Internal combustion engine

A technology of internal combustion engine and fuel injection system, which is applied in the field of vehicles and can solve problems such as difficulty in starting, wear of plunger parts of fuel injection pumps, fuel leakage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

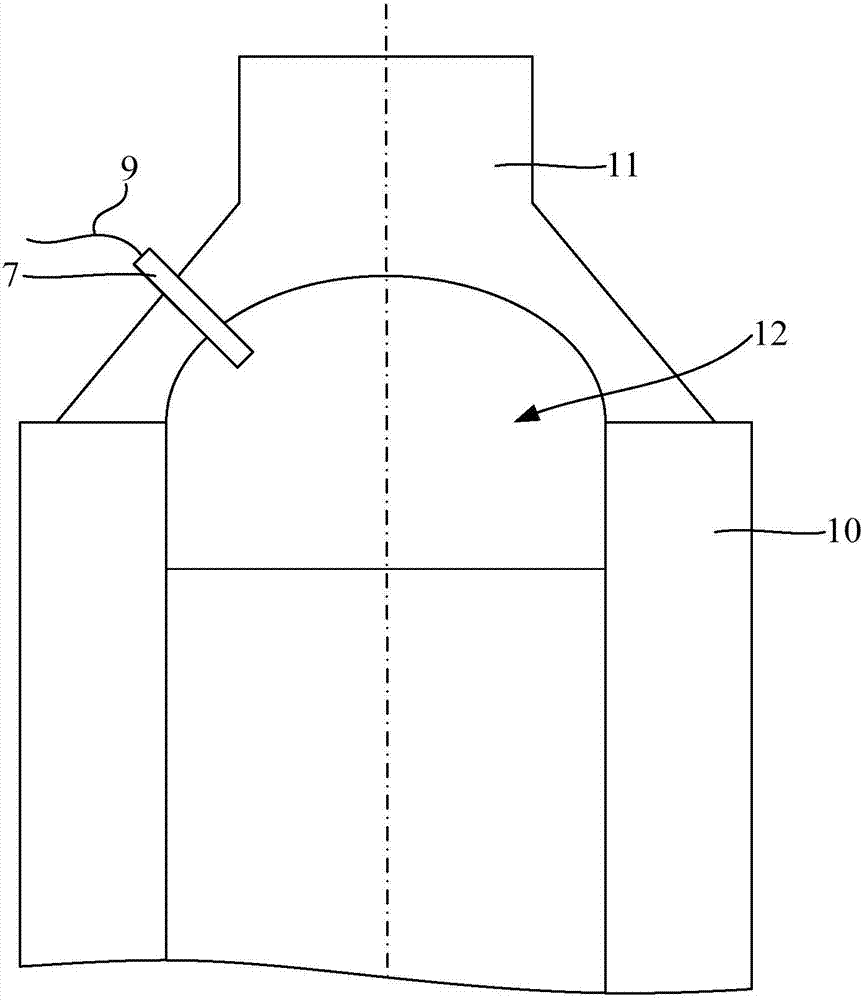

[0033] In order to make the above objects, features and advantages of the present invention more comprehensible, specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] This embodiment provides an internal combustion engine, which can not only burn traditional diesel fuel, but also burn low-viscosity fuels, such as alternative fuels such as methanol, ethanol, dimethyl ether, and gasoline. These alternative fuels have high energy efficiency, low pollution, and Low cost, energy diversification and energy security, therefore, the internal combustion engine has a good application prospect. It should be noted that, in the technical solution of the present invention, the so-called low-viscosity fuel refers to a fuel whose viscosity is lower than that of diesel. combine Figure 1 to Figure 2 As shown, the internal combustion engine includes a body 1 and a fuel injection system P. in:

[0035] The body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com