Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

215 results about "Order of accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In numerical analysis, order of accuracy quantifies the rate of convergence of a numerical approximation of a differential equation to the exact solution. Consider u, the exact solution to a differential equation in an appropriate normed space (V,|| ||). Consider a numerical approximation uₕ, where h is a parameter characterizing the approximation, such as the step size in a finite difference scheme or the diameter of the cells in a finite element method.

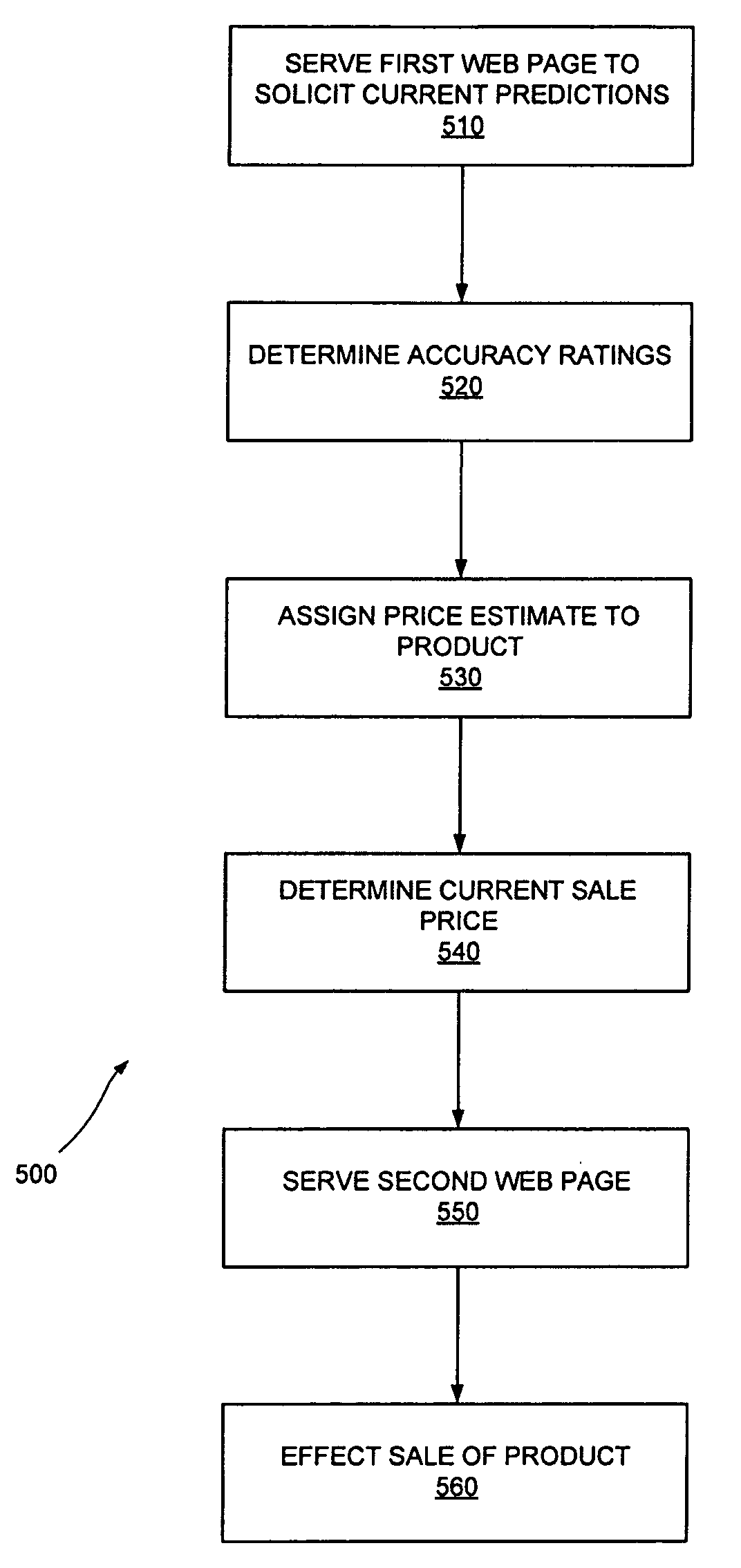

Determining and presenting product market prices

A system includes an electronic device coupled over a network to first and second computing devices. The electronic device is configured to serve to the first computing device a first web page displayable on a display device. The displayed first web page includes a user interface operable to solicit from an individual of a plurality of individuals a current prediction of a plurality of current predictions of market prices of a product. The electronic device is further configured to determine an accuracy rating for each individual of the plurality based on a correlation between previous predictions provided by each said individual and actual market prices of the product. The electronic device is further configured to assign to the product a price estimate associated with a first predetermined time interval, the price estimate being a function of the accuracy ratings and current predictions. The electronic device is further configured to determine a current sale price based on the assigned price estimate. The electronic device is further configured to effect, via a second web page, a sale transaction of the product at the current sale price.

Owner:SILVARIS CORP

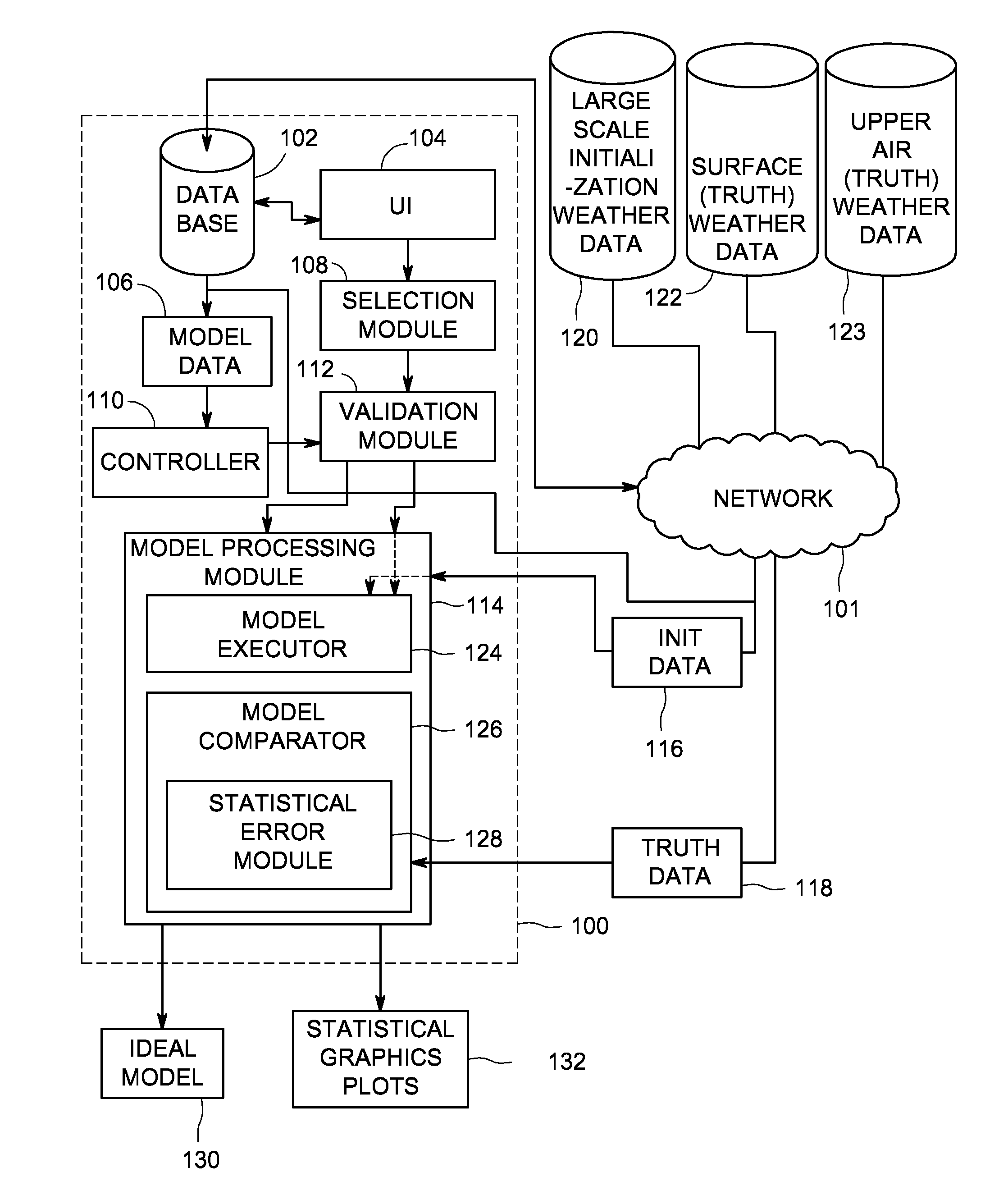

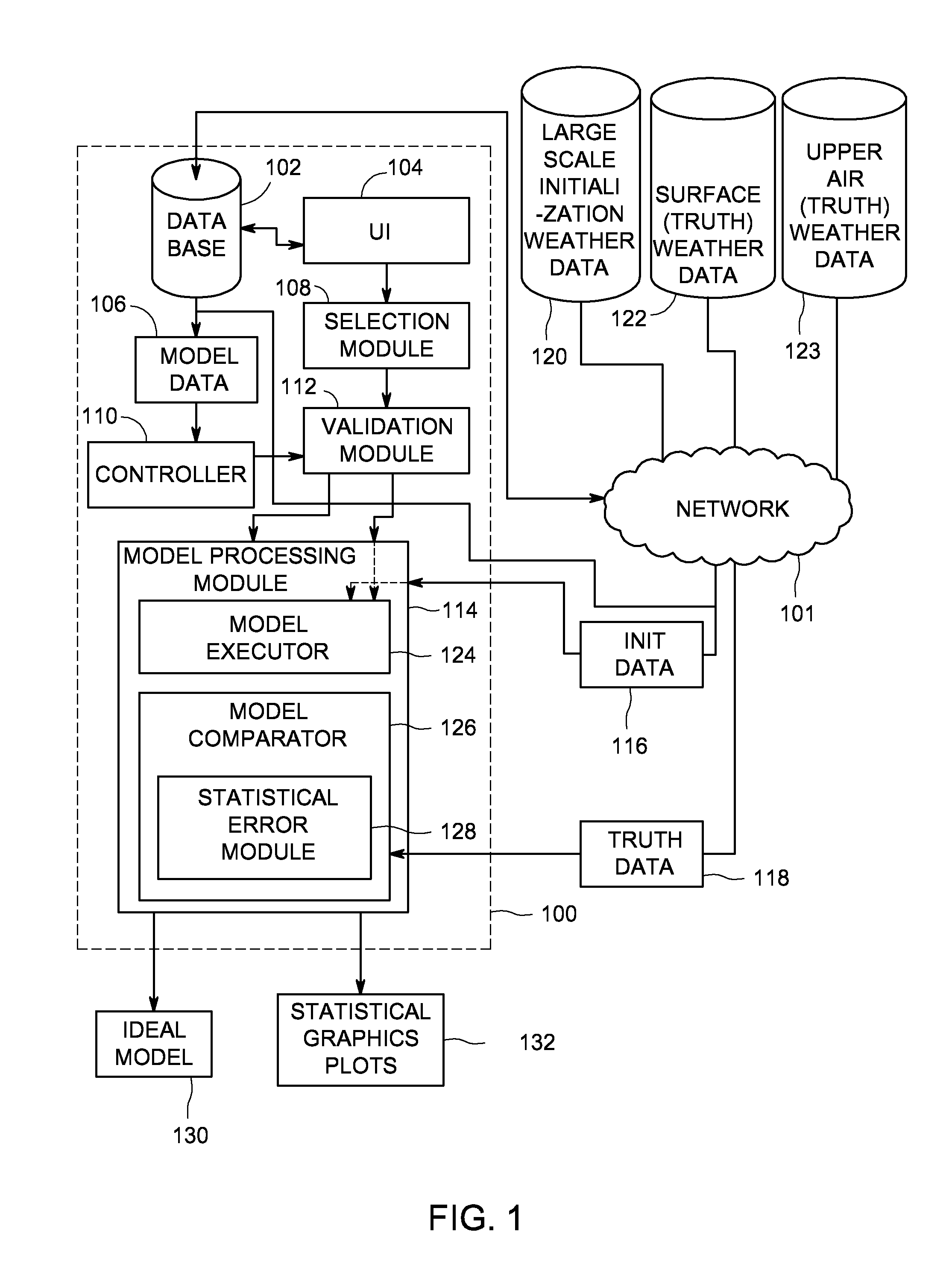

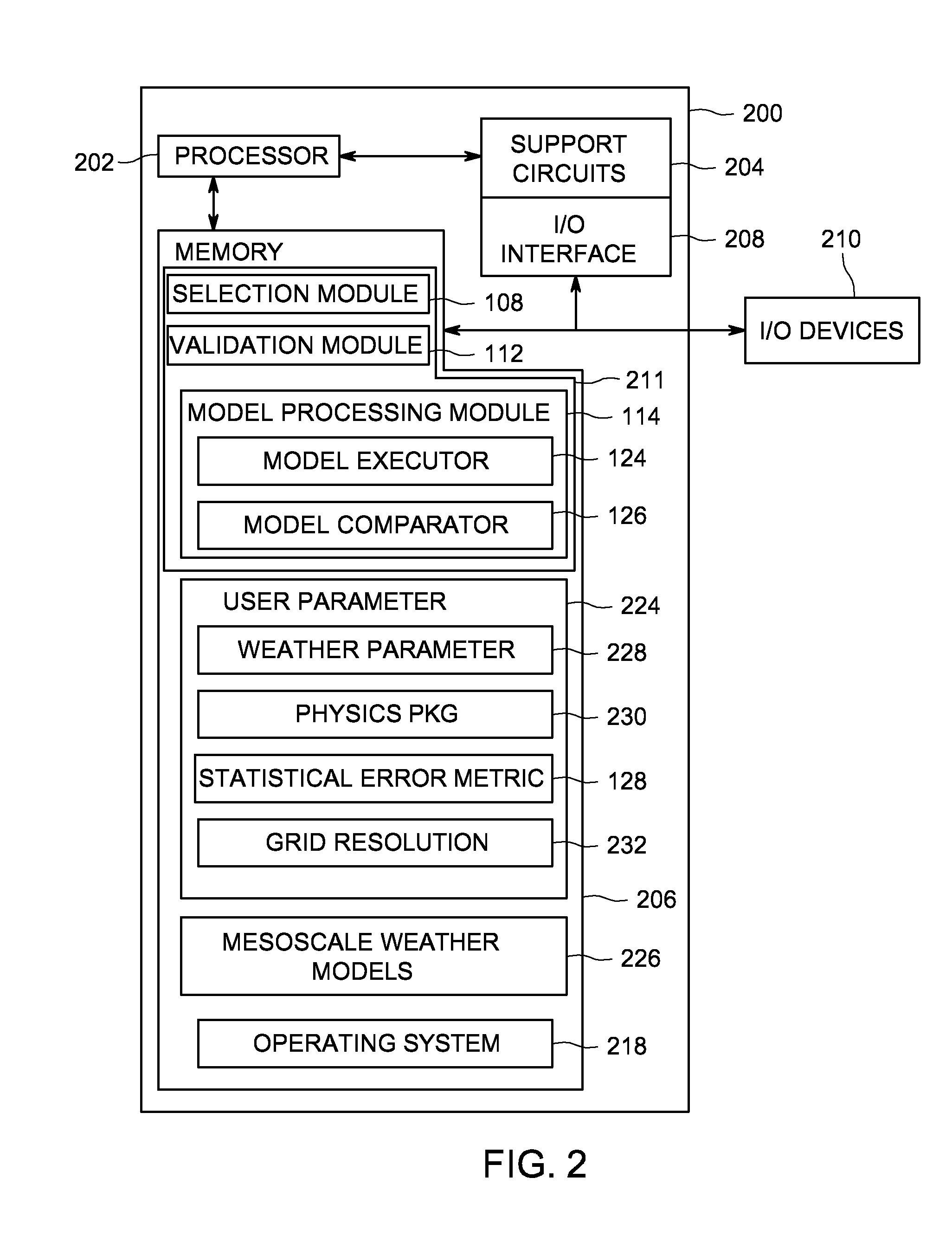

Method and system for determining accuracy of a weather prediction model

ActiveUS20130117608A1Weather condition predictionError detection/correctionSurface levelAtmospheric sciences

A method and system for determining the accuracy of a mesoscale weather model comprising at least one processor having at least one input for inputting a preexisting weather model and initial weather data comprising surface level and upper air temperatures and wind conditions, and actually measured surface level and the upper-air level weather conditions; the at least one processor operating to use the mesoscale weather model to generate output data comprising forecasted temperatures, wind conditions, and predicted weather conditions; the at least one processor operating to compare the output data to actually measured data obtained when same or similar initial weather data were present and subsequent resulting temperatures, wind conditions and weather conditions were measured; and the at least one processor operating to generate an accuracy rating reflecting the deviation of temperature, wind conditions and weather conditions predicted by the mesoscale weather model as compared to those actually measured.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

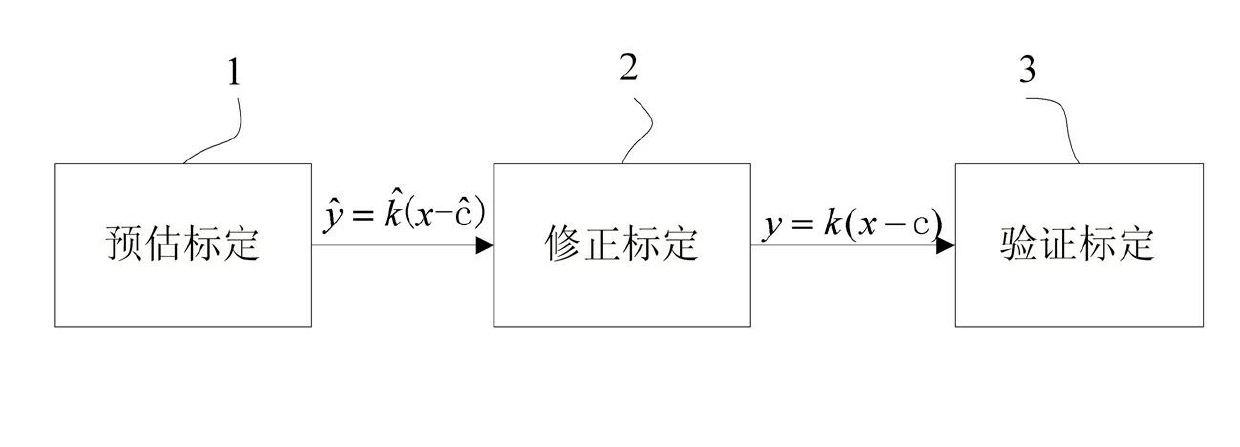

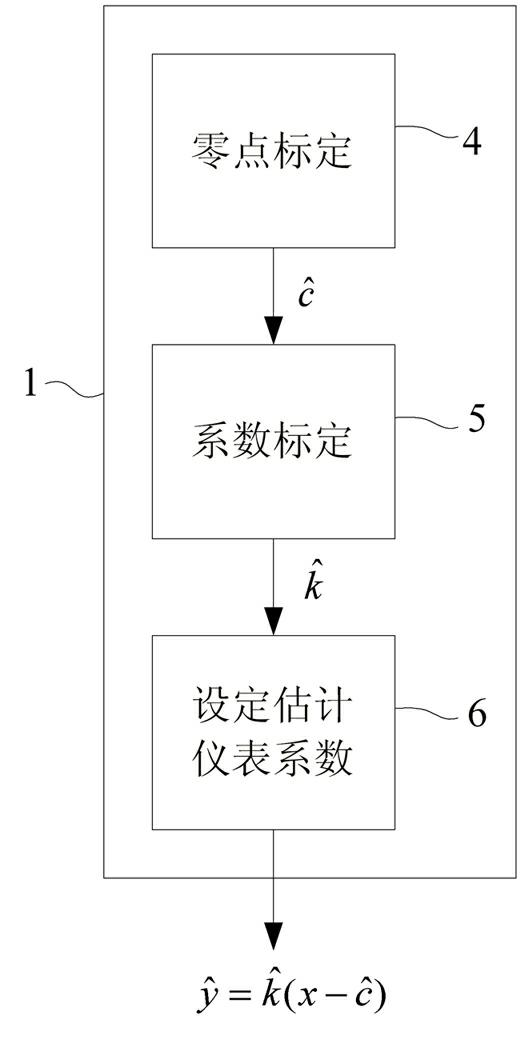

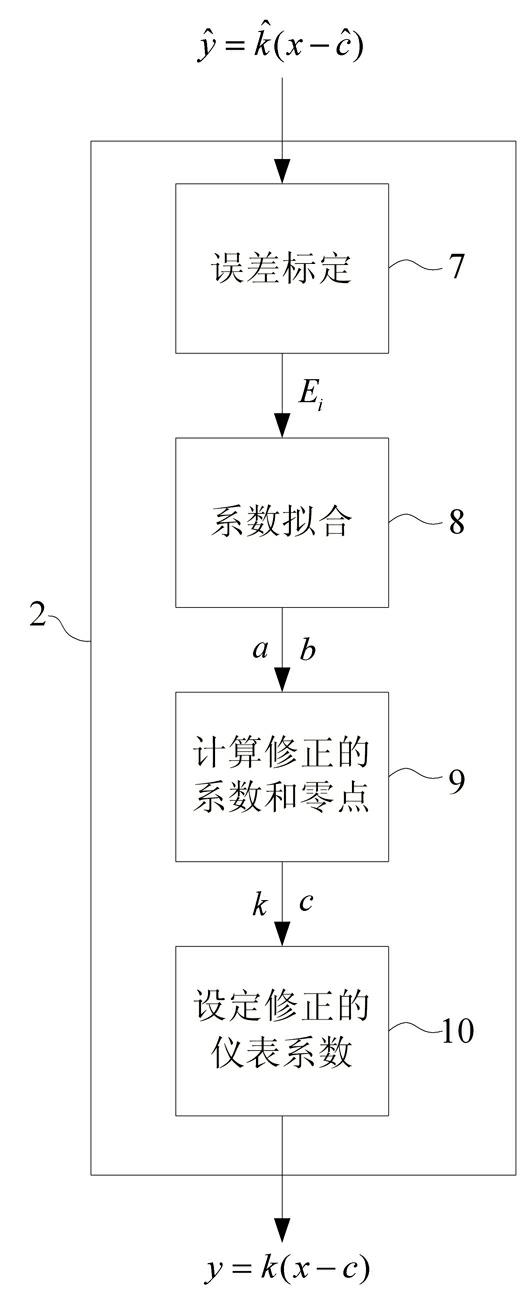

Method for calibrating Coriolis mass flowmeter

ActiveCN102128666AImprove calibration accuracyIncreased accuracy levelTesting/calibration apparatusComputer scienceStreamflow

The invention provides a method for calibrating a Coriolis mass flowmeter. The method comprises the following steps of: firstly, performing estimated calibration on the meter, measuring an estimated zero point of the meter at zero flow of a full pipe, and setting the estimated zero point into the meter; selecting a larger flow point, measuring an estimated meter coefficient and setting the estimated meter coefficient into the meter; secondly, performing correction calibration on the meter, executing three flow accumulation experiments under each flow point, calculating an error of the accumulated mass flow under each flow point, obtaining a corrected coefficient of the estimated meter coefficient and a corrected coefficient of the estimated zero point by a linear fitting method according to the error so as to obtain a corrected meter coefficient and a corrected zero point, and setting the corrected meter coefficient and the corrected zero point into the meter; and finally, performing validation calibration on the meter, namely taking five flow points within a full measurement range of the meter, executing three flow accumulation experiments under each flow point, and calculating the error of the meter and the repetitiveness so as to determine a precision level of the meter. By the method, the precision level of the meter can be increased effectively.

