Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Satisfy rotation requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

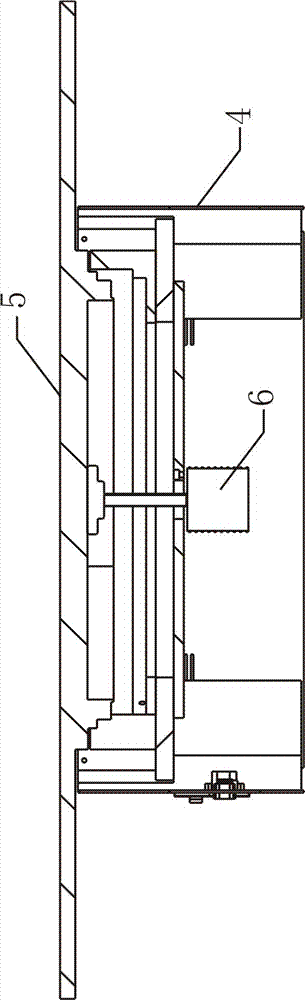

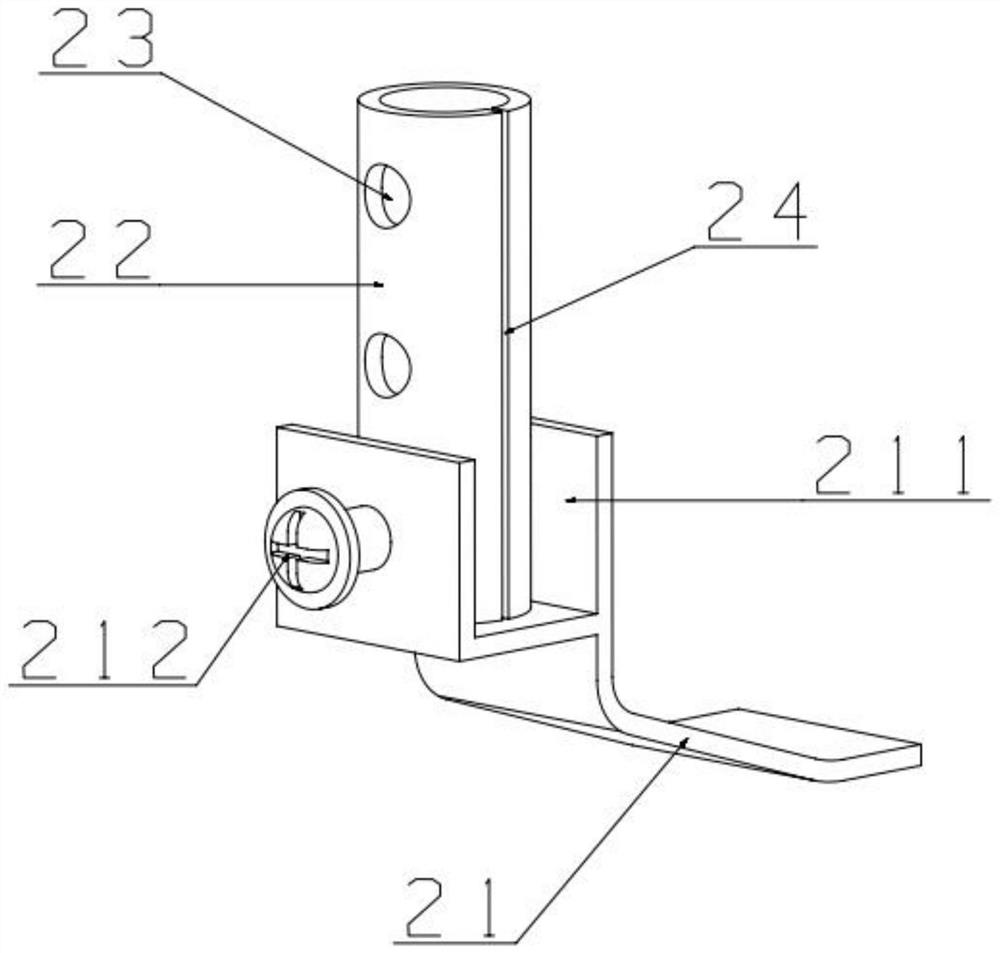

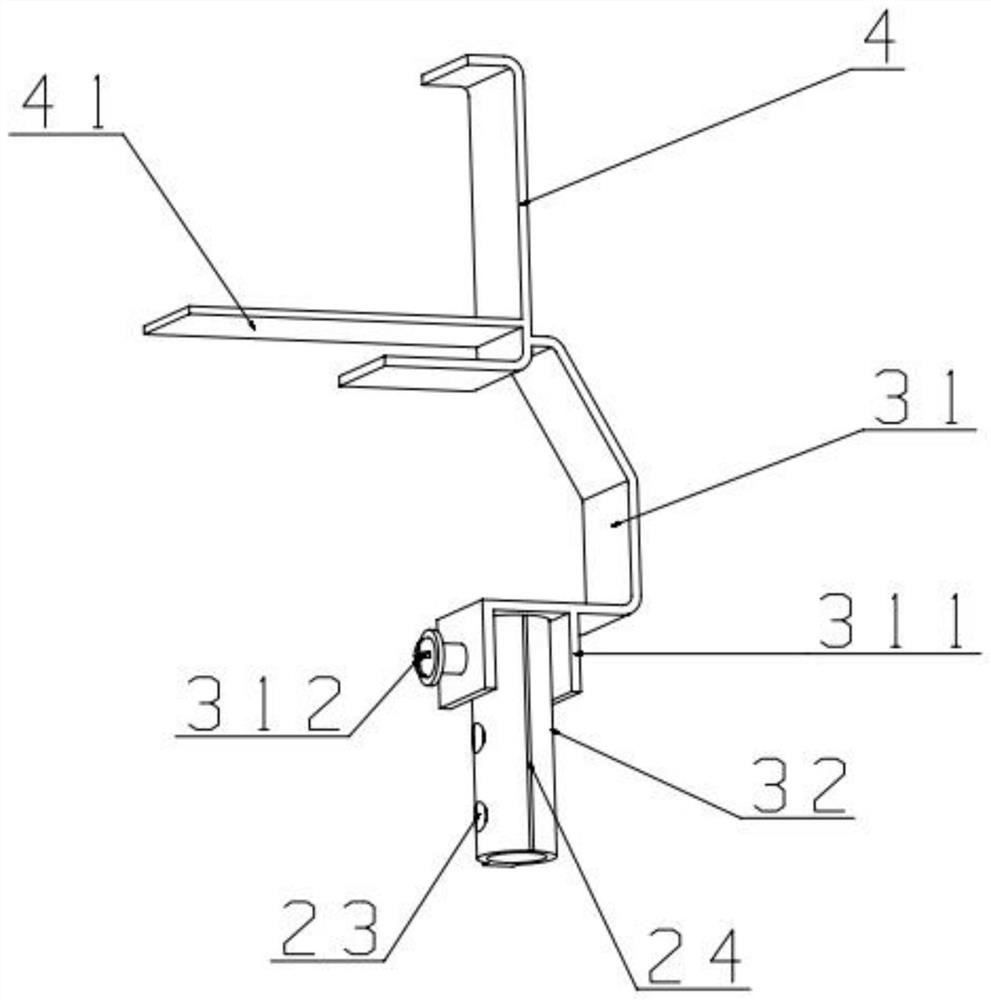

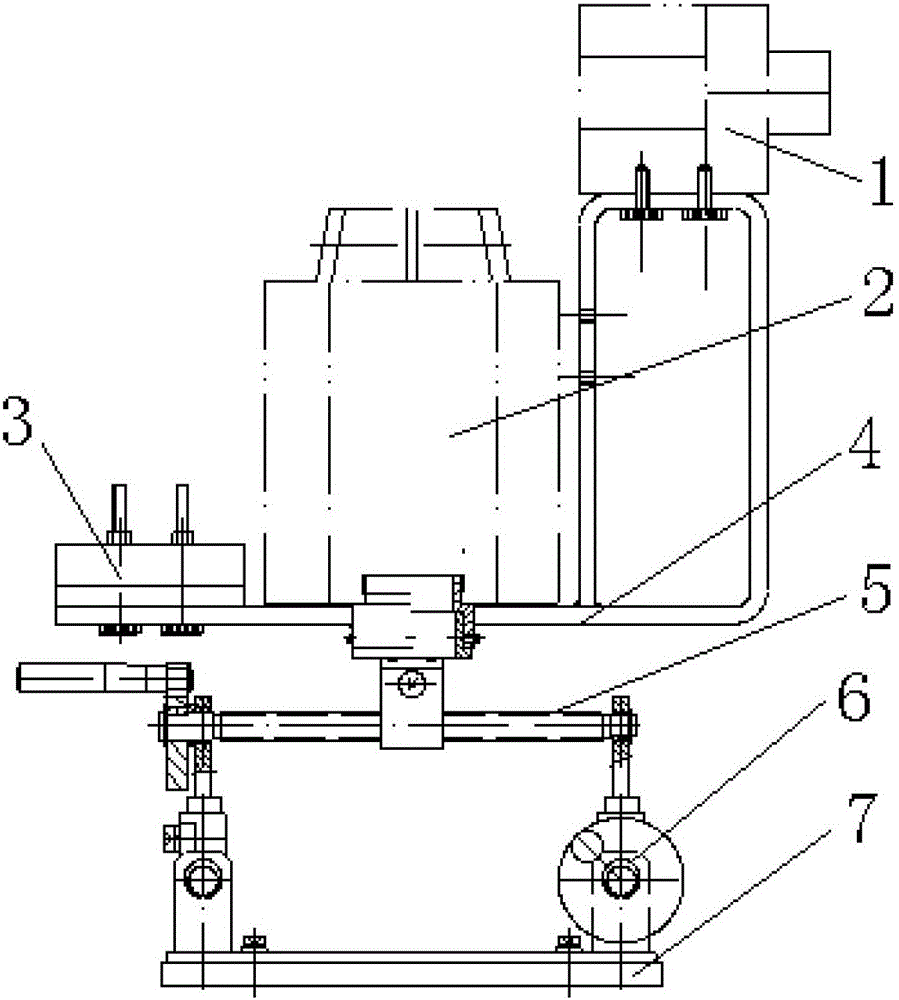

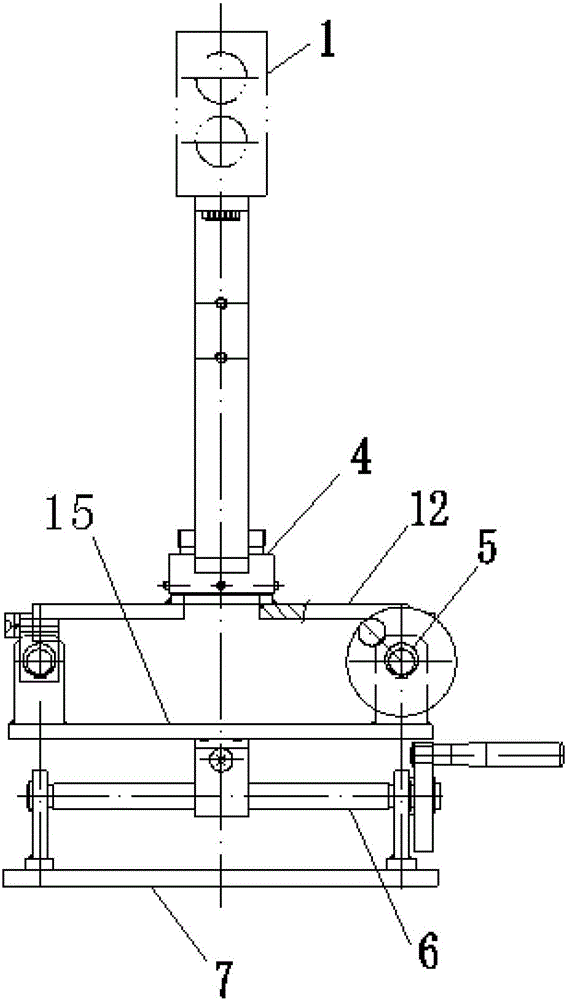

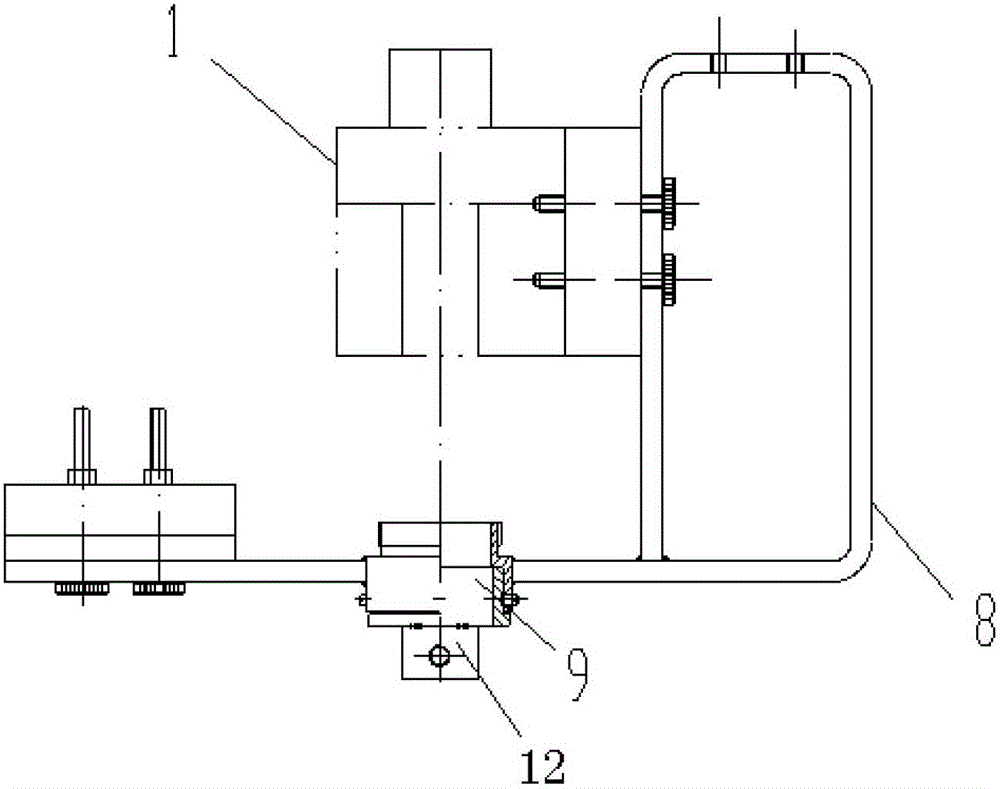

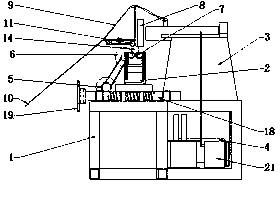

Laser measuring device installation frame

ActiveCN103277639ACompact designLow costSurveying instrumentsUsing optical meansMicrocomputerLaser ranging

The invention discloses a laser measuring device installation frame. A laser measuring device comprises a laser swinger and a laser range finder. The laser range finder comprises a range finder outer shell body. A laser emitter and a laser receiver are arranged on the front end portion of the range finder outer shell body, a light reflector mirror, a microcomputer lightning reflecting micromirror and an optical surface mirror are arranged inside the range finder outer shell body, a displaying screen and a voice number reporting device are arranged on the upper surface of the range finder outer shell body, and a compass and a remote positioning device are arranged on the side face of the range finder outer shell body. The installation frame comprises a base plate and a reverse U-shaped support which is arranged at one end of the base plate, a cushion block is arranged at the other end of the base plate, the base plate is movably connected with an axial rail, and the two ends of the axial rail are movably connected with a radial rail. The laser measuring device installation frame is small and exquisite in overall structure, flexible and convenient to operate and low in cost, and has many adjustment functions.

