Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Increased air gap flux density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

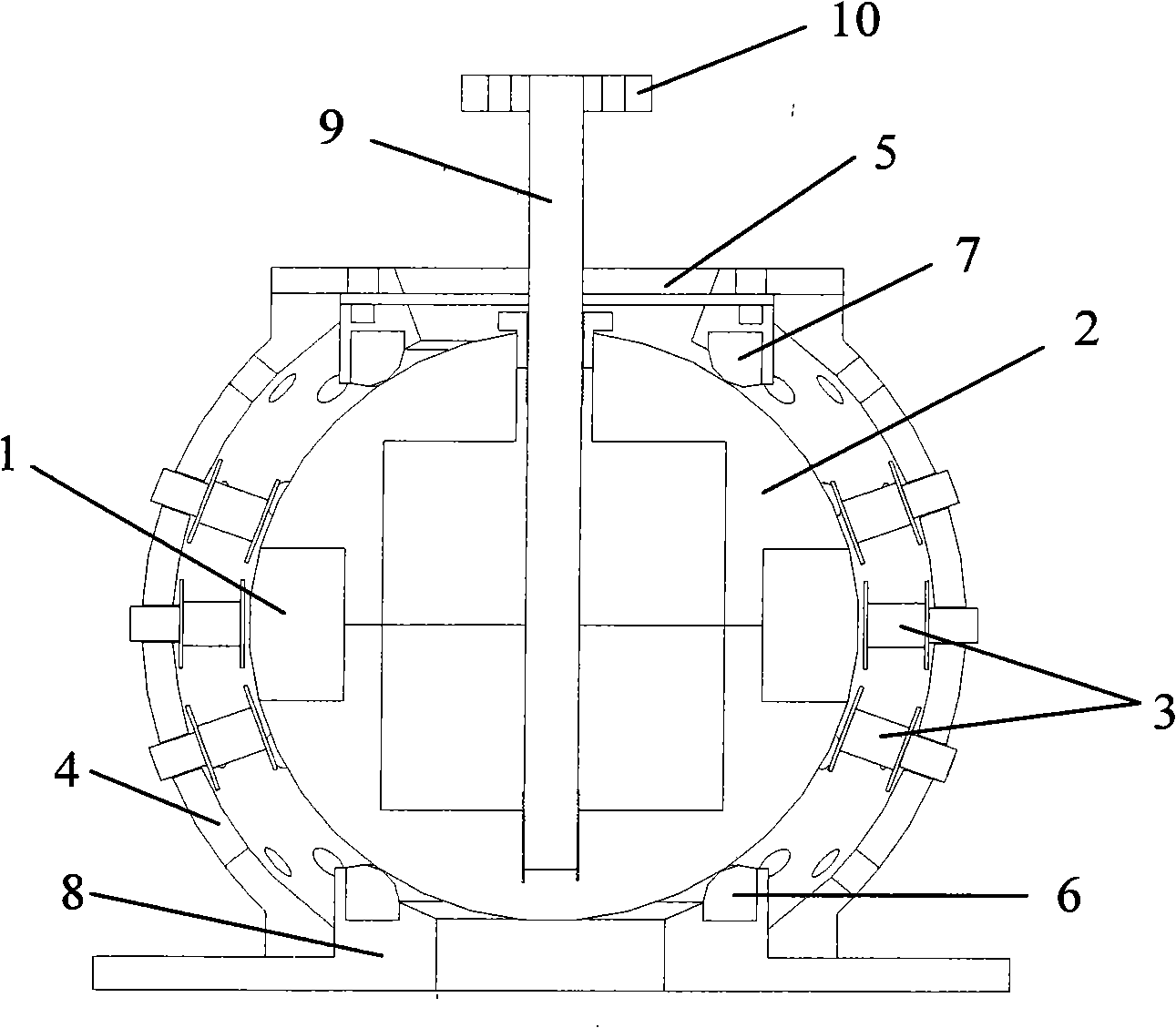

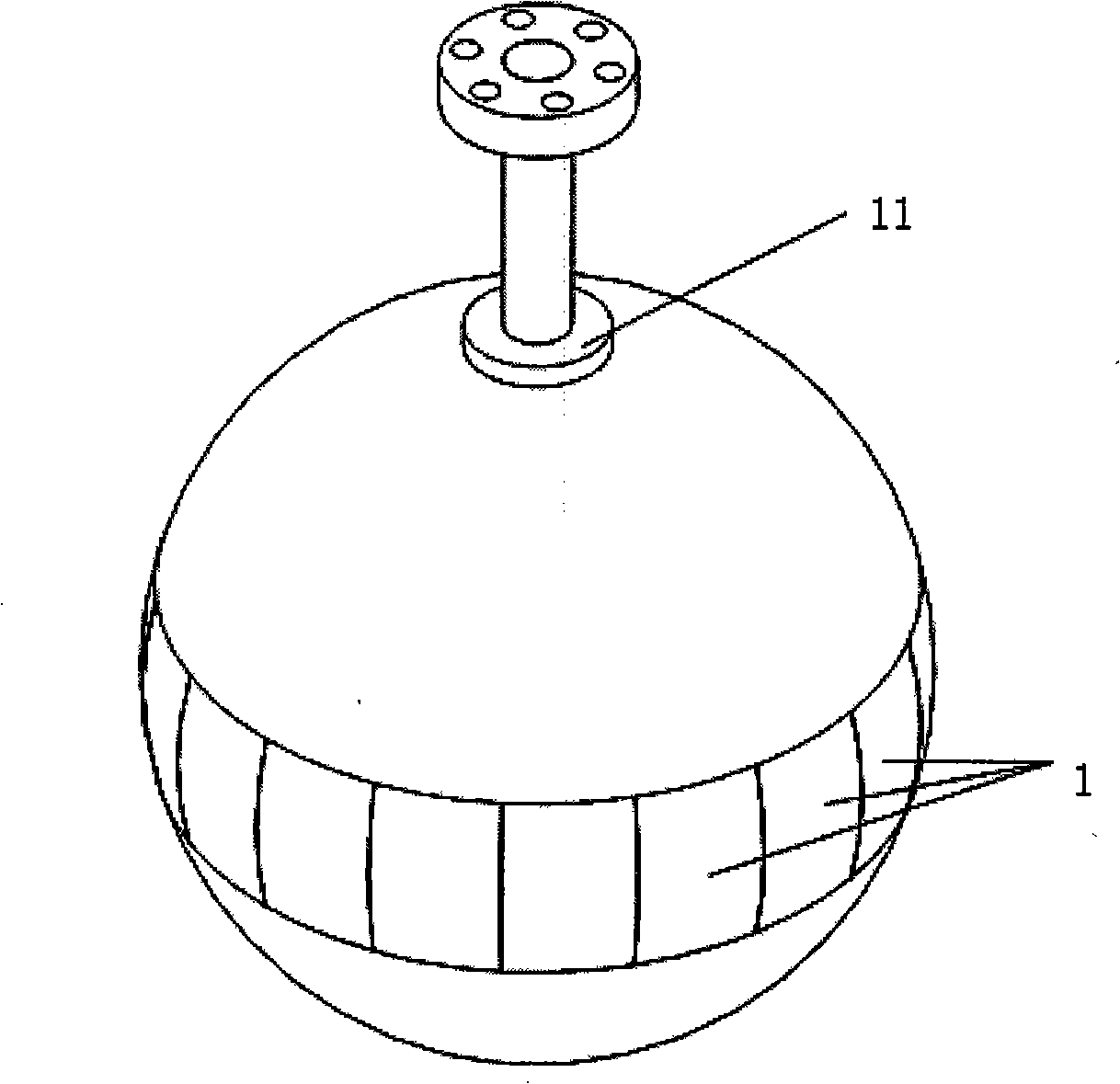

Three-freedom Halback array permanent magnetism sphericity synchronous motor

InactiveCN101282070AHigh positioning accuracySimple mechanical structureMagnetic circuit rotating partsSynchronous machine detailsFixed bearingSynchronous motor

The invention relates to a three-freedom degree Halbach array permanent magnetism spherical synchronous motor, belonging to spherical electric machine manufacturing technical field, which comprises a base, a support bearing positioned on the base, a spherical rotor body, an outside stator, an output shaft, the spherical rotor body comprises a hollow spherical rotor yoke made by non-guide magnetism materials and a Halbach array permanent magnetism body, the output shaft is through the upper of the hollow spherical rotor yoke and is fixingly connected with the hollow spherical rotor yoke, column-shaped slots are provided around a cycle of the hollow spherical rotor yoke equator, the Halbach array permanent magnetism body are fixed evenly on one cycle of the rotor yoke equator along the column-shaped slots, the contact surface of the rotor yoke lower and the support bearing is ring-shaped arc surface; the outer stator comprises a stator casing and multi-row coils, an adjustable fixing bearing is provided on the lower side of the stator casing cover. The spherical synchronous motor of the invention can realize three-freedom degree movement, has simple mechanical structure and improved dynamic and static performance of the drive system.

Owner:TIANJIN UNIV

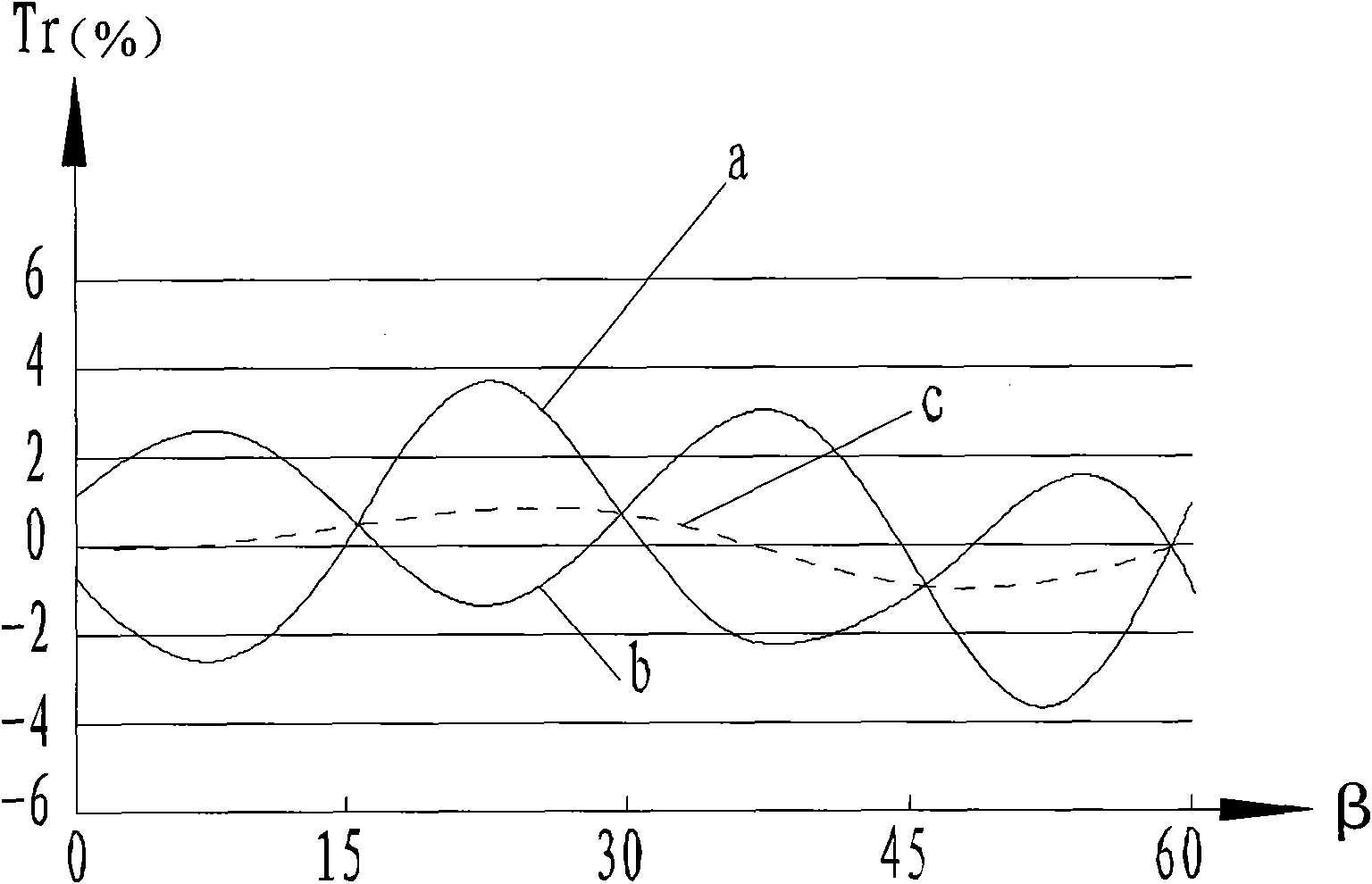

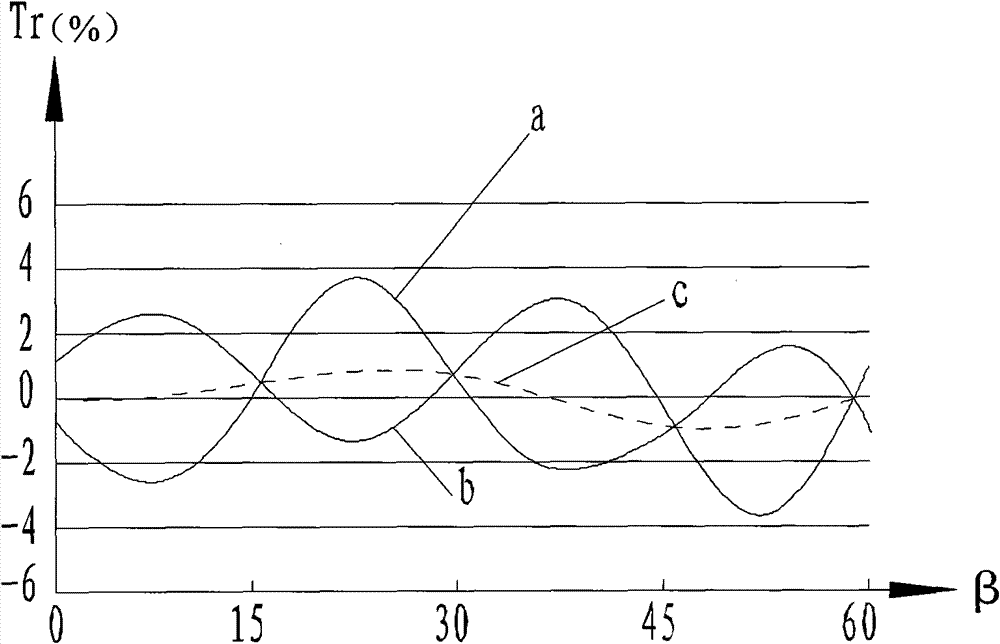

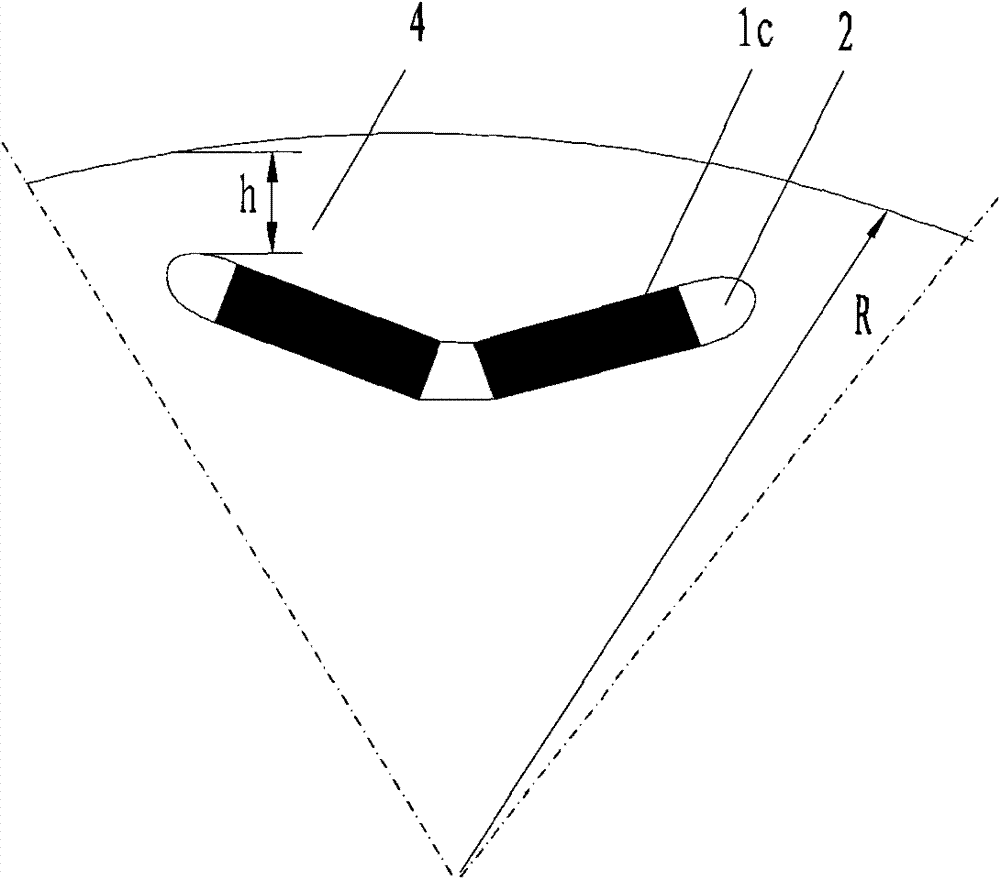

Permanent magnet drive motor for solar tracking system

ActiveCN101917076AReduced resultant torque fluctuationSmall torque fluctuationMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsSEMI-CIRCLEDrive motor

The invention relates to a permanent magnet drive motor for a solar tracking system, which comprises an enclosure, a stator and a rotor which are arranged in the enclosure, wherein, the stator comprises a stator core and a stator winding which are fixed on an inner wall of the enclosure, and the stator core comprises a stator magnetic yoke, a stator slot and stator teeth; the rotor comprises a rotating shaft and a rotor core, and a permanent magnet slot is uniformly arranged along the periphery of the rotor core; the permanent magnet slot is internally inlaid with radial magnetized rectangular strip magnetic steel, the radial magnetized rectangular strip magnetic steel and a pole piece form a permanent magnet pole, and an excircle of a rotor pole piece is in a concentric or excentric arc curved surface shape to form uniformly or non-uniformly symmetrical air gap; semi-circle grooves are arranged on two ends of the permanent magnet slot in which one of two pieces of adjacent radial magnetized rectangular strip magnetic steel is arranged; and rectangular supporting bars are radially inserted in the permanent magnet slot in which the V-shaped radial magnetized rectangular strip magnetic steel is arranged. The permanent magnet drive motor has the characteristics of high efficiency, high output power, high reliability, low moment fluctuation and the like.

Owner:苏州和鑫电气股份有限公司 +1

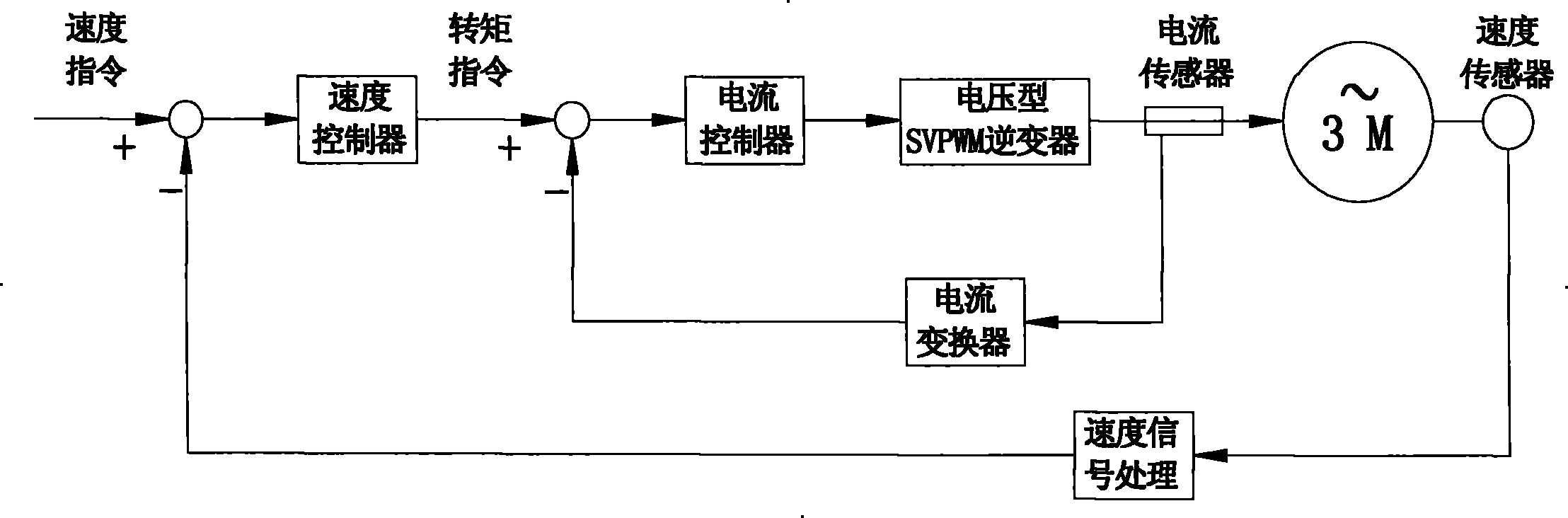

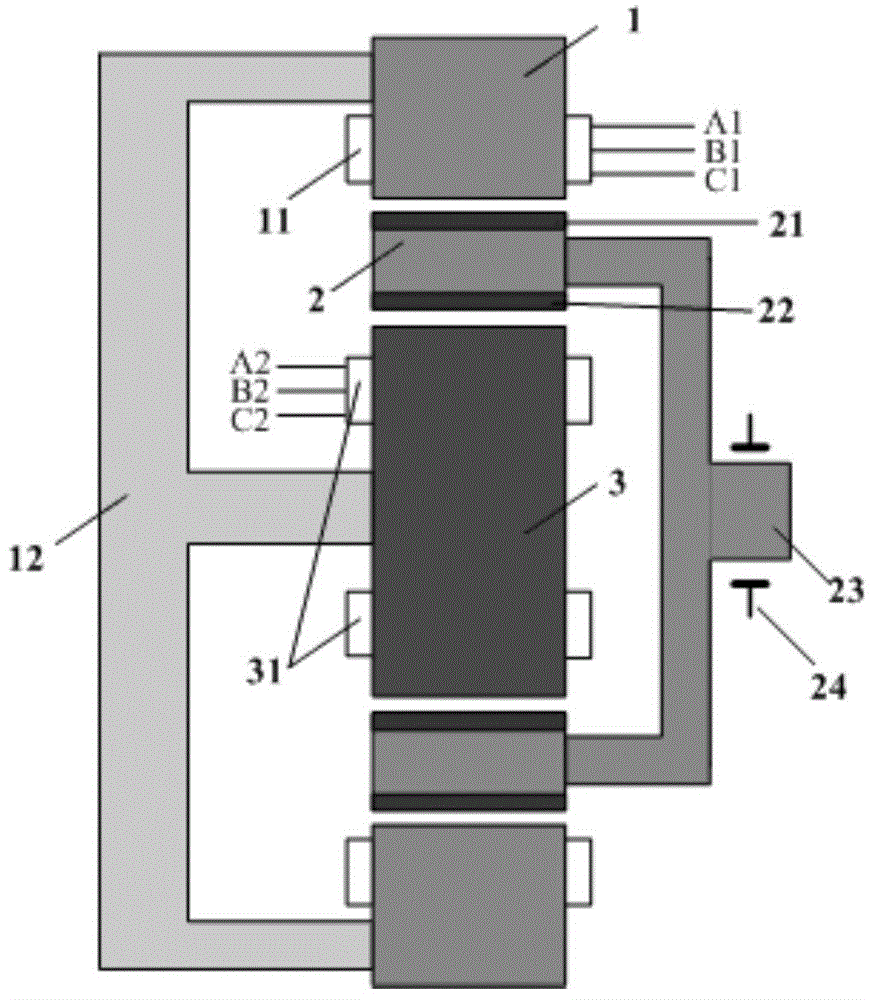

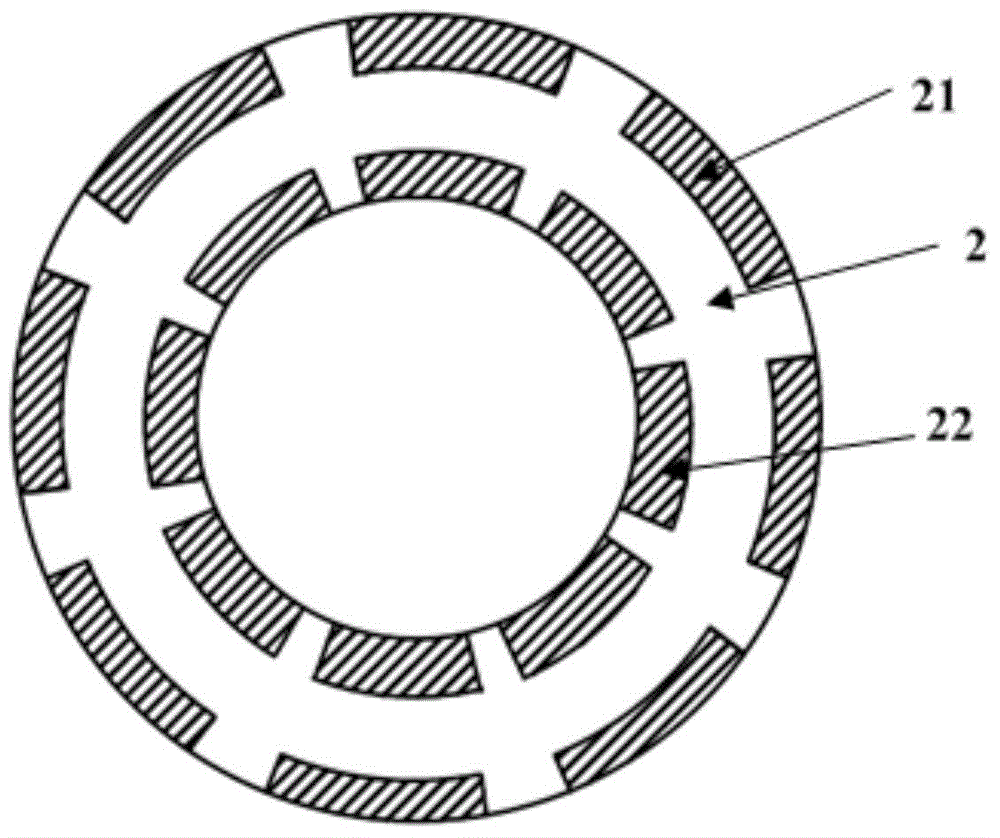

Novel synchronous electric motor and electric motor control system

InactiveCN102355105AEasy windingIncreased air gap flux densityElectronic commutation motor controlMagnetic circuit rotating partsElectric machineryPermanent magnet synchronous motor

The invention relates to a novel synchronous electric motor and an electric motor control system thereof, and realizes the special advantages of 'one electric motor and three states' and 'one state and multiple characteristics'. The invention is characterized in that on the basis of the existing permanent magnetic synchronous electric motor used for an electric automobile and a controller thereof, an exciting winding is added on a rotor, and the current of the exciting winding is controlled by an electric motor controller to change the intensity of a magnetic field of the electric motor so as to change the external characteristics of the electric motor and achieve the target of 'one electric motor and multiple characteristics'. The characteristic overcomes the defects of insufficient torque and poor dynamic property when the existing permanent magnetic synchronous electric motor used for the electric automobile is used for climbing, simultaneously solves the problem of insufficient electric motor speed when the electric automobile is in cruise control or high-speed running, and completely meets the requirements on road conditions of the electric motor used for the electric automobile. An advanced topology and control algorithm is adopted for the electric motor controller adaptive to the invention, and the electric motor is controlled more efficiently, and has better dynamic property and a longer running range.

