Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

99 results about "Glow plug" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A glow plug engine, or glow engine, is a type of small internal combustion engine typically used in model aircraft, model cars and similar applications. The ignition is accomplished by a combination of heating from compression, heating from a glow plug and the catalytic effect of the platinum within the glow plug on the methanol within the fuel.

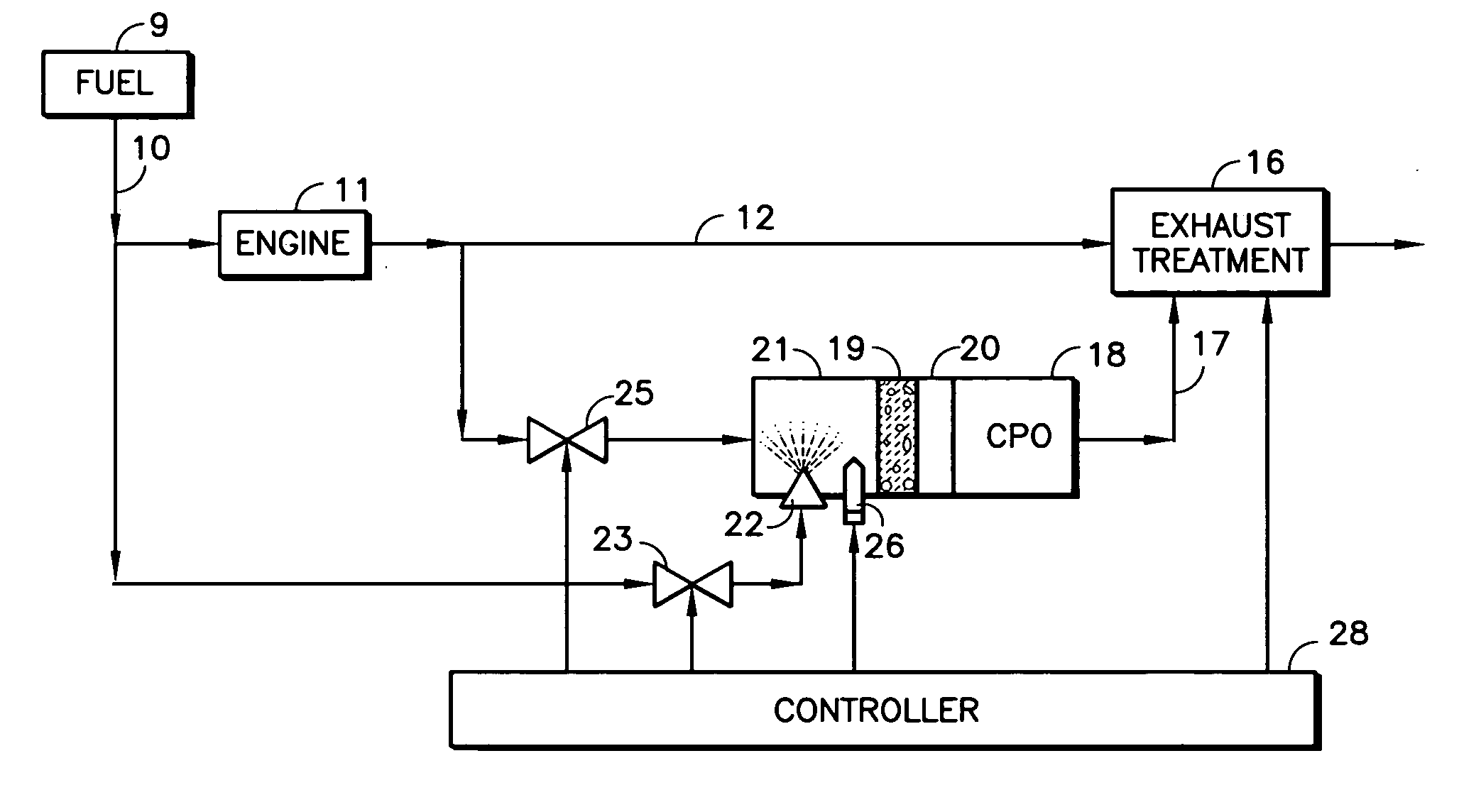

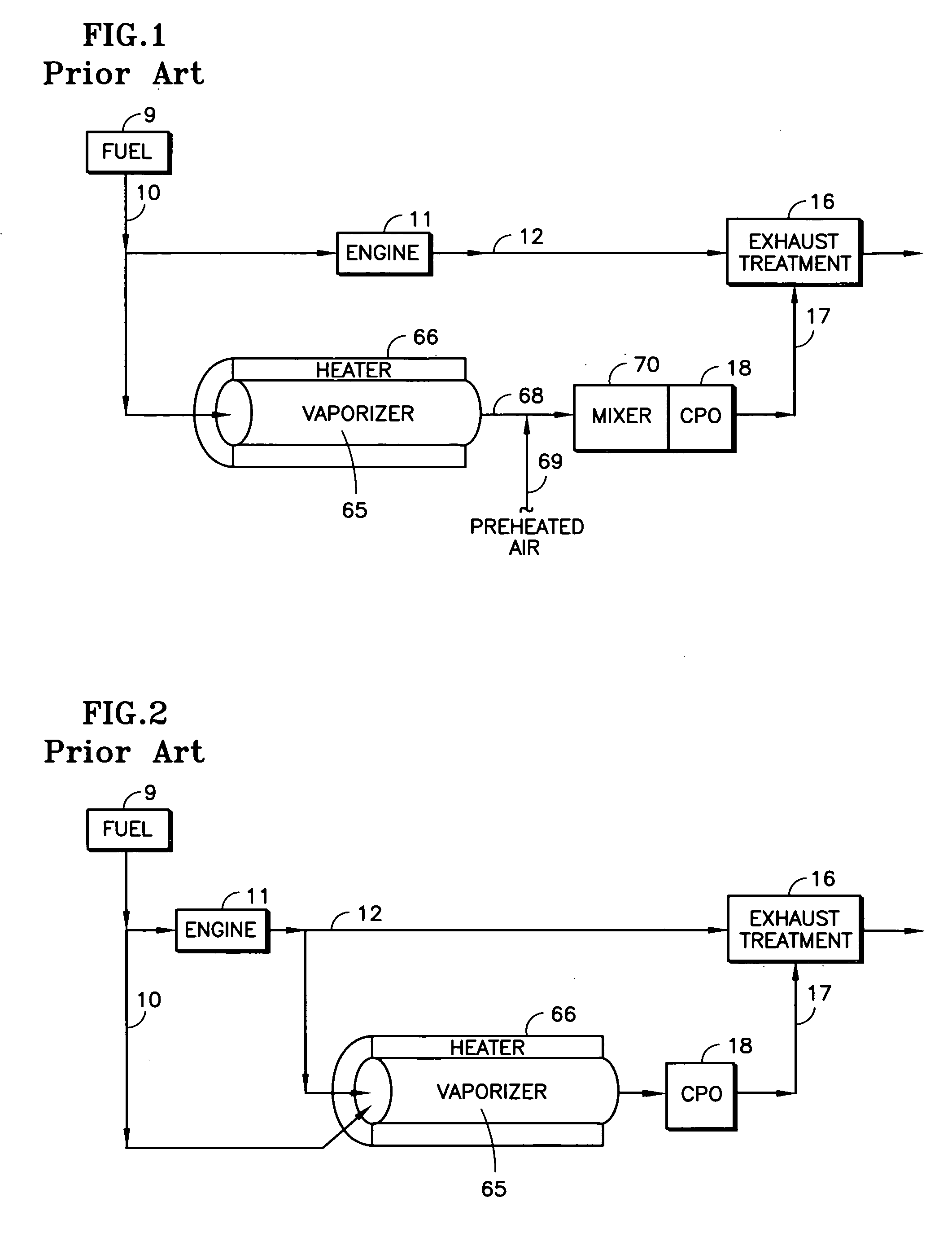

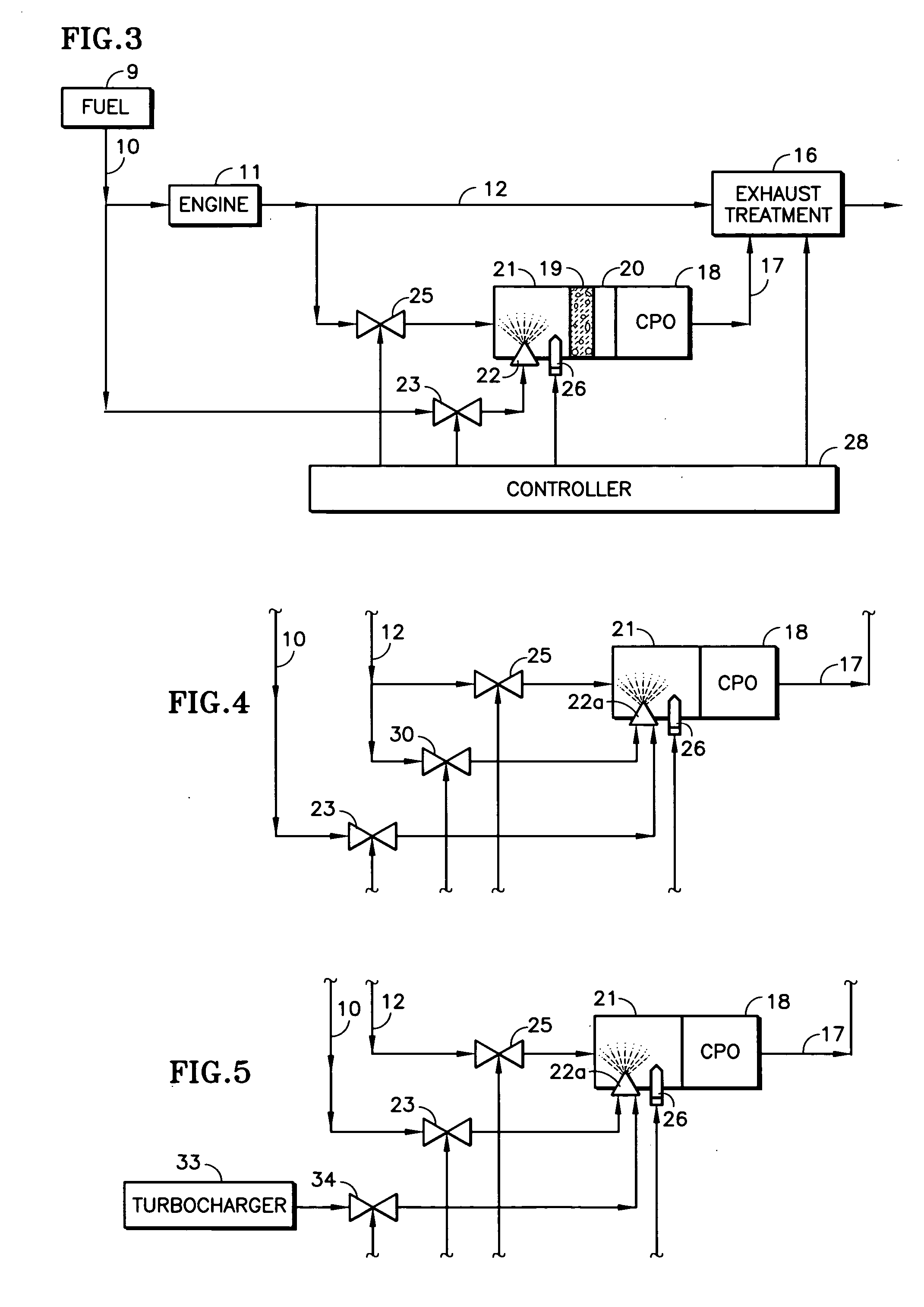

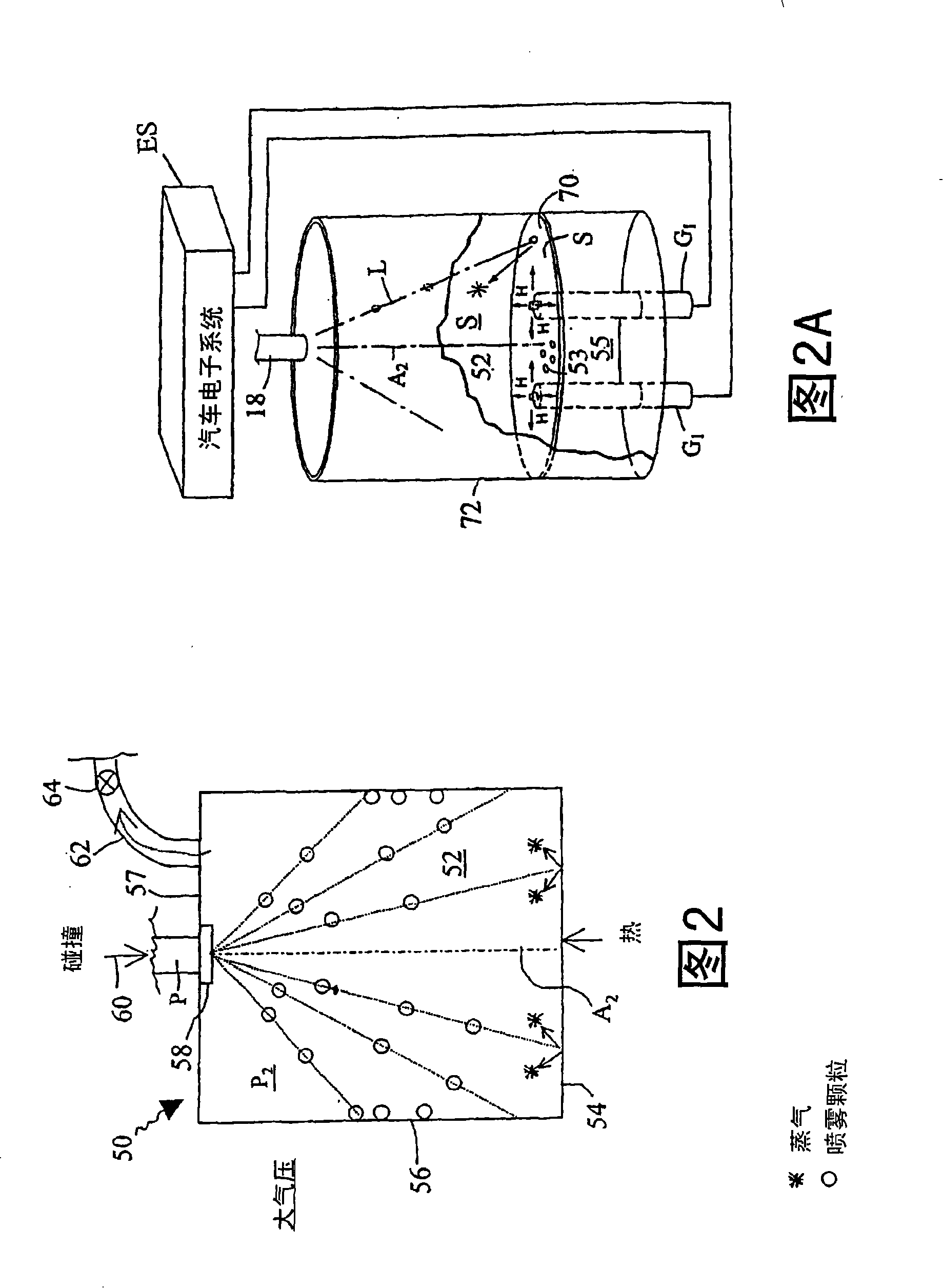

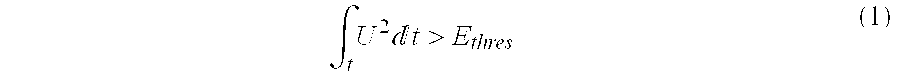

Reforming unvaporized, atomized hydrocarbon fuel

InactiveUS20050274107A1Improved hydrogen generationLow costHydrogenExhaust apparatusKeroseneTurbocharger

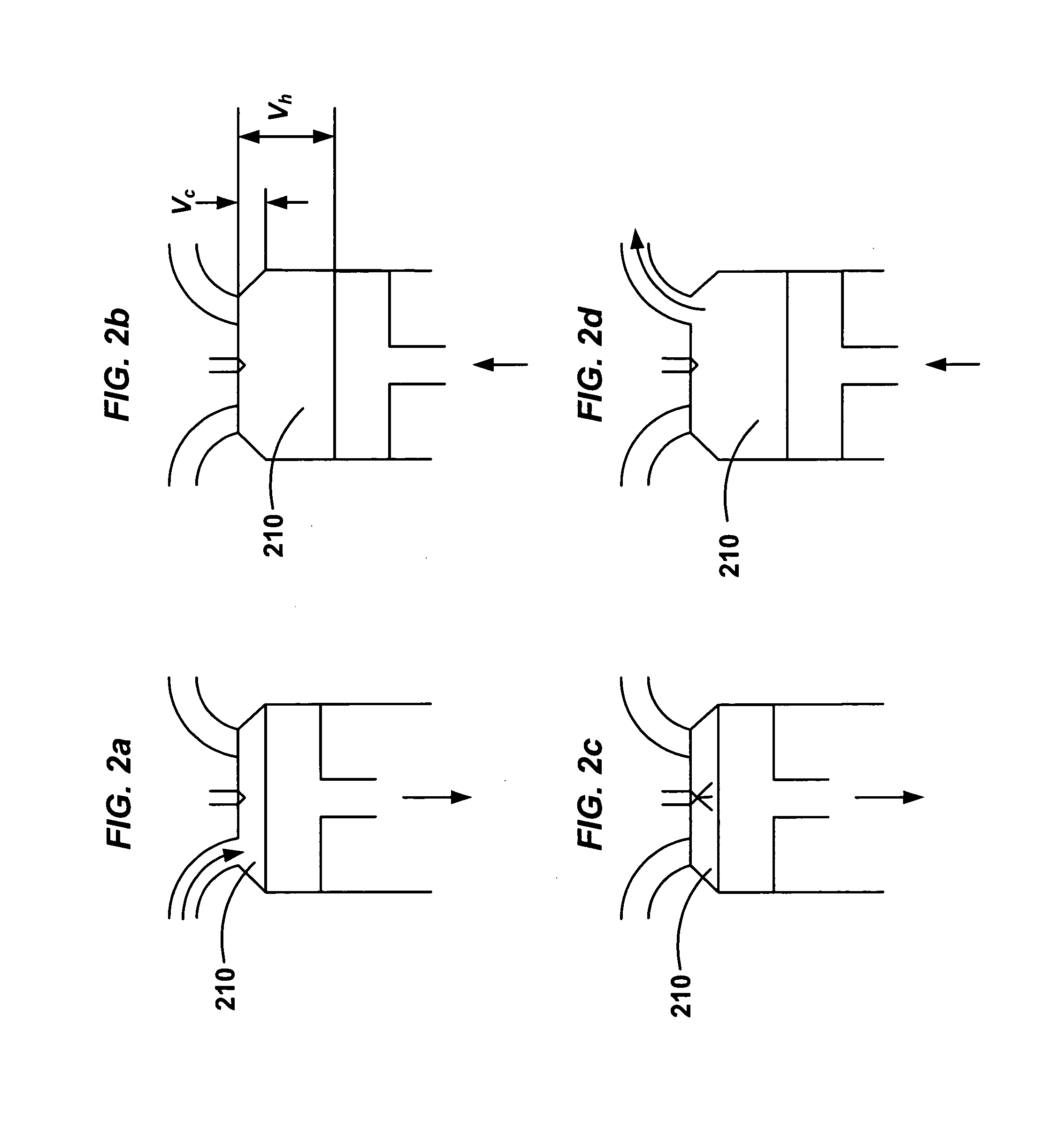

A reformer such as a CPO (18) receives a mix of fuel, moisture and oxygen from a mixing region (21) having an igniter (26, 66), which may include an inert ceramic foam (19), the fuel being provided by an atomizing nozzle (22), thereby avoiding the need for a vaporizer before use. The oxygen and moisture may comprise engine exhaust (11, 12). Fuel from a vehicle fuel tank (9), may be gasoline, diesel fuel, kerosene, jet fuel, or JP-8. The atomizing nozzle may be a gas-assist nozzle (22a), receiving the assisting gas from (a) engine exhaust (10), (b) a turbocharger (33), (c) an air pump (50) or (d) a steam generator (57). The oxygen and moisture may comprise moisturized air, which may be achieved by an ejector (41) which ingests water from a tank (43) in response to the flow of air from a pump (50) through a conduit (47). The air may be regeneratively heated (48) with the CPO exhaust. The igniter may be a glow plug (26) or a heater wire (66) coated with catalyst.

Owner:SHELL OIL CO

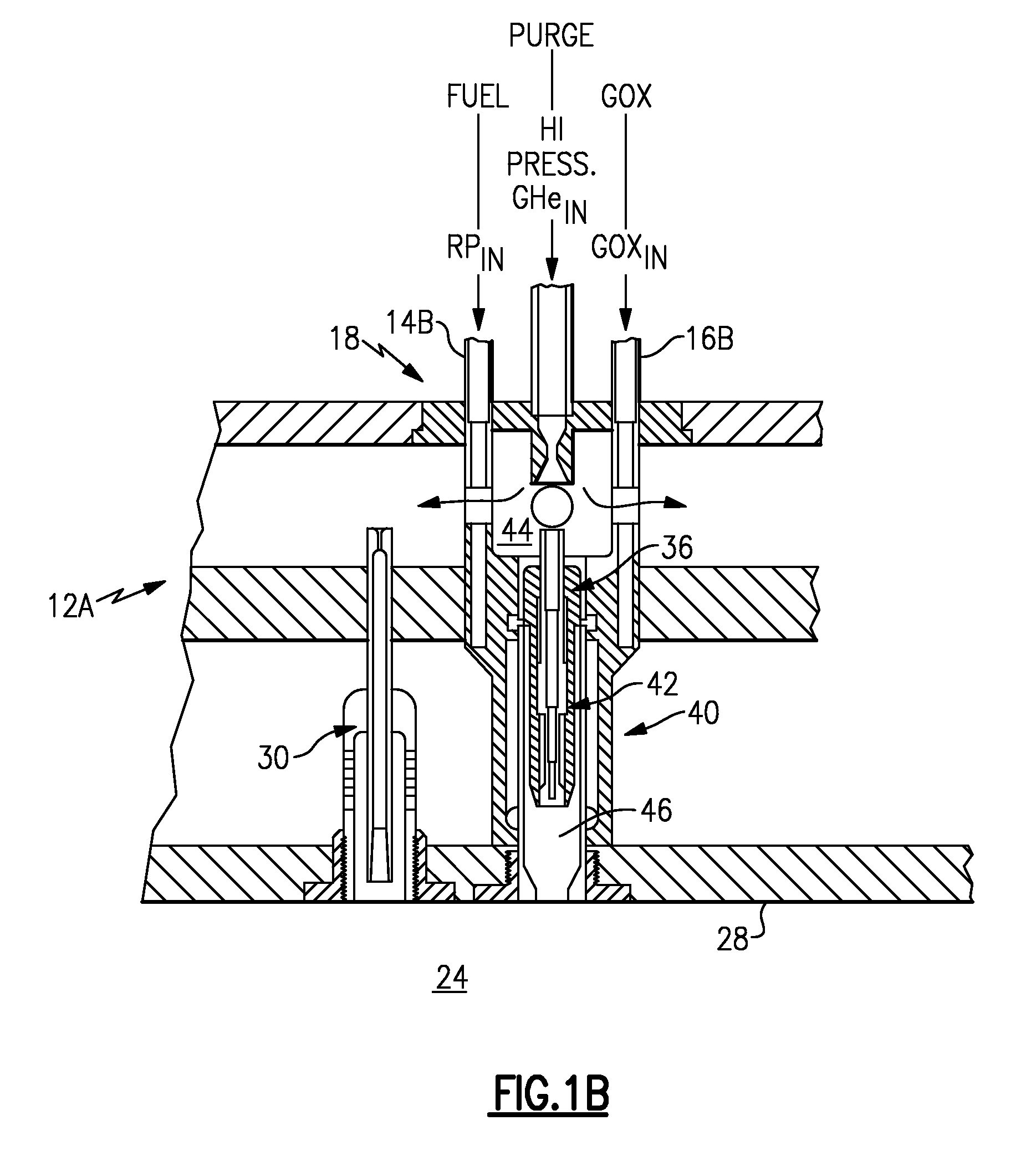

Resonance driven glow plug torch igniter and ignition method

InactiveUS20080299504A1Easy to integrateImprove reliabilityContinuous combustion chamberPulsating combustionThermal energyCombustion chamber

An ignition system for a combustion device utilizes an oscillating pressure force in a resonance system to generate thermal energy within a resonance driven glow plug. The resonance driven glow plug stores the thermal energy for transfer to ignitable propellant combinations within a torch assembly and thus within the combustion chamber.

