Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

223 results about "Surface equation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Construction method for digital elevation model for discrete expression of landform on earth surface

InactiveCN101900546AHigh precisionHeight/levelling measurementProfile tracingOriginal dataDiscretization

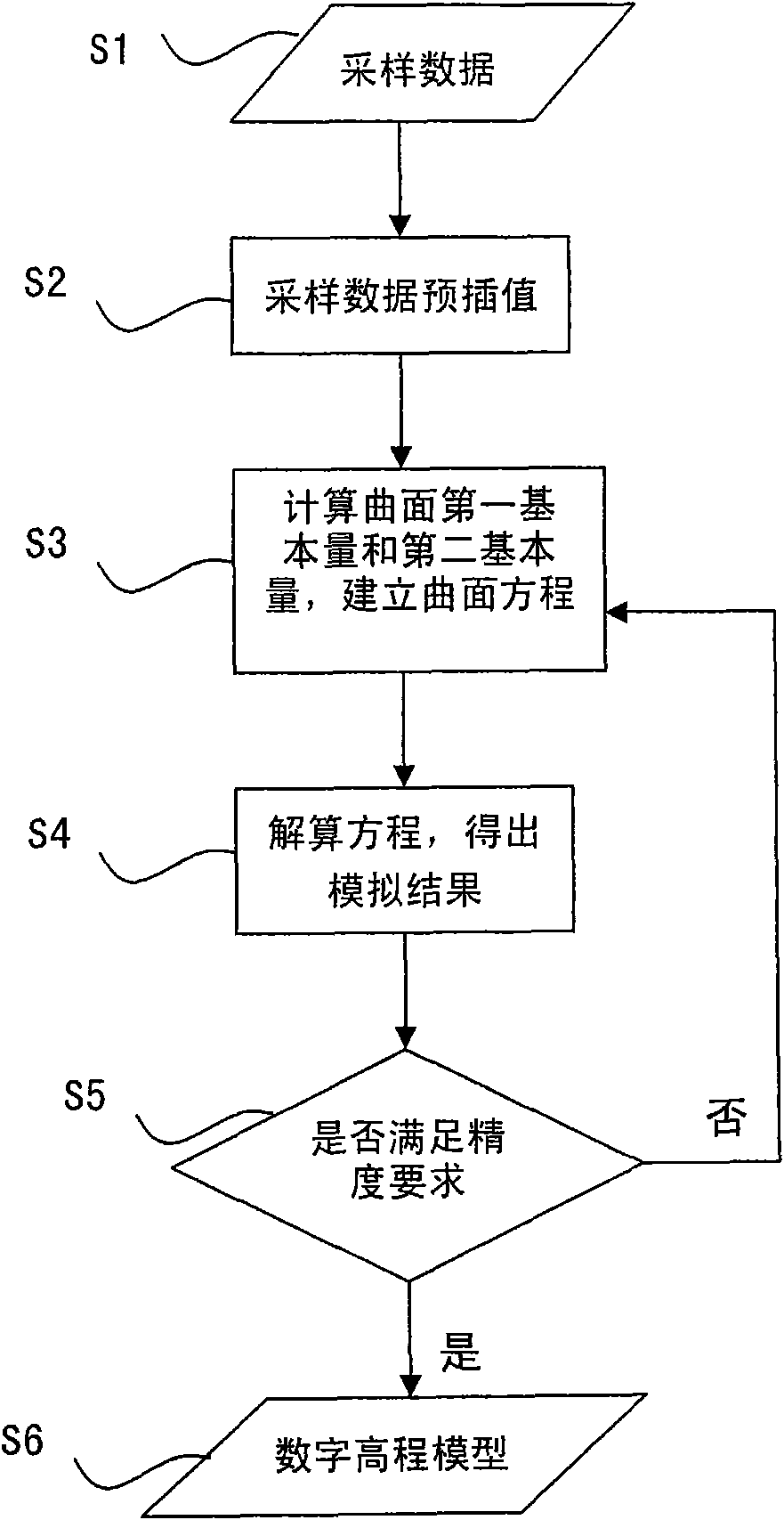

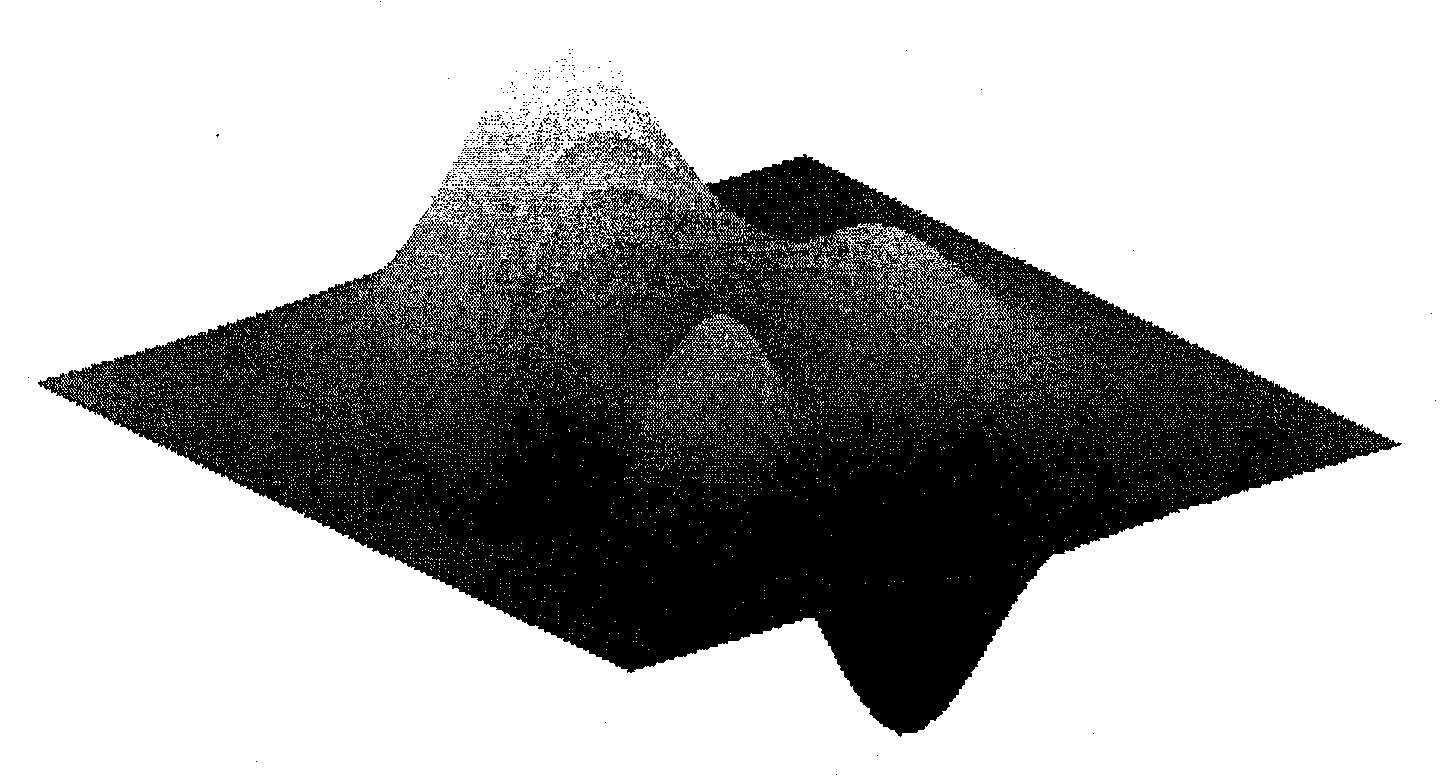

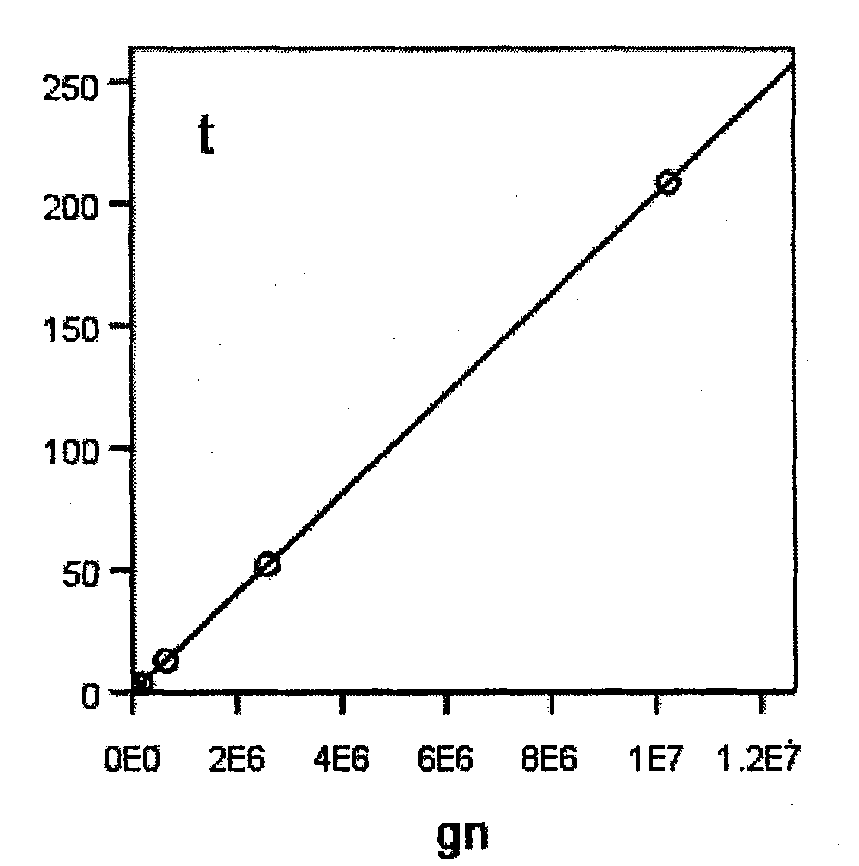

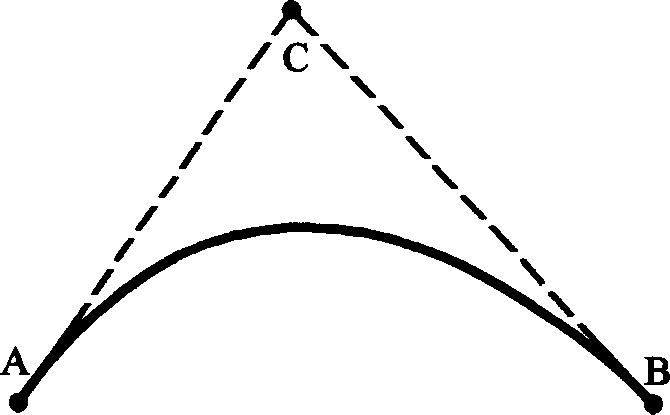

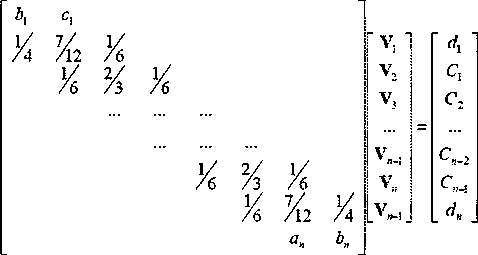

The invention discloses a construction method for a digital elevation model for discrete expression of landform on the earth surface. The construction method comprises the following steps of: extracting elevation values of sampling points from the original data of the earth surface and performing spatial discretization on the elevation values to generate a plurality of landform curved surface grid points of the known elevation values of the sampling points; solving the elevation values of the landform curved surface grid points of non-sampling points; calculating first fundamental quantity and second fundamental quantity of each landform curved surface grid point according to the elevation values of all landform curved surface grid points and establishing a landform curved surface equation set by using a Gauss equation and elevation sampling points; solving the landform curved surface equation set by using a Gauss-Seidel iterative algorithm, wherein a simulation result of the digital elevation model is obtained after each iteration is finished; judging whether the simulation result of the digital elevation model meets the accuracy requirement; if the simulation result meets the requirement, stopping the iterative computation and outputting a group of ordered values to express the digital elevation model of a ground elevation entity in an array form, wherein the digital elevation model is used for the discrete expression of the landform on the earth surface; and if the simulation result does not meet the requirement, repeating the iterative computation.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

Human limb three-dimensional model building method based on image cutline

InactiveCN1617174AReduce computational complexitySimple method3D modellingCircular coneCurve fitting

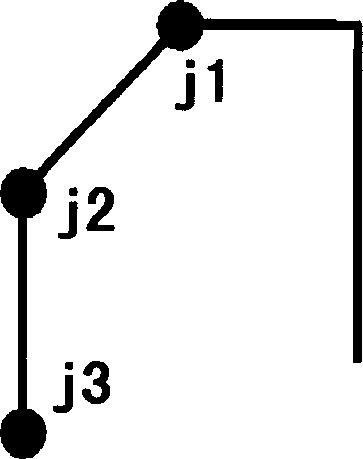

The 3D human limb model building method based on image outline adopts rotating conic curved surface, and has joint points and line segments connecting the joint points to constitute skeleton layer to represent the human limb skeleton structure and rotating conic curved surface to represent the skin layer, with human limb skin deformation being reflected in two deforming parameters. Human limb edge contour information is first extracted from human limb image sequence obtained with binocular stereo vision system, the limb contours of the right and left images in different times are fitted with 2D conic curve, the deformation parameters of 2D conic curve equation are found out, corresponding 3D conic curve equation is found out and made to rotate around the skeleton line to find out the 3D rotating conic curved surface equation, and three spherical bodies and two rotating conic curved surfaces are adopted to draw human limb model. The method is simple and easy to realize.