Owner:HEFEI UNIV OF TECH

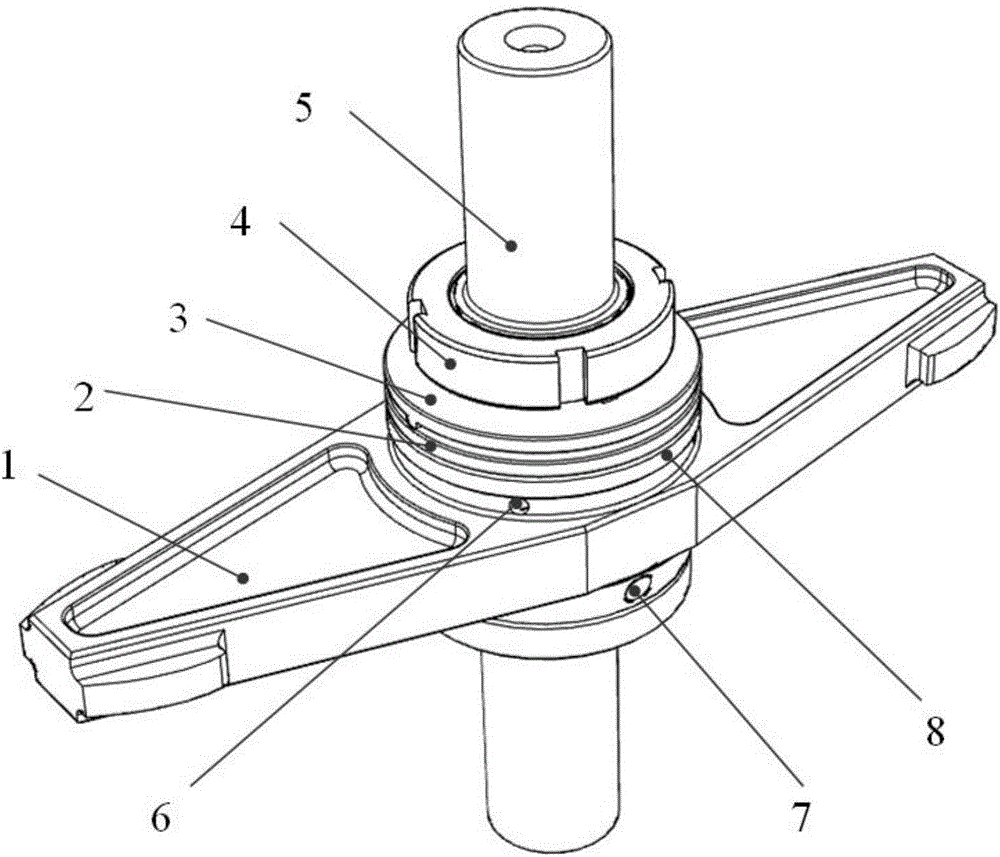

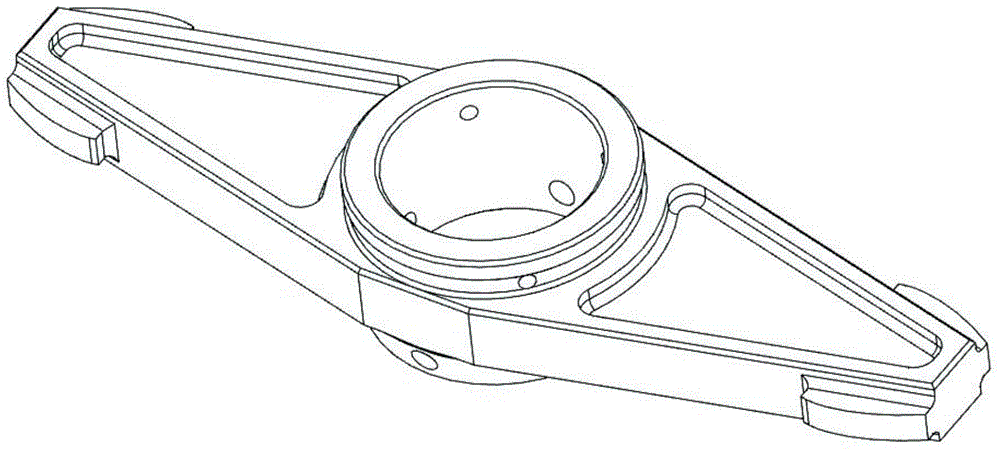

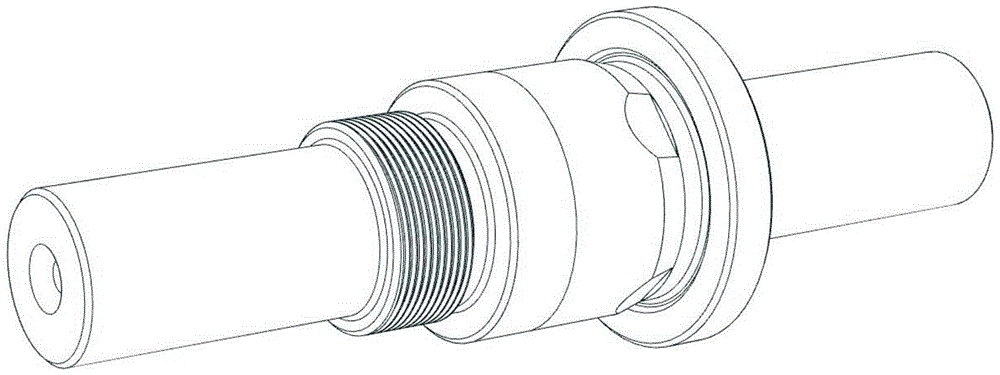

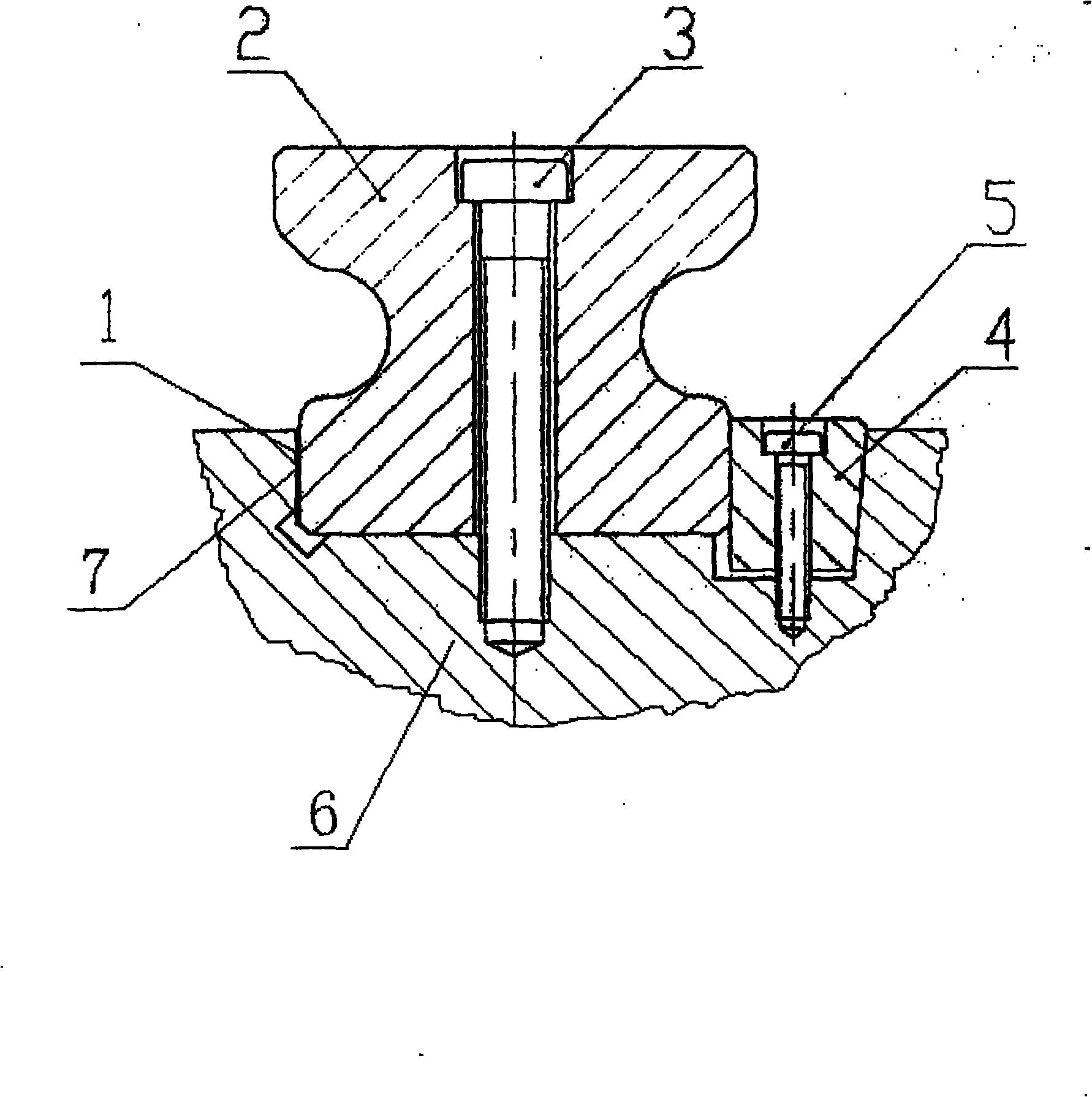

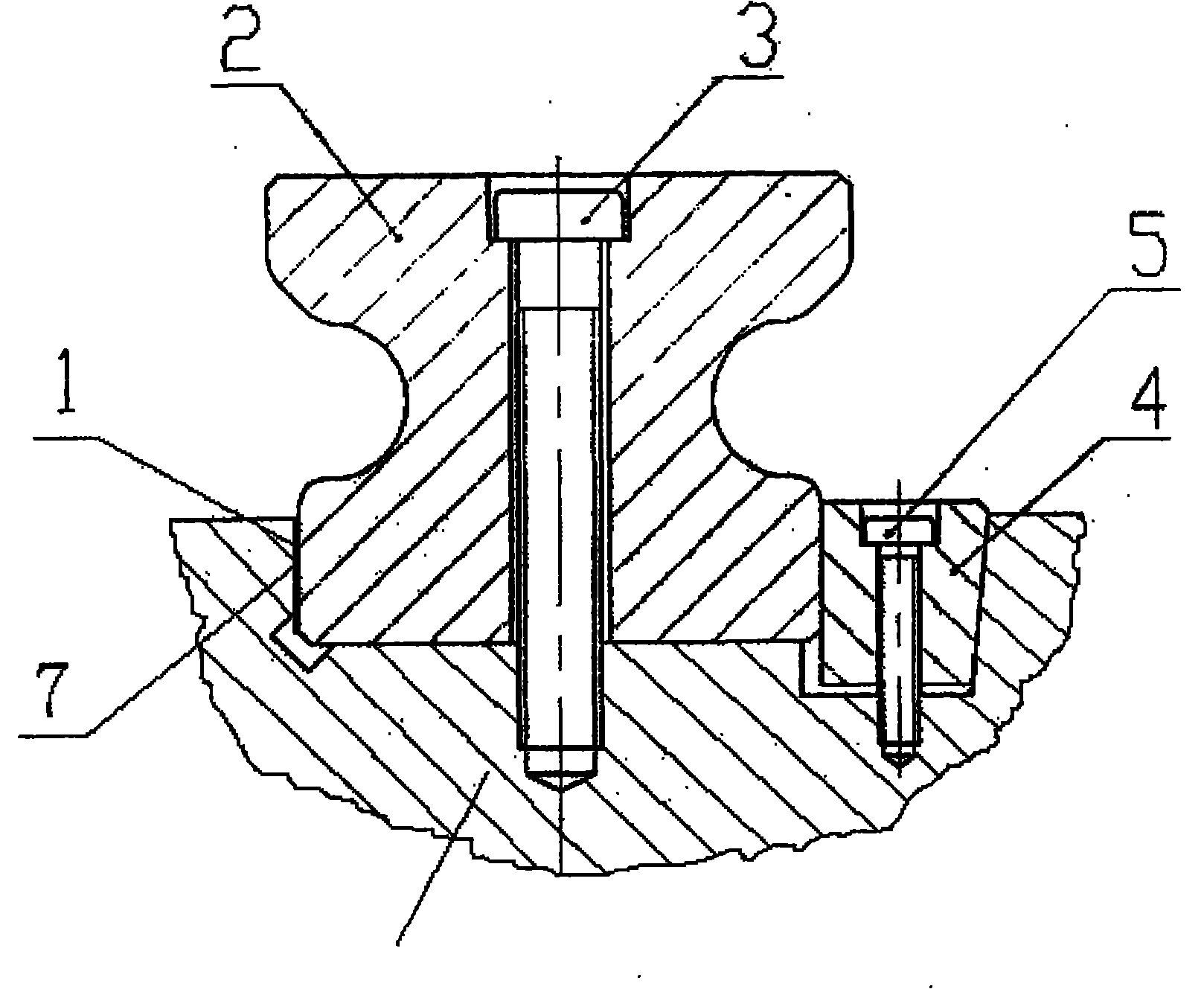

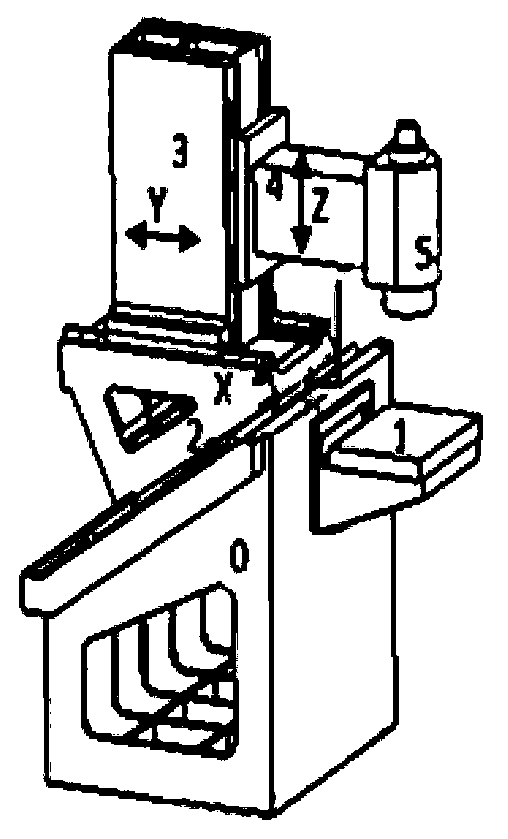

High-precision radial adjustable involute master of gear and adjusting method

ActiveCN104655080AHigh precisionImprove connection stiffnessMeasurement devicesMeasuring instrumentShape deviation

The invention discloses a high-precision radial adjustable involute master of gear and an adjusting method. One tooth face of four tooth faces is selected to be not precisely ground, has higher tooth profile shape deviation and is used for detecting a frequency response characteristic, a filtering effect and sensitivity of an instrument; another three tooth faces are precisely processed and have smaller tooth profile shape deviation, one precisely processed surface has certain tooth profile slope deviation and is used for detecting an amplification factor of the instrument, and other two tooth faces on opposite sides have tooth profile slope deviation which is approximate to zero and are used for representing the precision grade of the involute master of gear, transmitting involute parameter values and determining and correcting an indication error of an involute measurement instrument. The high-precision radial adjustable involute master of gear is simple in structure, convenient to adjust, high in connecting rigidity and reliable in connection with a master core shaft and high in precision, has a stable size, and can simultaneously meet demands for frequency response characteristic, filtering effect, sensitivity, amplification factor detection and instrument indication error correction of the involute measuring instrument.

Owner:DALIAN UNIV OF TECH

Processing technique of 9Cr18 stainless steel capable of being improved to G3 level

InactiveCN101186005AOptimize processing parametersSpherical surface grinding machinesMetal working apparatusCold treatmentProcess quality

The invention relates to a 9Cr18 stainless steel ball processing technique which can be raised to G3 grade. The processing technique sequentially includes raw material inspection, ball-forging, stress-relief and anneal, hot-acid pickling, polishing, quenching plus cold treatment plus backfire, hard milling, a first-time stabilizing treatment, fine milling, a second-time stabilizing treatment, fine grinding, washing, fine appearance-forming and lubricating and packing. On a basis of making a full use of the existing steel ball processing technology, machine-tool equipments and testing equipments, the technique of the invention adopts a reinforced steel ball manufacturing equipment, industrial preparations, and a novel abrasive to optimize various machining process parameters in the steel ball processing technique and to strengthen a process quality testing and has a proper washing, packing and conserving proposals, etc. process technology. The invention can raise the precision grade of the stainless steel ball to G3 grade and solves the processing technology, testing control and finished-product washing of the 9Cr18 stainless steel ball, and then a batch manufacture is realized finally.

Owner:LUOYANG BEARING SCI & TECH CO LTD

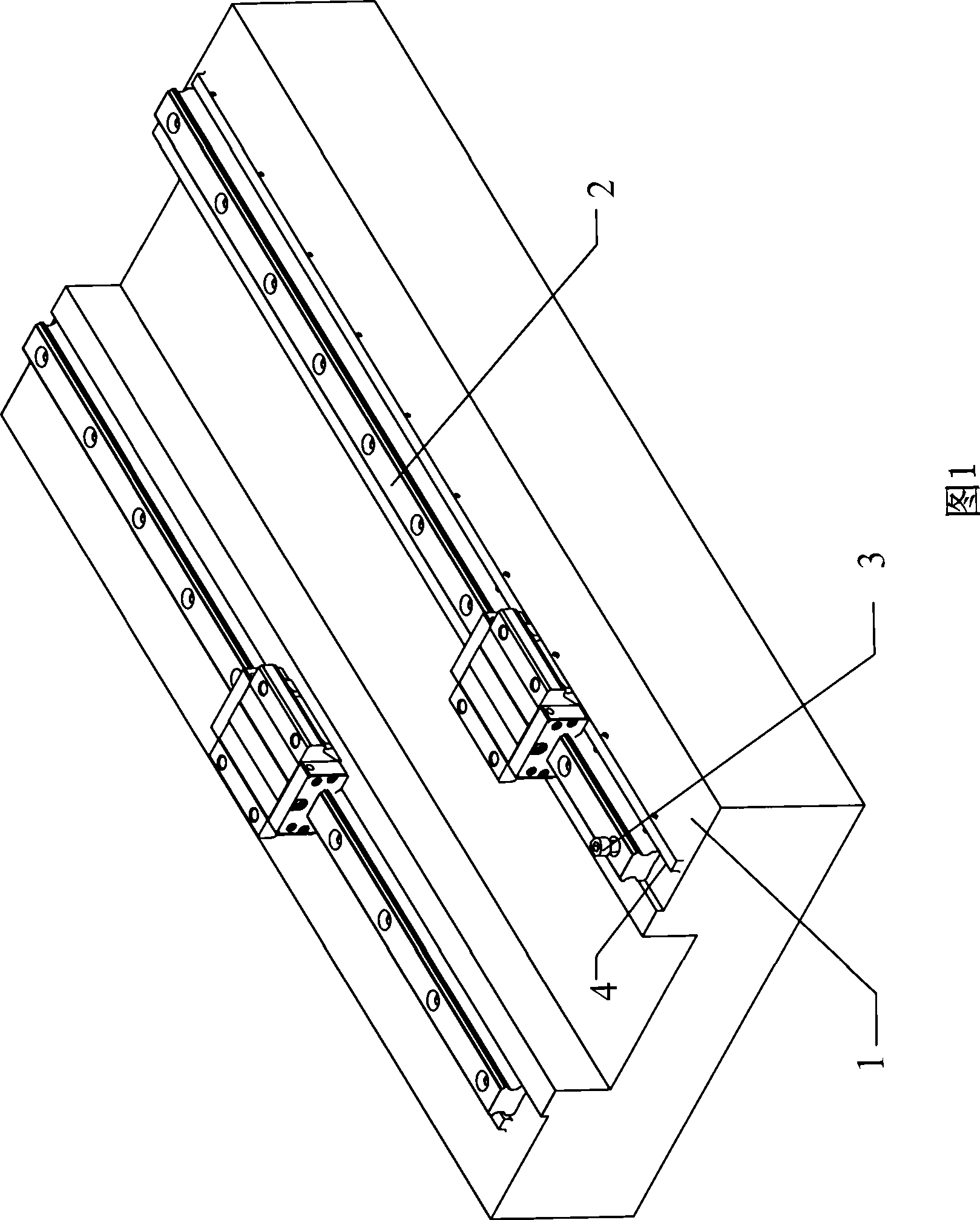

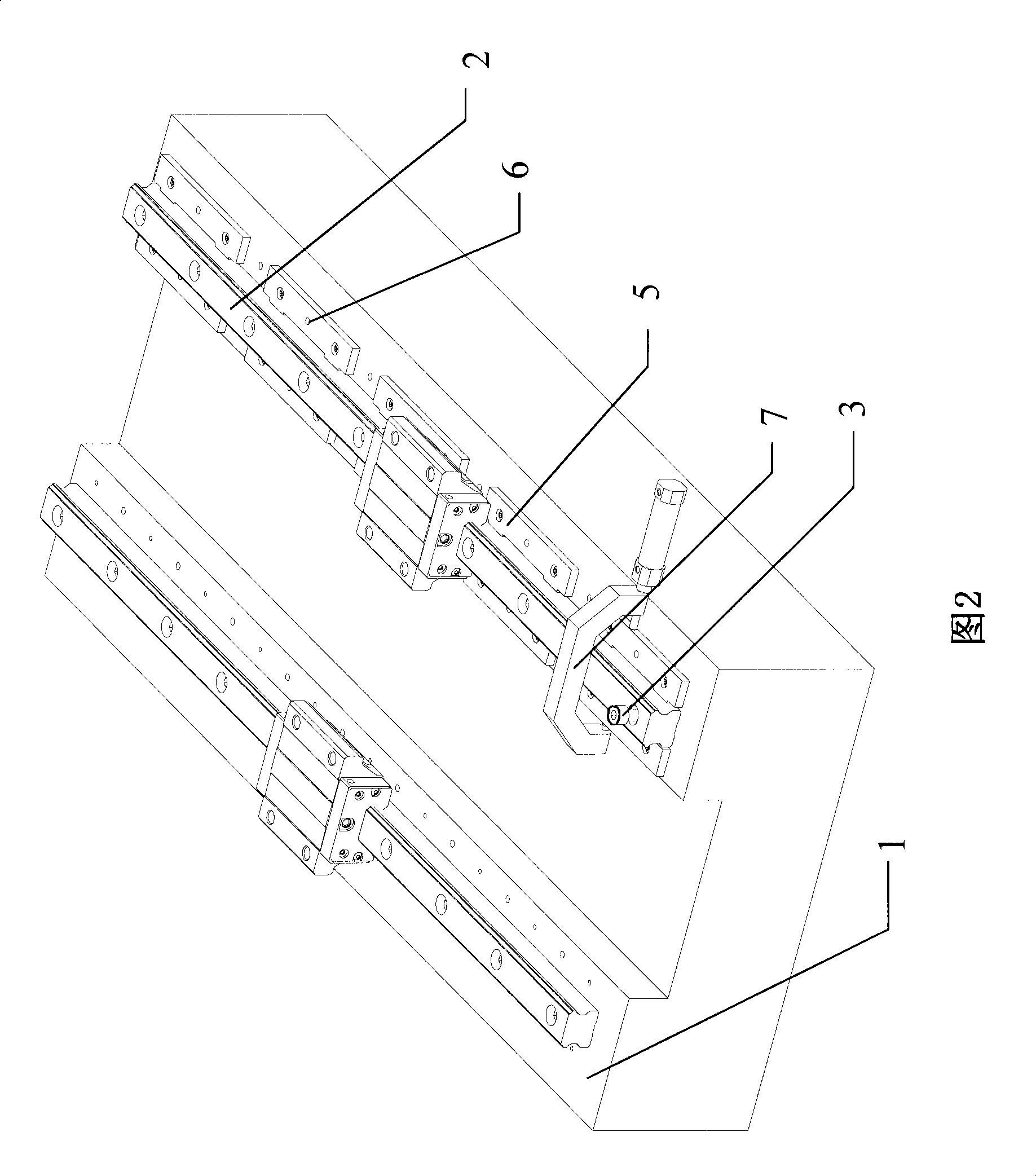

Installing and positioning method of linear guide rail

InactiveCN102179699AMeet the requirements of the accuracy classImprove installation efficiencyLarge fixed membersMechanical engineeringOrder of accuracy

