Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

363 results about "Geometric error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

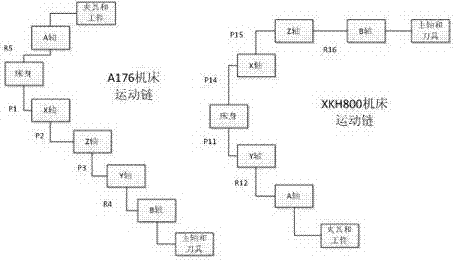

Method for measuring geometric error parameter value of rotary oscillation axis of five-axis linkage numerical control machine tool

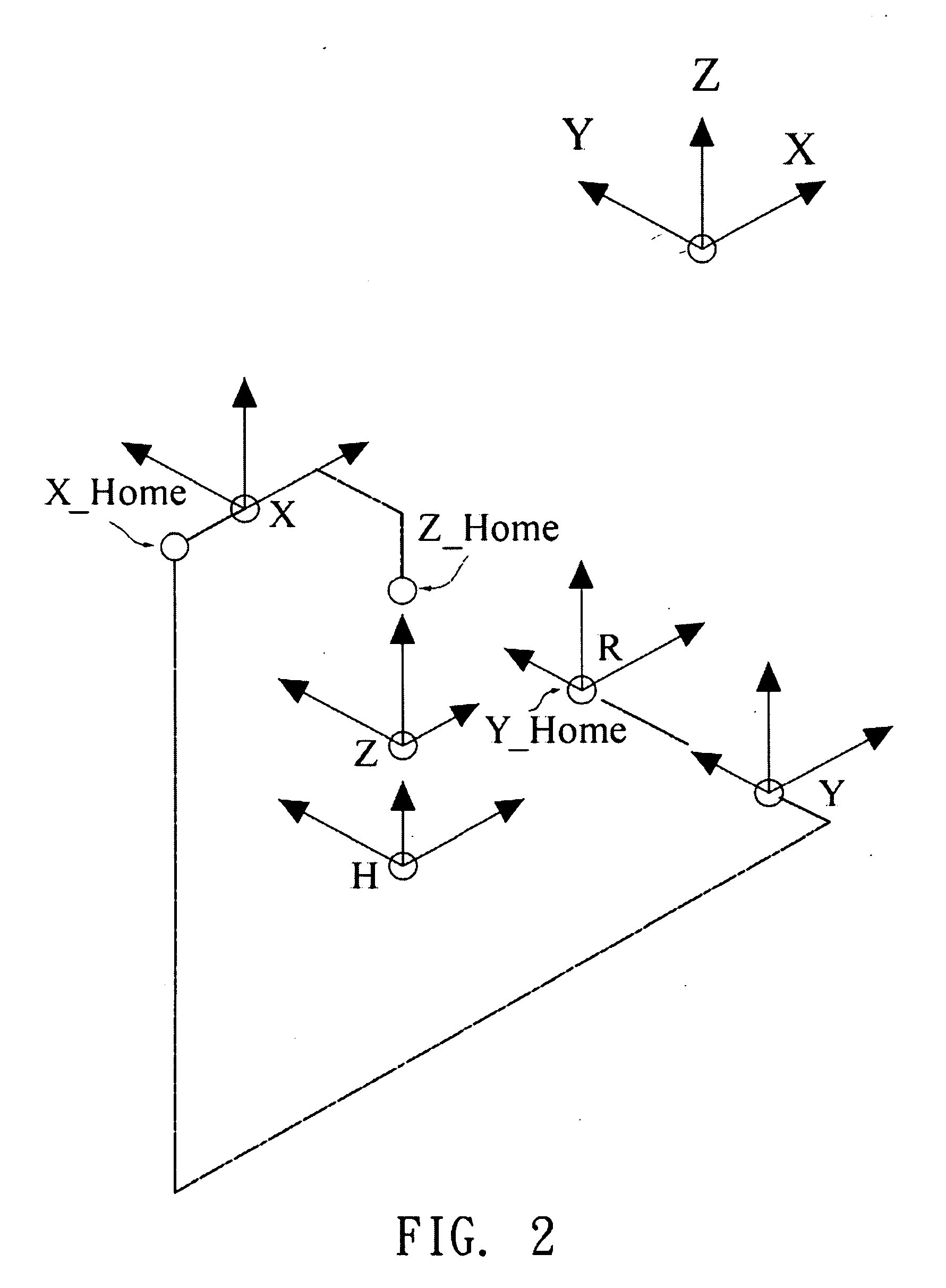

The invention discloses a method for measuring a geometric error parameter value of a rotary oscillation axis of a five-axis linkage numerical control machine tool. The method comprises the following steps of: measuring displacement errors of X, Y and Z directions on at least three positions under different rotating angles of the rotary oscillation axis respectively by using a ballbar, wherein translation axis linkage coordinates provided by a revolving tool central point (RTCP) cutter central point movement control function of a five-axis machine tool serve as measurement datum; and performing data processing according to the displacement errors to identify and calculate the geometric error of each rotating angle of the rotary oscillation axis. The rotary oscillation axis is measured independently by the method, so the geometric error value of the five-axis linkage numerical control machine tools of various structures at each rotary oscillation angles can be obtained. The method is not limited by the structures of the machine tools, is convenient to arrange and has high measuring precision.

Owner:成都天佑创软科技有限公司

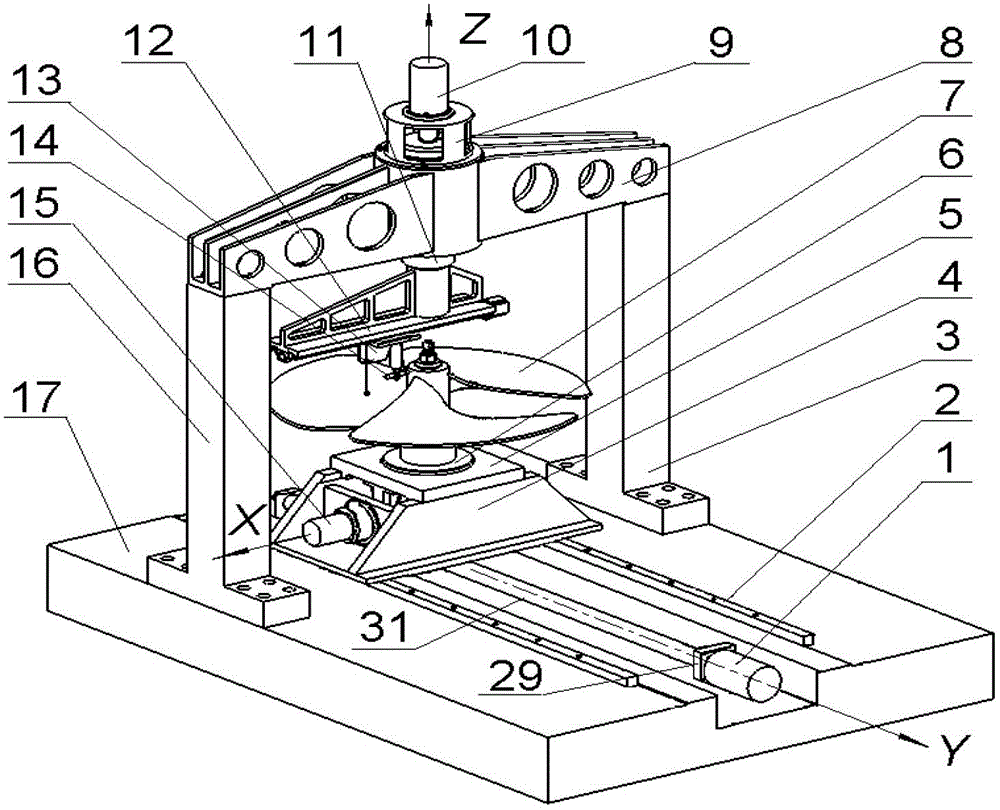

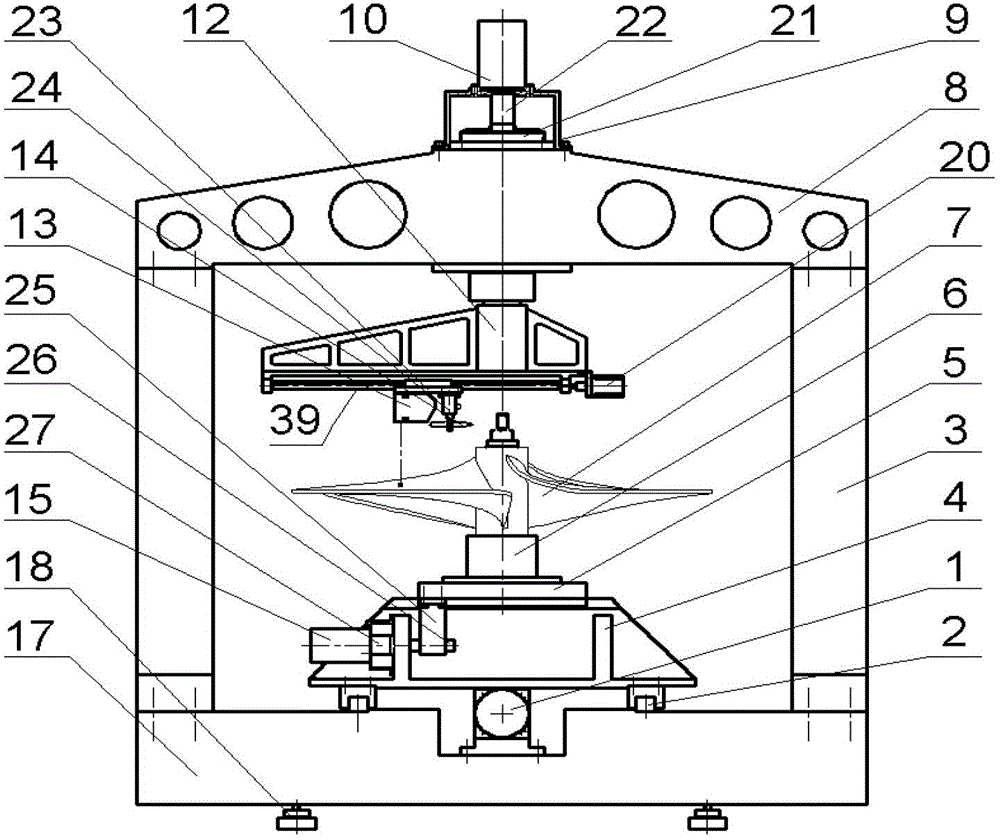

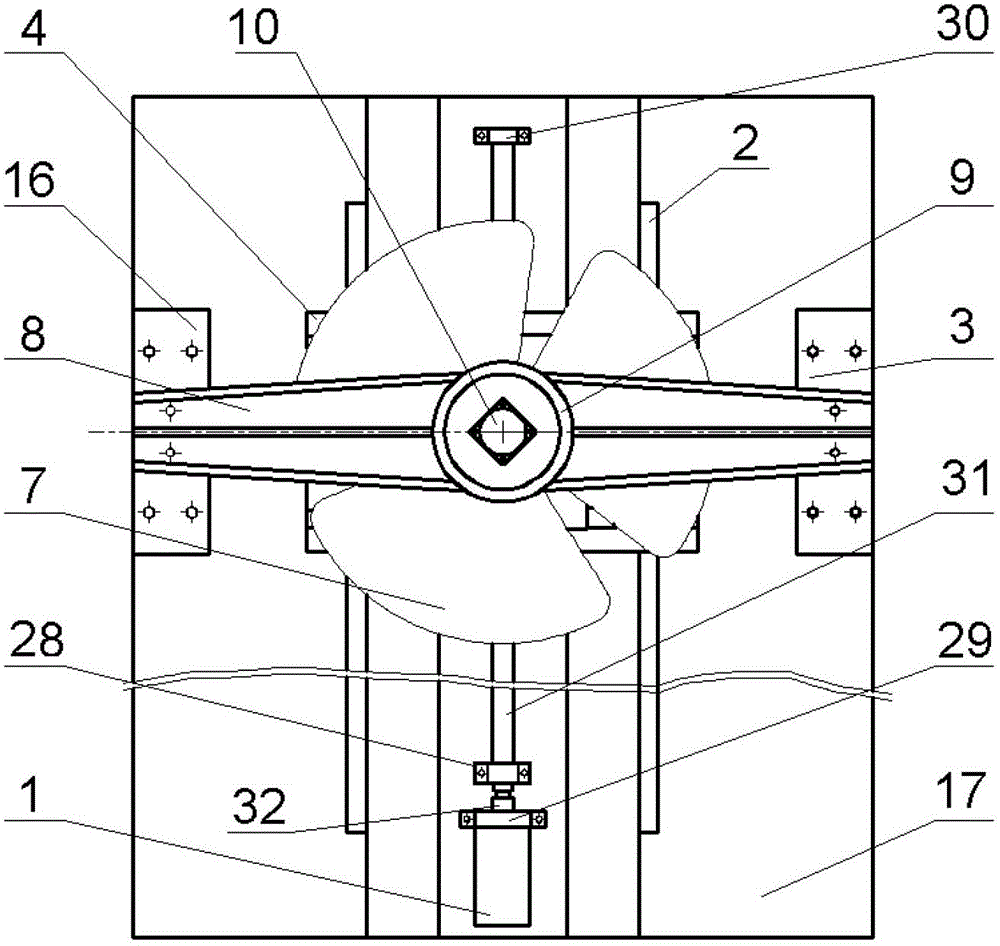

Propeller type surface contour error measurement instrument and method

ActiveCN102749041AEasy to achieve 3D reconstructionAvoiding Probe Radius Compensation ProblemsElectric/magnetic contours/curvatures measurementsUsing optical meansGeometric errorMeasurement device

