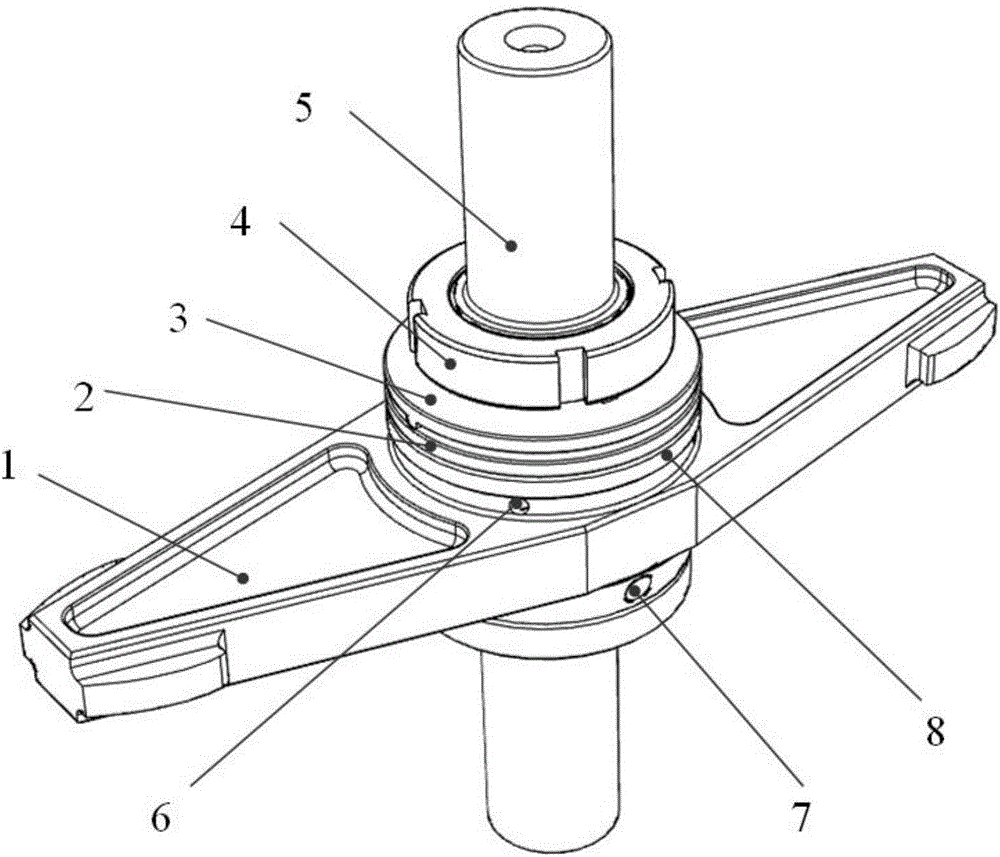

High-precision radial adjustable involute master of gear and adjusting method

An involute and adjustable technology, applied in the direction of measuring devices, instruments, etc., can solve difficult problems and achieve the effect of simple structure, high precision, good promotion value and market application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

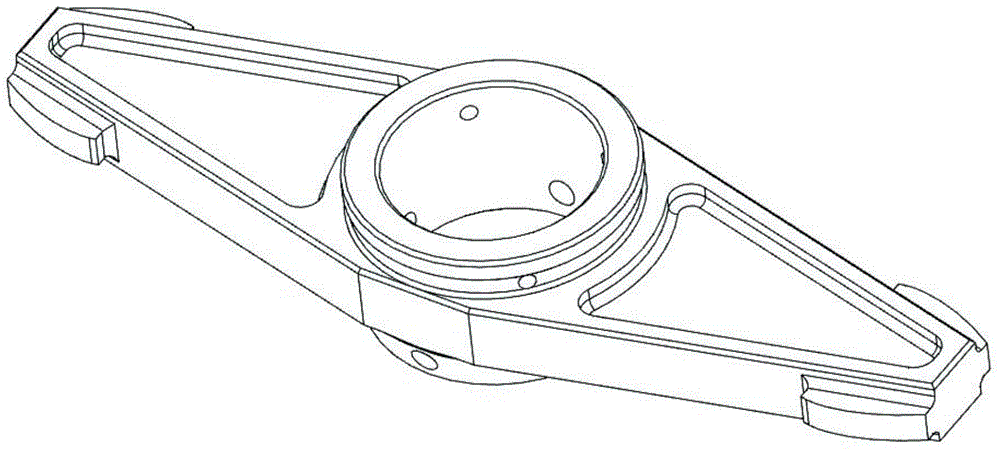

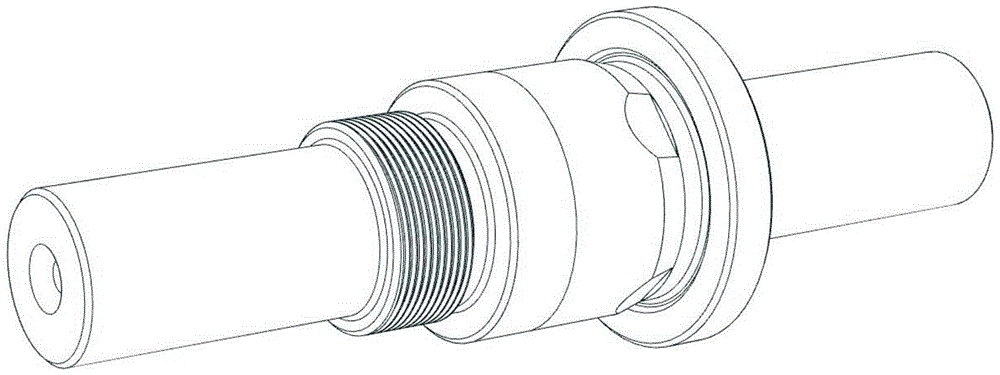

[0018] The rough machining and semi-finishing machining of the high-precision radially adjustable involute sample plate provided by the present invention is carried out on a Y7125 or Y7431 large plane grinding wheel gear grinding machine. Disconnect the indexing system of the machine tool during grinding, and use the unrefined involute cam (surface error 2-3μm) to carry out precision grinding on the four tooth surfaces of the radially adjustable involute template. The tooth profile shape deviation of the involute sample after grinding can reach 2-3 μm, which meets the detection requirements of the instrument for frequency response characteristics, filtering effect and sensitivity. One of the tooth surfaces (such as the right tooth surface of the second tooth) is reserved, and the remaining three tooth surfaces are precisely machined on the double-roller-double-rail involute cam grinding device provided by the open patent [CN102941519A]. Tooth profile shape deviation of finishe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roundness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com