Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

749results about How to "Reduce the time required for installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

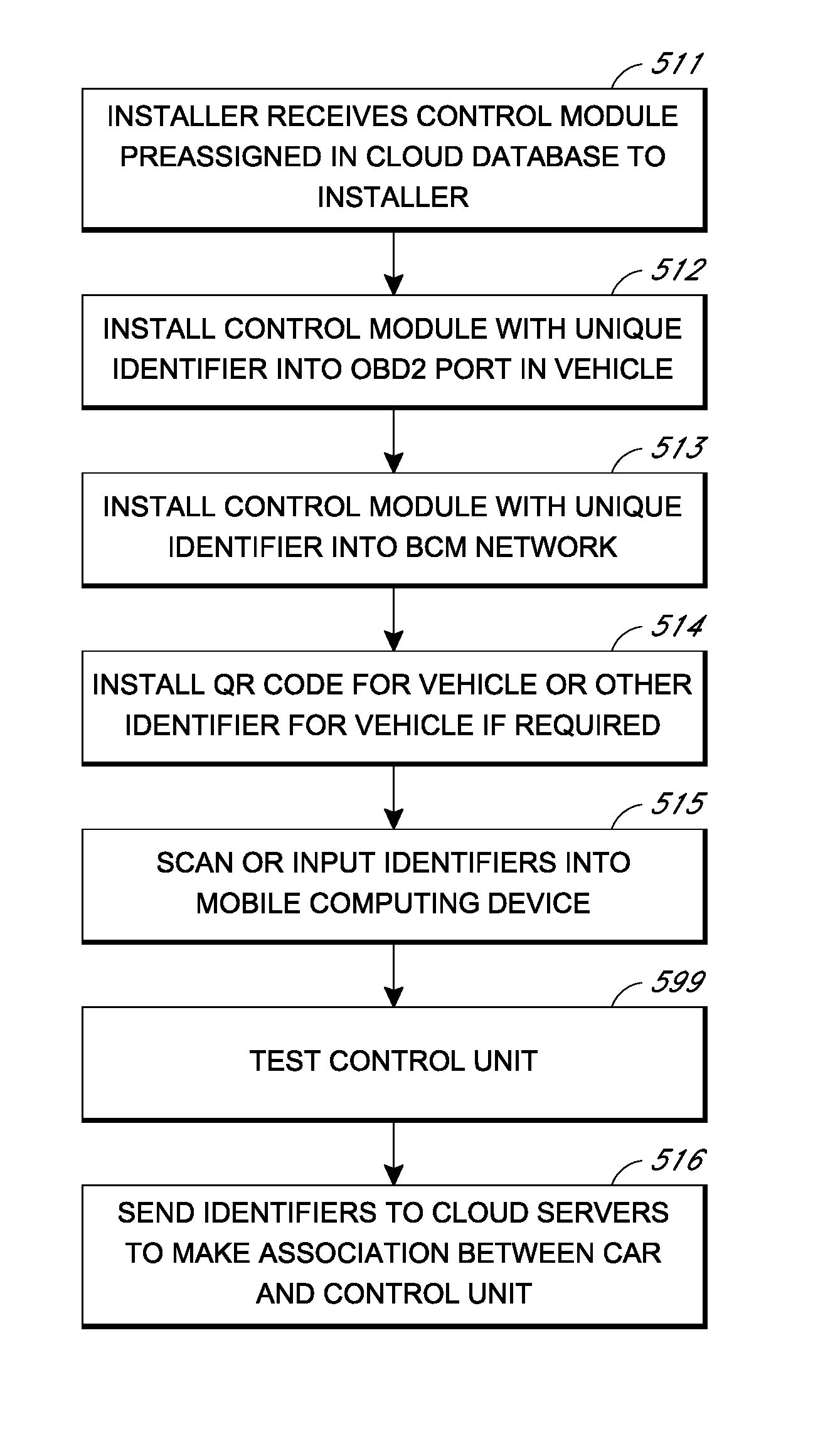

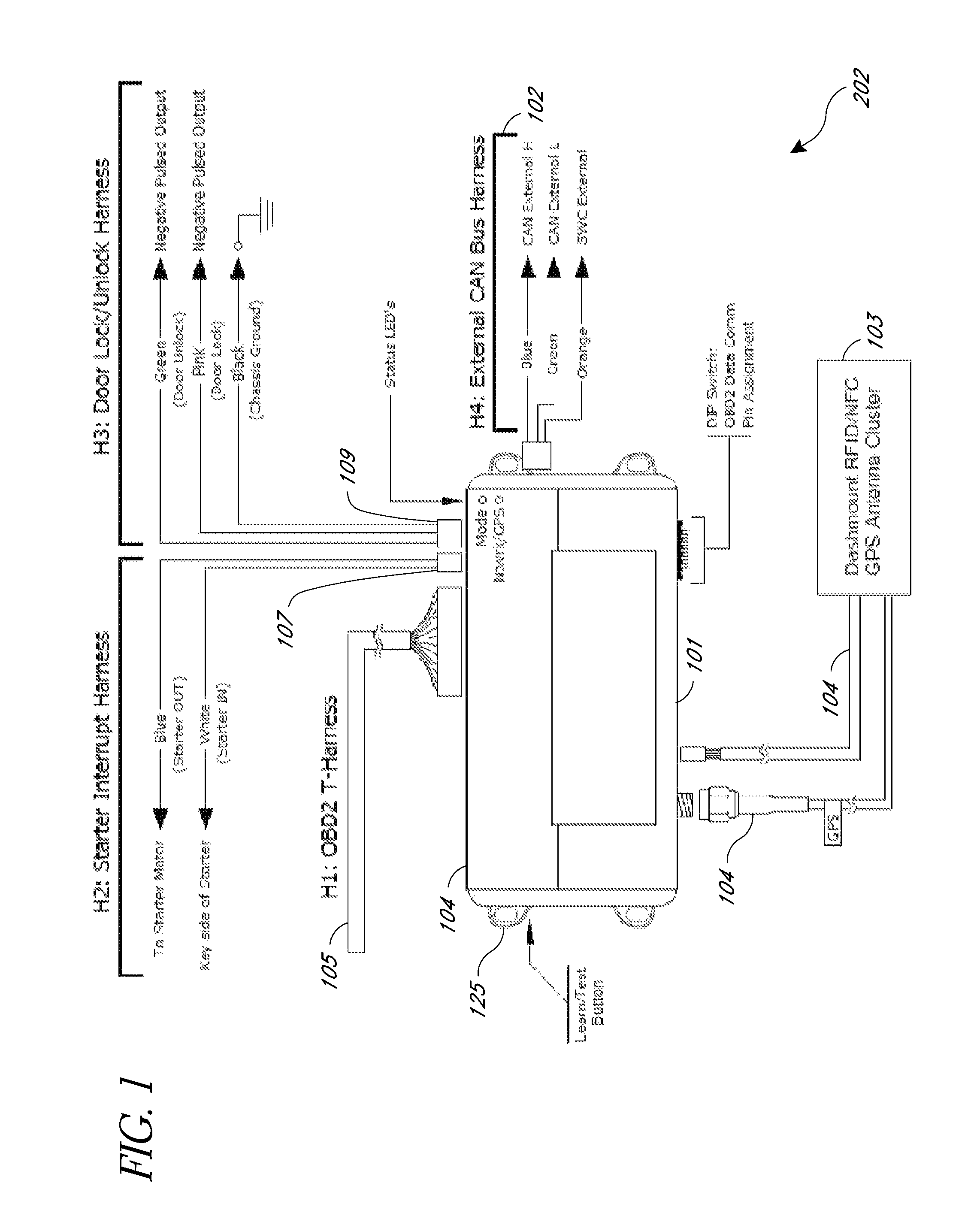

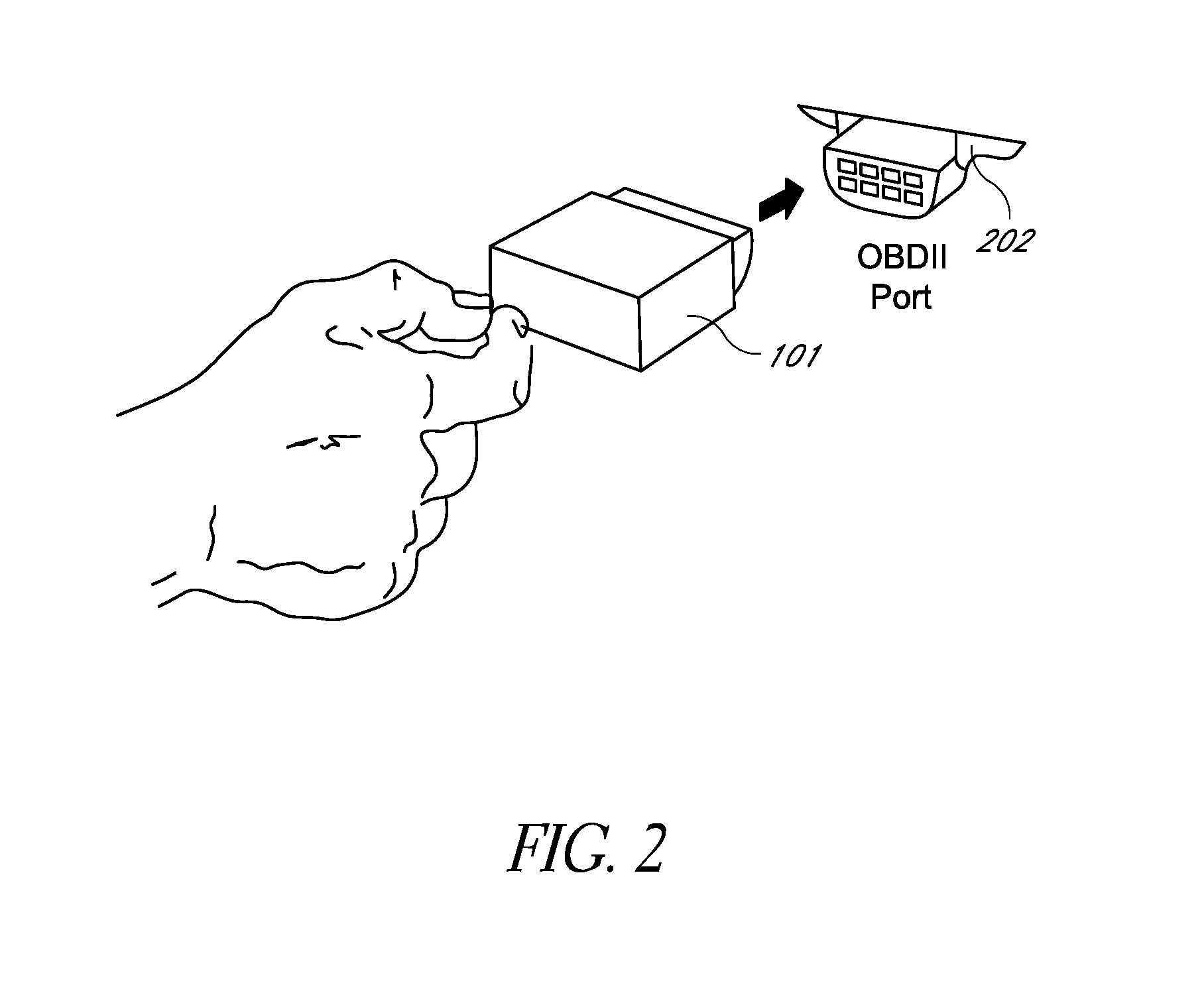

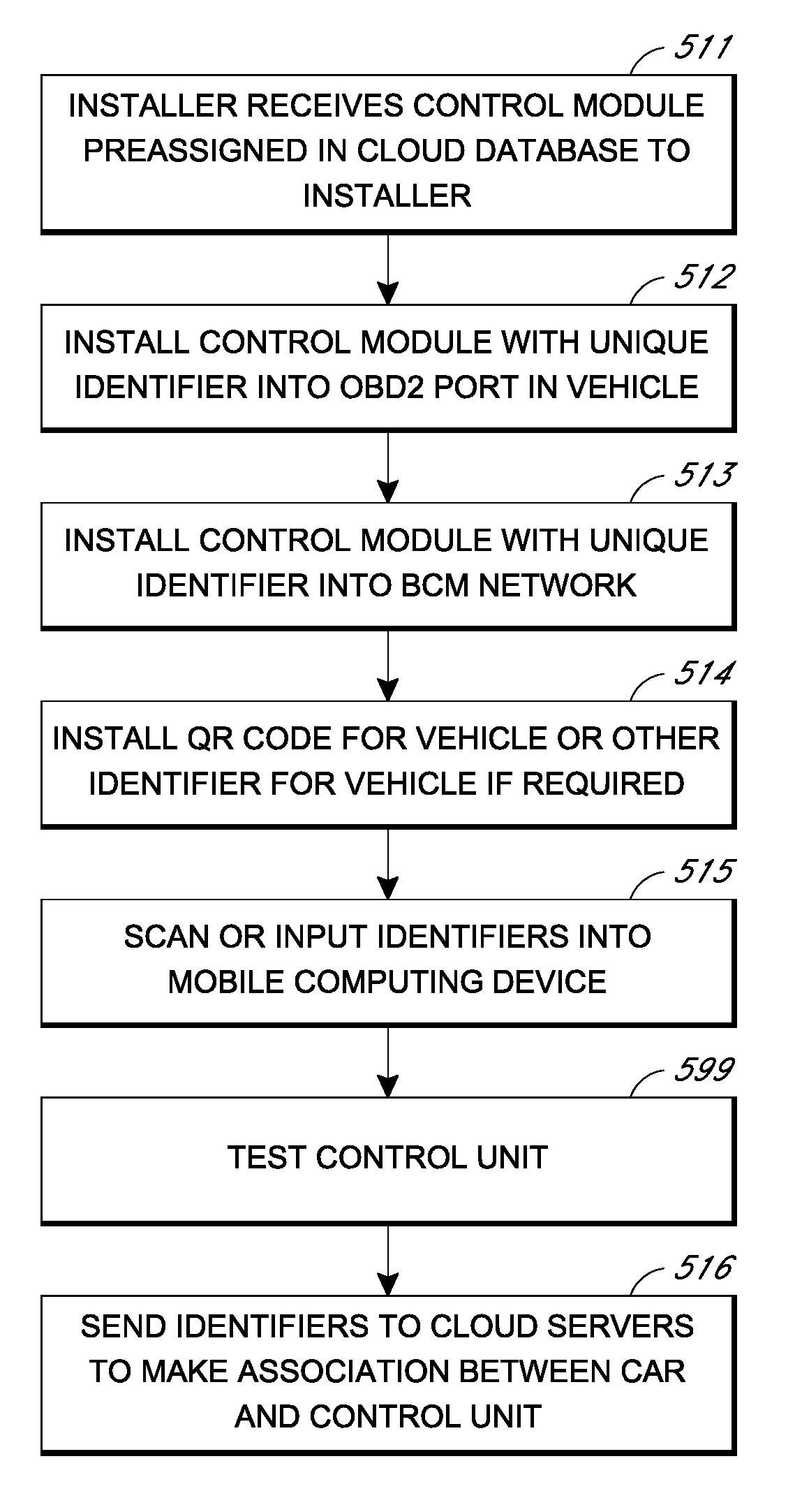

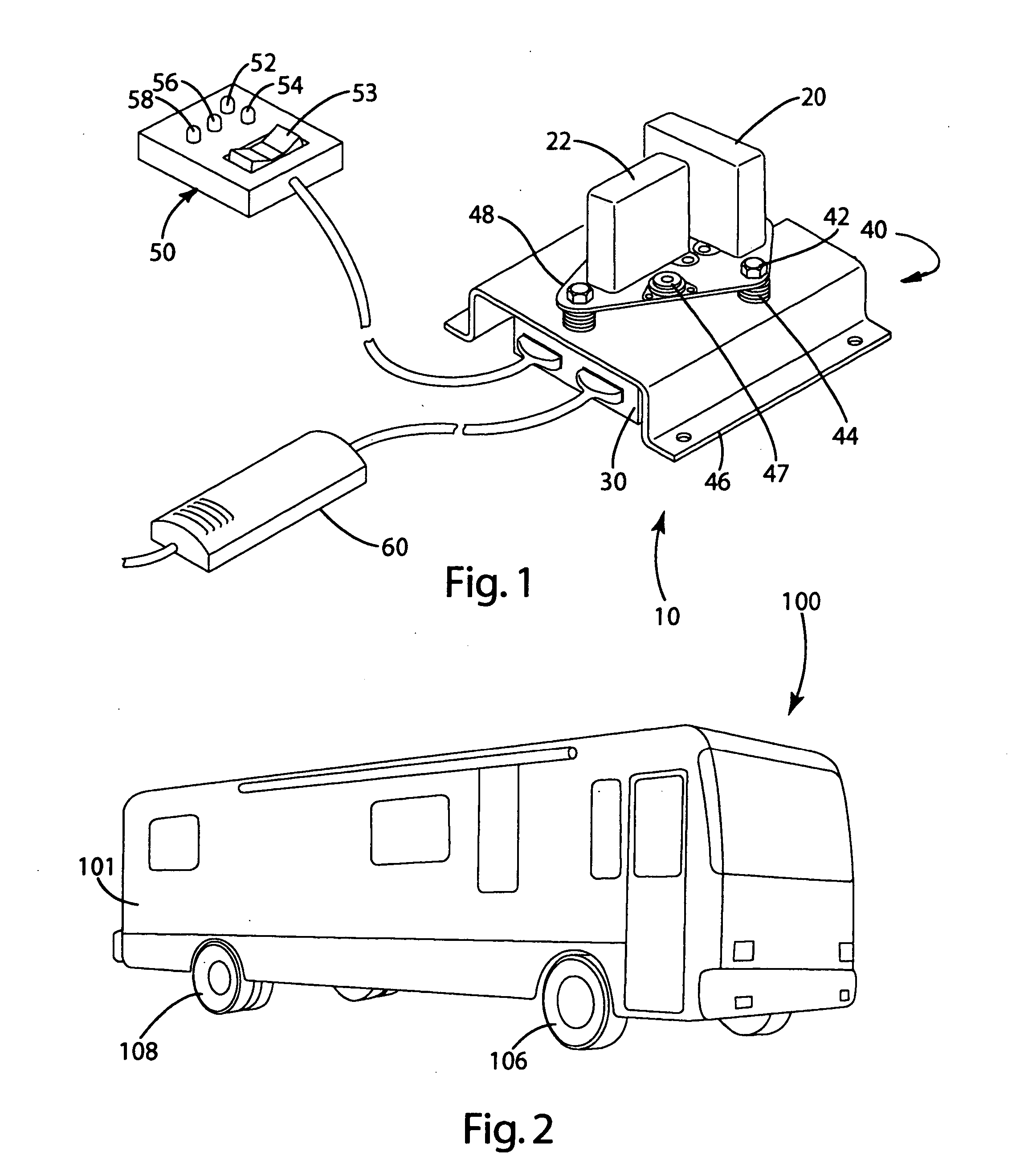

Rental/car-share vehicle access and management system and method

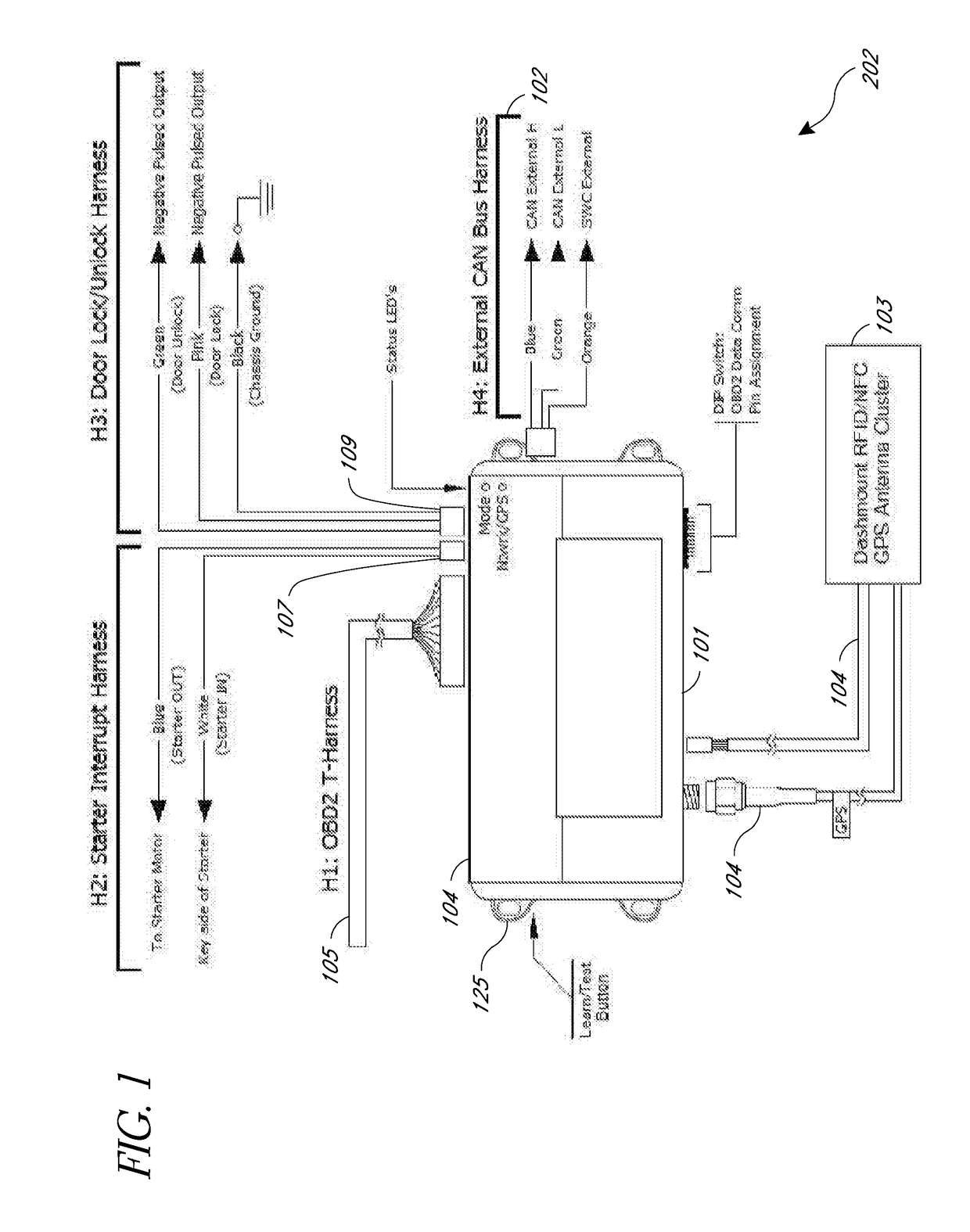

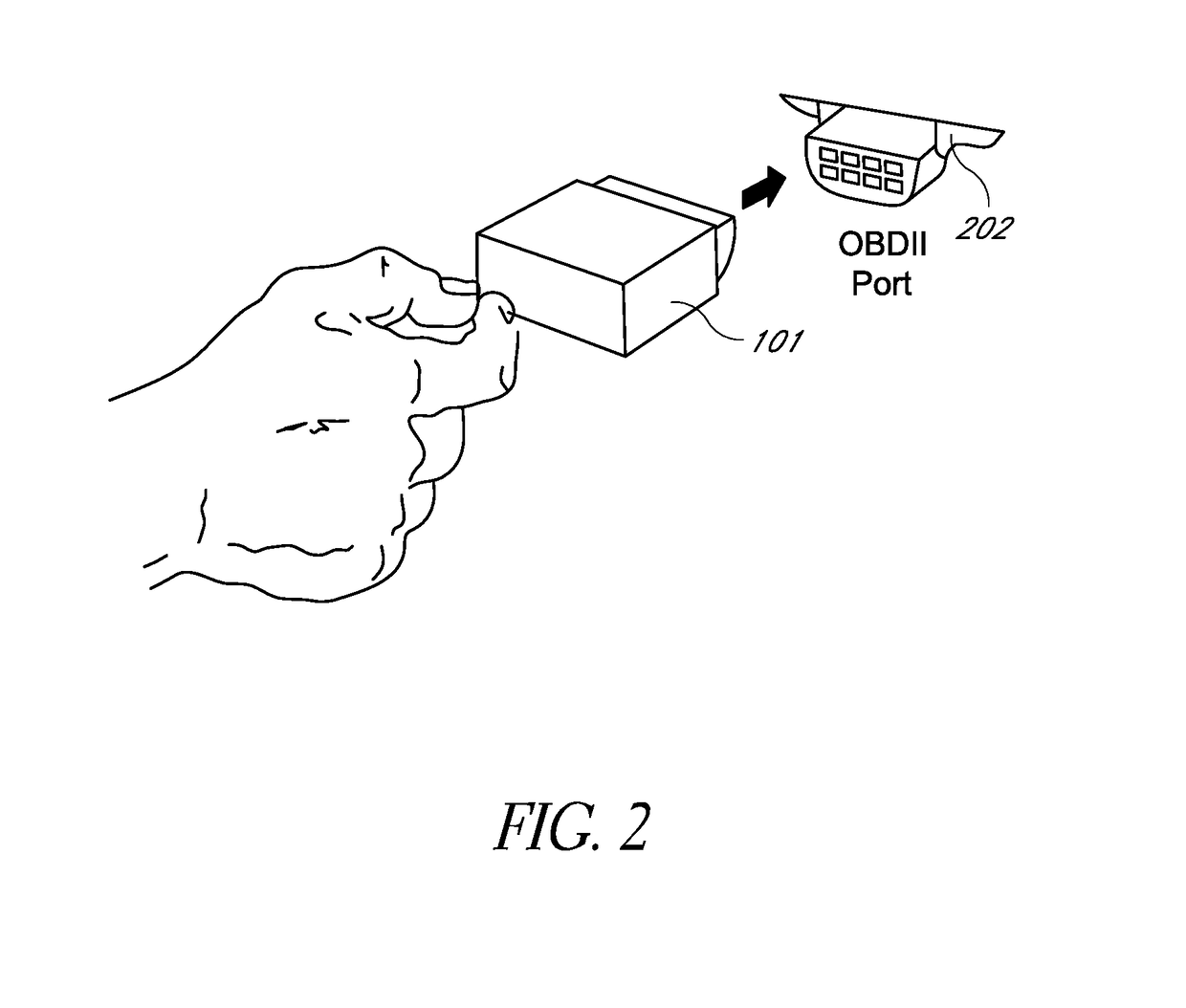

ActiveUS20130317693A1Reduce the time required for installationImprove reliabilityVehicle testingTicket-issuing apparatusMobile appsTablet computer

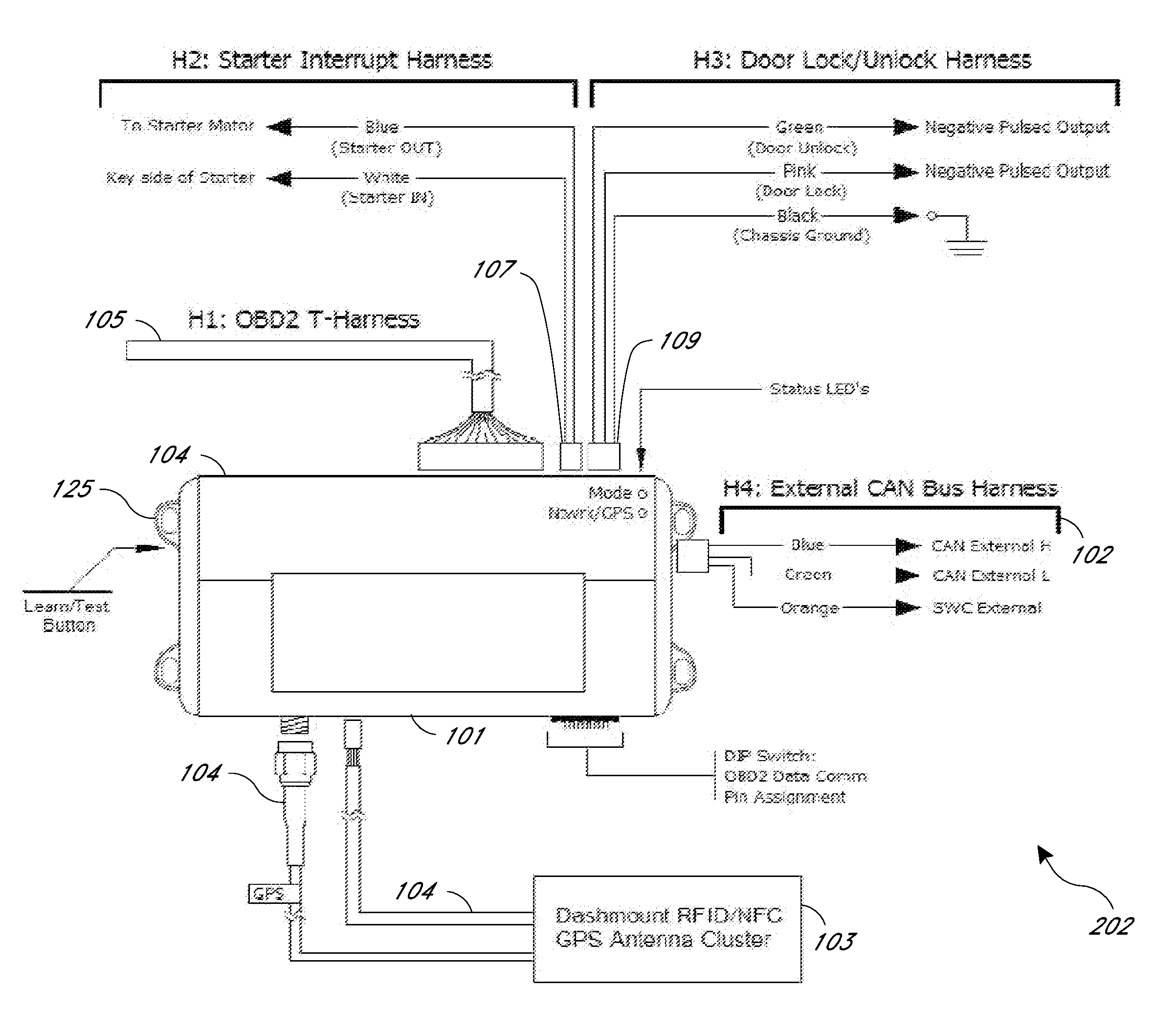

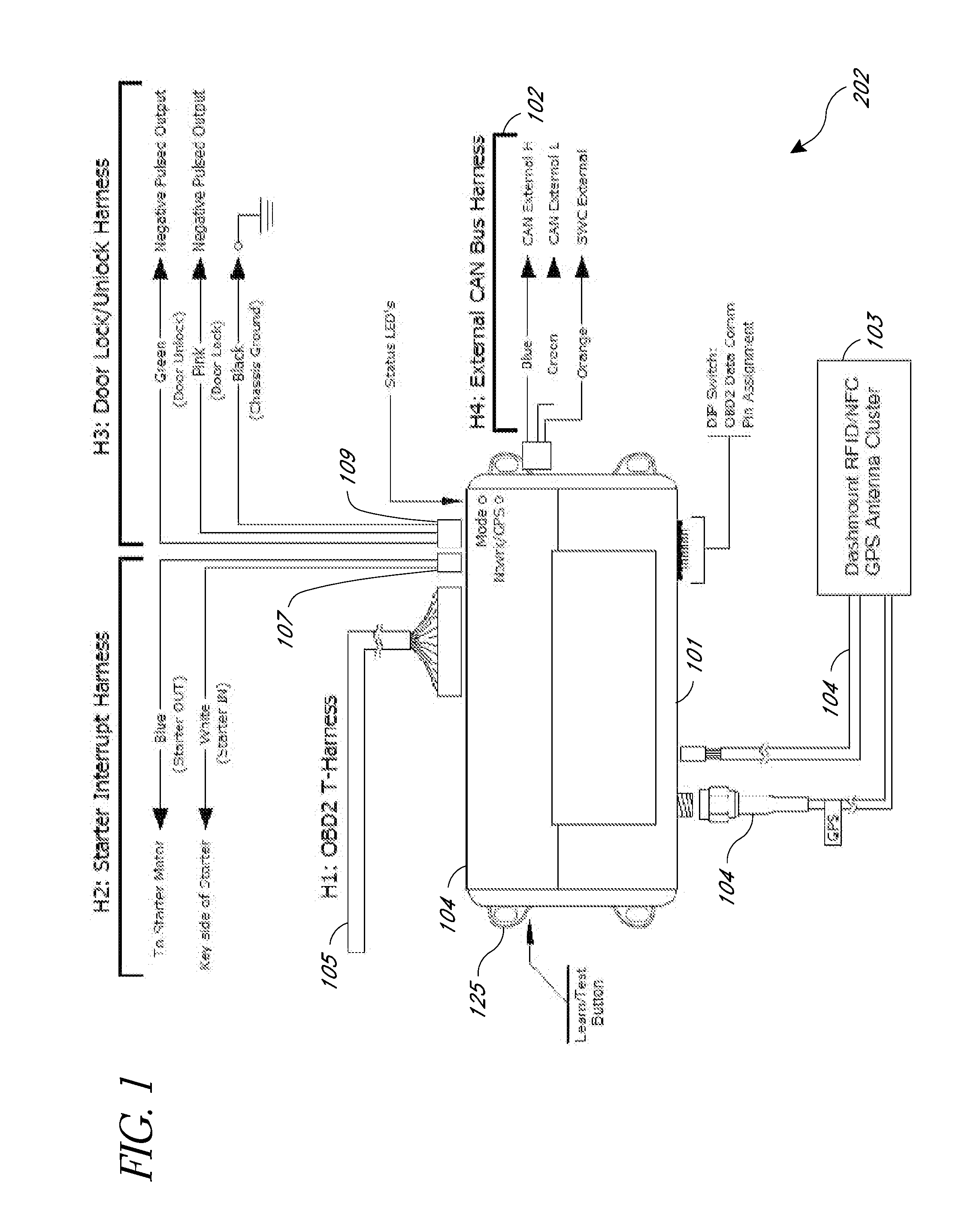

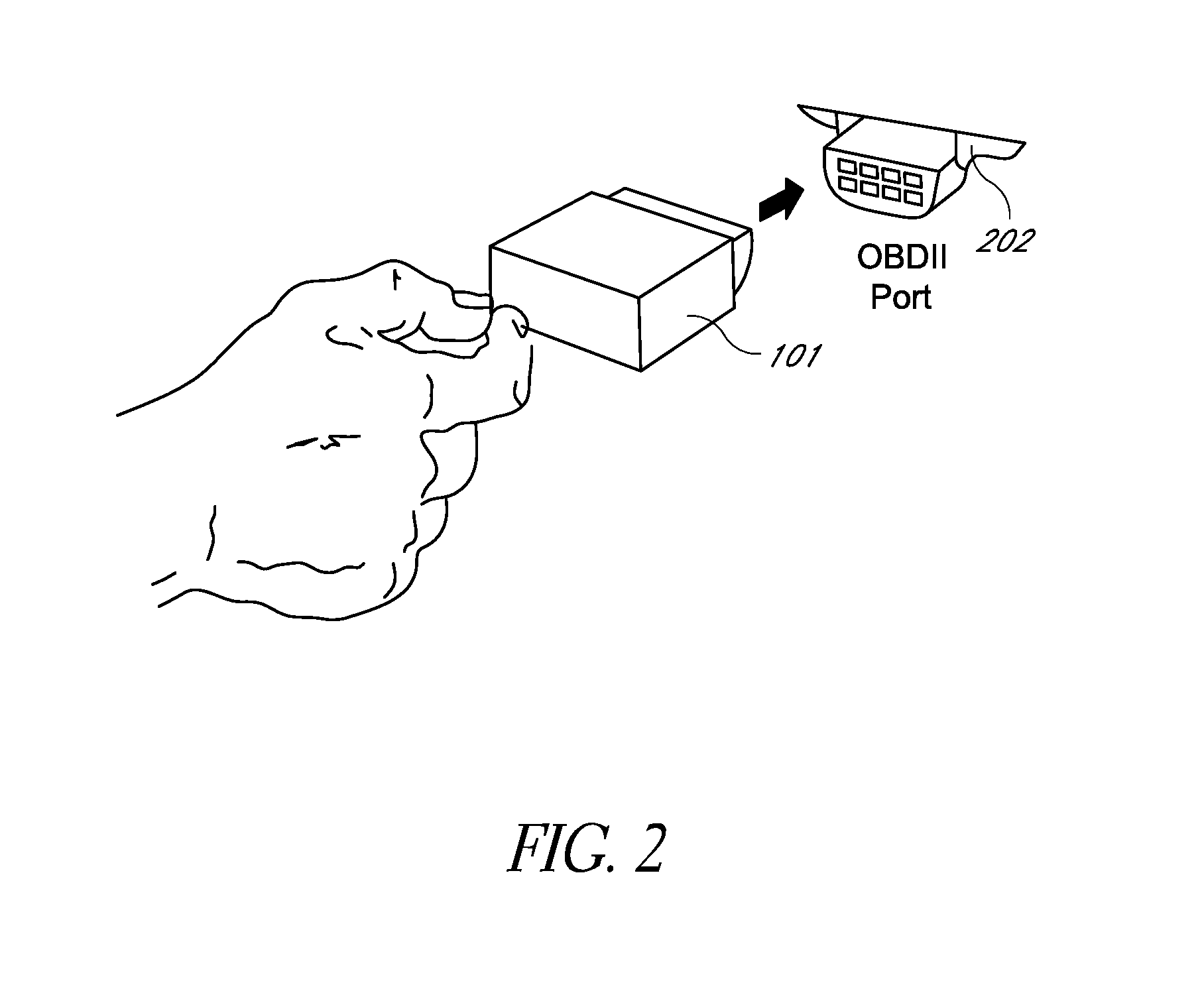

A rental / car-share (RCS) vehicle access and management system and method, in some embodiments, utilizes barcodes, QR codes (or NFC / RFID), GPS, and a mobile app coupled with a wireless network to enable customers to bypass the reservation desk and pickup and drop off reserved RCS vehicles using a mobile phone, tablet or laptop. The QR code, RFID, or NFC communication with the mobile application allows for identification of the vehicle by a mobile application, which, if authorized, can access the vehicle via a temporary access code issued by remote servers. The remote servers and / or mobile application communicates with a control module that plugs into the on-board diagnostics module of the rental / car-share (RCS) vehicle and includes a host processing unit with a processor, an accelerometer, data storage, a GPS with internal GPS antenna; a wireless modem with internal antenna, and CAN bus transceivers connected with the processor, and a USB programmable interface.