Owner:SHANGHAI JIAO TONG UNIV

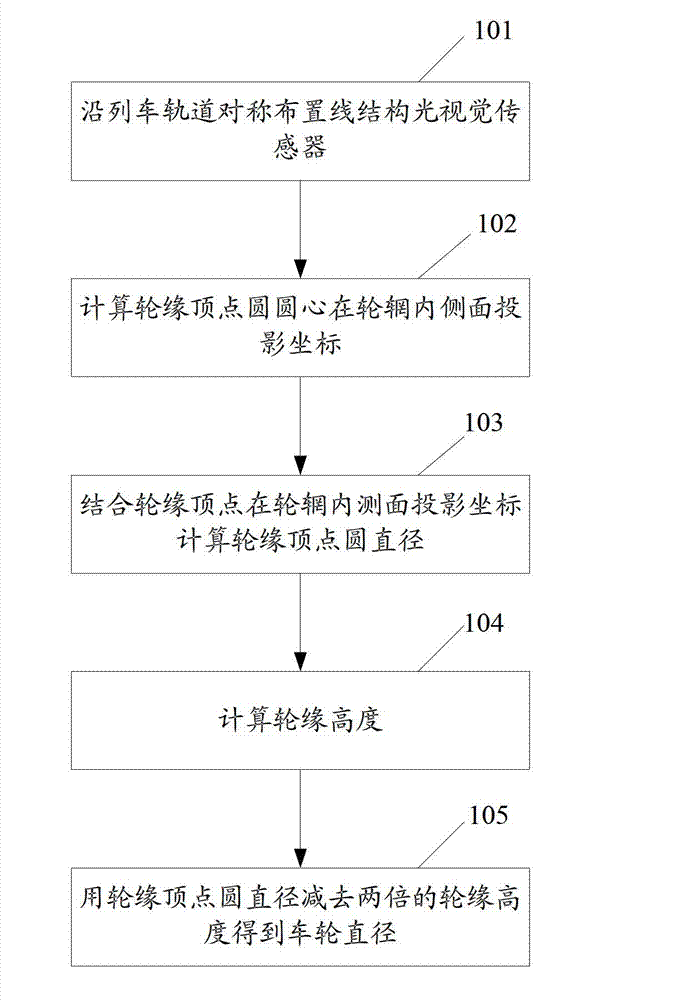

Dynamic measurement method and system for train wheel diameter

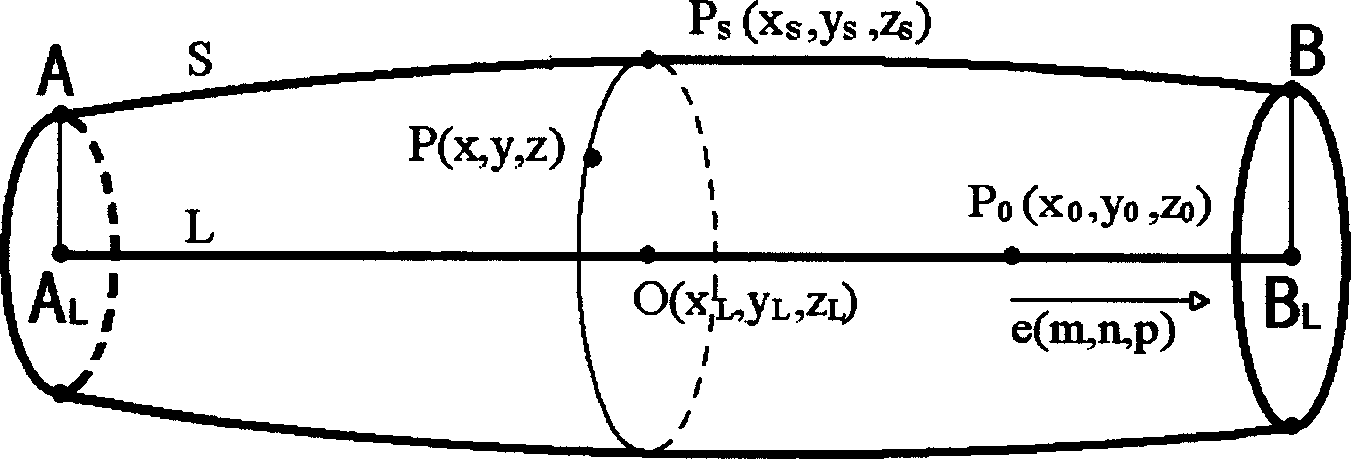

ActiveCN102901457AReduce processing costsLow on-site installation requirementsUsing optical meansContact highStraight segment

The invention discloses a dynamic measurement method for train wheel diameter. The dynamic measurement method comprises the following steps of: symmetrically arranging line-structured light vision sensors along a train track and acquiring light bar images of fracture surface contours of a train wheel and an axle; determining an inner side surface equation of a rim through the light bar of the fracture surface contour of the wheel and a straight segment corresponding to the inner side of the rim, determining an axis equation of the axle through the light bar of the fracture surface contour of the axle, and calculating projection coordinates of the inner side surface of the center of a vertex circle of a wheel flange through the intersection of the axis and the inner side surface of the rim; calculating the diameter of the vertex circle of the wheel flange through projection coordinates of the center of the vertex circle of the wheel flange and the vertex of the wheel flange in the inner side surface of the rim; recovering complete fracture surface contour of the wheel through the light bars of the local contours of the inner side and the outer side of fracture surface of the wheel, and calculating the height of the wheel flange; and subtracting the height of the wheel flange twice from the diameter of the vertex circle of the wheel flange to obtain the diameter of the wheel. The invention discloses a dynamic measurement system for the train wheel diameter simultaneously. The dynamic measurement method and the dynamic measurement system provided by the invention can be adopted for non-contact high-precision dynamic measurement of the train wheel diameter.

Owner:BEIHANG UNIV

Rapid quality inspection method for steel structure based on three-dimensional scanning technology

The invention, which belongs to the technical field of building construction, discloses a rapid quality inspection method for the steel structure based on a three-dimensional scanning technology. Themethod comprises the following steps: step one, performing rapid scanning; to be specific, scanning a component lifting unit rapidly by using a high-precision full-station scanner to obtain point cloud data of the component lifting unit; step two, performing feature point coordinate calculation; to be specific, carrying out plane and cylindrical surface fitting by the point cloud data, establishing plane and cylindrical surface equations, and calculating three-dimensional coordinates of feature point locations; and step three, performing the quality analysis; to be specific, calculating and analyzing the three-dimensional coordinates of feature point locations to obtain three-dimensional coordinates of feature points of the component lifting unit in a construction coordinate system and a design coordinate system, calculating errors of three directions, and determining the splicing quality. According to the invention, plane and cylinder fitting, three-dimensional coordinate calculationof key point locations, and three-dimensional coordinate transformation are carried out to obtain the three-dimensional coordinates of rod nodes of the lifting unit in the design coordinate system; and the component quality of the lifting unit is evaluated based on the coordinate difference of three directions.

Owner:NO 1 CONSTR ENG CO LTD OF CHINA CONSTR THIRD ENG BUREAU CO LTD

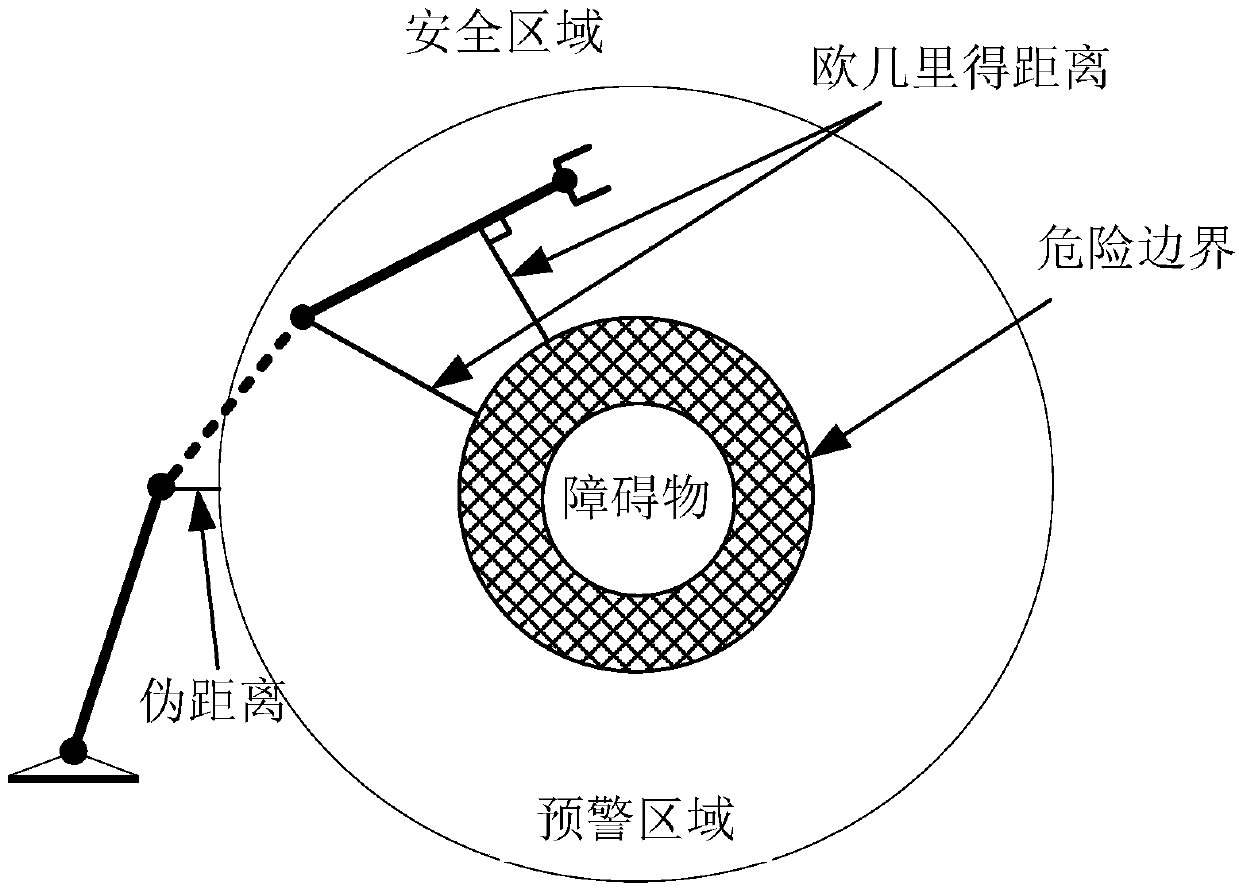

Obstacle avoiding method and system for super-redundant flexible robot and computer storage medium

ActiveCN108908331AImplement obstacle avoidance detectionAchieving processing powerProgramme-controlled manipulatorSimulationEuclidean distance

The invention discloses an obstacle avoiding method and system for a super-redundant flexible robot, and a computer storage medium. The obstacle avoiding method comprises the following steps: modelingan obstacle in a space by using a space super quadratic curved surface equation and a space geometric model respectively; partitioning the space around the obstacle into a safety area, an early-warning area and a danger area by taking the obstacle as the center, wherein a boundary between the safety area and the early-warning area is an early-warning boundary expressed by a super quadratic function, and a boundary between the early-warning area and the dangerous area is a danger boundary expressed by a geometric function; detecting whether the minimum pseudo-distance between the super-redundant flexible robot and the early-warning boundary is less than or equal to zero or not in real time, if so, judging that the super-redundant flexible robot reaches the early-warning area; implementingobstacle avoiding processing on the super-redundant flexible robot; detecting whether the minimum Euclidean distance between the super-redundant flexible robot and the danger boundary is larger than zero or not in real time, and if so, judging that the super-redundant flexible robot avoids the obstacle successfully; finishing the obstacle avoiding plan of the super-redundant flexible robot.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Multibeam depth measuring method based on roll stabilization strategy and system thereof

ActiveCN104181523AReal-time computing is easy to implementEnsuring Beamwidth CoverageRadio wave reradiation/reflectionAcoustic wave reradiationPhase controlTime shifting

The invention provides a multibeam depth measuring method based on a roll stabilization strategy and a system thereof. The multibeam depth measuring method comprises the steps of: a step 101), forming a receiving wavebeam according to a phase control angle beta after rolling stabilization; a step 102) estimating an echo arriving time T0 by means of amplitude phase information of a signal after wave beam formation; a step 103) determining a synthetic wavebeam angle-of-spread gamma of an echo arriving time according to an emitting surface equation and a receiving surface equation; and a step 104) using the synthetic wavebeam angle-of-spread gamma as an initial incidence angle alpha0 of a sound ray, and utilizing echo time T0 for performing sound speed correction and coordinate homing. The step 101) further comprises steps of: step 101-1) receiving a relative gesture yawing phi, a pitch P and a roll R through a sensor in system operation period; and a step 101-2) operating a receiving phase control angle betan=thetan+R according to the roll angle R, and performing time shift wavebeam forming according to the obtained phase control angle.