Owner:CHAOYANG BOWEN MACHINE TOOL

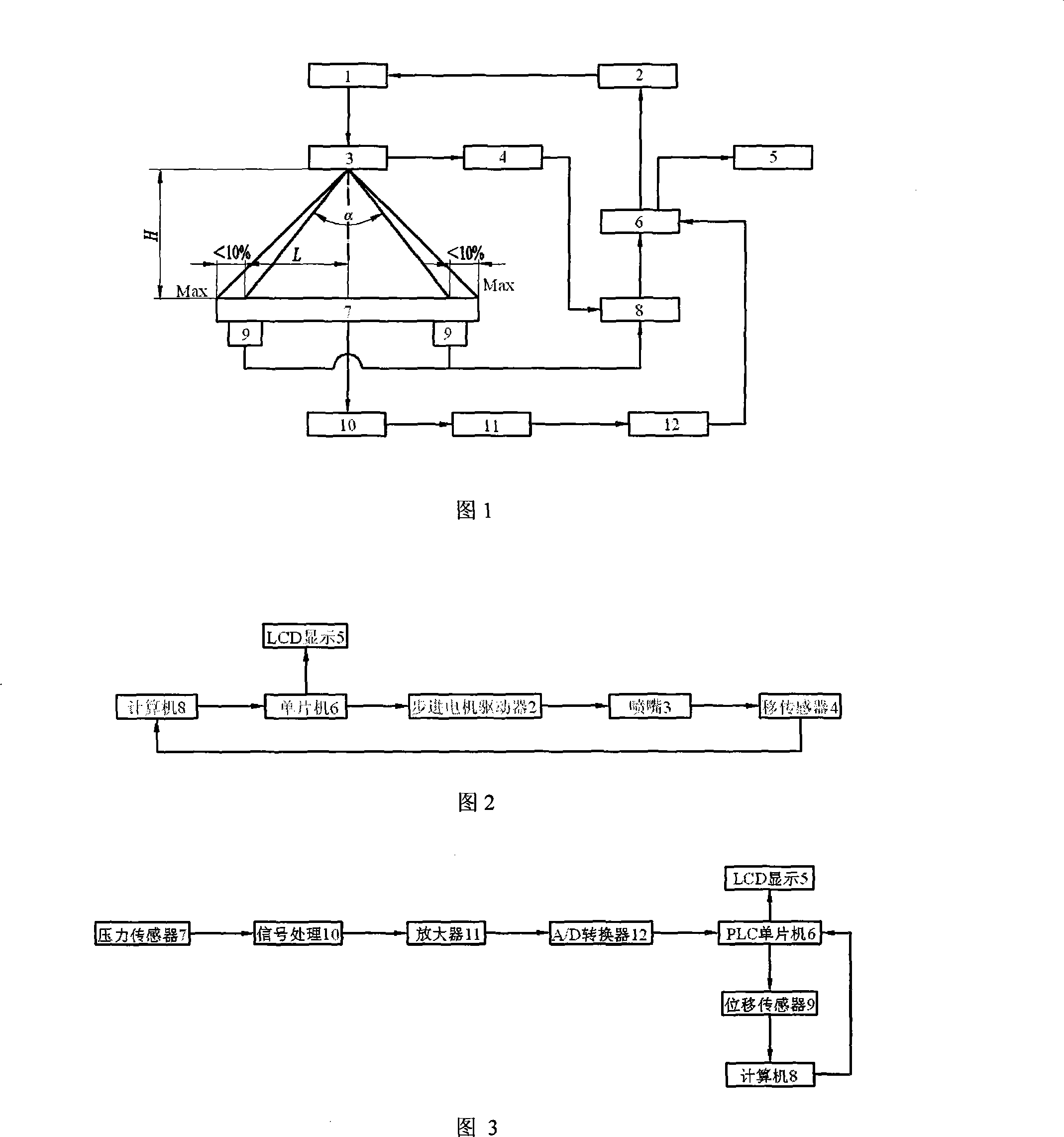

Method and apparatus for automatically detecting spray angle of nozzle

InactiveCN101226109AAccurate measurementSmall step lengthStructural/machines measurementMicrocontrollerEngineering

The invention relates to an injector spray angle automatic detection method based on PLC and a relative device, which spray quality is represented by the working characteristic parameters as droplet size distribution, spray angle and flux density. The device comprises a spray height H detecting system and an effective spray distance L detecting system, wherein the spray height H detecting system comprises serially connected a computer, a PLC single chip, a step motor driver, an injector and a displacement sensor, while a step motor is connected with the step motor driver and a LCD display unit is connected with the PLC single chip, the effective spray distance L detecting system comprises serially connected a displacement sensor, a signal processor, an amplifier, an A / D converter and a PLC single chip, while the LCD display unit is connected with the PLC single chip, displacement sensor and computer in turn. The invention utilizes the combination method of triangle method and water accumulation vessel method and utilizes the pressure sensor with high accuracy to measure the spray force, with small step and the application for automatically measuring injector spray angle accurately.

Owner:JIANGSU POLYTECHNIC UNIVERSITY

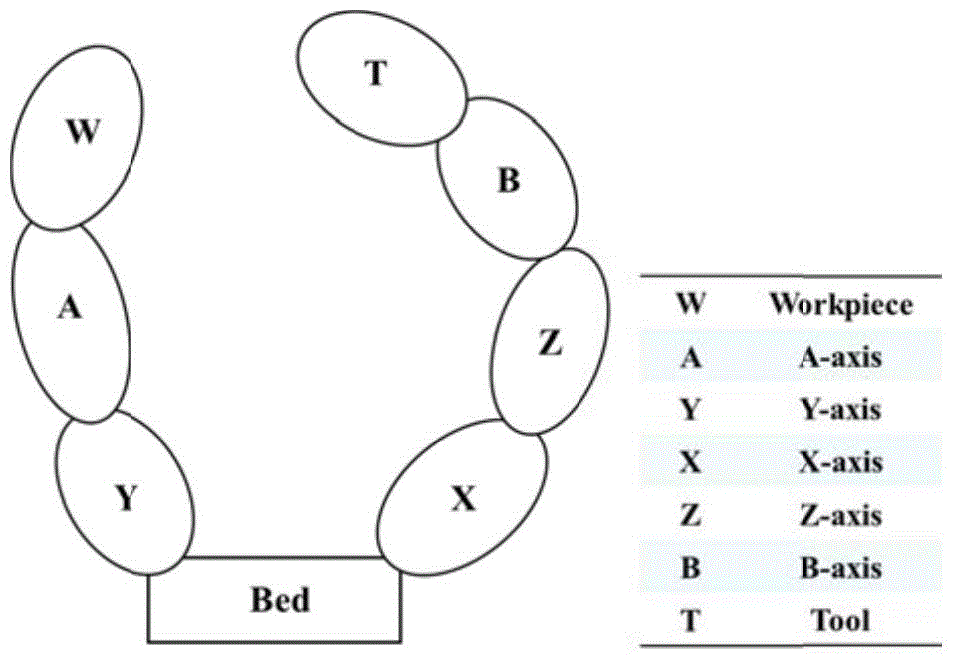

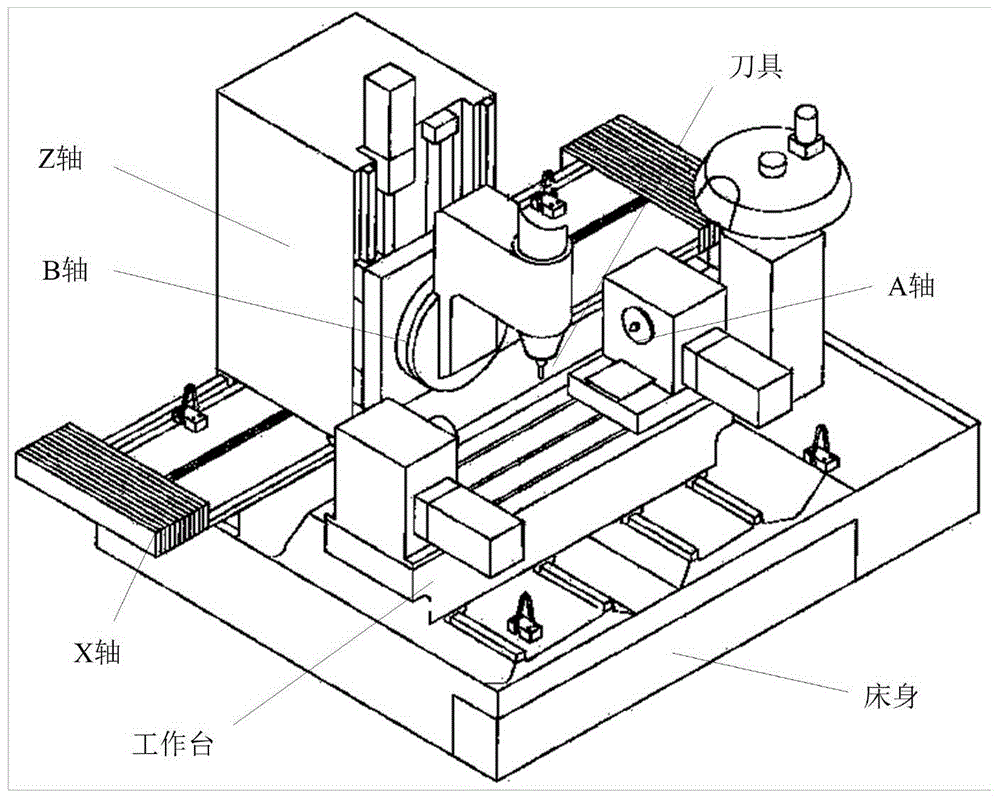

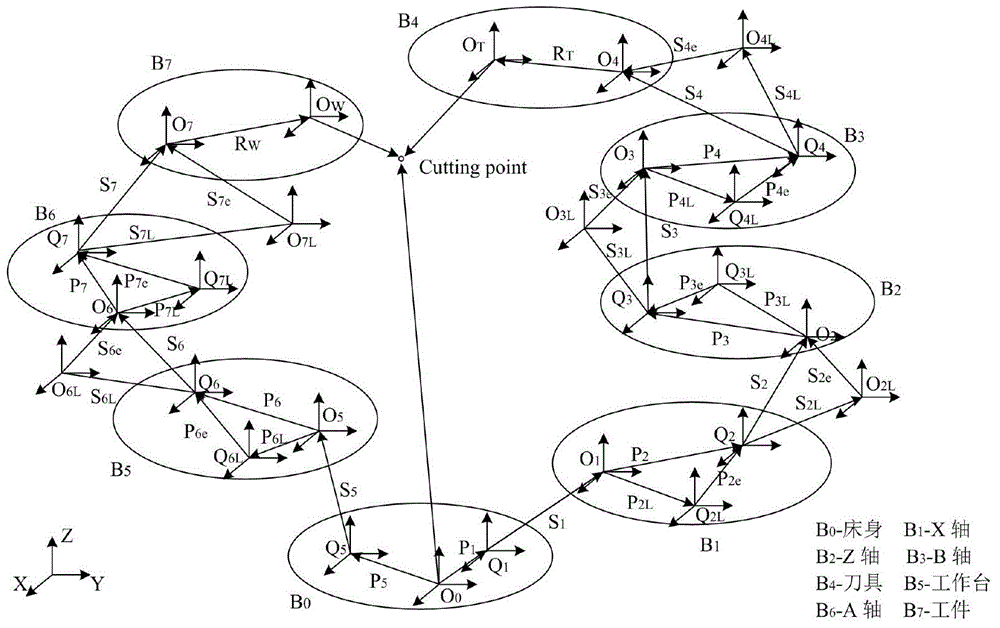

Multi-axis numerical-control machine tool processing precision retaining ability optimization method based on robust design

A multi-axis numerical-control machine tool processing precision retaining ability optimization method based on a robust design belongs to the machine tool precision design field. The invention especially relates to a modeling method of a space error of a multi-axis numerical-control machine tool, a machine tool reliability optimization design method and a robust optimization design method. A space error model of the multi-axis numerical-control machine tool, a reliability model under a multi-failure mode, a sensitive degree model and a machine-tool total cost model are established. A process is characterized in that a minimum sensitivity and lowest cost are taken as an object; the reliability is taken as a constraint; a machine tool geometry parameter error is optimized and a machine tool processing precision retaining ability is increased. By using the method, a multi-axis numerical-control machine tool geometry error acquisition problem and a machine-tool main transmission assembly precision grade determination problem are radically solved.

Owner:BEIJING UNIV OF TECH

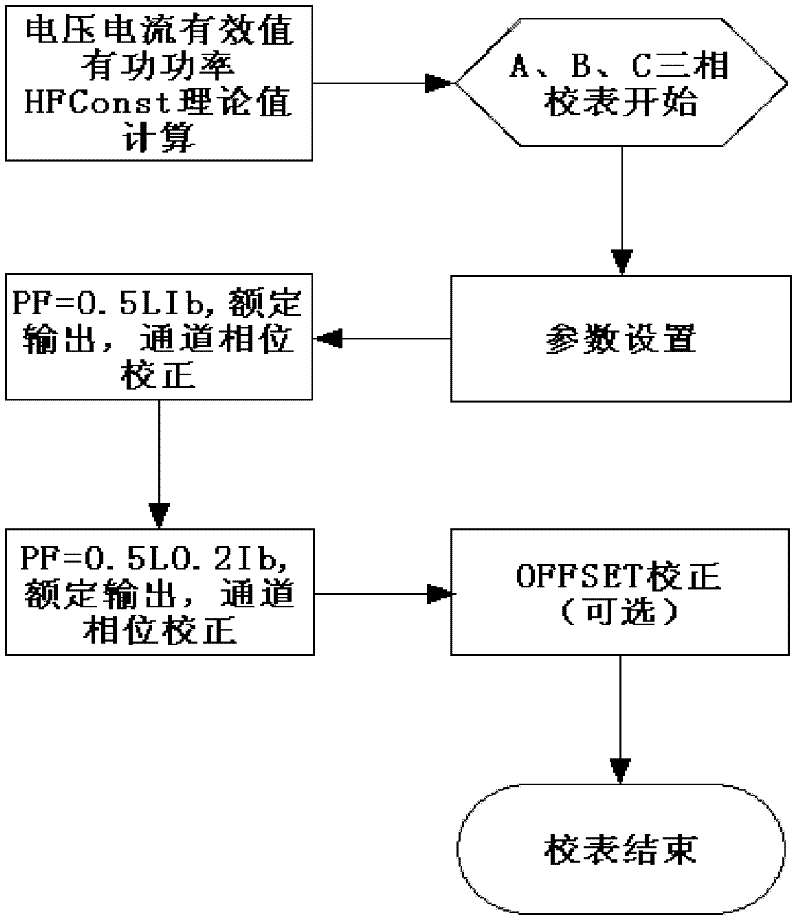

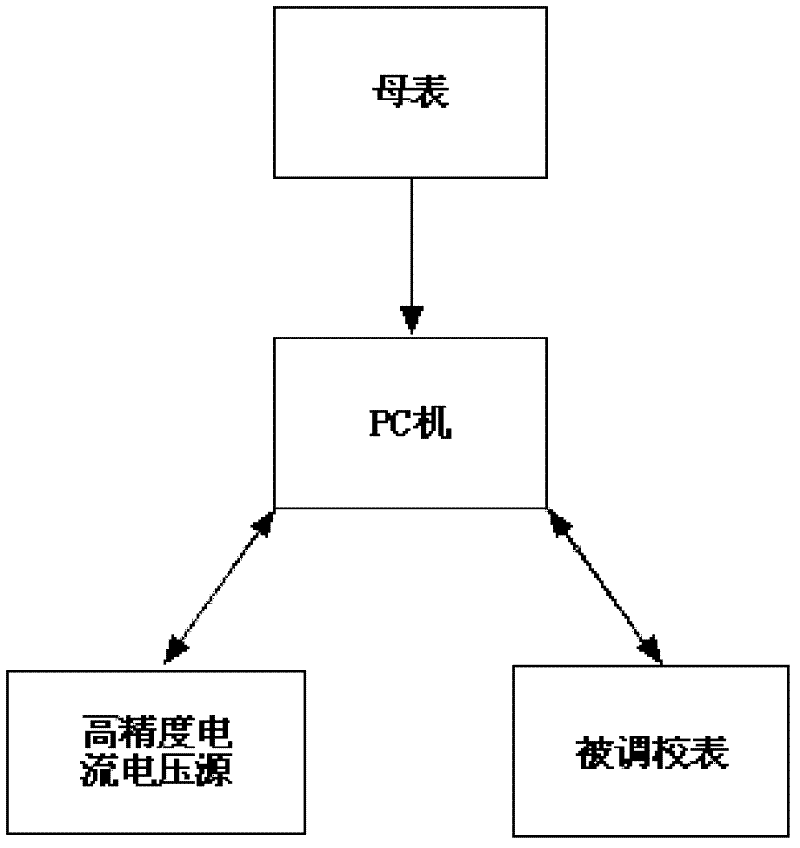

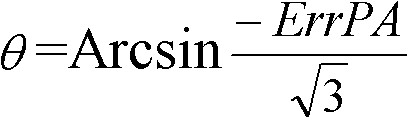

Calibration method of three-phase electric energy meter

ActiveCN102520386AReduce the difficulty of productionIncrease productivityElectrical measurementsPhase correctionThree-phase

The invention relates to a calibration method of a three-phase electric energy meter. The calibration method comprises the following steps that: (1) first taking a voltage current source of which the accuracy class is higher than the class requested by a tested electric energy meter, a PC (Personal Computer) machine used for issuing synchronous orders for the voltage current source and the electric energy meter, a mother meter as a reference and a three-phase electric energy meter needing to be calibrated; (2) the PC machine reads a measurement parameter data of the mother meter through an RS 485 communicating interface to be synchronous with the calibrated three-phase electric energy meter, and the parameter setting of the calibrated three-phase electric energy meter is realized; and (3) the voltage current source PF is equal to 0.5L, wherein when the voltage current source outputs rated voltage and current, the PC machine broadcasts calibrating voltage, calibrating current, a channel gaining order of an A phase, a B phase and C phase and a phase correction order for the calibrated three-phase electric energy meter. The invention discloses an automatic calibration method of a three-phase intelligent electric energy meter, which combines a meter calibrating method with power and a traditional meter calibrating method with pulses. Therefore, the production difficulty of the three-phase intelligent electric energy meter is greatly reduced, and the production efficiency is increased.

Owner:宁夏隆基宁光仪表股份有限公司

Method for designing geometric accuracy of multi-axis numerical control machine tool to improve processing accuracy and reliability

The invention belongs to the field of machine tool accuracy designing, and relates to a method for designing geometric accuracy of a multi-axis numerical control machine tool to improve processing accuracy reliability, in particular to a modeling method of space errors of the multi-axis numerical control machine tool and an analyzing method of processing accuracy reliability and reliability sensitivity of the machine tool. A space error model of the multi-axis numerical control machine tool and a processing accuracy reliability model as well as a processing accuracy sensitivity model of the multi-axis numerical control machine tool under a multi-failure mode are built, geometric error items high in processing accuracy reliability sensitivity are optimized, processing accuracy reliability of the machine tool is improved, a basis is provided for acquiring interrelation among geometric errors of the multi-axis numerical control machine tool and setting accuracy grade of main transmission components of the machine tool, and the problem of accuracy distribution of the machine tool is solved fundamentally.

Owner:BEIJING UNIV OF TECH

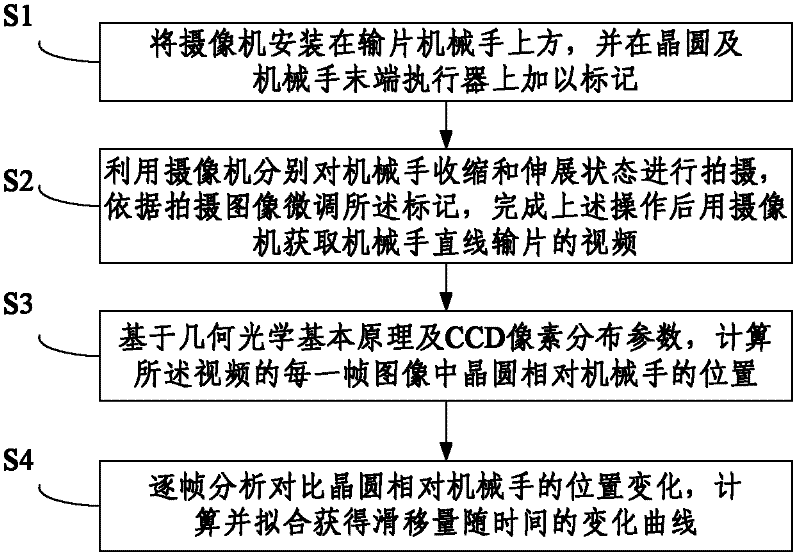

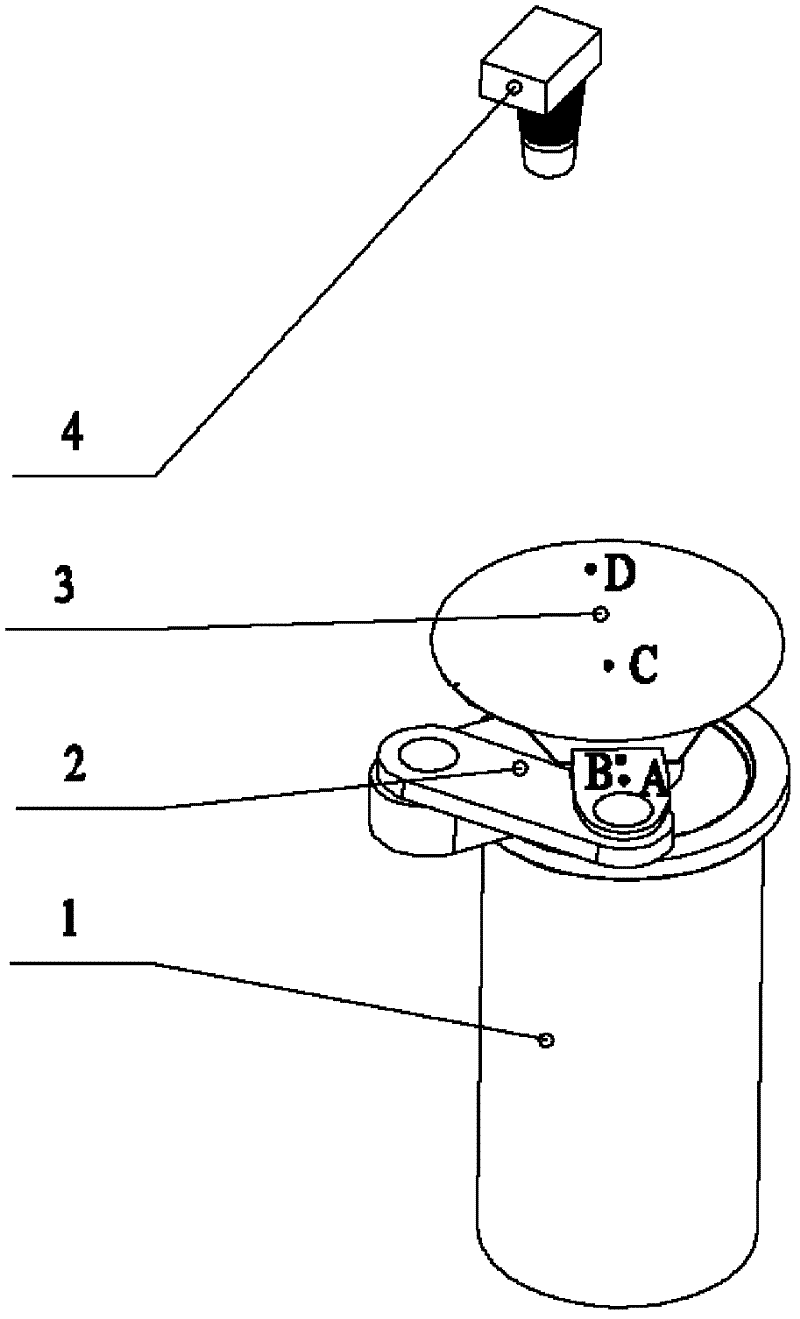

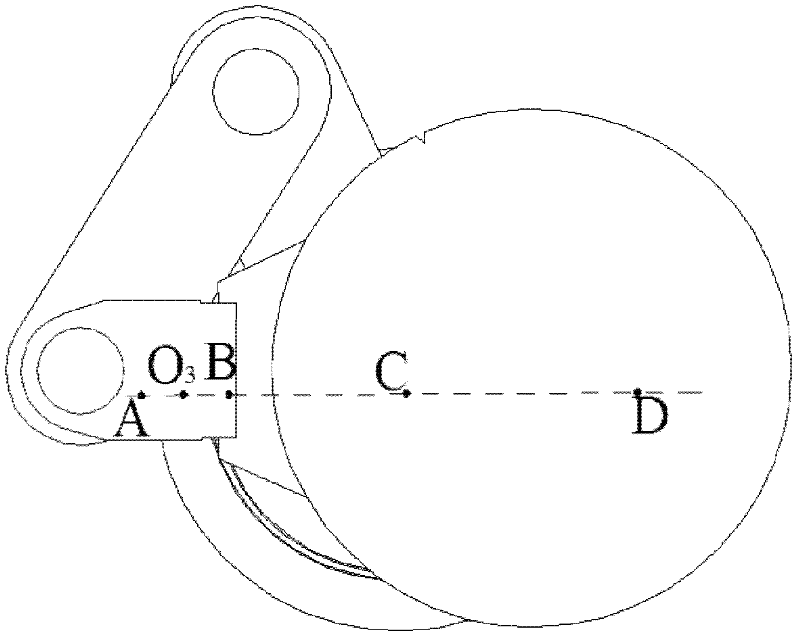

Method for detecting slip during linear delivery of wafer by using image processing technology

InactiveCN102564319AImprove delivery efficiencyMeet the requirements of slippage detection under different precision levelsSemiconductor/solid-state device testing/measurementUsing optical meansPattern recognitionActuator

The invention discloses a method for detecting slip during the linear delivery of a wafer by using an image processing technology. The method comprises the following steps: S1, mounting a video camera above a wafer delivering manipulator, and marking the wafer and the tail end actuator of the manipulator; S2, shooting the contraction and the extending states of the manipulator through the video camera, trimming the marks according to the shot images, and then obtaining a linear wafer delivering video of the manipulator through the video camera; S3, calculating the position of the wafer in each frame of the video on the basis of the geometrical optics fundamental principle and a CCD (charge-coupled device) pixel distribution parameter; and S4, analyzing and contrasting the change of the positions of the wafer relative to the manipulator frame by frame, and calculating and fitting to obtain a slip time history curve. The method can meet the requirements for detecting slip under different accuracy classes, and provide a theoretic and experimental reference for optimizing and controlling the speed and the acceleration of the wafer delivering manipulator, so as to achieve higher transmission efficiency under the premise that the delivering accuracy is met.

