Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

10306results about "Synchronous machines with stationary armatures and rotating magnets" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

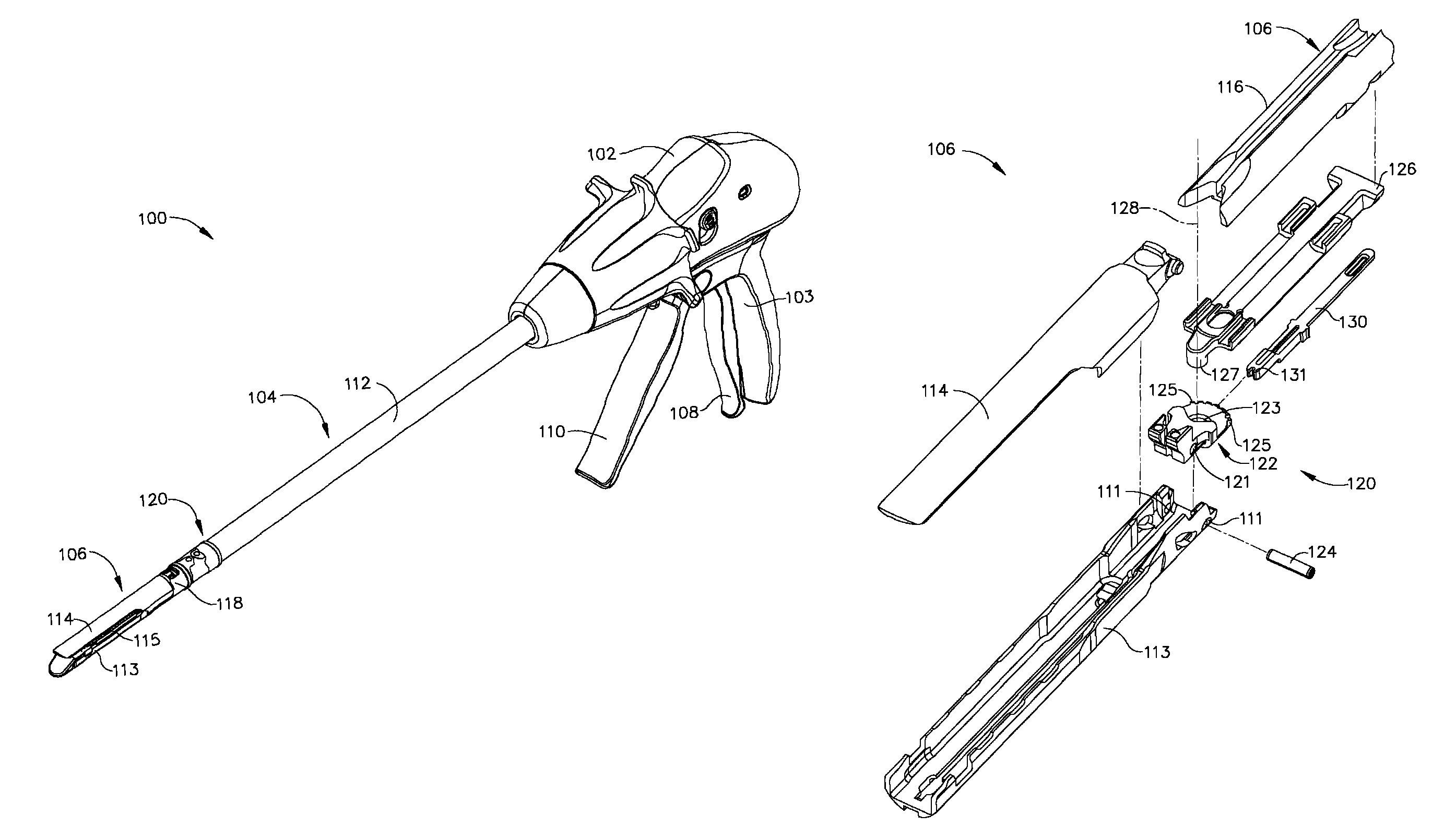

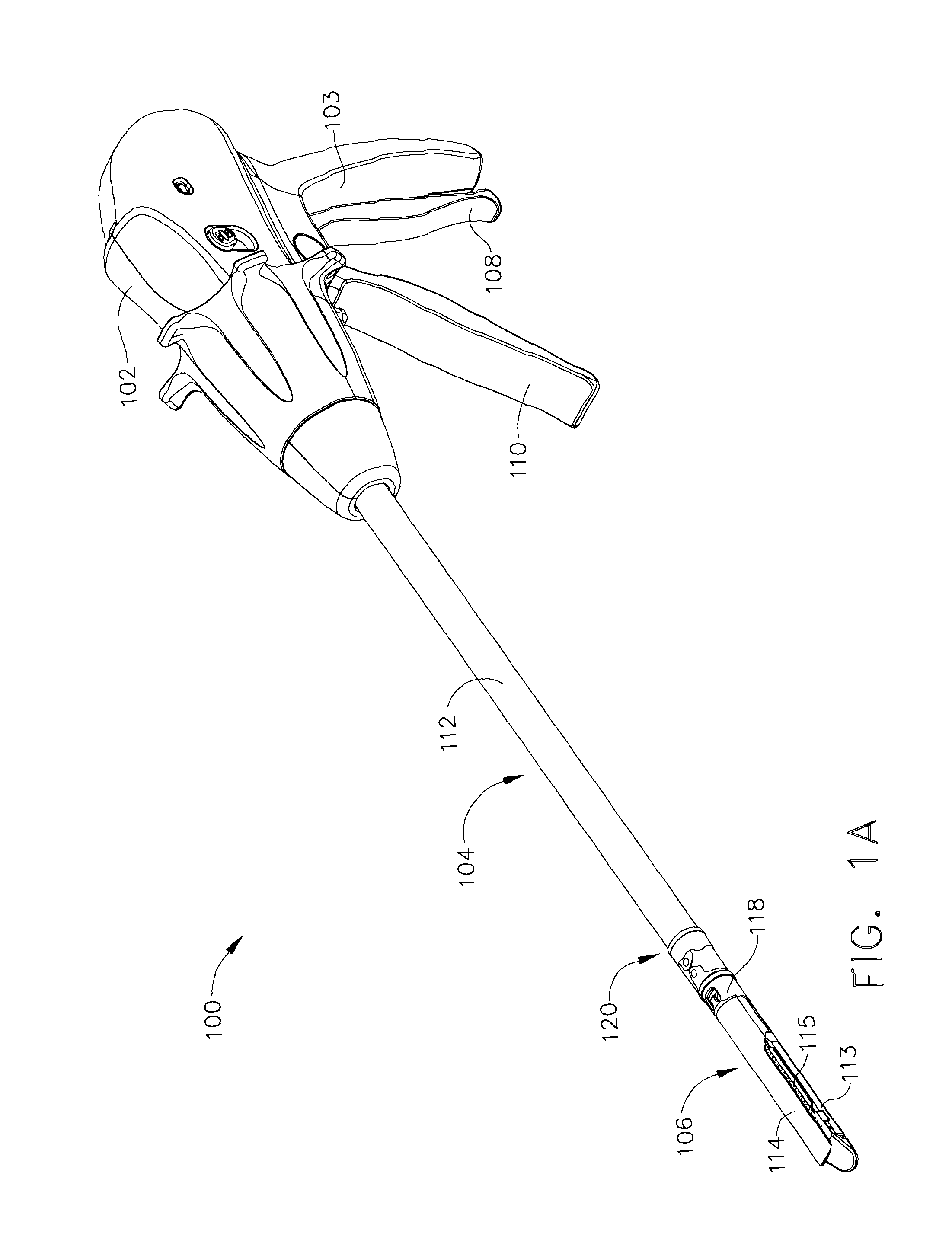

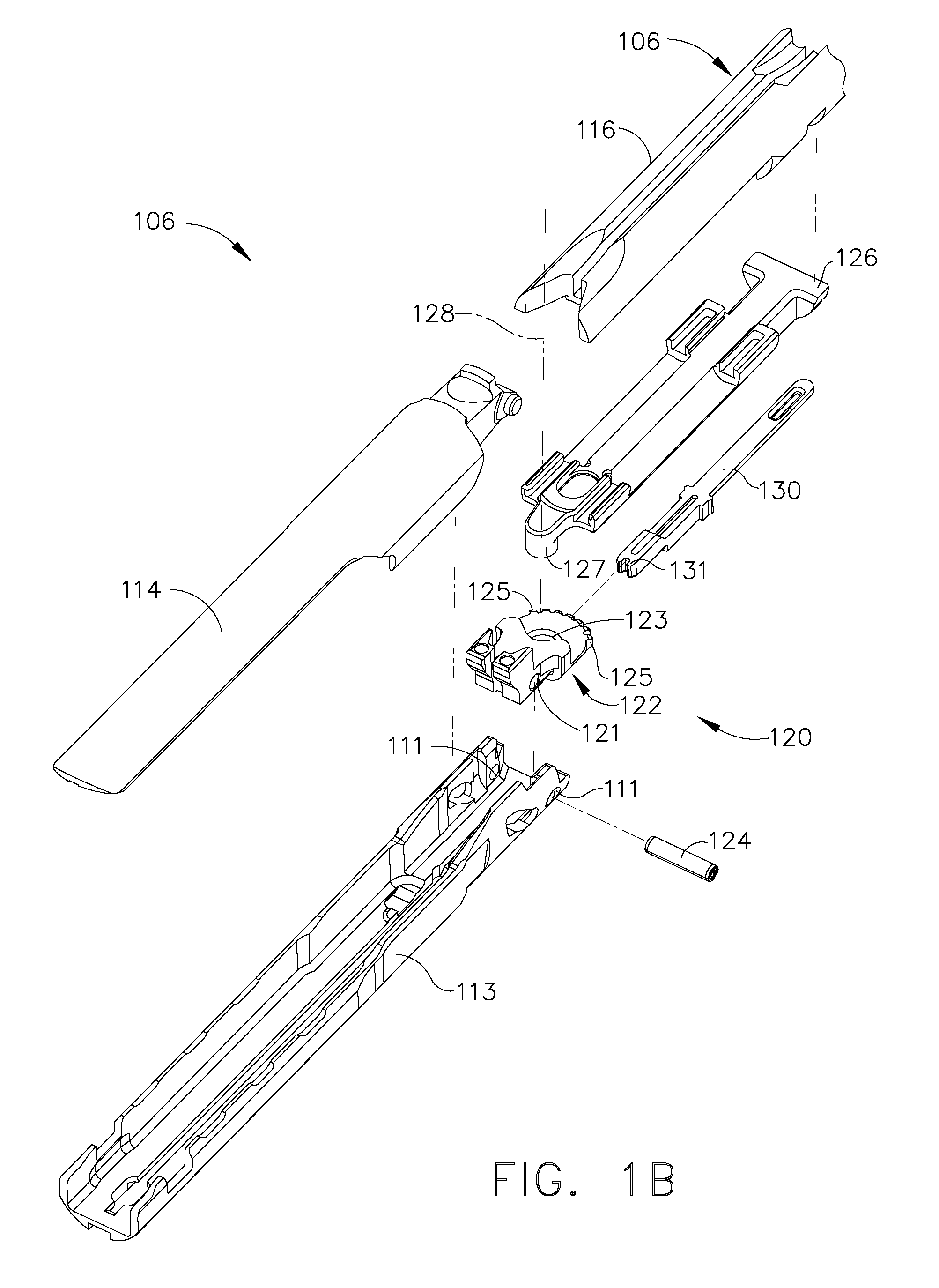

Surgical stapling instrument comprising a magnetic element driver

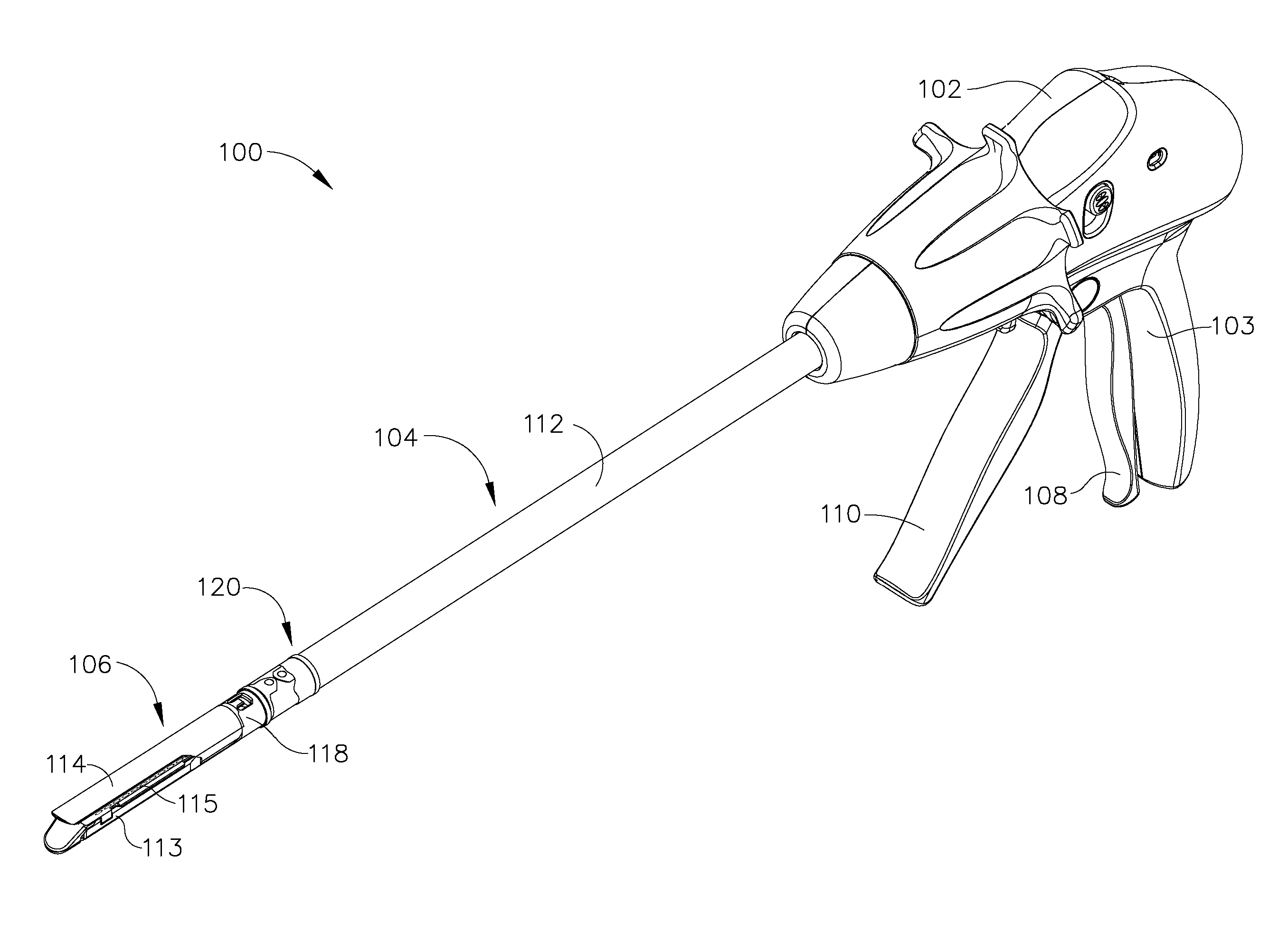

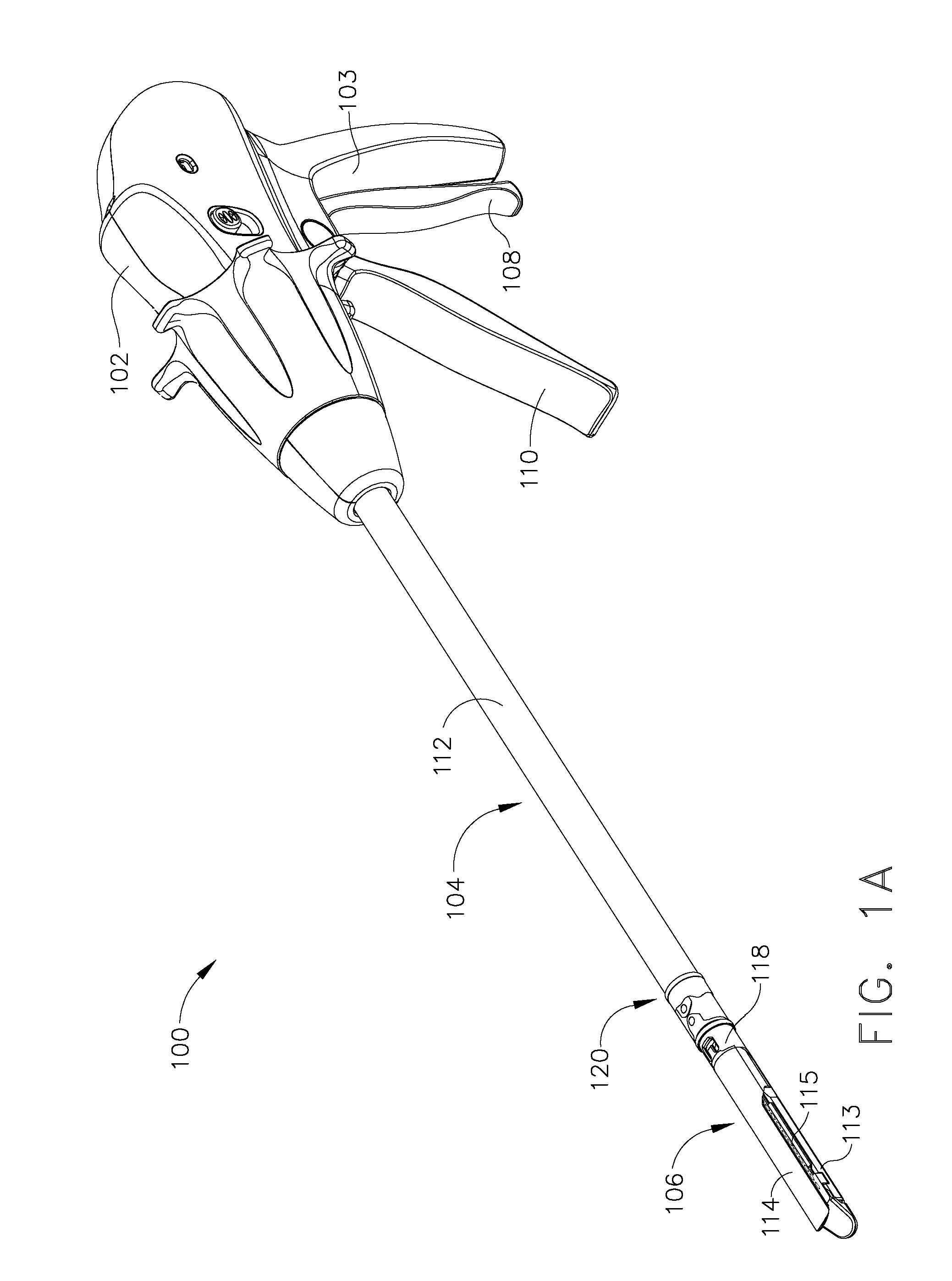

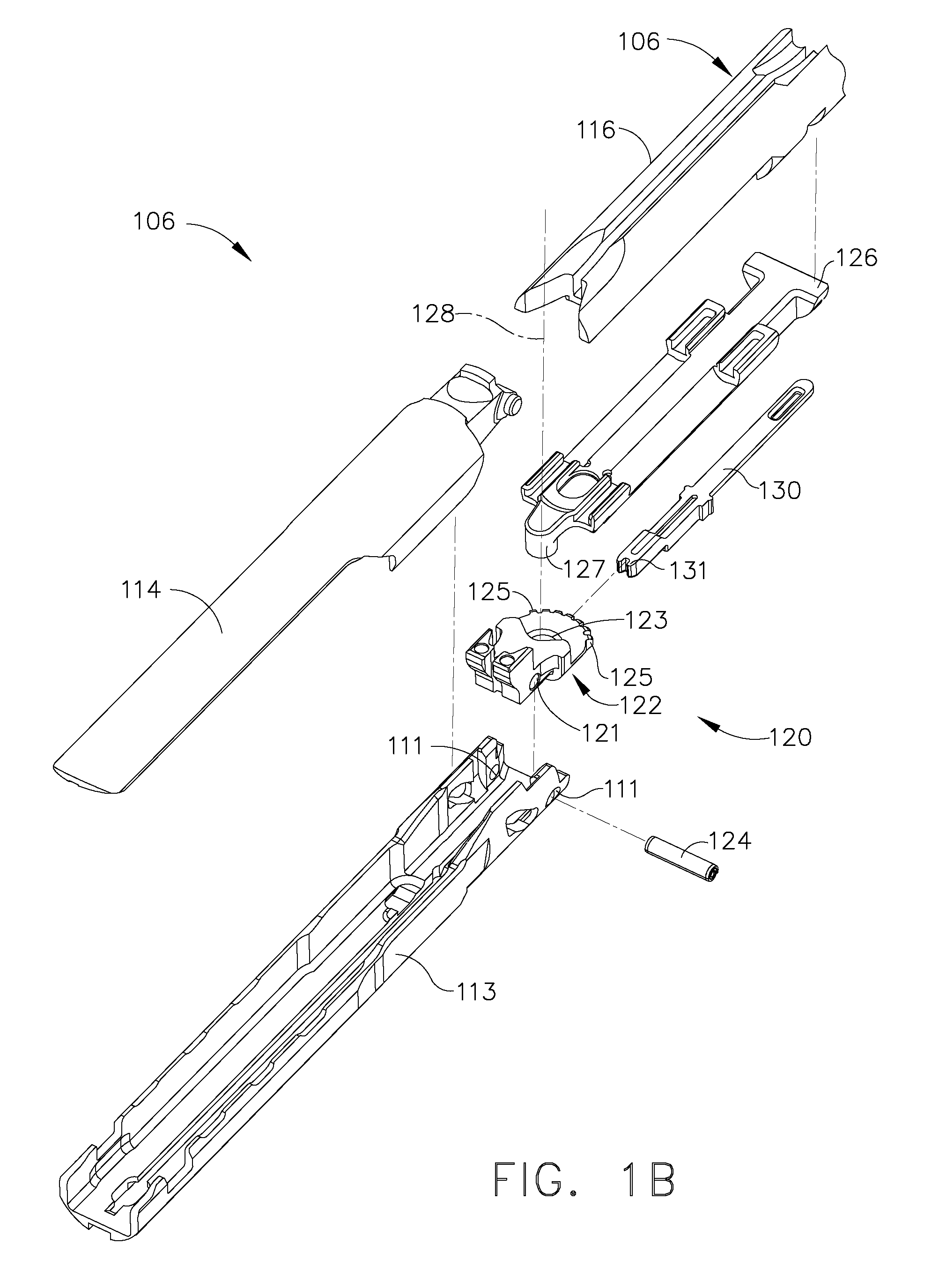

In various embodiments, a surgical stapling instrument can comprise a plurality of magnetic elements configured to articulate an end effector of the surgical instrument. The surgical instrument can comprise at least one electromagnet which can be selectively activated, or polarized, to generate a magnetic field sufficient to motivate a second magnetic element, such as a permanent magnet and / or an iron core, for example, mounted to the end effector. In certain embodiments, a surgical stapling instrument can comprise a plurality of magnetic elements configured to open and / or close an end effector of the surgical instrument. In at least one embodiment, a surgical stapling instrument can comprise a plurality of magnetic elements configured to advance and / or retract a firing bar, cutting member, and / or staple sled within the surgical instrument in order to incise and / or staple tissue positioned within an end effector of the surgical instrument.

Owner:CILAG GMBH INT

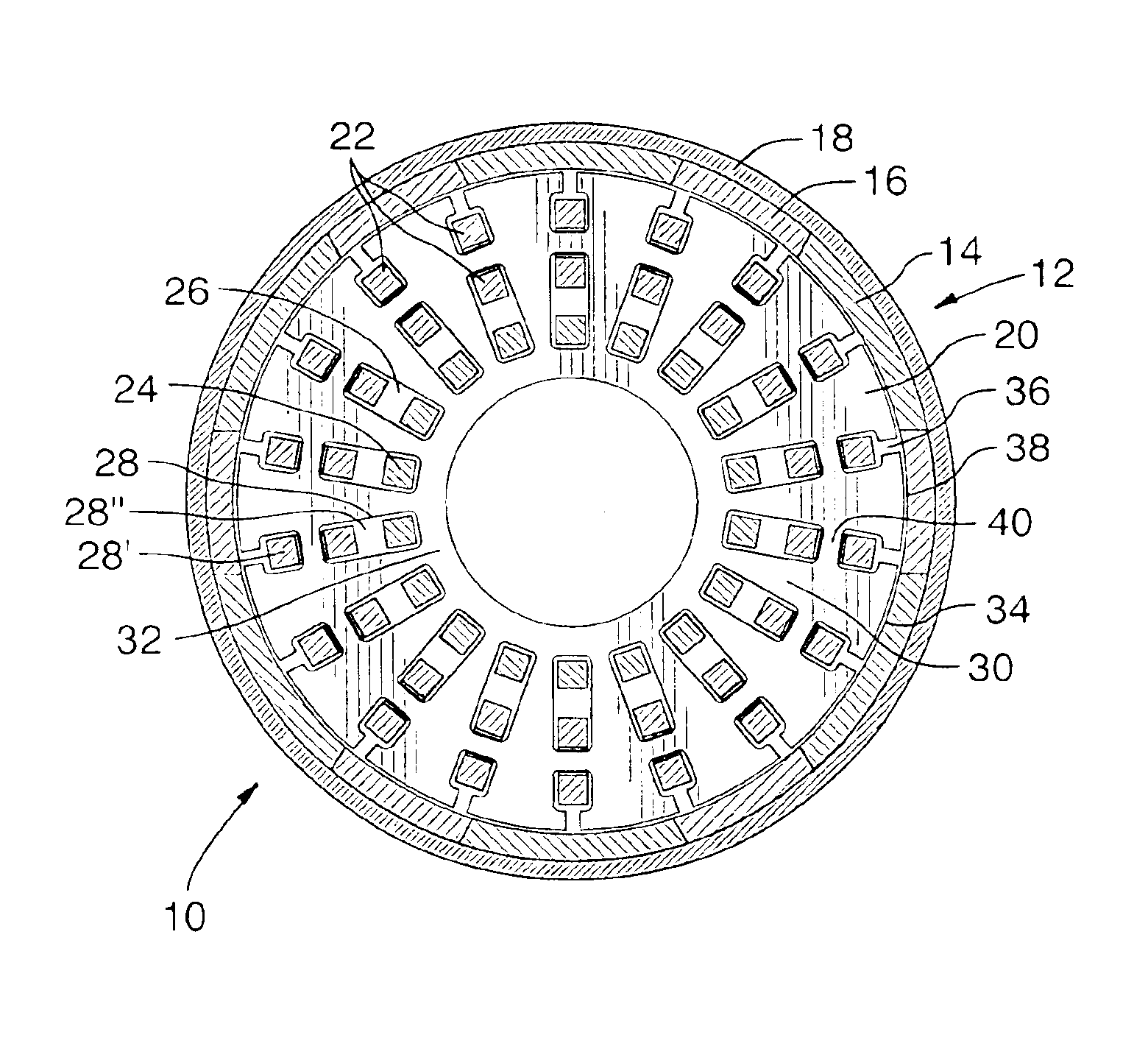

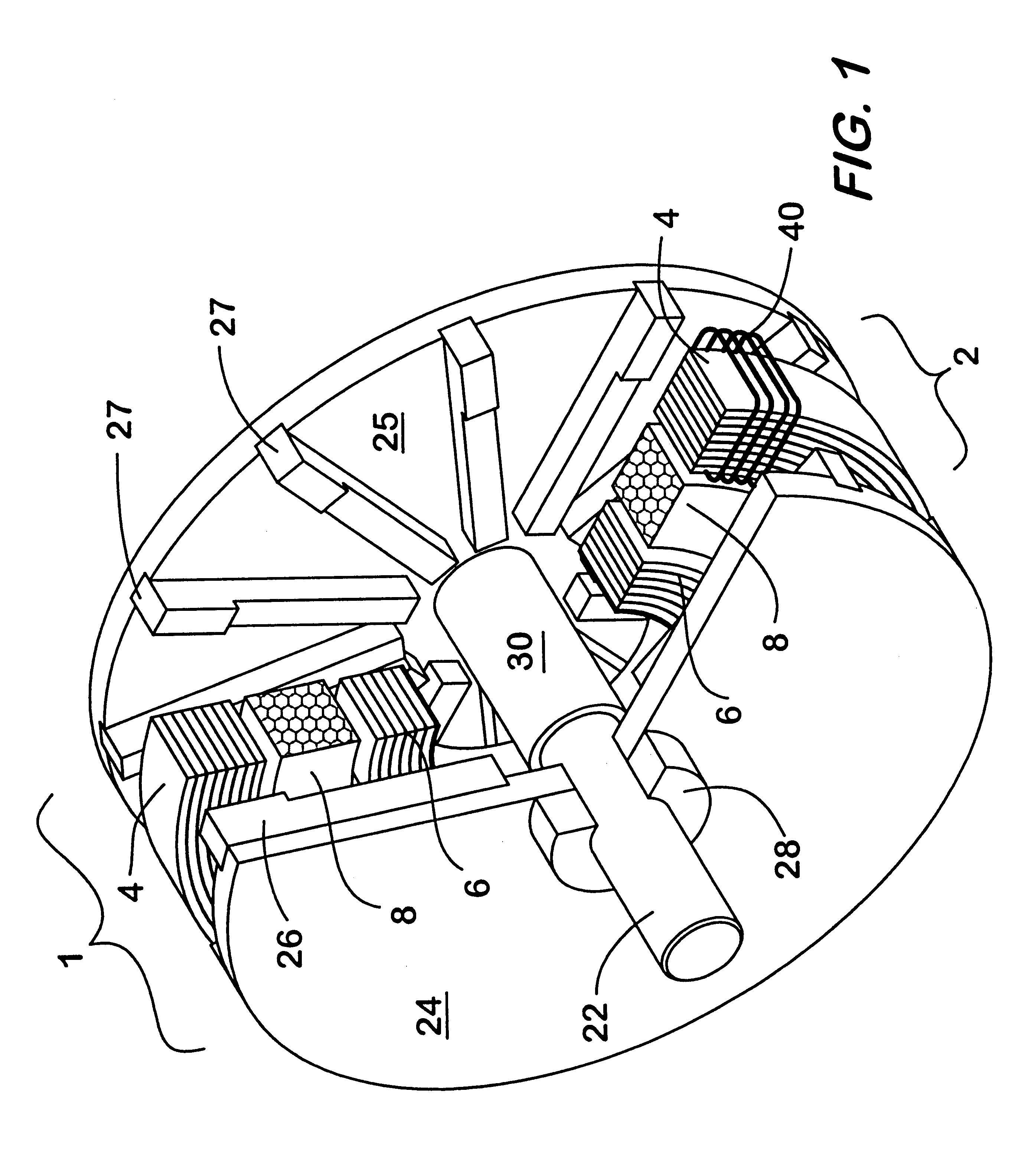

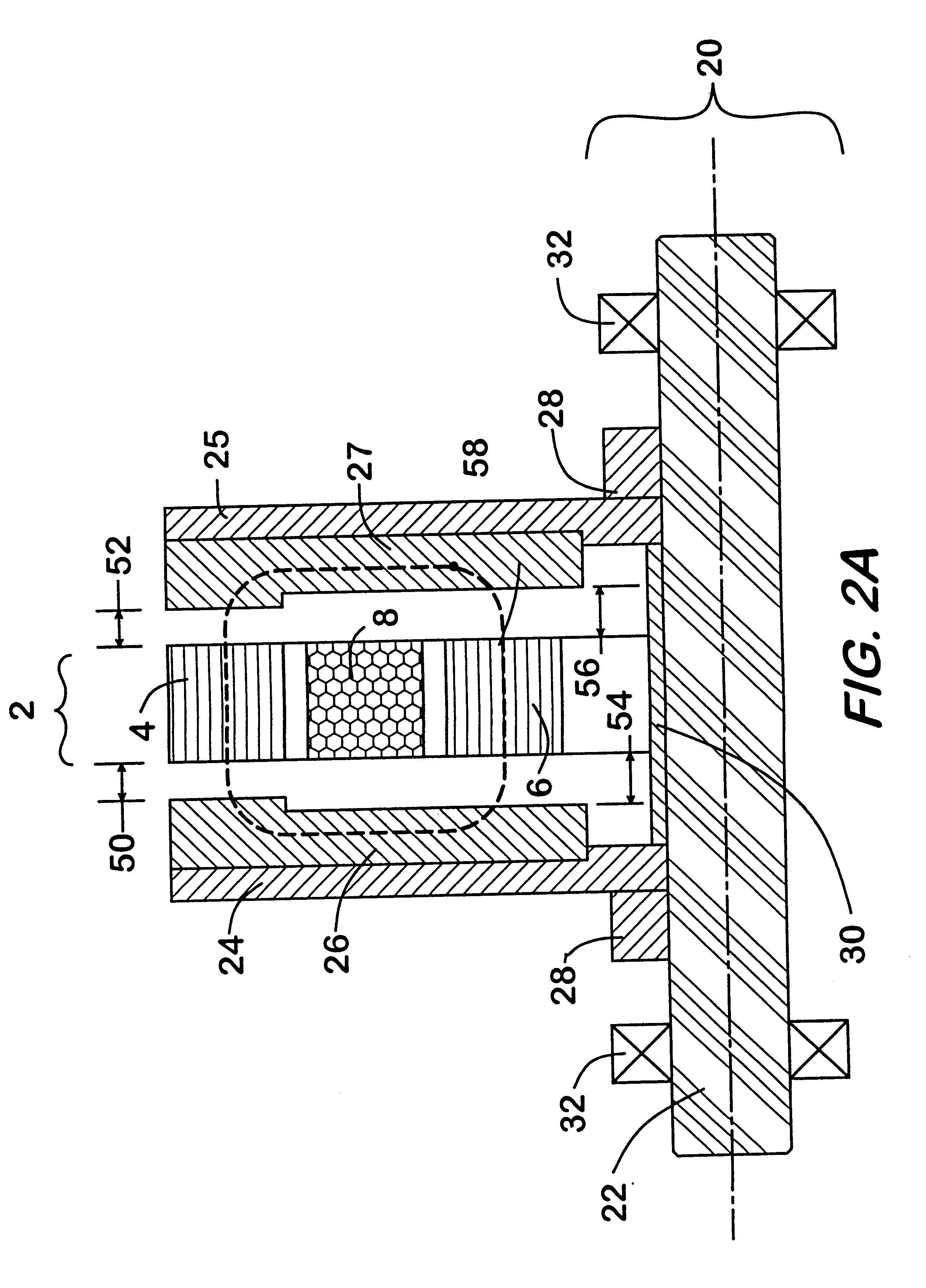

Electric machine having an integrally continuous stator winding and stator slot bridges

The invention includes an electric machine having a rotor, stator and at least one winding in the stator adapted to conduct a current, and a secondary winding, electrically isolated from the first winding and inductively coupled to the first winding, which may be used to control at least one of the output voltage and current of the first winding.

Owner:PRATT & WHITNEY CANADA CORP

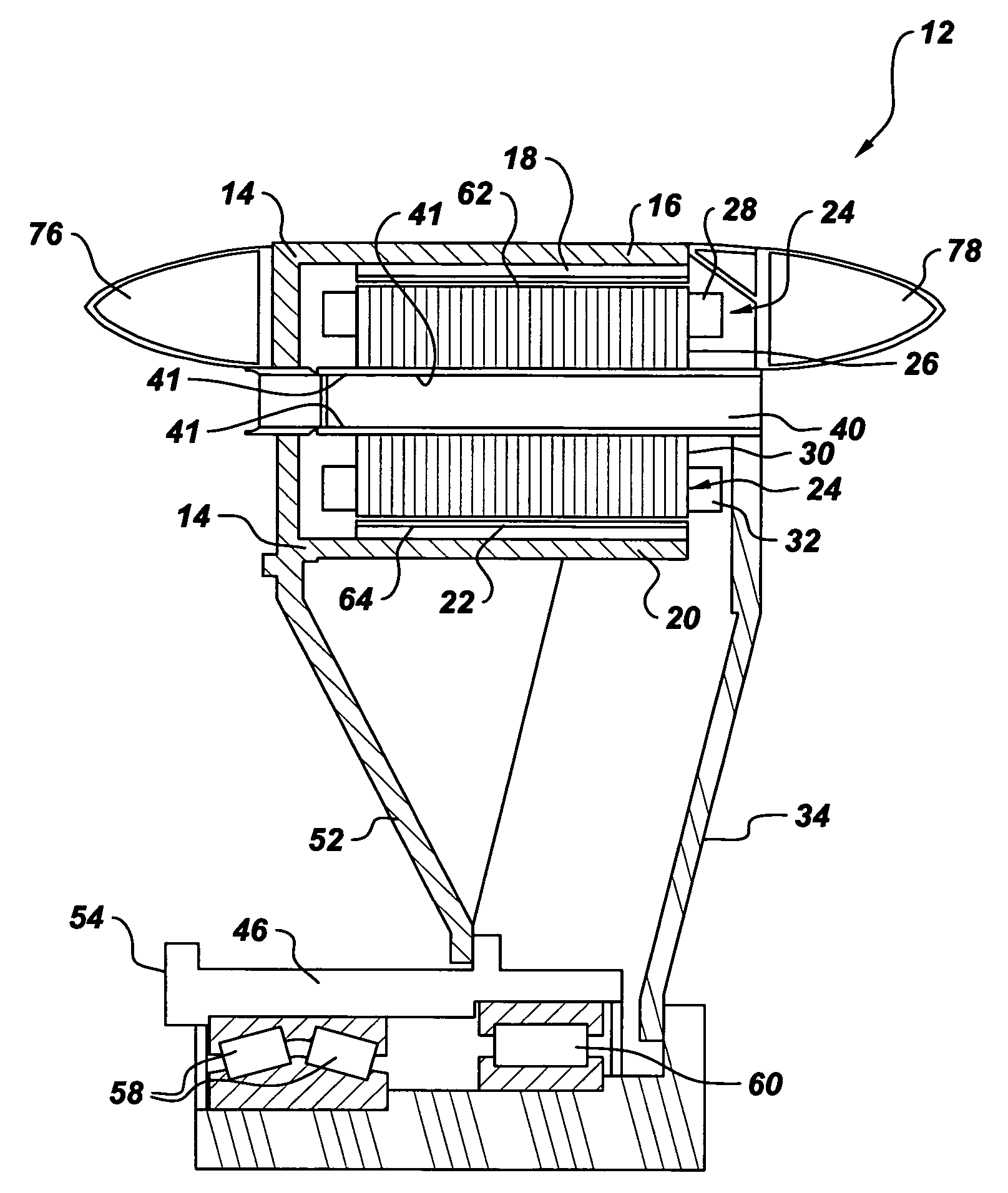

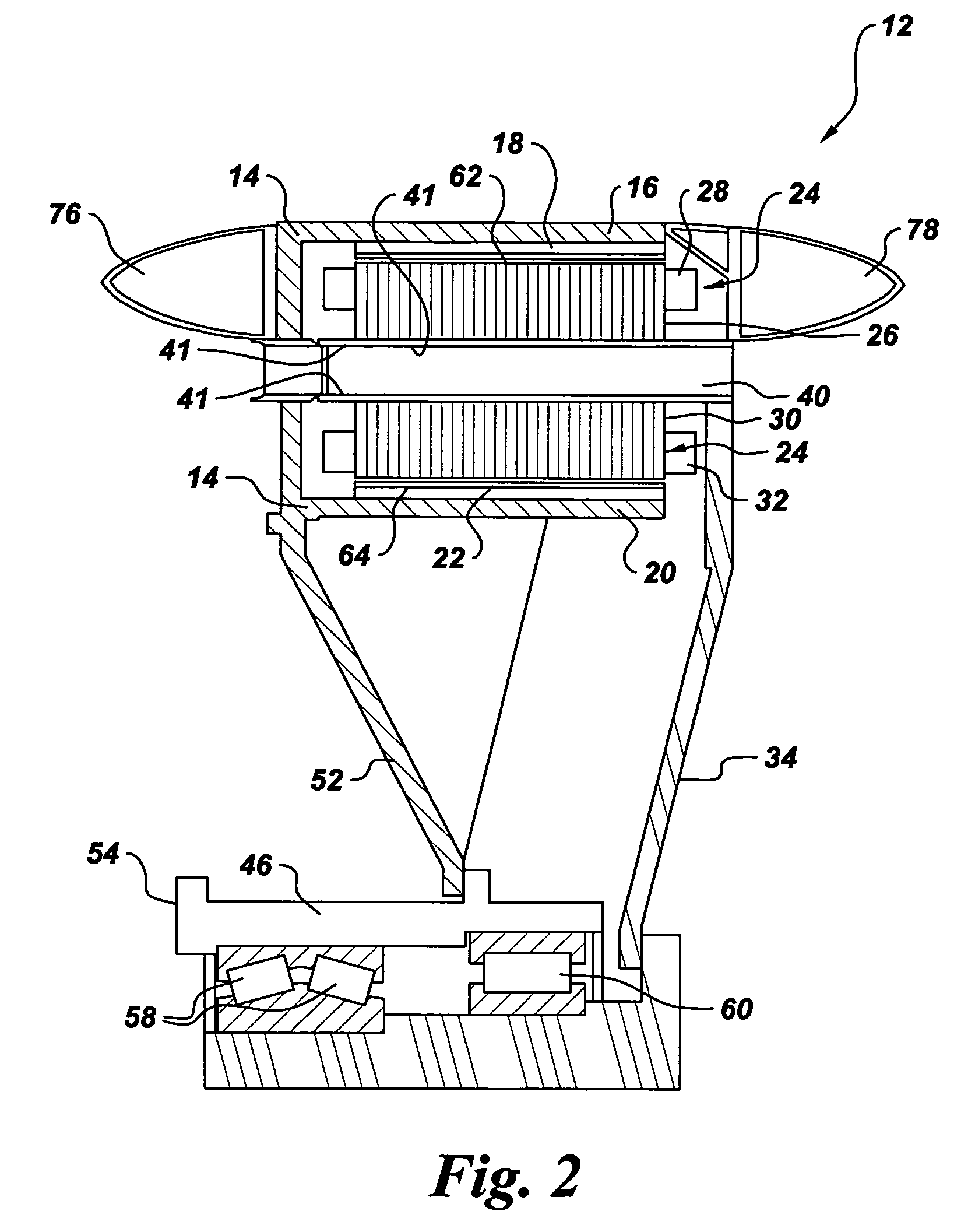

Architecture for electric machine

InactiveUS7583063B2Magnetic circuitEmergency protective circuit arrangementsElectricityElectric machine

The invention includes an electric machine having a rotor, stator and at least one winding in the stator adapted to conduct a current, and a secondary winding, electrically isolated from the first winding and inductively coupled to the first winding, which may be used to control at least one of the output voltage and current of the first winding.

Owner:PRATT & WHITNEY CANADA CORP

Surgical stapling instrument comprising a magnetic element driver

In various embodiments, a surgical stapling instrument can comprise a plurality of magnetic elements configured to articulate an end effector of the surgical instrument. The surgical instrument can comprise at least one electromagnet which can be selectively activated, or polarized, to generate a magnetic field sufficient to motivate a second magnetic element, such as a permanent magnet and / or an iron core, for example, mounted to the end effector. In certain embodiments, a surgical stapling instrument can comprise a plurality of magnetic elements configured to open and / or close an end effector of the surgical instrument. In at least one embodiment, a surgical stapling instrument can comprise a plurality of magnetic elements configured to advance and / or retract a firing bar, cutting member, and / or staple sled within the surgical instrument in order to incise and / or staple tissue positioned within an end effector of the surgical instrument.