Owner:INST OF ACOUSTICS CHINESE ACAD OF SCI

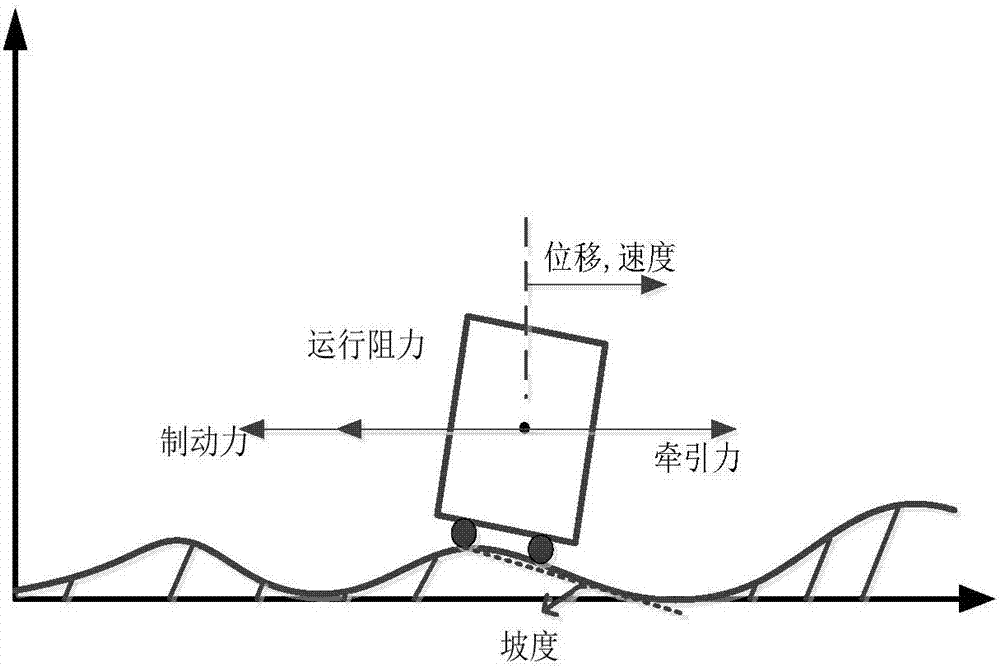

Adaptive fault tolerant control method for train input limitation and actuator fault

ActiveCN106873369AEffective compensation impactEffect attenuation or removalAdaptive controlClosed loopSelf adaptive

The invention discloses an adaptive fault tolerant control method for the train input limitation and the actuator fault. The method comprises the steps that S1, a train longitudinal movement kinetic equation for the train input limitation and the actuator fault is established; S2, approximation to the unknown additional resistance of the train is performed by using a neural network; S3, an approximate PID sliding mode surface is constructed by using an approximate PID sliding mode surface equation; S4, a controller equation, the adaptive law of each unknown parameter estimation value and the parameter equation of the sliding mode surface parameters in the approximate PID sliding mode surface equation are designed; and S5, the approximate PID sliding mode surface equation, the controller equation, the adaptive law of each unknown parameter estimation value of each equation and the parameter equation of the sliding mode surface parameters are substituted in the train longitudinal movement kinetic equation so that a train closed-loop dynamic control equation is obtained, and adaptive fault tolerant control for the train input limitation and the actuator fault is performed by using the train closed-loop dynamic control equation. The train system is enabled to have great position tracking performance and speed tracking performance.

Owner:BEIJING JIAOTONG UNIV

Ground multiline three-dimensional laser radar point cloud data filtering method

InactiveCN105354811AOvercome limitationsSolve ground pointImage enhancementImage analysisPoint cloudRadar

The present invention belongs to a filtering method and particularly relates to a ground multiline three-dimensional laser radar point cloud data filtering method. The method comprises: 1, establishing a ground curve surface equation, i.e. firstly, determining a ground point, then establishing the ground curve surface equation, and finally, fitting relevant parameters to obtain the ground curve surface equation; and 2, filtering out a misjudgement point. The ground multiline three-dimensional laser radar point cloud data filtering method has the effects that the ground multiline three-dimensional laser radar point cloud data filtering method is simple in implementation, is fast in operation speed, overcomes a limitation of a conventional airborne laser radar and ground single-line laser radar point cloud filtering method, and effectively solves the problem of separation between the ground point and a non-ground point of ground multiline laser radar point cloud data; and a filtering effect of the point cloud data is improved.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

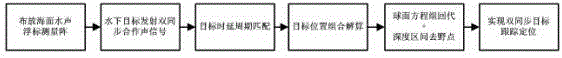

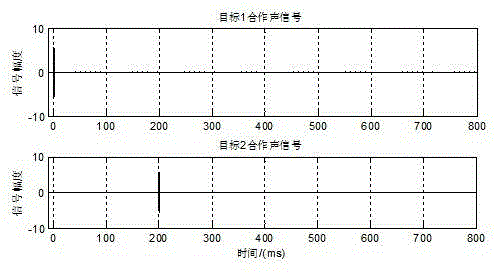

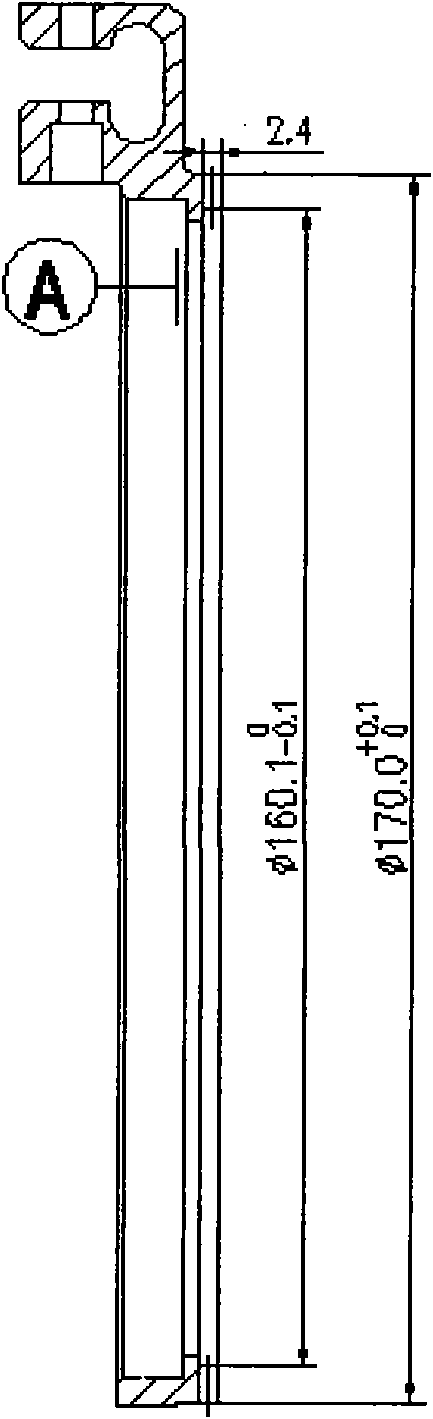

Tracking and positioning method for double-synchronization underwater cooperative targets

The invention relates to a tracking and positioning method four double-synchronization underwater cooperative targets, wherein the system according to the method comprises a sea-level underwater acoustic buoy measurement array and a measurement mother ship. The tracking and positioning method finishes positioning through the following steps: laying the sea-level underwater acoustic buoy measurement array; transmitting a double-synchronization cooperative acoustic signal by underwater targets; receiving returned data of the sea-level underwater acoustic buoy measurement array by the measurement mother ship through a mounted antenna, and finishing target time delay period matching, target position combined resolving, spherical surface equation set solved value returning and target position depth interval by a base station which is composed of a master control computer and an on-ship comprehensive processor, thereby realizing resolving and display to the target position, and realizing tracking and positioning for each underwater target in an area. The tracking and positioning method has functions of effectively reducing frequency band resource required in tracking and positioning multiple underwater targets, reducing confliction or interference between frequency bands used by a positioning system and other mounted equipment, reducing risk in engineering practice, saving designing cost, effectively reducing calculation amount, effectively reducing power consumption of a hardware circuit, and reducing size of the mounted equipment.

Owner:中国人民解放军91388部队

Helical teeth elliptic gear as well as method for three-dimensional model-building accurately and entity shaping producing thereof

The invention relates to an elliptic gear with skewed teeth and a manufacturing method for a three-dimensional precise modeling and an entity shaping thereof, wherein in the method, by simulating the principle that a helical rack is meshed with the elliptic gear with skewed teeth and utilizing that a cutter pitch line plane of a standard normal surface parameter helical rack is always tangent to and keeps a relative generating motion of the pure rolling against a pitch curve cylindrical surface of the skewed tooth elliptic gear blank, a three-dimensional design software precisely shows a space tooth profile curved surface of the elliptic gear with skewed teeth by a helical tooth surface of the helical rack, thereby directly obtaining a three-dimensional model of the elliptic gear with skewed teeth; moreover, the shaping manufacturing entity of the elliptic gear with skewed teeth can be further obtained by utilizing the quick shaping technology. The method of the invention successfully avoids design bottlenecks of the deduction of the complex space curved surface equation of the tooth profile of the elliptic gear with skewed teeth and the corresponding three-dimensional modeling of the space curved surface, and opens up a new shortcut for the precise design and manufacturing of the elliptic gear with skewed teeth.

Owner:DONGHUA UNIV

Face gear hobbing cutter design method based on repeatable cutter grinding

InactiveCN101862867AImprove machining accuracyImprove processing efficiencyGear teeth manufacturing toolsSpecial data processing applicationsHobbingGear wheel

The invention relates to a face gear hobbing cutter design method based on repeatable cutter grinding, which is characterized by comprising the following steps of: (1) selecting basic parameters of a face gear and an involute straight gear meshed with the face gear; (2) according to the point contact face gear transmission gear, confirming the number of teeth of a slotting cutter of the face gear; (3) analyzing and establishing face gear hobbing principle, and establishing face gear hobbing processing coordinate system; (4) according to the face gear slotting cutter tooth surface equation and slotting cutter tooth surface parameters, establishing face gear slotting cutter molded surface fundamental equation; (5) analyzing and studying the face gear slotting cutter molded surface boundary limiting condition, and establishing face gear slotting cutter molded surface parameter numeric area; (6) according to face gear slotting cutter molded surface equation and the slotting cutter molded surface parameter numeric area, discretizing the numerical value of the face gear slotting cutter molded surface equation, and obtaining slotting cutter molded surface integer value point; (7) by meshing discrete digitizing curved surfaces, establishing a face gear slotting cutter worm basic model; and (8) according to the processing accuracy of the face gear, confirming the accuracy grade of the face gear slotting cutter, confirming other cutting parameters of the face gear slotting cutter according to the basic parameters of the face gear slotting cutter, and designing an engineering drawing of the face gear slotting cutter with repeatable cutter grinding. The invention establishes a set of complete face gear hobbing cutter design method, and the designed slotting cutter improves processing accuracy and efficiency of the face gear, has repeatable cutter grinding, prolongs the service life of the cutter, and lays foundation for grinding the face gear.

Owner:王端 +3

Global sliding mode control method of micro gyroscope

InactiveCN103389648ARobustOvercoming non-robust featuresAdaptive controlLyapunov stabilityResponse process

The invention discloses a global sliding mode control method of a micro gyroscope. A global sliding mode control system is established, a signal which can be measured by the micro gyroscope is taken as an input, the stability of a closed-loop system is verified on the basis of a Lyapunov stability theory, and the global sliding mode control is realized through designing a dynamic nonlinear sliding mode surface equation. According to the global sliding mode control, the defect that the sliding mode control doesn't have the robustness when reaching a movement stage is eliminated, so that a system has the robustness in a whole response process, and the disadvantage that a mode reached in conventional sliding mode variable structure control doesn't have the robustness is overcome. According to the control method, the selection of sliding mode coefficients can be simplified, the transient characteristic and the robustness of the sliding mode control system are improved, a closed-loop control system has the global robustness, the contradiction between the transient characteristic and the robustness is resolved, and a powerful foundation is provided for expansion of the application range of the micro gyroscope.

Owner:HOHAI UNIV CHANGZHOU

Vehicle control method and device

The invention provides a vehicle control method and device. The vehicle control method comprises the steps that the current transverse displacement deviation and the transverse angle deviation are determined according to state information of a target vehicle and pavement information of a road where the target vehicle is located; the transverse displacement deviation of the preview position is determined according to the current transverse displacement deviation, the transverse angle deviation and the preview distance; then the sliding mode control rate is determined according to the current transverse displacement deviation, the transverse angle deviation, the transverse displacement deviation of the preview position, a sliding mode switching surface equation and sliding mode control parameters; and finally, through a sliding mode control method and by taking the sliding mode control rate as input, the output steering angle is determined, the target vehicle is controlled according to the steering angle, and the steering angle is used for adjusting the target vehicle to travel along the target path. Due to the fact that the vehicle control method adopts the nonlinear sliding mode control method, the effect of adjusting the traveling trajectory of the target vehicle is more ideal.