Owner:TSINGHUA UNIV

Steady optimal distributing method for geometric accuracy of multi-shaft machine tool

ActiveCN103390082AGuaranteed machining accuracyReduce manufacturing costSpecial data processing applicationsGeometric errorMultibody system

Along with increasing demand on machining precision, how to reasonably configure geometric error of a machine tool under the premise of ensuring the machining performance of the machine tool to balance the cost and machining precision is the problem demanding a prompt solution in manufacturing of the machine tool. The invention provides a novel multi-target optimal distributing method for geometric accuracy based on the manufacturing cost and quality loss of parts. The method comprises the following steps of: establishing a comprehensive spatial error model of geometric error of the machine tool by a multibody system theory; establishing a manufacturing cost model of a machine tool part according to the machining characteristic of the machine tool part which affects the geometric error to the maximum extent; meanwhile, combining the quality loss cost to establish a cost-based target function; establishing an optimal model associated to precise level of the part by identifying the geometric error, namely, maximizing European norms of all precision parameter variables as another target function; and realizing optimal distribution through Isight and Matlab integrated and combined with NSGA-II (Nondominated Sorting Genetic Algorithm-II).

Owner:BEIJING UNIV OF TECH +1

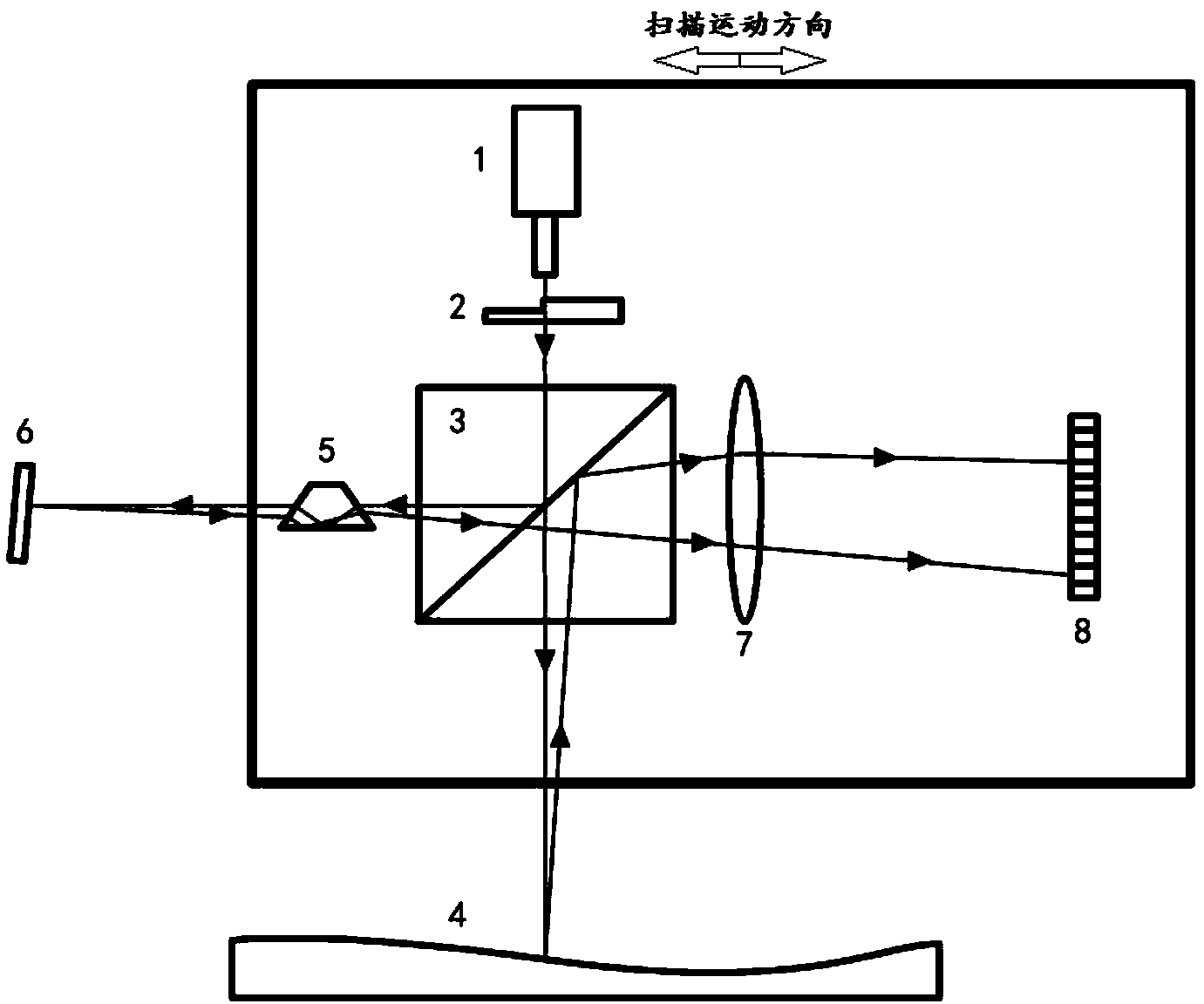

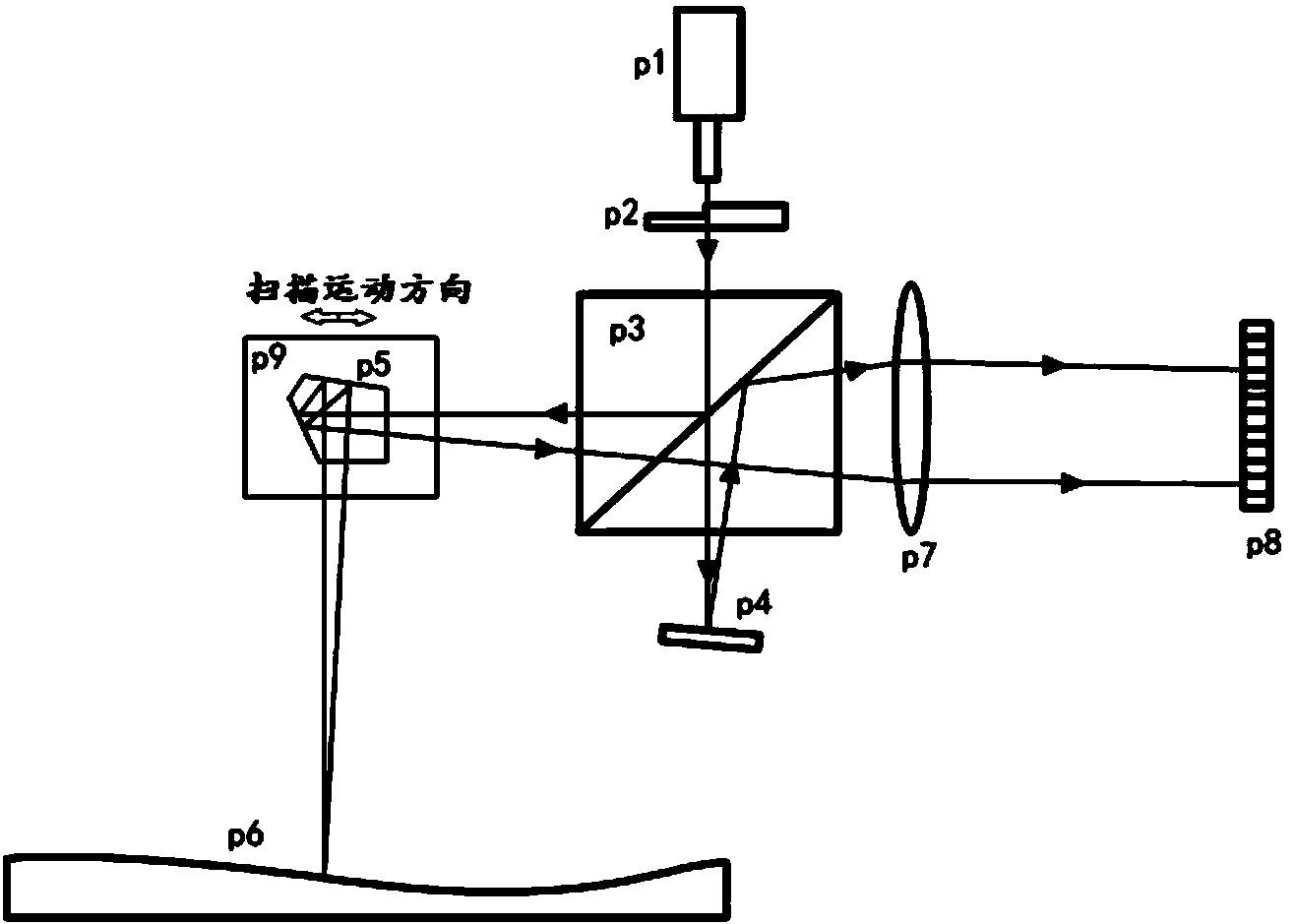

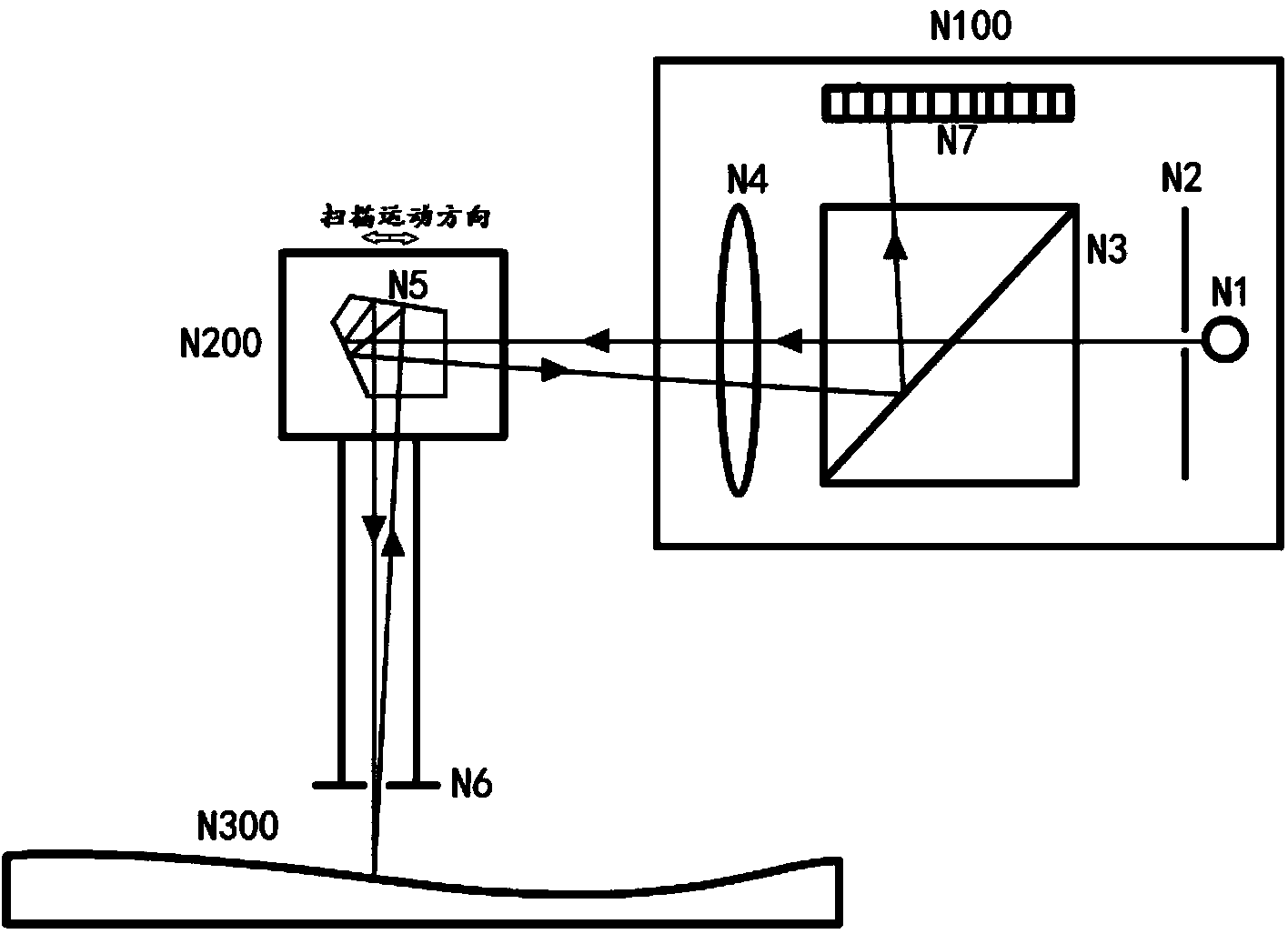

High-precision long-range surface shape detector for optical surface

ActiveCN104019762AAccurate measurementNot easy to interfereUsing optical meansOptical pickupLight beam

The invention discloses a high-precision long-range surface shape detector for an optical surface. The high-precision long-range surface shape detector for the optical surface comprises a first optical head, a reference mirror and a second optical head. The first optical head is used for scanning optical elements to be detected, the reference mirror is fixedly arranged on the side wall of the first optical head, the second optical head projects reference beams to the reference mirror and detects the reference beams reflected by the reference mirror, and the first optical head and the second optical head are different in precision level. According to the high-precision long-range surface shape detector for the optical surface, the first optical head and the second optical head are adopted, the first optical head scans and detects the optical elements to be detected, the second optical head carries out error detection of scanning motion of the first optical head, the precision, the detecting ranges and the beam widths of the two optical heads are set according to different detecting needs and levels, the optical elements to be detected can be detected more accurately, and the high-precision long-range surface shape detector for the optical surface is not prone to being interfered by external environments.

Owner:INST OF HIGH ENERGY PHYSICS CHINESE ACADEMY OF SCI

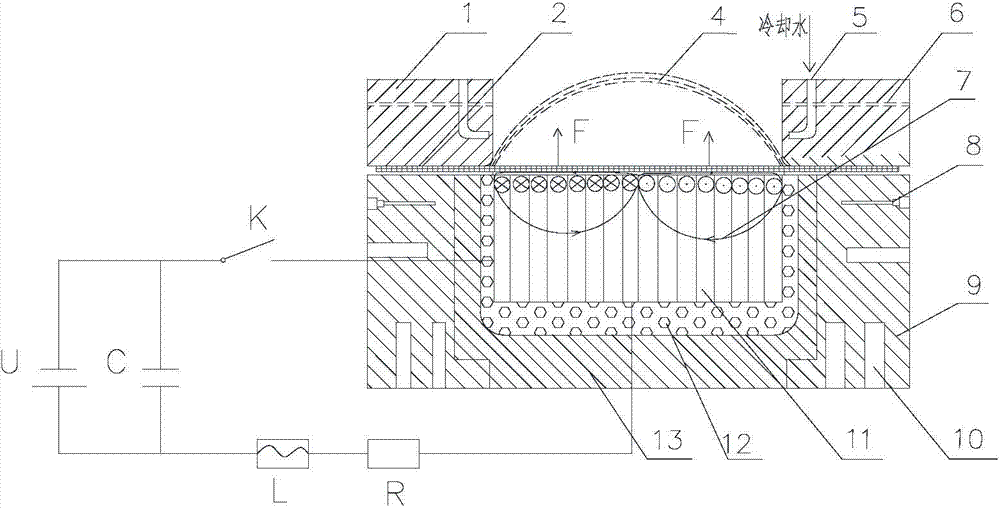

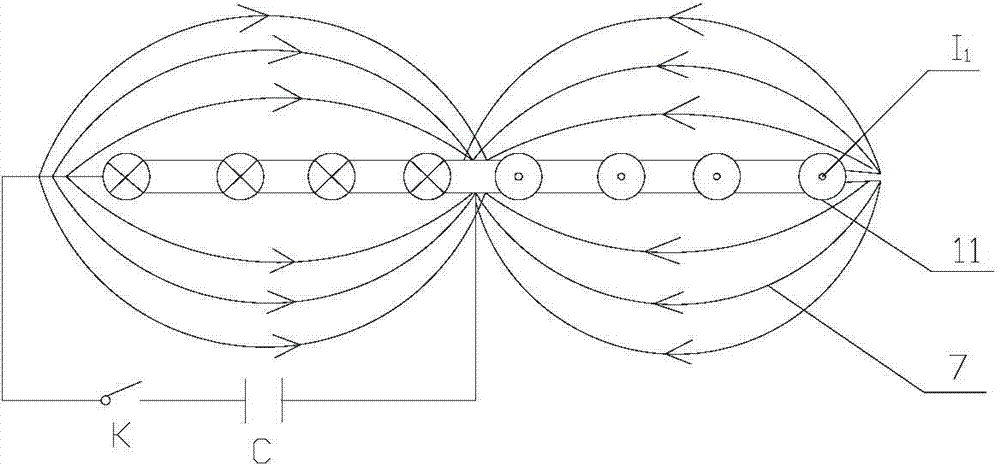

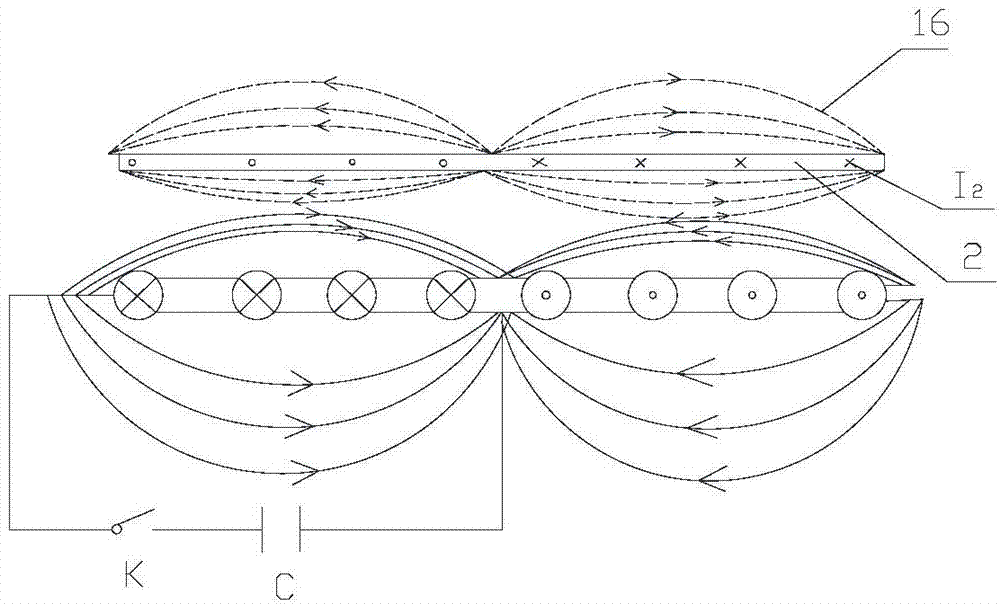

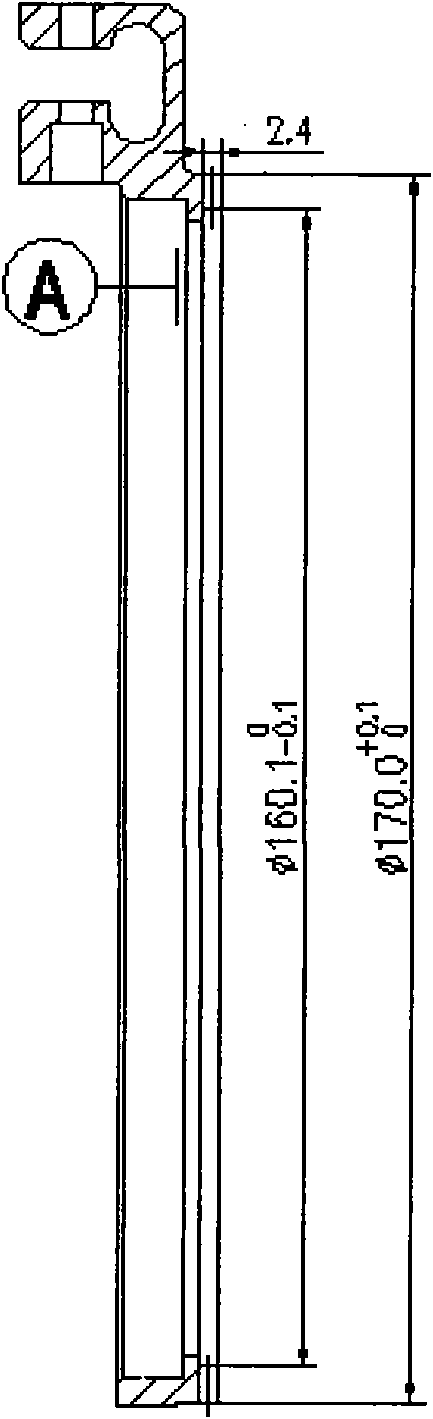

Magnetic impulse warm-hot dynamic drive forming device and forming method for titanium alloy plate

InactiveCN104772380AImprove ductilityReduce residual stressShaping toolsWater channelElectromagnetic forming

The invention discloses a magnetic impulse warm-hot dynamic drive forming device and a forming method for a titanium alloy plate. On the basis of a warm-hot electromagnetic forming method of the prior art, the problems of wrinkling and resilience in a forming process of a titanium alloy material are effectively solved for a purpose of carrying out plastic processing on a titanium alloy by means of simple technical means, such as additionally arranging aluminum driving pieces, respectively forming a plurality of ventilation holes in the front wall surface, the back wall surface, the left wall surface and the right wall surface of a concave die respectively and arranging a cooling water channel, which is communicated with the interior of the concave die, in the top of the concave die. The method for forming the aluminum alloy plate by adopting the magnetic impulse warm-hot dynamic drive forming device for the aluminum alloy plate is good in forming quality of parts, high in precision level, high in forming speed and short in workpiece forming period. The forming device and the forming method disclosed by the invention can be used for finishing forming of the titanium alloy plate through simple technical transformation on the basis of the prior art, the input-output benefit is very remarkable, and thus the forming device and the forming method have favorable market promotion application prospect.

Owner:SHANDONG UNIV OF SCI & TECH

Face gear hobbing cutter design method based on repeatable cutter grinding

InactiveCN101862867AImprove machining accuracyImprove processing efficiencyGear teeth manufacturing toolsSpecial data processing applicationsHobbingGear wheel

The invention relates to a face gear hobbing cutter design method based on repeatable cutter grinding, which is characterized by comprising the following steps of: (1) selecting basic parameters of a face gear and an involute straight gear meshed with the face gear; (2) according to the point contact face gear transmission gear, confirming the number of teeth of a slotting cutter of the face gear; (3) analyzing and establishing face gear hobbing principle, and establishing face gear hobbing processing coordinate system; (4) according to the face gear slotting cutter tooth surface equation and slotting cutter tooth surface parameters, establishing face gear slotting cutter molded surface fundamental equation; (5) analyzing and studying the face gear slotting cutter molded surface boundary limiting condition, and establishing face gear slotting cutter molded surface parameter numeric area; (6) according to face gear slotting cutter molded surface equation and the slotting cutter molded surface parameter numeric area, discretizing the numerical value of the face gear slotting cutter molded surface equation, and obtaining slotting cutter molded surface integer value point; (7) by meshing discrete digitizing curved surfaces, establishing a face gear slotting cutter worm basic model; and (8) according to the processing accuracy of the face gear, confirming the accuracy grade of the face gear slotting cutter, confirming other cutting parameters of the face gear slotting cutter according to the basic parameters of the face gear slotting cutter, and designing an engineering drawing of the face gear slotting cutter with repeatable cutter grinding. The invention establishes a set of complete face gear hobbing cutter design method, and the designed slotting cutter improves processing accuracy and efficiency of the face gear, has repeatable cutter grinding, prolongs the service life of the cutter, and lays foundation for grinding the face gear.

