Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "Reduce the number of mold repairs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

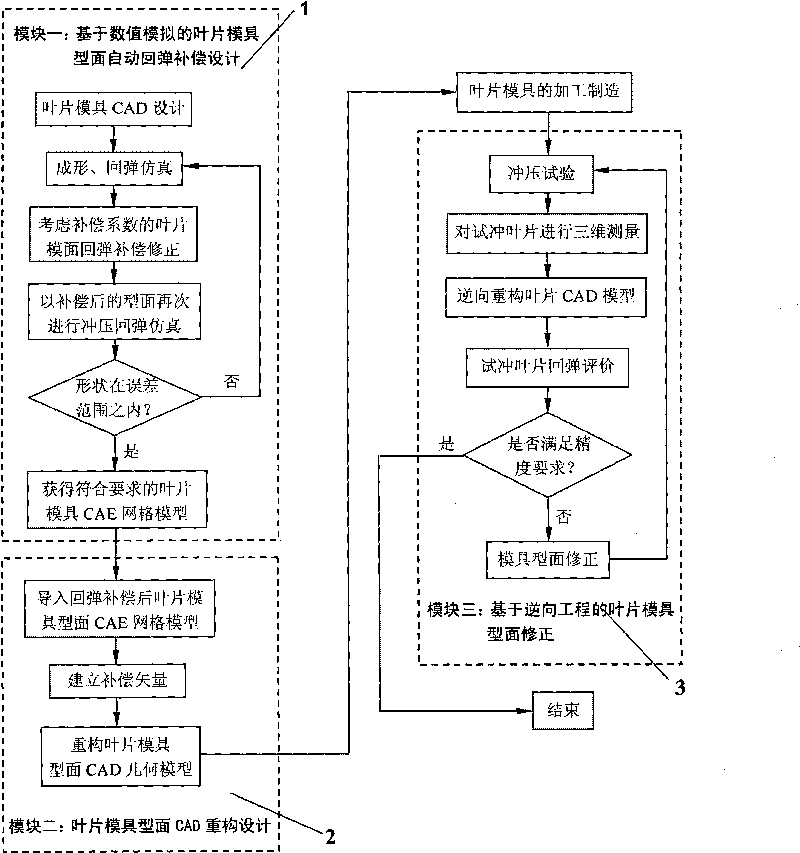

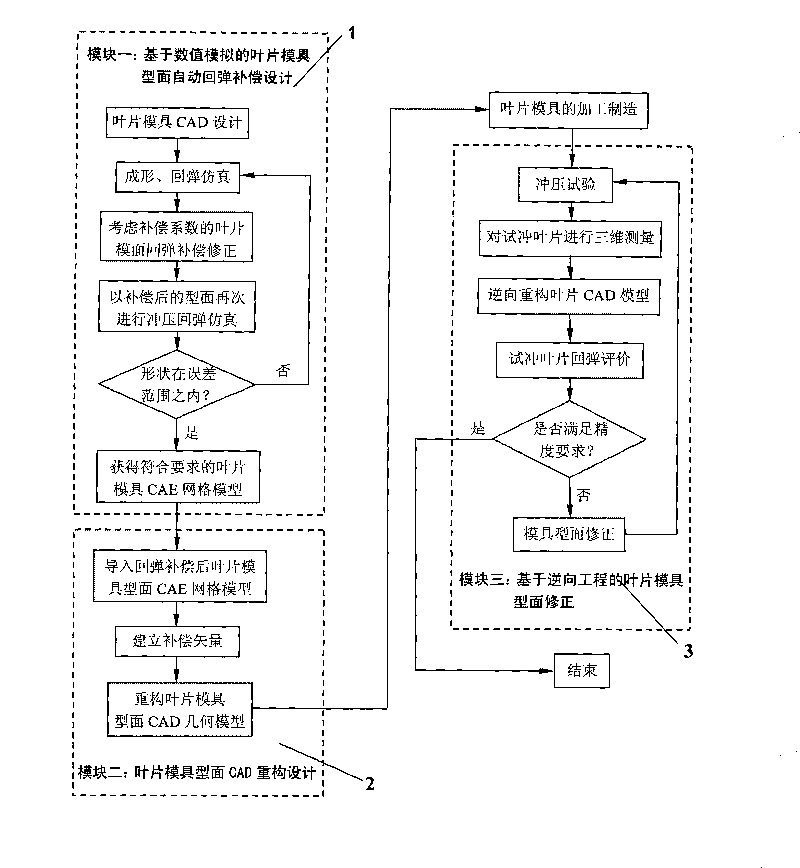

Concrete stirring vane die face design system and method based on springback compensation

InactiveCN101339574ASpeed up the Springback Compensation Design ProcessReduce the number of mold repairsSpecial data processing applicationsGeometric errorEngineering

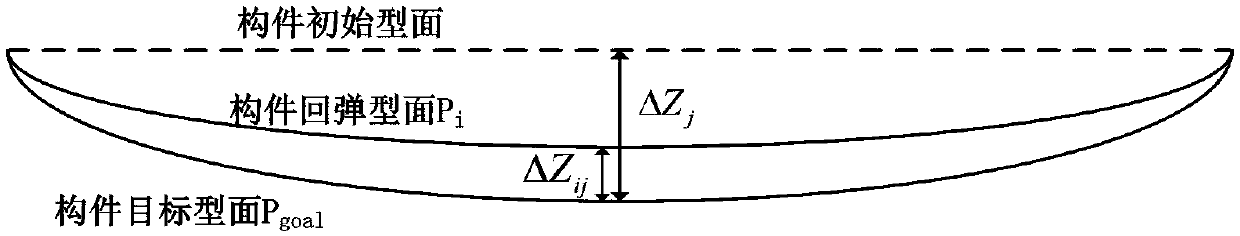

The invention provides a concrete mixing blade die-face design system and a method based on springback compensation, which comprises three modules, that is, a die-face automatic springback compensation design module based on numerical simulation, a die-face CAD reconstruction design module, and a die-face correction module based on reverse engineering, thus a concrete mixing blade die-face CAD-CAE-CAD integrated system based on the springback compensation is formed, and geometric errors produced after the blade being formed are required to satisfy design requirements on the level of numerical simulation, thus reducing correction times; and the process of converting a CAE model after a virtual die repair into a CAD geometric model which can be designed and manufactured is finished, a digital model after the blade being actually pressed is acquired by utilizing a reverse engineering technology and then is compared with the required design shape of the blade, and springback deviation is obtained so as to be used for guiding the actual die repair process of the blade, thus correcting the residual springback deviation and further improving the precision of the springback compensation on the basis of numerical simulation springback compensation.

Owner:JIANGSU UNIV

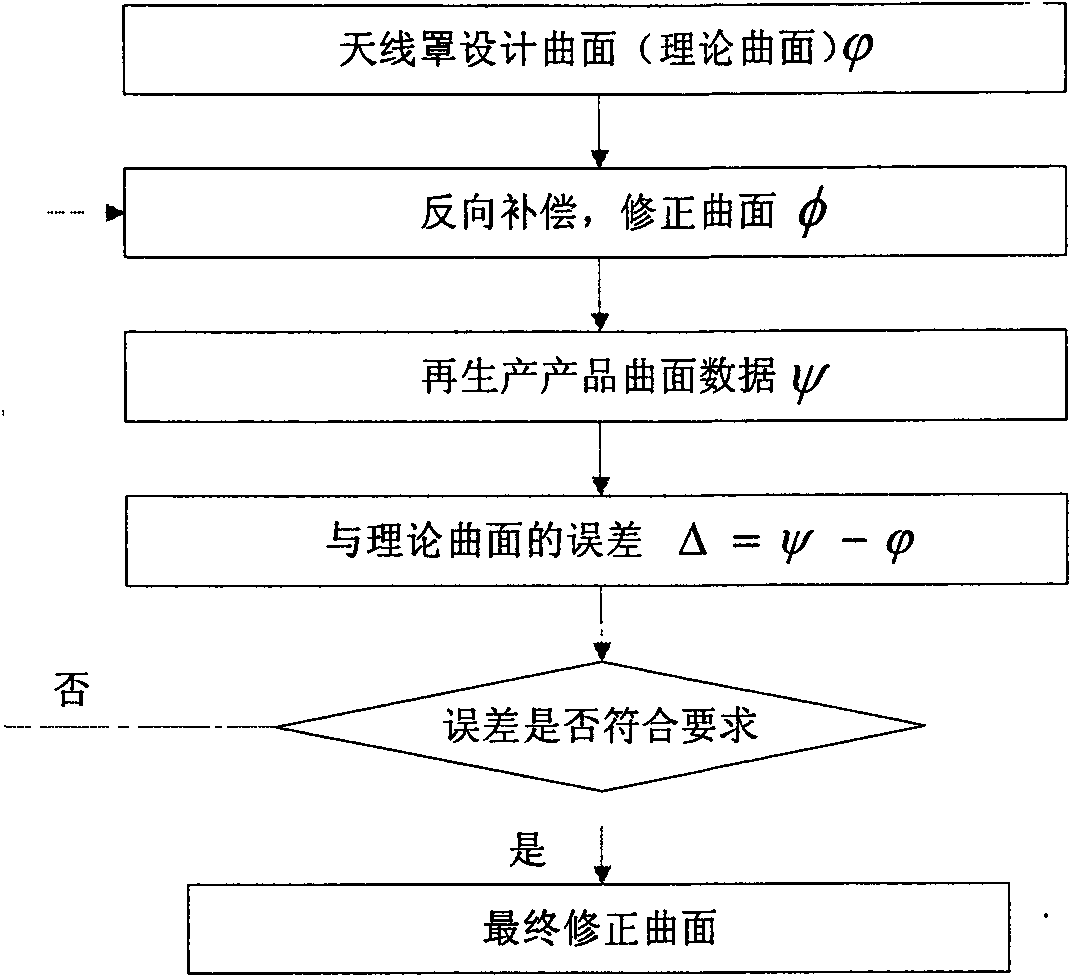

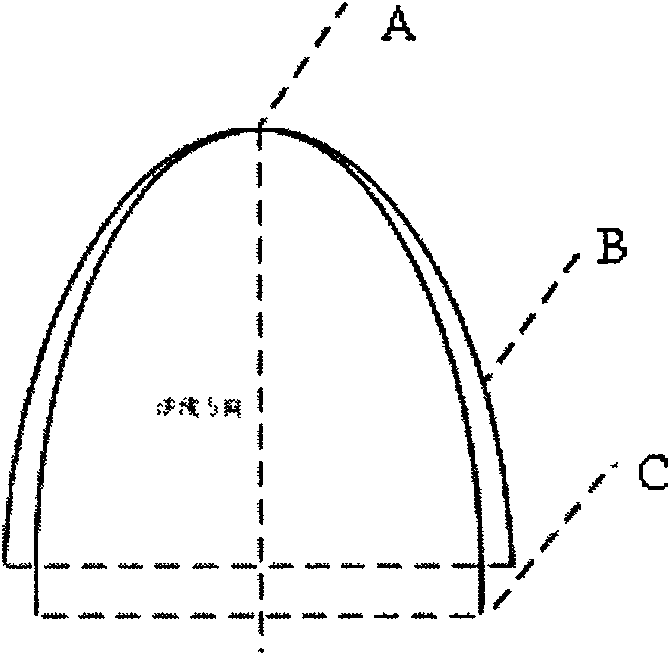

Method for correcting moulding surface of forming mould for antenna cover

InactiveCN102082319AFast preparationHigh precisionAntenna adaptation in movable bodiesFoundry mouldsNumerical controlPoint cloud

The invention relates to a method for correcting a moulding surface of a forming mould for an antenna cover, which is technically characterized in that a numerical control measuring machine is utilized for measuring the shape curved surface of a real object of the antenna cover, thus the measured point cloud data of the antenna cover is further obtained. By matching the measured point cloud data of the antenna cover with the designed curved surface of the antenna cover, the deviation between the measured point cloud data of the antenna cover and the designed curved surface of the antenna cover is calculated, the deviation value is taken as a deformation amount, the moulding surface of the mould is correspondingly corrected when the forming mould is designed for the antenna cover, and the high-precision antenna cover is further rapidly manufactured. The moulding surface of the forming mould for the antenna is corrected through deformation laws and deformation calculation of all points,and the forming precision of the antenna cover is improved. Compared with the conventional mould testing and mould repair method, the method provided by the invention has the advantages that the frequency of mould testing and mould repair and the design time of the mould are reduced, the utilization rate of materials is improved, and the manufacturing cost of the antenna cover is significantly reduced.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

