Thermosetting resin composite facing material and preparation method thereof

A resin composite, thermosetting technology, applied in epoxy resin coatings, chemical instruments and methods, synthetic resin layered products, etc., can solve the problem of epoxy coatings with long curing time, poor compression resistance, tensile resistance and chemical resistance. It can improve the physical and chemical properties of instant noodles, protect the integrity and beauty, and solve the uneven tension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

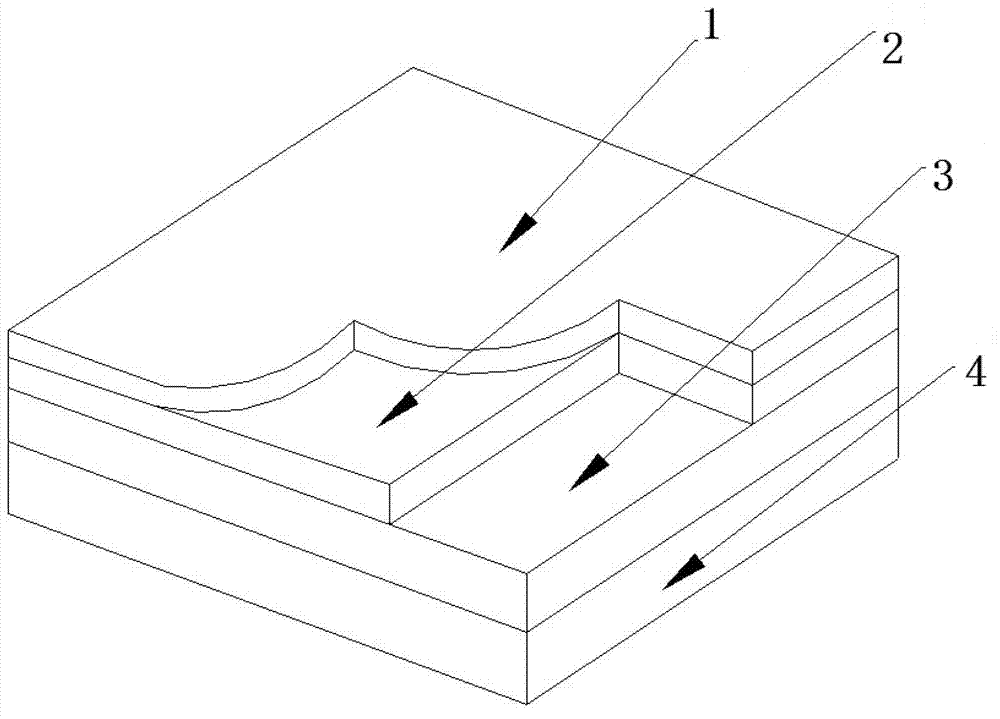

Image

Examples

Embodiment 1

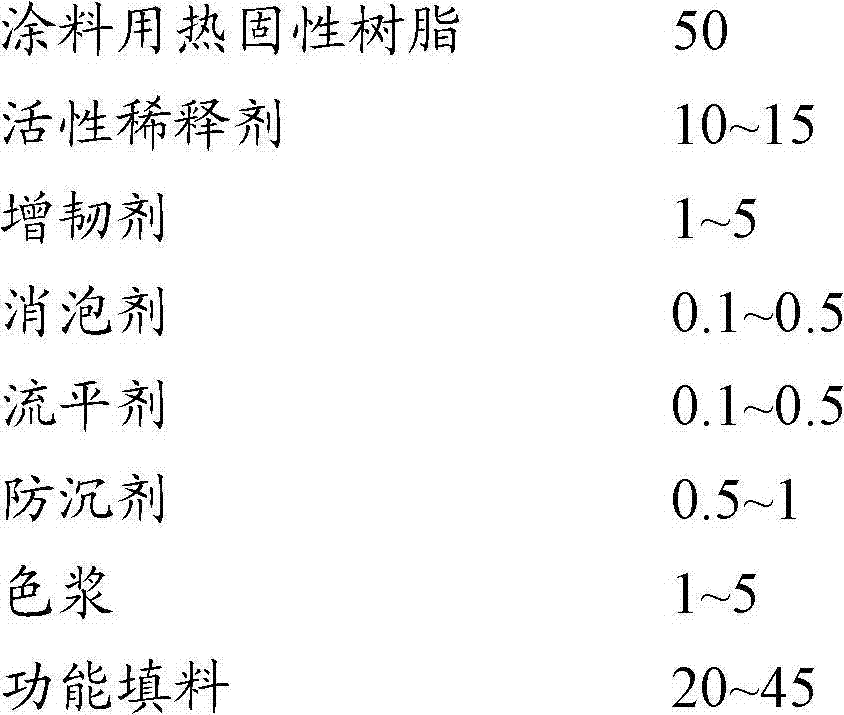

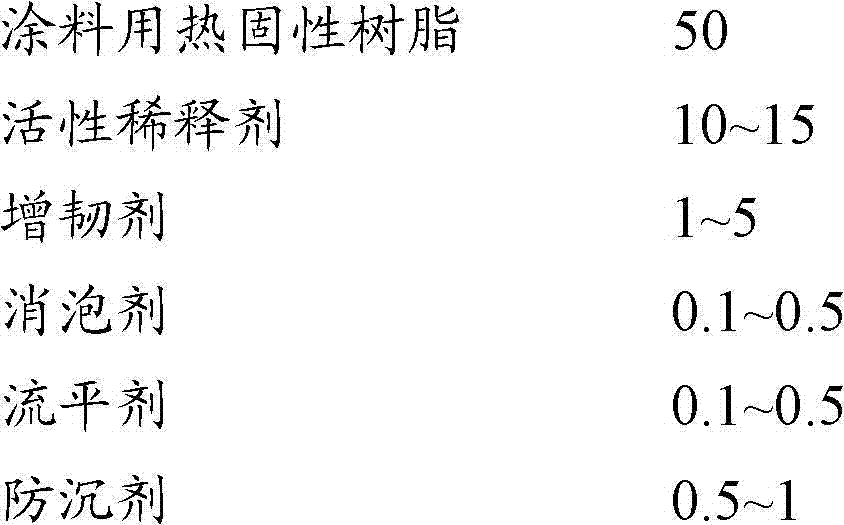

[0061] Preparation of antistatic composite veneer material:

[0062] (1) Antistatic type thermosetting resin coating: take two components of antistatic thermosetting resin coating respectively, wherein A component weight part consists of: 50 parts of epoxy resin 128, 10 parts of benzyl glycidyl ether ( reactive diluent), 3 parts of linoleic acid dimer diglycidyl ether (toughening agent), 0.2 parts of defoamer BYK088, 0.2 parts of leveling agent BYK054, 0.6 parts of organic bentonite (anti-settling agent), 0.2 parts of 2-(2'-hydroxy-5'-tert-octylphenyl) benzotriazole (ultraviolet absorber), 15 parts of conductive mica powder, 10 parts of conductive titanium dioxide, 8 parts of mica powder and 3 parts of color paste CSB201W; component B by weight percentage: 99 parts of modified alicyclic amine curing agent BONSEN 3318 and 1 part of benzyldimethylamine. Mix component A and component B in a weight ratio of 10:3 to prepare an antistatic thermosetting resin coating.

[0063] (2) ...

Embodiment 2

[0065] Preparation of antistatic composite veneer material:

