3D printing method and system

A 3D printing and 3D printer technology, applied in the field of 3D printing, can solve problems such as complex user operations, and achieve the effect of reducing complexity and solving complex user operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

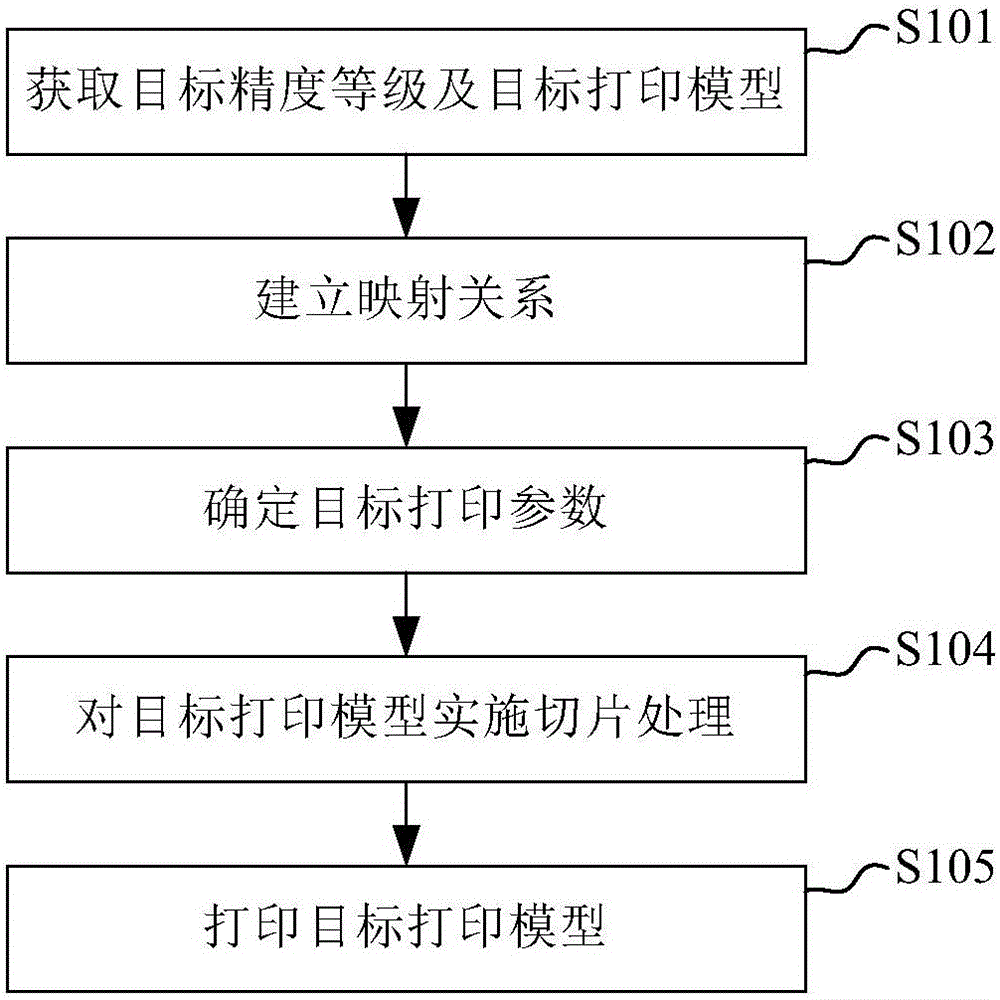

[0049] Please refer to the attached figure 1 , figure 1 The flow of the 3D printing method provided by Embodiment 1 of the present invention is shown.

[0050] figure 1 The flow shown includes the following steps:

[0051] S101. Obtain a target accuracy level and a target printing model.

[0052] Usually (3D) printing models are stored in storage devices in the form of model collections, such as cloud servers. When 3D printing, users need to select the print model they want to print from the model collection, that is, the target print model. As mentioned in the background art, the current printing model is open, and the user can design the printing model by himself, and store it in the model collection for obtaining when printing.

[0053] In Embodiment 1 of the present invention, obtaining the target accuracy level refers to selecting the printing accuracy level of the target printing model to determine the printing accuracy required by the user to print the target print...

