Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Increase the difficulty of assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

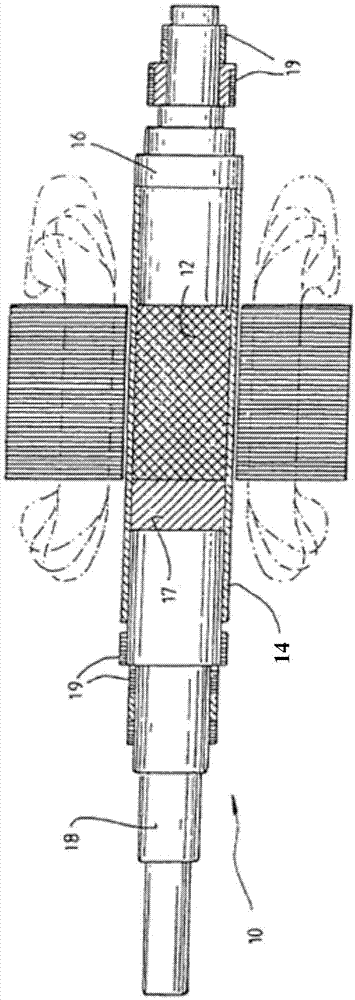

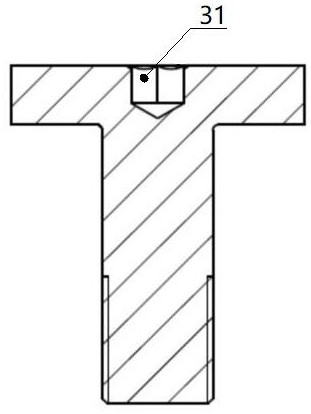

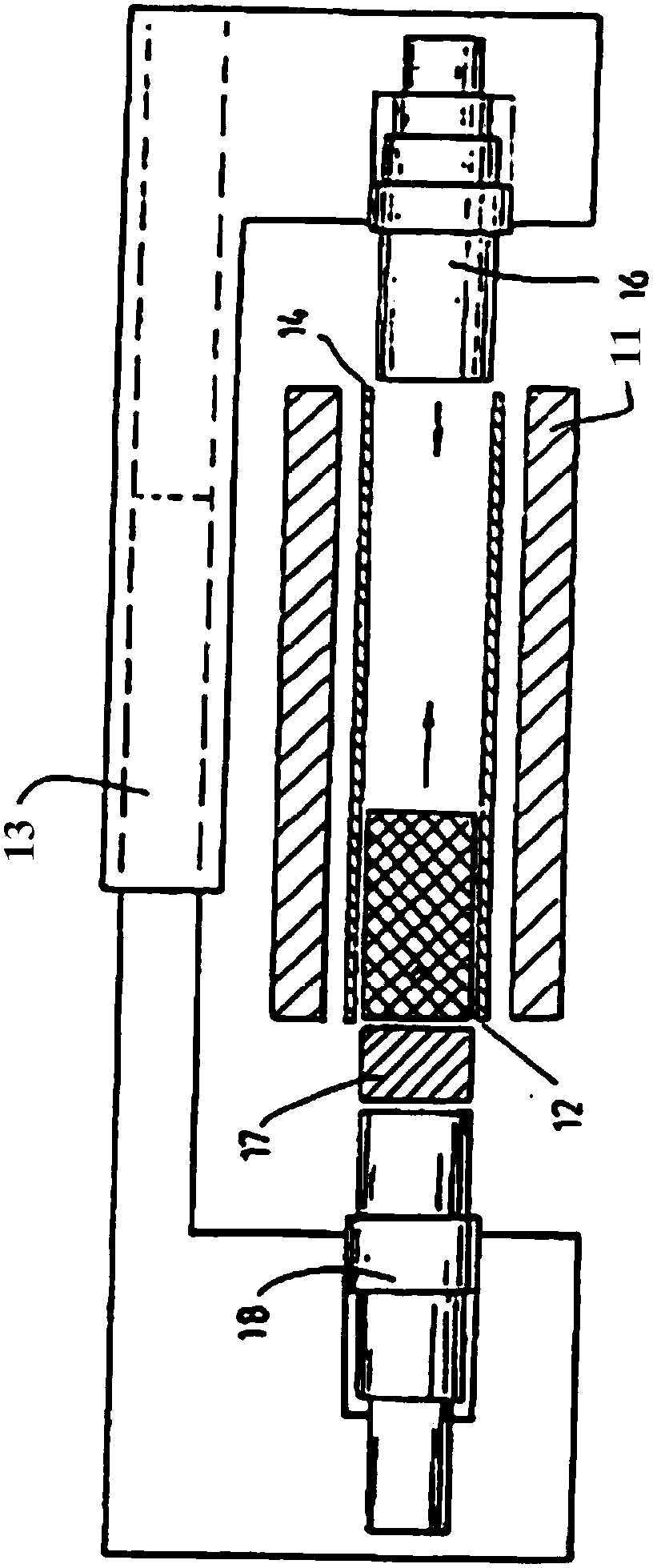

Shafting structure for motor, and assembling method

ActiveCN105449895AReduce in quantityReduce assembly coaxiality is difficult to guarantee the problemMagnetic circuit rotating partsManufacturing stator/rotor bodiesElectric machineryStructural engineering

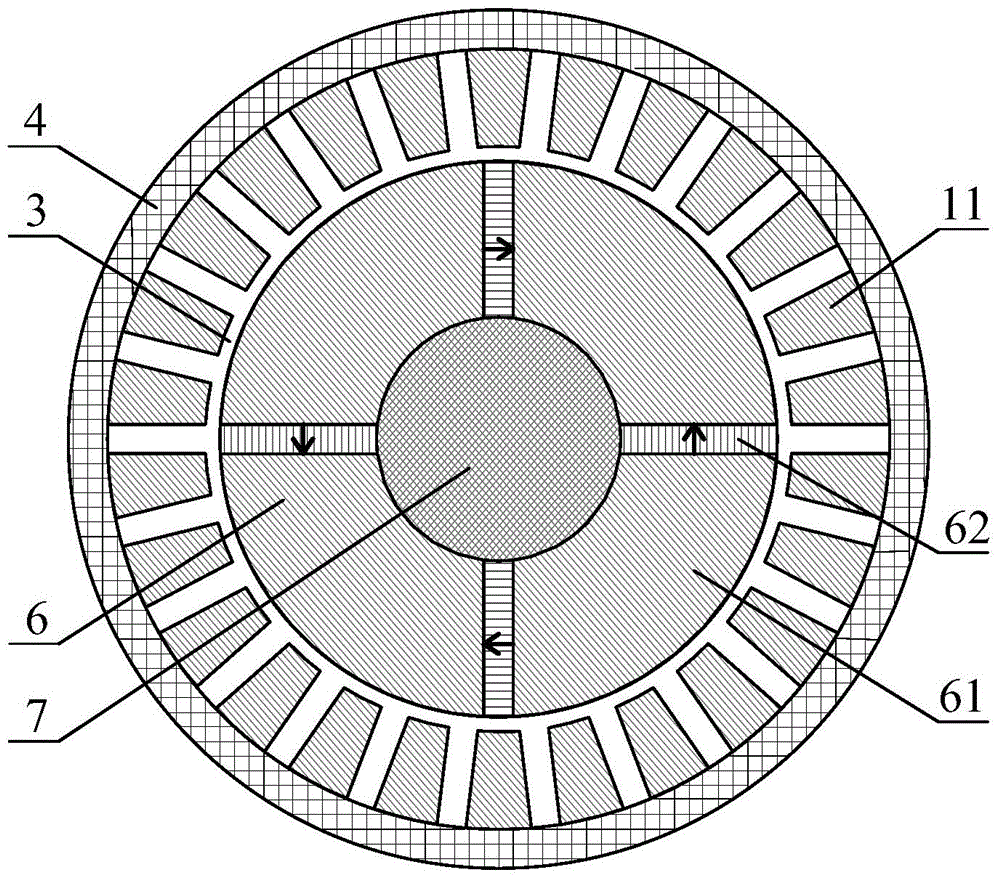

The invention discloses a shafting structure for a motor, and an assembling method. The shafting structure comprises a front-segment shaft (62), a rear-segment shaft (63), annular magnetic steel (61) and an alloy sheath (60), wherein the rear-segment shaft (63) successively comprises a first shaft joint (631) and a second shaft joint (633) from front to back, and the diameter of the first shaft joint (631) is smaller than that of the second shaft joint (633); the annular magnetic steel (61) sleeves the first shaft joint (631) of the rear-segment shaft (63); the external diameter of the rear end of the front-segment shaft (62) is the same as the external diameter of the annular magnetic steel (61); and the alloy sheath (60) sleeves the front-segment shaft (62) and the annular magnetic steel (61). According to the scheme provided by the invention, the shafting structure and the assembling method overcome the defects of complex structure, large assembling difficulty, poor safety and the like in the prior art and also have the advantages of simple structure, small assembling difficulty and good safety.

Owner:GREE ELECTRIC APPLIANCES INC +1

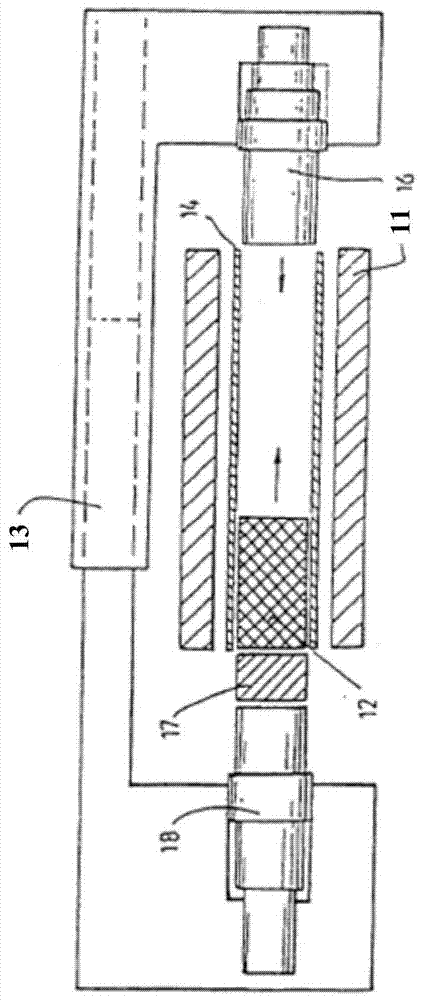

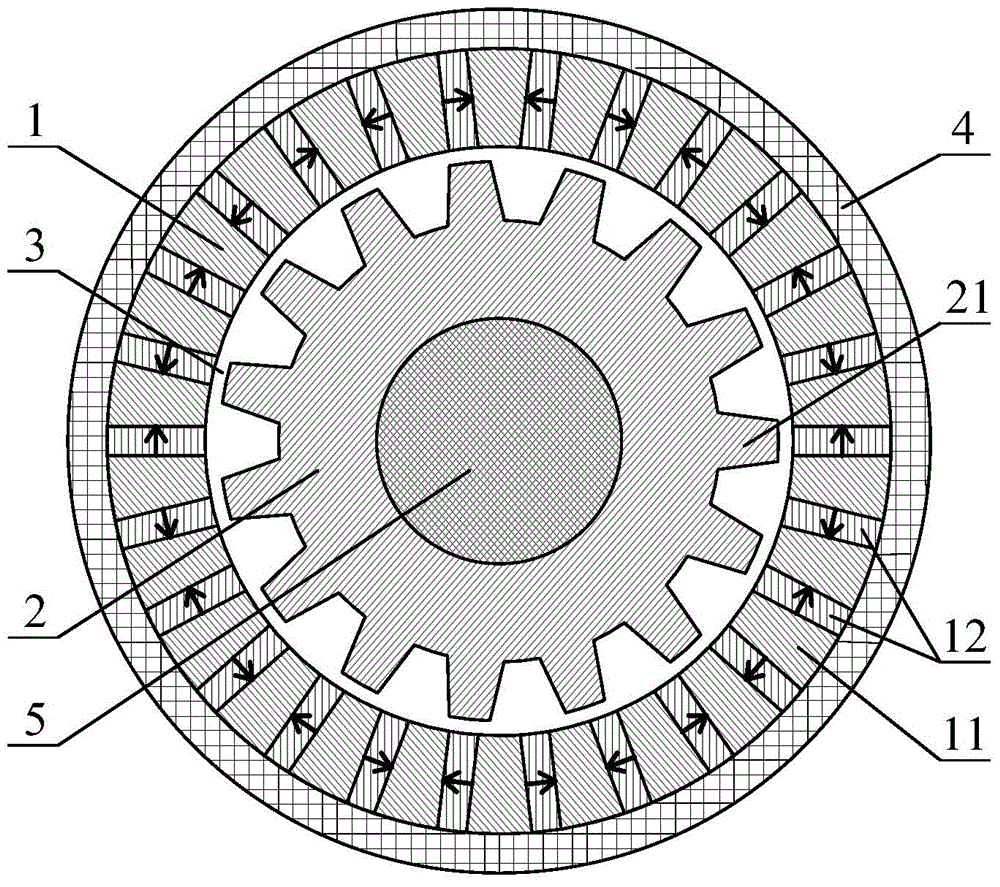

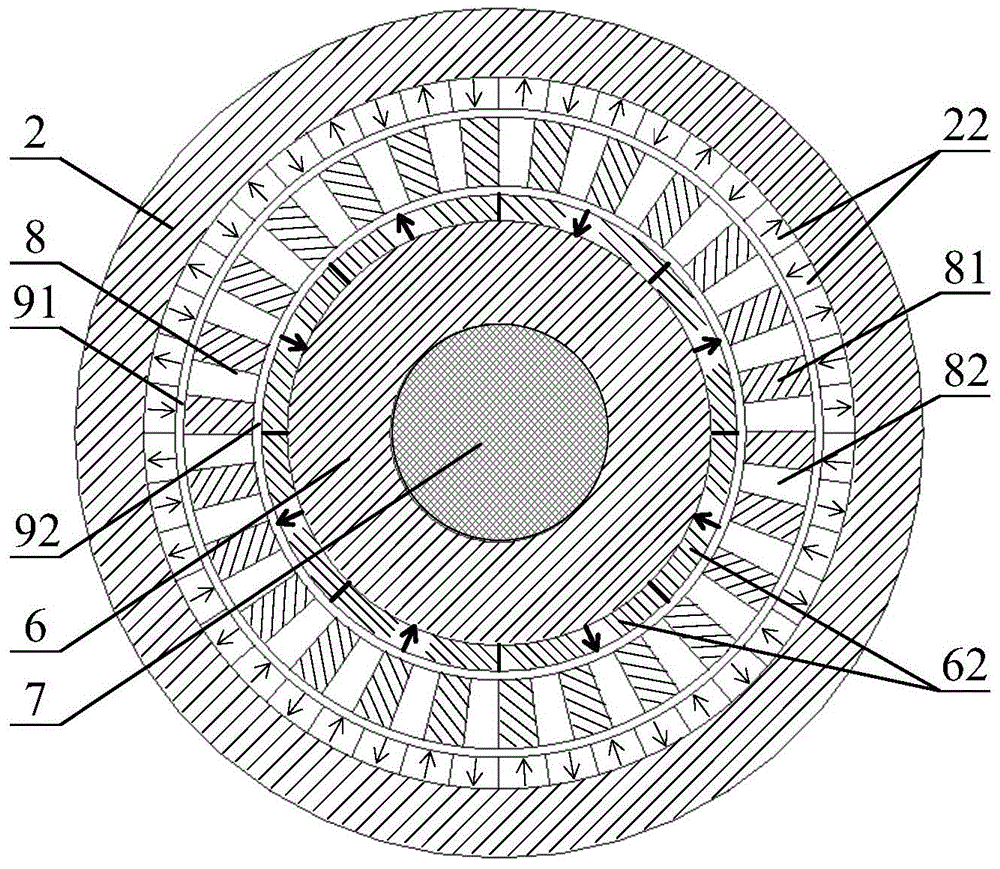

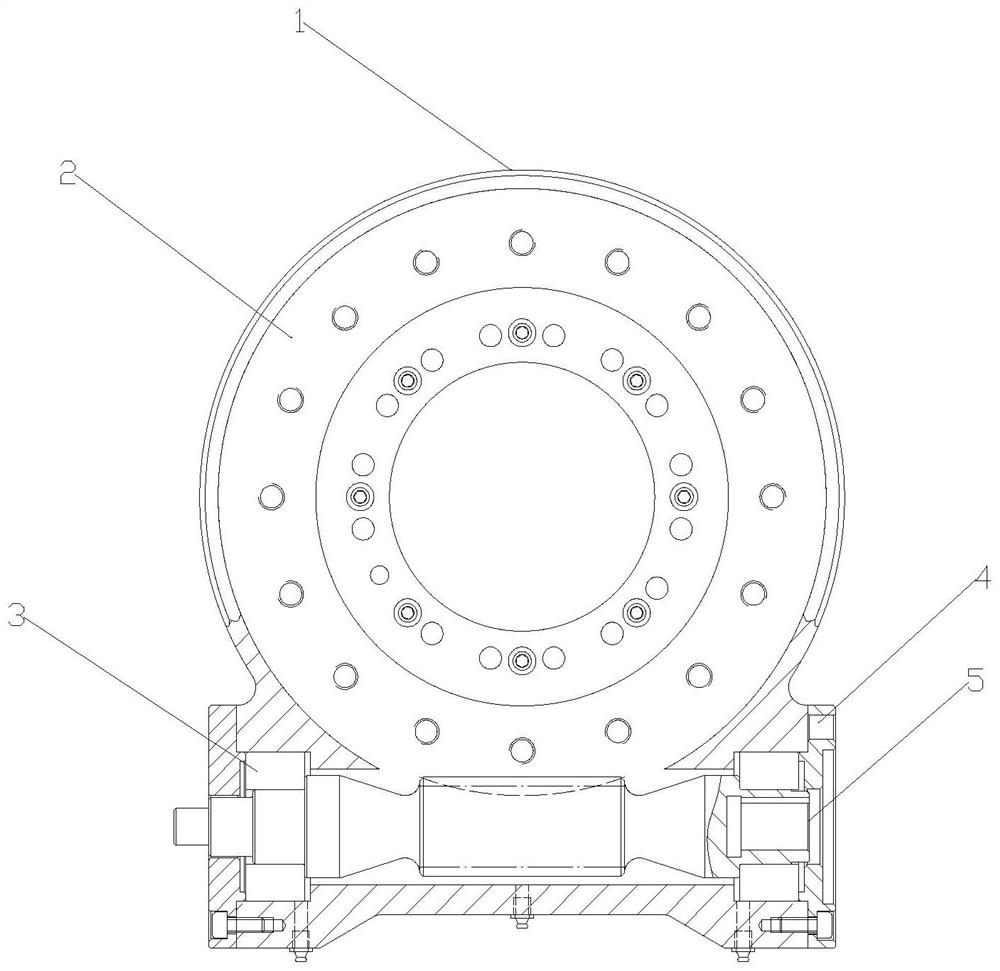

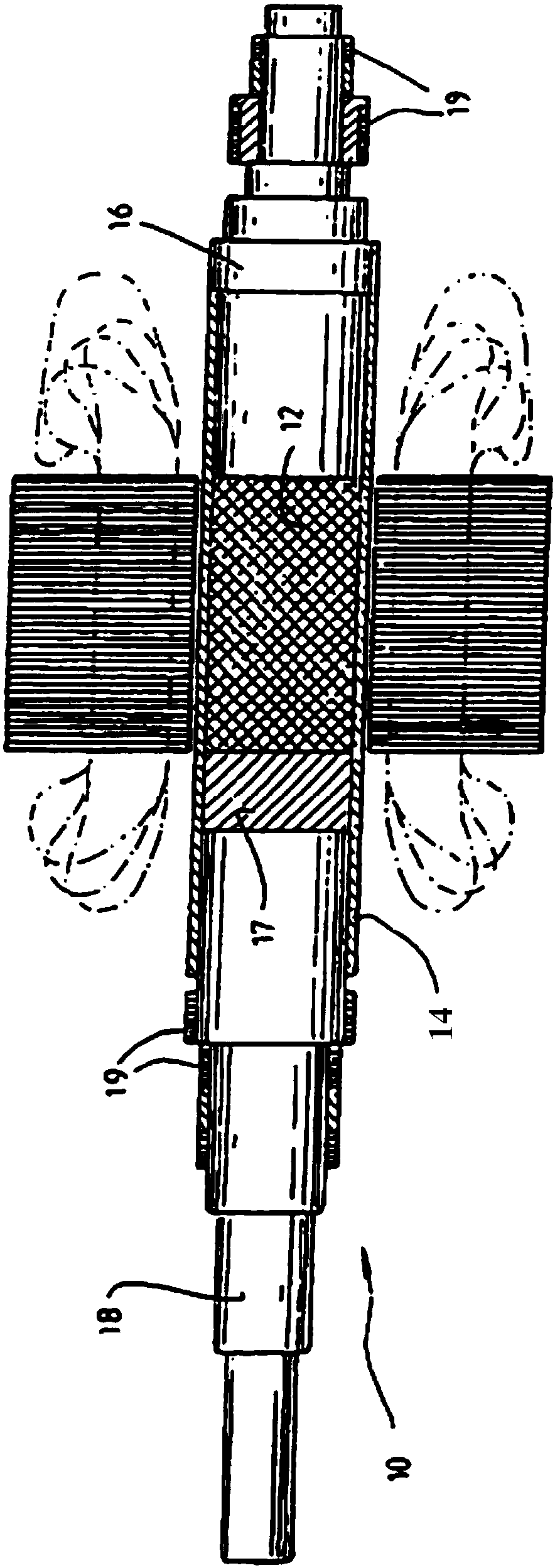

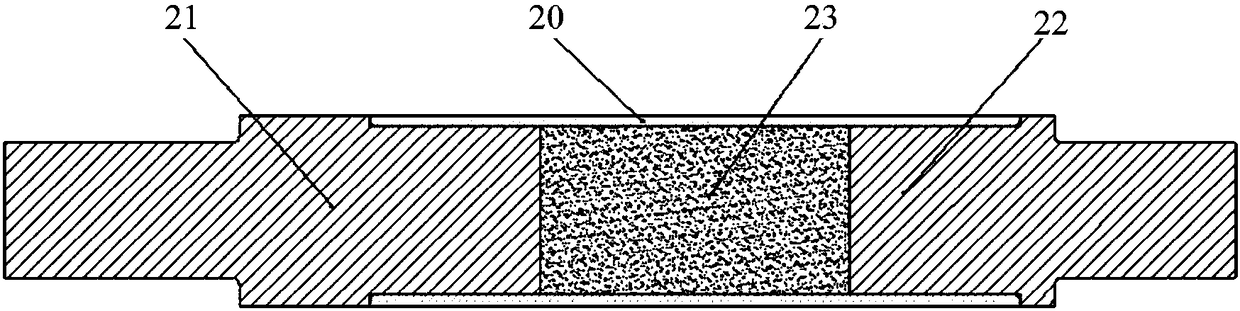

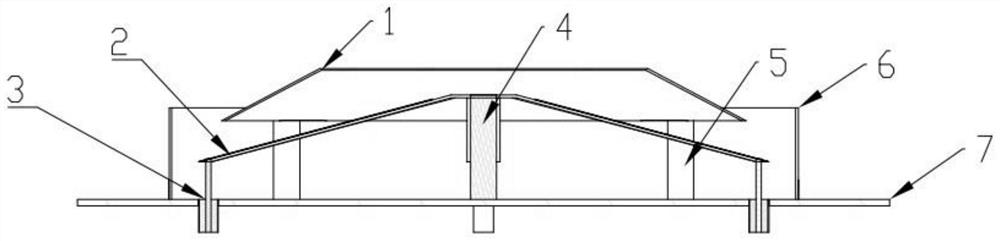

Axial magnetic gear employing stator permanent magnetism structure at low-speed rotor side

ActiveCN104967279AEasy extractionReduce manufacturing costMagnetic circuit rotating partsDynamo-electric gearsFree rotationLow speed

The invention discloses an axial magnetic gear. The axial magnetic gear comprises a low-speed rotor, a high-speed rotor and a stator. The low-speed rotor and the high-speed rotor are arranged coaxially in the axial direction and have the same outer diameter. The low-speed rotor is an annular magnetizer. Evenly spaced low-speed rotor salient poles are arranged on the outer ring of the annular magnetizer. The high-speed rotor comprises a high-speed rotor iron core and a high-speed rotor permanent magnet embedded in the high-speed rotor iron core. The stator has an annular structure composed of evenly-spaced magnetic conductive blocks. The stator is fixed outside the high-speed rotor and the low-speed rotor coaxially. Two end faces of the stator are parallel and level to the outer end faces of the high-speed rotor and the low-speed rotor. A permanent magnet is filled between adjacent stator magnetic conductive blocks corresponding to the low-speed rotor side. Air gaps are arranged between the stator and the high-speed rotor and between the stator and the low-speed rotor. A gap is arranged between the high-speed rotor and the low-speed rotor in the axial direction, and free rotation of the high-speed rotor and the low-speed rotor can be ensured. The axial magnetic gear achieving variable transmission by utilization of the harmonic wave magnetic field coupling effect has characteristics of high mechanical reliability and convenient processing and manufacturing.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

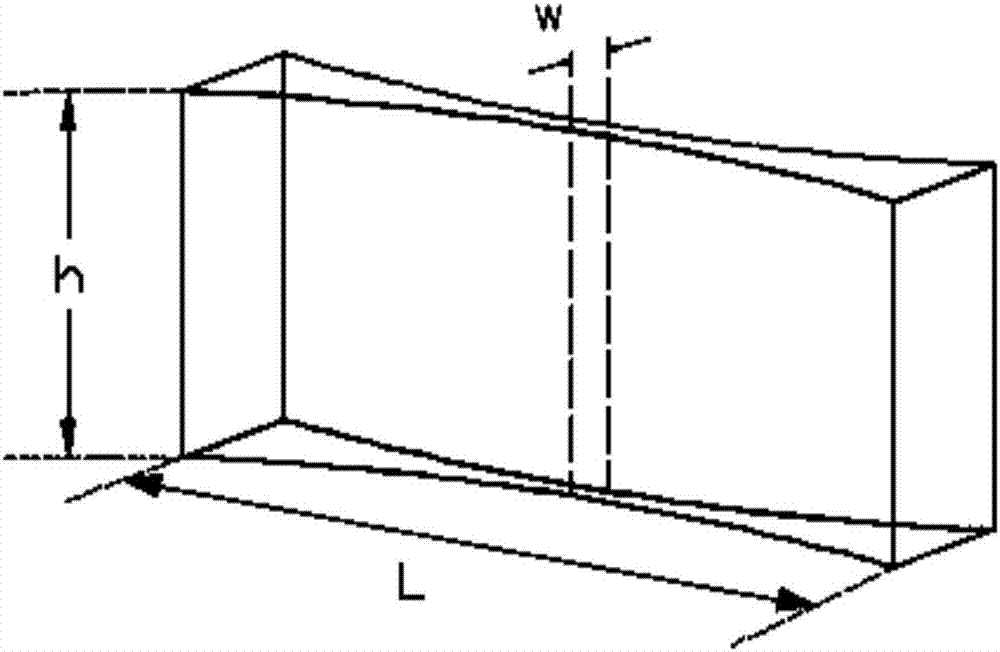

Method for designing die molded surface for forming groove-shaped part

InactiveCN104924633AIncrease the difficulty of the processIncrease the difficulty of assemblySurface fittingEngineering

