Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3450results about "Mechanical roughness/irregularity measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

System and method for monitoring and estimating energy resource consumption

ActiveUS20080224892A1Good estimateEasy to understandEnergy efficient ICTElectric signal transmission systemsElectricityEngineering

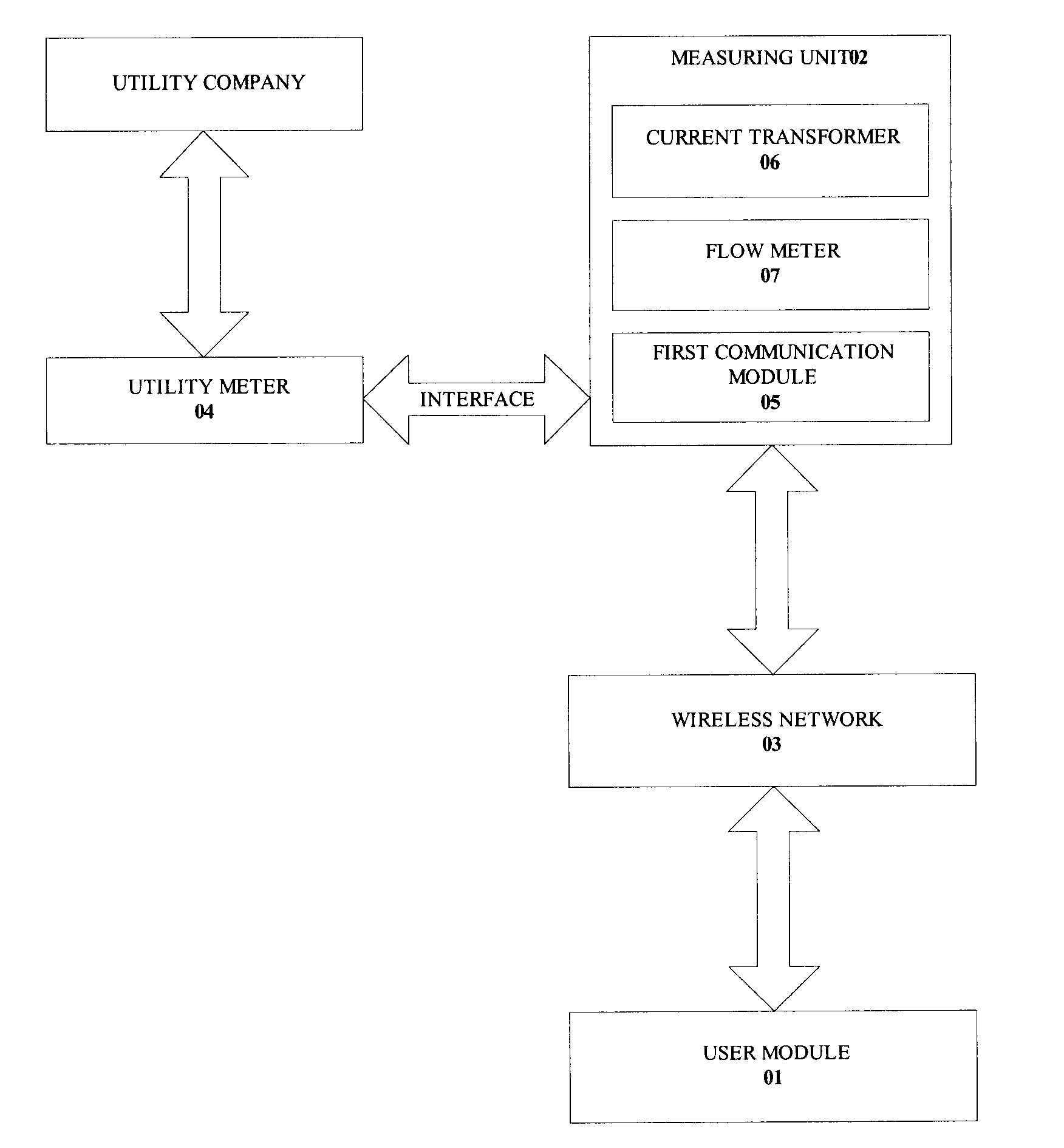

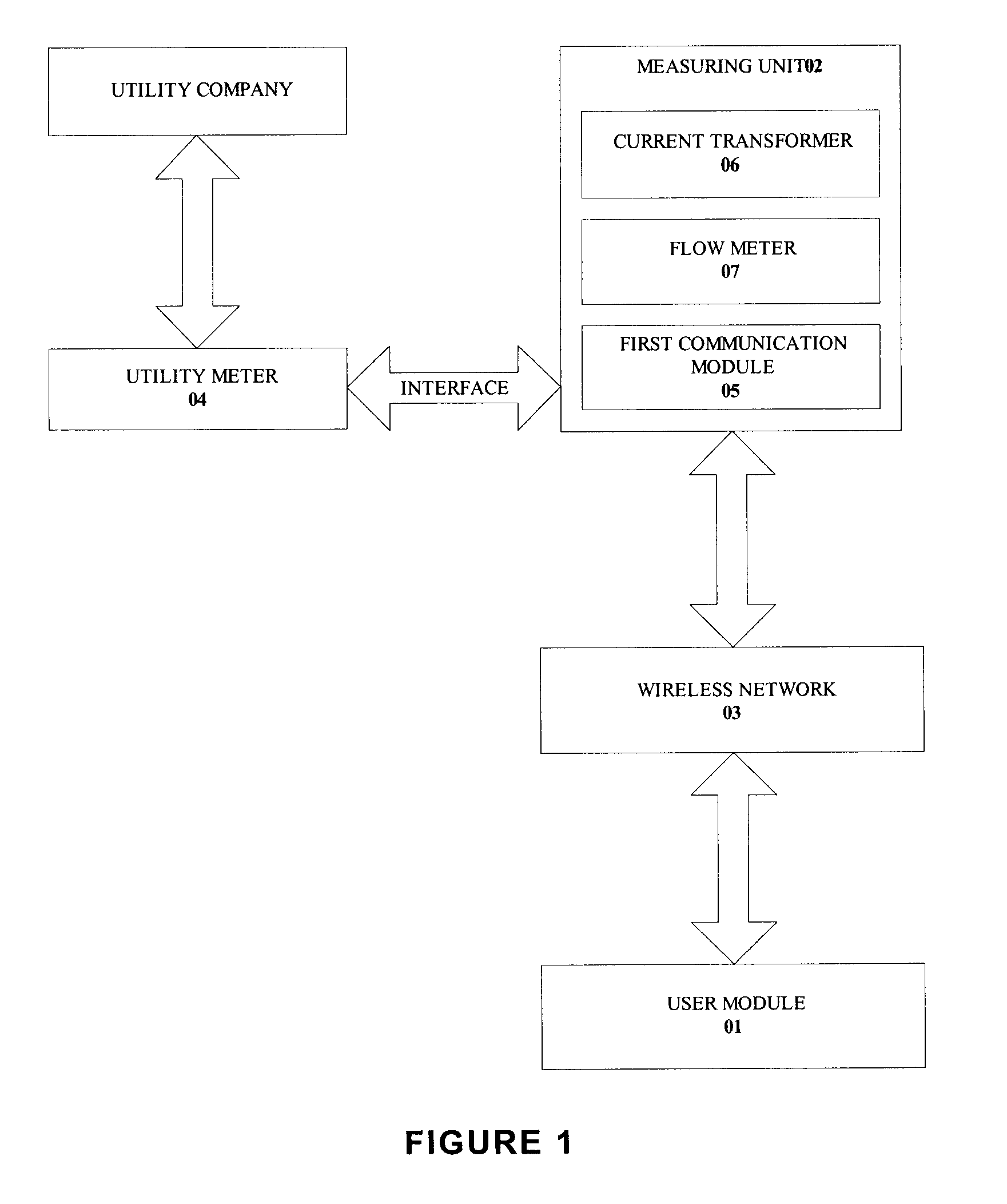

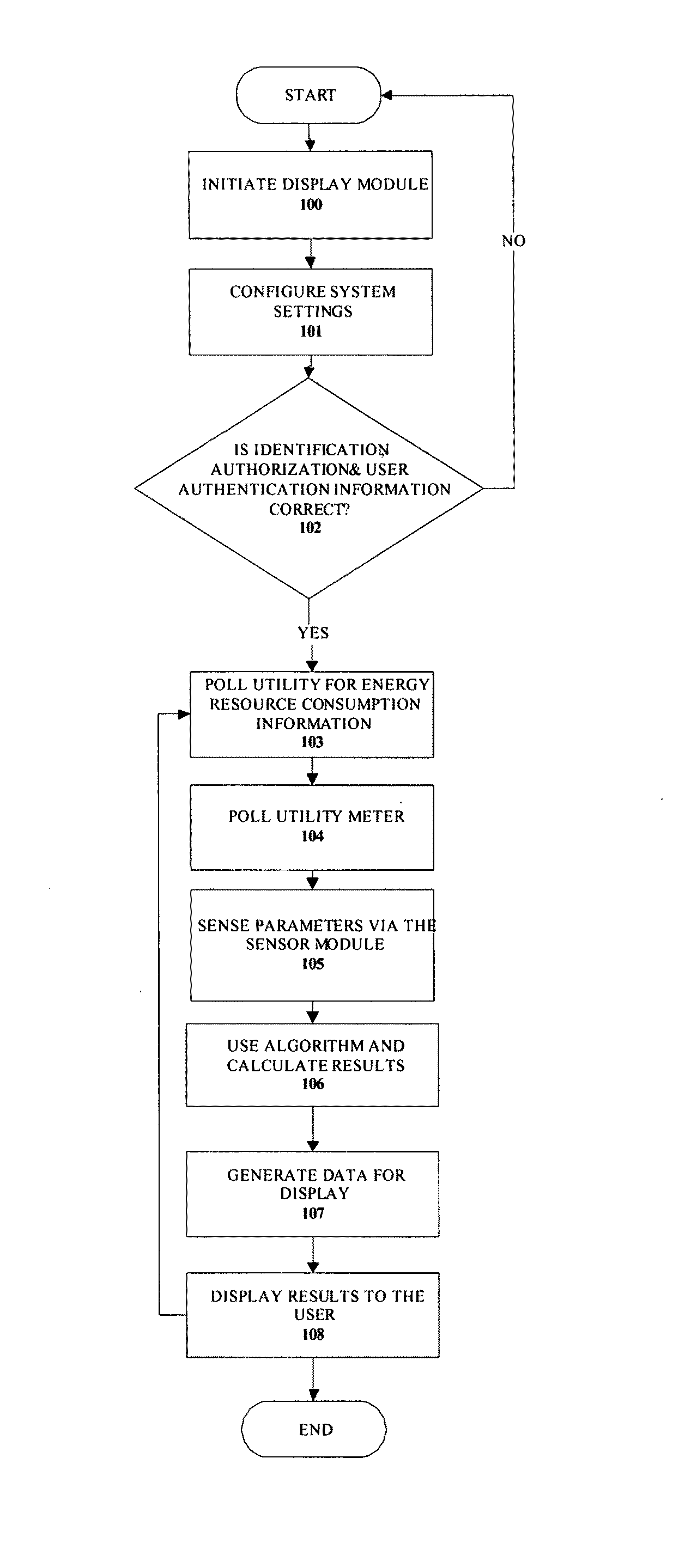

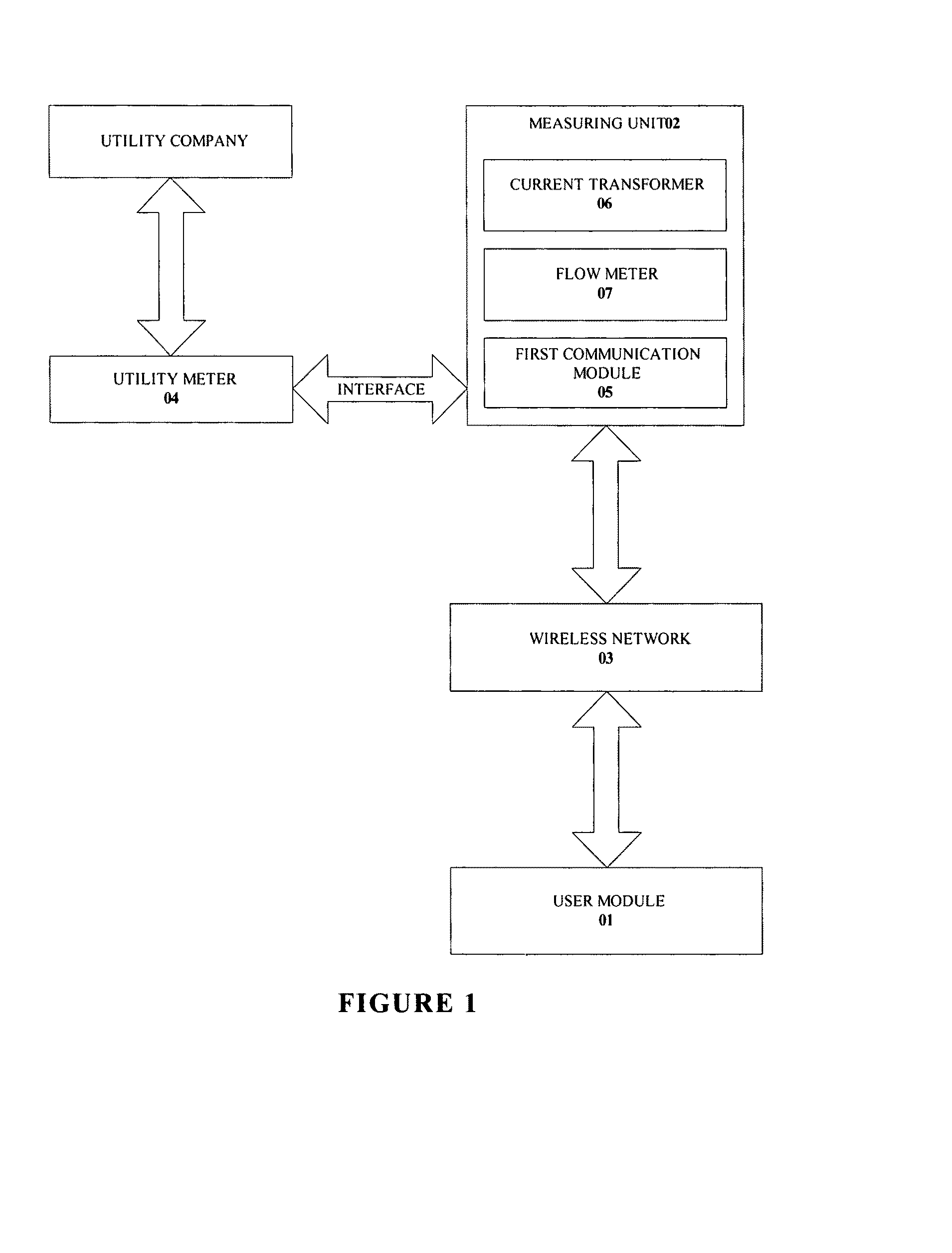

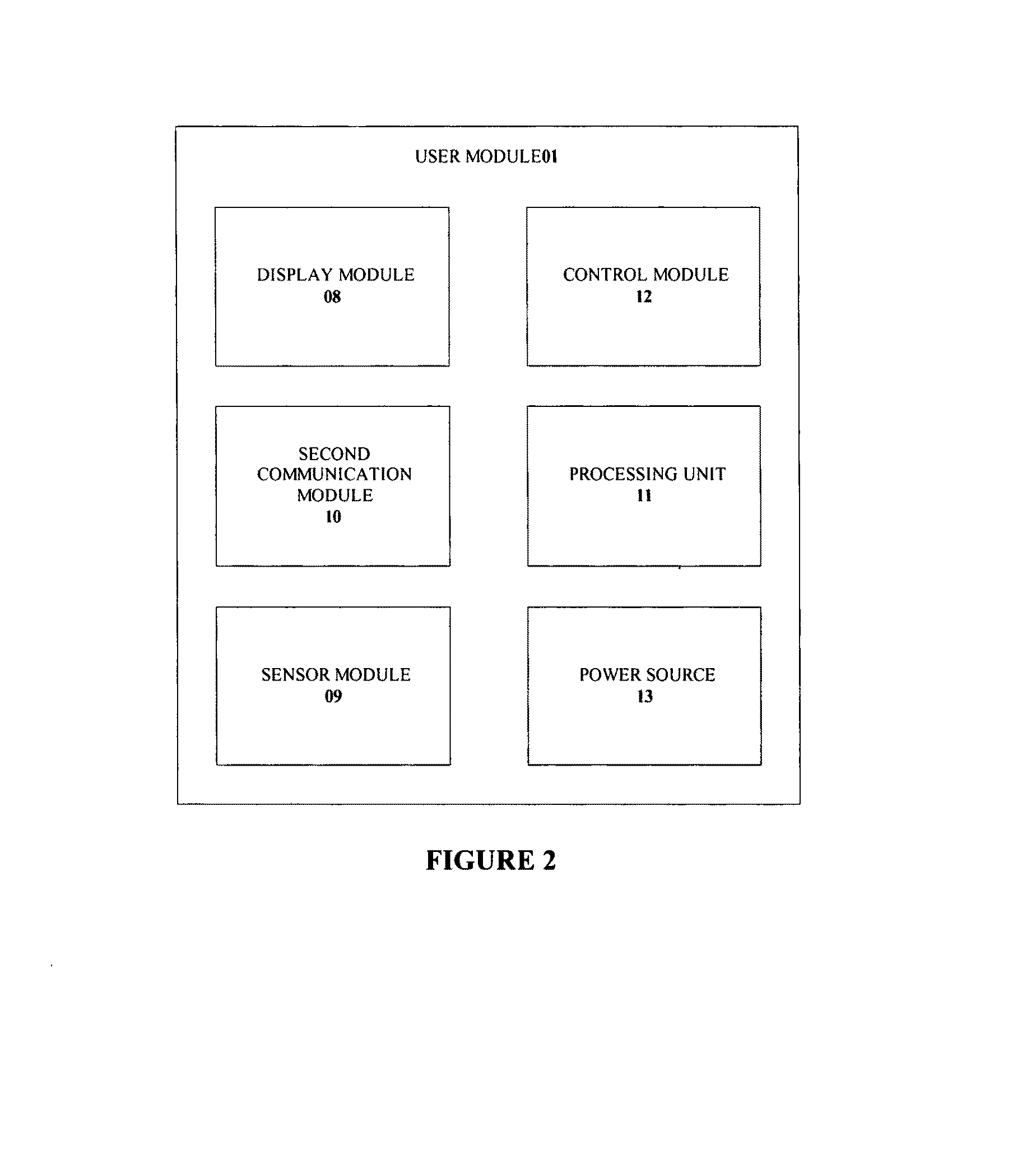

The present invention discloses a system for monitoring and estimating the consumption of energy resources in real-time. The system includes an interactive user module, a measuring unit and a wireless network. The measuring unit is interfaced to a utility meter. Optionally, the measuring unit can also function as a stand alone device. The measuring unit is further connected to the interactive user module via the wireless network. The system monitors energy resource consumption such as electricity, gas or water consumption in real-time, generates and displays graphs of energy resource consumption over user selected time periods and enables communication with at least one utility company. The system increases the users' awareness of their energy consumption and aids users in dynamic or deregulated pricing environments to shed load when the energy resource is most expensive. With knowledge of their energy use, the users can take proactive steps to control their energy consumption and save money. A method of estimating the energy resource consumption over a period of time is also provided.

Owner:ITRON NETWORKED SOLUTIONS INC

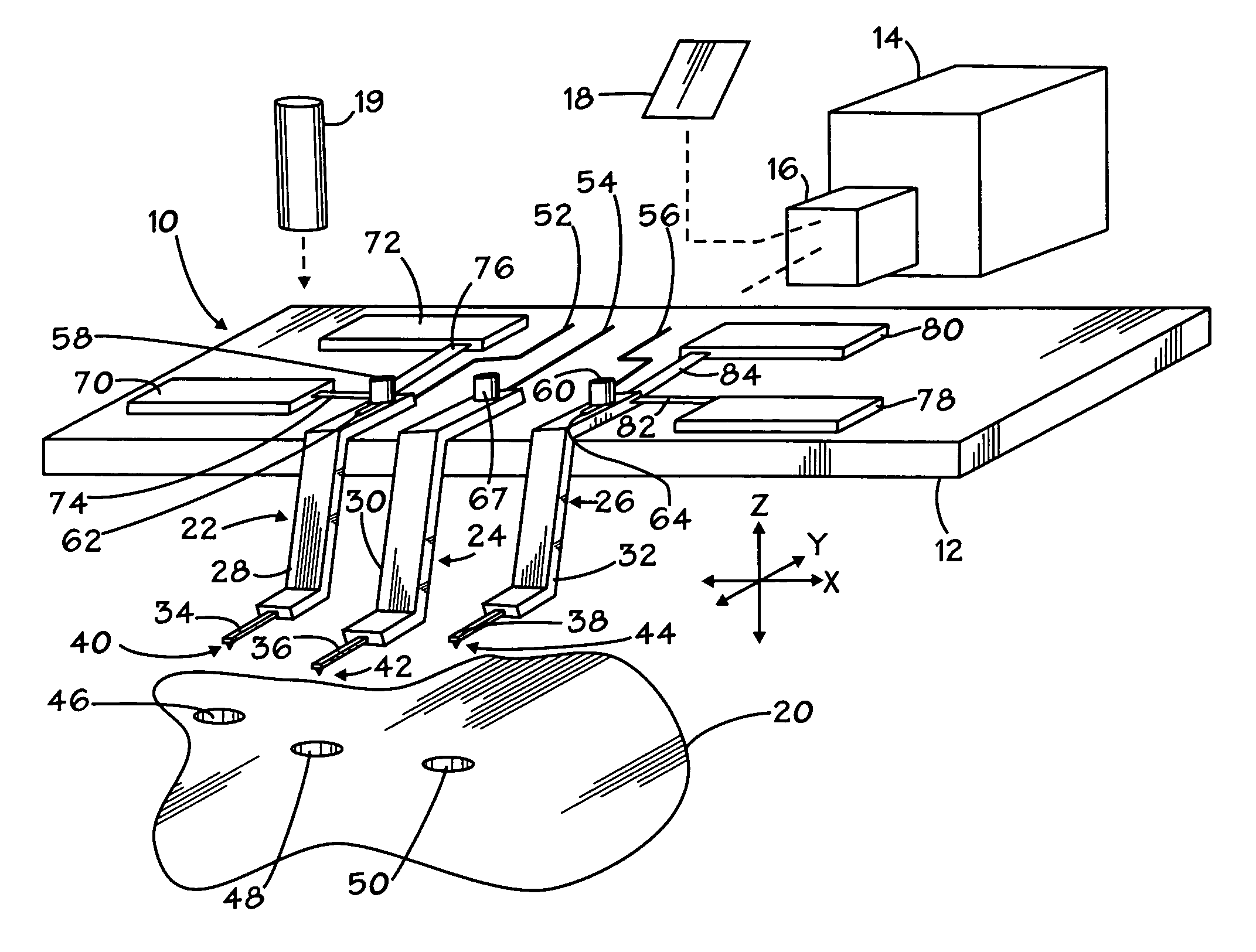

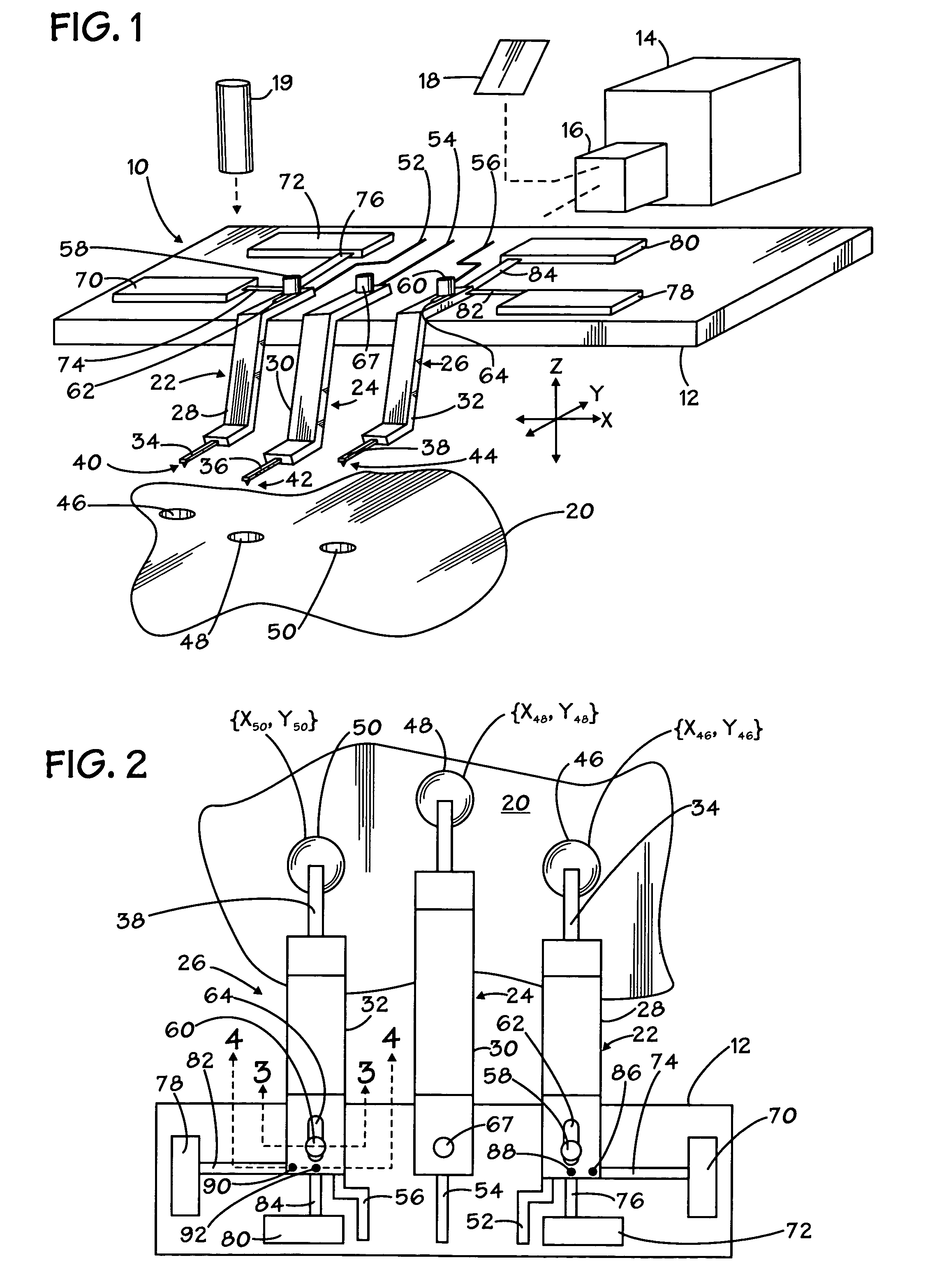

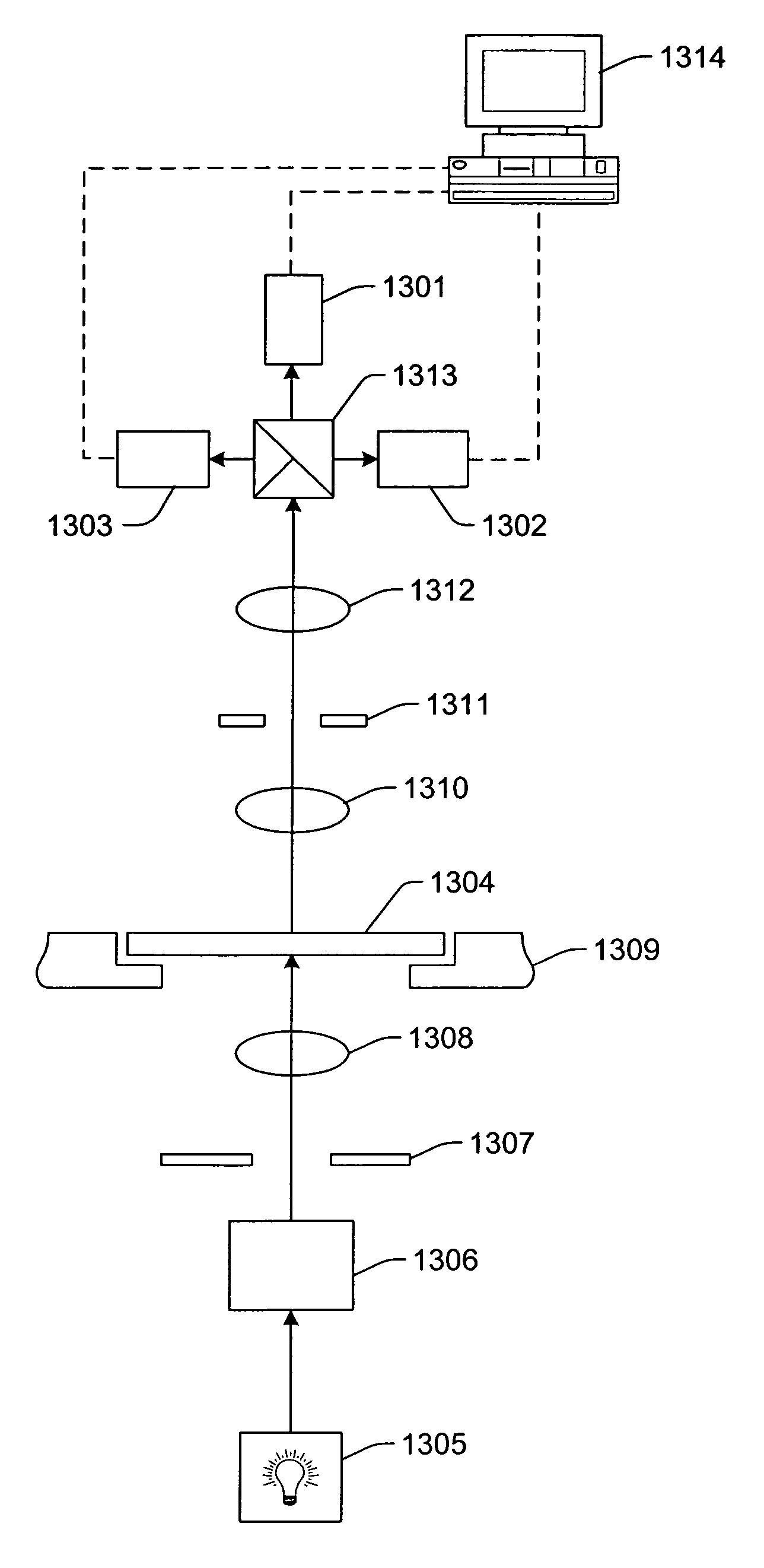

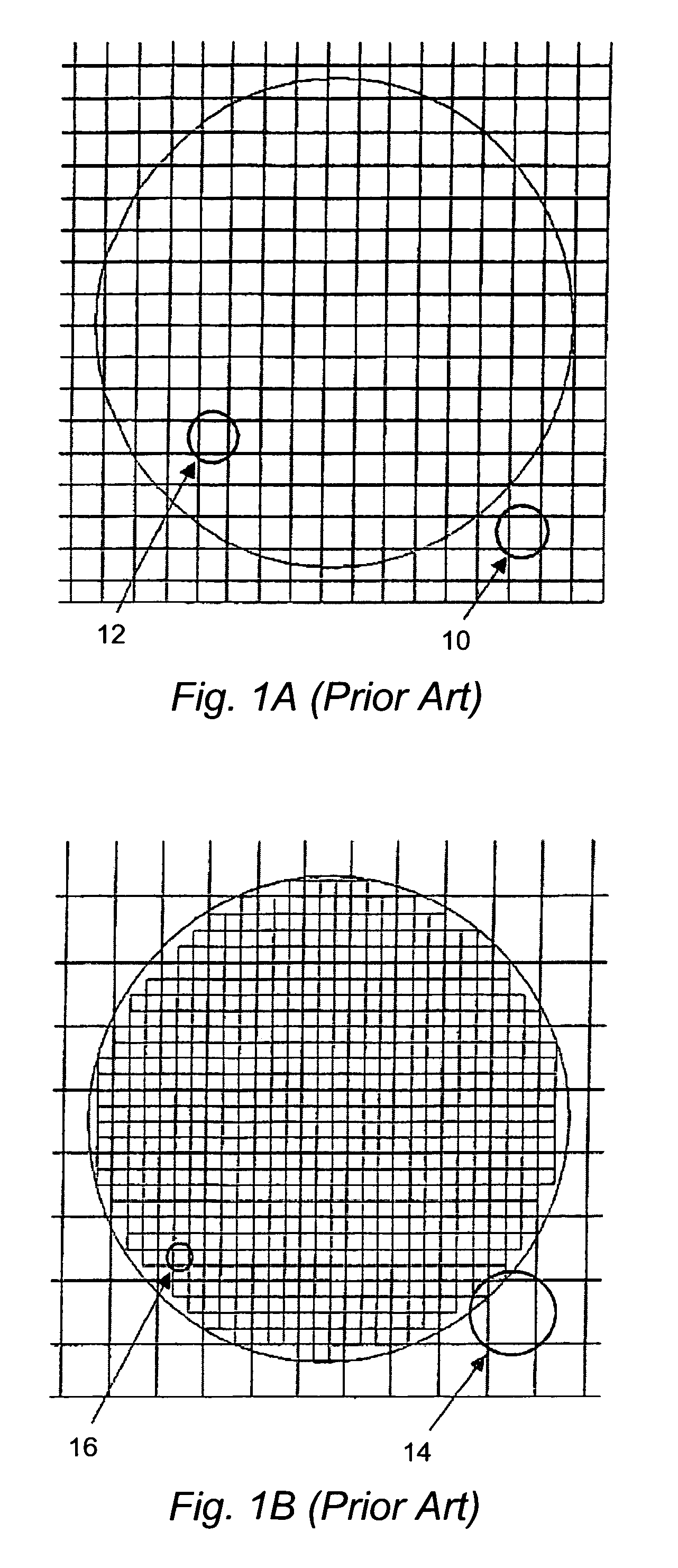

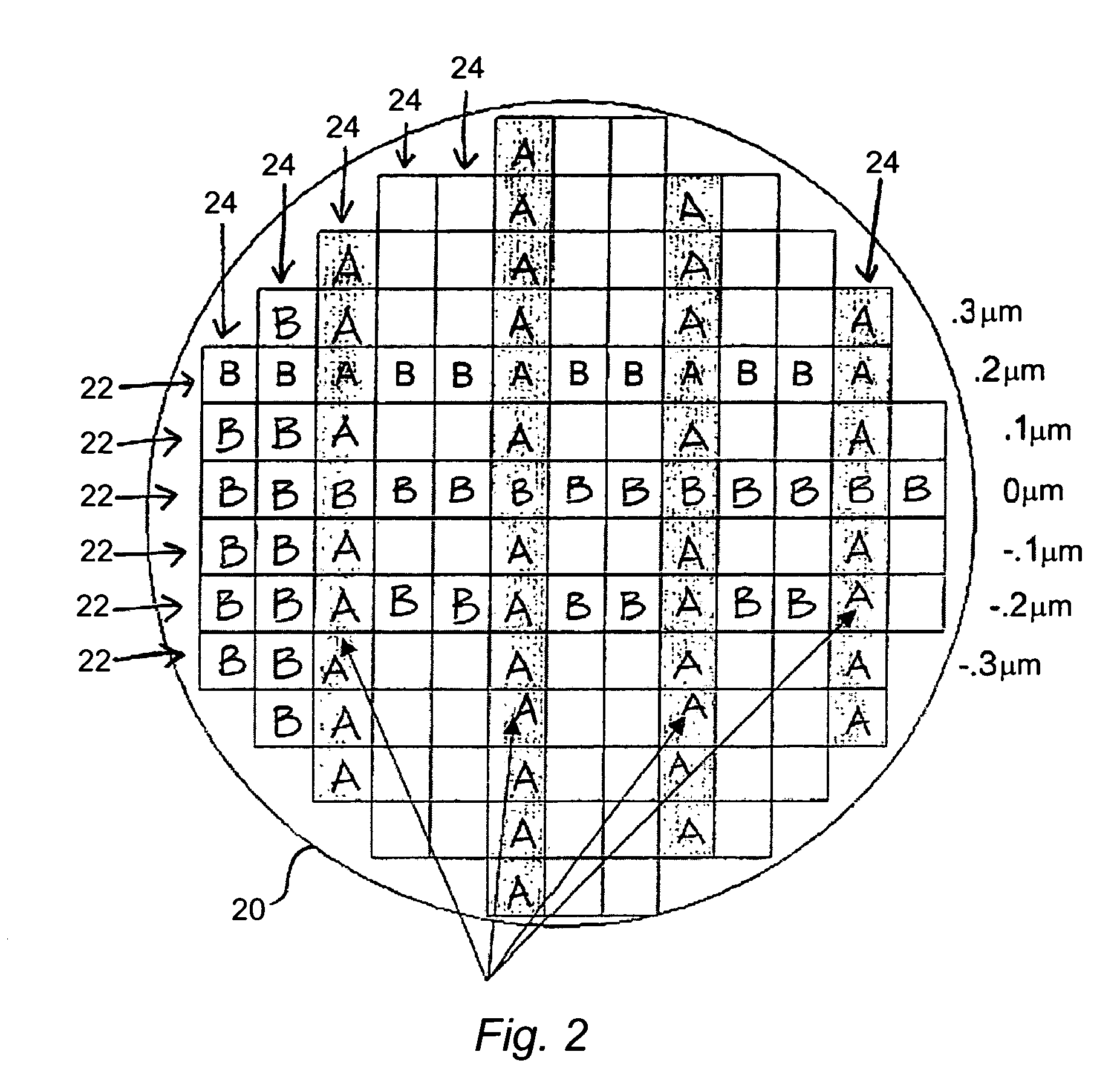

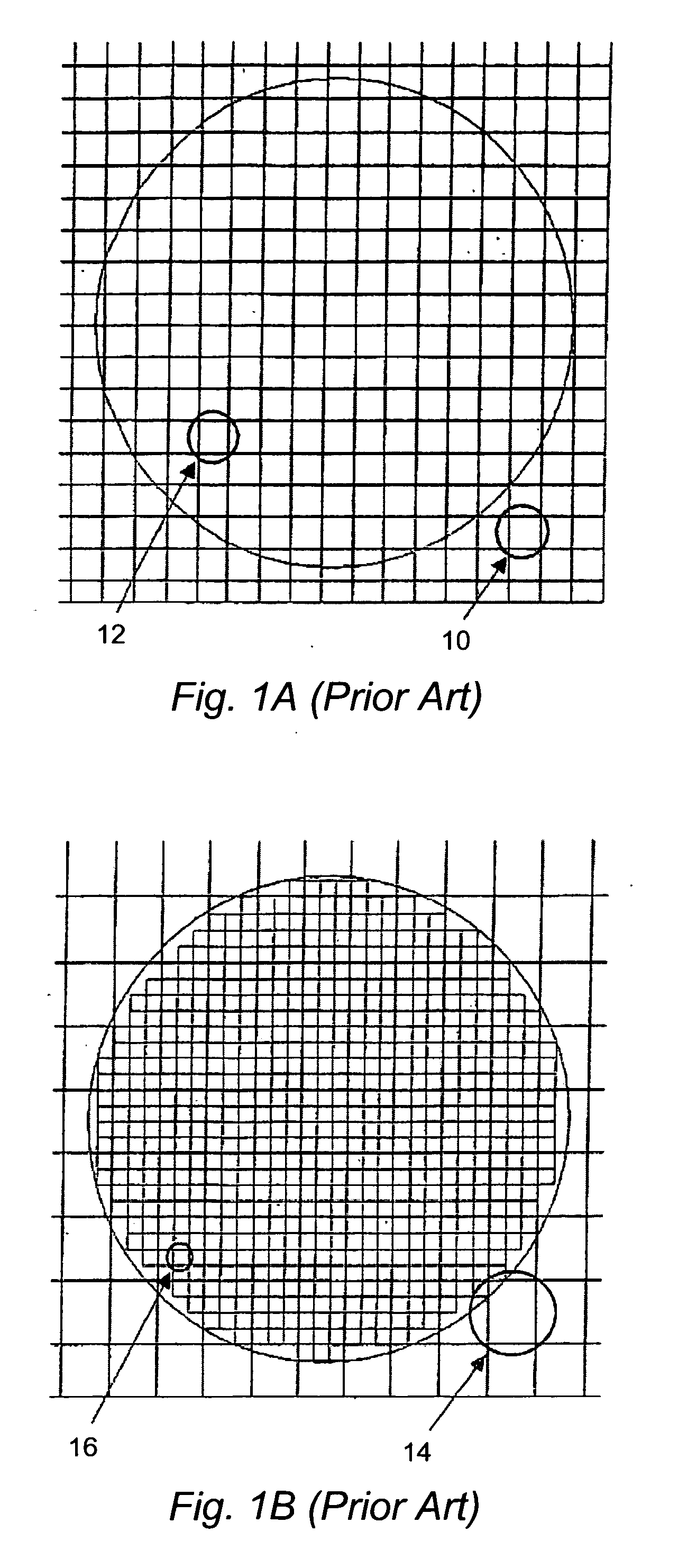

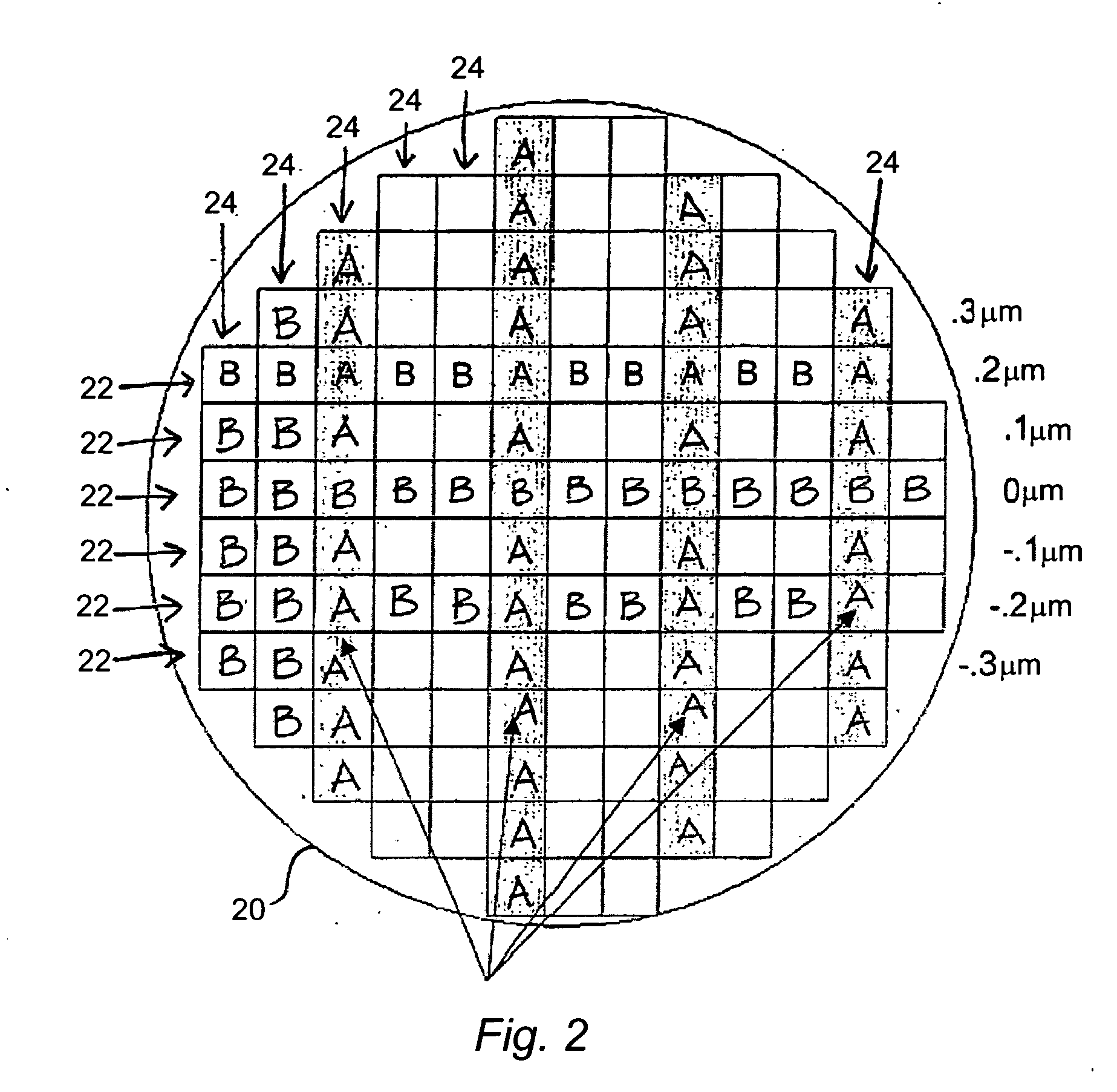

Overlay alignment measurement of wafers

InactiveUS6079256AMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementControl systemEngineering

The present invention is a method and apparatus that uses a microscopic height variation positioned relative to a semiconductor device to scan a target on the device to produce an electrical signal representative of height variations of first and second periodic structures of the target in a selected path across the device, and a computing and control system to provide translation between the microscopic height variation detector and the target on the device in a selected path, and to calculate any offset between the first periodic structure and the second periodic structure of the target from the electrical signals from the microscopic height variation detector. The first periodic structure of the target is on a first layer of the device, and the second periodic structure, that complements the first periodic structure, is on a second layer of the device at a location that is adjacent the first periodic structure.

