wall of a microhole (3) is a coated inner wall, and multiple micro channels (12) are defined by the microcolumn (2) array or a nicotine liquid flow channel (15) which runs through the microhole (3) is formed inthe silicon substrate (1); the glass cover (5) is provided with an air hole (6) which runs through the glass cover (5); the glass cover (5) is fixedly connected with the silicon substrate (1) througha bonding technology. According to the atomization chip, silicon is used as a base material of the atomization chip, the cost of the atomization chip is low, the cost of manufacturing the electronic cigarette atomization chip is greatly lowered, and convenience is provided for large-scale production of the atomization chip of the type.

Owner:CHINA TOBACCO YUNNAN IND

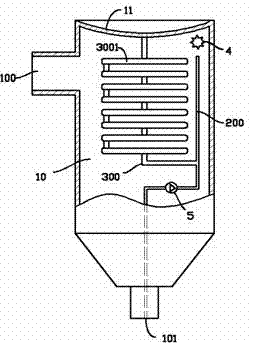

Novel nebulizer with reflux structure

InactiveCN109513076ALarge particle sizeParticle size andMedical devicesMedical atomisersRefluxNebulizer

The invention discloses a novel nebulizer with a reflux structure. The novel nebulizer comprises a bottle body for holding liquid medicine, the upper side of the bottle body is connected to a seal cover and a fixed block, the fixed block is internally provided with an airflow channel and a nebulizing chamber, a liquid accumulating slot is disposed at a bottom middle part of the nebulizing chamber,a reflux pipe is disposed under the liquid accumulating slot, a connecting pipe is movably inserted on the nebulizing chamber, the seal cover is internally equipped with a drain pipe, the upper end of the drain pipe is communicated with the airflow channel, one side of the drain pipe is equipped with an impact plate, and the lower end of a regulation block is provided with a flow velocity port. The novel nebulizer provided by the invention regulates the nebulization effect through up-and-down sliding of the regulation block, also is equipped with the reflux structure and the like, so that nolarge amount of liquid accumulates in the nebulizing chamber, connecting pipe and other cavities communicated with the mouth, the risk of mis-suction of liquid cannot be caused, and while the drug application precision is improved, the waste of liquid medicine is also reduced.

Owner:黄梅

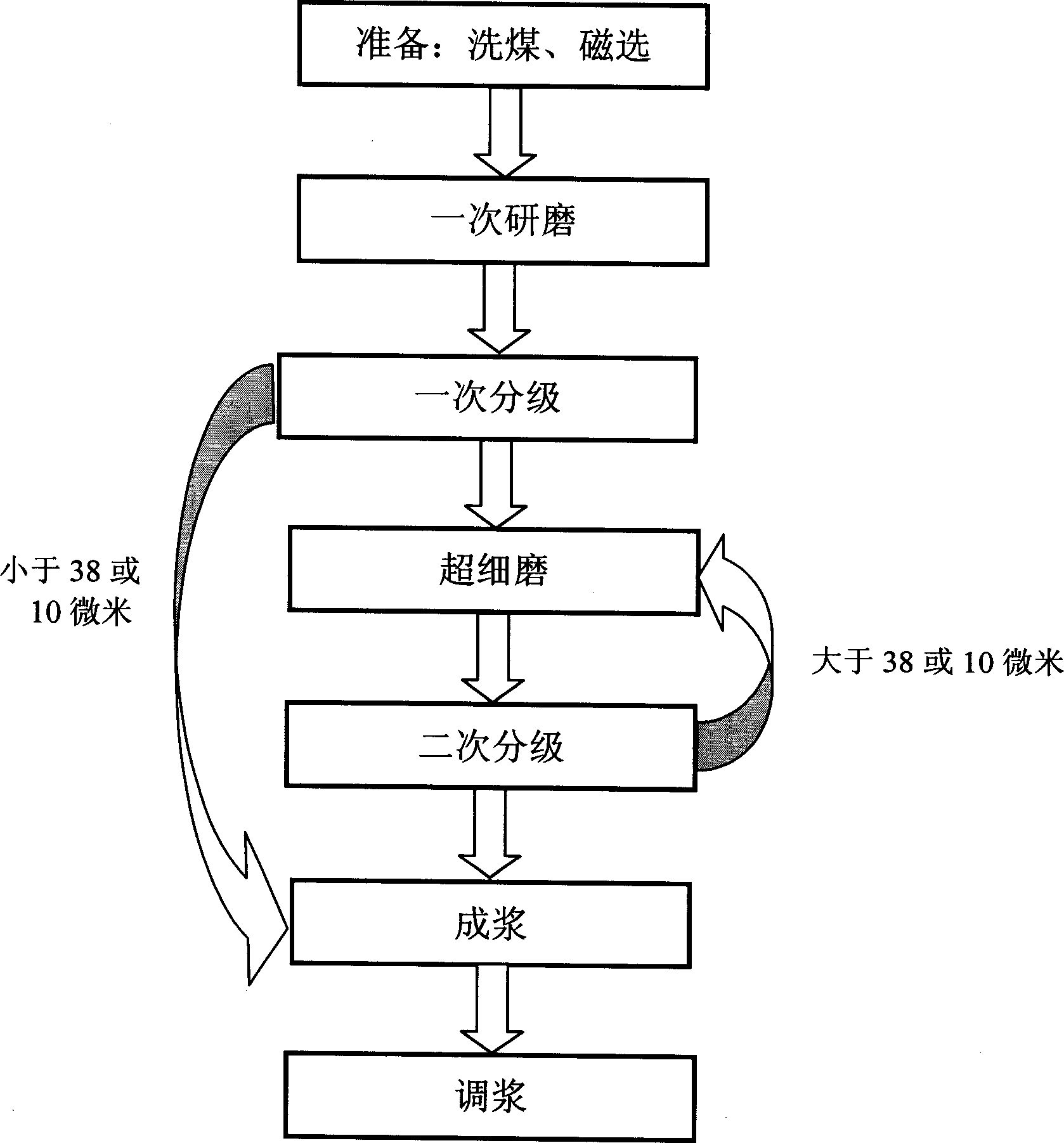

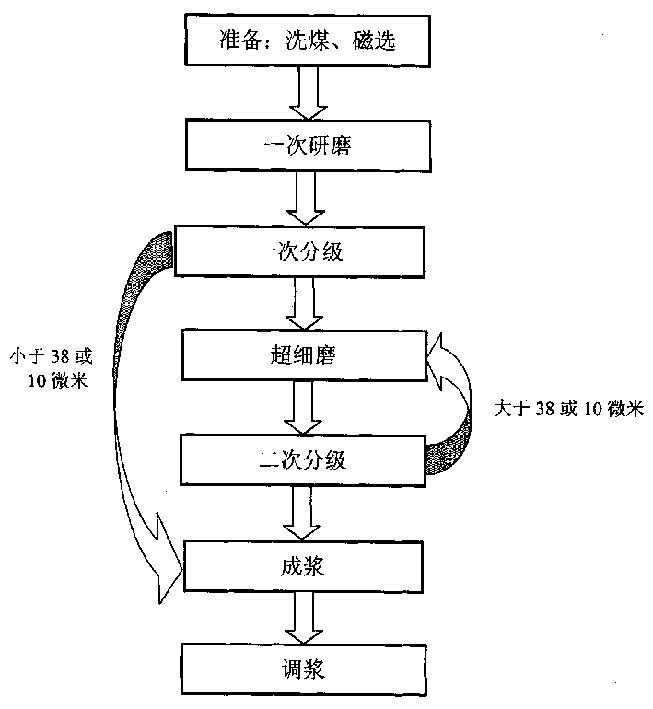

Superfine coal based fluid fuel and its preparation

InactiveCN1456642AReduce apparent viscosityEasy to pumpLiquid carbonaceous fuelsApparent viscositySlurry

A superfine coal-base fluid fuel is prepared from coal particles (4-5 microns in average), water, disperser, stabilizer, sulfur-fixing agent and combustion promoter through preparing raw materials, grinding, classifying, superfine grinding, classifying again, preparing slurry and regulating. Its advantages are low apparent viscosity, high atomizing and combustion effect, and good stability.