Owner:王荣华

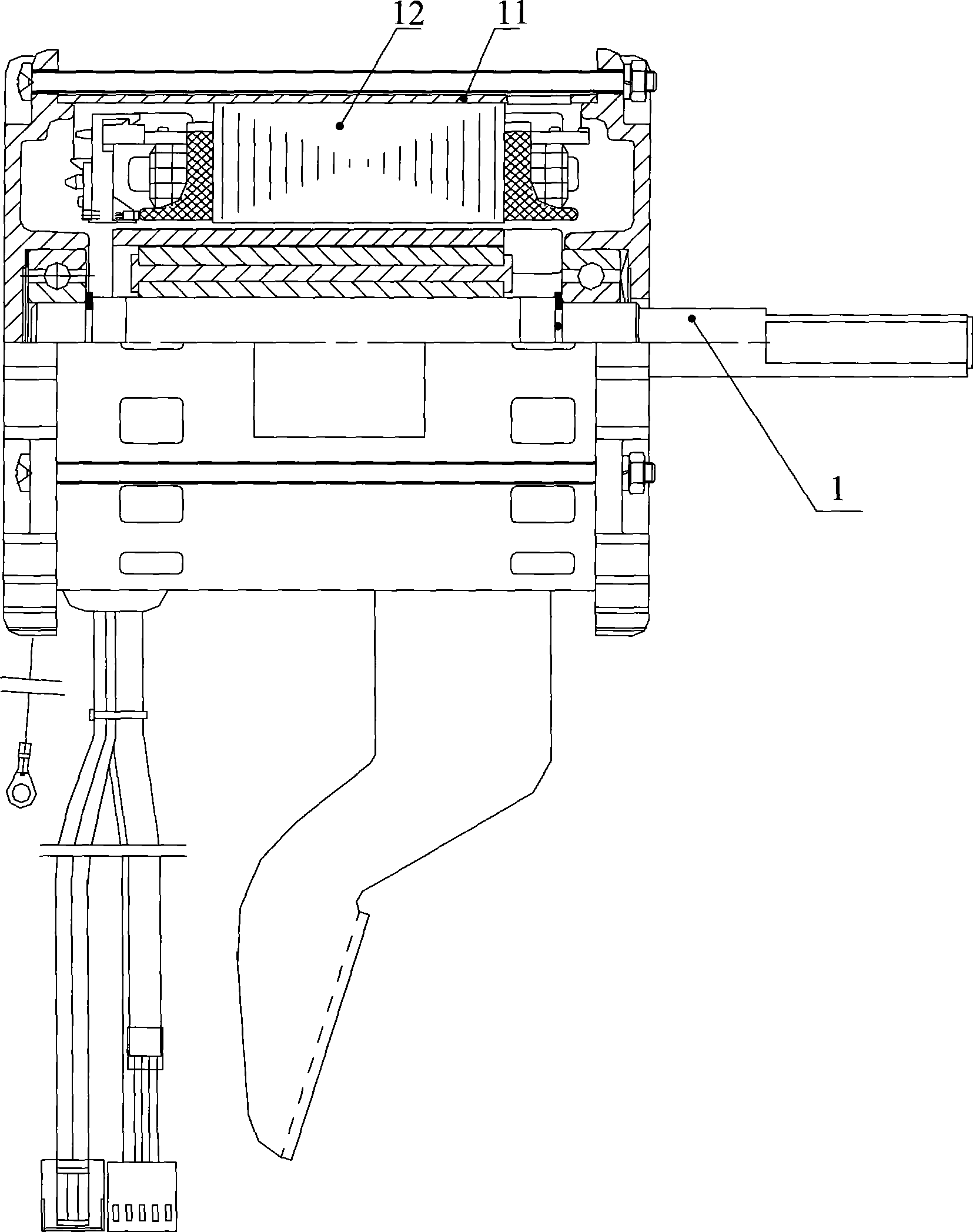

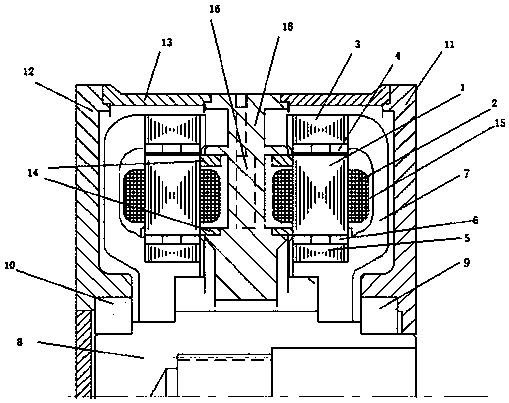

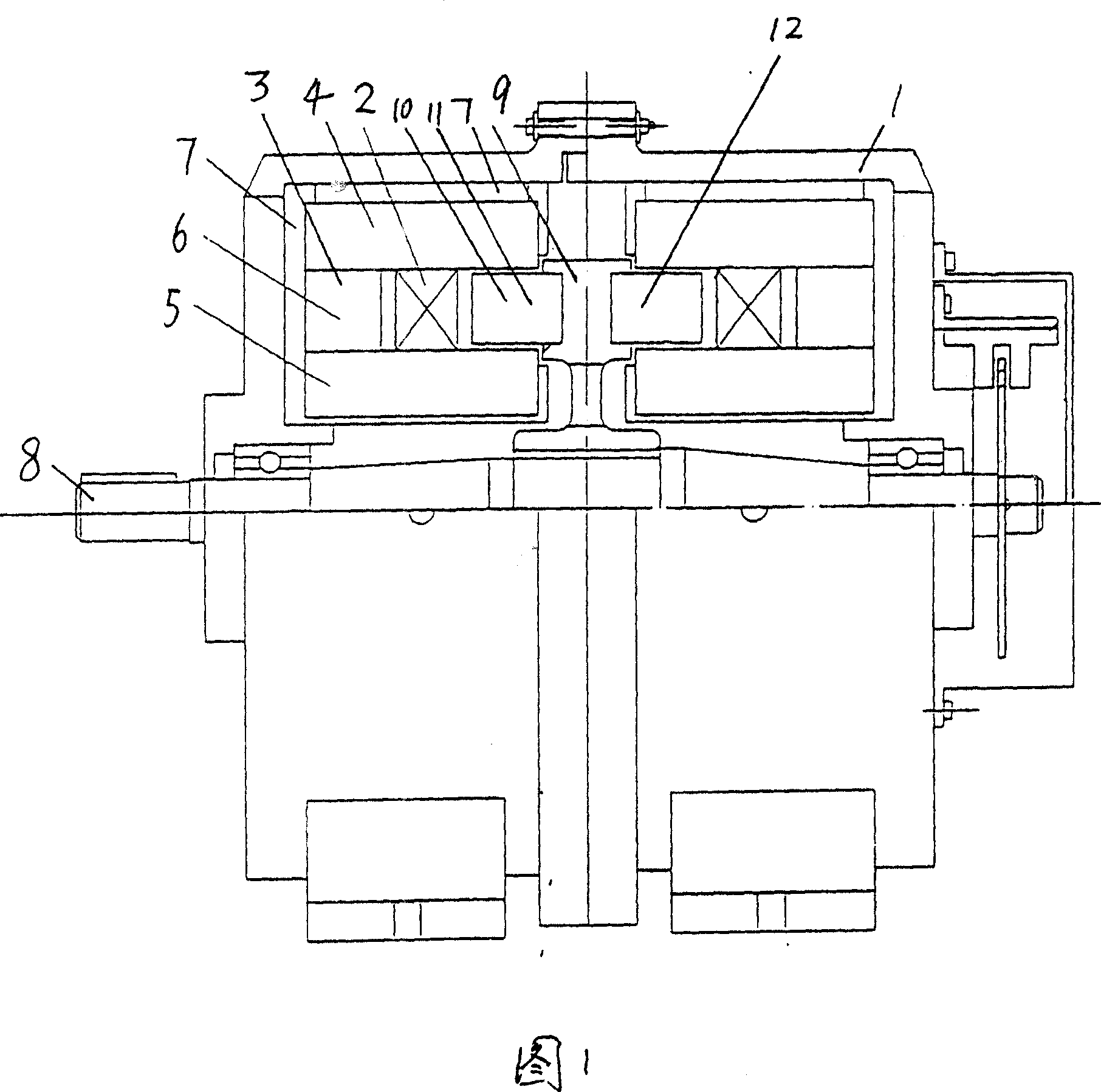

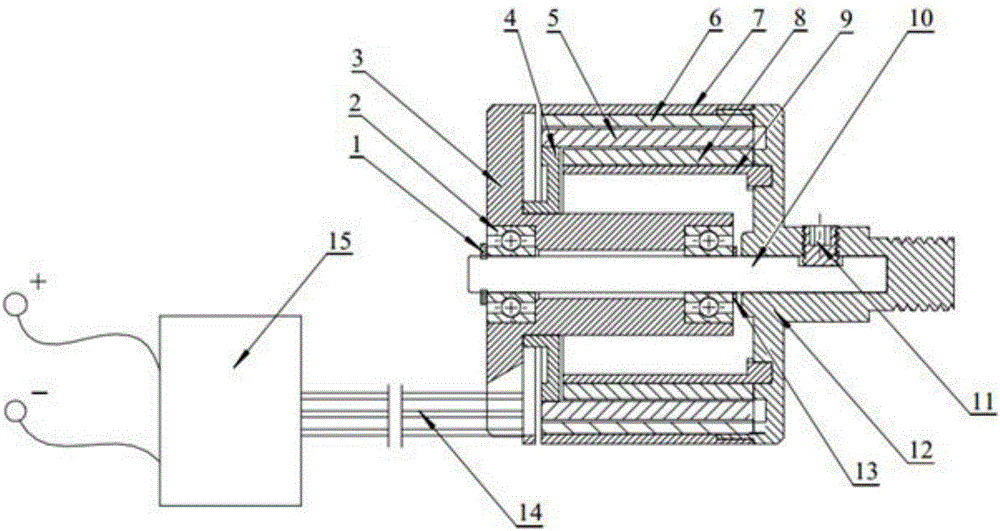

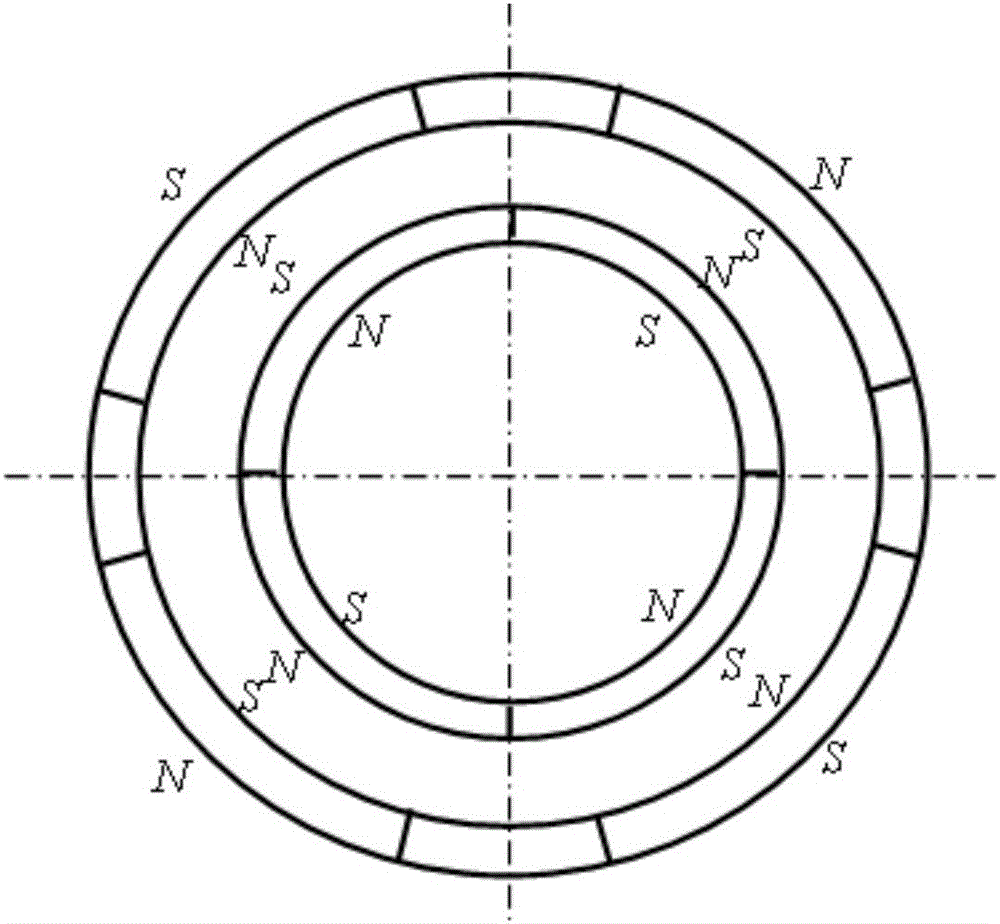

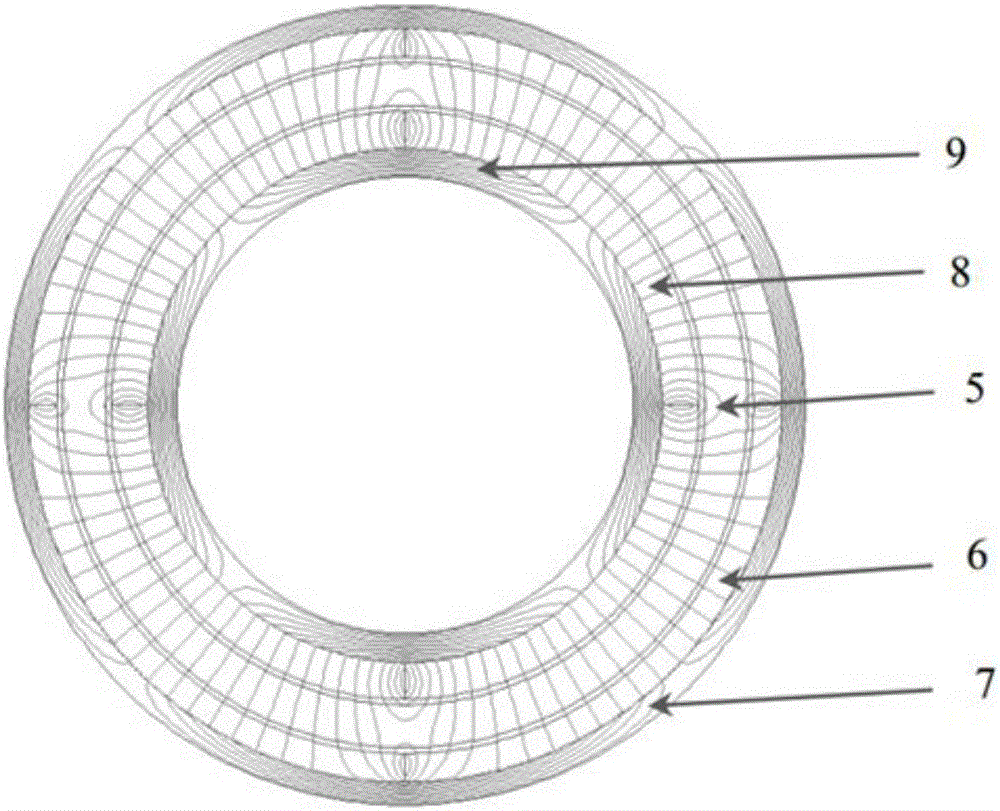

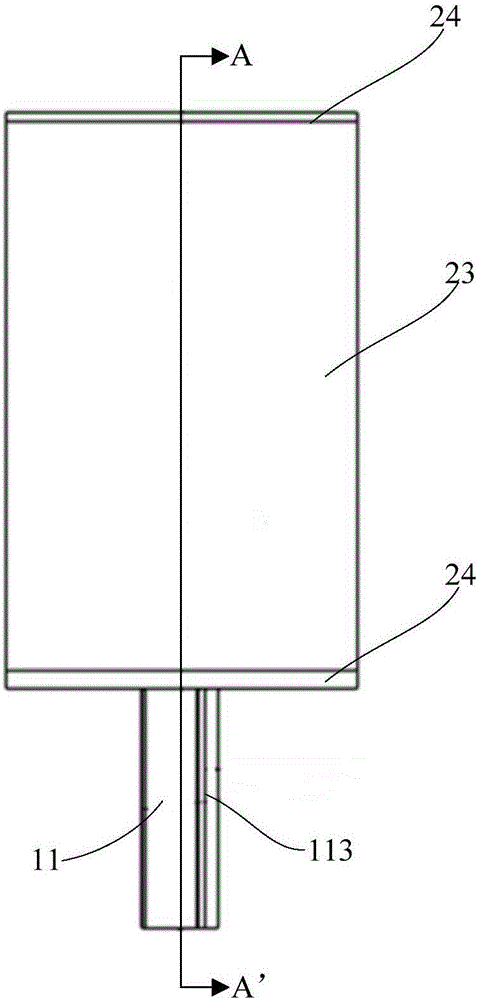

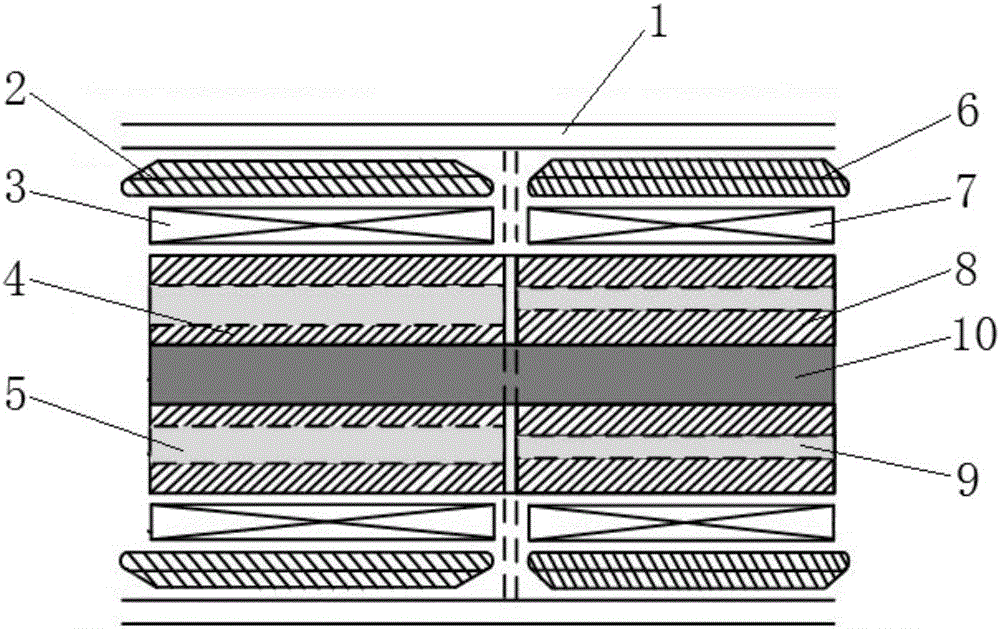

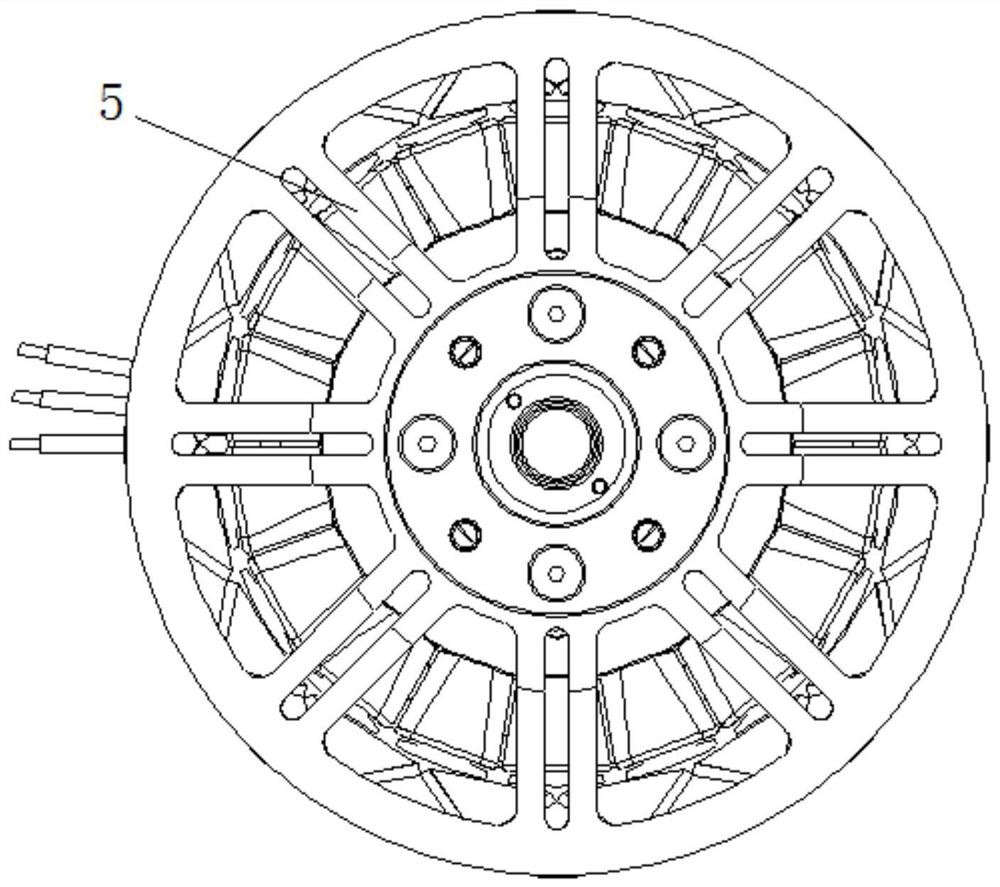

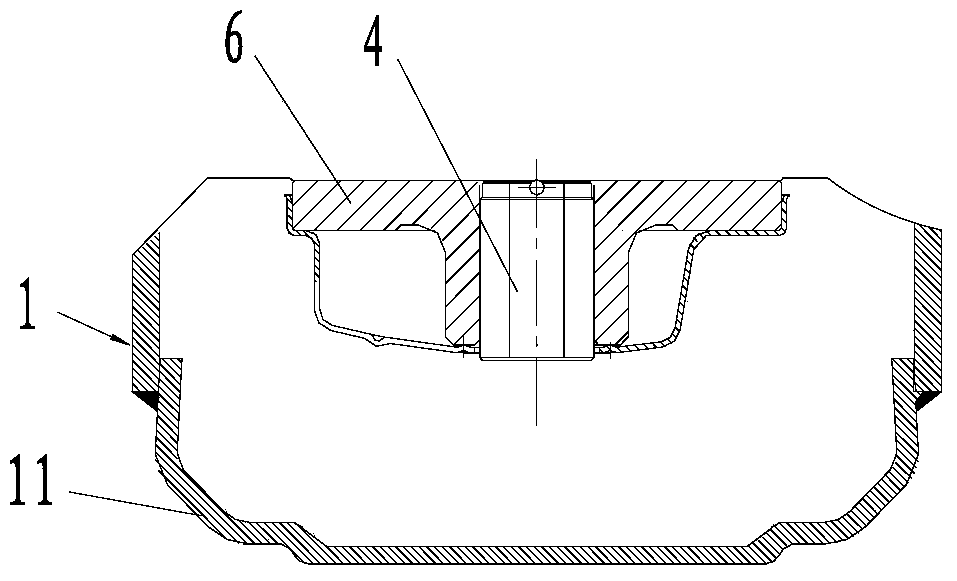

Momentum wheel based on disc type structure

InactiveCN106059226ACompact structureHigh torqueMechanical energy handlingStructural associationMomentumPermanent magnet motor

The invention relates to a momentum wheel based on a disc type structure. The momentum wheel comprises a lower layer stator and an upper layer stator, wherein the upper layer stator and the lower layer stator are fixed in parallel; an air gap is formed between the upper layer stator and the lower layer stator; a rotor is arranged in the air gap; a mass block is arranged at the outer side of the rotor; the upper and lower planes of the inside are provided with annular sector grooves in the radial direction; a permanent magnet is fixed in each groove; the magnetizing directions of the permanent magnets at the upper and lower layers are identical; the N poles and the S poles are alternately arranged; stator tooth grooves are formed in the upper layer stator and the lower layer stator; a coil is wound in each stator groove; the stators are fixed with the outer sides of bearings; the center of the rotor is a motor middle shaft; the bearings sheath the middle shaft; and the top of the middle shaft is provided with a photoelectric encoder. The momentum wheel has the advantages that in the moving process, the input is a three-phase power supply; a permanent magnet motor of an axial magnetic field structure is used, the momentum wheel can output great torque; by using the disc type structure of the momentum wheel, the structure of the momentum wheel is compact, and the axial size of the momentum wheel is effectively reduced; fractional-slot structure windings are used, so that the tooth groove torque of the momentum wheel can be effectively reduced, and the movement of the momentum wheel is smooth and stable; and meanwhile, the photoelectric encoder is used, so that the rotation condition of the momentum wheel can be precisely measured.

