Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

111 results about "Spacing tooth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

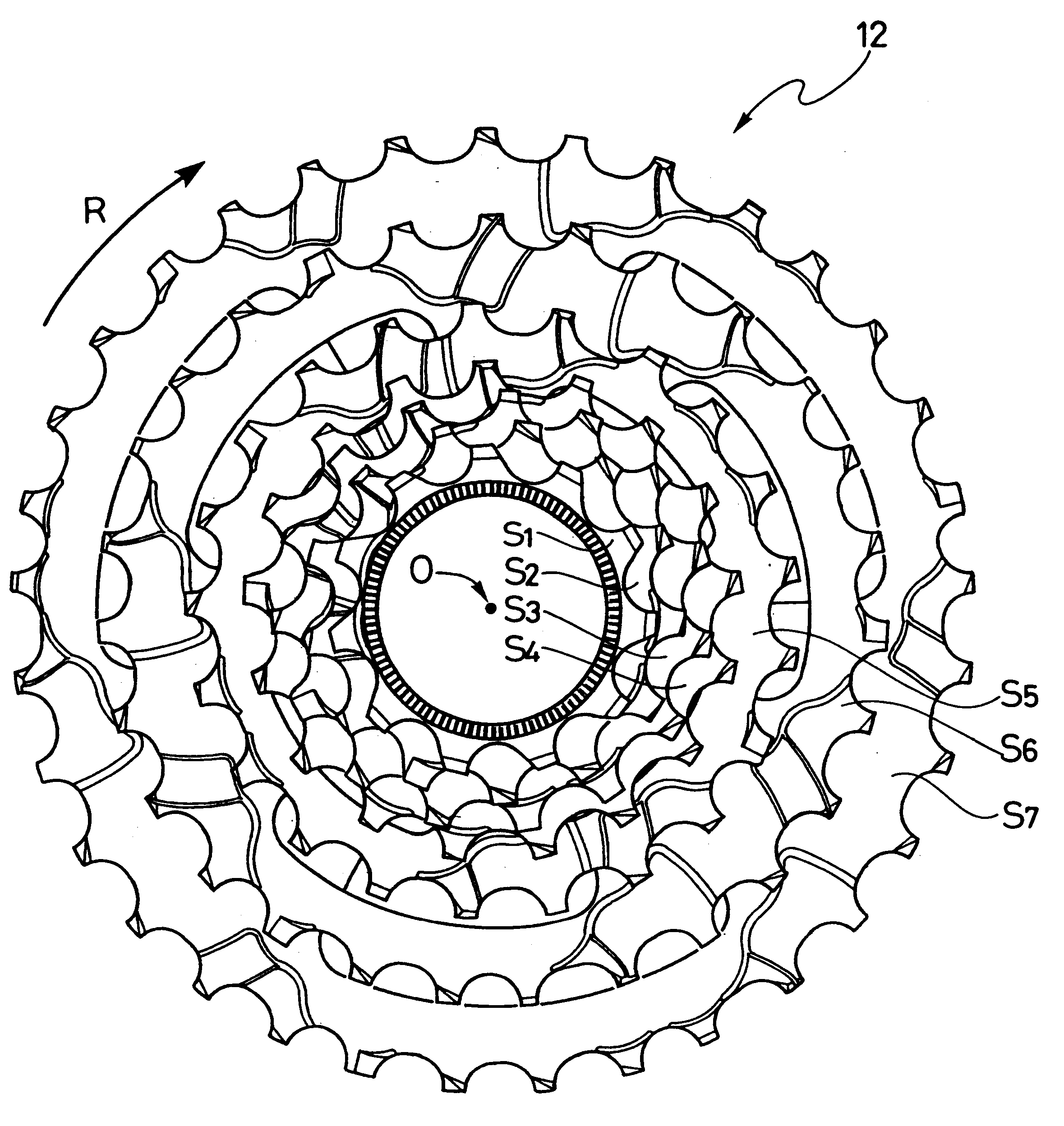

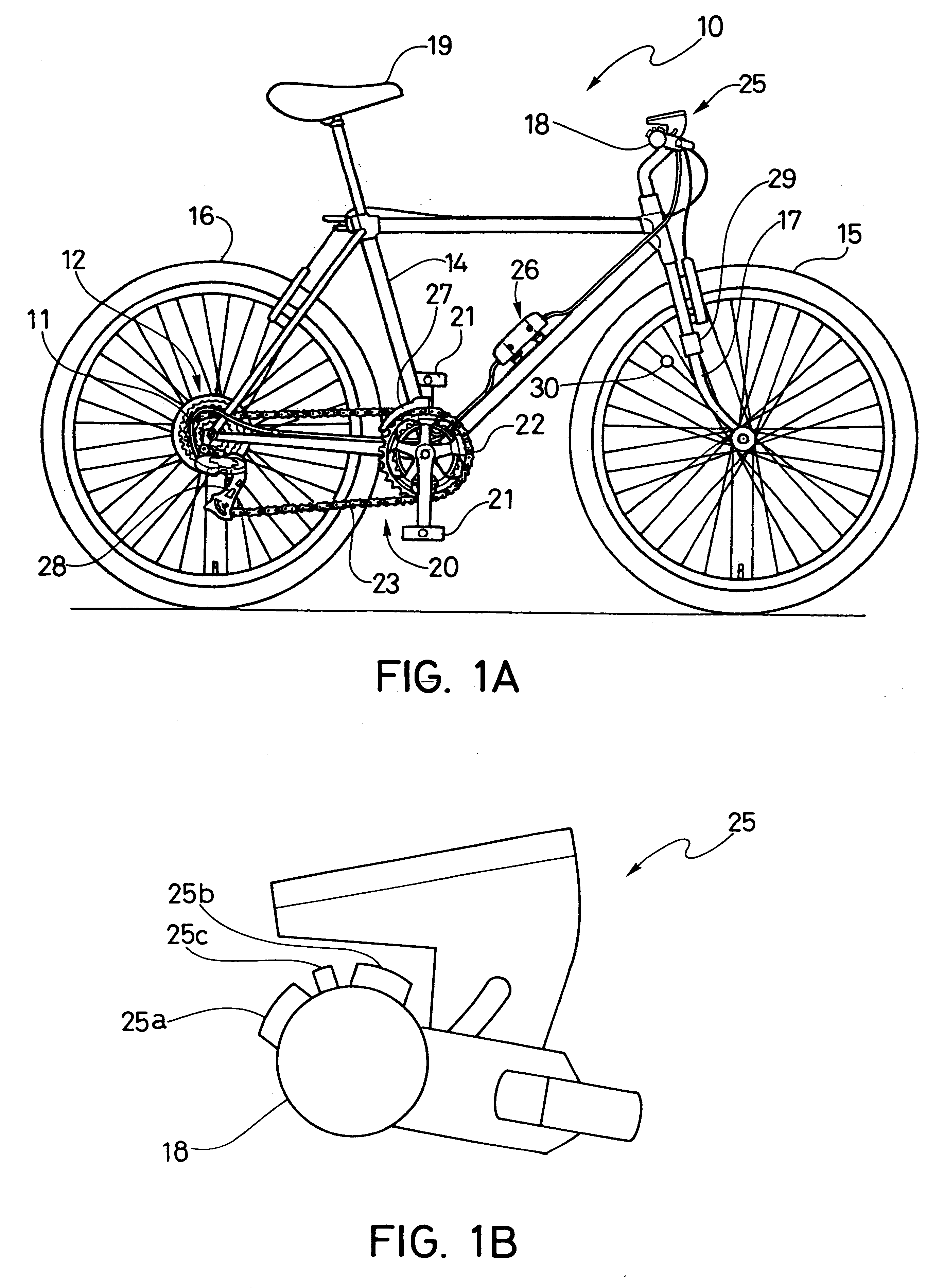

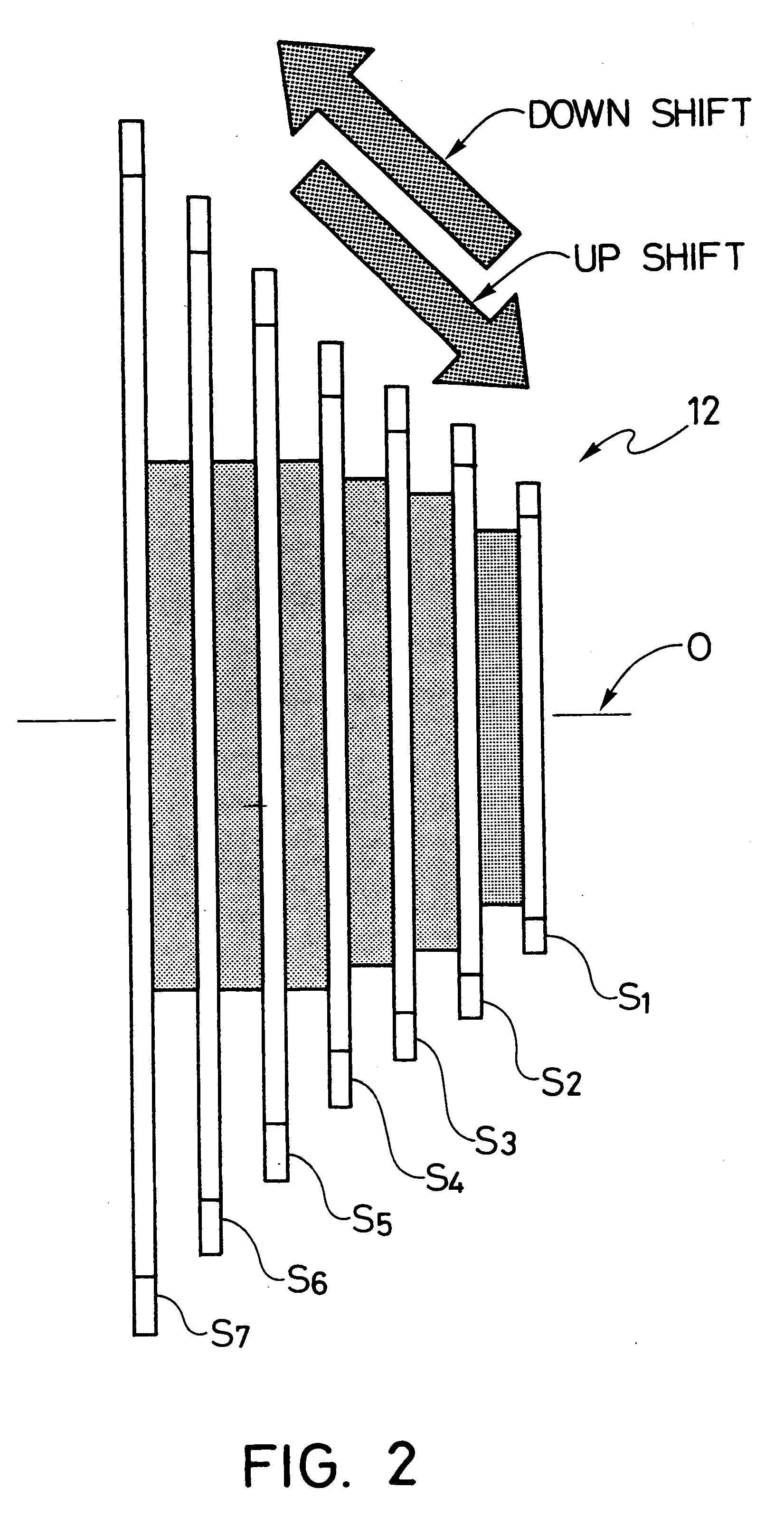

Bicycle sprocket

InactiveUS6340338B1Superior up shifting pathChain/belt transmissionCycle equipmentsSpacing toothSprocket

A sprocket assembly for a bicycle is provides with at least one large sprocket and at least one small sprocket. The large sprocket is modified to allow a bicycle chain to move smoothly from the large sprocket to the small sprocket during an up shift operation. The large sprocket basically has a sprocket body with a first axial side and a second axial side, and a plurality of circumferentially spaced teeth extending radially and outwardly from an outer periphery of the sprocket body. The teeth of the sprocket include a plurality of up shift teeth. The up shift teeth has at least a first up shift tooth, a second up shift tooth located adjacent the first up shift tooth and a third up shift tooth located adjacent the second up shift tooth. The first, second and third up shift teeth are dimensioned to maintain alignment of a bicycle chain to prevent an up shift of the chain when an outer link plate of the bicycle chain meshes with the second up shift tooth, and to permit an up shift the bicycle chain when an inner link plate meshes with the second up shift tooth along a first up shift path.

Owner:SHIMANO INC

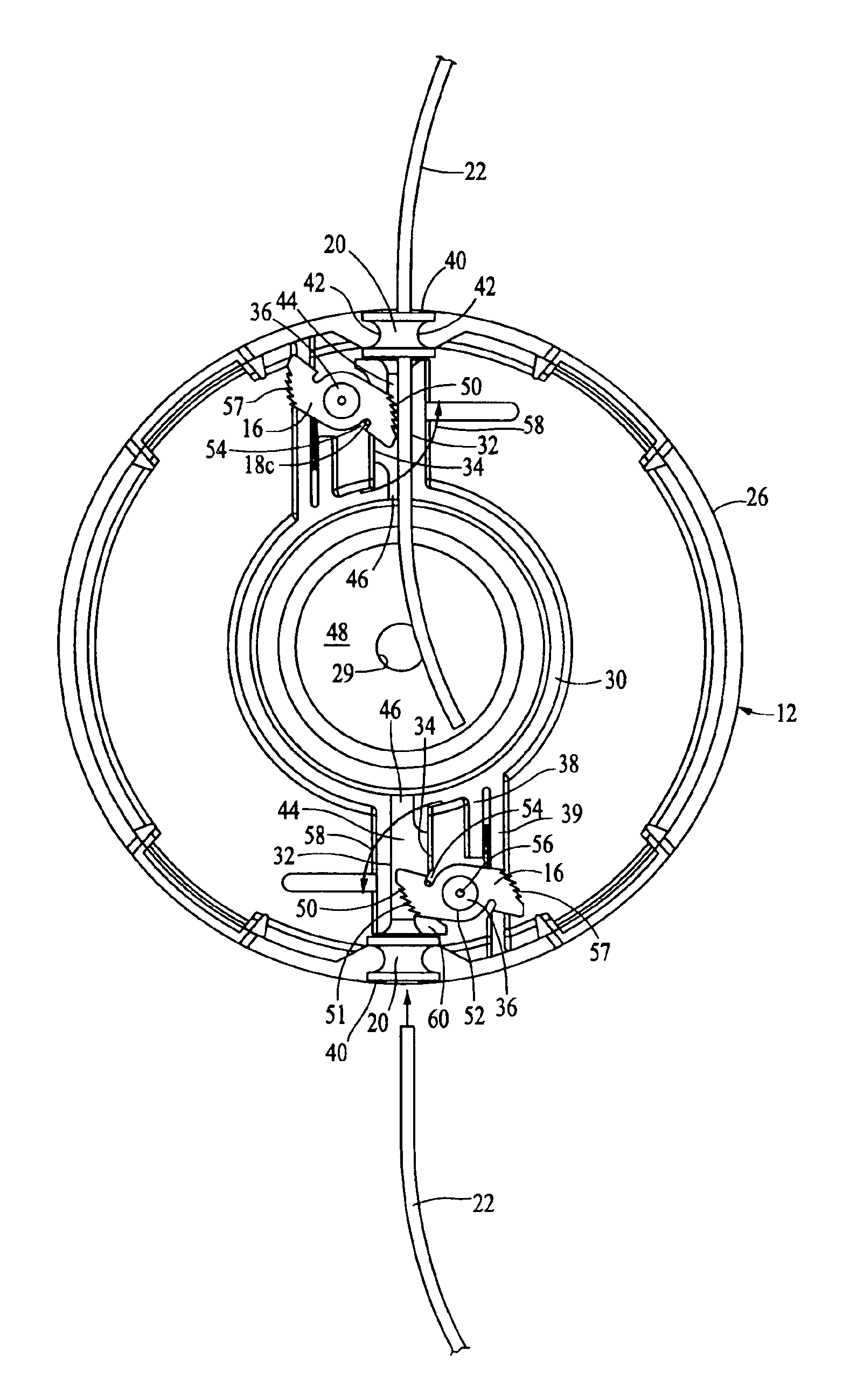

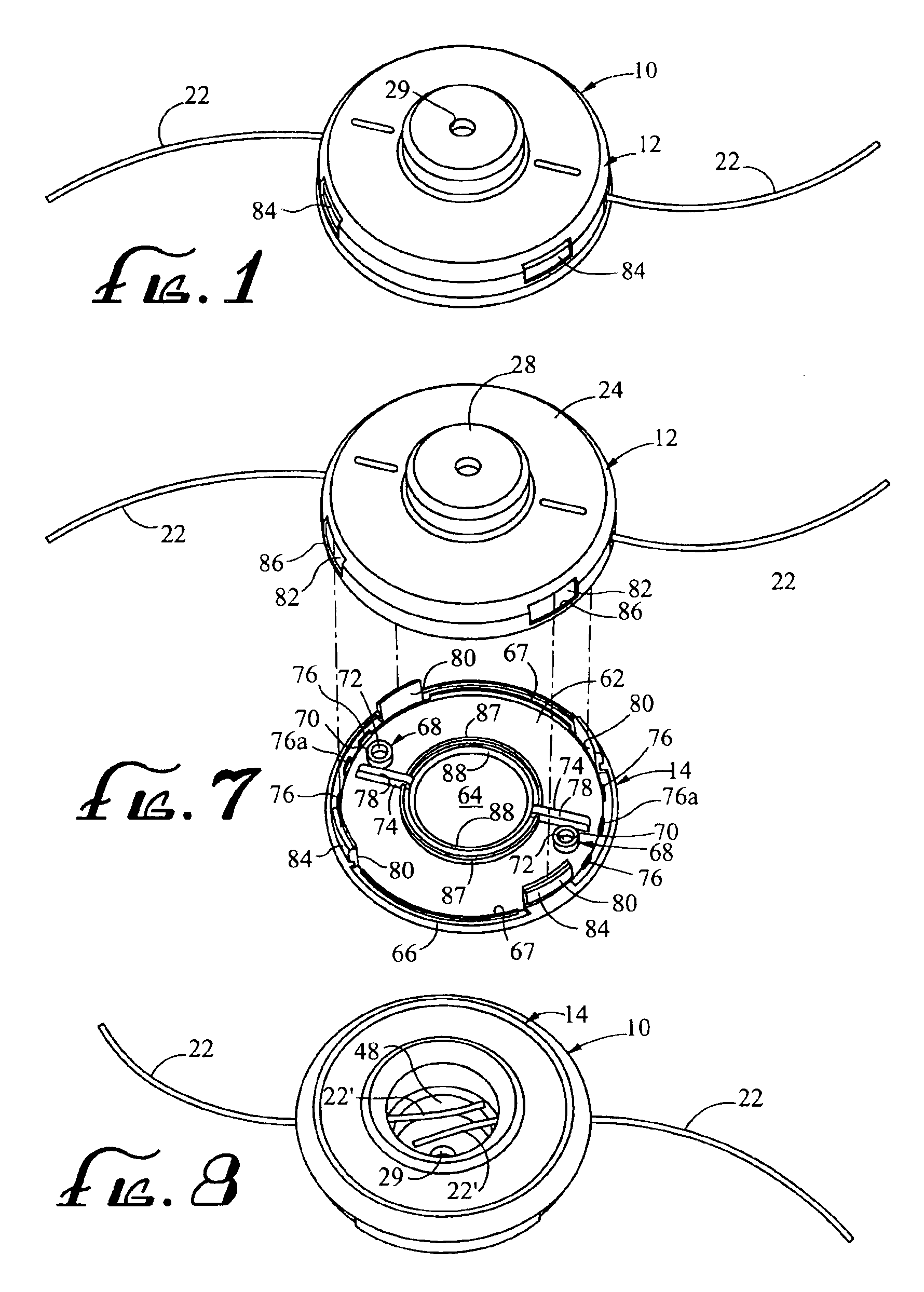

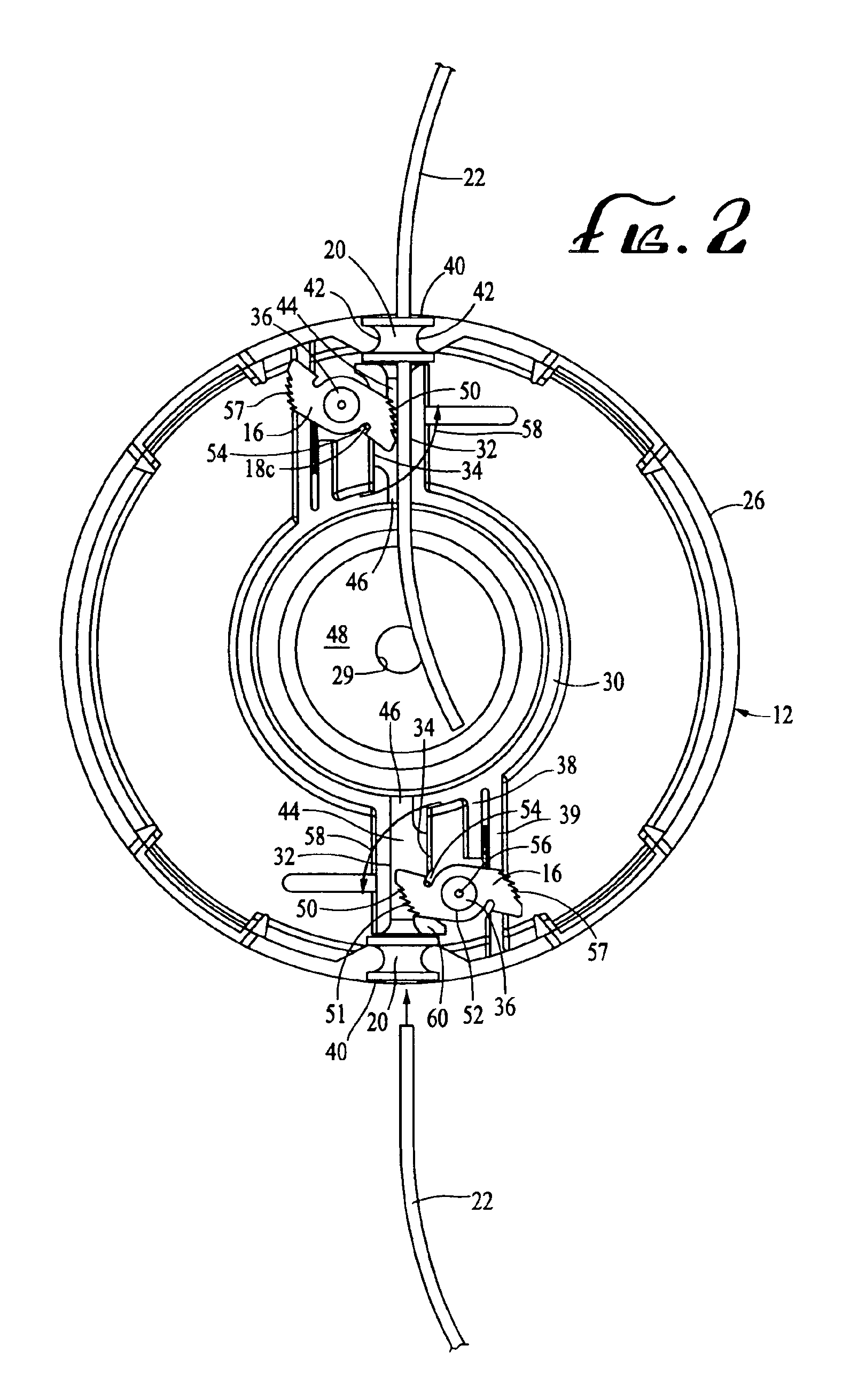

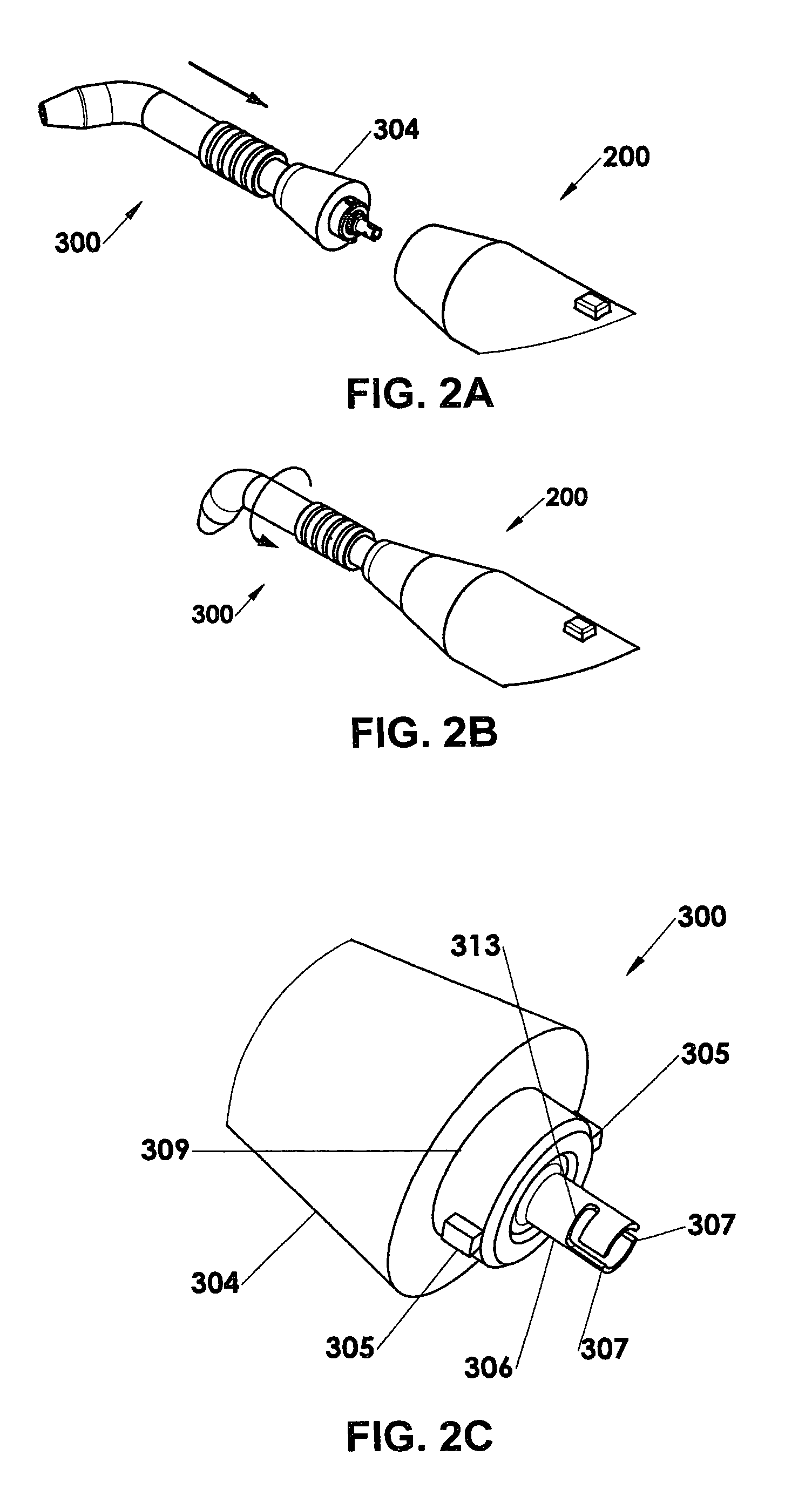

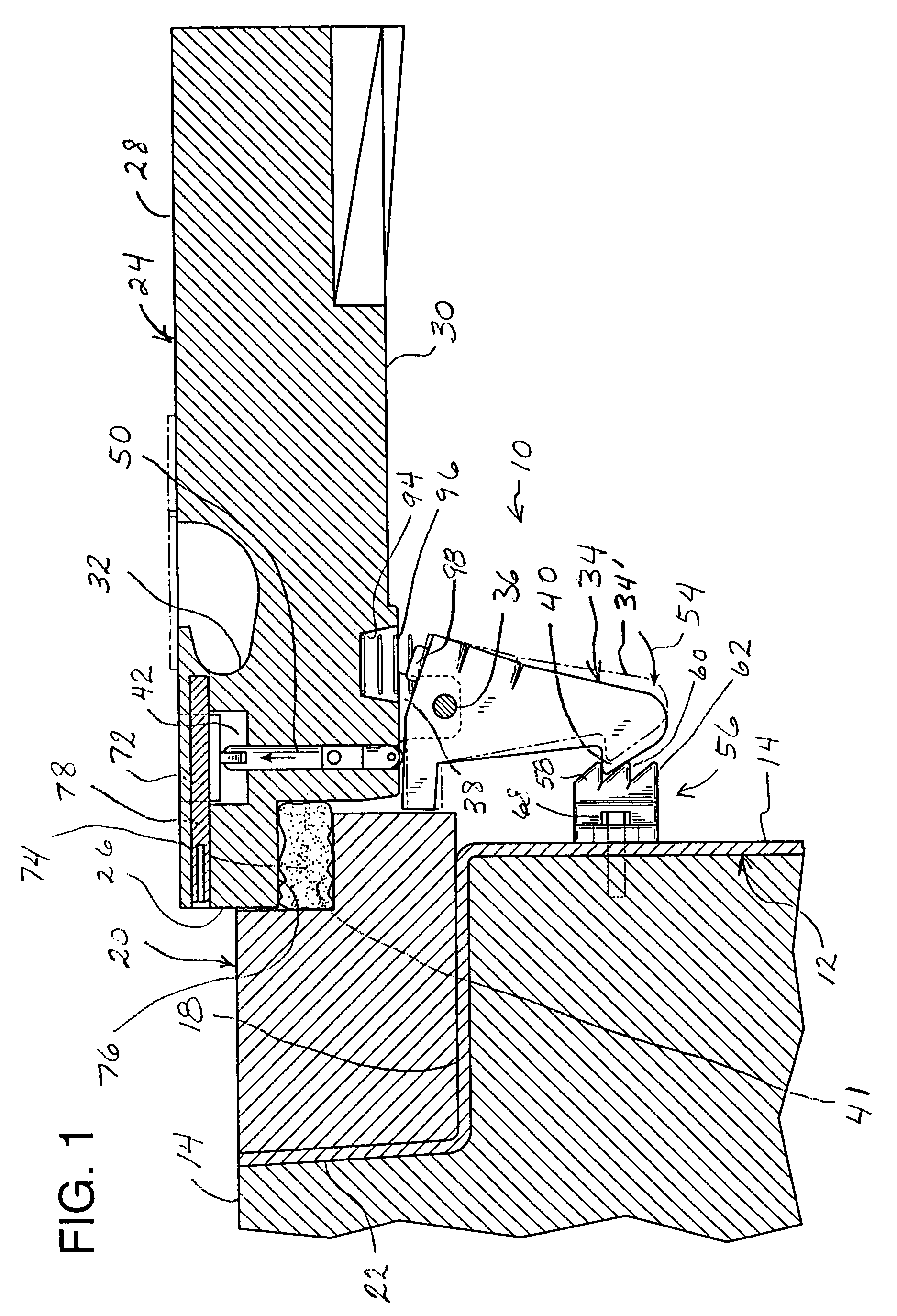

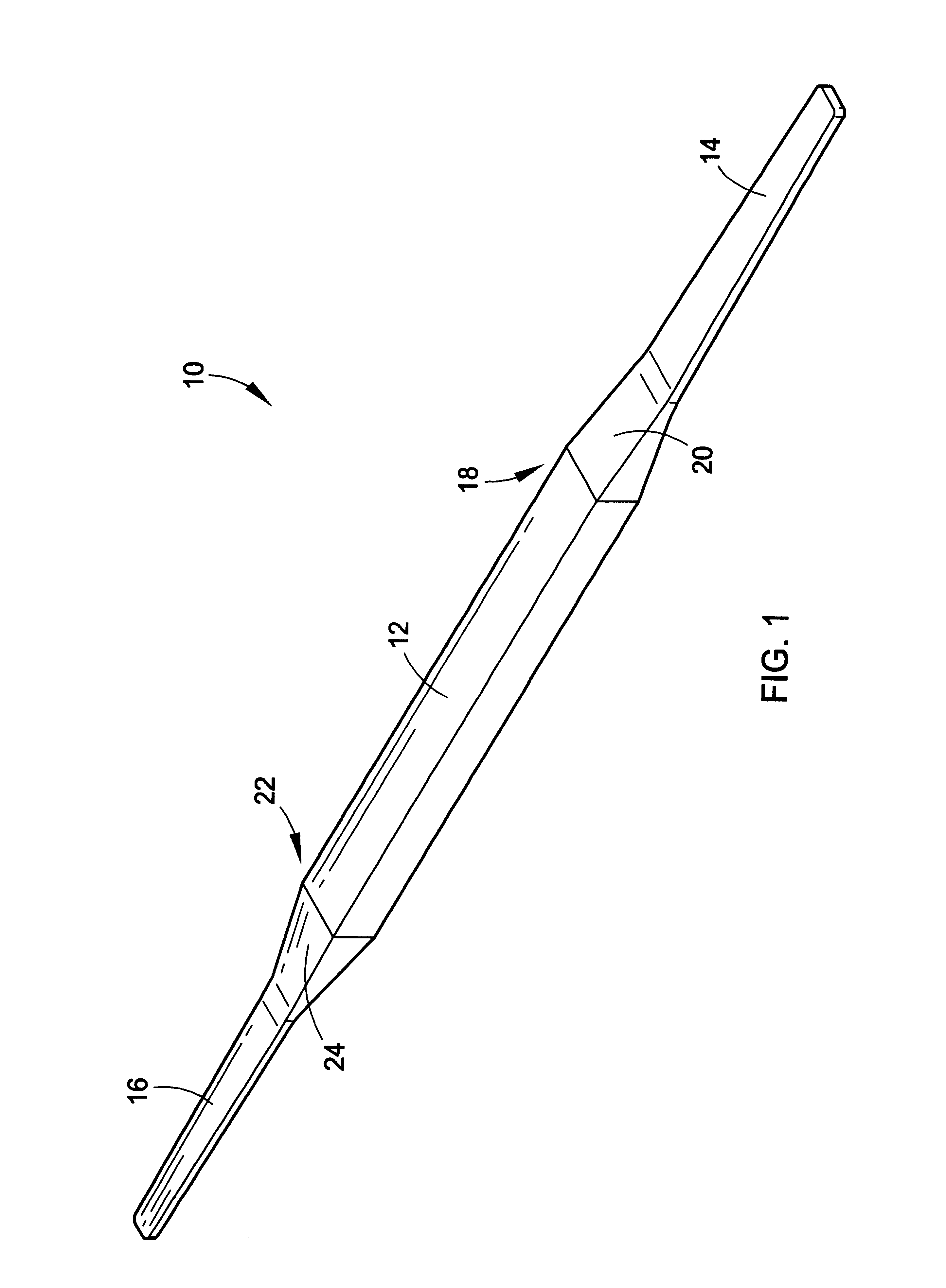

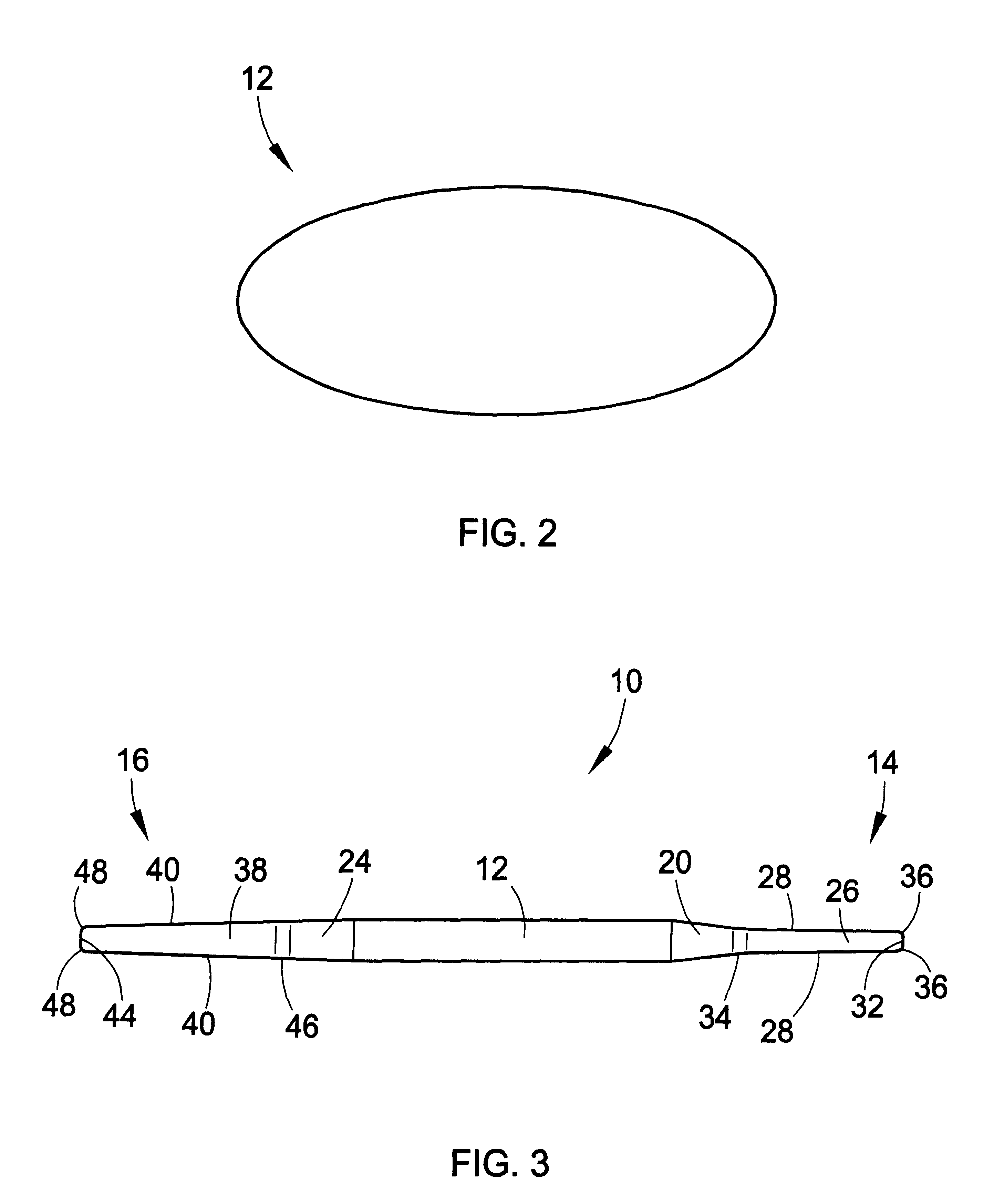

Fixed line head for flexible line rotary trimmers

InactiveUS6928741B2Simplifies line removalSolve the complicated replacementMowersMetal working apparatusSpacing toothCam

A cutting head for rotary trimmers in which at least one, and preferably two relatively short fixed lengths of flexible cutting line are inserted into opposed channels in the head and are secured in place by a pair of spring biased toothed cams. Each of the cams is pivotally mounted on a post within the housing adjacent one of the channels and defines a curvilinear camming surface having a plurality of uniformly spaced teeth thereon that project into the channels at increasing angles of inclination from the outermost tooth to the innermost tooth for engaging the line. A pair of torsion springs bias the cams to pivot on their mounting teeth such that the backsides of the teeth are continually urged toward the openings to the channels thereby allowing line to be inserted inwardly into the head past the toothed cams but retained by the cams against any outwardly directed forces acting on the line. The cams are symmetrically balanced about their axes of rotation so as to be unaffected by centrifugal force acting thereon during use.