Owner:北京金泓毅新技术有限公司

Atomized acid shaft flow simulation platform for gas injection development of fracture-cavity type oil reservoir and working method thereof

The invention discloses an atomized acid shaft flow simulation platform for gas injection development of a fracture-cavity type oil reservoir. The atomized acid shaft flow simulation platform mainly comprises a double-flow venturi atomization generation device, a shaft flow simulation device and an atomization evaluation device. The atomization generation device comprises an air path system, a liquid path system and an atomization generator; the airpath system comprises an air compressor, an air throttle valve and an air pressure gauge; the liquid path system comprises a high-pressure acid-proof pump, a liquid throttle valve and a liquid pressure gauge; the simulation wellbore is used for being connected with the double-flow venturi atomization generation device and comprises a vertical wellbore, a horizontal simulation stratum and an effusion collecting device. The observation system comprises a nano laser particle size analyzer. The invention also discloses a working method of the atomized acid shaft flow simulation platform for gas injection development of the fracture-cavity type oil reservoir. The simulation platform can be applied to an oil field site, the injection displacement is controlled through the air path system and the liquid path system, the high acid liquor atomization rate is kept according to site construction requirements, the acidification effect of the fracture-cavity type oil reservoir is improved and effective communication of the fracture-cavity type storage and collection unit bodies can be realized.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Heating slurry material printed on ceramic atomization core, ceramic atomization core and production method thereof

InactiveCN110731551ALow costLess componentsTobacco devicesHeating element materialsEpoxyElectronic cigarette

The invention discloses a heating slurry material printed on a ceramic atomization core, the ceramic atomization core and a production method thereof. The heating slurry material printed on the ceramic atomization core comprises the following components in percentage by weight: 89%-91% of 306 stainless steel nanometer powder, 3.5%-4.5% of 209 glass powder and 5.5%-6.5% of epoxy resin. According tothe heating slurry material, a resistance value is 0.9-1.3 Ohm, between high and low resistance values of the existing ceramic atomization core; and the heating slurry material has fewer components,and is low in cost and simple and convenient to produce. When the ceramic atomization core is atomizing tobacco tar, a resistance variation is within 0.1 Ohm when a user puffs on an electronic cigarette for 600 times; and smog is continuous without breaking, and the ceramic atomization core is good in stability and good in taste. According to the production method of the ceramic atomization core,via many times of baking, high-temperature sintering, cleaning and disinfecting, finally the ceramic atomization core that is safe, non-poisonous, stable in atomization performance and good in taste is acquired.

Owner:宜宾聚智科技有限公司

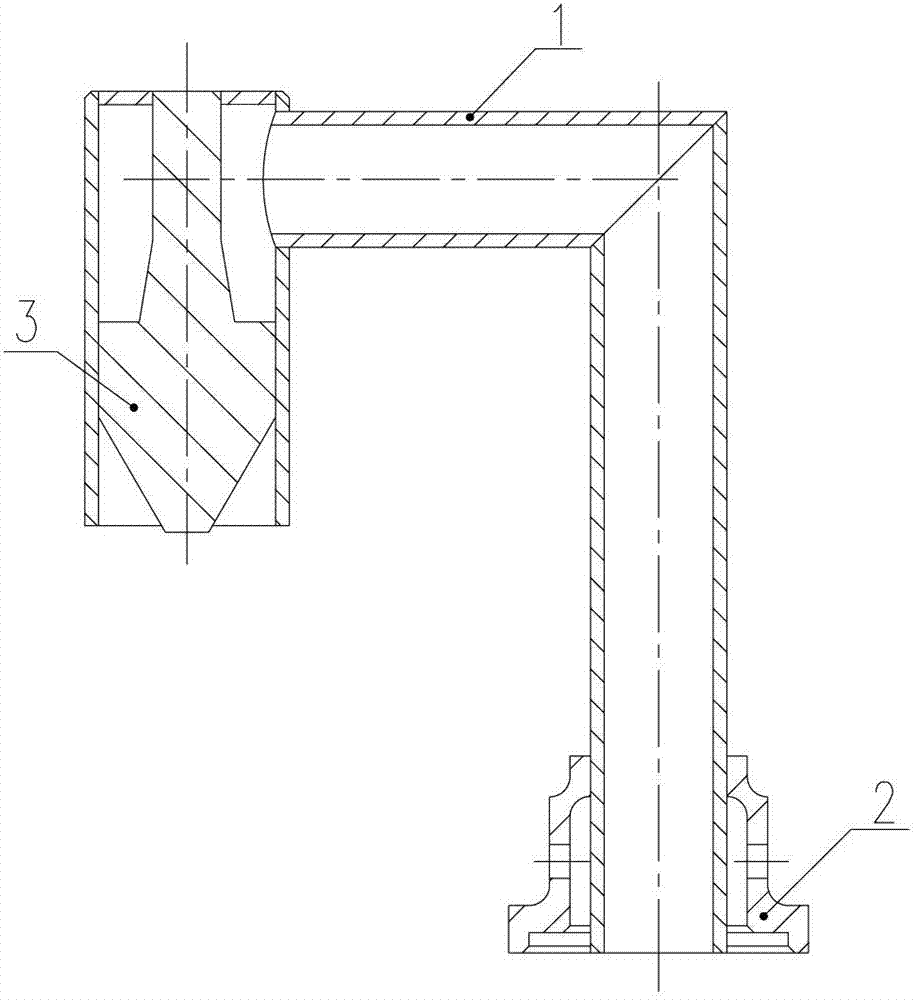

Fuel oil atomizing device

InactiveCN102889615AReduce axial jet velocityIncrease the average areaContinuous combustion chamberCombustion typesCombustionFuel oil

The invention relates to a fuel oil atomizing device which comprises an evaporation pipe, an air cup and an oil rotating device, wherein the evaporation pipe is formed by three sections of reversed-L-shaped pipes which form angles of 90 degrees; the oil rotating device is arranged at the inner part of a fuel oil outlet of the evaporation pipe; 4-6 spiral grooves are arranged on the outer surface of the oil rotating device; the air cup is mounted at the outer part of the evaporation pipe at the fuel oil inlet; a cup opening of the air cup is leveled with the fuel oil inlet of the evaporation pipe; and an air outlet is arranged on the side wall of the air cup. The fuel oil atomizing device disclosed by the invention realizes the aim of sufficiently atomizing under the condition of a very short oil mist range so that the evaporation rate is improved and good conditions are provided for stable and efficient combustion.

