Welding manufacturing process method of large-scale fully welded structure water turbine ball valve

A manufacturing process and full welding technology, which is applied in the field of welding manufacturing process of large-scale fully welded structure water turbine ball valves, can solve the problems of difficulty in guaranteeing weld quality and dimensional accuracy, inability to complete production and high weld quality requirements, and achieve welding reliability. Improvement of accessibility and operability, improvement of welding quality, and quality assurance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention provides an assembly and welding manufacturing process method for ensuring the tolerance and quality of a large fully welded structure water turbine ball valve. Technical scheme of the present invention is:

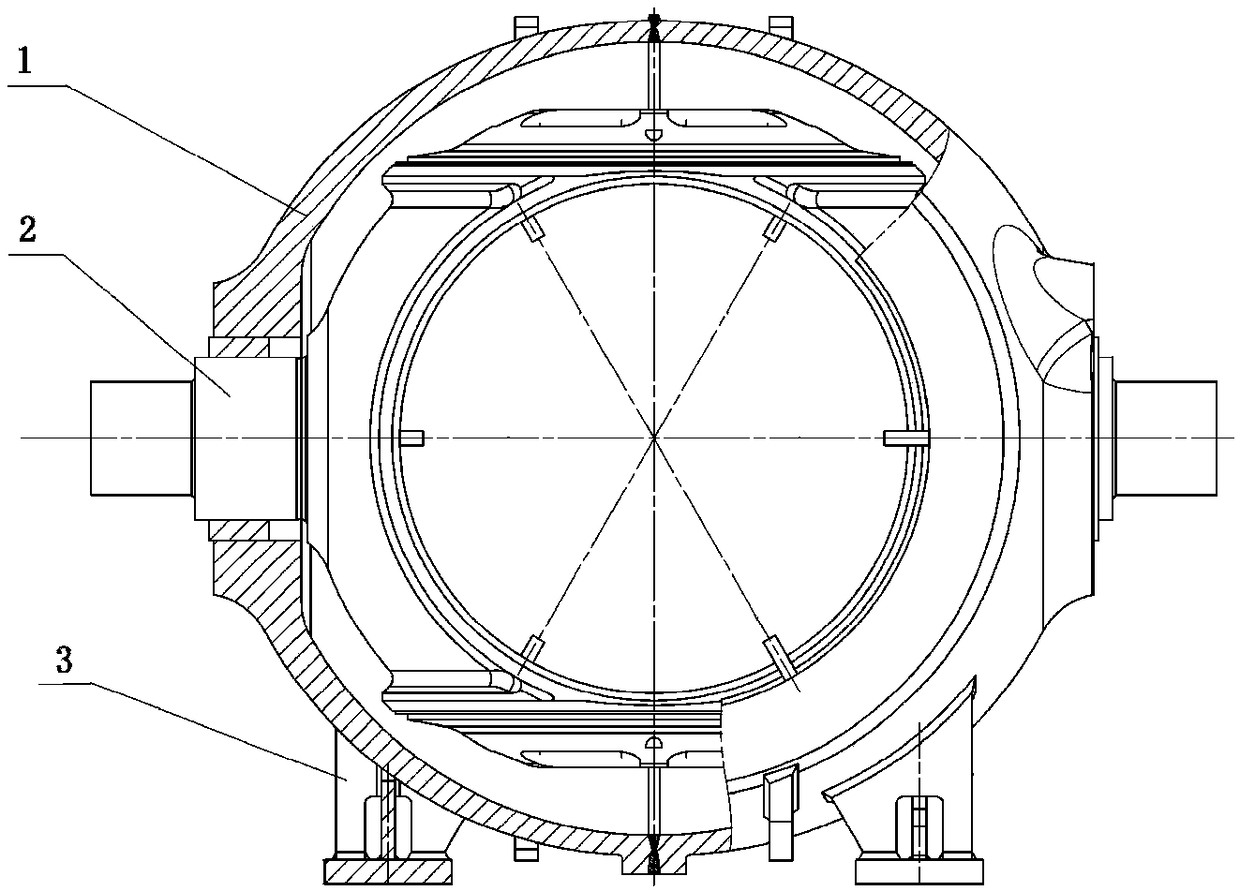

