Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

862results about How to "Increased torque density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

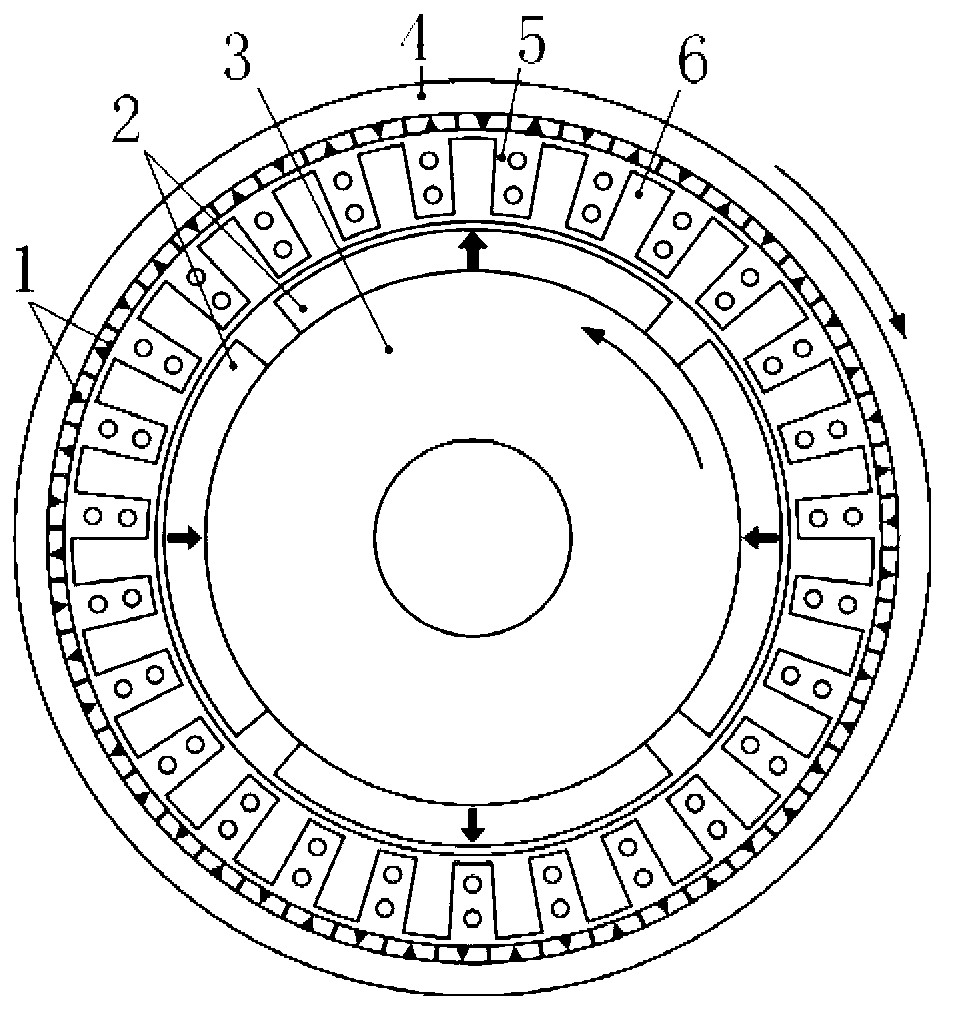

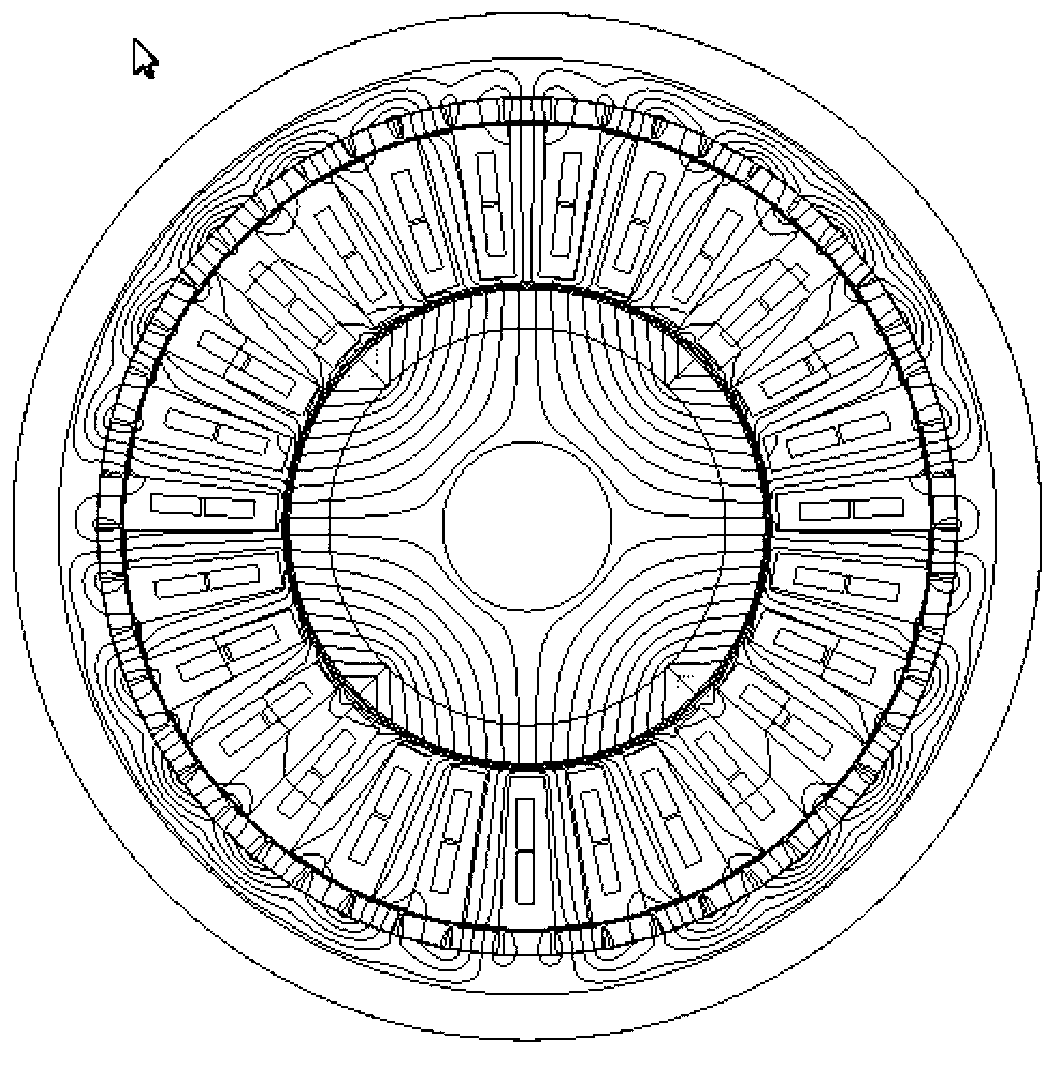

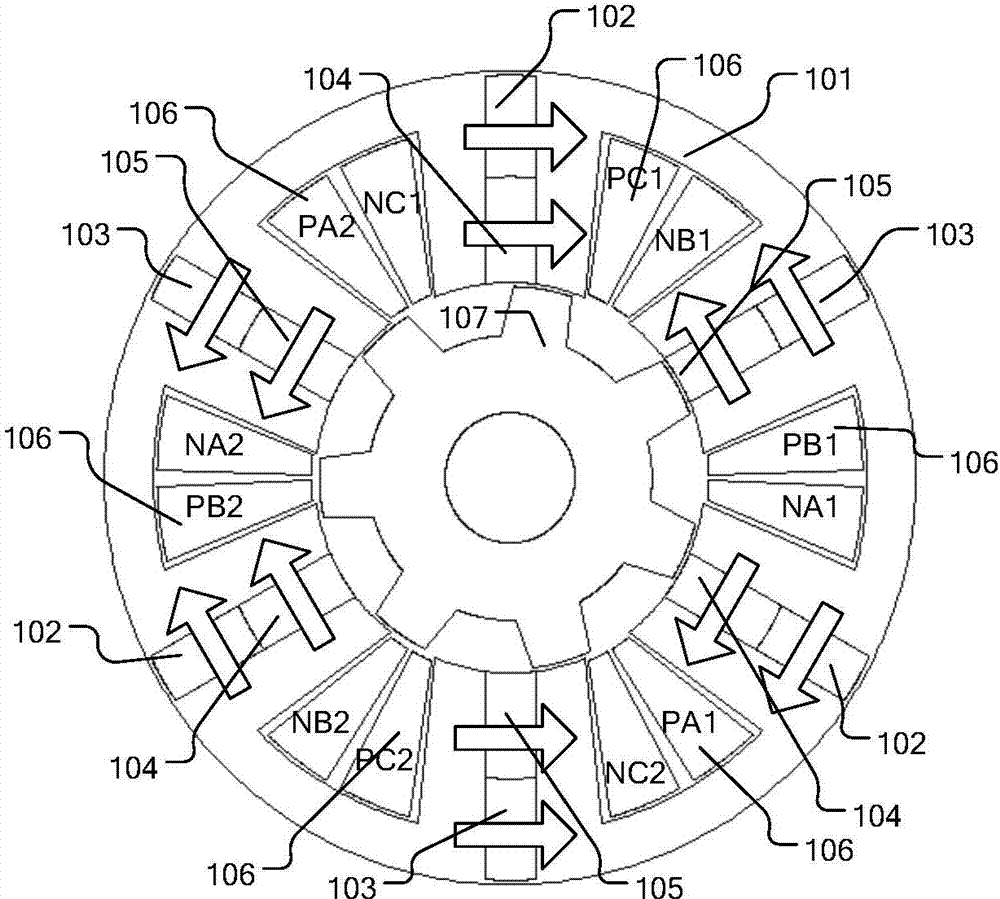

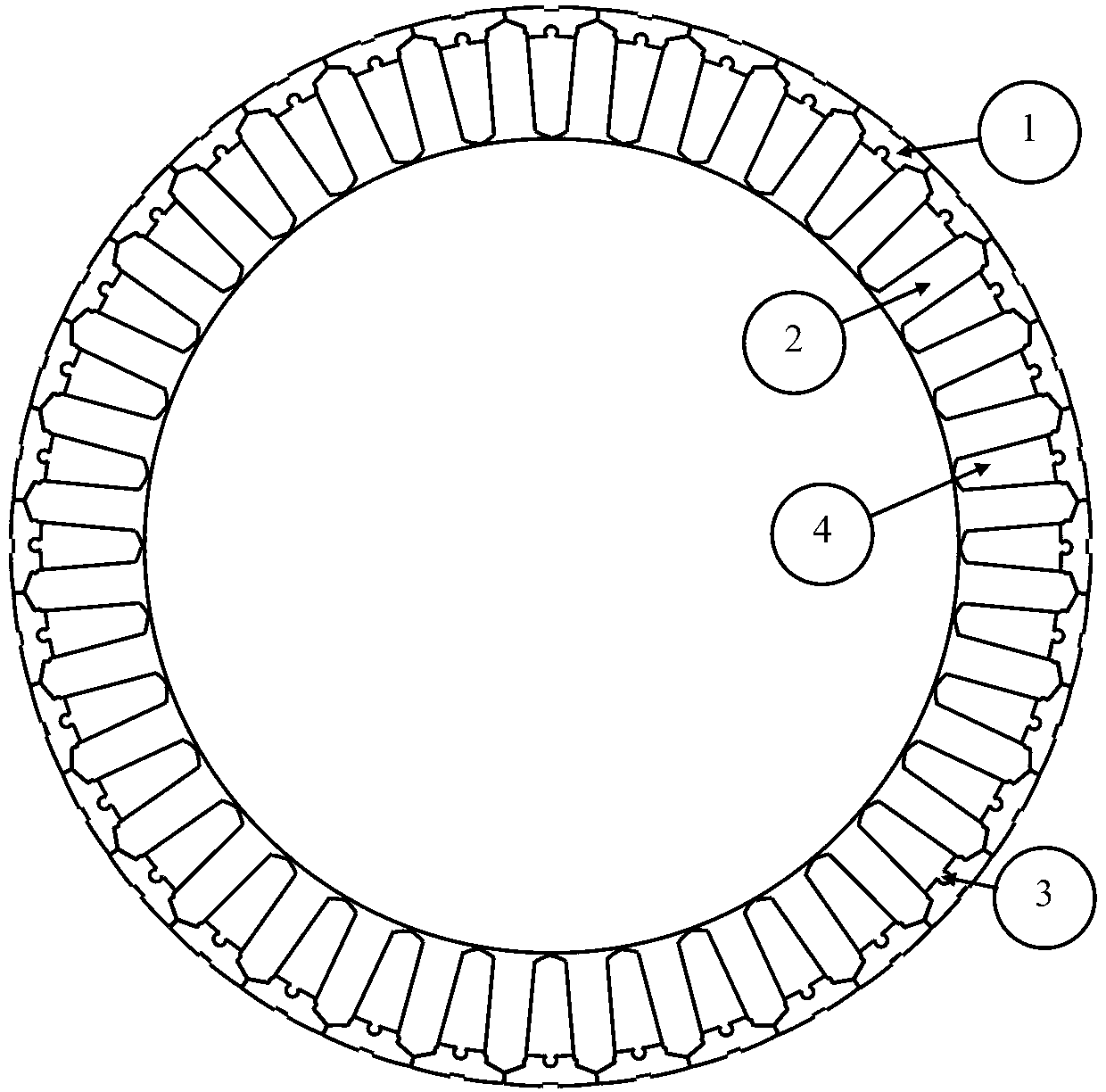

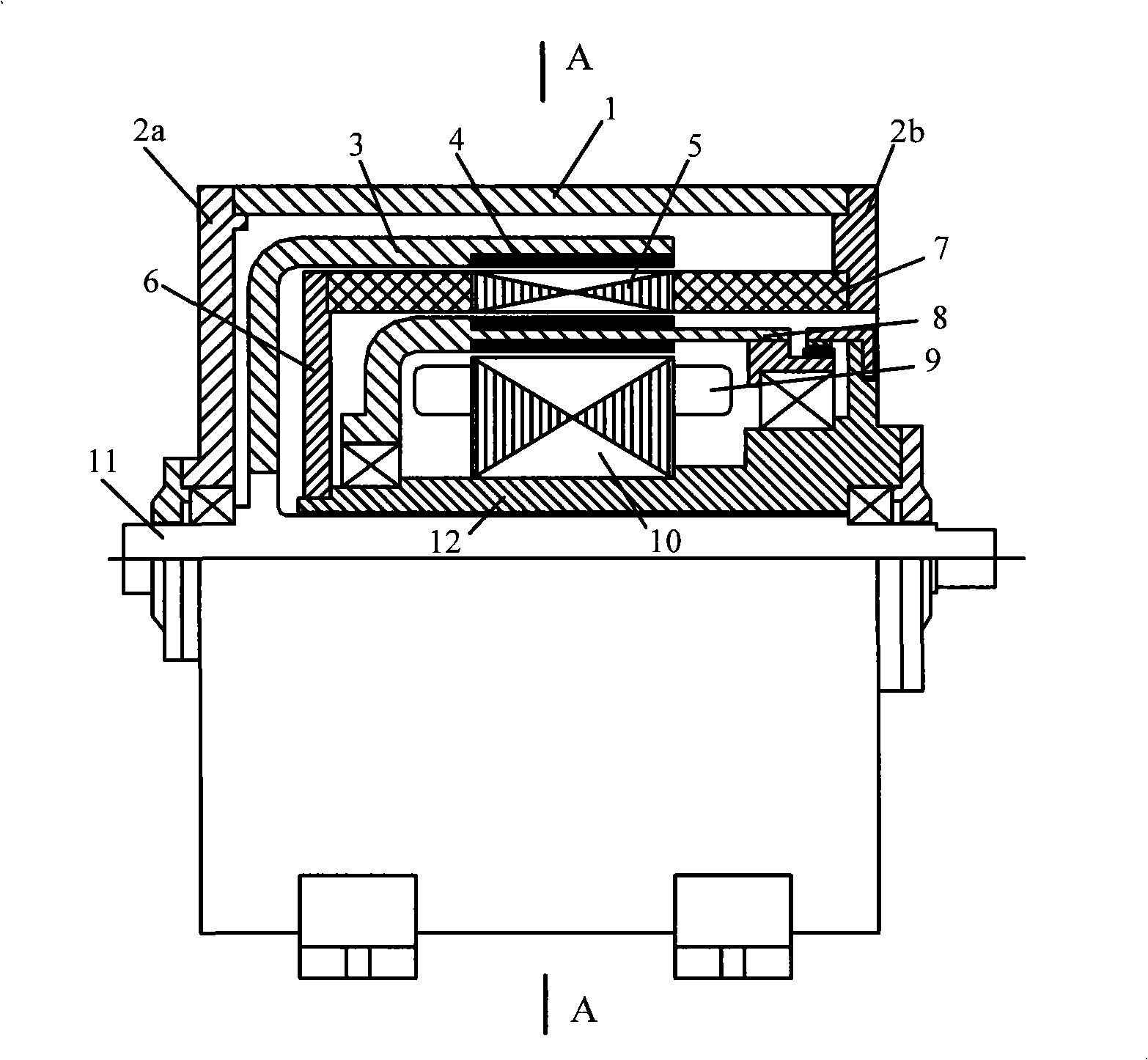

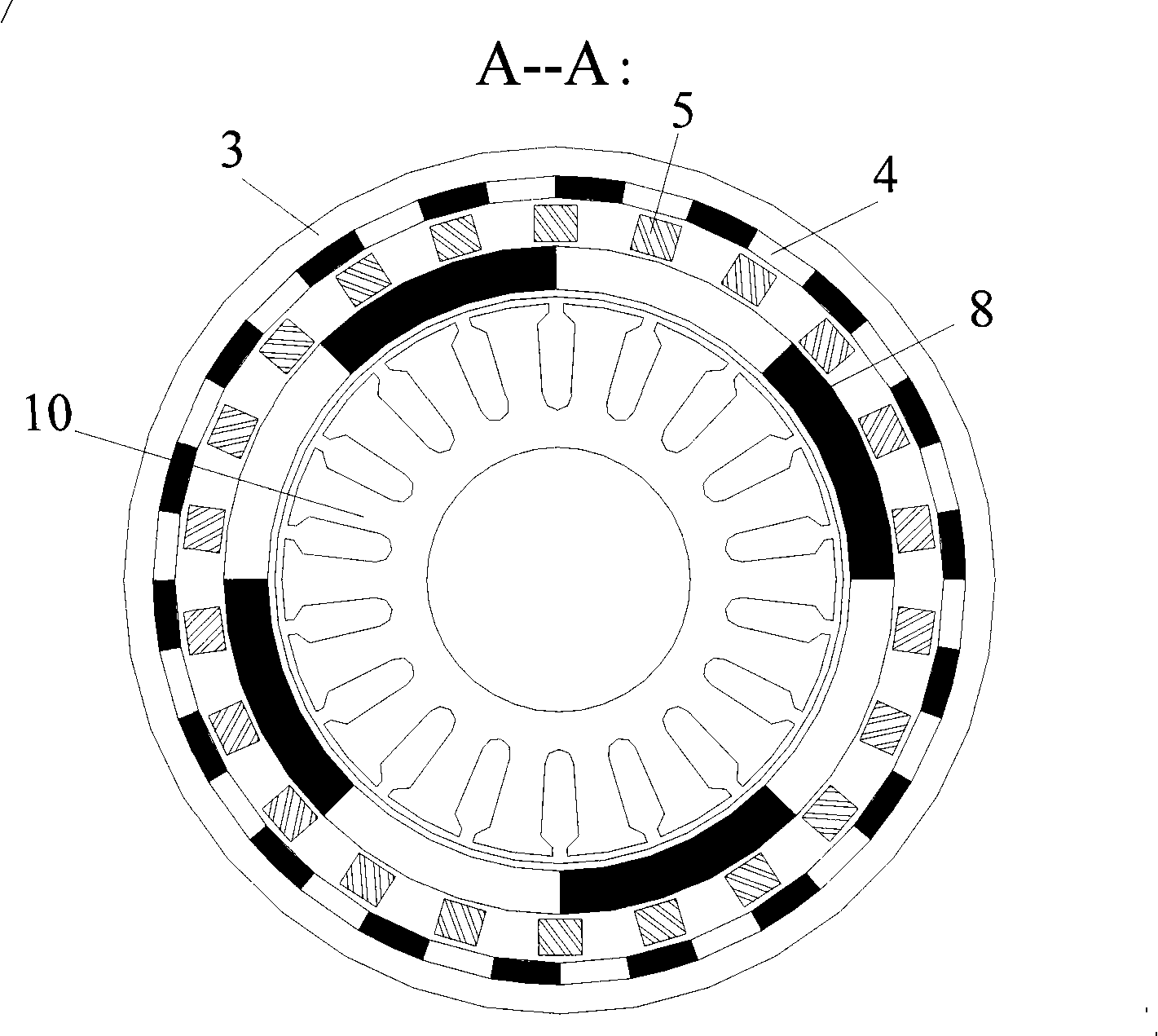

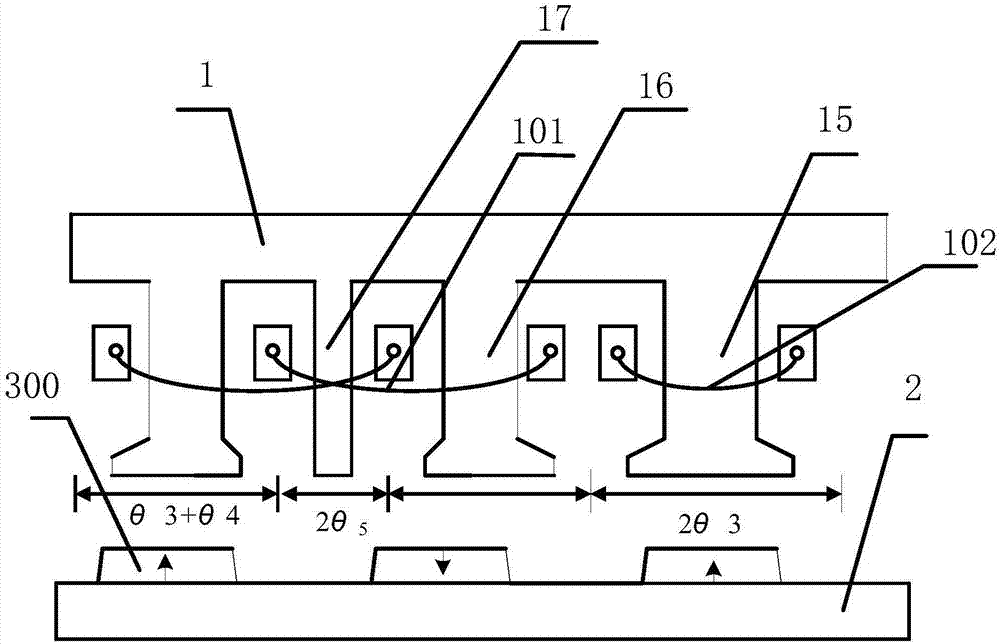

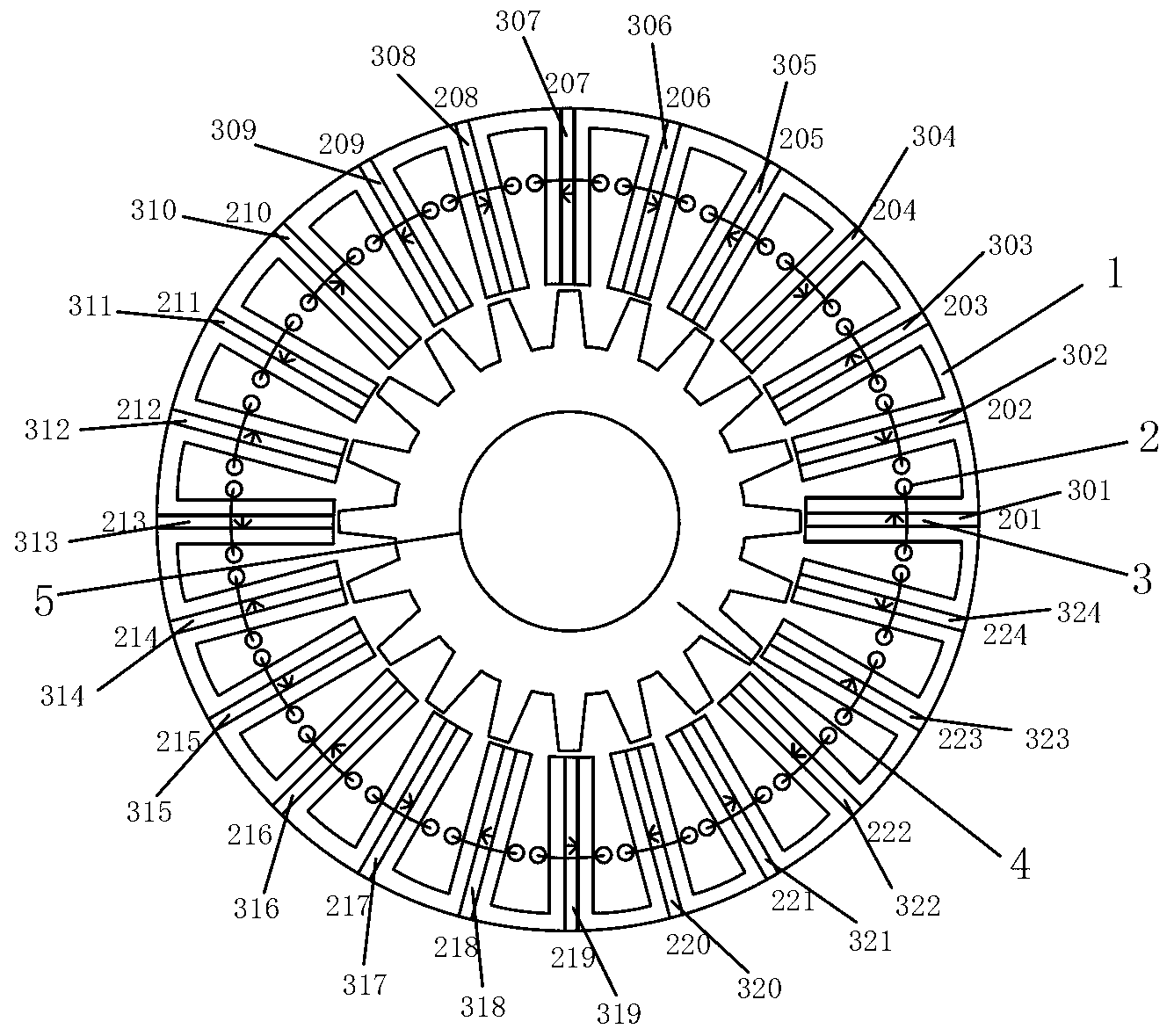

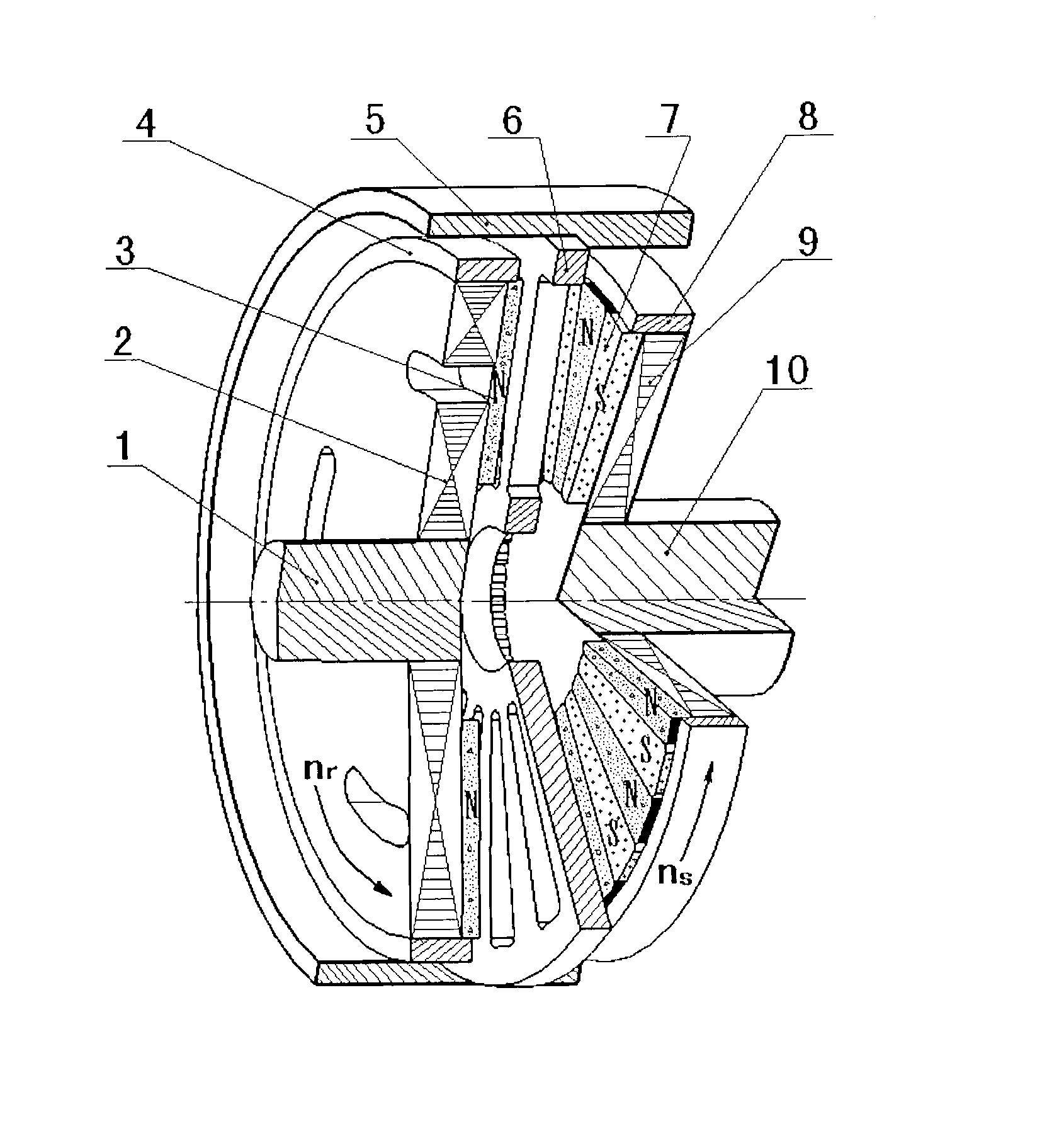

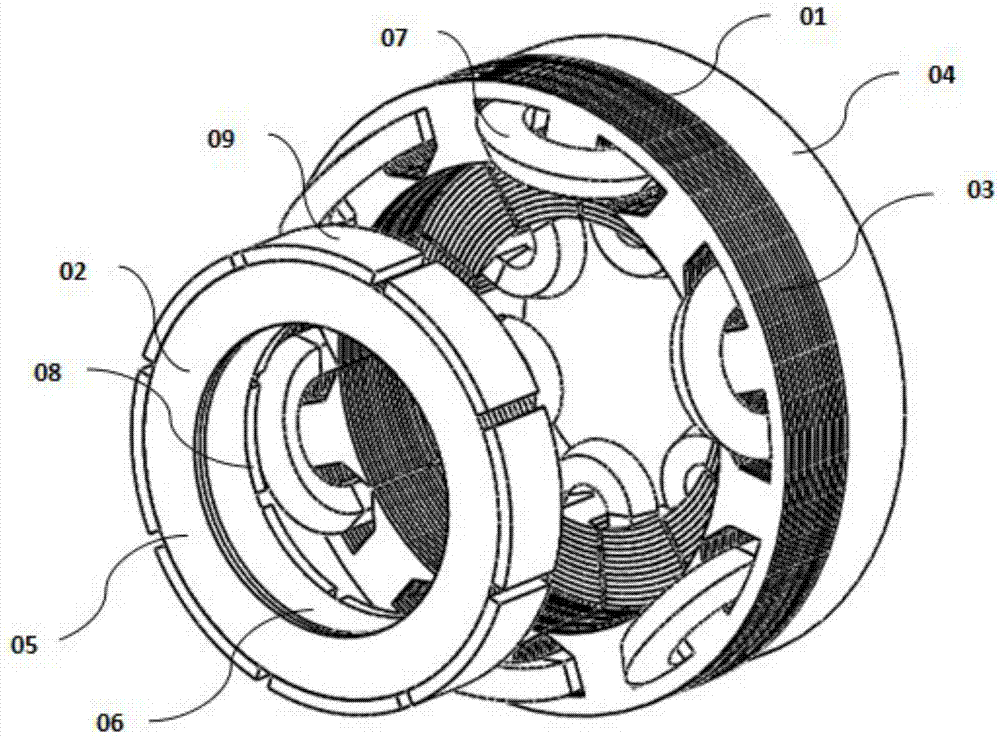

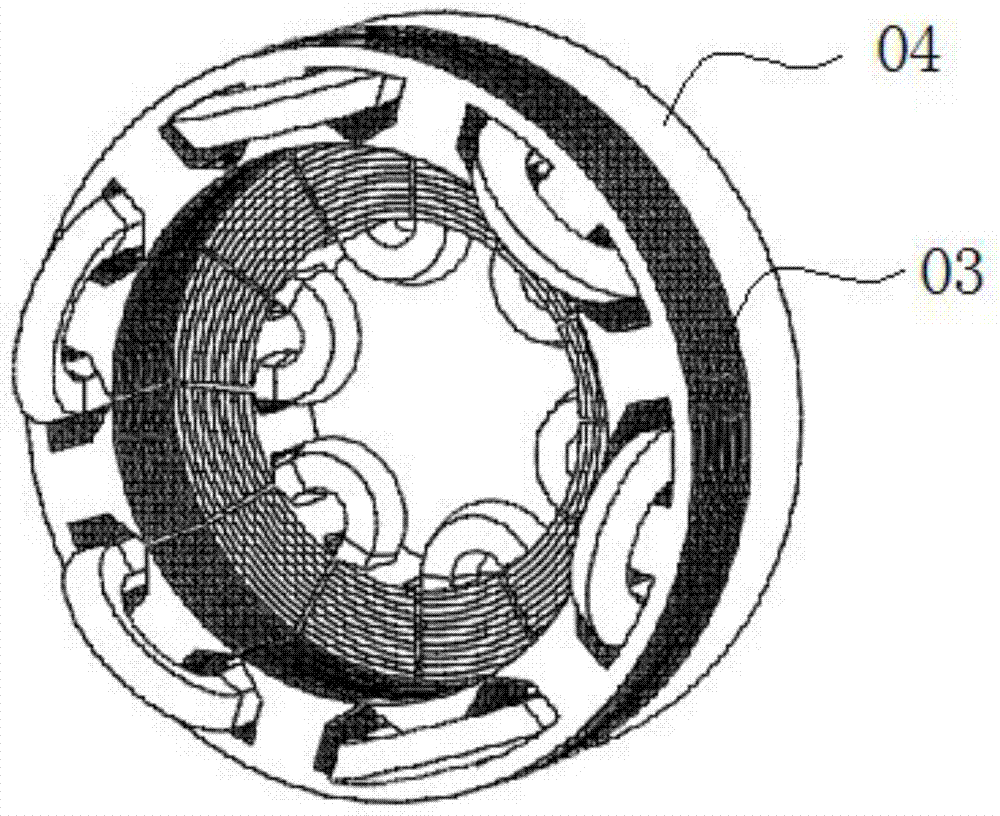

Birotor permanent magnet motor and washing machine

ActiveCN103346655ASpeed effectAppropriate speedMagnetic circuit rotating partsOther washing machinesPermanent magnet rotorElectric machine

The invention provides a birotor permanent magnet motor and a washing machine with the same. The birotor permanent magnet motor comprises an inner rotor, a stator and an outer rotator which are sequentially arranged from inside to outside, and is characterized in that both the inner rotor and the outer rotor are permanent magnet rotors, and the stator comprises a magnetic modulation ring and a stator winding arranged on the magnetic modulation ring in a wound mode. The birotor permanent magnet motor is based on the magnetic field modulation principle and has a birotor structure, the outer rotor and the inner rotor can rotate according to certain proportional relation, and high-performance output of the motor under operating conditions of a low speed and a high speed can be met at the same time. When the birotor permanent magnet motor drives the washing machine to operate, not only are design requirements for low-speed large torque output and high-speed small torque output of the motor under the optimal operating state met, but also the structures of a belt pulley, a reduction gearbox and the like in a traditional washing machine are eliminated, transmission efficiency of the motor is improved, and meanwhile the defects of high noise, machine body vibration and the like of the traditional washing machine are overcome.

