System and method for correcting precision of sensors of pressure acquisition system

A pressure sensor and acquisition system technology, applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problem of inability to correct the pressure acquisition system sensor with PVC data table, and achieve the effect of flexible and convenient working mode, high efficiency and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

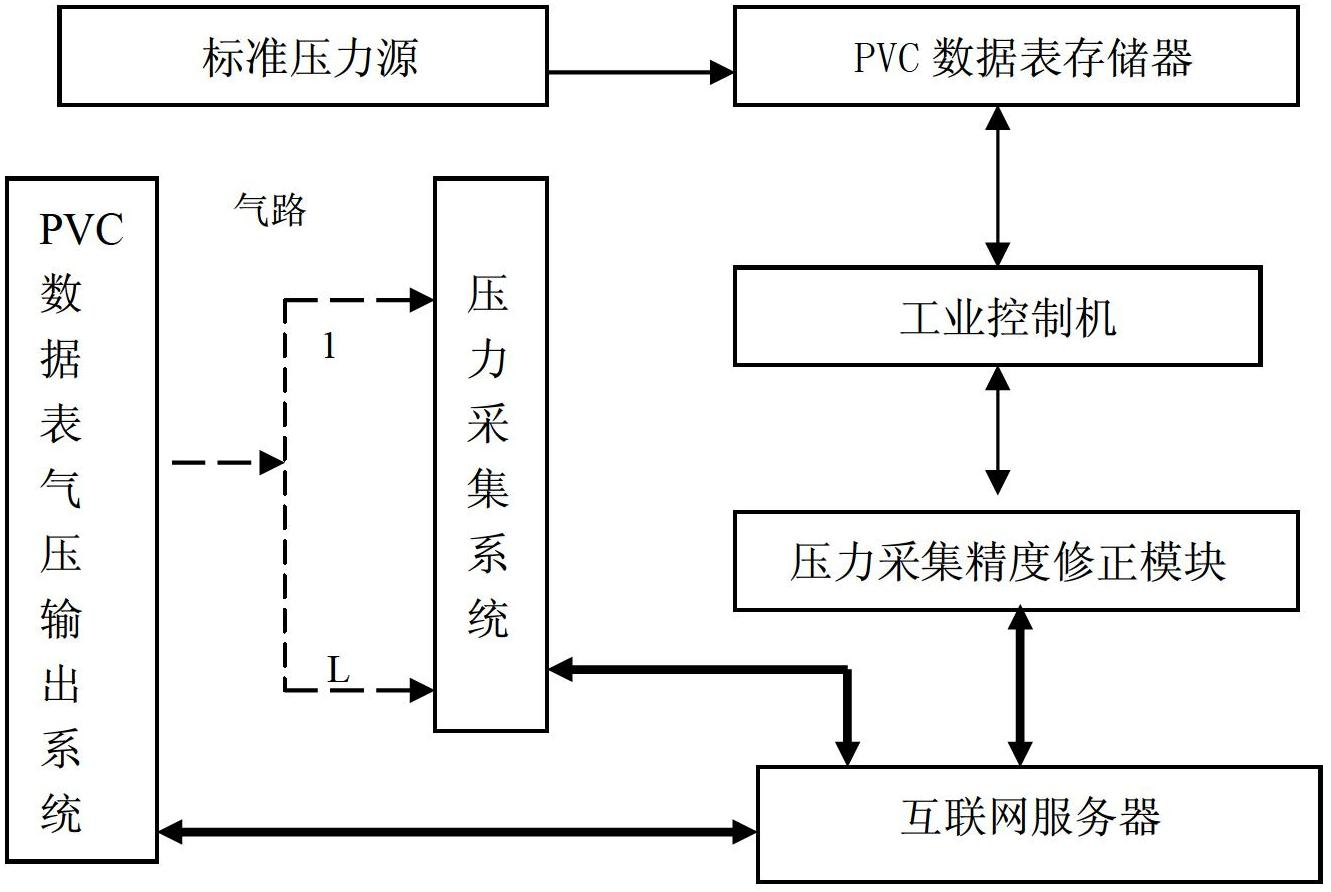

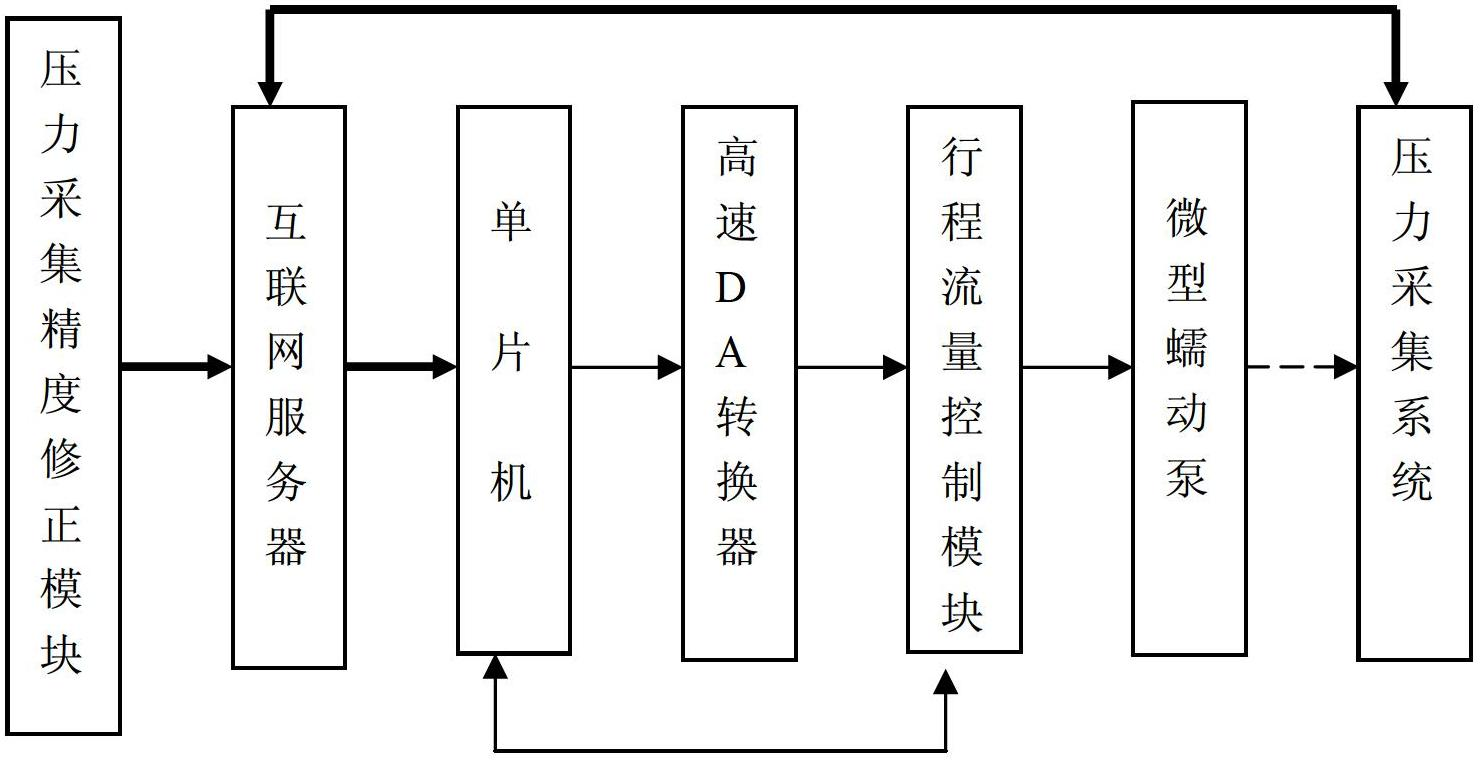

