Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1006 results about "Atomizer nozzle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An atomizer nozzle can take many forms. The first atomizer nozzle, also called an aspirator nozzle, was invented by Dr. Thomas DeVilbliss of Toledo, Ohio, in the late 19th century for producing a fine spray of a liquid based on the Venturi effect. His device was used for spraying medicine on the back of his patients' throats. Atomizer nozzles can create atomization from a variety of mechanical means, which includes but is not limited to electrostatics processes, ultrasonic nozzle and centrifugal forces.

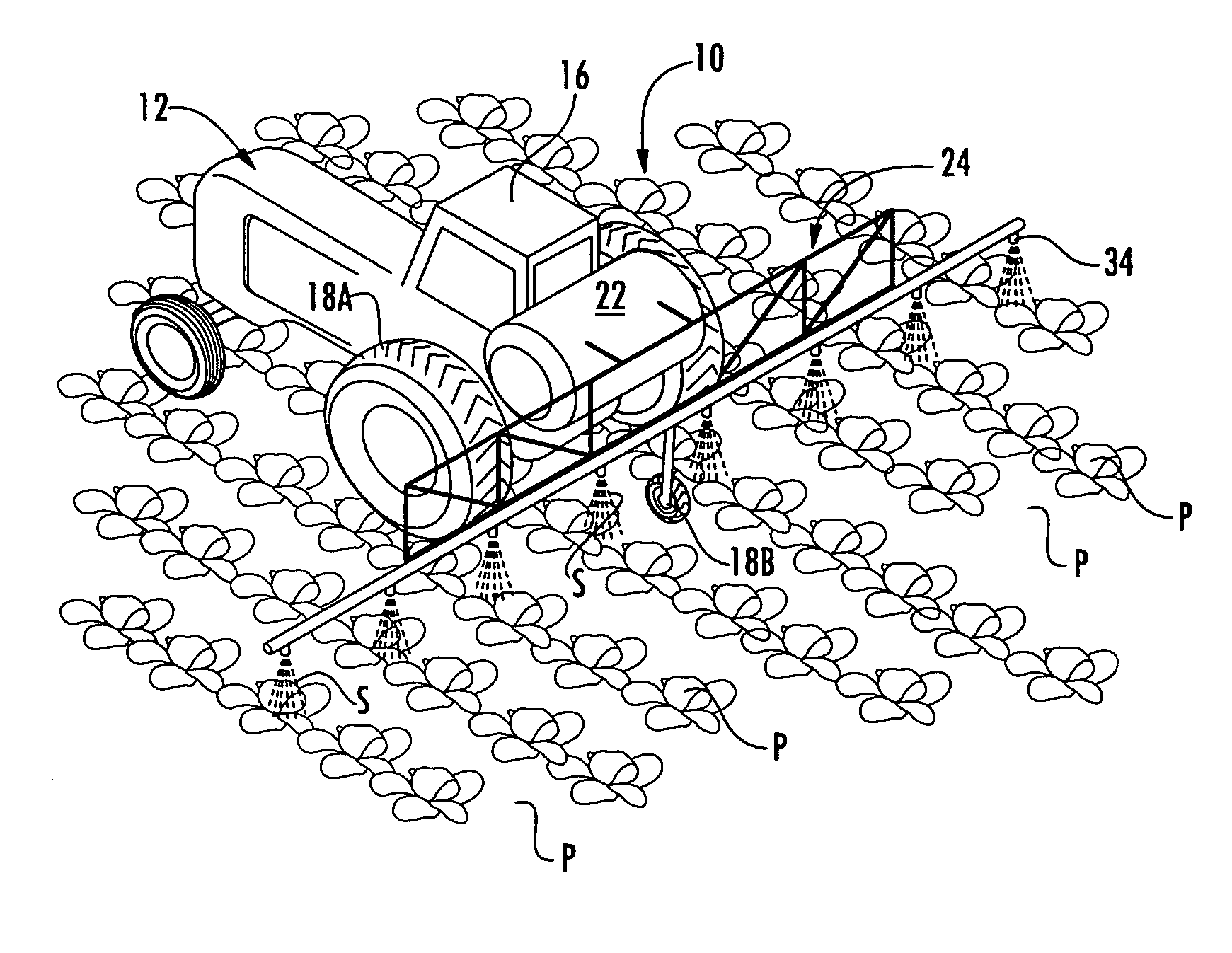

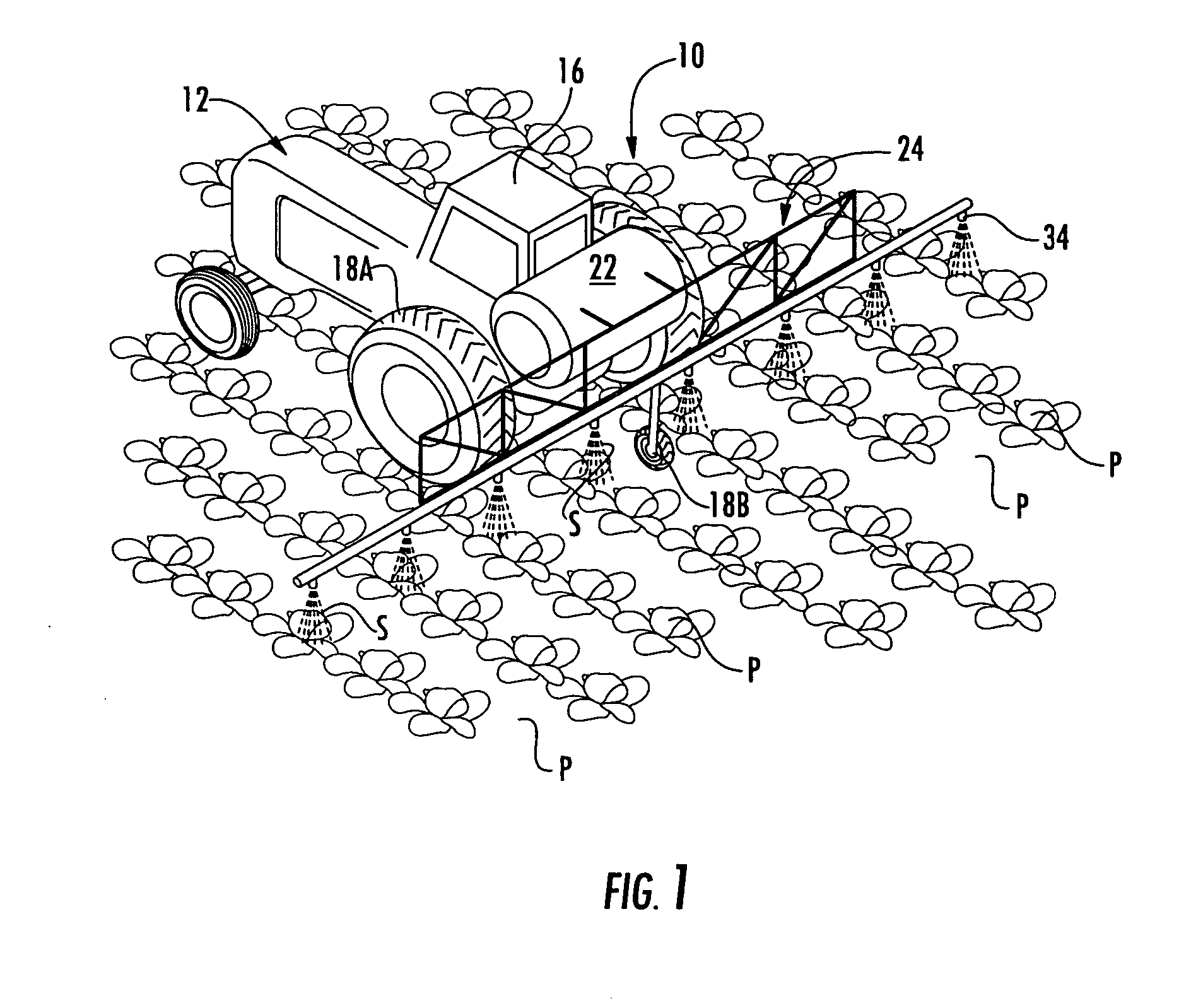

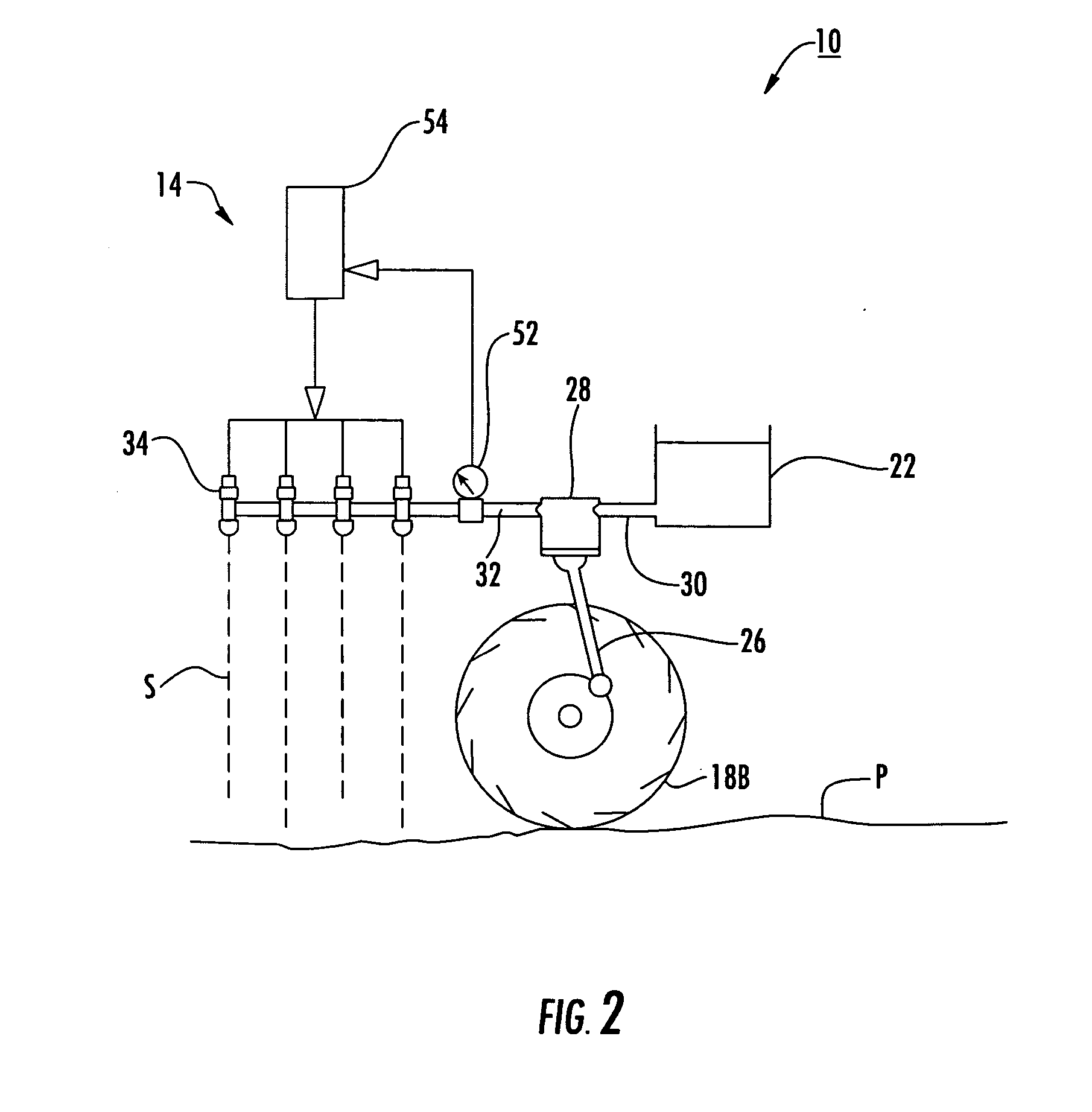

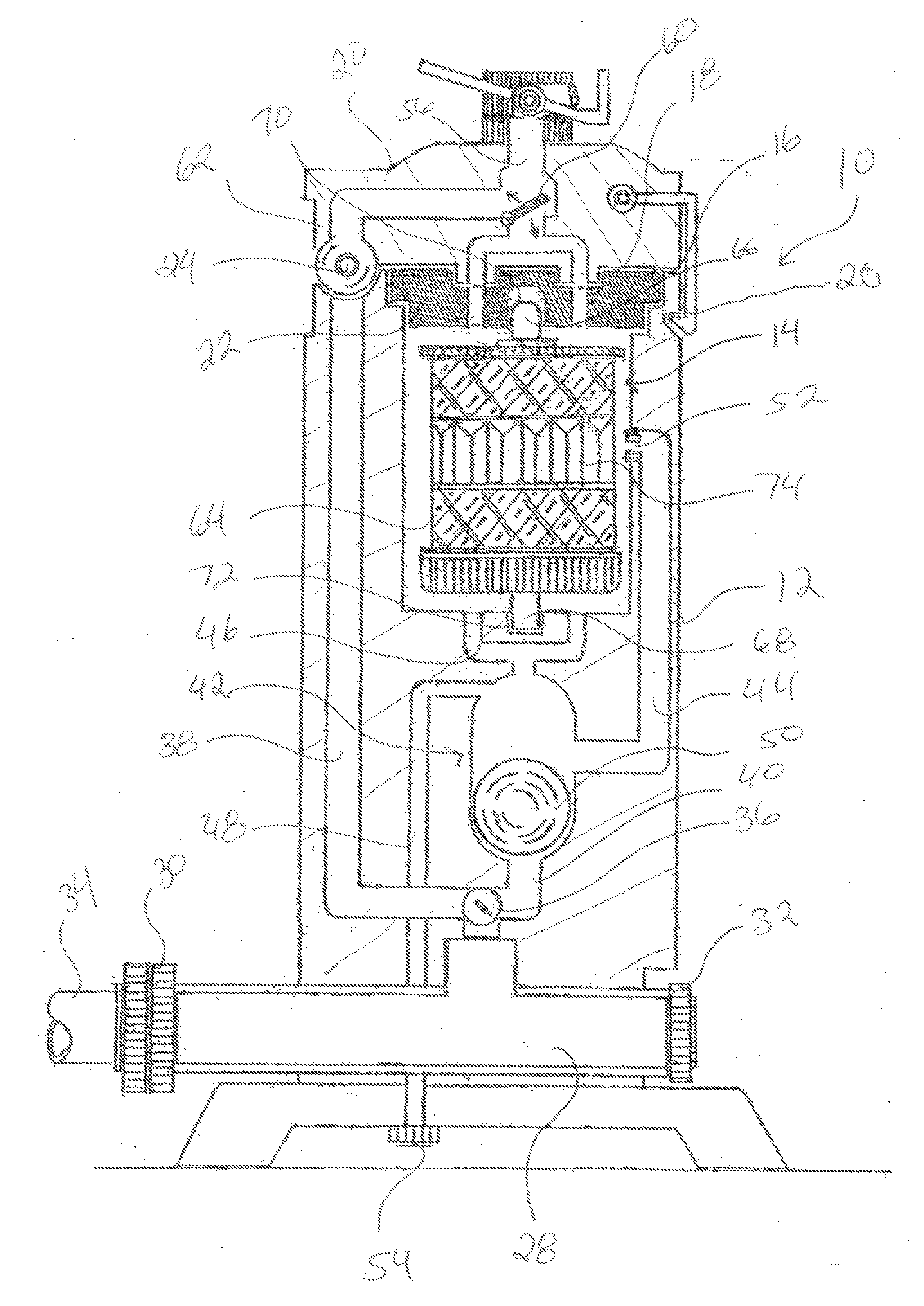

Electrically actuated variable pressure control system

InactiveUS20060273189A1Increase flow resistanceLow flow resistanceOperating means/releasing devices for valvesSelf-acting watering devicesSolenoid valveAtomizer nozzle

An electrically-actuated variable pressure control system for use with flow-controlled liquid application systems. Direct acting solenoid valves are pulsed at varying frequencies and duty cycles to change the resistance to flow encountered by the flow-controlled liquid application system. This pulsing solenoid valve technique preserves a high degree of accuracy and uniformity through a wide range of pressure control. This wide range of pressure control indirectly allows the flow-controlled liquid application system to operate over a wider range of flow control, yielding indirect benefits to performance and productivity. When the solenoid valves are attached to pressure-atomization spray nozzles, control over spray pattern and droplet size is further achieved.

Owner:CAPSTAN

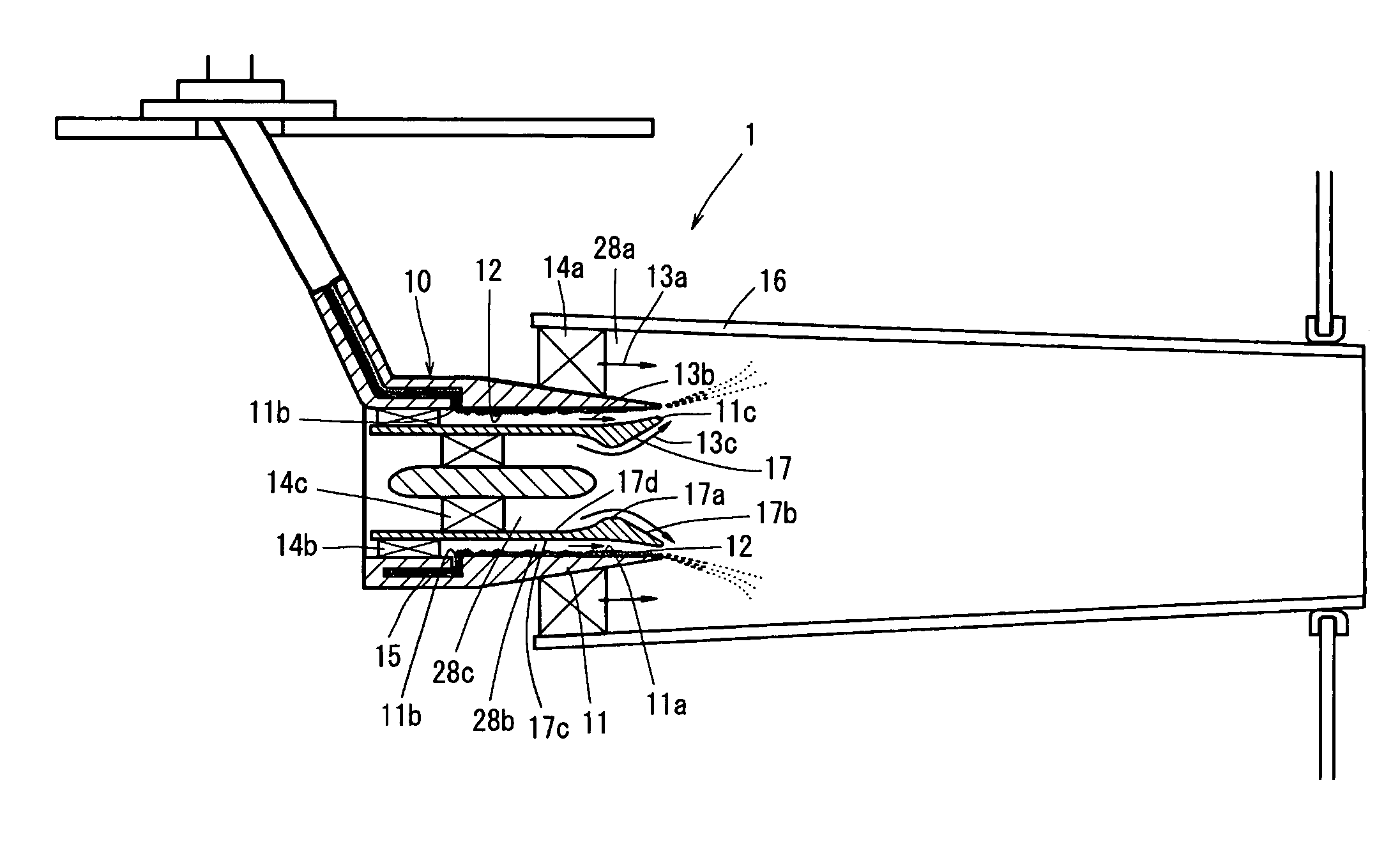

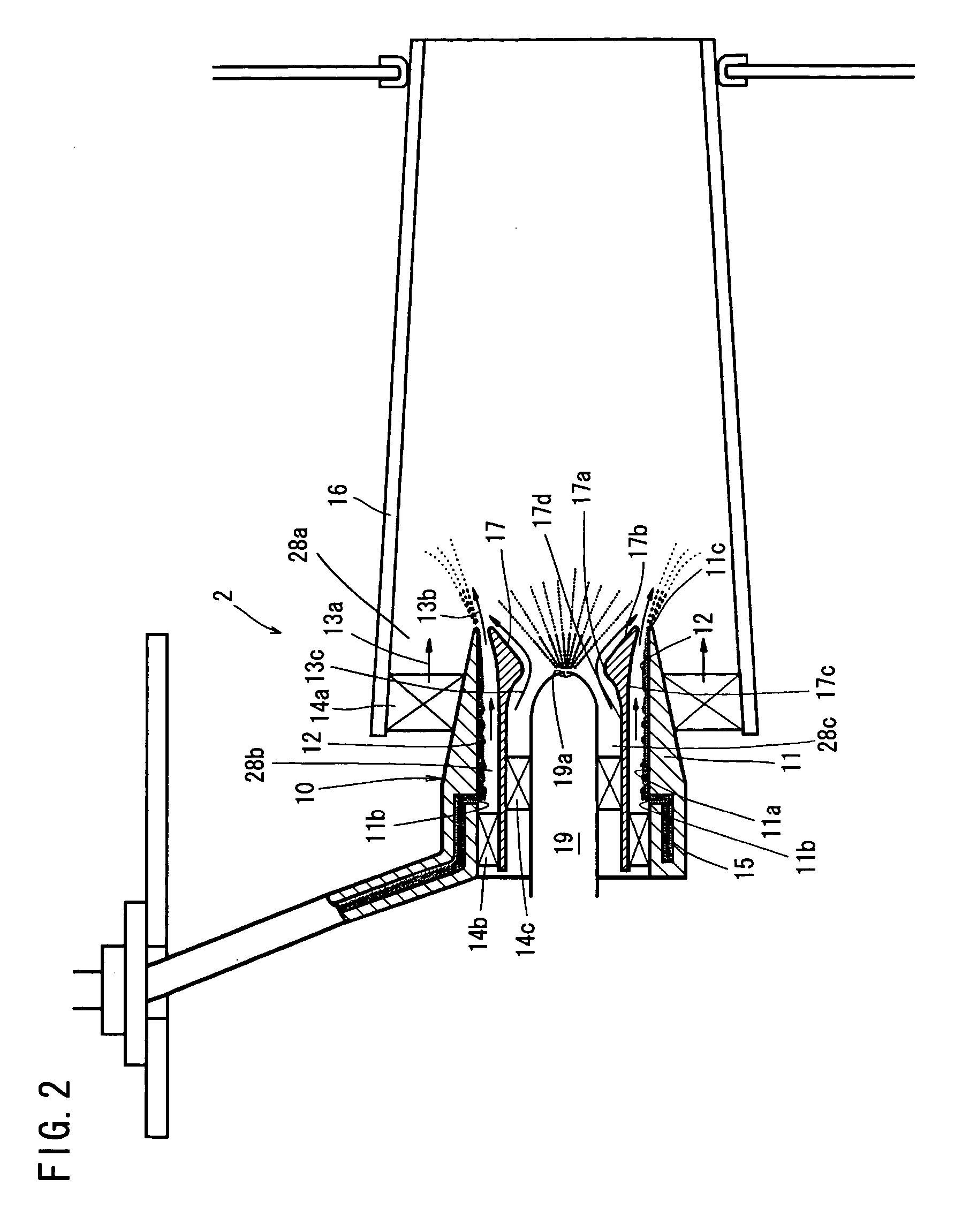

Fuel/air premixer for gas turbine combustor

InactiveUS20050039456A1Reduce weightReduce overall outer diameterBurnersContinuous combustion chamberCombustorCombustion chamber

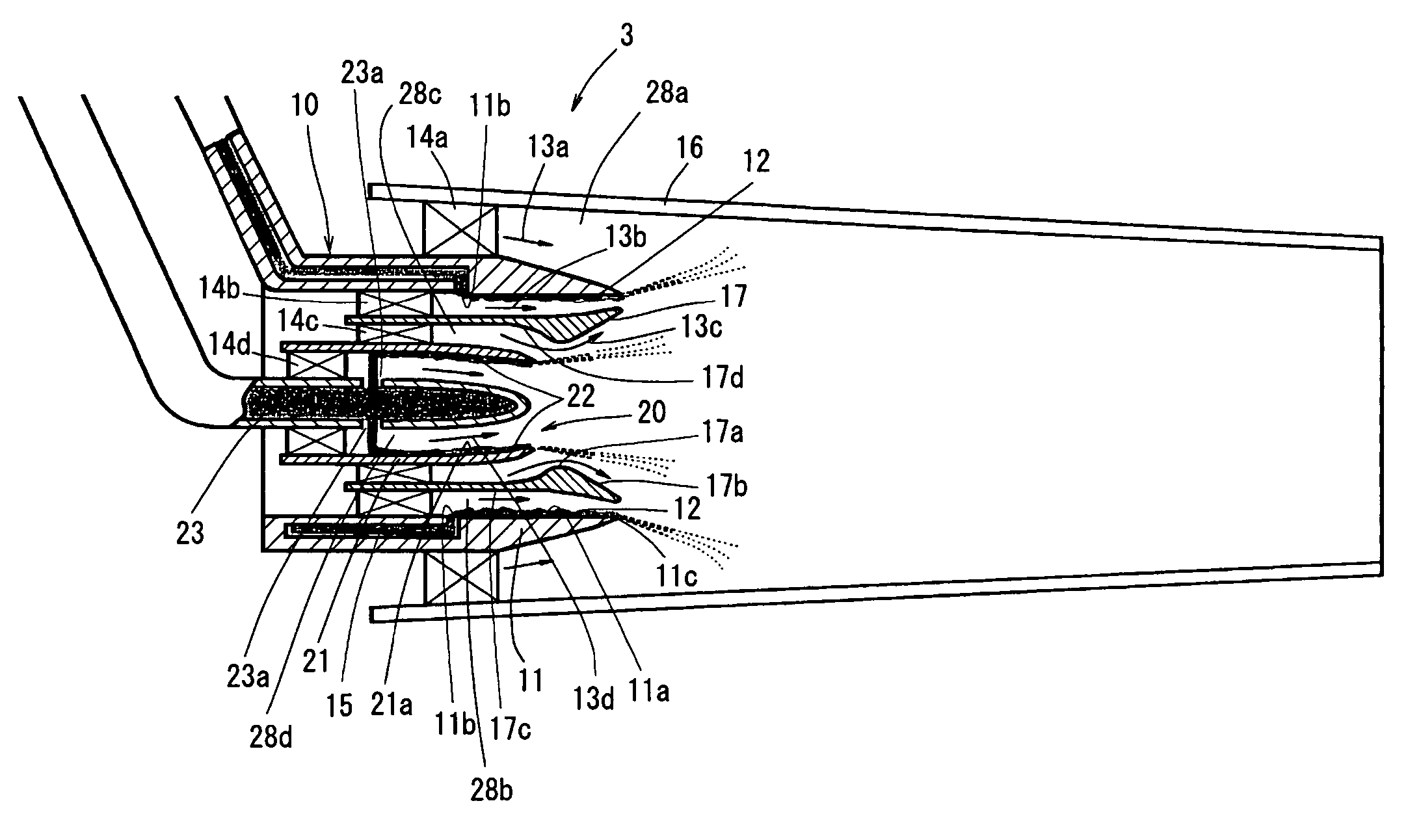

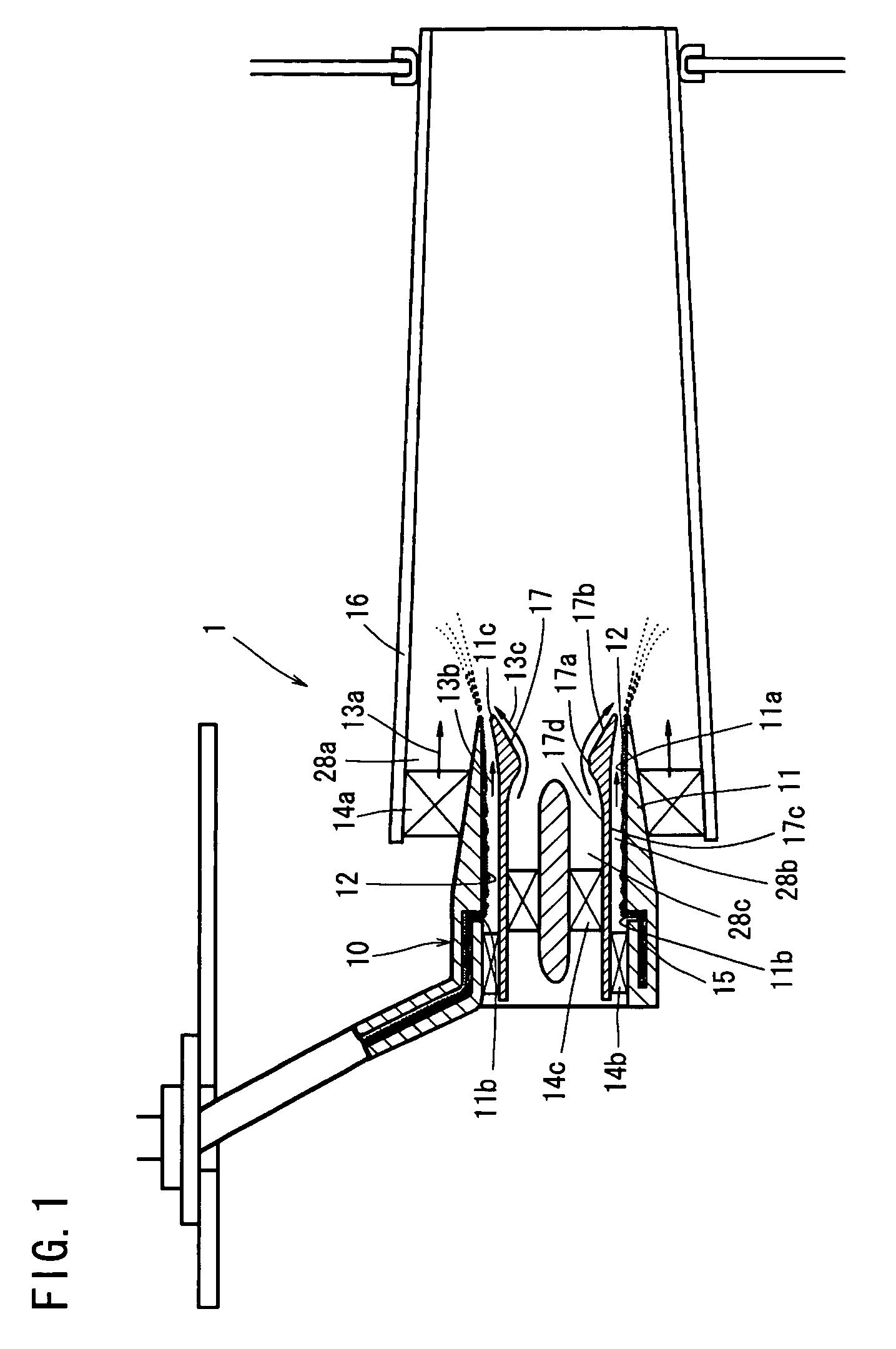

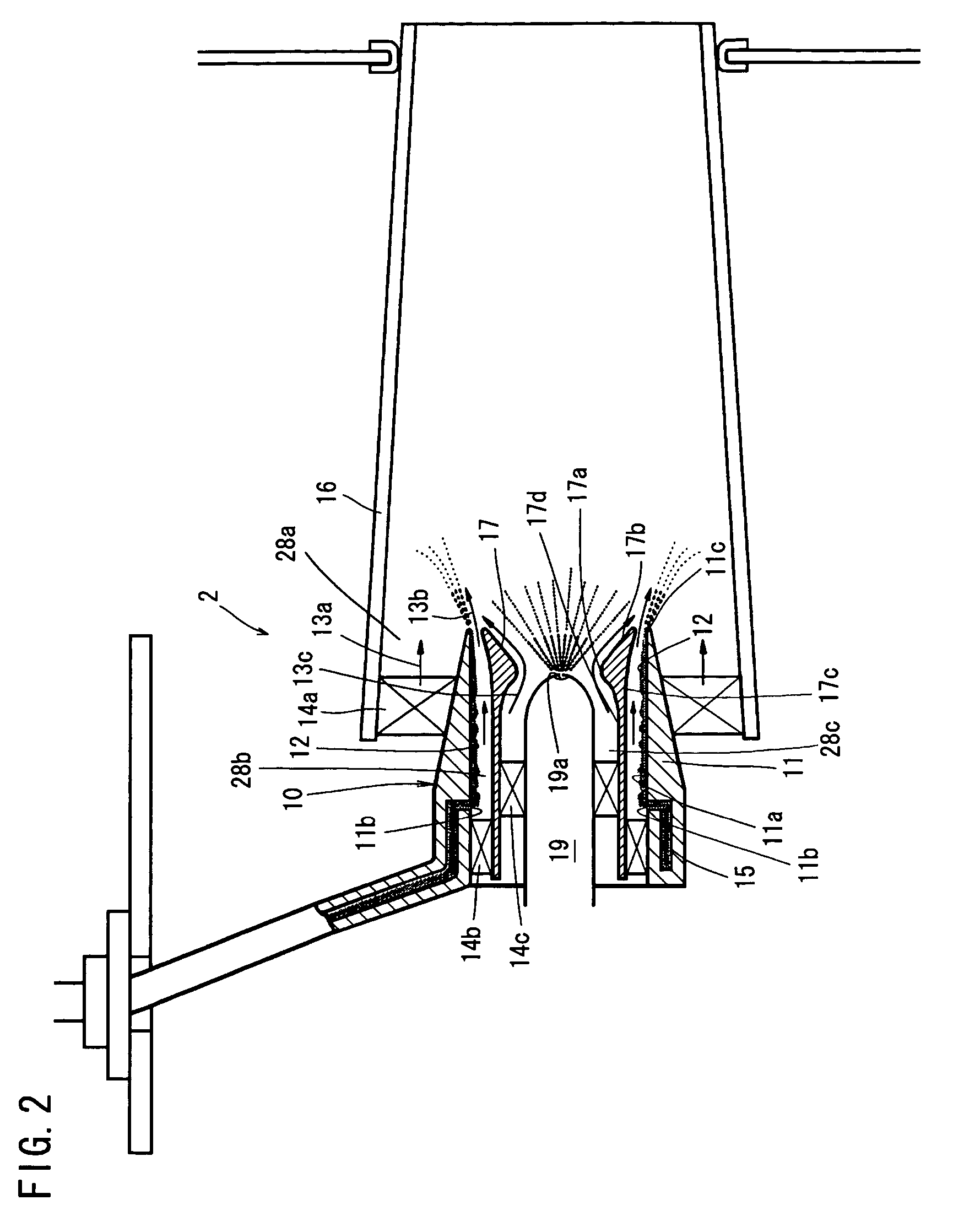

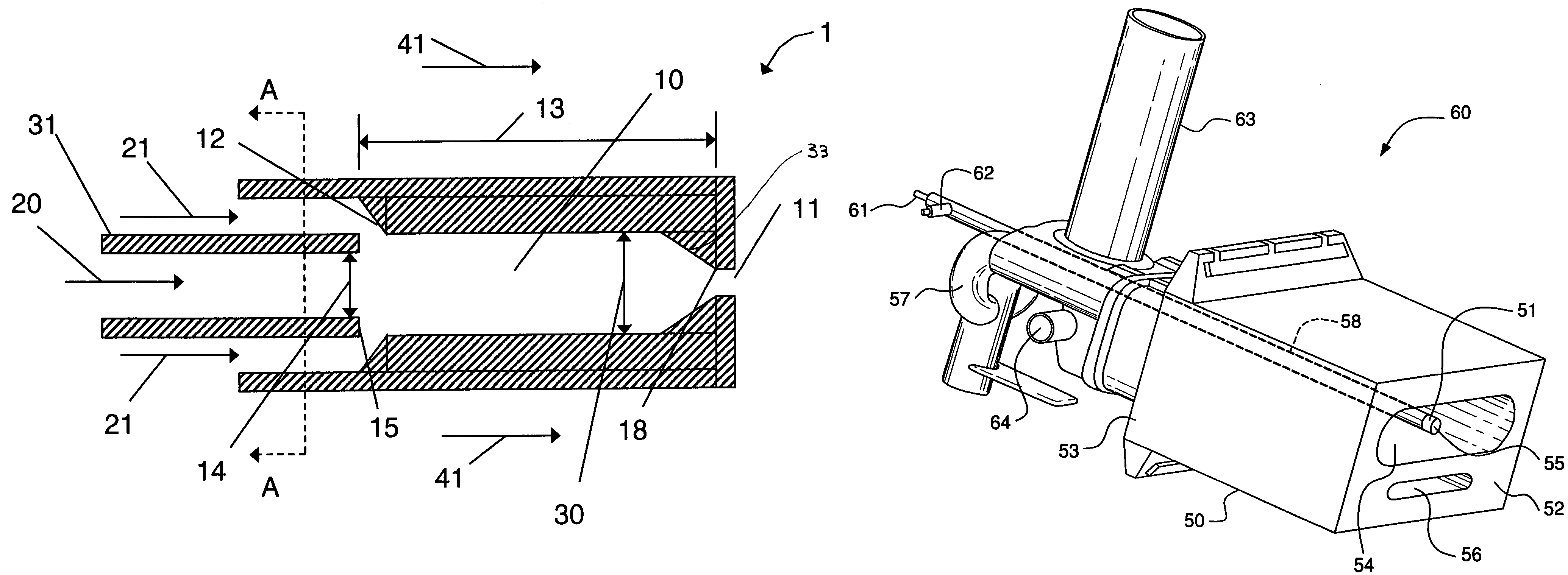

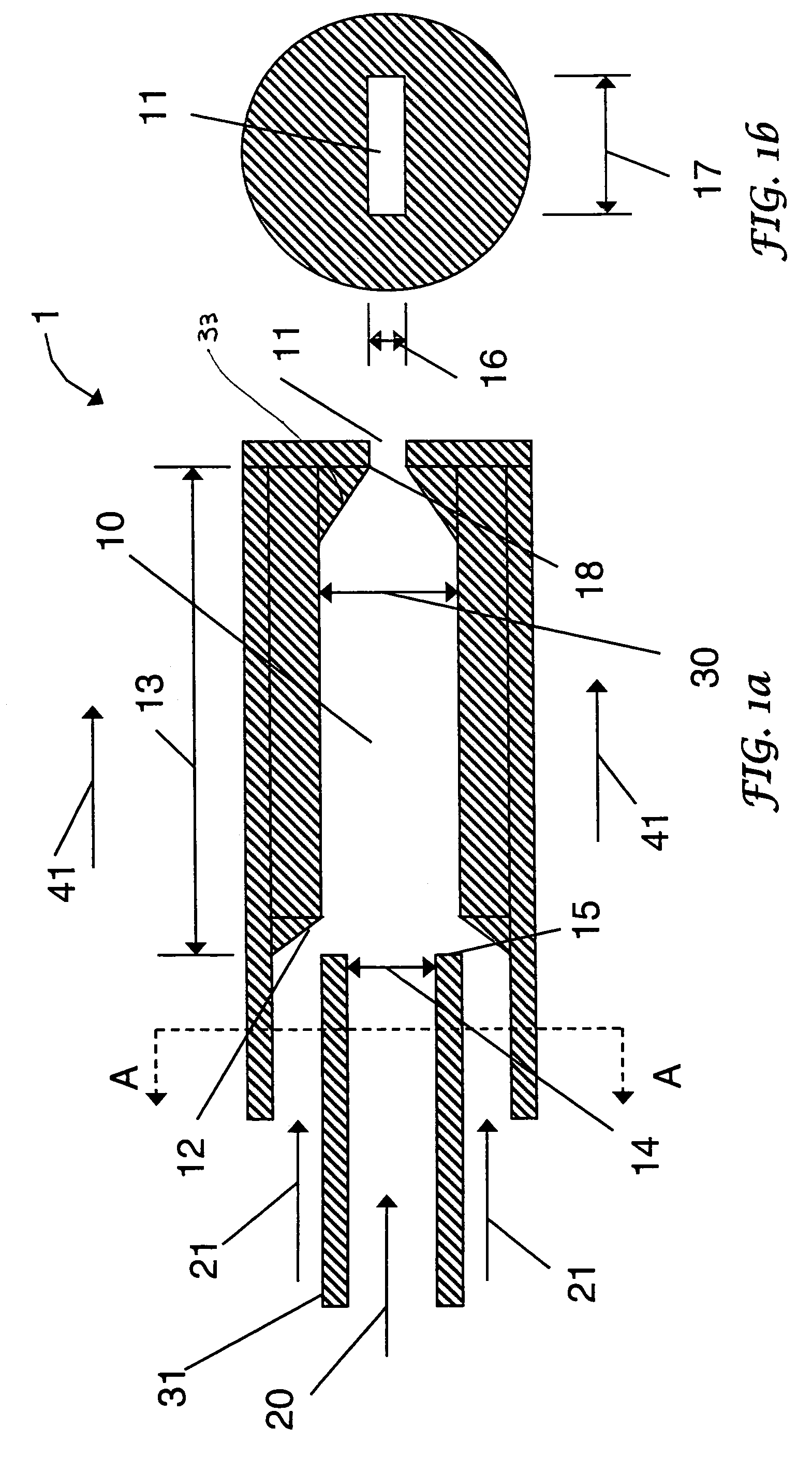

A fuel / air premixer for use in a gas turbine improves the atomization performance and mixing performance of the fuel by guiding an air so as to flow in an outward radial direction. A flow-deflecting tubular body having an annular cross section is disposed on the inside of and coaxially with a liquid film-forming body of an airblast atomizer nozzle disposed at the inlet portion of a premixing tube. The outer peripheral surface of the flow-deflecting tubular body has a wall surface which increases in outer diameter toward the tip end of a first annular passage. The inner peripheral surface of the flow-deflecting tubular body has a form in which the inner diameter has a minimum to form a contracted portion, and then increases dramatically toward the tip end.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