Owner:STATE GRID CORP OF CHINA +1

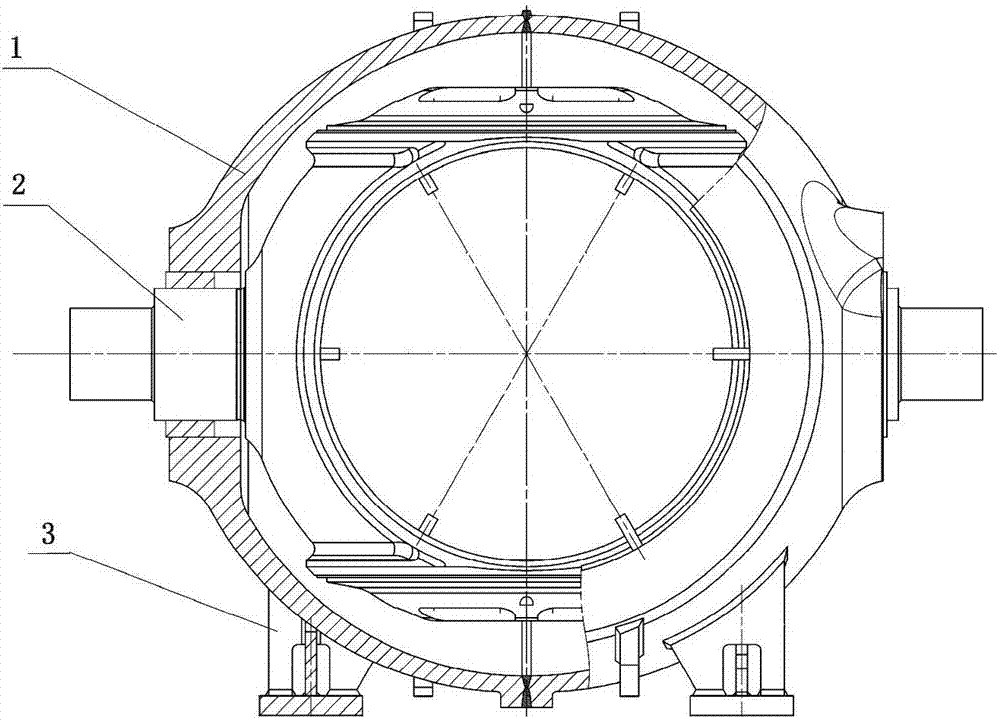

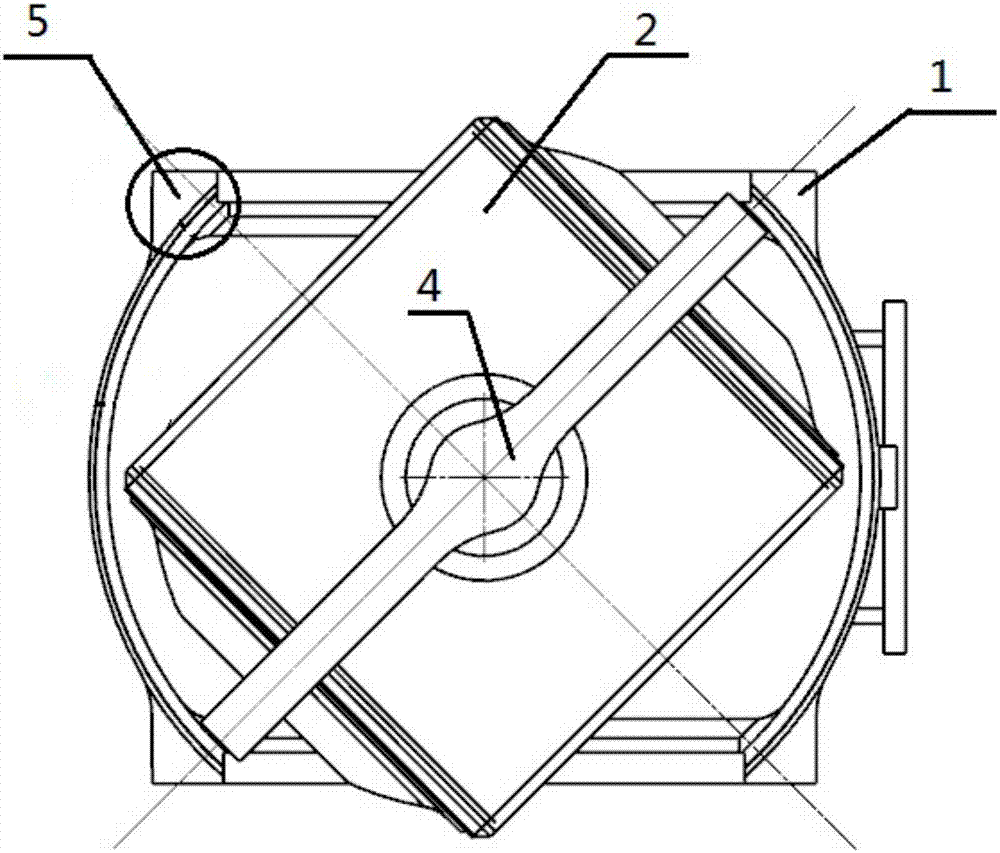

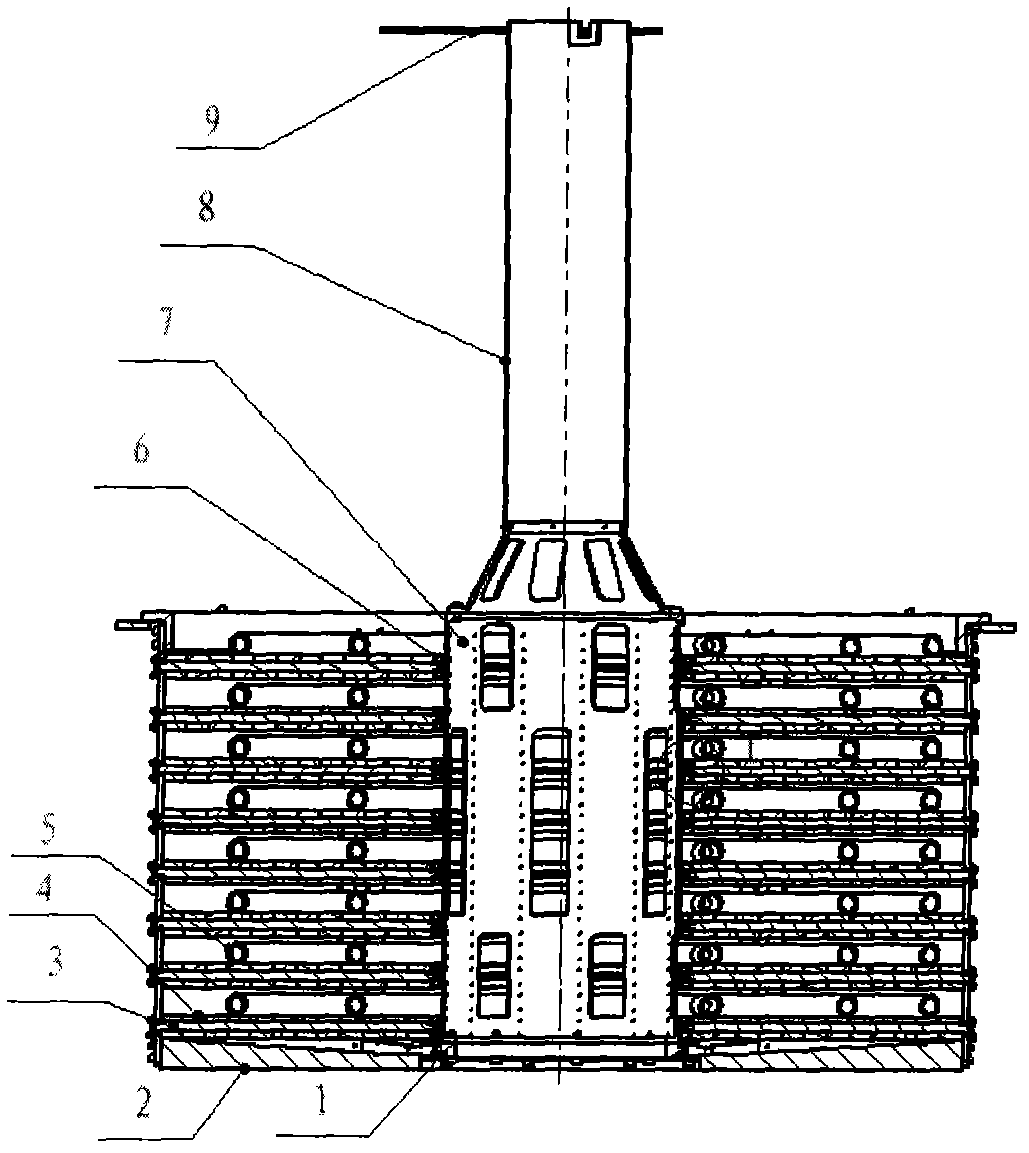

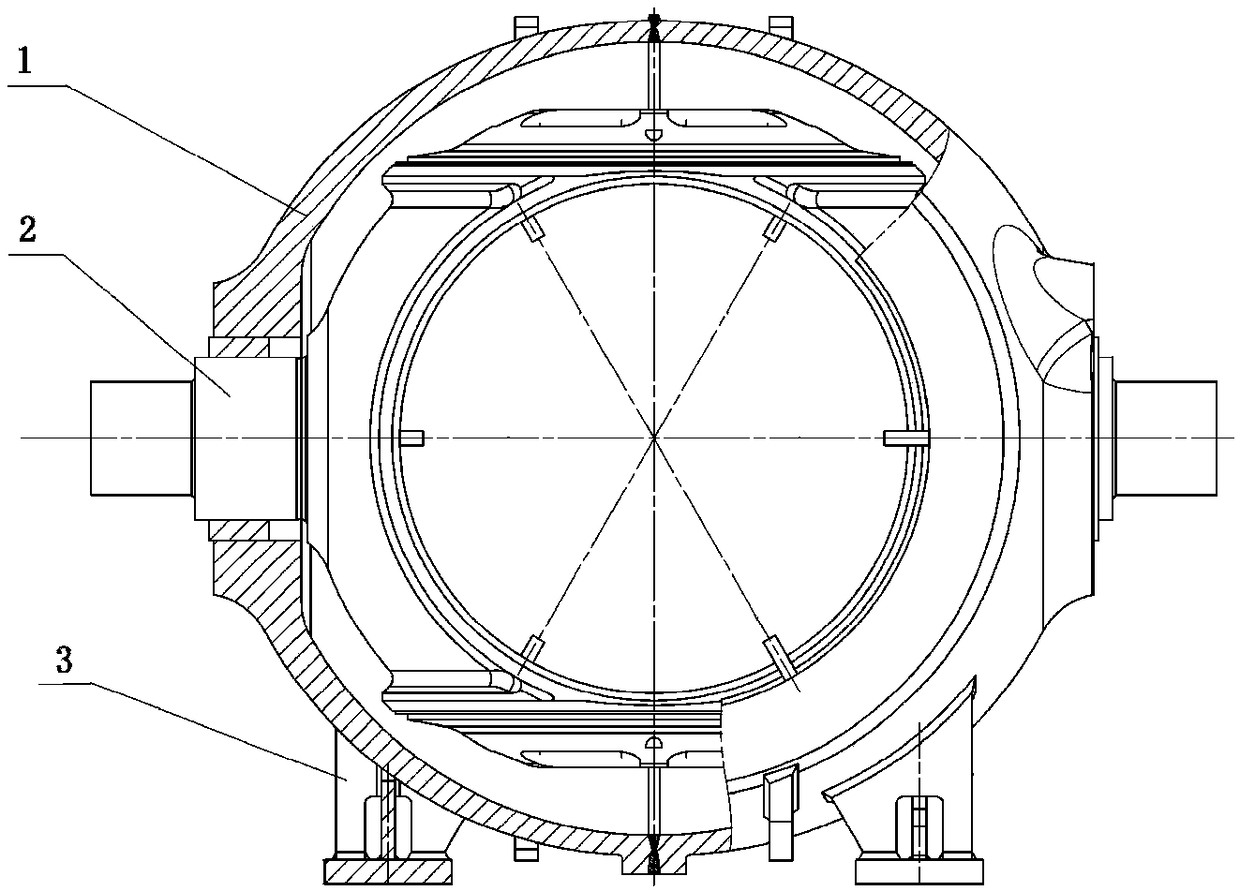

Welding manufacturing technology method of large water turbine ball valve of all-welded structure

ActiveCN107243704AIncrease the difficulty of assemblyIncrease in sizeWelding apparatusManufacturing technologyWater turbine

The invention discloses a welding manufacturing technology method of a large water turbine ball valve of an all-welded structure. The method represents innovation of an assembly-welding technology method of the large water turbine ball valve of the all-welded structure and is the essential change of the manufacturing method. The technological scheme of coating high-temperature-resistant paint before assembly welding of a shaft sleeve as a welding auxiliary tool, a valve and a valve body single-piece and performing symmetric welding in the vertical welding position during rotating of the valve is applied for the first time, with the adoption of the method, accessibility and operability of welding are greatly improved, welding deformation is effectively controlled, quality of a ball valve welding seam is guaranteed by intermediate flaw detection, critical dimensional stability of the ball valve is guaranteed, and the assembly-welding quality of the large water turbine ball valve of the all-welded structure is remarkably improved accordingly.

Owner:HARBIN ELECTRIC MASCH CO LTD

Underground opening self-locking casing centering device

ActiveCN104234647AEasy to install on siteShorten the lengthDrilling rodsDrilling casingsSelf lockingEngineering