Owner:XI AN JIAOTONG UNIV

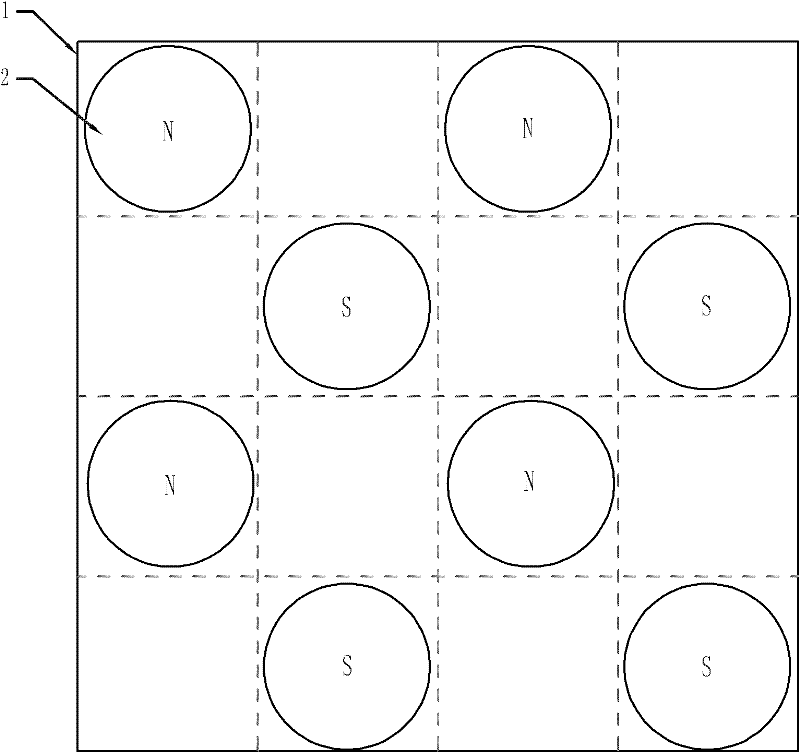

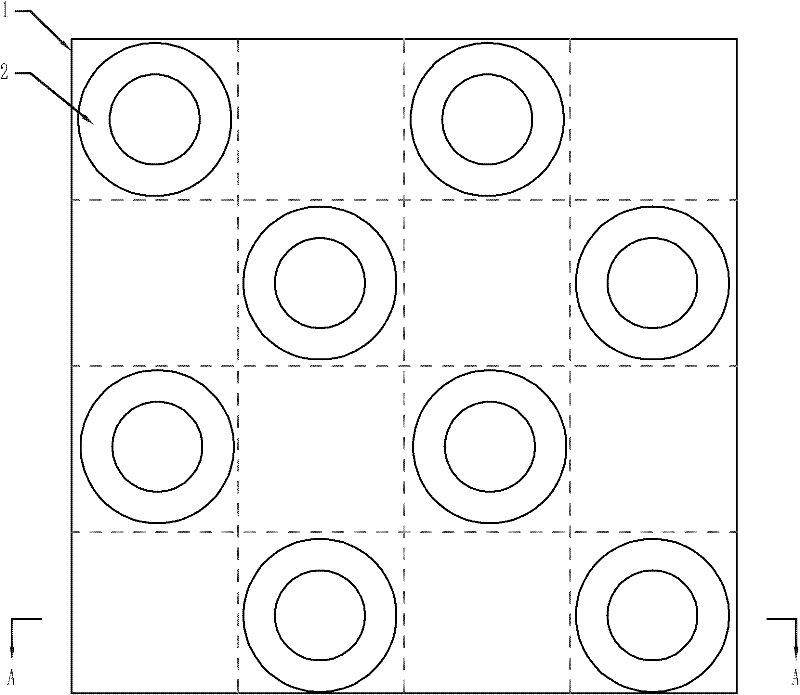

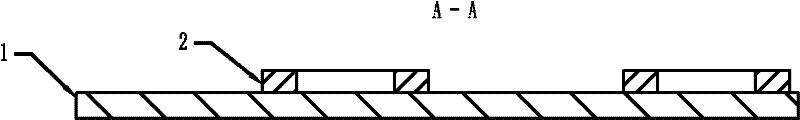

Magnetic suspension planar motor with superconductor excitation structure

ActiveCN102594220ALarge output thrustGreatly increased output thrustMagnetic circuitMechanical energy handlingSuperconducting CoilsPlanar motor

The invention relates to a magnetic suspension planar motor with a superconductor excitation structure, belongs to the technical field of motors and solves the problems of complicated structure, large planer movement scope, low winding utilization efficiency, small reasoning density and low system efficiency existing in the existing permanent magnet synchronous planar motor. In the magnetic suspension planar motor, a primary substrate is flat plate-shaped; an armature winding is fixedly arranged at the air gap side of the primary substrate; a secondary substrate is uniformly divided into 2h*2h magnet cells; 2h<2> superconducting magnets are respectively and fixedly arranged in the superconducting magnet cells adjacent at opposite angles on the secondary substrate and are not adjacent parallelly and vertically; the superconducting magnets are magnetized in parallel, the magnetizing directions of the superconducting magnets are vertical to a surface at the air gap side of the secondary substrate; the magnetizing directions of the superconducting magnets positioned on the same line or row are identical; the magnetizing directions of the superconducting magnets positioned on adjacent lines or rows are opposite; and a cooling container is covered outside all the superconducting magnets. The magnetic suspension planar motor has the beneficial effects that the primary suspension motion is realized, the suspension height is large, the bearing capacity is strong, and the magnetic suspension planar motor can be applied to the vacuum environment.

Owner:HARBIN INST OF TECH

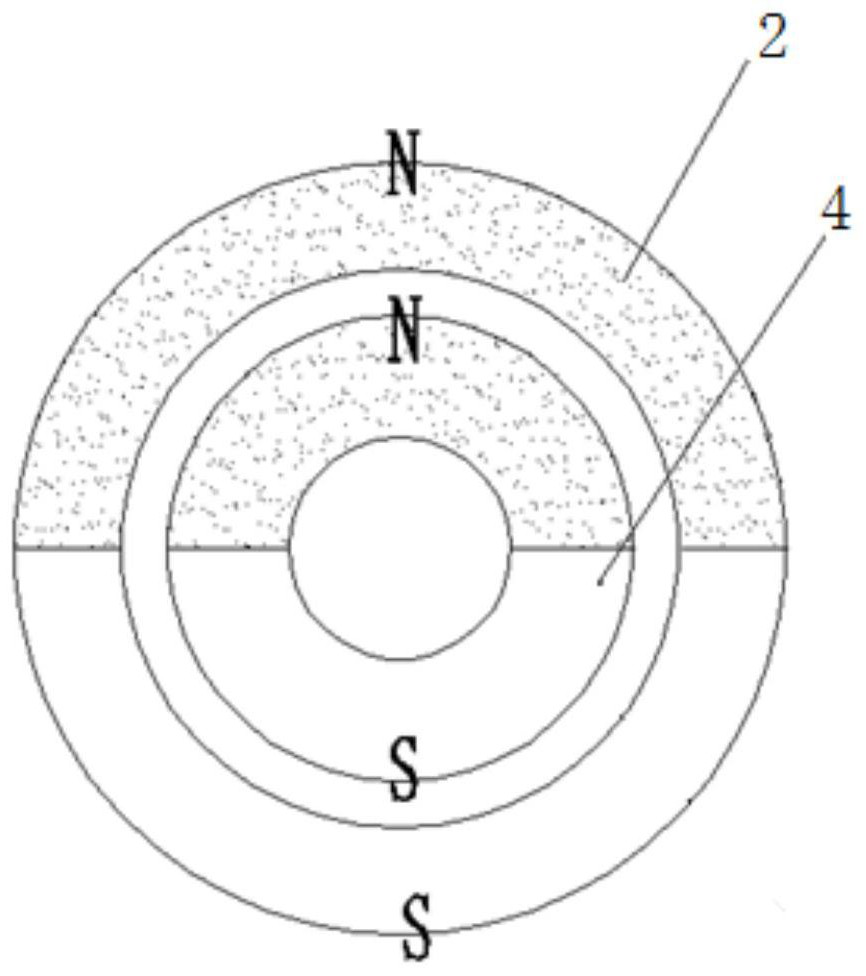

Low noise fast response permanent magnet DC brushless motor for constant wind control

InactiveCN101459370AImprove qualityReduce torque fluctuationMagnetic circuit rotating partsMagnetic circuit stationary partsLow noiseBrushless motors

The invention provides a low noise fast response permanent magnet direct current brushless motor for controlling constant air volume, which comprises a shell, a stator and a rotor in the shell, wherein the stator comprises a stator iron core and a stator winding which are fixed on the inner wall of the shell, the rotor comprises a main shaft and a rotor iron core, the external circumferential direction of the rotor iron core is evenly fixed with rotor magnetic poles which comprise radial magnetized magnetic steel and tangential magnetized magnetic steel, the radial magnetized magnetic steel is a main magnetic pole, and the tangential magnetized magnetic steel which is arranged between adjacent main magnetic poles is a side magnetic pole. Or, the inner circumferential direction of the rotor iron core is evenly embedded with built-in radial magnetized rectangular strip magnetic steel which is the main magnetic pole, and the tangential magnetized magnetic steel which is arranged between adjacent main magnetic poles is the side magnetic pole. The low noise fast response permanent magnet direct current brushless motor gathers magnetic through two ways of radial and tangential direction, thereby observably increasing the air gap flux density, greatly reducing the mechanical time constant, increasing fast response, controlling the constant air volume in a high performance, which leads a motor to steadily operate in high efficiency, saving energy, low fluctuation, low noise, frequent starting and rapid response, and the low noise fast response permanent magnet direct current brushless motor can achieve the miniaturization and lightening of the motor.

Owner:苏州和鑫电气股份有限公司

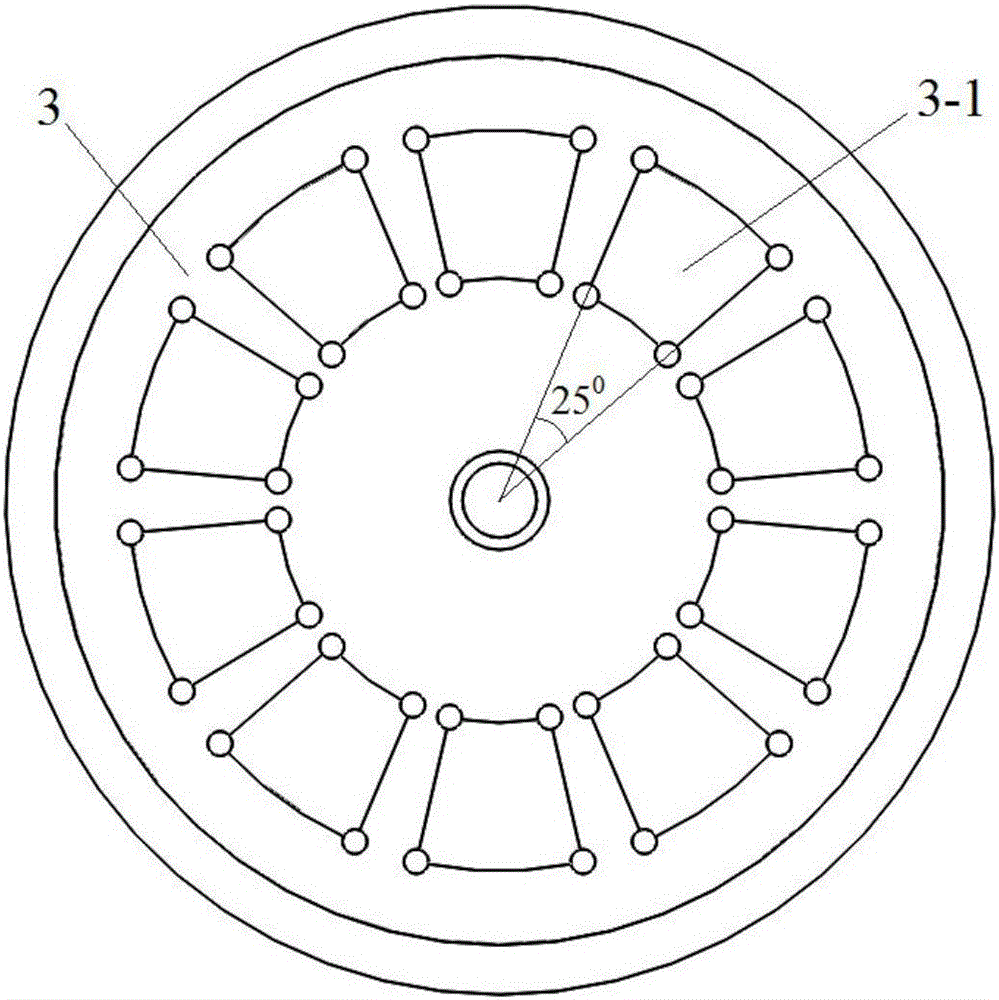

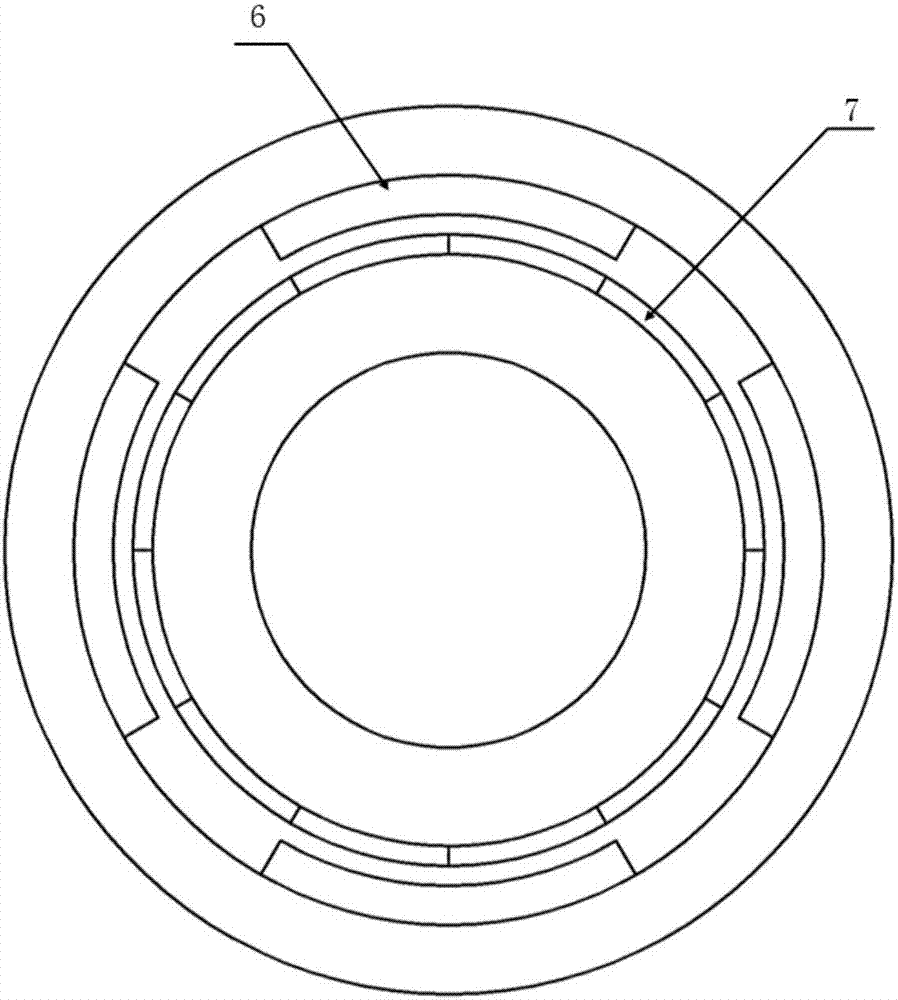

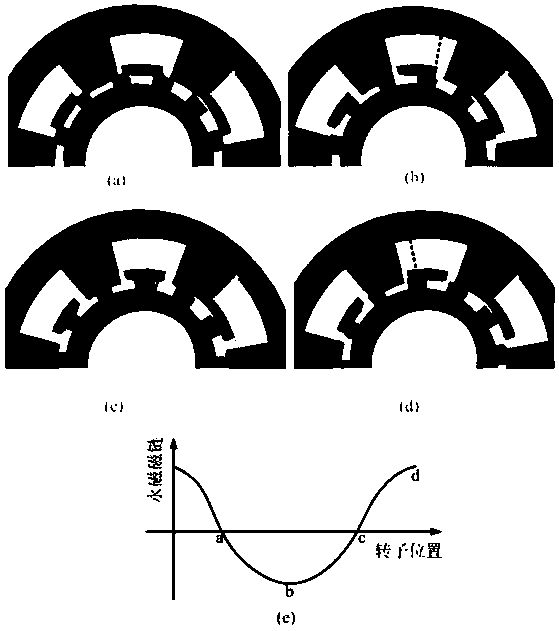

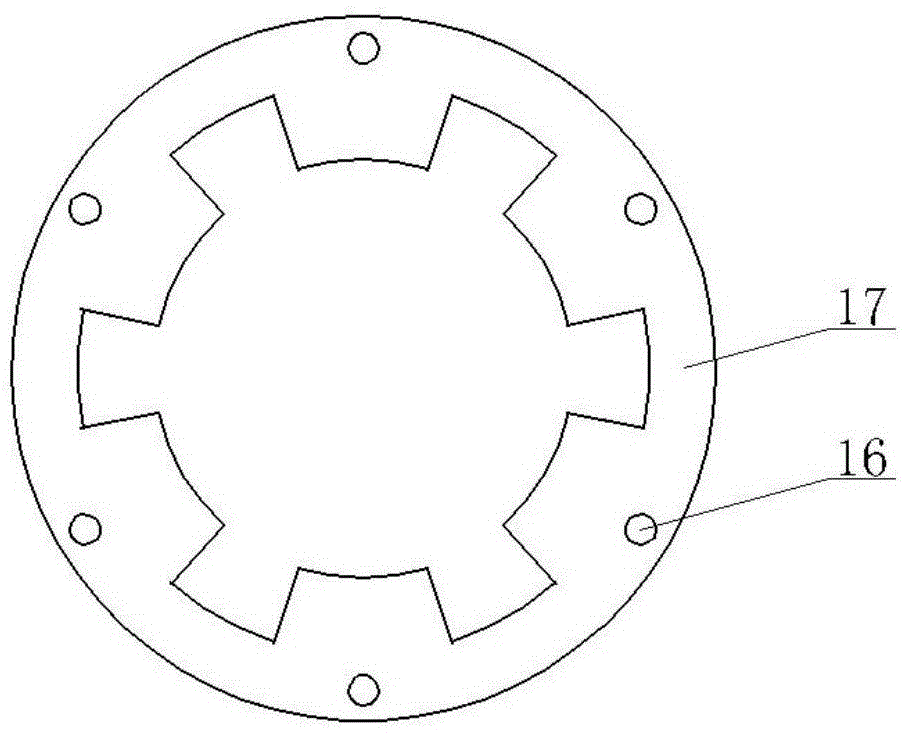

Magnetism-gathering transverse magnetic field motor with claw-pole type stator

InactiveCN101588119AReduce lossSimple structureMagnetic circuit rotating partsMagnetic circuit stationary partsTransverse magnetic fieldAir gap flux density

The invention belongs to the field of permanent-magnetic motors, and provides a magnetism-gathering transverse magnetic field motor with a claw-pole type stator. The motor comprises a stator fixing shaft and a motor rotating shaft, wherein a shell of the motor and the motor rotating shaft are connected with the stator fixing shaft through a bearing; a stator bracket is arranged on the fixing shaft; a stator core is connected with the stator bracket; the stator core is provided with holes evenly distributed along the circumferential direction; a stator claw tooth is arranged on the stator core; a stator winding is arranged in the middle of the claw tooth; a rotor structure is arranged in an inner cavity of the shell; a rotor core is provided with a radial hole and a circumferential hole; a radial permanent magnet is arranged in the radial hole of the rotor core; a circumferential permanent magnet is arranged in the circumferential square hole of the rotor core; an air gap exists between the stator core and the rotor core; and stator teeth among phases m of the motor differ from each other by 1 / m polar distance. As a rotor of the motor adopts a three-surface magnetism-gathering structure, the motor has the advantages of reducing core loss and increasing the magnetic flux density of the air gap, along with simple structure and easy manufacture.

Owner:XI AN JIAOTONG UNIV

High-voltage and low-voltage compatible built-in brushless direct-current power generation system

ActiveCN111009992AReduce volumeEasy to operateElectronic commutation motor controlWindings insulation shape/form/constructionDC - Direct currentElectric machine

The invention discloses a high-voltage and low-voltage compatible built-in brushless direct-current power generation system, which belong to the technical field of aerospace electrical design and manufacturing. The power generation system comprises a brushless power generator, a starting controller and a power generation controller; the brushless power generator is arranged in an engine and is directly connected with an engine rotating mechanism; the brushless generator is used as a starter in an engine starting state and works in an electric state, drags the engine to an ignition rotating speed and assists power after ignition, and is used as a generator after ignition of the engine and works in a power generation state; the starting controller is used for driving and controlling the electric operation of the generator, and in the starting stage of the engine, the starting controller drives and controls the motor to drag the engine from a static state to a rotating speed meeting the ignition requirement of the engine and assists the engine to operate to reach the required rotating speed to automatically stop the electric driving control of the motor; and the power generation controller rectifies the three-phase alternating current output by the generator into 28.5 V direct current to supply power to a load on an unmanned aerial vehicle.

Owner:BEIJING POWER MACHINERY INST

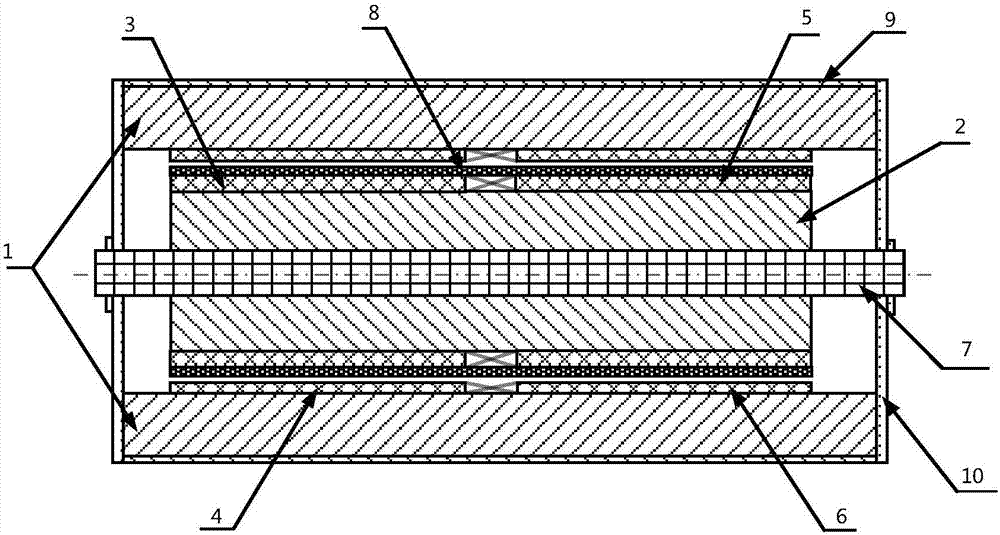

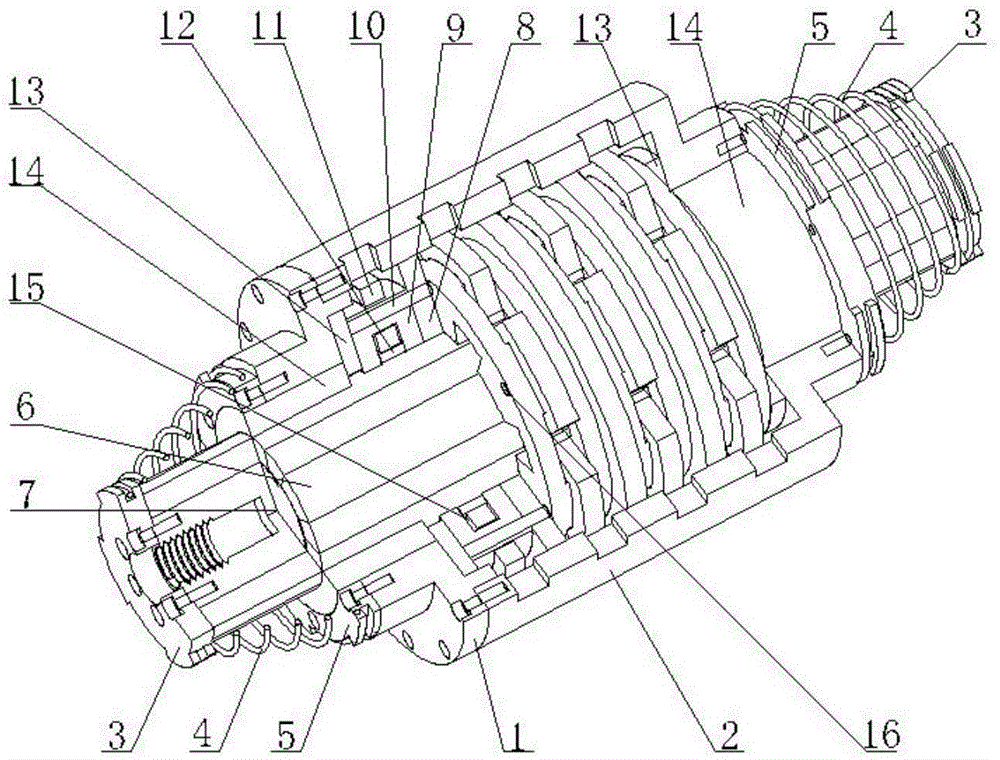

Stator and rotating linear two-degree-of-freedom permanent magnet motor with modular structure

ActiveCN111082551AImprove the winding factorReduced end windingMagnetic circuit rotating partsElectric machinesLinear motionElectric machine

The invention provides a stator and a rotating linear two-degree-of-freedom permanent magnet motor with a modular structure. The rotating linear two-degree-of-freedom permanent magnet motor with the modular structure comprises a stator and a rotor, and the stator comprises a stator core, a rotating motion winding and a linear motion winding; the stator iron core is formed by a plurality of same modular iron core units in a three-phase mode on the circumference. Stator grooves are formed in the axial direction and the circumferential direction of an inner surface of the stator iron core at thesame time, so that stator teeth are distributed in an array mode and evenly distributed on all the modular iron core units. The rotating motion winding is wound on stator teeth which are axially arranged along an inner surface of the stator core along the linear motion direction to form a phase group centralized winding for driving rotary motion; and the linear motion winding is wound on the stator teeth arranged along the circumferential direction of the inner surface of the stator iron core along the circumferential direction to form a phase group centralized winding for driving linear motion. The structure is simple, the manufacturing is easy, and the material utilization rate is increased.