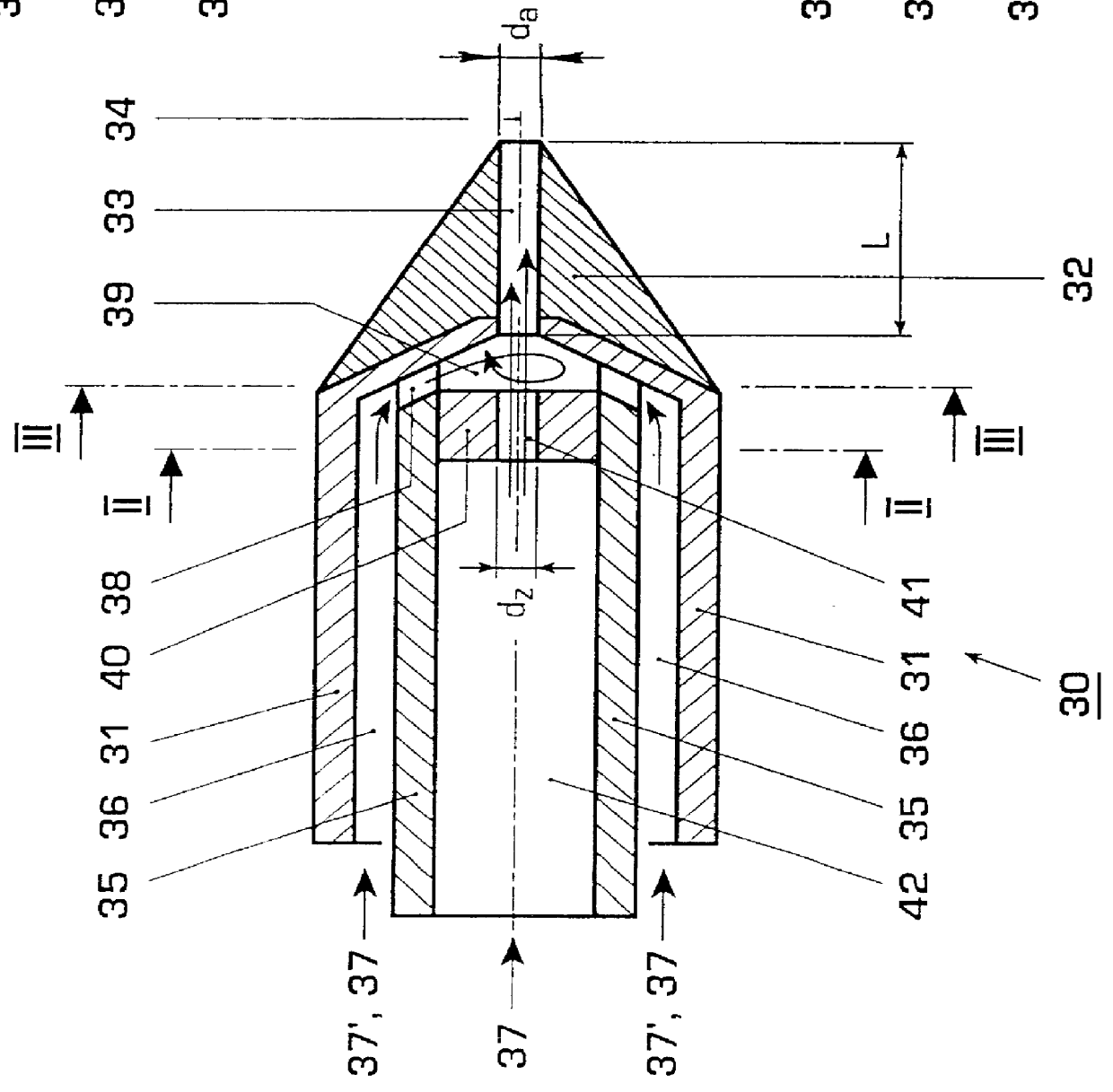

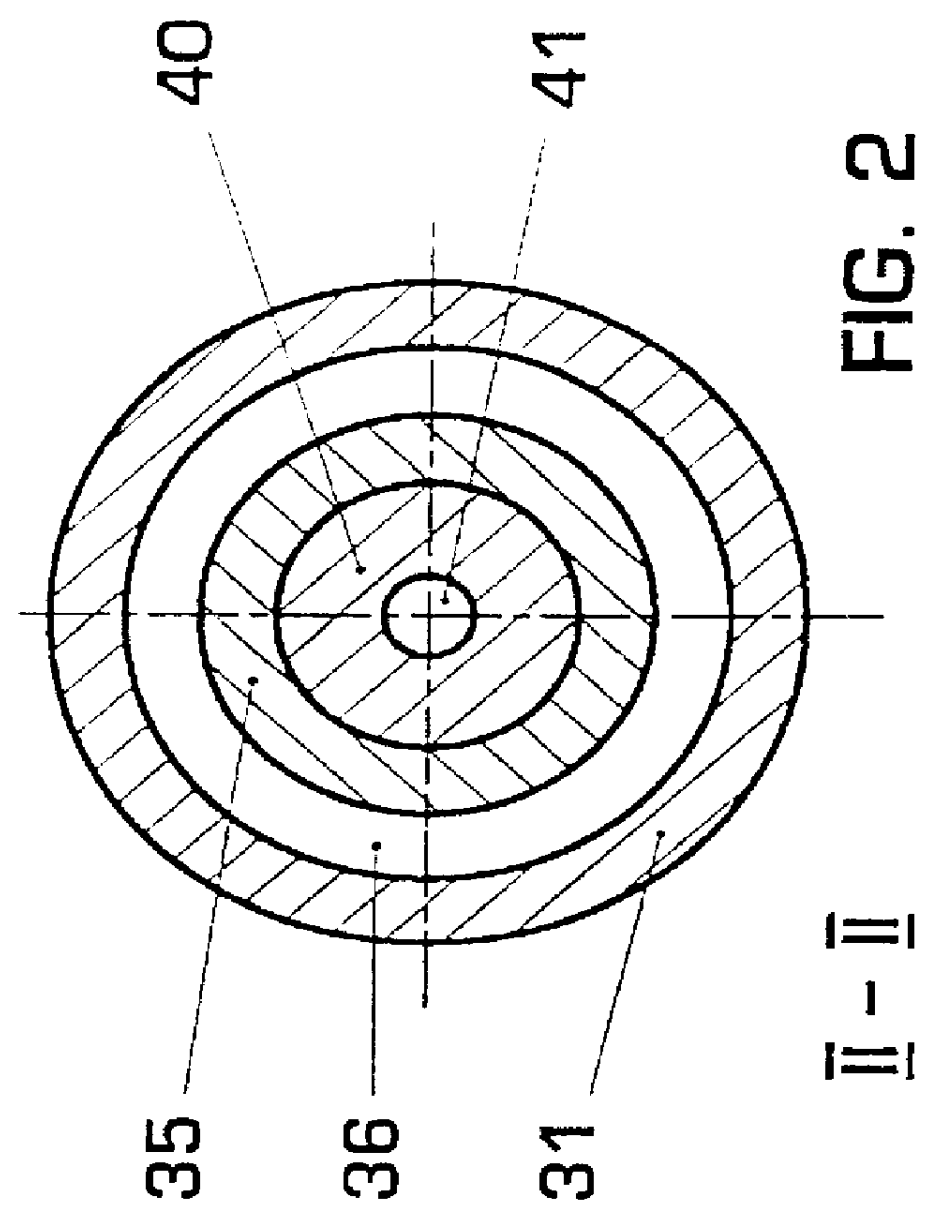

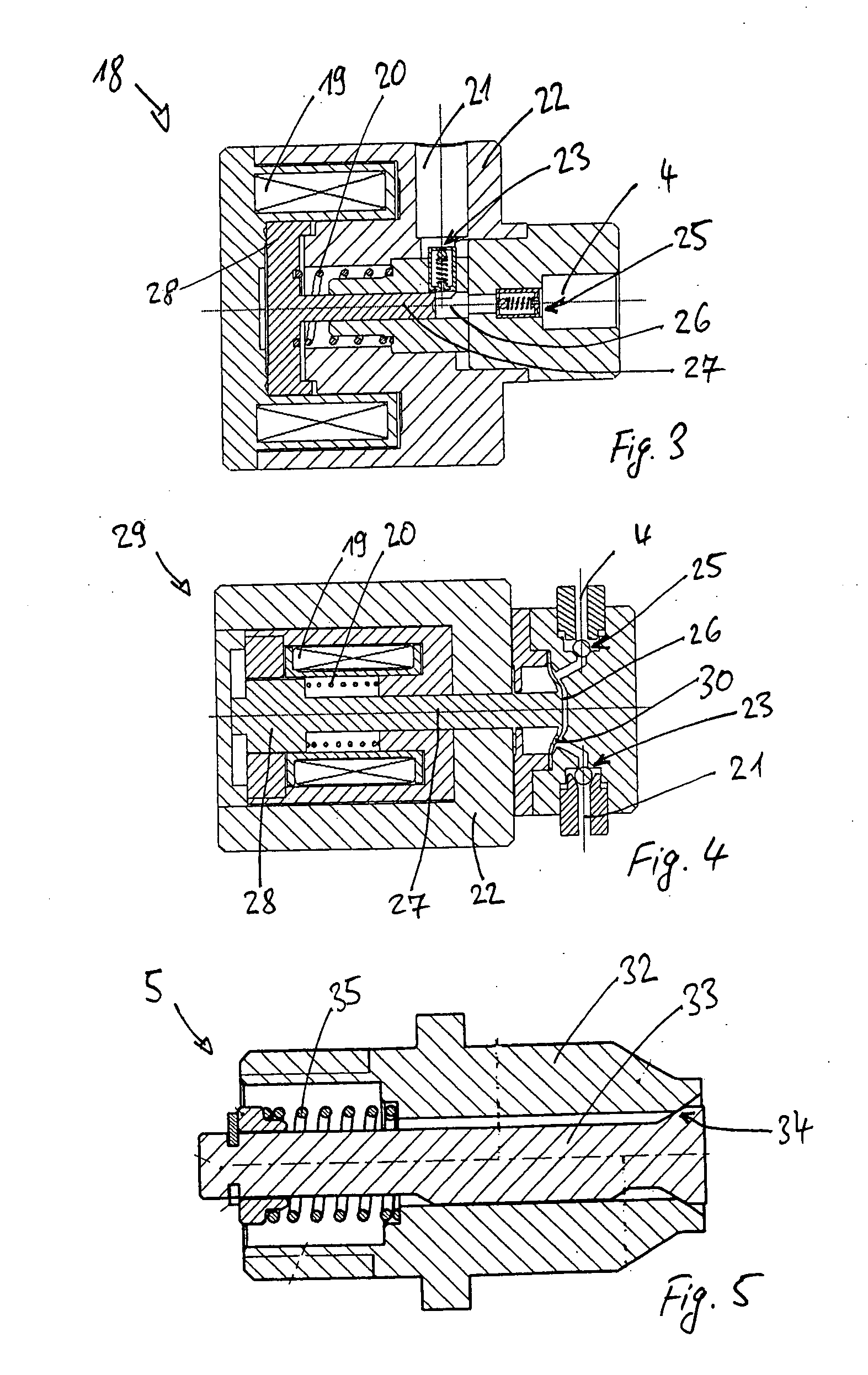

Pressure atomizer nozzle

InactiveUS6045058ASlow disintegrationReduce friction lossBurnersSpray nozzlesNebulizerAtomizer nozzle

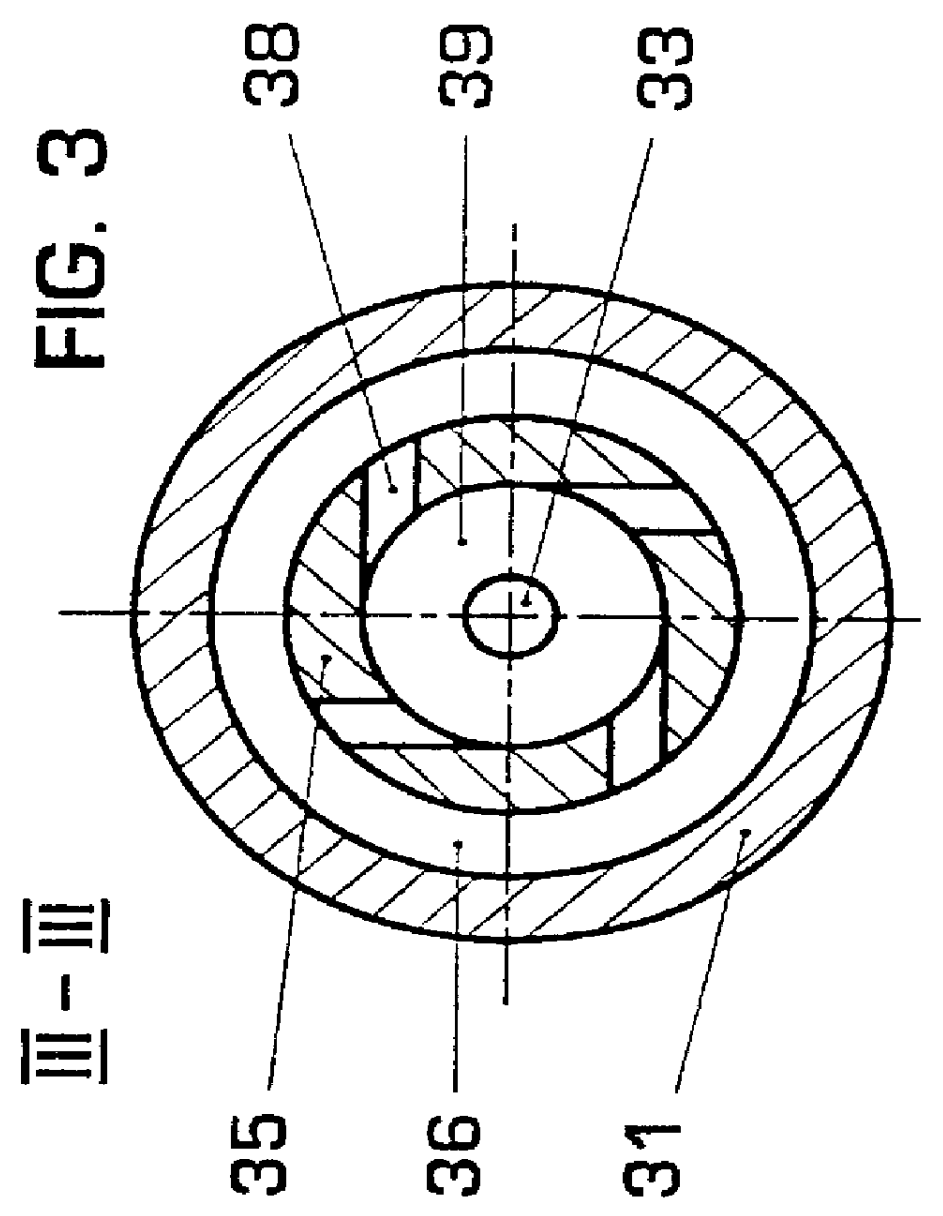

The invention relates to a two-stage pressure atomizer nozzle with a nozzle body (30) having a mixing chamber (39) which is connected to an outside space via a nozzle outlet bore (33), and with a first feed duct (42) with a feed bore (41) for a liquid (37) to be atomized, through which feed bore said liquid (37) can be fed, free of swirling and under pressure, at least one further feed duct (36) for a portion of the liquid (37) to be atomized or for a second liquid (37') to be atomized opening into the chamber (39), through which feed duct said liquid (37, 37') can be fed under pressure and with swirling. The feed bore (41) of the first feed duct (42) lies on one axis (34) with the nozzle outlet bore (33). It is defined in that the outlet-side diameter (da) of the nozzle outlet bore (33) is at most as large as the diameter (dz) of the feed bore (41) and the length (L) of the nozzle outlet bore (33) is at least twice to at most ten times the outlet-side diameter (da) of the nozzle outlet bore (33).

Owner:ANSALDO ENERGIA SWITZERLAND AG

Fuel/air premixer for gas turbine combustor

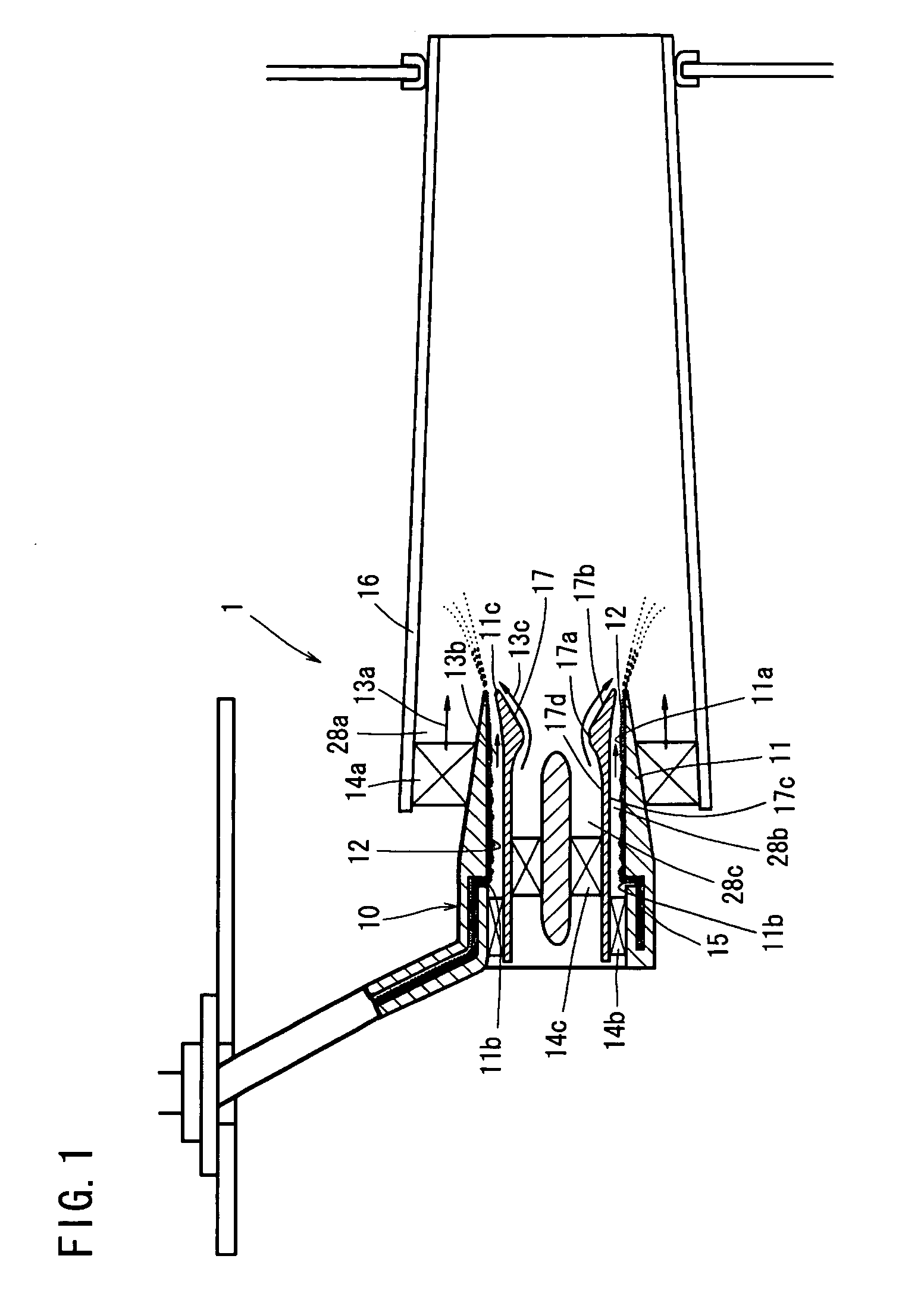

InactiveUS7434401B2Improve performanceAvoid burnsBurnersContinuous combustion chamberCombustorCombustion chamber

A fuel / air premixer for use in a gas turbine improves the atomization performance and mixing performance of the fuel by guiding an air so as to flow in an outward radial direction. A flow-deflecting tubular body having an annular cross section is disposed on the inside of and coaxially with a liquid film-forming body of an airbiast atomizer nozzle disposed at the inlet portion of a premixing tube. The outer peripheral surface of the flow-deflecting tubular body has a wall surface which increases in outer diameter toward the tip end of a first annular passage. The inner peripheral surface of the flow-deflecting tubular body has a form in which the inner diameter has a minimum to form a contracted portion, and then increases dramatically toward the tip end.

Owner:JAPAN AEROSPACE EXPLORATION AGENCY

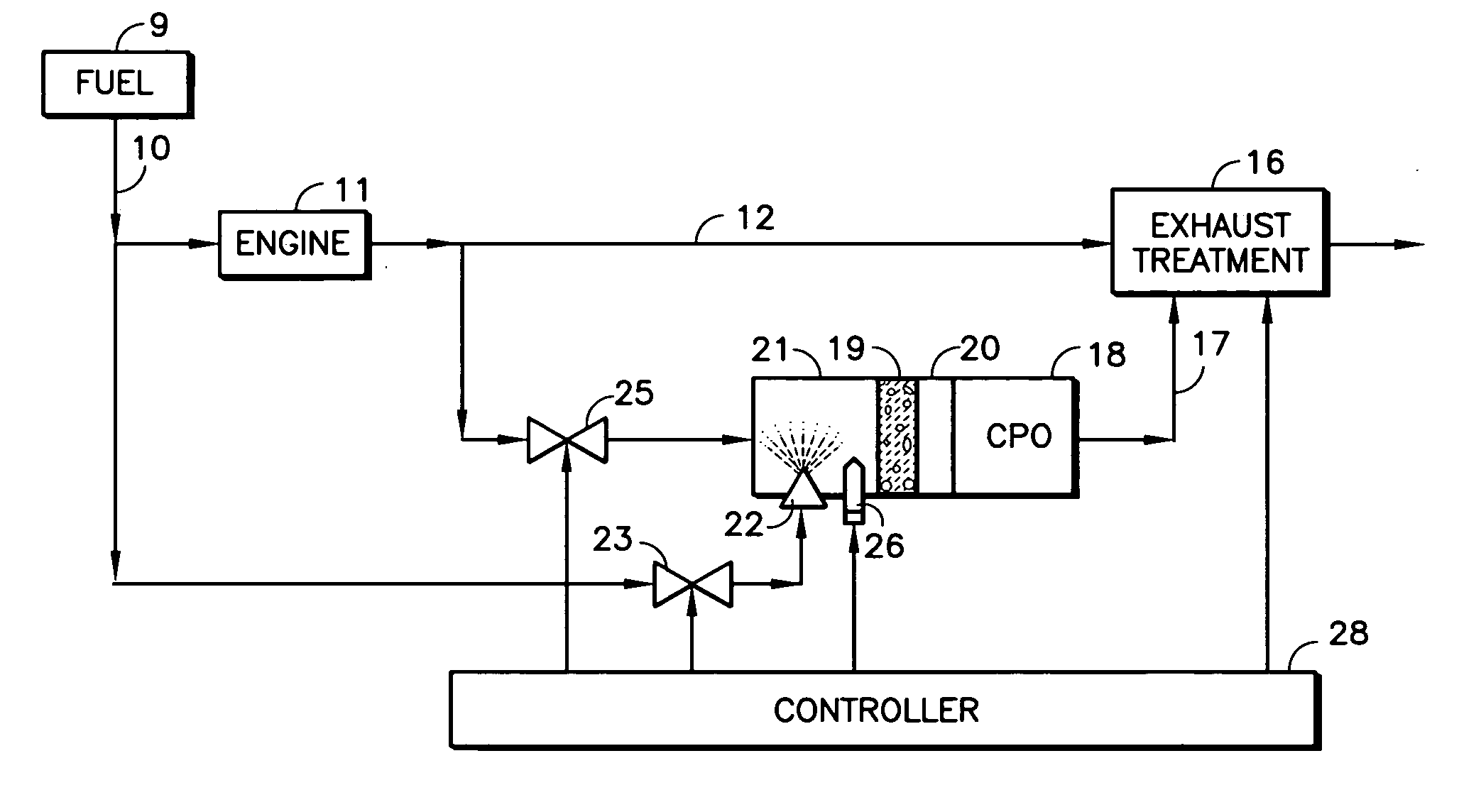

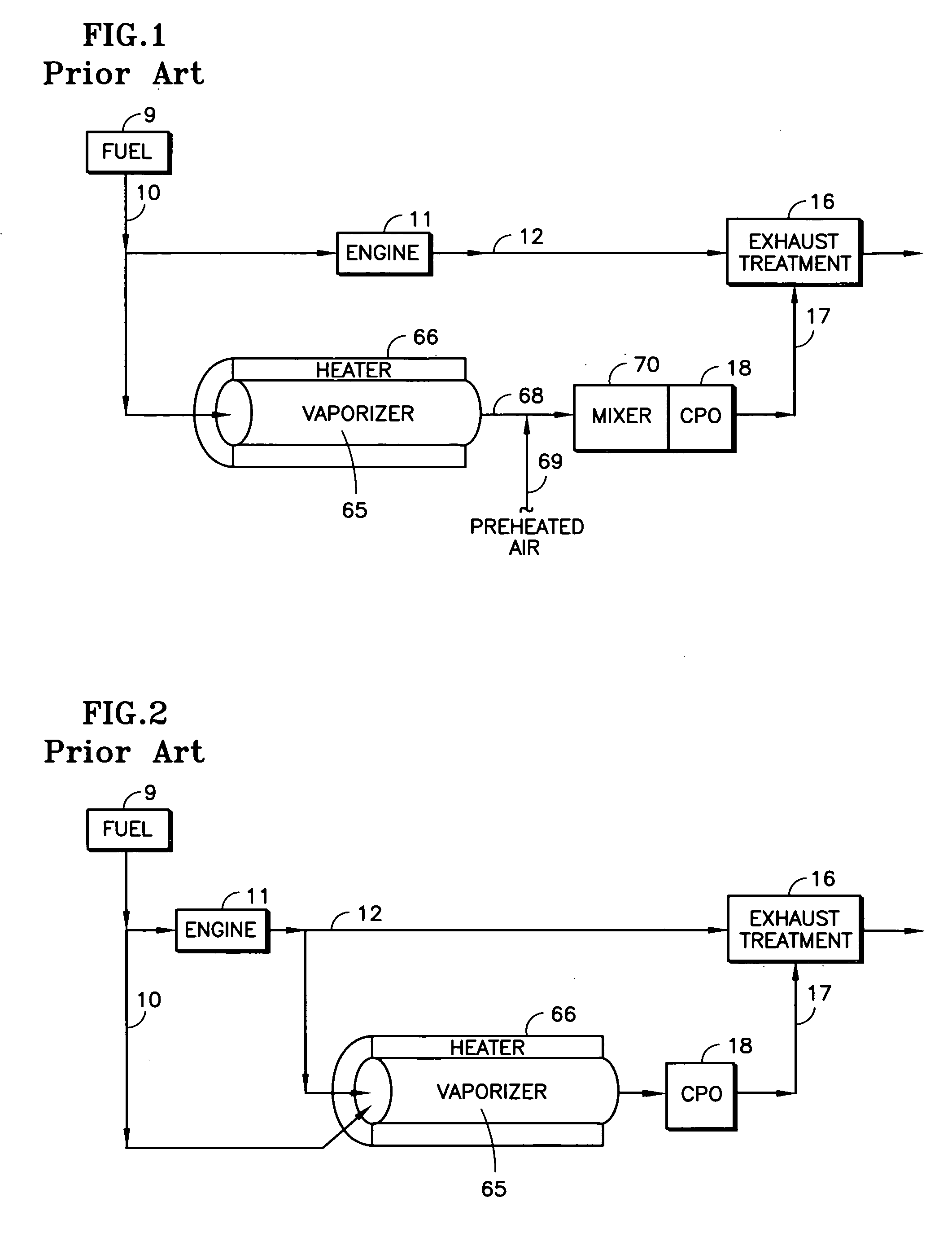

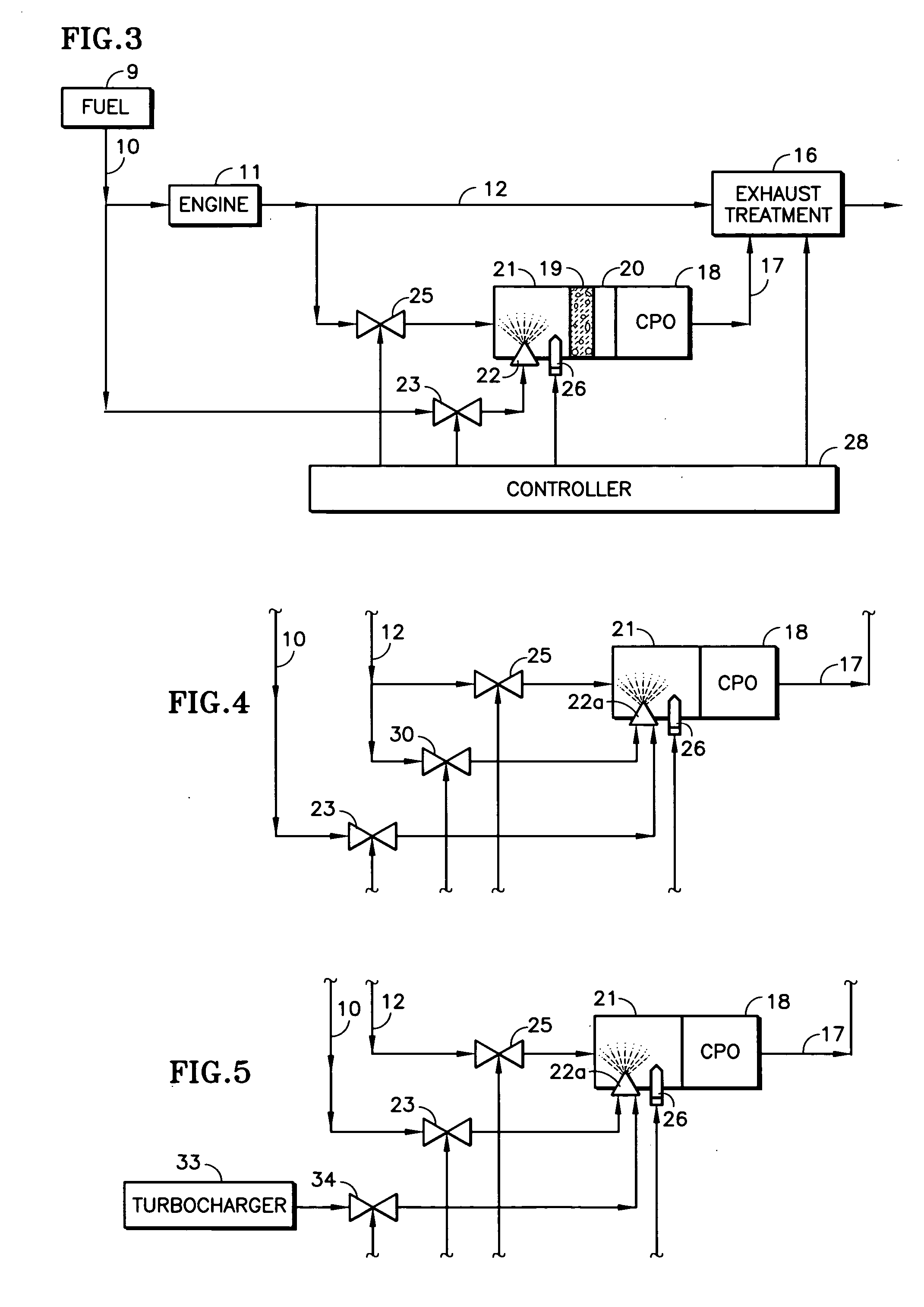

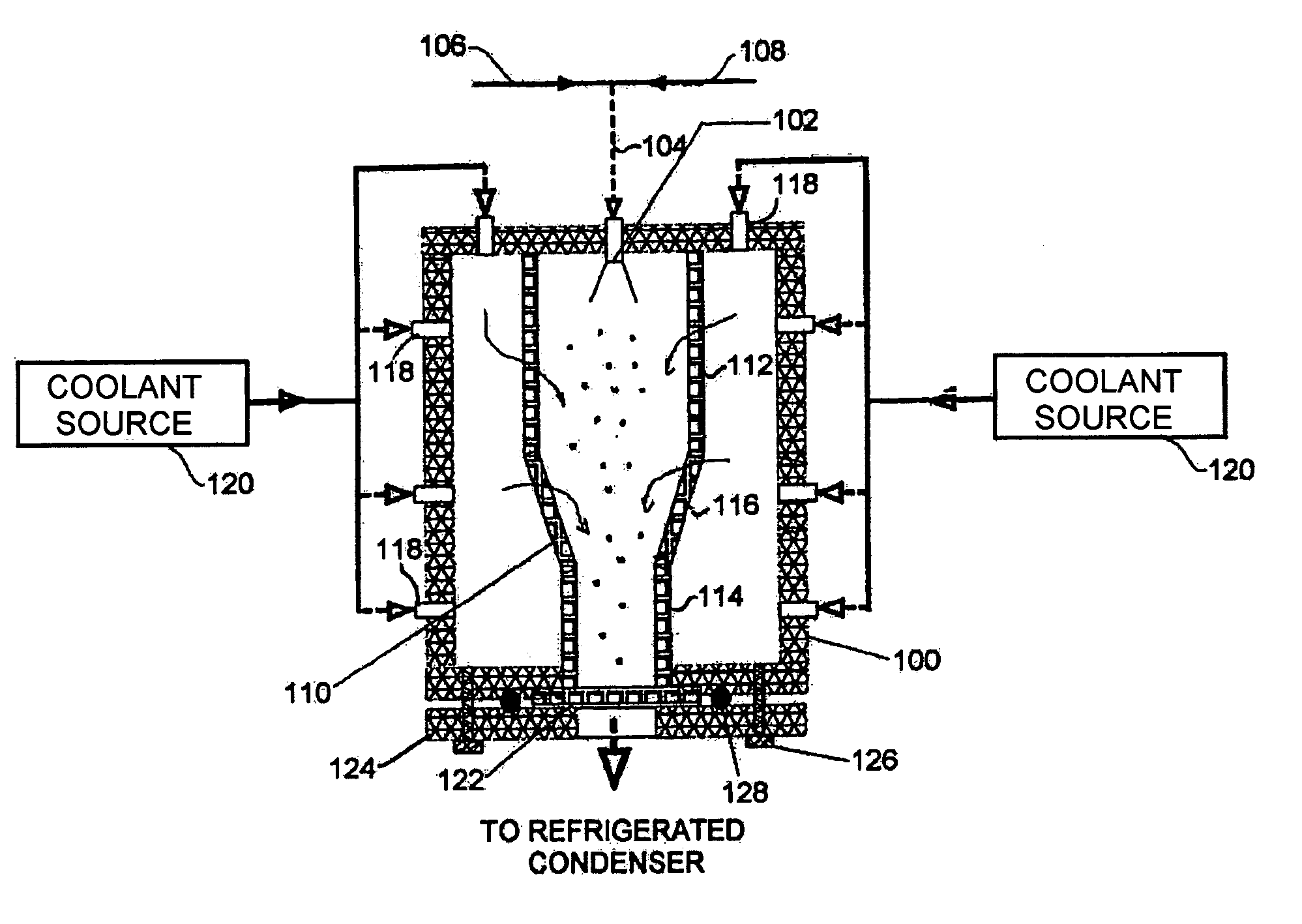

Reforming unvaporized, atomized hydrocarbon fuel

InactiveUS20050274107A1Improved hydrogen generationLow costHydrogenExhaust apparatusKeroseneTurbocharger

A reformer such as a CPO (18) receives a mix of fuel, moisture and oxygen from a mixing region (21) having an igniter (26, 66), which may include an inert ceramic foam (19), the fuel being provided by an atomizing nozzle (22), thereby avoiding the need for a vaporizer before use. The oxygen and moisture may comprise engine exhaust (11, 12). Fuel from a vehicle fuel tank (9), may be gasoline, diesel fuel, kerosene, jet fuel, or JP-8. The atomizing nozzle may be a gas-assist nozzle (22a), receiving the assisting gas from (a) engine exhaust (10), (b) a turbocharger (33), (c) an air pump (50) or (d) a steam generator (57). The oxygen and moisture may comprise moisturized air, which may be achieved by an ejector (41) which ingests water from a tank (43) in response to the flow of air from a pump (50) through a conduit (47). The air may be regeneratively heated (48) with the CPO exhaust. The igniter may be a glow plug (26) or a heater wire (66) coated with catalyst.