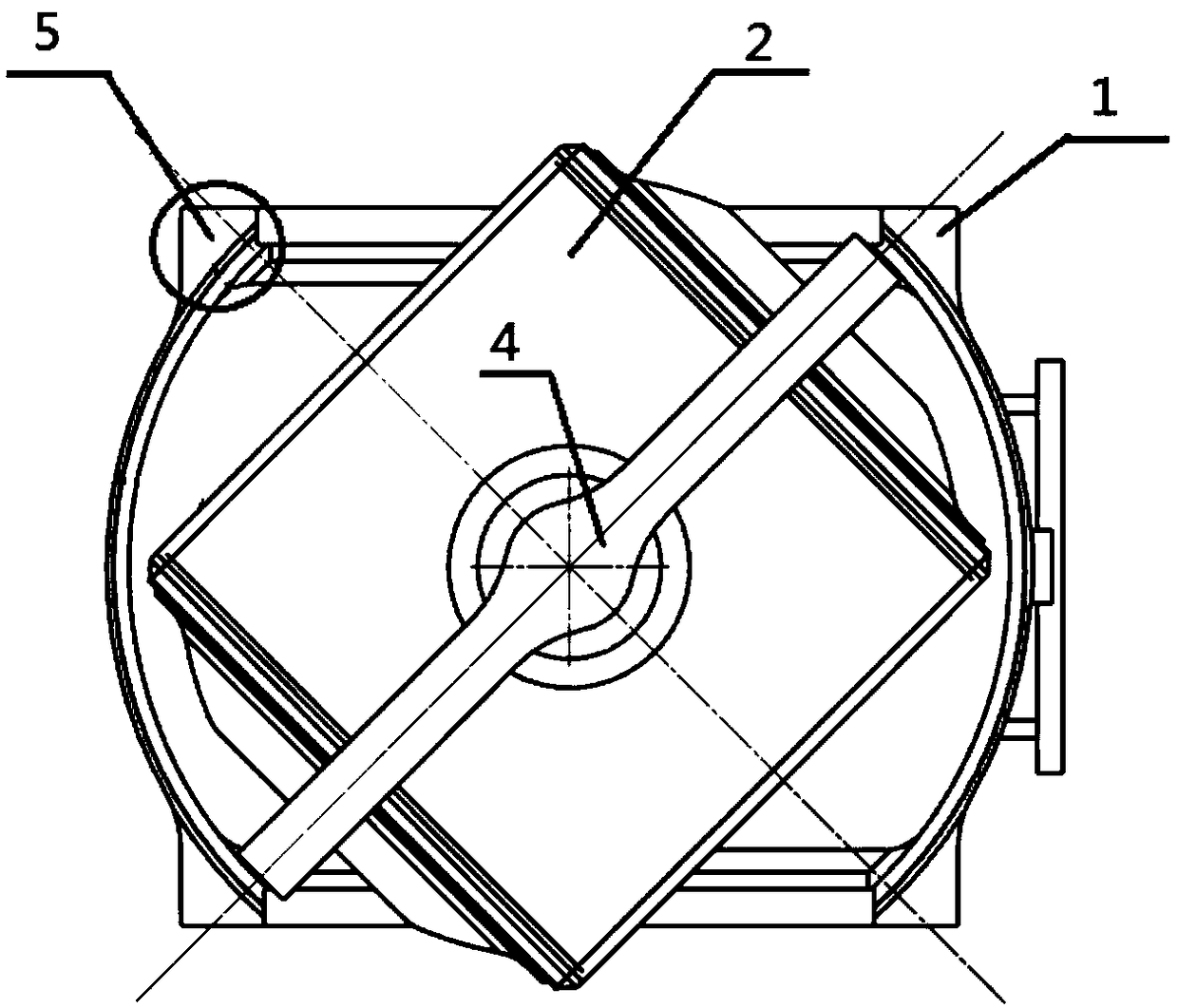

[0022] 1) Material preparation for valve body 1 and valve 2: According to the requirements of the drawing, use the casting method to manufacture the two-piece valve body 1 and the integral valve 2. After the valve body 1 is combined into a whole, the double-sided U-shaped welding groove at the seam is processed;

[0023] 2) Valve body 1 and support 3 are assembled and welded separately: Assemble the valve body 1 and support 3 according to the requirements of the drawings, and weld and fix them;

[0024] 3) Valve body 1 and valve 2 are coated with high-temperature-resistant paint: Sandblast and clean the valve body 1 and valve 2 on which the welding support 3 is installed, apply high-temperature-resistant paint for protection, and perform low-temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com