Disclosed is a method for designing a die molded surface for forming a groove-shaped part. An inner molded surface M of the part is extracted, and section lines Pj of the extracted inner molded surface of the part are manufactured; the various section lines Pj are corrected sequentially through correction basis points, and new section lines are obtained; and surface fitting is carried out on the obtained section lines, and a new mold outer molded surface is obtained. The maximum deformation of the groove-shaped part formed through the mold outer molded surface determined through the method is reduced to 0.2mm from 1.5mm, and the design requirements of the part are met. Compared with the traditional technology, when the mold molded surface is designed, rebound deformation obtained after part deformation is considered in the method, and the problem that according to a traditional method, an inner molded surface of a composite material groove-shaped part is directly extracted to serve as the mold molded surface for manufacturing the composite material part, the part size cannot meet the design requirement is solved; and the mold repairing frequency of a follow-up mold is reduced, and therefore the production manufacturing cost is reduced, and the production efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

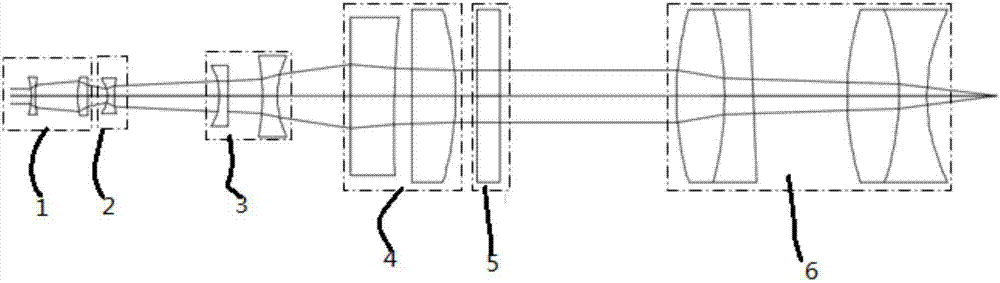

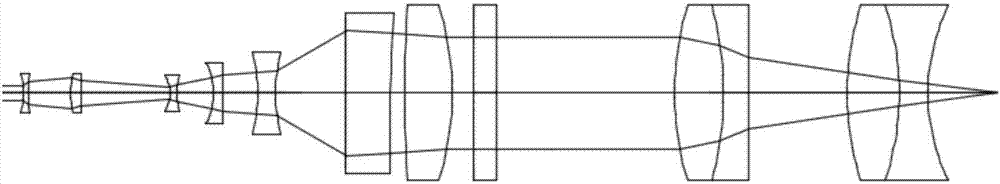

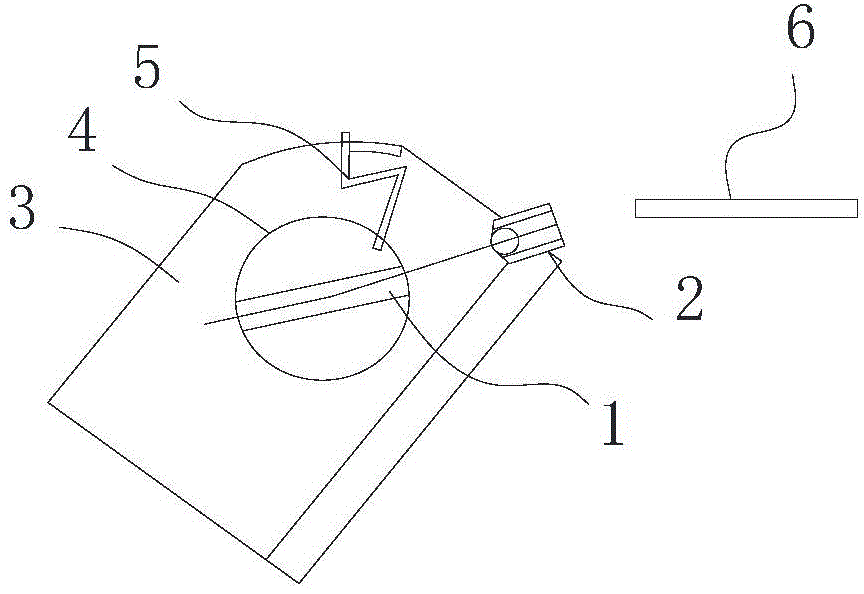

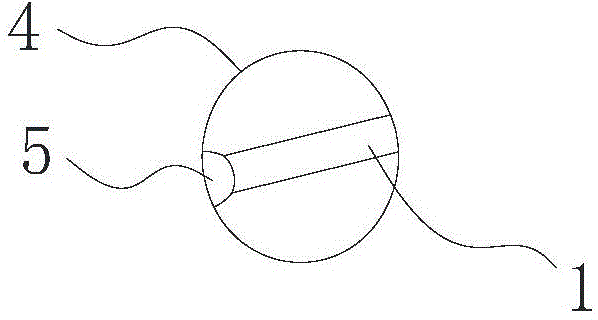

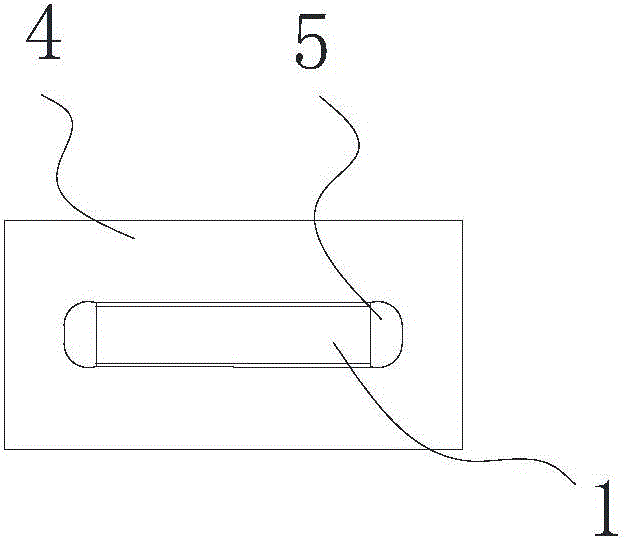

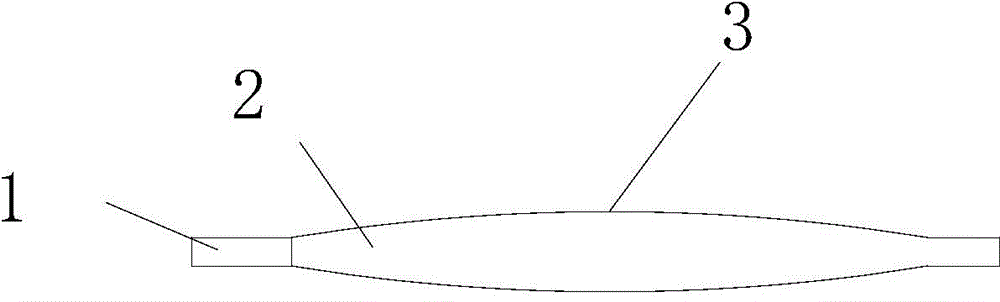

Lighting system of plate lighting microscope with variable thickness and length of plate

ActiveCN107976794AEasy to observeSimplify mechanical designMicroscopesVariable thicknessEffect light

The invention belongs to the technical field of microimaging, in particular to a lighting path of a plate lighting microscope and provides a lighting system of a plate lighting microscope with variable thickness and length of a plate. The system successively comprises a laser light source, a four-component mechanical compensation afocal zooming beam expanding system of a full spherical mirror, a cylindrical lens and a microobjective arranged along the optical axis from the object side to the image side; light emitted by the laser light source changes in aperture of a laser beam by means of theafocal zooming beam expanding system and then passes through the cylindrical lens rotating at 90 degrees by taking the optical axis as the rotating axis to form the plate light. The plate light undergoes subduction of spherical aberration generated by the afocal zooming beam expanding system and the cylindrical lens through a spherical aberration subduction microobjective, and the light intensityof the whole plate is more uniform; the plate lighting microscope can be used for observing biological samples in a certain dimensional range under the circumstance of not replacing the plate lighting system.

Owner:SUZHOU UNIV

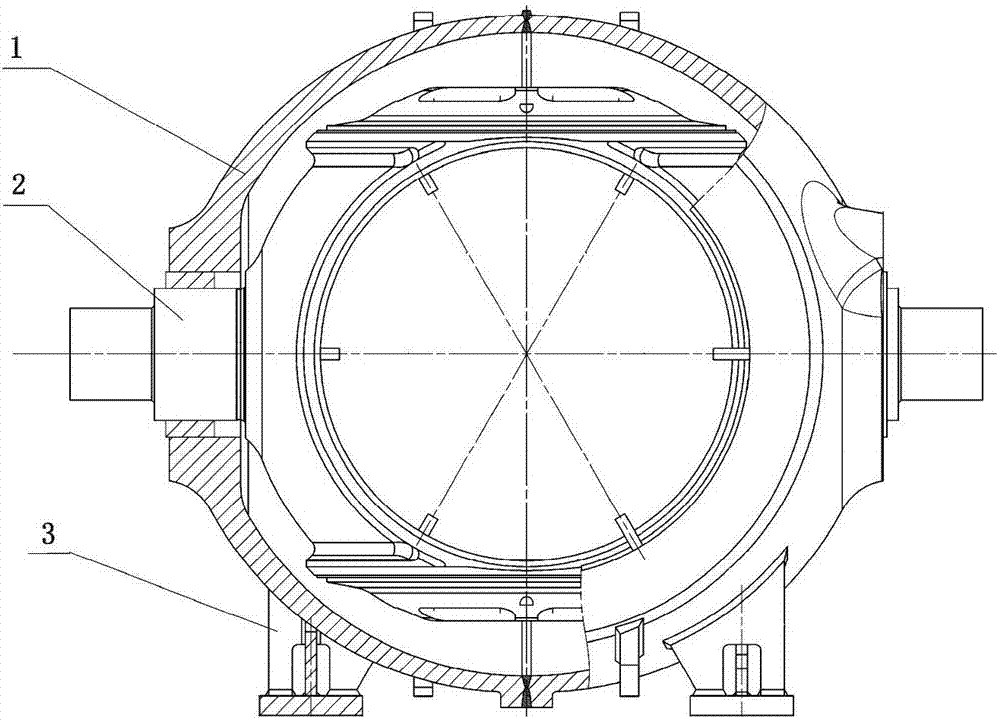

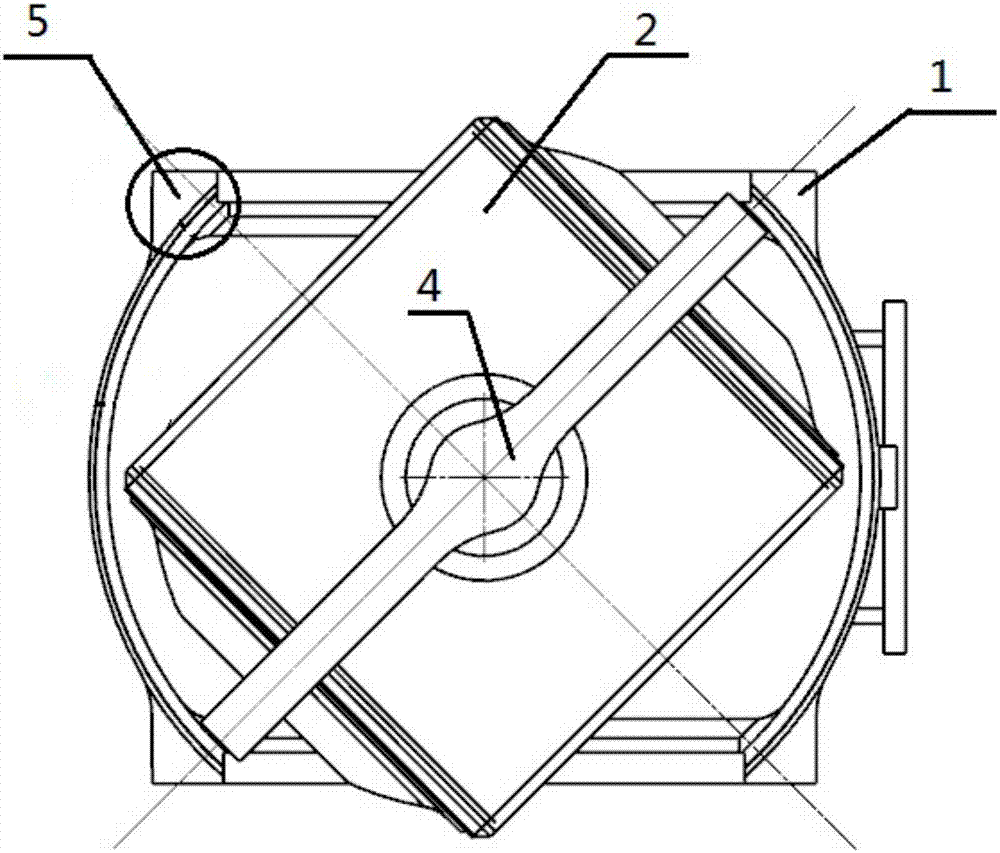

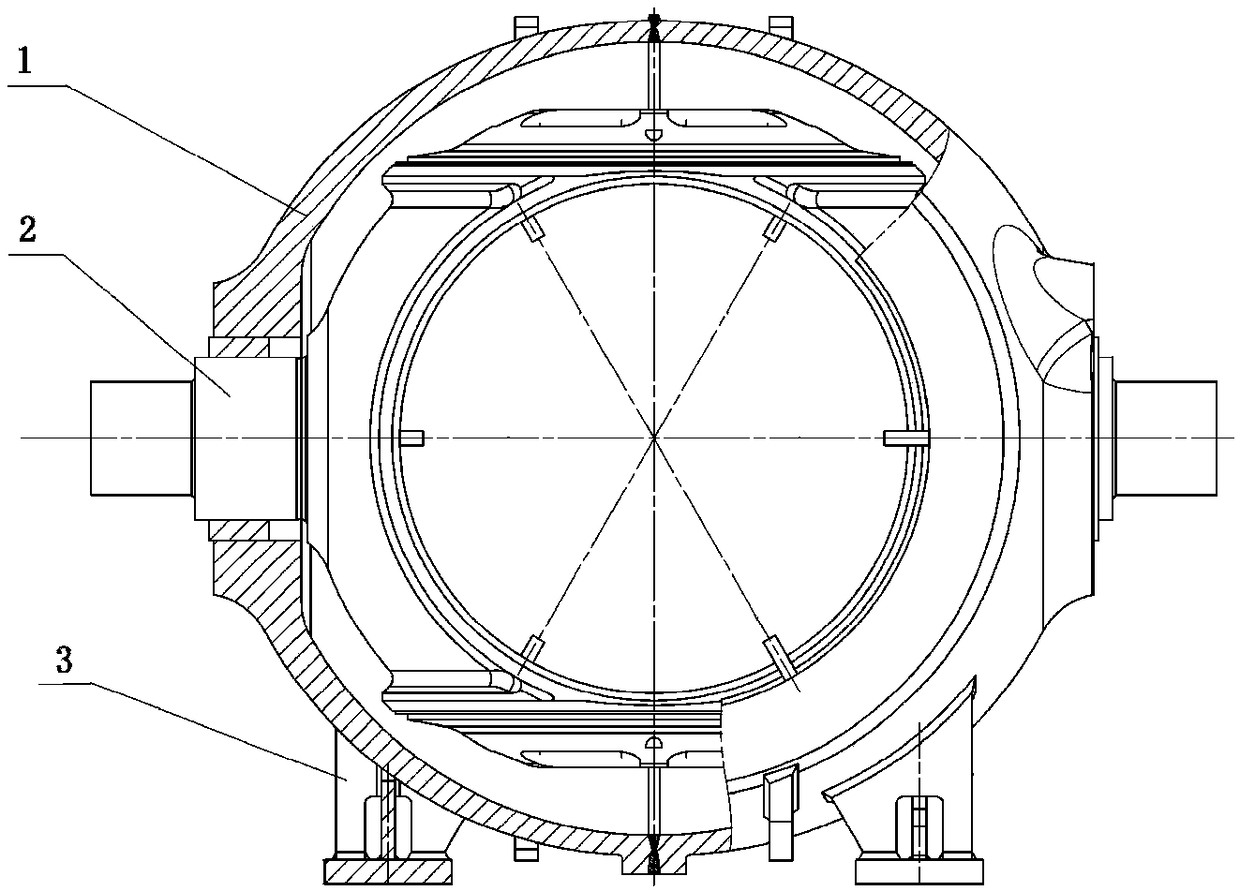

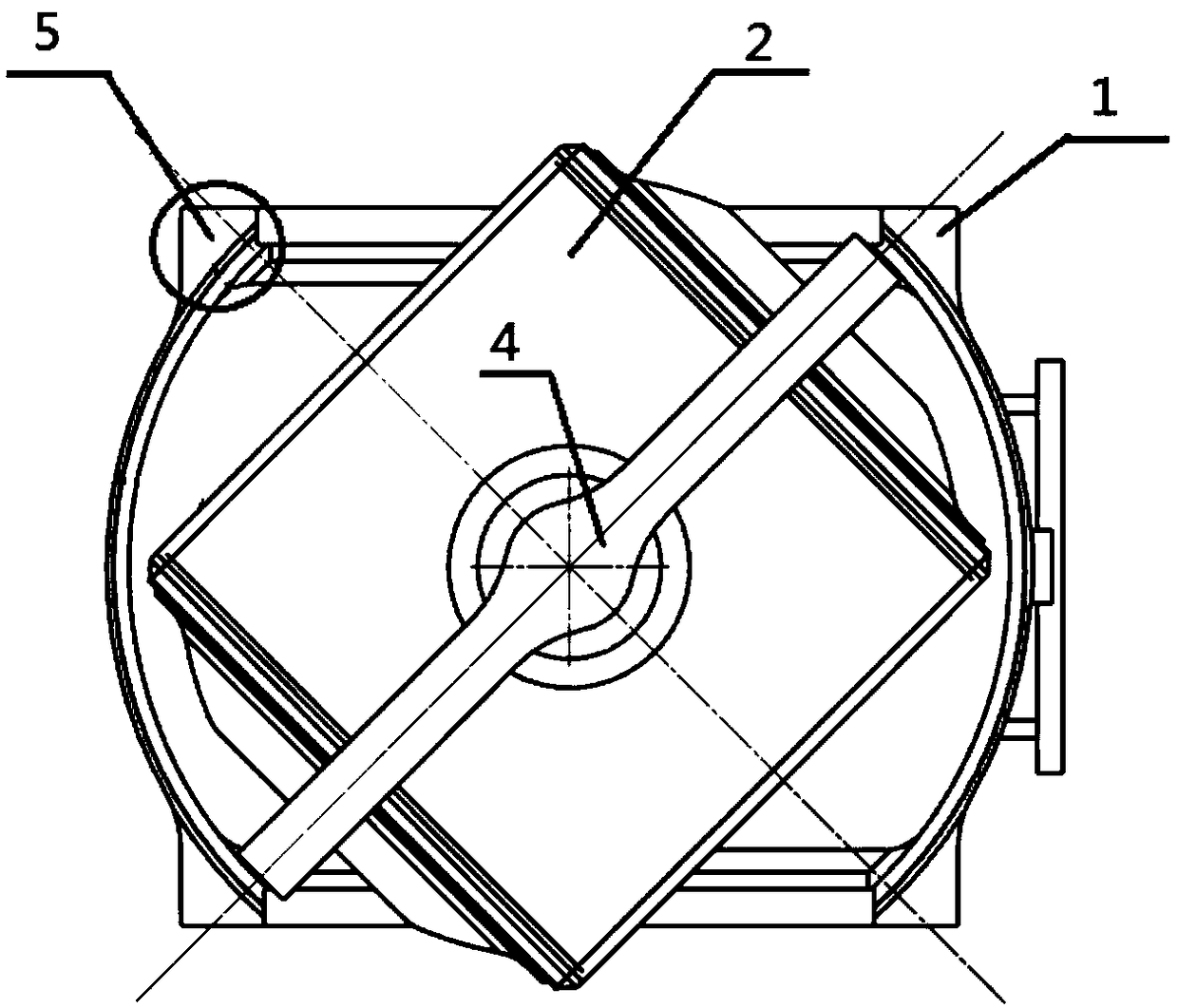

Welding manufacturing technology method of large water turbine ball valve of all-welded structure

ActiveCN107243704AIncrease the difficulty of assemblyIncrease in sizeWelding apparatusManufacturing technologyWater turbine

The invention discloses a welding manufacturing technology method of a large water turbine ball valve of an all-welded structure. The method represents innovation of an assembly-welding technology method of the large water turbine ball valve of the all-welded structure and is the essential change of the manufacturing method. The technological scheme of coating high-temperature-resistant paint before assembly welding of a shaft sleeve as a welding auxiliary tool, a valve and a valve body single-piece and performing symmetric welding in the vertical welding position during rotating of the valve is applied for the first time, with the adoption of the method, accessibility and operability of welding are greatly improved, welding deformation is effectively controlled, quality of a ball valve welding seam is guaranteed by intermediate flaw detection, critical dimensional stability of the ball valve is guaranteed, and the assembly-welding quality of the large water turbine ball valve of the all-welded structure is remarkably improved accordingly.