Owner:SHELL OIL CO

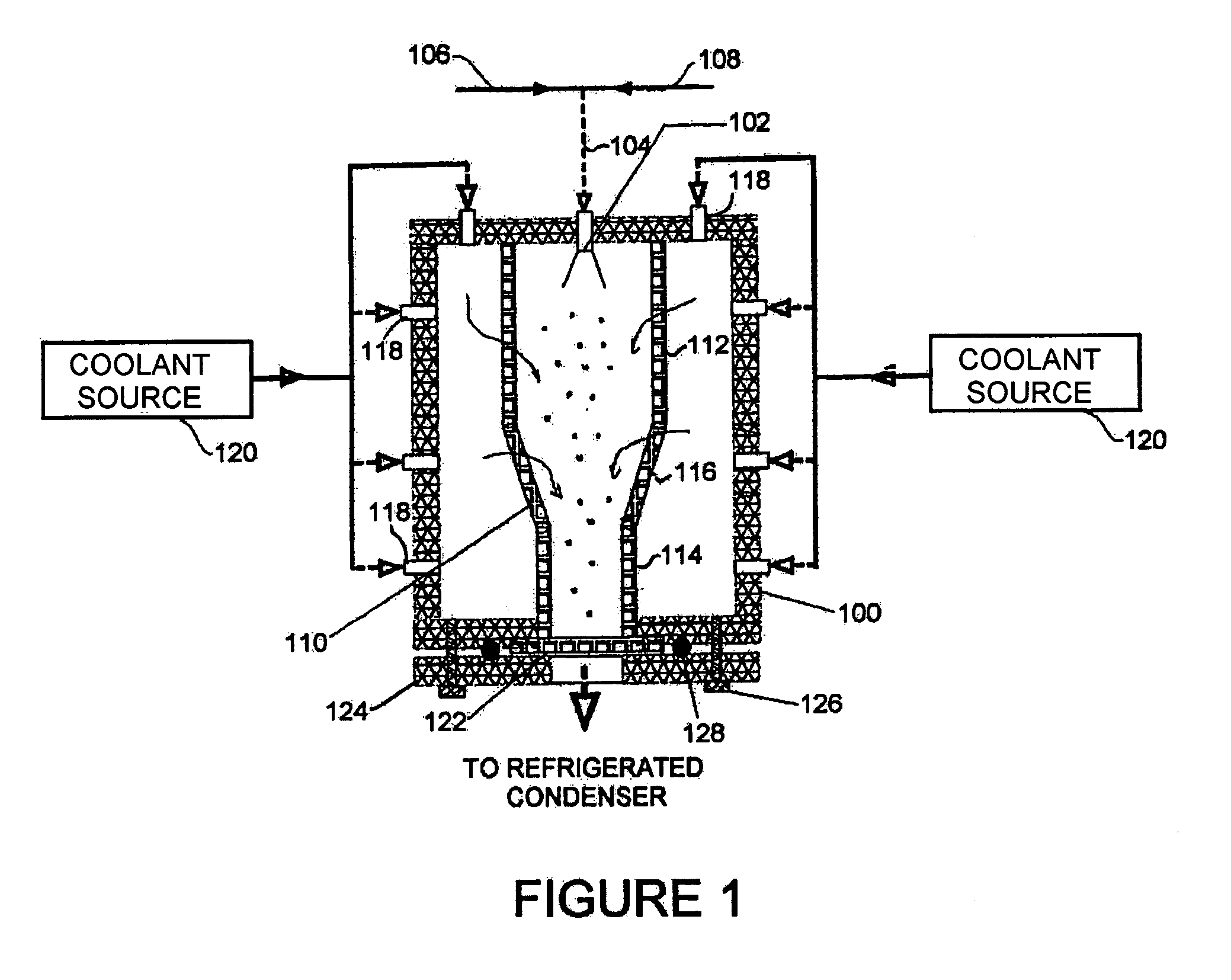

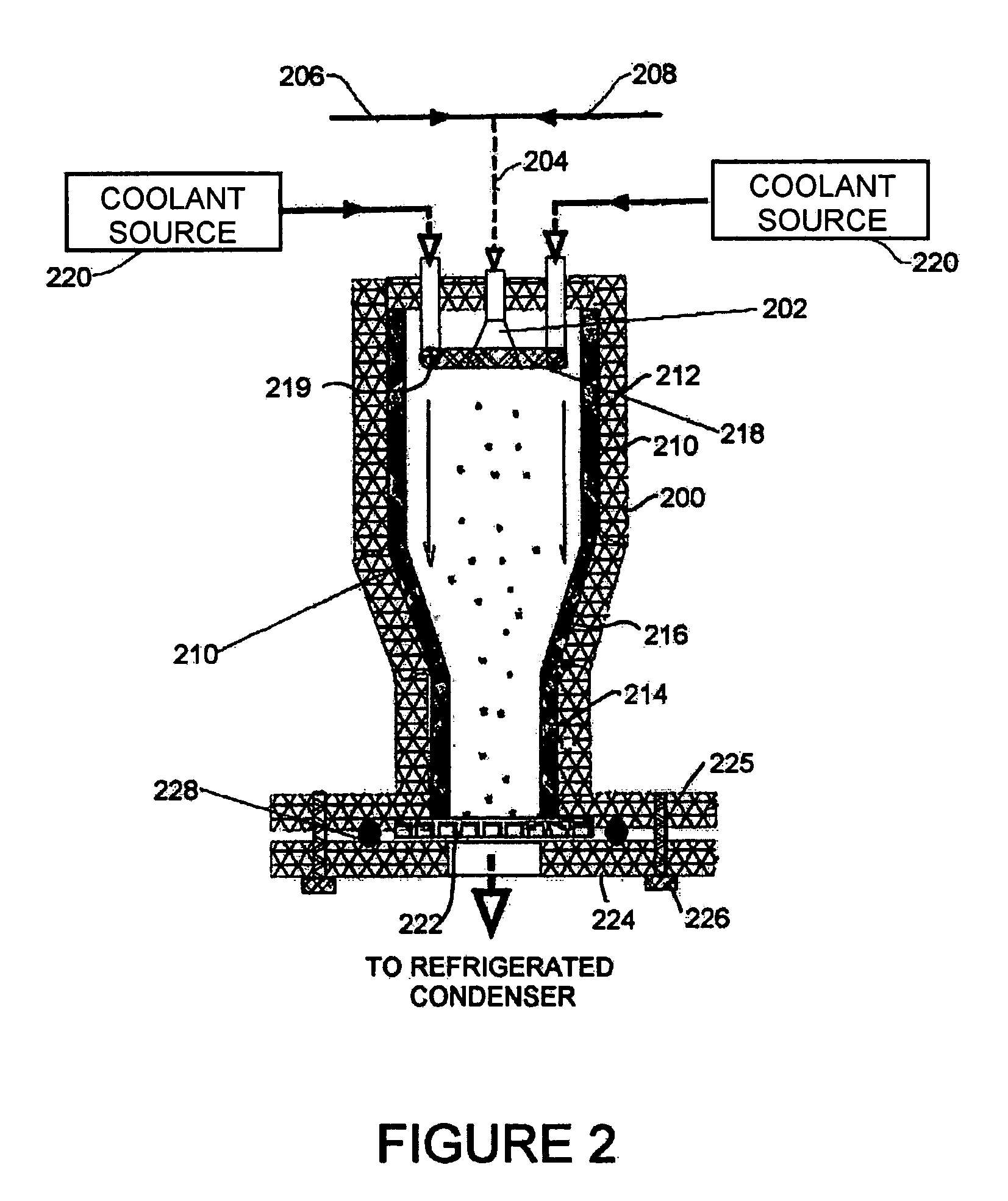

Powder formation by atmospheric spray-freeze drying

ActiveUS7007406B2High emitted doseEasy to storeDrying solid materials without heatDrying machines with progressive movementsFreeze-dryingAtomizer nozzle

A method of manufacturing heat-sensitive pharmaceutical powder is disclosed. The original pharmaceutical substances are dissolved in a solution or suspended in a suspension, which is sprayed through an atomizing nozzle and frozen in a cold gas phase or liquid nitrogen atomized directly in the spray-freeze chamber or gas jacket at the same time (for cooling purposes). The particles are freeze-dried at roughly atmospheric pressure in a down-stream fluid flow with exit filter thereby to remove moisture entrapped on or inside the frozen particles. The system has applicability for forming other powders.

Owner:AEROSOL THERAPEUTICS

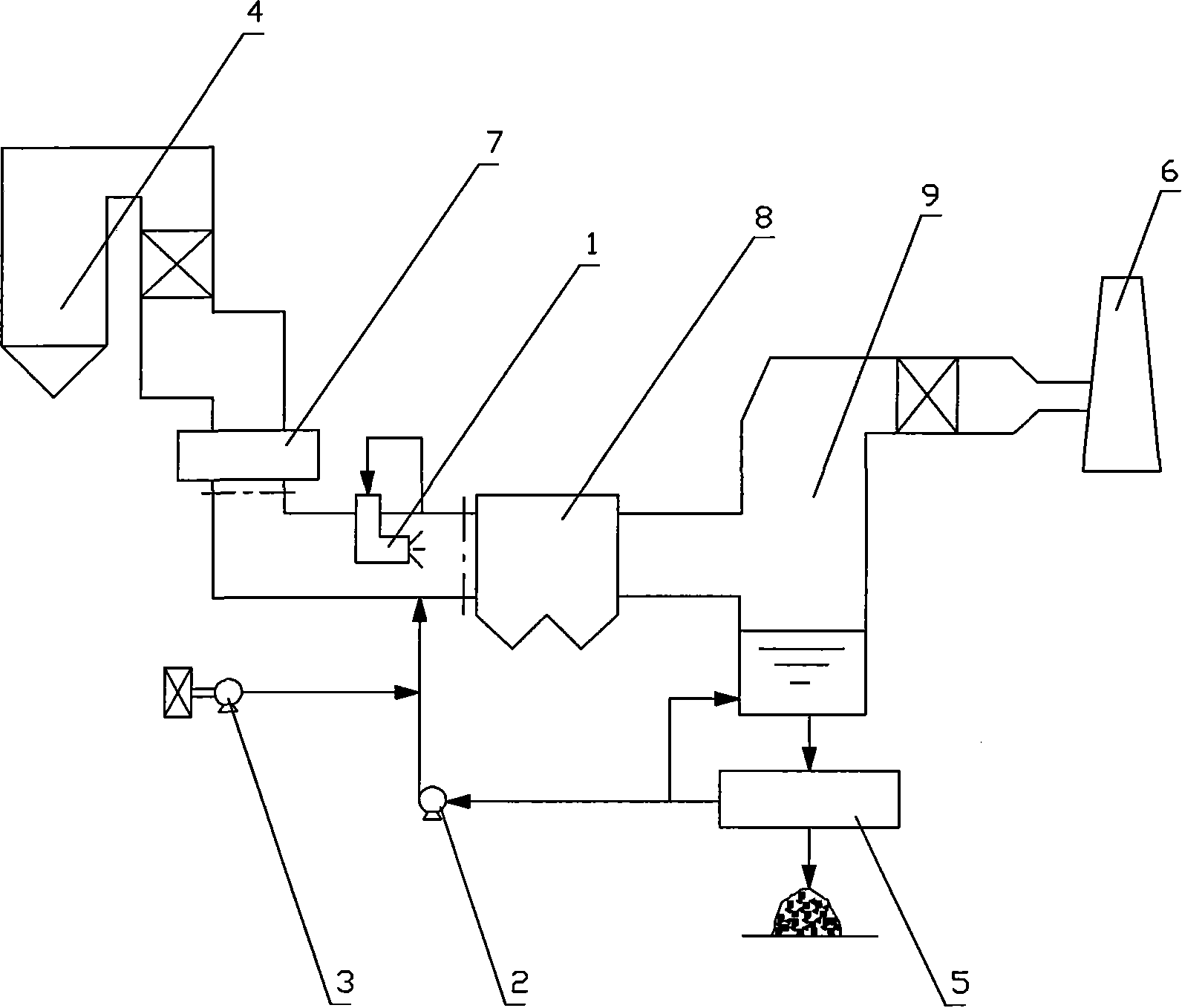

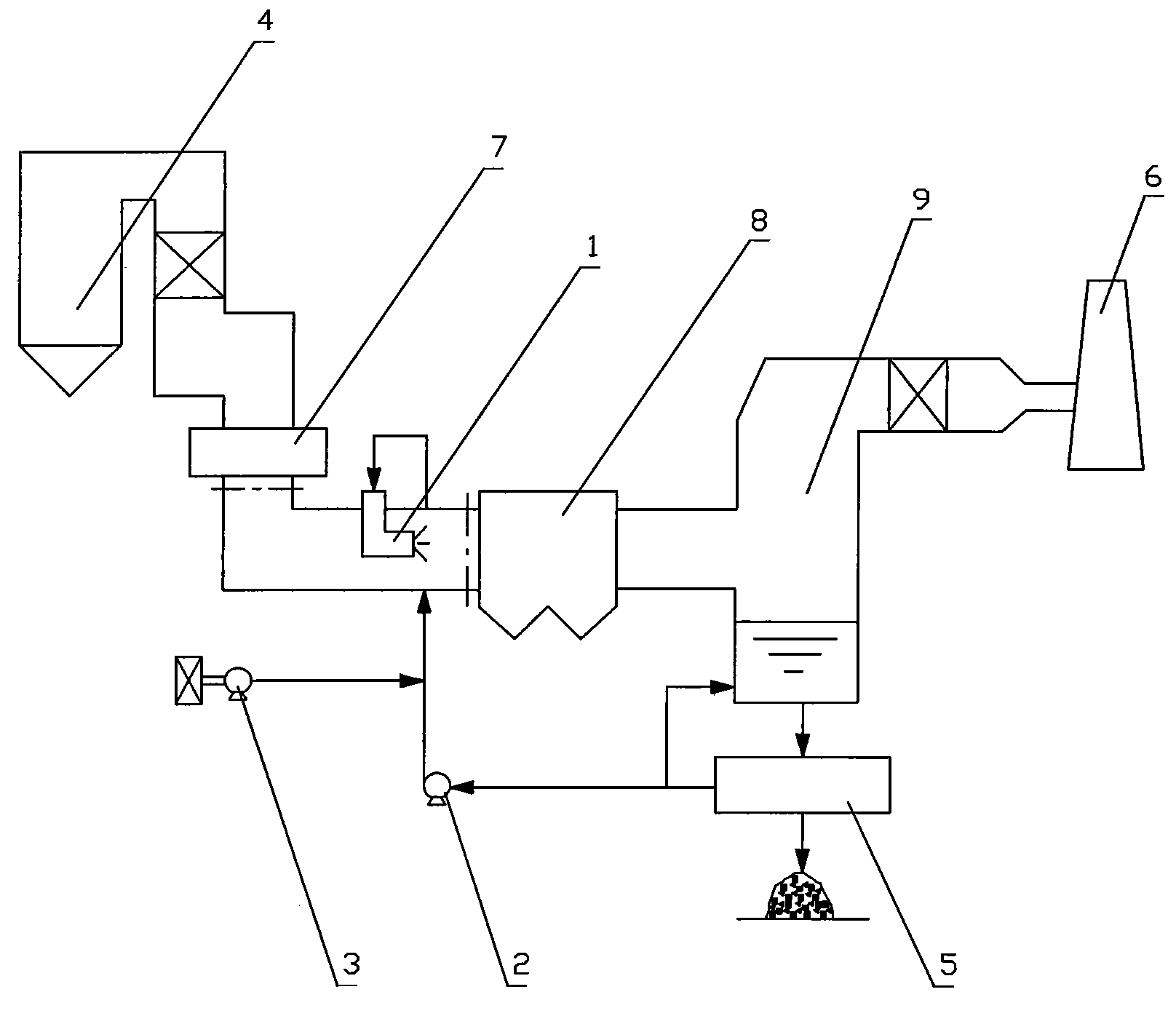

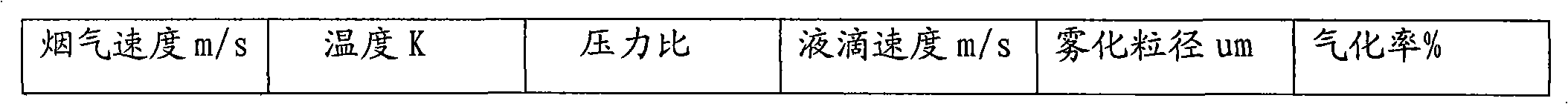

Spray evaporation treatment method of wet method flue gas desulfurization wastewater in thermal power station

ActiveCN101844819AOvercoming multiple configuration devicesSmall investmentDispersed particle separationWater/sewage treatmentEvaporationTreatment system

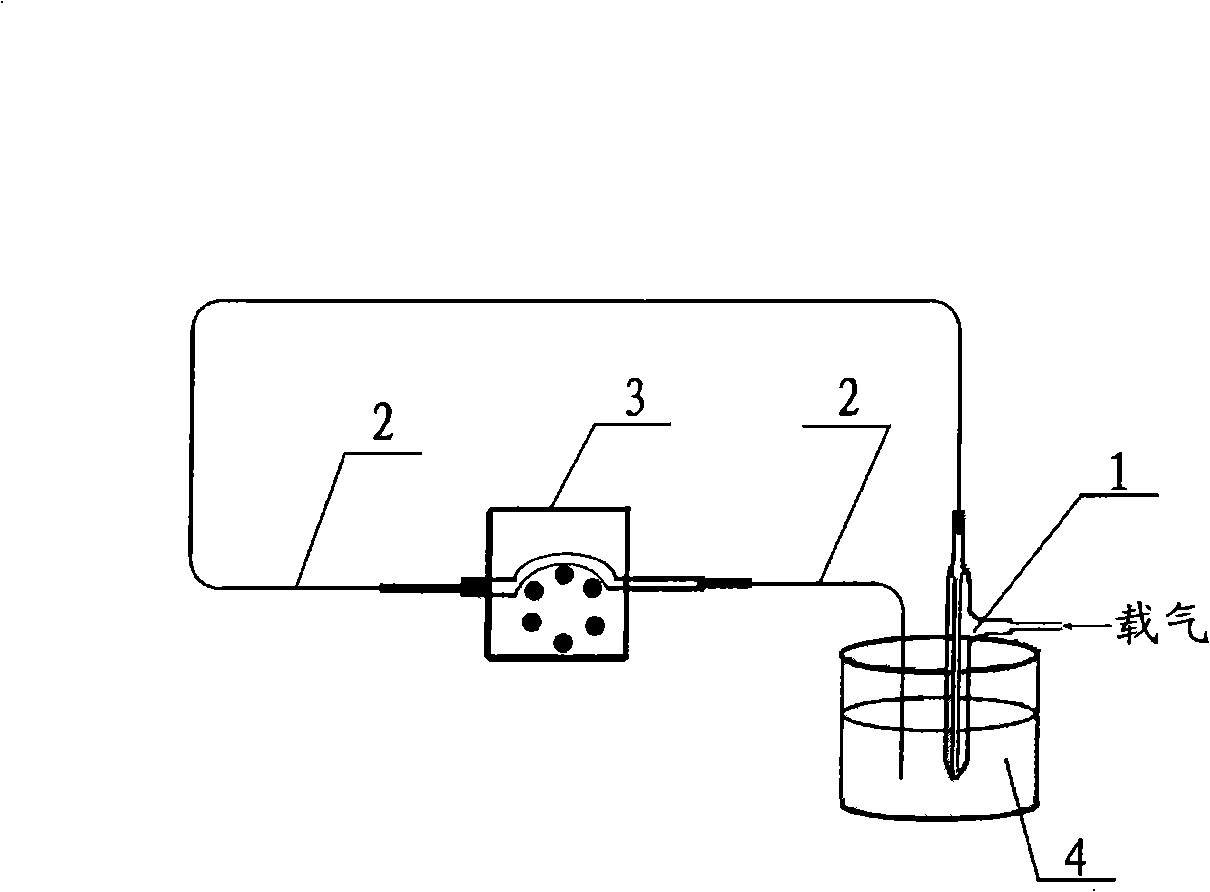

The invention discloses a spray evaporation treatment method of the wet method flue gas desulfurization wastewater in a thermal power station. In the method, an atomizing nozzle is arranged in the region with the temperature at 413-470 K and the flue gas speed of 5-11 m / s in a flue of the boiler tail part; desulfurization wastewater is pumped by utilizing a water pump, air is compressed by a compressor, and the pressure ratio of the compressed air to the desulfurization wastewater entering into the atomizing nozzle is 0.25-0.6; the speed of liquid droplets atomized by the atomizing nozzle is 50-80 m / s, and particle diameters of the liquid droplets are less than 50 mu m; and the liquid droplets are evaporated and then exhausted out of a chimney together with the flue gas. The invention can save chemical drugs utilized in the conventional wastewater treatment method; overcome the defects of many apparatuses, large investment, high running cost and heavy apparatus repair and maintenance load of a wastewater treatment system in the prior art, overcome the great corrosion influence of chlorine ions in water meta-acidity environment, reduce the specific resistance of ashes in a dust collector and improve the dust collector efficiency through increasing the flue gas humidity and properly lowering the flue gas temperature.

Owner:WUHAN TIANHE TECH

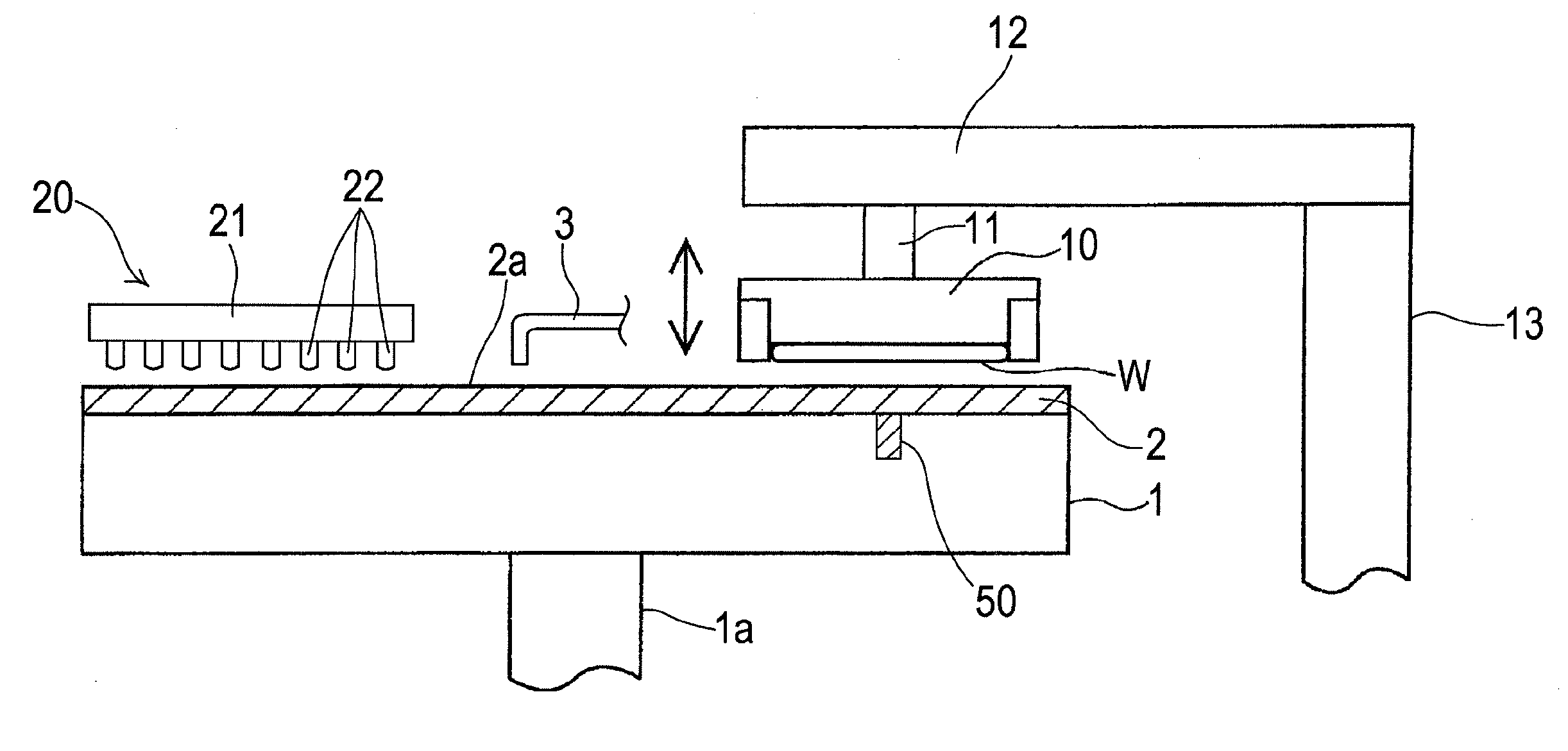

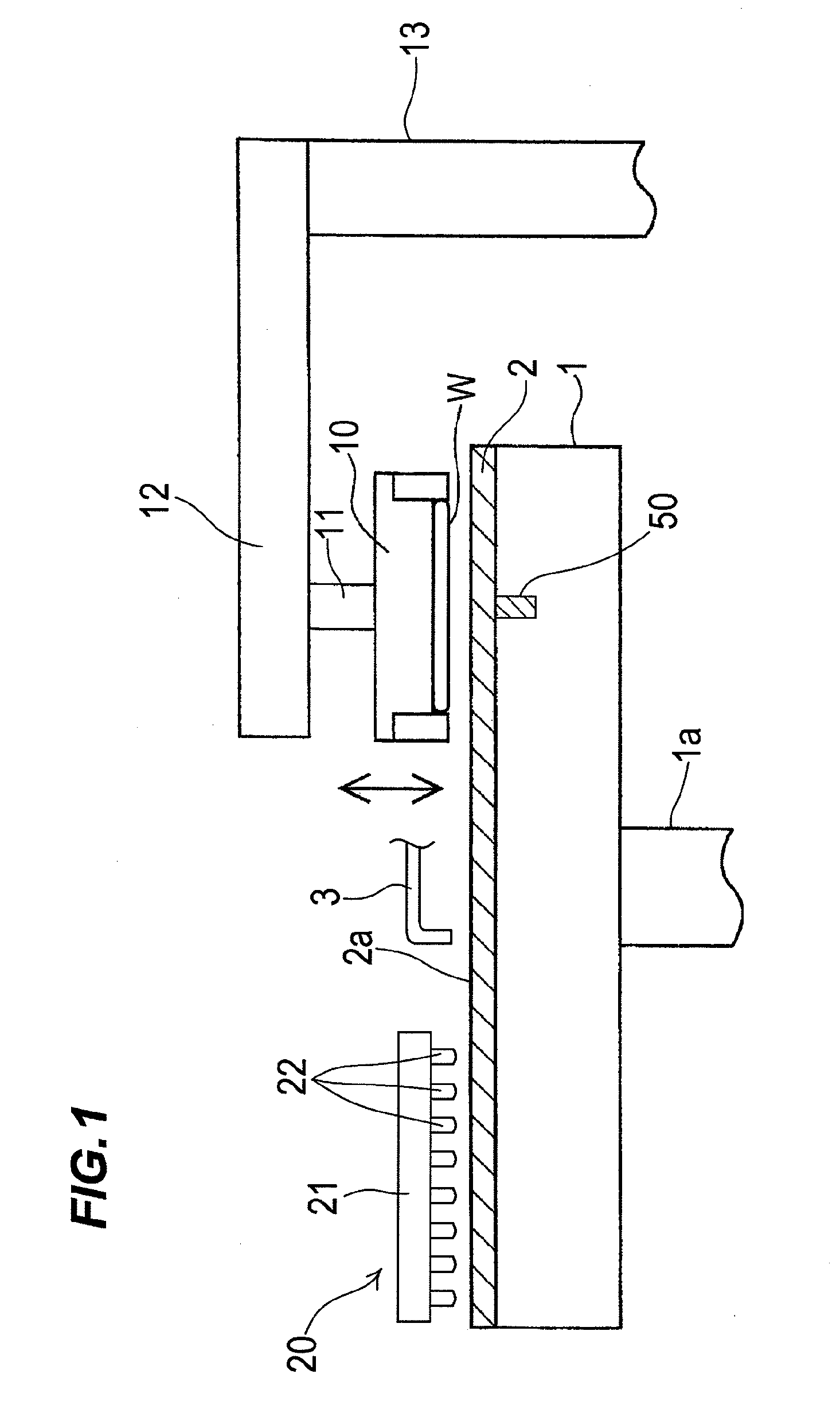

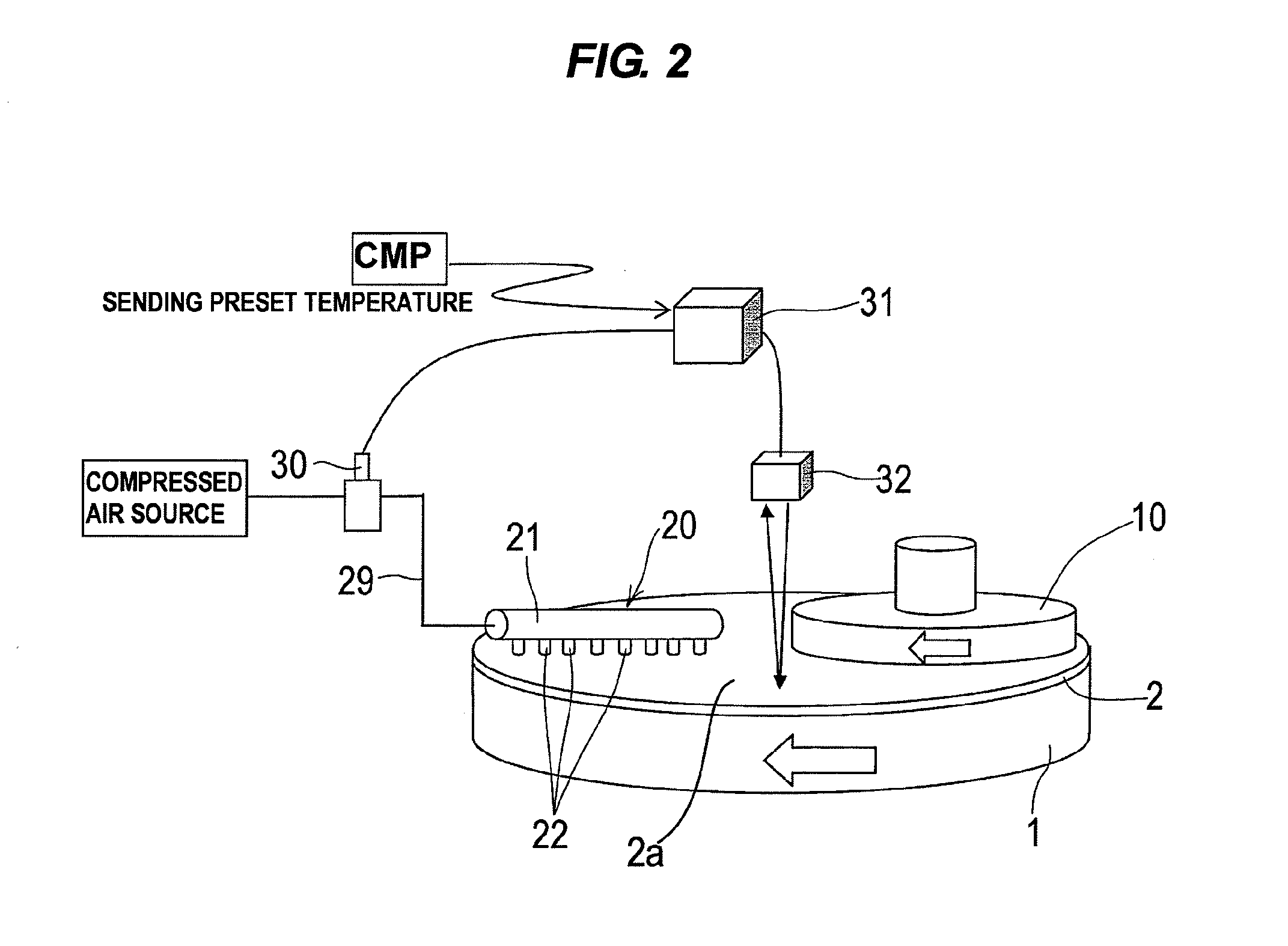

Method and apparatus for polishing a substrate

ActiveUS20130023186A1Increase ratingsShorten polishing timeGrinding drivesBelt grinding machinesForeign matterTemperature control

A polishing apparatus polishes a surface of a substrate by pressing the substrate against a polishing pad on a polishing table. The polishing apparatus is configured to control a temperature of the polishing surface of the polishing pad by blowing a gas on the polishing pad during polishing. The polishing apparatus includes a pad temperature control mechanism having at least one gas ejection nozzle for ejecting a gas toward the polishing pad and configured to blow the gas onto the polishing pad to control a temperature of the polishing pad, and an atomizer having at least one nozzle for ejecting a liquid or a mixed fluid of a gas and a liquid and configured to blow the liquid or the mixed fluid onto the polishing pad to remove foreign matters on the polishing pad. The pad temperature control mechanism and the atomizer are formed into an integral unit.