Owner:大庆恩博科技开发有限公司

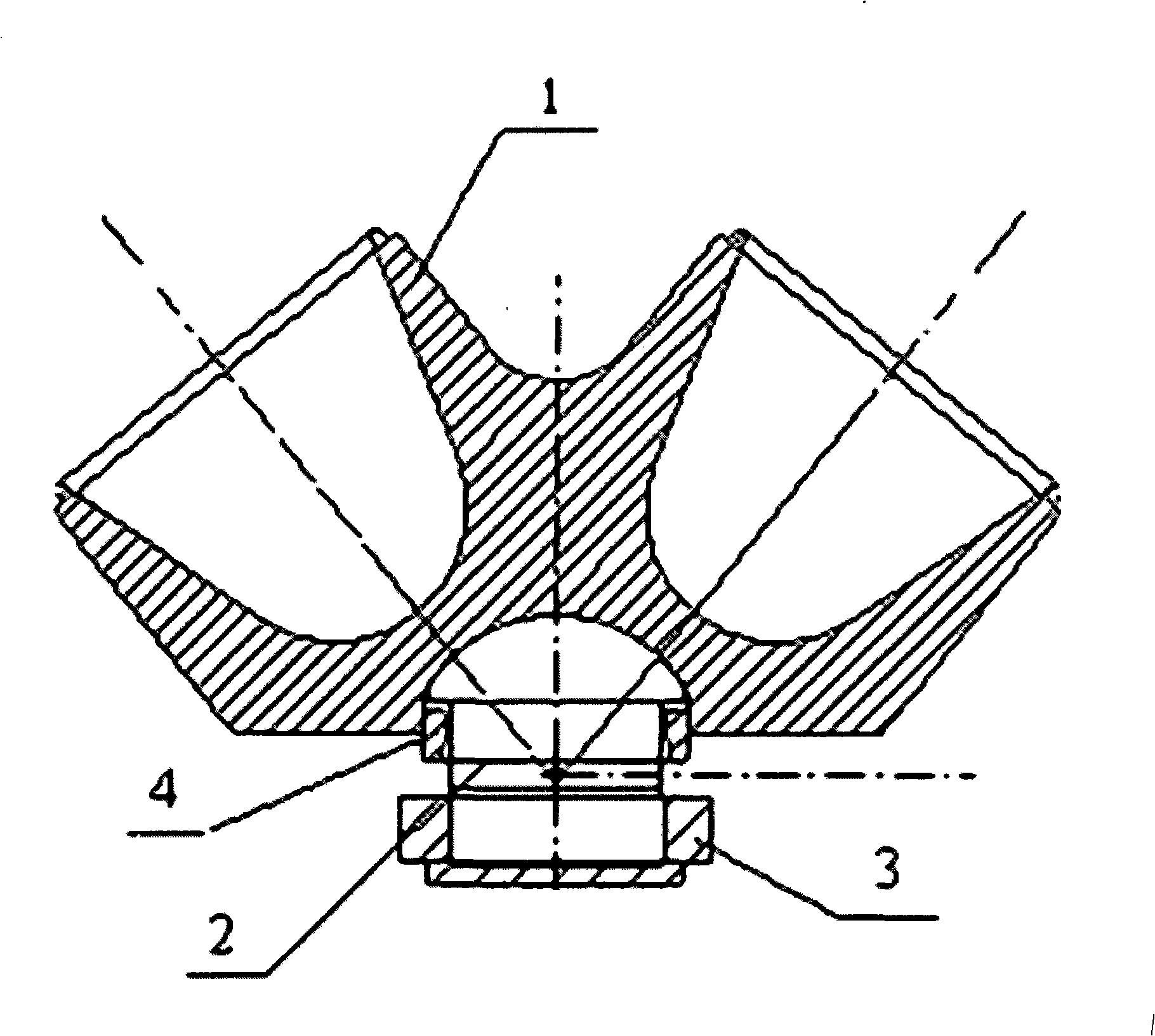

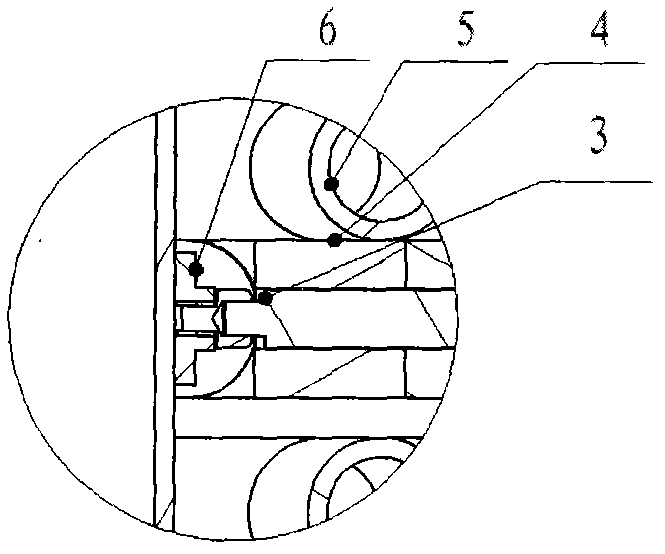

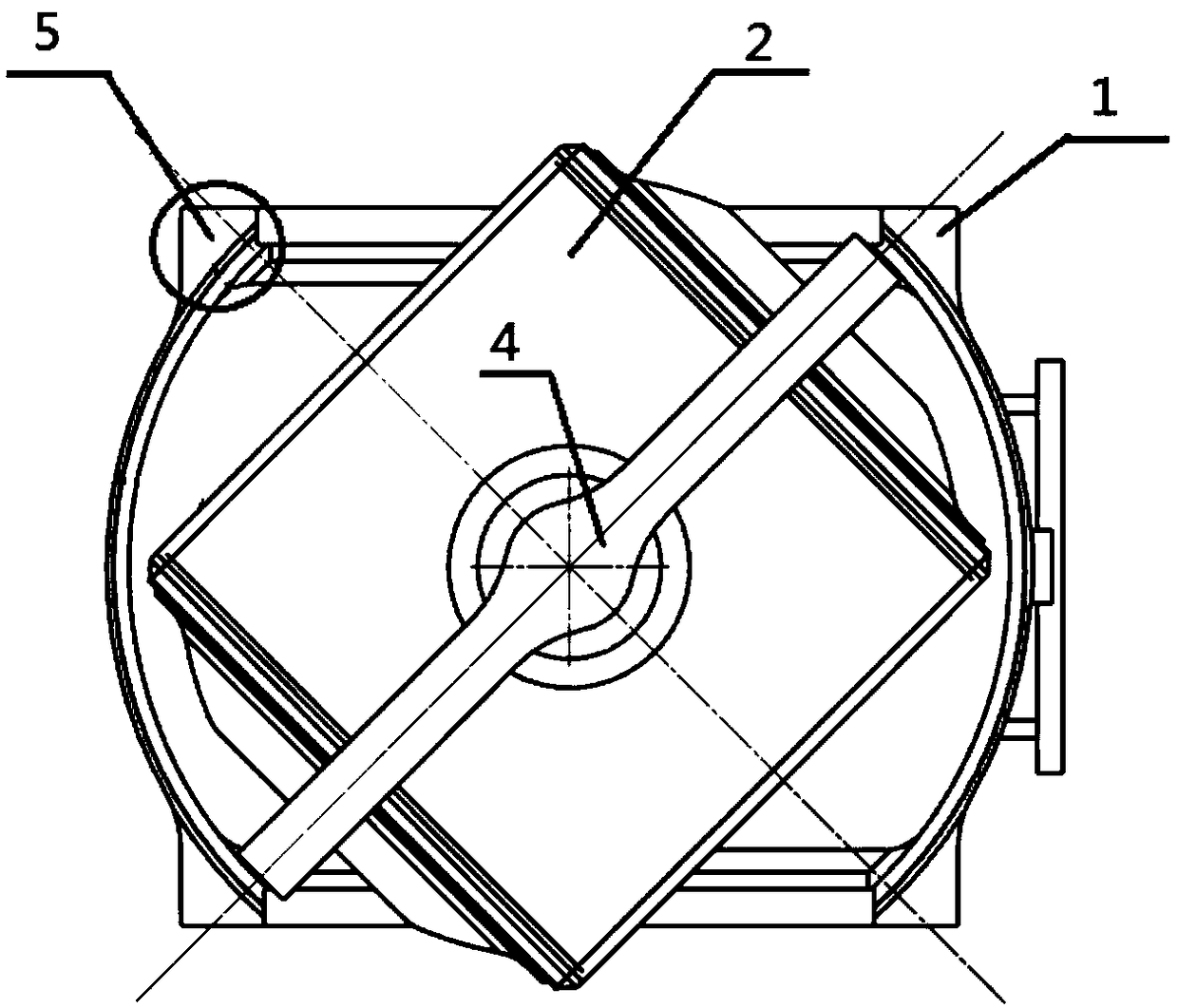

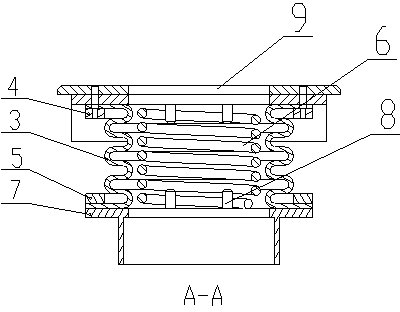

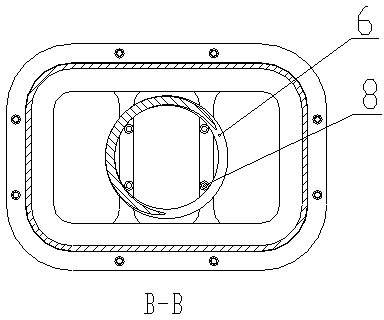

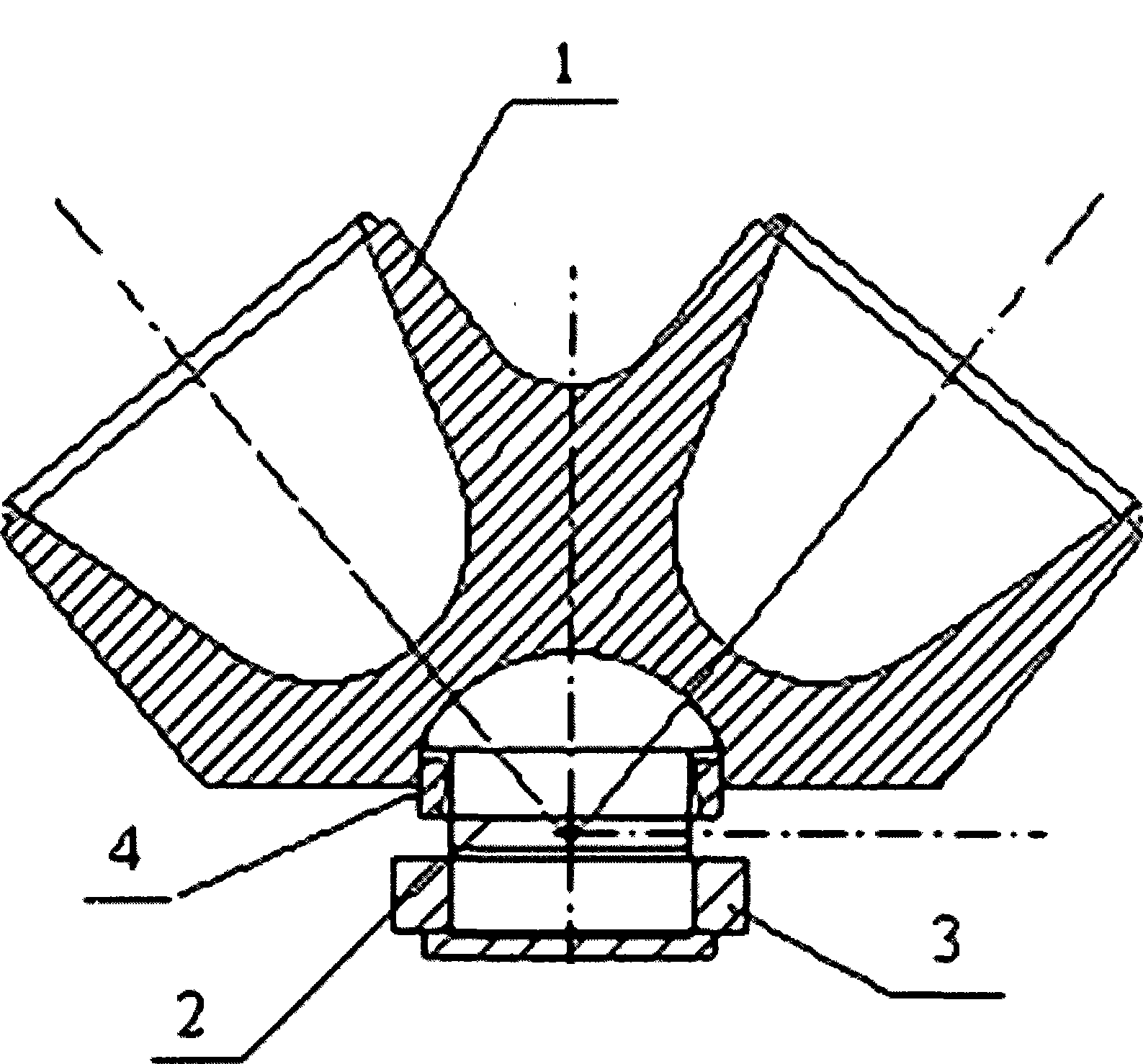

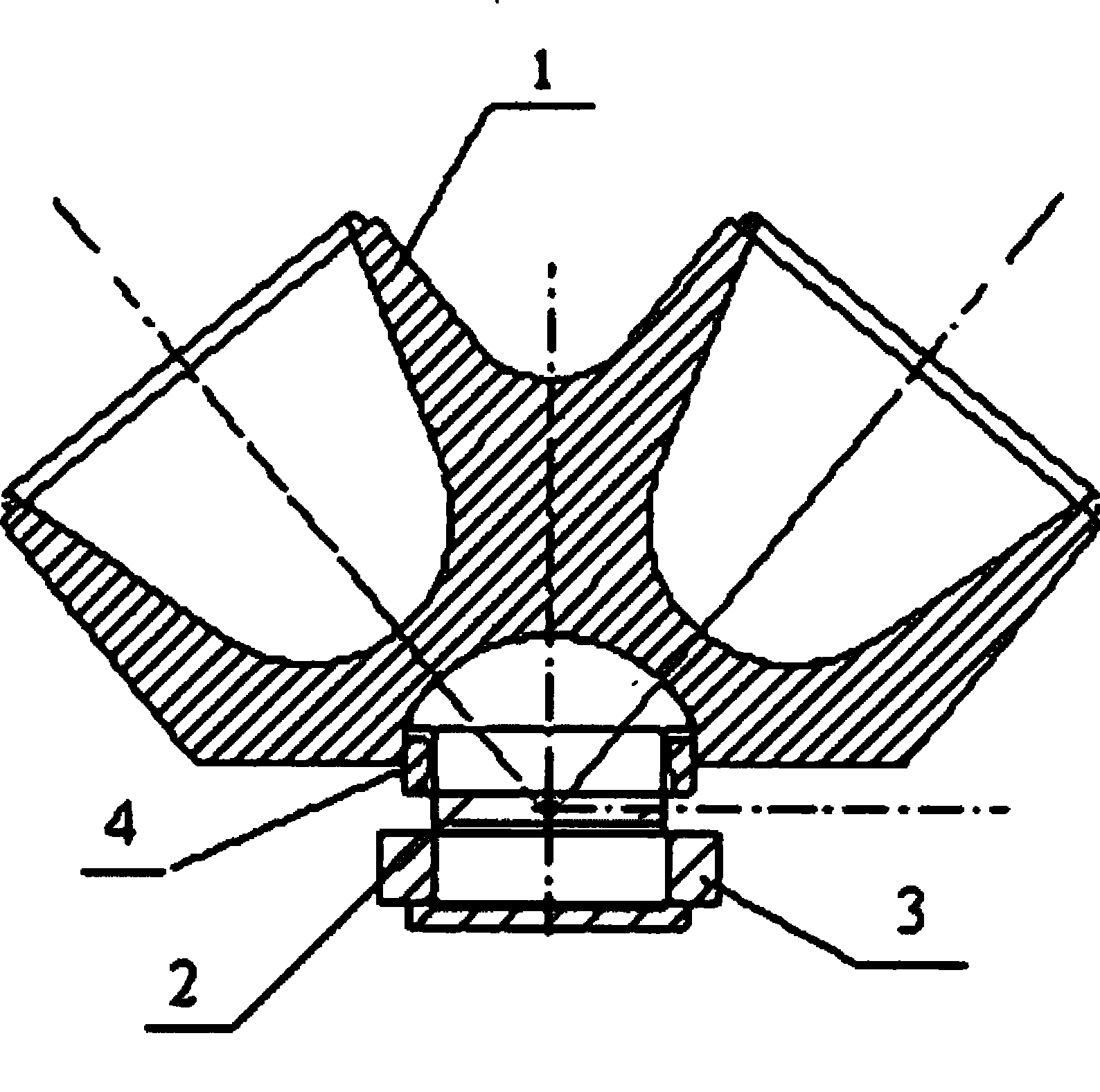

Cast steel ball hinged support

ActiveCN101403242ASatisfy rotation requirementsThe force mode is no longer singleBuilding constructionsHorizontal forcePull force

The invention discloses a novel cast-steel spherical hinge support, which comprises a base fixedly connected with a column-shaped supporting body with the top being an evagination crown body which is embedded in a provided groove on the lower end surface of a rolling body, the shape of the inner surface of the provided groove corresponds to that of the evagination crown body, the inner side wall of the provided groove is connected with a baffle ring in a screw way, and the baffle ring is arranged outside the column at the lower part of the evagination crown body. The support can not only meet the rolling demands of the nodes, but also can bear horizontal force and the vertical pull force as well as pressure, thus being mainly used for large-span space structure bearing complicated forces and heavy shaped steel structure.