Owner:AEROJET ROCKETDYNE OF DE

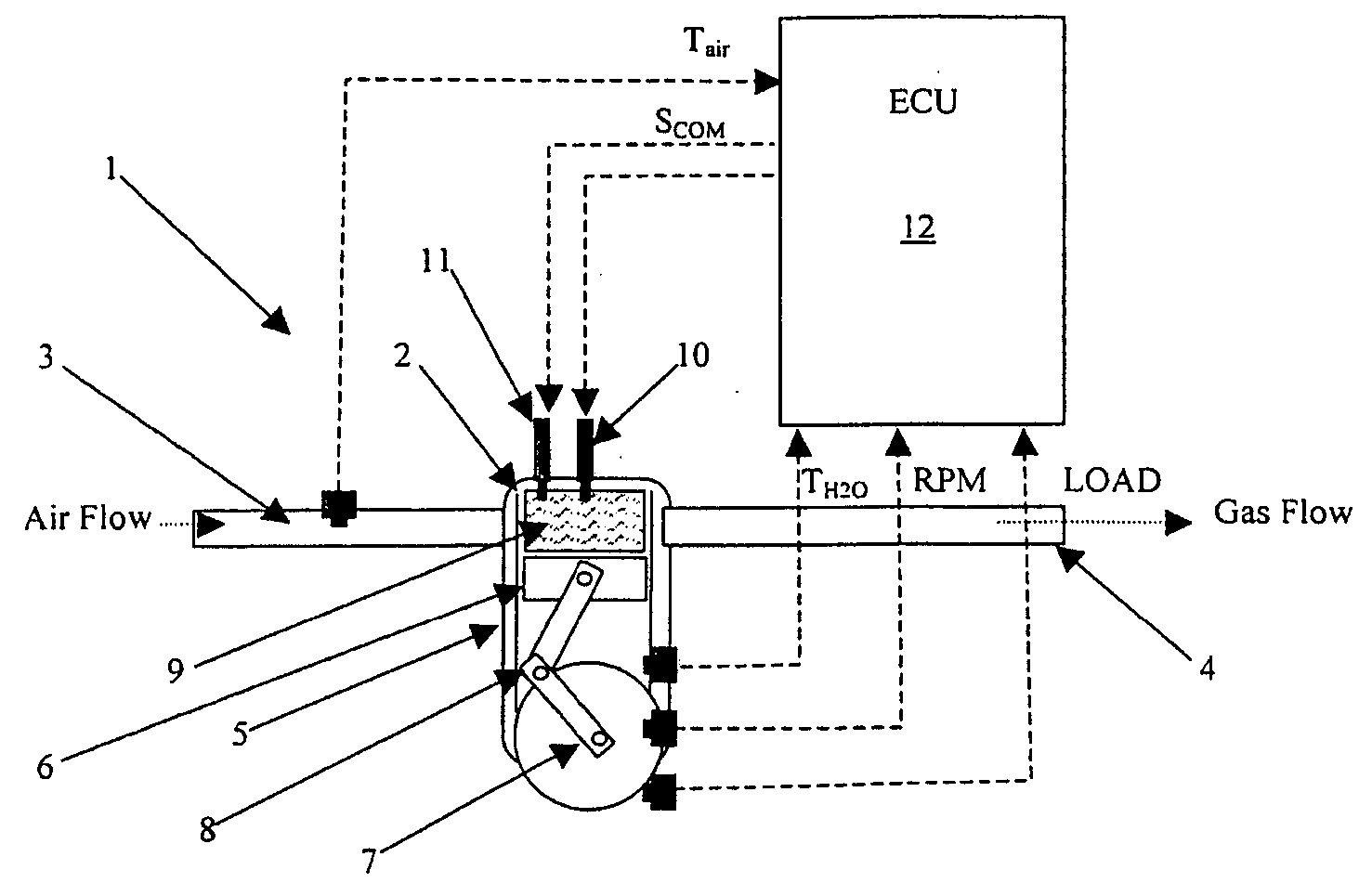

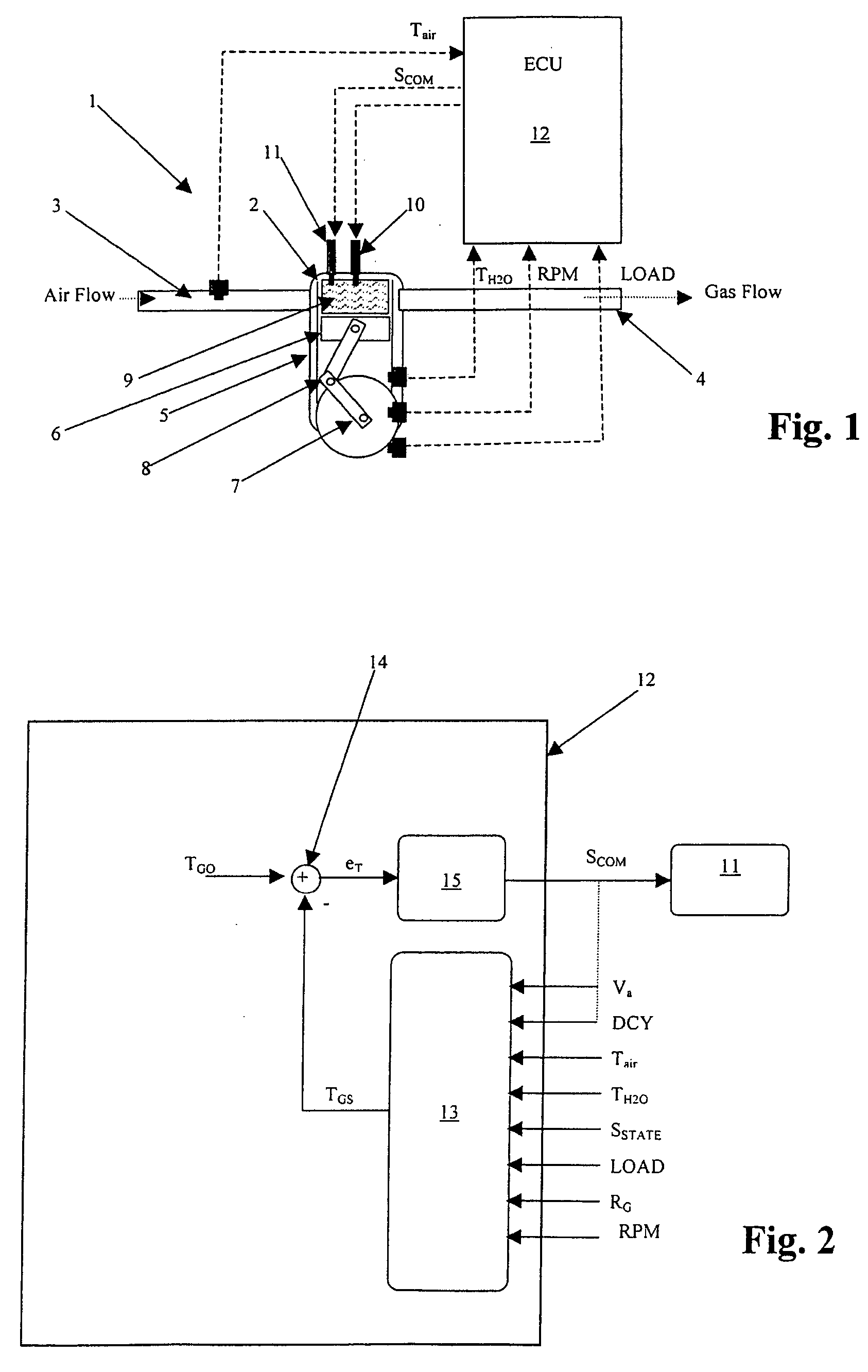

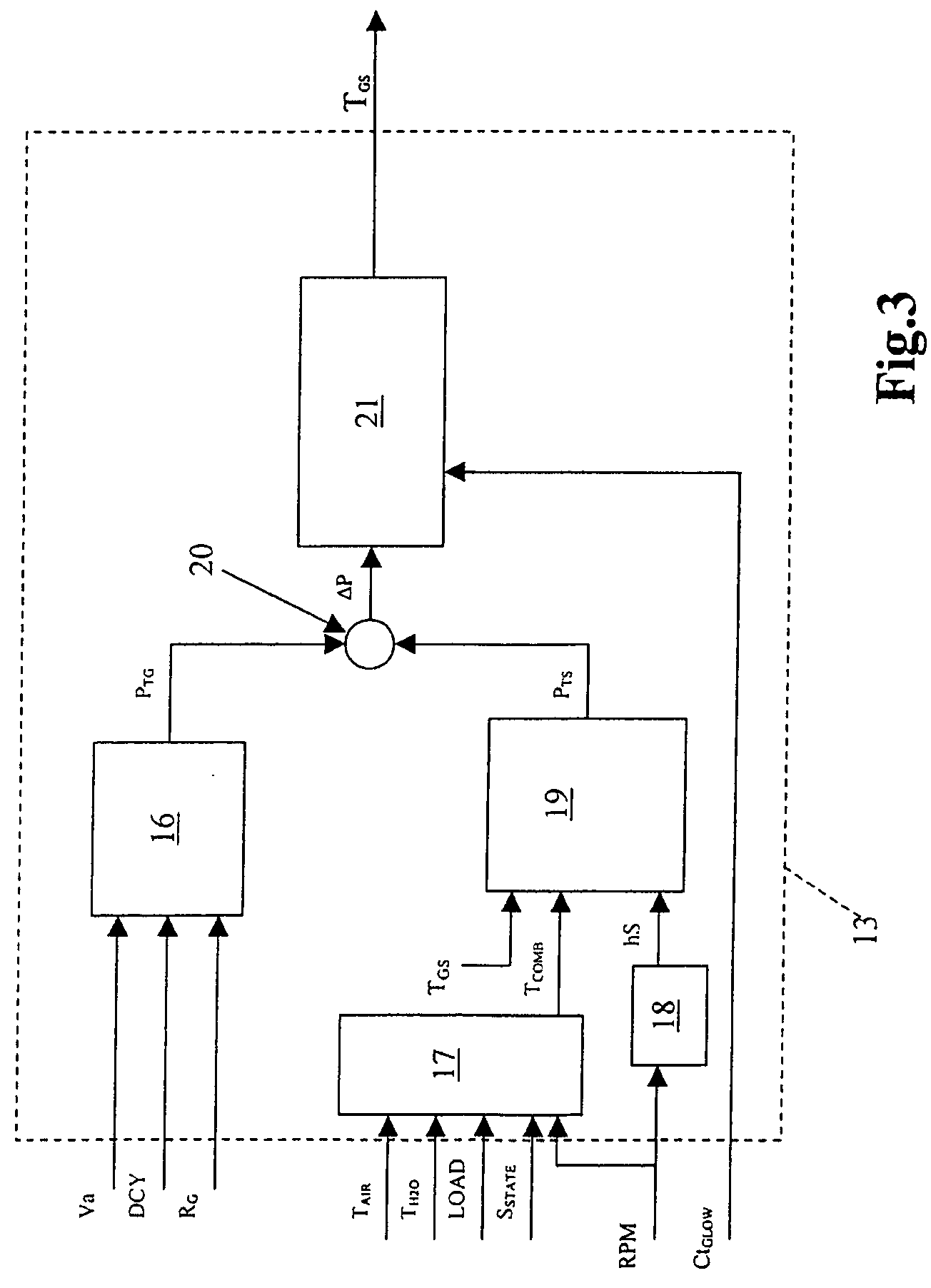

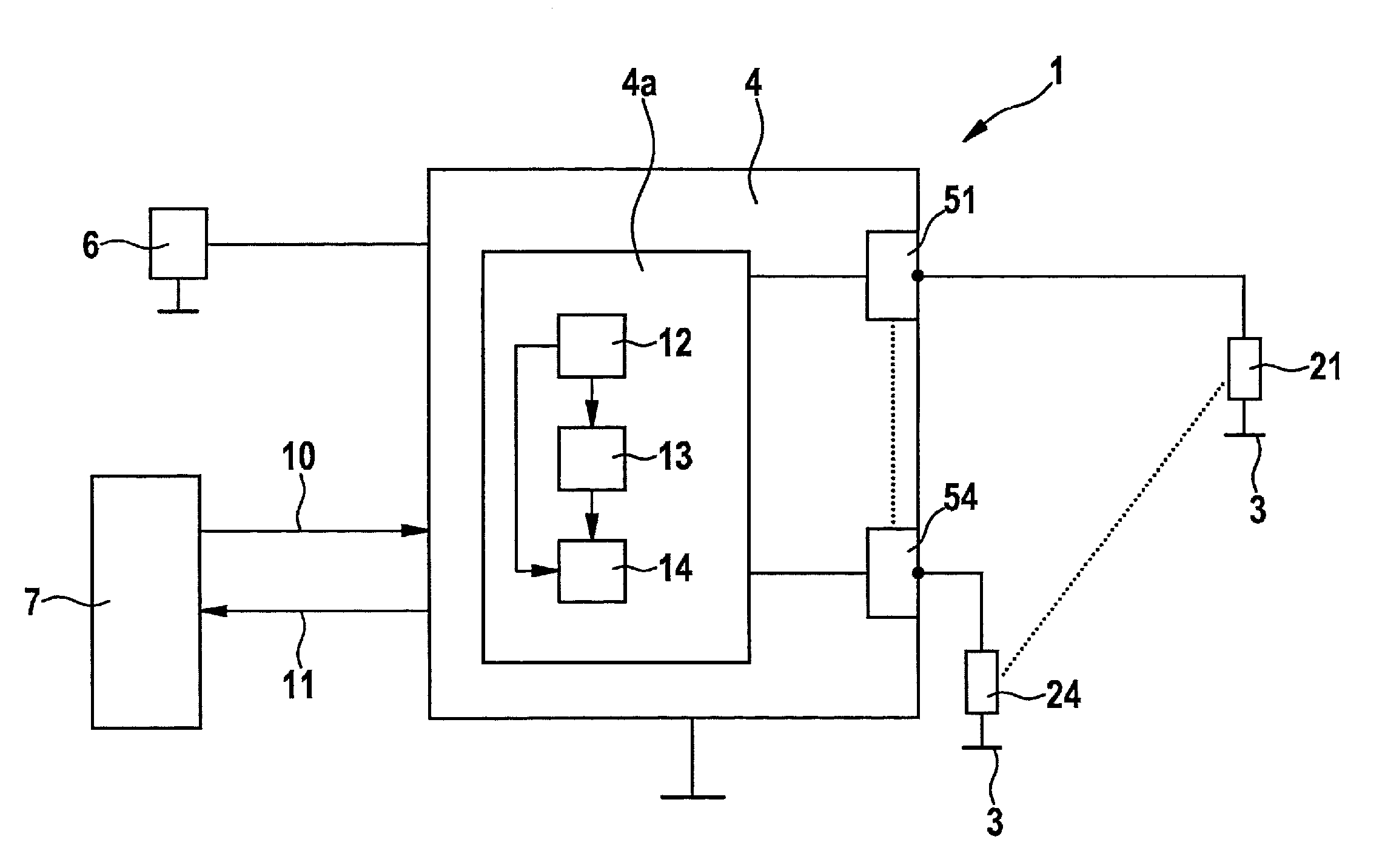

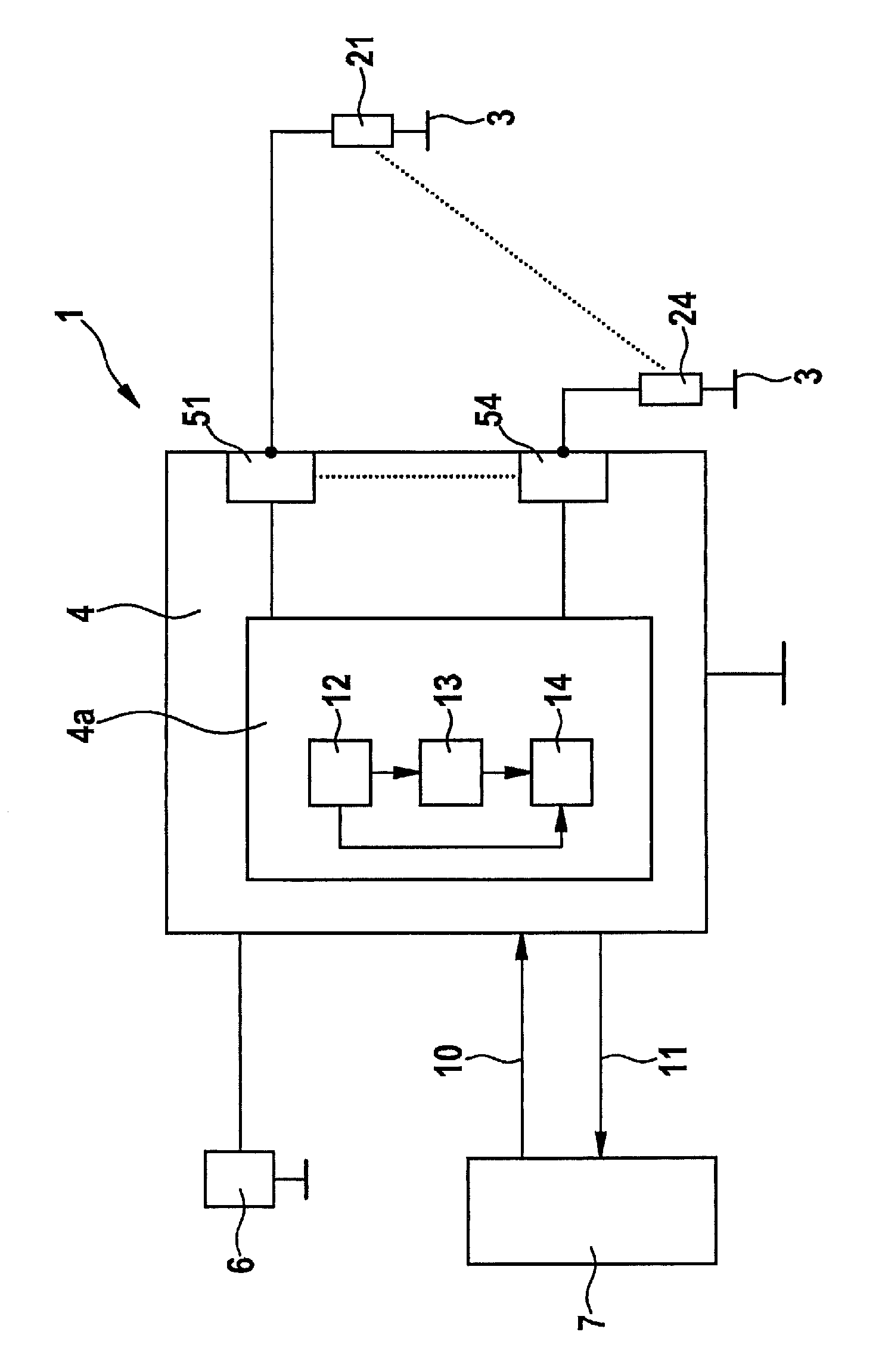

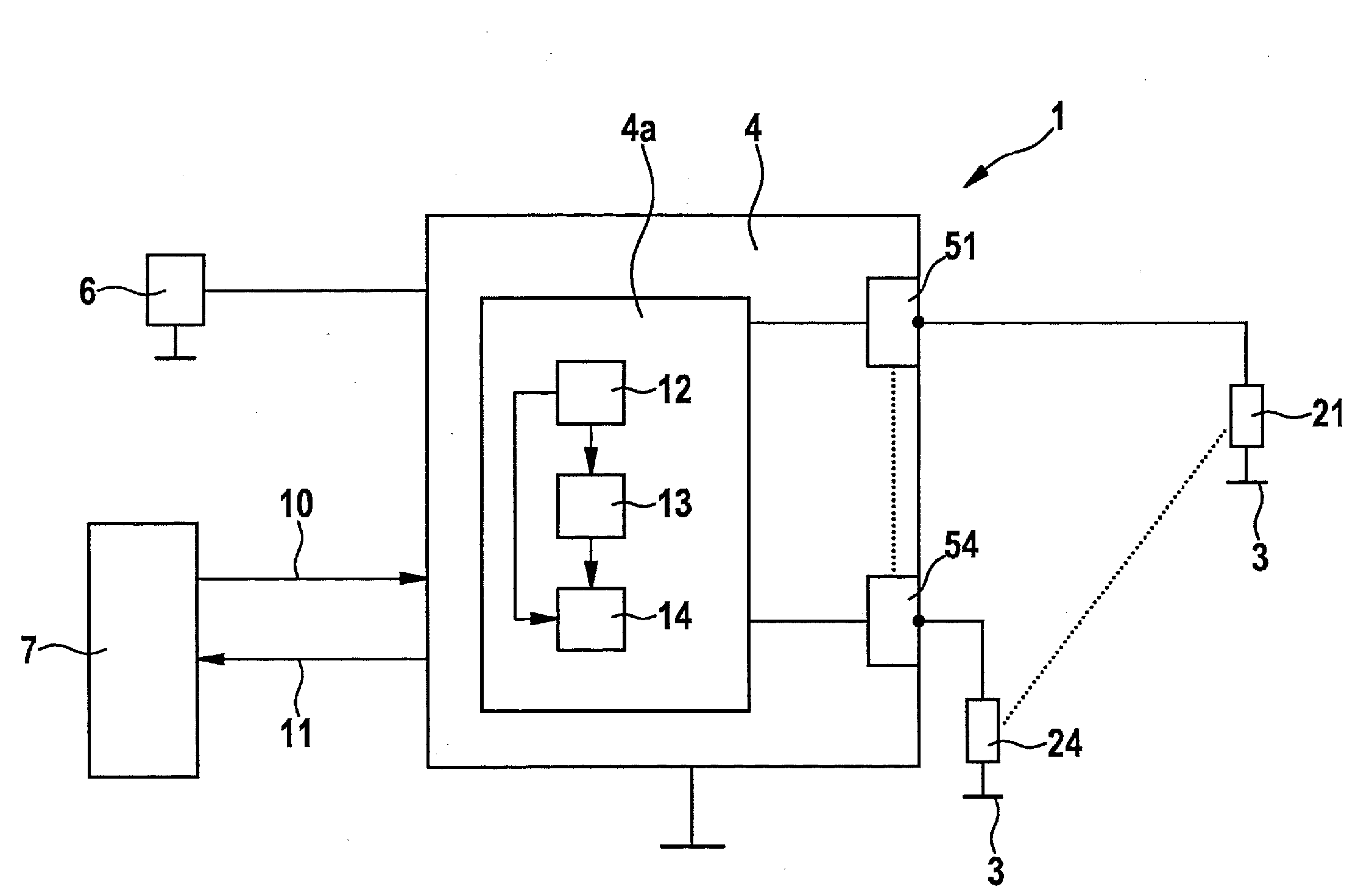

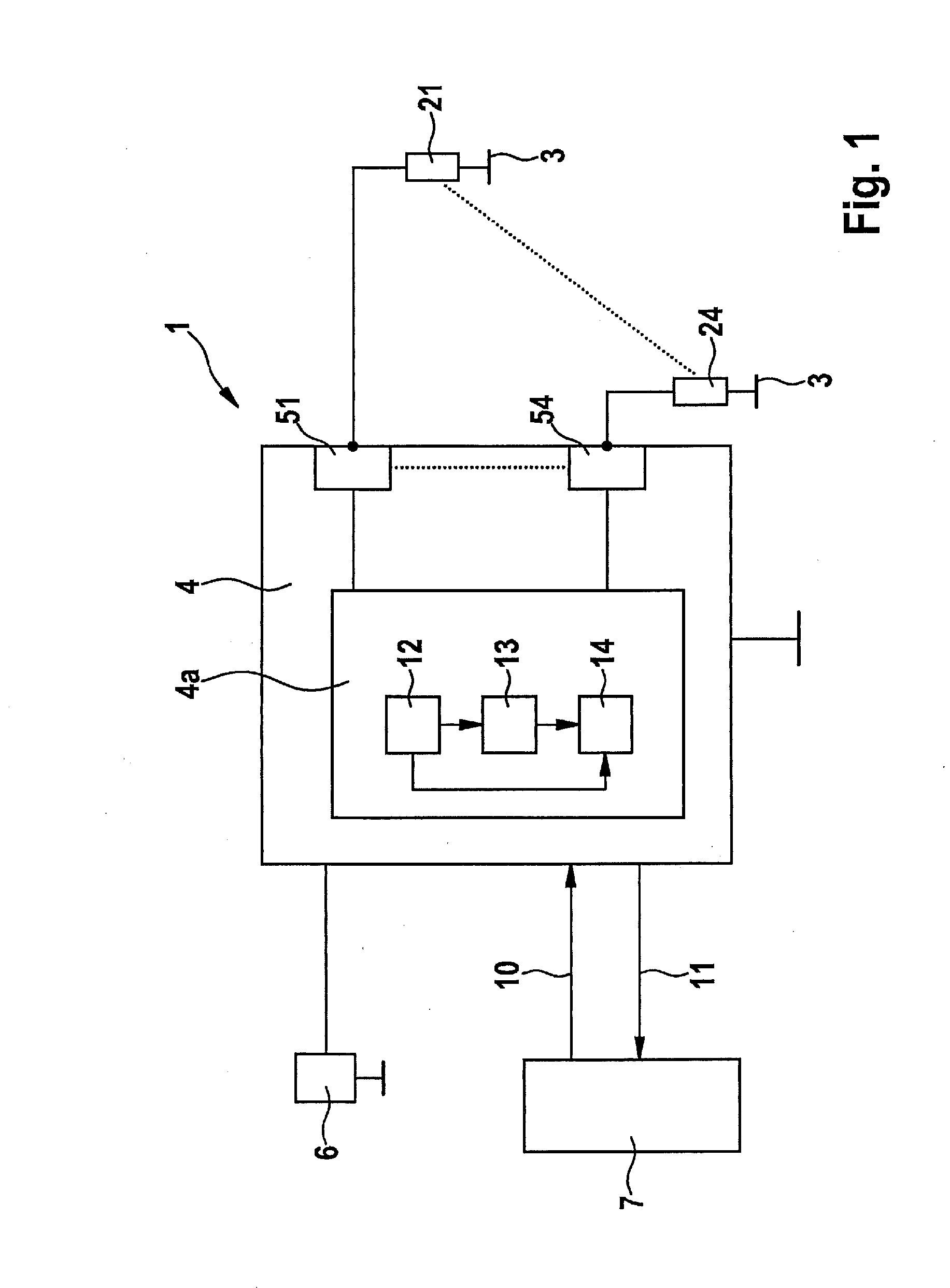

Internal combustion engine provided with a heating device in a combustion chamber and a control method for the heating device

ActiveUS20060289425A1Shorten warm-up timeStable temperatureIncandescent ignitionInternal combustion piston enginesCombustion chamberInternal combustion engine

An internal combustion engine comprising at least one cylinder provided with at least one glow plug adapted to heat a variable volume combustion chamber within the cylinder, and an electronic control unit which in turn comprises an estimation module adapted to estimate the temperature of the glow plug within the combustion chamber and a control module which is adapted to drive the glow plug as a function of the estimated temperature.

Owner:FAB ITAL MAGNETI MARELLI SPA

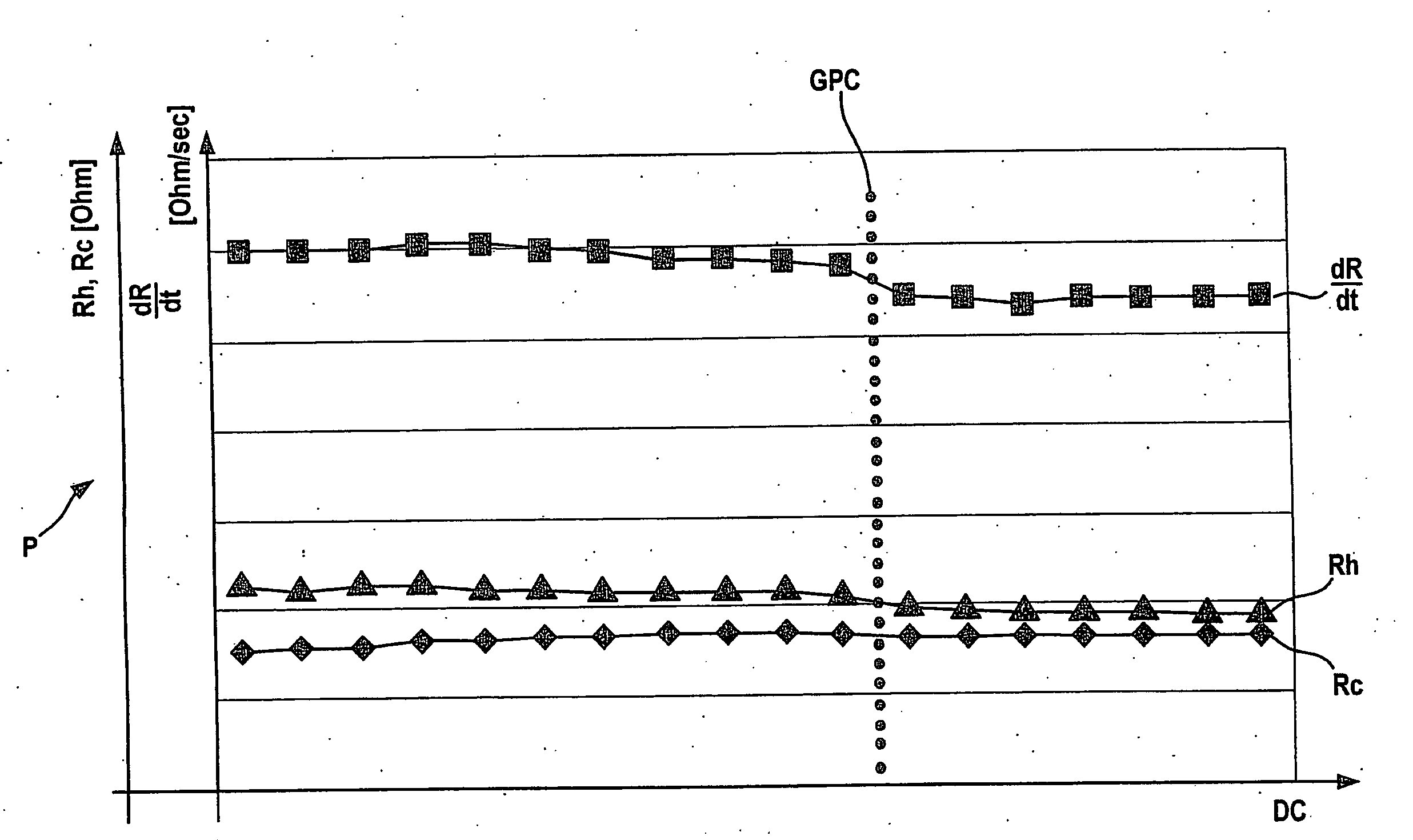

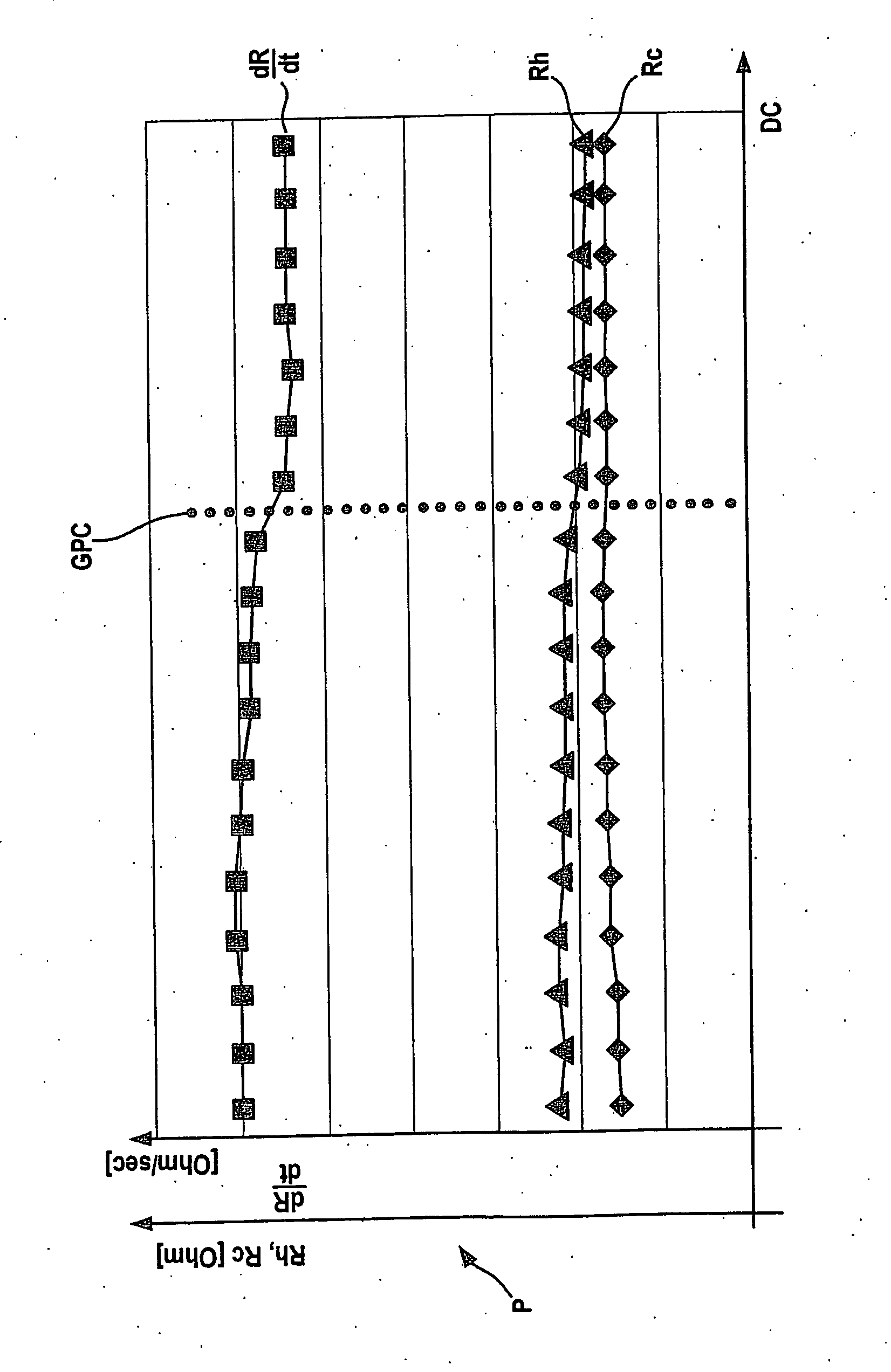

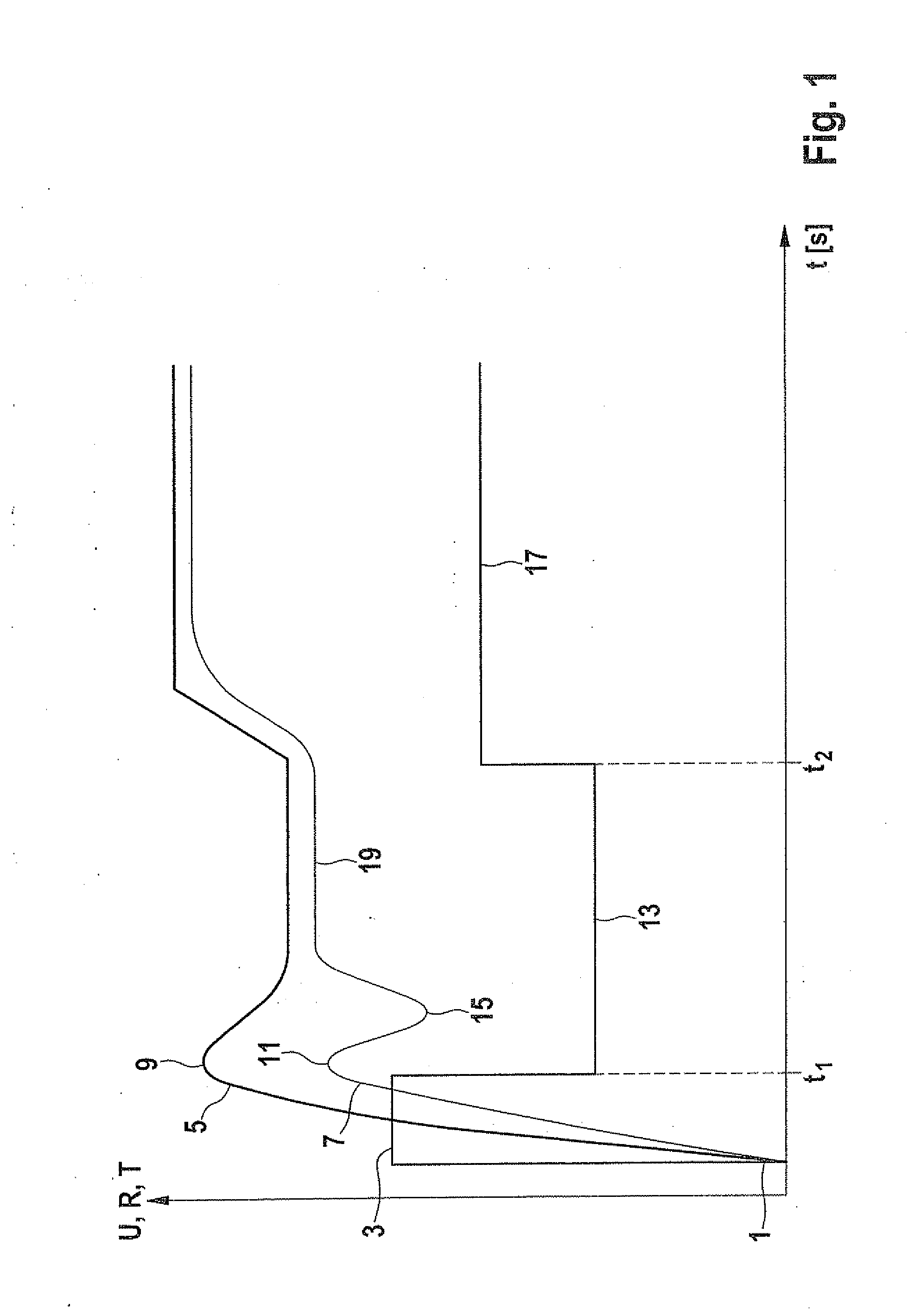

Method and device for detecting the exchange of sheathed-element glow plugs in a combustion engine

InactiveUS20090193882A1Easy to implementRapid and reliableInternal-combustion engine testingElectric ignition installationGlow plugEngineering

A method and a device for detecting the exchange of sheathed-element glow plugs (GPE) in a combustion engine, in which at least one electric characteristic quantity of at least one glow plug is measured at the beginning of a driving cycle, an instantaneous value of this characteristic quantity is determined and compared to at least one stored value of the same electric variable quantity of this glow plug, which was determined at the beginning of at least one preceding driving cycle, and if the deviation of the instantaneous value from the stored value exceeds a specifiable threshold value, an exchange of the glow plug (GPE) will be inferred.

Owner:ROBERT BOSCH GMBH

Igniter for gas turbine engine