Owner:ENTERPRISE HOLDINGS

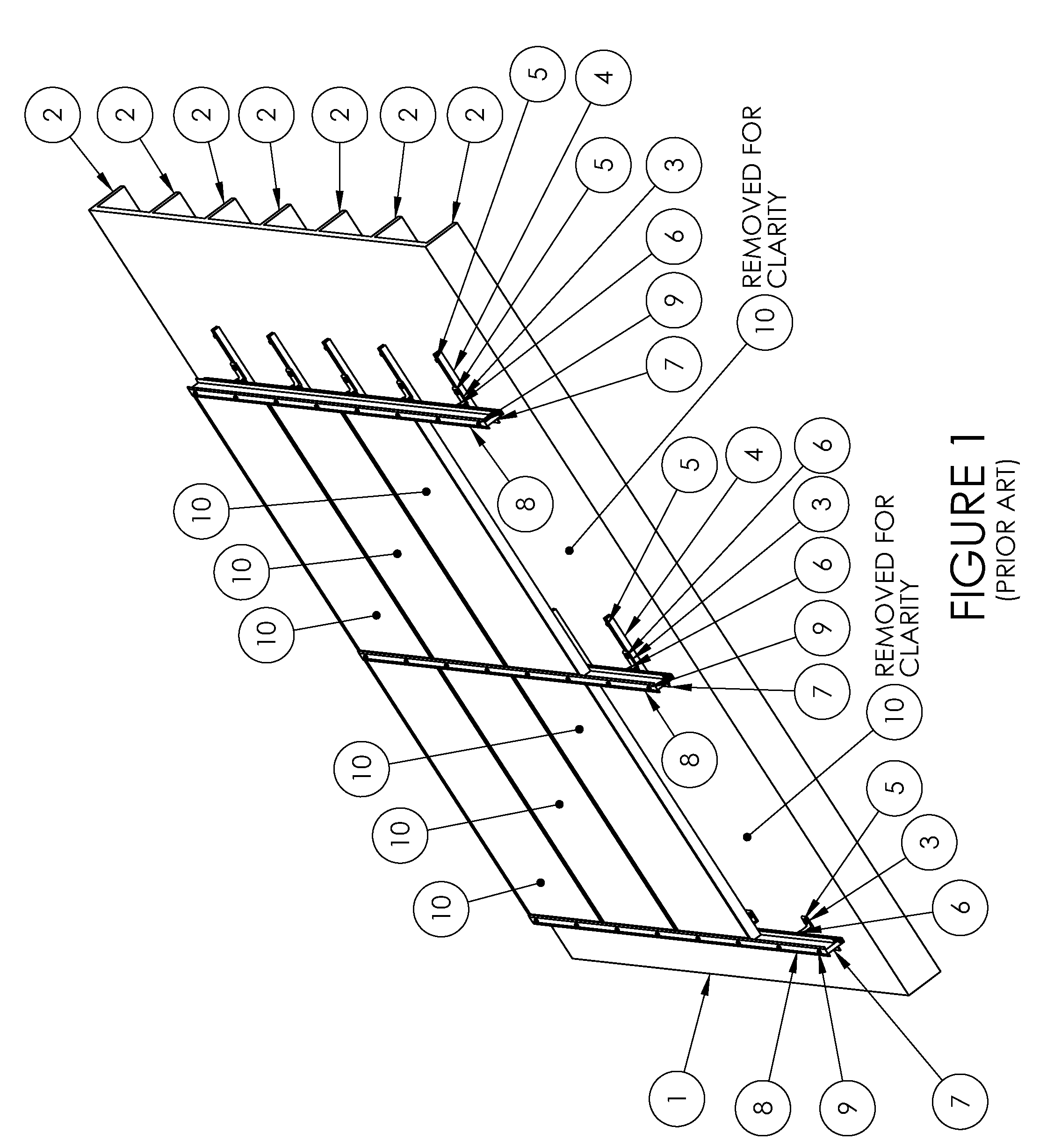

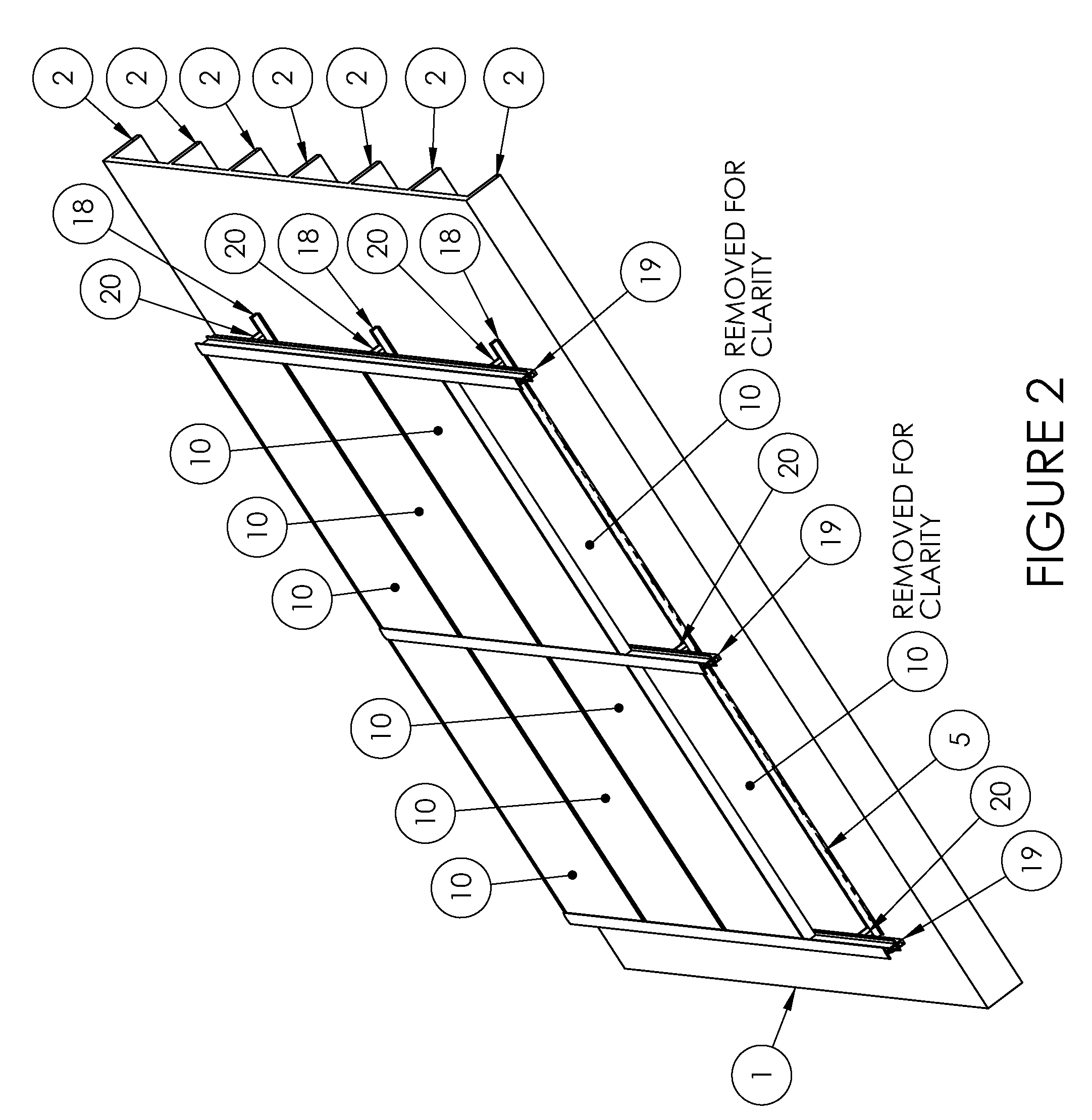

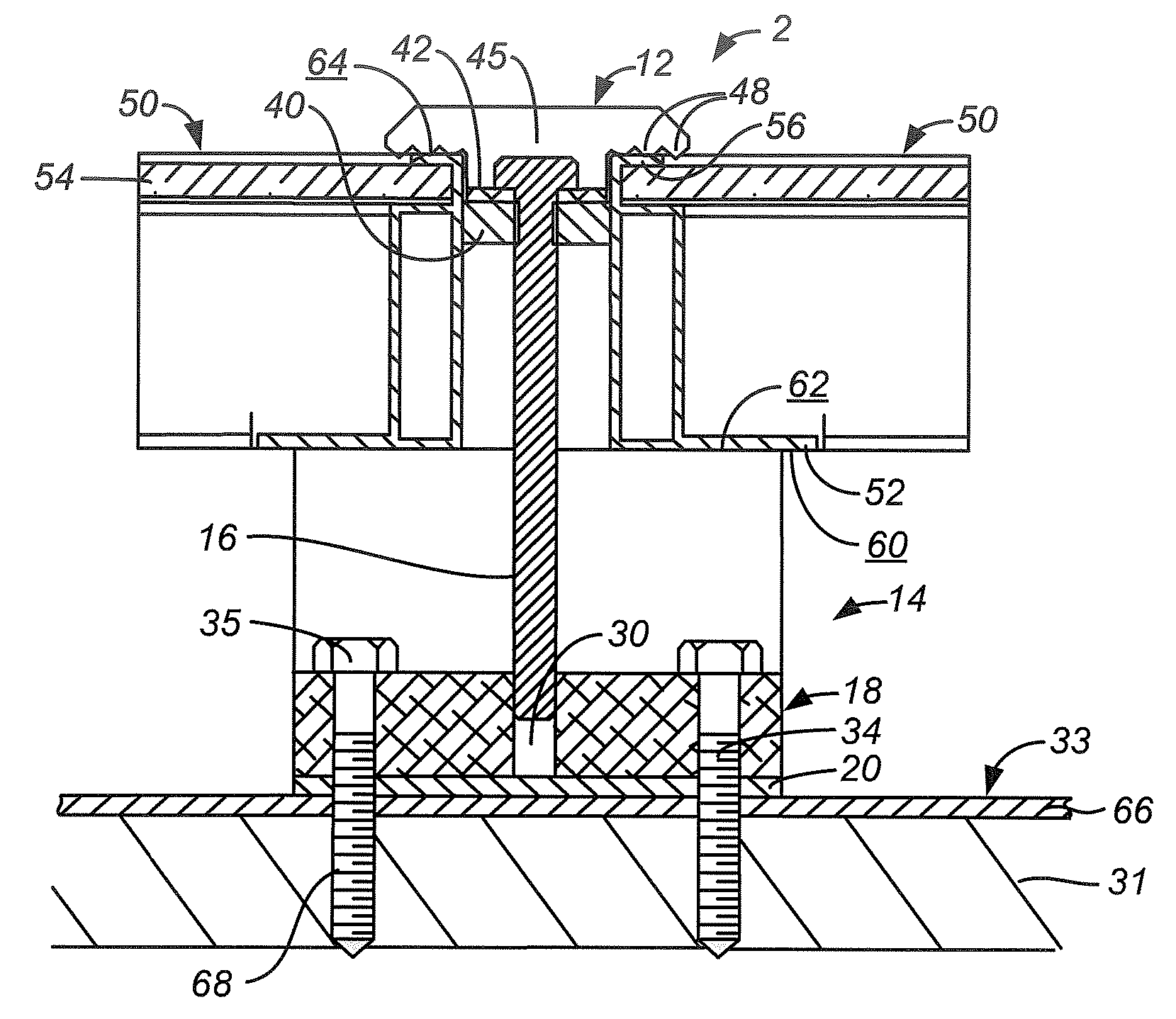

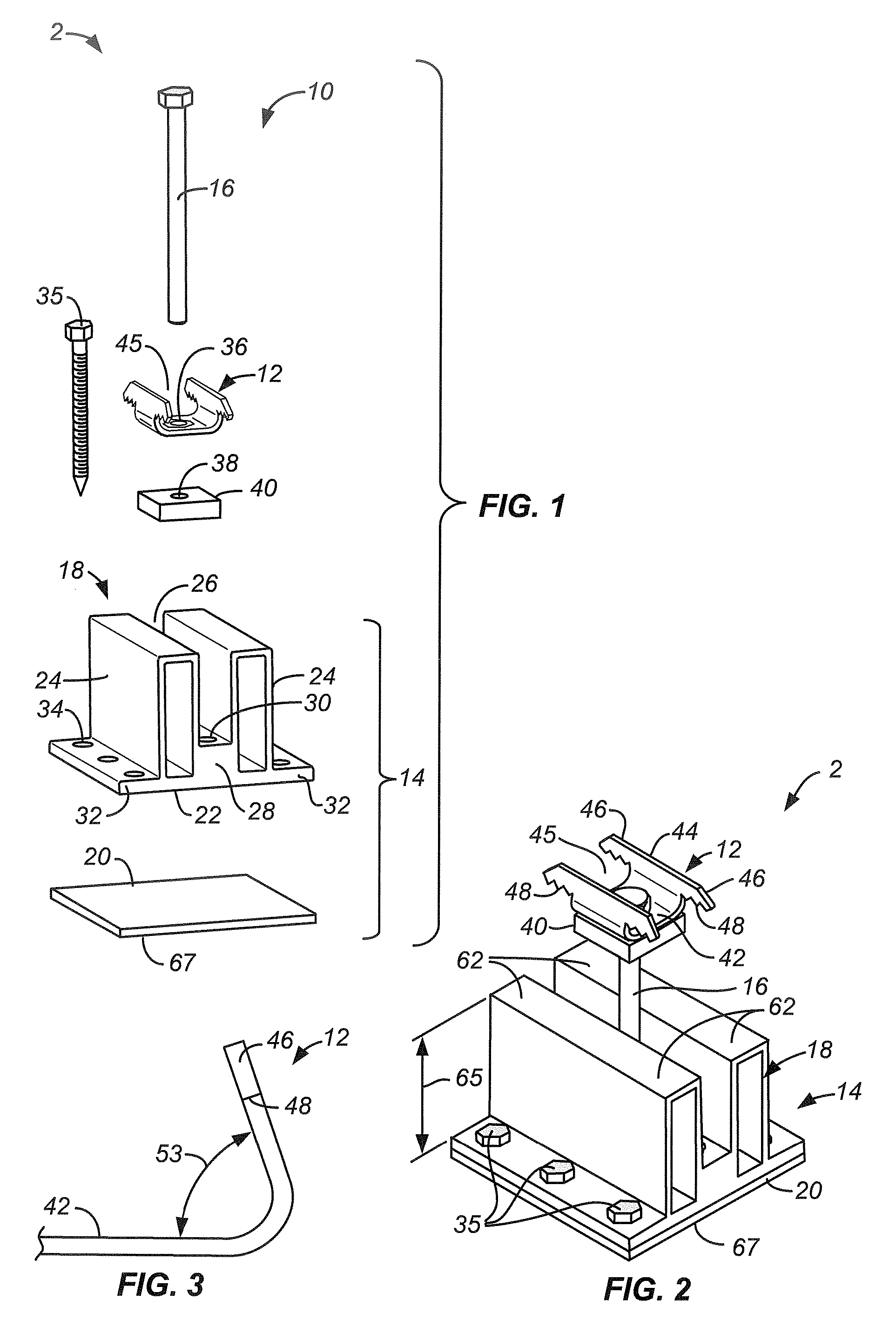

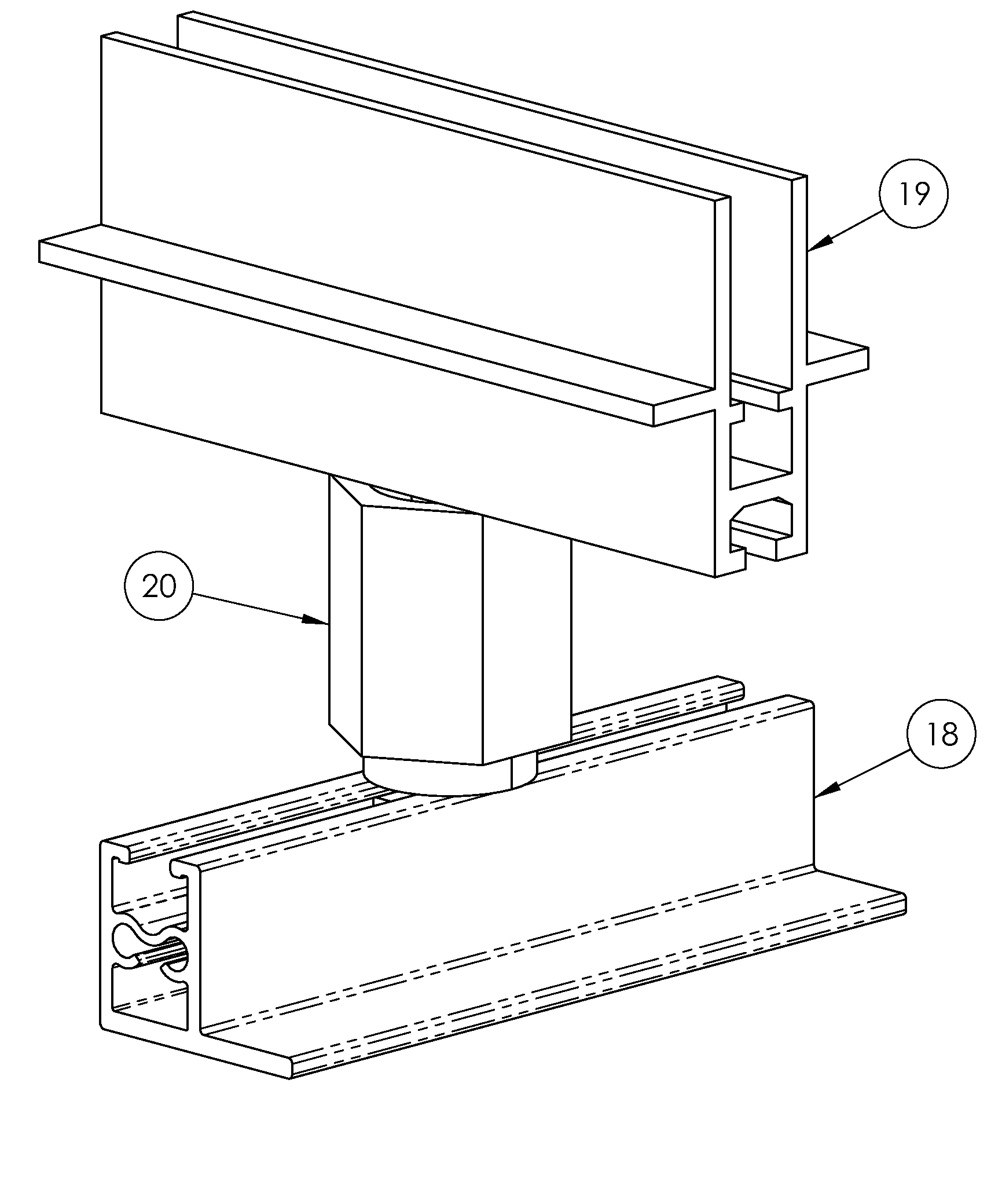

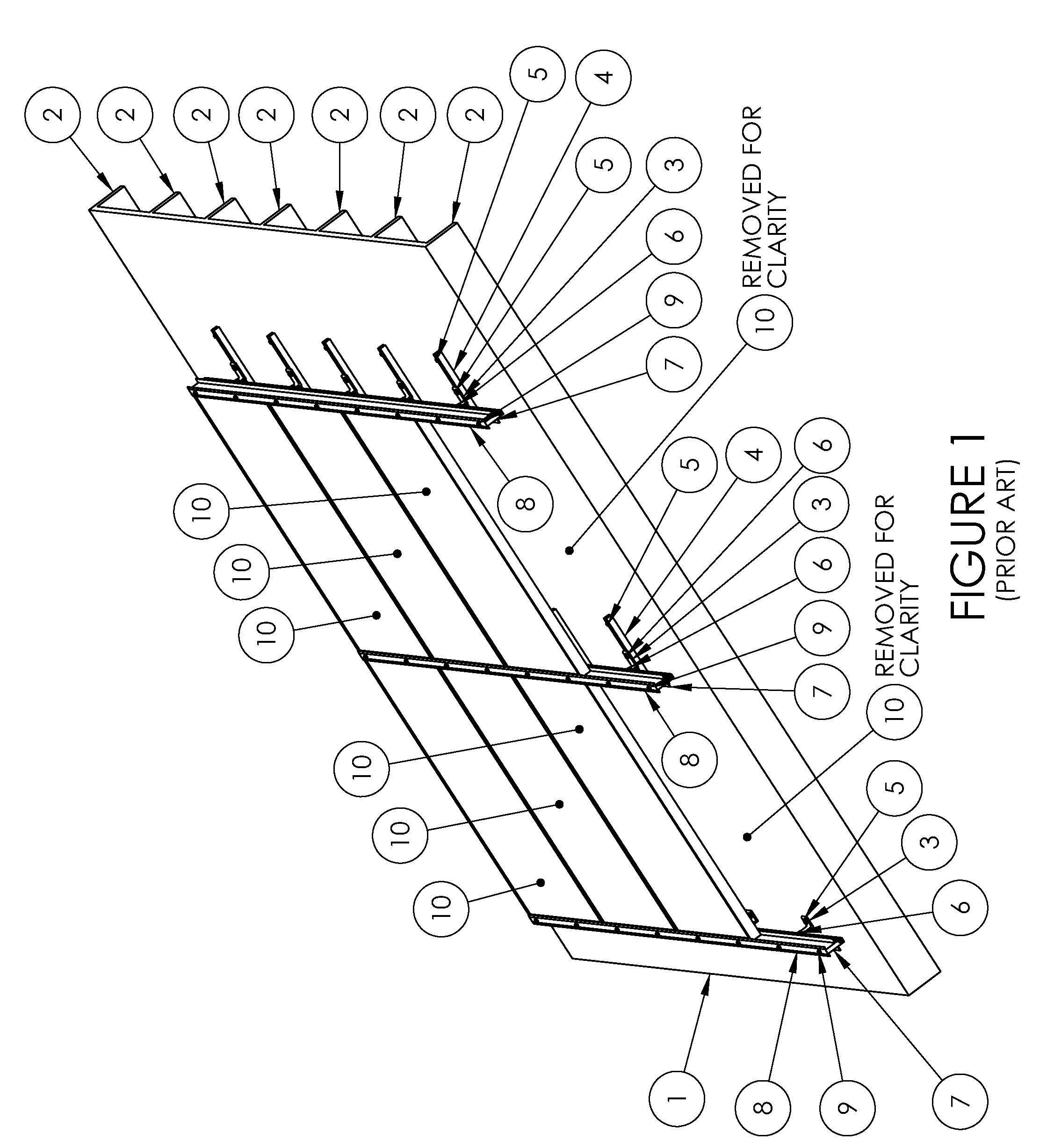

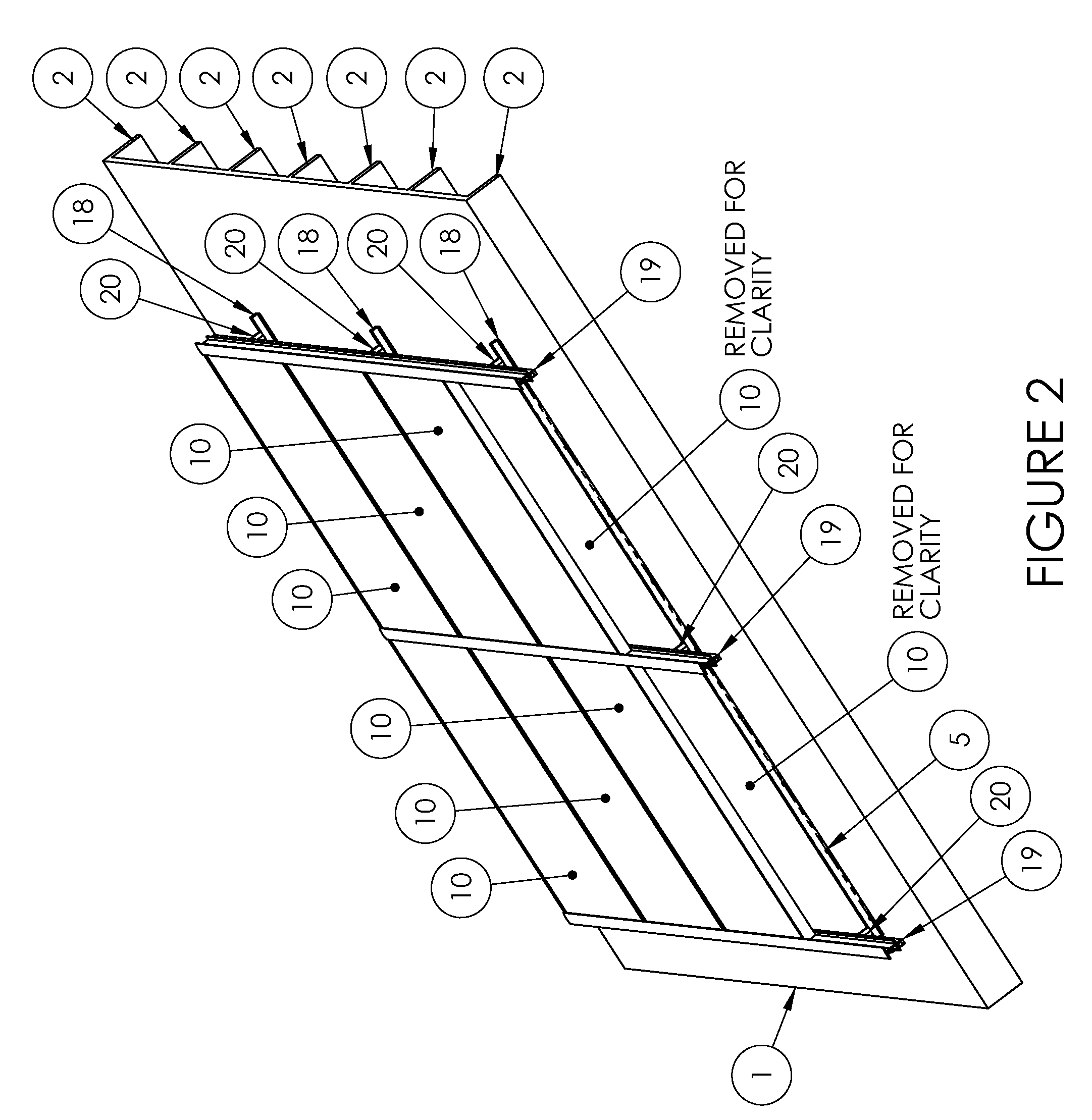

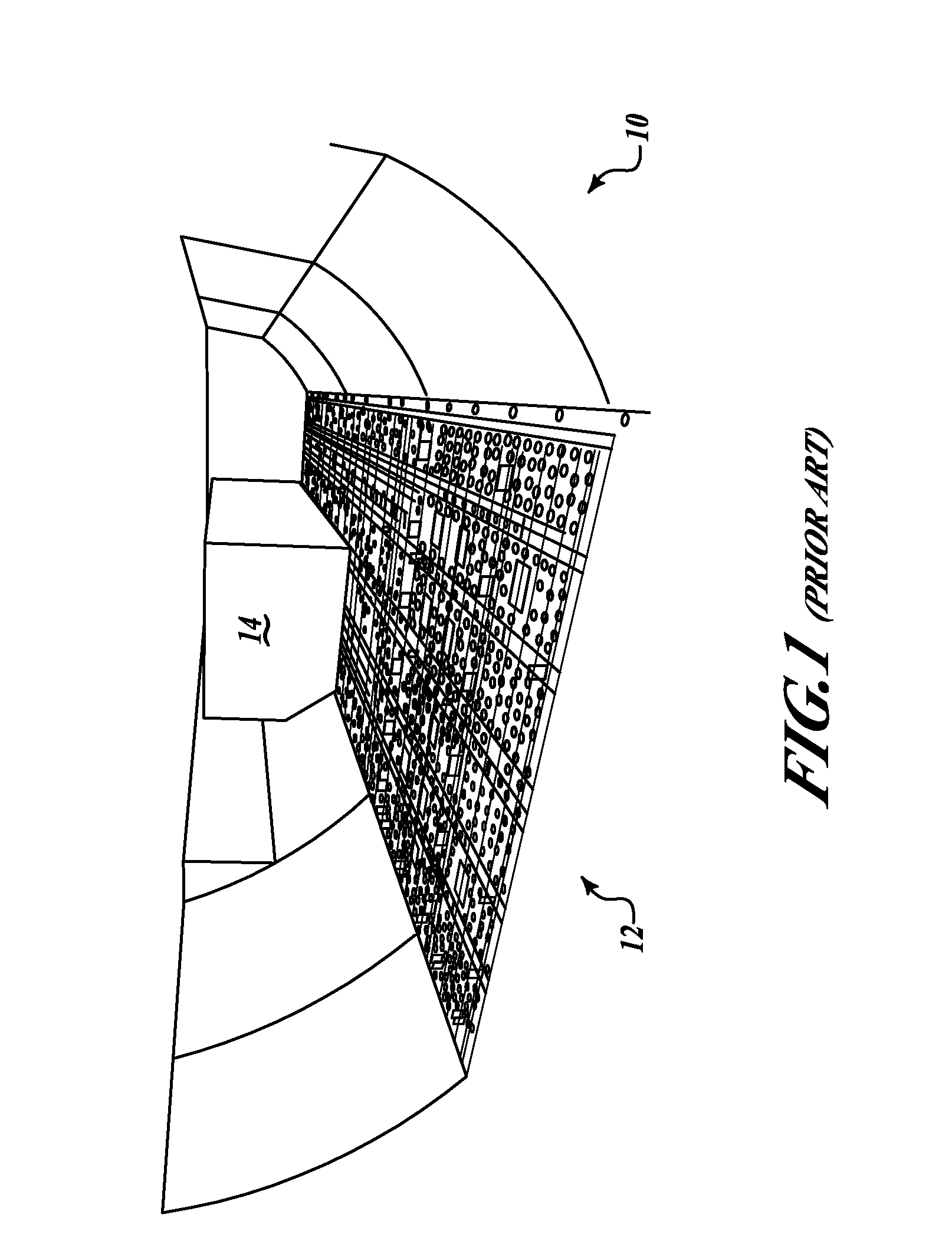

Photovoltaic mounting system with locking connectors, adjustable rail height and hinge lock

InactiveUS20090282755A1Cost-effectiveTurn easilyPhotovoltaic supportsSolar heating energyElectricityPhotovoltaic mounting system

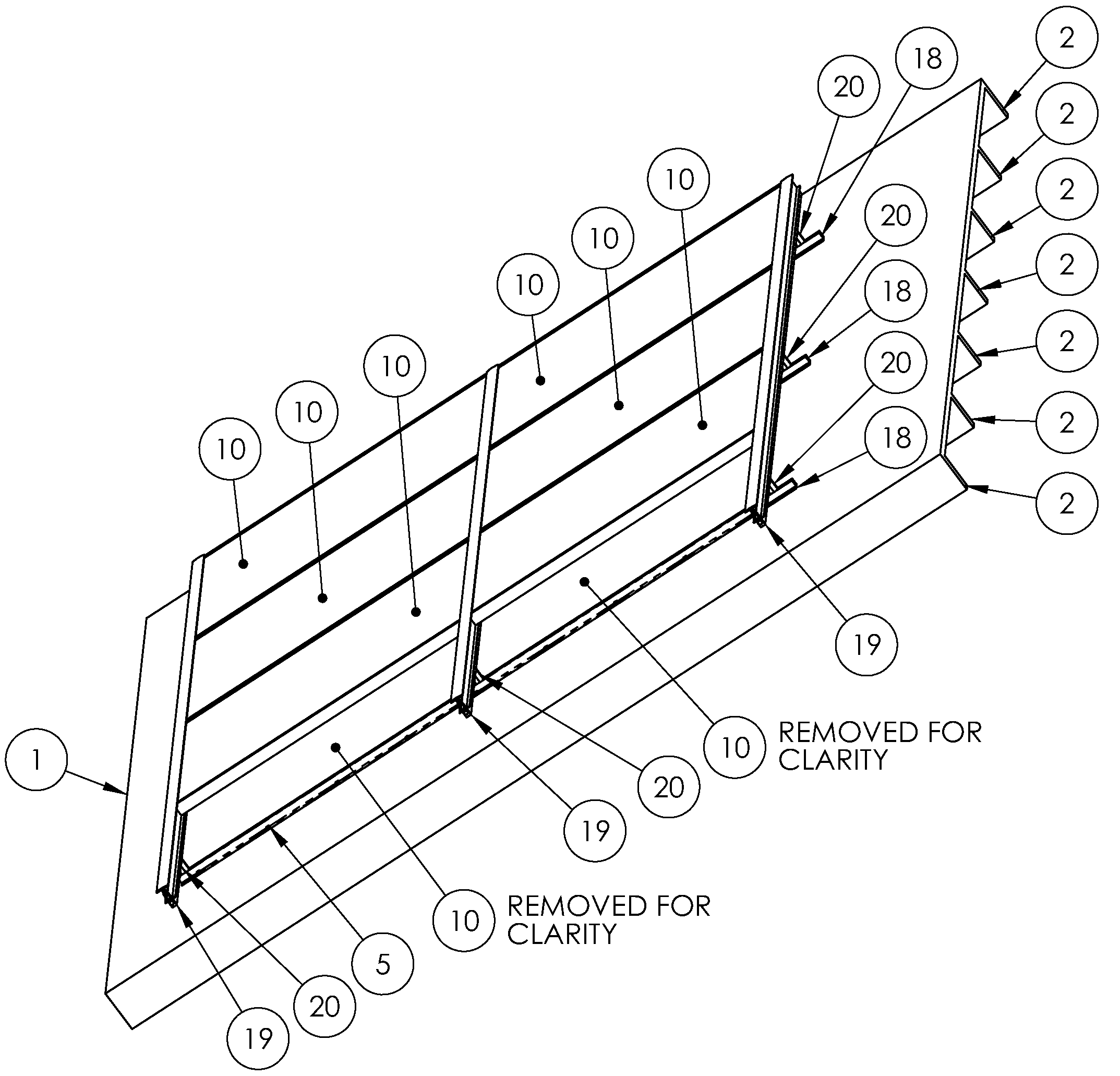

A cam-actuated connection device joins rail mounting members of a photovoltaic panel array. The connection device slides within channels of mounting members until the members are in a properly positioned grid. When in position, the connection device is rotated to lock the mounting members in a rigid grid network. The connecting device can be subsequently loosened, repositioned and locked into position. The rail-mounting members create a grid for installation of multiple PV panels. The mounting rail allows the unit to remain relatively compact in nature but still covers a wide range of PV panel thicknesses. The rail system has a hinged connection with the mounting rail that allows an installer to assemble the module in a near perpendicular fashion to the mounting rail, make the required electrical connections and then lower the PV module into its working position. The unit is then locked into its working position.