Owner:TIANJIN UNIV

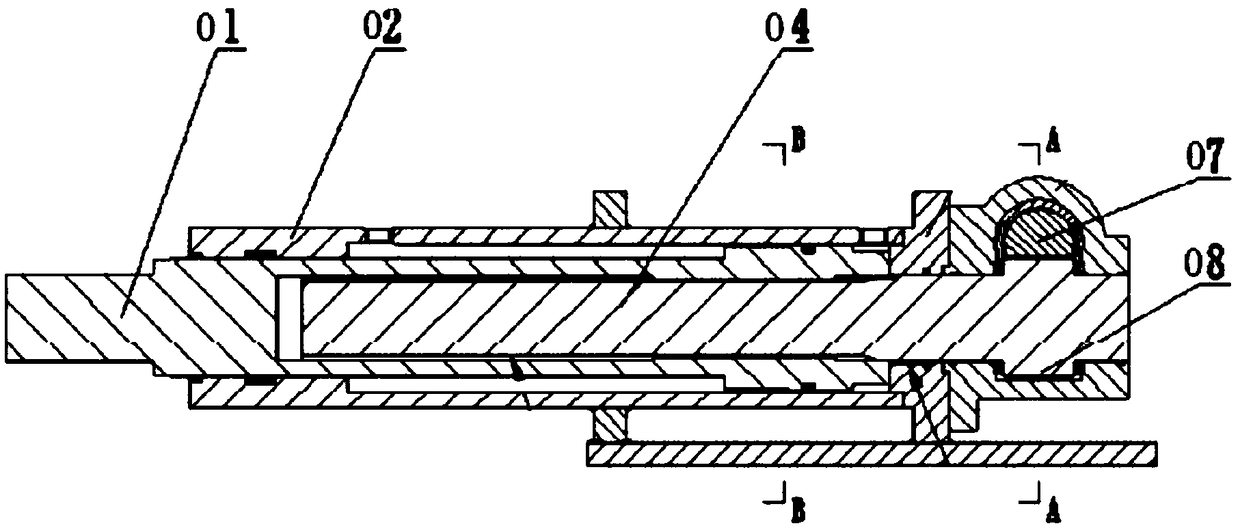

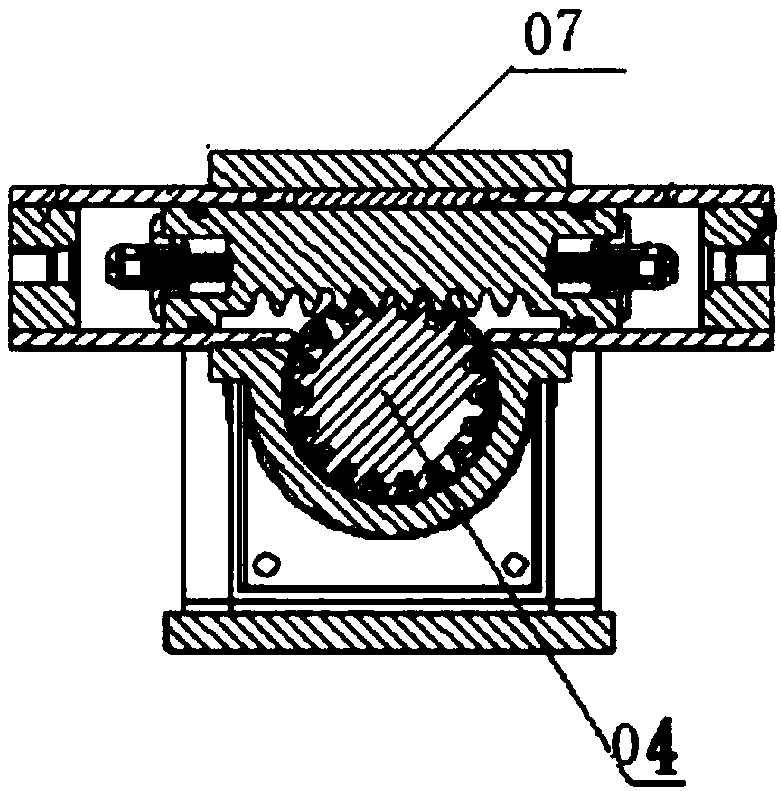

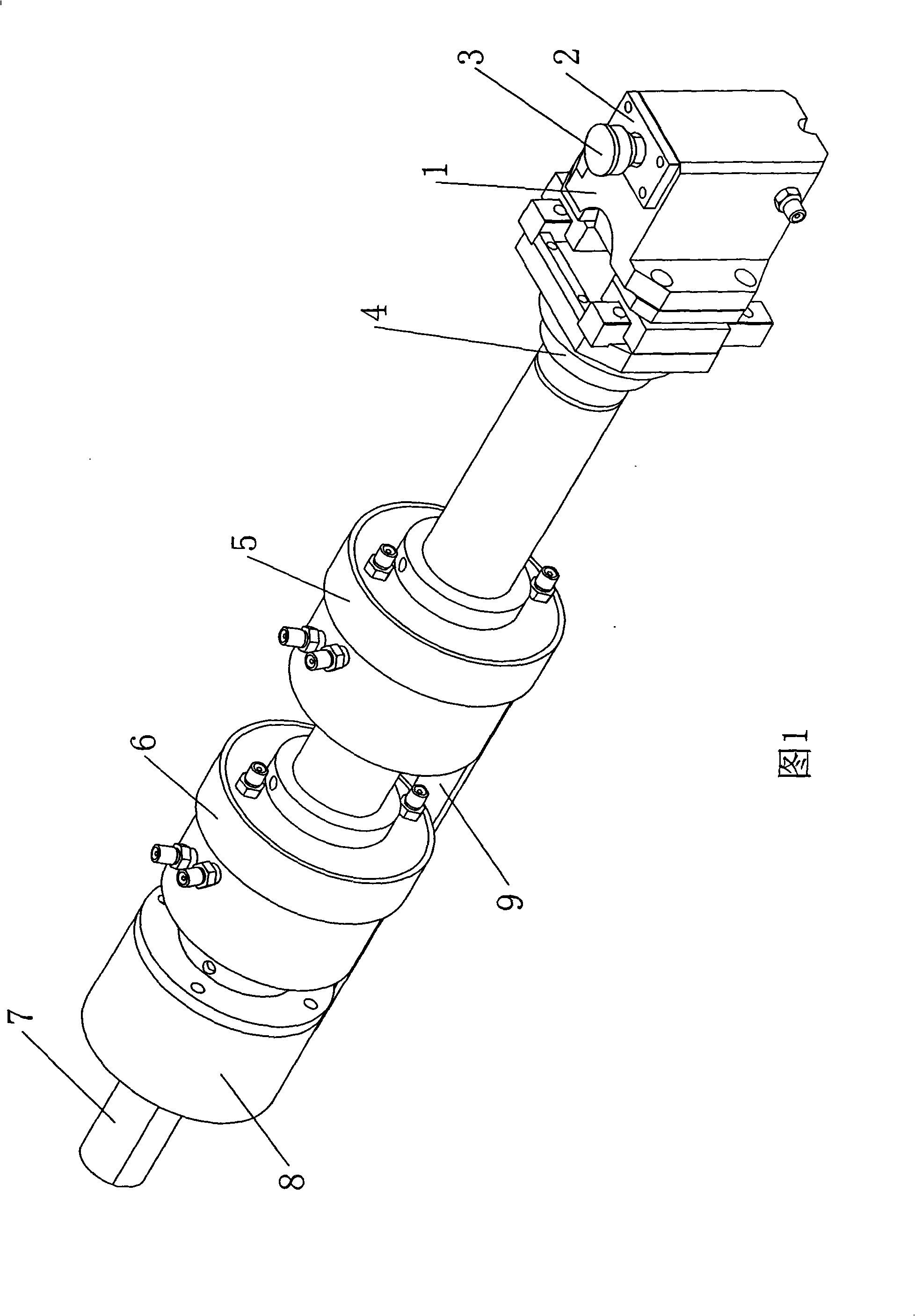

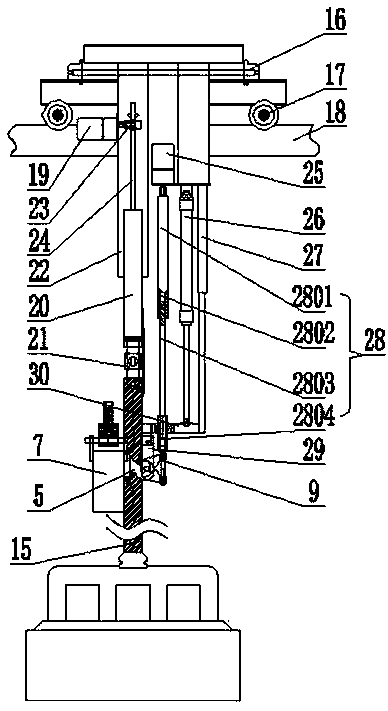

Rotary telescopic combined oil cylinder

PendingCN108302083ASatisfy rotation requirementsCompact layoutFluid-pressure actuatorsPiston rodSpiral line

The invention discloses a rotary telescopic combined oil cylinder. The rotary telescopic combined oil cylinder comprises a telescopic cylinder body and a rotary cylinder body; the telescopic cylinderbody comprises a first cylinder barrel and a telescopic piston rod; the rotary cylinder body comprises a second cylinder barrel, a spiral piston and a rotary transmission rod; two oil cavities are arranged in the cylinder barrel of the telescopic cylinder body and the cylinder barrel of the rotary cylinder body respectively, and the cylinder barrels are provided with corresponding oil ports correspondingly; one end of a rotary transmission rod is rotationally installed in the rotary cylinder body, and the other end of the rotary transmission rod penetrates into the interior of the first cylinder barrel; an outer circumferential part of a spiral piston is in threaded connection with an inner circumferential part of the second cylinder barrel, the inner peripheral part is in threaded connection with the rotary transmission rod, and the spiral direction of the outer peripheral part of the spiral piston is opposite to the spiral direction of a spiral line of the inner peripheral part; anda blind hole is formed in the telescopic piston rod, a peripheral part of the hole wall of the blind hole is in transmission connection with the rotary transmission rod through a spline so that the rotary transmission rod can drive the telescopic piston rod to rotate, and the telescopic piston rod can move in the axial direction relative to the rotary transmission rod. According to the rotary telescopic combined oil cylinder, enough steering resistance moment can be provided, steering and suspension expansion can be realized, and meanwhile, the space arrangement of a whole vehicle can be compact.

Owner:JIANGSU XCMG CONSTR MASCH RES INST LTD

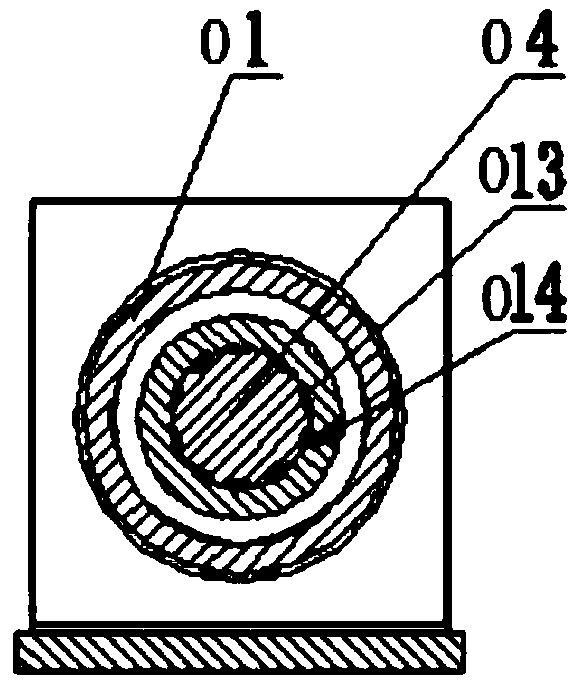

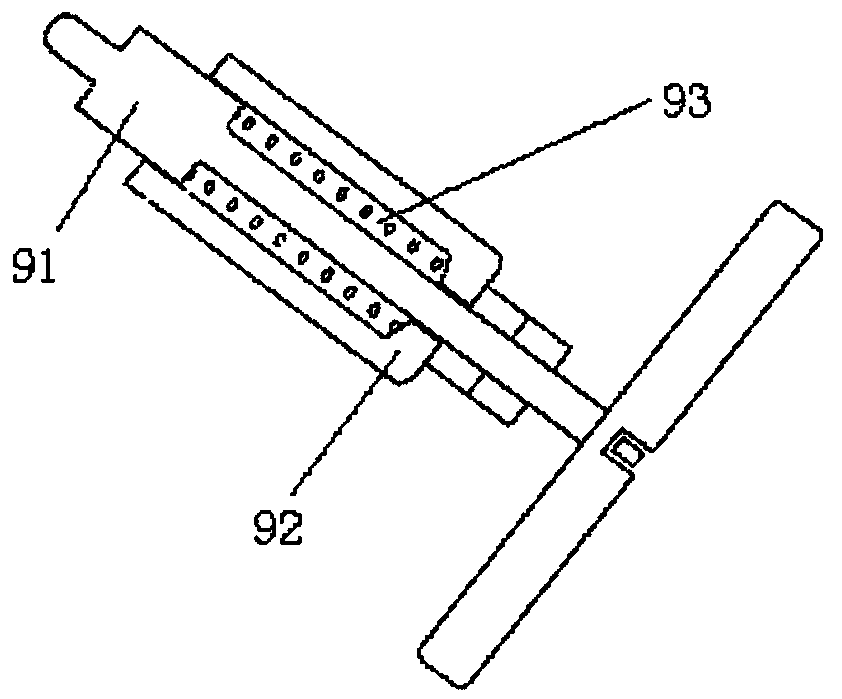

Direction line winding mechanism for telescope

The invention relates to a direction line winding mechanism for a telescope, which is of a structure capable of independently assembling and running and is provided with a bearing capable of rotating, the outer race of the bearing is connected with a fixed base frame set, the inner race of the bearing is connected with a rotary barrel and can be driven to synchronously rotate together with a direction shaft of the telescope by a connecting pipe and a cross-shaped slide ring, and the fixed base frame set is fixed on a base of equipment to ensure that the inner race and the outer race of the bearing oppositely rotate well. The direction line winding mechanism ensures function realization on the telescope, simultaneously meets the rotation requirement on the telescope and improves the adaption of the telescope.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Centrifugal pump shell processing clamp

ActiveCN110900230AAdjustable support sizeEasy to operateWork clamping meansMetal working apparatusFixed frameEngineering

The invention discloses a centrifugal pump shell processing clamp which comprises a fixed frame, a compressing mechanism, a rotary mechanism and a clamping mechanism, wherein the compressing mechanism, the rotary mechanism and the clamping mechanism are mounted in the fixed frame; the rotary mechanism is connected with the compressing mechanism; the compressing mechanism is connected with the clamping mechanism; the fixed frame comprises a bottom plate, a support plate, a fixed plate, a sliding chute, a threaded hole, a positioning rod, a rectangular frame, a rotary tray and a connecting plate; the compressing mechanism, the rotary mechanism and the clamping mechanism are sequentially combined; a connecting sleeve is arranged to meet the rotary requirement of a second rotary shaft; a limiting sliding strip and a straight groove are arranged to meet the sliding requirement of a lantern ring when a central rotary shaft rotates, so that all mechanisms run independently; all running mechanisms do not need to load the weight of other driving equipment and are excellent in cooperating effect, and the space utilization ratio is high; and a pump body is fixed through a fixing flange, so that the defect that only a specific clamping model can effectively fix the pump body is avoided.