Owner:ZHEJIANG UNIV

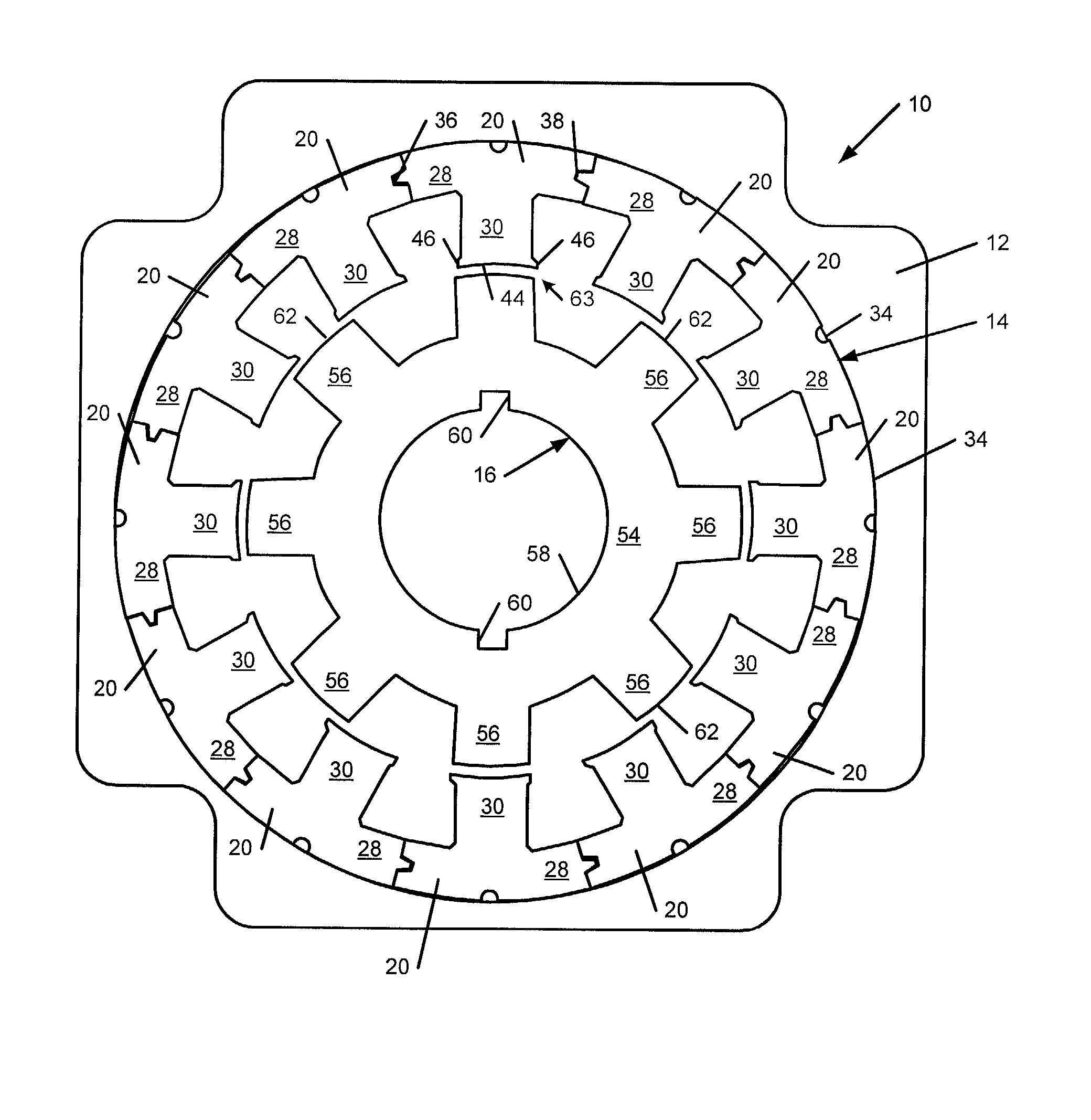

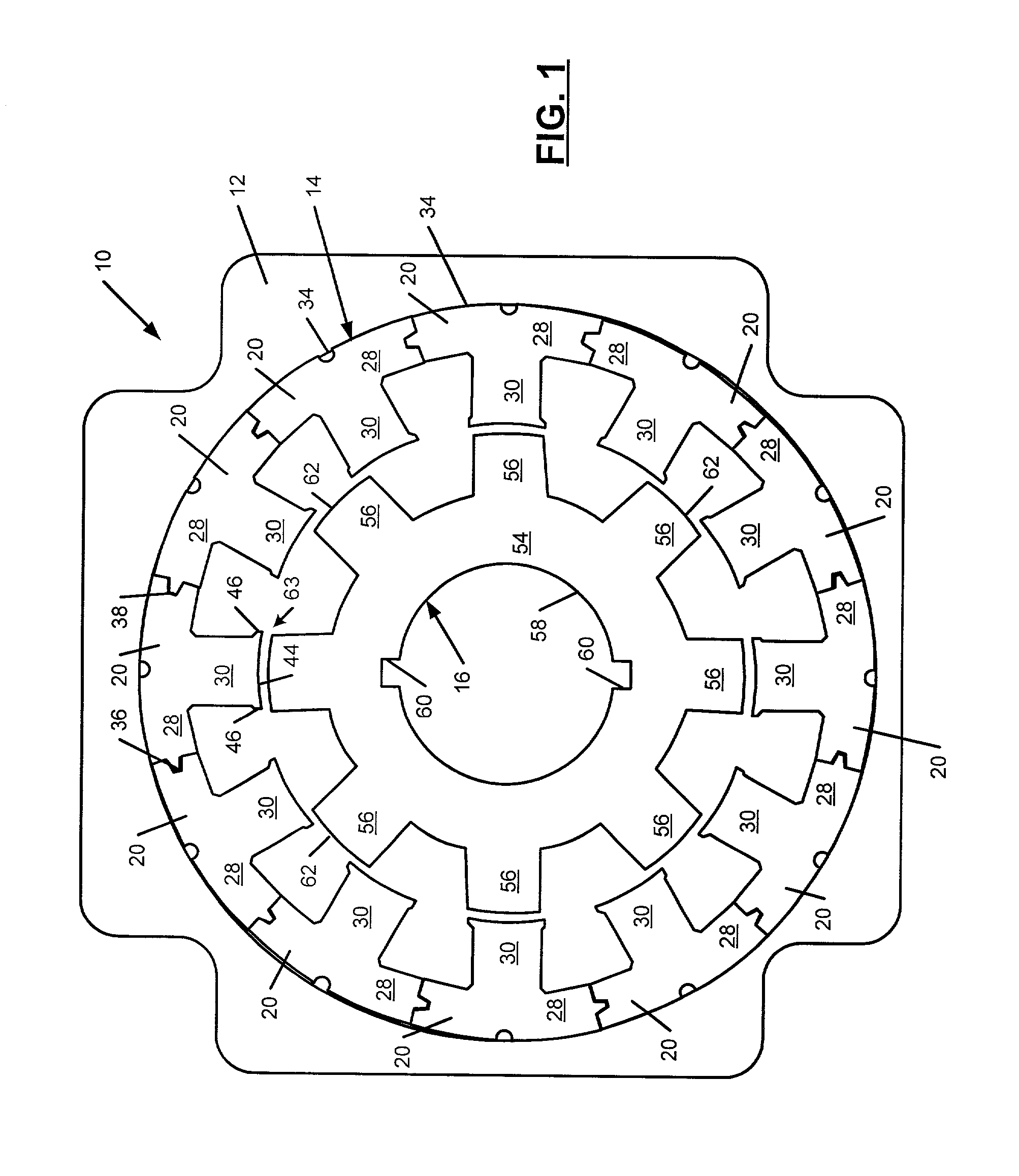

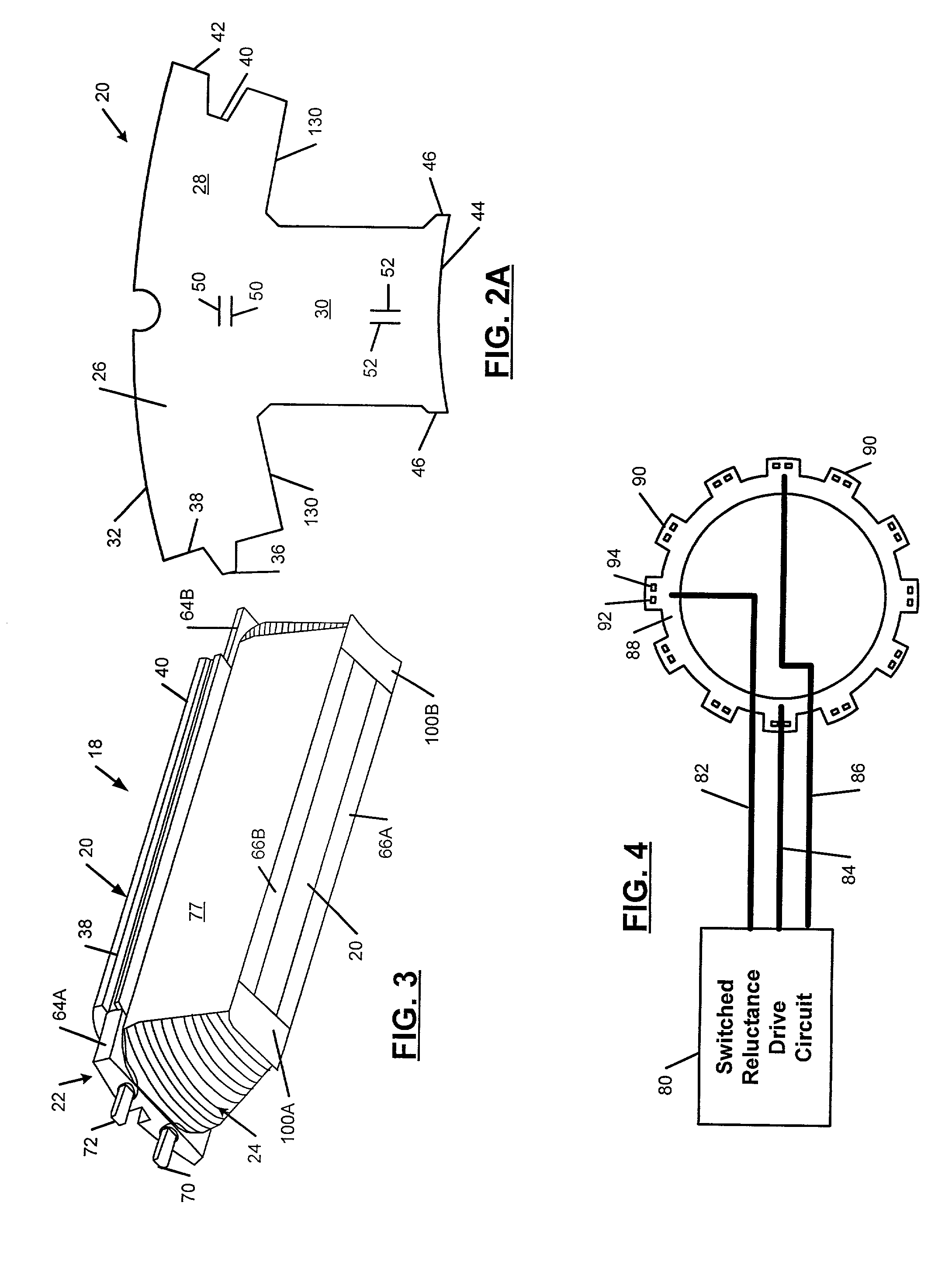

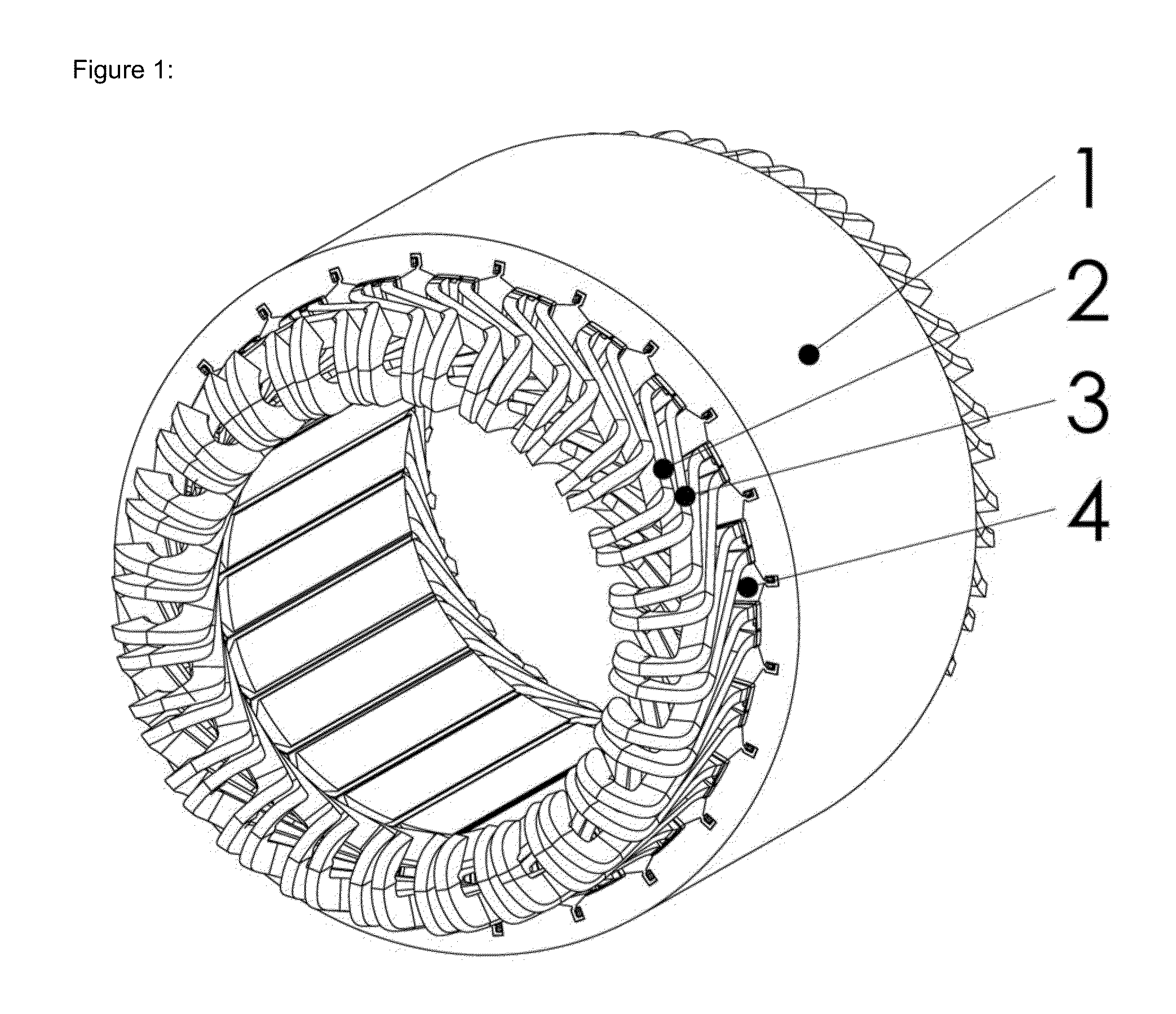

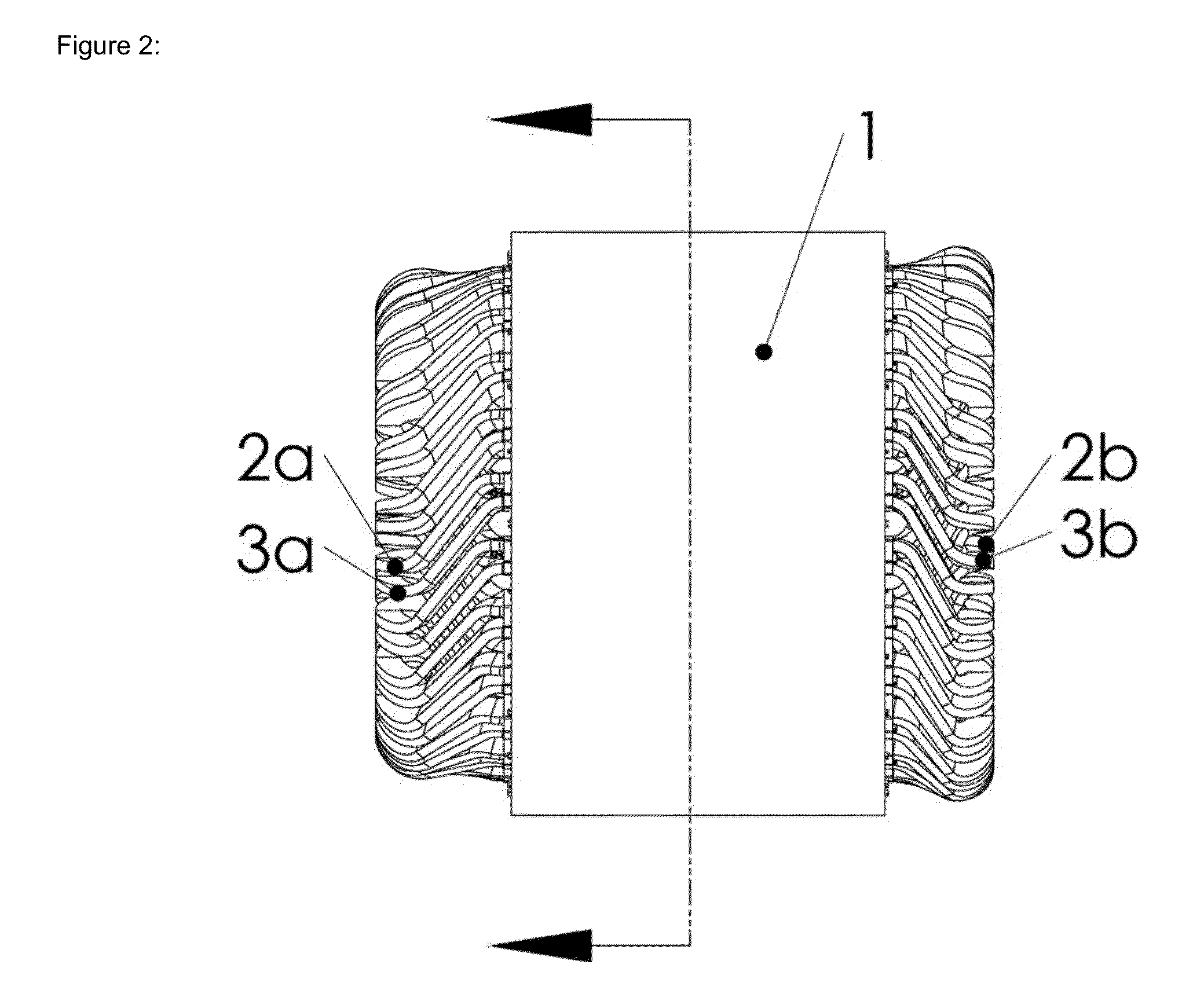

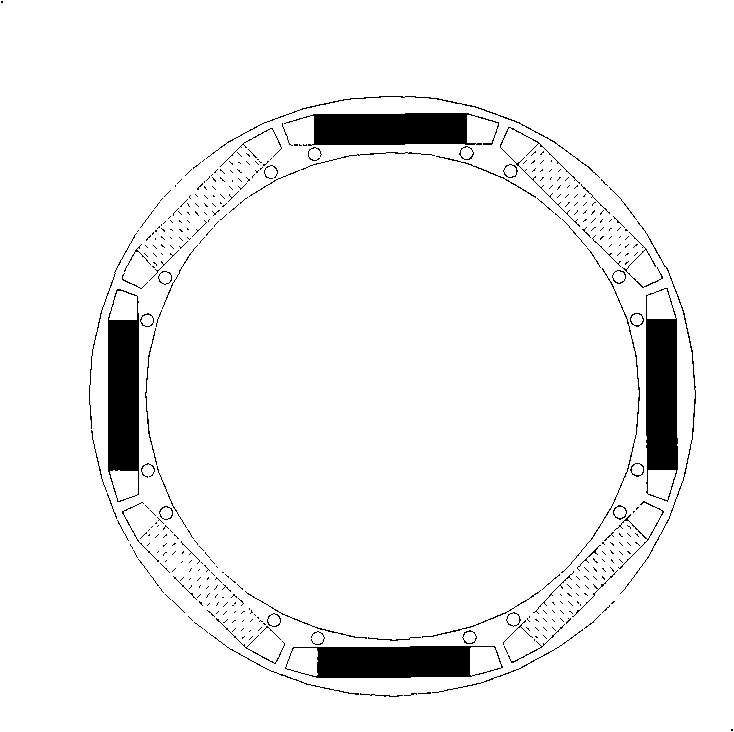

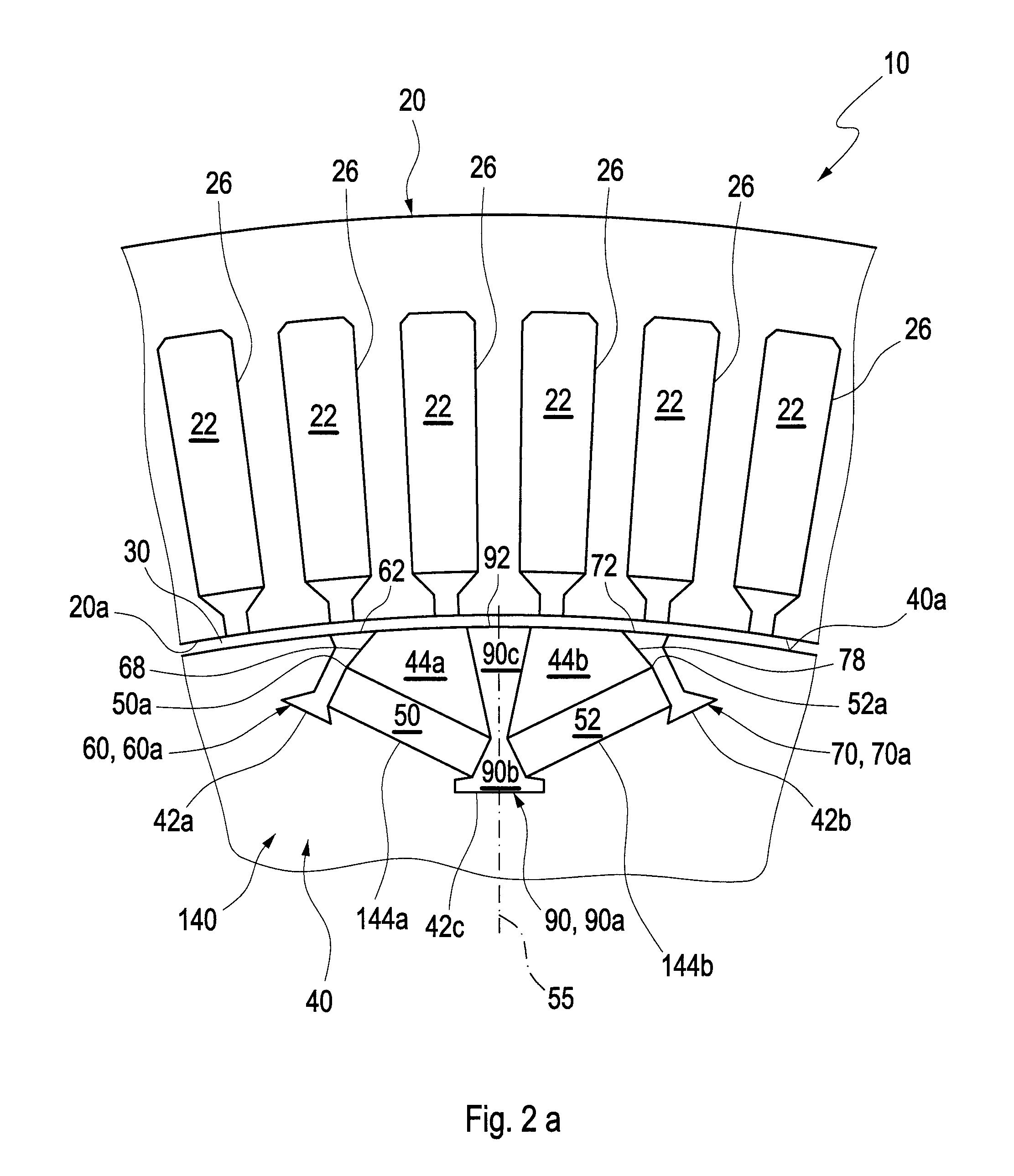

Segmented stator switched reluctance machine

InactiveUS20020125782A1Facilitate the improvement of precisionReduce usageElectronic commutation motor controlMotor/generator/converter stoppersConductor CoilMechanical engineering

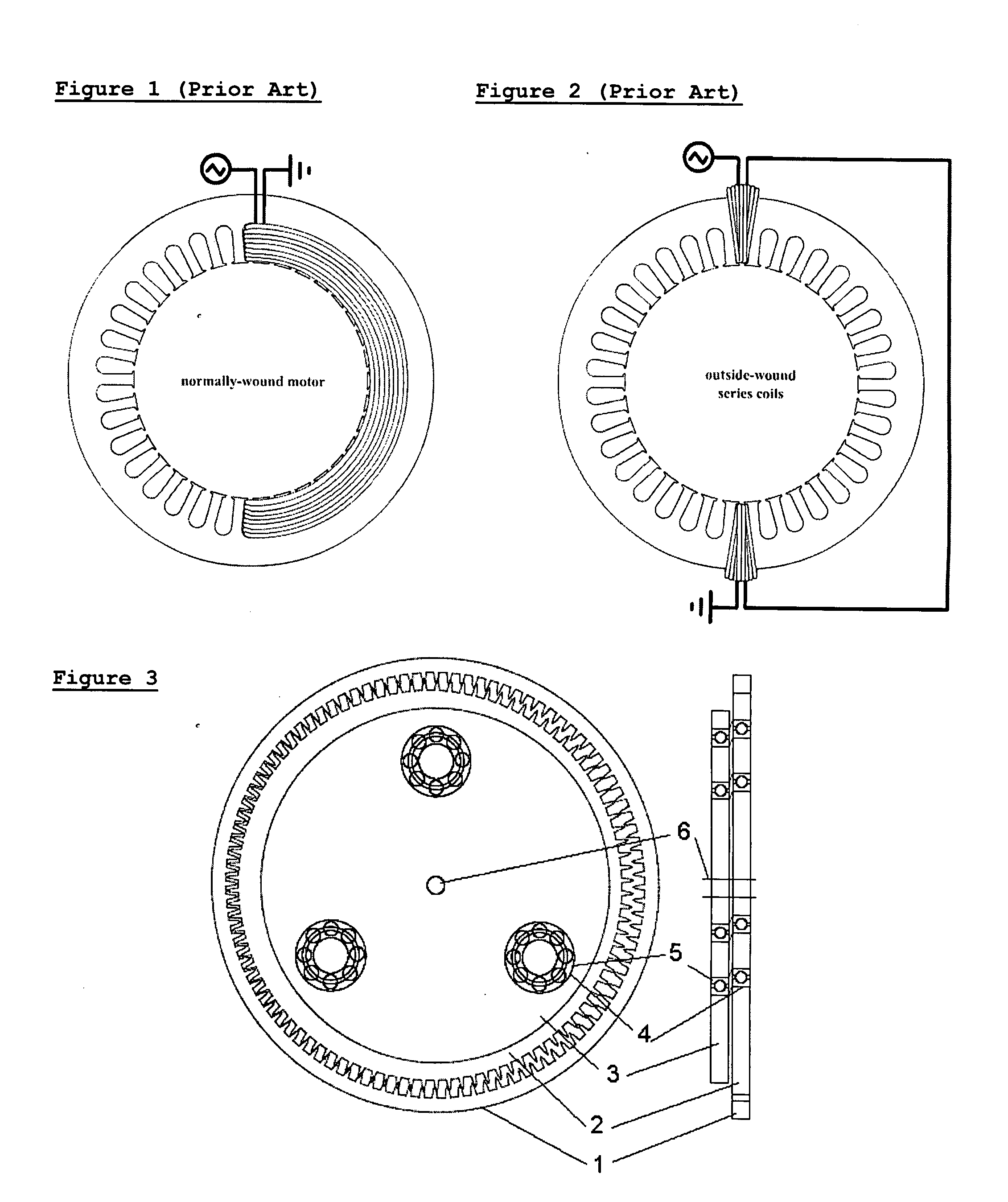

A switched reluctance machine includes a stator with a plurality of circumferentially-spaced stator segment assemblies that include salient stator poles and inter-polar stator slots. Each of the stator segment assemblies includes a stack of stator plates forming a stator segment core, an end cap assembly, and winding wire wound around the stator segment core and the end cap assembly. The rotor defines a plurality of rotor poles. The rotor tends to rotate relative to the stator to maximize the inductance of an energized winding. A drive circuit energizes the winding wire around the stator segment assemblies based on a rotational position of the rotor. Each stator plate includes a first radially outer rim section and a tooth section that extends radially inwardly from a first center portion of the first radially outer rim section.