Owner:HUAWEI TECH CO LTD

High-rockfill-dam transient-rheological-parameter inversion method based on response surface method

ActiveCN105787174ATo achieve reasonable applicationImprove forecast accuracyDesign optimisation/simulationSpecial data processing applicationsElement modelEngineering

The invention discloses a high-rockfill-dam transient-rheological-parameter inversion method based on the response surface method.The method includes the steps that a rockfill-dam three-dimensional finite element model is built in combination with dam body material sections and construction grading conditions, the sensitivity of the transient parameters and the rheological parameters of rockfill of the material sections is analyzed, and the transient parameters with the high sensitivity and the rheological parameters with the high sensitivity are selected as to-be-inversed parameters jointly; a material static force model is a Duncan EB model, and a rheological model is a Nanjing-Hydraulic-Research-Institute five-parameter model; the implicit relationship between the finite-element-calculated settling volume and the calculation parameters is represented through a specific-form response surface function, undetermined coefficients of a response surface equation set are solved through several times of finite element calculation, and therefore the nonlinear mapping relationship between the settling volume and the calculation parameters is built.On the bases of the response surface equation, the objective function aims at obtaining the minimum root-mean-square error between the calculated settling volume and the practically-measured settling volume, the transient parameters and the rheological parameters are inversed with the genetic algorithm at the same time, and the obtained set of optimal calculation parameters are the inversion result.

Owner:WUHAN UNIV

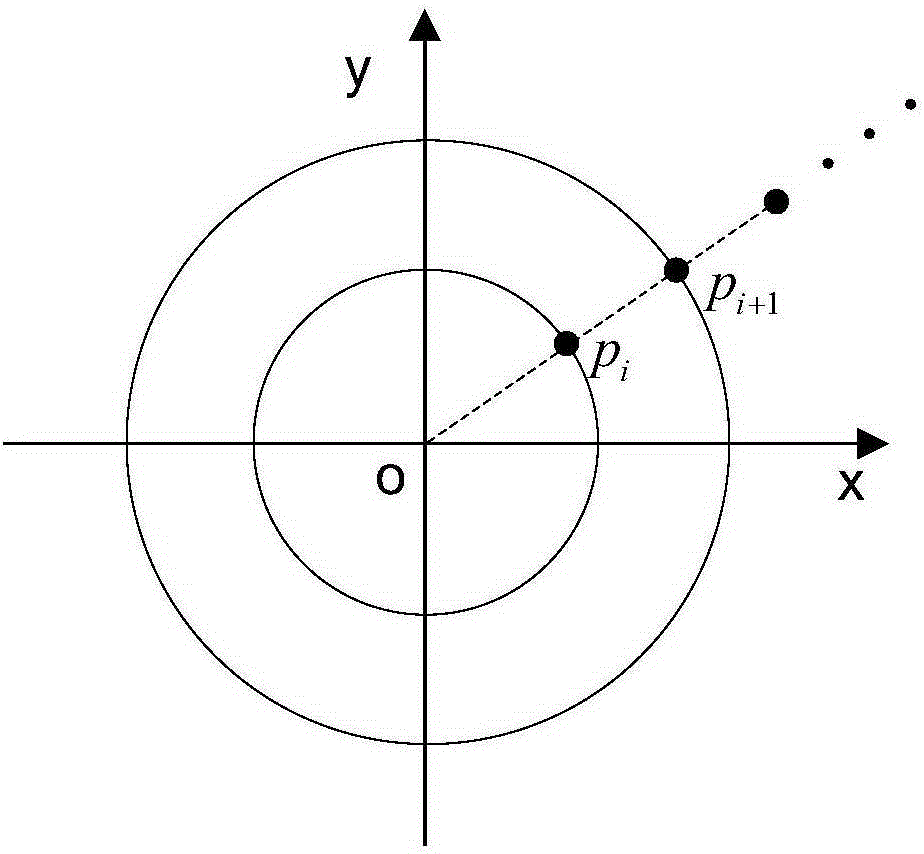

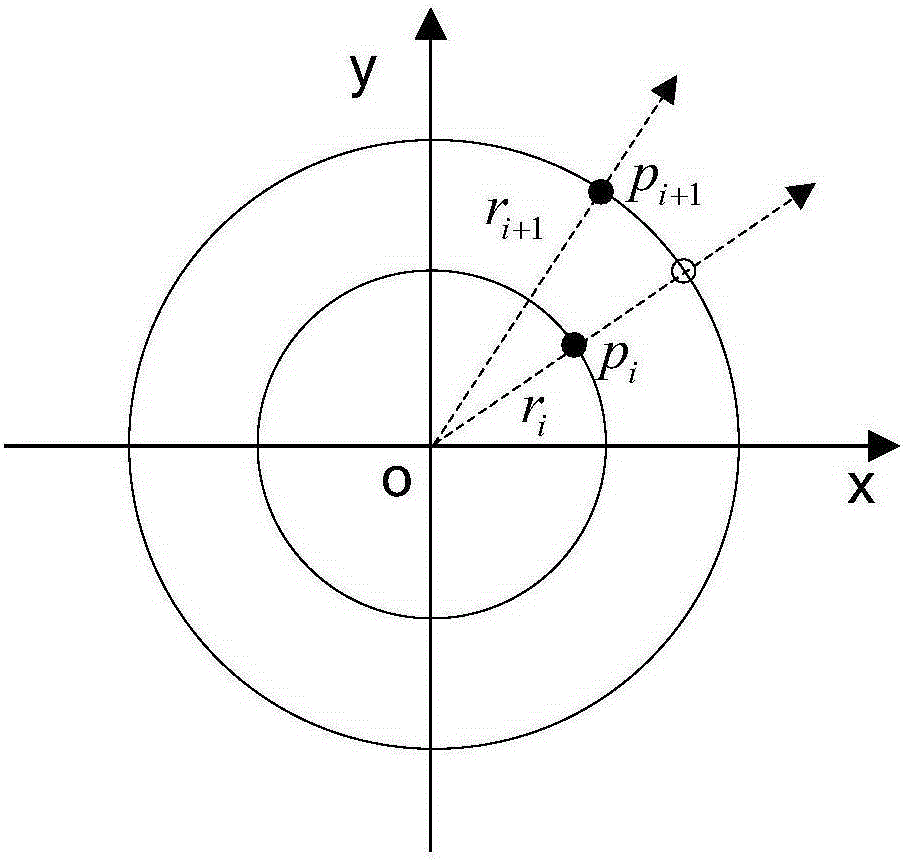

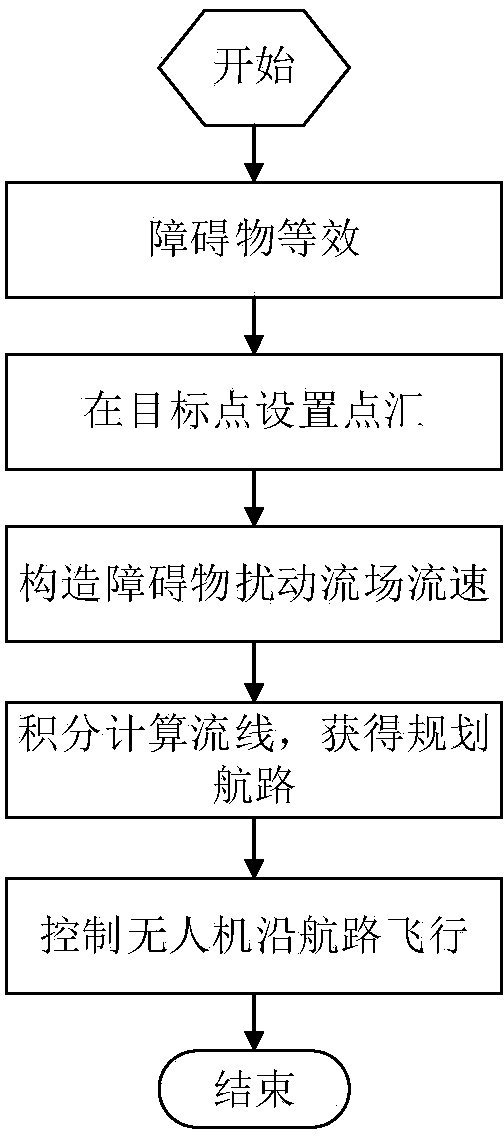

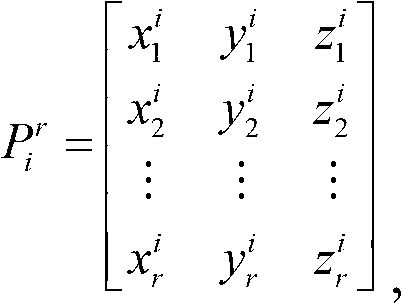

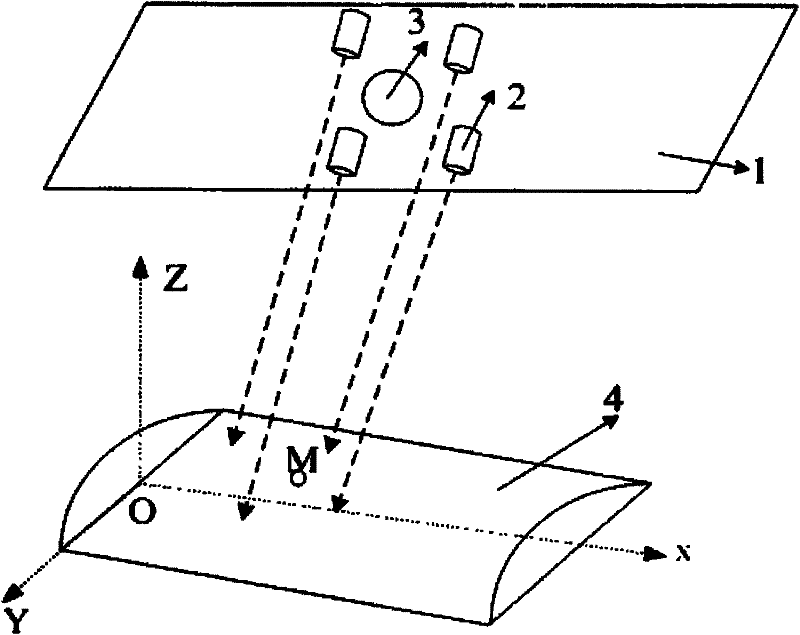

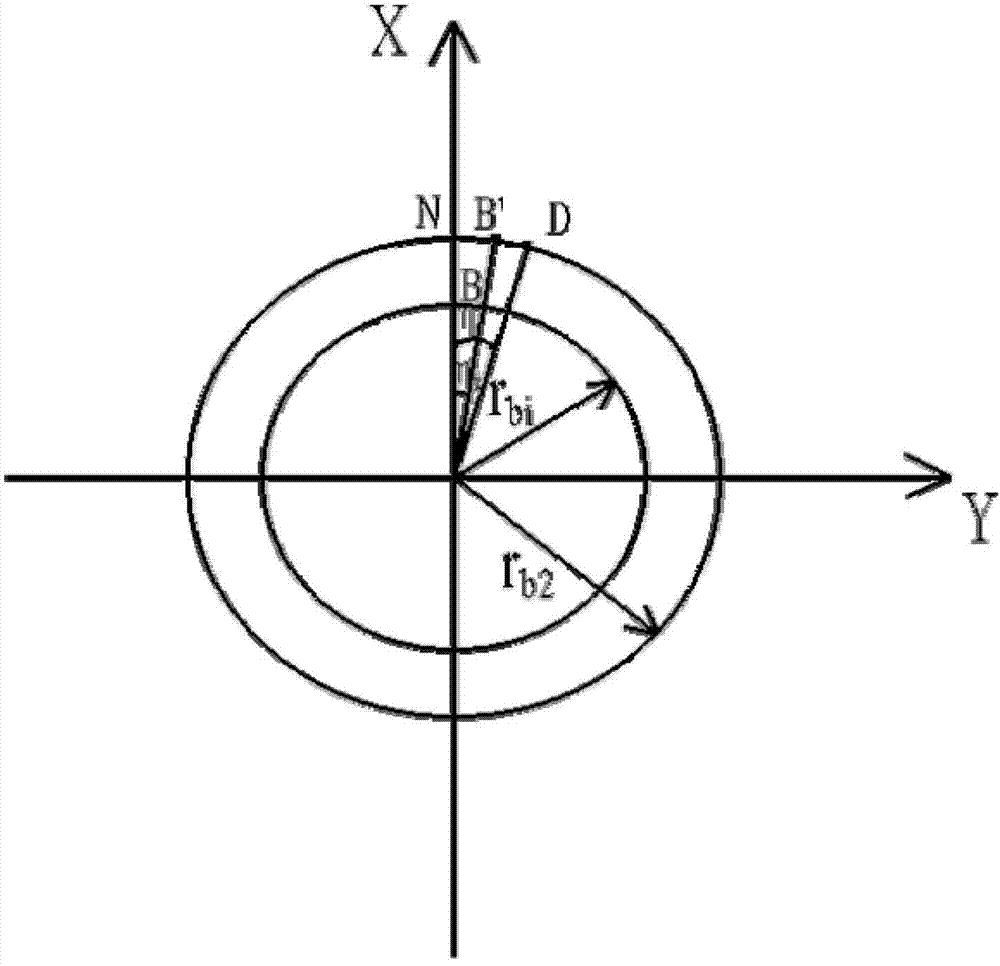

Unmanned plane three dimensional route program method based on disturbed fluid dynamic system

ActiveCN103713642ASolve the blockageImprove solution efficiencyPosition/course control in three dimensionsRadarObstacle avoidance

The invention discloses an unmanned plane three dimensional route program method based on a disturbed fluid dynamic system. An unmanned plane low-attitude flight three dimensional route program problem under a complex landform environment containing enemy ground air defence firepower is abstracted into a three dimensional streamline solution problem during fluid obstacle avoidance. Through the method, solution of a fluid equation having complex boundary conditions is not required, a flow field equation generated by obstacle disturbance is directly constructed, and computational complexity is relatively low. The unmanned plane three dimensional route program method specifically comprises steps that: (1), equivalent processing on an landform obstacle, an enemy radar and a ground firepower threat in an unmanned plane flight area is carried out through regular geometries such as cylinders, cones, balls and parallelepipeds to acquire positions and surface equations of the geometry obstacles; (2), point convergence is set at a target point to acquire a flow field flow velocity under the conditions of no obstacle disturbance; (3), when the obstacle position and the obstacle surface equation are known, a flow field flow velocity after obstacle disturbance is constructed according to non-penetrable conditions of the obstacle; (4), integration for the flow field flow velocity is carried out from a start point to acquire an obstacle avoidance streamline from the start point to a target point, and the obstacle avoidance streamline is taken as the unmanned plane flight route; and (5), the unmanned plane is controlled to flight along the programmed route.