Owner:HARBIN DONGAN ENGINE GRP

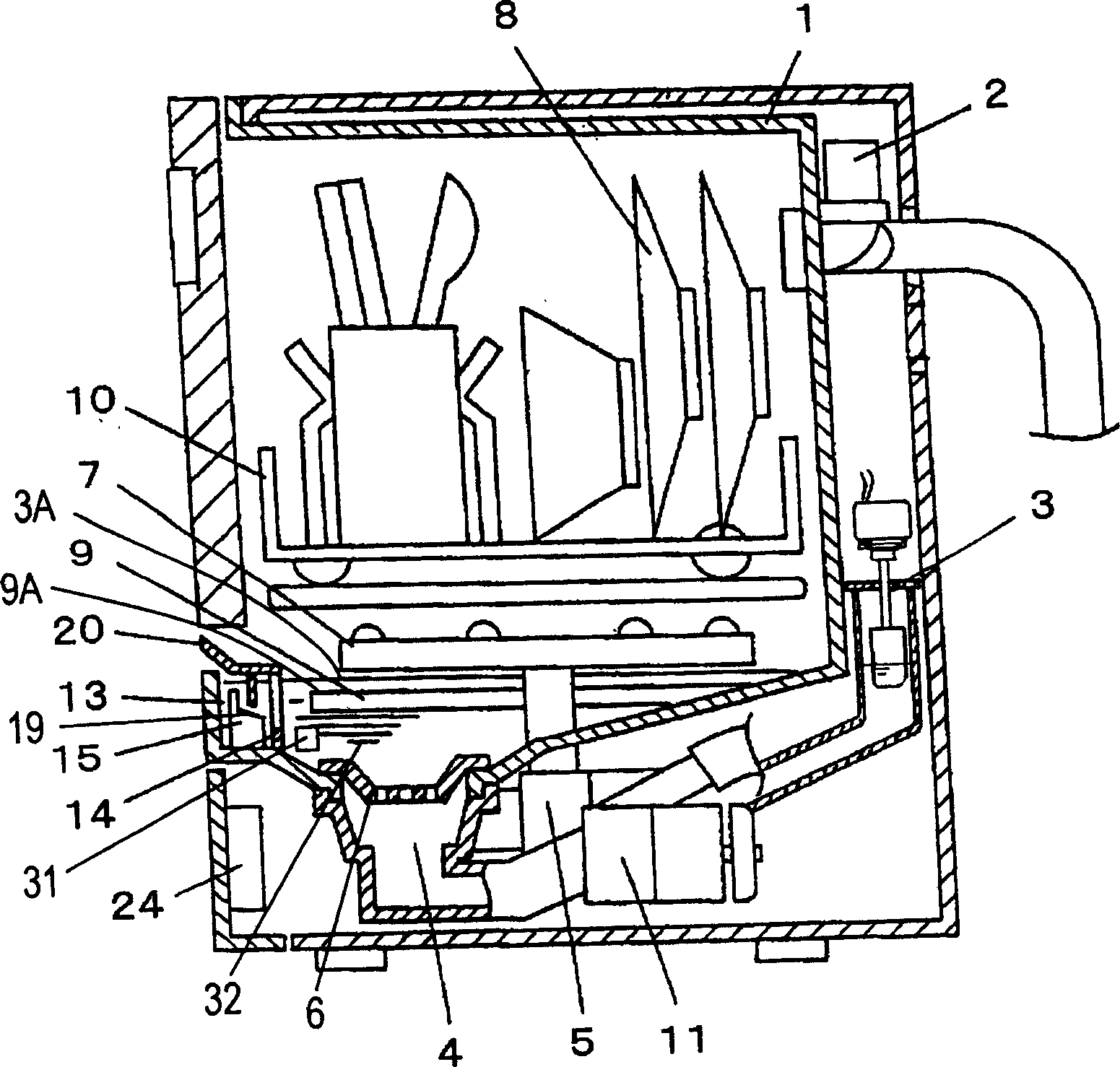

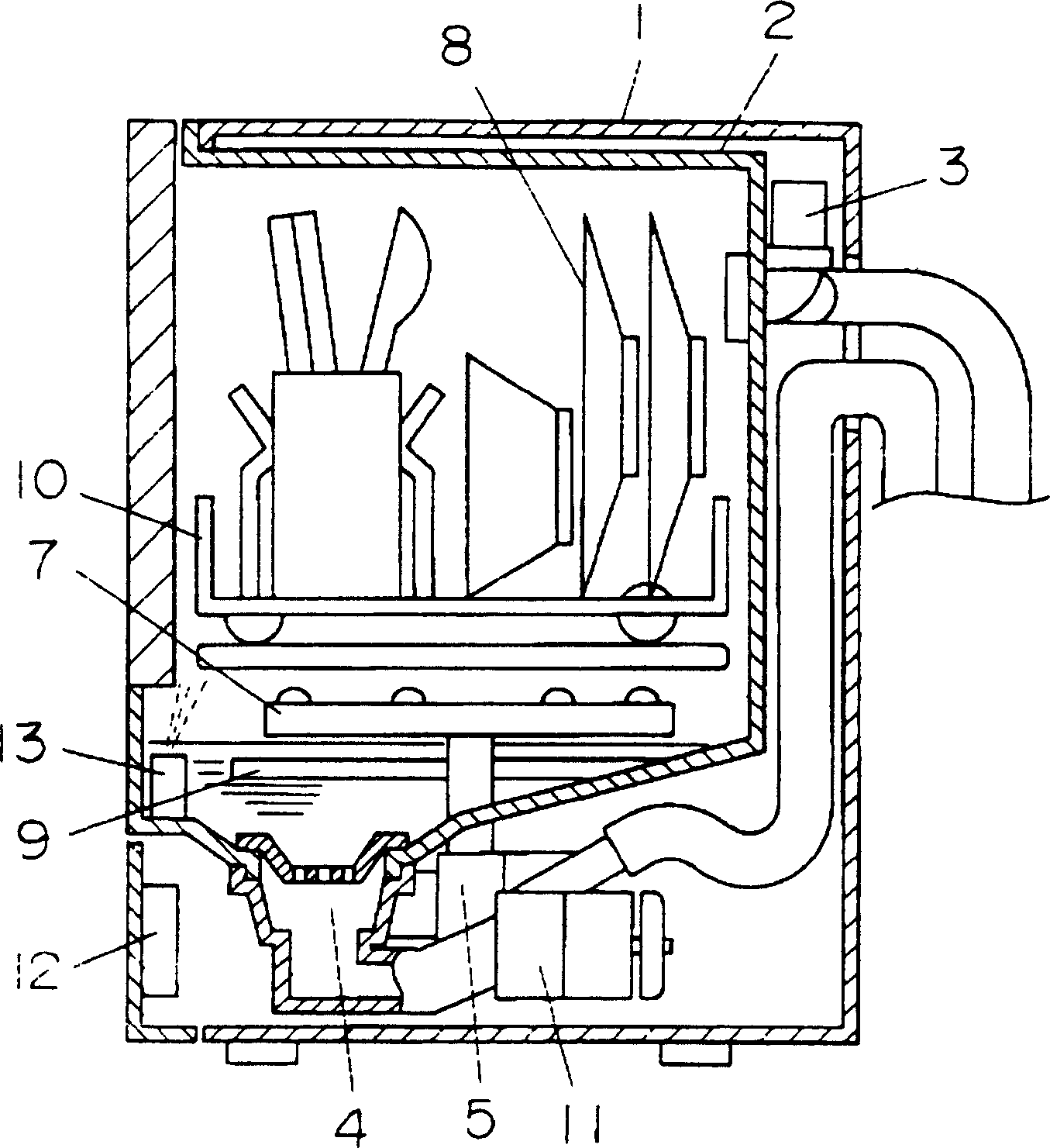

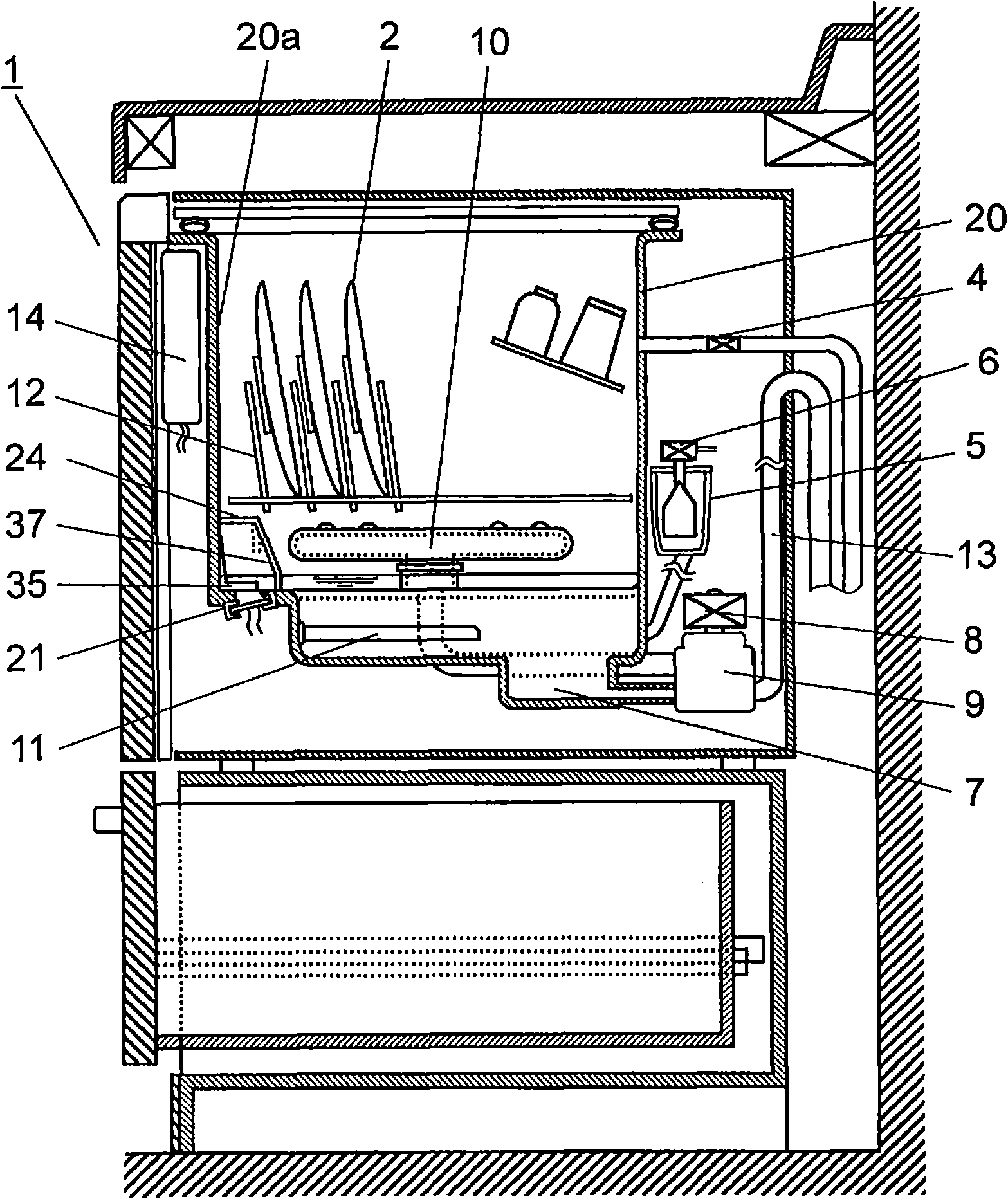

Tableware cleaning machine

ActiveCN1706338AStable atomizationTableware washing/rinsing machine detailsEngineeringCleansing Agents