There is disclosed an igniter for a gas turbine engine including: a base; a glow plug heater rod extending from the base along an axis and terminating in a rod end; and a fuel receiver adjacent the heater rod, the fuel receiver including a portion located closest to the heater rod, the rod end protruding axially relative to the axis from the fuel receiver portion located closest to the heater rod.

Owner:PRATT & WHITNEY CANADA CORP

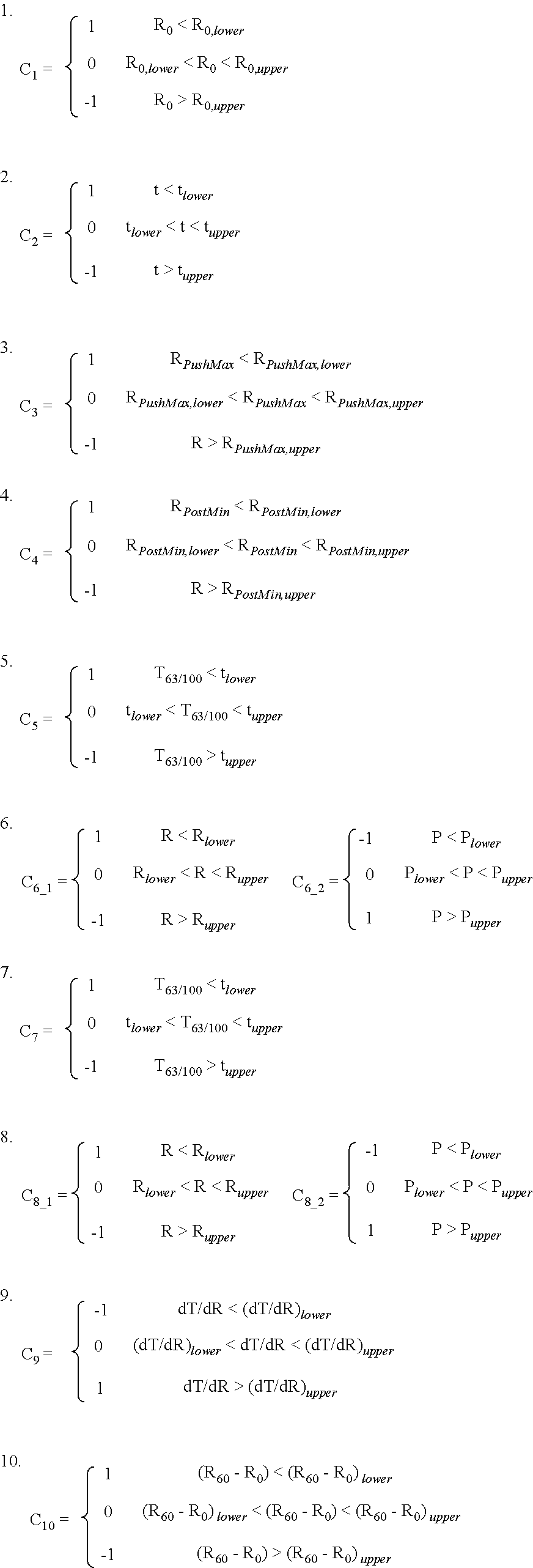

Method and Device for Controlling at Least One Glow Plug of a Motor Vehicle

ActiveUS20100280735A1Sufficient energySufficient supportAnalogue computers for vehiclesElectrical controlTime conditionMobile vehicle

A device and a method for controlling at least one glow plug of a motor vehicle are described. The at least one glow plug is controlled as a function of the operating state of the internal combustion engine. In this case, the control is effected as a function of a variable which depends on the exhaust gas temperature and / or as a function of the fulfillment of a fuel quantity condition and / or time condition.

Owner:ROBERT BOSCH GMBH

Fuel vapor systems for internal combustion engines

InactiveCN101208508AInternal combustion piston enginesEngine componentsCombustionExternal combustion engine

Fuel is vaporized under substantial super-atmospheric pressure. Surfaces are heated by the engine's electrical system. Vapor heated by a wall bounding a vaporization space turbulently mixes with incoming liquid spray, helping to produce new vapor. Useful for cold start, liquid spray reaching a rapidly heated impact plate is vaporized. Multiple heat-transfer surfaces are exposed to the same vapor volume, one, a surface of revolution surrounding the spray, another, a transverse surface across the spray. The spray is in pulses. Glow plugs are arranged perpendicular to heat-distributing members. A volume-surrounding wall receives heat from an annular medium. A fuel vaporizer dedicated to a single combustion region has a cup-shaped vaporization chamber heated by a central heater in opposition to liquid spray. In such a system also having a vapor injection valve synchronized with engine timing, the internal between operations of the valves is controlled to enable heat-transfer to vaporize the fuel and build up pressure.