Owner:EBARA CORP

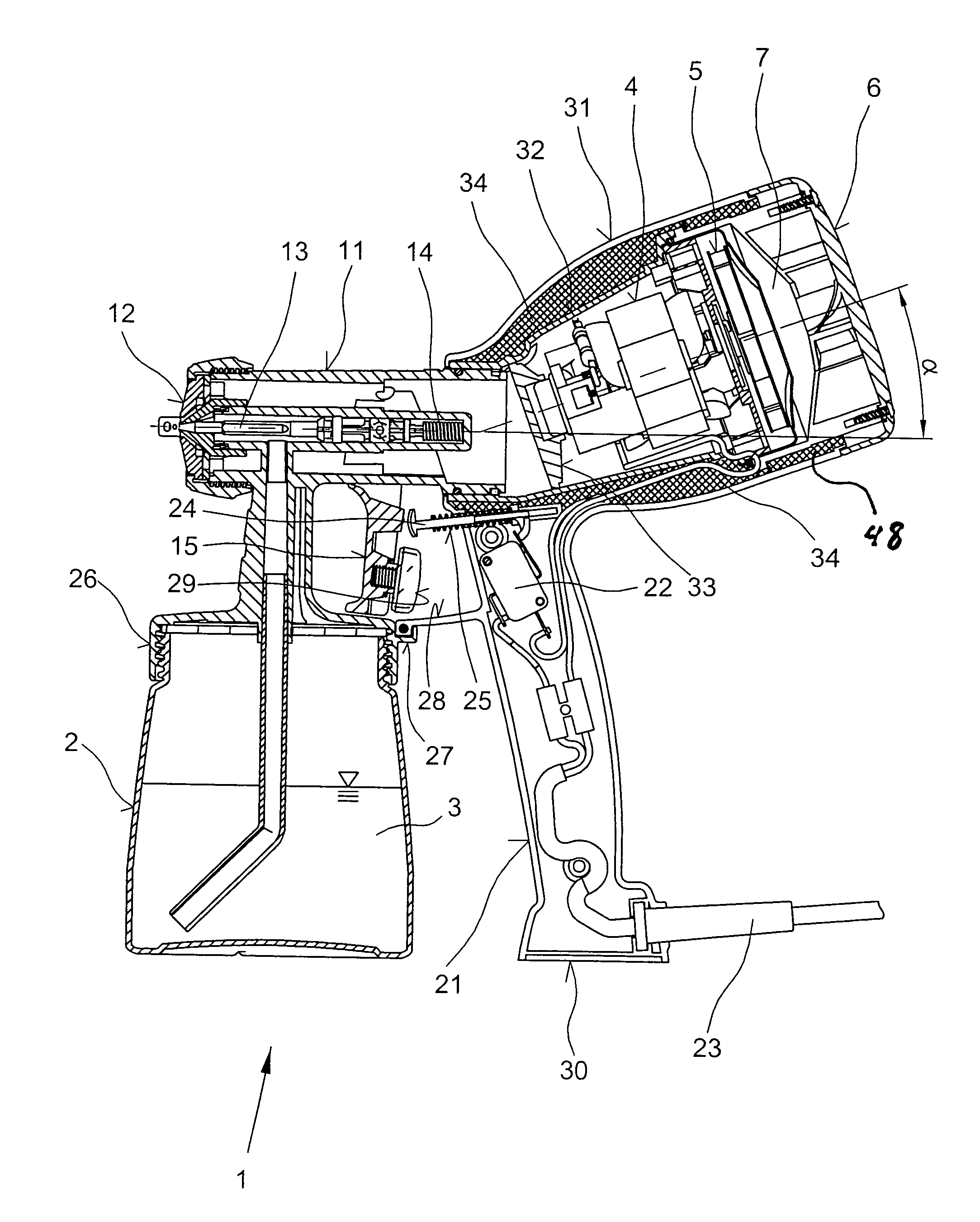

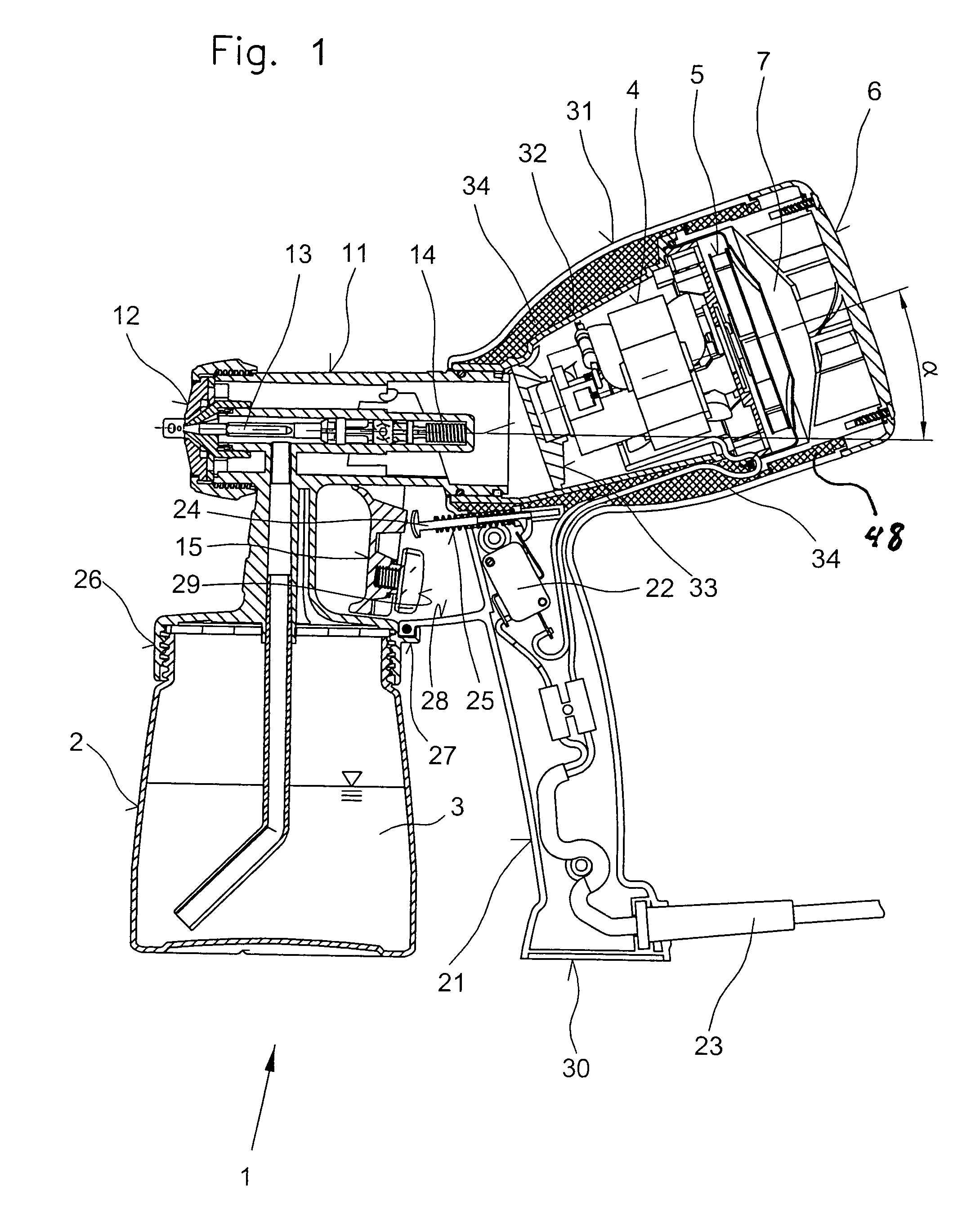

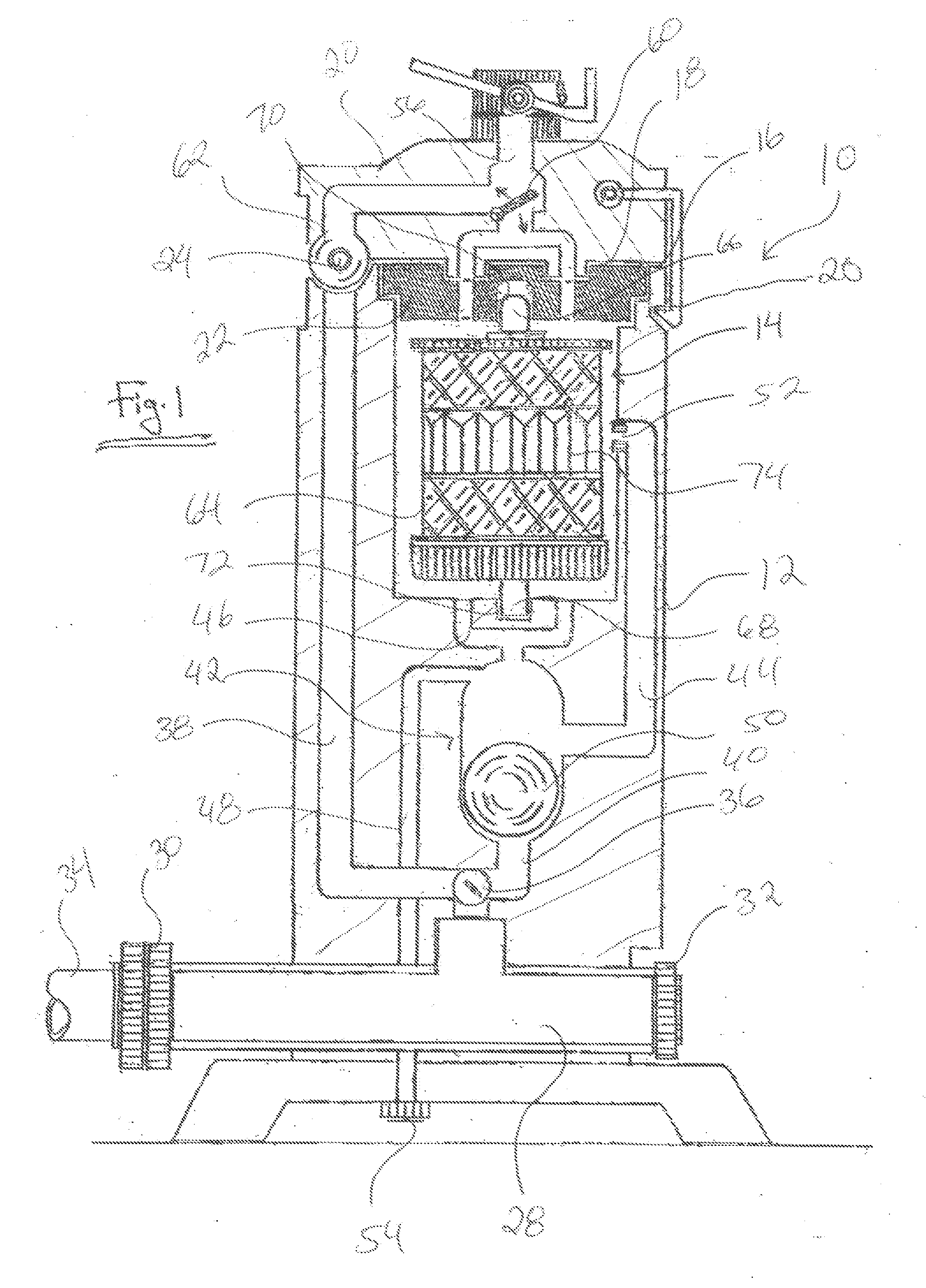

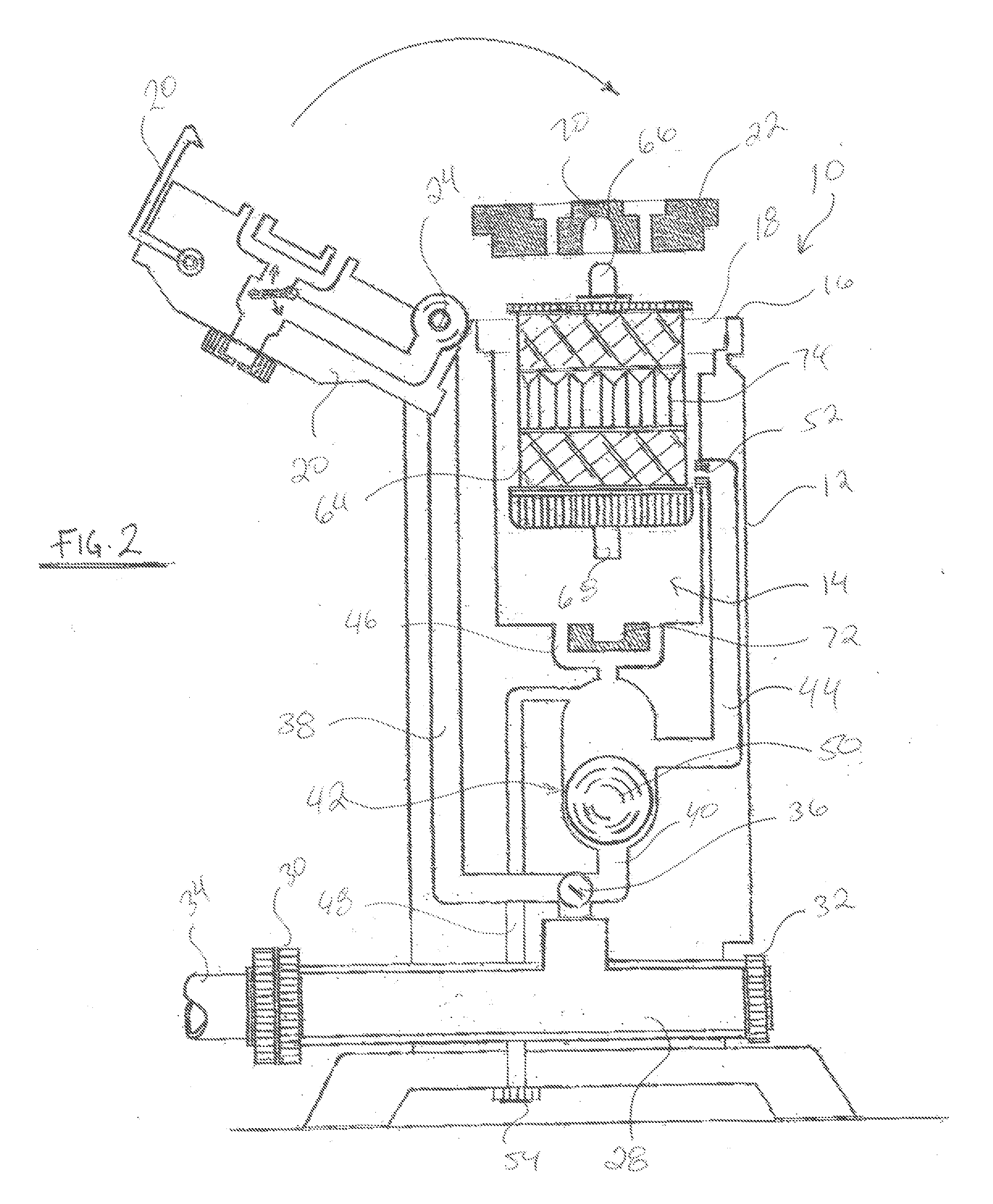

Spray gun

ActiveUS7360720B2Reduce flow noiseLiquid surface applicatorsWatering devicesNebulizerAtomizer nozzle

In a spray gun (1) for atomizing fluids, that can be actuated using a lever (15) mounted in a pivoting arrangement on a sleeve (11) which accommodates an atomizer nozzle (12) and in which the air flow can be generated by an air turbine (5) that is assigned to the spray gun (1), the air turbine (5) and its electric drive motor (4) are arranged substantially coaxially to the sleeve (11) on the opposite side of a handle (21) and the air flow is supplied from the air turbine (5) in a substantially straight line through the sleeve (11) of the atomizer nozzle (12). The air turbine (5) is provided with a muffler (6). Loud operating noise of the air turbine (5) does not have a disruptive effect and practically no flow noise is generated due to deflections of the air flow. The components of the spray gun (1) are arranged in such a way that no more than slight tilting torques are generated, permitting work over long periods without leading to fatigue.

Owner:J WAGNER GMBH

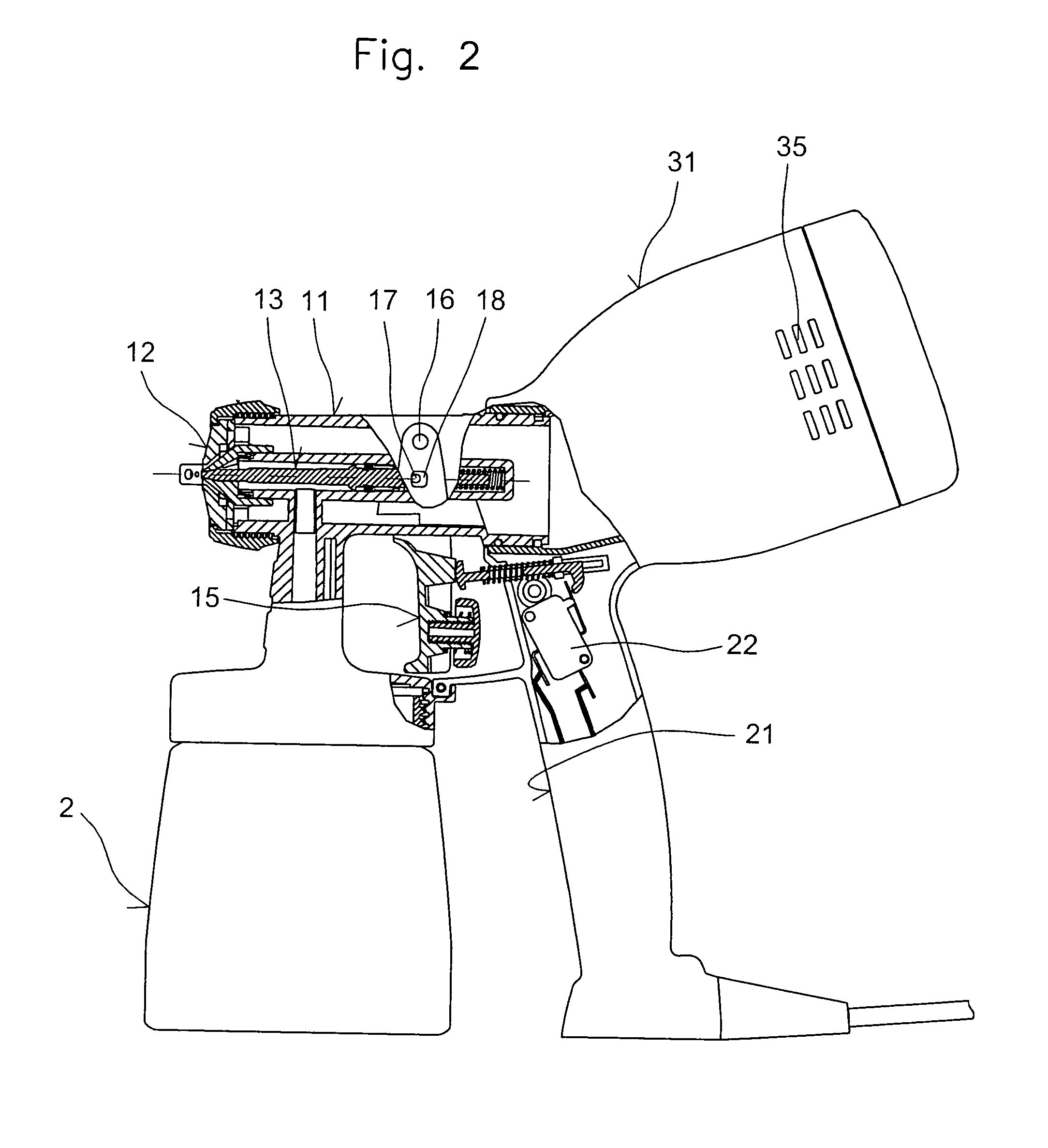

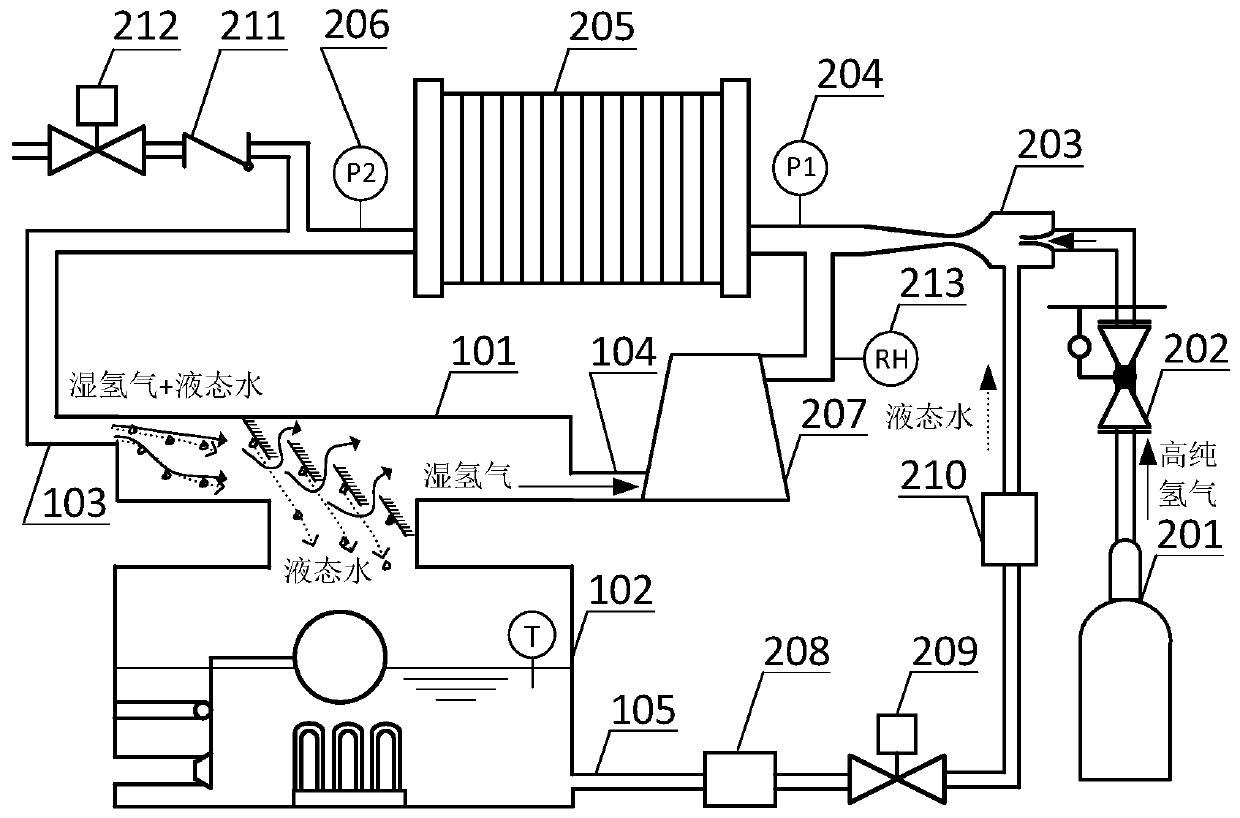

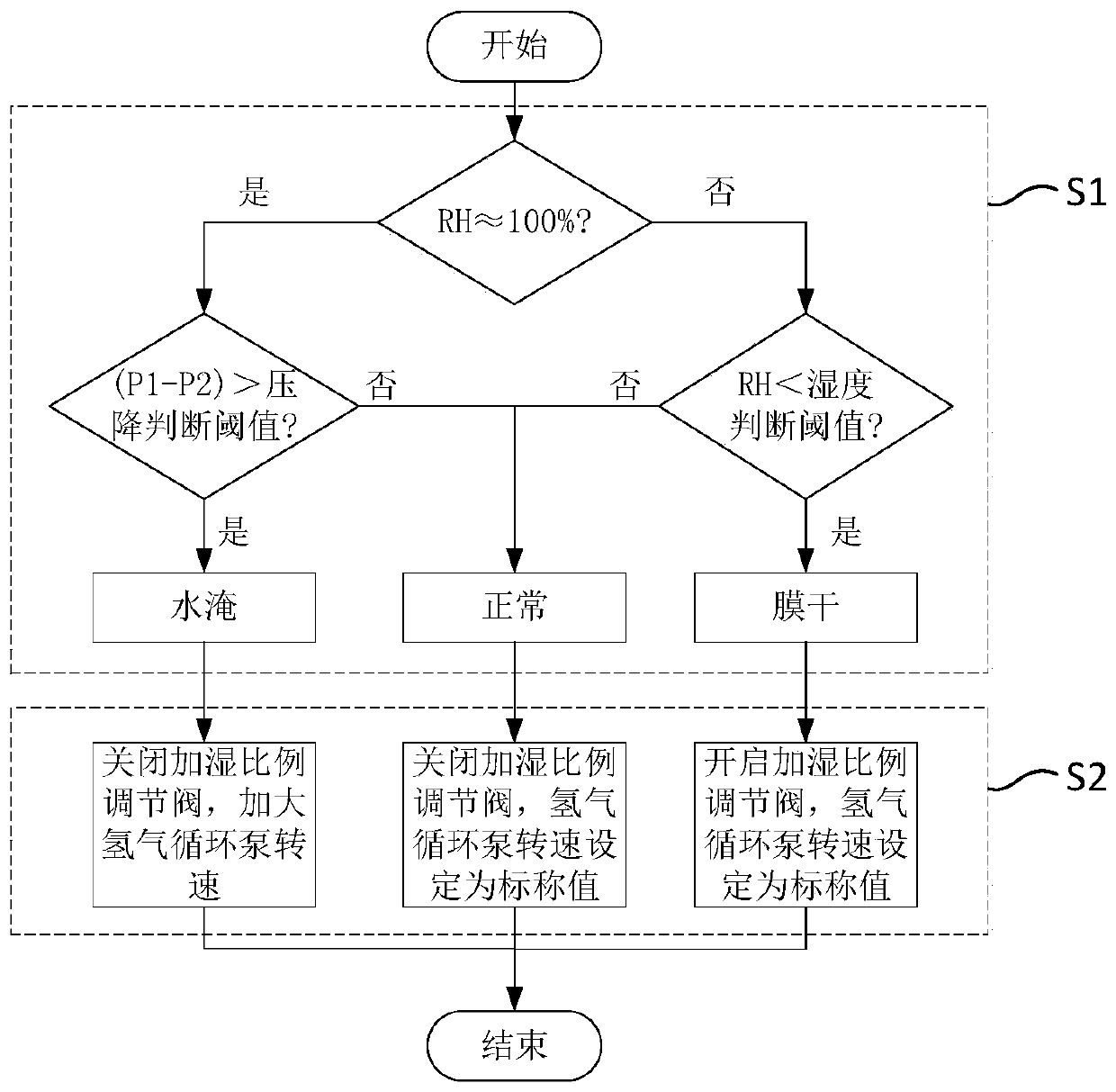

Fuel cell anode water management system and control method

ActiveCN111063916AImprove environmental adaptabilityIncrease power consumptionFuel cell heat exchangeAtomizer nozzleLiquid water

The invention discloses a fuel cell anode water management system and a control method, and belongs to the technical field of proton exchange membrane fuel cells. Aiming at the problem of anode watermanagement in the operation process of a proton exchange membrane fuel cell, the scheme provided by the invention can realize two functions of water removal and humidification, and liquid water separated from a baffle in a gas-water separation device in the water removal process is stored and supplemented to an ejector when the fuel cell membrane is dry and needs to be humidified. Liquid water inthe electric pile tail gas is fully recycled, so that the environmental adaptability of a humidifying system to a water shortage condition and a low-temperature condition is improved. Liquid water issucked into a mixing chamber through high-pressure hydrogen and the ejector, and extra system power consumption increased by humidifying devices such as an atomizing nozzle and an ultrasonic atomizeris avoided.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