Owner:王端 +3

Fusion method of different-accuracy three-dimension point cloud data based on mean shift

ActiveCN103106632AAccurate descriptionAccurately reflectImage enhancementUsing optical meansSmall amplitudePoint cloud

The invention discloses a fusion method of different-accuracy three-dimension point cloud data based on mean shift. Aiming at two groups of three-dimension point cloud data in different accuracy levels, through utilizing of high-accurate point cloud, error distribution of low-accuracy point cloud is set up, and the mean shift is carried out on the low-accuracy point cloud to eliminate shift errors of the low-accuracy point cloud, and therefore fusion of two groups of data information is realized. The method includes steps: (1) setting up topological structure information of the low-accuracy point cloud, and the topological structure information comprises neighborhood point sets and unit normal vector of every sample point; (2) utilizing the high-accurate point cloud to carry out density clustering on the low-accuracy point cloud, and ensuring shift errors of every sample point of the low-accuracy point cloud according to a clustering result; and (3) utilizing the topological structure information of the low-accuracy point cloud and shift errors to ensure the shift vector of every sample point of the low-accuracy point cloud, and then carrying out shift on every sample point of the low-accuracy point cloud according to the shift vector to realize fusion. According to the fusion method, shift errors of the low-accuracy point cloud are eliminated, and fairing of small-amplitude noises can be realized at the same time.

Owner:HUAZHONG UNIV OF SCI & TECH

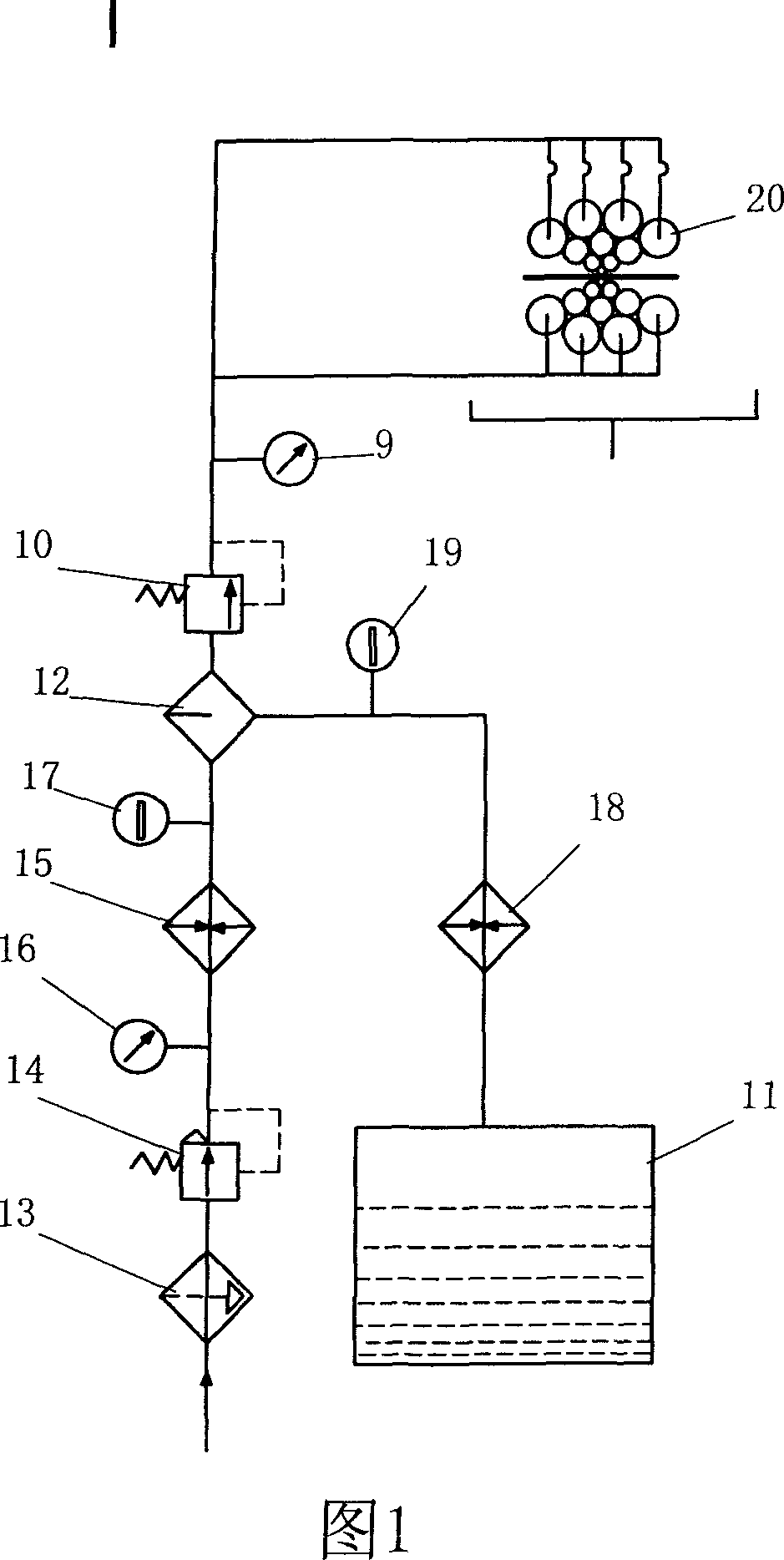

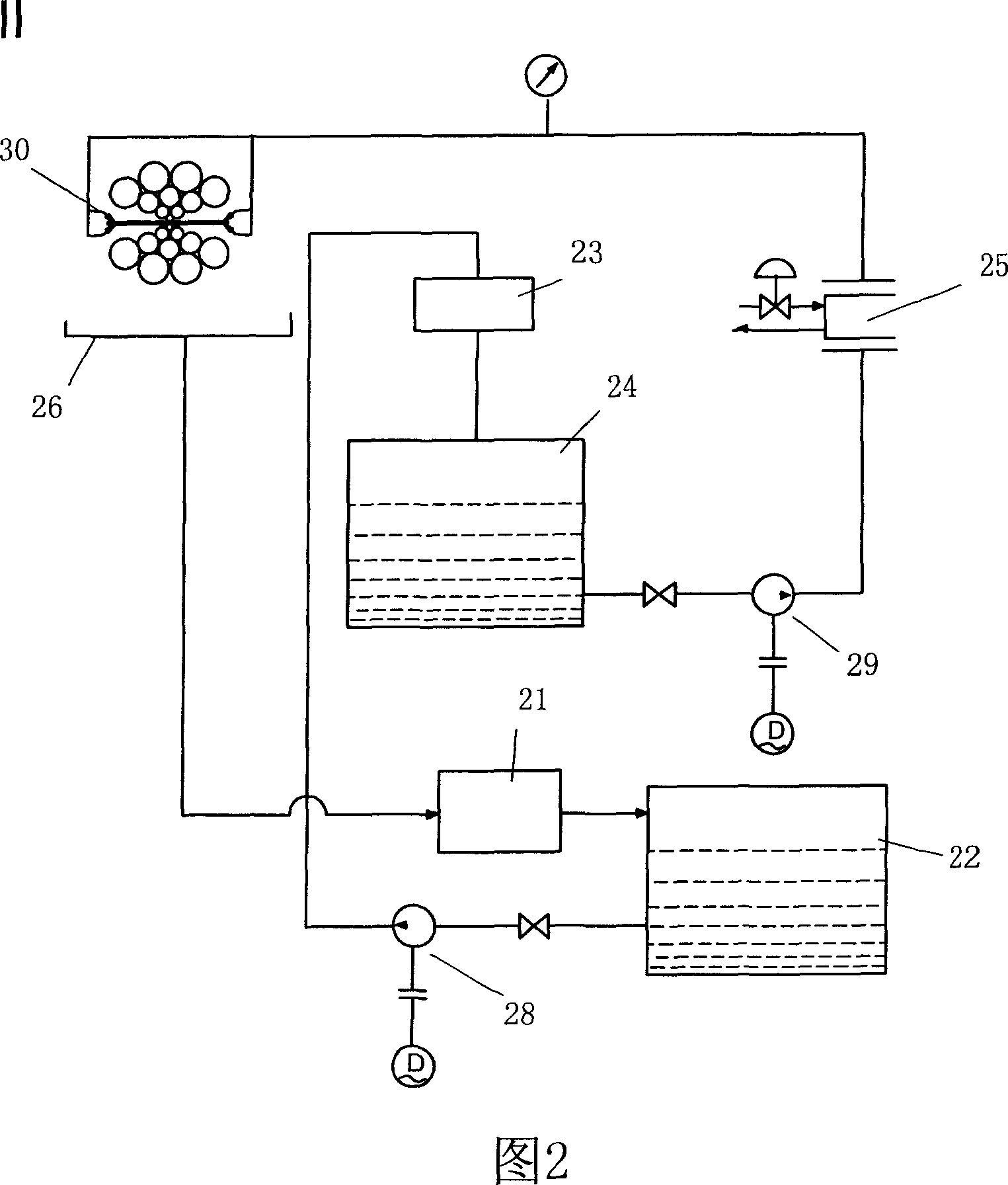

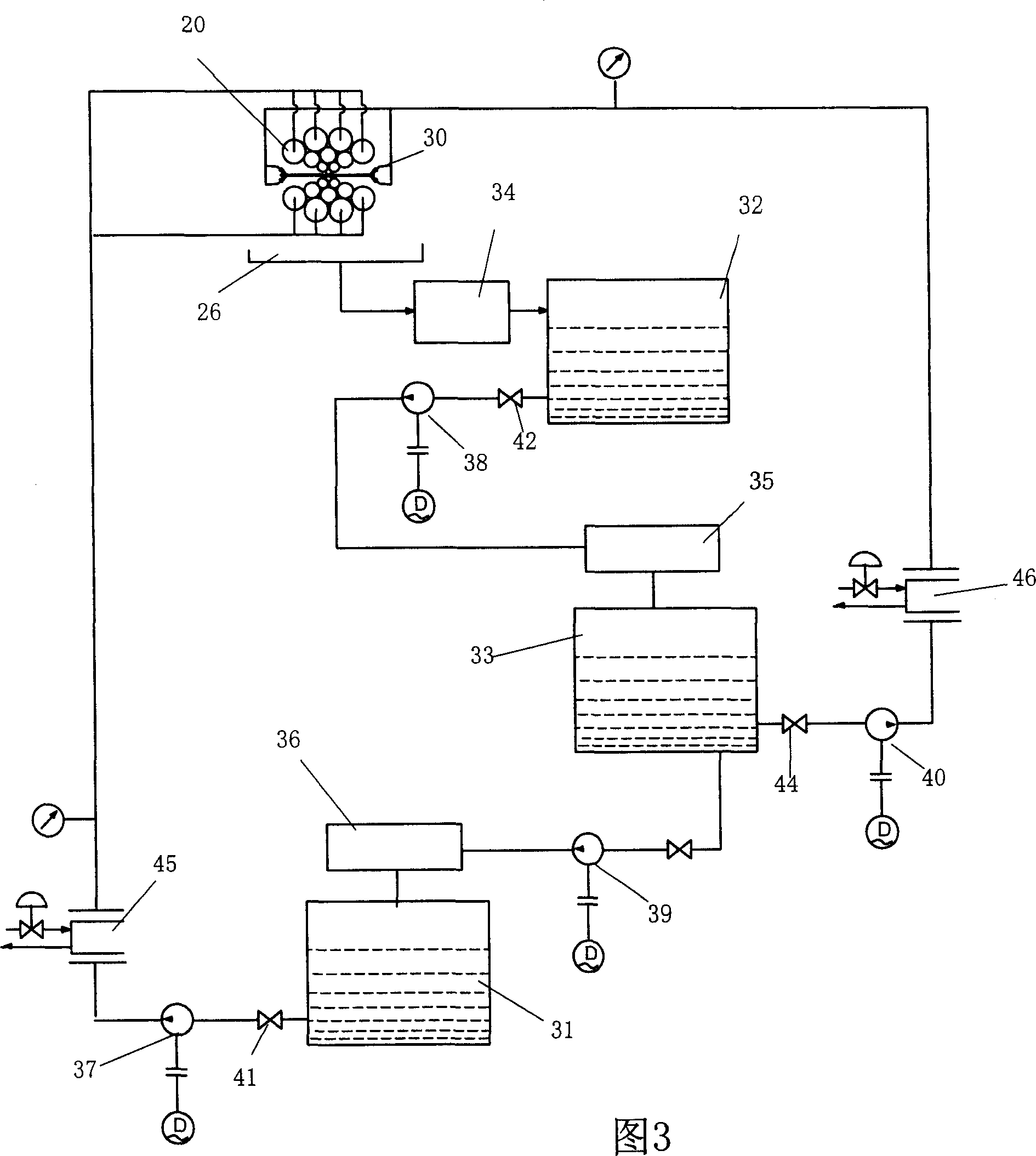

Bearing lubricating and cooling method and device

ActiveCN1931459AImprove the lubrication effectImprove cooling effectRolling equipment maintainenceWork treatment devicesEmulsionBelt filter

The present invention is bearing lubricating and cooling method and device, and features utilizing emulsion as lubricating and cooling medium and adopting an emulsion circulating device to provide the bearing, roller and the rolled plate with emulsion. The present invention can meet different lubricating and cooling requirements of rolling process in a two-stage paper belt filtering mode and has the pressure, flow rate, temperature, concentration and other parameters of the emulsion separately adjustable. The present invention can cool bearing, roller and the rolled plate effectively, save lubricating and cooling medium, improve rolled plate quality, prolong the service life of the bearing and make best use of the rolling machine.

Owner:BEIJING WEISHIJIE HYDRAULIC EQUIP +1

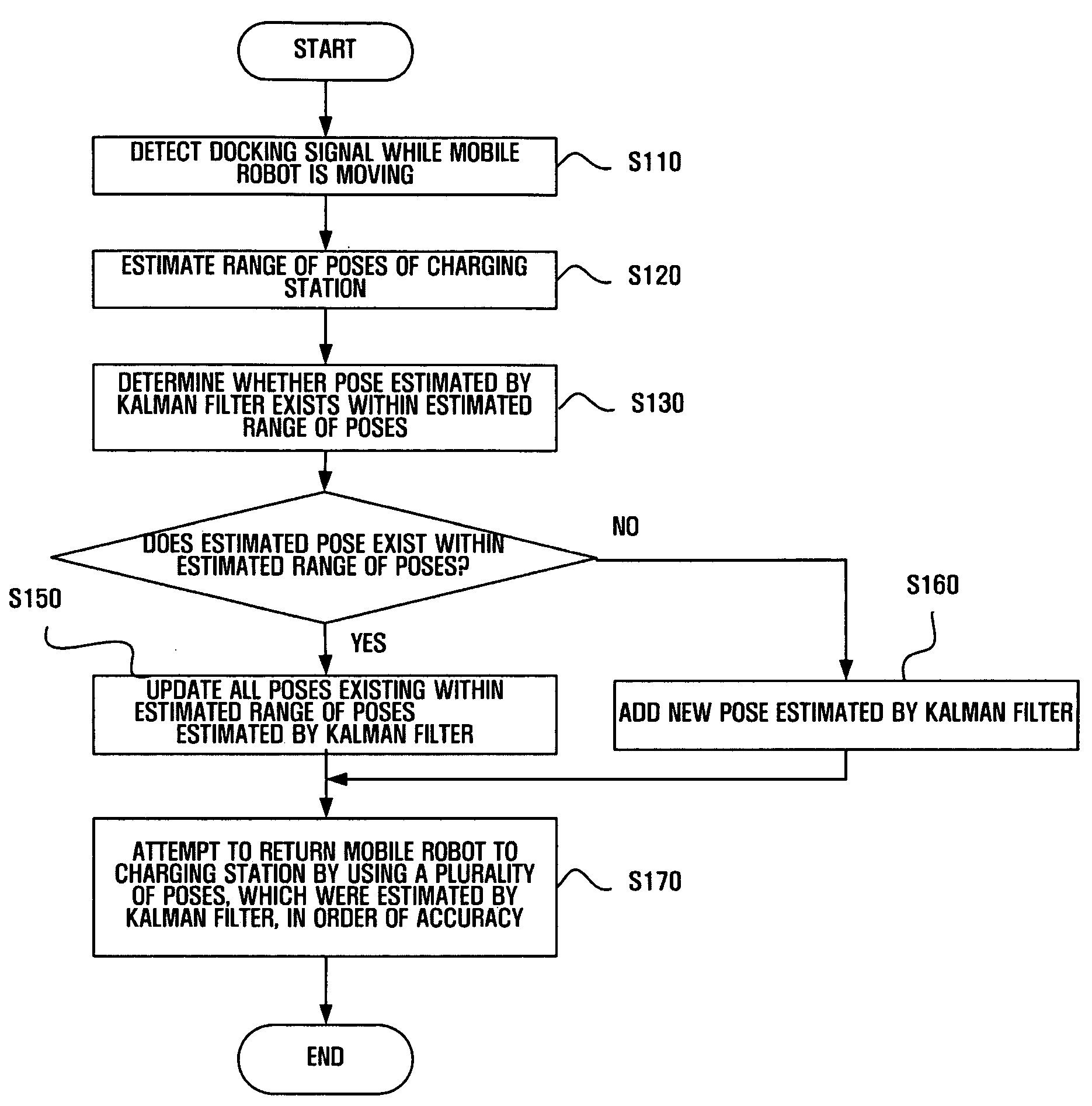

Method, Medium, and Apparatus for Docking Mobile Robot

ActiveUS20090177320A1Improve accuracyManipulatorSpecial data processing applicationsEngineeringSequential estimation

Provided are a method, medium, and apparatus for docking a mobile robot. The method includes: (a) receiving a docking signal, which is transmitted from a signal transmitting unit, by using a signal receiving unit loaded in the mobile robot while the mobile robot is moving; (b) estimating a range of poses of the signal transmitting unit based on the received docking signal; (c) updating estimated poses of the signal transmitting unit by reflecting the estimated range of poses in a pose estimation algorithm when the pose of the signal transmitting unit, which was estimated using the pose estimation algorithm, exists within the estimated range of poses and adding a new pose of the signal transmitting unit, which is to be estimated using the pose estimation algorithm by reflecting the estimated range of poses, when the pose of the signal transmitting unit, which was estimated using the pose estimation algorithm, does not exist within the estimated range of poses; and (d) attempting to return the mobile robot to a charging station by using a plurality of poses of the signal transmitting unit, which were estimated by repeating operations (a) through (c) and using the pose estimation algorithm, in order of accuracy, until the mobile robot is docked in the charging station.

Owner:SAMSUNG ELECTRONICS CO LTD

Method of guaranteeing fan high-strength bolt pretightening force to be accurately exerted

InactiveCN103423274AGuarantee stabilityAvoid the risk of mixingScrewsSpecial data processing applicationsSurface roughnessEngineering

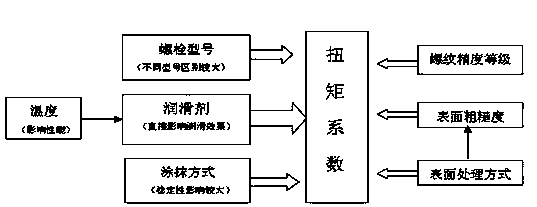

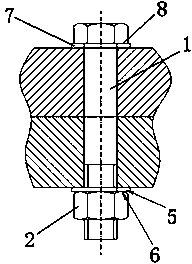

The invention discloses a method of guaranteeing a wind generating set high-strength bolt pretightening force to be accurately exerted, which is characterized in that according to influence factors on a torque coefficient, such as lubricant which is used when a high-strength bolt is screwed down, a smearing mode, a thread precision grade, the surface roughness of a matched surface, a surface processing mode, a bolt model specification and temperature, the torque coefficient is confirmed on the basis of the theory of a torque method, and the range of dispersion coefficient of each specification of bolt in each batch when the torque method is adopted is controlled within 1.25 through controlling the lubricant, the smearing mode, the thread precision grade, the roughness of the matched surface, the surface processing mode, the bolt model specification and the temperature.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