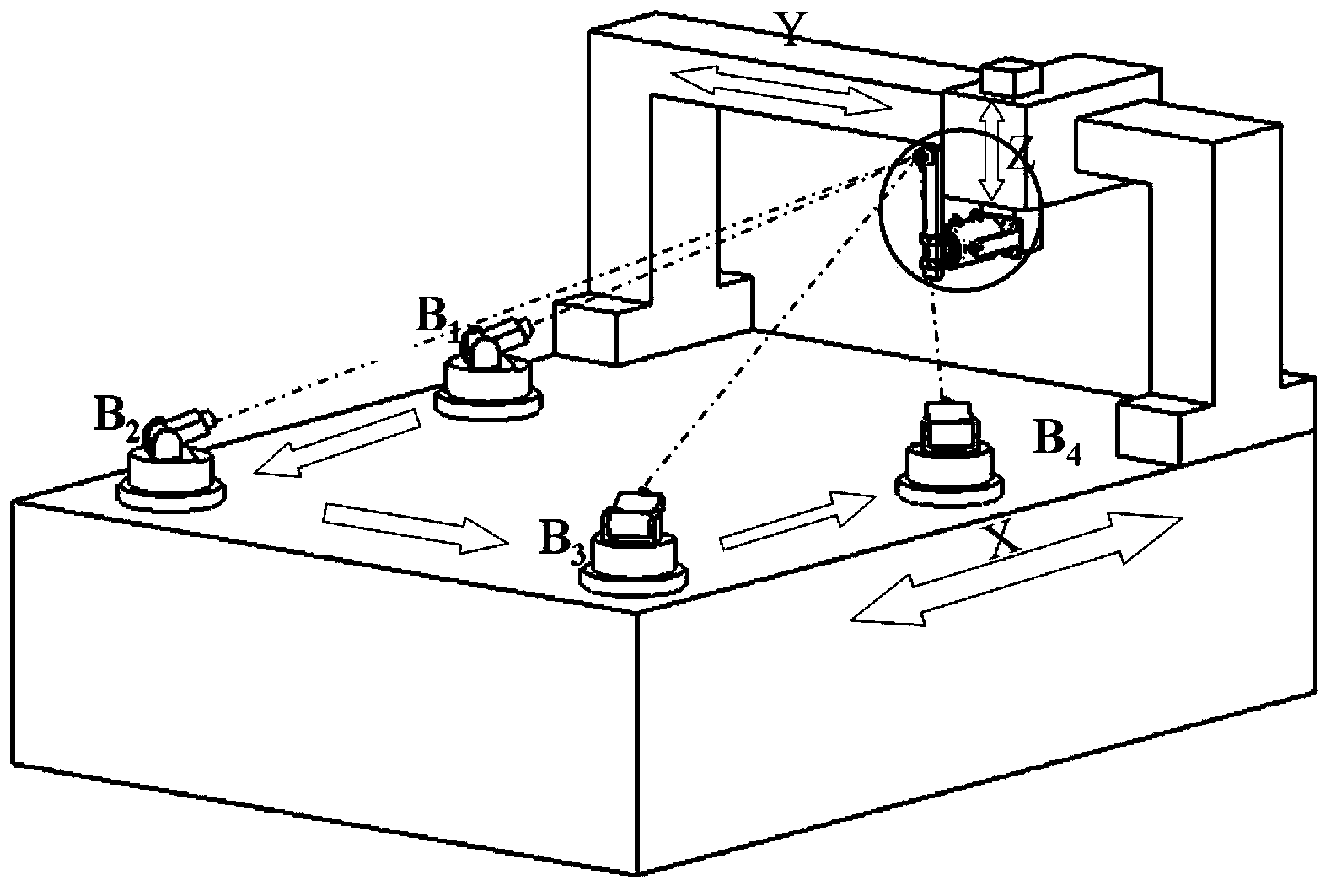

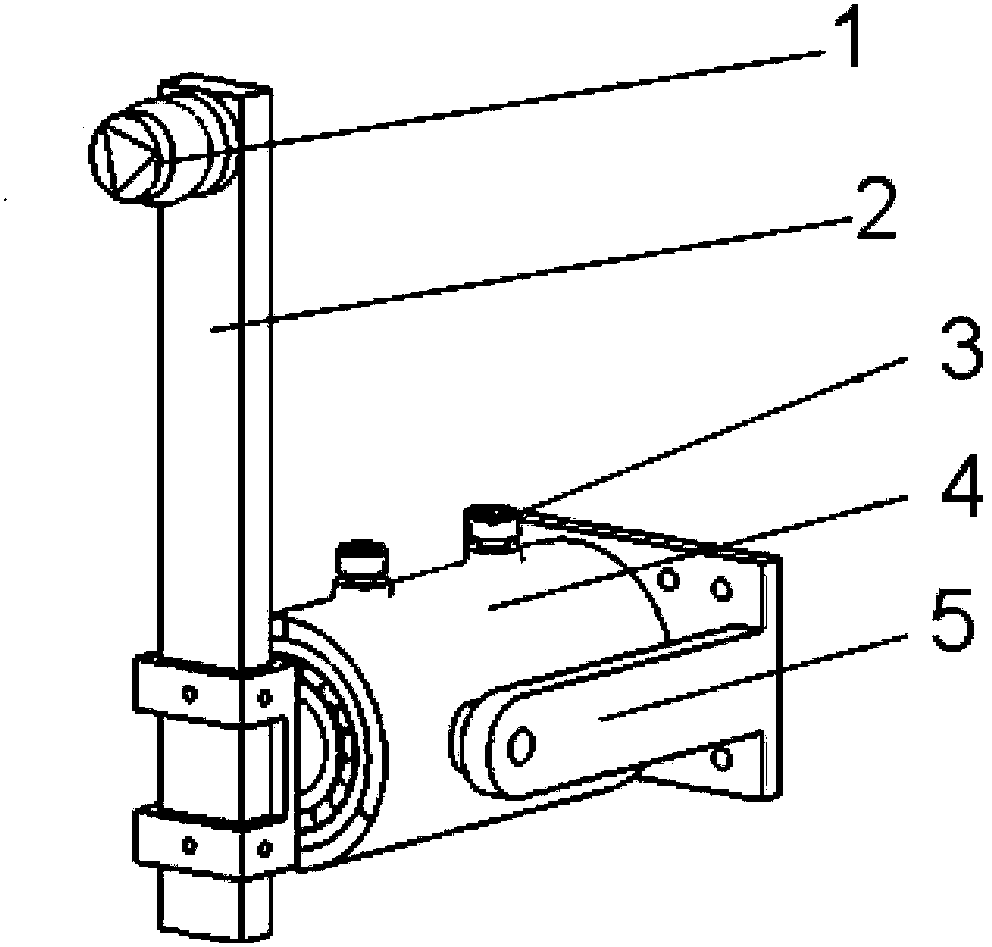

The invention discloses propeller type surface contour error measurement instrument and method. The propeller type surface contour error measurement instrument is characterized in that a gantry structure is adopted, a left upright, a right upright and a top cross beam are arranged on a base, and a revolving spindle is arranged on a cross beam; the lower end of the revolving spindle is horizontally and fixedly connected with a measuring arm; a linear guiderail is arranged on the bottom surface of the measuring arm along the radial direction of the revolving plane of the measuring arm, a working platform capable of doing linear movement along the linear guiderail is arranged on the linear guiderail, and a displacement sensor is arranged on the working platform; and a Y-direction working platform and an X-direction working platform are arranged on the base in an overlapping, and the blade of a detected propeller is arranged in a positioning groove at the top surface of the X-direction working platform. The measuring device and the measuring method are established by adopting a cylindrical coordinate system according to the axial symmetry structure characteristics of the propeller blade. The measuring device and the measuring method are fast in data acquisition, have no objective errors of an operator, and are simple in follow-up error processing and analysis, and can be used for precision measurement on size parameters and geometric error parameters of large revolving parts.

Owner:HEFEI UNIV OF TECH

Thermal deformation error compensation method for coordinate measuring machine

InactiveUS20100299094A1Testing/calibration of speed/acceleration/shock measurement devicesSpecial data processing applicationsGeometric errorMotion parameter

A thermal deformation error compensation method for a coordinate measuring machine creates thermal deformation and geometric error data at different ambient temperatures including temperatures and machine kinematic parameters to obtain a thermal deformation and geometric error model, and inputs the model into central control unit of the coordinate measuring machine, and converts a 3D error compensation to obtain a thermal deformation and geometric error compensation model, and uses the thermal deformation and geometric error compensation model for performing compensations, so as to complete a thermal deformation and geometric error compensation of the coordinate measuring machine.

Owner:CARMAR TECH

Numerical control machine tool translational shaft geometric error measuring device and measuring and identifying method

ActiveCN103447884AHigh precisionOperation diversificationMeasurement/indication equipmentsGeometric errorNumerical control

The invention discloses a numerical control machine tool translational shaft geometric error measuring device and measuring and identifying method. A laser tracker is used for successively measuring axial feed movements of three fixed points of a single machine tool translational shaft at four different positions, the real-time poses of the translation shaft is calculated by the special continuous moving trajectory of the three fixed points, and errors of a machine tool are identified. Due to the fact the real-time poses of the translation shaft are measured, the acquired machine tool information is much richer than the information acquired by only measuring cutter moving trajectory, and error identification algorithm is quite simple. The method suitable for fast data processing, machine tool error fast compensation and precision detection in the field of machine tools has the advantages of high precision, fast and simple operation, rich measuring information, and the like.

Owner:XI AN JIAOTONG UNIV

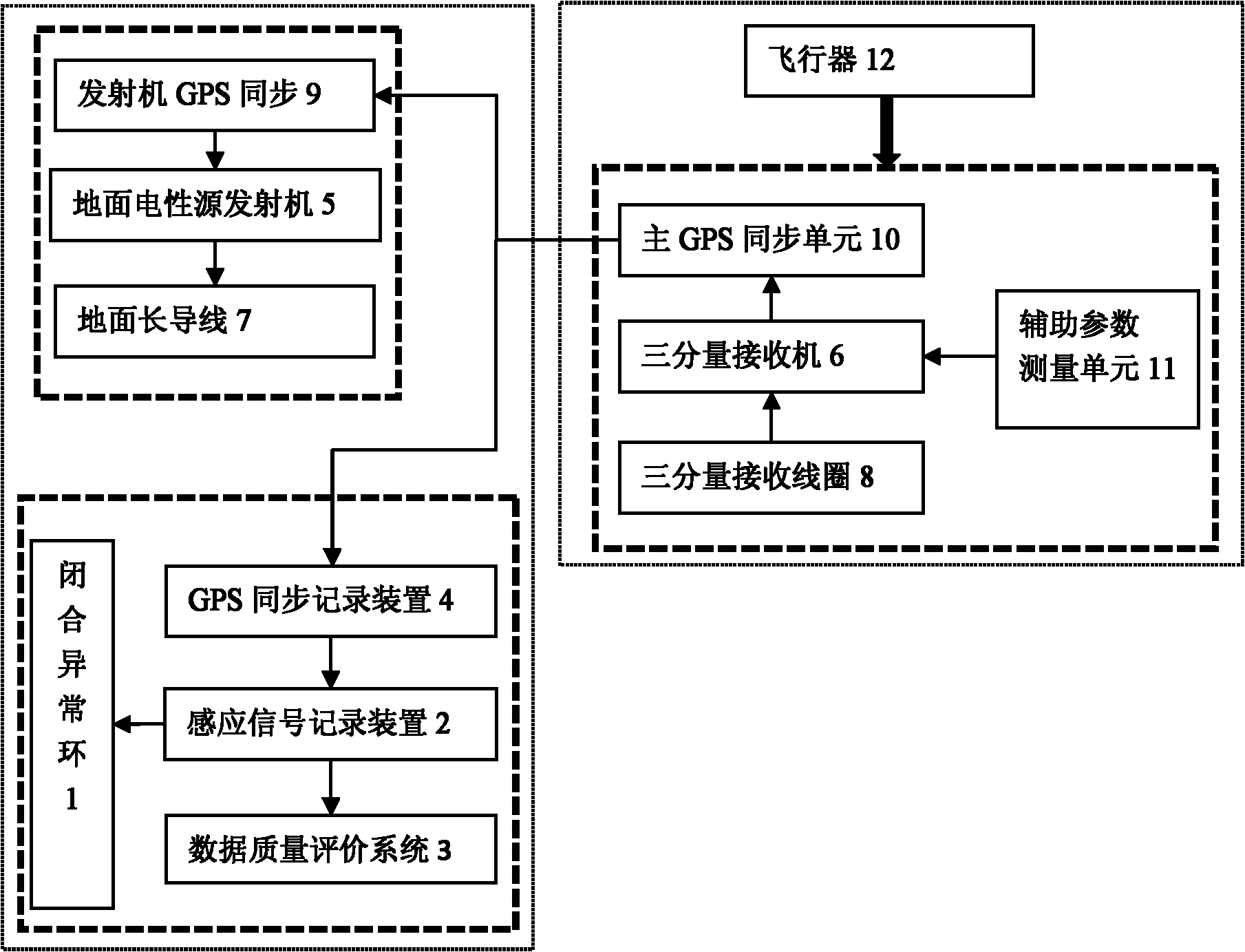

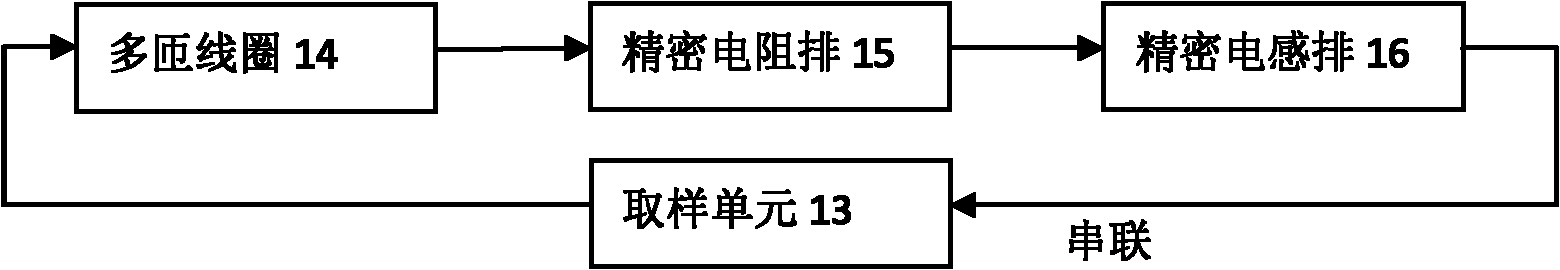

Time-domain ground-air electromagnetic detection system and calibration method

InactiveCN102096113AImplement testRealize CalibrationElectric/magnetic detection for transportGeometric error24-bit

The invention relates to a time-domain ground-air electromagnetic detection system and a calibration method, in particular to a system consisting of an induction signal recording device connected with a ground recording device global position system (GPS) synchronization unit, a closed abnormal ring and a data quality evaluation system, and a calibration method for the time-domain ground-air electromagnetic detection system. The closed abnormal ring and the induction signal recording device are adopted, the induction current and induction voltage are simultaneously recorded, and the 24-bit 200Hz sampling rate, a bandwidth of 0-13KHz and a dynamic range of an amplifier of 160dB are achieved. Moreover, the system is synchronous with a ground transmitter and an air receiver GPS, and during measurement, by removing earth background field data, a pure closed abnormal ring electromagnetic signal containing a geometric error is extracted, is input into the data quality evaluation system, andis compared and fitted with the computed closed abnormal ring theoretical value, the system error, the geometric parameter error and the detection resolution of the time-domain ground-air electromagnetic detection system are determined, and the performance of the electromagnetic detection system is tested and calibrated.

Owner:JILIN UNIV

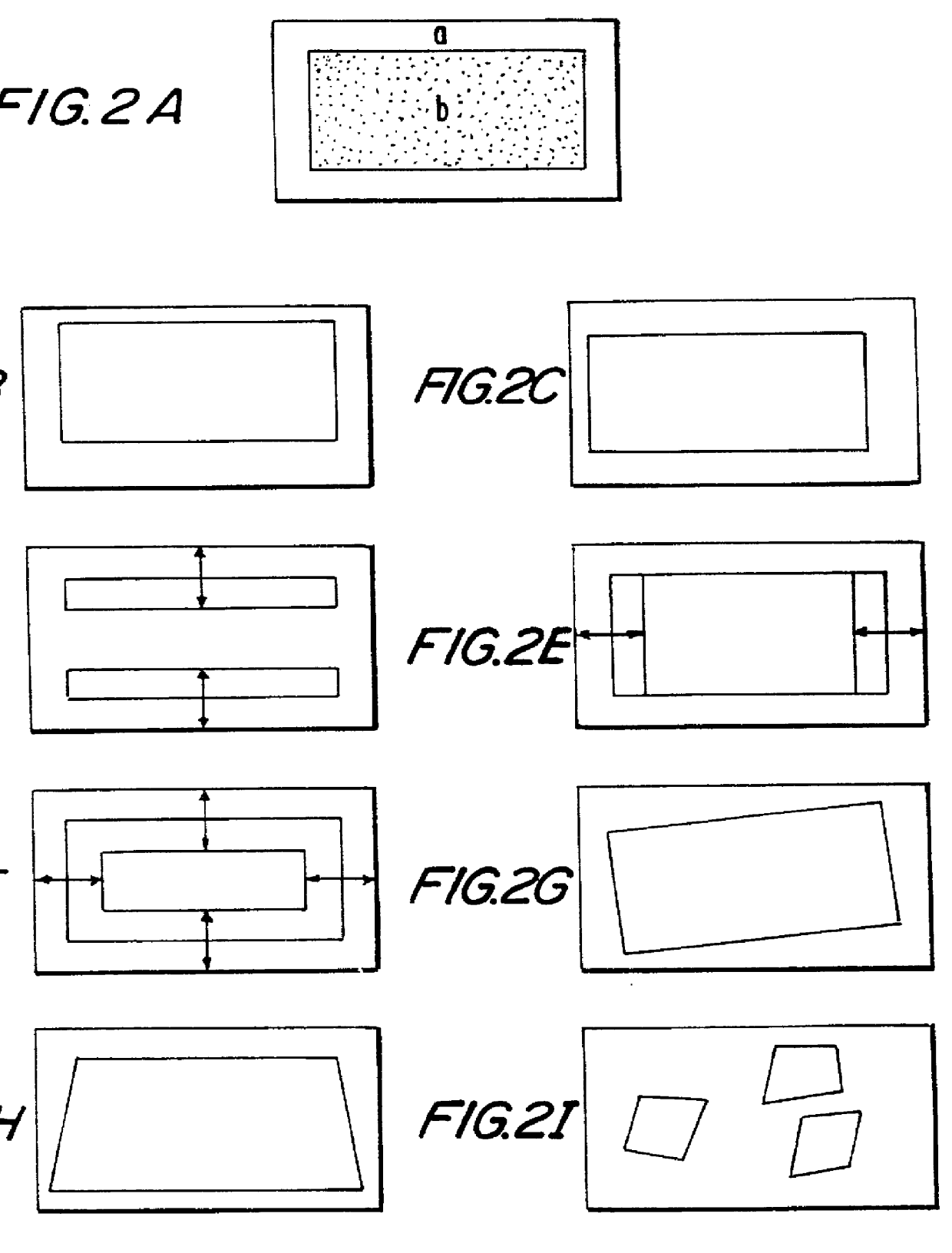

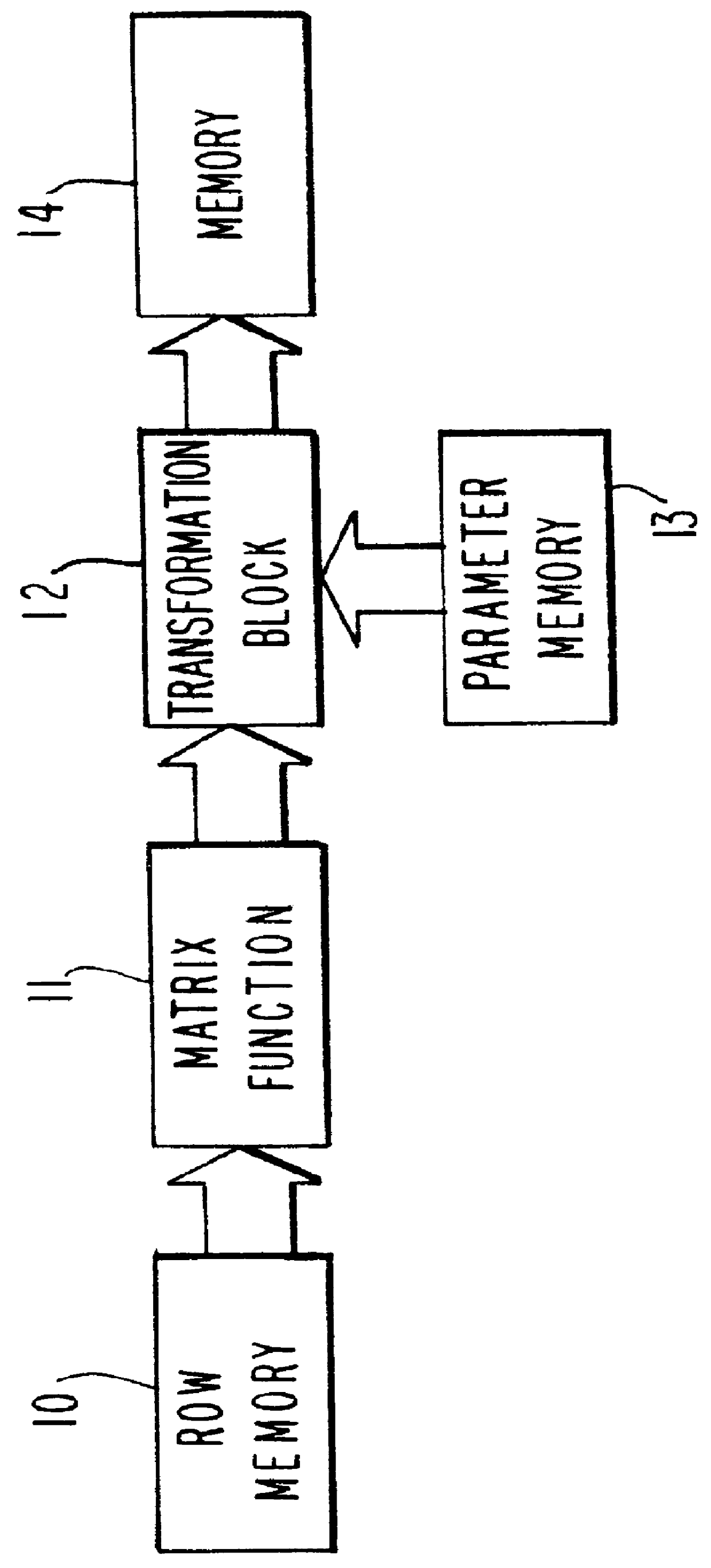

Process for correcting geometric errors in the transfer of information to a printing stock

InactiveUS6024504ACharacter printing data arrangement from carrierError detection/correctionGeometric errorDigital imaging

A process corrects geometric errors in the transfer of information without mechanical intervention on the printing form, to compensate for the errors that occur and thus attain optimized print quality prior to imaging. The corrections are visually indiscernible, so that the artifacts created in the printed result by the corrections do not stand out in the image. A device-independent description of the page information to be printed is converted by a Raster Imaging Process into at least one device-dependent digital matrix. Each matrix with m rows and n columns contains the information for a certain color to be printed. After the individual matrices are produced, they are supplied to a matrix manipulation device, which subjects each matrix to a correction transformation using specific parameters. After the matrices are adjusted, they are supplied by a matrix transfer device to the digital imaging devices in the printing mechanisms.