PROBLEM TO BE SOLVED: To provide a dishwasher with significantly improved convenience for washing objects to be washed such as tableware by spraying washing water. SOLUTION: The dishwasher comprises a mist generating means 15 for misting a detergent liquid inside a washing tub 1, a water level detecting means 3 for detecting the water level inside the washing tub 1, and a control means 24 for receiving signals from the water level detecting means 3 and controlling the motion of each load. The control means 24 drives the mist generating means 15 when the water level detecting means 3 detects the water level. COPYRIGHT: (C)2006,JPO&NCIPI

Owner:PANASONIC CORP

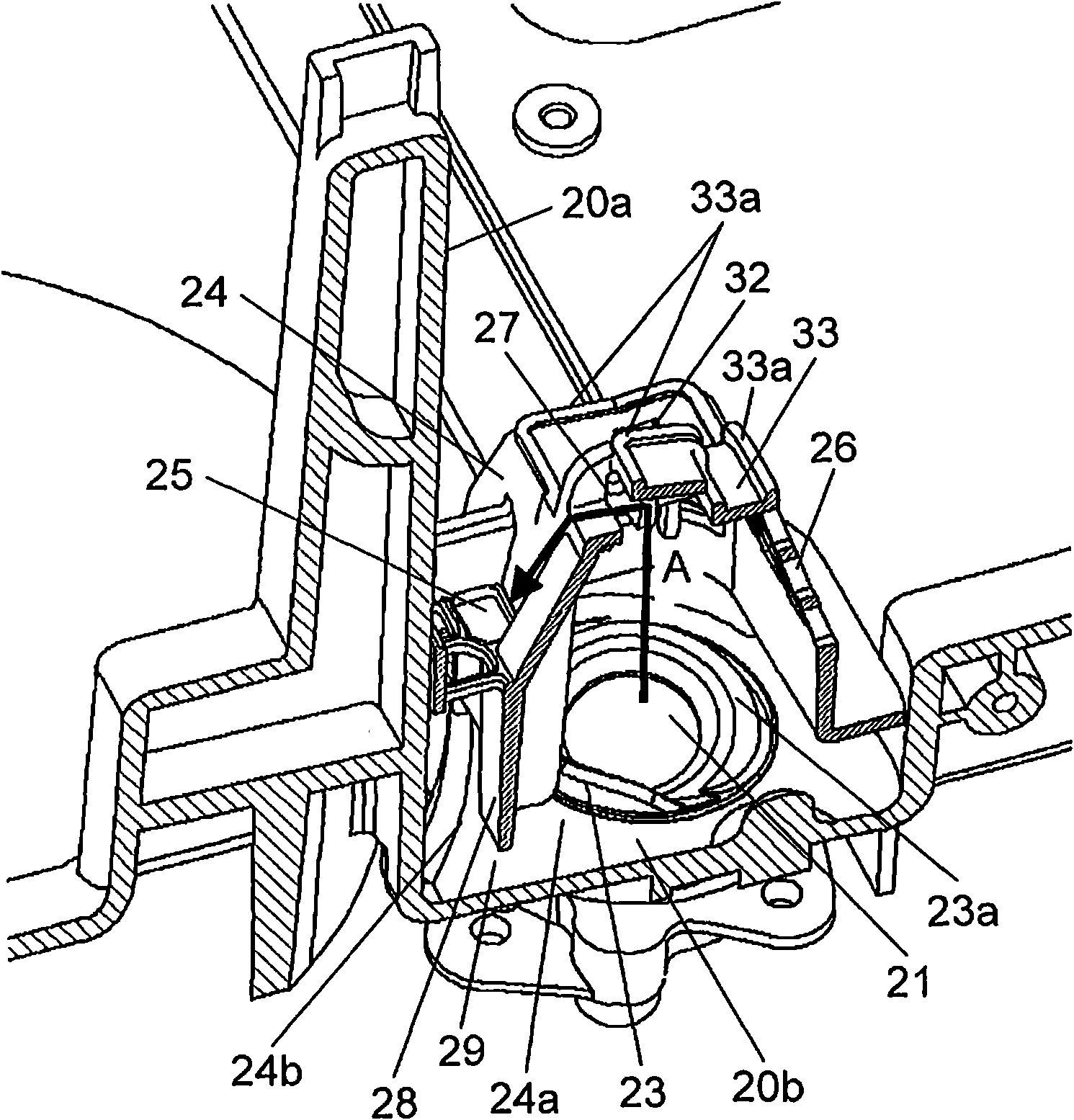

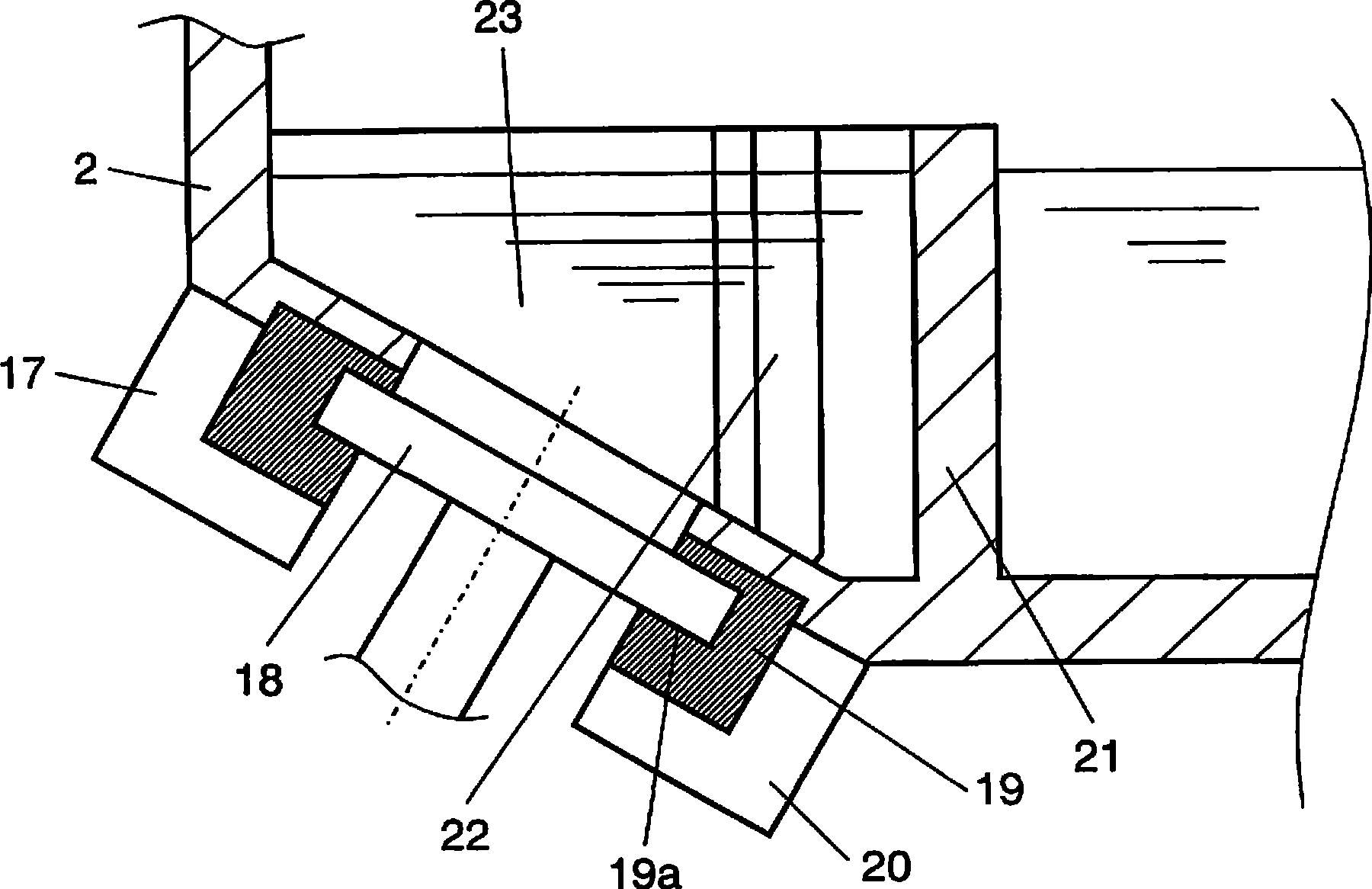

Pulverization generating device, dishware cleaning machine and washing machine mounting with the apparatus

InactiveCN1606955APrevents direct attachment/curingOperational impactTableware washing/rinsing machine detailsOther washing machinesForeign matterEngineering

The present invention is an atomization generating device (13) that atomizes liquid through an atomization generating oscillator (14), which can prevent foreign matter from directly adhering / solidifying on the vibrating surface of the atomizing generating oscillator (13), therefore Stable atomization is possible even in dirty wash water. The specific method is that a container (16) is provided on the vibrating surface side of the ultrasonic oscillator (14), and liquid (15) has been sealed in the container (16); The liquid to be atomized outside the container (16) is atomized.