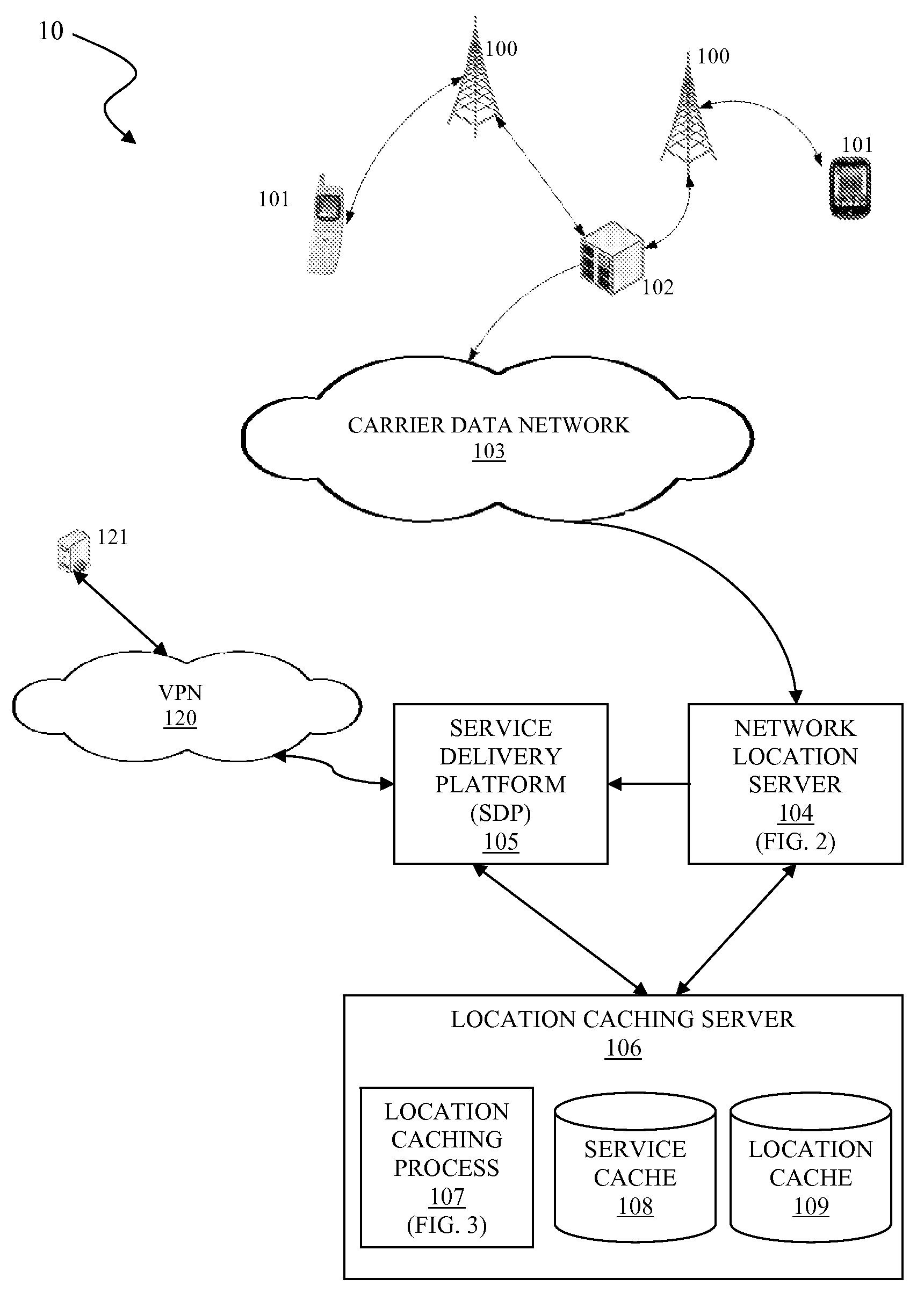

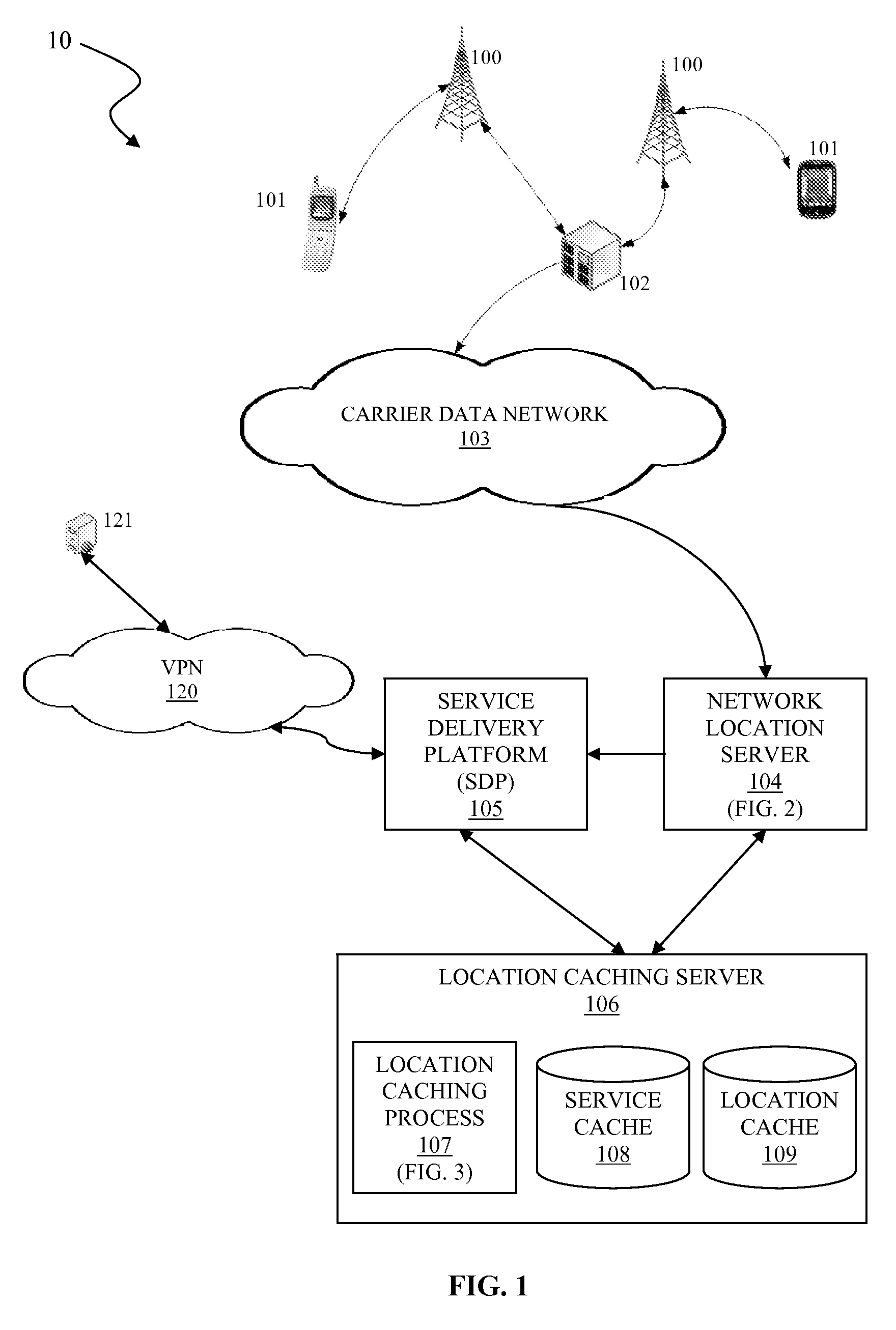

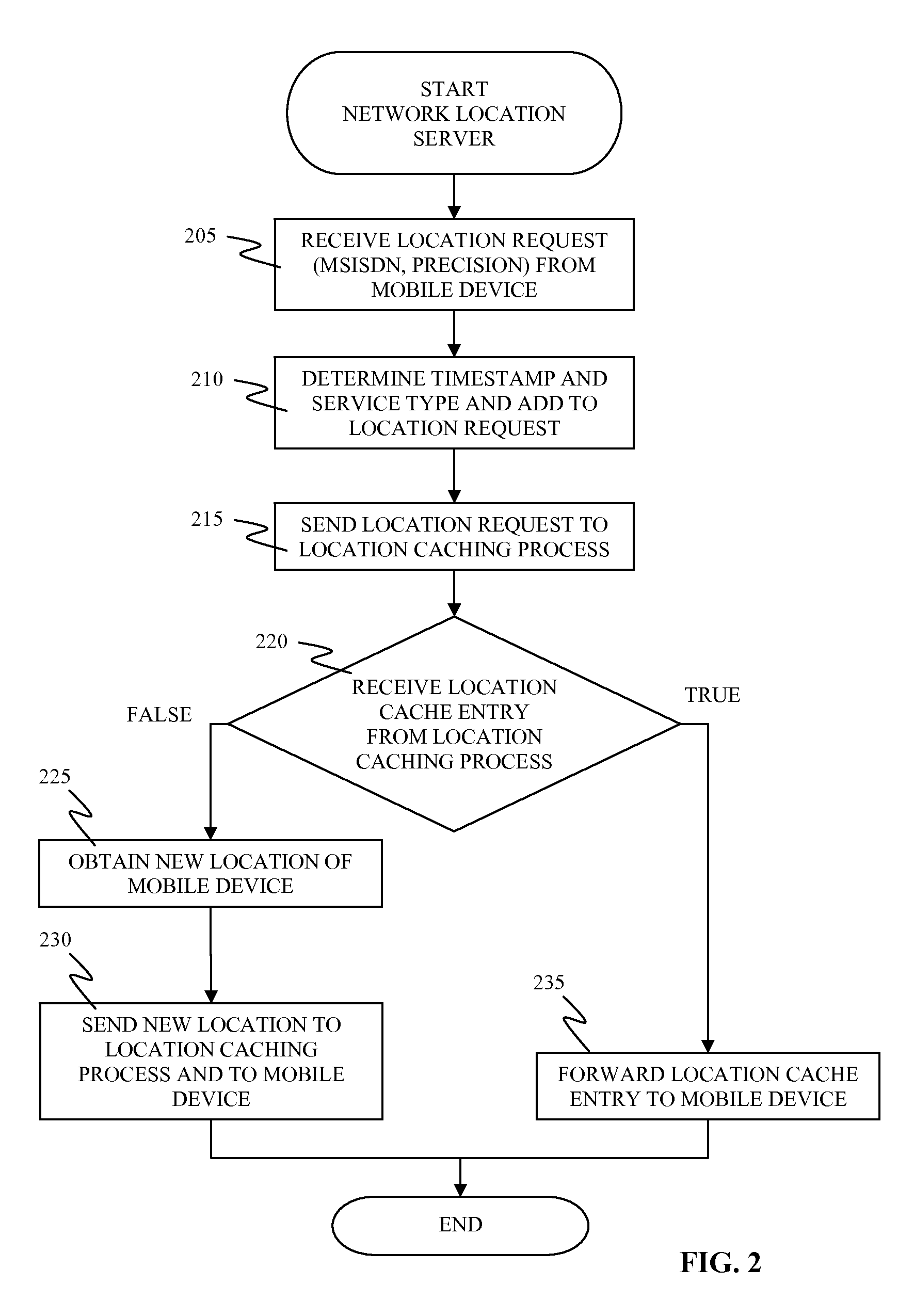

Optimizing caching period of location data for network based location services

InactiveUS20110131197A1Digital data processing detailsMultiple digital computer combinationsCache serverMobile device

A system and associated method for optimizing caching period of location data for network based location services. A location caching server receives a location request from a mobile device. The location caching server calculates, pursuant to a predefined calculation rule, a caching period of a location cache entry for the mobile device based on a precision level requested by the mobile device and a service precision level assigned for a type of location service for which the location request was made. The location caching server obtains real location data of the mobile device of the calculated caching period is expired. The location caching server subsequently adjusts the caching period based on a distance traveled by the mobile device pursuant to a predefined adjustment rule, and updates the location cache entry.

Owner:IBM CORP

Turntable bearing machining technique

The invention discloses a turntable bearing machining technique. The turntable bearing machining technique includes the following processes: 1) checking a forge piece blank; 2) performing lathe work machining; 3) performing heat treatment, 3.1) performing quenching on a surface of a ball track: performing medium-frequency quenching on the surface of the ball track, wherein the hardness is not less than 55 HRC, the depth of a hardened layer is not less than 4 mm, and the width of a soft zone is less than 50 mm; 3.2) performing tempering after heating: performing medium-frequency quenching on an inner ring and an outer ring of a bearing at the temperature of 200 DEG C for 48 hours, and then performing discharge to ensure the situation that internal stress vanishes; 4) performing rolling and milling machining, 4.1) performing hobbing on a turntable bearing with inner and outer teeth before abrasive machining, wherein the accuracy class should reach over 8 class; 5) performing hole drilling; 6) performing abrasive machining, 6.1) performing coarse grinding, wherein a medium-corundum resin wheel with the soft-three-granularity of 36 is adopted to perform grinding, the linear velocity is controlled to be 1500 revolutions / minute to prevent the ball track form burn, and the maximum grinding depth is not greater than 1 mm; and 6.2) performing accurate grinding, wherein a resin wheel with the granularity of 46 or 60 is adopted to perform grinding, and the grinding amount is less than that of coarse grinding machining.

Owner:CHONGQING HUANDE TECH CO LTD

Measuring method of flatness of honeycomb cores of combined frame structures

InactiveCN103557777AOvercome usabilityOvercoming the problem of measuring with mirrorsMechanical roughness/irregularity measurementsHoneycombClassical mechanics

The invention belongs to the field of measuring technique, and relates to a measuring method of flatness of honeycomb cores of combined frame structures. A high-accuracy knife straight edge and a set of measuring blocks with a third or higher accuracy class are used, a height difference computational method is combined, and therefore measurement of the flatness of the honeycomb cores is completed. The measuring method has the advantages that the problem that a gradienter or a reflector cannot be used for measuring the flatness of the honeycomb cores because thicknesses of foil sheets are too small, measured values are obtained by using the knife straight edge and the measuring blocks in a combined measuring method, and the measuring method fills gaps in detection methods of the flatness of the honeycomb cores.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

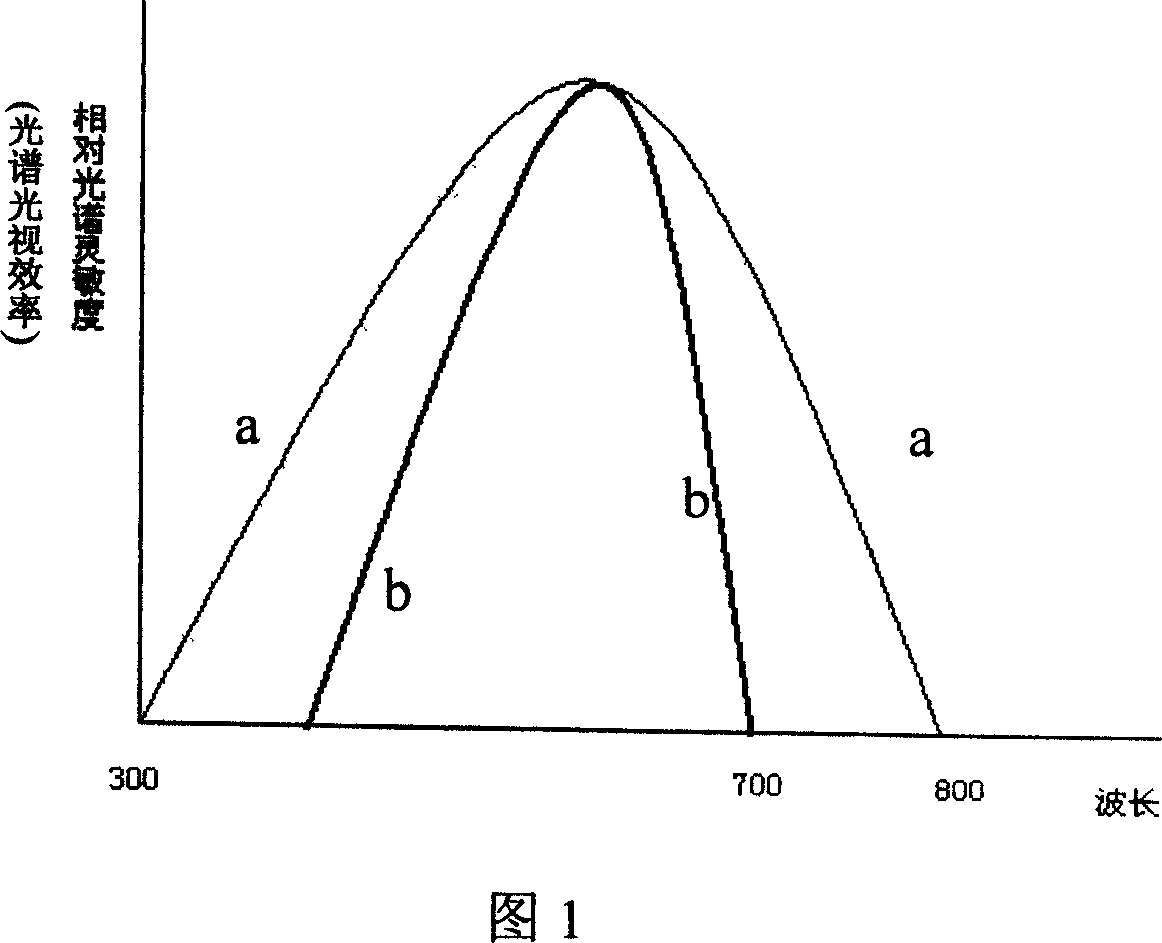

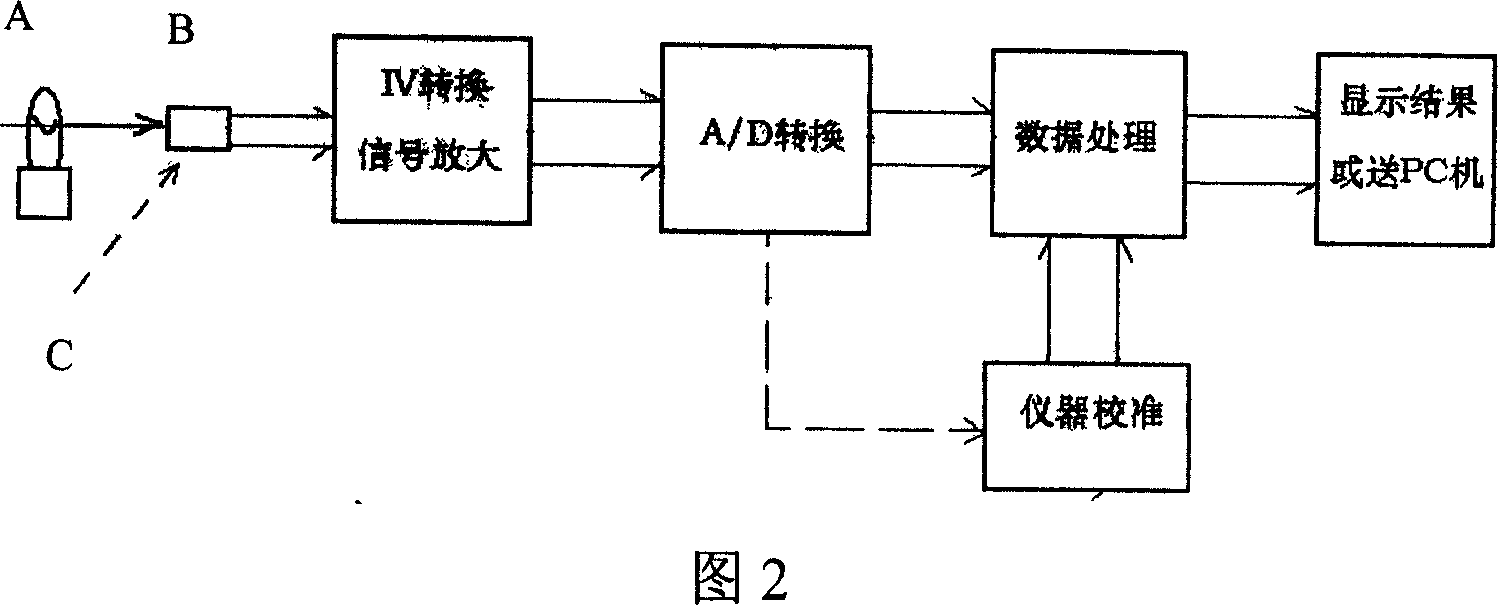

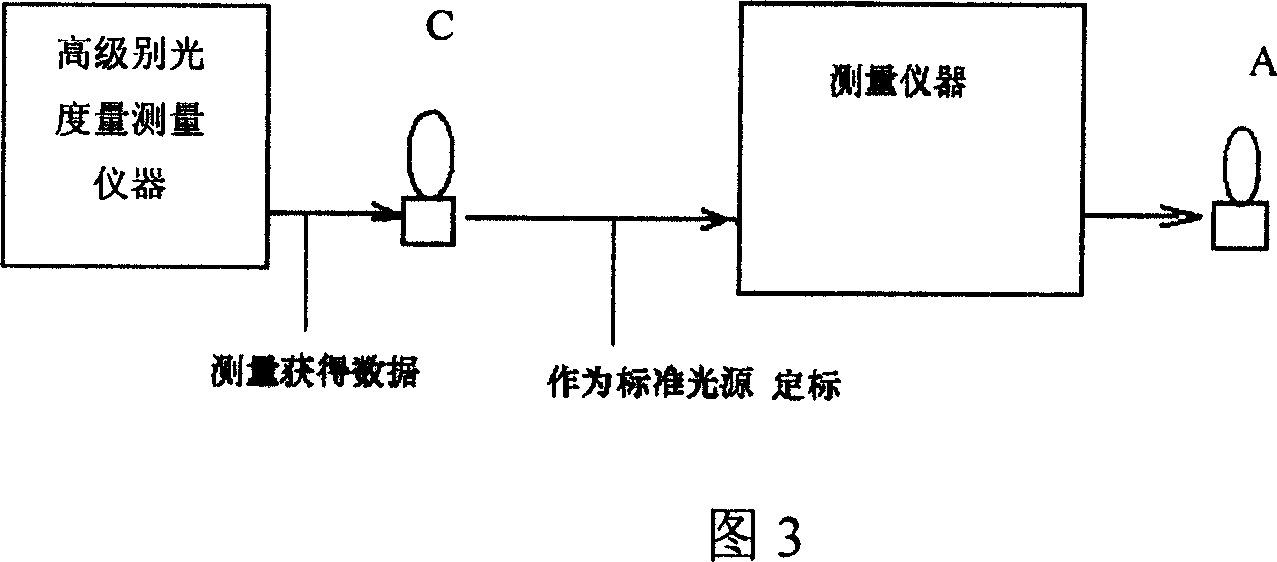

Method for improving measurement precision of photometry measuring instrument

InactiveCN101034006AEasy to changeHigh measurement accuracyPhotometry using electric radiation detectorsMeasuring instrumentDisplay device

This invention relates to a method of advancing photometric quantity measuring apparatus accuracy of measurement. Method include; measured light through V ( lambda) regulation then be received by detector to turn to current signal, passing iv transducer turn ro voltage alarm, after magnifying then passing A / D transducer turn to digital signal; processing the digital signal, and send the results to PC machine or scope for presentation;this instrument beforehand has passed difference spectral range standard light source adjust, gain different instrument calibration coefficient; And use homologize wave band's instrument calibration coefficient while use this instrument to measure difference wave band light source. The described standard light source is linear light source that has scaling measured by instrument of higher order of accuracy. The described difference spectral range divided into red green blue yellow white five colors.