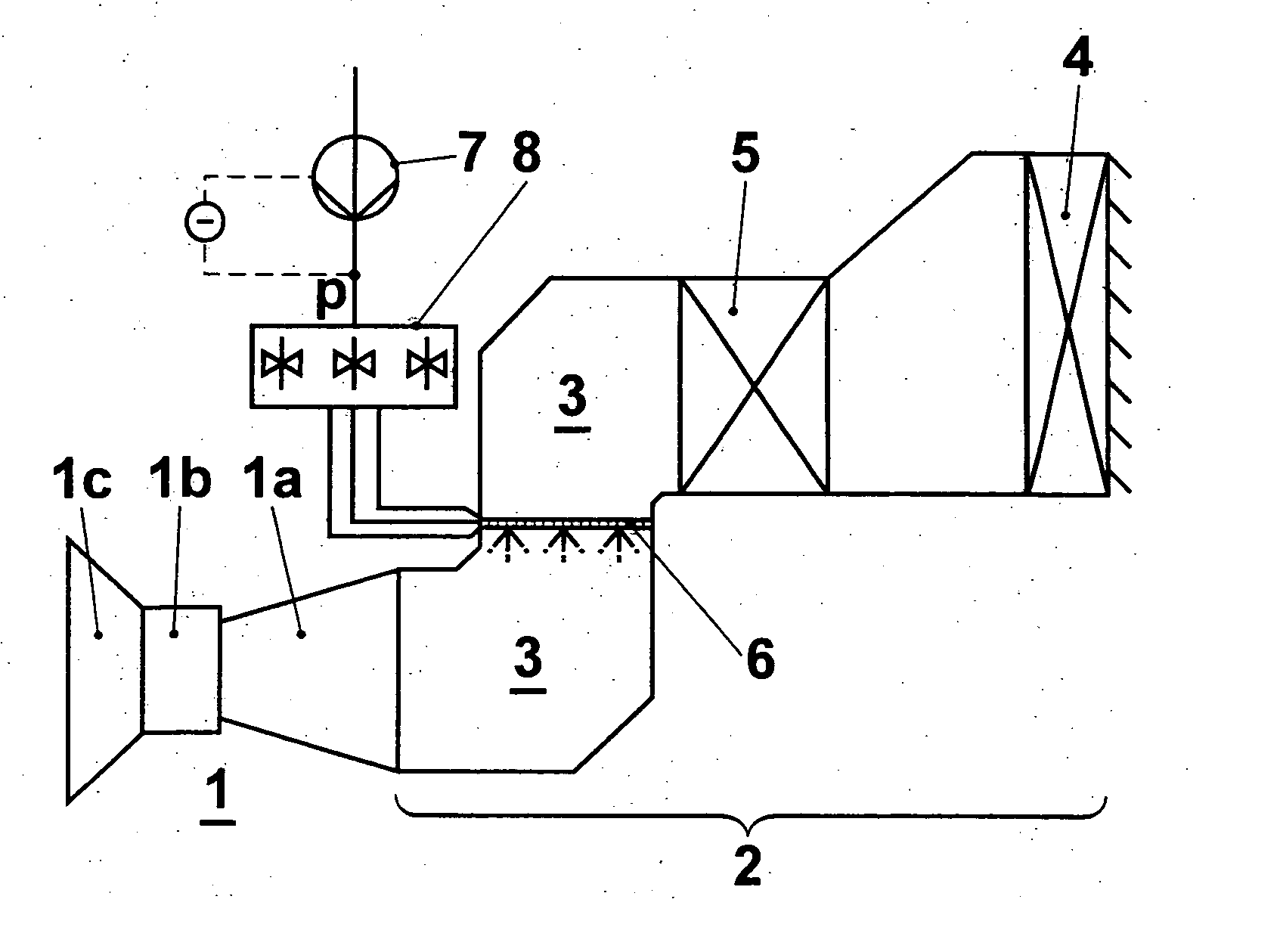

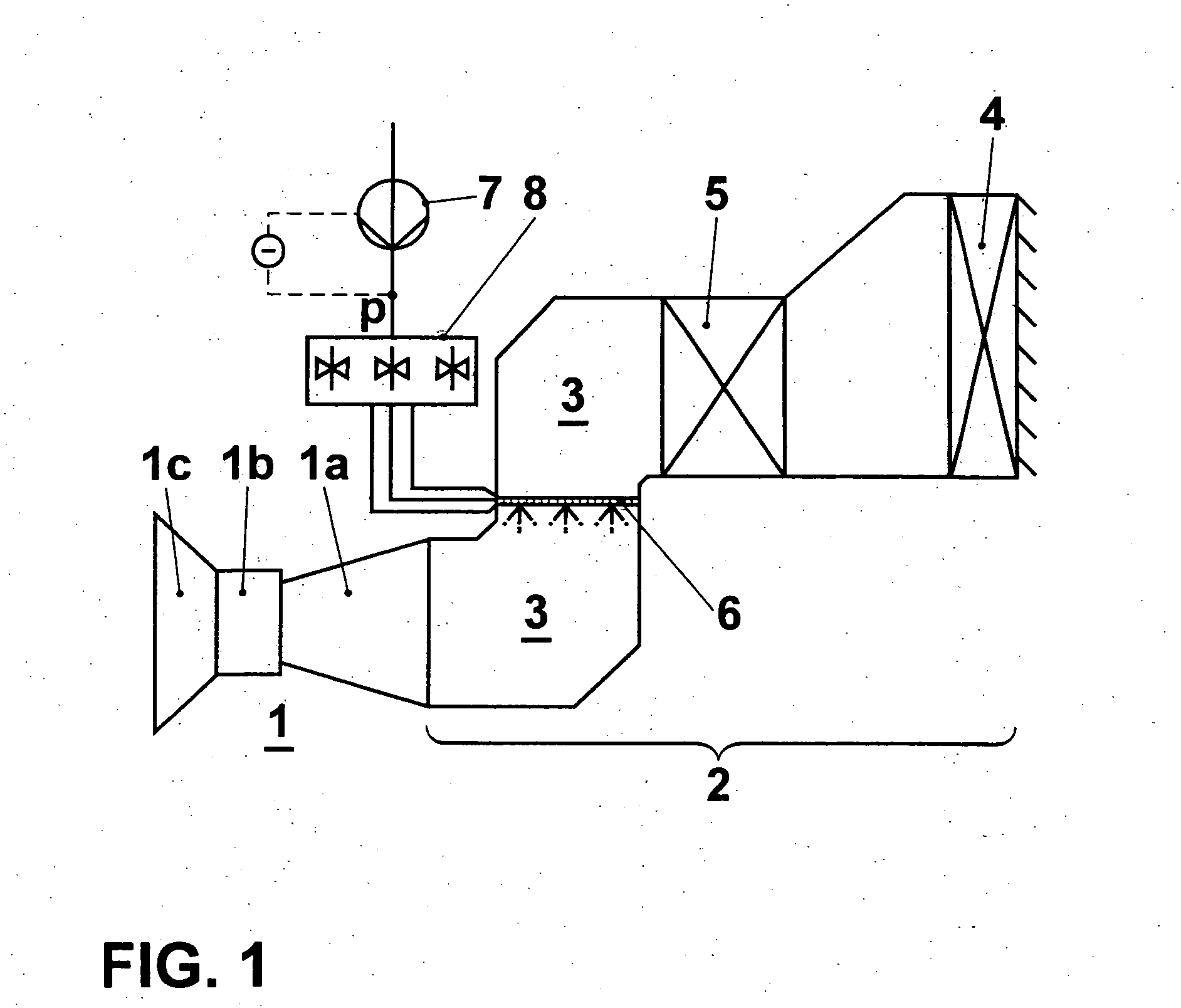

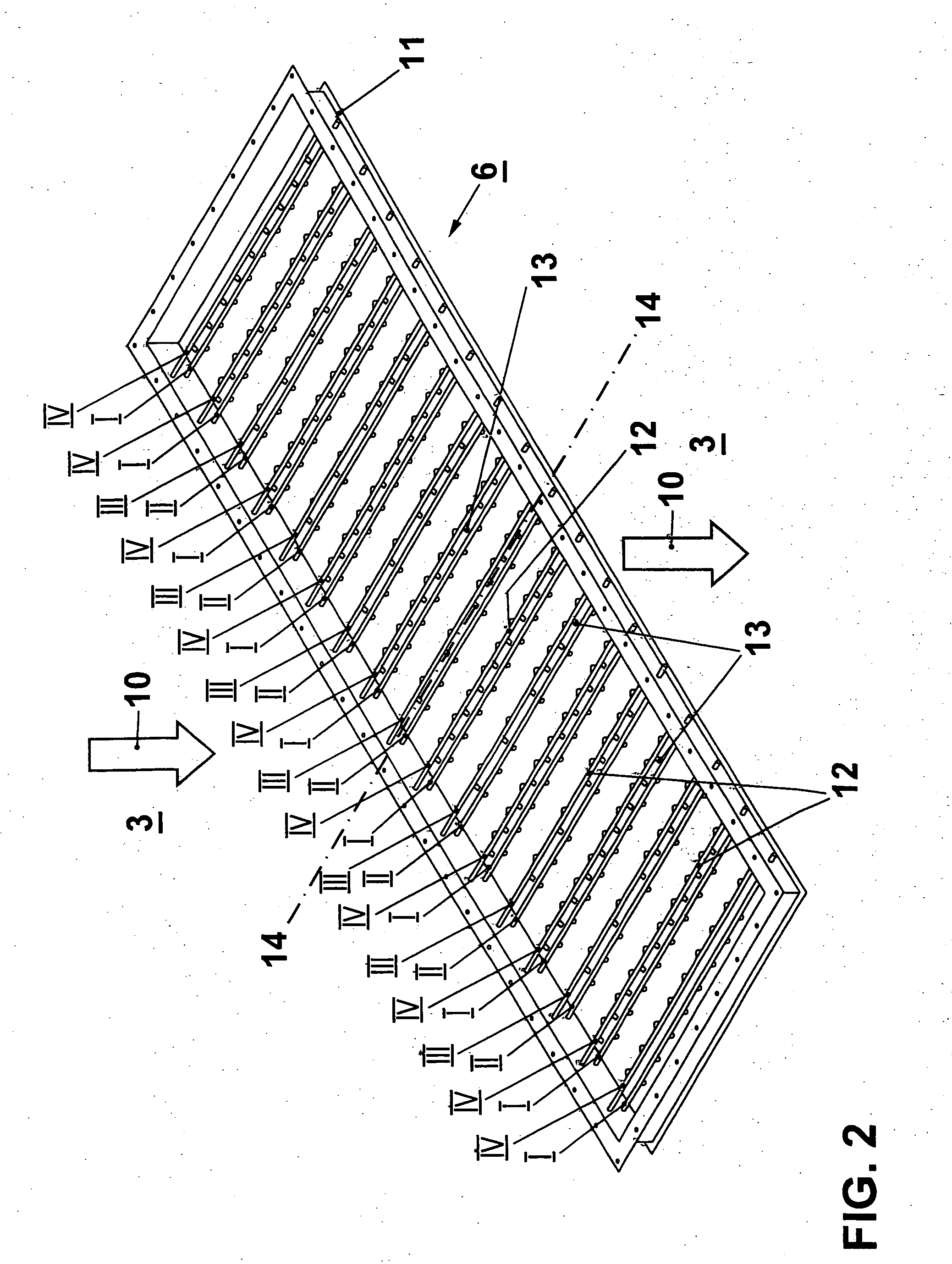

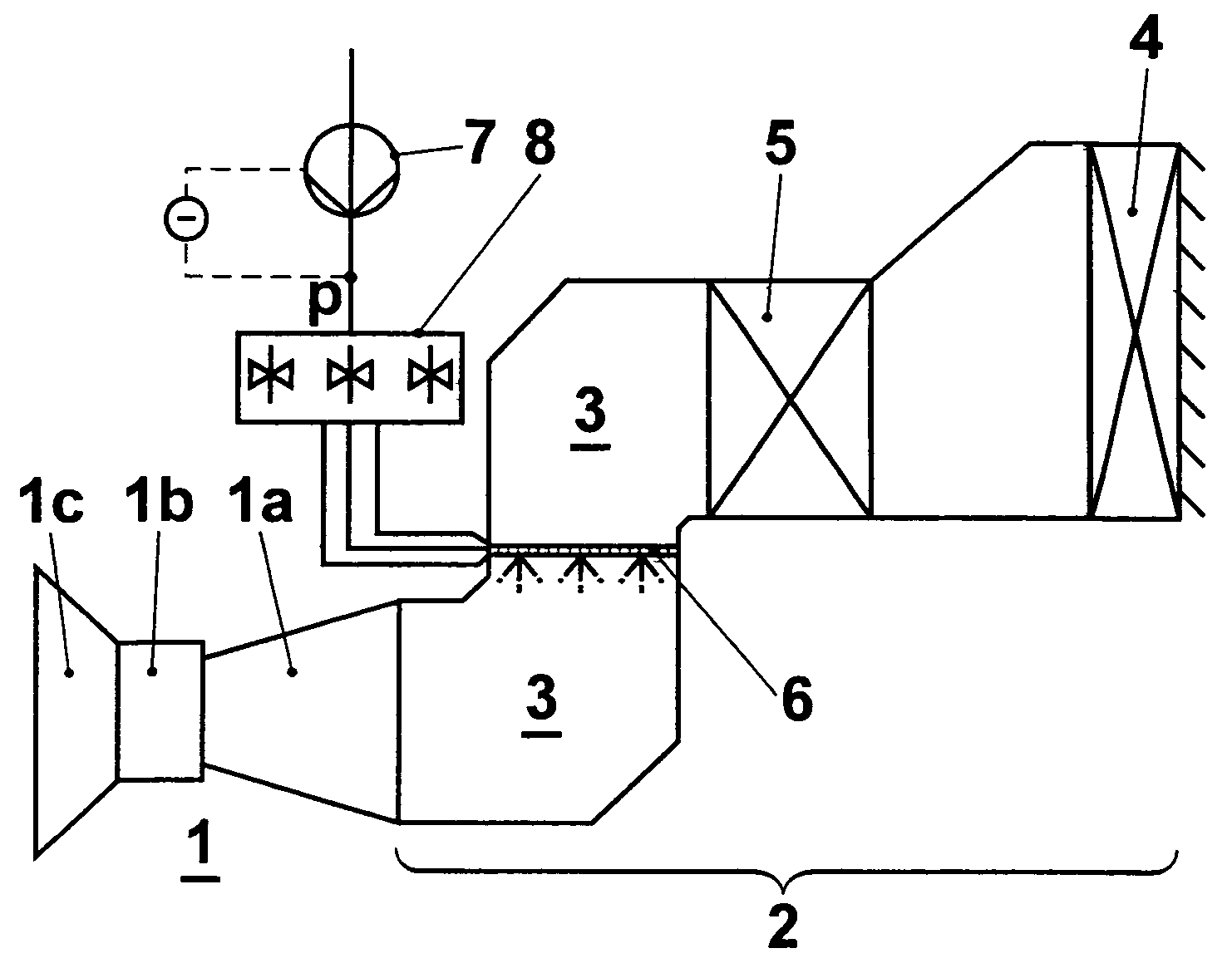

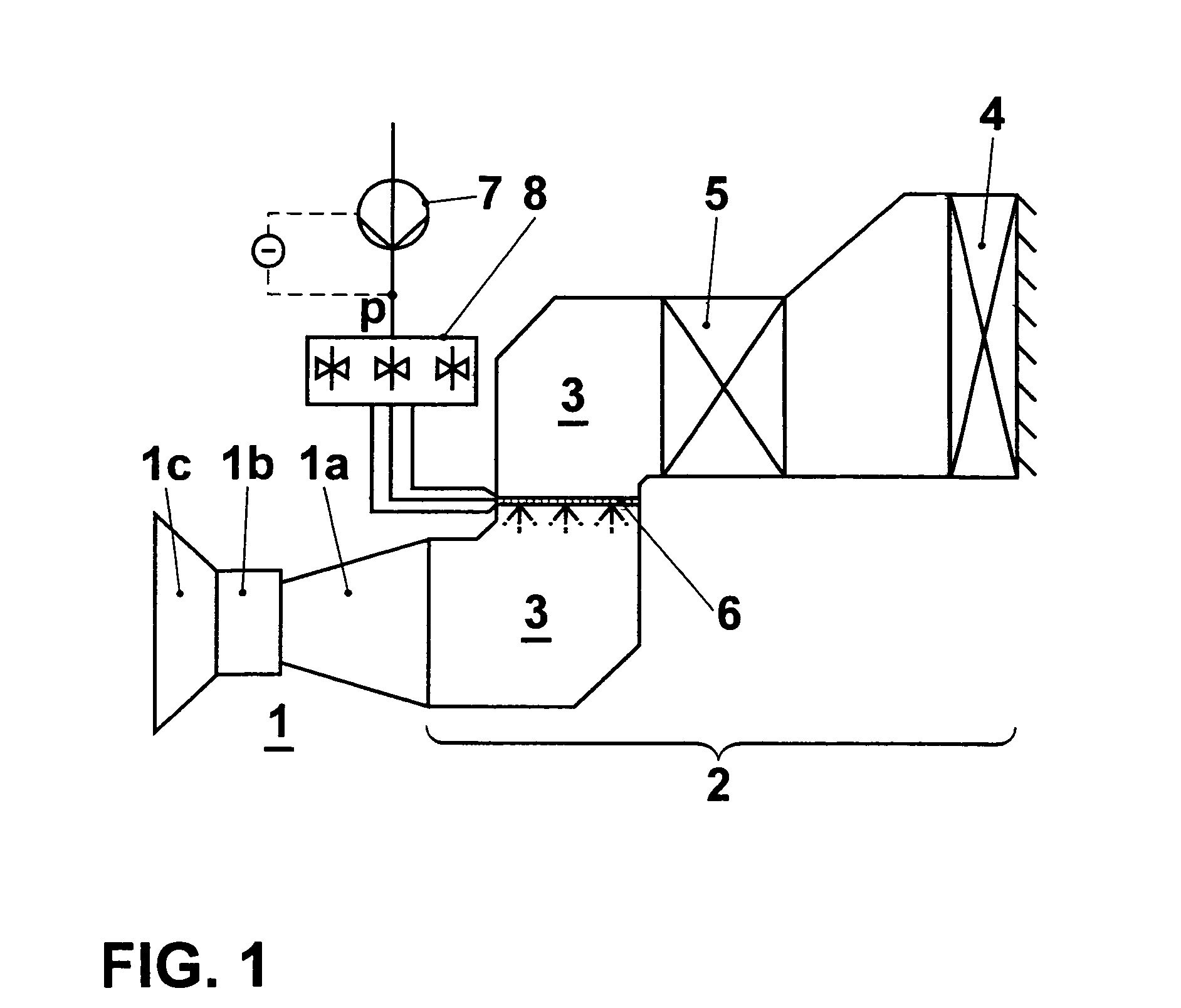

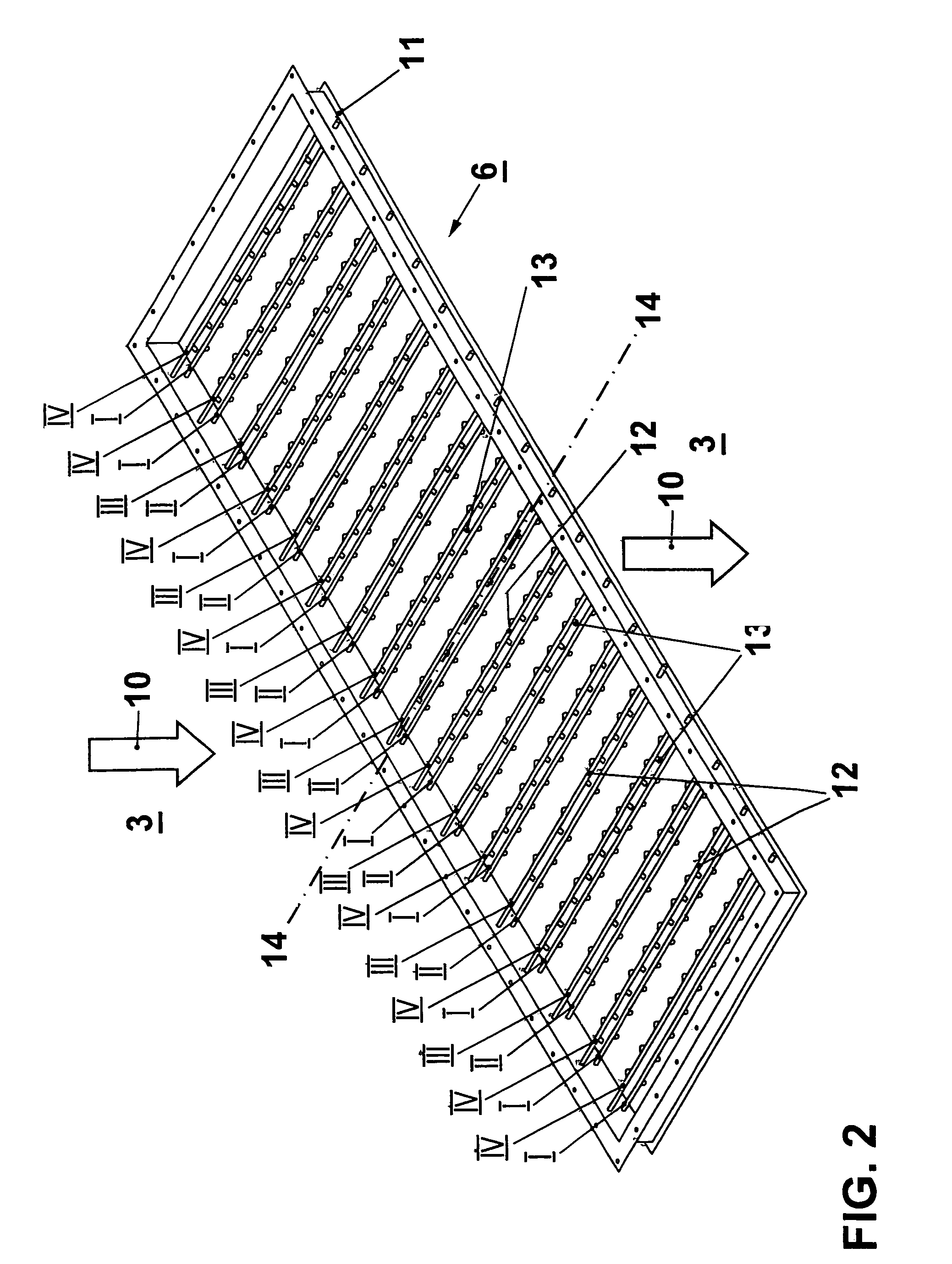

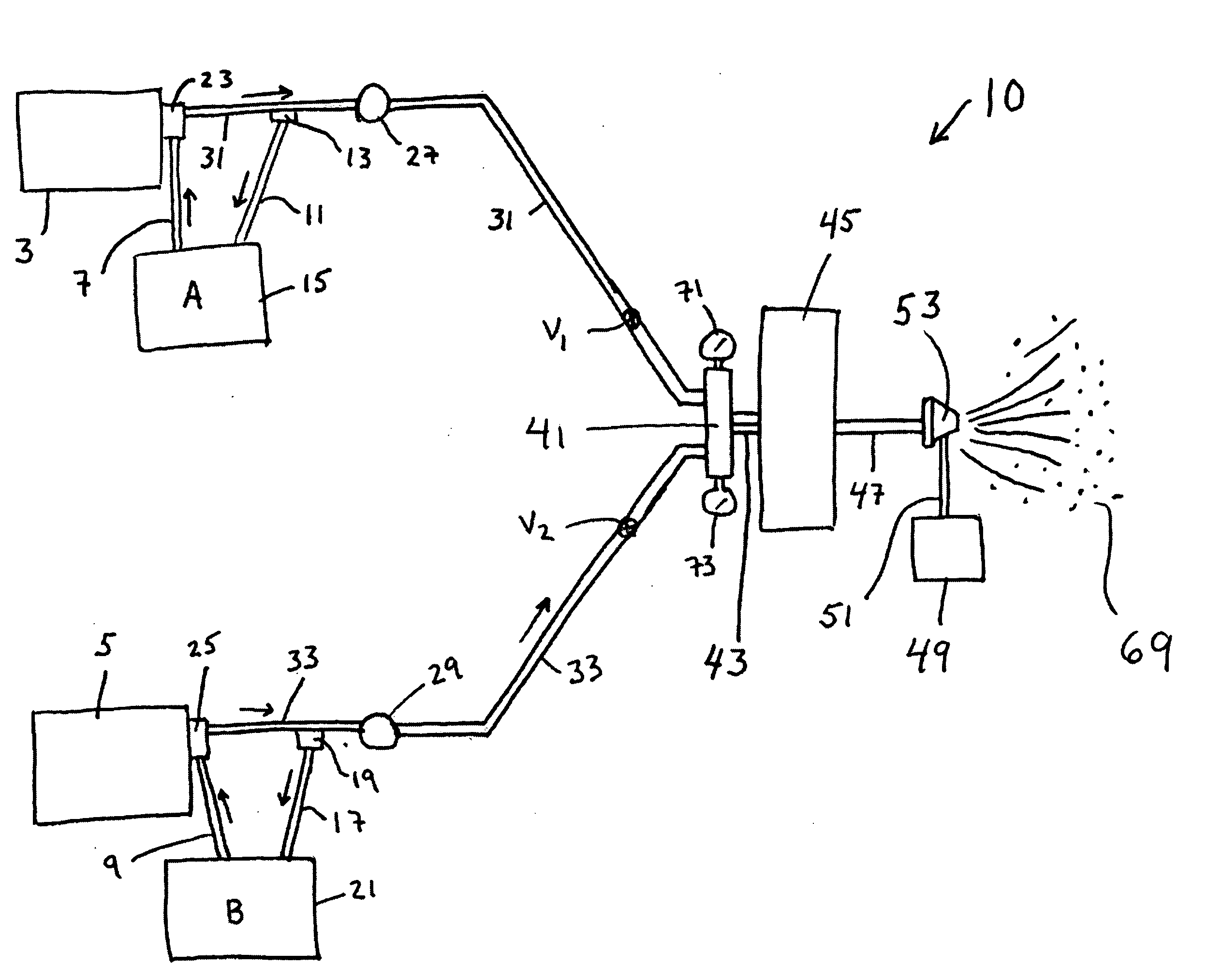

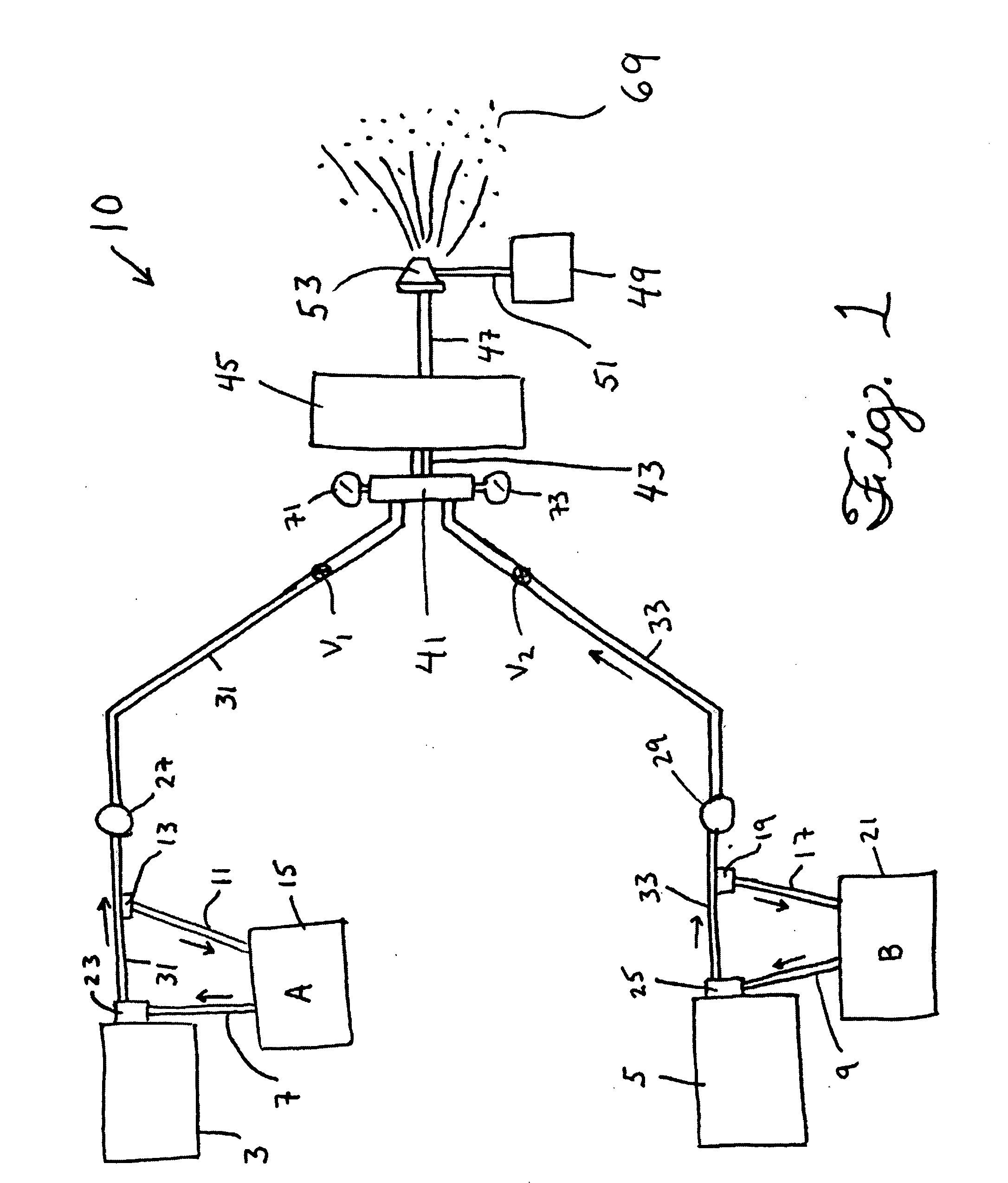

Method of controlling the injection of liquid into an inflow duct of a prime mover or driven machine

InactiveUS20050279101A1Good flexibilityEasy to controlEngine manufactureEngine fuctionsAtomizer nozzleSymmetry line

The injection of finely atomized liquid-droplets into the intake air flow of a compressor is used, for example, to improve the output of a gas turbine. If the atomization is effected via pressure atomizer nozzles, it is advantageous, when the injection device is operated with a portion of the design mass flow, to admit liquid to only some of the atomizer nozzles of the injection device. The atomizer nozzles may be arranged on nozzle tubes, liquid being jointly admitted to all the atomizer nozzles arranged on a respective nozzle tube, operated in such a way that the same mass flow is injected on each side of a symmetry line. To this end, nozzle tubes may be combined to form groups, to which liquid is jointly admitted, and the tubes of a group may be arranged in mirror image to one another relative to the symmetry line.

Owner:ANSALDO ENERGIA IP UK LTD

Method of controlling the injection of liquid into an inflow duct of a prime mover or driven machine

InactiveUS7520137B2Good flexibilityEasy to controlEngine manufactureEngine fuctionsSymmetry lineAtomizer nozzle

The injection of finely atomized liquid-droplets into the intake air flow of a compressor is used, for example, to improve the output of a gas turbine. If the atomization is effected via pressure atomizer nozzles, it is advantageous, when the injection device is operated with a portion of the design mass flow, to admit liquid to only some of the atomizer nozzles of the injection device. The atomizer nozzles may be arranged on nozzle tubes, liquid being jointly admitted to all the atomizer nozzles arranged on a respective nozzle tube, operated in such a way that the same mass flow is injected on each side of a symmetry line. To this end, nozzle tubes may be combined to form groups, to which liquid is jointly admitted, and the tubes of a group may be arranged in mirror image to one another relative to the symmetry line.

Owner:ANSALDO ENERGIA IP UK LTD

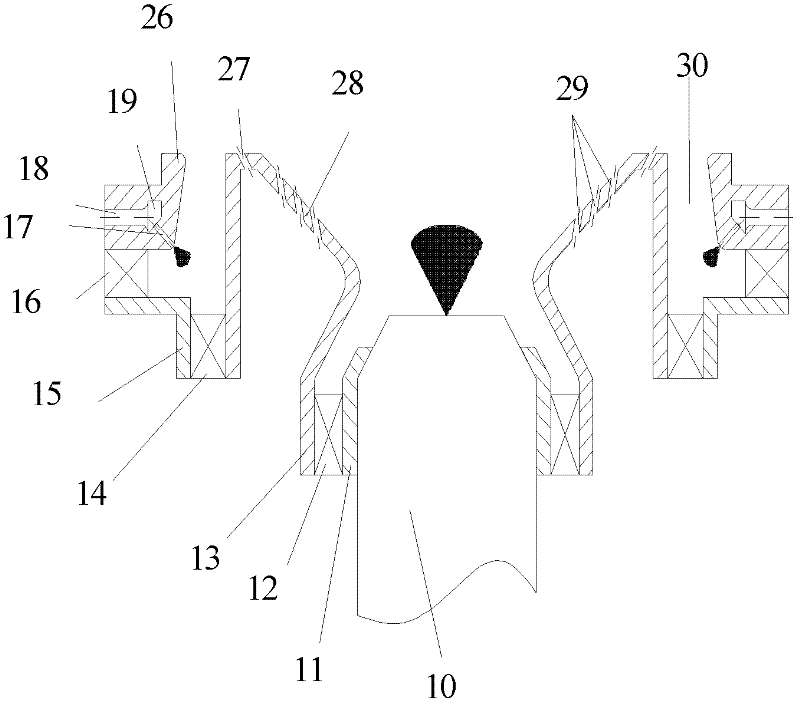

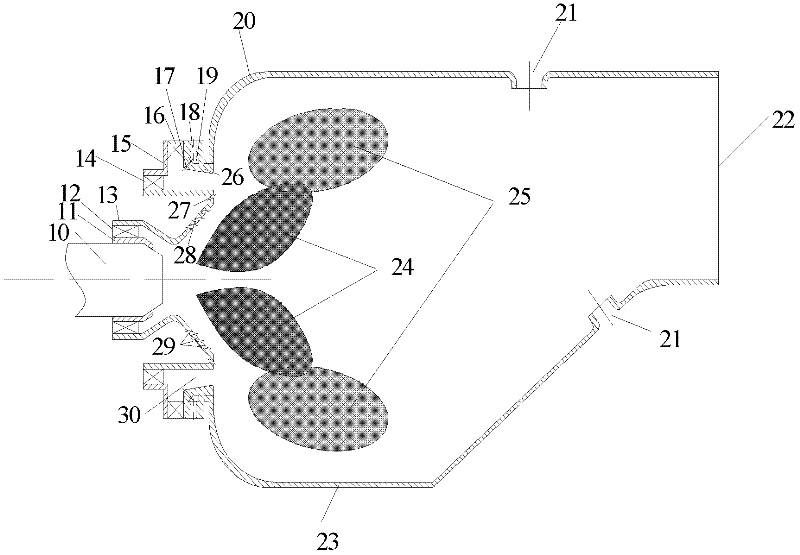

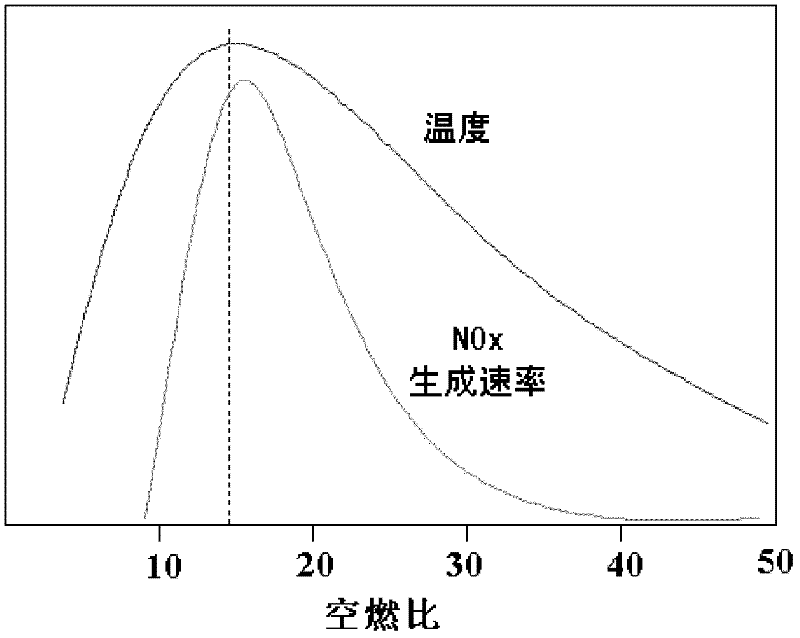

Fuel and air mixing device for low-pollution burning chamber of gas turbine

ActiveCN102506446AFast evaporationQuick blendContinuous combustion chamberIndustrial gasCombustion chamber

The invention discloses a fuel and air mixing device for a low-pollution burning chamber of a gas turbine. Fuel comprises a main burning level and a duty burning level; and air is supplied by a three-stage cyclone. The fuel and air mixing device is characterized in that the central duty level adopts diffusive burning, and the peripheral main burning level adopts premixing or semi-premixing burning. The central duty level consists of a centrifugal atomizing nozzle and first-stage cyclone air; and the rotating directions of the first-stage cyclone air and second-stage cyclone air are opposite. The fuel of the main burning level is supplied by a multipoint direct-injection type nozzle, the air is respectively supplied by the second-stage cyclone air and third-stage cyclone air, and the rotating directions of the second-stage cyclone air and third-stage cyclone air are opposite. The central duty level is used when in low working conditions such as starting and slowing and the like, so that the stable burning range can be widened, the burning efficiency can be improved and the emission of CO and UHC is reduced; and when in large working conditions, the duty level and the main burning level work simultaneously, the duty level provides a stable ignition source for the main burning level, a main burning area is in a lean-oil state, and the temperature is far lower than the temperatureof insulated flame, so that the emission of NOx under the large working conditions can be obviously reduced. The fuel and air mixing device can be used for an aerial gas turbine engine or an industrial gas turbine.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

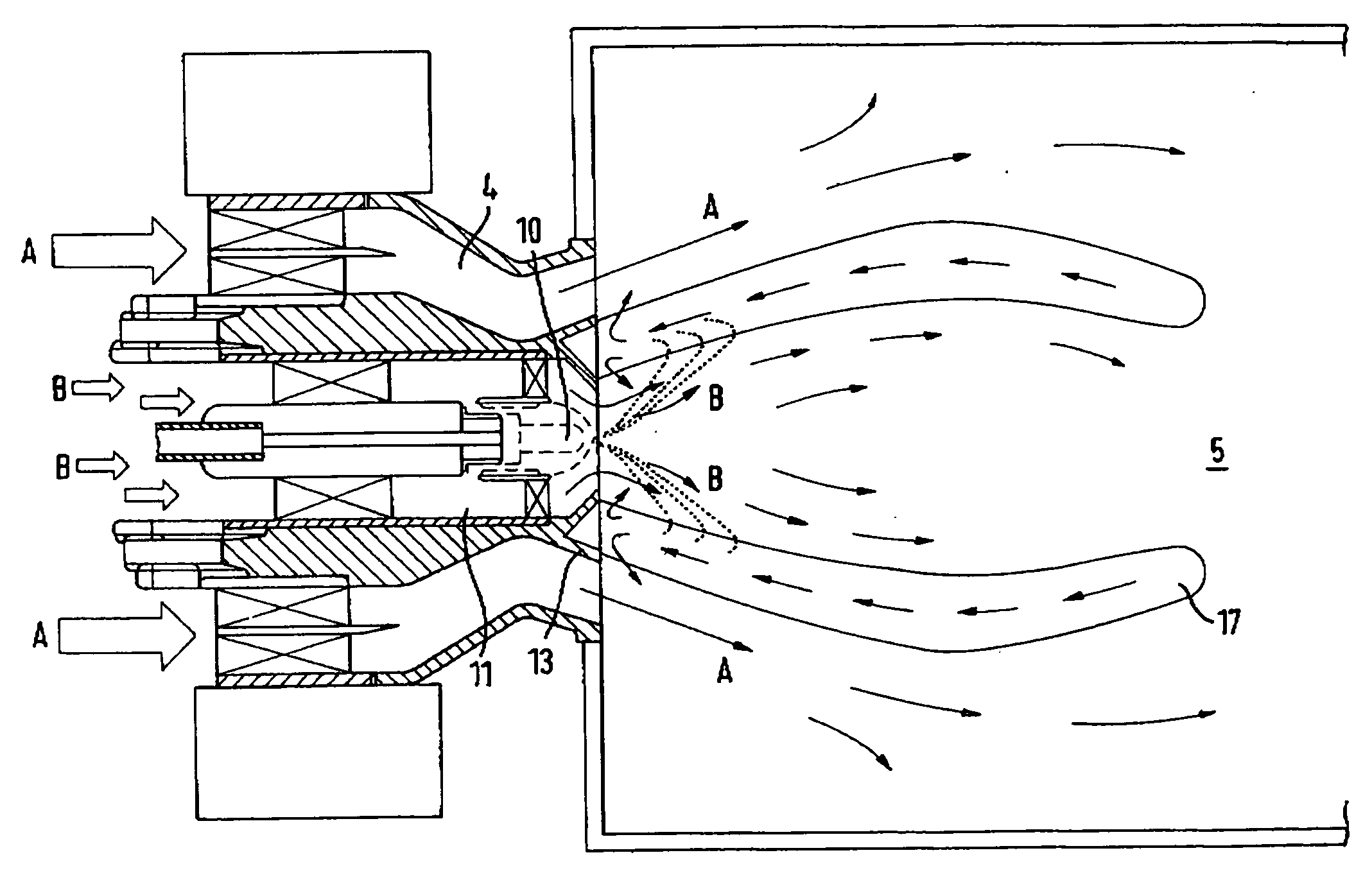

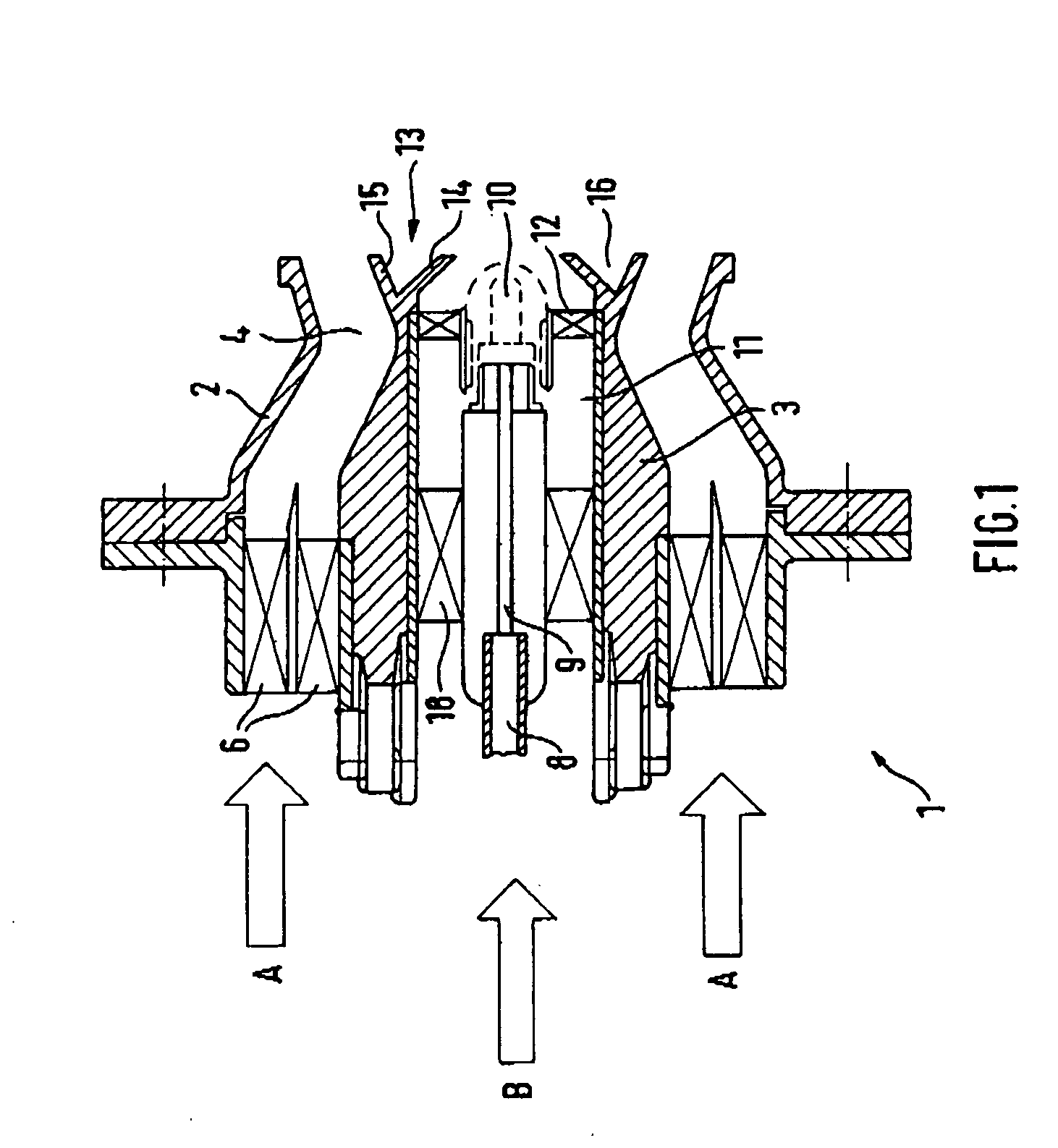

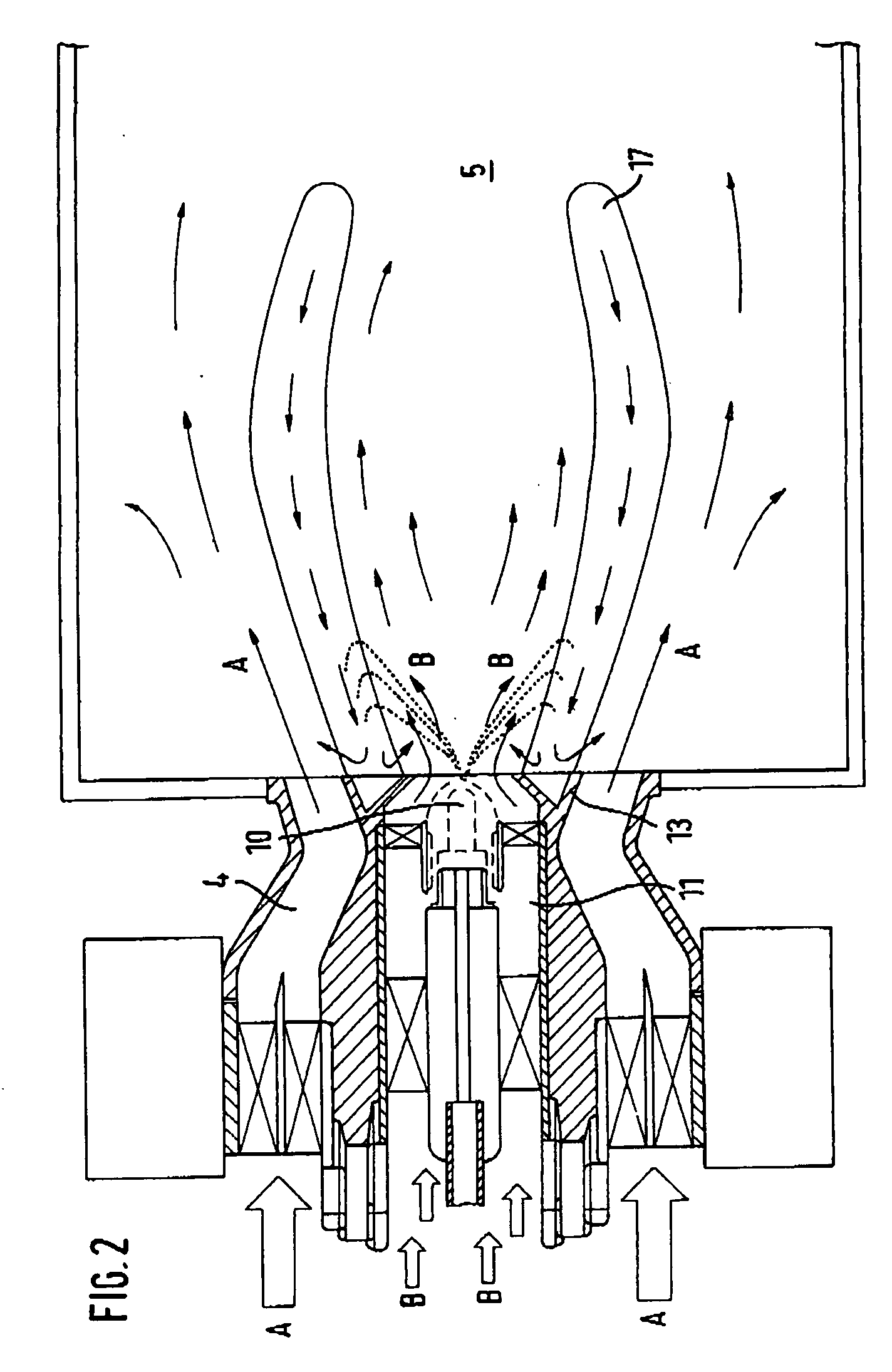

Burner for a gas-turbine combustion chamber

InactiveUS20050028526A1Guarantee stabilityOperational securityBurner safety arrangementsBurnersCombustorCombustion chamber

On a burner for a gas-turbine combustion chamber which comprises a lean premix burner with centrally integrated stabilizing burner, a core air annulus (11) accommodating the atomizer nozzle (10) of the stabilizing burner is concentrically surrounded by a main air annulus (4) supplying the weak air-fuel mixture. In the adjacent issuing areas of the main air annulus and the core air annulus, a flame stabilization ring (13), which is heated by the combustion gases and whose cross-sectional surface increases in area toward the combustion chamber (5), is provided to produce an approximately hollow-cylindrical hot-gas recirculation zone (17) originating at the flame stabilization ring which ensures a stable flame formation throughout the range of operating conditions of the gas turbine.

Owner:ROLLS ROYCE DEUT LTD & CO KG

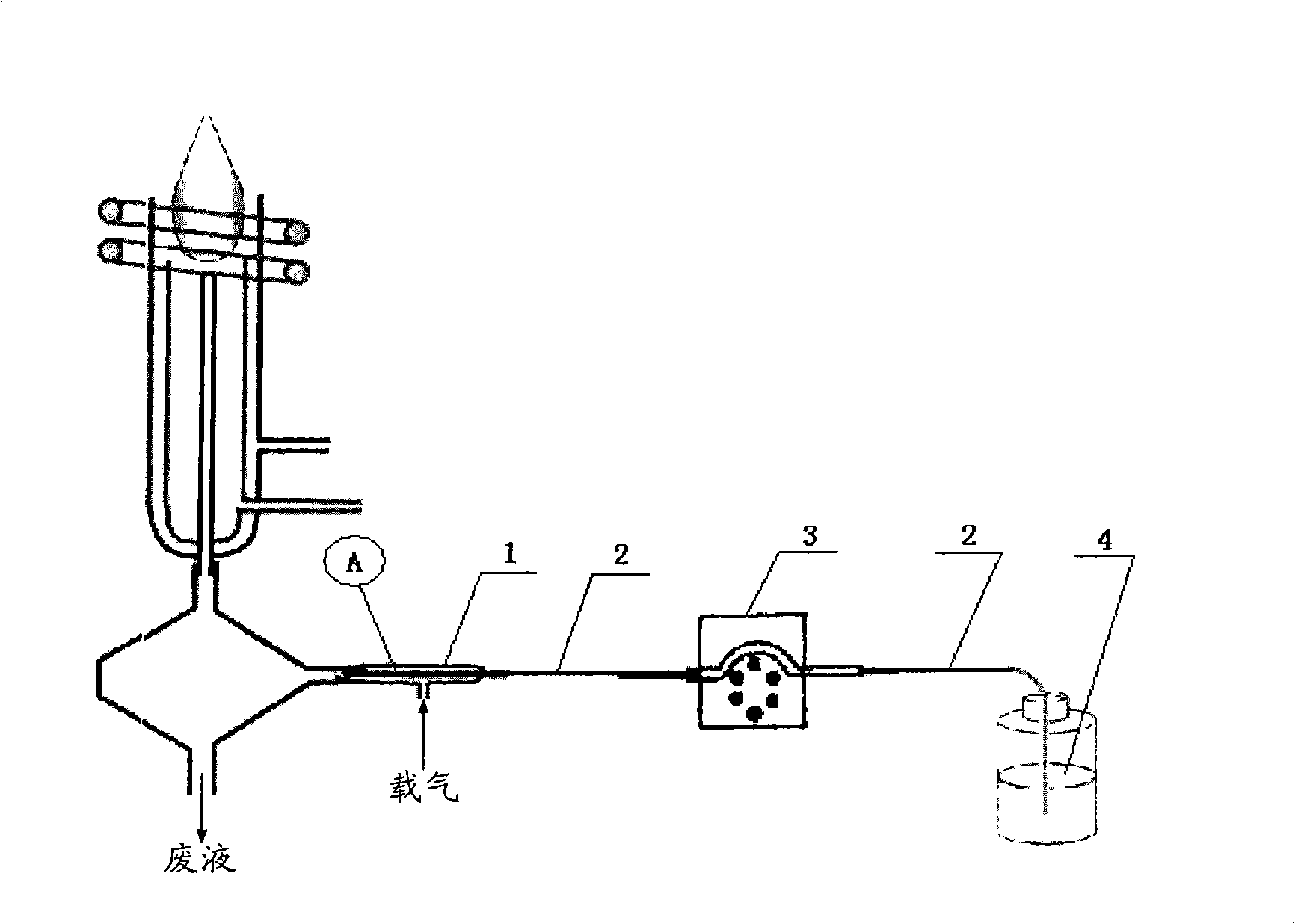

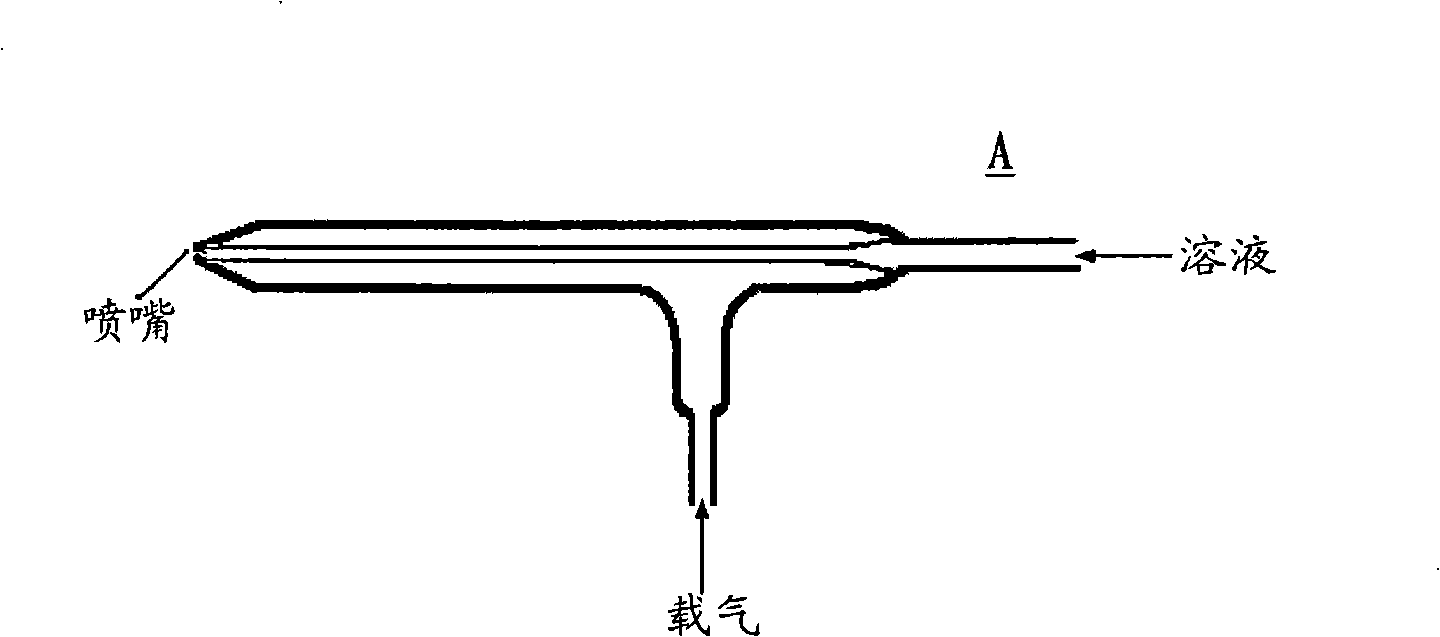

Method for removing obstruction of atomizer

InactiveCN101314154ASimple and quick to implementOperational securitySpraying apparatusAtomizer nozzleEngineering

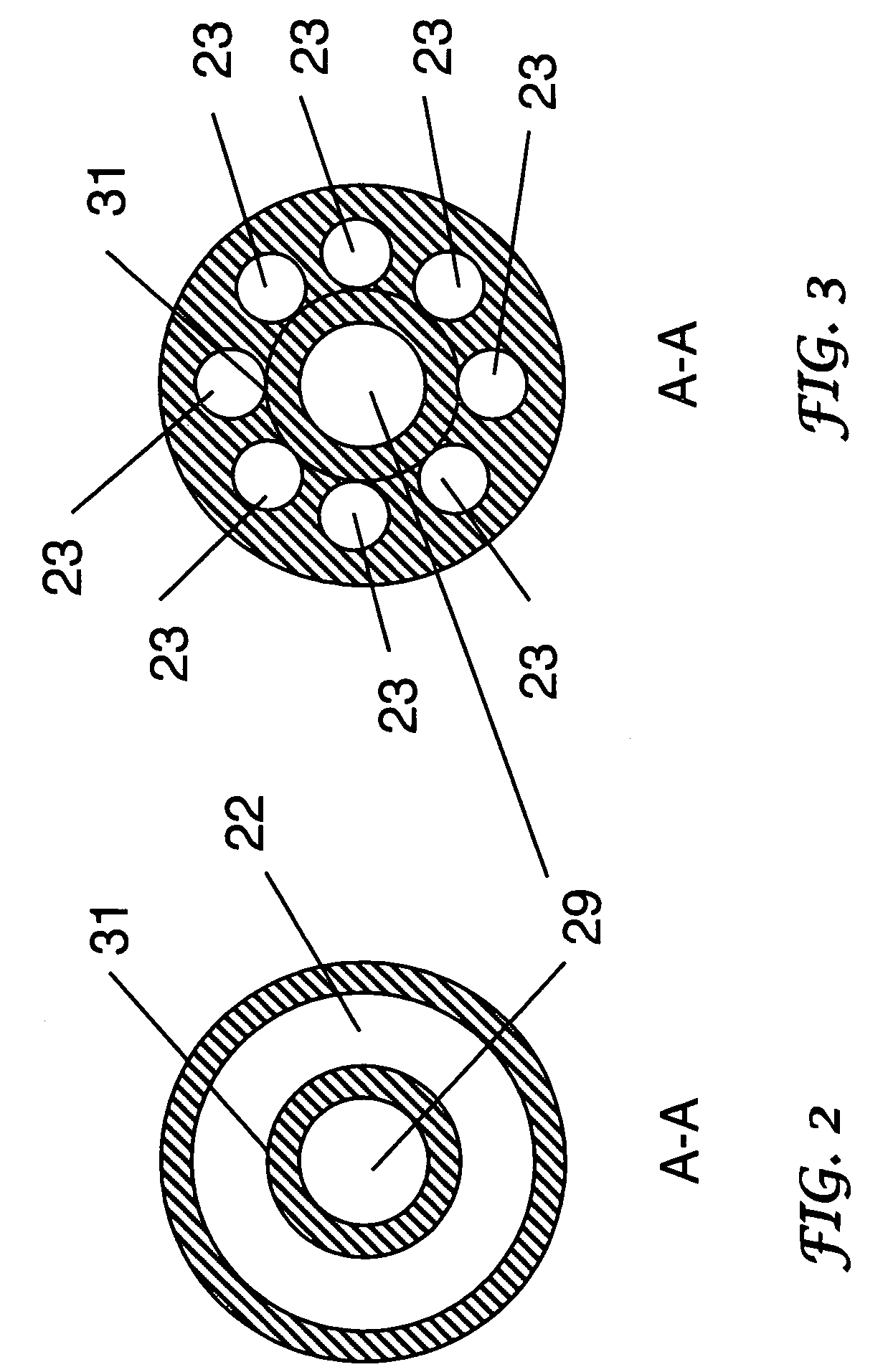

The invention discloses two methods for removing clogging matters in an atomizer. One is a method for removing the clogging matters by adopting cleaning solution, which is to place one end of a nozzle of the atomizer into the cleaning solution, blow atomized airflow into the atomizer, so that the cleaning solution passes through a sampling capillary inner pipe at high speed and is dashed out from the nozzle of the atomizer under the action of negative pressure produced by high-speed airflow, thereby washing and cleaning the clogging matters in the atomizer at high speed; the other method is to adopt reverse blowing of the atomized airflow to remove the clogging matters in the atomizer, block an airflow channel on the atomizer, connect one end of the nozzle of the atomizer with an atomized airflow pipeline, and use the high-speed airflow to reversely wash the sampling capillary inner pipe of the atomizer from a nozzle end of the atomizer, thereby washing and cleaning the clogging matters in the atomizer at high speed. The methods satisfy the need of removing the clogging matters in the atomizer under the condition of smartly keeping the original connecting state, reduce the frequency of replacing the atomizer due to clogging damage, and ensure that the production cost is greatly reduced.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +1

Emulsion atomizer nozzle, and burner, and method for oxy-fuel burner applications

InactiveUS7500849B2Combustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEmulsion

A method for oxy-fuel combustion, the method comprising the steps of: introducing a liquid fuel into an emulsion chamber through a liquid fuel conduit having an effective diameter, the emulsion chamber having a length that is 2 times or less than 2 times of said effective diameter of said liquid fuel conduit; introducing an atomizing gas into the emulsion chamber through at least one atomizing gas conduit; mixing the liquid fuel and the atomizing gas in said emulsion chamber to create an emulsion mixture that has a mean residence time in said emulsion chamber of from 500 to 800 μs, the emulsion mixture having an emulsion mixture velocity less than or equal to 12 m / s; and discharging said emulsion mixture through a generally rectangular-shaped orifice into an oxygen-enriched oxidizer stream. A nozzle and burner for oxy-fuel combustion are also disclosed.