Owner:HARBIN ELECTRIC MASCH CO LTD

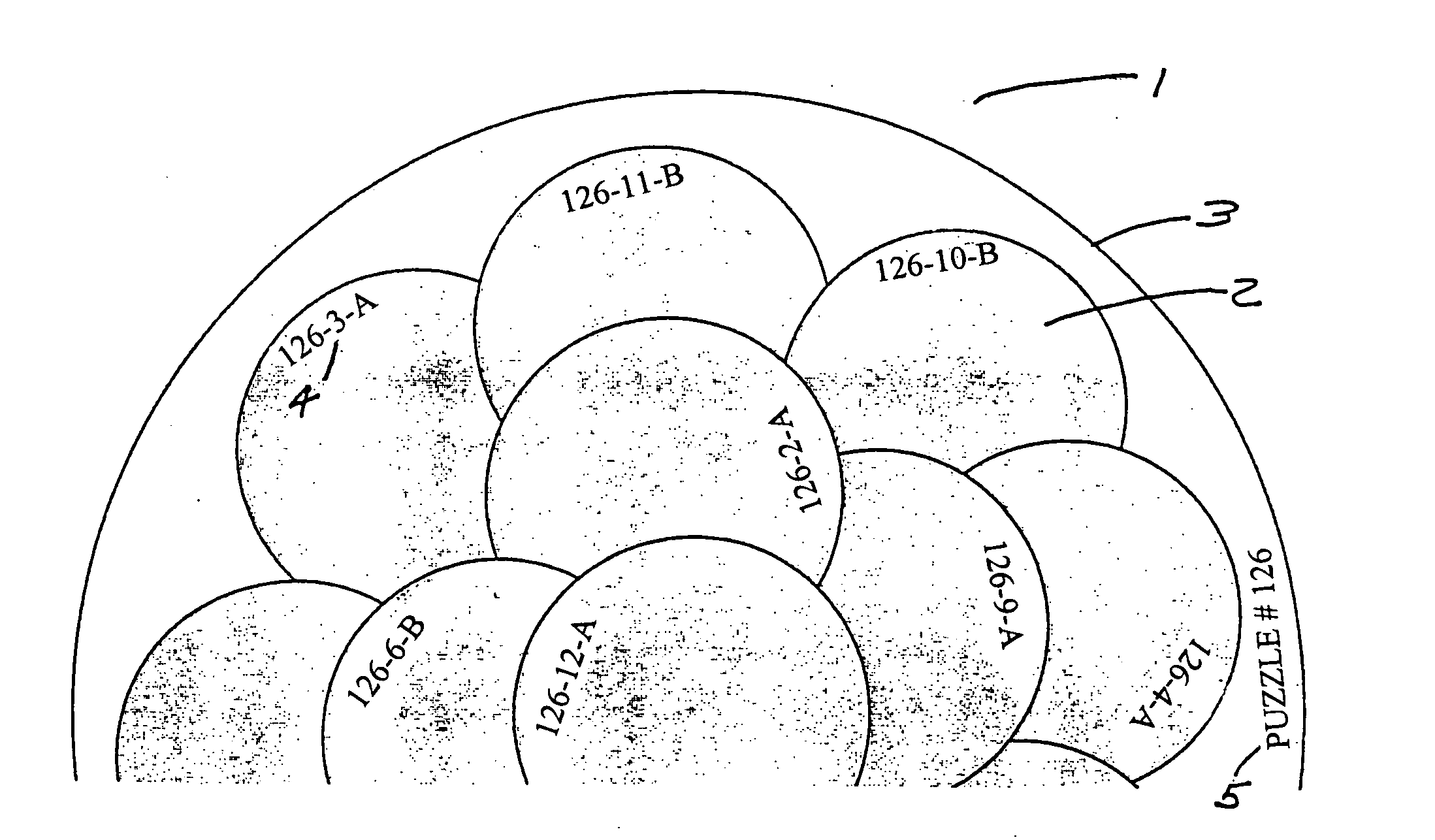

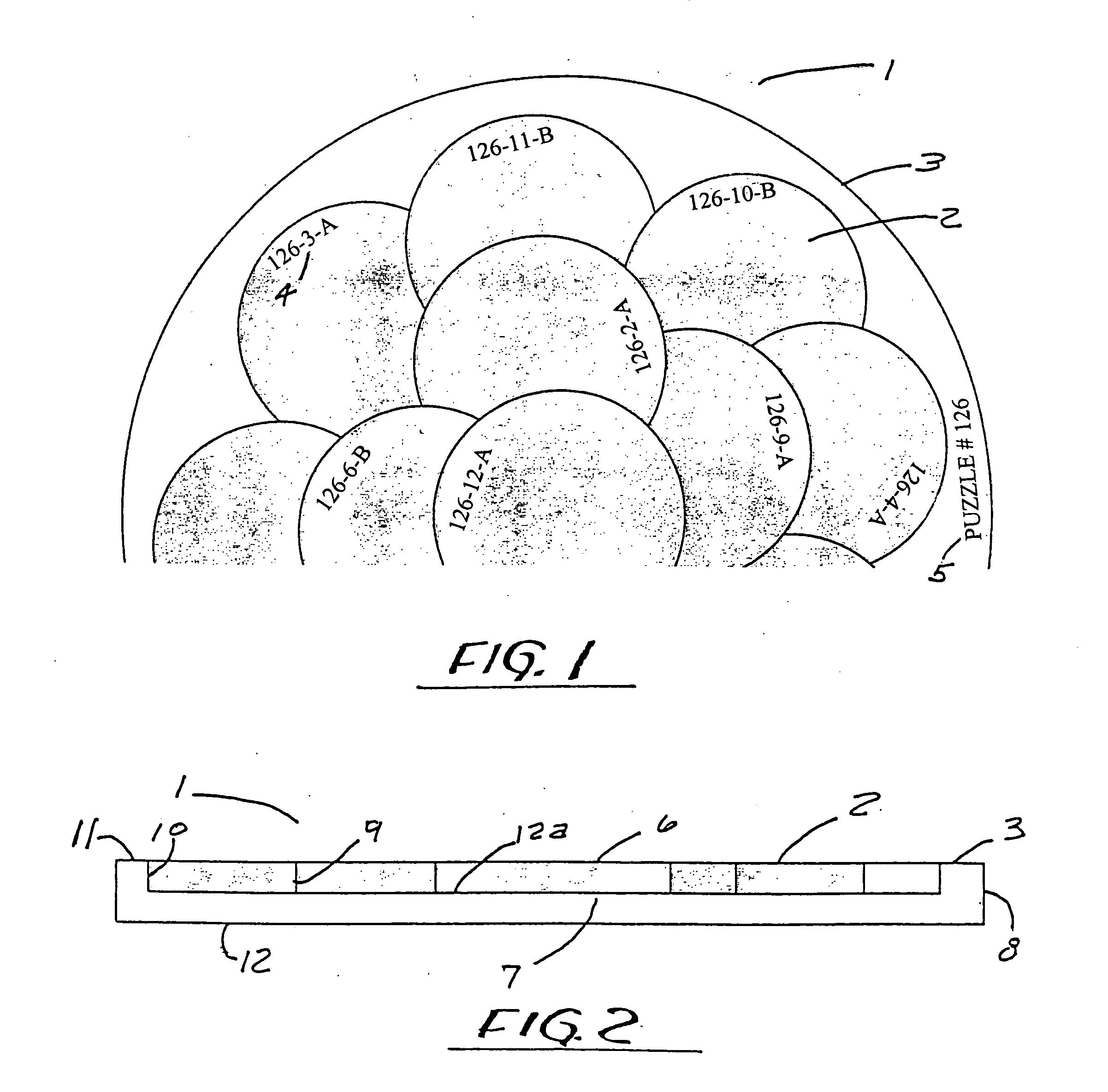

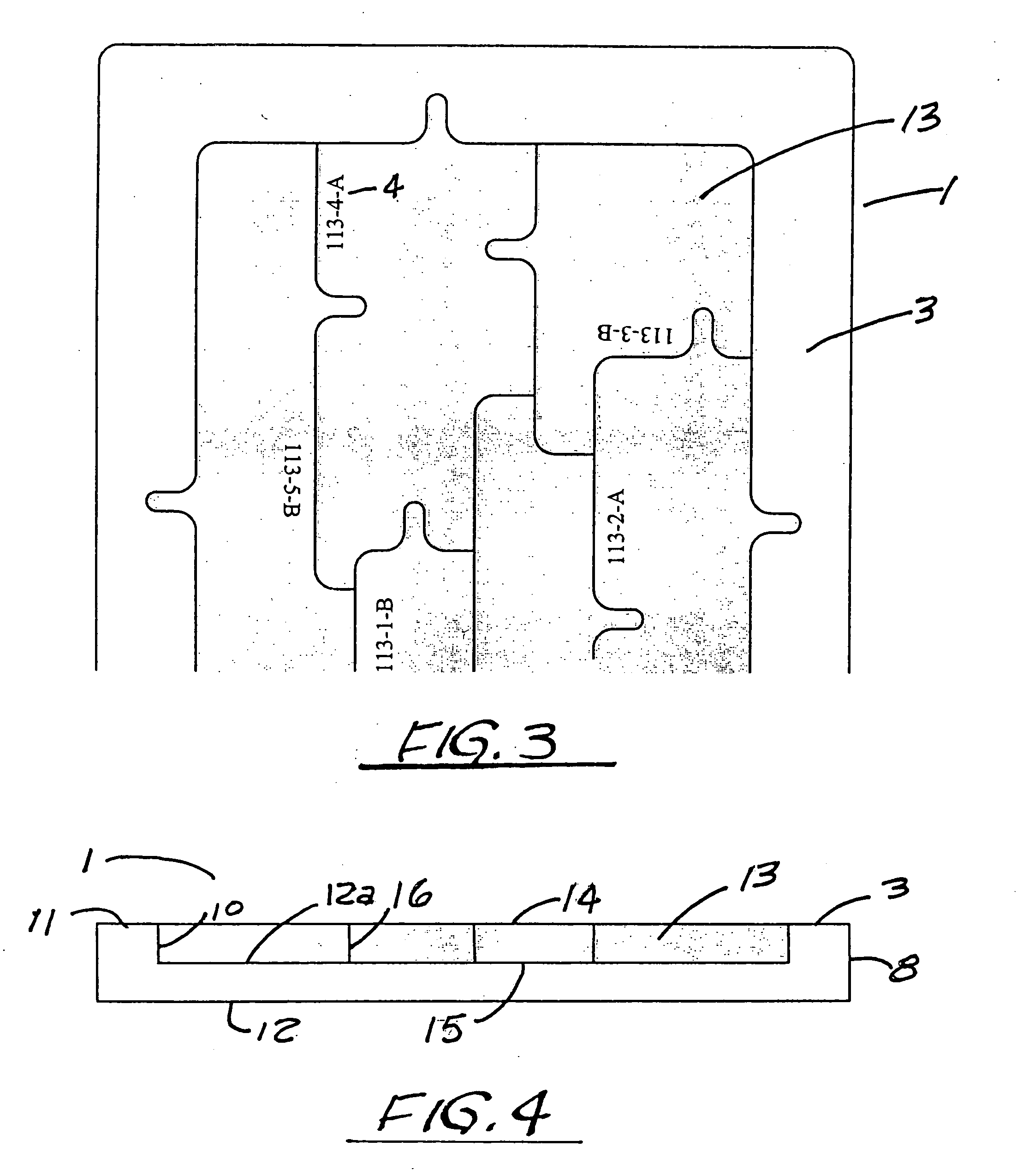

Jigsaw puzzle game system

InactiveUS20060151947A1Increase the difficulty of assemblyImprove the level ofIndoor gamesMarking outEngineering

A jigsaw puzzle game system has a number of inter-fitting pieces which combine to create a finished visual effect. None of the puzzle pieces are interchangeable. All pieces have identical top and bottom surfaces and thus could be used on either side. The pieces do not carry a visual marker or design to assist in determining where the individual pieces fit in the overall puzzle scheme. Each puzzle is a unique design with a combination of pieces that will fit no other puzzle with similar visual appearance. Each puzzle is assigned a serial number and individual part numbers are assigned to each puzzle piece. A puzzle solution map is included with each puzzle. This map includes the unique serial number of the corresponding puzzle along with a completed visual scheme with each puzzle piece indicated with a part number that corresponds with the assigned number for each puzzle piece. A method is provided for computer-generated replacement of the puzzle solution map or individual puzzle pieces through an Internet website.

Owner:FREDRICKSON SCOTT

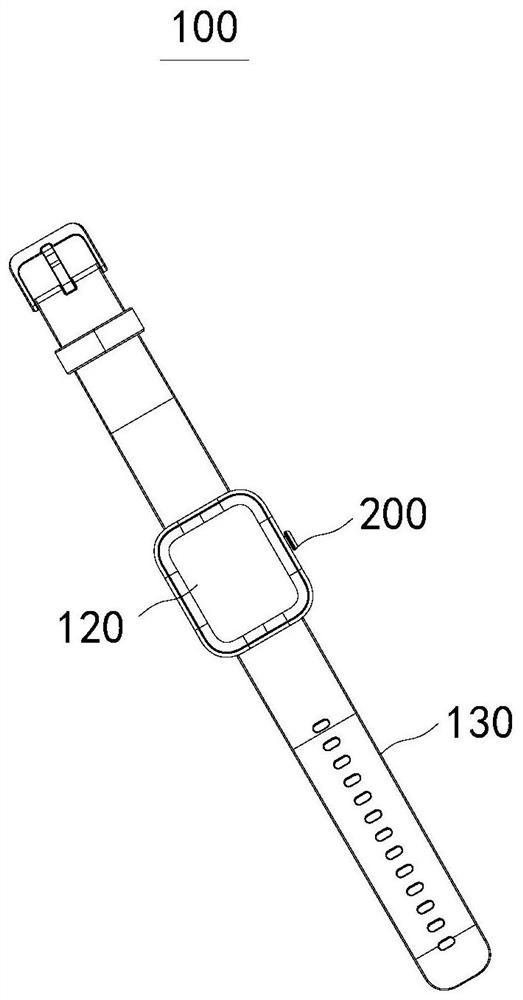

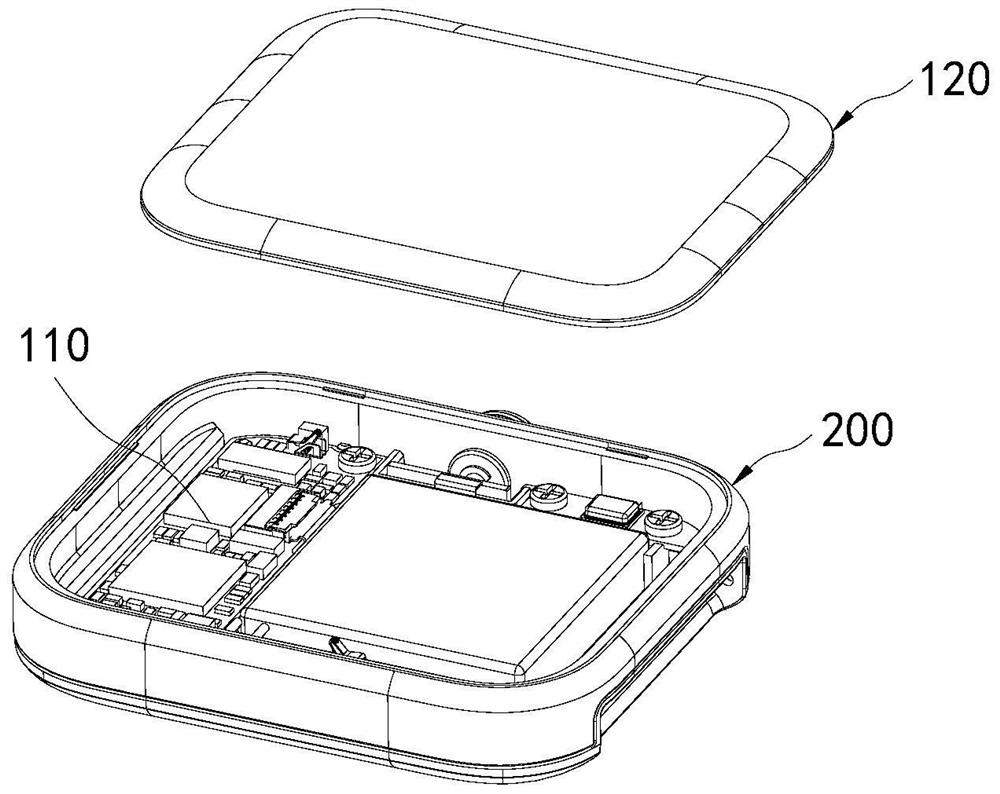

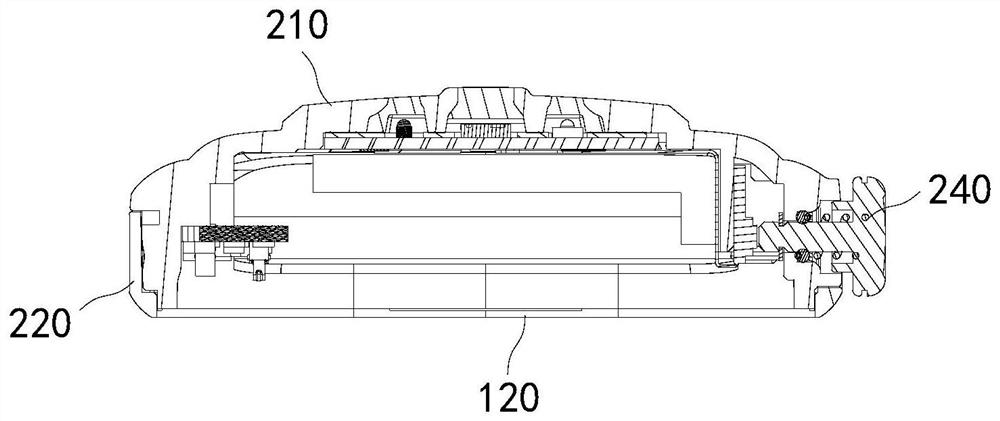

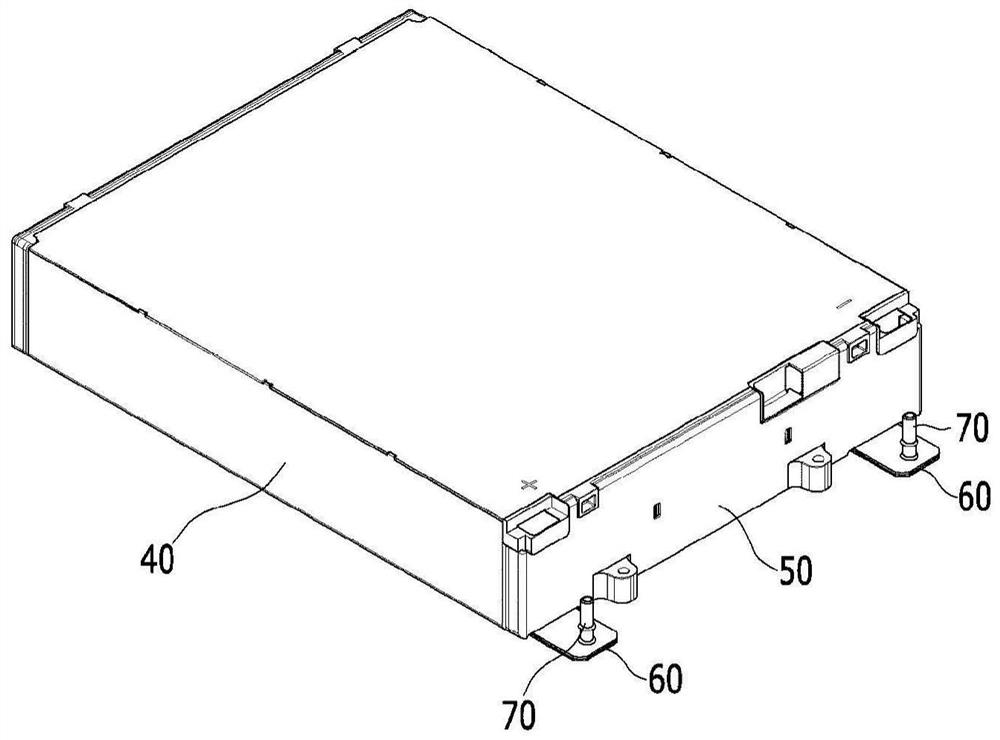

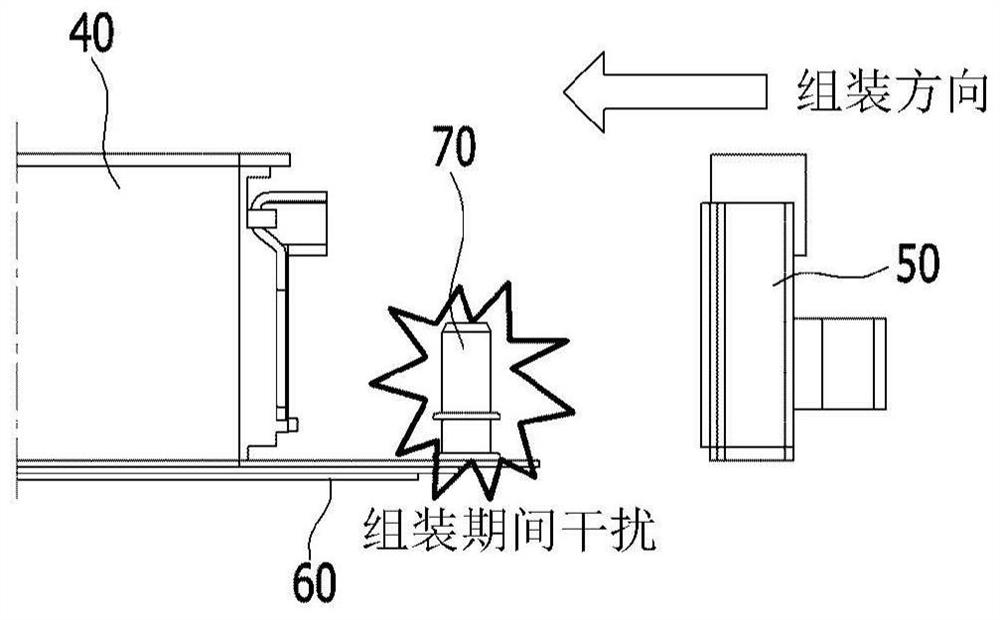

Watch body and smart watch

PendingCN112799294AGuaranteed aestheticsGuaranteed structural strengthElectronic time-piece structural detailsTime-pieces with integrated devicesEngineeringStructural engineering

The invention relates to the technical field of wearable equipment, in particular to a watch body and a smart watch. The watch body comprises a plastic seat body, a metal frame body and a display screen; a mounting groove is formed in the plastic seat body; the mounting groove is used for mounting electrical elements of a smart watch; the metal frame body is arranged on the outer side face of the plastic seat body in a sleeving mode; and the display screen is arranged on the mounting groove in a covering mode. The watch body is simple in structure, and the manufacturing and assembling difficulty and cost of the watch body can be reduced while the attractiveness and the structural strength of the watch body are guaranteed; and the metal frame body can be used as a communication antenna of the smart watch, so that the signal strength of the smart watch is improved.

