Installing and positioning method of linear guide rail

A linear guide rail, installation and positioning technology, applied in the field of mechanical processing and manufacturing, can solve the problems of linear guide rail accuracy reduction, failure to meet the use requirements, etc., achieve the effect of improving efficiency, solving the requirements of process equipment accuracy, and the method is fast and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

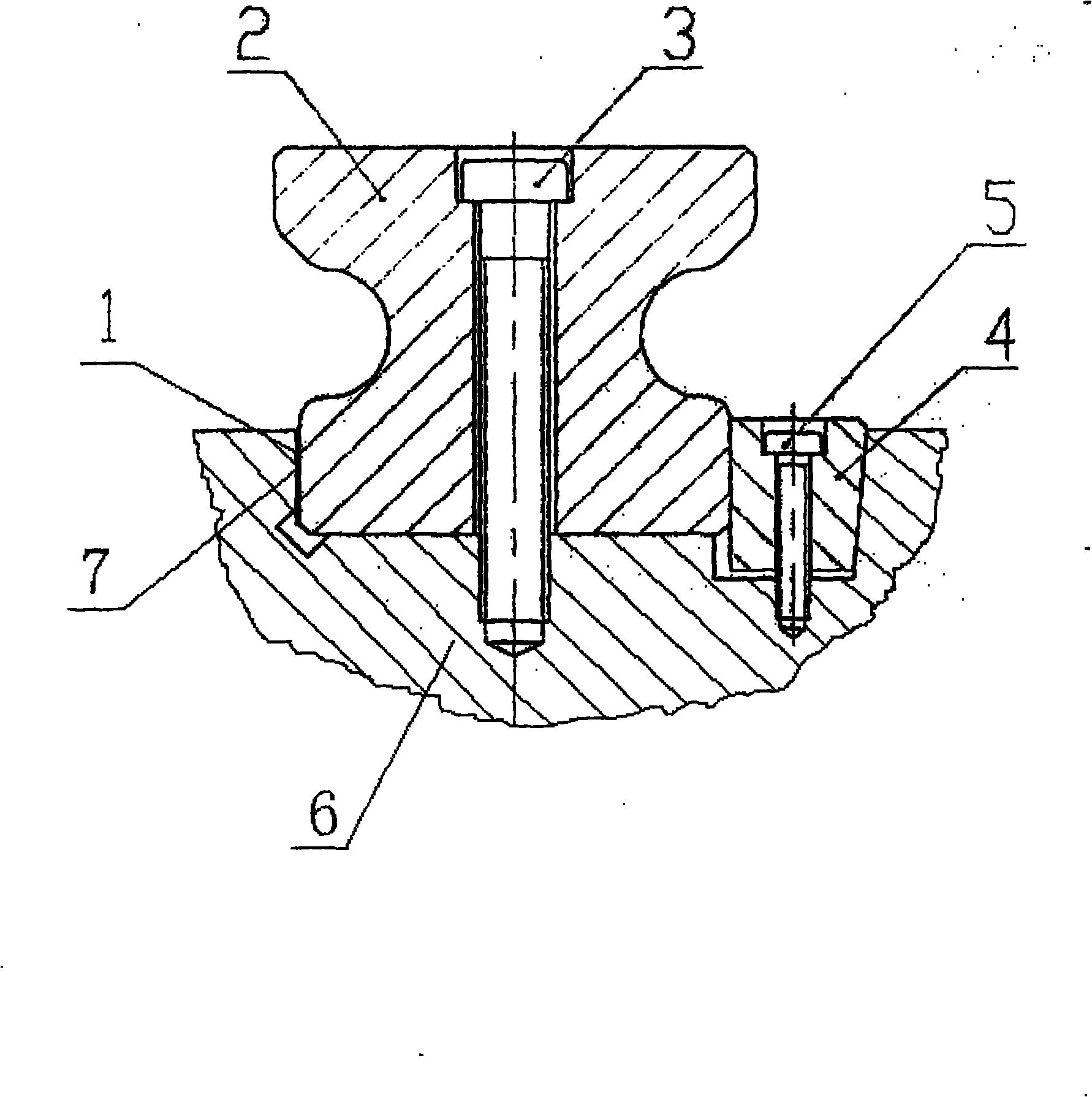

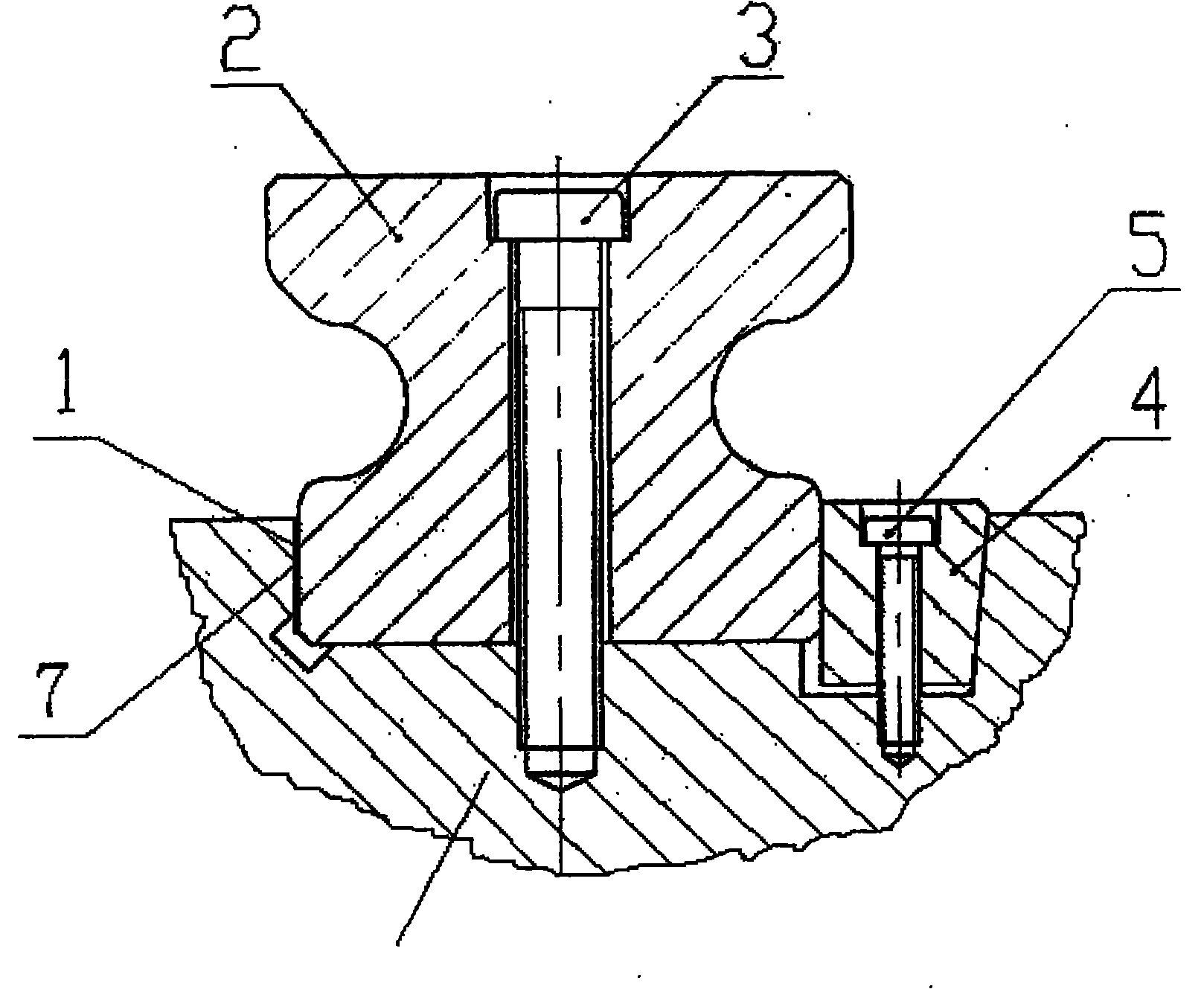

[0017] Referring to the accompanying drawings, taking the MK2860 CNC internal grinding machine as an example, the installation and positioning method of the linear guide rail is carried out in the following steps:

[0018] 1) First confirm a linear guide rail as the reference guide rail, and confirm the installation reference surface of the guide rail, and place the linear guide rail 2 on the installation reference surface of the base 6, so that the guide rail installation base surface and the base installation base surface correspond to each other;

[0019] 2) Install the guide rail screw 3 to make the guide rail in step 1) slightly tightened with strength, and then calibrated by the micrometer calibration table, gradually tighten the guide rail screw 3 from one end along the guide rail 2, so that the straightness of the guide rail is guaranteed within the accuracy requirement range;

[0020] 3) On the side of the guide rail 2 and between the vertical side reference plane of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com