Owner:FINE TUNING

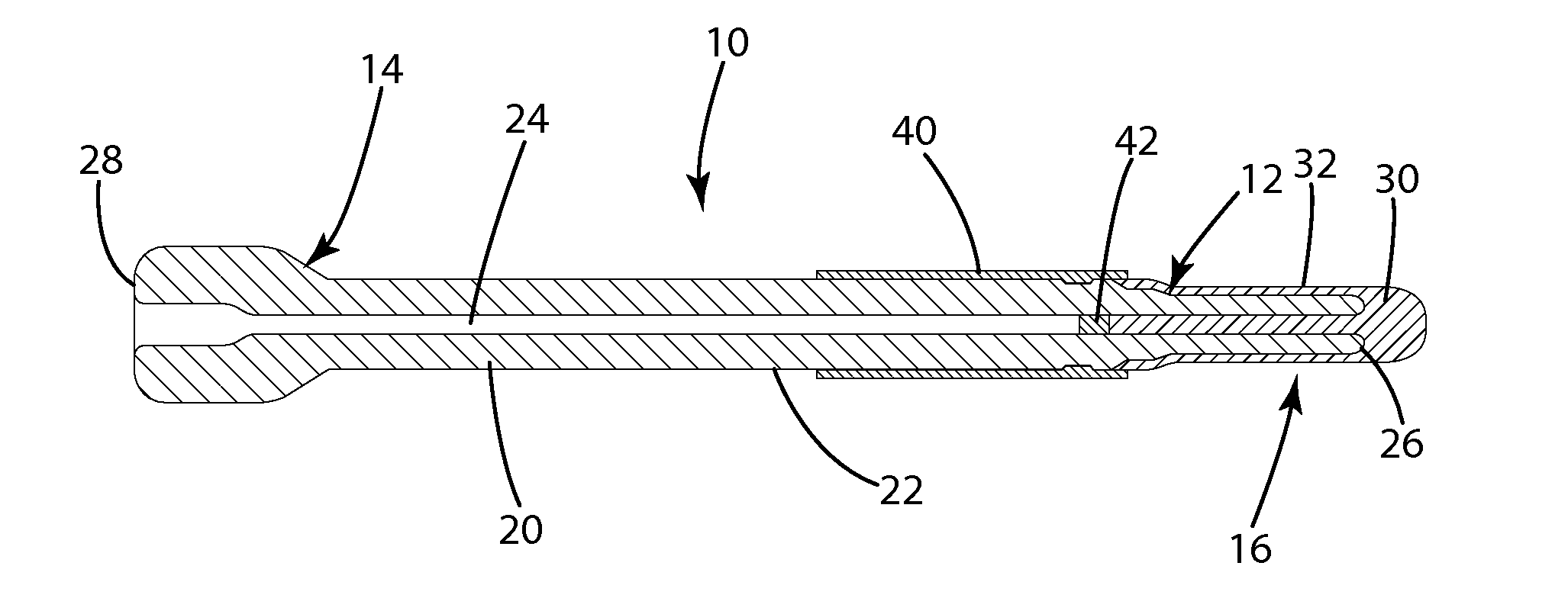

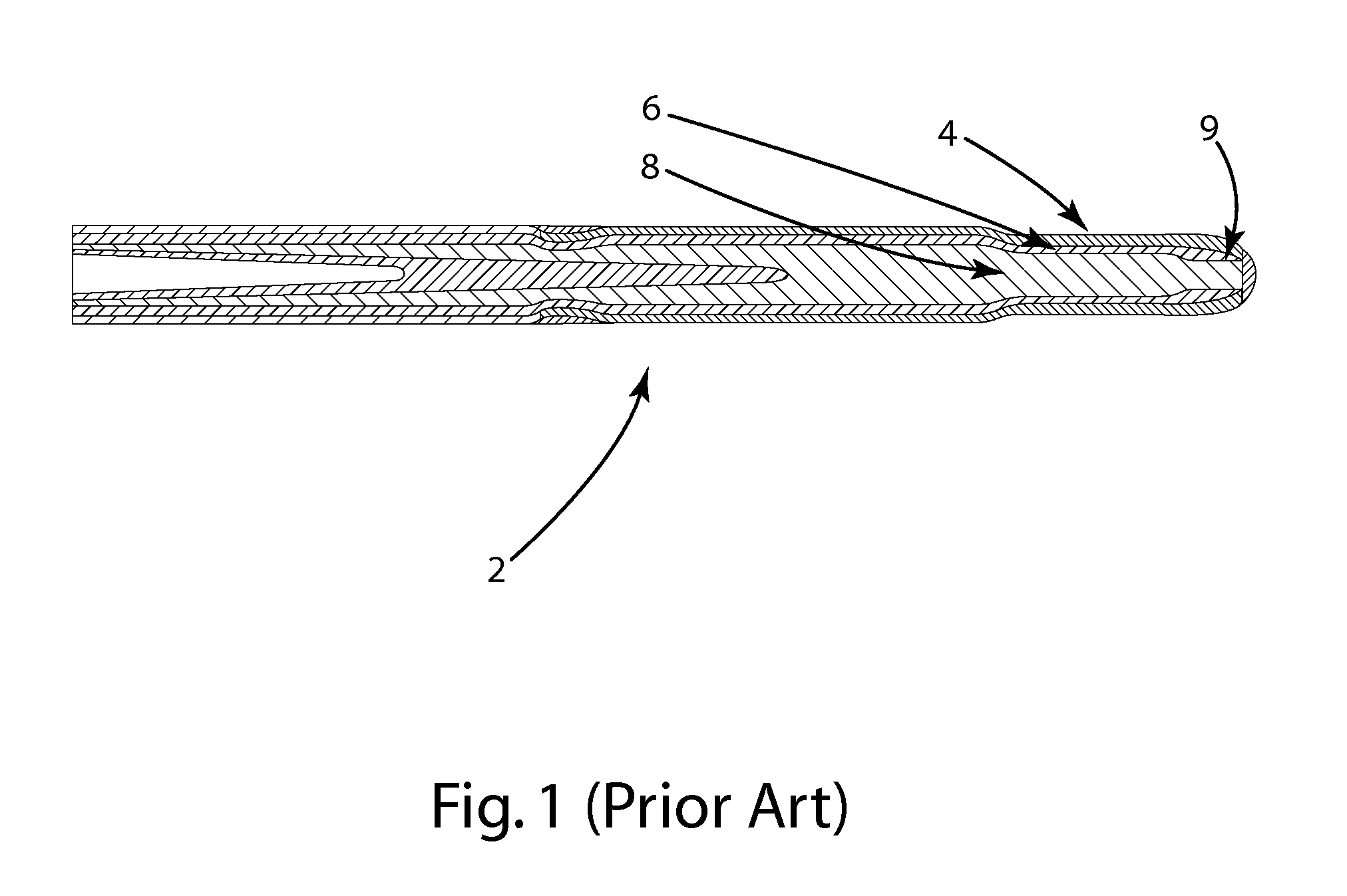

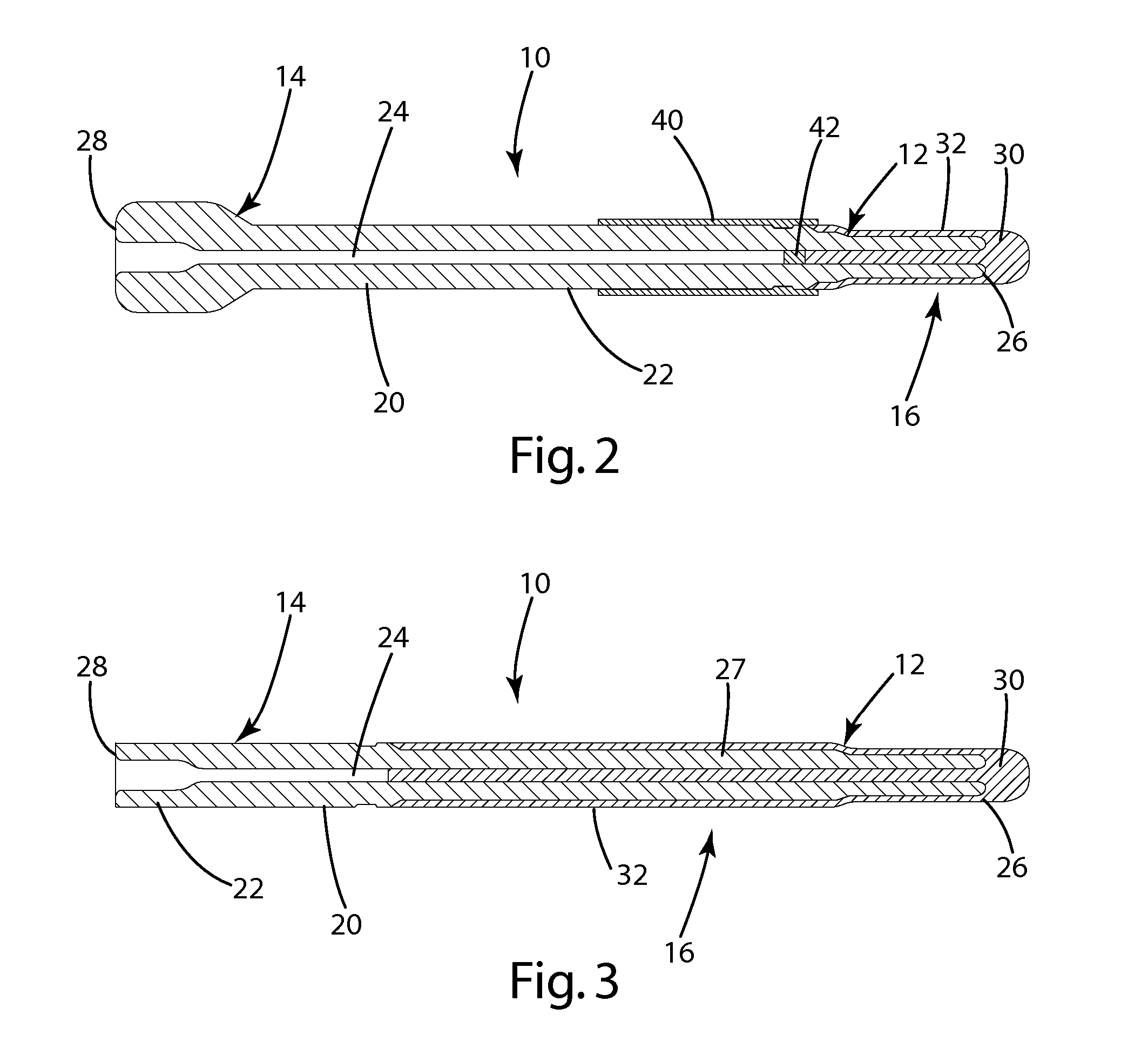

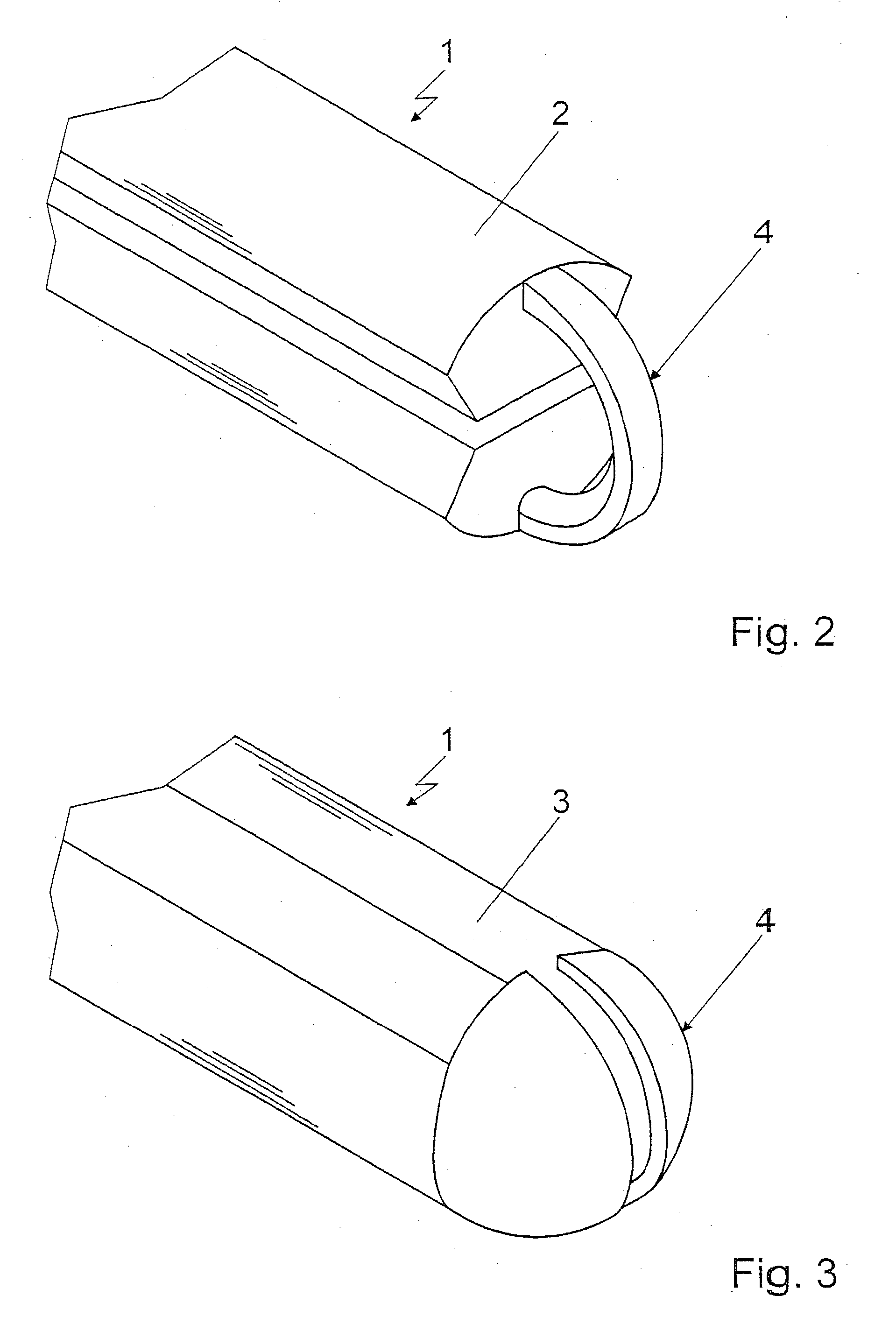

Multi-layer heating element

InactiveUS20070221647A1Incandescent ignitionHeating element shapesElectrically conductiveHeating element

A heating element and, in particular, a ceramic heating element, such as ceramic heating elements used in high temperature glow plugs for diesel engines and gas igniters. The heating element includes an electrical insulator and an electrically conductive layer. The conductive layer is formed from a single material and single composition. The method of manufacture includes the steps of forming the insulative layer and molding a conductive layer around the insulative layer.

Owner:FEDERAL MOGUL WORLD WIDE

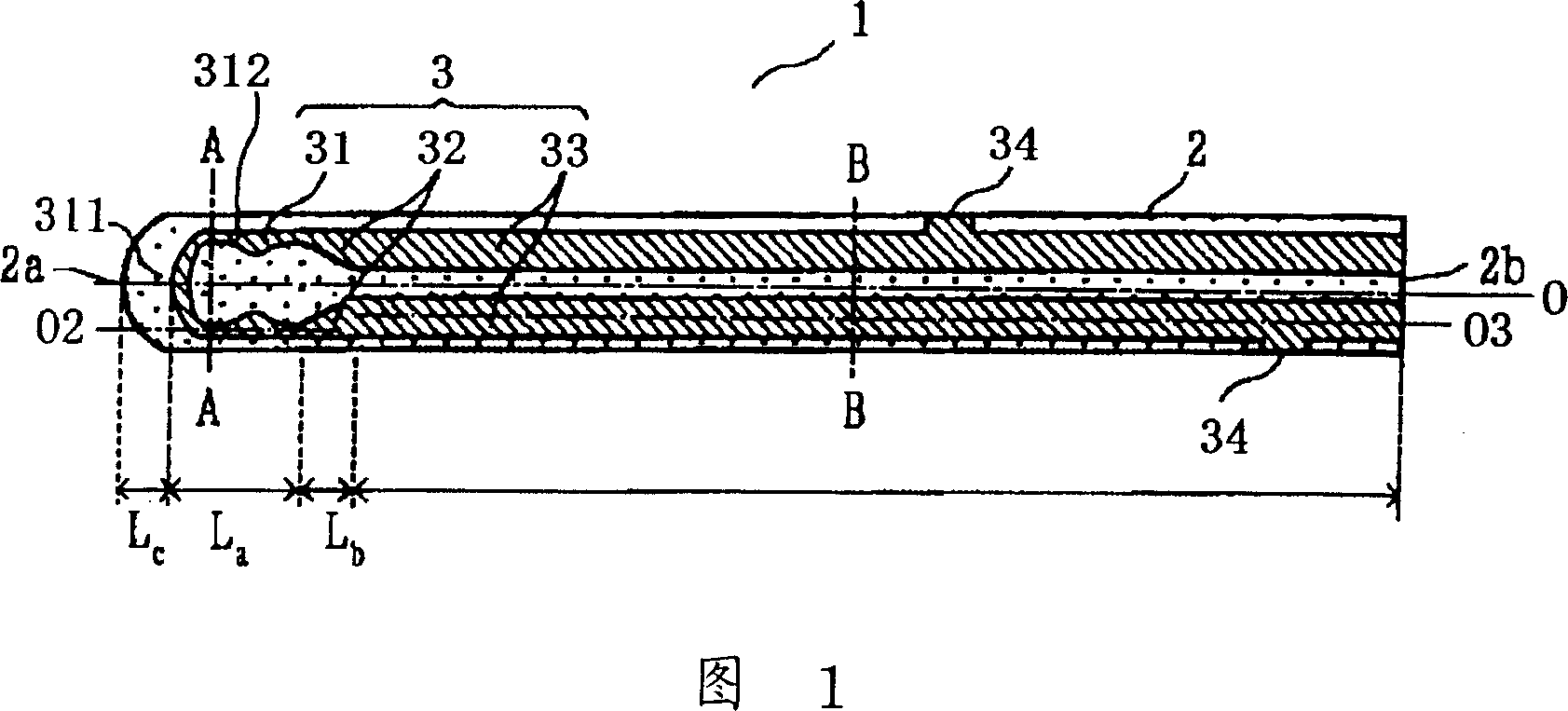

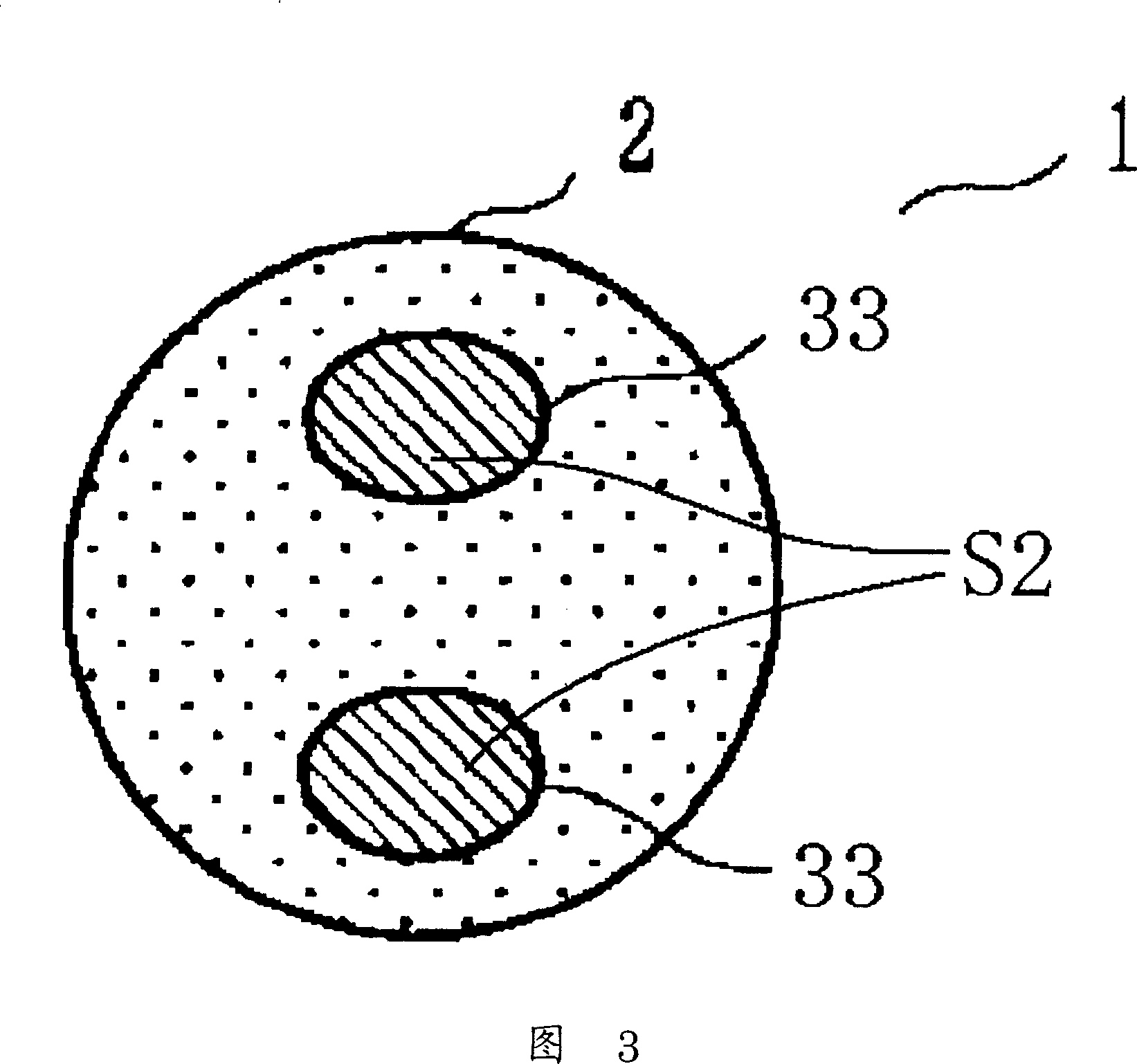

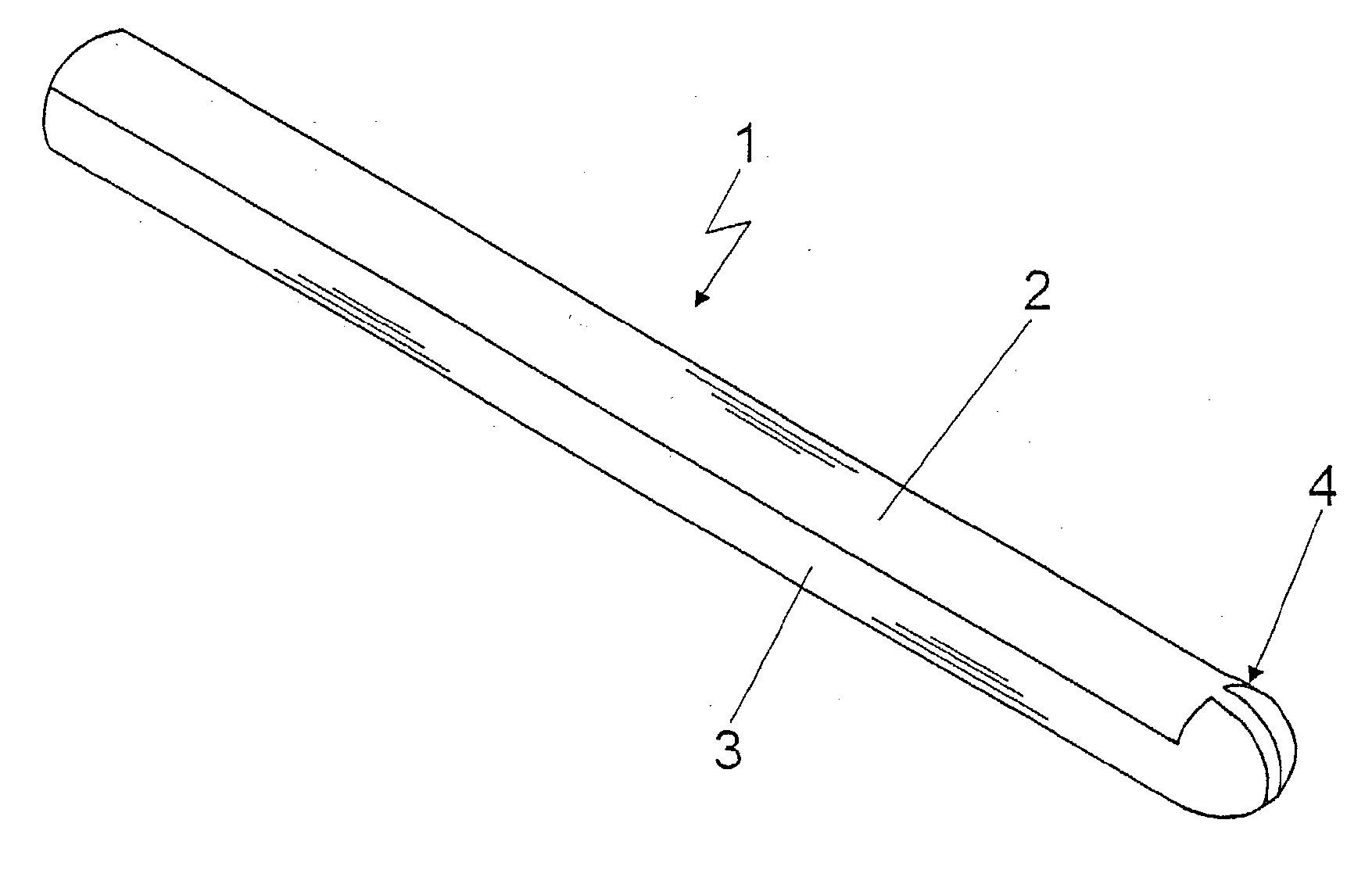

Ceramic heater and manufacturing method thereof, and glow plug using ceramic heater

InactiveCN1942709AReduce spacingEasy to separateIncandescent ignitionOhmic-resistance electrodesResistorElectric heating

Provided is a ceramic heater in which damage to a joint portion between a heating portion and a lead portion is suppressed and is excellent in reliability. A ceramic heater (1) includes: a rod-shaped support (2) made of insulating ceramics; and a resistor element (3) including a heating portion (31) embedded in a top end portion of the support (2) and a pair of lead parts (33) extending from the heating part (31) to the rear end side of the support (2), in the ceramic heater (1), the heating part (31) and The lead part (33) is made of the same conductive ceramic.