Owner:哈尔滨凯泉泵业有限公司

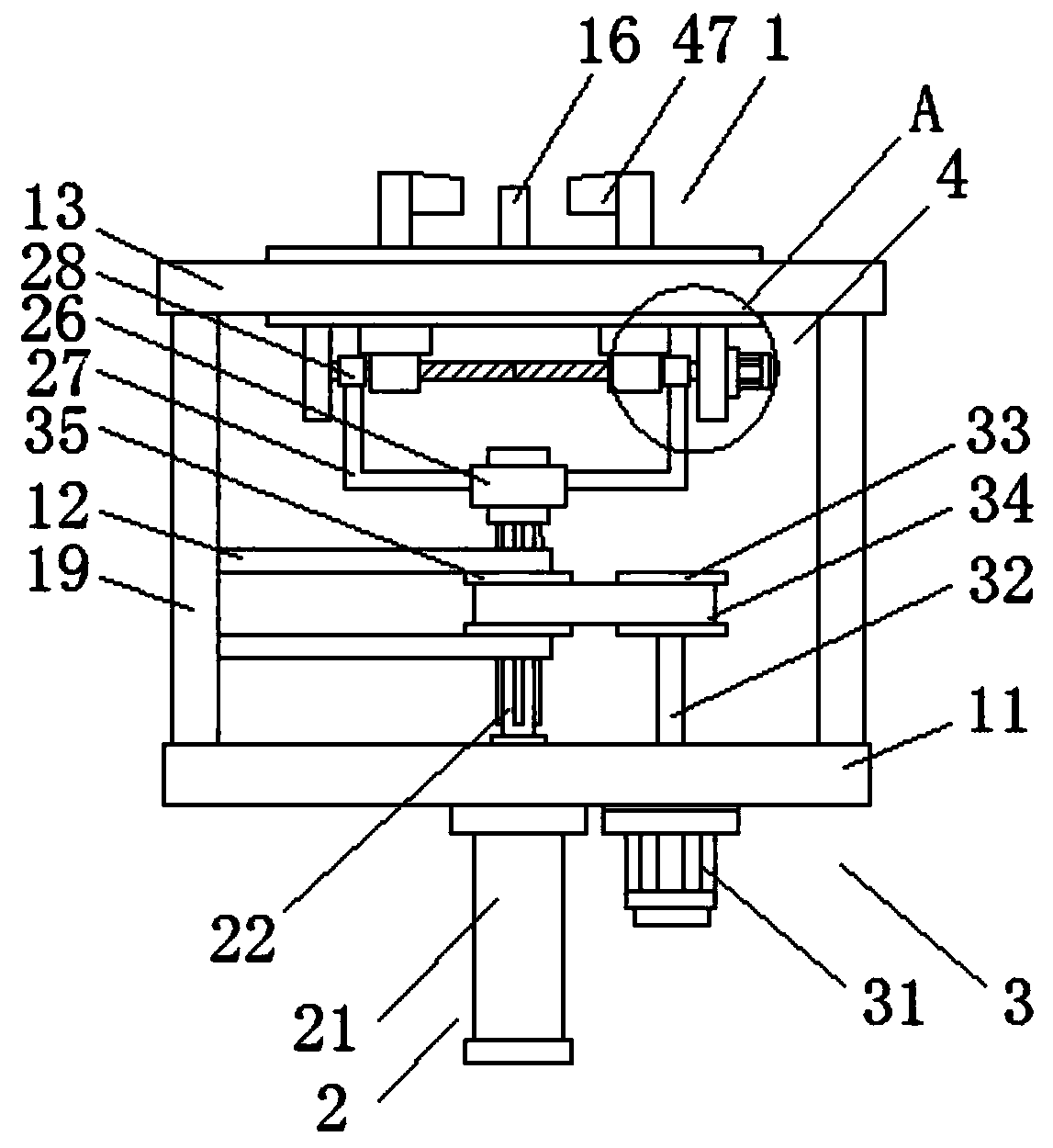

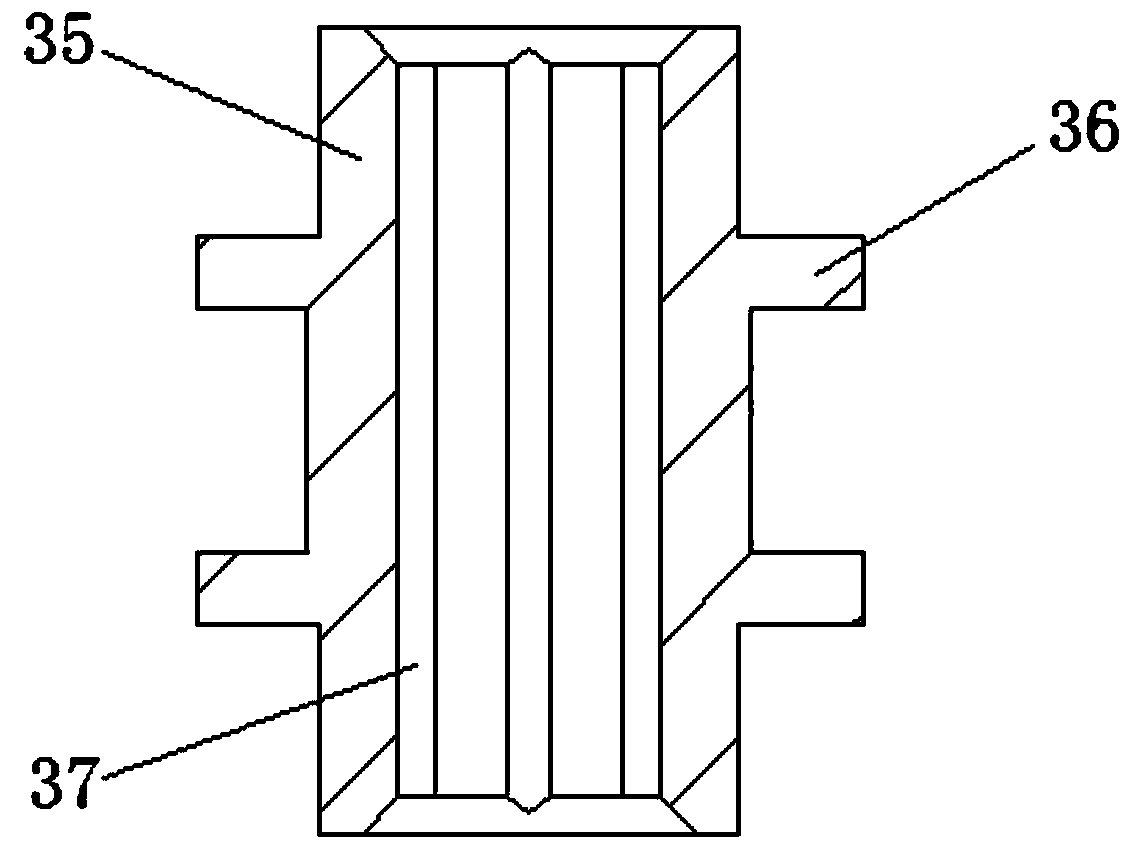

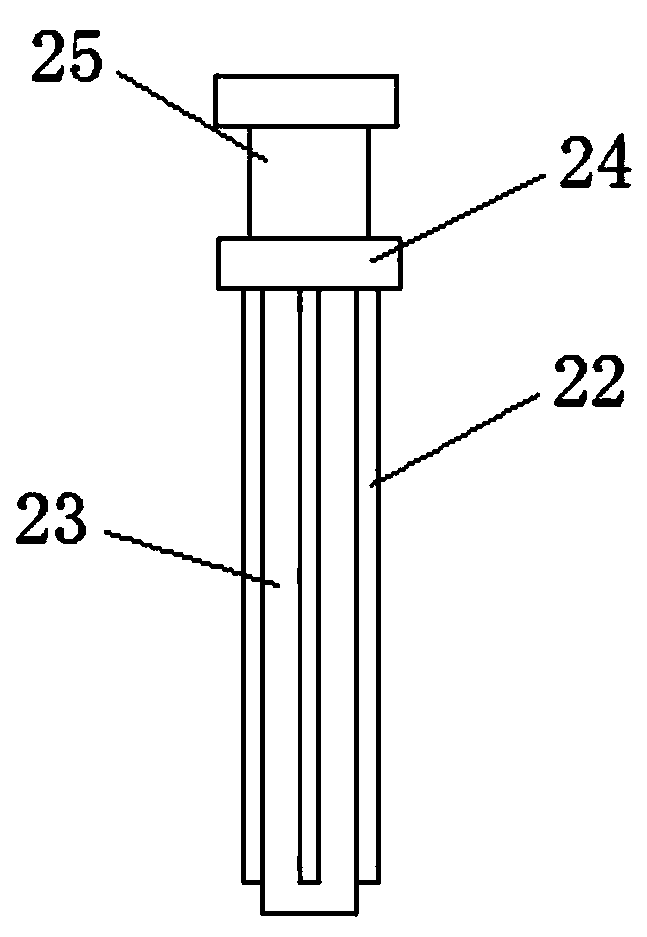

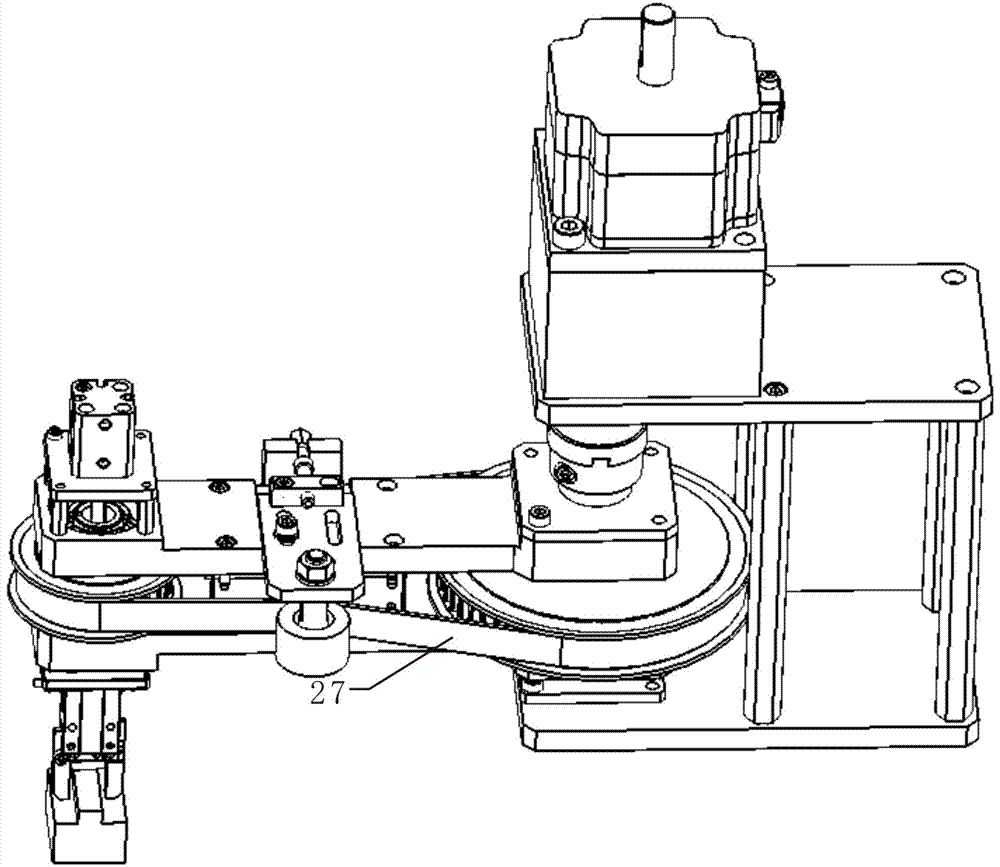

Part machining clamping and rotating control device

The invention discloses a part machining clamping and rotating control device. The device comprises three parts of a rotating table, a rotating and support mechanism, a mechanical clamping hand lifting and support mechanism. An internal motor rotates to drive rotation of the surface of the rotating table so as to drive the rotating and support mechanism and the mechanical clamping hand lifting and support mechanism thereon to totally rotate; through rotation, a mechanical clamping hand is positioned above parts to be clamped; a rotating motor drives a large rotating gear to rotate through a coupling; and at the same time, the large rotating gear drives a small rotating gear to rotate through a conveying belt. As the rotating table can realize 360-degree rotation of a rotating part, the clamping of the parts to be clamped can be efficiently and conveniently realized, the working range is widened, and the efficiency is improved. Before or after the parts are clamped by the mechanical clamping hand, a mechanical clamping hand lifting cylinder can drive the mechanical clamping hand to move up and down through a lifting mode, so that the parts can be clamped in different positions.