Owner:PROULX MFG

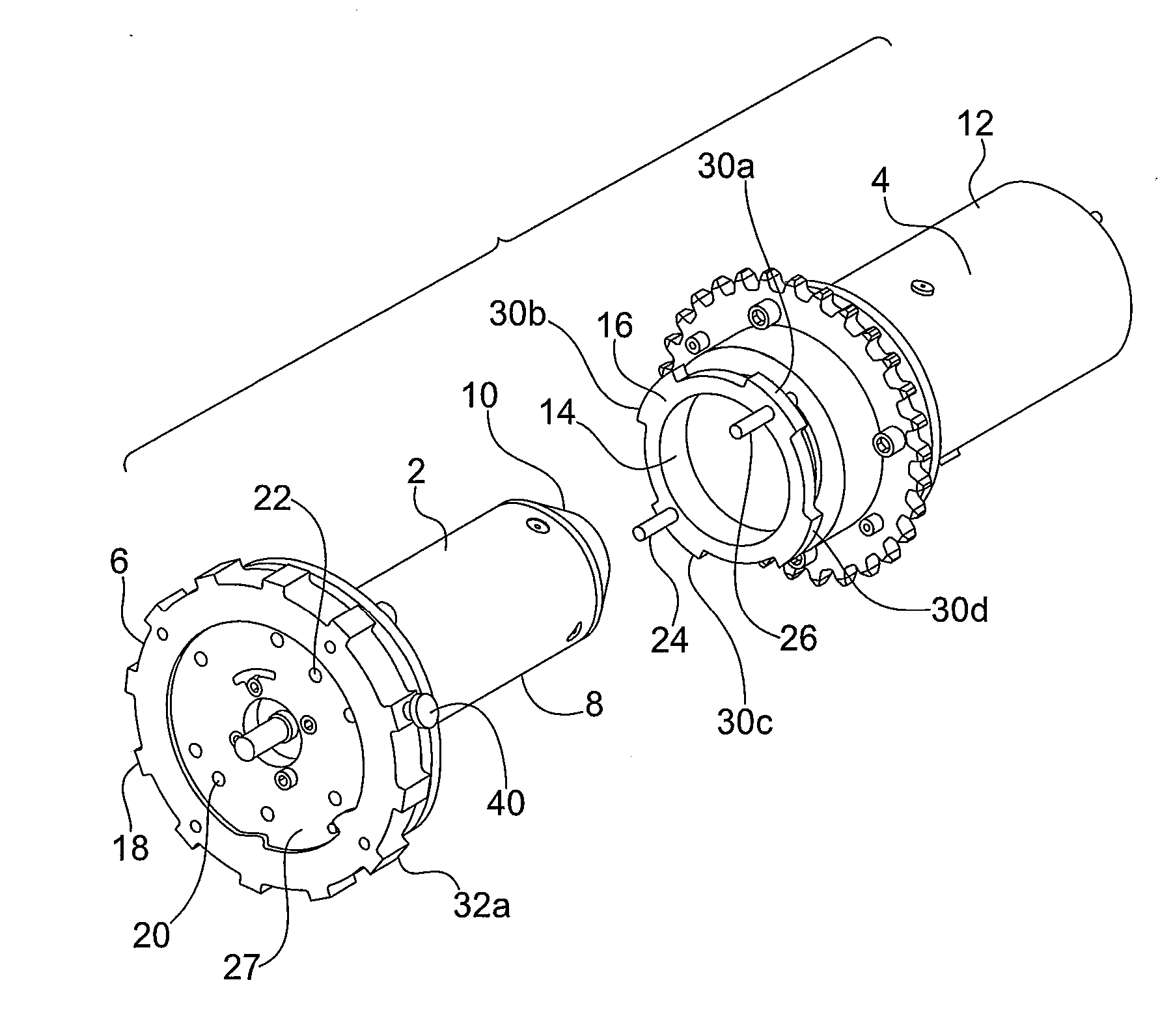

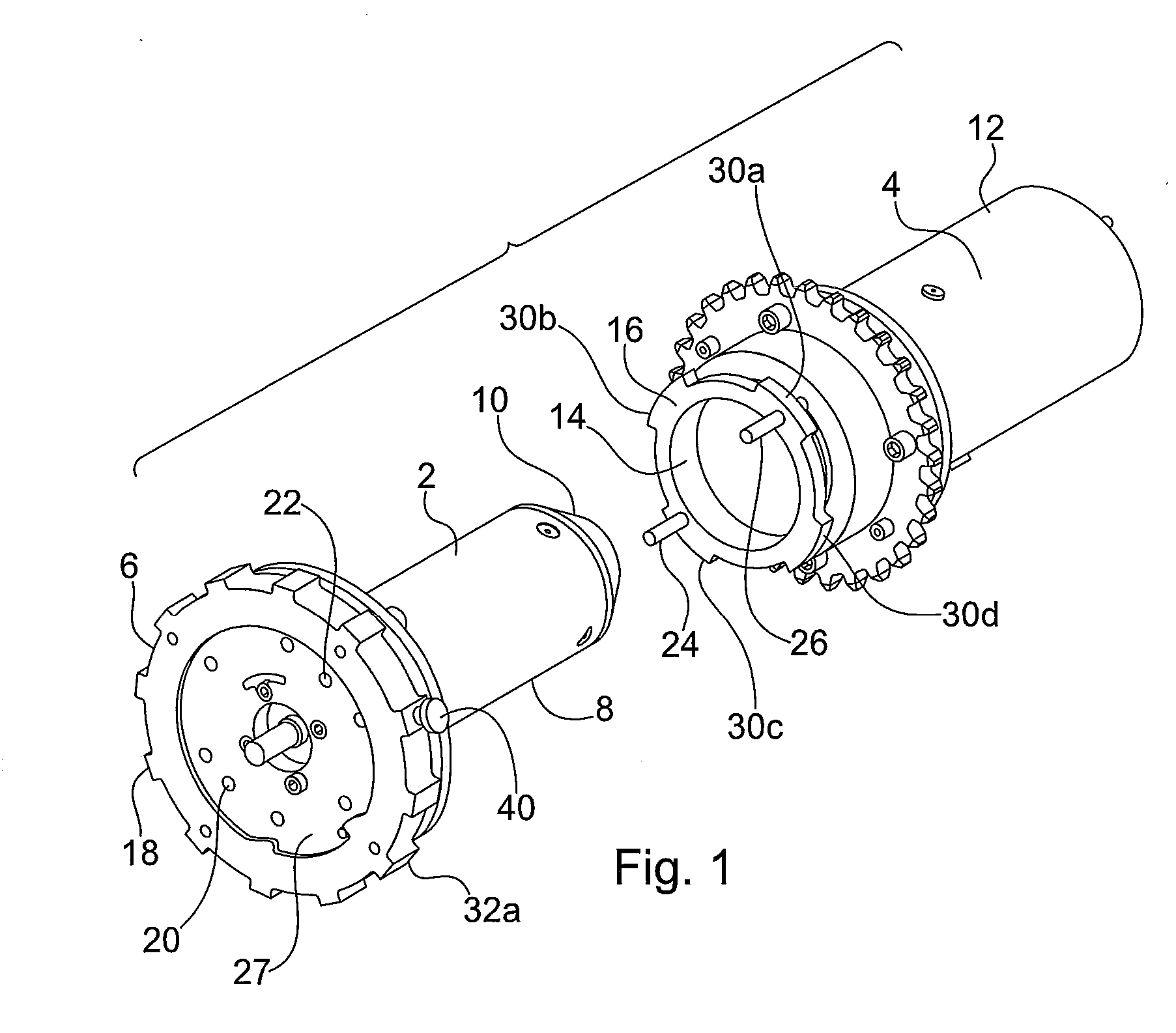

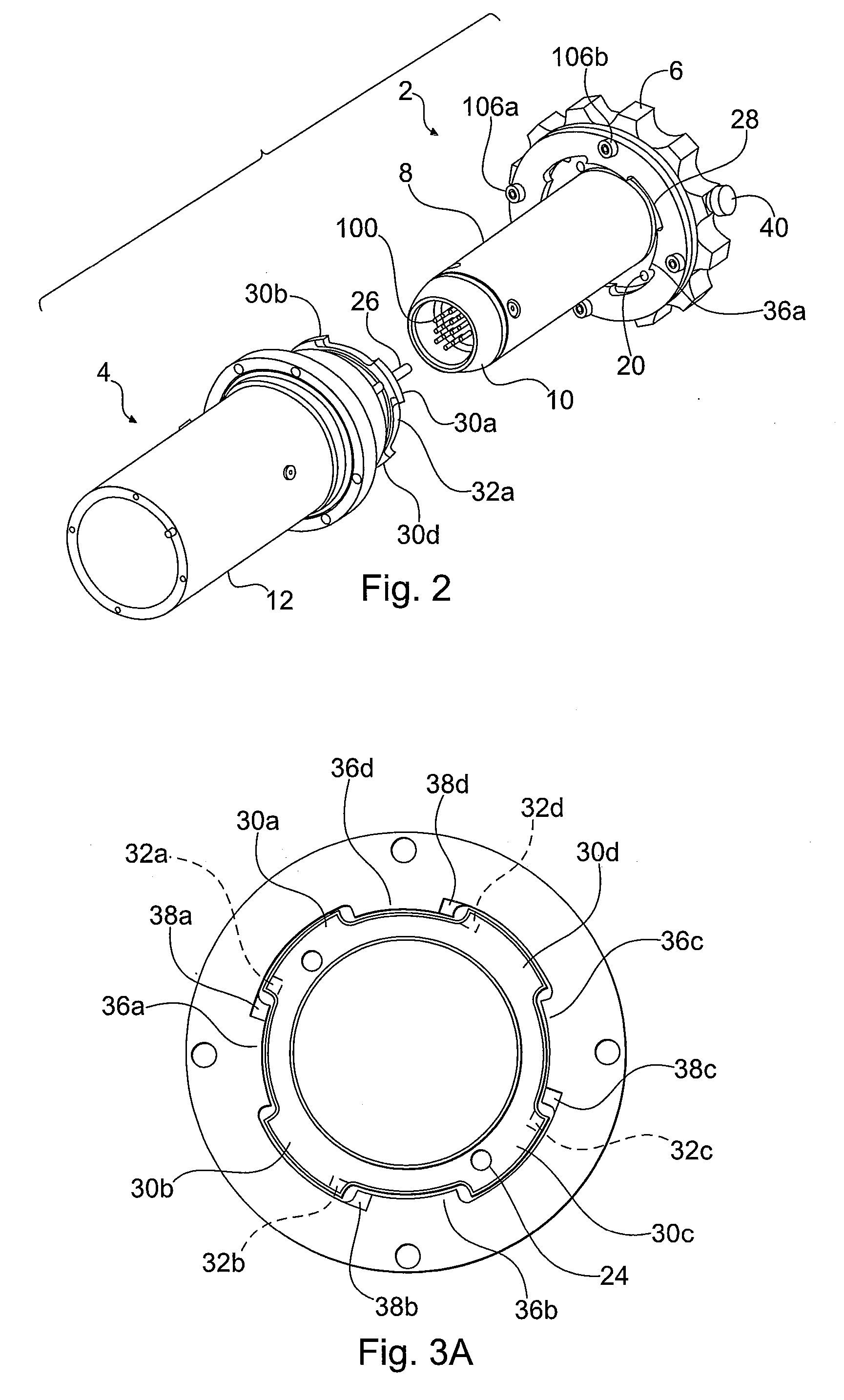

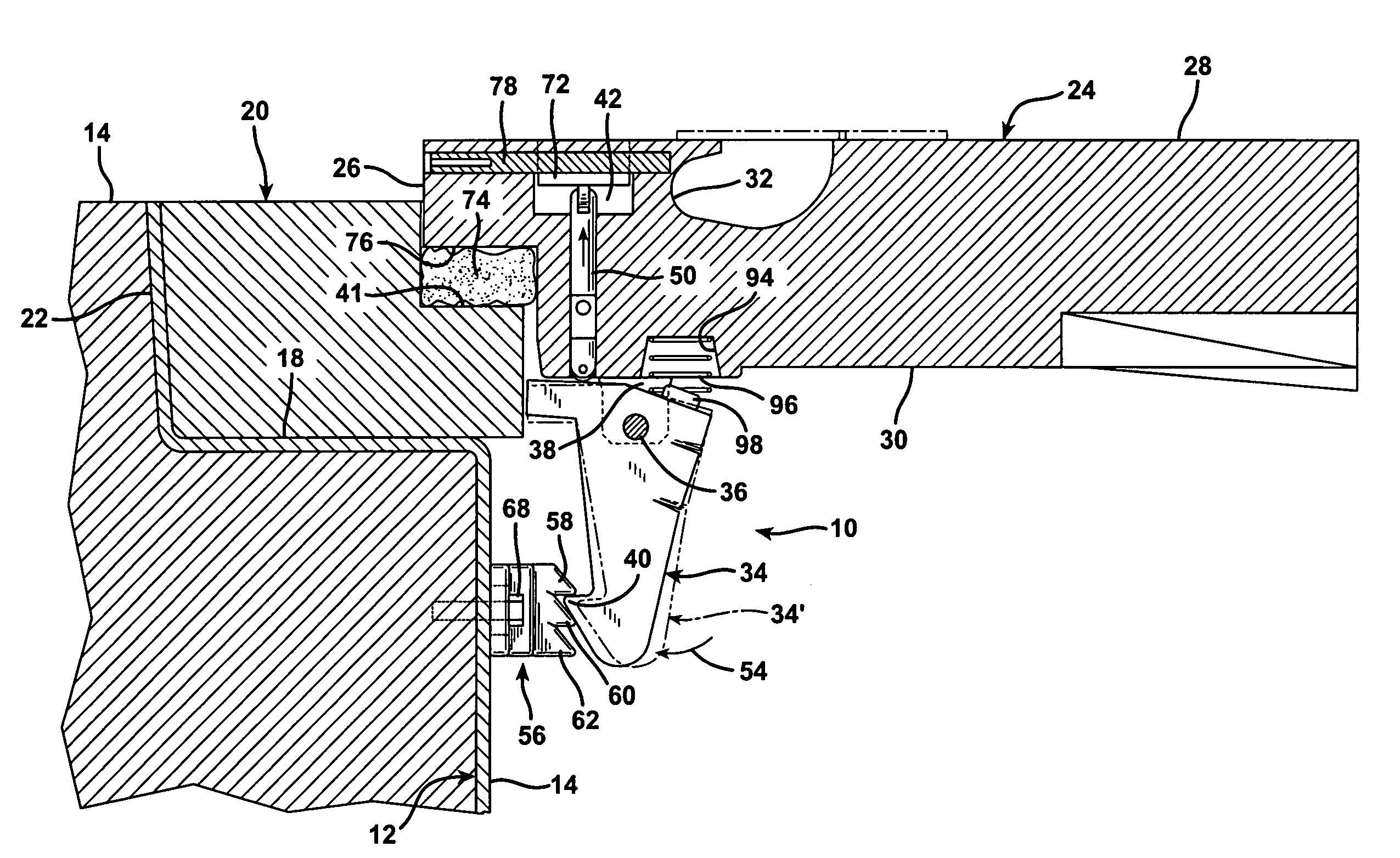

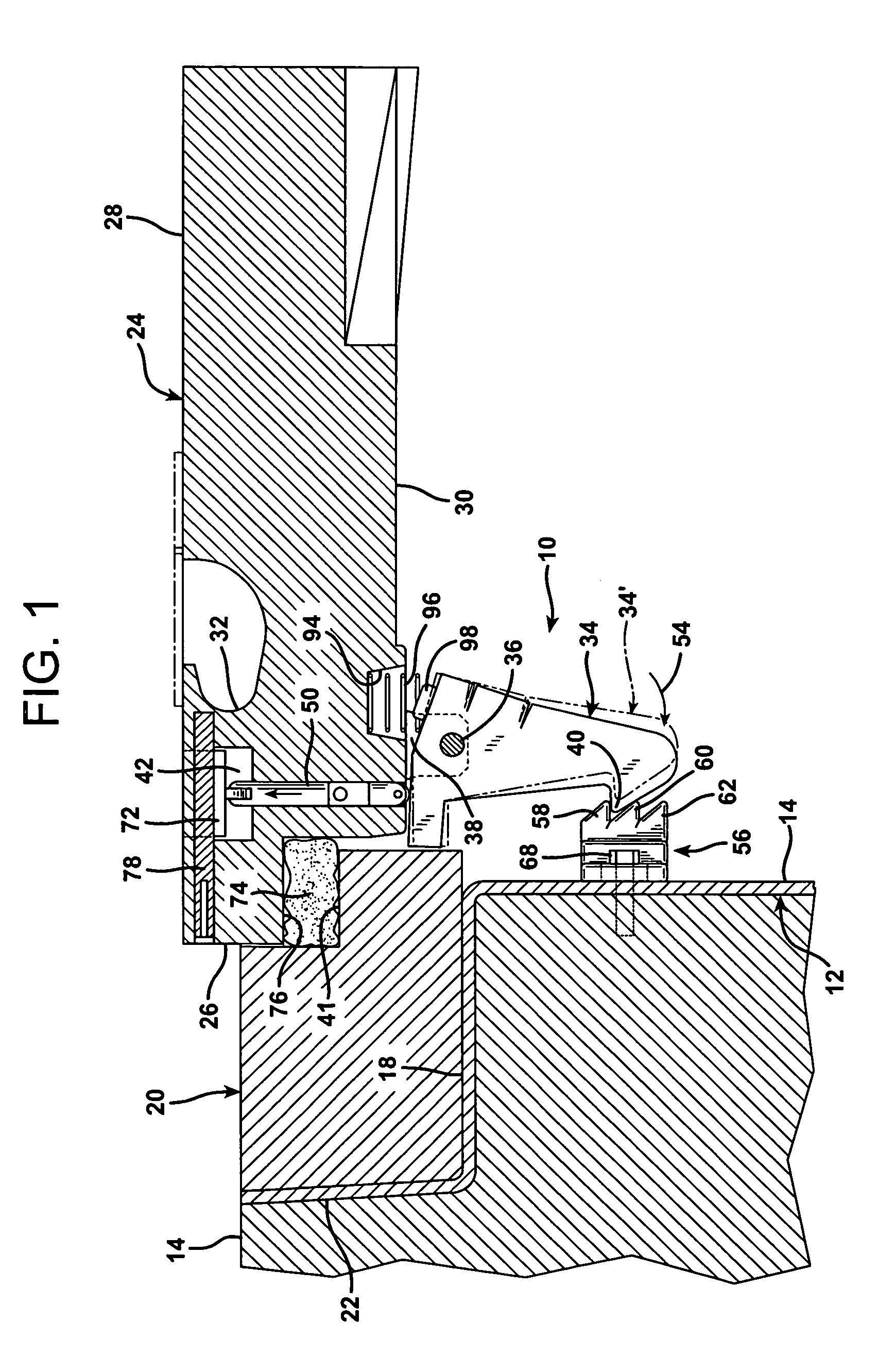

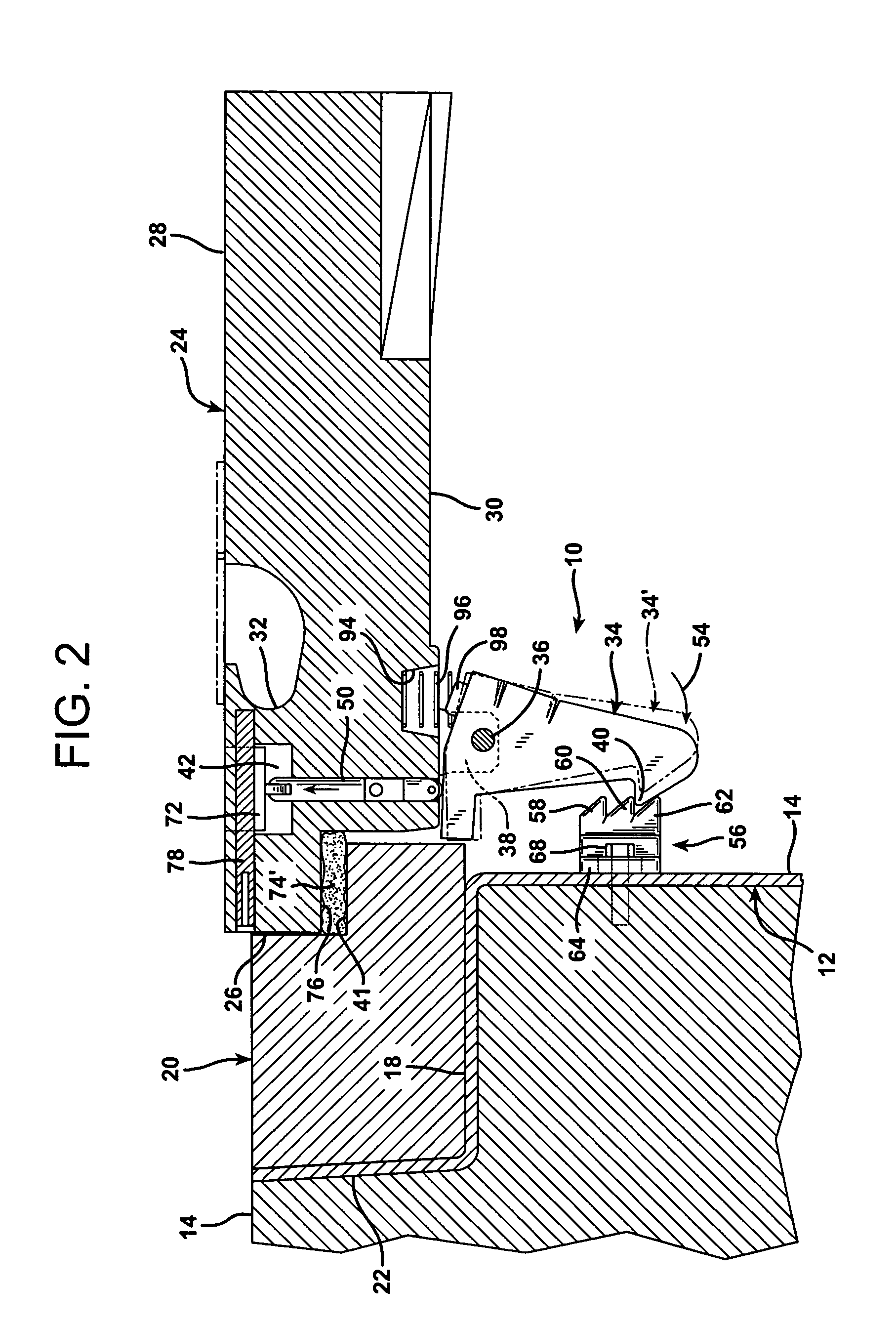

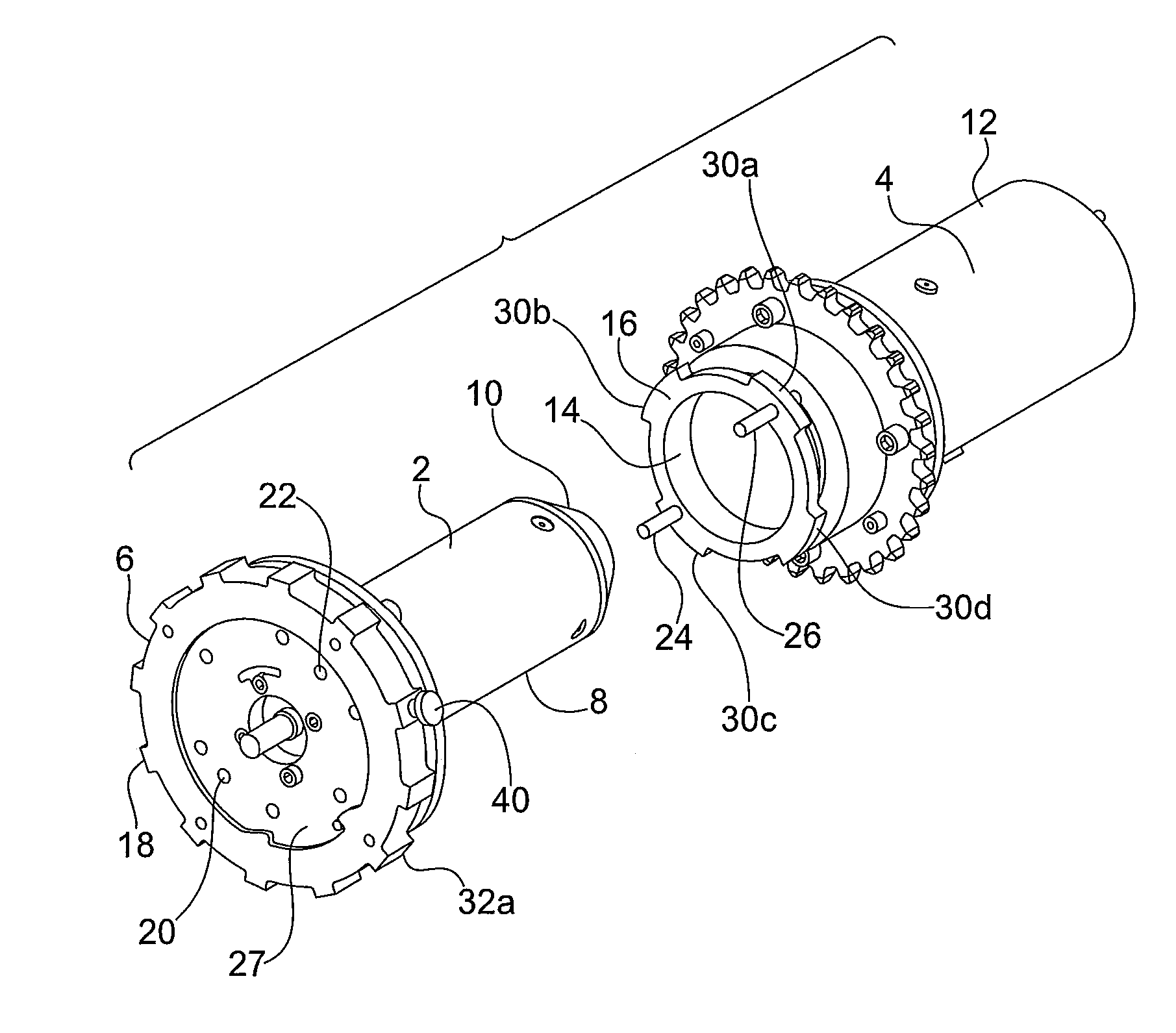

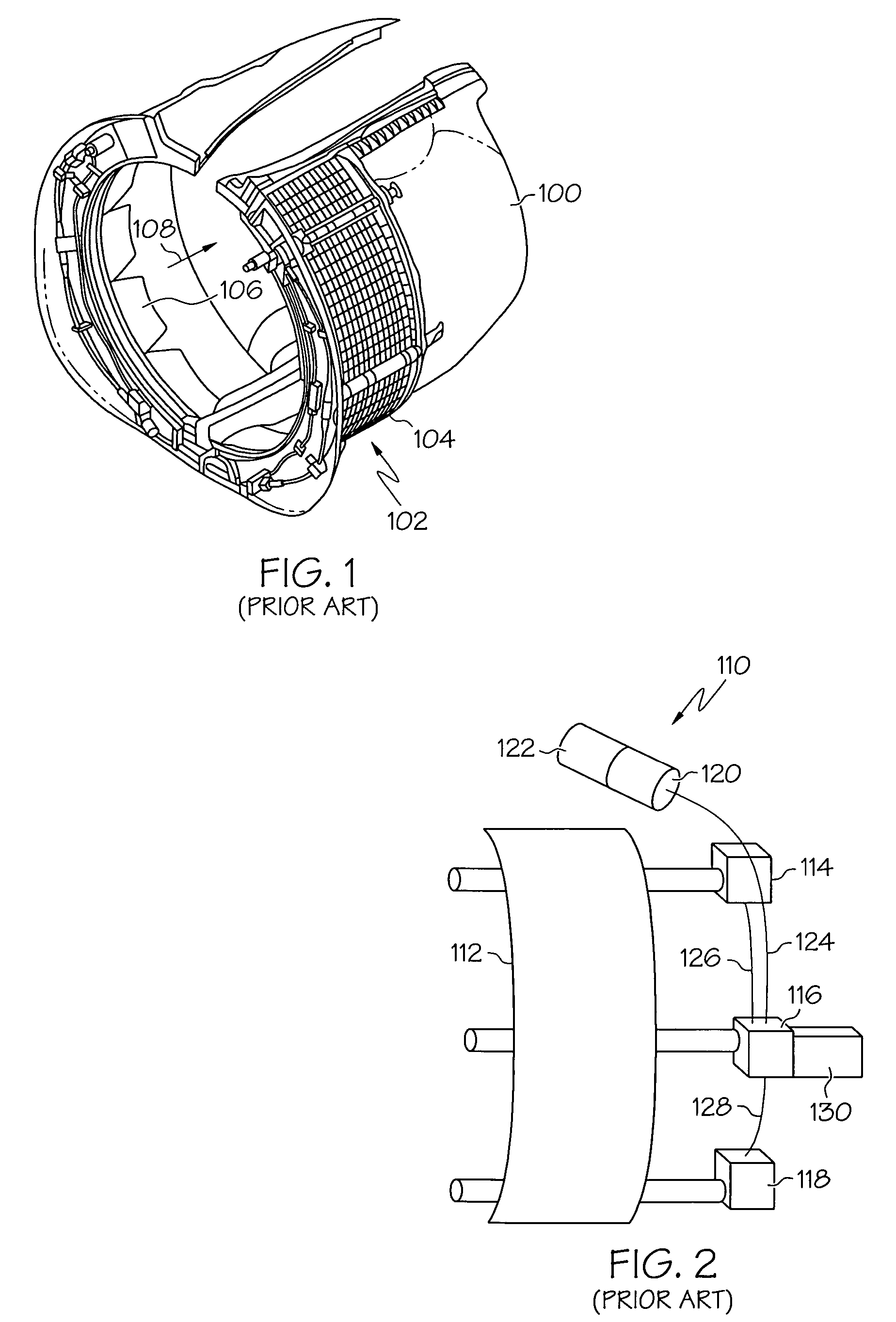

Robust Manual Connector for Robotic Arm End Effector

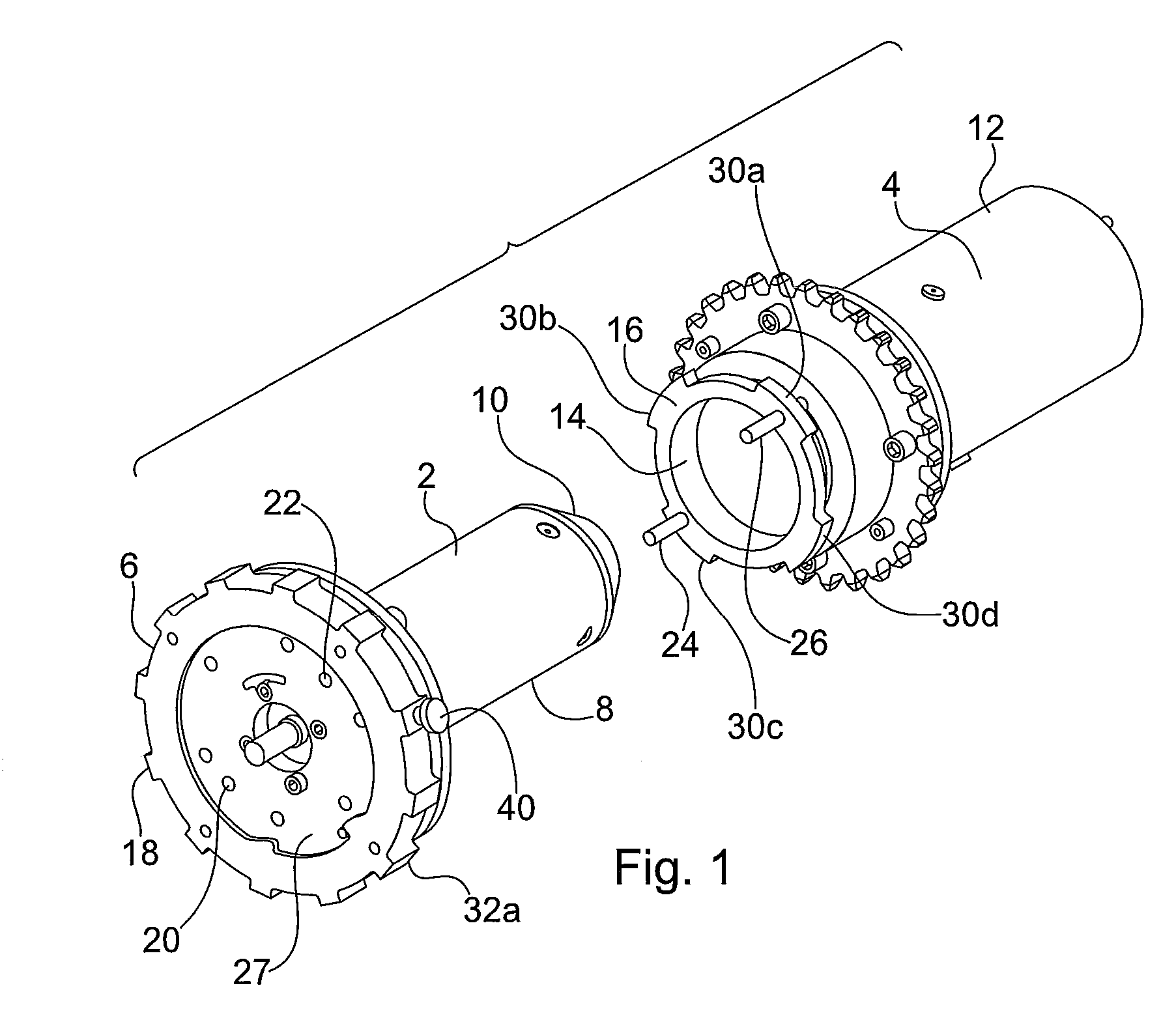

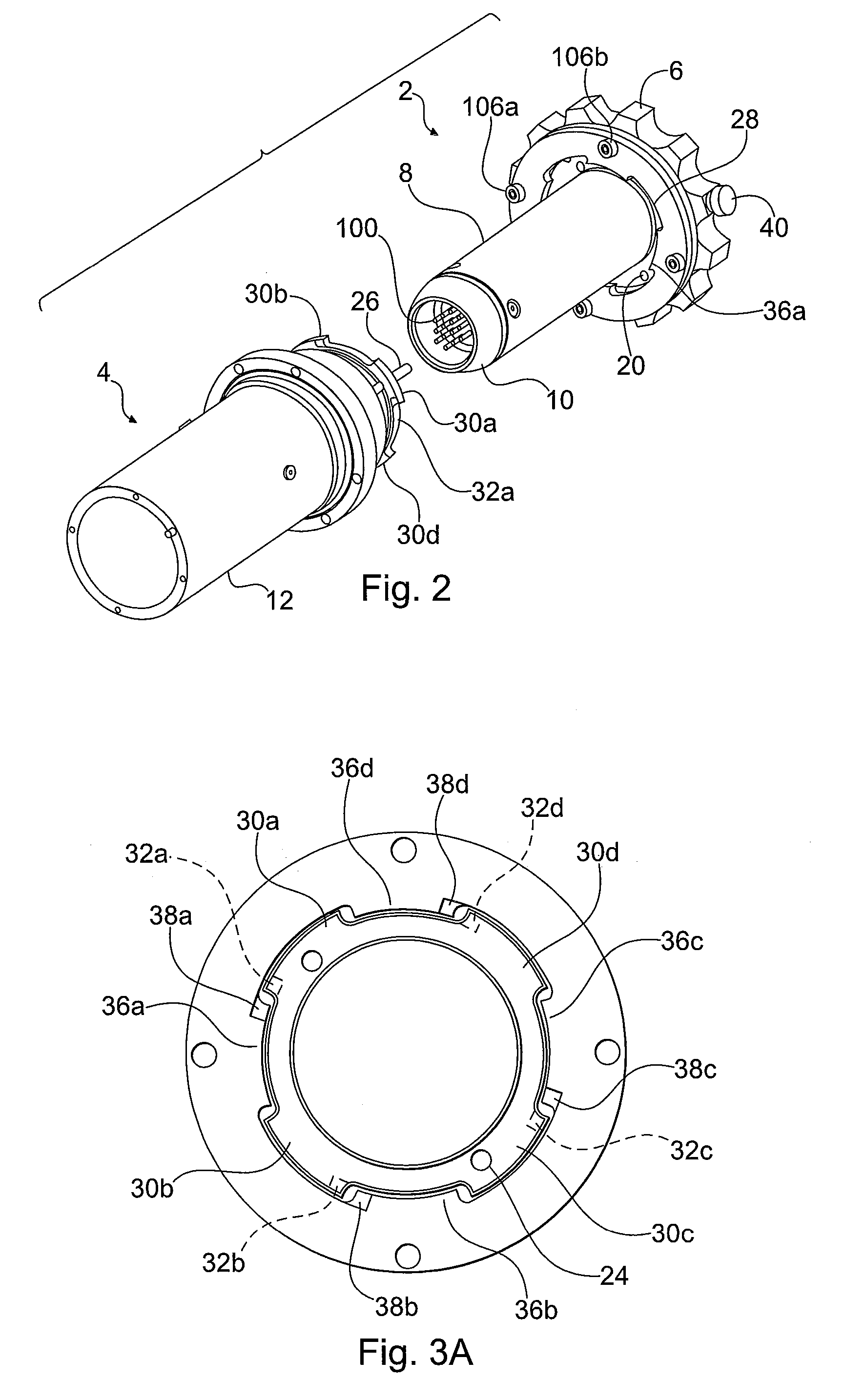

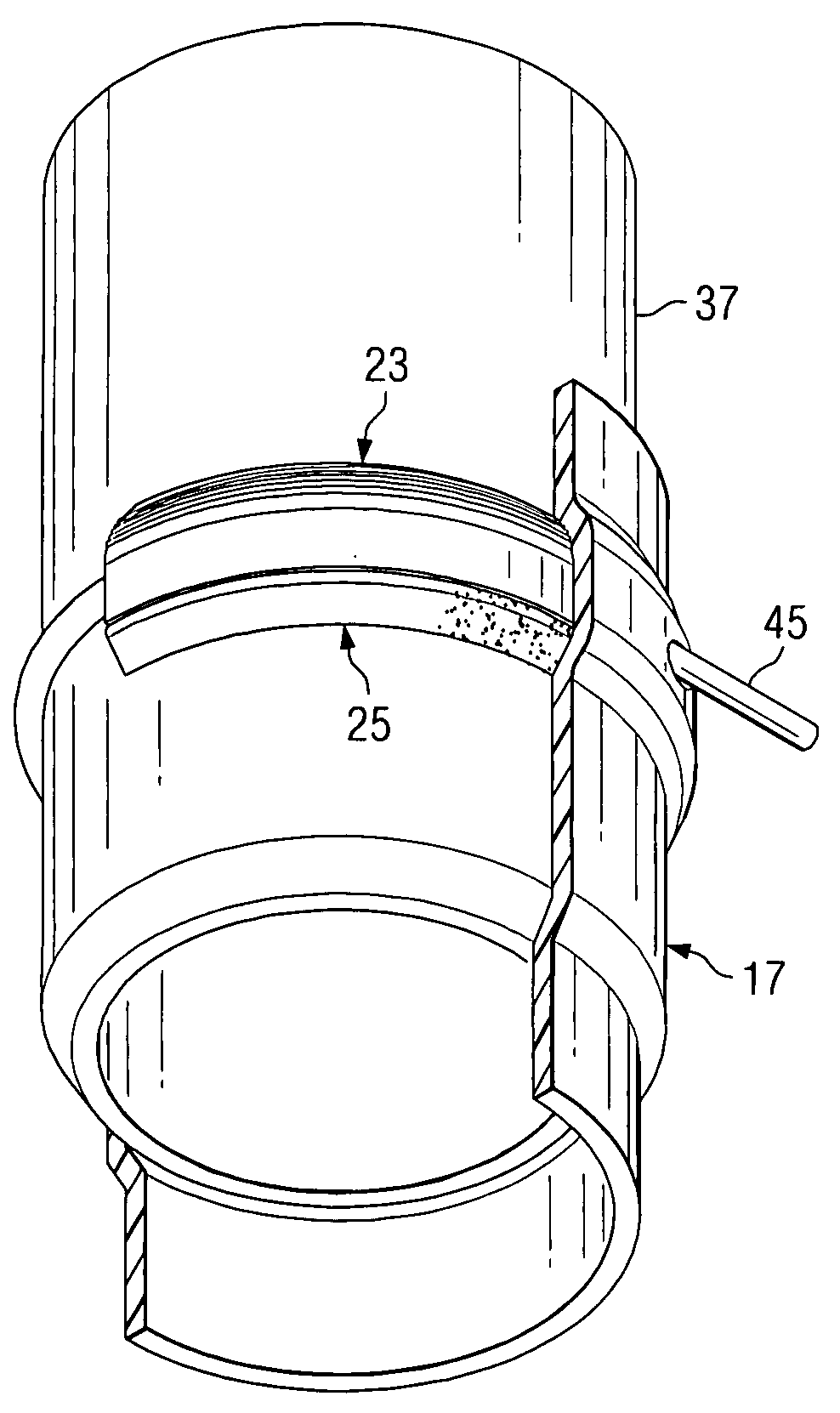

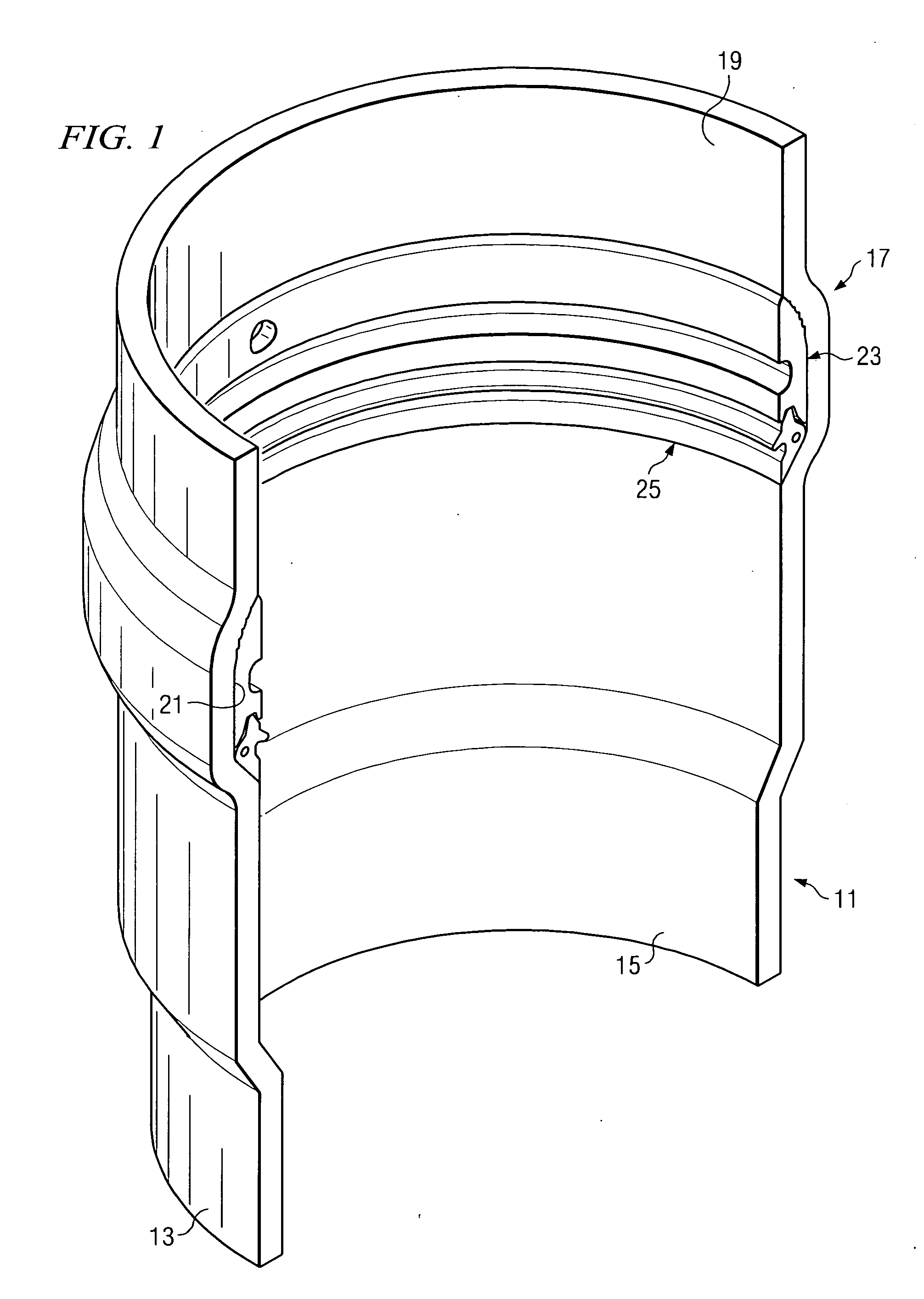

The present invention is an assembly for releasably connecting an end effector in the form of a robotic tool or component to a robotic arm. The connection is manually operated and formed of a first and second joint member including a cylindrical body, a locking collar, and a locking wall extending from the cylindrical body. The locking collar is coaxially aligned with and rotatably connected to the first joint member. The second joint member has a cylindrical mating body and a coupler, and engages the first joint member. The coupler also includes key pins, the pins being engageable in keyed relationship with the locking wall, the coupler and locking collar further includes intervening circumferentially spaced teeth, wherein the collar is rotatable to releasably engage the first joint member with the second joint member.