Owner:SHENZHEN DO INTELLIGENT TECH CO LTD

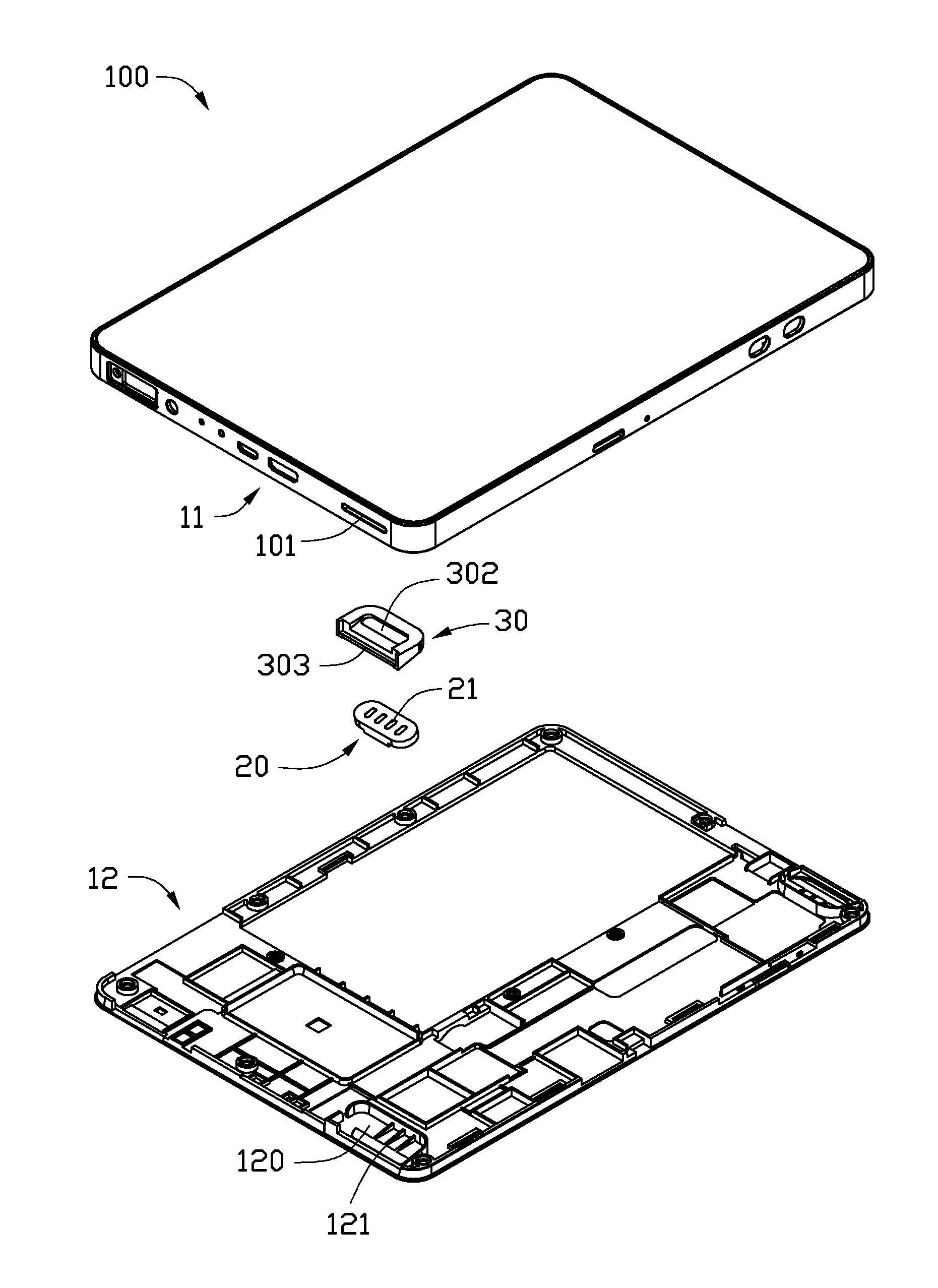

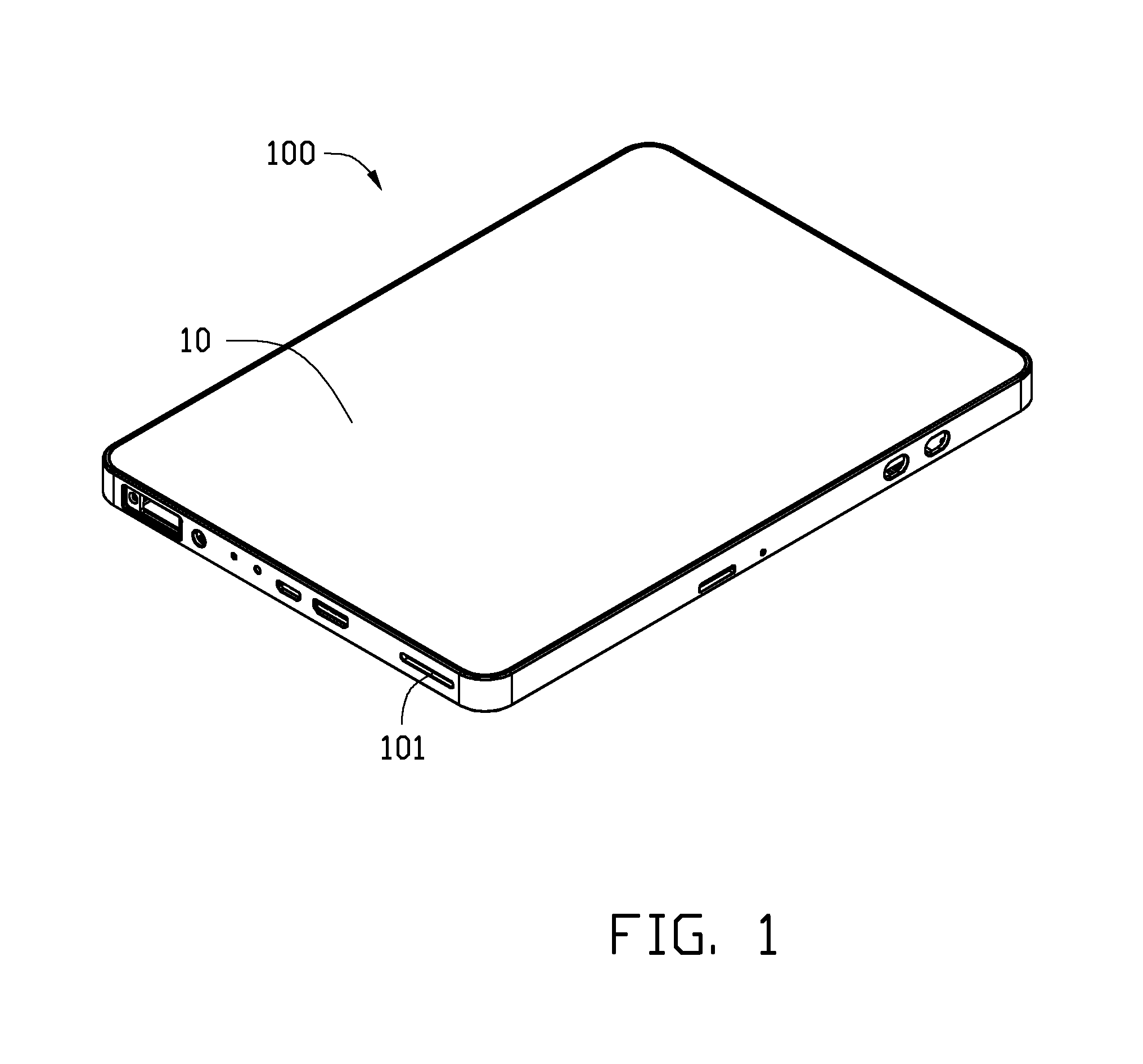

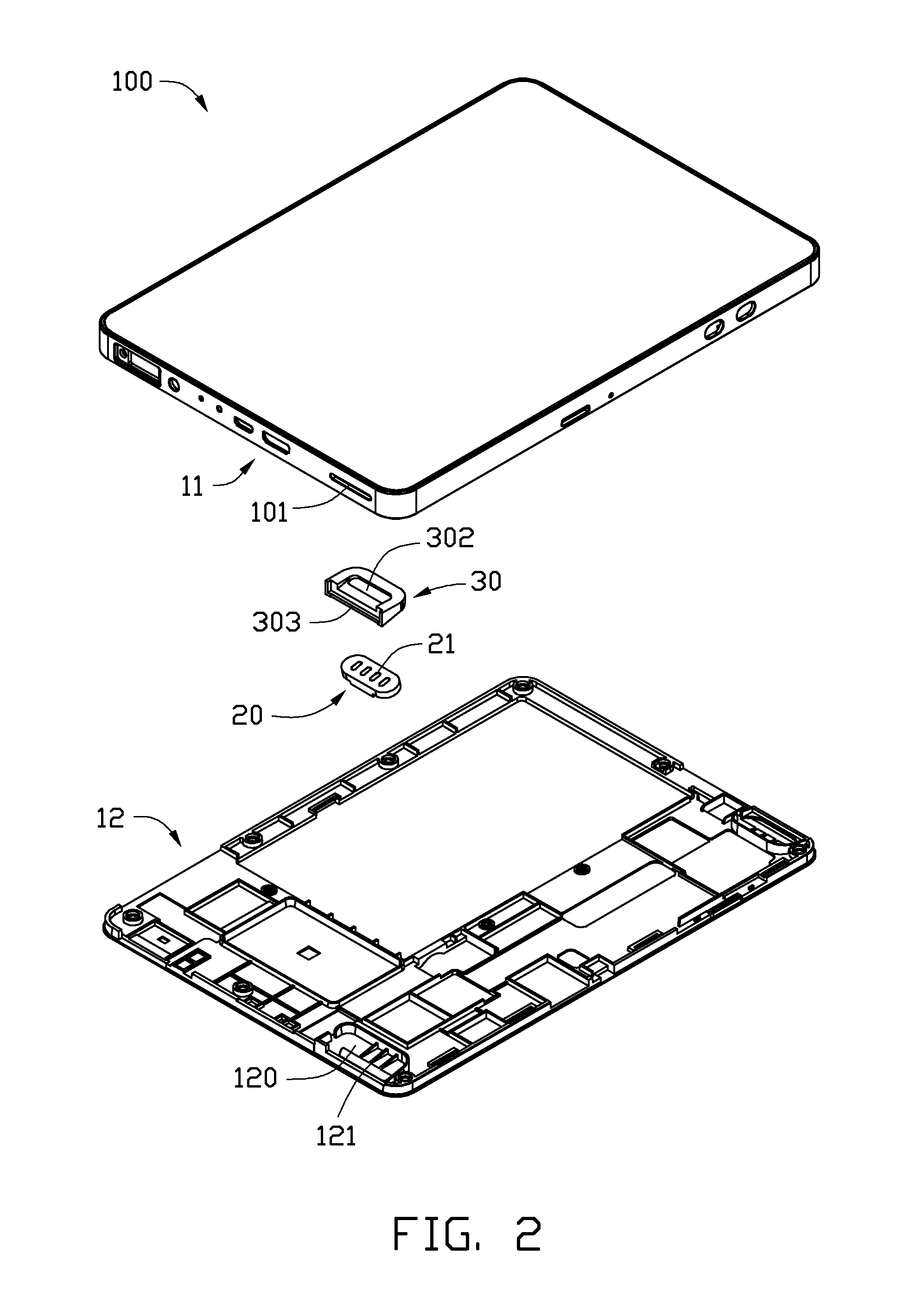

Electronic device with sound chamber

InactiveUS20130051595A1Increase the difficulty of assemblyTransducer casings/cabinets/supportsEngineeringLoudspeaker

An electronic device includes an enclosure, a speaker fixed in the enclosure, and a rubber element. The enclosure defines an exposed slot, and a speaker receiving chamber communicating with the slot. The speaker includes a first surface and a opposite second surface. The speaker is configured for radiating sound at the first surface. The rubber element includes a main body a recess and a through hole penetrating through a bottom of the recess. The speaker is inserted in the recess with the first surface facing the bottom of the recess. The combined the speaker and the rubber element are engagingly received in the speaker receiving chamber.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

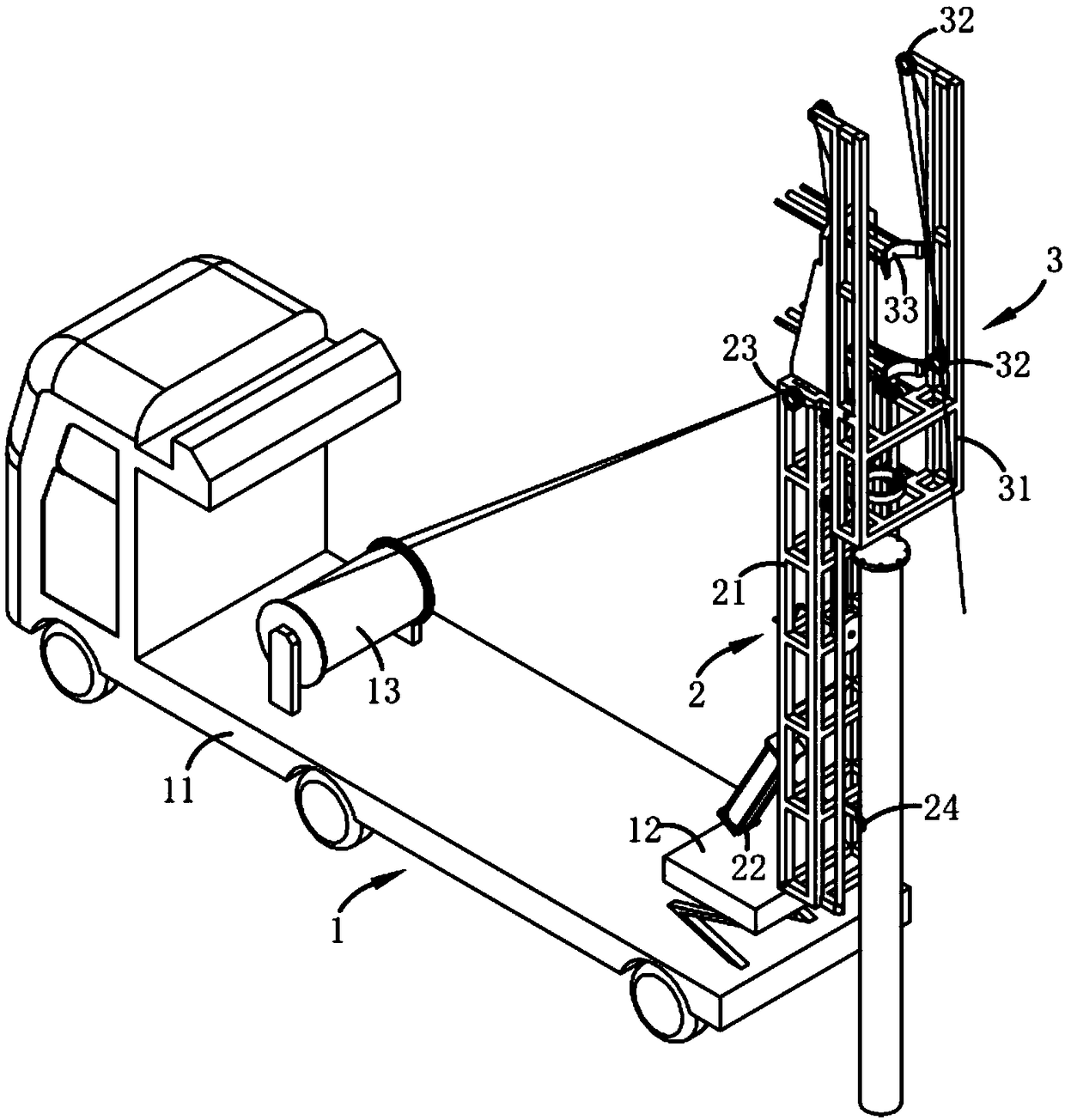

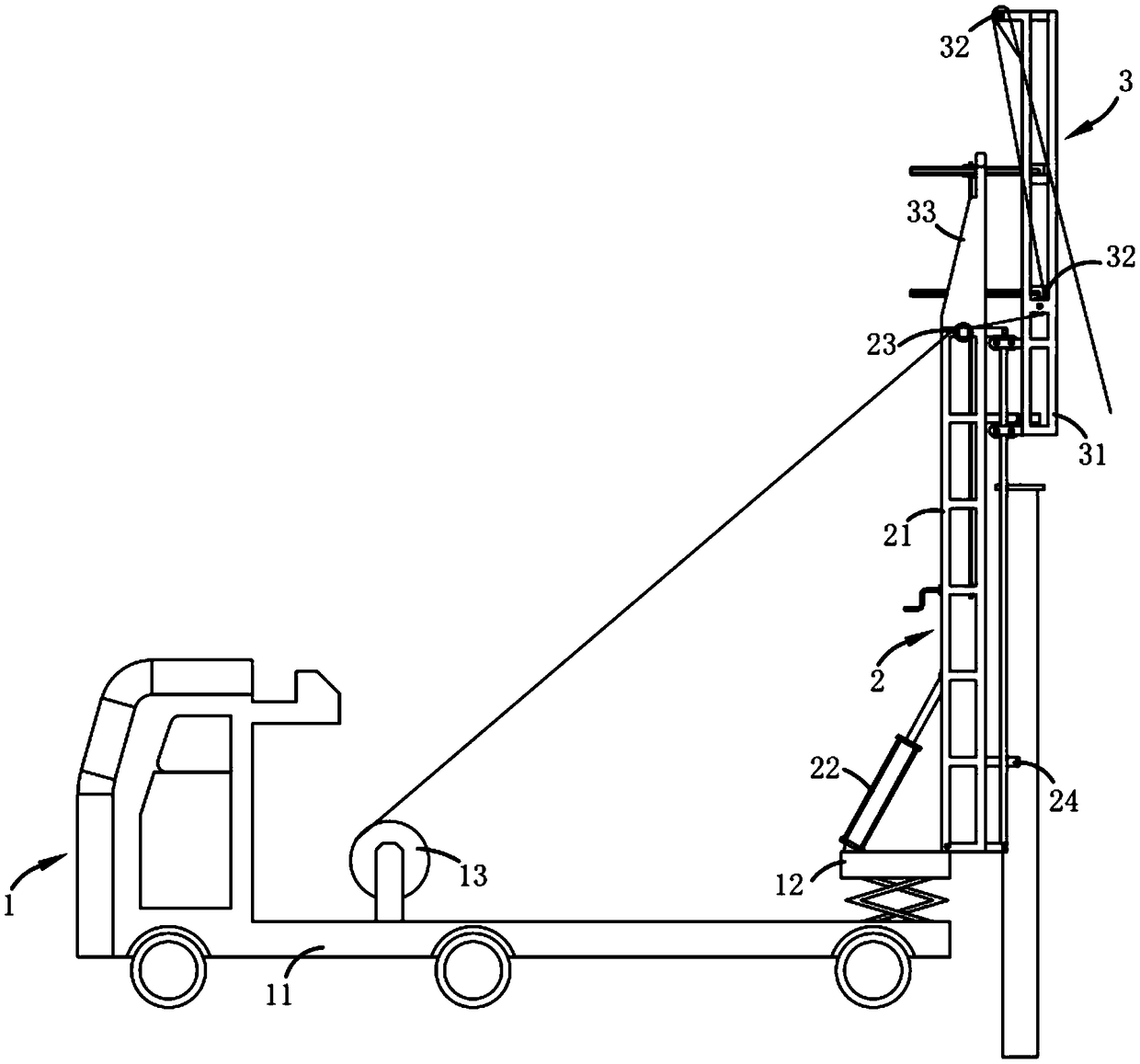

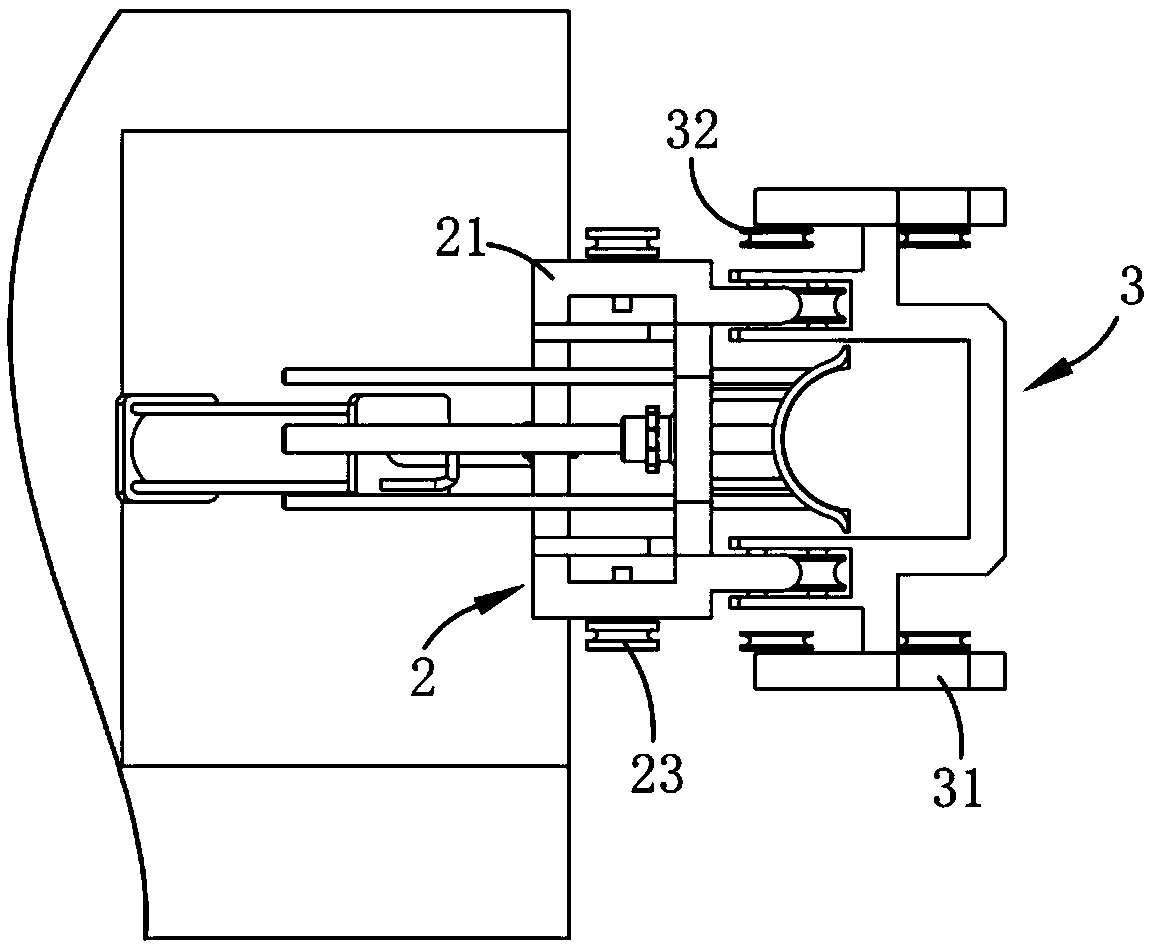

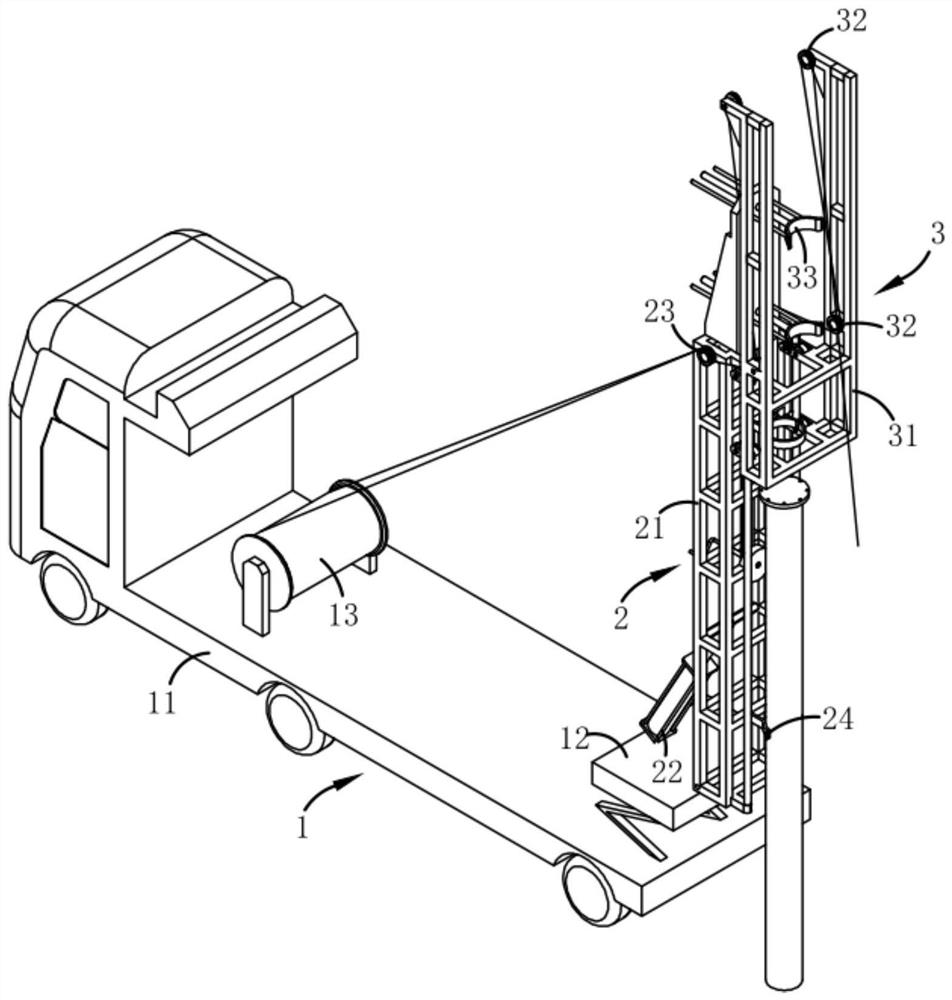

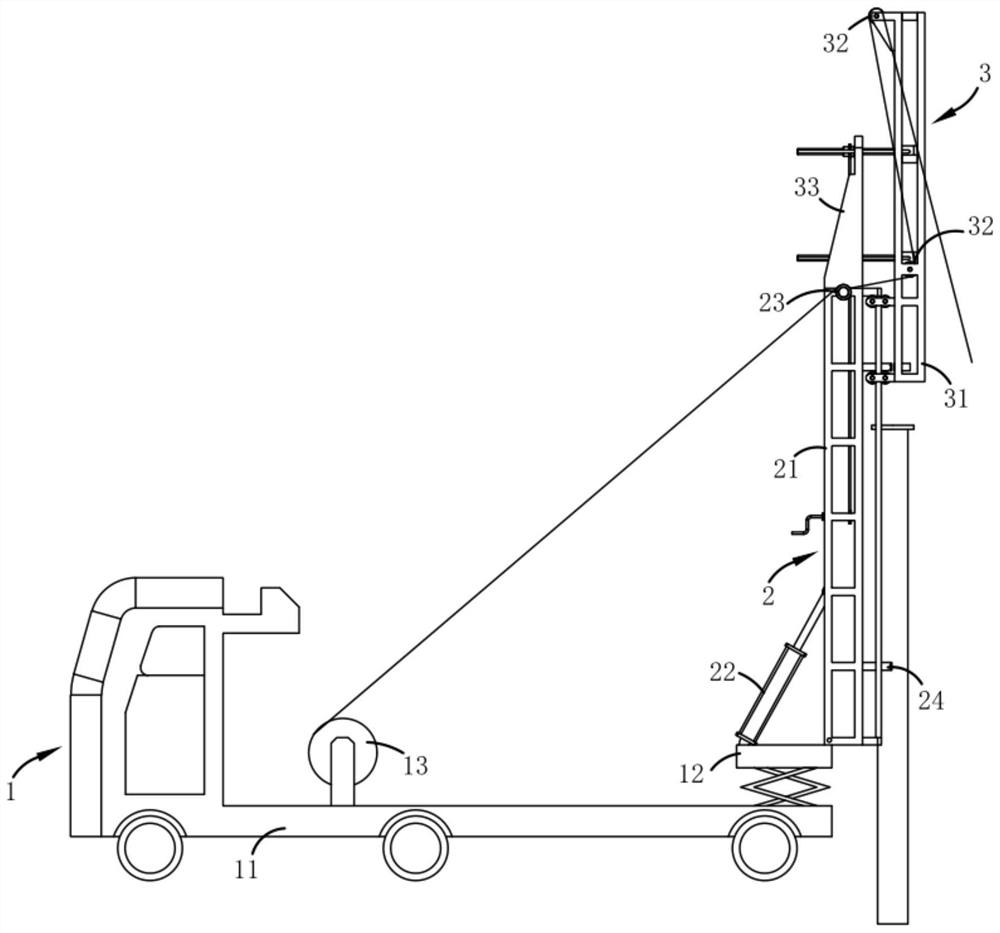

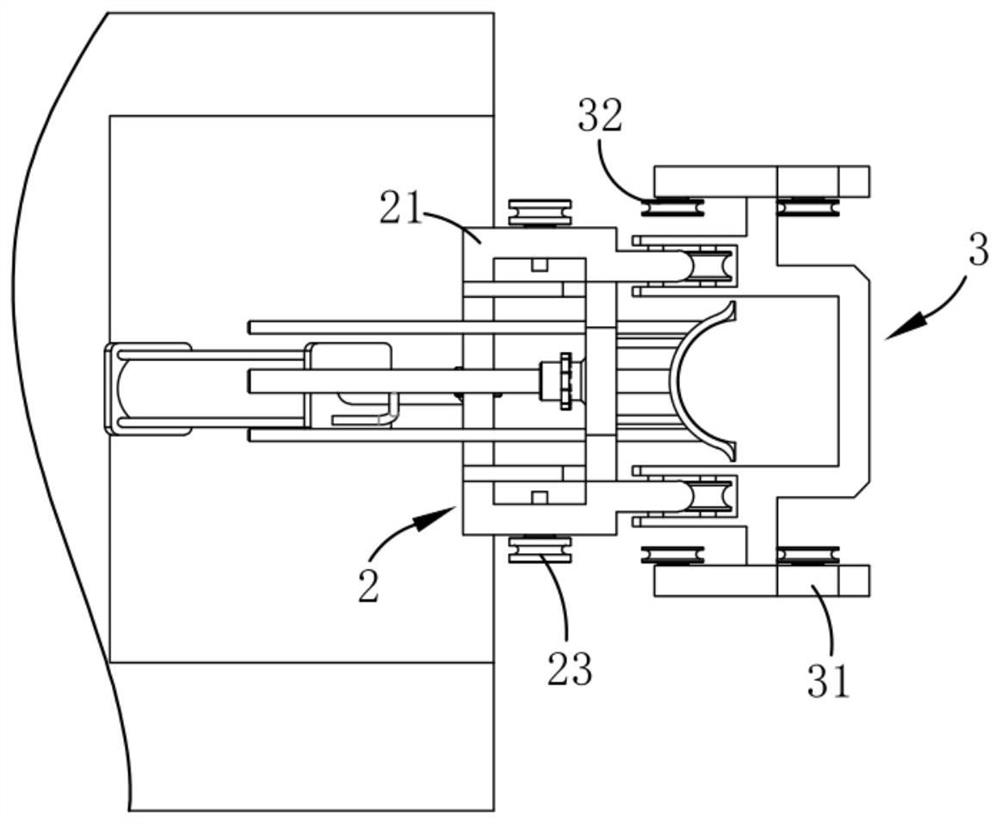

Multi-section cement pole automatic assembly and installation device

ActiveCN109083486AImprove assembly efficiencySolve complex technical problems in constructionTowersEngineeringMoving frame

The invention relates to the technical field of telegraph pole construction, in particular to a multi-section cement pole automatic assembly and installation device. The multi-section cement pole automatic assembly and installation device comprises a bearing mechanism, a primary lifting mechanism and a secondary lifting mechanism. The bearing mechanism comprises a transfer vehicle, a bearing platform and a dragging assembly. The primary lifting mechanism comprises a bracket, a drive assembly, a supporting assembly and a positioning assembly. The secondary lifting mechanism comprises a moving frame arranged on the bracket, a lifting assembly arranged on the moving frame, connected with the supporting assembly and used for lifting an auxiliary rod, and a translation assembly arranged on thebracket and used for positioning and transferring the auxiliary rod on the lifting assembly. Through the special structure arrangement of the primary lifting mechanism and the secondary lifting mechanism, a main rod and the auxiliary rod are constructed in sequence, the auxiliary rod is laterally dragged through the lifting assembly, the auxiliary rod is supported through the translation assembly,the auxiliary rod is lifted above the main rod and then stably and accurately subjected to translation, and the auxiliary rod and the main rod are rapidly assembled. The technical problem that in theprior art, a multi-section telegraph pole is complex in construction is solved.