Owner:CILAG GMBH INT

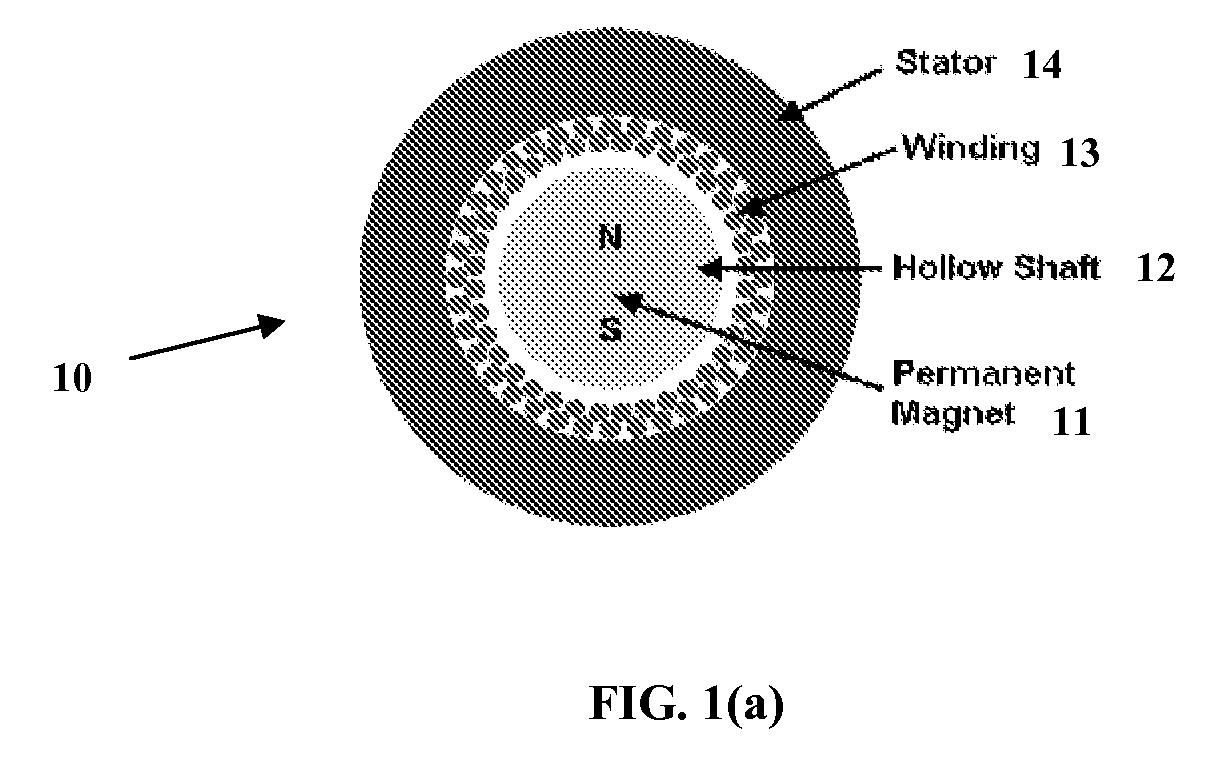

Brushless DC motor with bearings

A brushless DC motor including a rotor, a magnet provided to the rotor, a pair of bearings to rotatably support the rotor, a stator assembly that at least partly surrounds the rotor and magnet thereof and adapted to control movement of the rotor, and a bearing tube having an exterior surface and an interior surface that defines a tube interior. The stator assembly is provided along the exterior surface of the tube and the bearings are provided along the interior surface of the tube to support the rotor and magnet within the tube interior. The motor has sample application for use in PAP devices for delivery of positive airway pressure therapy for users or patients.

Owner:RESMED MOTOR TECH

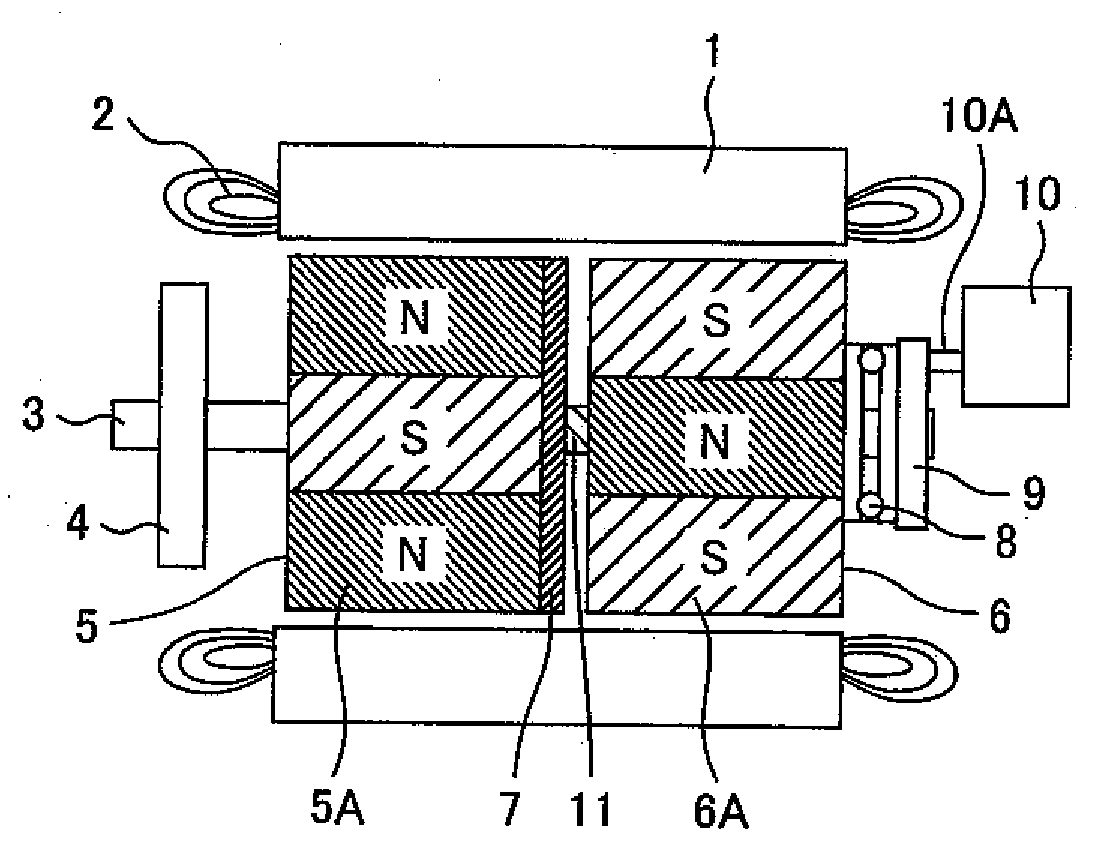

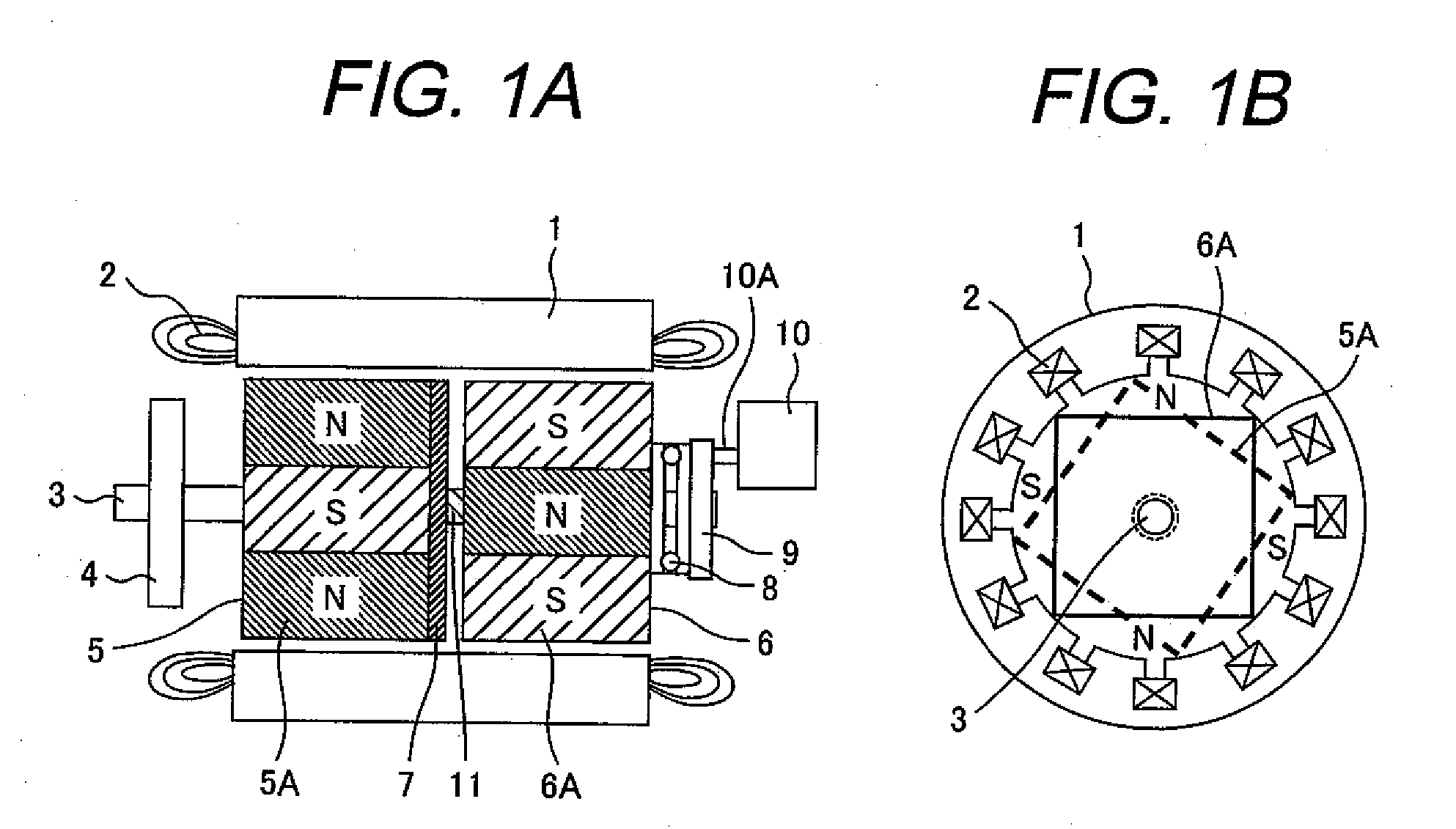

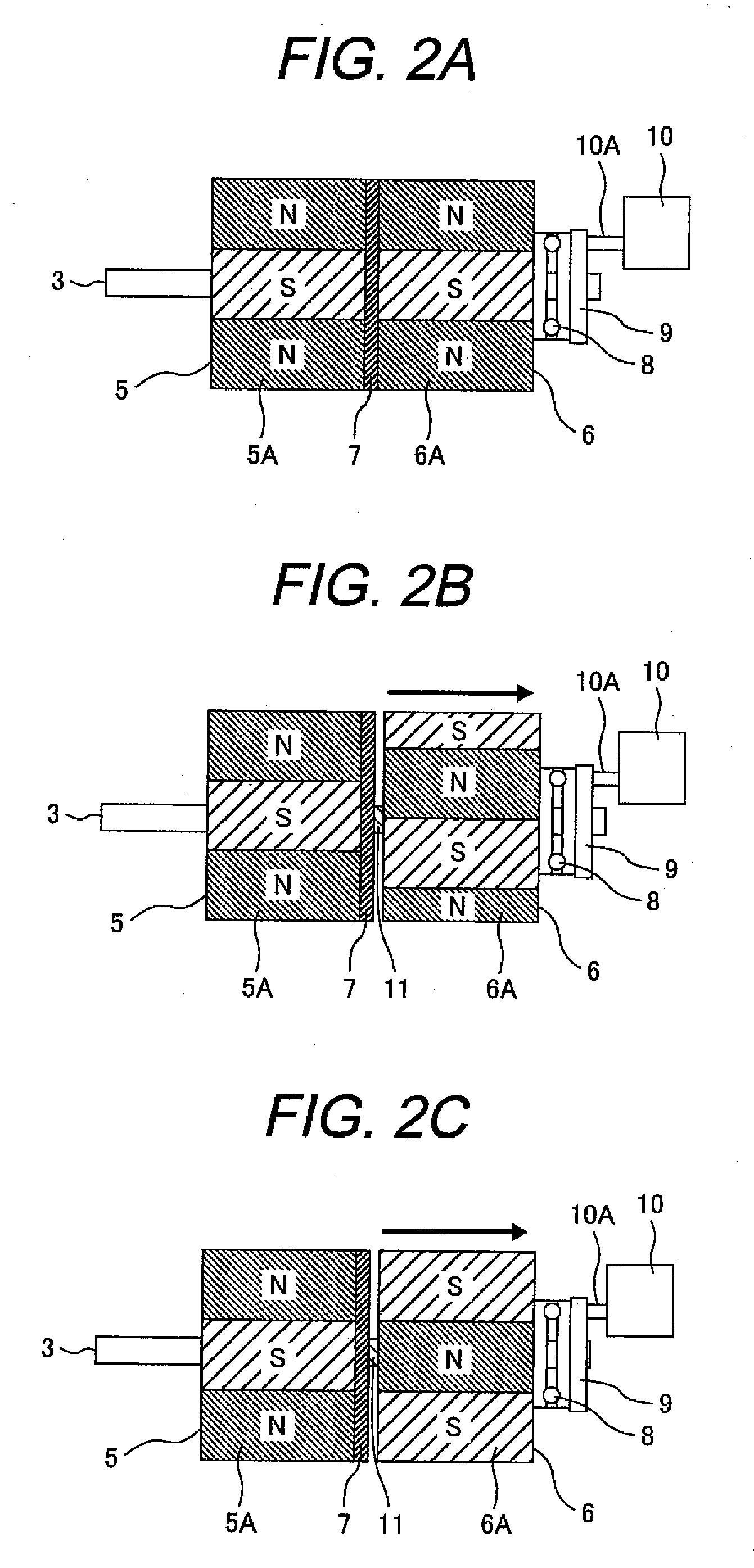

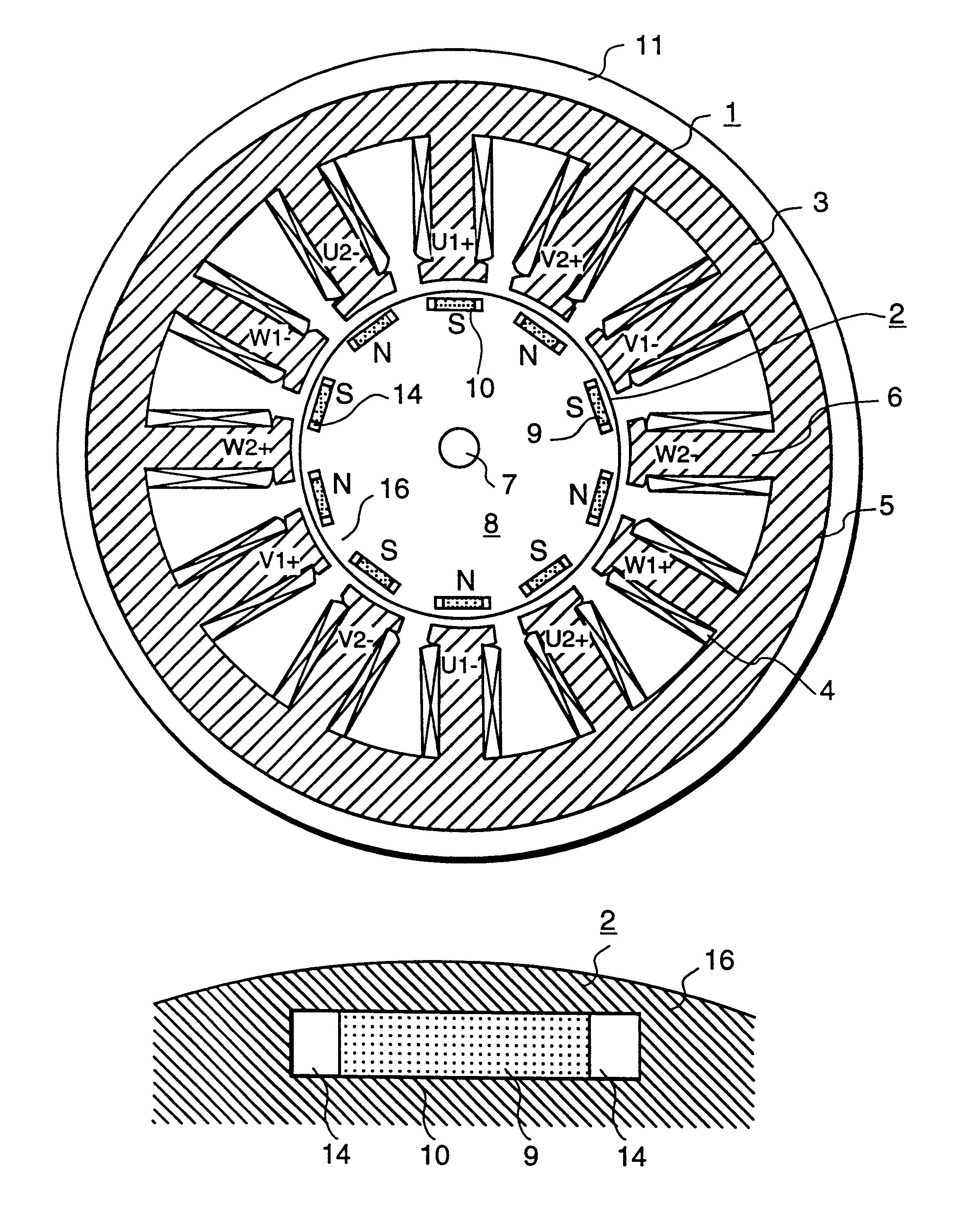

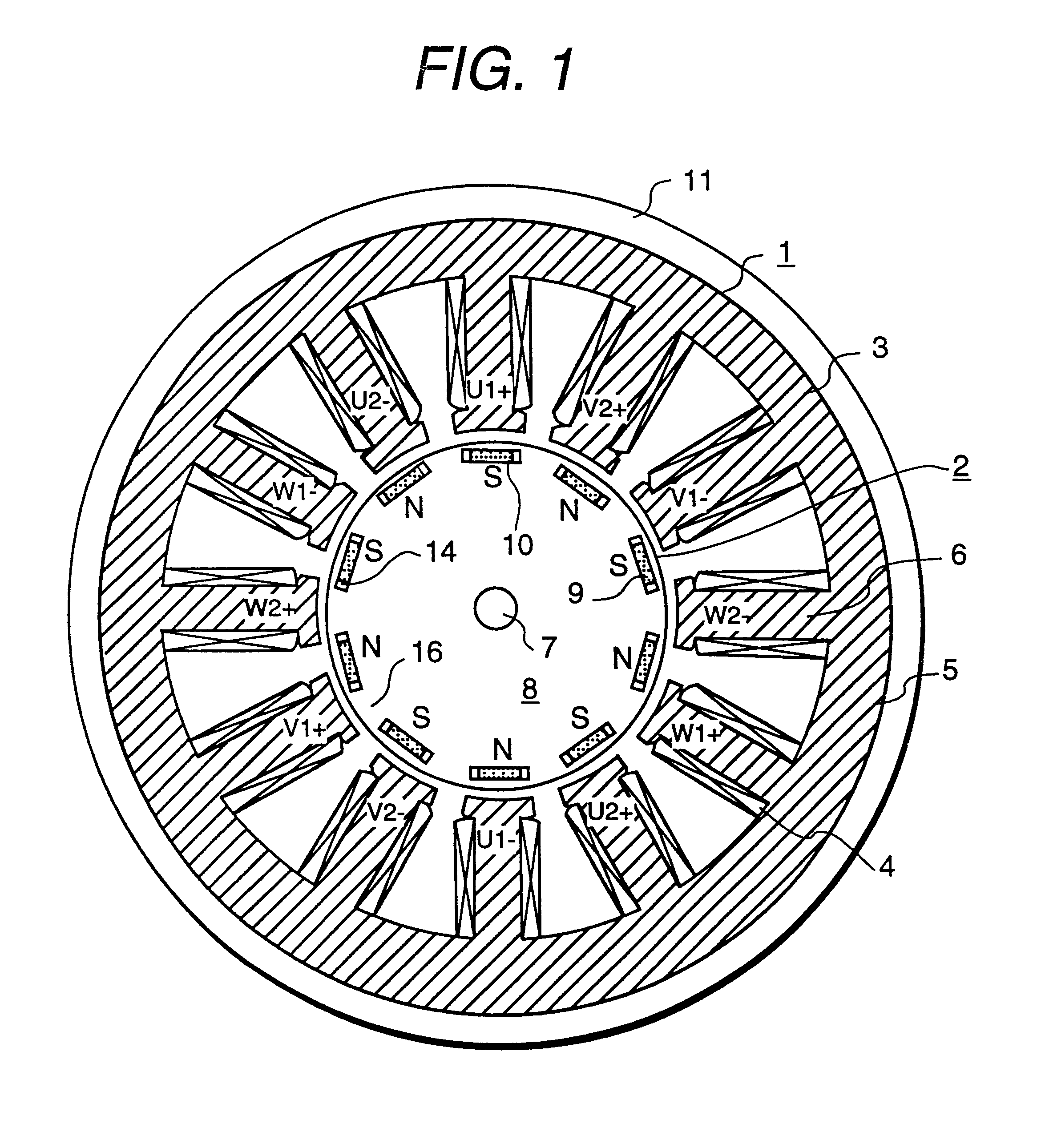

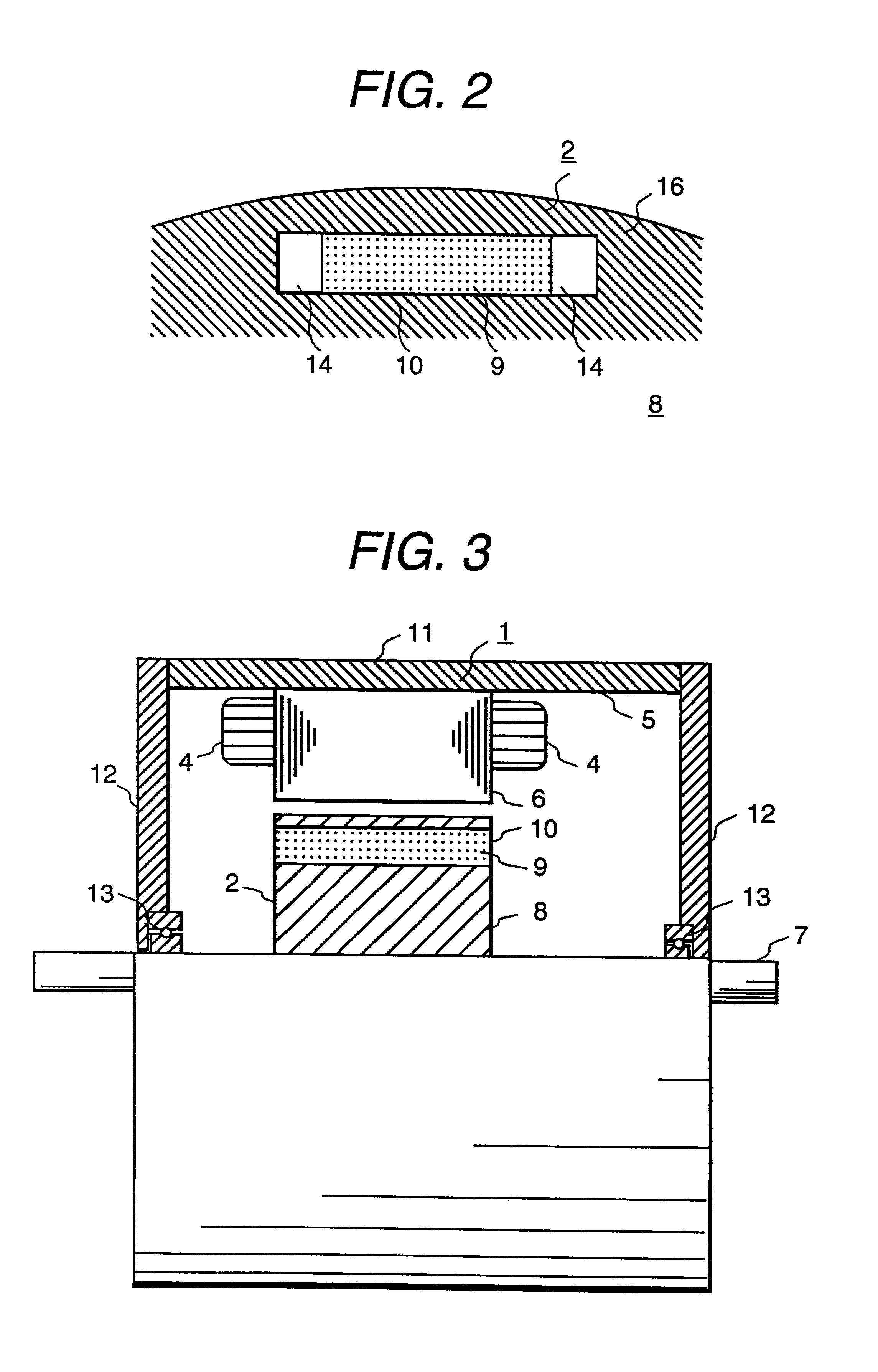

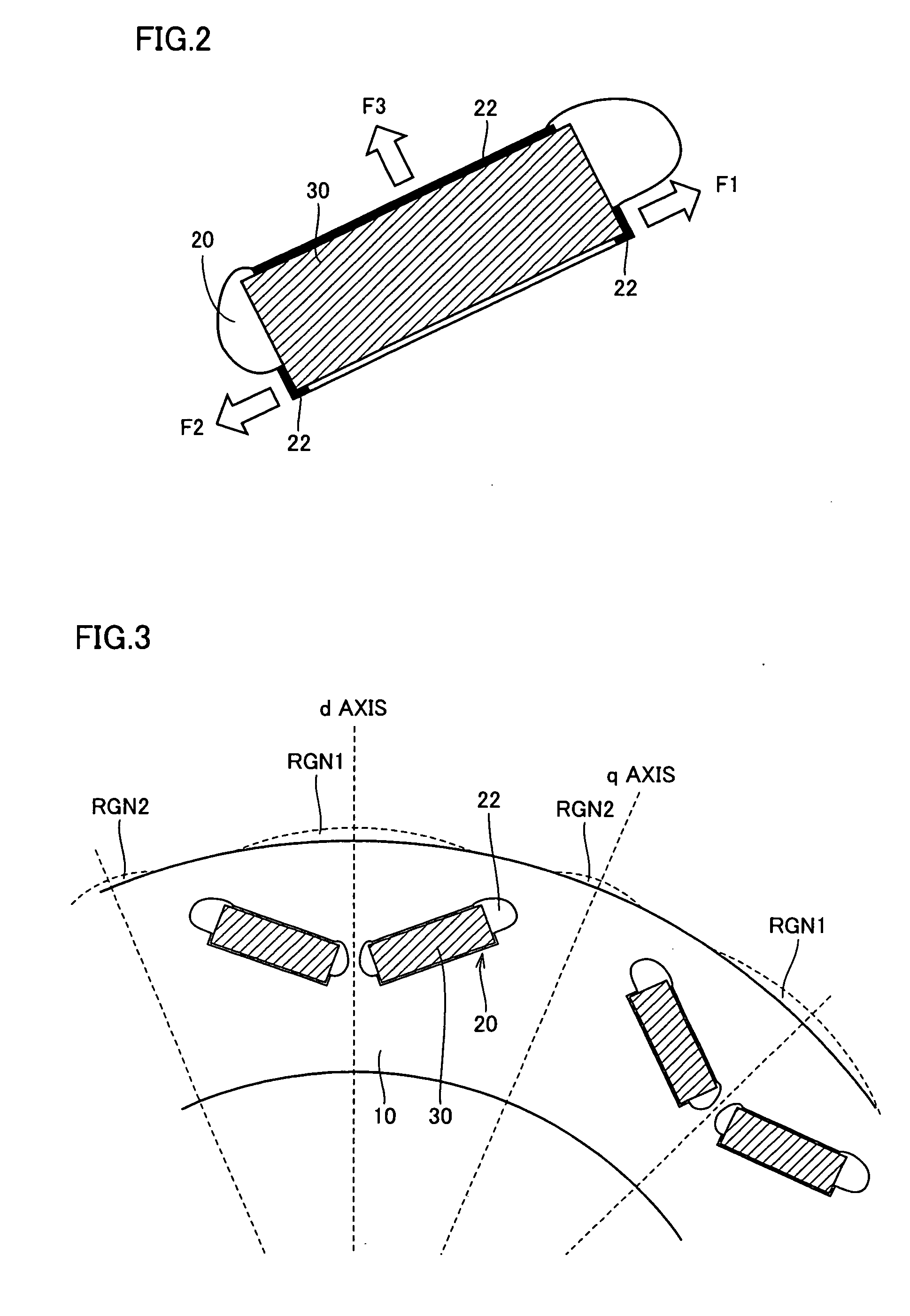

Variable magnetic flux electric rotary machine

InactiveUS20100164422A1Easy to operateWide operating speed rangeDC motor speed/torque controlRailway vehiclesElectrical polarityEngineering

An electric rotary machine is disclosed which can adjust relative angles of sub-rotors continuously and regardless of torque direction without generating an attractive force between the field magnets of the sub-rotors. The electric rotary machine includes: a stator having a winding; a dual rotor which is rotatably disposed with a gap from the stator and divided axially along a shaft into a first rotor and a second rotor each having field magnets with different polarities arranged alternately in a rotation direction; a mechanism for varying the axial position of the second rotor relative to the first rotor continuously; and a non-magnetic member located between the first rotor and the second rotor.

Owner:HITACHI LTD

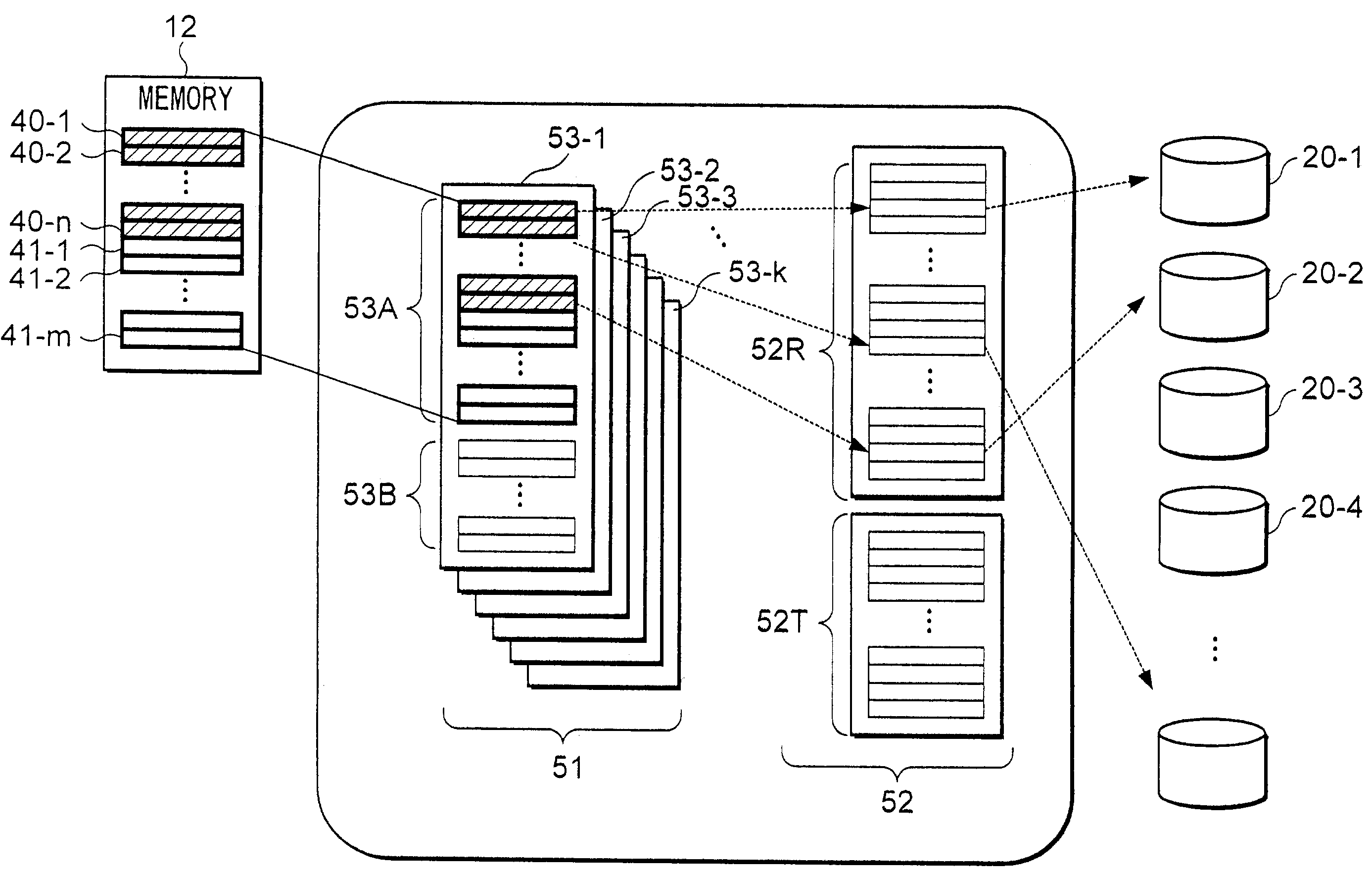

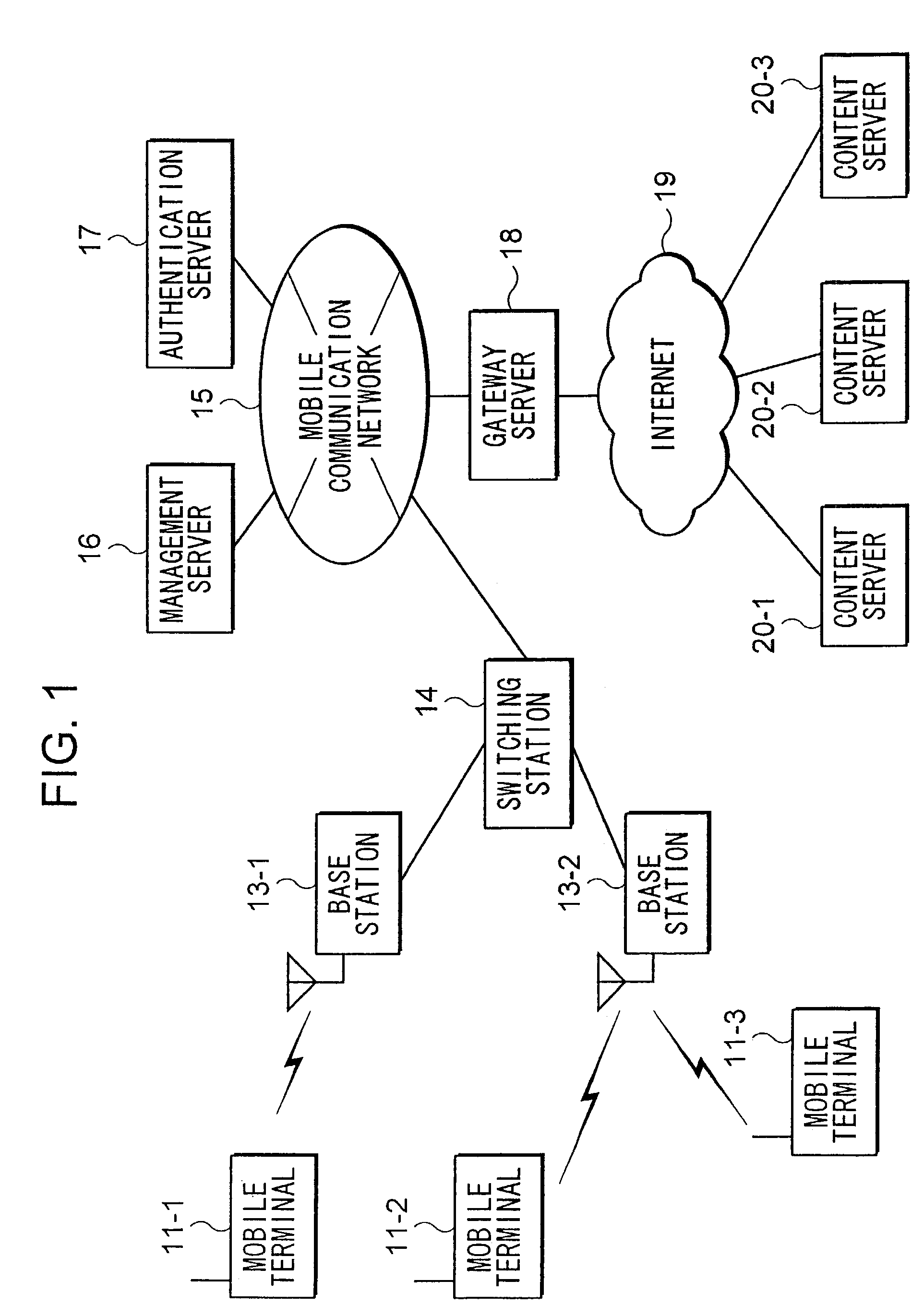

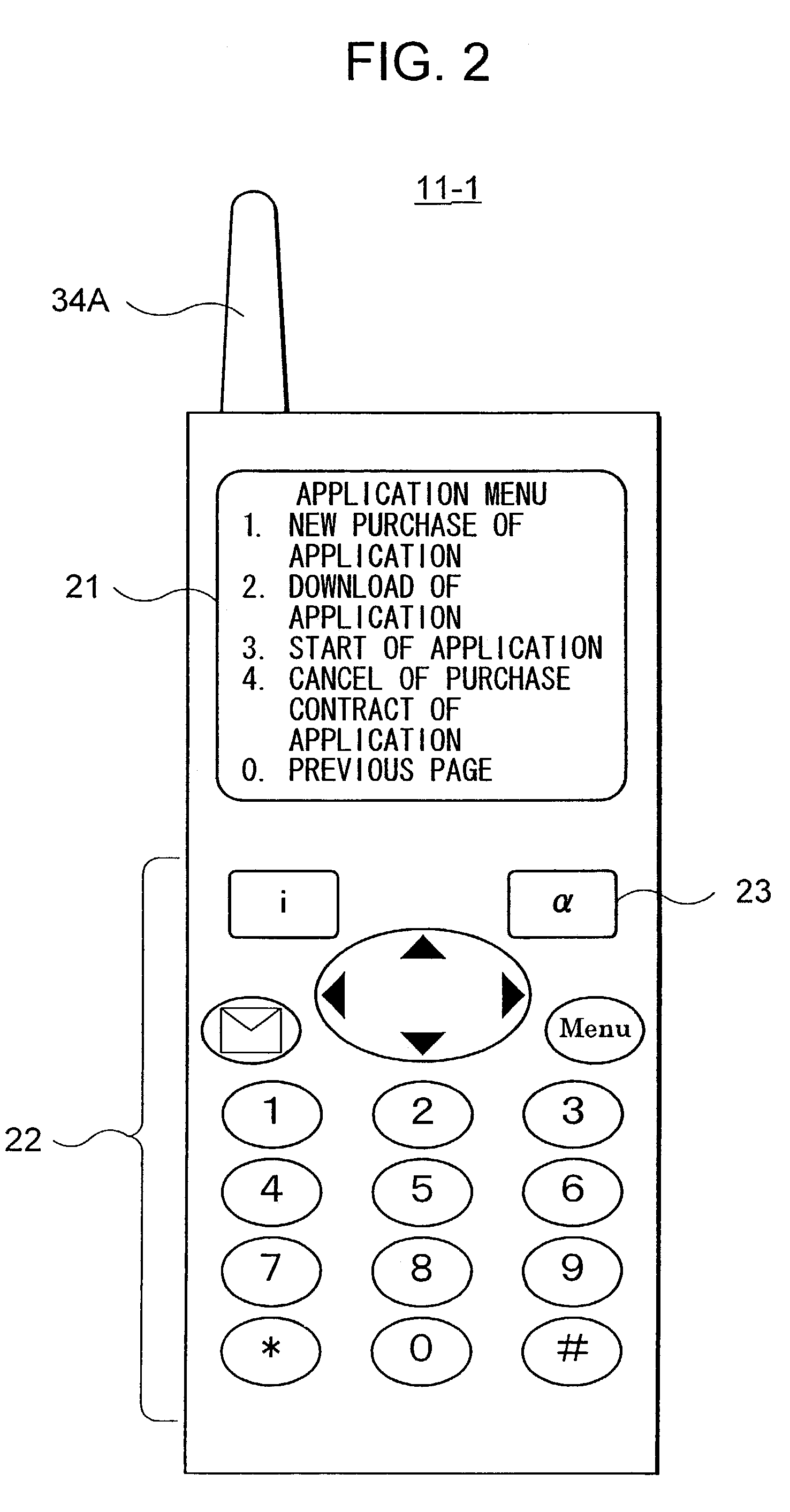

System for managing program applications storable in a mobile terminal

ActiveUS7379731B2Ensure safetyLow reliabilityProgram control using stored programsMultiple digital computer combinationsComputer terminalApplication software

Management server 16 may obtain application programs from content server 20 in response to requests of mobile terminal 11. Management server 16 may transmit the obtained application programs to mobile terminal 11 with information concerning reliabilities of the application programs. After mobile terminal 11 receives the application programs from management server 16, mobile terminal 11 manages operations of the application programs. Operations of the application programs are coordinated with operations of other programs using the information concerning the reliabilities corresponding to the application programs. Management of the coordinated operations of the application programs avoids problems concerning information security, where valuable information may be distributed unexpectedly because of operations of low reliable application programs. As a result, convenience of users of mobile terminals 11 can be improved without deteriorating the information security of mobile terminals 11.