Owner:NIDEC MOTOR CORP

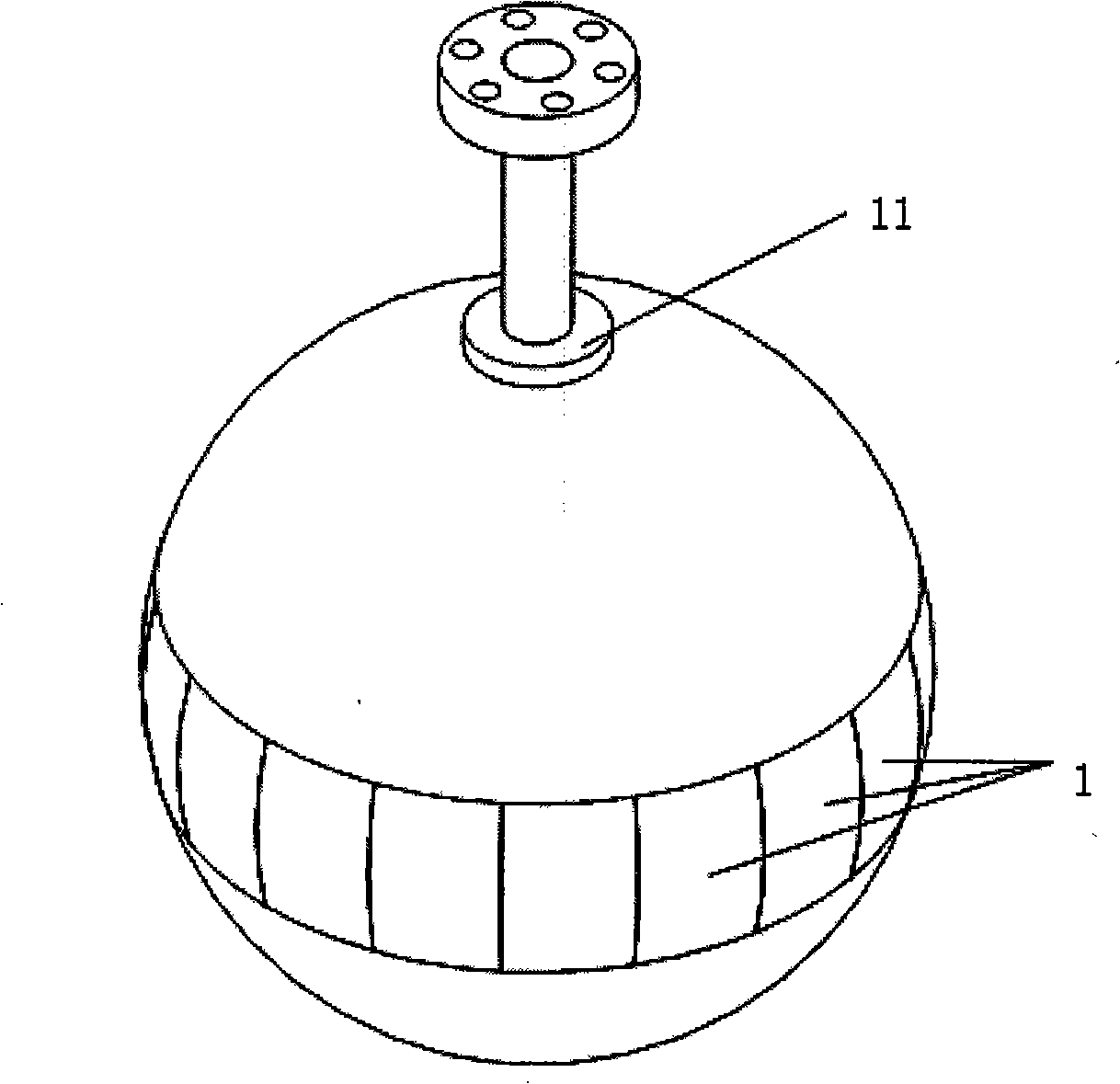

Three-freedom Halback array permanent magnetism sphericity synchronous motor

InactiveCN101282070AHigh positioning accuracySimple mechanical structureMagnetic circuit rotating partsSynchronous machine detailsFixed bearingSynchronous motor

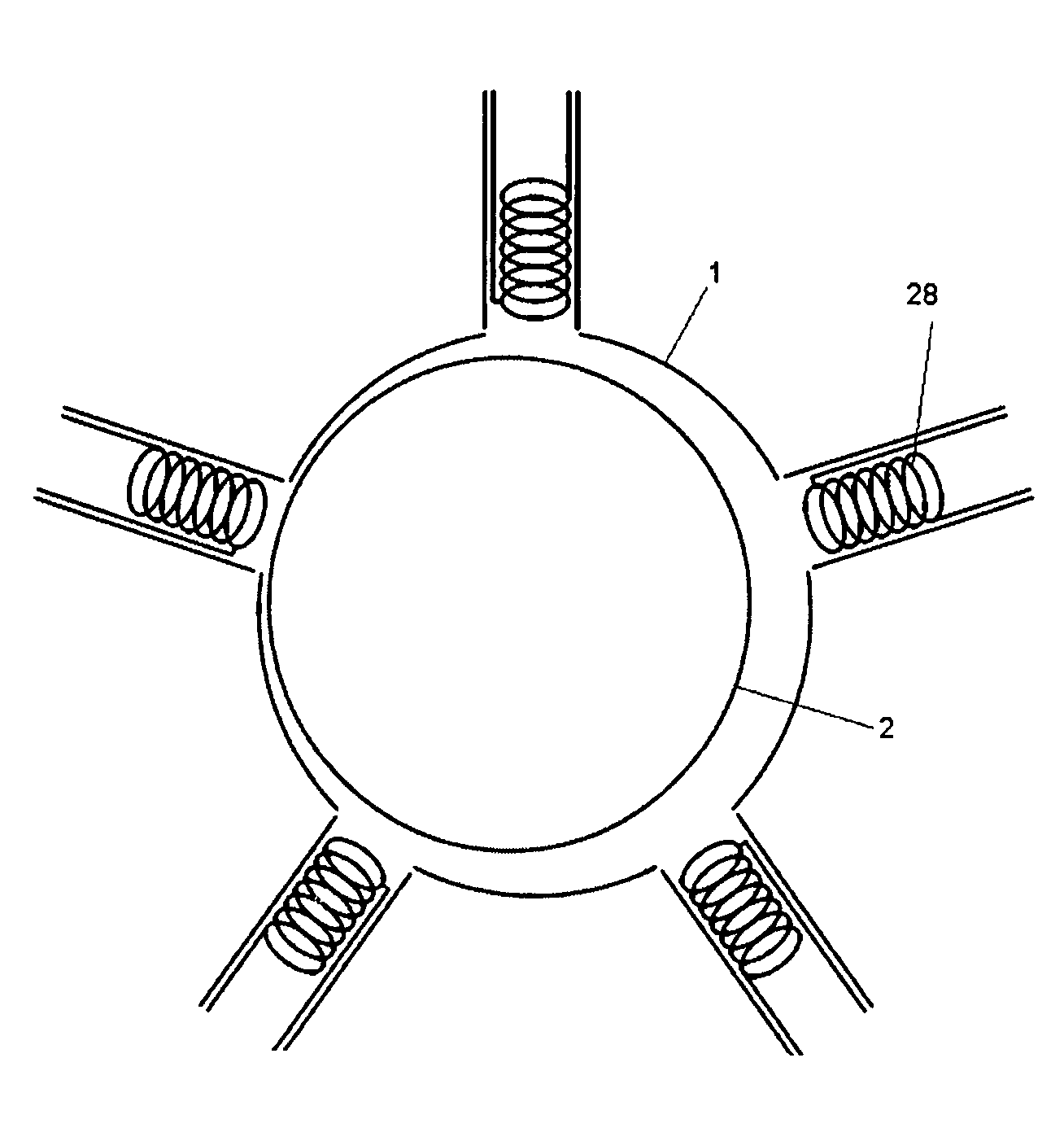

The invention relates to a three-freedom degree Halbach array permanent magnetism spherical synchronous motor, belonging to spherical electric machine manufacturing technical field, which comprises a base, a support bearing positioned on the base, a spherical rotor body, an outside stator, an output shaft, the spherical rotor body comprises a hollow spherical rotor yoke made by non-guide magnetism materials and a Halbach array permanent magnetism body, the output shaft is through the upper of the hollow spherical rotor yoke and is fixingly connected with the hollow spherical rotor yoke, column-shaped slots are provided around a cycle of the hollow spherical rotor yoke equator, the Halbach array permanent magnetism body are fixed evenly on one cycle of the rotor yoke equator along the column-shaped slots, the contact surface of the rotor yoke lower and the support bearing is ring-shaped arc surface; the outer stator comprises a stator casing and multi-row coils, an adjustable fixing bearing is provided on the lower side of the stator casing cover. The spherical synchronous motor of the invention can realize three-freedom degree movement, has simple mechanical structure and improved dynamic and static performance of the drive system.

Owner:TIANJIN UNIV

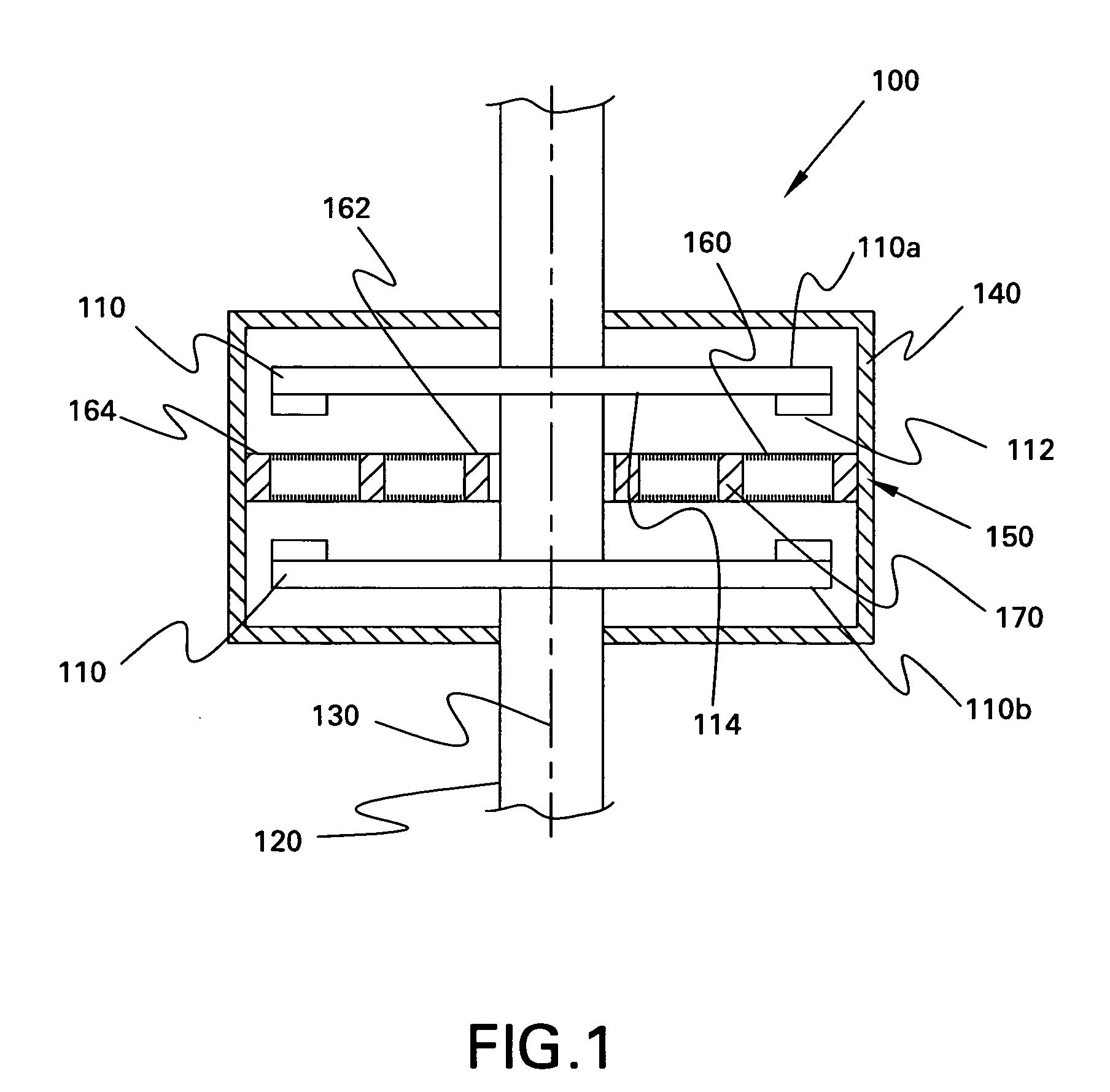

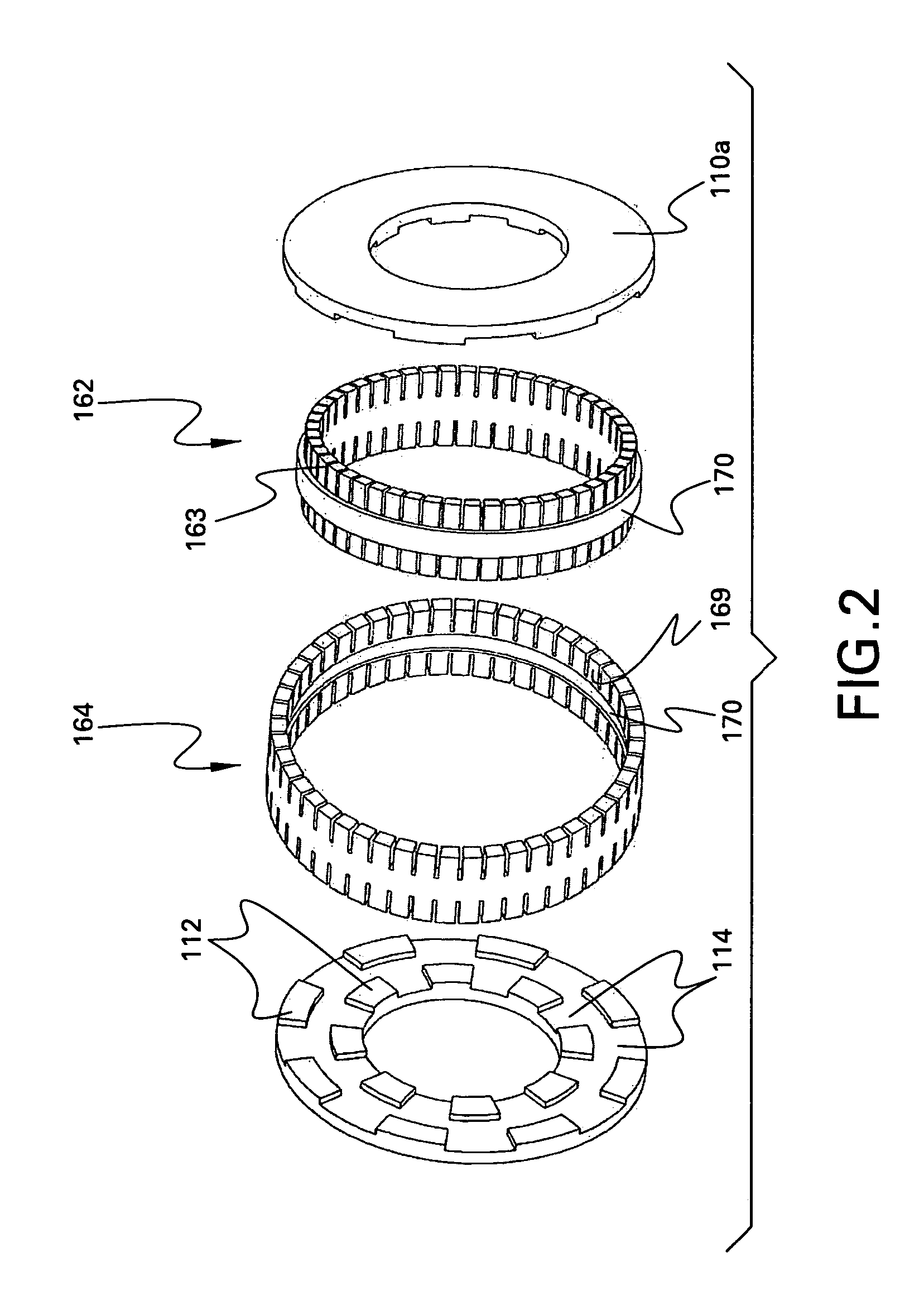

Optimized electric machine for smart actuators

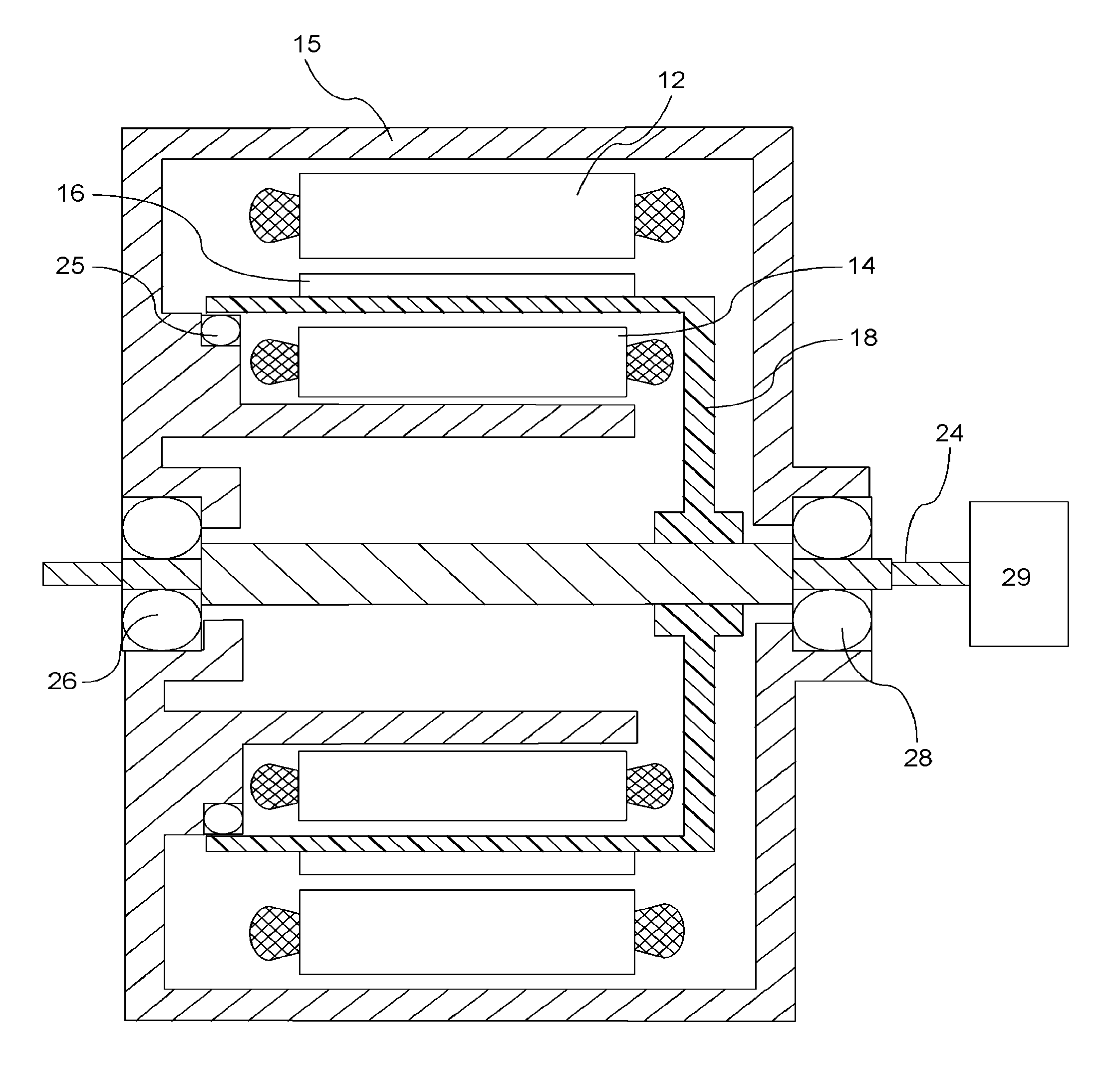

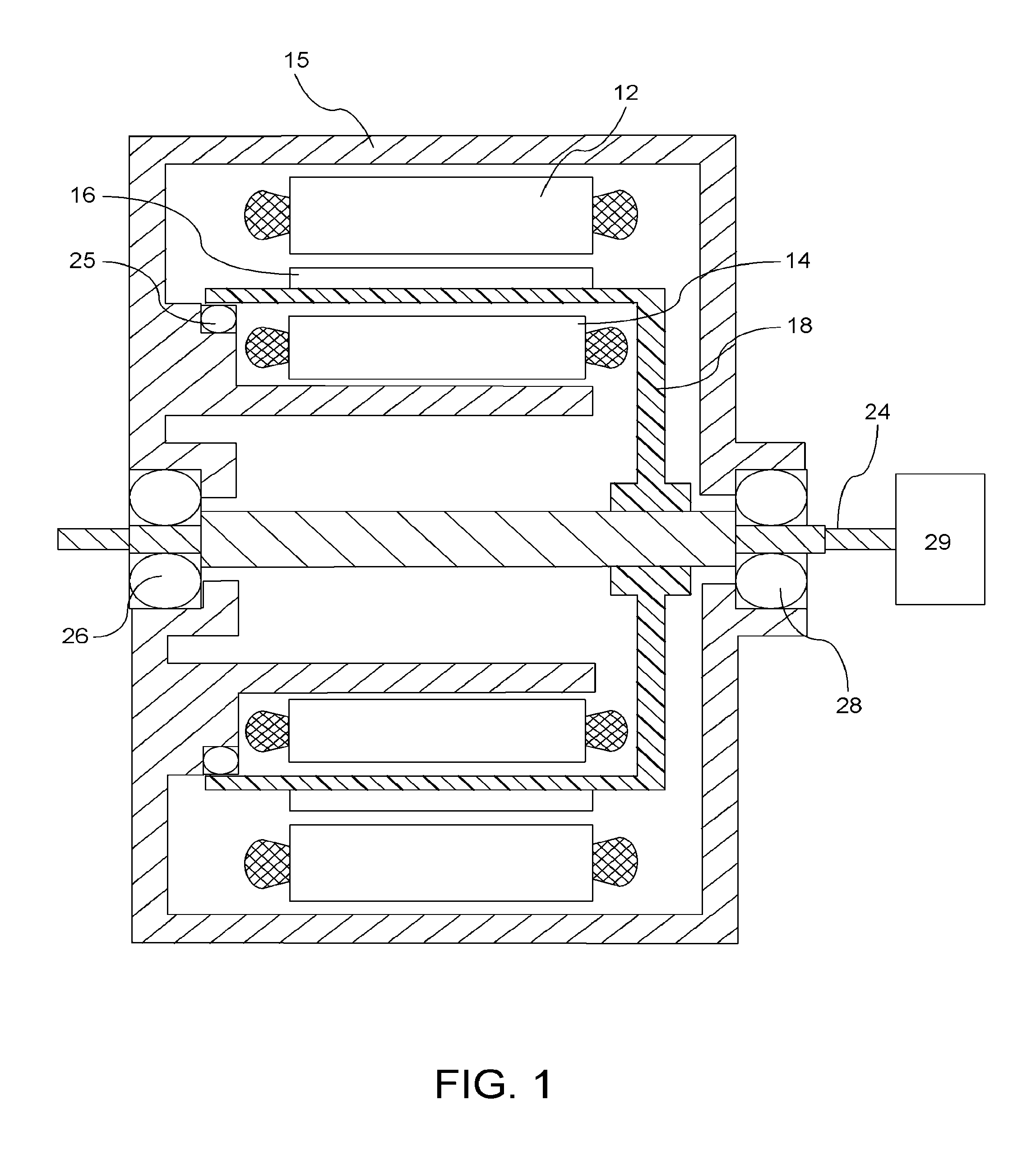

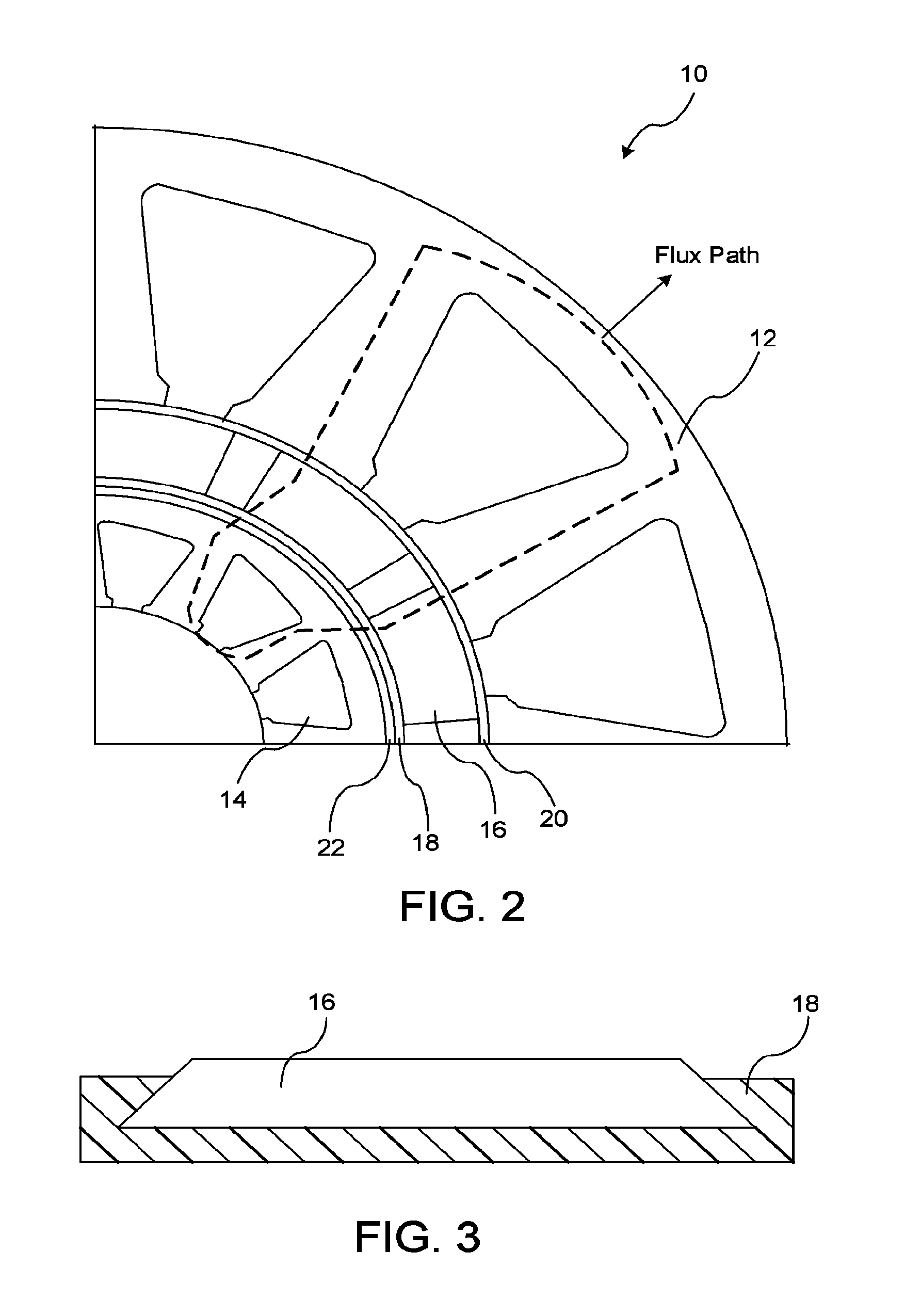

InactiveUS7791245B1Optimal operating characteristicRaise the ratioSynchronous generatorsMagnetic circuit rotating partsElectric machineEngineering

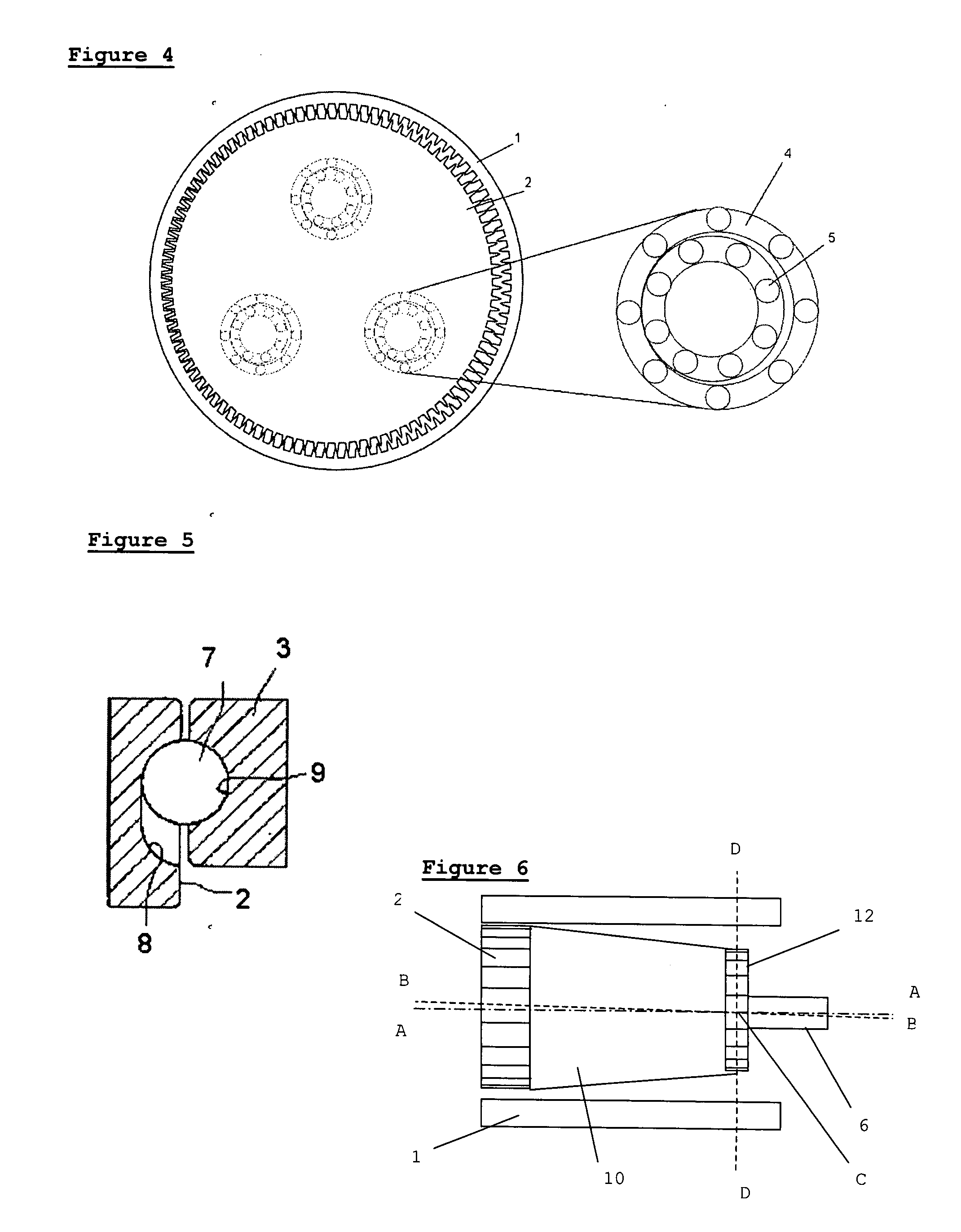

An electric machine includes a plurality of magnets for generating a first magnetic field. A magnet holder retains the plurality of magnets. A first stator is disposed radially outward from the magnet holder for generating a second magnetic field. The first stator includes a plurality of stator poles separated by slots with each of the stator poles having a concentrated winding with a respective number of turns formed around each respective stator pole. A second stator is disposed radially inward from the magnet for generating a third magnetic field. The second stator has a plurality of stator poles separated by slots with each of the stator poles having a concentrated winding with a respective number of turns formed around each respective stator pole. The magnet holder and magnets retained therein are rotatable between the first stator and second stator.

Owner:GM GLOBAL TECH OPERATIONS LLC

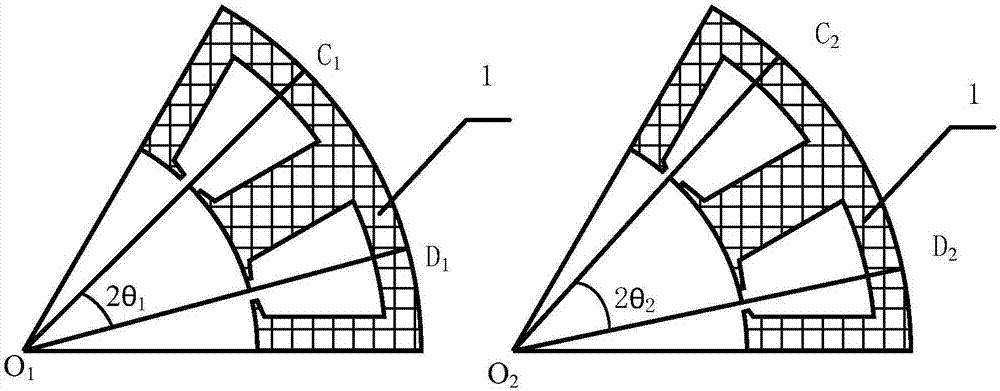

Application method of mixed permanent magnets in flux-switching permanent magnet motor

InactiveCN104242501ASignificant progressHighlight substantiveMagnetic circuit stationary partsMagnetic circuit characterised by magnetic materialsRare earthPermanent magnet motor

Owner:HEBEI UNIV OF TECH

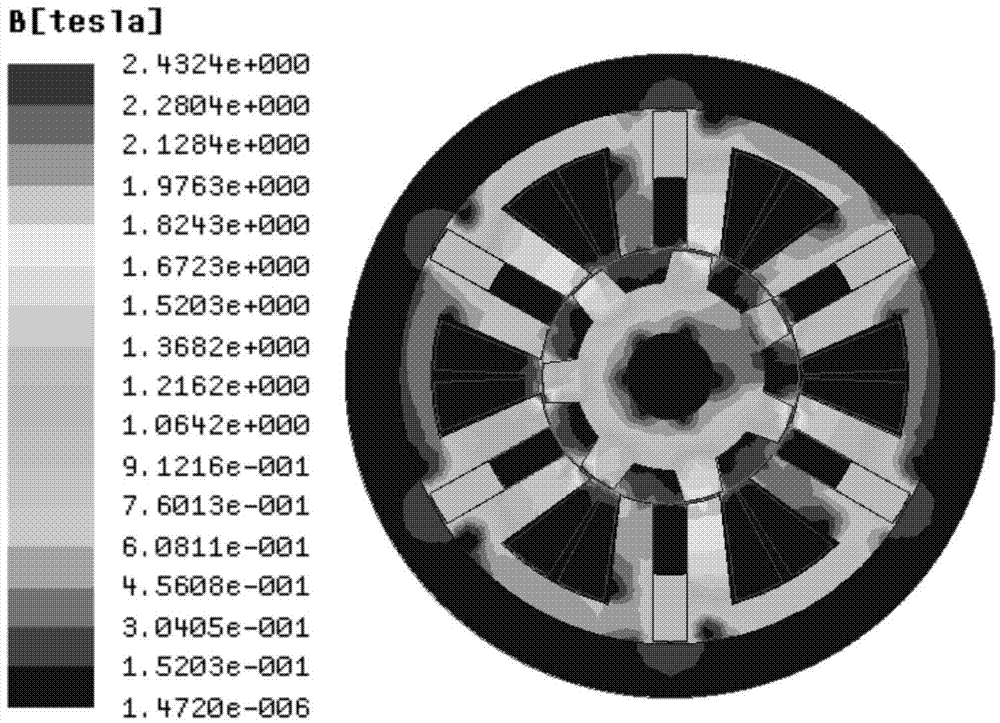

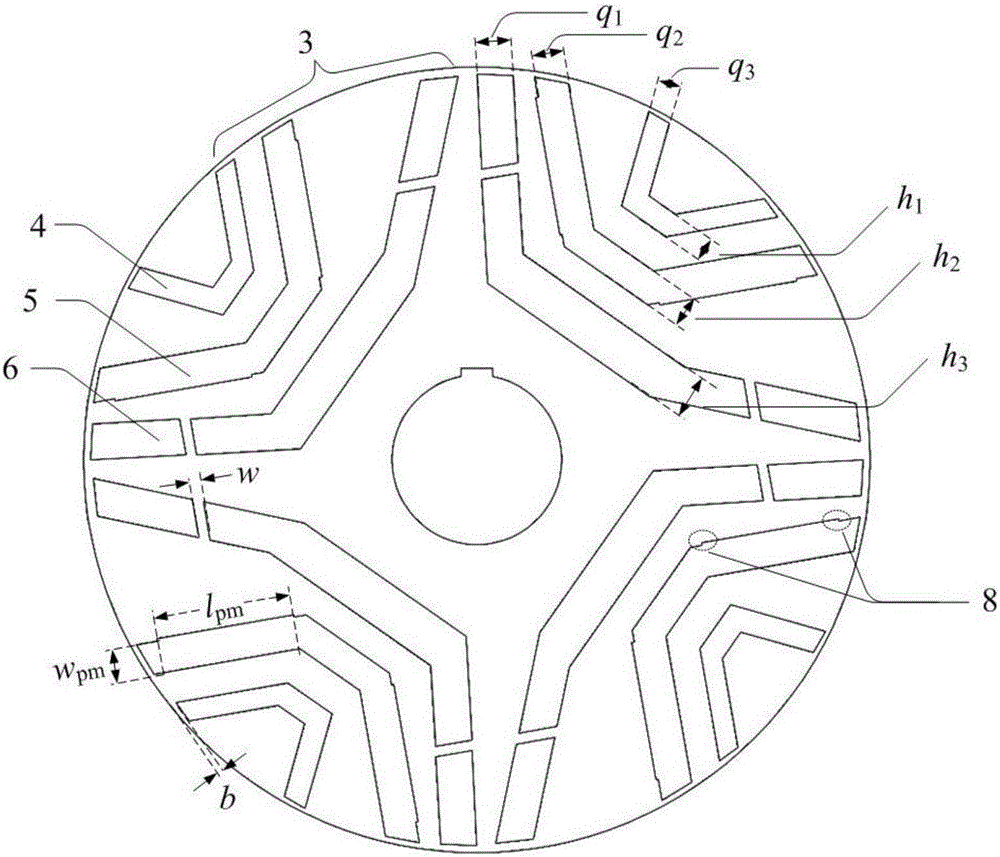

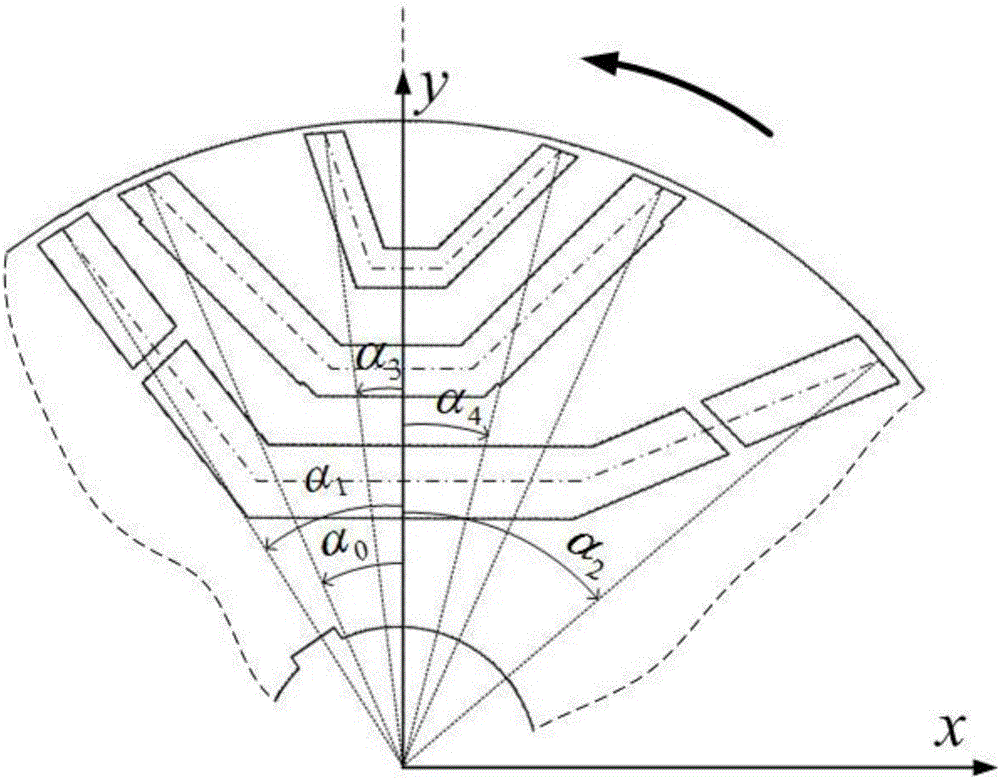

High-torque-density permanent magnet reluctance synchronous motor rotor structure

ActiveCN105914925AReduce manufacturing costReduce consumptionMagnetic circuit rotating partsSynchronous motorTorque density

The invention discloses a high-torque-density permanent magnet reluctance synchronous motor rotor structure, which comprises a central rotating shaft and a rotor core, wherein P groups of through slots are evenly formed in the rotor core along the circumferential direction, each group of through slots includes three layers of U-shaped through slots formed along a radial direction of the rotor core at intervals, and a permanent magnet is embedded in each of two wings of the middle U-shaped through slot; and the middle U-shaped through slot among the three layers of U-shaped through slots is of a symmetric structure, and the outer-layer and inner-layer U-shaped through slots are each of asymmetric structure. The high-torque-density permanent magnet reluctance synchronous motor rotor structure can change torque characteristics of a built-in permanent magnet synchronous motor, makes the maximum synthesized torque fully utilize a permanent-magnet torque component and a reluctance torque component, and increases torque density of a motor.