Owner:PANASONIC CORP

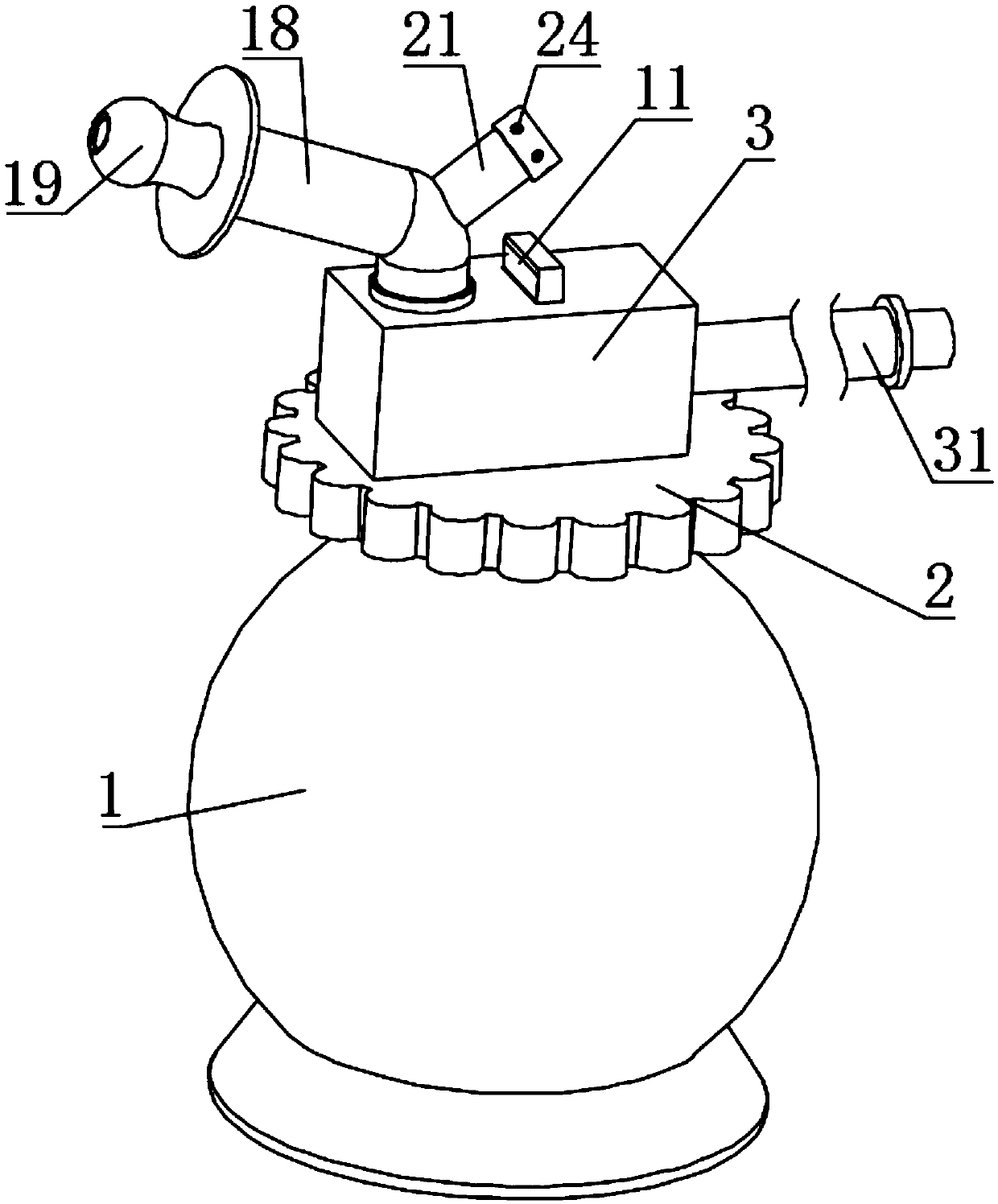

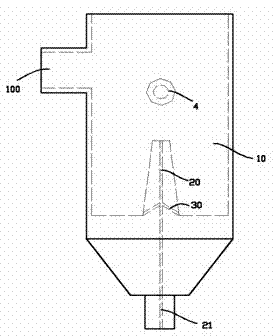

Medical atomizer

The invention provides a medical atomizer which comprises a liquid medicine cavity, wherein an air inlet is formed in the lower end of the liquid medicine cavity; one section of injection pipe is arranged by extending upwards from the air inlet; a collider is arranged above the injection pipe; a mist outlet is formed in the side face of the liquid medicine cavity; the upper end of the liquid medicine cavity is sealed by a funnel-shaped sealing plate; the center of the sealing plate is downwards communicated with a liquid medicine pipe; the liquid medicine pipe comprise more than two spiral coil pipes which are mutually connected in series; all the spiral coiled pipes are arranged in the liquid medicine cavity from top to bottom in a parallel manner; the lower end of the liquid medicine pipe is transversely communicated to the injection pipe. When the medical atomizer is used, even if the medical atomizer is positioned in a shake or turnover state, liquid medicine can be stably atomized, and actual operation is facilitated.

Owner:THE FIRST AFFILIATED HOSPITAL OF MEDICAL COLLEGE OF XIAN JIAOTONG UNIV

Tableware cleaner

InactiveCN101658408APrevent adhesionDecongestionTableware washing/rinsing machine detailsCleansing AgentsPeripheral

The invention provides a tableware cleaner, comprising a storage portion arranged in a wash tank for storing the atomized liquid, an ultrasonic vibrator arranged in the storage portion for atomizing the cleaning fluid, and a cleaning agent feeding portion arranged above the storage portion for feeding the cleaning agent into the storage portion, wherein the cleaning agent feeding portion has dripping holes through which the cleaning water can drip to the ultrasonic vibrator. In this way, the block of water at the peripheral of the vibration plane of the ultrasonic vibrator can be eliminated, un-dissolved cleaning agent, orts and the like can be prevented from adhering on the vibrating surface of the ultrasonic vibrator, therefore, the atomizing amount can be prevented from being substantially reduced and the ultrasonic vibrator can be prevented from going wrong.

Owner:PANASONIC CORP

Acid liquid atomization device for deep acidification of fractured-vuggy reservoir and atomization method thereof

ActiveCN111085349AInto the uniformEasy to assembleFluid removalDrilling compositionAtomizer nozzleAir compressor

The invention discloses an acid liquid atomization device for deep acidification of a fractured-vuggy reservoir. The acid liquid atomization device for deep acidification of the fractured-vuggy reservoir comprises a gas path system, a liquid path system and an atomization nozzle; the gas path system comprises a gas inlet and an air compressor; the liquid path system comprises acid liquid inlets, ahigh-pressure acid-proof pump and a double-flow type Venturi tube; air is pressurized by the air compressor and then enters the gas inlet; and acid liquid is pressurized by the high-pressure acid-proof pump and then enters an annular cavity, the annular cavity is used for accumulating the acid liquid, the acid liquid in the annular cavity enters a cylindrical cavity through the acid liquid inletsformed in the wall, acid mist is formed in the cylindrical cavity as the hydrodynamic cavitation effect, the acid mist is constrained by the cylindrical cavity to form acid mist columnar fluid, the acid mist columnar fluid moves at high speed in an atomization generator and is finally sprayed out from the atomization nozzle of the atomization generator, and the atomization nozzle is directly connected with a shaft. The acid liquid atomization device for deep acidification of the fractured-vuggy reservoir has the good high temperature resistance, high pressure resistance and acid resistance, the injection displacement can be controlled through the gas path system and the liquid path system, the high acid liquid atomization rate is kept, and the acidification effect of the fractured-vuggy reservoir is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Flame stabilizing device for TBCC subsonic combustion ramjet engine combustion chamber

ActiveCN106642202AImprove atomization effectReliable ignitionContinuous combustion chamberRamjetCombustion chamber

The invention provides a flame stabilizing device for a TBCC subsonic combustion ramjet engine combustion chamber. The flame stabilizing device for the TBCC subsonic combustion ramjet engine combustion chamber comprises a supporting plate, a cover hood and an on-duty fuel injector bar. The supporting plate and the cover hood are connected together to form a cavity, the on-duty fuel injector bar is arranged in the cavity, the supporting plate has an upper surface and a lower surface, the lower surface has a concave cavity while the upper surface has a convex cavity, the supporting plate has a front cavity and a back cavity, the front cavity is located between the cavity and the back cavity, the front cavity is used for introducing cooling gas, a primary oil way fuel injector bar is arranged in the back cavity, a cooling gas round channel communicating the front cavity with the back cavity is formed between the front cavity and the back cavity, and a cooling gas round channel communicating the front cavity with the cavity is formed between the front cavity and the cavity. By reasonably arranging the fuel supply positions of the on-duty fuel injector bar and the primary oil way and improving the atomizing effect by way of various modes such as pressure atomization, pneumatic atomization and colliding atomization, the ignition property of the TBCC subsonic combustion ramjet engine combustion chamber is improved, the combustion property in a wide range is considered, and the integral property of the TBCC subsonic combustion ramjet engine combustion chamber is improved.