Owner:吴荣山

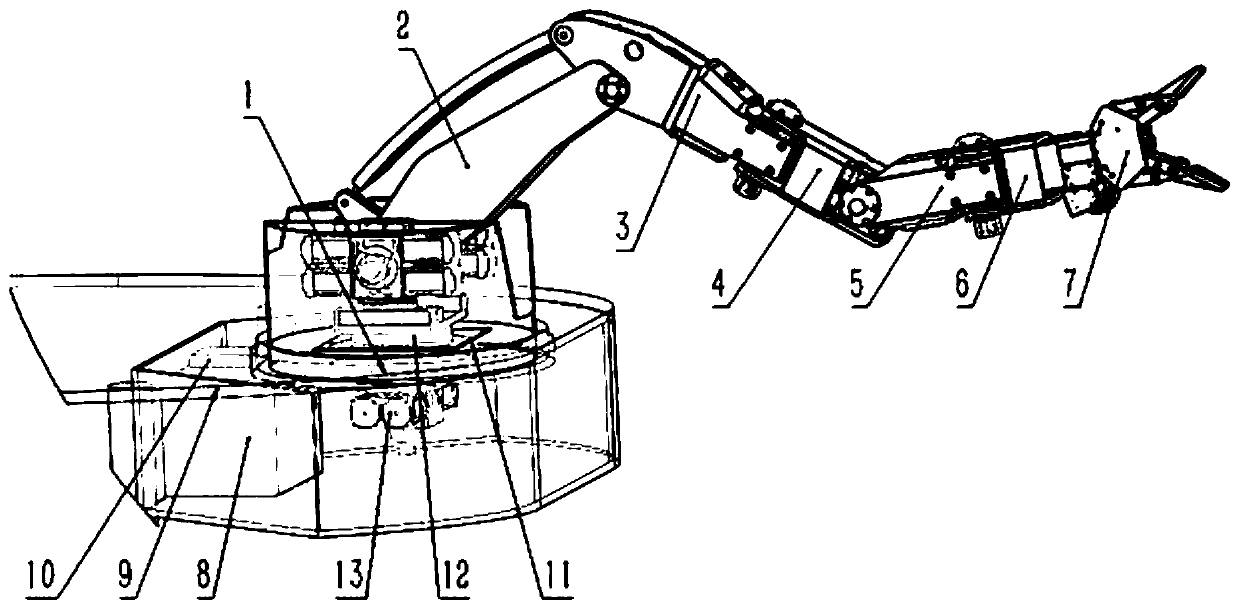

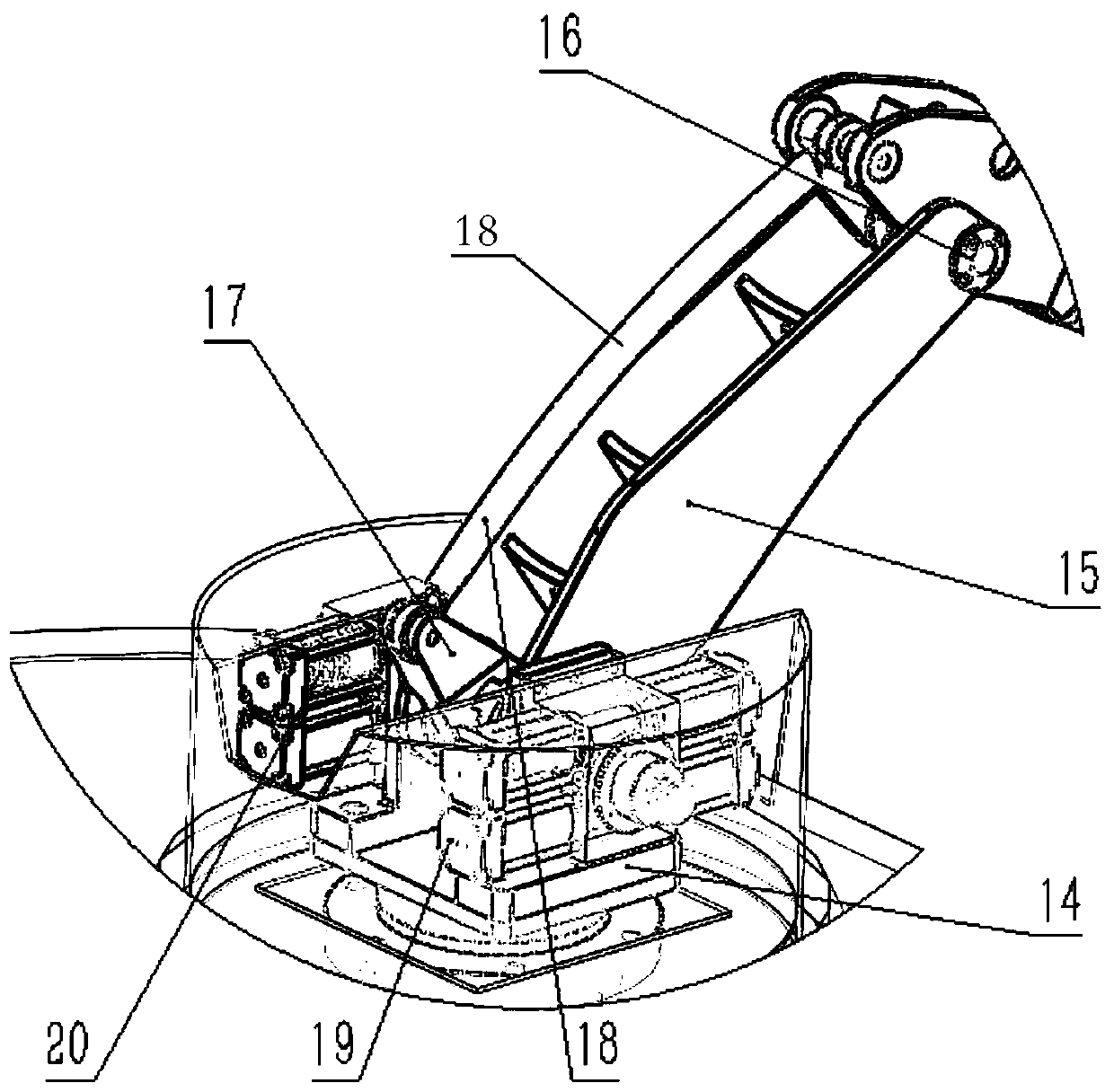

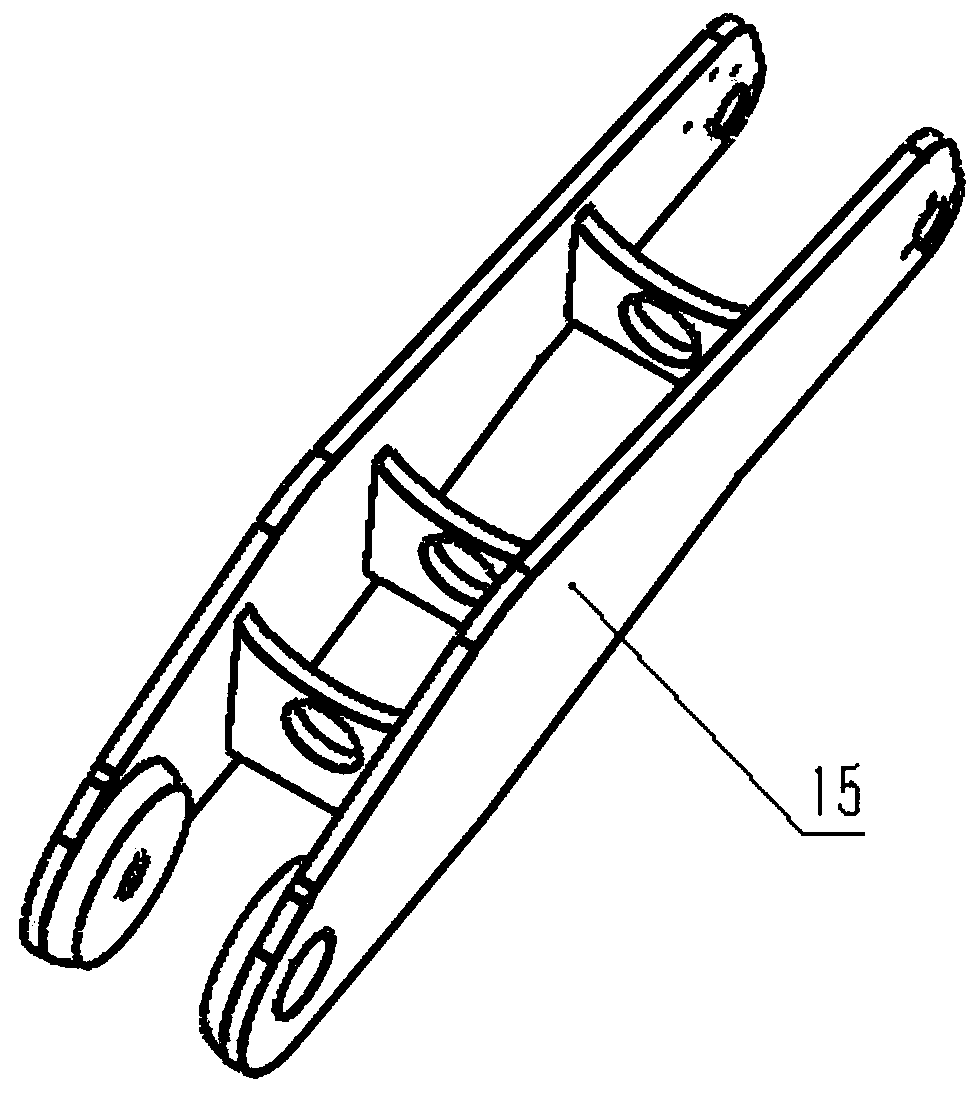

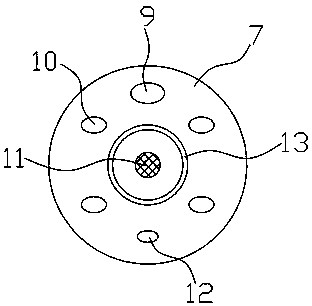

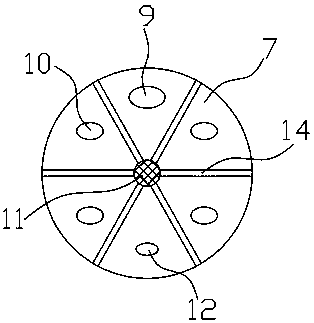

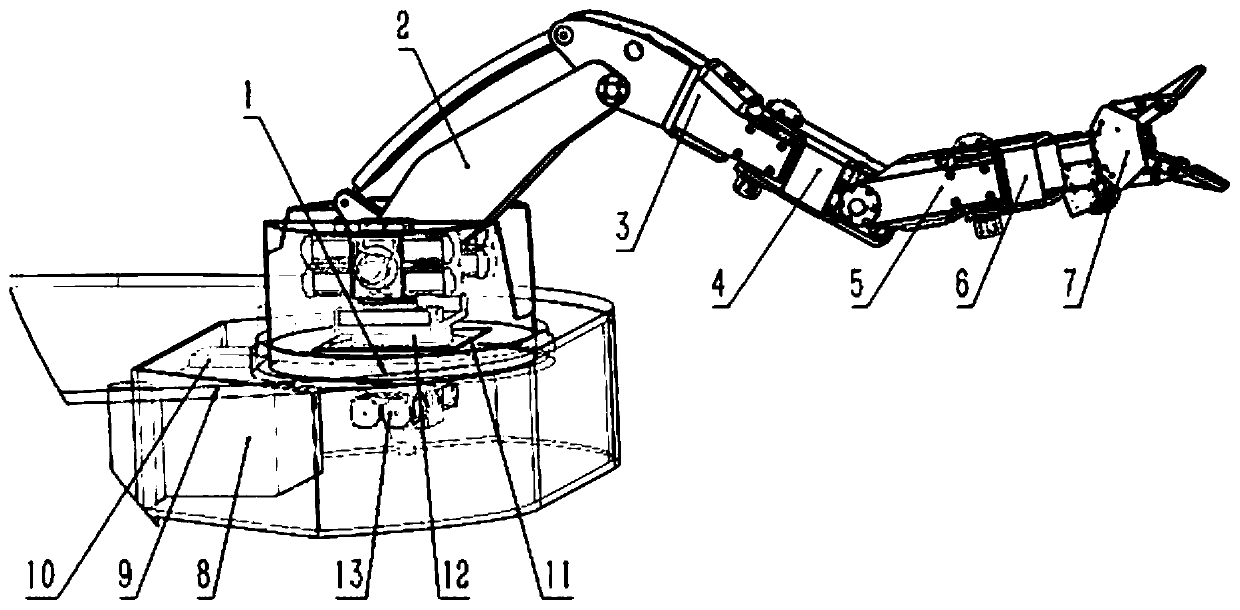

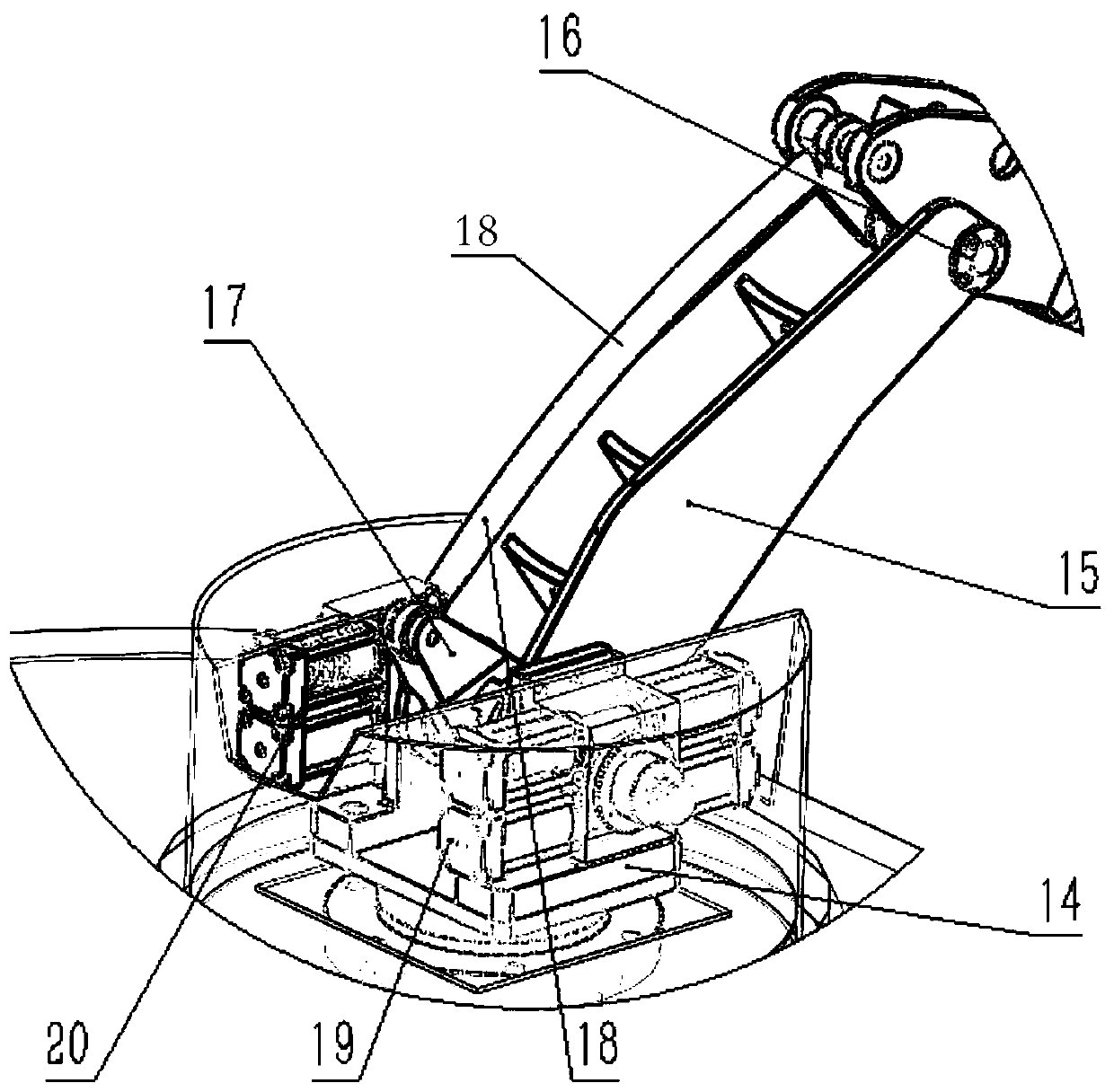

Underwater redundant hydraulic mechanical arm and work method thereof

ActiveCN110630596ALarge working spaceCompact structureServomotor componentsAccumulator installationsMarine engineeringUnderwater

The invention relates to an underwater redundant hydraulic mechanical arm and a work method of the underwater redundant hydraulic mechanical arm and belongs to the technical field of underwater mechanical robots. The underwater redundant hydraulic mechanical arm adopts a chain type series structure and comprises a rotating arm, a big arm, a middle arm, a forearm A, a forearm B, a wrist arm, a gripper, a hydraulic system and an STM32 control panel. The rotating arm, the big arm, the middle arm, the forearm A, the forearm B, the wrist arm and the gripper are sequentially connected. The hydraulicsystem provides power for the whole mechanical arm. The STM 32 control panel is used for controlling the mechanical arm to act. The rotating arm is installed on an underwater moving platform to support the whole hydraulic mechanical arm and achieves fixation and rotation of the whole mechanical arm. The big arm and the middle arm achieve pitching within a large range of the mechanical arm. The forearm A achieves transverse swinging of the mechanical arm. The forearm B achieves pitching within a small range of the mechanical arm. The wrist arm achieves transverse swinging and rotation of the gripper. The gripper achieves the clamping function. The underwater redundant hydraulic mechanical arm is compact and reasonable in structure, large in effective operation space, capable of expanding the freedom degree and suitable for different water depths.

Owner:SHANDONG UNIV

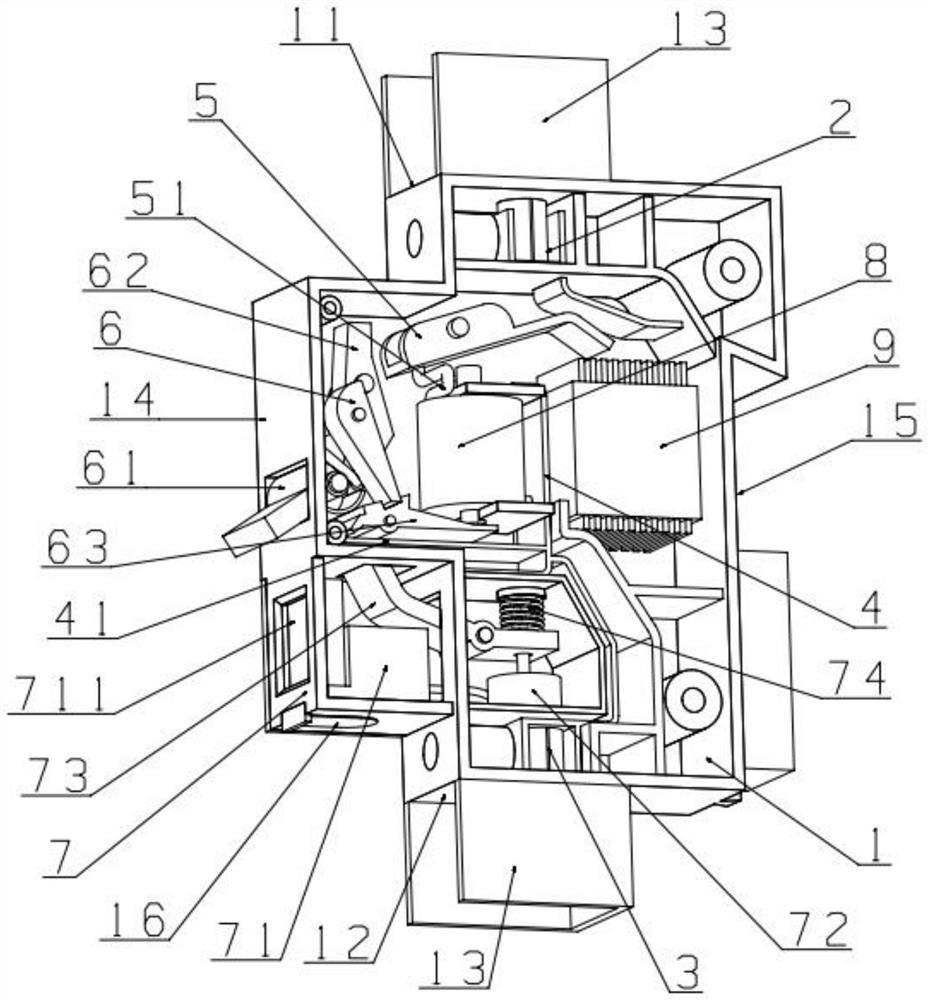

Novel air switch

InactiveCN114171354AEasy to observeImprove cooling effectElectric switchesSwitching device condition indicationThermodynamicsEngineering

The invention relates to the field of air switches, and particularly discloses a novel air switch which comprises a shell, an input terminal with an input sleeve, an output terminal with an output sleeve, a conducting strip, an overload protection bimetallic strip, a rotating piece, a wire and a mechanical locking handle assembly. The thermal inductance device is provided with a controller, a display screen, a temperature sensor and an electromagnetic pull rod assembly. According to the invention, the input sleeve is arranged on the input terminal, the output sleeve is arranged on the output terminal, and the input sleeve and the output sleeve of which the end parts are exposed wrap the end part of the wire and are fixed through the screw, so that the wiring condition can be conveniently observed, the wiring end can be reinforced, virtual connection is avoided, and the wiring quality is improved. The heat dissipation effect of the wiring end is improved; and the temperature of the wiring end and the external temperature of the air switch can be monitored in real time through the thermal inductance device, so that internal and external dual overheating protection is performed on the air switch, and a temperature value is fed back in real time.