Owner:江苏仪能电机有限公司 +1

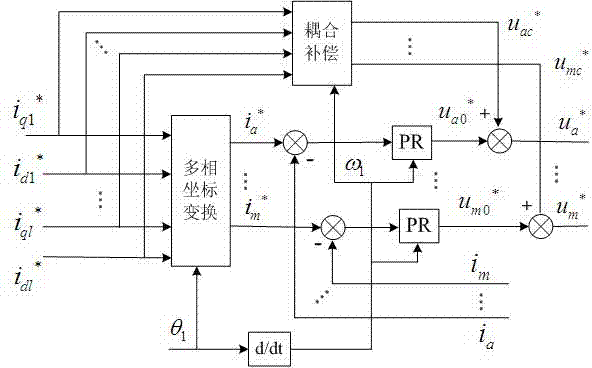

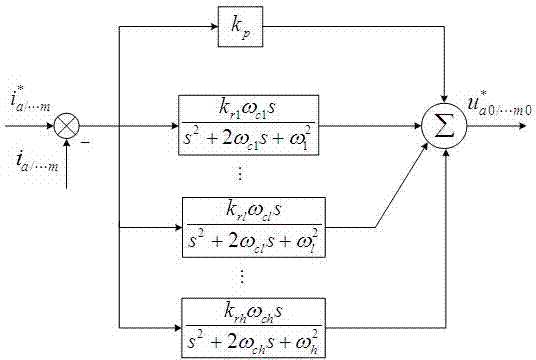

Polyphase permanent magnet synchronous motor current waveform optimal control method

ActiveCN103490692AEffective amplitudeEffective Phase Gain ControlElectronic commutation motor controlVector control systemsControl vectorElectric machine

The invention discloses a polyphase permanent magnet synchronous motor current waveform optimal control method, comprising the following steps of A, current reference value coordinate transformation; B, current multiple proportion resonance regulation; and C, coupling compensation. In the control method, based on polyphase permanent magnet synchronous motor vector control, a polyphase synchronous rotating coordinate system current reference value is transformed to a current reference value of each phase in a polyphase static coordinate system through polyphase coordinate transformation, the current reference value of each phase and a current feedback value of each phase of a motor are respectively subjected to improved multiple superposition proportion resonance regulation, and a resonance separation method is introduced, decoupling is realized by feed-forward compensation, and floating tracking and harmful subharmonic restraining for highly dynamic property fundamental waves and usable subharmonic are realized. The method can restrain the adverse impacts, such as motor loss, torque ripple and vibration noise, caused by a harmful harmonic current of the polyphase motor, can explore the positive effects of the usable harmonic current, gives full play to the advantages of the polyphase motor and improves the system performance.

Owner:武汉长海电力推进和化学电源有限公司

Rotor of permanent magnetic composite excitation synchronous motor

ActiveCN104242509AReduce the effect of the air gap magnetic fieldImproving Salient Pole Torque UtilizationMagnetic circuit rotating partsSynchronous motorTorque density

The invention aims at disclosing a rotor of a permanent magnetic composite excitation synchronous motor. The rotor comprises a double-layer embedded type rotor sheet, first magnetic steel grooves are formed in the outer side of the rotor sheet, second magnetic steel grooves are formed in the inner side of the rotor sheet, magnetic bridges are arranged between the second magnetic steel grooves, and magnetic steel is arranged in the first magnetic steel grooves and the second magnetic steel grooves. Compared with the prior art, different permanent materials are embedded in the rotor sheet according to a certain rule to form the rotor, the usage number of rare-earth permanent magnetic materials is effectively reduced, the effect of the temperature on a motor air-gap magnetic field is reduced, the excitation stability is improved, the utilization rate of salient pole torque of the motor is increased, the torque density of the motor is increased, and the purpose of the rotor is achieved.

Owner:ZHEJIANG LOONGSON ELECTRIC DRIVE TECH CO LTD

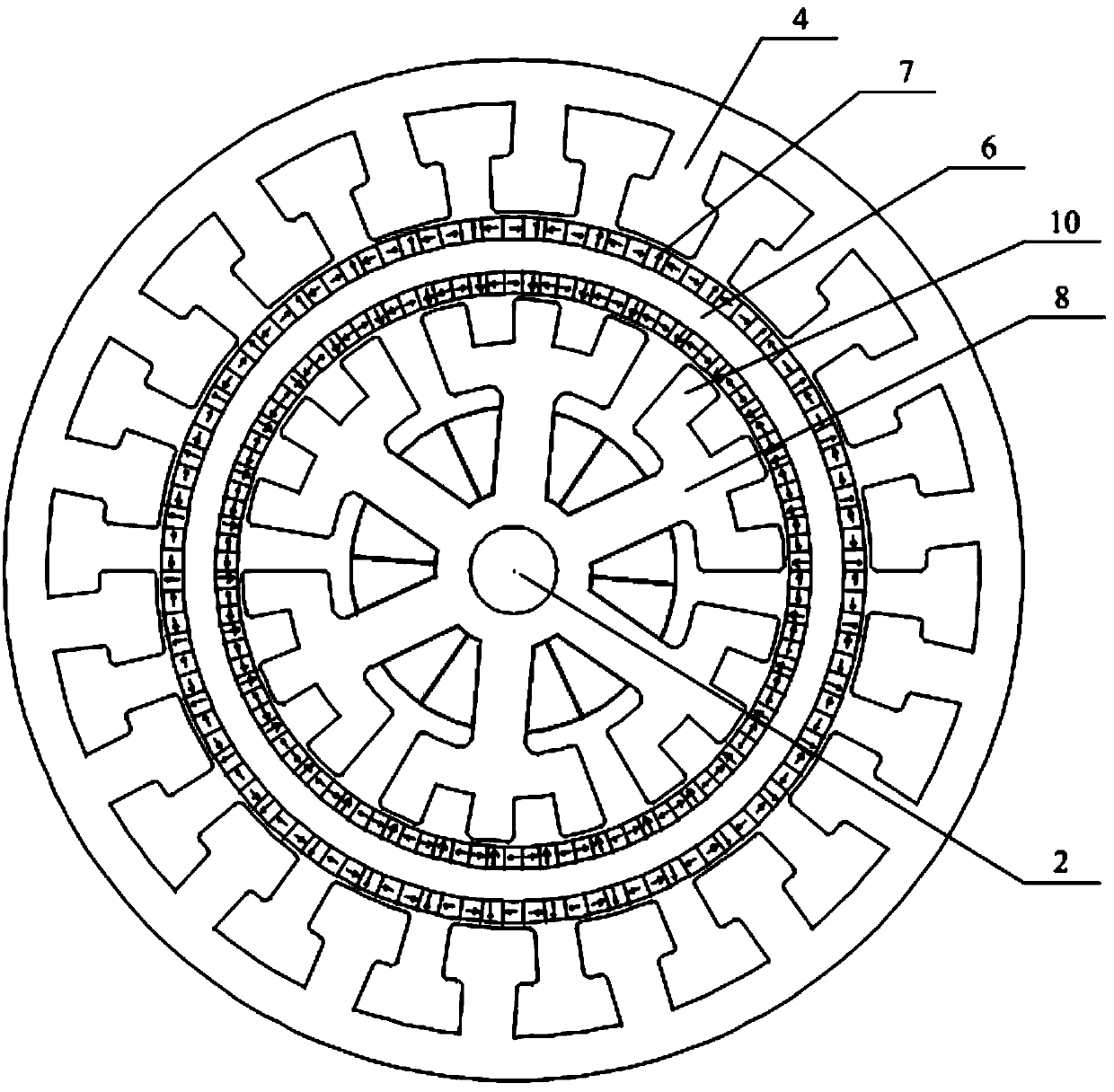

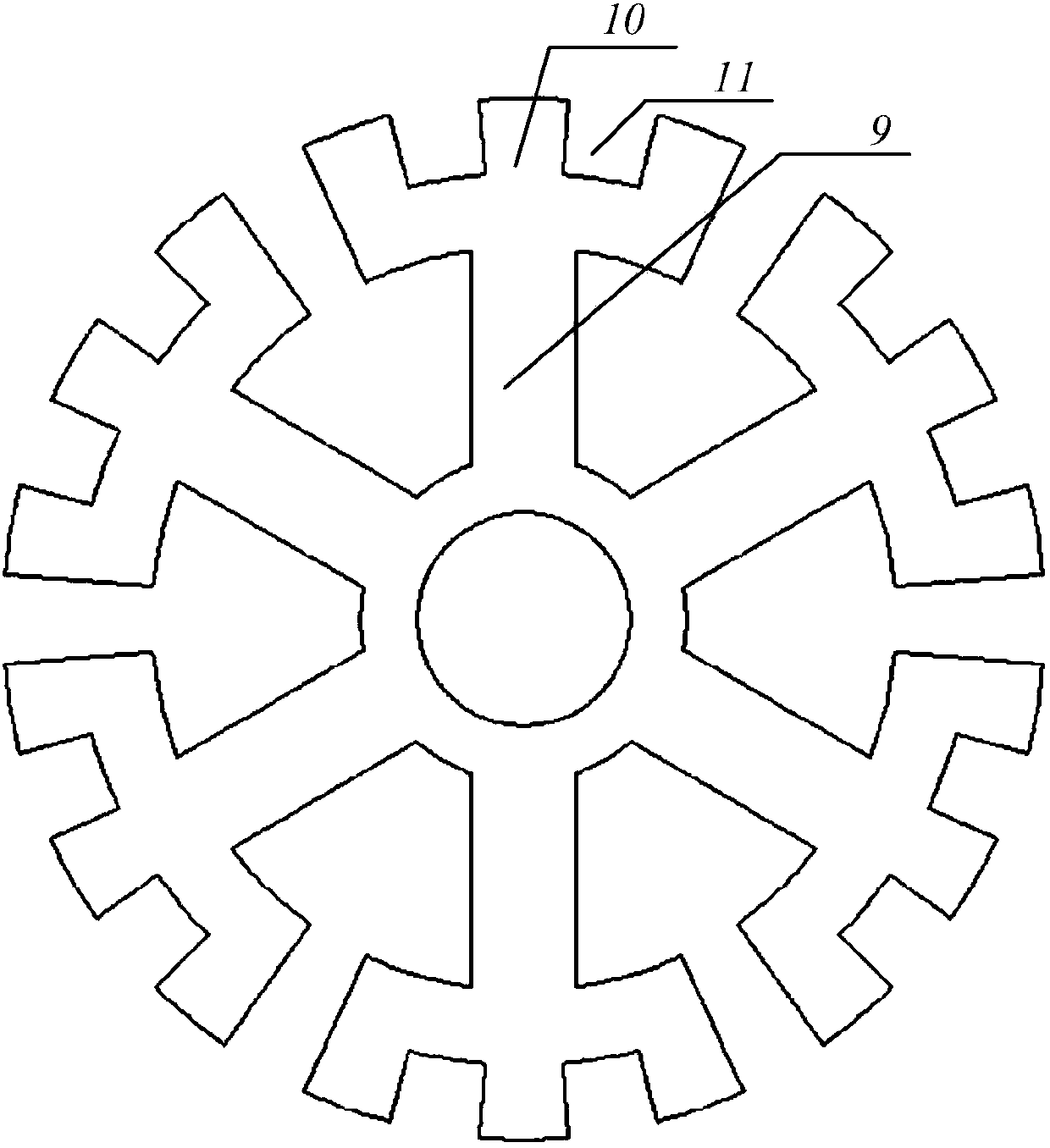

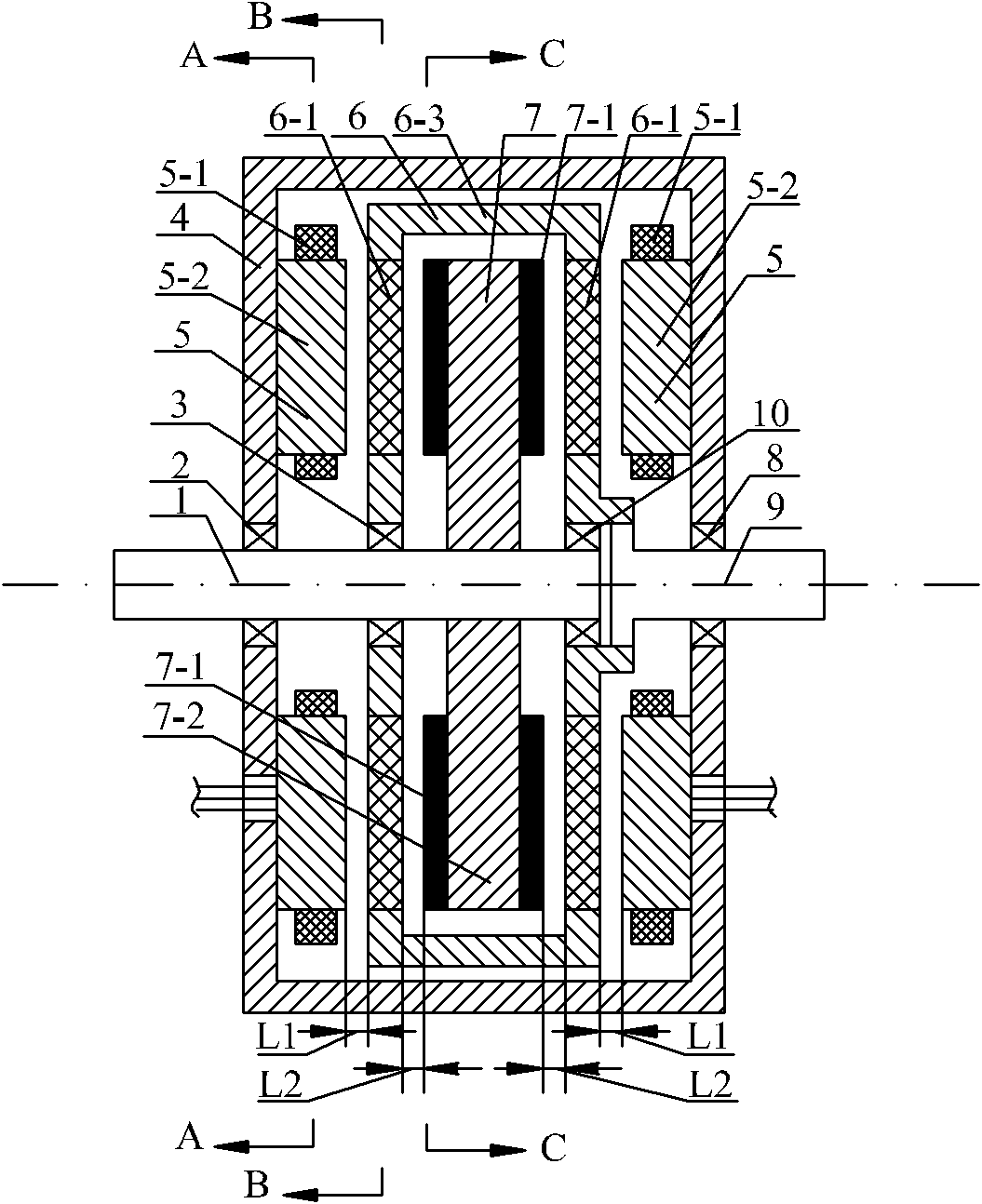

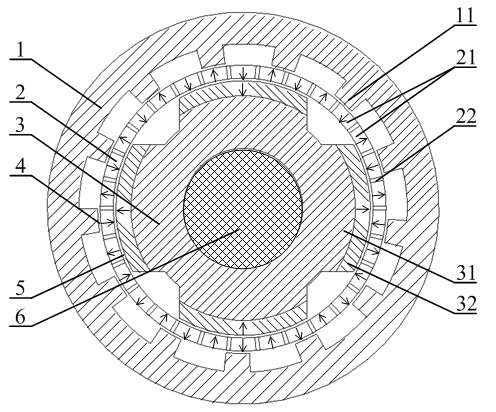

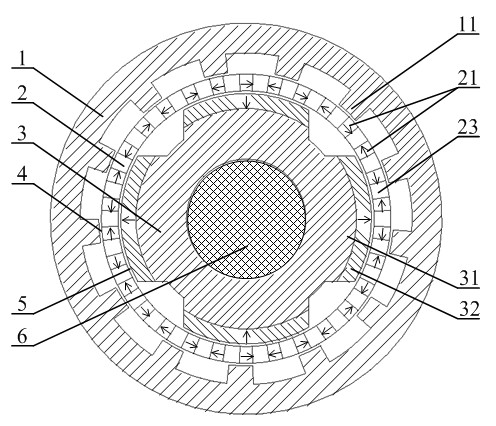

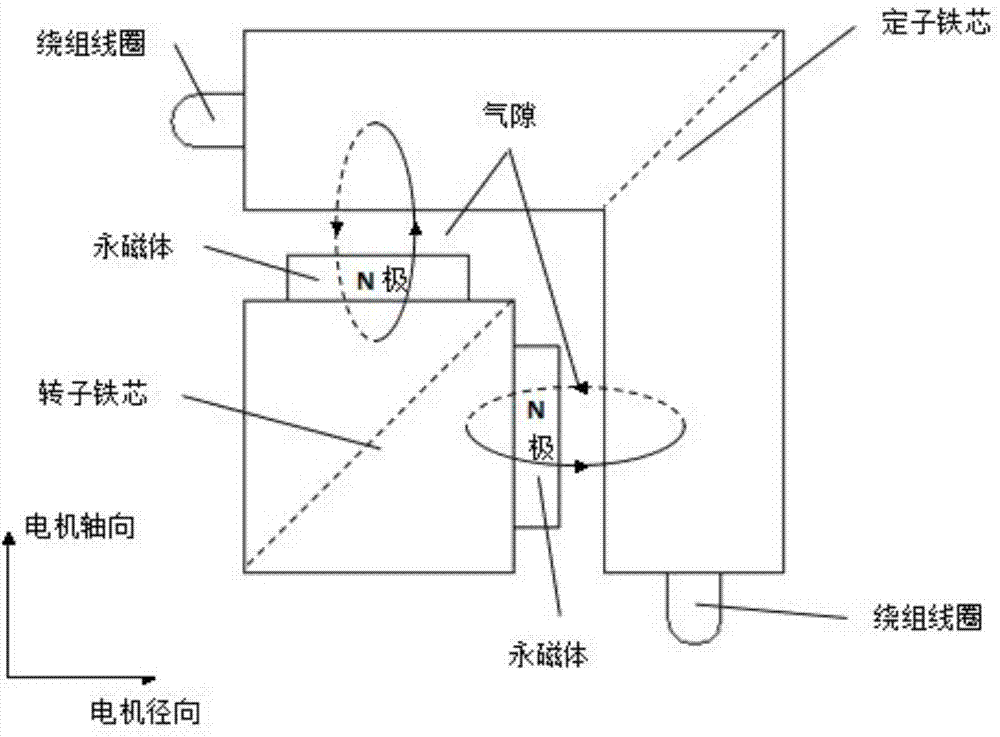

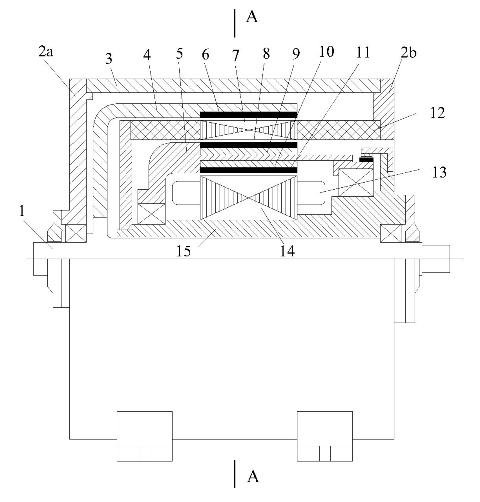

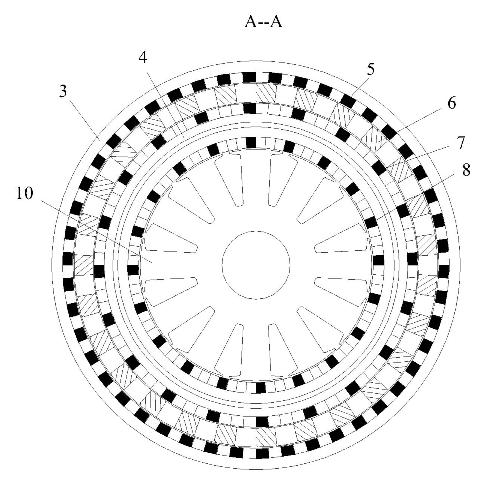

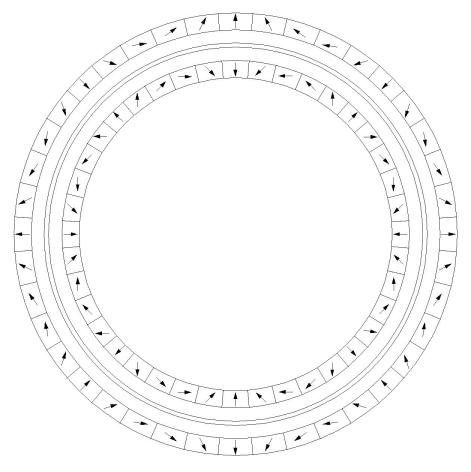

Double-stator permanent-magnet vernier wind driven generator

ActiveCN104201848AIncreased torque densityIncrease sineMagnetic circuit rotating partsMagnetic circuit stationary partsWind drivenThermodynamics

The invention discloses a double-stator permanent-magnet vernier wind driven generator, and belongs to the field of motor manufacturing. The double-stator permanent-magnet vernier wind driven generator comprises an outer stator (4), an inner stator (8) and a rotor (6), wherein the outer stator is provided with a pear-shaped groove and first stator teeth; the inner stator (8) is provided with second stator teeth (9), and each second stator tooth (9) is provided with a flux modulation electrode (10) and a flux modulation electrode groove (11); the rotor (6) is of a cup-shaped structure, and a Halbach-structure permanent magnet (7) is arranged on the rotor; the tooth number of the first stator teeth of the outer stator (4) is equal to that of the teeth of the flux modulation electrode (10); moreover, the pear-shaped groove of the outer stator (4) and the flux modulation electrode (10) are oppositely distributed and arranged, and the first stator teeth of the outer stator (4) and the flux modulation electrode groove (11) are oppositely distributed and arranged. The double-stator permanent-magnet vernier wind driven generator disclosed by the invention is capable of generating a high-sine air-gap magnetic field, and has the characteristic of a high output torque.

Owner:SOUTHEAST UNIV

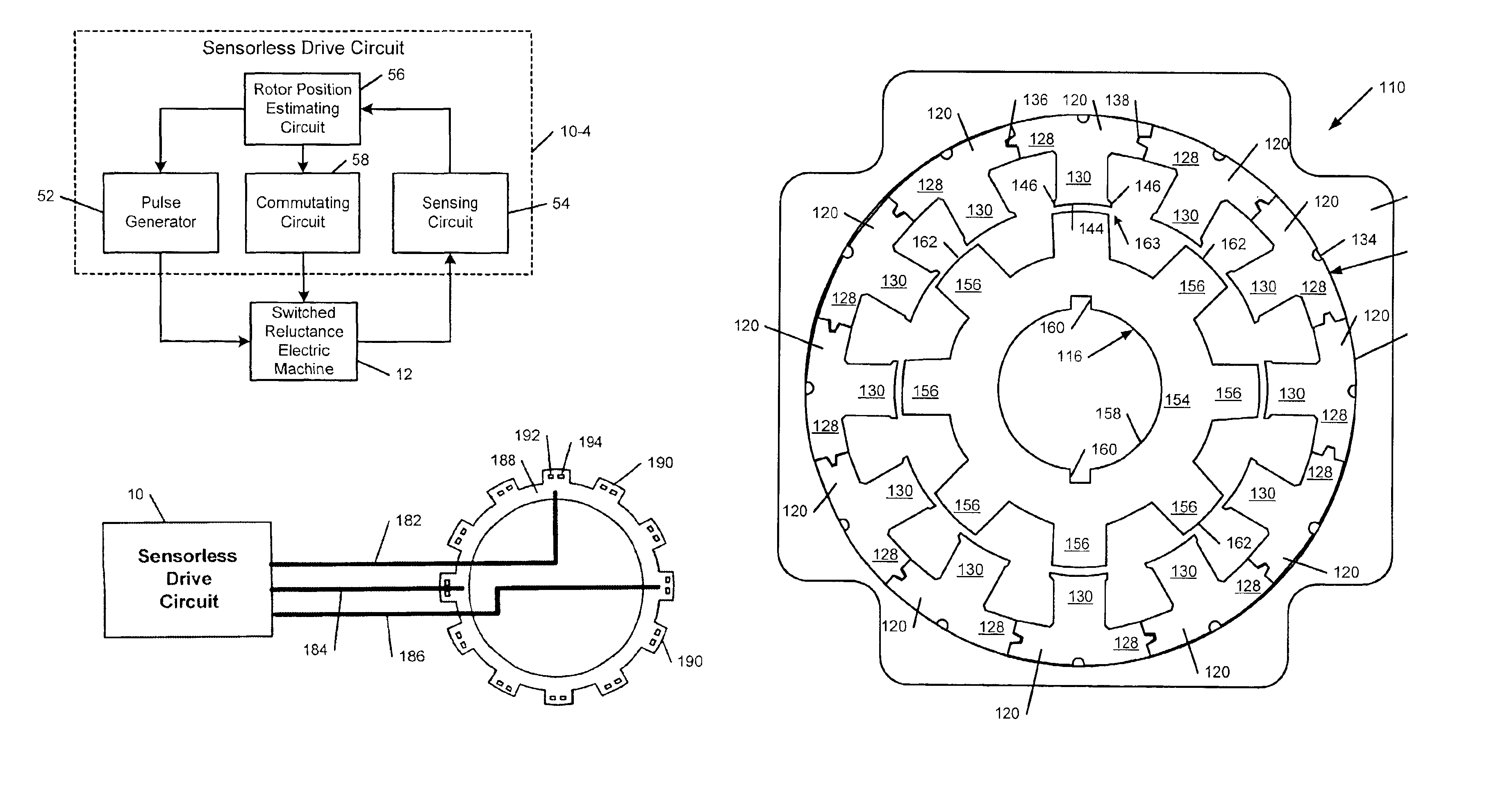

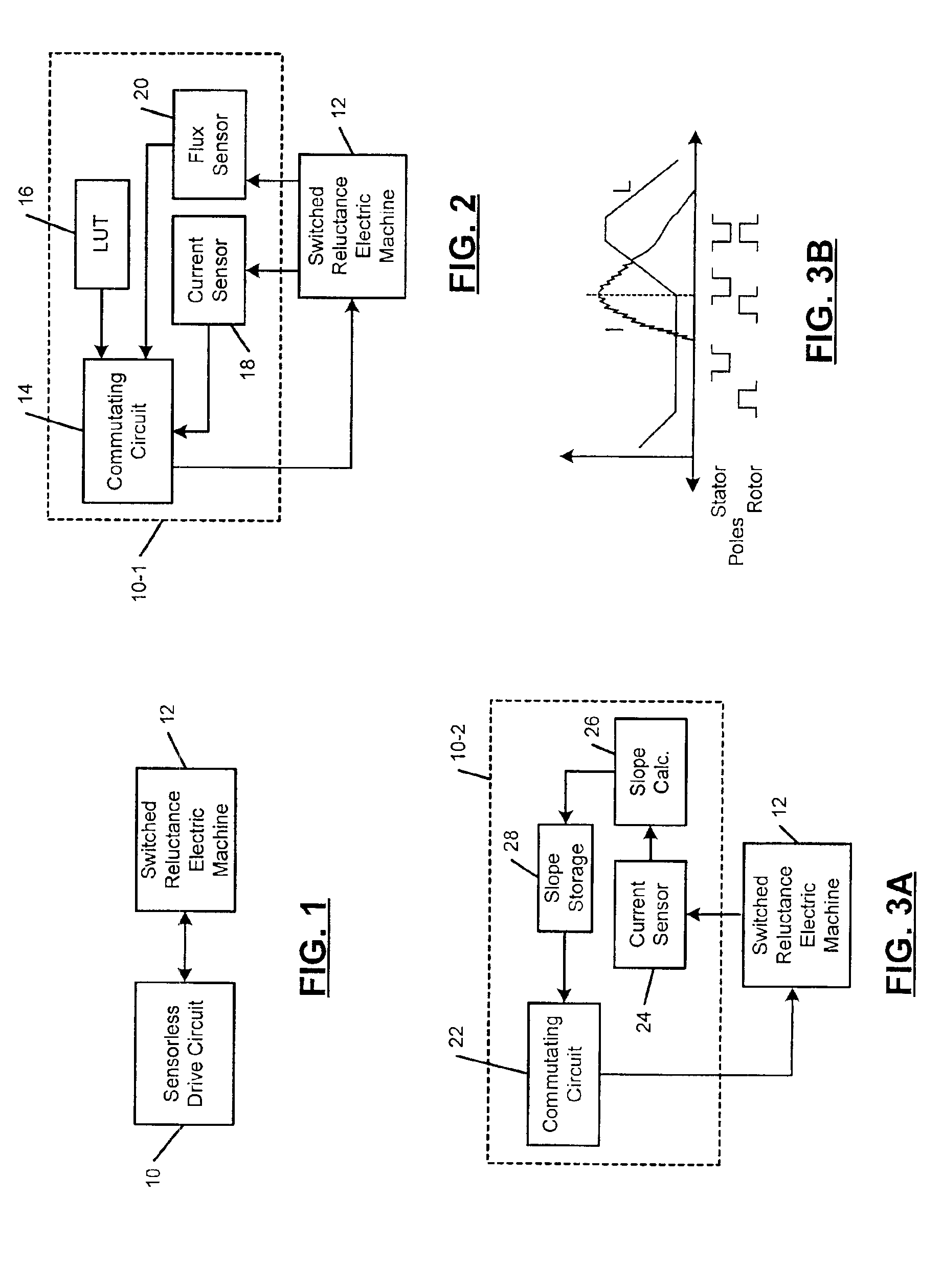

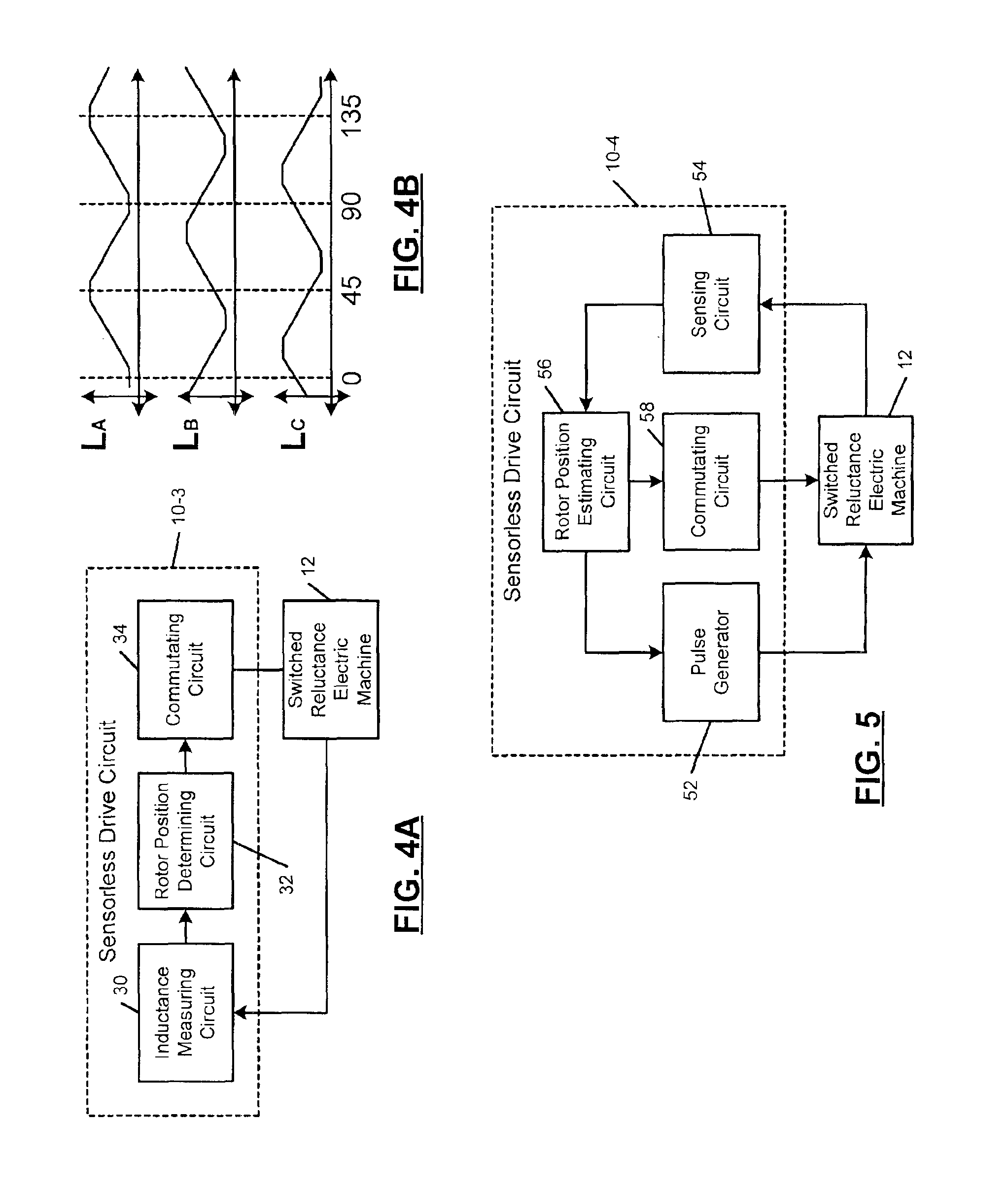

Sensorless switched reluctance electric machine with segmented stator

InactiveUS6897591B2Facilitate the improvement of precisionReduce usageElectronic commutation motor controlMotor/generator/converter stoppersElectric machineEngineering

A sensorless switched reluctance machine includes a stator with a plurality of circumferentially-spaced stator segment assemblies that include salient stator poles and inter-polar stator slots. Each of the stator segment assemblies includes a stack of stator plates forming a stator segment core, an end cap assembly, and winding wire wound around the stator segment core and the end cap assembly. The rotor defines a plurality of rotor poles. The rotor tends to rotate relative to the stator to a rotational position that maximizes the inductance of an energized winding. A sensorless drive circuit derives rotor position and energizes the winding wire around the stator segment assemblies based on the derived rotor position. Each stator plate includes a first radially outer rim section and a tooth section that extends radially inwardly from a first center portion of the first radially outer rim section.

