Method for correcting moulding surface of forming mould for antenna cover

A technology for forming molds and radome, which is applied in casting molding equipment, suitable for antennas on movable objects, casting molds, etc., and can solve problems such as deformation of aircraft radome

- Summary

- Abstract

- Description

- Claims

- Application Information

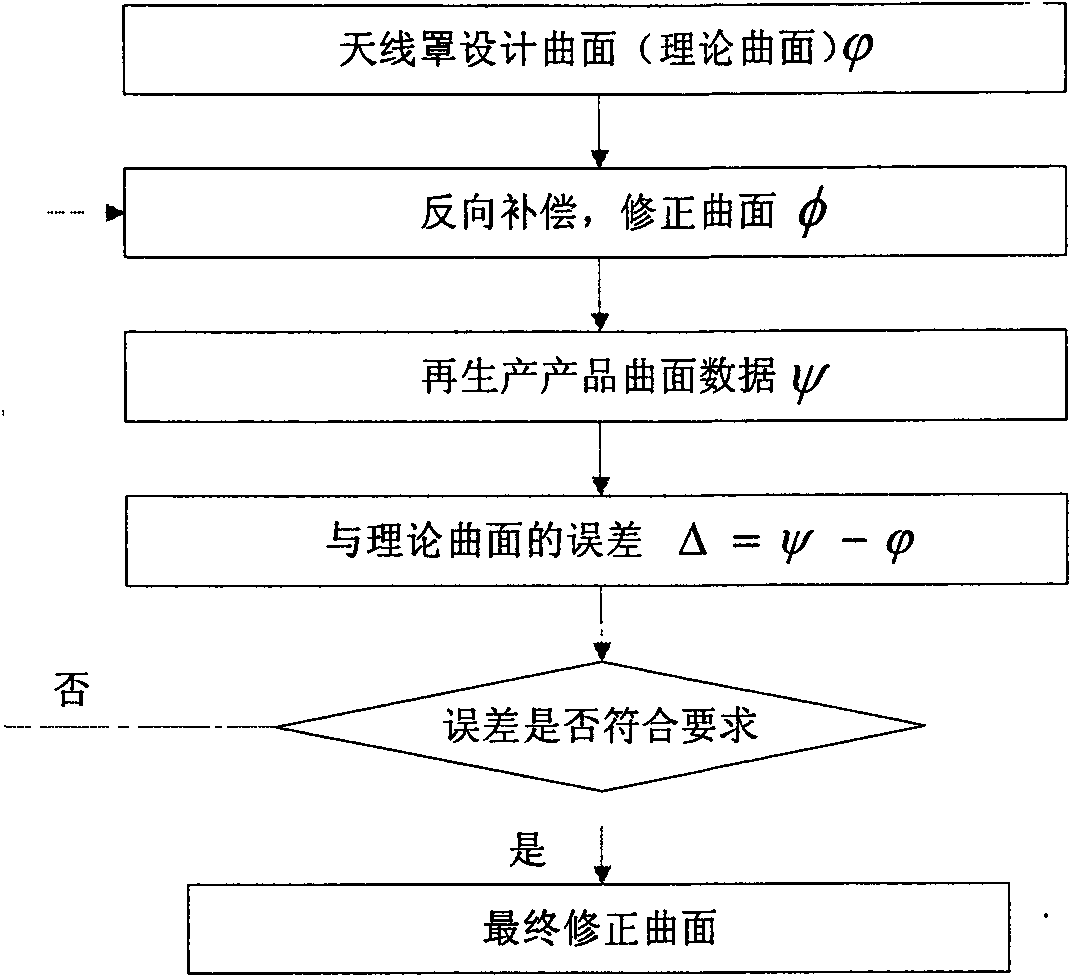

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

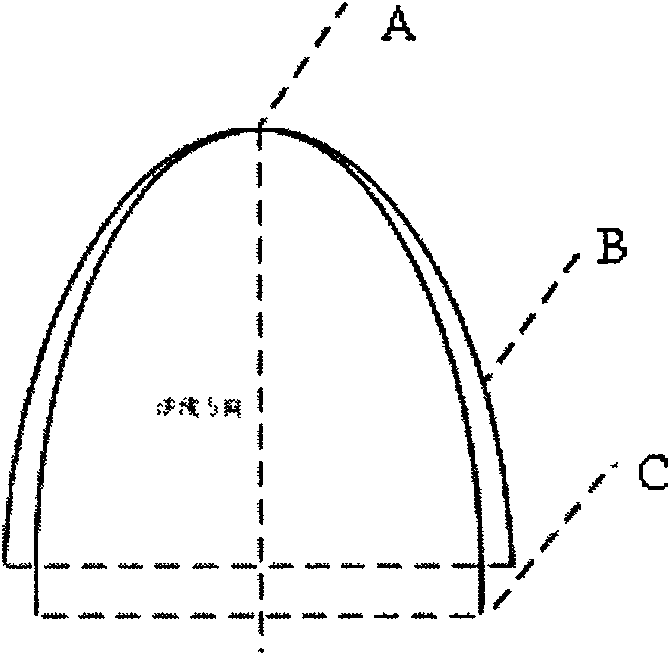

[0049] The radome is processed by the initial mold, and the contour surface of the radome is measured by a numerical control measuring machine to obtain the measurement point cloud data of the radome. The profile of the initial mold is derived from the design surface of the radome. Sort the measured point cloud data of the radome according to the Z-axis coordinates, and the point with the largest Z-axis coordinates is the highest point of the radome processed by the initial mold (x h ,y h ,z h ); use CATIA software to discretize the design surface of the radome to obtain the point cloud data of the design surface of the radome, and the coordinate origin (0, 0, 0) is the highest point when modeling the design surface.

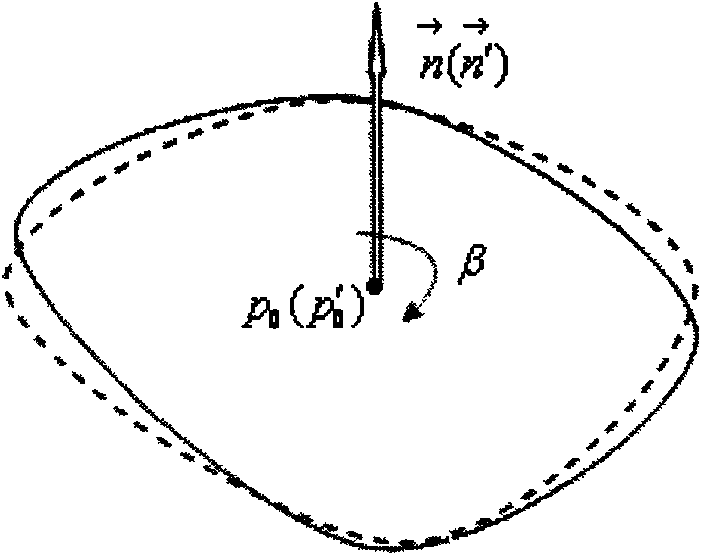

[0050] ●Determine the highest point normal of the radome design surface point cloud data and the highest point normal of the measured point cloud ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com