Owner:NGK SPARK PLUG CO LTD

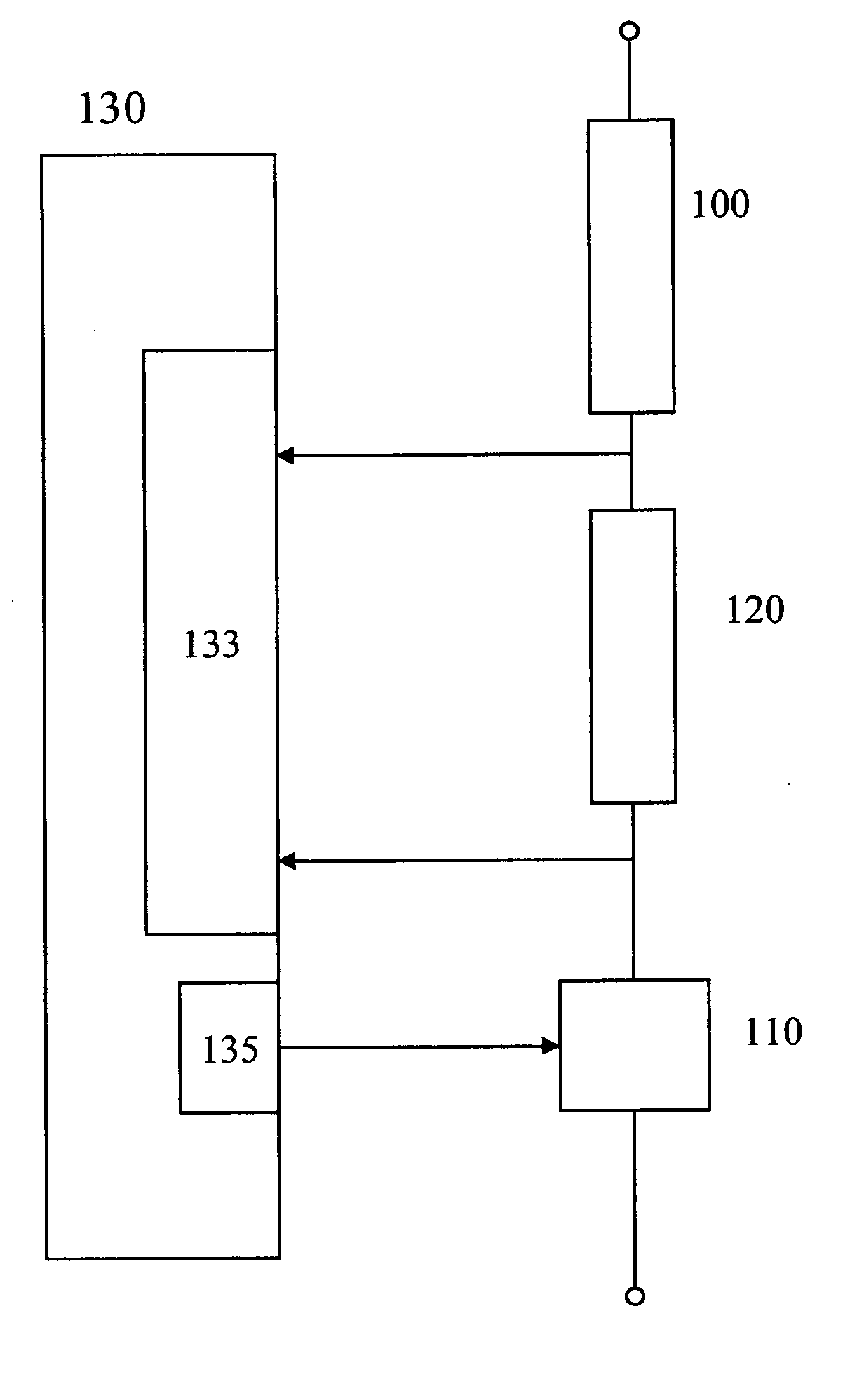

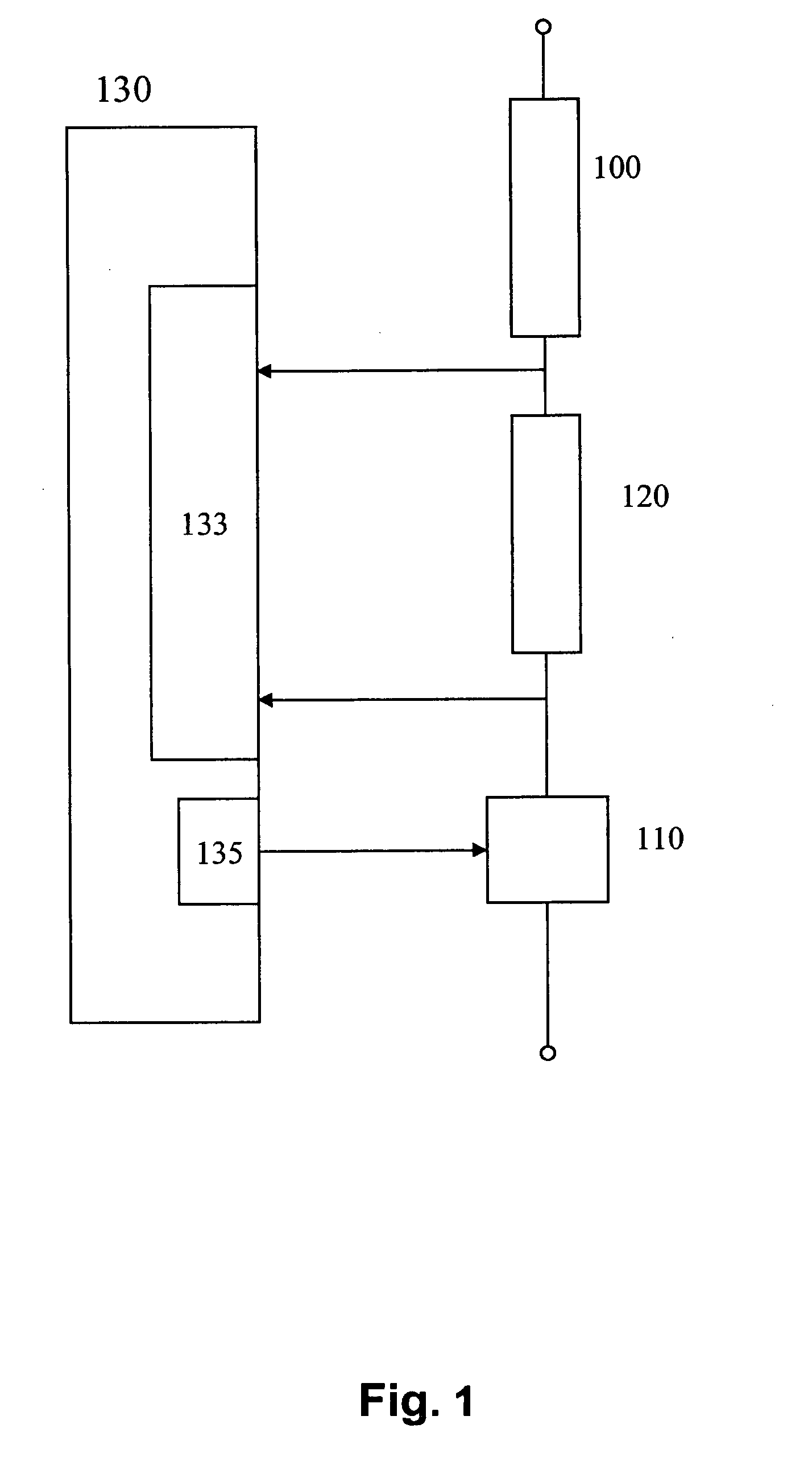

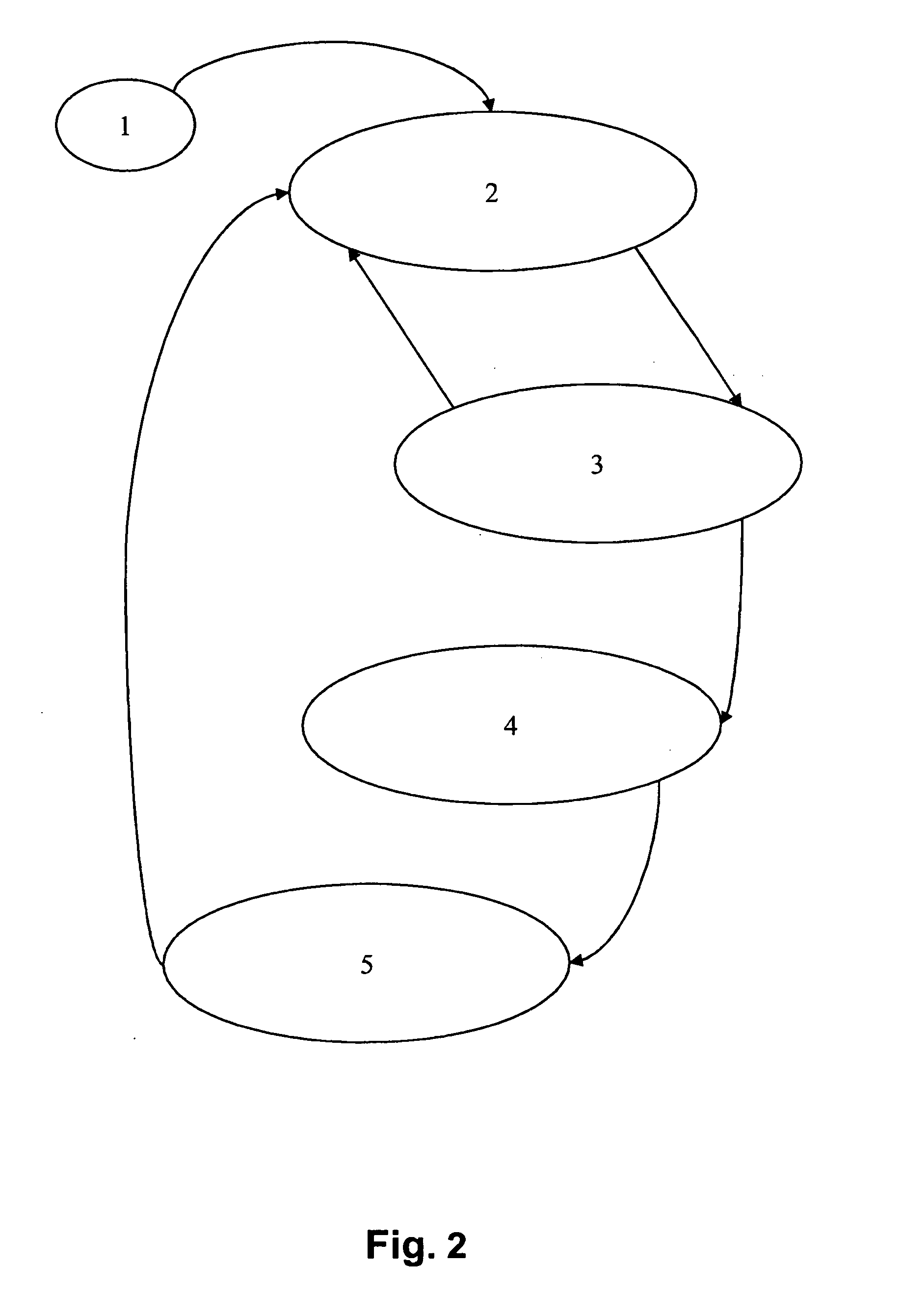

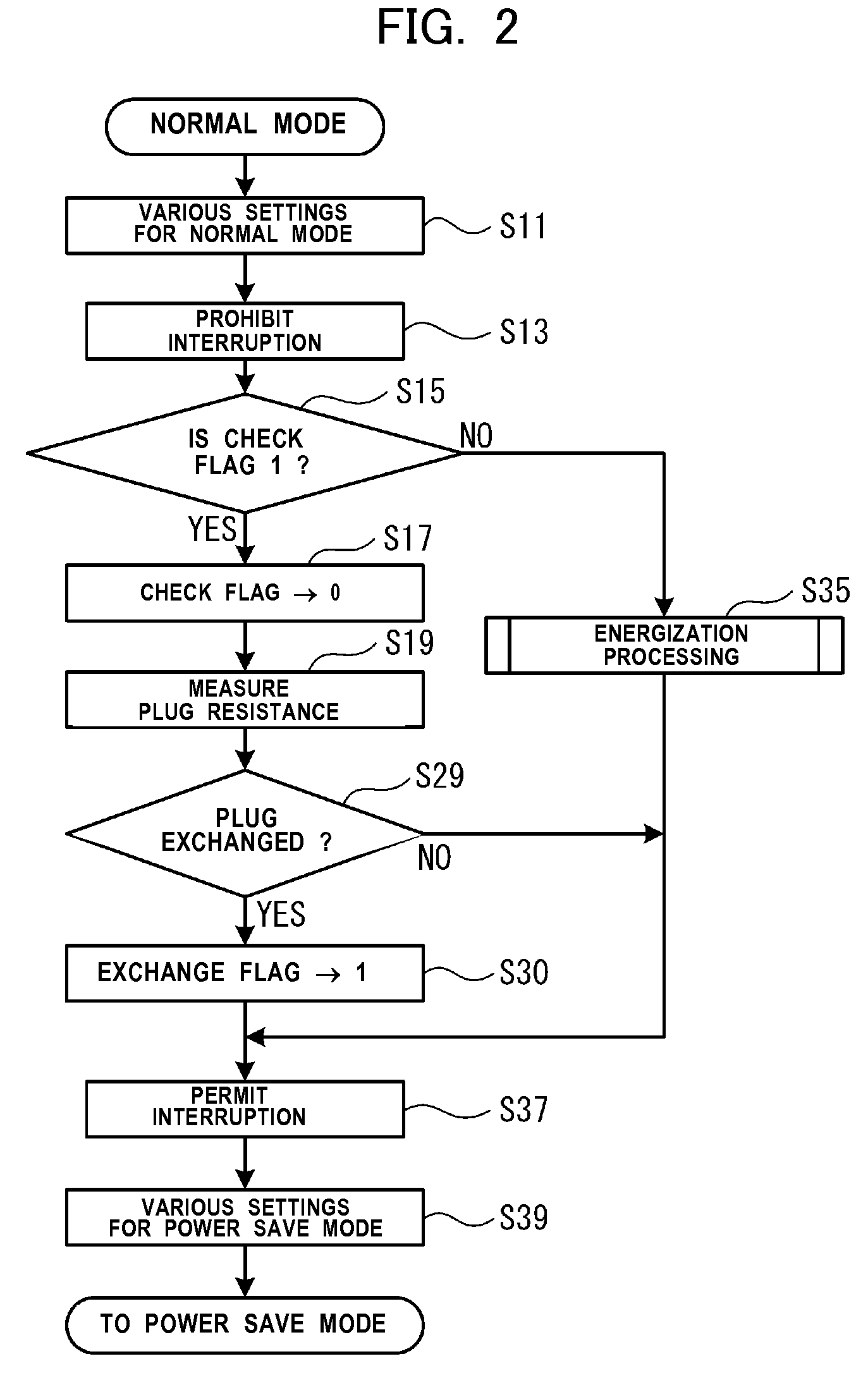

Apparatus for controlling the energizing of a heater

InactiveUS8423197B2Improve accuracyEnsure correct executionMechanical power/torque controlElectrical controlMicrocomputerElectrical resistance and conductance

A heater energization control apparatus. When an engine is stopped, a microcomputer of a GCU enters a power save mode. When the microcomputer returns to a normal mode in response to an interruption signal periodically generated from an interruption timer, the microcomputer supplies electricity to a heating resistor for a short time and obtains its resistance (S19). When the resistance is greater than a first reference value, the microcomputer determines that a glow plug is removed from the engine; that is, the glow plug is being exchanged (S29). The microcomputer sets an exchange flag to “1” (S30), and performs calibration for the heating resistor of a new glow plug after the engine is operated next time (S35). When the current resistance becomes smaller than the past resistance, the microcomputer determines that the glow plug has been exchanged.

Owner:NGK SPARK PLUG CO LTD

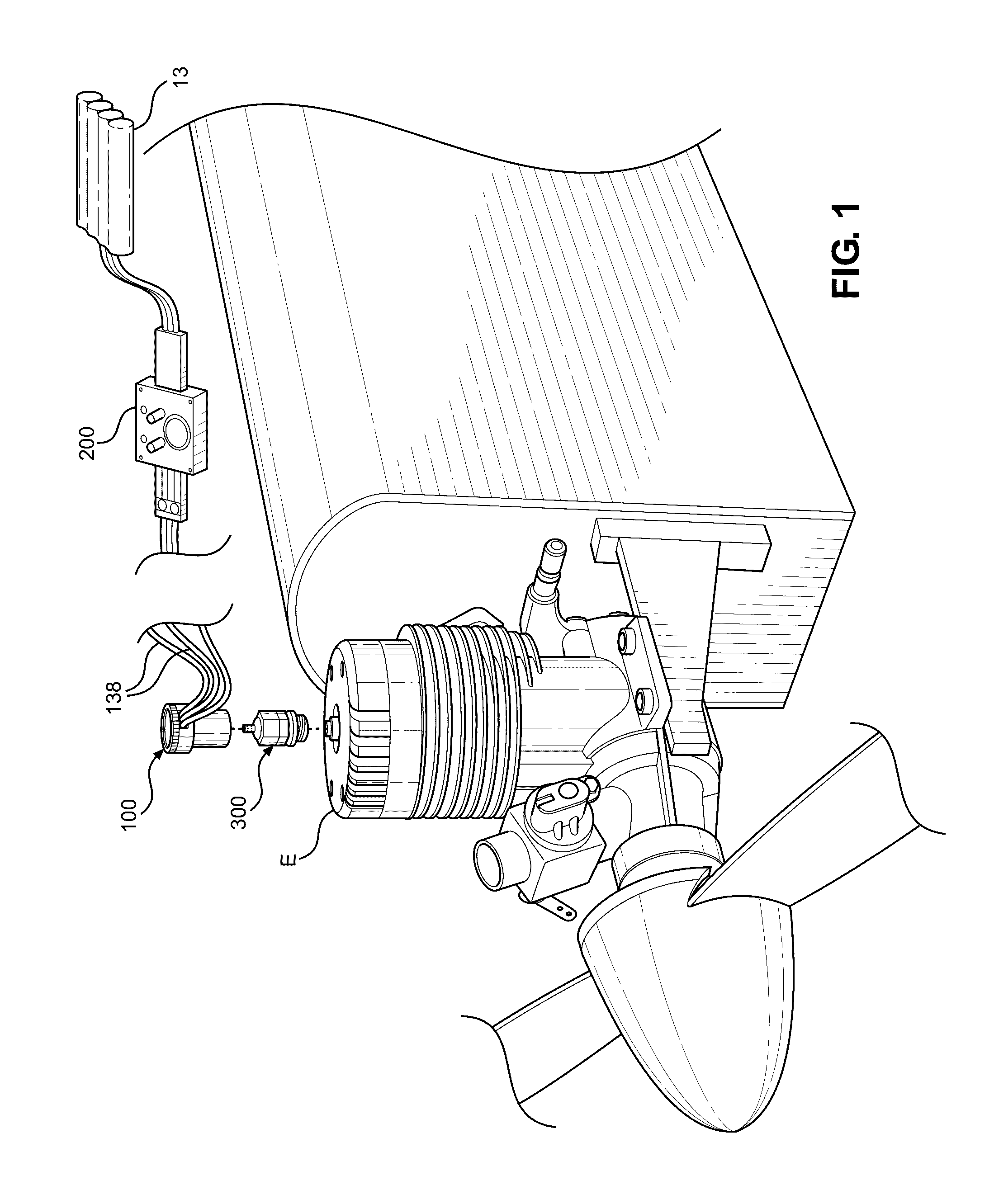

Autonomous Glow Driver For Radio Controlled Engines

ActiveUS20160305394A1Reduce exerciseSuperior and one-point connectionElectric motor startersMachines/enginesElectricityElectrical resistance and conductance

An autonomous glow driver system for radio controlled (RC) engines. Aspects of the system include a connector that securely attaches to the glow plug to maintain good electrical contact with the glow plug and reduce signal noise and using a current and differential amplifiers to determine the temperature of the glow element and the RPMs of the glow engine from a voltage signal (obtained via the connector) that varies with the temperature as induced changes in the resistance of the glow element occur. Using the data of temperature, non-running RPM, and running RPM to control operation of the glow driver leads to a very reliable approach to automatically activating the glow driver to maintain the combustion chamber temperature of the glow engine at a selected level because RPM is indicative of a rotating engine whereas temperature is not.

Owner:DEMMONS SHELDON J

Method and device for reducing the temperature tolerance of sheathed-element glow plugs

InactiveUS20130087114A1Reduce temperature toleranceReduce scrap rateIncandescent ignitionCombustion enginesGlow plugTwo temperature

A method for reducing the temperature tolerance of sheathed-element glow plugs is described, in which, in a first step, the sheathed-element glow plugs of an auto-ignition internal combustion engine are classified into at least two temperature classes, at least one temperature class including a temperature range above a setpoint temperature range, at least one temperature class including a temperature range below the setpoint temperature range, and / or one temperature class including the setpoint temperature range. In a second step, the control voltage of sheathed-element glow plugs which were assigned to a temperature class which includes a temperature range above the setpoint temperature range is reduced, and the control voltage of sheathed-element glow plugs which were assigned to a temperature class which includes a temperature range below the setpoint temperature range is increased. A device for performing the method is also described.