Owner:MANROLANAD AG

Concrete stirring vane die face design system and method based on springback compensation

InactiveCN101339574ASpeed up the Springback Compensation Design ProcessReduce the number of mold repairsSpecial data processing applicationsGeometric errorEngineering

The invention provides a concrete mixing blade die-face design system and a method based on springback compensation, which comprises three modules, that is, a die-face automatic springback compensation design module based on numerical simulation, a die-face CAD reconstruction design module, and a die-face correction module based on reverse engineering, thus a concrete mixing blade die-face CAD-CAE-CAD integrated system based on the springback compensation is formed, and geometric errors produced after the blade being formed are required to satisfy design requirements on the level of numerical simulation, thus reducing correction times; and the process of converting a CAE model after a virtual die repair into a CAD geometric model which can be designed and manufactured is finished, a digital model after the blade being actually pressed is acquired by utilizing a reverse engineering technology and then is compared with the required design shape of the blade, and springback deviation is obtained so as to be used for guiding the actual die repair process of the blade, thus correcting the residual springback deviation and further improving the precision of the springback compensation on the basis of numerical simulation springback compensation.

Owner:JIANGSU UNIV

Method for analyzing machining precision reliability sensitivity of numerically-controlled machine tool

ActiveCN104375460AImprove machining accuracy and reliabilitySmall amount of calculationProgramme controlComputer controlNumerical controlGeometric error

The invention provides a method for analyzing the machining precision reliability sensitivity of a numerically-controlled machine tool, belongs to the field of machine tool precision design, and particularly relates to a space error modeling method of a three-axis machine tool and a method for analyzing the machining precision reliability and the machining precision reliability sensitivity of the machine tool. A multi-body system motion feature analysis method is used for setting up a space error model of the machine tool, and combined with a Monte-carlo digital analogy method for analyzing the machining precision reliability of the machine tool, and the degree of influence on the machining precision reliability from the wave action of all items of geometric errors of the machine tool, so that the critical geometric errors influencing the machining precision reliability are identified. Guiding advice can be given for designing, assembling and machining of the machine tool, and the machining precision reliability of the machine tool is improved fundamentally.

Owner:BEIJING UNIV OF TECH

LaserTRACER-based method for detecting and identifying geometrical errors of translational shafts of numerical control machine tool

InactiveCN106141814AQuick calibrationAccurate measurementMeasurement/indication equipmentsGeometric errorNumerical control

The invention discloses a LaserTRACER-based method for detecting and identifying geometrical errors of translational shafts of a numerical control machine tool. The geometrical error detecting and identifying method comprises the following steps of: constructing a measuring system consisting of the numerical control machine tool and LaserTRACER, and measuring by utilizing the measuring system to obtain machine tool tail end pose errors; establishing a mapping model between 21 geometrical errors of the numerical control machine tool and the abovementioned machine tool tail end pose errors; establishing a mapping model between the machine tool tail end pose errors and multinomial coefficient vectors of the 21 geometrical errors; establishing an identification equation set of the abovementioned multinomial coefficient vectors; carrying out identifiability analysis on the identification equation set of the multinomial coefficient vectors p; and carrying out simulating optimization on a measurement trajectory in a working space by use of Matlab, and the like. On the premise of measuring a relatively small amount of data, a relatively good identification effect is achieved, and data support is provided for machining capability evaluation and error compensation of the numerical control machine tool.

Owner:TIANJIN UNIV

Three-axis numerical control machine tool key geometric error identification method based on global sensitivity analysis

ActiveCN104007700AImprove machining accuracyProgramme controlComputer controlGeometric errorNumerical control

The invention provides a three-axis numerical control machine tool key geometric error identification method based on global sensitivity analysis, belongs to the field of machine tool accuracy design, and particularly relates to a three-axis machine tool space error modeling method and a three-axis machine tool geometric error global sensitivity analysis method. On the basis of machine tool space error models built through the multi-body theory and geometric error measurement, global sensitivity analysis is conducted on various geometric errors of a machine tool, and influence on machining accuracy of the coupling effect of the geometric errors is obtained. A new machine tool design concept is provided, and the problem of machine tool accuracy is fundamentally solved. Guiding suggestions can be put forward for practical assembly and machining, therefore, output of errors is reduced, the machining accuracy of the numerical control machine tool is improved, and the problem of the machine tool accuracy is fundamentally solved.

Owner:BEIJING UNIV OF TECH

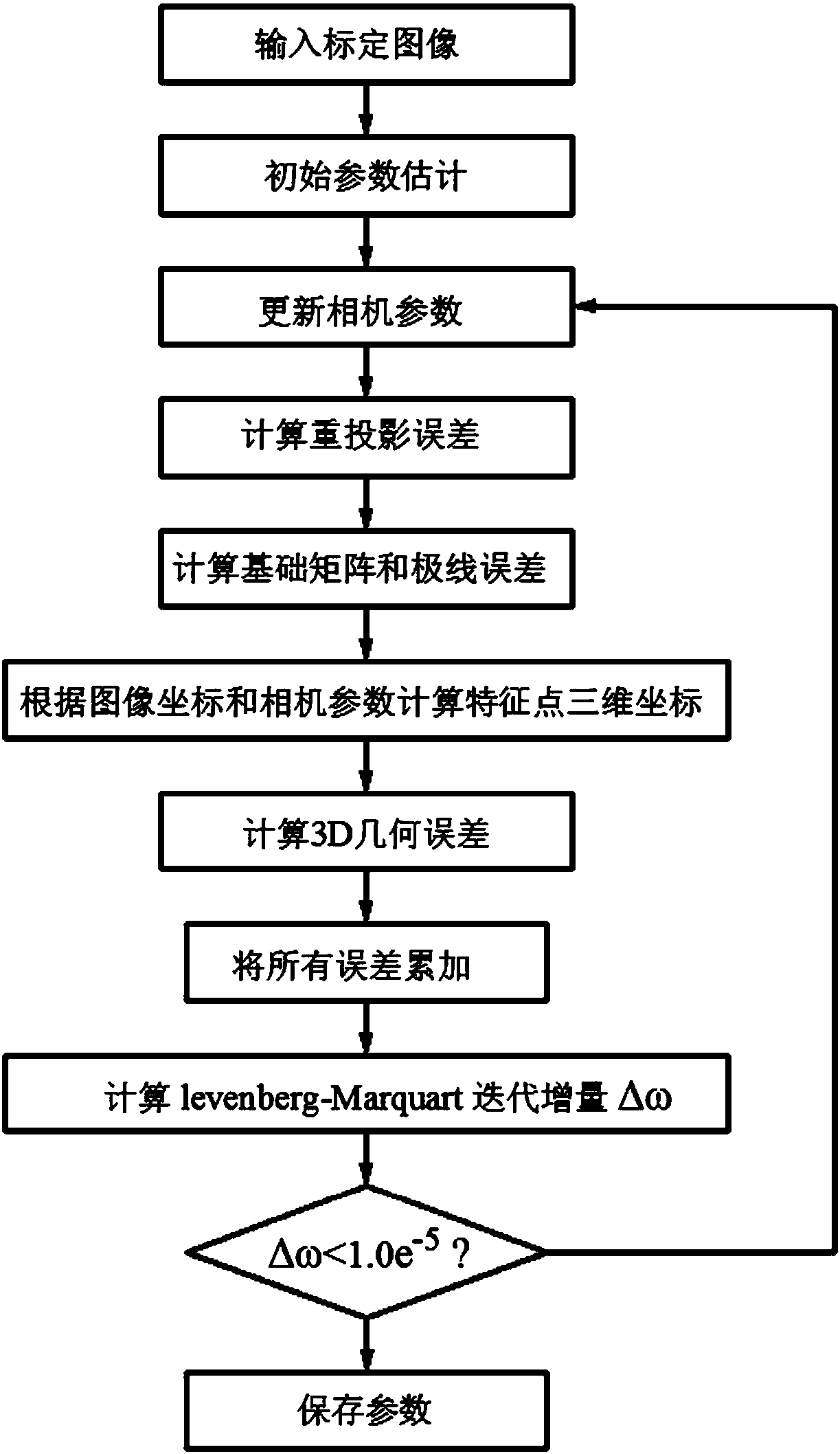

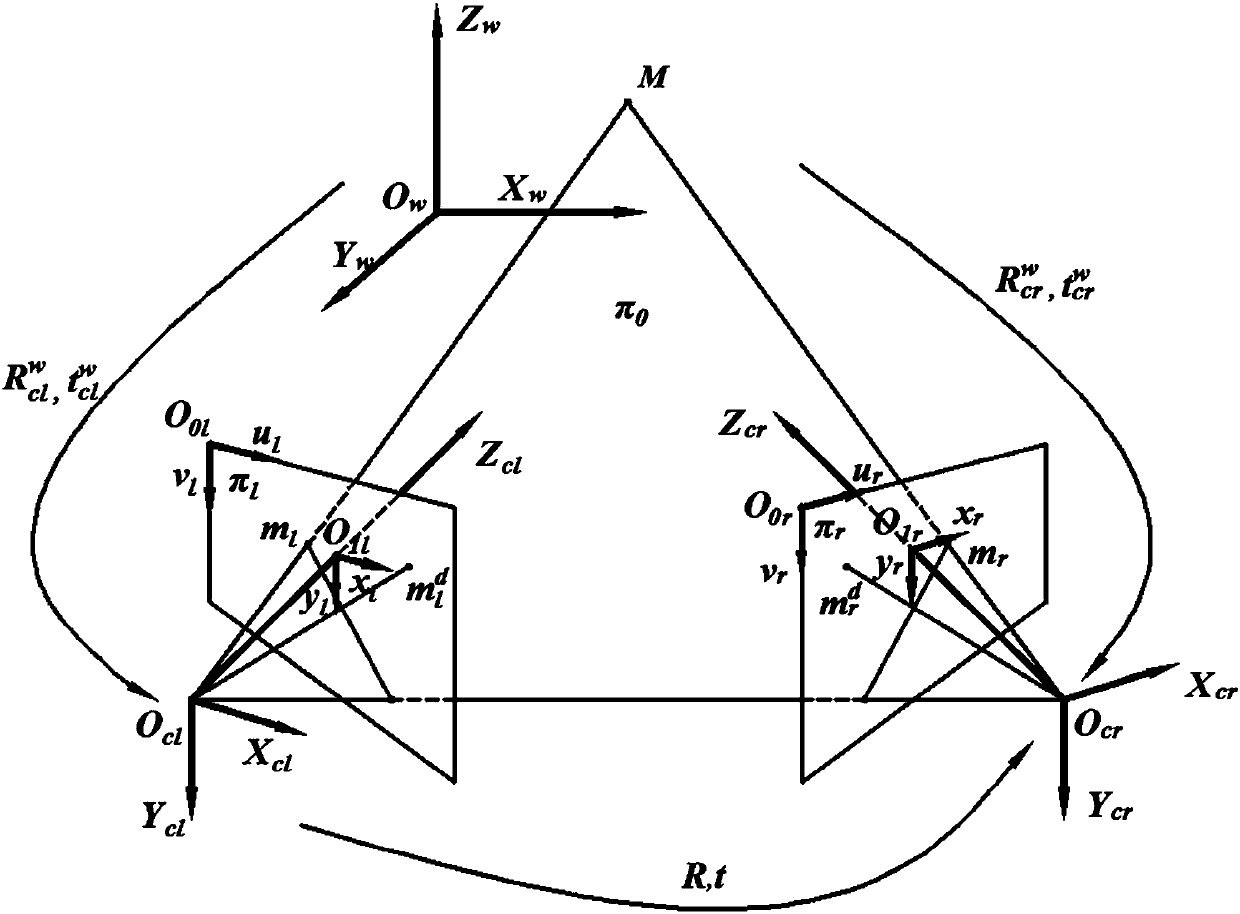

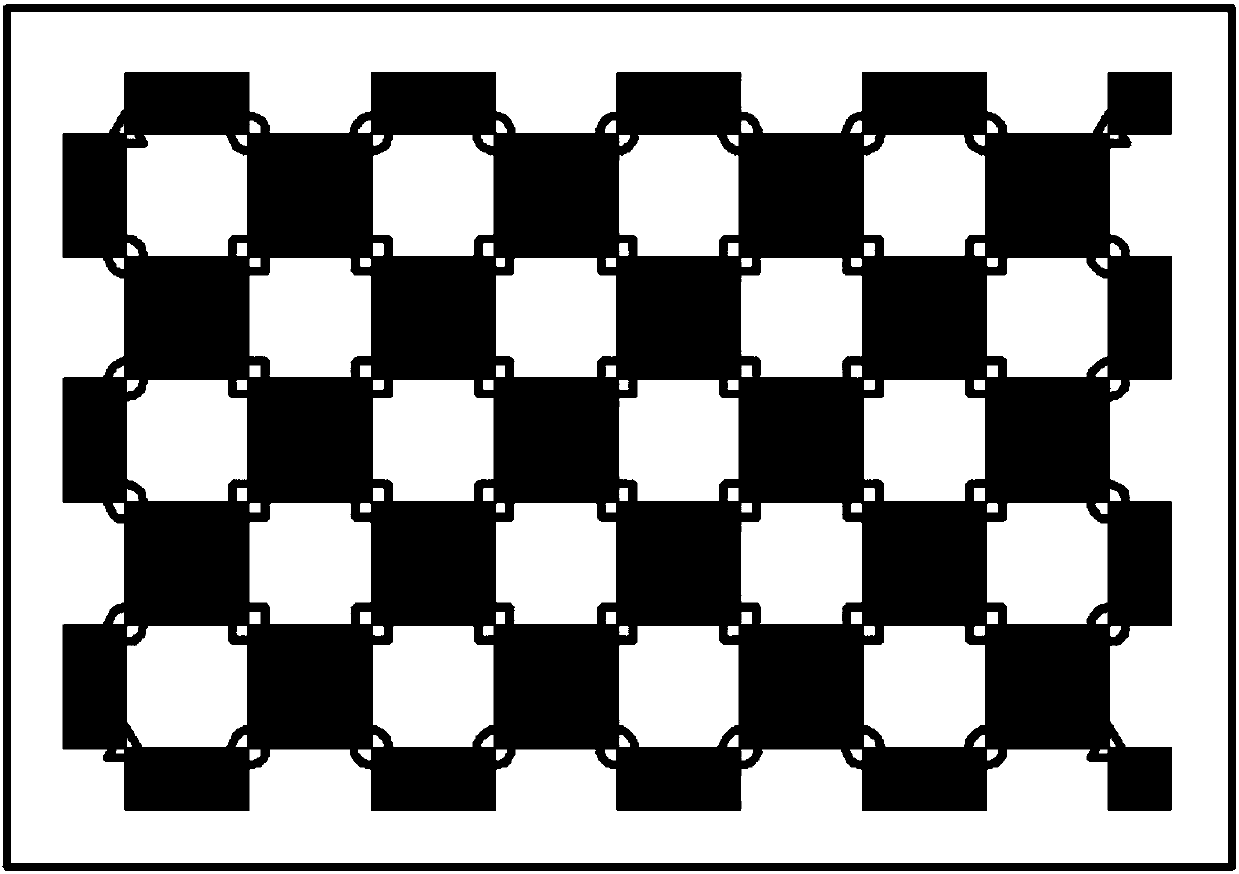

Muti-constraint-based high-precision binocular camera calibration method

ActiveCN108053450AHigh precisionImprove stabilityImage enhancementImage analysisGeometric errorCamera image

The invention discloses a muti-constraint-based high-precision binocular camera calibration method. The method comprises the steps that initial binocular camera parameters are calculated through a Zhang zhengyou calibration method, and re-projection errors and polar line errors are calculated, and then according to feature point coordinates in left and right camera images and the binocular cameraparameters, three-dimensional feature points are rebuilt; 3D geometric errors formed by adjacent distance errors, collinear errors and right angle errors are calculated. An optimized objective function formed by re-projection error cumulative sum, adjacent distance error cumulative sum, collinear error cumulative sum and right angle error cumulative sum is built, the optimized objective function is solved through a Levenberg-Marquardt method, and the optimal binocular camera parameters are obtained. Compared with the Zhang zhengyou calibration method, a binocular camera is calibrated, the distance measurement errors, collinear errors and right angle errors are obviously lowered.