Owner:郑晓明

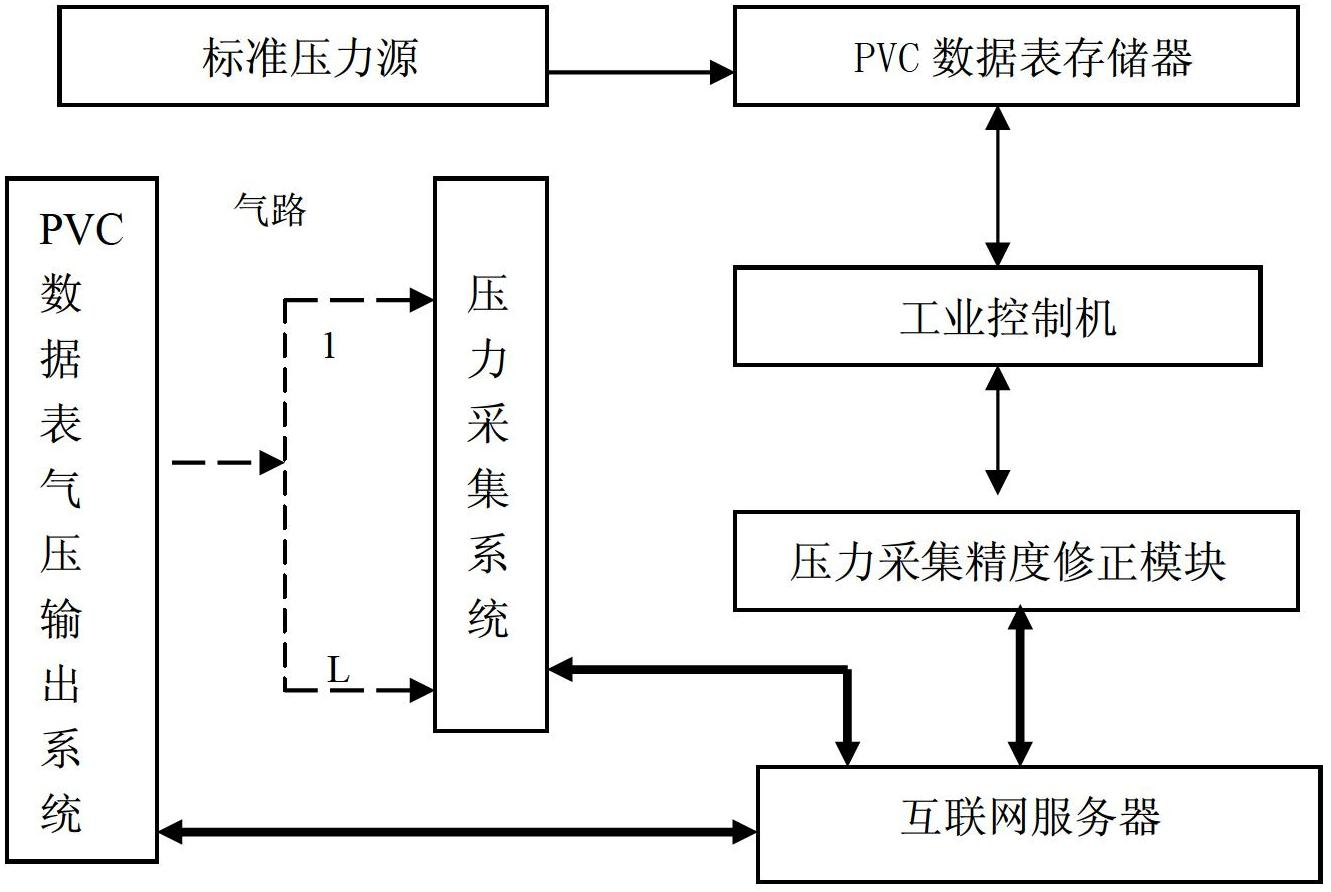

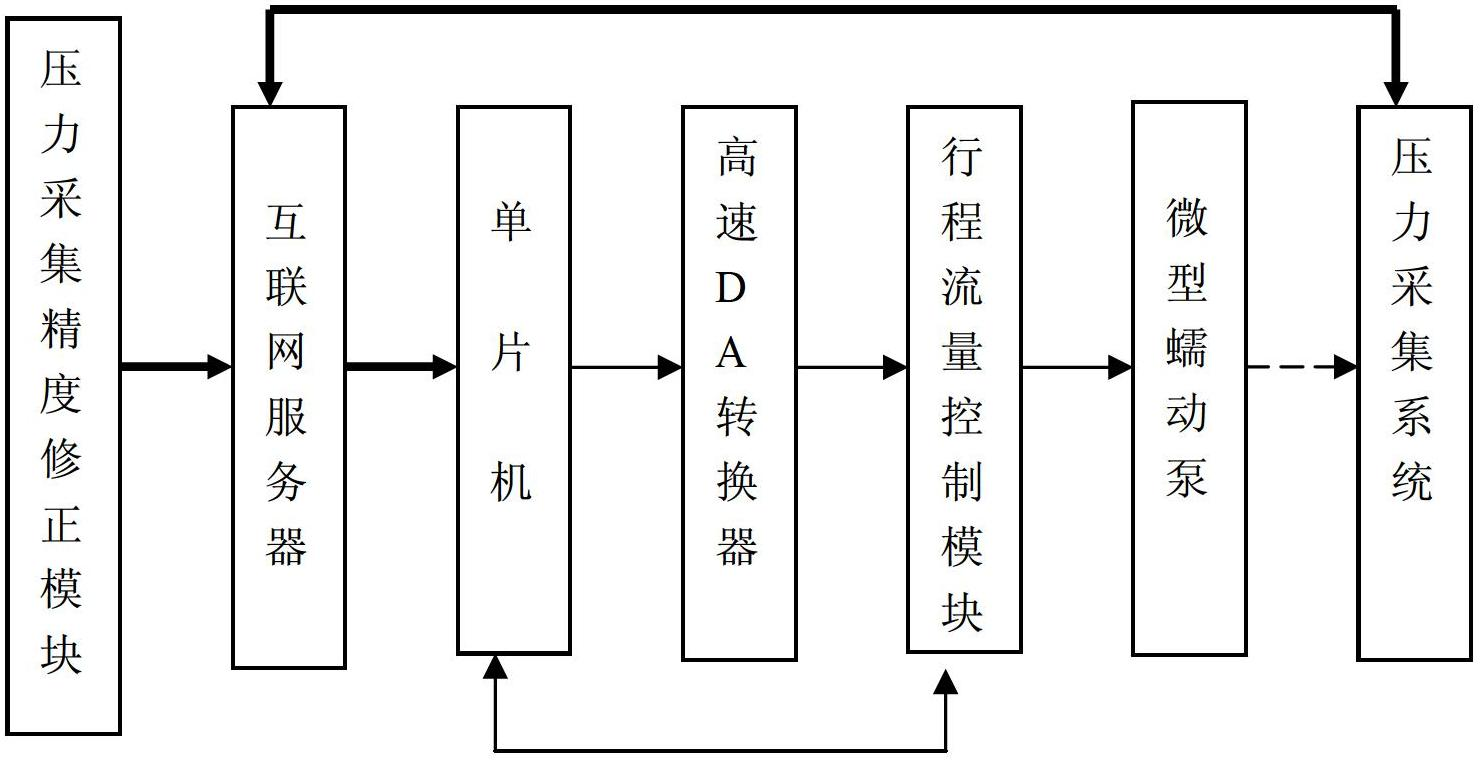

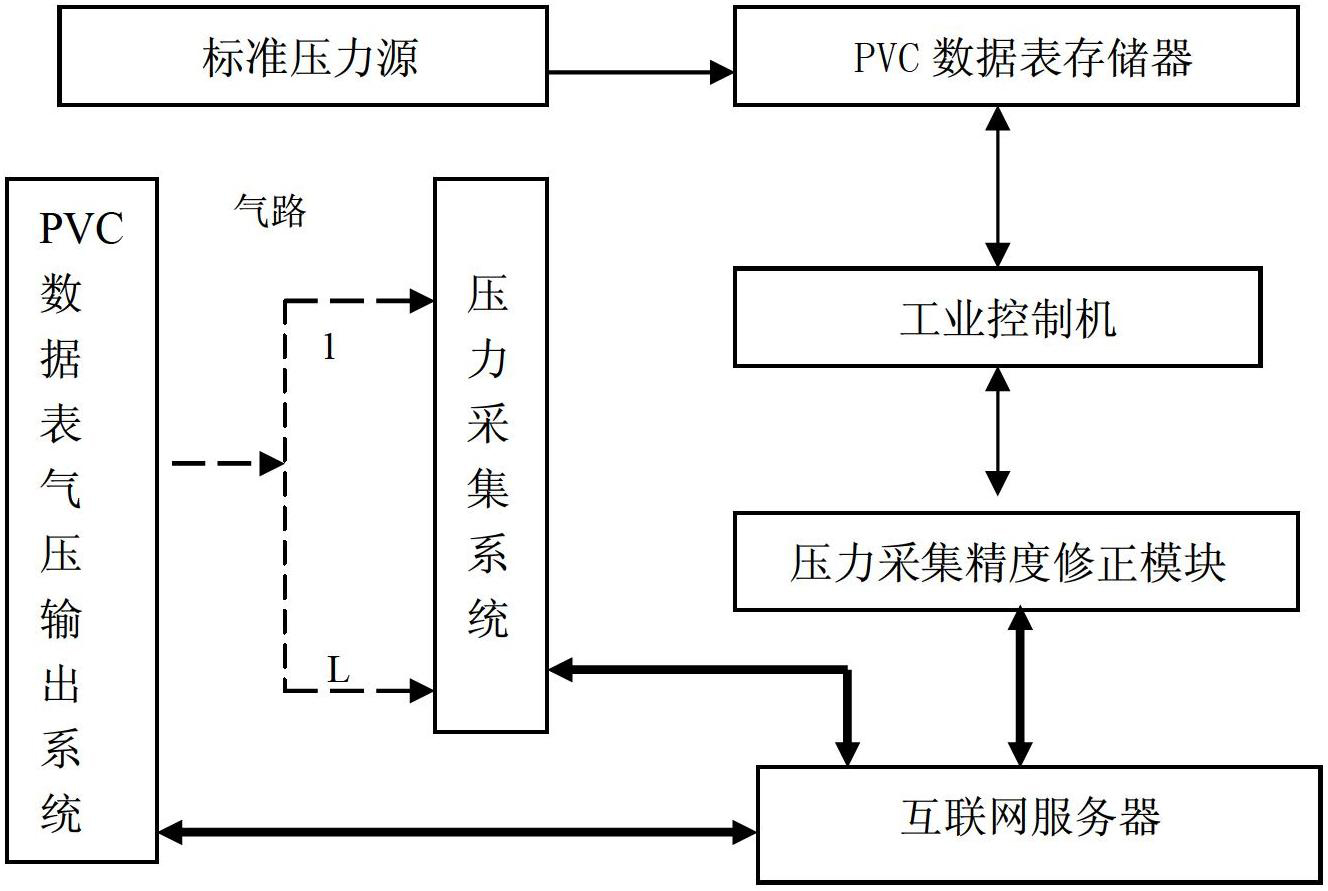

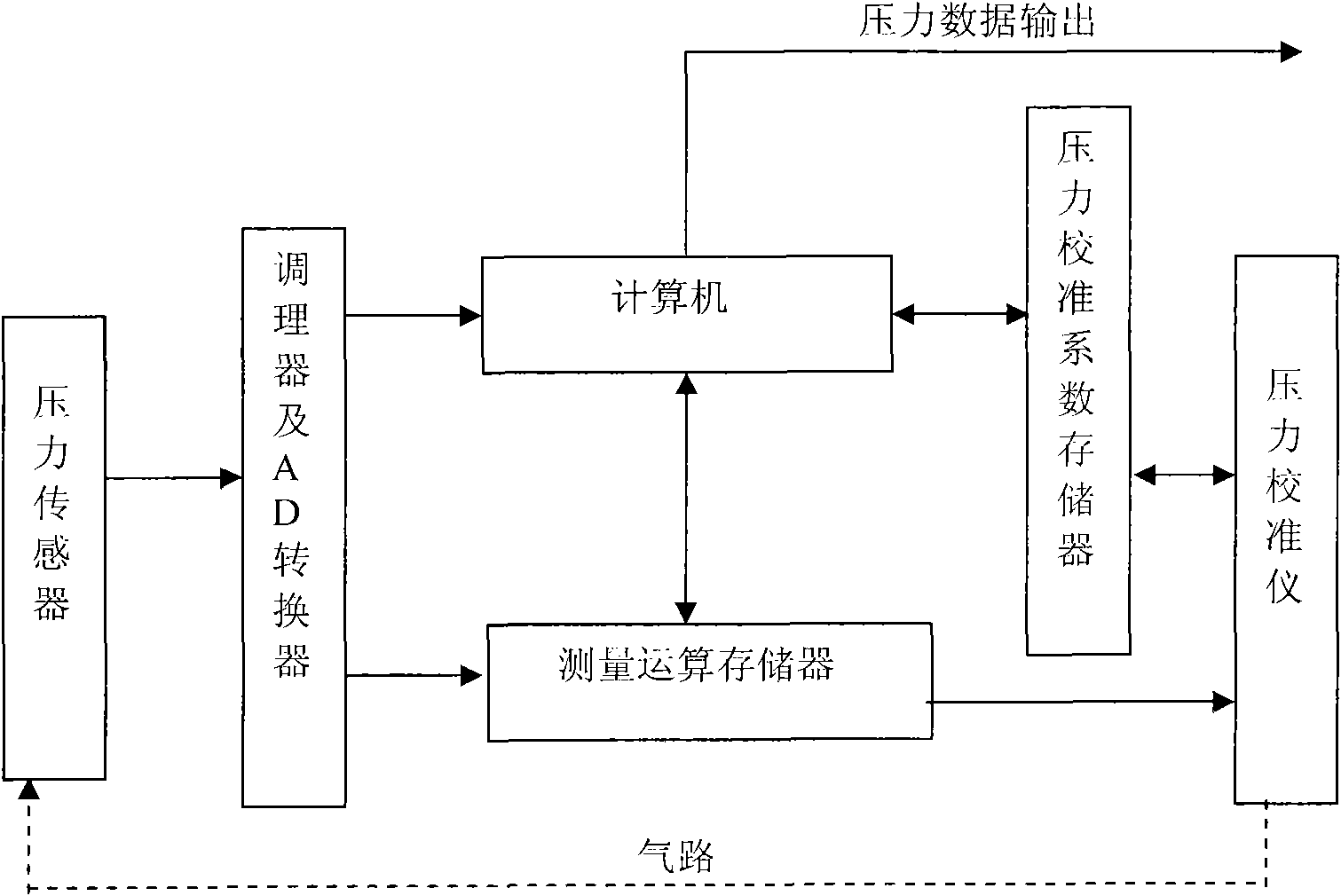

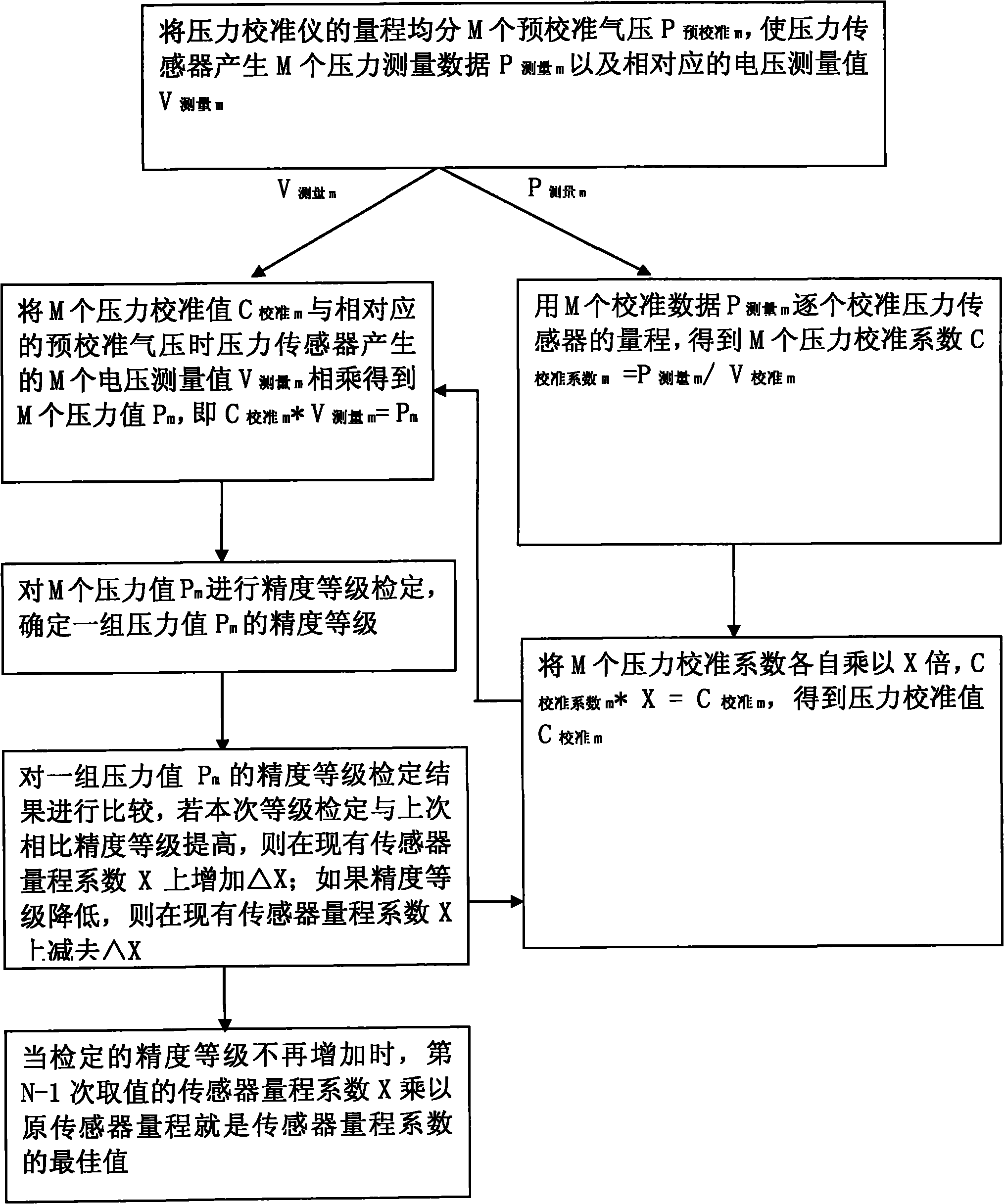

System and method for correcting precision of sensors of pressure acquisition system

InactiveCN102661832ALow costImprove efficiencyFluid pressure measurementSocial benefitsMaterial resources

The invention discloses a system and a method for correcting precision of sensors of a pressure acquisition system. The method includes: a standard pressure source generates standard data tables of different ranges and precision levels and stores the standard data tables in a PVC (pressure, voltage and coefficient) data table memory, the pressure acquisition system acquires data tables of each pressure sensor and transmits to an industrial computer through an internet server and a pressure acquisition precision correcting module sequentially, and the industrial computer judges the precision level of each pressure sensor and sends higher-precision standard data tables to pressure sensors beyond the error requirement and outputs corresponding pressure to the pressure acquisition system through a PVC data table air pressure output system to correct the precision level of the pressure sensors. By the system and the method for correcting precision of sensors of the pressure acquisition system, peripheral equipment such as nitrogen gas cylinders can be omitted, the method is simple, cost is low, efficiency is high, operating modes are flexible and convenient, a great amount of labor, material resources and financial resources are saved, cost for correction of the pressure acquisition system is lowered, and the system and the method have certain economic and social benefits.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Method for positioning and clamping straight-line guiding rail

ActiveCN101434037AEliminate cumulative errorsAvoid influenceLarge fixed membersEngineeringMechanical engineering

The invention relates to a positioning and clamping method for a linear guide rail, which belongs to the technical field of a rail fixture for adjusting and fixing the position of the guide rail. Upper clamping blocks are attached to both sides of the guide rail, so that the squeezing stress of a clamper is converted into the clamping force of the clamping blocks and the clamping force of the clamping blocks is then converted into the pretightening force for fixing the guide rail, thereby the straightness accuracy of the linear guide rail can be accurately matched and effectively positioned, consequently the positioning and clamping method for the linear guide rail avoids high-cost investment for improving the accuracy grade of the guide rail and the processing precision of assembly of a reference surface, and really improves the rigidity and the stability of the guide rail.

Owner:HANS CNC SCI & TECH

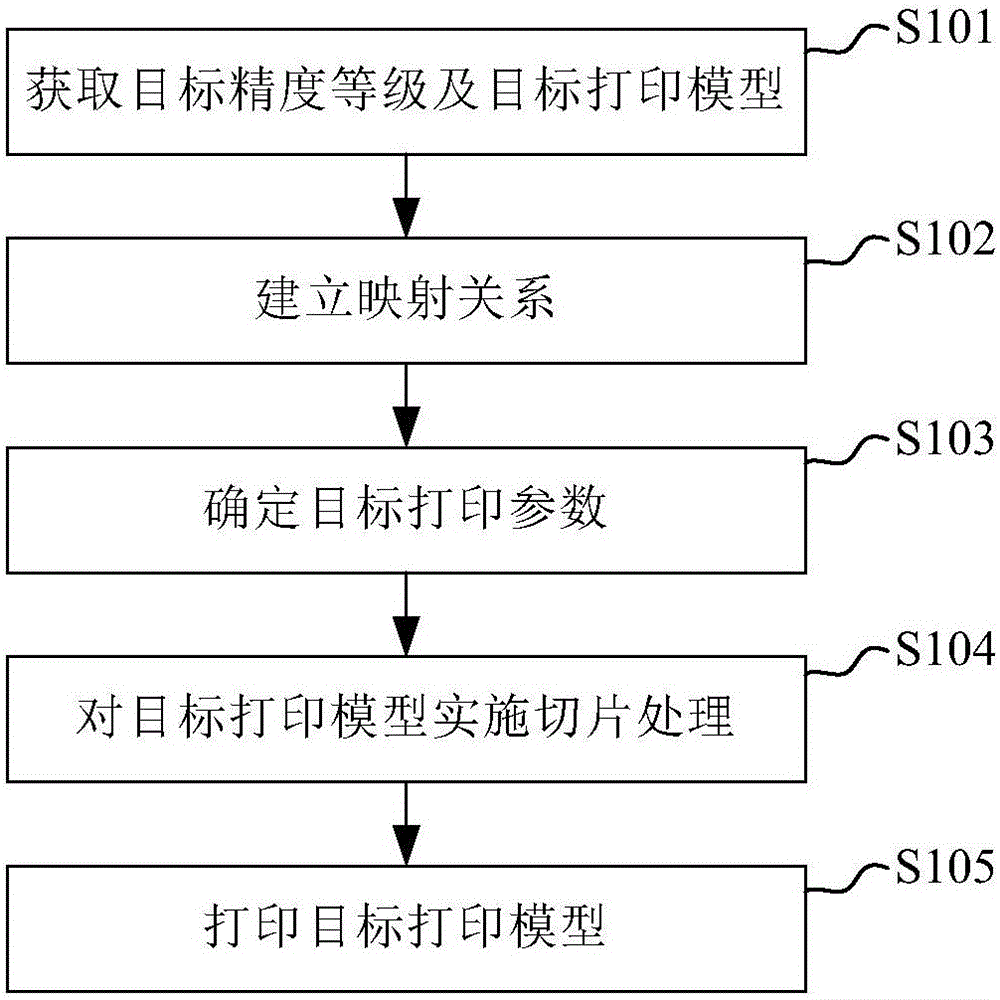

3D printing method and system

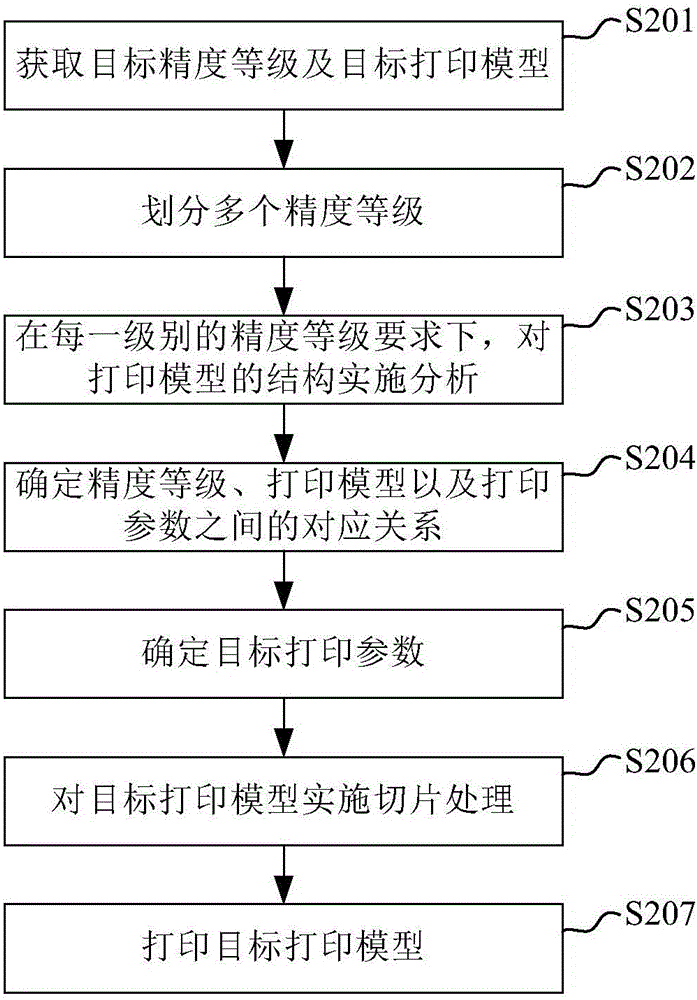

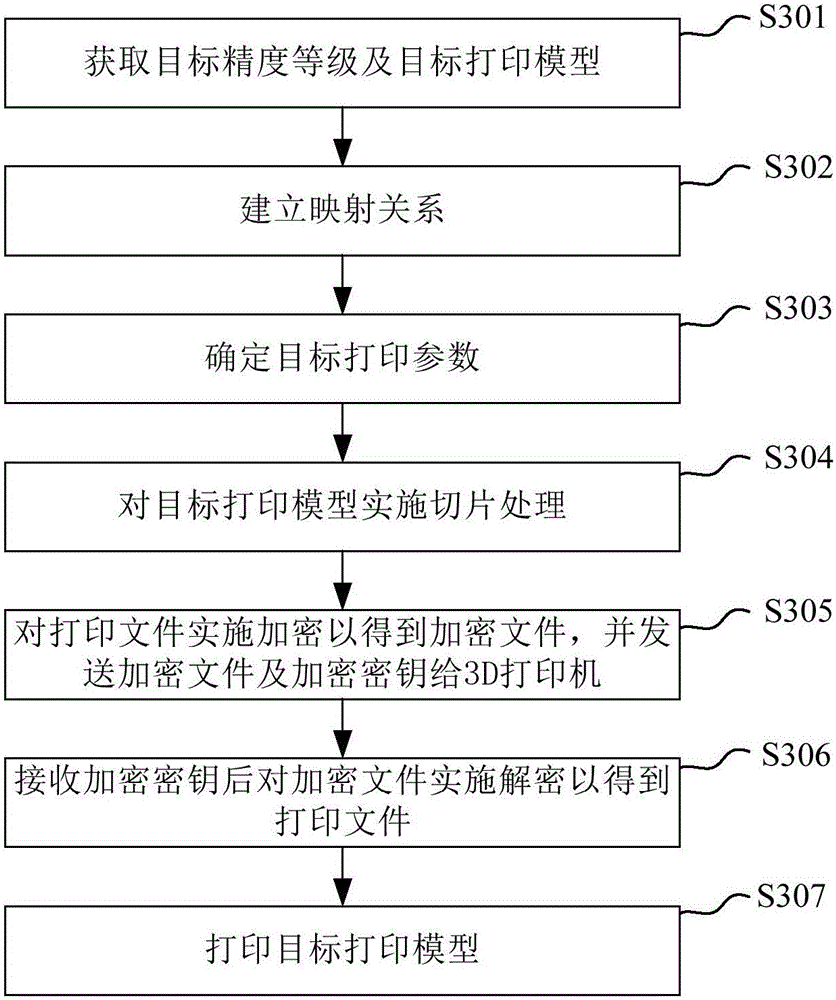

InactiveCN105159626AReduce complexitySolve more complicated problemsAdditive manufacturing apparatusDigital output to print unitsModel implementationOrder of accuracy

The present invention provides a 3D printing method, comprising the following steps: (11) obtaining a target accuracy grade and a target printing model, and establishing a mapping relationship among an accuracy grade, a printing model, and printing parameters corresponding to the accuracy grade and the printing model; (12) determining, according to the mapping relationship, target print parameters corresponding to the target accuracy grade and the target printing model; (13) performing slicing processing on the target printing model according to the target printing parameters to obtain a print file; and (14) printing the target printing model according to the print file. According to the method, a problem that a user operation in a current 3D printing process is relatively complicated can be solved. The present invention further provides a 3D printing system.