Owner:ROBERT BOSCH GMBH

Surface Ignition Mechanism For Diesel Engines

The present disclosure relates to combusting fuel during cold start. A glow-plug may be provided within a combustion chamber having a volume including a piston, wherein the glow plug may provide a localized heated region. Air may then be provided into the chamber and compressed. A mass of fuel may also be provided into the combustion chamber, wherein an amount of the fuel mass may be directed towards the localized heated region of the glow plug, wherein the heated region of the glow plug may have a temperature T1, and the equivalence ratio of the fuel in the heated region achieves a value that the temperature T1 provides auto-ignition. All or a portion of the mass of fuel directed towards the heated region of said glow plug may be ignited, and then the remainder of the fuel may be ignited by auto-ignition and / or flame propagation.

Owner:SOUTHWEST RES INST +1

Internal combustion engine provided with a heating device in a combustion chamber and a control method for the heating device

ActiveUS7528346B2Shorten warm-up timeStable temperatureIncandescent ignitionInternal combustion piston enginesExternal combustion engineInternal combustion engine

An internal combustion engine comprising at least one cylinder provided with at least one glow plug adapted to heat a variable volume combustion chamber within the cylinder, and an electronic control unit which in turn comprises an estimation module adapted to estimate the temperature of the glow plug within the combustion chamber and a control module which is adapted to drive the glow plug as a function of the estimated temperature.

Owner:FAB ITAL MAGNETI MARELLI SPA

Diesel engine and flame glow plug thereof

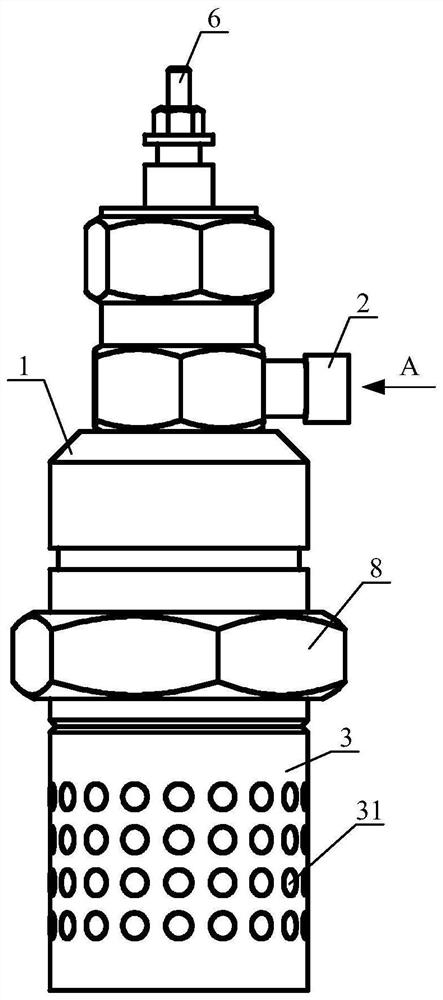

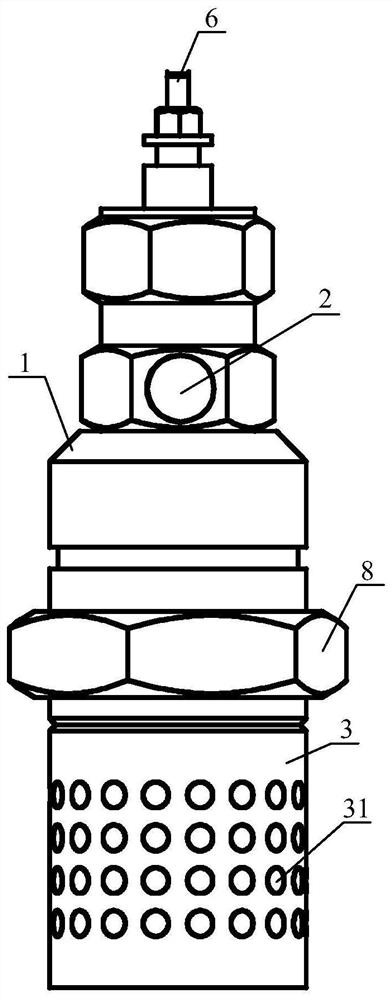

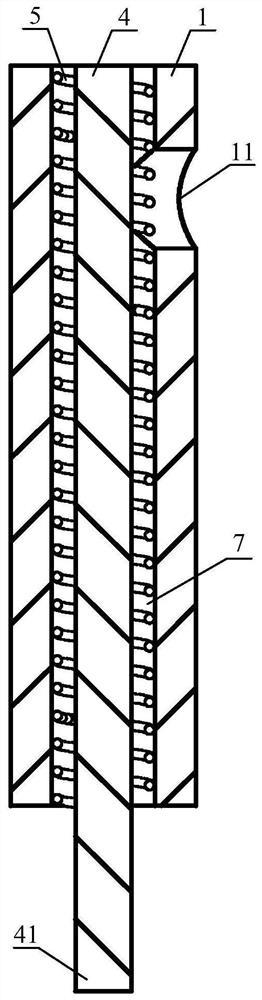

ActiveCN111997808AVaporization fastPromote gasificationMachines/enginesEngine startersGlow plugGlowplug

The invention discloses a diesel engine and a flame glow plug thereof. The flame glow plug comprises a shell, an oil inlet nozzle, a flame cover, an electromagnetic induction heating element, an electromagnetic induction coil and an electrode; the electrode is arranged at the top end of the shell, and a cavity is formed in the bottom of the electrode; the oil inlet nozzle is fixedly installed on the outer side of the shell and communicates with the top of the cavity; the flame cover is fixedly connected with the bottom end of the shell and provided with a plurality of ventilation holes; the electromagnetic induction heating element is fixedly installed in the cavity, and the bottom end of the electromagnetic induction heating element protrudes out of the shell and extends into the flame cover; a gasification flow guide channel is formed between the shell and the electromagnetic induction heating element and is used for guiding, heating and gasifying diesel oil entering the cavity; theelectromagnetic induction coil is of a spiral structure, is installed in the gasification flow guide channel, is electrically connected with the electrode and is used for forming an electromagnetic field; and a mixed gas cavity is formed in the flame cover. The flame glow plug can guarantee normal cold start of the diesel engine under the extremely cold condition.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

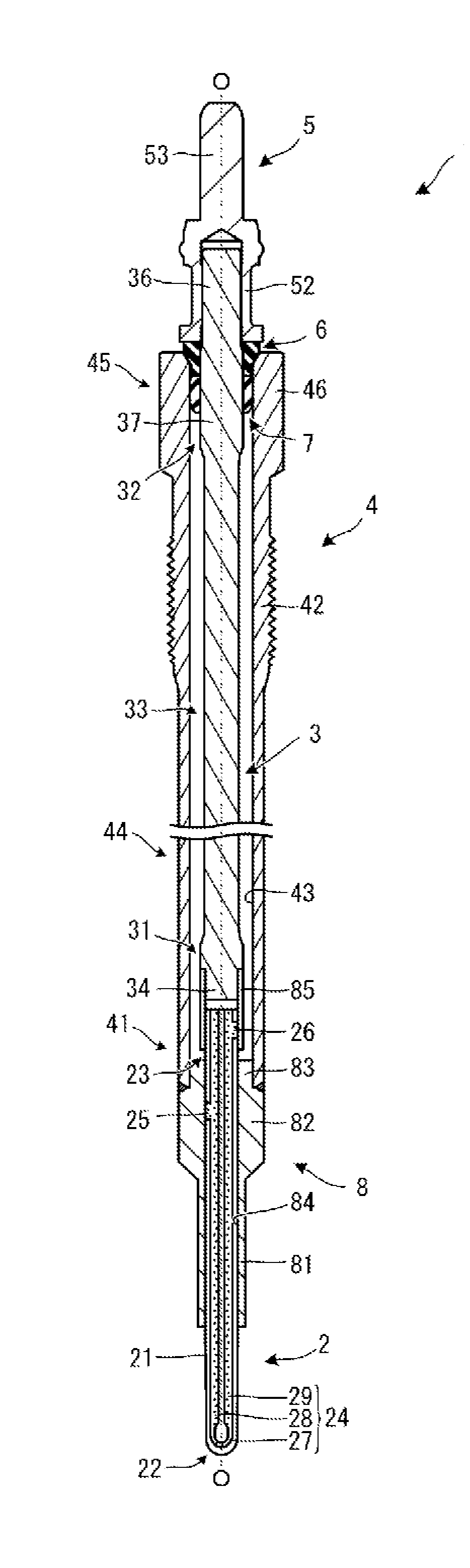

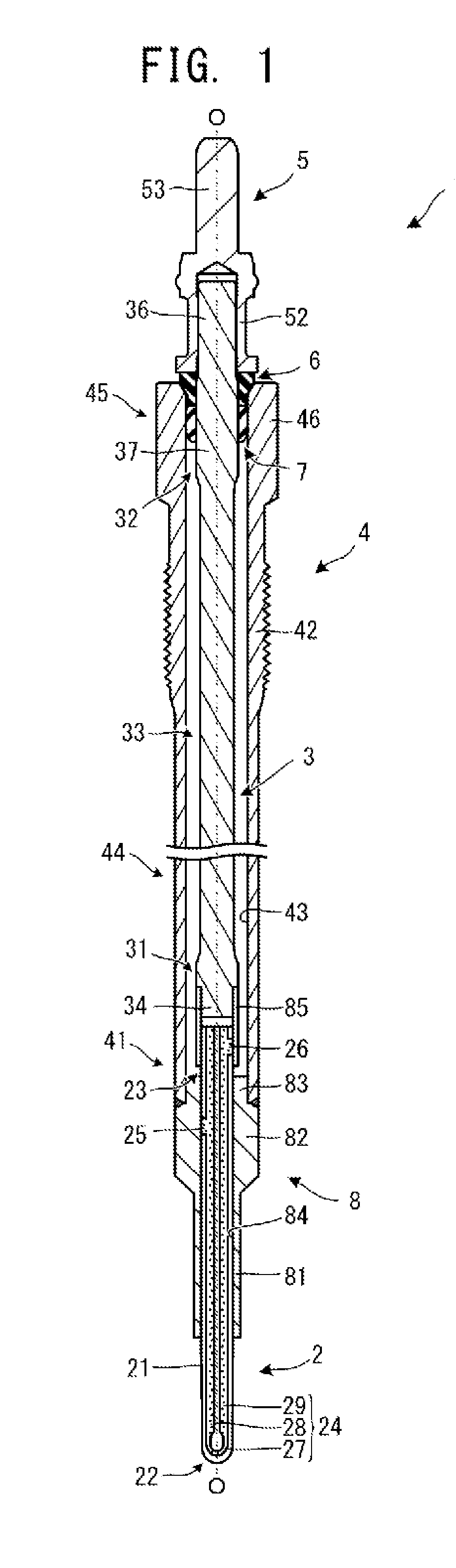

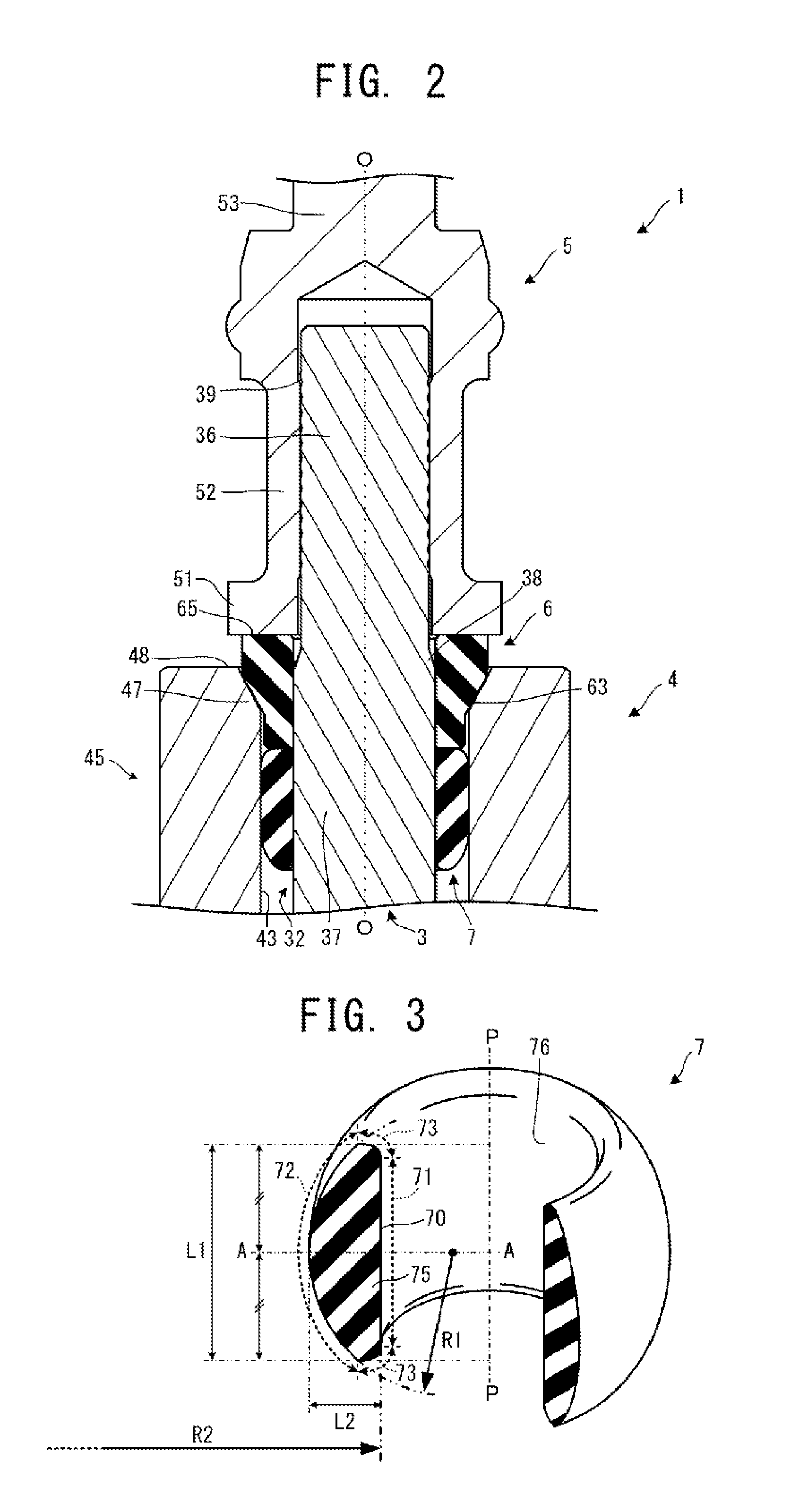

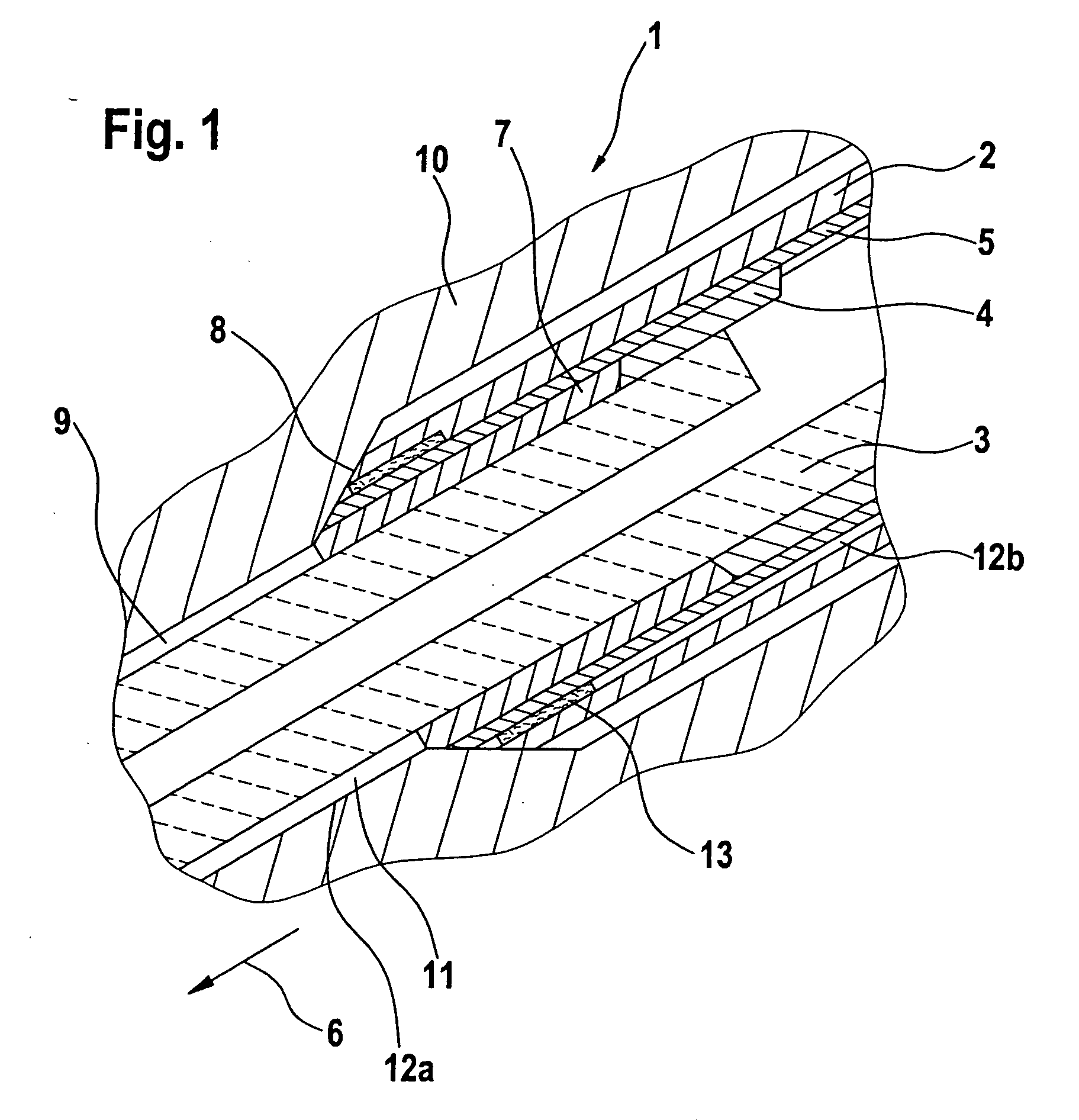

Glow plug

A glow plug (1) including a heater (2), a metallic shell (4) assuming the form of a tube having an axial bore, a center shaft (3) and a contact member (7). The contact member (7) is configured such that a contour (70) of a cross section (75) includes a second contour segment (71) in the form of a straight line, a first contour segment (72) in the form of a curve swelling radially, and third contour segments (73) in the form of curves connecting the second contour segment (71) and the first contour segment (72).