Owner:NTT DOCOMO INC

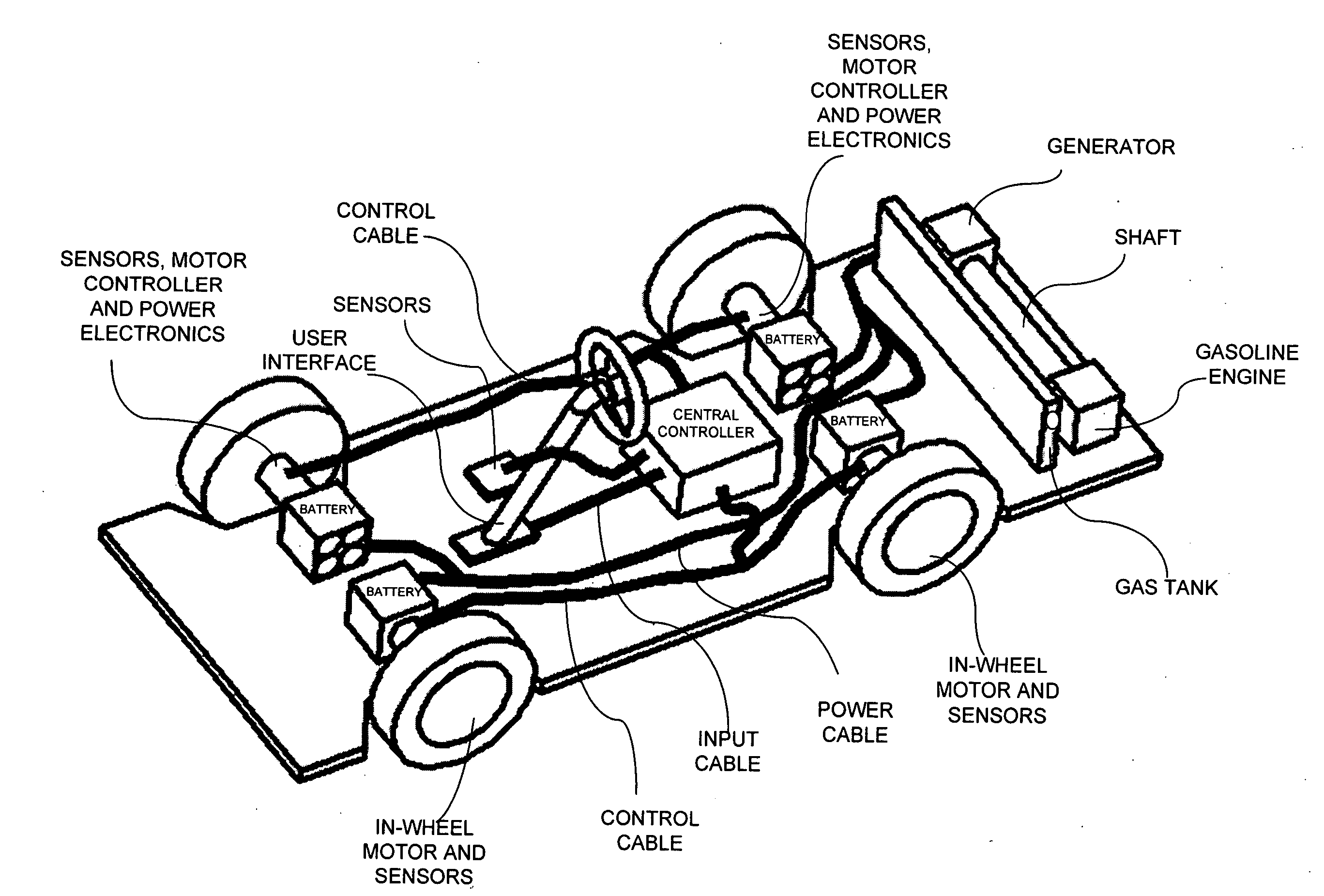

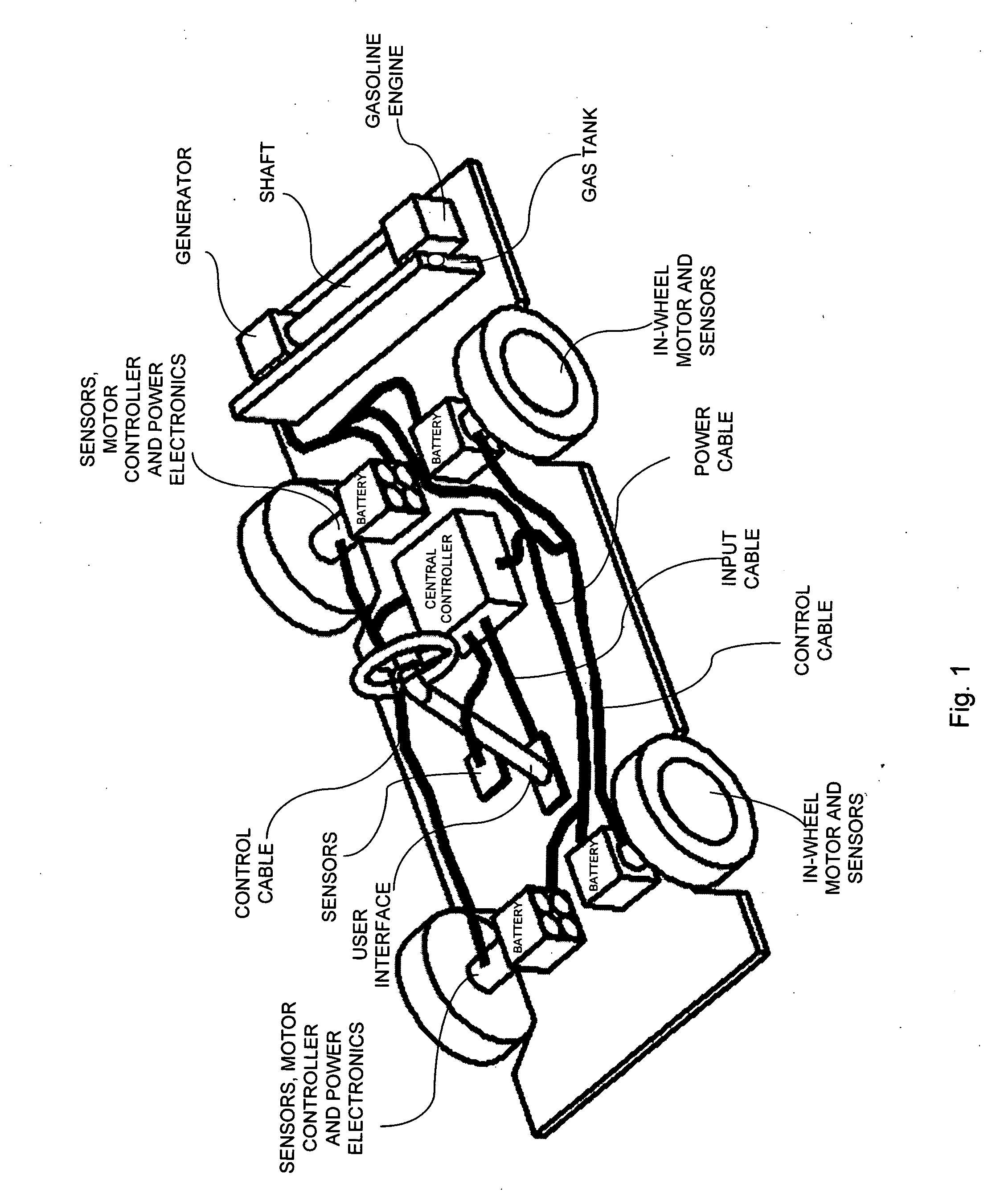

Adaptive electric car

InactiveUS20050052080A1Eliminate electromagneticEliminate electrical interferenceRailway vehiclesAc-dc conversionGasolineMotor control

An adaptive electric car or other vehicle with potentially better performance—power, efficiency, range—than a gasoline vehicle, at a competitive cost. The motor control system can dynamically adapt to the vehicle's operating conditions (starting, accelerating, turning, braking, cruising at high speeds) and other inputs and parameters. That consistently provides better performance. Isolating the vehicle's motor or generator electromagnetic circuits allows effective control of more independent parameters. That gives great freedom to optimize. Adaptive motors and generators for an electric vehicle are cheaper, smaller, lighter, more powerful, and more efficient than conventional designs. An electric vehicle with in-wheel adaptive motors delivers high power with low unsprung mass and high torque and power-density. Total energy management of the vehicles entire electrical system allows for large-scale optimization. An adaptive architecture improves performance of a wide variety of vehicles, particularly those that need optimal efficiency over a range of operating conditions.

Owner:BLUWAV SYST LLC

Magnetic coupling using halbach type magnet array

InactiveUS6841910B2Reduce leakageIncrease the magnetic field strengthMagnetic circuit rotating partsPermanent-magnet clutches/brakesCouplingMagnetization

A magnetic coupling having two opposed annular arrays of angularly spaced permanent magnets magnetized to create magnetic north poles and magnetic south poles alternately spaced about each array. The north-pole and south-pole magnets of each array are tapered in cross-section from their surfaces at the gap to an annular surface of the array spaced from the gap, and permanent magnet spacer magnets completely fill in the space between the north-pole and south-pole magnets from the annular surface of the array at the gap to the spaced annular surface with the spacer magnets being magnetized generally transversely to the direction of magnetization of the adjacent north-pole, south-pole magnets so that the magnetic field created by the permanent magnets extends across the gap and annularly through each array to cause one of the arrays to rotate in synchronism with the other array.

Owner:QUADRANT TECH CORP

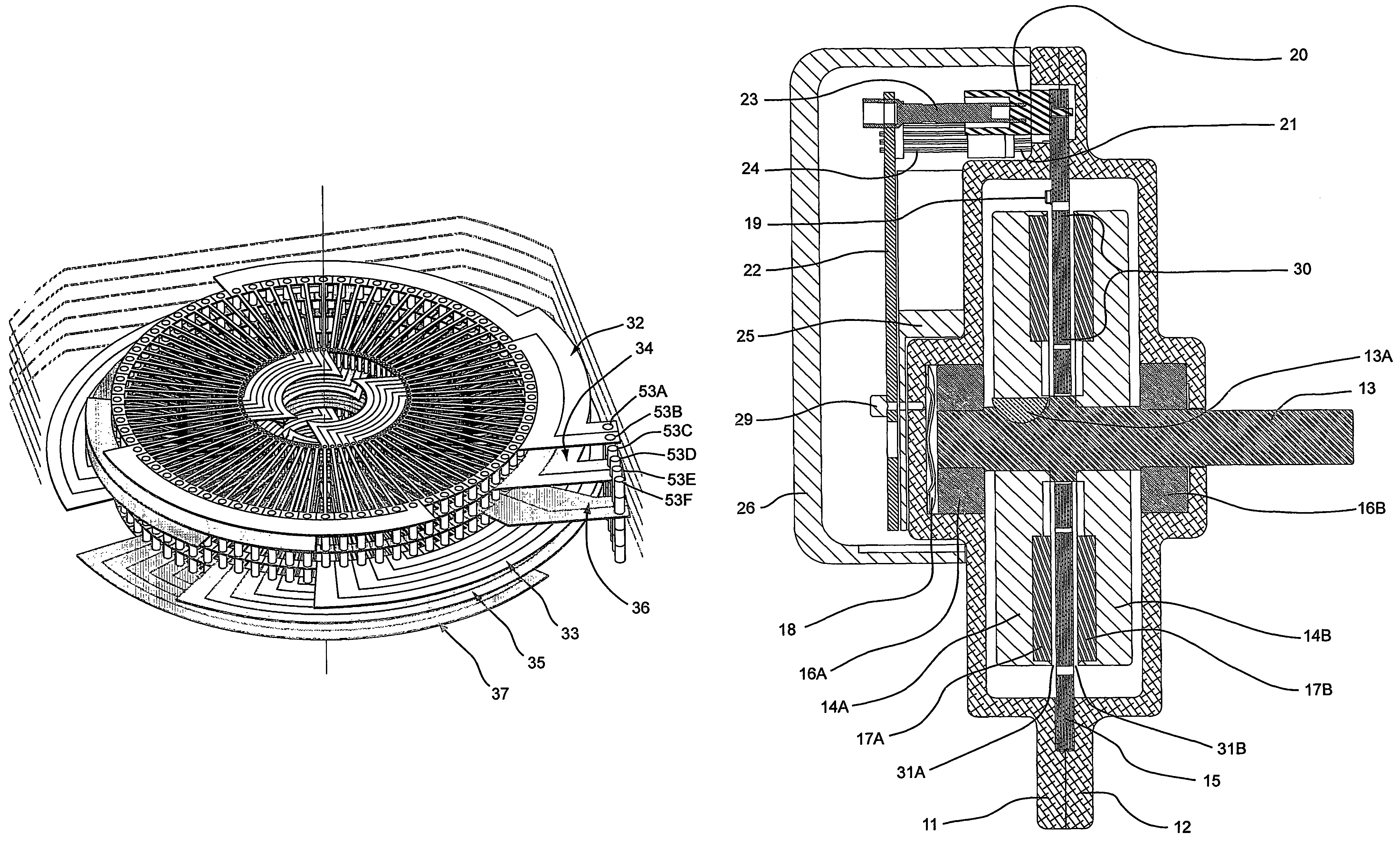

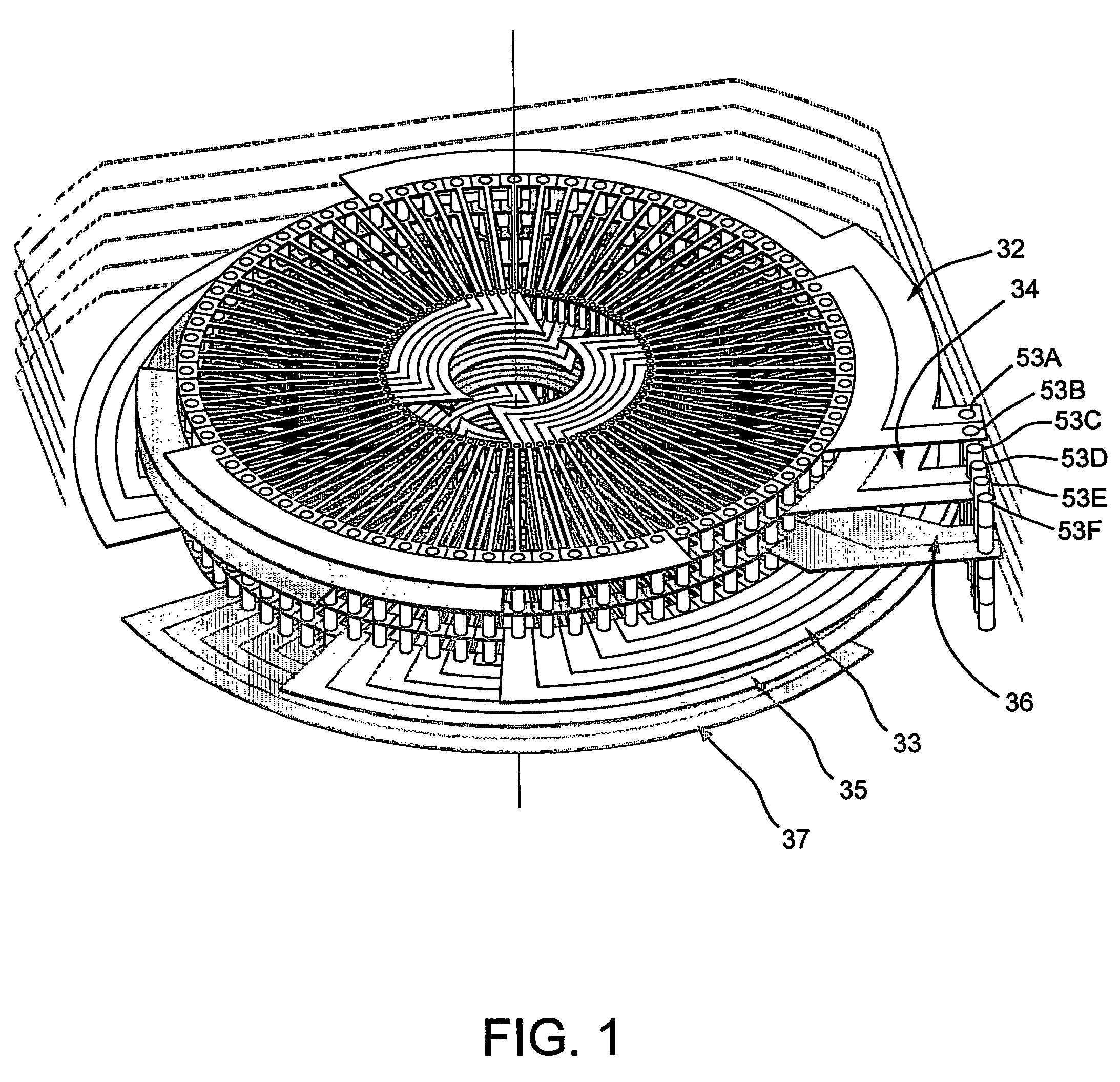

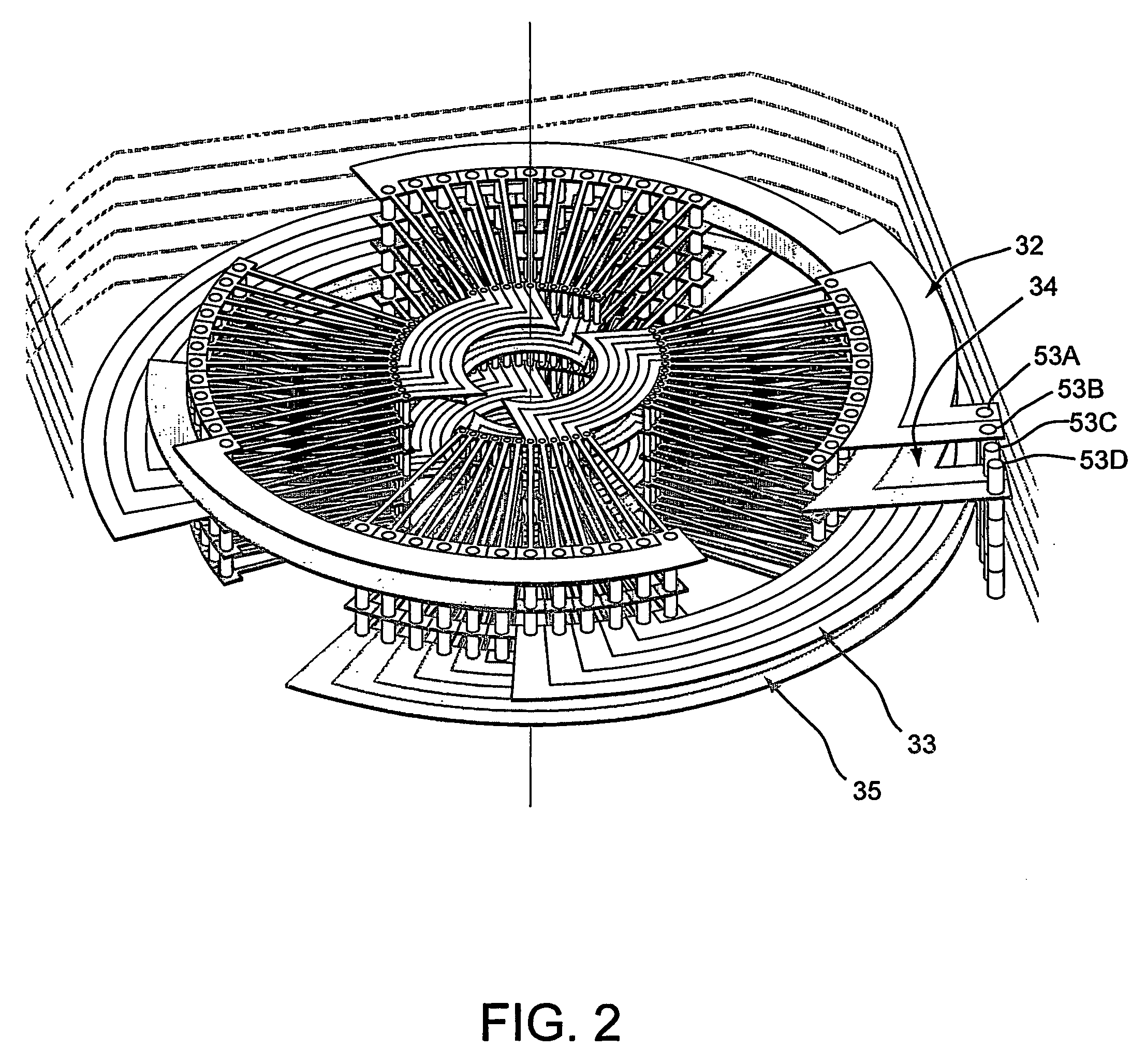

Conductor optimized axial field rotary energy device

ActiveUS7109625B1Association with control/drive circuitsMagnetic circuit rotating partsElectrical conductorEngineering

The present invention provides an axial rotary energy device which is arranged in a multi-phase electric current configuration. The device includes a rotor having a plurality of permanent magnet poles secured thereto and further includes a stator formed by stacking a plurality of printed circuit board working conductor layers together with a plurality of printed circuit board connecting layers. The stator having at least one working conductor layer for each phase of the electric current and at least one connecting conductor layer associated with one working conducting layer. The working conductor layer and the connecting conductor layer each having radial conductors extending from an inner diameter through-hole to an outer diameter through-hole. A plurality of via conductors are provided for electrically connecting selected ones of the radial connectors of the connecting conductor layer to selected ones of the radial connectors of the working conductor layers through the through-holes.

Owner:CORE MOTION

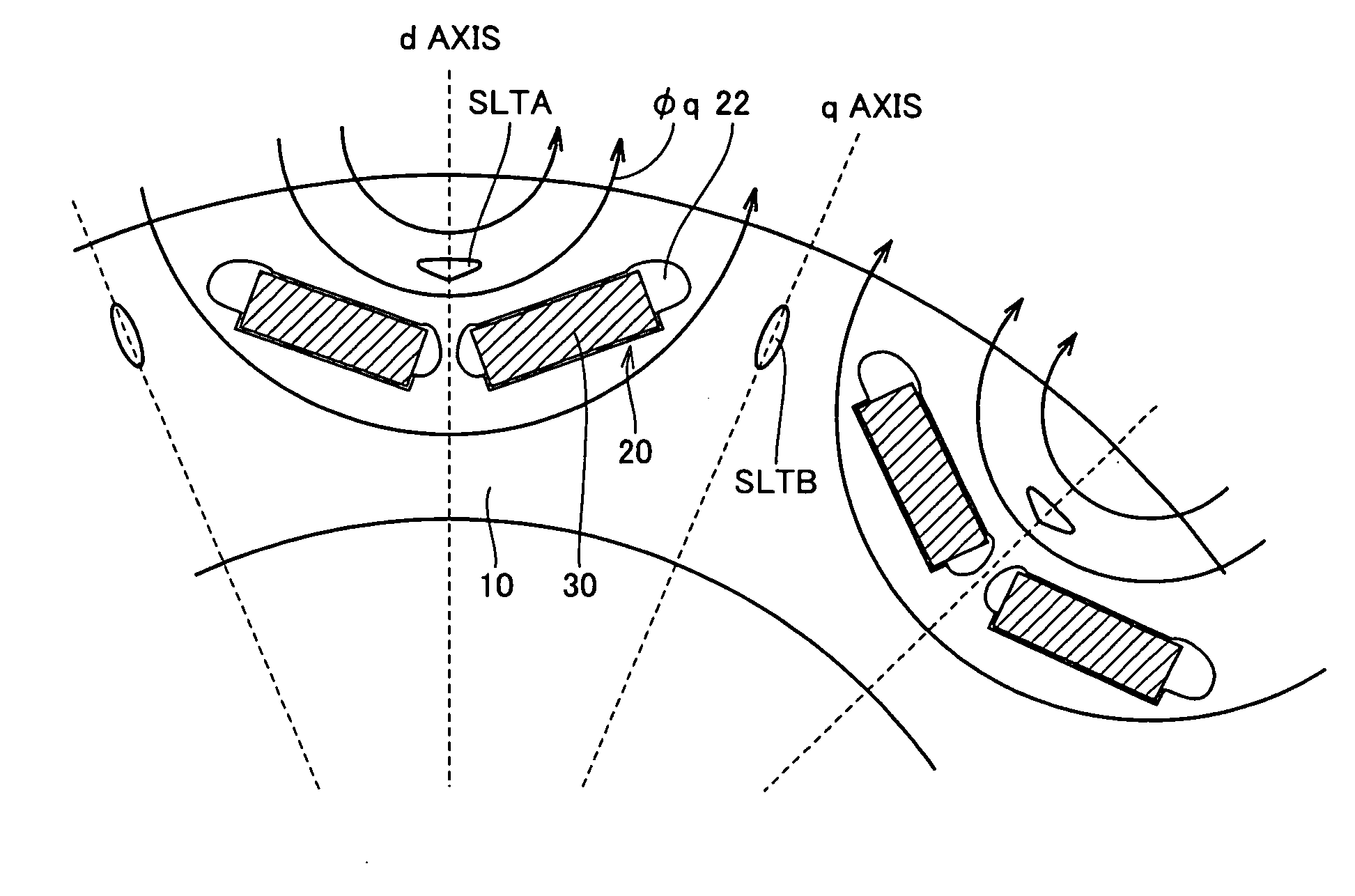

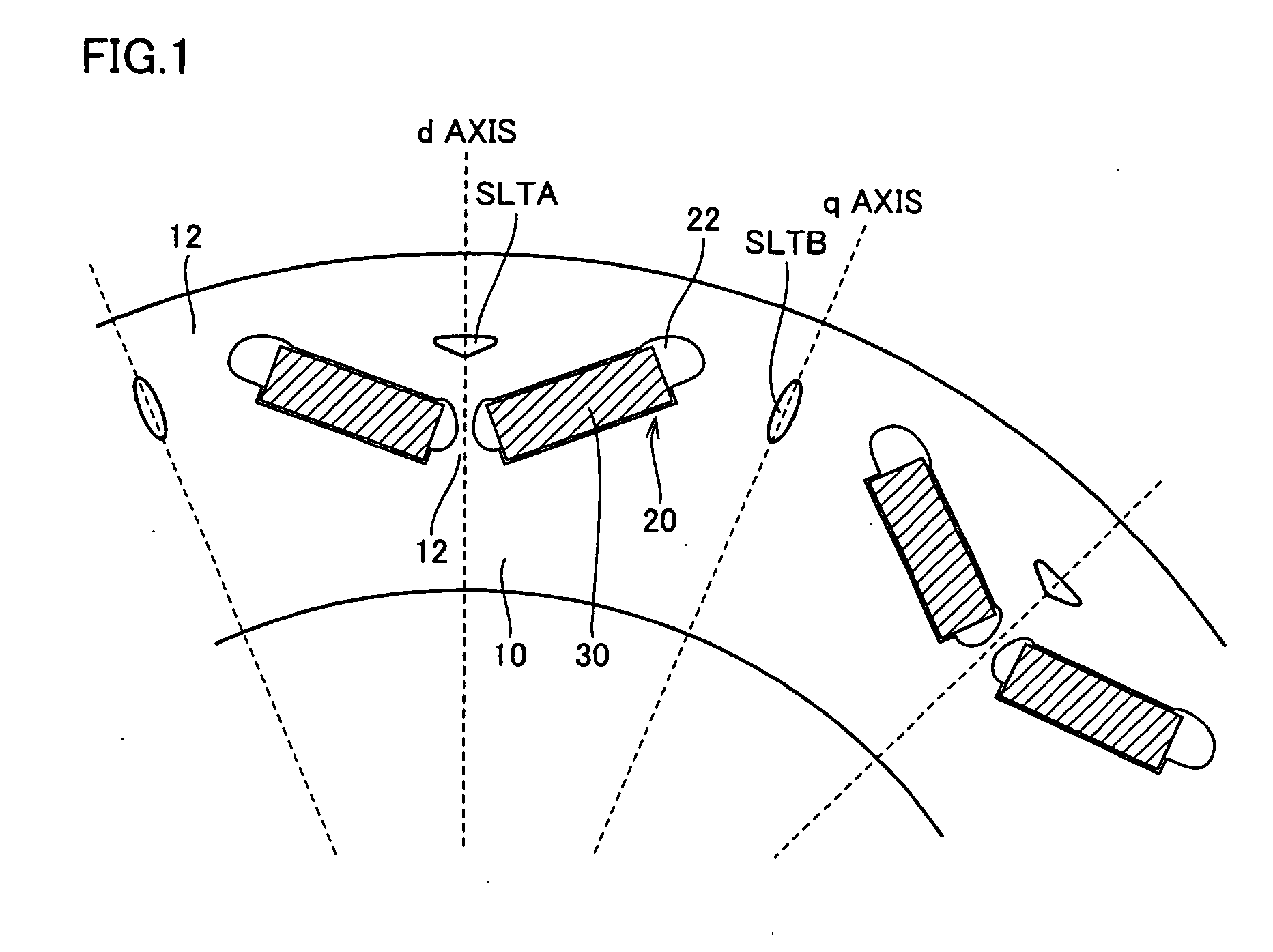

Reluctance motor with improved stator structure

InactiveUS20100123426A1Reduce efficiency of motorHigh cost of controlMotor/generator/converter stoppersAC motor controlReluctance motorEngineering

Owner:DENSO CORP

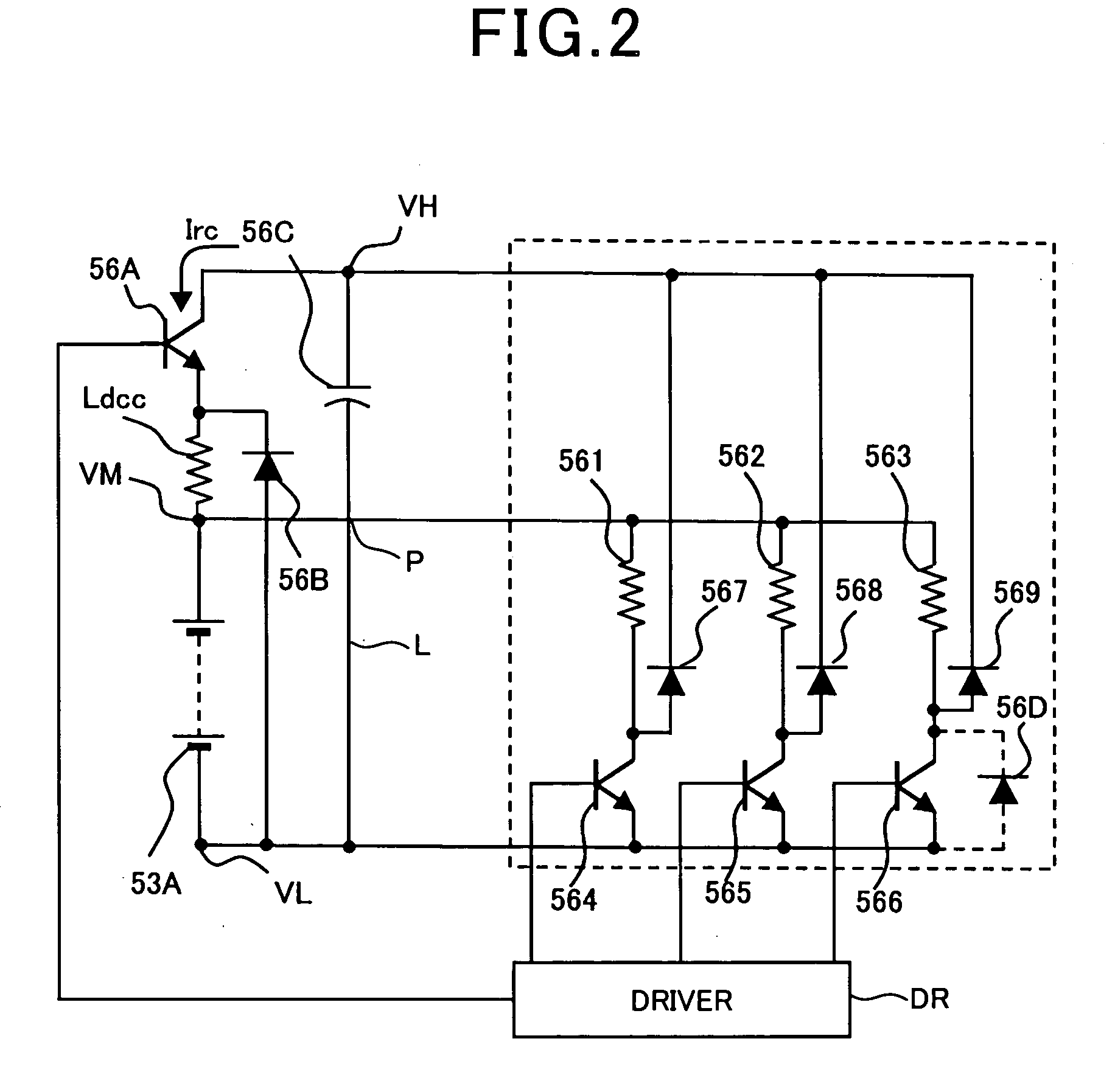

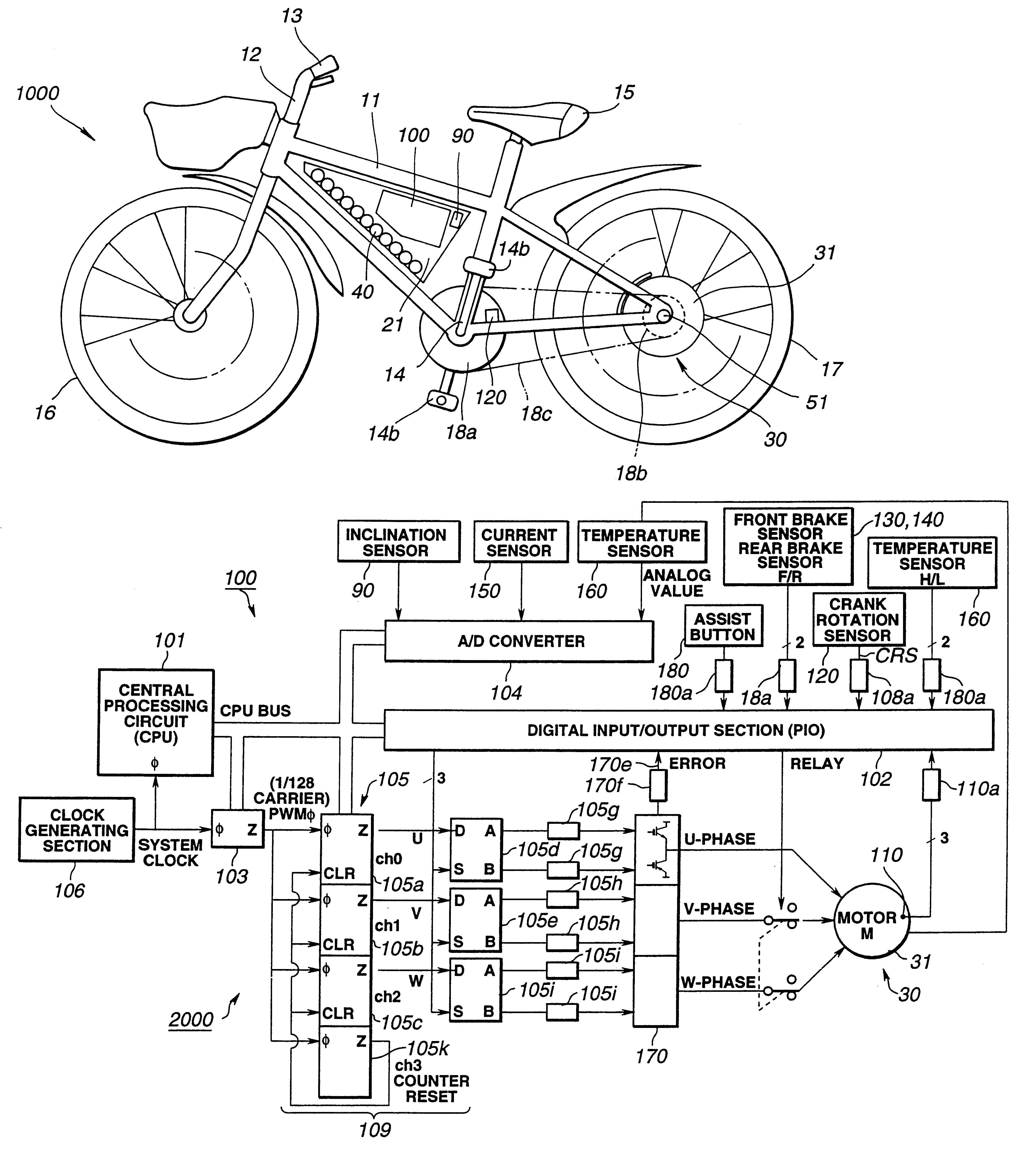

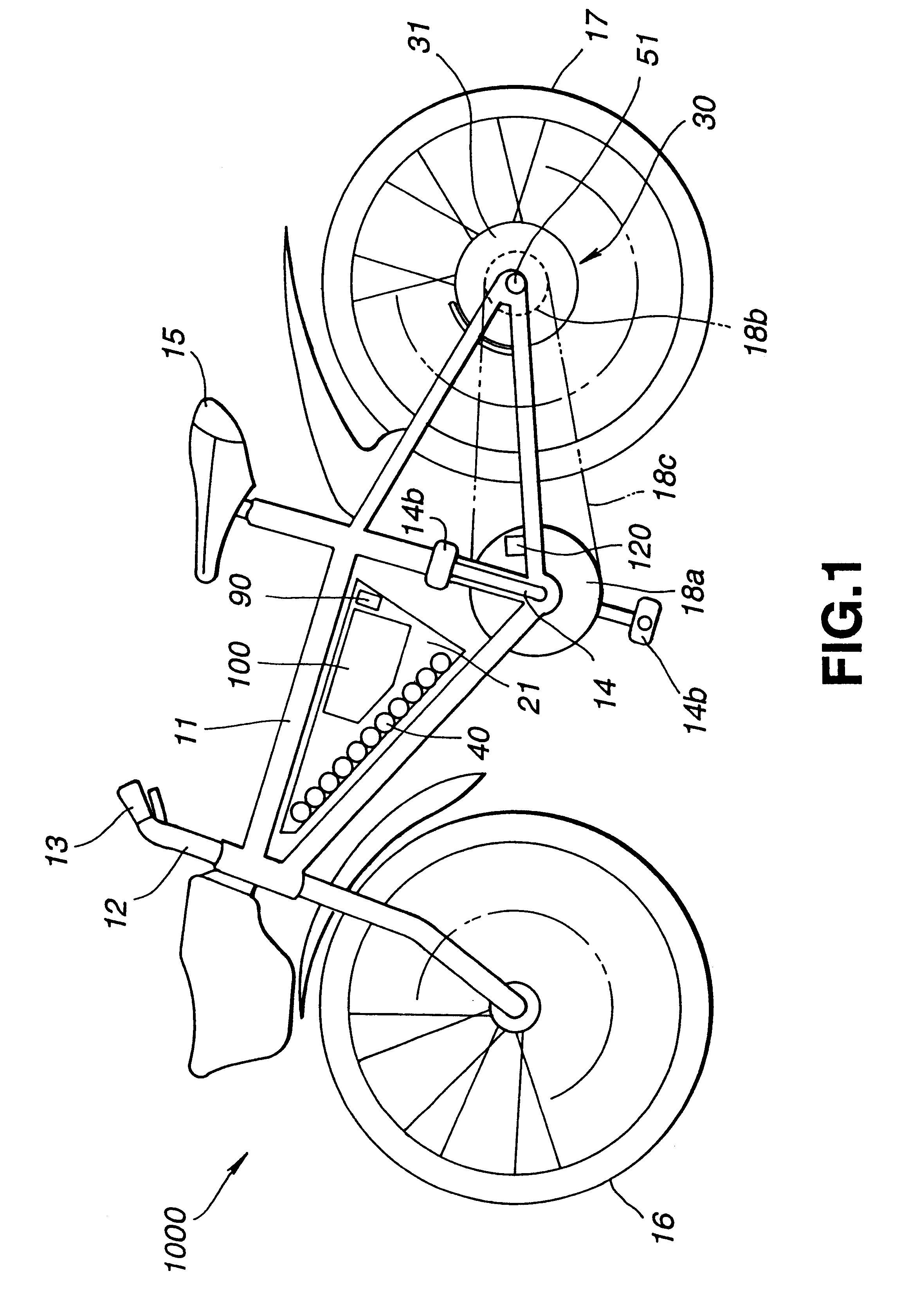

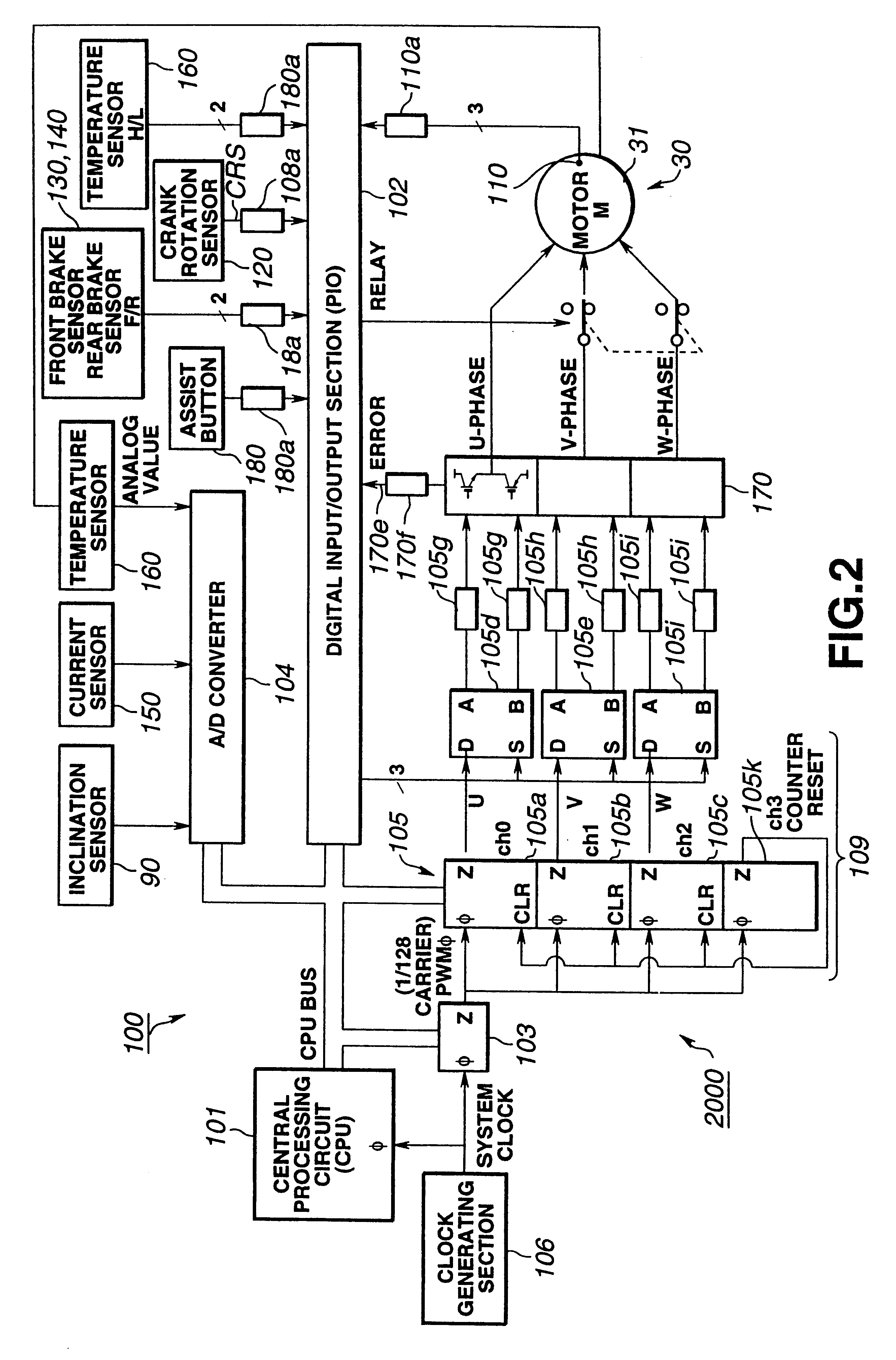

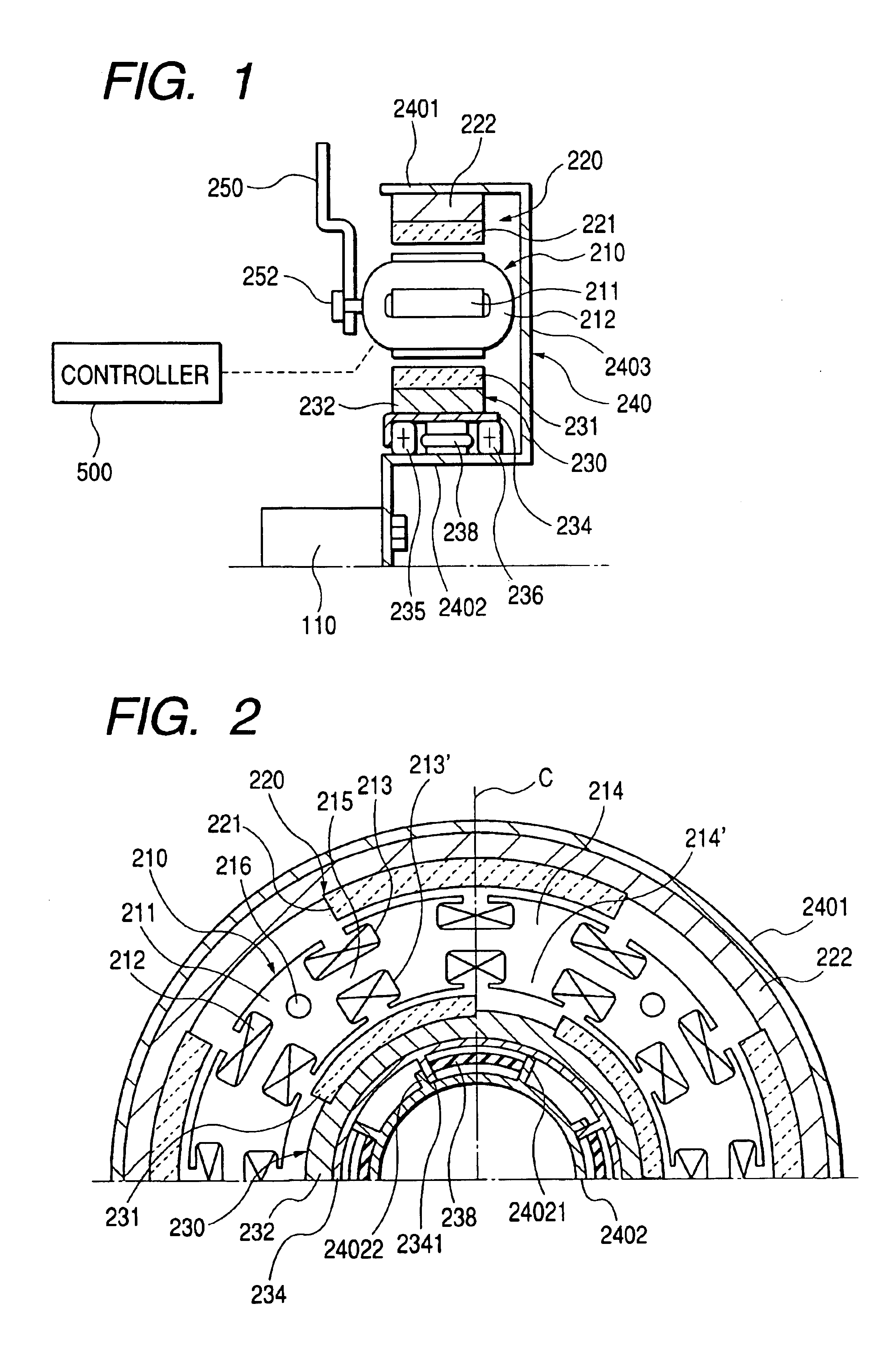

Moving apparatus with drive power assisting device and movement controlling method

A moving apparatus with a driving force assist mechanism traveled mainly by human power. This moving apparatus detects, in a non-contact manner, with respect to rotating portion such as traveling wheel, etc., rotation speed of the rotating portion to detect traveling state to deliver, from the driving force assist mechanism, assistant driving force corresponding to speed change information that a person who operates the moving apparatus intends to give on the basis of the detected traveling information to carry out traveling to thereby permit smooth traveling even in the case where traveling by only human power becomes difficult.