Owner:BEIHANG UNIV

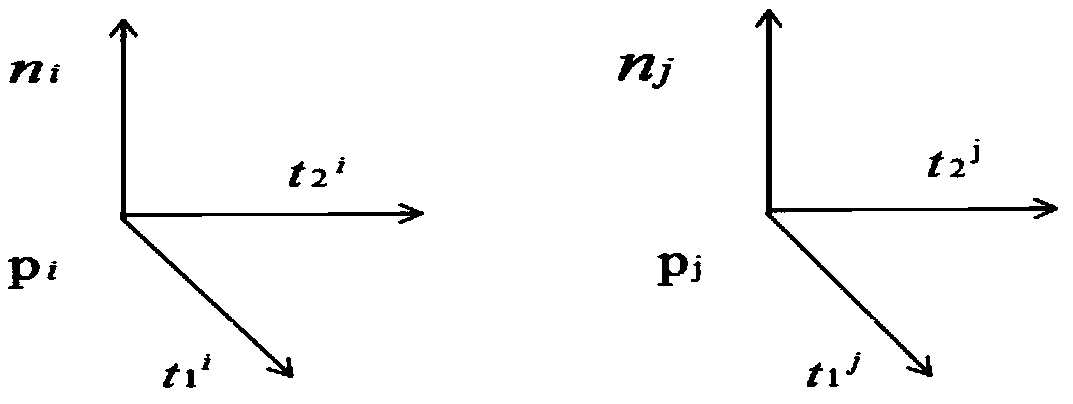

Point cloud posture standardization-based method for extracting linear characteristic of point cloud

InactiveCN102799763AImprove search efficiencyImprove feature extraction efficiencyUsing optical meansSpecial data processing applicationsMachine visionFeature extraction

The invention provides a point cloud posture standardization-based method for extracting the linear characteristic of point cloud, which comprises six steps, is used for extracting the linear characteristic in disordered and three-dimensional point cloud, can conveniently measure the relative posture of a target, and belongs to the technical field of the three-dimensional measurement and the machine vision. The method comprises the following steps of: firstly, building a KD-TREE structure of point cloud, so that the searching speed of the adjacent point set of the point cloud can be improved; secondly, building the adjacent point set of each point according to the density of the whole point cloud, obtaining the main direction of the point set, and building a Householder transformation matrix to adjust the posture of the point cloud; thirdly, carrying out surface fitting on the adjacent point set to obtain two main curvature of the point based on a curved surface equation, and selecting the main curvature with the higher absolute value as the curvature estimation of the point; and finally, obtaining the curvature estimation value of all point cloud, and taking the point which is larger than a given threshold value as a linear characteristic point, so that the linear characteristic can be extracted.

Owner:BEIHANG UNIV

Method for determining normal vector of wallboard curved surface

InactiveCN102411336AEasy to solveEliminate problems such as interferenceProgramme controlComputer controlControl systemMATLAB

The invention provides a method for determining a normal vector of a wallboard curved surface. According to the method, a theoretical normal vector of a wallboard curved surface is obtained by a numeral control system of an automatic drilling and riveting machine; and then, four range-finding sensors are used to measure coordinates of four characteristic points; and a secondary curved surface equation of the wallboard is fit based on coordinate optimization of the four characteristic points and a to-be-drilled riveting point, so that an actual normal vector of the to-be-drilled riveting point can be solved. According to the invention, a range-finding sensor mode is employed to carry out measurement and possible problems like interference and the like are eliminated, wherein the problems are caused by contact measurement. Besides, a secondary curved surface optimization fitting is utilized; and the solution efficiency is high and the speed is fast. In practice, it only takes 0.047 seconds to measure and determine a normal vector of single drilled riveting point by using a complied MATLAB program and there is little time consumption; and normal vectors of lots of different drilled riveting points on a same wallboard can be rapidly and accurately measured.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for conveniently realizing variable curvature accurate drum correcting of parameterized involute straight bevel gear

InactiveCN103034751AEasy to implement parametric modelingImprove carrying capacitySpecial data processing applicationsNumerical controlElement modeling

A method for conveniently realizing the variable curvature accurate drum correcting of a parameterized involute straight bevel gear belongs to the field of gear production. The scheme fully utilizes ANSYS / LS-DYNA, Imageware, Matlab and Solid works to realize the accurate modeling of a variable curvature drum shape correcting straight bevel gear model, moreover, according to a variable curvature drum shape tooth surface equation which is derived by the method, programming is carried out based on the uniform B-spline surface equation theory so as to realize the parametric modeling of a variable curvature drum correcting tooth surface, the accuracies of the shape correcting straight bevel gear model and subsequent finite element modeling are improved, and shape correcting straight bevel gear products or die electrodes are directly processed through a numerical control technique; and for a straight bevel gear pair, a drive gear is only subjected to the variable curvature shape correcting, a driven gear is not corrected, so that the design and processing difficulty of the shape correcting gear are reduced.

Owner:UNIV OF JINAN

Wall type large target surface bullet coordinate test system

InactiveCN101245983ASave spaceAvoid damageAmmunition testingUsing optical meansData acquisitionOptoelectronics

The invention discloses a wall-mounted projectile targeting coordinates testing system with a large target surface, which comprises a testing light curtain array of six intersected light curtains, a data collecting and analyzing system, a computer and display processing software. The wall-mounted projectile targeting coordinates testing system adopts an LED array that is arranged in an approximate arc as a light source (L) and forms a lens-typed light curtain detector (D) by coordinating an optical lens with a rectangular slit diaphragm and a photoelectric receiving device, thus forming a single large light curtain detecting scene (S); six array light sources and the lens-typed light curtain detector are hung on a wall with indoor target lanes and arranged in a certain geometrical shape, and the testing light curtain array is formed in the target lane space. When a projectile runs through the light curtain array, the data collecting and analyzing system collects a projectile targeting signal, and according to a spatial curtain surface equation, the targeting coordinates of the projectile running through the target surface are obtained. The wall-mounted structure of the wall-mounted projectile targeting coordinates testing system with the large target surface has convenient protection, avoids the damage of the target body that is caused by a live firing test, greatly saves the space of the target lane, and can successfully solve the indoor target lane testing problem of heavy-caliber projectiles, exuviates bullets and flame tracers.

Owner:XIAN TECHNOLOGICAL UNIV

Real-time rendering method of algebra B-spline surface

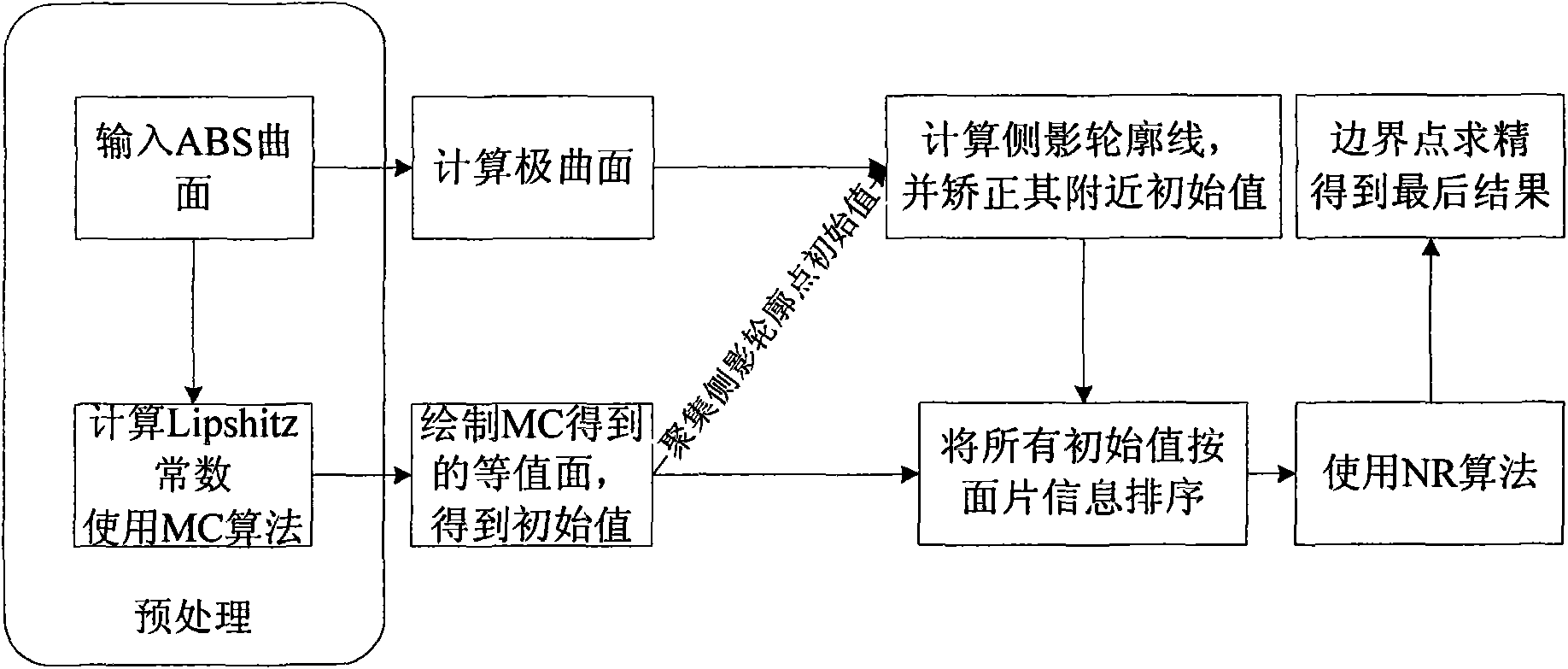

InactiveCN101599181AHigh quality displayGuaranteeing the effect of quadratic convergence3D-image renderingRelevant informationIntersection of a polyhedron with a line

The invention discloses an ABS real-time rendering method based on NR iterative algorithm, comprising seven steps: 1) inputting the relevant information of ABS to be rendered and calculating the Lipschitz constant, and converting ABS into piecewise Bezier surface patches; 2) using MC algorithm to extract the iso-surface of ABS; 3) calculating the polar surface of ABS in real time; 4) rendering iso-surface to obtain the iso-surface and the initial values of the silhouette contour line of the iso-surface; 5) aggregating the initial values of the silhouette contour line of the iso-surface, according to ABS and the polar surface equation thereof, using NR iterative algorithm to calculate the initial silhouette contours, so as to be obtain the silhouette contour line with floating point precision, and correcting the silhouette contour line; 6) calculating the intersections of each pixel sight line of the silhouette contour line and Bezier surface; 7) by NR iterative algorithm, using adjacent Bezier surfaces information to iterate and get accuracy, so as to obtain right intersections of all light and algebra B-spline surface, and then using the intersections information, the relative location of light source and viewpoint, and the material of a curved surface itself to calculate illumination. The method of the invention can realize the rendering of an algebraic surface for arbitrary frequency.