Owner:SHANDONG UNIV

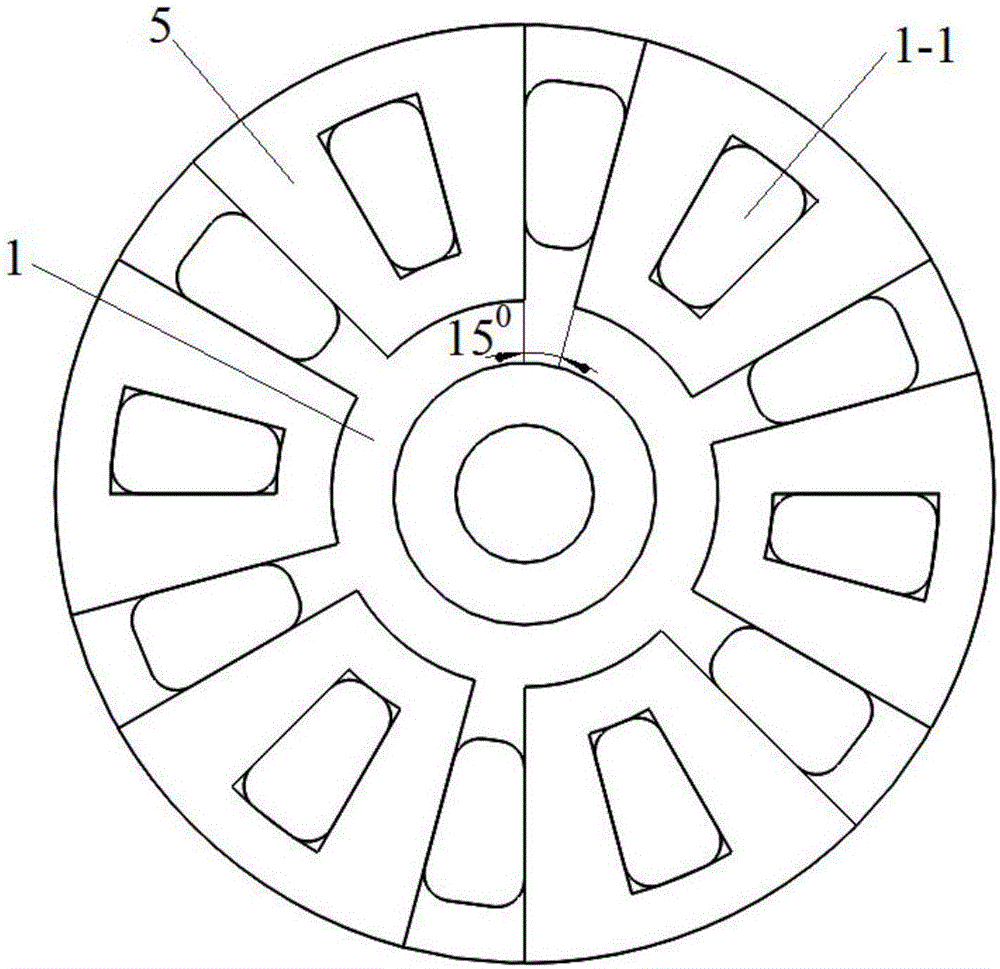

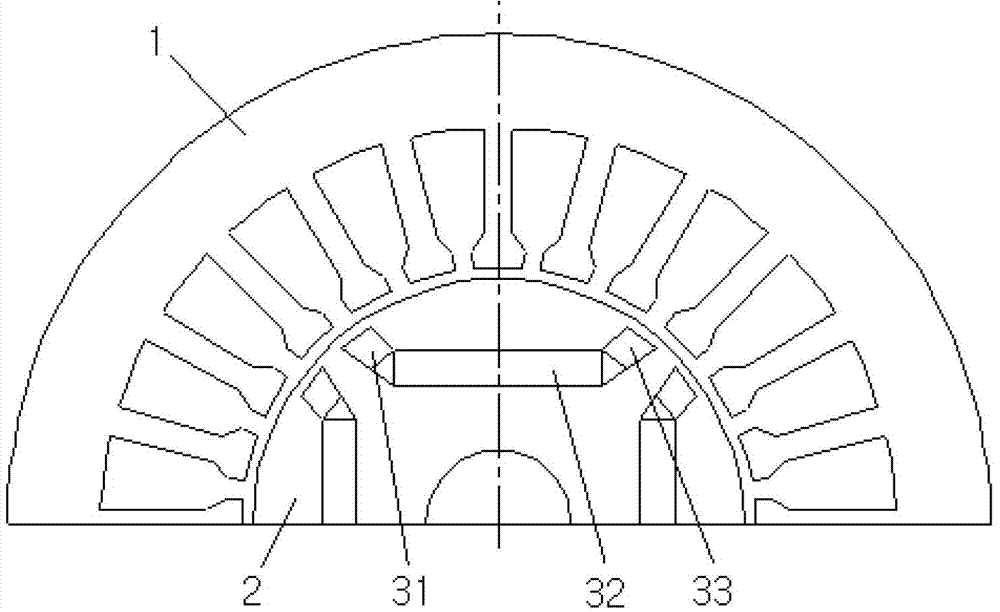

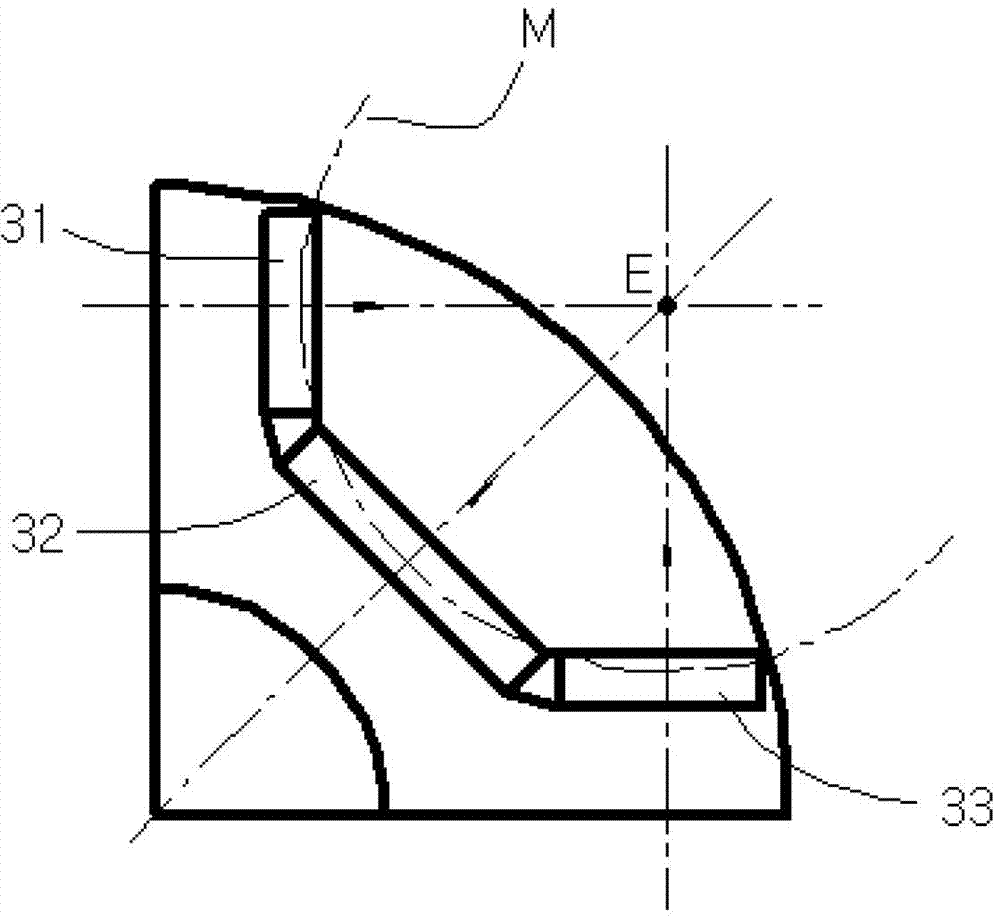

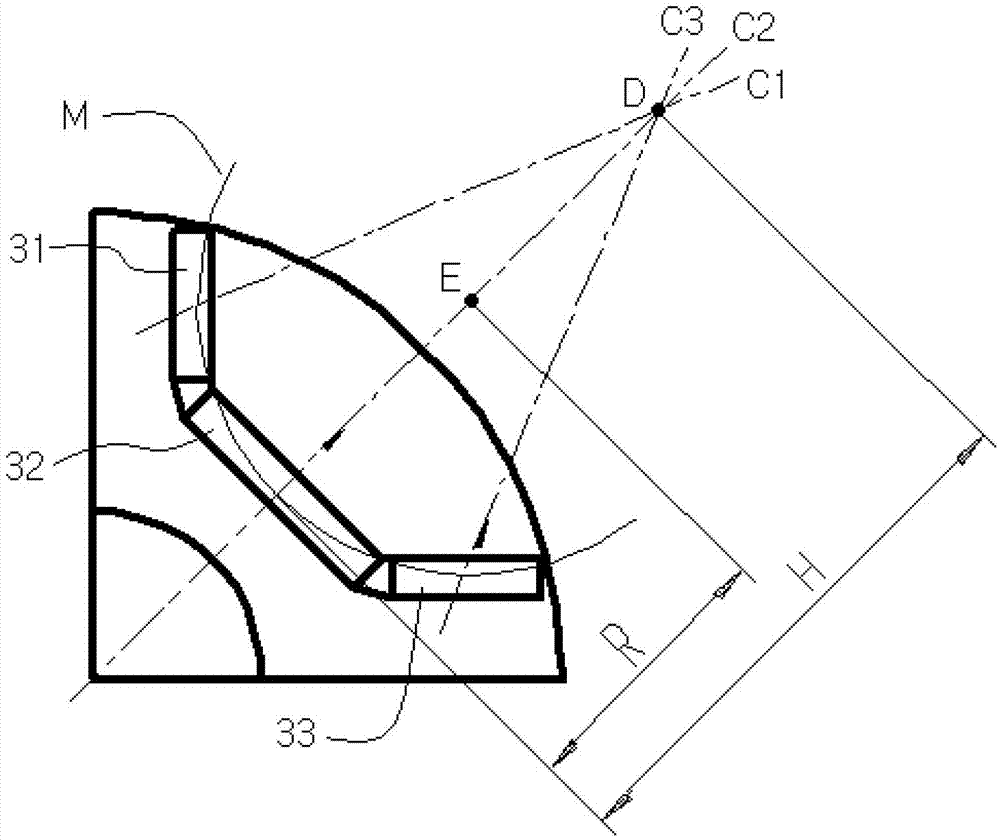

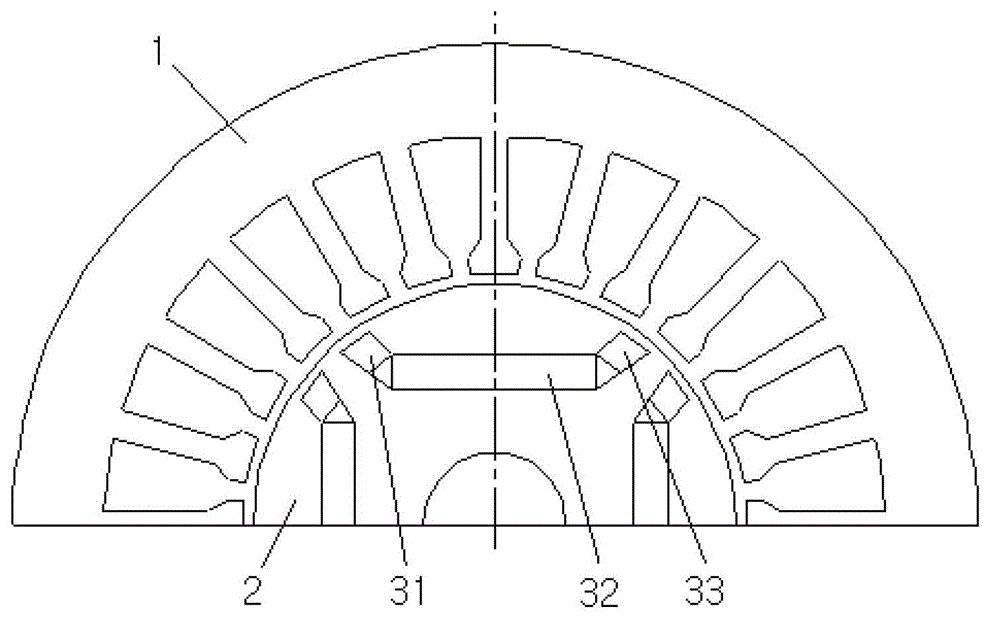

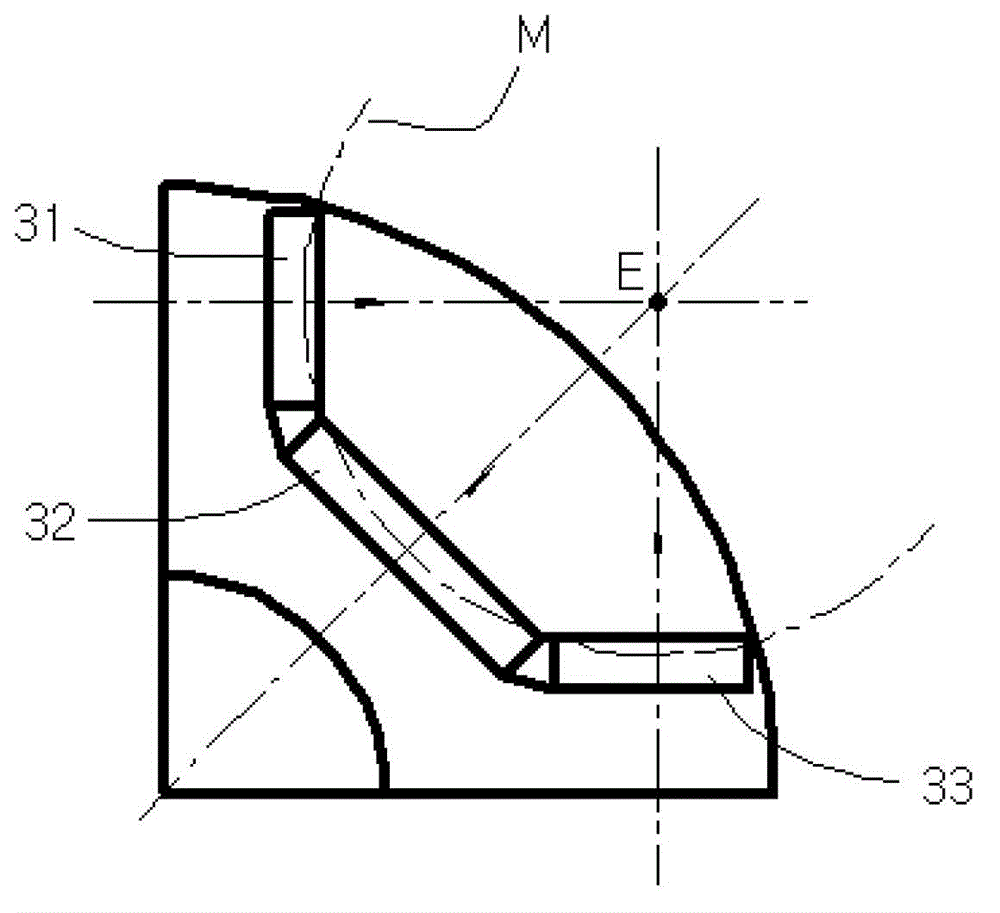

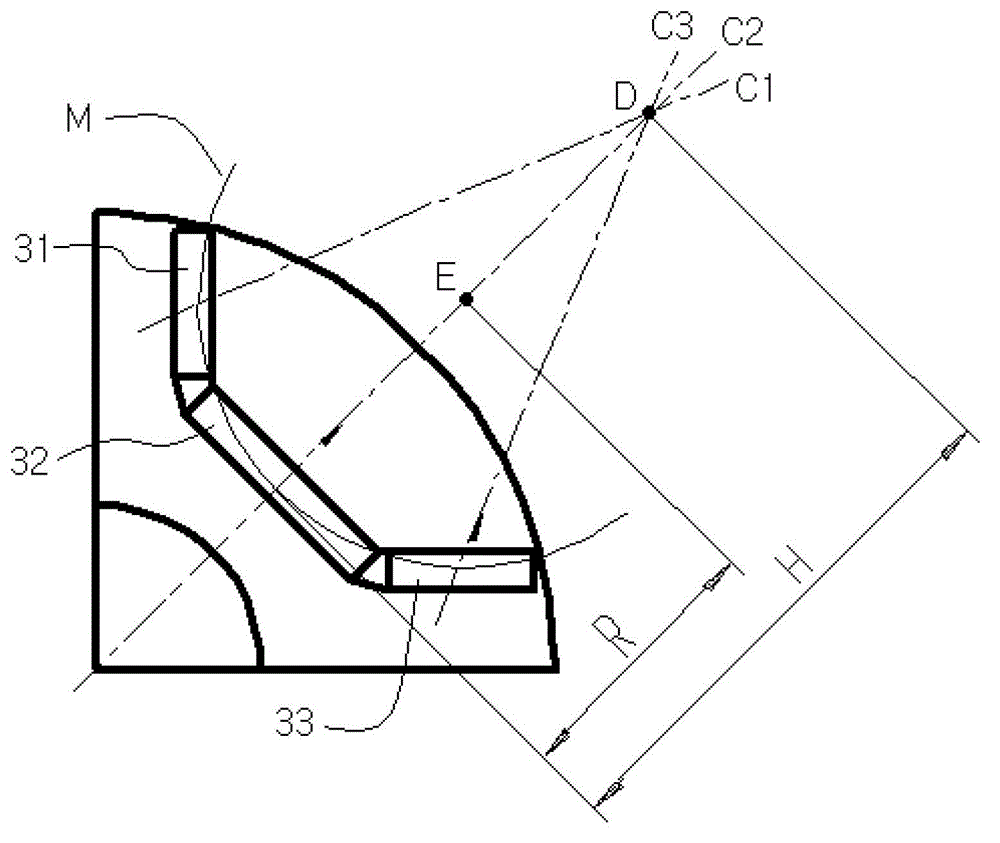

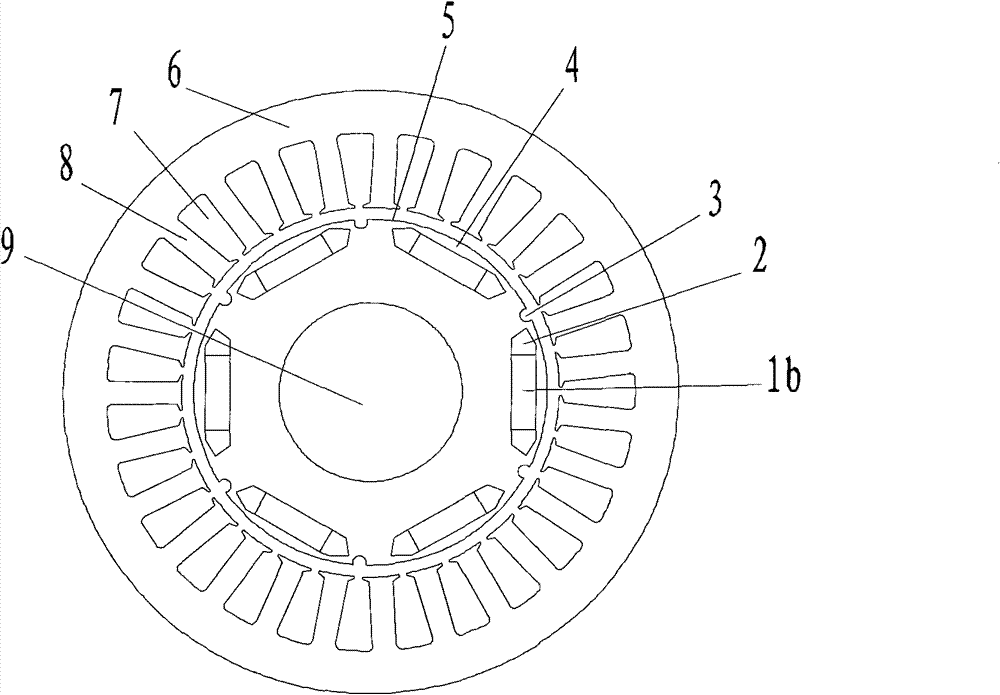

Built-in permanent magnet synchronous motor

ActiveCN103078464AImprove qualityImprove air gap flux density waveformMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsBand shapePermanent magnet synchronous motor

The invention discloses a built-in permanent magnet synchronous motor, relates to the technical field of a motor and aims to solve the technical problem of improving the comprehensive quality of the motor. Multiple permanent magnet slots are axially and symmetrically arranged in a rotor of the motor along the central axis of the rotor at intervals, three permanent magnets distributed in an arc band shape are arranged in each permanent magnet slot, wherein one permanent magnet is a middle steel magnet, and the other two permanent magnets are side steel magnets; the built-in permanent magnet synchronous motor is characterized in that each middle steel magnet adopts the normal magnetization vertical to the surface of the steel magnet, and each two side steel magnets in one slot adopt the non-normal magnetization, so that the arc center of a magnet arrangement arc of each permanent magnet slot is enabled not to coincide with the magnetization orientation point of permanent magnets in the corresponding permanent magnet slot. According to the motor provided by the invention, the comprehensive quality of the motor is greatly improved.