Owner:临泉鹏成机电技术有限公司

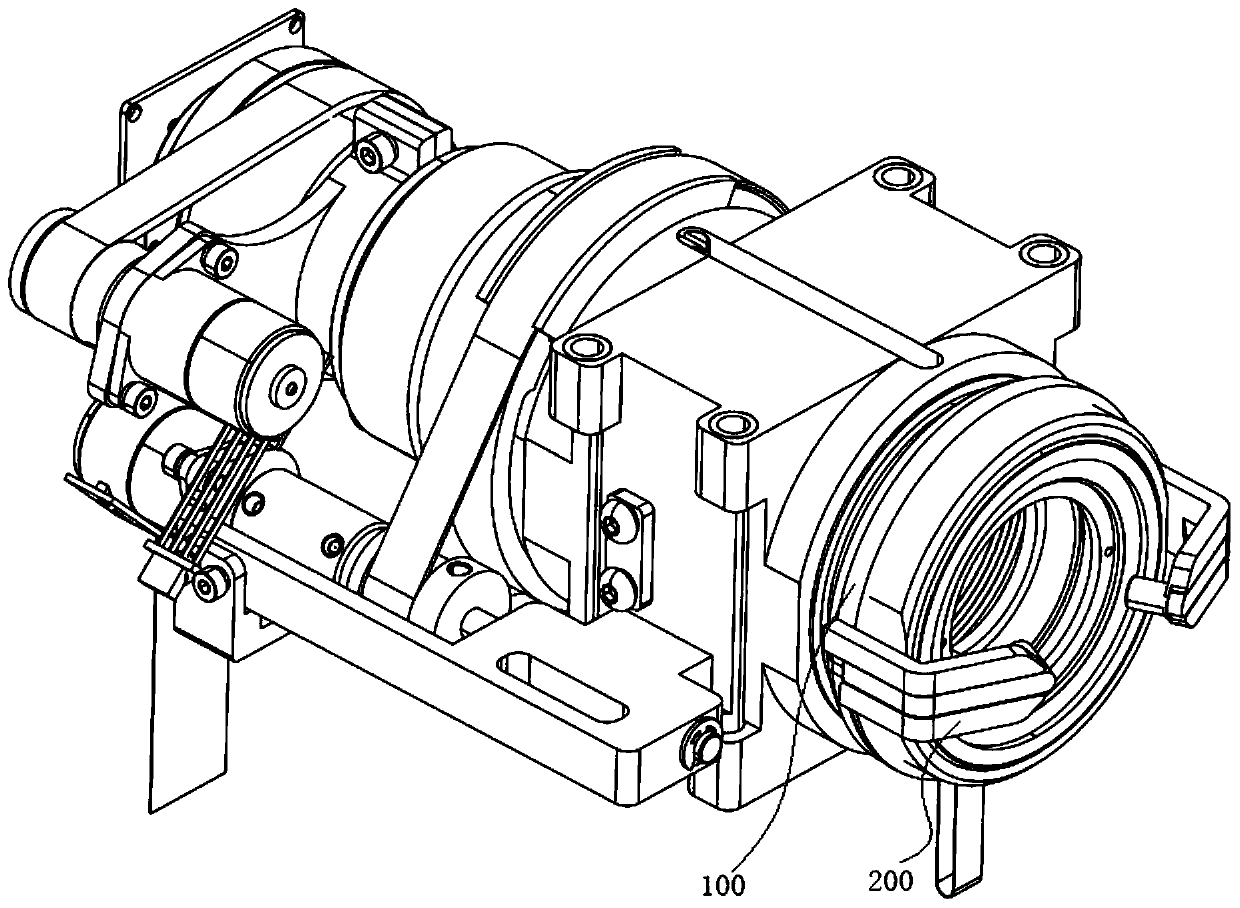

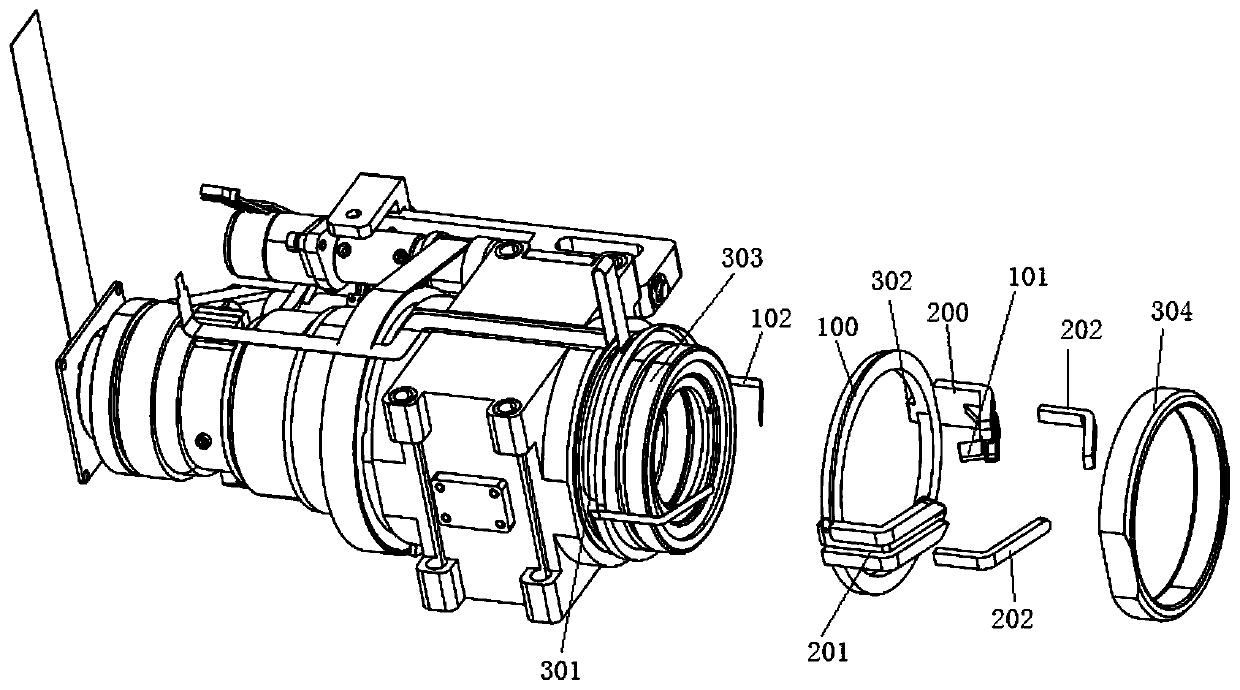

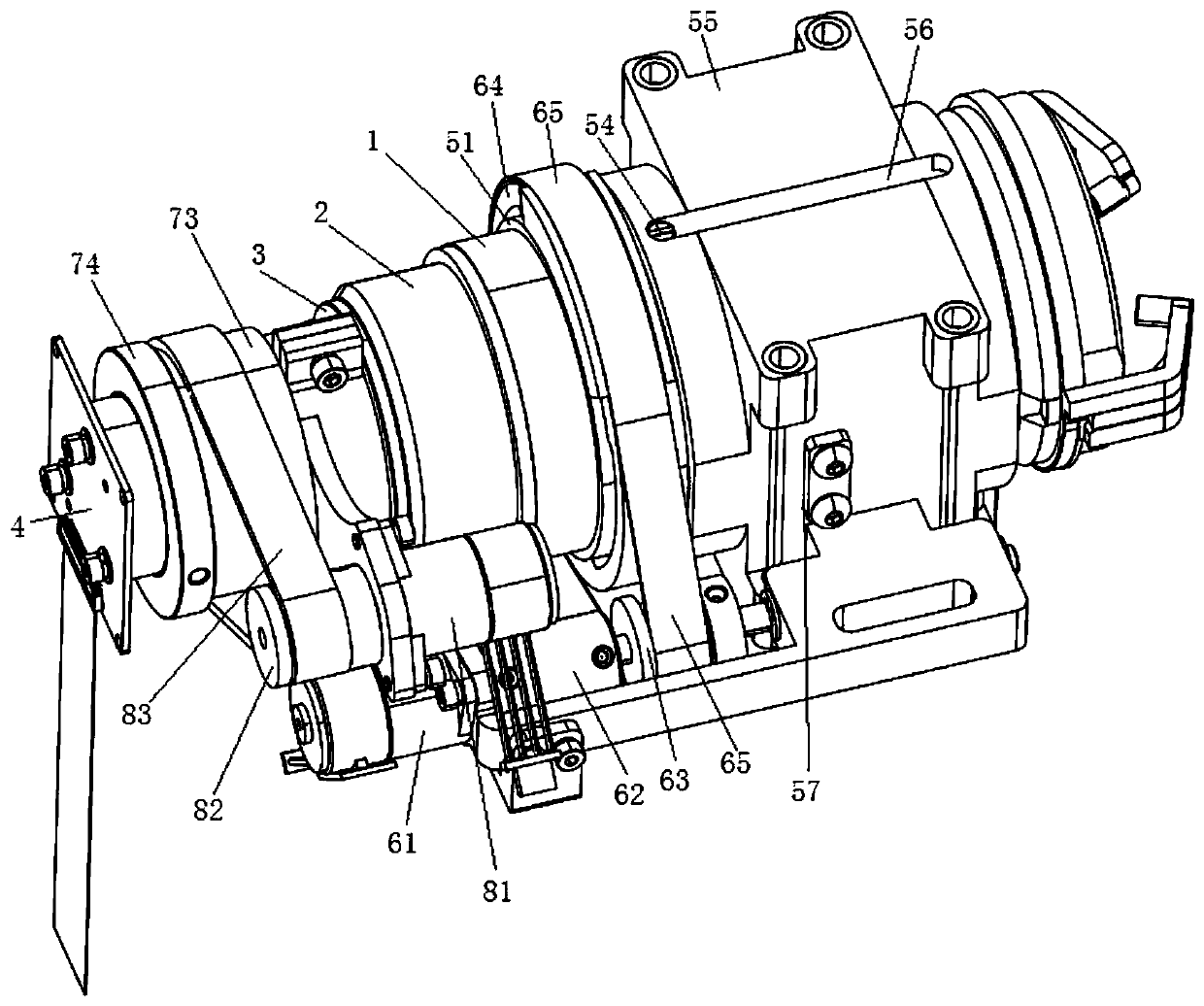

Fundus camera fixation device and fundus camera

PendingCN110960188AIncrease the difficulty of assemblyIncrease the volume of the lens barrelOthalmoscopesOphthalmologyOptics

The invention provides a fundus camera fixation device and a fundus camera. The fixation device comprises an annular fixing piece which is fixedly connected to the outer side of one end of a front lens cone through a fixation structure and at least one mounting arm. One end of the at least one mounting arm is fixedly connected with the annular fixing piece and the other end of the at least one mounting arm extends to be opposite to one end part of the front lens cone and is provided with a mounting position for mounting a fixation lamp. According to the fundus camera fixation device, a fixation lamp is installed outside the lens cone through the fixation device, so that the assembly difficulty of the fundus camera is not increased, the size of the lens cone is not increased, and the cost increase is small.

Owner:SHANGHAI EAGLEVISION MEDICAL TECH CO LTD

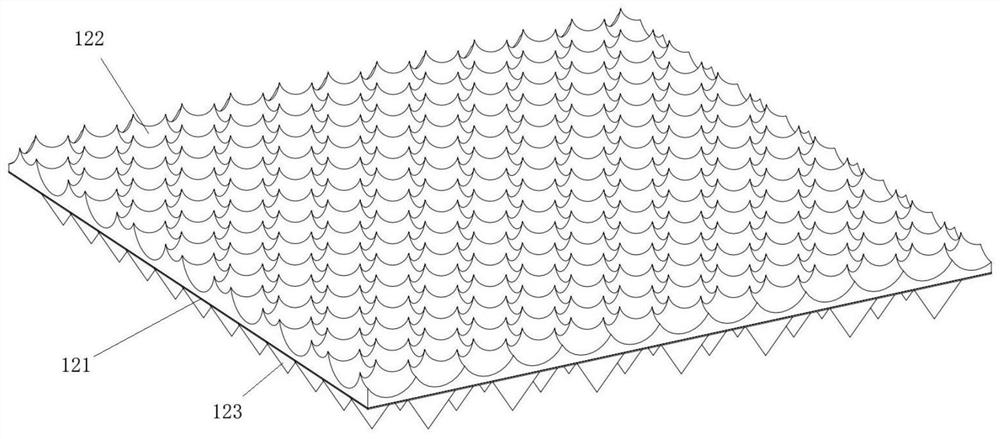

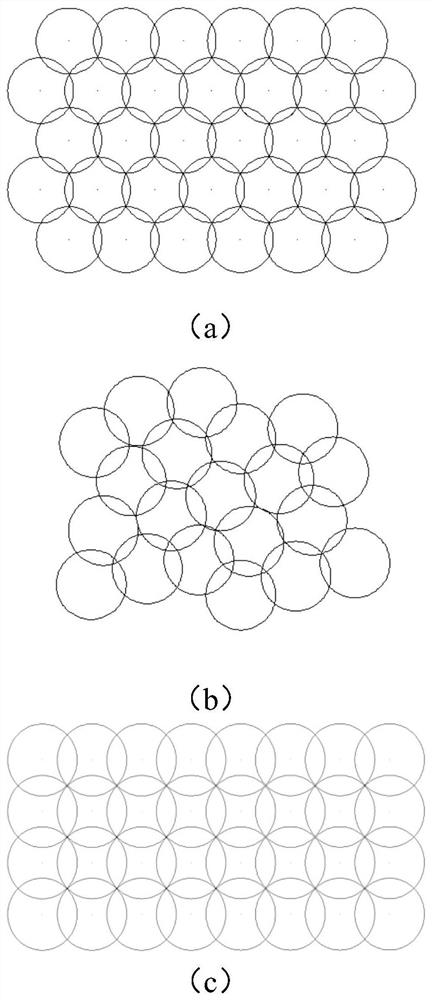

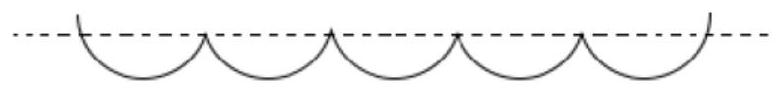

Mini LED dodging sheet, preparation process thereof, and backlight module

PendingCN113156550AHigh light transmittanceReducing Mini LED Power RequirementsDiffusing elementsNon-linear opticsMicrolensTransmittance

The invention discloses a Mini LED dodging sheet, a preparation process thereof and a backlight module, the dodging sheet comprises a substrate, a plurality of micro lens structures arranged at one side of the substrate and a convex lens structure arranged at the other side of the substrate, the plurality of micro lens structures are arranged in a plurality of rows, and the convex lens structure is arranged on the other side of the substrate. The multiple micro-lens structures in two adjacent rows are arranged in a staggered mode or a random mode or an orthogonal mode, the two adjacent micro-lens structures are partially overlapped, each micro-lens structure comprises a concave structure and / or a convex structure, and the convex lens structure comprises multiple convex lens bodies with set shapes. According to the Mini LED dodging sheet, the micro lens structure is arranged at one side of the Mini LED dodging sheet, the convex lens structure is arranged at the other side of the Mini LED dodging sheet, so that a lamp bead panel emits light uniformly, the utilization efficiency of the light is improved, the light transmittance is enhanced while the haze is guaranteed, the superposition photoetching technology is adopted, and the duty ratio of the micro lens structure on the Mini LED dodging sheet can reach 100%.

Owner:NICROTEK +2

Welding manufacturing process method of large-scale fully welded structure water turbine ball valve

ActiveCN107243704BIncrease the difficulty of assemblyIncrease in sizeWelding apparatusManufacturing technologyWater turbine

The invention discloses a welding manufacturing technology method of a large water turbine ball valve of an all-welded structure. The method represents innovation of an assembly-welding technology method of the large water turbine ball valve of the all-welded structure and is the essential change of the manufacturing method. The technological scheme of coating high-temperature-resistant paint before assembly welding of a shaft sleeve as a welding auxiliary tool, a valve and a valve body single-piece and performing symmetric welding in the vertical welding position during rotating of the valve is applied for the first time, with the adoption of the method, accessibility and operability of welding are greatly improved, welding deformation is effectively controlled, quality of a ball valve welding seam is guaranteed by intermediate flaw detection, critical dimensional stability of the ball valve is guaranteed, and the assembly-welding quality of the large water turbine ball valve of the all-welded structure is remarkably improved accordingly.

Owner:HARBIN ELECTRIC MASCH CO LTD

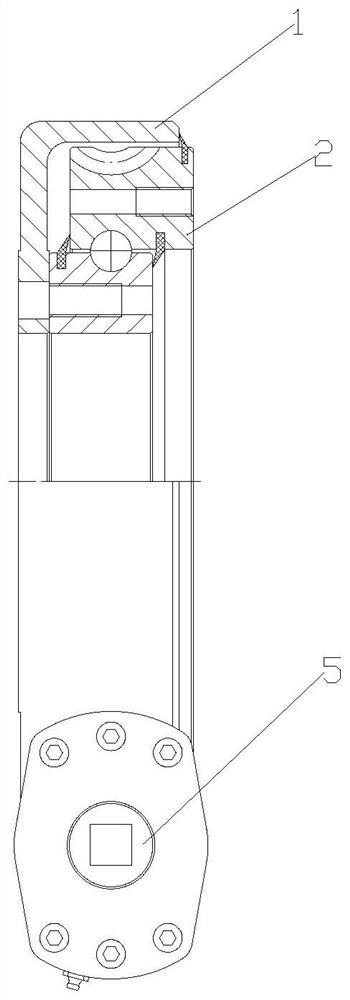

Slewing bearing worm wheel outer gear ring processing method and rotary driving device

InactiveCN111618542AImprove carrying capacityHigh strengthToothed gearingsGearing detailsSlewing bearingWorm drive

The invention discloses a slewing bearing worm wheel outer gear ring processing method and a rotary driving device. The processing method comprises the following steps: rough turning, semi finish turning, roller path thermal treatment, tempering, finish turning, hobbing, hole processing and roll path lathing and grinding. The rotary driving device comprises a worm wheel slewing bearing and a worm;conical roller bearings are arranged on the two side walls of the worm; a slewing bearing worm wheel outer gear ring is processed through a large-diameter hob; when the worm wheel and the worm drivefor operation, certain space exists between the dedendum circle of the worm wheel and the addendum circle of the worm, and an artificial oil culvert is formed in the space, so that the lubricating condition can be effectively improved and the actual contact area can be enlarged, the coefficient of friction and the contact stress value are reduced, and the purpose of improving the driving bearing capacity of the worm wheel and the worm is finally realized; and in addition, the worm wheel is processed by adopting the large-diameter hob, drum type modification is carried out in the tooth direction, and along with load increase, the contact spot becomes larger and larger, so that the bearing capacity of the worm wheel is improved, the transmission noise of a rod pair is lowered, and the service life is prolonged.

Owner:MAANSHAN JINGYI ENG MACHINERY

Electric control actuator, tail gas treatment system and vehicle

ActiveCN114017212ACompact locationIncrease profitElectrical controlOperating means/releasing devices for valvesGear wheelElectric machinery

The invention provides an electric control actuator, a tail gas treatment system and a vehicle, the electric control actuator comprises a lower shell and an upper shell, and the lower shell or the upper shell is provided with a plurality of first matching holes; wherein the lower shell and the upper shell are matched to form a mounting space; the actuator further comprises an isolation plate which is clamped between the lower shell and the upper shell, and the isolation plate is provided with a plurality of second matching holes, wherein the first matching holes and the second matching holes are connected in a matched mode through positioning pieces; and a compact gear assembly and a driving motor arranged in the mounting space, wherein the compact gear assembly is connected with the driving motor in a matched mode. The electric control actuator solves the technical problem that the overall size of the electric control actuator is large due to the fact that the internal structure of the electric control actuator is not finely arranged.

Owner:NINGBO COLET ELECTRICAL APPLIANCE +1

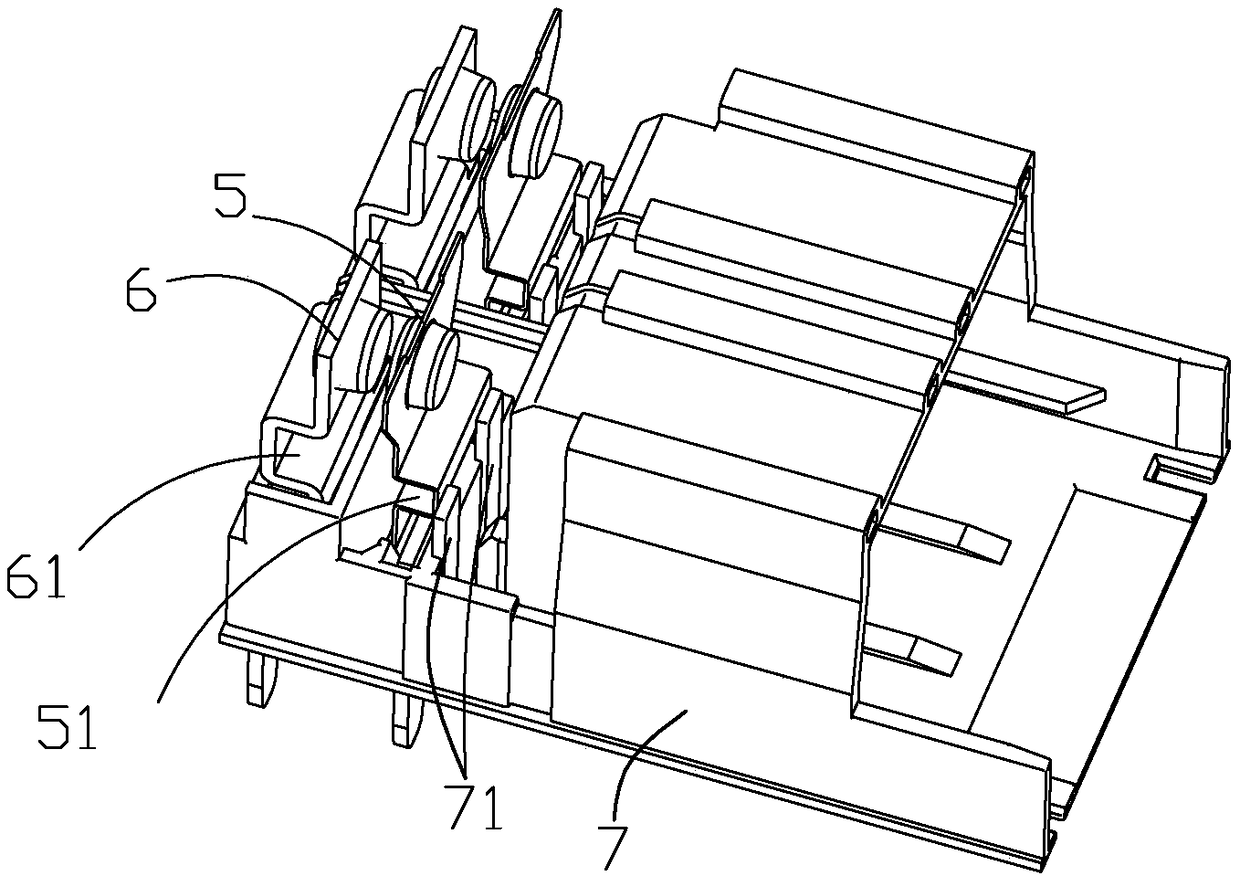

Small-sized electromagnetic relay applicable to intelligent socket

PendingCN108321034AReliable breakingImprove current carrying capacityElectromagnetic relay detailsCarrying capacityEngineering

The invention discloses a small-sized electromagnetic relay applicable to an intelligent socket. The small-sized electromagnetic relay comprises a body, and a magnetic circuit part and at least two groups of contact parts which are arranged on the body, wherein the magnetic circuit part comprises a coil, a yoke and an armature; all the groups of contact parts comprise dynamic springs and static springs; the dynamic springs and the static springs are matched; first bent parts are respectively arranged on the dynamic springs and the static springs. By arrangement of the first bent parts, the flat plate design of the conventional static springs and dynamic springs is changed, so that on the basis of not increasing the manufacturing cost and the assembling difficulty, aims that the relay enlarges a current carrying area of a reed under a finite volume and improves the current carrying capacity of the reed are fulfilled; according to the quantity of the contact parts, at least two groups offirst bent parts are designed, so that the relay disclosed by the invention can switch on and switch off a zero line and a live wire; the safety of the intelligent socket is improved; mounting requirements of the socket for a high load and a small size are met.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

Spherical support with additional anti-drawing function

InactiveCN113005889ARealize synchronous rotationFirmly connectedBridge structural detailsEngineeringSlide plate

The invention provides a spherical support with an additional anti-drawing function. The spherical support comprises an upper support plate, a sliding plate, a piston and a lower support plate, wherein the piston and the lower support plate are matched with each other; a concave spherical surface and a convex spherical surface are arranged at the two ends of the piston respectively, a second middle seat plate is placed in the concave spherical surface, and a first middle seat plate is placed on the convex spherical surface; the second middle seat plate is located between the piston and the lower support plate. The second middle seat plate and the first middle seat plate are spherical surfaces with the same arc direction. The problems existing in two existing technical schemes in the background technology are ingeniously solved, including the defects that the structural size of the first technical scheme is too large, and the second technical scheme is difficult to assemble, complex in structure and prone to loosening.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

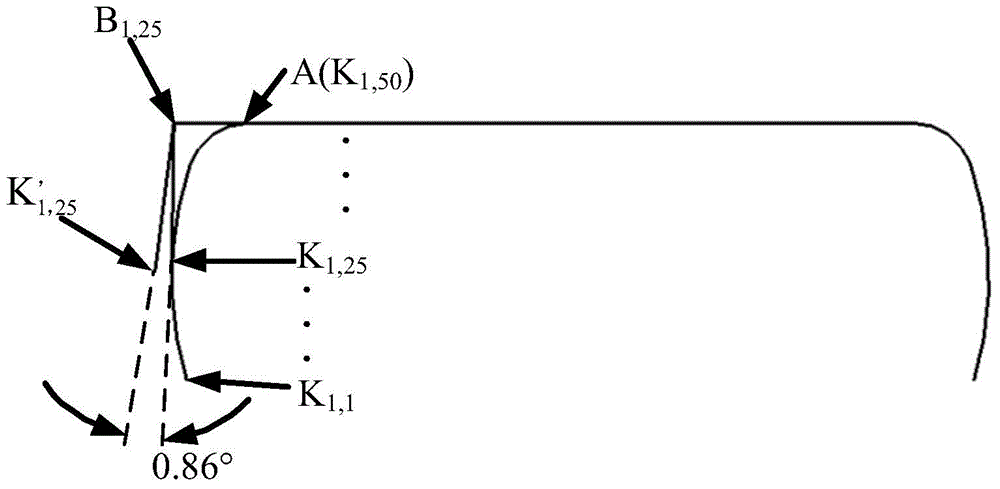

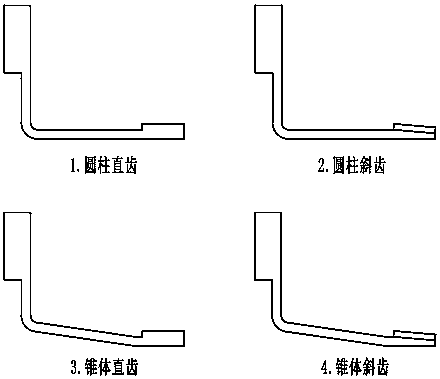

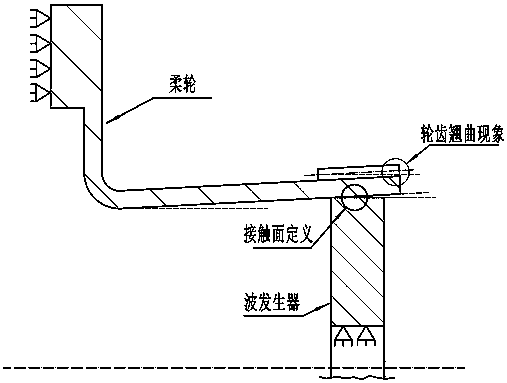

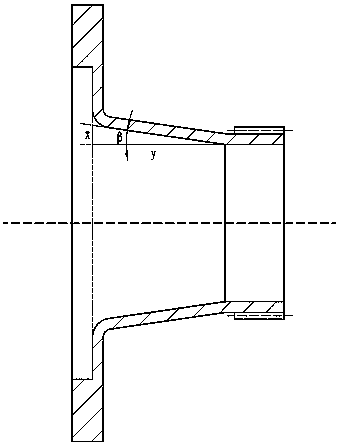

Flexible gear structure designing and optimizing method

InactiveCN108460227ASimple structureReduce processing costsGeometric CADDesign optimisation/simulationExtended finite element methodHarmonic

The invention provides a harmonic reducer flexible gear structure designing and optimizing method. The harmonic reducer flexible gear structure designing and optimizing method comprises, firstly, forsolving the problem that existing harmonic flexible gears have radial warping of gear teeth after being assembled, performing similarity and contradiction analysis to acquire a number of initial design schemes; extracting the eigenvalues of every scheme through FEM (finite element method) for analysis; performing universal solution of an optimal scheme through response surface analysis and CCD (cyclic-coordinate descent) algorithm. The flexible gear structure designing and optimizing method designs a novel form of tapered flexible gear structure and is of great significance to reducing tooth warping of flexible gears and improving the contact ratio of teeth of the flexible gears.