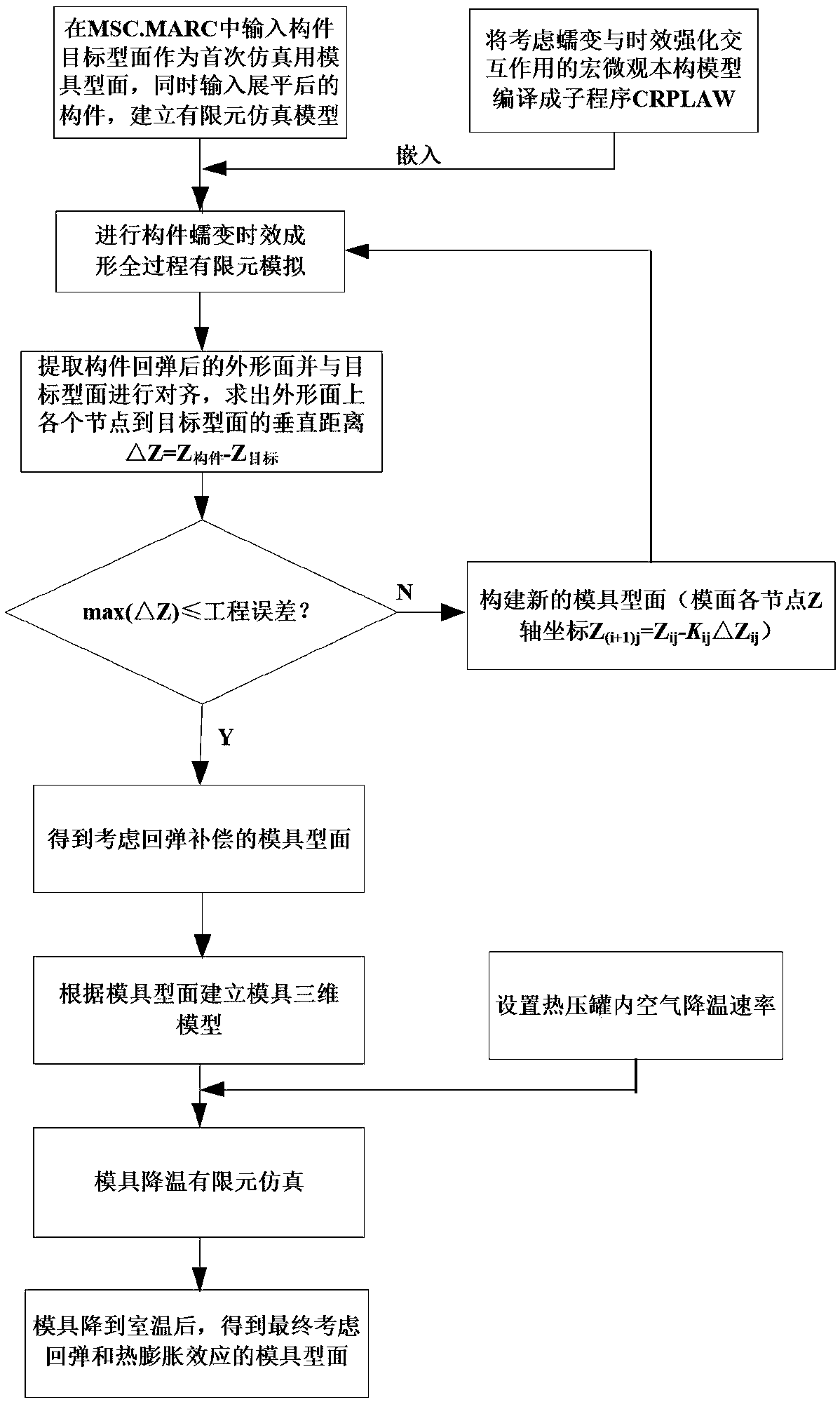

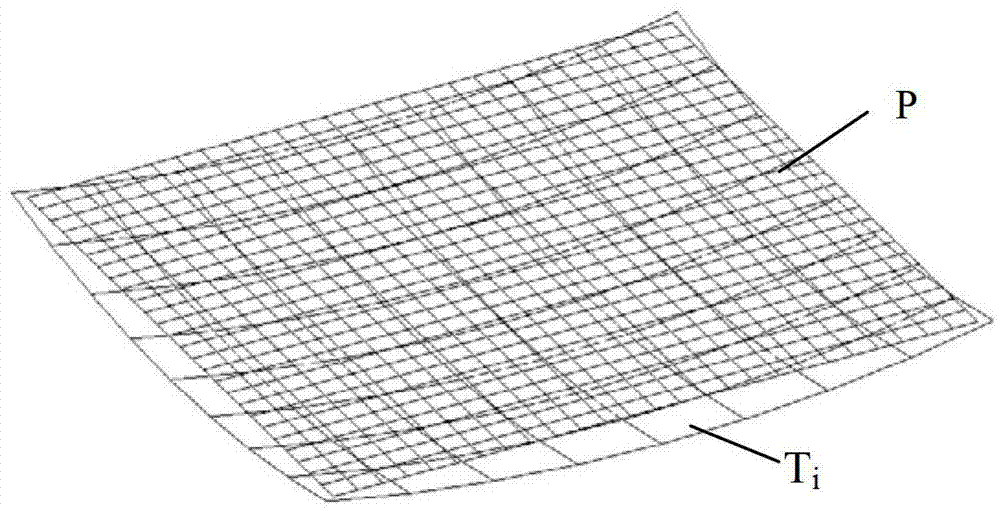

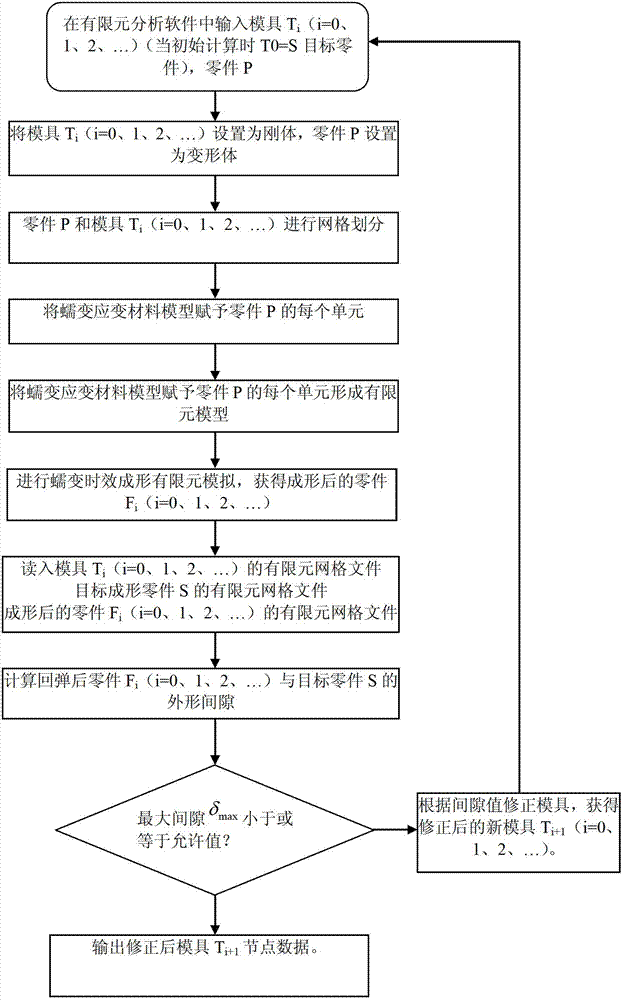

Springback compensation method for creep age forming

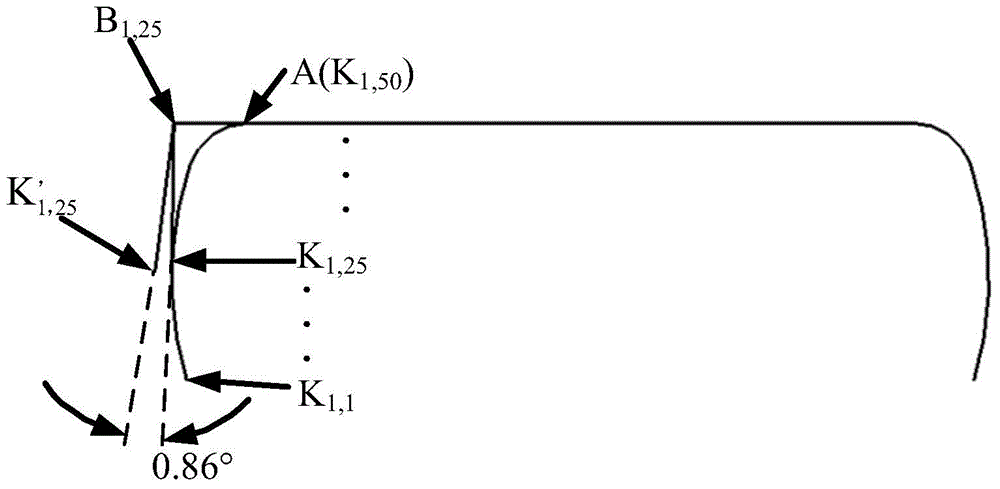

InactiveCN108920847AReduce the number of mold repairsPrecise Tooling Surface Design MethodDesign optimisation/simulationSpecial data processing applicationsThermal expansionEngineering

The invention provides a springback compensation method for creep age forming. The method comprises the following steps: Step S100, based on MSC.MARC commercial finite element software, constructing creep age forming finite element simulation; Step S200, weighting a springback iterative compensation process based on a molding surface of a finite element simulation result; and Step S300, considering a reverse compensation process of high temperature molding surface thermal expansion effect. The method considers the influence of the strength of a component on surface compensation, the influenceof a component feature structure on surface compensation, and reverse compensation of thermal expansion of a high temperature molding surface. A component formed by the model can still meet the engineering error requirement after being cooled.

Owner:CENT SOUTH UNIV

Method for designing die molded surface for forming groove-shaped part

InactiveCN104924633AIncrease the difficulty of the processIncrease the difficulty of assemblySurface fittingEngineering

Disclosed is a method for designing a die molded surface for forming a groove-shaped part. An inner molded surface M of the part is extracted, and section lines Pj of the extracted inner molded surface of the part are manufactured; the various section lines Pj are corrected sequentially through correction basis points, and new section lines are obtained; and surface fitting is carried out on the obtained section lines, and a new mold outer molded surface is obtained. The maximum deformation of the groove-shaped part formed through the mold outer molded surface determined through the method is reduced to 0.2mm from 1.5mm, and the design requirements of the part are met. Compared with the traditional technology, when the mold molded surface is designed, rebound deformation obtained after part deformation is considered in the method, and the problem that according to a traditional method, an inner molded surface of a composite material groove-shaped part is directly extracted to serve as the mold molded surface for manufacturing the composite material part, the part size cannot meet the design requirement is solved; and the mold repairing frequency of a follow-up mold is reduced, and therefore the production manufacturing cost is reduced, and the production efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

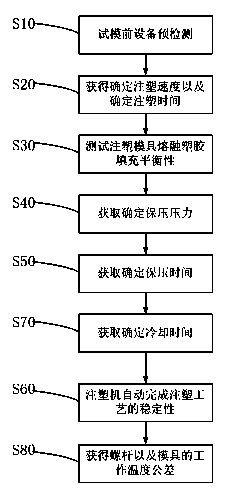

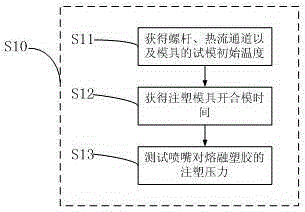

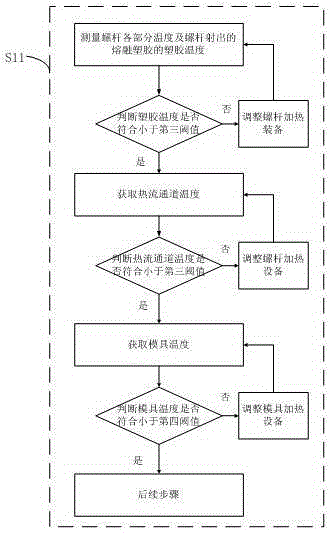

Mould testing technology of injection mould

ActiveCN103575554AImprove accuracyReduce the number of mold repairsStructural/machines measurementMaterials science

Owner:肇庆星诺奇传动科技有限公司

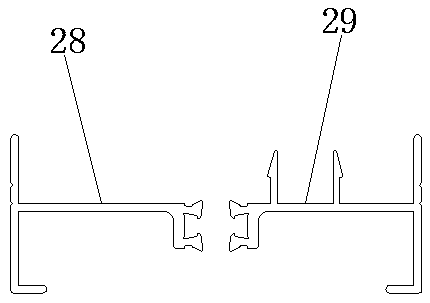

Aluminum profile production process

ActiveCN109396003ASave production costIncrease storage spaceLiquid surface applicatorsSpraying apparatusBody regionPowder Spray

The invention discloses an aluminum profile production process. According to the aluminum profile production process, a mold and an extrusion process used in an existing aluminum profile extrusion process are improved, so that extruded aluminum profile A and B surfaces are integrated, two matched products of an aluminum profile variety can be simultaneously extruded, and the turnover rate of a finished frame is improved; and meanwhile, a horizontal powder spraying process is improved into a vertical powder spraying process to enable the powder spraying to be more comprehensive and thorough, the quality of powder coating is improved, the appearance is better molded, a powder spraying system in the powder coating process is improved, and the improved powder spraying system does not have thephenomenon of powder spraying outwards during use, so that the environment of a powder coating workshop is improved, workers are further protected from threat of spilled powder to body parts such as the respiratory tract, and more environmental protection and hygiene are achieved.