Owner:ZHEJIANG UNIV

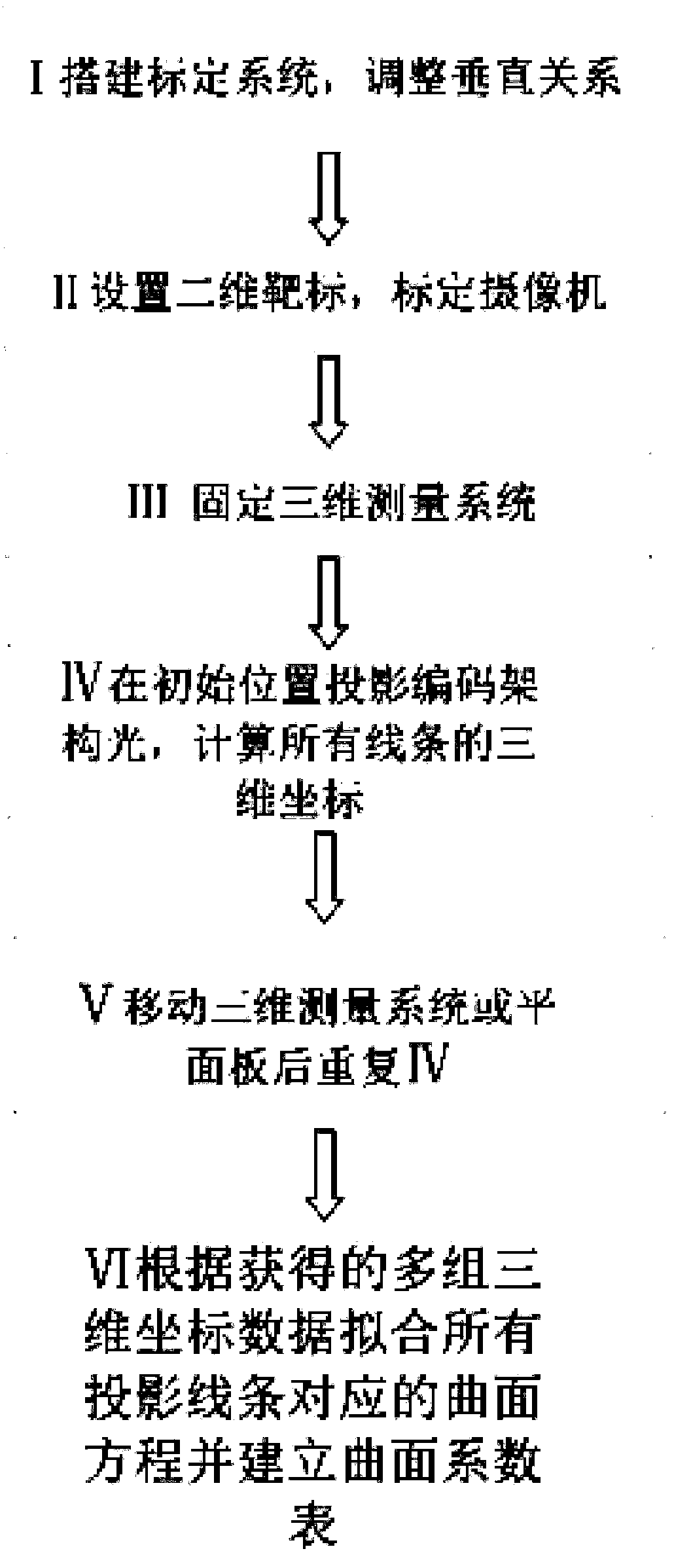

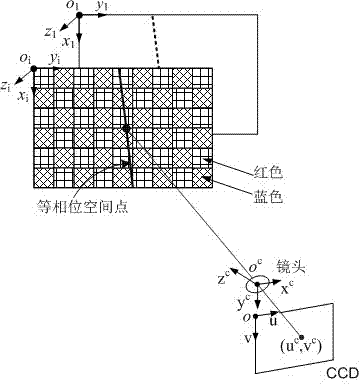

Calibration method of linear structured light three-dimensional measurement system

ActiveCN108458671AAvoid the effects of solvingImprove accuracyUsing optical meansImaging processingThree dimensional measurement

The invention relates to a calibration method of a linear structured light three-dimensional measurement system. According to the calibration method, a camera is calibrated according to a conventionalmethod, so that the internal parameters and external parameters of the camera can be obtained; coded structured light is projected onto the plane plate of a calibration system through using a projector; the sub-pixel-level coordinates of all lines in a photo which are projected by the projector are obtained by means of image processing or decoding; a line-plane equation is established according to the internal parameters and the external parameters of the camera; the three-dimensional coordinates of all the projected lines on the plane plate are calculated through line-plane intersection points; after the three-dimensional measurement system or the plane plate is moved, the three-dimensional coordinates of all the projected lines after the system or the plane plate is moved are obtained;and surface fitting is performed on each projected line according to the obtained three-dimensional coordinate data, and the surface equations of light surfaces formed by all the projected lines are obtained; and a surface coefficient table is established with the coefficients of the surface equations, and calibration is completed. With the calibration method adopted, the influence of the bendingof a line source can be eliminated. The method has the advantages of simple and quick calibration process, easiness in operation, error small and high calibration accuracy.

Owner:XI AN ZHISENSOR TECH CO LTD

NURBS (Non-Uniform Rational B-Splines)-curved surface description-based five-axis linkage 3D printing method

InactiveCN107457995AAchieve preparationAdditive manufacturing apparatusManufacturing data aquisition/processingComputer graphics (images)3d printer

The invention discloses an NURBS (Non-Uniform Rational B-Splines)-curved surface description-based five-axis linkage 3D printing method which comprises the following calculating steps: 1, obtaining a basic surface curved surface equation of the bottom of a workpiece; 2, planning a printing route; 3, determining coordinates of all points on a curved surface; 4, determining coordinates of the top end of a printing head; and 5, determining rotational coordinates. According to the NURBS-curved surface description-based five-axis linkage 3D printing method provided by the invention, a curved surface function can be directly generated based on the curved surface of an object, and curved surface printing data are generated with a five-axis linkage 3D printer based on the curved surface function; one curved surface is printed for each layer; and the NURBS-curved surface description-based five-axis linkage 3D printing method is applicable to printing of complicated curved surfaces and objects of which printed parts having non-planar bottoms.

Owner:ANYANG INST OF TECH

Microwave near-field medicine body detecting method and use thereof

The invention relates to a testing method of microwave near-field medical body, which is characterized in that through a difference time-domain method, relevant information between direct wave and scattered wave is extracted by the use of a finite element confocal imaging method to process the finite element segmentation of an imaging region, and then time delay from each antenna to each grid is calculated to obtain a grid group accords with a three-dimensional trajectory surface equation. According to the superposition of the grid group after the intersection of a plurality of trajectories, the position of early breast tumor of the female is determined. Compared with commonly used X ray, CT or nuclear magnetic resonance (NMR) at present, the testing method of microwave near-field medical volume proposed by the technical proposal can reliably determine the three-dimensional spatial location of the early breast tumor of the female and also cause much less damage to human bodies.

Owner:EAST CHINA NORMAL UNIV

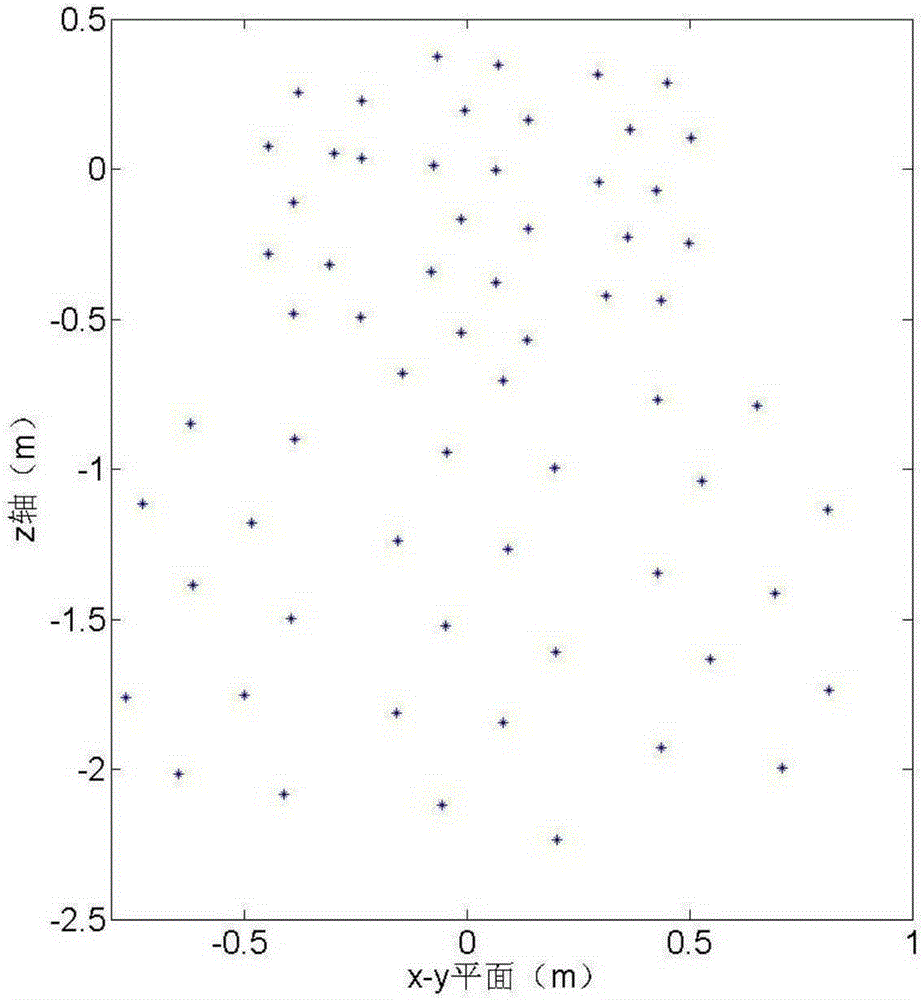

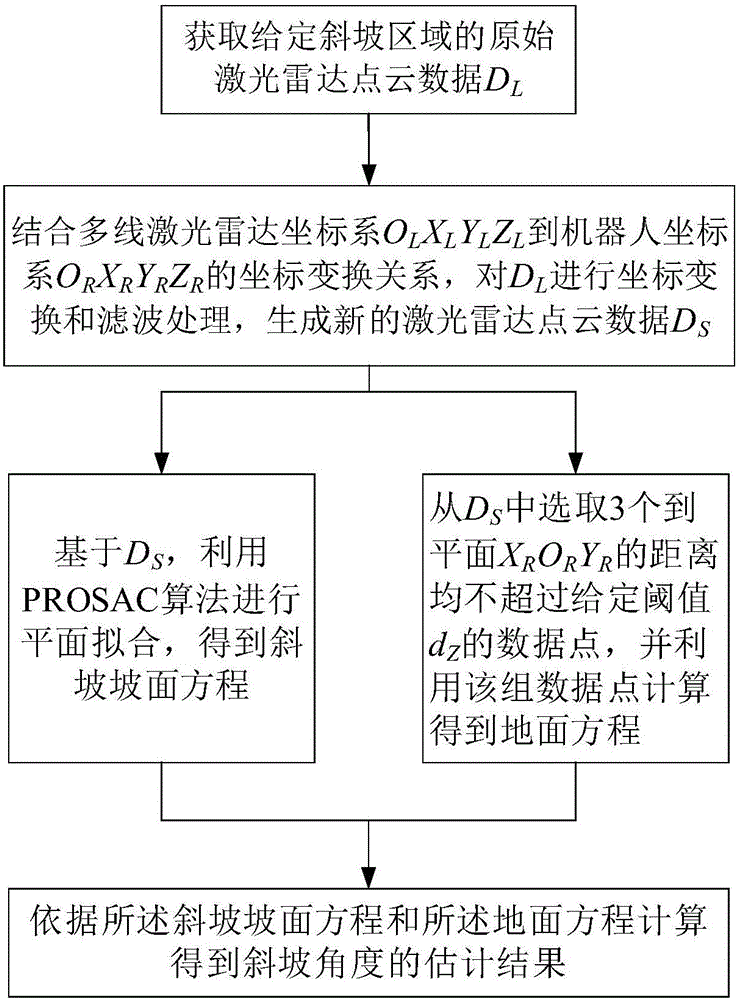

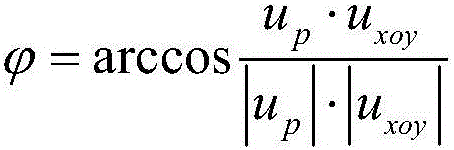

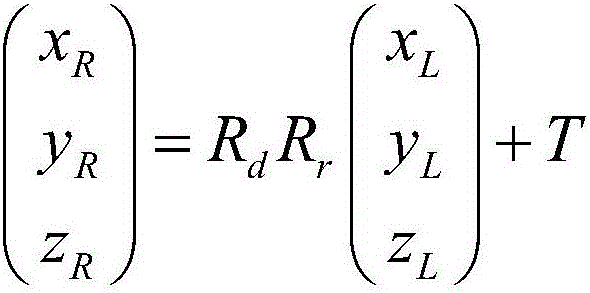

Slope angle estimation method for slope region based on multiline laser radar

ActiveCN106646508AQuality improvementElectromagnetic wave reradiationIncline measurementEuclidean vectorSurface equation

The invention discloses a slope angle estimation method for slope region based on a multiline laser radar, and the method comprises the steps: obtaining original laser radar point cloud data DL of a given slope region; carrying out the coordinate transformation and filtering of the DL through combining with the relation of coordinate transformation from a multiline laser radar coordinate system OLXLYLZL to a robot coordinate system ORXRYRZR, and generating new laser radar point cloud data DS; carrying out the plane fitting through a PROSAC algorithm based on DS, and obtaining a slope surface equation; selecting three data points from the DS, and calculating a ground equation through the data points, wherein the distances between the data points and a plane XRORYR do not exceed a given threshold value dZ; and calculating a slope angle estimation result according to the slope surface equation and the ground equation. The method obtains the distance information of the slope region through the multiline laser radar, achieves the estimation of the slope angle based on a slope surface normal vector, improves the estimation quality of the slope angle, and provides technical support for the application of robot environment understanding.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Method for achieving scene three-dimensional reconstruction by directly using phase with non-linear error

ActiveCN103942830ALoose requirementsAvoid errorsImage analysis3D modellingPhase correctionSurface fitting

The invention discloses a method for achieving scene three-dimensional reconstruction by directly using a phase with a non-linear error. The method comprises the steps of for each given absolute phase value, calculating three-dimensional coordinates of spatial points with the absolute phase value in different depths in a scene area, and carrying gout surface fitting. When reconstruction is carried out, a corresponding surface equation is found according to the phase values of spatial points to be reconstructed, the surface equation and a sight line equation determined by video camera image pixel coordinates are combined, the three-dimensional coordinates of the spatial points are obtained through solution, and therefore the scene three-dimensional reconstruction is achieved. According to the method, the three-dimensional reconstruction is carried out by directly using the phase with the non-linear error, the situation that errors are generated due to the fact that an assumptive model does not conform to actual response situations of a projector in a phase correction method is avoided, and the precision of reconstruction is improved.