Owner:POWERMOUNT SYST +1

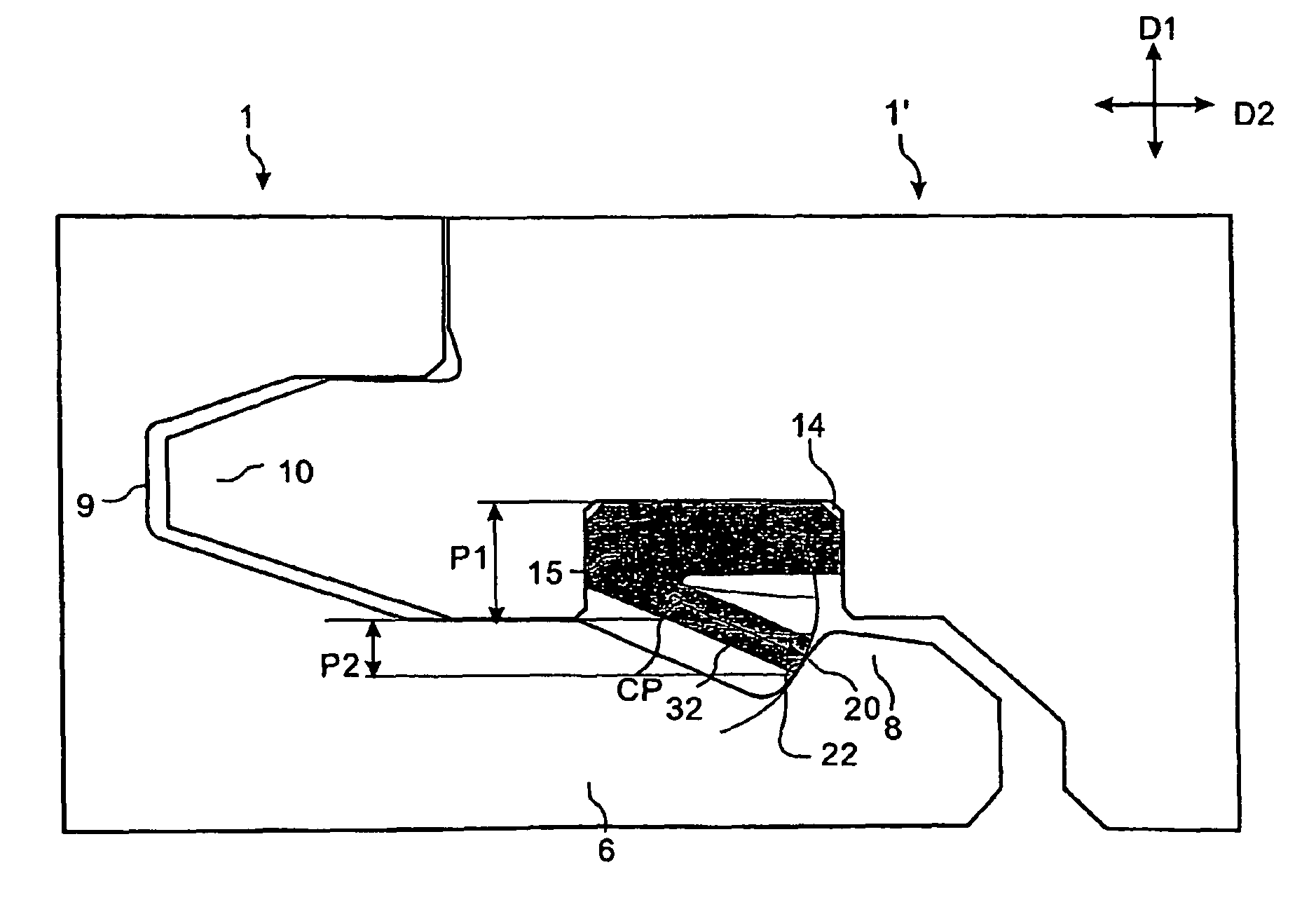

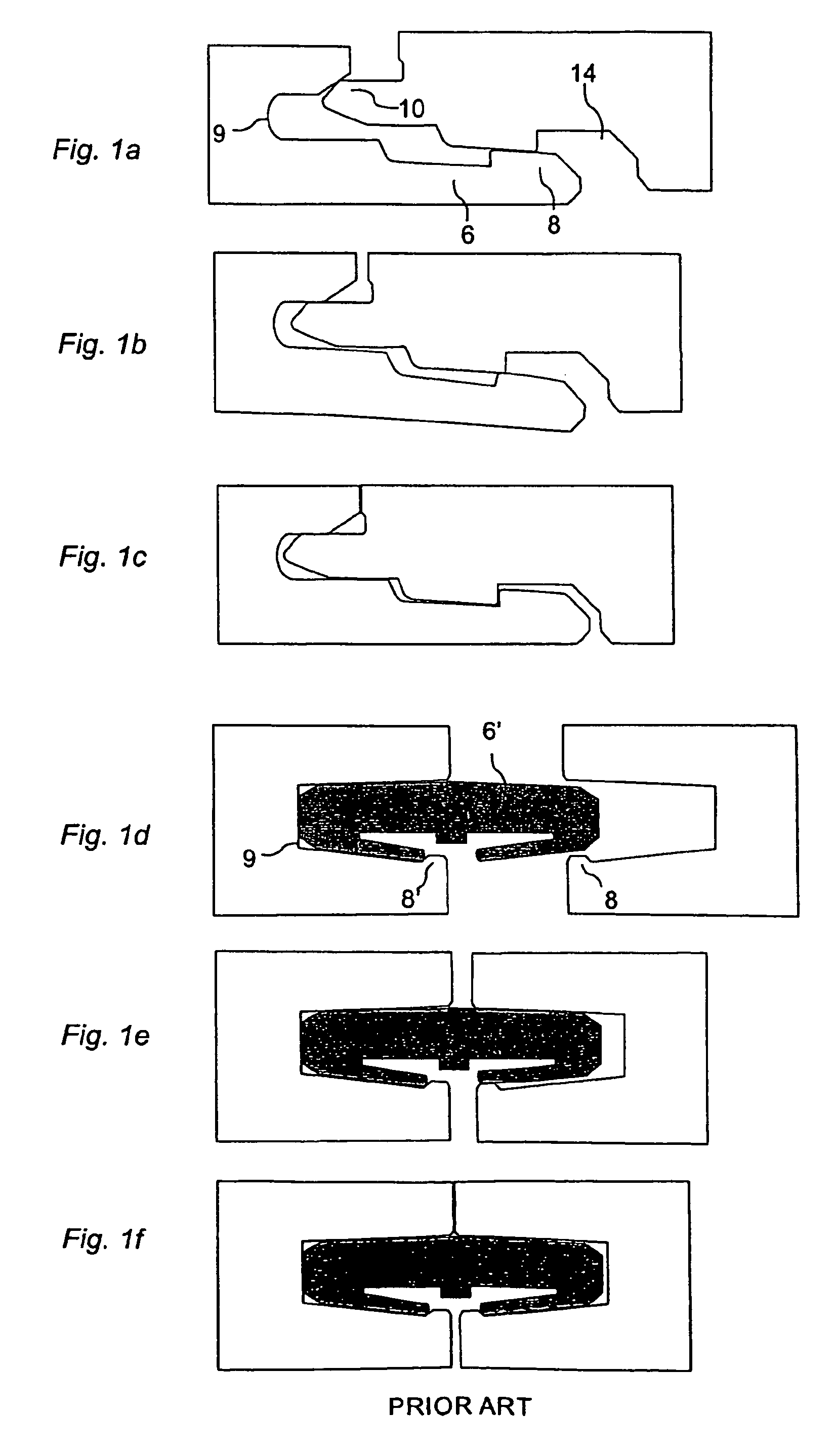

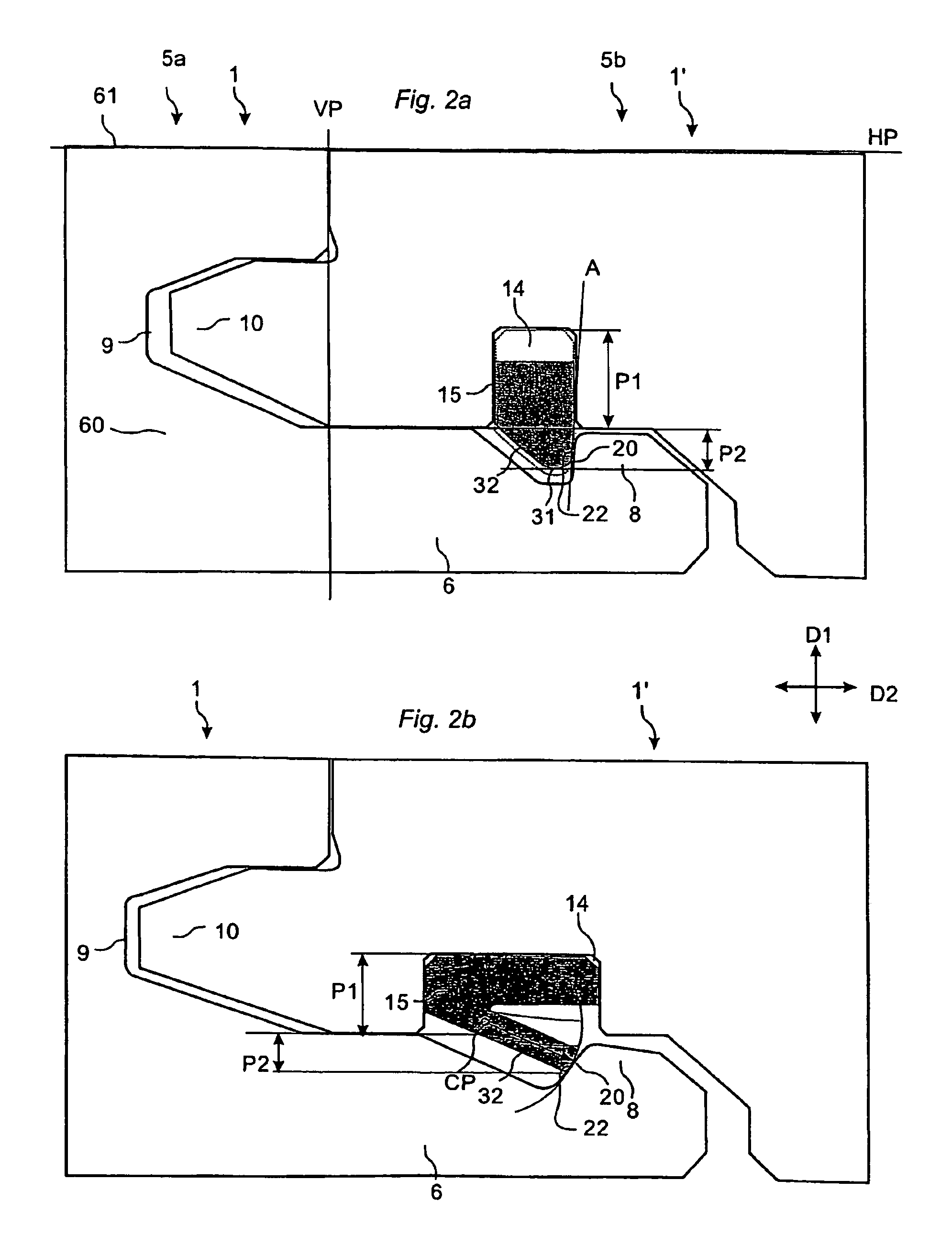

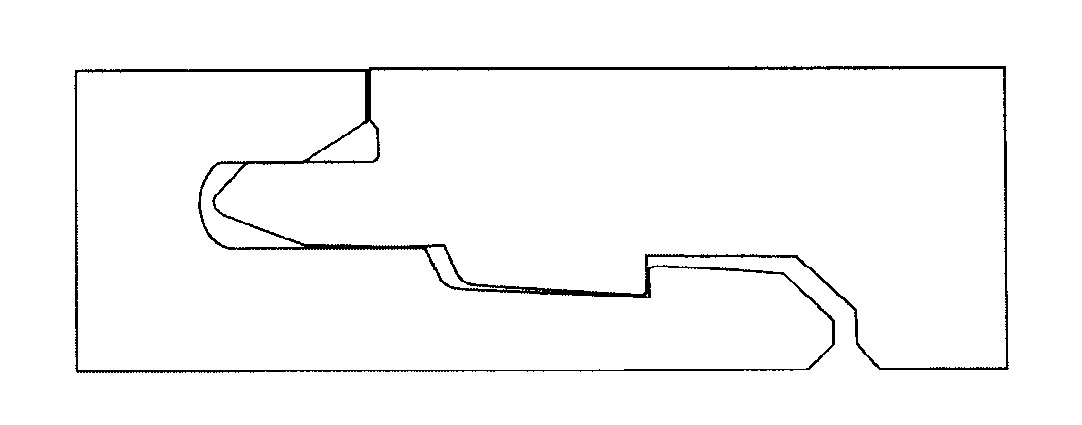

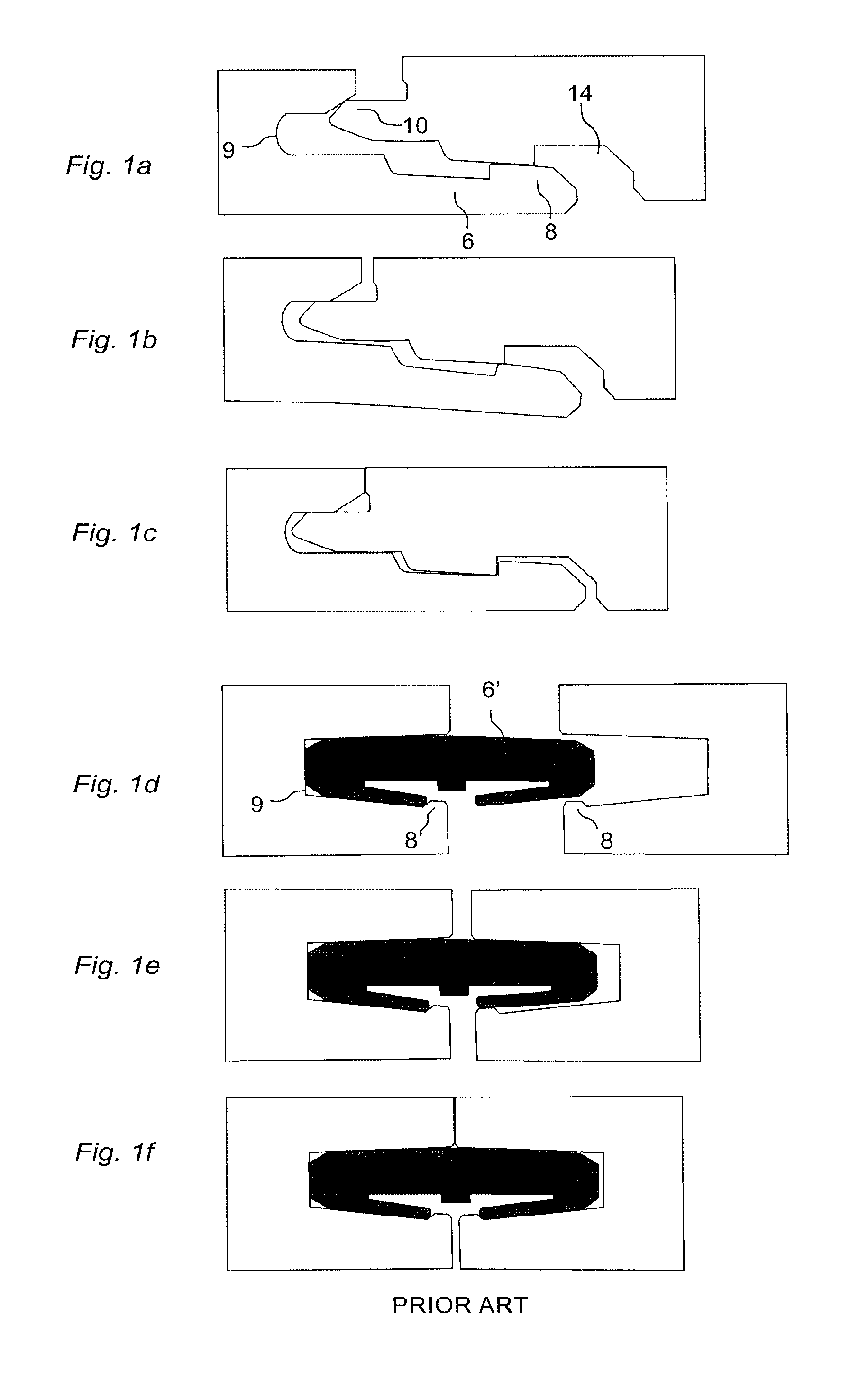

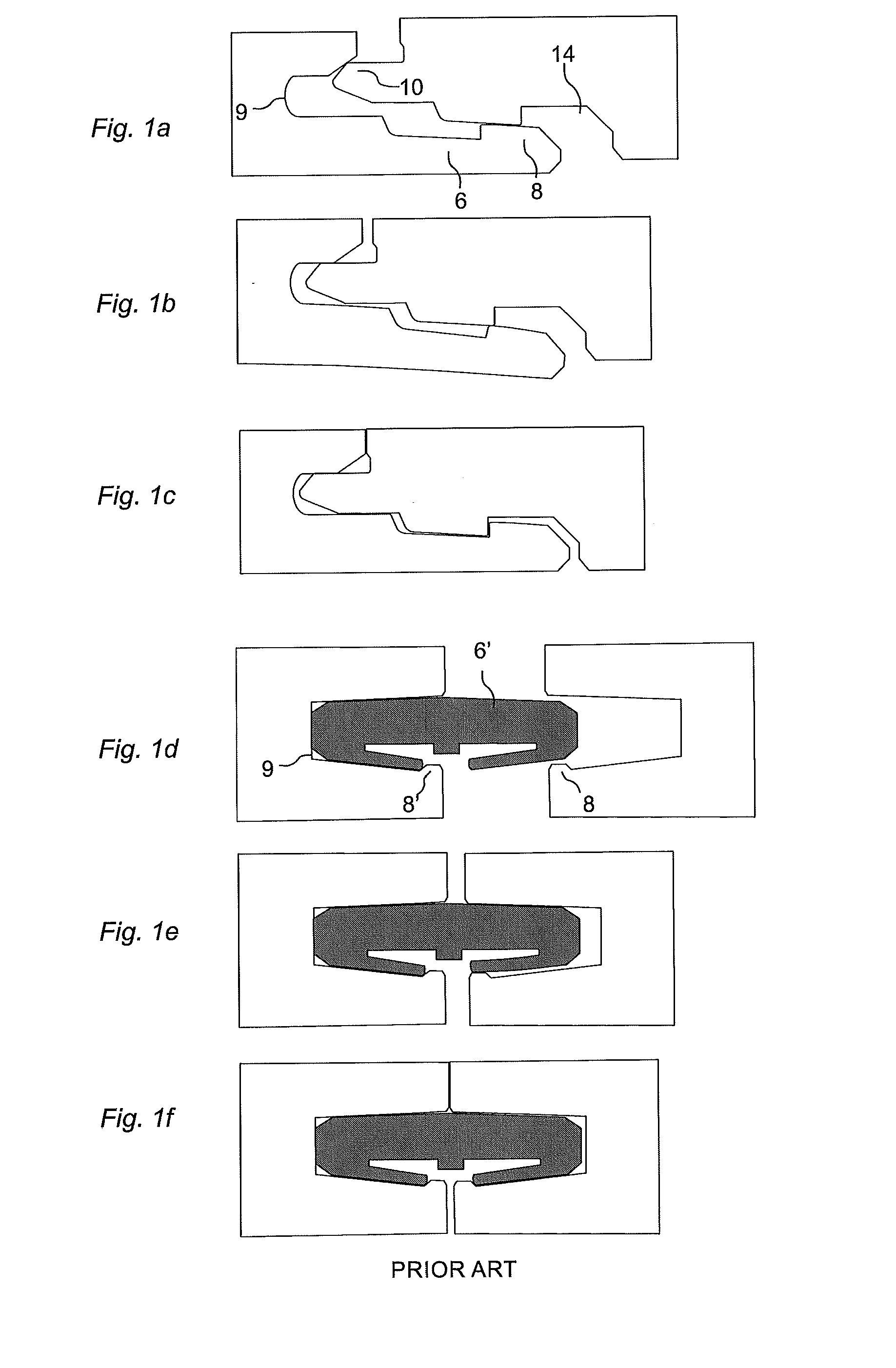

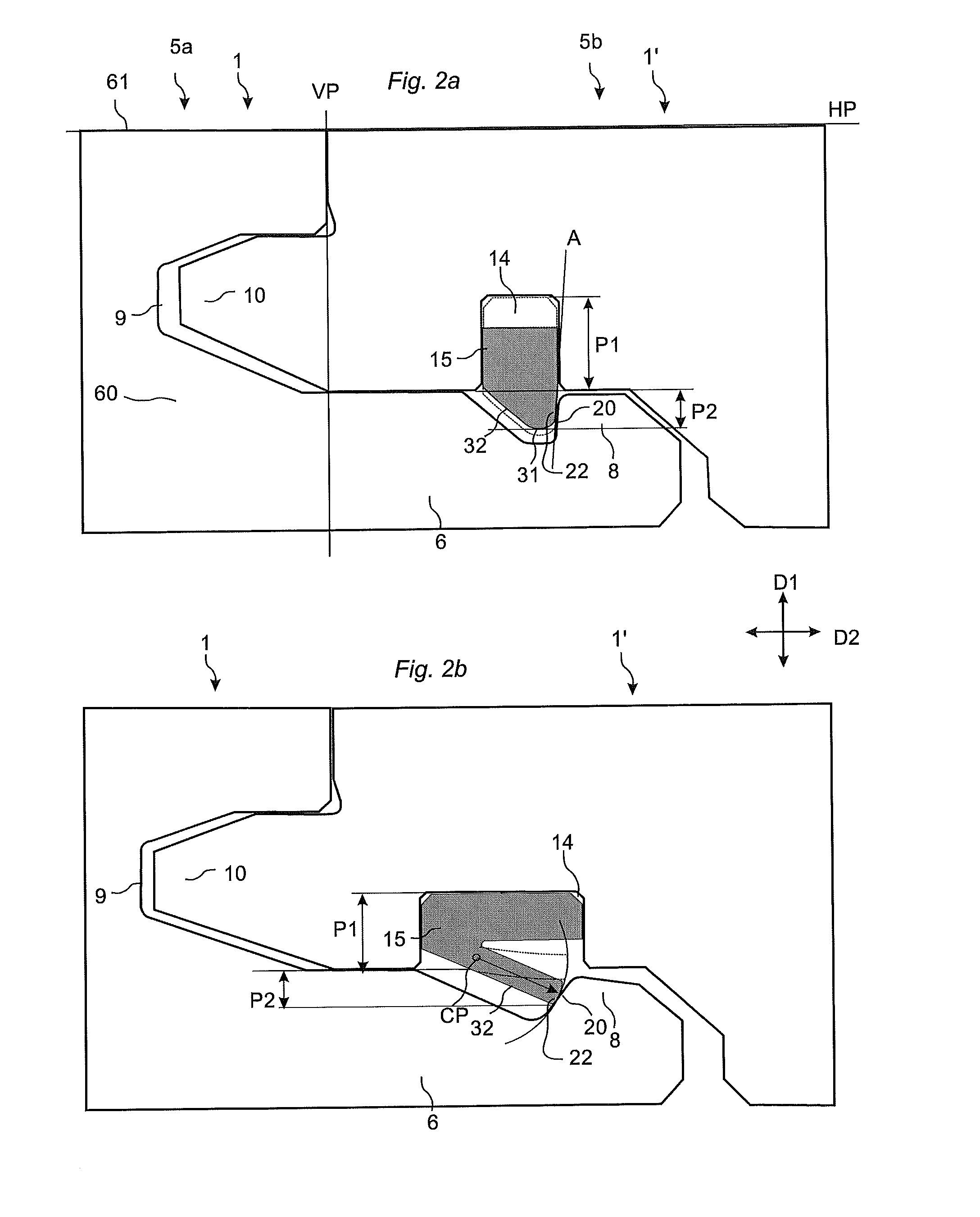

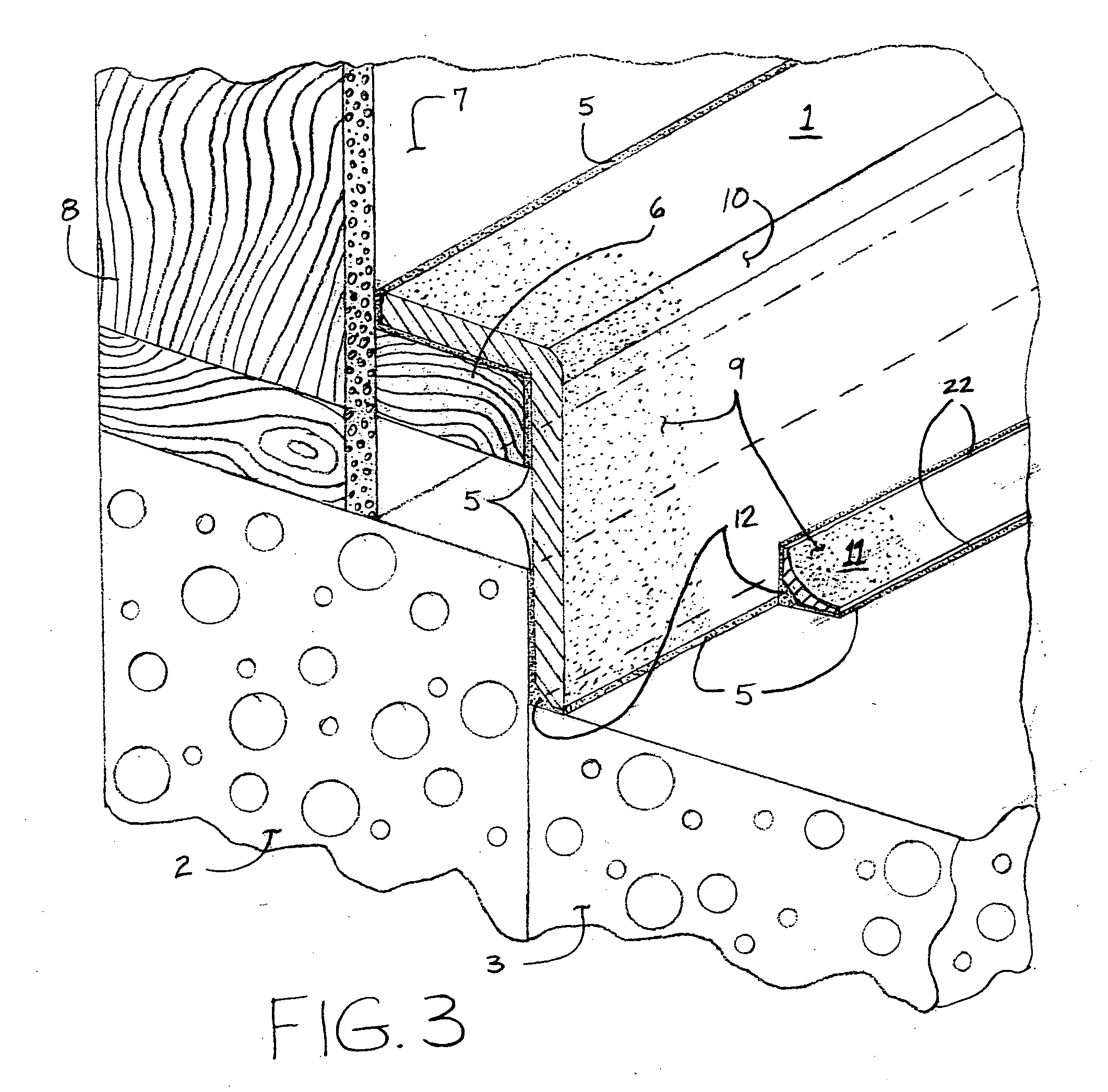

Mechanical locking system for panels and method of installing same

ActiveUS7841145B2Function increaseLower resistanceCovering/liningsWallsEngineeringMechanical engineering

Floor panels are provided with a mechanical locking system including a flexible locking element in a locking groove, which during a horizontal motion is displaced vertically.

Owner:VÄLINGE INNOVATION AB

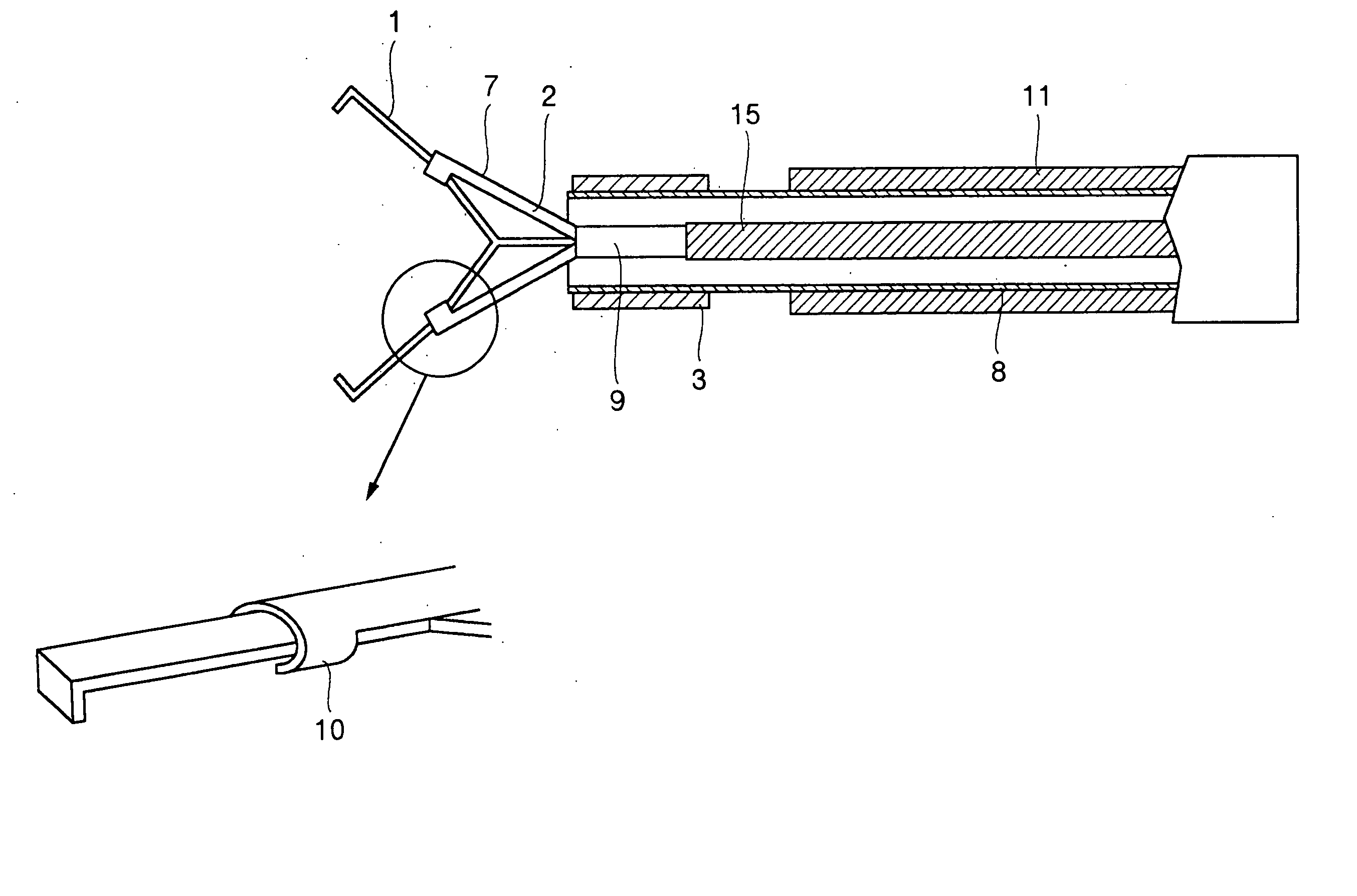

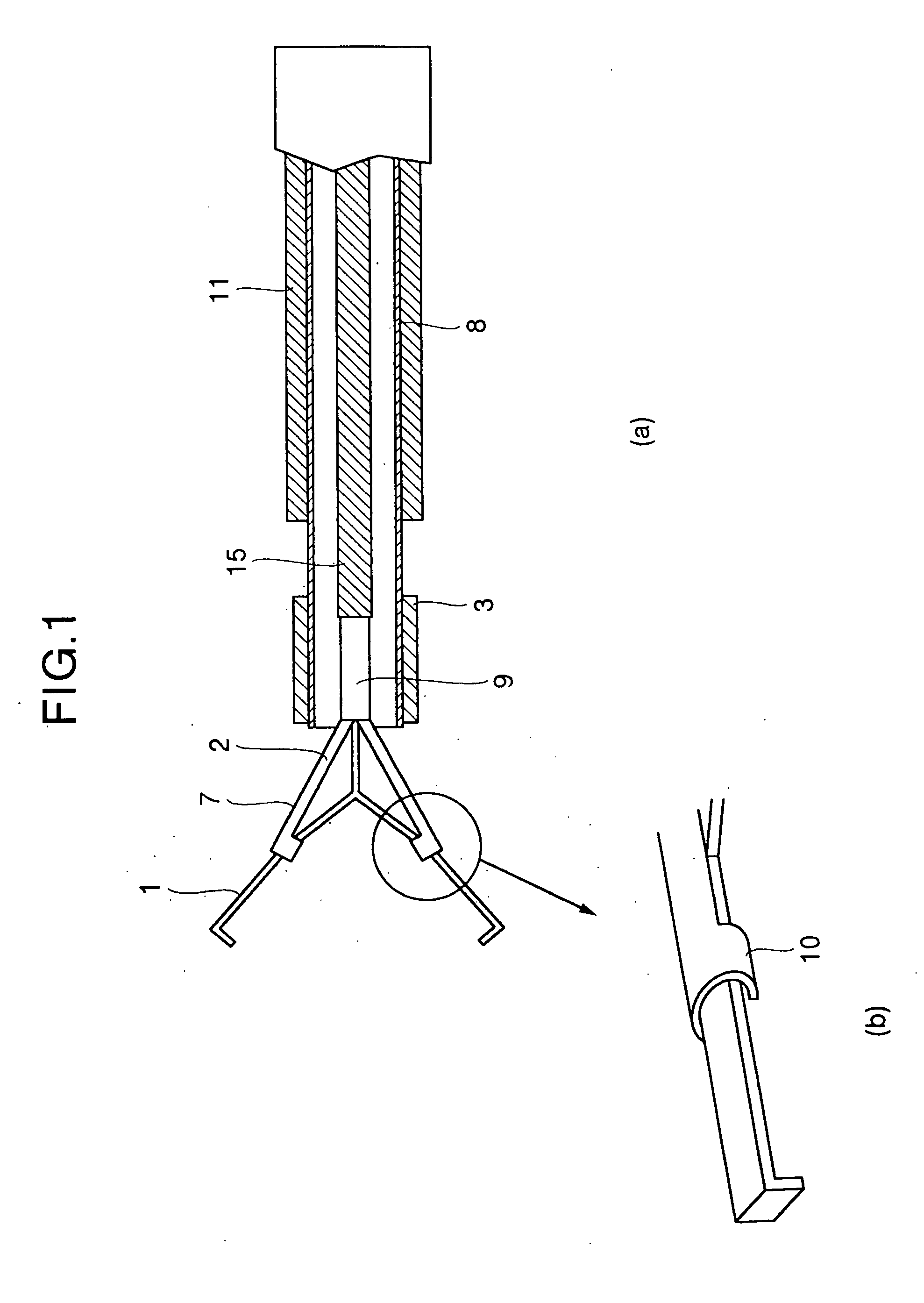

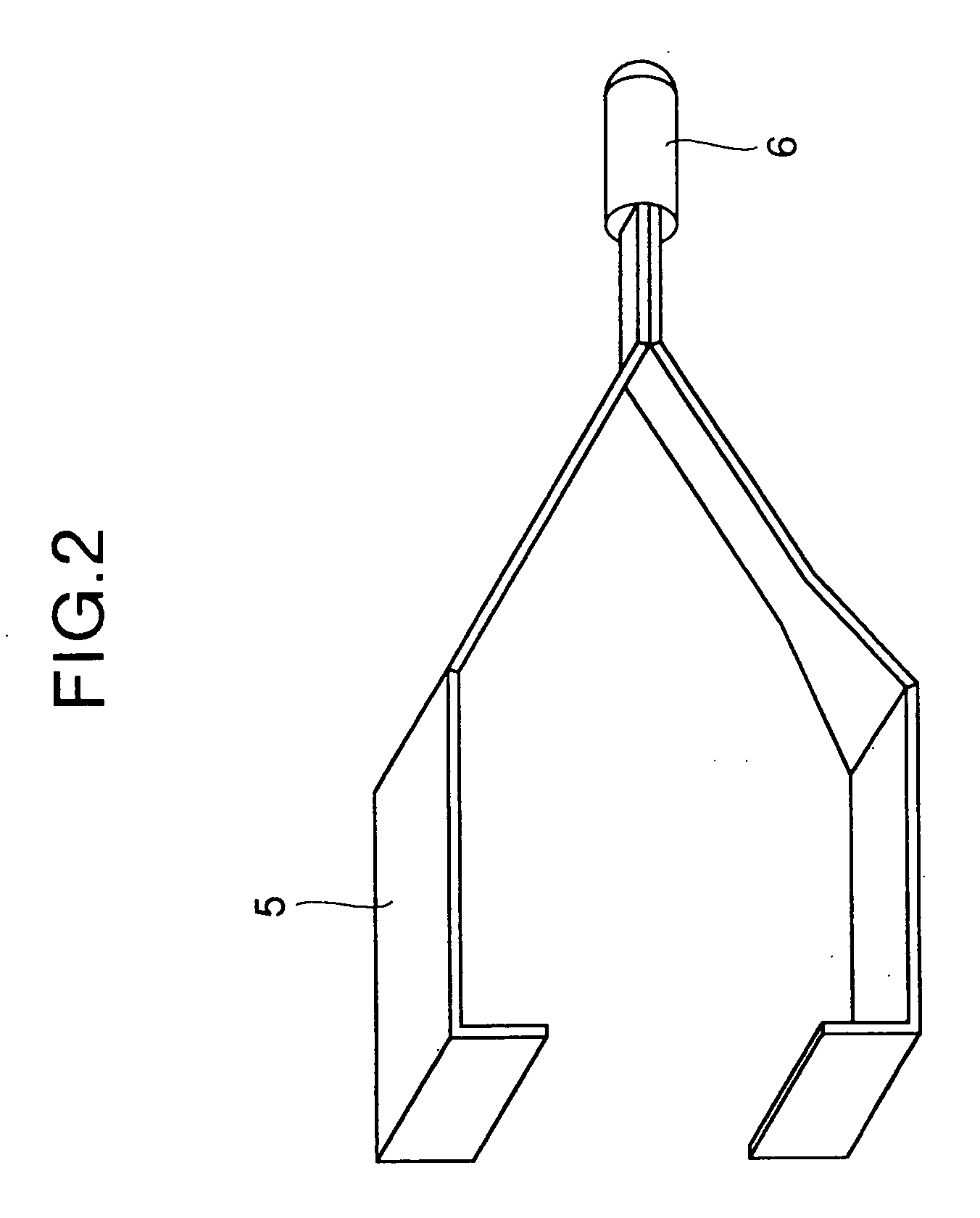

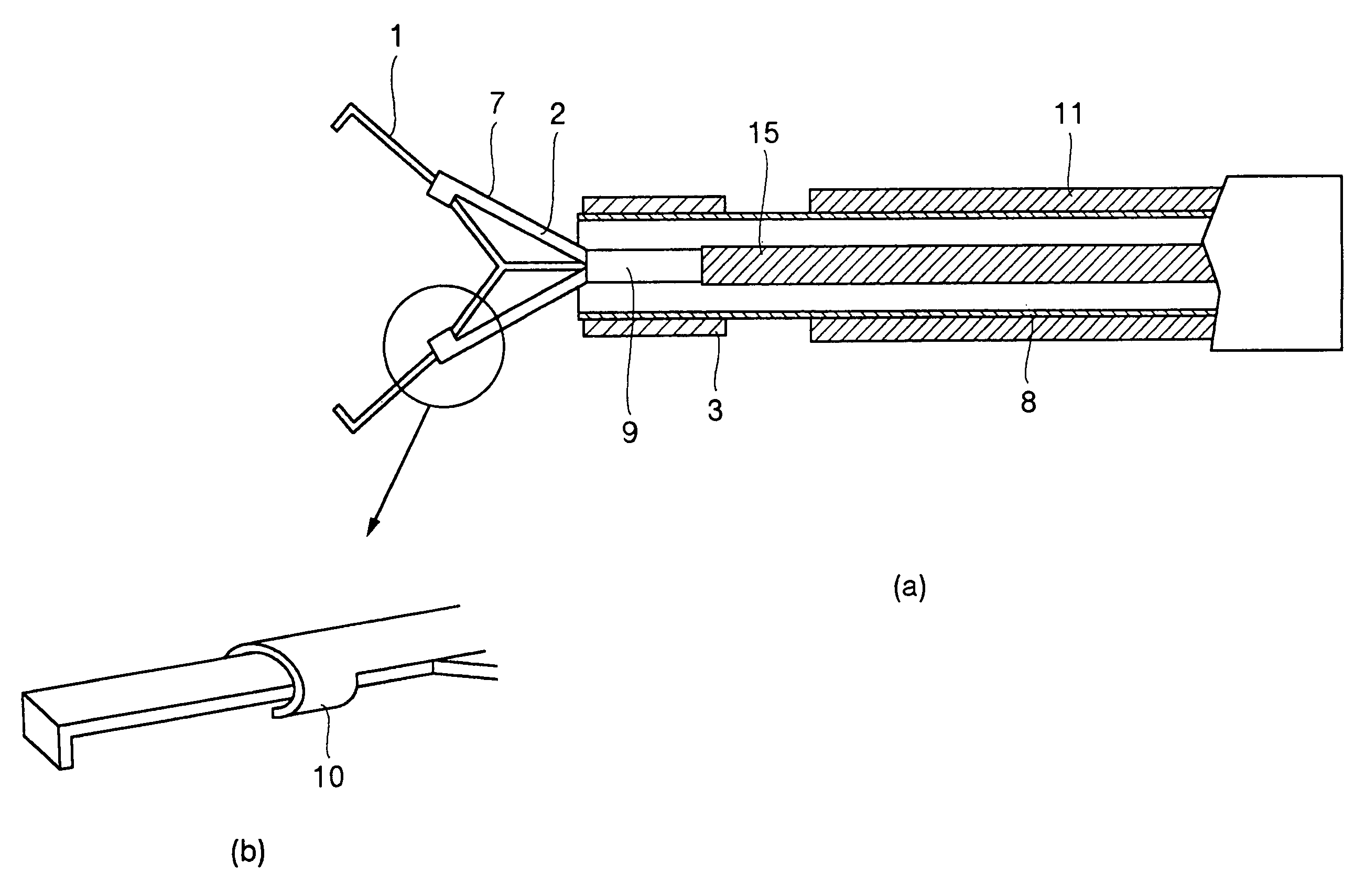

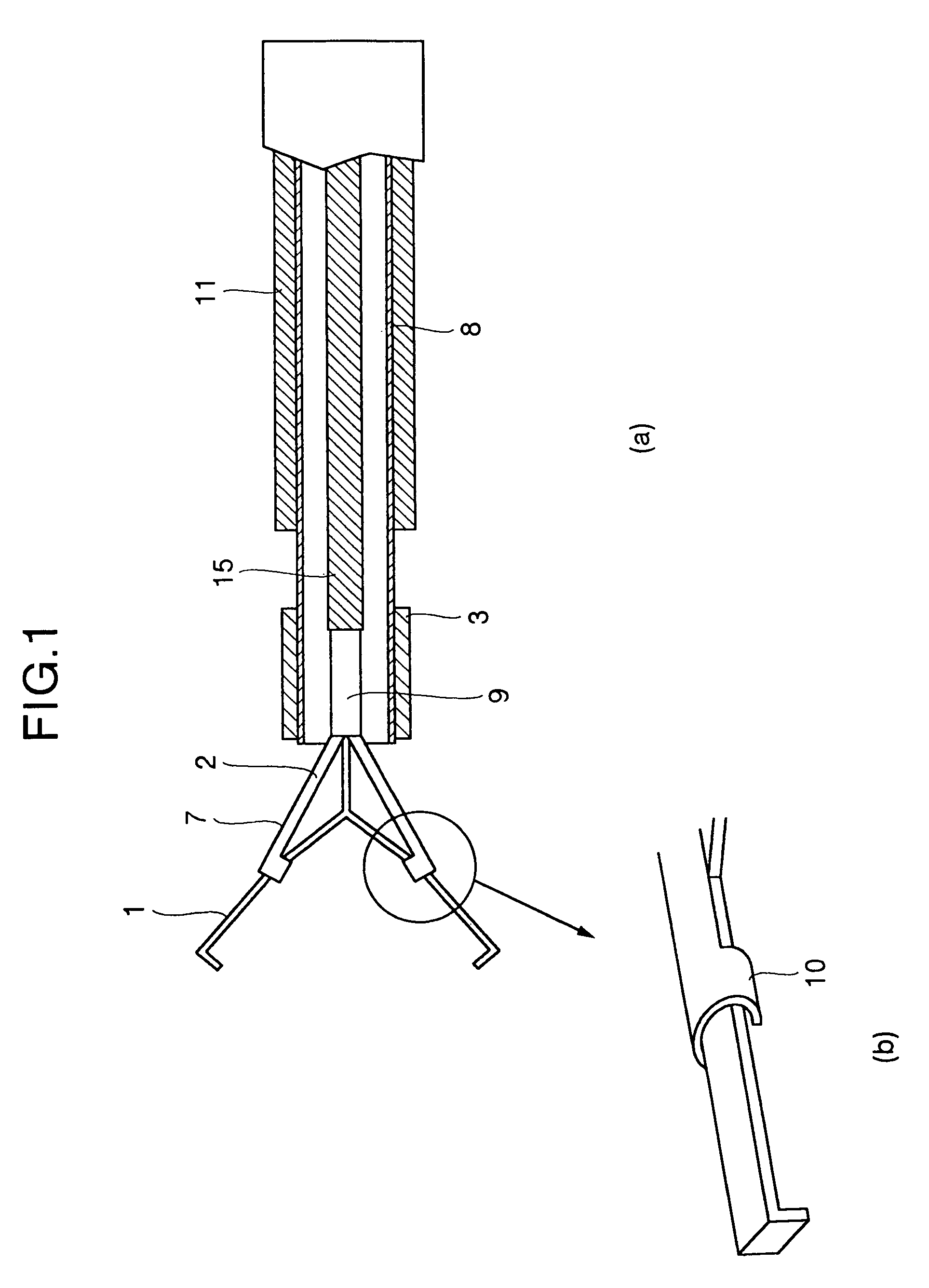

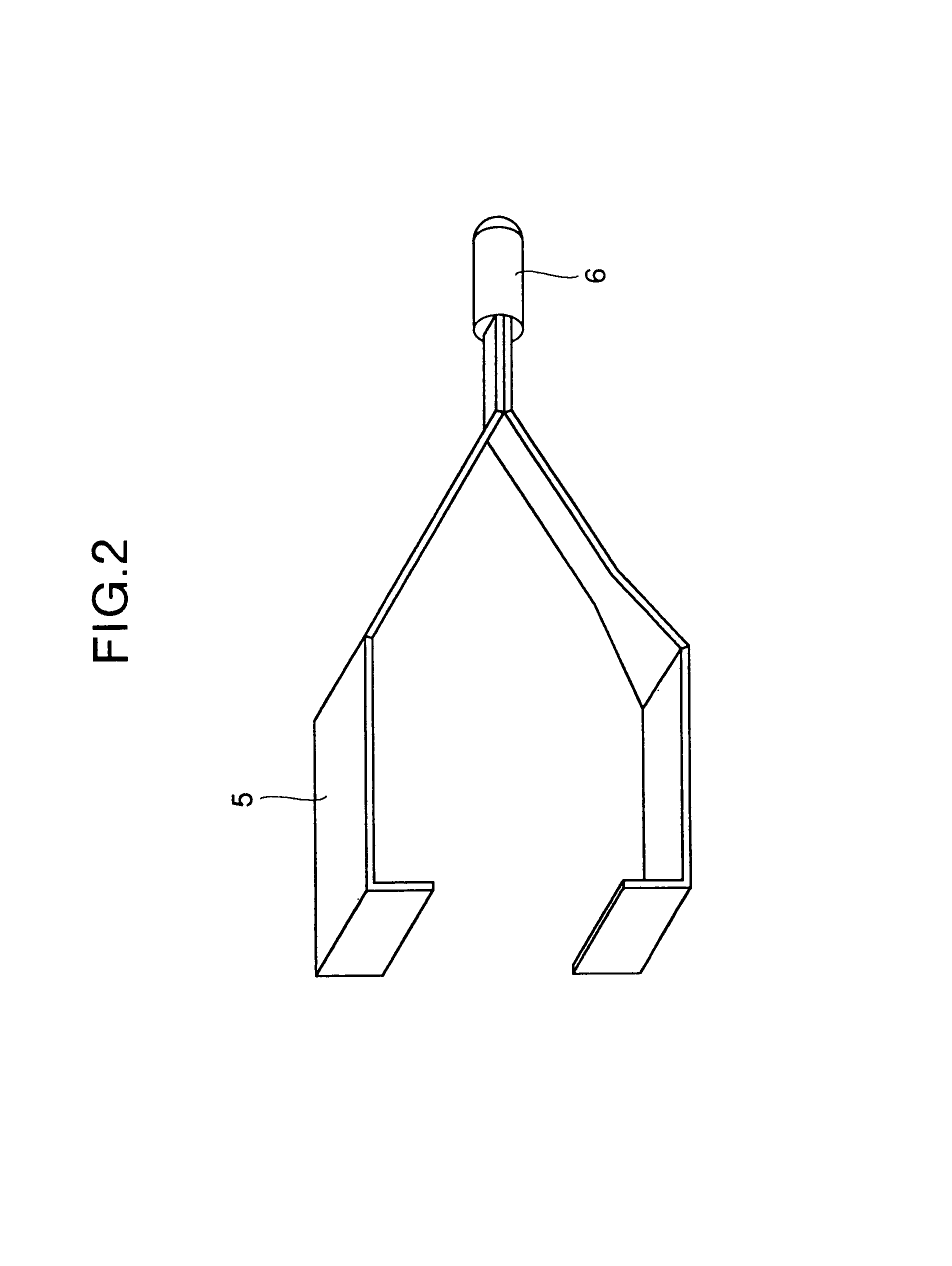

Clip device for endoscope and clip for endoscope for use therein

InactiveUS20050049618A1Improve defectImprove defectsStaplesSurgical pincettesClip deviceBiomedical engineering

A clipping device improves defects that the clip can not be again opened once the clip is closed, and that it is necessary to execute the operation in a state in which the clip is not sufficiently opened. The invention provides a clip device for an endoscope constituted by a clipping means having a pair of arm portions which are allowed to be opened and closed, an operating means for holding the arm portions of the clipping means so as to open and close the arm portions, a fixing means for fixing the arm portions after closing the arm portions, and an arranging means for arranging the fixing means in an outer side of the arm portion.