Owner:NGK SPARK PLUG CO LTD

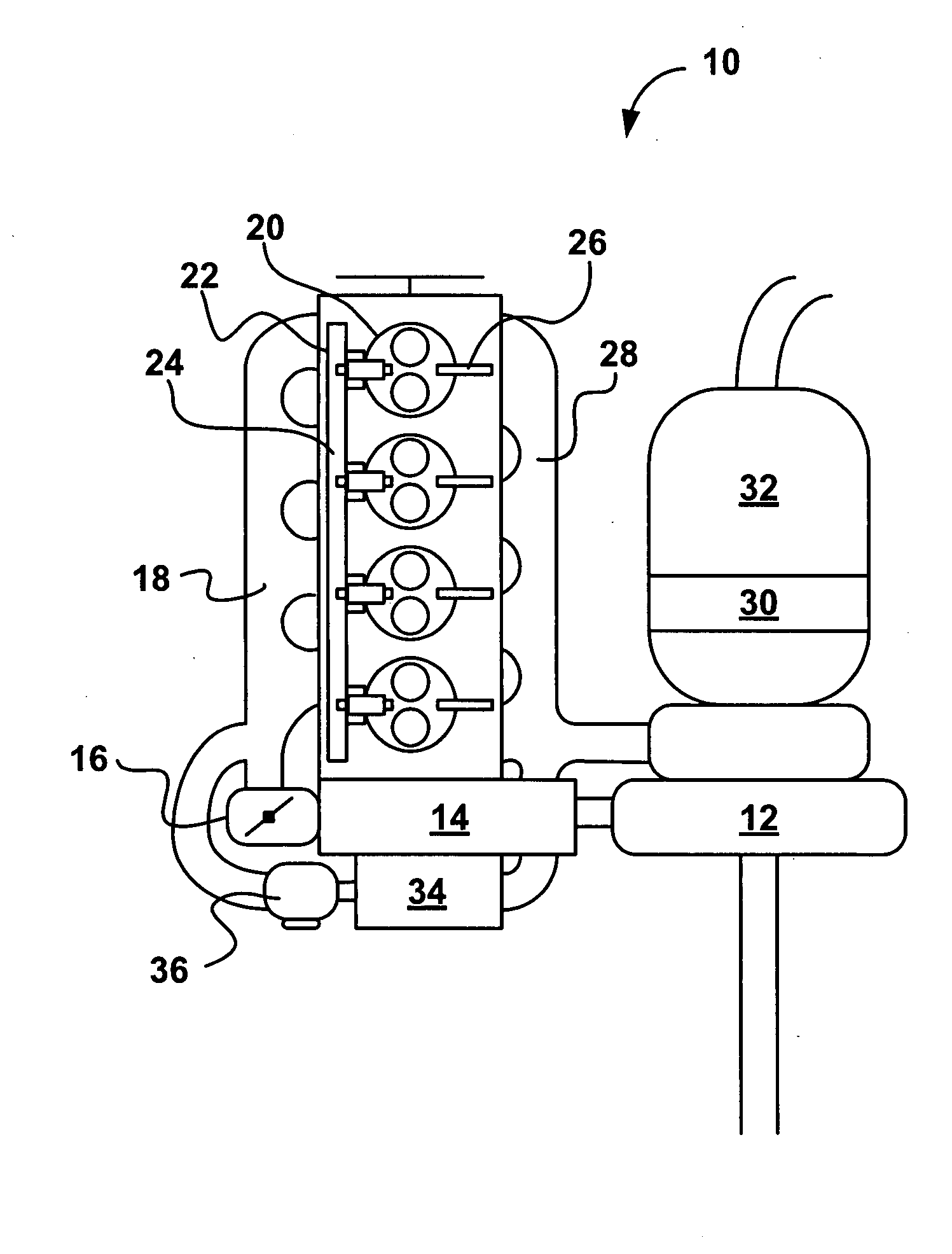

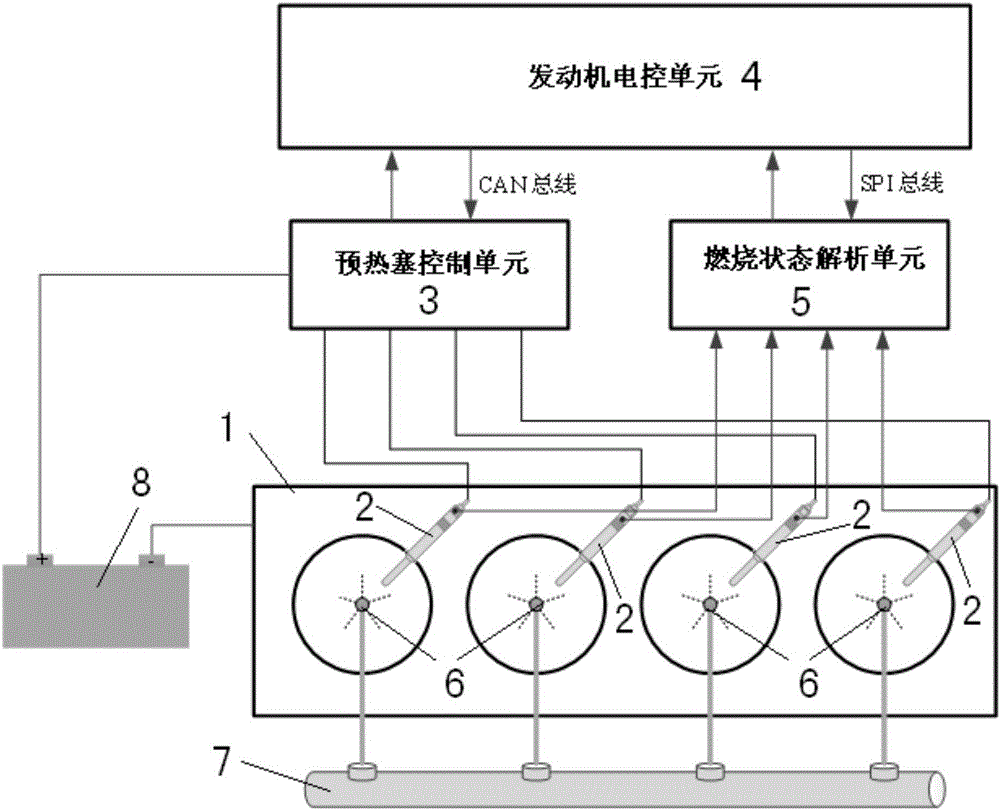

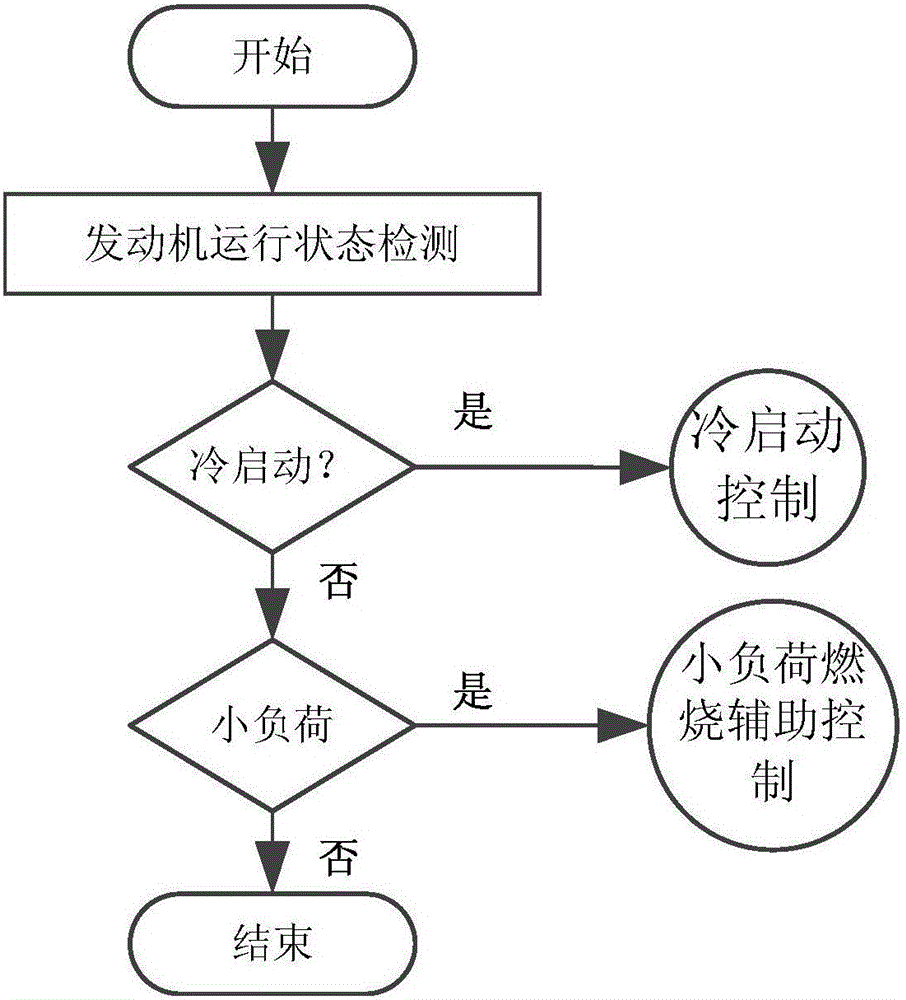

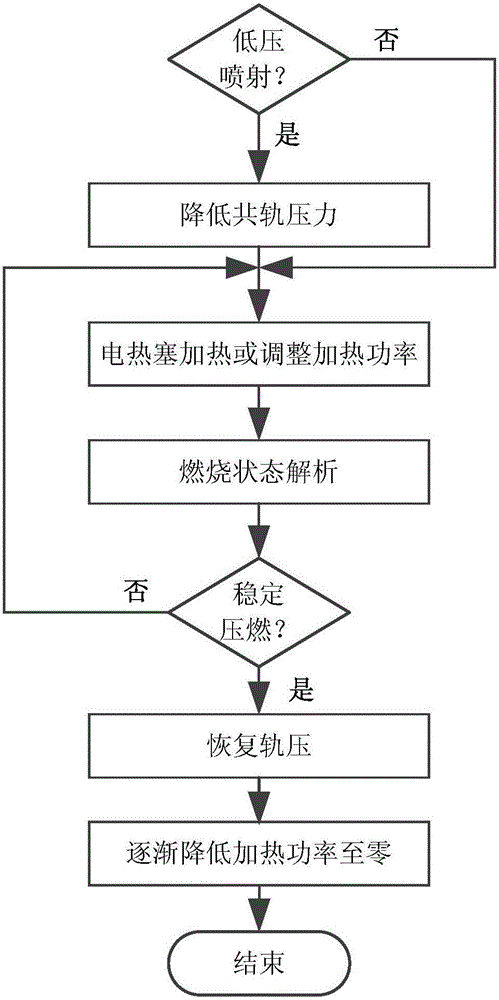

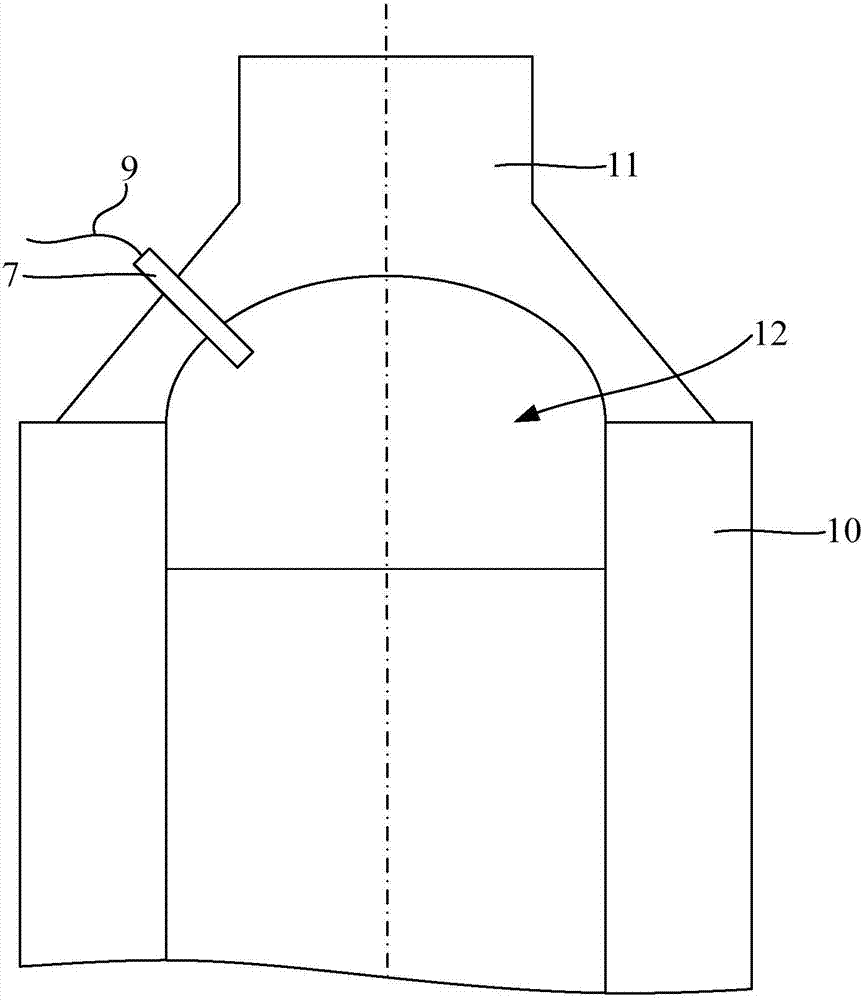

Cold-start and small-load combustion control system and method for low-temperature combustion engine

InactiveCN105863864AStable ignition and combustionFire stableElectrical controlMachines/enginesInlet temperatureIntake pressure

The invention relates to a cold-start and small-load combustion control system and method for a low-temperature combustion engine. The cold-start and small-load combustion control method for the low-temperature combustion engine comprises the steps that a control system which comprises cylinder pressure detection glow plugs, oil nozzles, common rail systems, batteries, engine electric-control units, glow plug control units and combustion state analysis units which are arranged in four air cylinders of an internal combustion engine correspondingly is arranged; the operating state information of the engine is detected, and the operating state information includes the temperature of the engine, the temperature of cooling liquid, the air inlet temperature, the air inlet pressure, the rotating speed of the engine, the torque of the engine, the torque required by a driver and the environment temperature and pressure; whether the engine is in a cold-start state or not currently is judged, and cold-start control is conducted if it is judged that the engine is in a cold-start state; the next step is executed if the engine is not in the cold-start state; whether the engine is under a small load working condition or not is judged, and small-load combustion assisting control is conducted if the engine is under the small load working condition; and otherwise, heating through the glow plugs and intervention of a low-pressure spraying method are not needed. The cold-start and small-load combustion control system and method for the low-temperature combustion engine can be widely applied to various electric-control diesel engines and electric-control gasoline engines.

Owner:TSINGHUA UNIV

Method for Making A Glow Element, A Spark Element, or A Heating Element for A Combustion Device and/or A Heating Device, and Device Thereof

InactiveUS20090302021A1Low melting pointSignificant positive effectSparking plugsIncandescent ignitionGlow plugSilicon

A method for making a glow element, a spark element, or a heating element for combustion and / or heating devices, in particular a glow plug, a spark plug, or a heater, having a corrosion-protective coating for parts of the glow element, spark element, or heating element having a silicon-containing ceramic, and the element thereof. The corrosion-protective coating is composed of a mixture of SiO2 and at least one other substance.

Owner:ROBERT BOSCH GMBH

Internal combustion engine

The invention discloses an internal combustion engine. The internal combustion engine comprises an engine body, an electric heater plug or a spark plug and a fuel injection system; the engine body comprises a cylinder block and a cylinder cover; the fuel injection system comprises a fuel injection pump and an oil injector; the fuel injection pump comprises a pump body and a plunger; the pump bodyis provided with a plunger hole and a first lubricating channel; the first lubricating channel penetrates through the pump body from the outside of the pump body and leads to the plunger hole; an outlet, at the plunger hole, of the first lubricating channel faces the plunger; the oil injector comprises an oil injector body and a needle valve; the oil injector body is provided with a needle valve hole and a second lubricating channel; the second lubricating channel penetrates through the oil injector body from the outside of the oil injector body and leads to the needle valve hole; and an outlet, at the needle valve hole, of the second lubricating channel faces the needle valve. The internal combustion engine has the advantages that when low-viscosity fuel is used for combustion, the defects that the low-viscosity fuel cannot achieve self-lubricating and self-sealing can be overcome, an additive does not need to be added into the low-viscosity fuel, and therefore the generation of new emission pollutants can be avoided, and the internal combustion engine can meet the emission standard.

Owner:上海夏雪科技有限公司

Method and device for detecting a replacement of pencil glow plugs in an internal combustion engine

InactiveUS8826729B2Accurate detectionIncrease the current valueInternal-combustion engine testingElectric ignition installationGlow plugEngineering

Owner:ROBERT BOSCH GMBH

Method and device for detecting a replacement of pencil glow plugs in an internal combustion engine

InactiveUS20130228007A1Reduce current and power consumptionMore detectableInternal-combustion engine testingElectric ignition installationElectric heatingElectricity

In a method for detecting a replacement of sheathed-element glow plugs in an internal combustion engine, an electrical parameter of the sheathed-element glow plug is determined during a driving cycle and is compared with a stored value of the same electrical parameter of the sheathed-element glow plug that was determined in a preceding driving cycle. In the driving cycle, the same electrical parameter is determined for all sheathed-element glow plugs installed in the internal combustion engine, and the determined pattern of the electrical parameter is compared with a pattern that was ascertained in a preceding driving cycle, a replacement of a sheathed-element glow plug being detected if the pattern of the driving cycle deviates from a pattern of the preceding driving cycle.

Owner:ROBERT BOSCH GMBH

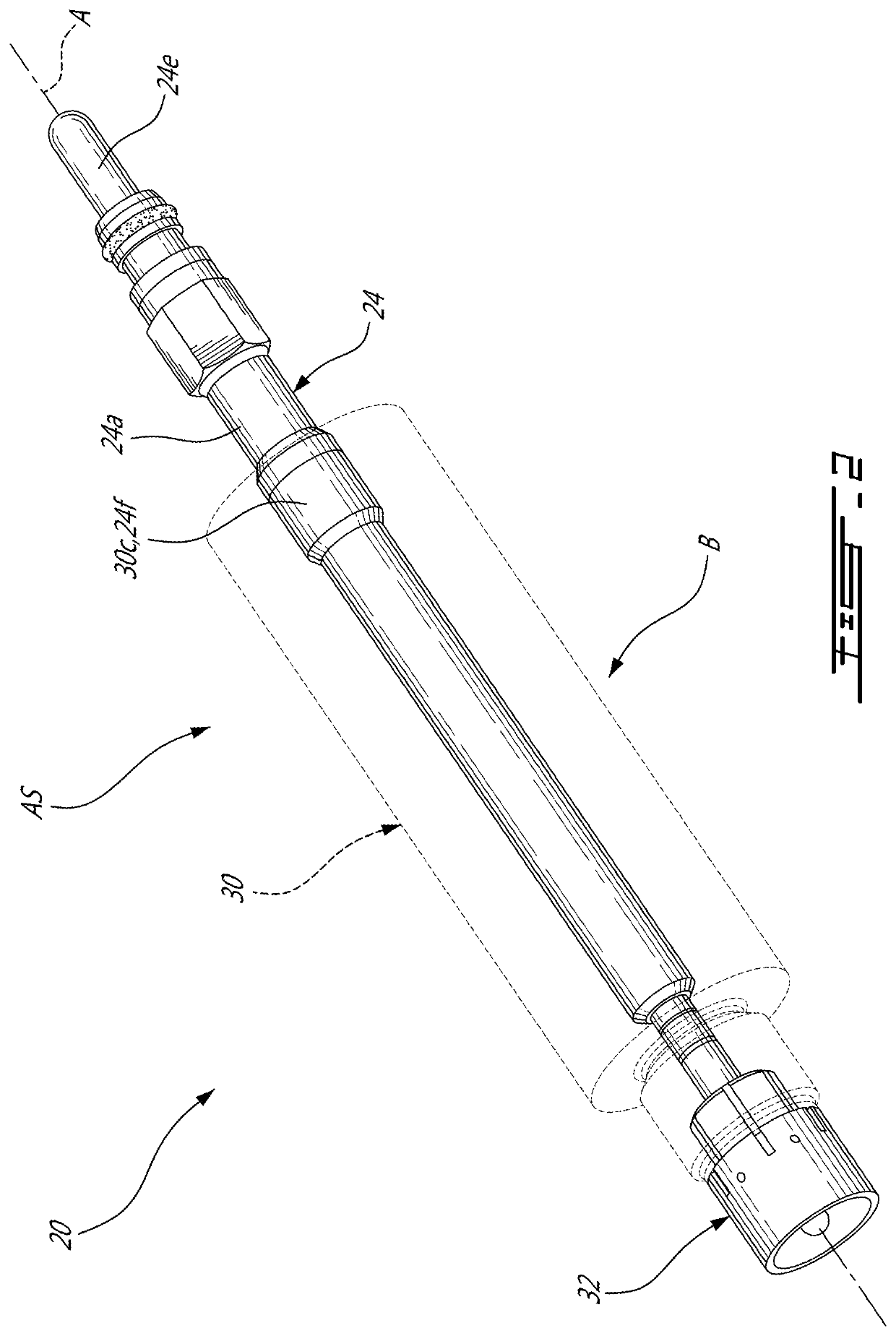

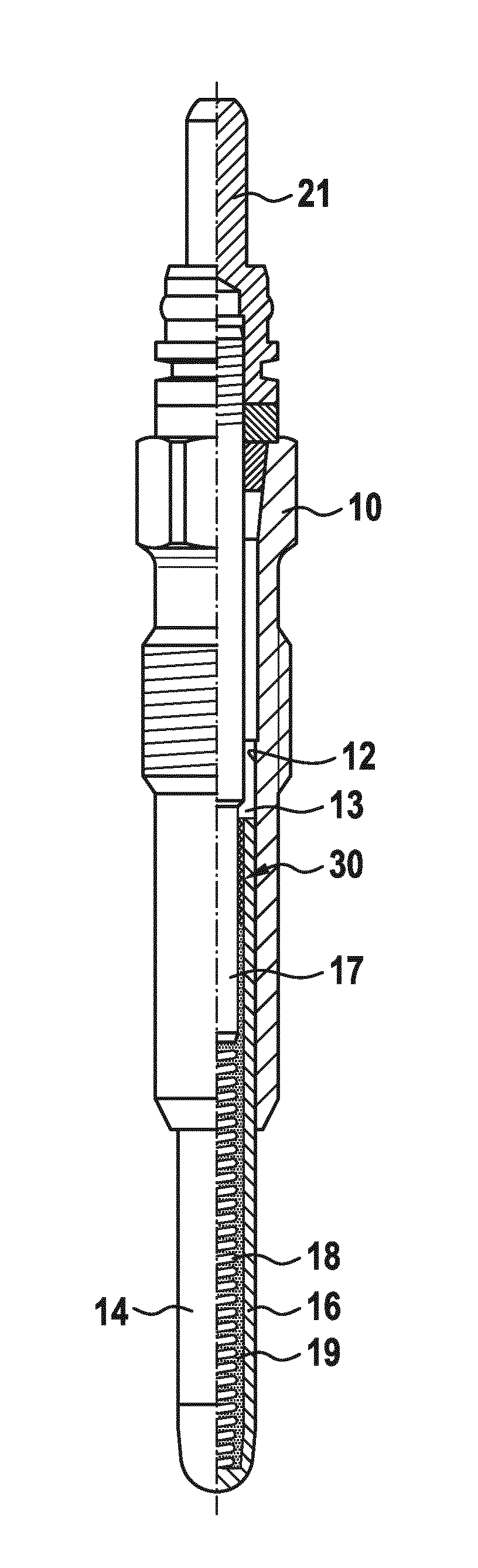

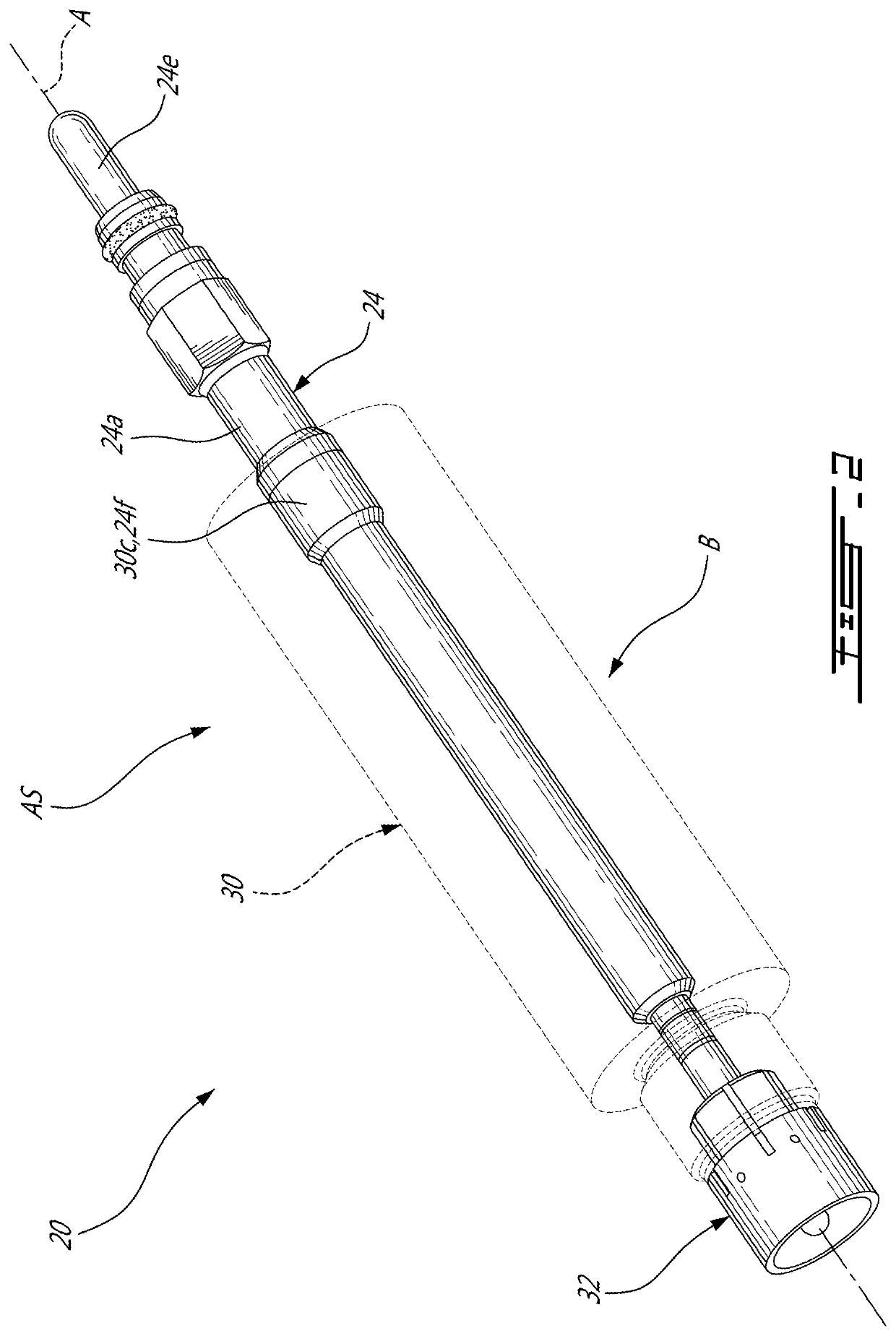

Igniter for gas turbine engine

There is disclosed a method of servicing a gas turbine engine having a spark plug igniter connected to a spark plug igniter socket of the engine, the method including: removing the spark plug from the spark plug igniter socket of the gas turbine engine; inserting a glow plug igniter having a base configured for matingly engaging the spark plug igniter socket; and securing the glow plug igniter to the gas turbine engine.