Owner:中航空天发动机研究院有限公司

Dishware washing machine

ActiveCN101601568AAvoid accumulationPrevents buildup and stickingTableware washing/rinsing machine detailsEngineeringMechanical engineering

The present invention provides a dishware washing machine comprising a washing groove for accommodating the dishware, a water supply part for supplying water to the groove, an ultrasonic oscillator arranged in the groove to atomize washing water supplied to the groove, a washing agent container part arranged in the groove to cover the oscillator, a partition wall arranged on at least a part of the periphery of the oscillator and higher than the oscillation surface. The washing machine may prevent the washing agent from depositing on bonding on the oscillation surface, may prevent effect to action of the oscillation, which causes greatly decrease of atomizing volume or fault of the oscillator.

Owner:PANASONIC CORP

Dishware cleaner

InactiveCN101449953APrevent adhesionStable atomizationTableware washing/rinsing machine detailsAutomatic washing/rinsing machine detectionResonatorBiomedical engineering

The present invention provides a dishware cleaning device comprising a cleaning groove (2) an opening section (2b) and an ultrasonic resonator (18), the cleaning groove (2) contains articles to be cleaned inside, the opening section (2b) is arranged on bottom of the cleaning groove (2b), the ultrasonic resonator (18) is arranged inside the opening section (2b), cleaning water supplied to the cleaning groove (2) is atomized, the ultrasonic resonator (18) slants to make the center of a vibration face higher than lowest section (2c) of higher opening end periphery of the opening section (2b), such that the opening section (2b) facing the inside of the cleaning groove (2) is arranged on bottom of the cleaning groove (2), the invention has above structure, thereby preventing residual offscourings from effecting action of the ultrasonic resonator (18).

Owner:PANASONIC CORP

Electrostatically atomizing device

InactiveUS7621470B2Stable atomizationPrevent precipitationBurnersLiquid spraying plantsEngineeringWater particle

Water is fed from a tank to a capillary carrier having an emitter end from which an ionized water particle is emitted by a voltage being applied across the emitter end and an opposed electrode. A cation exchanger is provided to remove minerals such as Ca2+ and Mg2+ from the water being fed through the capillary carrier or from the water to be fed to the carrier from the tank, thereby avoiding the ions from precipitating at the emitter end as CaCO3 or MgO in reaction with CO2 in the surrounding air, and therefore assure reliable electrostatic atomization over a long period of time.

Owner:MATSUSHITA ELECTRIC WORKS LTD

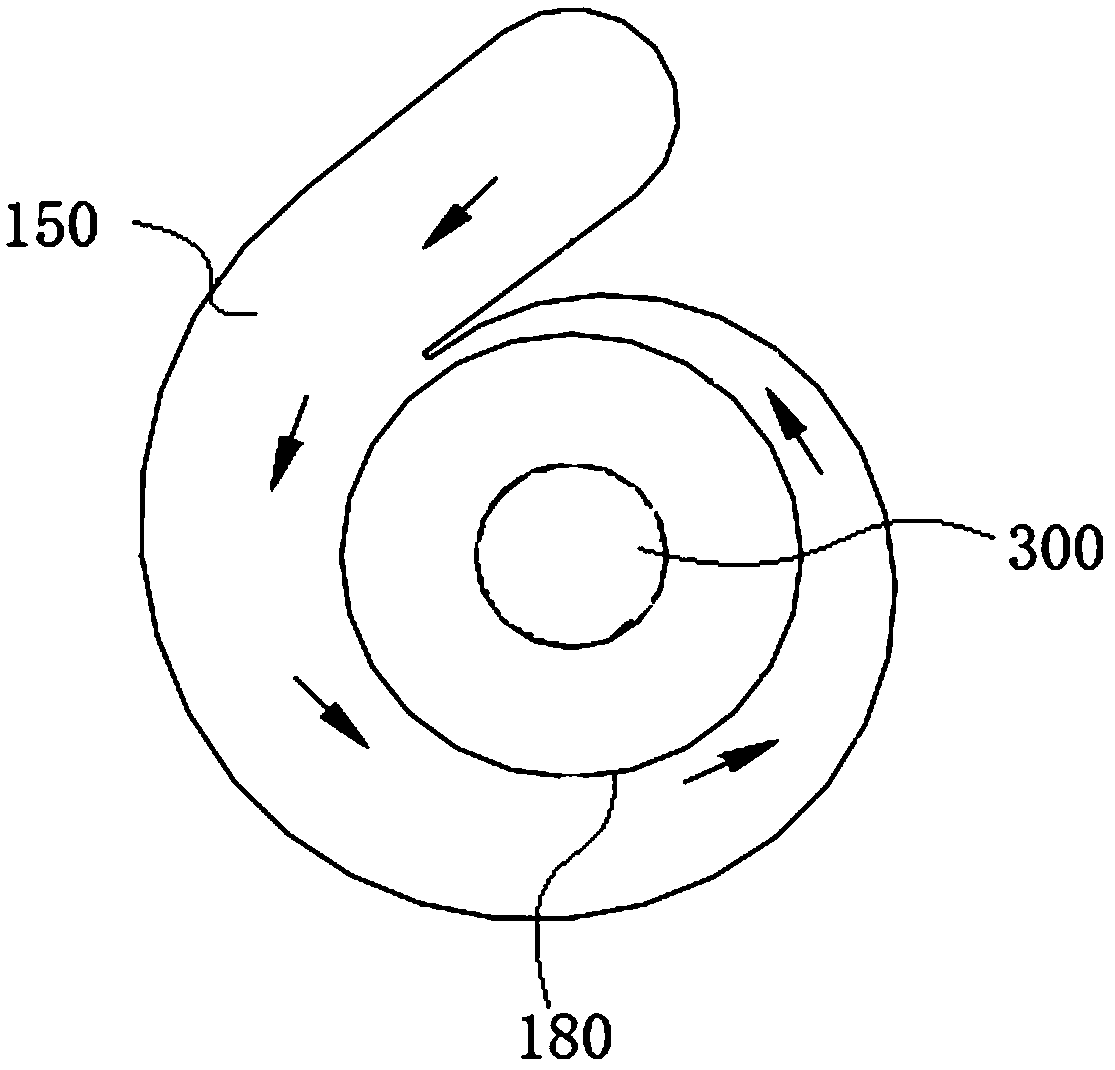

Rotary atomizer system

PendingCN108296038AReduce wearExtended service lifeMovable spraying apparatusLiquid spraying apparatusSpray nozzleEngineering

The invention discloses a rotary atomizer system, and belongs to the technical field of atomizers. The system comprises a feed liquid distributor, a rotary atomizing wheel and a rotary main shaft, wherein the discharge pipe of the feed liquid distributor corresponds to the atomizing wheel inlet of the rotary atomizing wheel, and second guiding blades are uniformly arranged in the circumferential direction of the inner wall of the discharge pipe at intervals; a nozzle is arranged at the atomizing wheel outlet of the rotary atomizing wheel, an inlet hole is formed in the inner circle inlet section of the nozzle, and the inlet hole is an eccentric variable-diameter hole. The invention aims at overcoming the defects of severe abrasion and nonuniform distribution of feed liquid of atomizers inthe prior art, and provides the rotary atomizer system; the system can ensure that the feed liquid enters the discharge pipe and the atomizing wheel with uniform distribution, so that the feed liquidis atomized uniformly, the nozzle is not easily blocked, and the service life of the atomizer is prolonged.