Owner:隆图节能铝材(宣城)有限公司

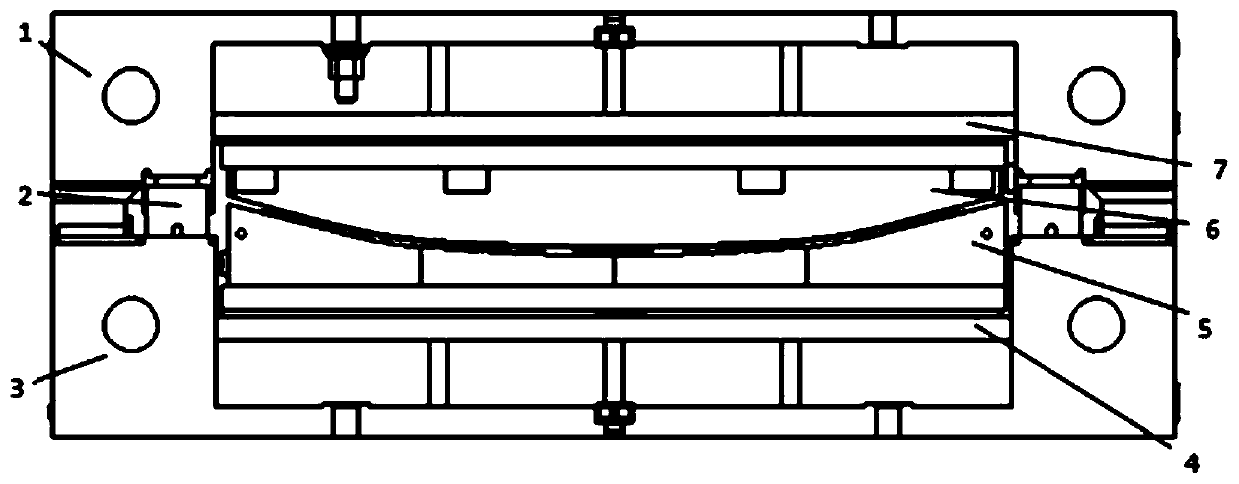

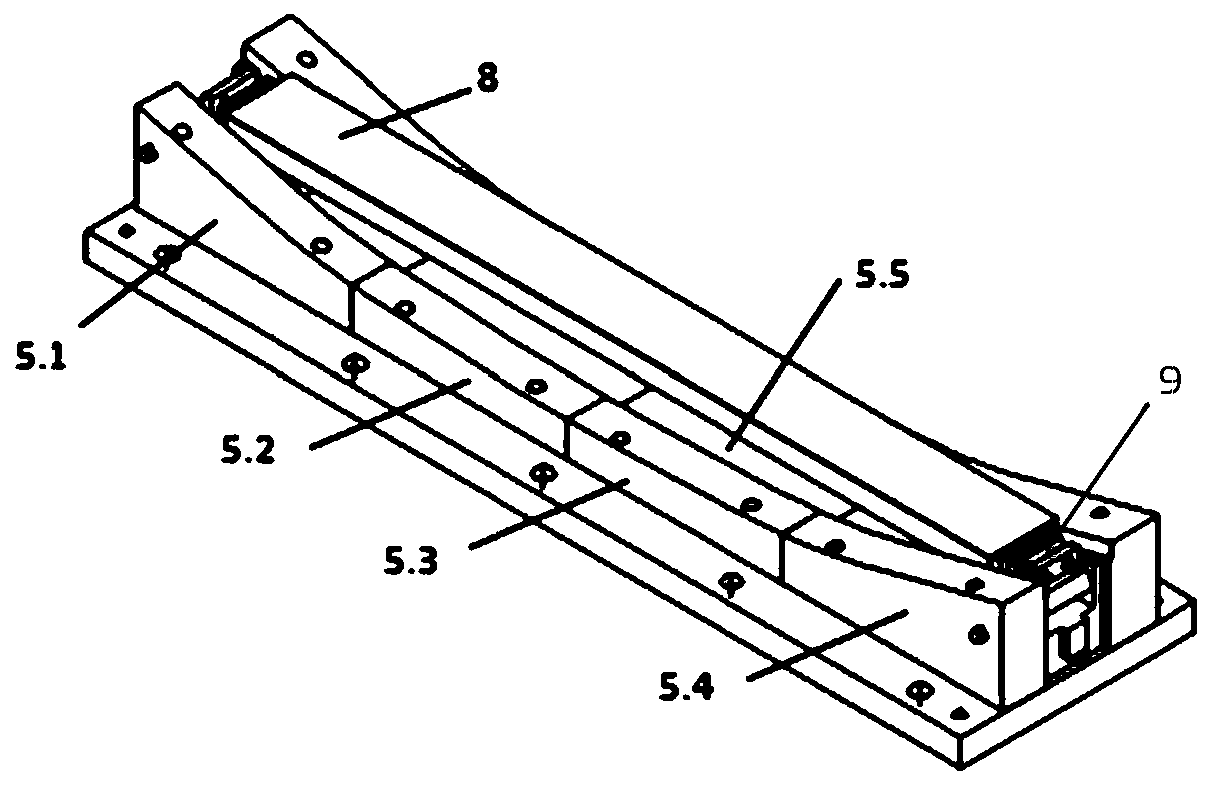

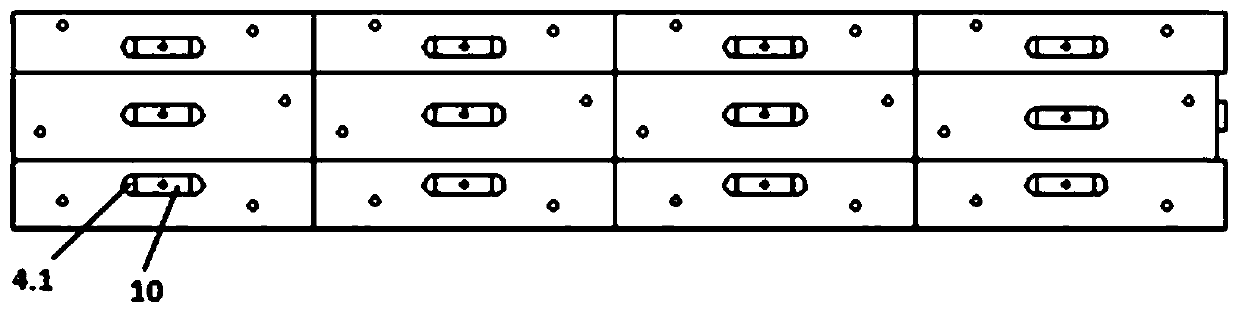

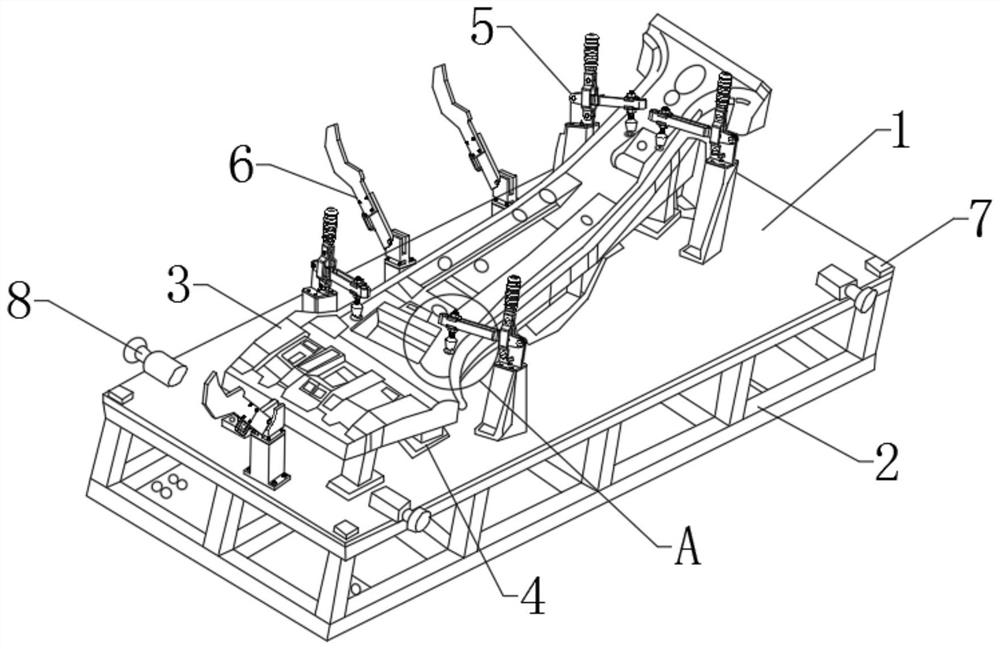

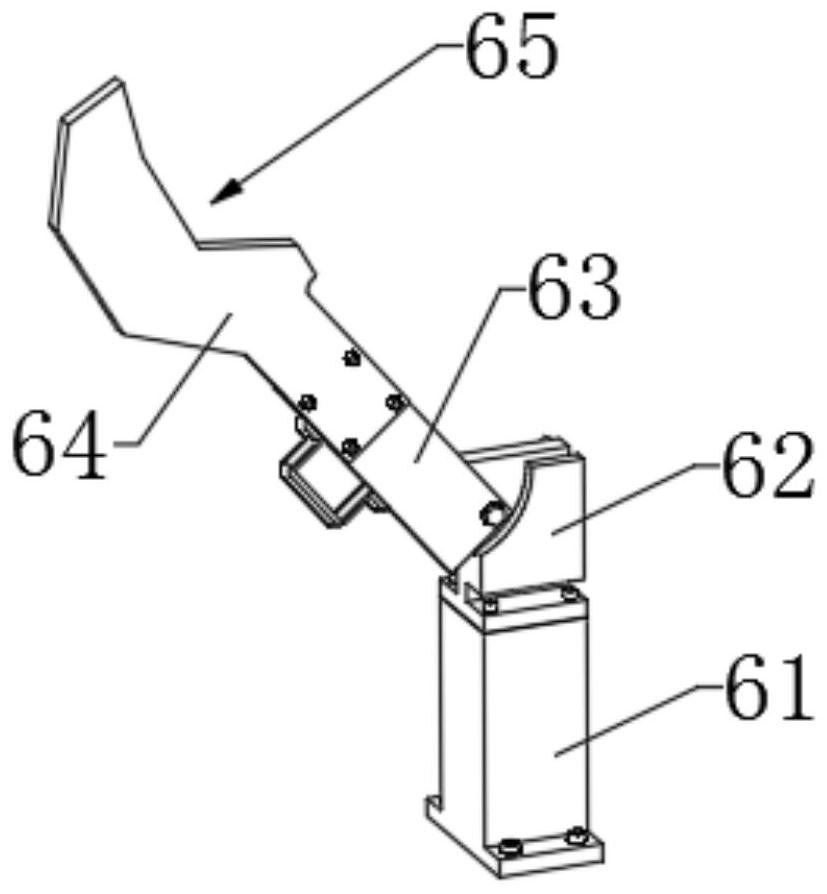

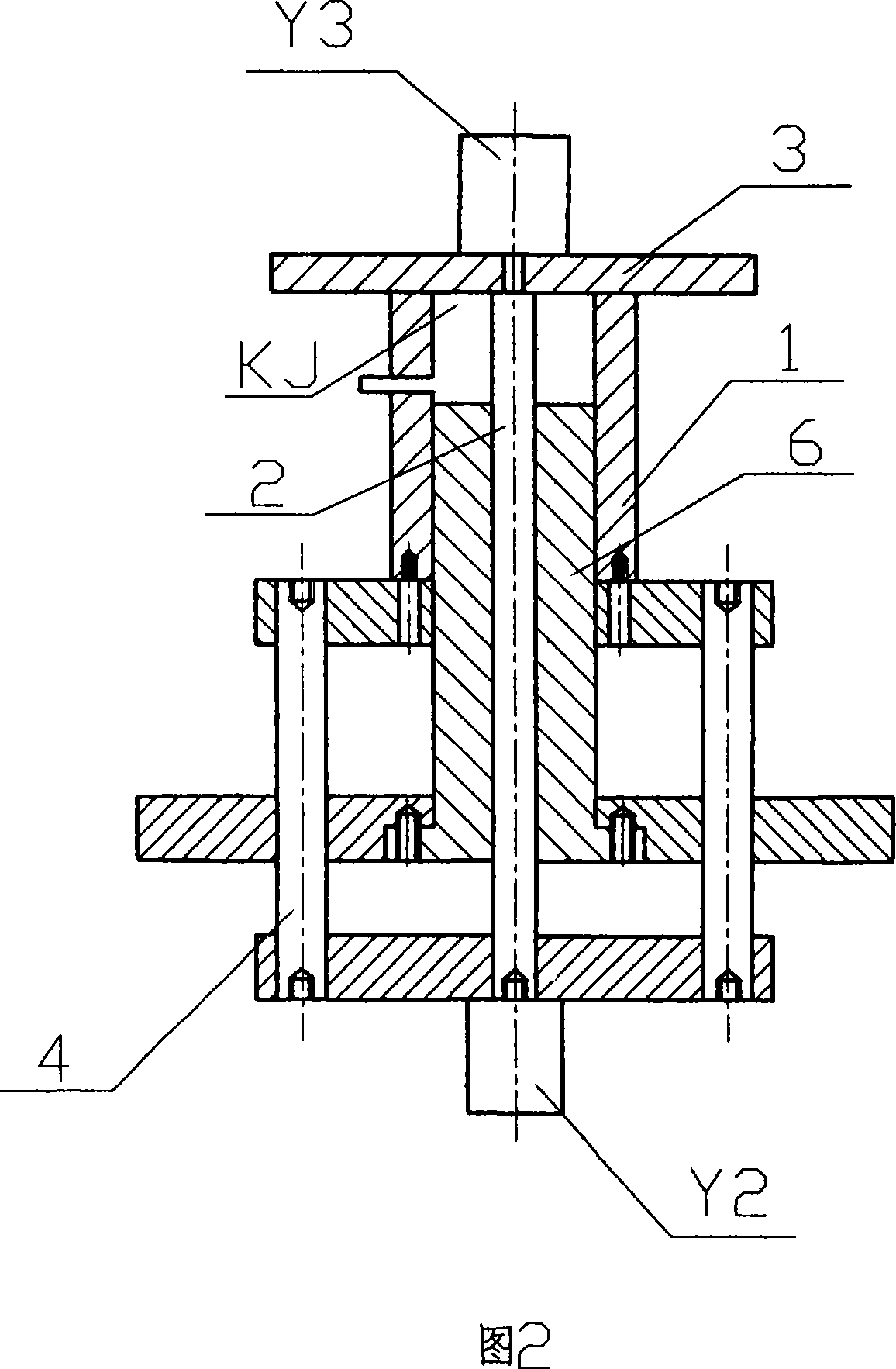

Modular bending die and bending method for aluminum profile

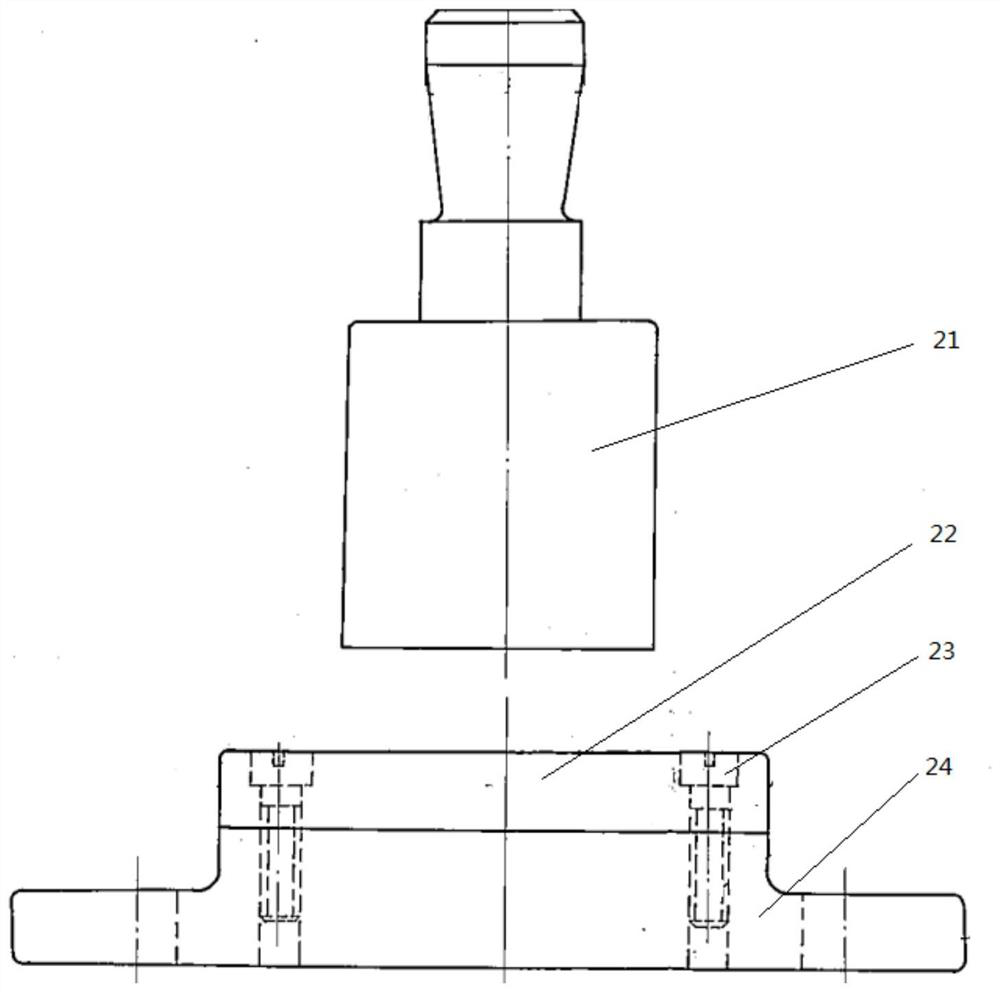

InactiveCN110238251AGuaranteed accuracyReduce the number of mold repairsShaping toolsMetal-working feeding devicesEngineeringBlock structure

The invention relates to a modular bending die and bending method for an aluminum profile. The bending die comprises an upper die base, a lower die base, a female die, a male die and a CAE analysis system; the CAE analysis system is used for designing parameters of the male die and the female die in combination with rebound compensation analysis, the male die and the female die are machined according to the parameters; the male die is arranged at the bottom of the upper die holder, the female die is arranged on the lower die holder, and the male die and the female die are oppositely arranged up and down; the female die is of a block structure and consists of a plurality of female die modules; a groove is formed in the female die, the aluminum profile is arranged on the groove, and the female die and the male die bend the aluminum profile according to stamping parameters set by the CAE analysis system; and the female die modules can be used for independently die repairing according to rebound amount of the aluminum profile. According to the modular bending die for the aluminum profile, the repeated die repairing process due to the fact that the difficulty of adjusting the rebound amount during bending forming of the aluminum profile is large is solved, the independent die repairing is realized, the die development period and cost are reduced, the production efficiency is improved, the debugging period is shortened, and the flexibility of the die is improved.

Owner:GUANGXI AISHENG CHUANGZHI SCI & TECH CO LTD

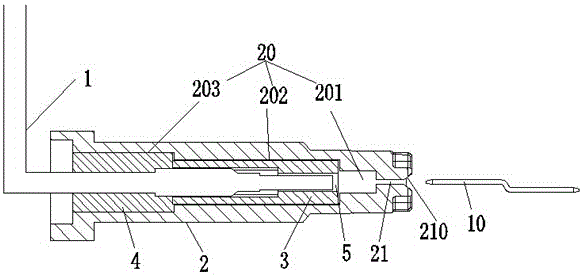

In-mold embedded type optical fiber

ActiveCN104175497AReduce mold removalReduce the number of mold repairsCoatingsBiochemical engineeringOptical fiber

The invention discloses an in-mold embedded type optical fiber. The in-mold embedded type optical fiber comprises an optical fiber and a mold body, wherein the mold body is internally provided with a stepped hole and a through hole for holding hardware; the stepped hole comprises a first stepped hole, a second stepped hole and a third stepped hole; an optical-fiber guiding block is held in the second stepped hole; an optical-fiber fixing block is held in the third stepped hole; the middle parts of the optical-fiber guiding block and the optical-fiber fixing block are respectively and horizontally provided with an inserted hole; the optical fiber is held in the inserted holes of the optical-fiber fixing block and the optical-fiber guiding block; and the other end of the optical fiber extends to the outer part of the mold body. By the mode, the in-mold embedded type optical fiber disclosed by the invention has the advantages that the service life of a mold can be prolonged, and the production efficiency is also improved.

