Numerical control machine tool translational shaft geometric error measuring device and measuring and identifying method

A geometric error and CNC machine tool technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of data processing troubles, increase measurement costs, etc., achieve low cost, high precision, and rich measurement information Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] A method for detecting and identifying the geometric accuracy of a translational axis of a CNC machine tool based on pose measurement, comprising the following steps:

[0054] (1) Multi-station time-sharing measurement pose steps

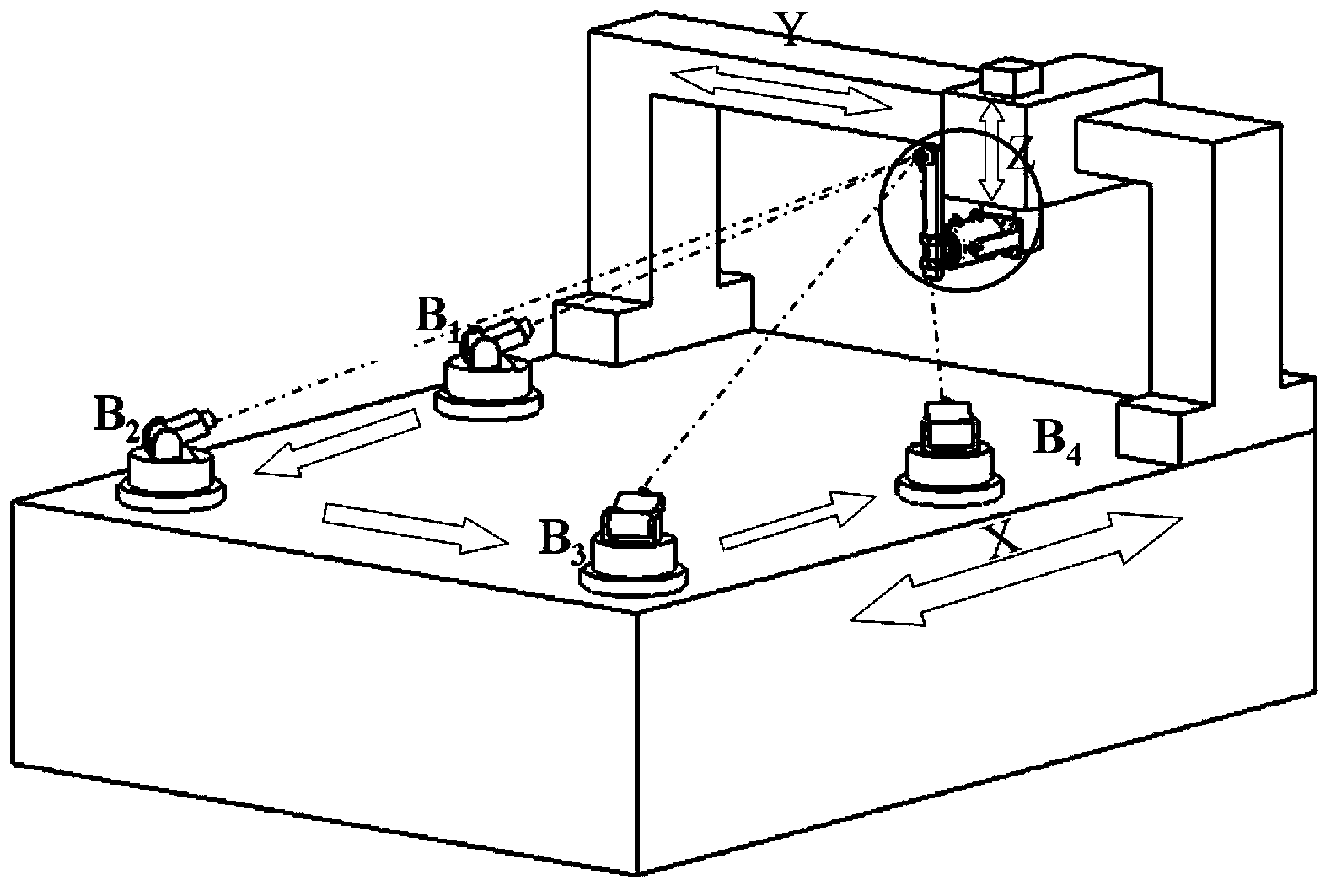

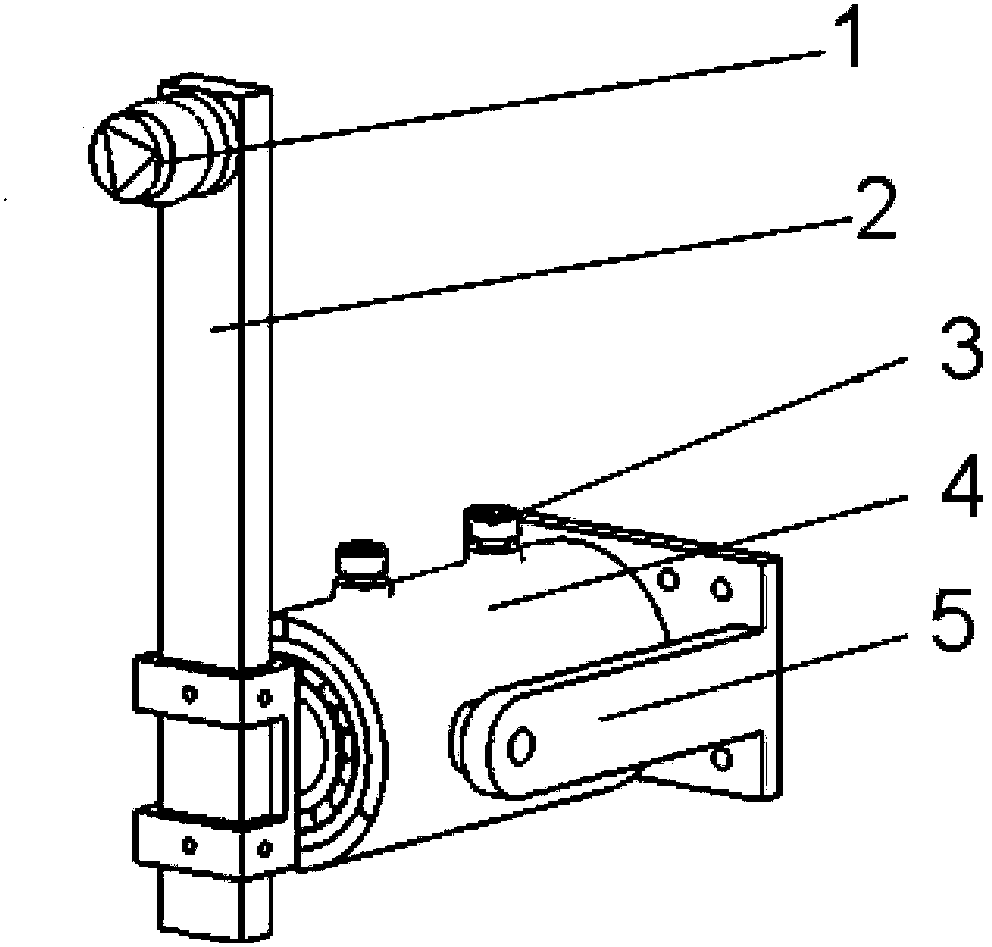

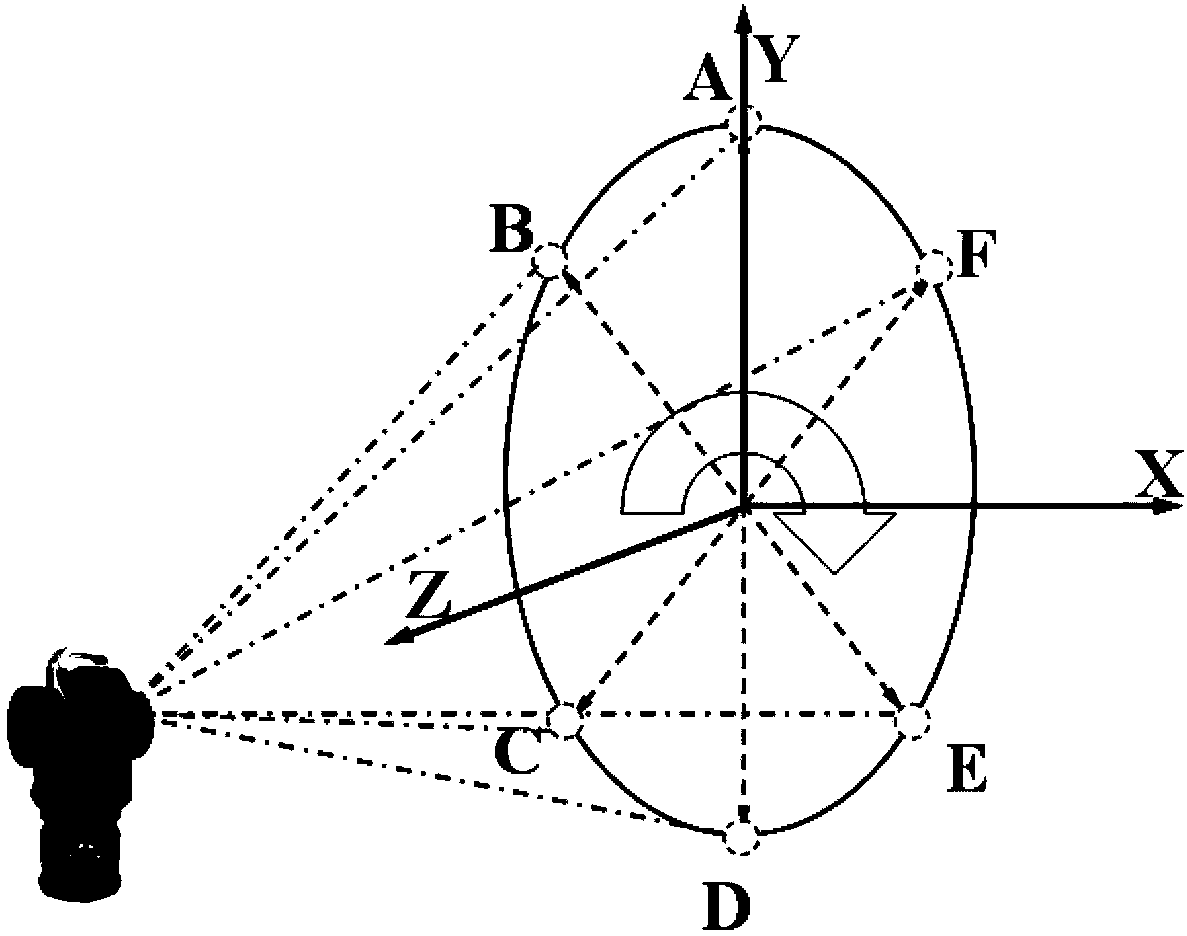

[0055] Before measuring, fix the cat's eye bracket near where the tool is installed. The cat's eye is installed at the end of the swing rod of the cat's eye bracket in advance, and the laser tracker is fixed on the B 1 location, such as figure 1 , figure 2 shown. The cat's eye bracket can rotate around the center of rotation, and can be precisely positioned every 60°. The cat's eye is installed at the end of the swing rod of the cat's eye bracket in advance, and the coordinates relative to the rotation center of the cat's eye bracket are strictly calibrated by a three-coordinate measuring machine. That is, take the center of rotation of the cat's eye bracket as the coordinate origin, the rotation plane as the XOY plane, and the starting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com