Owner:AIR PROD & CHEM INC

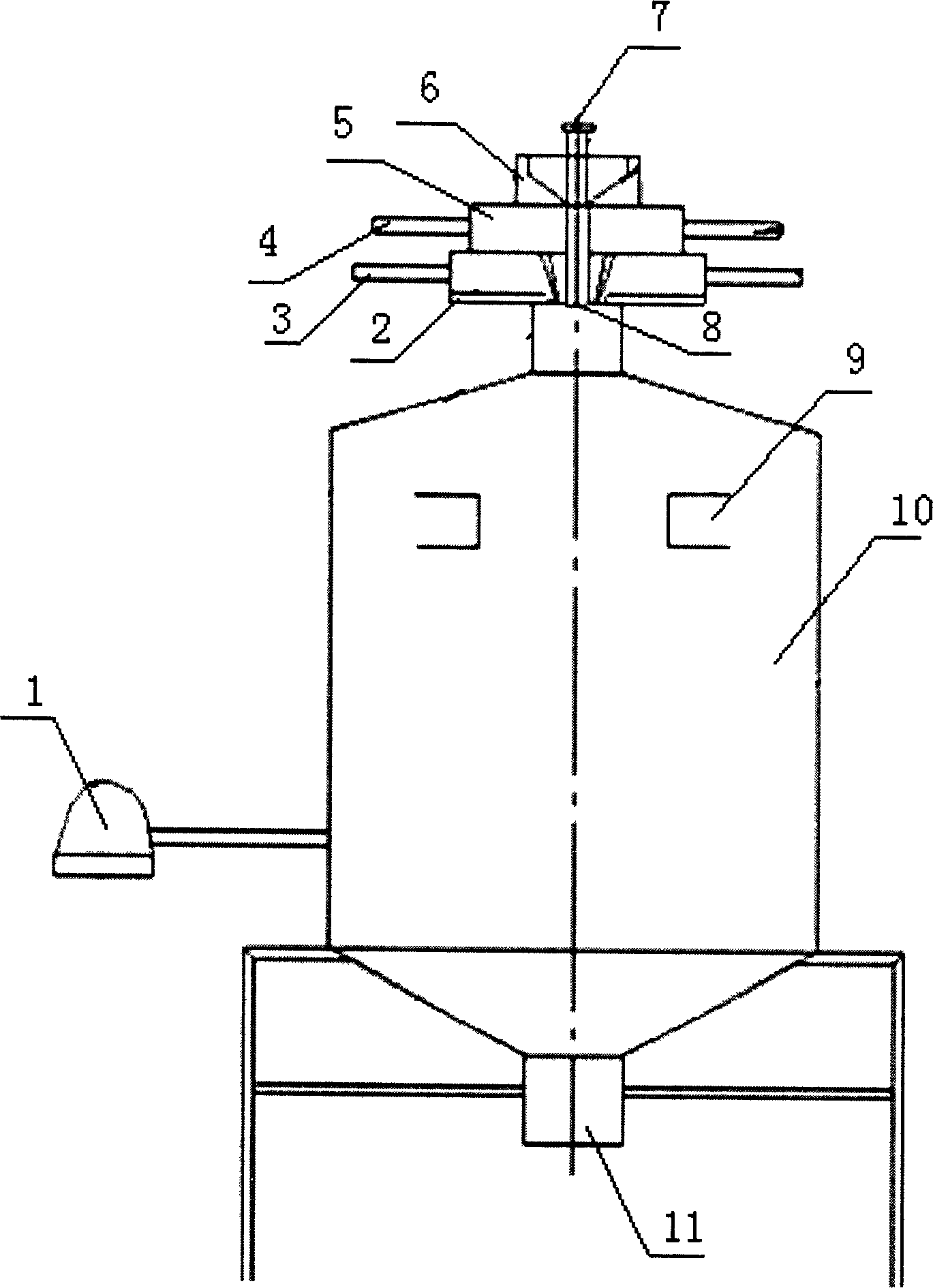

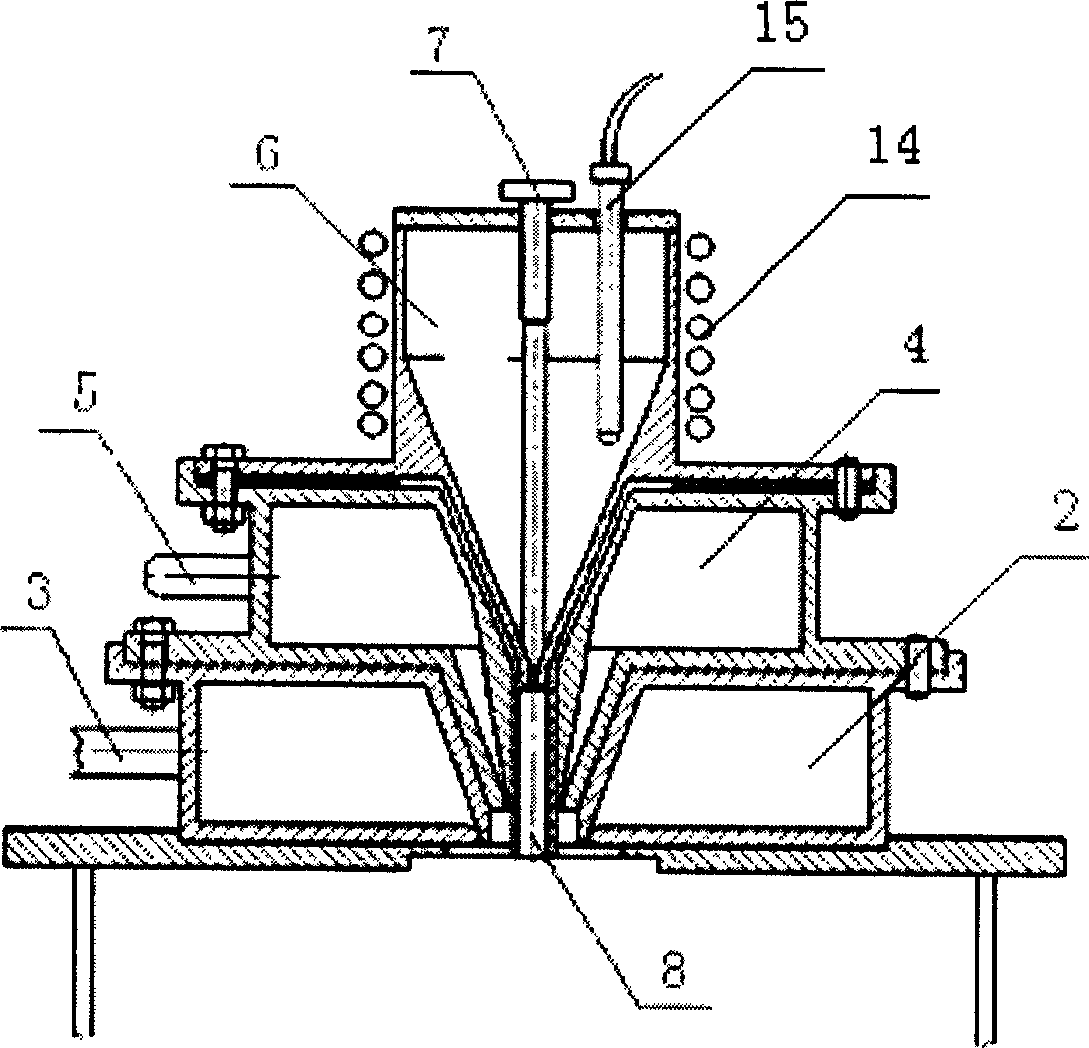

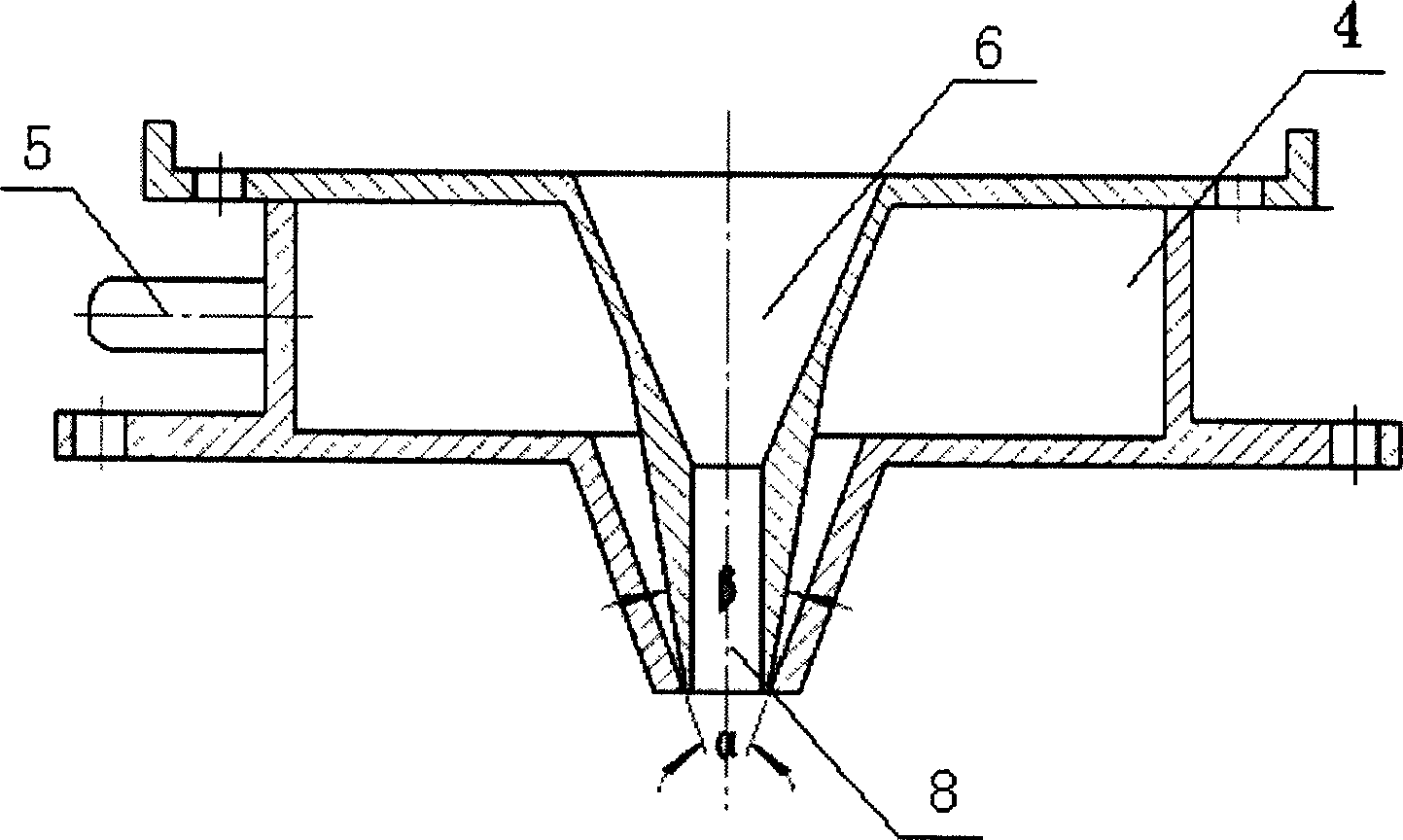

Device for preparing metal ultrafine powder and its method

The superfine metal powder preparing apparatus and method adopts double-layered composite atomizing nozzle and bipolar atomizing mode. The double-layered composite atomizing nozzle has one upper layer in traditional atomizing structure and one lower layer in Laval nozzle structure and has double-layered metal liquid tearing effect and ultrasonic metal liquid exciting effect. The present invention also adopts doped powder and vortex structure and thus has homogeneous mixing between solid and gas, vortex gas flow impulse and increased gas flow impact force on metal liquid for deep tearing of metal liquid and even small grains. In addition, present invention has increased electric field to make the falling metal powder produce surface charge effect to avoid agglomeration.

Owner:SHAANXI UNIV OF SCI & TECH

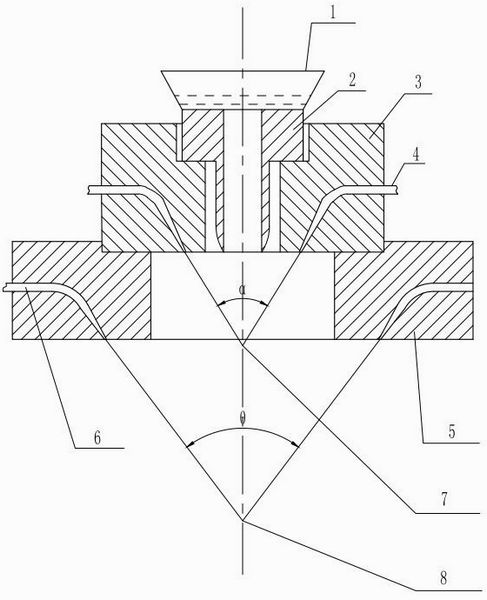

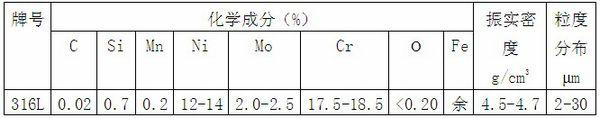

Method for producing spherical stainless steel powder material by using high pressure water atomization method

The method discloses a method for producing a spherical stainless steel powder material by using a high pressure water atomization method, which comprises the following steps: preparing required stainless steel raw materials according to the contents of components in the grade of the spherical stainless steel powder; adding the stainless steel raw materials into an intermediate frequency induction heating furnace, wherein the degree of superheat of melt is 150-200DEG C; pouring the molten metal of the stainless steel raw materials into a crucible, and enabling the molten metal to flow from the tundish, wherein the flow velocity of the molten metal is 38-45g / s; spraying the high-pressure water from an atomizer nozzle, wherein the jet angle of the atomizer nozzle is 10-20 degrees, the pressure of the high-pressure water is 35-90MPa, and the water flow quantity is 3.3-6m<3> / min. The nozzle of the atomizer is a double-layer annular ring nozzle. The spherical stainless steel powder produced by the method of the invention has even components, high sphericity, and low cost, and the method is simple to operate.

Owner:SHIJIAZHUANG TIEDAO UNIV

High-solids, reactive components spray application systems

InactiveUS20080173728A1Liquid transferring devicesLiquid/solution decomposition chemical coatingPeristaltic pumpChemical composition

Provided herein is a system useful for producing polymeric coatings on substrates, by means of a spray that is produced from impinging a compressed gas on a mixture that comprises an organic polyisocyanate and an isocyanate-reactive component. When a coating is produced from two components in accordance with the invention, each component is metered to an atomizing nozzle through peristaltic pumps, which enable increased control over flow characteristics as compared with prior art methods, and which importantly also enables greatly-reduced levels of wasted chemical components and attendant alleviated need for the use of volatile or expensive solvents in equipment cleaning operations. Uncured coating precursor material is allowed greater residence time on the target substrate prior to final cure using a system an process of the invention, which results in coatings having greater integrity over those produced using prior art equipment and methods, as well as reduced overall cost.

Owner:CITADEL RESTORATION & REPAIR

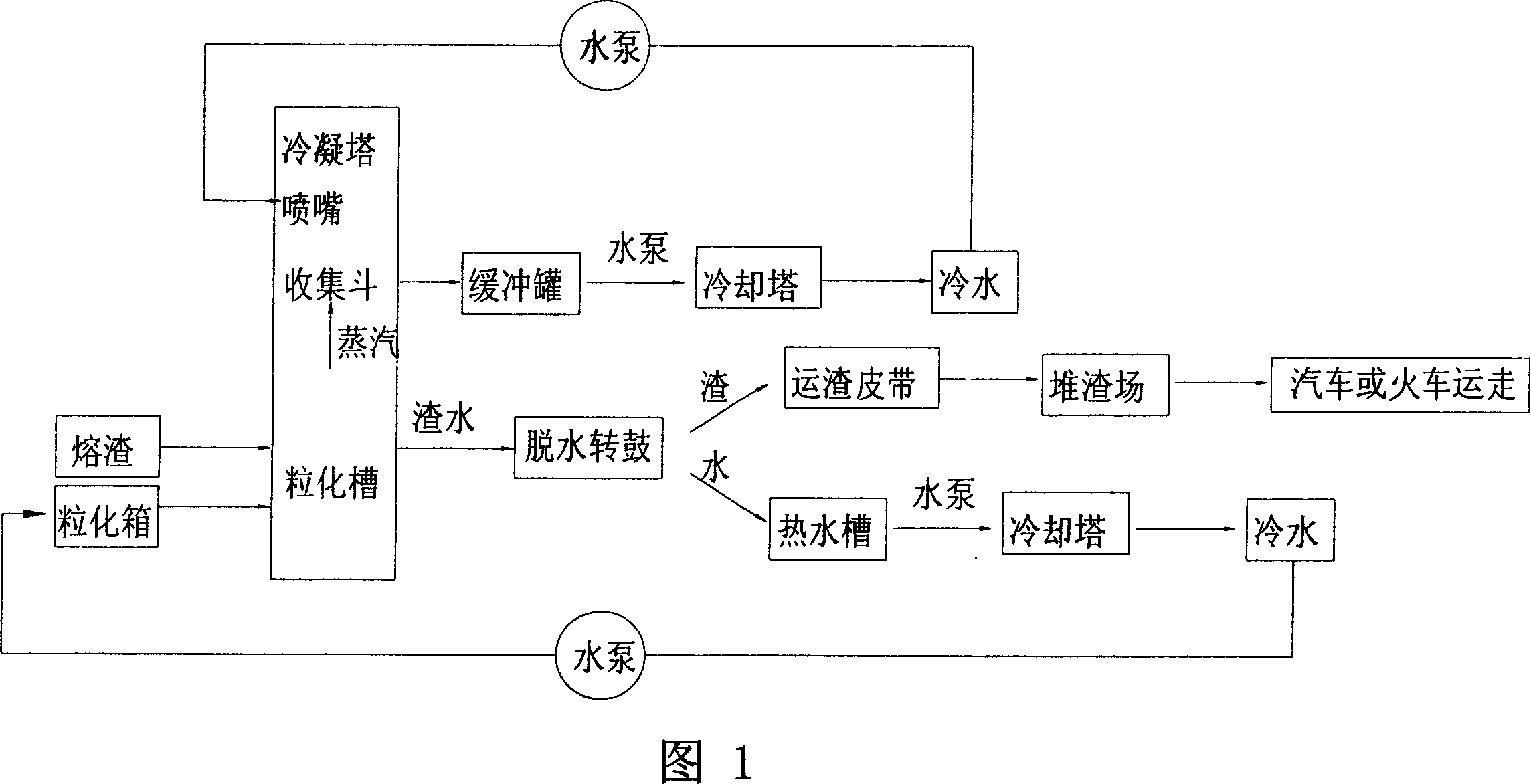

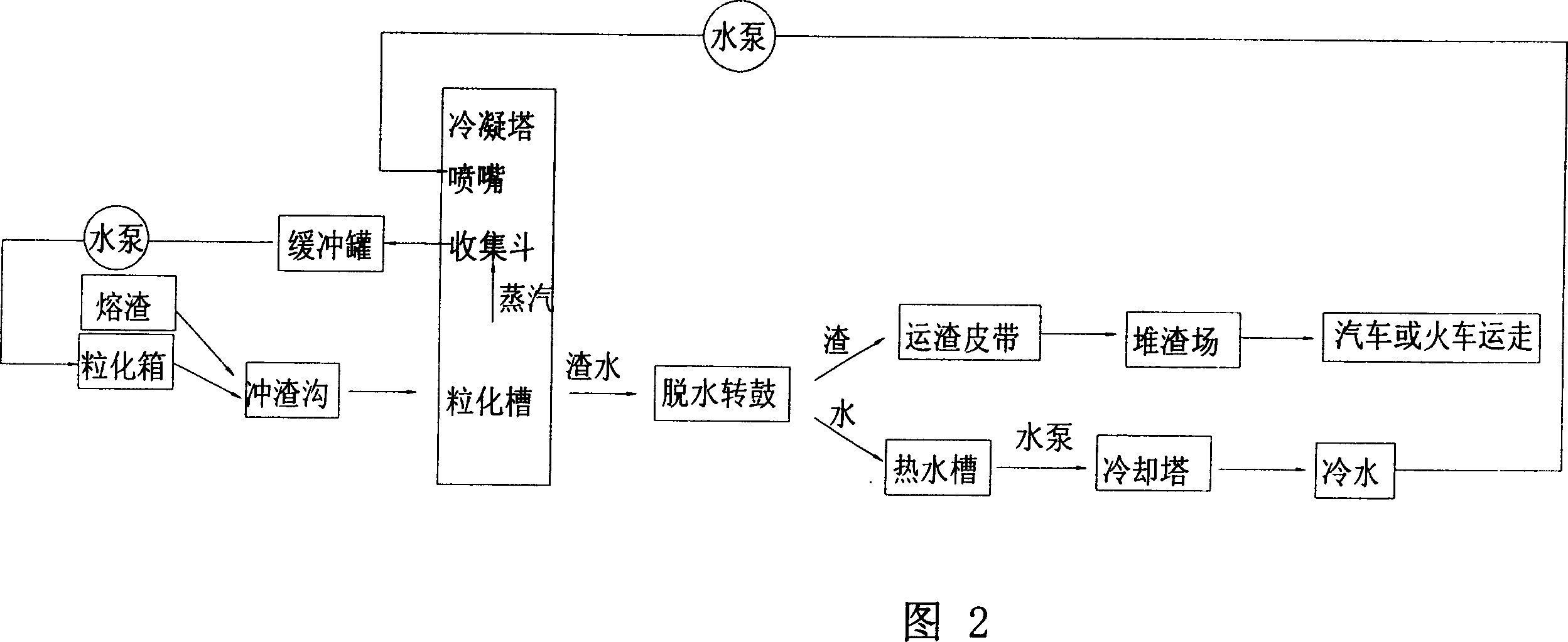

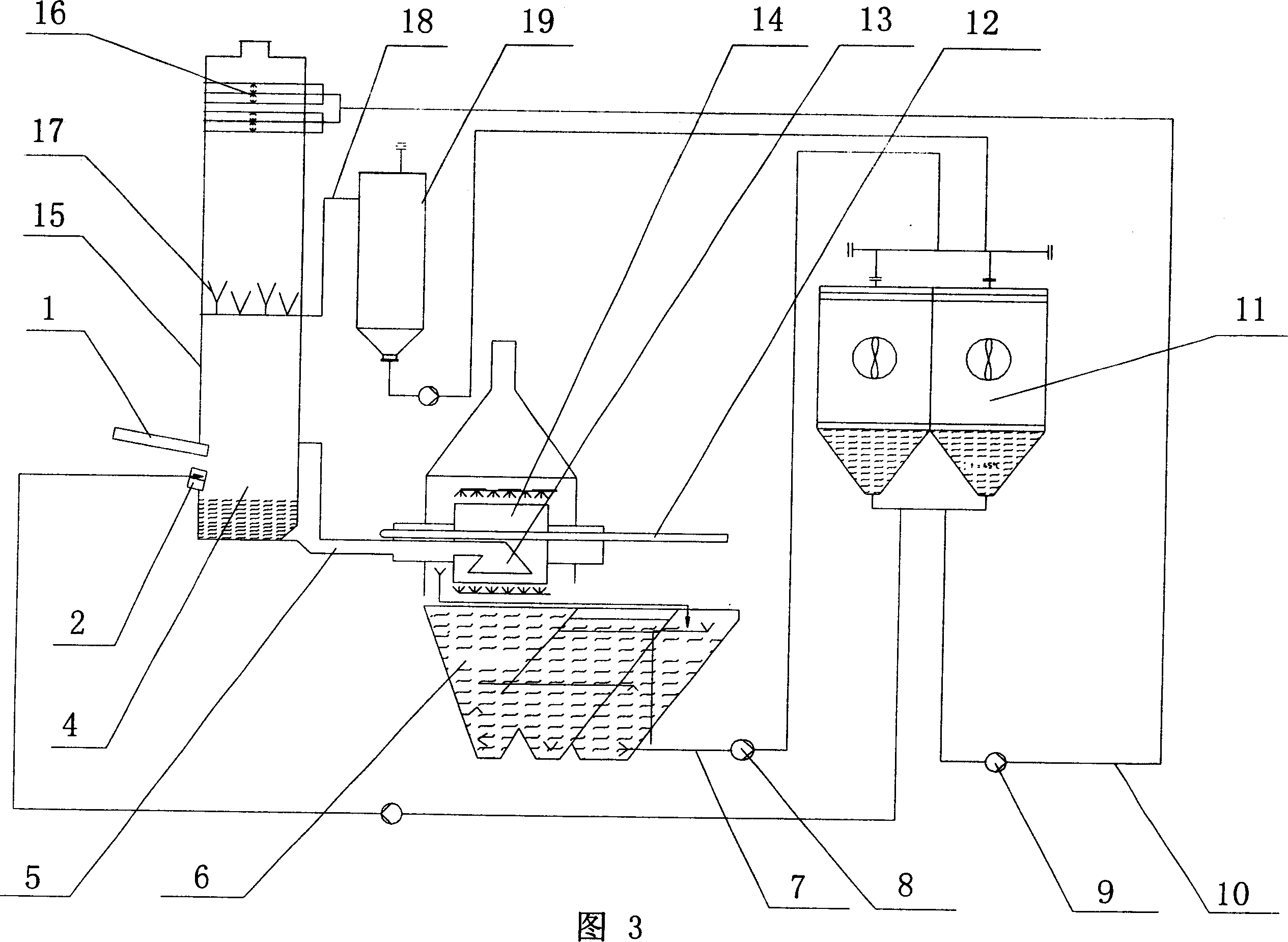

Environment friendly blast furnace slag treating process and system

InactiveCN1986836AImprove protectionReduce trafficRecycling and recovery technologiesCooling towerSteam condensation

The present invention is environment friendly blast furnace slag treating process and system. The blast furnace slag treating process includes water quenching the red slag for fast cooling with the granulating tank sprayed cooling water and collecting in the collecting pipeline; conveying to the distributor of dewatering drum and separating into water granulated slag falling to the belt conveyer for being transported to the slag yard and filtered hot water; collecting hot water, pumping to cooling tower for cooling and condensing through the atomizing nozzle in the condensing tower; and collecting the condensated water and returning through the third water pipe, the buffering tank and the fourth water pipe to the granulating tank for reuse. The present invention has the advantages of simple system composition, environment friendship, low power consumption, etc.