Owner:ZHEJIANG UNIV

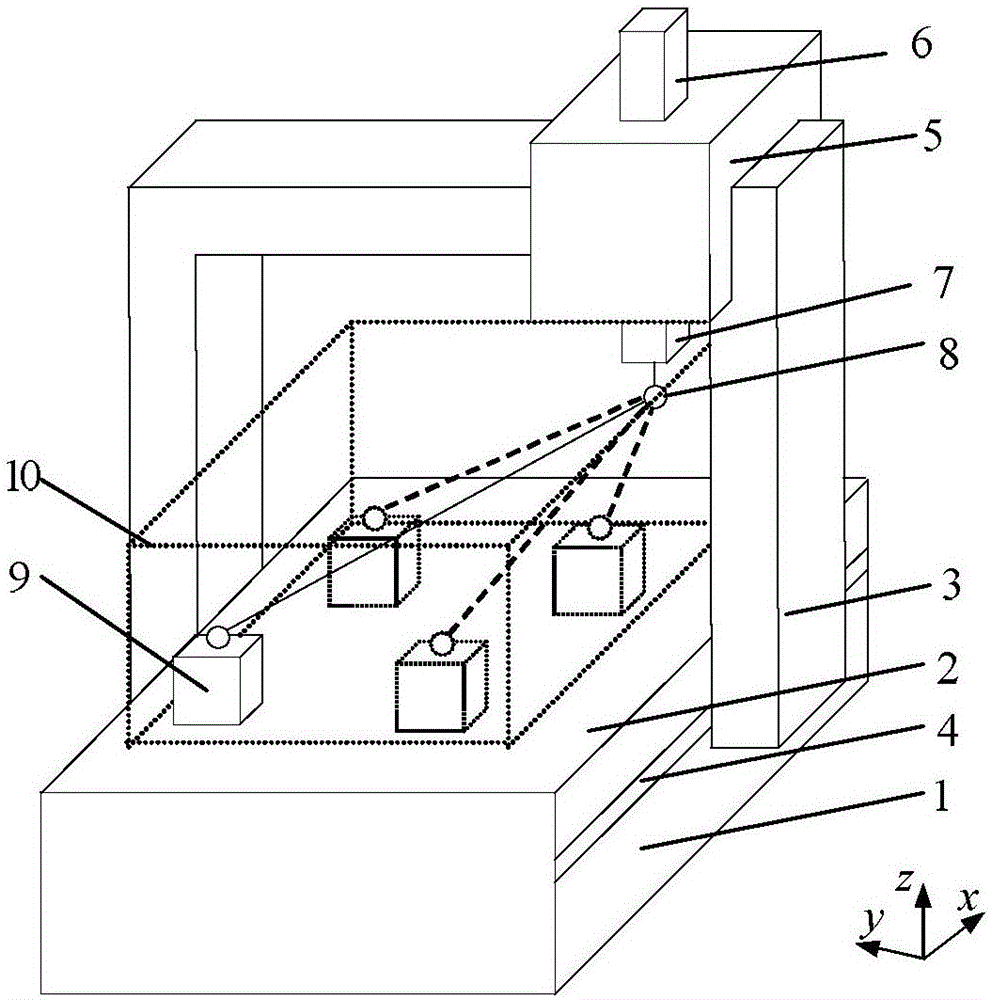

Dynamic error vision measurement method for five-axis numerical control machine tool

ActiveCN105252341ASolve the problem of space trajectory error measurementImprove error measurement accuracyMeasurement/indication equipmentsGeometric errorNumerical control

The invention belongs to the field of geometric error measurement for machine tools and relates to a method for measuring dynamic space track errors of the machine tools by means of binocular vision, in particular to a dynamic error vision measurement method for a five-axis numerical control machine tool. The measurement method includes the steps that according to a three-dimension perceptive function of binocular vision measurement, multiple errors are measured and separated at a single time; and four types of spherical mark points are reasonably distributed at a machine tool cutter end and on the surface of a working table, and the position relation among a vision coordinate system, a machine tool reference coordinate system and a machine tool cutter principal axis coordinate system is calibrated by means of feature information of the spherical mark points. During measurement, a vision measurement system continuously, statically and dynamically collects images of the spherical mark points, then moving errors of all machine tool axes are solved, and the obtained theoretical value and actual machine tool moving amount are combined, so that the moving errors of each axis are solved. According to the dynamic error vision measurement method for the five-axis numerical control machine tool, the machine tool space track errors are measured by means of a binocular high-speed camera, so that the error measurement accuracy is improved, the measurement range of the machine tool moving track is widened, the measurement method is simple and reliable, and the measurement process is simplified.

Owner:DALIAN UNIV OF TECH

Linear axis geometric error detecting method of five-axis numerically-controlled machine tool

ActiveCN106863014ARealize measurementImprove error measurement efficiencyMeasurement/indication equipmentsGeometric errorNumerical control

The invention discloses a linear axis geometric error detecting method of a five-axis numerically-controlled machine tool, belongs to the technical field of machine tool precision detecting and relates to linear axis geometric error detecting and identifying method of the five-axis numerically-controlled machine tool. The detecting method comprises the following steps that a three-eye measuring unit is set up through three high-resolution cameras, and three self-luminous characteristic target sphere images fixed to a working table and making rectilinear motion along with the X axis or the Y axis of the machine tool are collected; and through combination of camera calibrating, characteristic point position information extracting and measured information of the three cameras, a three-dimensional coordinate of the sphere center of a characteristic target sphere is obtained, and the X and Y axis linear axis geometric errors of the machine tool are measured. According to the linear axis geometric error detecting method, linear axis error measuring efficiency of the numerically-controlled machine tool is effectively improved, a complex identifying model and a fussy measuring process are avoided, and linear axis geometric error measuring of the numerically-controlled machine tool is achieved; and the linear axis geometric error detecting method has the characteristics of being convenient, rapid, high in noise-resisting property, good in robustness and capable of simultaneously measuring the geometric errors of the multiple linear axes of the machine tool.

Owner:DALIAN UNIV OF TECH

Numerical control machine tool space error modeling method based on space grid compensation mode

The invention discloses a numerical control machine tool space error modeling method based on a space grid compensation mode. The numerical control machine tool space error modeling method mainly comprises the following steps that step one, a three-axis numerical control machine tool space error universal model is established by utilizing a homogenous coordinate transformation method based on the multi-body system theory according to the type of a machine tool; step two, 21 geometric error elements in the model are measured by using a laser interferometer and modeling is performed; and step three, numerical control machine tool space error is compensated. According to the modeling method, static geometric error and dynamic thermal error modeling methods are integrated, a comprehensive model expression combination is separated into independent position influence terms and temperature influence terms, a space grid compensation list mode is adopted for the position error influence terms, and a real-time acquisition mode is adopted for the temperature error influence terms so that comprehensive compensation is realized. Therefore, the modeling method is scientific and effective and has the characteristics of being easy to compensate and convenient to apply.

Owner:HUBEI UNIV OF ARTS & SCI +1

Geometric error identification method of multi-axis machine tool and multi-axis machine tool

ActiveUS20150160049A1High precision machiningHigh precisionProgramme controlMechanical counters/curvatures measurementsGeometric errorEllipse

A geometric error identification method of multi-axis machine tool includes a measuring step of indexing a position of a target ball mounted on one of a main spindle and a table into a plurality of angles around an rotation axis, and measuring the position of the target ball at respective indexed positions by using a touch probe mounted on the other one of the main spindle and the table, a geometric error calculation step of calculating a geometric error from the measured position of the target ball, an ellipse-expression calculation step of calculating an ellipse approximate expression by an arc trajectory measured by operating the rotation axis, and an error correcting step of calculating and correcting a scaling error of translation axes from the calculated ellipse approximate expression.