[0066] (1) Preparation of antistatic thermosetting resin coating: take two components of antistatic thermosetting resin coating respectively, wherein A component weight part is composed of: 50 parts of epoxy resin E44, 15 parts of resorcinol Bisglycidyl ether (reactive diluent), 2 parts of polyurethane modified epoxy resin (toughener), 0.2 part of defoamer BYK067, 0.2 part of leveling agent BYK307, 0.5 part of fumed silica (anti-settling agent), 0.3 parts of 2-(2'-hydroxy-5'-methylphenyl) benzotriazole (ultraviolet absorber), 30 parts of conductive mica powder as conductive filler, 10 parts of talcum powder and 2 parts Color paste SB101; B component weight percent composition: 95 parts of polyamide 125 type and 5 parts of 2,4,6-tris(dimethylaminomethyl)phenol. Mix component A and component B in a weight ratio of 10:2 to prepare an antistatic thermosetting resin coating.

[0067] (2) Utilize the coating machine to ...

Embodiment 3

[0069] Preparation of flame-retardant color composite veneer material:

[0070] (1) Preparation of wear-resistant thermosetting resin coating: take two components of wear-resistant thermosetting resin coating respectively, wherein C component weight part consists of: 50 parts of epoxy resin 1828, 10 parts of styrene ( Reactive diluent), 1 part of nitrile rubber with carboxyl end group (toughener), 0.5 part of defoamer BYK306, 0.2 part of leveling agent BYK354, 0.5 part of modified hydrogenated castor oil (anti-settling agent ), 0.4 parts of 2-(2'-hydroxy-5'-methylphenyl) benzotriazole (ultraviolet absorber), 13 parts of cristobalite, 10 parts of glass powder and 2 parts of color paste SB301; Component D consists of 99 parts of modified alicyclic amine curing agent BONSEN 3318 and 1 part of 2,4,6-tris(dimethylaminomethyl)phenol. Mix component C and component D at a weight ratio of 10:3 to prepare a wear-resistant thermosetting resin coating.

[0071] (2) Preparation of flame-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com