Owner:WISDRI ENG & RES INC LTD

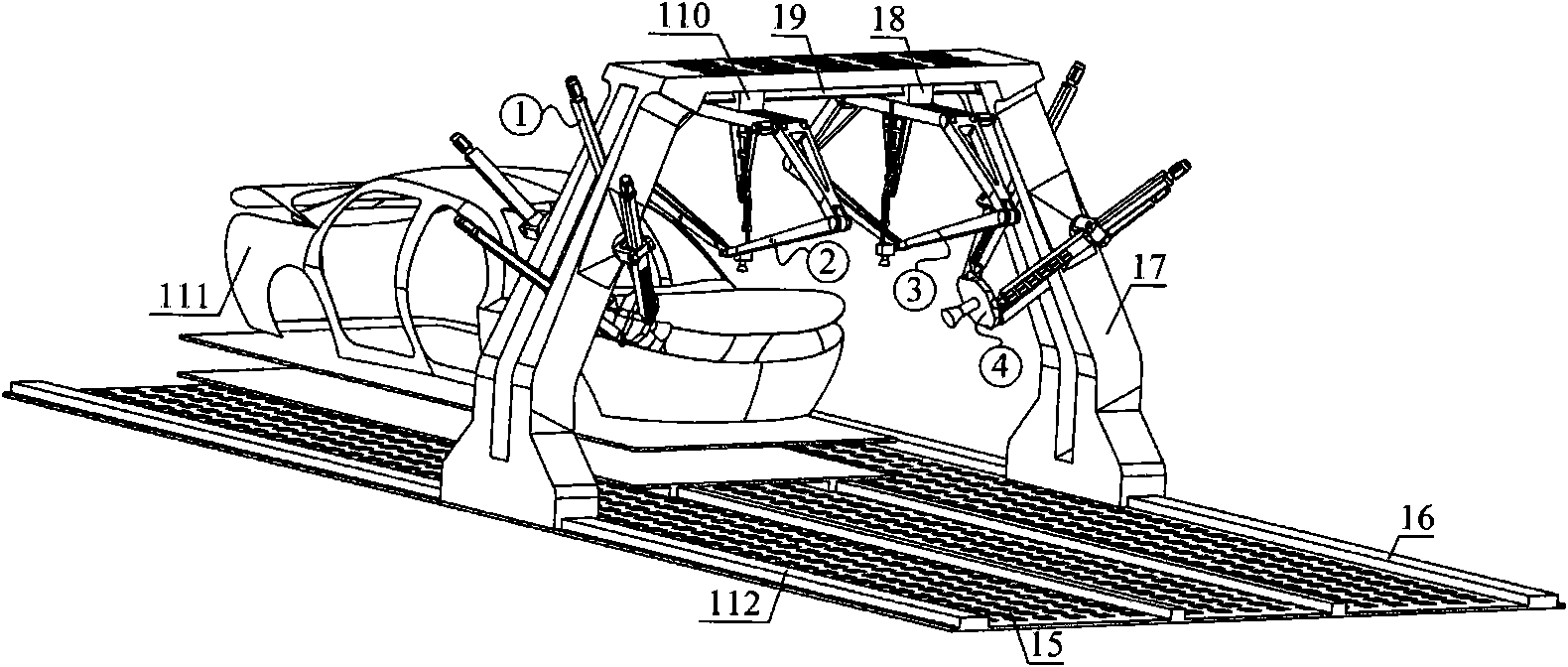

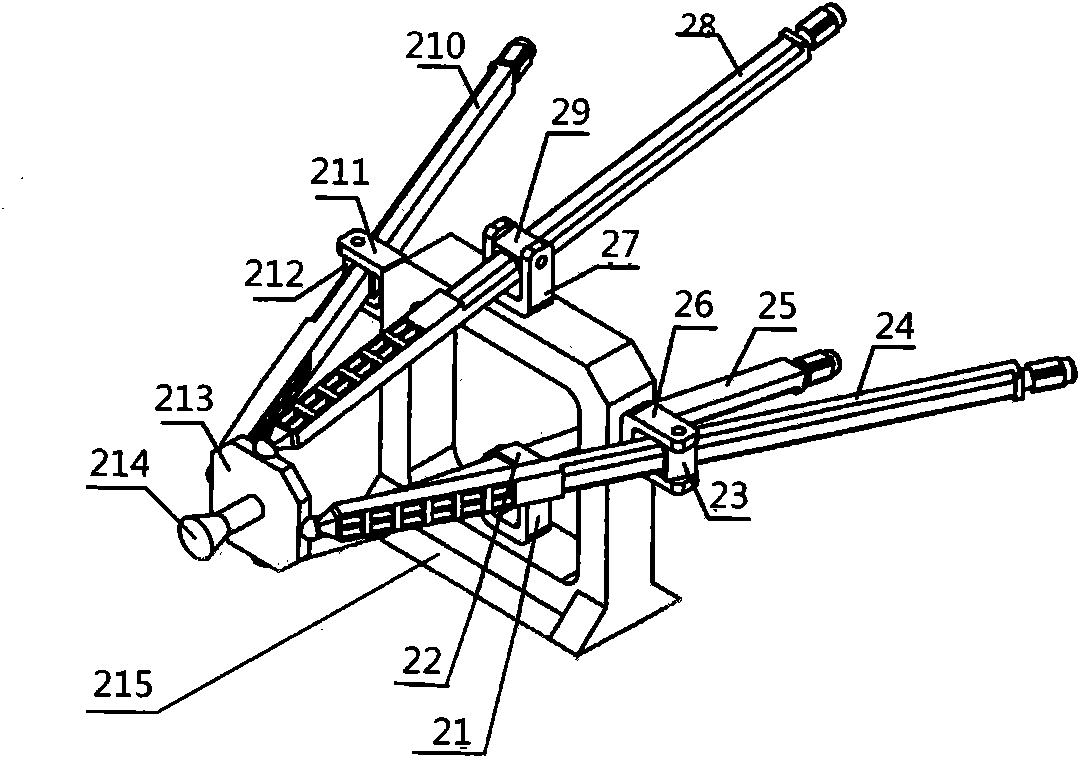

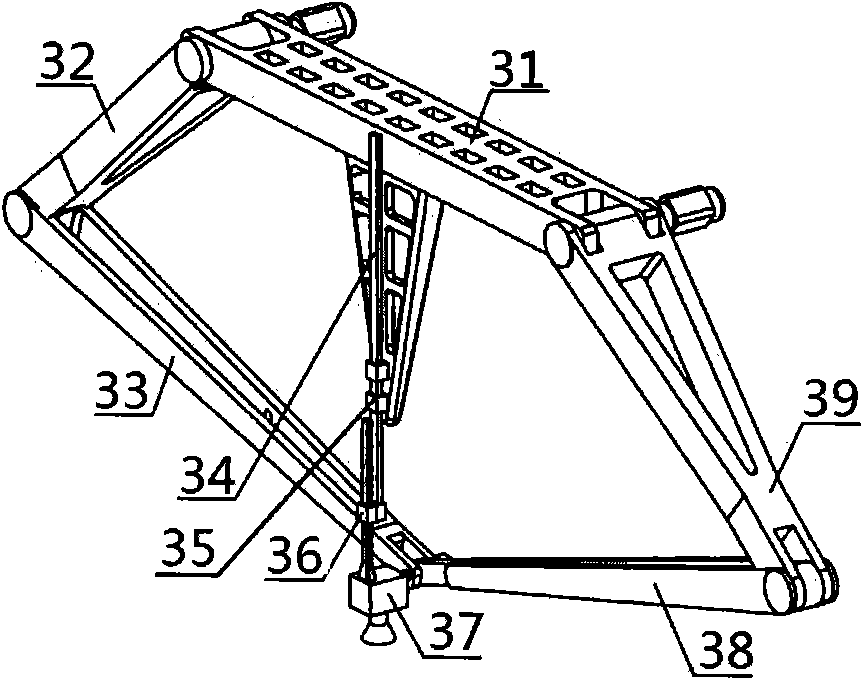

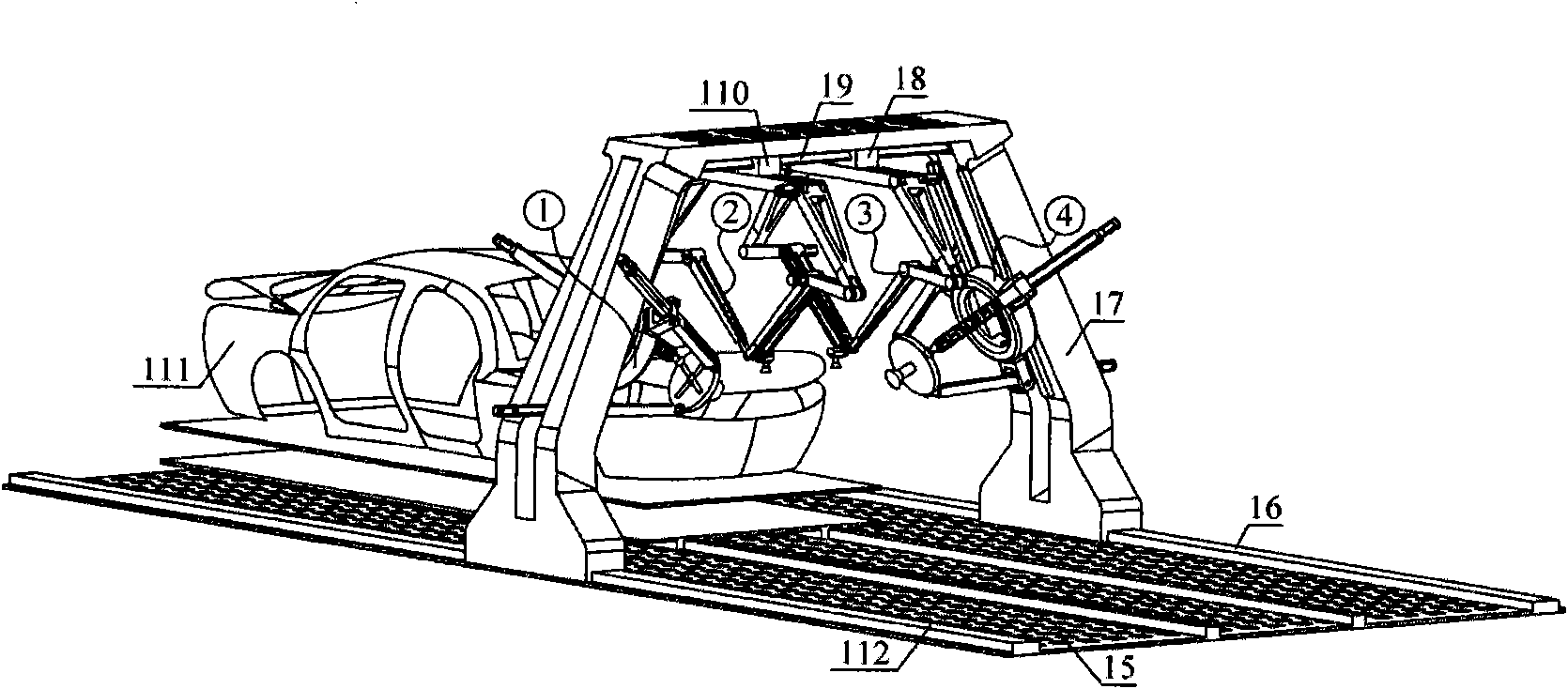

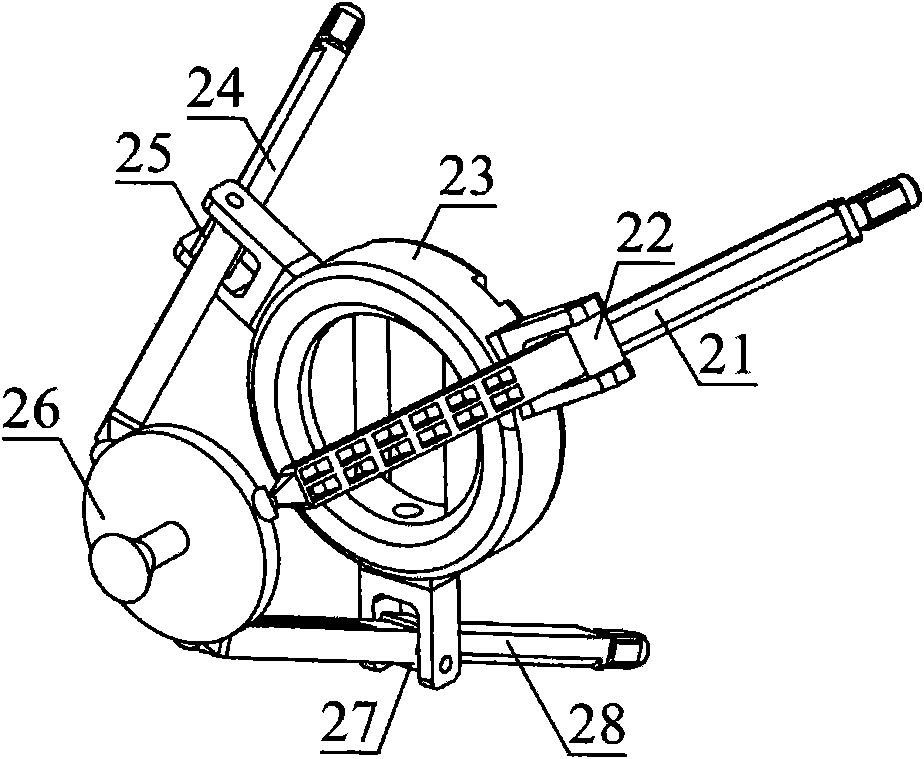

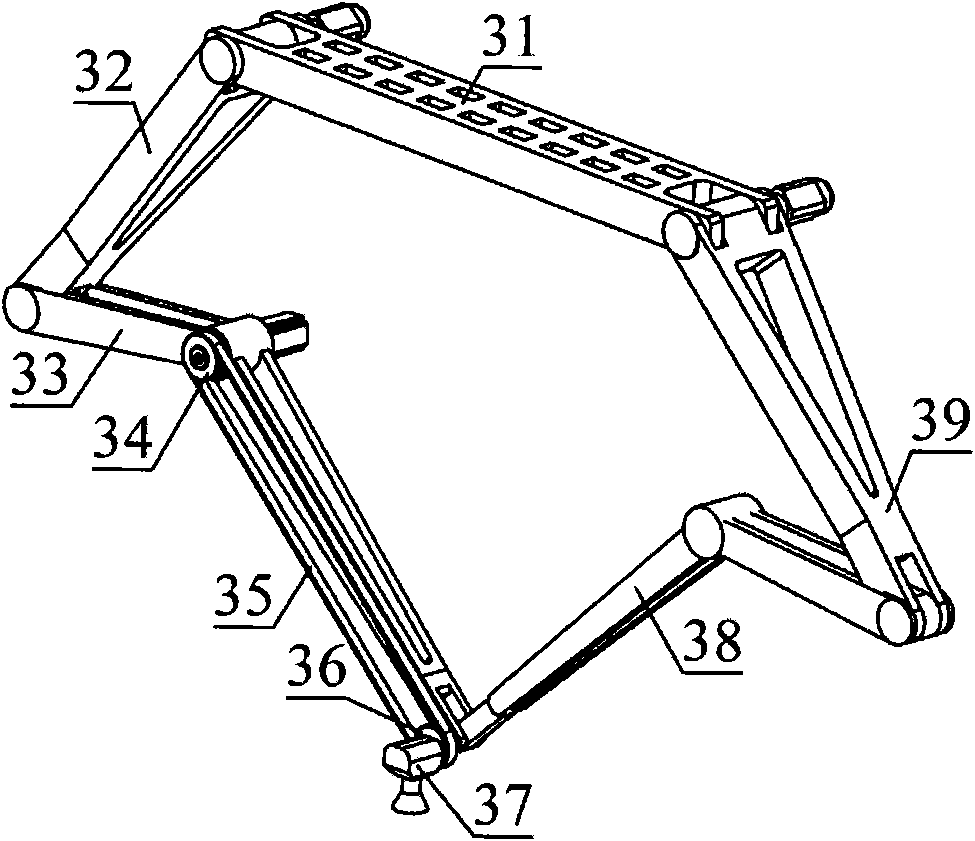

Hybrid connected combined vehicle spraying robot based on 3-DOF (Degrees Of Freedom) and 4-DOF parallel mechanism

ActiveCN101966500AStructural symmetryEasy to manufactureProgramme-controlled manipulatorSpraying apparatusAtomizer nozzleDegrees of freedom

The invention relates to a hybrid connected combined vehicle spraying robot based on a 3-DOF (Degrees Of Freedom) and 4-DOF parallel mechanism, comprising a gantry stand and four spraying operation module units, wherein the gantry stand can realize horizontal motion on a horizontal guide rail, and the pose of an atomizer nozzle of each spraying operation module unit can be controlled by combining the horizontal motion of the gantry stand and motion of the spraying operation module units, thereby finishing whole vehicle spraying operation of a vehicle to be sprayed. The hybrid connected combined vehicle spraying robot has the advantages of symmetric structure, good flexibility, high accuracy and rigidity, easy manufacture, convenient control, easy modularization realization and high flexibility degree, can increase and decrease an amount of spraying modules according to the needs and carrying spraying operation on different whole vehicles.

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD +1

Multistage decompression and micro flow atomizing nozzle

InactiveUS20160375449A1Extended service lifeAccurate flowSpray nozzlesVena contracta diameterOrifice plate

An atomizing nozzle including a nozzle body, a flow orifice plate, a multi-stage decompression sleeve and a dual-conical surface nozzle head. One end of the nozzle body opposite to the dual-conical surface nozzle head is provided with an external thread; one end of the nozzle body close to the dual-conical surface nozzle head is provided with an internal hole and an internal thread. The external thread of the nozzle body is connected to external equipment. The flow orifice plate, the multi-stage decompression sleeve and the dual-conical surface nozzle head are arranged in the internal hole. The flow orifice plate is arranged on one end of the dual-conical surface nozzle close to the external thread of the nozzle body. The multi-stage decompression sleeve is arranged on the flow orifice plate.

Owner:WUXI VOCATIONAL & TECHN COLLEGE

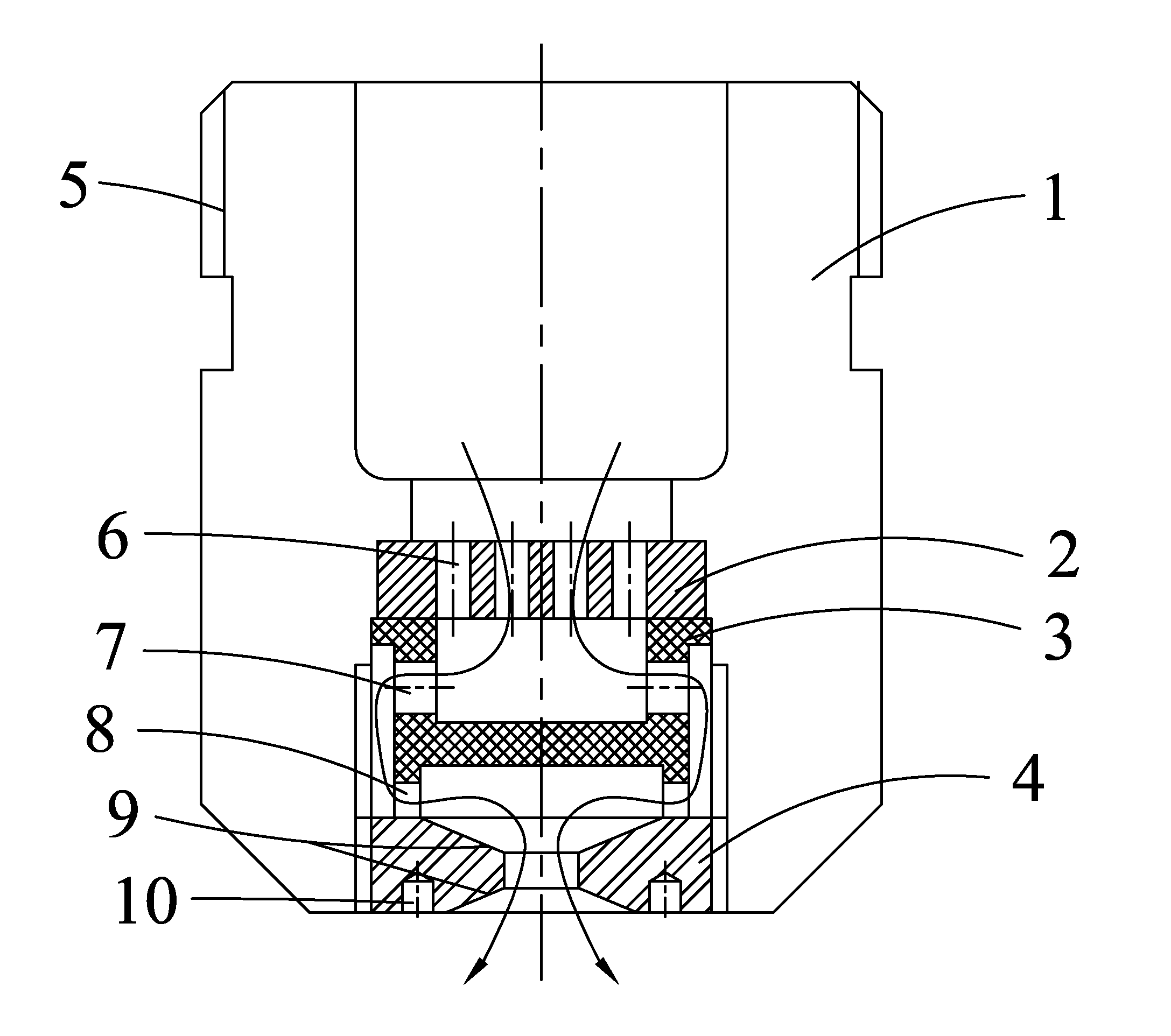

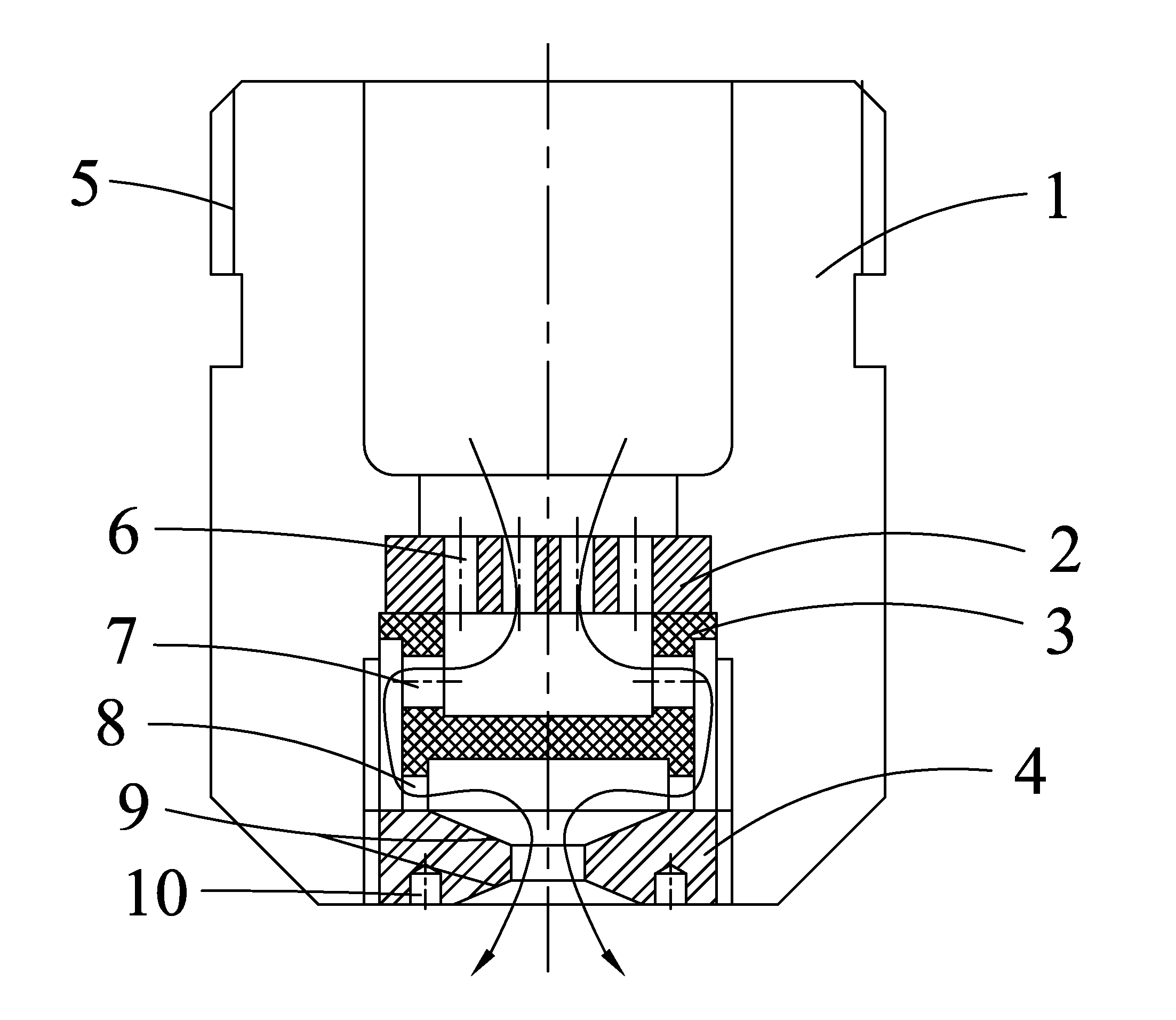

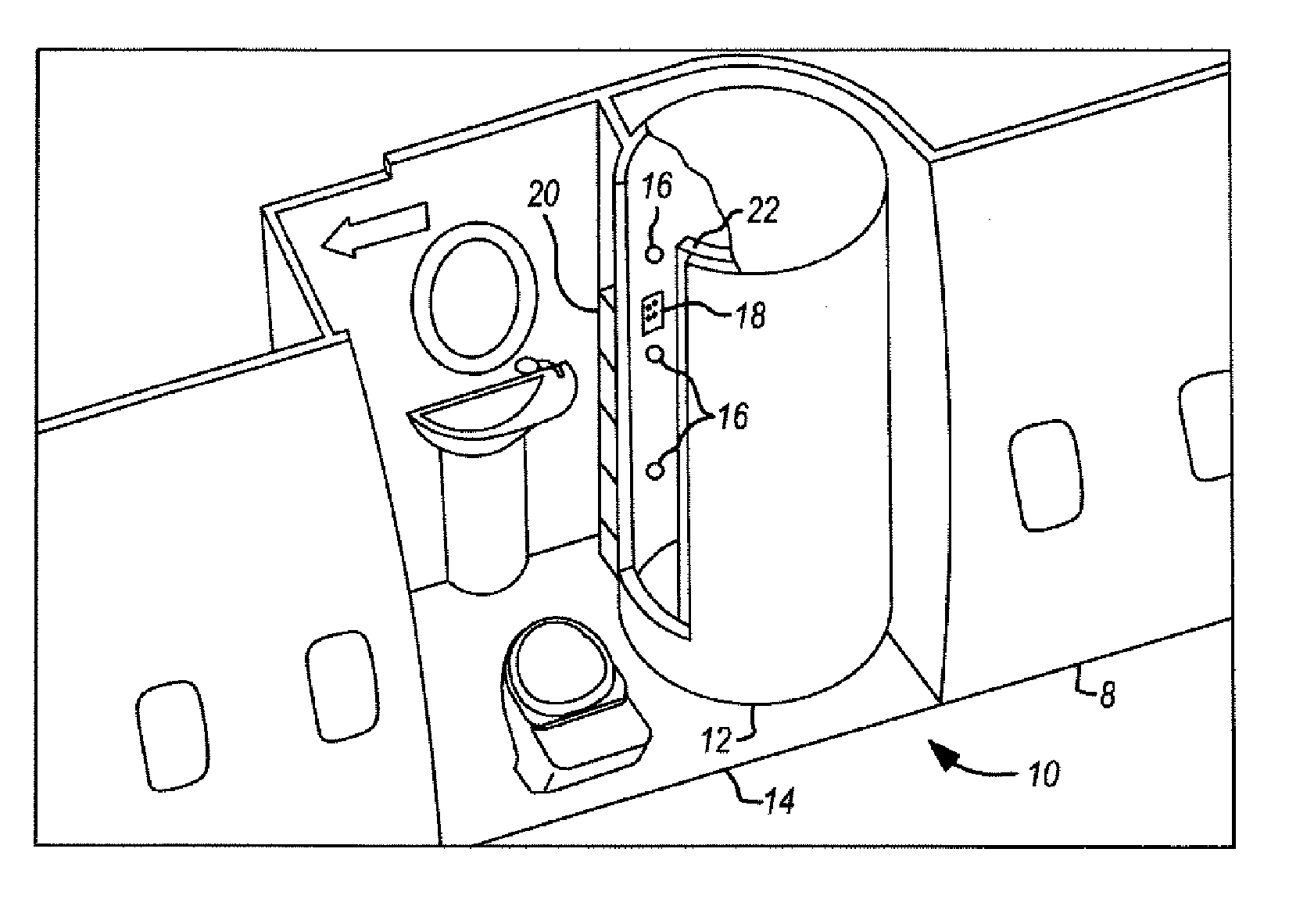

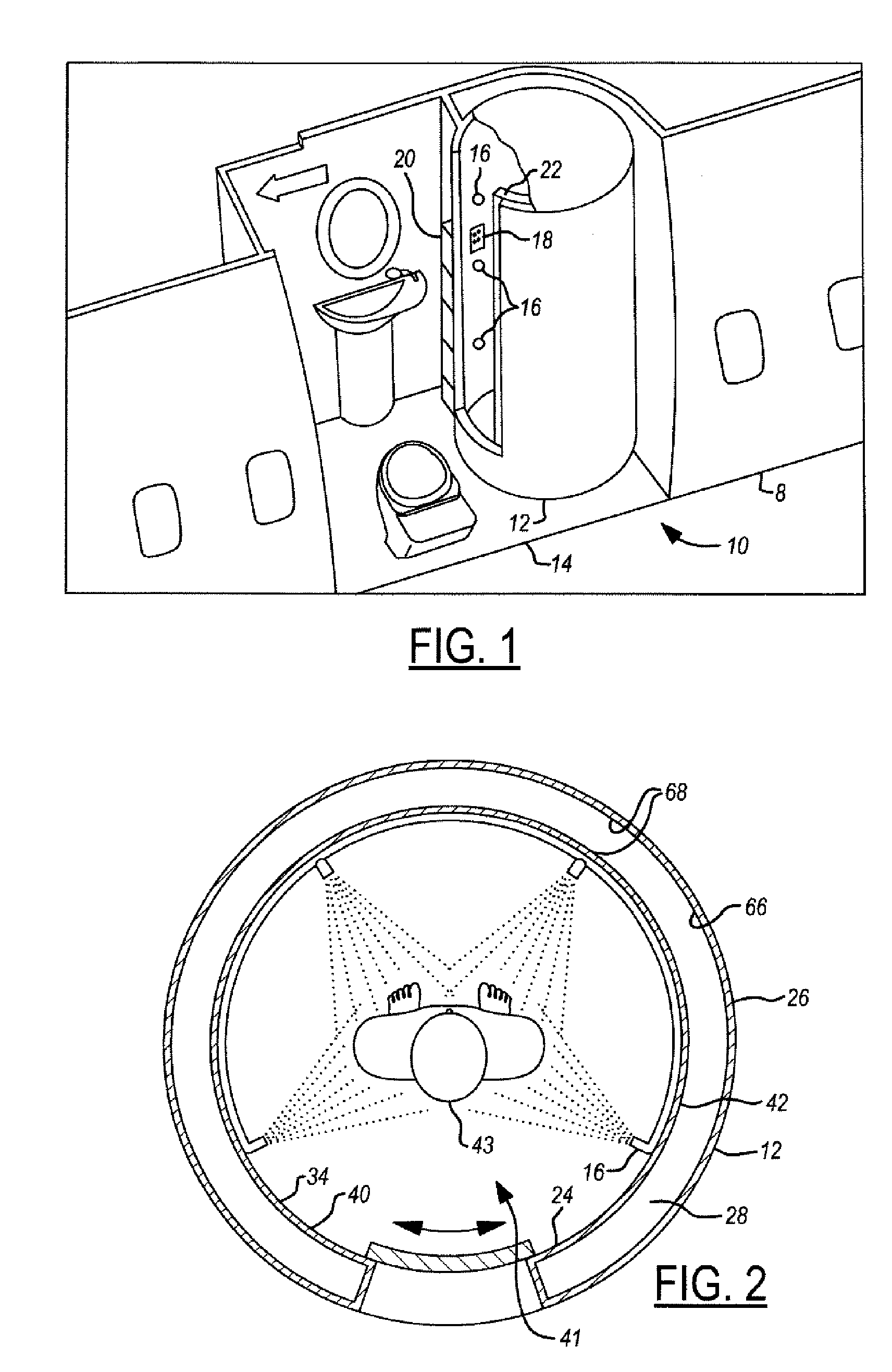

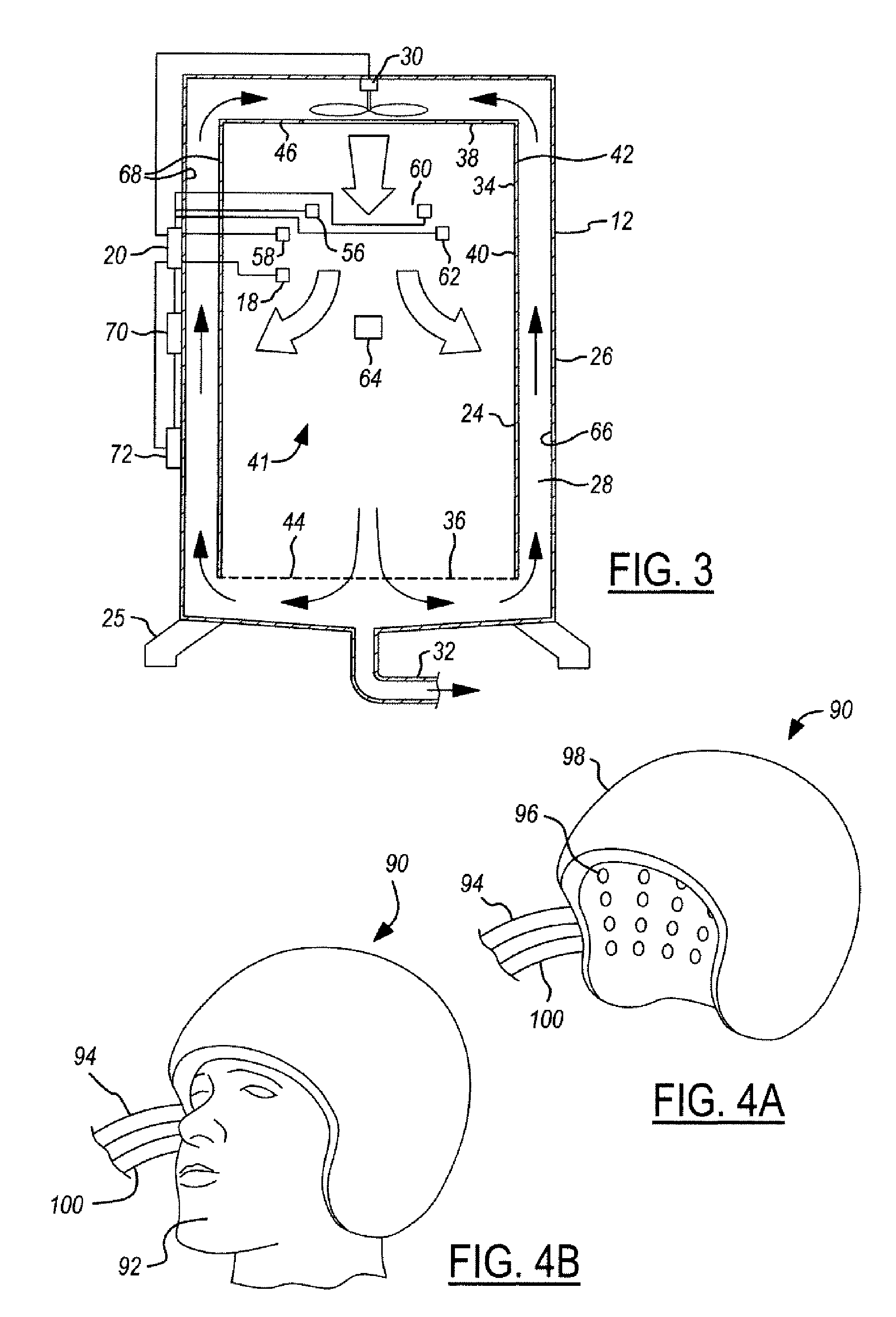

Mist Delivery System

A mist delivery system includes an enclosure having at least one misting nozzle coupled thereto. The enclosure includes a primary wall and a secondary wall, whereby an air channel is defined between the primary wall and the secondary wall. A controller directs misted air through the misting nozzle and further activates an air flow system such that misted air within the shower area flows through and is dried in the air channel.

Owner:THE BOEING CO

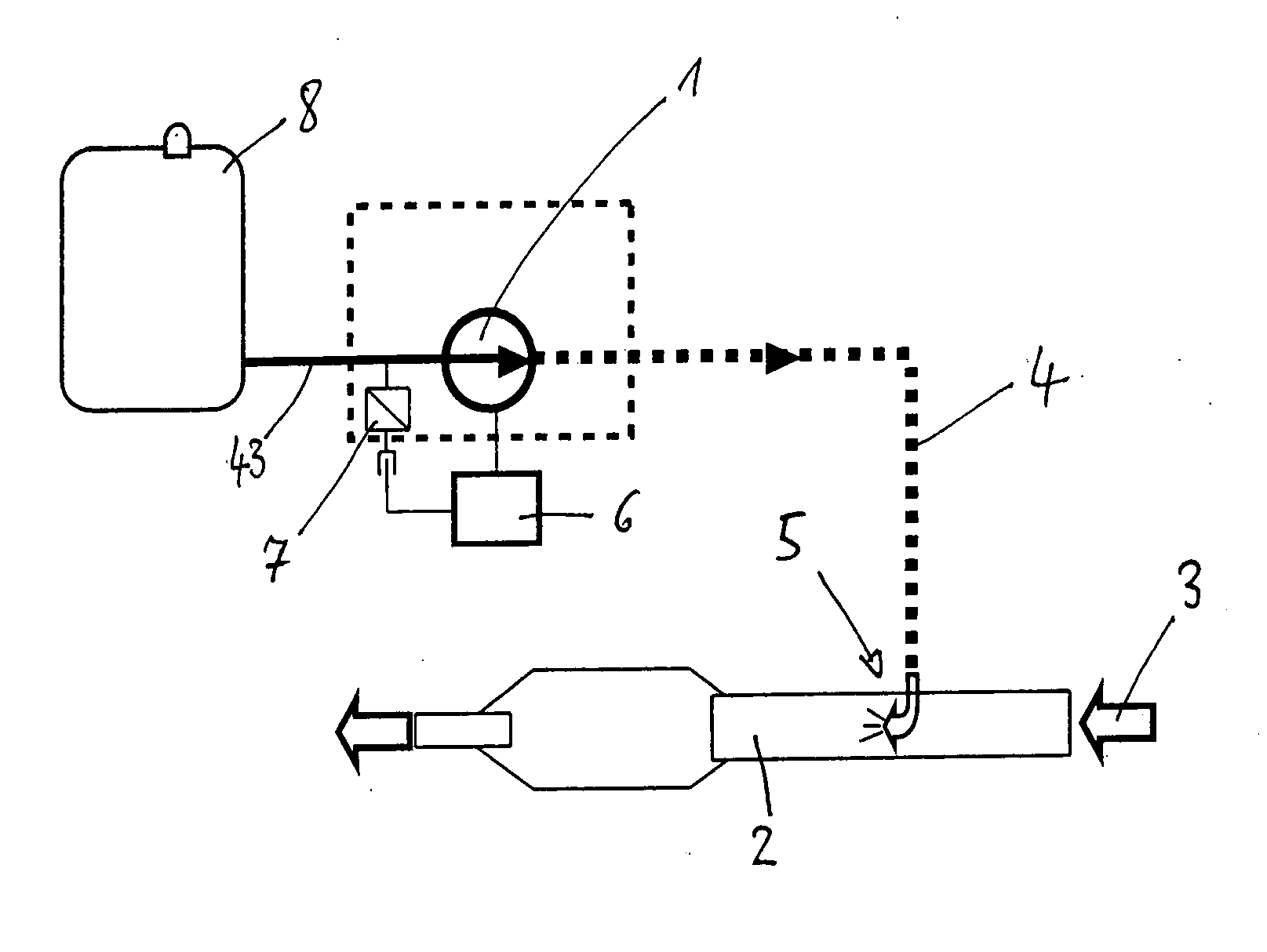

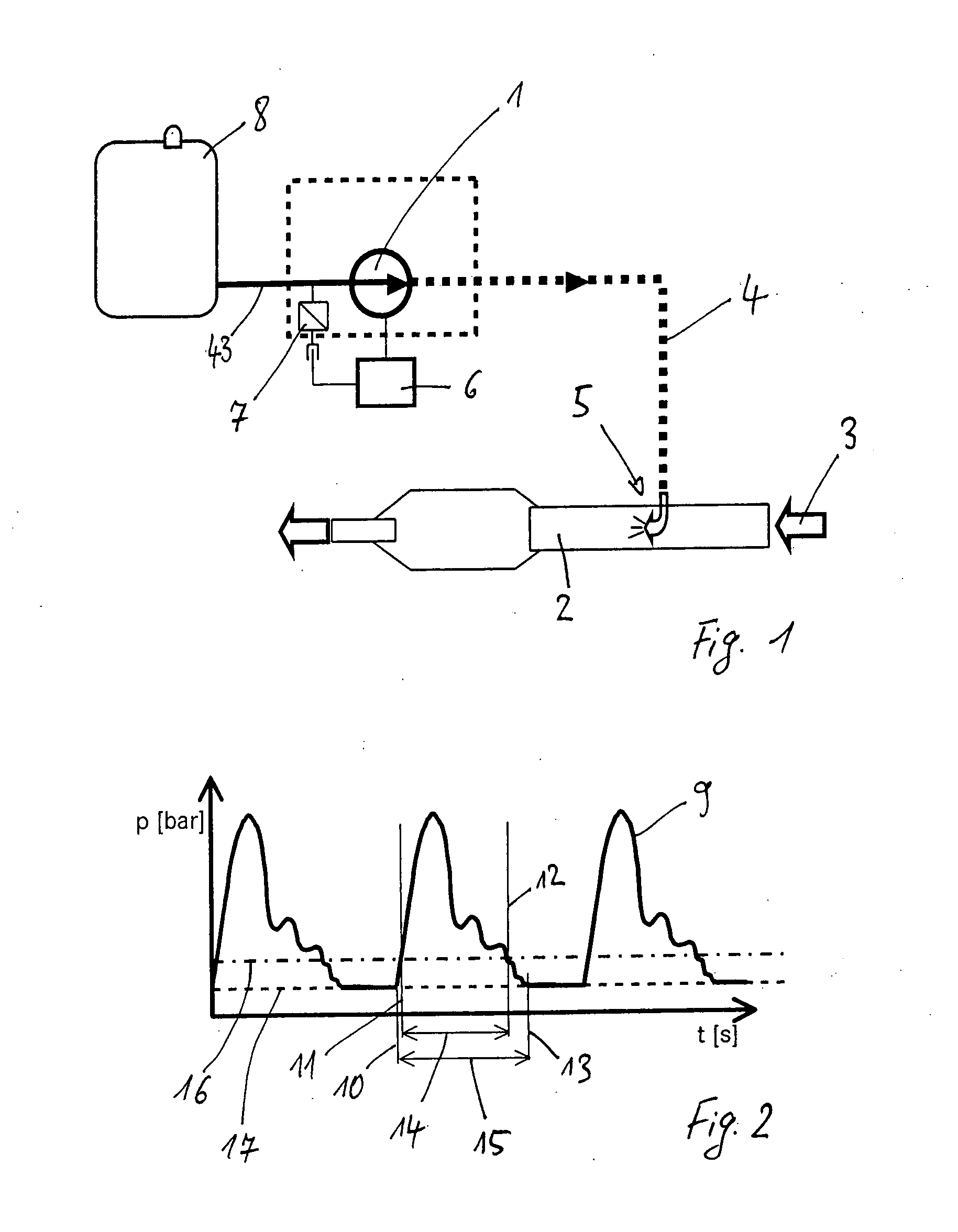

Arrangement for the dosed injection of a reducing medium into the exhaust tract of an internal combustion engine

InactiveUS20070186543A1Improve atomization qualityReduce pressureInternal combustion piston enginesExhaust apparatusExternal combustion engineInternal combustion engine

In an arrangement for the dosed injection of a reducing agent into the exhaust tract of an internal combustion engine, comprising a pump for the pulsed pumping of the reducing agent and an atomizing injection nozzle disposed in the exhaust tract of the internal combustion engine, the injection nozzle includes a valve element which opens and closes the injection nozzle depending on the pressure generated by the pump and permits the injection of the reducing agent into the exhaust tract only when the pressure of the reducing agent is in excess of a certain value in order to ensure proper atomization of any reducing agent injected into the exhaust tract.