Owner:RE2

Multi-position aircraft servicing pit lid latch

InactiveUS6951318B1Avoid bad consequencesEasy to close and latchArtificial islandsHelicopter landing platformSpacing toothEngineering

Owner:CAVOTEC ACQUISITION US

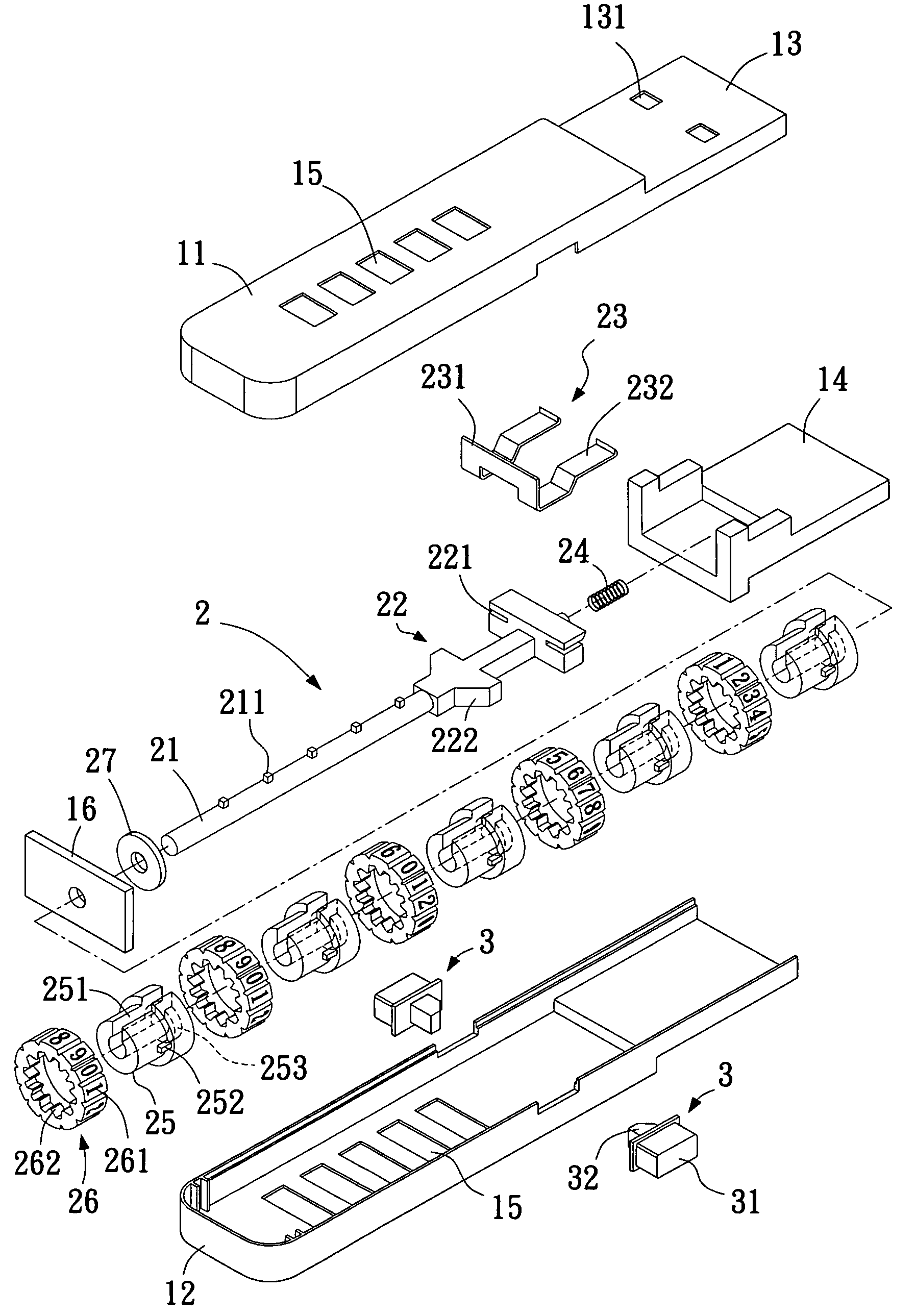

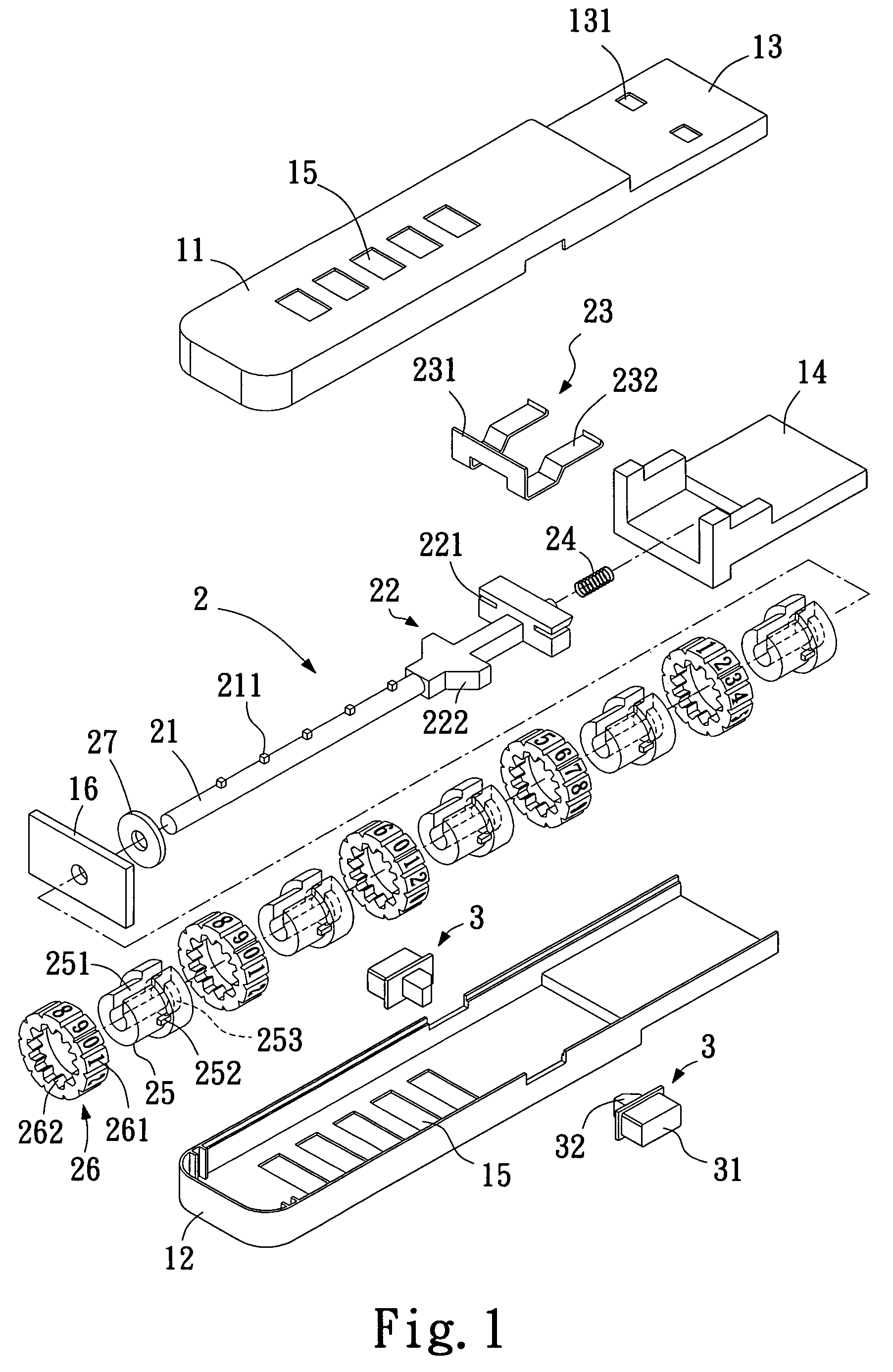

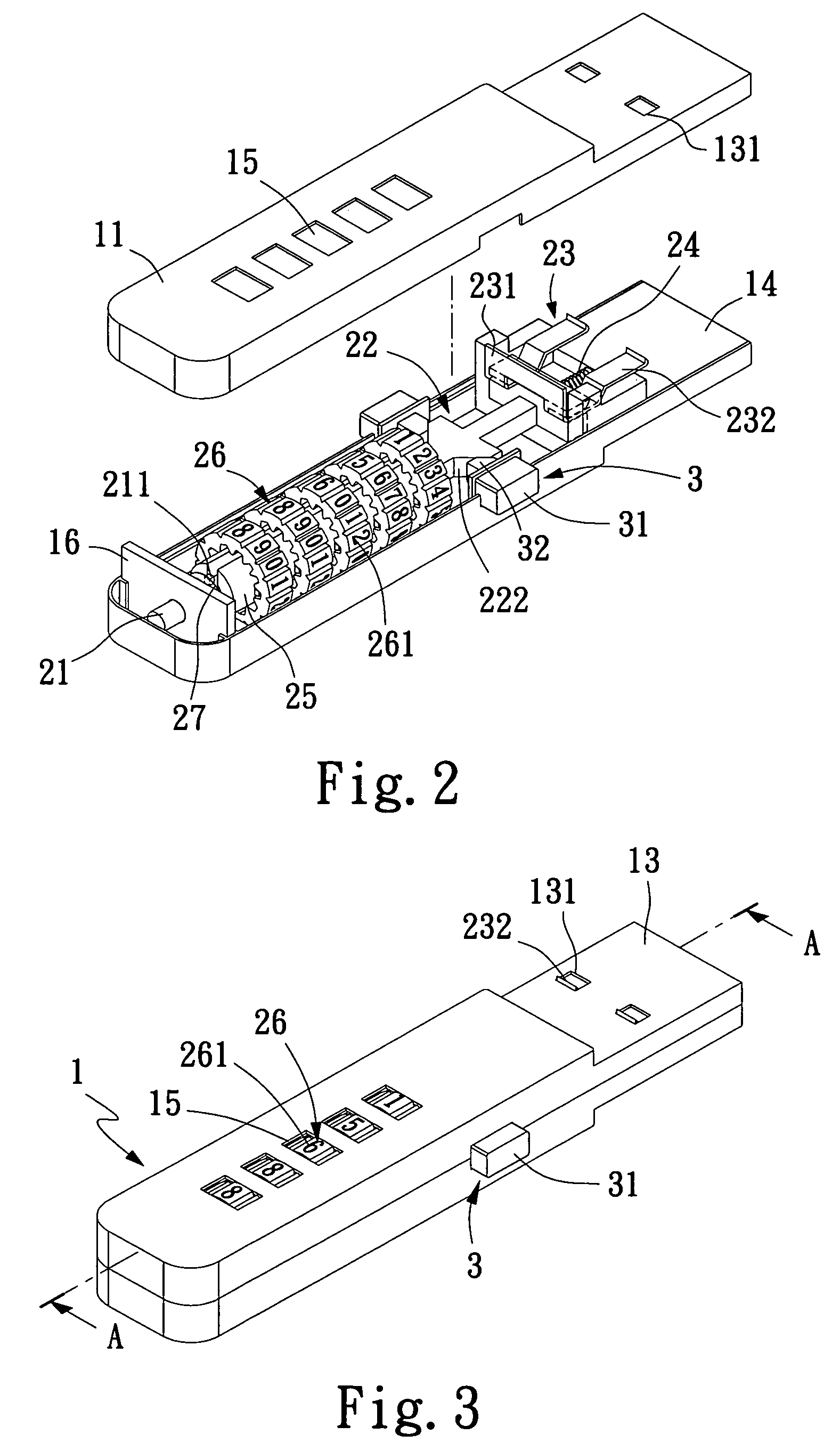

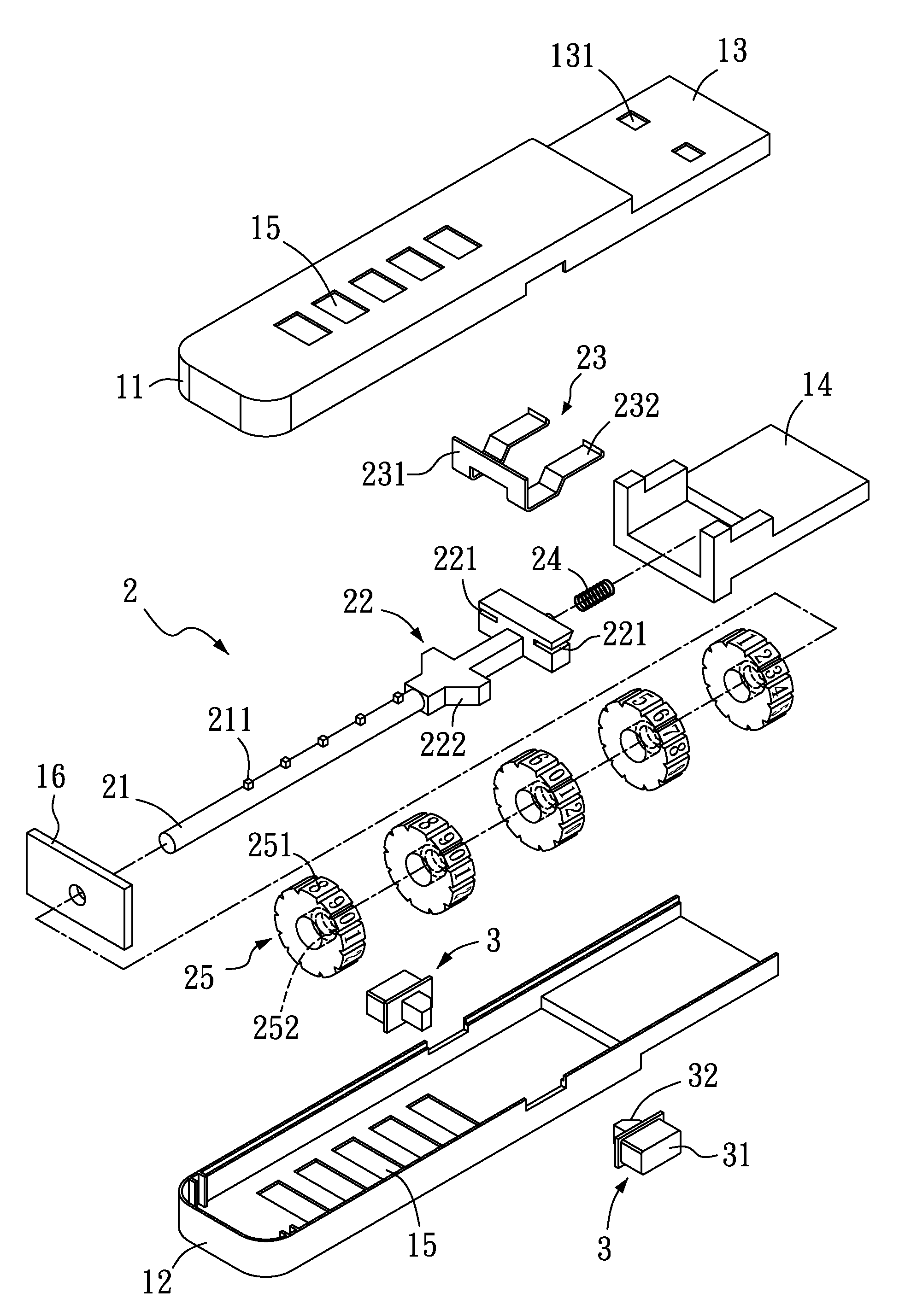

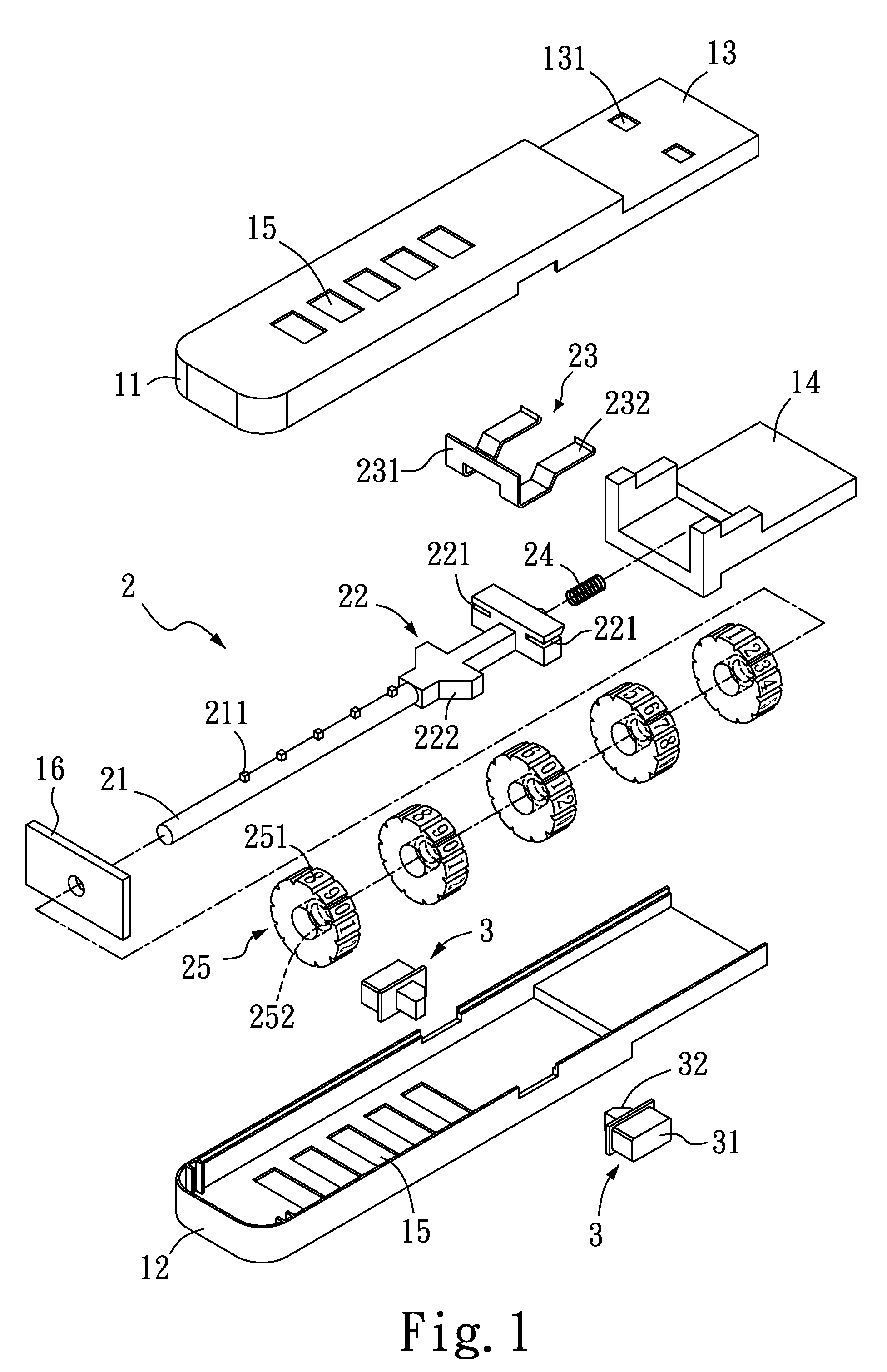

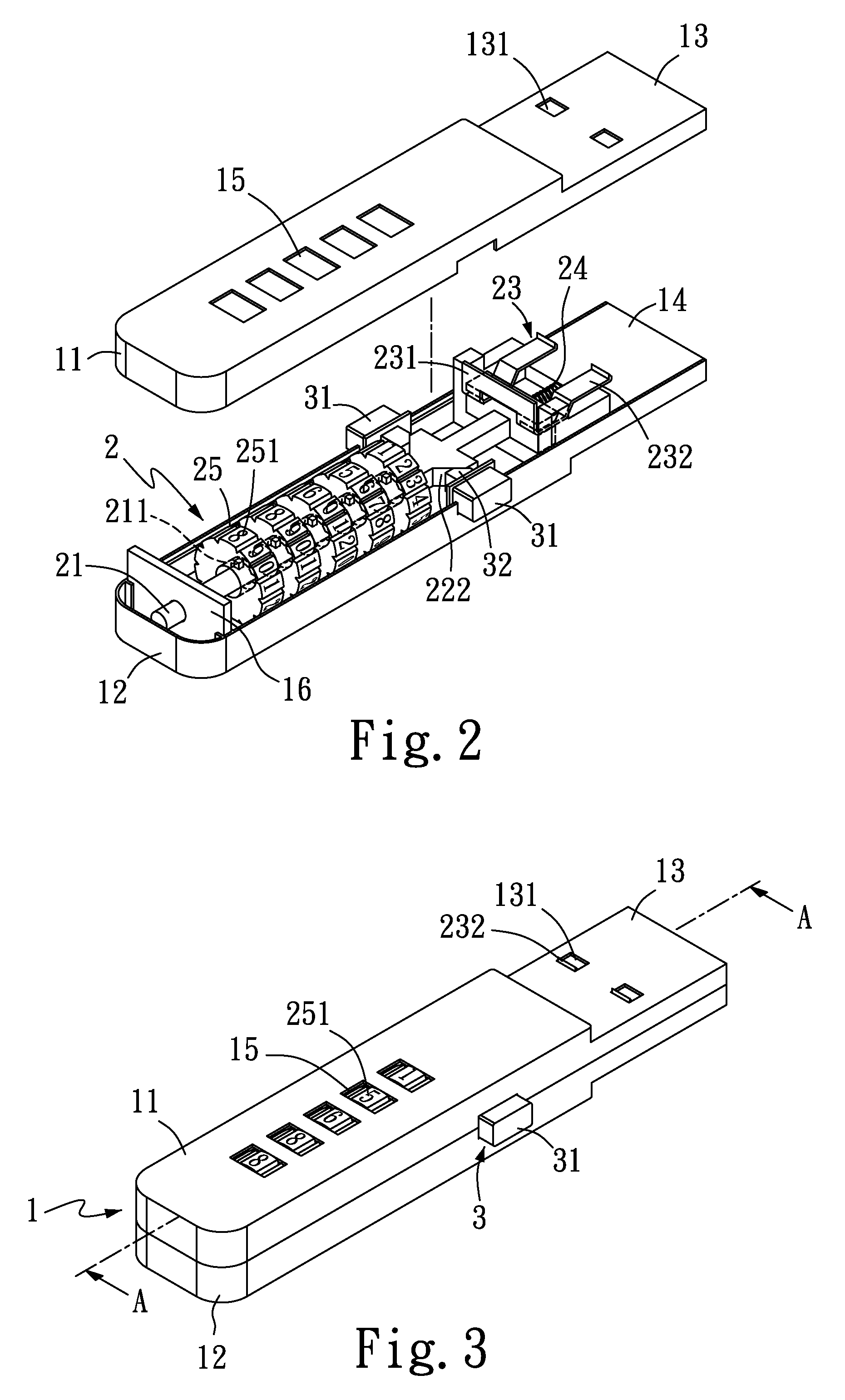

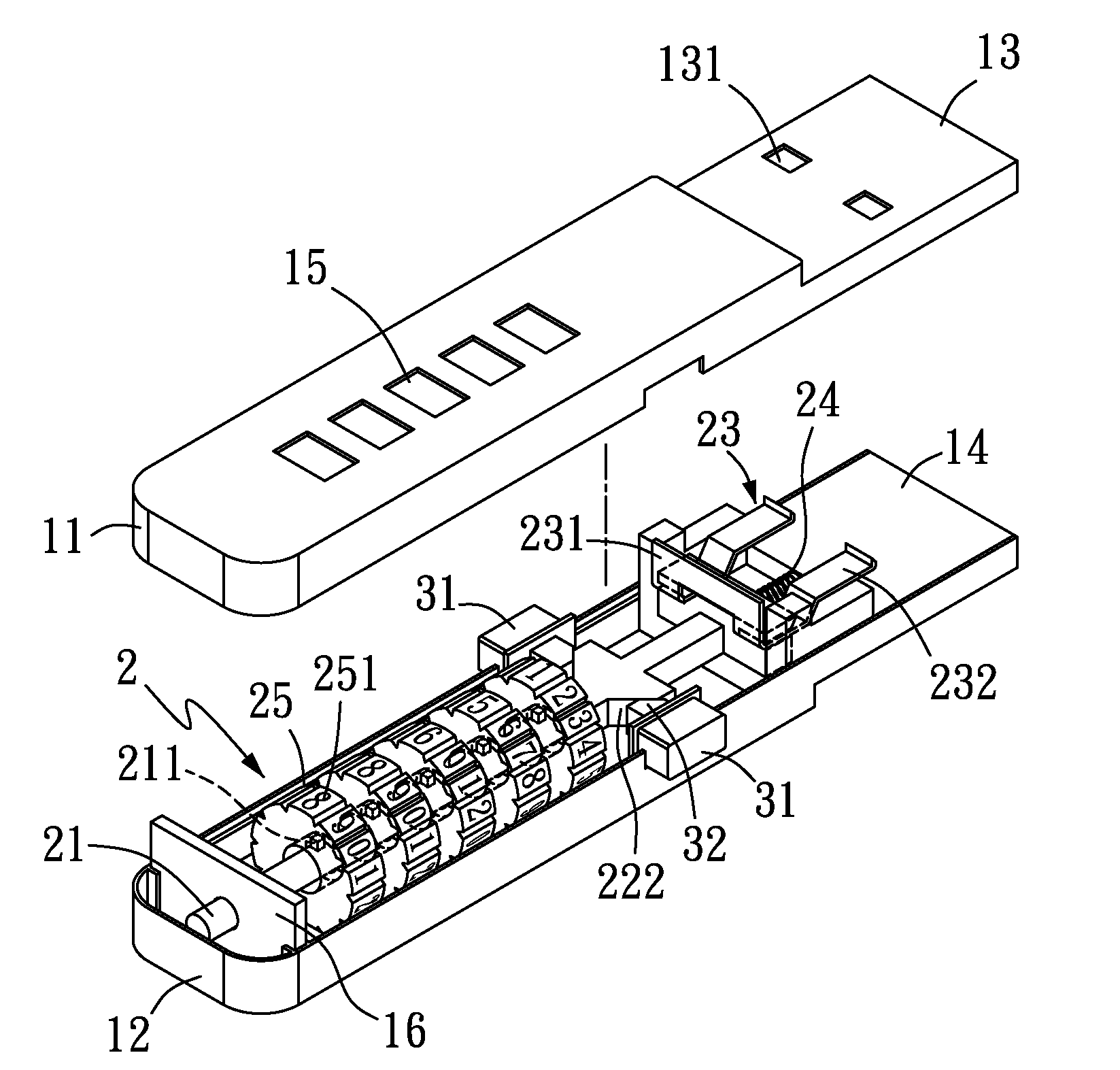

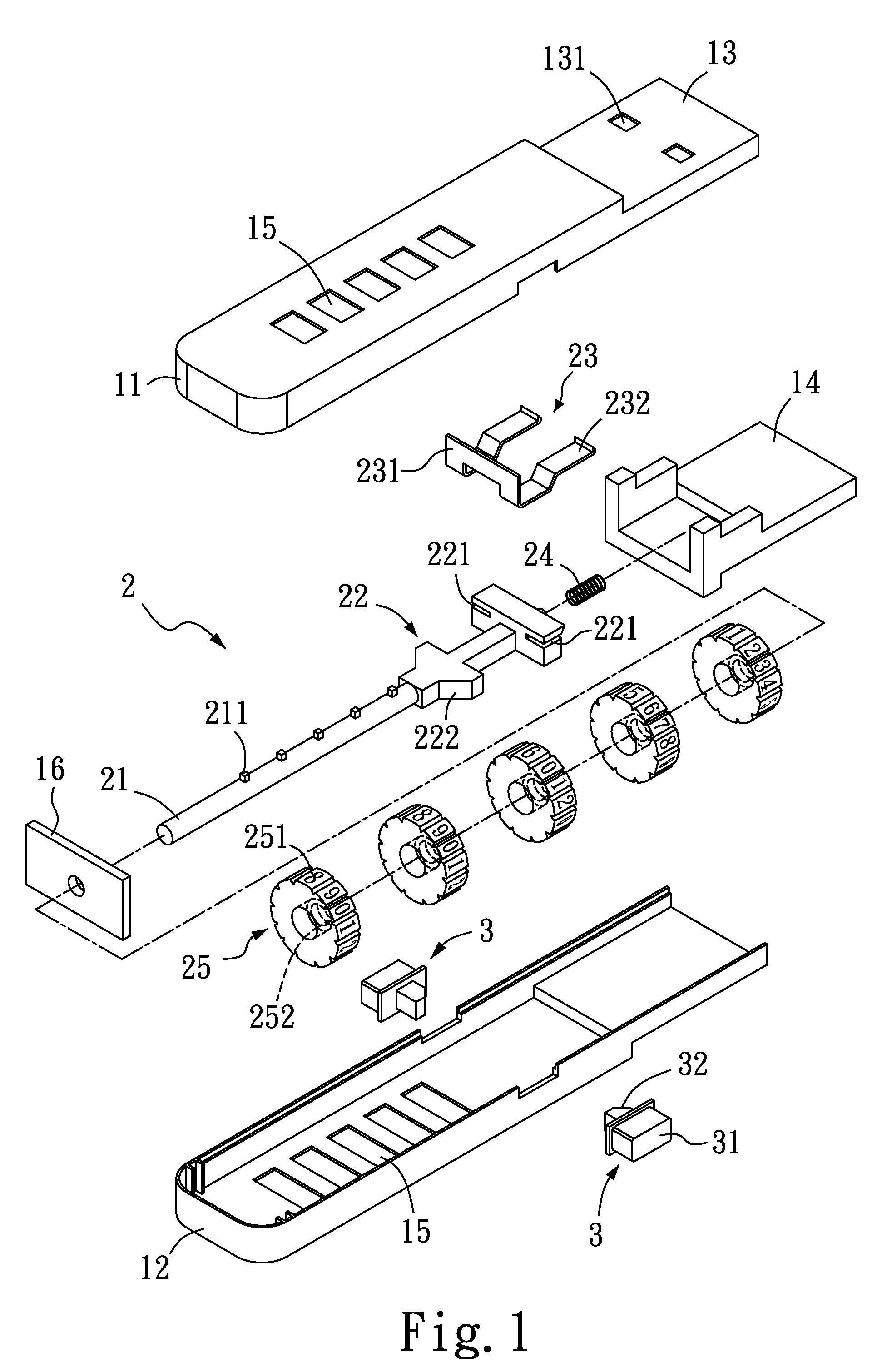

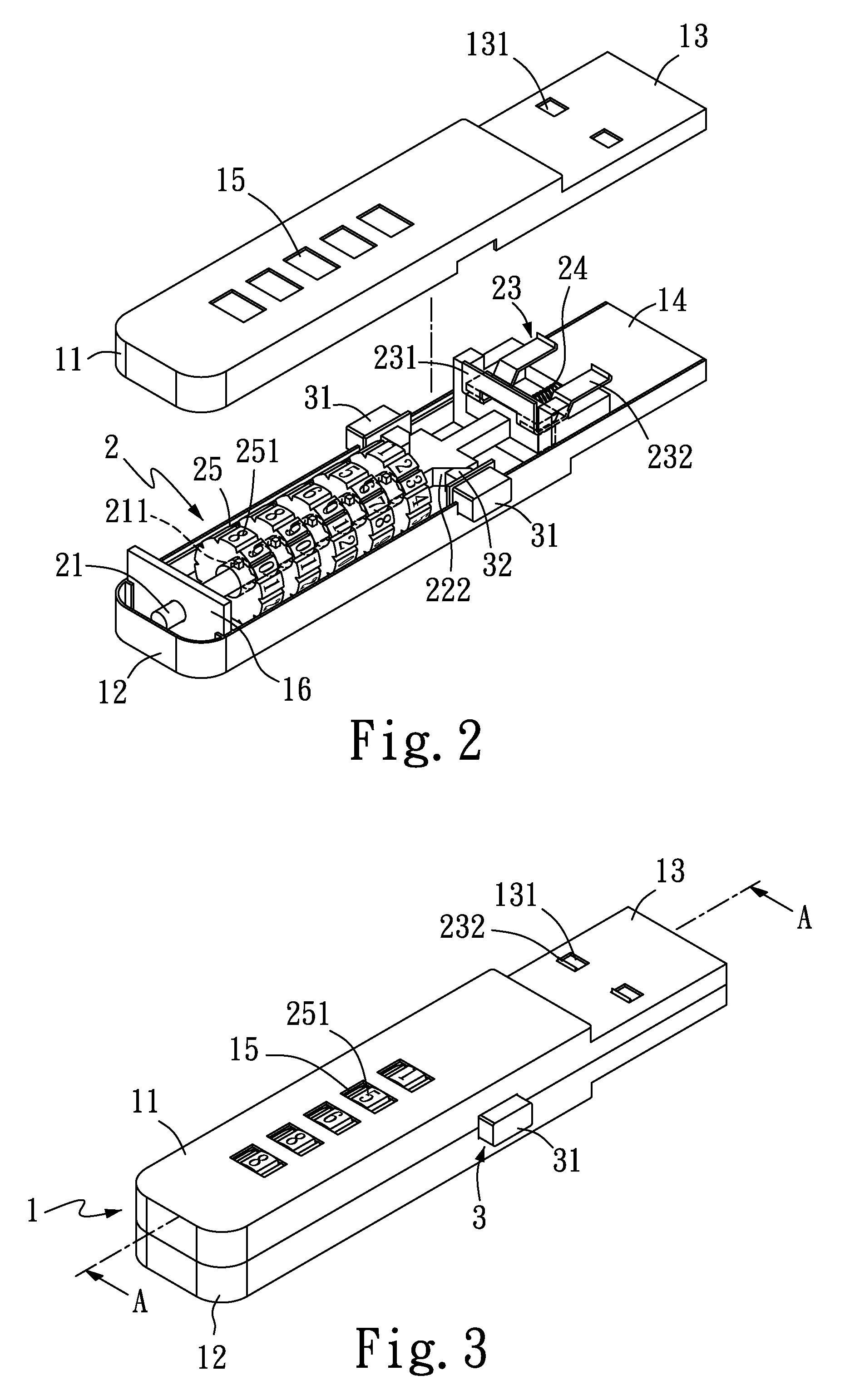

Locking device with changeable combination of numerals for locking a connecting port on a computer

A locking device with changeable combination of numerals includes an enclosure having an insertion section and an axial row of windows; a locking unit arranged in the enclosure and including a rod having axially spaced teeth, a push member connected to one end of the rod, a hooking member connected to the push member with two hooking arms extended into two holes on the insertion section, an elastic member located between the push member and the insertion section, sleeves mounted on the rod, rotating discs fitted on the sleeves corresponding to the windows, and a push disc mounted to another end of the rod; and a push button on the enclosure to interfere with the push member. By pushing the push disc, the rotating discs can be turned to change the combination of numerals set for the locking unit.

Owner:CHEN YEN HSIANG

Robust manual connector for robotic arm end effector

An assembly for releasably connecting an end effector in the form of a robotic tool or component to a robotic arm is disclosed. The connection is manually operated and formed of a first and second joint member including a cylindrical body, a locking collar, and a locking wall extending from the cylindrical body. The locking collar is coaxially aligned with and rotatably connected to the first joint member. The second joint member has a cylindrical mating body and a coupler, and engages the first joint member. The coupler also includes key pins, the pins being engageable in keyed relationship with the locking wall, the coupler and locking collar further includes intervening circumferentially spaced teeth, wherein the collar is rotatable to releasably engage the first joint member with the second joint member.