Owner:长沙大衡智能科技有限公司

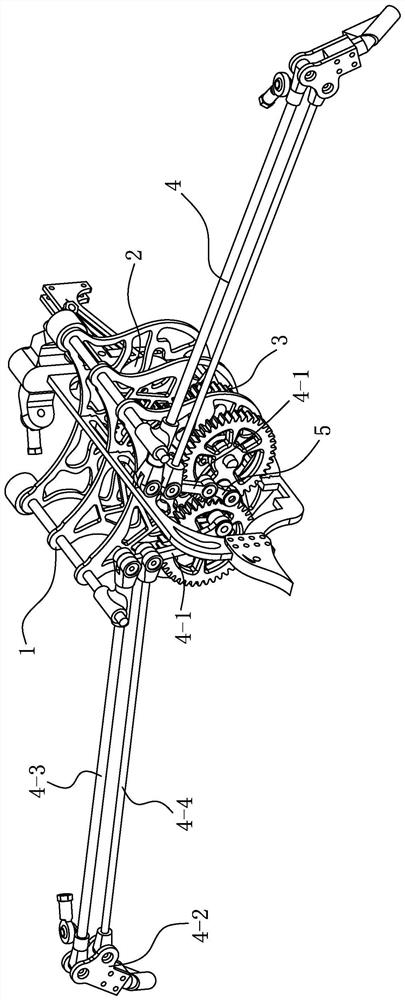

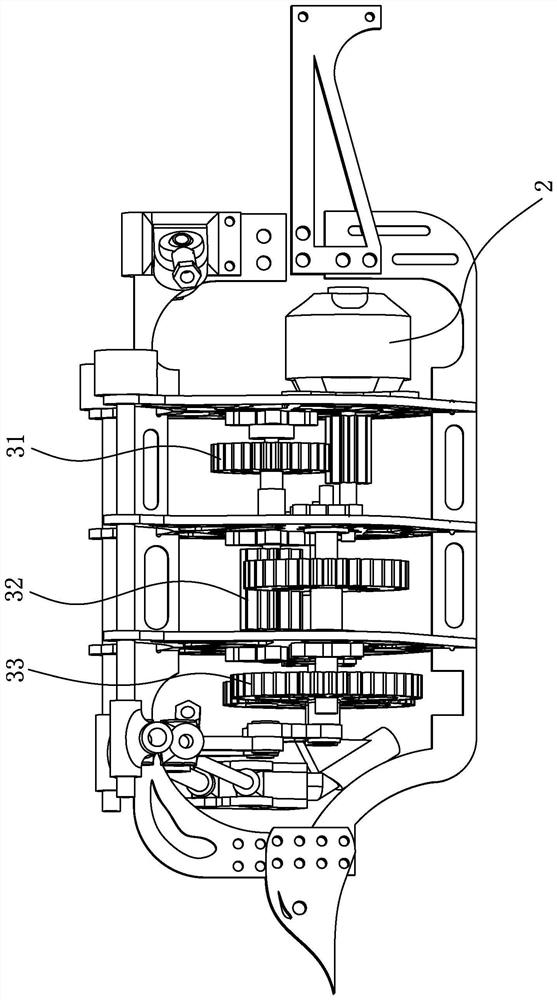

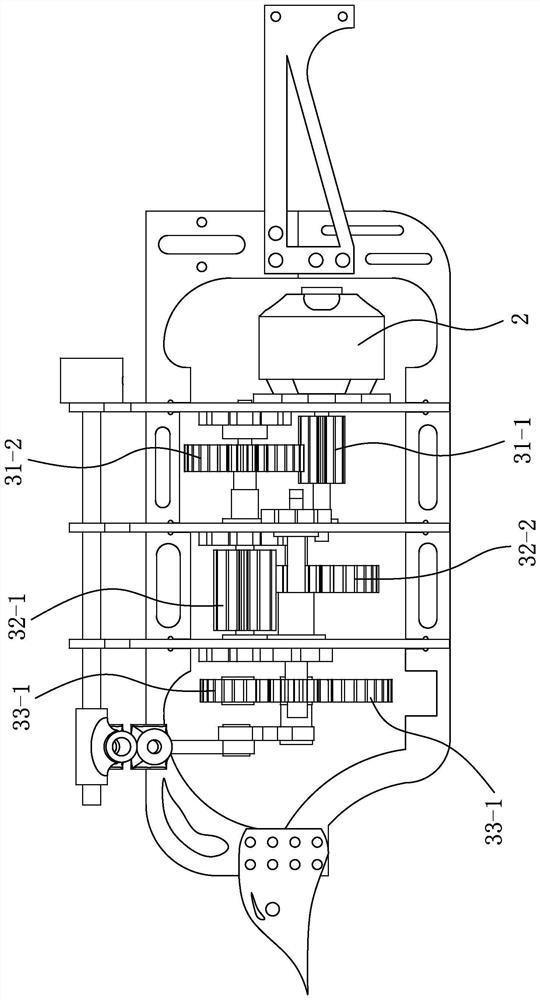

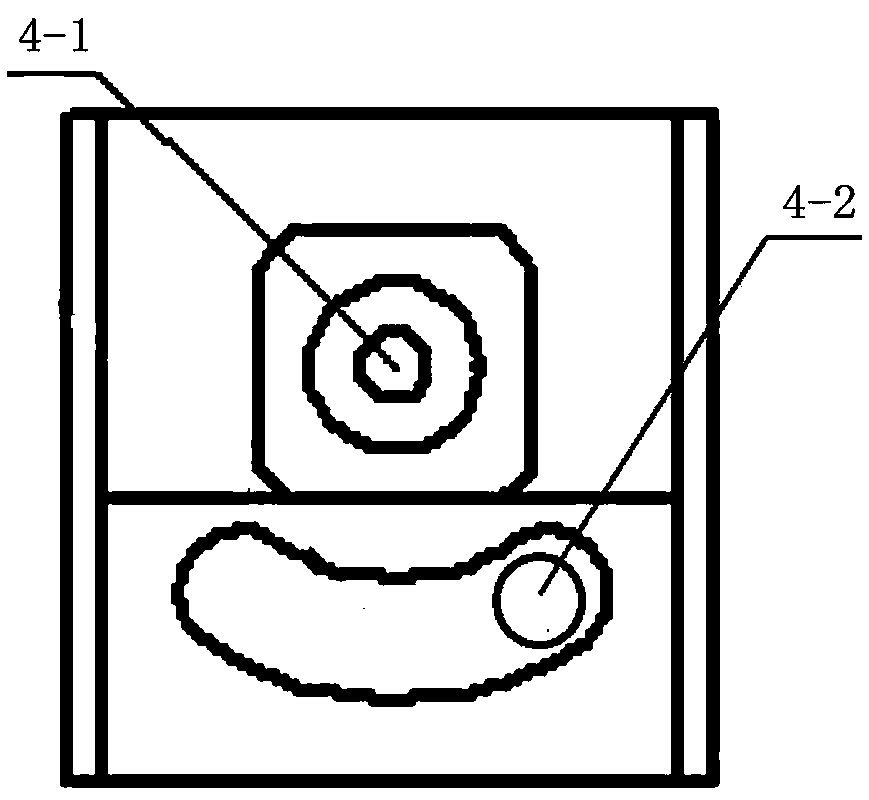

Transmission device of bionic flapping wing aircraft

InactiveCN114537660AEasy to assembleSave disassembly timeWeight reductionAircraft power transmissionRotational axisFlapping wing

A transmission device of a bionic flapping-wing aircraft comprises a rack, a motor, a gear train and a hinge four-bar mechanism. The gear train is arranged on the machine frame and is driven by the motor installed on the machine frame, the output end of the gear train is connected with the hinge four-bar mechanisms, one connecting rod of each hinge four-bar mechanism is rotationally connected with the machine frame, the rotating axis of the connecting rod is the same as the axis of the gear train, and the two hinge four-bar mechanisms are symmetrically arranged. The device has good stability, and the manual assembly difficulty and the assembly error are reduced.

Owner:DONGGUAN UNIV OF TECH

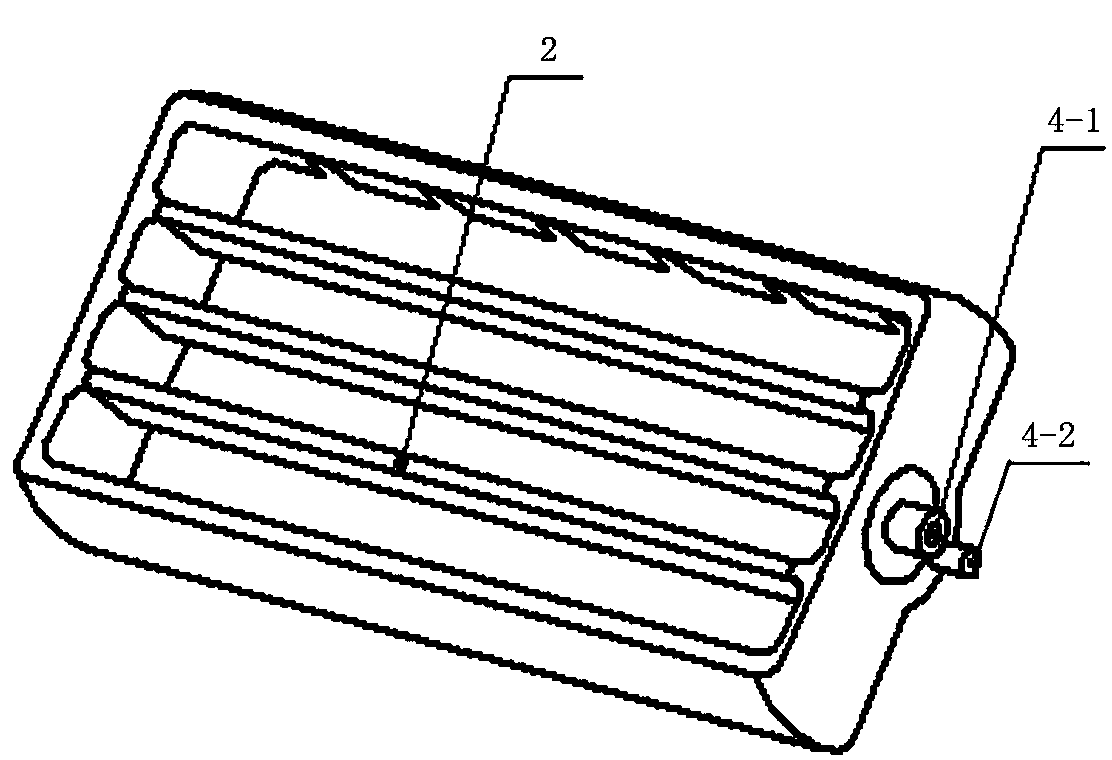

Vehicle-mounted air conditioner air outlet assembly

InactiveCN104121679ASimple structureIncrease the difficulty of assemblyAir-flow control membersCar manufacturingLinkage concept

The invention discloses a vehicle-mounted air conditioner air outlet assembly, and belongs to the technical field of automobile manufacturing. The vehicle-mounted air conditioner air outlet assembly comprises an air opening shell. A fan blade support is arranged in the air opening shell. The two ends of the fan blade support transversely extend to form a rotating shaft and a positioning pin respectively. The rotating shaft and the positioning pin is arranged in corresponding through holes in the two side walls of the air opening shell in a penetrating mode respectively. A plurality of fan blades are arranged in the fan blade support. The fan blades include the transversely-arranged first layer fan blades and the longitudinally-arranged second layer fan blades. The first layer fan blades are arranged in grooves of the second layer fan blades in a penetrating mode. Each first layer fan blade is provided with an adjustment piece used for adjusting the rotation direction of the corresponding second layer fan blade. Linkage rods for connecting the second layer fan blades with one another are fixed to the second layer fan blades. By means of the vehicle-mounted air conditioner air outlet assembly, the structure of an air outlet device is simplified, complex functions are achieved through the simple structure, and therefore manufacturing cost is reduced, and meanwhile assembly difficulty caused by too many parts in the air outlet device is reduced.

Owner:DONGFENG LIUZHOU MOTOR

Teflon component and mobile terminal having same

ActiveCN107566573BEasy to assembleIncrease the difficulty of assemblySynthetic resin layered productsPaper/cardboard layered productsPolymer scienceAdhesive

The invention discloses a Teflon component and a mobile terminal with the same. The Teflon component comprises a Teflon layer, a reinforced layer arranged on one side surface of the Teflon layer; anda piece of release paper arranged on one side surface of the reinforced layer far away from the Teflon layer, wherein a double-sided adhesive is arranged between the release paper and the reinforced layer. The Teflon component disclosed by the invention is convenient for assembling and high in reliability.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

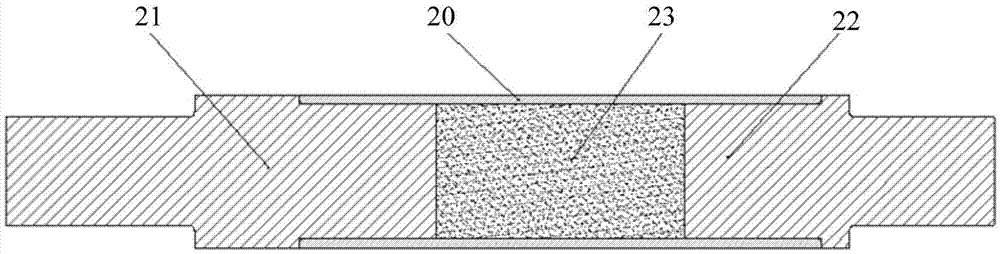

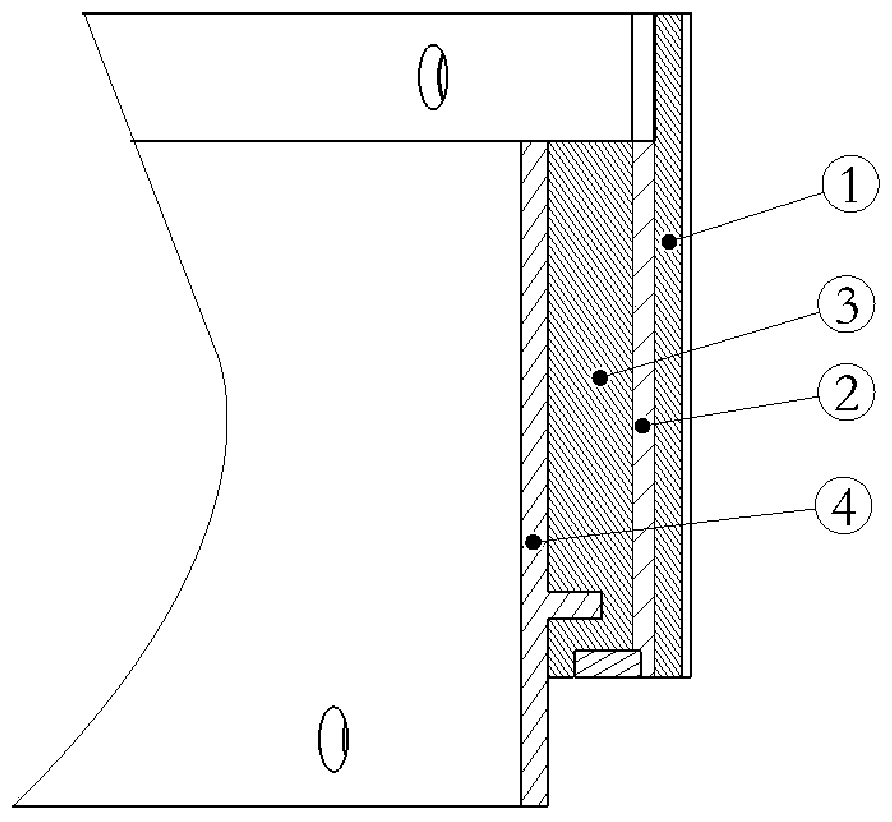

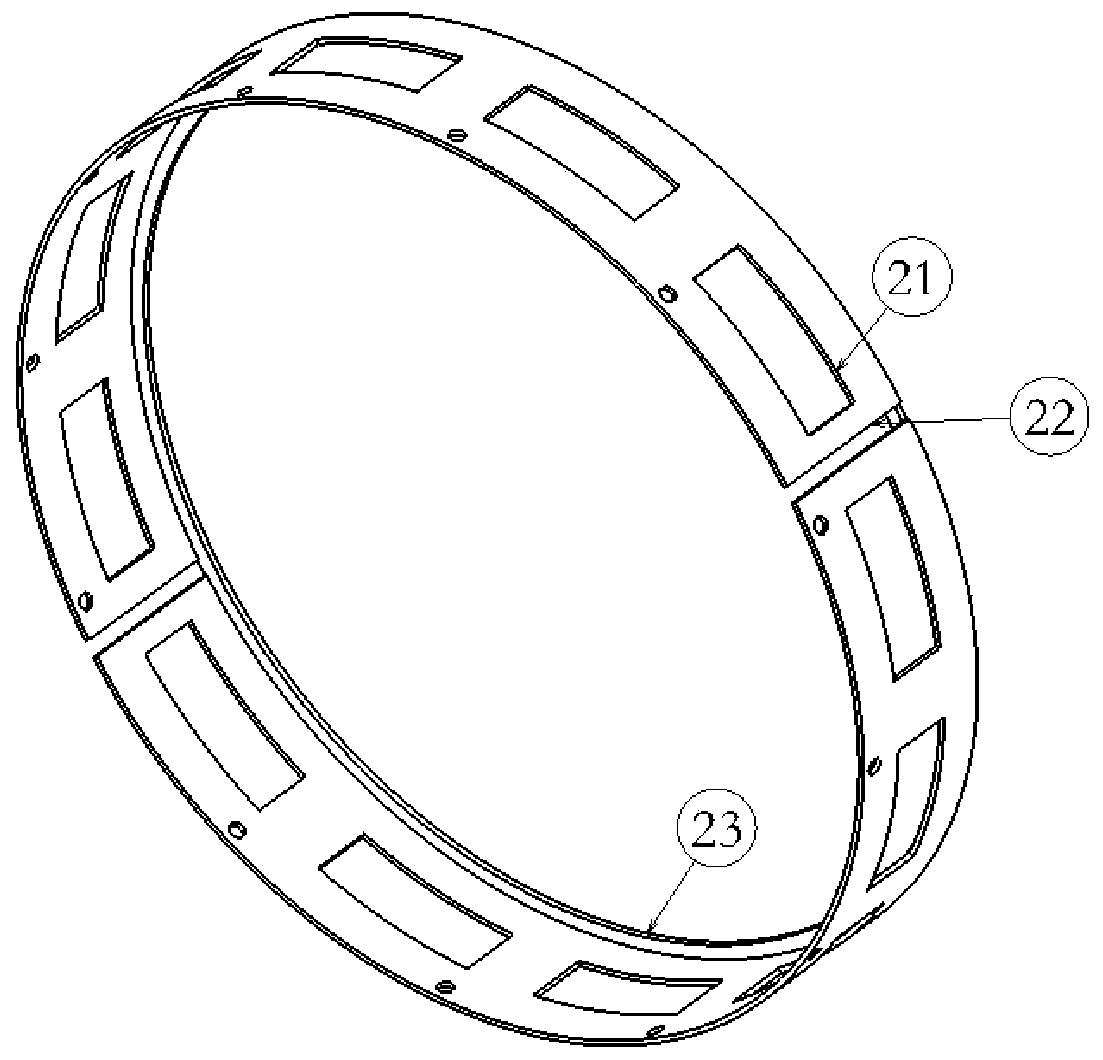

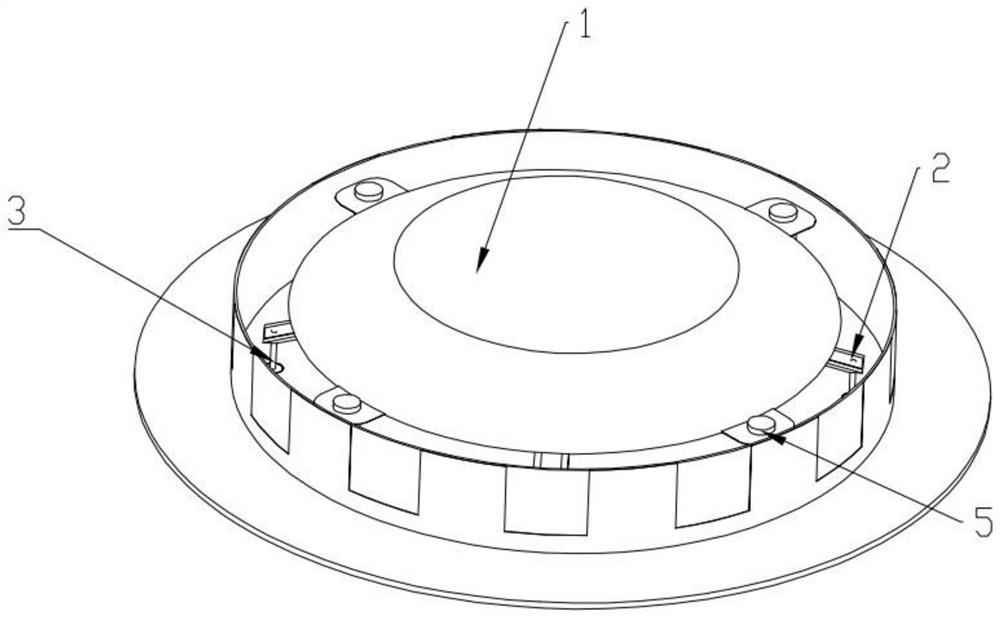

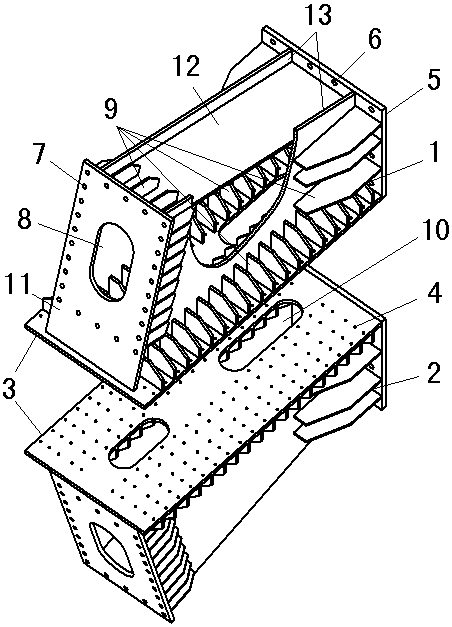

Vibration isolation device for electro-optical pod

ActiveCN111038720AIncrease stiffnessSolve Vibration ProblemsNon-rotating vibration suppressionFreight handlingViscoelastic dampingVibration isolation

The invention provides a vibration isolation device for an airborne electro-optical pod. The vibration isolation device comprises an outer mounting elastic adjusting layer, an outer mounting ring, a viscoelastic damping layer and an inner mounting ring; the inner mounting ring is connected with an inner cabin, the outer mounting ring is connected with an outer cabin, and the outer mounting elasticadjusting layer can realize seamless connection between the vibration isolation device and the outer cabin; the vibration isolation device has a three-direction vibration isolation buffering effect;slotted holes are distributed in the outer mounting ring, and the rigidity of the vibration isolation device can be adjusted by designing the sizes and shapes of the slotted holes and the rigidity ofthe viscoelastic damping layer; furthermore, bosses of the inner mounting ring and the outer mounting ring mutually form a limiting and interlocking device, large displacement in three directions canbe limited, meanwhile, self-locking in an ultimate failure state can be achieved, and the equipment safety and reliability are improved.

Owner:CHINA AIRPLANT STRENGTH RES INST +1

Shaft system structure and assembly method for electric motor

ActiveCN105449895BReduce in quantityReduce assembly coaxiality is difficult to guarantee the problemMagnetic circuit rotating partsManufacturing stator/rotor bodiesEngineeringAlloy

The invention discloses a shafting structure for a motor, and an assembling method. The shafting structure comprises a front-segment shaft (62), a rear-segment shaft (63), annular magnetic steel (61) and an alloy sheath (60), wherein the rear-segment shaft (63) successively comprises a first shaft joint (631) and a second shaft joint (633) from front to back, and the diameter of the first shaft joint (631) is smaller than that of the second shaft joint (633); the annular magnetic steel (61) sleeves the first shaft joint (631) of the rear-segment shaft (63); the external diameter of the rear end of the front-segment shaft (62) is the same as the external diameter of the annular magnetic steel (61); and the alloy sheath (60) sleeves the front-segment shaft (62) and the annular magnetic steel (61). According to the scheme provided by the invention, the shafting structure and the assembling method overcome the defects of complex structure, large assembling difficulty, poor safety and the like in the prior art and also have the advantages of simple structure, small assembling difficulty and good safety.