Owner:SUMITOMO BAKELITE CO LTD

Clip device for endoscope and clip for endoscope for use therein

InactiveUS7357805B2Improve defectsEasy to installStaplesSurgical pincettesEndoscopeBiomedical engineering

A clipping device improves defects that the clip can not be again opened once the clip is closed, and that it is necessary to execute the operation in a state in which the clip is not sufficiently opened. The invention provides a clip device for an endoscope constituted by a clipping means having a pair of arm portions which are allowed to be opened and closed, an operating means for holding the arm portions of the clipping means so as to open and close the arm portions, a fixing means for fixing the arm portions after closing the arm portions, and an arranging means for arranging the fixing means in an outer side of the arm portion.

Owner:SUMITOMO BAKELITE CO LTD

Mechanical locking system for panels and method of installing same

ActiveUS20080155930A1Function increaseLower resistanceCovering/liningsFloorsEngineeringMechanical engineering

Floor panels are provided with a mechanical locking system including a flexible locking element in a locking groove, which during a horizontal motion is displaced vertically.

Owner:VÄLINGE INNOVATION AB

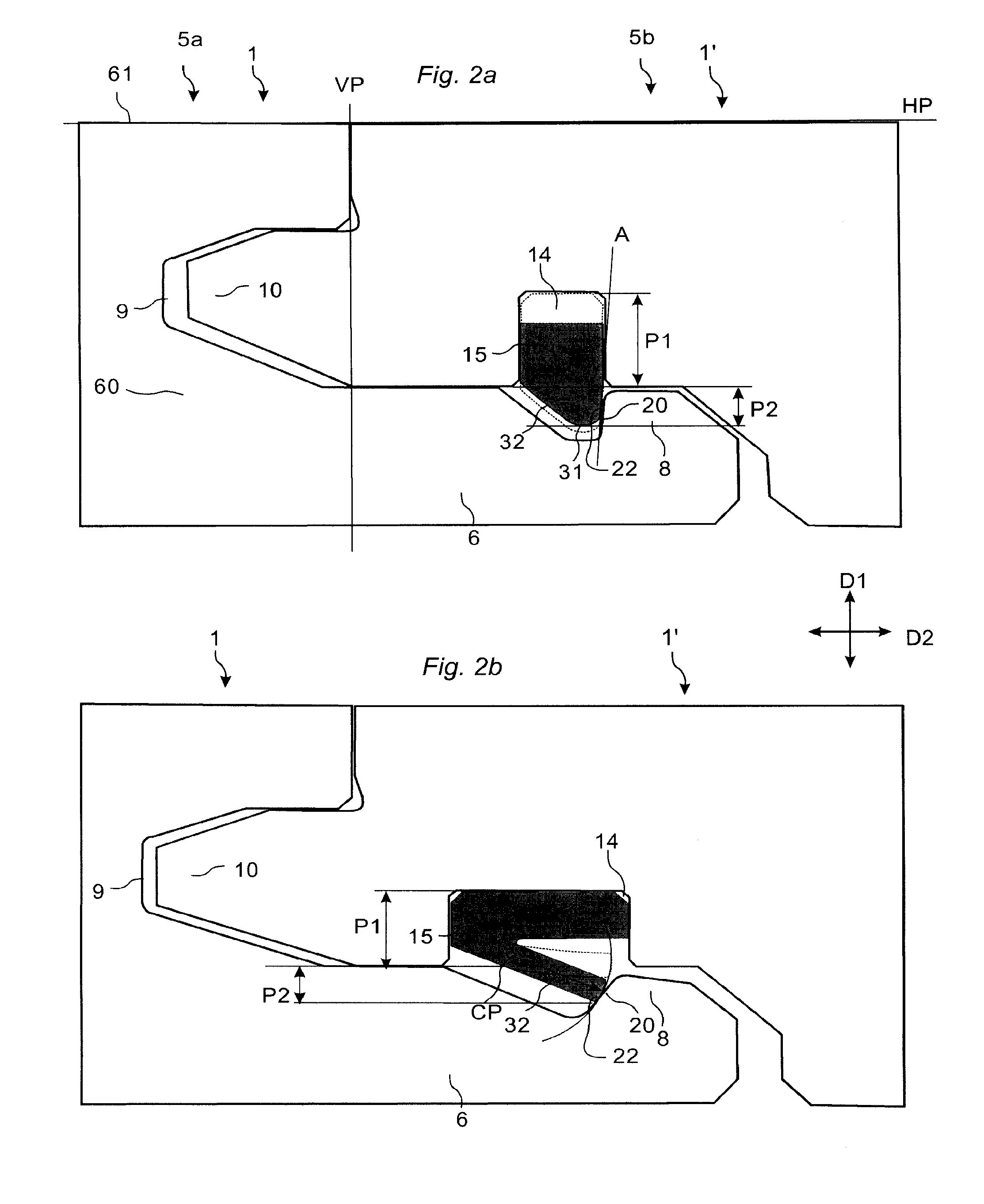

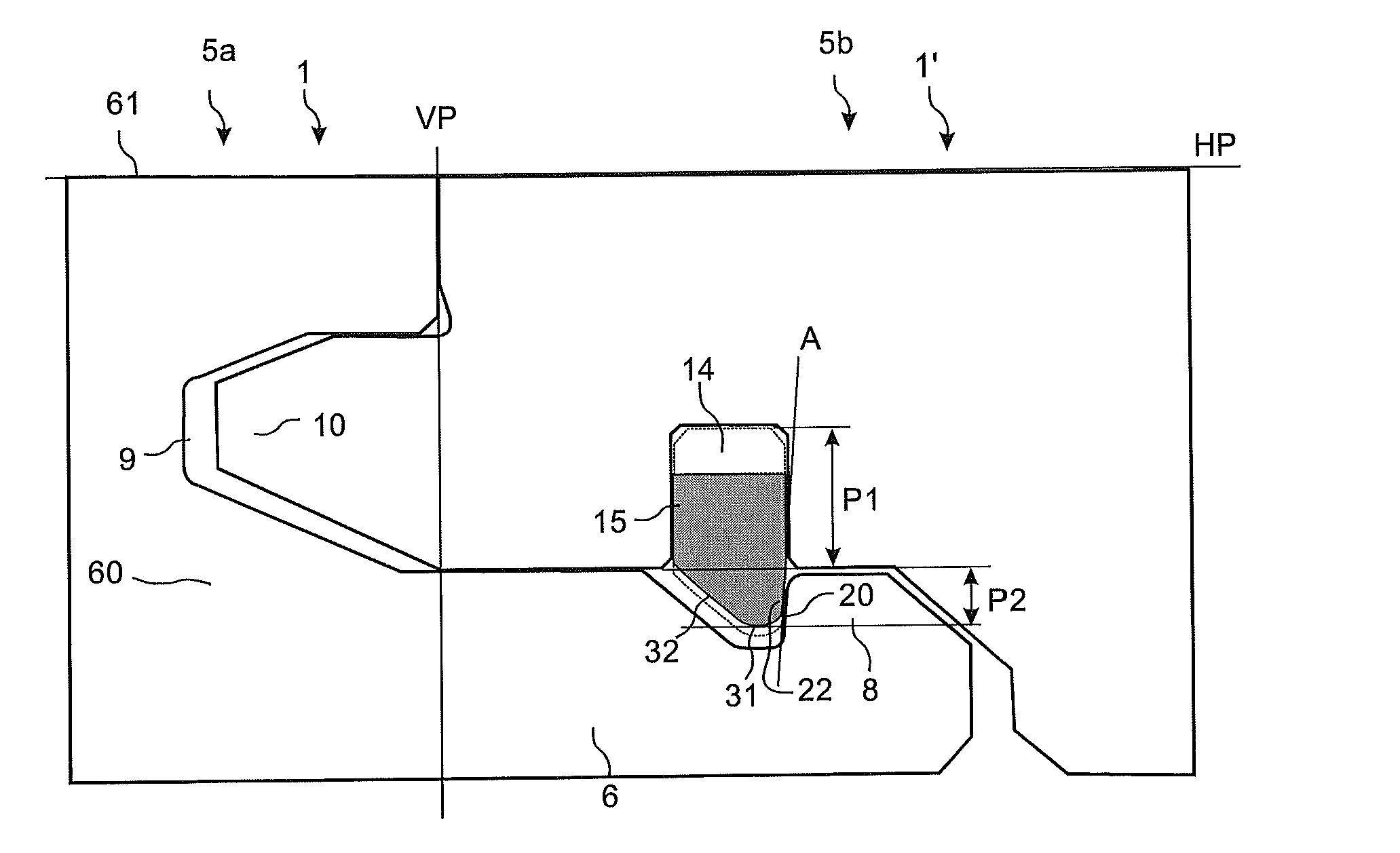

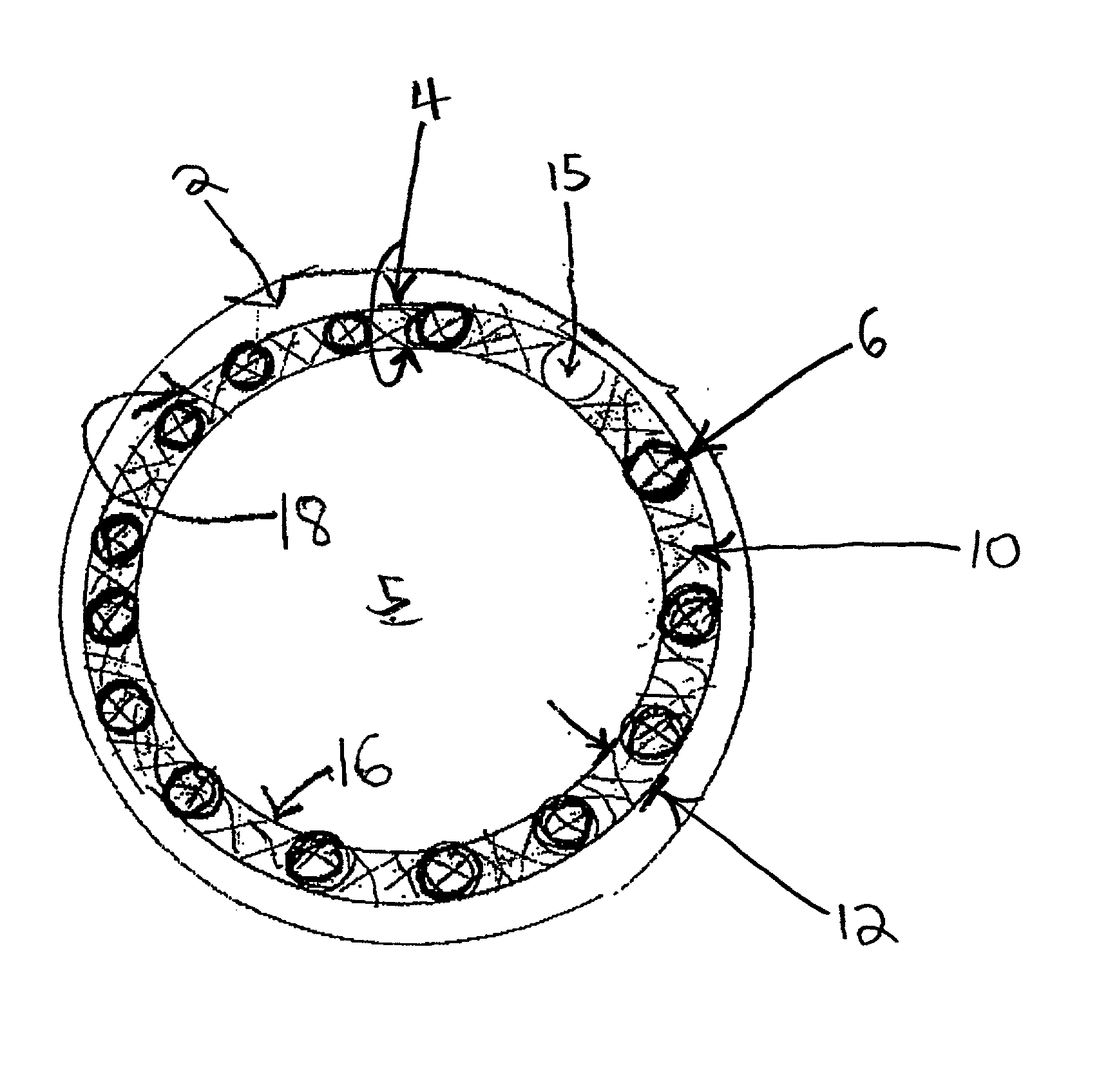

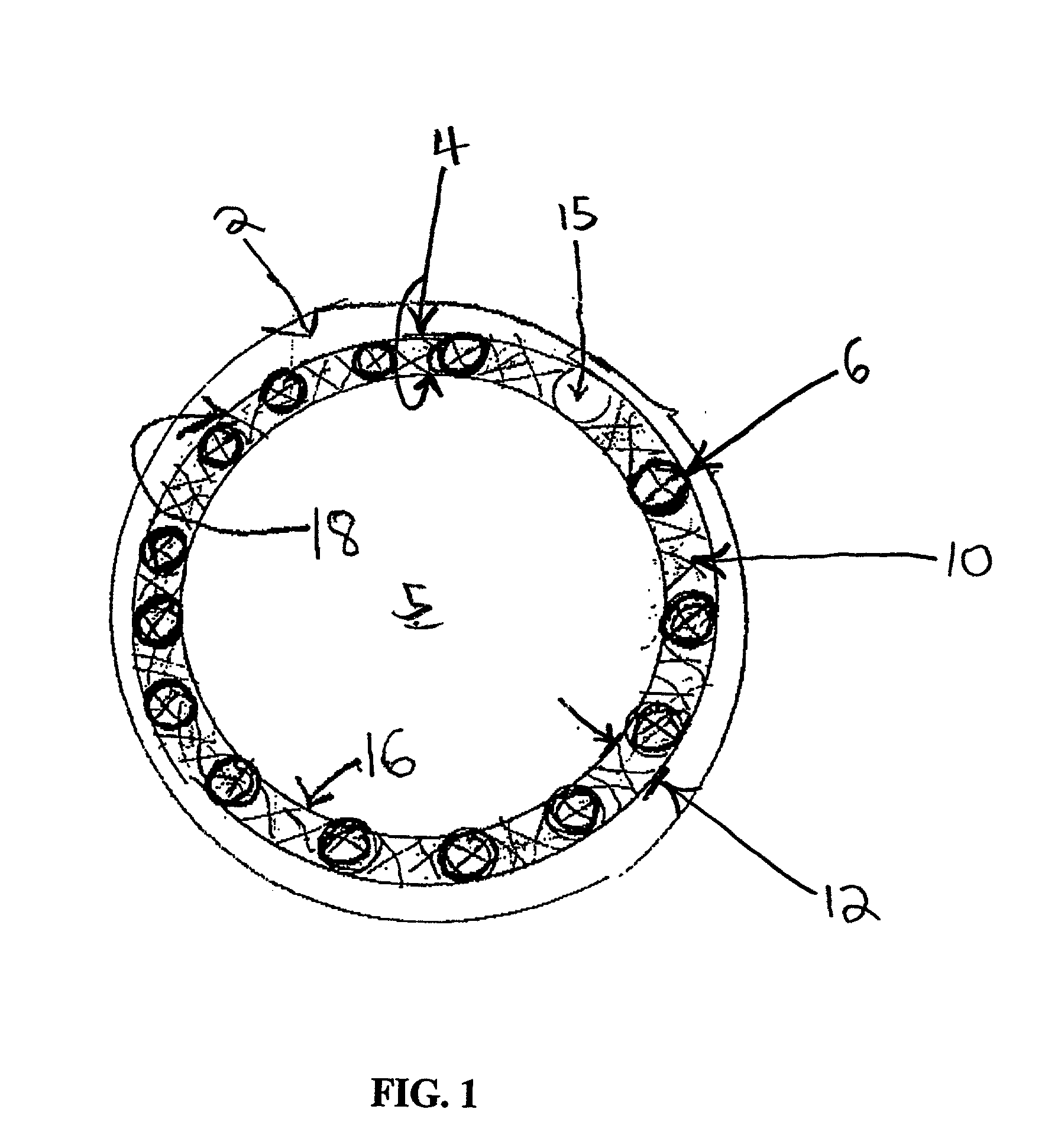

Mechanical locking system for floor panels

ActiveUS20120036804A1Function increaseLower resistanceConstruction materialCovering/liningsMechanical engineering

Floor panels (1, 1′) are shown, which are provided with a mechanical locking system consisting of a flexible locking element 15 in a locking groove 14 which during a horizontal motion is displaced vertically.

Owner:VÄLINGE INNOVATION AB

Rental/car-share vehicle access and management system and method

ActiveUS8768565B2Reduce the time required for installationImprove reliabilityVehicle testingTicket-issuing apparatusMobile appsTablet computer

A rental / car-share (RCS) vehicle access and management system and method, in some embodiments, utilizes barcodes, QR codes (or NFC / RFID), GPS, and a mobile app coupled with a wireless network to enable customers to bypass the reservation desk and pickup and drop off reserved RCS vehicles using a mobile phone, tablet or laptop. The QR code, RFID, or NFC communication with the mobile application allows for identification of the vehicle by a mobile application, which, if authorized, can access the vehicle via a temporary access code issued by remote servers. The remote servers and / or mobile application communicates with a control module that plugs into the on-board diagnostics module of the rental / car-share (RCS) vehicle and includes a host processing unit with a processor, an accelerometer, data storage, a GPS with internal GPS antenna; a wireless modem with internal antenna, and CAN bus transceivers connected with the processor, and a USB programmable interface.

Owner:ENTERPRISE HOLDINGS

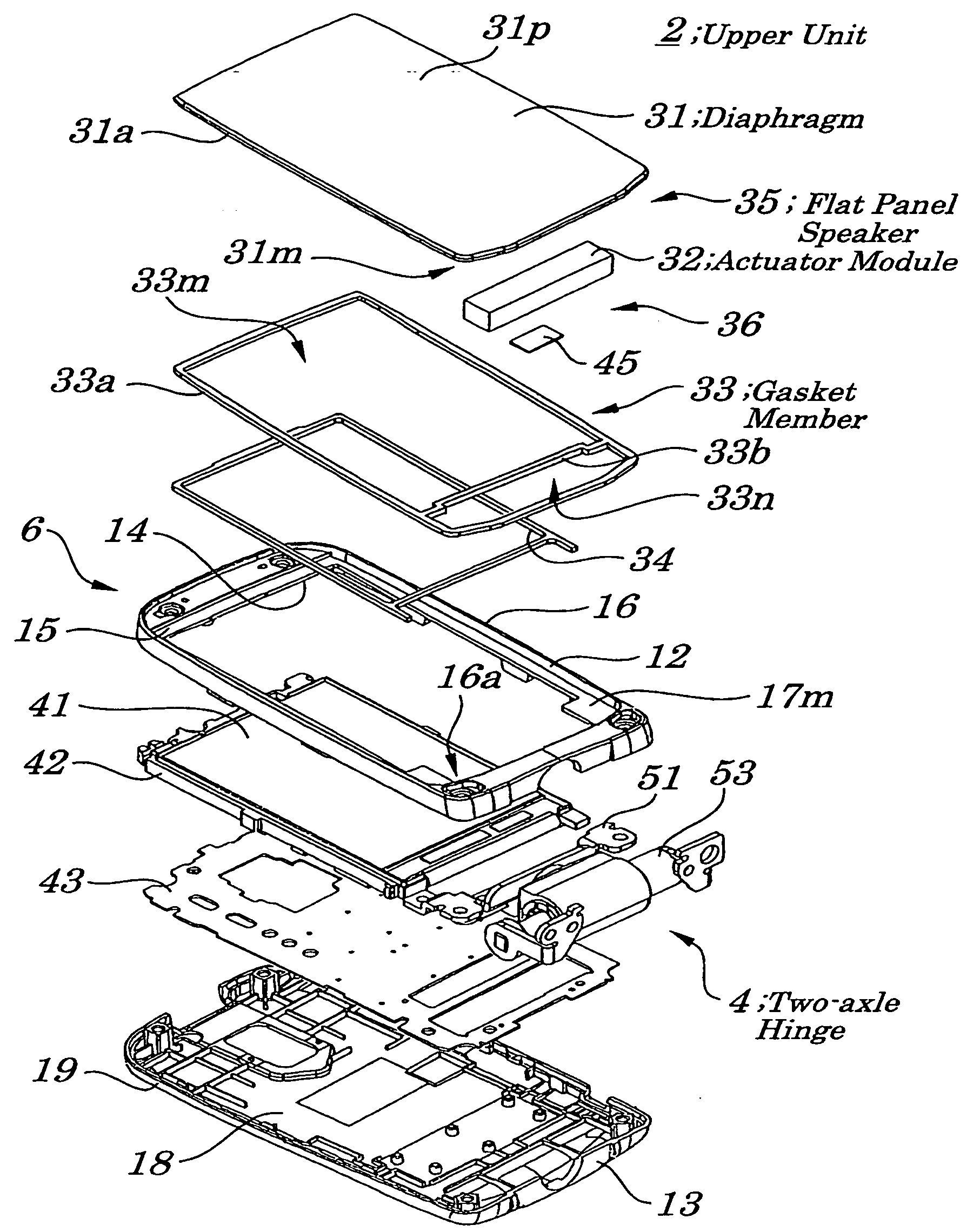

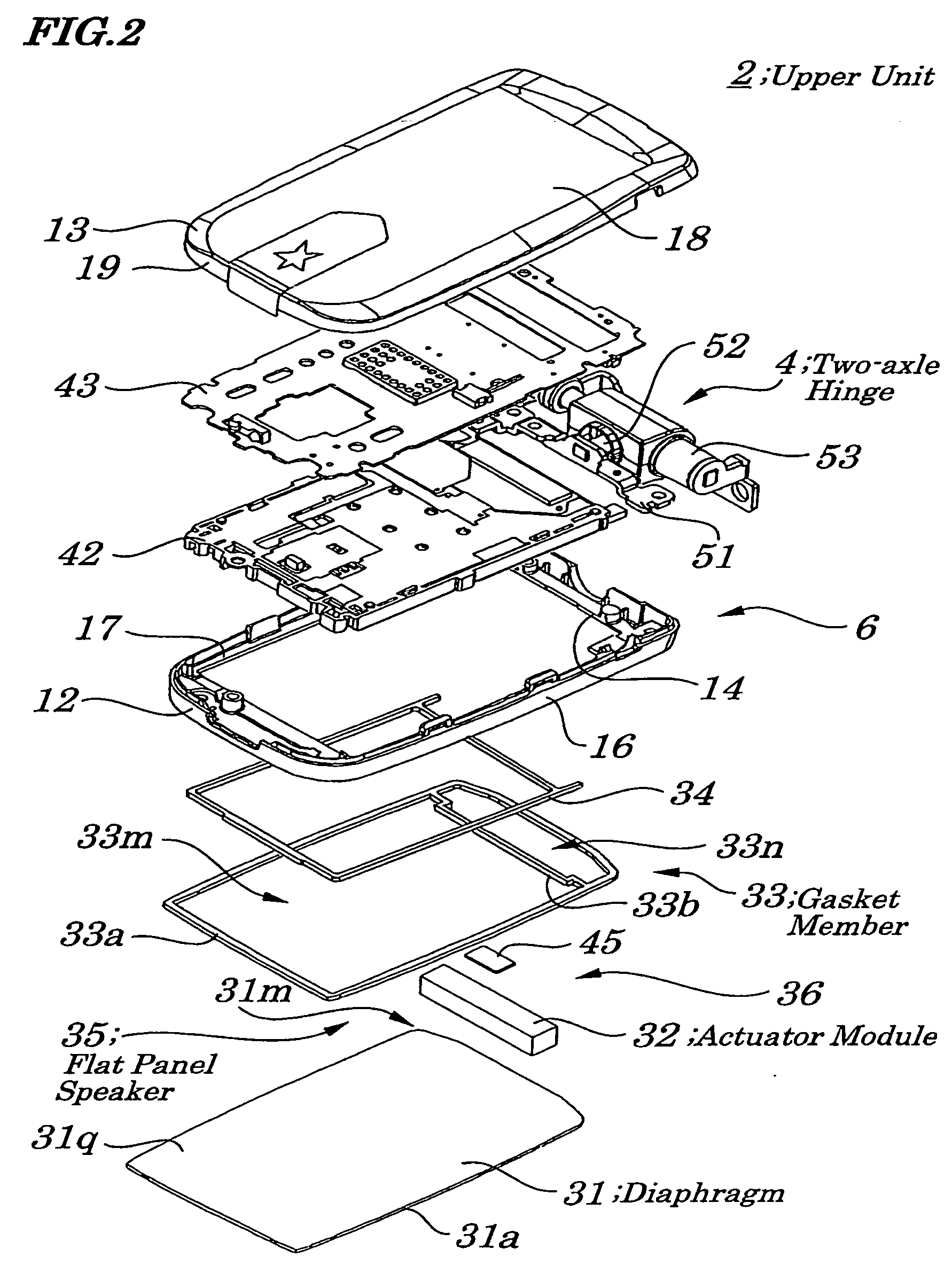

Gasket member, diaphragm, flat panel speaker, method of mounting same flat panel speaker, and method of assembling electronic device

InactiveUS20060140439A1Improve display qualityImprove featuresLoudspeaker transducer fixingPiezoelectric/electrostrictive transducersLiquid-crystal displayEngineering

A method of mounting a flat panel speaker is provided which is capable of reliably preventing entry of dust and of shortening assembling time. By bonding a gasket member to a diaphragm, by pasting a separator to a gasket member side opposite to the diaphragm and, by sandwiching the diaphragm and the gasket member from both sides, a gasket-attached diaphragm is fabricated. After peeling off a protecting sheet on a rear side of the gasket-attached diaphragm, the actuator module is bonded to the diaphragm. Then, after peeling the separator from the gasket-attached diaphragm, positioning is performed on the diaphragm and the gasket member is bonded to a putting-face of the front case. The entry of dust into a region corresponding to a liquid crystal display panel is blocked by a partitioning portion of the gasket member.

Owner:LENOVO INNOVATIONS LTD HONG KONG

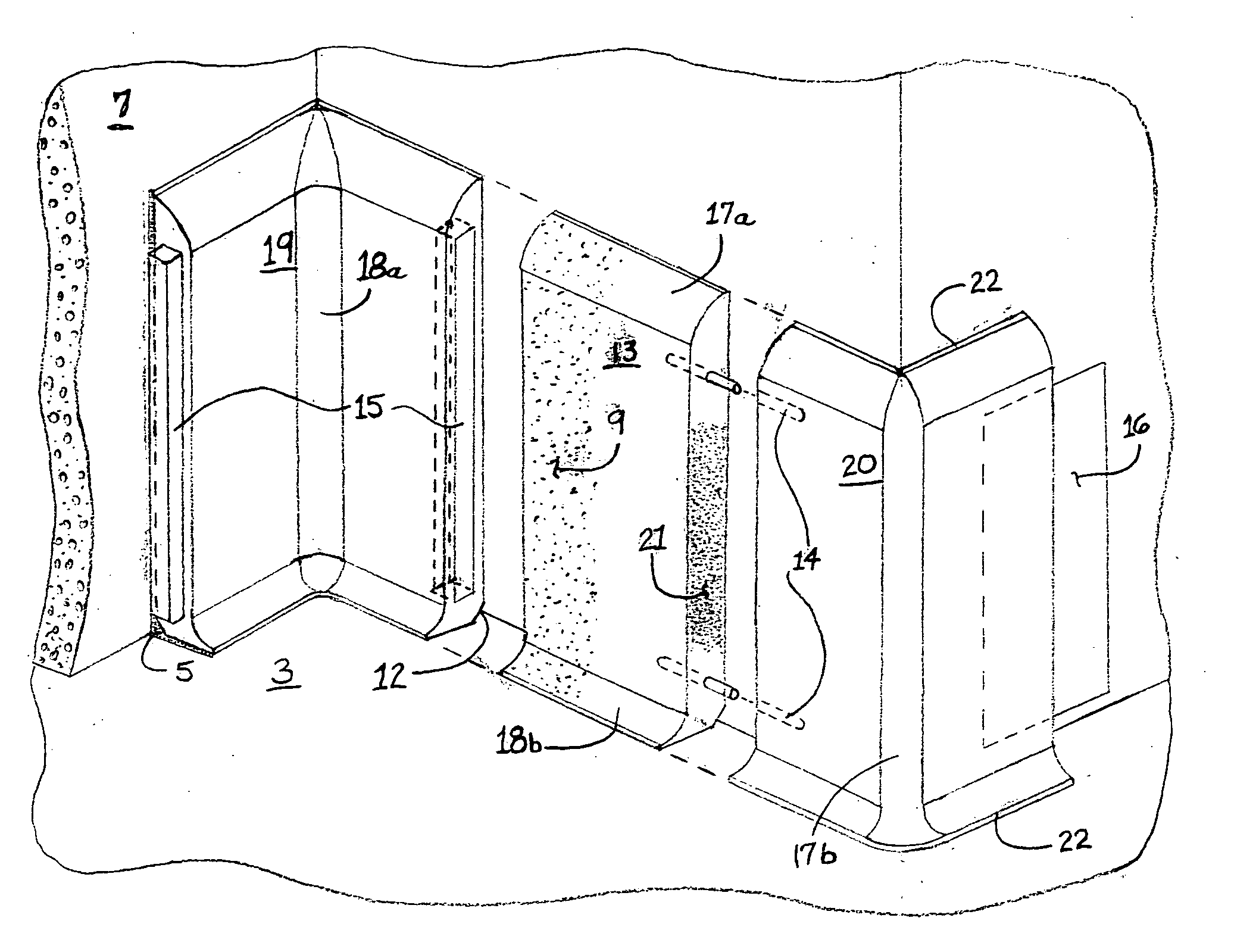

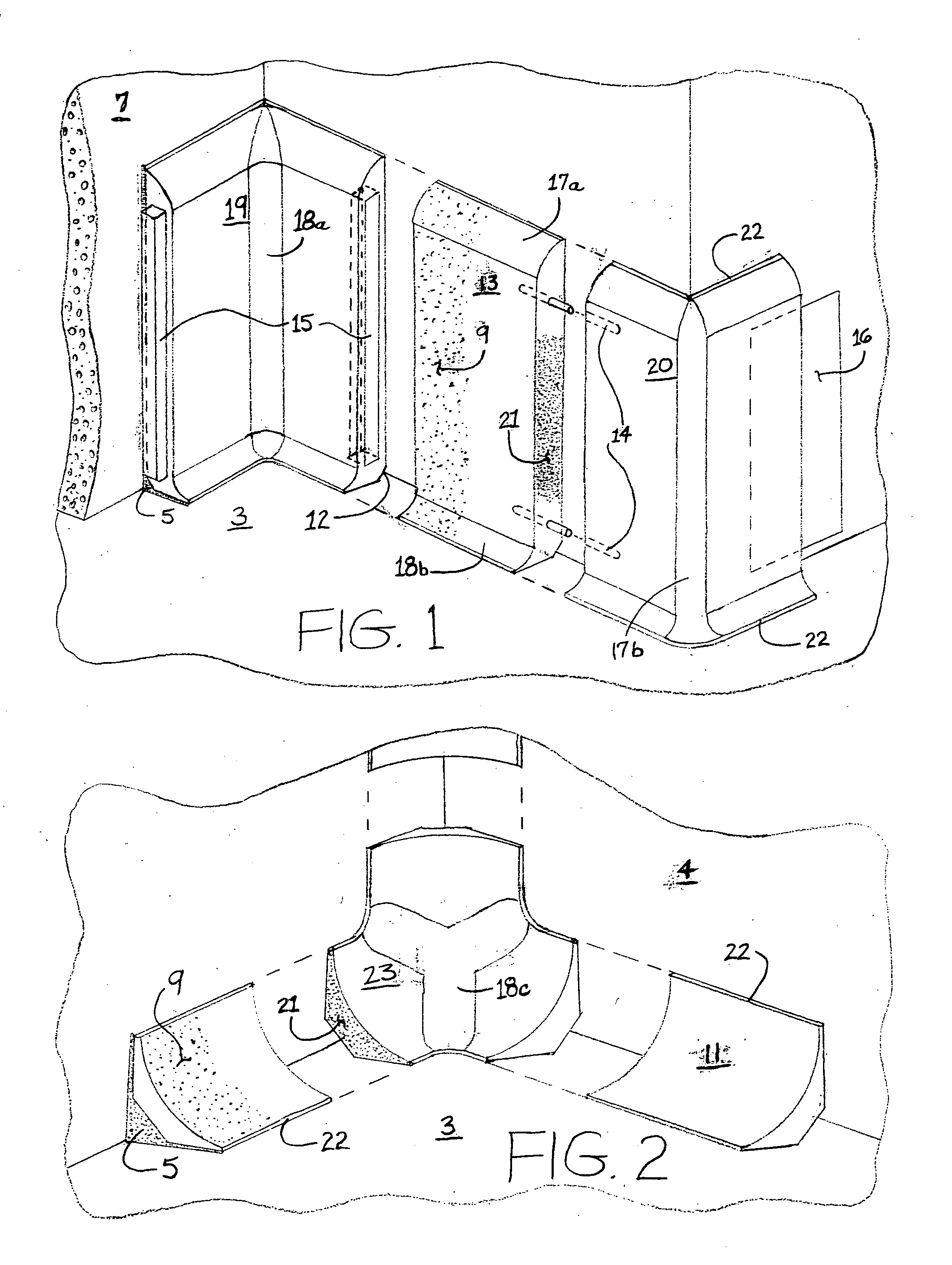

Cove elements and floor coatings and methods for installing

InactiveUS20050011159A1Less-expensive to installSuitable for mass productionWallsMouldsEngineeringShape formation

Described herein is a monolithic flooring system that includes cove elements that are shaped to provide a transition between floor and wall such that a floor coating may be installed over the cove elements and sub-flooring to create a unitary floor-cove covering making for a surface that is more sanitary and easier to clean. Also described are various shaped cove elements that enable creation of a good transition between wall and floor. The cove elements are preferably made of material similar to the sub-floor, for instance a cementitious material. The floor coating is preferably a resinous material.