Owner:KENTA ELECTRONIC MFG KUNSHAN CO LTD

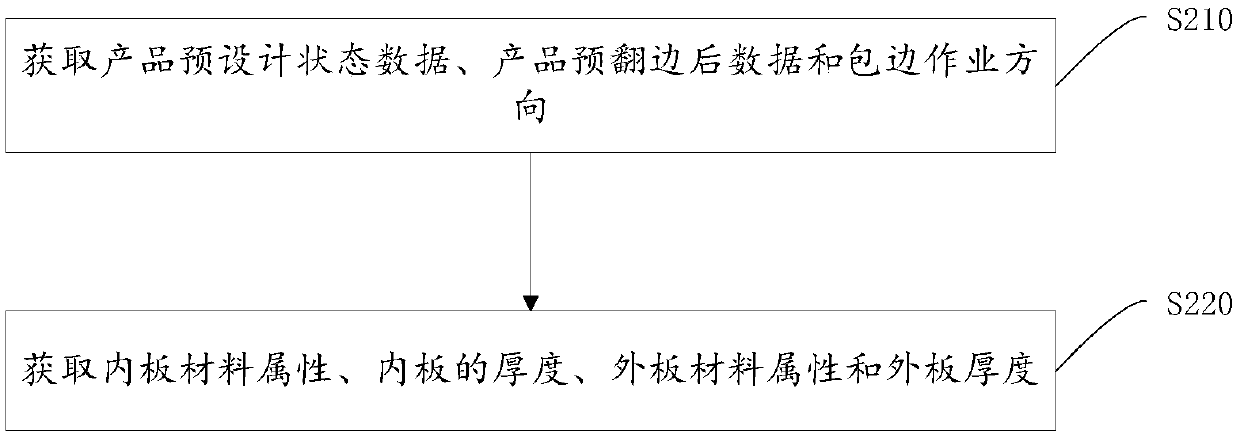

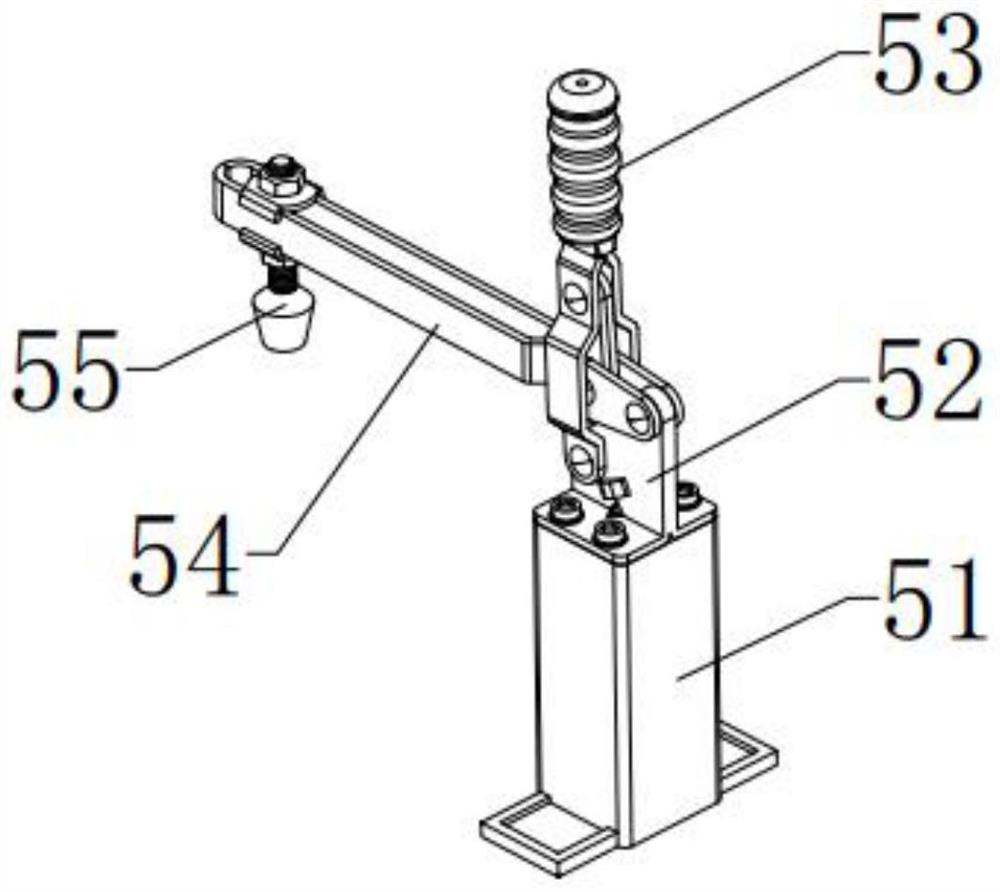

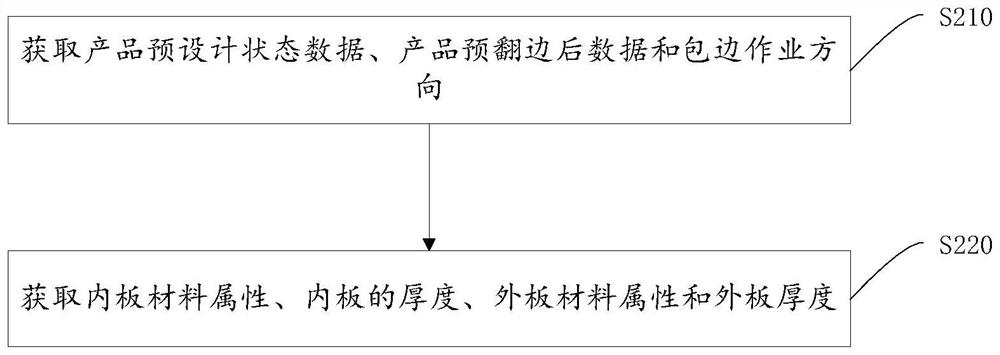

Covered edge forming method and device

ActiveCN109093013AReduce the number of mold repairsReduce design change costsMetal working apparatusRepair timeComputer science

The invention provides a covered edge forming method and device. The covered edge forming method comprises the following steps that obtaining is carried out, a preset product parameter and a preset process parameter are obtained; determining is carried out, a product simulation forming parameter is determined according to the preset product parameter and the preset process parameter; and judging is carried out, the product simulation forming parameter is compared with the preset product parameter, if a comparison result does not meet the preset requirement, the preset process parameter is modified, the determining step and the judging step are repeated, until the product forming meets the quality requirement. According to the covered edge forming method, if the comparison result does not meet the quality requirement, the preset process parameter can be modified repeatedly until meets the quality requirement, that is, whether a product forming state meets the quality requirement or notis verified in advance, and mould repairing times are reduced, so that product design cost is reduced; and meanwhile, the covered edge forming method no longer depends on the technical requirement andexperience for molding analysis, so that the analysis result is more accurate.

Owner:BAIC MOTOR CORP LTD

Simultaneous extrusion process of broken bridge heat-insulating aluminum profile A and B surfaces

The invention discloses a simultaneous extrusion process of a broken bridge heat-insulating aluminum profile A and B surfaces. According to the simultaneous extrusion process, dies and extrusion processes used in existing extrusion processes of aluminum profiles are improved, thus extruded aluminum profile A and B surfaces are integrated, a new integrated die is adopted, the A and B surfaces matched with an aluminum profile can be extruded integrally and simultaneously, then materials are cut and divided, the problem that product matching is wrong can be solved, and the cost is saved, so thatextrusion operation is convenient. The simultaneous extrusion process of the broken bridge heat-insulating aluminum profile A and B surfaces has the advantages that extrusion can simultaneously extrude two matched products of aluminum profile type, and the extrusion yield is improved; the two products are combined together and put in a frame, the using number of finished frames is reduced, the turnover rate of the finished frames is increased; and after combining, original products are various, a plurality of similar or indistinguishable products are relatively reduced, that is the error rateof front-line workers is decreased, and the qualification rate of products is increased.