Owner:OKUMA CORP

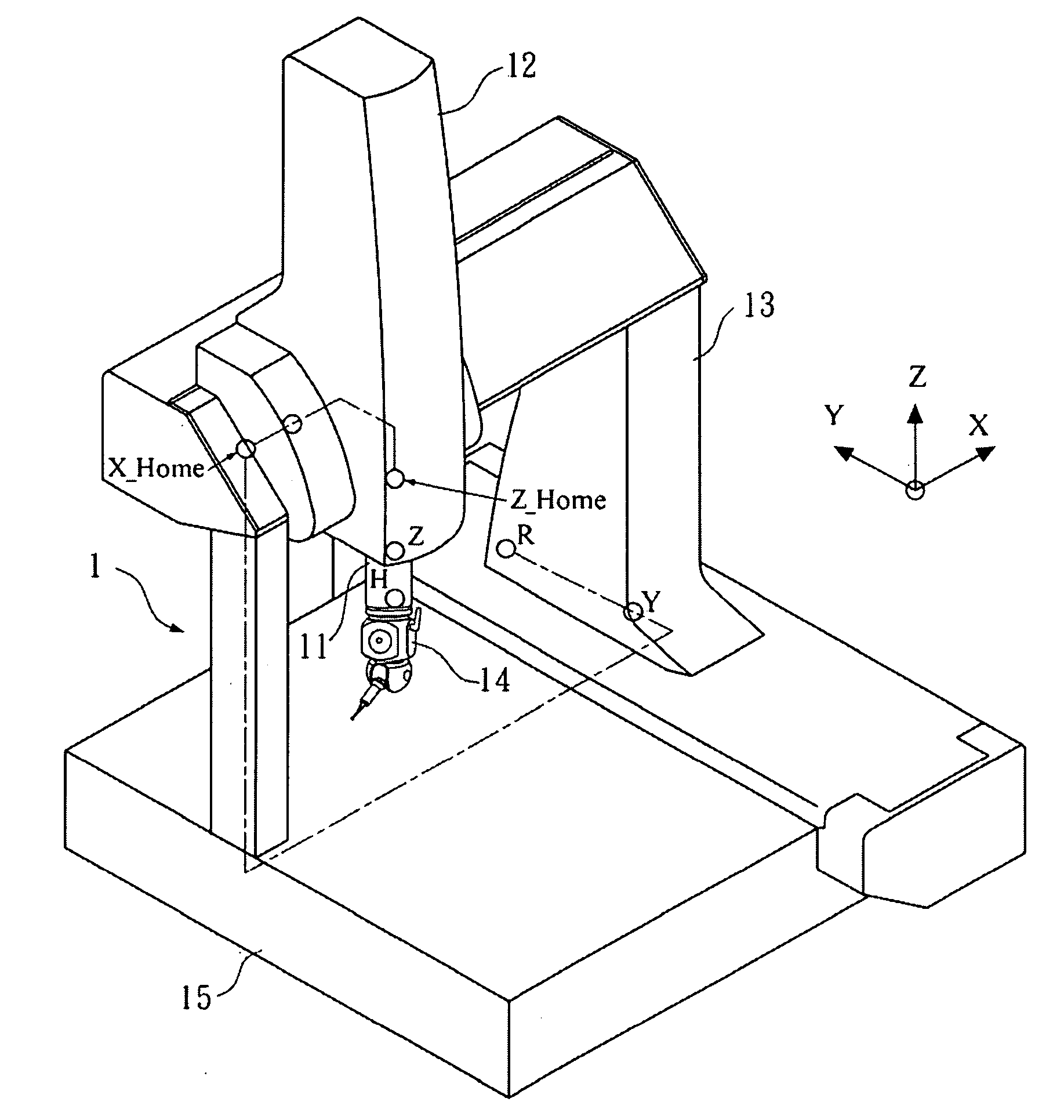

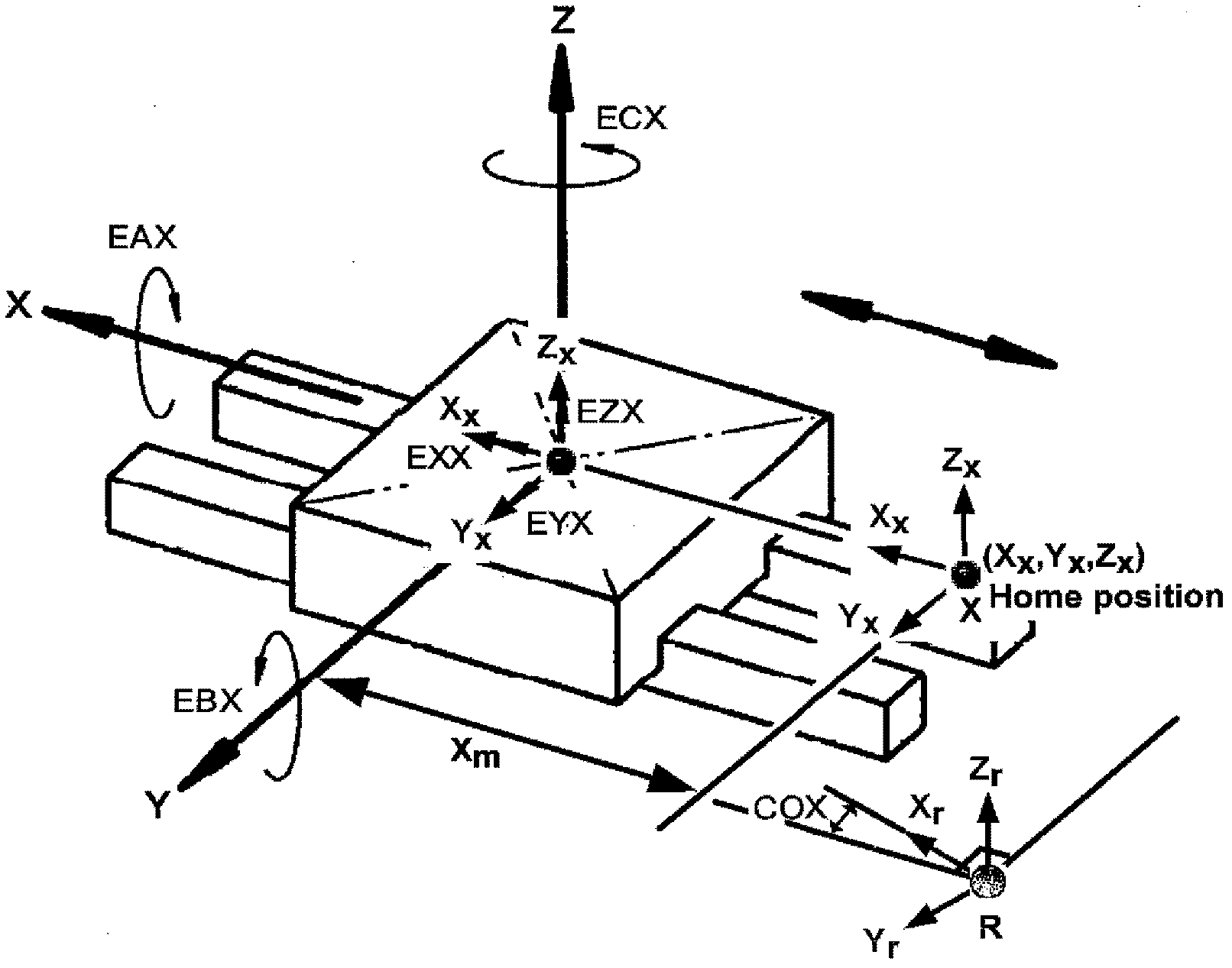

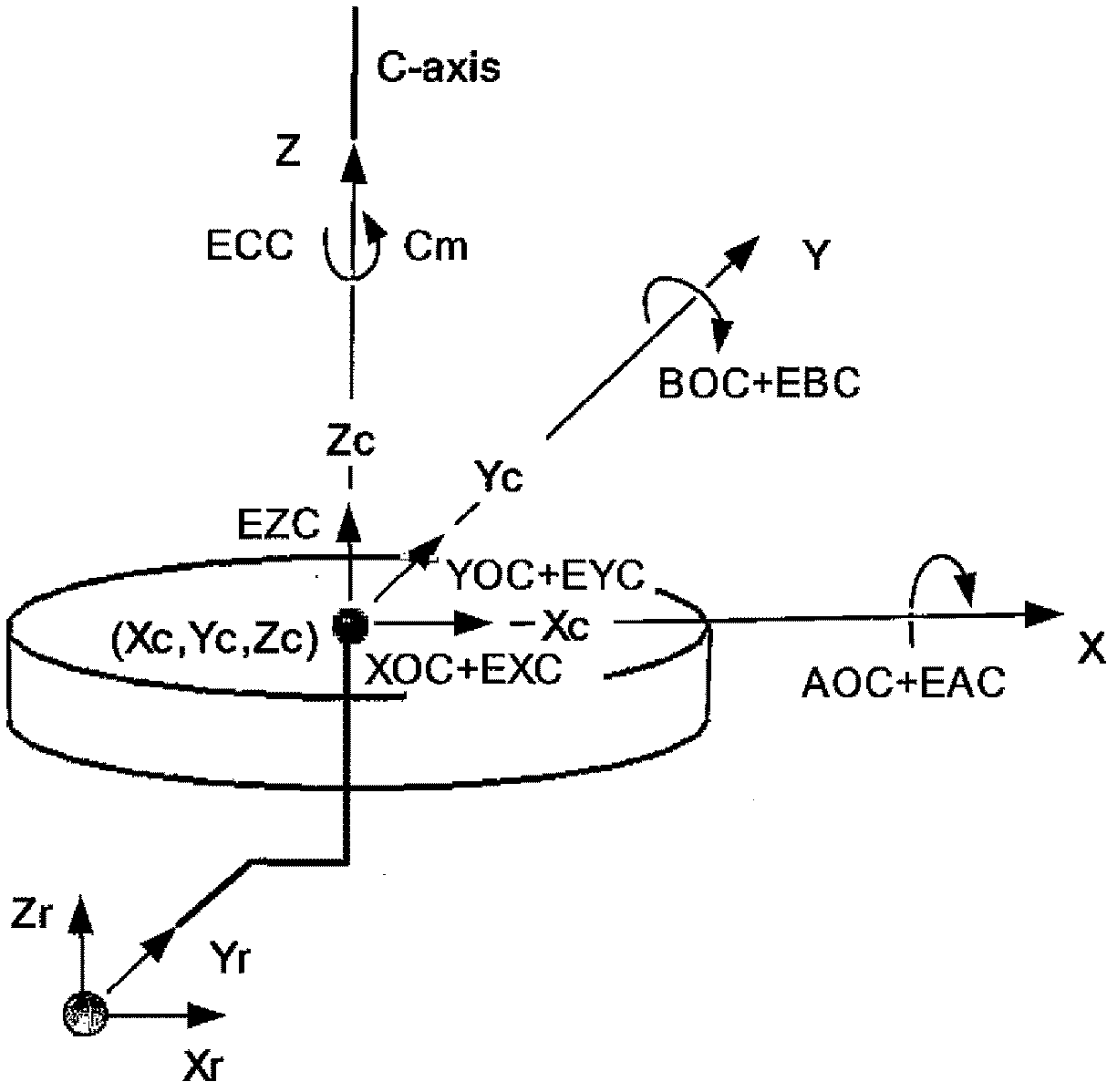

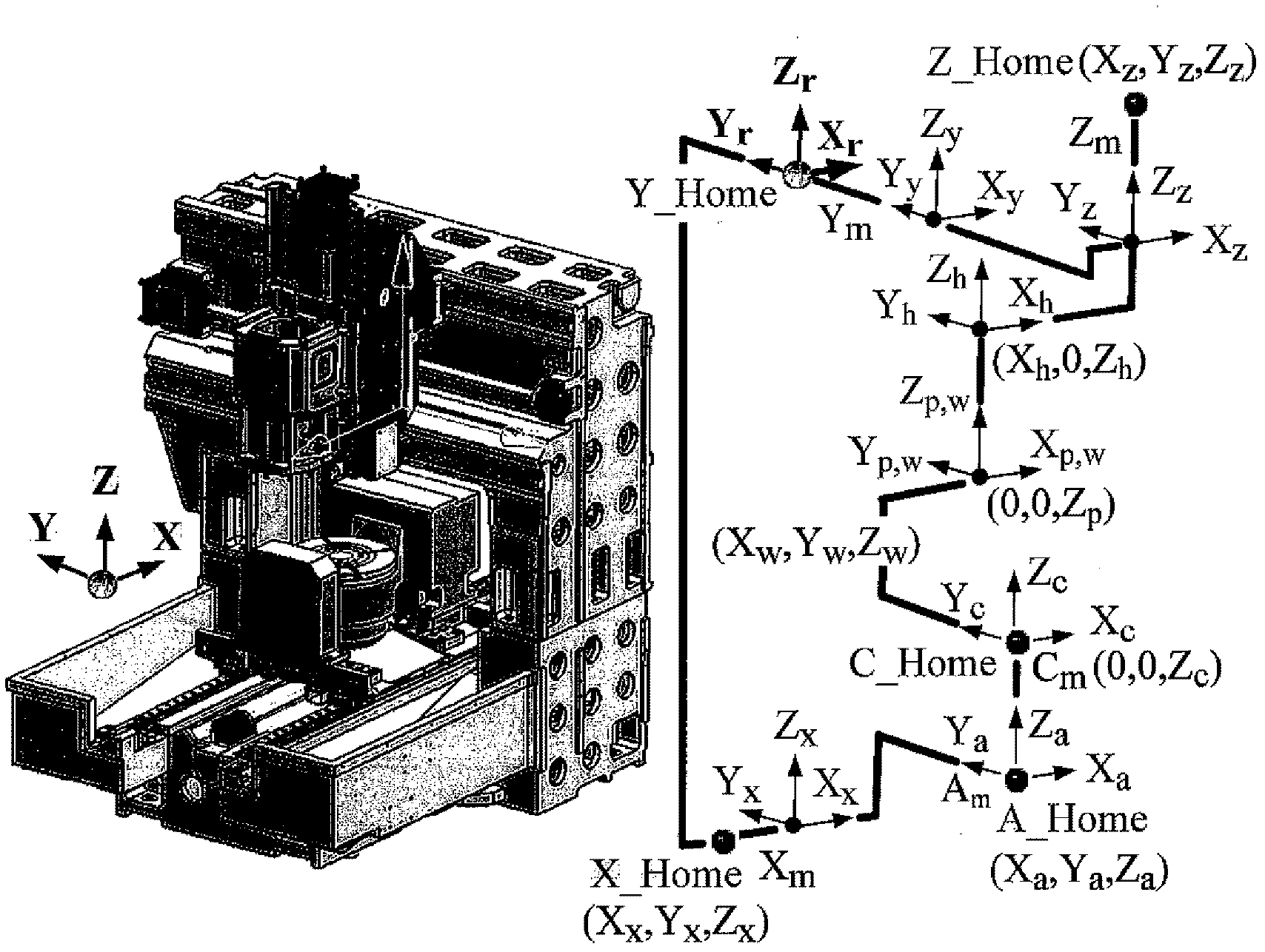

Method and Apparatus for Estimating Error in Multi-Axis Controlled Machine

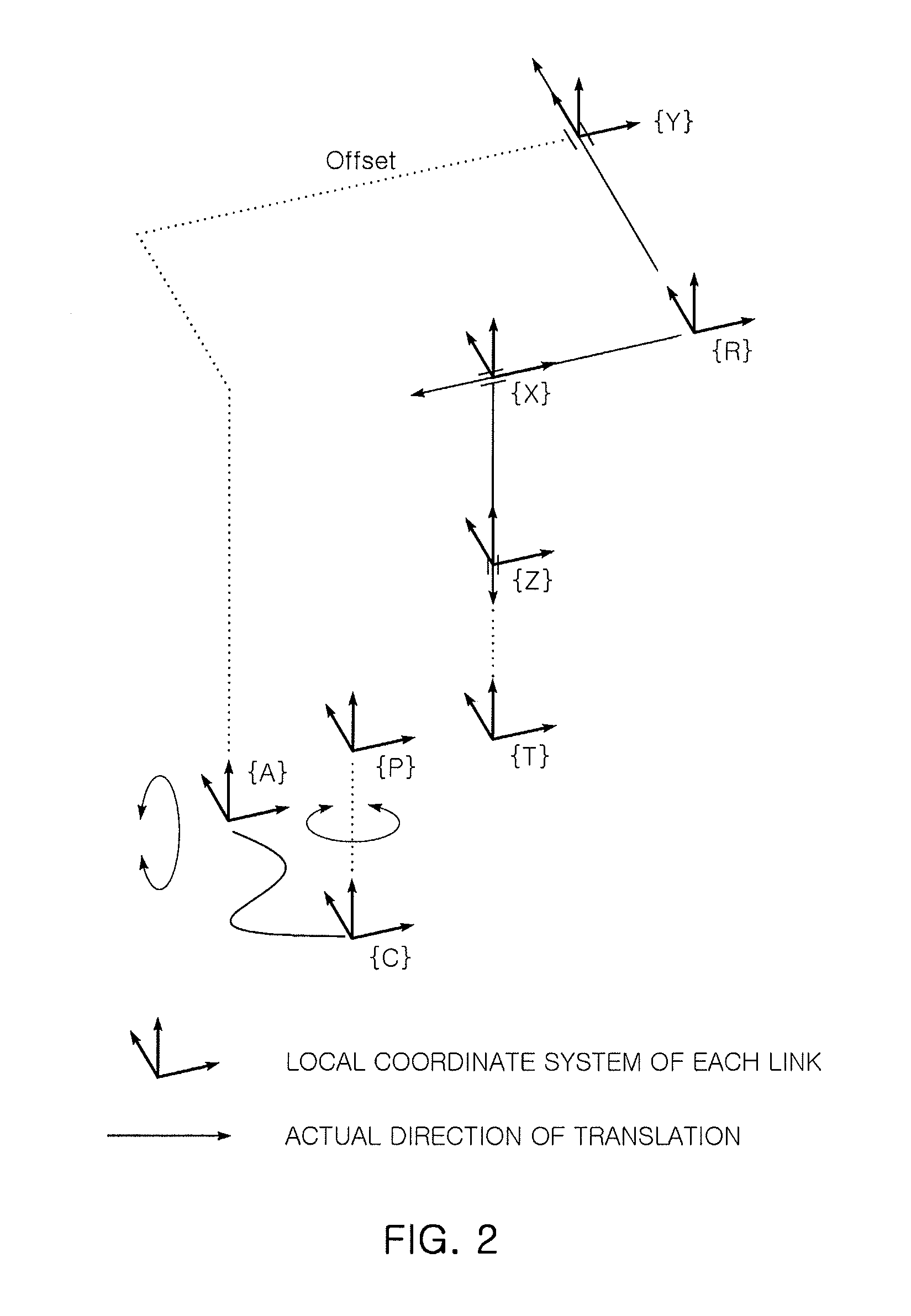

ActiveUS20110218780A1Computation using non-denominational number representationComplex mathematical operationsGeometric errorMulti axis

A method and apparatus for estimating error in a multi-axis controlled machine is applicable to any type of machine configuration in order to estimate and confirm in advance the final position and the posture of the machine, which are produced when geometric errors of the machine are synthesized. The method includes defining the structure of the multi-axis controlled machine subjected to error estimation; and defining parameters, which represent behaviors of drive axes having geometric error and relationships between the drive axes according to the defined structure of the multi-axis controlled machine, adding the defined parameters by applying the parameters to a generalized error synthesis model, and generating an error synthesis model of the multi-axis controlled machine by applying a result of parametric modeling in response to a result of the adding.

Owner:KYUNGPOOK NAT UNIV IND ACADEMIC COOP FOUND

Device and method for detecting geometric errors of single-axis motions of machine tool

InactiveCN104390586AHigh measurement accuracyFast measurementUsing optical meansGeometric errorGrating

The invention discloses a device and a method for detecting geometric errors of single-axis motions of a machine tool. The detection device comprises a processor, a laser interferometer, an interference mirror unit, a bracket and a fixed platform; a sliding rail is horizontally arranged at the lower part of the fixed platform; a Y-direction rail vertical to the sliding rail and capable of sliding along the sliding rail is arranged on the sliding rail; an X-direction rail vertical to the Y-direction rail and capable of sliding along the Y-direction rail is arranged on the Y-direction rail; a Z-direction rail vertical to the X-direction rail and capable of sliding along the X-direction rail is arranged on the X-direction rail; a first grating ruler arranged on the fixed platform, a second grating ruler arranged on the X-direction rail and a third grating ruler arranged on the Y-direction rail are connected with the processor; and a reflection mirror unit is installed on a Z-direction sliding platform. The device and the method for detecting geometric errors of the single-axis motions of the machine tool have high measuring accuracy and high measuring speed and can be widely applied to the detection field of geometric errors of the single-axis motions of the machine tool.

Owner:GUANGDONG UNIV OF TECH

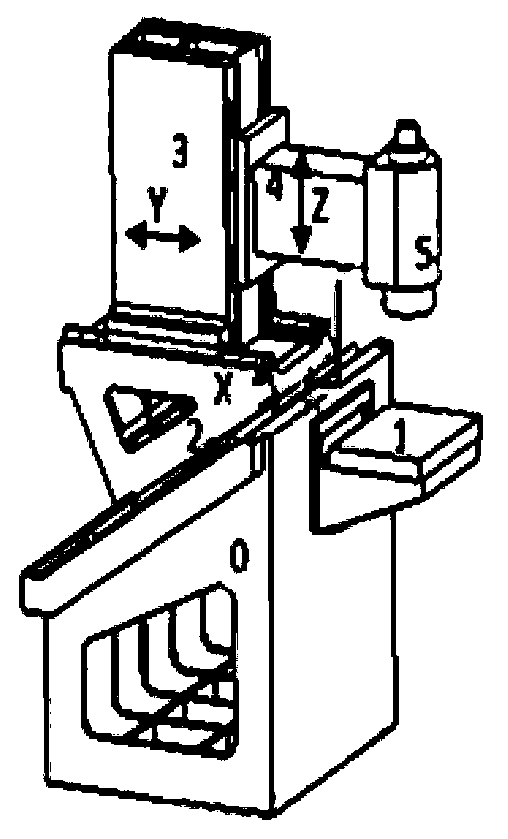

Numerical control precision progressive forming device and precision progressive forming method for plates

ActiveCN102211121AReduce development costsAvoid occupyingMetal-working feeding devicesMetal working apparatusNumerical controlGeometric error

The invention discloses a numerical control precision progressive forming device and a precision progressive forming method for plates, and belongs to the technical field of plate processing. The device comprises a five-axis numerical control forming machine, a plate fixture, a data acquisition system and an optimal control module, wherein the plate fixture is arranged on a worktable of the machine; the data acquisition system is connected with the five-axis numerical control forming machine and the optimal control module respectively, and transmits processing parameters and control instructions; the tail end of a spindle of the five-axis numerical control forming machine is provided with a forming pressure head or a laser ranging system; and the laser ranging system is connected with thedata acquisition system and transmits a laser ranging signal. By alternately using the forming pressure head and the laser ranging system, cyclic operation including plate progressive forming, error measurement and formed path modified forming is completed. The device can save development cost of a die, avoid occupying a press, ensure the dimensional accuracy of sheet metal parts, and reduce material loss due to geometric errors in actual production.