Owner:ANHUI XINCHUANG ENERGY SAVING & ENVIRONMENTAL PROTECTION SCI & TECH +1

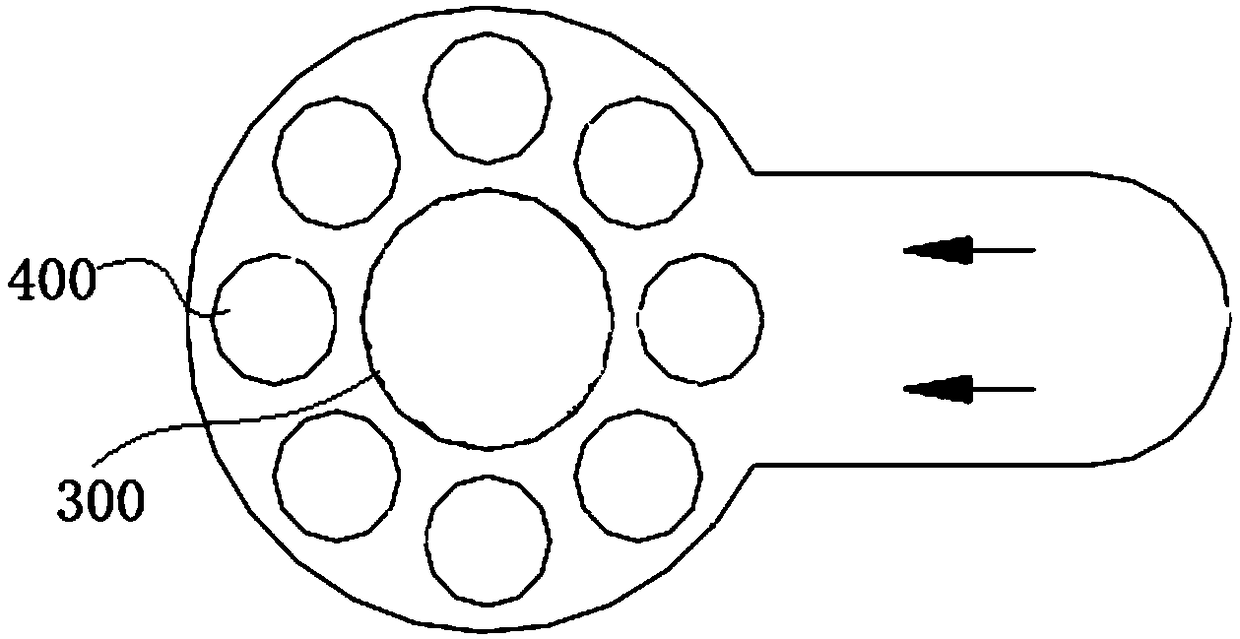

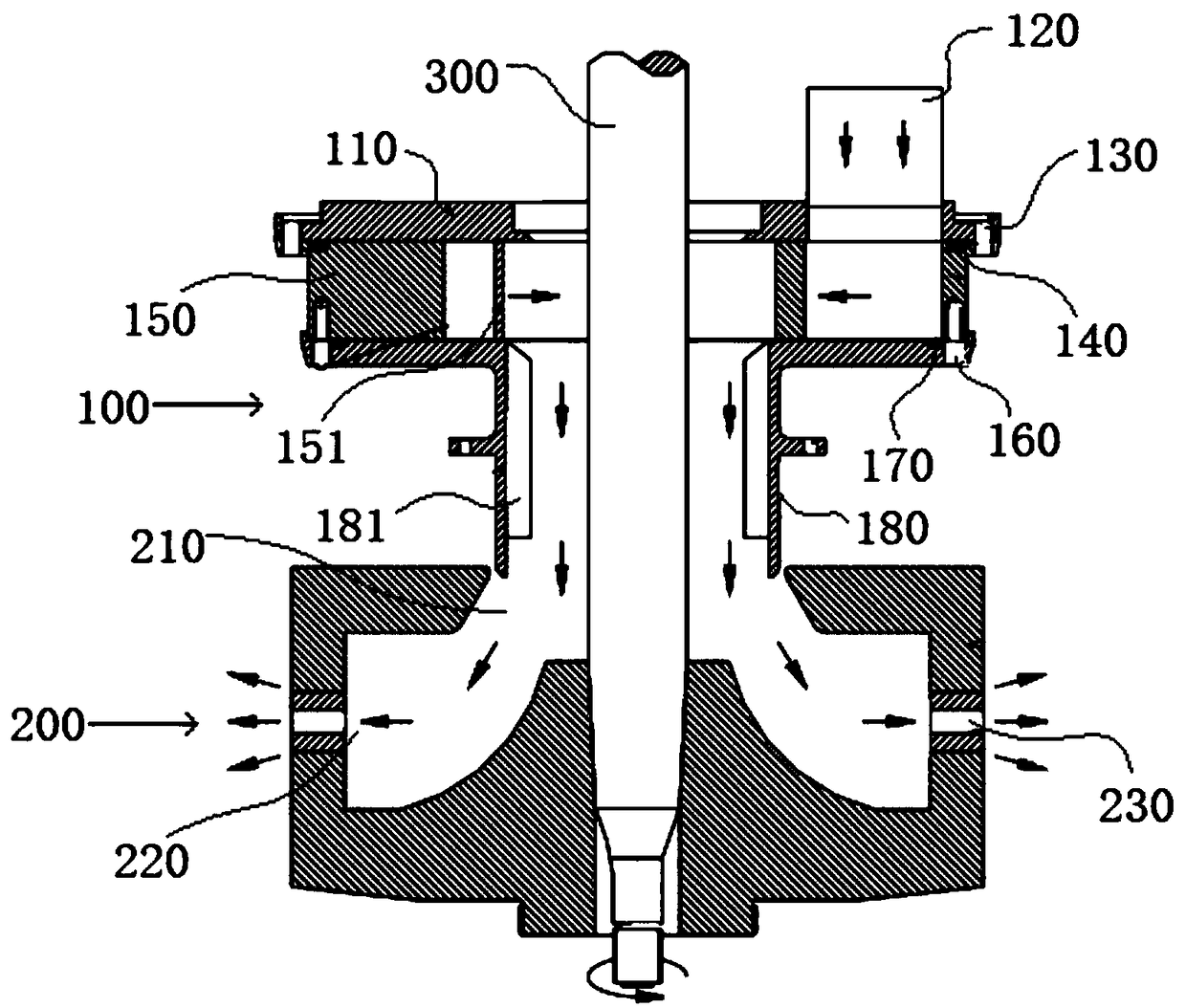

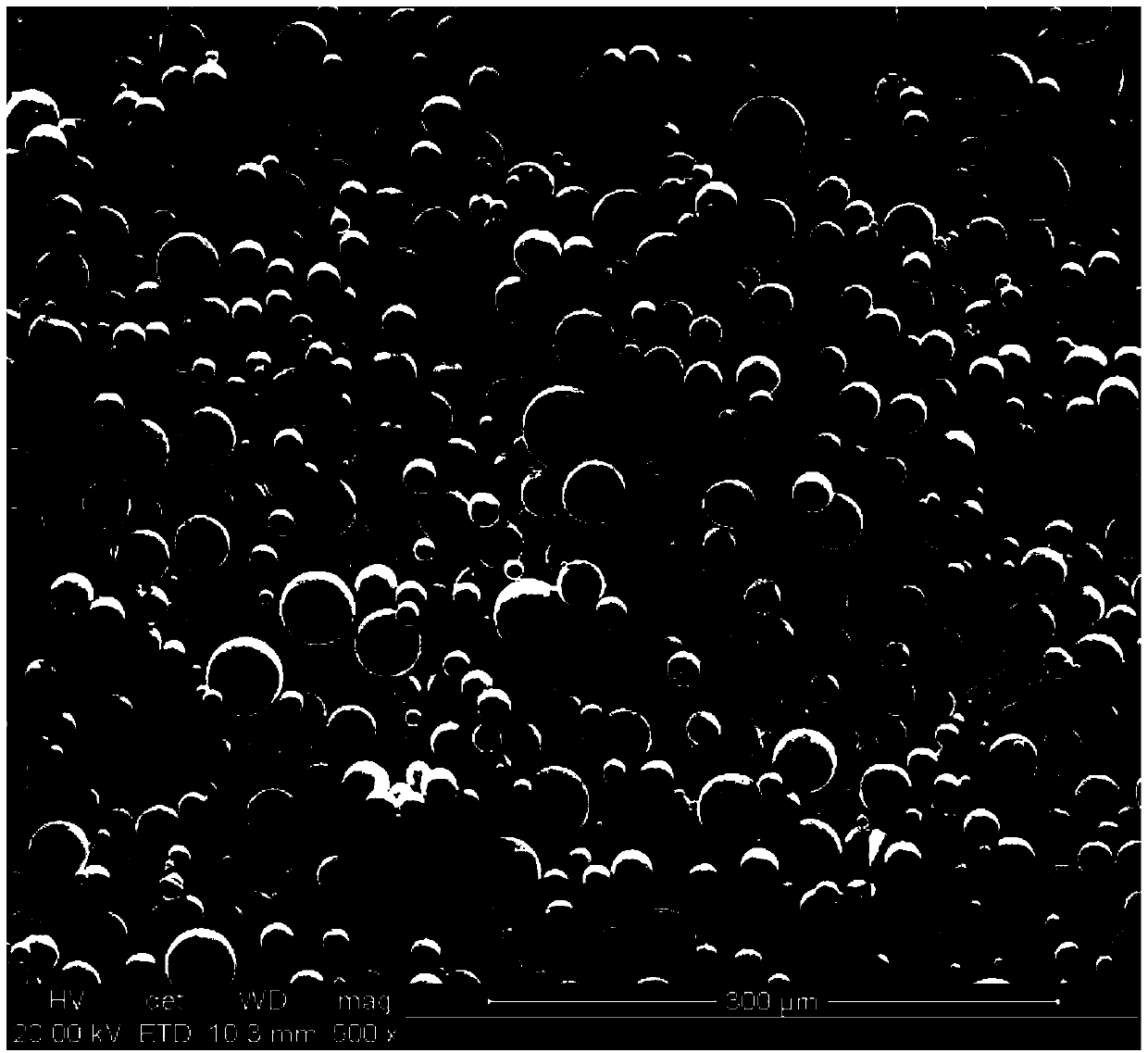

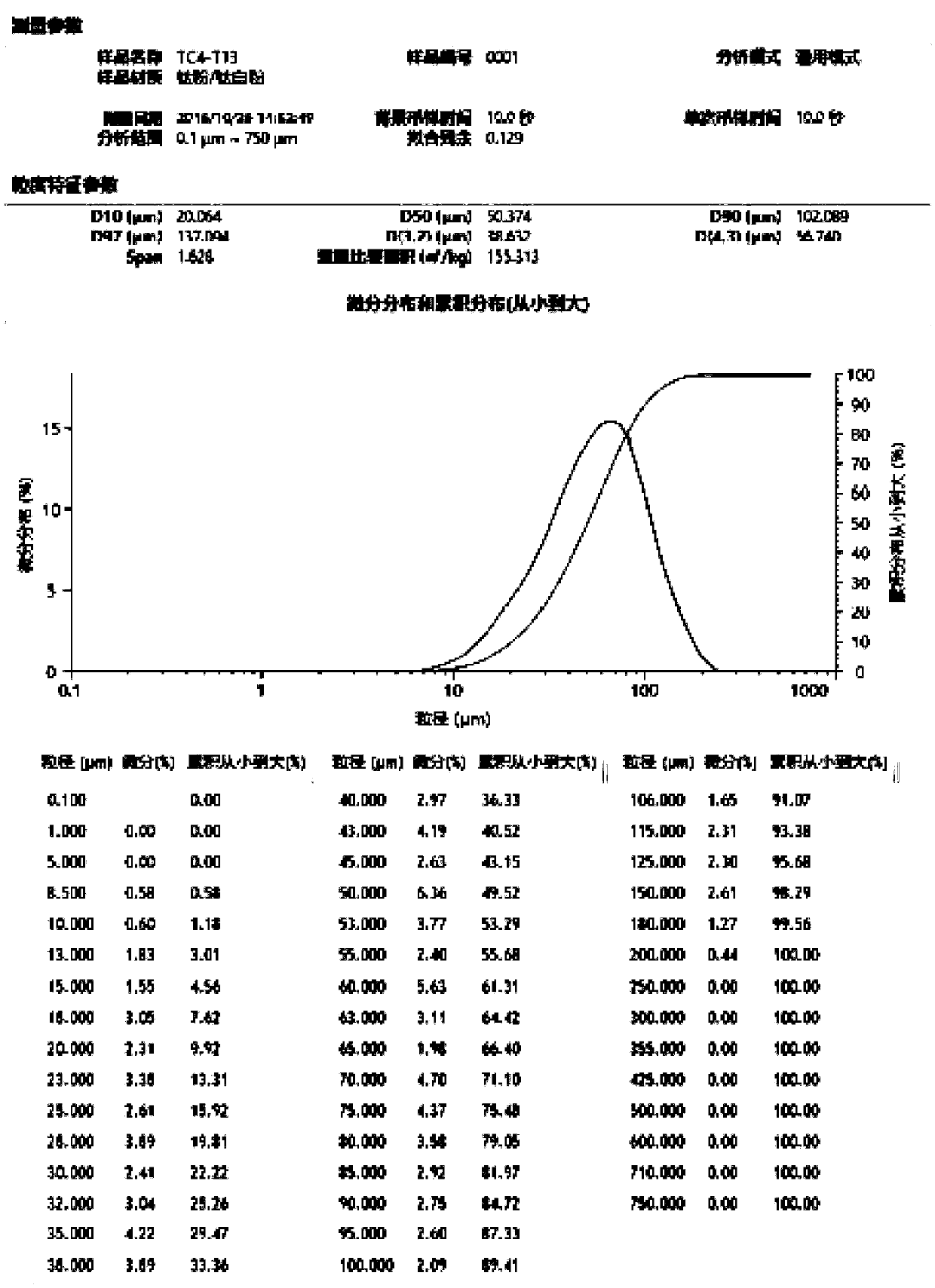

Multi-stage free-style gas atomization spray disc with gas self-circulation function

ActiveCN107598178BReduce negative pressureAchieve gas balanceAdditive manufacturing apparatusEngineeringMolten steel

The invention relates to a multilevel free-type gas atomization spraying tray with the gas self-circulation function. The multilevel free-type gas atomization spraying tray comprises an auxiliary nozzle, a main nozzle and a recycling gas flow guide part. The auxiliary nozzle is connected with the upper end of the recycling gas flow guide part, and the lower end of the recycling gas flow guide partis connected with the main nozzle. A melt channel of the auxiliary nozzle, a melt channel of the recycling gas flow guide part and a melt channel of the main nozzle communicate with one another up and down. A recycling flow guide channel is formed between the recycling gas flow guide part and the main nozzle. The recycling flow guide channel communicates with the melt channel of the main nozzle,and when the main nozzle is installed on a partition plate between a smelting chamber and an atomizing chamber, the recycling flow guide channel can communicate with the atomizing chamber. Compared with the prior art, auxiliary nozzle airflow is used for draining molten steel and further lowering negative pressure of a main nozzle atomization area, main nozzle jacket holes and the recycling gas flow guide part are used for achieving atomizing gas self-circulation, and therefore gas balancing of the main nozzle atomization area is realized, and stable and smooth execution of the atomizing process is guaranteed.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

Ultrasonic atomization device

InactiveCN103223391AExtended service lifeInternal and external pressure regulationLiquid spraying apparatusUltrasonic atomizationMaterials science

The invention discloses an ultrasonic atomization device which comprises an atomized liquid storage chamber for storing atomized liquid, and an atomization chamber communicated with the atomized liquid storage chamber by a first through hole (54), wherein a piezoelectric ceramic atomization sheet (4) is arranged on an external wall of the atomization chamber; a power supply device (518) supplies power to the piezoelectric ceramic atomization sheet (4); the