Owner:KLA INSTR

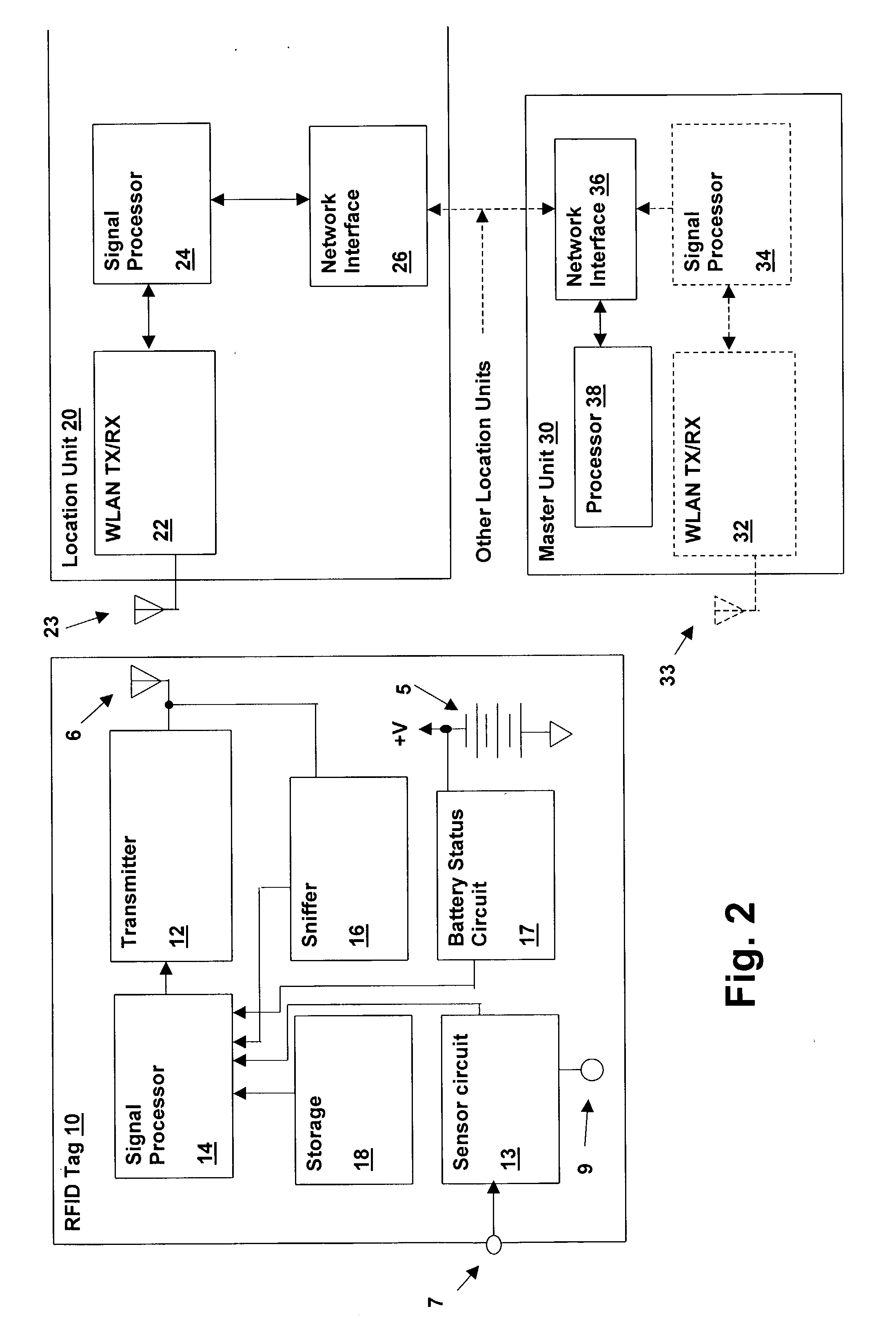

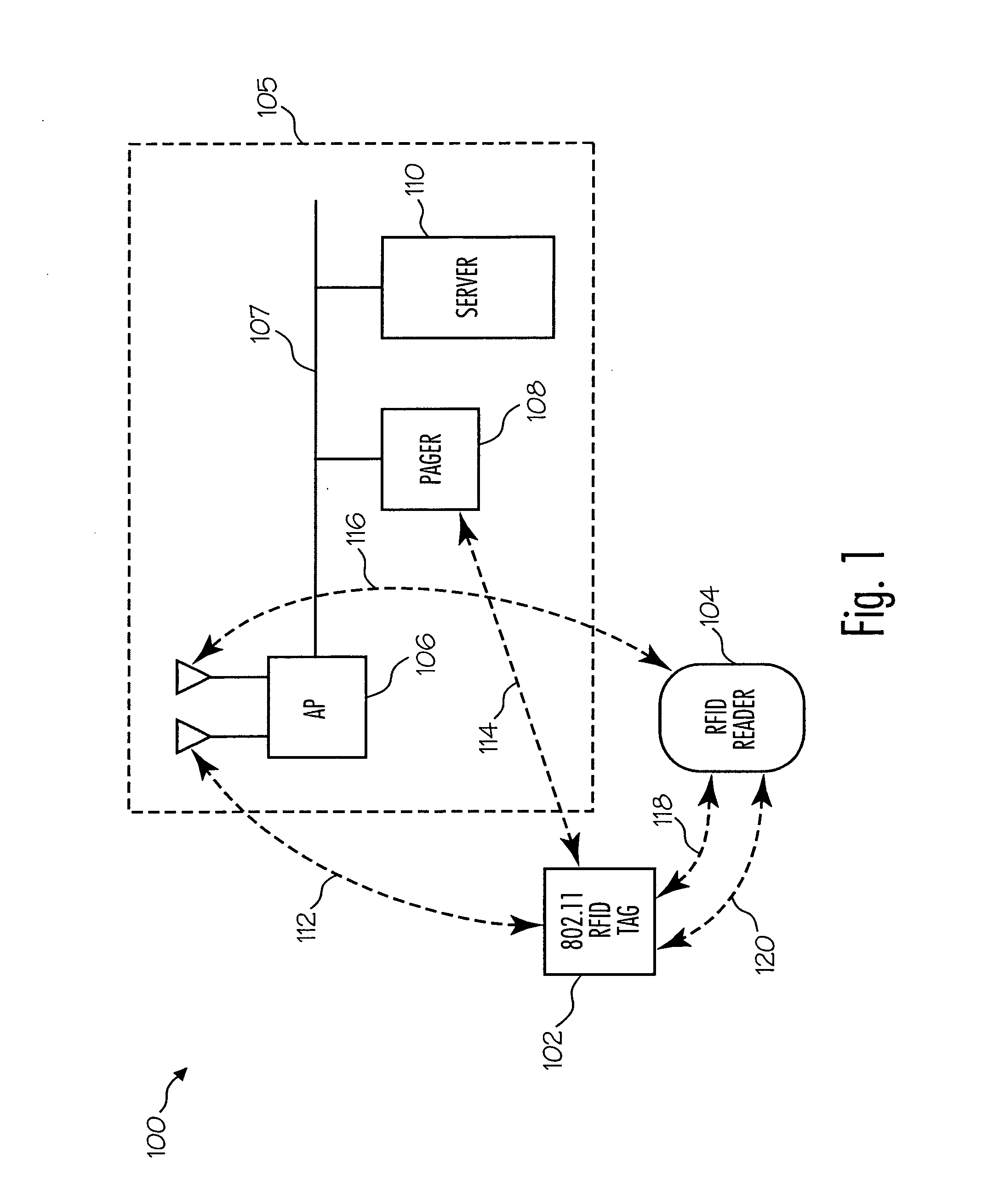

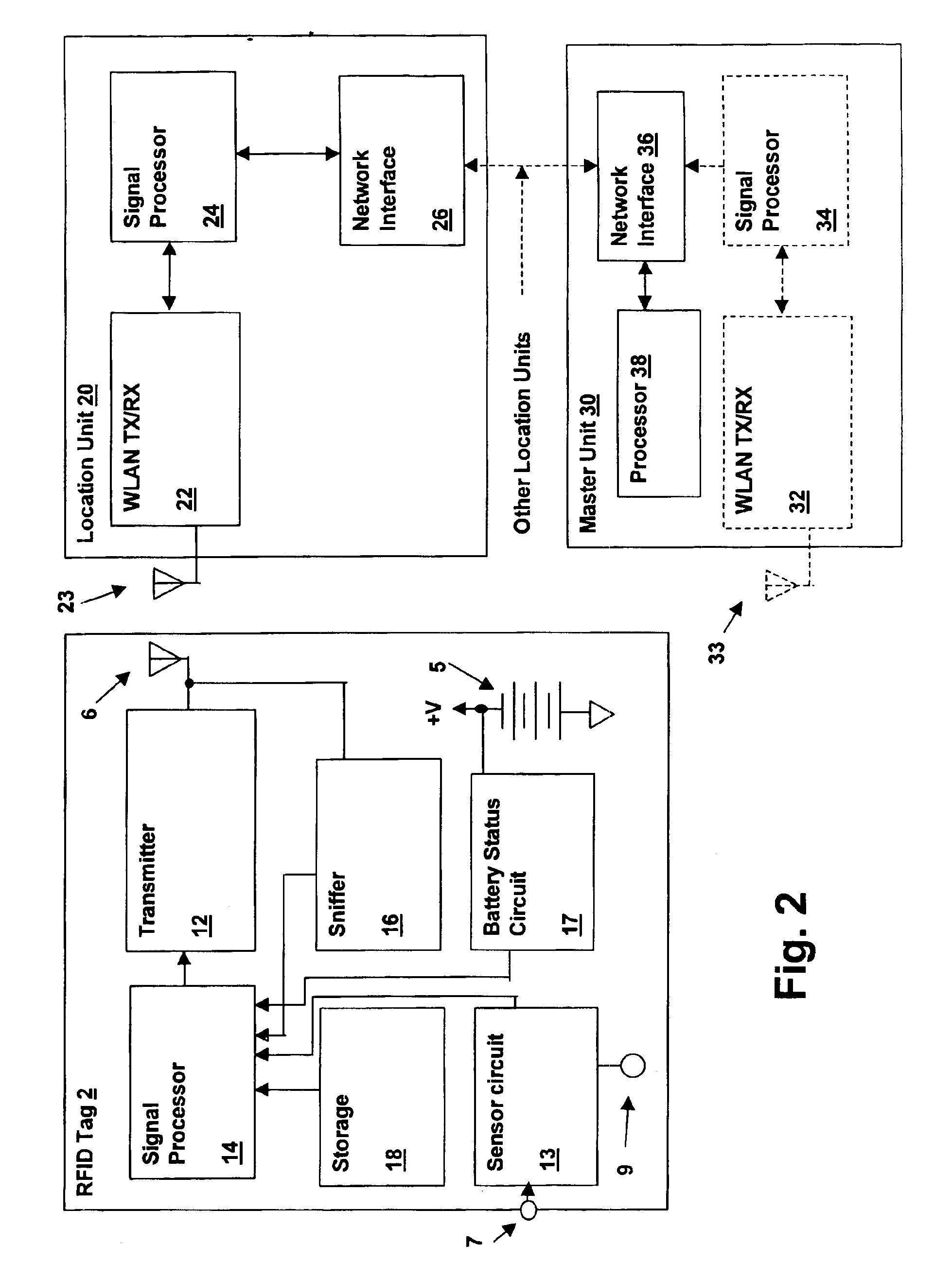

Wireless local area network (WLAN) channel radio-frequency identification (RFID) tag system and method therefor

InactiveUS20040078151A1Network topologiesPosition fixationNetworked Transport of RTCM via Internet ProtocolTelecommunications

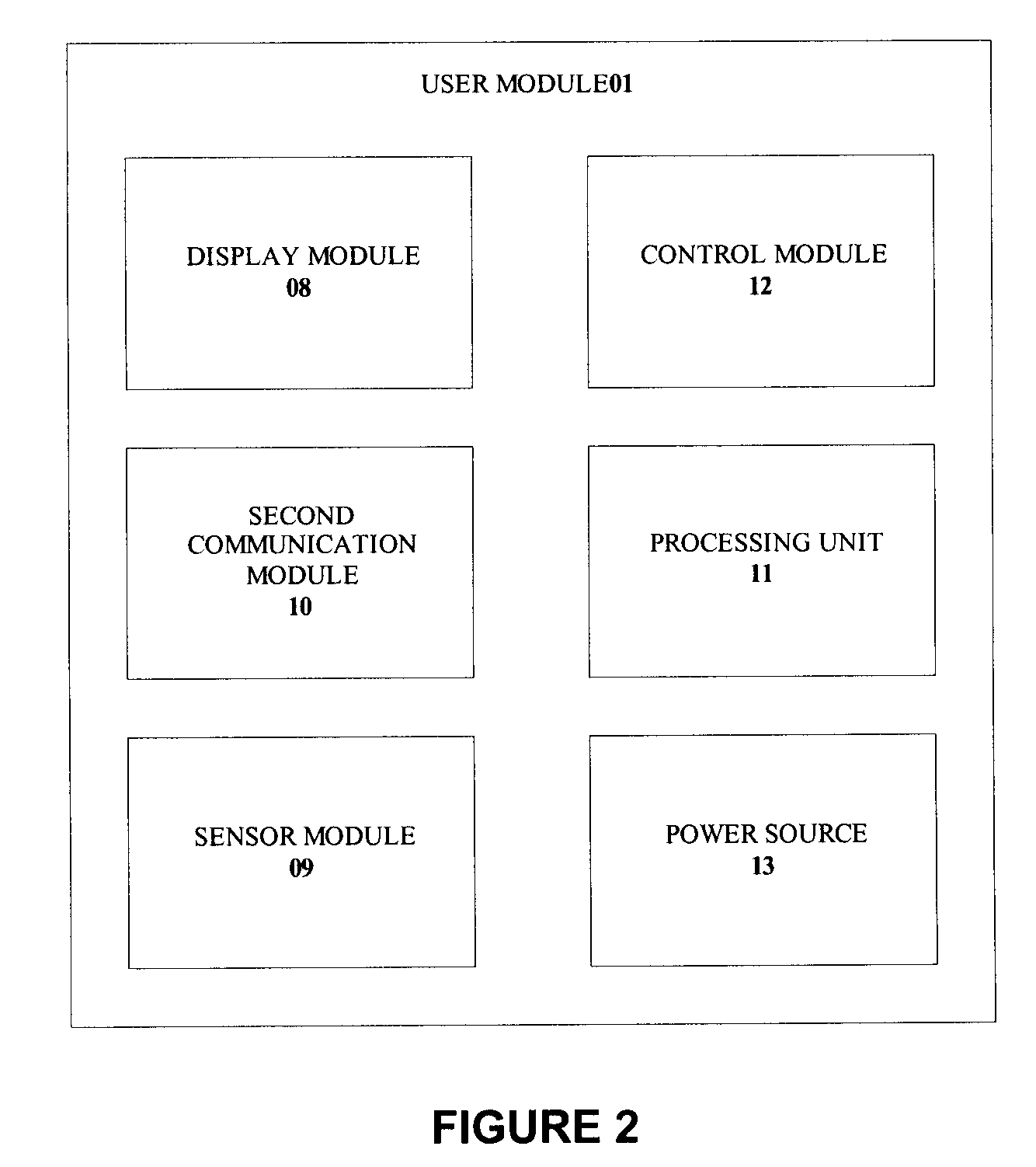

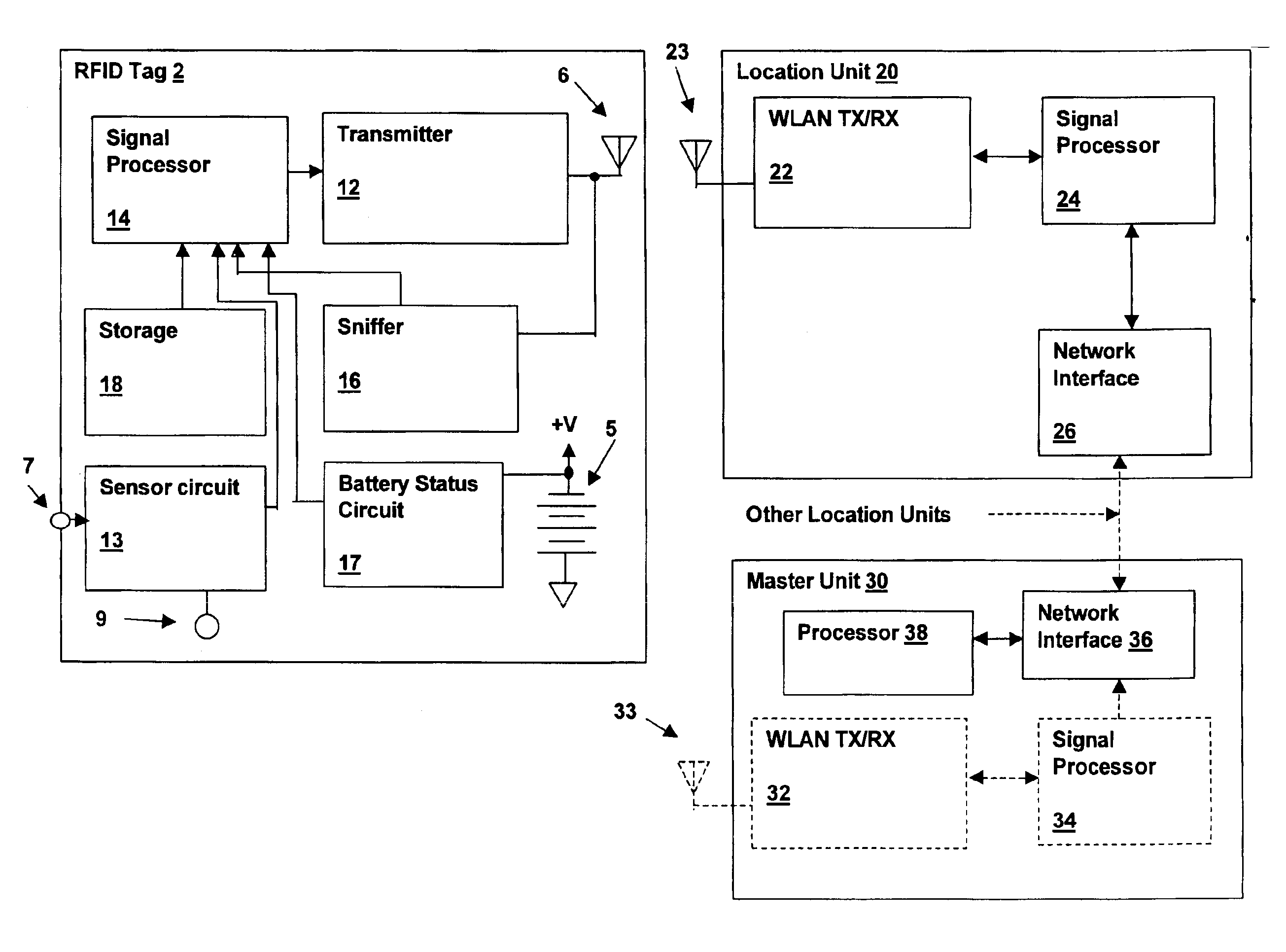

A wireless local area network (WLAN) radio-frequency identification (RFID) tag system provides location finding in a wireless local area network (WLAN), using a WLAN channel. Interference with the WLAN is prevented by either using a sniffer circuit to determine that no network transmission is in progress, using a modified coding sequence or preamble to cause standard WLAN receivers to ignore the RFID tag transmissions, or transmitting a message using a standard WLAN signal addressed to an address not corresponding to a unit within the WLAN. Location units (LUs) and a master unit (MU) within the WLAN receive the RFID tag transmissions and can determine the location of a tag by triangulation based on differences between the signals received at the location units from the tag. The master unit receives the signal information from the location units and computes the location of the tag. Time-difference-of-Arrival (TDOA), received signal strength indication (RSSI) or other triangulation techniques may be used.

Owner:AEROSCOUT

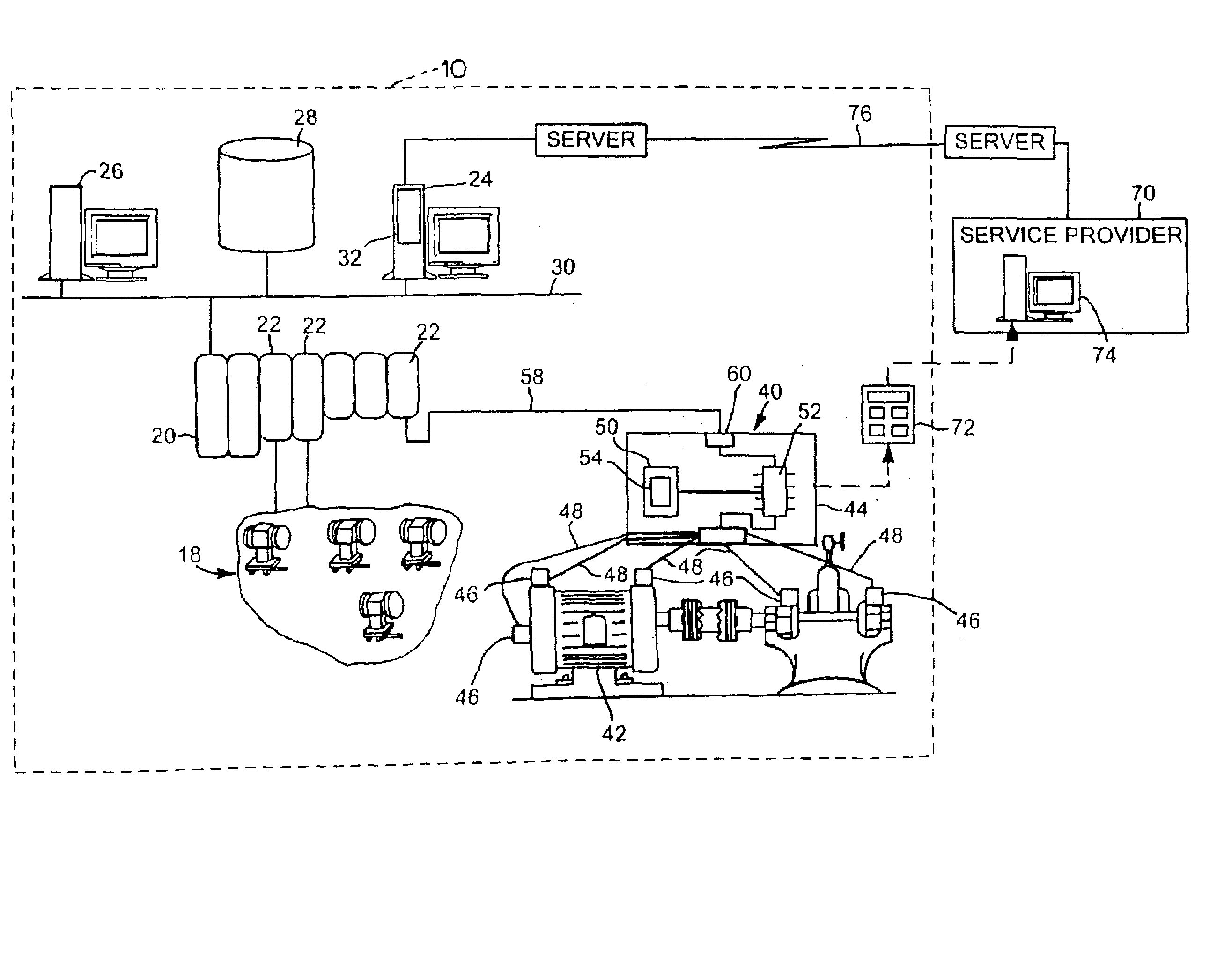

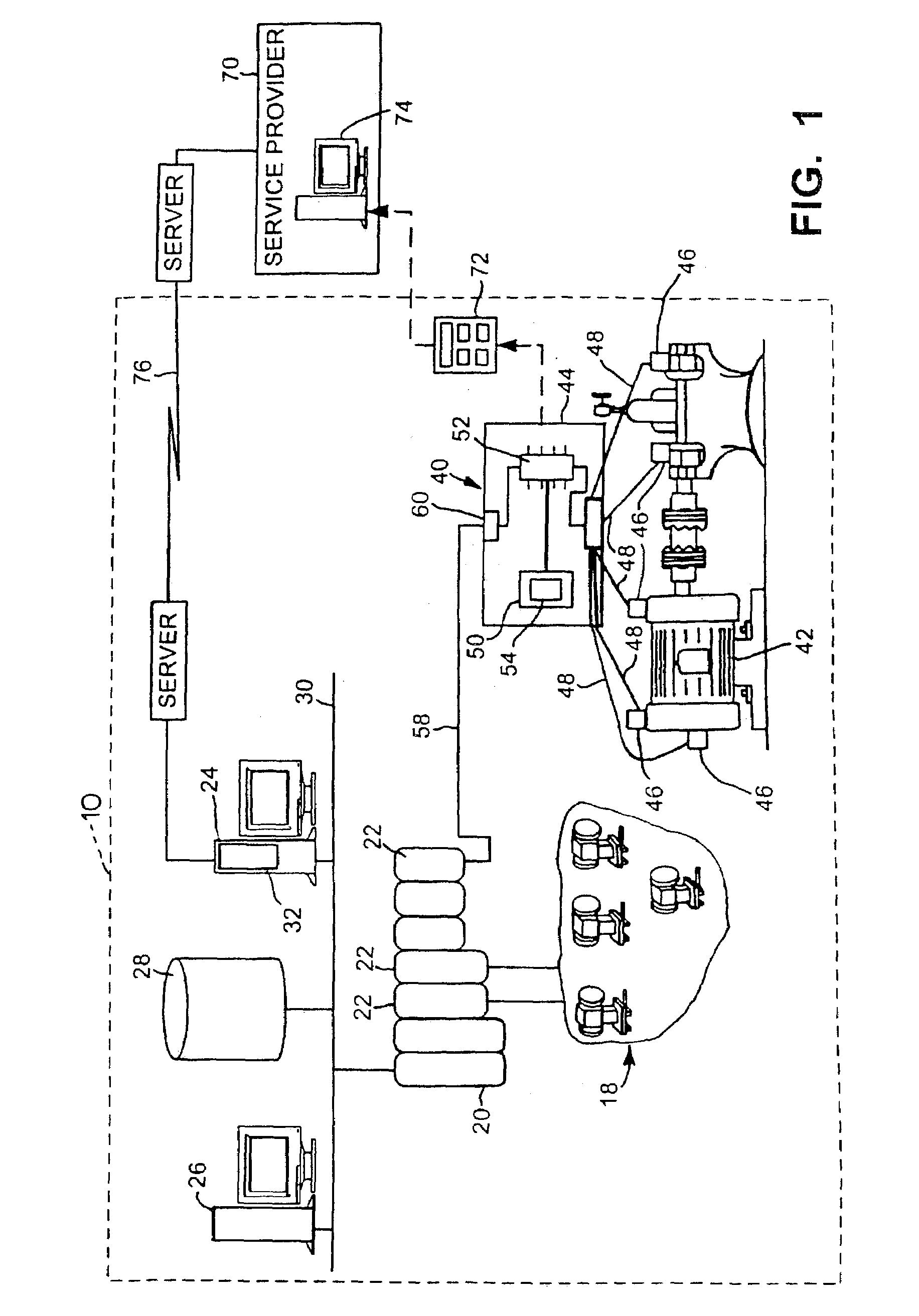

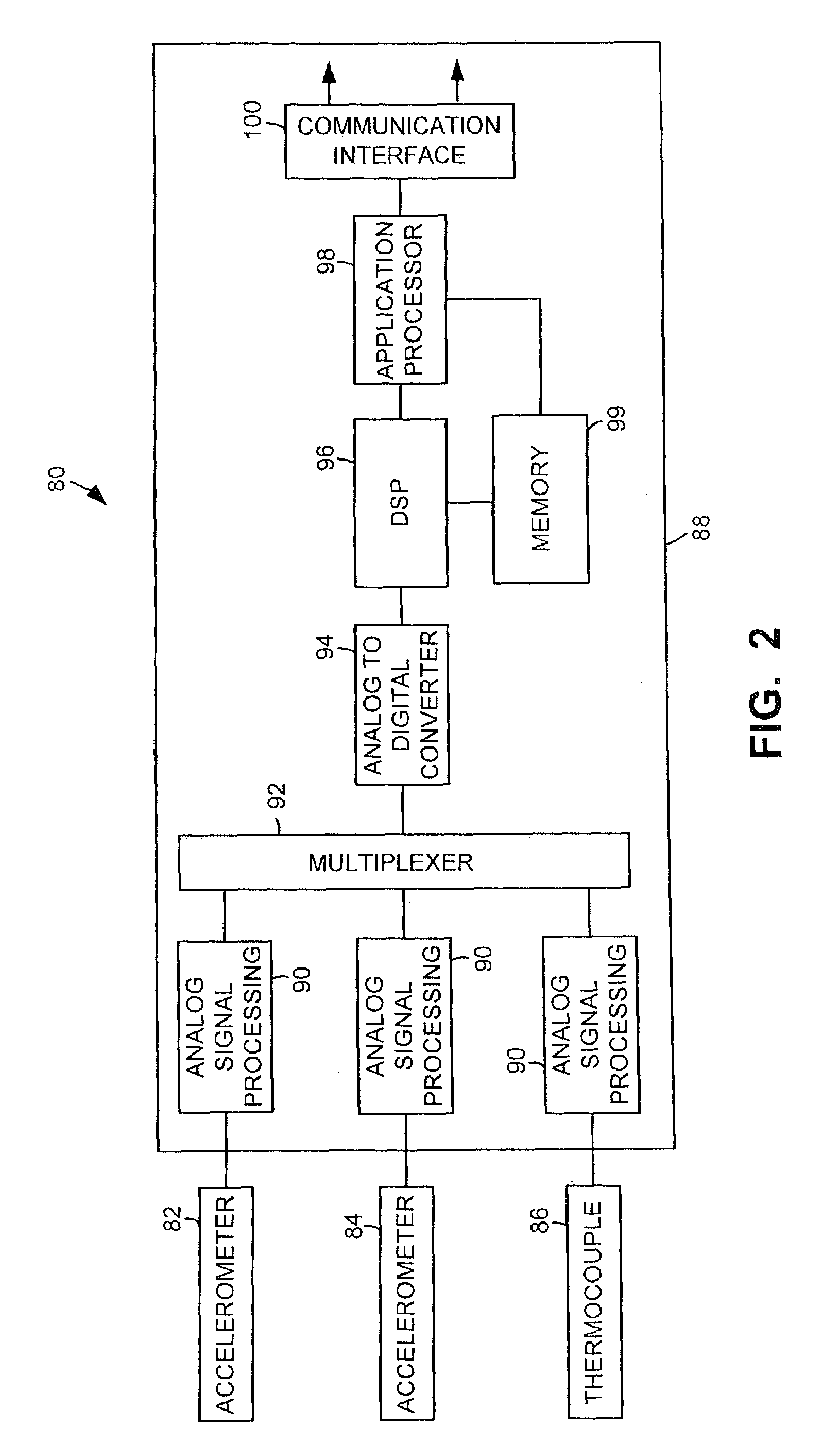

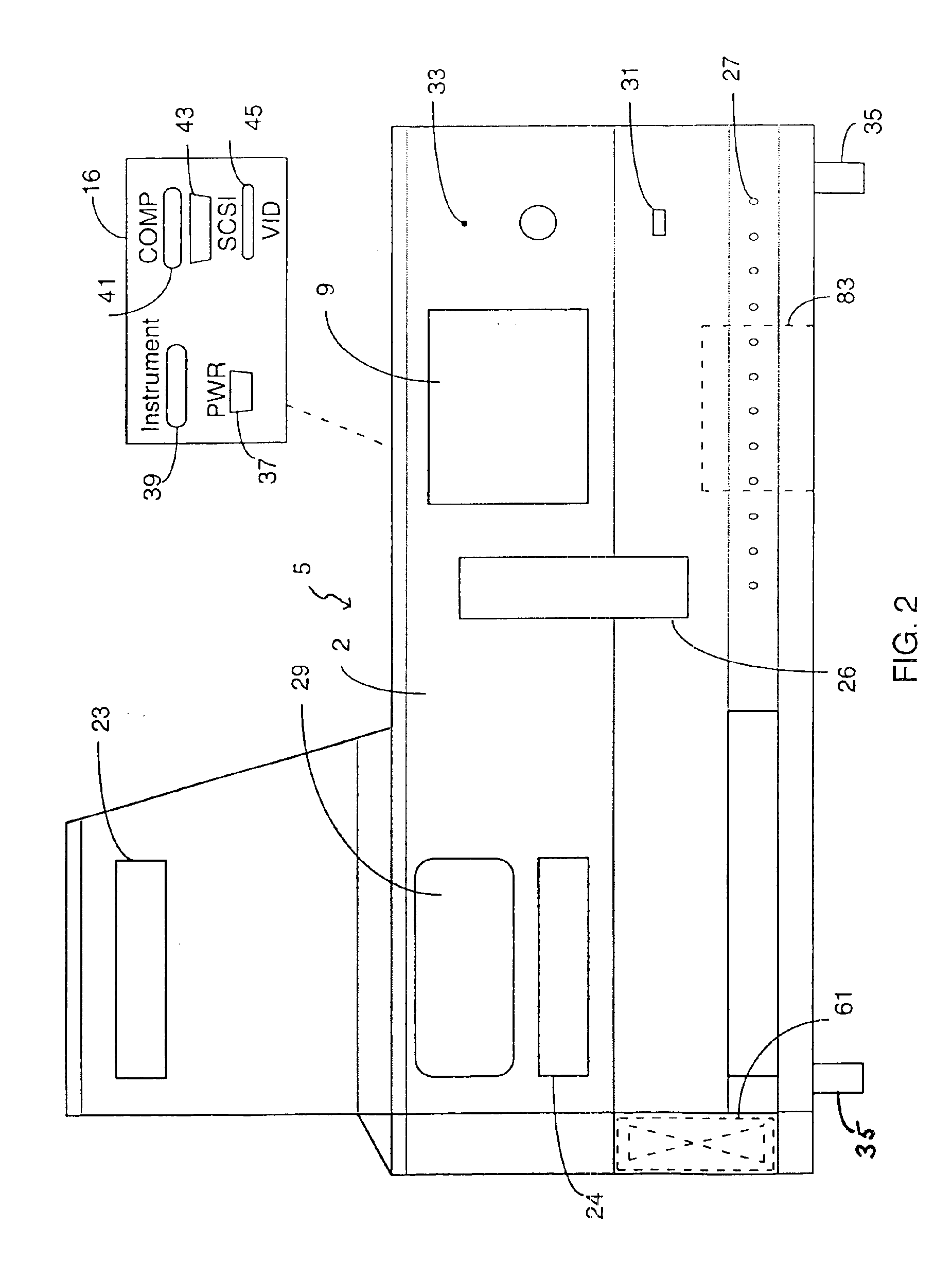

Machine fault information detection and reporting

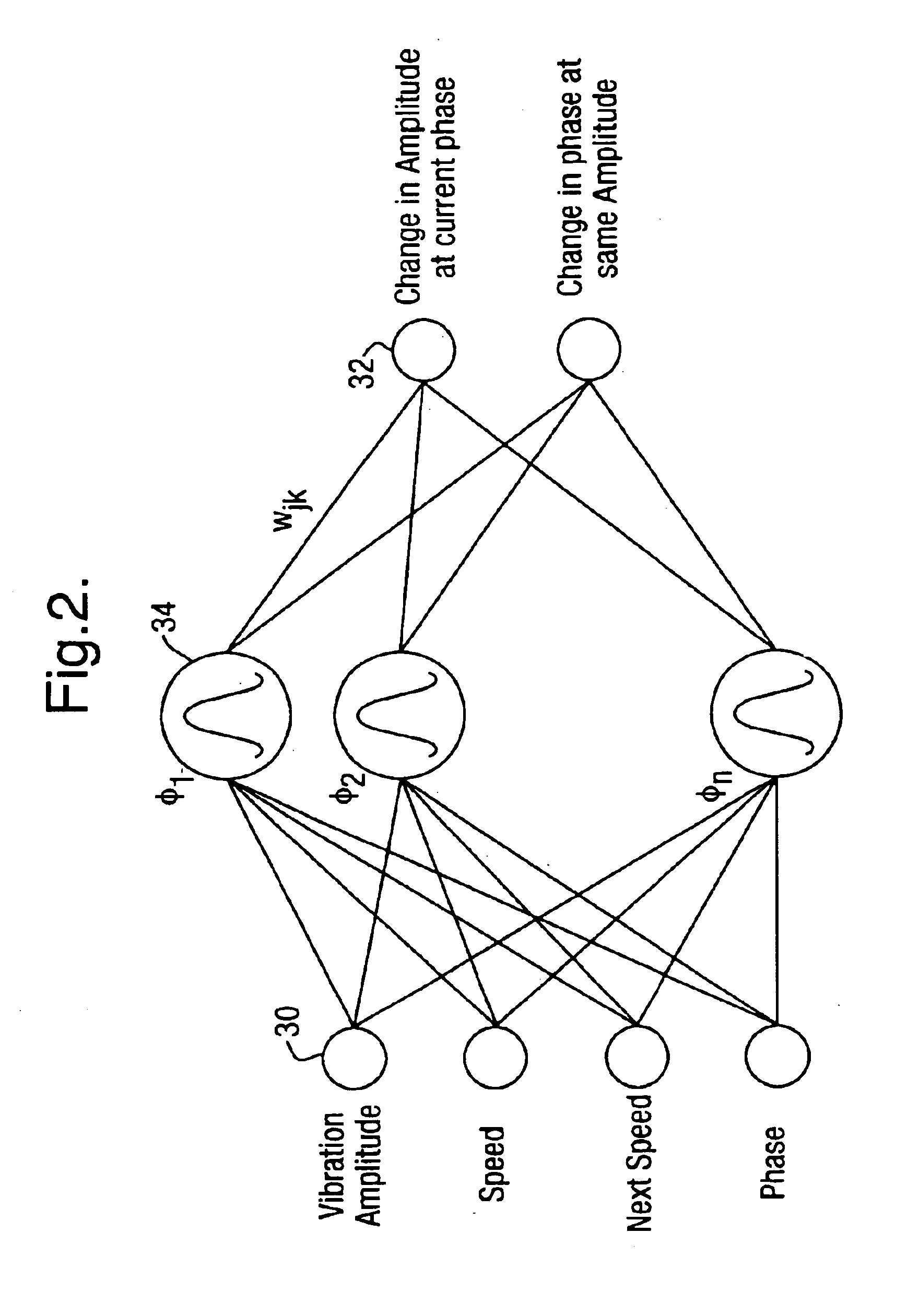

InactiveUS7142990B2Quick identificationEasy to installAmplifier modifications to reduce noise influenceComputer controlCavitationLogical operations

Sensors detect machine parameters such as vibration, turning speed, and temperature, and a local processor performs logic operations based on the parameters and inference rules to produce fault information that is reported to a system processor, which selectively uses the fault information to control the plant machines. The inference rules include rules for determining faults as to balance, alignment, bearing condition, electrical condition, and cavitation. The inference rules are contained in rules code that is separate from the analysis code that performs the logical operations. Thus, the inference rules may be easily changed without changing other code, such as the analysis code.