Owner:SHANGHAI JIAO TONG UNIV

Error compensation method for multi-axis controlled machines

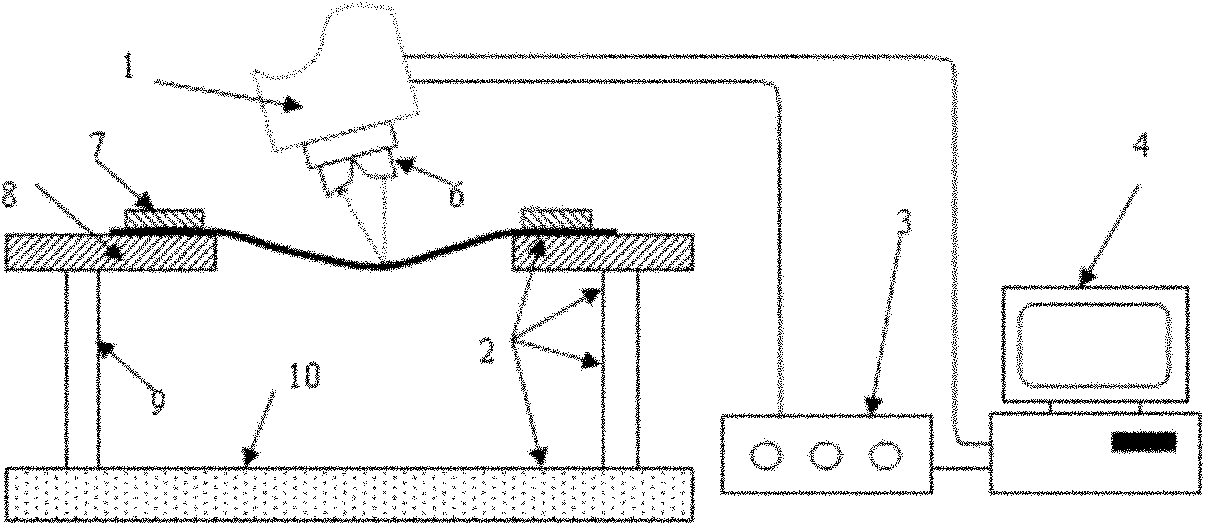

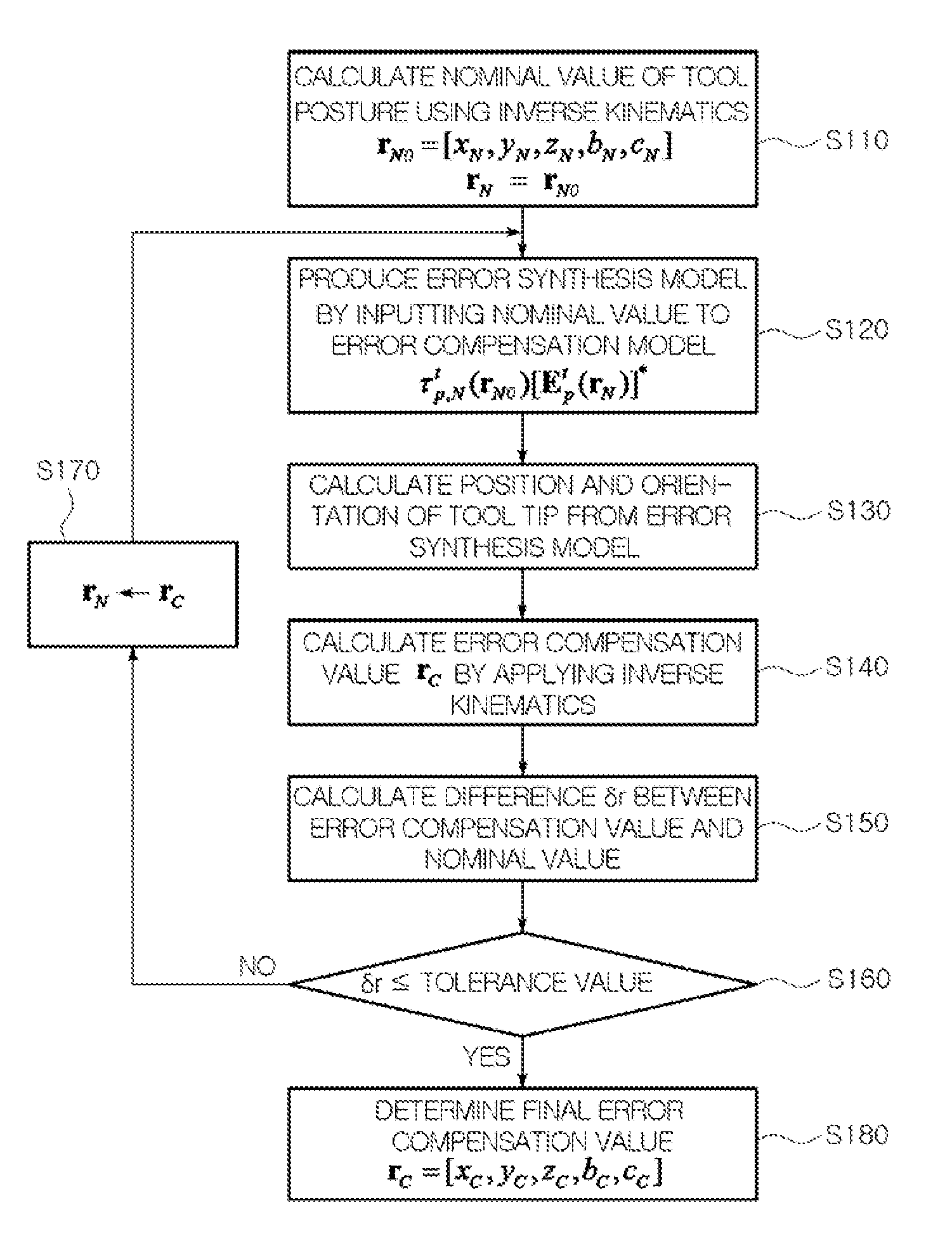

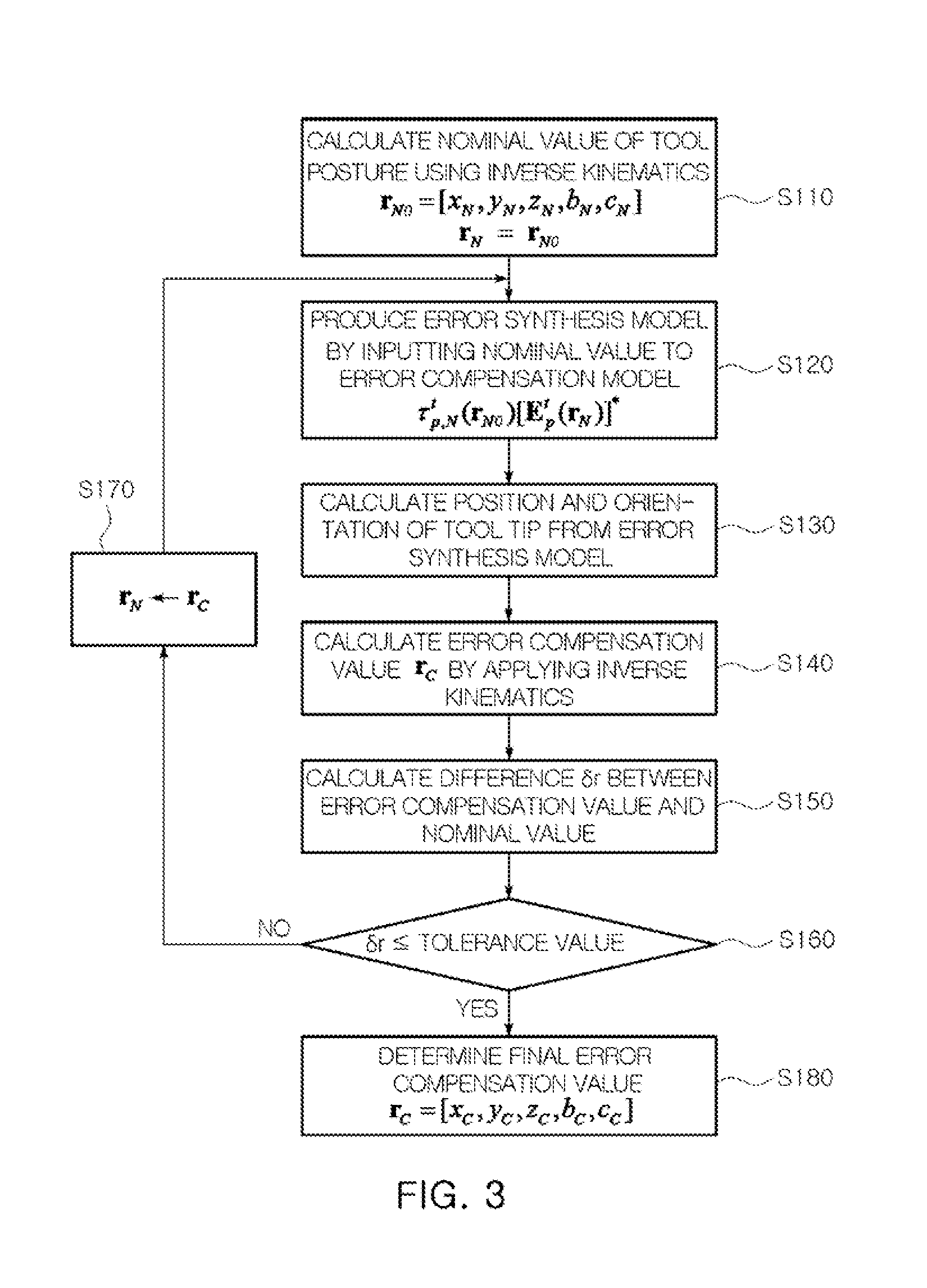

ActiveUS20110224958A1Efficient productionReduce errorsProgramme controlMeasurement devicesGeometric errorPartition of unity

An error compensation method for multi-axis controlled machines generates an error compensation model for compensating for geometric error of a multi-axis controlled machine by separating an error matrix of a tool tip from an error synthesis model of a multi-axis controlled machine and calculates an error compensation value using the error compensation model and an inverse kinematic model so that the error matrix becomes an identity matrix. The error compensation method can reduce calculation error and calculation time due to complicated numerical analysis and compensate for error in the multi-axis controlled machine, regardless of its configuration.

Owner:KYUNGPOOK NAT UNIV IND ACADEMIC COOP FOUND

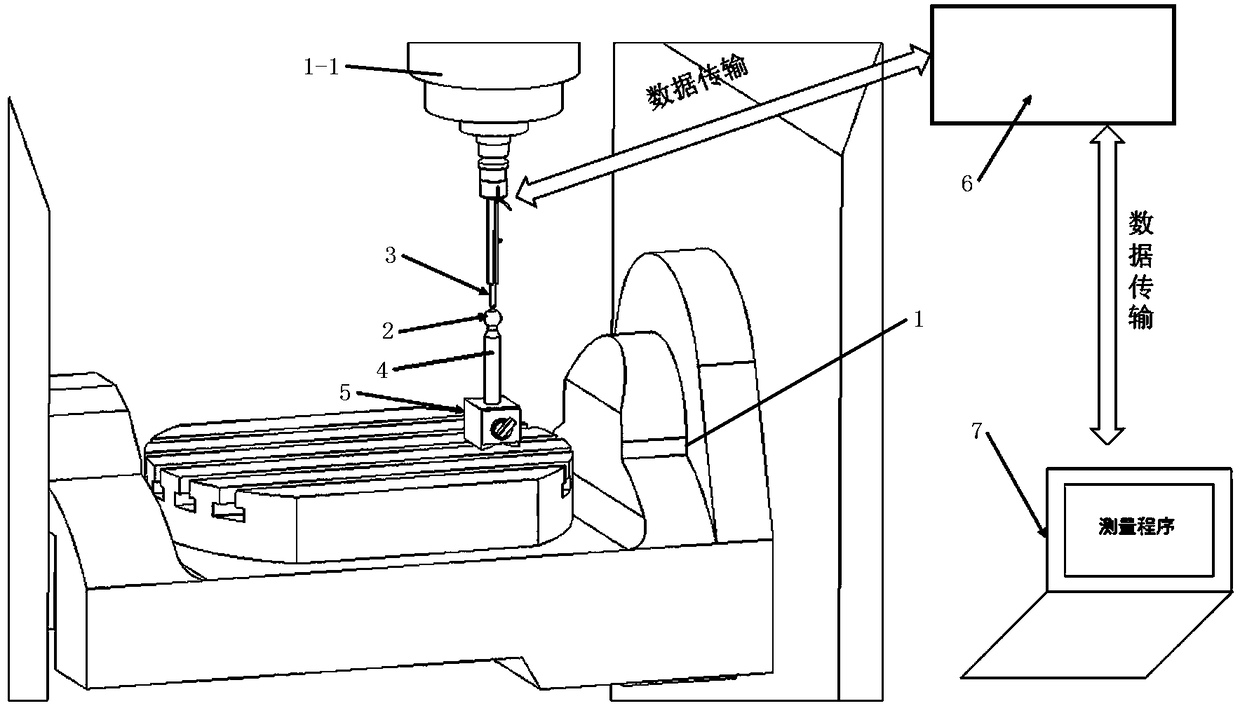

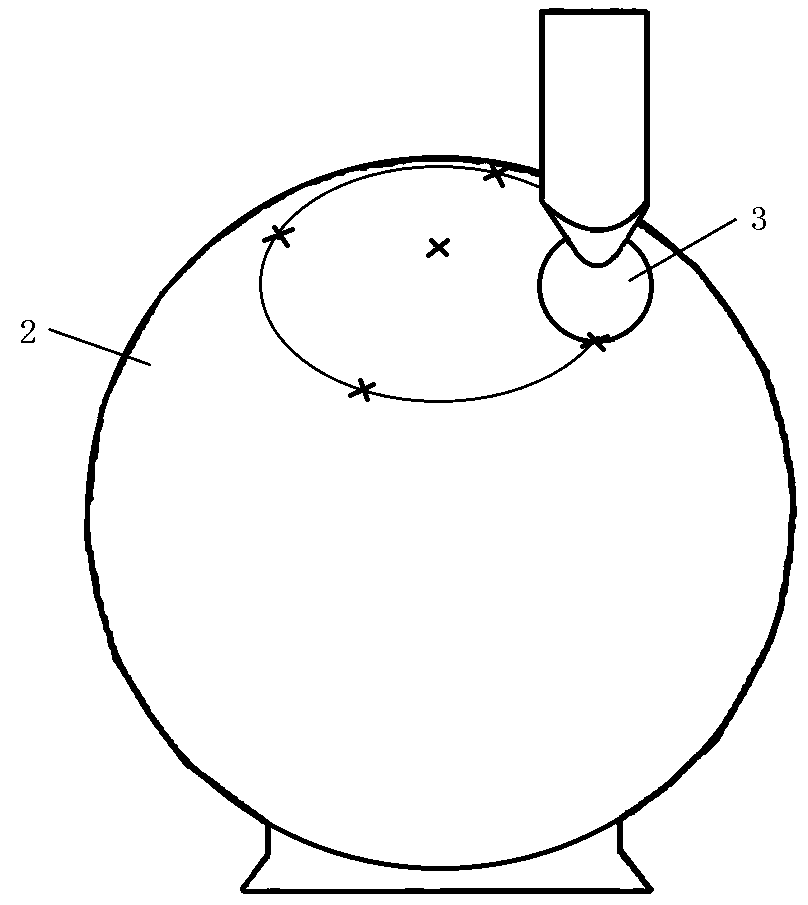

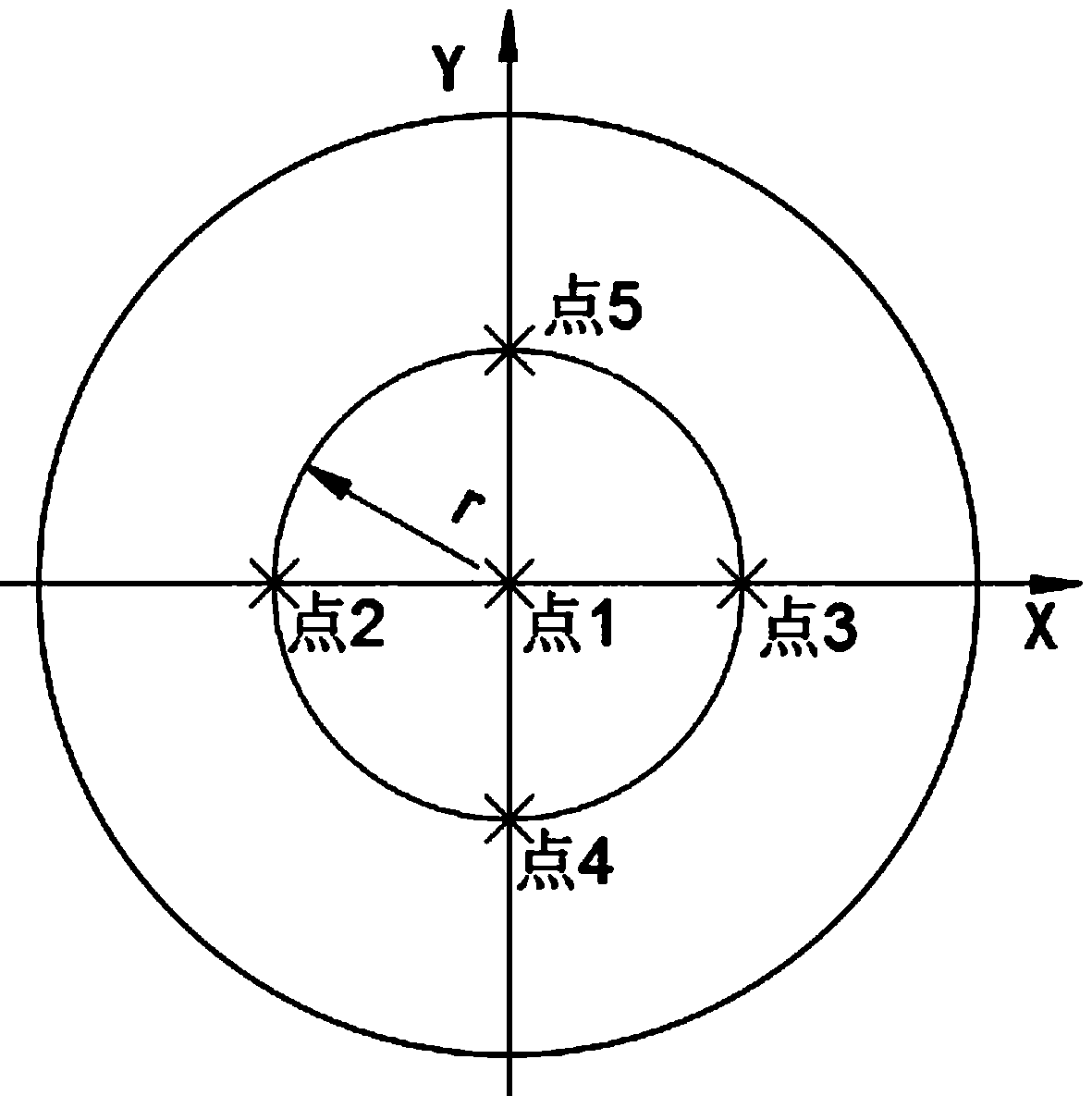

Method and system for measuring geometric error of machine tool based on one-dimensional measuring head and standard balls

ActiveCN108227622AEasy to identifyHigh measurement accuracyProgramme controlComputer controlNumerical controlGeometric error

The invention relates to a method and a system for measuring geometric error of a machine tool based on a one-dimensional measuring head and standard balls. The method comprises the following steps ofS1, according to the type of a numerically-controlled machine tool, arranging the standard balls at multiple position points on the numerically-controlled machine tool, and utilizing the one-dimensional measuring head in the vertical direction to measure the three-dimensional offset of the center of each standard ball on the numerically-controlled machine tool; S2, on the basis of a geometric error model of the numerically-controlled machine tool, obtaining the position-related geometric error of the numerically-controlled machine tool according to the obtained three-dimensional offset of thecenter of each standard ball at each position point in S1. Compared with the prior art, the method has the advantages that the eccentricity of the center of each standard ball due to the geometric error of the machine tool is measured by the one-dimensional measuring head, the measuring value is used as coordinate reference, and the problem of failure of the machine-mounted measuring head due todegrading of the accuracy of the machine tool is effectively solved; the geometric constraint on the measuring head in the measuring process is avoided, the difficulty in numerical control programmingof the movement track of the measuring head is effectively decreased, and the damage risk of the measuring system due to mistake of the movement track is eliminated.

Owner:FUZHOU UNIV

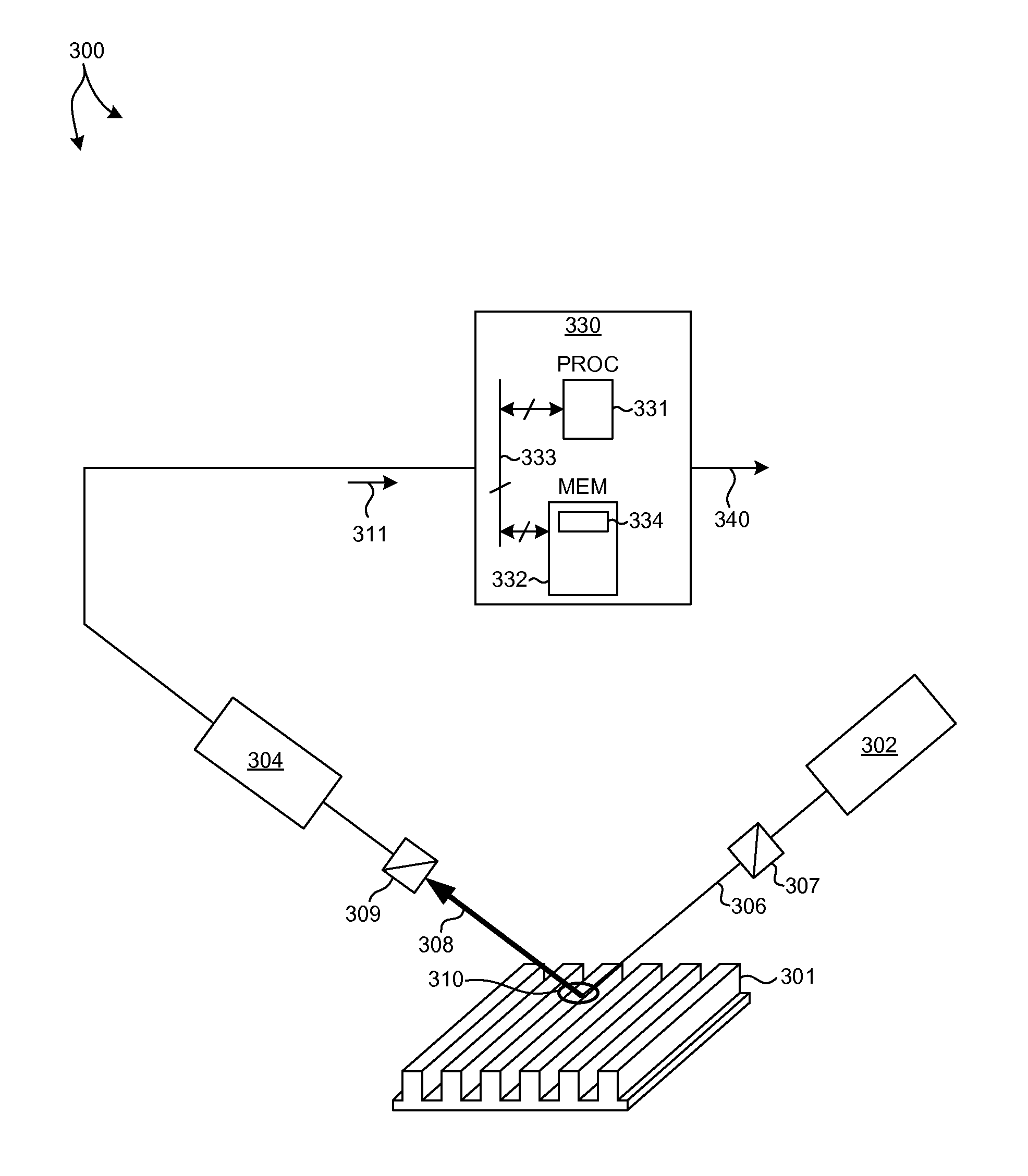

Metrology Of Multiple Patterning Processes

Methods and systems for evaluating the performance of multiple patterning processes are presented. Patterned structures are measured and one or more parameter values characterizing geometric errors induced by the multiple patterning process are determined. In some examples, a primary, multiple patterned target is measured and a value of a parameter of interest is directly determined from the measured data by a Signal Response Metrology (SRM) measurement model. In some other examples, a primary, multiple patterned target and an assist target are measured and a value of a parameter of interest is directly determined from the measured data by a Signal Response Metrology (SRM) measurement model. In some other examples, a primary, multiple patterned target is measured at different process steps and a value of a parameter of interest is directly determined from the measured data by a Signal Response Metrology (SRM) measurement model.