Owner:GUANGXI POWER GRID CO LTD NANNING POWER SUPPLY BUREAU

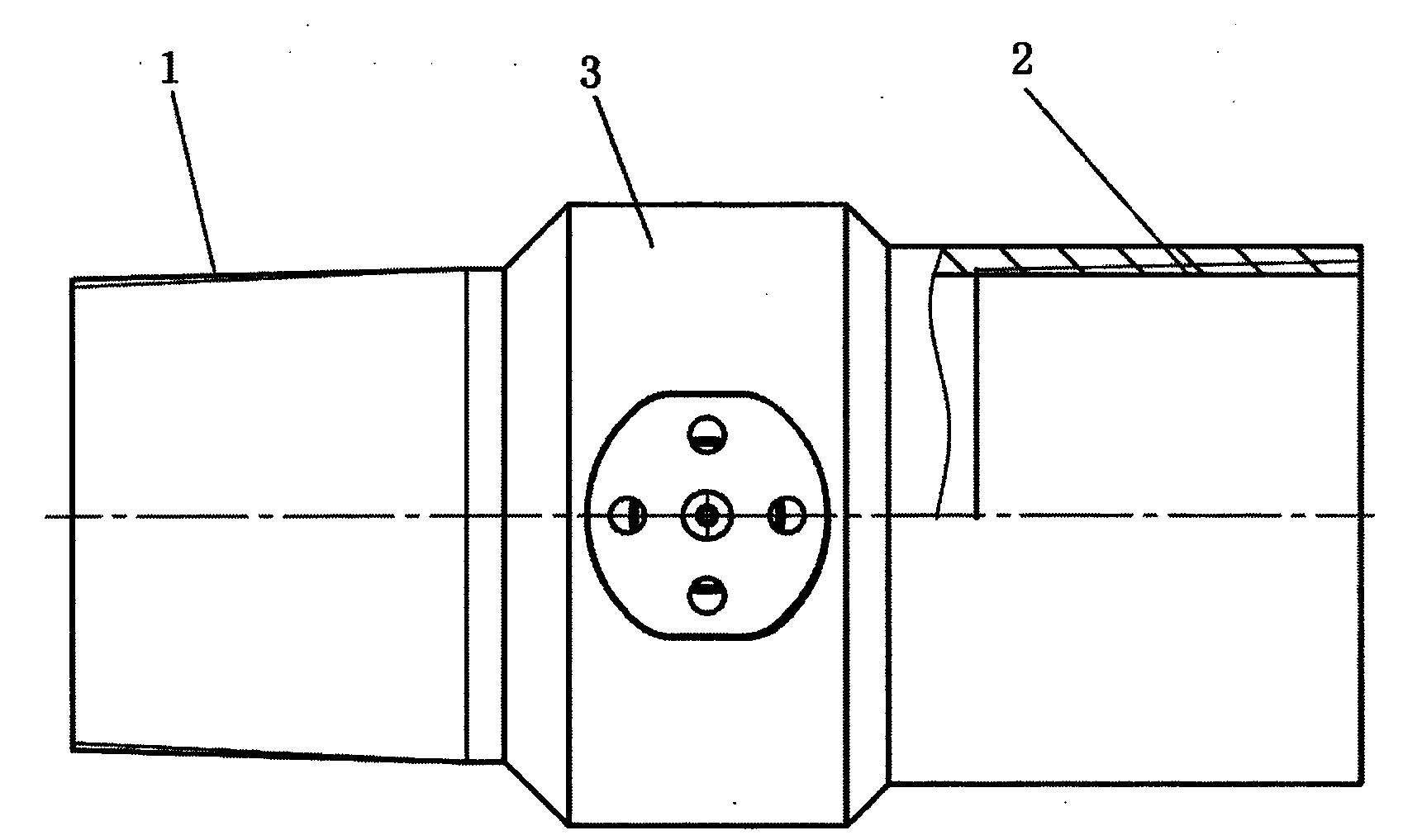

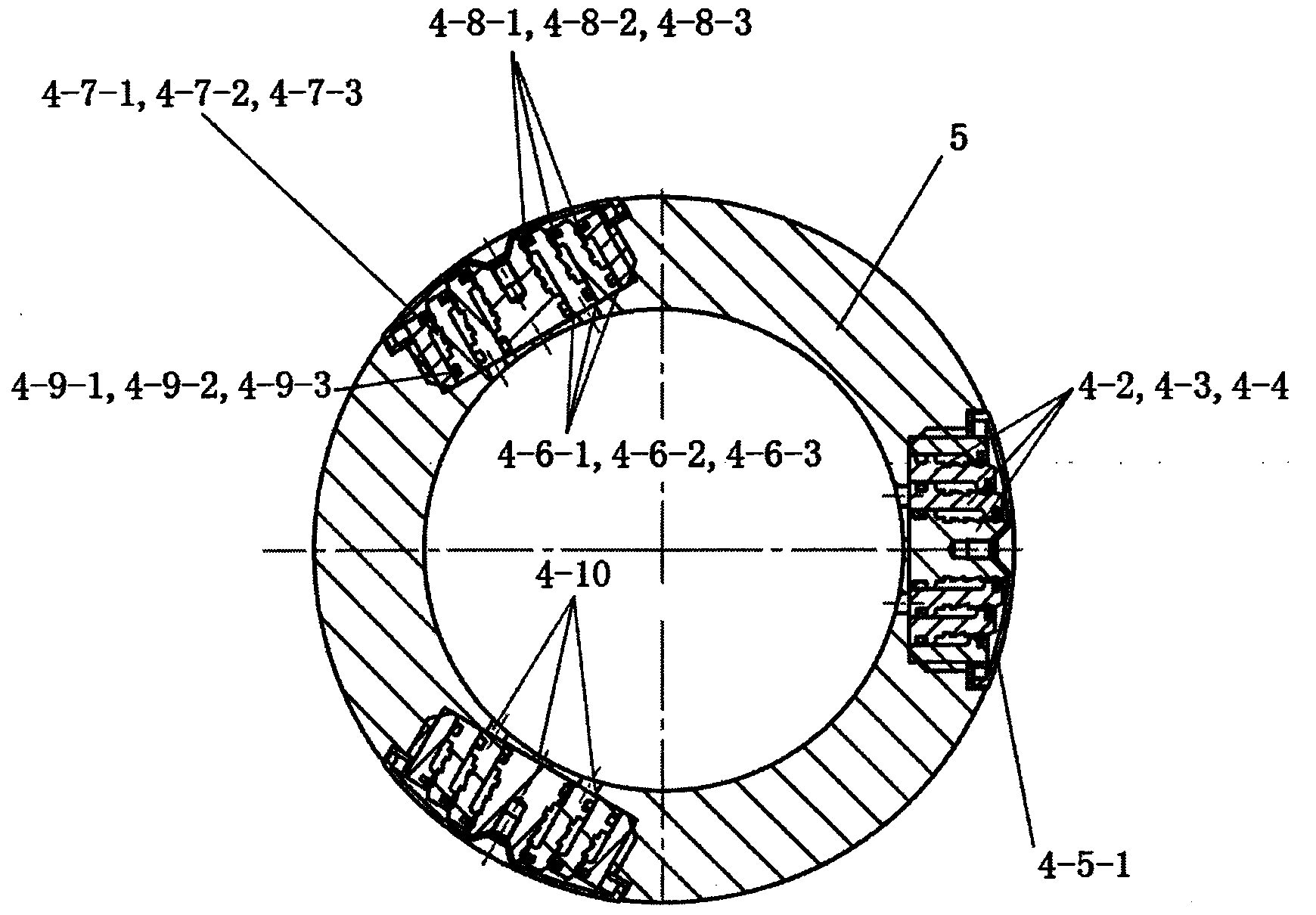

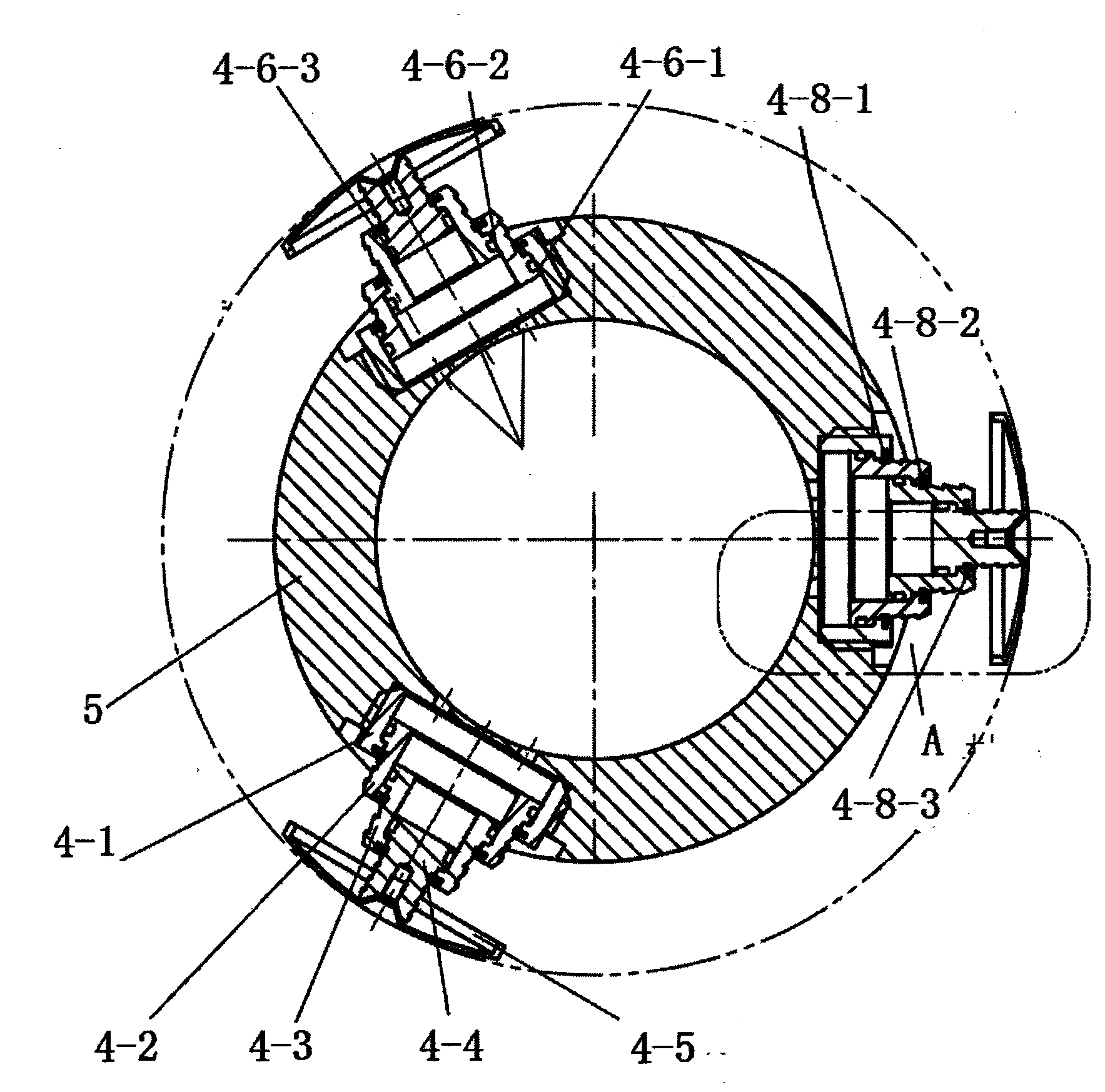

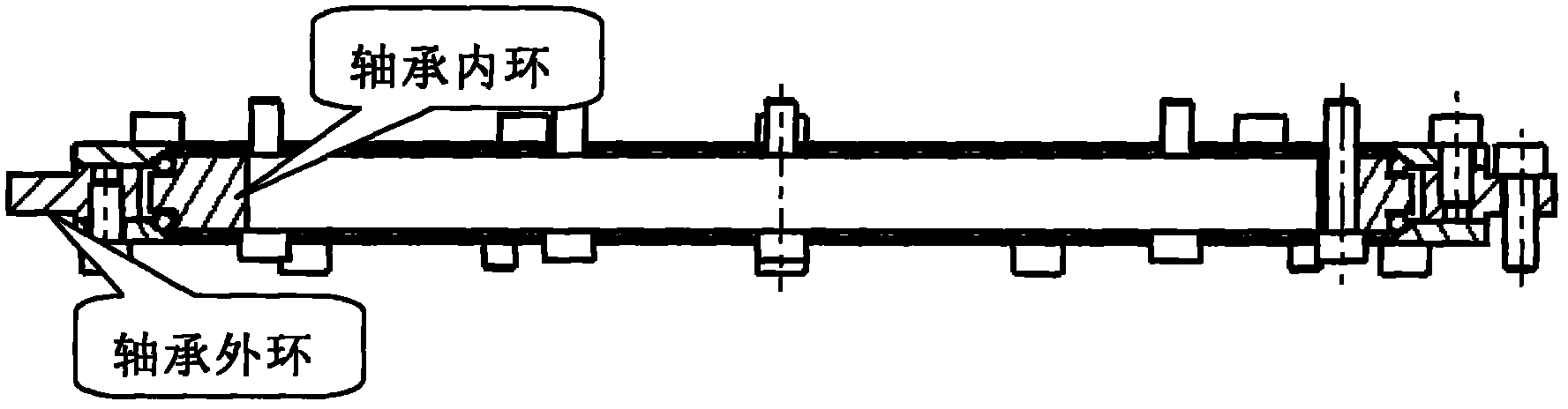