Owner:RE2

Two handed power driven flossing apparatus with removable head for attachment to power driven toothbrush

InactiveUS7464716B1Easy to usePower economyGum massageTooth cleaningSpacing toothReciprocating motion

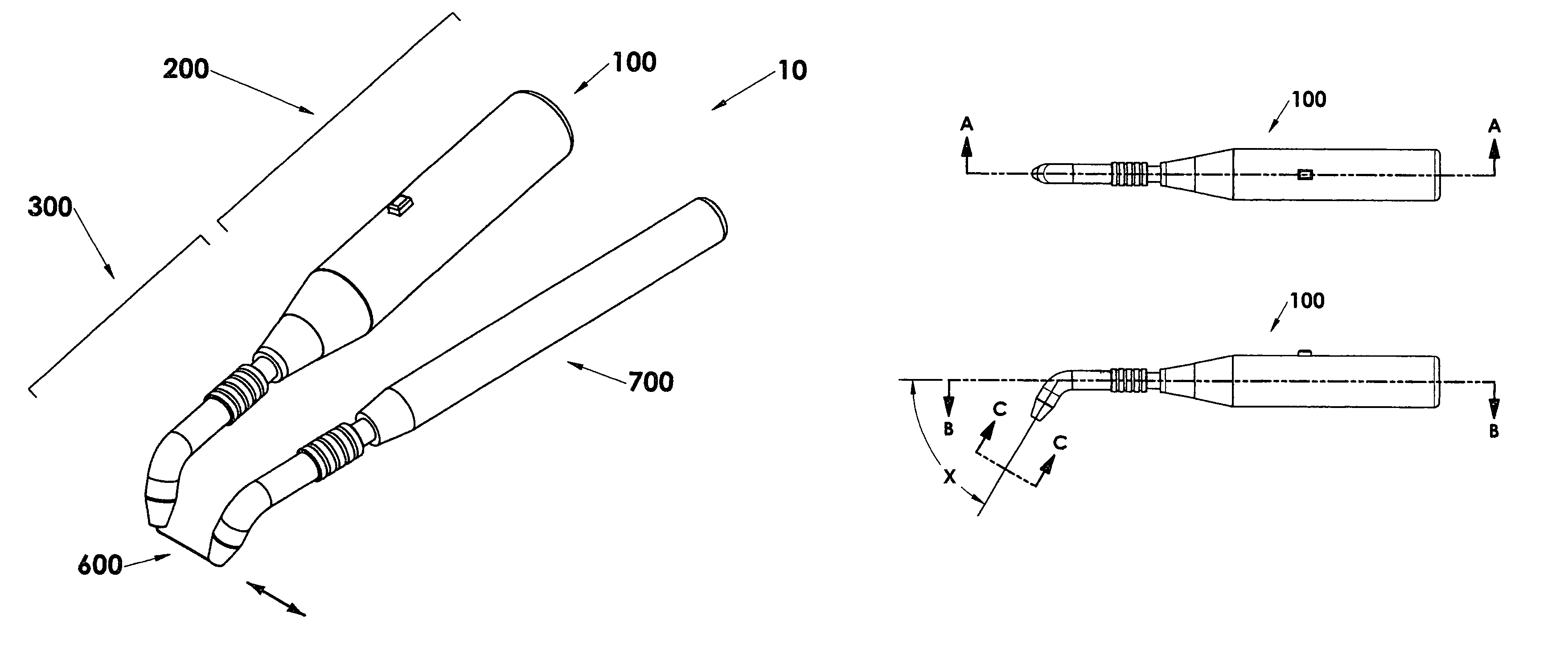

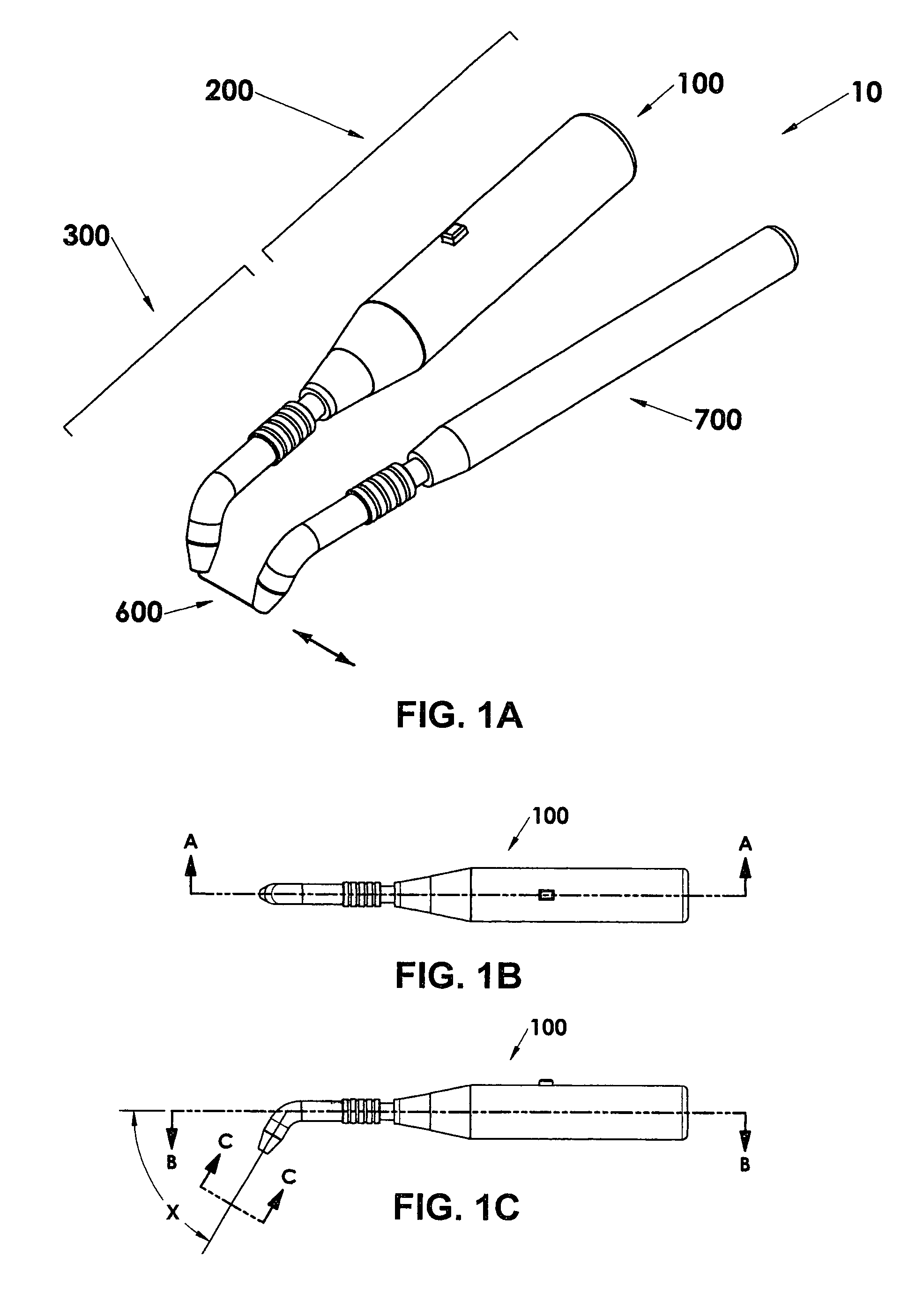

An electric flossing apparatus comprising a flossing head which is detachably connected to a handle containing a reciprocating drive unit, a non-powered second handle to allow for the increased controllability of two-handed powered flossing and a disposable floss assembly that can be easily be attached to or released from the flossing head and handle. The floss is releasably attached to the flossing head in a manner that allows reciprocating motion to be imparted along the length of the floss no matter which direction that the floss exits the end of the flossing head or the shape of the path it takes. By using both hands for flossing the floss may be pulled straight and tensioned to facilitate insertion between tightly spaced teeth and then wrapped around a tooth to facilitate cleaning of the front, sides, and back of each tooth above, near, or just below the gum line. The reciprocating motion is imparted to the floss whenever the floss is tensioned. The intensity of the motion is then controlled by the amount of tension and the “rigidity” of the users grip on the two handles. The drive unit handle assembly may be from an inexpensive commercially available electric toothbrush such as a Crest Spinbrush™.

Owner:NYGREN JR WILLIAM D

Locking device for a connecting port on a computer

A locking device includes an enclosure having an insertion section formed with two holes for inserting into a connecting port on a computer, and a plurality of windows axially spaced on at least one side of the enclosure; a locking unit arranged in the enclosure and including a rod having axially spaced teeth, a push member connected to one end of the rod and having an engaging portion, a hooking member movably connected to the engaging portion with two hooking arms extended into the two holes on the insertion section; an elastic member located between the push member and the fixing seat; a plurality of rotating discs fitted on the rod corresponding to the windows and each having a plurality of numeral areas and a notch; and at least one push button movably arranged on at least one lateral side of the enclosure to interfere with the push member.

Owner:CHEN YEN HSIANG

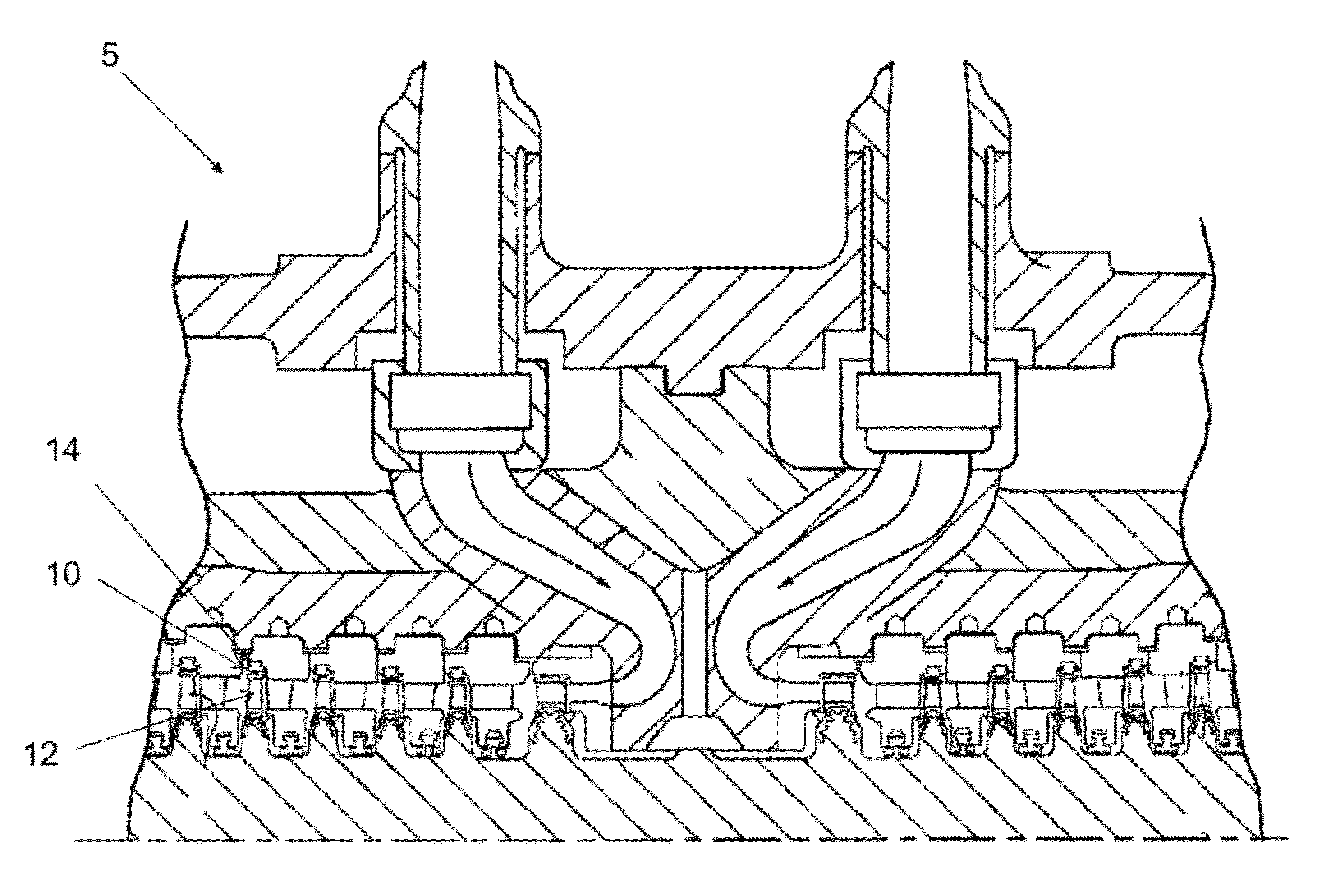

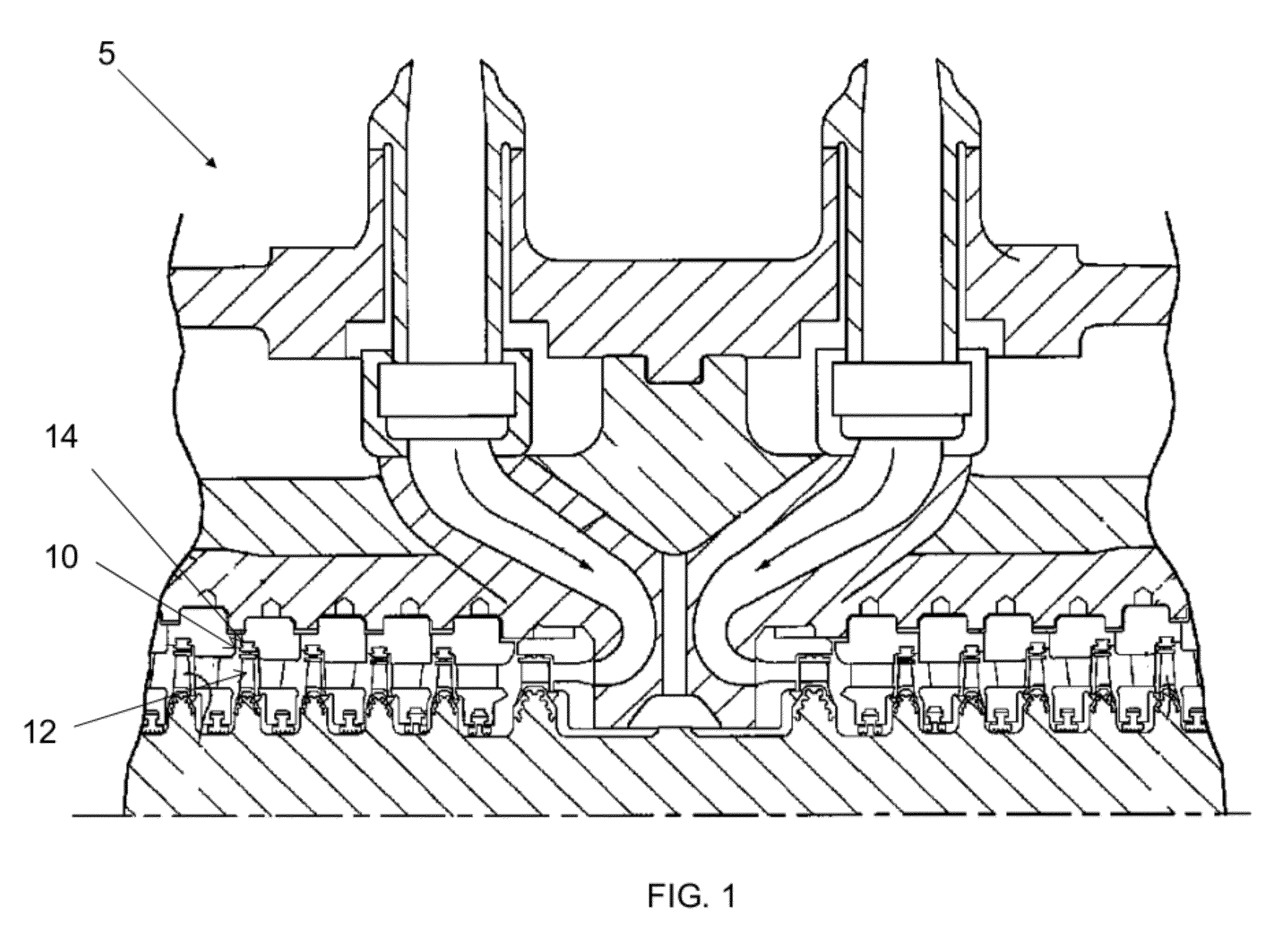

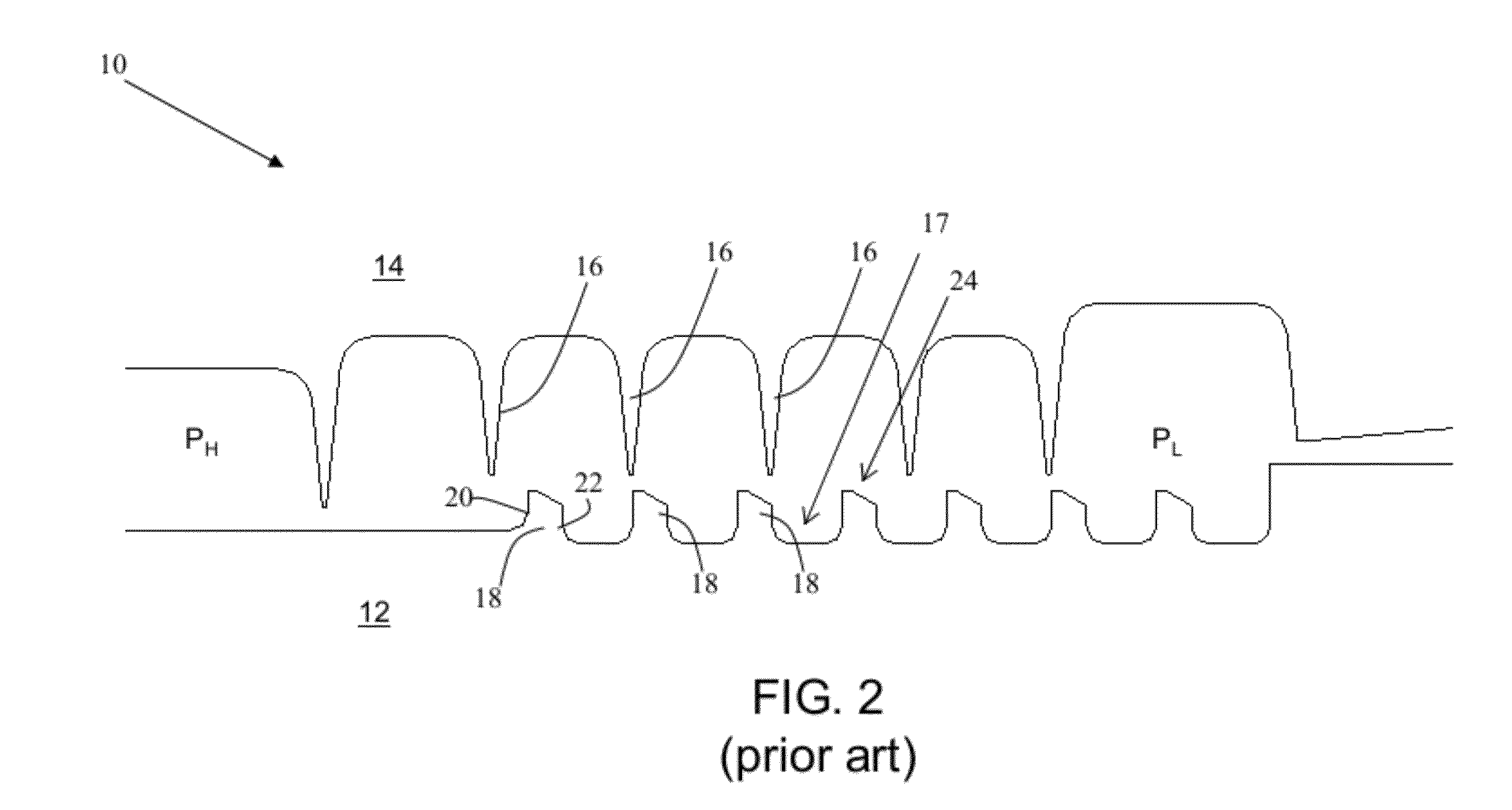

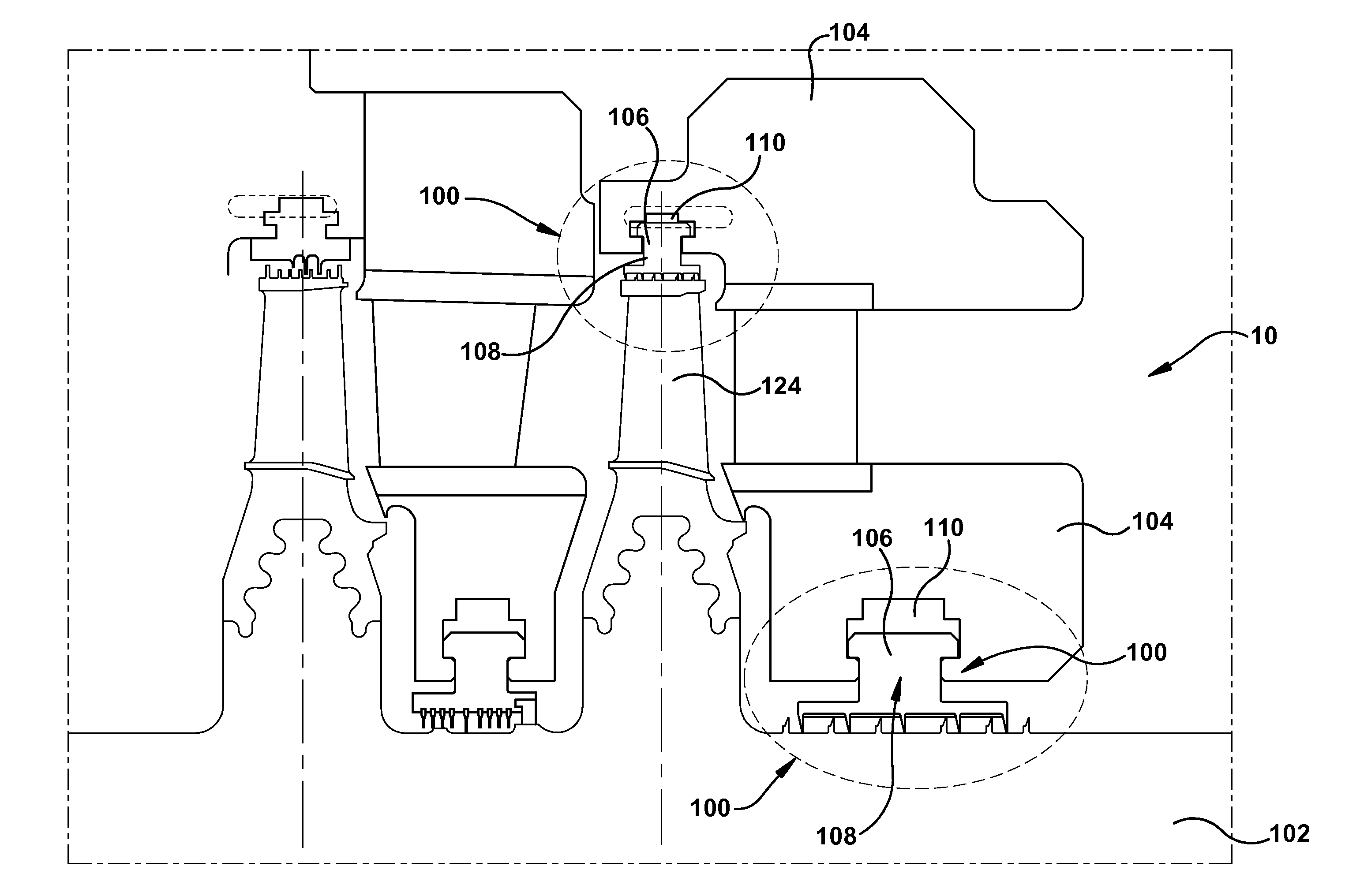

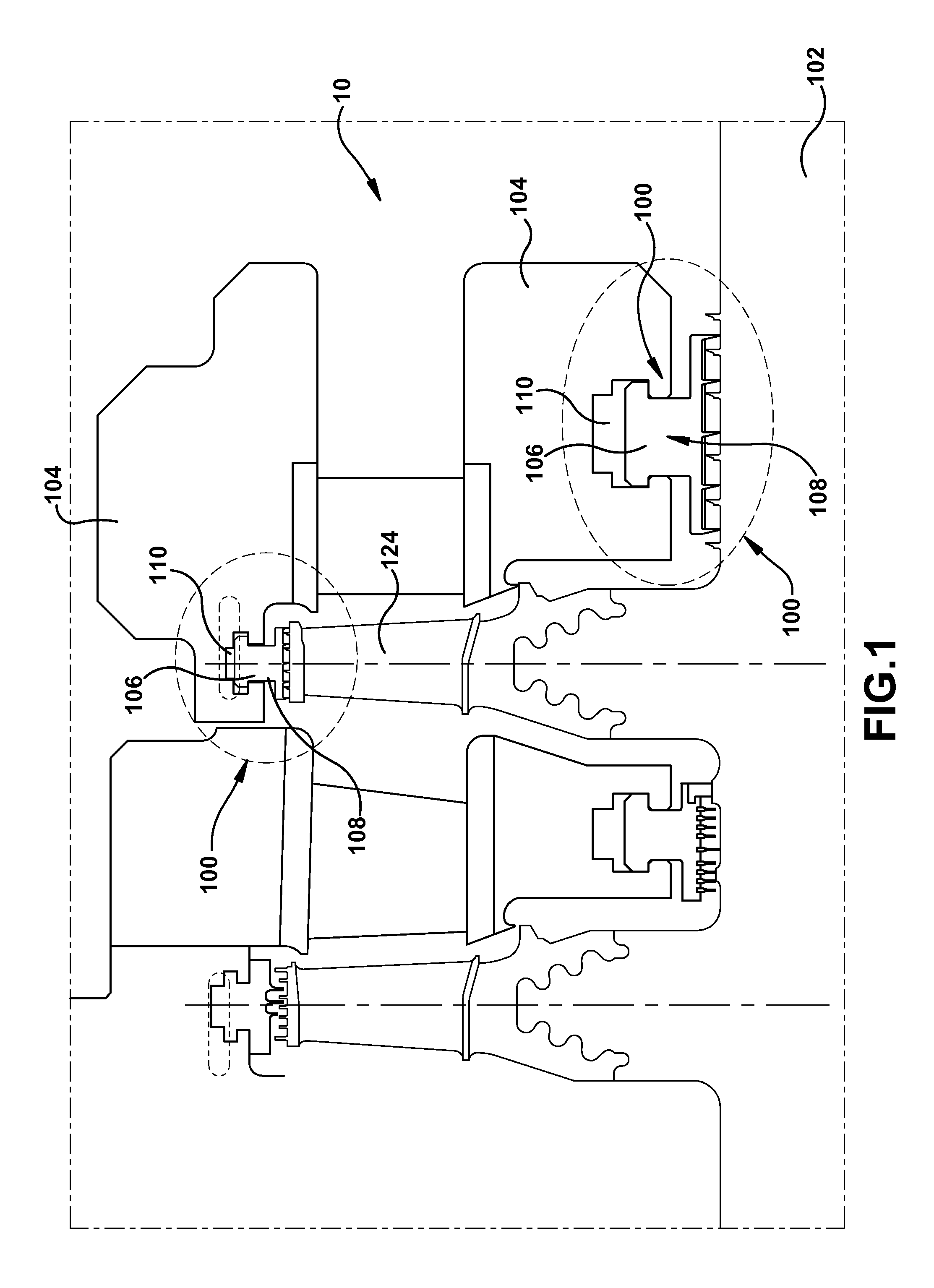

Labyrinth seal system

A labyrinth seal system is disclosed, including a stationary component having a plurality of radially inwardly projecting, axially spaced teeth extending therefrom; and a rotor having a plurality of radially outwardly projecting, axially spaced protrusions, each protrusion having a low pressure side and a high pressure side, wherein the low pressure side of at least one protrusion extends farther in a radial direction than the high pressure side.

Owner:GENERAL ELECTRIC CO

Multi-position aircraft servicing pit lid latch

InactiveUS7261332B1Avoid bad consequencesEasy to close and latchArtificial islandsBuilding locksSpacing toothEngineering

Owner:CAVOTEC ACQUISITION US INC

Helical teeth elliptic gear as well as method for three-dimensional model-building accurately and entity shaping producing thereof

The invention relates to an elliptic gear with skewed teeth and a manufacturing method for a three-dimensional precise modeling and an entity shaping thereof, wherein in the method, by simulating the principle that a helical rack is meshed with the elliptic gear with skewed teeth and utilizing that a cutter pitch line plane of a standard normal surface parameter helical rack is always tangent to and keeps a relative generating motion of the pure rolling against a pitch curve cylindrical surface of the skewed tooth elliptic gear blank, a three-dimensional design software precisely shows a space tooth profile curved surface of the elliptic gear with skewed teeth by a helical tooth surface of the helical rack, thereby directly obtaining a three-dimensional model of the elliptic gear with skewed teeth; moreover, the shaping manufacturing entity of the elliptic gear with skewed teeth can be further obtained by utilizing the quick shaping technology. The method of the invention successfully avoids design bottlenecks of the deduction of the complex space curved surface equation of the tooth profile of the elliptic gear with skewed teeth and the corresponding three-dimensional modeling of the space curved surface, and opens up a new shortcut for the precise design and manufacturing of the elliptic gear with skewed teeth.

Owner:DONGHUA UNIV

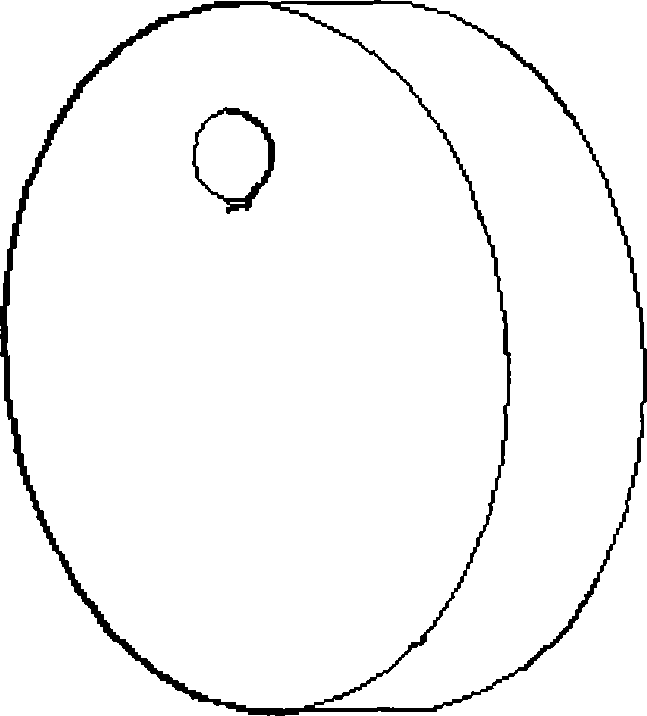

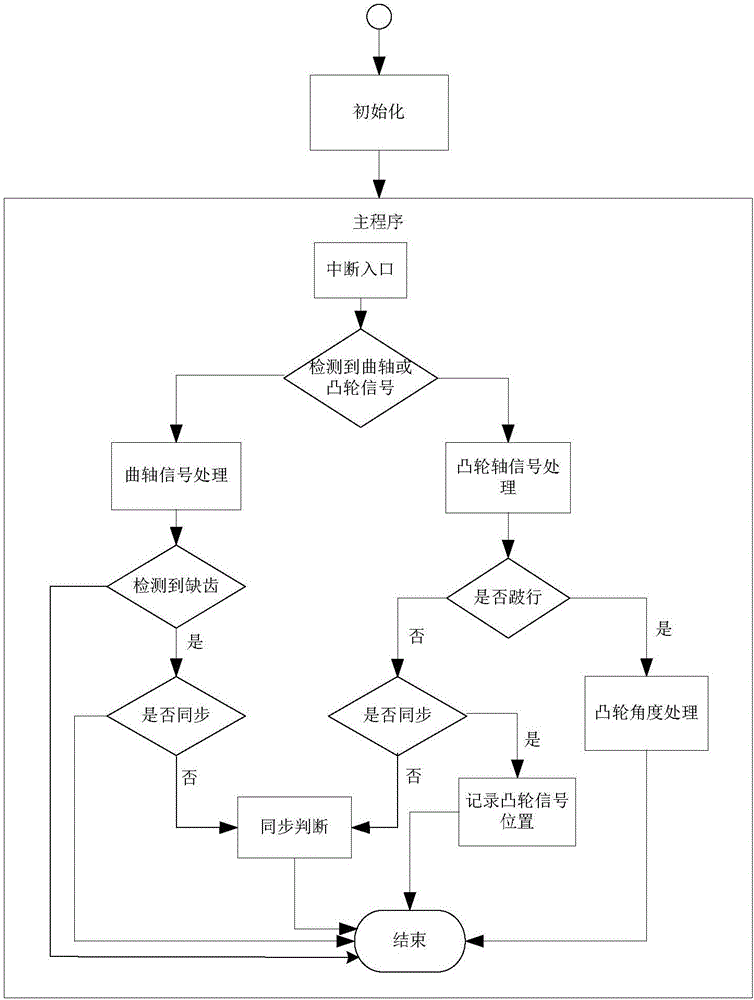

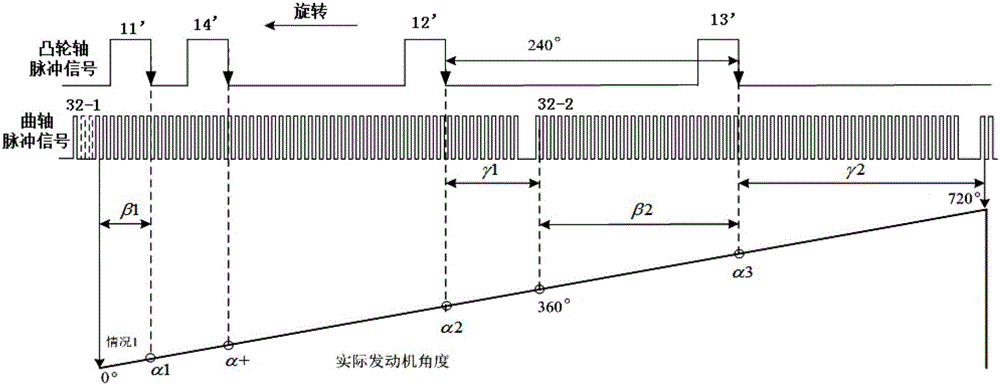

Phase detection device and system of engine

InactiveCN105840327AReduce startup timeImprove performanceElectrical controlMachines/enginesSpacing toothStart time

The invention relates to a phase detection device of an engine. A cam shaft signal panel of the device is fixedly installed on a cam shaft. A crankshaft signal panel is fixedly installed on a crankshaft. Three normal teeth and an extra tooth are distributed at the edge of the cam shaft signal panel at equal intervals, and the extra tooth is located between two of the three normal teeth. N continuous equally-spaced teeth and a missing tooth are distributed at the edge of the crankshaft signal panel. A first Hall sensor is fixed to the edge of the cam shaft signal panel, and a second Hall sensor is fixed to the edge of the crankshaft signal panel. A cam shaft pulse signal which is generated by the first Hall sensor and represents cam shaft phase information and a crankshaft pulse signal which is generated by the second Hall sensor and represents crankshaft phase information are transmitted to an engine phase detection module. The engine phase detection module carries out analysis treatment on the cam shaft pulse signal and the crankshaft pulse signal so that engine phase data can be obtained. By means of the phase detection device of the engine, the start time of the engine is shortened, performance of an electric control system of the engine is improved, and the robustness of the electric control system is enhanced.

Owner:CHINA FIRST AUTOMOBILE

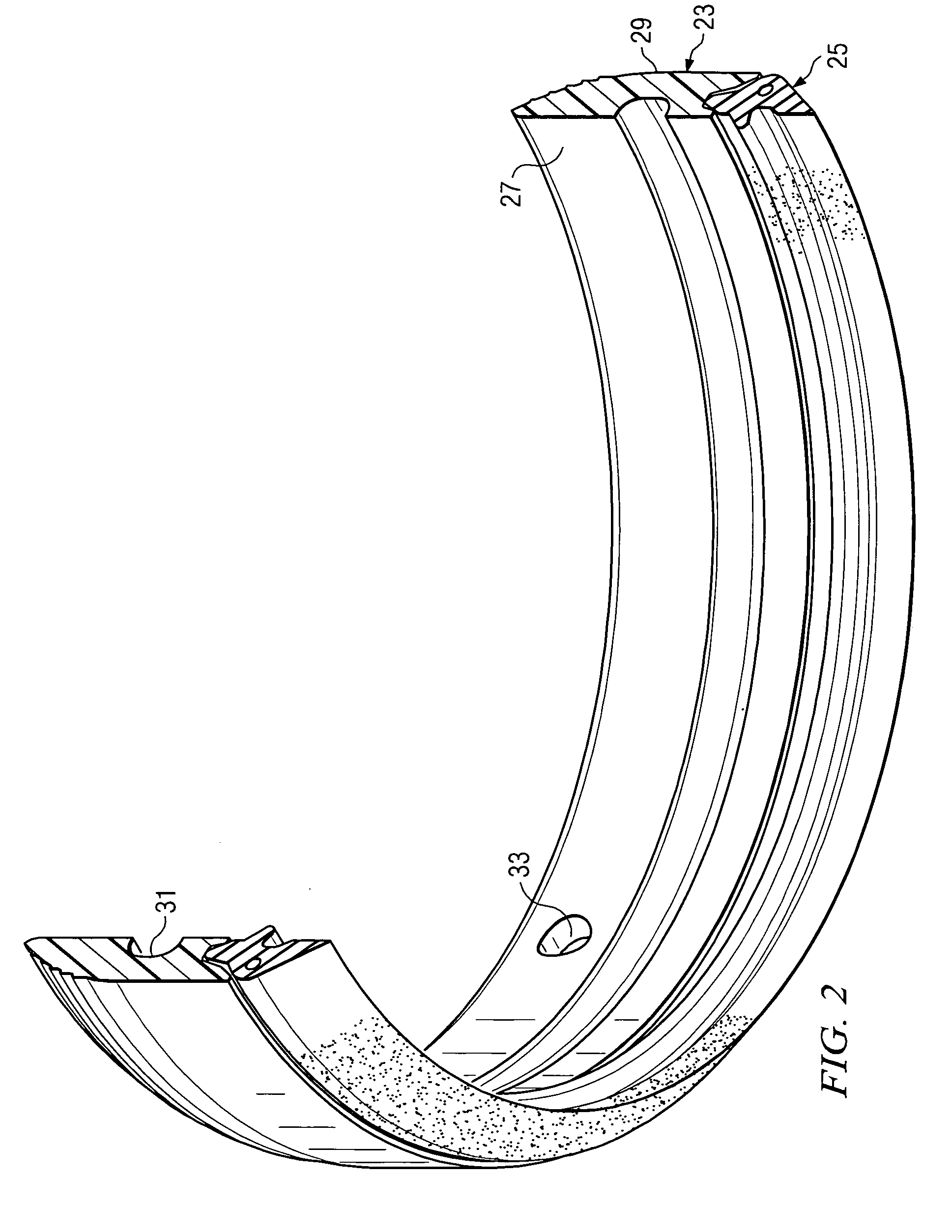

Restrained pipe joining system for plastic pipe

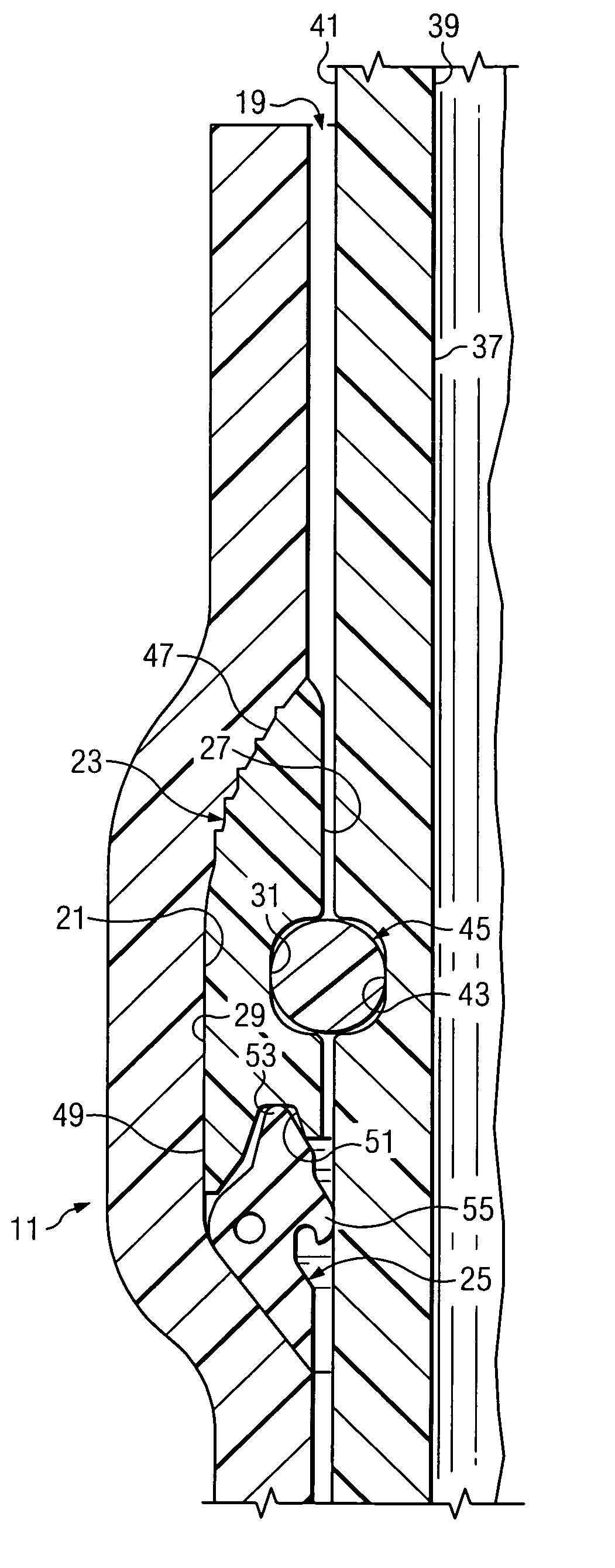

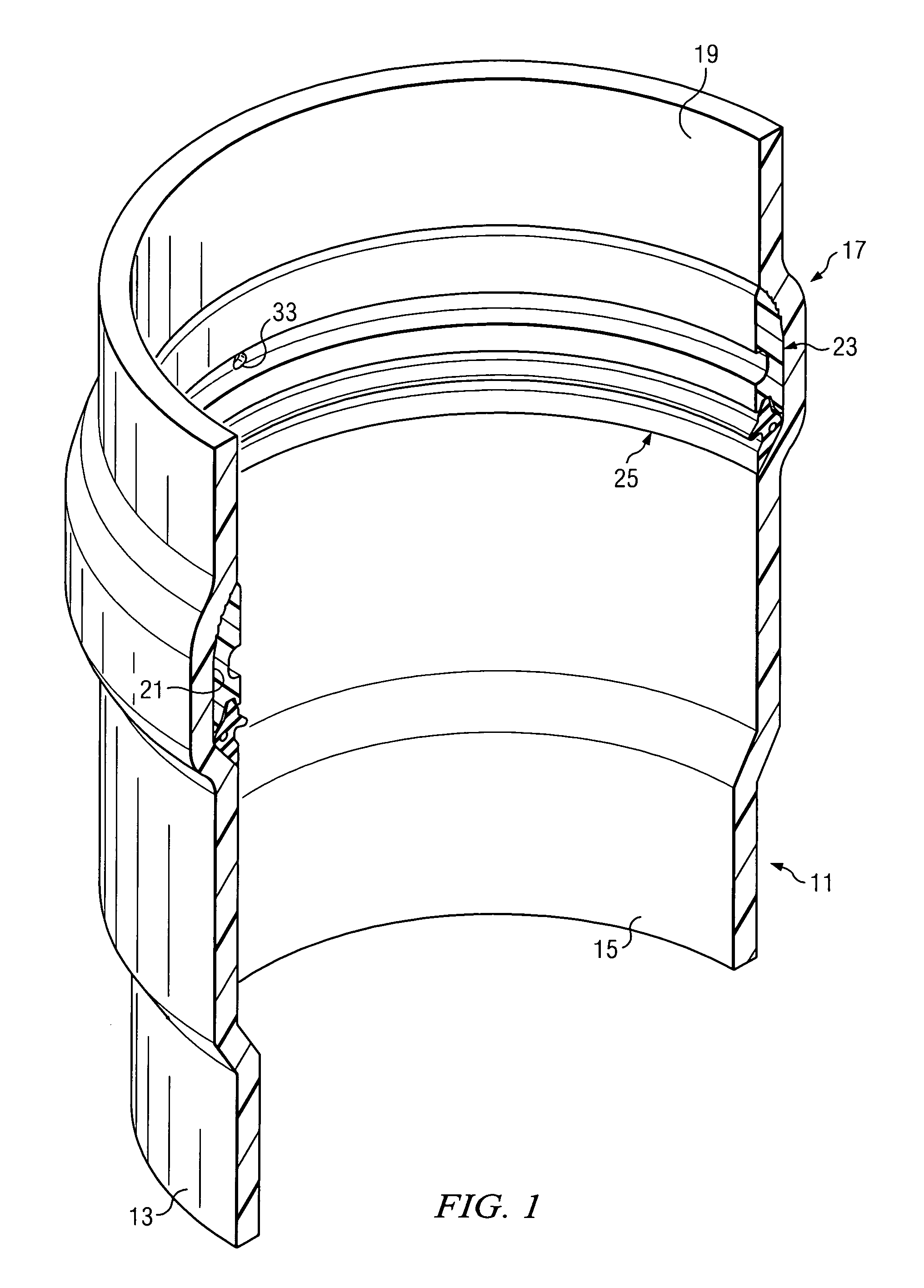

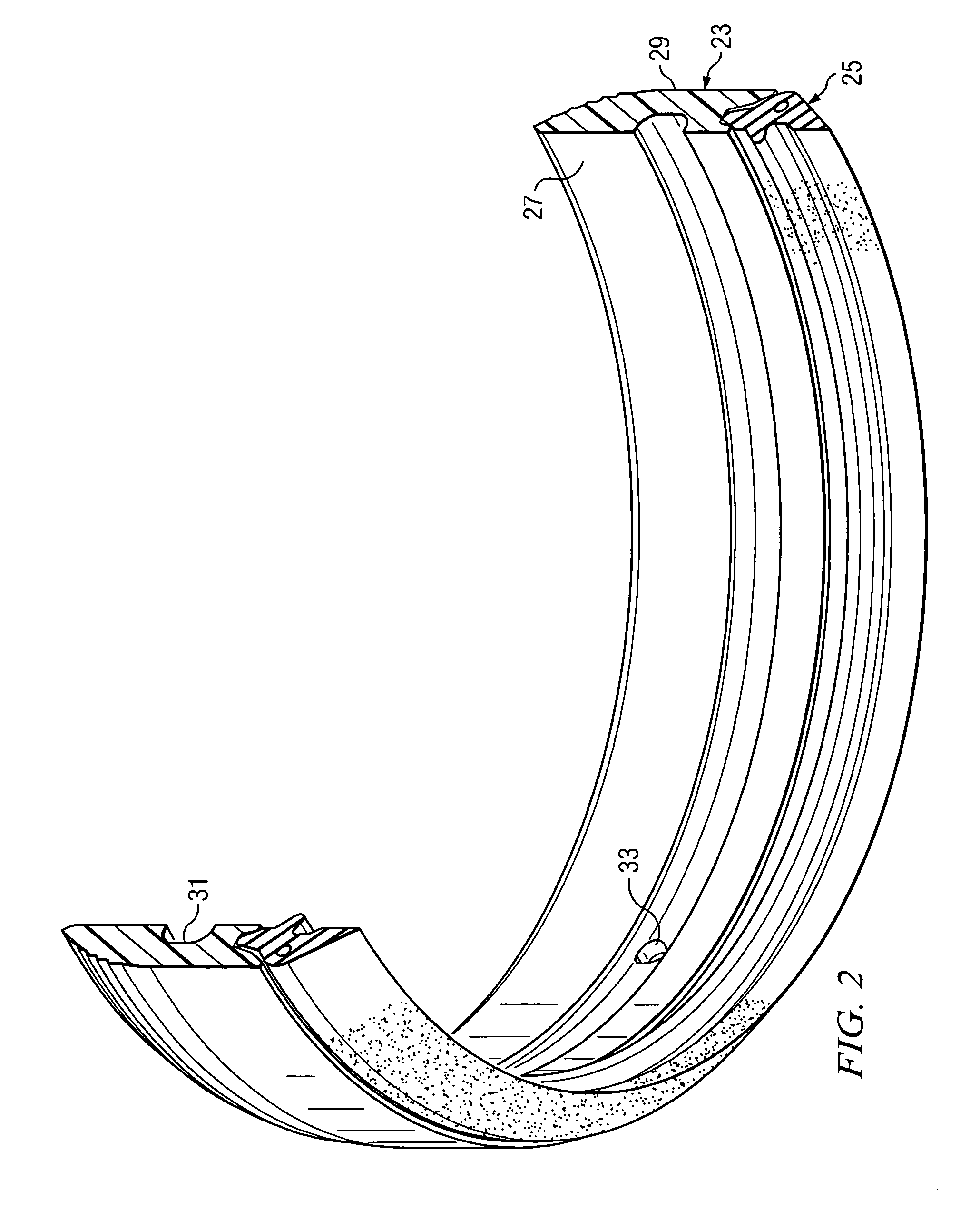

ActiveUS20090152863A1Dimensional precision can be increasedConveniently formedSleeve/socket jointsFluid pressure sealed jointsSpacing toothPlastic pipework

A restrained pipe joining system is shown comprising male and female ends each having aligned circumferential grooves which form a canal for passage of a locking key strap. During manufacture, the female belled end is sequentially formed over a Rieber style gasket and then over a ring shaped casing member having an inner circumferential groove formed on its inner circumferential surface. Preferably, the ring shaped casing has circumferentially spaced teeth that act as a pipe stop in cooperation with an outer circumferential groove on the male spigot to index the pipes to be coupled.