Owner:深圳马顿科技有限公司

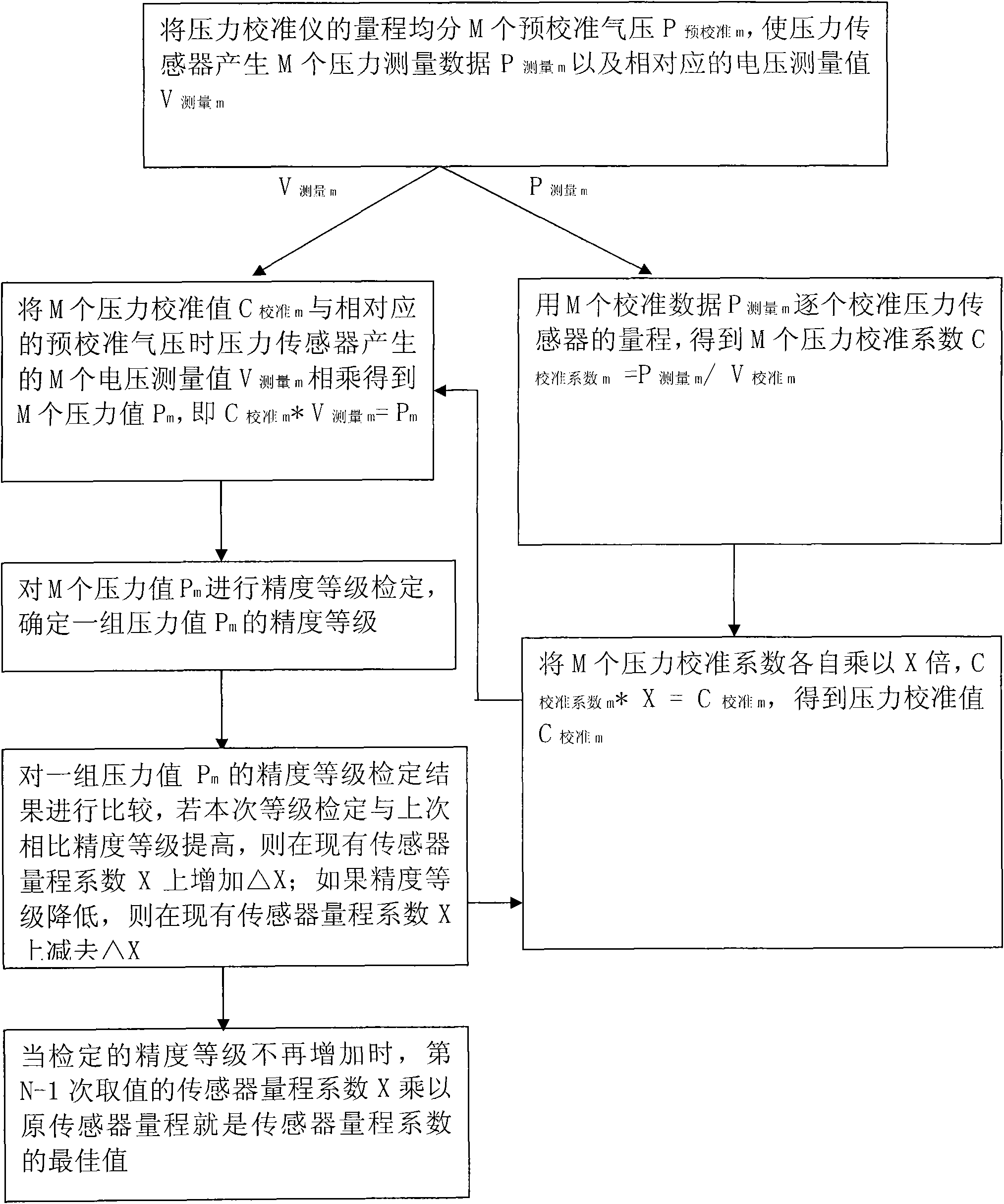

Method for decreasing basic error of pressure sensor

InactiveCN101846572ABasic error reductionImprove basic measurement accuracyFluid pressure measurementAtmospheric pressureCalibration coefficient

The invention discloses a method for decreasing the basic error of a pressure sensor. The measuring range of a pressure calibration instrument is equally divided, the pressure sensor generates M pressure measurement data and the corresponding voltage, the measuring range of the pressure sensor is calibrated one by one to obtain M pressure calibration coefficients, the M pressure calibration coefficients are respectively multiplied by X times to obtain the calibration m of pressure calibration values C, the calibration m of the M pressure calibration values C is multiplied by the measurement m of M voltage measurement values V generated by the pressure sensor at the corresponding pre-calibrated air pressure to obtain M pressure values Pm, and the accuracy grades of a group of pressure values Pm are determined and are compared; and when the detected accuracy grades are not increased any more, the optimal value of the coefficients of the measuring range of the sensor is obtained. The invention can decrease the basic error of the pressure sensor and enhances the basic measurement accuracy of the measurement of the pressure sensor.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Numerical control milling method for micro threaded holes of titanium alloy

InactiveCN107127406AImprove shape and position accuracyImprove processing efficiencyThread cutting machinesNumerical controlDiameter ratio

The invention relates to a numerical control milling method for micro threaded holes of titanium alloy. The method comprises the specific machining operation steps of replacing a traditional manual tapping method for the titanium alloy with numerical control machining to improve the quality and efficiency of threads, selecting a threaded tool made of hard alloy to ensure high efficiency and batch production of part machining, and selecting a reasonable technical machining method to ensure specification consistency of the threads, circumferential stress uniformity during threaded milling and prevent the tool from being broken. The numerical control milling method is suitable for the micro threaded holes, with the machining range smaller than M3 and the length-diameter ratio higher than 2.5, of the titanium alloy, and the bottleneck problem of tapping of the micro threaded holes, with the large-length-diameter ratio, of the titanium alloy is solved successfully. Meanwhile, drilling and tapping are completed jointly, efficiency is improved by 6-8 times, the grade of precision of the threads of the holes and specification consistency of the threaded holes are improved, and the machining requirement for high precision of titanium alloy parts can be met.

Owner:中国船舶重工集团公司第七〇七研究所

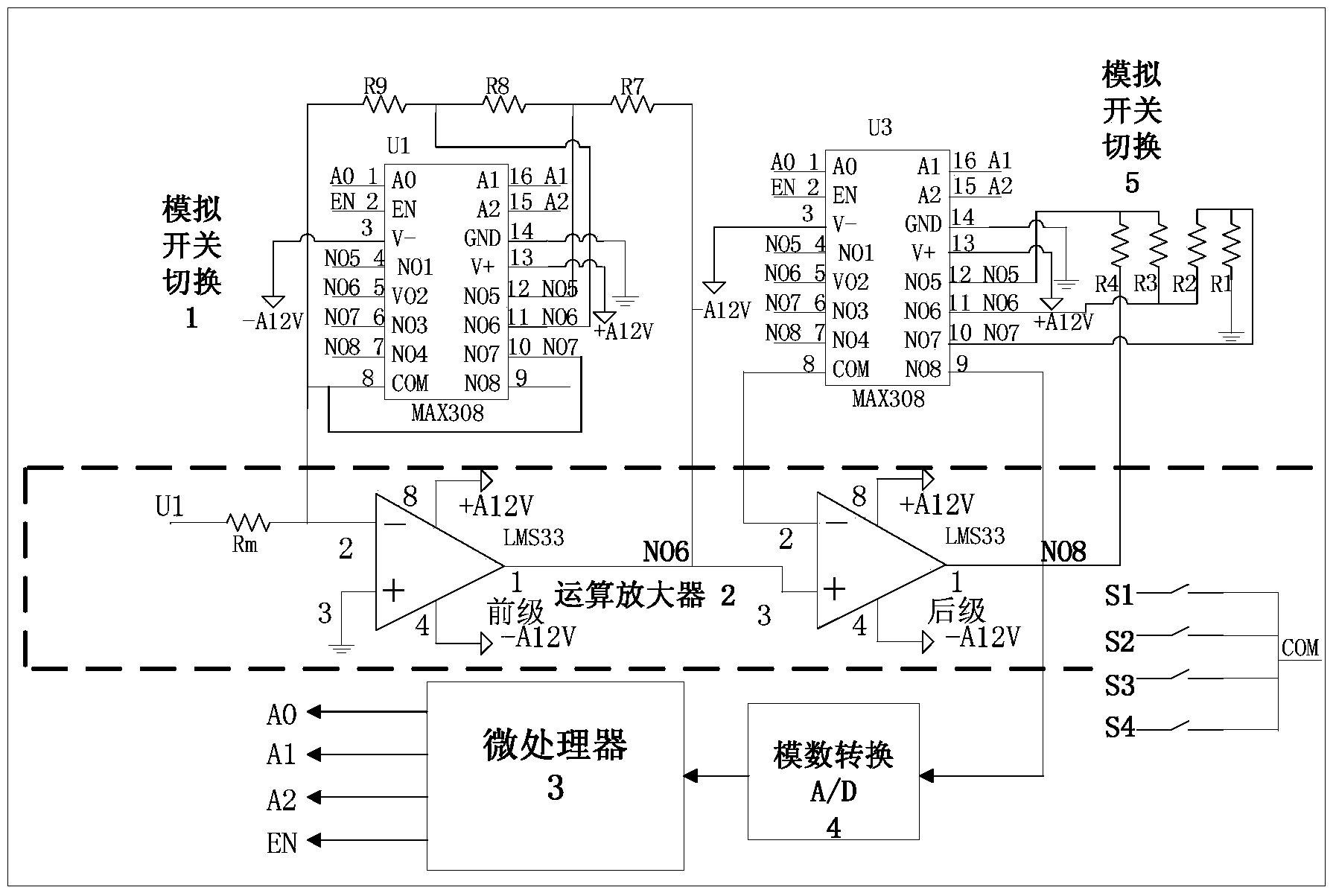

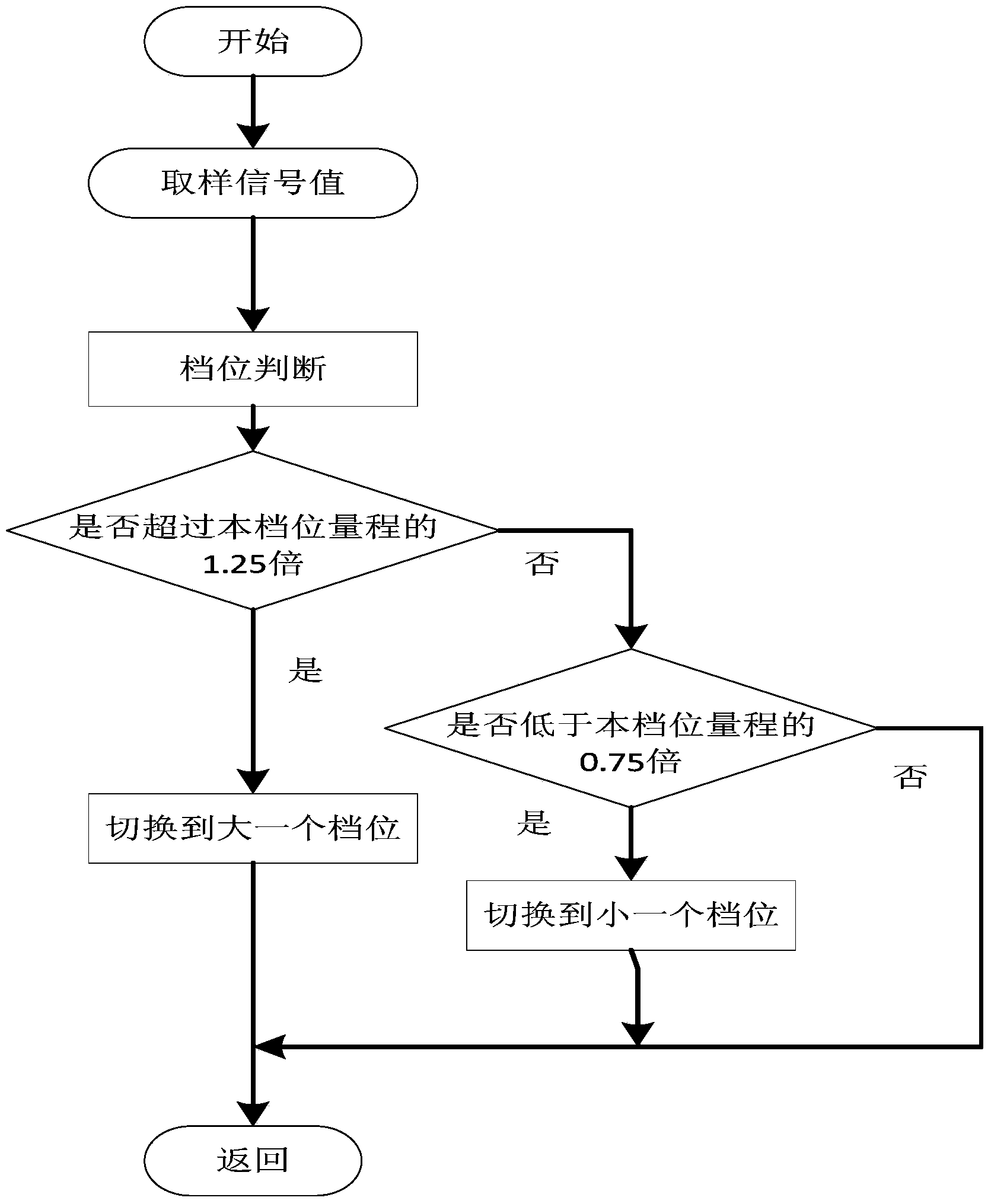

Program control self-adaption switching circuit of meter ranges and switching control method thereof

InactiveCN104267233ARealize automatic switchingRealize automatic measurementAltering measuring range circuitsAudio power amplifierEngineering

The invention discloses a program control self-adaption switching circuit of meter ranges and a switching control method thereof. In a traditional measuring meter, the method of manually rotating a meter plate to switch the meter ranges is mostly used in the measuring process, and the problem that consideration can not be given to both the precision of the big meter ranges and the precision of the small meter ranges simultaneously is caused. The program control self-adaption switching circuit of the meter ranges and the switching control method thereof are characterized in that a first analog switch switching circuit and a second analog switch switching circuit are connected with the front stage and the rear stage of an operational amplifier respectively; the rear stage of the operational amplifier is further connected with the input end of an analog-to-digital converter; the output end of the analog-to-digital converter is connected with the input end of a microprocessor, and the output end of the microprocessor is connected with the first analog switch switching circuit and the second analog switch switching circuit. Self-adaption automatic switching of the meter ranges is achieved, the modes of manually checking meter display measuring data and manually switching the meter ranges are replaced, it can be guaranteed that the precision classes of all the meter ranges are the same, meanwhile, automatic measuring is achieved, and labor cost is lowered.

Owner:STATE GRID CORP OF CHINA +1

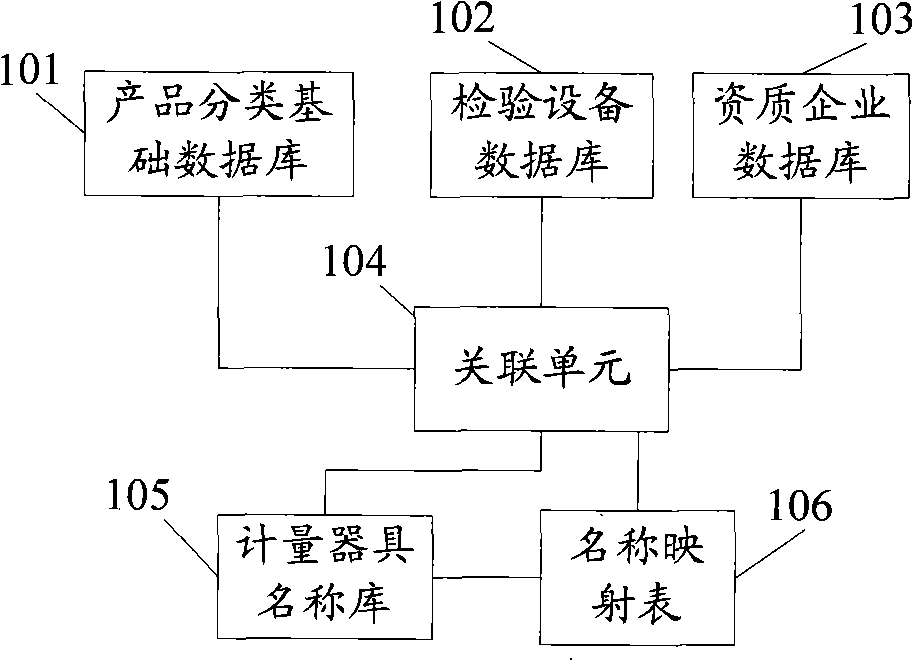

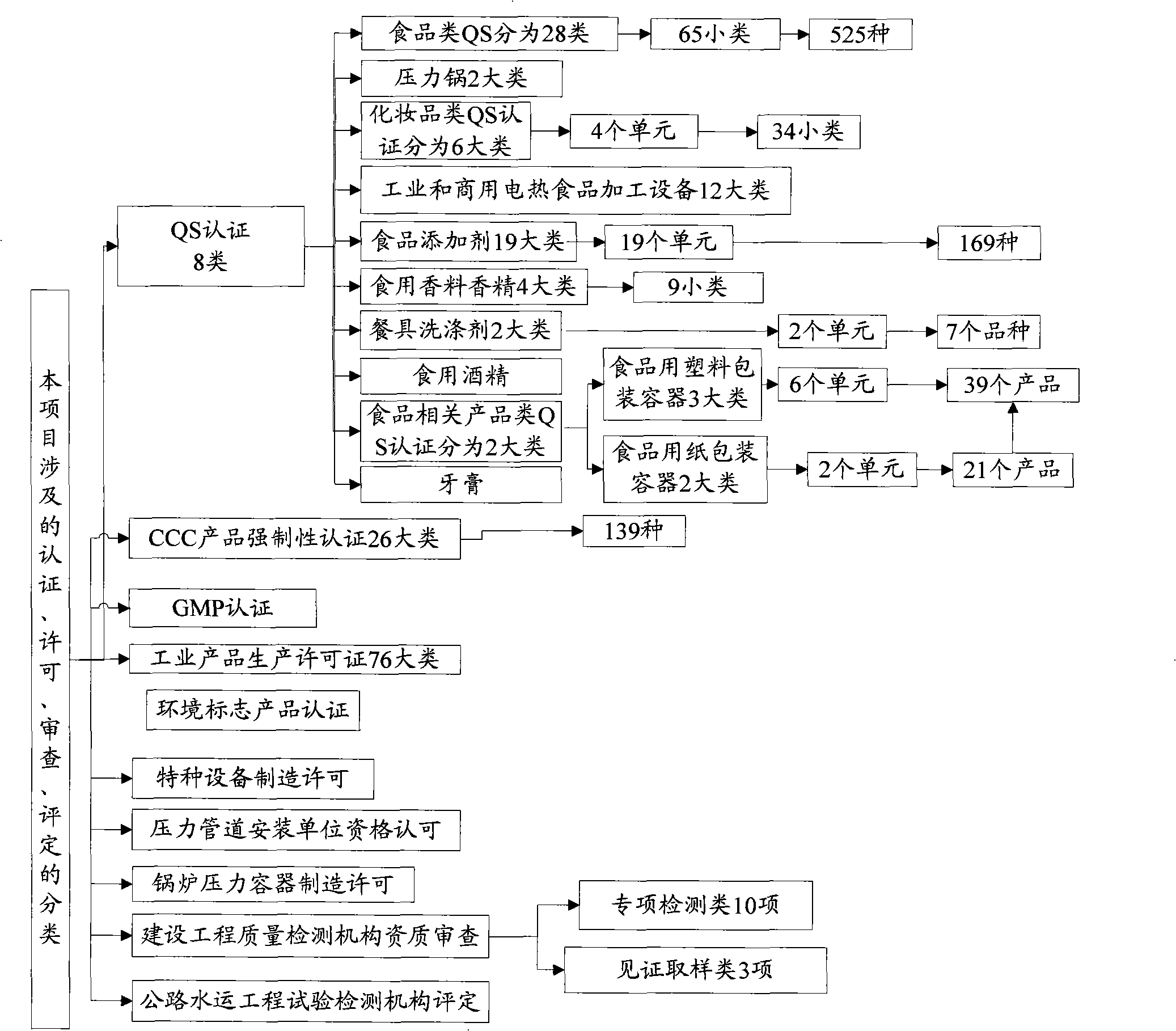

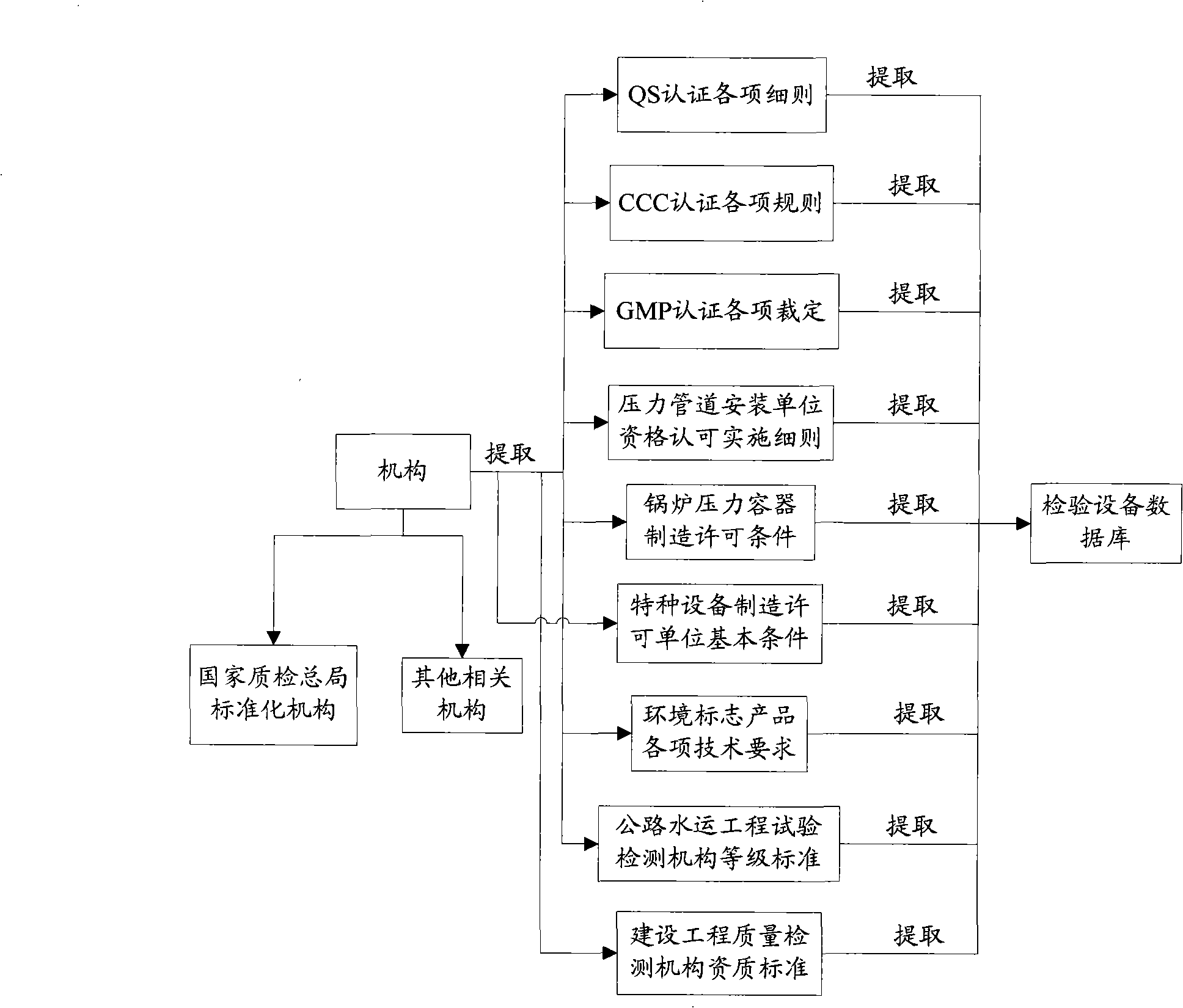

Dynamic supervision system for checking equipment of qualification certification products

InactiveCN101515343AEasy to viewEffective supervisionData processing applicationsSpecial data processing applicationsData miningOrder of accuracy

The invention relates to the field of metrological technique, and concretely discloses a dynamic supervision system for checking equipment of qualification certification products. The system comprises: a product classification fundamental database which stores classification information of the qualification certification products; a checking equipment database which stores the name of the checking equipment required by the products corresponding to qualification certifications, measurement scope and accuracy class information of the checking equipment; a qualification enterprise database which stores information of each enterprise in each type of the qualification certification, wherein, the information comprises enterprise name and enterprise product information; an association unit for associating the qualification enterprise database, the product classification fundamental database and the checking equipment database, and for acquiring checking equipment information which is requisite for each qualification product of each qualification certification enterprise. Applying the system can offer fast, convenient and safe data resources for users and supervision departments so that the functions such as declaration, inquiry, assessment, gathering, analysis and the like can be easily applied to the checking equipment information.

Owner:西安计量技术研究院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com