Owner:隆图节能铝材(宣城)有限公司

Precision machining control method and machining die for single-layer closed wave spring

PendingCN114346130ADimensionally stableReliable mechanical propertiesShaping toolsFurnace typesStampingMachine parts

The invention belongs to the technical field of part machining, and relates to a single-layer closed wave spring precision machining control method and a machining die, and the method comprises the following steps: 1) according to the design requirement of a part to be machined, a stamping die is used for manufacturing a raw material into an annular blank; (2) the annular blank in the step (1) is subjected to cold stamping forming, and a rough machining part is obtained; (3) the rough machining part obtained in the step (2) is corrected, so that the size of the rough machining part is consistent with the prefabricated height size of the part to be machined, and the parallelism between wave crests of the rough machining part is kept within 0.1 mm; (4) the corrected rough machining part is subjected to heat treatment, and a semi-finished machining part is obtained; and (5) the semi-finished machined part is subjected to strong pressing treatment, and machining is completed. The wave spring manufactured through the method is stable in size, reliable in mechanical property and good in fatigue resistance and deformation resistance, and the service requirement of the wave spring on an aero-engine can be completely met.

Owner:XIAN AERO ENGINE CONTROLS

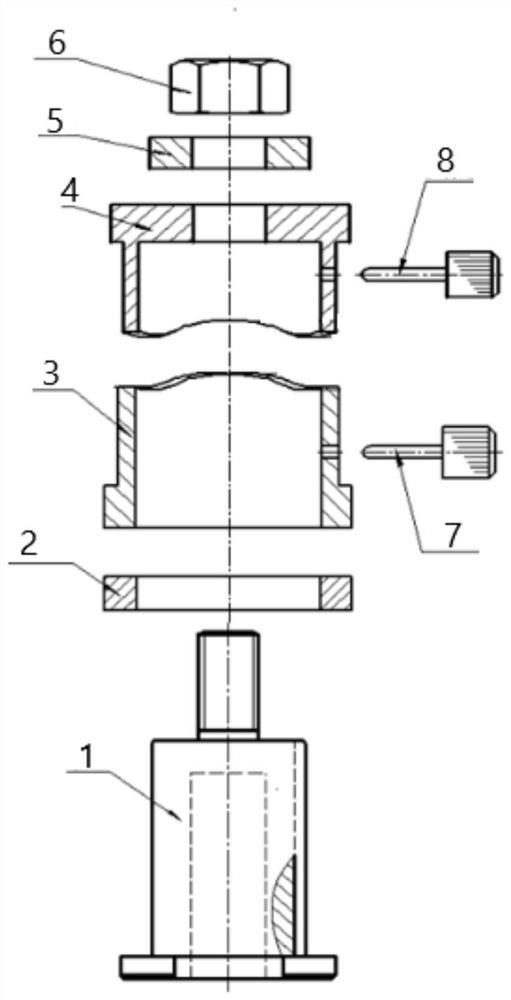

Wall board creep age forming method based on finite element mould profile rebound compensation

ActiveCN102930115BReduce auto-optimizationExtended service lifeSpecial data processing applicationsRepair timeWelding residual stress

The invention belongs to the technical field of metal plate forming, and relates to a wall board creep age forming method based on finite element mould profile rebound compensation. By the wall board creep age forming method, a finite element method is used for determining a mould profile, technological tests and mould repairing times are largely reduced, appearance control of formed parts can be realized, and forming precision is improved; according to the data through analog computation of forming process and rebound process of a formed piece, the mould profile is compensated, revised and optimized, so that rebound parts are the same as or close to the appearance of an ideal formed piece, and automatic optimization to the mould appearance during a creep age forming process is realized. The forming method can be applicable to various wallboard structures; except for overall wallboard parts, the forming method can be used for welding overall wallboards; welding residual stress can be effectively reduced, stress corrosion resistance capability is enhanced, and service lives of parts are prolonged.

Owner:BEIJING AERONAUTICAL MFG TECH RES INST

Touch panel, touch feedback method and terminal equipment

PendingCN113760127AReduce in quantityReduce the difficulty of assemblyInput/output processes for data processingTouch panelEngineering

The invention relates to the technical field of touch, and provides a touch panel, a touch feedback method and terminal equipment. The touch panel can be applied to terminal equipment, the touch panel comprises a touch module and a vibration motor, and the vibration motor and the touch module are fixed; and the vibration motor vibrates by adopting the corresponding target parameters in response to a touch operation acting on the touch module. According to the technical scheme provided by the embodiment of the invention, vibration feedback is used for replacing a springback structure with a stroke in an existing structure for touch feedback, many defects of the structure are avoided, stroke-free design can be realized, and stroke-free touch sensing is achieved; and mechanical springback design is not needed, so that the assembly difficulty of parts is reduced, the yield is increased, the aesthetic property is improved, the fatigue life is prolonged, and the like. In addition, reduction of design adjustment, testing and mold repairing times in the research and development stage is facilitated, manpower and material resources are saved, and the production research and development cost is reduced.

Owner:XIAN WINGTECH INFORMATION TECH CO LTD

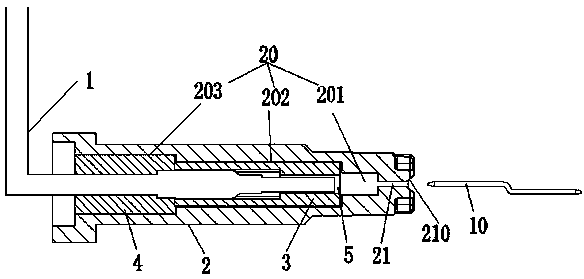

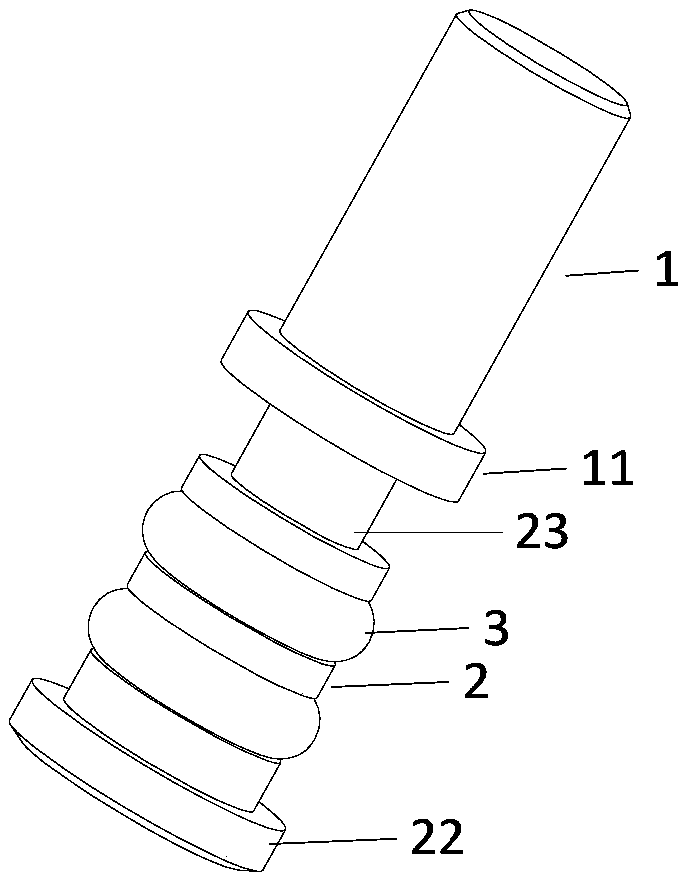

A pin needle structure and an electronic device including the pin needle structure

InactiveCN109244715AAvoid damageReduce the number of mold repairsCoupling contact membersCouplings bases/casesPins needlesElectrical connection

The invention discloses a pin needle structure and an electronic device comprising the pin needle structure. The pin needle comprises a first body part located at an upper position and a second body part located at a lower position. An end portion of the first body portion remote from the second body portion and for forming an electrical connection with an internal conductive member of the electronic device; An end portion of the first body portion adjacent to the second body portion and an end portion of the second body portion adjacent to the first body portion are combined and fixed to forman electrical connection; An end portion of the second body portion remote from the first body portion is used for forming an electrical connection with an external circuit. The two-stage pin pin structure and the electronic device including the pin pin structure can avoid damage to the pin pin and the device plastic housing during in-mold injection molding.

Owner:GOERTEK INC

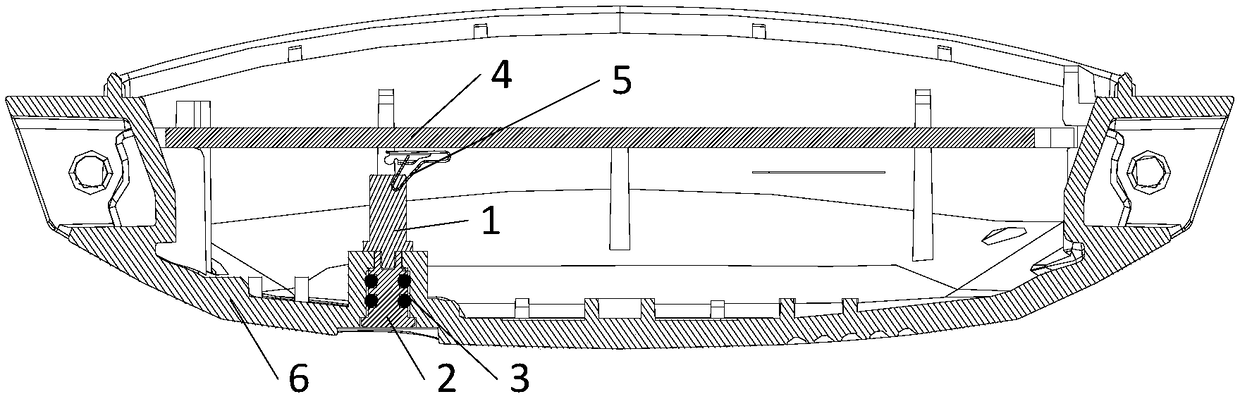

Die repairing method of stamping die

ActiveCN114719717AImprove mold repair accuracyEasy to measureMechanical clearance measurementsMechanical engineeringIndustrial engineering

The invention discloses a stamping die repairing method which is carried out according to the following steps that S1, an initial die is subjected to stamping production, and a stamping workpiece is obtained; s2, the obtained stamping workpiece is detected on a detection tool, and core data of all parts of the stamping workpiece are detected; s3, the corresponding part of the stamping die is trimmed through the core data obtained through reference; s4, the steps S1 to S3 are circulated until the size of the stamping die meets the tolerance requirement; by the adoption of the method, the stamping workpiece is comprehensively detected through the special detection tool, after core data of stamping die repairing are obtained through detection of the detection tool, accurate die repairing is conducted on the stamping die according to the core data, therefore, the number of times of die repairing of the stamping die is reduced, the stamping workpiece can reach the qualified tolerance more quickly, and the production efficiency is improved. The die repairing efficiency of the stamping die is effectively improved, the production efficiency and the percent of pass are improved, and the cost is saved.

Owner:CHONGQING COLLEGE OF ELECTRONICS ENG

Anti-corner-bending-cracking die

PendingCN112605262AReduce float heightReduce the risk of badShaping toolsStructural engineeringNitrogen gas

The invention provides an anti-corner-bending-cracking die. The anti-corner-bending-cracking die can meet the requirement for the height of a covered edge of a product without affecting strength of the product. The anti-corner-bending-cracking die comprises an upper die part and a lower die part, wherein the upper die part comprises an upper die base, a clamping plate, a large stripper plate, a forming slotting tool and an upper die pressing-in block, the clamping plate is arranged on the lower surface of the upper die base, a first nitrogen spring is fixedly arranged on the upper die base, the lower end of the first nitrogen spring penetrates through the clamping plate and then is connected with an upper mounting groove of the large stripper plate, and the lower surface of the large stripper plate is fixedly provided with a downwards-protruding forming slotting tool and a downwards-protruding upper die pressing-in block; the lower die part comprises a lower die base and a foot pad, the lower die base is fixedly installed on the upper surface of the foot pad, an overall area of the lower die base and the foot pad corresponds to the forming slotting tool, an inner groove is formed in the area of the upper die pressing-in block, and a slotting tool leaning tool, a wear-resisting fixing block, a driving block and a punch wear-resisting guide plate are arranged in the inner groove.

Owner:LEMTECH PRECISION MATERIAL (CHINA) CO LTD

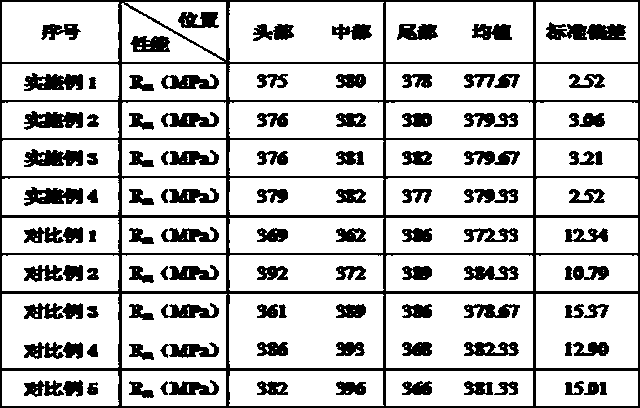

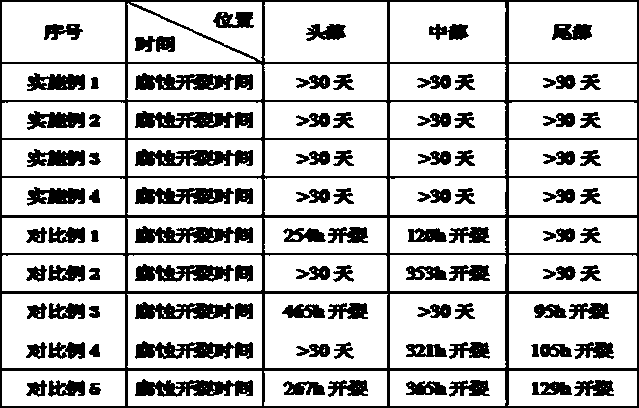

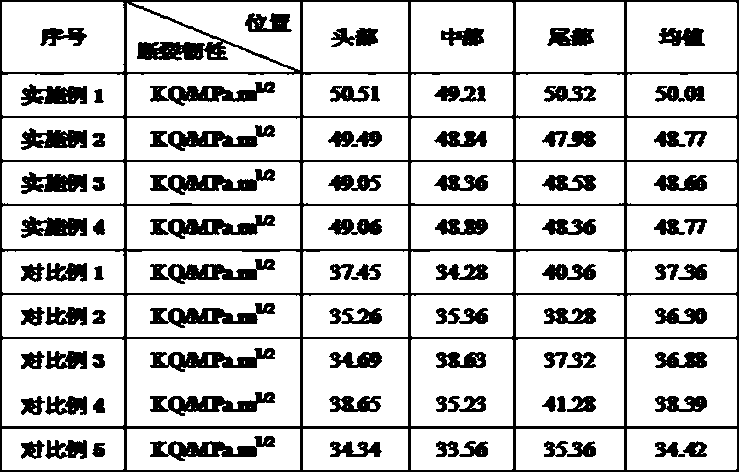

A kind of al-zn-mg alloy profile for rail transit car body and preparation method thereof

ActiveCN108251723BHigh tensile strengthImprove stress corrosion resistanceMetallic materialsToughness

The invention belongs to the technical field of metal materials and machining thereof, discloses an Al-Zn-Mn alloy profile for a rail transit vehicle body and a preparation method thereof, and relatesto the technical field of aluminum alloy machining. The alloy comprises the following chemical components of, by mass, 4.4-4.6 % of Zn, 0.1-0.15% of Cu, 0.3-0.4% of Mn, 0.16-0.24% of Cr, 0.04-0.08% of Ti, 0.12-0.20 of Zr, less than or equal to 0.12% of Fe, less than or equal to 0.06% of Si, and the balance Al, wherein the ratio of the mass percentage of the Zn to the mass percentage of the Mg is3.2 to 3.5. The Al-Zn-Mn alloy material prepared through the preparation method has high toughness, corrosion resistance, anti-fatigue and weldable characteristics, and can meet the running requirements of the high-speed rail transit vehicle body.