Owner:S & B TECHN PRODS

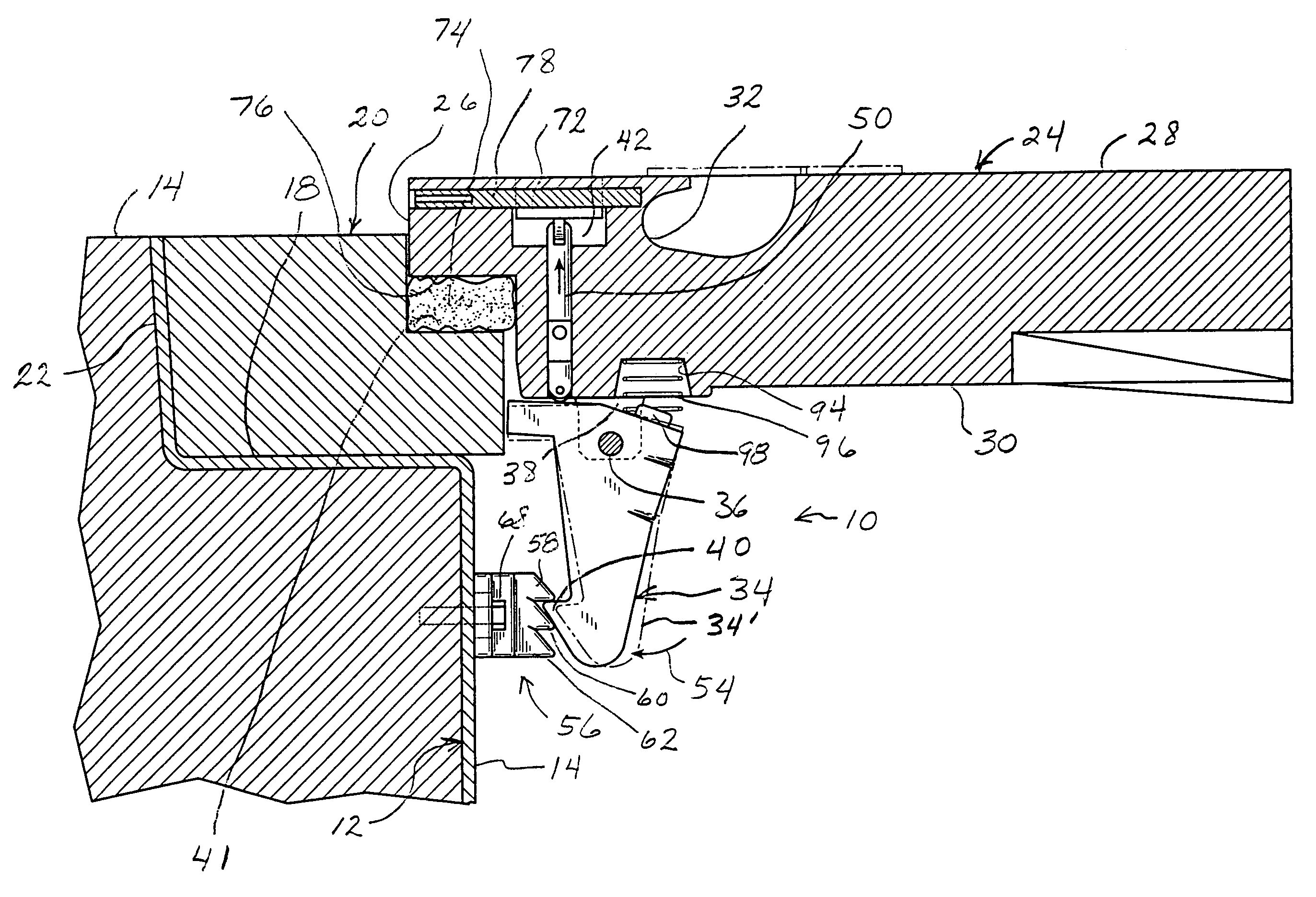

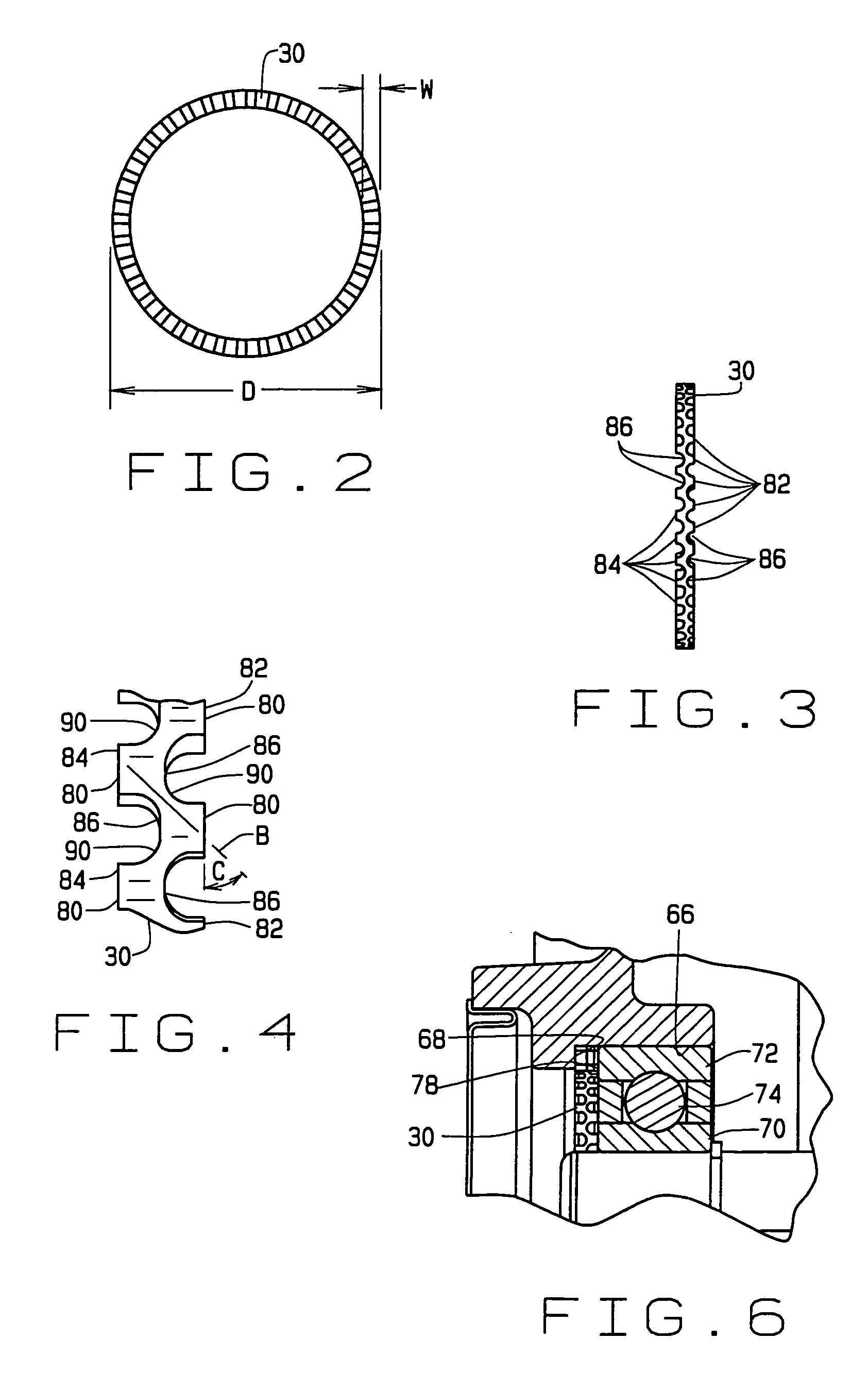

Swirl interruption seal teeth for seal assembly

ActiveUS20140072415A1Reducing steam forceLittle strengthEngine sealsEngine manufactureSpacing toothEngineering

A seal assembly for sealing between a rotating component and a stationary component in a turbomachine. The seal assembly includes a plurality of radially inwardly projecting, axially spaced teeth extending from the stationary component, wherein at least one of the plurality of teeth has at least one axially extending hole therethrough. Axial flow of an operating fluid through the holes acts as an air-curtain to interrupt swirl flow in a seal cavity, therefore reducing steam force that could act to destabilize rotordynamics.

Owner:GENERAL ELECTRIC CO

Restrained pipe joining system for plastic pipe

ActiveUS7845686B2Conveniently formedSleeve/socket jointsFluid pressure sealed jointsSpacing toothPlastic pipework

A restrained pipe joining system is shown comprising male and female ends each having aligned circumferential grooves which form a canal for passage of a locking key strap. During manufacture, the female belled end is sequentially formed over a Rieber style gasket and then over a ring shaped casing member having an inner circumferential groove formed on its inner circumferential surface. Preferably, the ring shaped casing has circumferentially spaced teeth that act as a pipe stop in cooperation with an outer circumferential groove on the male spigot to index the pipes to be coupled.

Owner:S & B TECHN PRODS

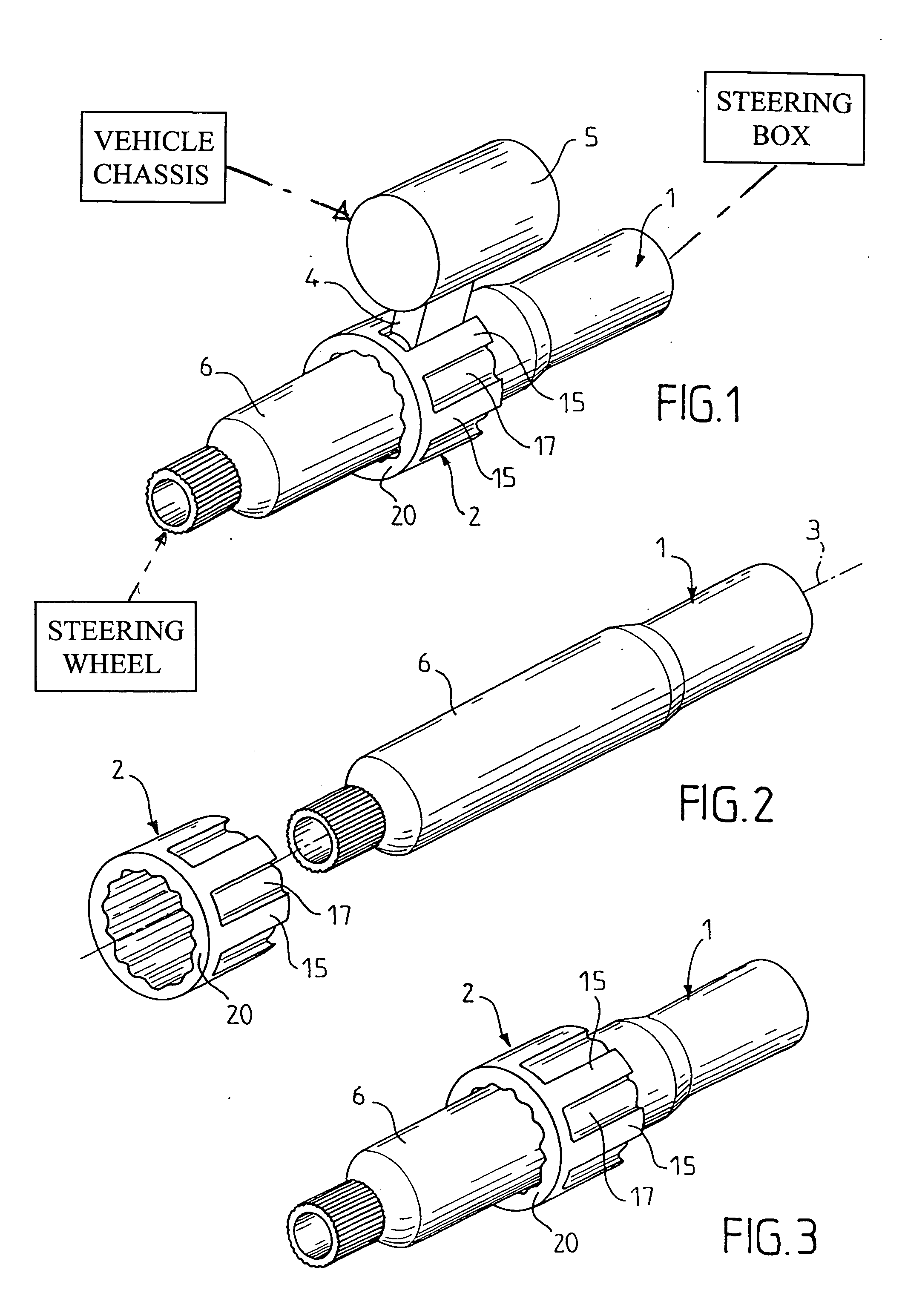

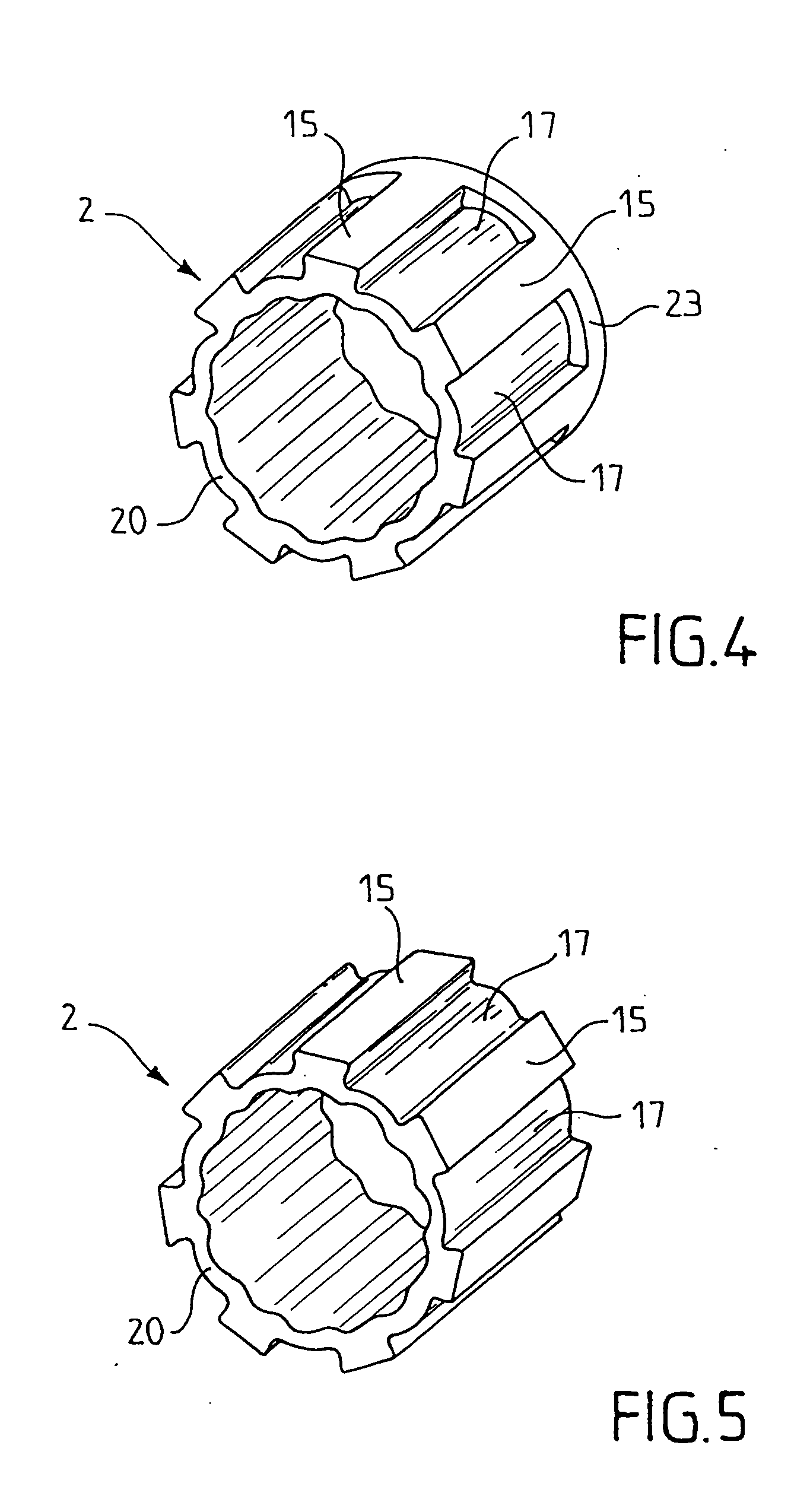

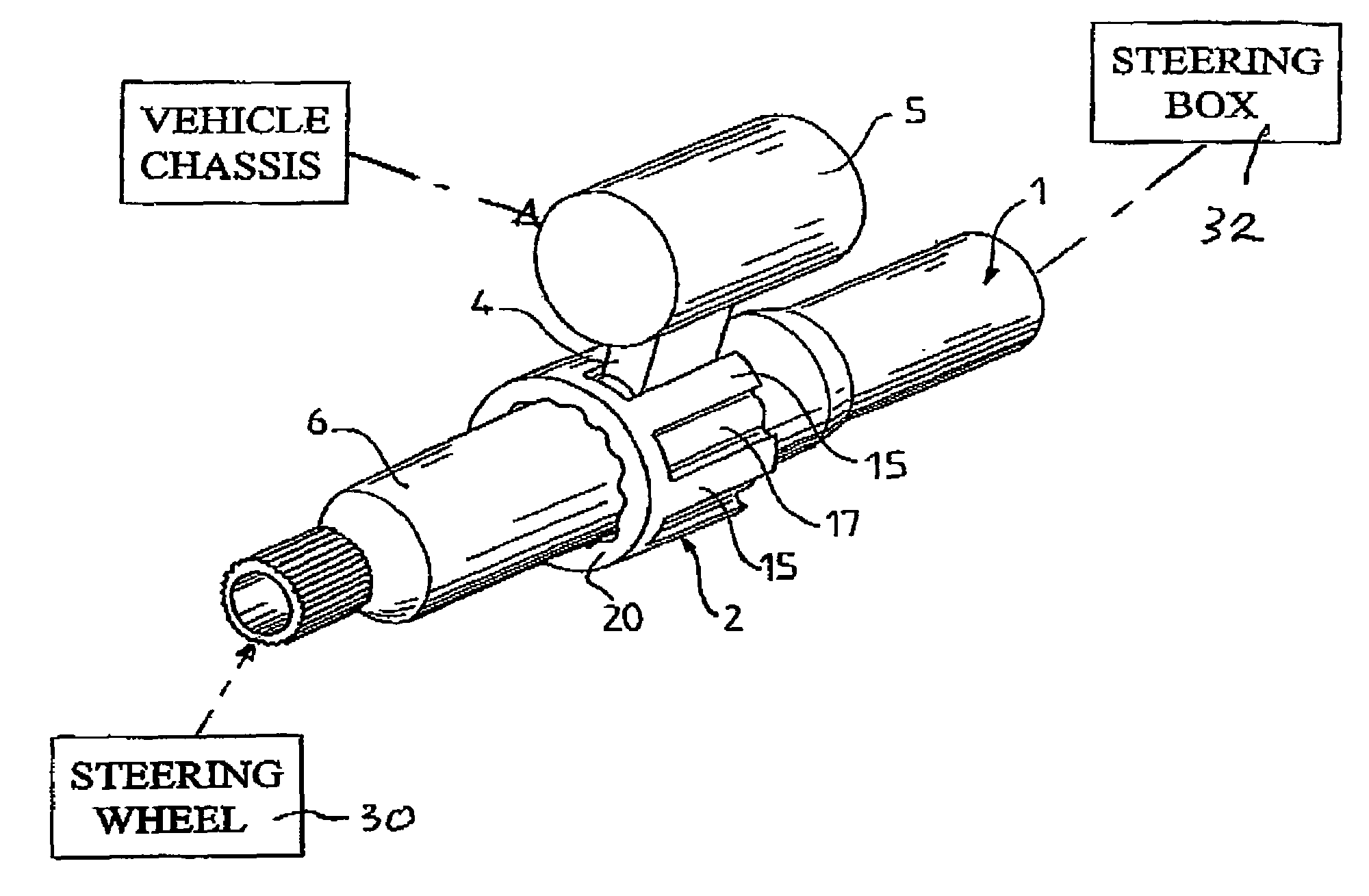

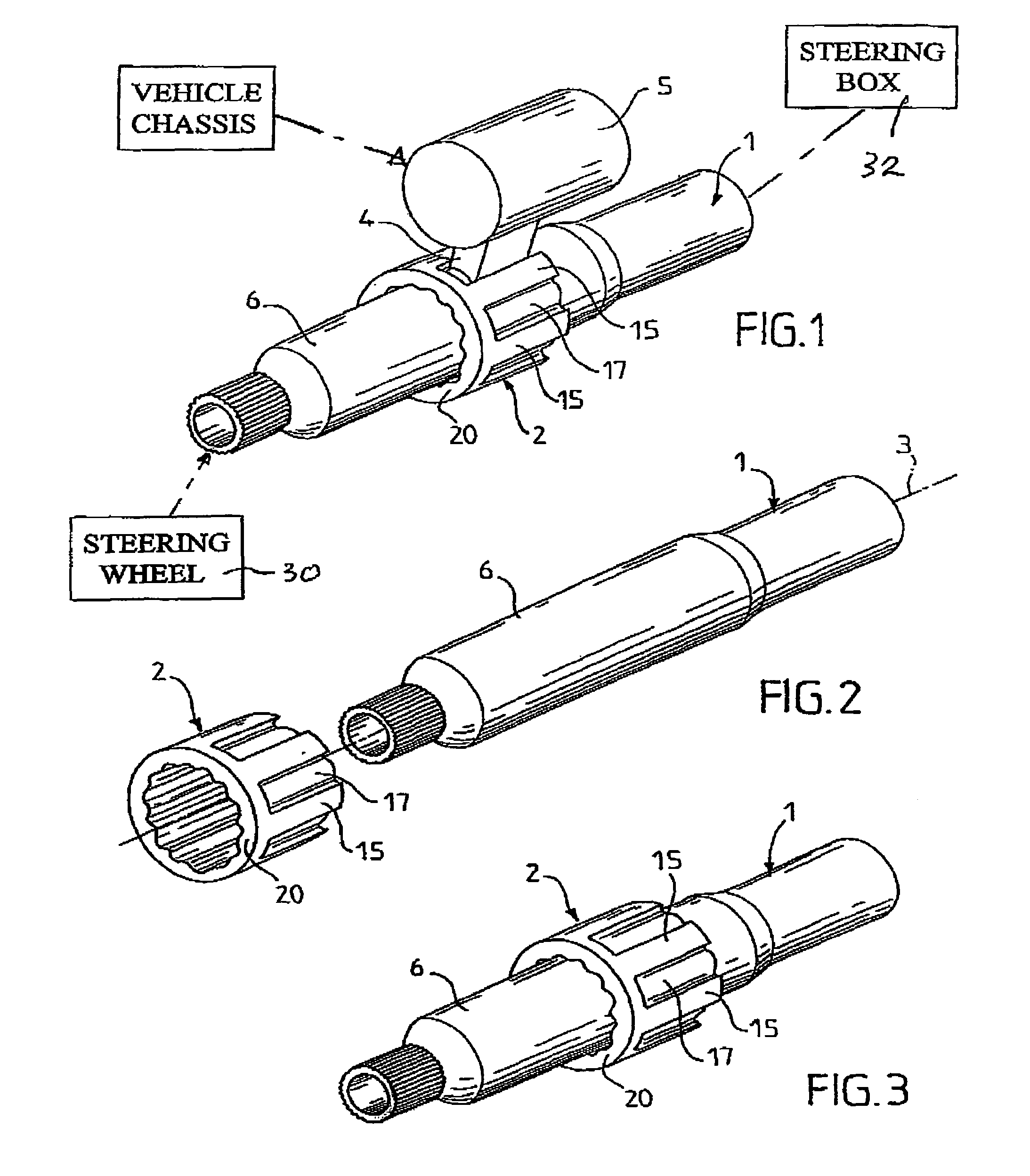

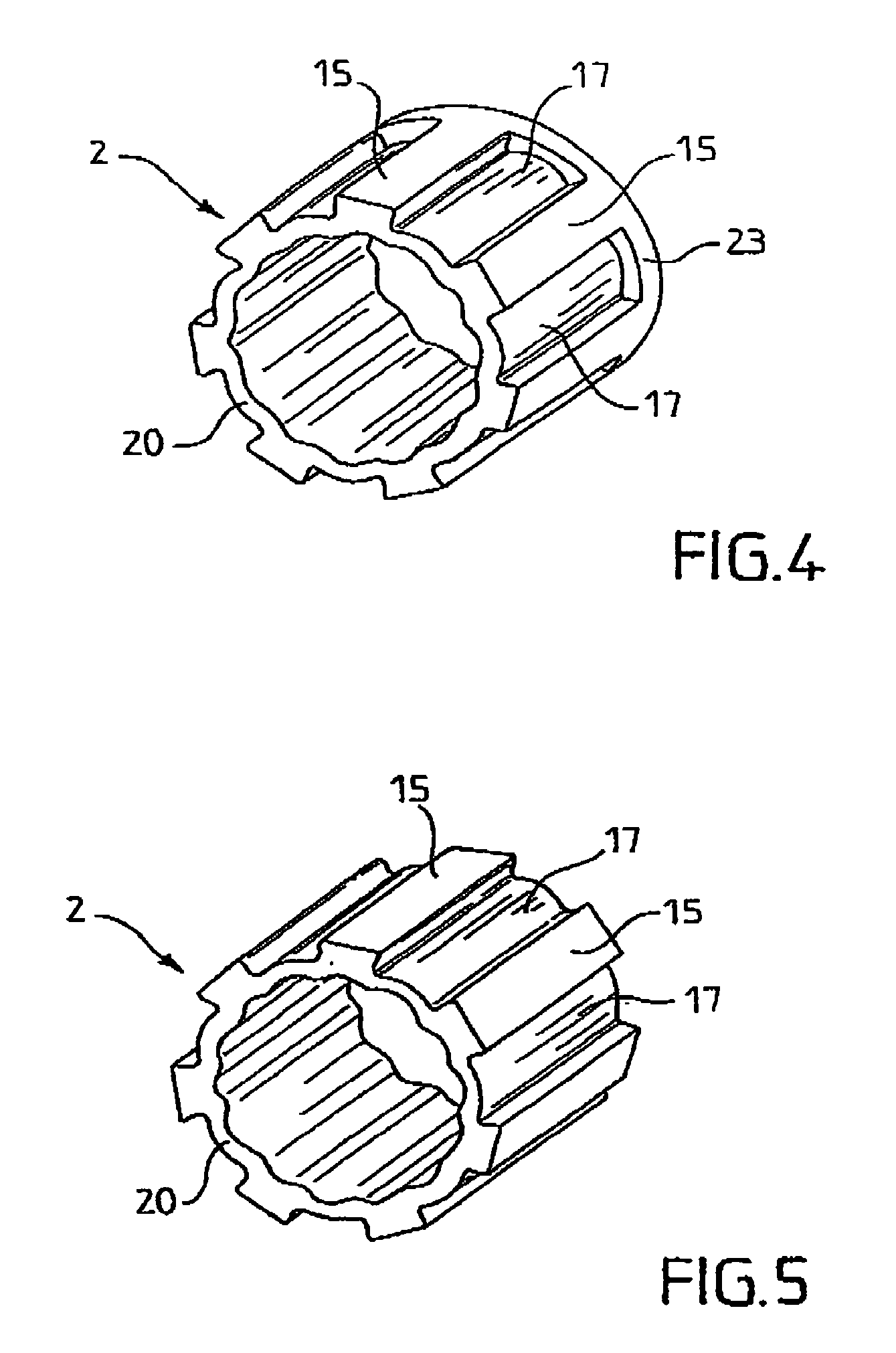

Anti-theft locking means for a vehicle steering shaft

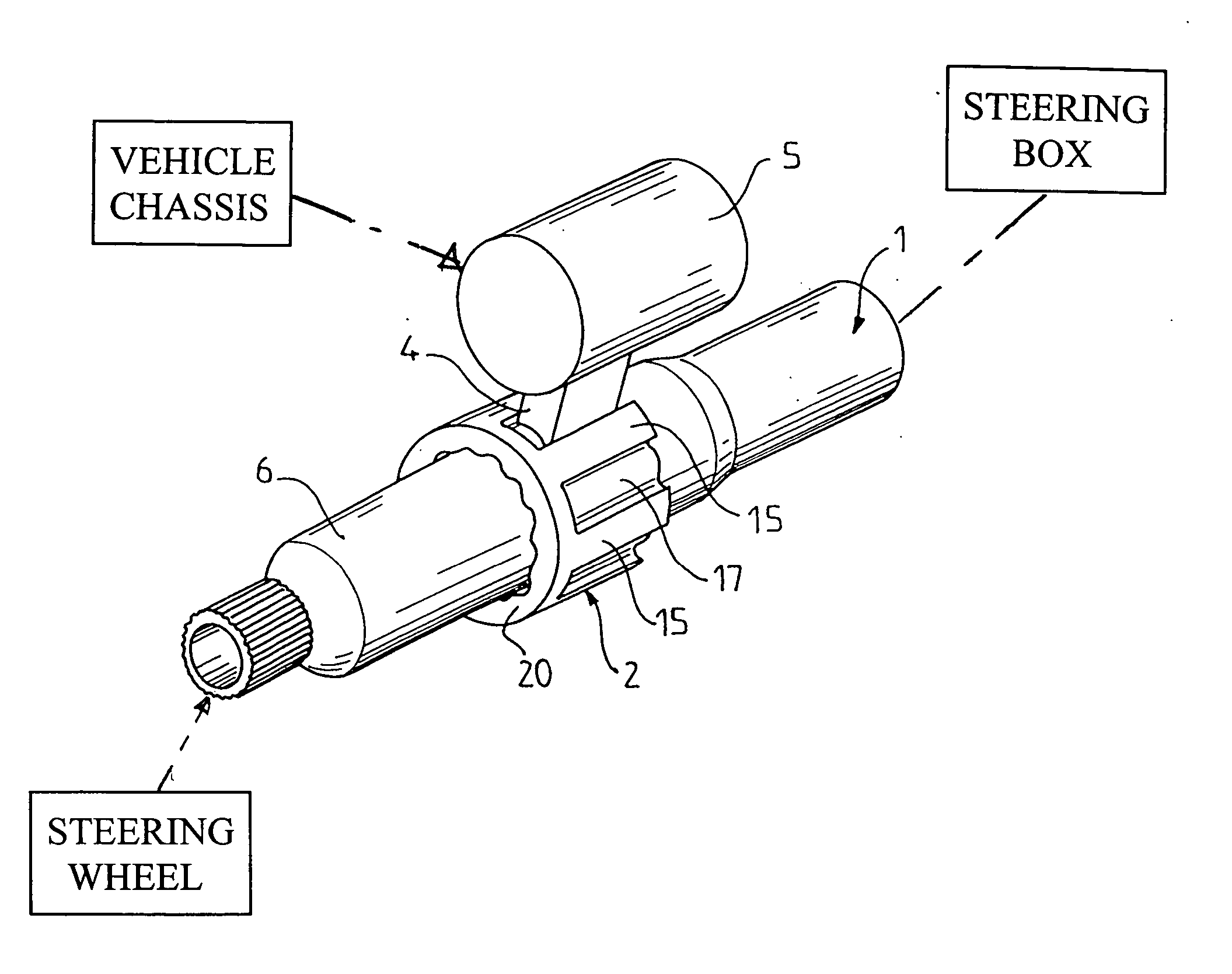

ActiveUS20050092044A1Avoid deformationAvoid destructionYielding couplingBuilding locksSpacing toothEngineering

Owner:NACAM FRANCE S

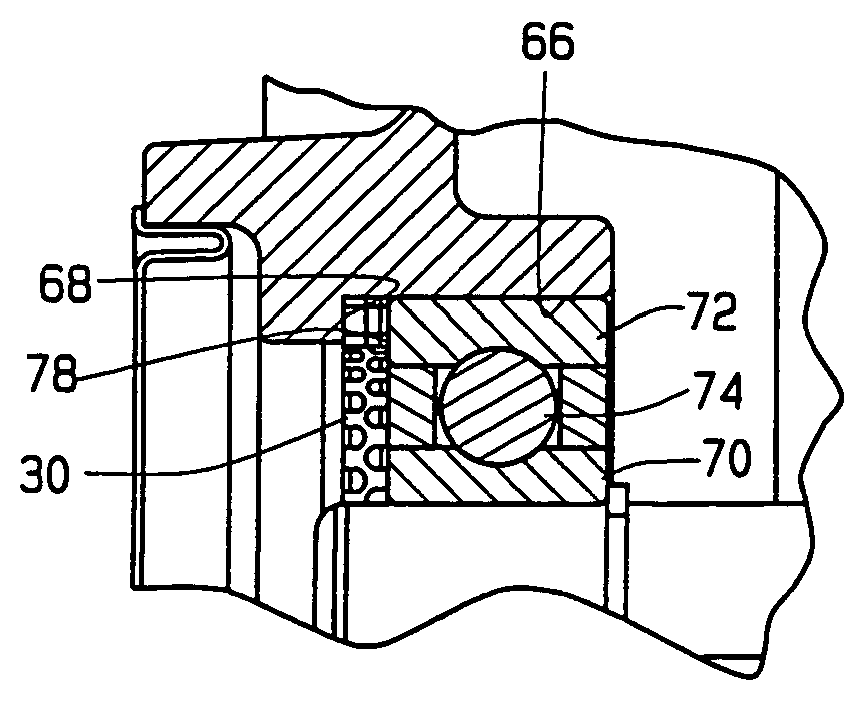

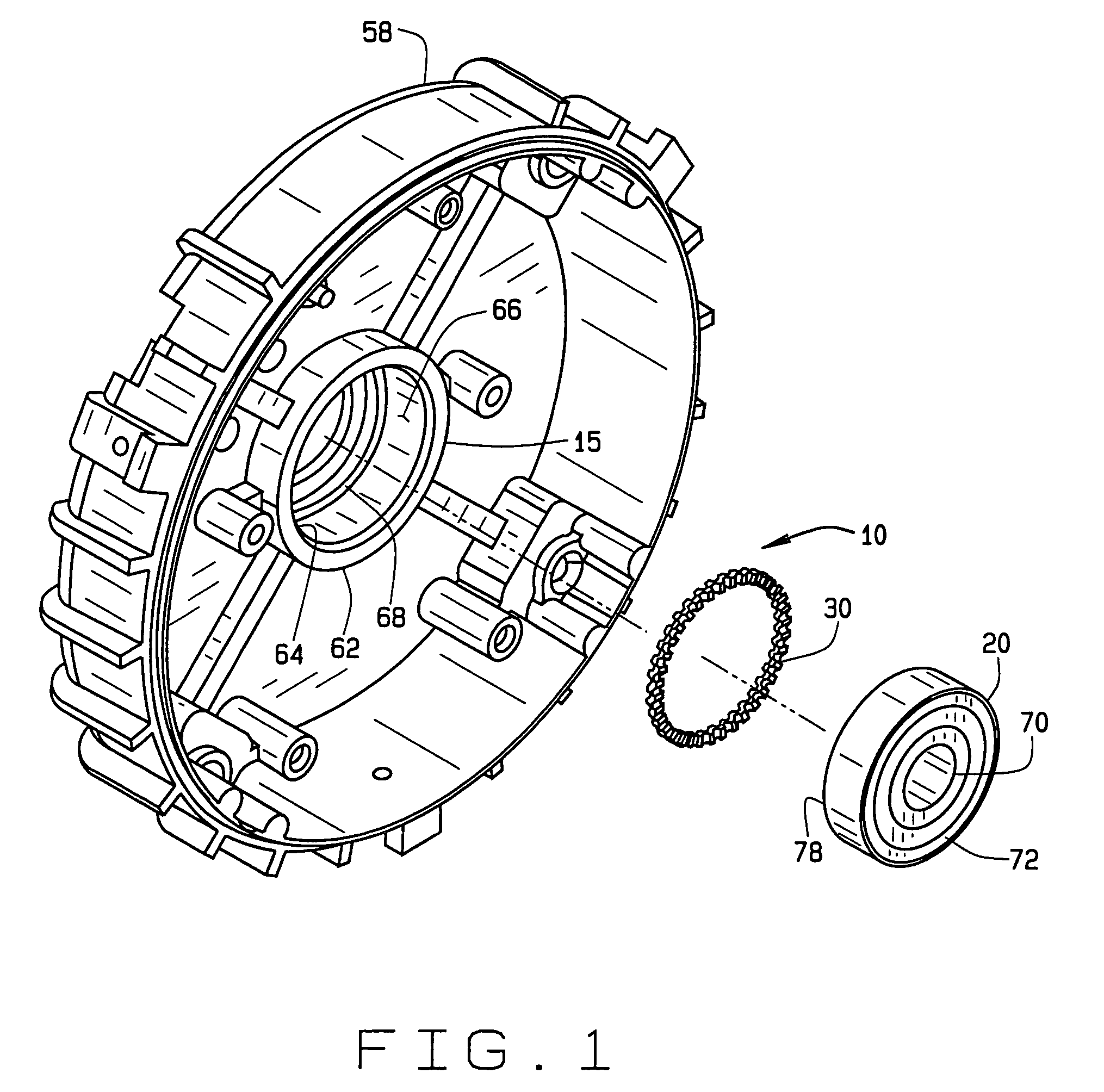

Bearing assembly with anti-slip spring

InactiveUS20050265645A1Extended service lifeEasy to assembleBearing assemblyBall bearingsSpacing toothEngineering

A bearing system which inhibits fretting to extend the life of a bearing. The system is usable in a machine, such as an electric motor, and includes an elastomeric spring positioned between the bearing and a bottom surface of a bore in which the bearing is received. The spring member applies force to the bearing in both an axial direction and a circumferential direction to oppose rotation of the bearing in the bore. The spring member has an annular shape with a plurality of circumferentially spaced teeth.