Embodiment 2

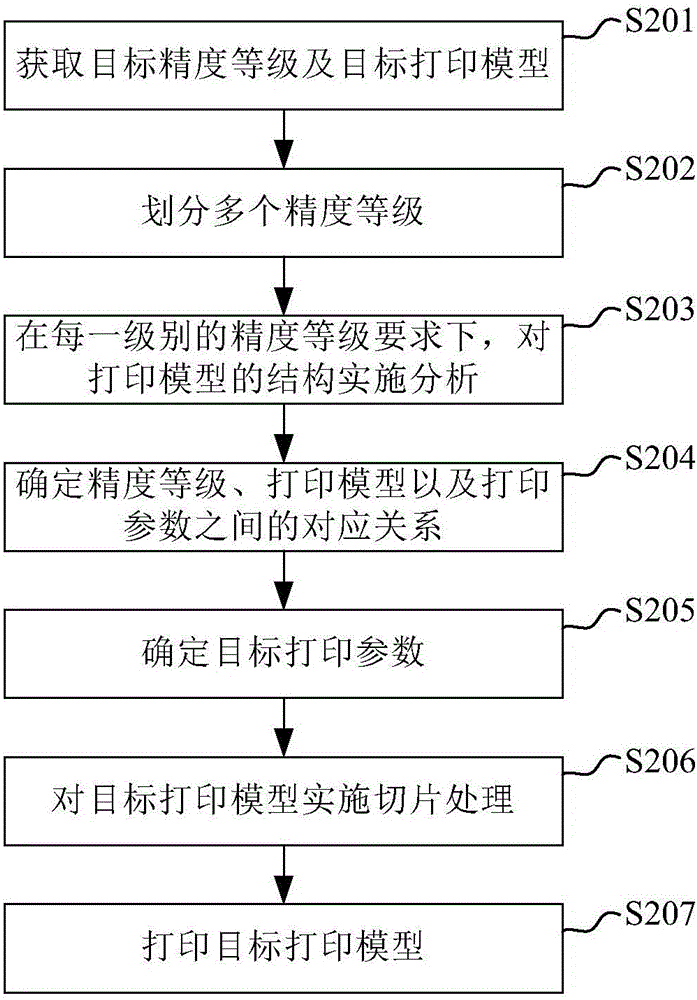

[0066] Please refer to the attached figure 2 , figure 2 The flow of the 3D printing method provided by Embodiment 2 of the present invention is shown.

[0067] figure 2 In the process shown, the mapping relationship between the accuracy level, the printing model and the printing parameters corresponding to the two is established, including:

[0068] S202. Divide multiple precision levels.

[0069] S203 , analyzing the structure of the printed model under the requirements of each level of precision.

[0070] The printing model has an impact on the printing parameters. This step analyzes the structure of the printing model. For special structures such as suspended parts, whether there is water leakage, protruding large-angle parts, the contact surface of the chassis, too small walls or components, too complicated Analyze the model structure and other parameters, repair the model with water leakage, and use the judgment tree principle to obtain the best printing parameters...

Embodiment 3

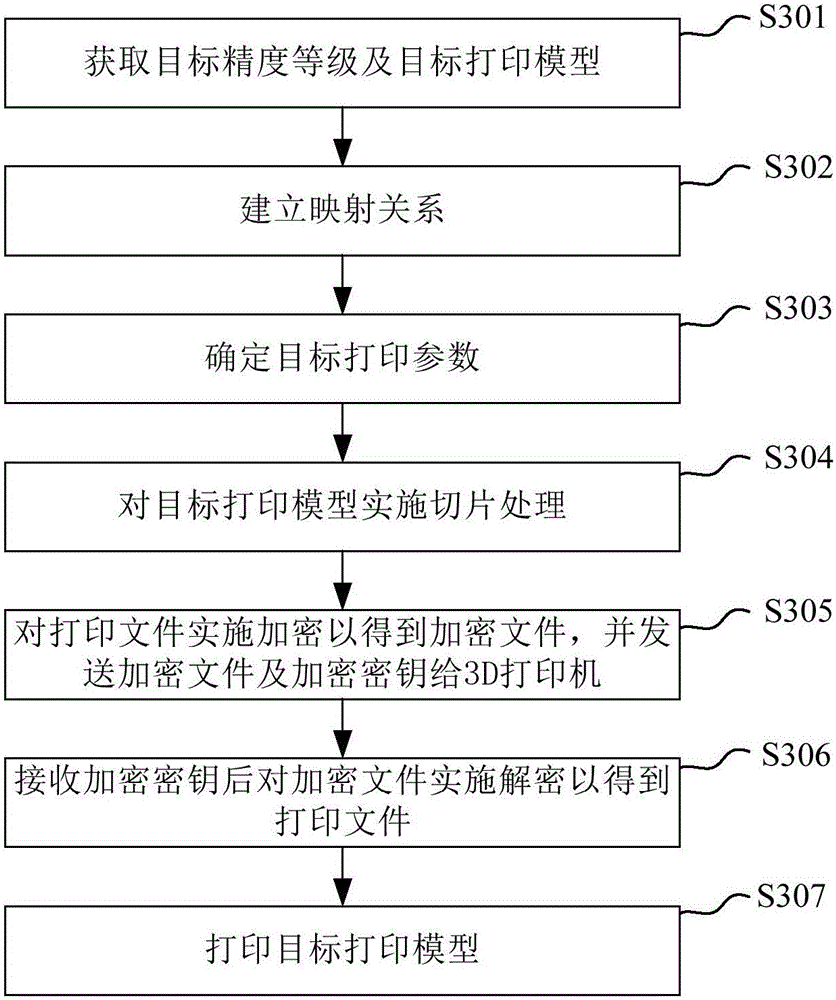

[0075] Please refer to the attached image 3 , image 3 The flow of the 3D printing method provided by Embodiment 3 of the present invention is shown.

[0076] image 3 In the flow shown, the following steps are also included between step S304 and step S307:

[0077] S305. Encrypt the printing file to obtain the encrypted file, and send the encrypted file and the encryption key to the 3D printer.

[0078] Generally, the slicing software used for slicing processing is installed on the cloud server or the client terminal, and the printing files formed after the slicing software completes the slicing processing need to be sent to the 3D printer, and the 3D printer implements 3D printing layer by layer according to the printing files. During the transmission of the print file, in order to ensure the security of the print file transmission, step S305 encrypts the print file and sends it to the 3D printer. Of course, the encryption key also needs to be sent to the 3D printer.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com