Owner:GREE ELECTRIC APPLIANCES INC +1

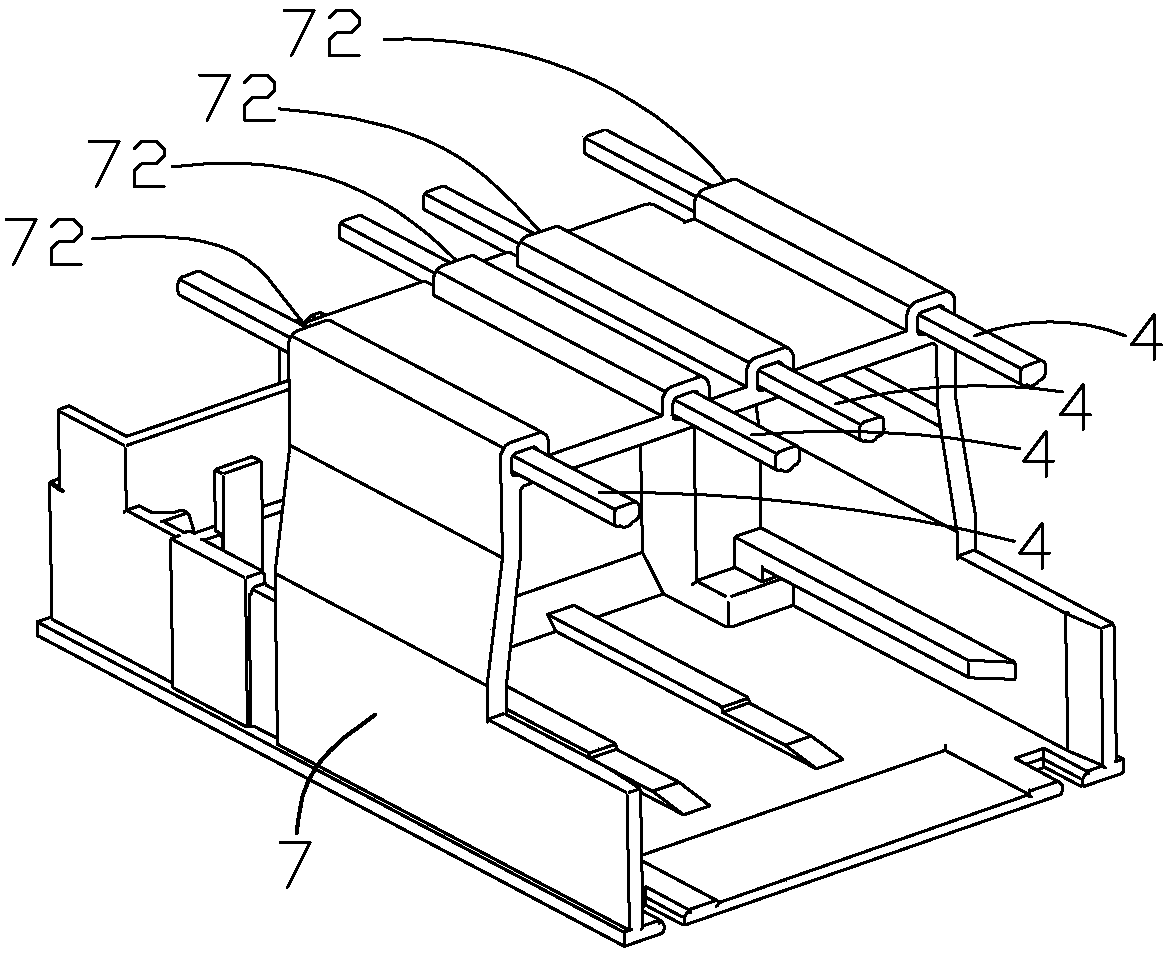

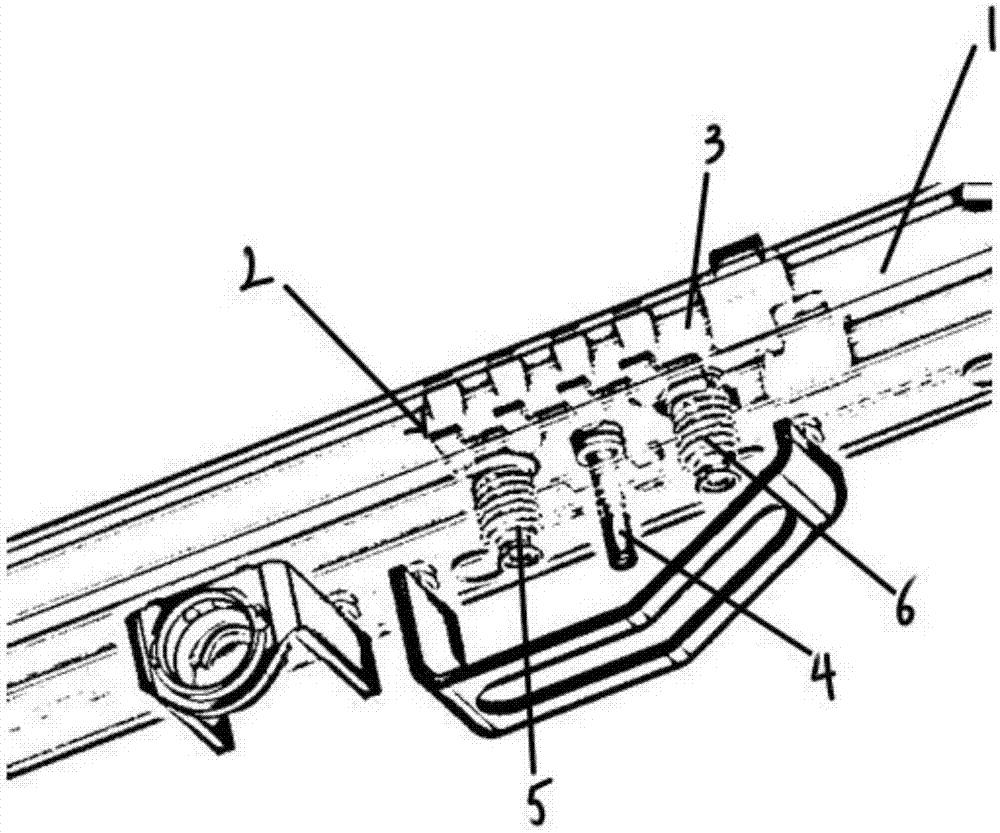

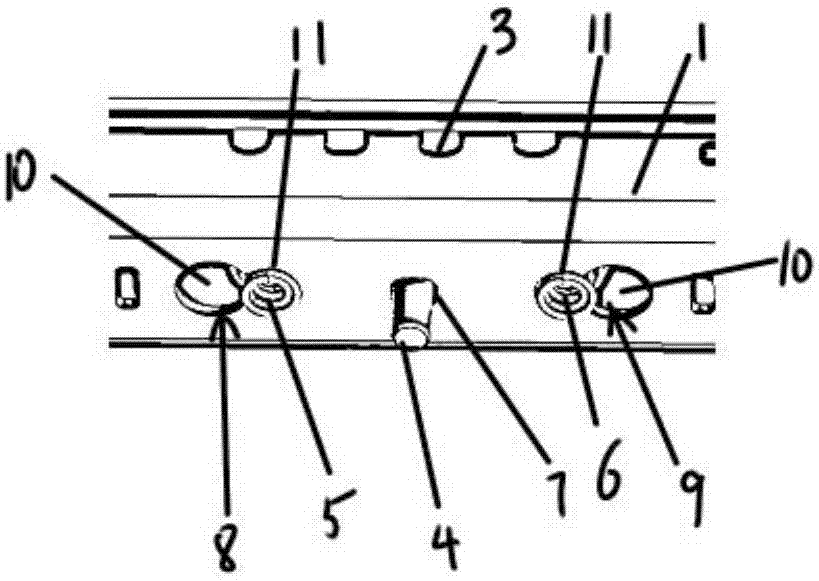

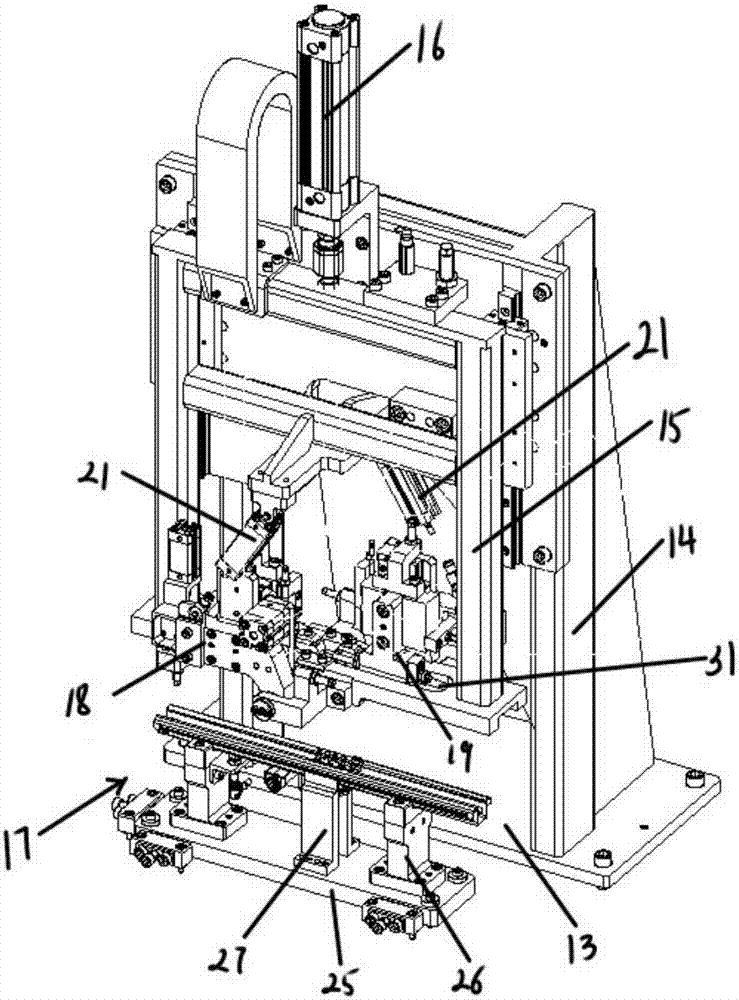

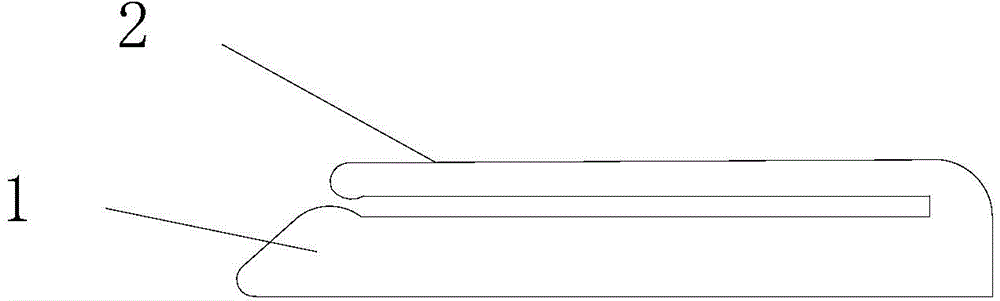

Slide rail and slide rail locking spring assembling device

PendingCN107971737AFast processingCompact structureMetal working apparatusLocking mechanismEngineering

The invention relates to a slide rail which comprises a male rail and a female rail embedded together, wherein a slide rail locking mechanism is arranged between the male rail and the female rail; theslide rail locking mechanism comprises a locking disc, and an unlocking tongue, a first spring and a second spring arranged on the locking disc; the first spring and the second spring are separatelylocated on two sides of the unlocking tongue; the locking disc is fixedly mounted on the male rail; the mail rail is provided with a tongue hole and a first mounting hole and a second mounting hole intwo sides of the tongue hole; the top end of the unlocking tongue is fixed to the locking disc and the bottom end of the unlocking tongue penetrates through the tongue hole; the first and second mounting holes are provided with large diameter ends and small diameter ends; the top ends of the first and second springs are fixed to the locking disc and the bottom ends separately penetrate through the large diameter ends of the first and second mounting holes and are locked to the small diameter ends, so that the first and second springs are elastically supported between the locking disc and themale rail. The slide rail provided by the invention is compact in structure and reliable to lock, and the invention also provides the slide rail locking spring assembling device capable of processingquickly, so that the production efficiency is relatively high.

Owner:苏州托克斯冲压设备有限公司

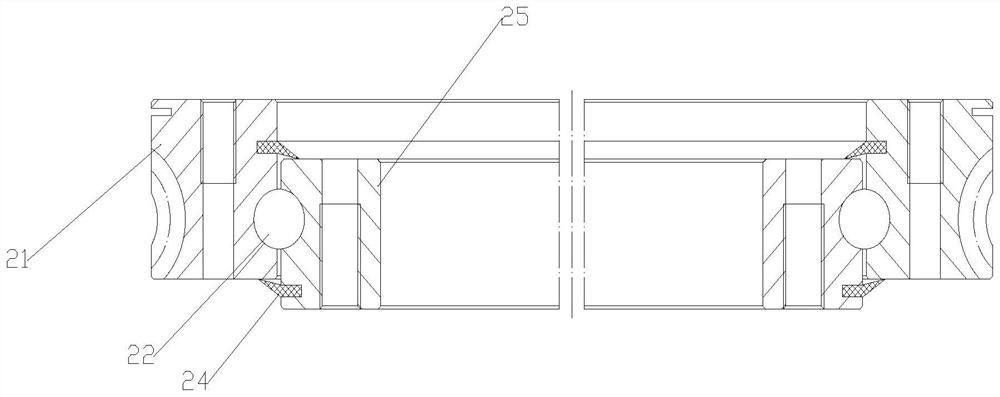

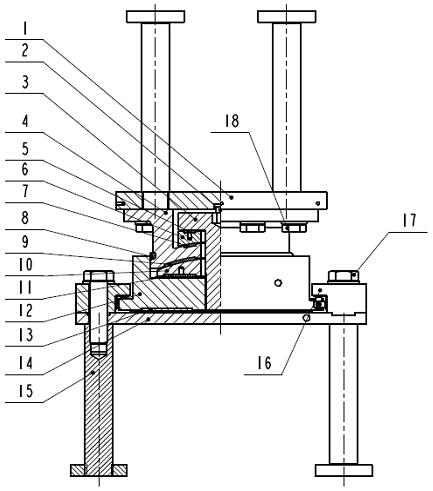

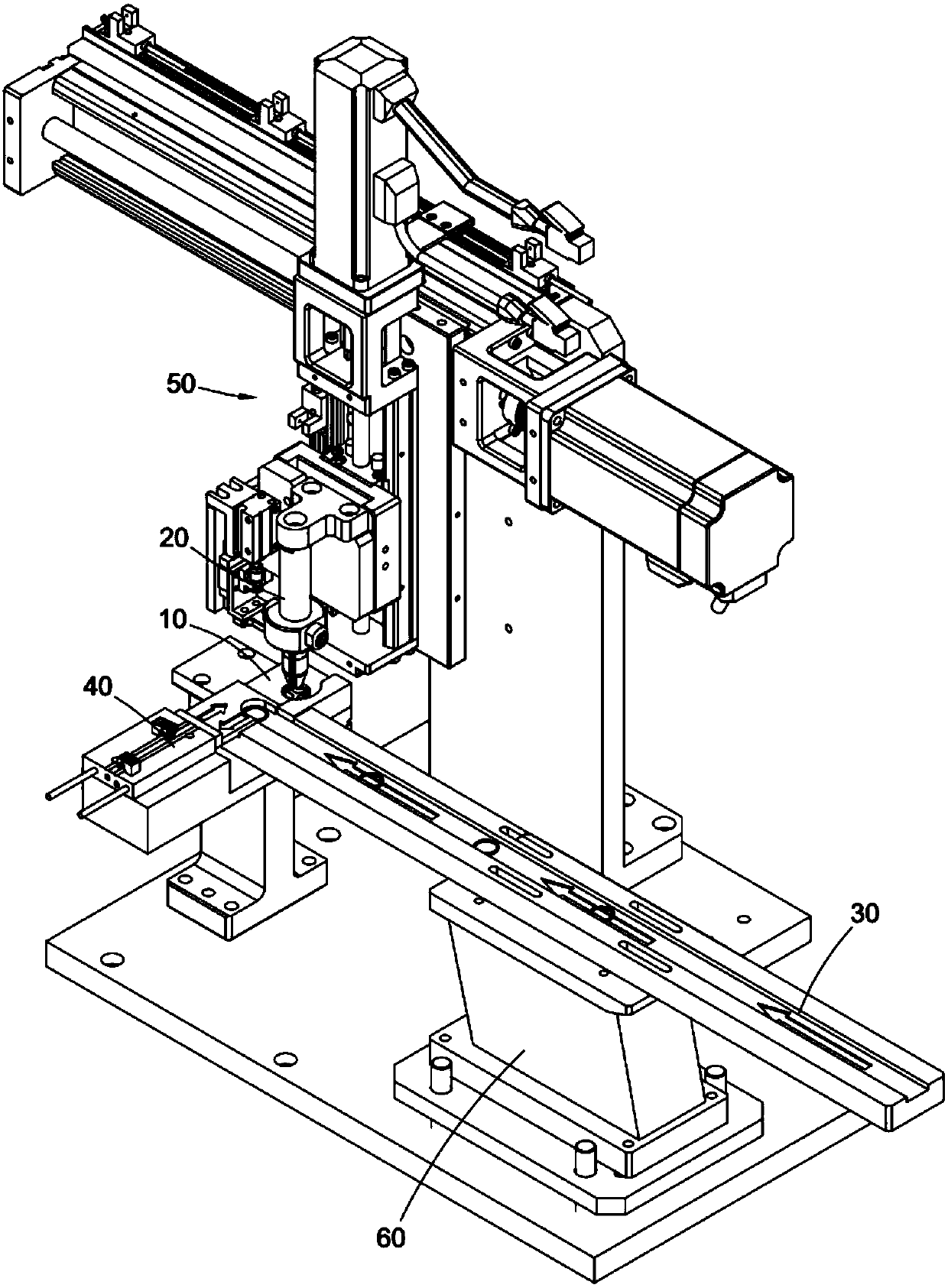

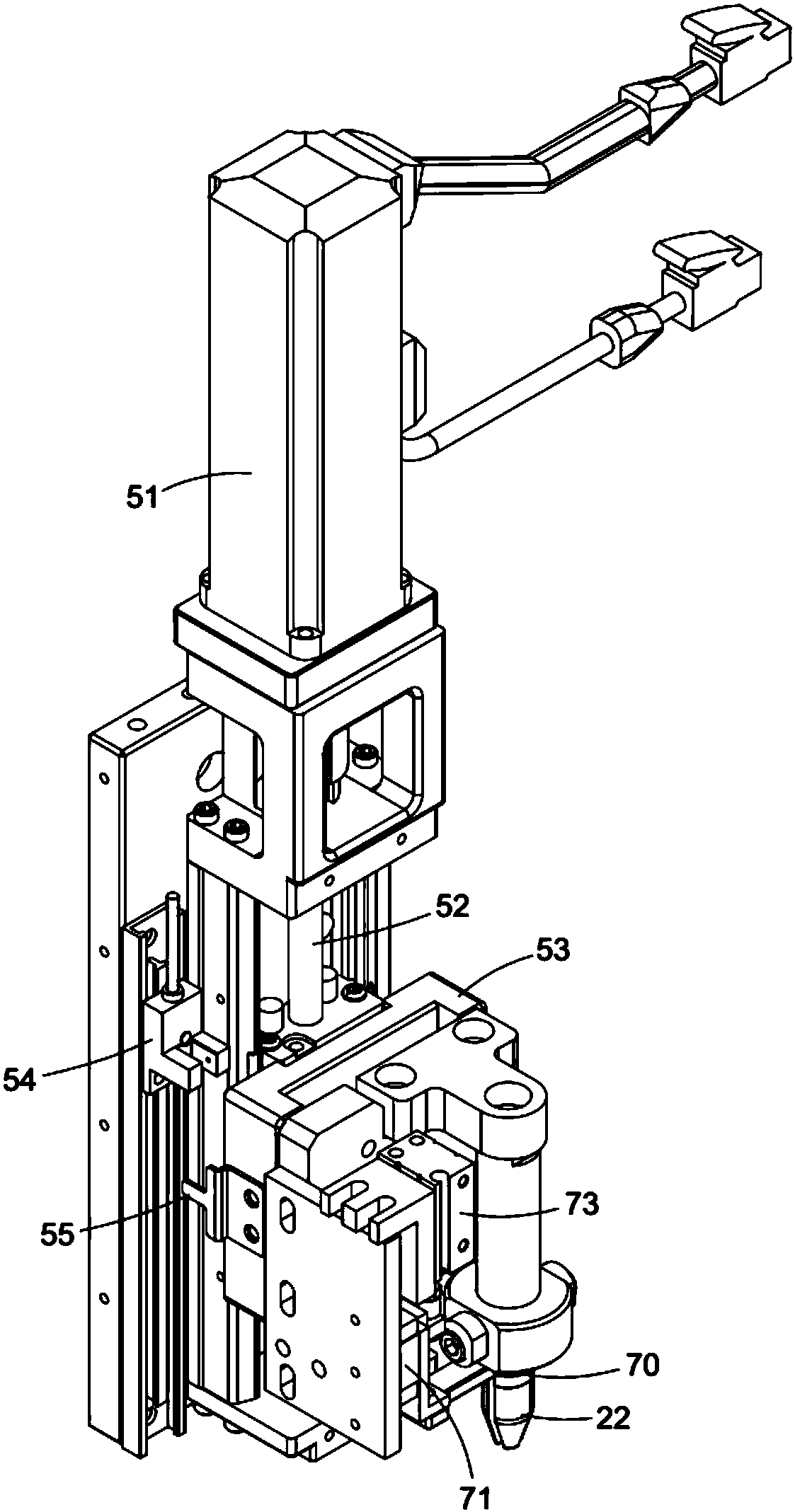

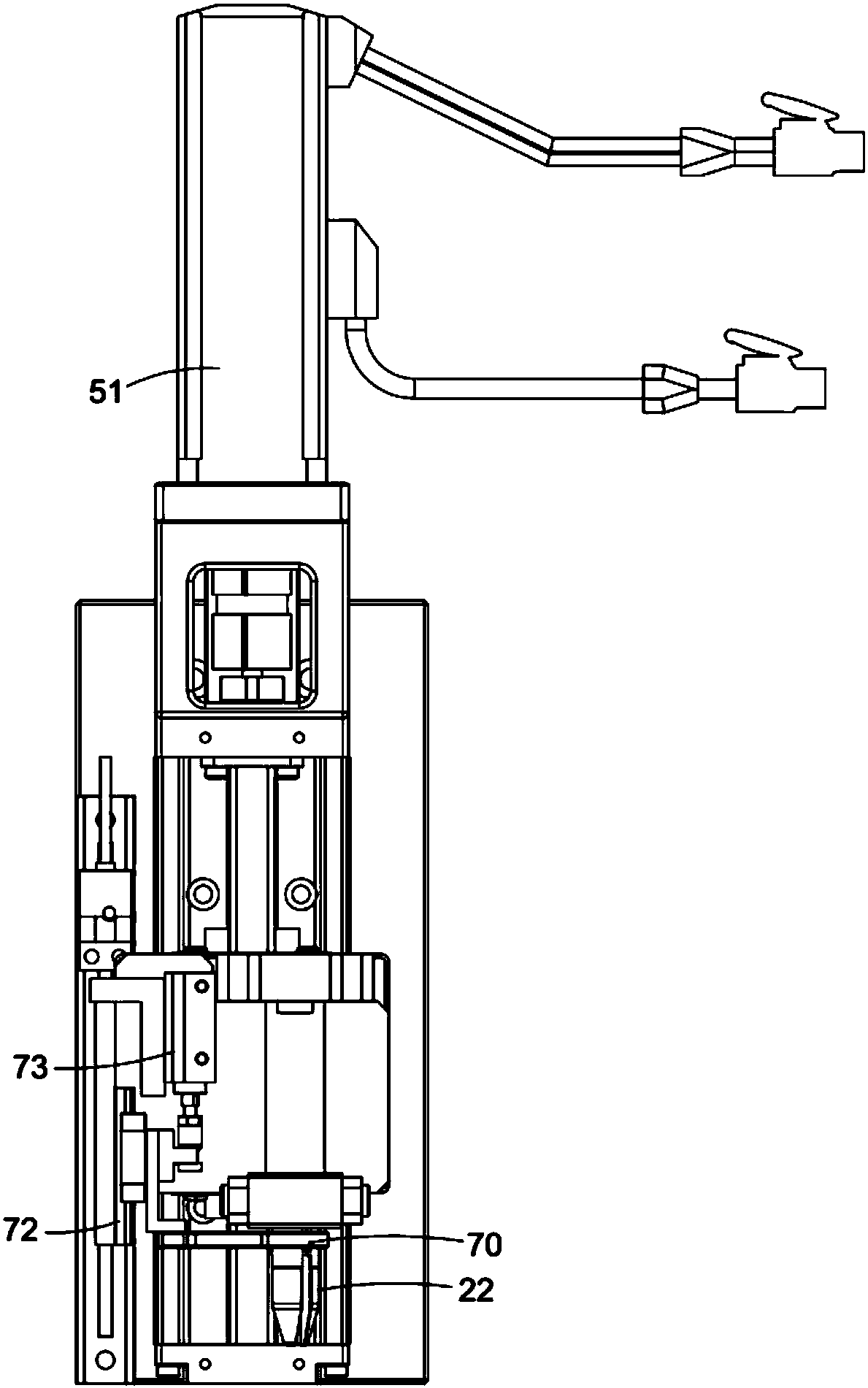

Assembly device for a sealing ring

ActiveCN106181352BResolve conflicting needsSolving Difficult to Pinpoint DifficultiesMetal working apparatusButt jointEngineering

An assembling device for a seal ring comprises a lifting assembling assembly; the assembling assembly comprises a cylindrical part; the external diameter of the cylindrical part is greater than the internal diameter of the seal ring; the cylindrical part is sleeved with a lifting material shifting ring; and when assembling is conducted, the cylindrical part is connected with a product to be assembled in a coaxial butt joint mode, the material shifting ring moves downwards so as to strip the seal ring from the cylindrical part, and continues to push the product to be assembled to a groove of the seal ring, so that assembling is completed. The assembling device for seal ring solves the assembling problem caused by the special structure of the product to be assembled and achieves highly efficient and stable assembling of the seal ring.