Owner:NIDEC MOTOR CORP

Locking device for a connecting port on a computer

InactiveUS20100031710A1Avoid connectionClothing locksLocks for portable objectsSpacing toothEngineering

A locking device includes an enclosure having an insertion section formed with two holes for inserting into a connecting port on a computer, and a plurality of windows axially spaced on at least one side of the enclosure; a locking unit arranged in the enclosure and including a rod having axially spaced teeth, a push member connected to one end of the rod and having an engaging portion, a hooking member movably connected to the engaging portion with two hooking arms extended into the two holes on the insertion section; an elastic member located between the push member and the fixing seat; a plurality of rotating discs fitted on the rod corresponding to the windows and each having a plurality of numeral areas and a notch; and at least one push button movably arranged on at least one lateral side of the enclosure to interfere with the push member.

Owner:CHEN YEN HSIANG

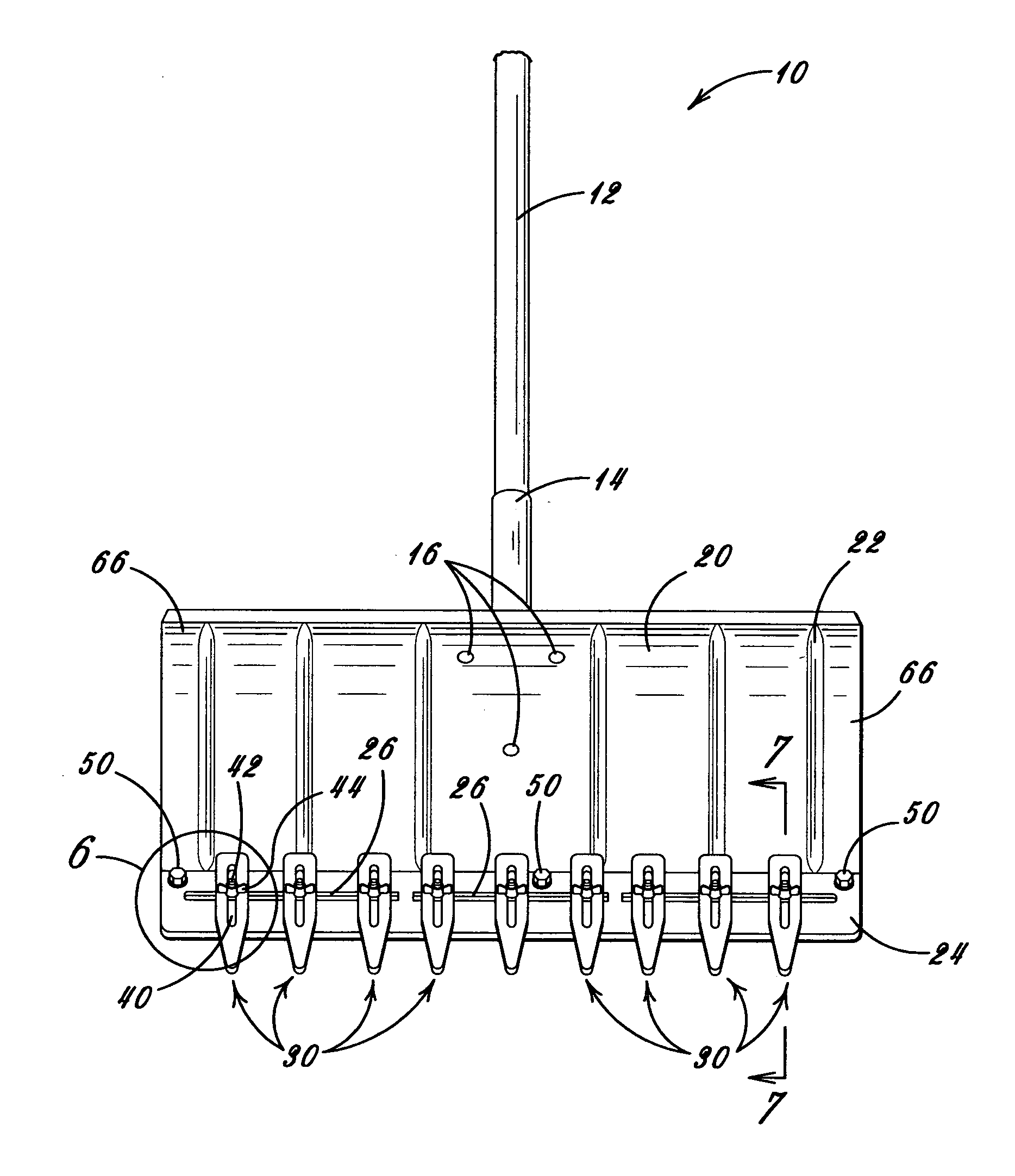

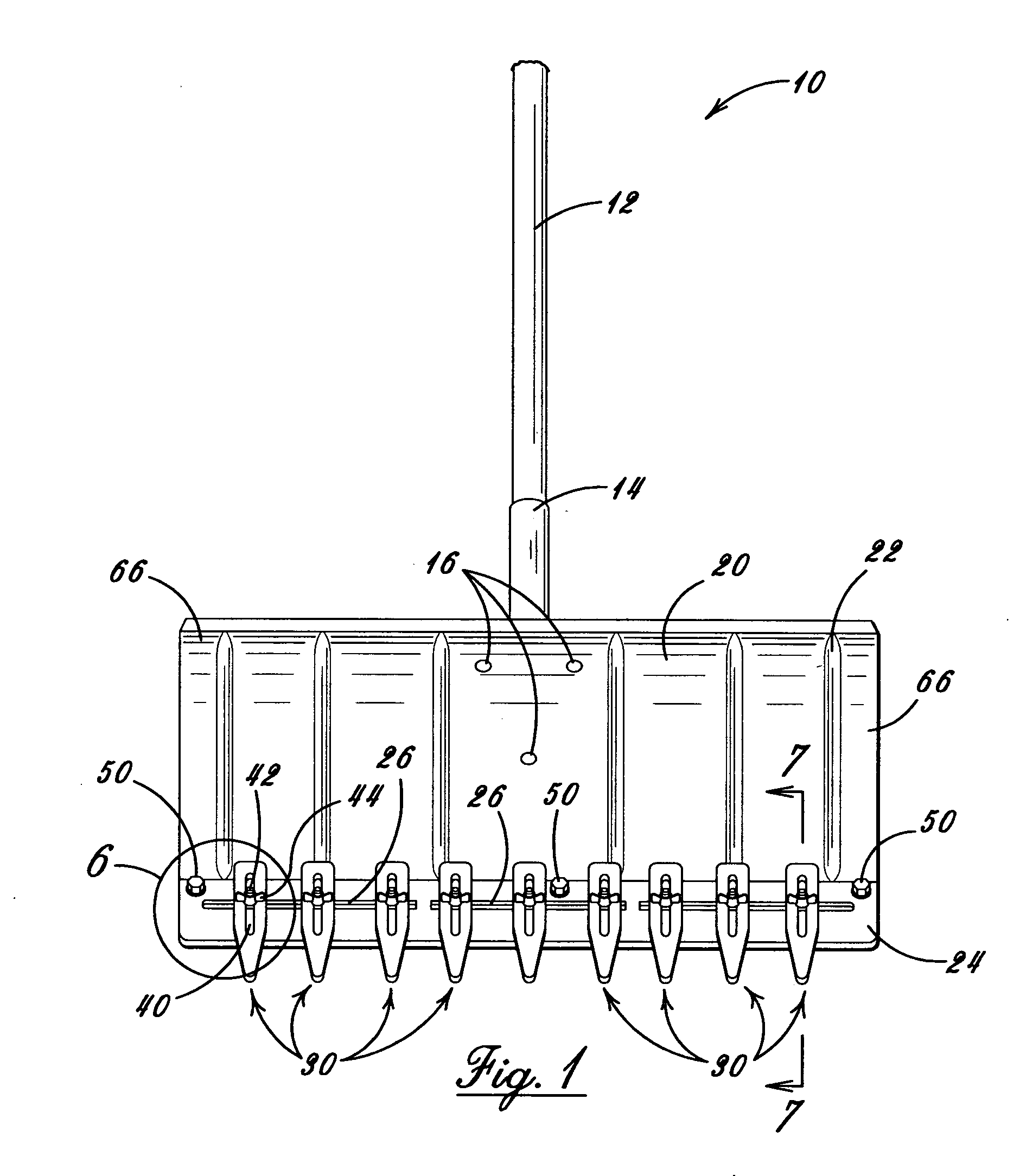

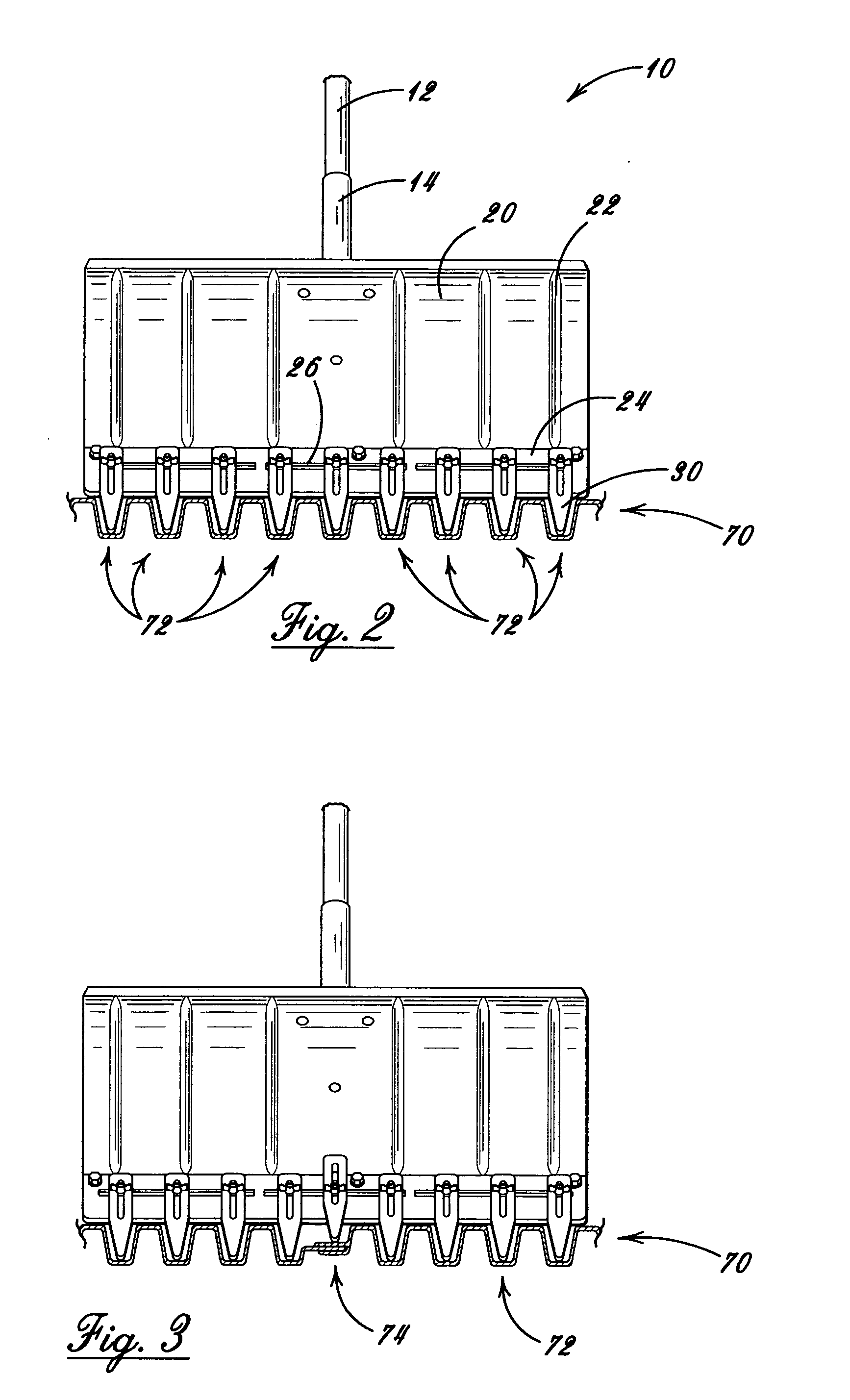

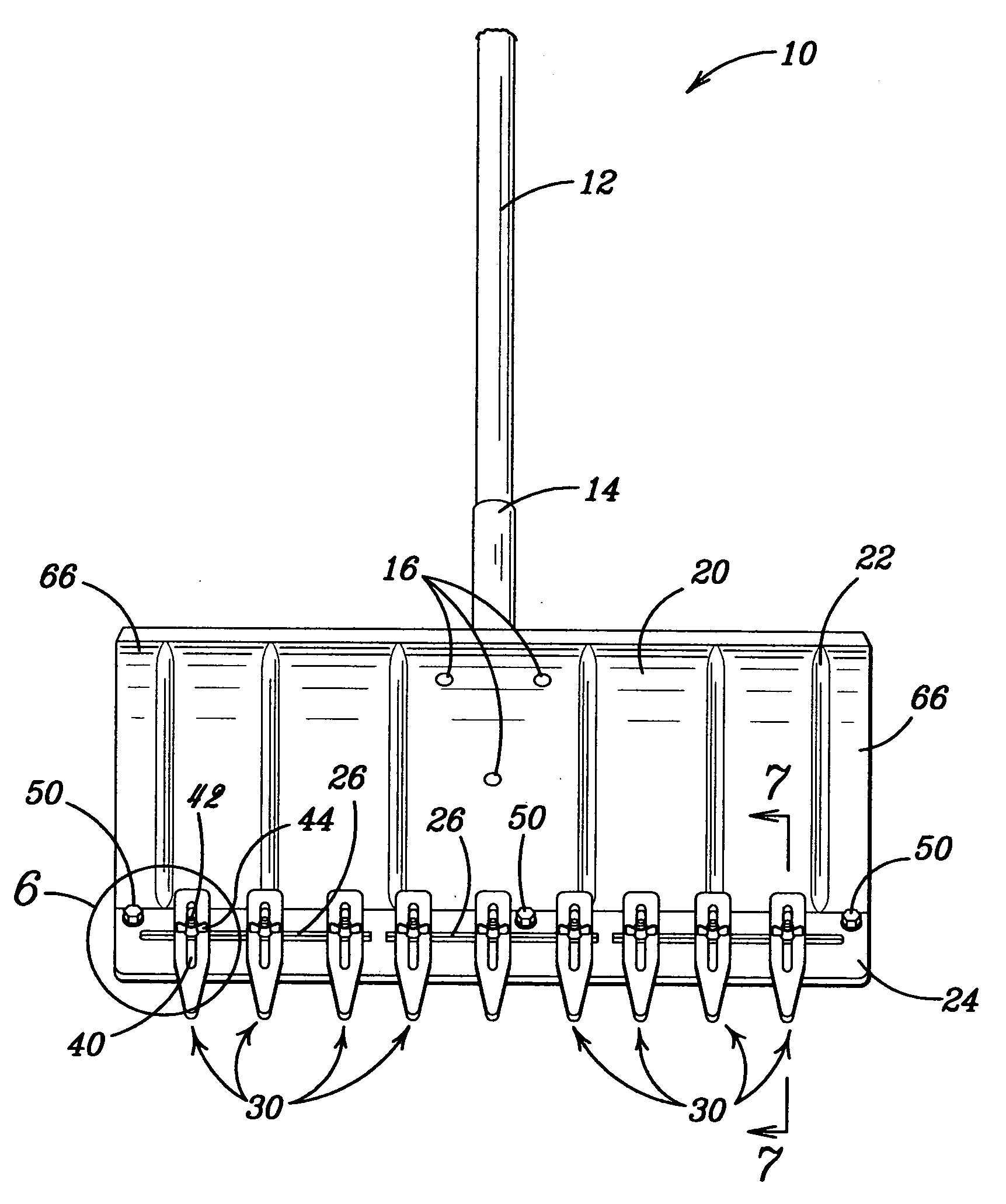

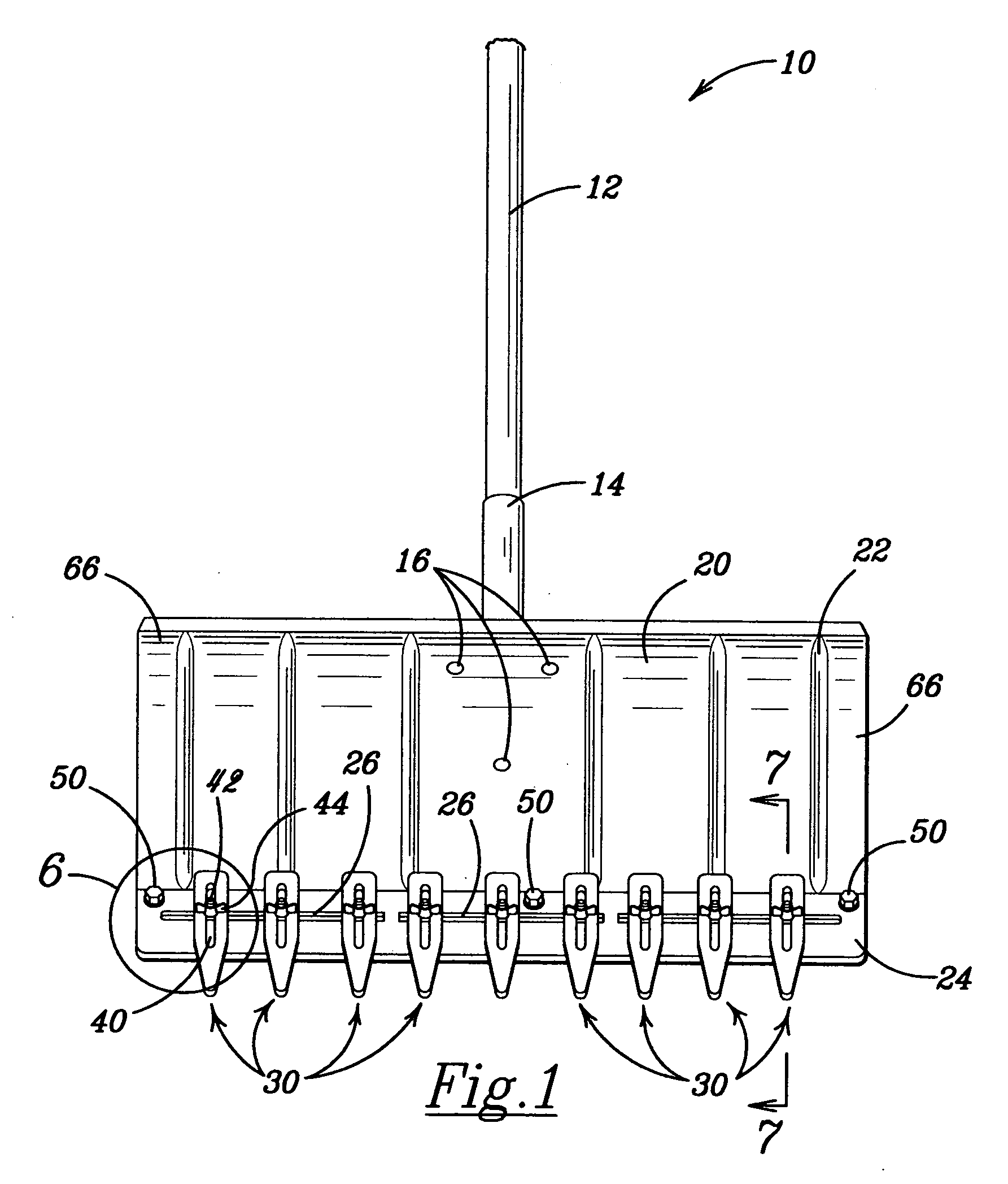

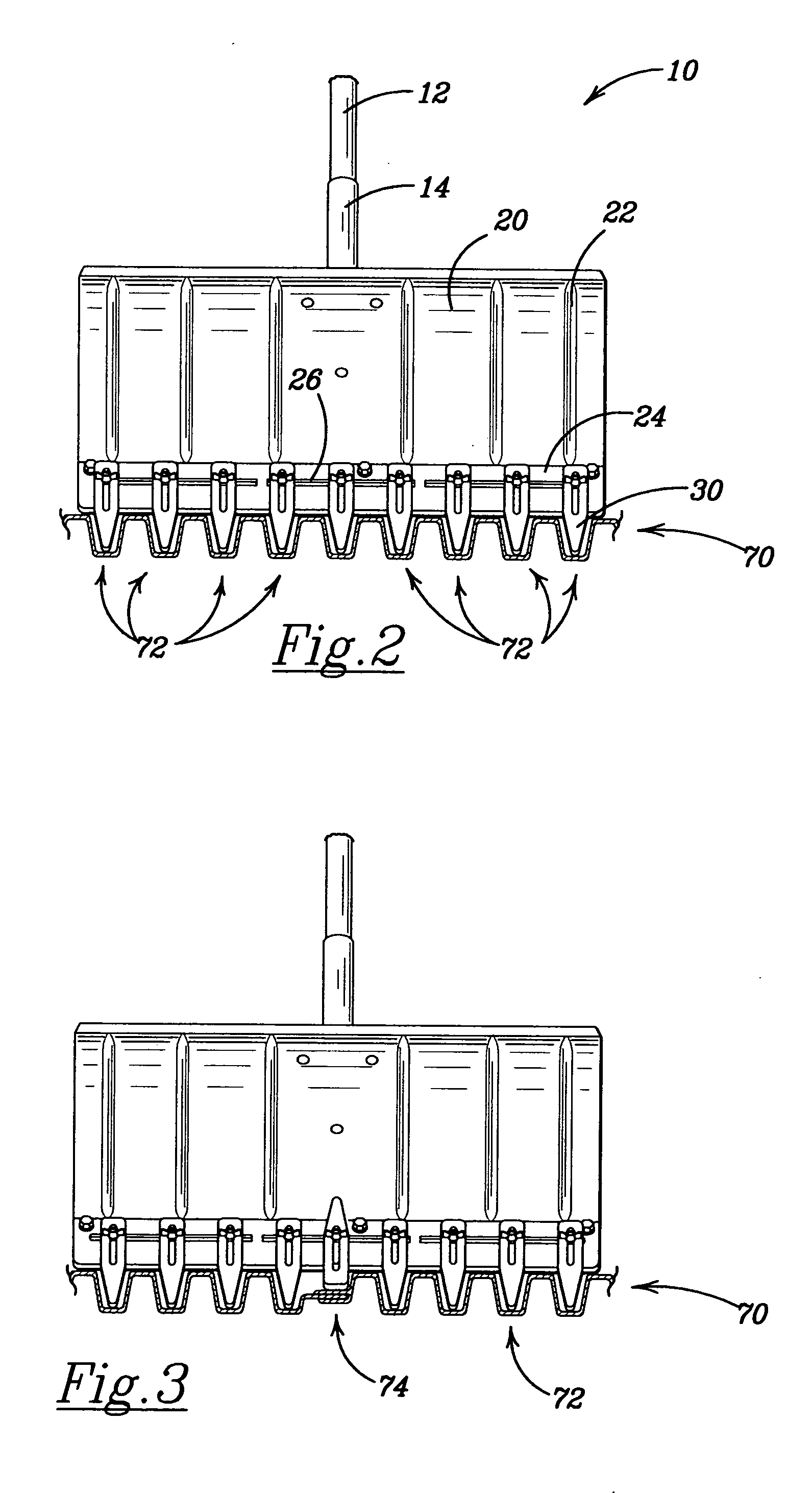

Hand manipulated pusher apparatus with adjustably spaced teeth for cleaning uneven corrugated surfaces

A manually manipulated shovel-like device for cleaning corrugated floors along the bottom of refrigerated containers and trailers having a blade, an elongate handle extending from the proximal end of the blade, and a plurality of elongate cleaning teeth extending perpendicularly from the opposed distal end of the blade, each of the cleaning teeth being individually slidably adjustable in both the lateral and the vertical directions with respect to the distal edge of the blade to enable the device to clean corrugated floors having unequally spaced apart corrugations of varying depth, joints between sections of corrugated panels, and uncorrugated sections near walls of the container, each of said teeth additionally being individually removable and replaceable from the blade so that teeth of various geometrical configurations and functional features may be used, including teeth tapered to a narrower distal tip, teeth of generally uniform width, and teeth having chisel-pointed edges, the blade optionally being curved to have a concave front side, the blade further optionally having frontwardly extending sidewalls.