ultrasonic atomization device further comprises a pressure regulation chamber; and a pressure regulation component (5) is arranged between the pressure regulation chamber and the atomized liquid storage chamber. The ultrasonic atomization device adopting a special structure decreases ionic compounds physically deposited in atomization micropores in the liquid, prevents an atomization element from long-term contact with the liquid, and prevents salt plasma compounds from being naturally deposited in the atomization micropores, the service life of the atomization device is prolonged, and the leakage of the atomized liquid is avoided. The atomization device integrates atomization, humidification and external charging, and is convenient and simple, and convenient to carry, and the practical value of the atomization device is improved.

Owner:张建辉

Multilevel free-type gas atomization spraying tray with gas self-circulation function

ActiveCN107598178AReduce negative pressureAchieve gas balanceAdditive manufacturing apparatusSpray nozzleEngineering

The invention relates to a multilevel free-type gas atomization spraying tray with the gas self-circulation function. The multilevel free-type gas atomization spraying tray comprises an auxiliary nozzle, a main nozzle and a recycling gas flow guide part. The auxiliary nozzle is connected with the upper end of the recycling gas flow guide part, and the lower end of the recycling gas flow guide partis connected with the main nozzle. A melt channel of the auxiliary nozzle, a melt channel of the recycling gas flow guide part and a melt channel of the main nozzle communicate with one another up and down. A recycling flow guide channel is formed between the recycling gas flow guide part and the main nozzle. The recycling flow guide channel communicates with the melt channel of the main nozzle,and when the main nozzle is installed on a partition plate between a smelting chamber and an atomizing chamber, the recycling flow guide channel can communicate with the atomizing chamber. Compared with the prior art, auxiliary nozzle airflow is used for draining molten steel and further lowering negative pressure of a main nozzle atomization area, main nozzle jacket holes and the recycling gas flow guide part are used for achieving atomizing gas self-circulation, and therefore gas balancing of the main nozzle atomization area is realized, and stable and smooth execution of the atomizing process is guaranteed.

Owner:SHANGHAI RES INST OF MATERIALS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com