Owner:ZHEJIANG UNIV

A 3D point cloud recognition method based on B-spline surface similarity detection

InactiveCN109447100AAchieve high-precision recognitionEfficient identificationCharacter and pattern recognitionPoint cloudSpectral clustering algorithm

The invention relates to a 3D point cloud recognition method based on B-spline surface similarity detection, which is characterized in that the method comprises the following steps of1 modeling and fitting the three-dimensional point cloud by using B-spline surface equation; 2 sampling that fitting B-spline surface by adopt different parameter sampling methods; 3 calculating a similar point by defining a geometric local characteristic of a description point, and carry out point-to-point matching; 4 calculating the equidistant distance between the features of the calculated point pairs; 5 classifying that equidistant transformation types of two point in a point pair; 6 comparing equidistant point pairs after equidistant classification; 7 applying that spectral clustering algorithm to obtainthe local correspond similar parts among the objects, and completing the detection of the similar area; 8 judging whether the proportion of the similarity point cloud and the sampling point cloud islarger than the set threshold value to complete the identification of the whole point cloud. The method of the invention realizes efficient and accurate object recognition.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Spur gear profile modification method based on thermal elastic deformation of gear teeth and deflection deformation of gear

ActiveCN107025367AHigh shape accuracyExtended service lifeGeometric CADPortable liftingCouplingEngineering

The invention discloses a spur gear profile modification method based on thermal elastic deformation of gear teeth and deflection deformation of a gear. The spur gear profile modification method comprises the following steps: 1, establishing a three-dimensional model of a gear based on UG; 2, introducing the gear three-dimensional model into finite element software, and analyzing thermal elastic coupling deformation of the gear under a working condition; 3, establishing an overall three-dimensional model of a gearbox based on UG; 4, introducing the three-dimensional model of the gearbox into the finite element software, and analyzing stress deformation of the gearbox under a working condition; 5, analyzing deformation of a tooth surface in different directions because of comprehensive deformation of the gearbox, and analyzing deformation characteristics; 6, taking influence characteristics of the thermal elastic deformation and deflection deformation inside different planes of the gear to tooth surface stress into profile modification; and 7, taking the thermal elastic deformation and the deflection deformation of the tooth surface inside a tangent plane into account, acquiring a profile modification curved surface equation, and performing profile modification. By adopting the method, the modification precision of a spur gear working under a high-speed heavy load working condition is improved, the uniform distribution situation of a tooth surface load is effectively improved, and the service life of the gear is prolonged.

Owner:SHANXI PINGYAO REDUCER

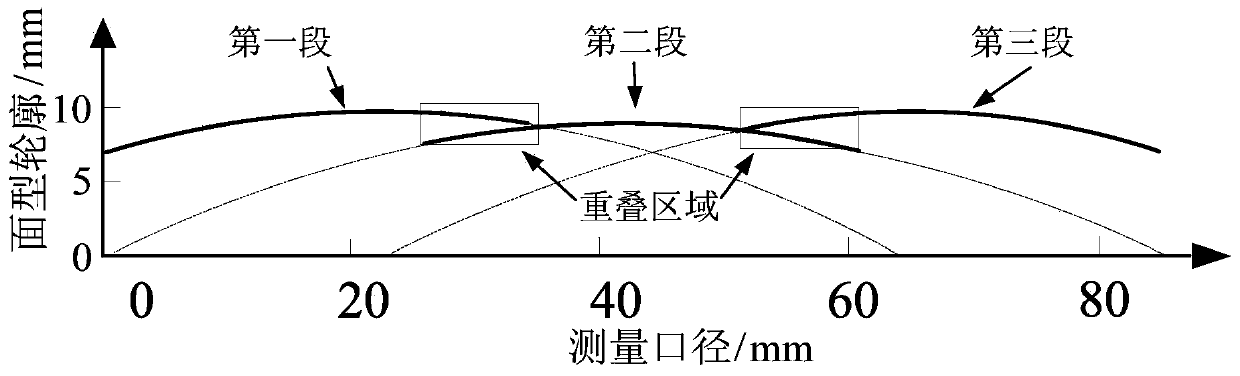

Method for measuring contour of large-caliber aspheric surface optical element at grinding stage

The invention discloses a method for measuring the contour of a large-caliber aspheric surface optical element at the grinding stage, and relates to the field of aspheric surface optical element measurement. A contour line of the large-caliber aspheric surface optical element at the grinding stage is divided into sections, the number of the sections is set to be M, and overlapping areas need to be reserved between every two adjacent sections and are set to be p1, p2, ..., pm-1. The divided M sections are respectively measured through a measuring device, and the measuring data of each section are obtained. The measuring data of the divided M sections of the large-caliber aspheric surface optical element are spliced based on the multi-body system theory, the Taylor series, the principle of least squares and the data of the overlapping areas. Redundant data, produced when the sections are spliced, of the overlapping areas are removed based on the curvature principle and the aspheric surface equation least square fit method. The contour of all the sections with the redundant data removed is comprehensively optimized, and the overall measuring result of the contour of all the sections is obtained.