Owner:NIDEC MOTOR CORP

Liquid cooled stator for high efficiency machine

ActiveUS20140300220A1Good thermal solutionHigh current densityManufacturing stator/rotor bodiesCooling/ventillation arrangementStatorWing configuration

Owner:LC ADVANCED MOTOR TECH CORP

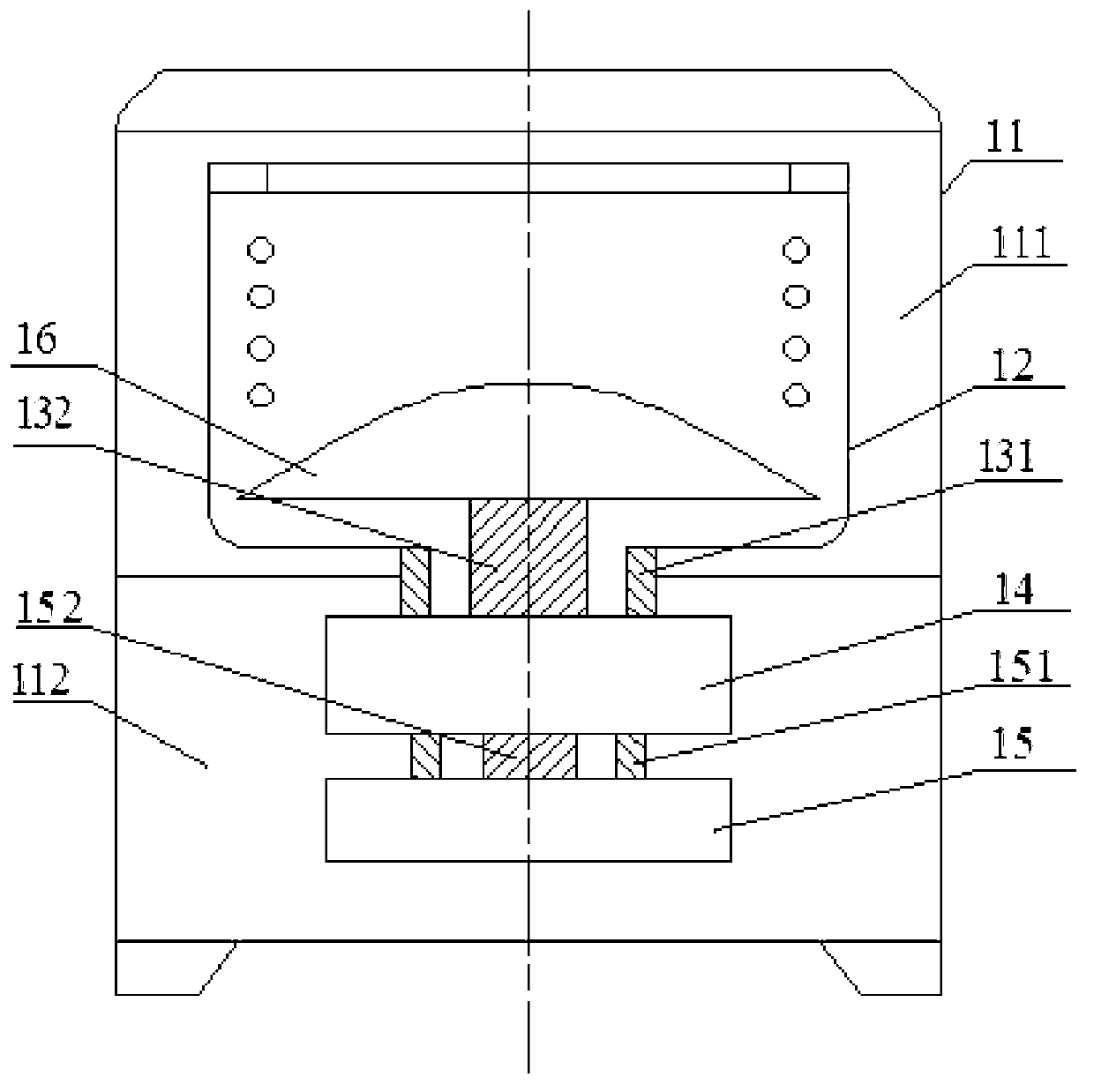

Structure of motor stator core and cooling method for motor stator based on structure of motor stator core

ActiveCN103280903ALow ferromagnetic lossImprove efficiencyWindings insulation shape/form/constructionMagnetic circuit stationary partsWater coolingOil cooling

The invention relates to a structure of a motor stator core and a cooling method for a motor stator based on the structure of the motor stator core. The structure is characterized in that the stator core is formed by splicing and combining stator yoke units and stator tooth units, wherein the quantities of the stator yoke units and the stator tooth units are the same, and are equal to the slot number Z1 of a stator; the stator yoke units and the stator tooth units are formed by laminating oriented silicon steel sheets; a stator yoke unit is connected between every two adjacent tooth units; the tooth units and the stator yoke units are in joggle joint; the silicon steel sheets of the stator yoke units are oriented circumferentially; and the silicon steel sheets of the stator tooth units are oriented radially. The cooling method is selected from one of air cooling, water cooling and oil cooling. The structure has the advantage that the motor has the characteristics of low ferromagnetic loss, high efficiency, low torque pulsation, low slot effect, low running noise, low wind resistance, high slot fullness rate of a stator winding, high utilization ratio of a silicon steel sheet material, suitability of the stator for automatic mass production and the like.

Owner:曹宇轩

Direct-drive composite type permanent magnet motor

InactiveCN101330234ACancel noiseEliminate vibrationMagnetic circuit rotating partsDynamo-electric gearsLow speedElectric machine

The invention relates to a direct-drive combined motor which comprises a self-control permanent-magnet motor and a concentric magnetic gear. The permanent-magnet motor and the magnetic gear are integrated by adopting the sleeve-type structure or the axial series connection structure. The combined permanent-magnet motor can automatically realize the high-speed low-torque power transfer and the low-speed high-torque power transfer therein without a mechanical gear case. The motor can serve as an electric motor and a power generator.