Owner:SONY CORP

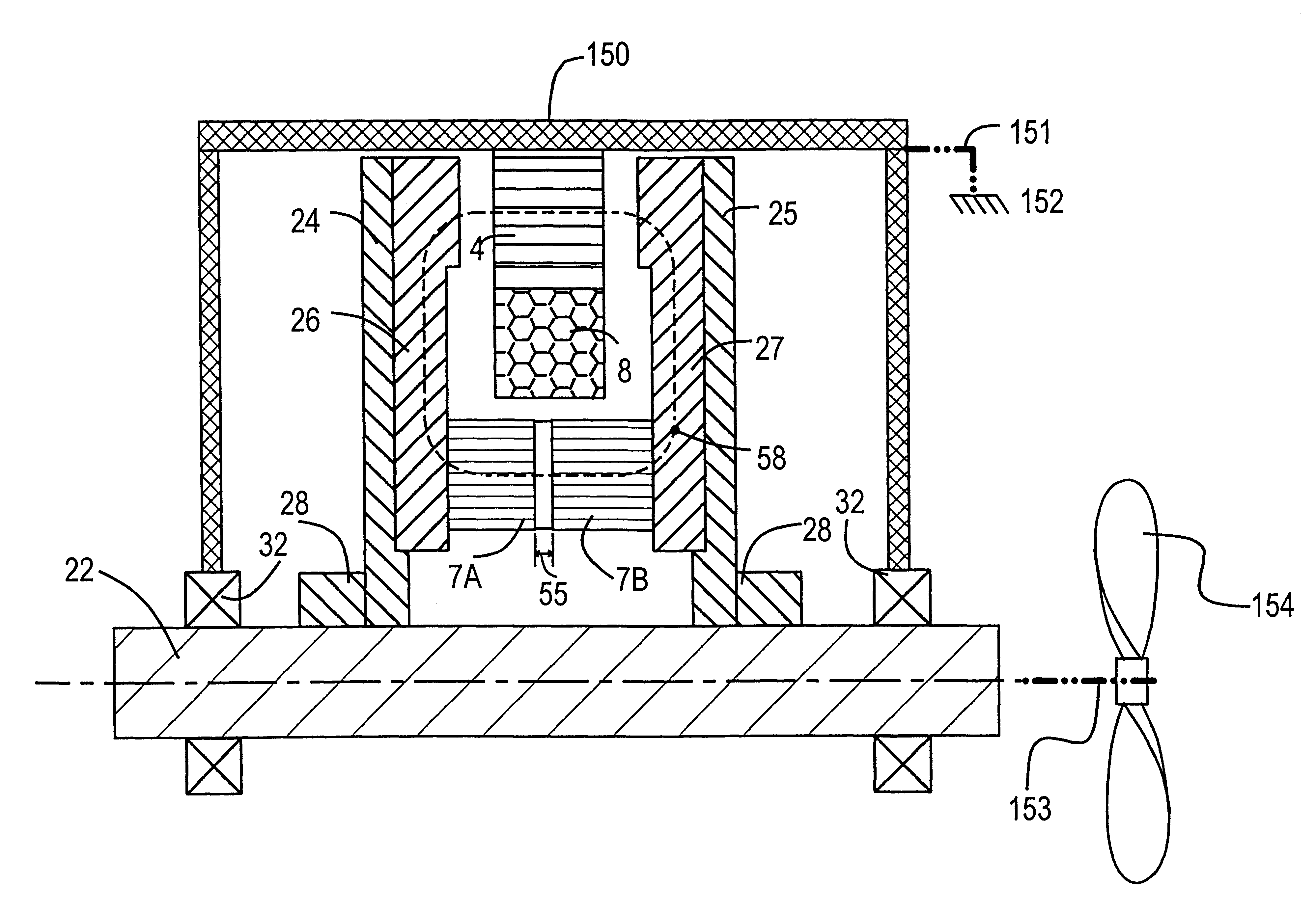

Electrical machine with double-sided stator

InactiveUS20060071575A1Increase rated powerReduce the overall diameterAsynchronous induction motorsMachines/enginesMarine propulsionTurbine

Machines useful for wind turbine and ship propulsion purposes include a wind turbine generator or a ship propulsion motor with two concentric air gaps. In one embodiment, the machine includes a rotor with an inner rotor core and an outer rotor core; and a double-sided stator with an inner stator side and an outer stator side. The double-sided stator is concentrically disposed between the inner rotor core and the outer rotor core.

Owner:GENERAL ELECTRIC CO

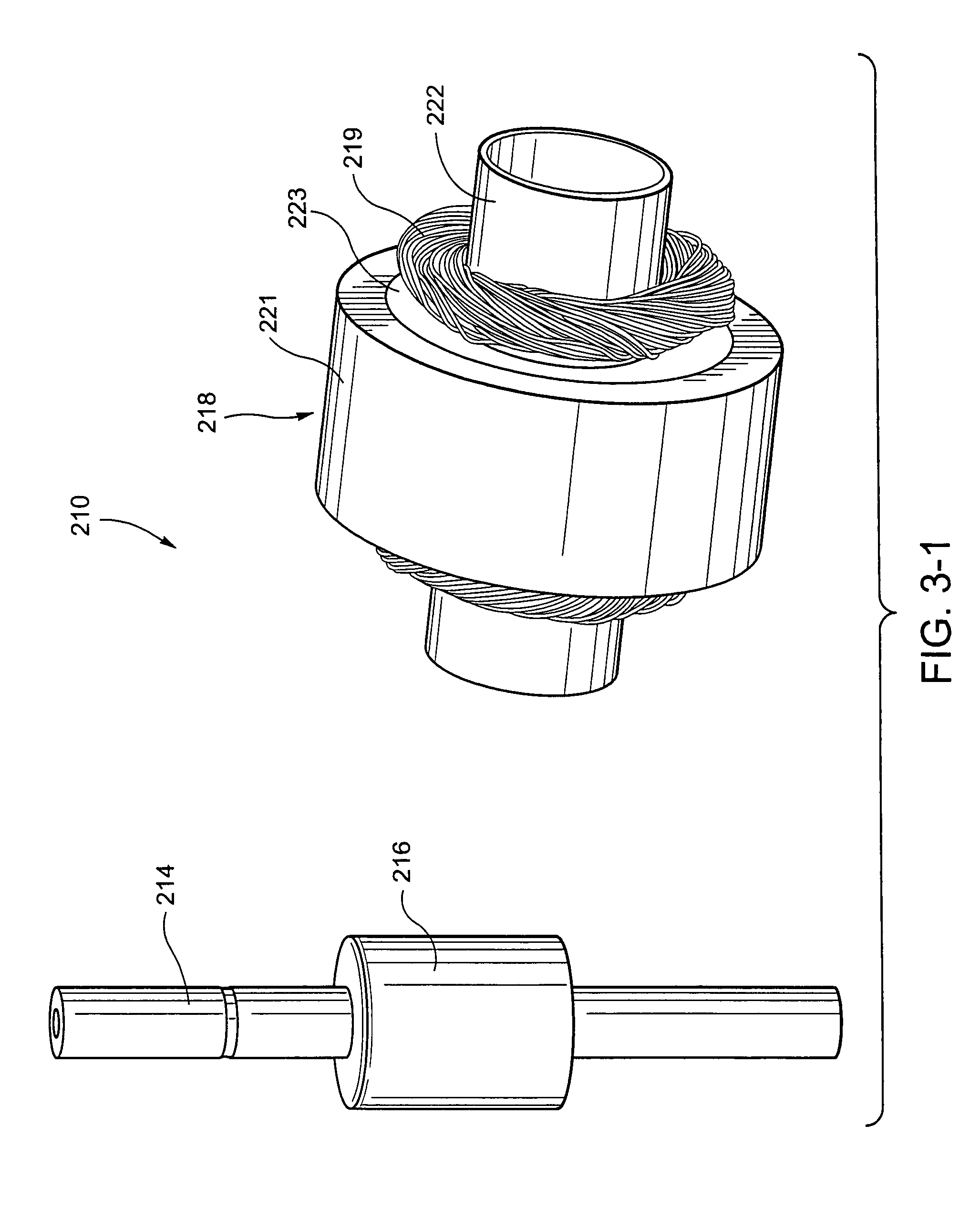

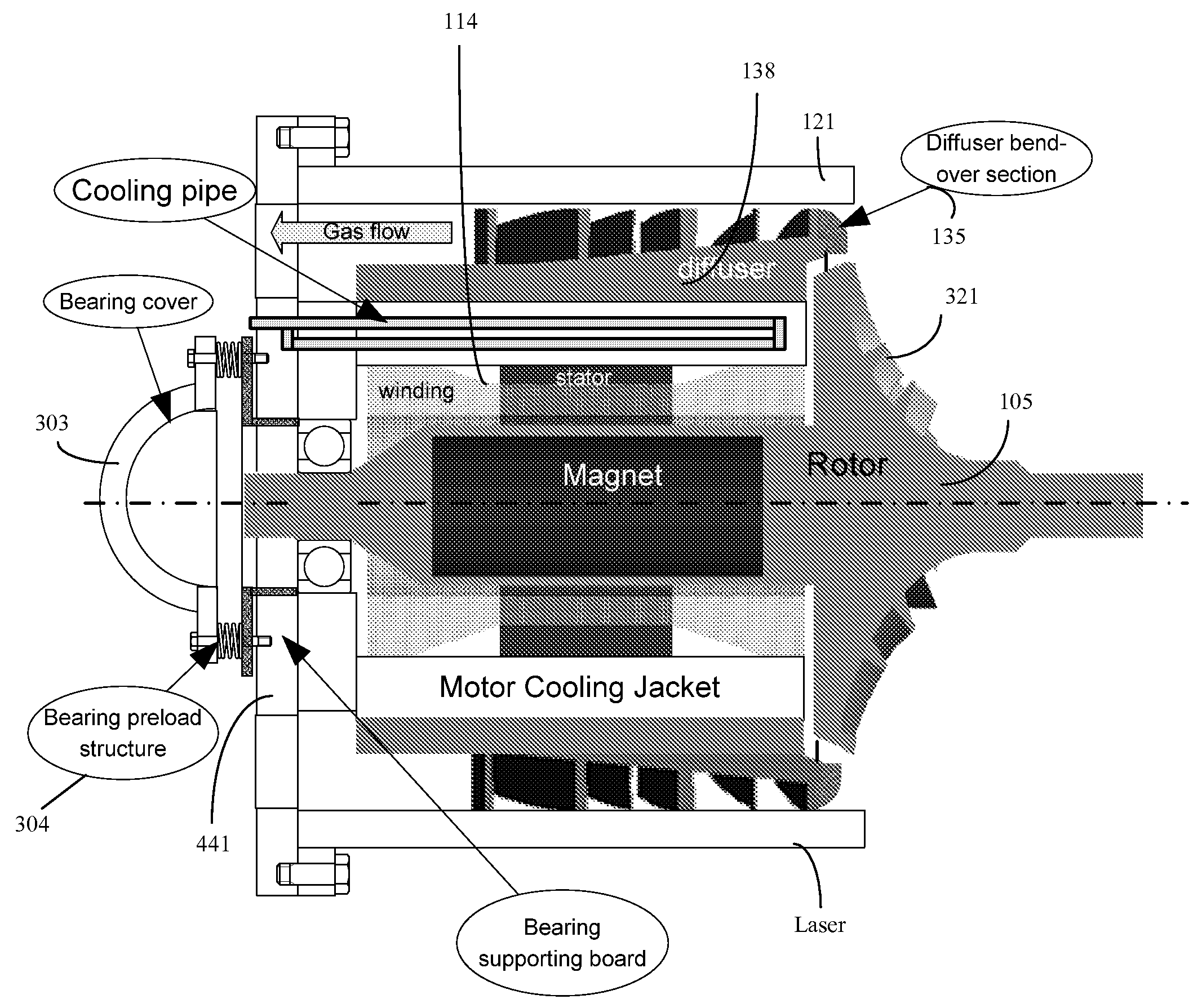

Miniature high speed compressor having embedded permanent magnet motor

InactiveUS20070269323A1Improve rigidityEasy to implementPositive displacement pump componentsEfficient regulation technologiesRigid rotorBall bearing

A high speed centrifugal compressor for compressing fluids includes a permanent magnet synchronous motor (PMSM) having a hollow shaft, the being supported on its ends by ball bearing comprising supports. A permanent magnet core is embedded inside the shaft. A stator with a winding is located radially outward of the shaft. The PMSM includes a rotor including at least one impeller secured to the shaft or integrated with the shaft as a single piece. The rotor is a high rigidity rotor providing a bending mode speed of at least 100,000 RPM which advantageously permits implementation of relatively low-cost ball bearing comprising supports.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Electrical machine with double-sided rotor

Machines useful for wind turbine and ship propulsion purposes include a double-sided generator or motor with two concentric air gaps. In one embodiment, the machine includes a double-sided rotor with an inner rotor side and an outer rotor side; and a stator with an inner stator core and an outer stator core, wherein the double-sided rotor is concentrically disposed between the inner stator core and the outer stator core.

Owner:GENERAL ELECTRIC CO

Permanent magnet electric rotating machine and electromotive vehicle using permanent magnet electric rotating machine

InactiveUS6208054B1Reduce pulsationMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsMagnetic polesMagnetic flux density distribution

A magnetic gap is provided between a permanent magnet of a rotor and an auxiliary magnetic pole portion which is arranged adjacent to the permanent magnet in a peripheral direction. A gradual change in a magnetic flux density distribution of a surface of the rotor is obtained and a cogging torque and a torque pulsation are restrained. By obtaining a reluctance torque according to the auxiliary magnetic pole, a permanent magnet electric rotating machine in which the cogging torque and the torque pulsation are restrained can be obtained and further an electromotive vehicle having the permanent magnet electric rotating machine can be provided.

Owner:HITACHI LTD +1

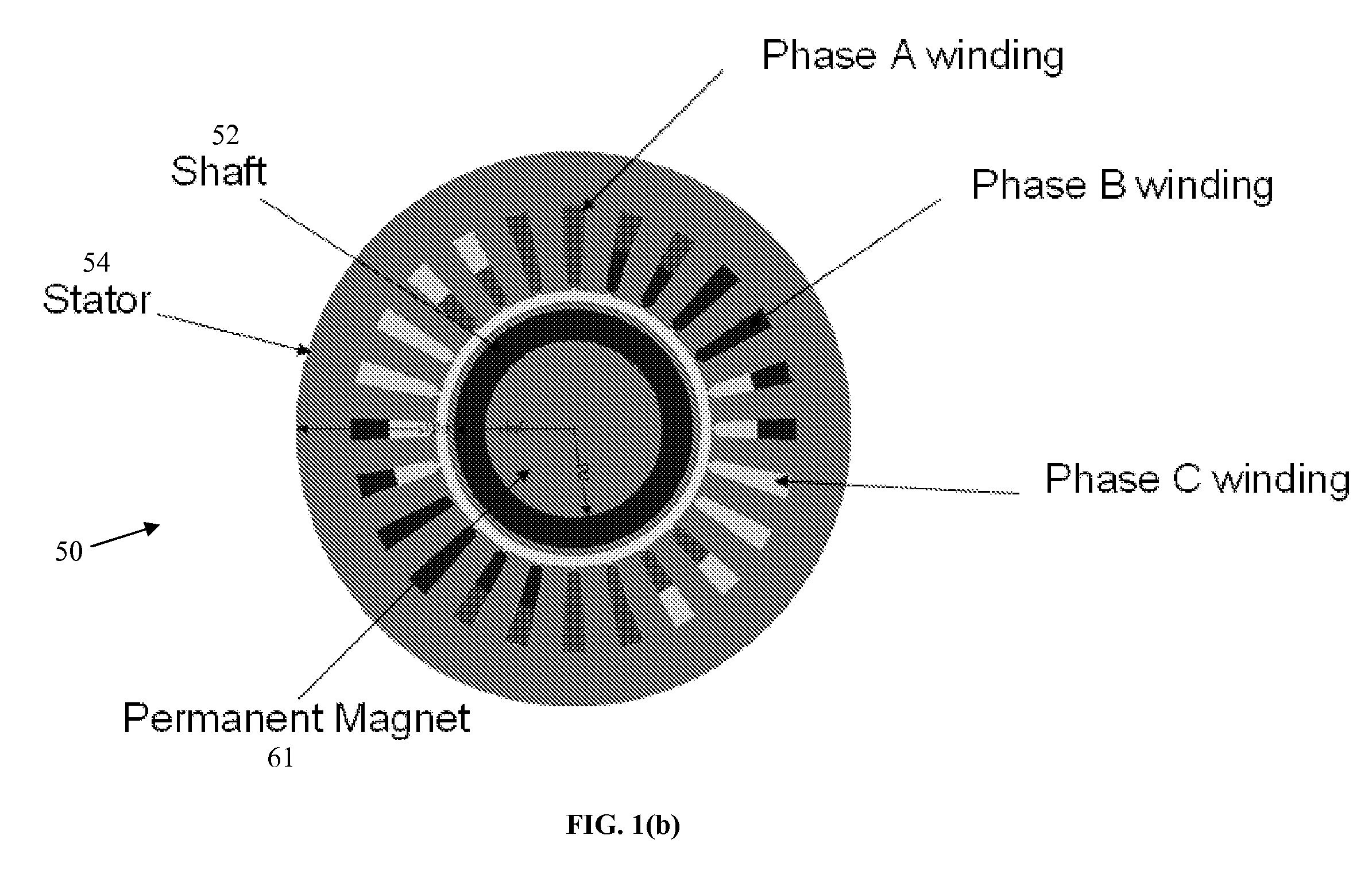

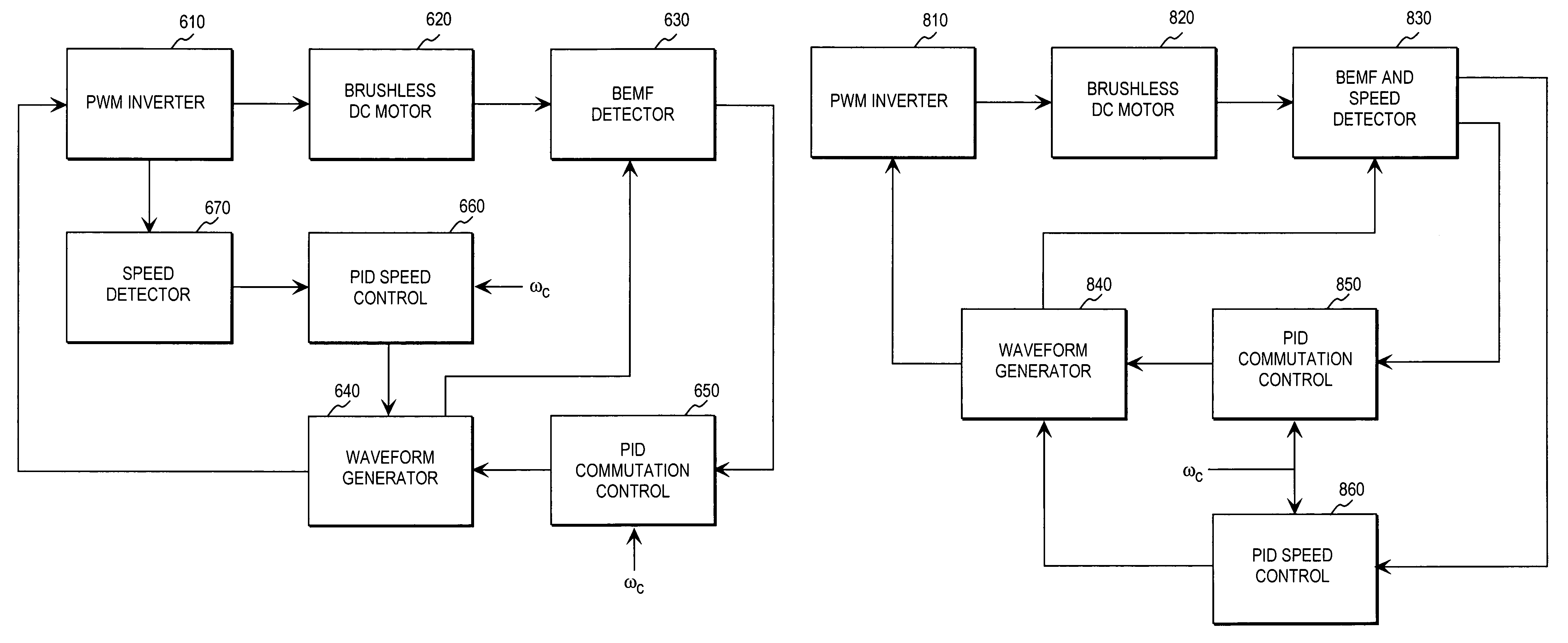

Method and apparatus for controlling brushless DC motors in implantable medical devices

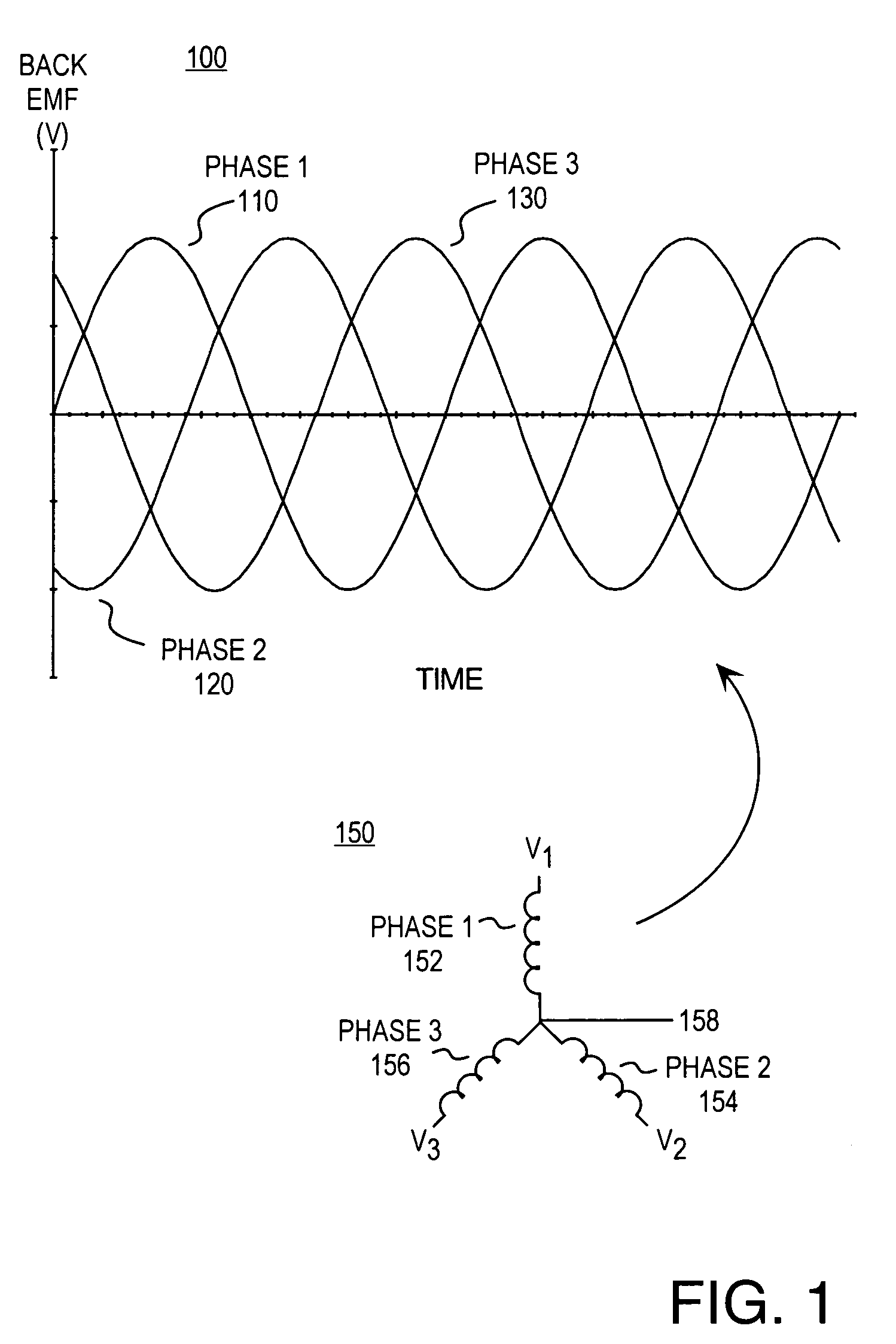

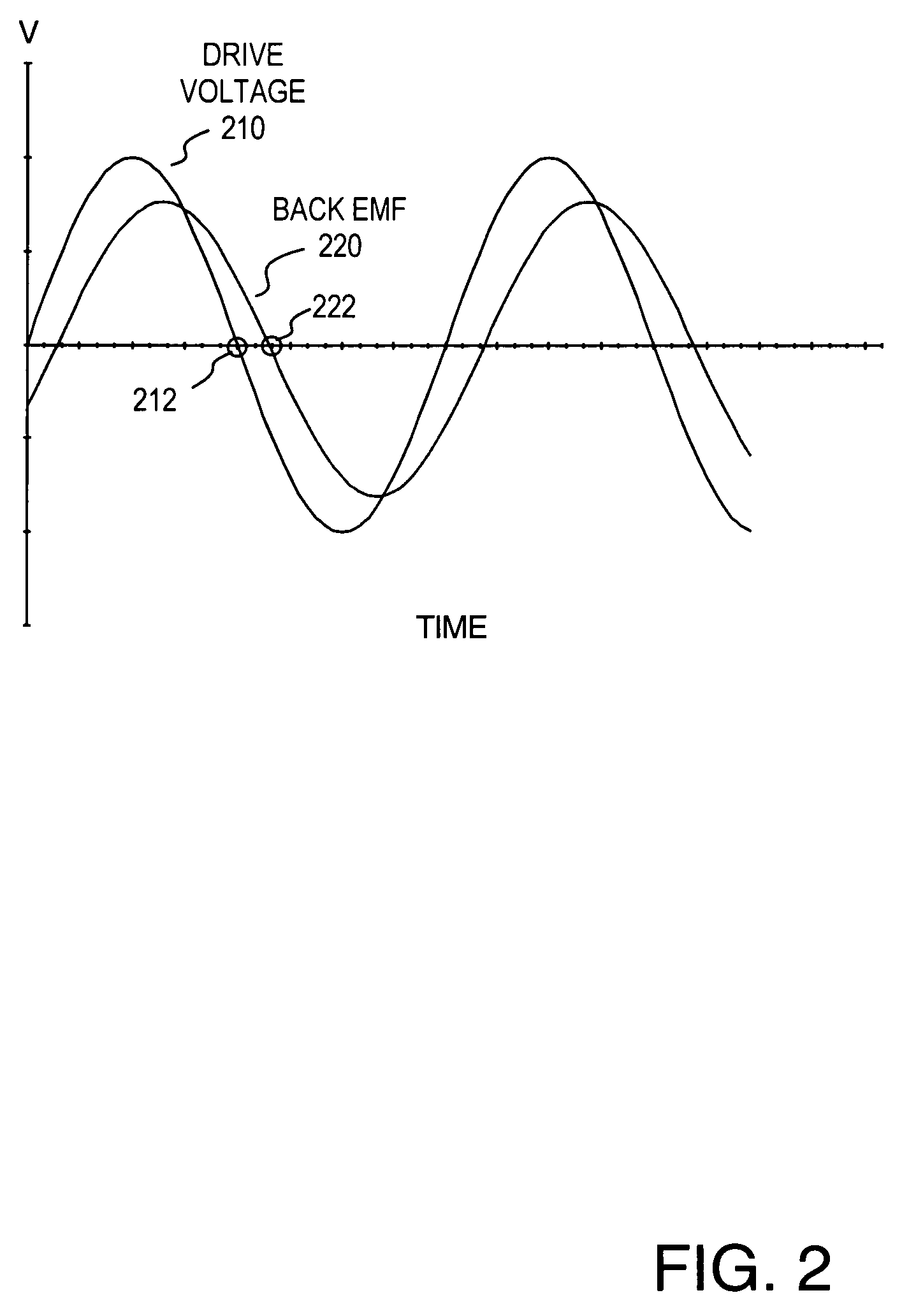

Methods and apparatus for controlling a polyphase motor in implantable medical device applications are provided. In one embodiment, the polyphase motor is a brushless DC motor. The back emf of a selected phase of the motor is sampled while a drive voltage of the selected phase is substantially zero. Various embodiments utilize sinusoidal or trapezoidal drive voltages. The sampled back emf provides an error signal indicative of the positional error of the rotor. In one embodiment, the sampled back emf is normalized with respect to a commanded angular velocity of the rotor to provide an error signal proportional only to the positional error of the motor rotor. The error signal is provided as feedback to control a frequency of the drive voltage. A speed control generates a speed control signal corresponding to a difference between a commanded angular velocity and an angular velocity inferred from the frequency of the drive voltage. The speed control signal is provided as feedback to control an amplitude of the drive voltage. In one embodiment, an apparatus includes a brushless DC motor and a commutation control. The commutation control provides a commutation control signal for a selected phase of the motor in accordance with a sampled back electromotive force (emf) of that phase. The back emf of the phase is sampled only while the corresponding drive voltage for the selected phase is substantially zero, wherein a frequency of a drive voltage of the motor is varied in accordance with the commutation control signal.

Owner:HEARTWARE INC

Permanent magnet type rotating electric machine capable of suppressing deformation of rotor core

ActiveUS20070063607A1Avoid deformationMagnetic circuitSynchronous machines with stationary armatures and rotating magnetsElectric machineMagnetic poles

A rotor core is provided with a plurality of slits extending in the rotation shaft direction, independently of openings. The first slit is arranged at the center of the magnetic pole of the rotor core to be capable of absorbing stress acting on an inner circumferential surface of each opening in a direction normal to a main surface of a permanent magnet. The second slit is arranged between the magnetic poles of the rotor core to be capable of absorbing stress acting in parallel with the main surface of the permanent magnet. Thus, the rotor core is prevented from deforming in a radial outward direction. Further, by forming the first and second slits each in a form not interfering the magnetic path of the magnetic flux by the stator passing inside the rotor core, the motor performance is ensured.