Owner:广西南南铝加工有限公司

Sifting and manufacturing method for macromolecule lens

InactiveCN101342769AEasy to achieve high precisionReduce the number of mold repairsOptical articlesScreening methodAspheric lens

The invention provides a screening method for macromolecule lenses, which comprises the steps of preparing preliminary dies; screening and obtaining die cavities having required functions by using the preliminary dies; manufacturing a production die; screening and obtaining die cavities having proper focal lengths for manufacturing a spherical lens by using the preliminary dies; screening and obtaining die cavities with required focal lengths and aberrations for manufacturing an aspheric lens by using the preliminary dies; screening and obtaining die cavity groups with required equivalent focal lengths and chromatic aberrations for manufacturing a lens battery by using the preliminary dies. The preliminary dies have 3 to 1000 die cavities, however, the preliminary dies preferably have 4 to 400 die cavities; the die cavities of the preliminary dies shall be marked with numbers or letters; the flow passages of the preliminary dies and the production die are balanced; the volumes of the die cavities of the preliminary dies are balanced. In the screening method, die cavities with required functions are screened and obtained by using the preliminary dies; the production die is used for manufacturing the macromolecule lens. The die screened and manufactured according to the functions can reach high precision easily; the frequency to repair the dies is reduced.

Owner:LINK UPON ADVANCED MATERIAL CORP

A kind of injection mold and injection method of automobile tire pad

The invention relates to an injection mold and an injection method for an automobile tire cushion belt. The injection mold comprises a front mold insert, a rear mold insert and a middle template, wherein the lower part of the front mold insert is provided with a first mold core which is composed of an inverted cone frustum and a cylinder; the cylinder is connected to the lower end of the inverted cone frustum; the upper part of the rear mold insert is provided with a second mold core which is composed of a cone frustum and a cylinder; the cylinder is connected to the upper end of the cone frustum; a through groove, of which the inner wall is in an arc form, is formed in the middle of the middle template, and is matched with the first mold core and the second mold core to form a mold cavity which is used for casting the tire cushion belt; the middle part of the front mold insert is provided with a positioning ring and a sprue bush; the sprue bush is arranged in the middle of the positioning ring and is communicated with a runner which is formed in a parting surface; the other end of the runner is communicated with the mold cavity; a material-pulling nail is arranged in the middle of the rear mold insert in a penetrating manner; longitudinal through holes are evenly distributed in the front mold insert, the rear mold insert and the middle template; heating rods are arranged in the longitudinal through holes; a middle template limiting mechanism is also arranged at one side end of the front mold insert. The injection mold is compact in structure; the injection method is convenient and fast; rapid formation of the tire cushion belt is facilitated.

Owner:陈友寿

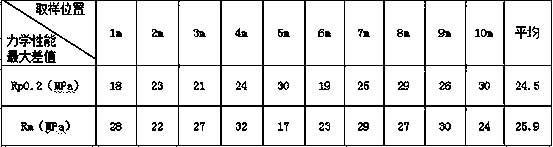

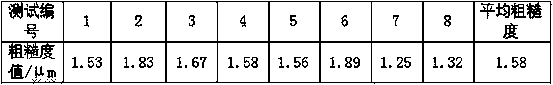

Production method of al-zn-mg aluminum alloy hollow profile for high-speed train

The invention discloses a production method of an aluminium alloy hollow profile for a high-speed train. The production method comprises the production steps of soft alloy dummy ingot extrusion, roller-hearth continuous solid solution quenching, stretch straightening, finished product sawing, sampling, gauging, framing, three-step integral aging furnace aging, performance testing and packaging andstorage. The production method is aimed at the problems that extrusion molding of the Al-Zn-Mg aluminium alloy profile for the high-speed train is difficult and the service life of a mold is too short, an Al-Mg-Si soft alloy is adopted as a dummy ingot to tract extrusion of an Al-Zn-Mg aluminium alloy ingot, formability of a hard alloy is greatly improved, the cracking and deformation tendency ofthe mold is greatly reduced, surface quality of the produced profile is improved, and application principles and methods of soft alloy extrusion are explored and summarized; and the produced profilehas good mechanical properties, stability of mechanical properties, elongation and surface roughness are greatly improved, the service life of the mold is remarkably prolonged, mold cost is reduced, the mold repairing time is decreased, production efficiency is greatly improved, and energy conservation and environment protection are achieved.

Owner:广西南南铝加工有限公司

Mold trial process of injection mold

ActiveCN103575554BImprove accuracyReduce the number of mold repairsStructural/machines measurementInjection molding processMaterials science

