Incineration treatment method of municipal sludge and device thereof

A technology for urban sludge and treatment methods, which is applied in combustion methods, incinerators, combustion types, etc., can solve the problems of large energy consumption and complex process, achieve continuous and reliable operation, simple process flow, and eliminate the need for sludge collection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

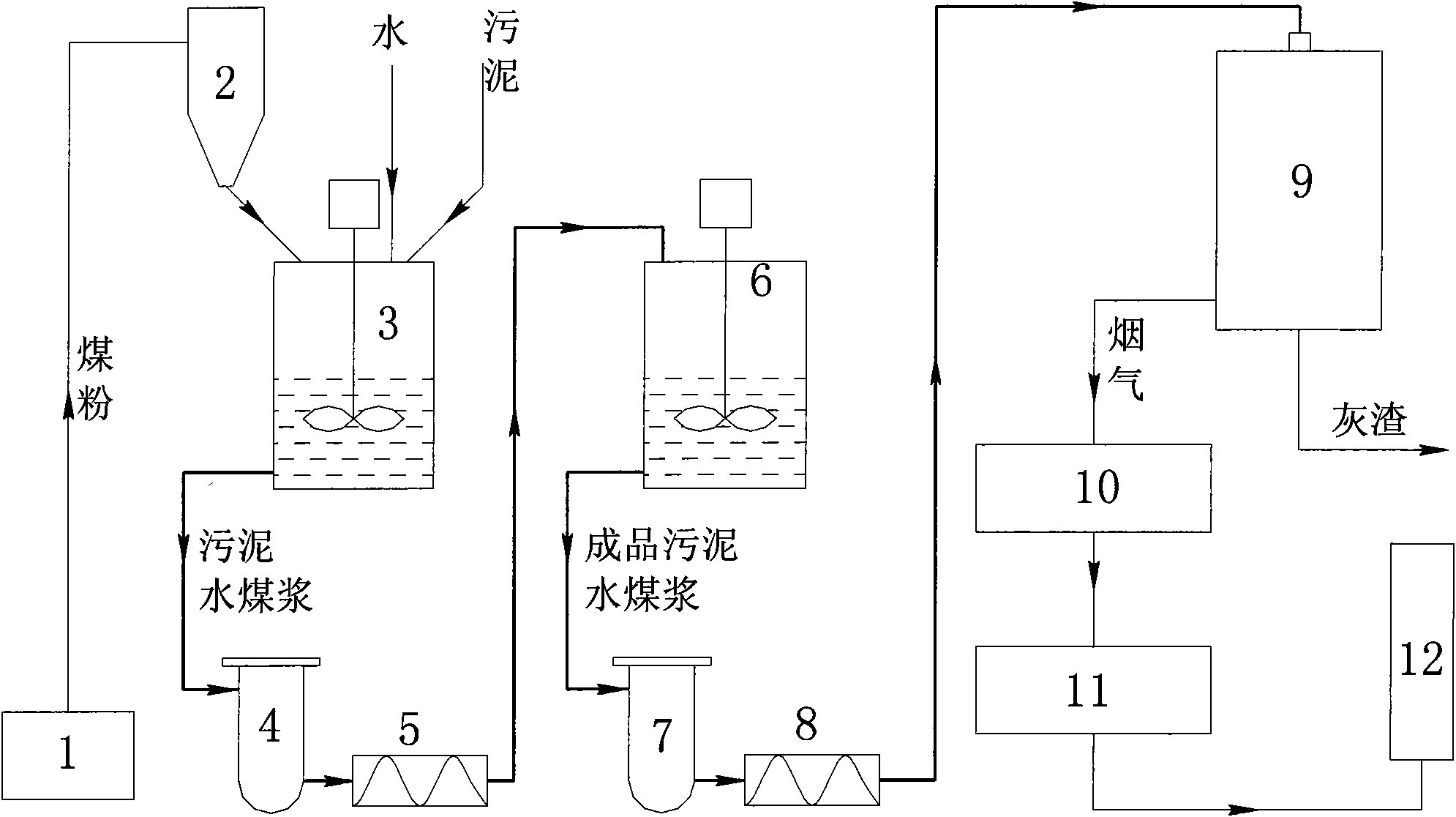

[0020] figure 1 Process flow chart for slurrying, combustion and heat recovery of sludge coal-water slurry. Coal powder, sludge and water are mixed and stirred and then pumped to the combustion chamber for combustion. The high-temperature flue gas passes through the waste heat boiler to recover heat, and then is discharged into the atmosphere after passing through the bag filter, and the ash is directly discharged from the lower part of the combustion chamber.