Owner:许晓华

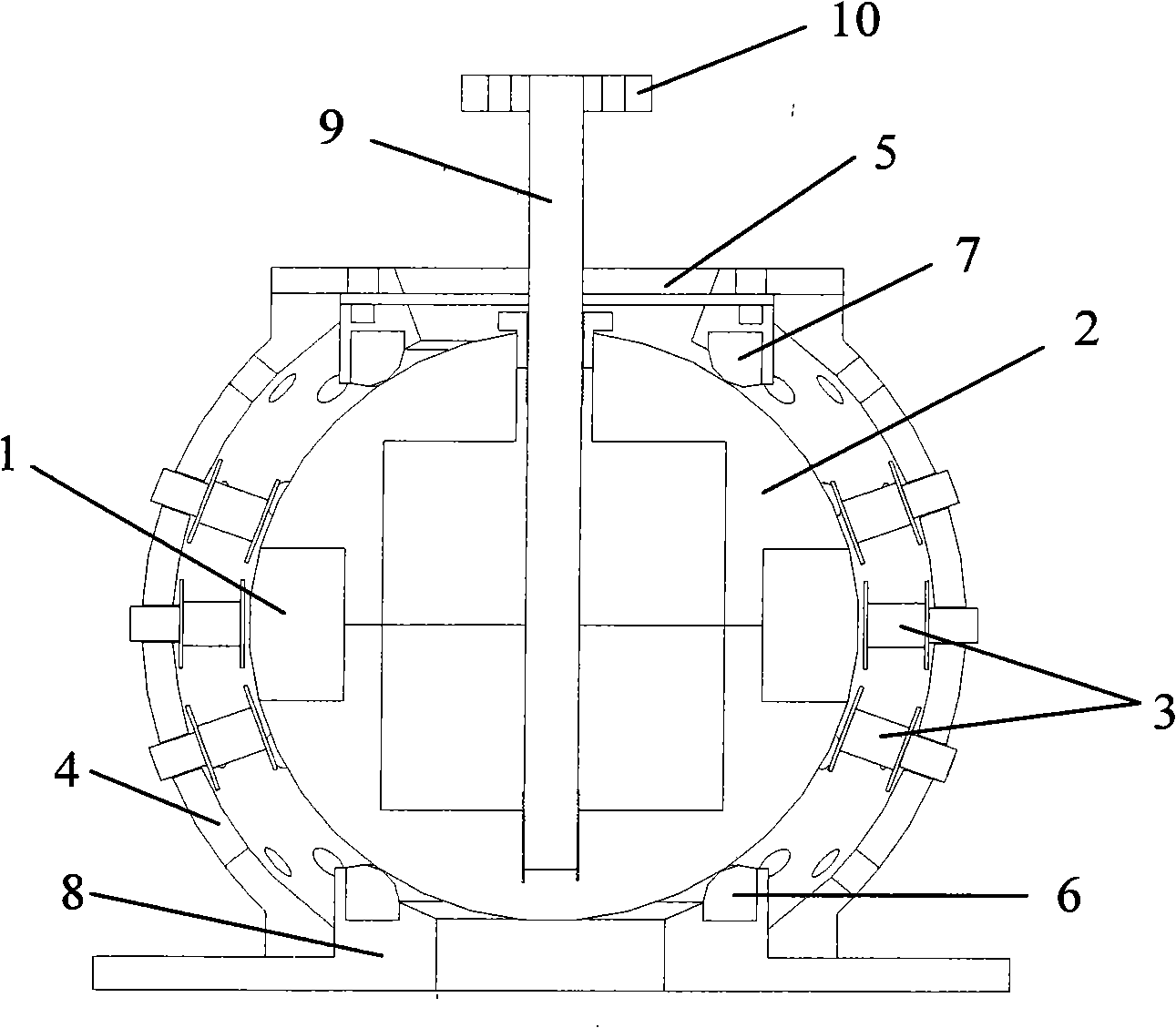

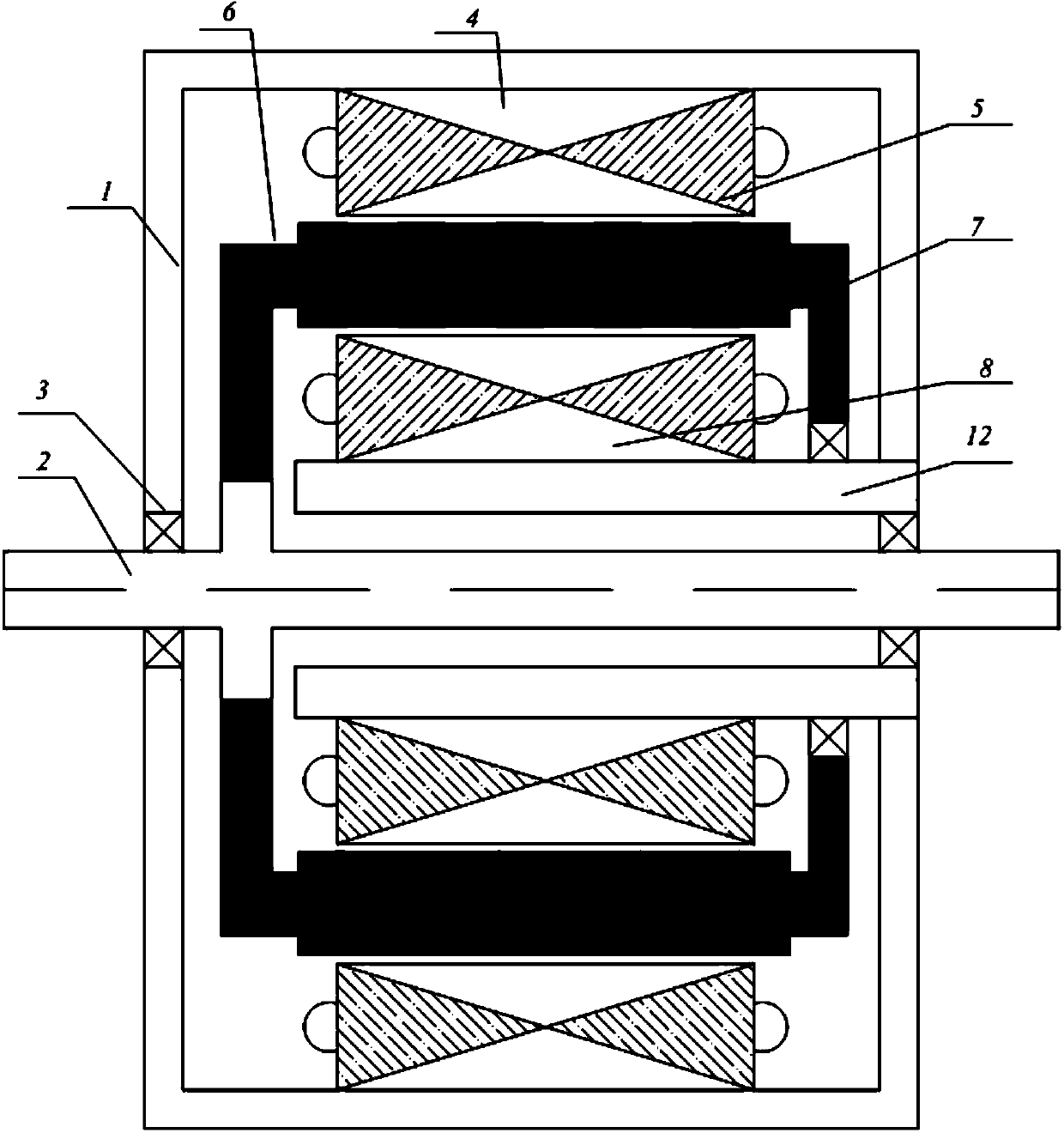

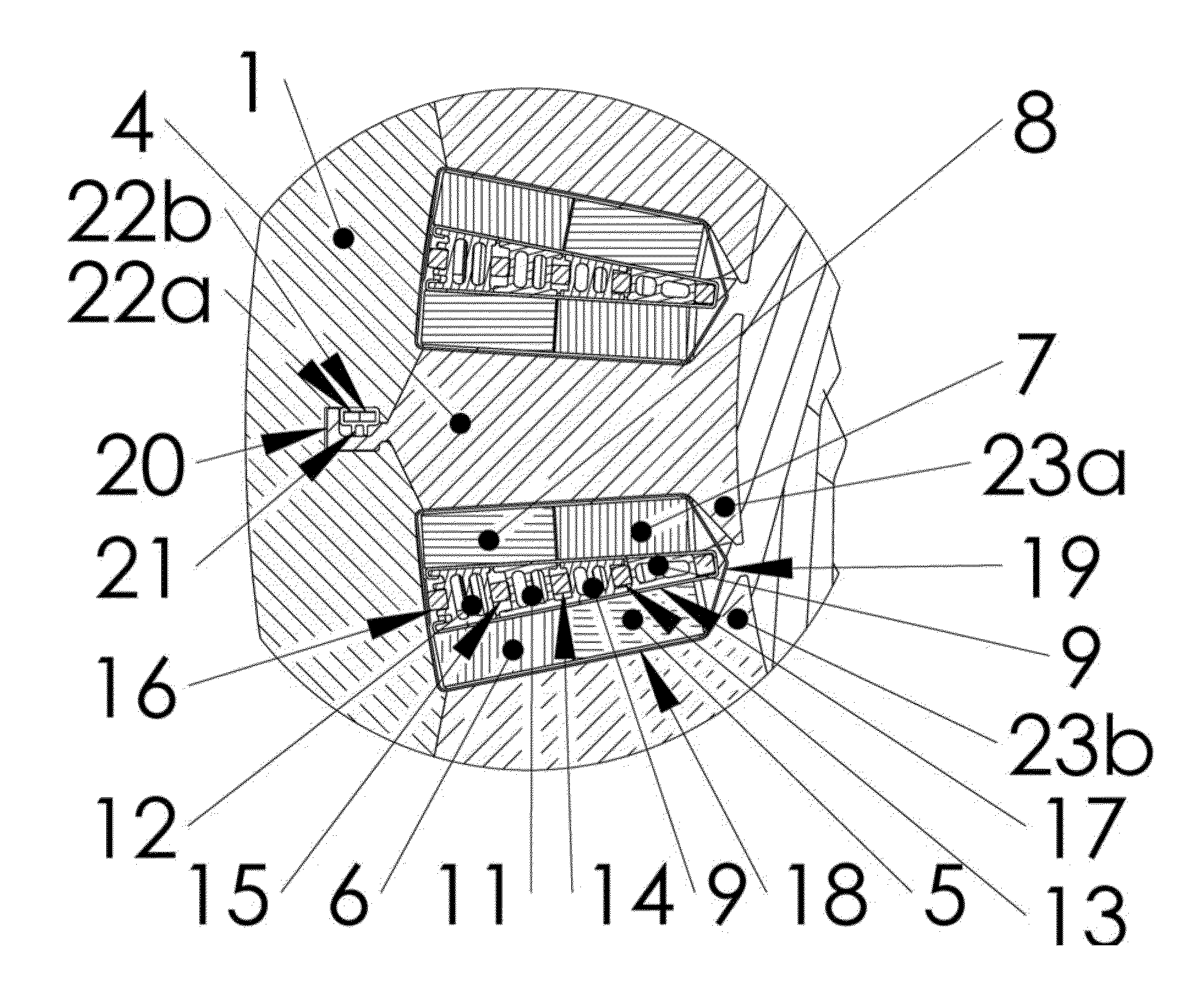

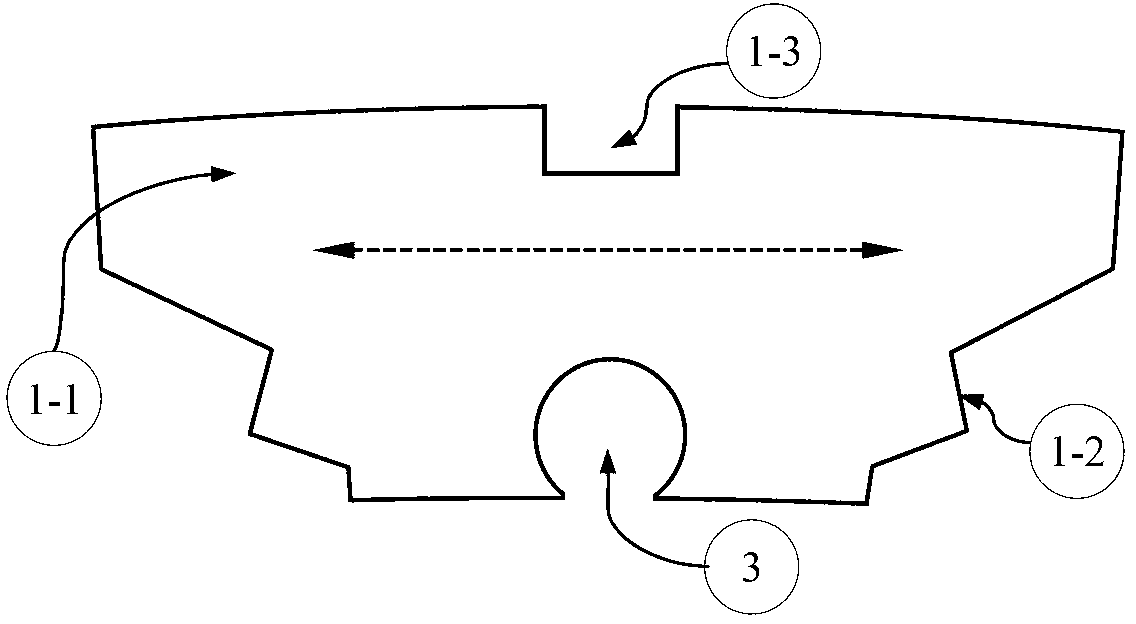

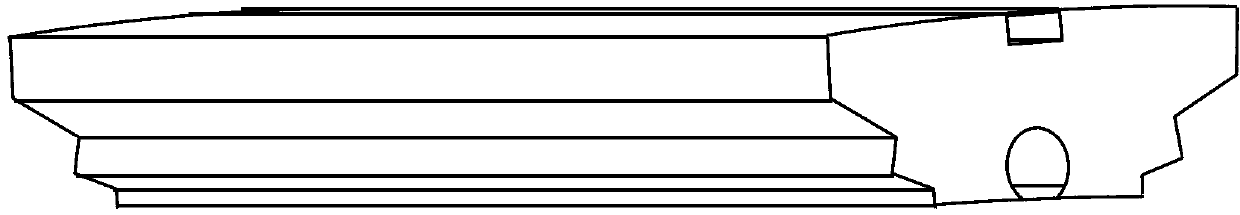

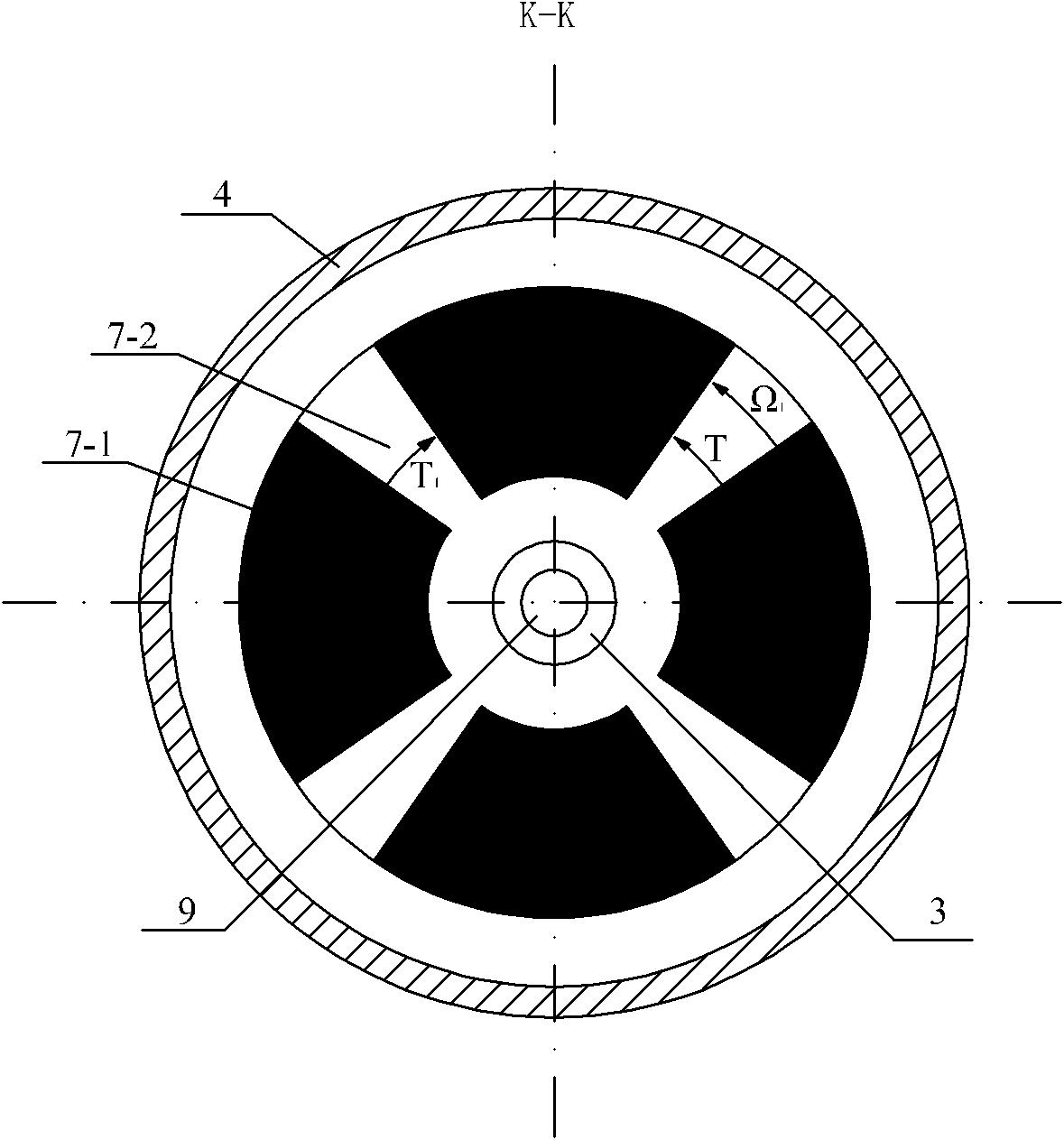

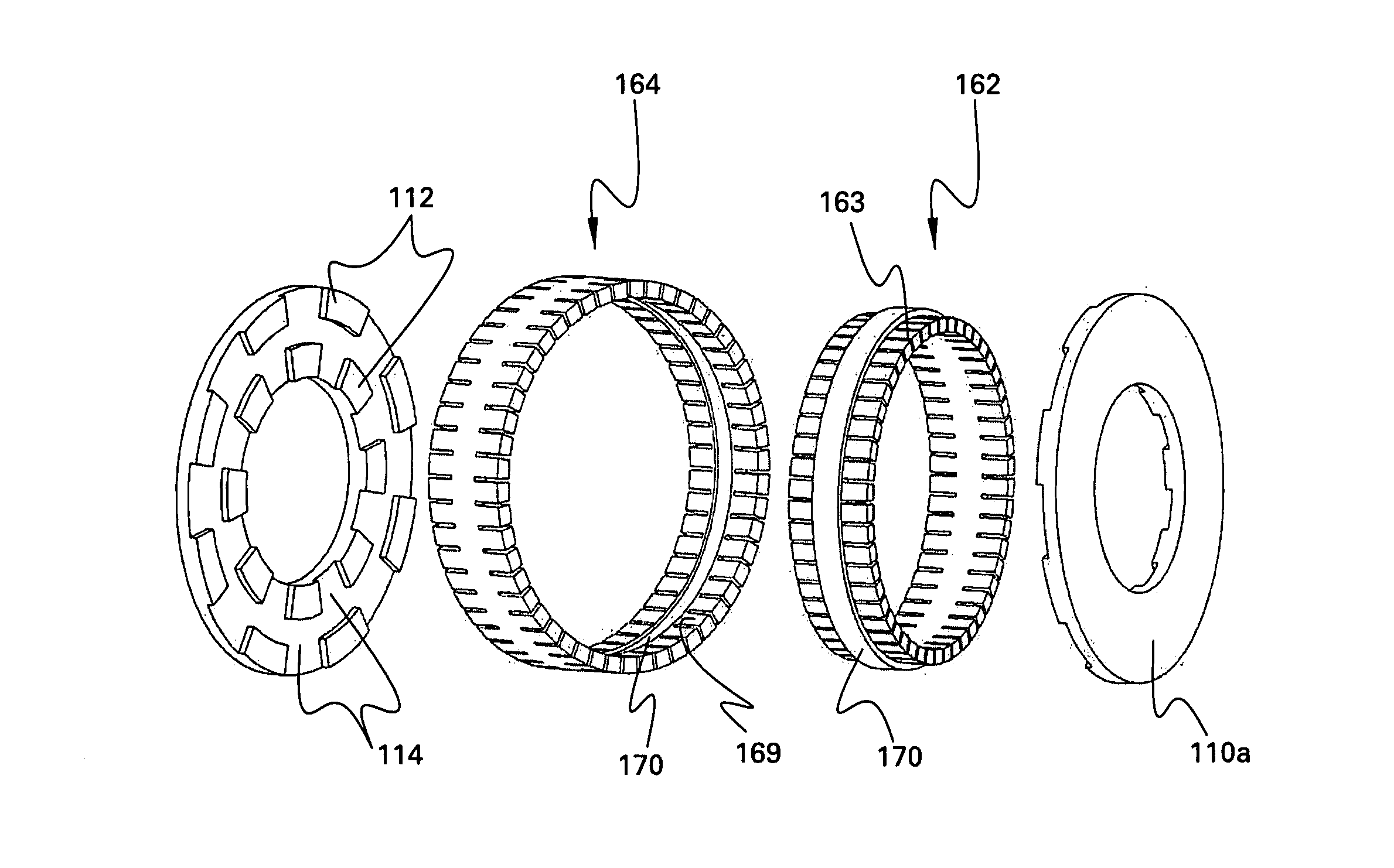

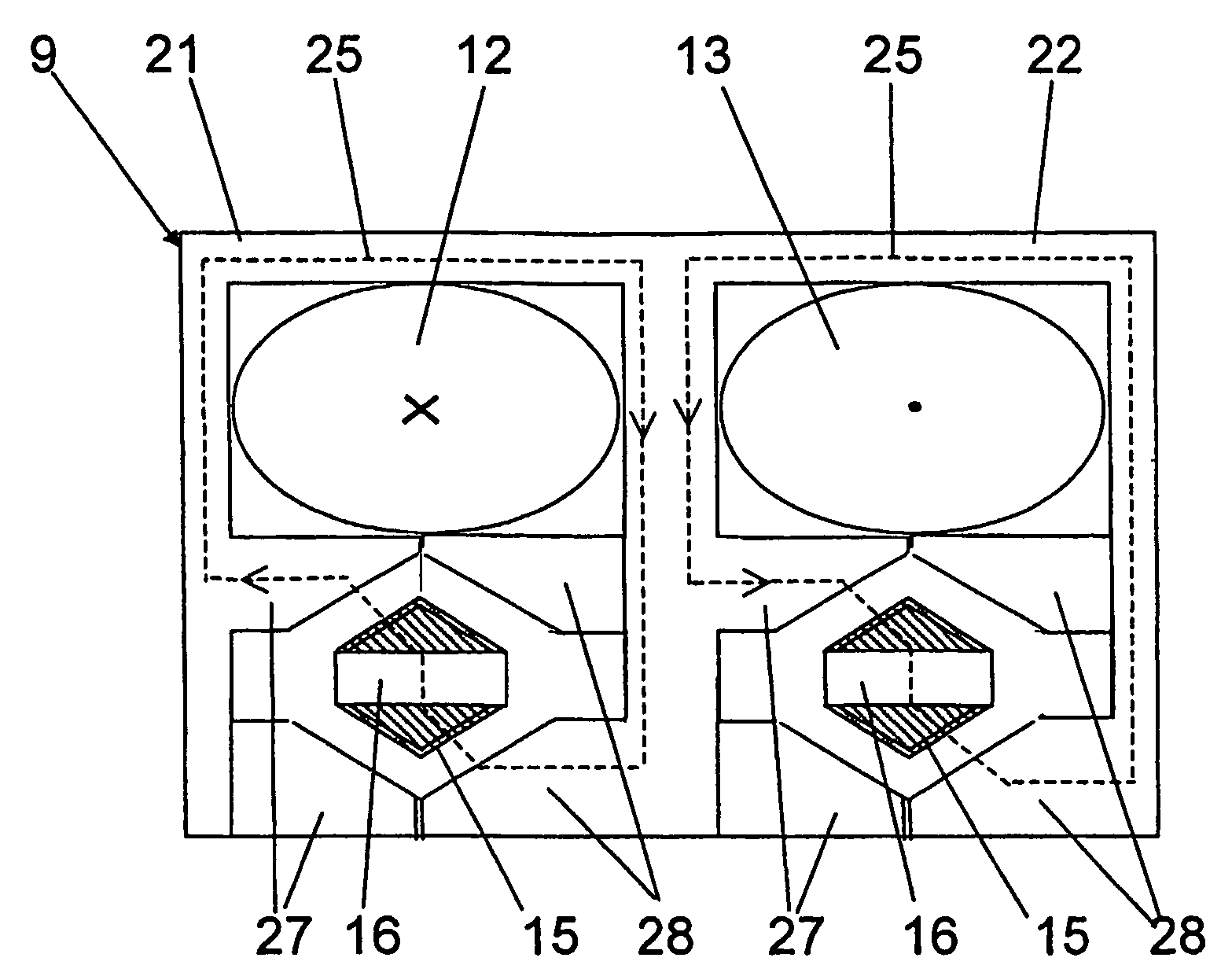

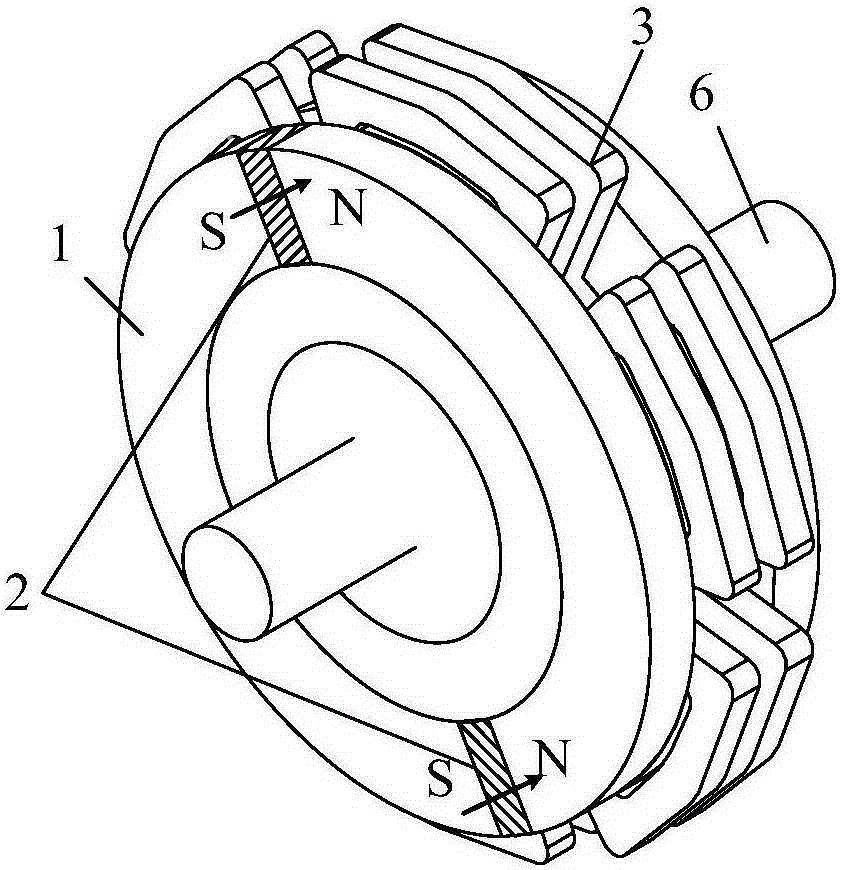

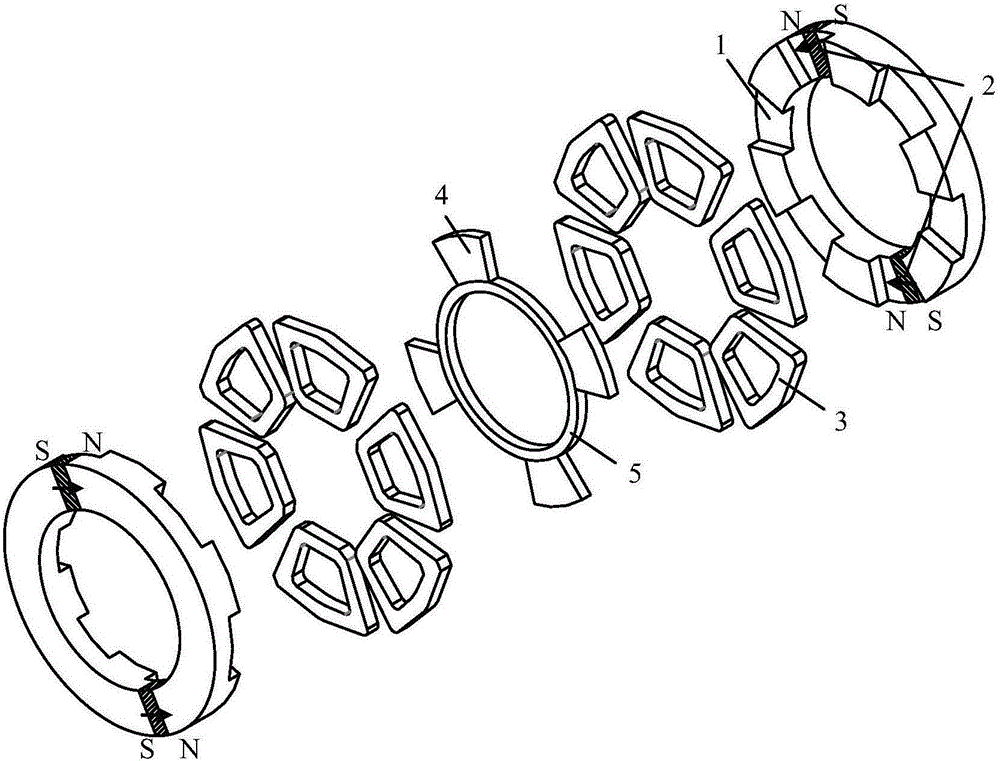

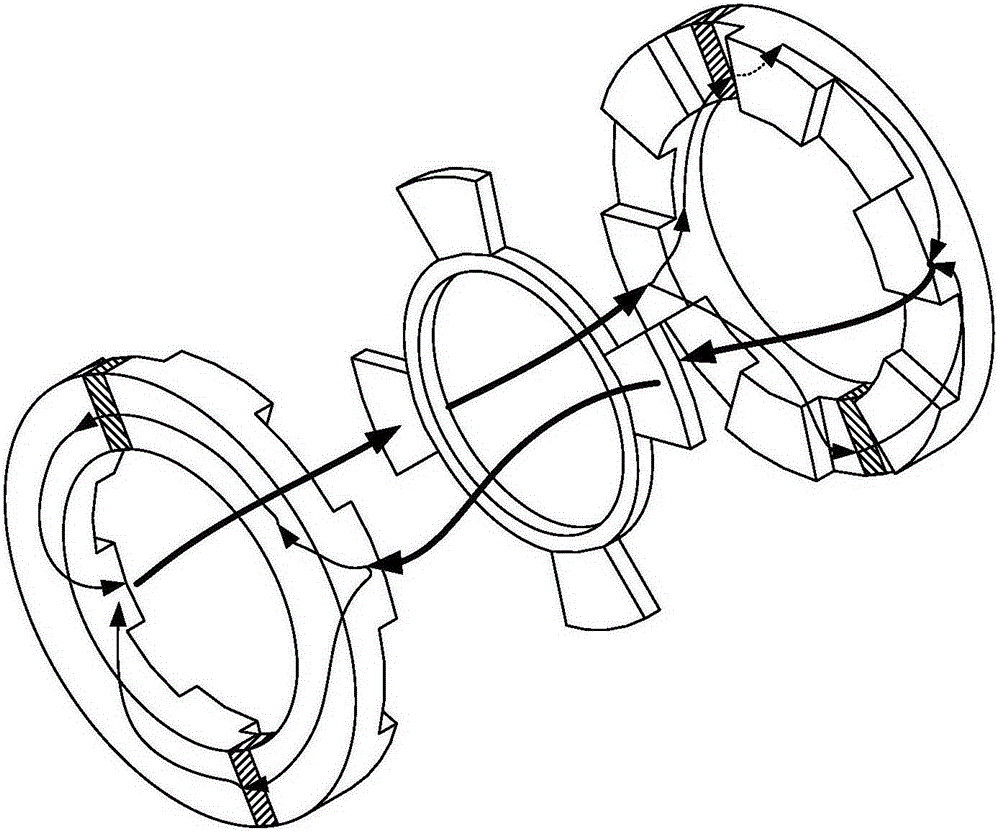

Axial magnetic field modulated brushless double rotor motor

ActiveCN101924436AReduce volumeLow costMagnetic circuit rotating partsElectric machinesPermanent magnet rotorMotor drive

The invention discloses an axial magnetic field modulated brushless double rotor motor, belonging to the motor field and solving the problems that the operating efficiency is lowered and the reliability is reduced because the winding rotation in a double rotor motor introduces the current through an electric brush and a slip ring, and the components, such as electric brushes and the like need to be maintained. The two stators of the invention are fixed the left end and the right end of a shell; a modulated ring rotor is positioned between the two stators and outside a permanent magnet rotor; a prime motor drives the permanent magnet rotor to rotate to form a 2n pole magnetic field; the stator is electrified to form a 2p pole magnetic field; the 2n pole magnetic field and the 2p pole magnetic field are modulated by the modulated ring rotor; q magnetic-conducting pieces and q insulated pieces are arranged on the end surface at the two sides of a stator frame of the modulated ring rotor along the peripheral direction in an interlacing manner; the relational expression that p is equal to the absolute value of the sum of hn and kq is satisfied, which is given to the load by the output shaft of the modulated ring rotor in different rotating speed; and the axial magnetic field modulated brushless double rotor motor of the motor of the invention has two structures, one structure is in axial symmetrical type, and the other structure is in axial unilateral type. The motor of the invention is used for the occasions of electric automobiles, wind power generation and torpedo drive.

Owner:HARBIN INST OF TECH

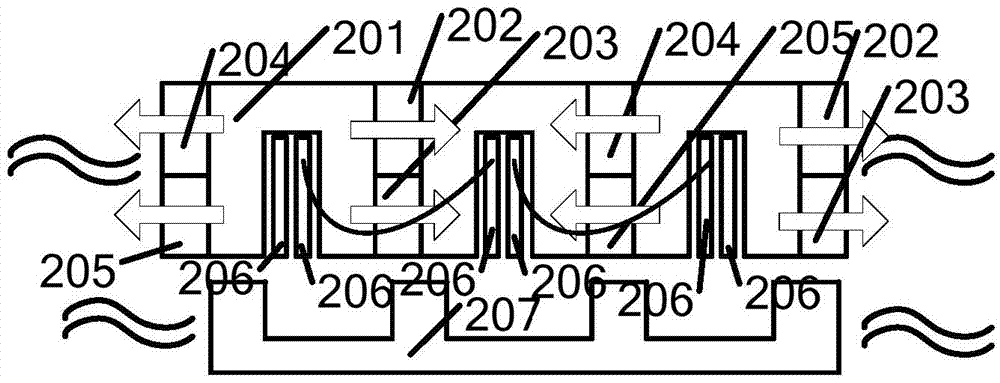

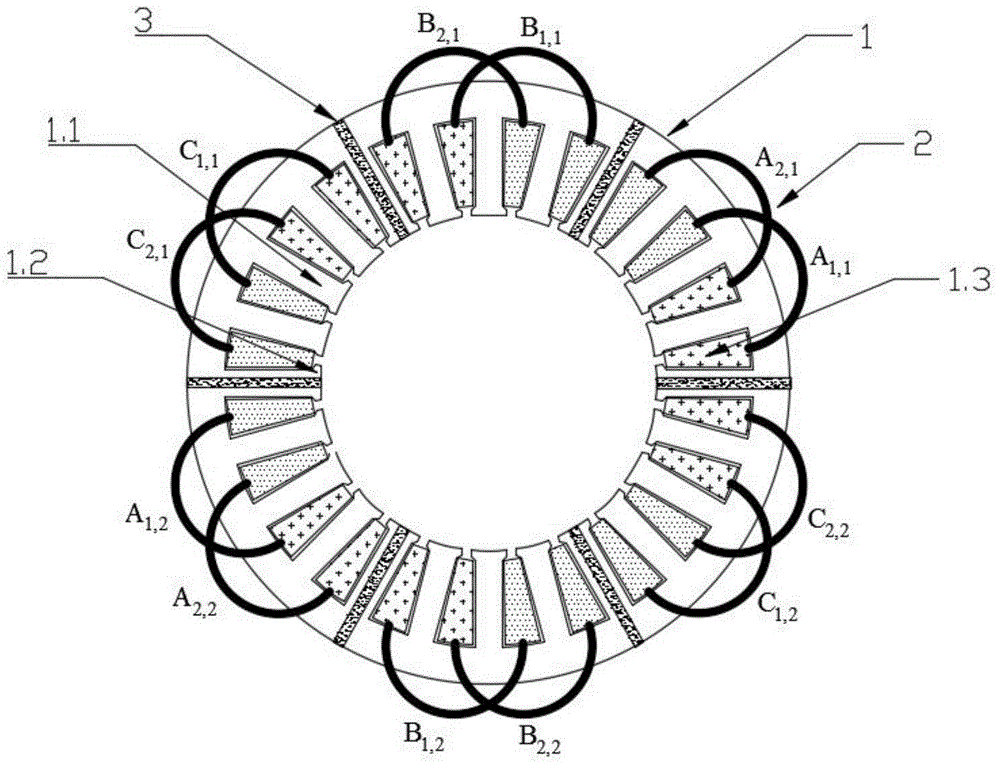

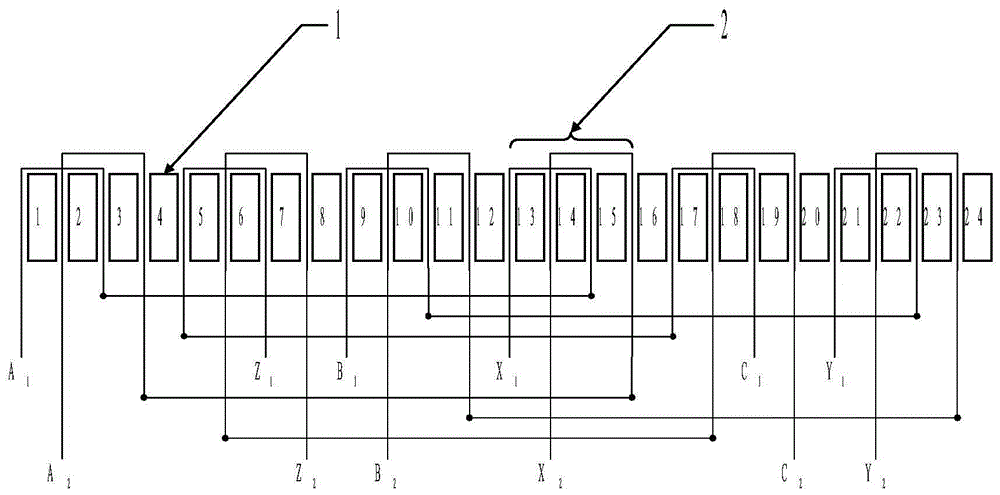

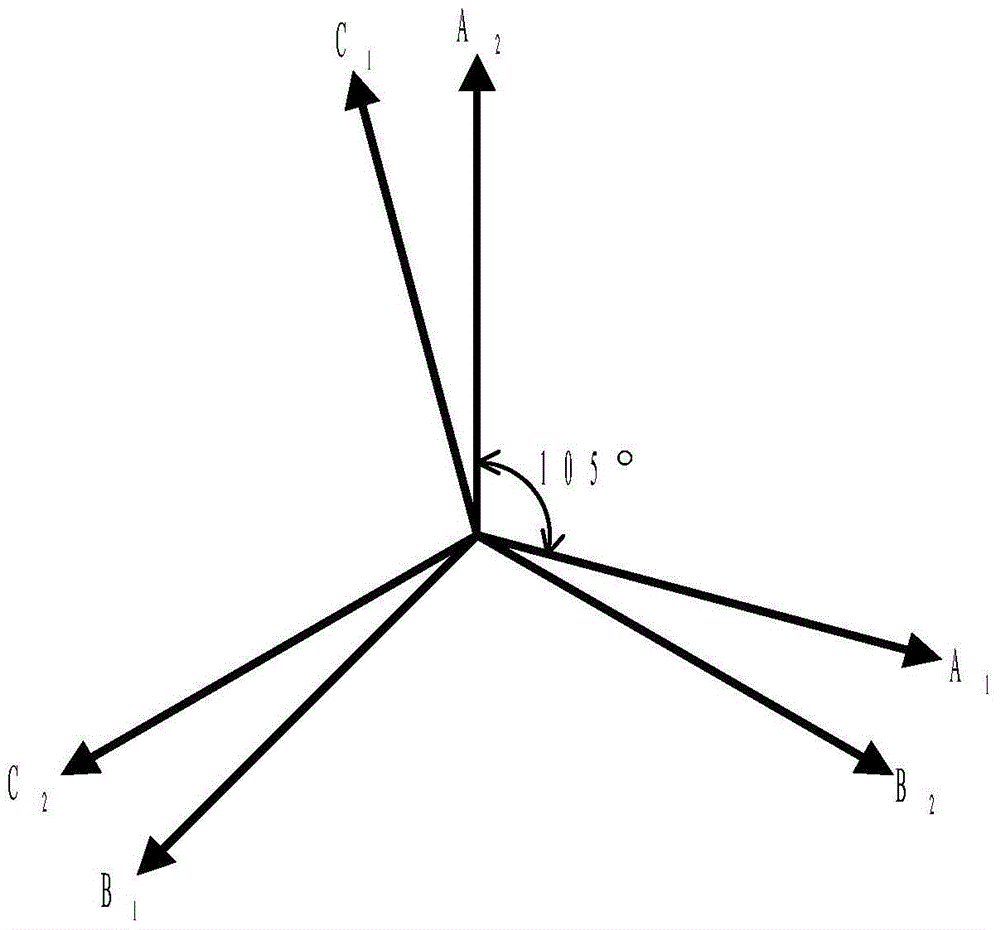

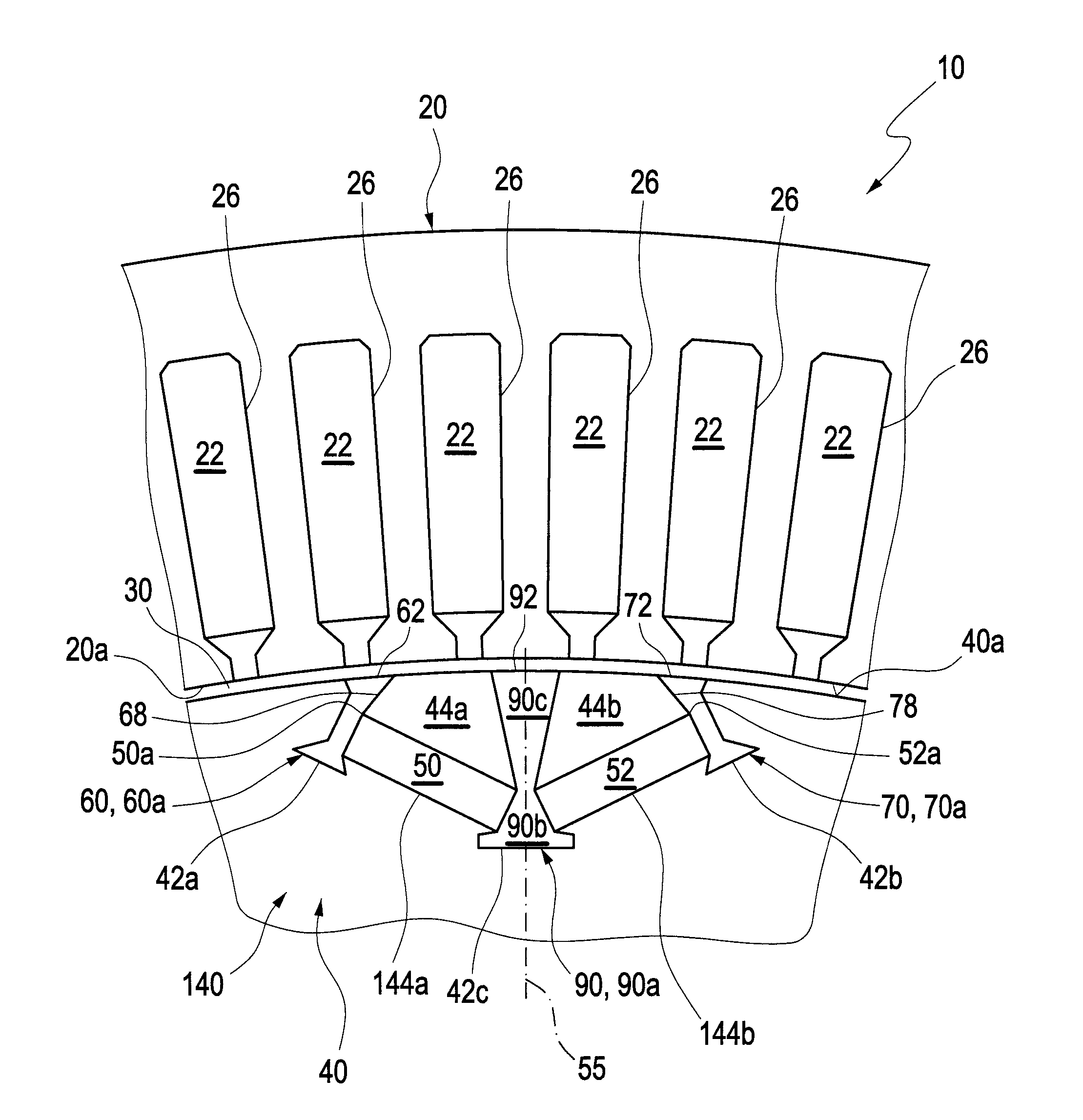

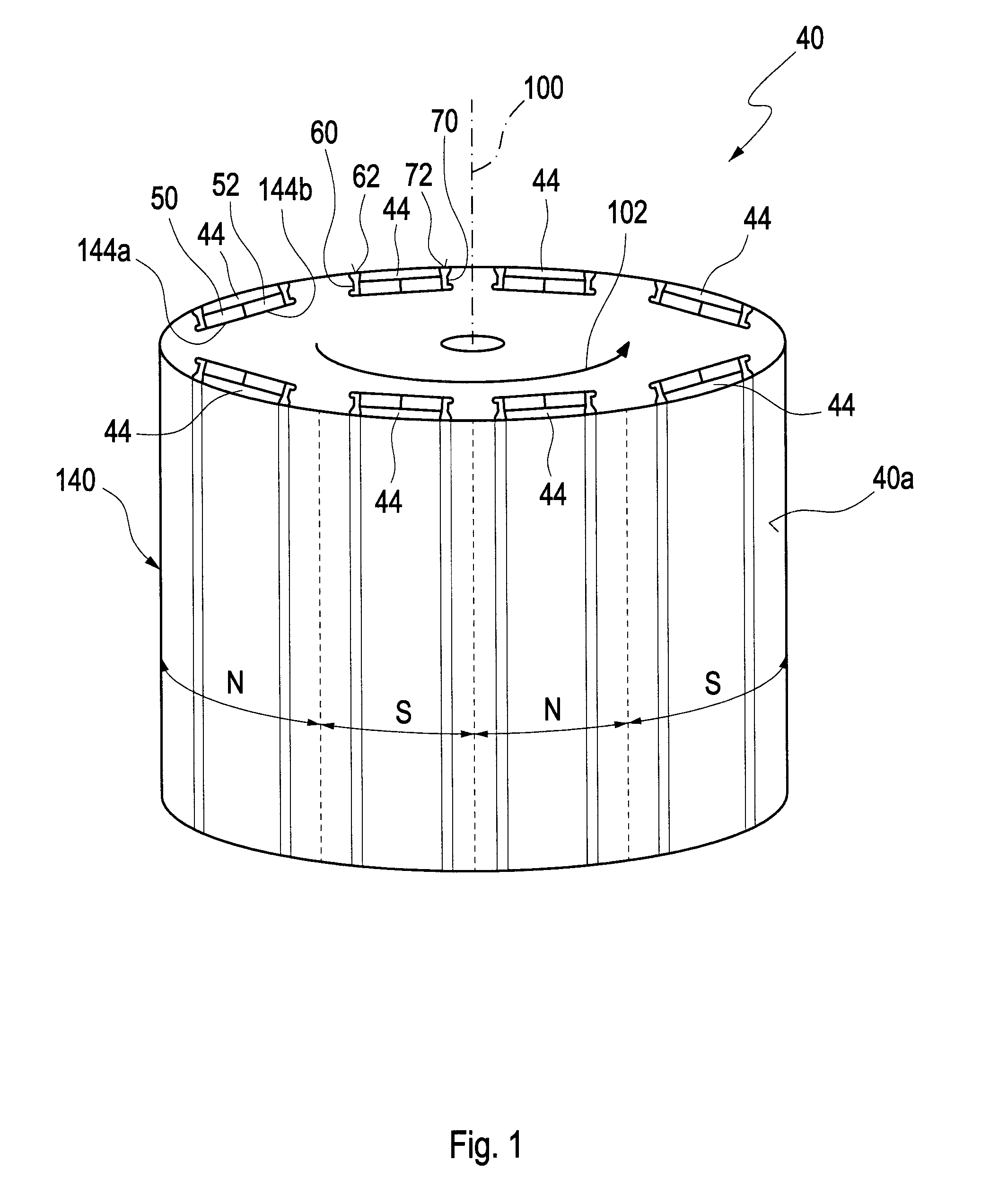

Structure for modular motor stator and end part overlapping fractional slot windings of modular motor stator

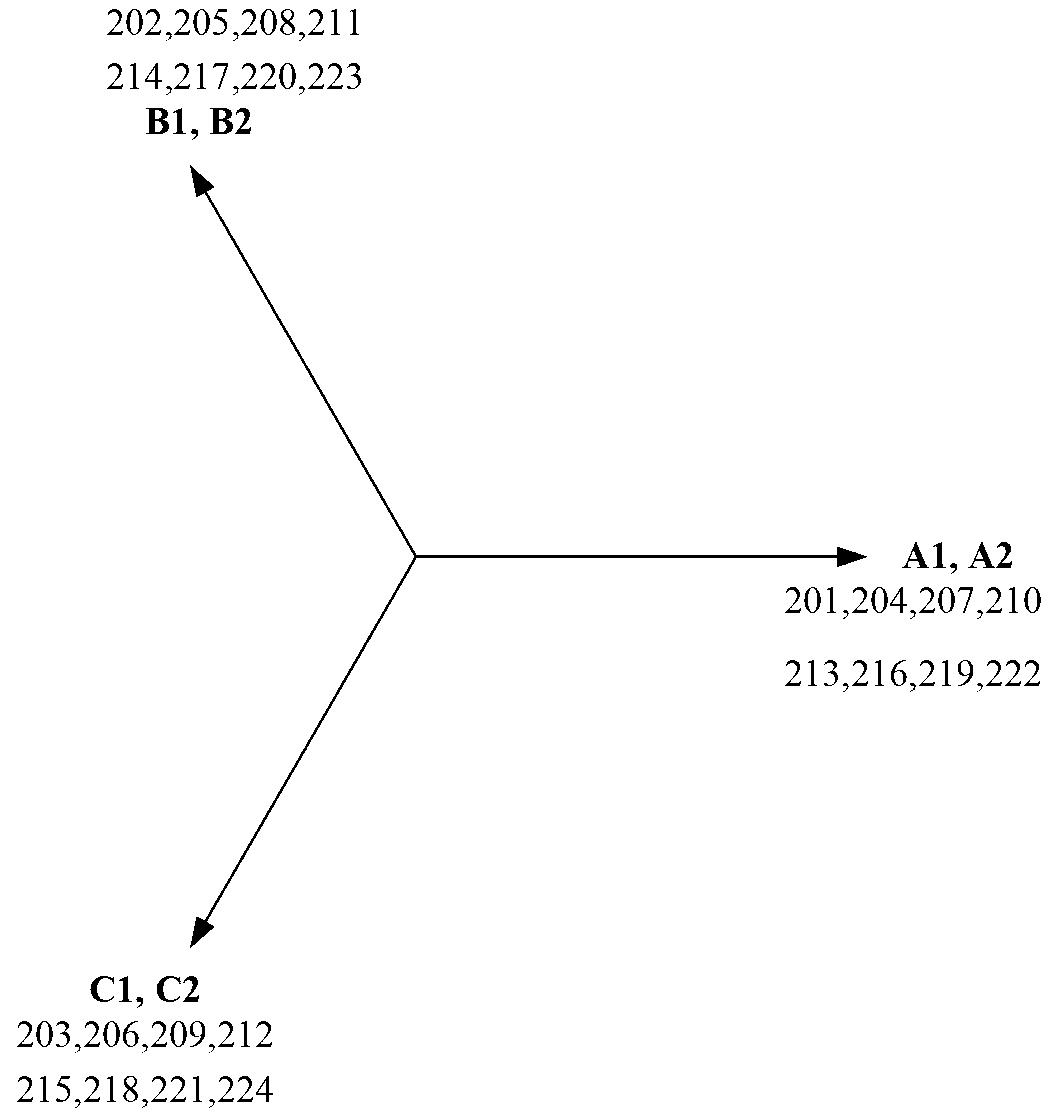

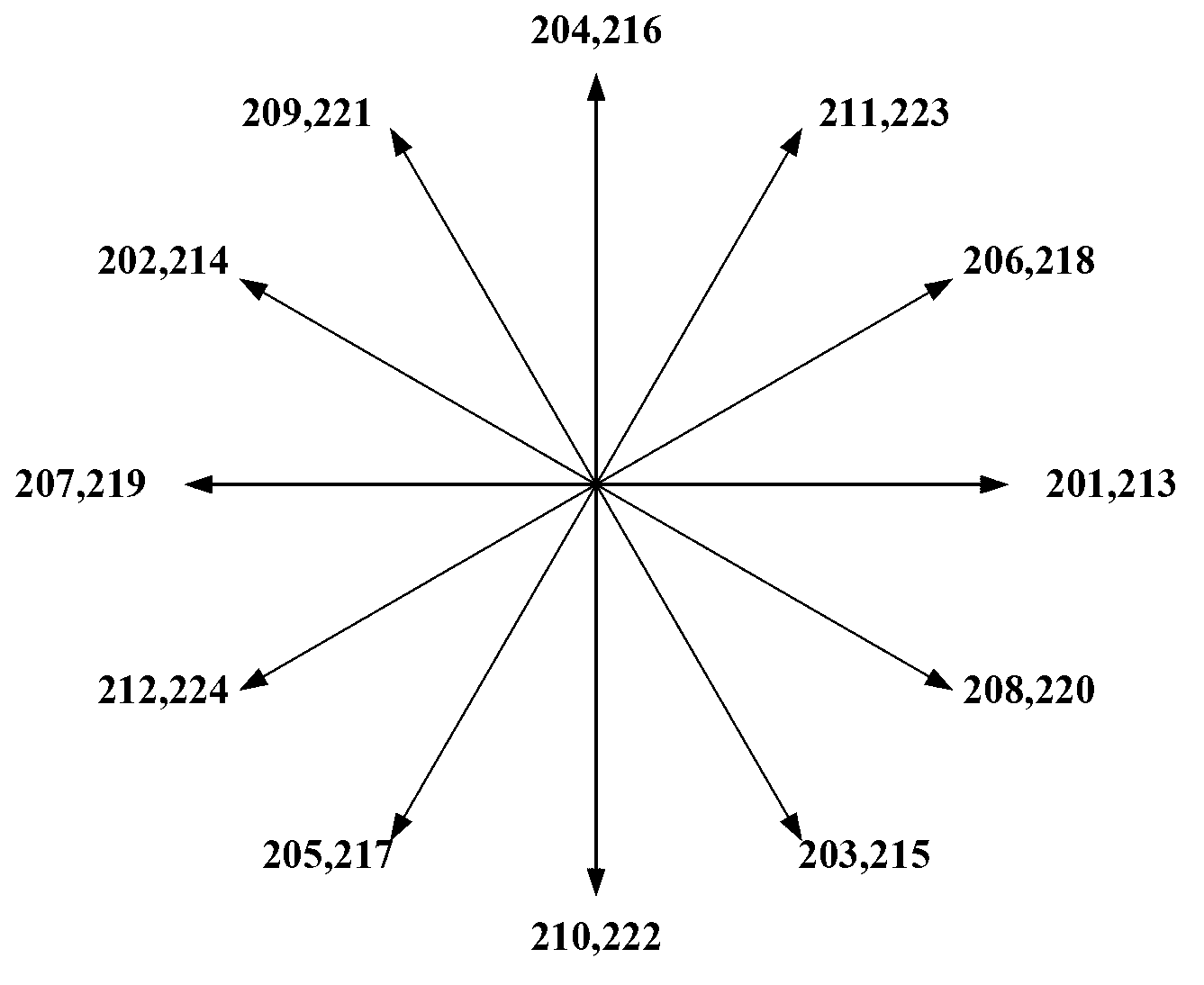

ActiveCN105680585ASmall torqueReduce torque rippleMagnetic circuit stationary partsWindings conductor shape/form/constructionMagnetomotive forceHarmonic

The invention provides a structure for a modular motor stator and end part overlapping fractional slot windings of the modular motor stator. The number of stator slots and the number of winding pole pairs are set to be 2Z and p respectively, wherein the stator slots are evenly distributed on the circumference; the stator comprises two sets of three-phase symmetric AC windings; the windings are evolved from traditional single-layer concentrated fractional slot windings; the arrangement of each set of windings is the same as that of the traditional single-layer concentrated fractional slot windings with Z slots and p pole pairs; the staggered angle of two sets of windings is one half of a coil span mechanically; overlapping regions at the end parts of the windings are distributed on the circumference of the stator at intervals; and modularization can be achieved by cutting the stator in the non-overlapping regions at the end parts of the windings. The structure can greatly reduce the non-working tooth harmonic content in magnetomotive force of the traditional concentrated fractional slot windings, so that the motor loss can be reduced; torque pulsation is stabilized; the noise is reduced; meanwhile, the structure has the advantage that the motor stator with the concentrated fractional slot windings can be modularized; manufacturing, transportation and assembly of a large motor are facilitated; the interphase mutual inductance is small; and improvement of the fault-tolerant capability of the motor is facilitated.

Owner:SOUTHEAST UNIV

Low-vibration noise performance fractional slot concentrated winding permanent magnet motor and design method

ActiveCN107579606AReduce harmonic amplitudeReduce MMF tooth harmonicsMagnetic circuit stationary partsWindings conductor shape/form/constructionControl theoryConductor Coil

The invention discloses a low-vibration noise performance fractional slot concentrated winding permanent magnet motor and a design method, and belongs to the field of rotating motors. On the basis ofa motor matched with an existing notched pole, and some stator additional teeth are correspondingly added (the specific number of the teeth is determined according to the matched notched pole of the motor). For a three-phase 18 / 16 motor, six additional teeth are added, the position of each stator notch is calculated, and the winding structure adopts a concentrated winding structure corresponding to the three-phase 18 / 16 motor. The rotor structure adopts the common surface-mounted structure, and radial magnetizing is adopted; the motor has the advantages that the stator structure is changed, the content of tooth harmonic waves in the winding magnetomotive force in an air gap is lowered, therefore, the motor vibration and noise are lowered, and meanwhile the rotating torque of the motor is ensured. In addition, due to changes of the stator structure, the content of subharmonic waves of the magnetomotive force in the air gap is lowered, and then eddy-current losses generated in the permanent magnet are lowered. Accordingly, the motor has the great significance in motor body designing.