Owner:肇庆星诺奇传动科技有限公司

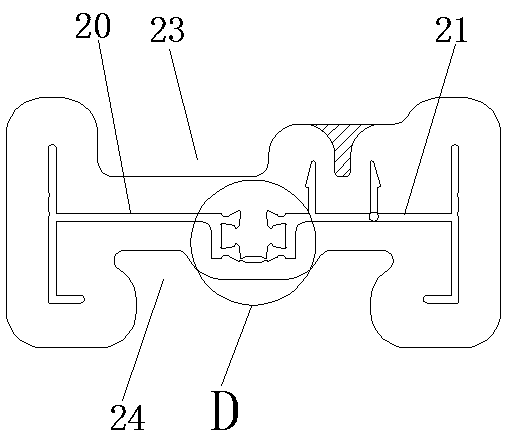

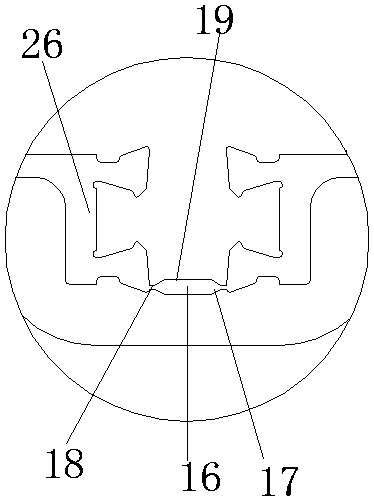

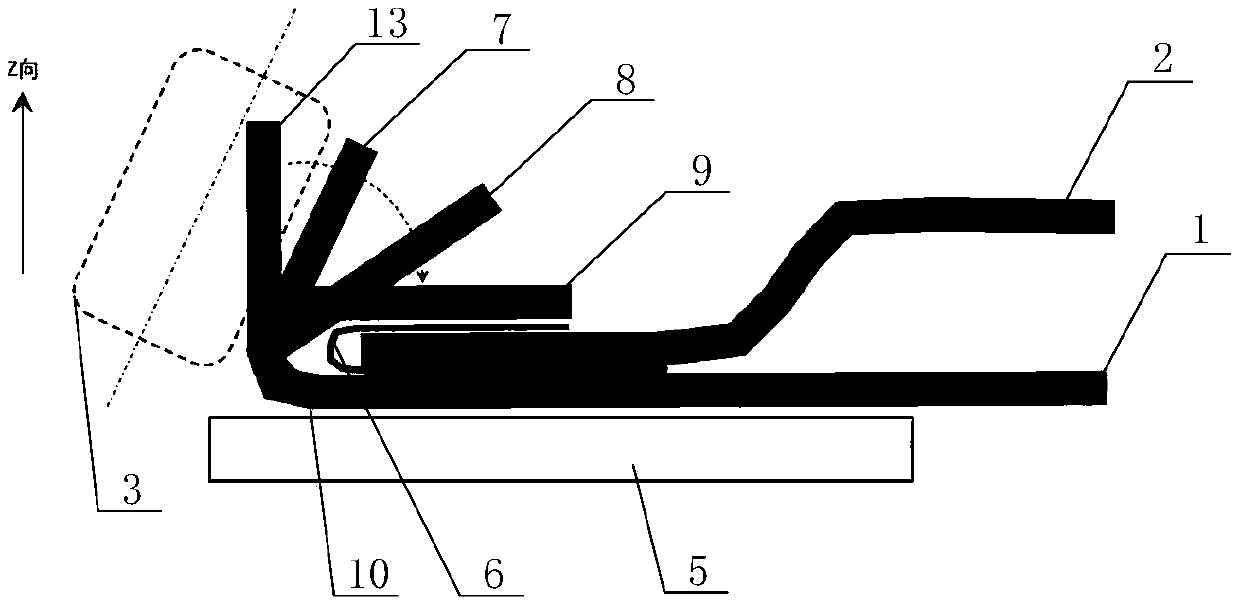

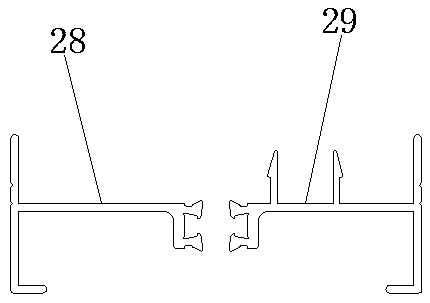

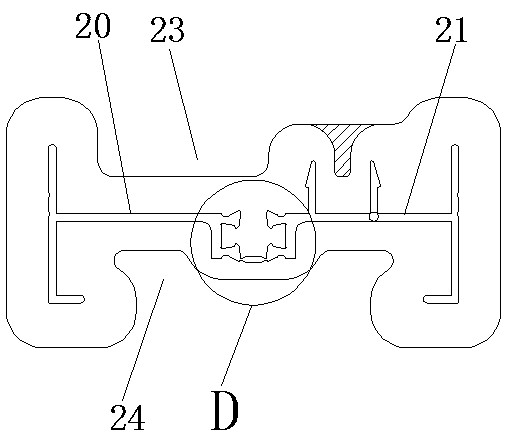

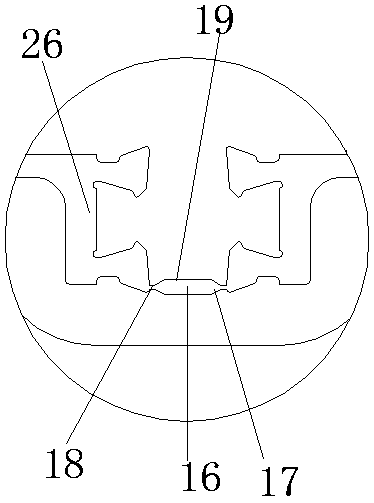

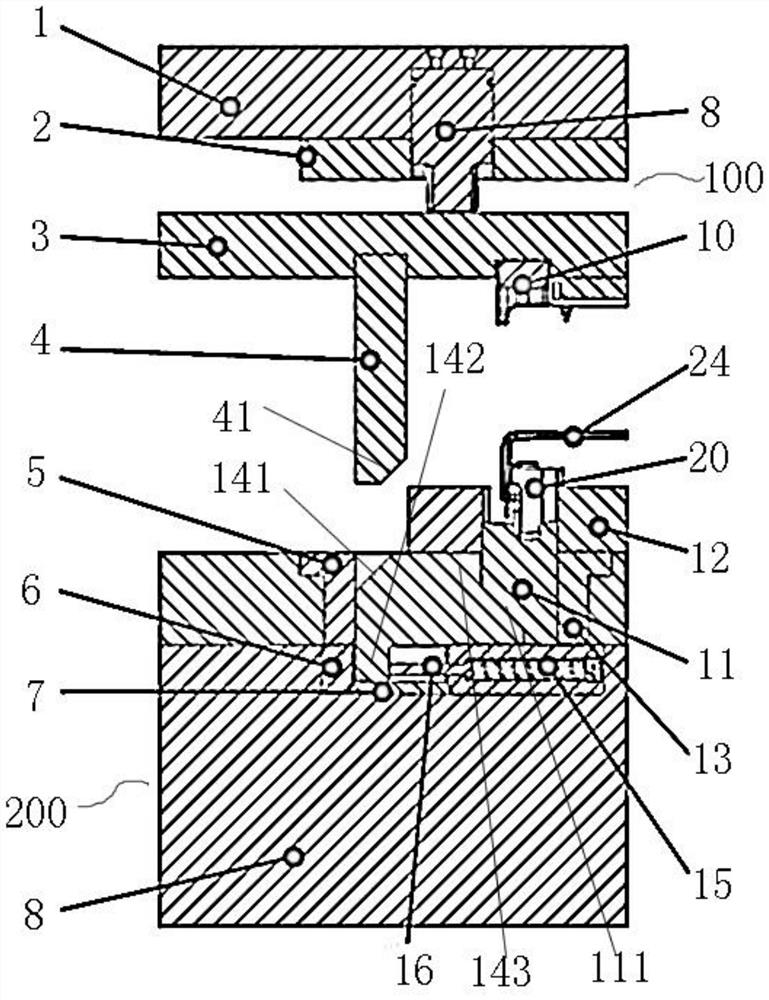

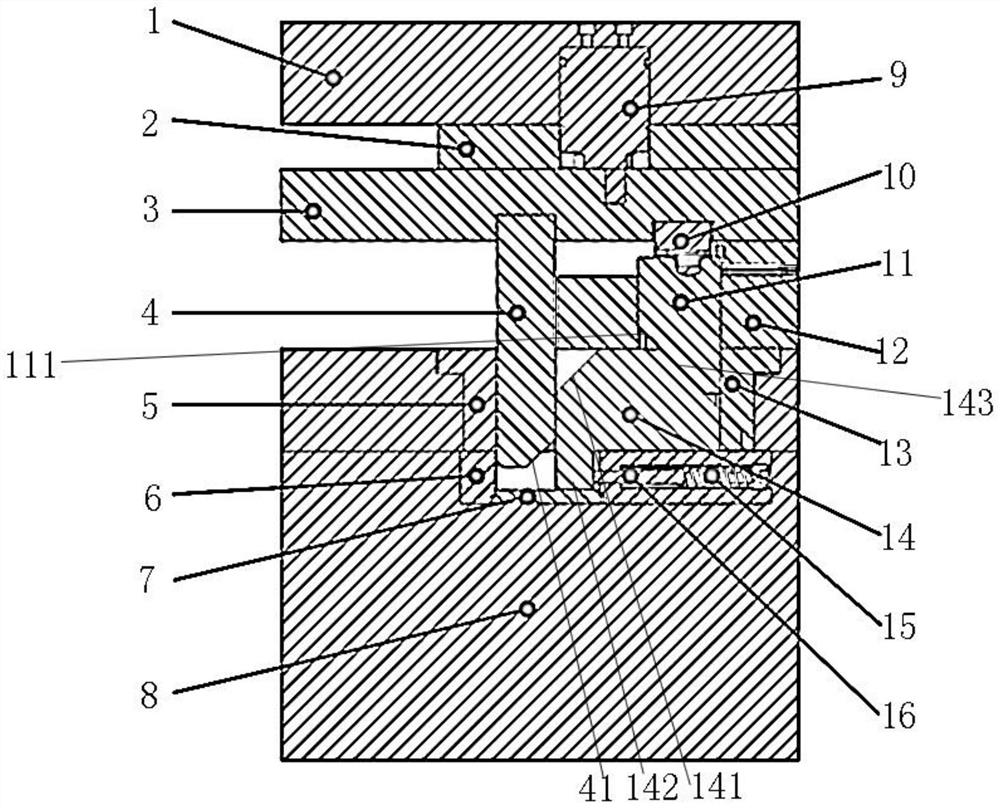

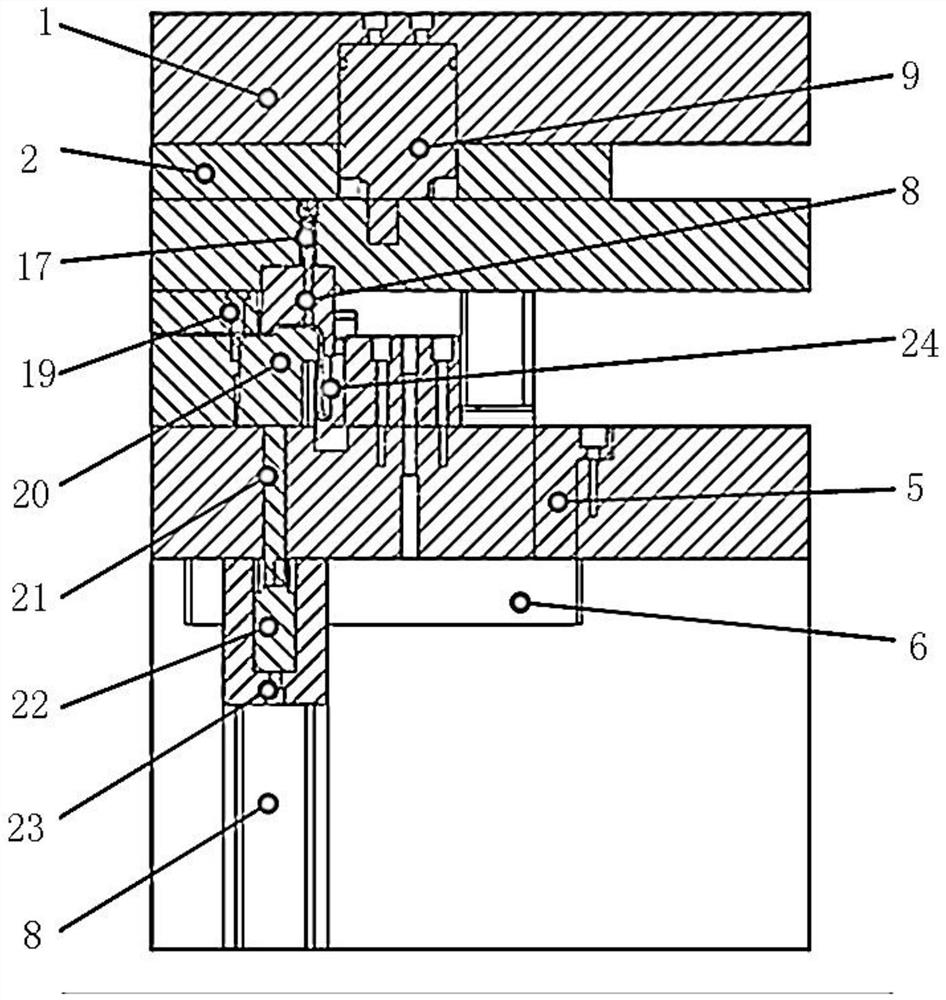

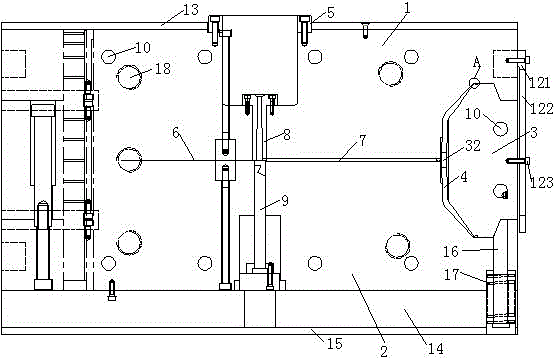

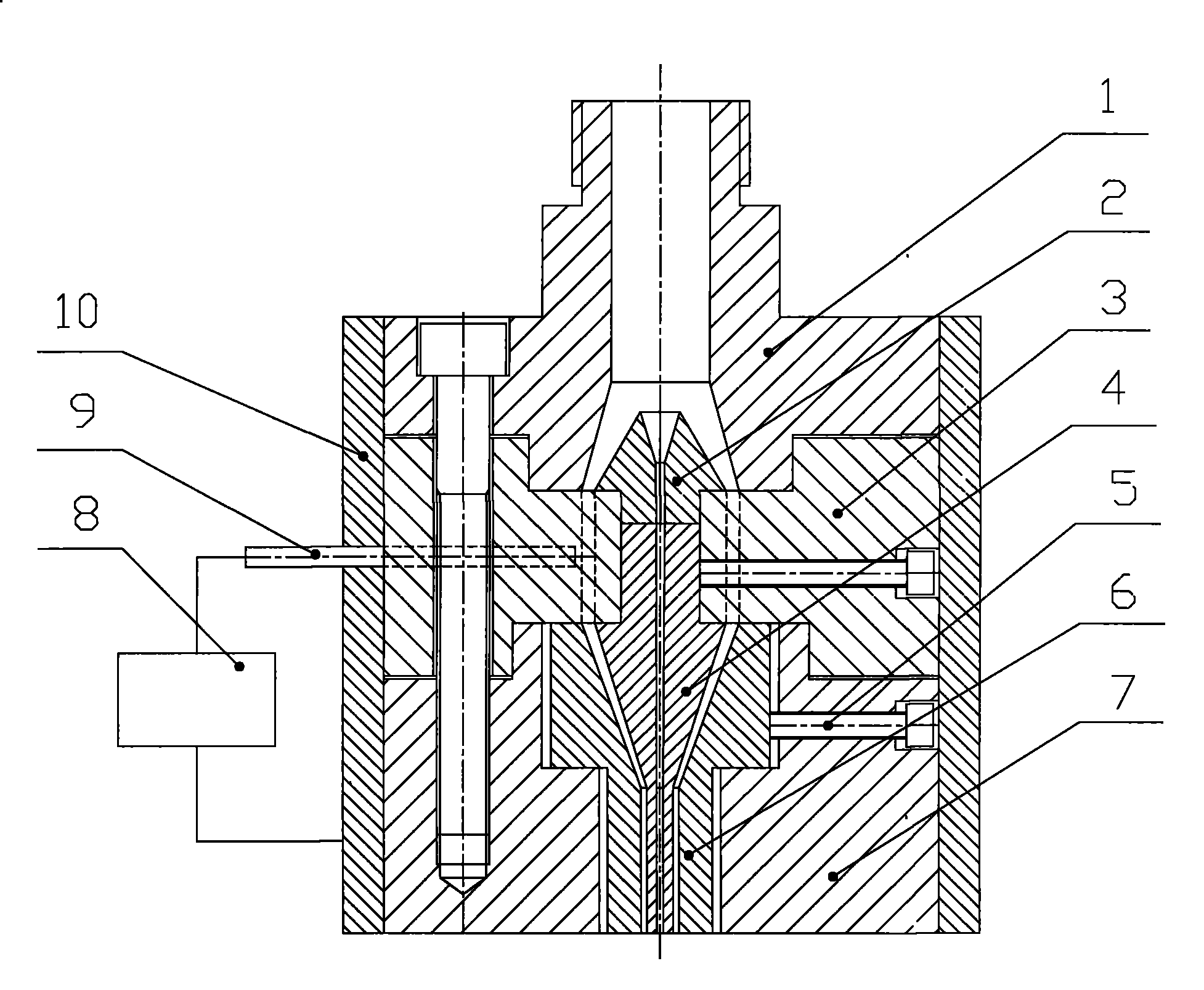

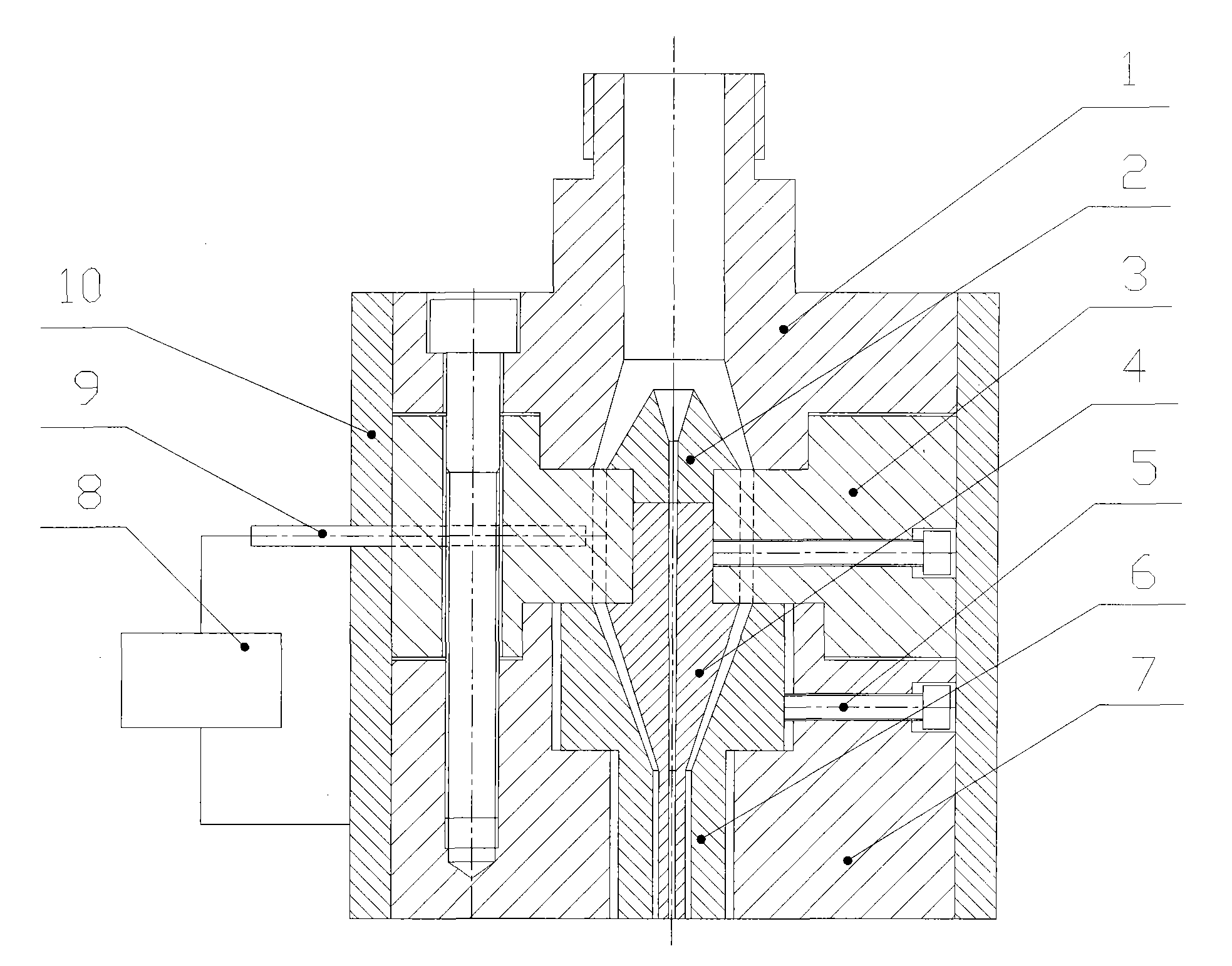

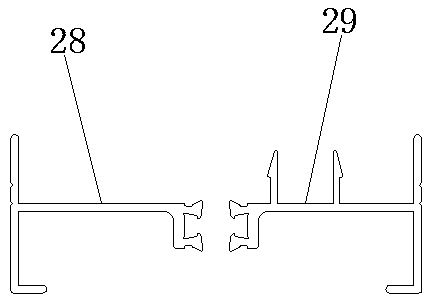

Plastic multi-cavity tube micro-extrusion flow equilibrium detection apparatus

InactiveCN101462354BReduce design costReduce manufacturing costTubular articlesEngineeringThermocouple