Owner:KUHNS MARK J +1

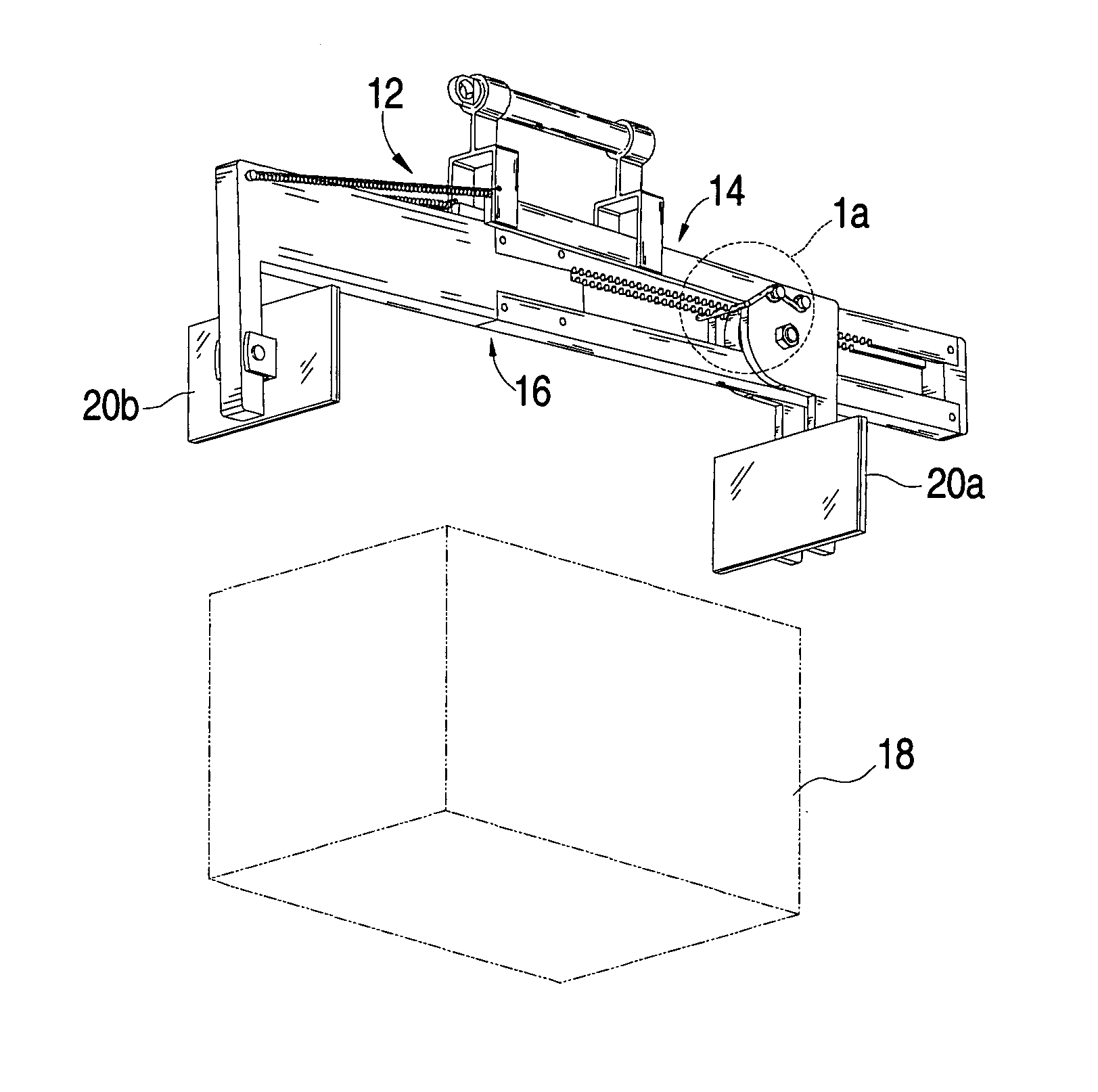

Single hand operated adjustable carrying device and method of use thereof

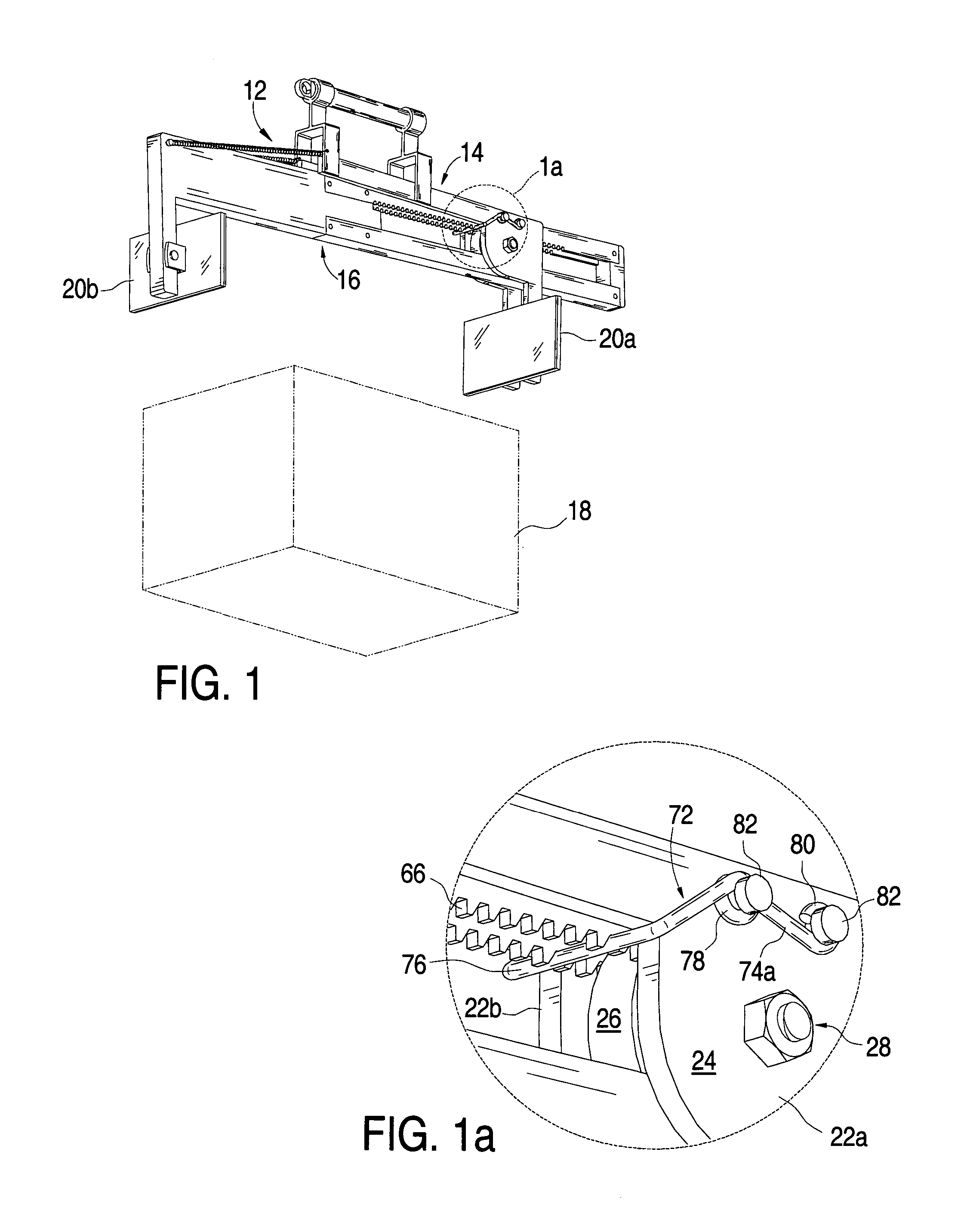

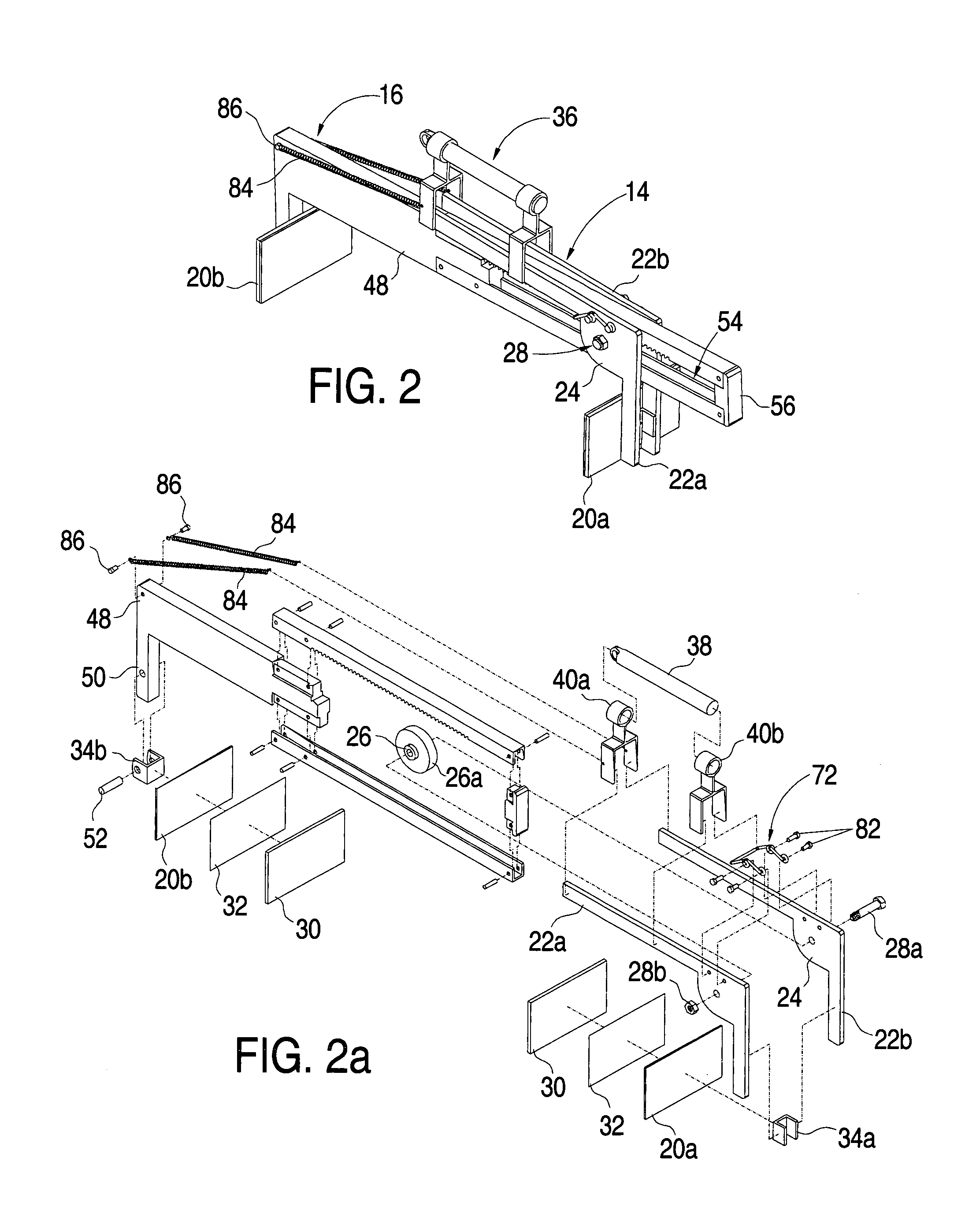

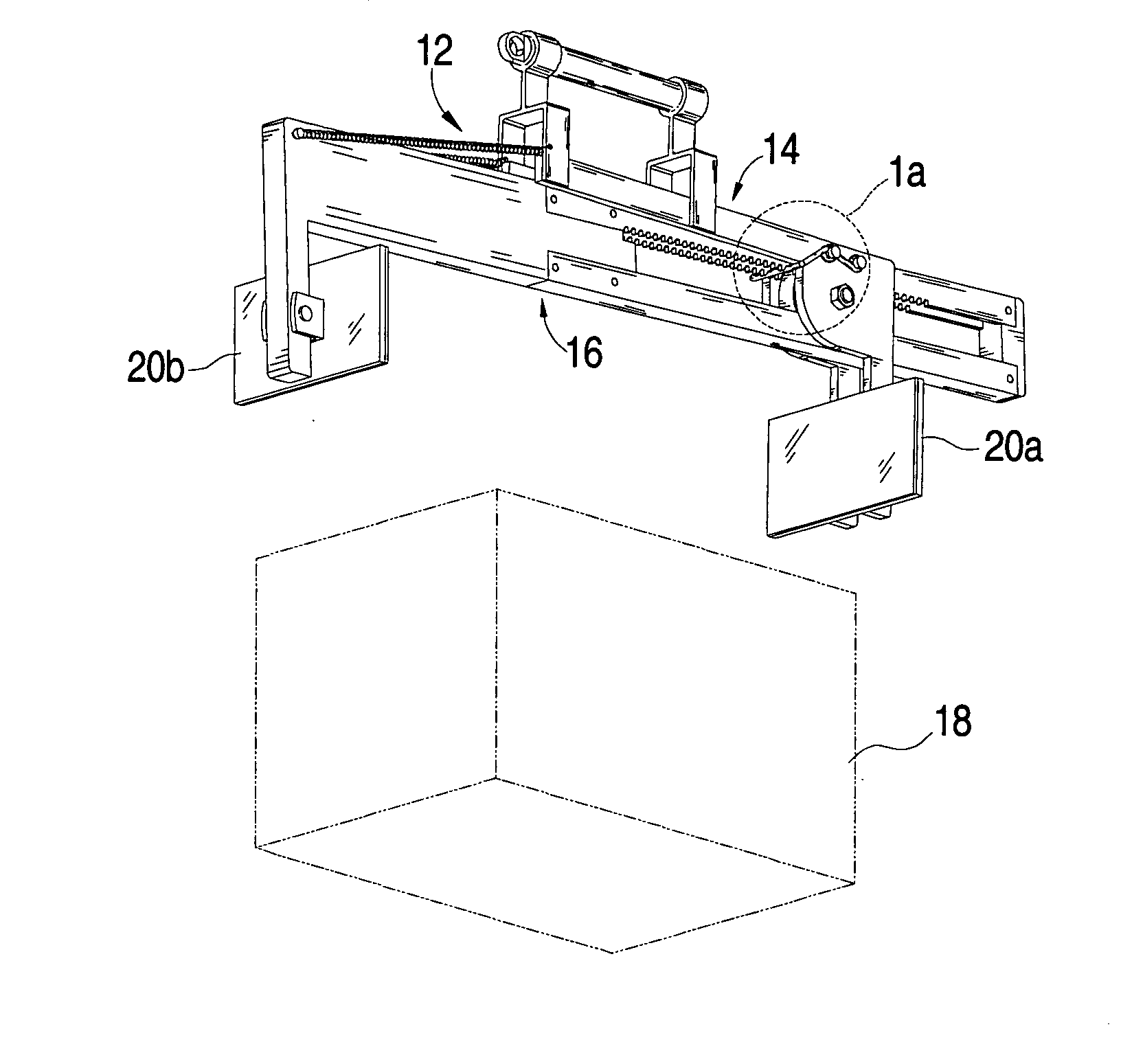

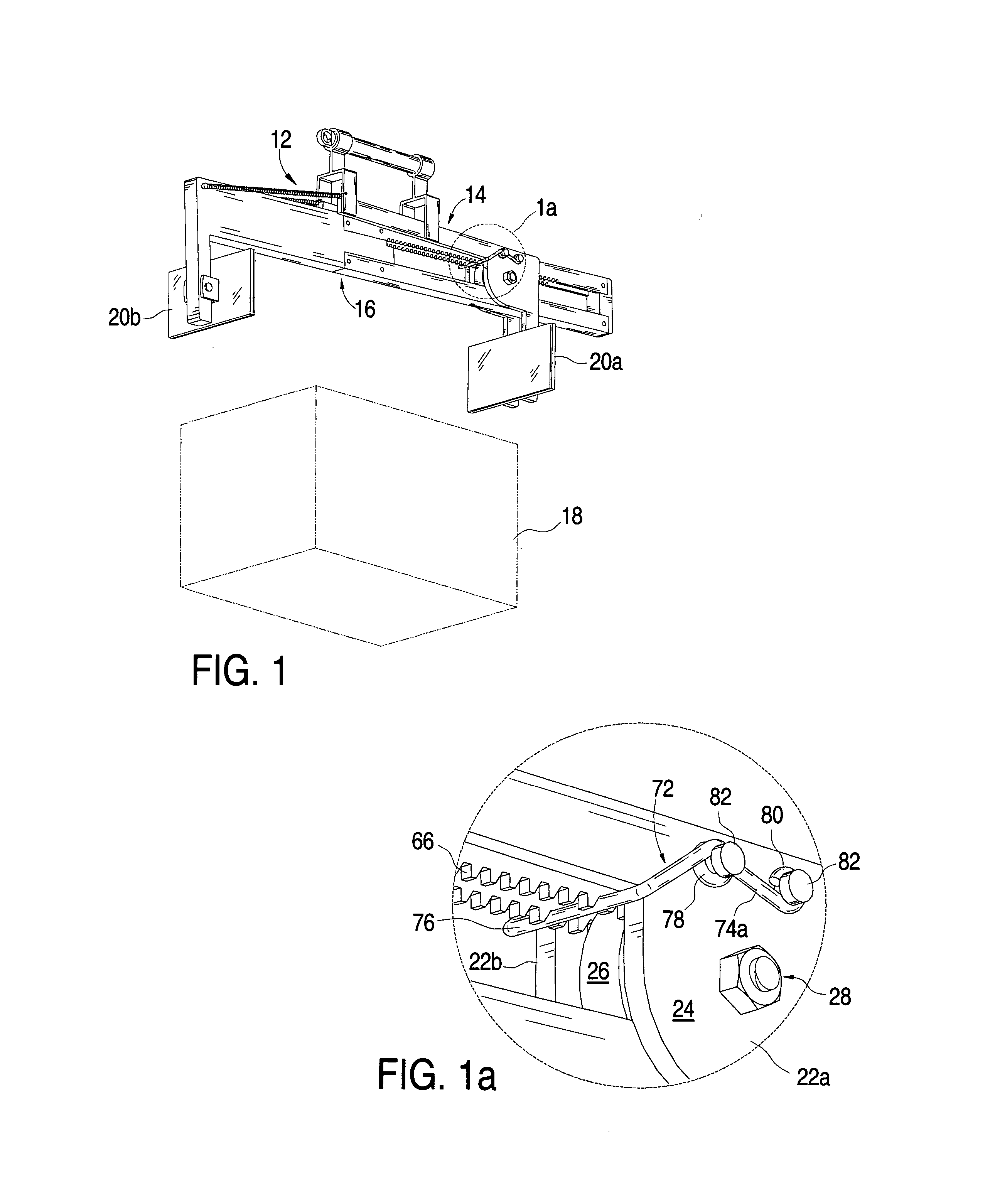

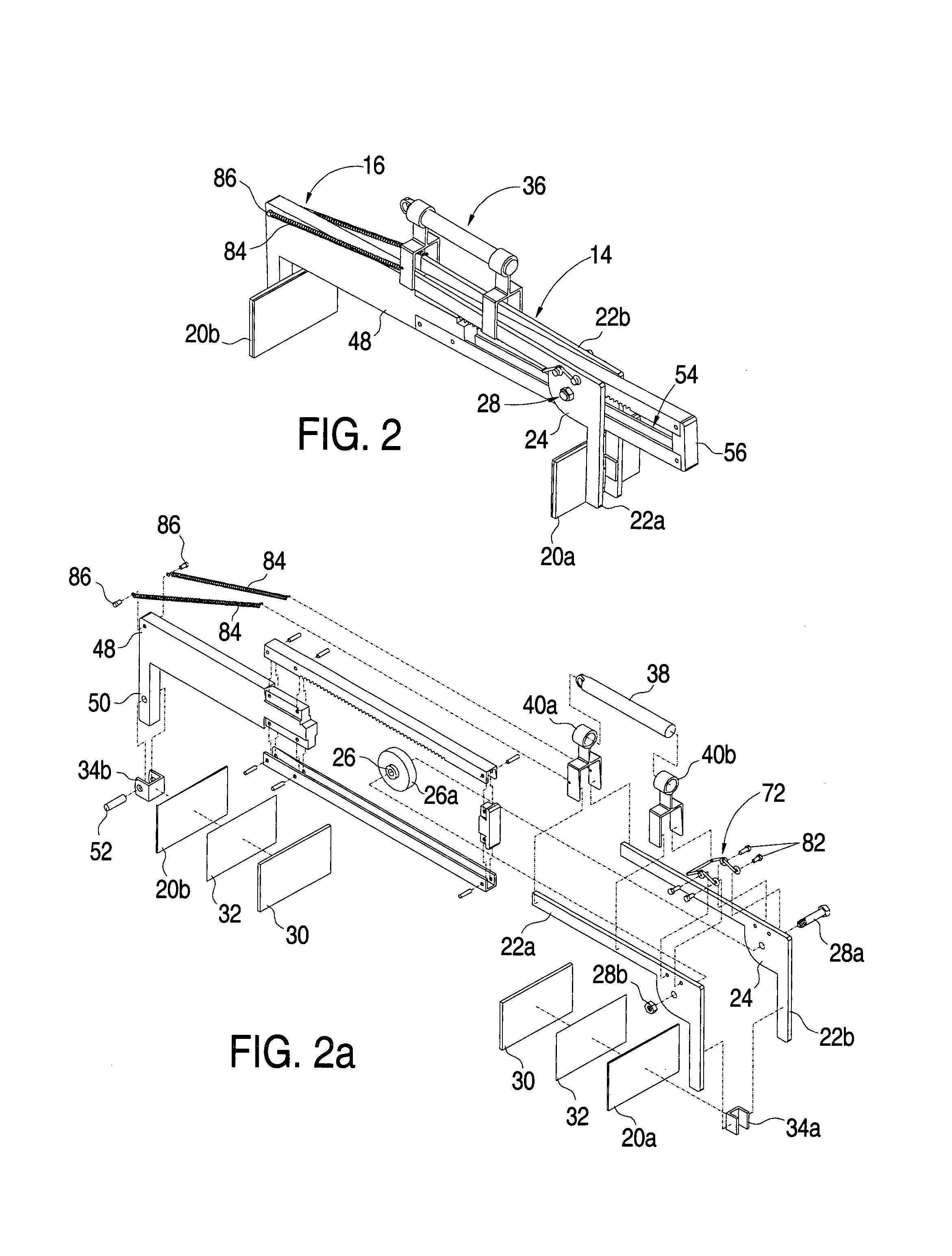

An adjustable carrying device (12) includes a pair of gripping members (14, 16) in a slip joint pivot connection having a handle assembly (36) and gripping plates (20a, 20b) for grasping and handling an object. A pivotally activated / deactivated locking mechanism includes a plurality of evenly spaced teeth (66) within a guide track (54) and a cross member (76) biased between lock and unlock positions by a pair of torsion springs (74a, 74b). A pair of levers (22a, 22b) moved in unison by handle assembly (36) activate and deactivate the locking mechanism. While in unlock position a pair of coil tension springs (84) assist in the single handed adjustment of the gripping plates against the object's opposed surfaces. A subsequent upward pivotal motion of handle assembly (36) activates the locking mechanism, forcing gripping plates (20a, 20b) towards each other, firmly gripping the object prior to its lift.

Owner:LAUSELL EMILIANO

Single hand operated adjustable carrying device and method of use thereof

InactiveUS20070046048A1Manual conveyance devicesLoad-engaging elementsSpacing toothLocking mechanism

An adjustable carrying device (12) includes a pair of gripping members (14, 16) in a slip joint pivot connection having a handle assembly (36) and gripping plates (20a, 20b) for grasping and handling an object. A pivotally activated / deactivated locking mechanism includes a plurality of evenly spaced teeth (66) within a guide track (54) and a cross member (76) biased between lock and unlock positions by a pair of torsion springs (74a, 74b). A pair of levers (22a, 22b) moved in unison by handle assembly (36) activate and deactivate the locking mechanism. While in unlock position a pair of coil tension springs (84) assist in the single handed adjustment of the gripping plates against the object's opposed surfaces. A subsequent upward pivotal motion of handle assembly (36) activates the locking mechanism, forcing gripping plates (20a, 20b) towards each other, firmly gripping the object prior to its lift.

Owner:LAUSELL EMILIANO

Hand manipulated pusher apparatus with adjustably spaced teeth for cleaning uneven corrugated surfaces

A manually manipulated shovel-like device for cleaning corrugated floors along the bottom of refrigerated containers and trailers having a blade, an elongate handle extending from the proximal end of the blade, and a plurality of elongate cleaning teeth extending perpendicularly from the opposed distal end of the blade. Each of the cleaning teeth are individually slidably adjustable in both the lateral and the perpendicular directions with respect to the distal edge of the blade to enable the device to clean corrugated floors having unequally spaced apart corrugations of varying depths and widths, joints between sections of corrugated panels, and uncorrugated sections near walls of the container. The teeth are also individually removable, reversible and replaceable from their respective positions on the blade so that teeth of various geometrical configurations and functional features may be used, including teeth tapered to a narrower distal tip, teeth of generally uniform width, and teeth having chisel-pointed edges. The blade may optionally be curved to have a concave front side, and further have frontwardly extending sidewalls.

Owner:KUHNS MARK J +1

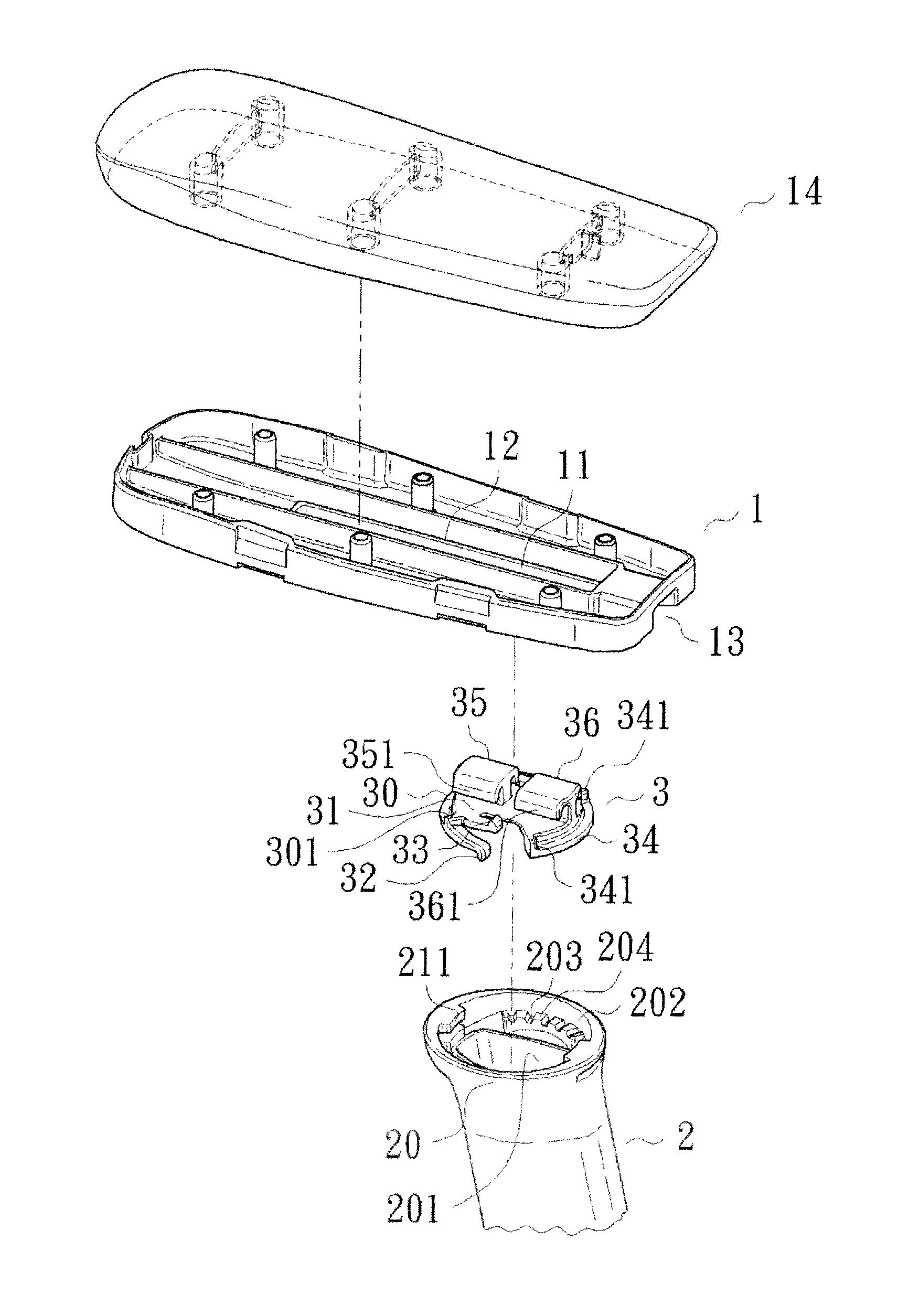

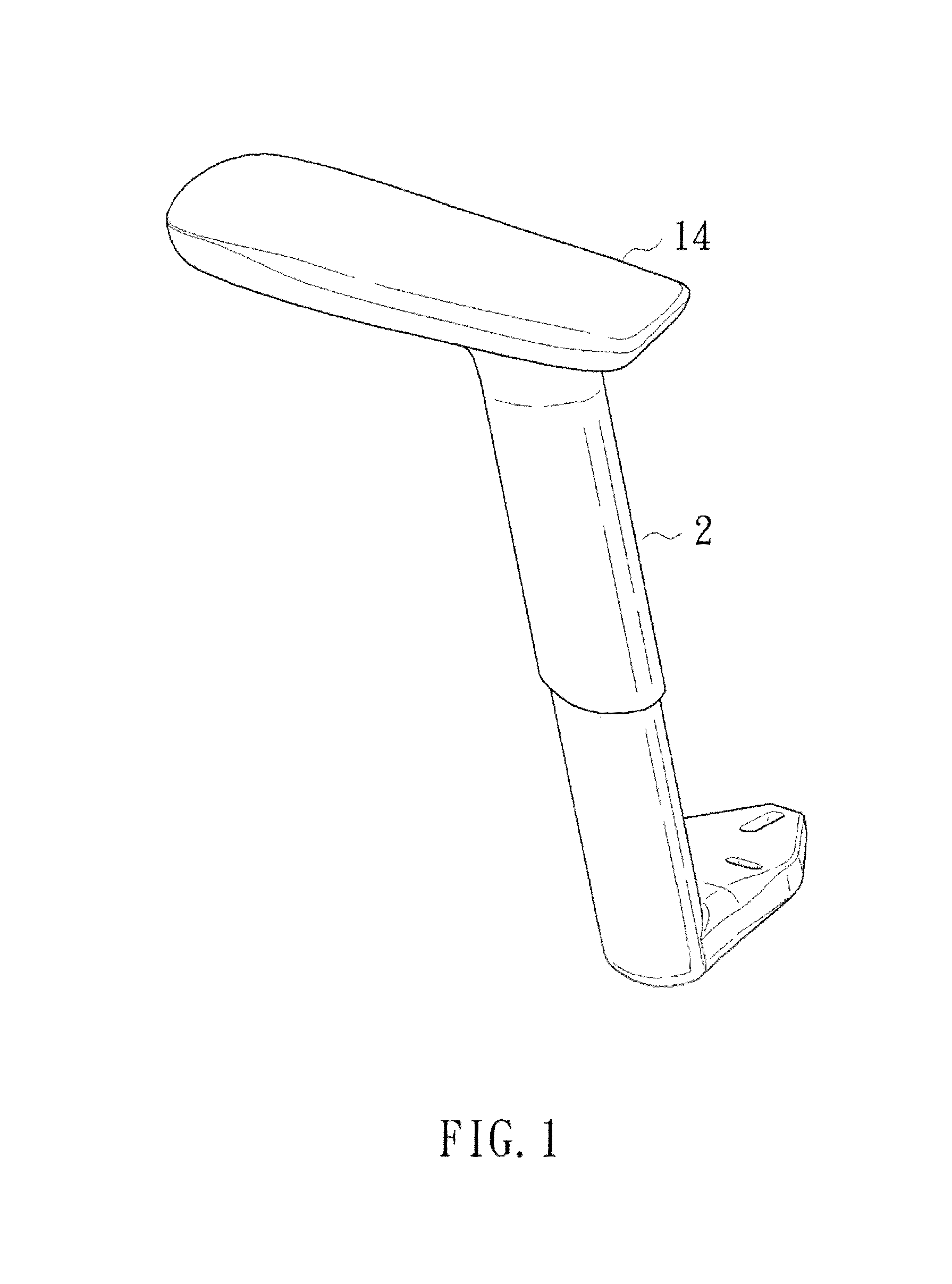

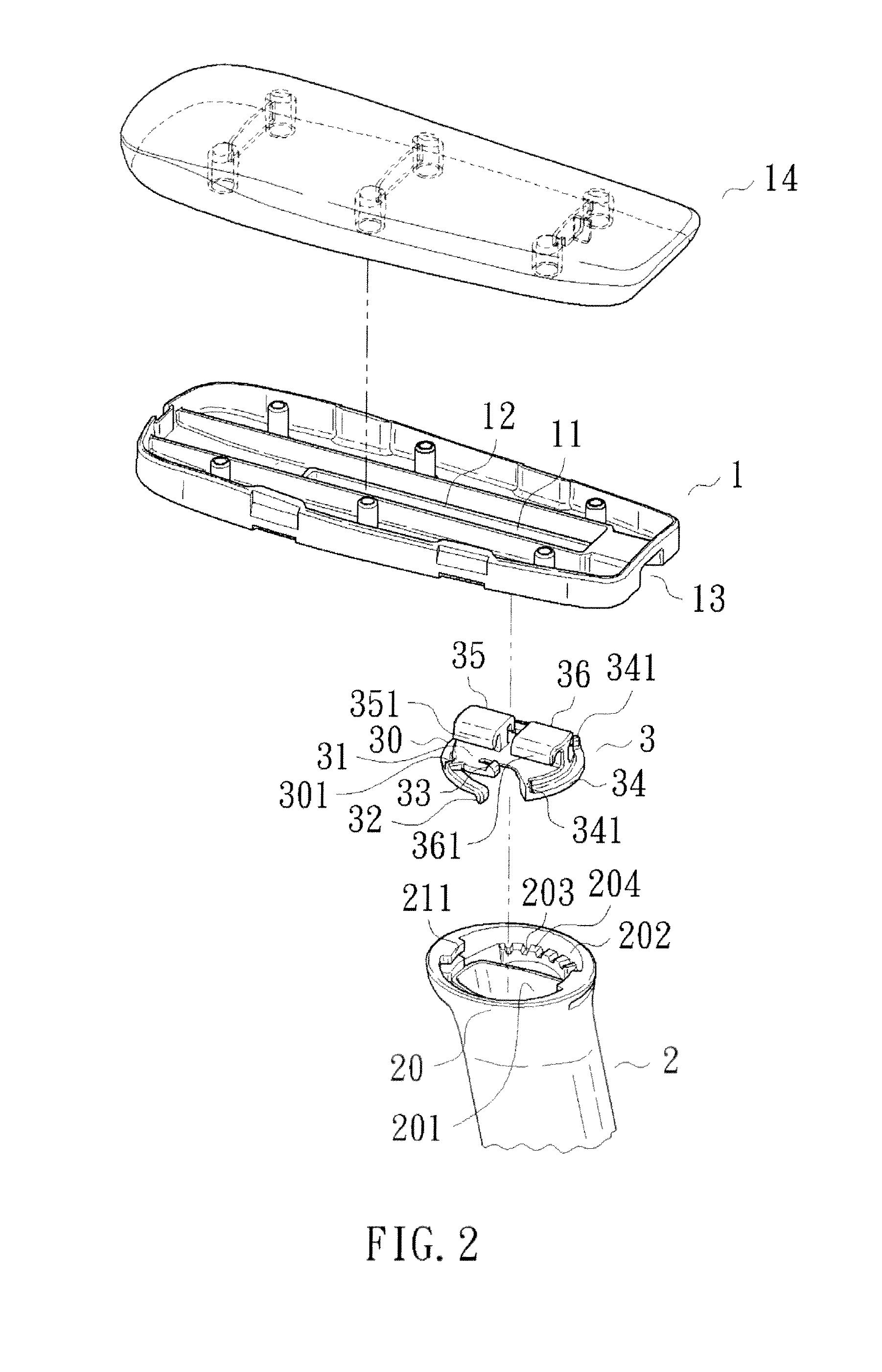

Armrest

ActiveUS8226171B2Optimization mechanismAvoiding complicated assemblageVehicle seatsStoolsSpacing toothHandrail

An armrest includes an armrest base having a guiding groove. A support is mounted below the armrest base. The support includes a top end having a restraining plate. An engaging member includes a body having an upper portion. A slider is formed on the upper portion of the body. The slider includes two arms slideably abutting two lateral walls of the guiding groove, allowing relative sliding movement between the slider and the armrest base along the guiding groove. The engaging plate further includes an insertion plate located below the restraining plate. The engaging member can be rotatably received in the compartment of the support. The top end of the support can include an annular portion having a plurality of annularly spaced teeth in the compartment. A groove is formed between two adjacent teeth. A positioning member projects downwardly from the engaging member and is selectively engaged in one of the grooves.

Owner:FANG TIEN CHING

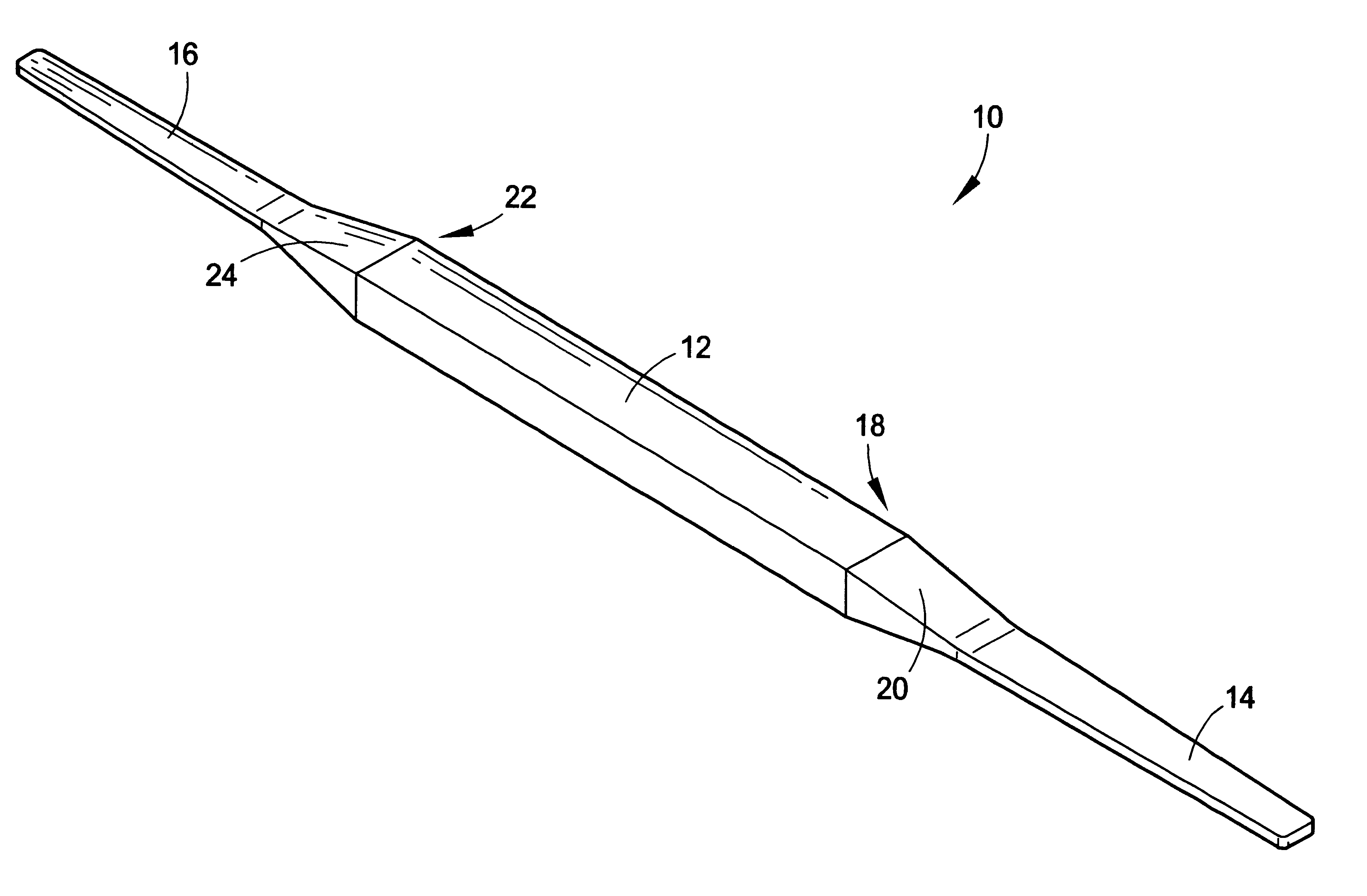

Dental device for cleaning between teeth

InactiveUS6701939B2Easy to installThinner and flexibleGum massageDental toolsSpacing toothThermoplastic

A dental device (10) broadly comprises a center section (12) flanked by a first picking section (14) and a second picking section (16). The first picking section (14) and the second picking section (16) are relatively flat and may include a roughened surface (50). The device (10) is preferably constructed in one-piece and molded from semi-rigid thermoplastic which resists breaking. The first picking section (14) is thicker and stronger than the second picking section (16) in order to dislodge most any debris caught between teeth. The second picking section (16) is narrow enough to reach between closely spaced teeth. In use, a person holds the device (10) by the center section (12) and inserts either picking section (14,16) between their teeth. The person works the device (10) back and forth using the roughened surface (50) or angles of either section (14,16) to disturb bacteria and other foreign substances.

Owner:FREEMAN ROGER J

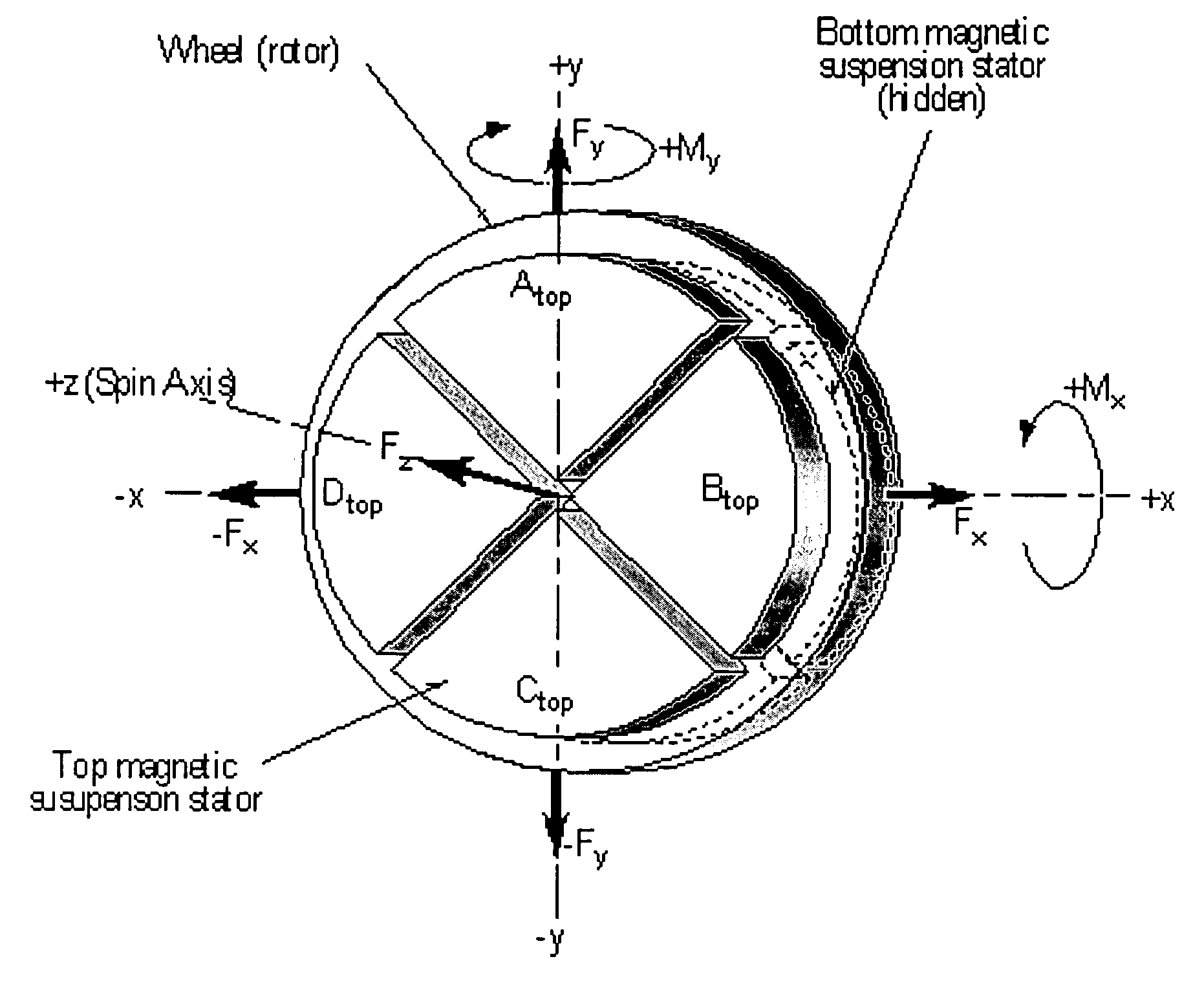

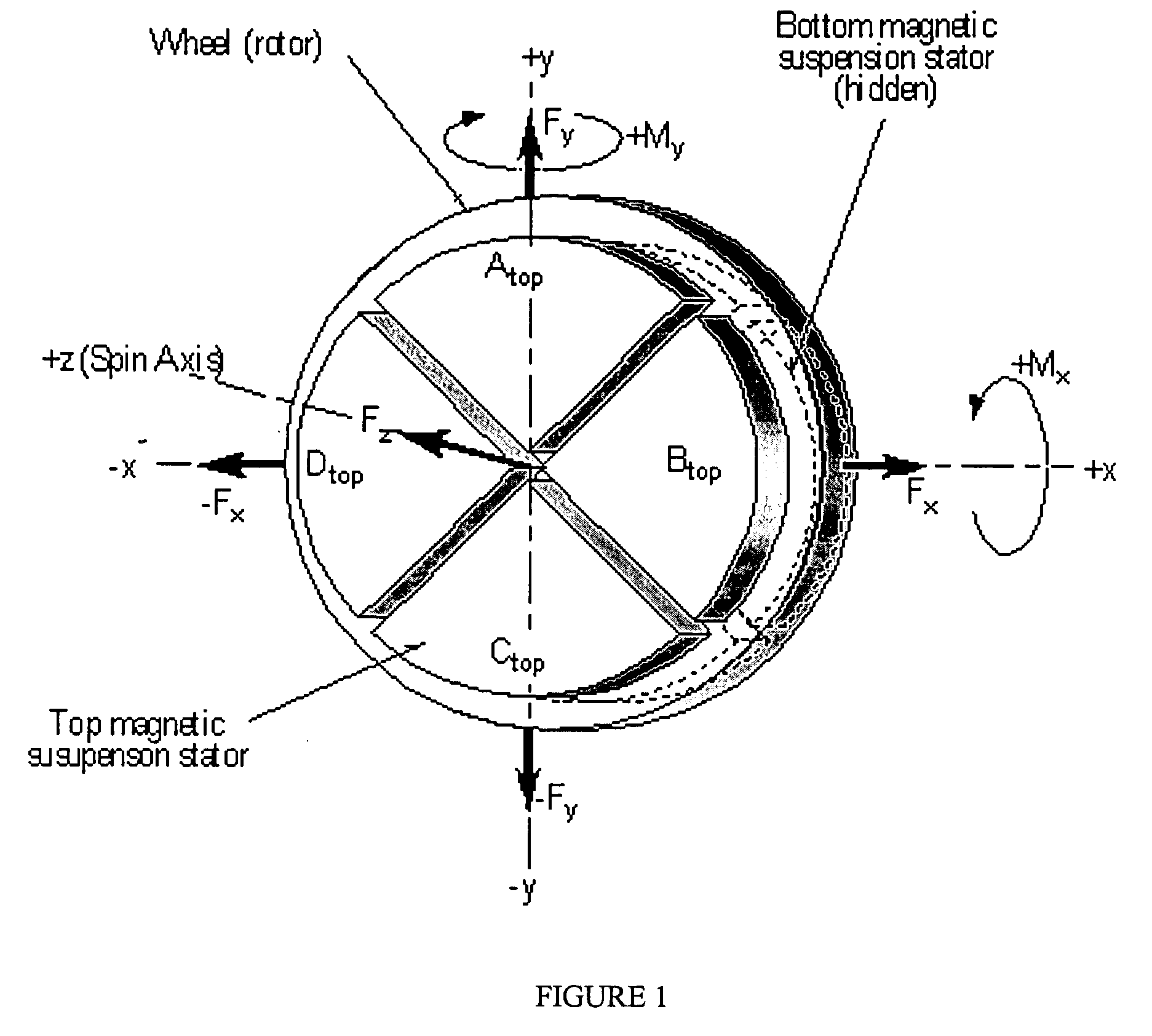

Rate gyroscope and accelerometer multisensor, and method of fabricating same

InactiveUS20050239220A1Useful angular momentumLarger angular momentumElectrical transducersAcceleration measurement using interia forcesSpacing toothAccelerometer

A rate gyroscope and accelerometer multisensor, and a process for fabricating the device. The device has an inner magnetically-suspended spinning wheel rotor, with outer stator portions adjacent both faces of the rotor. In one embodiment of the process, three substrates of magnetic material are provided. A first substrate is used to form the portion comprising the rotor. The other two substrates are used to form the outer stator portions. A series of spaced concentric grooves are formed in the central region of both faces of the first substrate. Outside of the grooves on both faces of the first substrate a series of spaced spiral grooves are formed. A hole is placed at the center of the spiral grooves, and filled with magnetic material. A conductor is then deposited into the spiral grooves. A central wheel is formed, the wheel carrying the spaced concentric grooves and defining along its edge a series of spaced teeth. A series of spaced serpentine grooves are formed on one active face of each of the other two substrates. On the same face, a series of generally radial grooves are formed. A conductor is then deposited into the serpentine grooves, and a magnetic material is deposited into the generally radial grooves. The active faces of the two outer substrates are then bonded against the first substrate such that the outer end of each magnetic path overlays a filled hole in the first substrate, to create the stator of an axial air gap reluctance motor.