Owner:JIANGSU UNIV

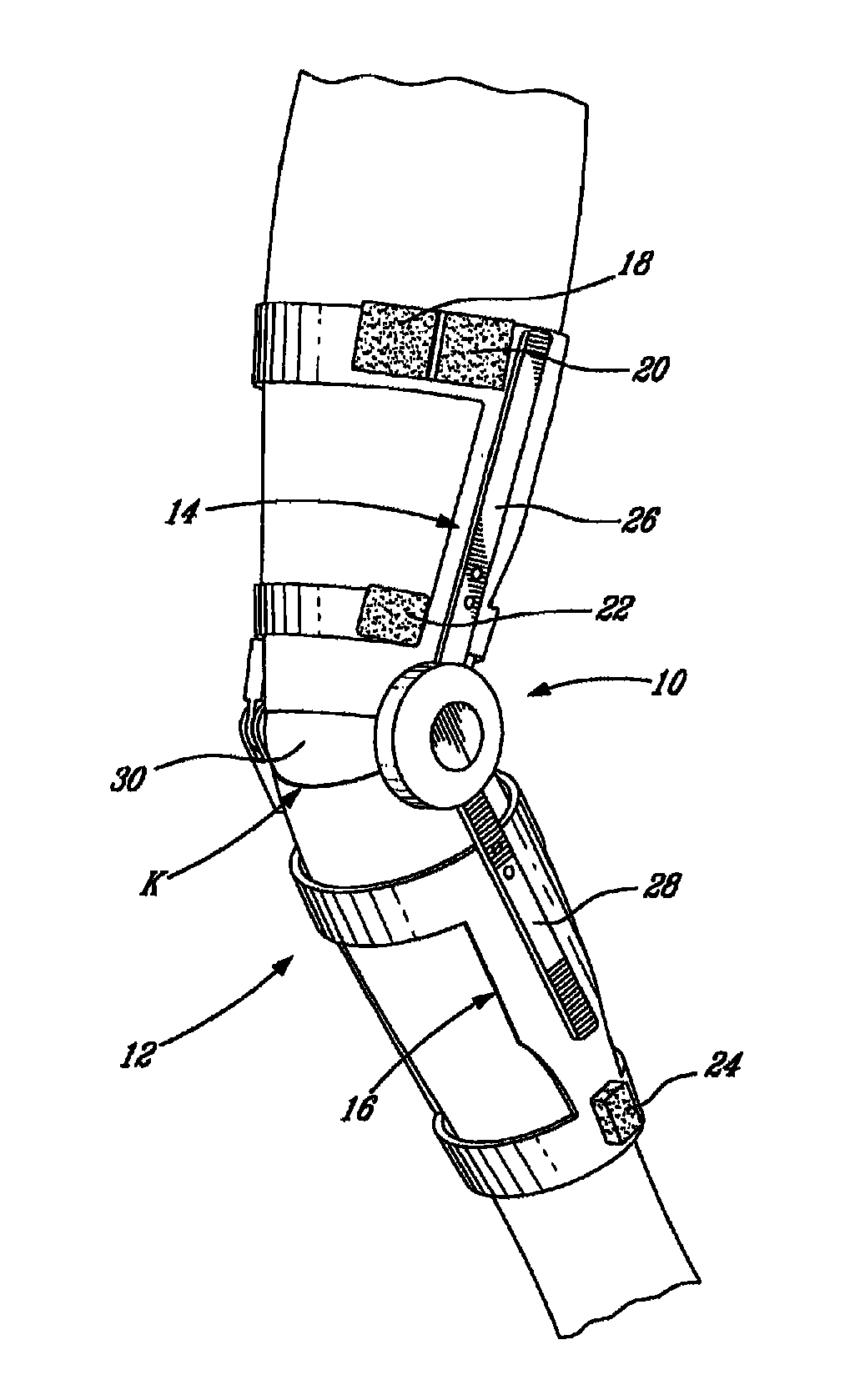

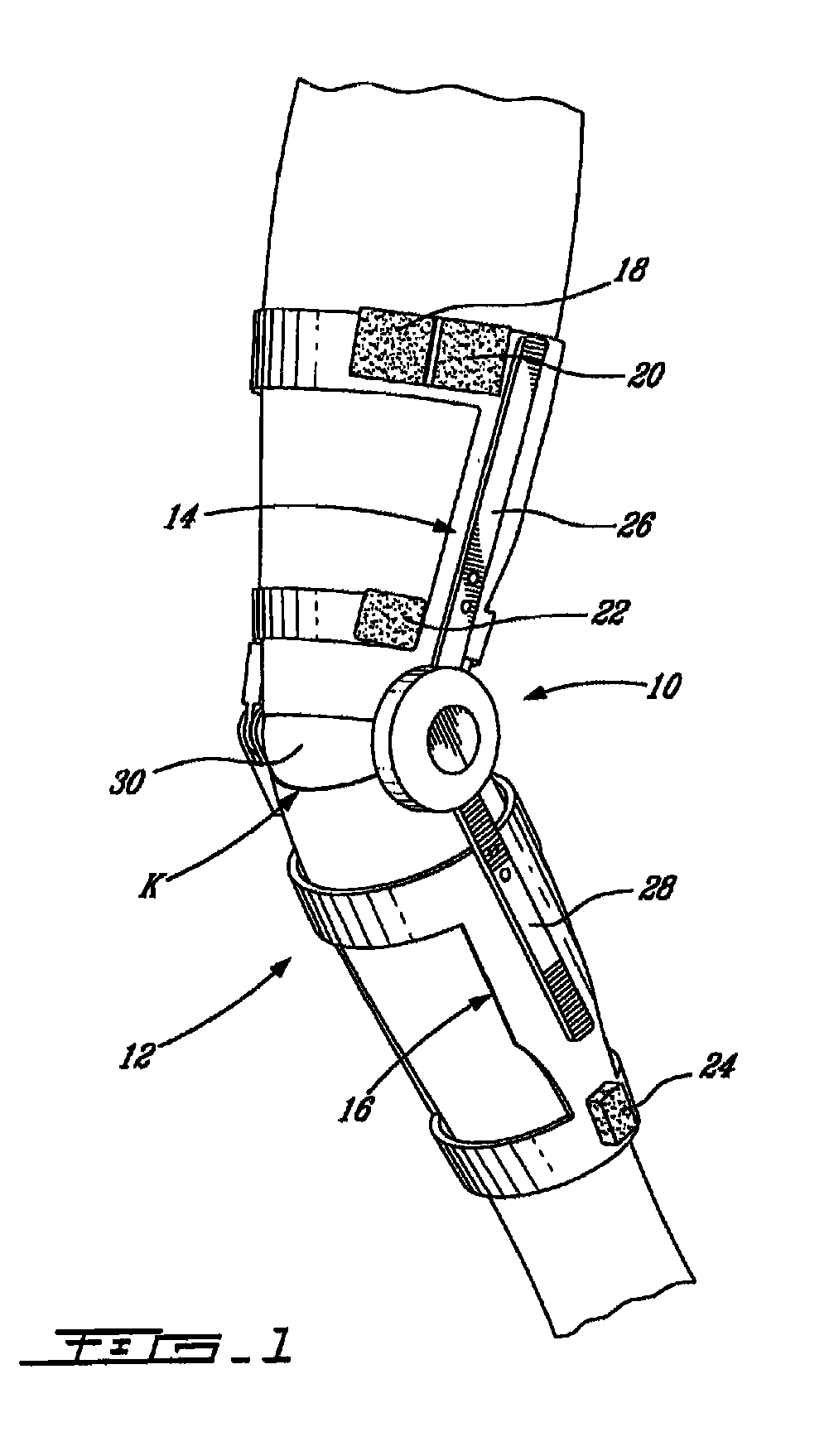

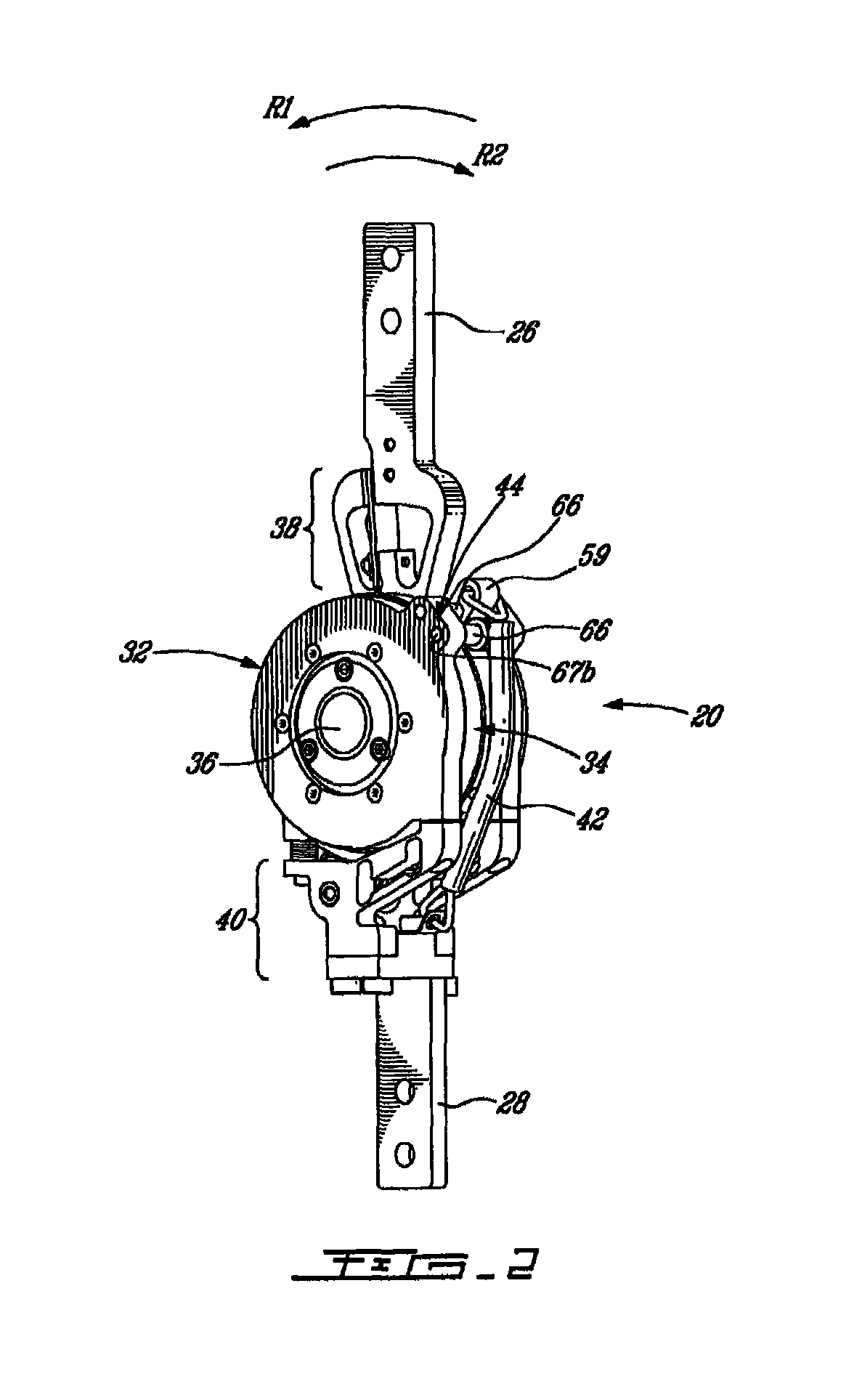

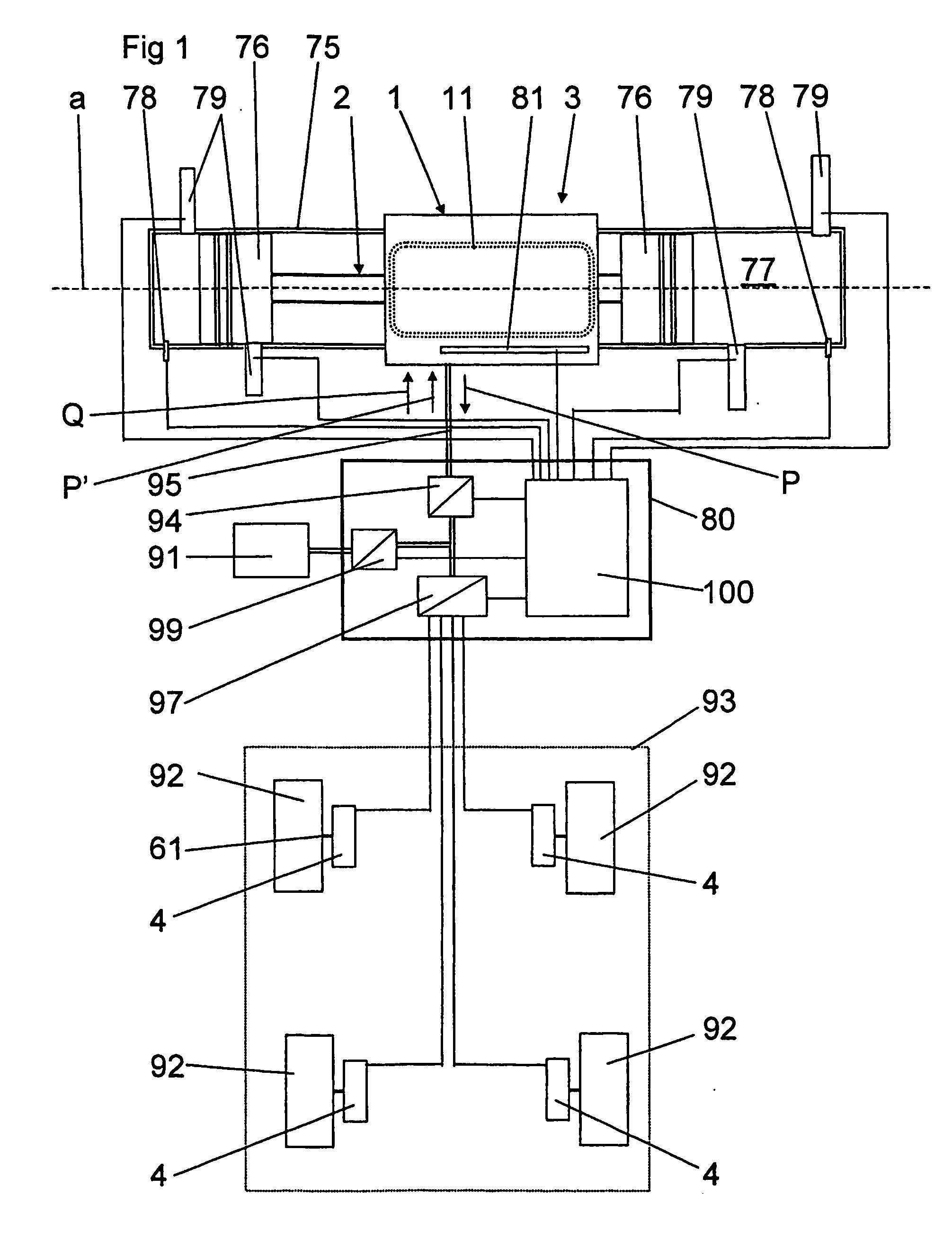

High torque active mechanism for orthotic and/or prosthetic devices

ActiveUS8211042B2Increased torque densityWork measurementNon-surgical orthopedic devicesBrake torqueEngineering

A high torque active mechanism for an orthotic and / or prosthetic joint using a primary brake which can be provide by magnetorheological (MR) rotational damper incorporating and an additional friction brake mechanism driven by the braking force generated by the MR damper. This combination of MR damper and friction brake mechanism allows an increase in torque density while keeping the same level of motion control offered by the MR damper alone. The increased torque density achieved by this high torque active mechanism allows to minimize the size of the actuating system, i.e. its diameter and / or breath, while maximizing its braking torque capability. In this regard, the friction brake mechanism is advantageously positioned around the MR damper, such that the dimension of the package is minimized.

Owner:NATIONAL BANK OF CANADA

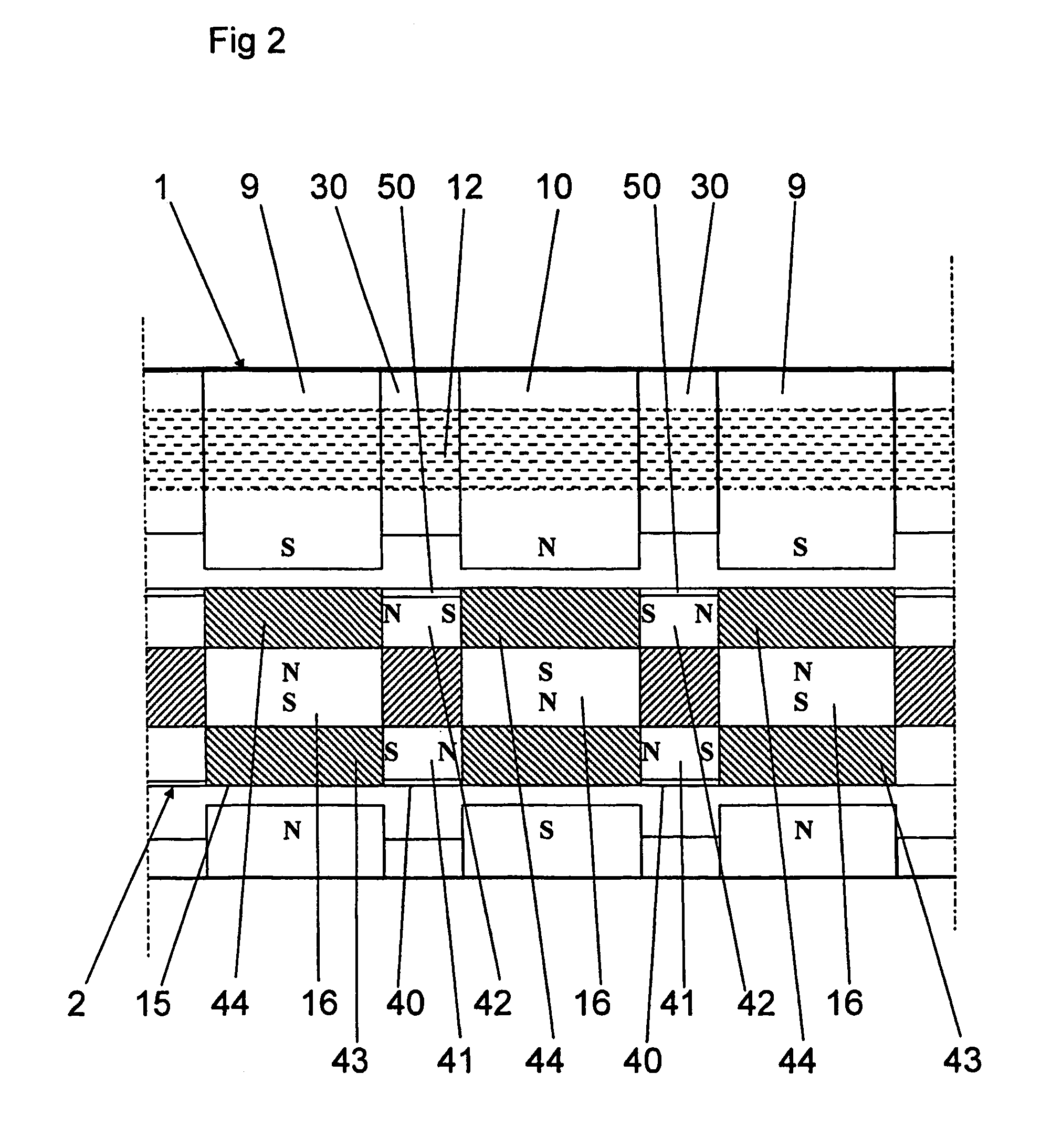

Superconducting rotating machines with stationary field coils

InactiveUS20060028085A1Improved performance characteristicsIncreased torque densitySynchronous generatorsMagnetic circuit rotating partsStator coilStationary field

A machine includes a rotatable rotor assembly having a number of salient poles. The machine further includes a stationary stator assembly having concentric inner and outer stators, at least one stationary superconducting field coil and at least one stator coil. The stationary superconducting field coil is disposed between the inner and outer stators and is mounted on at least one of the inner and outer stators. The stationary superconducting field coil and the salient poles are configured relative to each other, such that when the rotor assembly is rotated relative to the stator assembly around a predetermined axis, a rotating magnetic field is produced with an airgap flux direction substantially along the predetermined axis. The interaction between the stationary superconducting field coil and the rotating poles provides the only source of a time varying magnetic flux supplied to the stator coil.

Owner:GENERAL ELECTRIC CO

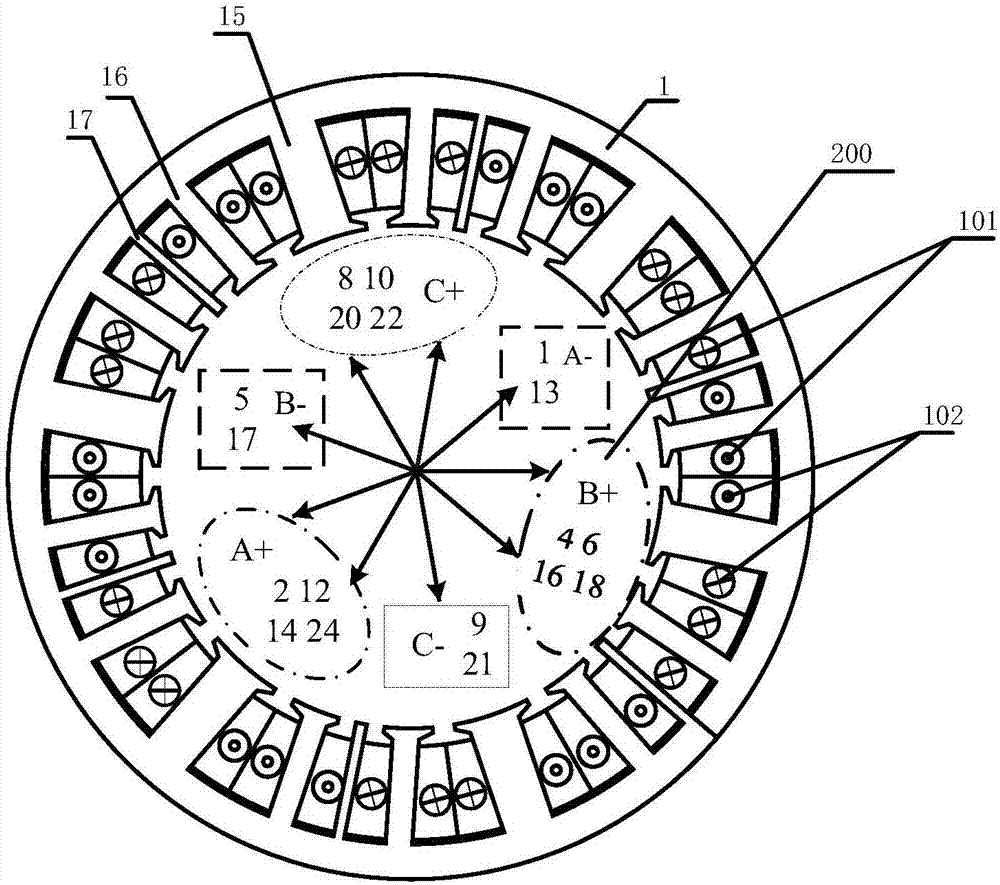

Six-phase flux switching type permanent magnet motor

InactiveCN103248158ASmall positioning torqueStable output torqueMagnetic circuit rotating partsMagnetic circuit stationary partsPhysicsMagnetic core

The invention provides a six-phase flux switching type permanent magnet motor which comprises stators, rotors and a rotating shaft, wherein each stator adopts a permanent magnet double salient structure, that is, the permanent magnet, the stator core and the armature winding are arranged on each stator, the stator core is assembled by an U-magnetic core and each permanent magnet embedded in the magnetic core, and the permanent magnets are of tangential alternate magnetization; the armature winding is of six-phase armature winding arranged on the stator, the six-phase armature winding adopts centralization coils, and the rotors are made of permeability magnetic material; the magnetizing directions of the permanent magnets are of the tangential of the stator circle, and the magnetizing directions of two adjacent permanent magnets are opposite to each other; the number of the armature coil and the stator groove is even number times of the phase number; and each phase 2n coils winding, and n coils are distributed at the two ends of the diameter of the stator circle respectively. And two three-phrase winding can conduct independent power supplying and generating.

Owner:SOUTHEAST UNIV

Rotor of an electric machine with embedded permanent magnets and electric machine

ActiveUS20130026872A1Easily arrange and shapeHigh torque densityMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsPhysicsElectric machine

A rotor for an electric machine excited by magnetic poles formed by one or more embedded permanent magnets includes a magnetic body and the one or more embedded permanent magnets associated with the magnetic body defining first magnetic poles and second magnetic poles of alternating magnetic polarity along a rotor direction. For at least one of the one or more embedded permanent magnets a rotor segment is arranged between the one or more embedded permanent magnets and a first surface of the magnetic body. At least one retainer element connects the rotor segment to a portion of the magnetic body.

Owner:VOLVO LASTVAGNAR AB

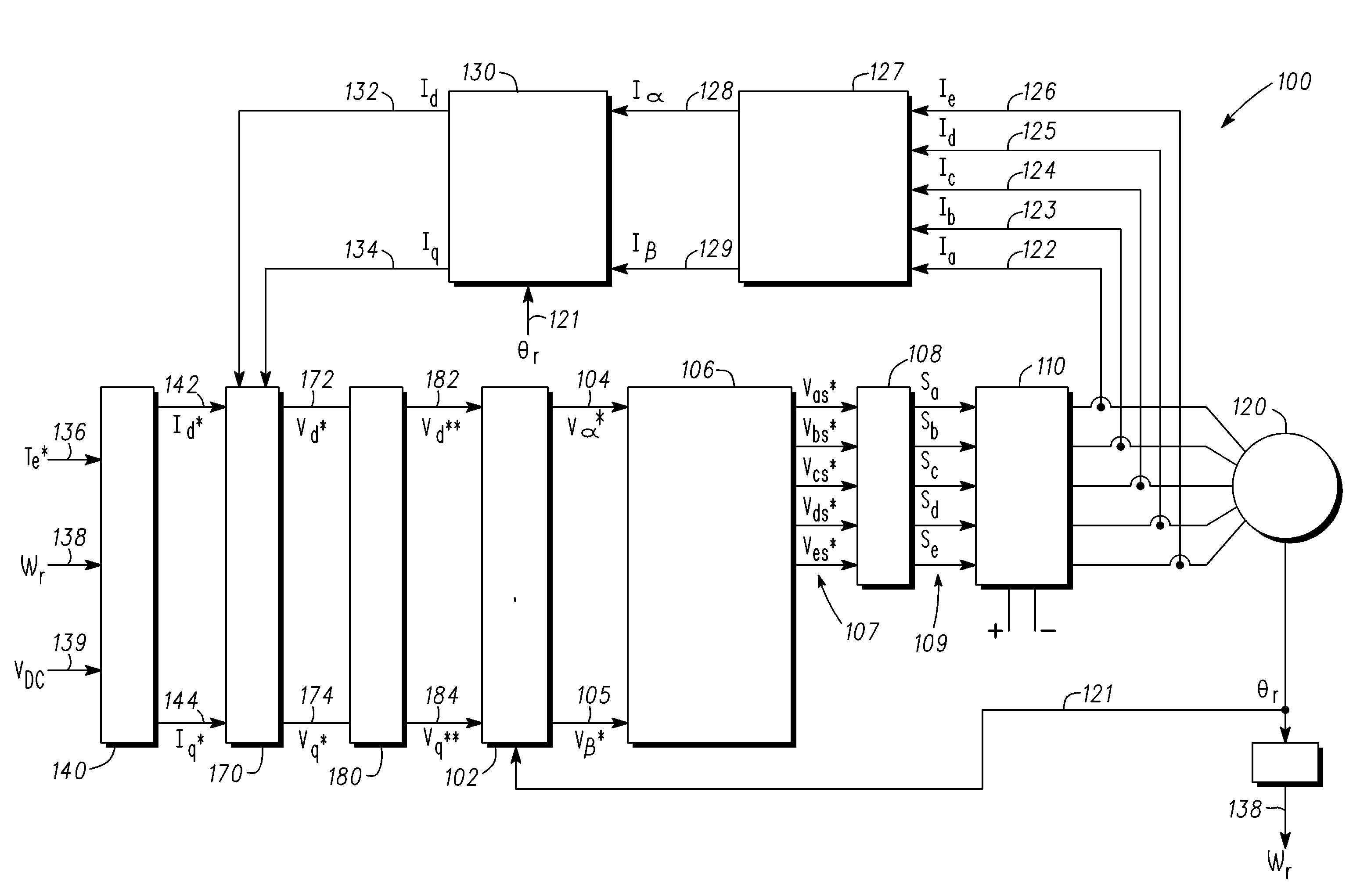

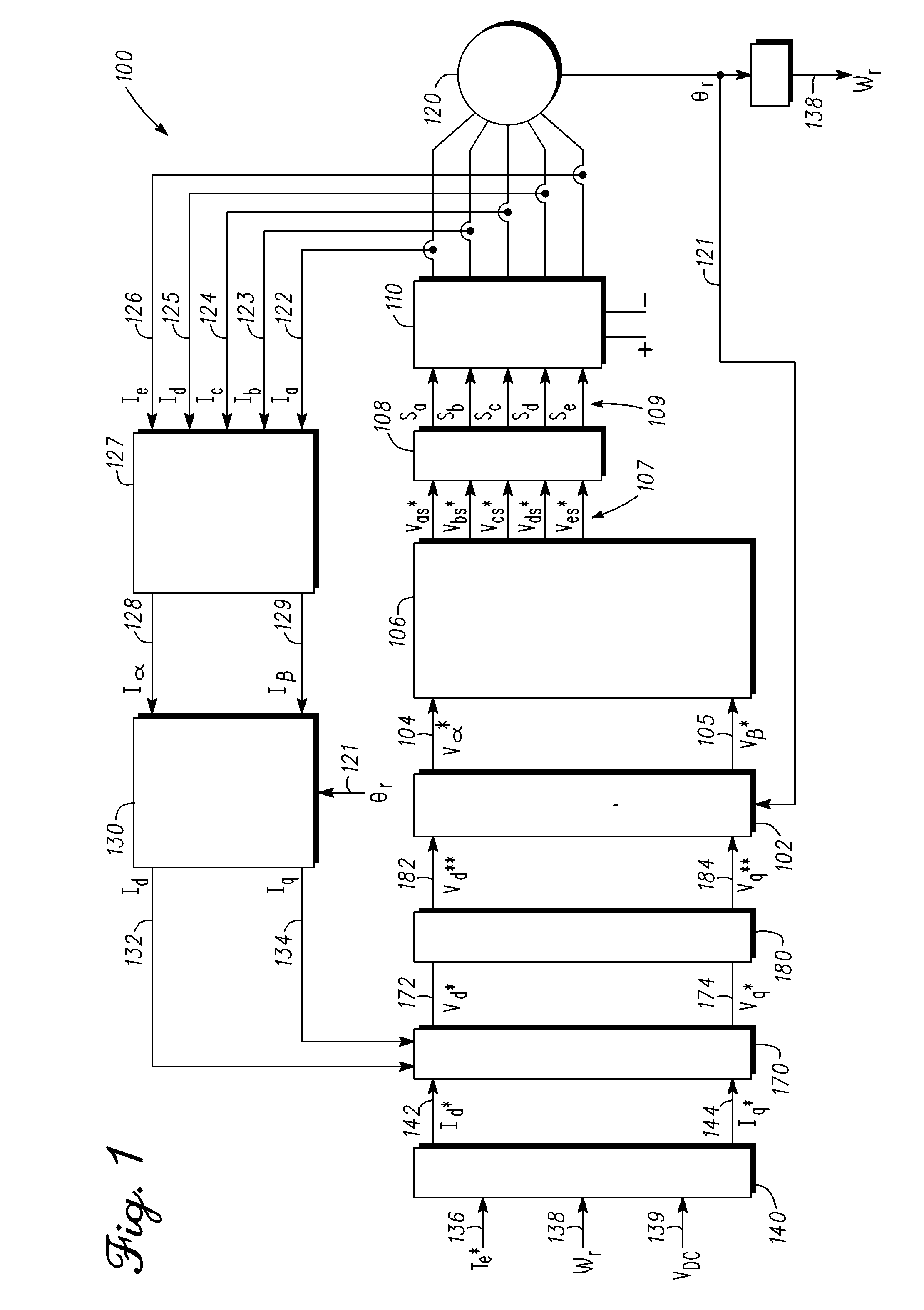

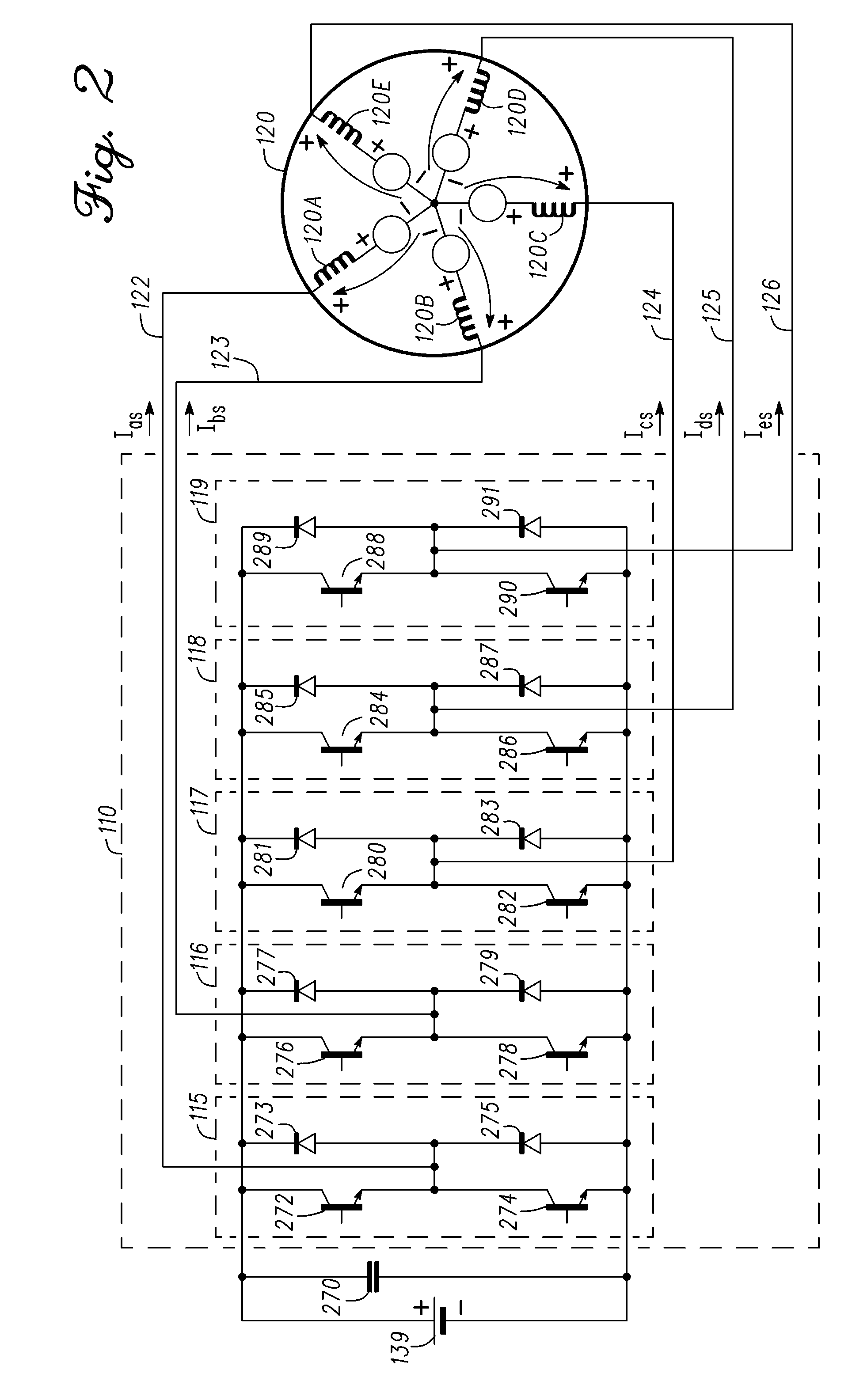

Methods, systems and apparatus for controlling third harmonic voltage when operating a multi-phase machine in an overmodulation region

InactiveUS20120187876A1Increased torque densityImprove mechanical powerElectronic commutation motor controlMotor/generator/converter stoppersVoltage vectorMotor drive

Methods, system and apparatus are provided for controlling third harmonic voltages when operating a multi-phase machine in an overmodulation region. The multi-phase machine can be, for example, a five-phase machine in a vector controlled motor drive system that includes a five-phase PWM controlled inverter module that drives the five-phase machine. Techniques for overmodulating a reference voltage vector are provided. For example, when the reference voltage vector is determined to be within the overmodulation region, an angle of the reference voltage vector can be modified to generate a reference voltage overmodulation control angle, and a magnitude of the reference voltage vector can be modified, based on the reference voltage overmodulation control angle, to generate a modified magnitude of the reference voltage vector. By modifying the reference voltage vector, voltage command signals that control a five-phase inverter module can be optimized to increase output voltages generated by the five-phase inverter module.