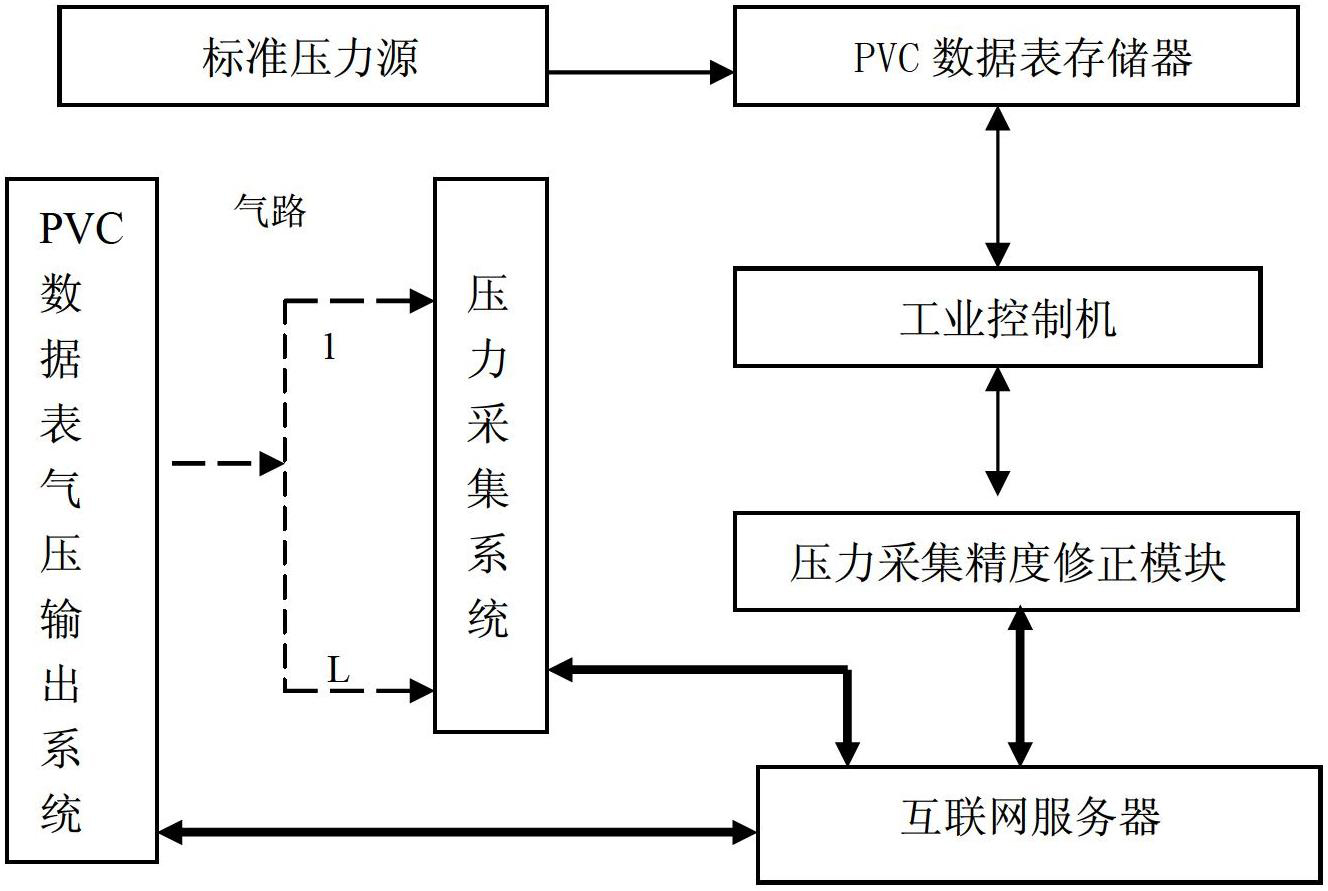

[0022] The invention includes a standard pressure source, a PVC data table memory, an industrial control machine, a pressure collection accuracy correction module, an Internet server, a PVC data table air pressure output system, and a pressure collection system.

[0023] The pressure acquisition system is composed of L pressure sensors, and the memory of each pressure sensor stores the pressure sensor PVC with input characteristics 传感器N data sheet, per PVC 传感器N The data table has three sets of P 传感器N , V 传感器N 、C 传感 器系数N Data table data, each data table has N input data and conforms to P 传感器N =V 传感器N *C 传感器系数N , where P 传感器N is the pressure sensor N input air pressure data, V 传感器N is the N voltage data at both ends of the pressure sensor, C 传感 器系数N It is the N pressure coefficient data of the pressure sensor, and the PVC of the L-way pressure sensor of the pressure acquisition system 传感器N The data table data is sent to the industrial control machine through the Inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com