Owner:STANDAL DOUGLAS J +1

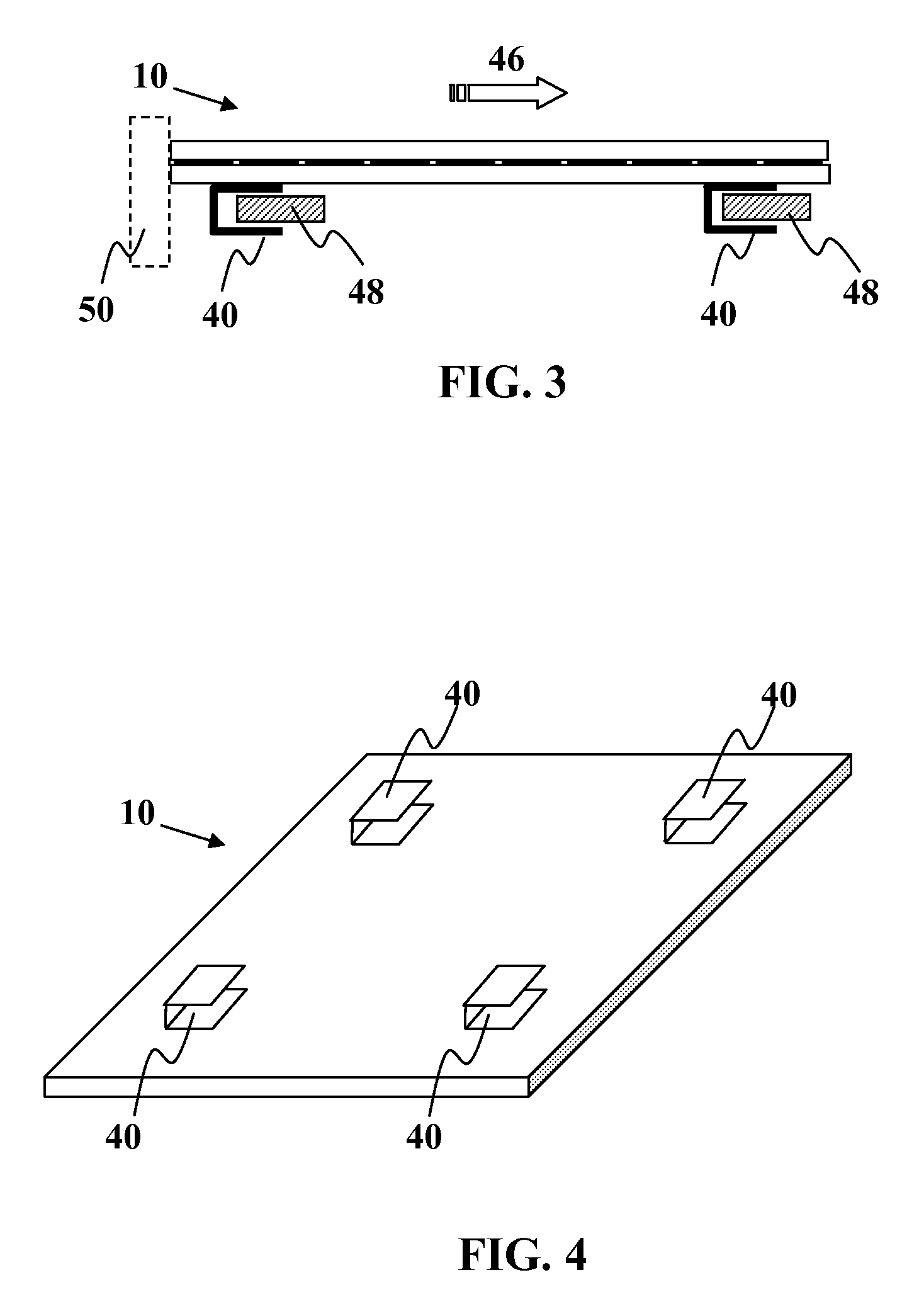

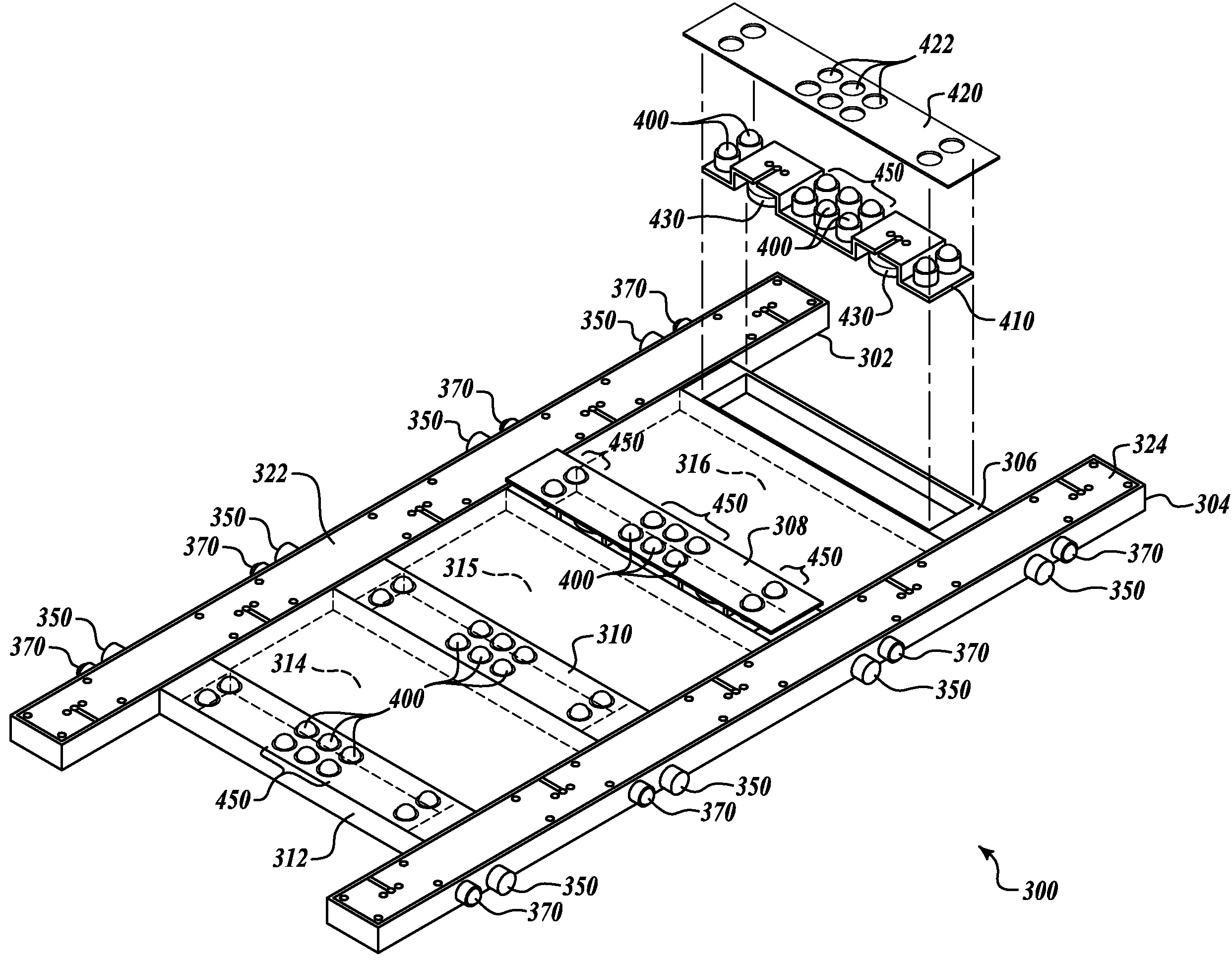

PV Module Mounting and Support Assembly and Installation

InactiveUS20070295391A1Reduce loadIncrease energy outputPhotovoltaic supportsSolar heating energyReady to useSupport surface

In some examples a PV module mounting and support assembly includes a base mountable to the deck, a deck-penetrating fastener for securing the base to the deck, and PV module mounting hardware. The PV module mounting hardware is used to secure an edge of a PV module on a PV module-support surface of the base with the edge of the PV module spaced apart from the deck. Flashing may be used between the lower surface and the deck. In some examples an internal PV mounting and support assembly is used to engage an internal lip of the PV module frame.

Owner:SUNPOWER CORPORATION

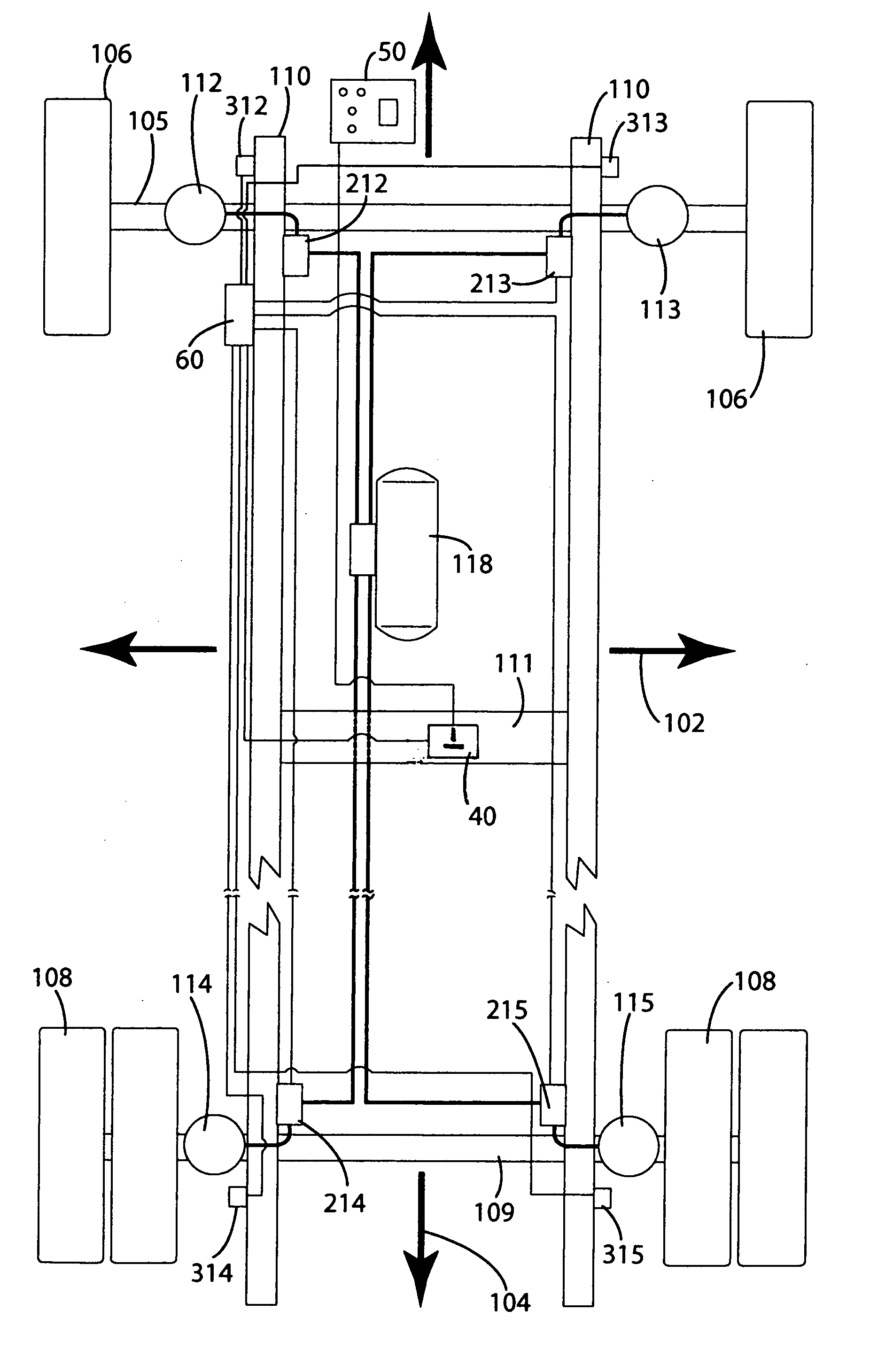

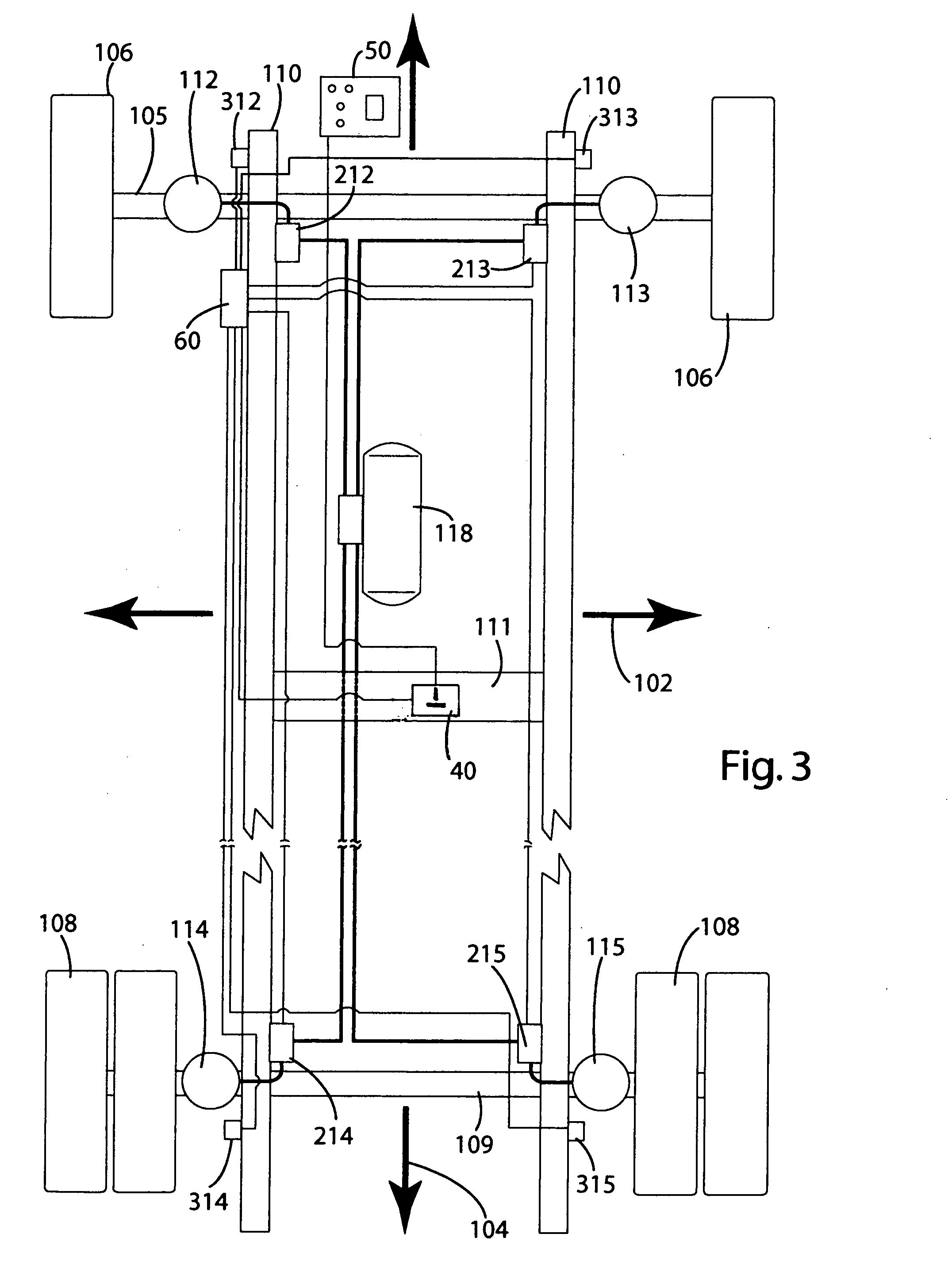

Rental/Car-Share Vehicle Access and Management System and Method

ActiveUS20170316621A1Reduce the time required for installationImprove reliabilityTicket-issuing apparatusRegistering/indicating working of vehiclesTransceiverCar sharing

An apparatus and operational method are disclosed that use control hardware resident in a vehicle to enable a remote computing system to wirelessly communicate with the vehicle. The control hardware includes a processor configured to interface with a wireless network and the vehicle through, respectively, a wireless network interface and a vehicle interface. A plurality of CAN (control area network) bus transceivers may exist within the vehicle interface operable to allow the processor to interface with multiple vehicle types. The processor may then be configured to automatically detect an identifier for the vehicle though the vehicle interface and automatically select a CAN bus transceiver from the plurality of CAN bus transceivers based on the detected identifier. The processor can then communicate with the vehicle's CAN bus via the selected CAN bus transceiver.

Owner:ENTERPRISE HOLDINGS

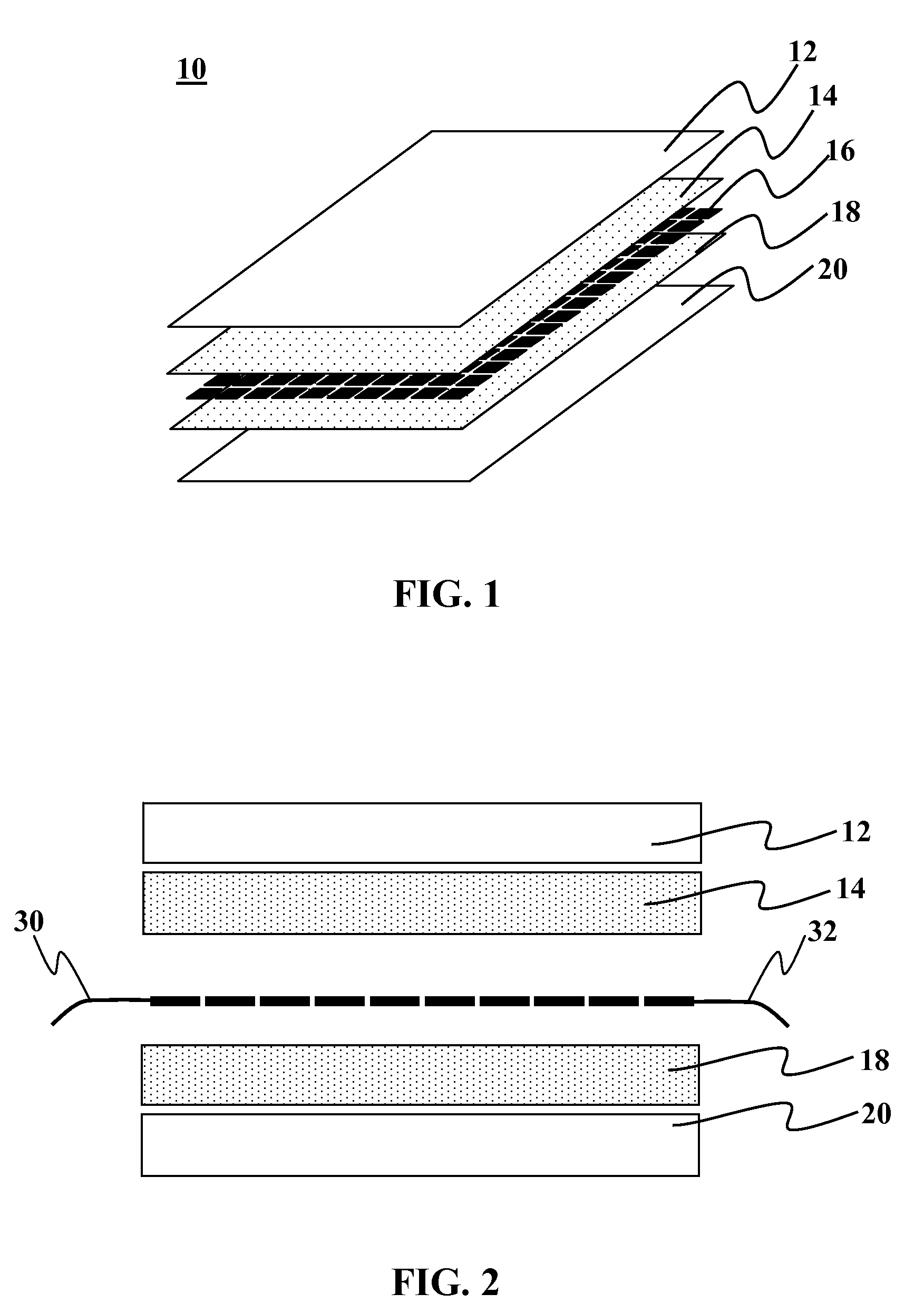

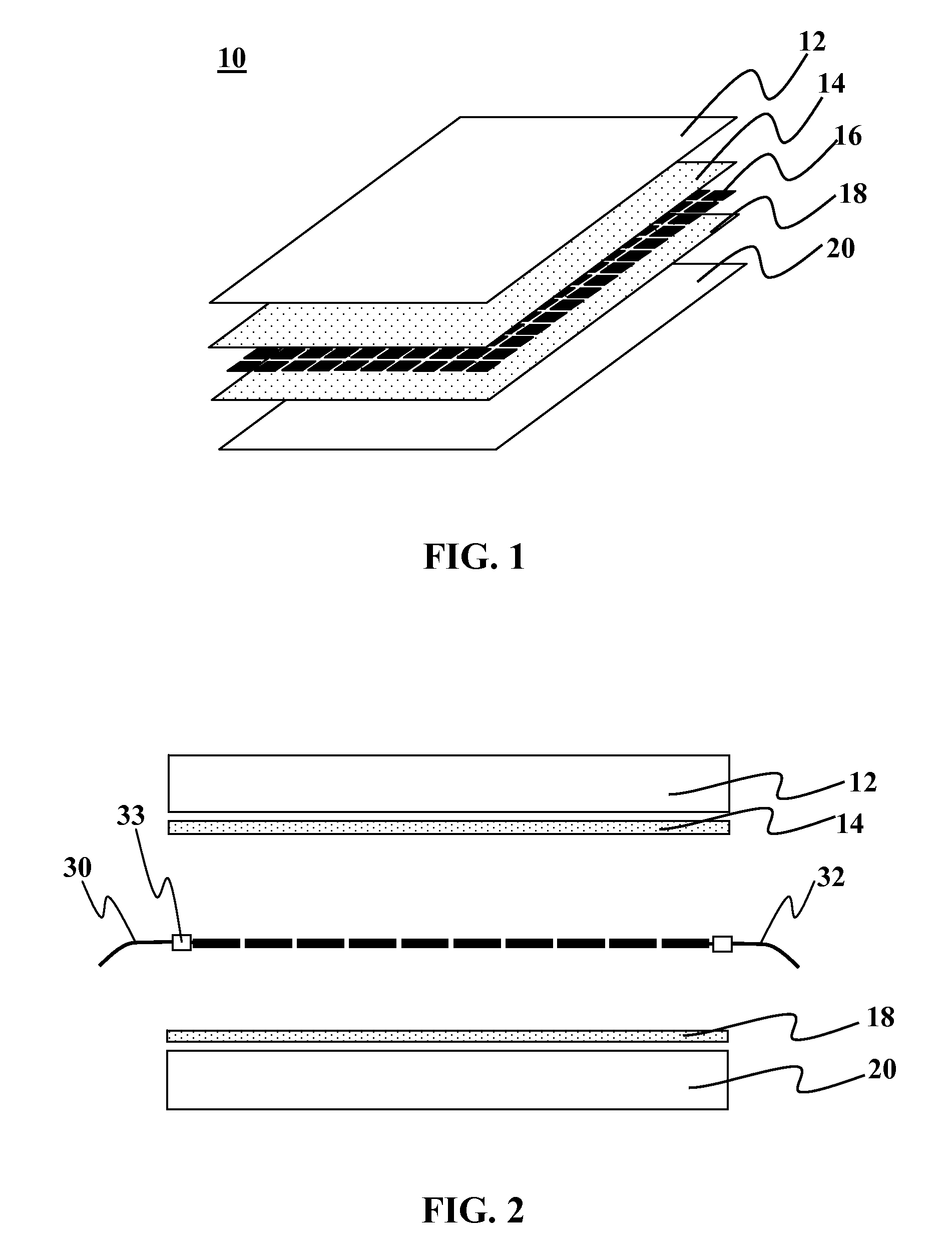

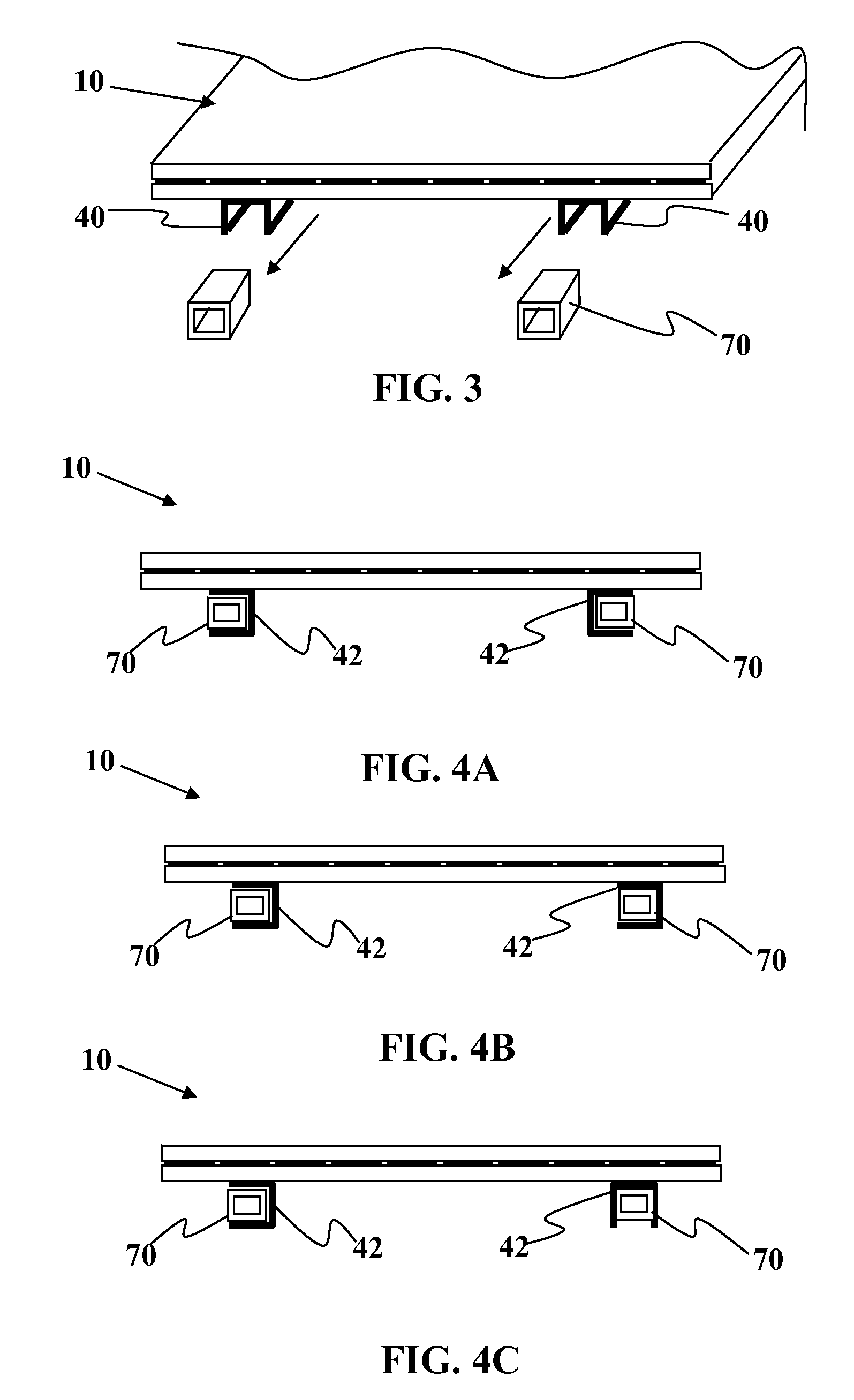

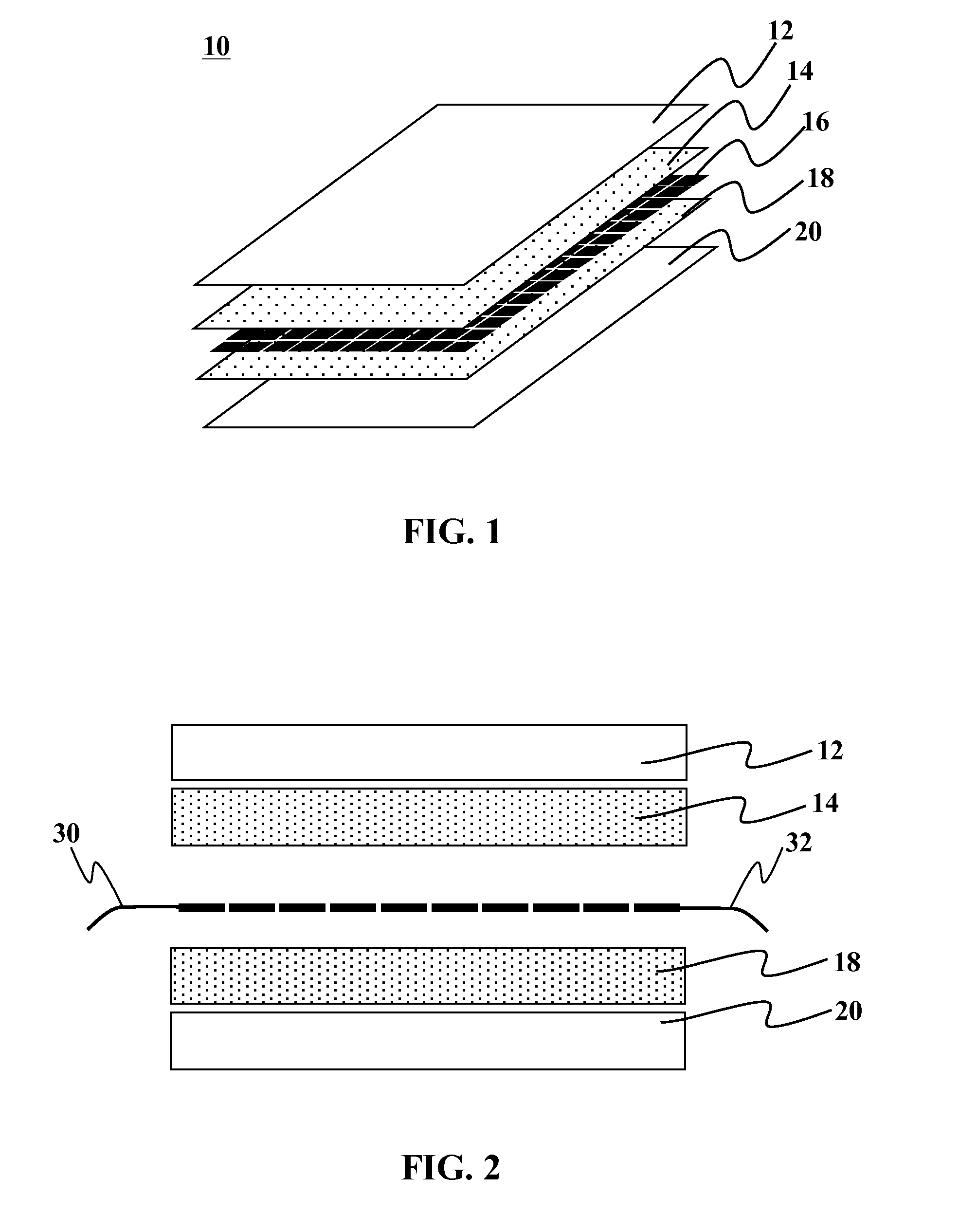

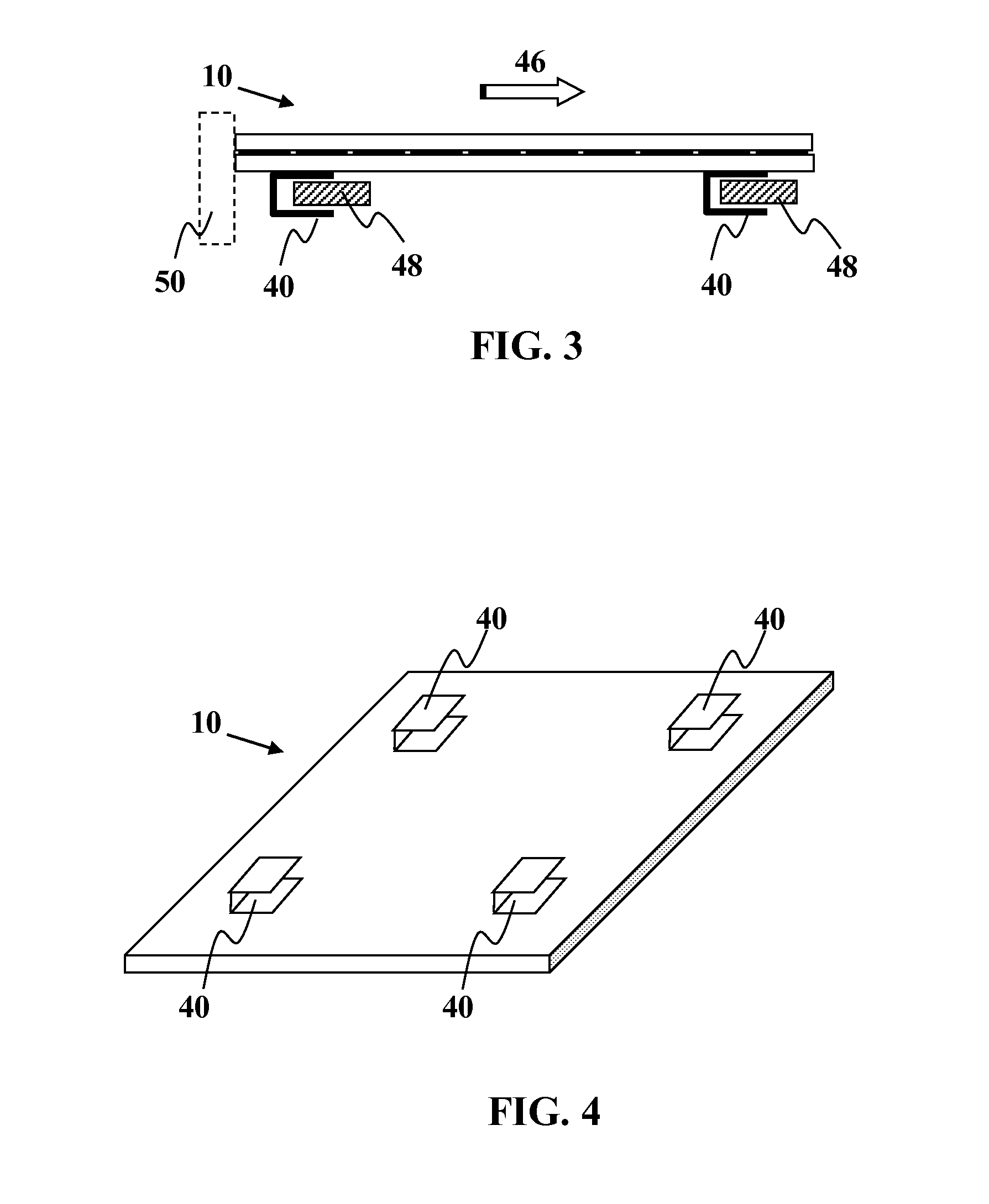

Rapid Mounting System for Solar Modules

InactiveUS20090114270A1Reduce manufacturing costReduce redundant partsPhotovoltaic supportsSolar heating energyEngineeringSolar module

Methods and devices are provided for rapid solar module installation. In one embodiment, a photovoltaic module is provided comprising of a plurality of photovoltaic cells positioned between a transparent module layer and a backside module layer. The module may be a frameless module. The module may have brackets that slidably engage a mounting structure.

Owner:STANCEL ROBERT

Vehicle leveling system

ActiveUS20050161891A1Precise positioningReduces and eliminates workDigital data processing detailsAnimal undercarriagesParking areaControl system

A vehicle leveling system including at least one level sensor, a controller and an output. The sensor measures how level the vehicle is relative to horizontal. Optionally, it does so dynamically, as the vehicle moves across a potential parking area. The controller analyzes the sensor measurements, and informs the operator via the output whether the vehicle is level in a given direction, whether the vehicle is leveling, whether the vehicle can be leveled at a given location, and / or the “best” leveling that the system is capable of at a location. The system also may automatically level the vehicle relative to the ground for the operator. In one embodiment, the leveling system communicates with an existing vehicle electronic height control system. The leveling system overrides or controls the normal operation of this system, and uses it to level the vehicle, for example, by adjusting the vehicle suspension.

Owner:LINK MFG

Photovoltaic mounting system with locking connectors, adjustable rail height and hinge lock

InactiveUS8176693B2Turn easilyQuick and securePhotovoltaic supportsSolar heating energyElectricityPhotovoltaic mounting system

Owner:POWERMOUNT SYST +1

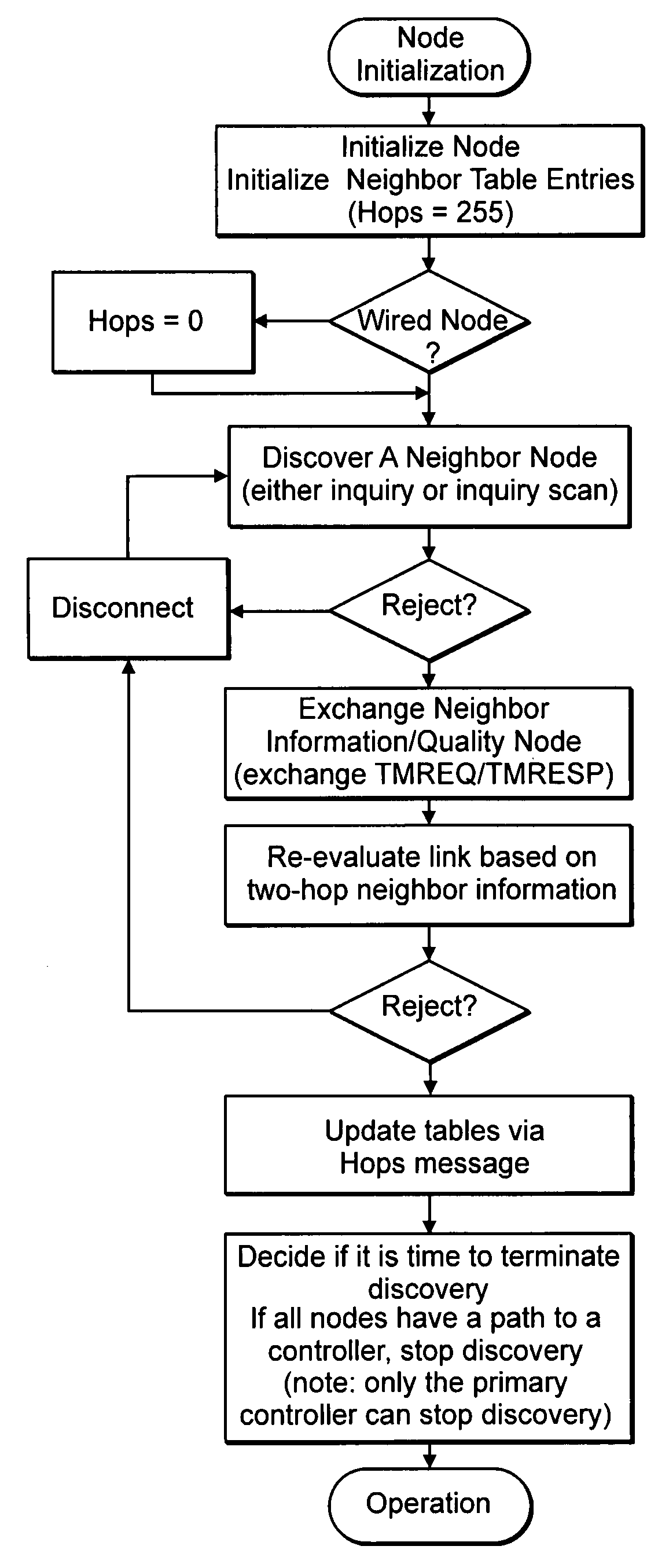

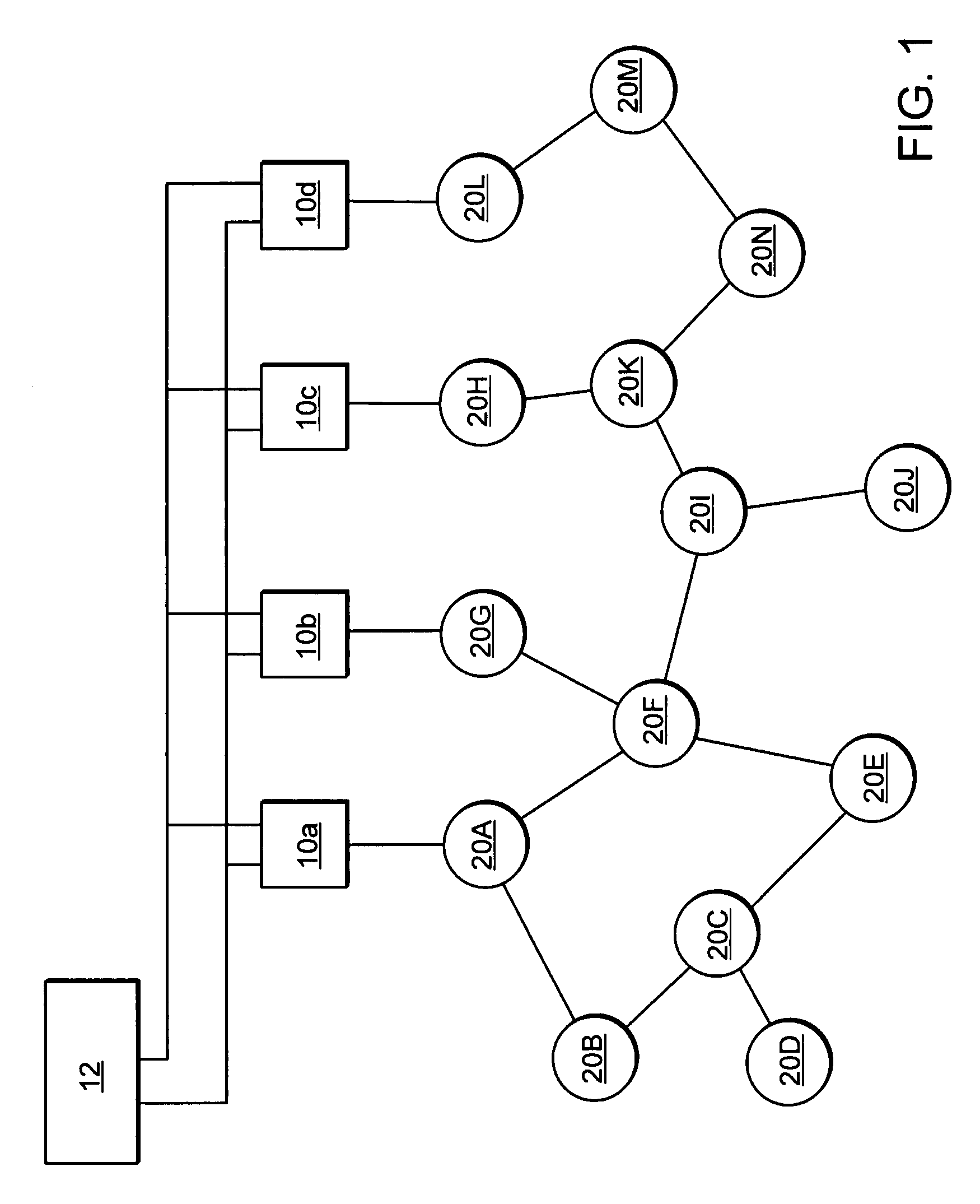

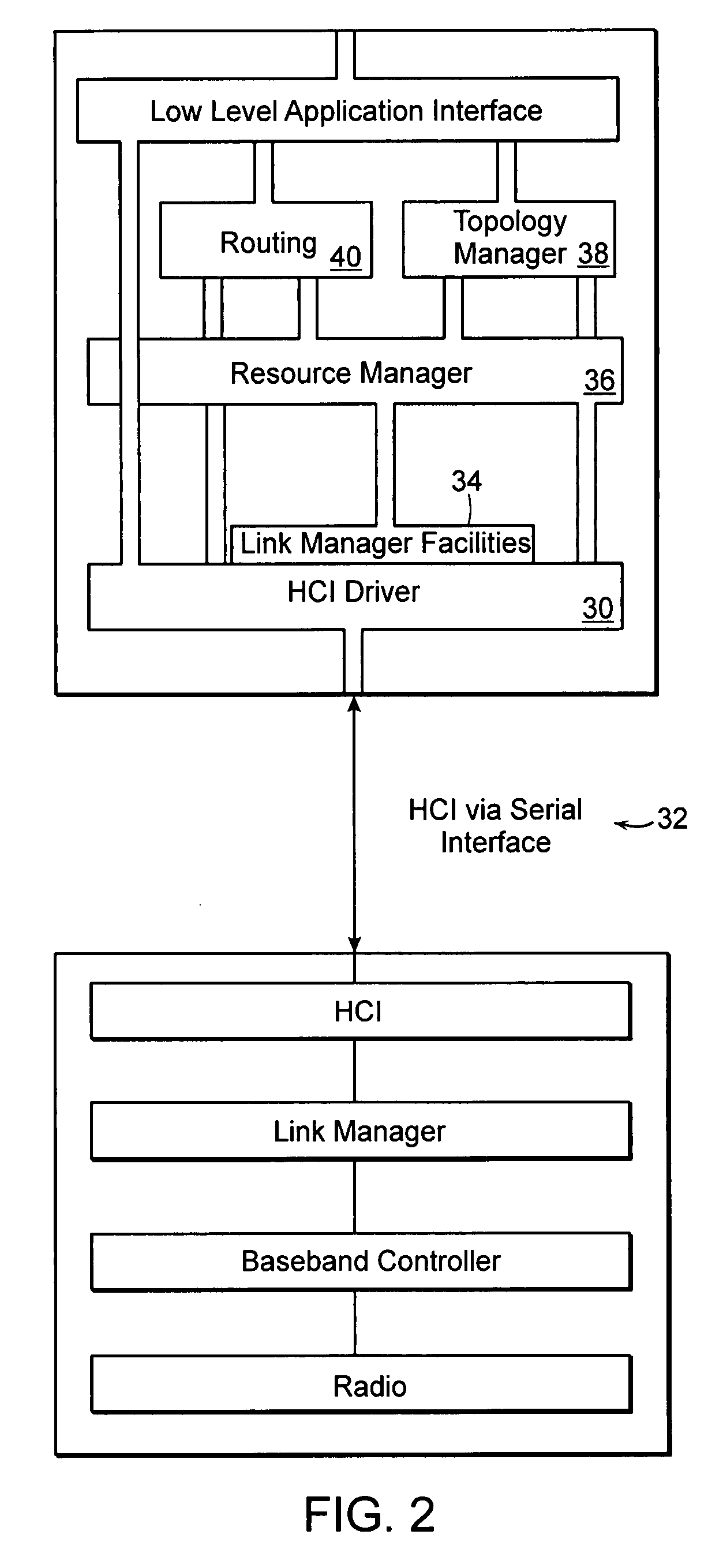

Wireless data bus

InactiveUS20080013502A1Reduce the time required for installationEliminate hazardsTransmission systemsNetwork topologiesTelecommunications linkTransceiver

A wireless device for use with a plurality of wireless nodes that includes a controller node, the wireless device including a wireless transceiver for wirelessly communicating with the plurality of wireless nodes; a processor system; and memory storing a neighbor table, the memory also storing code which when executed on the processor causes the wireless device to initiate a discovery process during which the wireless device discovers neighbor nodes with which the wireless device establishes wireless communication links, identifies the discovered neighbor nodes in the neighbor table, and for each identified neighbor in the neighbor table indicates whether the corresponding link has an active status or a parked status, wherein the wireless device uses links having active status to send communications and does not use links having parked status to send communications.