Owner:KLA TENCOR CORP

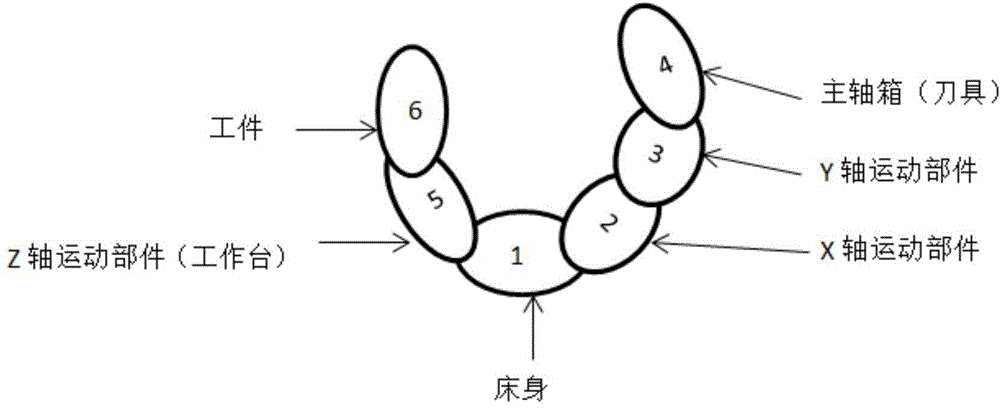

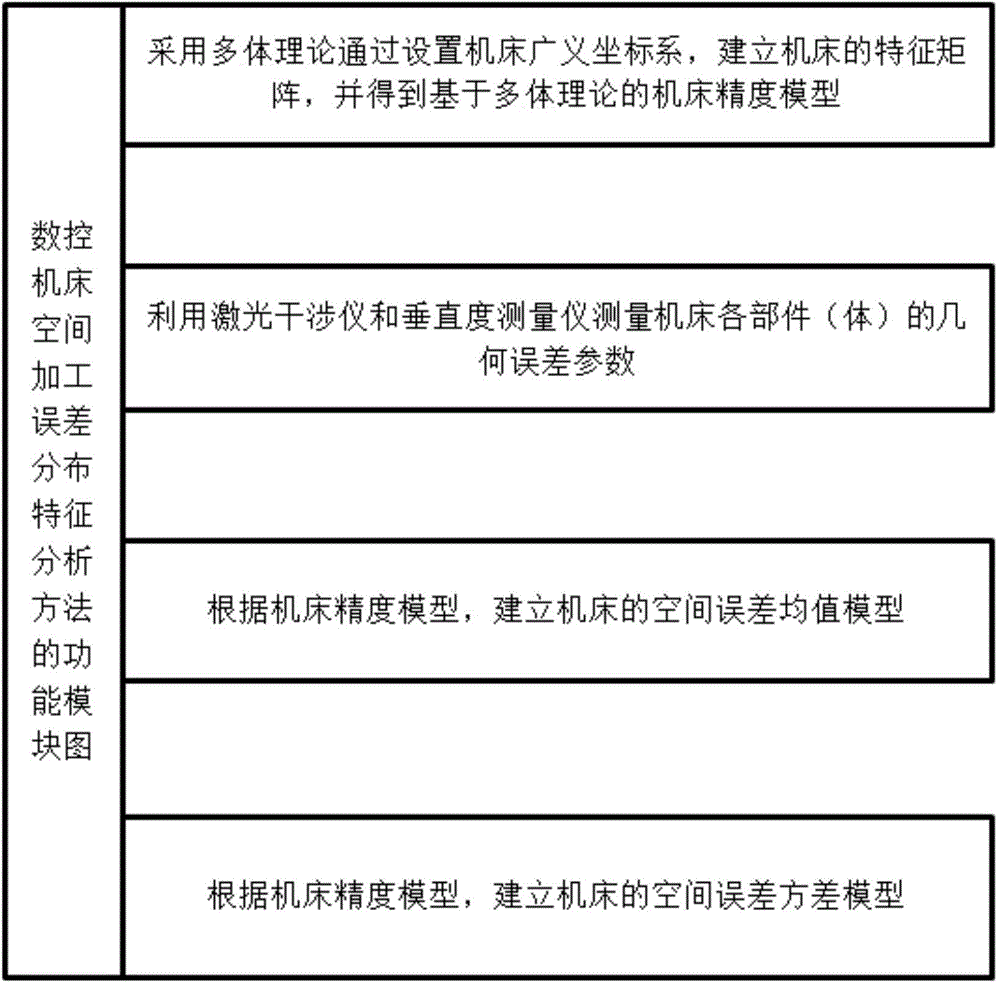

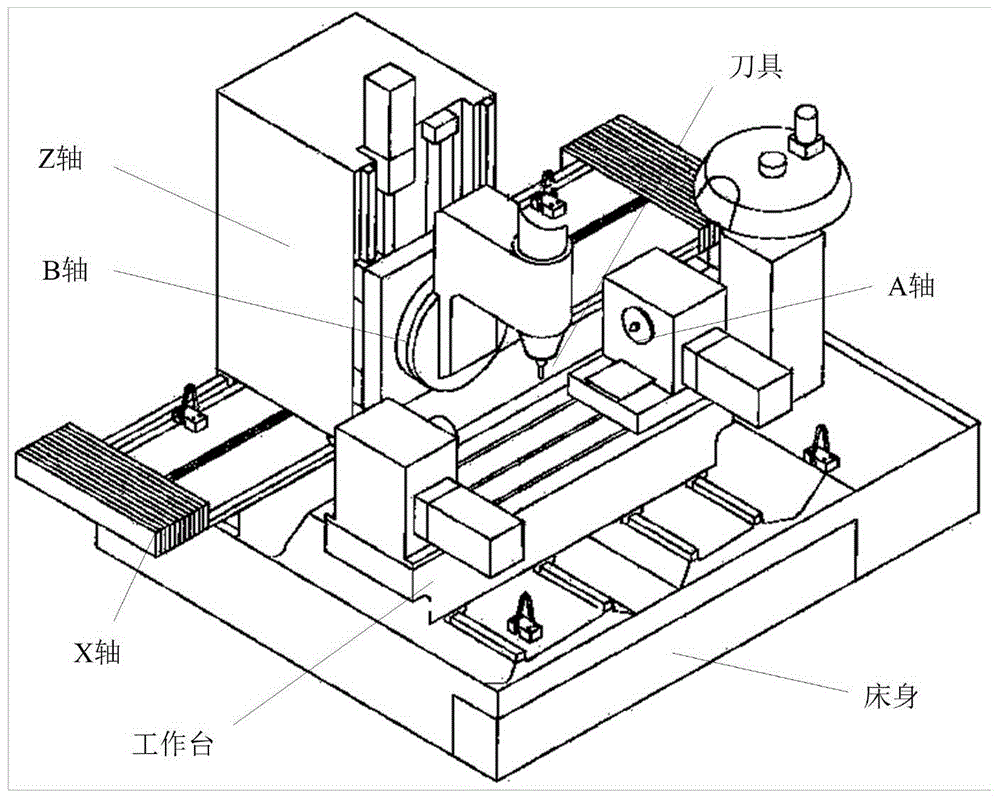

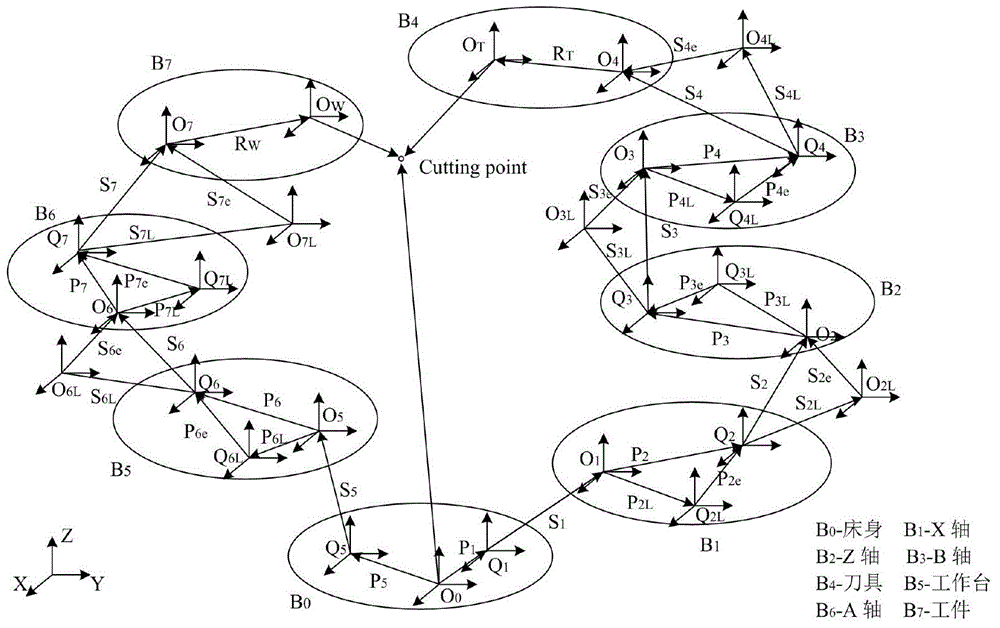

Analysis method on basis of distribution characteristics of space machining error of numerical control machine tool

ActiveCN104050316AReduce uncertaintySpecial data processing applicationsGeometric errorNumerical control

The invention discloses an analysis method on the basis of distribution characteristics of a space machining error of a numerical control machine tool, belongs to the field of accuracy design of a machine tool and particularly relates to an analysis method on the basis of the distribution characteristics of the space error. On the basis of space geometric error deterministic modeling and geometric error measurement which are established by a multibody system and the matrix total differential and random process principle, a space error deterministic analysis model of a precision horizontal machining center is established and the distribution characteristics of a geometric error and the space machining error of the machine tool are analyzed. The invention discloses a novel machine tool design concept and fundamentally solves the problem of accuracy of the machine tool. Guiding suggestions also can be given to actual assembling and machining, so that output of the error is reduced, machining accuracy of the numerical control machine tool is improved and the problem of accuracy of the machine tool is fundamentally solved.

Owner:BEIJING UNIV OF TECH +1

Method for assessing composite space type face geometric error

The invention relates to a method for evaluating geometrical error of a compound spatial moulding surface, belonging to the field of mechanic parts geometrical error evaluation. The method comprises the following steps: (1) a three-dimensional CAD model of a work piece to be evaluated is read and an ideal work piece model is reconstructed; (2) geometrical data of the work piece to be evaluated is measured to obtain the coordinate information of each measured point; (3) the error value of the measured moulding surface is calculated according to the geometrical error evaluation items of the work piece to be measured including spatial straightness accuracy, cylindricity and punch combination compound position; and (4) the error evaluation result is compared with the read ideal work piece model for analyzing, the processing error information is displayed by adopting colour cloud points, and the error evaluation report is obtained finally. The invention, by the approaching process for constructing minimum zone, realizes fast and accurate evaluation on the geometrical error of the compound spatial moulding surface.

Owner:TIANJIN UNIV

Method for designing geometric accuracy of multi-axis numerical control machine tool to improve processing accuracy and reliability

The invention belongs to the field of machine tool accuracy designing, and relates to a method for designing geometric accuracy of a multi-axis numerical control machine tool to improve processing accuracy reliability, in particular to a modeling method of space errors of the multi-axis numerical control machine tool and an analyzing method of processing accuracy reliability and reliability sensitivity of the machine tool. A space error model of the multi-axis numerical control machine tool and a processing accuracy reliability model as well as a processing accuracy sensitivity model of the multi-axis numerical control machine tool under a multi-failure mode are built, geometric error items high in processing accuracy reliability sensitivity are optimized, processing accuracy reliability of the machine tool is improved, a basis is provided for acquiring interrelation among geometric errors of the multi-axis numerical control machine tool and setting accuracy grade of main transmission components of the machine tool, and the problem of accuracy distribution of the machine tool is solved fundamentally.

Owner:BEIJING UNIV OF TECH

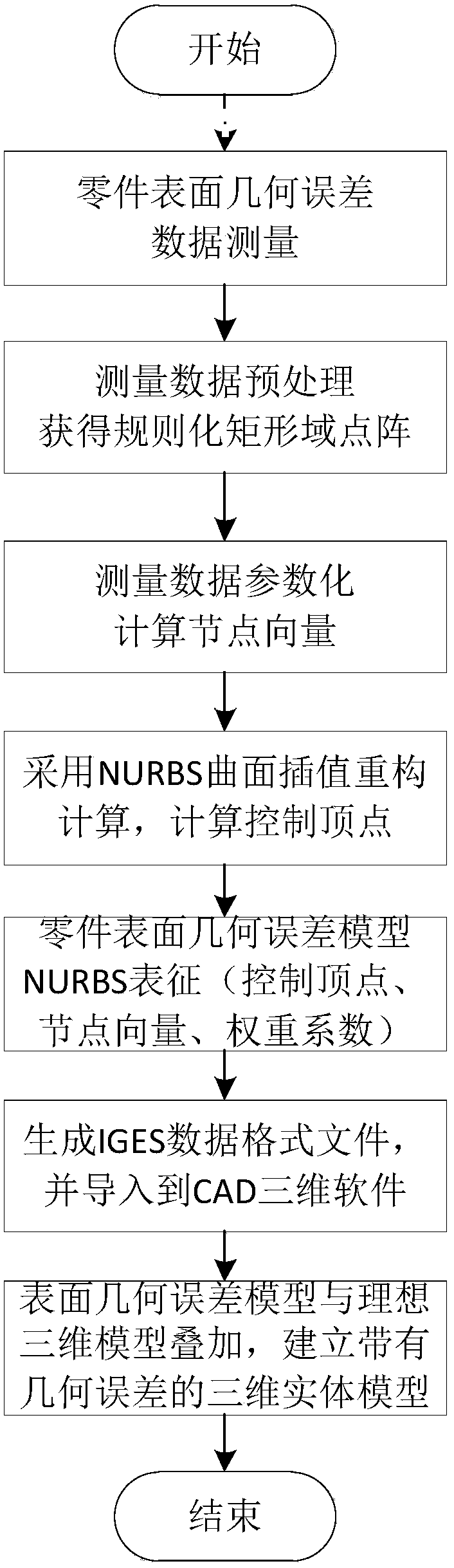

NURBS curved surface reconstruction-based geometric error representation method

InactiveCN107067472AAccurately responds to surface geometry errorsAchieve integrationGeometric CADDesign optimisation/simulationGeometric errorSurface reconstruction

Owner:BEIJING INST OF TECH

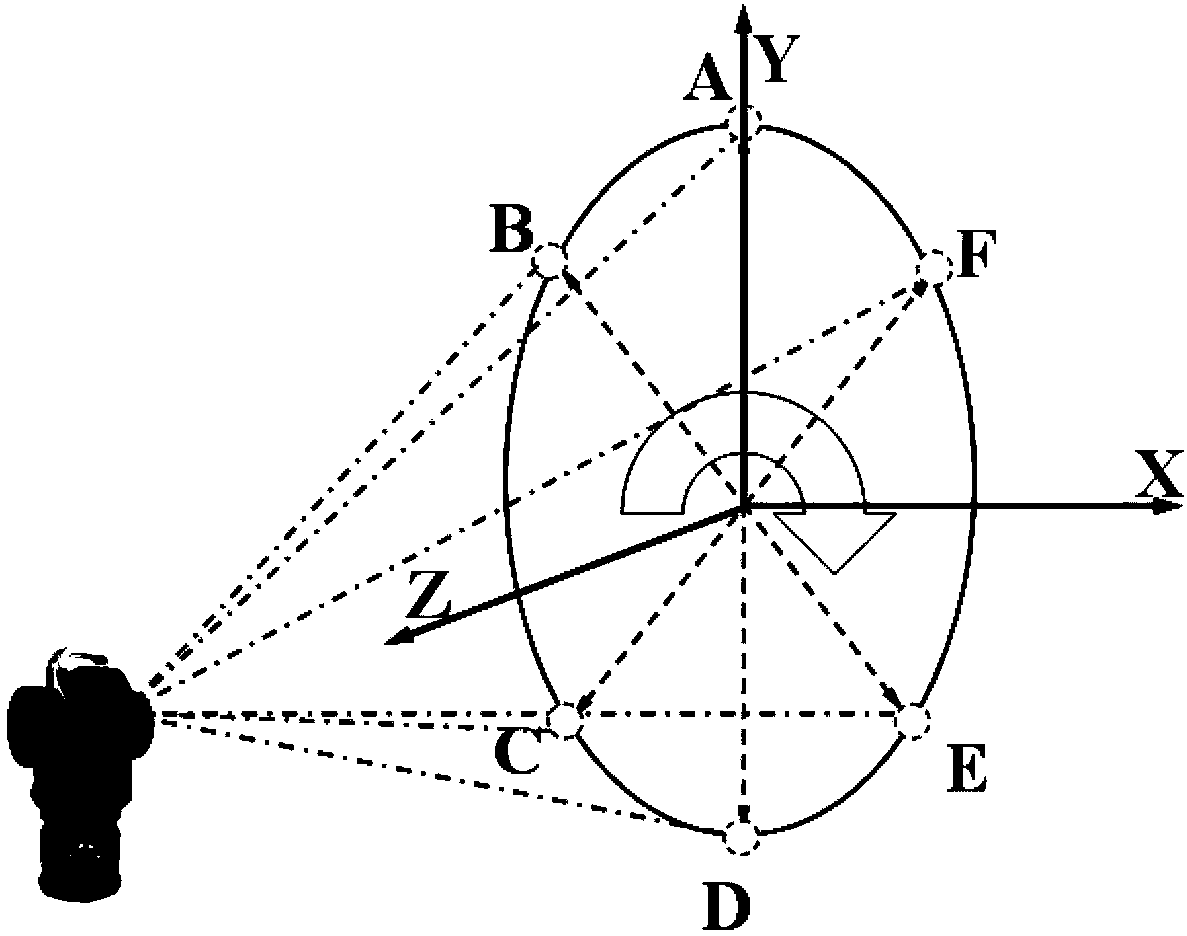

Assessment method for geometric errors of five-axis tool machine

InactiveCN103206932AAccurate and fast measurementFast and Accurate EstimationMeasurement devicesGeometric errorLeast squares

The invention discloses an assessment method for geometric errors of a five-axis tool machine, and the assessment method can be applied to a five-axis processing machine. The assessment method includes the steps that an R-test measuring tool with a probe and a standard ball is arranged on the five-axis machining machine, the sphere center of the standard ball serves as the original point of a reference coordinate system, a five-axis synchronous movement path serves as a measuring path to measure the assembly error of the five-axis tool machine, the assembly error obtained through measuring and a known mechanism parameter of the five-axis tool machine are substituted in a geometric error model, and values of 11 items of geometric errors of the five-axis tool machine are obtained through solving by using a method of least square. The assessment method has the advantages of being fast and accurate.