Owner:TOYOTA JIDOSHA KK

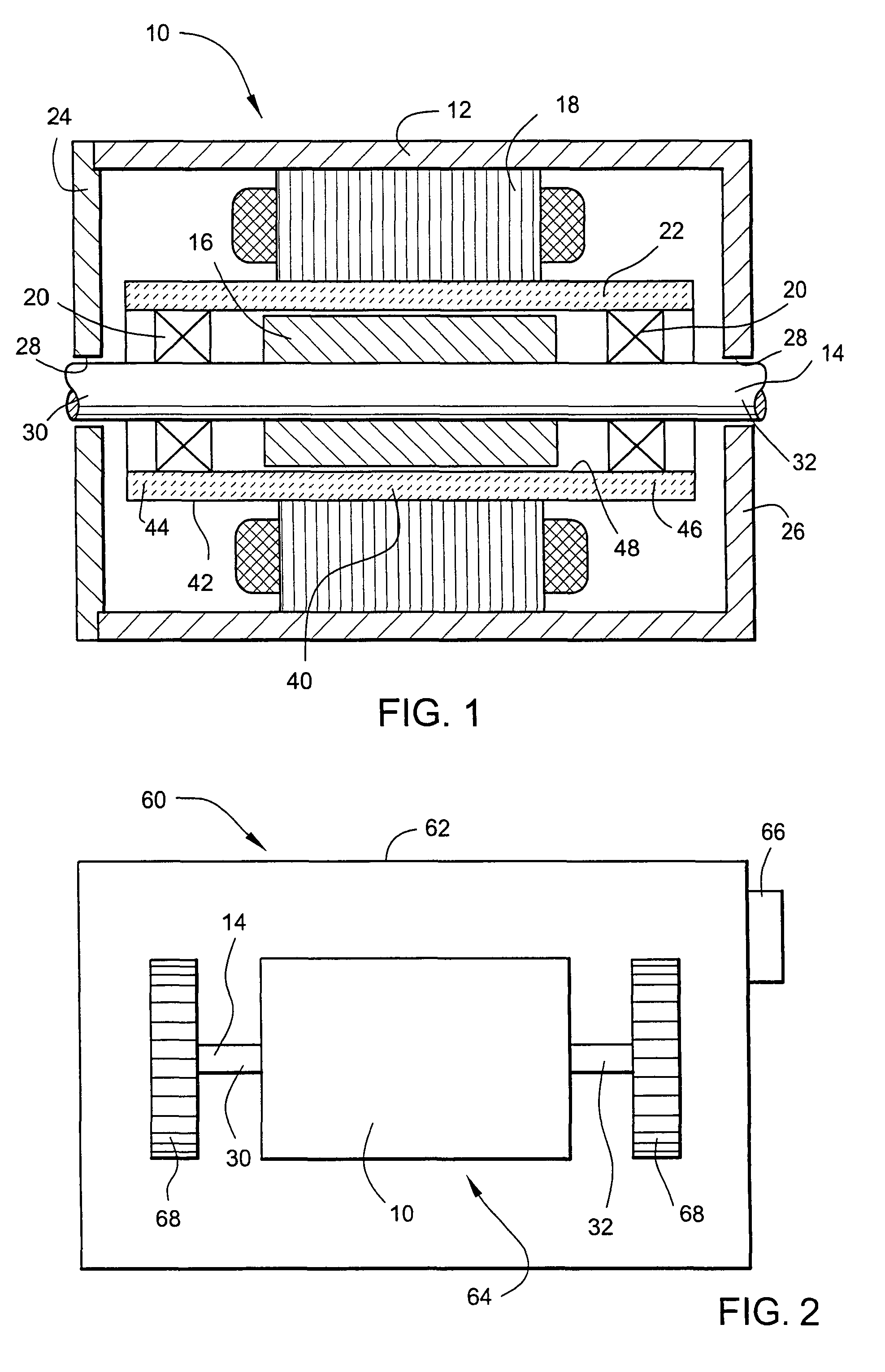

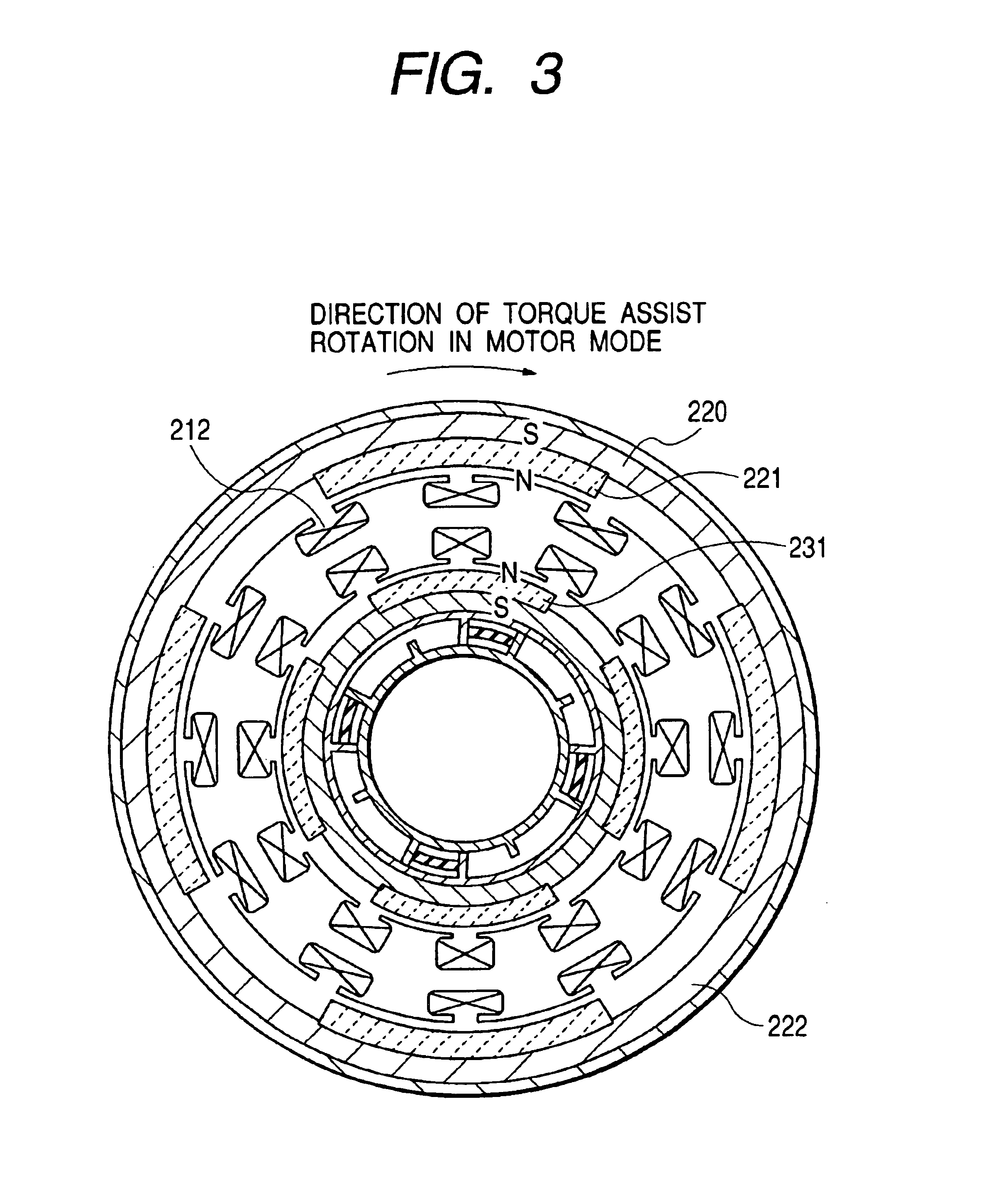

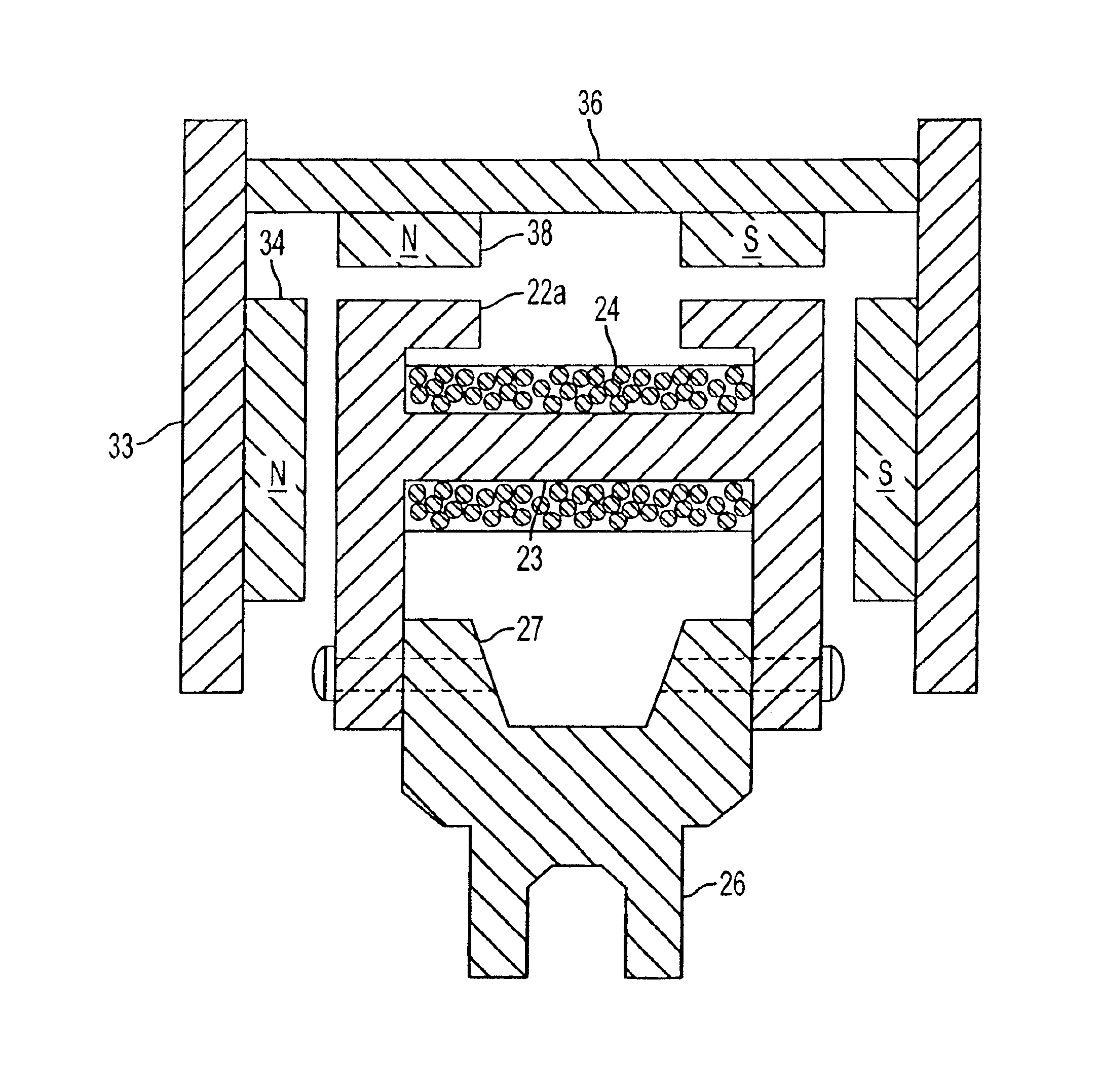

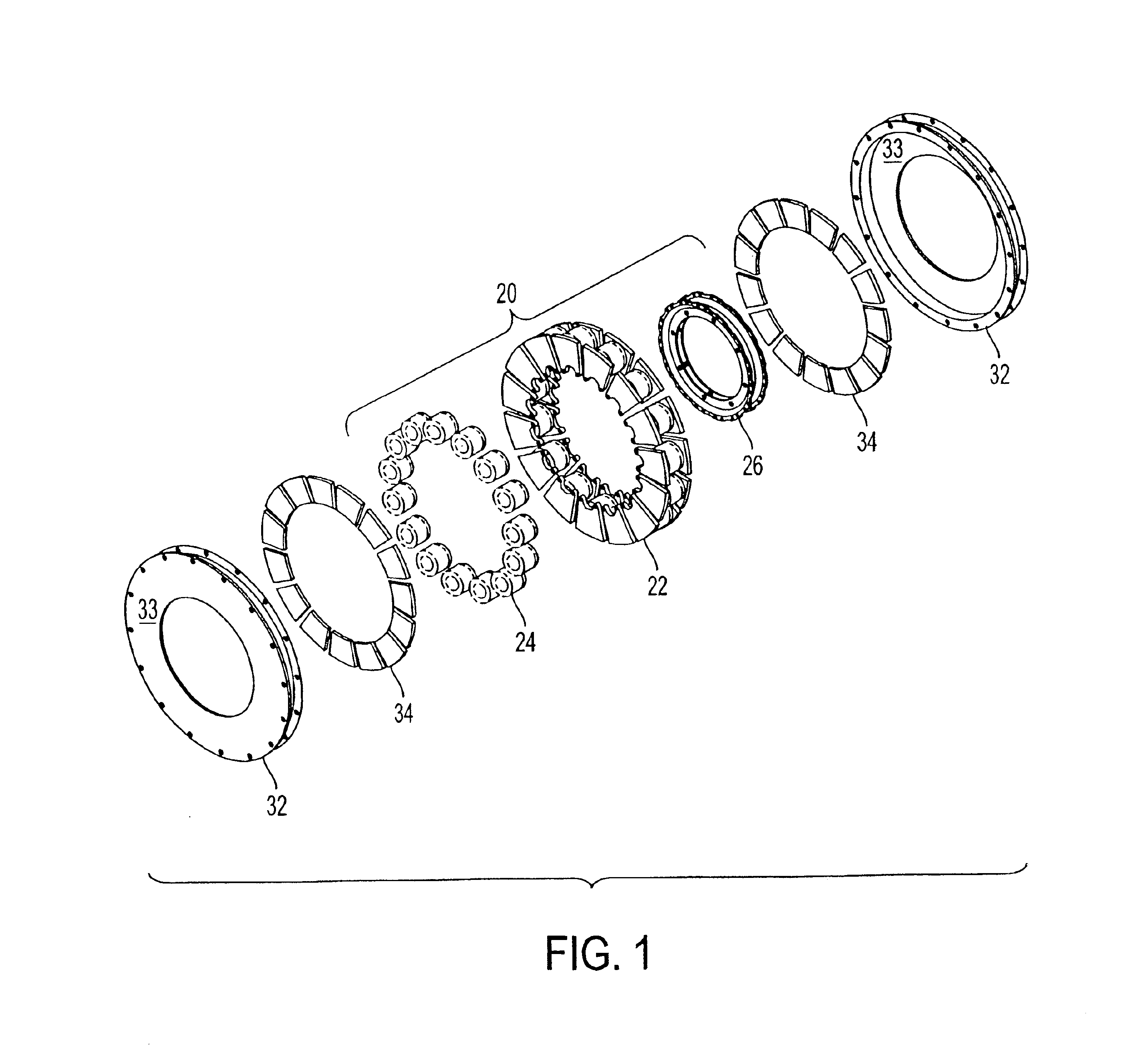

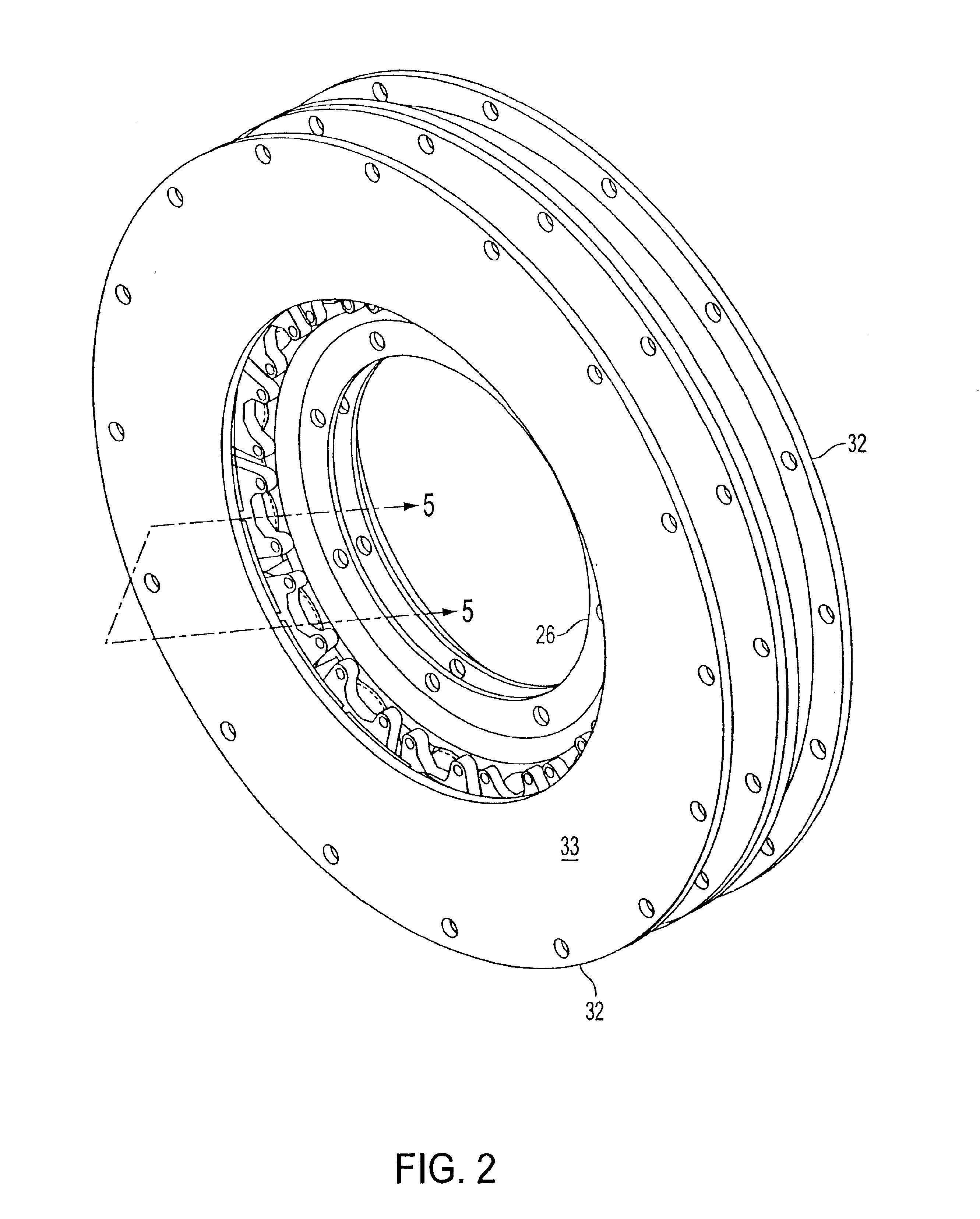

Low inductance electrical machine

A low inductance electrical machine that may be used as an alternator or motor with low armature inductance is disclosed. Arrangements of complementary armature windings are presented in which the fluxes induced by currents in the armature windings effectively cancel leading to low magnetic energy storage within the machine. This leads to low net flux levels, low core losses, low inductance and reduced tendency toward magnetic saturation. The inclusion of additional gaps in the magnetic circuit allows for independent adjustment of air gap geometry and armature inductance. Separately excited field arrangements are disclosed that allow rotor motion to effect brush-less alternator or brush-less motor operation. An exemplary geometry includes a stator including two annular rings and a concentric field coil together with a rotor structure separated from the stator by four air gaps.

Owner:RAVEN TECH

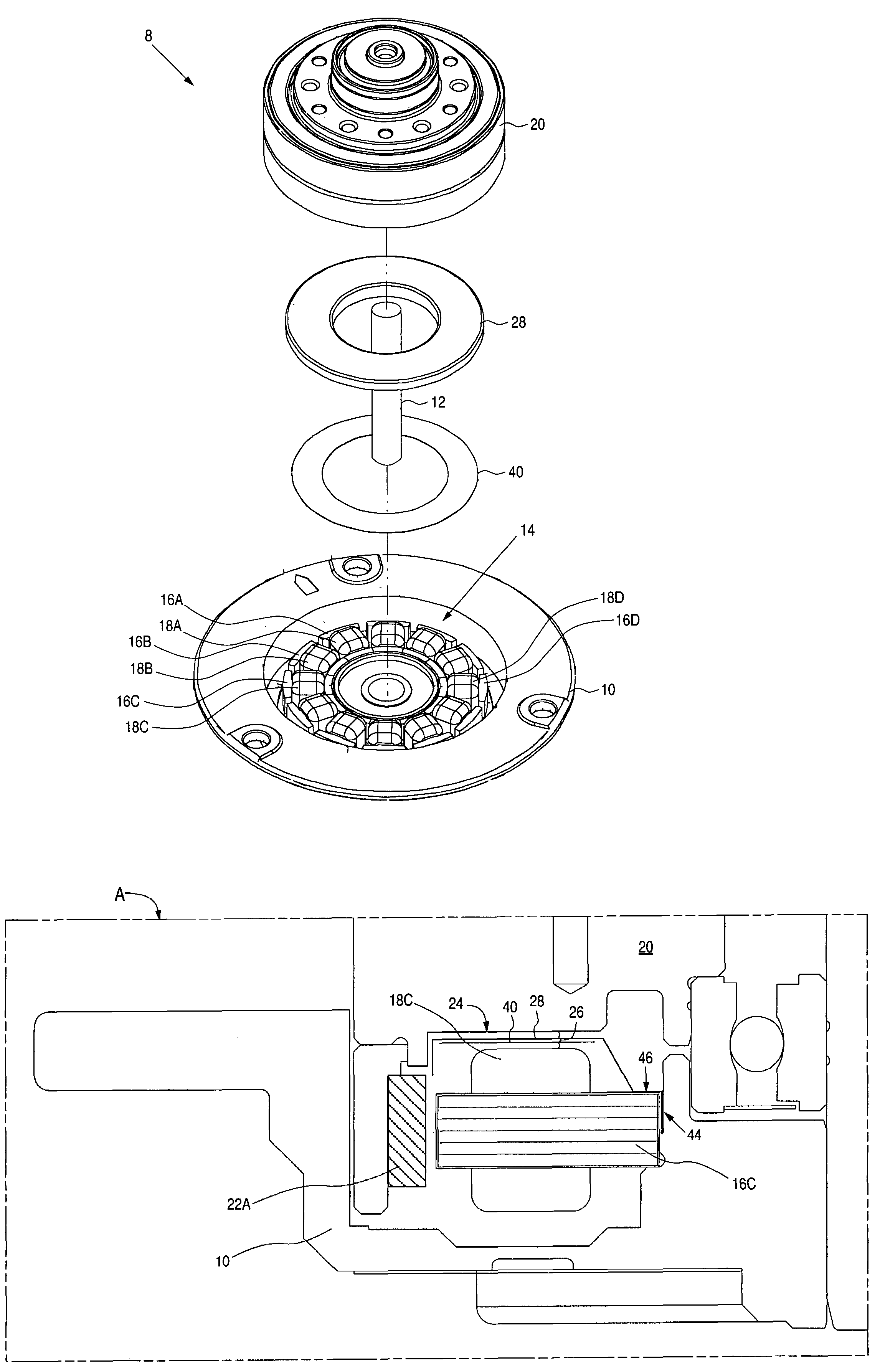

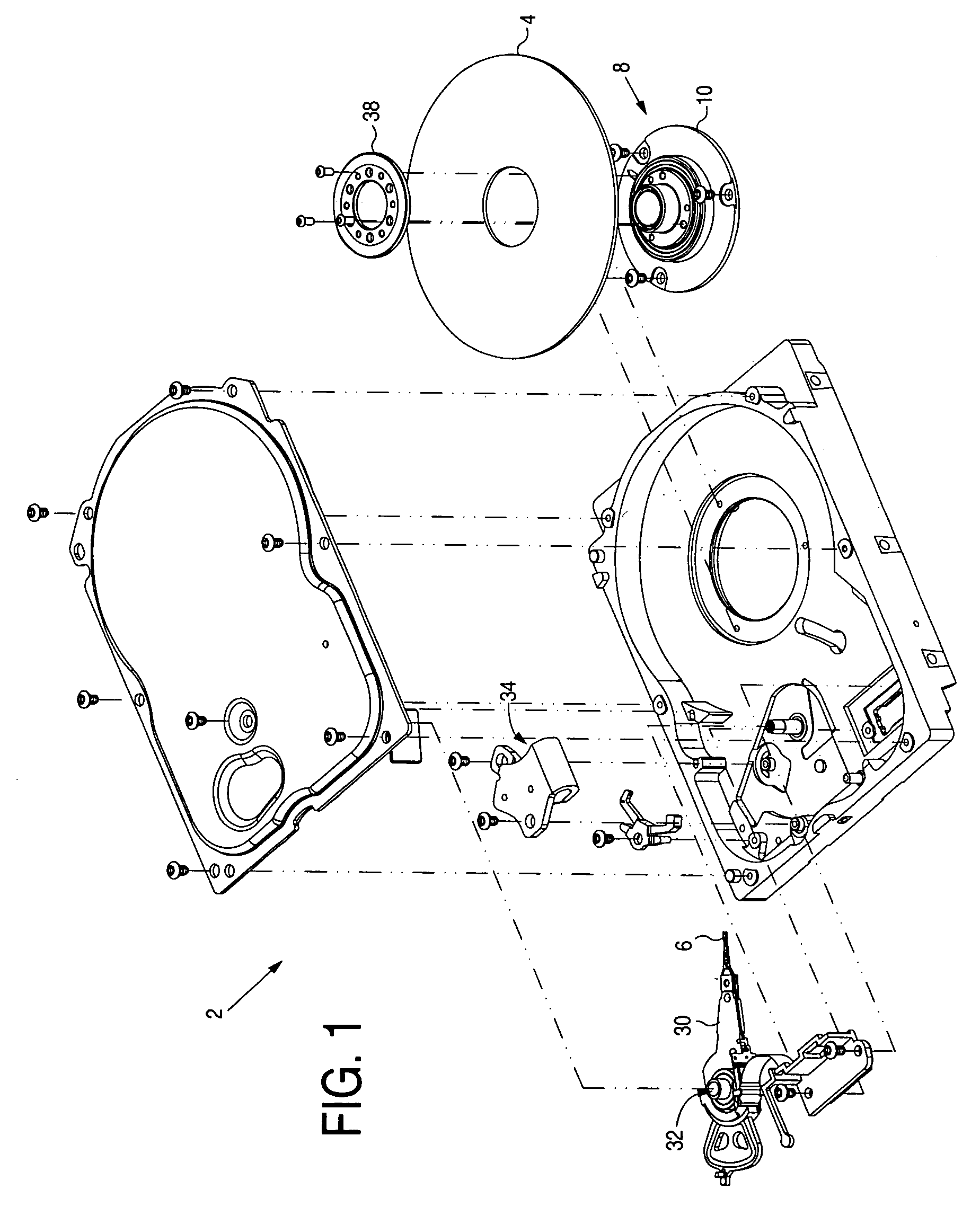

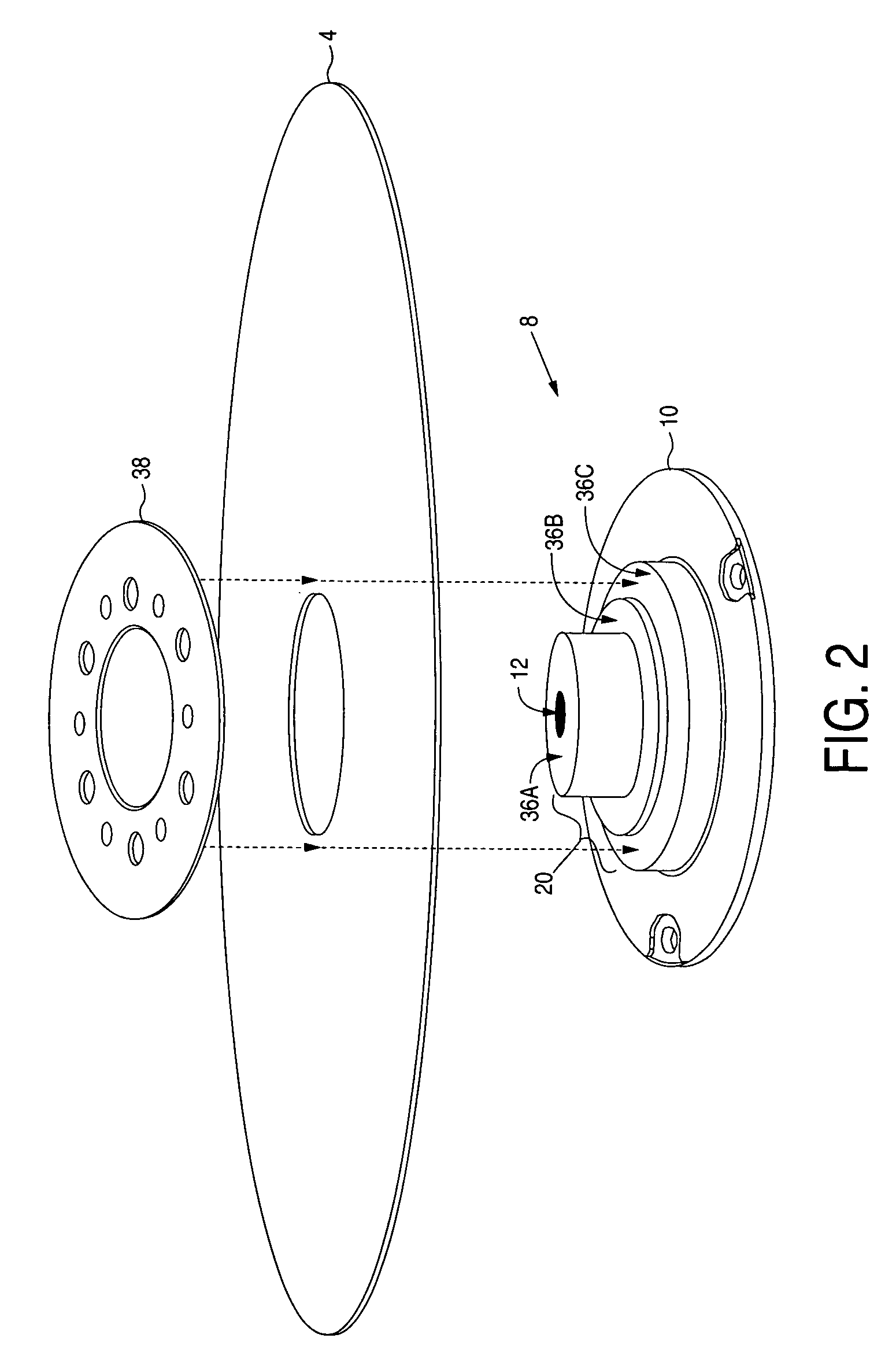

Disk drive comprising a spindle motor having a windings shield for reduced disk voltage coupling

A disk drive is disclosed comprising a disk, a head actuated over a surface of the disk, and a spindle motor for rotating the disk. The spindle motor comprises a ring-shaped stator having a plurality of stator teeth each wound with a winding. The spindle motor further comprises a hub having a plurality of magnets for interacting with the stator teeth to rotate the hub about the shaft when the windings are energized. A ring-shaped shield is disposed in a vertical gap between the windings and the hub to reduce a voltage coupled from the windings to the surface of the disk.

Owner:WESTERN DIGITAL TECH INC

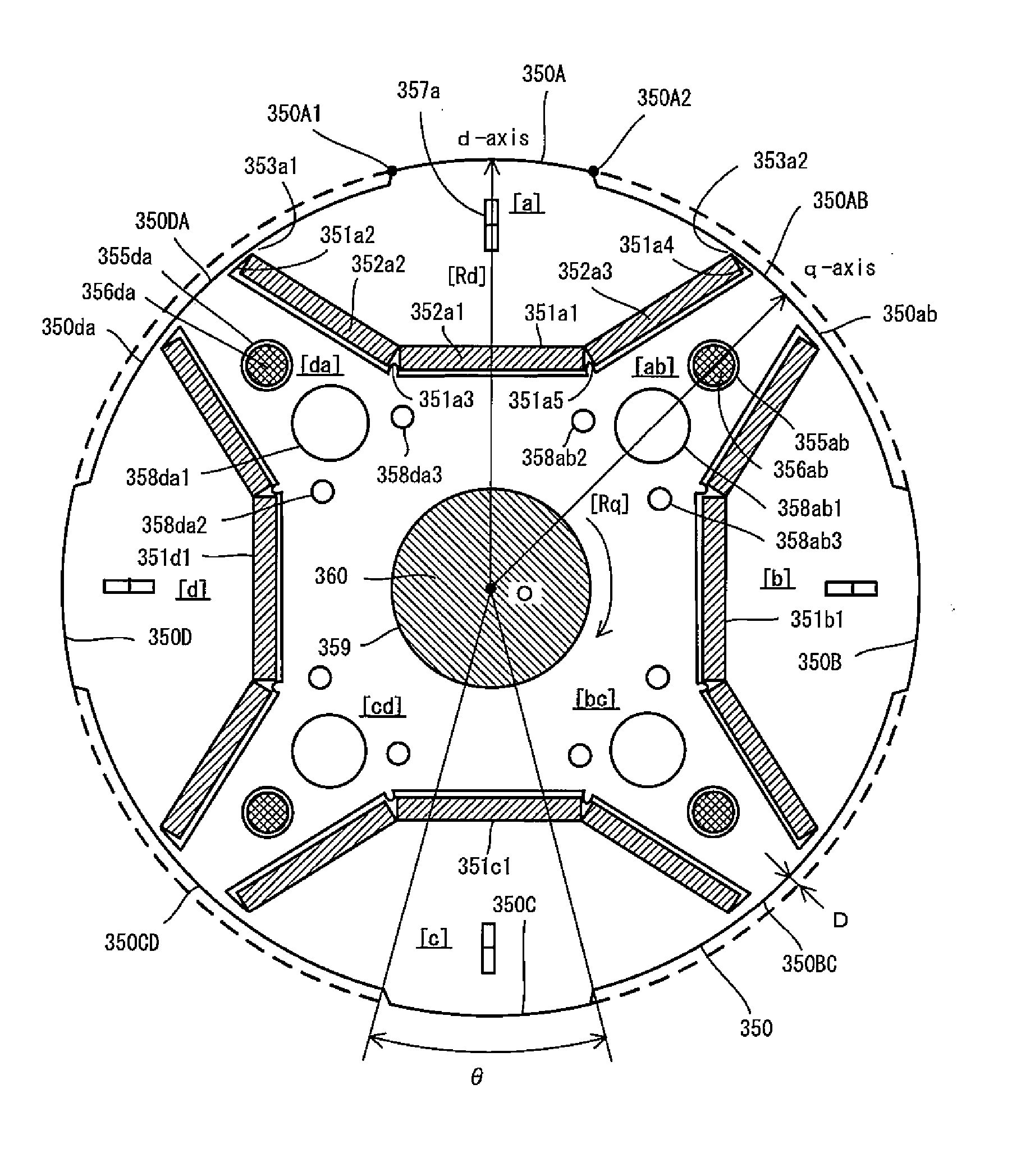

Permanent magnet rotating machine

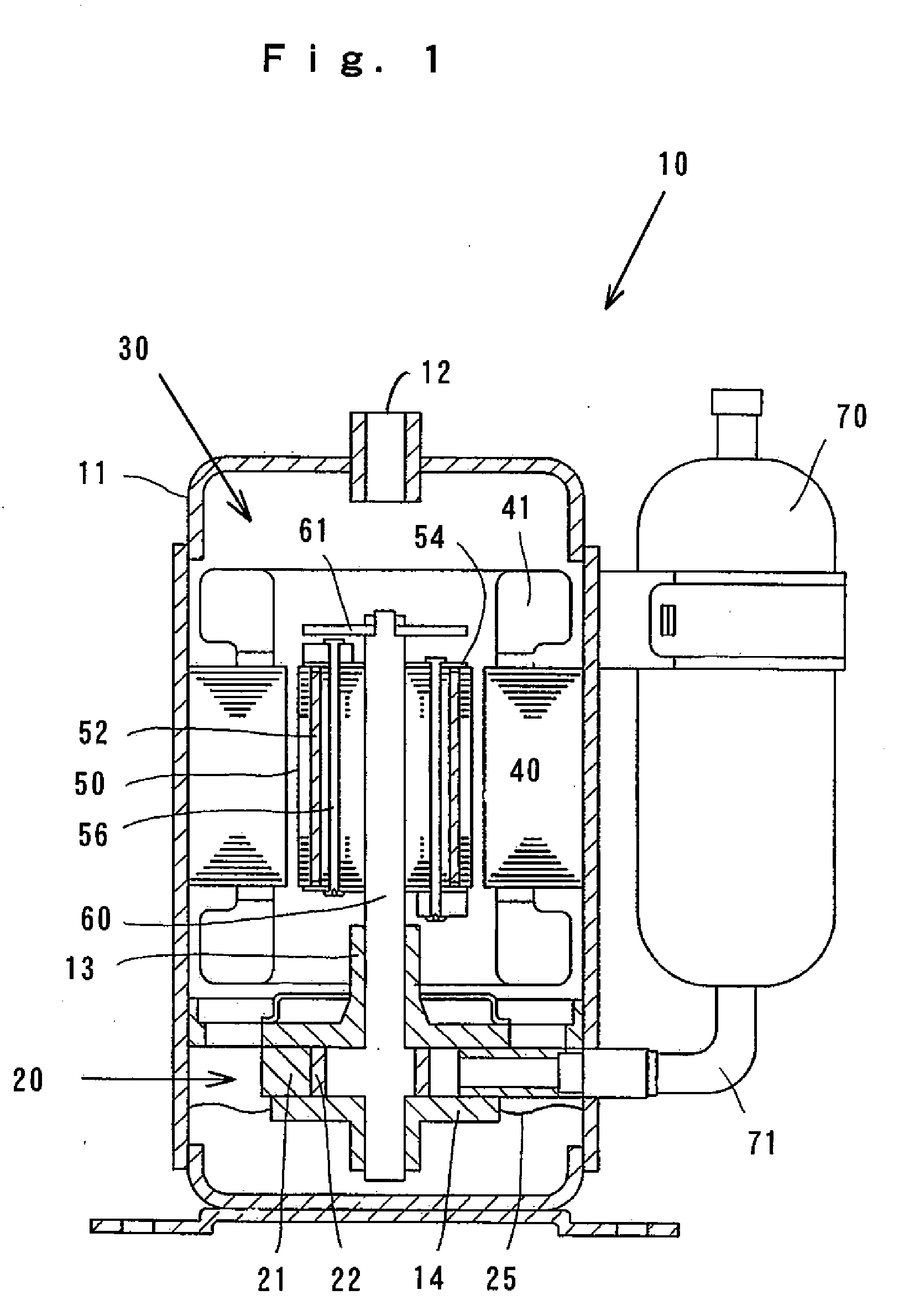

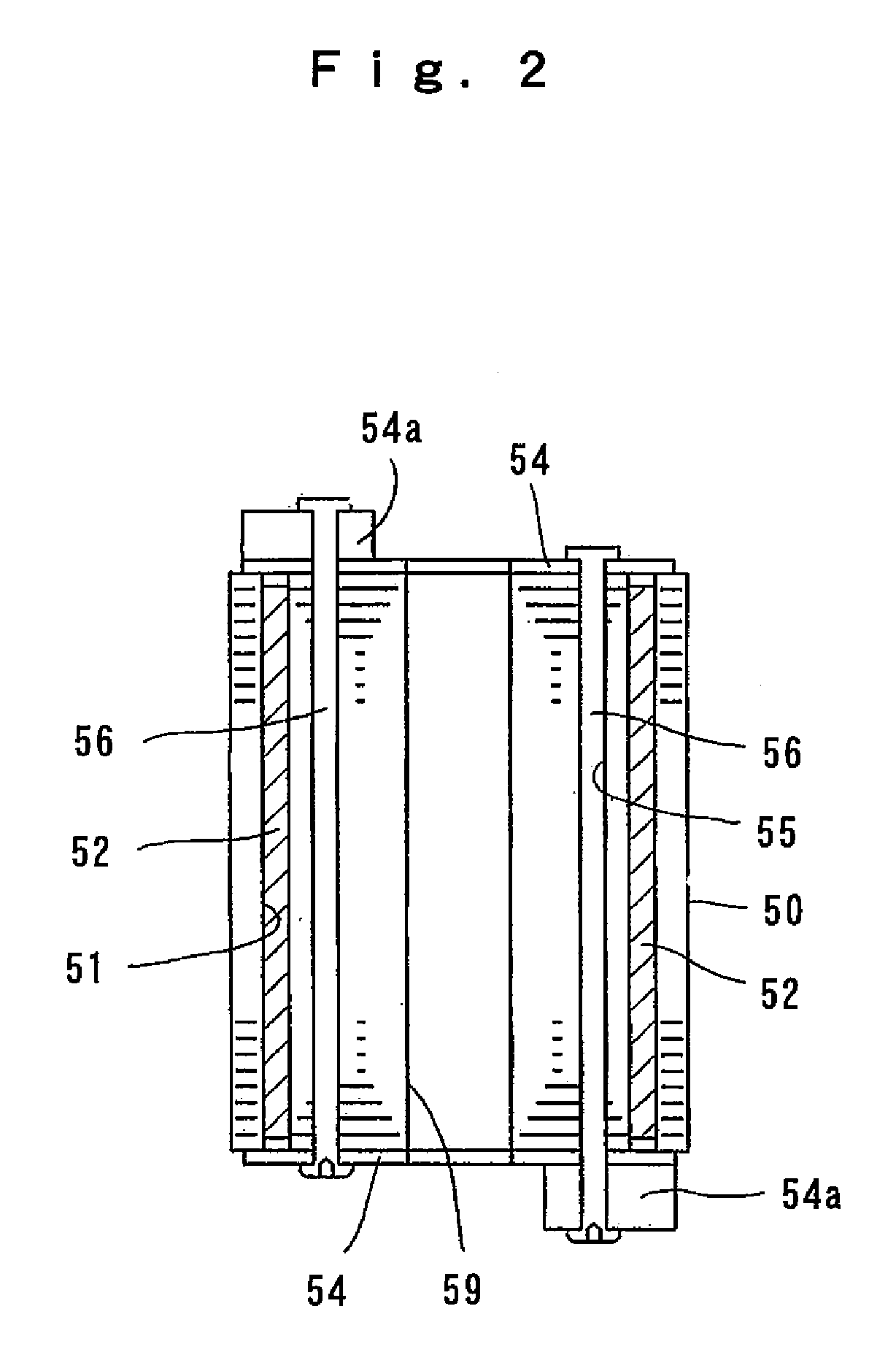

ActiveUS20070126304A1Reduce the impactReduce impactMagnetic circuit rotating partsPiston pumpsMagnetic polesEngineering

A rotary shaft 60 having an outside diameter larger than the bore diameter of a rotary shaft insert hole 59 of a rotor 50 is inserted into the rotary shaft insert hole 59. A magnet insert hole 51a1 is provided in a main magnetic pole [a] of the rotor 50. Permanent magnets 52a1 to 52a3 are inserted into the magnet insert hole 51a1 such that a gap is formed between the permanent magnets 52a1 to 52a3 and the magnet insert hole 51a1. A semi-tubular rivet insert hole 55a and interlocks 57a1, 57a2 elongated in the radial direction of the rotor are disposed radially outward of the magnet insert hole 51a in the rotor. A semi-tubular rivet 56a is inserted into the semi-tubular rivet insert hole 55a such that a gap is formed between the semi-tubular rivet 56a and the semi-tubular rivet insert hole 55a. Passage holes 58ab, 58da are provided in the auxiliary magnetic poles [ab], [da].

Owner:AICHI ELECTRIC

Rotary electric machine having a flux-concentrating rotor and a stator with windings on teeth

InactiveUS20020047425A1Increase powerReduce manufacturing costMagnetic circuit rotating partsMagnetic circuit stationary partsElectric machinePole piece

The invention relates to a rotary electric machine comprising a flux-concentrating rotor with permanent magnets disposed between pole pieces, and a stator with windings on teeth.

Owner:MOTEURS LEROY SOMER

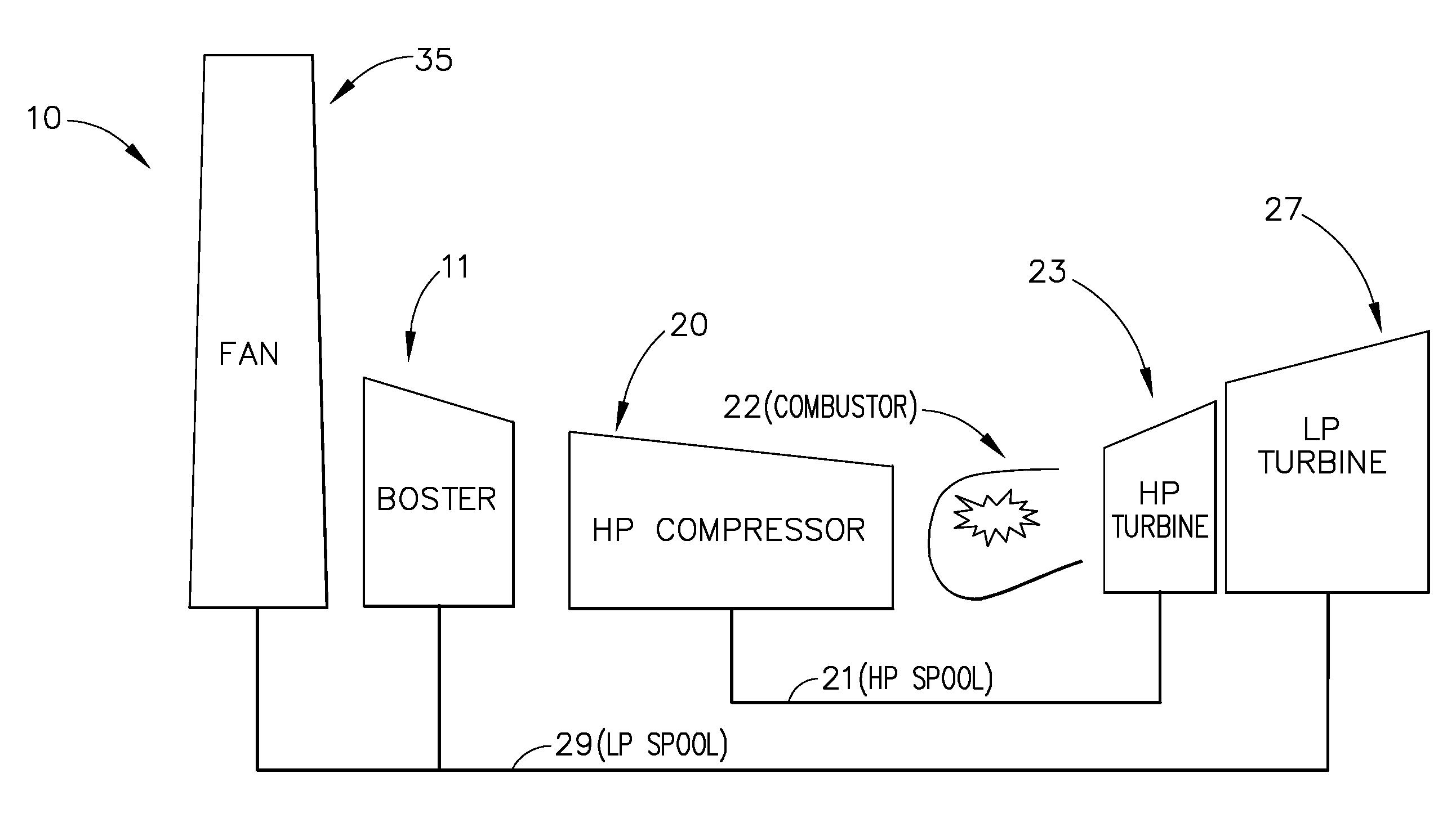

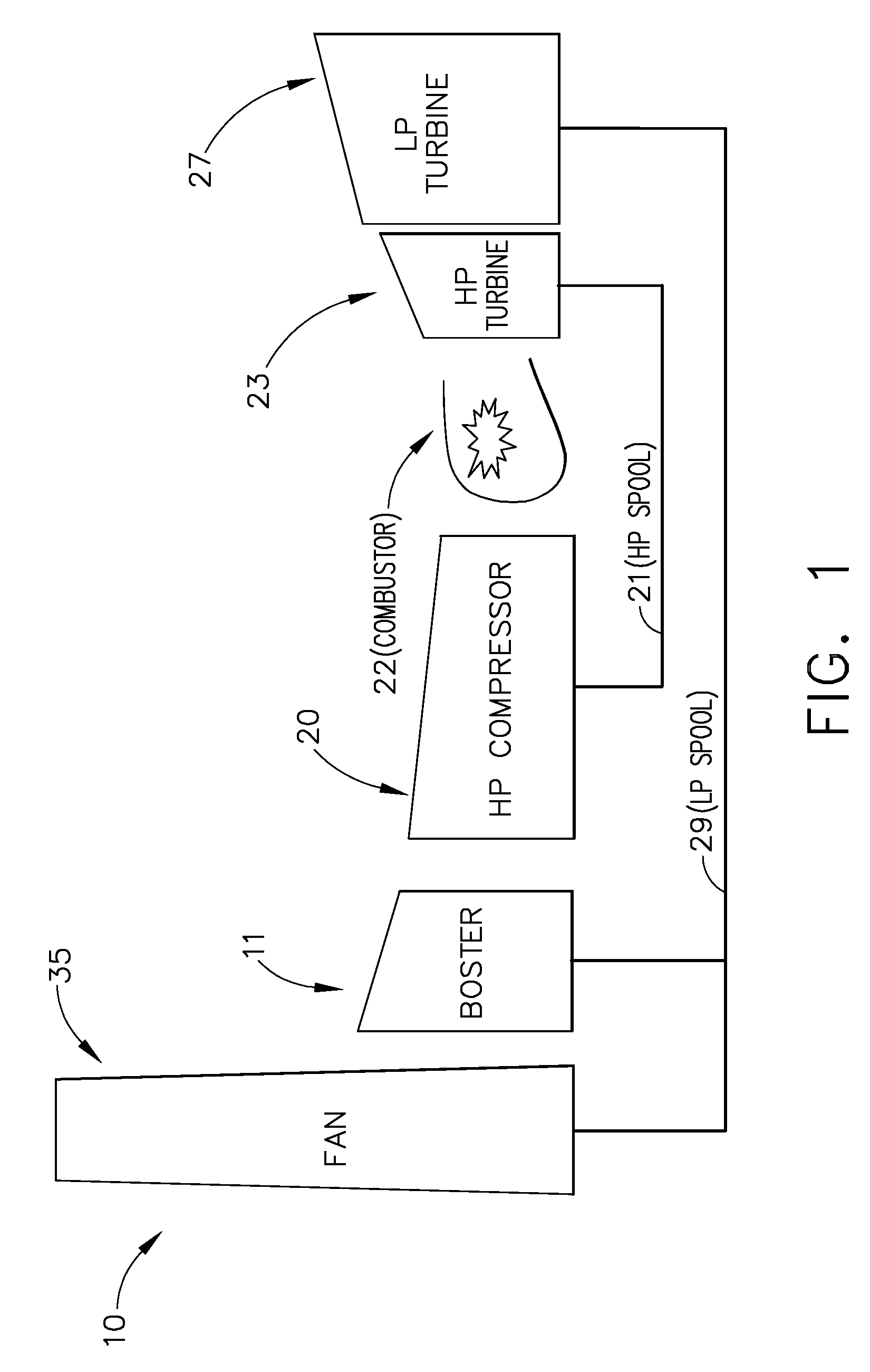

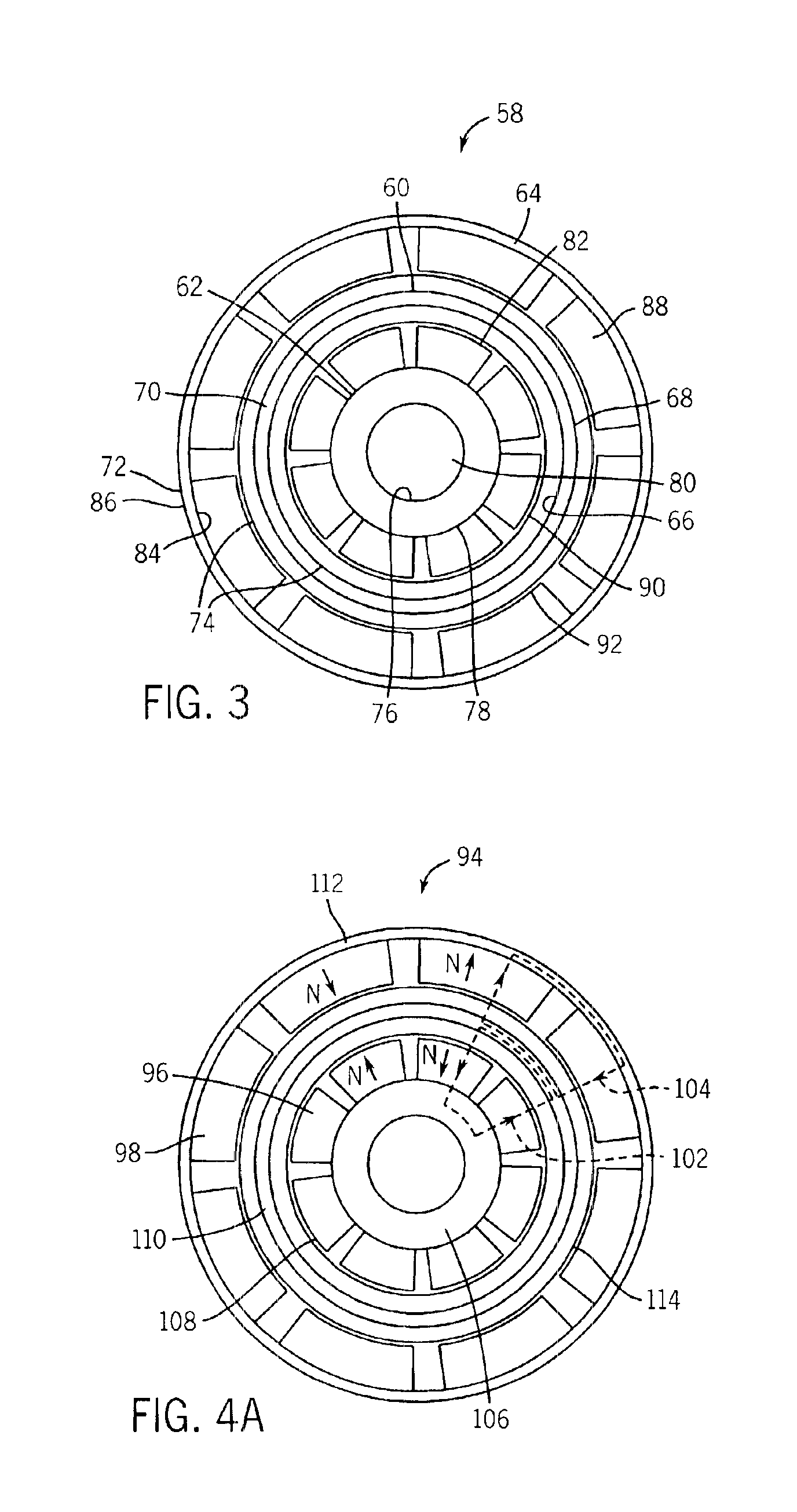

Variable Magnetic Coupling of Rotating Machinery

ActiveUS20080149445A1Reduce vibration transmissionMechanical actuated clutchesEngine fuctionsCouplingEngineering

A system for transferring torque between a pair of independently, concurrently rotating shafts of a turbofan engine includes a magnetic gearbox. The magnetic gearbox has a first ring structure, a second ring structure and an intermediate ring structure. Each ring structure has an annular aperture therethrough and a plurality of permanent magnets embedded therein. The intermediate ring structure is disposed between the first and the second ring structures. Each ring structure is coaxially concentric with, and independently rotatable with respect to the remaining ring structures. The first and second ring structures are each coupled to separate ones of the rotating engine shafts, and the intermediate ring is operable to transfer torque between the pair of shafts. Preferably, the intermediate ring structure is coupled to a rotating machine. The rotating machine has a controller, and is operable for adjusting a ratio of torque transferred between the pair of shafts.