Owner:COMPUTATIONAL SYST

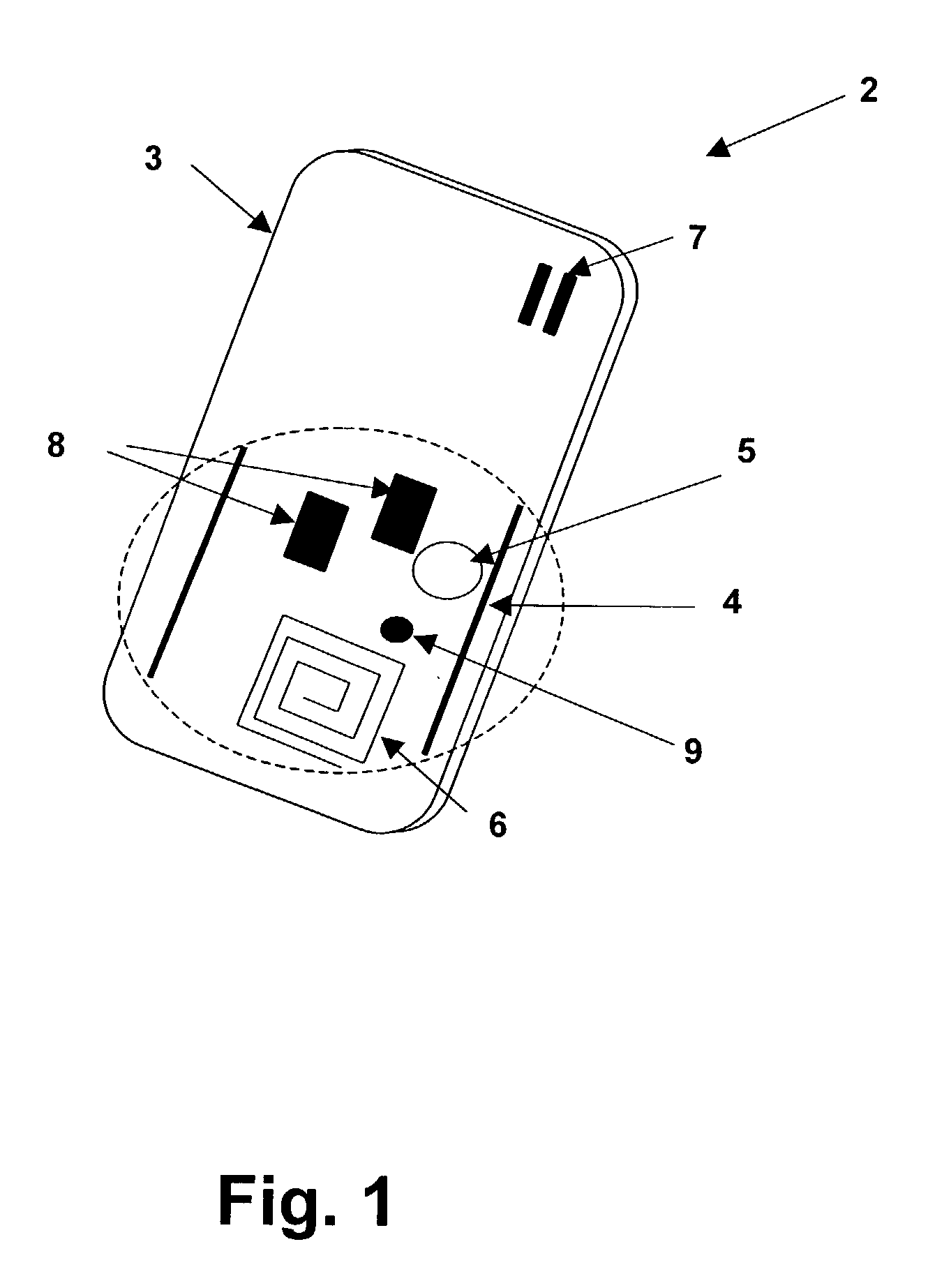

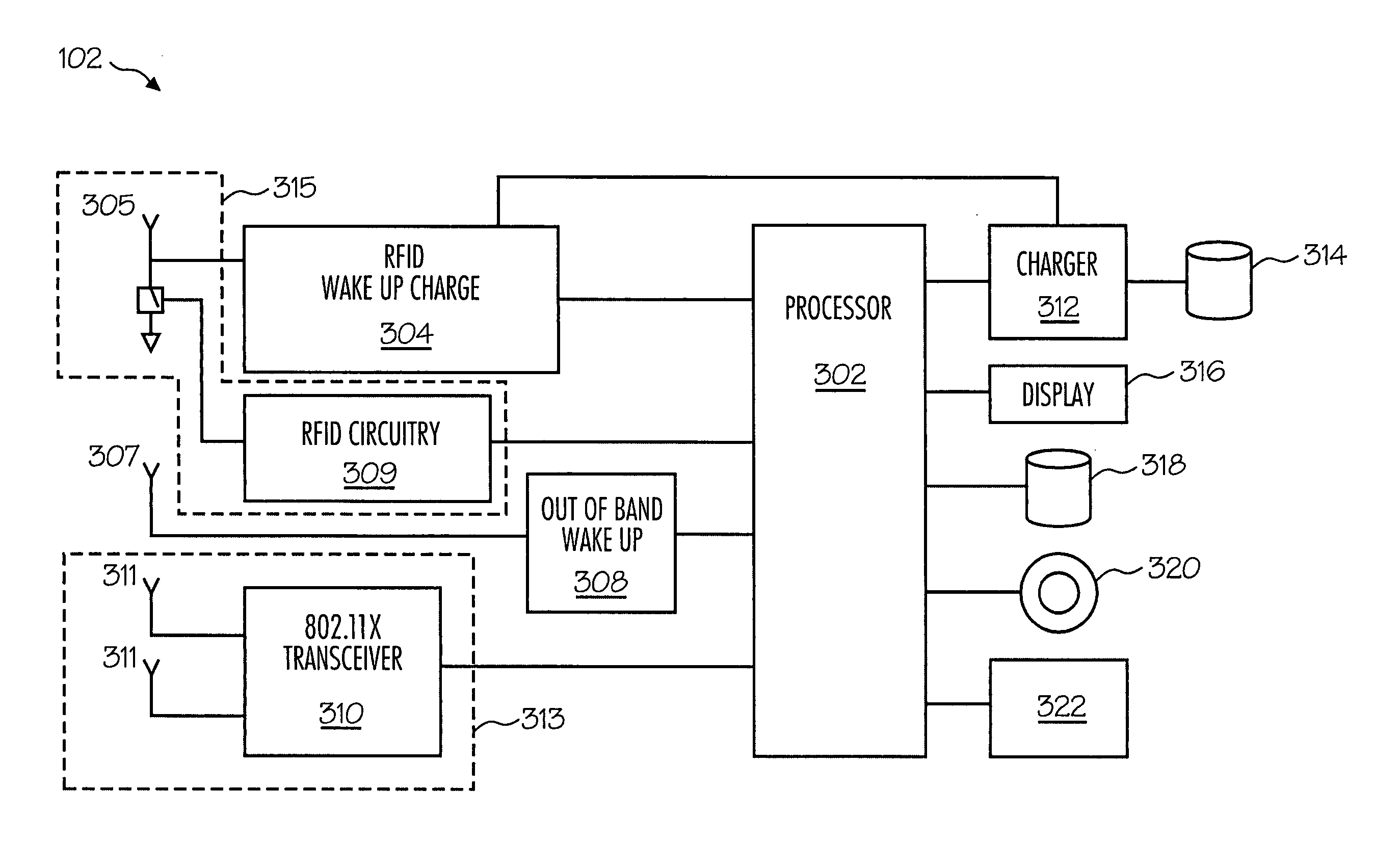

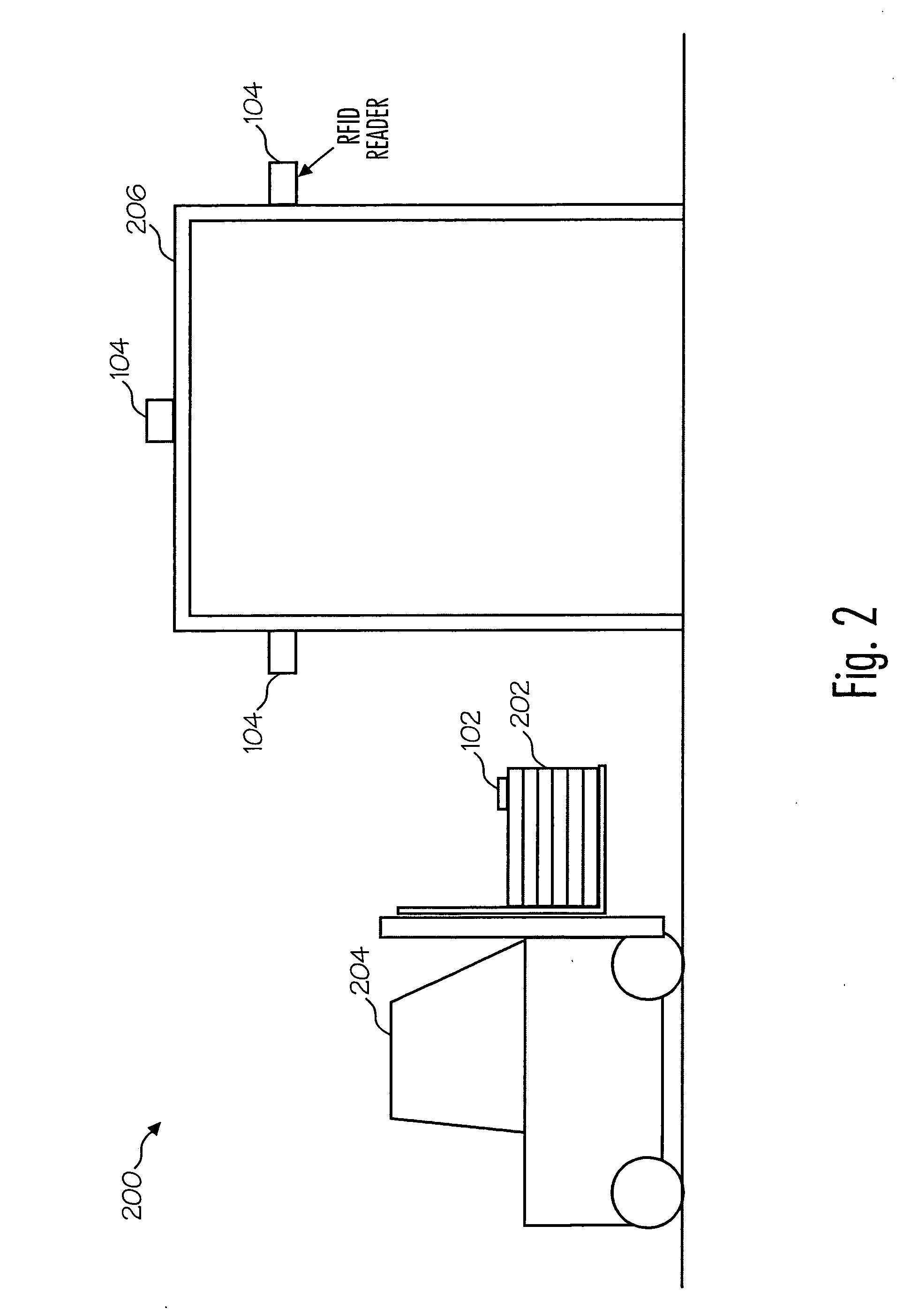

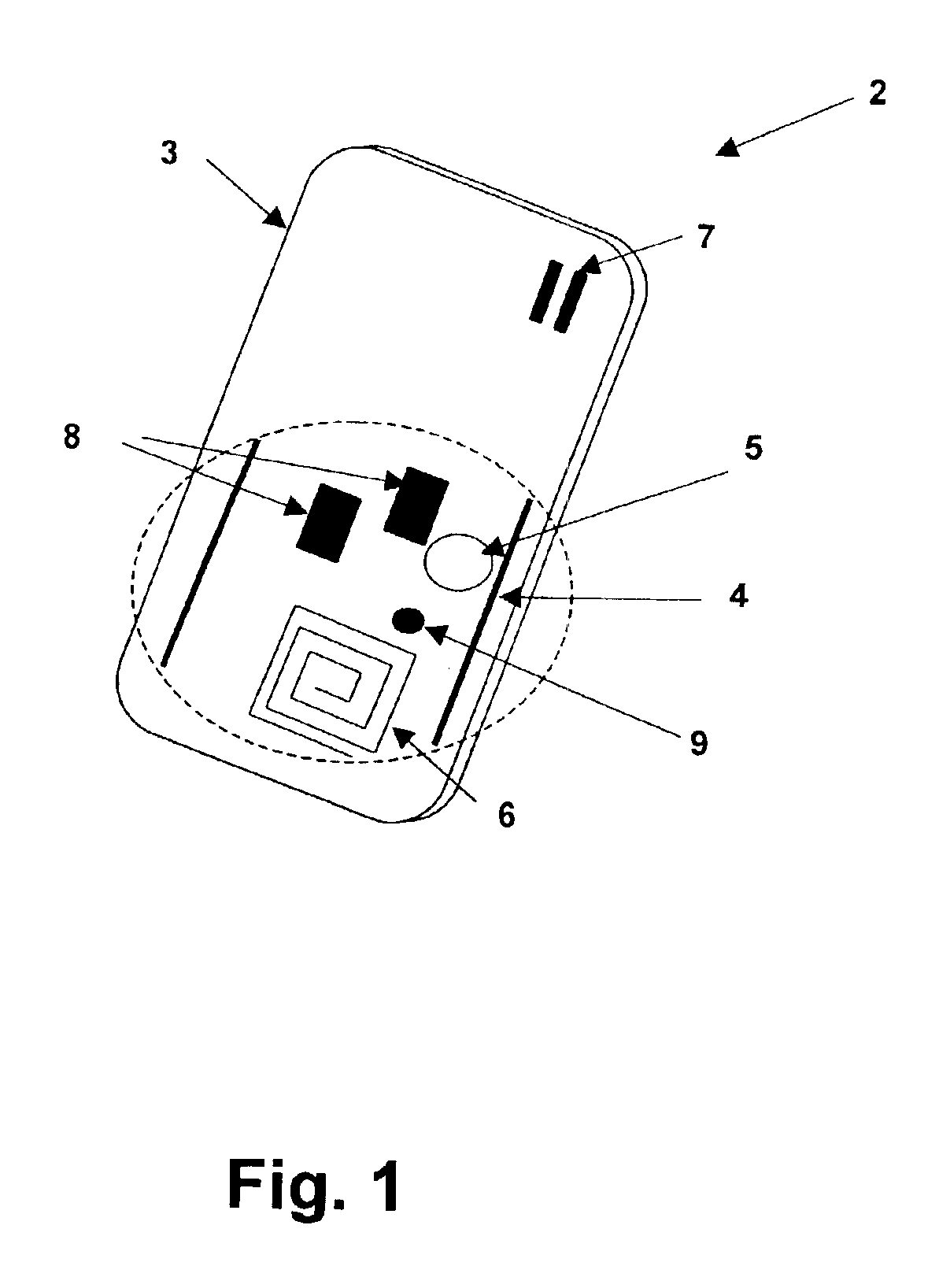

Multimode wireless local area network/radio frequency identification asset tag

InactiveUS20050030160A1Save powerMemory record carrier reading problemsNetwork topologiesTransceiverWireless transceiver

Asset tags for use in a WLAN / RFID system are provided. The asset tag comprises a processor, an RFID antenna coupled to the processor and configured to receive interrogations from an RFID reader and send replies to the RFID reader; and a wireless transceiver coupled to the processor, the wireless transceiver configured to receive information from and send information to a wireless access port of a wireless local area network.

Owner:SYMBOL TECH INC

System and method for monitoring and estimating energy resource consumption

ActiveUS7541941B2Good estimateEasy to understandEnergy efficient ICTElectric signal transmission systemsElectricityEngineering

The present invention discloses a system for monitoring and estimating the consumption of energy resources in real-time. The system includes an interactive user module, a measuring unit and a wireless network. The measuring unit is interfaced to a utility meter. Optionally, the measuring unit can also function as a stand alone device. The measuring unit is further connected to the interactive user module via the wireless network. The system monitors energy resource consumption such as electricity, gas or water consumption in real-time, generates and displays graphs of energy resource consumption over user selected time periods and enables communication with at least one utility company. The system increases the users' awareness of their energy consumption and aids users in dynamic or deregulated pricing environments to shed load when the energy resource is most expensive. With knowledge of their energy use, the users can take proactive steps to control their energy consumption and save money. A method of estimating the energy resource consumption over a period of time is also provided.

Owner:ITRON NETWORKED SOLUTIONS INC

Wireless local area network (WLAN) channel radio-frequency identification (RFID) tag system and method therefor

InactiveUS6963289B2Reduce stepsNetwork topologiesPosition fixationTelecommunicationsNetworked Transport of RTCM via Internet Protocol

A wireless local area network (WLAN) radio-frequency identification (RFID) tag system provides location finding in a wireless local area network (WLAN), using a WLAN channel. Interference with the WLAN is prevented by either using a sniffer circuit to determine that no network transmission is in progress, using a modified coding sequence or preamble to cause standard WLAN receivers to ignore the RFID tag transmissions, or transmitting a message using a standard WLAN signal addressed to an address not corresponding to a unit within the WLAN. Location units (LUs) and a master unit (MU) within the WLAN receive the RFID tag transmissions and can determine the location of a tag by triangulation based on differences between the signals received at the location units from the tag. The master unit receives the signal information from the location units and computes the location of the tag. Time-difference-of-Arrival (TDOA), received signal strength indication (RSSI) or other triangulation techniques may be used.

Owner:AEROSCOUT

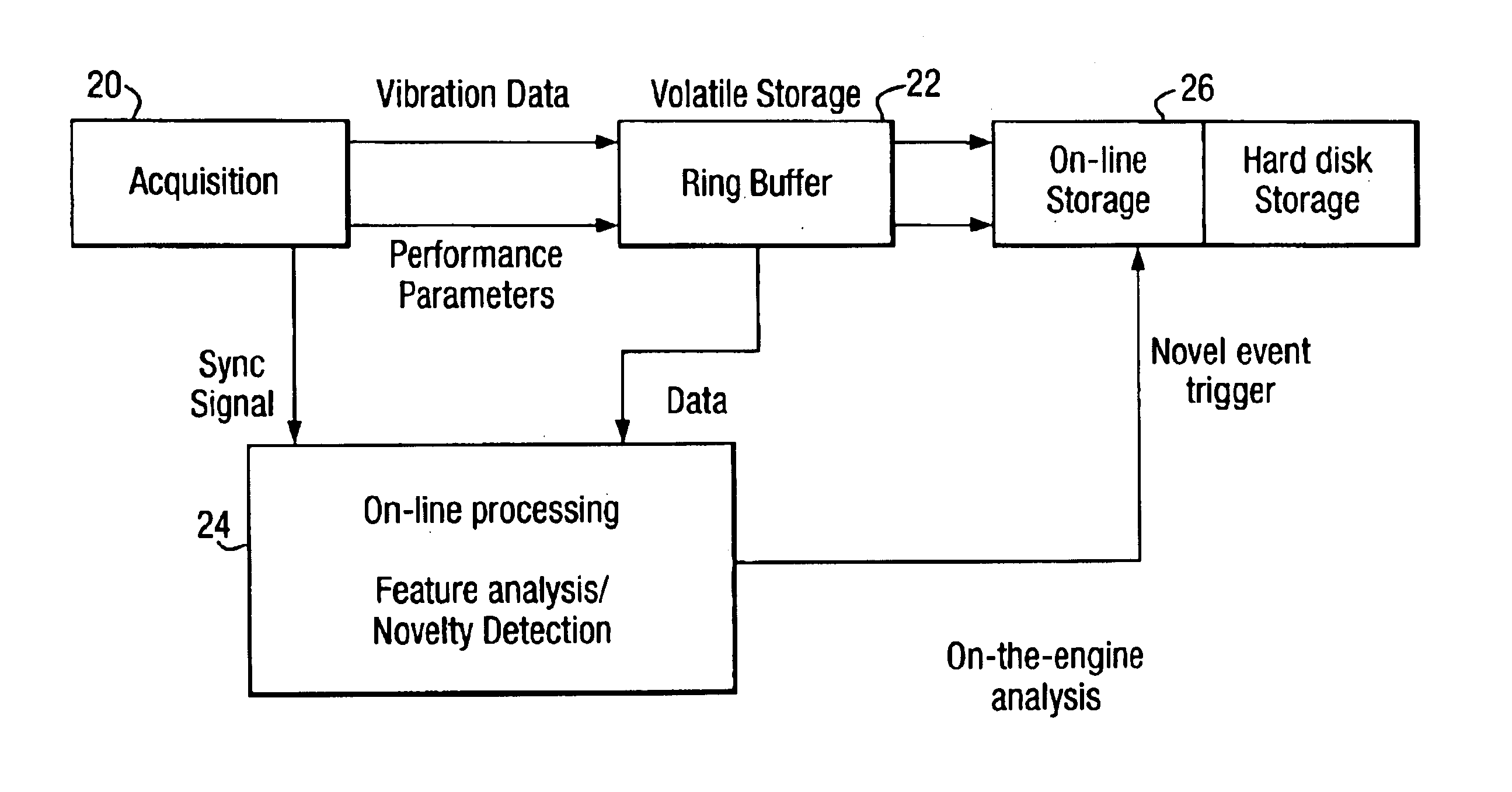

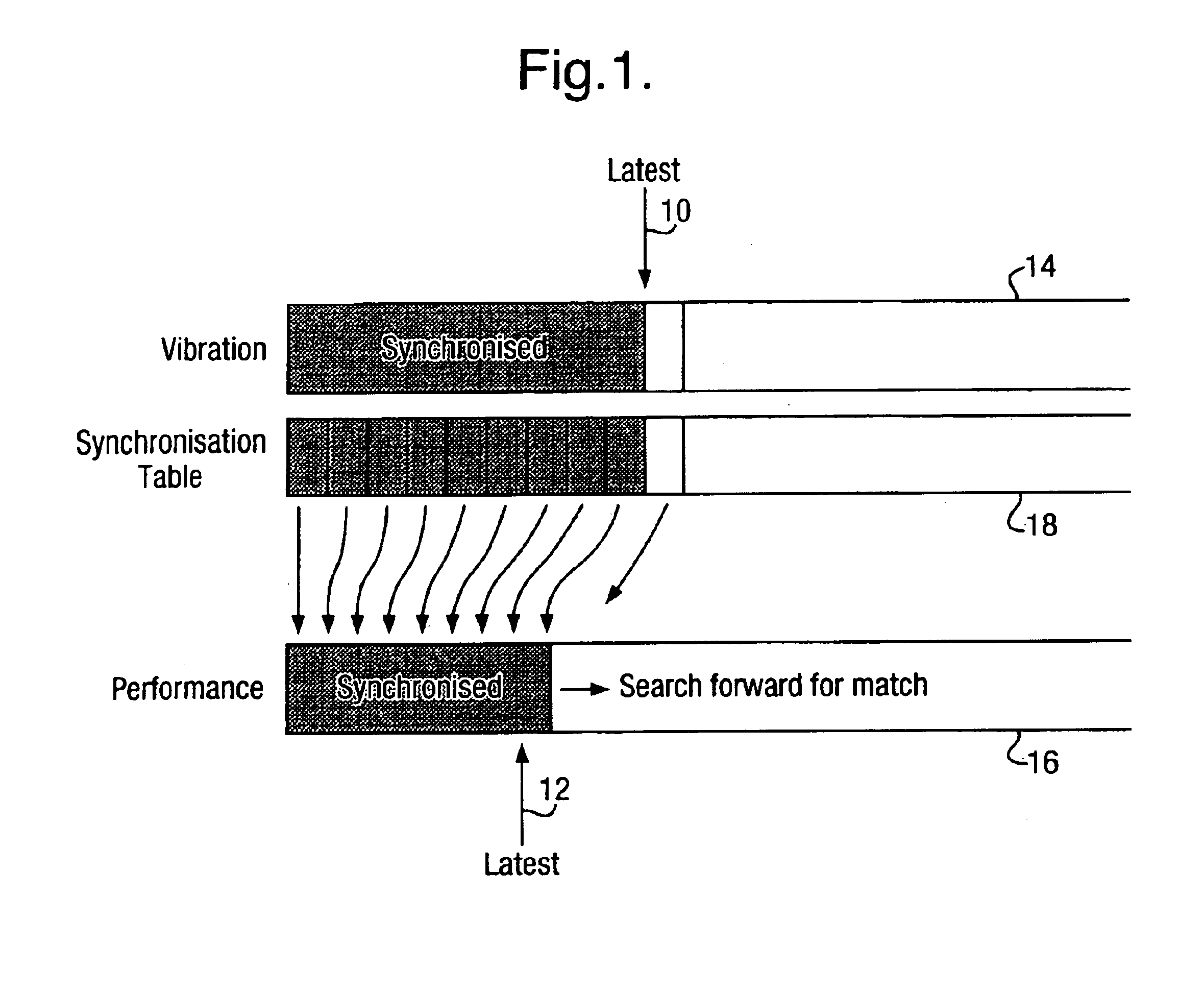

Health monitoring

InactiveUS6928370B2Facilitate acquisitionEasy to analyzeVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesVibration measurementMonitoring system

A method for monitoring the health of a system comprises performing at each of a plurality of times the steps of:constructing a condition signature from a plurality of condition indicators including (a) a plurality of vibration measurements acquired from the system or (b) one or more vibration measurements and one or more performance parameter measurements acquired from the system;predicting a normal signature from a model defining one or more inter-dependencies between said condition indicators, the normal signature corresponding to the condition signature for a healthy system;comparing the condition signature with the normal signature; andregistering an event if the condition signature differs from the normal signature by more than a predetermined threshold.

Owner:ROLLS ROYCE PLC

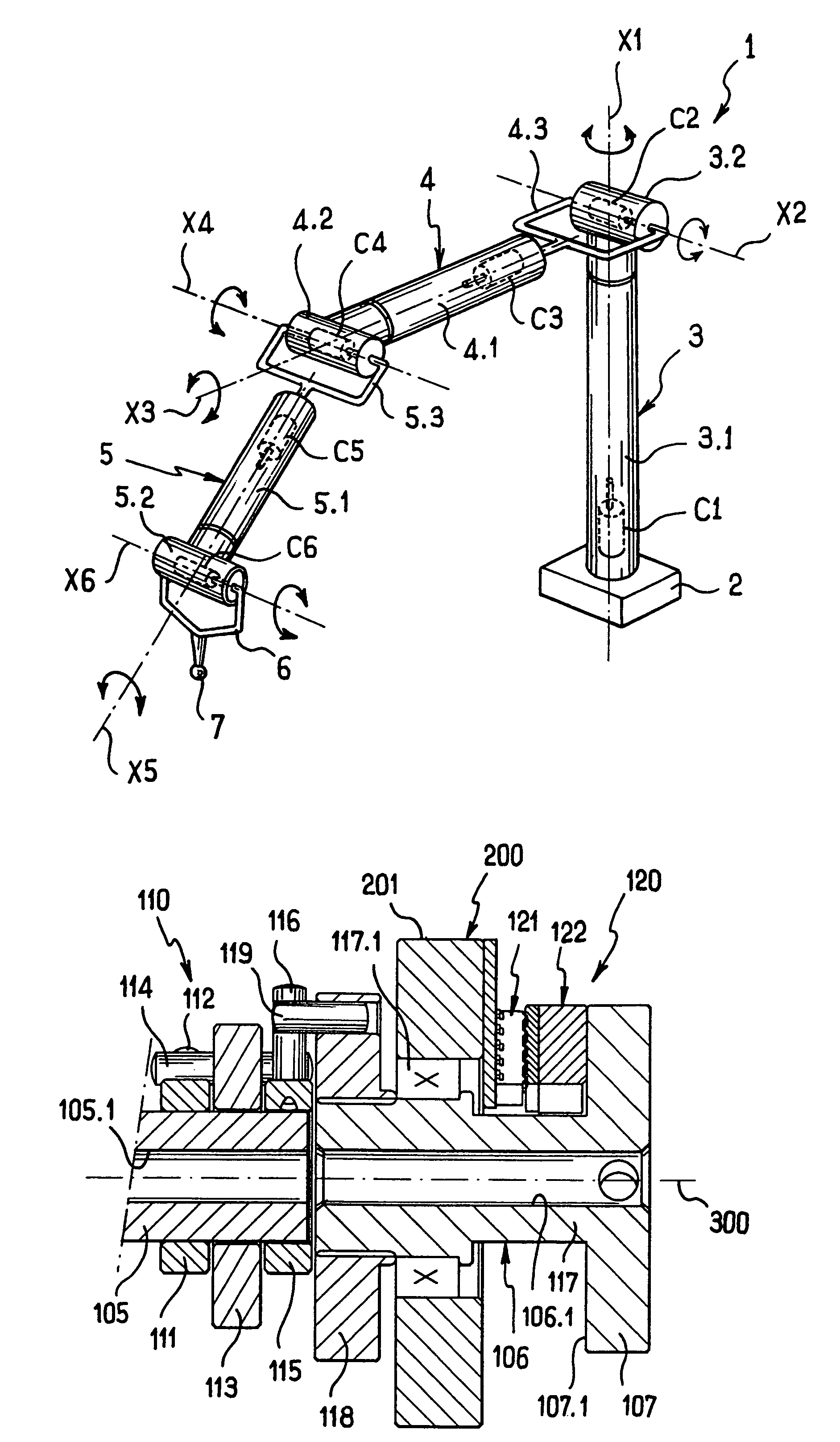

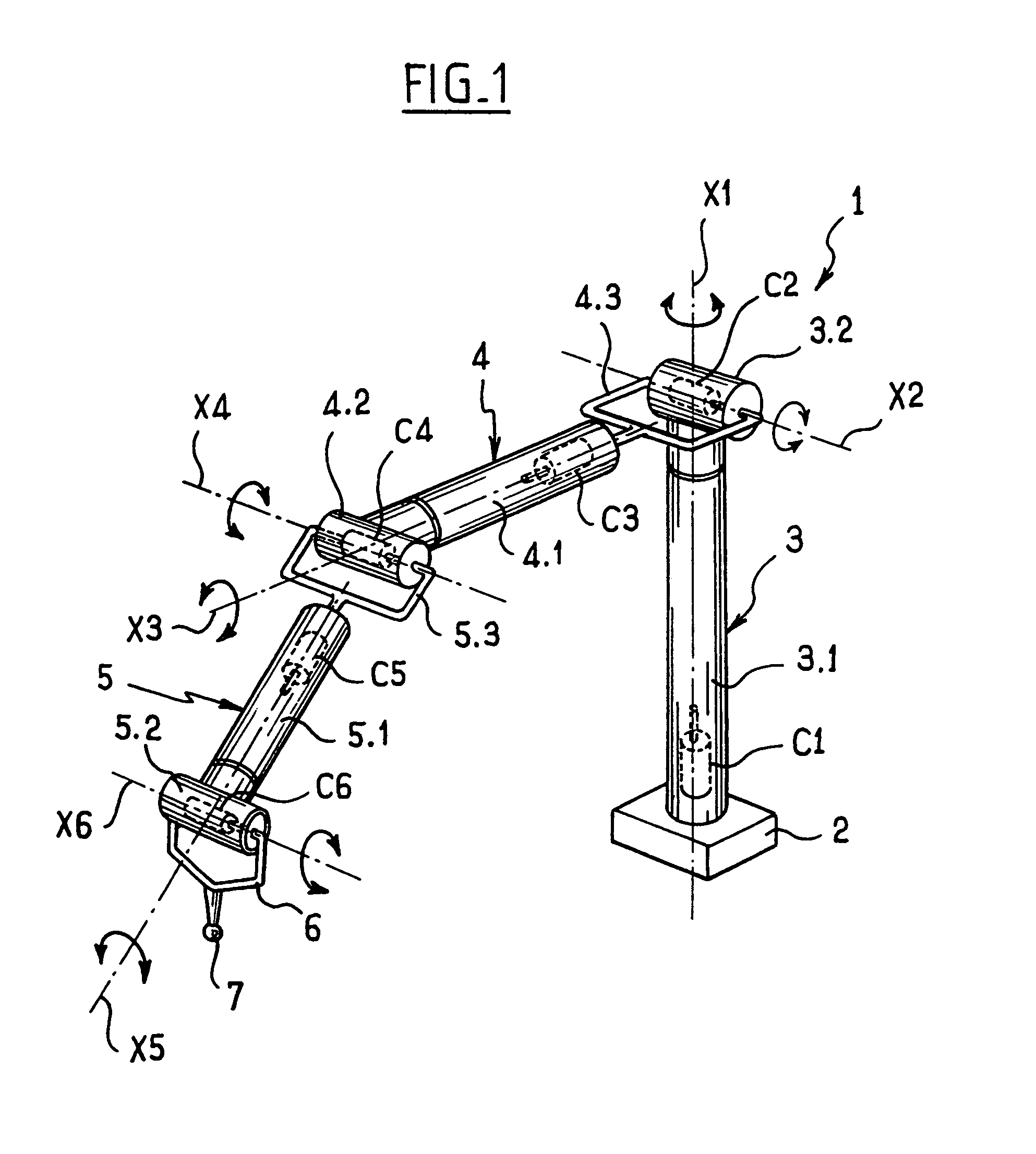

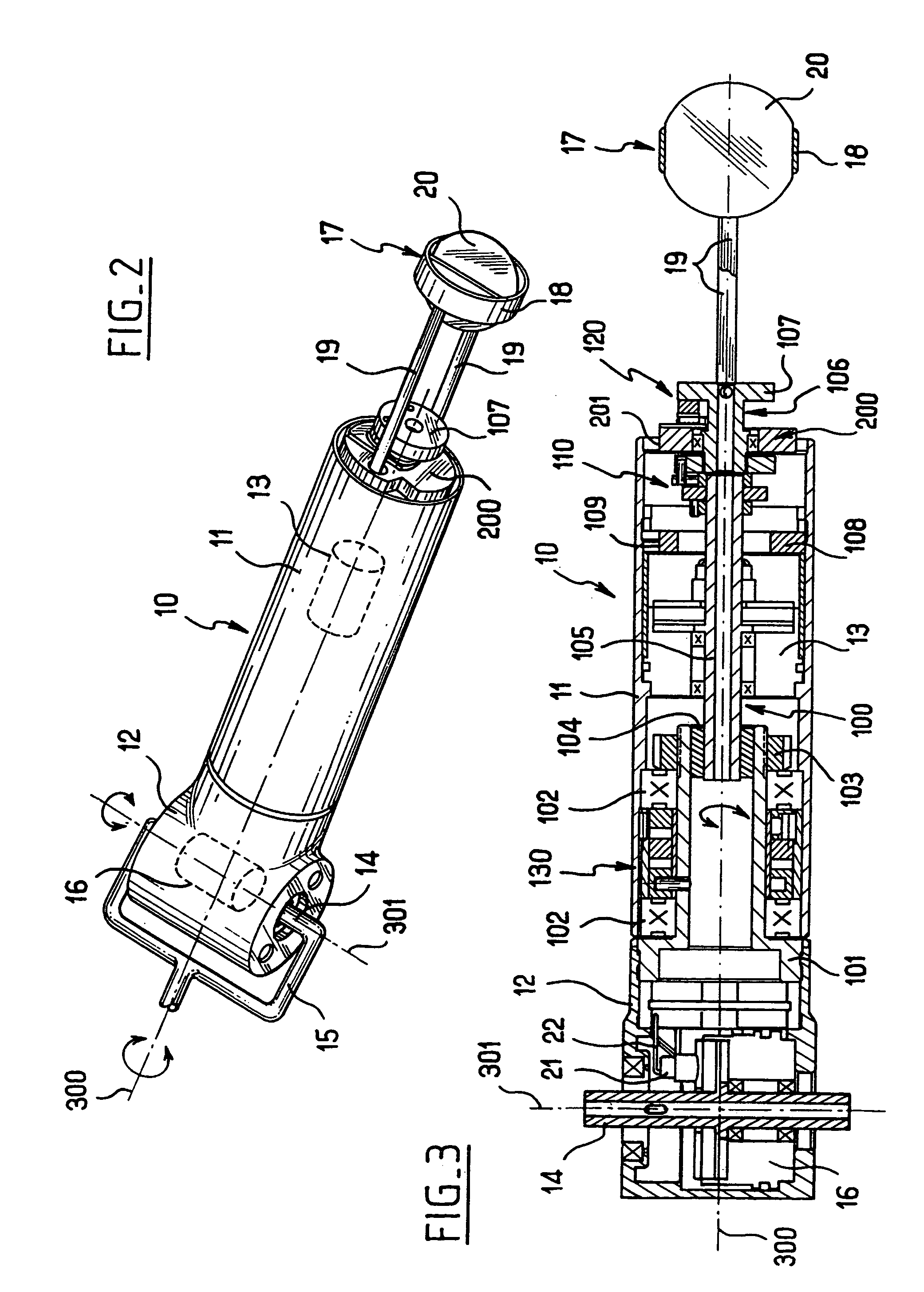

Connection device associated with an arm of an articulated three-dimensional measuring appliance

ActiveUS6931745B2Large rotation rangeRunning riskAngles/taper measurementsRotary current collectorElectricityEngineering

The invention relates to a connection device associated with an arm of an articulated three-dimensional measuring appliance, the device comprising a moving assembly and a fixed assembly, together with connection means for providing an electrical link between said two assemblies. In accordance with the invention, the moving assembly comprises first and second adjacent components on a common axis, the first component being constrained to rotate with the jointed end of the arm and being connected to the second component by a coupling system having successive dogs so that said second component is entrained in rotation only after said first component has turned through significantly more than one revolution in the same direction, and the connection means comprise facing contact members carried respectively by the fixed assembly and by the second component, arranged to provide a continuous electrical link in normal operation and a link that is restricted to a short angular range of rotation once the second component is entrained in rotation by the first component.