Owner:XIAMEN UNIV

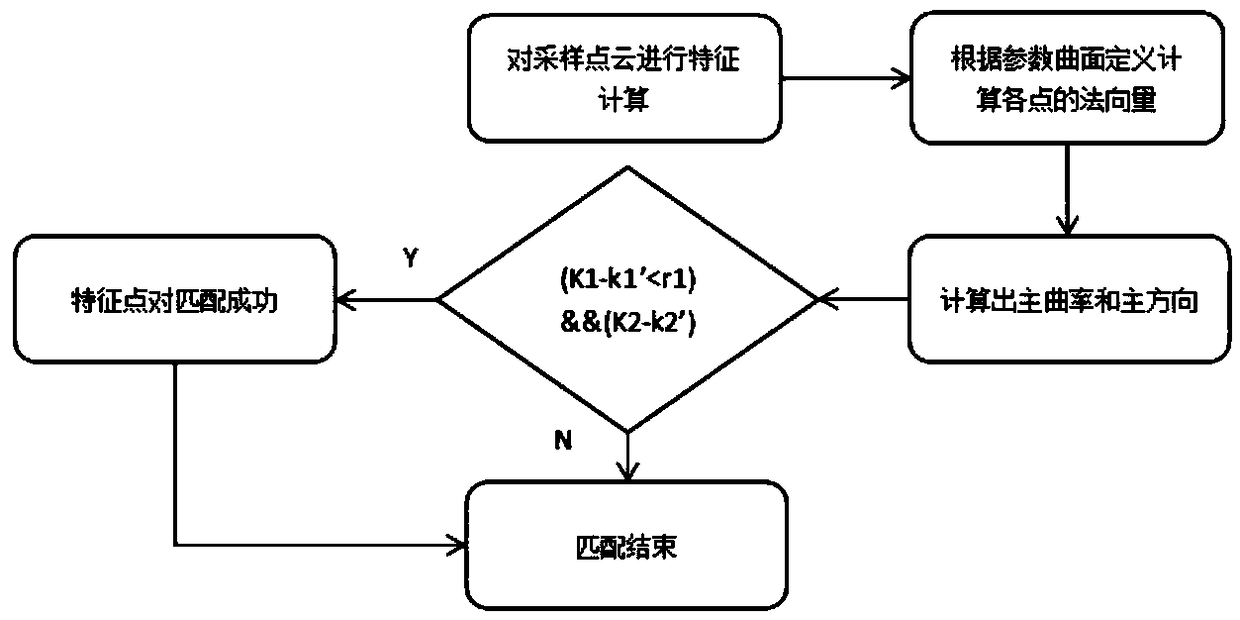

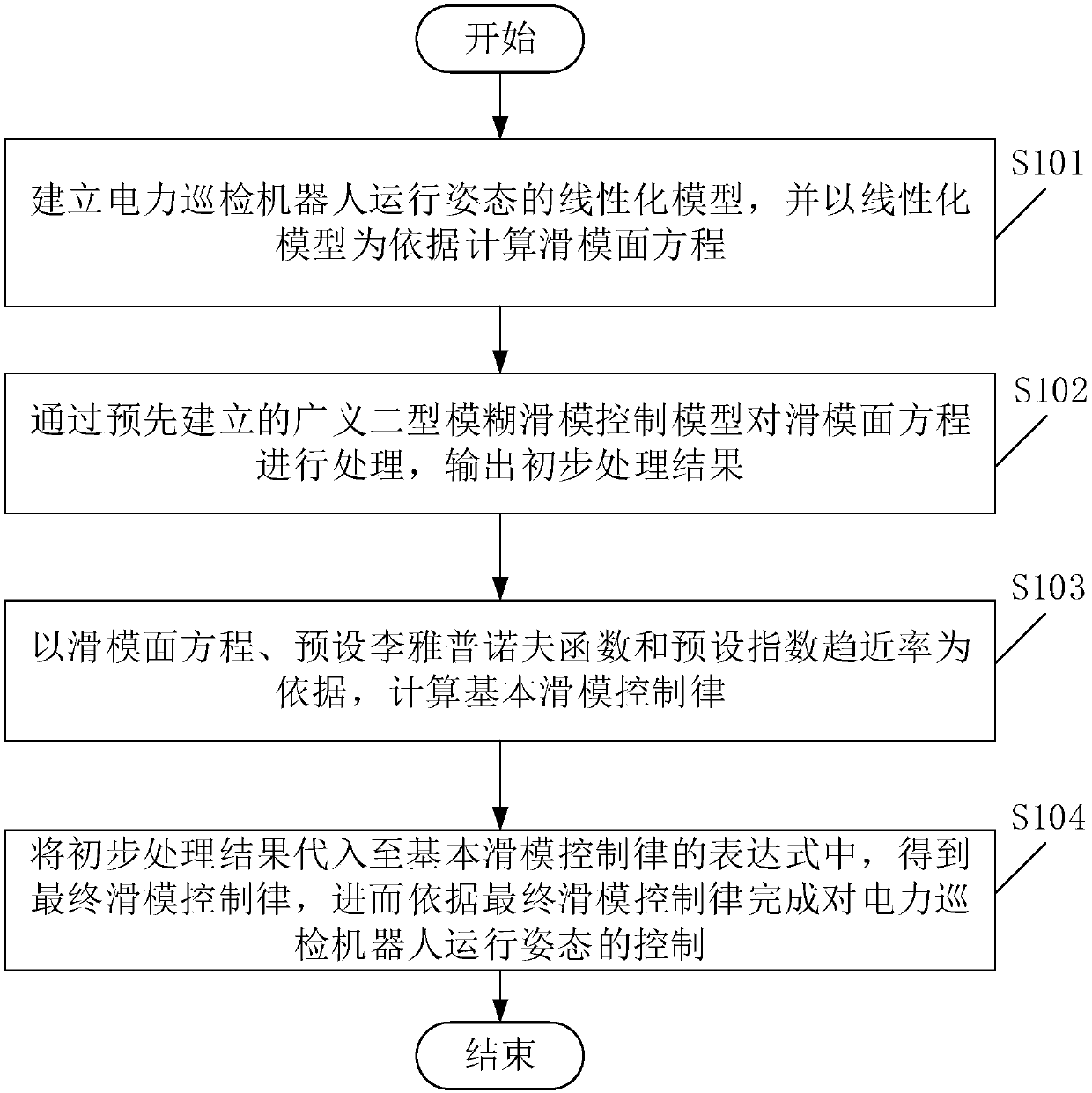

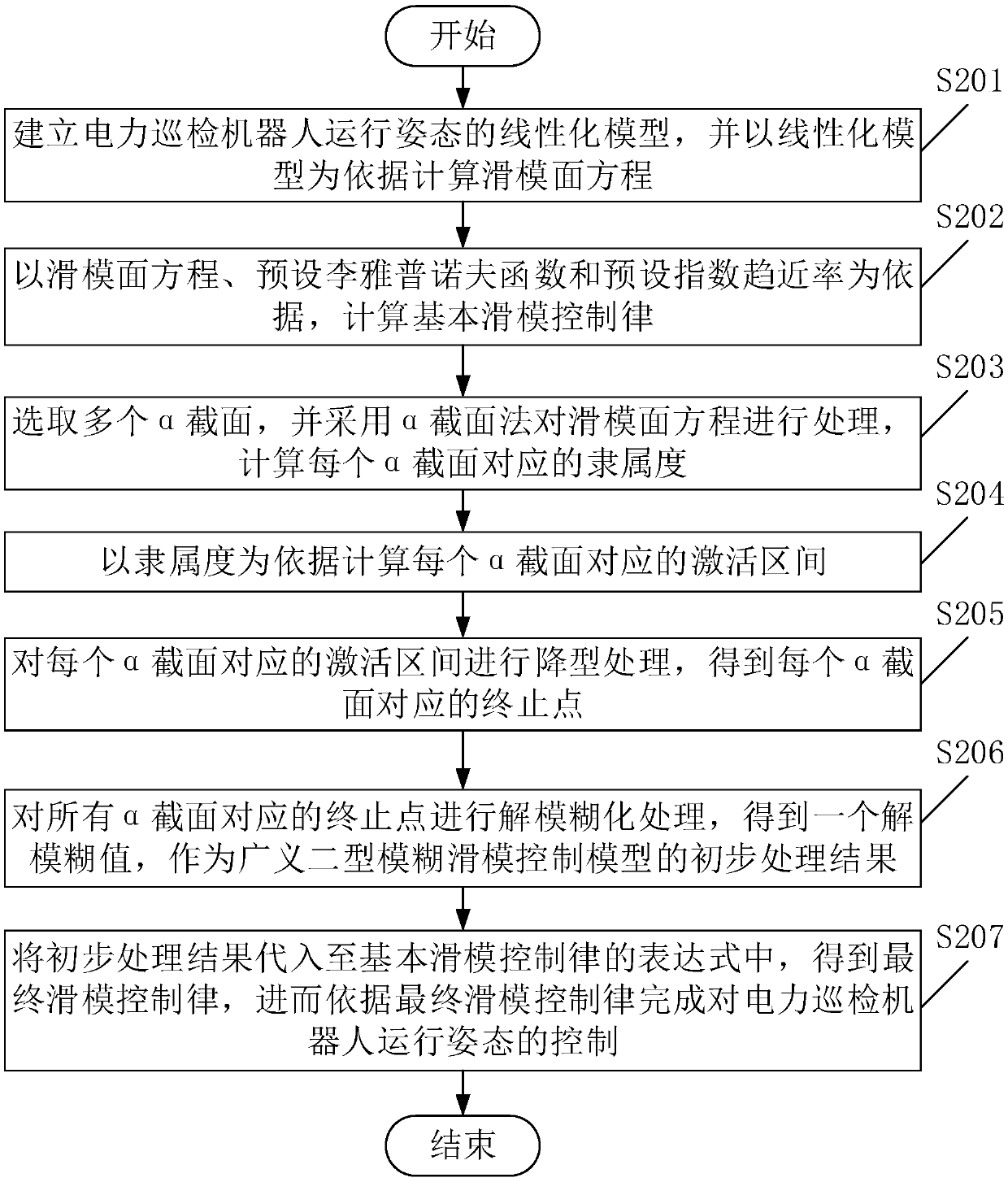

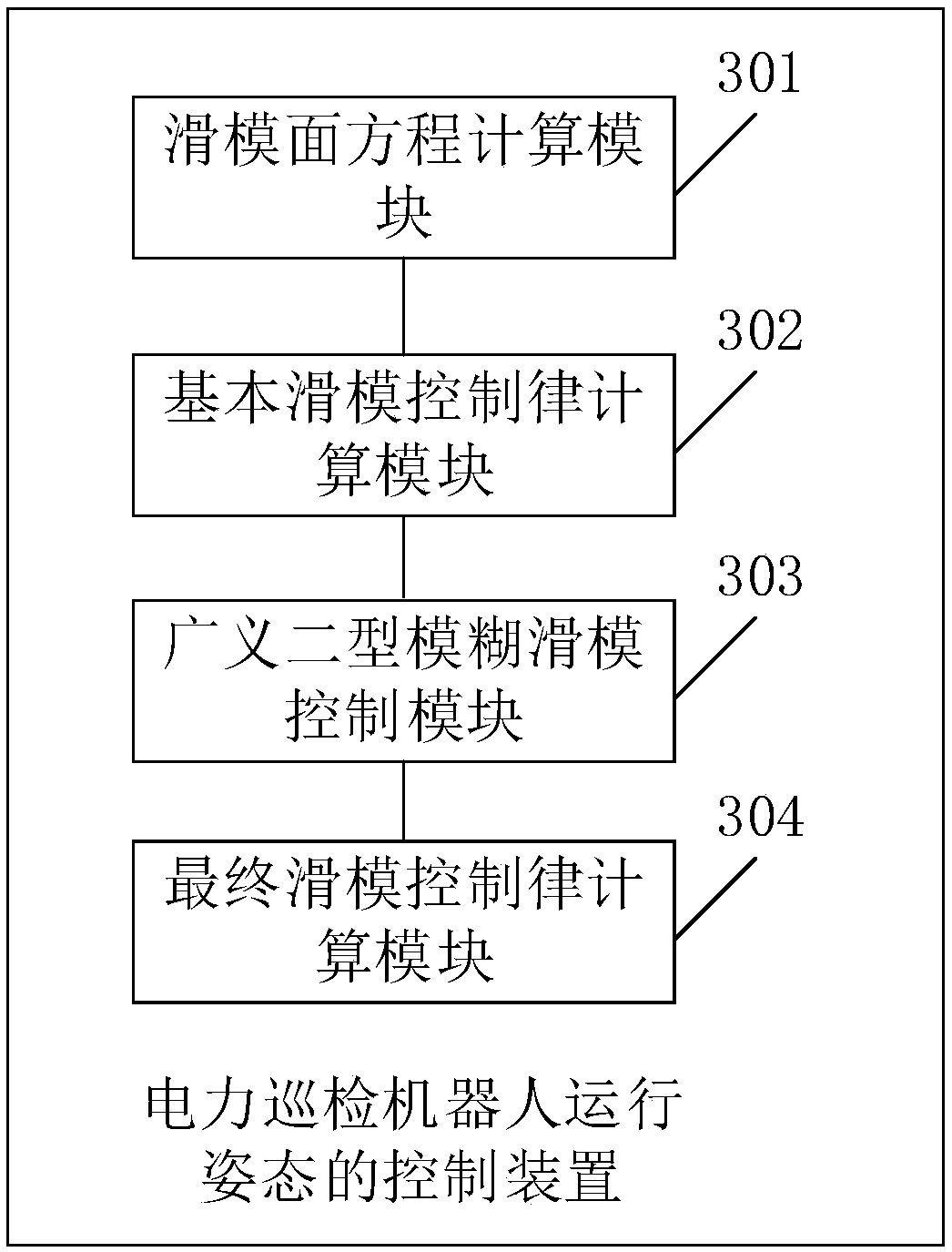

Electric inspection robot operating posture control method and device

ActiveCN108673513AFix jitterImprove anti-interference abilityProgramme-controlled manipulatorAnti jammingFuzzy sliding mode control

The invention discloses an electric inspection robot operating posture control method and device. The control method comprises the steps that an electric inspection robot operating posture linearizedmodel is built, and a sliding mode surface equation is calculated based on the linearized model; a basic sliding mode control law is calculated on the basis of the sliding mode surface equation, a preset lyapunov function and a preset index reaching law, the sliding mode surface equation is processed through a generalized type two fuzzy sliding mode control model built in advance, and a preliminary processing result is output; and the preliminary processing result is substituted into an expression of the basic sliding mode control law, a final sliding mode control law is obtained, and accordingly, control over the electric inspection robot operating posture is completed based on the final sliding mode control law. In this way, through the electric inspection robot operating posture controlmethod and device, the anti-jamming capability of an electric inspection robot in the inspection moving process can be effectively improved, the slip resistance and the obstacle avoidance performanceare good, and accordingly, the safety performance of the electric inspection robot in the inspection moving process is effectively improved.

Owner:SICHUAN UNIV

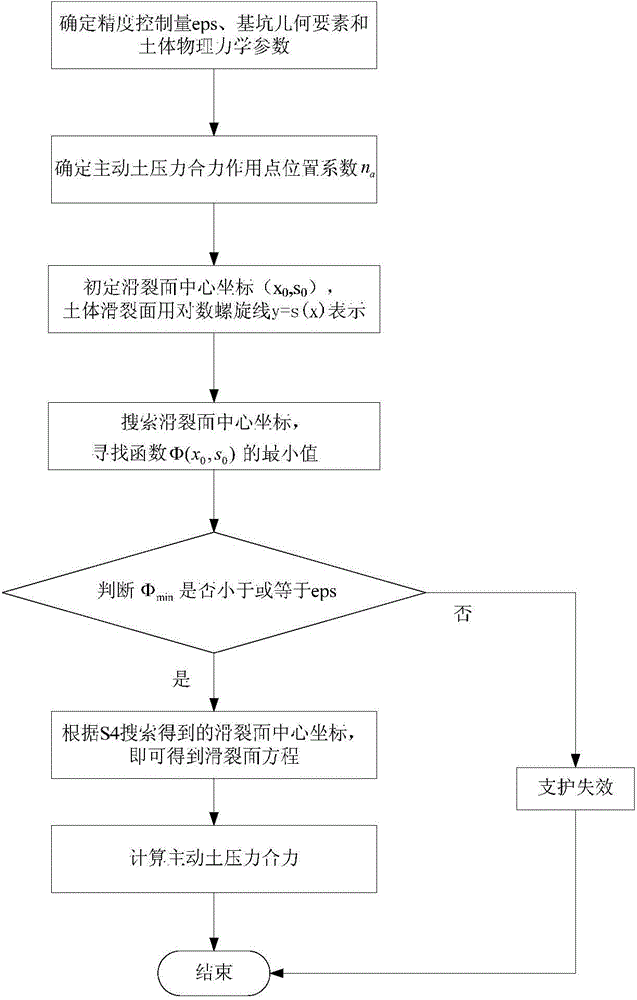

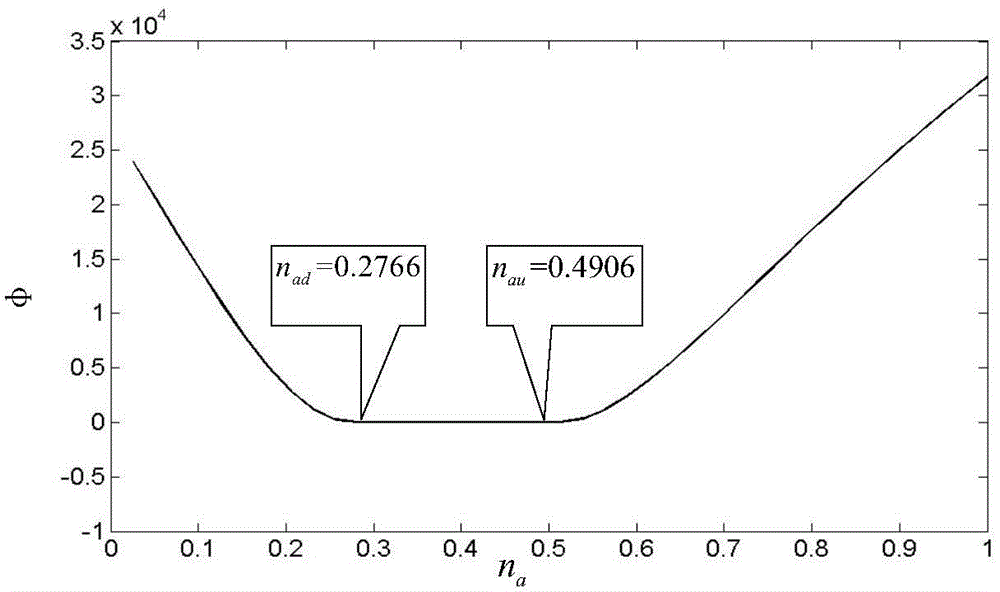

Foundation pit flexible support active earth pressure calculating method considering action point position

InactiveCN104484503AEasy to manage scientificallyImprove reliabilityExcavationsSpecial data processing applicationsStructure of the EarthEngineering

The invention relates to a foundation pit flexible support active earth pressure calculating method considering action point position. The method overcomes the shortcomings of a coulomb earth pressure calculating method and a rankine earth pressure calculating method. The method includes the following steps: determining accuracy control quantity eps, foundation pit geometric elements and earth body physical dynamic parameters; determining the position coefficient na of the active earth pressure resultant force action point; utilizing the curve y=s(x) to represent the earth body slip surface; determining the minimum value phi min of the function phi (x0,s0) to judge whether phi min is smaller than or equal to eps; finally calculating the resultant force of the slip surface equation and the active earth pressure. The foundation pit flexible support active earth pressure calculating method is line with reality, high in reliability and favorable for reasonable design and scientific management of pit foundation engineering.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com