Owner:SECURAPLANE TECH

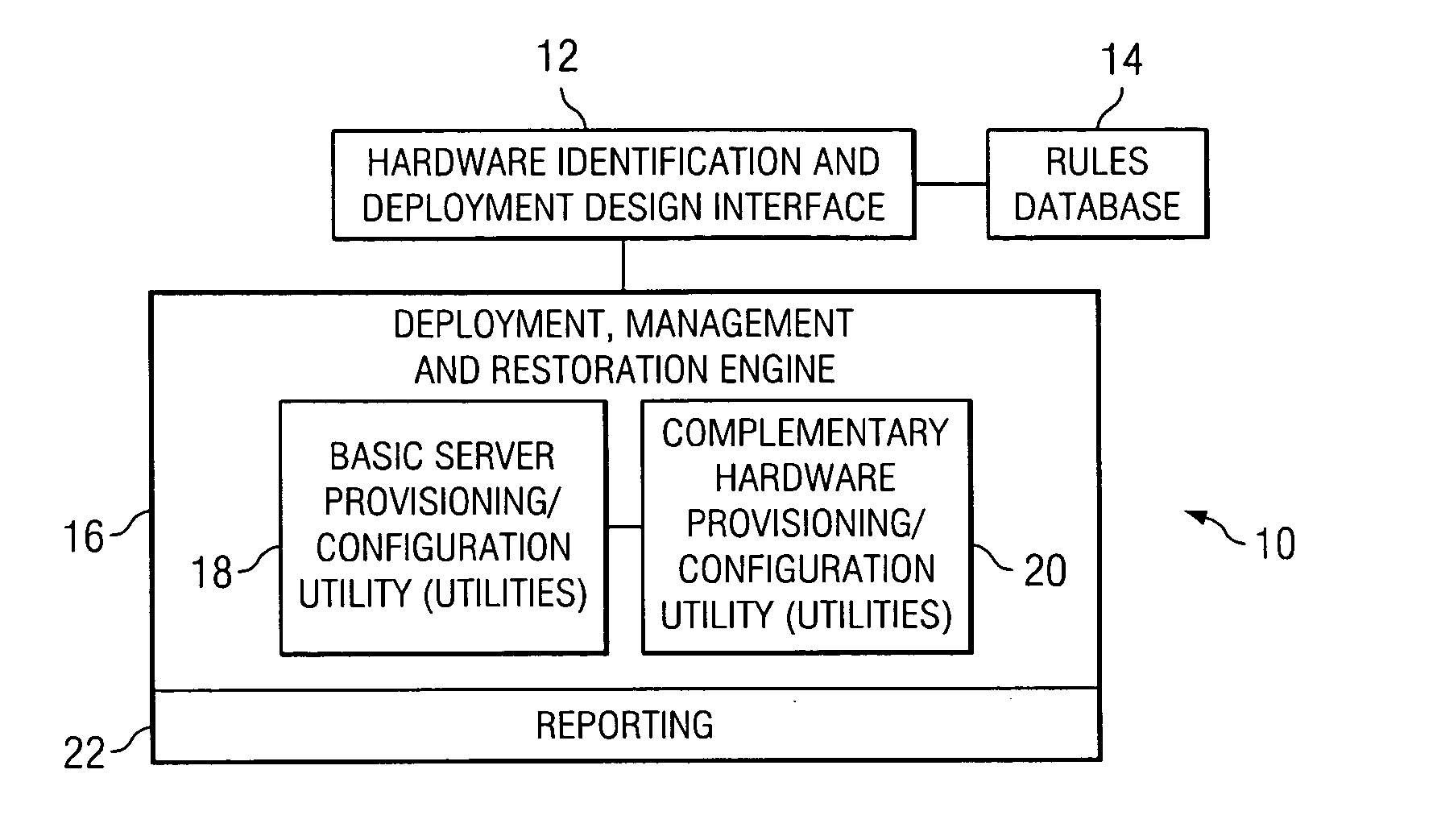

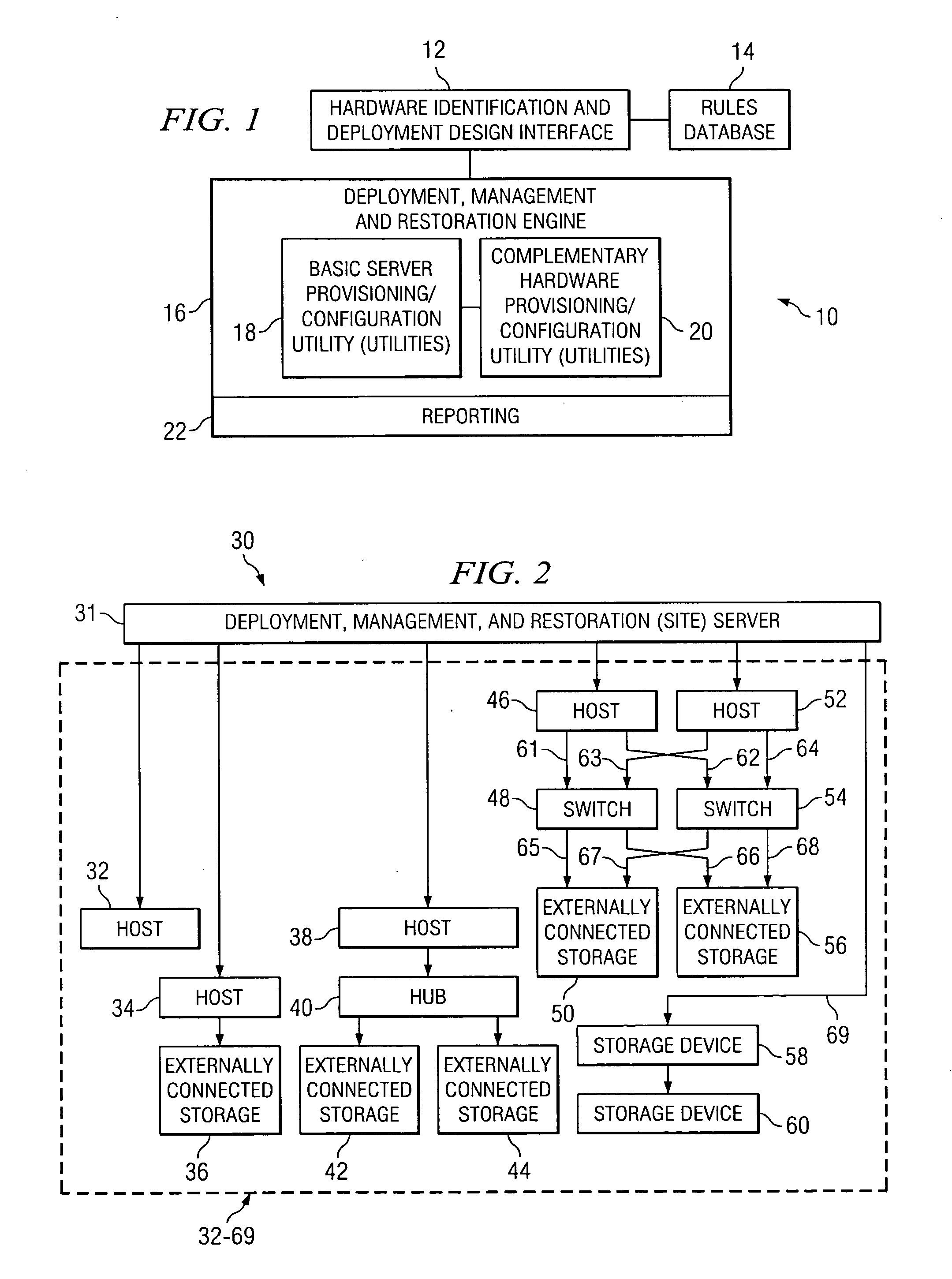

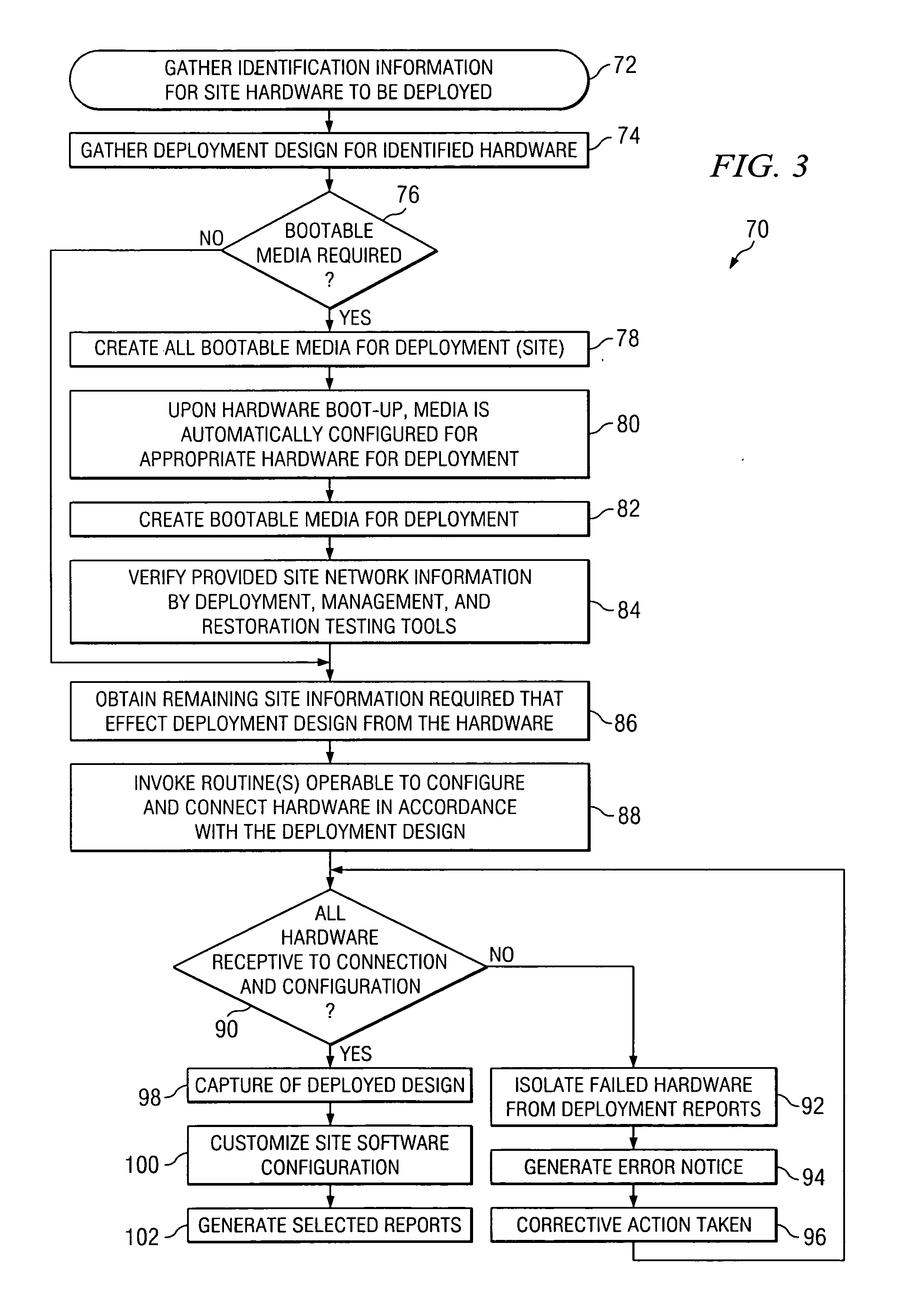

Method, software and system for deploying, managing and restoring complex information handling systems and storage

InactiveUS20050198631A1High deployment accuracyImprove reusabilityProgram loading/initiatingTransmissionSystems approachesOperating system

A system, method and software are provided for the automated deployment of complex server and standalone server, server-to-storage, SAN and / or standalone storage solutions. After collection of information identifying hardware to be included in a site deployment as well as a deployment design for the site, provision is made for the automated gathering of any remaining additional information required for implementation. Once all necessary information has been gathered and obtained, the system method and software of the present disclosure provide for the automated verification of availability and connectivity of deployment hardware. In addition, all necessary settings and configurations between one or more servers, switches and / or storage devices are automatically implemented. During implementation, bootable media may be automatically created as needed. Following implementation, a deployment design capture of the system may be performed and one or more reports concerning the standalone server, server-to-storage, SAN and / or standalone storage solution generated.

Owner:DELL PROD LP

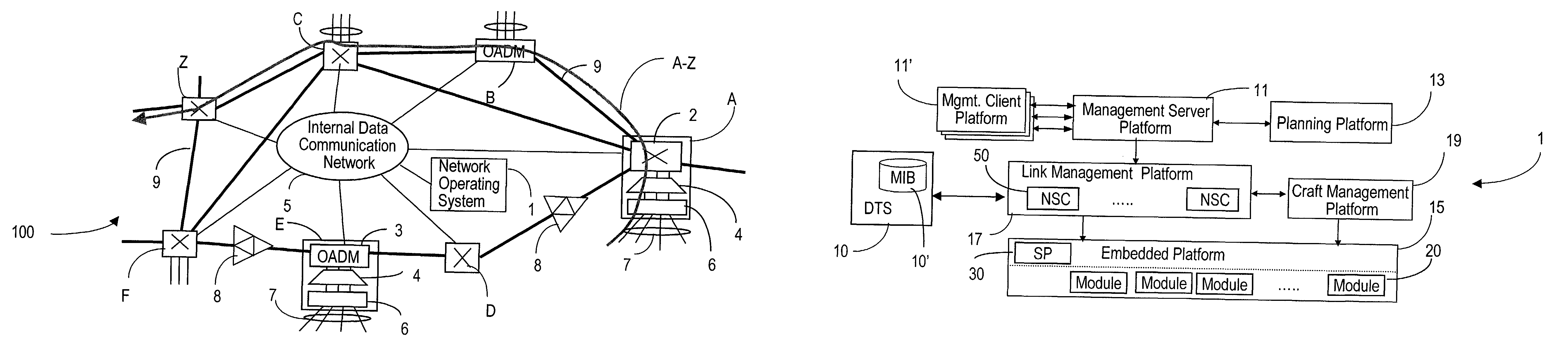

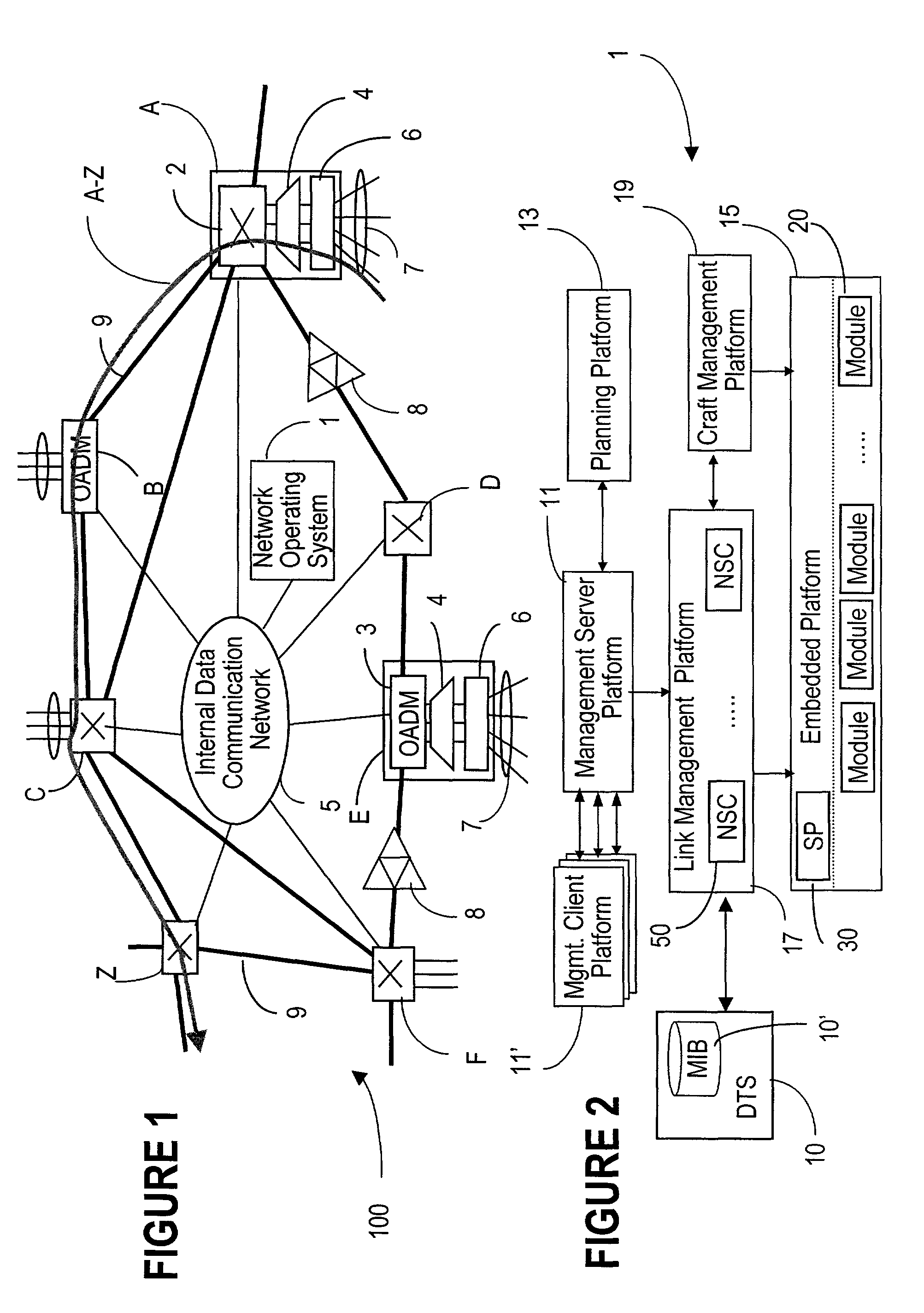

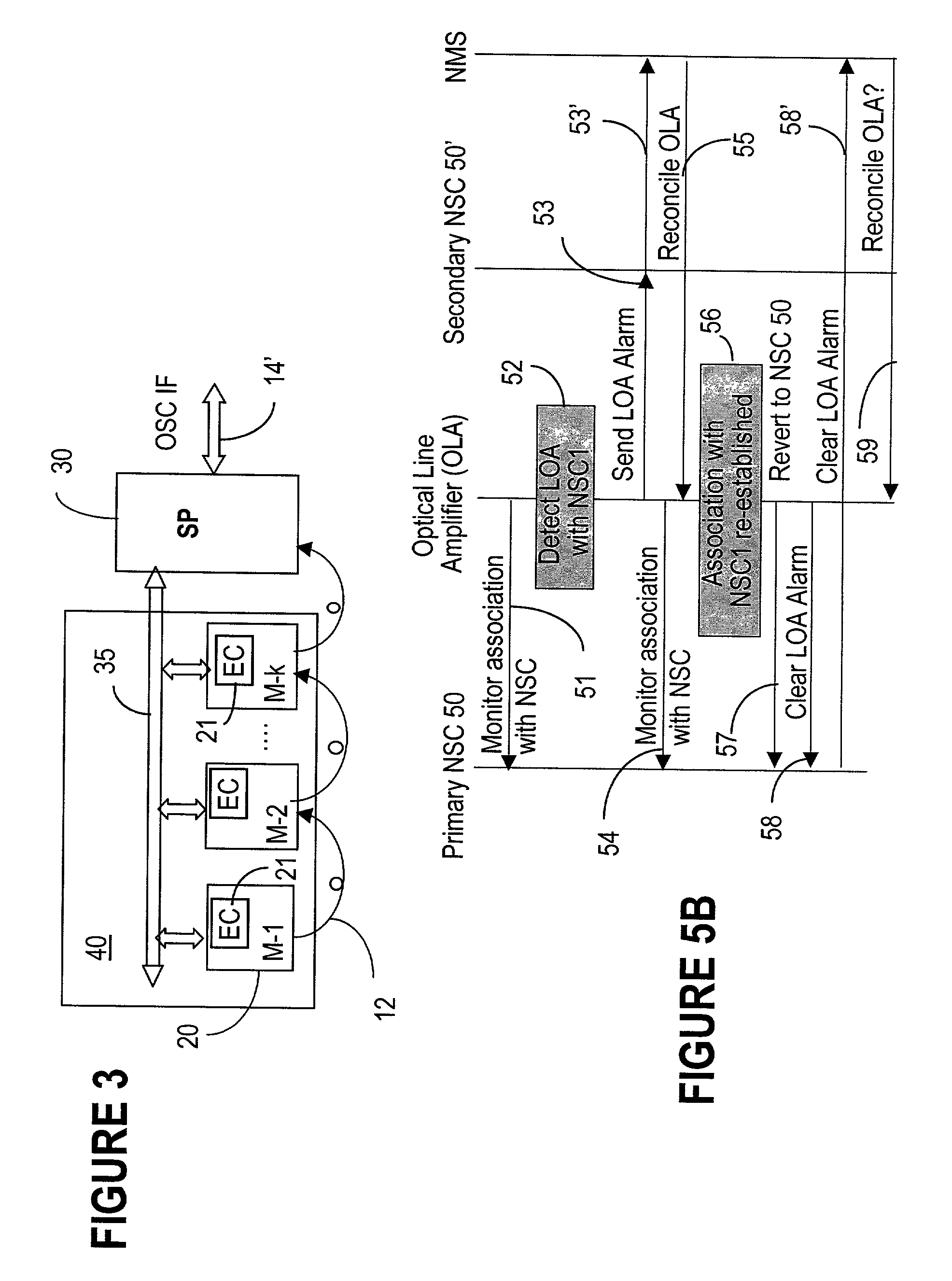

Network operating system with topology autodiscovery

ActiveUS7747165B2Reduce the time required for installationReduce configuration timeMultiplex system selection arrangementsCoupling light guidesNetwork operating systemOperational system

The network operating system includes an embedded platform for controlling operation of an agile optical network at the physical layer level. At the module embedded level, each module (card-pack) is provided with an embedded controller EC that monitors and control operation of the optical modules. At the next level, each shelf is provided with a shelf processor SP that monitors and control operation of the ECs over a backplane network. All optical modules are connected over an optical trace channel to send / receive trace messages that can then be used to determine network connectivity. At the next, link management level, a network services controller NSC controls the SPs in a negotiated span of control, over a link network. The control is address-based; each NSC receives ranges of addresses for the entities in its control, and distributes these addresses to the SPs, which in turn distribute addresses to the ECs in their control. One of the SPs operates as a router on the link network to relay signaling and control to all entities based on their address. Each NSC constructs, from queried information, a network topology fragment for the embedded elements under its control. A distributed topology system (DTS) shares this topology information with neighboring NSC's to build a complete network view, which can be used by all interested network applications.

Owner:WSOU INVESTMENTS LLC

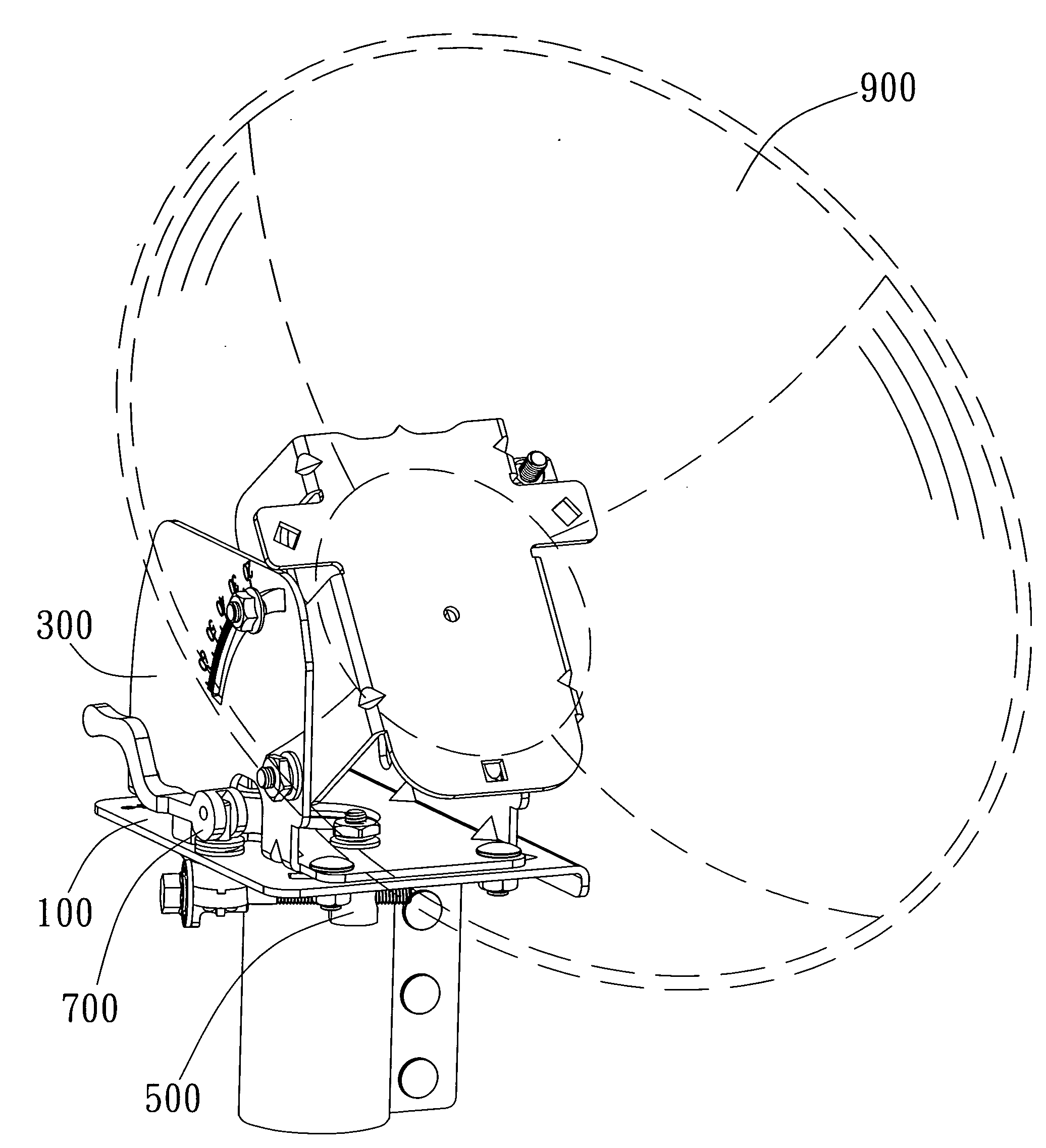

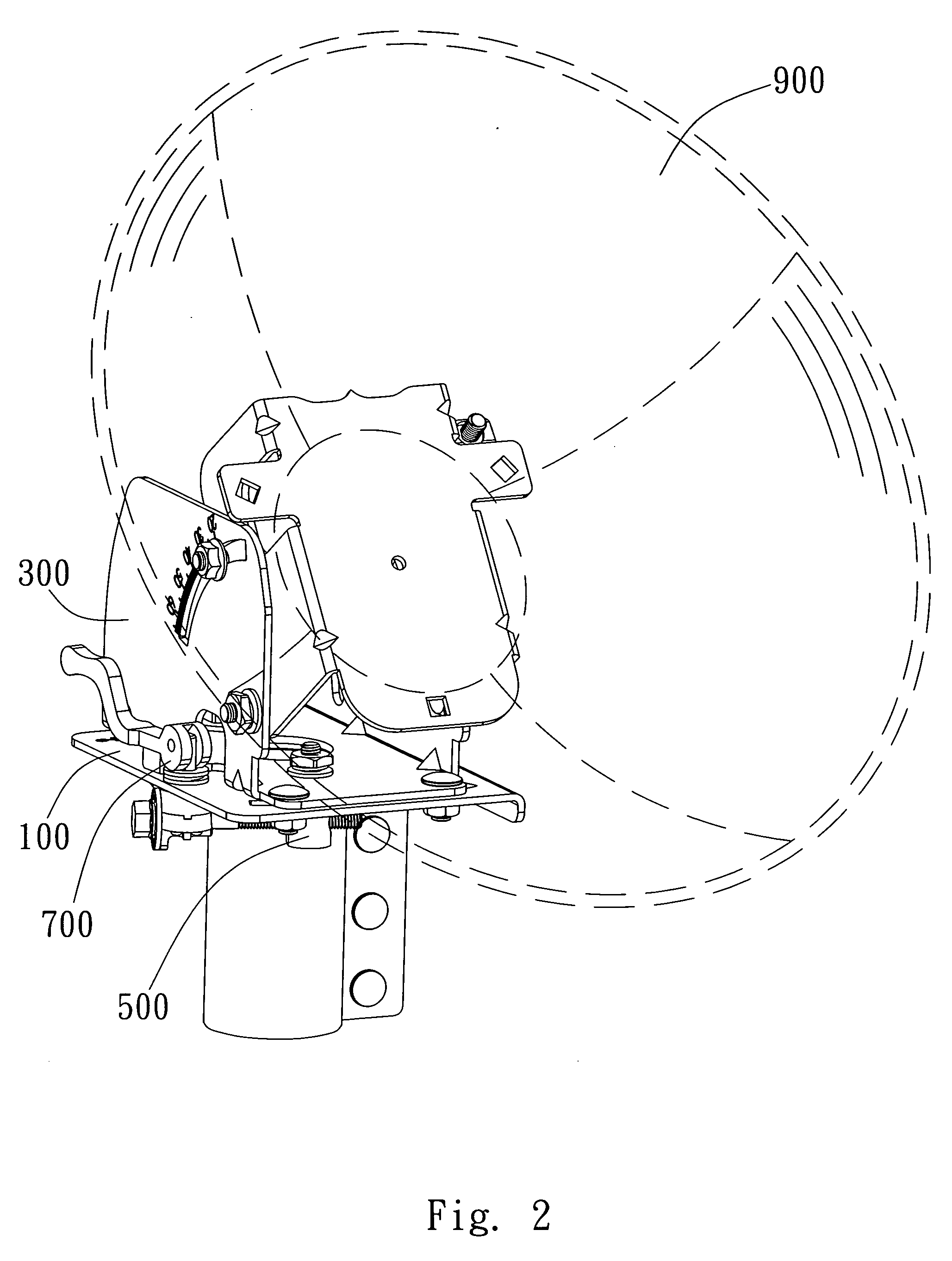

Satellite receiver

ActiveUS20090061761A1Control displacementEasy to adjustPipe supportsAntenna supports/mountingsRelative displacementEngineering

The present invention provides a satellite receiver comprising a base, a rotation stand, an adjusting mechanism, and a positioning device. The base has an axis aperture and a first slot. The rotation stand is rotatably attached to the base through the axis aperture. The adjusting mechanism has a connection end and an adjusting end. The connection end is coupled with the rotation stand and is movable together with the upper stand to generate displacement relative to the base. The positioning device is coupled with the adjusting end and passes through the first slot. When the upper stand rotates relatively to the base, the adjusting mechanism drives the positioning device to move along the first slot. The first slot limits the angular rotation of the rotation stand and the positioning device and selectively constrains the relative displacement between the connecting unit and the base.

Owner:WISTRON NEWEB

Method and apparatus for lining a conduit

InactiveUS20020033554A1Facilitates inspection and installation and servicingReduce or eliminate "slLaminationTyresFiberSlurry

Method and apparatus for installing a liner material into a host conduit such as, e.g., a sewer pipe, hydrocarbon pipeline, gas line, water line, industrial chemical pipe, or a saltwater line. The liner material may include a compression liner and / or a preliner that is attached to the inner wall of the host conduit to repair or reinforce the host conduit or separate the host conduit from materials transported within the new liner formed from the liner material. Curable resin, slurry, or cement can be placed between the liner material and the host conduit to affix the liner material into place. Before and during curing, a fluid such as air or water can be used to inflate the compression liner outwardly toward the host conduit. Spacers positioned between at least a portion of the liner material and the host conduit may be used to (i) calibrate the thickness of the liner material and curable material that is cured to form the new liner, and (ii) form communication channels adapted to house devices such as wire, cable, fiber optic cable, telephone lines, power lines, etc. The spacers and channels can be selectively inflatable to various sizes to allow calibration of the liner thickness and to form communication channels having a selected width or height. Additionally, the liner material may be formed into a one-piece, tubular lining member having an inflatable enclosure defined between an inner and an outer layer of the lining member. The enclosure can be selectively inflated to (i) calibrate the resulting thickness of the cured liner material, and (ii) form communication channels running along the length of the host conduit.