Owner:GM GLOBAL TECH OPERATIONS LLC

Motor using magnetic normal force

InactiveUS20080007130A1Reduce wear and tearIncreased torque densityGearingMechanical energy handlingInternal cavityEngineering

A motor is disclosed, comprising at least one fixed member comprising at least one magnetic winding, having an internal cavity; at least one driven member inside said fixed member, comprising magnetically conductive materials; constraining means for constraining said driven member to a path of movement with respect to said fixed member, said driven member being able to move within said fixed member, wherein magnetic normal force is induced in said fixed member periodically, whereby said driven member is periodically moved around said path by magnetic force, whereby rotary motion is produced.

Owner:BOREALIS TECH LTD

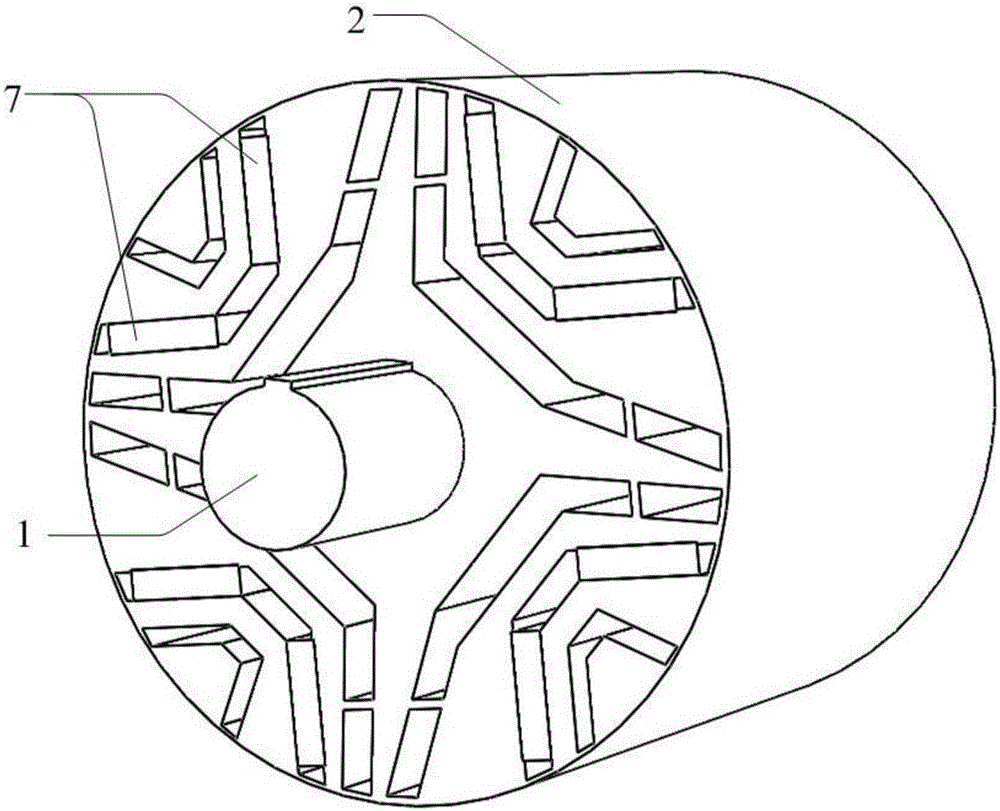

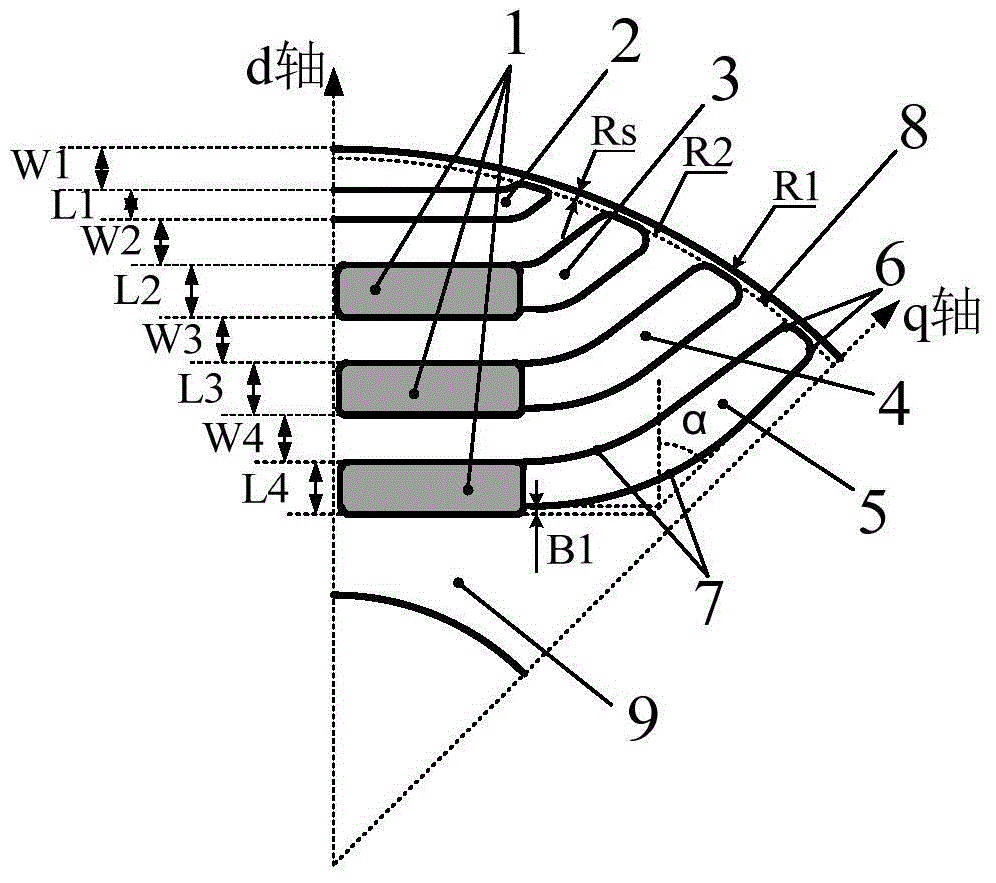

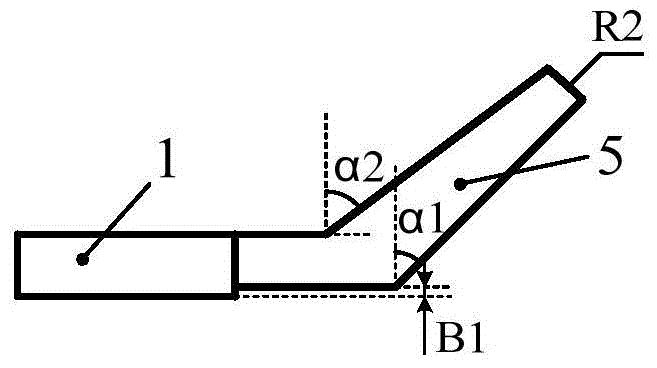

Permanent magnet assisted synchronous reluctance motor rotor which can be used in high-speed situation

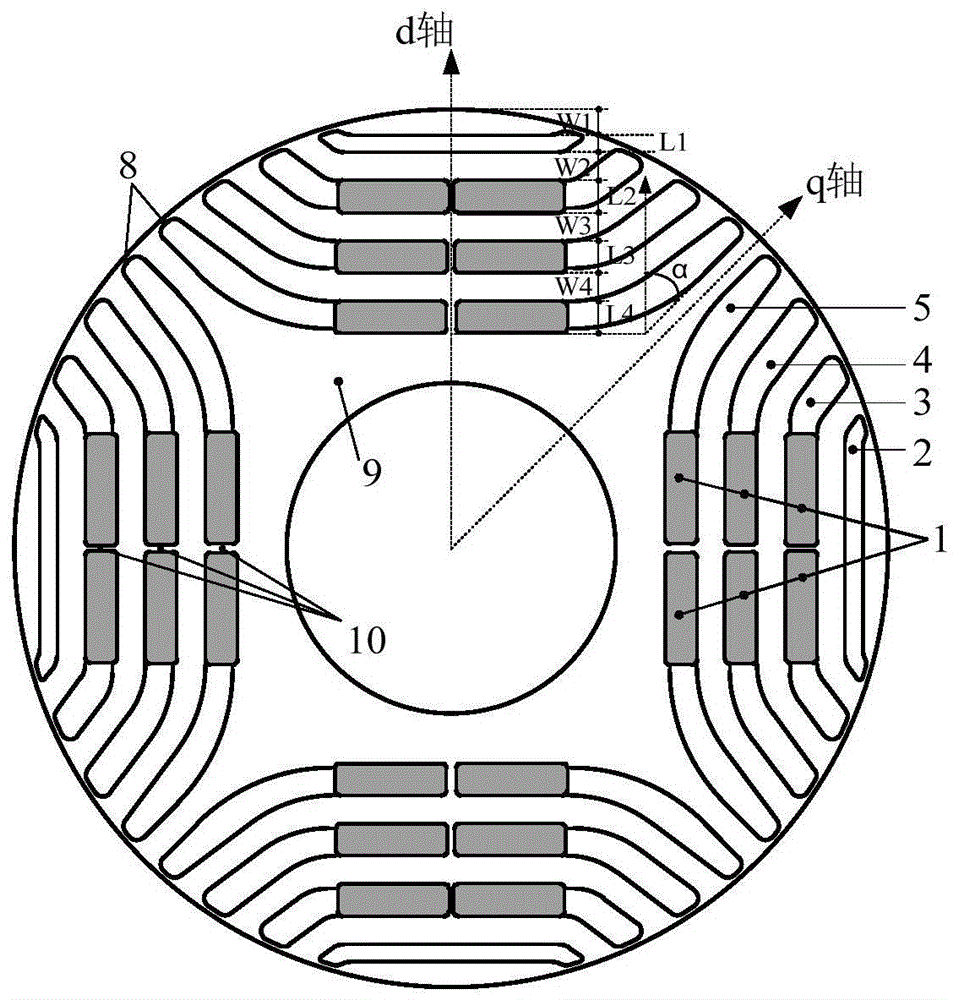

ActiveCN104901452ASafe high-speed operation capabilityMaximize output capacityMagnetic circuit rotating partsSynchronous machine detailsMagnetic barrierSynchronous reluctance motor

The present invention discloses a permanent magnet assisted synchronous reluctance motor rotor which can be used in a high-speed situation. The permanent magnet assisted synchronous reluctance motor rotor comprises a rotor core, magnetic barriers distributed on the rotor core and magnetic steels arranged in the magnetic barriers. Four layers of ship-shaped magnetic barriers are distributed under each pole of the rotor core, and each layer of magnetic barriers is formed by the connection closing of a straight line part which is in the middle and is perpendicular to a d axis direction and oblique straight line parts which are at two ends and are in an alpha angle direction with the d axis. According to the permanent magnet assisted synchronous reluctance motor rotor, the optimal design of the motor rotor is carried out, and thus a motor has the advantages of high efficiency, high torque density, high power factor, strong anti-demagnetization ability and convenient manufacture.

Owner:SHANGHAI GIE EM

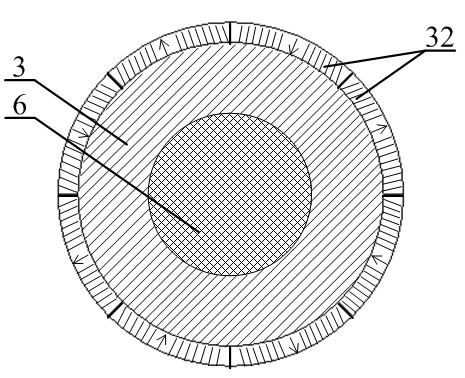

Coaxial magnetic gear

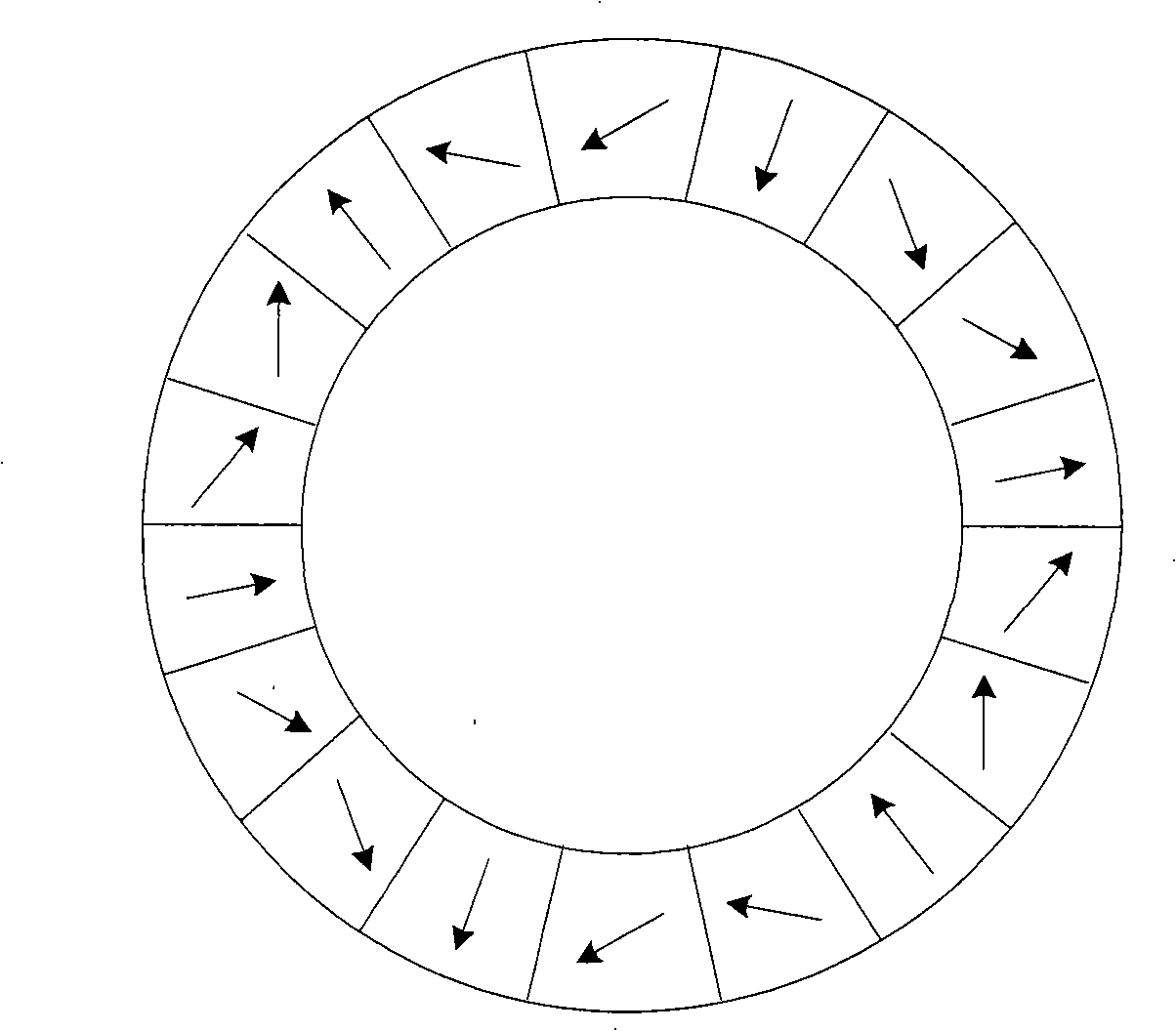

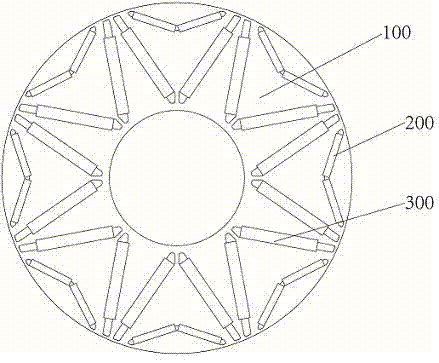

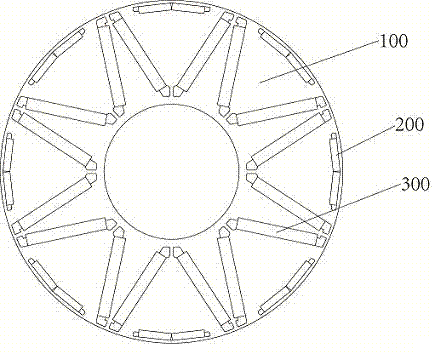

ActiveCN102324821AIncreased torque densityHigh mechanical strengthDynamo-electric machinesGear wheelMagnetic poles

The invention discloses a coaxial magnetic gear comprising an external rotor, a static magnetic ring and an internal rotor which are lined from outside to inside and share the same axis. The external rotor is a circular magnetic conductor, and external rotor convex poles which are lined with equal spacing are arranged on the inner ring of the external rotor; the static magnetic ring is fixedly arranged between the internal rotor and the external rotor, and comprises permanent magnets and non-permanent magnets which are lined at intervals; internal rotor convex poles are lined on the outer ring of the internal rotor with equal spacing, and internal rotor permanent magnet bodies are arranged on the outer ring of the internal rotor; the internal rotor can be also in other structural forms capable of producing effective N-S magnetic poles; and in order to ensure the normal rotation of the internal rotor and the external rotor, air gaps are left between the three parts. Through the convex pole structure of the external rotor, the coaxial magnetic gear enables a static magnetic ring magnetic field to modulate a series of harmonic rotation magnetic fields on an inner air gap side, the number of the polar pairs of the selected internal rotor permanent magnet bodies is the same with that of the pole pairs of a required harmonic magnetic field, and the stable torque transmission is realized by the coupling action of the polar pairs of the selected internal rotor permanent magnet bodies and the pole pairs of a required harmonic magnetic field. The magnetic gear has the characteristics of high torque density, high mechanical strength of the external rotor, and convenience in processing and manufacturing.

Owner:SOUTHEAST UNIV

Electrical machine and use thereof

InactiveUS20060131974A1Increased torque densityImprove power factorMagnetic circuitCombustion enginesElectrical conductorElectric machine

The invention relates to an electrical machine of the transversal-flux type. The machine comprises a stator and a movable element. The stator has a plurality of stator elements with magnetic flux conductors and an electric winding extending in a closed winding path through each magnetic flux conductor. The movable element comprises a number of permanent-magnet members and is movable in relation to the stator along a movement path. The winding path comprises a first current-carrying section extending along the movement path. Each magnetic flux conductor forms, together with one of the permanent-magnet members, a closed magnetic flux circuit around said current-carrying section. Each permanent-magnet member comprises a primary magnet with a magnetic direction across the movement path. Adjacently located permanent-magnet members are separated from each other by an intermediate member comprising at least one secondary magnet that has a magnetic direction essentially across the magnetic direction of the primary magnet.

Owner:VOLVO TECH

Stator permanent-magnetic doubly salient disc-type motor

ActiveCN105245073AAvoid damageEasy to installMagnetic circuit rotating partsElectric machinesTorque densityNon magnetic

The present invention discloses a stator permanent-magnetic doubly salient disc-type motor, which comprises stator mechanisms, a rotor mechanism and a motor shaft, wherein the rotor mechanism is arranged between the two stator mechanisms, the rotor mechanism and the stator mechanisms are arranged on the motor shaft, each stator mechanism comprises a stator core, two permanent magnets and 2N annular armature windings, 2N stator teeth are evenly distributed on the inner wall of each stator core, a groove between every two adjacent stator teeth is a stator groove, the permanent magnets magnetized in the peripheral direction are arranged in centers of any pair of stator grooves on the same diameter, and the 2N annular armature windings respectively sleeve the 2N stator teeth; and the rotor mechanism comprises a plurality of rotor cores and a non-magnetic-conductive rotor bracket, the plurality of rotor cores are evenly distributed on the outer circumference of the non-magnetic-conductive rotor bracket, and the rotor cores form rotor salient poles. The stator permanent-magnetic doubly salient disc-type motor can effectively improve the reliability of the motor, reduces size and weight of the motor, improves power density and torque density of the motor, and is suitable to be used in occasions with strict requirements on size of generators or motors.

Owner:NANJING UNIV OF SCI & TECH

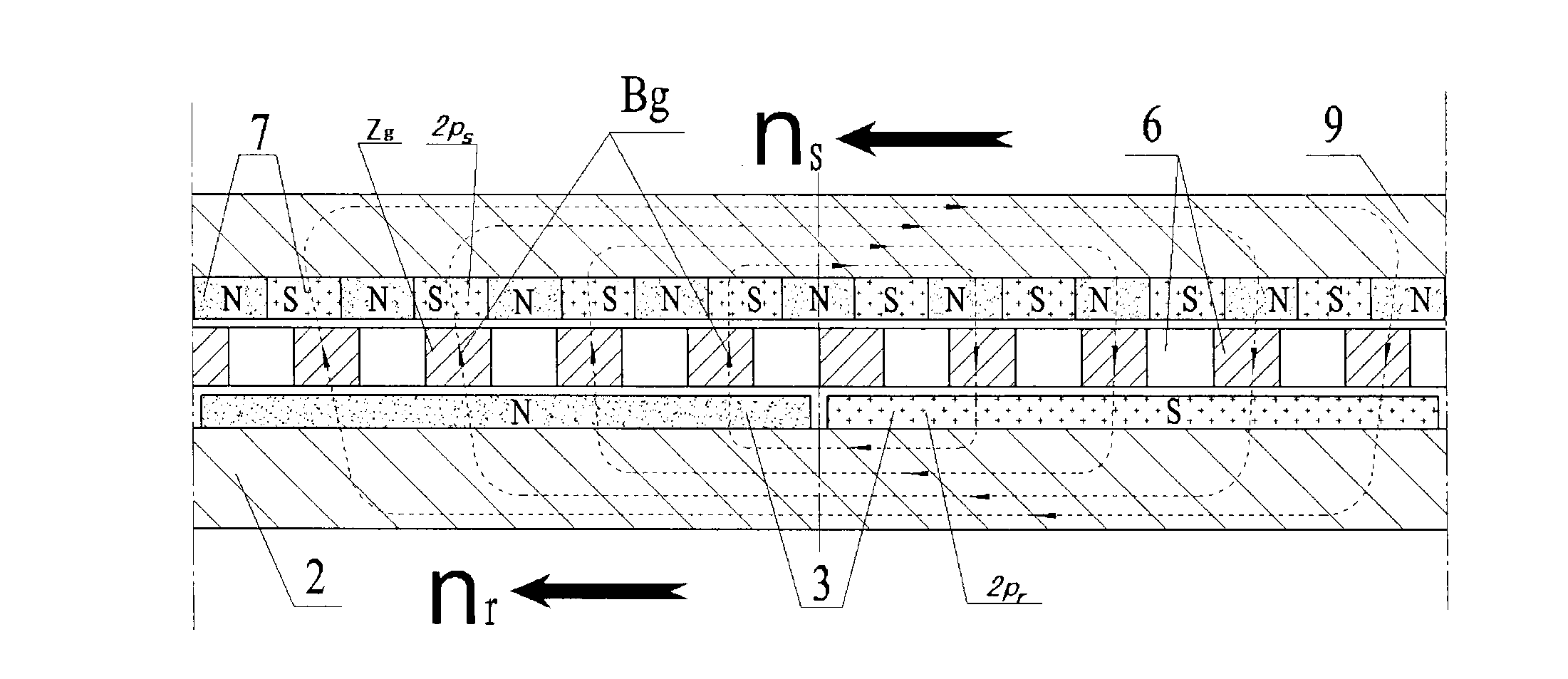

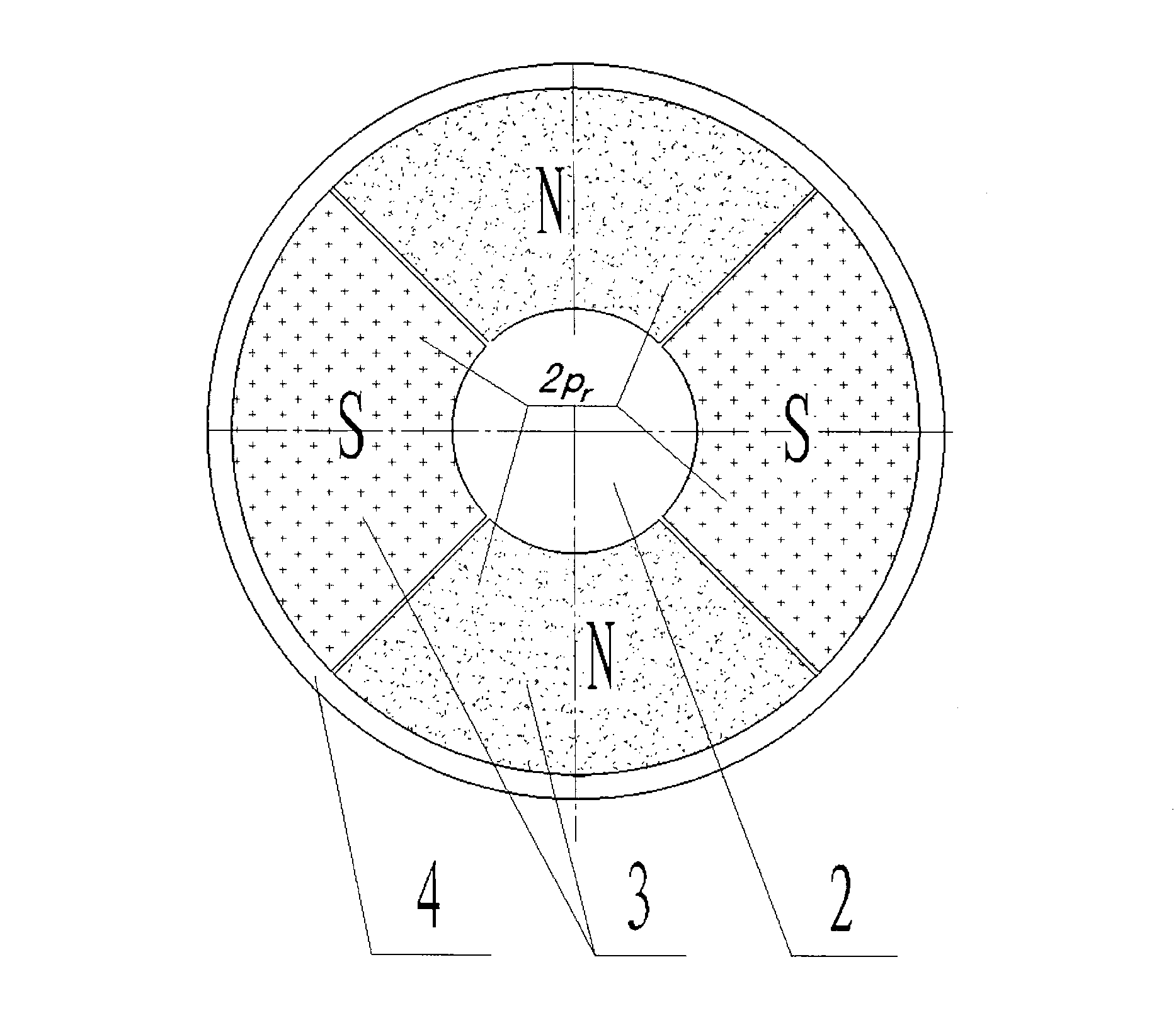

Magnetism transmission gear pair of novel transverse magnetic field

The invention relates to a magnetism transmission gear pair of a novel transverse magnetic field, which can be widely applied to wind power generation, electric cars, ship drive and other industrial transmission fields requiring direct drive. The magnetism transmission gear pair is characterized in that a driving wheel and a driven wheel of the magnetism transmission gear pair are of a flat disk shape, 2pr driving wheel permanent magnets 3 are distributed on the driving wheel, and 2ps driven wheel permanent magnets 7 are distributed on the driven wheel; a ferromagnetic magnetic modulation grid 6 playing a role of modulating an air-gap magnetic field is arranged between the driving wheel and the driven wheel, air gaps are reserved between the ferromagnetic magnetic modulation grid 6 and the end surfaces of the driving wheel and the driven wheel, and the ferromagnetic magnetic modulation grid 6, the driving wheel and the driven wheel have no mechanical contact and are distributed along the same axis; the air-gap magnetic field Bg passes through an air-gap plane along a route parallel to a rotation axis to form a transverse magnetic field of the magnetism transmission gear pair; and during working, power speed change transmission without mechanical contact and friction is realized by utilizing a principle of heteropolarity attraction of an N pole and an S pole of a permanent magnet material.

Owner:余虹锦

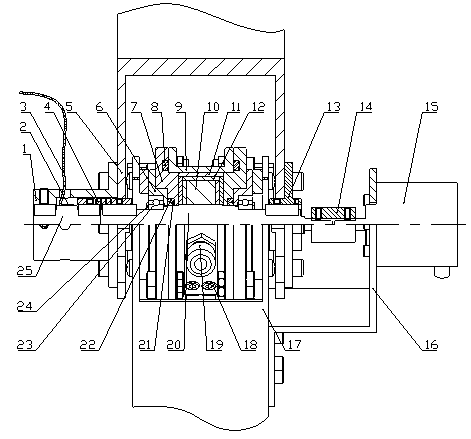

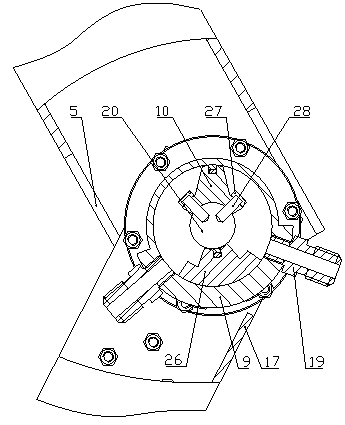

Robot joint rotating hydraulic cylinder with torque and angle feedback functions

InactiveCN103711741AIncreased torque densityHigh densityJointsFluid-pressure actuatorsHydraulic cylinderCoupling

The invention discloses a robot joint rotating hydraulic cylinder with torque and angle feedback functions. The robot joint rotating hydraulic cylinder comprises an open type sealed hydraulic oscillating cylinder, a torque sensing module and an angular displacement sensing module, wherein the open type sealed hydraulic oscillating cylinder comprises an oscillating cylinder output shaft, an elastic retainer ring, a bearing, a shaft sleeve, an outward leakage radial O-shaped sealing ring, an outward leakage O-shaped polytetrafluoroethylene ring, an open type cylinder cover, a leakage axial O-shaped sealing ring, a cylinder body, a fixed blade, a movable blade, an inward leakage polytetrafluoroethylene bar, an inward leakage sealing bar and an oil inlet and outlet channel connecting piece; the torque sensing module comprises an elastic shaft coupling, a torque detection shaft, a strain gauge, a torque detection signal line, a torque transmission flange, a torque transmission and support dual-purpose flange and a larger leg; the angular displacement sensing module comprises a shaft coupling, an encoder bracket, an encoder and a smaller leg. The hydraulic cylinder can provide large torques, is simple in structure, and is easy and convenient to control. Meanwhile, a modular structure is adopted, thereby realizing torque feedback and angle feedback functions.

Owner:SOUTHEAST UNIV

Method for improving motor torque density and radial and axial magnetic flux parallel-connected permanent magnet motor

InactiveCN104716754AIncreased torque densityIncrease profitMagnetic circuit stationary partsElectric machineClosed loop

The invention provides a method for improving motor torque density. According to the method for improving the motor torque density based on a radial and axial magnetic flux parallel-connected permanent magnet motor, radial magnetic flux and axial magnetic flux are combined. In a motor rotor, the radial magnetic flux and the axial magnetic flux are provided with independent magnetic flux paths respectively, the space utilization rate of the rotor and the utilization rate of an iron core are effectively improved, and the limitation of iron core saturation to the motor torque density and the power density is reduced. The axial magnetic flux forms a closed loop through a rotor front portion, a rotor end face permanent magnet set, a rotor end face air gap and a stator. The radial magnetic flux forms a closed loop through a rotor, a rotor circumference face permanent magnet set, a rotor circumference face air gap and the stator. The invention further provides the radial and axial magnetic flux parallel-connected permanent magnet motor.

Owner:WUHAN HUADA NEW TYPE MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com