Owner:PRECISION MACHINERY RES & DEV CENT

Steady optimal distributing method for geometric accuracy of multi-shaft machine tool

ActiveCN103390082AGuaranteed machining accuracyReduce manufacturing costSpecial data processing applicationsGeometric errorMultibody system

Along with increasing demand on machining precision, how to reasonably configure geometric error of a machine tool under the premise of ensuring the machining performance of the machine tool to balance the cost and machining precision is the problem demanding a prompt solution in manufacturing of the machine tool. The invention provides a novel multi-target optimal distributing method for geometric accuracy based on the manufacturing cost and quality loss of parts. The method comprises the following steps of: establishing a comprehensive spatial error model of geometric error of the machine tool by a multibody system theory; establishing a manufacturing cost model of a machine tool part according to the machining characteristic of the machine tool part which affects the geometric error to the maximum extent; meanwhile, combining the quality loss cost to establish a cost-based target function; establishing an optimal model associated to precise level of the part by identifying the geometric error, namely, maximizing European norms of all precision parameter variables as another target function; and realizing optimal distribution through Isight and Matlab integrated and combined with NSGA-II (Nondominated Sorting Genetic Algorithm-II).

Owner:BEIJING UNIV OF TECH +1

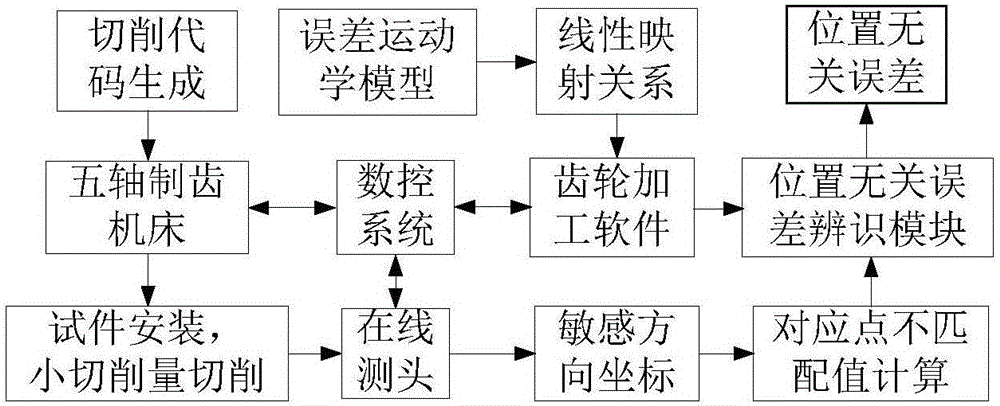

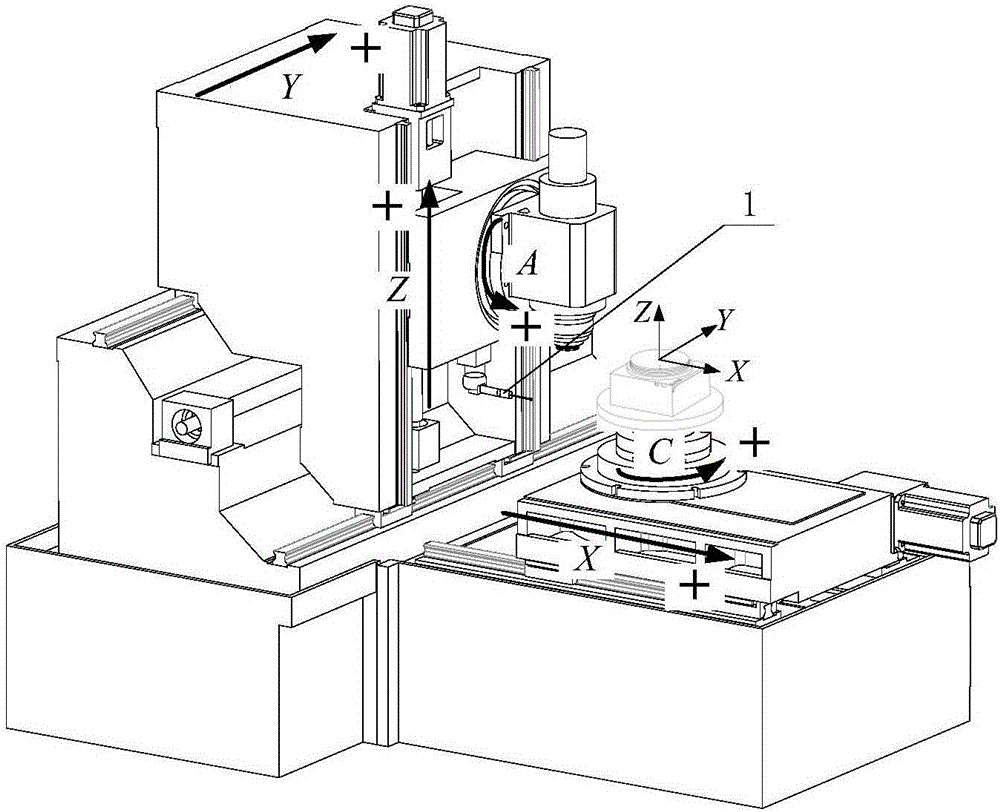

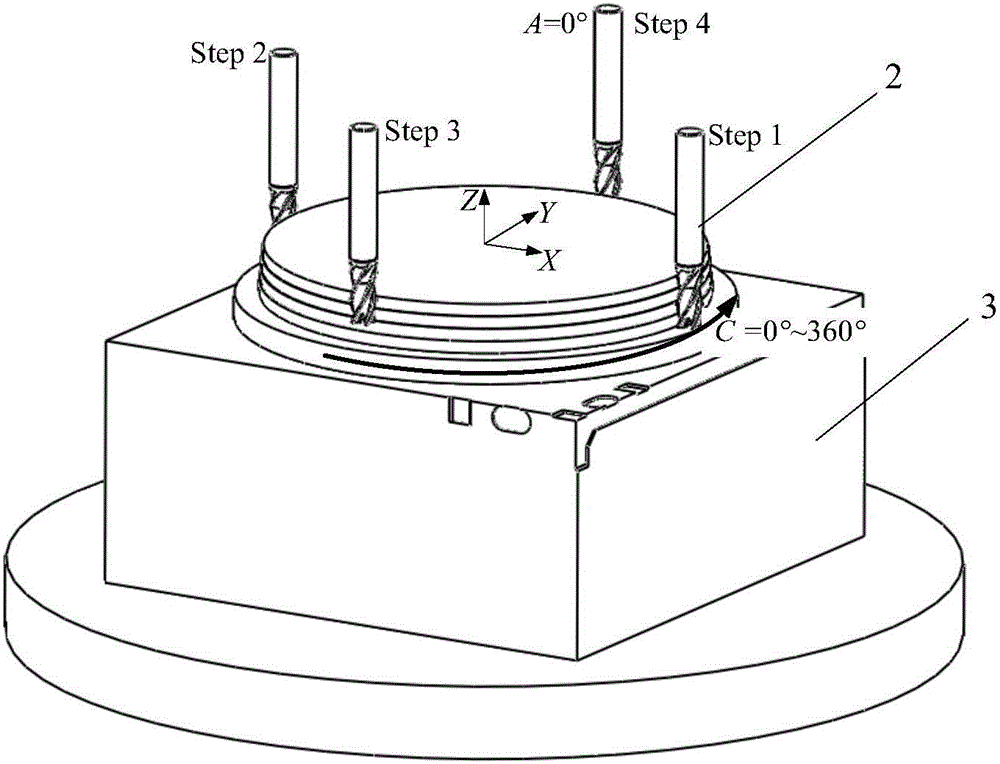

Five-axis gear making machine tool position independent error detection method based on small-cutting-amount test piece

ActiveCN106181583AAvoid influenceImprove detection accuracyMeasurement/indication equipmentsGeometric errorKinematics equations

The invention relates to the technical field of machine tool geometric error measuring and calibration, in particular to a five-axis gear making machine tool position independent error detection method based on a small-cutting-amount test piece. The detection method comprises the following steps that firstly, a track is compiled according to the shape of a designed test piece, a processing code is generated, small-amount cutting is conducted on the designed test piece, and a cutting test piece with a specific to-be-tested object is obtained; secondly, sensitive direction coordinates of the cutting surface of the specific to-be-tested object on the cutting test piece are detected and acquired by utilization of an on-line measuring head, and coordinate mismatching values corresponding to the cutting surface are calculated; thirdly, a homogeneous kinematic equation containing a position independent error is established, and the mapping relation between the coordinate mismatching values corresponding to the cutting surface, and the position independent error is determined; and fourthly, a position independent error item is obtained according to the mapping relation between the coordinate mismatching values corresponding to the cutting surface, and the position independent error. The fixe-axis gear making machine tool position independent error detecting and identifying method is efficient and easy to operate.

Owner:NANJING UNIV OF TECH +1

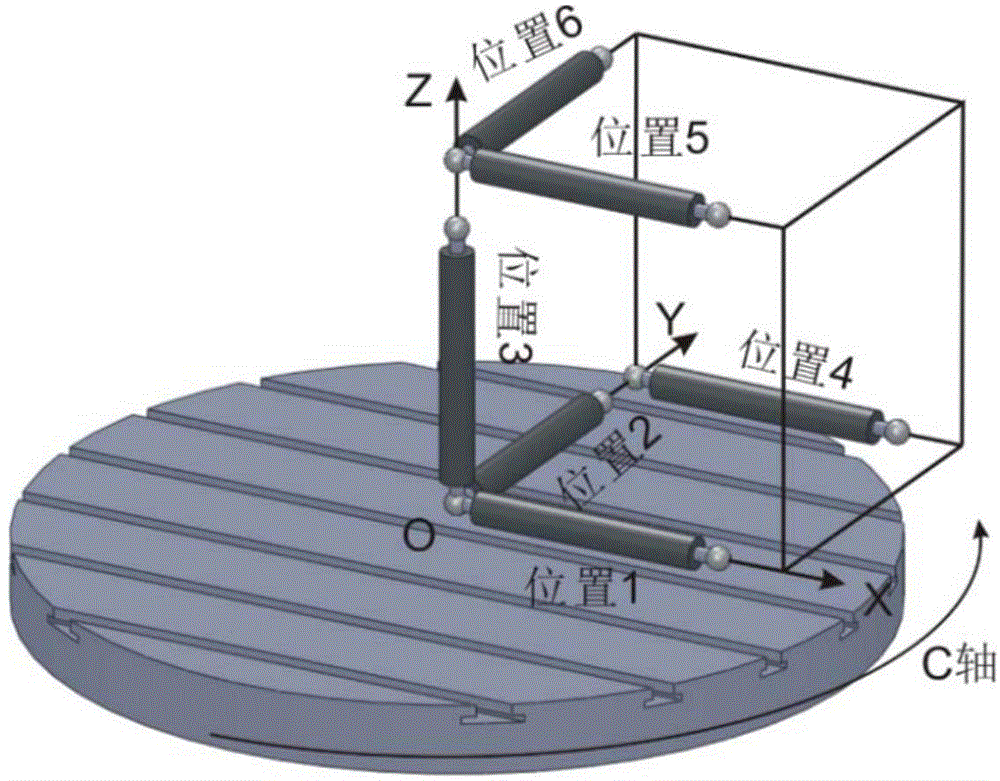

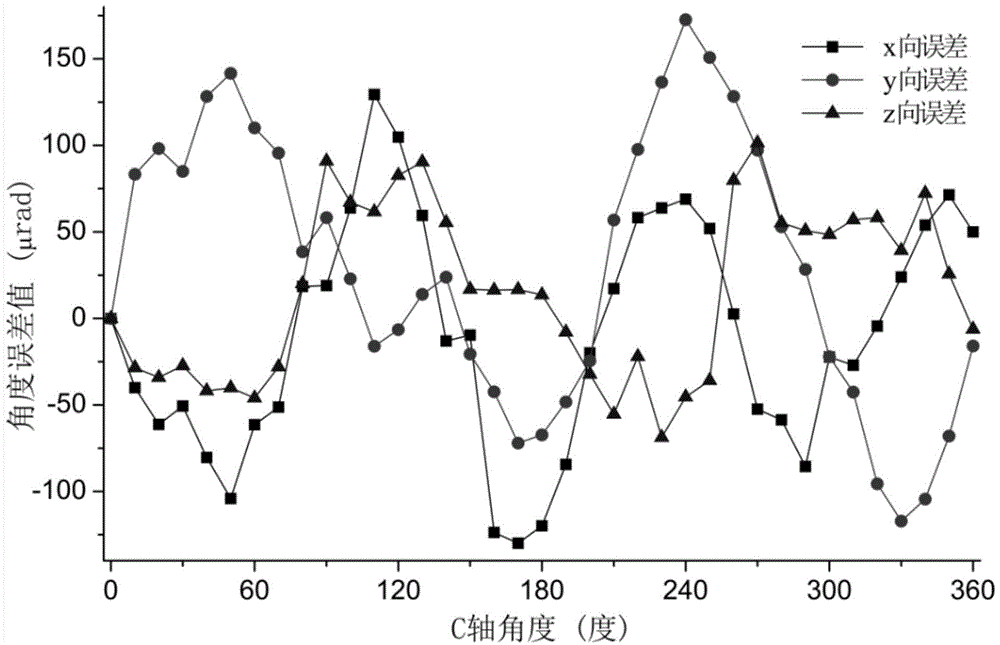

Machine tool rotating shaft geometry error six-circle identifying method based on measuring of ball bar instrument

ActiveCN104308657AThere is no principle errorThe method is systematicMeasurement/indication equipmentsRotational axisGeometric error

The invention discloses a machine tool rotating shaft geometry error six-circle identifying method based on measuring of a ball bar instrument. The method comprises the following steps of determining six measuring positions of the ball bar instrument according to the type and position of a machine tool rotating shaft, obtaining the relation of the readings of the ball bar instrument at all positions and the geometry error of the rotating shaft according to the influence of the geometry error of the rotating shaft to the machine tool precision and in combination with the direction of the ball bar instrument at six measuring positions, obtaining an identifying matrix M of the geometry error of the rotating shaft, by combining each geometry error definition of the rotating shaft, obtaining an identifying formula of the geometry error of the rotating shaft, selecting appropriate coordinates for the six measuring positions to install the ball bar instrument, operating corresponding machine tool codes, obtaining the corresponding readings of the ball bar instrument at the six positions of the rotating shaft, substituting the readings of the ball bar instrument and the measuring position coordinates into the identifying formula of the geometry error of the rotating shaft, and obtaining all 10 geometry errors of each rotating shaft. The method is suitable for the rotating shafts in different types without principle error, the system entry is good, the measuring is convenient, and the identifying precision is high.

Owner:ZHEJIANG UNIV

Numerical control program post-processing method for five-coordinate linkage machine tools

ActiveCN103048947AThe solution is not universalImprove programming efficiencyNumerical controlNumerical controlGeometric error

The invention discloses a numerical control program post-processing method for five-coordinate linkage machine tools, which includes the following steps: (1) a machine tool geometric error compensation parameter method is adopted to compile a numerical control program, so that codes can be universally used on machine tools with like systems; (2) the numerical control program points generated by the machine tool software are reversely calculated into the points in a programming coordinate system, the points in the programming coordinate system are then normally calculated into machine tools with other systems, and therefore the codes are universally used on machine tools with various systems. The method solves the problem that programs complied in the conventional mode cannot be universally used, and also solves the contradiction between the RPCP (Rotation Around Part Center Point) and RTCP (Rotation Around Tool Center Point) programming modes and the conventional program-debugging habit of workshop workers, debugging is simple, rapid and reliable, and mistakes are prevented.

Owner:DONGFANG TURBINE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com