Owner:BOZHON PRECISION IND TECH CO LTD

A multi-section cement pole automatic assembly and installation device

ActiveCN109083486BImprove assembly efficiencySolve complex technical problems in constructionTowersClassical mechanicsMoving frame

The invention relates to the technical field of telegraph pole construction, in particular to a multi-section cement pole automatic assembly and installation device. The multi-section cement pole automatic assembly and installation device comprises a bearing mechanism, a primary lifting mechanism and a secondary lifting mechanism. The bearing mechanism comprises a transfer vehicle, a bearing platform and a dragging assembly. The primary lifting mechanism comprises a bracket, a drive assembly, a supporting assembly and a positioning assembly. The secondary lifting mechanism comprises a moving frame arranged on the bracket, a lifting assembly arranged on the moving frame, connected with the supporting assembly and used for lifting an auxiliary rod, and a translation assembly arranged on thebracket and used for positioning and transferring the auxiliary rod on the lifting assembly. Through the special structure arrangement of the primary lifting mechanism and the secondary lifting mechanism, a main rod and the auxiliary rod are constructed in sequence, the auxiliary rod is laterally dragged through the lifting assembly, the auxiliary rod is supported through the translation assembly,the auxiliary rod is lifted above the main rod and then stably and accurately subjected to translation, and the auxiliary rod and the main rod are rapidly assembled. The technical problem that in theprior art, a multi-section telegraph pole is complex in construction is solved.

Owner:临泉鹏成机电技术有限公司

An ultra-wideband high-precision satellite navigation antenna

ActiveCN110739532BLow costReduce weightSimultaneous aerial operationsRadiating elements structural formsTerminal equipmentEconomic benefits

The invention discloses an ultra-broadband high-precision satellite navigation antenna, which comprises a radiation piece, a feeding coupling piece and a feeding PIN needle; the feeding coupling piece is evenly distributed around the radiation piece, and the feeding PIN needle and the feeding The electric coupling sheet is connected, and the present invention reduces the weight of the high-precision satellite navigation antenna, which is beneficial to the reduction of the shrinkage of the terminal equipment, especially for land resource surveying and mapping measurement and aviation navigation; and the electroplating process or copper foil attached And the processing method is mature, and the production cost is low, which is conducive to the large-scale application of the product. With good economic benefits.

Owner:SHANGHAI SHUANGWEI NAVIGATION TECH CO LTD

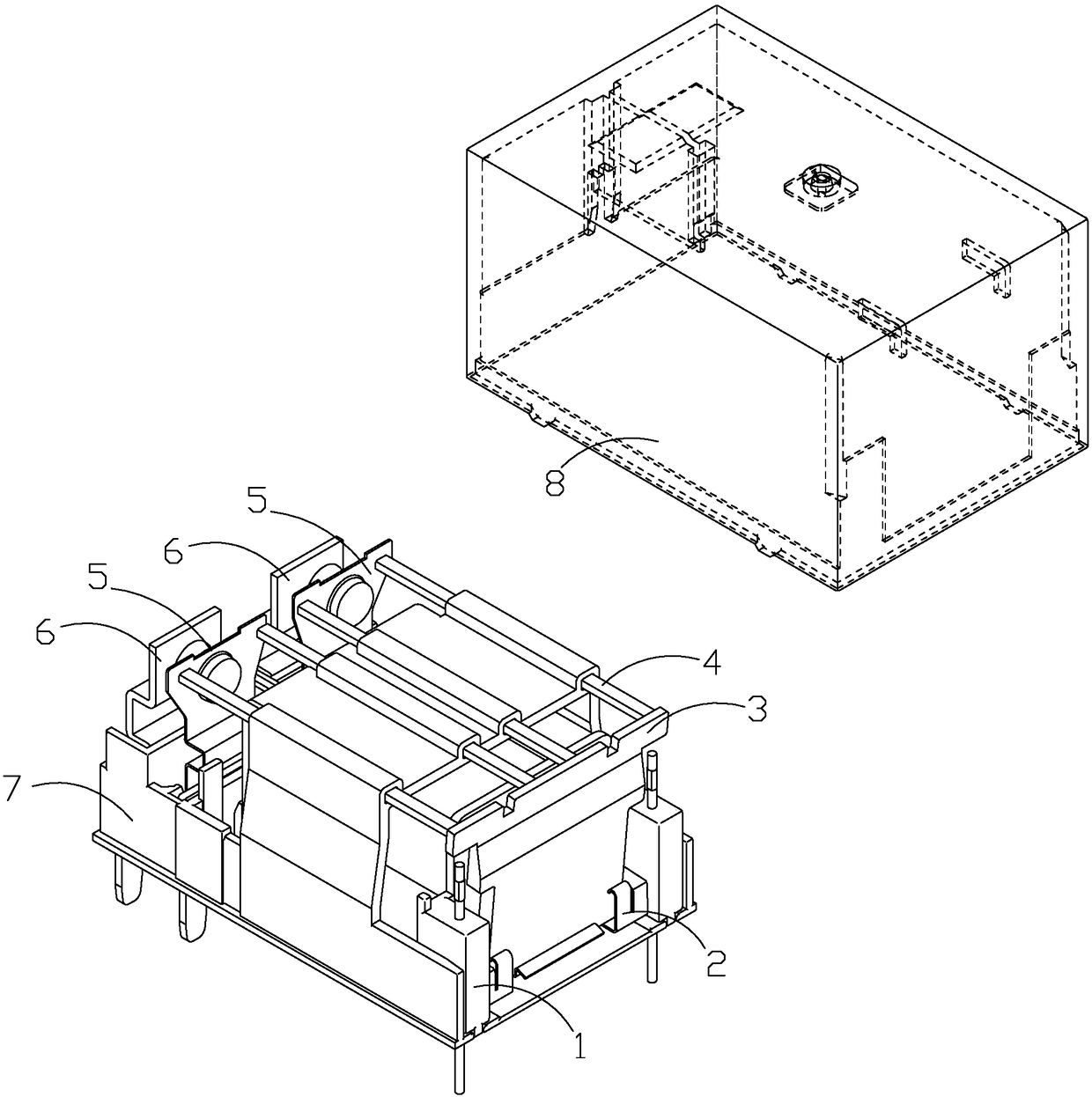

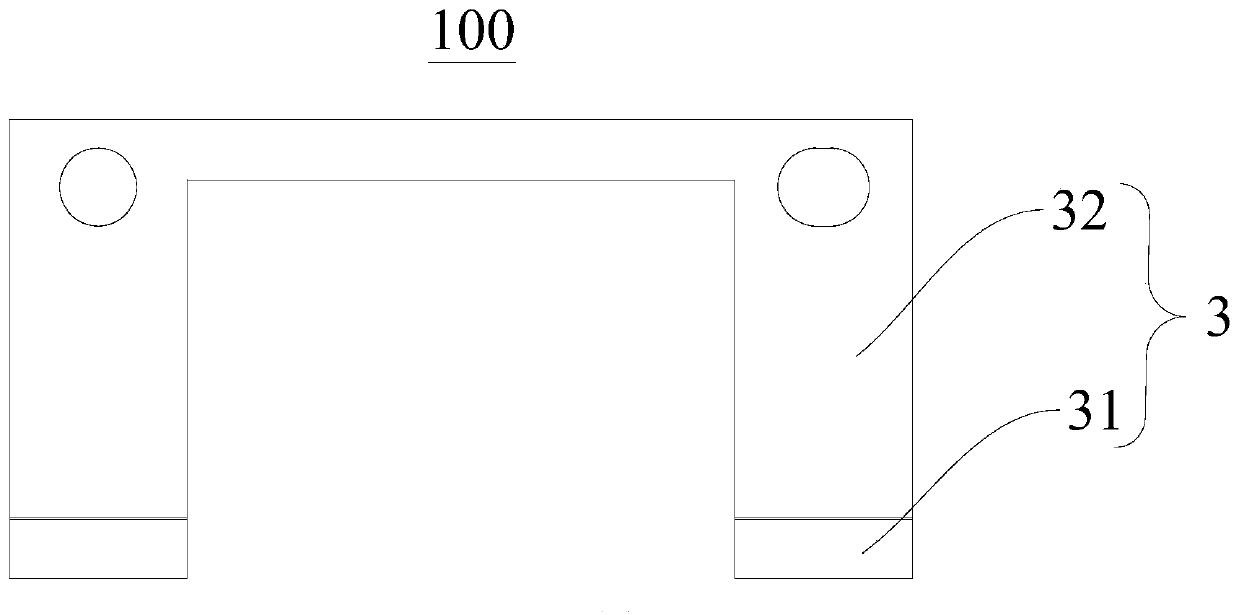

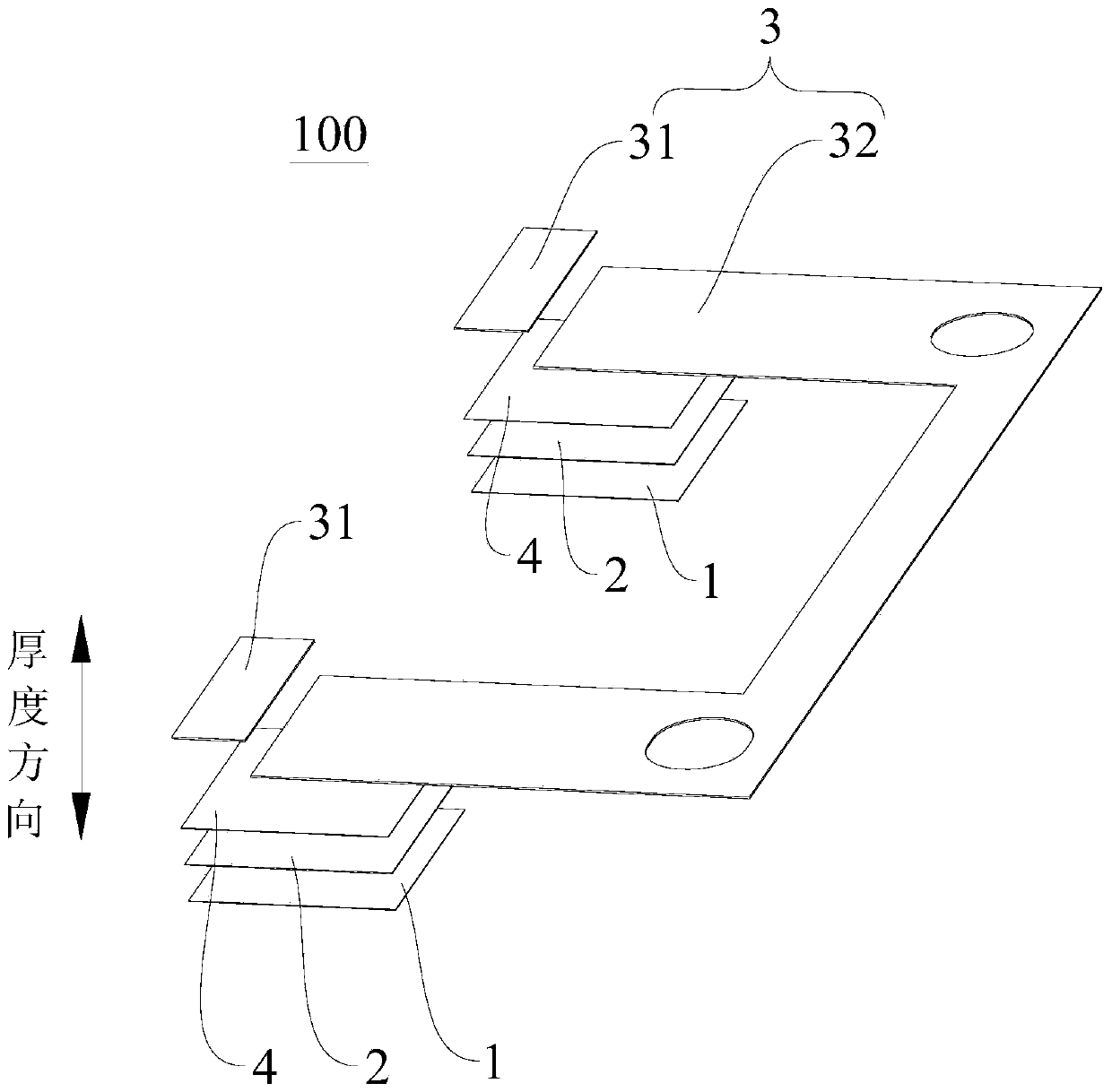

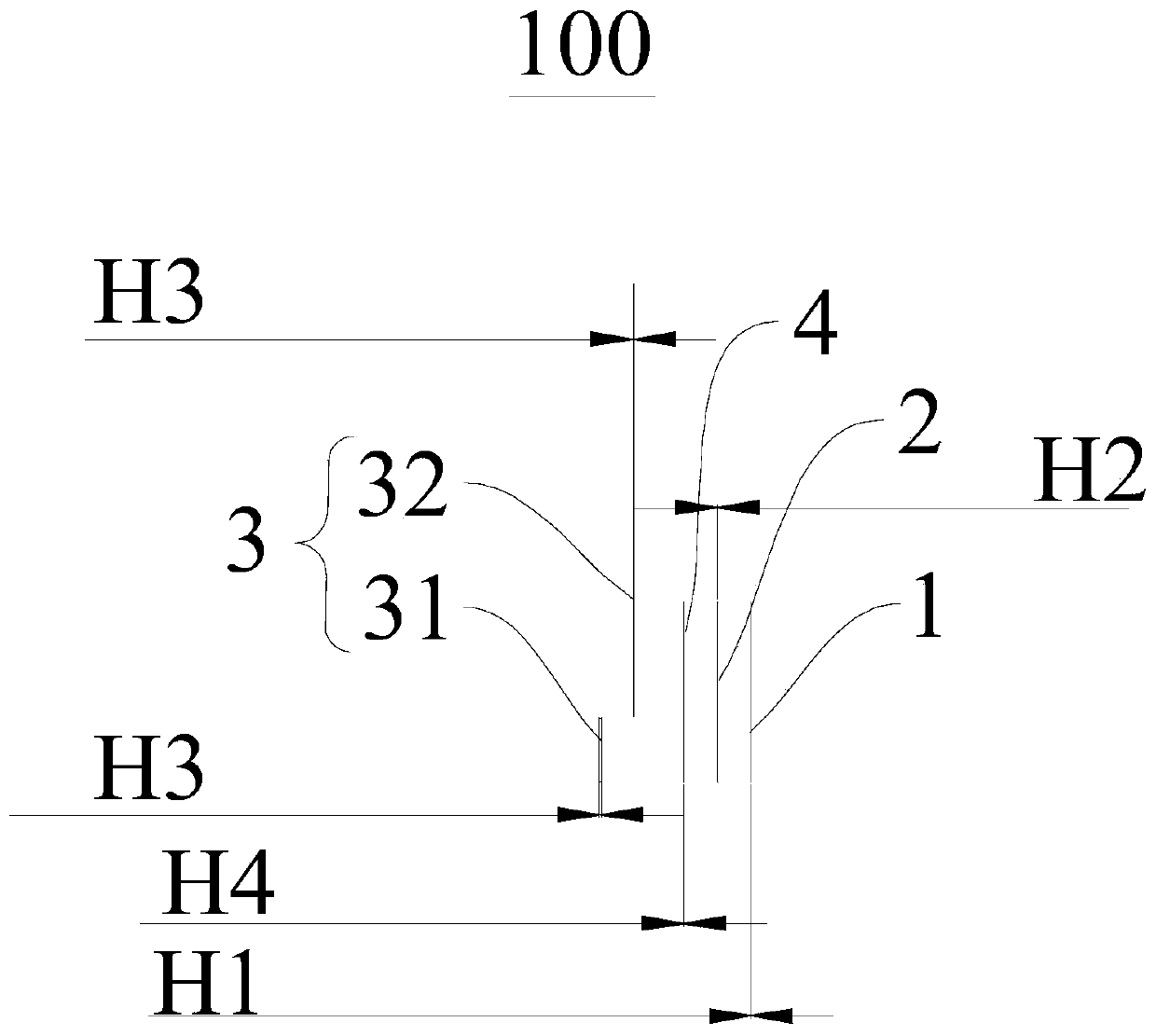

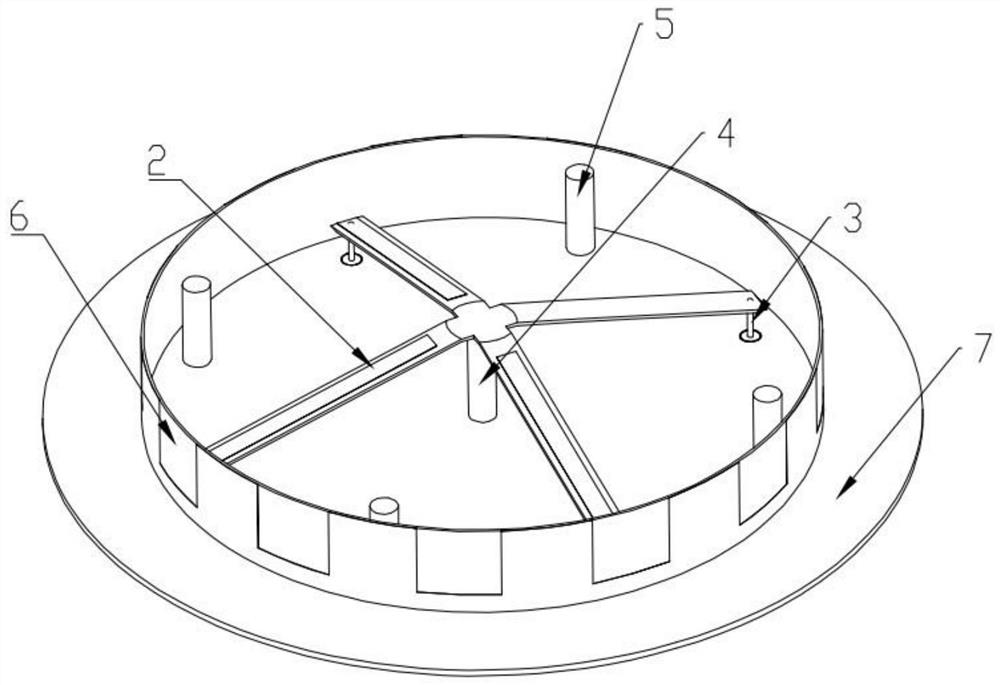

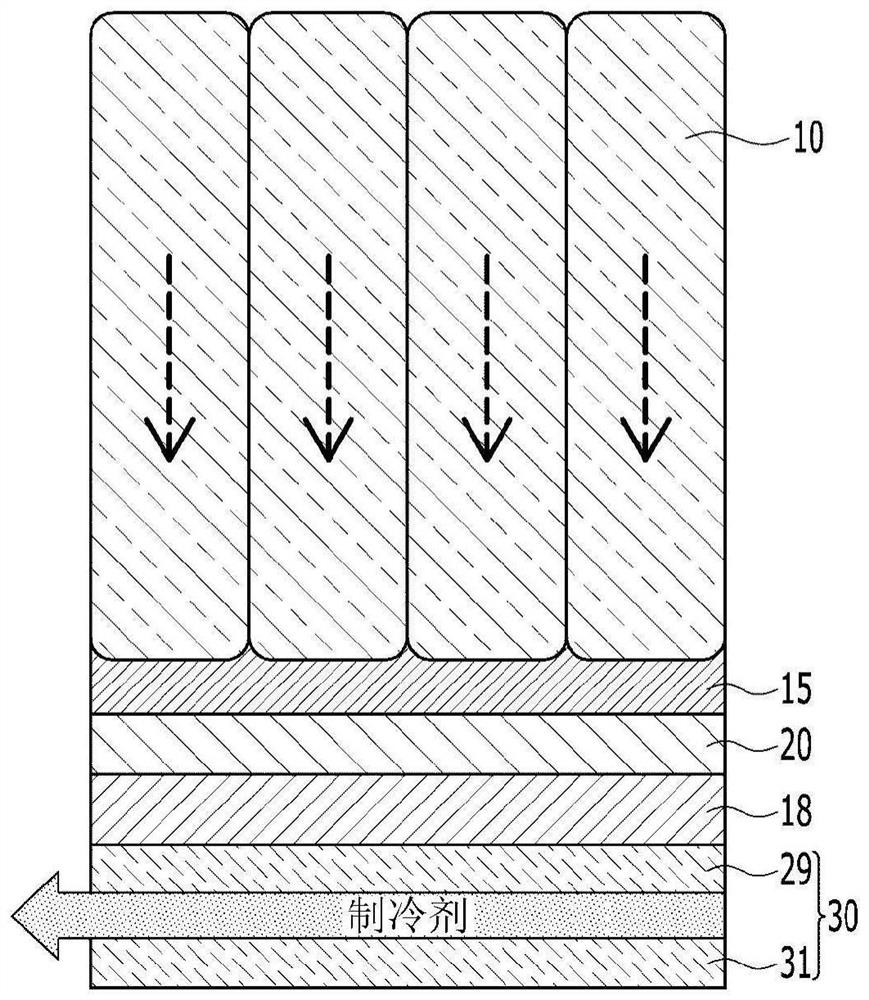

Battery module and method for manufacturing battery module

PendingCN114556668ASimplify the assembly processImprove assembly difficultySecondary cellsCell component detailsEngineeringBattery cell

A battery module according to one embodiment of the present invention comprises: a battery cell laminate in which a plurality of battery cells are laminated; a module frame for accommodating the battery cell stack; an end plate for covering the front surface and the rear surface of the battery cell stack; a heat sink formed on the bottom of the module frame; and a cooling port for supplying a refrigerant to the heat sink, in which the module frame includes a module frame protrusion formed to extend such that a bottom of the module frame passes through the end plate, and the cooling port is arranged in a shape protruding upward from an upper surface portion of the module frame protrusion.

Owner:LG ENERGY SOLUTION LTD

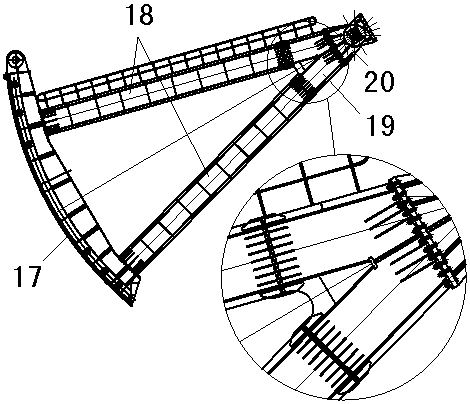

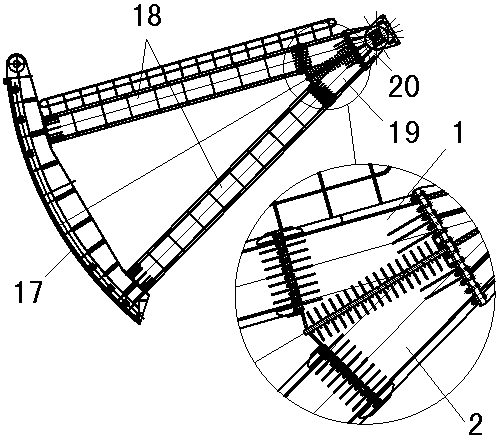

A method for solving the transportation difficulty of a super large support arm base and a detachable support arm base

ActiveCN105603936BMeet the technical problems of transportation difficultiesReduce distortionBarrages/weirsBolt connectionBuilding construction

The invention discloses a method for solving the transportation difficulty problem of a huge support arm base and the detachable support arm base. A traditional integral support arm base is sectioned into two sections or more than two sections of small parts in the radial direction of a rotating fulcrum, and each small part is transported by one vehicle; the section cutting plane of each small part is provided with an inter-section end face connecting plate, and when the parts are transported to a construction site, all the parts are connected together to be assembled into the support arm base by enabling bolts to penetrate through connecting holes. According to the method, by sectioning the integral support arm base into the small parts, the transportation weight can be reduced, the size of the parts is decreased, and the technical problem that the traditional integral support arm base is difficult to transport is solved. On the site, the bolts are adopted for fixed connection without needing welding, and therefore stress generated in welding can be reduced. All the parts are provided with operation holes, and therefore the assembly difficulty of the bolts can be reduced. A symmetrical structure is beneficial for transmitting force and reducing deformation of the support arm base and also beneficial for uniform force transmitting of the bolts.

Owner:贵州建工第八建设集团有限公司

Assembly process of safety belt and safety belt winder

InactiveCN104890613AOptimize assembly processIncrease the difficulty of assemblyBelt retractorsEngineeringBelt safety

The invention belongs to an automobile part production process, and particularly relates to an assembly process of a safety belt and a safety belt winder. The assembly process has the advantages that the assembly process of the safety belt and the safety belt winder is improved; the assembly process of firstly connecting the safety belt onto the safety belt winder in a penetrating way and then sewing the end part of the safety belt is adopted; the problem of assembly difficulty of the safety belt and the safety belt winder in the prior art is solved; the work difficulty of workers is reduced; and the production efficiency is improved.

Owner:常州市东晨车辆部件有限公司

Metal pin for wire harness connectors

InactiveCN104617409AHigh strengthImprove yieldFastening/insulating connecting partsUltimate tensile strengthBiomedical engineering

The invention belongs to the field of wire harness production equipment, and particularly relates to a metal pin for wire harness connectors. The metal pin for wire harness connectors comprises a lower pin foot connected with a wire harness connector, an upper pin foot is integrally arranged at the tail end of the lower pin foot, and the upper pin foot and the lower pin foot are arranged in parallel. The metal pin is characterized in that each of the two sides of the upper pin foot is extended outward to form a reinforcing bulge. The reinforcing bulges are additionally arranged at the two sides of the upper pin foot of the metal pin, which effectively improves the strength of the upper pin foot, effectively reduces the possibility of deformation caused by external impact, improves the yield of product assembly and the difficulty of assembly, and improves the production efficiency.

Owner:CHANGZHOU NUODE ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com