Owner:L'ORANGE GMBH

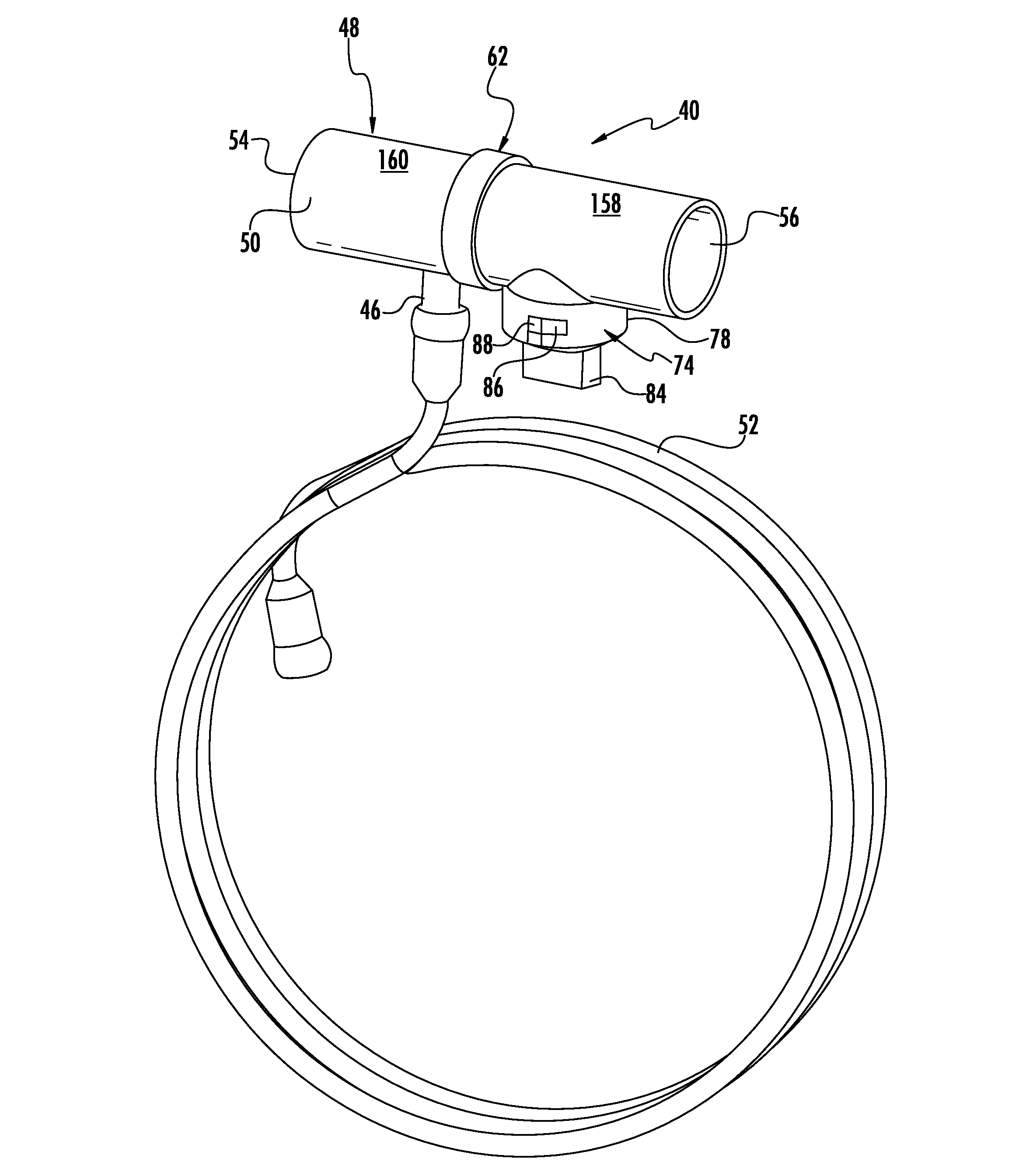

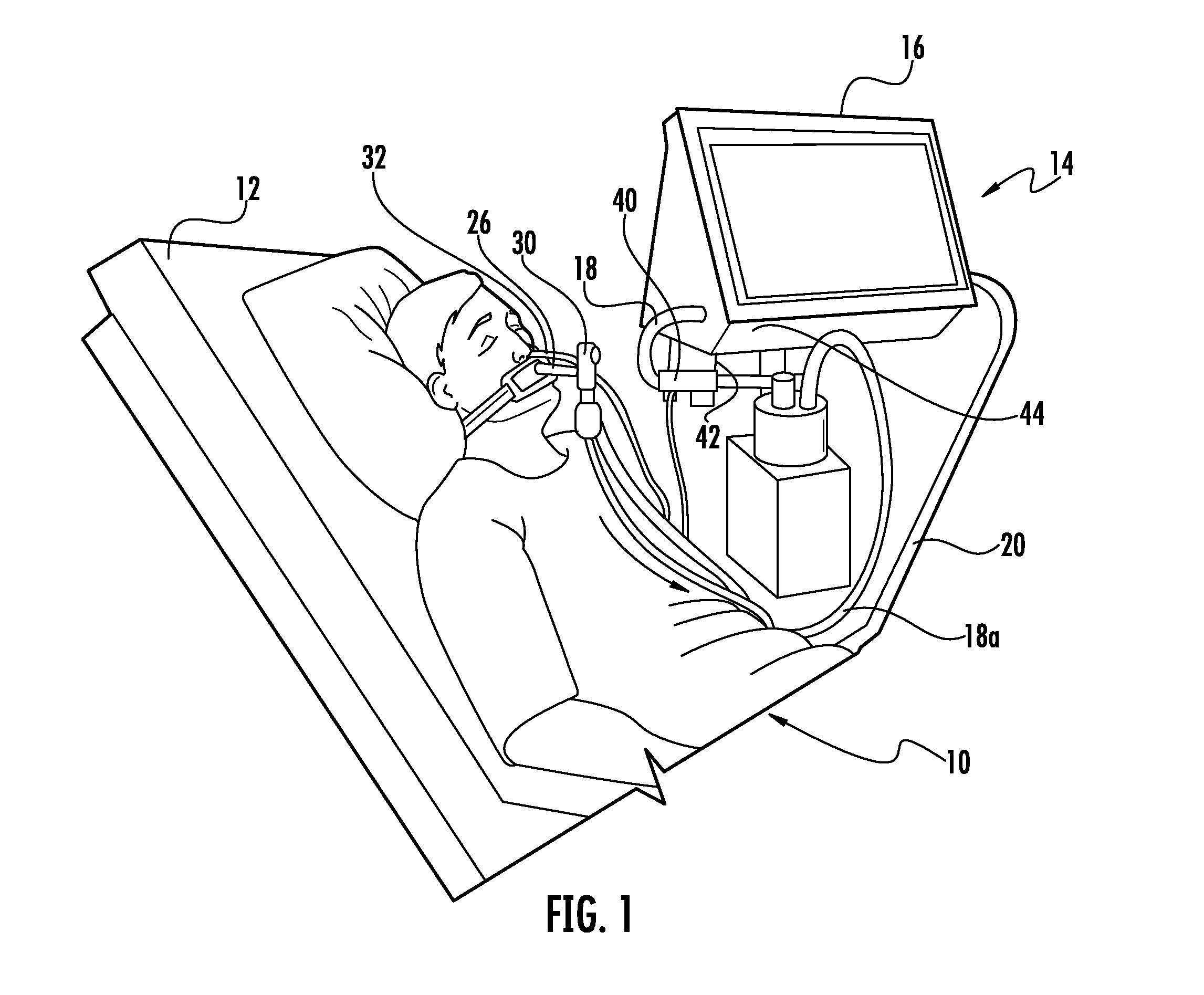

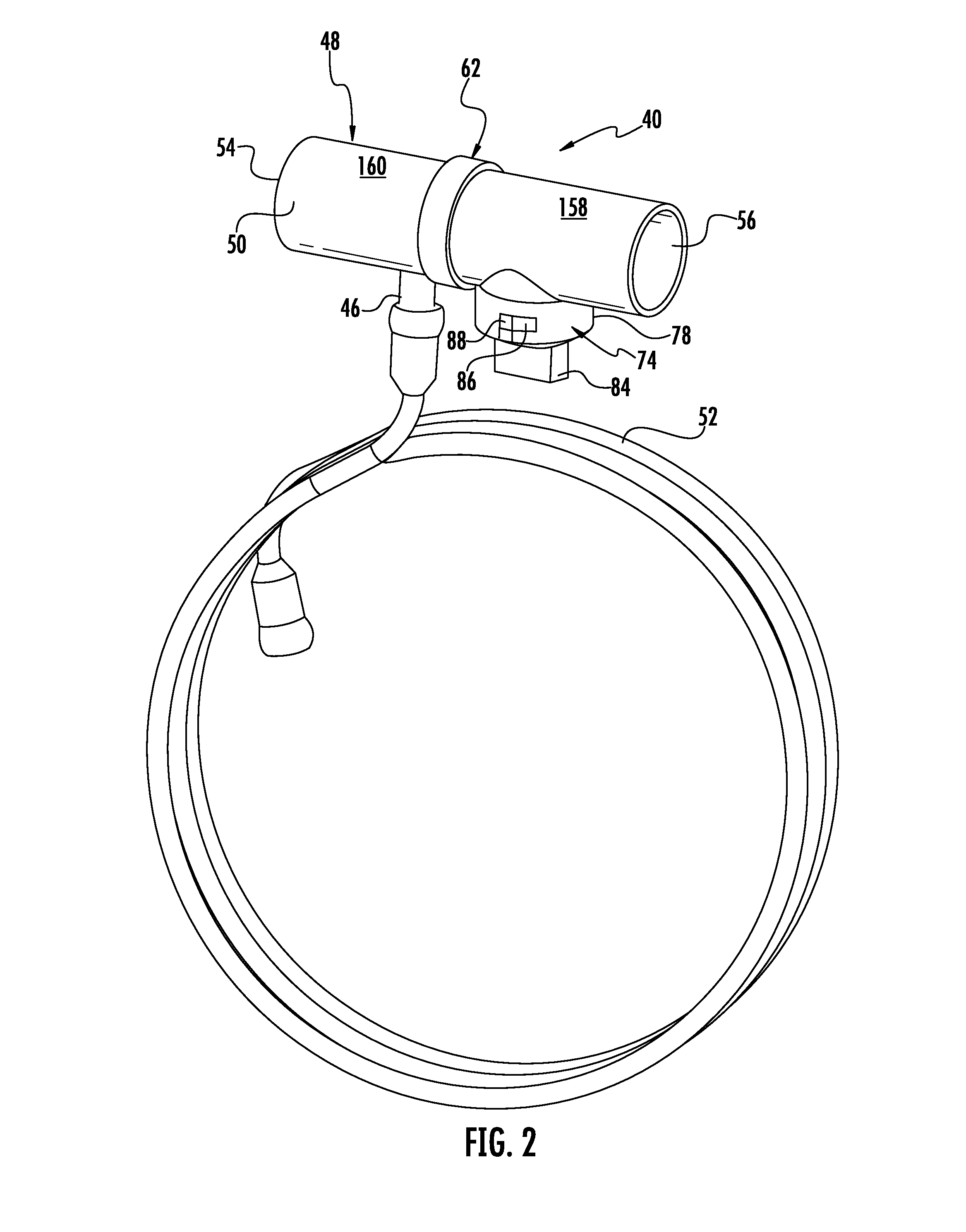

Nebulized ventilation system

A nebulizer is connected to an inspiratory air line of a ventilator and forms an air path along a longitudinal axis through which air is delivered to a patient from a ventilator. A nebulizer nozzle is carried within the nebulizer housing and aligned with the longitudinal axis through which gas is mixed with medication and discharged into the air path. A suction line extends from the discharge end of the nebulizer nozzle through the outer surface of the nebulizer housing to a medication receiver that draws medication upward from a medication container contained within the medication receiver and mixes the medication with gas passing through the nebulizer nozzle and nebulizes the medication for discharge into the air path to a patient.

Owner:PNEUMOFLEX SYST

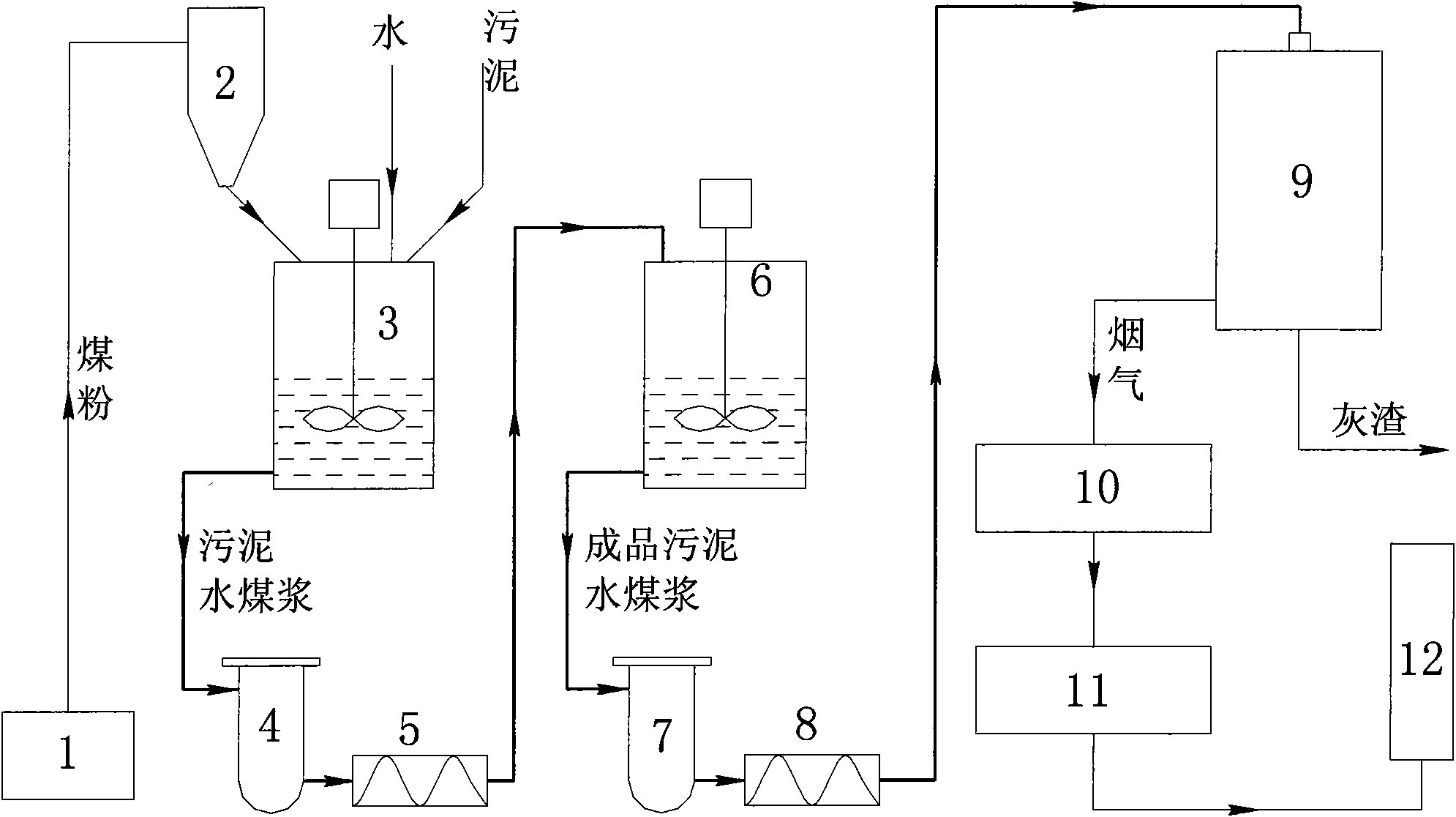

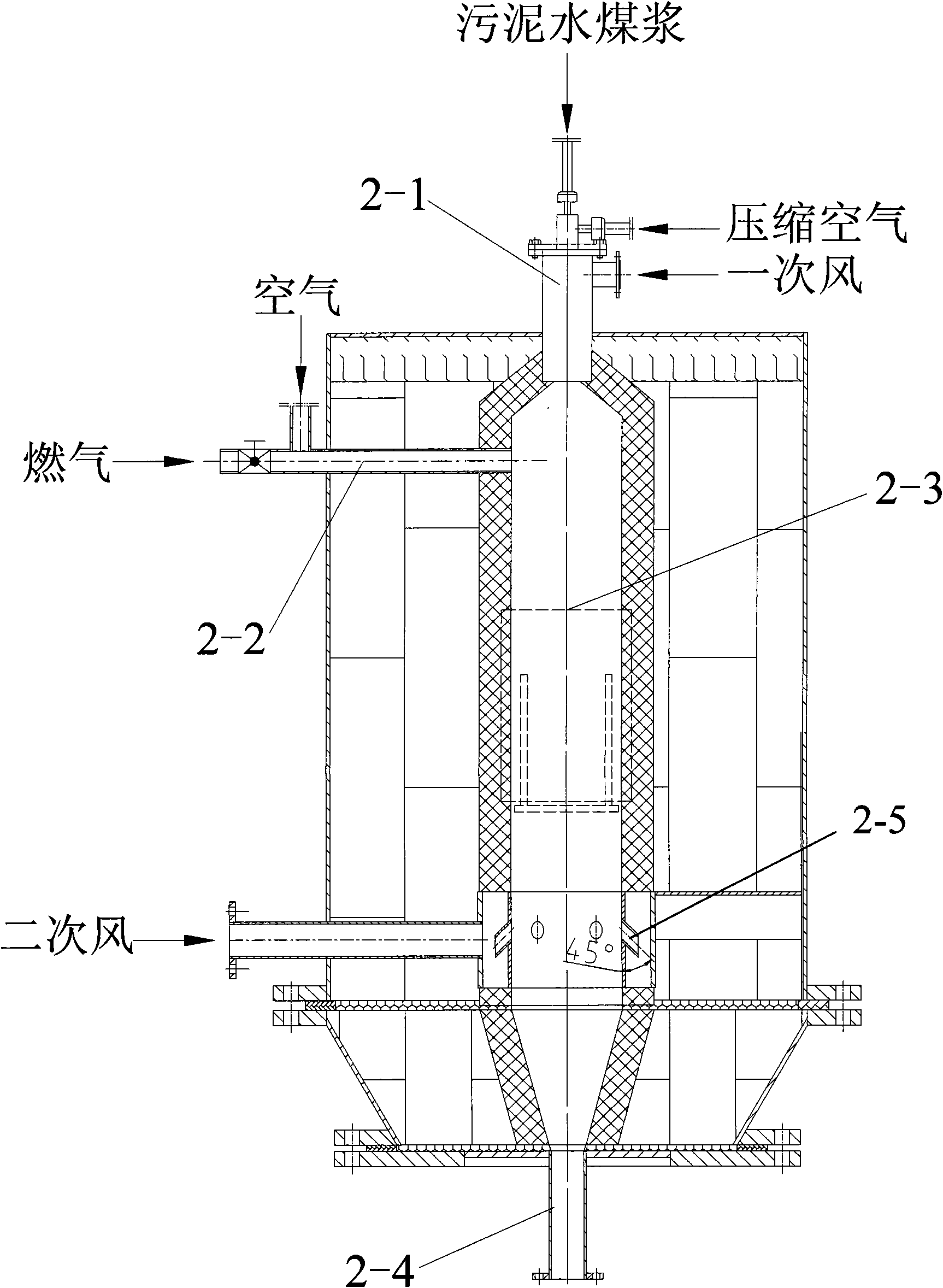

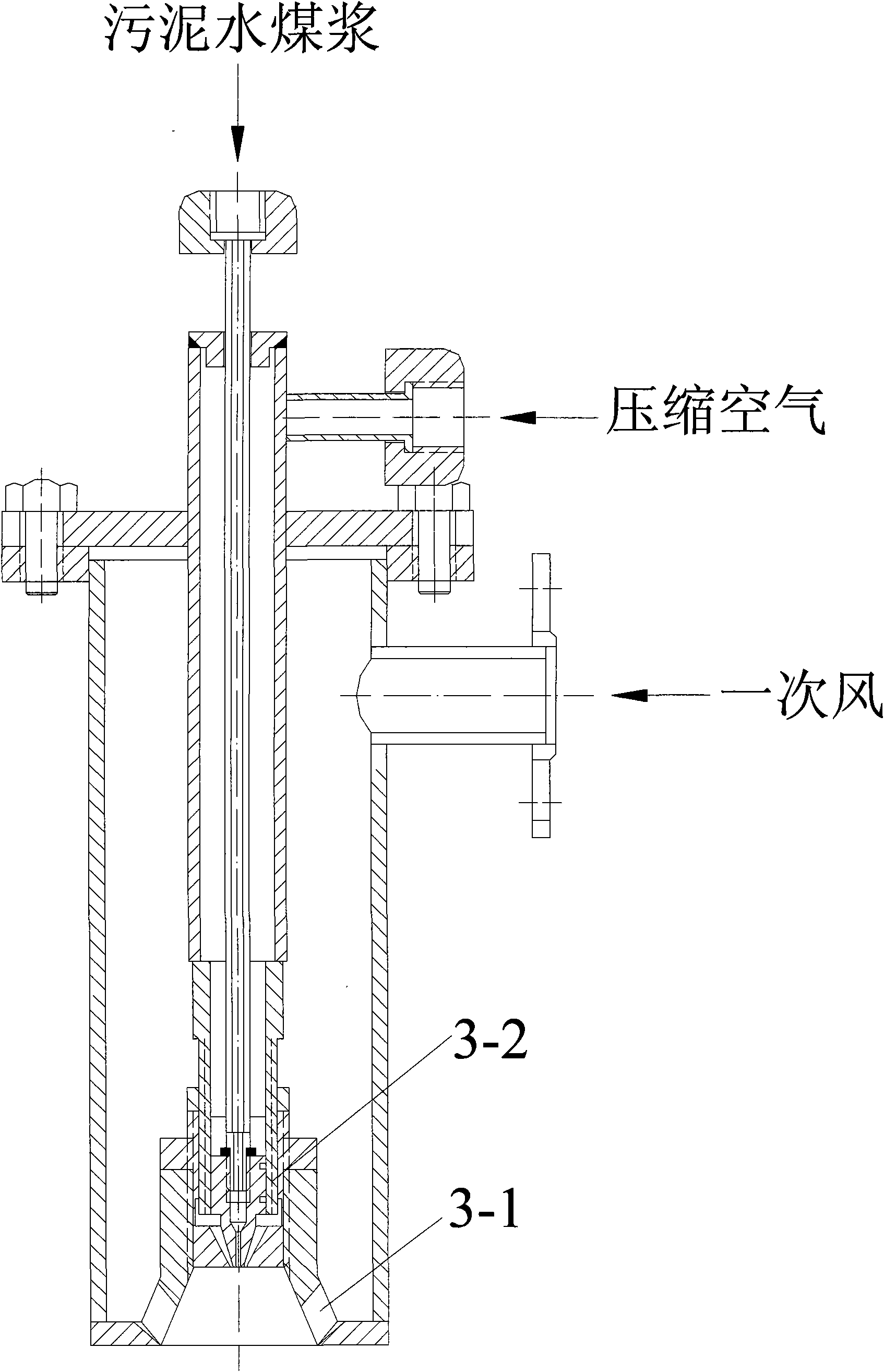

Incineration treatment method of municipal sludge and device thereof

InactiveCN101551108AReduce collectionSave storageIncinerator apparatusCombustion chamberAtmospheric air

The invention relates to an incineration treatment method of municipal sludge and a device thereof. The method comprises the steps of directly mixing powdered coal with average particle diameter of 75 to 90 micrometers, municipal sludge with water content of 95 wt percent and water according to the mass ratio of 60:25:15, then stirring for two times and filtering to manufacture finished sludge water-coal-slurry, directly adopting a screw pump for pressurizing, feeding the sludge water-coal-slurry into a sludge water-coal-slurry atomizing nozzle, and simultaneously feeding compressed air and primary air into the atomizing nozzle to ensure that the sludge water-coal-slurry is injected into a combustion chamber in a good spray pattern. Generated high-temperature flue gas is discharged into atmosphere after heat is recycled by a waste-heat boiler, and clinker is recycled. The device mainly consists of a coal grinding mill, a powder storage bin, an agitator tank, a first filter, a first screw pump, a storage tank, a second filter, a second screw pump, a combustion chamber, a waste-heat boiler and a bag-type dust collector. The disadvantages in the conventional sludge incineration method that the process is complex and the energy consumption during the sludge drying is high are overcome, and the low pollution emission of the flue gas and the comprehensive utilization of the clinker are realized.

Owner:SOUTHEAST UNIV

Yard and garden chemical dispenser

InactiveUS20110315790A1Dissolving using flow mixingTransportation and packagingInterior spaceAtomizer nozzle

A chemical dispensing apparatus includes a housing that is connectable to a source of water, such as a standard garden house, and an internal space in which is disposed a rotatable container containing a quantity of chemical concentrate to be mixed with the source of water as it flows through the housing and is dispensed from the housing from a sprinkler head or misting nozzle. The flow of water through the housing is directed to imping vanes on the rotatable container, such that the container is rotated as water flows through the housing. In an alternative embodiment, the vanes are replaced with an electric motor. Rotation of the container cause the chemical concentrate to dissolve which is then mixed with the water before it is dispensed through the sprinkler or mister.

Owner:ORUBOR LAWRENCE

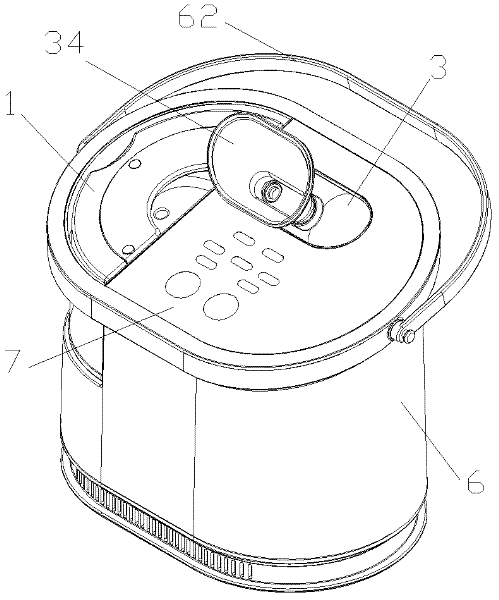

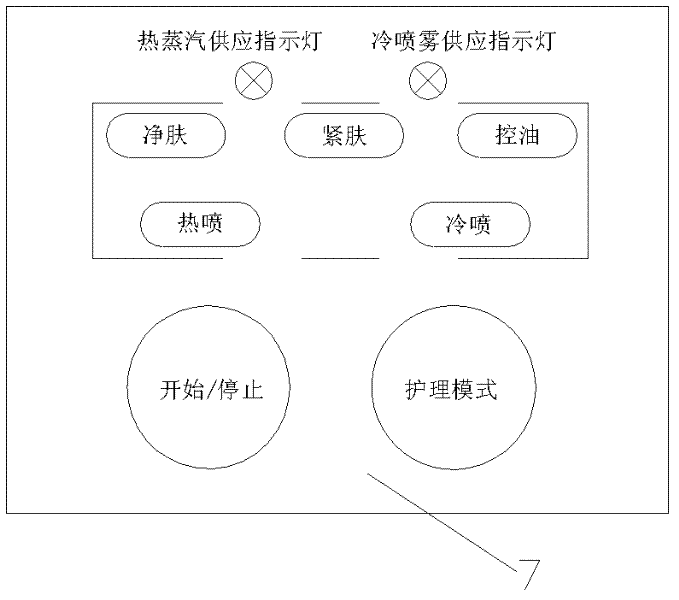

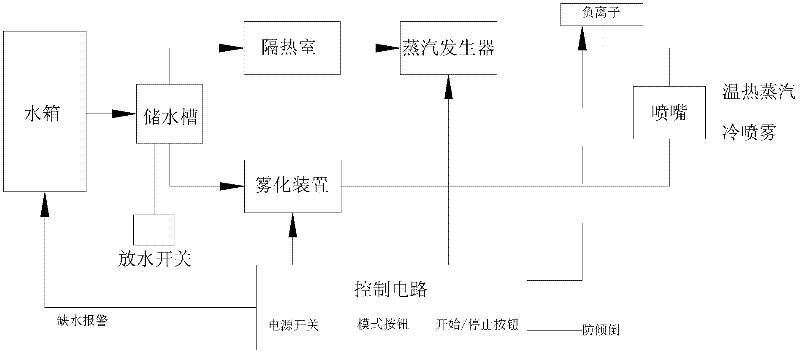

Ion cosmetic steamer and control mode thereof

The invention discloses an ion cosmetic steamer and a control mode thereof. The ion cosmetic steamer comprises a host, wherein the host is provided with a water supply device, a steam generator, an atomizer and a nozzle; hot water is added into the steam generator to release the steam; the atomizer atomizes water; the nozzle is provided with a hot spout and a cold spout; the hot spout and the cold spout are not communicated; steam released from the steam generator and moisture atomized by the atomizer are respectively sprayed out from the hot sprout and the cold sprout; and a control device controls the steam generator and the atomizer to open and close to cause the ion cosmetic steamer to have three modes of hot spraying, cold spraying, and alternately hot spraying and cold spraying. Thecold spraying structure is added on the traditional ion cosmetic steamer, the ion cosmetic steamer can generate cold water mist and hot steam at equal speed, and can spray hot water mist and cold water mist alternately by different stages in a scientific nursing mode, the effect on cleaning skin, tensioning skin and controlling oil can be achieved by the cold and hot irritation on the skin of thehuman body by the water mist and the steam.

Owner:ZHEJIANG HUAGUANG ELECTRIC APPLIANCE GRP

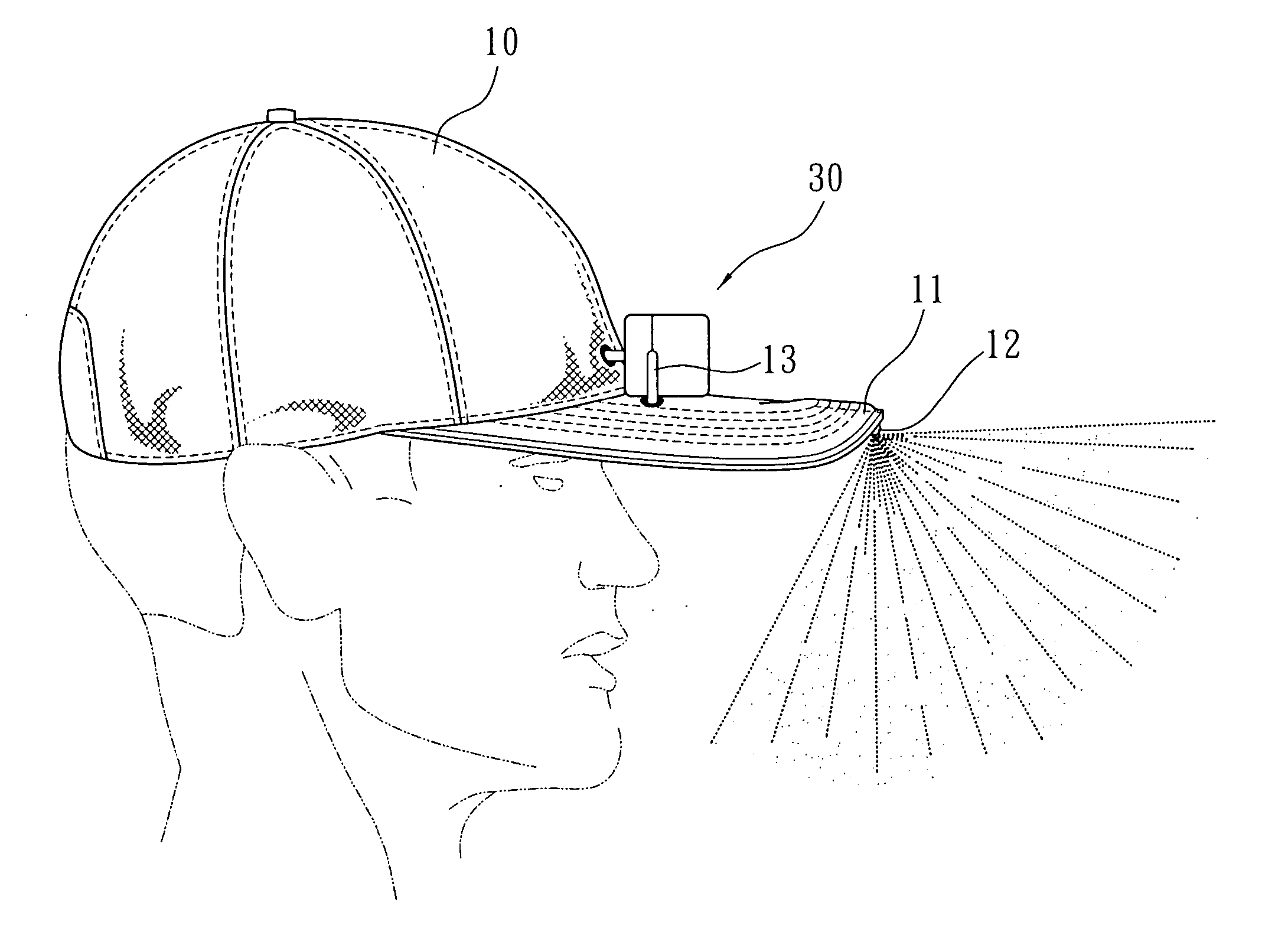

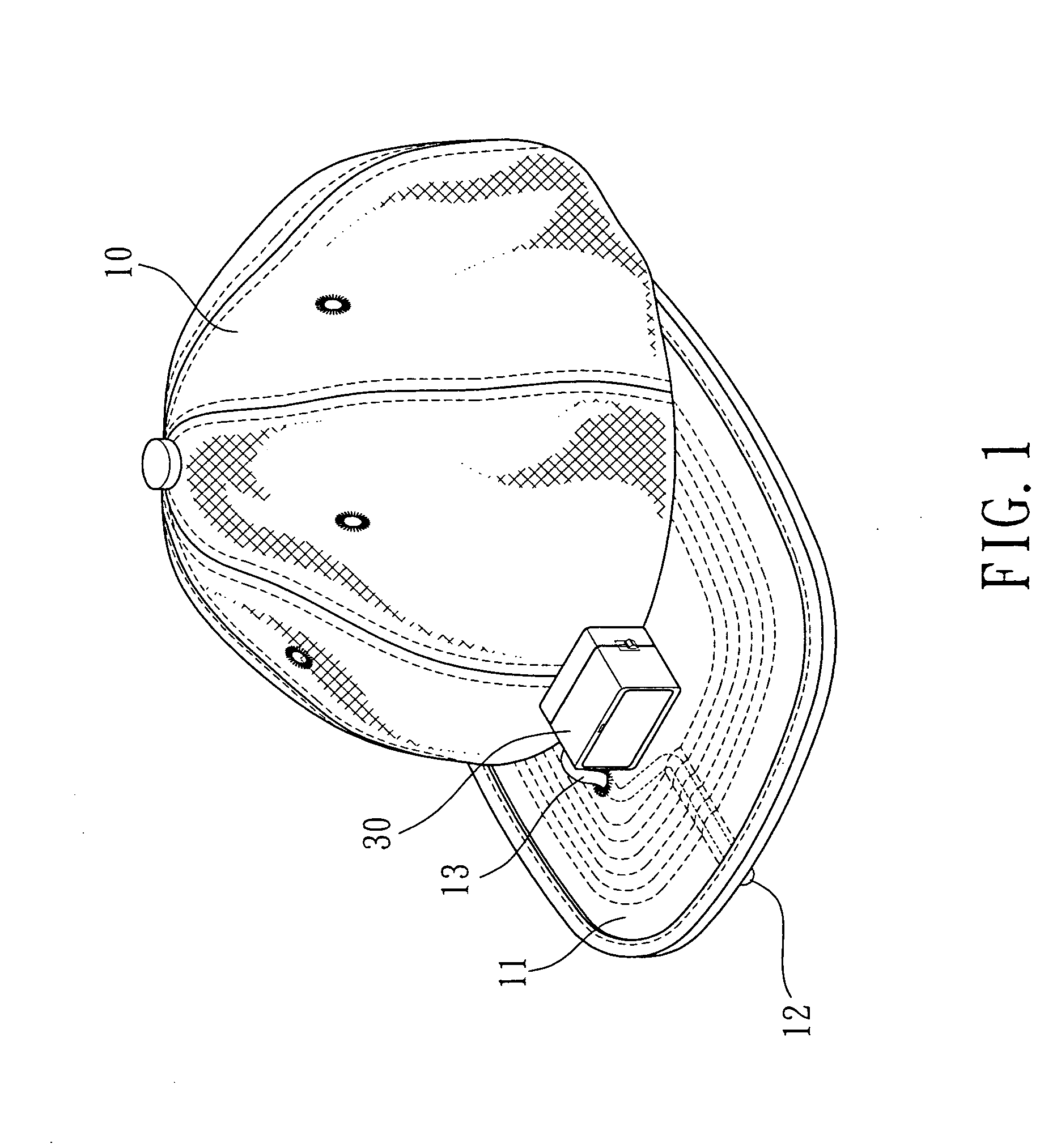

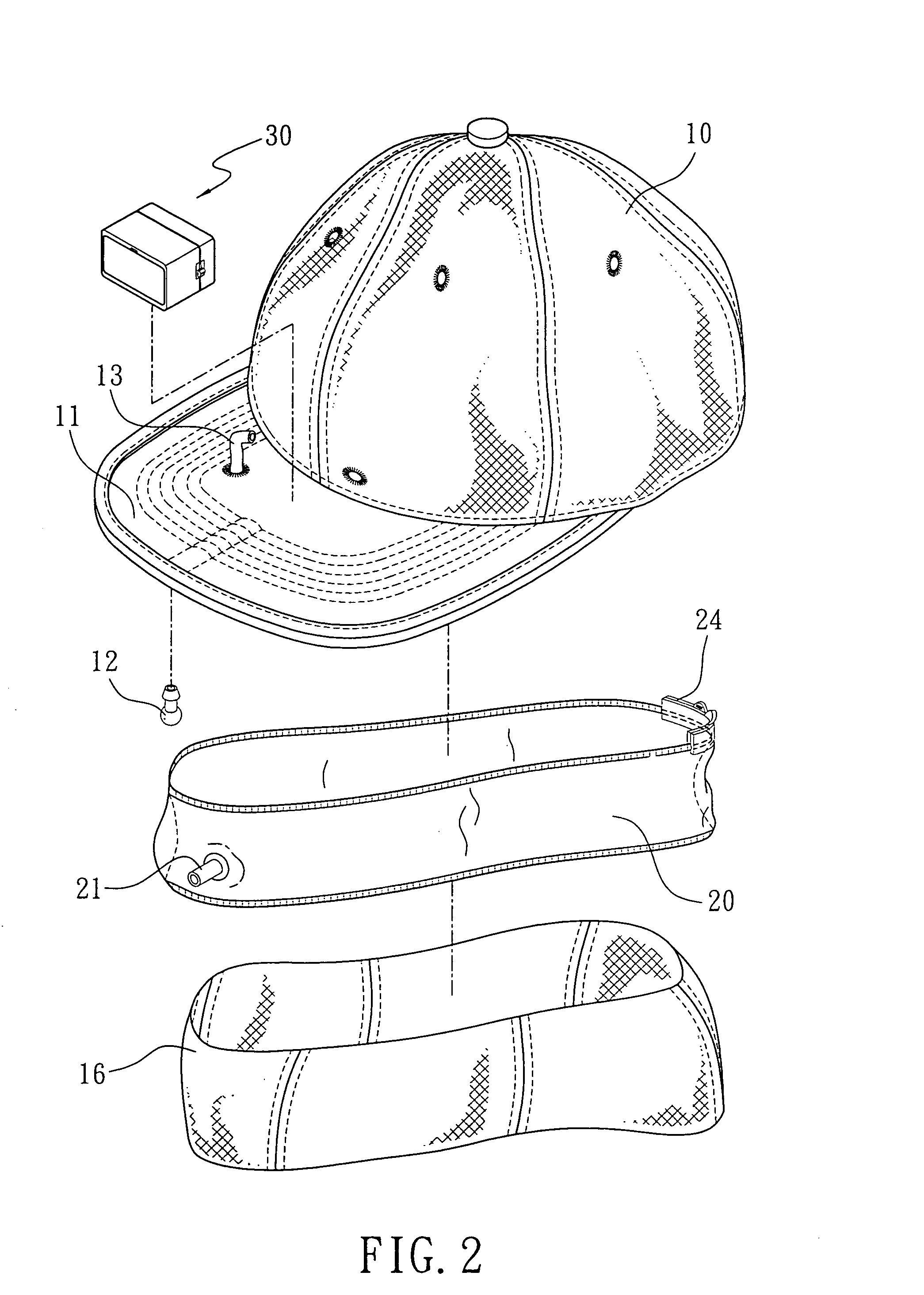

Headgear capable of sprinkling and cooling

A headgear capable of sprinkling and cooling comprises at least a crown, a water pouch and a liquid dispenser. The front end of the peak is provided with an atomizing nozzle, which is connected with a connecting tube at one end. A water pouch provided at the inner rim of the crown is provided with a water outlet at the outer edge. The liquid dispenser includes a squeezing device, a switch, and batteries; all of the above elements are assembled and contained in a casing composed of an upper portion and a lower portion, and then installed at an upper position of the peak. The liquid dispenser is connected to the water outlet of the water pouch with its inlet end, and to the nozzle with its outlet end via a connecting tube. Accordingly, the water contained in the pouch can be transmitted by the liquid dispenser to the nozzle at the front end of the peak for praying purpose, thereby accomplishing a headgear capable of sprinkling and cooling.

Owner:TU MING TE

Vehicle painting hybrid rotor based on spatial and planar parallel mechanism with three degrees of freedom

InactiveCN101966502AStructural symmetryEasy to manufactureProgramme-controlled manipulatorSpraying apparatusThree degrees of freedomAtomizer nozzle

The invention relates to a vehicle painting hybrid rotor based on a spatial and planar parallel mechanism with three degrees of freedom, which comprises a gantry frame and four painting module units. The first painting module unit is identical to the fourth painting module unit in structure while the second painting module unit is identical to the third painting module unit in structure. Through combination of horizontal movement of the gantry frame and movement of the painting module units, positions and orientations of the atomizer nozzles of all the painting module units can be controlled so as to realize the painting of the entire vehicle to be painted. The vehicle painting hybrid rotor has the characteristics of symmetrical structure, good flexibility, and high precision, rigidity and flexible degree, is easy to manufacture, convenient to control and easy to realize modularization and can be used to paint different entire vehicles by increasing or decreasing painting modules as required.

Owner:JIANGSU CHANGHONG INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com