Method and apparatus for automatically detecting spray angle of nozzle

A nozzle spray and angle technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of inability to achieve accuracy and repeatability, and unfixed judgment standards, so as to improve atomization characteristics and make full use of resources , Improve the effect of spray utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

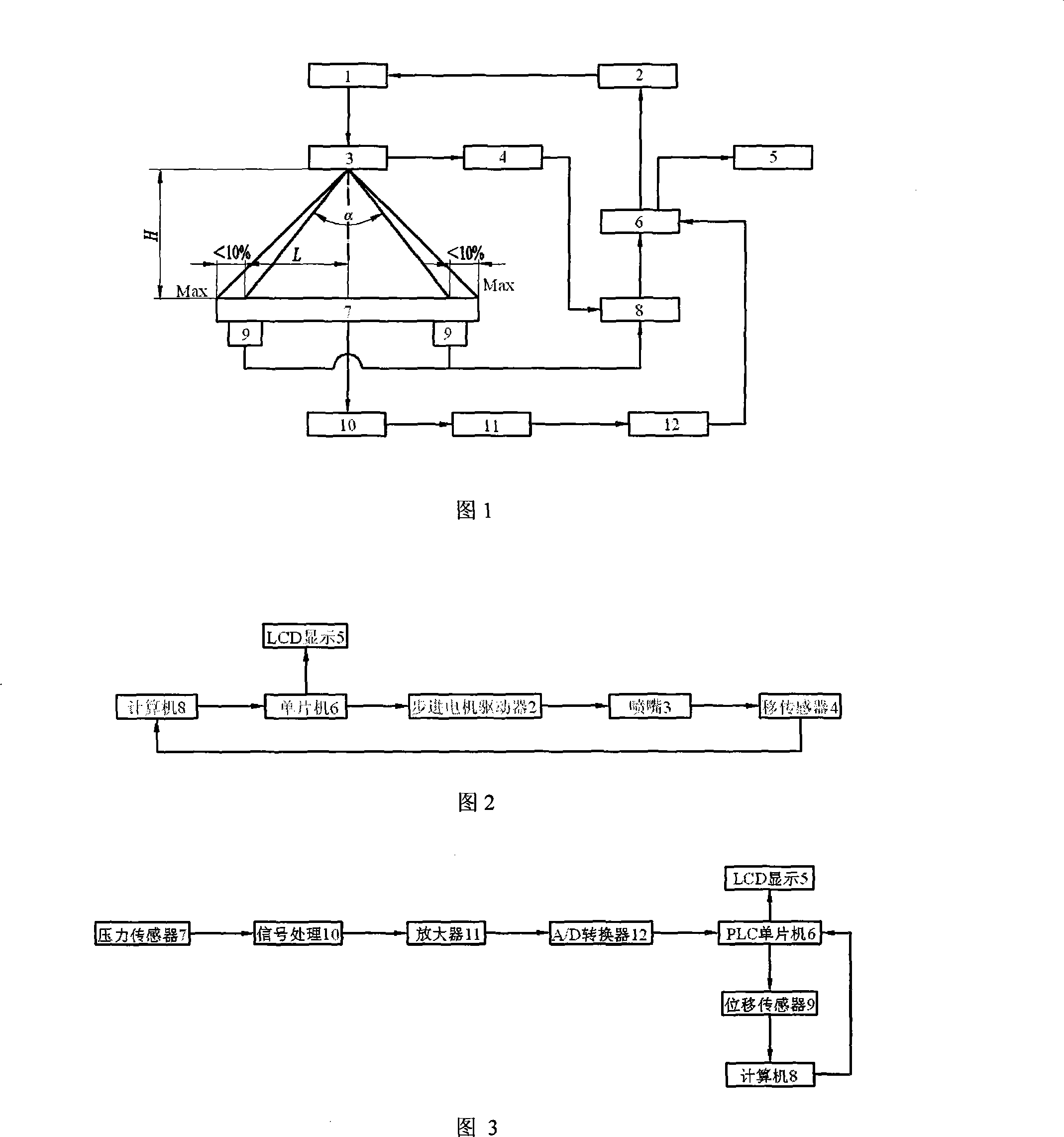

[0015] The operation of the device proposed by the present invention will be described in detail below in conjunction with FIG. 1 .

[0016] The nozzle spray angle automatic detection device of the present invention comprises: (1) spray height H detection system, mainly by stepper motor 1, stepper motor driver 2, nozzle 3, displacement sensor 4, computer 8, PLC single-chip microcomputer 6, LCD display 5 (2) The effective spray distance L detection system is mainly composed of displacement sensor 9, signal processing 10, amplifier 11, A / D converter 12, PLC single-chip microcomputer 6, LCD display 5 and so on.

[0017] Its working process: computer 8, PLC single-chip microcomputer 6, stepping motor driver 2 control stepping motor 1 to drive the transmission shaft, so that the screw controls the nozzle 3 on the workbench to move up and down, and the displacement sensor 4 and computer 8 can accurately control the spraying The height H ensures that the distance between the nozzle 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com