Owner:GENERAL ELECTRIC CO

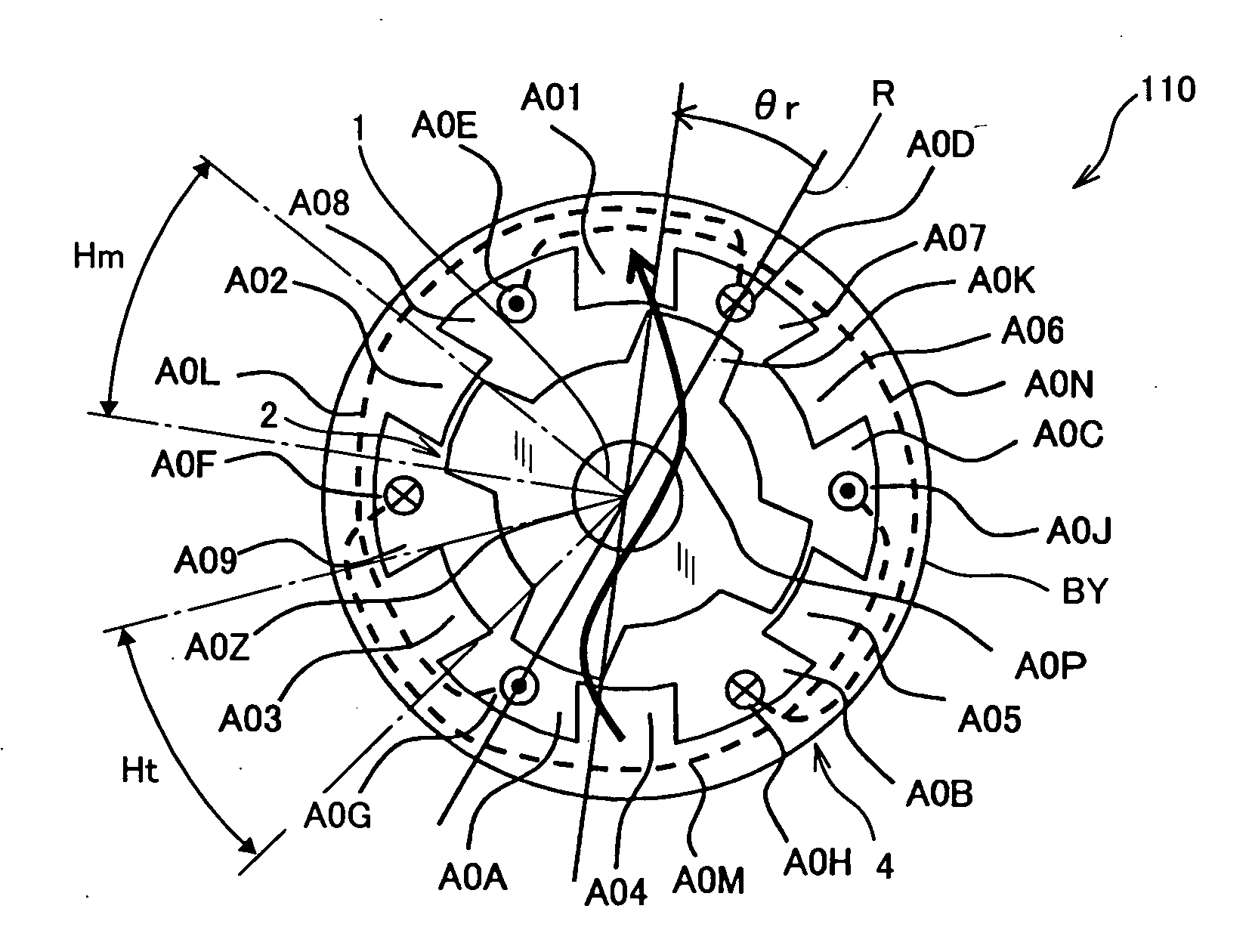

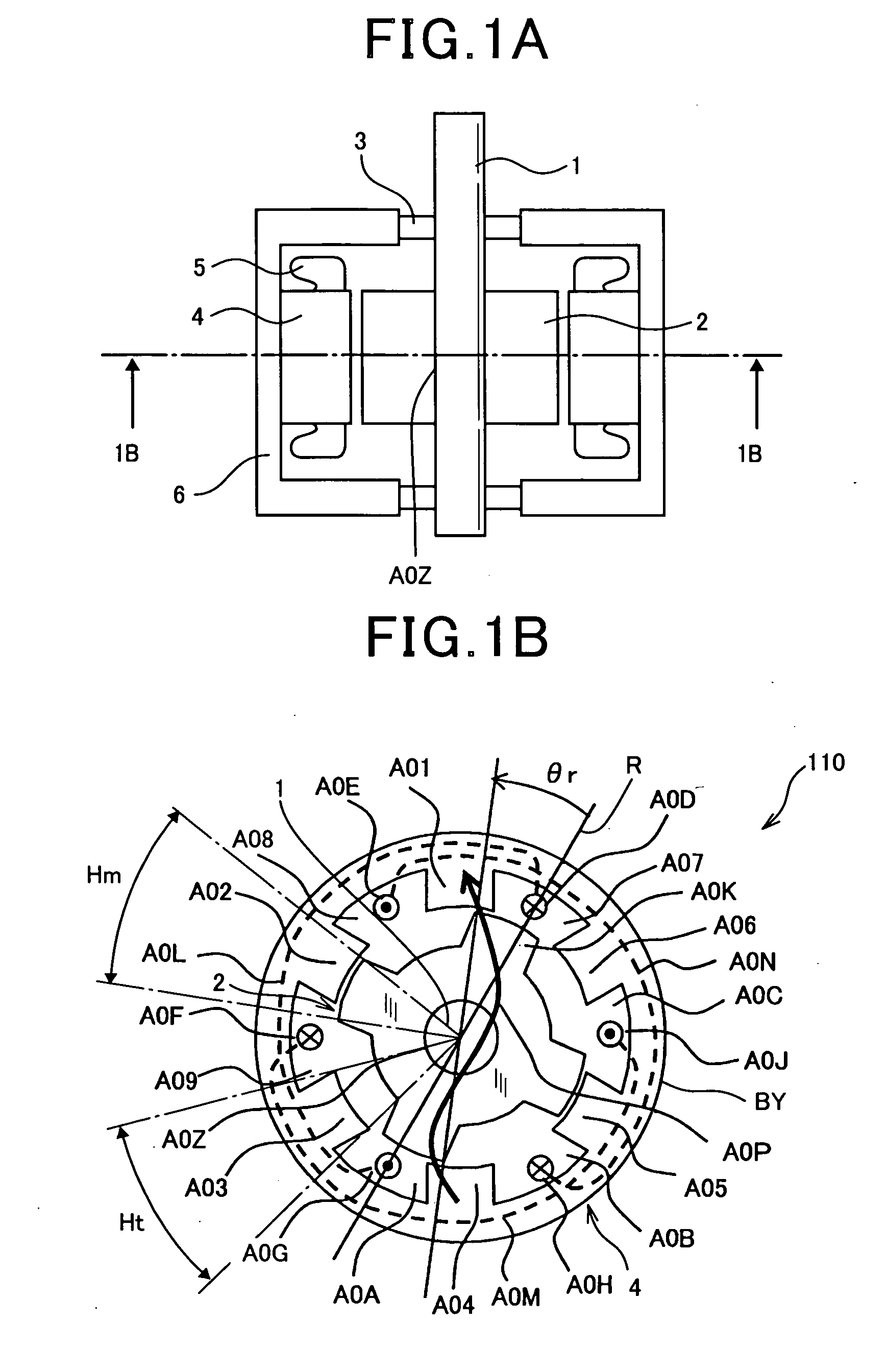

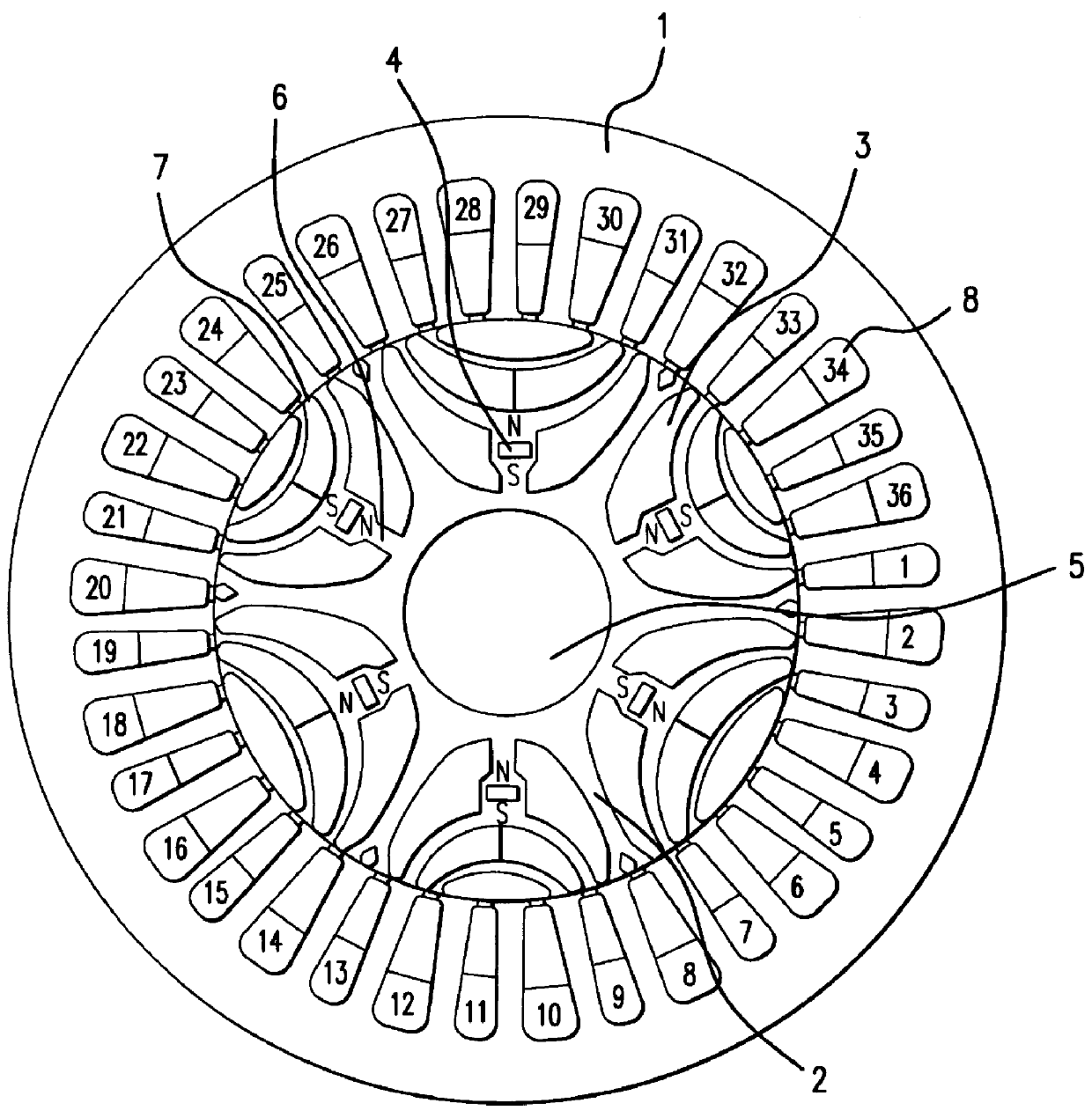

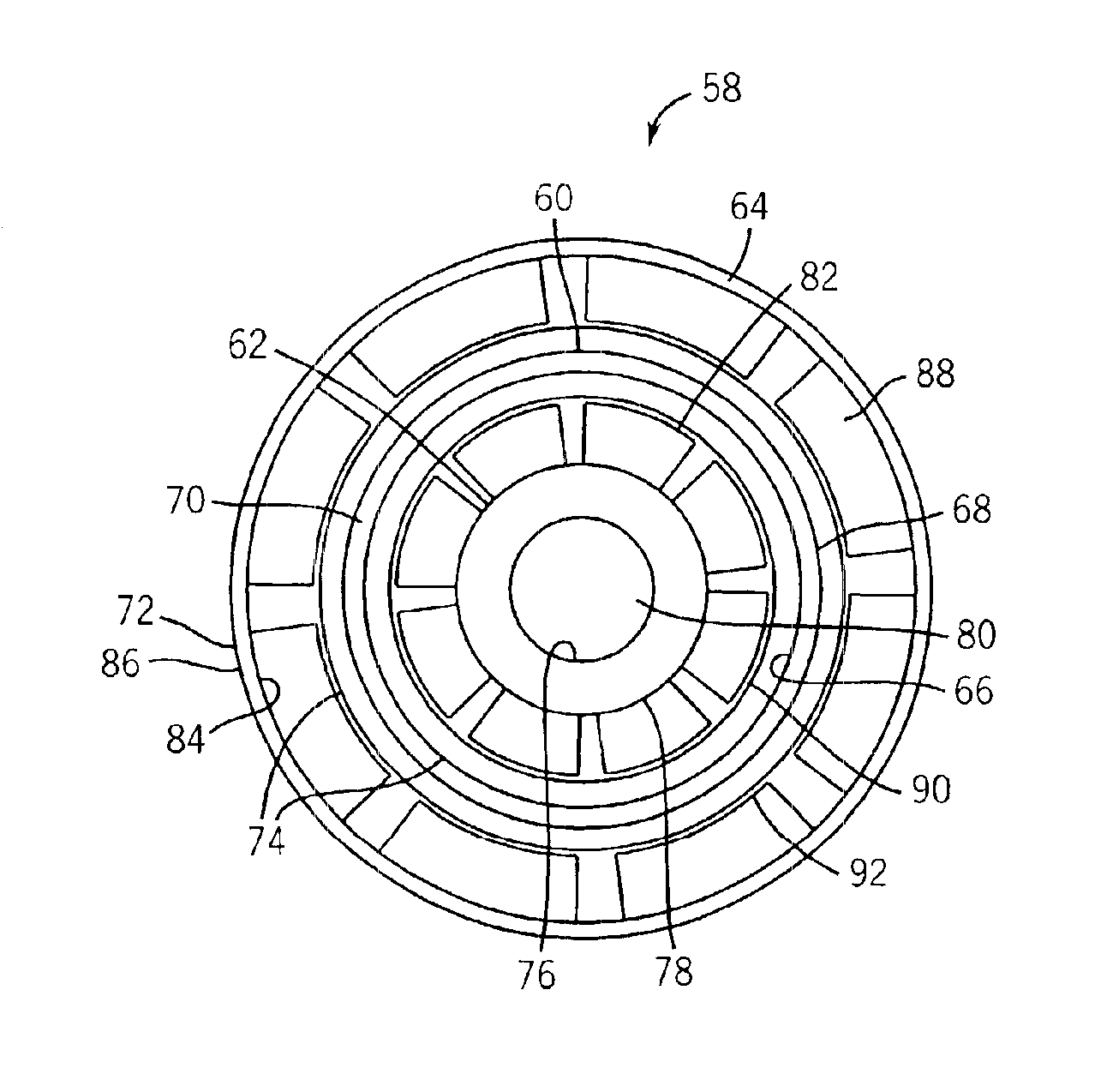

Reluctance motor

InactiveUS6121706ASynchronous generatorsMagnetic circuit rotating partsMagnetic polesReluctance motor

A reluctance motor is provided that reduces leaking magnetic flux. To generate magnetic flux between adjacent magnetic poles in a rotor 2, permanent magnets 4 are disposed in approximate centers of split magnetic paths near a borderline area between two magnetic poles in an internal portion of the rotor. Further, each of slots 8 in a stator 1 is wound with a coil of a corresponding phase such that the vector phase and amplitude expressed by the products of the number of coil turns and the amount of passing current, namely, ampere-turns, become almost identical for each of the slots. By reducing leaking magnetic flux according to this arrangement, generated torque can be increased. As the rotor mechanical strength is enhanced, the rotor can be safely driven at a higher speed. A practical motor is obtained that simultaneously achieves improved motor characteristics and reduced torque ripples.

Owner:OKUMA CORP

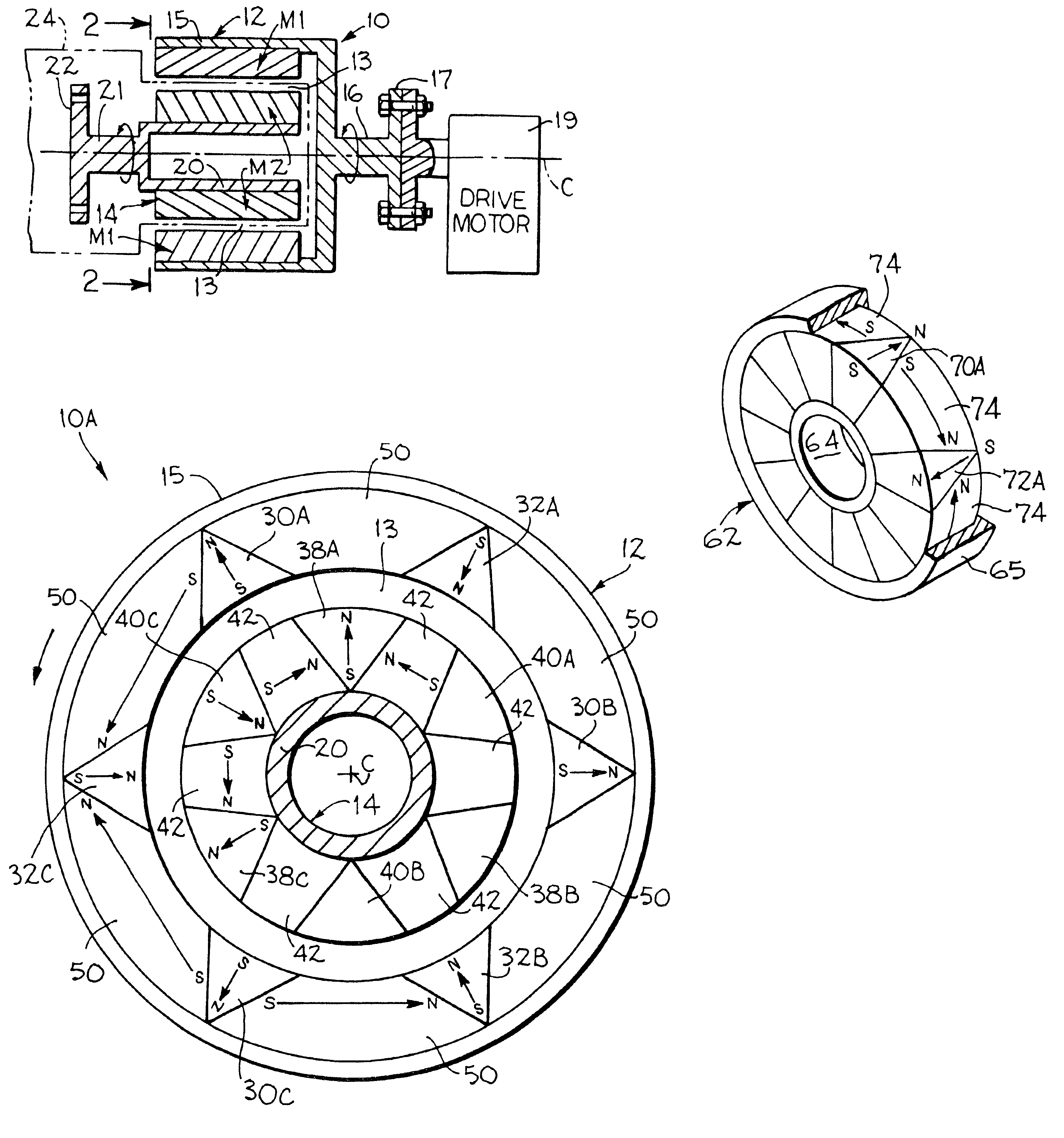

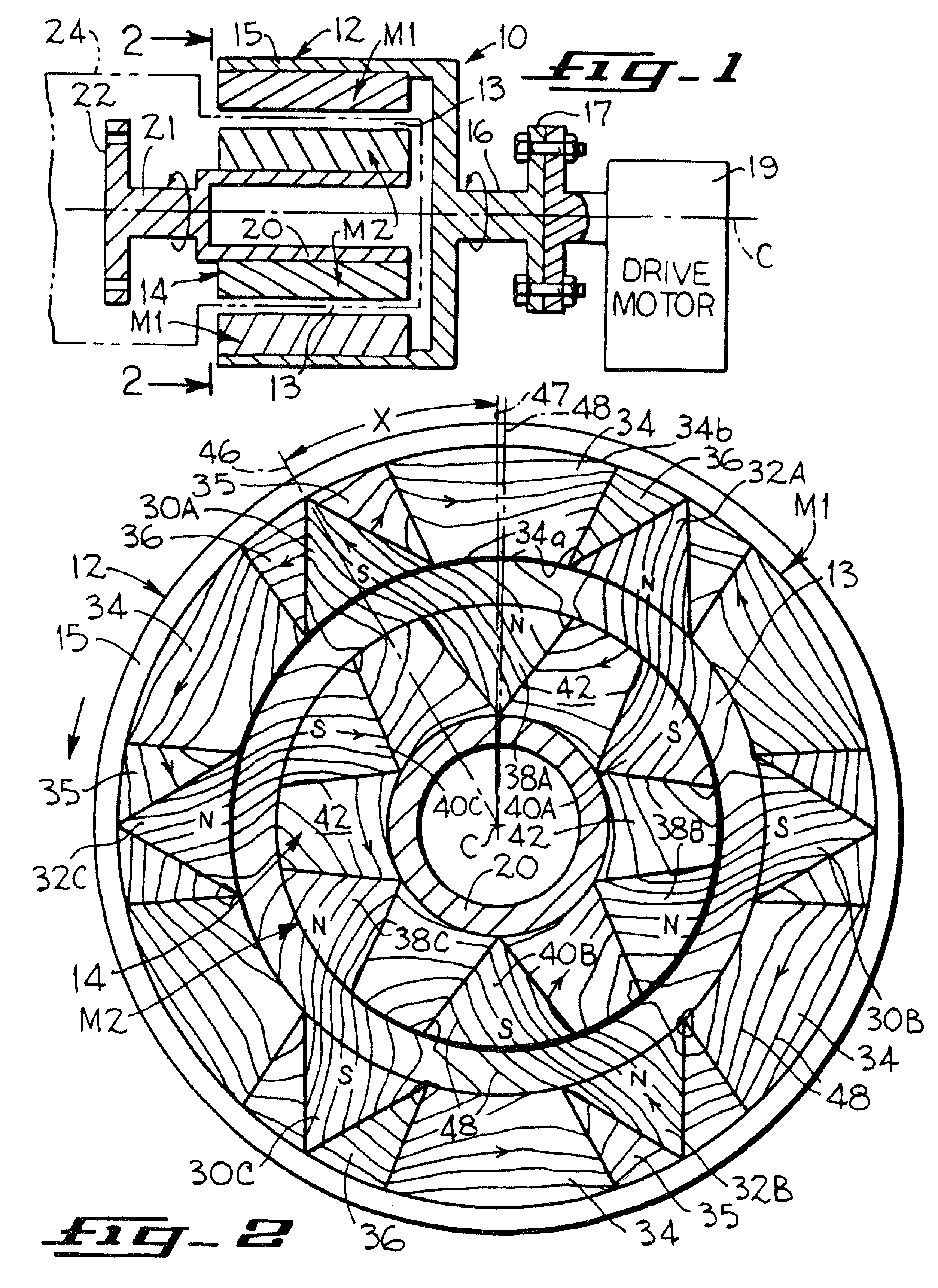

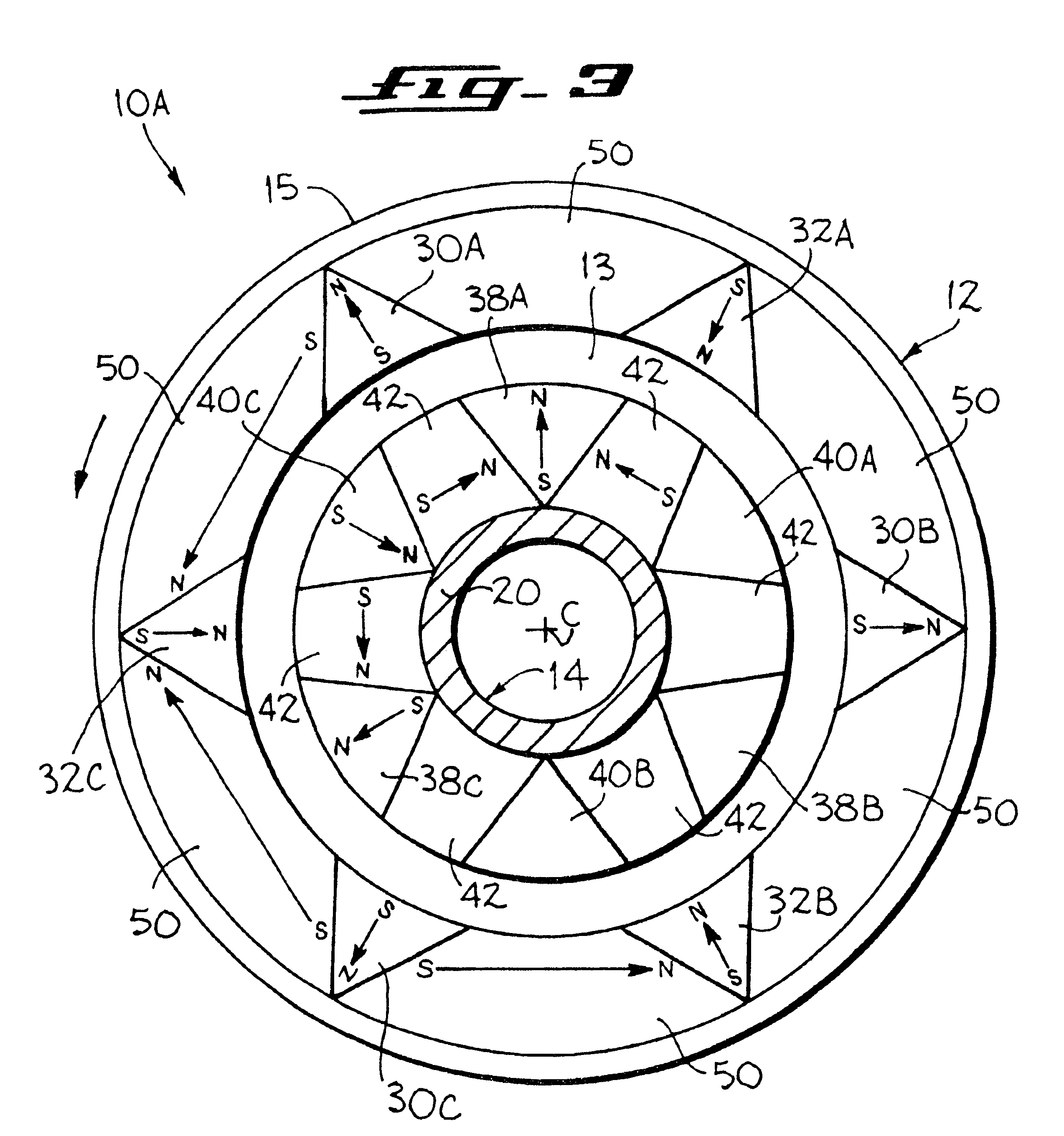

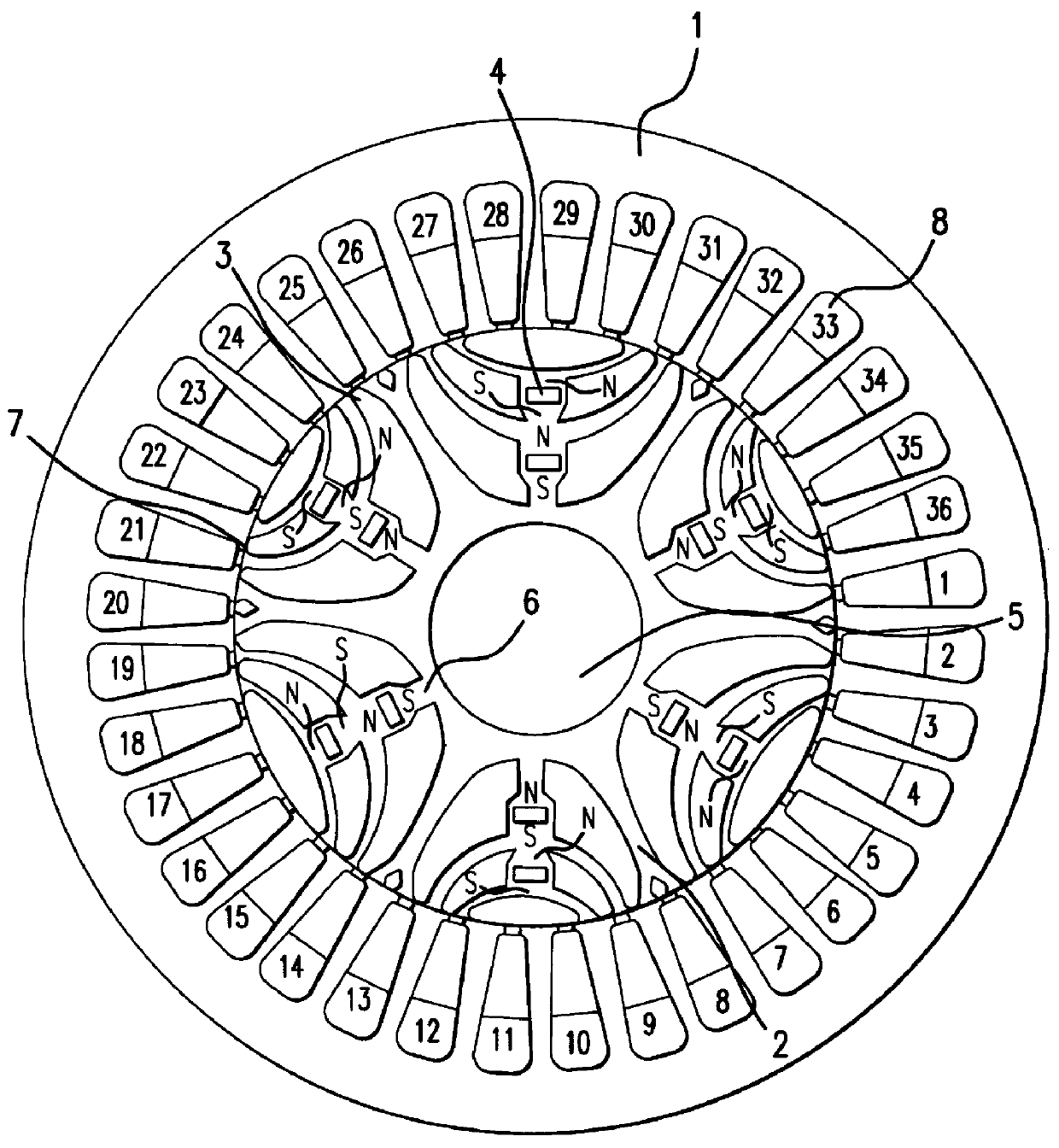

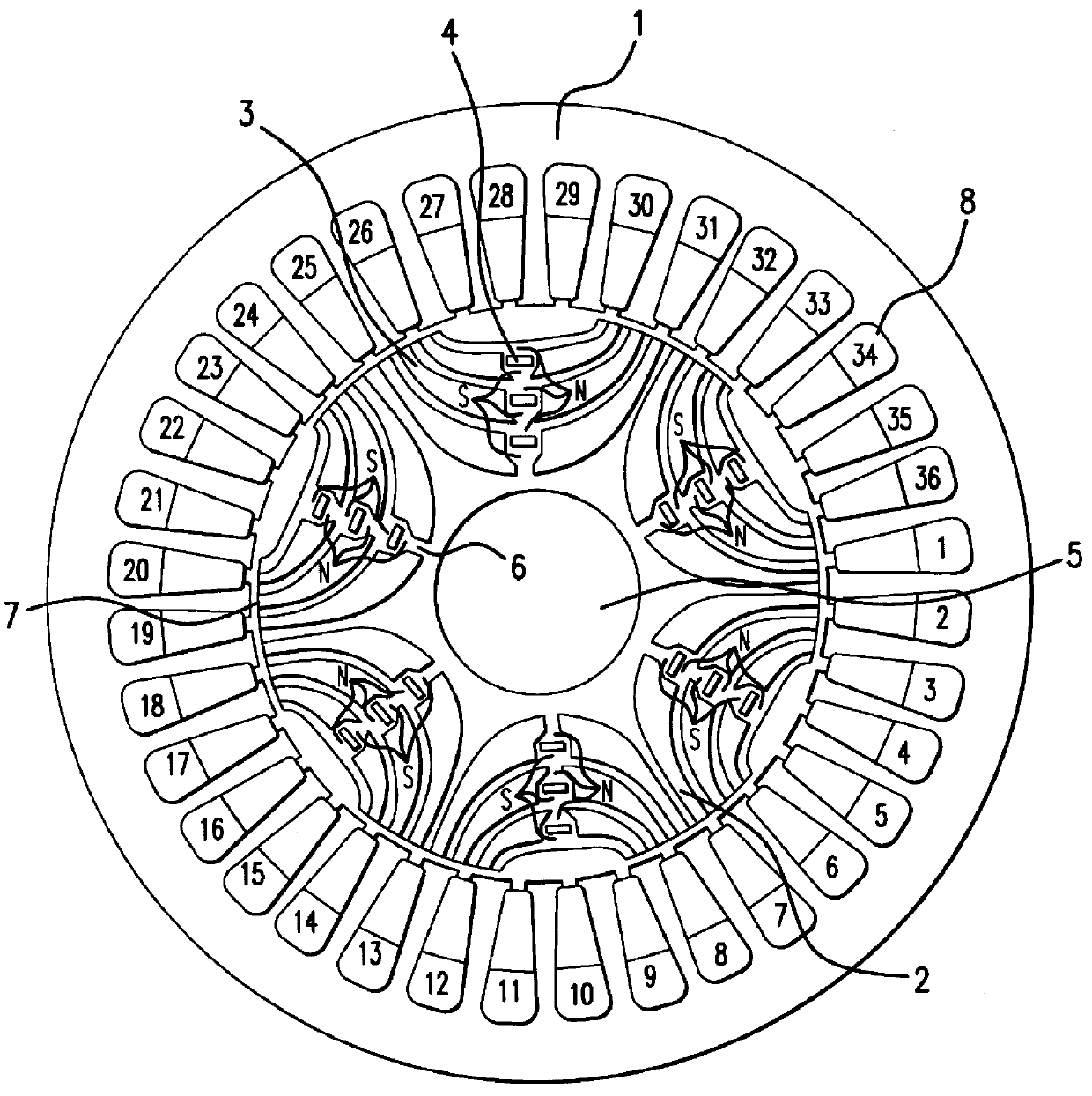

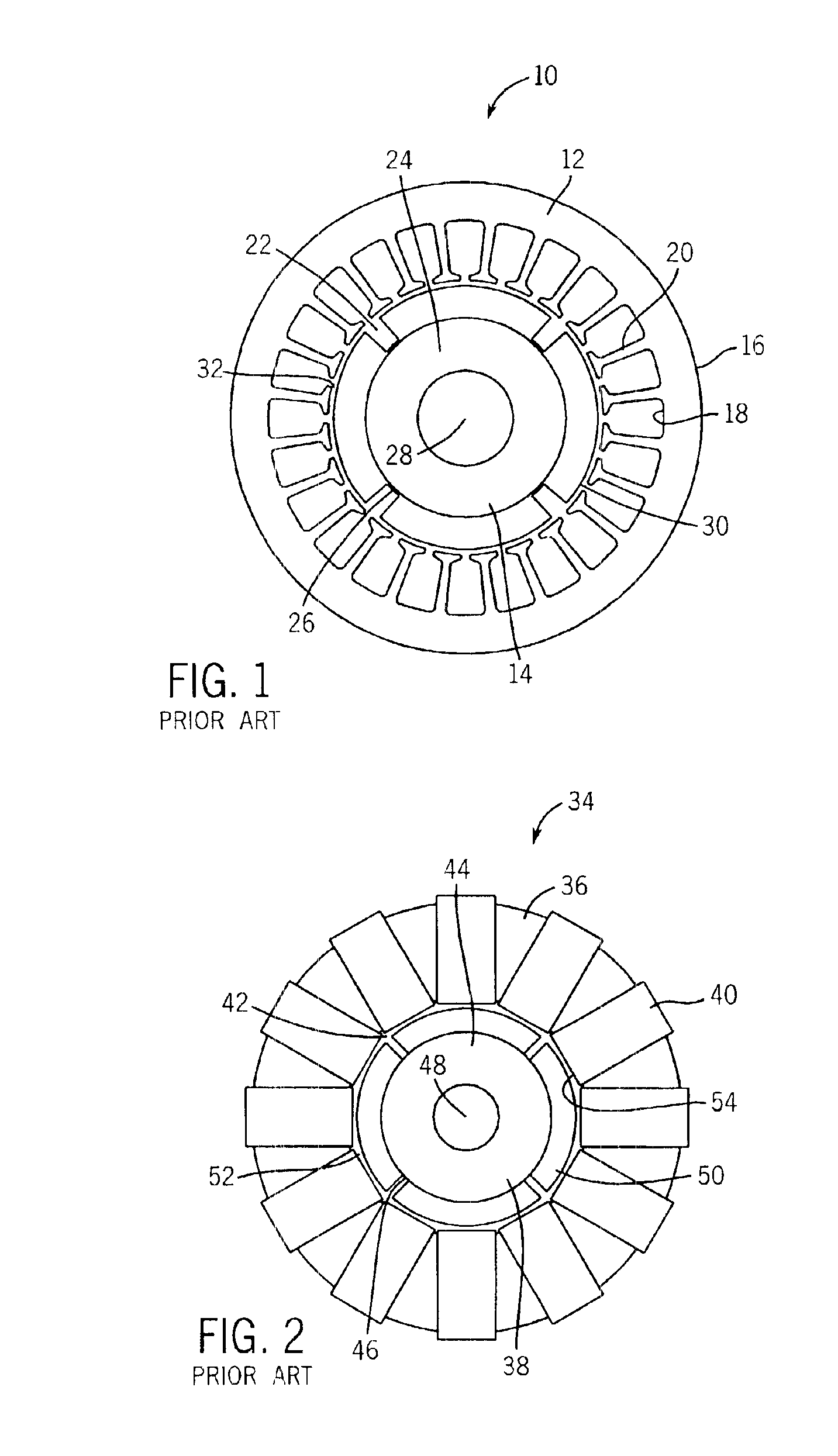

Multi-rotor synchronous machine permitting relative movement between rotors

InactiveUS6998757B2Improve reliabilityCompact structureMagnetic circuit rotating partsElectric motor startersRelative motionEngineering

A compact and reliable structure of a multi-rotor synchronous machine which may be employed as a generator / motor for automotive vehicles is provided. The machine includes an outer rotor having permanent magnets, an inner rotor having permanent magnets disposed to be rotatable relative to the outer rotor, a stator core having armature coils interlinking with field magnetic fluxes produced by the outer and inner rotors, and a rotor-to-rotor relative rotation controlling mechanism. A relative angle between the outer and inner rotors is controlled within a given angular range by controlling the phase and quantity of current flowing through the armature coils to rotate the inner rotor relative to the outer rotor through the rotor-to-rotor relative rotation controlling mechanism, thereby changing the magnetic fluxes interlinking with the armature coils as needed.

Owner:DENSO CORP

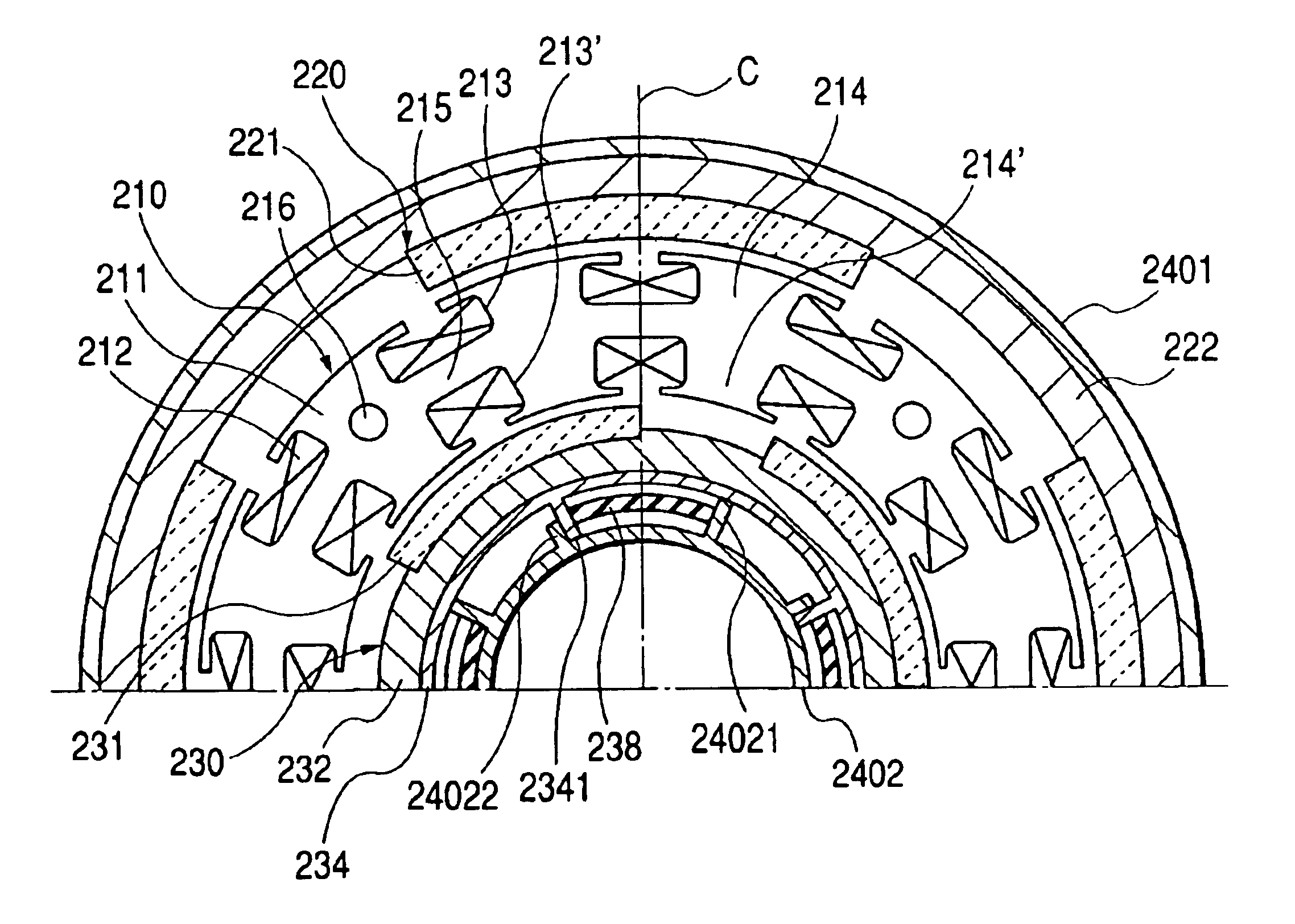

Dual-rotor, radial-flux, toroidally-wound, permanent-magnet machine

InactiveUS6924574B2Increased torque densityReduce the cost of the whole machineSynchronous generatorsMagnetic circuit rotating partsSurface mountingElectric machine

The present invention provides a novel dual-rotor, radial-flux, toroidally-wound, permanent-magnet machine. The present invention improves electrical machine torque density and efficiency. At least one concentric surface-mounted permanent magnet dual-rotor is located inside and outside of a torus-shaped stator with back-to-back windings, respectively. The machine substantially improves machine efficiency by reducing the end windings and boosts the torque density by at least doubling the air gap and optimizing the machine aspect ratio.