Owner:MILLI SENSOR & ACTUATOR SYST

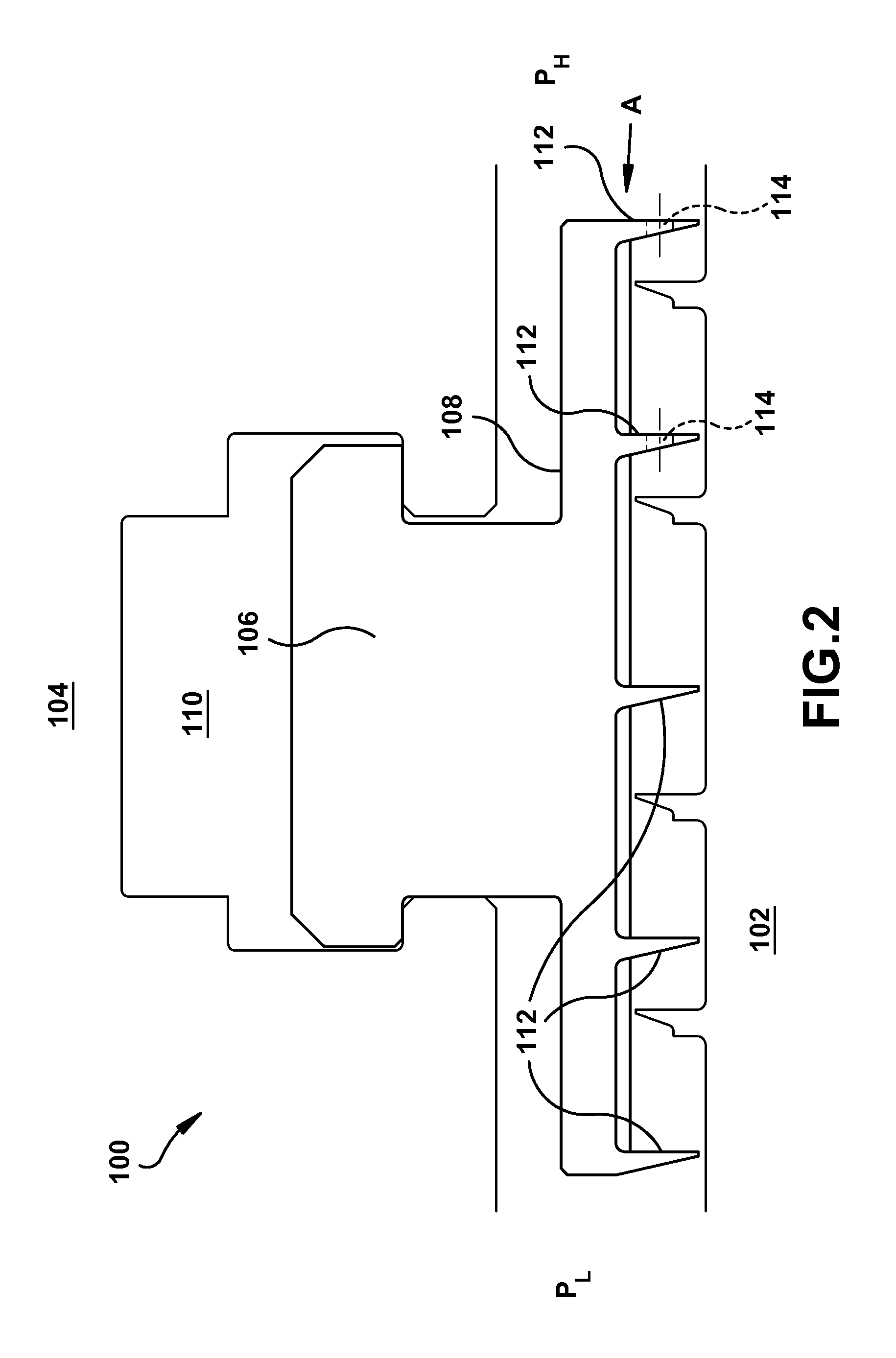

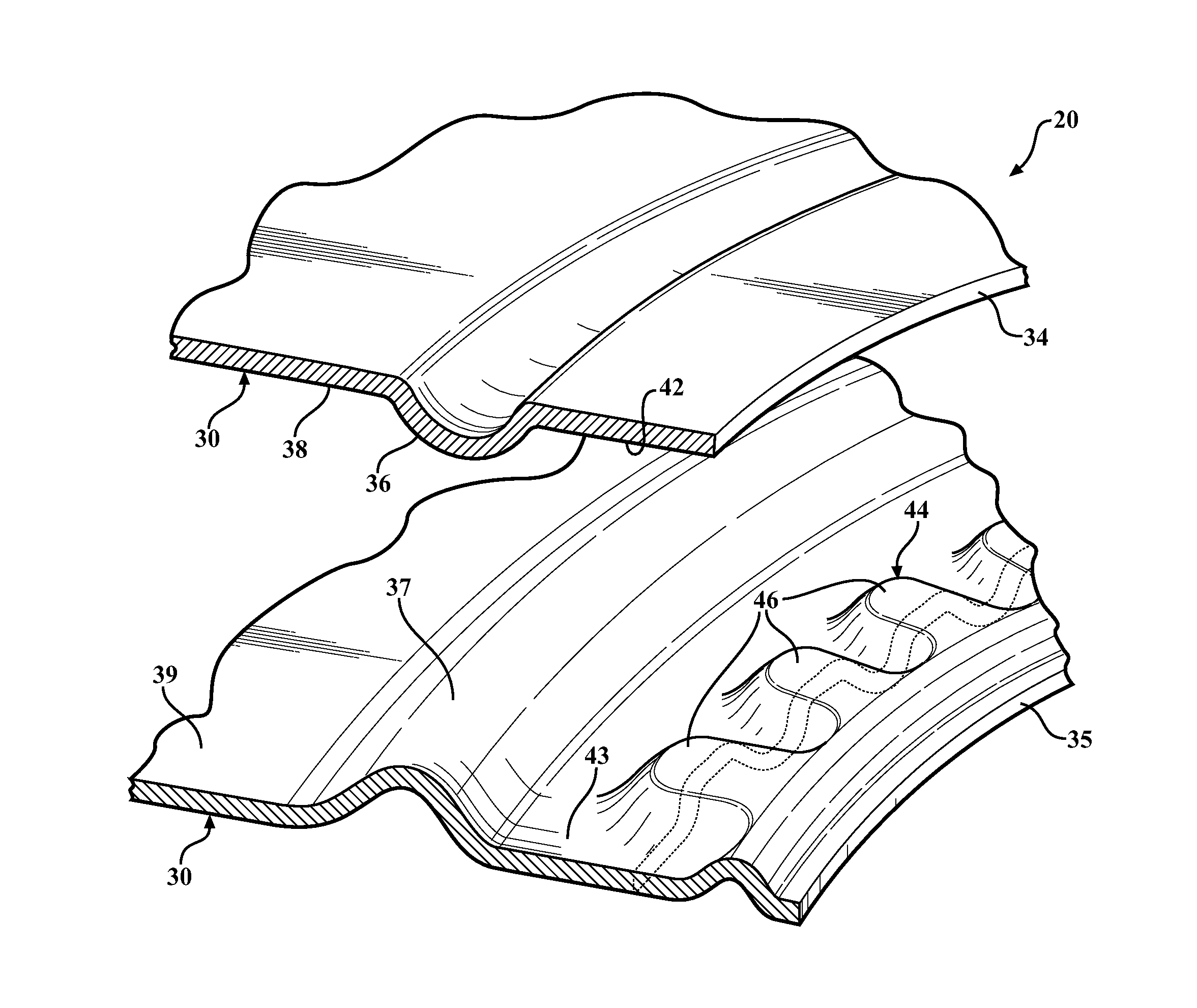

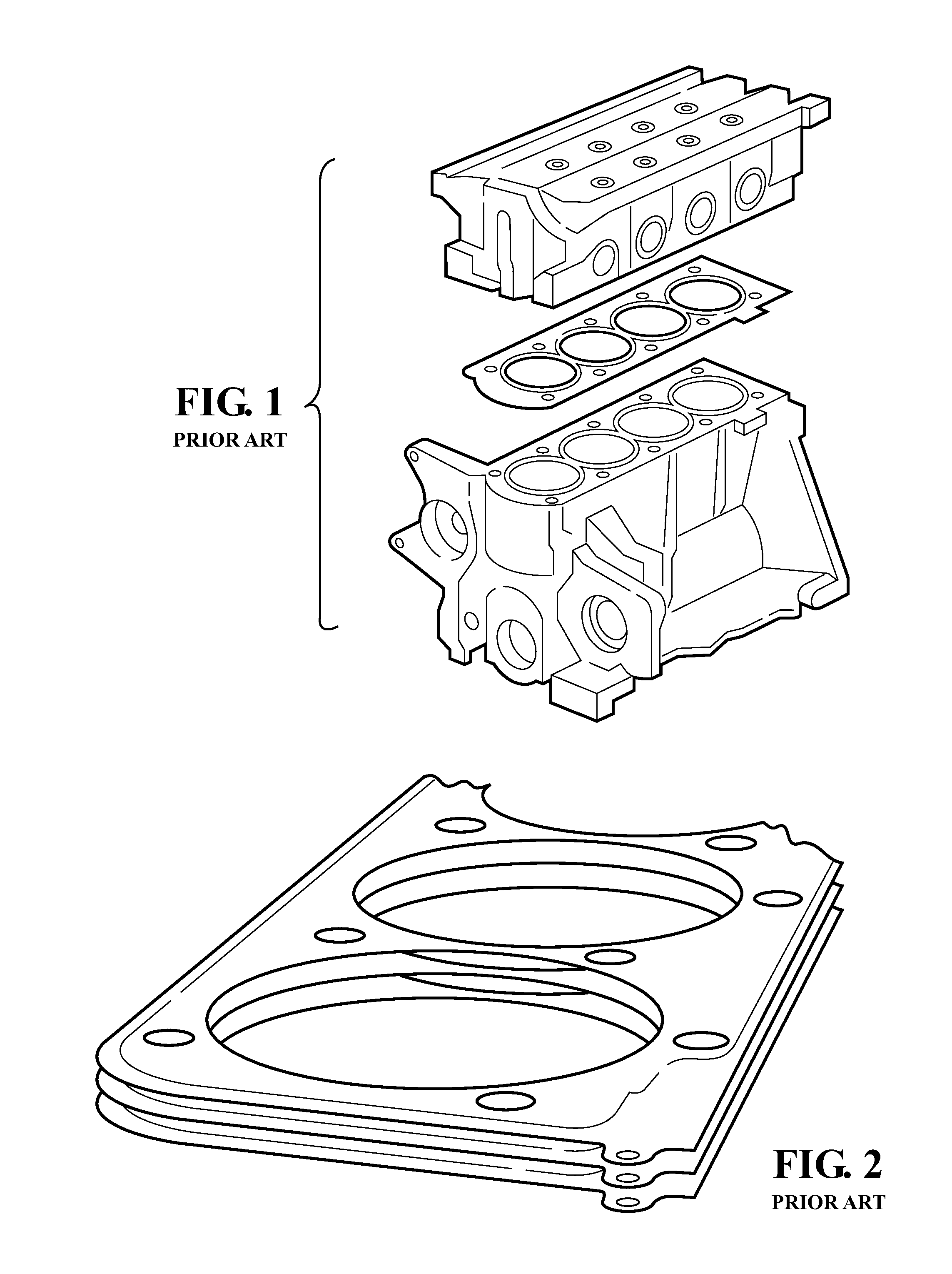

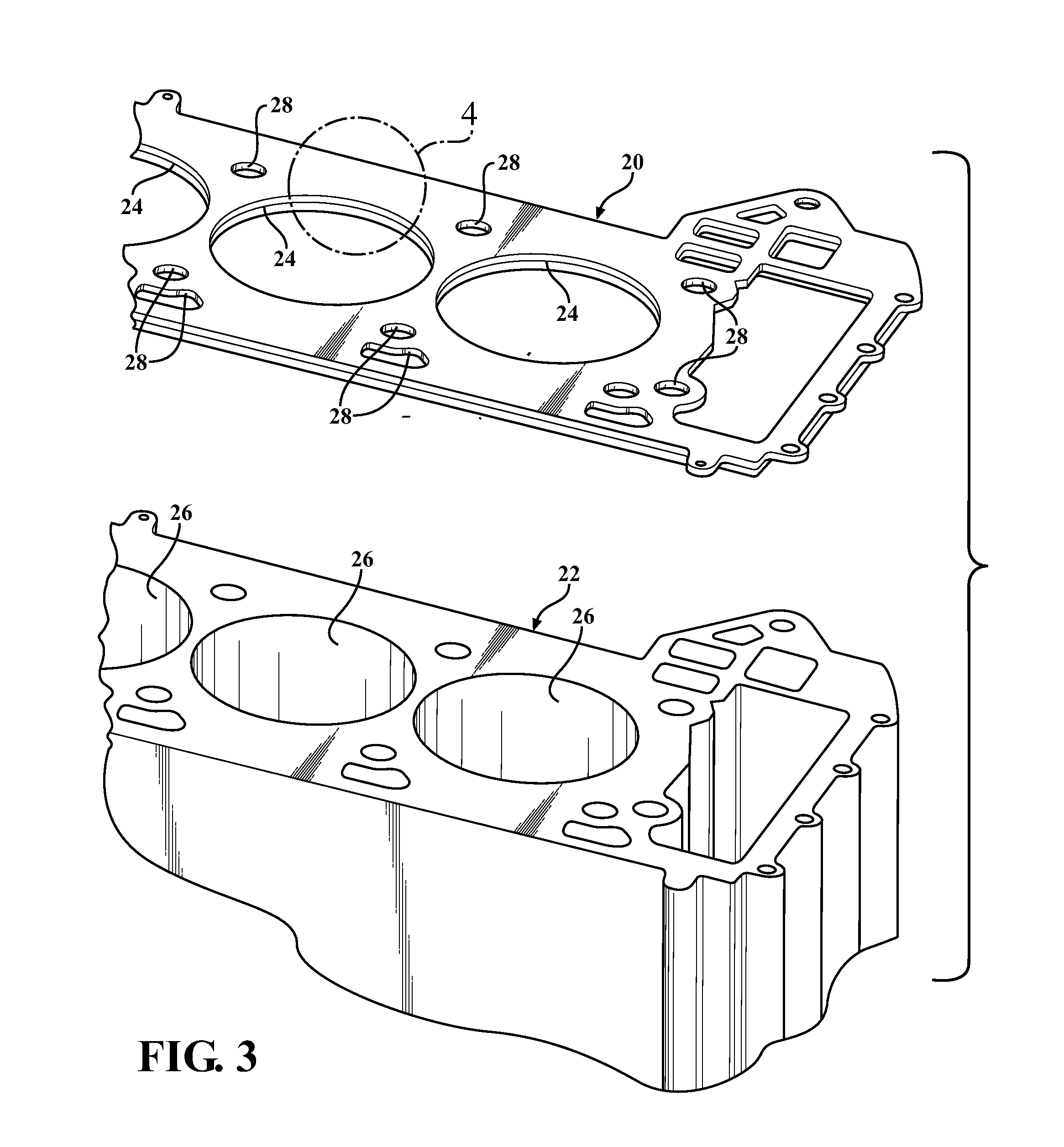

Gasket with a compression limiter

InactiveUS20130193651A1Avoid compressionConstant highEngine sealsSealing arrangements for enginesSpacing toothCylinder head

A multi-layer gasket including first and second functional layers, each having an opening. Each of the functional layers includes a compression bead, and the compression beads contact and seal against one another when the gasket is compressed between a cylinder head and an engine block. At least one of the functional layers includes a stopper disposed between the compression bead and the opening. The stopper has a gear-like shape including a plurality of circumferentially spaced teeth. Each tooth extends upwardly from a plane by a distance which is less than the combined height of the compression beads. When the gasket is compressed between the cylinder head and engine block, the stopper ensures that the compression beads remain elastically biased against one another and maintain a gas-tight seal.

Owner:FEDERAL MOGUL MOTORPARTS LLC

Anti-theft locking means for a vehicle steering shaft

ActiveUS7107801B2Avoid deformationAvoid destructionYielding couplingBuilding locksSpacing toothEngineering

Owner:NACAM FRANCE S

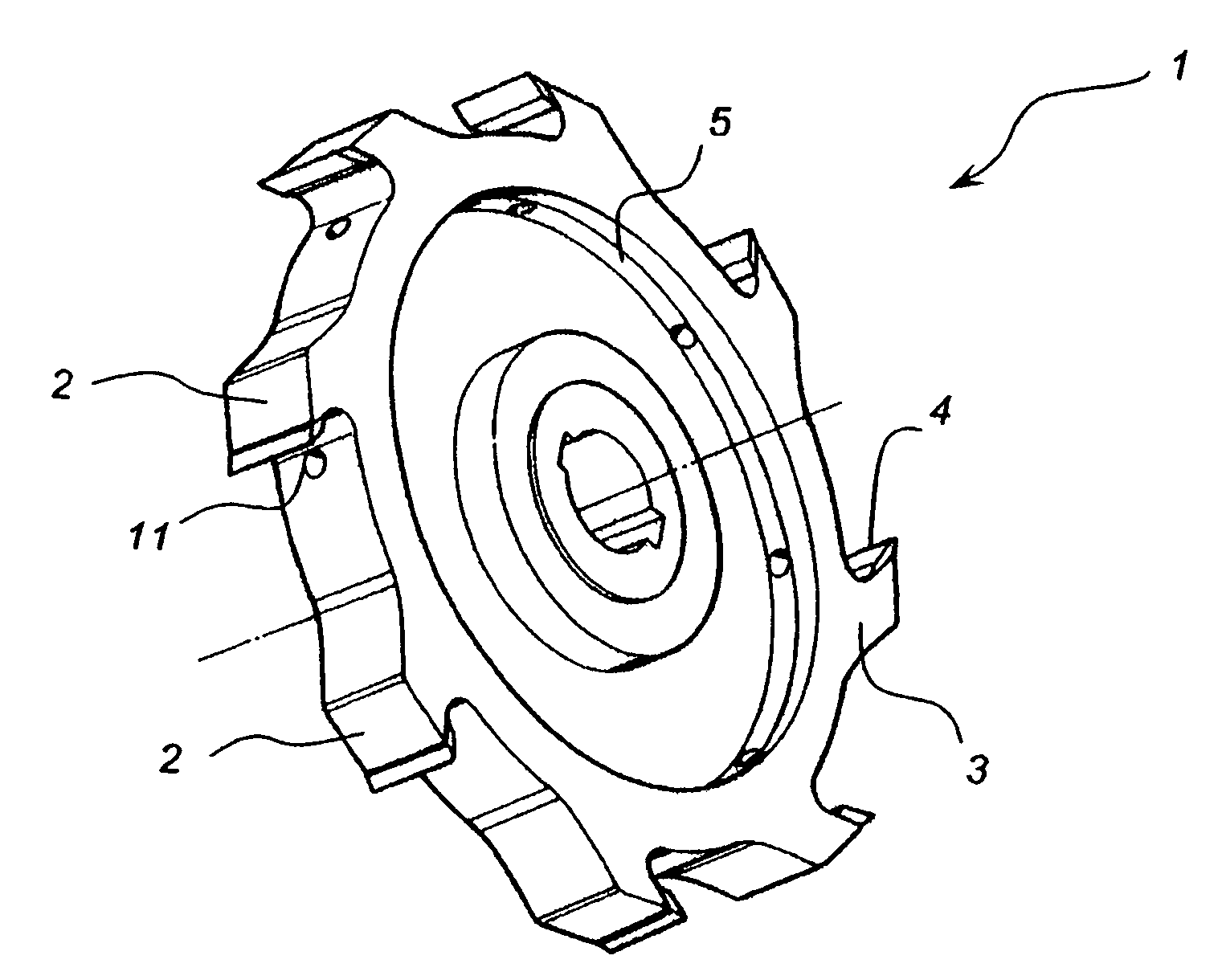

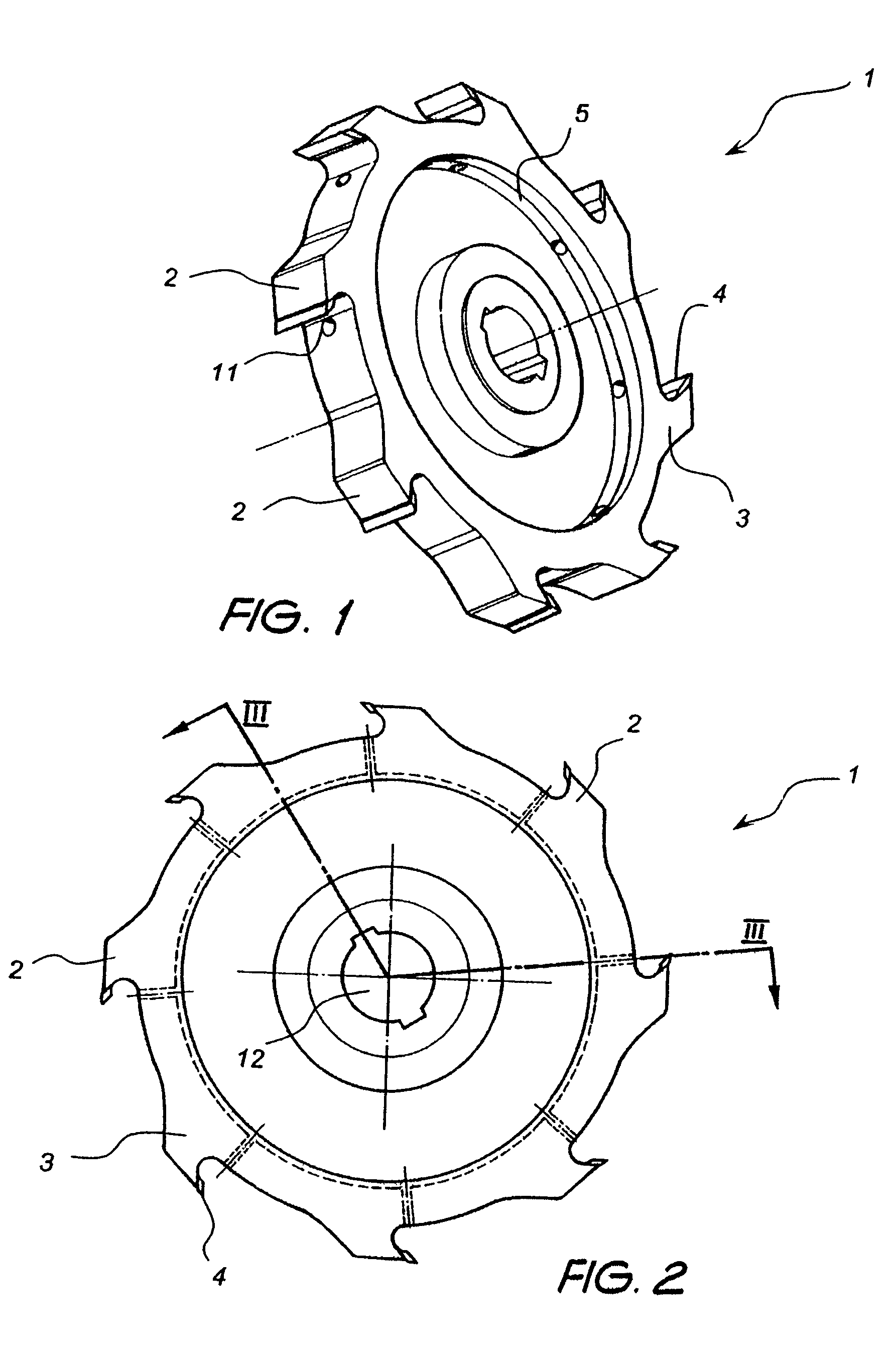

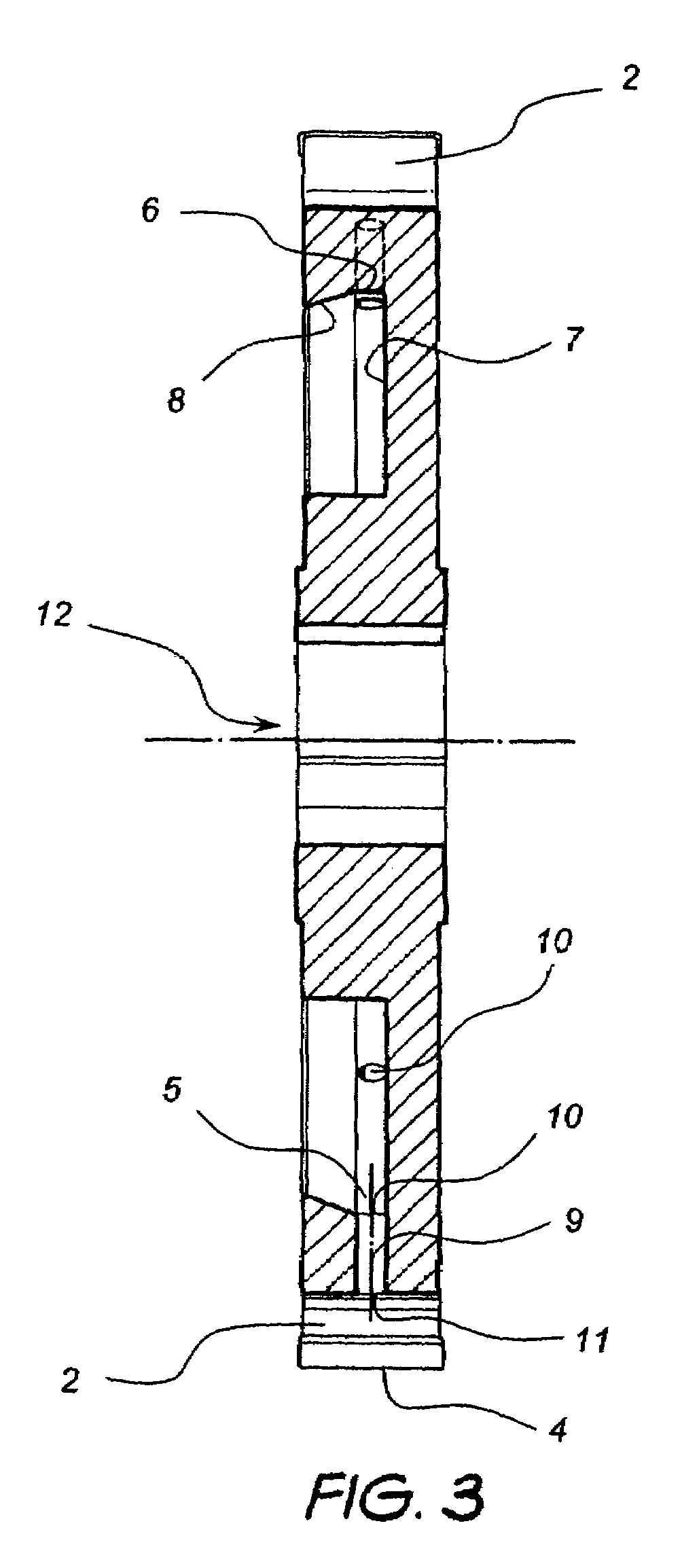

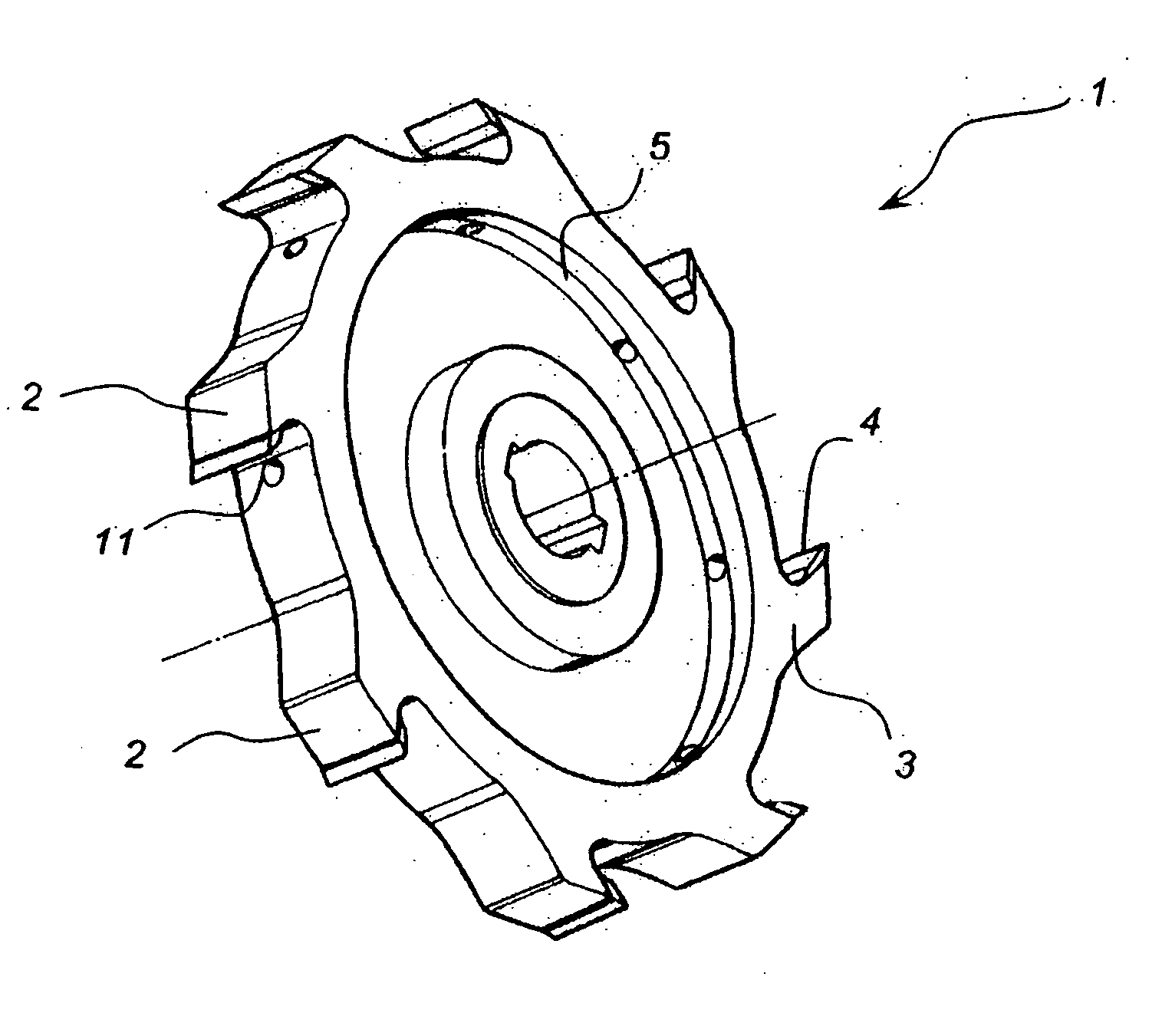

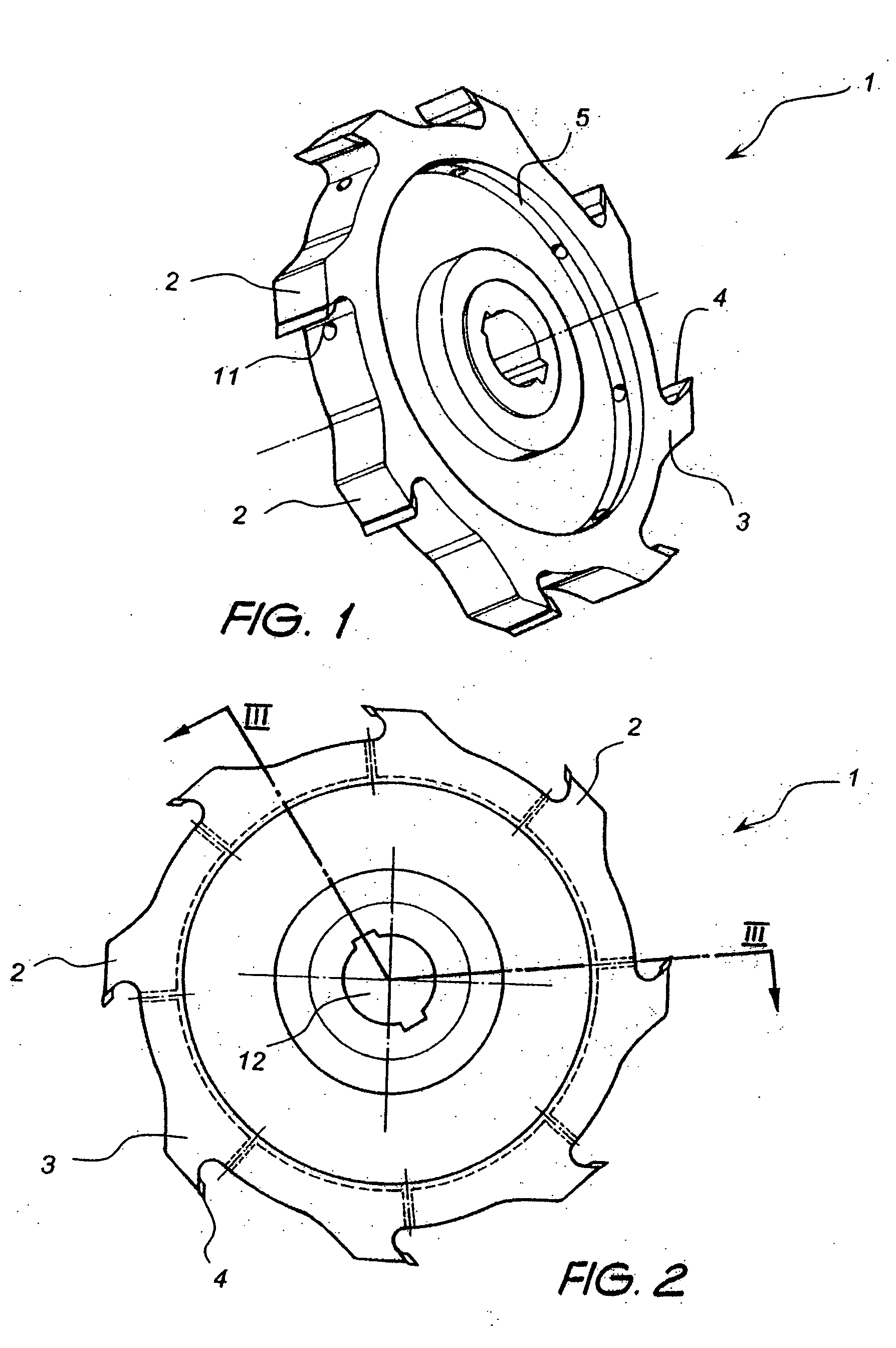

Cutting tool and method of use

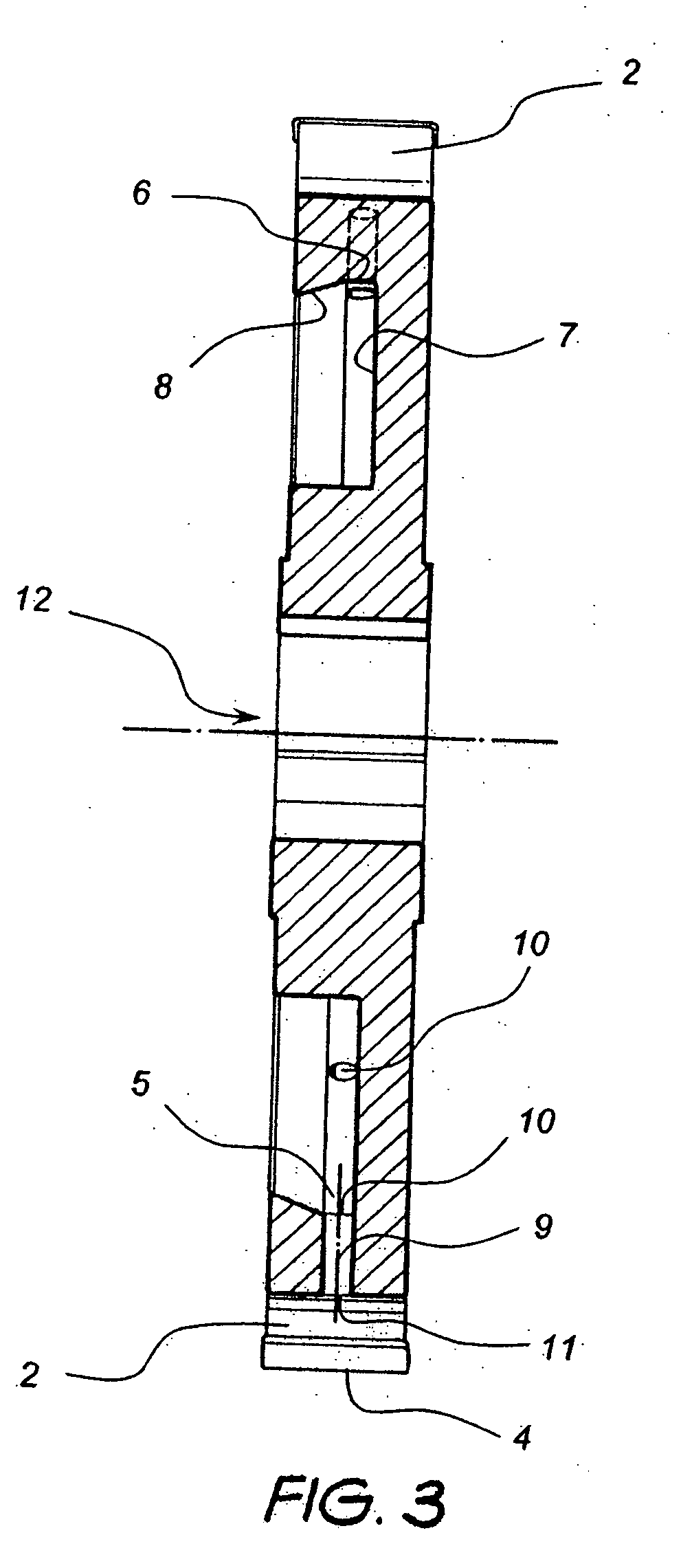

The cutting tool shown generally as 1, has a disc with a peripheral cutting face. In this embodiment the cutting face includes an array of eight circumferentially spaced teeth 2. An open circumferential gutter 5 is located inboard of the teeth and is recessed into a lateral face of the disc. Fluid in the gutter drains into the passageways through the respective inlets under the apparent force due to rotation. A fluid passageway 9 runs between the gutter and the base of the each tooth. The fluid is thereby forced through the passageway and out of outlet 11.

Owner:JAMES HARDIE TECH LTD

Cutting tool and method of use

The cutting tool shown generally as 1, has a disc with a peripheral cutting face. In this embodiment the cutting face includes an array of eight circumferentially spaced teeth 2. An open circumferential gutter 5 is located inboard of the teeth and is recessed into a lateral face of the disc. Fluid in the gutter drains into the passageways through the respective inlets under the apparent force due to rotation. A fluid passageway 9 runs between the gutter and the base of the each tooth. The fluid is thereby forced through the passageway and out of outlet 11.

Owner:JAMES HARDIE TECH LTD

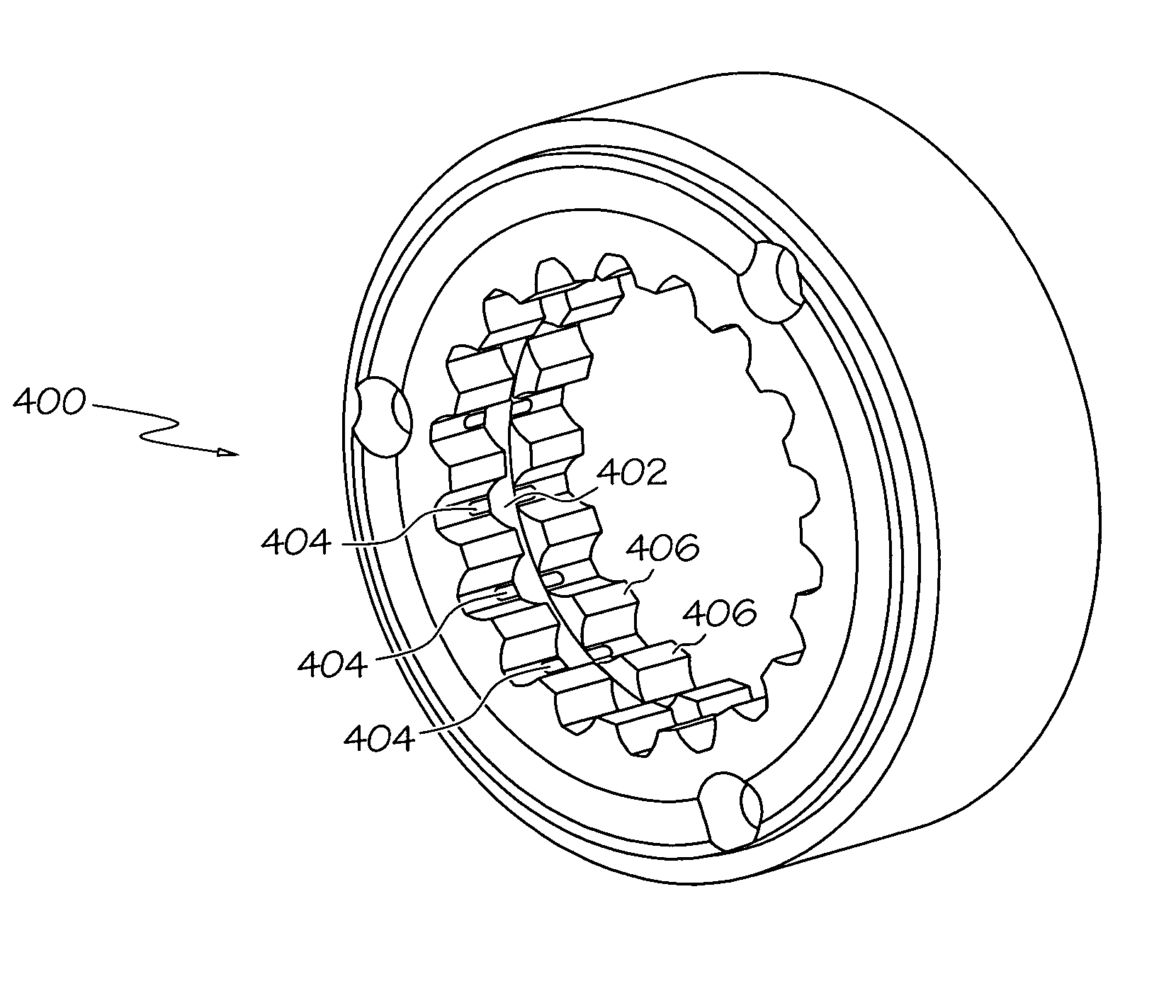

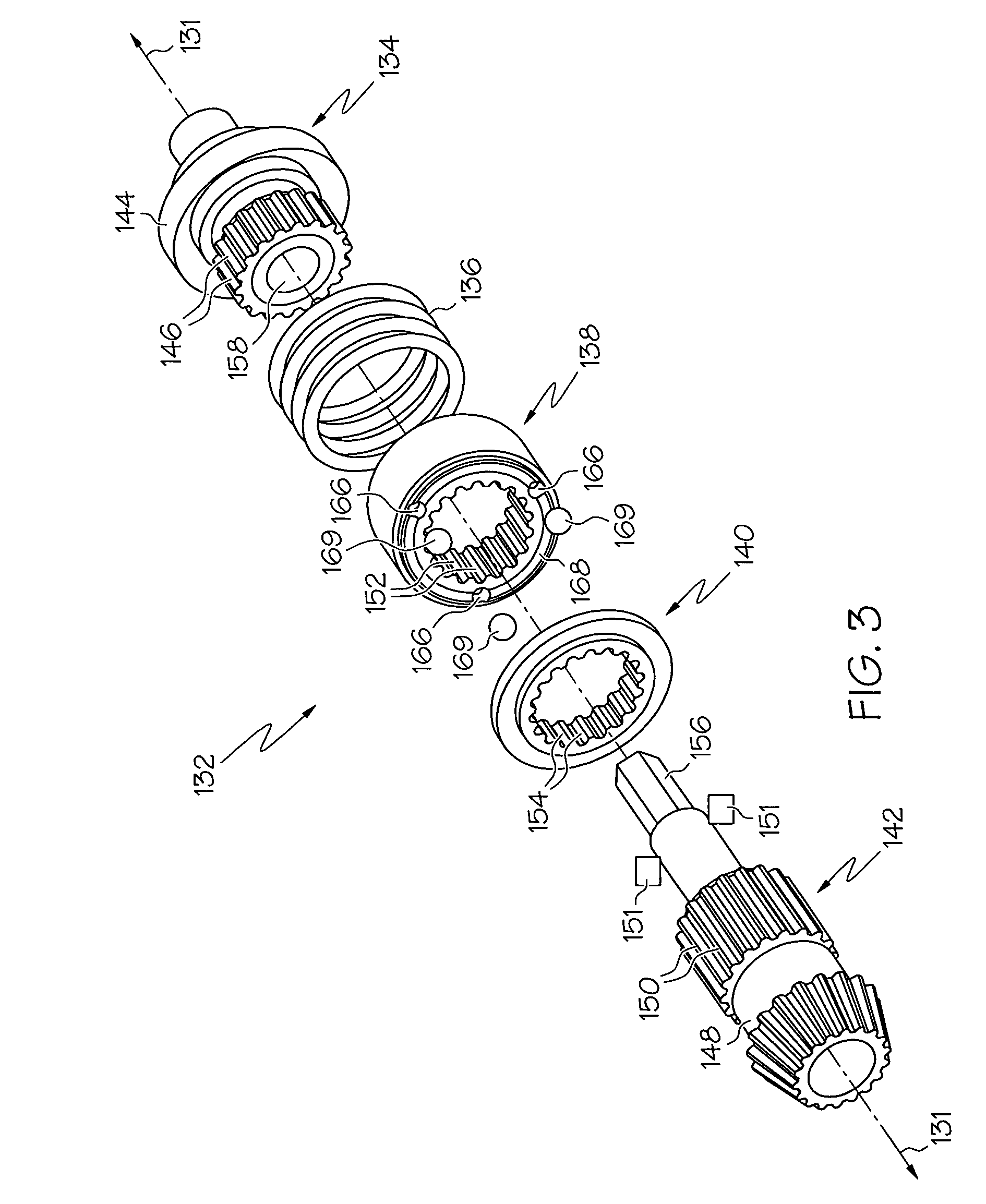

Spline with lubricant retention feature for use in torque limiter

A torque limiter for use on an aircraft comprises a drive shaft having a toothed outer portion, an output shaft, and a spline having an aperture therethrough for receiving the toothed portion. The spline is configured to rotationally couple the drive shaft to the output shaft and to rotationally disengage from the output shaft when the torque at the drive shaft exceeds a predetermined torque threshold. The spline comprises an outer annular portion and an inner annular portion configured to receive a lubricant. The inner annular portion comprises a plurality of circumferentially-spaced tooth structures and root structures. At least one of the root structures has at least one slot therein for receiving and retaining the lubricant.

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com