Owner:HEXAGON TECH CENT GMBH

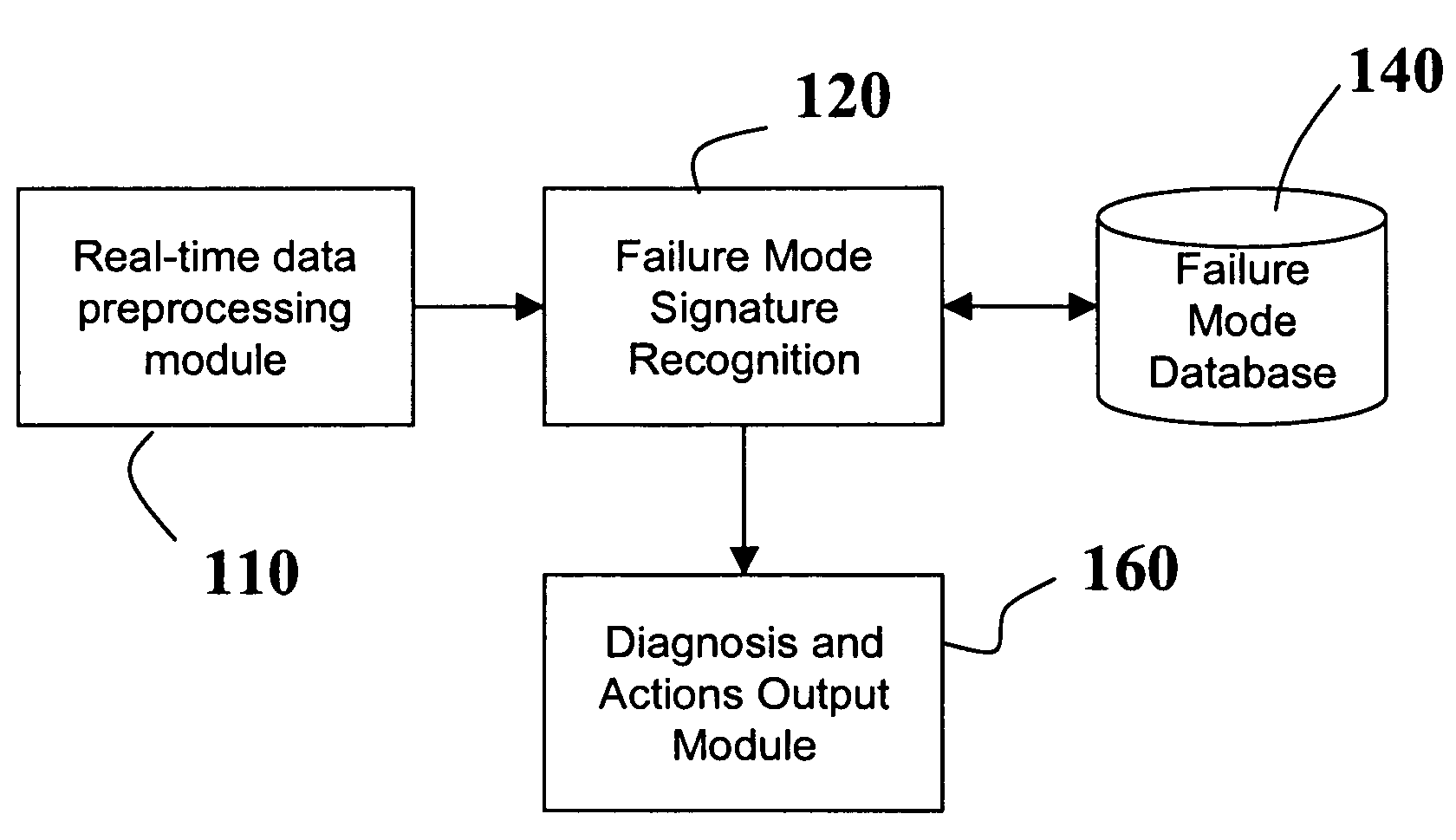

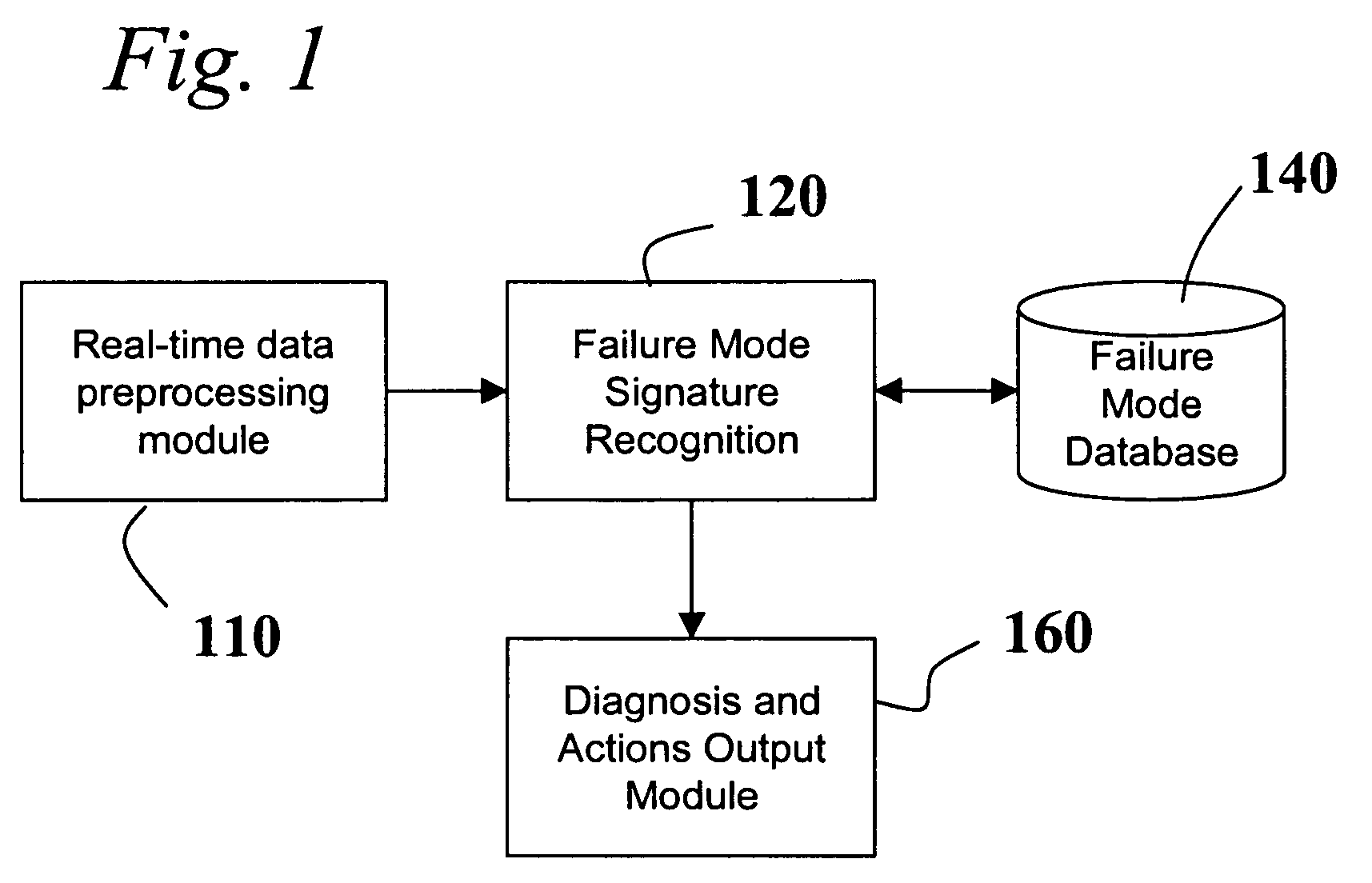

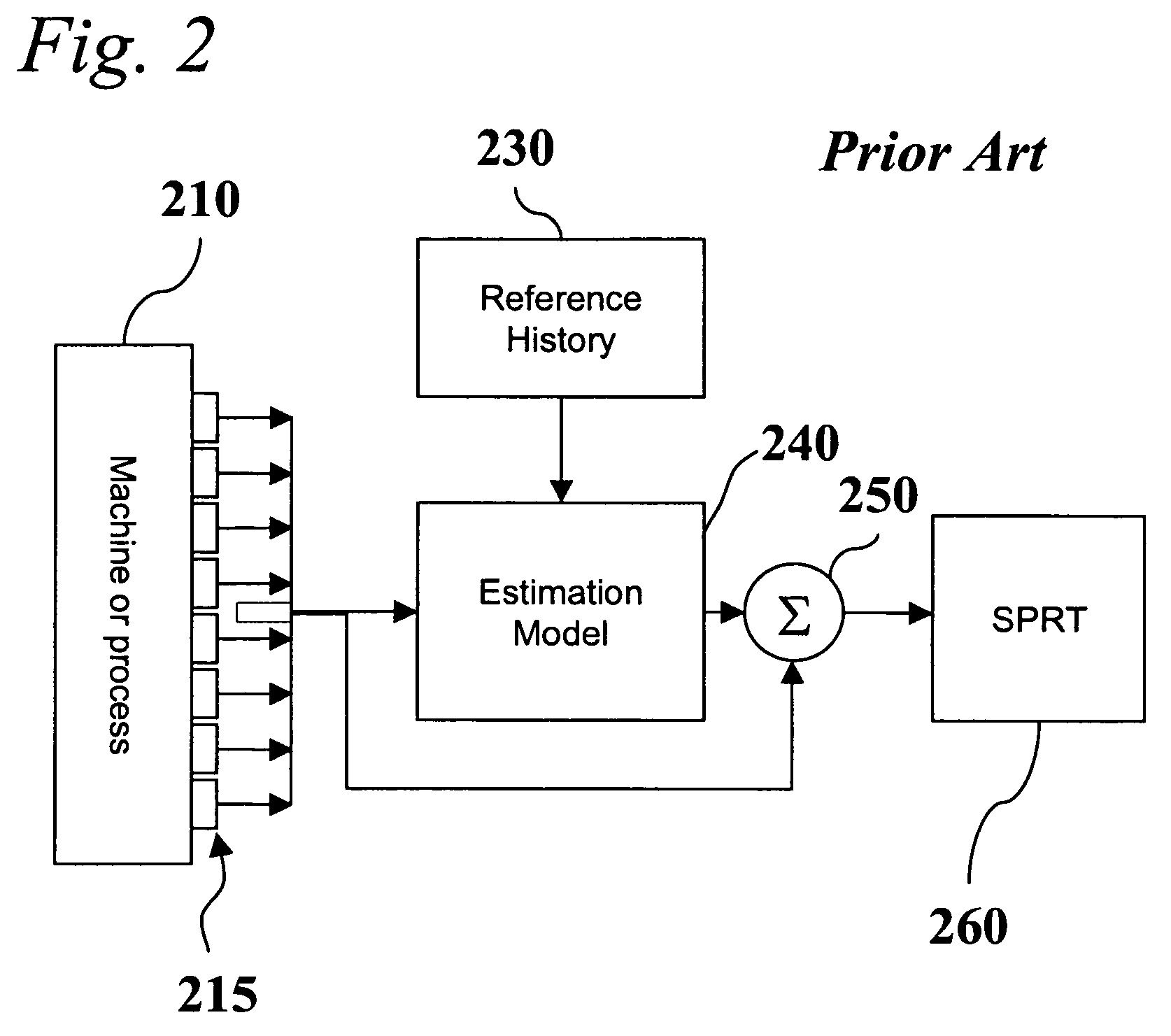

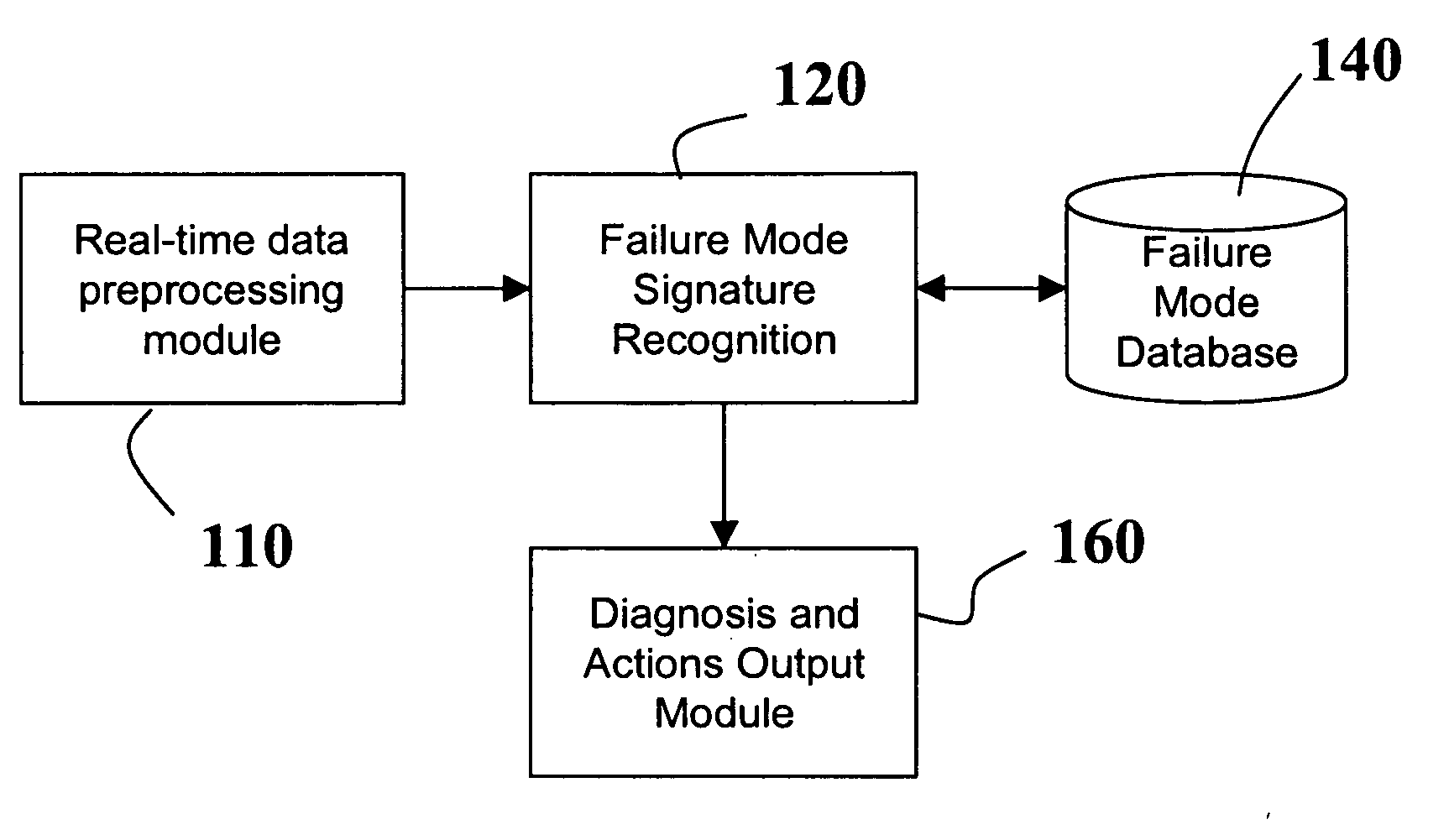

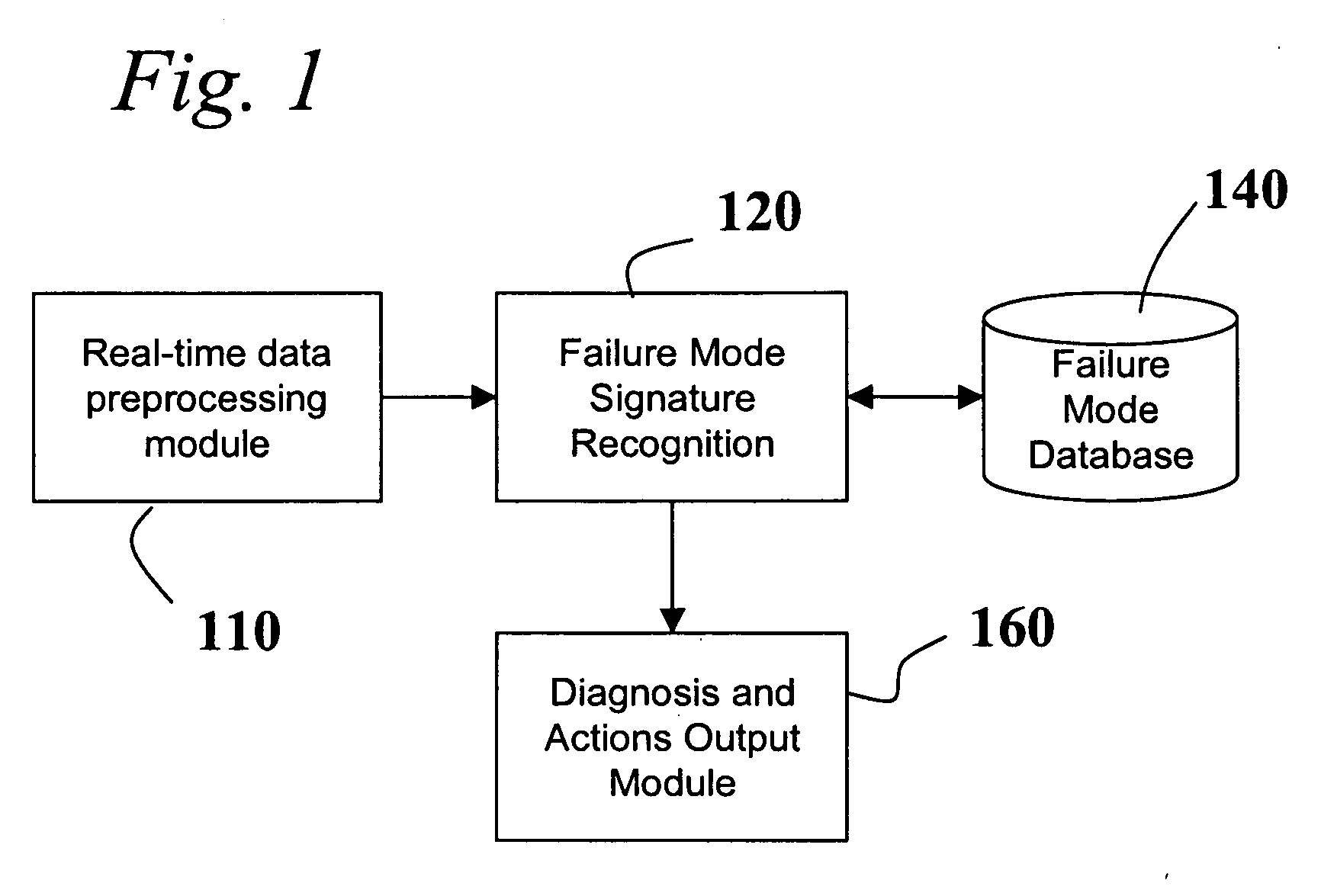

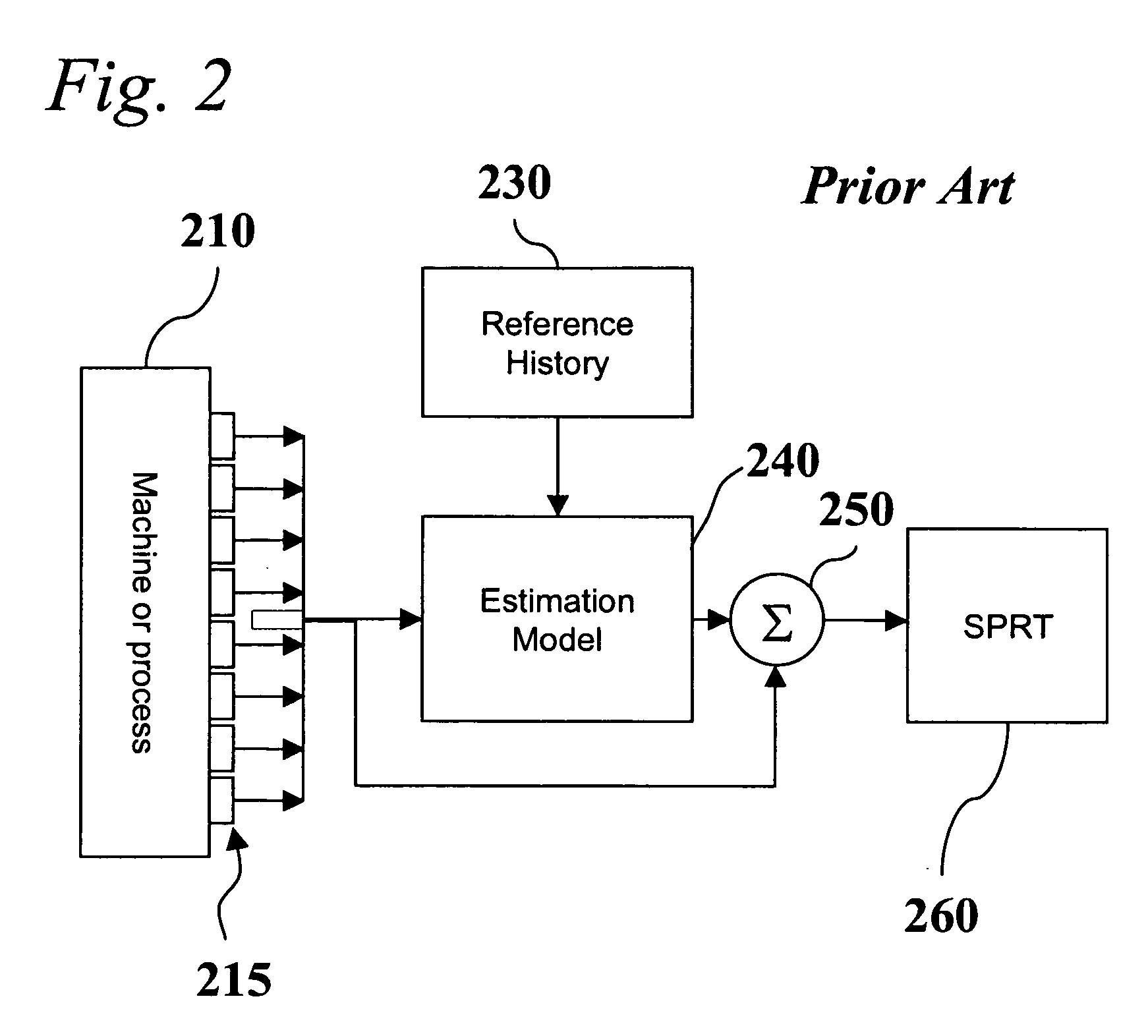

Diagnostic systems and methods for predictive condition monitoring

A system for empirically diagnosing a condition of a monitored system. Estimates of monitored parameters from a model of the system provide residual values that can be analyzed for failure mode signature recognition. Residual values can also be tested for alert (non-zero) conditions, and patterns of alerts thus generated are analyzed for failure mode signature patterns. The system employs a similarity operator for signature recognition and also for parameter estimation. Failure modes are empirically determined, and precursor data is automatically analyzed to determine differentiable signatures for failure modes.

Owner:SMARTSIGNAL CORP

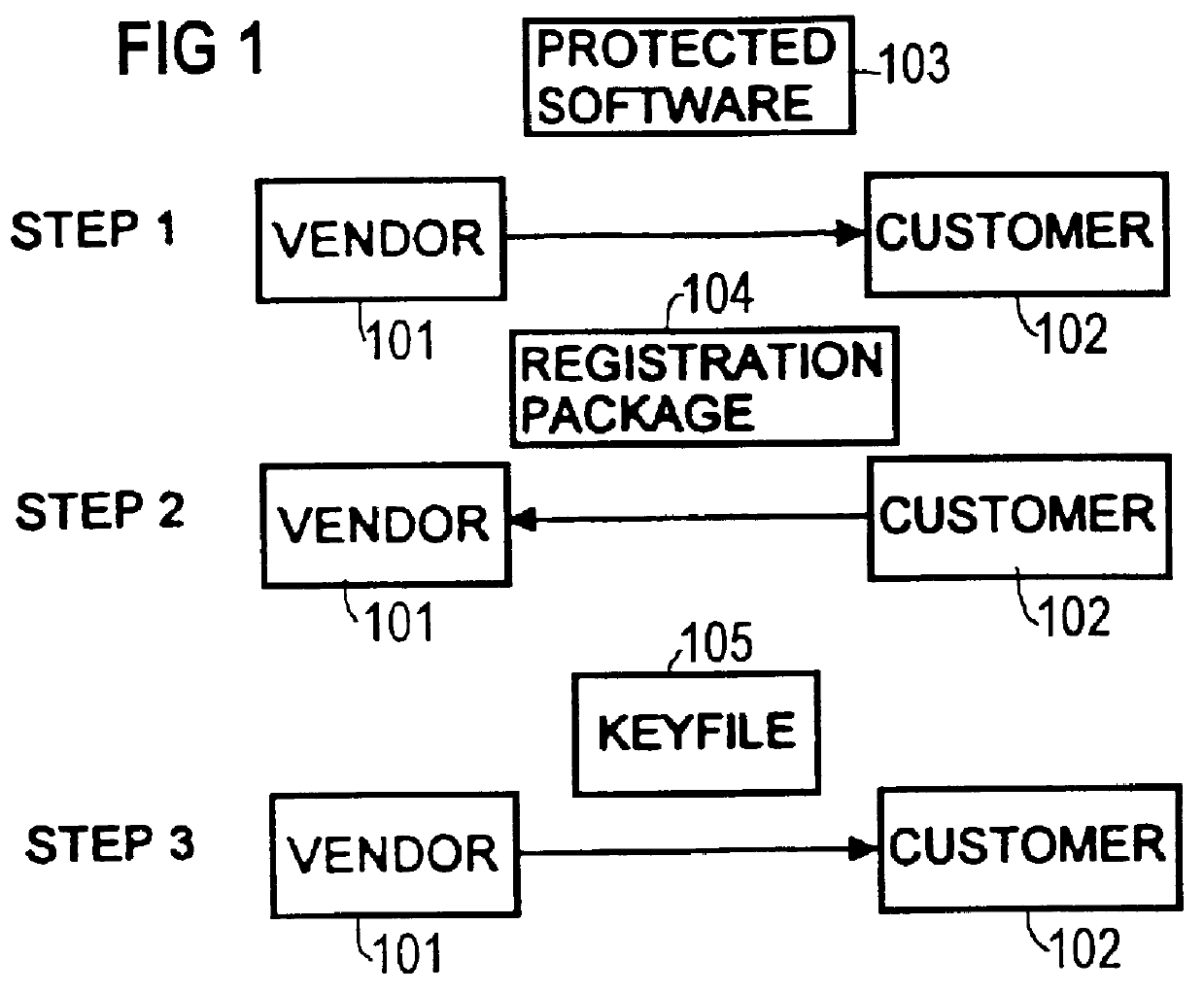

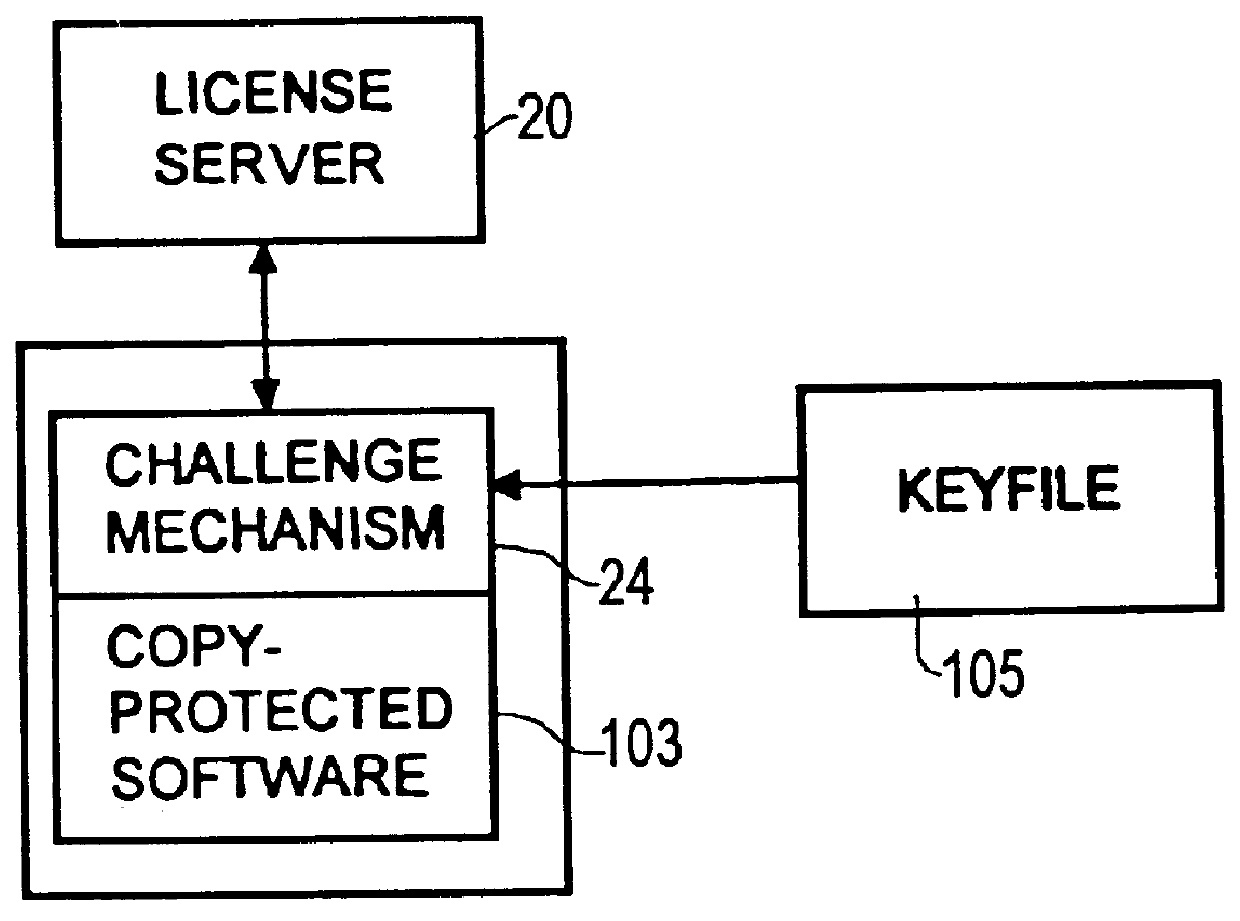

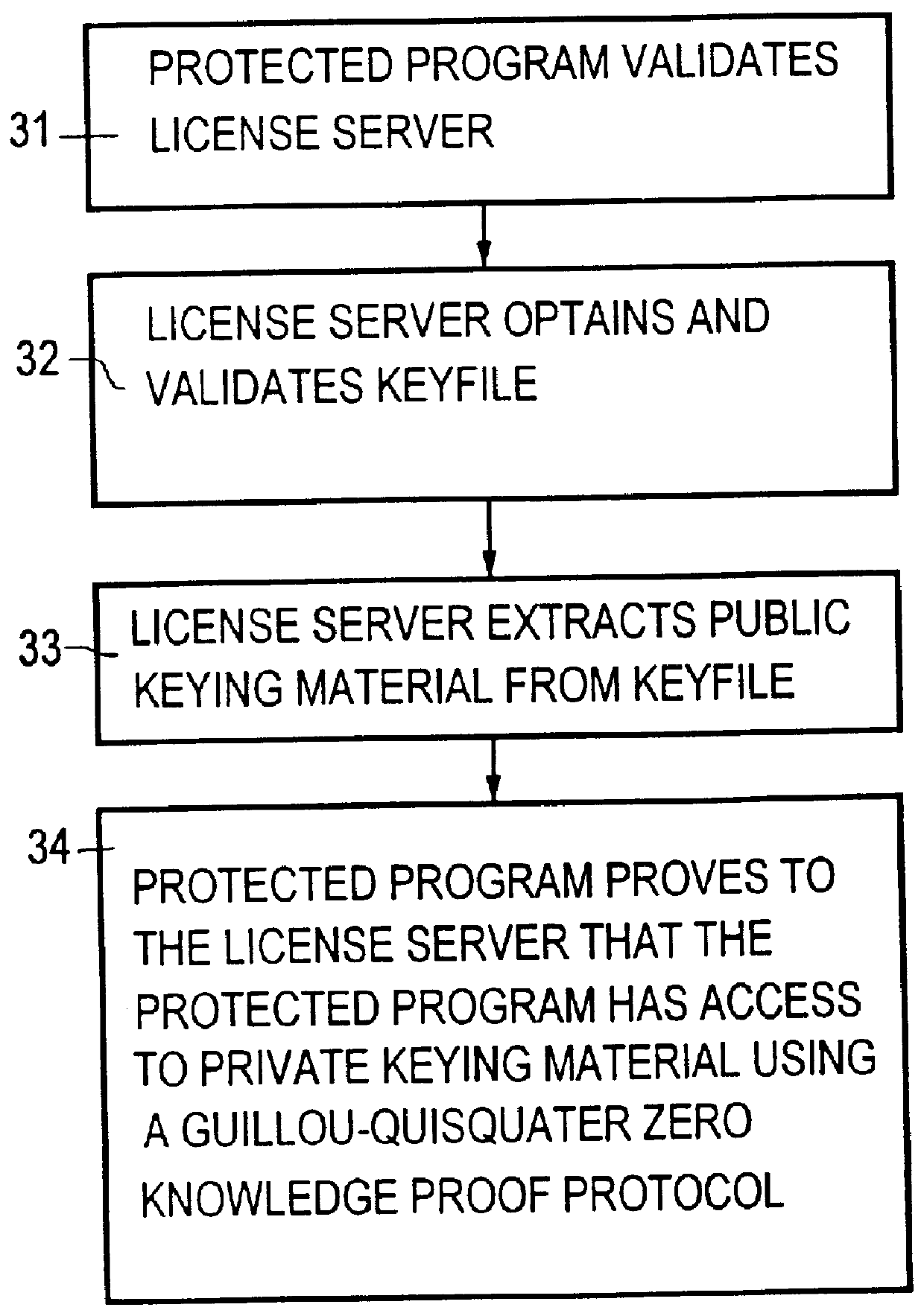

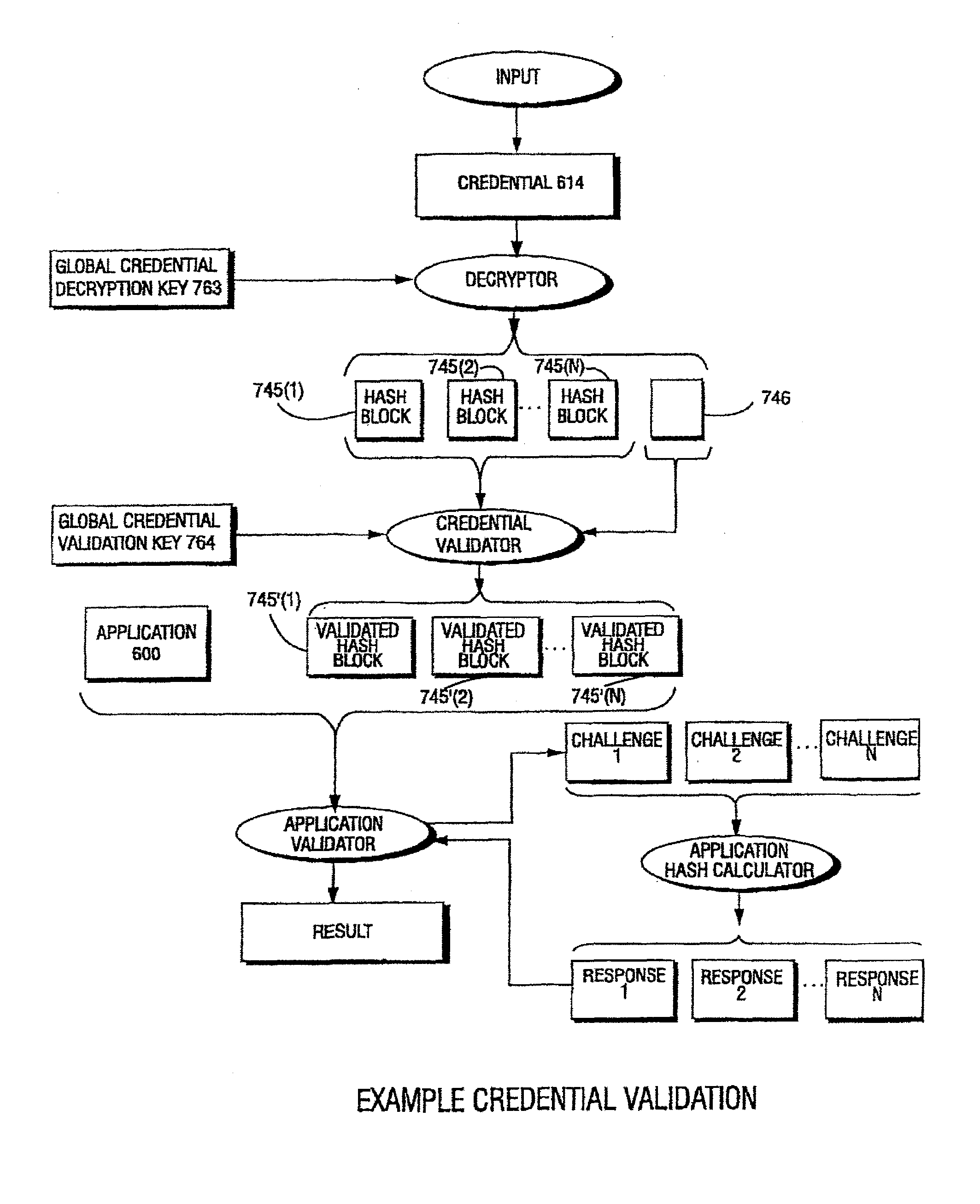

Computer system for protecting software and a method for protecting software

InactiveUS6047242AOptimization mechanismEasy to useKey distribution for secure communicationFinanceComputerized systemSoftware

A method for protecting an item of software, wherein at least one first challenge means is associated with said protected item of software, and at least one first response means accesses one private keying material. At least a third means (either challenge or response also exists). The first challenge means has no access to the said private keying material. The first response means proves to the first challenge means that the first response means has access to the private keying material. The first challenge means validates this proof using the public keying material that corresponds to the first response means' private keying material.

Owner:FUJITSU SIEMENS COMP GMBH

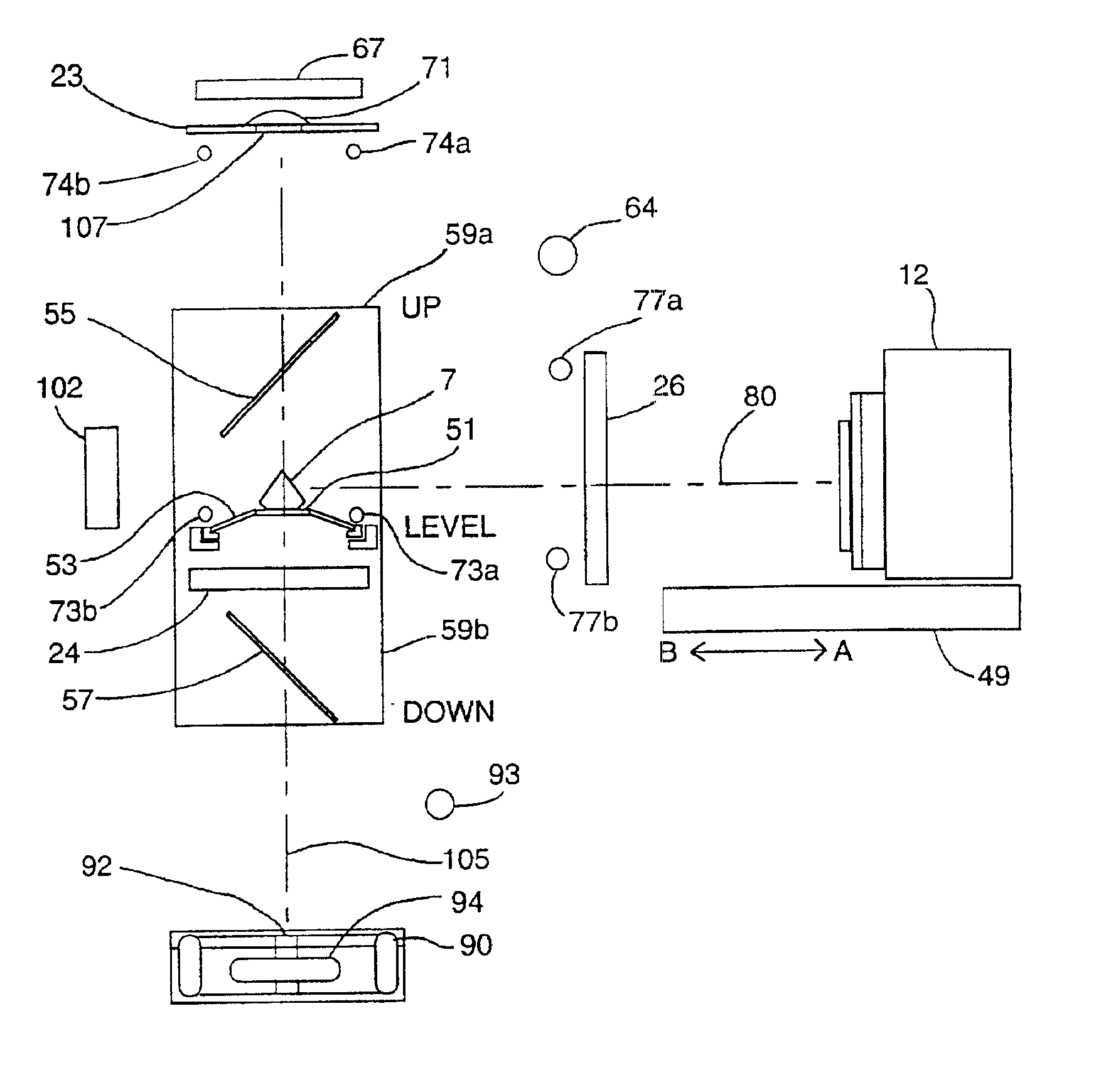

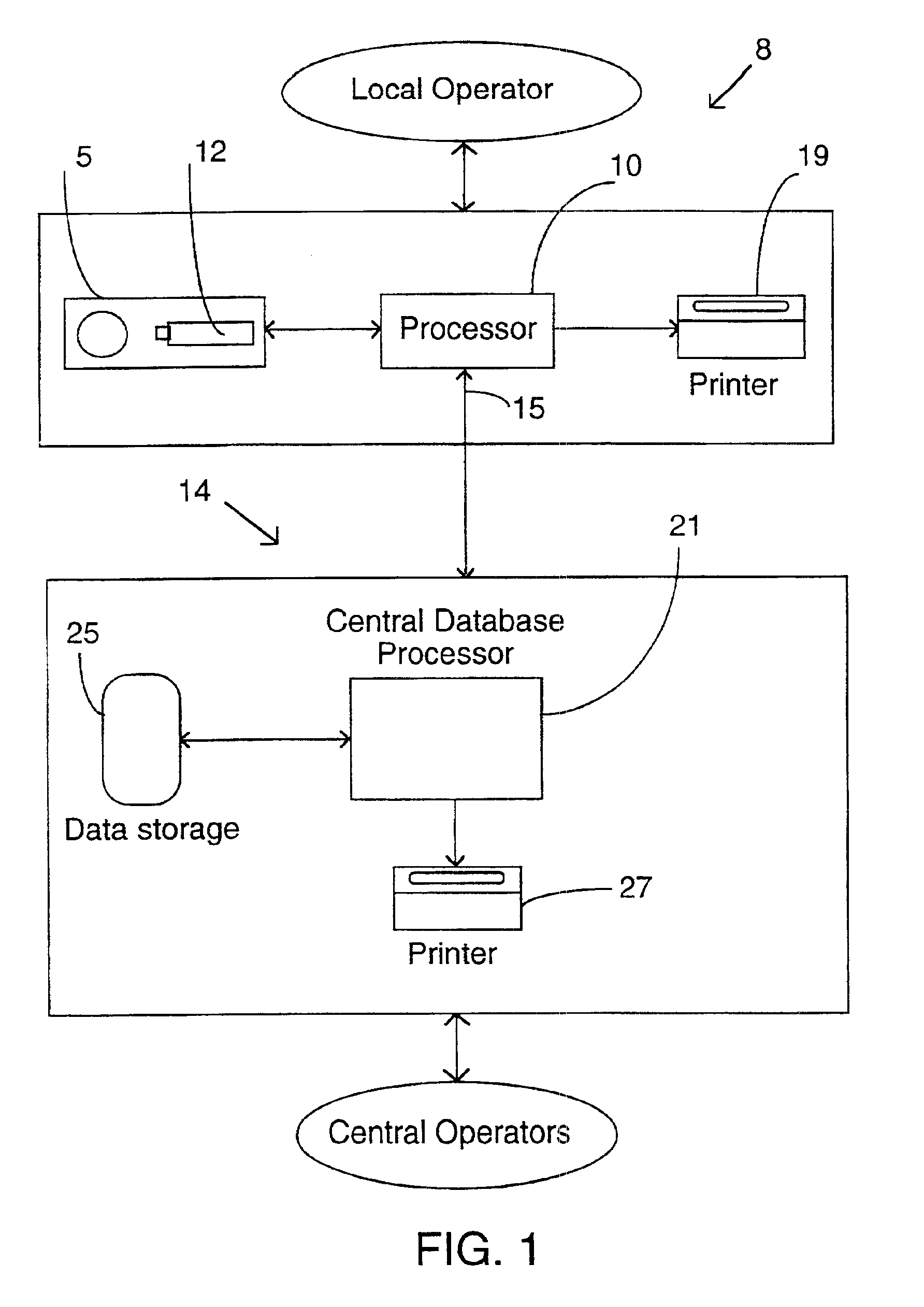

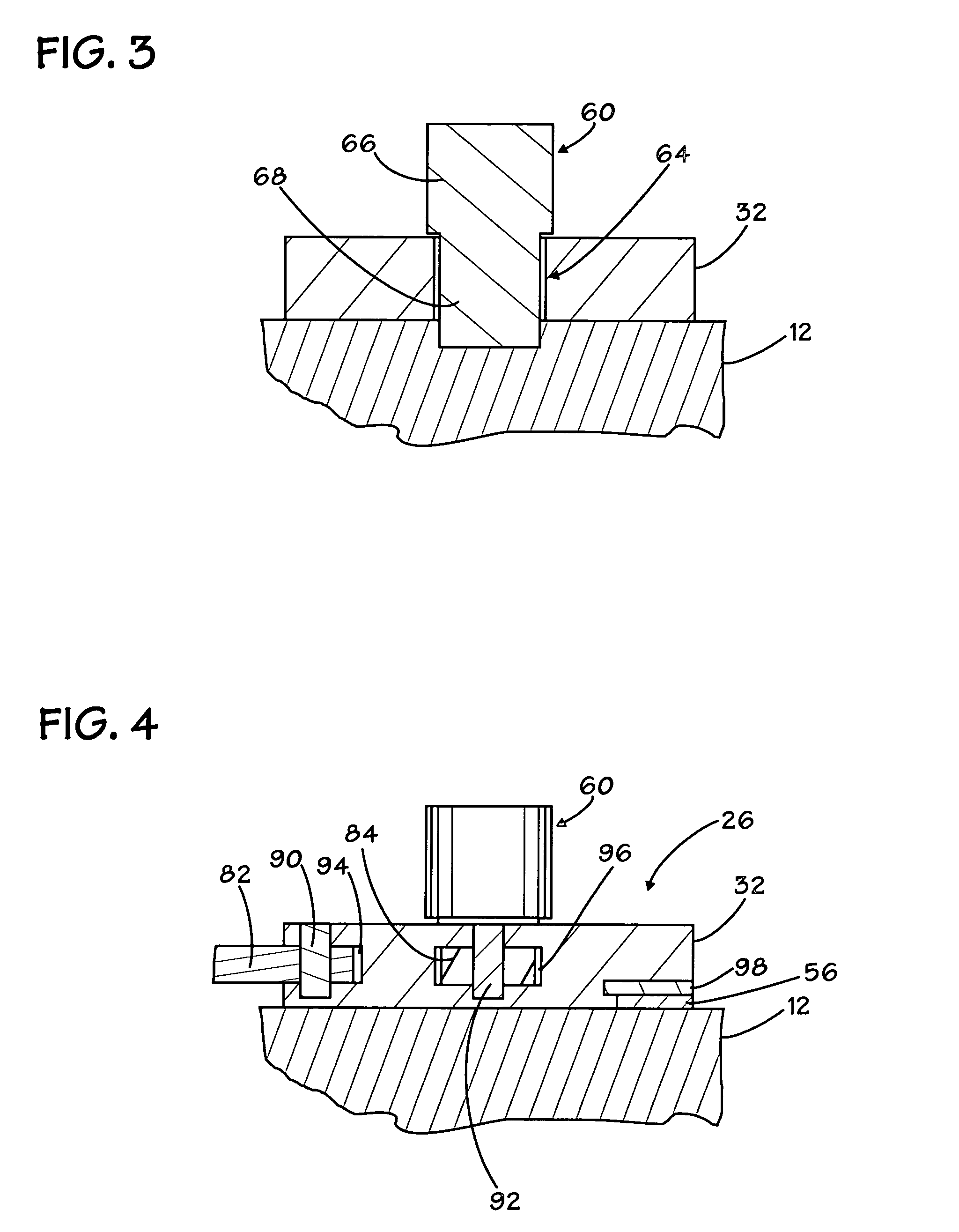

Method and associated apparatus for the standardized grading of gemstones

InactiveUS6980283B1Process safetyInvestigating jewelsSpecial data processing applicationsSpectral responseData set

A method and associated apparatus (5) for the standardized grading of gemstones is provided. The system gauges the spectral response of a gemstone subject to a plurality of incident light sources (77, 64, 90, 92, 102) within an imaging apparatus. The operation of the imaging apparatus is controlled by an instruction set of a local station control data processor (12). Light energy data is captured in the form of pixel data sets via a charge coupled device of the imaging apparatus of the local station (8). The control data processor data of the local station is operably linked to analysis station (14). Gemstones qualities are analyzed by the plurality of light sources (92, 90, 102) of the imaging apparatus (5) and quantified relative to model pixel data sets of the database and recorded for future reference therein.