The invention discloses a flow balance detecting device for the micro-extrusion of plastic multi-cavity pipes, which belongs to the technical field of plastic extrusion molding. The detecting device is characterized in that the detecting device comprises a connecting base, a shunt cone, a shunt bracket plate, a core, a finish mold backing plate, a finish mold insert, a centring adjustment bolt, atemperature controller, a thermocouple and a heating ring; the shunt cone, the core and the finish mold insert on the detecting device are replaced according to the measurement results of the sectionshape-size of plastic melt after cooling and molding; the concentricity of the finish mold insert and the core is regulated through the centring adjustment bolt arranged on the finish mold backing plate; and the temperature controller, the thermocouple and the heating ring are used for controlling the required temperature of detection in the process of extruding and molding the plastic melt. The matching relation and change law among the section shape-size of multi-cavity pipes, the structural parameters of runners and extrusion process parameters during the micro-extrusion flow balance of the plastic melt is directly obtained through the detecting device, so as to establish a theory of designing micro-extrusion dies for the plastic multi-cavity pipes.

Owner:DALIAN UNIV OF TECH

In-mold buried fiber

ActiveCN104175497BReduce mold removalReduce the number of mold repairsCoatingsFiberBiochemical engineering

The invention discloses an in-mold embedded type optical fiber. The in-mold embedded type optical fiber comprises an optical fiber and a mold body, wherein the mold body is internally provided with a stepped hole and a through hole for holding hardware; the stepped hole comprises a first stepped hole, a second stepped hole and a third stepped hole; an optical-fiber guiding block is held in the second stepped hole; an optical-fiber fixing block is held in the third stepped hole; the middle parts of the optical-fiber guiding block and the optical-fiber fixing block are respectively and horizontally provided with an inserted hole; the optical fiber is held in the inserted holes of the optical-fiber fixing block and the optical-fiber guiding block; and the other end of the optical fiber extends to the outer part of the mold body. By the mode, the in-mold embedded type optical fiber disclosed by the invention has the advantages that the service life of a mold can be prolonged, and the production efficiency is also improved.

Owner:KENTA ELECTRONIC MFG KUNSHAN CO LTD

Concrete stirring vane die face design system and method based on springback compensation

InactiveCN101339574BSpeed up the Springback Compensation Design ProcessReduce the number of mold repairsSpecial data processing applicationsGeometric errorEngineering

The invention provides a concrete mixing blade die-face design system and a method based on springback compensation, which comprises three modules, that is, a die-face automatic springback compensation design module based on numerical simulation, a die-face CAD reconstruction design module, and a die-face correction module based on reverse engineering, thus a concrete mixing blade die-face CAD-CAE-CAD integrated system based on the springback compensation is formed, and geometric errors produced after the blade being formed are required to satisfy design requirements on the level of numericalsimulation, thus reducing correction times; and the process of converting a CAE model after a virtual die repair into a CAD geometric model which can be designed and manufactured is finished, a digital model after the blade being actually pressed is acquired by utilizing a reverse engineering technology and then is compared with the required design shape of the blade, and springback deviation is obtained so as to be used for guiding the actual die repair process of the blade, thus correcting the residual springback deviation and further improving the precision of the springback compensation onthe basis of numerical simulation springback compensation.

Owner:JIANGSU UNIV

Gear-changing automatic core-pulling device

Owner:SHANGHAI JIUTIAN AUTOMOBILE PARTS MFG

Simultaneous extrusion production process of environment-friendly aluminum profile ab surface

The invention discloses a production technology for simultaneously extruding A and B sides of an environment-friendly aluminum profile. According to the production technology disclosed by the invention, by improving a mold used by an priorexisting extrusion artprocess of the aluminum profile and the extrusion process, the A and B sides of the extruded aluminum profile are integrated, and two aluminum profile products which are matched with each other can be extruded at the same time and further the turnover rate of a finished frame is improved; meanwhile, by improving a horizontal powder injection process into a vertical powder injecting process, powder injection is more comprehensive and thorough, the quality of powder painting is improved and the appearance is better; in addition, by improving a powder injecting system in the powder paintinginjecting process, the improved powder injecting system does not have the phenomenon of injecting powder outward in the use process, so that theenvironment of an powder painting workshop is improved and threat to body parts of workers such as respiratory tract is avoided and better environment-friendly and hygienic properties are achieved.

Owner:隆图节能铝材(宣城)有限公司

Edge forming method and device

ActiveCN109093013BReduce the number of mold repairsReduce design change costsMetal working apparatusProcess engineeringIndustrial engineering

The invention provides a covered edge forming method and device. The covered edge forming method comprises the following steps that obtaining is carried out, a preset product parameter and a preset process parameter are obtained; determining is carried out, a product simulation forming parameter is determined according to the preset product parameter and the preset process parameter; and judging is carried out, the product simulation forming parameter is compared with the preset product parameter, if a comparison result does not meet the preset requirement, the preset process parameter is modified, the determining step and the judging step are repeated, until the product forming meets the quality requirement. According to the covered edge forming method, if the comparison result does not meet the quality requirement, the preset process parameter can be modified repeatedly until meets the quality requirement, that is, whether a product forming state meets the quality requirement or notis verified in advance, and mould repairing times are reduced, so that product design cost is reduced; and meanwhile, the covered edge forming method no longer depends on the technical requirement andexperience for molding analysis, so that the analysis result is more accurate.

Owner:BAIC MOTOR CORP LTD

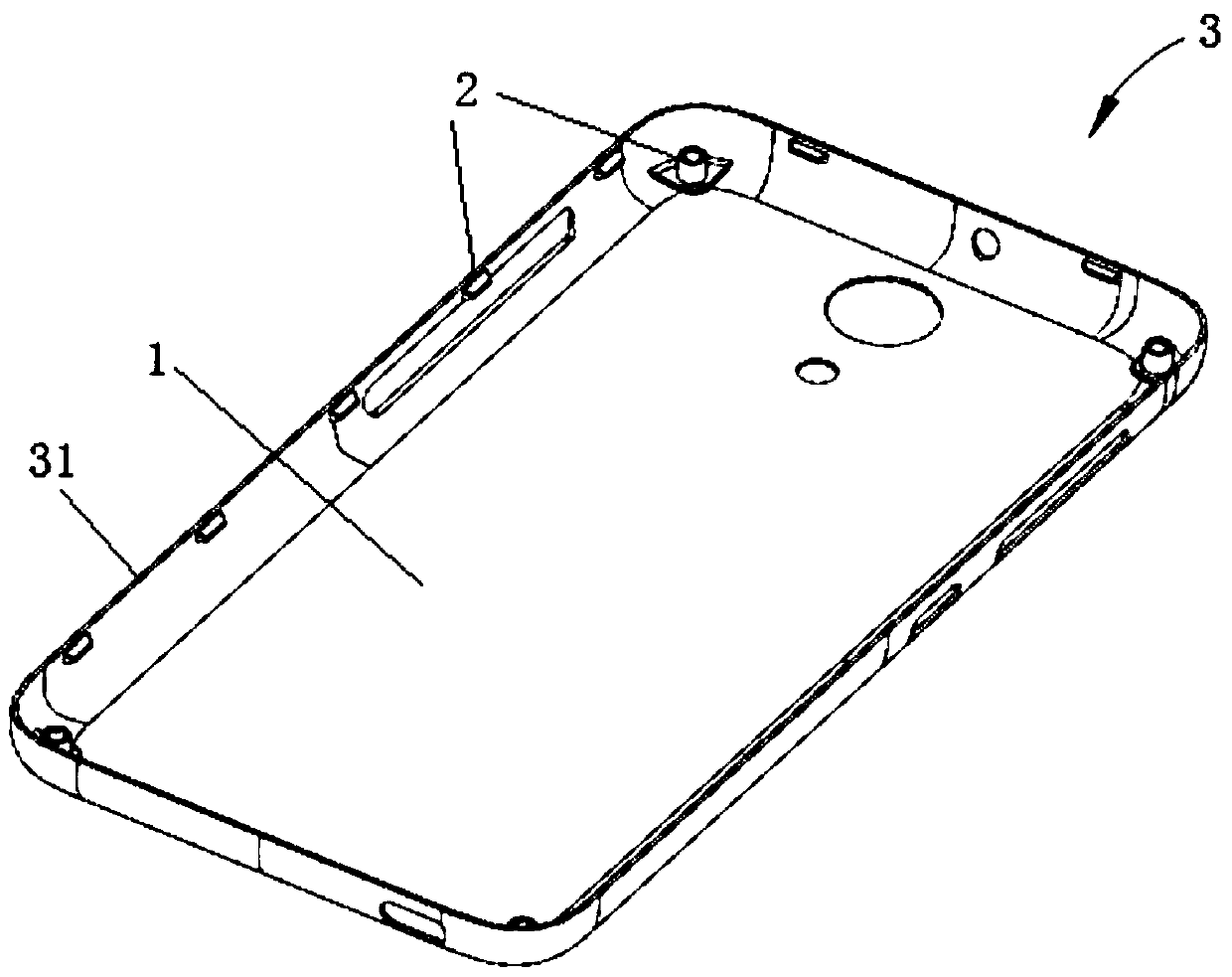

A waterproof mobile phone case and its manufacturing method

ActiveCN104994189BImprove adhesionSimple structureTelephone set constructionsInterference fitEngineering

The invention discloses a waterproof mobile phone shell and a manufacturing method thereof. The manufacturing method comprises the following steps: preparing a body and assembly parts, and combining the body with the assembly parts to form a combined body; performing plasma treatment on a surface of the combined body; forming a whole-ring waterproof body on at least the edges of the combined body after the plasma treatment to form the waterproof mobile phone shell, wherein the waterproof body is made of silicone or fluororubber. According to the waterproof mobile phone shell and the manufacturing method thereof provided by the invention, the whole-ring waterproof body made of silica gel or fluororubber is formed on at least the edges of the combined body formed by the body of the mobile phone shell and the assembly parts, the interference fit is formed between the waterproof body and the interior of the mobile phone to realize the mobile phone shell with the waterproof and sealing functions; and meanwhile, a mold structure is simplified, and the development period of the product is shortened.

Owner:GUANGDONG JANUS SMART GRP CO LTD

Method for producing magnetic steel molding product by full-automatic wet process and molding machinery thereof

InactiveCN101335128BReduce labor intensityShorten press molding timeInductances/transformers/magnets manufactureSlurryEnergy consumption

The invention discloses a full-automatic wet method for producing magnetic steel molded products and molding equipment thereof, pertaining to the field of production methods of the magnetic steel molded products. The method of the invention comprises the steps of preparing slurry, pressing and molding a green body, sintering the green body to a rough cast and post-processing the rough cast to form a product, etc. In the steps of pressing and molding the green body, the equipment using the method of the invention is adopted to independently control the ascending movement and descending movement of a mold cavity so as to cause the mold cavity to do ascending movement relative to a core bar, thereby providing a feeding space; the center of the core bar is provided with a feeding hole, a feeding port at the lower part of the feeding hole is communicated with a feed bin and the slurry is fed from an opening at the top part of the feeding hole to a material containing space; after the completion of the feeding, the mold cavity is fast controlled to return to a position which is parallel to the top part of the core bar, and then pressed, after pressing, a mould is opened, an upper oil cylinder and a lower oil cylinder return in sequence. The lower oil cylinder returns and drives the mold cavity and the core bar descends to the same plane with a punch simultaneously. The green body isdemolded. The full-automatic wet method of the invention greatly shortens the time of pressing and molding, reduces energy consumption, greatly improves production efficiency and reduces the labor intensity of workers.

Owner:WUHAN JINGHONG MAGNETIC IND

Method for preparing multiple layers of thin films on die surface through arc ion plating

InactiveCN108220889AEasy to demouldReduce the number of mold repairsVacuum evaporation coatingSputtering coatingSand blastingSurface plasmon

The invention relates to a film coating technology, in particular to a method for preparing multiple layers of thin films on a die surface through arc ion plating. According to the technical scheme, the method comprises the following steps that (1) nitridation is carried out on plasmas on the die surface; (2) an arc ion plating manner is adopted for preparing the first layer of thin film on the die surface to be plated; (3) the arc ion plating manner is adopted for preparing the second layer of thin film on the first layer of thin film; (4) the arc ion plating manner is adopted for continuously preparing the third layer of thin film on the second layer of thin film; and (5) thin film micro-sand blasting treatment is carried out. By means of the method for preparing the multiple layers of thin films on the die surface through arc ion plating, the forging die surface quality can be improved, and the service life can be prolonged.

Owner:新锐咨询(辽宁)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com