Owner:SHANGHAI TOP MOTOR +2

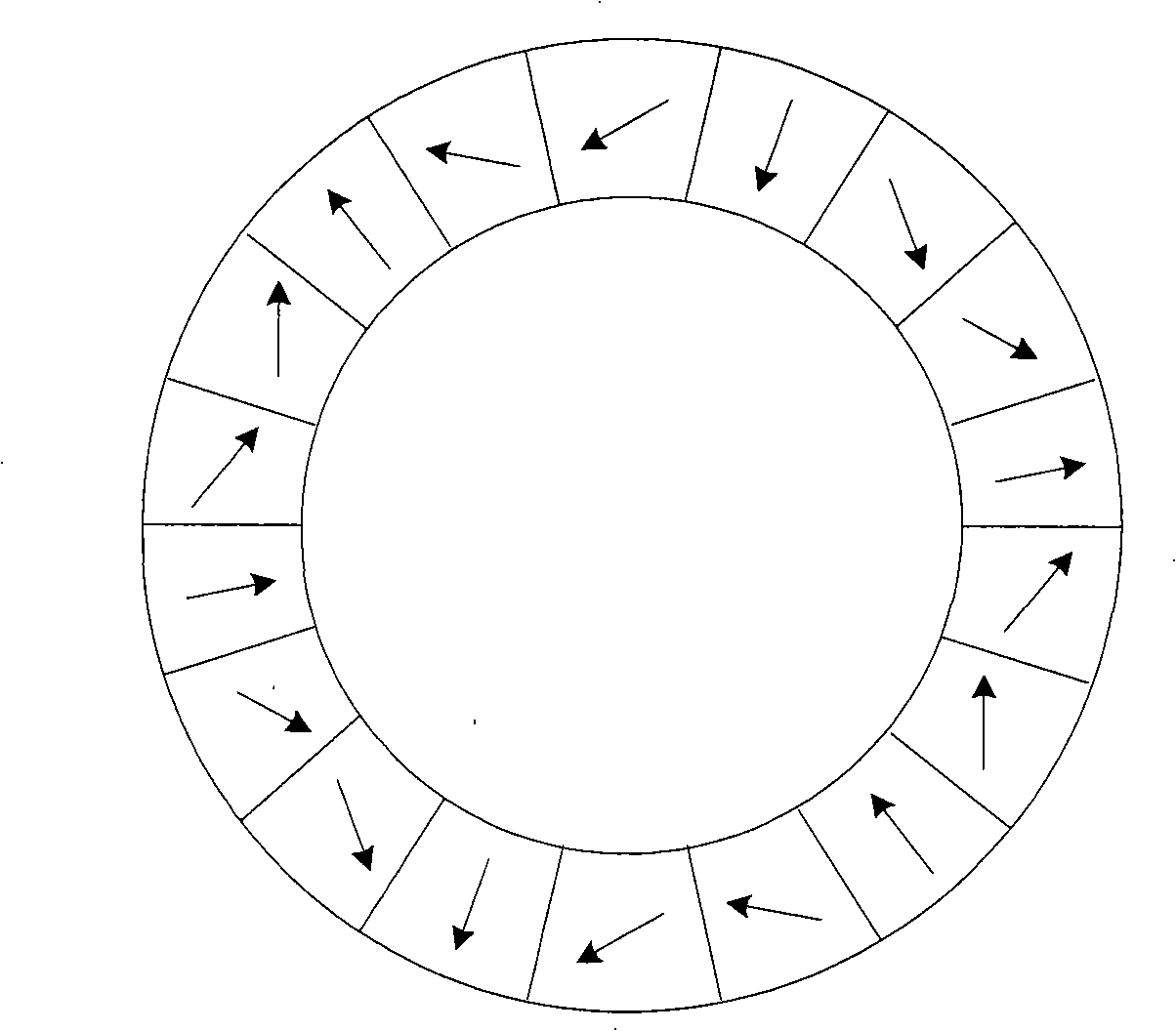

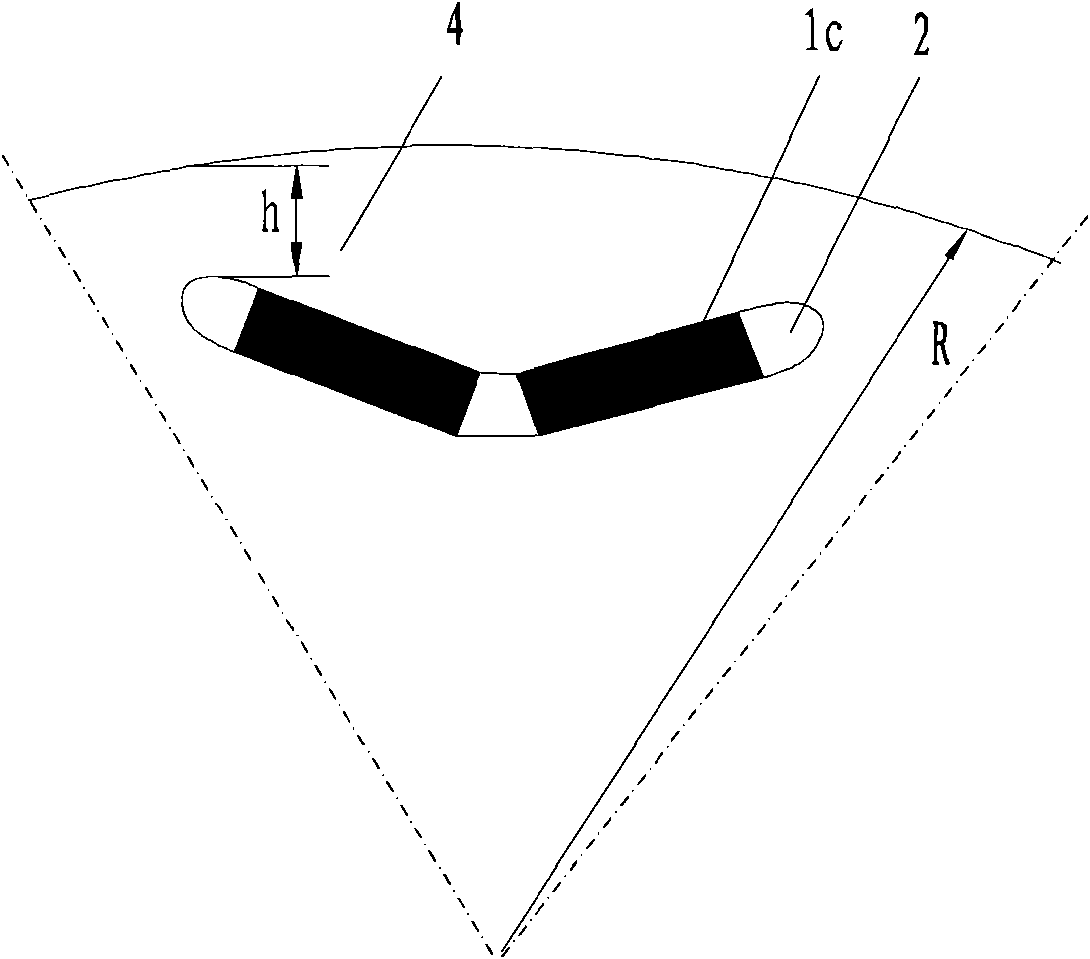

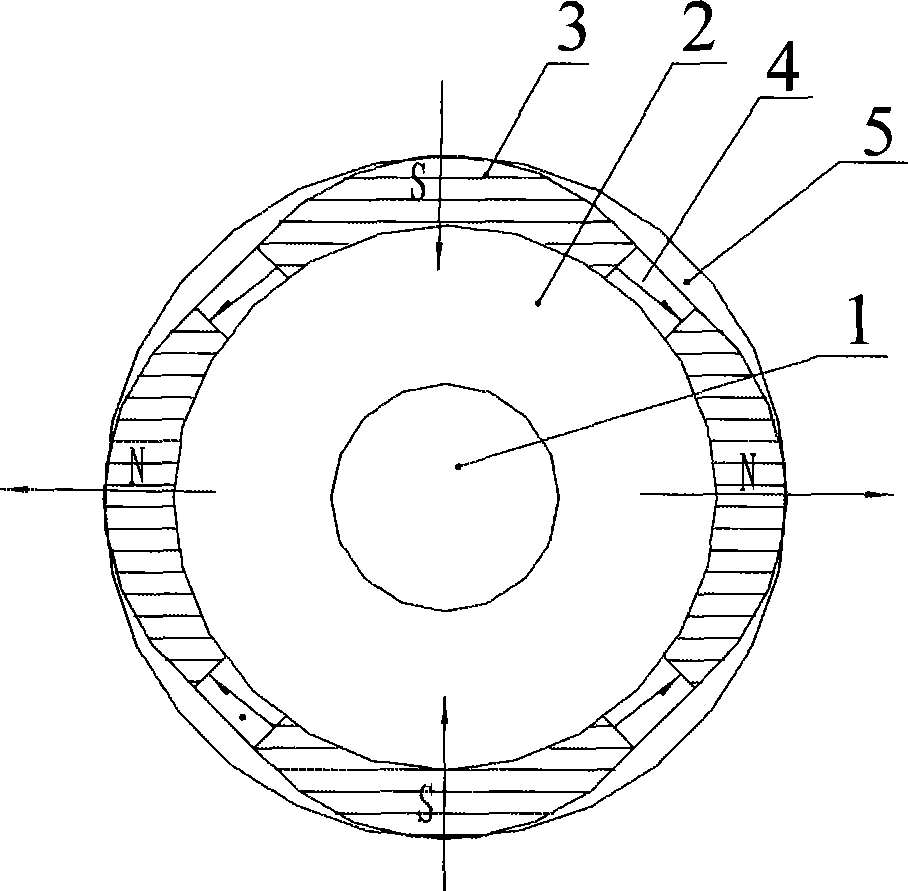

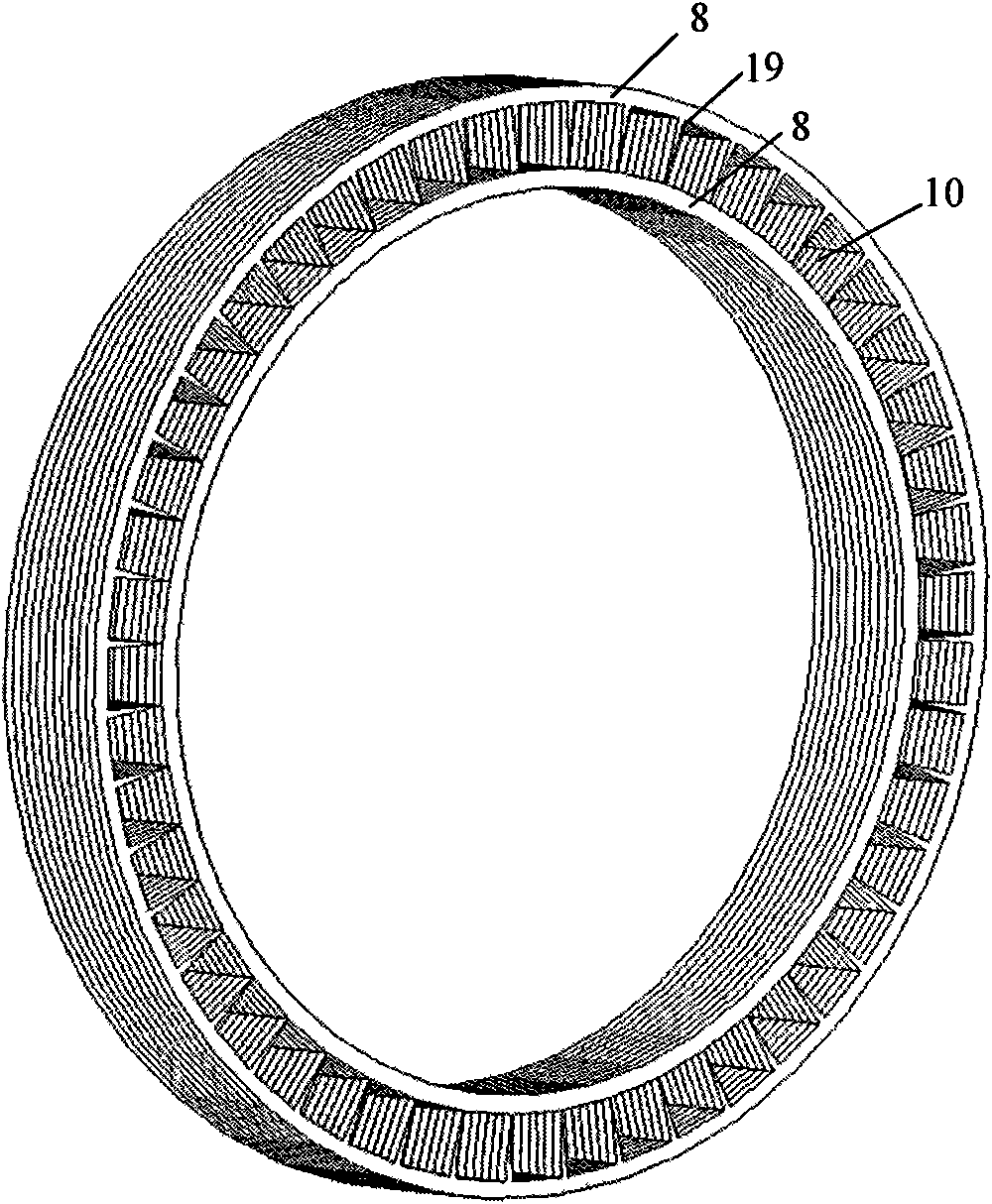

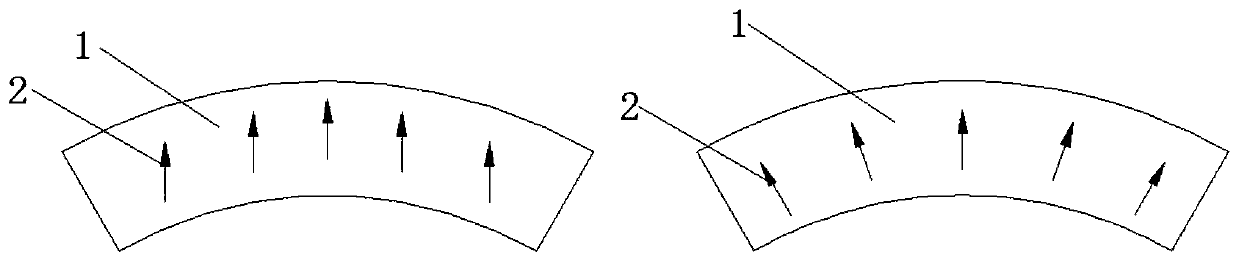

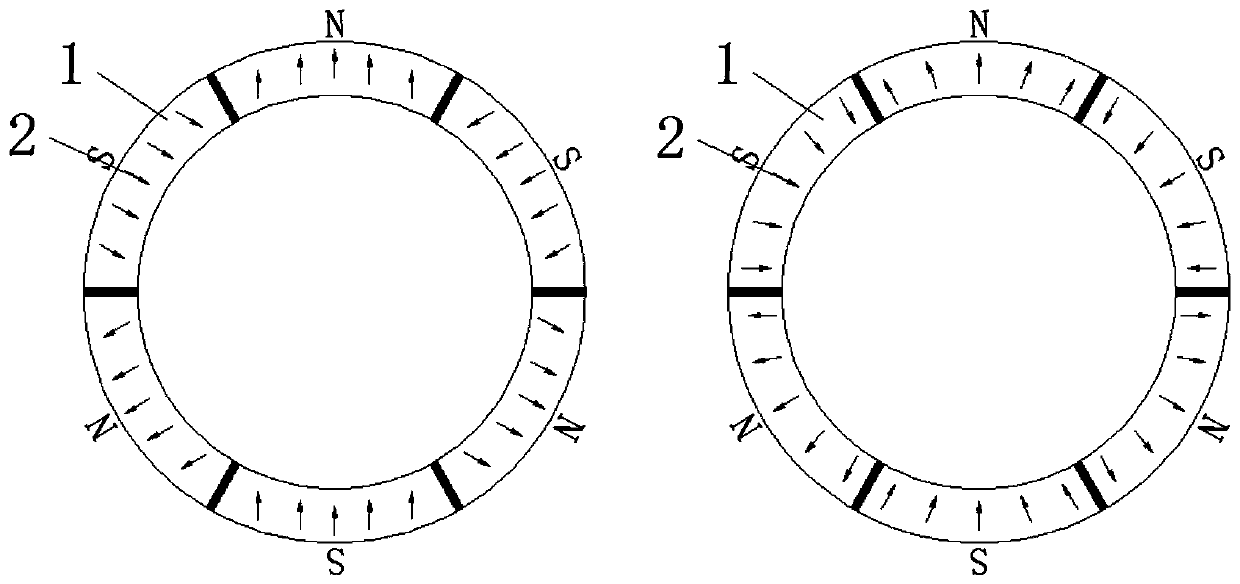

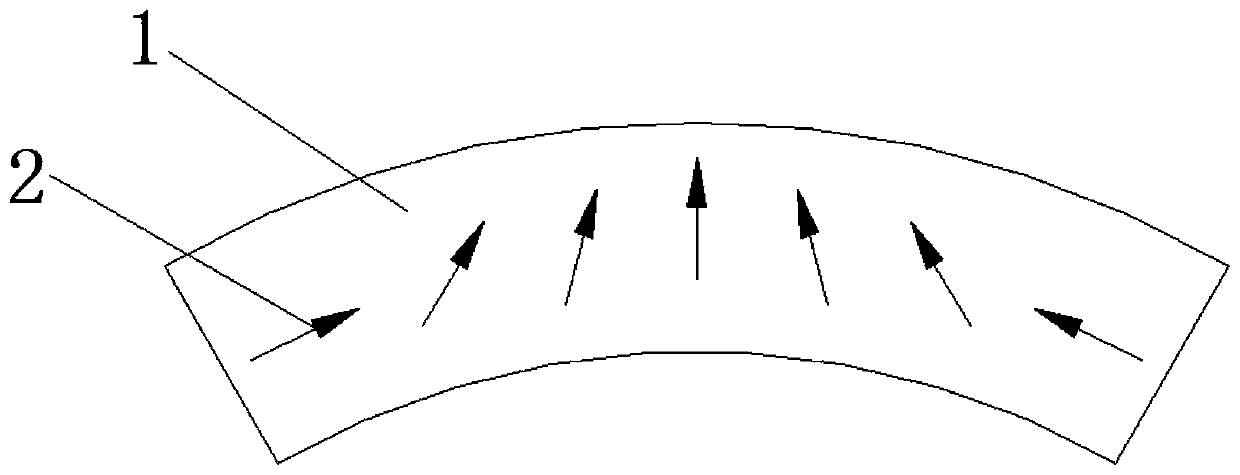

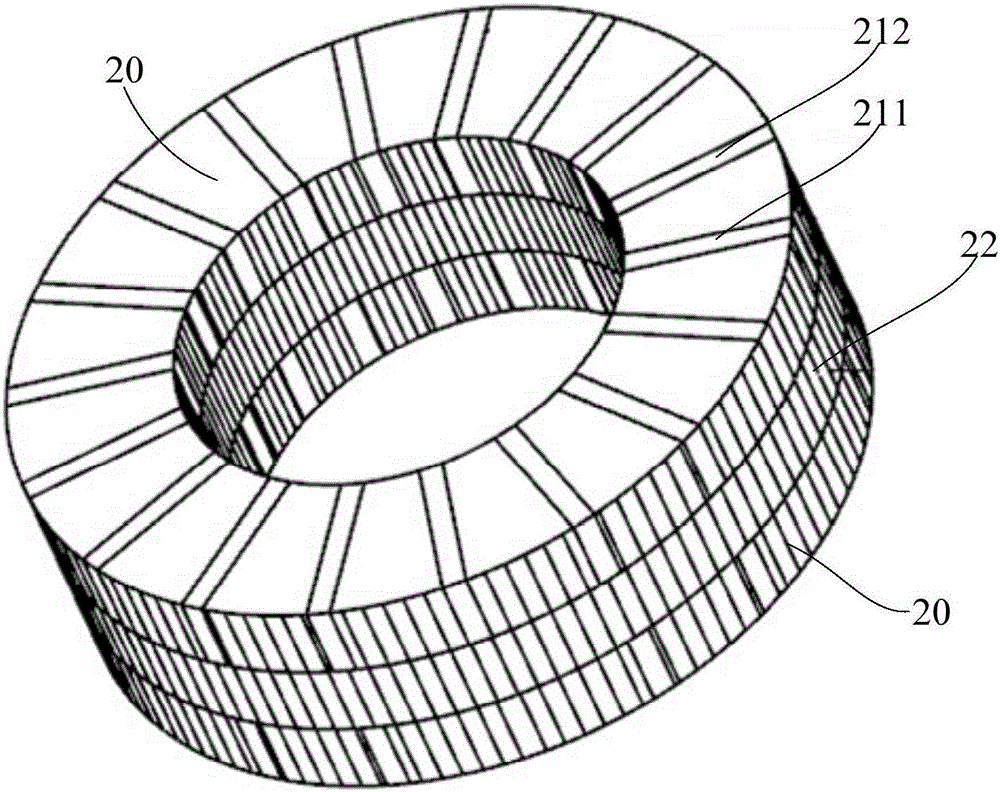

Tile-shaped magnet with halbach array structure effect and manufacturing method

PendingCN110943554AWith unilateral magnetic concentration effectIncreased air gap flux densityMagnetic circuit rotating partsMagnetic circuit stationary partsMagnetic effectElectric machinery

The invention discloses a tile-shaped magnet with a halbach array structure effect and a manufacturing method, relating to the field of magnetic shoe forming orientation A parallel orientation or radiation orientation mode in a traditional magnetic shoe forming process is changed, and a unique magnetic field orientation forming system is designed, so that magnetic moments in a magnetic shoe are arranged in a halbach array structure. The surface magnetic flux density of the magnetic ring assembled and combined by magnetic shoes prepared by the method is in good sine wave distribution, and the magnetic ring has a unilateral magnetism gathering effect, the working surface air gap magnetic field intensity is improved, the magnetic energy utilization rate is high, no performance loss exists, and the magnetic ring can be widely applied to motor design.

Owner:HANGZHOUSNNER MACHINERY EQUIP

Radial magnetic field stator yoke-free double-rotor disc type permanent magnet synchronous motor

InactiveCN110120729AImprove efficiencyIncrease energy densityMagnetic circuit rotating partsCooling/ventillation arrangementLiquid waterPermanent magnet synchronous motor

The invention discloses a radial magnetic field stator yoke-free double-rotor disc type permanent magnet synchronous motor. The motor comprises a stator, an outer rotor, an inner rotor, a rotor support, a rotating shaft, a front bearing, a rear bearing, a front end cover, a rear end cover and a housing. The stator is composed of a stator iron core and a stator winding. The outer rotor is composedof an outer rotor iron core and outer magnetic steel. The inner rotor is composed of an inner rotor iron core and inner magnetic steel. The rotor support is connected with the outer rotor, the inner rotor and the rotating shaft, the rotating shaft is supported by the front bearing and the rear bearing, the front end cover is connected with the stator iron core and the housing and provided with a bearing chamber and a cooling liquid water channel, the rear end cover is connected with the housing and provided with a bearing chamber, and the outer magnetic steel and the inner magnetic steel are permanent magnets. The radial magnetic field stator yoke-free double-rotor permanent magnet disc type motor has the outstanding advantages of high peak torque density, high efficiency, small size, light weight and disc-type thin appearance, and is particularly suitable for being used as an electric vehicle wheel edge driving motor, a hub motor, an integrated generator and the like.

Owner:SHANGHAI FUTIAN ELECTRIC TECH

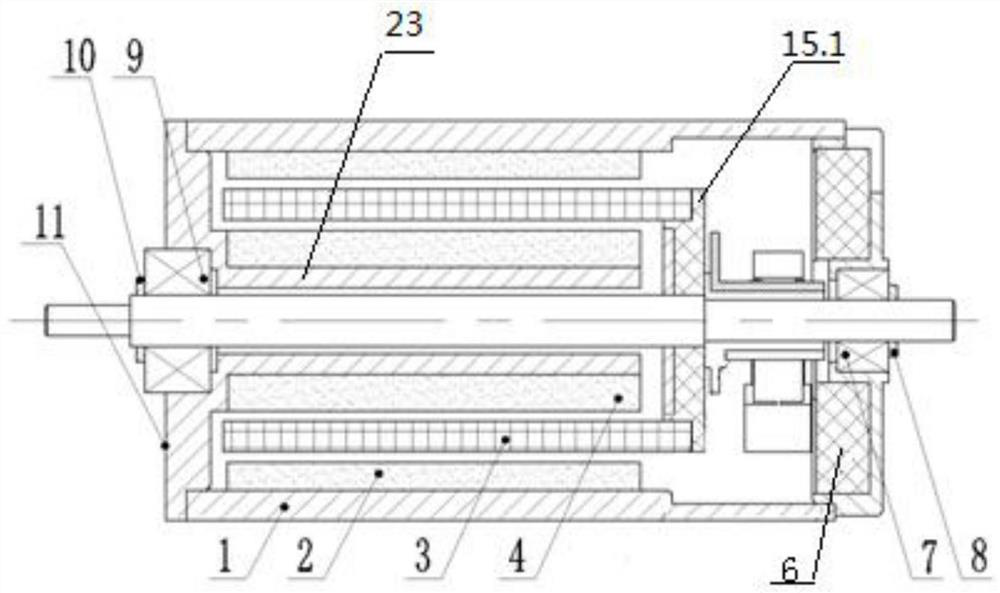

High power density permanent magnet brushless double-feed electric motor in novel structure

InactiveCN104811002AAvoid power supplyImprove cooling effectCooling/ventillation arrangementManufacturing cost reductionElectric machine

The invention provides a high power density permanent magnet brushless double-feed electric motor in a novel structure. The motor comprises a first stator, a second stator and a rotor; the first stator and the second stator are arranged on two sides of the rotor; an external air gap is formed between the first stator and the rotor; an internal air gap is formed between the rotor and the second stator; the first stator and the second stator are connected through a stator support to be fixed; permanent magnets are arranged on the internal side and the external side of the rotor; the rotor is fixed on a rotary shaft; the first stator and the second stator are respectively provided with an armature winding. The high power density permanent magnet brushless double-feed electric motor in the novel structure can reduce manufacturing costs and improve the motor power density and efficiency.

Owner:HUAQIAO UNIVERSITY

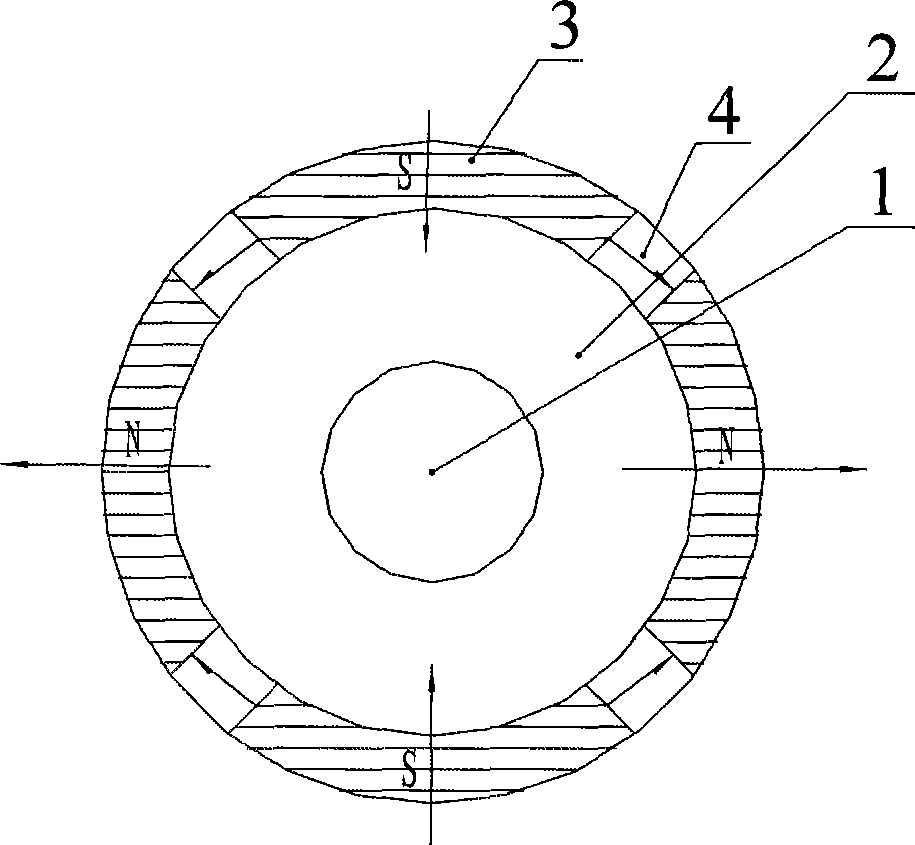

Outer rotor motor of polygonal dovetail type spliced magnetic steel structure

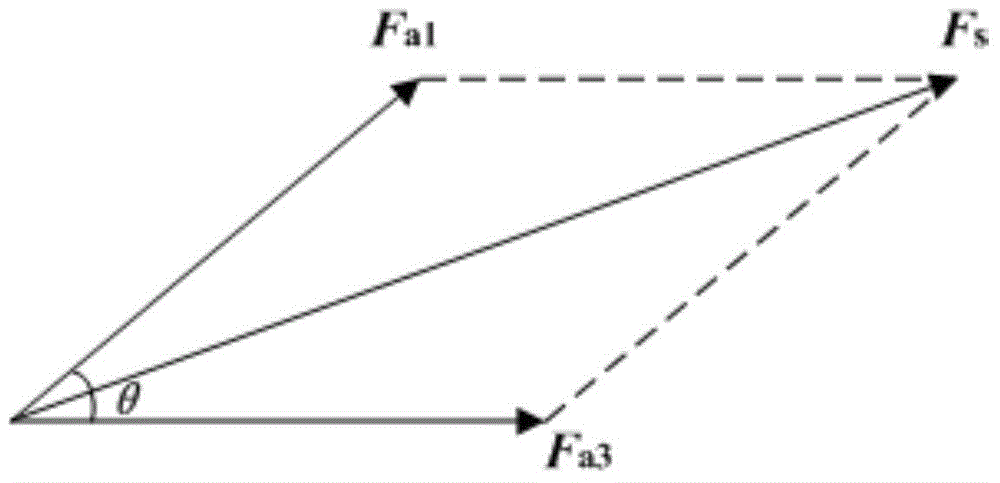

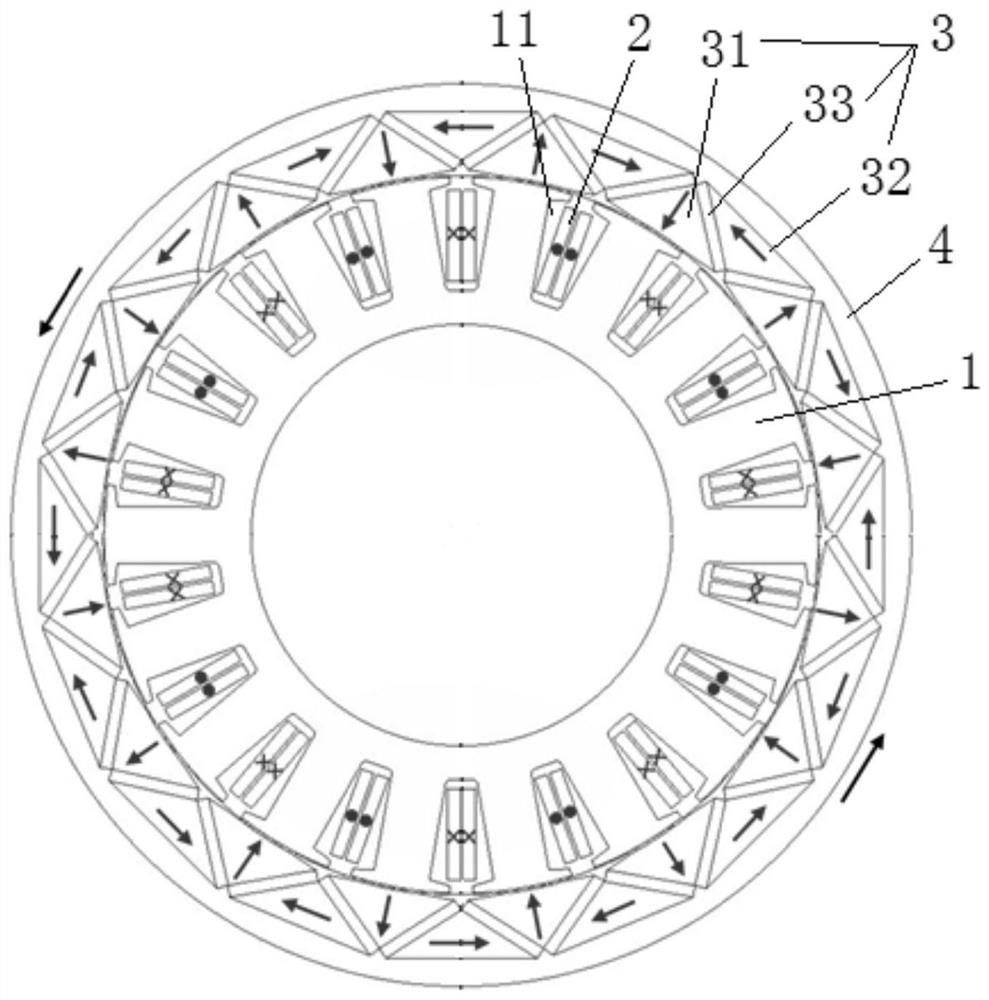

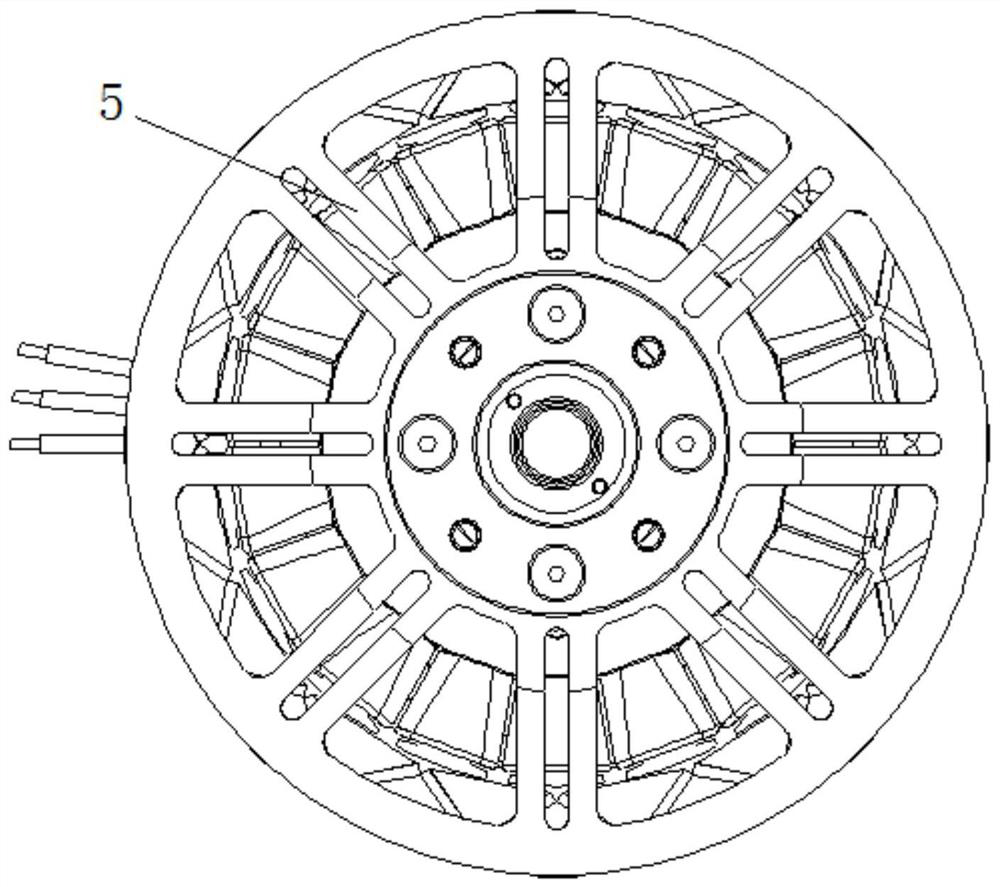

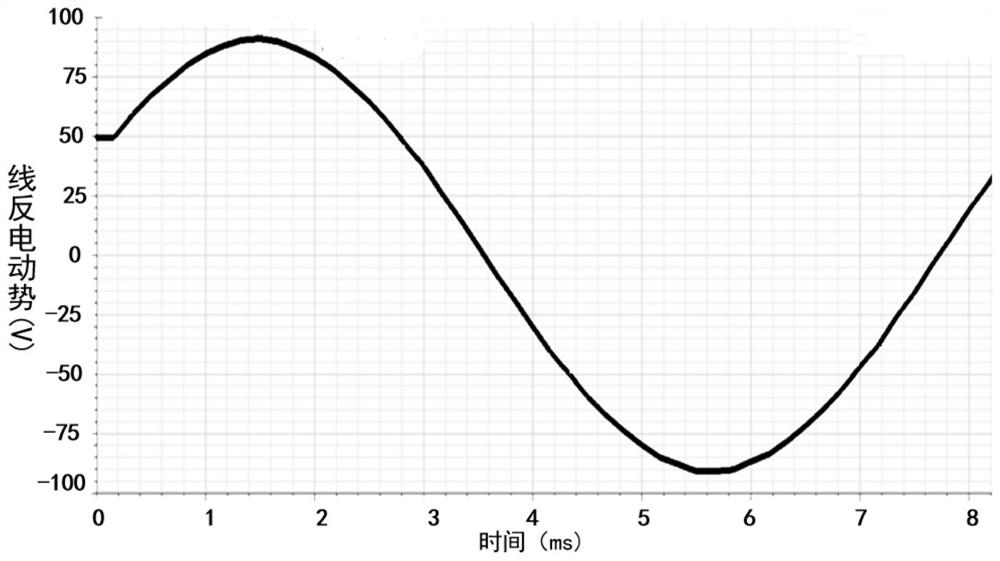

ActiveCN112953151AIncreased air gap flux densityImprove dynamic performanceMagnetic circuit rotating partsCooling/ventillation arrangementElectric machineStator coil