Owner:IMAGESTATISTICS

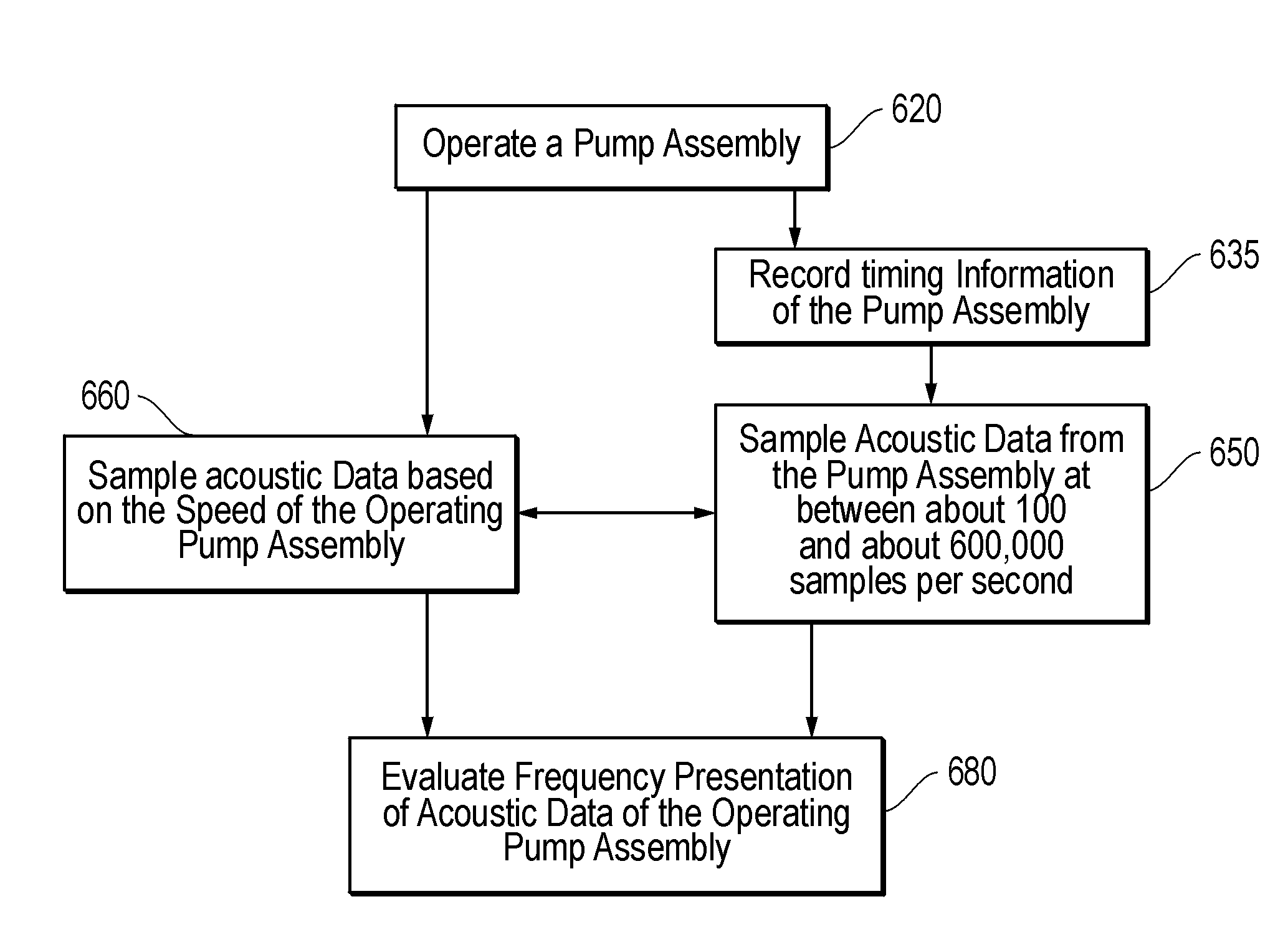

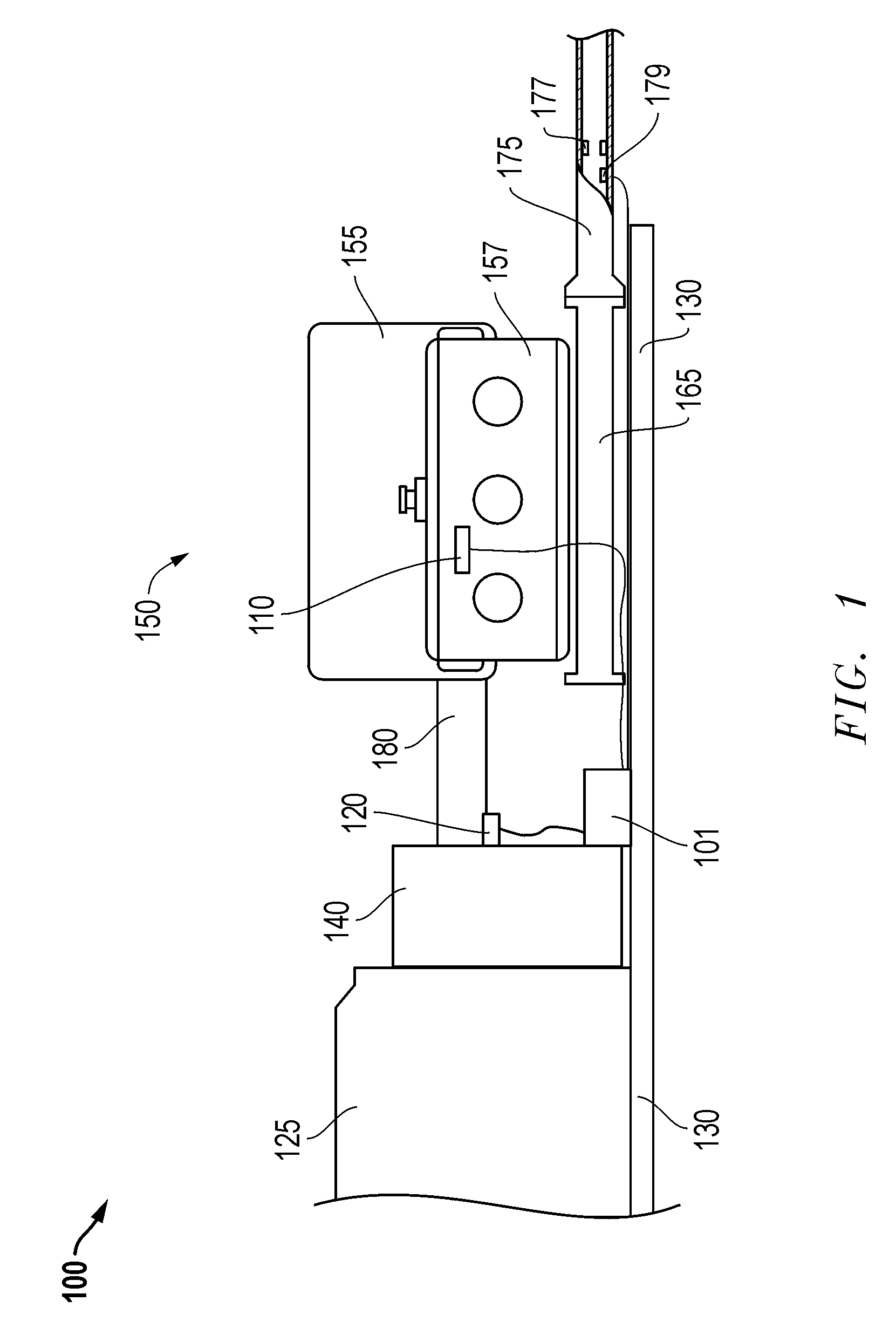

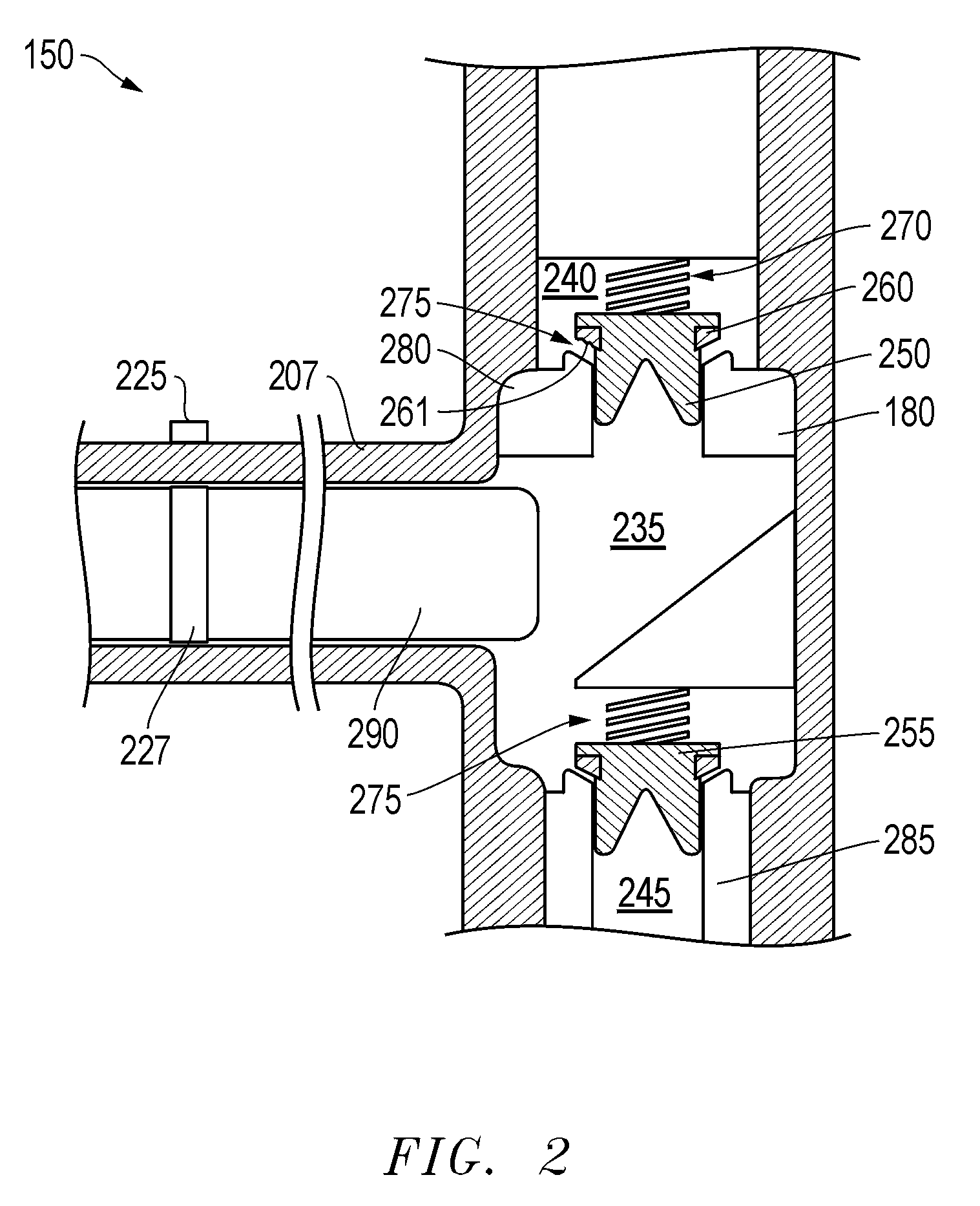

Pump integrity monitoring

InactiveUS20080006089A1Vibration measurement in solidsDetection of fluid at leakage pointImage resolutionComputer science

A method of monitoring integrity of a pump. The method may include recording timing information of the pump during operation while simultaneously sampling acoustic data with a high speed equidistant acquisition mechanism or at a rate based on the speed of the pump in operation. The acquisition of acoustic data is followed by evaluation thereof. Such techniques may improve resolution of acquired data while substantially increasing processor capacity for evaluation. A pump integrity monitor for carrying out such techniques is also described.

Owner:SCHLUMBERGER TECH CORP

Dynamically adjustable probe tips

ActiveUS7022976B1Beam/ray focussing/reflecting arrangementsMaterial analysis by optical meansEngineeringActuator

Various probe systems and probes are provided. In one aspect, a probe is provided that includes a base and a first member coupled to the base. The first member has a first tip for probing a circuit device. A first actuator is coupled to the first member for moving the first member relative to the base. Electrical and / or topographical probing is possible.

Owner:GLOBALFOUNDRIES US INC

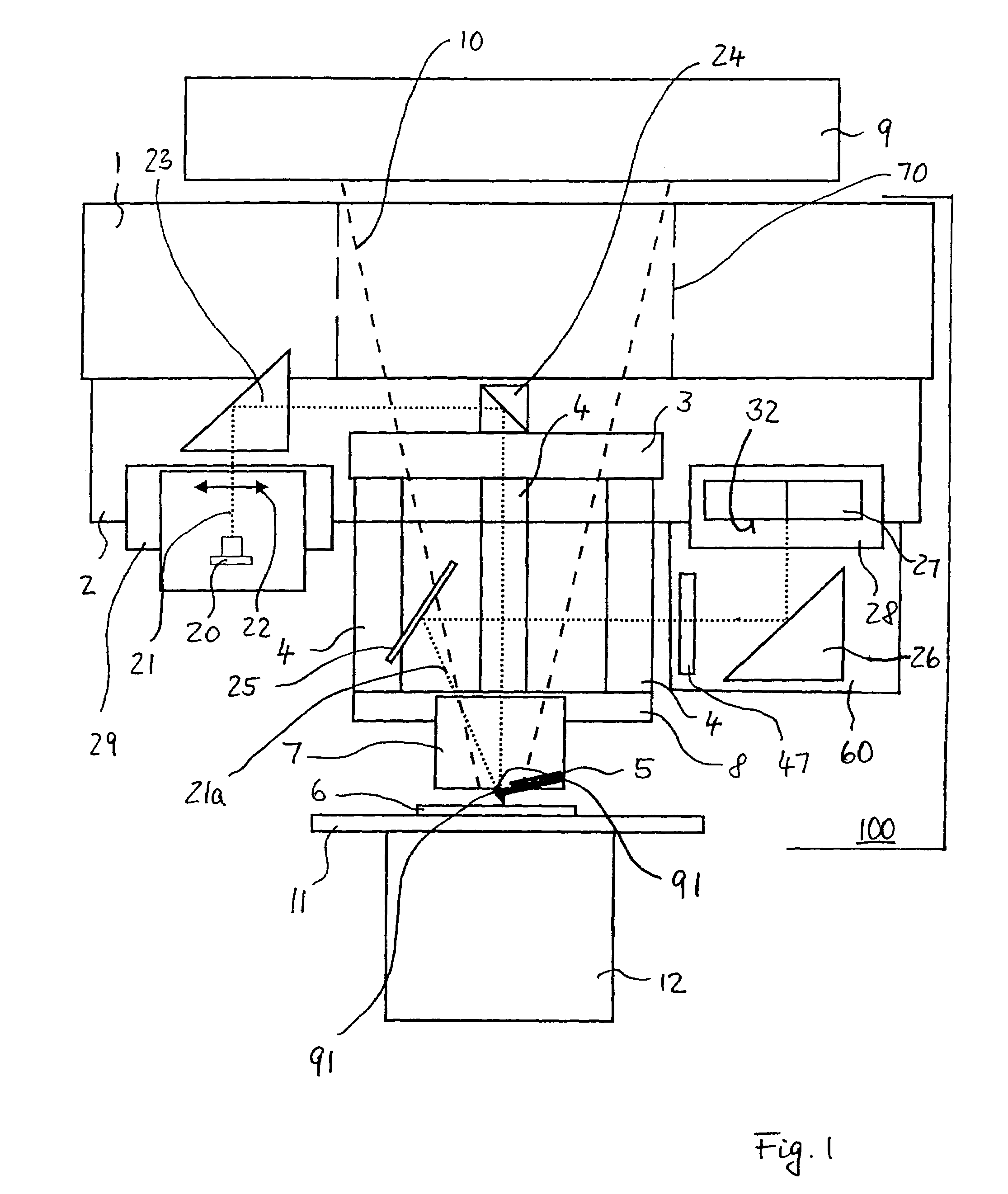

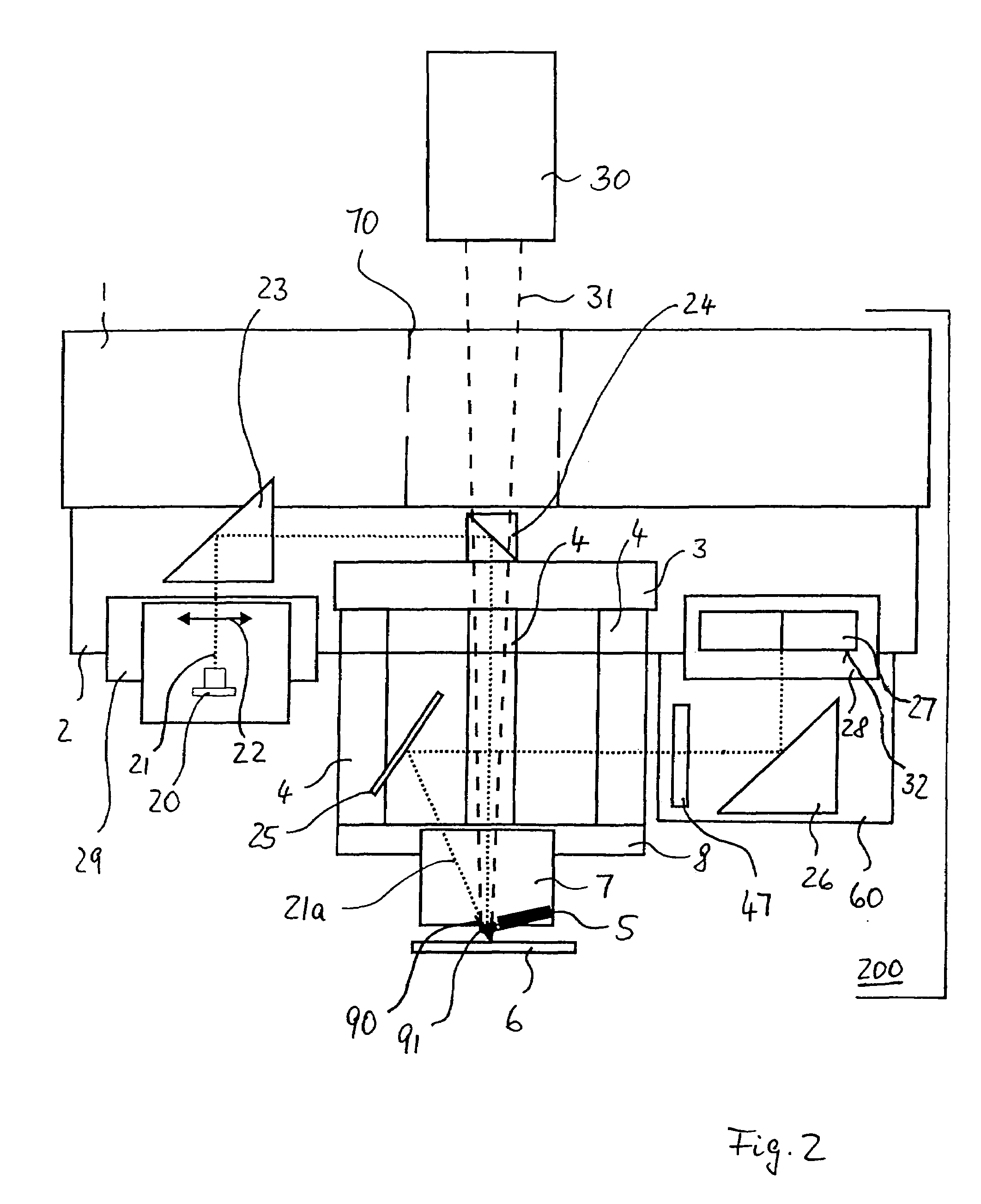

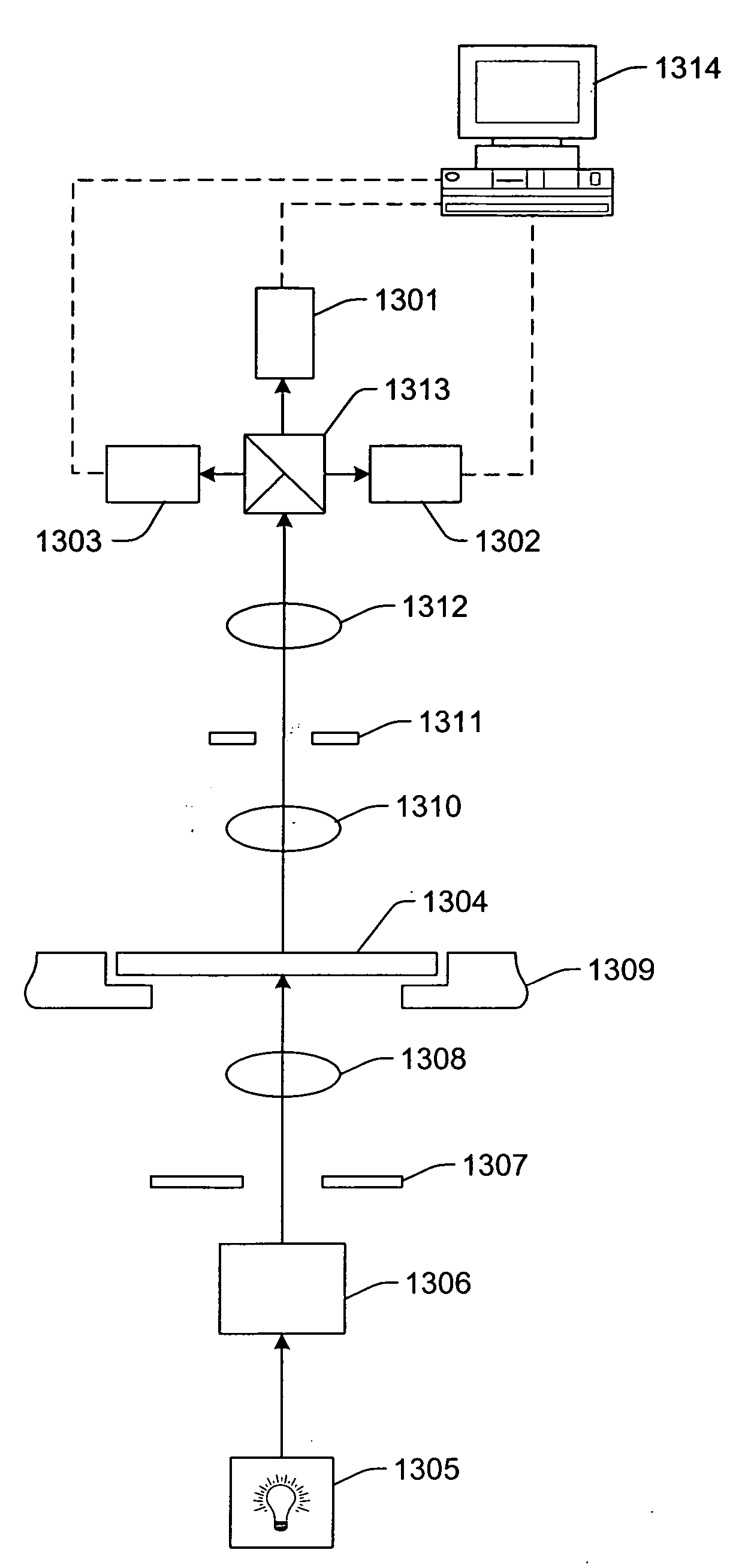

Apparatus and method for a scanning probe microscope

InactiveUS7022985B2Easy to modifyImprove measurement stabilityNanotechMaterial analysis using wave/particle radiationScanning electron microscopeScanning probe microscopy

The invention relates to an apparatus and a method for a scanning probe microscope, comprising a measuring assembly which includes a lateral shifting unit to displace a probe in a plane, a vertical shifting unit to displace the probe in a direction perpendicular to the plane, and a specimen support to receive a specimen. A condenser light path is formed through the measuring assembly so that the specimen support is located in the area of an end of the condenser light path.

Owner:JPK INSTR

Diagnostic systems and methods for predictive condition monitoring

InactiveUS20060036403A1Picture changing apparatusElectric testing/monitoringResidual valueComputer science

A system for empirically diagnosing a condition of a monitored system. Estimates of monitored parameters from a model of the system provide residual values that can be analyzed for failure mode signature recognition. Residual values can also be tested for alert (non-zero) conditions, and patterns of alerts thus generated are analyzed for failure mode signature patterns. The system employs a similarity operator for signature recognition and also for parameter estimation. Failure modes are empirically determined, and precursor data is automatically analyzed to determine differentiable signatures for failure modes.

Owner:SMARTSIGNAL CORP

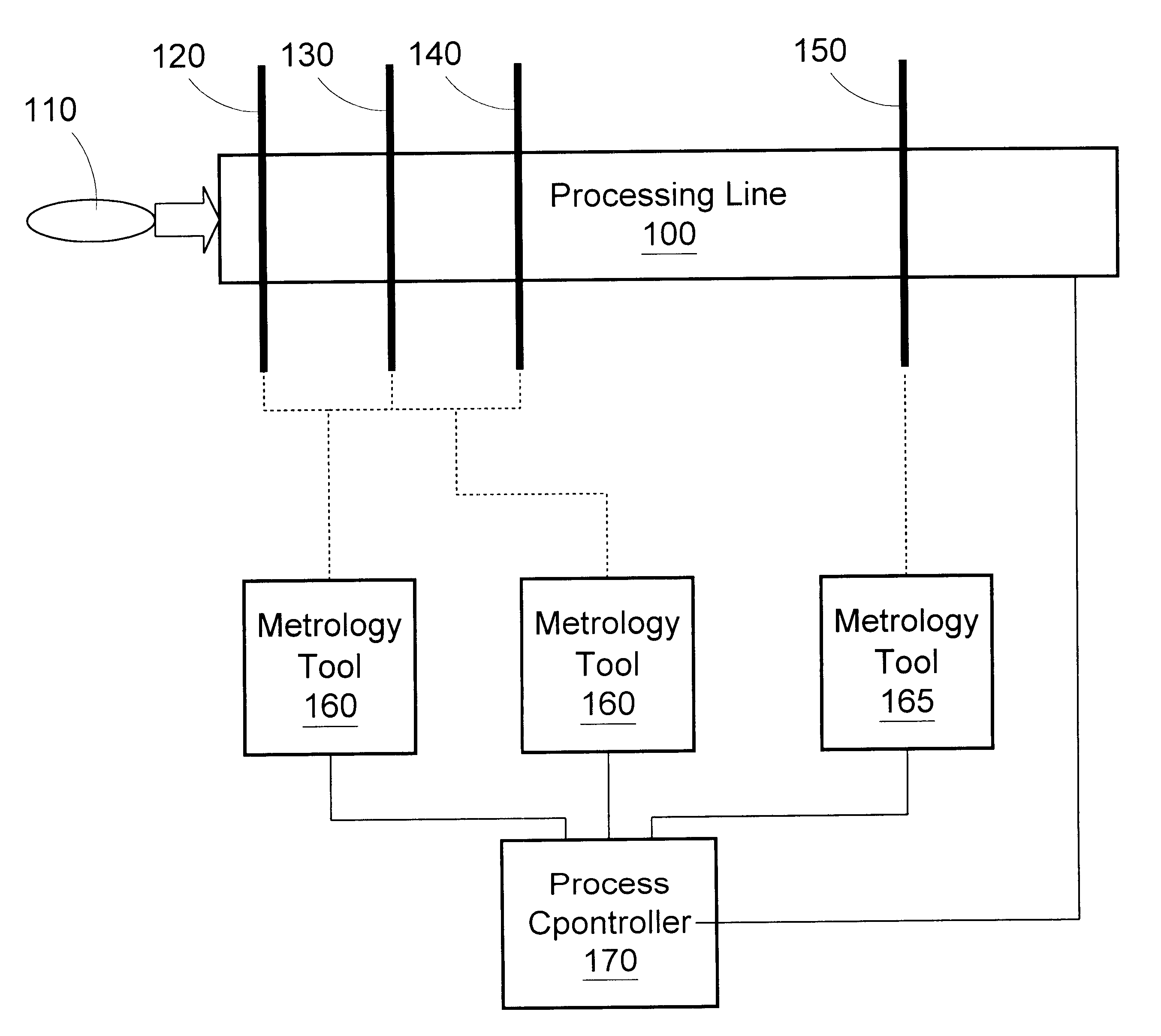

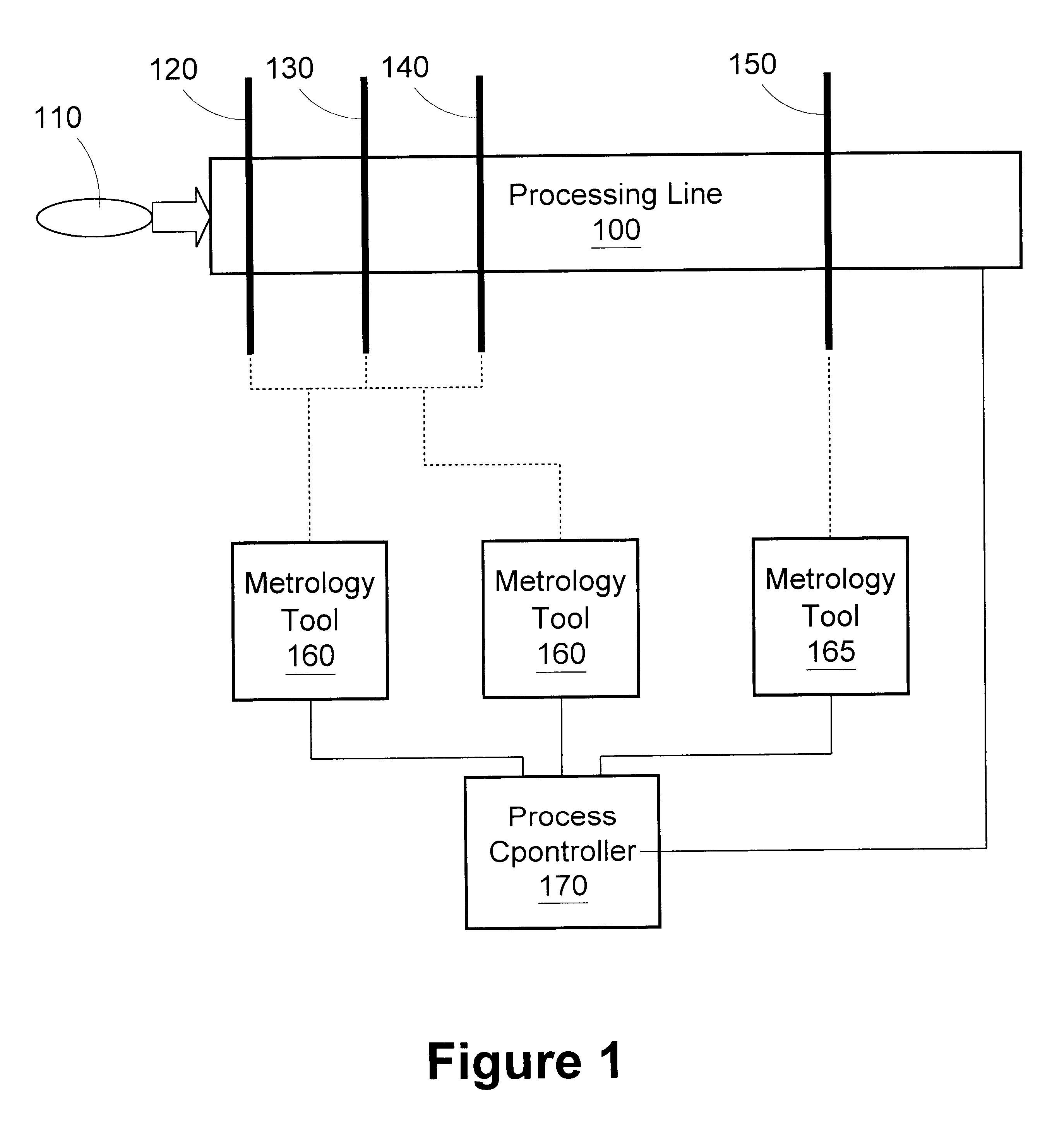

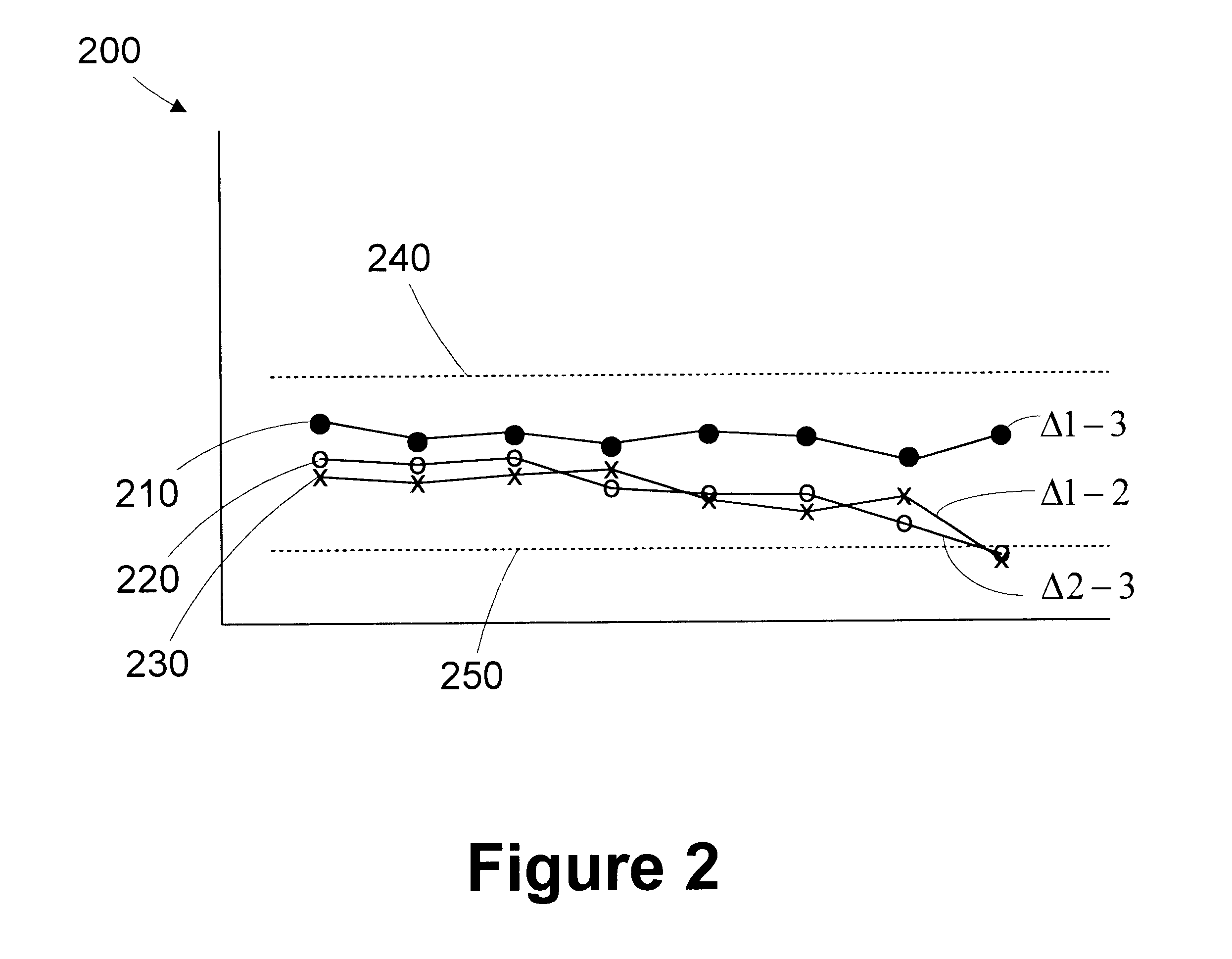

Method and apparatus for characterizing semiconductor device performance variations based on independent critical dimension measurements

InactiveUS6346426B1Semiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingMetrologyEngineering

A method for characterizing semiconductor device performance variations includes processing a wafer in a processing line to form a feature on the wafer; measuring a physical critical dimension of the feature in a first metrology tool to generate a first critical dimension measurement; measuring the physical critical dimension of the feature in a second metrology tool to generate a second critical dimension measurement independent of the first critical dimension measurement; determining an effective critical dimension of the feature in a third metrology tool to generate a third critical dimension measurement; and comparing the first, second, and third critical dimension measurements to identify a metrology drift in one of the first and second metrology tools. A system for characterizing semiconductor device performance variations includes a processing line, first, second, and third metrology tools, and a process controller. The processing line is adapted to process a wafer to form a feature on the wafer. The first metrology tool is adapted to measure a physical critical dimension of the feature to generate a first critical dimension measurement. The second metrology tool is adapted to measure the physical critical dimension of the feature to generate a second critical dimension measurement independent of the first critical dimension measurement. The third metrology tool adapted to determine an effective critical dimension of the feature to generate a third critical dimension measurement. The process controller is adapted to compare the first, second, and third critical dimension measurements to identify a metrology drift in one of the first and second metrology tools.