Owner:HEAGY RICHARD T +3

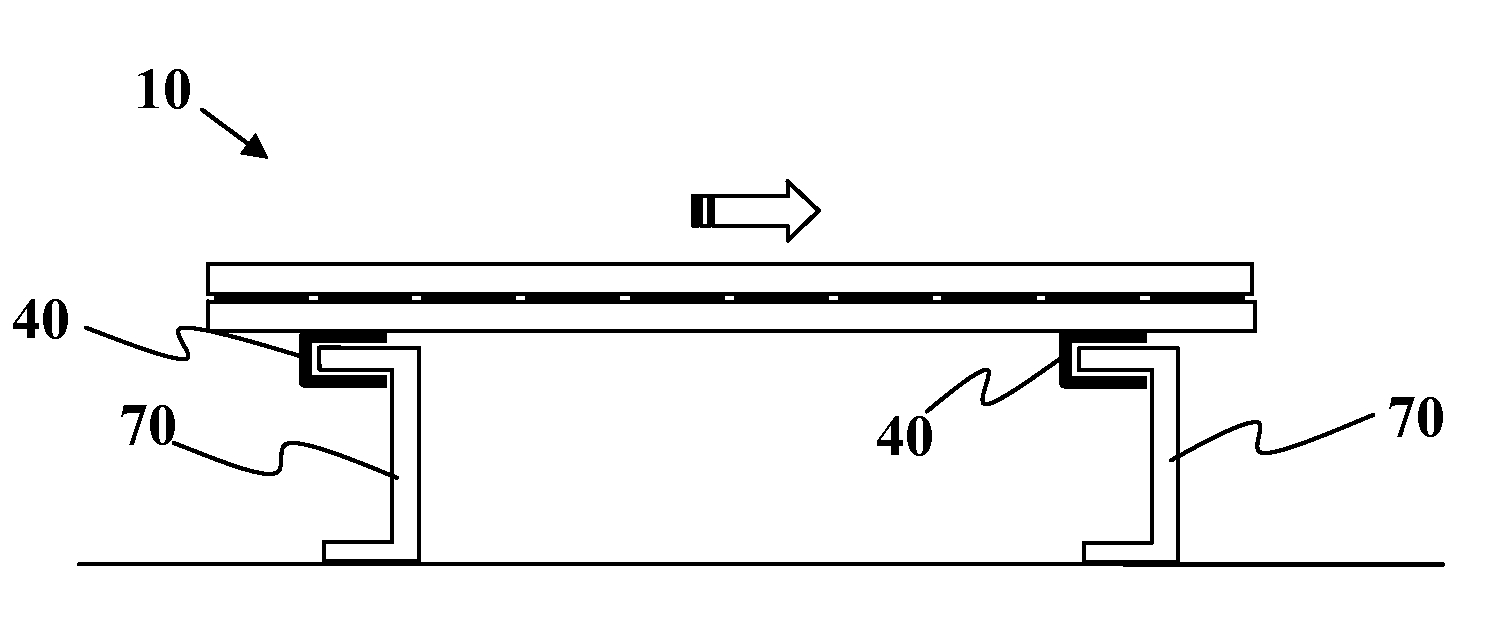

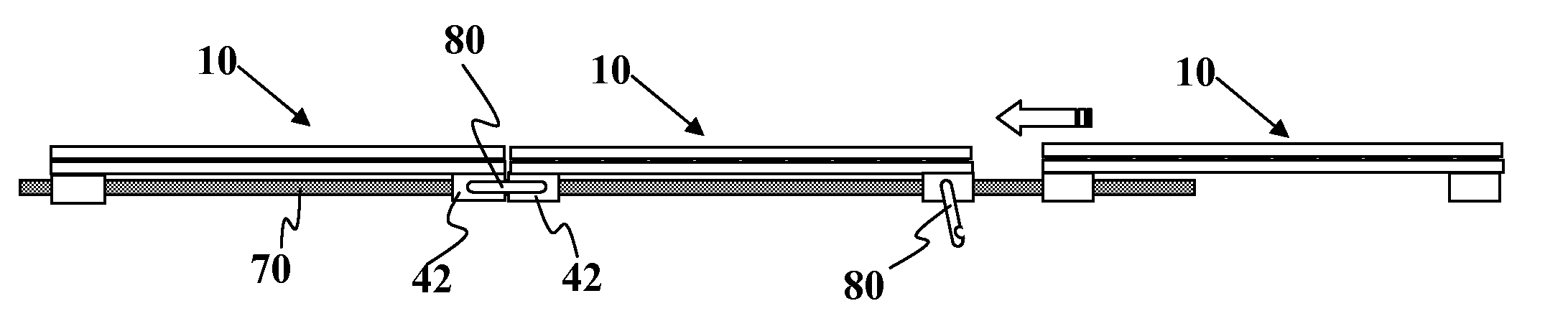

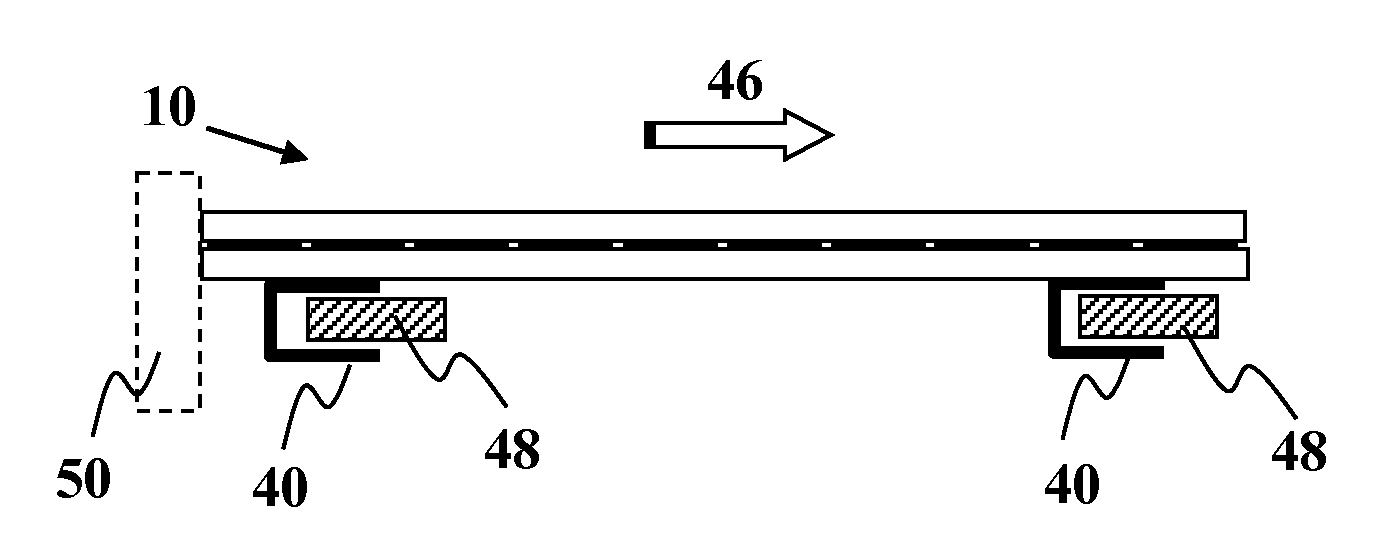

Slidable Mounting System for Solar Modules

InactiveUS20090114271A1Reduce the time required for installationPhotovoltaic supportsSolar heating energySolar modulePhotovoltaics

Methods and devices are provided for rapid solar module installation. In one embodiment, a photovoltaic module is provided comprising of a plurality of photovoltaic cells a plurality of photovoltaic modules; at least a first type of mounting bracket in contact with the module; at least a second type of mounting bracket, wherein the brackets are configured to interlock and connect multiple modules together.

Owner:AERIS CAPITAL SUSTAINABLE IP

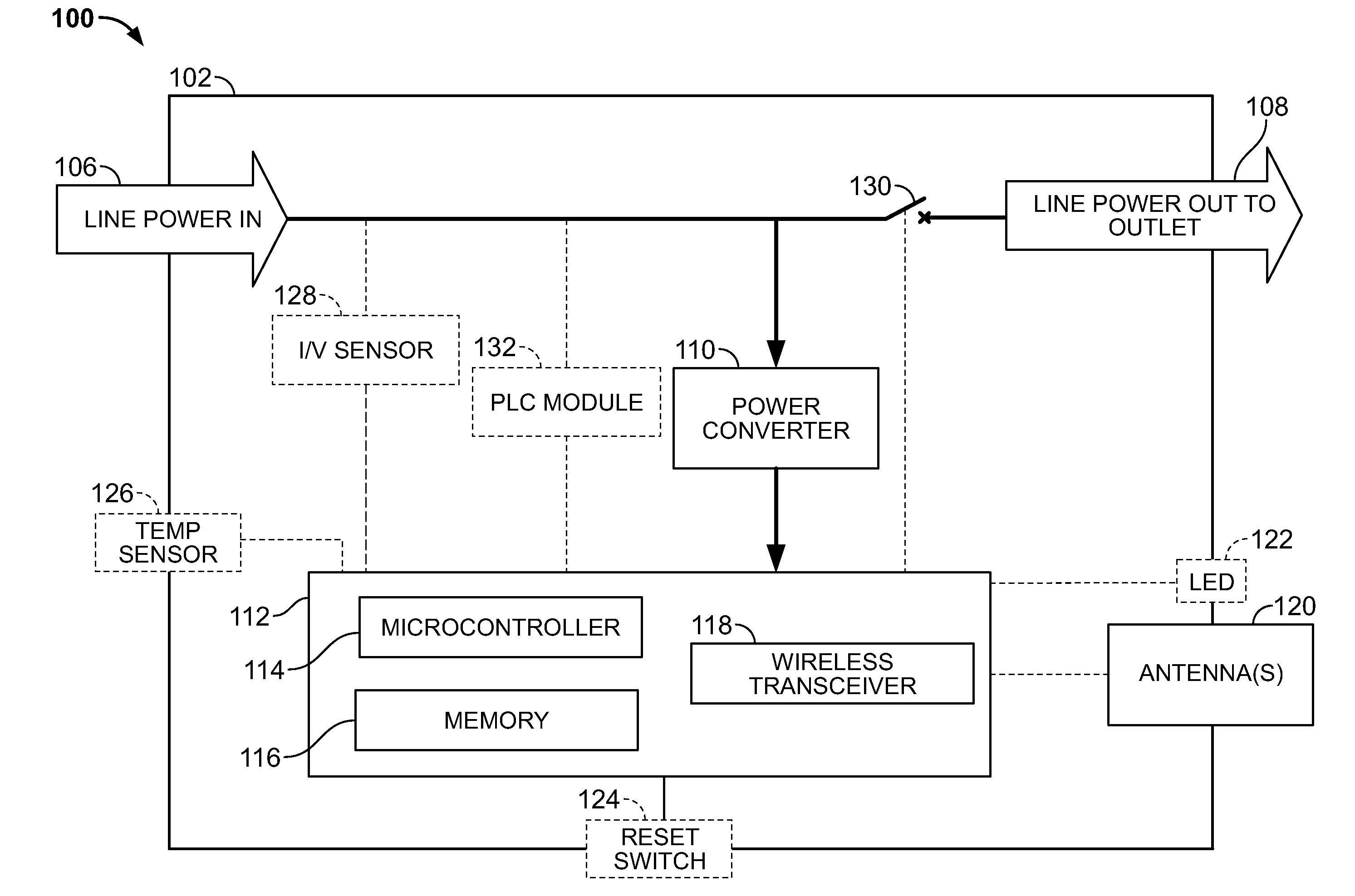

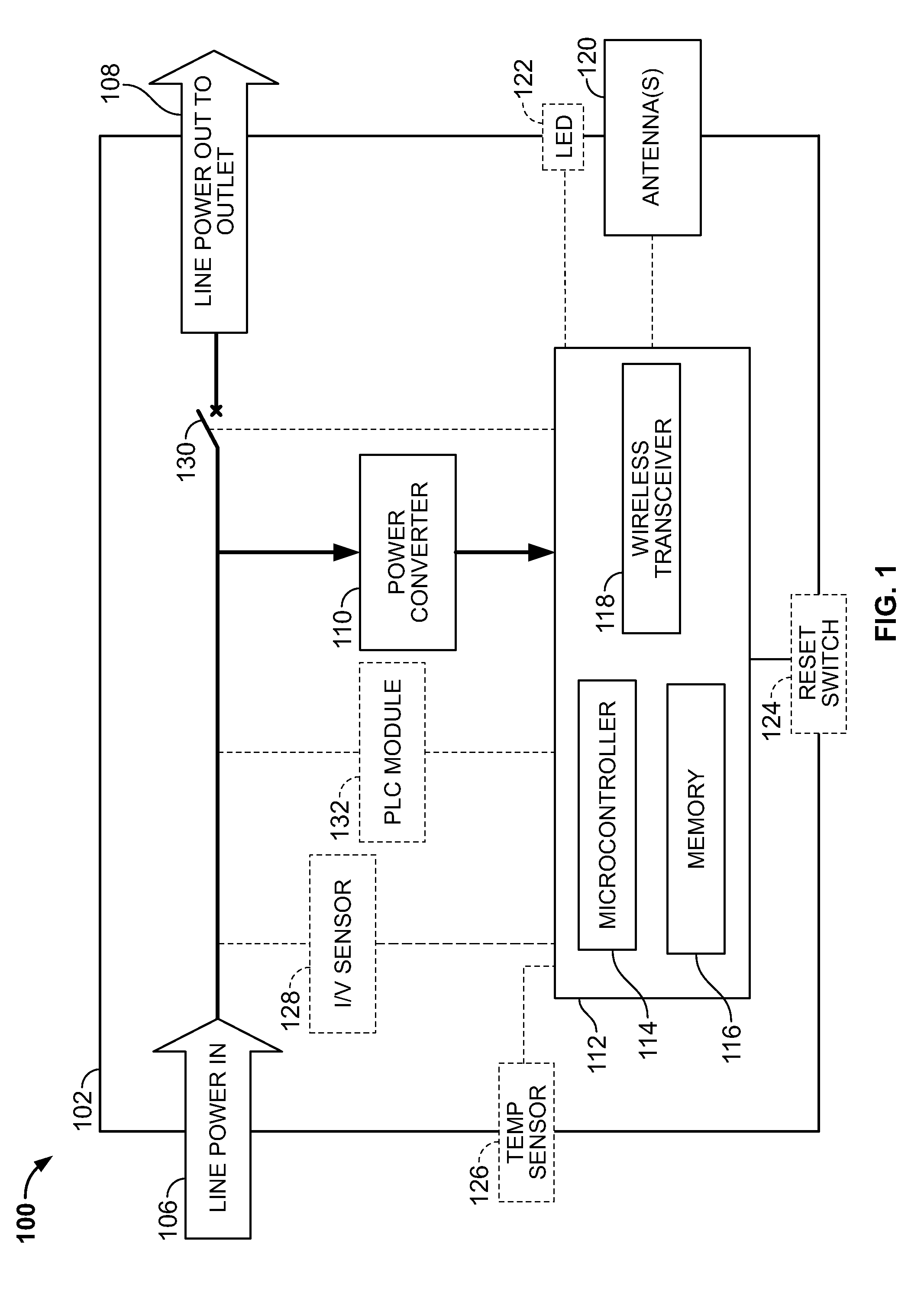

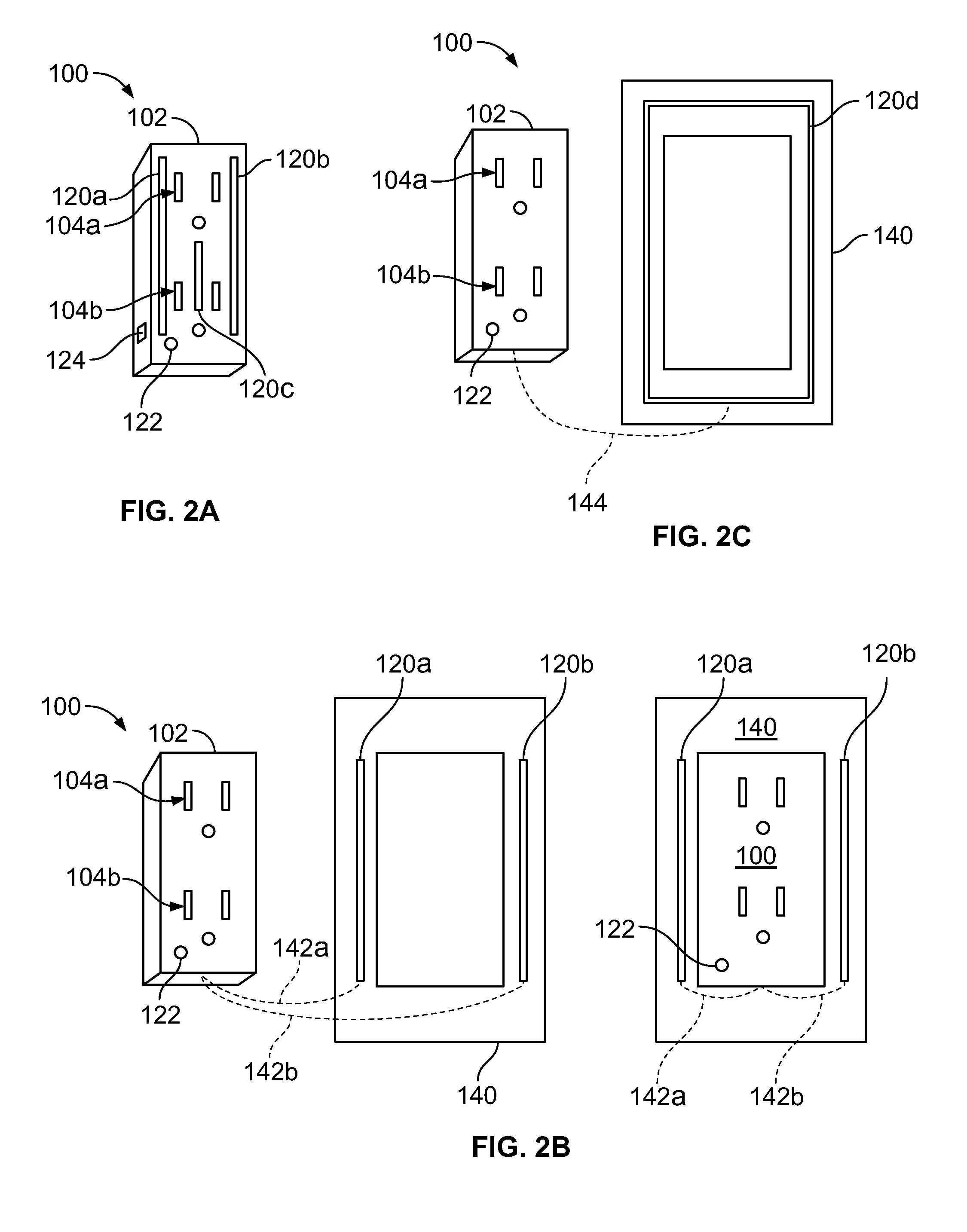

Wireless transceiver within an electrical receptacle system

ActiveUS20100130142A1Quick changeRadio network layoutCoupling device detailsWireless systems/telephoneWireless transceiverTransceiver

An electrical receptacle assembly having a housing that includes a wireless transceiver electrically coupled to one or more antennas that can be integrated into the receptacle housing itself or in the receptacle's faceplate. The one or more antennas can be one or more dipoles or a single loop antenna. The housing also houses a power converter that derives its power directly from the line connection to the outlet. A junction box includes an integrated antenna reflector for improved radio direction and propagation relative to the antenna(s). Or, an antenna reflector insert is placed within the junction box behind the electrical receptacle assembly. The electrical receptacle assembly further includes a temperature sensor, a PLC module, or a current / voltage sensor and communicates associated data via its wireless transceiver. A status indicator is disposed on the front of the housing. A reset switch on housing resets the electronics to a default state.

Owner:SCHNEIDER ELECTRIC USA INC

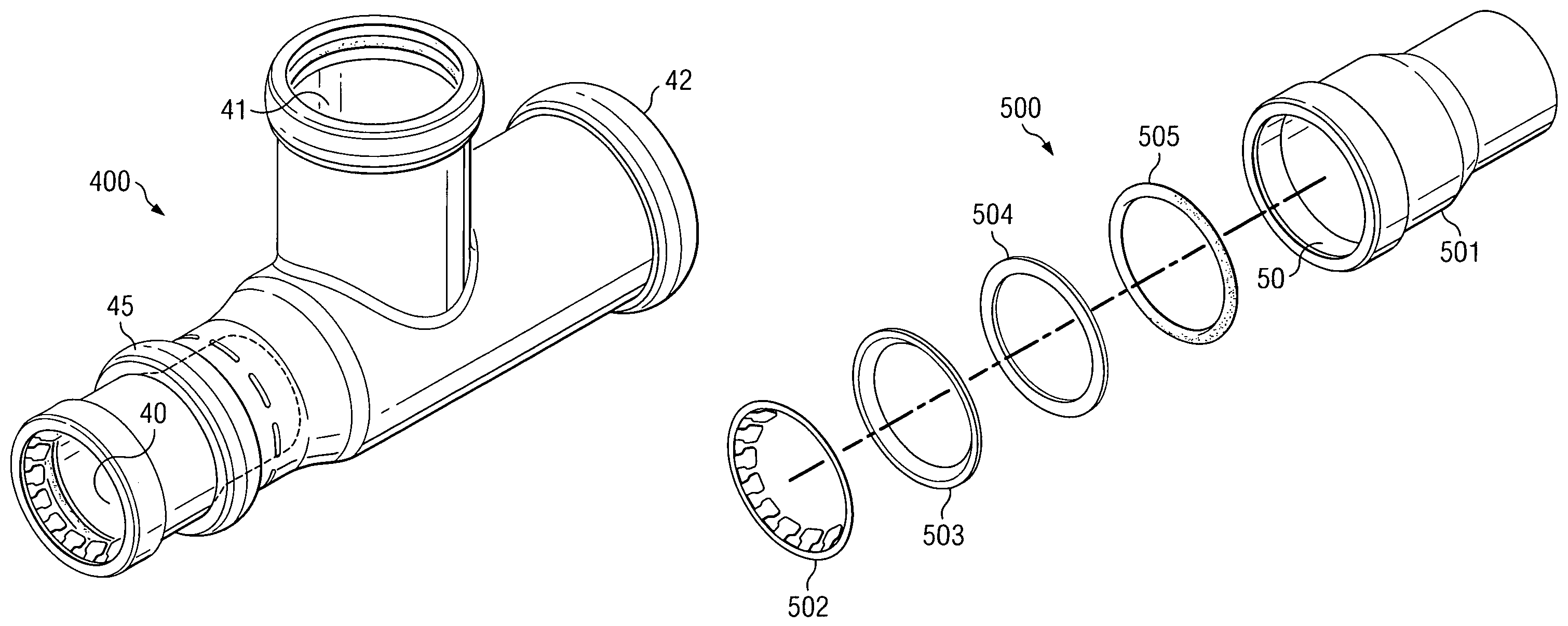

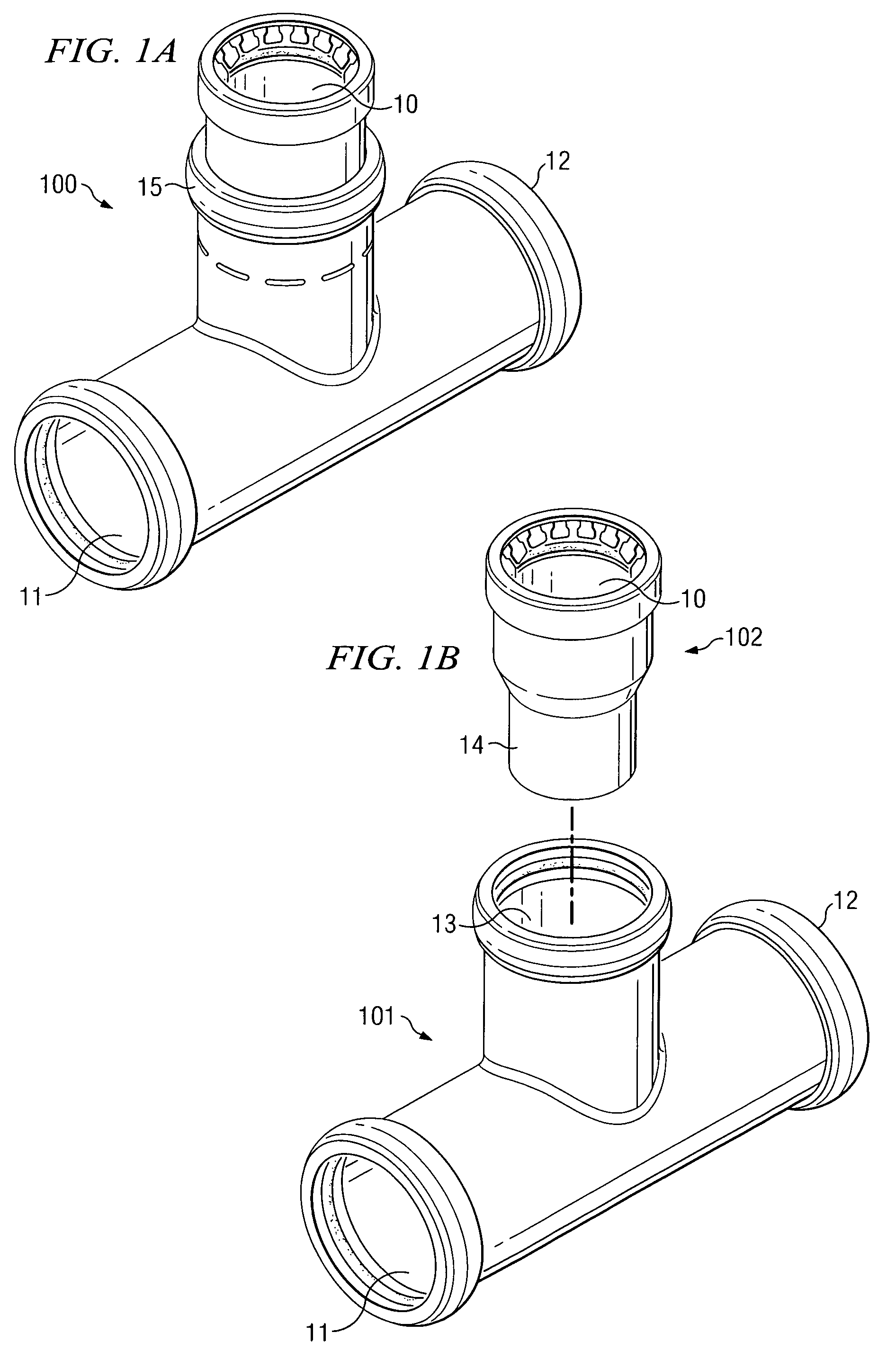

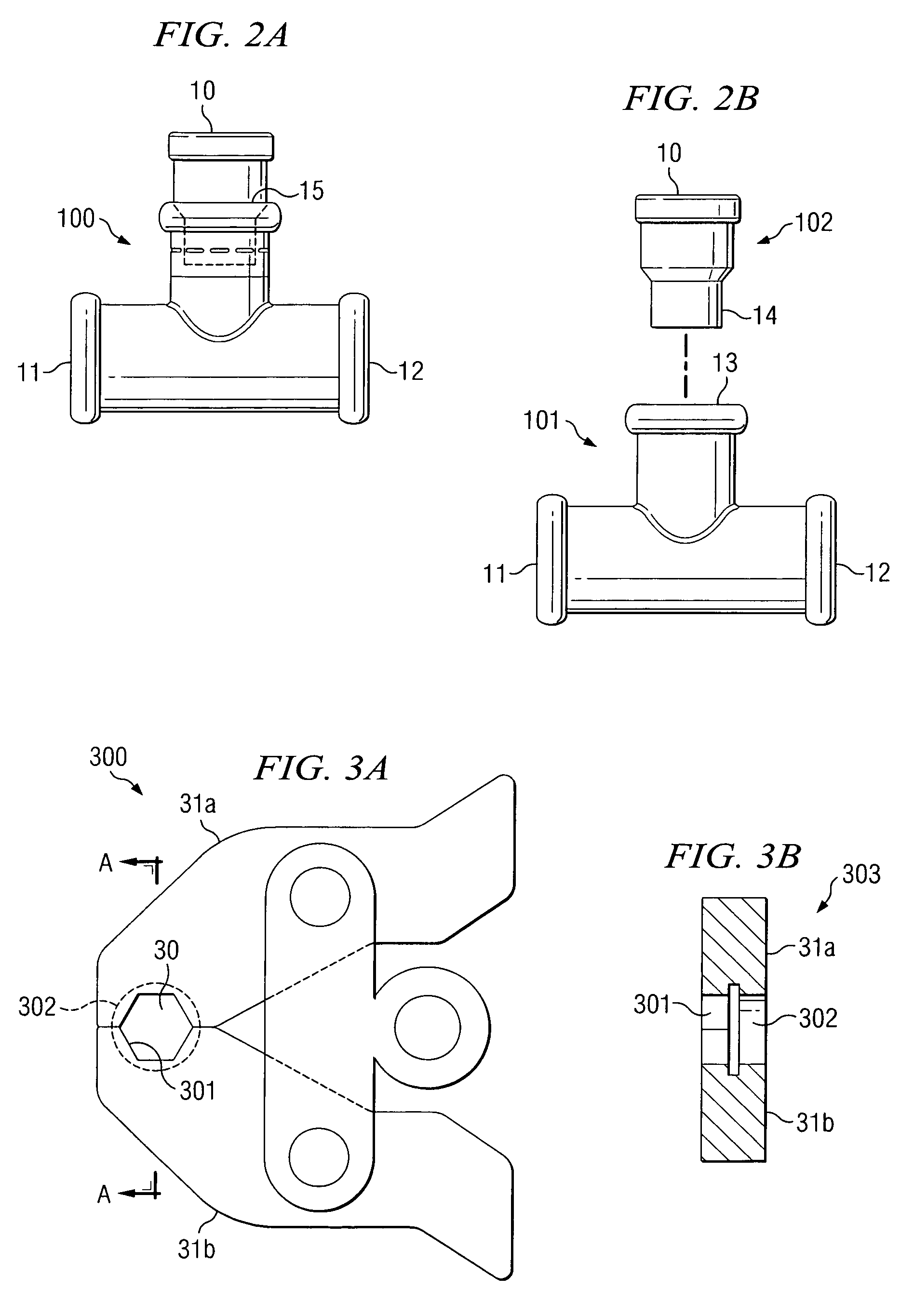

Transition tee coupling

InactiveUS7686346B1Installation time for fittingReduce the time required for installationSleeve/socket jointsFluid pressure sealed jointsCouplingEngineering

An improved coupling, such as a transition tee coupling, is described having press-connect fittings on the ends and a push-connect fitting on the outlet. The improved transition tee coupling is formed using a reduced-outlet tee having press-connect fittings on all three sockets. An unfinished end of a tailpiece having a push-connect fitting on the opposite end is inserted into the outlet socket of the press-connect tee. The press-connect fitting of the outlet tee is crimped using a special press tool jaw that does not damage the push fitting on the tailpiece.

Owner:ELKHART PRODS CORP

Rapid mounting system for solar modules

InactiveUS20120260977A1Reduce the time required for installationPrevent movementPhotovoltaic supportsSolar heating energyComputer moduleSolar module

Methods and devices are provided for rapid solar module installation. In one embodiment, a photovoltaic module is provided comprising of a plurality of photovoltaic cells positioned between a transparent module layer and a backside module layer. The module may be a frameless module. The module may have brackets that slidably engage a mounting structure.

Owner:NANOSOLAR

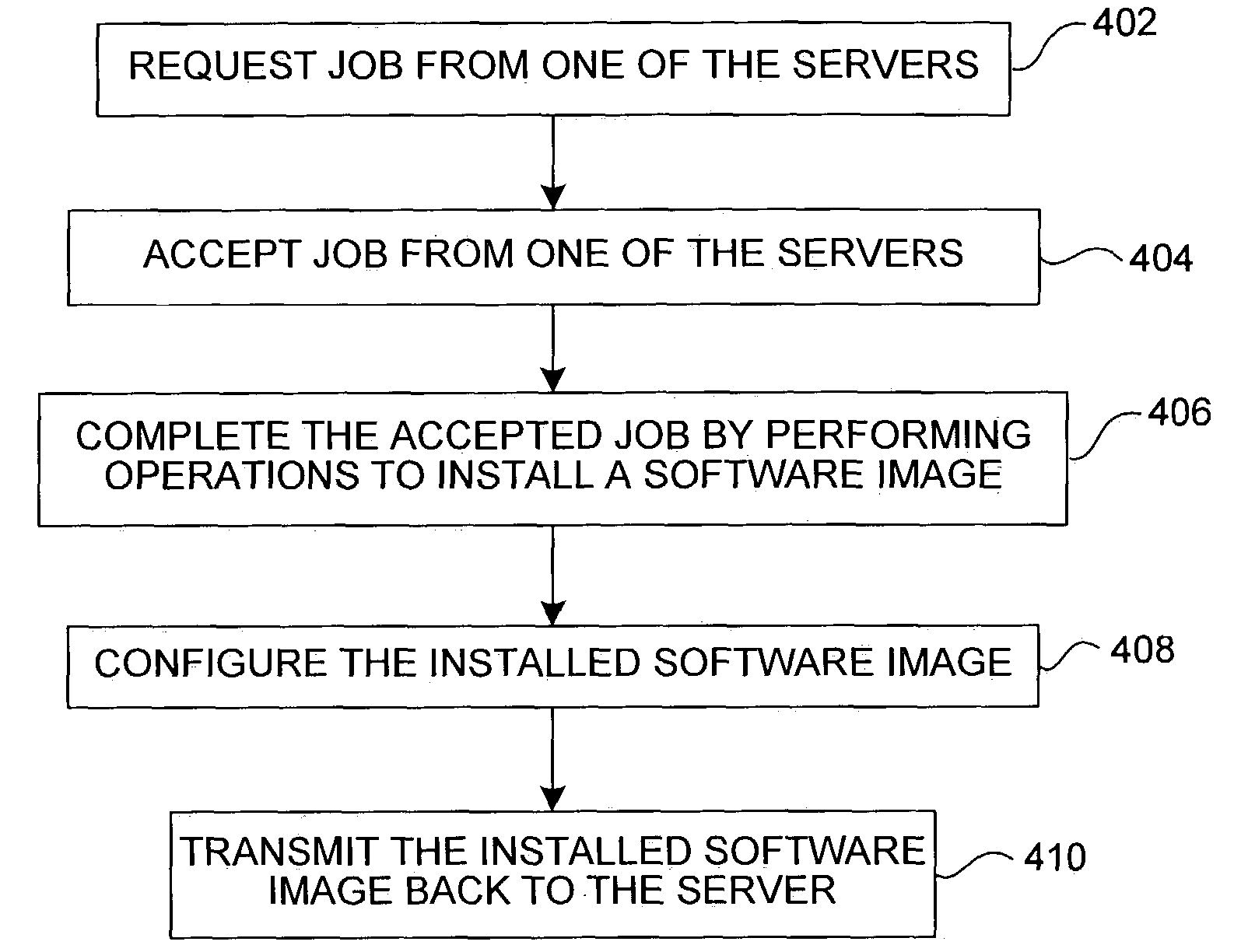

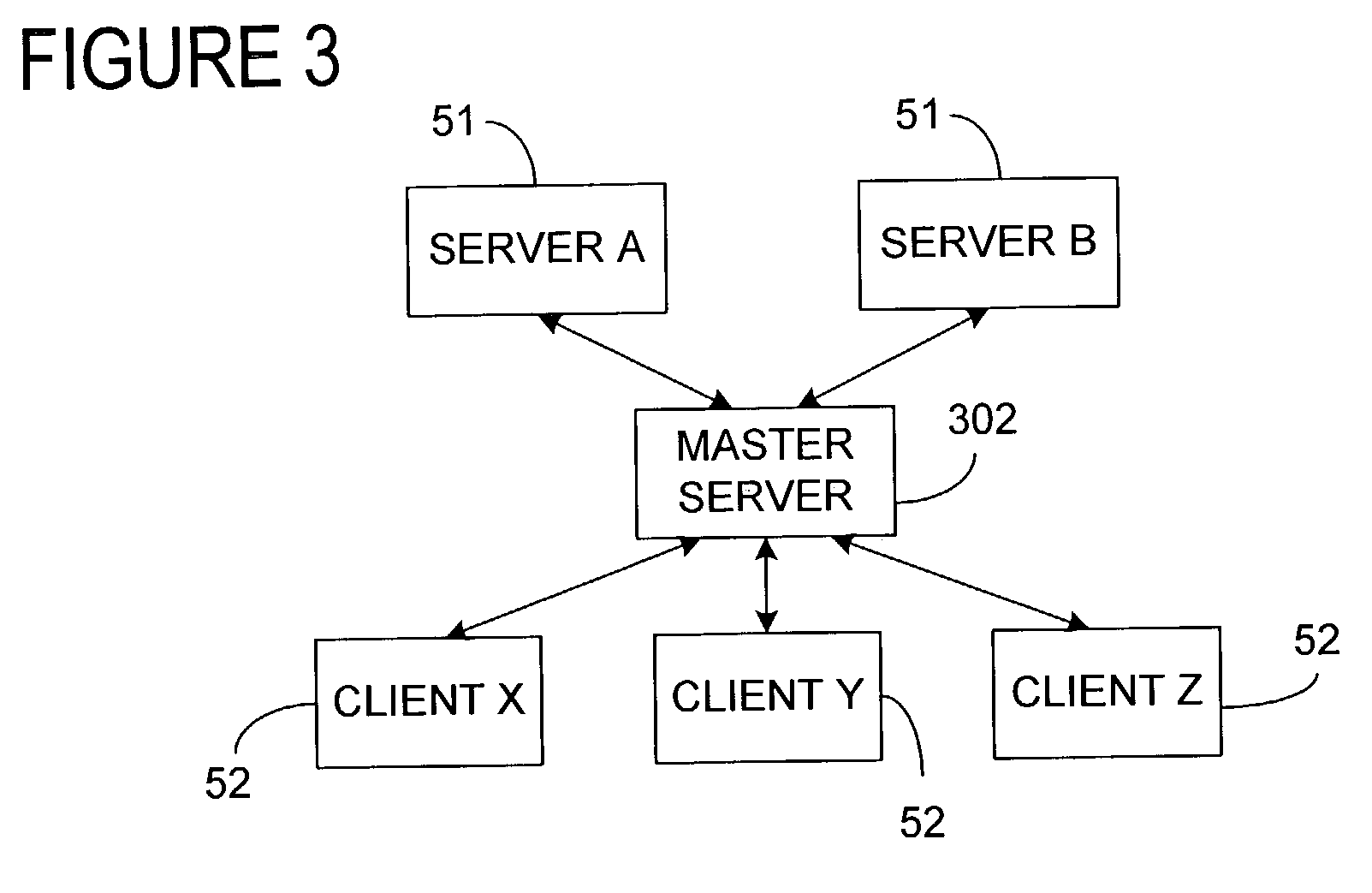

Software image creation in a distributed build environment

ActiveUS7281247B2Reduce in quantityEasily modify and create and imageResource allocationVersion controlResource consumptionOriginal equipment manufacturer

Distributing software image creation and configuration among a plurality of client computers. Server computers define jobs related to software image creation. Each of the client computers communicates with the servers to identify, accept, and complete jobs. The server and client computers maintain data structures indicating job availability and status. In the distributed build environment, original equipment manufacturers (OEMs) and system builders may easily modify, create, and image software in the factory to dramatically reduce resource consumption and time.

Owner:MICROSOFT TECH LICENSING LLC

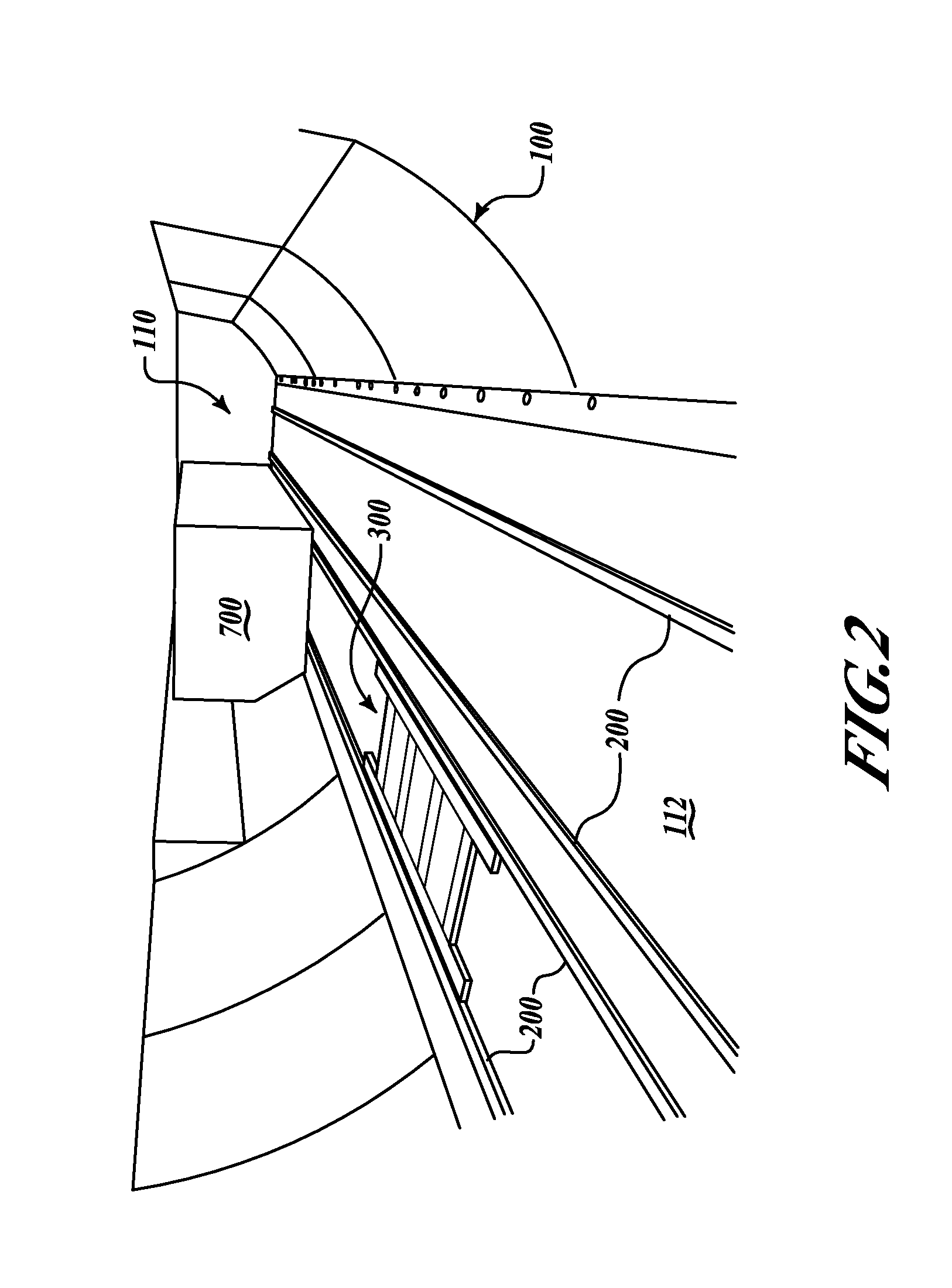

Cargo transport system and method

ActiveUS7785056B2Reduce weightReduce harmRefuse receptaclesWeight reductionTransport systemTransit system

A system for loading cargo containers into a storage hold, and offloading cargo containers from the storage hold, especially of a vehicle, such as an aircraft. The system includes at least one guide rail and a motorized platform, onto which cargo containers are loaded, cooperating mechanically with the guide rail. The guide rail guides the cargo laden motorized platform into the storage hold, and the motorized platform deposits the cargo upon remote command. The motorized platform has a chassis; a power source; a control module controlling drive motors of the wheels of the platform; and a device for reciprocating at least a portion of an upper surface of the platform sufficient to elevate a load placed thereon above the guide rail height.