The invention relates to the technical field of motors, and discloses an outer rotor motor of a polygonal dovetail type spliced magnetic steel structure. The outer rotor motor comprises a stator core, a stator coil, rotor magnetic steel and rotor back iron, wherein the rotor magnetic steel adopts the design of a first permanent magnet, a second permanent magnet and a third permanent magnet, a plurality of permanent magnets of which the cross sections are isosceles triangles or quadrangles are spliced into a circle to form the annular closed rotor magnetic steel, and a Halbach magnetizing mode is adopted, so that electromagnetic force borne by the stator coil in each stator tooth groove forms a closed loop in the tangential direction of the circumference, and therefore, an outer rotor is subjected to stable torque, and stable rotation is realized. Meanwhile, self-shielding can be formed in the Halbach magnetizing mode, the output torque can be increased, the torque pulsation can be reduced and the power density can be improved while the air gap magnetic flux density in the motor is ensured to be large enough, the vibration amplitude is obviously reduced under the condition of low order through radial force wave two-dimensional Fourier FFT2 analysis, and therefore, the dynamic performance of the motor is improved.

Owner:BEIHANG UNIV +1

Voltage-stabilized single-phase brushless neodymium-iron-boron alternating-current generator

InactiveCN1471220ASimple structureNo slip ringMagnetic circuit rotating partsSynchronous machinesCapacitanceAlternator

A pair of additive electromagnetical pole is added to rotor of the generator, and a group of lateral axis winding is installed on the stator to produce the invented AC generator. Proper capacitance is connected to the said winding so that leading current is generated. Thus, when the load current is raised, the total flux is raised so as to improve output voltage characteristic in order to meet the requirement of use. The invented generator possesses the features of simple structure, without sliding ring, brush and without need of DC excitation source so as to have the performances of high efficiency, low temperature rise. The technique is also suitable to three-phase magneto alternator.

Owner:夏红元

Two-phase twenty-pole radial stator and rotor combined magnetic field electric motor

InactiveCN101154833AIncrease output torqueIncrease output powerMagnetic circuit rotating partsMagnetic circuit stationary partsManufacturing technologyMagnetic poles

A combined type magnetic field motor of two phase twenty poles radial stator and rotor is provided, each group of stators forms a transverse concave stator by an outer stator core, an inner stator core and a transition core, three of which are riveted by rivets stacked by core stampings , the outer stator core and the inner stator core are staggered with one polar distance along the cross section of an axial direction, two phase stators are relatively staggered with half a polar distance, the outer stator core and the inner stator core have the same length and height, the stator is limited by an end plate on a casing in up, down, left and right directions, and fixed in the casing by a bolt, a rotating shaft is provided with a rotor spoke which is provided with a rotor excitation ring formed by permanent magnet poles and rotor cores which are alternately connected, adjacent permanent magnet poles on the rotor excitation ring are opposite. The invention has the following advantages: an air gap magnetic flux density is improved, the output torque and the output power of the motor are improved, the structure and manufacturing technology of the stator are simplified, and production cost is reduced.

Owner:TIANJIN DEXIN ELECTRIC MACHINERY

Brushless excitation air core pulse generator

InactiveCN107482870AImprove reliabilitySimplify the excitation systemDynamo-electric machinesExcitation currentNegative phase

The invention discloses a brushless excitation air core pulse generator, which belongs to the technical field of generators. The brushless excitation air core pulse generator, in the structure, comprises an air core stator base, an air core rotor base, a generator excitation winding, a generator armature winding, an exciter armature winding, an exciter excitation winding, a rotation shaft, a binding sleeve, a housing and an end cover. The brushless excitation air core pulse generator is divided to two parts of the generator and the exciter; the rotor winding is formed by the generator excitation winding and the exciter armature winding and is integrally cast through epoxy resin and is connected with the air core rotor base, and both are multi-phase windings and are in negative-phase-sequence connection. Thus, the frequency of the armature winding of a magnetic field cutting generator in a generator can be improved, the induction potential of the generator armature winding can be increased, the air core pulse generator is brushless, the whole reliability and the safety of the motor are improved, the excitation current upper limit is increased, and the energy storage density and the power density of the motor can be improved.

Owner:HUAZHONG UNIV OF SCI & TECH

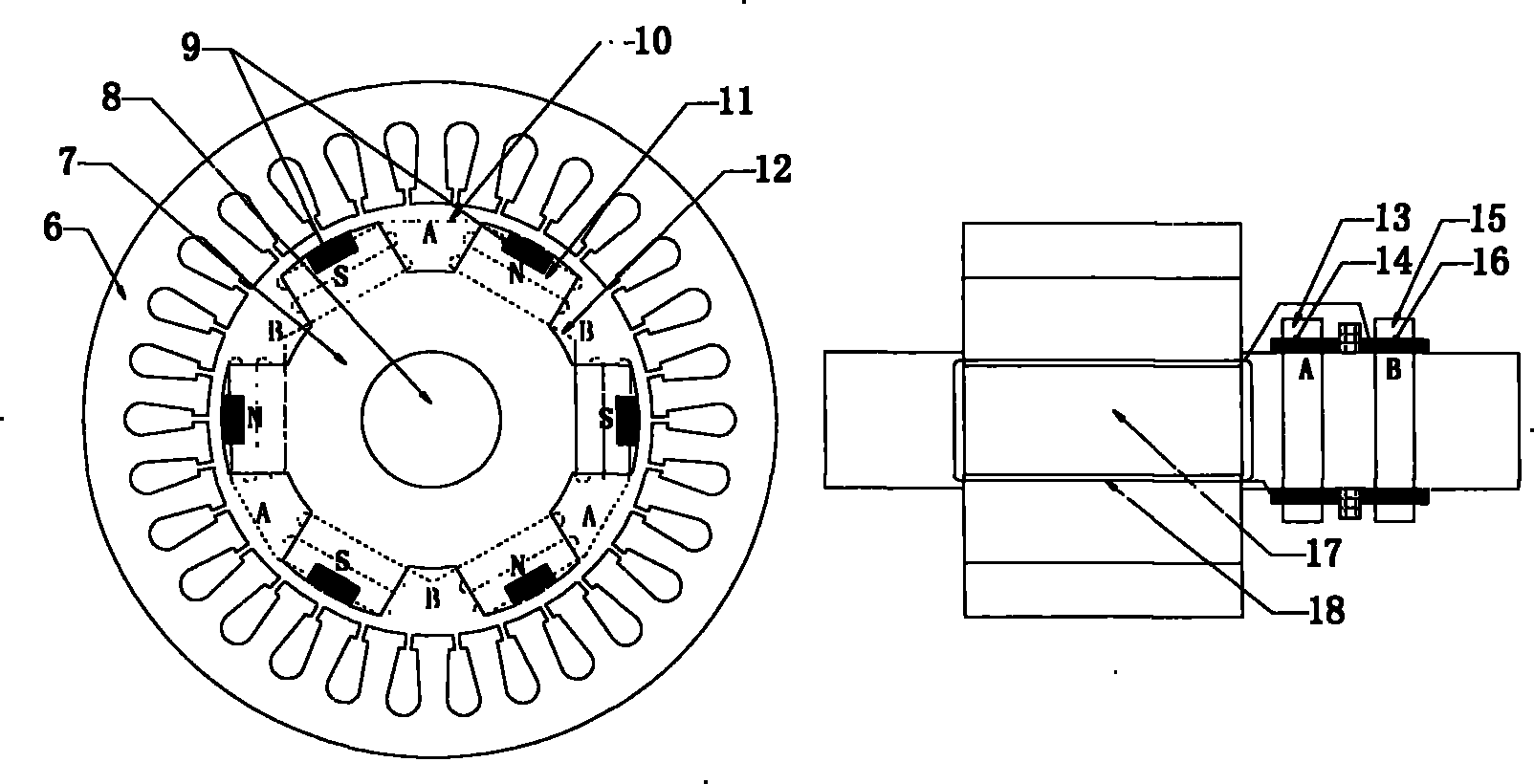

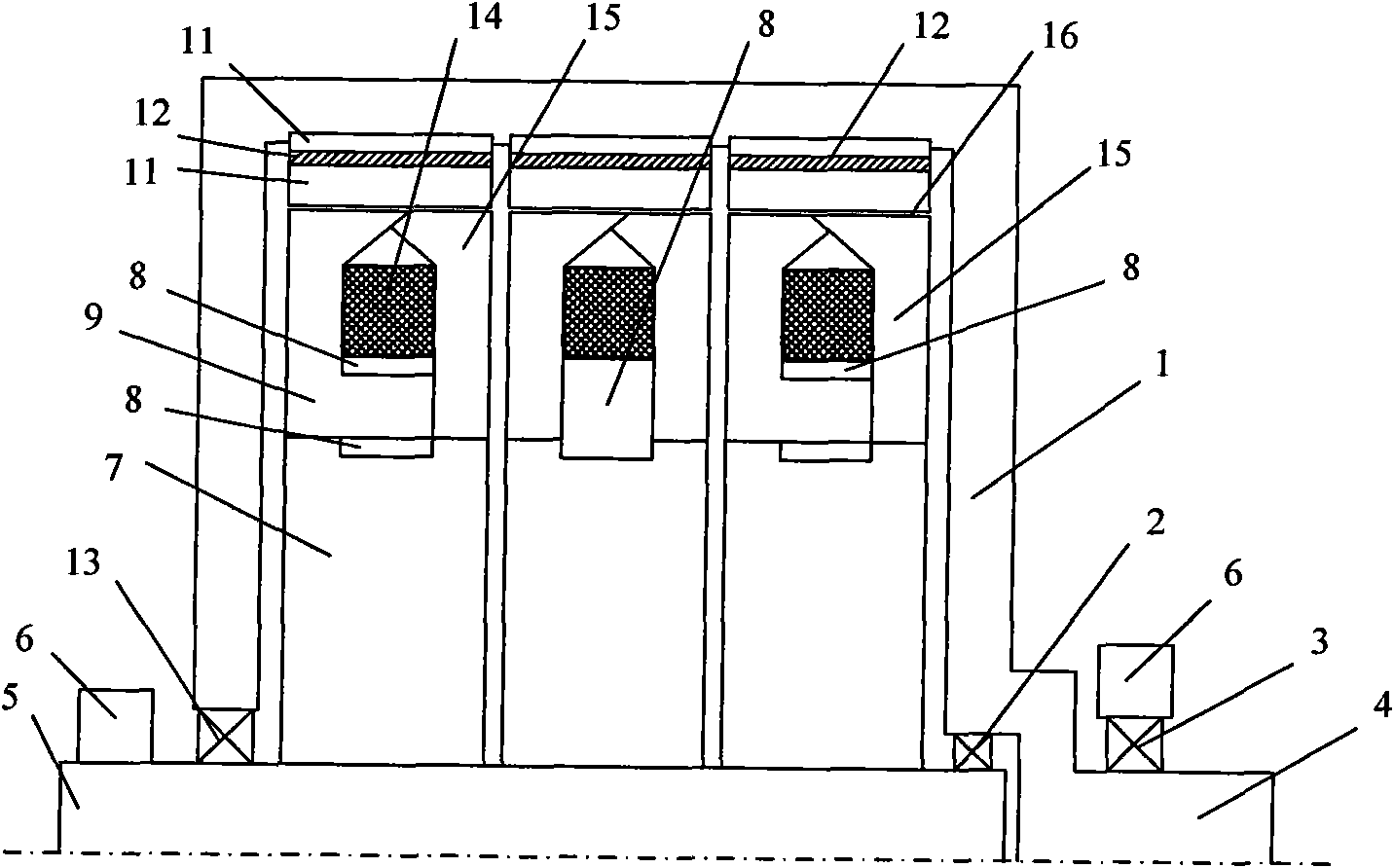

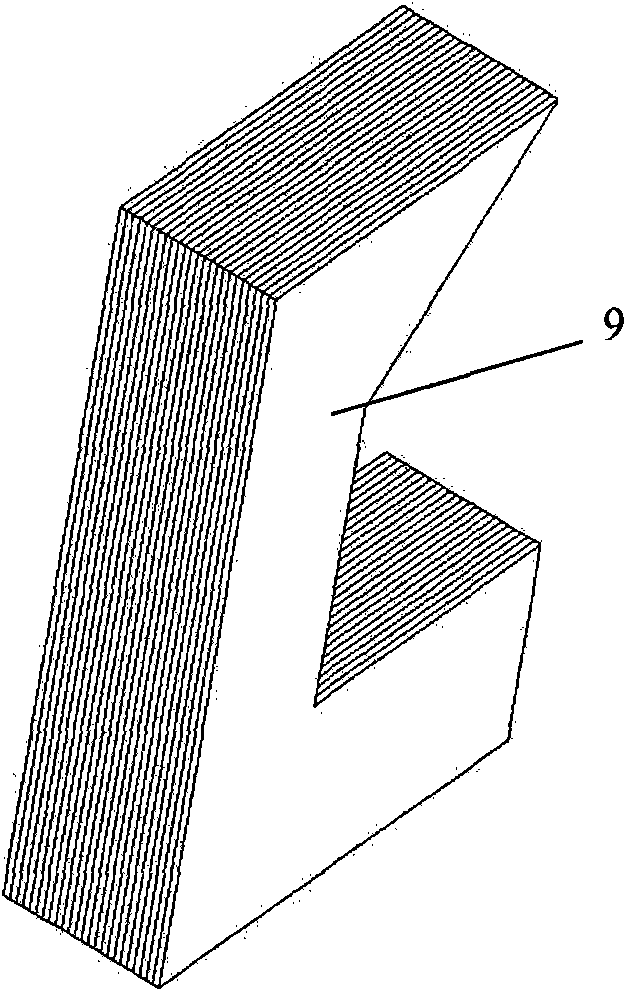

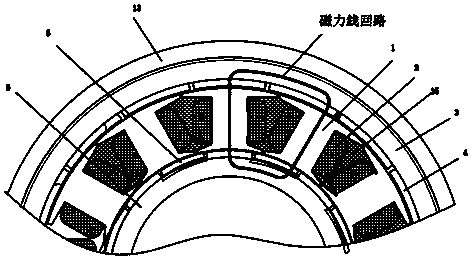

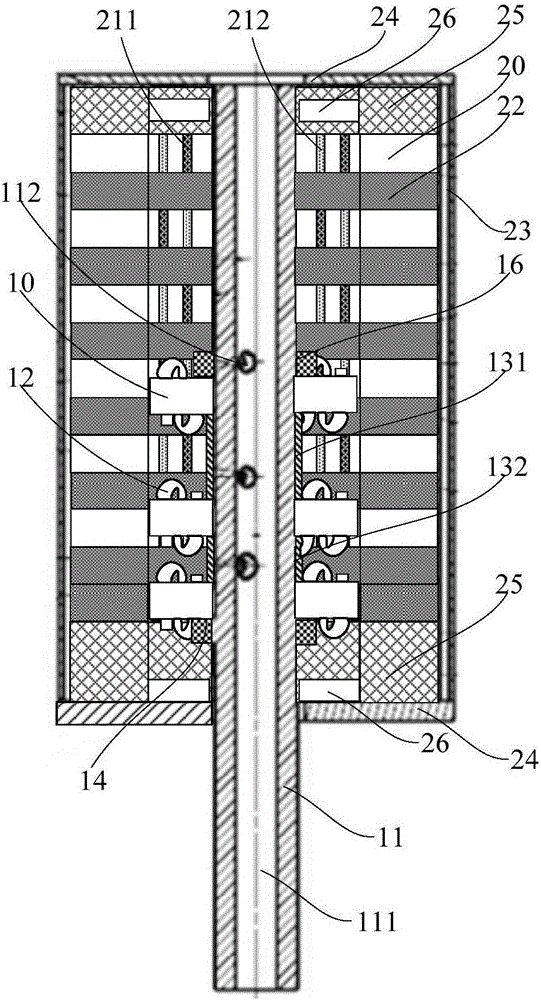

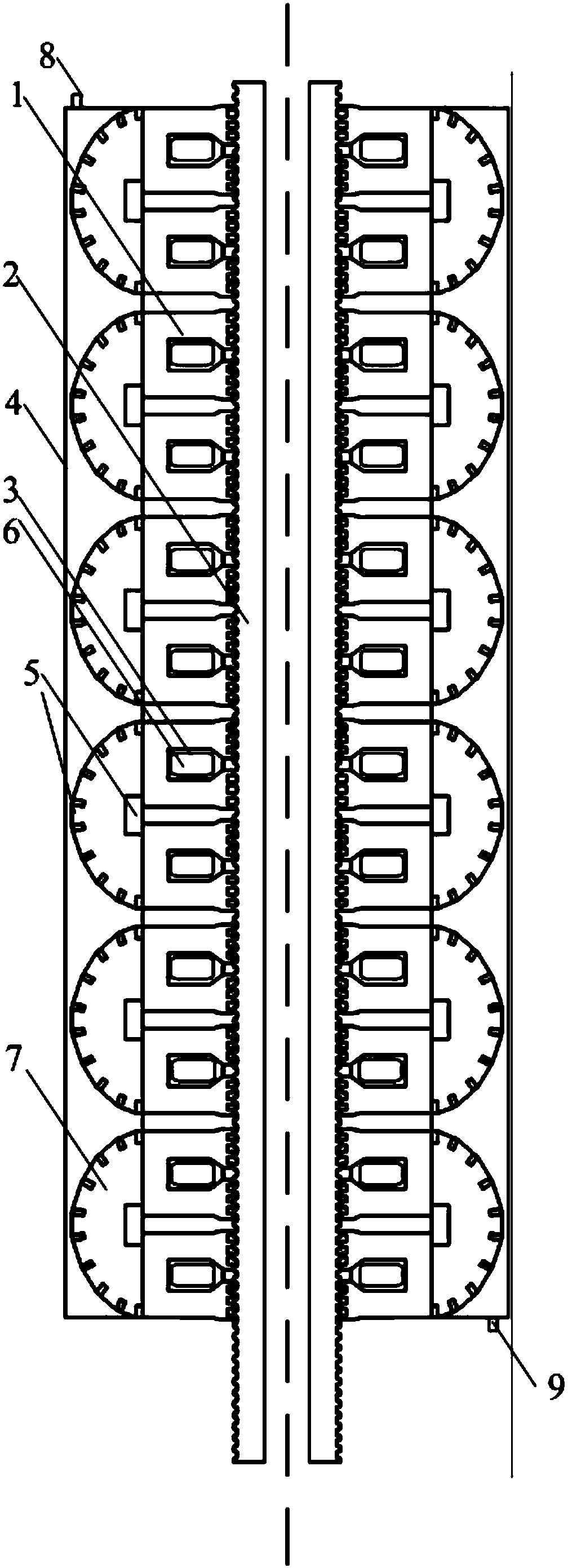

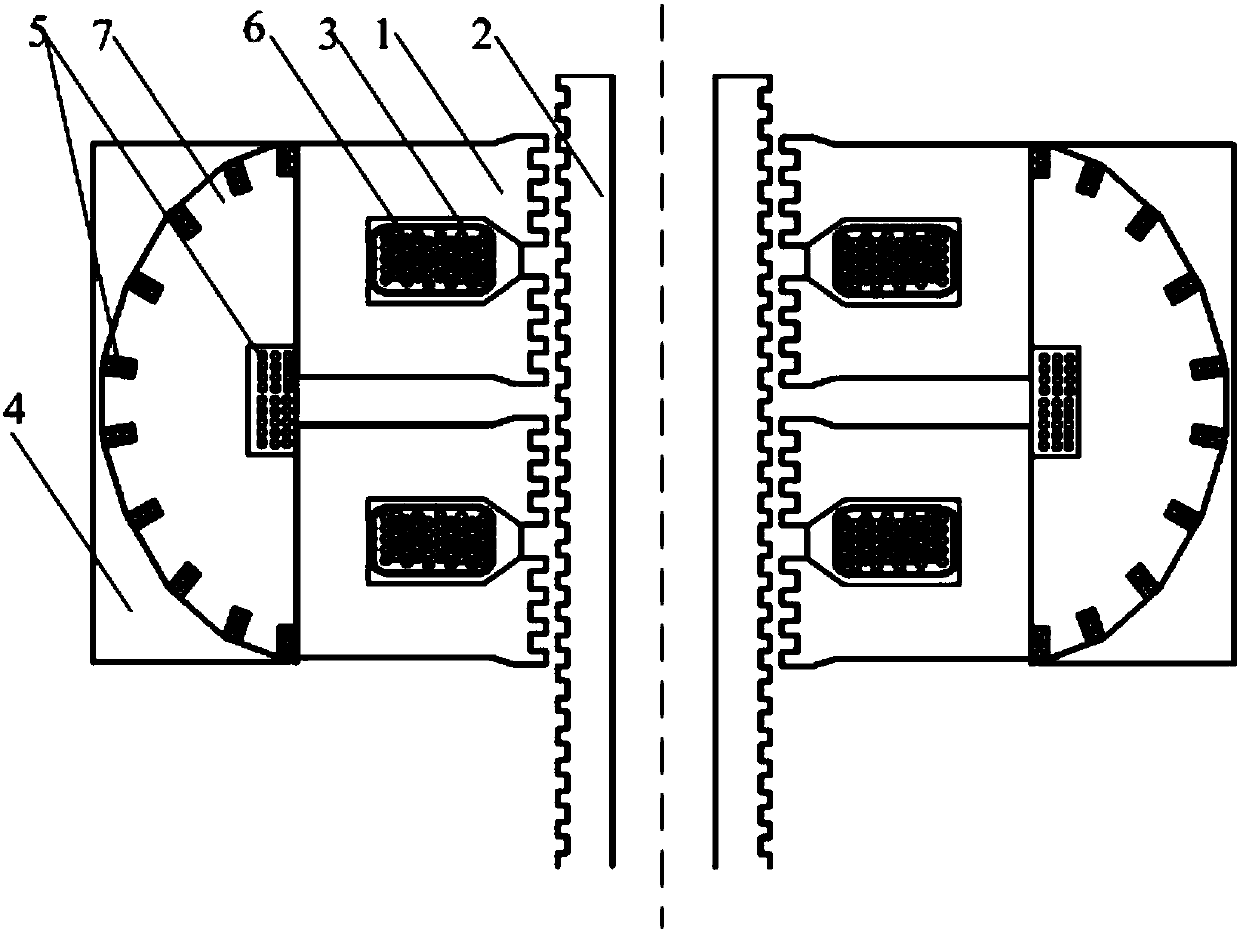

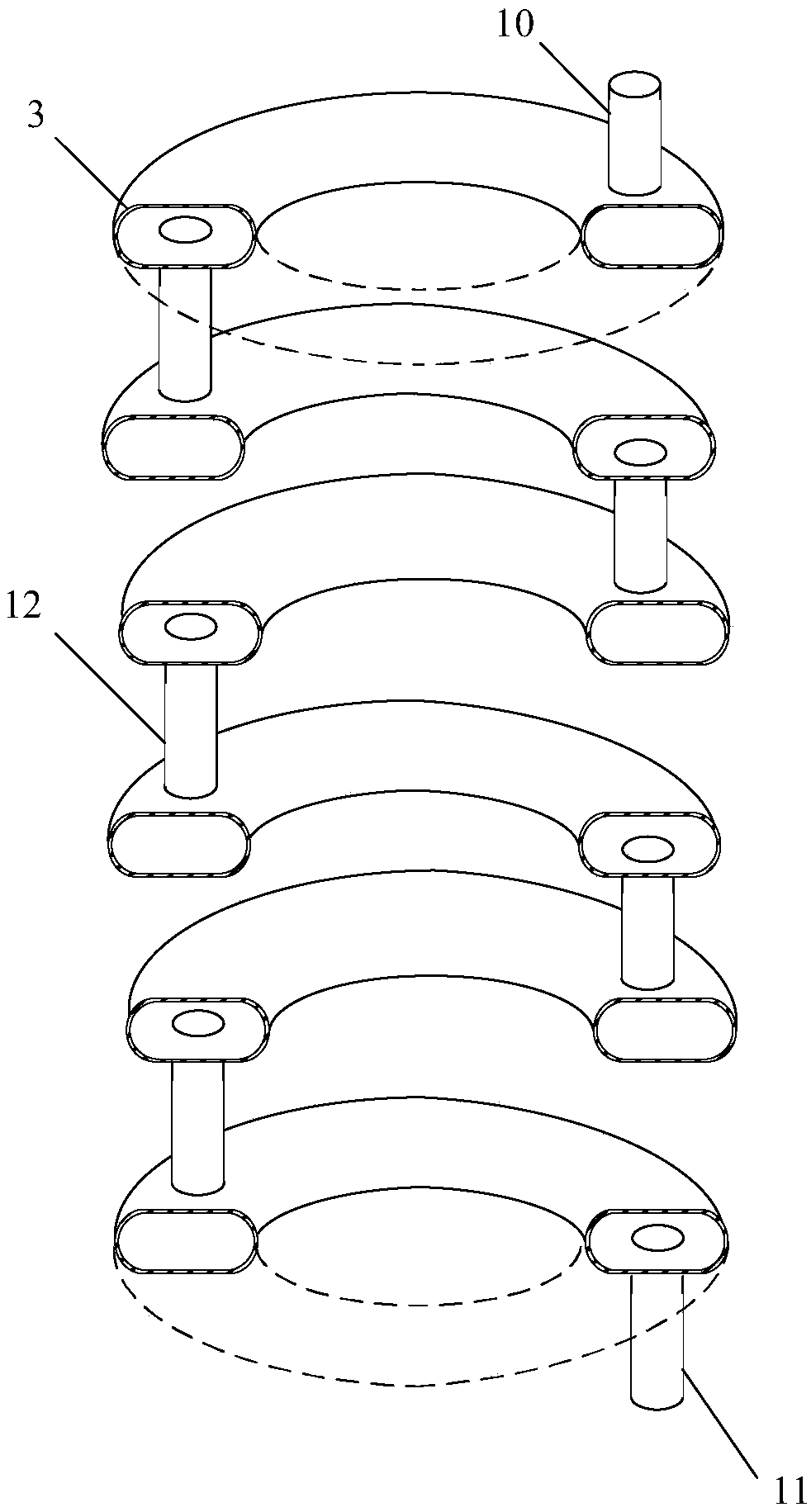

High-power-density high-efficiency high-reliability magnetic claw motor

PendingCN108832791AIncreased air gap flux densityImprove power densitySynchronous machines with rotating armatures and stationary magnetsElectric machineHigh power density