Owner:ADVANCED MICRO DEVICES INC

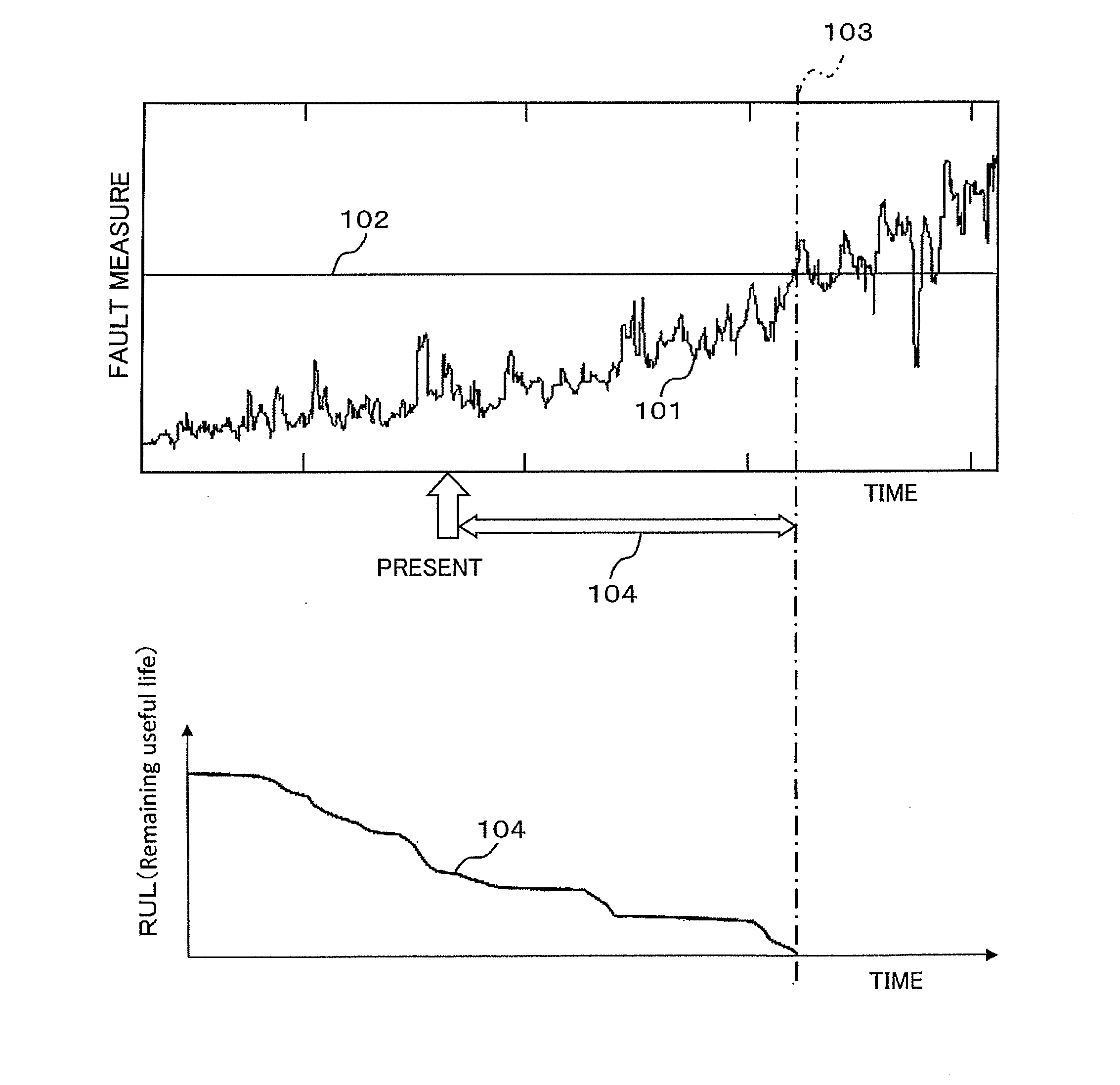

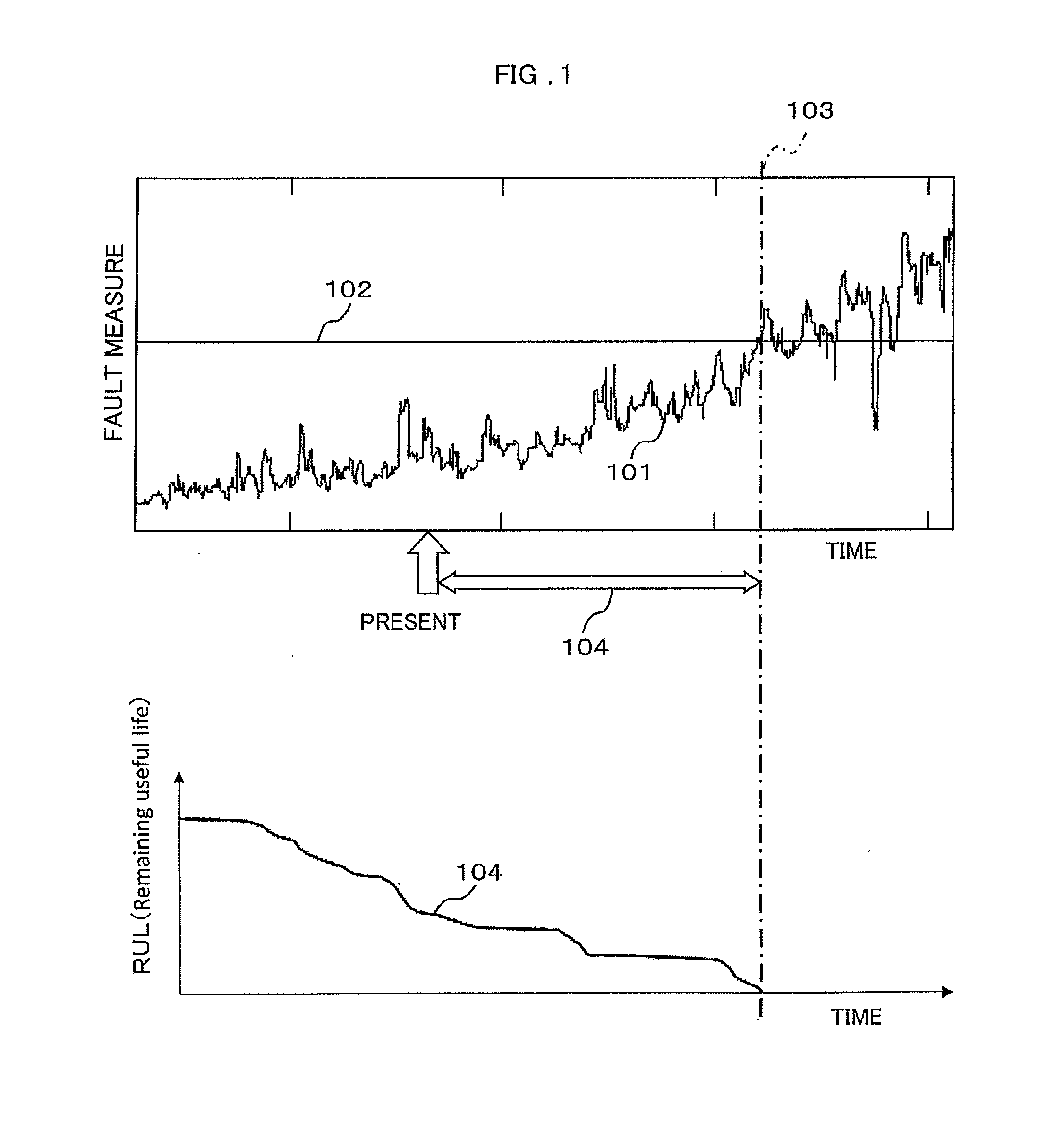

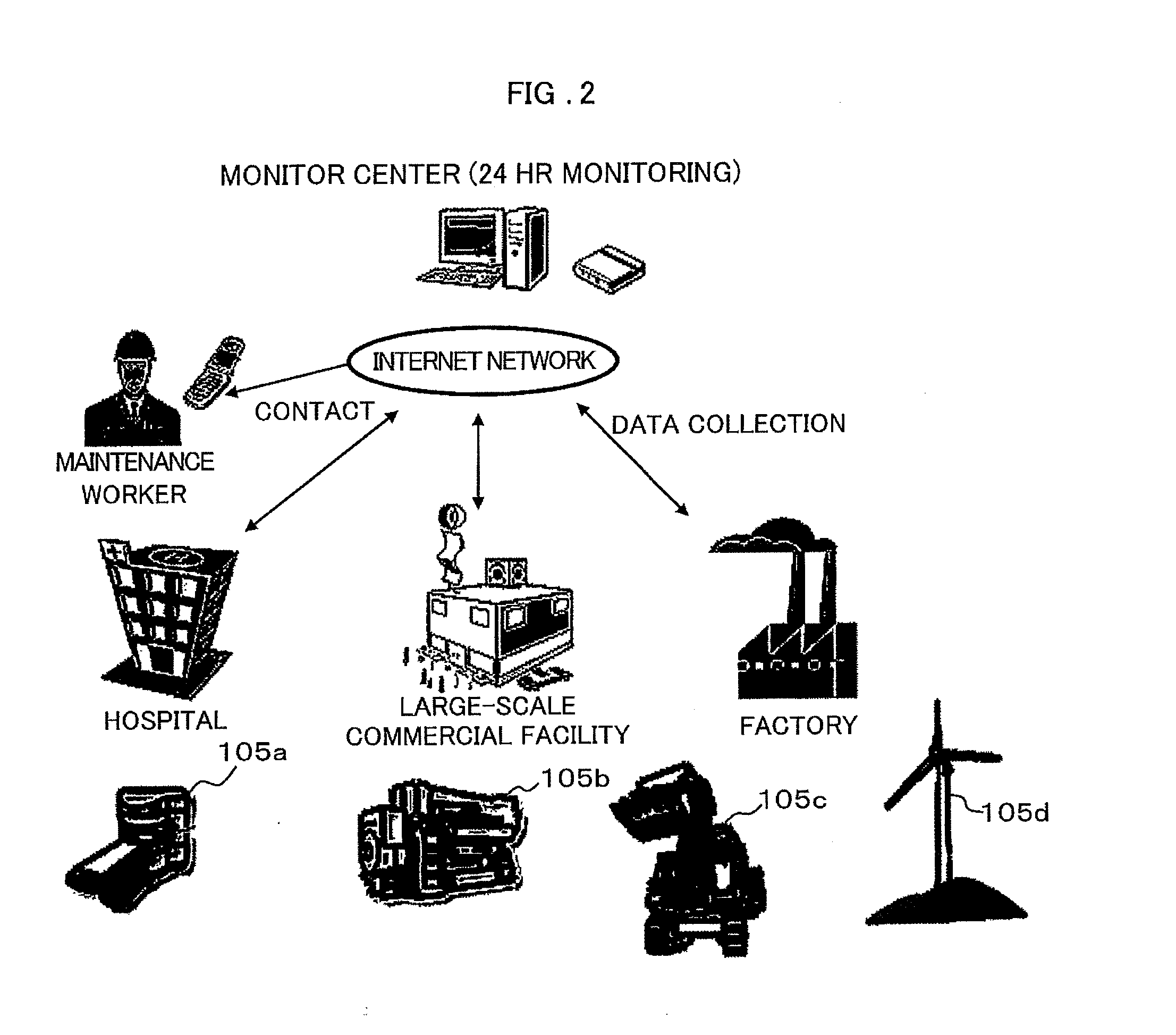

Health management system, fault diagnosis system, health management method, and fault diagnosis method

ActiveUS20150160098A1Easy to identifyTesting/monitoring control systemsStructural/machines measurementLearning dataMechanical equipment

An objective is to identify the health state of mechanical equipment and provide information usable for determining maintenance work timing or the like. A health management system includes a time-series data acquisition unit configured to acquire multi-dimensional sensor data and environmental data from mechanical equipment; a first discrimination unit configured to quantify the equipment state of the mechanical equipment by a statistical method using normal data as learning data; a second discrimination unit configured to quantify the health state indicating the performance or quality of the mechanical equipment by a statistical method using normal data; and an output unit configured to display and / or output to the outside the quantified equipment state and health state.

Owner:HIATACHI POWER SOLUTIONS CO LTD +1

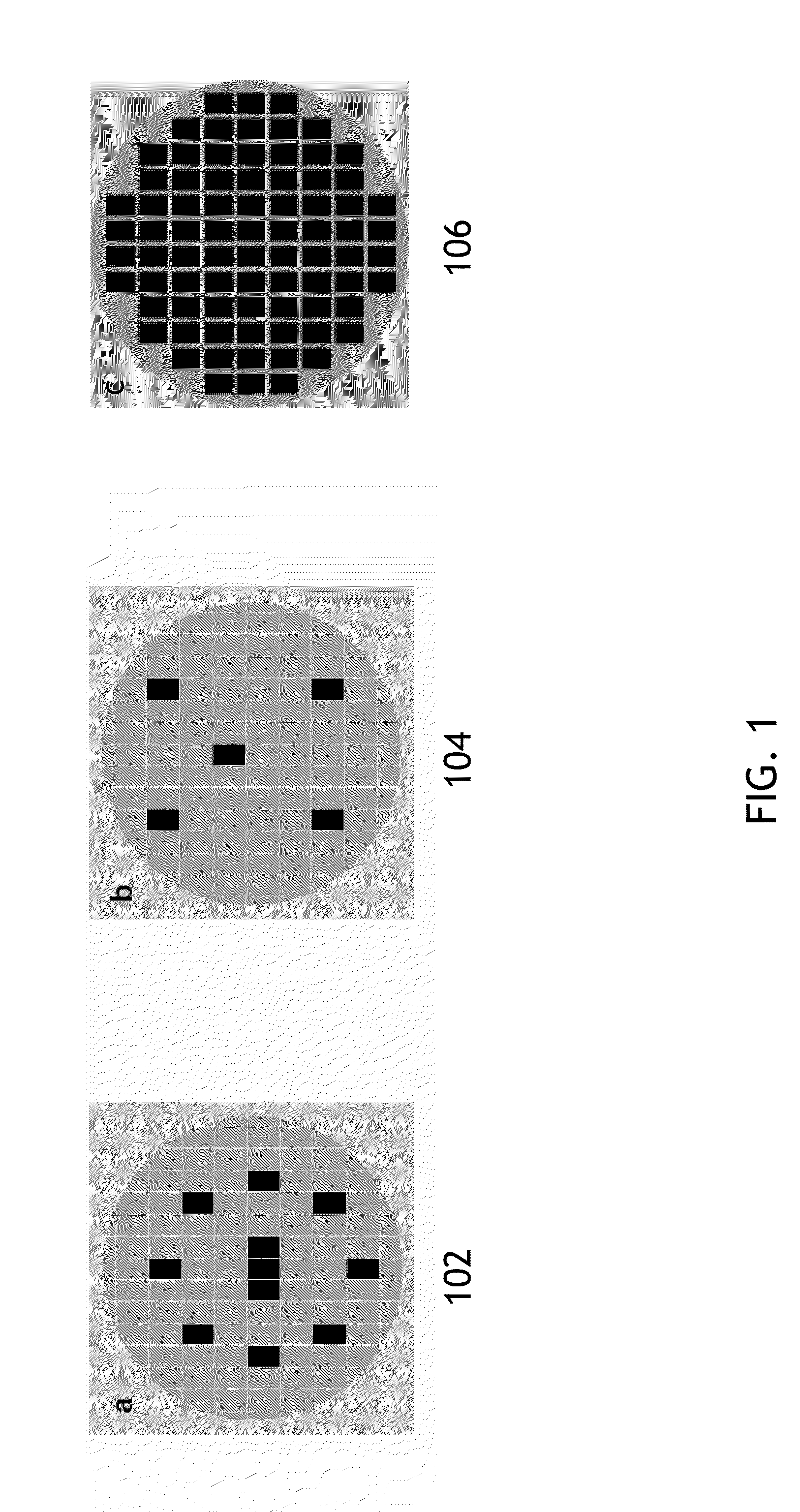

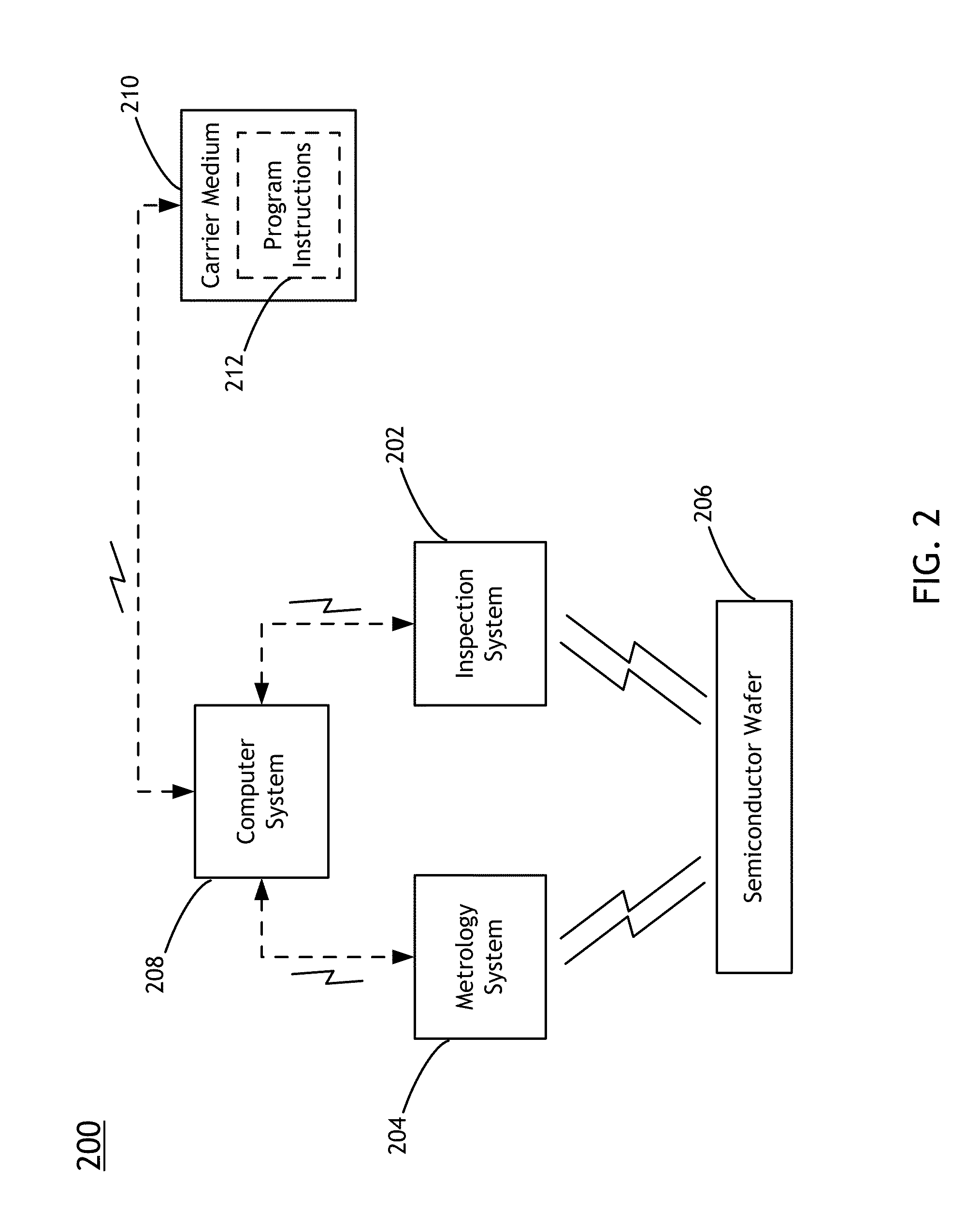

Inspection guided overlay metrology

ActiveUS20110170091A1Semiconductor/solid-state device testing/measurementSolid-state devicesMetrologySemiconductor

Inspection guided overlay metrology may include performing a pattern search in order to identify a predetermined pattern on a semiconductor wafer, generating a care area for all instances of the predetermined pattern on the semiconductor wafer, identifying defects within generated care areas by performing an inspection scan of each of the generated care areas, wherein the inspection scan includes a low-threshold or a high sensitivity inspection scan, identifying overlay sites of the predetermined pattern of the semiconductor wafer having a measured overlay error larger than a selected overlay specification utilizing a defect inspection technique, comparing location data of the identified defects of a generated care area to location data of the identified overlay sites within the generated care area in order to identify one or more locations wherein the defects are proximate to the identified overlay sites, and generating a metrology sampling plan based on the identified locations.

Owner:KLA TENCOR TECH CORP

Methods and systems for detecting defects in a reticle design pattern

ActiveUS7769225B2Material analysis by optical meansCharacter and pattern recognitionReticleDesign pattern

Computer-implemented methods and systems for detecting defects in a reticle design pattern are provided. One computer-implemented method includes acquiring images of a field in the reticle design pattern. The images illustrate how the field will be printed on a wafer at different values of one or more parameters of a wafer printing process. The field includes a first die and a second die. The method also includes detecting defects in the field based on a comparison of two or more of the images corresponding to two or more of the different values. In addition, the method includes determining if individual defects located in the first die have substantially the same within die position as individual defects located in the second die.

Owner:SADRA MEDICAL INC +1

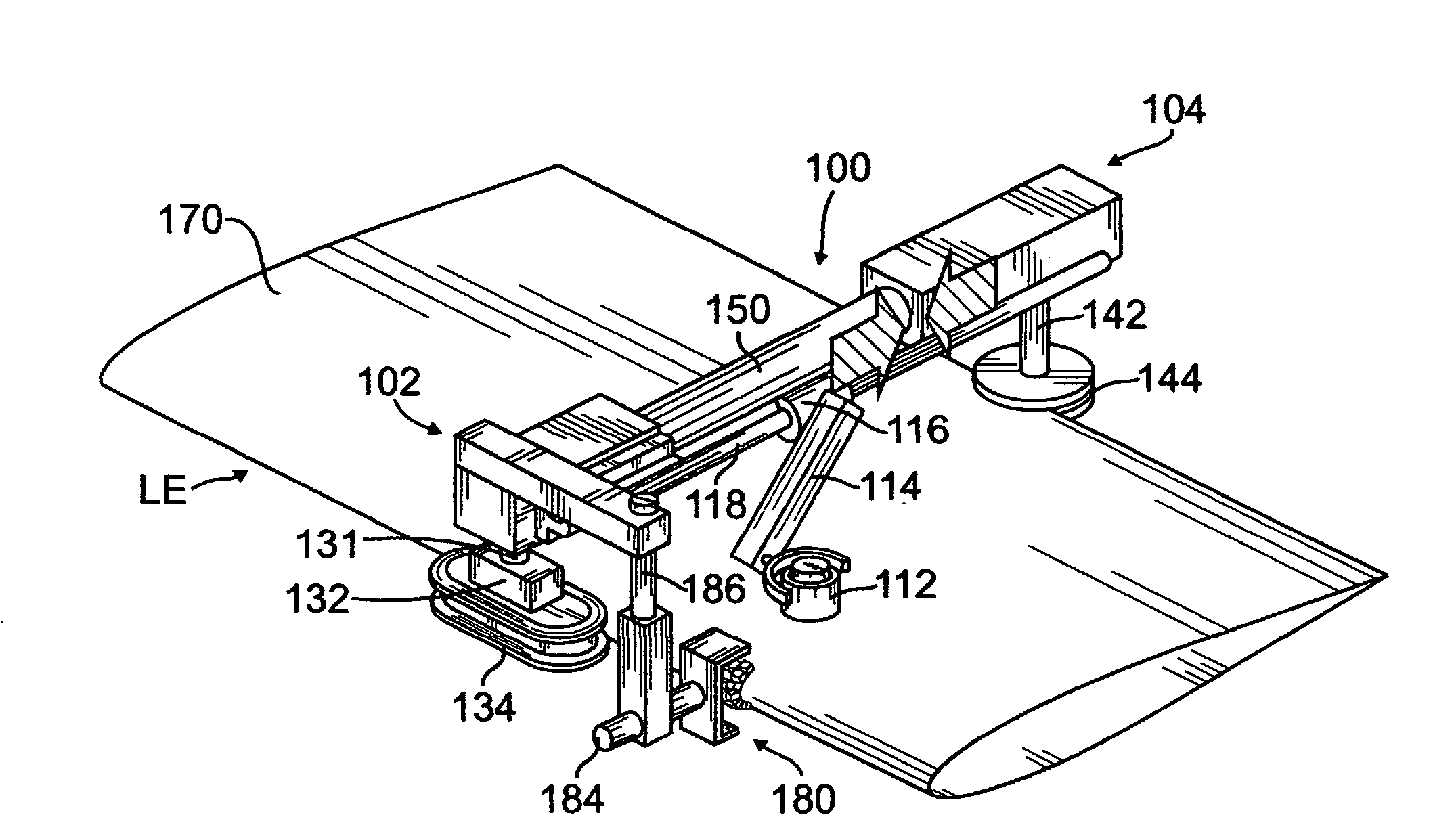

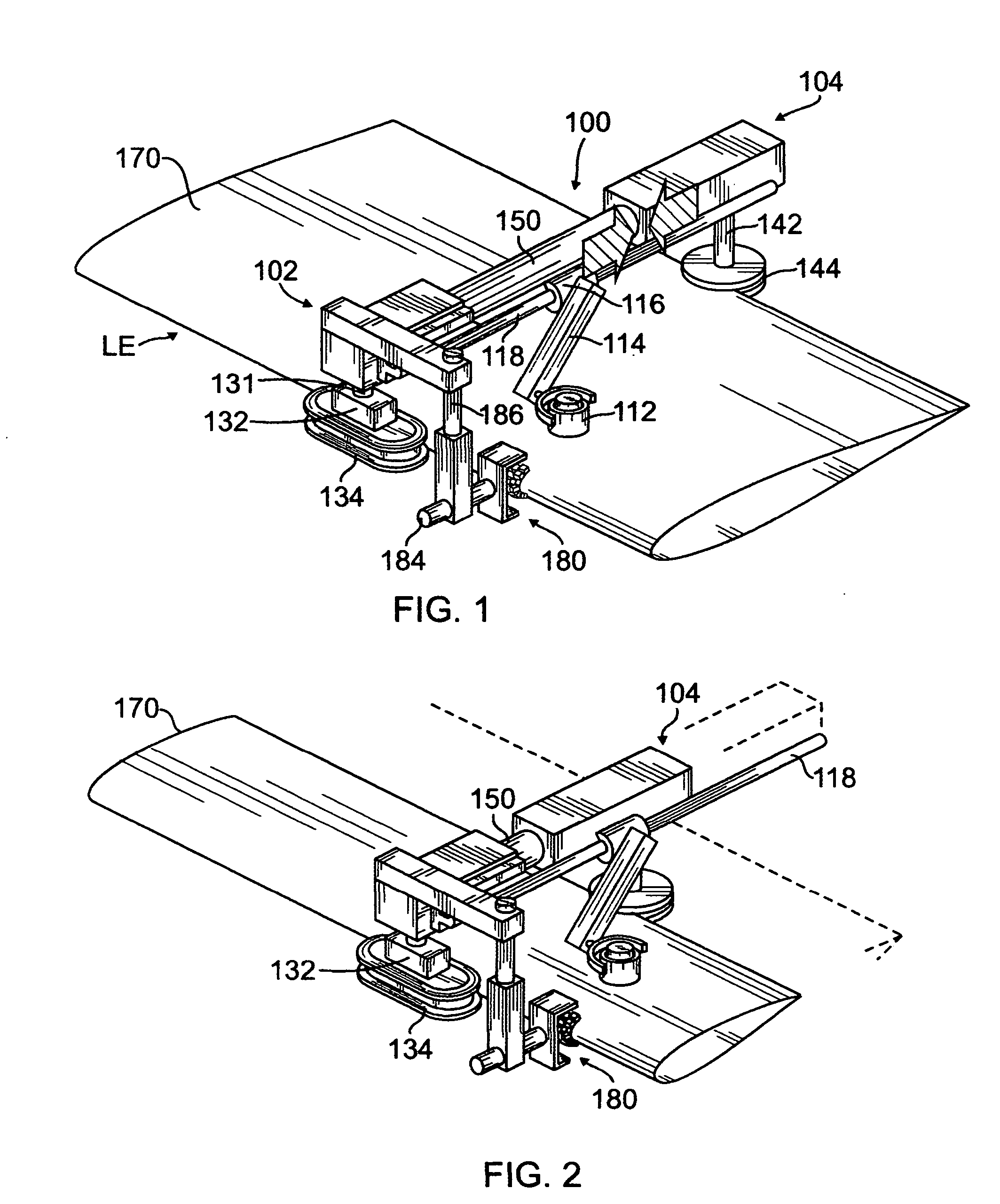

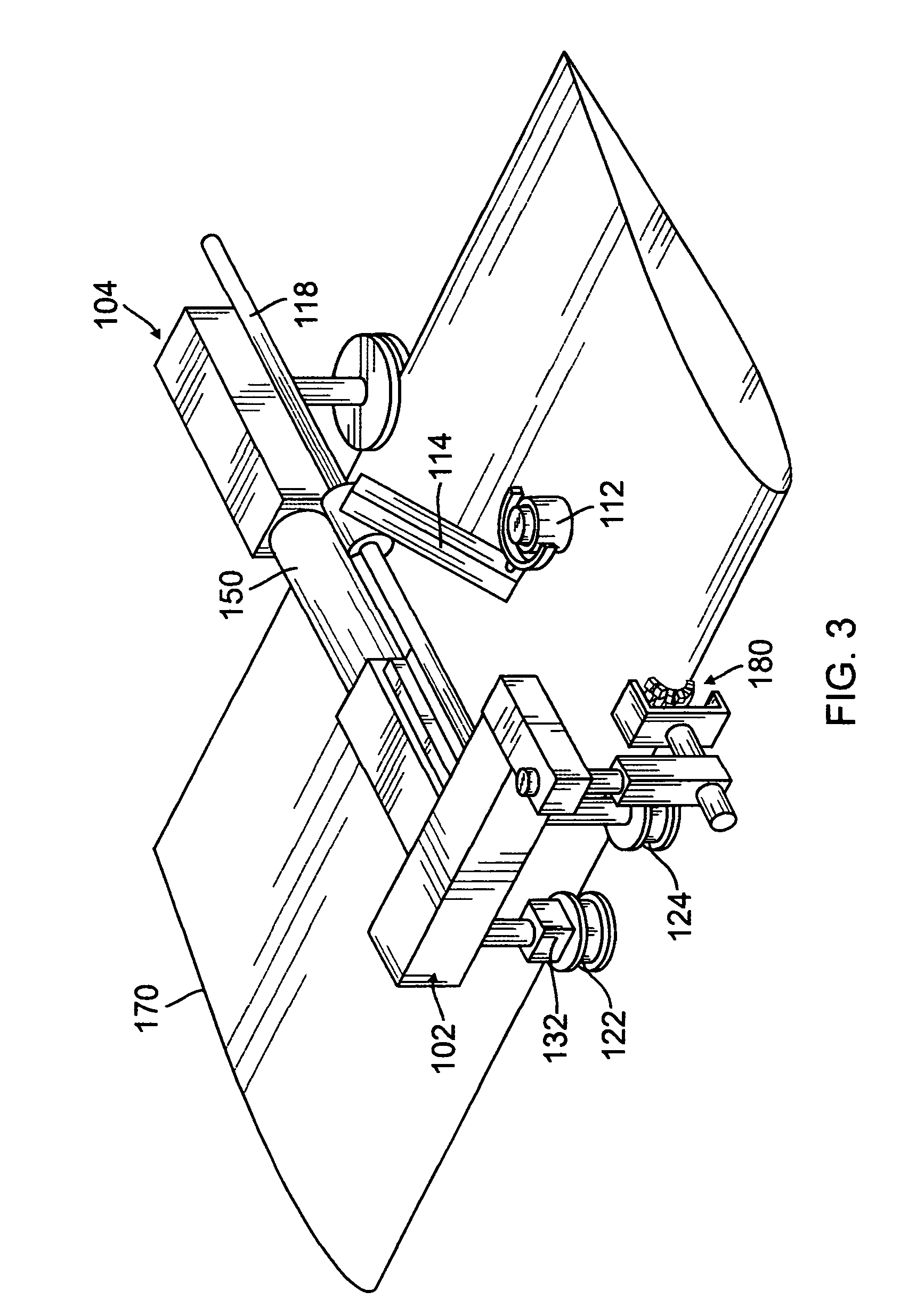

Crawling automated scanner for non-destructive inspection of aeropace structural elements

ActiveUS20110178727A1Material analysis using sonic/ultrasonic/infrasonic wavesBlade accessoriesAviationLeading edge

Apparatus for non-destructive inspection of structural elements or workpieces, in particular those having an airfoil configuration, that moves a scanning sensor across the width (span) of a structural element or workpiece for the purpose of detecting structural damage. In one embodiment, the apparatus simultaneously traverses the length (chord) of the structural element or workpiece. In another embodiment, the apparatus includes a guide rail that encompasses the structural element or workpiece and the scanning sensor travels along the guide rail from a first location at an upper rear region, to the front, of the structural element or workpiece, and then around the leading edge toward the lower rear region. The apparatus includes a processor and a display device to display the processed, sensed, information.

Owner:THE BOEING CO

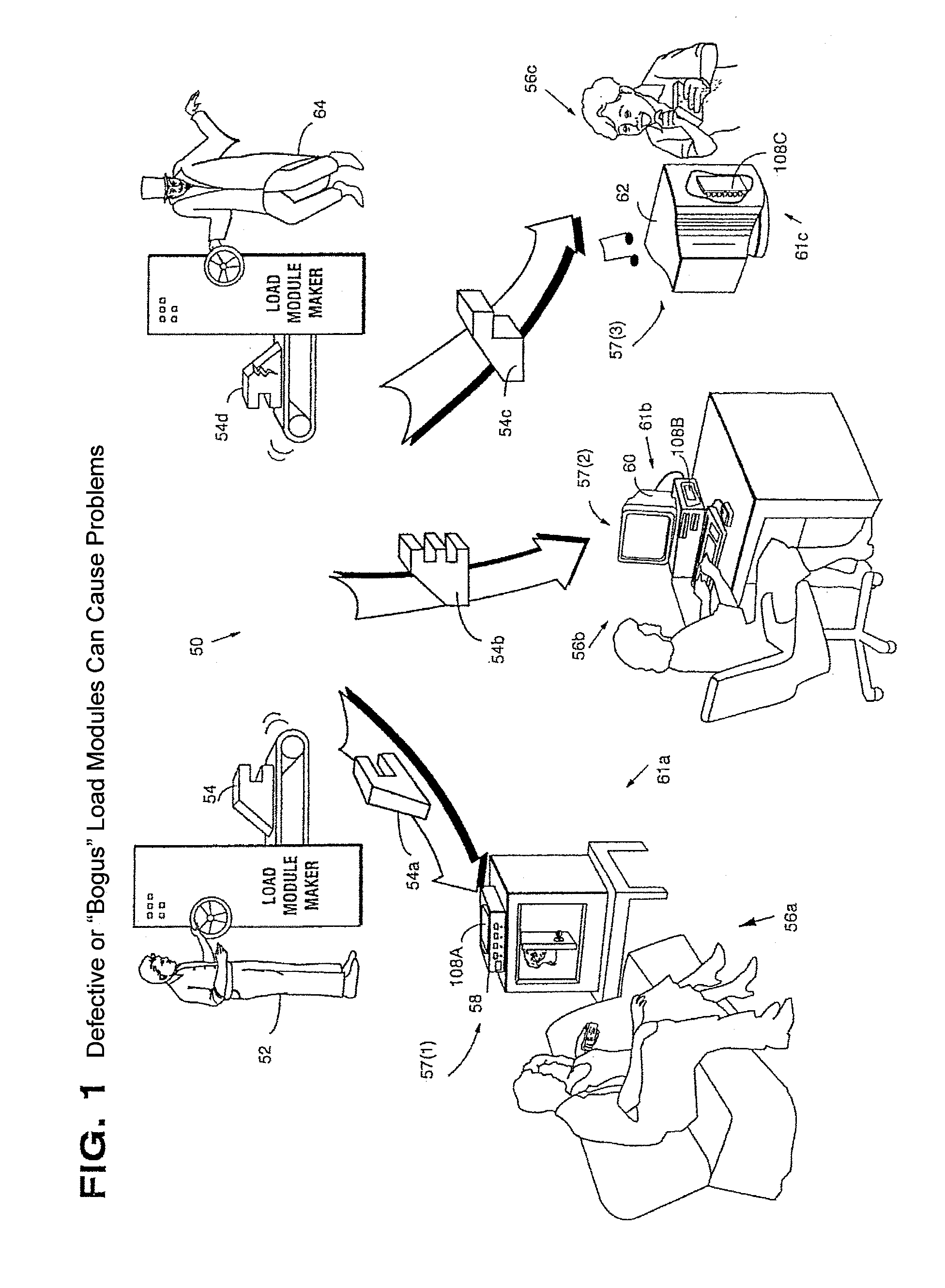

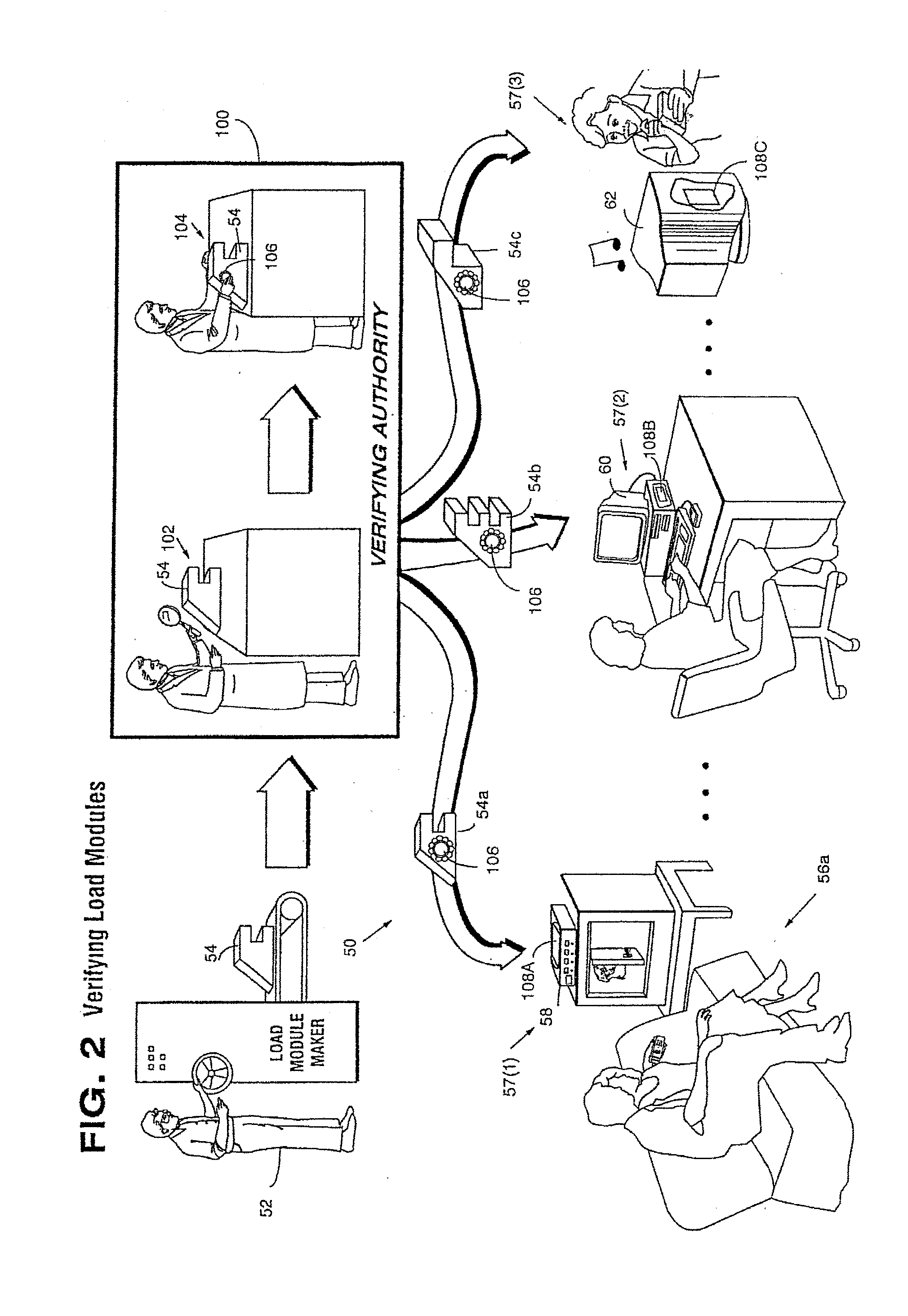

Systems and methods for using cryptography to protect secure and insecure computing environments

InactiveUS7243236B1Digital data processing detailsUser identity/authority verificationTamper resistanceThird party

Computation environments are protected from bogus or rogue load modules, executables, and other data elements through use of digital signatures, seals, and certificates issued by a verifying authority. A verifying authority—which may be a trusted independent third party—tests the load modules and / or other items to verify that their corresponding specifications are accurate and complete, and then digitally signs them based on a tamper resistance work factor classification. Secure computation environments with different tamper resistance work factors use different digital signature authentication techniques (e.g., different signature algorithms and / or signature verification keys), allowing one tamper resistance work factor environment to protect itself against load modules from another tamper resistance work factor environment. The verifying authority can provide an application intended for insecure environments with a credential having multiple elements covering different parts of the application. To verify the application, a trusted element can issue challenges based on different parts of the authenticated credential that the trusted element selects in an unpredictable (e.g., random) way, and deny service (or take other appropriate action) if the responses do not match the authenticated credential.