[0021] The specific method of starting the combustion system is as follows:

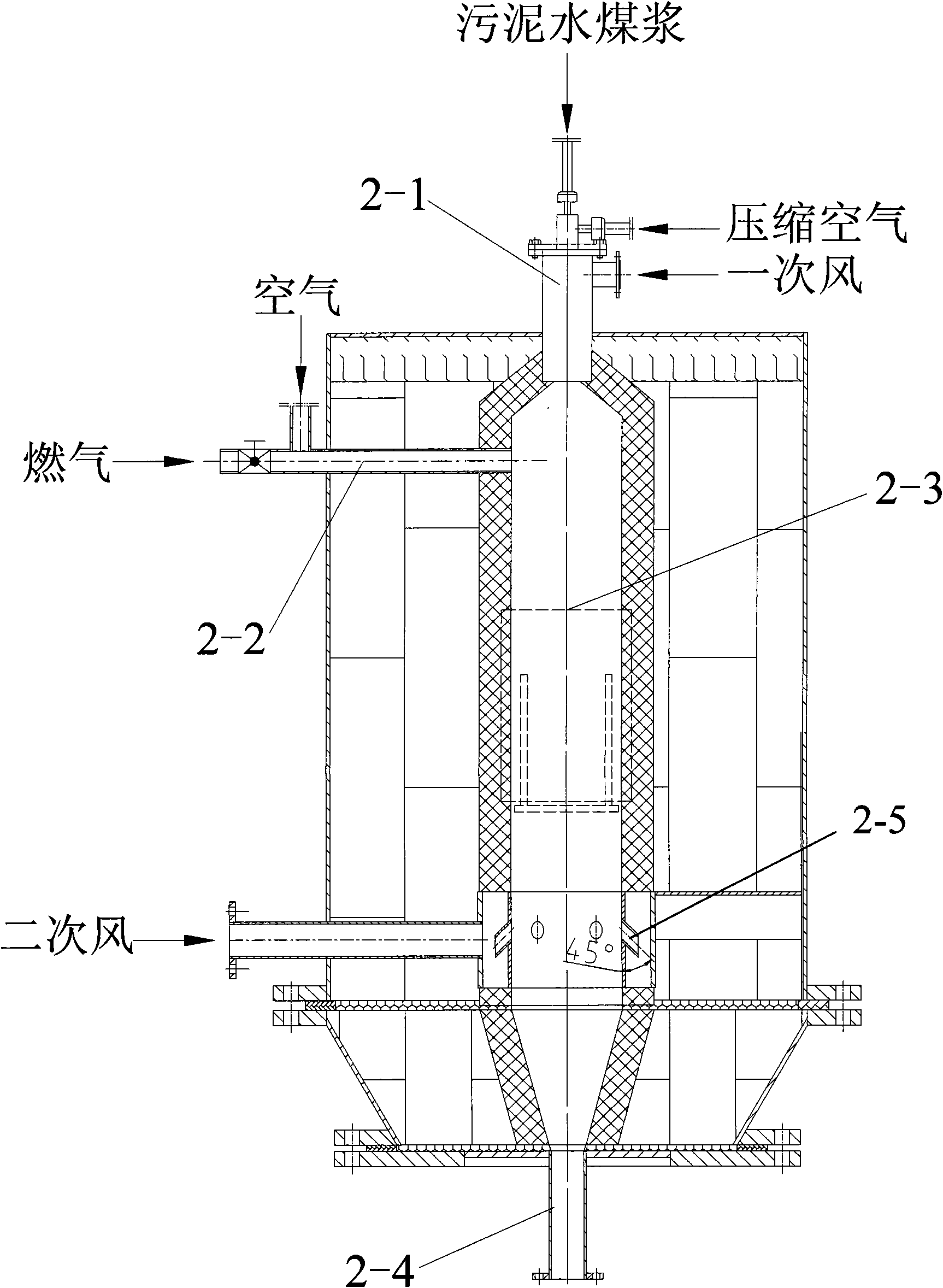

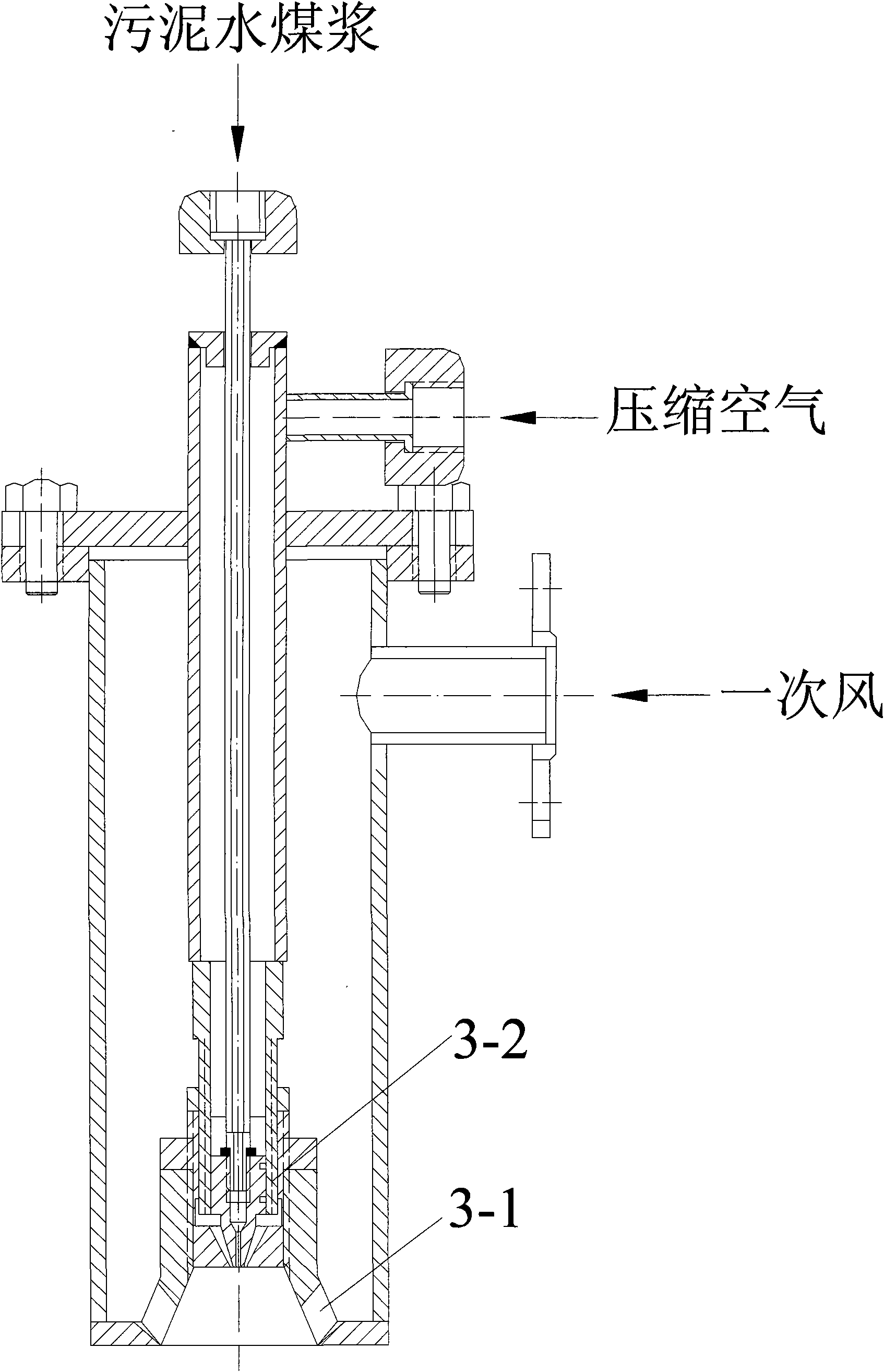

[0022] When the combustion system starts, gas and air are sent into the ignition gun 2-2 located at the top of the combustion chamber 9 to mix earlier, and then sent into the combustion chamber 2-3 to ignite. When the temperature in the chamber 2-3 of the combustion chamber reaches 850°C, start to send the sludge coal-water slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com