Owner:WISCONSIN ALUMNI RES FOUND

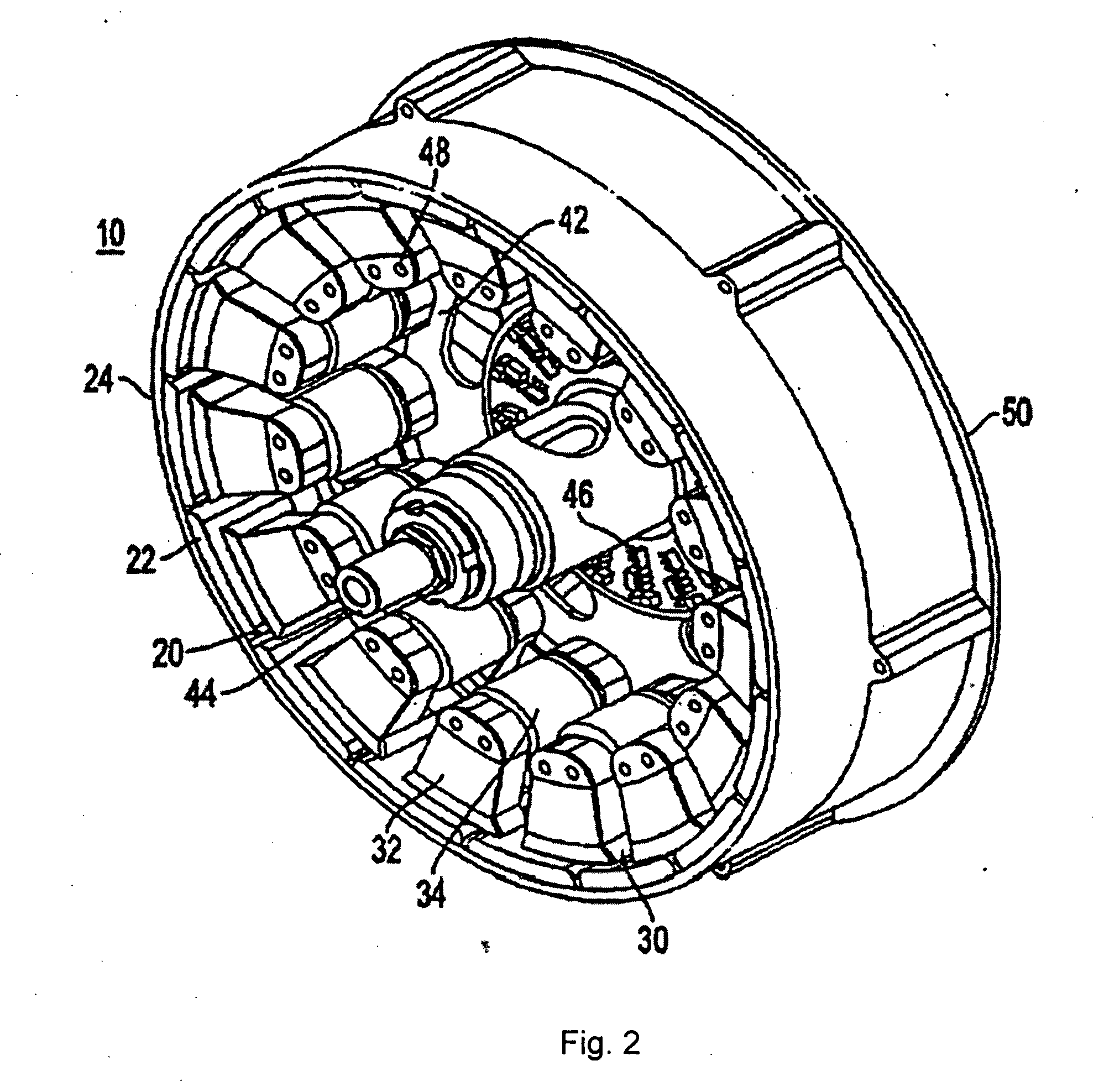

Rotary electric motor having both radial and axial air gap flux paths between stator and rotor segments

InactiveUS6891306B1Low flux lossEliminate the effects ofMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic polesElectrical polarity

In a rotary electric motor, a stator contains a plurality of separate electromagnet core segments disposed coaxially about an axis of rotation. The core segments are affixed, without ferromagnetic contact with each other, to a non-ferromagnetic support structure. The rotor is configured in a U-shaped annular ring that at least partially surrounds the annular stator to define two parallel axial air gaps between the rotor and stator respectively on opposite axial sides of the stator and at least one radial air gap. Permanent magnets are distributed on each inner surface of the U-shaped rotor annular ring that faces an air gap. A winding is formed on a core portion that links axially aligned stator poles to produce, when energized, magnetic poles of opposite polarity at the pole faces.

Owner:BLUWAV SYST LLC

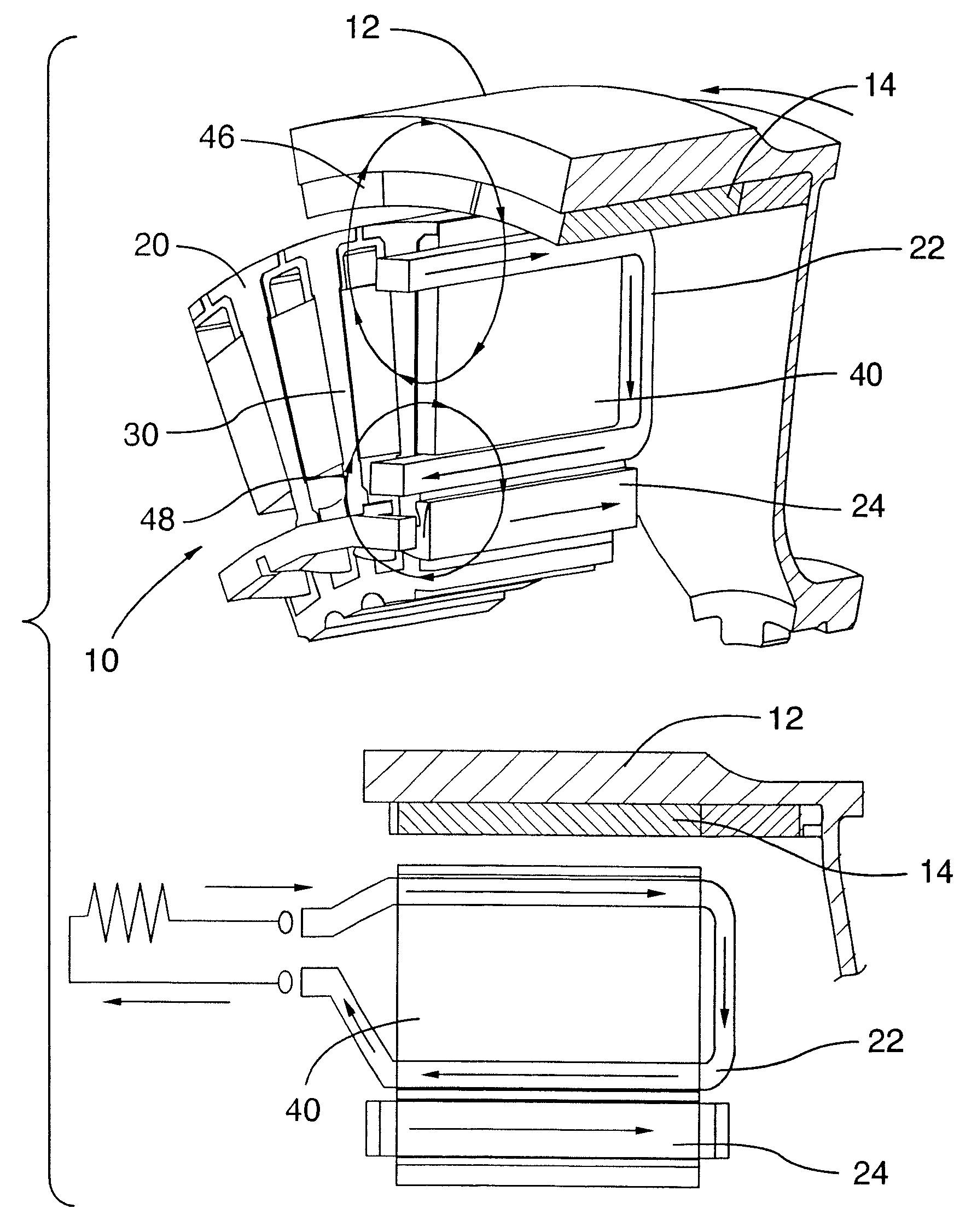

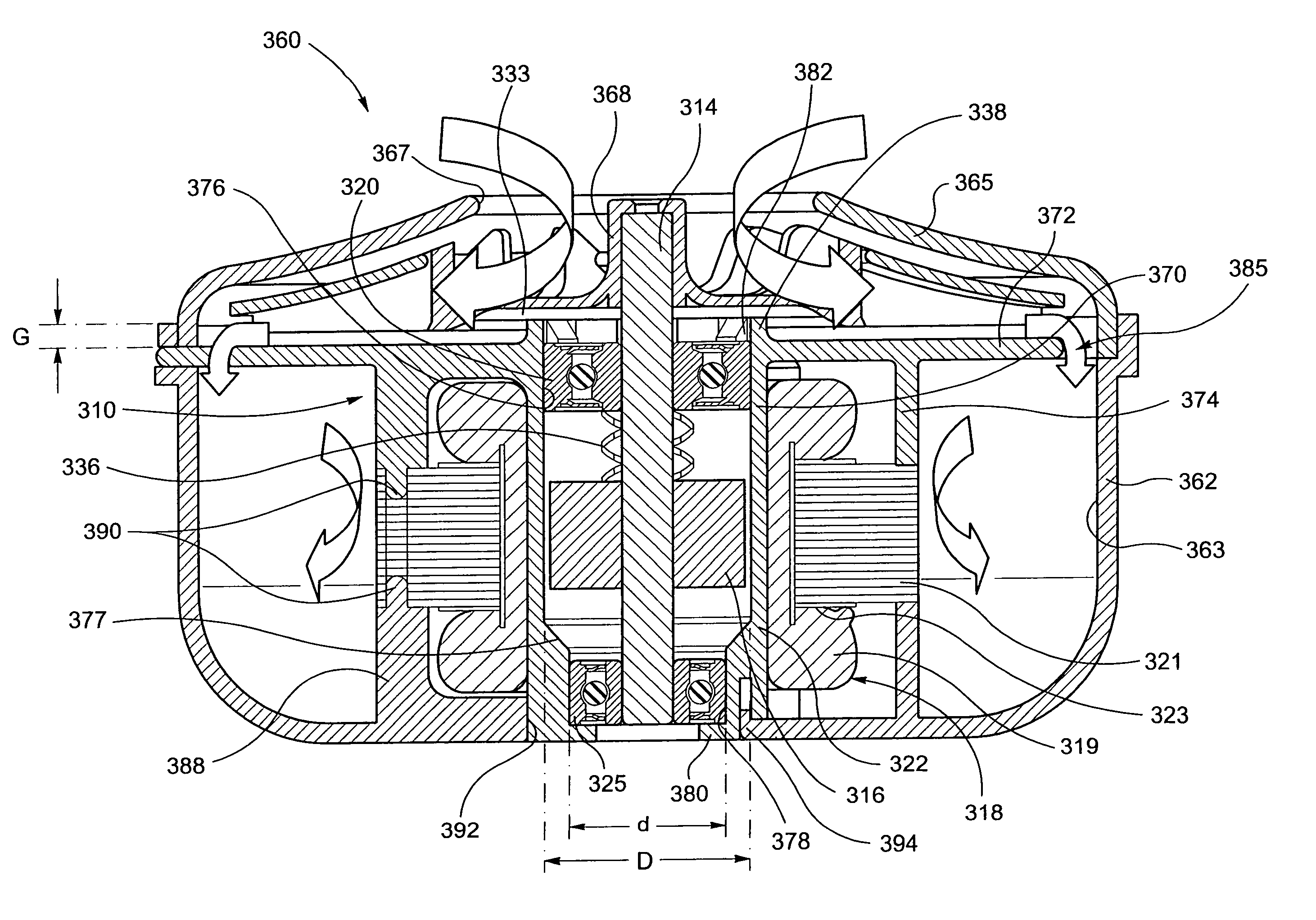

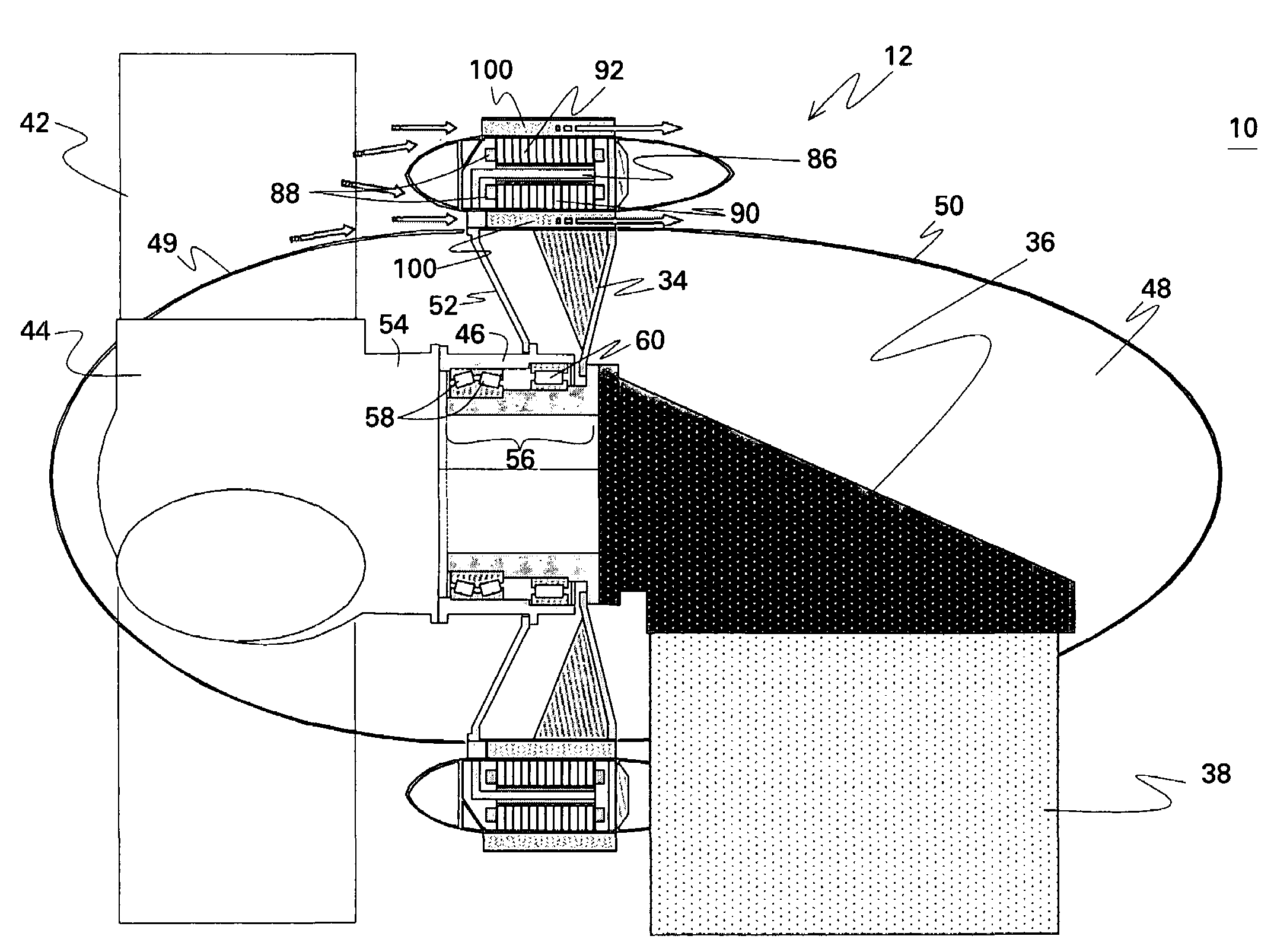

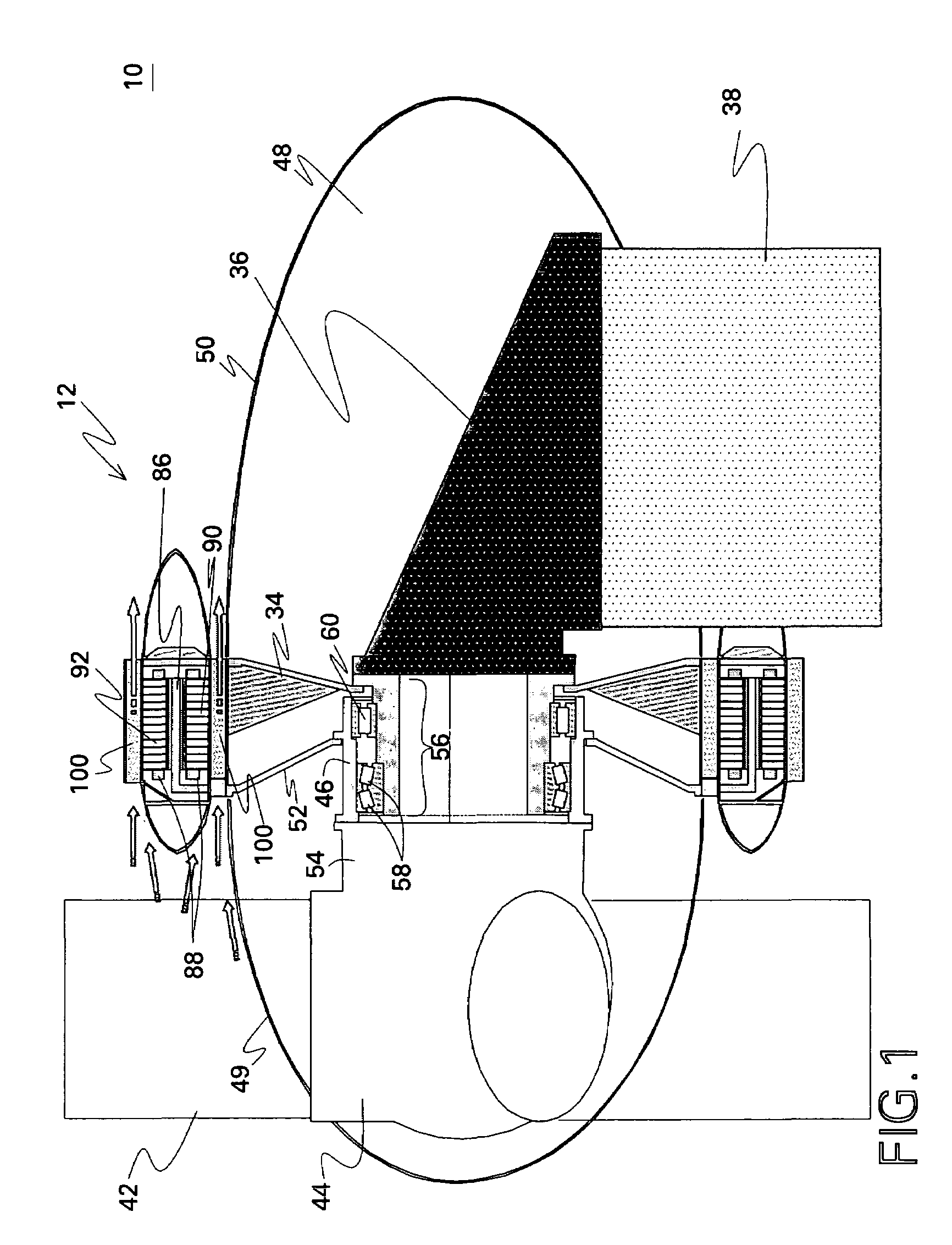

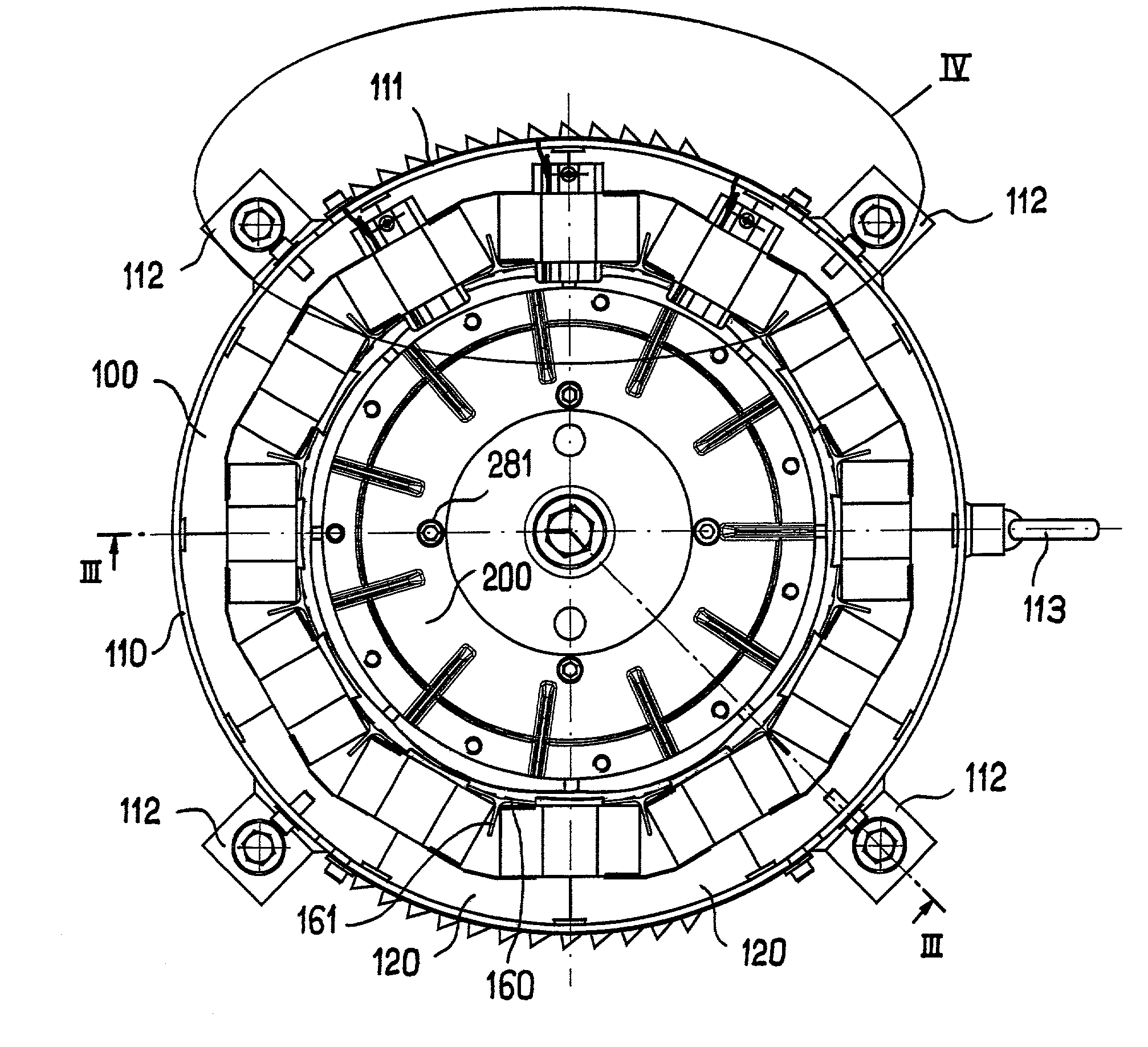

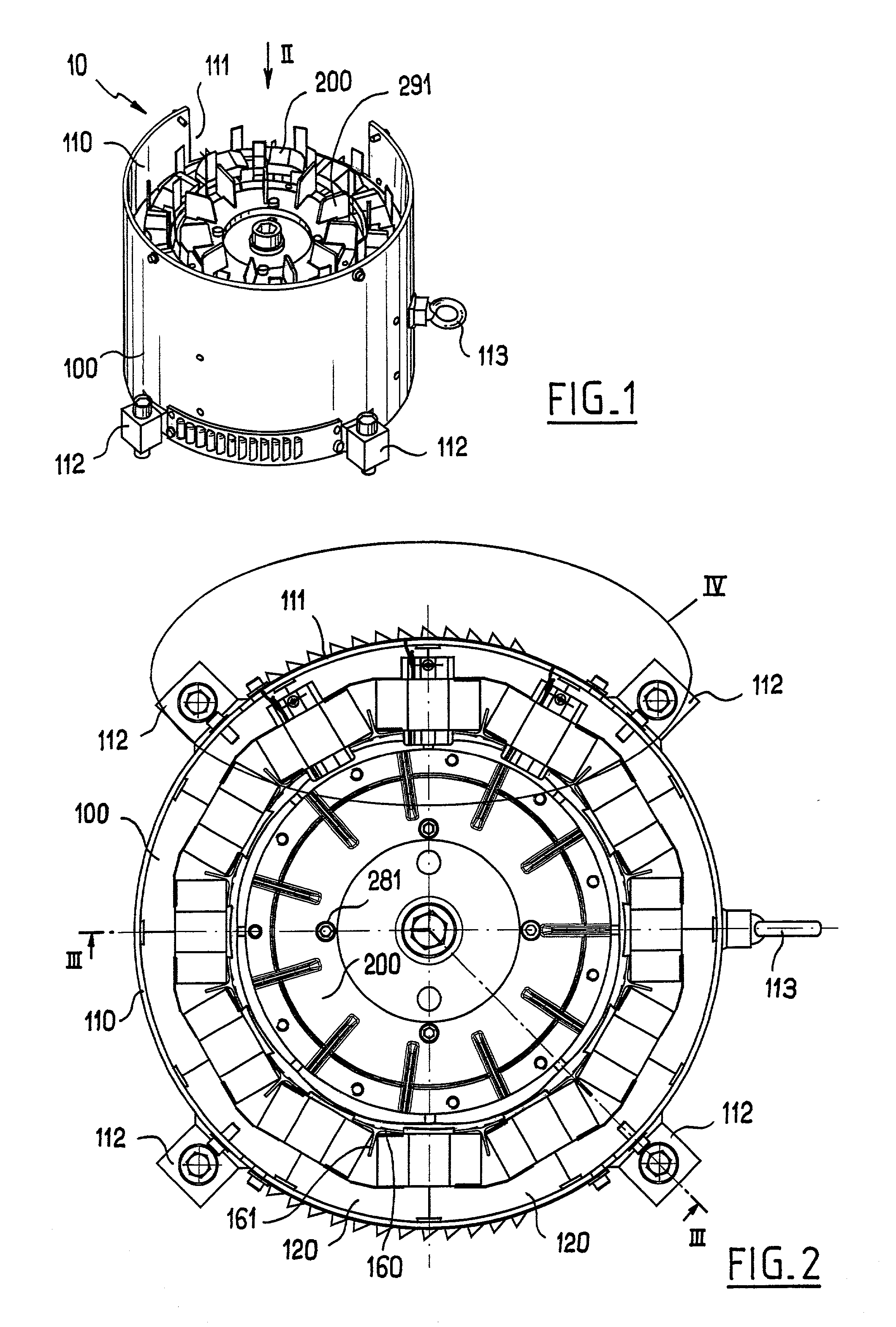

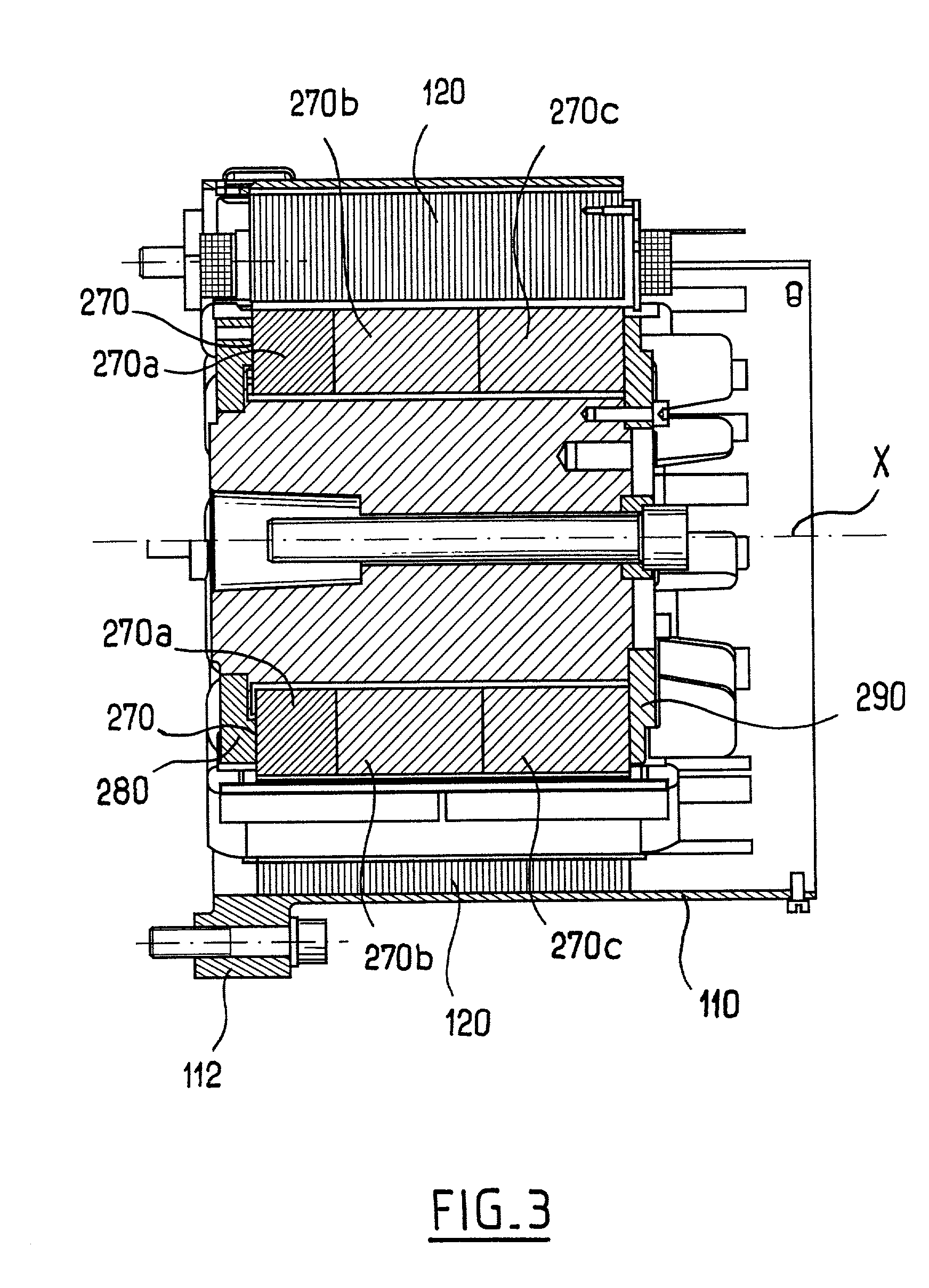

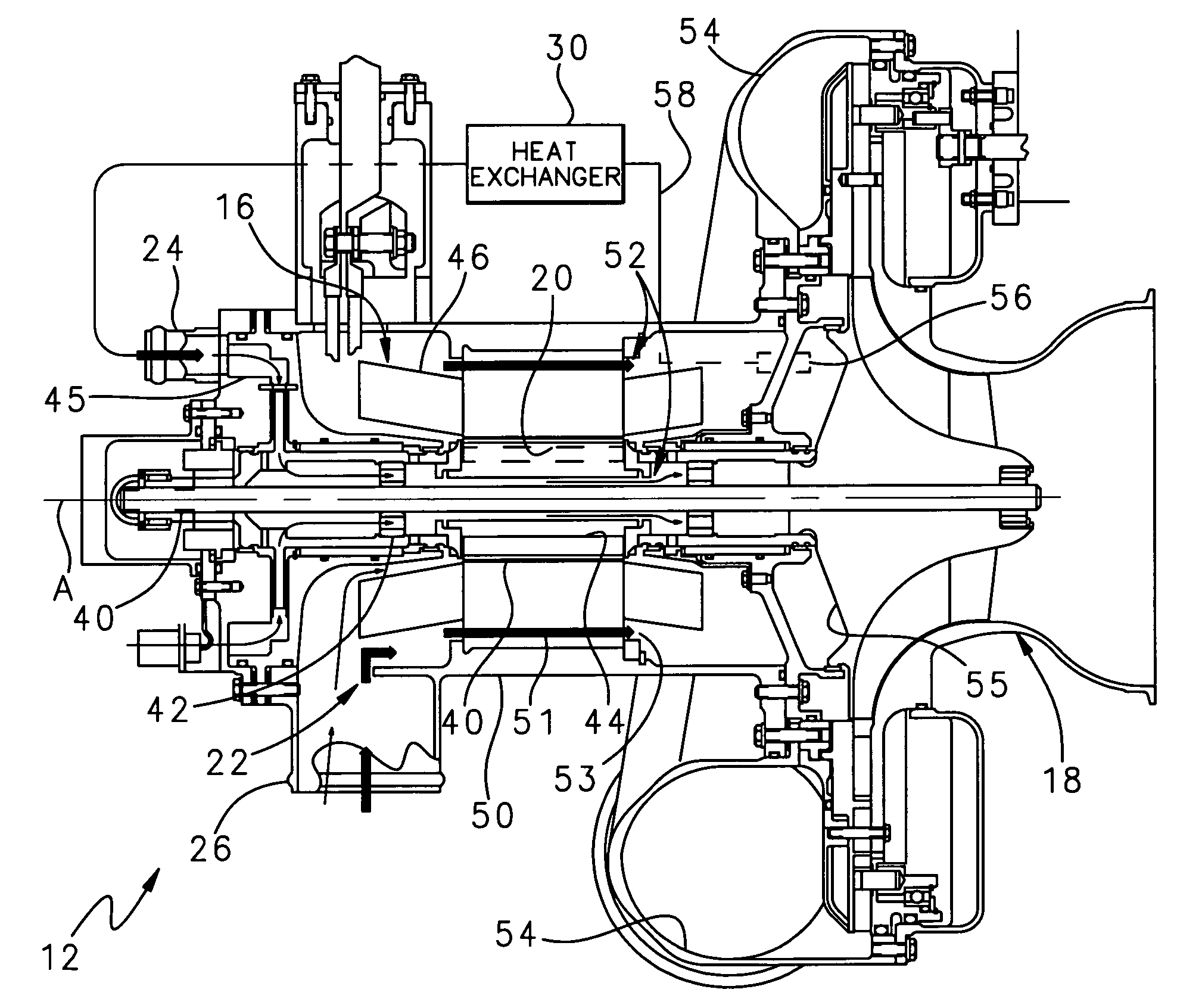

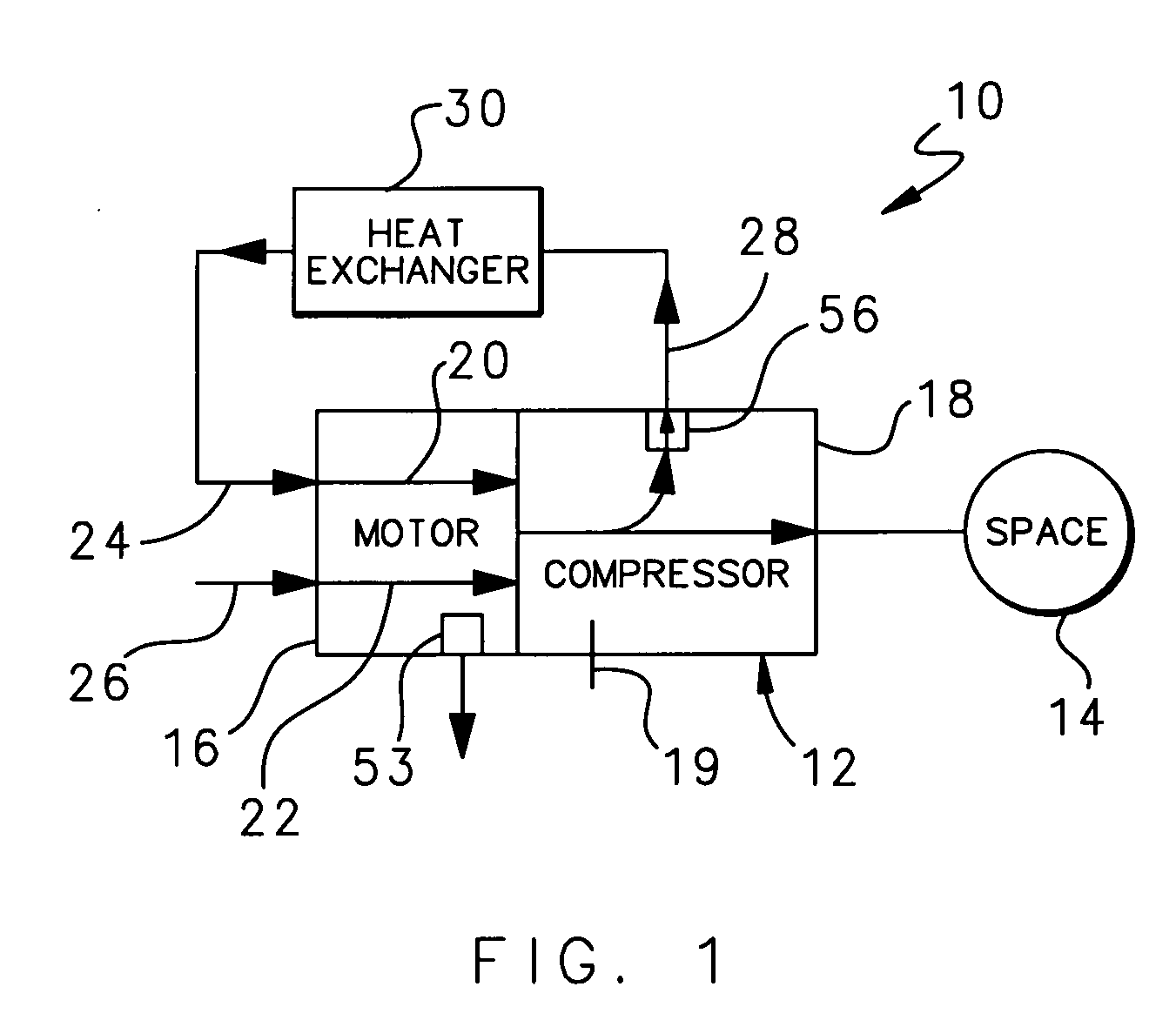

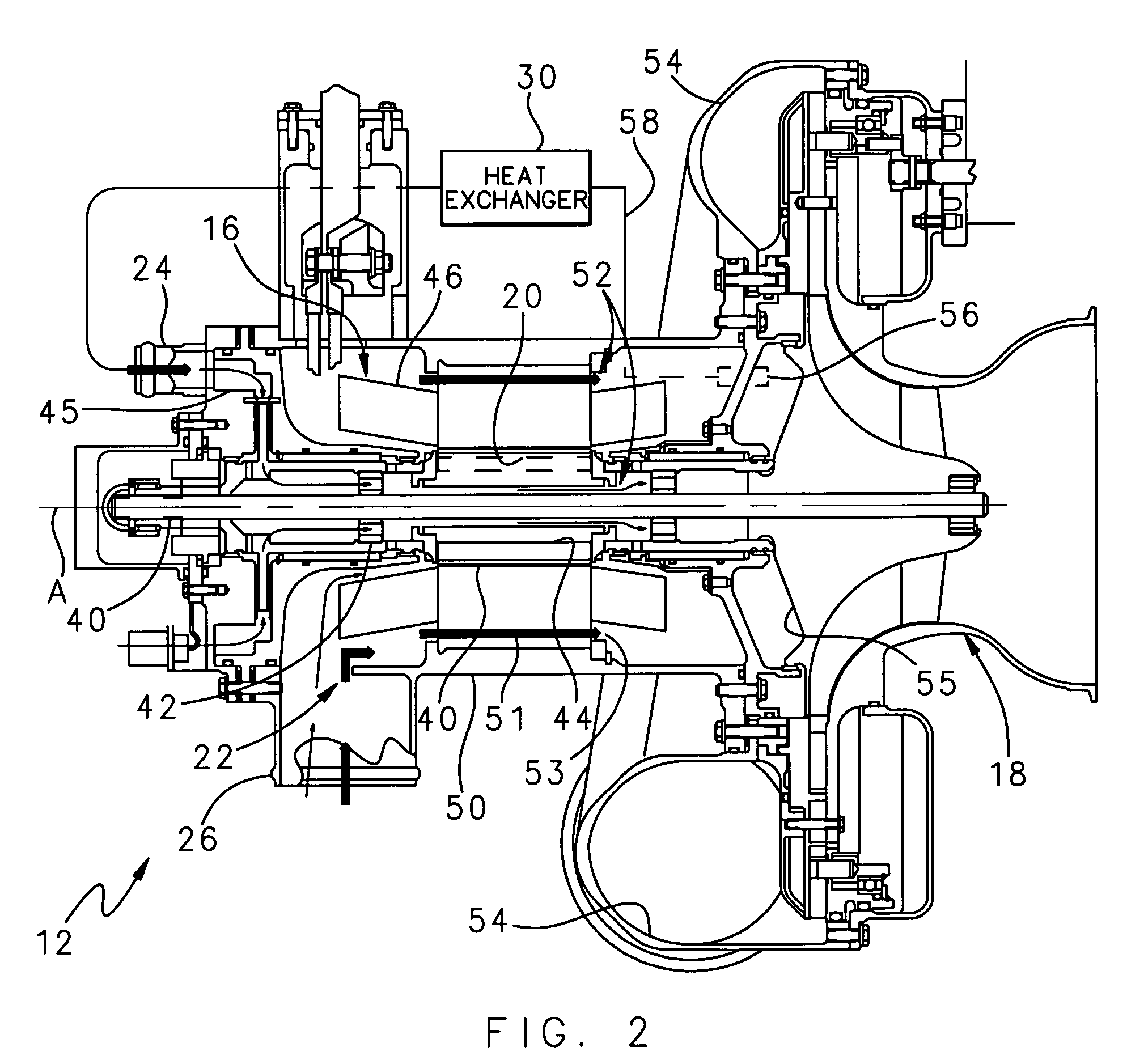

Internal thermal management for motor driven machinery

InactiveUS20070018516A1Efficient thermal managementMagnetic circuit rotating partsPump componentsRotational axisMotor drive

A motor driven assembly includes a motor having a motor shaft mounted for rotation about a rotational axis and a rotor radially located about the shaft. The motor drives a compressor that receives air from the motor, compresses the air, and circulates the compressed air to a space. The motor includes a first cooling flow passage and a second cooling flow passage that each receive air to provide internal cooling of the motor. A portion of the air compressed in the compressor is diverted from the compressor to a heat exchanger. The heat exchanger cools the compressed air from before the air circulates into the first cooling flow passage to cool the motor. The second cooling flow passage receives air from the environment surrounding the motor driven assembly to further cool the motor.