Owner:INTERTRUST TECH CORP

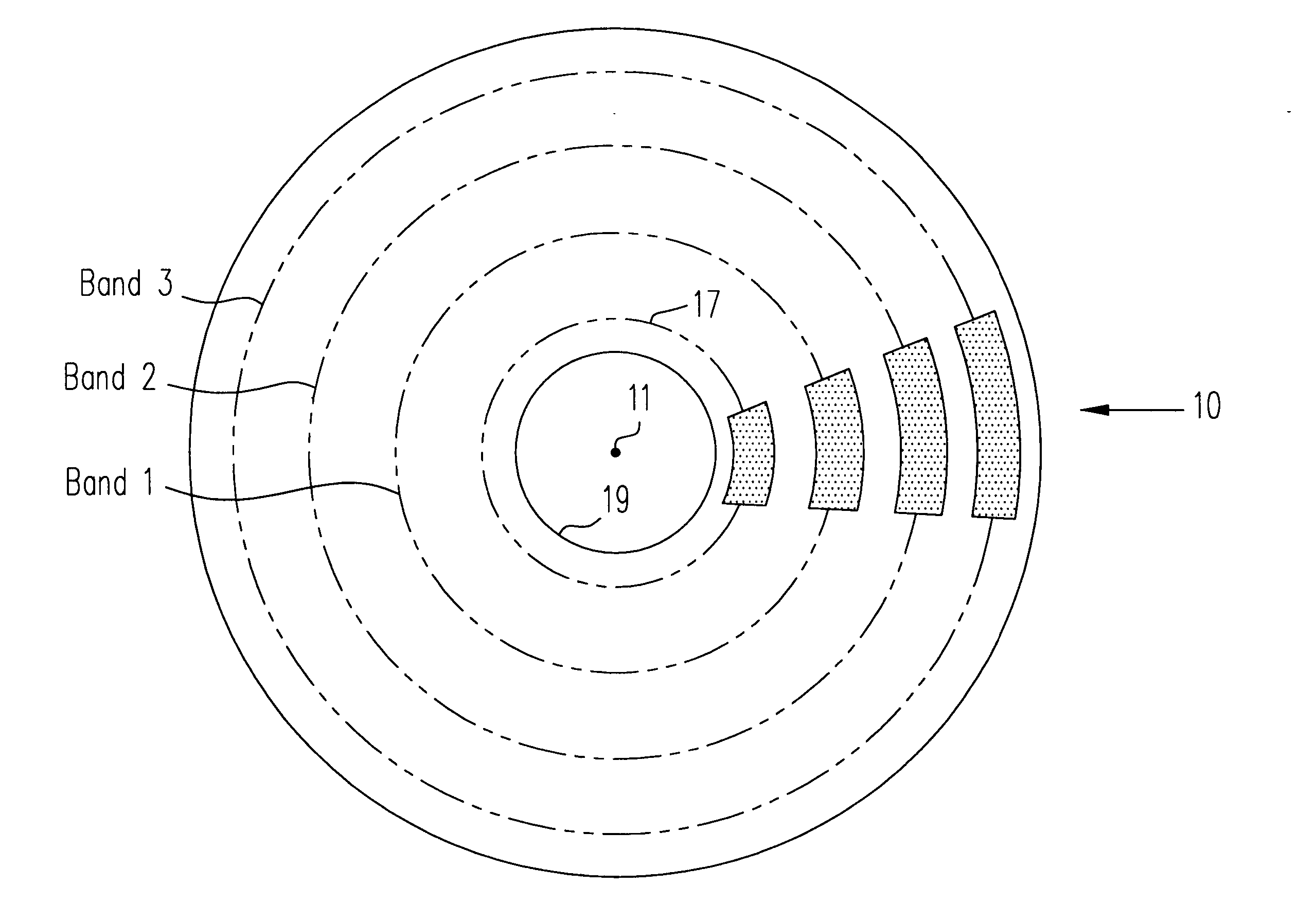

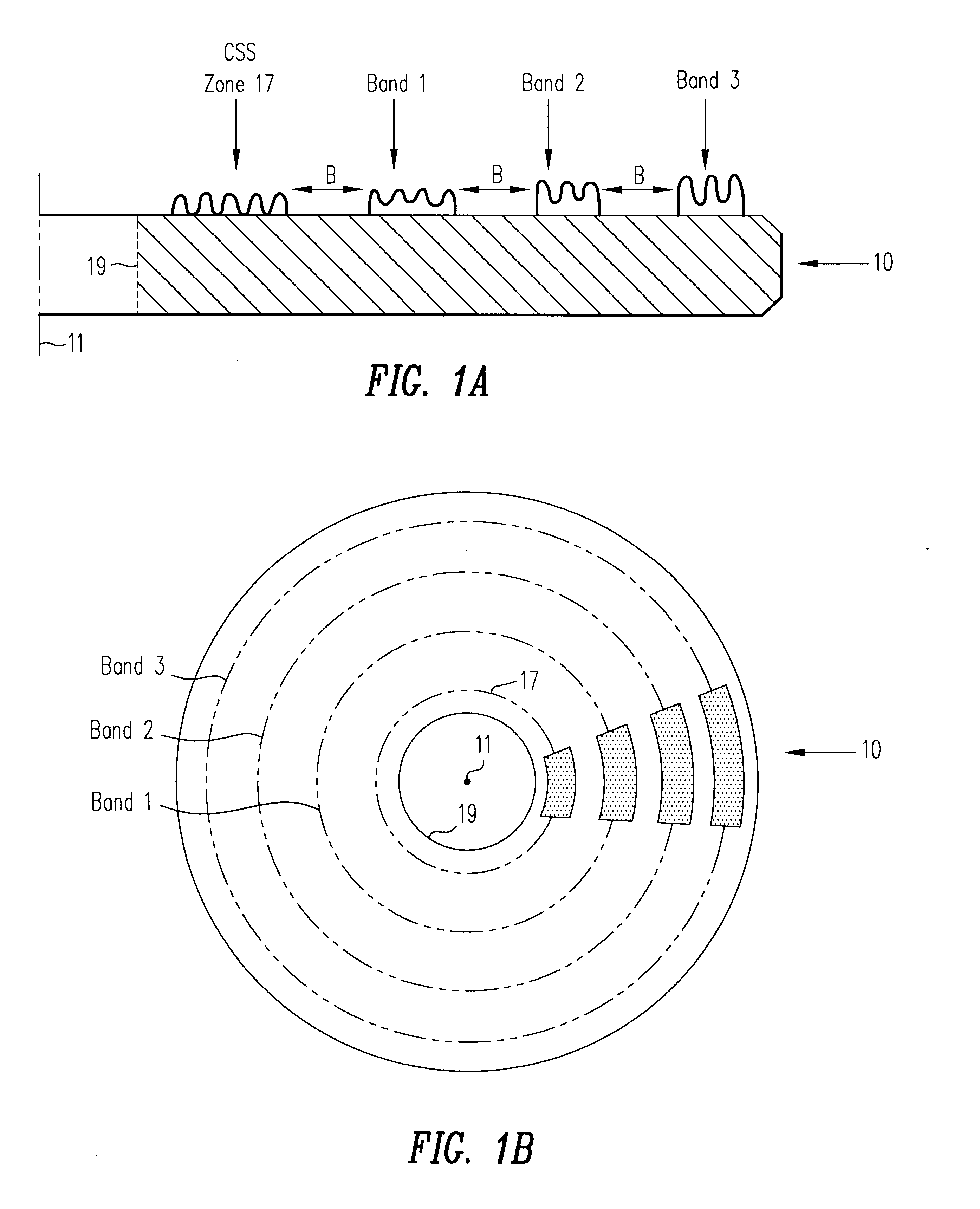

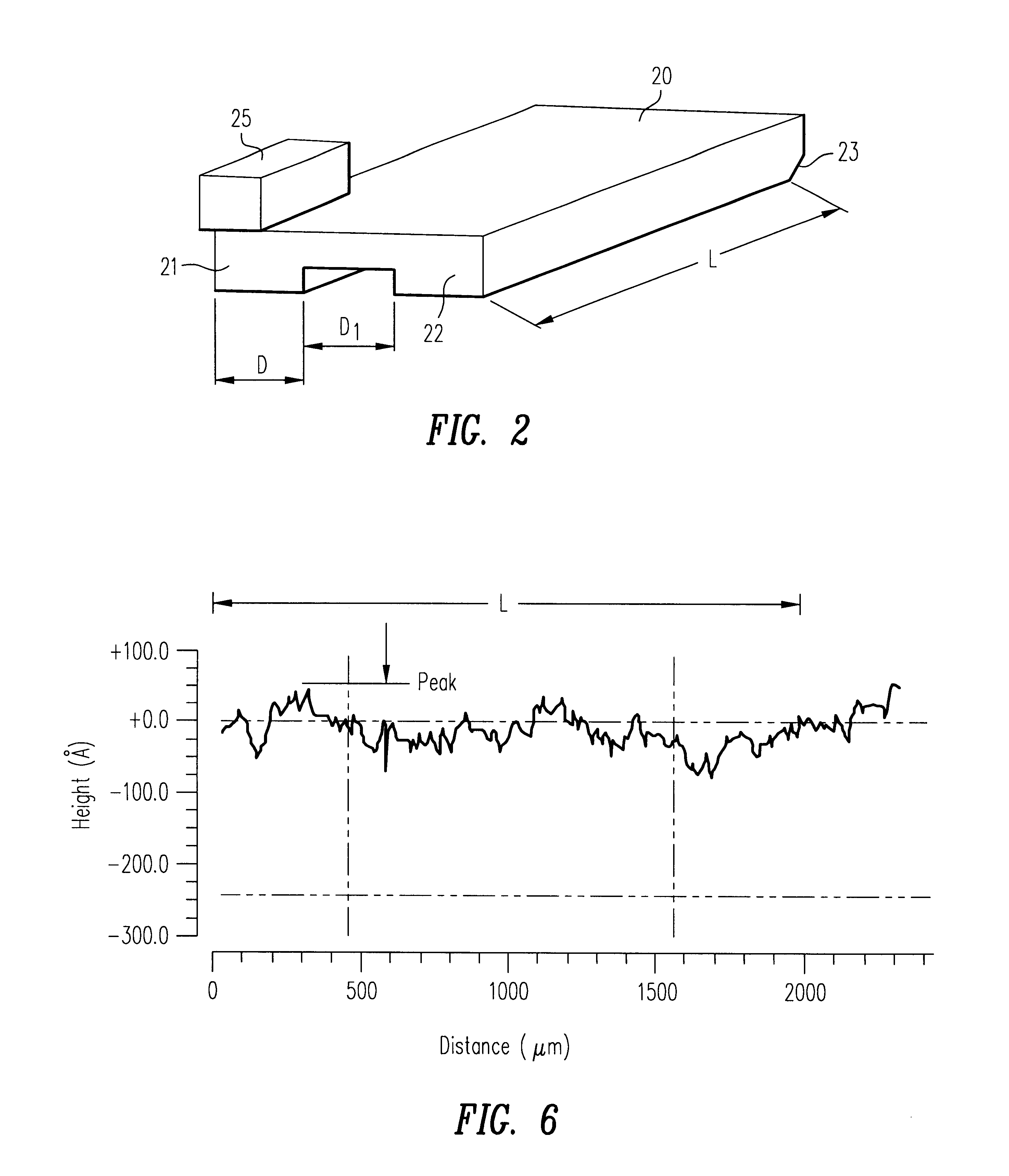

Calibration disk having discrete bands of composite roughness

InactiveUS6408677B1Carrier indicating/warning arrangementsRecord information storageEngineeringFlying height

A calibration disk includes calibration areas that allow a glide head to be calibrated as to the glide's head's avalanche height, fly height and the like. The calibration areas may be, for example, configured in a circumferential band (or, alternatively, a series of circumferential bands extending substantially concentric to one another), one or more spiral bands or some other suitable configuration. Such bands can, for example, extend from adjacent an outer diameter of the calibration disk to adjacent an inner portion of the calibration disk. Each of the circumferential bands is a textured area on the calibration disk having a given degree of composite roughness, as measured by the given circumferential band's average composite roughness height, and as such is referred to herein as a calibration band. Preferably, the given circumferential band is textured in a uniform manner, sufficient to produce a constant and continuous output signal from a sensor mounted on a glide head when the glide head flies lower than a maximum composite roughness height. Also preferably, the average composite roughness height within an individual calibration band is substantially uniform, and the average composite roughness height of each calibration band is slightly different from that of the other calibration bands.

Owner:KOMAG CORP

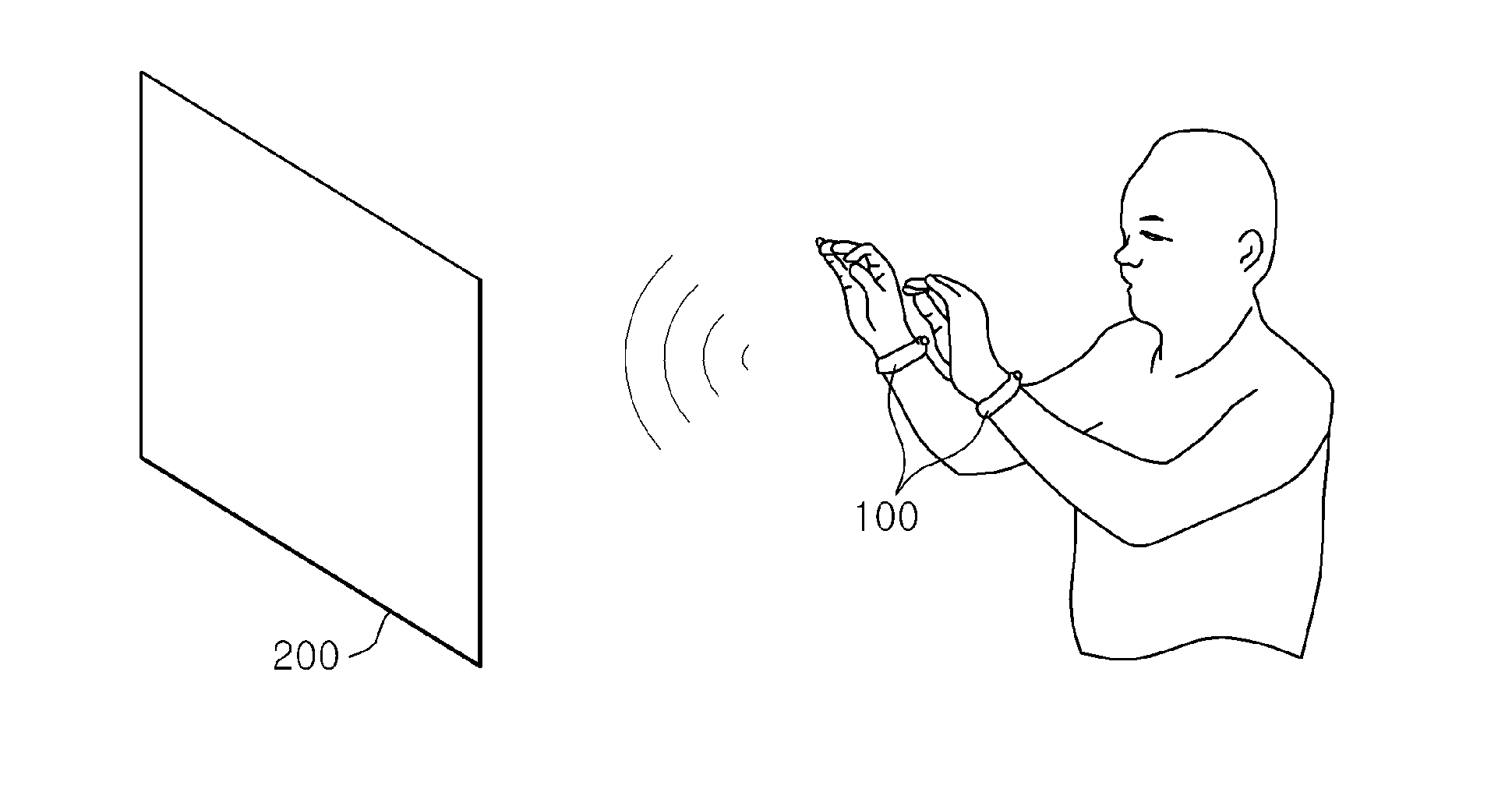

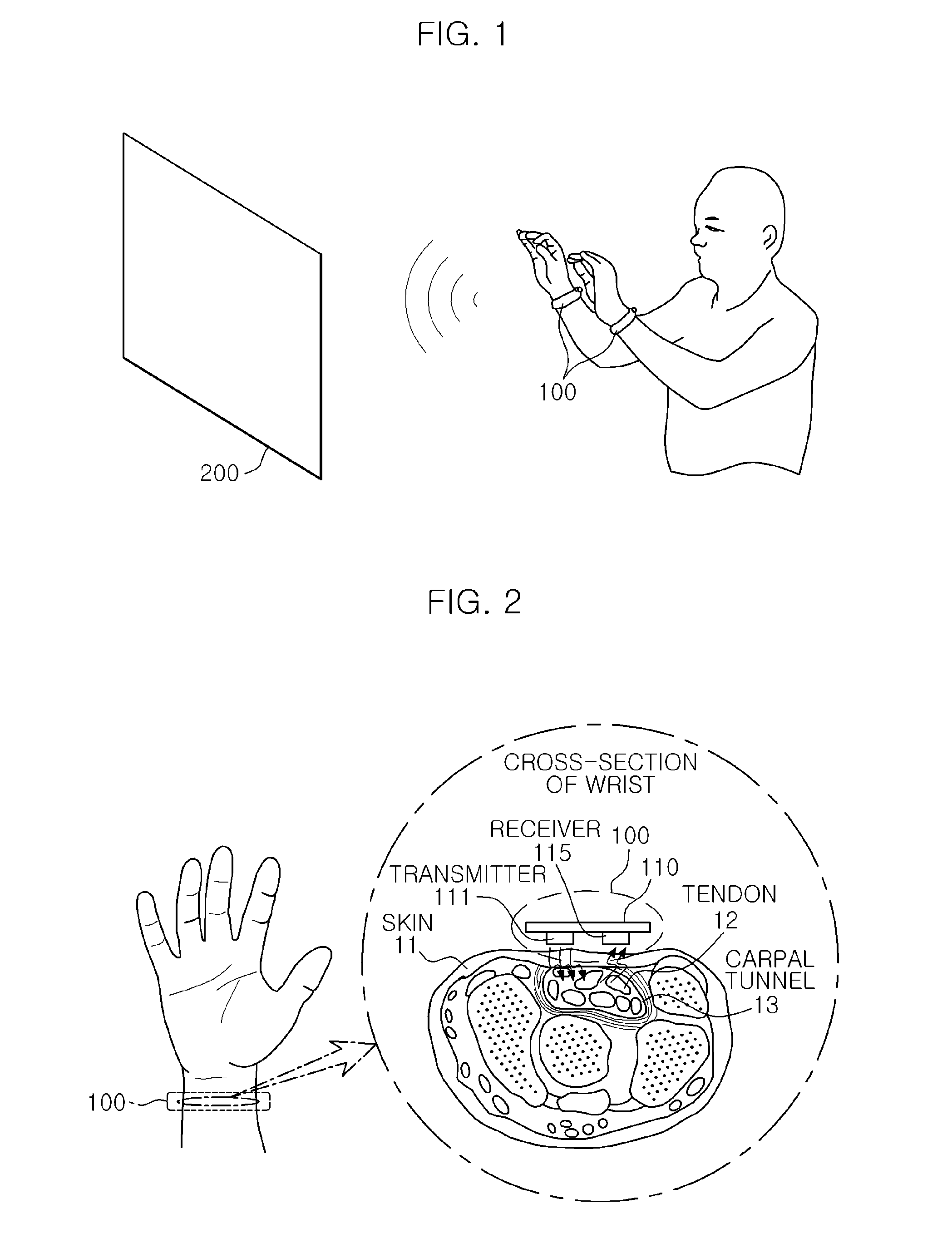

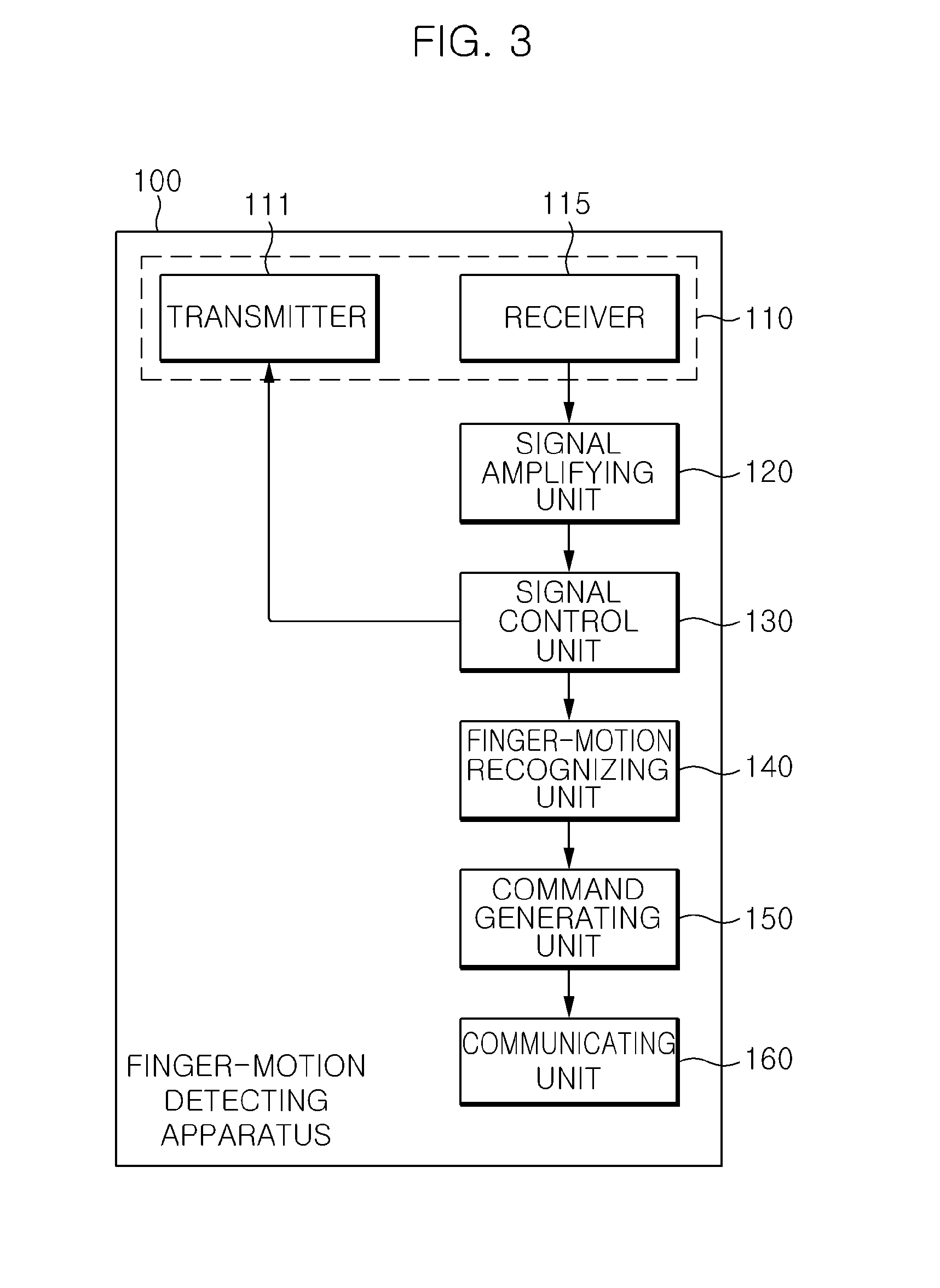

Finger motion detecting apparatus and method

ActiveUS20110054360A1Problem of inconvenienceEasy to detectMangetographic processPerson identificationSignal onEngineering

The present invention relates to a finger-motion detecting apparatus and method and includes a sensing unit to be disposed on a wrist of a subject person, said sensing unit being configured to output a measurement signal into the wrist of the subject person and to receive a reflected signal of the measurement signal according to the motion of tendons in the wrist of the subject person, a signal control unit configured to control whether the measurement signal is outputted and to adjust the measurement signal on the basis of the reflected signal, and a finger-motion recognizing unit configured to detect finger motion of the subject person from the reflected signal. According to the present invention, since a sensor capable of detecting finger motion is worn on a wrist, the problem of inconvenience in existing methods is resolved.

Owner:ELECTRONICS & TELECOMM RES INST

Methods and systems for detecting defects in a reticle design pattern

ActiveUS20070035728A1Character and pattern recognitionOptically investigating flaws/contaminationReticleDesign pattern

Computer-implemented methods and systems for detecting defects in a reticle design pattern are provided. One computer-implemented method includes acquiring images of a field in the reticle design pattern. The images illustrate how the field will be printed on a wafer at different values of one or more parameters of a wafer printing process. The field includes a first die and a second die. The method also includes detecting defects in the field based on a comparison of two or more of the images corresponding to two or more of the different values. In addition, the method includes determining if individual defects located in the first die have substantially the same within die position as individual defects located in the second die.

Owner:SADRA MEDICAL INC +1

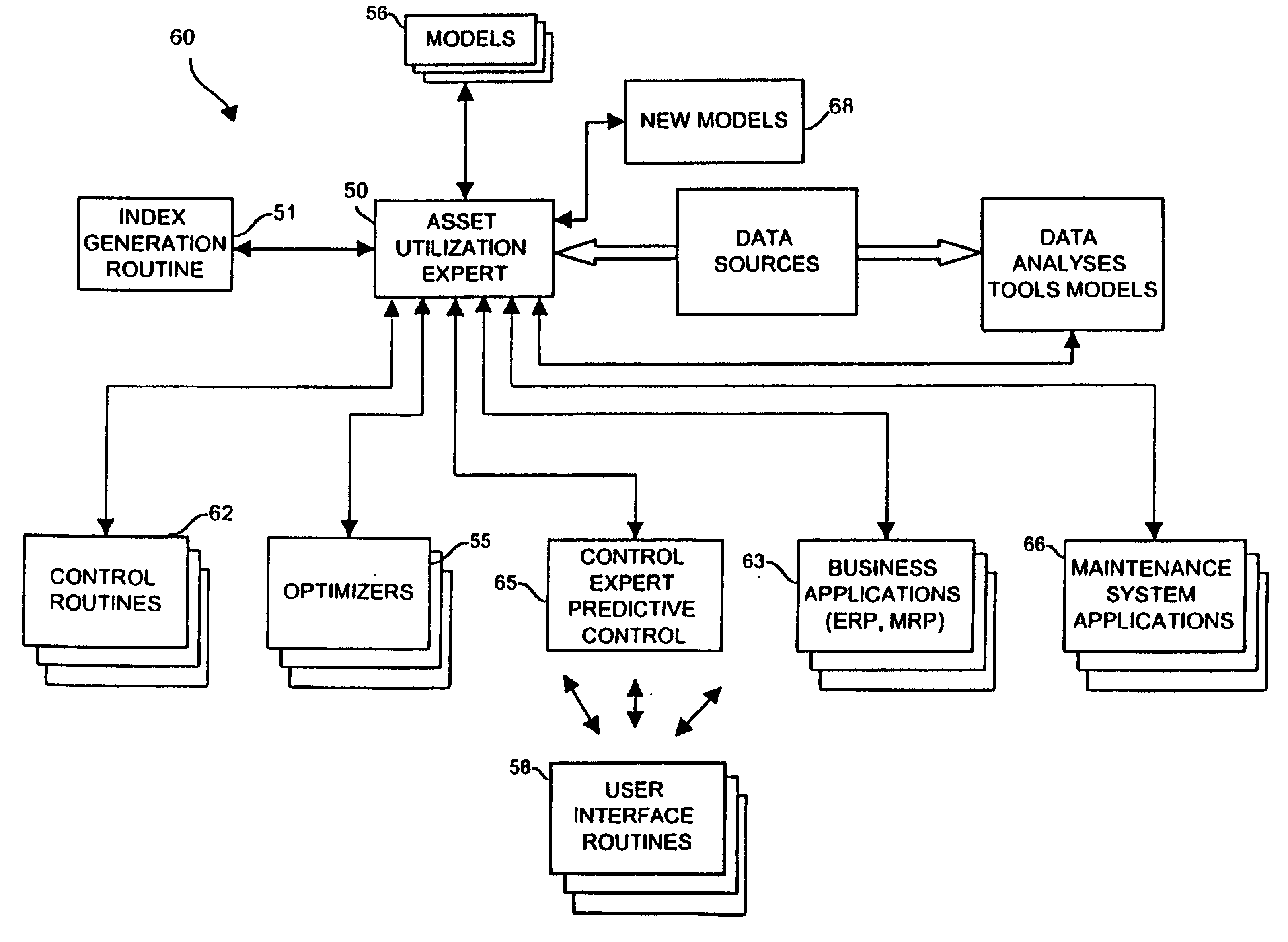

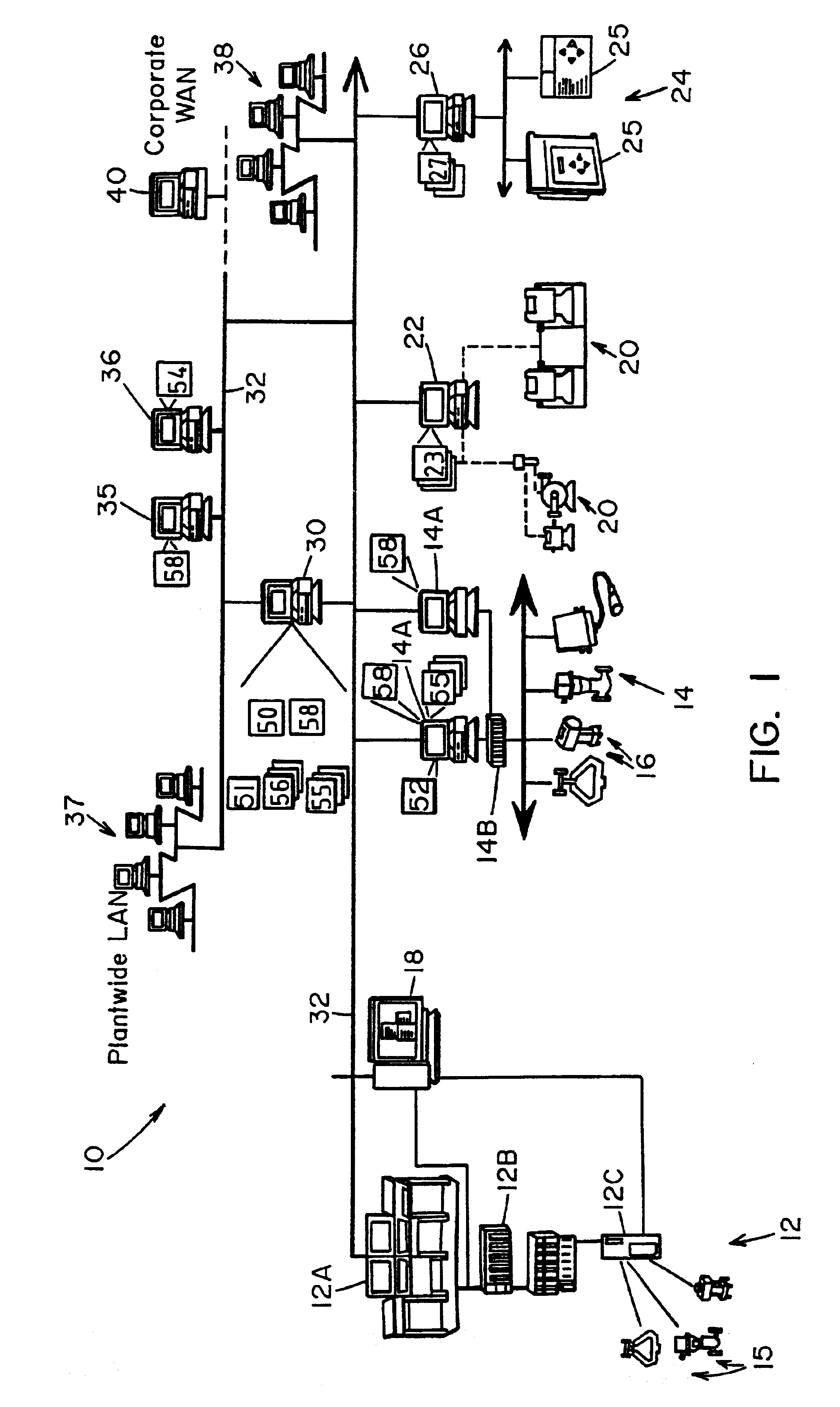

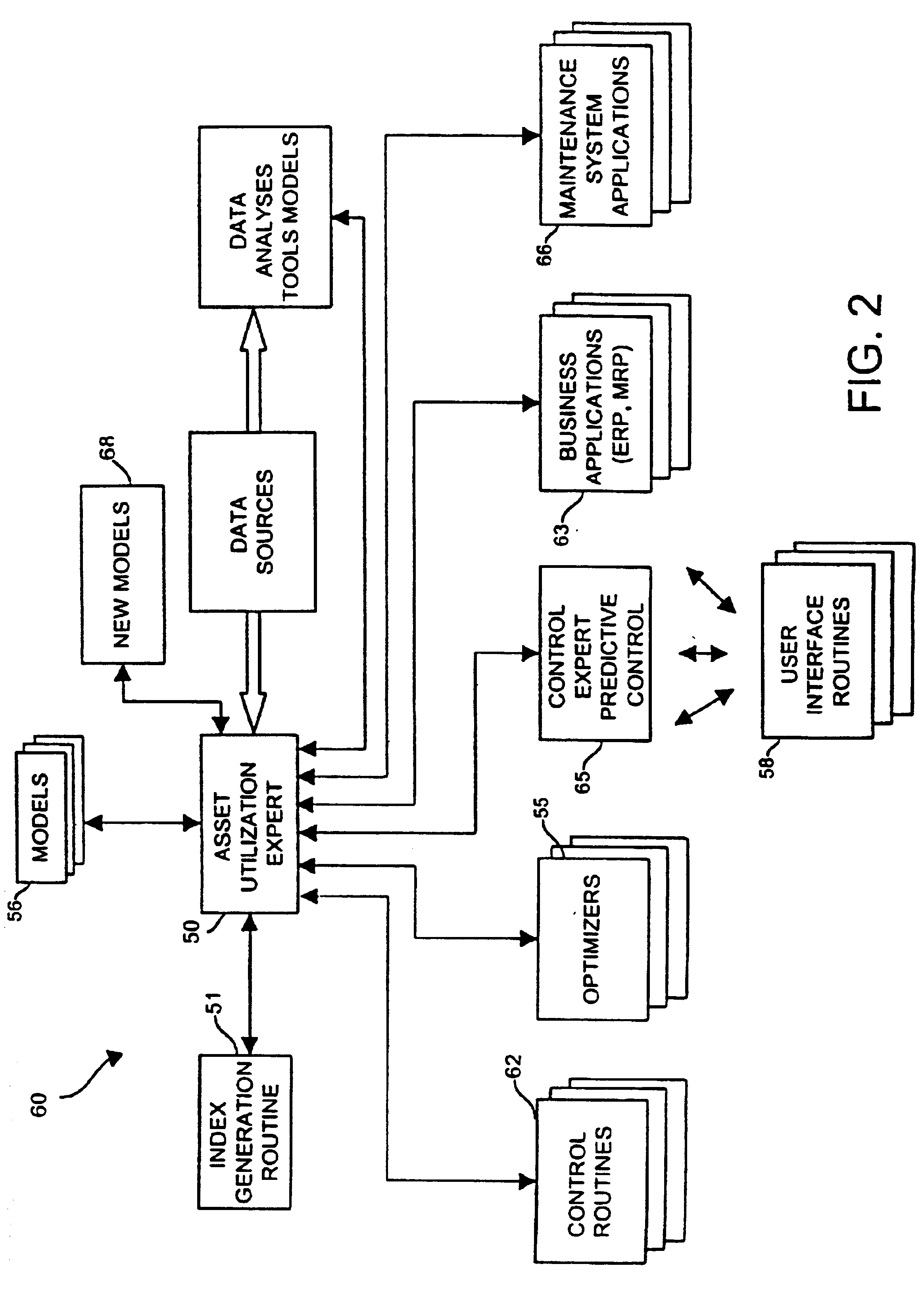

Fiducial technique for estimating and using degradation levels in a process plant

A process plant uses an asset utilization expert to collect data or information pertaining to the assets of the process plant from various sources or functional areas of the plant including, for example, the process control functional areas, the maintenance functional areas and the business systems functional areas. Some of this data, such as data indicative of one or more process parameters associated with a process entity like a furnace, may be used to estimate a degradation level, such as a coking level, of the process entity at a first time. The estimated level of the degradation of the process entity at the first time may then be compared to a predetermined desired level of degradation of the process entity at the first time and the operation of the process entity may be altered based on the comparison to drive the estimated amount of degradation of the process entity at a second time to be approximately equal to a predetermined desired level of degradation at the second time.