Owner:PRATT & WHITNEY CANADA CORP

Igniter for gas turbine engine

There is disclosed an igniter for a gas turbine engine including: a base, a glow plug heater rod extending from the base along an axis and terminating in a rod end, a sleeve extending circumferentially around the glow plug heater rod along at least a portion of a length of the glow plug heater rod, the igniter having a ventilation path extending from an inlet to an outlet, the inlet fluidly connectable to a spacing located between a casing and a combustor liner of the gas turbine engine, the outlet extending circumferentially around the glow plug heater rod and oriented axially relative to the axis, the outlet fluidly connectable to a combustion chamber of the gas turbine engine delimited by the combustor liner.

Owner:PRATT & WHITNEY CANADA CORP

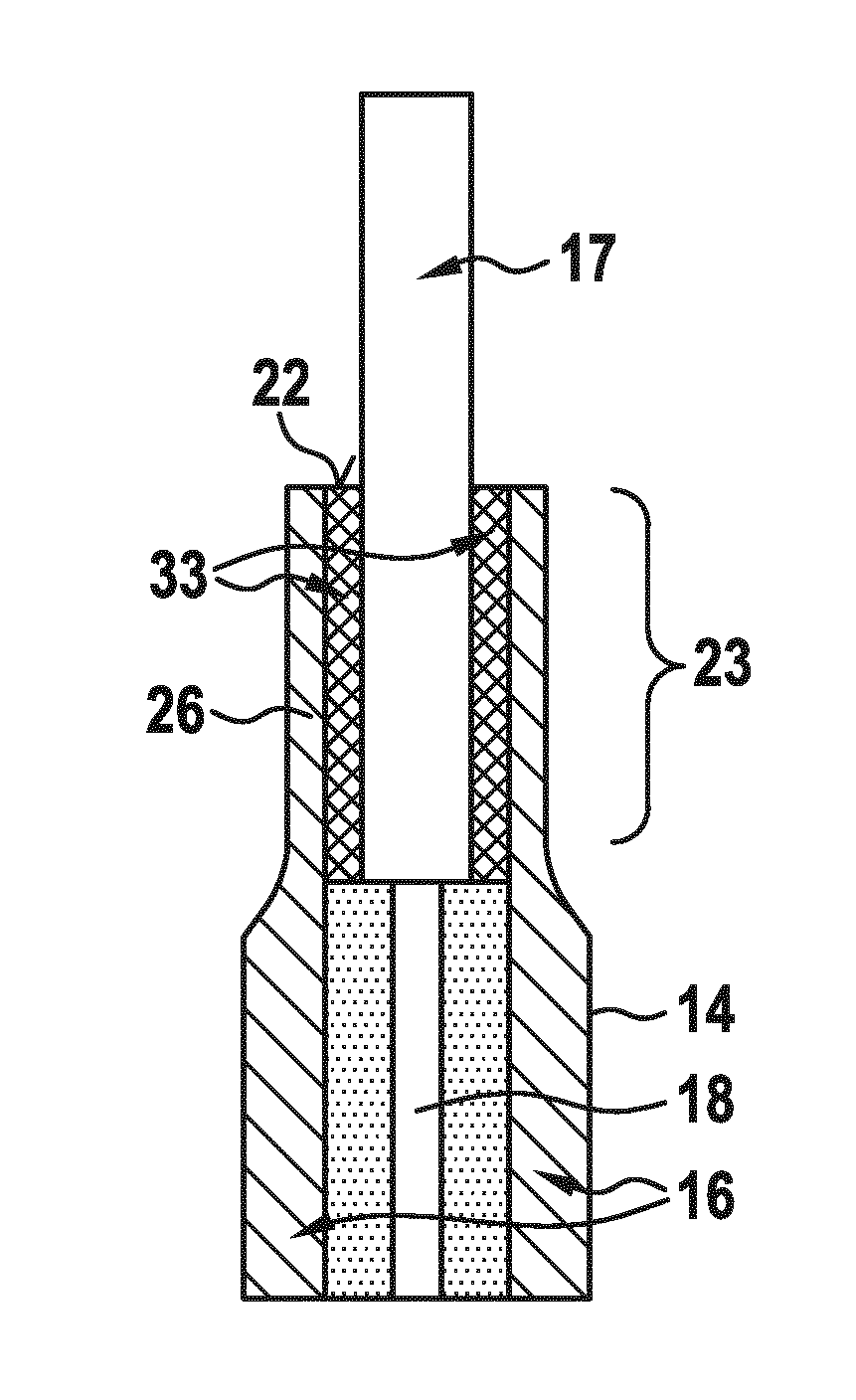

Glow plug and method for the production thereof

InactiveCN103228992ALow costImprove heat resistanceIncandescent ignitionElectrical contactsGlow plug

Disclosed is a glow plug comprising a sheathed element (14) which is accommodated in a metallic housing. The sheathed element comprises a glow tube (16) and a coiled element (18) arranged in the glow tube (16), wherein one end of the coiled element is in electrical contact with the glow tube and the other end is in electrical contact with a connecting pin (17). The connecting pin protrudes into an axial opening (22) of the glow tube where the connecting pin is connected in a sealing section (23) to the glow tube in an electrically insulating manner by means of a heating body seal. An electric insulating layer (33) is formed at least in the sealing section on the glow tube and / or the connecting pin. In order to provide a heating body seal, the glow tube is pressed in the region of the electric insulating layer onto the connecting pin.

Owner:ROBERT BOSCH GMBH

Sheath Heater

A sheath heater in a sheathed-type glow plug for diesel engines is described, having at least one generally internal insulation layer and at least one generally external conductive layer, both layers making up a ceramic composite structure. The sheath heater has a generally uniform overall cross-section, generally over its entire length, and, in the area of a tip of the sheath heater, the proportion of the insulation layer in the overall cross-section increases, whereas the proportion of the conductive layer in the overall cross-section decreases.

Owner:ROBERT BOSCH GMBH

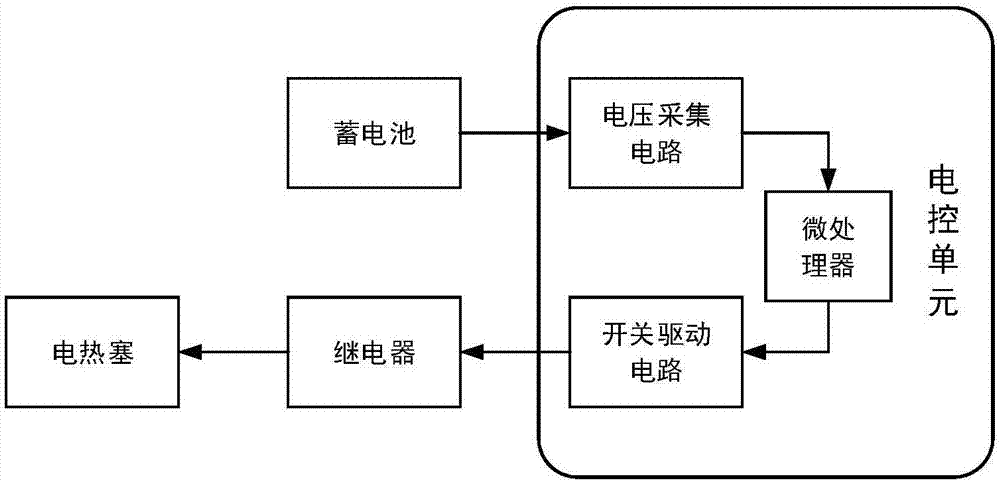

Automobile glow plug fault diagnosis system and diagnosis method

PendingCN107064696AGuaranteed cold start performanceSimple circuitElectrical testingElectric heatingPositive power

The invention relates to an automotive glow plug fault diagnosis system, which includes a battery, an electric control unit, a relay and a glow plug. The electric control unit includes a voltage acquisition circuit, a microprocessor and a switch drive circuit connected in sequence. The negative pole of the electronic control unit and the relay is grounded; the positive input terminal of the electric control unit power supply is connected to the positive pole of the battery, the negative pole input terminal of the power supply is grounded, the relay 87 contact is connected to the positive pole of the glow plug; the negative pole of the glow plug is grounded. The detection method is to measure the voltage at both ends of the battery before and after the relay is turned on by the electronic control unit, and calculate the amplitude of the battery voltage change before and after the relay is turned on; then compare the battery voltage change amplitude with the set threshold to diagnose the fault of the glow plug . Beneficial effects: the invention can accurately detect the fault of the glow plug, promptly remind the vehicle owner to replace it, and ensure the cold start performance of the vehicle or the normal operation of the burner.

Owner:MILITARY TRANSPORTATION UNIV PLA

Igniter for gas turbine engine

Owner:PRATT & WHITNEY CANADA CORP

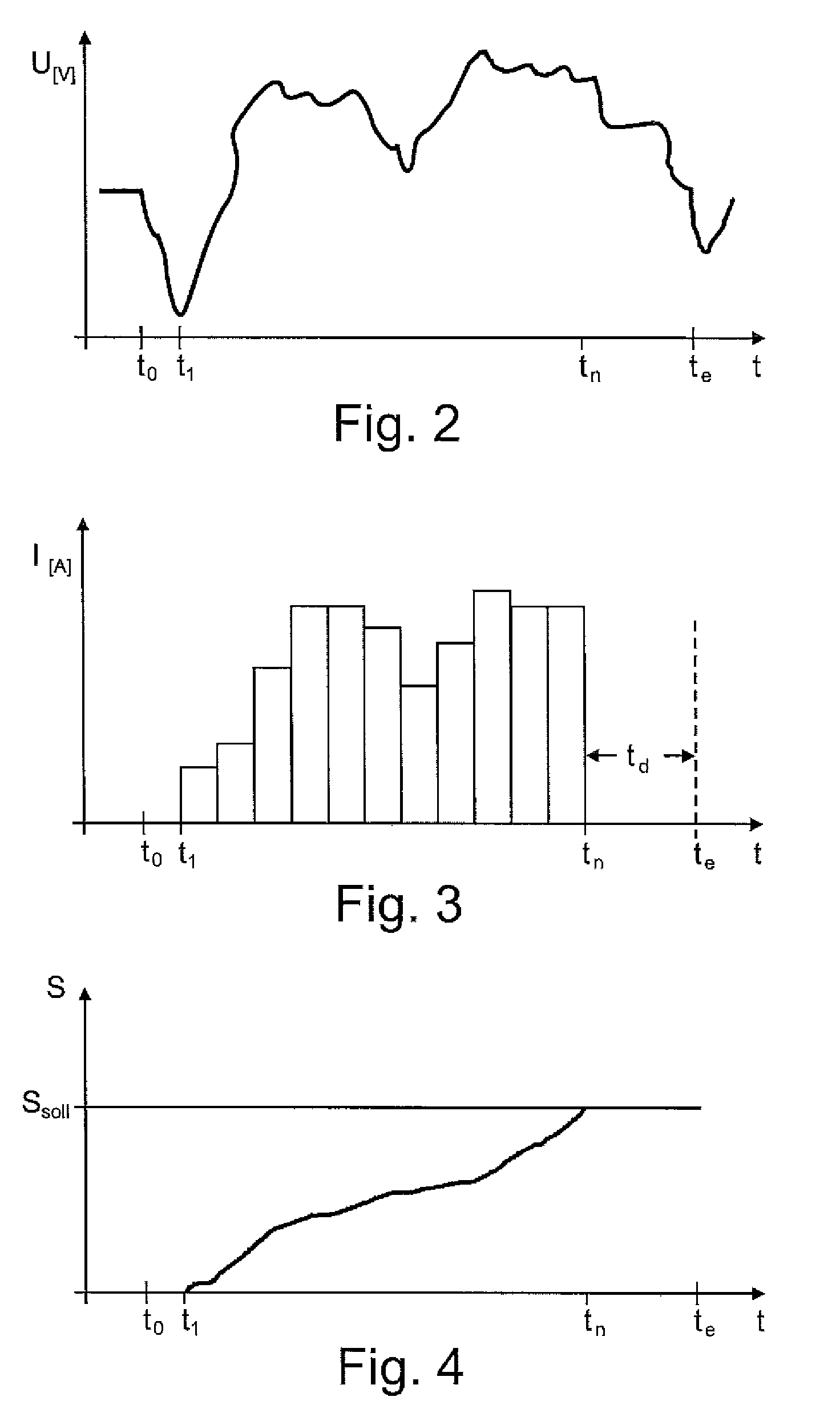

Method for Operating a Heating Element in a Motor Vehicle by Pulse Width Modulation

InactiveUS20110062138A1Increase supplyExtended service lifeElectrical controlIncandescent ignitionVoltage pulseEngineering

The invention relates to a method for operating a heating element in a motor vehicle by pulse width modulation, wherein fluctuations in the supply voltage are compensated for by adapting the duty cycle so as to achieve a desired heating output. According to the invention, during a voltage pulse the voltage that is present at the heating element and / or the current flowing through the heating element are measured at specified intervals, and the measured values or values determined therefrom are added to calculate a sum value, which rises with the energy that is fed into the heating element by the voltage pulse, and the voltage pulse is ended at the latest when the sum value has reached a target value. The invention furthermore relates to a glow plug controller for carrying out the method according to the invention.

Owner:BORGWARNER BERU SYST

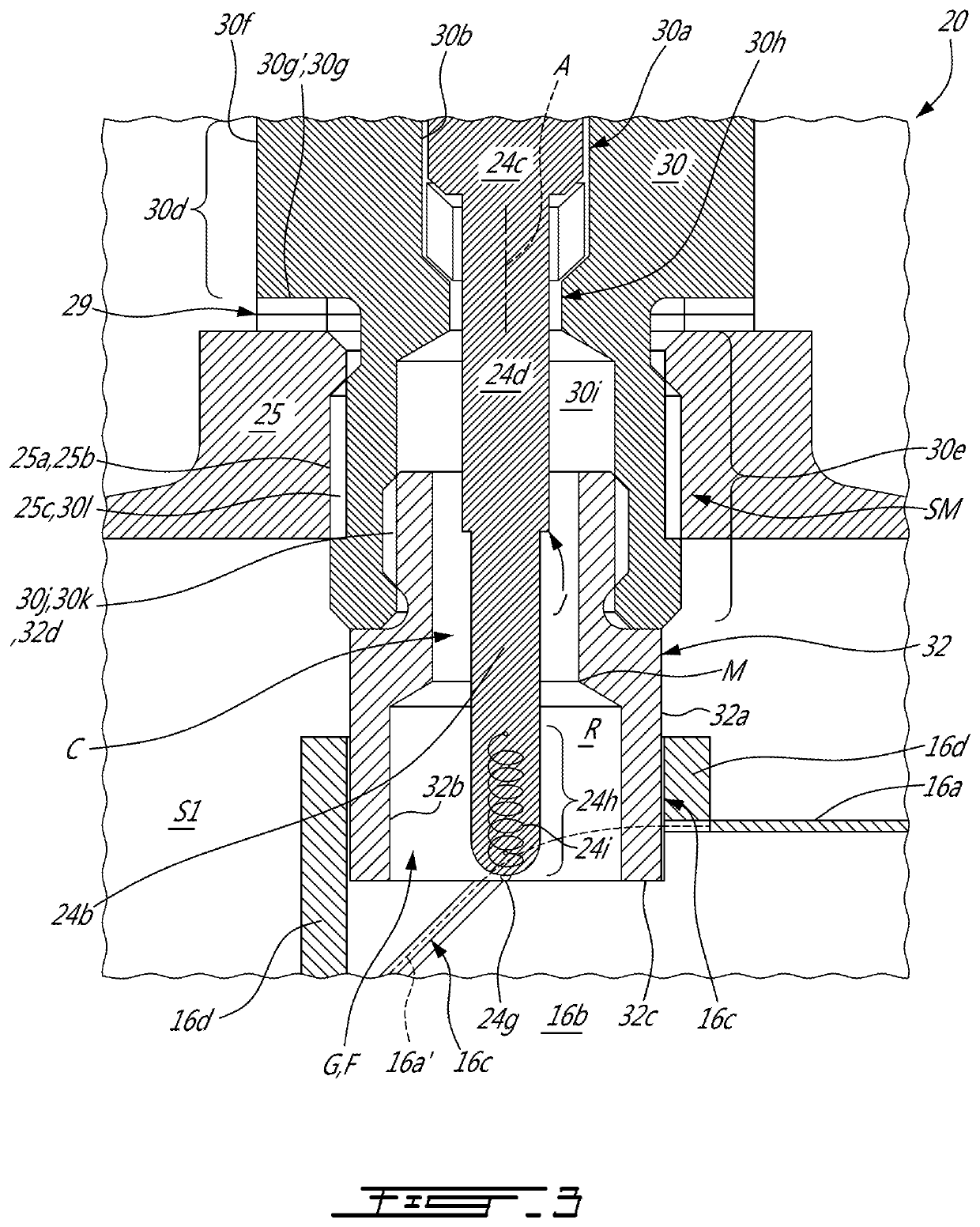

Carbon-Deposit Protection System For A Sheathed-Element Glow Plug Having A Gas Conduit For Pressure Measurement

InactiveUS20080067165A1Lower Level RequirementsAvoid cloggingIncandescent ignitionHeater elementsCombustion chamberEngineering

A sheathed-element glow plug for an internal combustion engine, made up substantially of a plug housing and a glow element disposed in the plug housing, having a gas conduit for measuring the combustion chamber pressure. A gas-permeable filter element, provided according to the present invention in the gas conduit, prevents the penetration of carbon residues or combustion residues into the interior of the sheathed-element glow plug, or reduces particle entry to a tolerable level.

Owner:ROBERT BOSCH GMBH

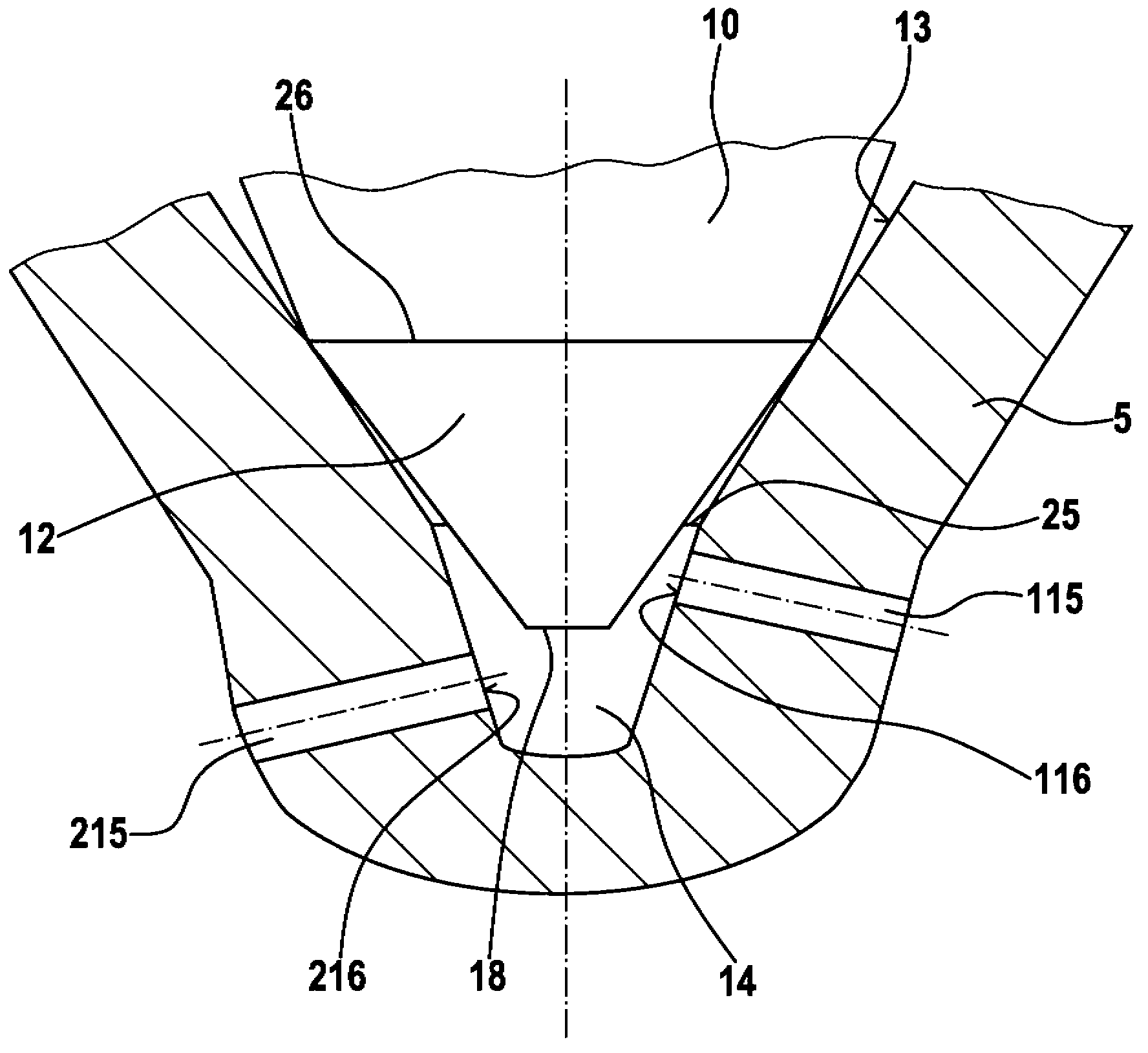

Fuel injection valve for internal combustion engines

InactiveCN103261665AOptimized control of fuel volumeOptimizing Fuel AtomizationInternal combustion piston enginesFuel injection apparatusBiomedical engineeringExternal combustion engine

The invention relates to a fuel injection valve (1) comprising a valve body (5), in which a pressure chamber (7) is designed which, at one end, is delimited by a conical valve seat (13) to which a blind hole (14) connects. A valve needle (10) is arranged longitudinally displaceably in the pressure chamber (7), a valve sealing face (12) of the needle cooperating with the conical valve seat (13) to control a fuel flow from the pressure chamber (7) to injection openings (15; 115; 215) designed in the valve body (5), wherein a valve needle tip (18) of the valve needle (10) protrudes in the blind hole (14) when the needle is seated against the valve seat (13).; The inlet opening (216) of an injection opening (215) is arranged downstream of the valve needle tip (18) in the blind hole (14) and the inlet openings (116) of the remaining injection holes (115) are arranged downstream of the valve needle tip (18) when the valve needle (10) is seated against the valve seat (13). An internal combustion engine comprising such a fuel injection valve (1) and a pencil-type glow plug (35) is designed such the fuel exiting the downstream injection opening (215) forms a pilot injection which is directed to or in the direct vicinity of the pencil-type glow plug (35). Because of the position of this injection opening, fuel is ejected in the direction of the pencil-type glow plug even when the valve needle is offset and even with small needle strokes.

Owner:ROBERT BOSCH GMBH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com