Owner:HAMILTON SUNDSTRAND CORP

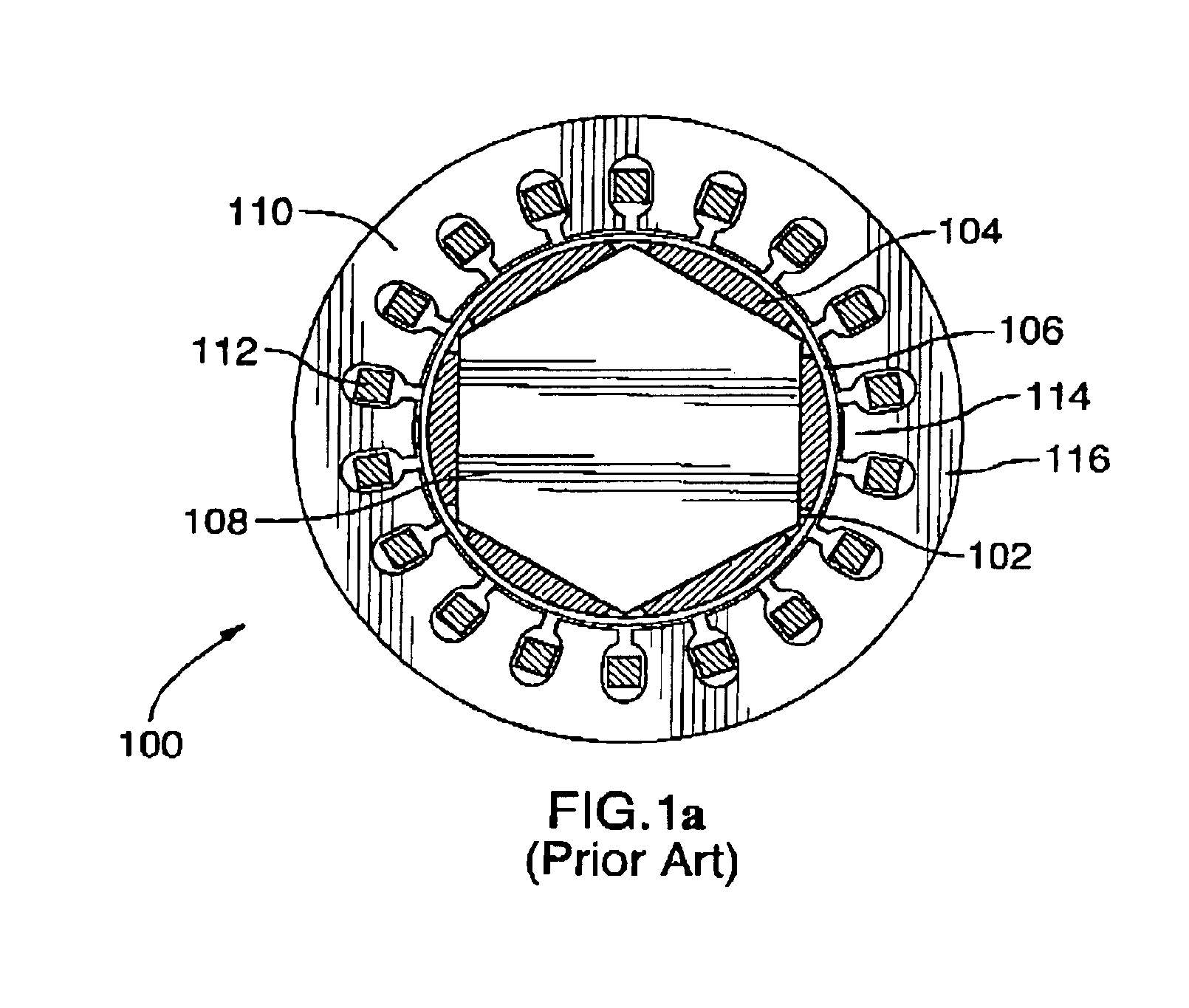

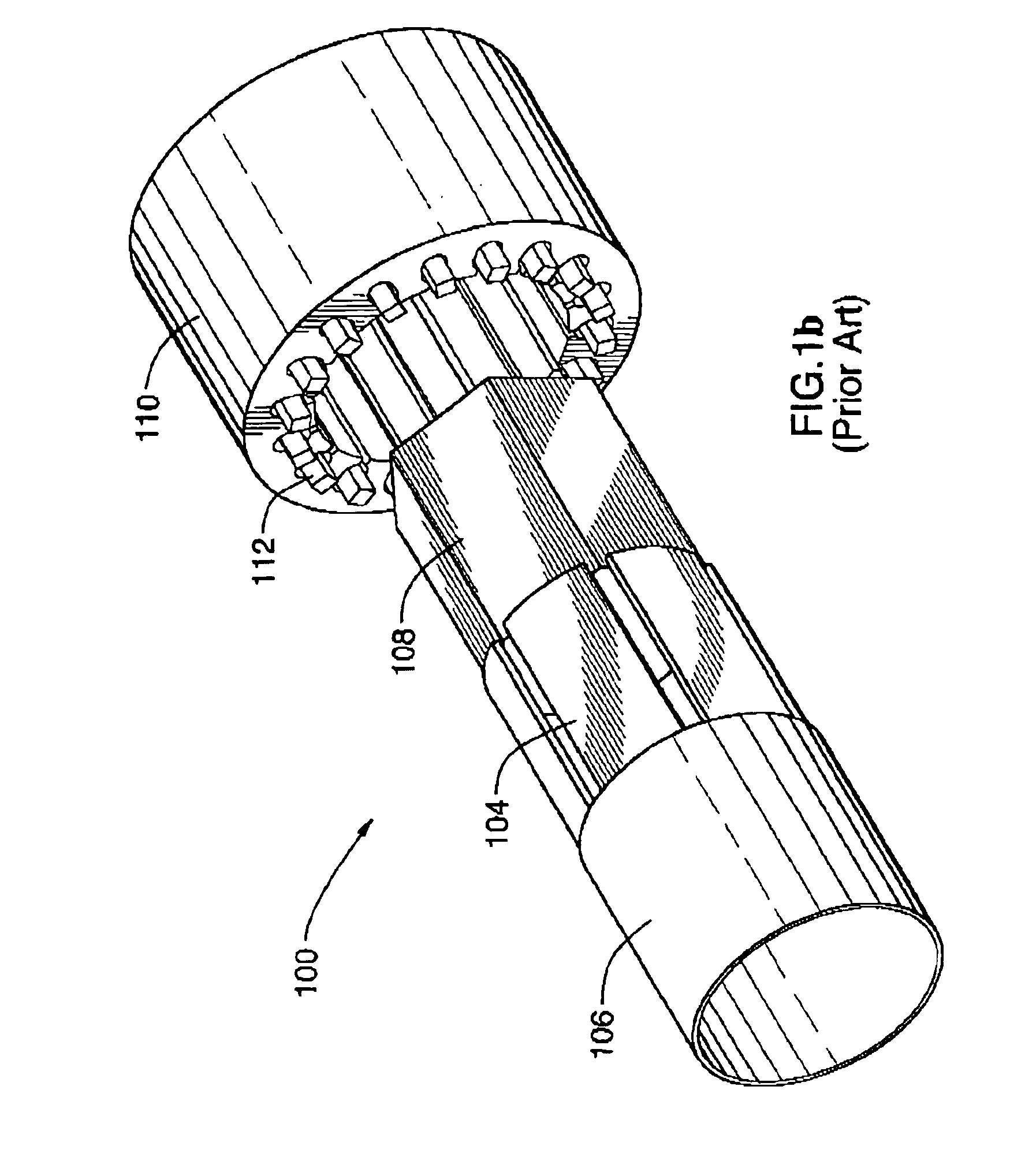

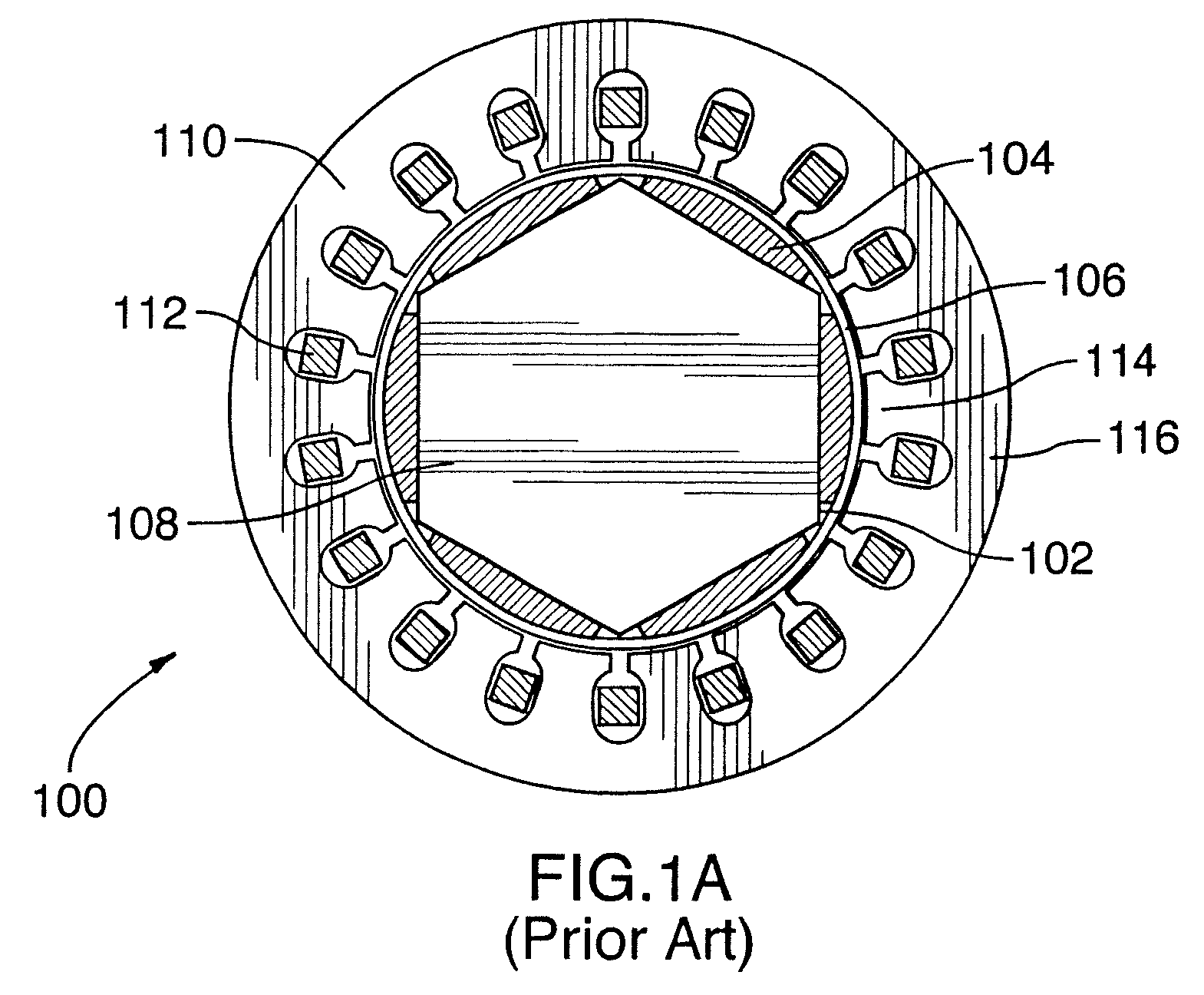

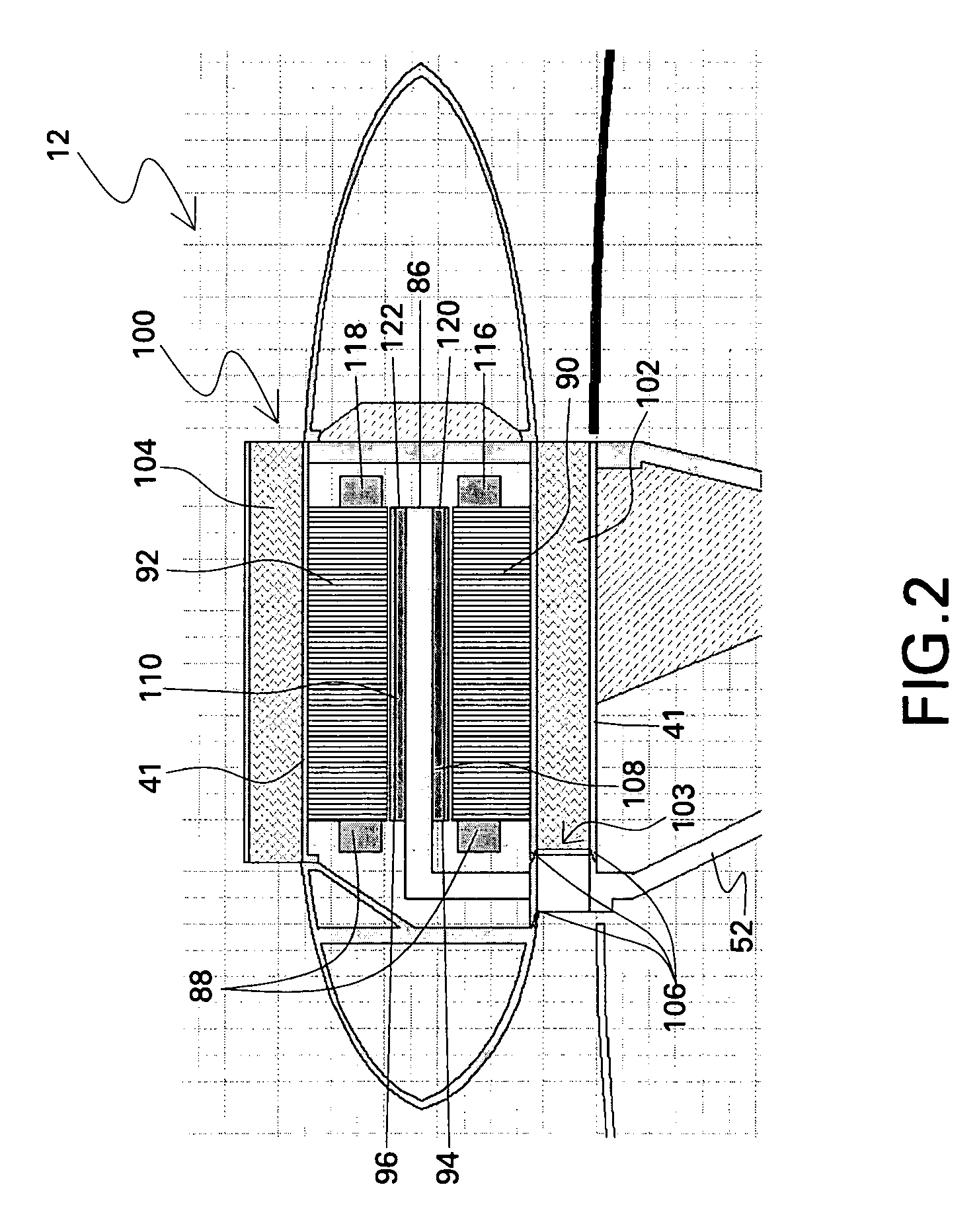

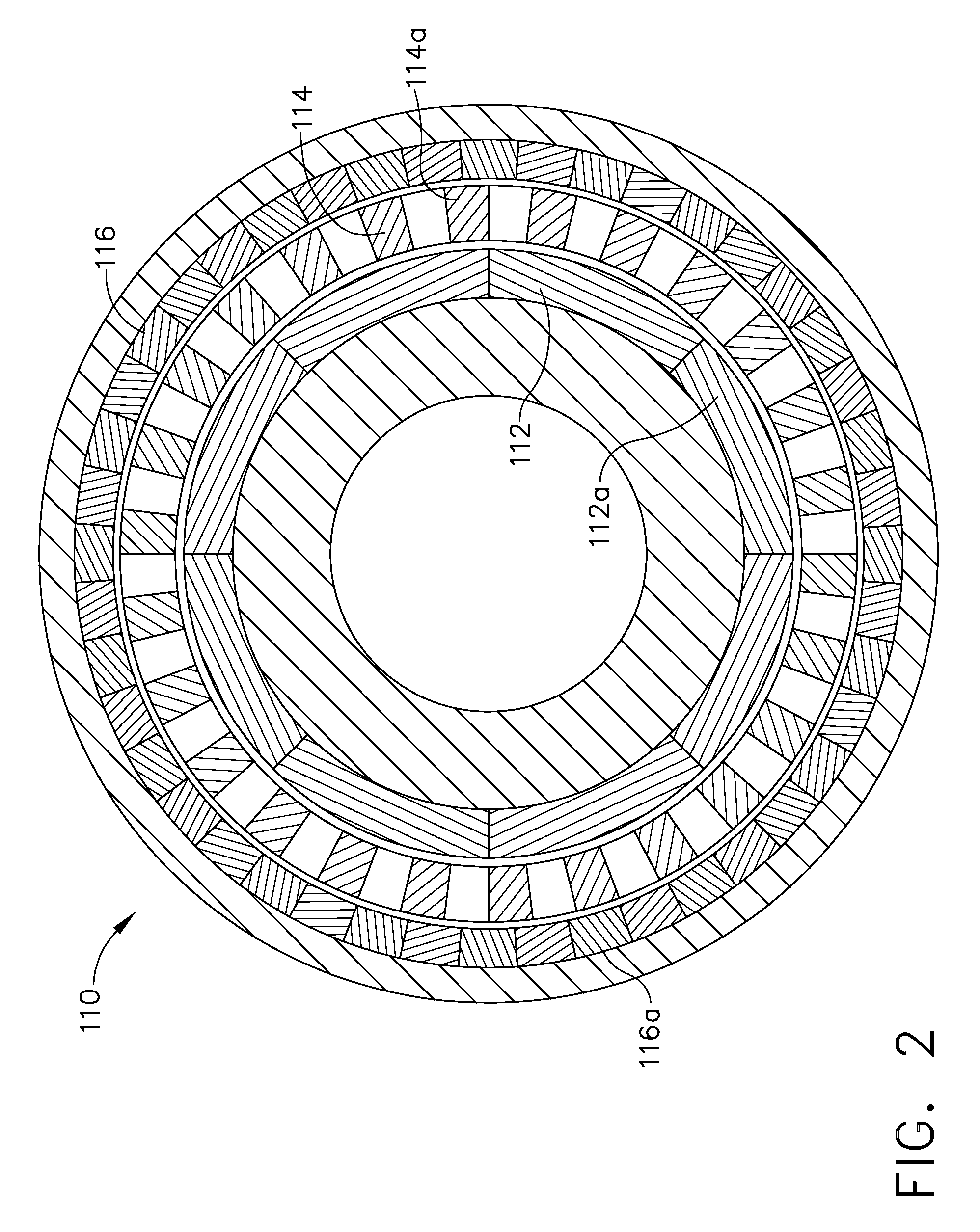

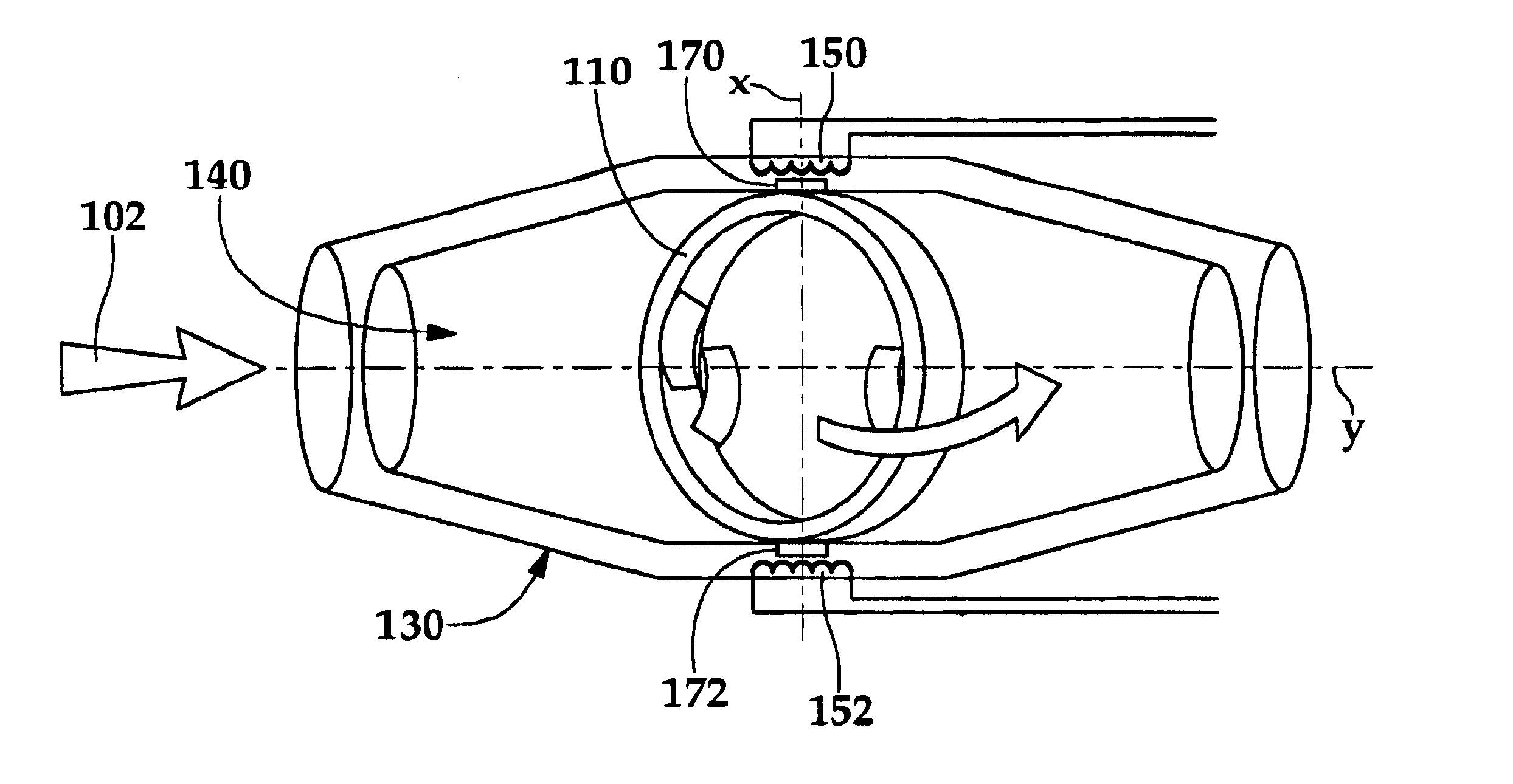

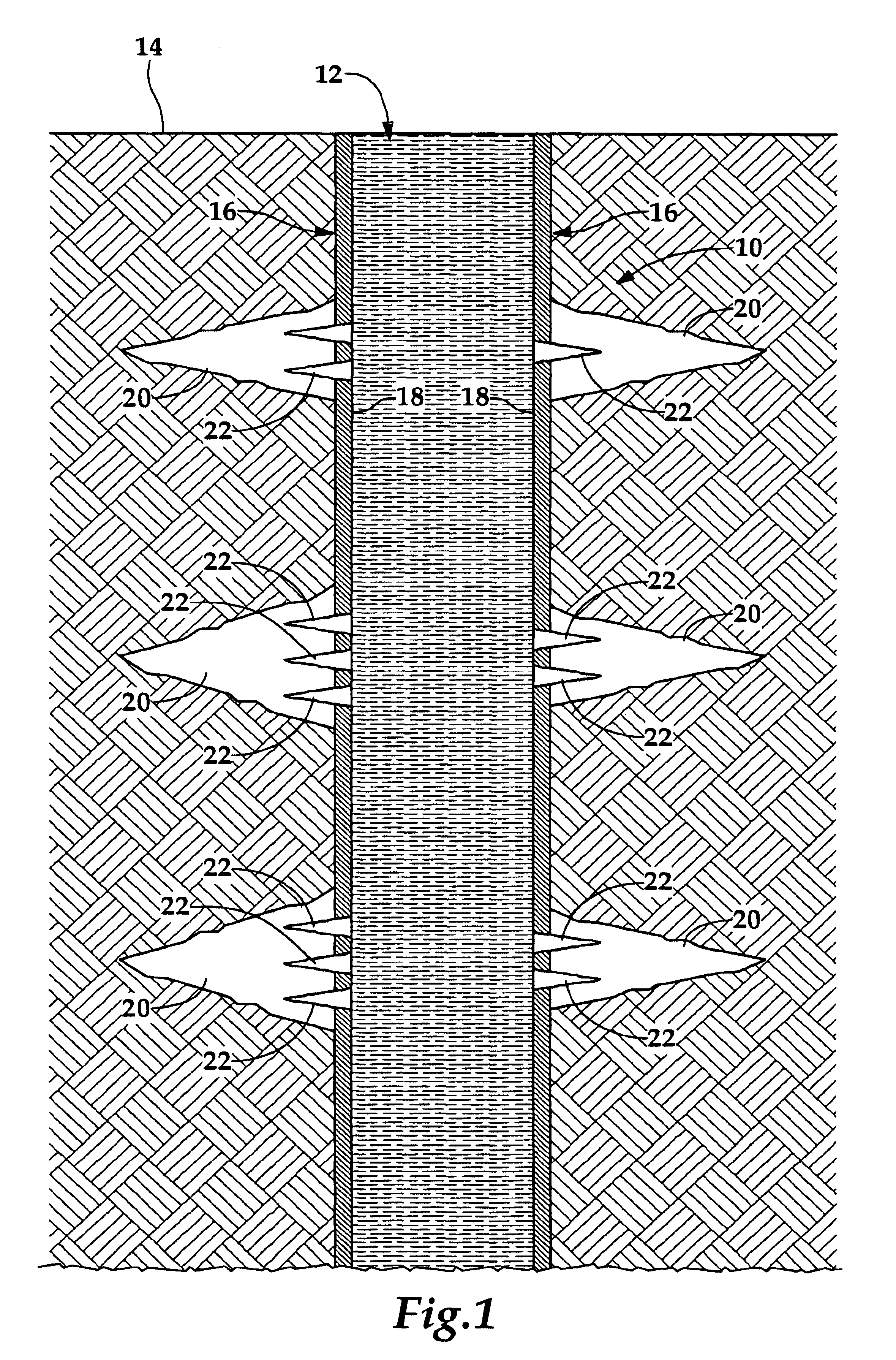

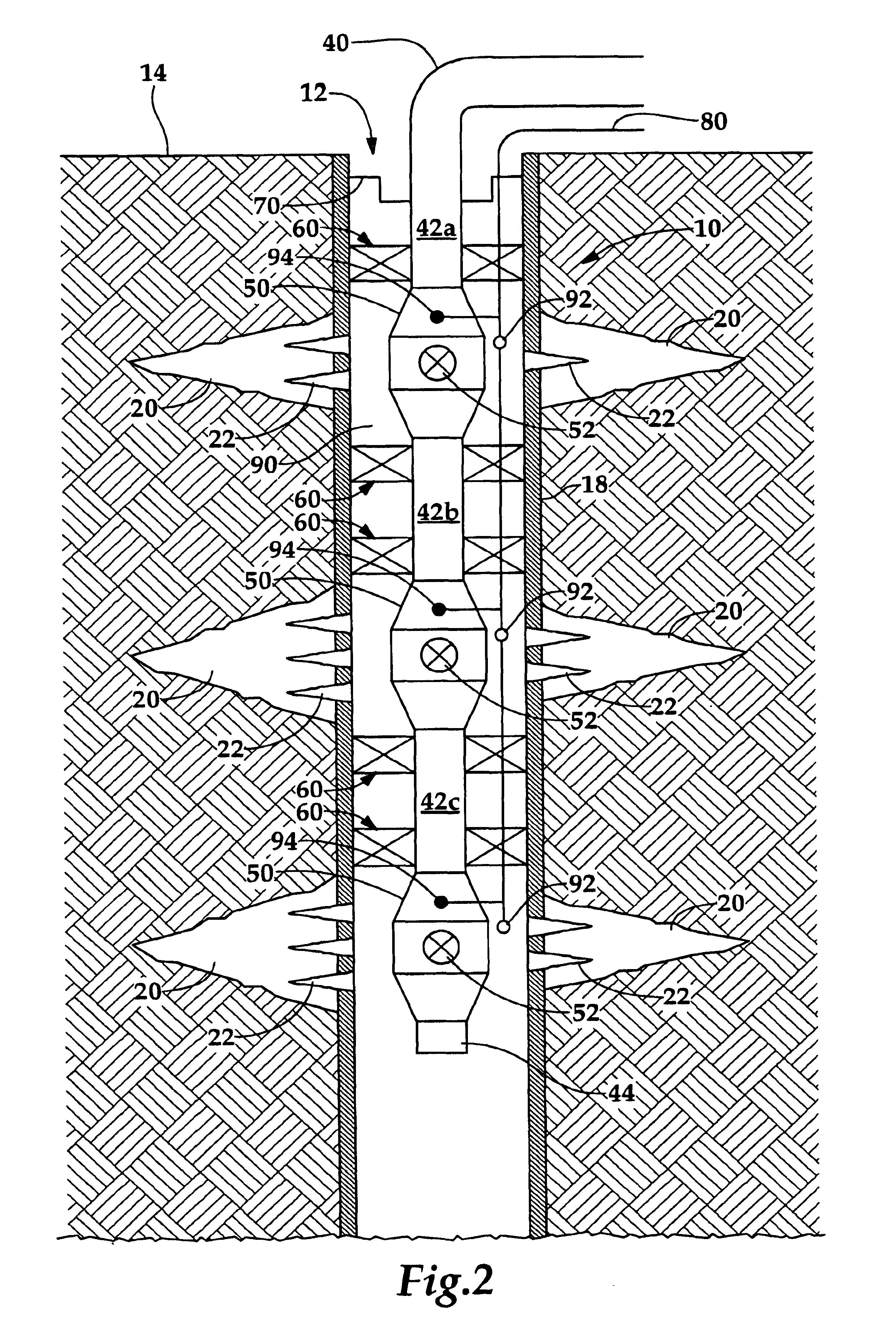

Wellbore power generating system for downhole operation

InactiveUS6848503B2Full accessSolution to short lifeMagnetic circuit rotating partsFluid removalElectricityPower conditioner

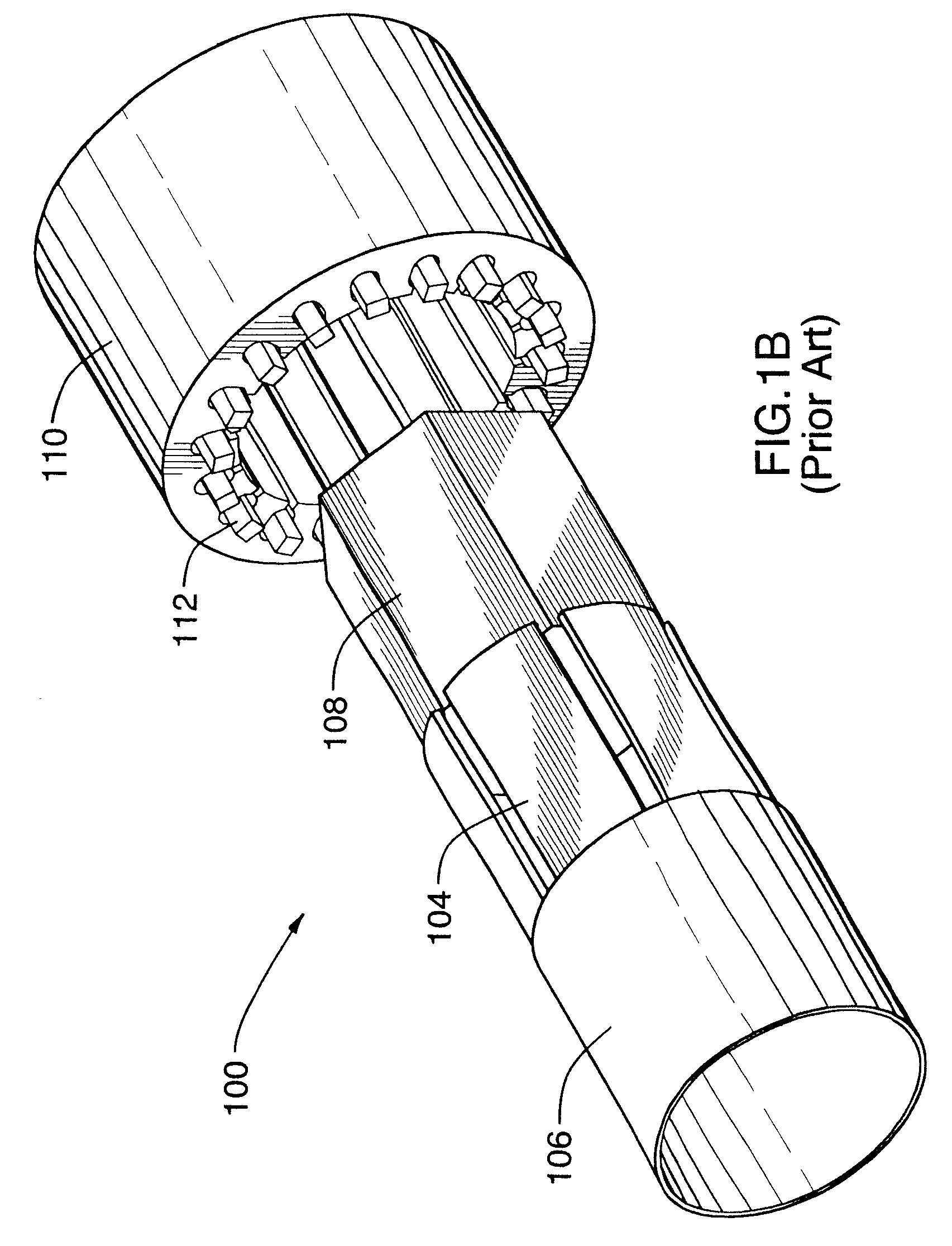

A power generating system (100) for a downhole operation (10) having production tubing (40) in a wellbore (12) includes a magnetized rotation member (110) coupled to the wellbore (12) within the production tubing (40), the rotation member (110) having a passageway (112) through which objects, such as tools, may be passed within the production tubing (40). Support braces (170, 172) couple the rotation member (110) to the production tubing (40) and allow the rotation member (110) to rotate within the production tubing (40). Magnetic pickups (150, 152) are predisposed about the rotation member (110) within the wellbore (12) and a power conditioner (200) is provided to receive currents from the magnetic pickups (150, 152) for storage and future use. The rotation member (110) rotates due to the flow of fluid, such as crude oil, through the production tubing (40) which causes the rotation member (110) to rotate and induce a magnetic field on the magnetic pickups (150, 152) such that electrical energy is transmitted to the power conditioner (200), the power conditioner able to store, rectify, and deliver power to any one of several electronic components within the wellbore (12).

Owner:HALLIBURTON ENERGY SERVICES INC

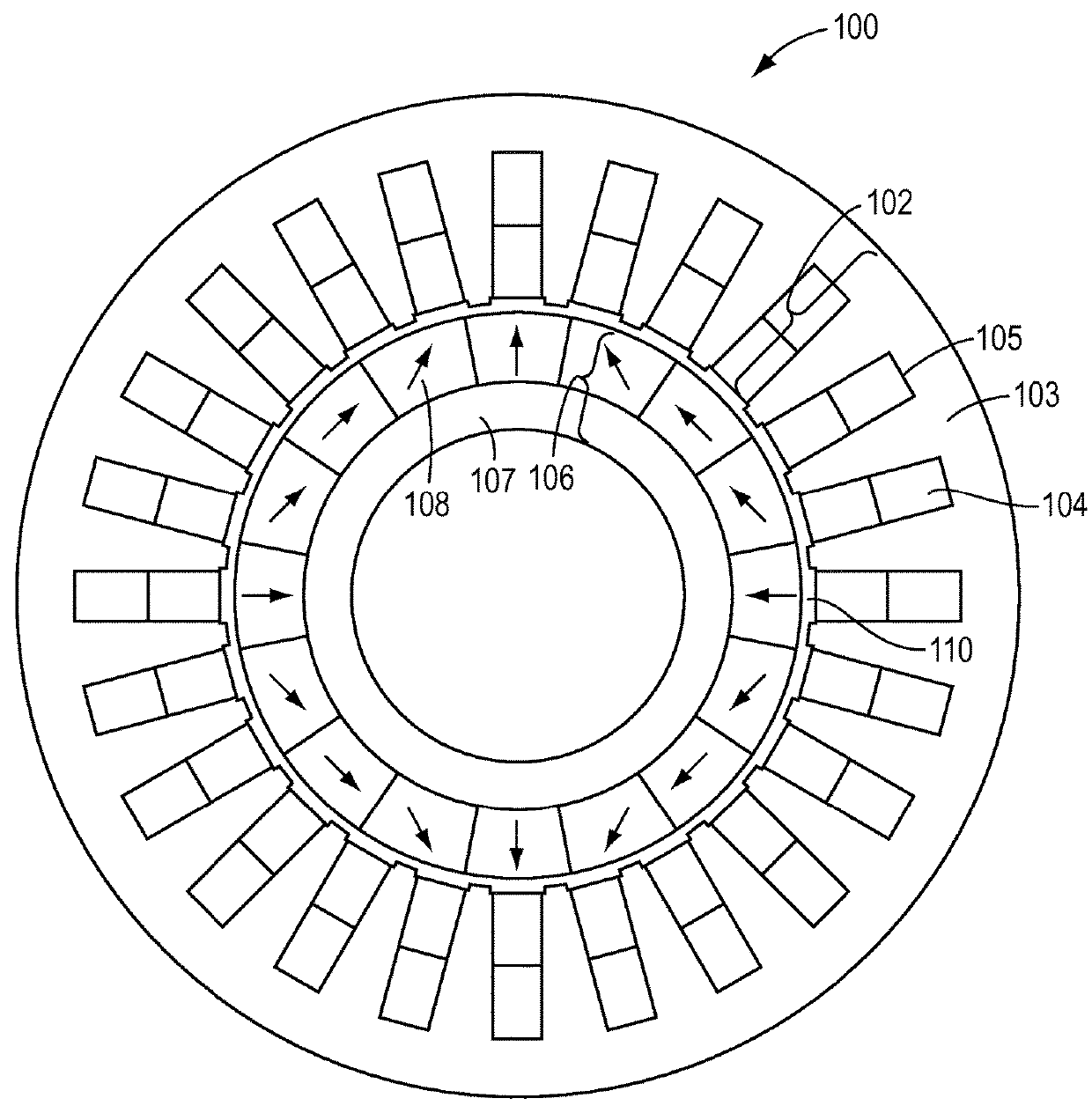

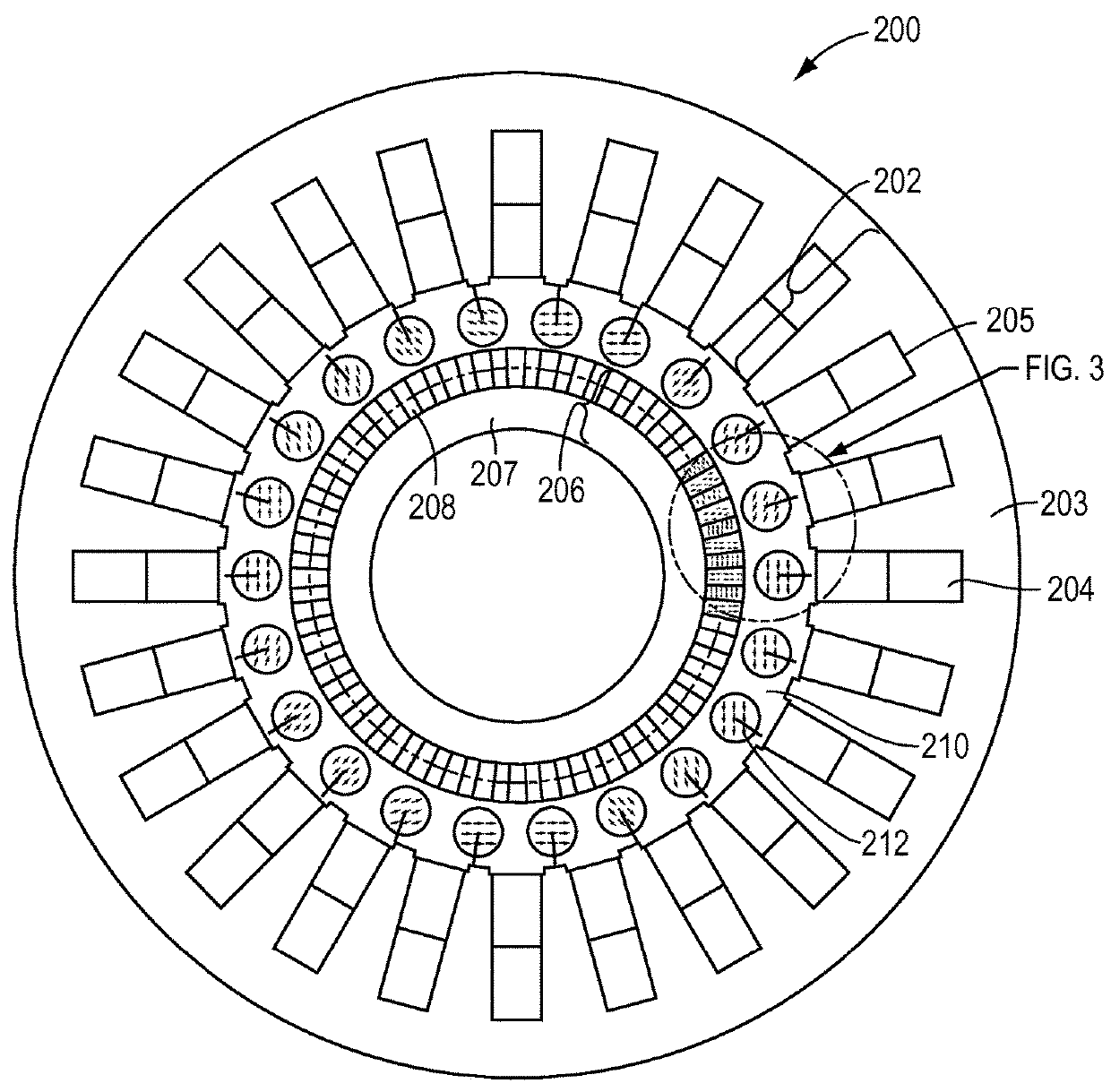

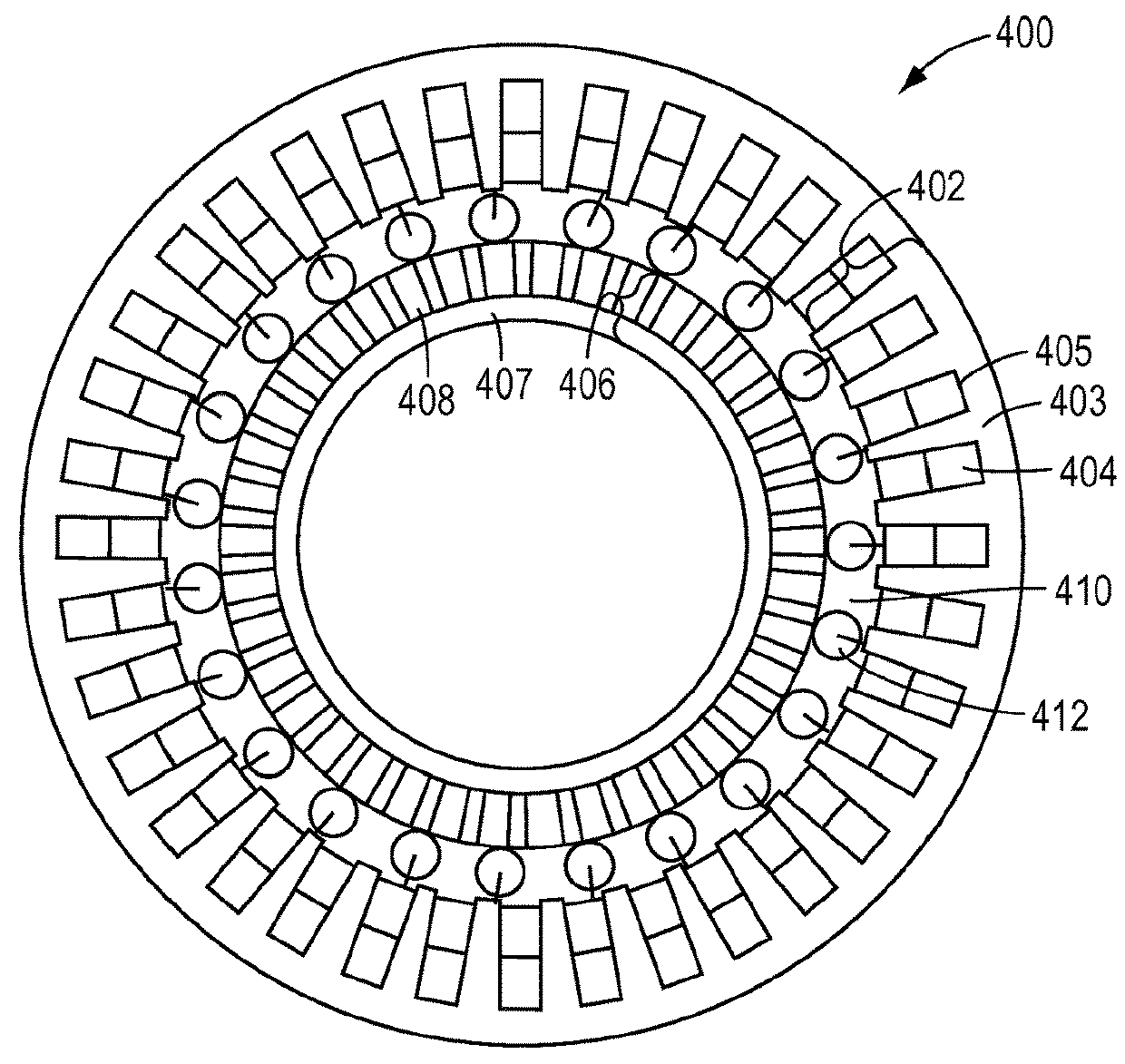

Magnetic drive devices, and related systems and methods

A magnetic drive device may comprise a stator comprising a plurality of windings for generating a first number of magnetic pole pairs and a rotor comprising a plurality of permanent magnets for generating a second number of magnetic pole pairs that differs from the first number of magnetic pole pairs. The magnetic drive device may further comprise a plurality of free-spinning interpole elements disposed within an air gap between the stator and the rotor. The interpole elements may produce a magnetomotive force and harmonically couple the magnetic pole pairs of the stator with the magnet pole pairs of the rotor.

Owner:NAT OILWELL VARCO LP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com