Face gear hobbing cutter design method based on repeatable cutter grinding

A design method and technology of face gears, applied in gear tooth manufacturing tools, gear tooth manufacturing devices, belts/chains/gears, etc., to achieve the effect of improving machining accuracy and efficiency and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

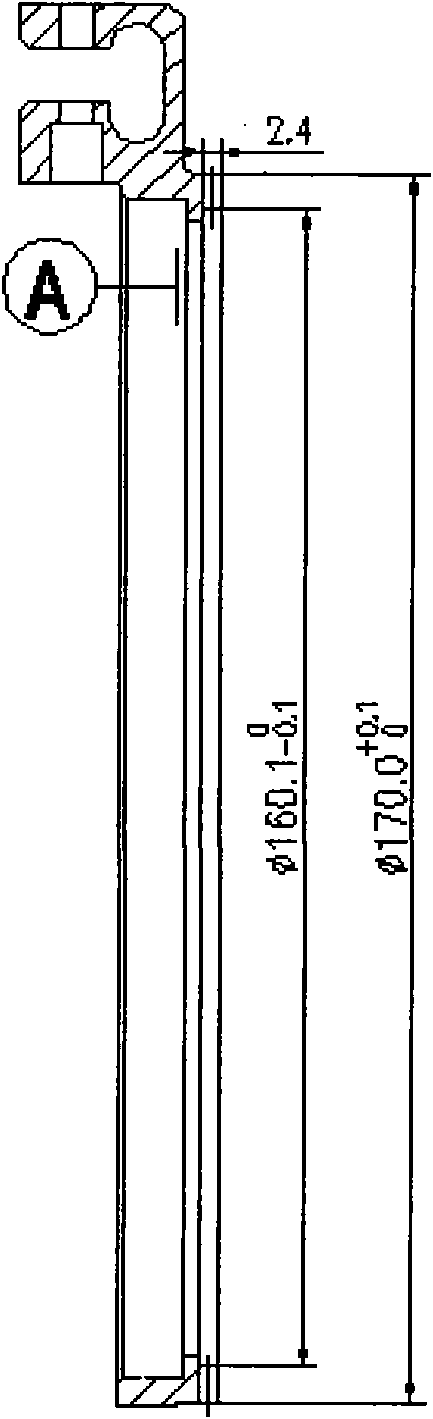

Image

Examples

Embodiment Construction

[0033] As shown in Figure 1, the method flow process of the present invention is as follows:

[0034] step one:

[0035] (1) Select the basic parameters of face gear and involute spur gear. The parameters of the face gear refer to the number of teeth of the face gear; the parameters of the involute spur gear include the number of teeth, modulus, and pressure angle of the spur gear; the intersection angle between the involute spur gear and the face gear axis.

[0036] (2) According to the principle of point contact surface gear transmission, determine the number of teeth of the face gear shaper cutter, which is usually taken as the number of teeth of the involute spur gear plus 1, plus 2, plus 3.

[0037] Step two:

[0038] (3) Using the principle of space surface meshing and the principle of face gear hobbing, establish the coordinate system of face gear hobbing, based on the equation of the tooth surface of the involute spur gear tool and the coordinate conversion from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com