Owner:FISHER-ROSEMOUNT SYST INC

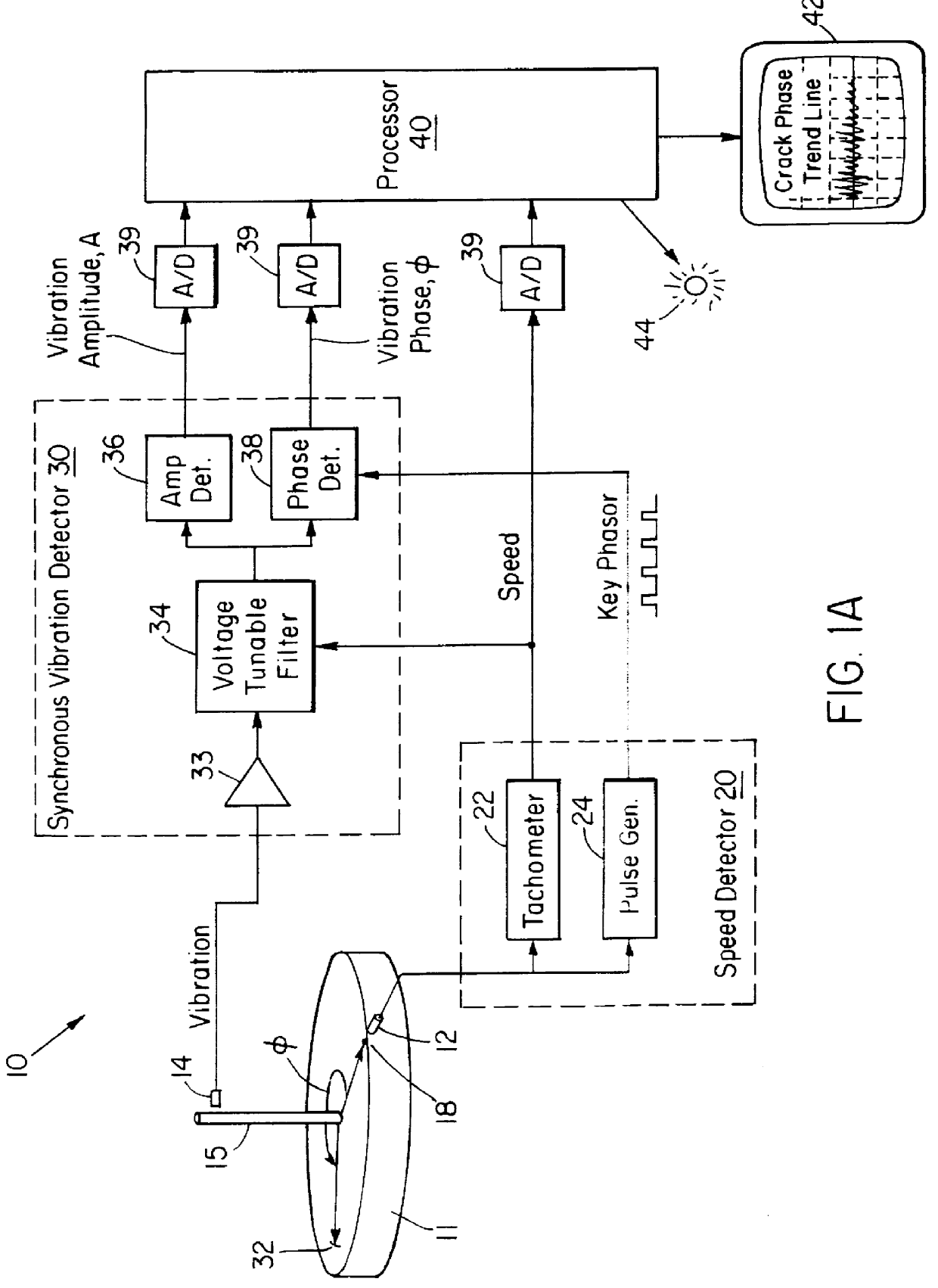

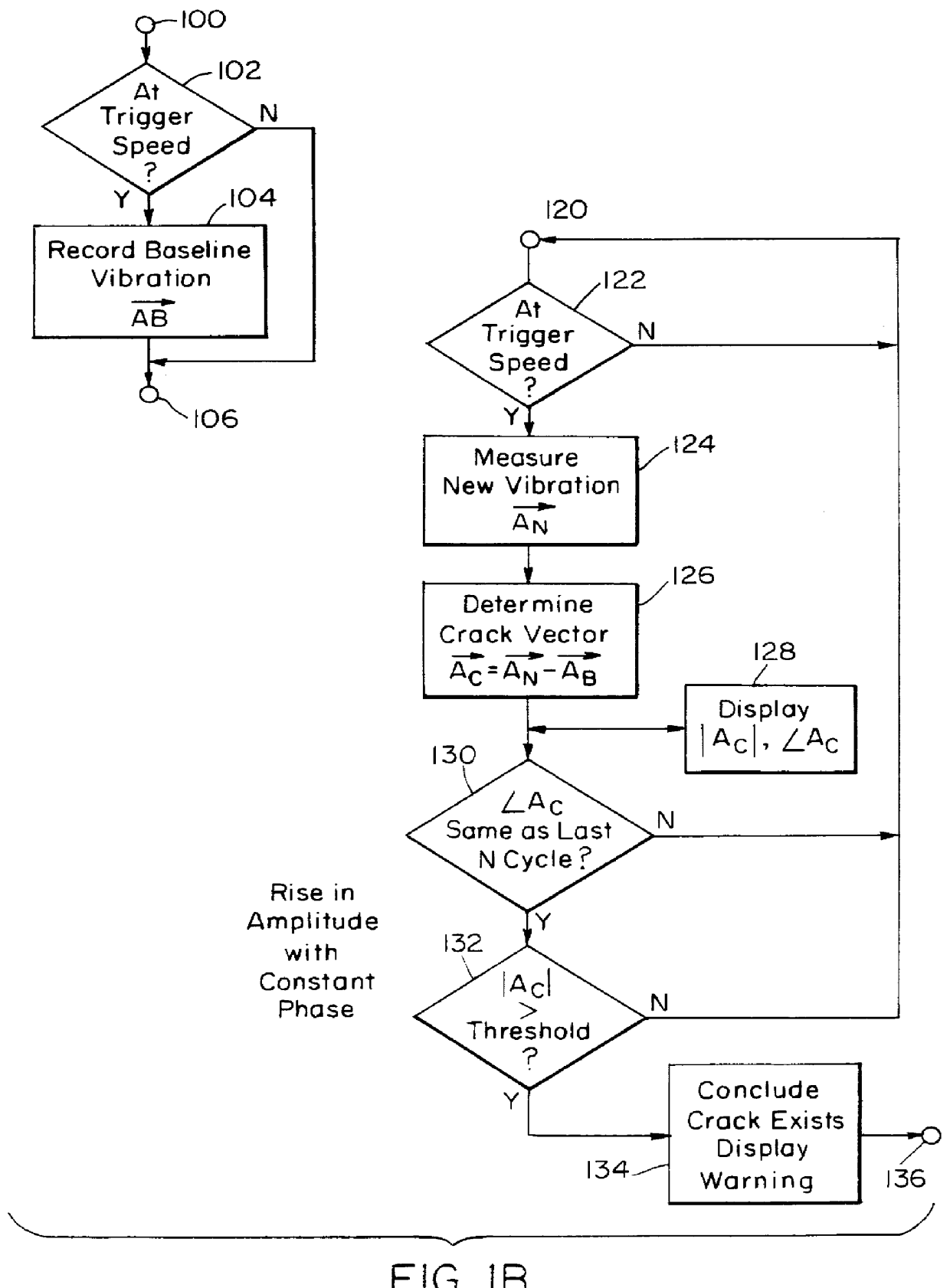

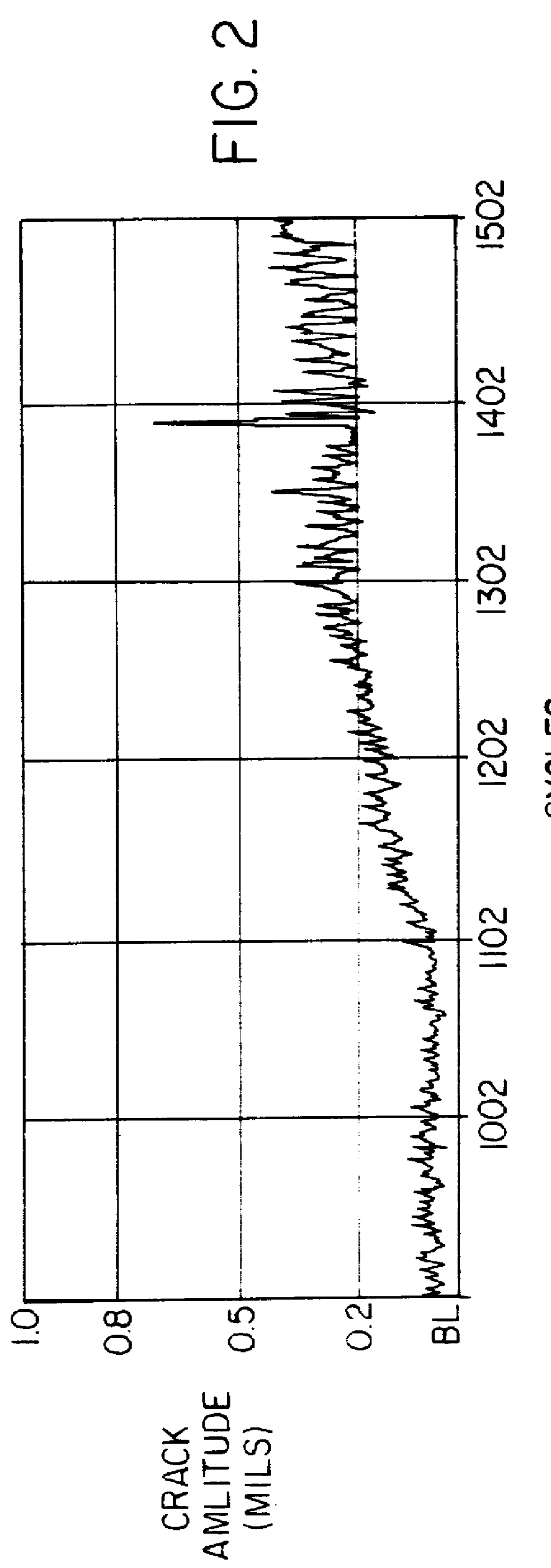

Detecting anomalies in rotating components

InactiveUS6098022AImprove accuracyHigh sensitivityMachine gearing/transmission testingFlow propertiesVibration measurementAcoustics

A method for detecting an anomaly, such as a crack, in a rotor includes measuring the rotational speed and vibration of the rotor. A vibration signal synchronous with the frequency of rotation is filtered from the vibration measurement. A background vibration vector is then subtracted from the synchronous vibration signal to produce a vibration difference signal. The phase and amplitude of the vibration difference signal are measured and evaluated to determine whether an anomaly has developed. An apparatus for performing this method includes vibration and speed sensors coupled to a filter for extracting a signal from the vibration measurement having a frequency synchronous with the rotation of the rotor. A processor is coupled to the filter and the speed sensor and is programmed to perform the processing steps, described above.

Owner:TEST DEVICES

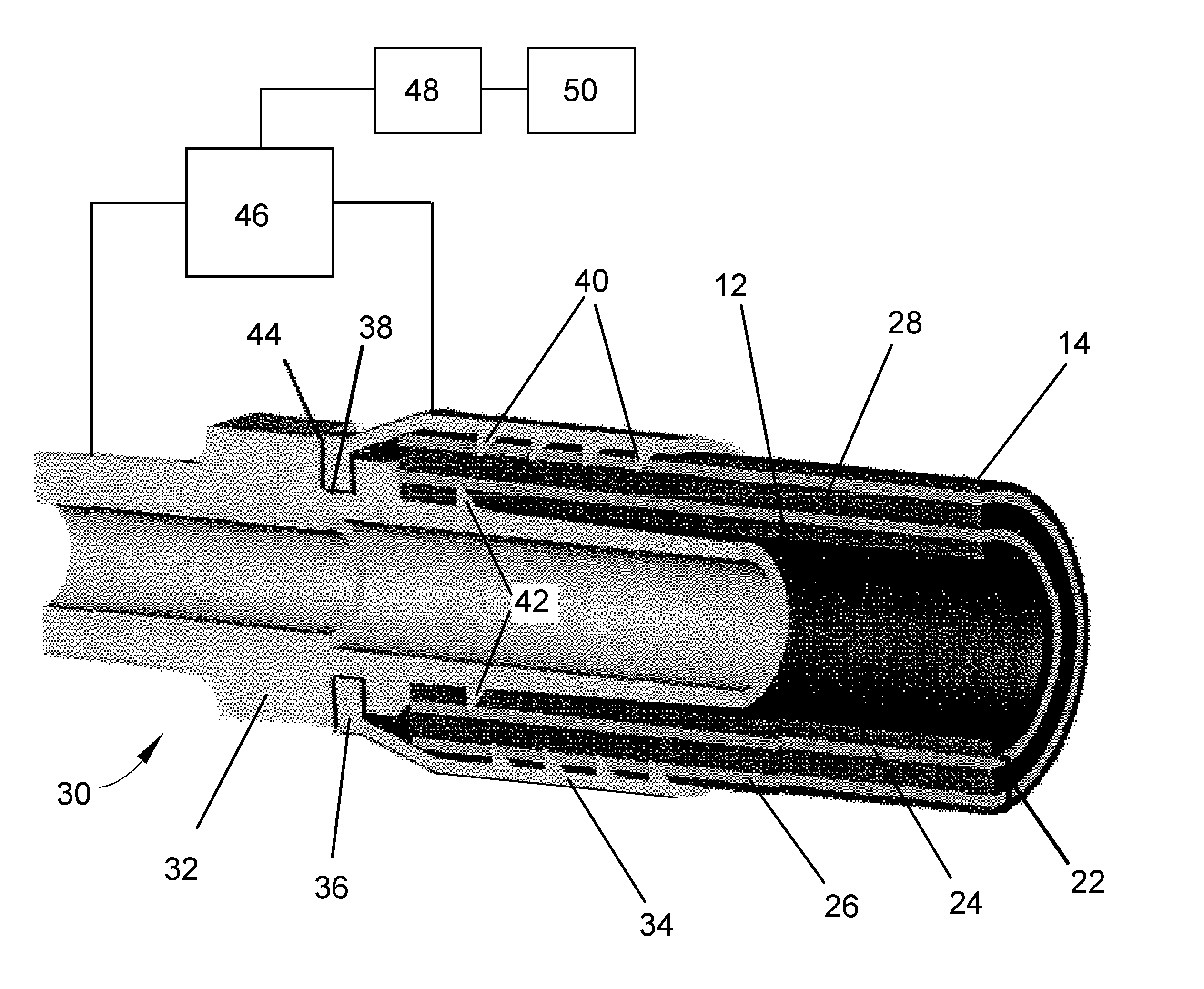

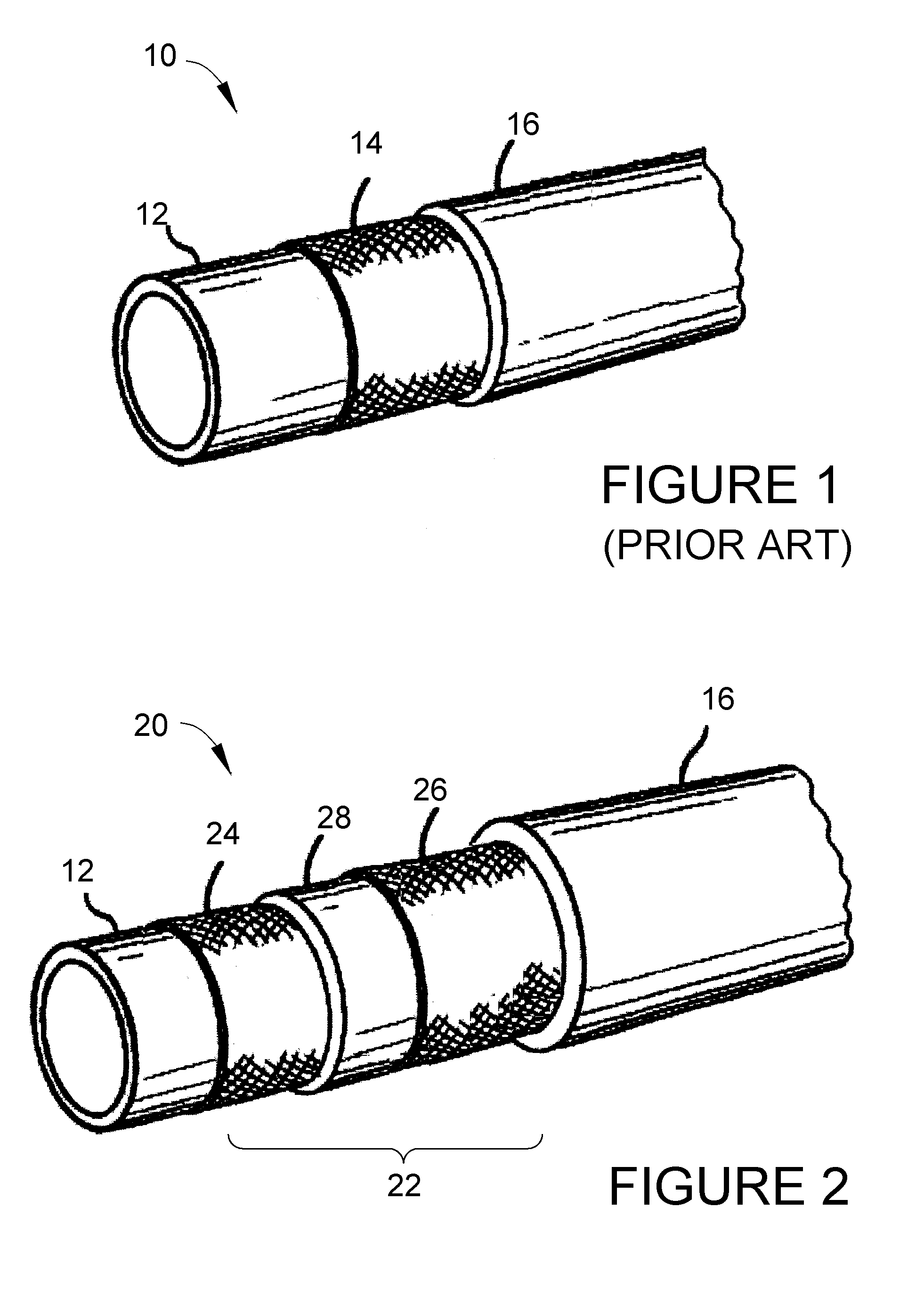

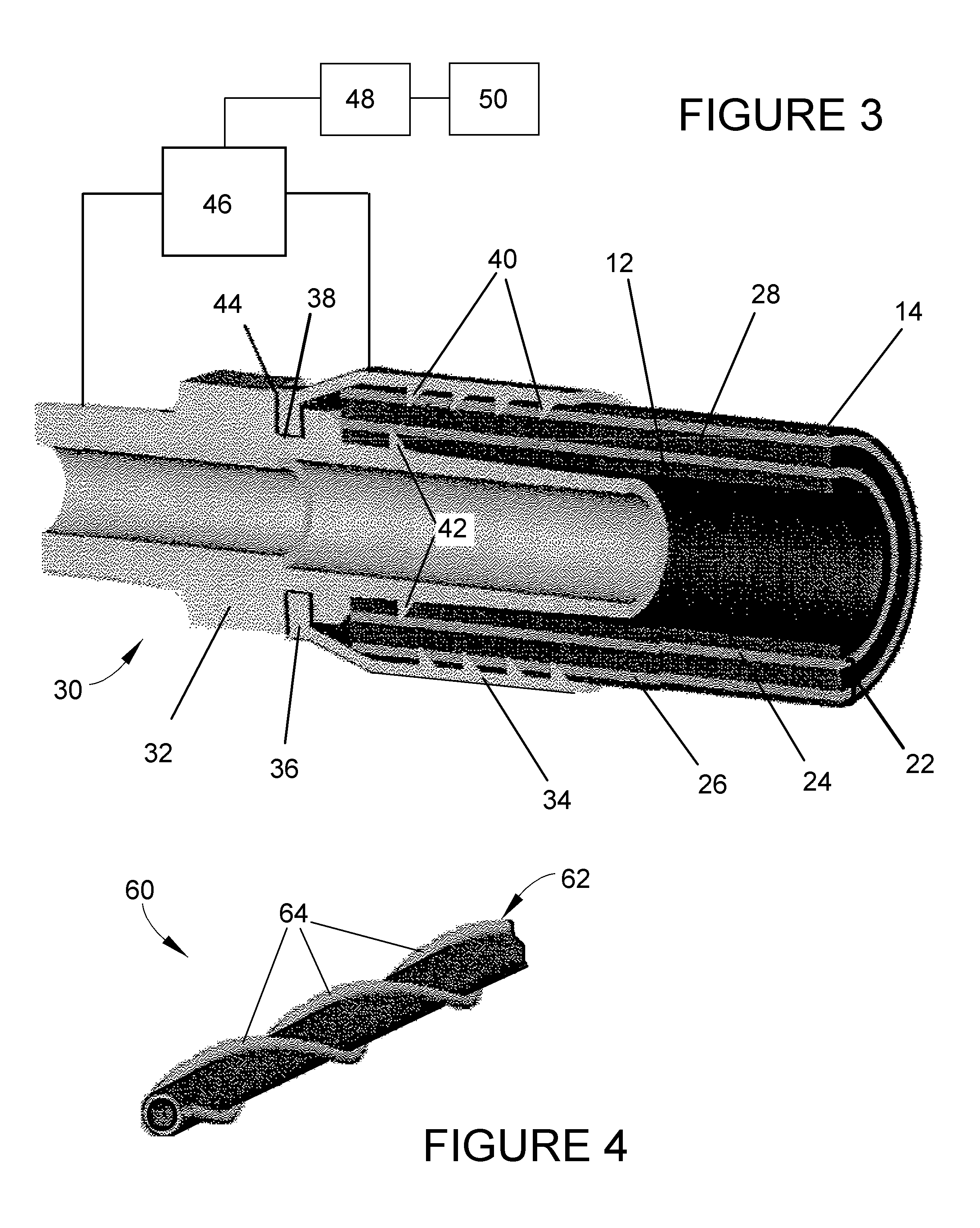

Hydraulic hose with integral life-sensing capability and method therefor

ActiveUS20060196252A1Detection of fluid at leakage pointTesting/calibration apparatusElectrical conductorProcess equipment

A system and method for predicting structural failure of a wall of a fluid containment vessel, such as a hydraulic hose or other type of pressurized conduit of types used in mobile machinery, automotive, aerospace, manufacturing, and process equipment. The wall of the vessel has an innermost layer for contact with the fluid contained by the vessel, and an outermost layer parallel with the innermost layer. The system includes strain-sensing means between the innermost and outermost layers and comprising at least one conductor parallel to the innermost layer of the wall. The system and method entail sensing changes in an electrical property associated with the at least one conductor resulting from distortion of the wall of the vessel causing distortion of the at least one conductor.

Owner:PURDUE RES FOUND INC

Precise location of buried metallic pipes and cables in the presence of signal distortion

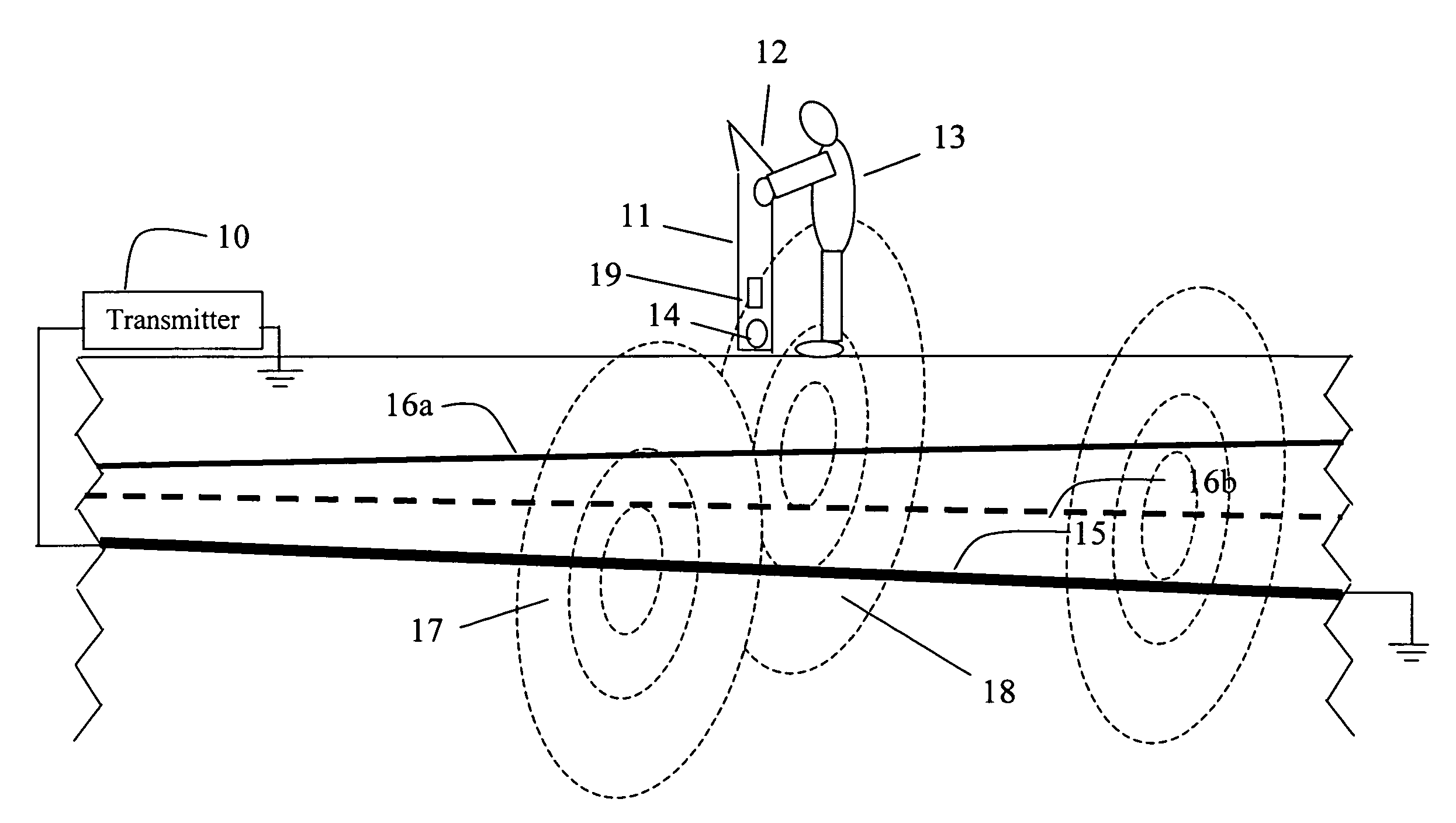

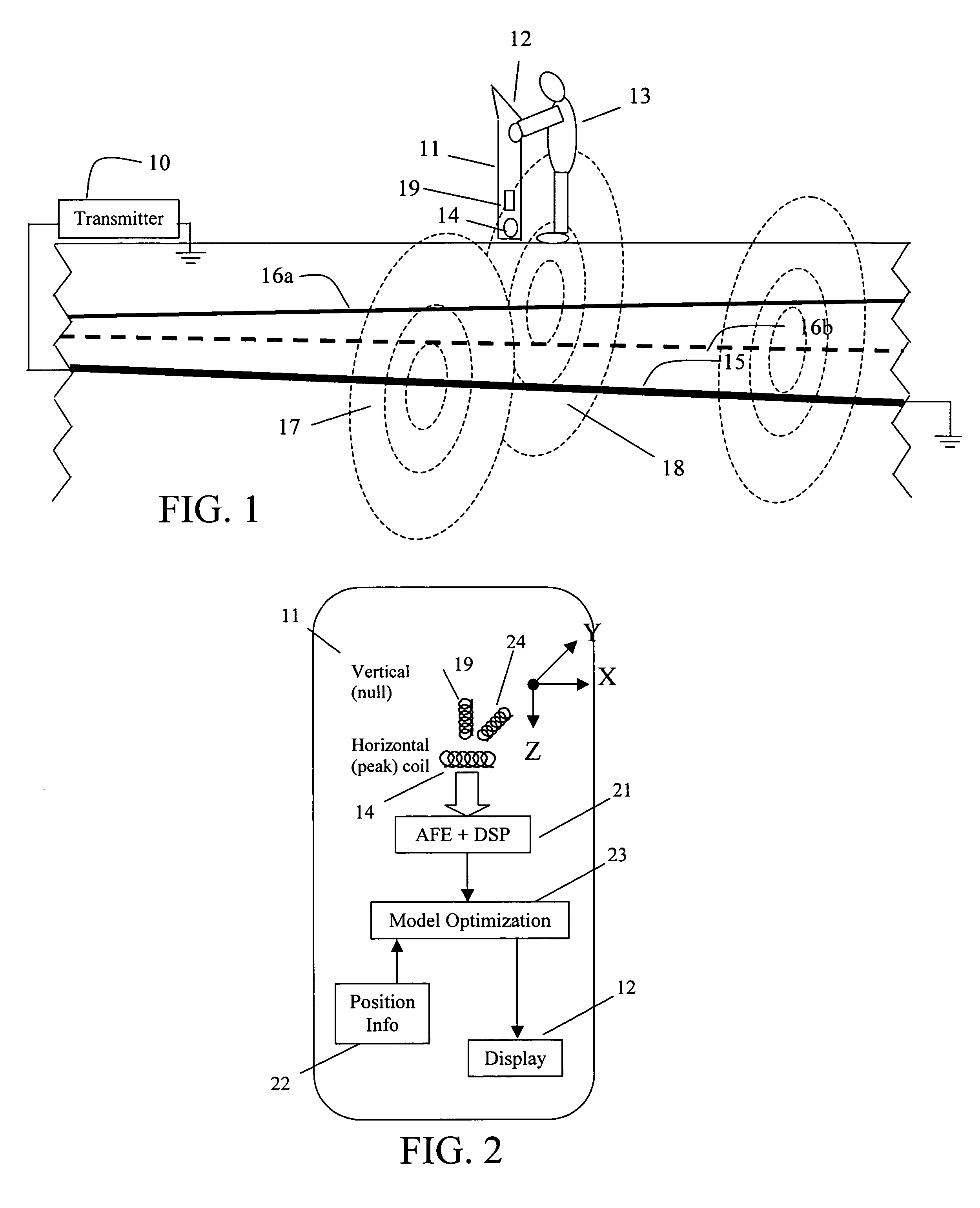

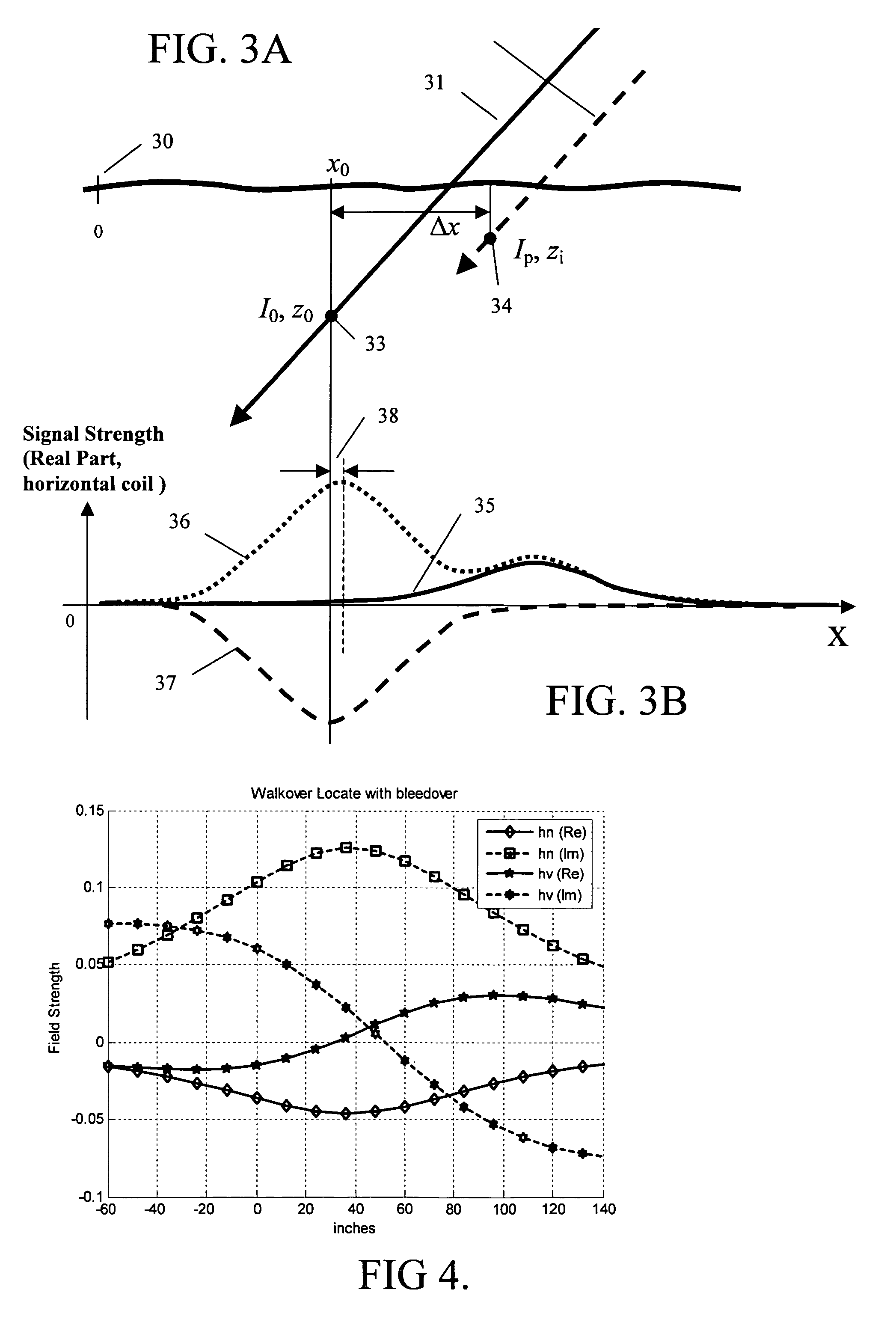

ActiveUS7356421B2Depth accurateCurrent/voltage measurementMagnetic property measurementsEngineeringUltimate tensile strength

A new approach for locating an underground line described herein remains accurate in the face of bleedover by including both amplitude and phase from at least two magnetic field strength sensors in the measurement set. A numerical optimization step is introduced to deduce the positions and currents of each of several cables, of which one is the targeted cable and the others are termed bleedover cables. Furthermore, some embodiments of the method accounts for practical problems that exist in the field that relate to reliable estimation of cable positions, like the phase transfer function between transmitter and receiver, the estimation of confidence bounds for each estimate, and the rejection of false positive locates due to the presence of noise and interference.

Owner:BUSAN TRANSPORTATION CORPORATION

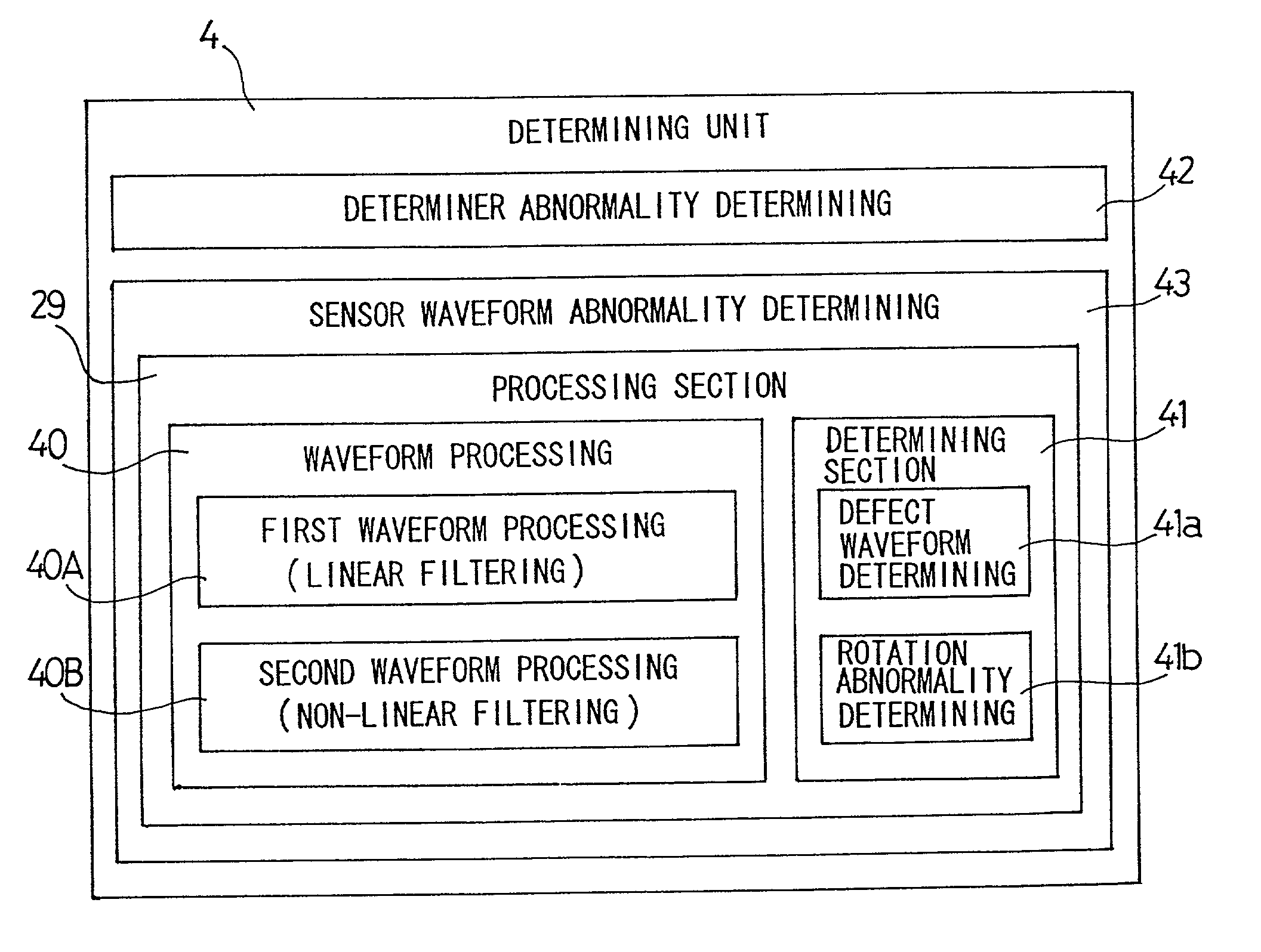

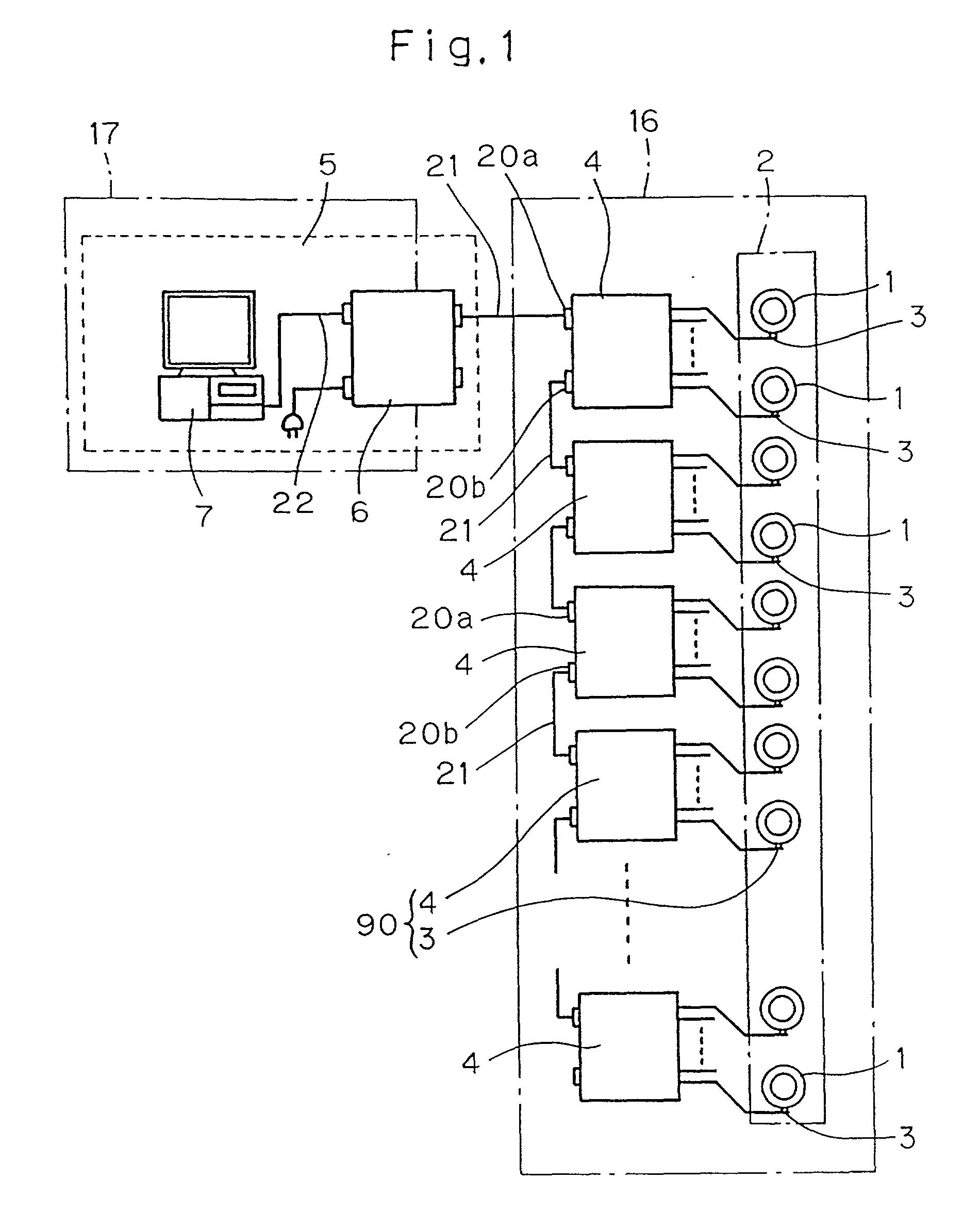

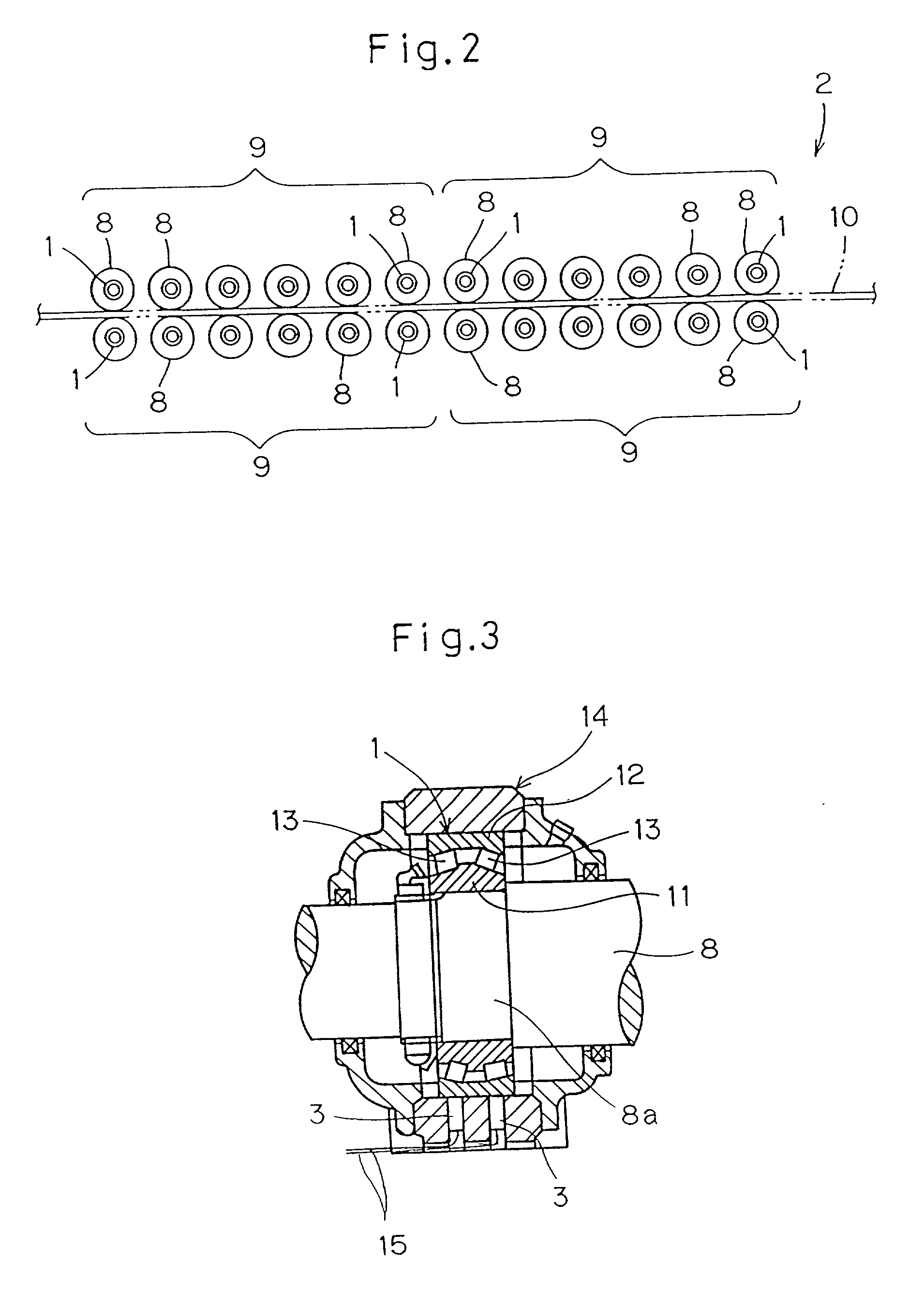

Machine component monitoring, diagnosing and selling system

InactiveUS20020013635A1Quick checkTime spanMachine part testingNuclear monitoringMonitoring statusEngineering

A system for monitoring statuses such as presence or absence of abnormality and lifetime of a machine component such as, for example, a bearing having rolling elements includes a plurality of determining units 4 each connected with a plurality of sensors 3, and a control means 5 connected with the determining units 4. Each sensor is disposed on the machine component 1 of the associated rolling bearing for detecting an influence signal resulting from passage of the rolling element induced in the machine component 1. Each determining unit 4 determines according a process set-up condition the presence or absence of an abnormality, lifetime and others of the machine component 1 associated with the sensor 3 in reference to an output signal from such sensor 3. The control means 5 collects a result of determination performed by each determining unit 4. In this way, with a simplified structure, monitoring can be achieved at a low cost, precisely and efficiently.

Owner:NTN CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com