Owner:THE BOEING CO

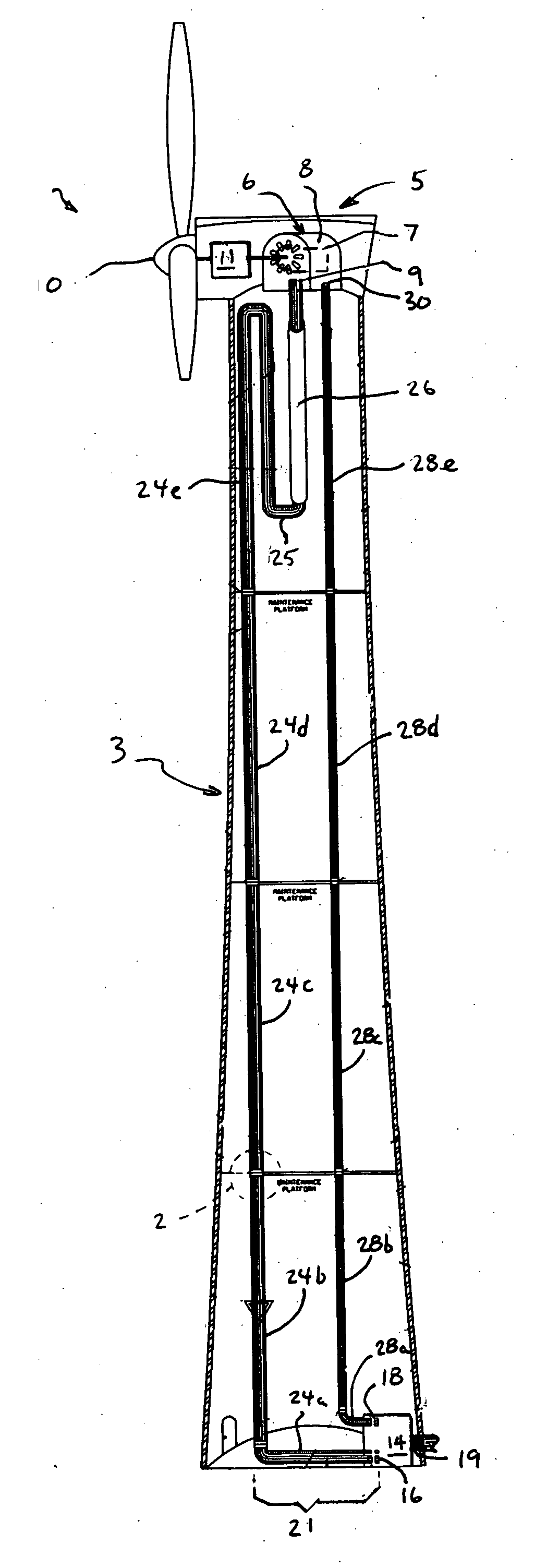

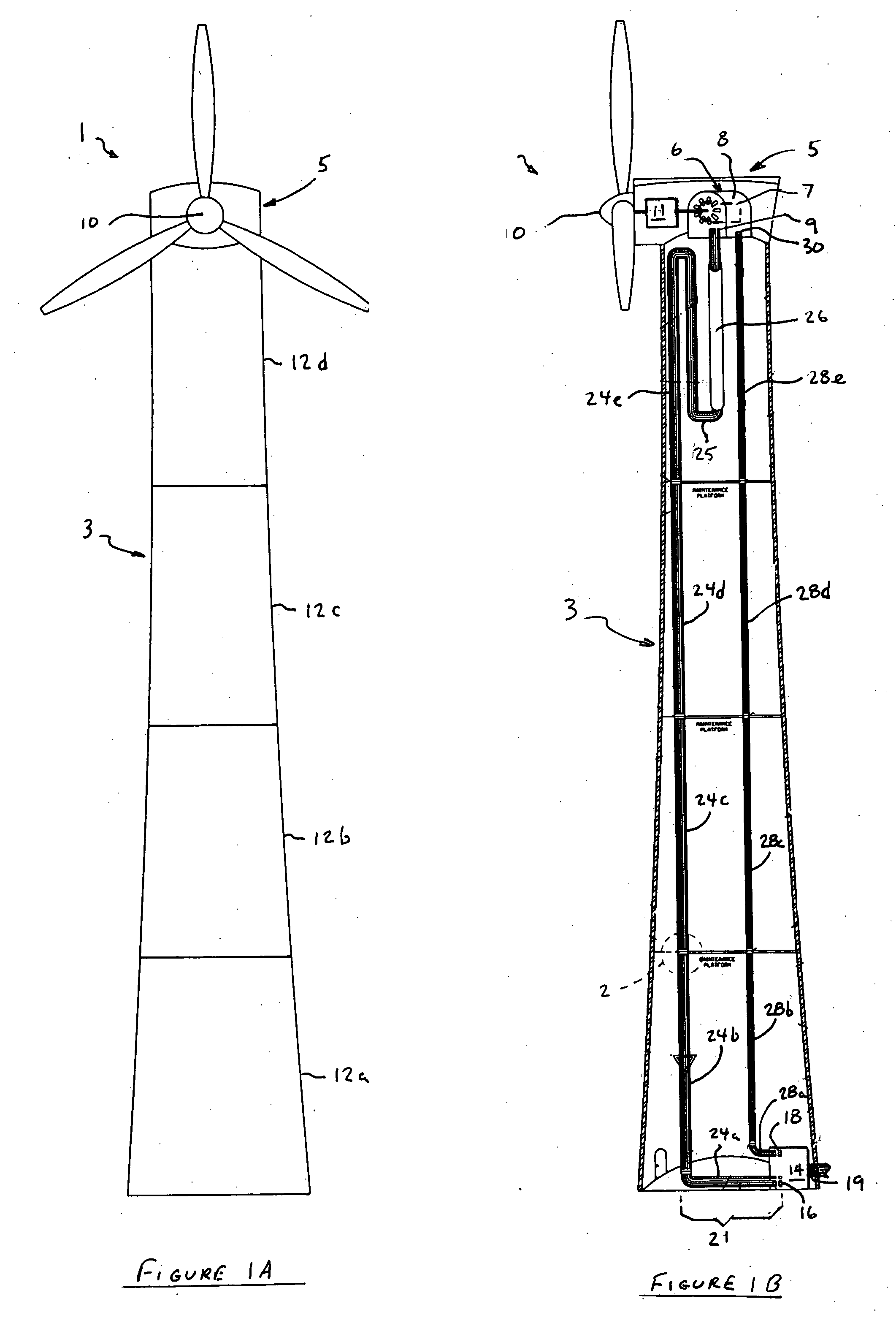

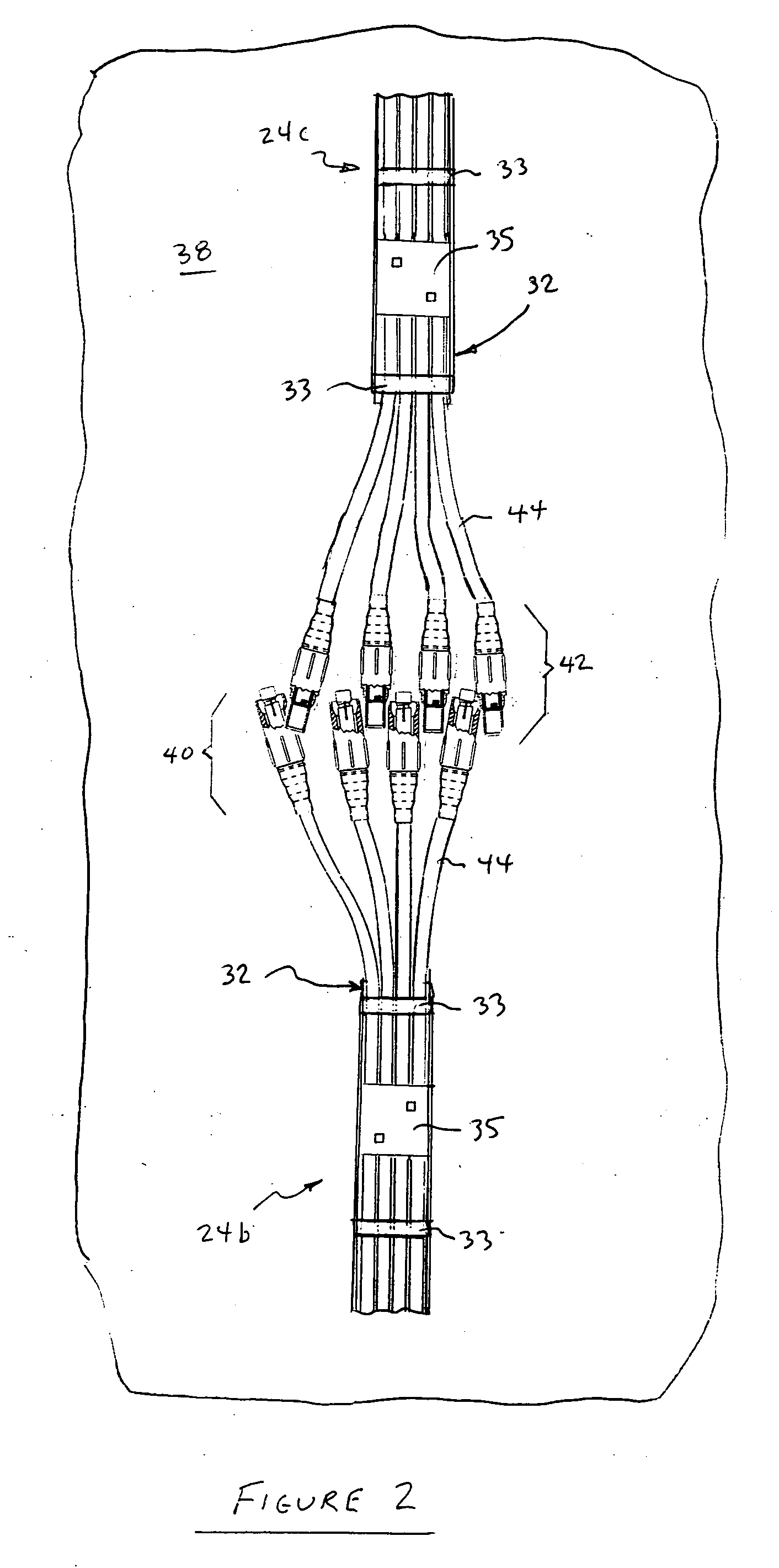

Windmill cable system and method

InactiveUS20060199411A1Quantity minimizationPrevent disengagementEngagement/disengagement of coupling partsMachines/enginesElectricityPower cable

An improved cable system and method for an electricity generating windmill having a base formed from a plurality of stacked base sections is provided. Each base section includes a bundle of both power and control cables which are alignable with one another when the base sections are stacked and assembled. Mating electrical connectors which may be easily interlocked are provided at the ends of the power and control cables, and in the terminals of the generator and inverter of the windmill. In the preferred embodiment, bayonet-type connectors are used to provide a secure, interlocking coupling between adjacent cable ends with a minimum amount of twisting motion between the cables, which are necessarily of heavy gauge to conduct the current produced by the generator. The system greatly facilitates installation of the cable system as well as repair or replacement of damaged or worn cables during the lifetime of the windmill.

Owner:RENEWABLES ENG SERVICES GROUP +1

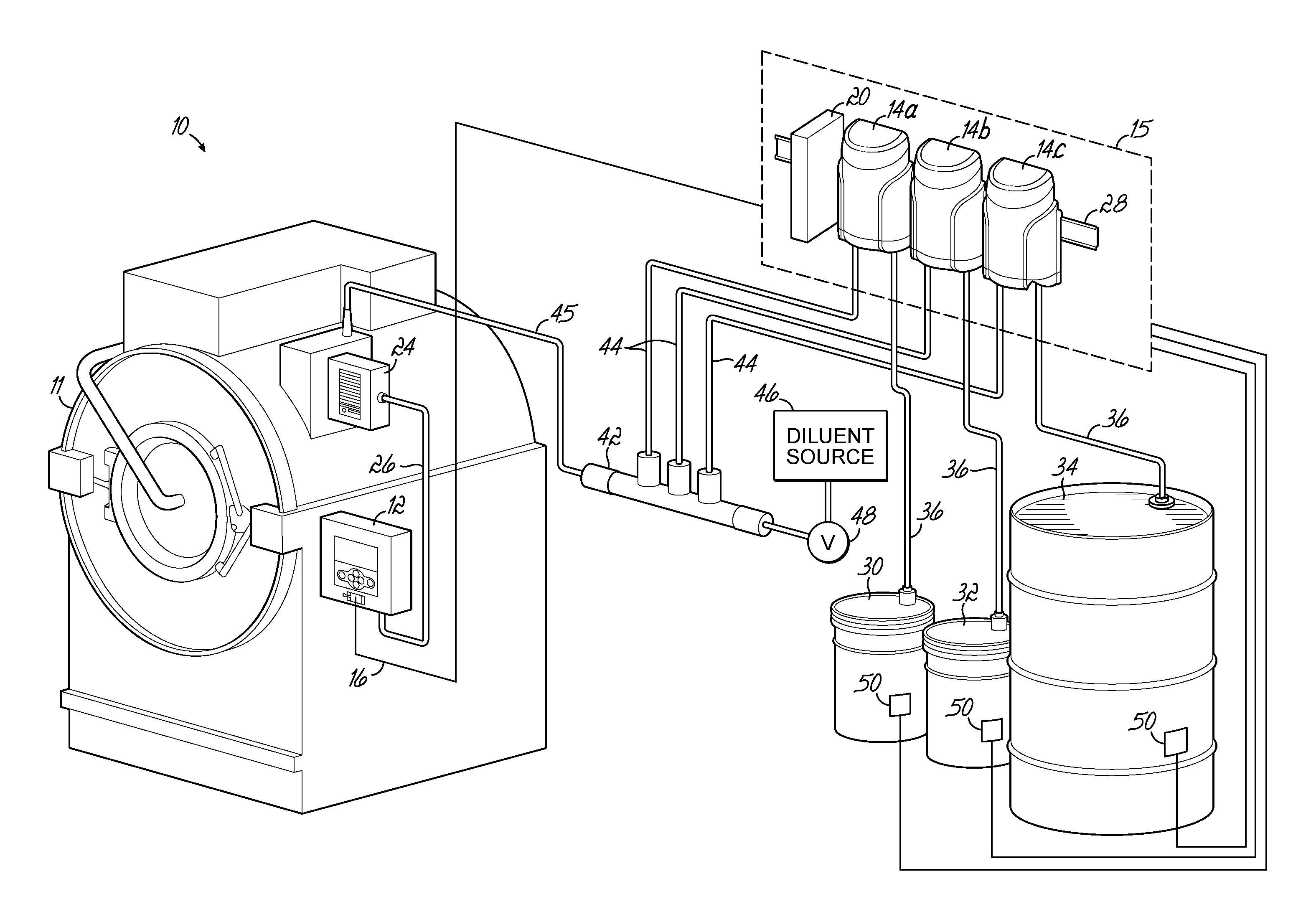

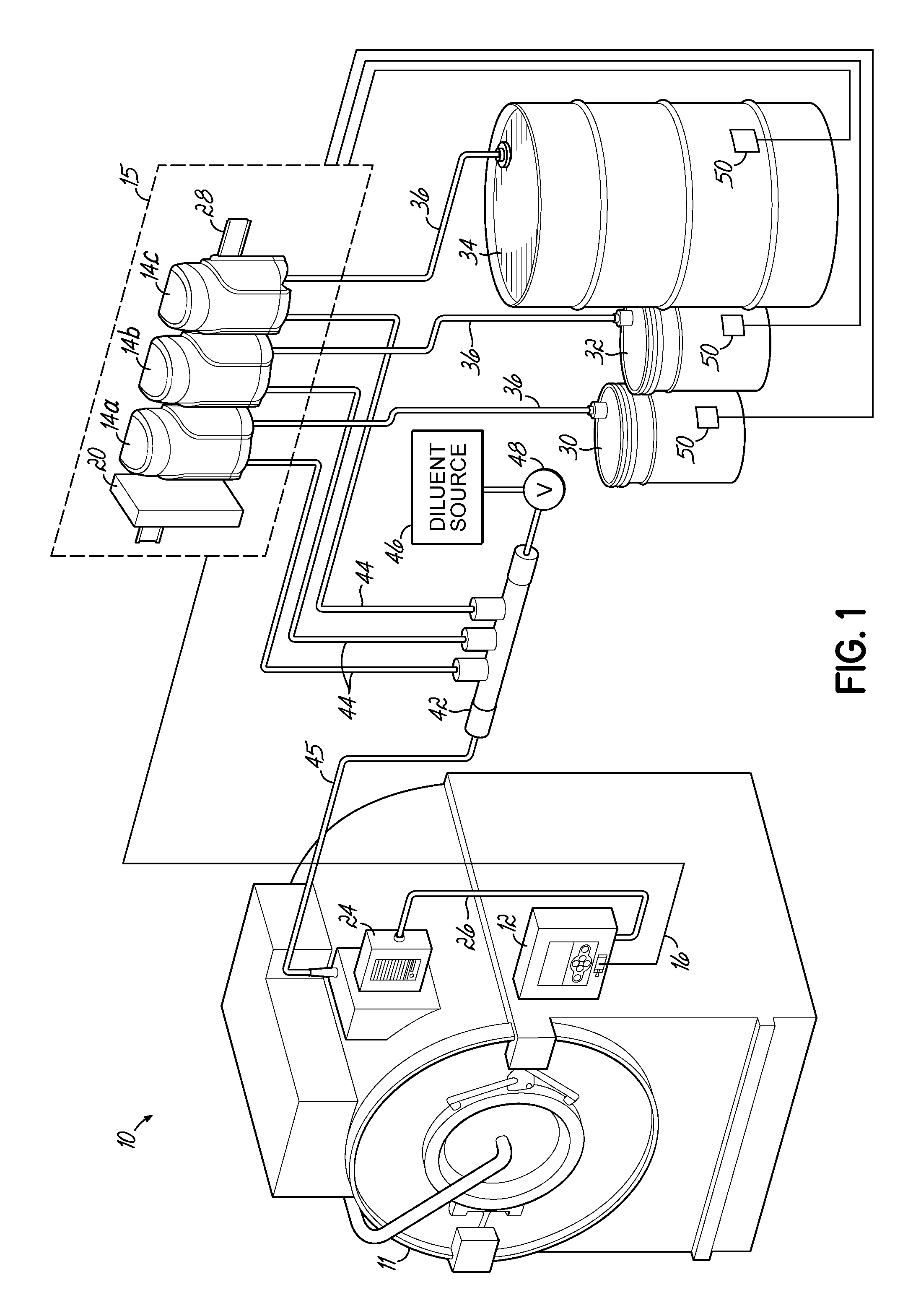

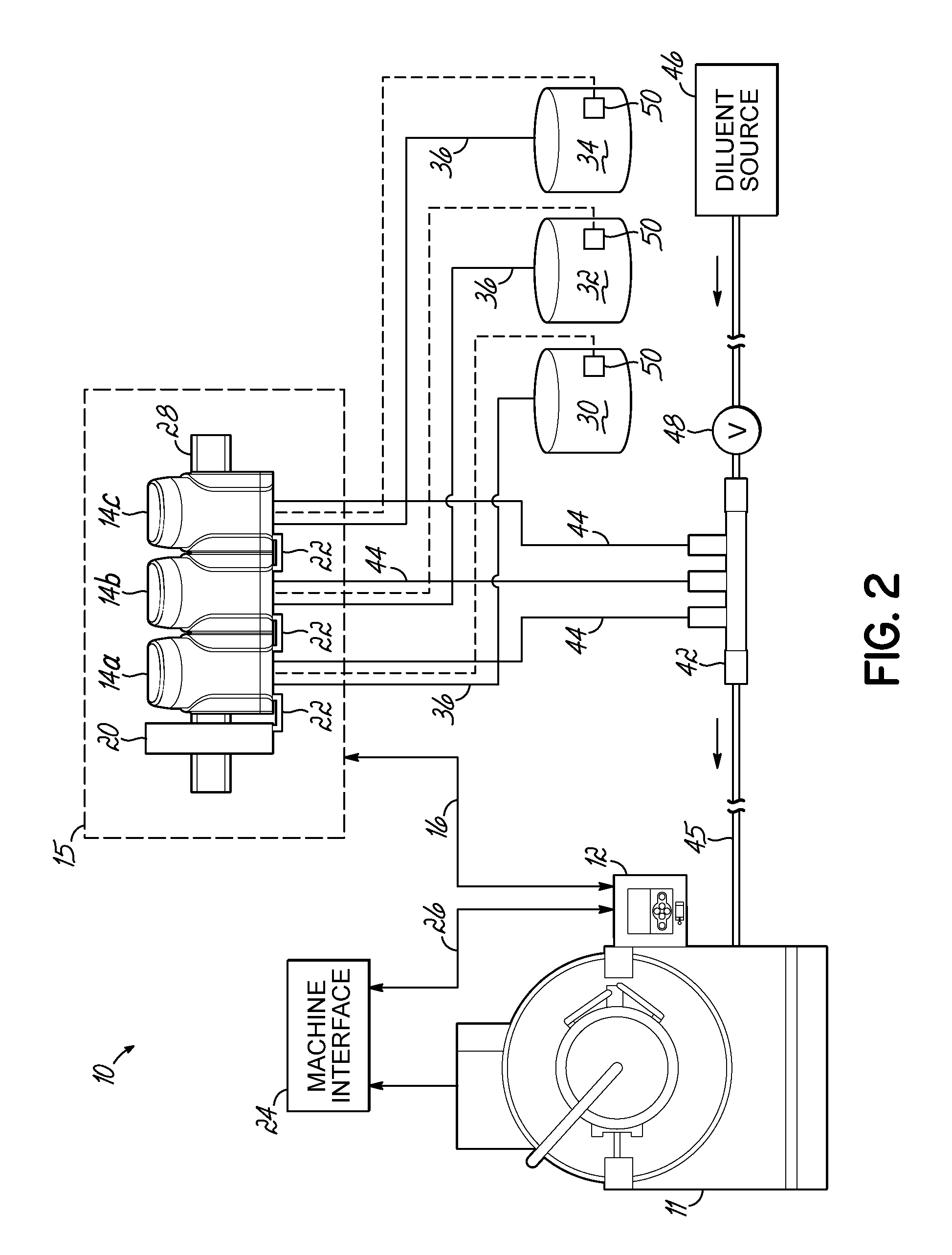

Intelligent Network For Chemical Dispensing System

ActiveUS20130092704A1Prevent injuryReduce mechanical stressPower operated devicesAutomatic washing/rinsing machine detectionPID controllerStress relief

System and method for dispensing product to a washing machine. A chemical dispensing system includes a system controller, machine interface, and pump controller that communicate through serial data buses. The system controller provides a user interface, retrieves washing machine status information from the machine interface, and issues product dispensing commands to the pump controller. The pump controller monitors pump status and dispenses product in response to commands from the system controller. The pump controller: (1) determines pump activation periods based on calibration data stored in a pump controller memory; (2) tracks pump usage and adjusts the activation period to compensate for pump wear as the pump ages; (3) disables the pump if conditions exists that preclude operating the pump; (4) monitors product levels, and (5) reports pump status to the system controller. Integral channels are included in the pump housing to provide stress relief to a squeeze tube.

Owner:DELAWARE CAPITAL FORMATION

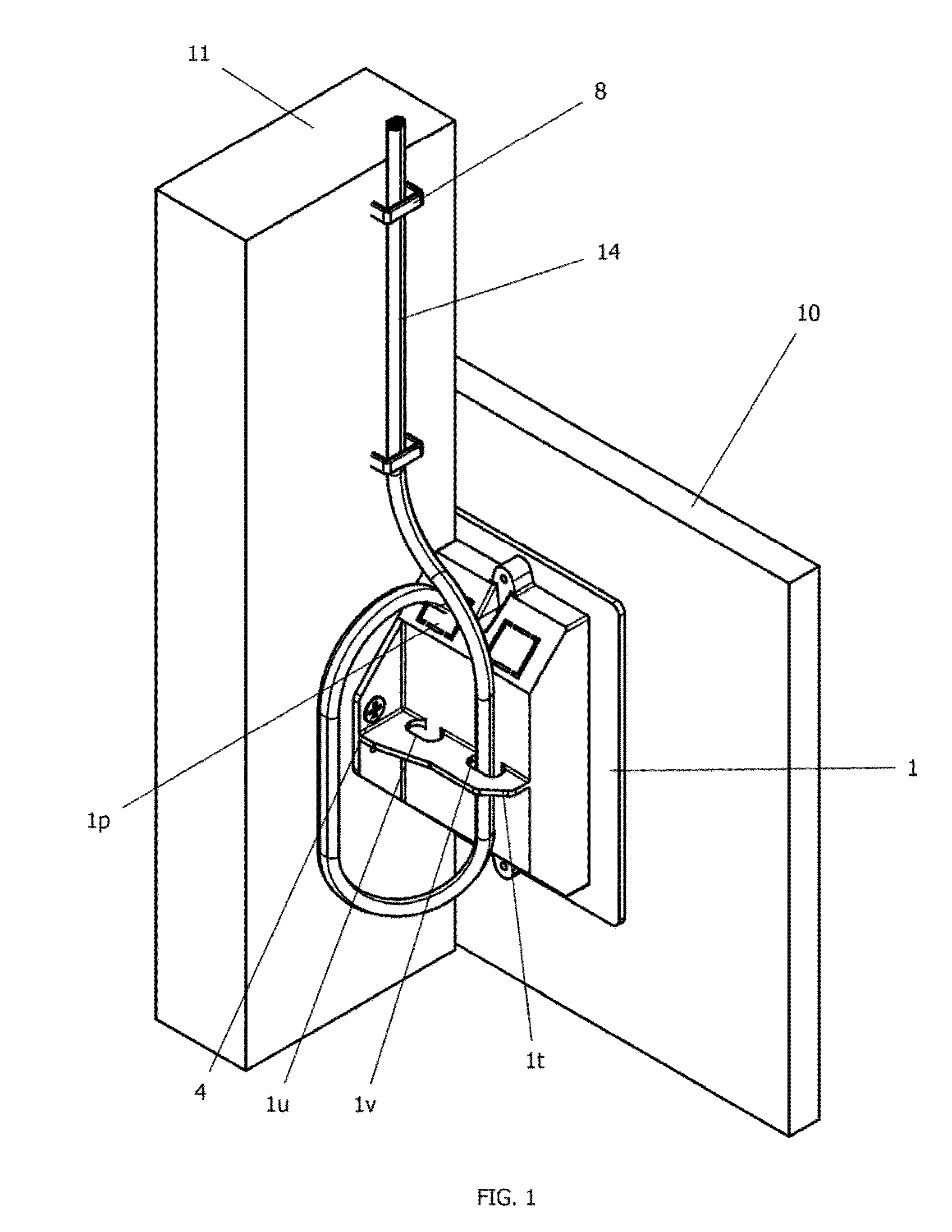

Efficient installation electrical hardware system and method of use

InactiveUS20150136437A1Elimination of extra wire lengthSimplifies electrical connectionsLine/current collector detailsCouplings bases/casesCeiling fanElectricity

An improved installation system for electrical hardware, such as power outlets, electrical switches, light fittings, ceiling fans and the like, whereby the cutting of their installation access holes in drywall panels is accomplished much faster than prior art methods and with a high degree of accuracy by the use of the hole cutting system, comprising the magnetic block assembly, corresponding magnetic template assembly and the hole cutter. In conjunction with the aforementioned; the electrical hardware's associated electrical boxes are wired directly to their electrical supply and the hardware is in turn, electrically connected to them by their respective sets of electrical terminals which make simultaneous contact with each other upon their installation. Additionally, the latching pawl mechanism and alignment device supports the weight of heavy light fittings and ceiling fans and aligns their electrical connections while they're being fixed into their installed position. These features taken together make this improved installation system substantially superior to all prior art.

Owner:HITCHMAN STEPHEN A

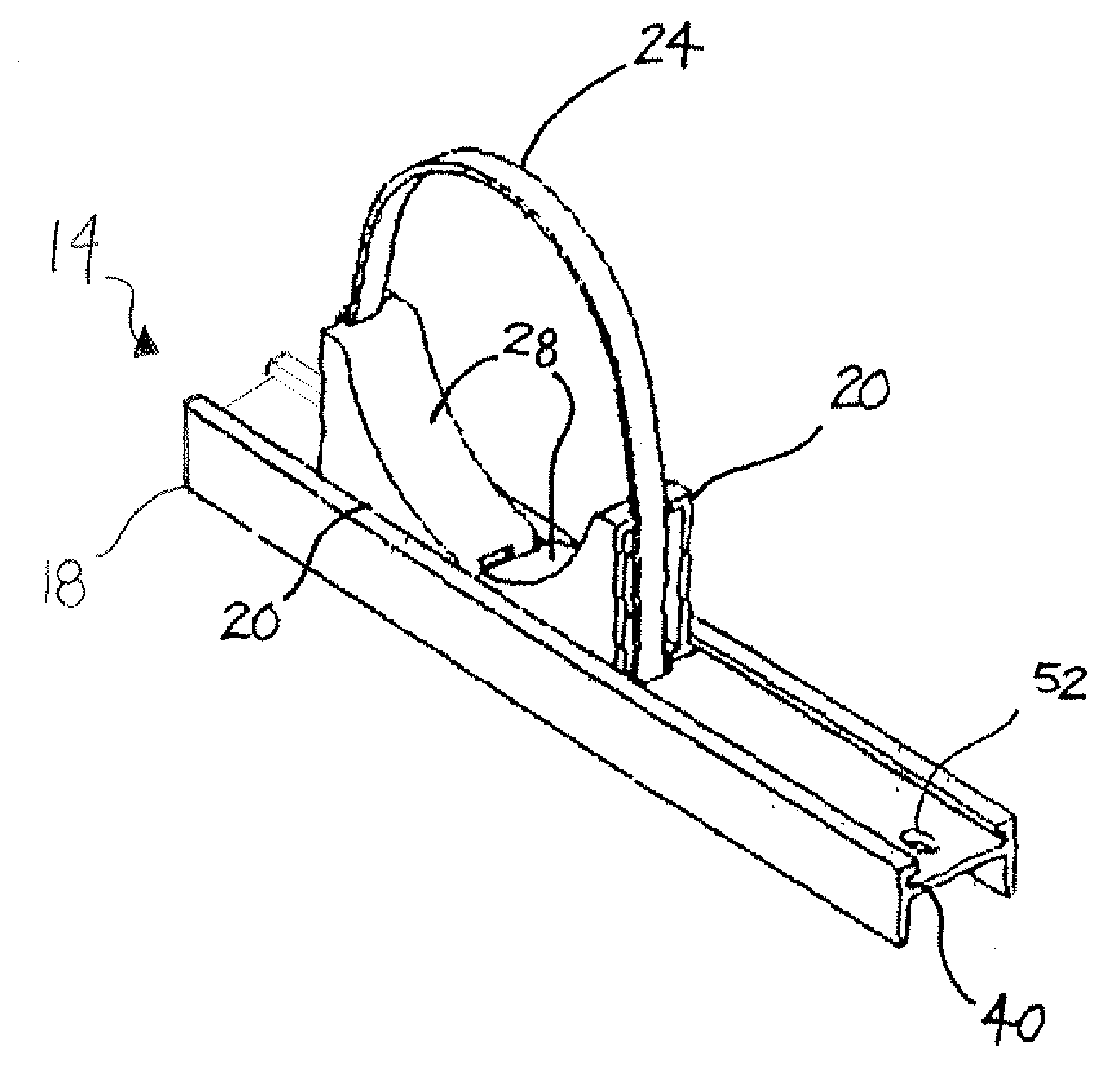

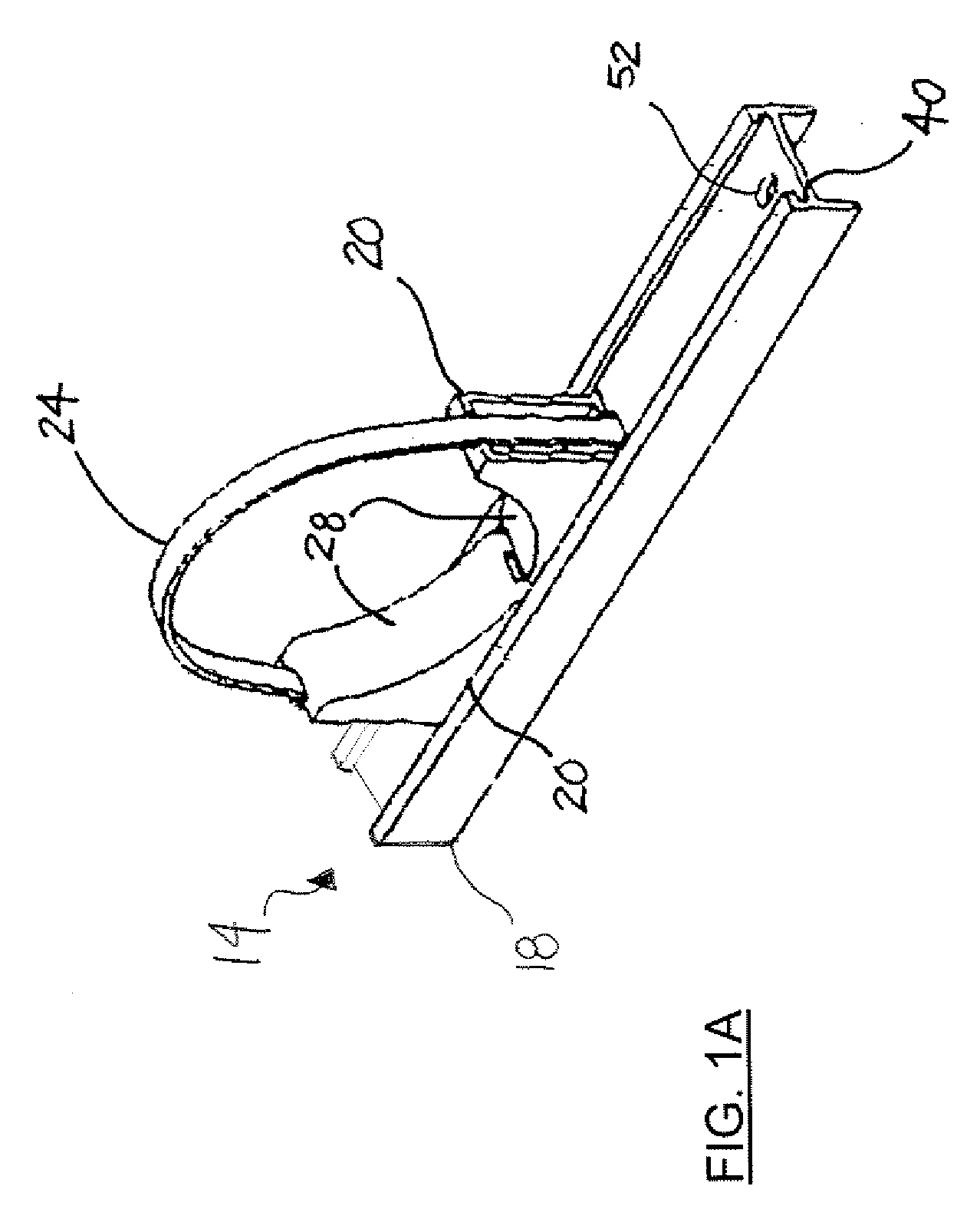

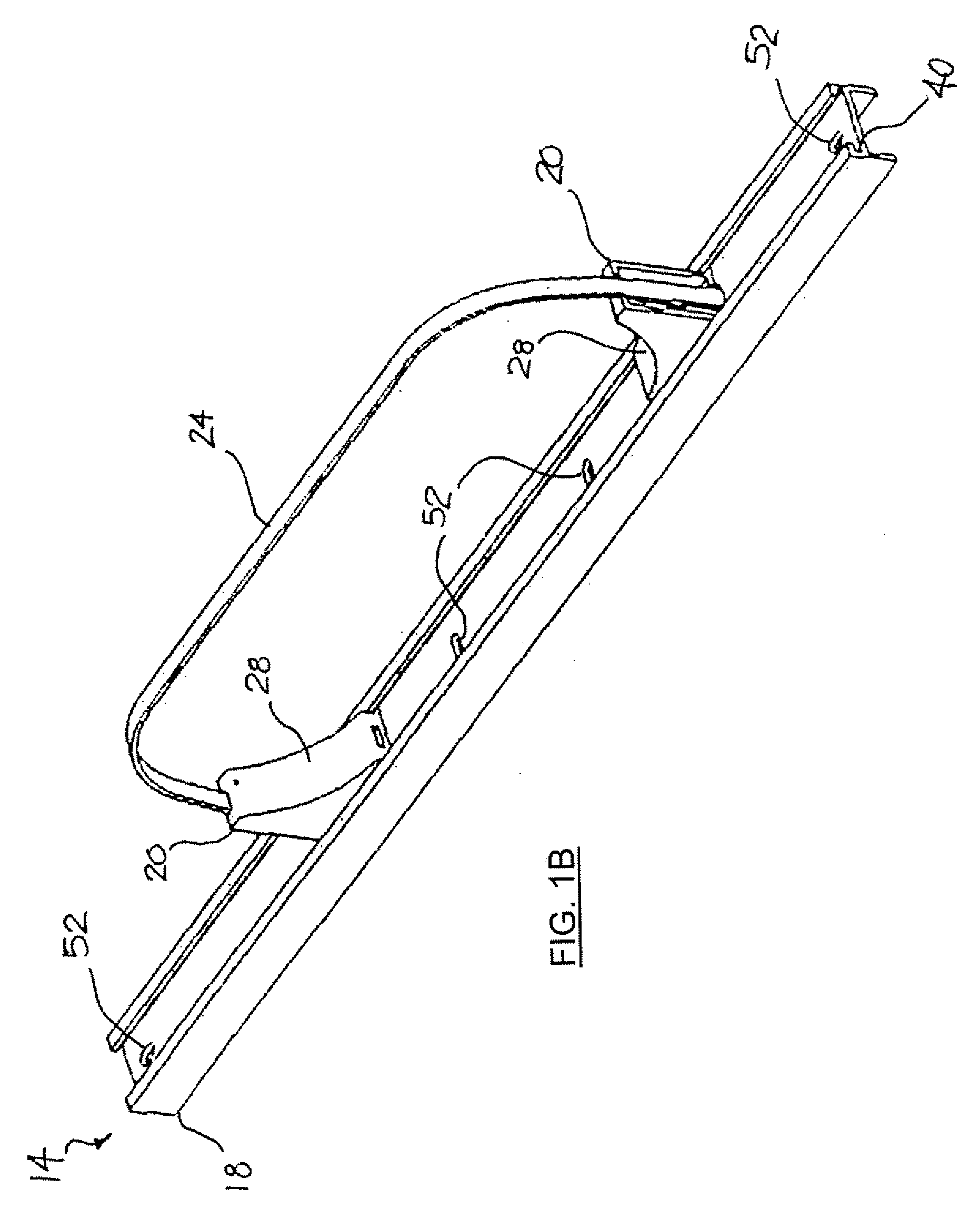

Variable-duct support assembly

InactiveUS20050211847A1Reduce the possibilityReduce the time required for installationPipe supportsElectrical apparatusPipe supportEngineering

One advantageous embodiment of the present invention is a variable-duct support assembly (14) for mounting one or more ducts (12a-12c) thereon. This variable-duct support assembly (14) includes one or more rails (18) each having a groove (40). Each groove (40) has one or more pairs of support brackets (20) positioned therein for supporting a proximal surface (22) of the ducts (12a-12c). The support brackets (20) are coupled to one or more flexible bands (24) and utilized for clamping the duct (12a-12c) between the support brackets (20) and the flexible bands (24). The flexible bands (24) are intended to contact and wrap around a distal surface (26) of the duct (12a-12c) so as to distribute a load substantially across the distal surface (26). Likewise, the support brackets (20) each include support portions (28) for distributing the load substantially across the proximal surface (22) of each duct (12a-12c).

Owner:THE BOEING CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com