The invention provides a high-power-density high-efficiency high-reliability magnetic claw motor. The motor is formed by a plurality of magnetic claw motor modules. Two adjacent magnetic claw motor modules deviate a specific angle in the axial direction at the stator side or the rotor side. Each magnetic claw motor module is a single-stator single-rotor structure, and comprises one rotor magneticcore, a plurality of stator magnetic cores, a plurality of special-shaped permanent magnets and armature windings, wherein the plurality of stator magnetic cores, the plurality of special-shaped permanent magnets and the armature windings form a stator; and the plurality of stator magnetic cores and the plurality of special-shaped permanent magnets are in cross arrangement to form a complete circle structure in the circumferential direction. Each stator magnetic core is internally provided with one armature winding; the armature windings adopt a global ring winding structure; the armature windings are wholly in a circle shape; and the number of the stator magnetic cores is equal to that of the special-shaped permanent magnets. The stator magnetic core is in a claw-pole structure. The special-shaped permanent magnets carry out magnetizing in the circumferential direction of the motor, and the adjacent special-shaped permanent magnets are opposite in magnetizing direction. The motor is high in power density, high in efficiency and high in reliability.

Owner:HEBEI UNIV OF TECH

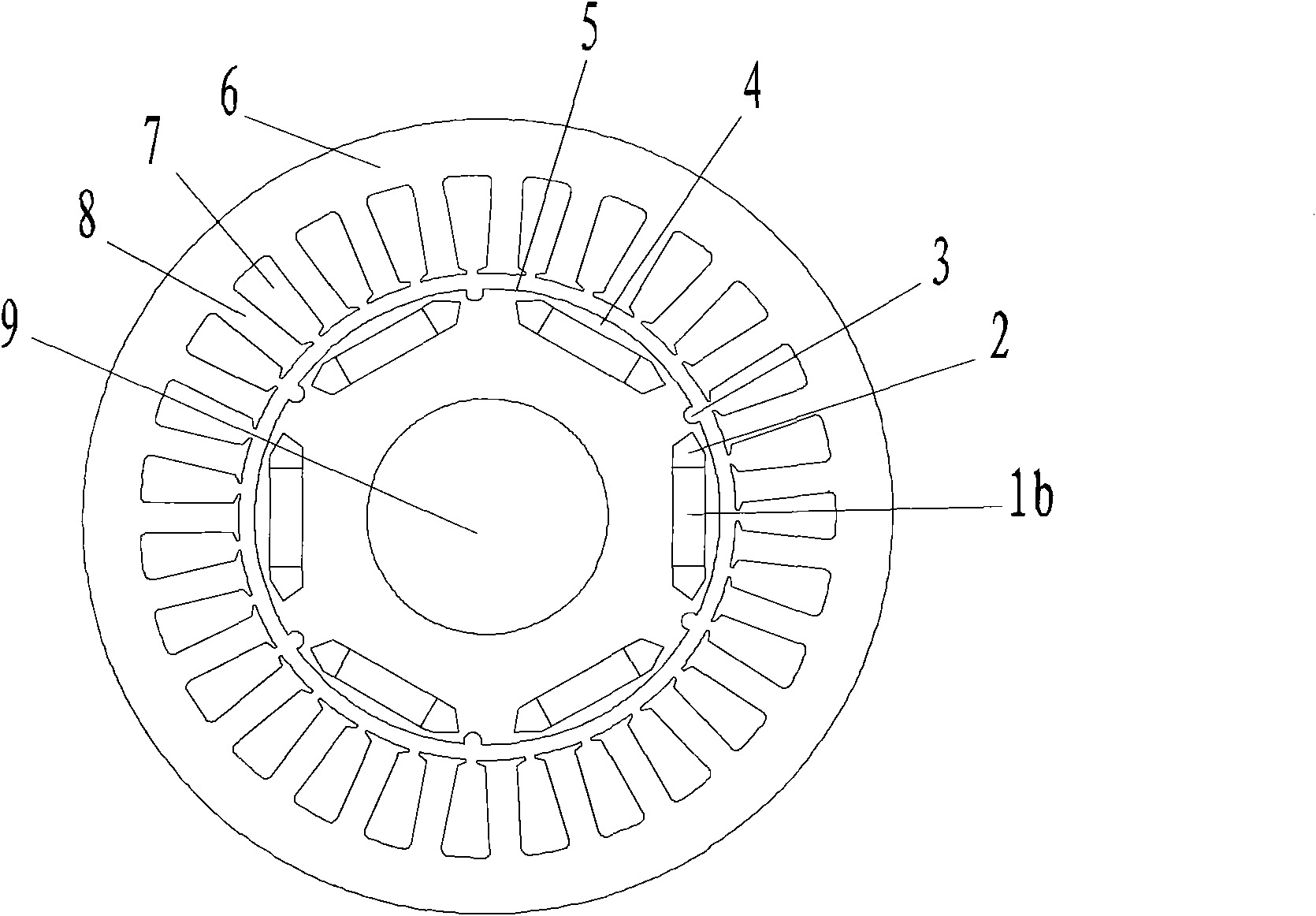

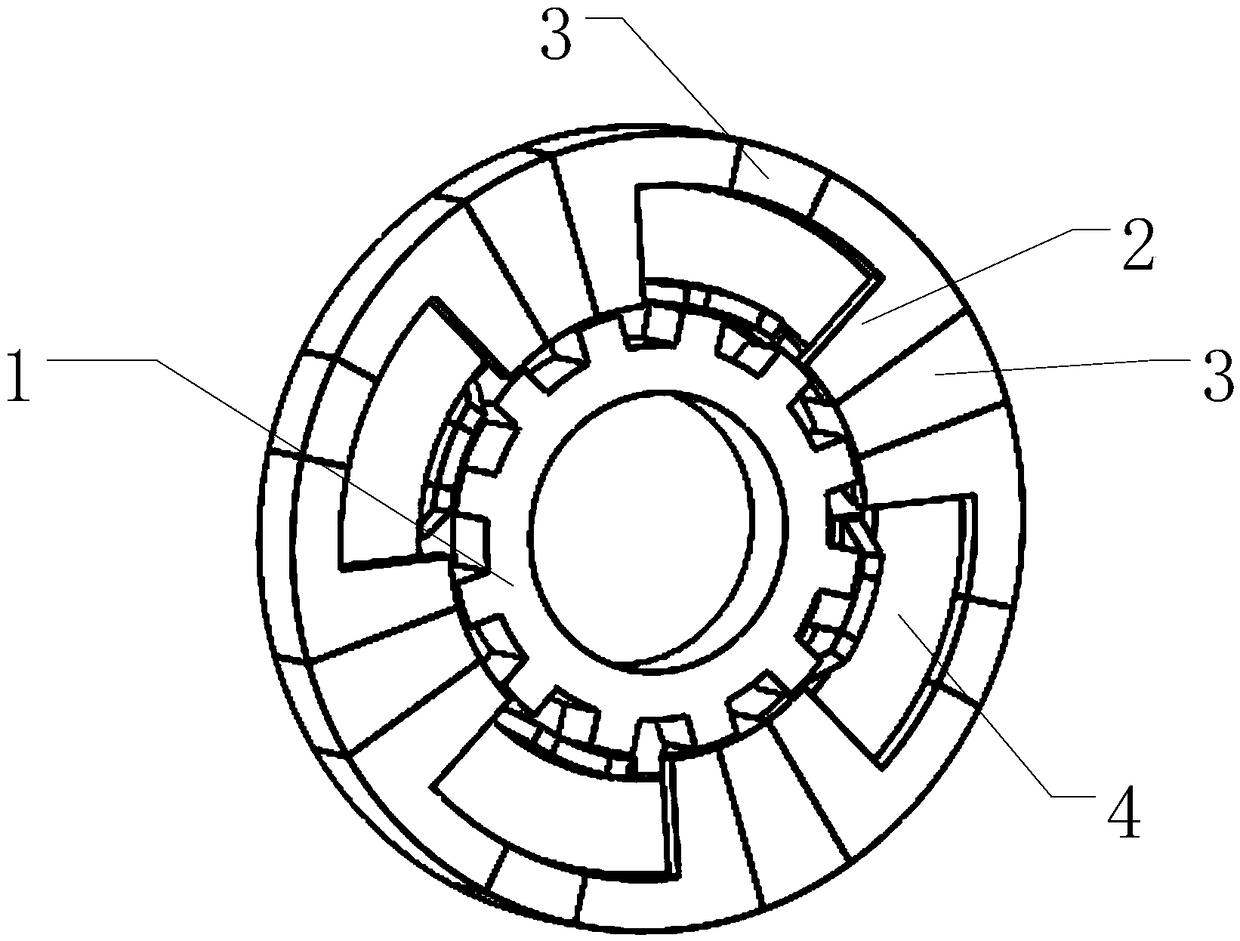

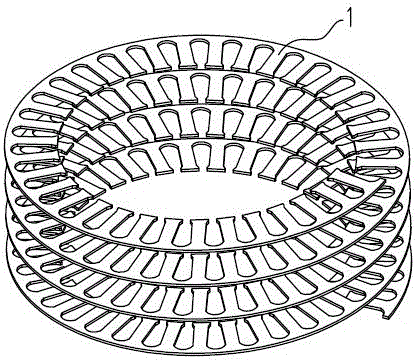

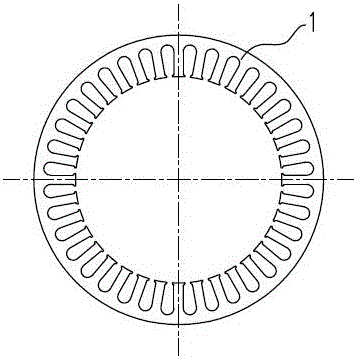

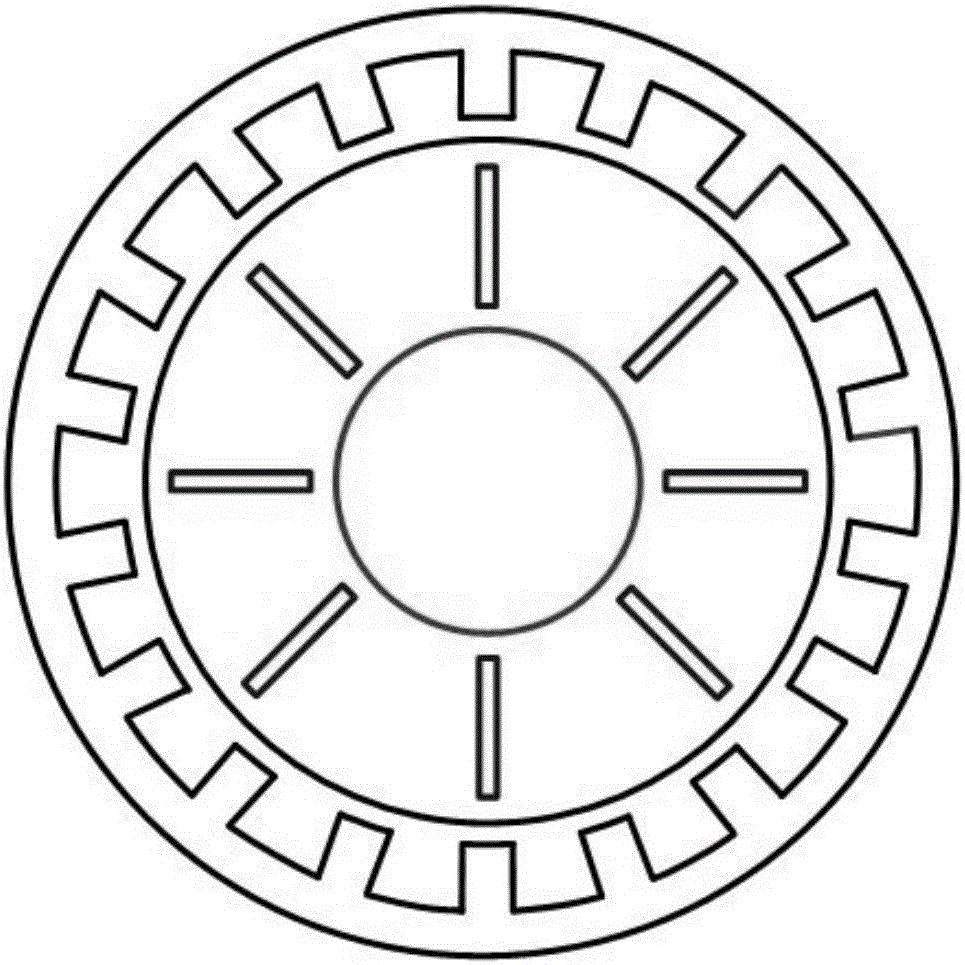

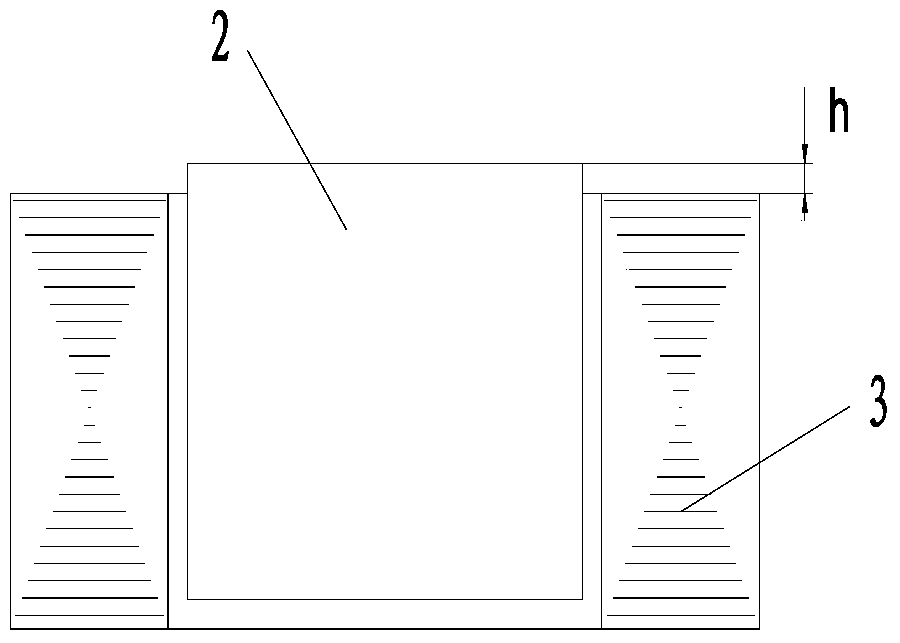

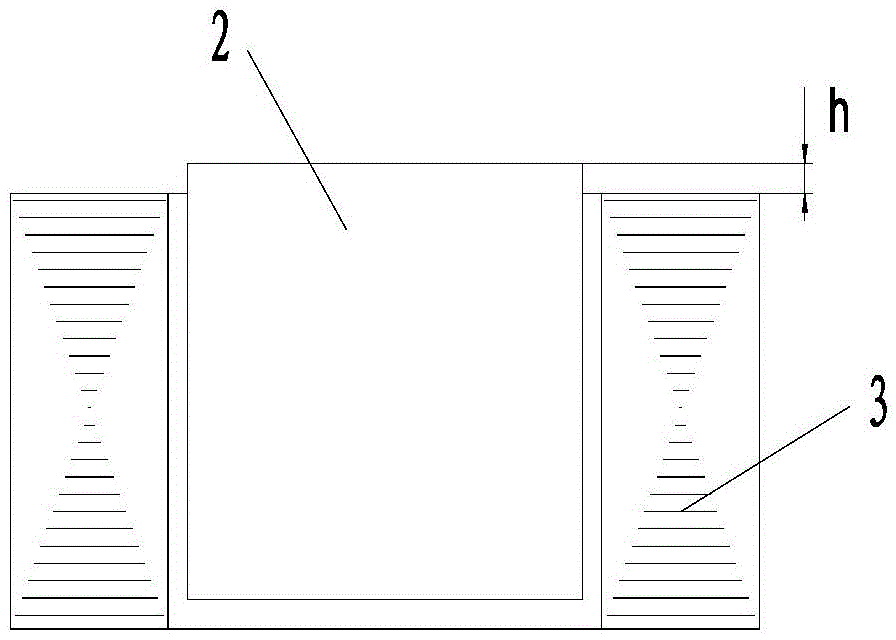

Improved structure of stator iron core

InactiveCN105958674AIncreased air gap flux densityIncreased torque densityMagnetic circuit stationary partsAir gap flux densityHigh torque

The invention discloses an improved structure of a stator iron core. The stator iron core comprises a groove-shaped part body and a yoke part body, wherein the two part bodies are wound into spiral circles in a winding manner and subjected to finishing forming, and the yoke part body subjected to the finishing forming is arranged on an outer circle of the groove-shaped part body in a sleeving manner to be integrated with the groove-shaped part body so as to form an iron core integral body. According to the improved structure provided by the invention, the stator iron core with a wide yoke part incapable of being produced in the winding manner originally comprises the groove-shaped part body and the yoke part body which can be separately formed in the winding manner, and the two parts are integrally formed by winding and integrated by utilizing a thermal sleeving process; and the stator iron core after the integration ensures relatively high air-gap magnetic flux density, easily realizes high torque density and serves as a transmission application of large torque driving.

Owner:CHANGYING XINZHI TECH CO LTD

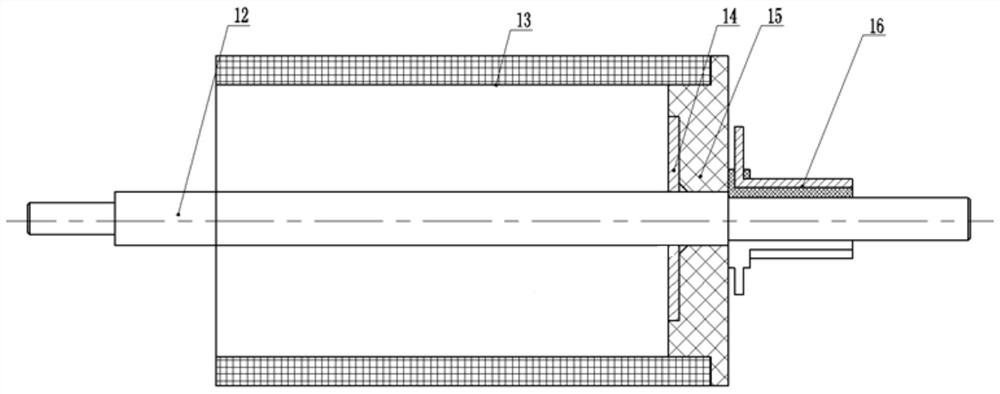

Moving-coil brushless DC (direct-current) permanent magnet motor with inner and outer rotor structure

ActiveCN105871158AIncreased air gap flux densitySolve the problem of large iron lossWindingsMagnetic circuit stationary partsPhysicsConductor Coil

The invention discloses a moving-coil brushless DC (direct-current) permanent magnet motor with an inner and outer rotor structure. The moving-coil brushless DC permanent magnet motor comprises a shaft assembly and a moving assembly, wherein the shaft assembly comprises a rotating shaft, bearings, a first end cover, a moving-coil stator and a flange plate; the moving assembly comprises a casing, an outer permanent magnet, an inner permanent magnet, a magnetic conducting ring and a second end cover; the moving-coil stator comprises a cup-shaped framework and a winding and is further fixedly connected onto the first end cover through connection with the flange plate, the inner permanent magnet is arranged on the radial inner side of the moving-coil stator, and the outer permanent magnet is arranged on the radial outer side of the moving-coil stator; the inner wall of the inner permanent magnet is arranged on the magnetic conducting ring in a sleeving manner; the outer wall of the outer permanent magnet is tightly attached to the inner wall of the casing; the magnetic conducting ring and the casing are embedded and fixed with the inner side of the second end cover through clamp ports; the first end cover and the second end cover are convex, the first end cover is connected with the rotating shaft through the bearings, the second end cover is fixed with the rotating shaft through screws, and magnetic polarity of the inner permanent magnet is the same as that of the outer permanent magnet in the radial direction.

Owner:ONCE TOP MOTOR MFG

Transverse magnetic field linear generator adapting to variable-speed operation within low-speed range

InactiveCN106533115AIncrease the number of polesIncrease the output voltageMagnetic circuit rotating partsMagnetic circuit stationary partsLow speedTransverse magnetic field

The invention provides a transverse magnetic field linear generator adapting to variable-speed operation within a low-speed range. The transverse magnetic field linear generator comprises a stator and a rotor, wherein the stator comprises stator cores, a stator fixing shaft and stator windings; the rotor comprises rotor cores, first permanent magnets, second permanent magnets and first non-magnetic conducting material structures; each stator core and the corresponding stator winding assembled in stator slots in the stator core form one phase of the stator, so that implementation of modularization is achieved; the number of phases of the generator and the arrangement mode among the phases are not limited; the number of poles of the generator is increased; on one hand, the stator and the rotor can be freely combined according to the amount of to-be-converted energy, and on the other hand, the generator can obtain relatively high output voltage during low-speed operation; the wire length of a single-phase armature coil of the generator for effectively cutting a magnetic line is increased by the structure, so that the magnitude of single-phase output voltage of the generator is increased, the low-speed output capability of the generator is improved and improvement of the energy conversion efficiency of the generator is finally facilitated.

Owner:SHANGHAI OCEAN UNIV

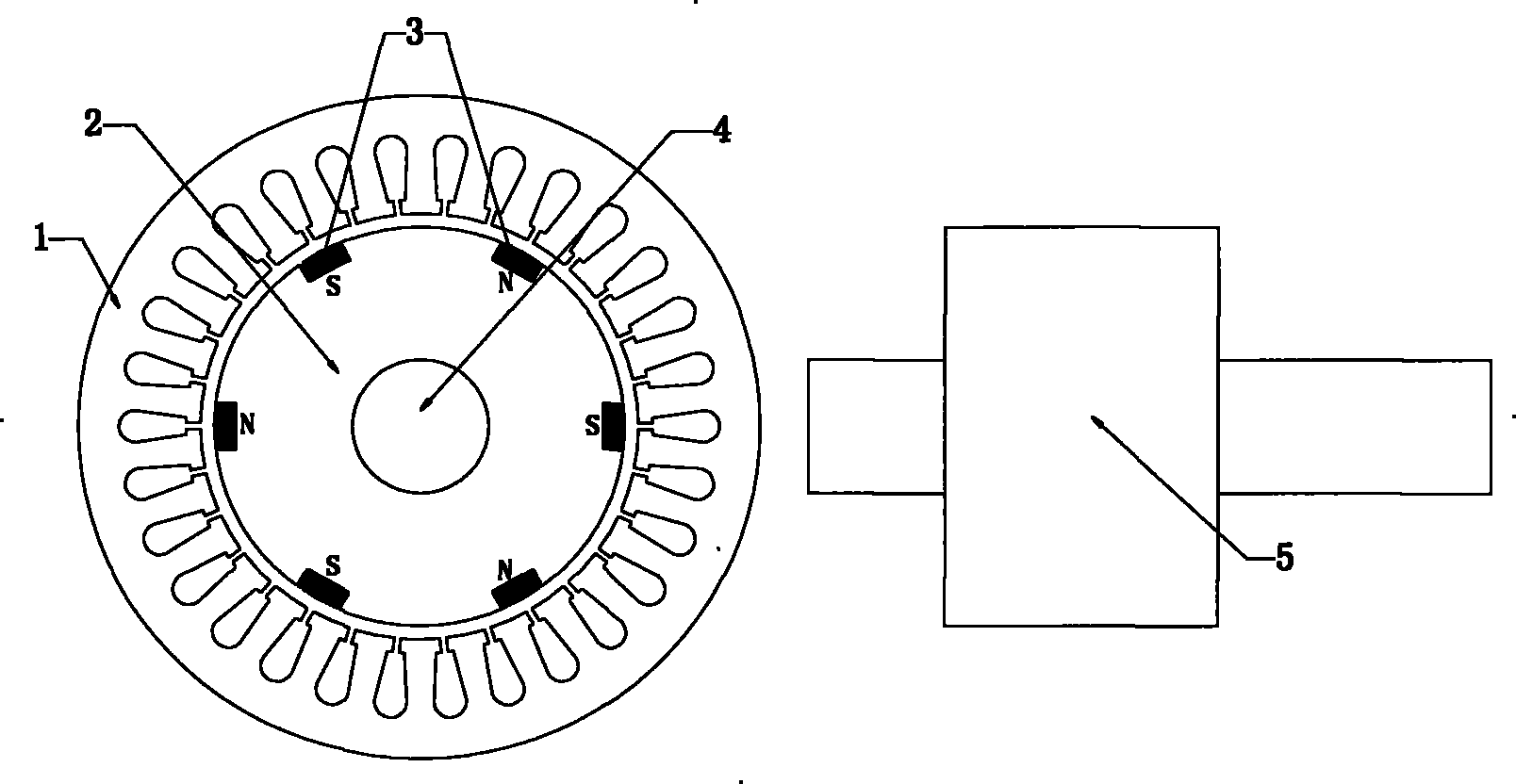

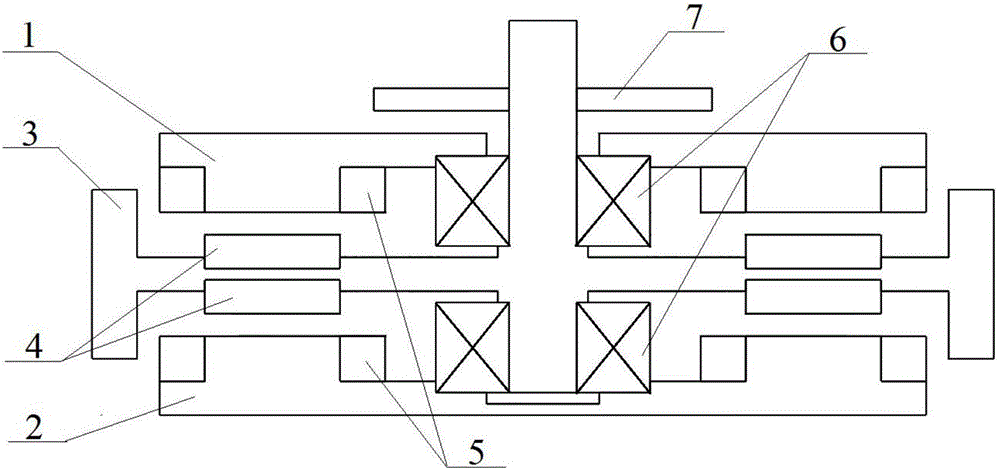

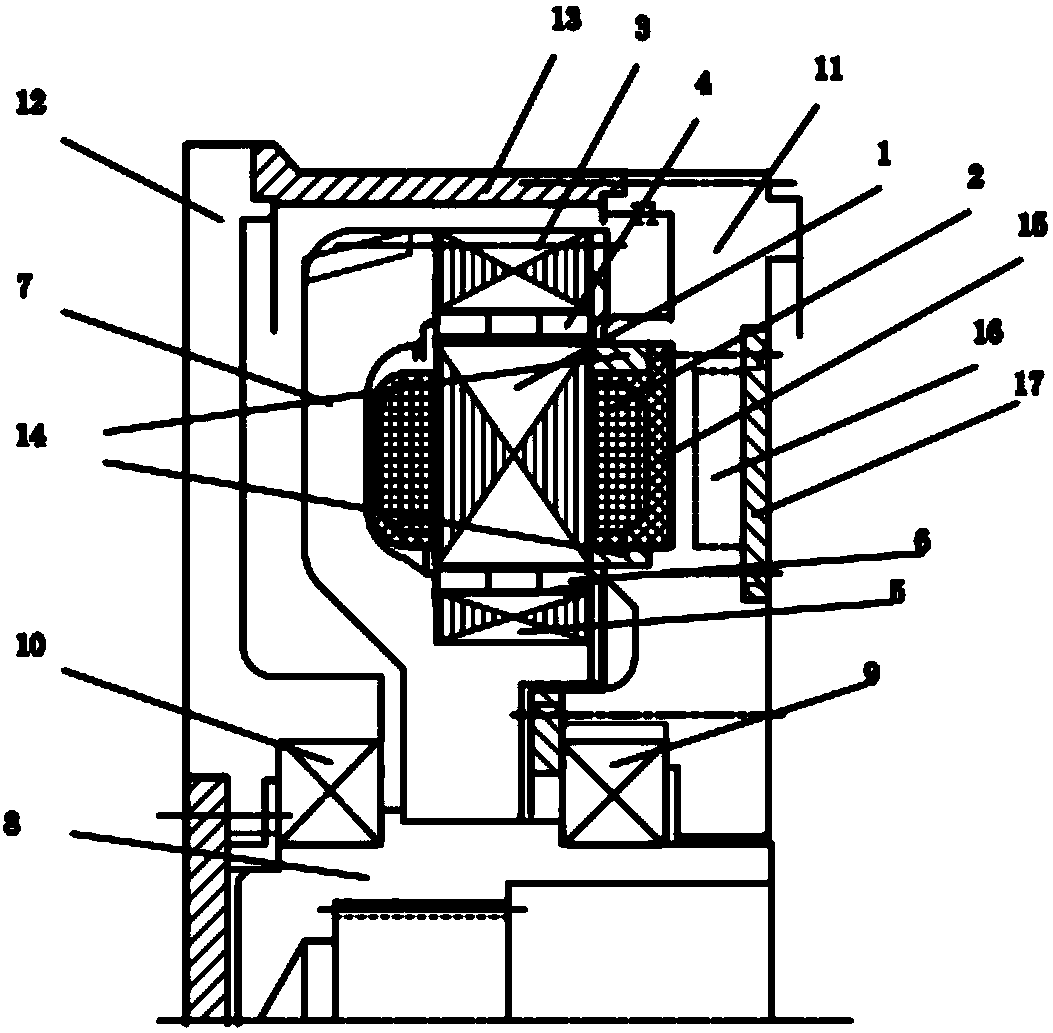

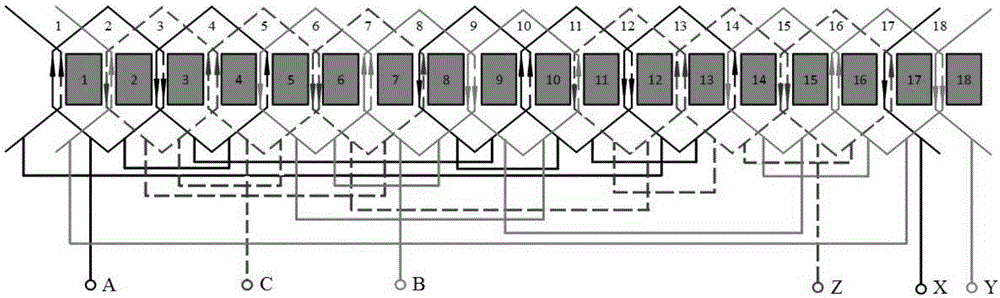

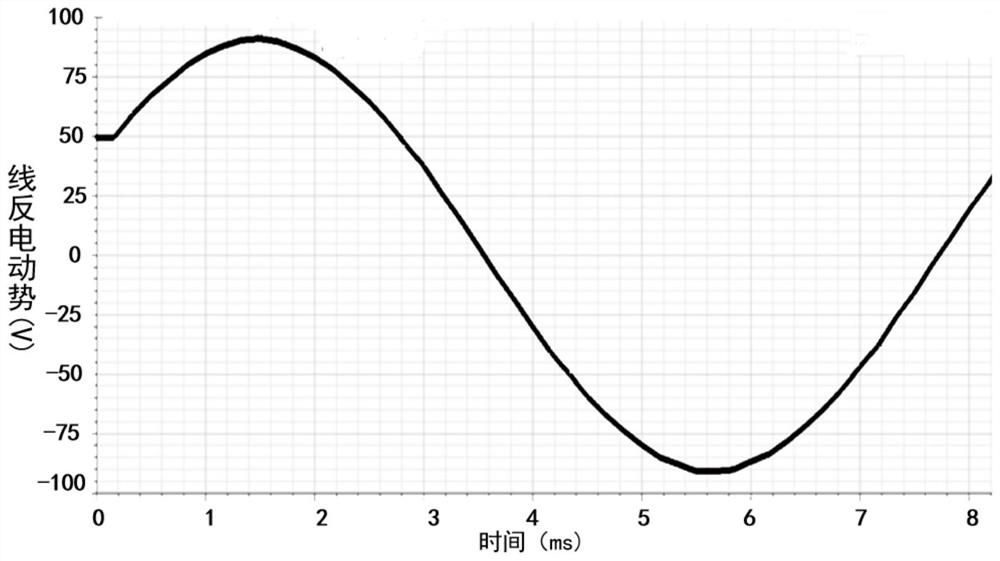

Parallel type double-stator hybrid excitation permanent magnet motor

ActiveCN106451964AWith low speed and high torque characteristicsSolve the problem of high efficiency demandMagnetic circuit rotating partsMagnetic circuit stationary partsOperating pointLow speed

The invention discloses a parallel type double-stator hybrid excitation permanent magnet motor, and belongs to the technical field of permanent magnet motors. The parallel type double-stator hybrid excitation permanent magnet motor comprises a shell, a motor set A and a motor set B, and is characterized in that the motor set A and the motor set B are arranged in the shell in a parallel mode, a stator A of the motor set A is provided with a winding A with a high back electromotive force, a rotor A is provided with an NdFeB permanent magnet, the motor set A selects an operating point with low rotating speed and high torque to act as a rated operating point A, and control is performed by adopting a weak magnetic control mode when the rotating speed exceeds the rated operating point A; and a stator B of the motor set B is provided with a winding with a low back electromotive force, a rotor B is provided with an AlNiCo permanent magnet or a ferrite permanent magnet, the motor set B selects an operating point with high rotating speed and capable of meeting the high-speed load bearing capacity to act as a rated operating point B, and control is performed by adopting a magnetic link control mode when the rotating speed exceeds the rated operating point B. The parallel type double-stator hybrid excitation permanent magnet motor not only has the characteristics of low speed and high torque, but also has the characteristic of high-speed running. Meanwhile, the parallel type double-stator hybrid excitation permanent magnet motor has the characteristics of wide rotating speed range and high efficiency, and can improve the energy utilization rate of a system.

Owner:JIANGSU UNIV

An external rotor motor with polygonal dovetail spliced magnetic steel structure

ActiveCN112953151BIncreased air gap flux densityImprove dynamic performanceMagnetic circuitCooling/ventillation arrangementRotor magnetsElectric machine

The invention relates to the technical field of motors, and discloses an outer rotor motor with a polygonal dovetail spliced magnetic steel structure, including a stator core, a stator coil, a rotor magnetic steel and a rotor back iron, wherein the rotor magnetic steel passes through the first permanent magnet, the second In the design of the second permanent magnet and the third permanent magnet, a plurality of permanent magnets whose cross-section is isosceles triangle or quadrilateral are spliced together for a circle to form a closed rotor magnet, and the Halbach magnetization method is used to make each stator The electromagnetic force received by the stator coil in the tooth slot forms a closed loop along the tangential direction of the circumference, so that the outer rotor receives a stable torque and realizes stable rotation. At the same time, using the Halbach magnetization method can also form self-shielding, which can ensure that the air gap magnetic flux density in the motor is large enough at the same time to increase the output torque, reduce torque ripple, and increase power density. The force wave two-dimensional Fourier FFT2 analysis found that in the case of low order numbers, the vibration amplitude is significantly reduced, thereby improving the dynamic performance of the motor.

Owner:BEIHANG UNIV +1

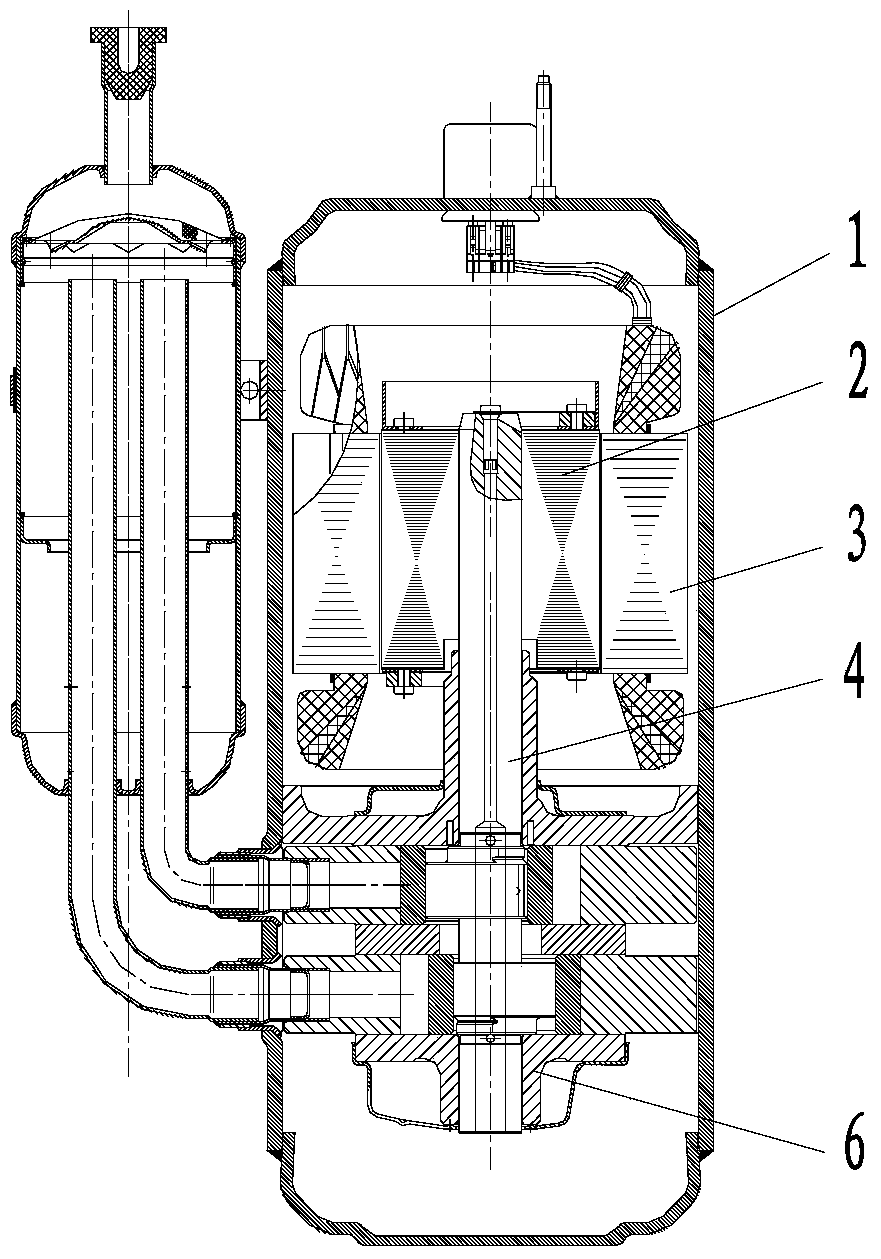

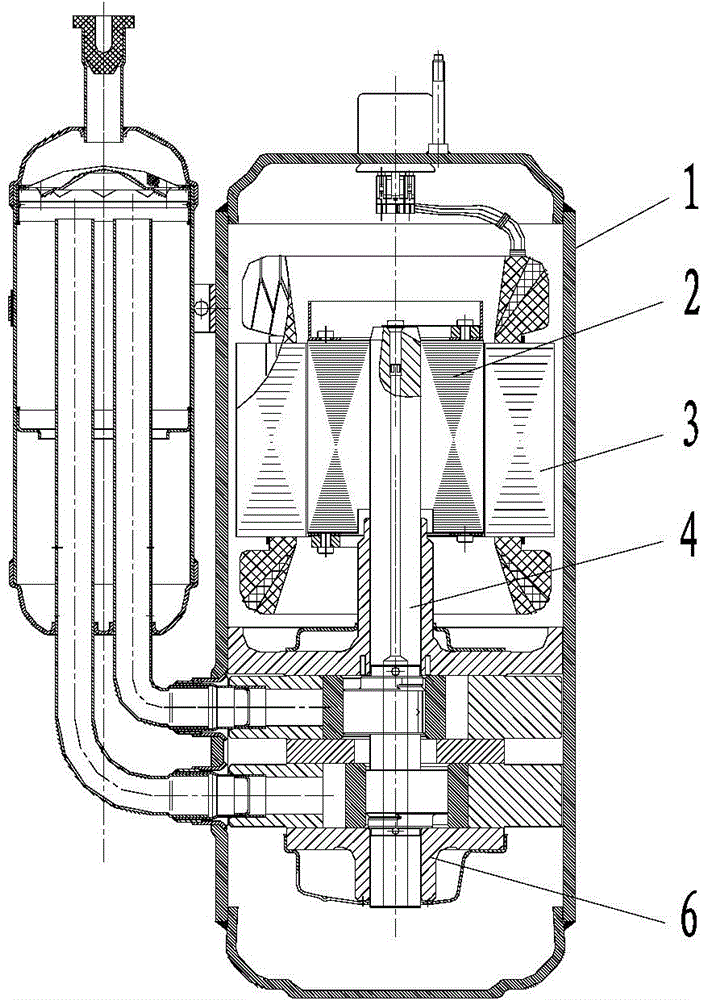

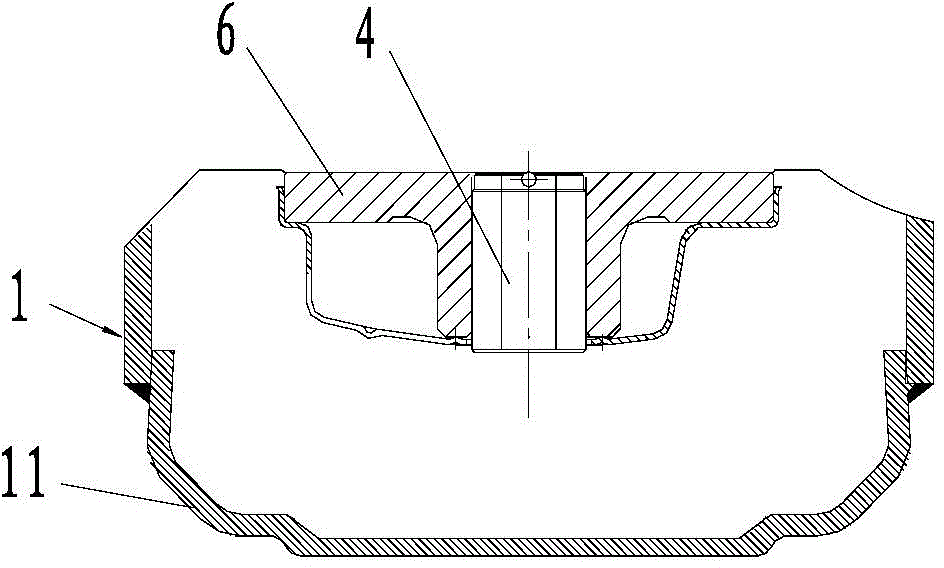

Compressors and Air Conditioners

ActiveCN105840553BEasy to mass produceAvoid stickingPump componentsPumpsMechanical impactMagnetic poles

The invention provides a compressor, comprising a housing, and a rotor, a stator, and a crankshaft in the housing. The lower end of the crankshaft is provided with a first magnet. The bottom cover of the housing is provided with a second magnet corresponding to the first magnet. The magnetic pole polarity of opposite magnetic pole surfaces of the first magnet and the second magnet is opposite. The invention also relates to an air conditioner. The compressor and the air conditioner are provided with the first magnets on the lower ends of the crankshafts, and the bottom covers of the housings are provided with second magnets. The magnetic pole polarity of opposite magnetic pole surfaces of the first magnet and the second magnet is opposite. Thus, strong downward acting forces are applied on a pump rotor assembly, and stable operation of the pump structure of the compressor is ensured. Up-down displacement would not occur, and mechanical impact noise is effectively prevented.

Owner:GREE ELECTRIC APPLIANCES INC +1

A fully superconducting primary excitation linear generator for direct drive wave power generation

ActiveCN105811738BLower requirementAvoid complexityPropulsion systemsSuperconductor elements usageSpacing toothWave power generation

The invention discloses a full-superconducting primary excitation linear generator for direct-drive type wave power generation. The full-superconducting primary excitation linear generator comprises a primary stator and a secondary mover, wherein the primary stator comprises multiple groups of stator units arranged in a straight line; each stator unit comprises a U-shaped core, primary armature windings and primary exciting windings; the U-shaped core comprises two primary cores; an opening of the U-shaped core faces the secondary mover; the primary armature windings are arranged in the primary cores; the primary exciting windings are arranged in the U-shaped core; the secondary mover is the core which does not contain a winding and has a cogging structure; and a corresponding cogging structure is arranged on each primary core. According to the full-superconducting primary excitation linear generator, an arc-shaped structure exciting winding sleeves the outside of each primary core; and a cooling system does not move, so that the complexity level is reduced. The magnetic field conversion rate and the terminal voltage can be increased by a multi-tooth structure secondary; the defect of a low low-speed voltage is compensated; and by unequally-spaced teeth, the voltage frequency and amplitude generated when the generator moves to the end part are increased by reducing the end-part tooth pitch.

Owner:SOUTHEAST UNIV

Compressor and air conditioner

ActiveCN105840553AEasy to mass produceAvoid stickingPump componentsPumpsMagnetic polesMechanical impact

The invention provides a compressor, comprising a housing, and a rotor, a stator, and a crankshaft in the housing. The lower end of the crankshaft is provided with a first magnet. The bottom cover of the housing is provided with a second magnet corresponding to the first magnet. The magnetic pole polarity of opposite magnetic pole surfaces of the first magnet and the second magnet is opposite. The invention also relates to an air conditioner. The compressor and the air conditioner are provided with the first magnets on the lower ends of the crankshafts, and the bottom covers of the housings are provided with second magnets. The magnetic pole polarity of opposite magnetic pole surfaces of the first magnet and the second magnet is opposite. Thus, strong downward acting forces are applied on a pump rotor assembly, and stable operation of the pump structure of the compressor is ensured. Up-down displacement would not occur, and mechanical impact noise is effectively prevented.

Owner:GREE ELECTRIC APPLIANCES INC +1

A high torque density coreless motor and its dynamic balance adjustment method

ActiveCN110971097BIncrease profitIncreased torque densityWindingsMagnetic circuit stationary partsDynamic balanceElectric machinery

The invention relates to a hollow cup motor with high torque density and a dynamic balance adjustment method thereof, aiming to solve the problems of low utilization rate of magnetic steel and low torque density of the motor in the prior art. A hollow cup motor with high torque density of the present invention comprises a casing, a front end cover, a motor shaft, an armature winding, and a winding support. The installation cylinder, the motor shaft passes through the front end cover, the installation cylinder and the center of the winding bracket in turn, and the winding bracket is used to install the armature winding; it also includes inner and outer magnets with the same magnetization direction; the inner magnet is fixed on the The outer wall of the installation cylinder; the outer magnetic steel is fixedly set on the inner wall of the casing; the armature winding is set between the inner magnetic steel and the outer magnetic steel. Based on the above-mentioned hollow cup motor with high torque density, the present invention also provides a method for adjusting dynamic balance of the hollow cup motor with high torque density.

Owner:XIAN AEROSPACE PRECISION ELECTROMECHANICAL INST

Permanent magnet DC linear flexible drive

InactiveCN104022615BThe principle is simple, reliable and feasibleEliminate force fluctuationsDynamo-electric machinesInterference fitReciprocating motion

The invention discloses a permanent magnet direct current linear flexible driver. The permanent magnet direct current linear flexible driver is characterized in that a rotor is formed by a magnetic steel supporting shaft and magnetic steel fixedly arranged on the magnetic steel supporting shaft in a sleeved mode, and the two ends of the rotor are provided with rotor end covers respectively; a cylinder-shaped stator is formed by a stator yoke, a stator winding, a winding wedge, a positioning rod and a positioning ring; the outer portion of the cylinder-shaped stator is provided with a cylindrical outer shell composed of an outer shell end cover and a shell, and the two ends of the cylindrical outer shell are provided with supporting end covers respectively; buffering springs are arranged between the supporting end covers and the rotor end covers to form a buffering limiting structure; linear bearings coaxially arranged with the stator and the cylindrical outer shell are fixedly arranged at the two ends of the cylindrical outer shell in an interference fit mode, and the rotor can do reciprocating movement in the linear bearings in the axial direction. The permanent magnet direct current linear flexible driver is light, small in size, good in controllability, free of fluctuation in output force, large in density of output force and very good in compatibility, and has driving flexibility and moving flexibility.

Owner:HEFEI UNIV OF TECH

Built-in permanent magnet synchronous motor

ActiveCN103078464BImprove qualityImprove air gap flux density waveformMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsBand shapePermanent magnet synchronous motor

The invention discloses a built-in permanent magnet synchronous motor, relates to the technical field of a motor and aims to solve the technical problem of improving the comprehensive quality of the motor. Multiple permanent magnet slots are axially and symmetrically arranged in a rotor of the motor along the central axis of the rotor at intervals, three permanent magnets distributed in an arc band shape are arranged in each permanent magnet slot, wherein one permanent magnet is a middle steel magnet, and the other two permanent magnets are side steel magnets; the built-in permanent magnet synchronous motor is characterized in that each middle steel magnet adopts the normal magnetization vertical to the surface of the steel magnet, and each two side steel magnets in one slot adopt the non-normal magnetization, so that the arc center of a magnet arrangement arc of each permanent magnet slot is enabled not to coincide with the magnetization orientation point of permanent magnets in the corresponding permanent magnet slot. According to the motor provided by the invention, the comprehensive quality of the motor is greatly improved.

Owner:SHANGHAI TOP MOTOR +2

Permanent magnet drive motor for solar tracking system

ActiveCN101917076BReduced resultant torque fluctuationSmall torque fluctuationMagnetic circuit rotating partsSynchronous machines with stationary armatures and rotating magnetsSEMI-CIRCLEPole piece

The invention relates to a permanent magnet drive motor for a solar tracking system, which comprises an enclosure, a stator and a rotor which are arranged in the enclosure, wherein, the stator comprises a stator core and a stator winding which are fixed on an inner wall of the enclosure, and the stator core comprises a stator magnetic yoke, a stator slot and stator teeth; the rotor comprises a rotating shaft and a rotor core, and a permanent magnet slot is uniformly arranged along the periphery of the rotor core; the permanent magnet slot is internally inlaid with radial magnetized rectangular strip magnetic steel, the radial magnetized rectangular strip magnetic steel and a pole piece form a permanent magnet pole, and an excircle of a rotor pole piece is in a concentric or excentric arc curved surface shape to form uniformly or non-uniformly symmetrical air gap; semi-circle grooves are arranged on two ends of the permanent magnet slot in which one of two pieces of adjacent radial magnetized rectangular strip magnetic steel is arranged; and rectangular supporting bars are radially inserted in the permanent magnet slot in which the V-shaped radial magnetized rectangular strip magnetic steel is arranged. The permanent magnet drive motor has the characteristics of high efficiency, high output power, high reliability, low moment fluctuation and the like.

Owner:苏州和鑫电气股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com