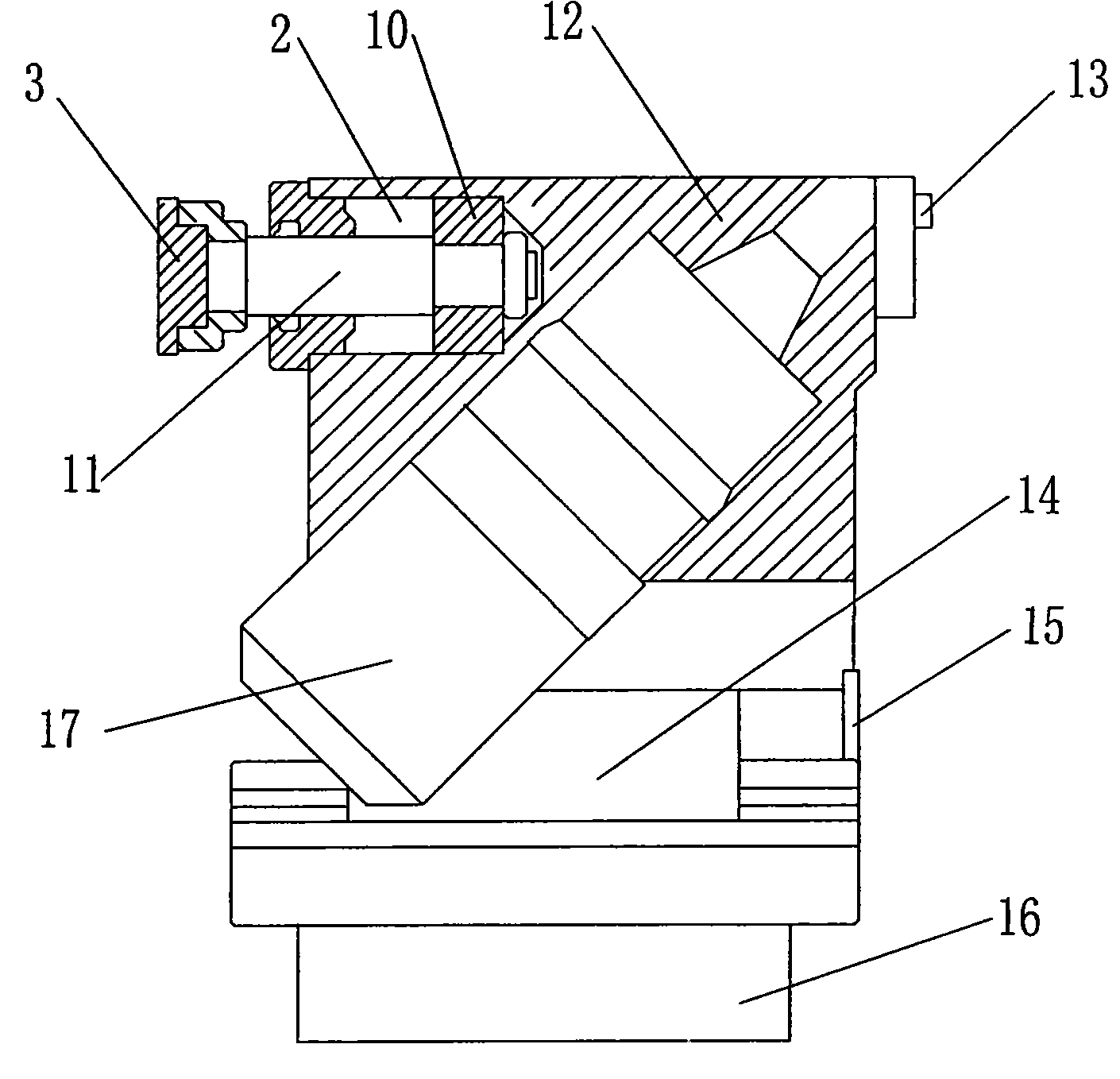

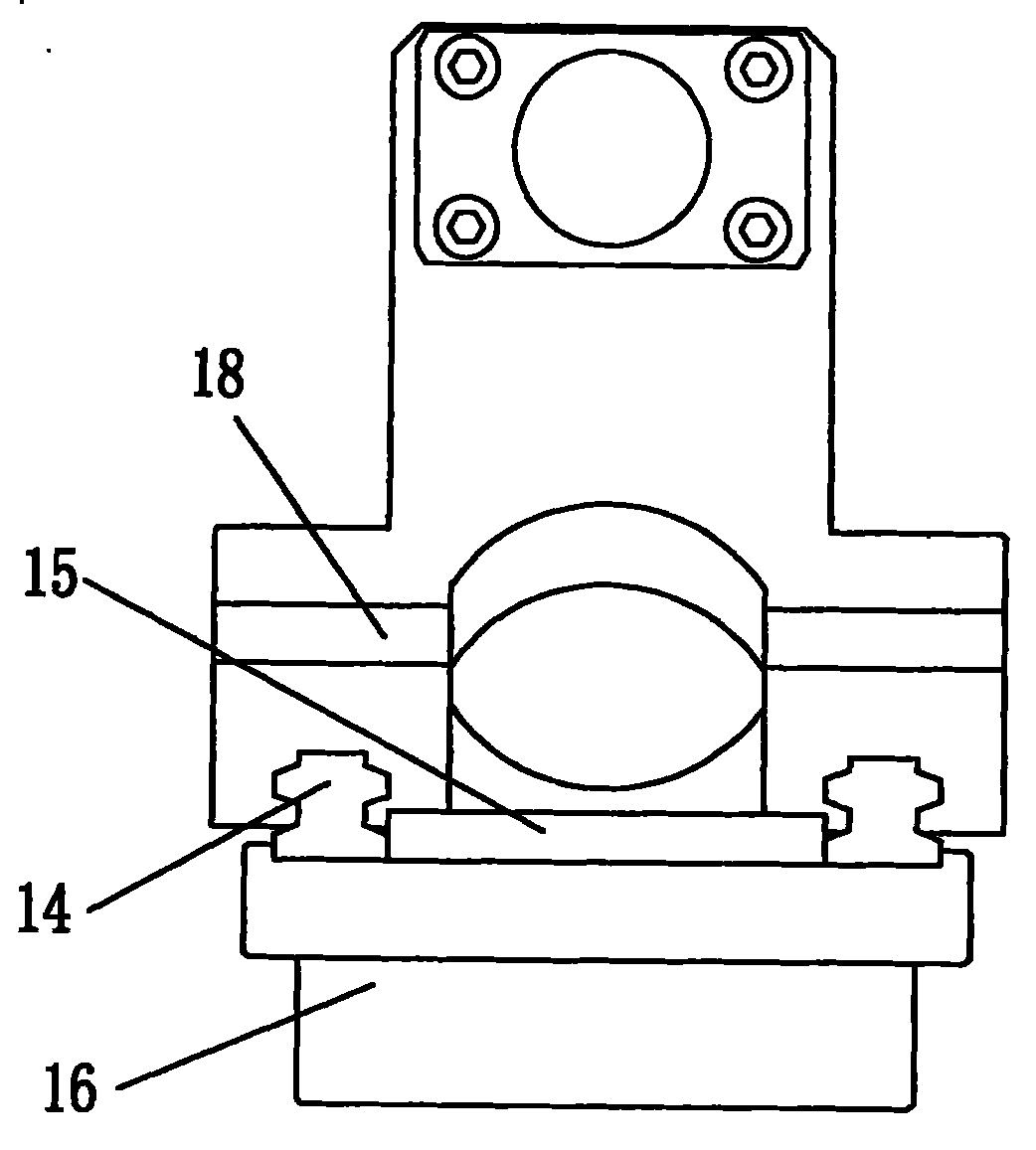

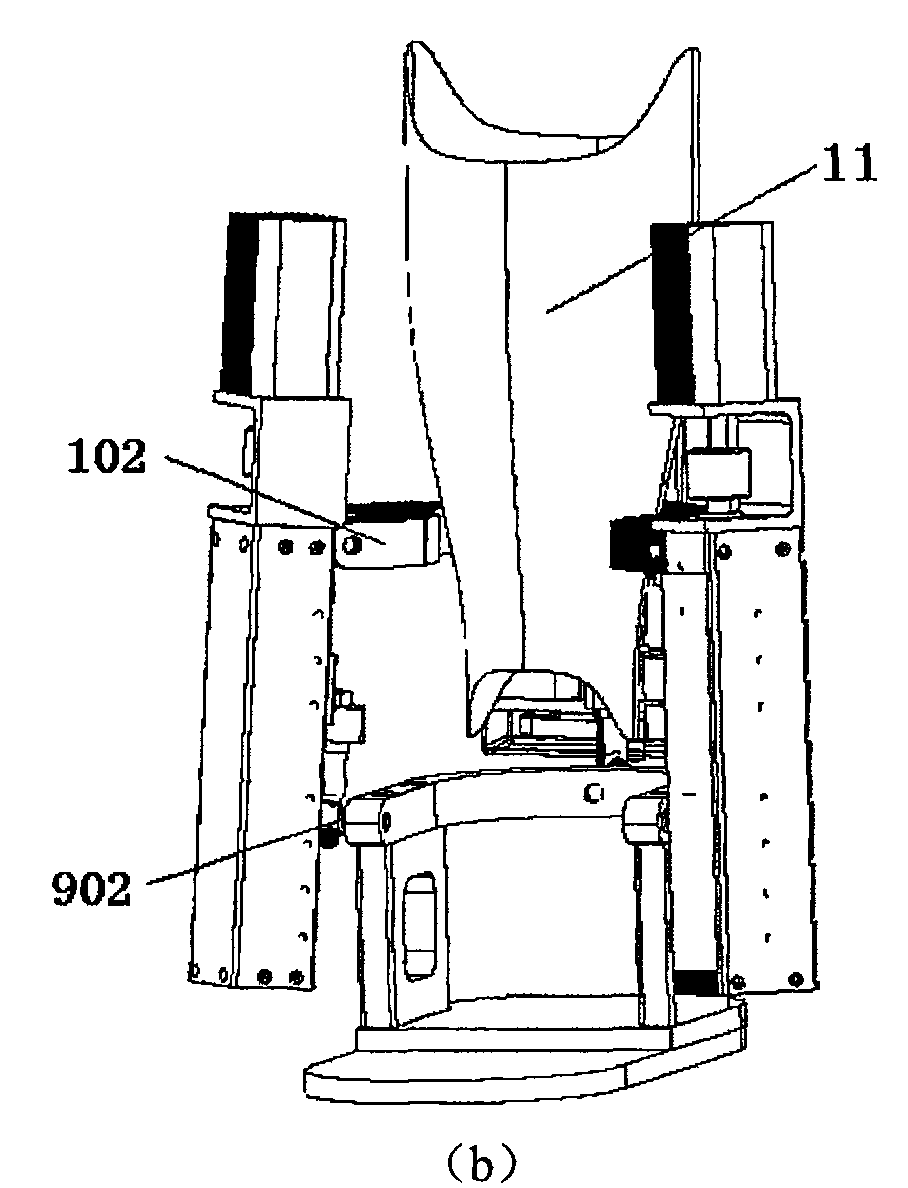

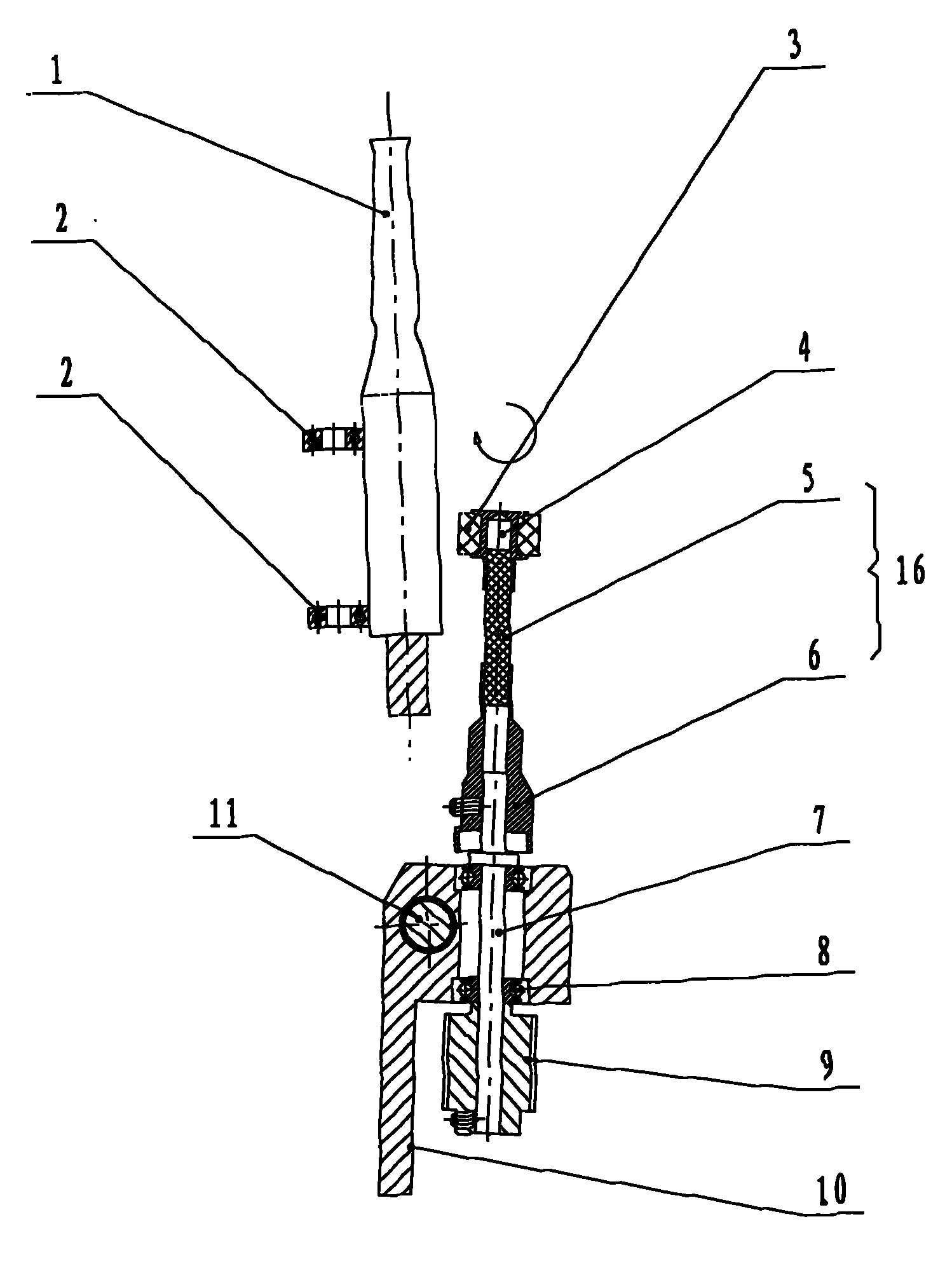

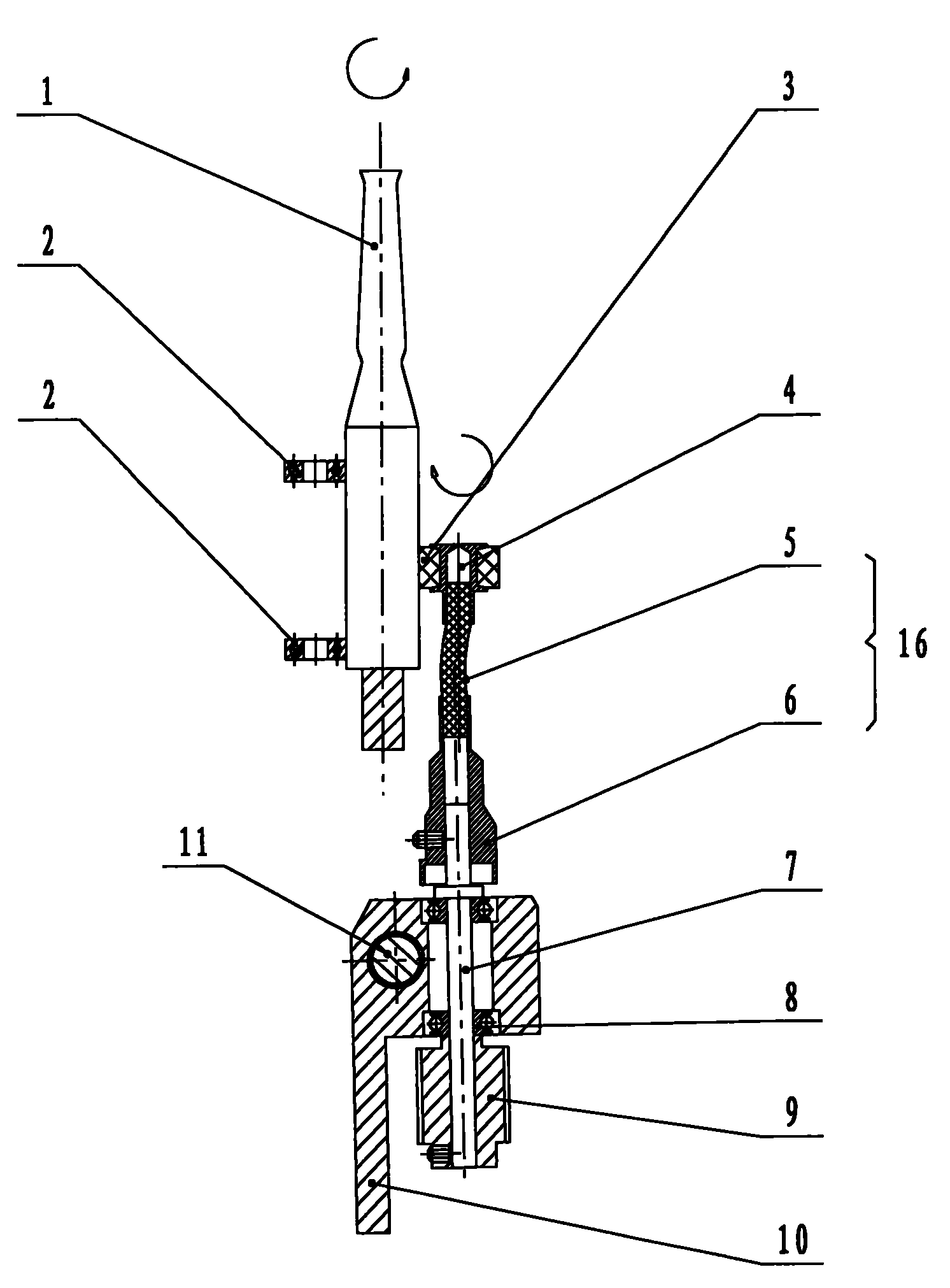

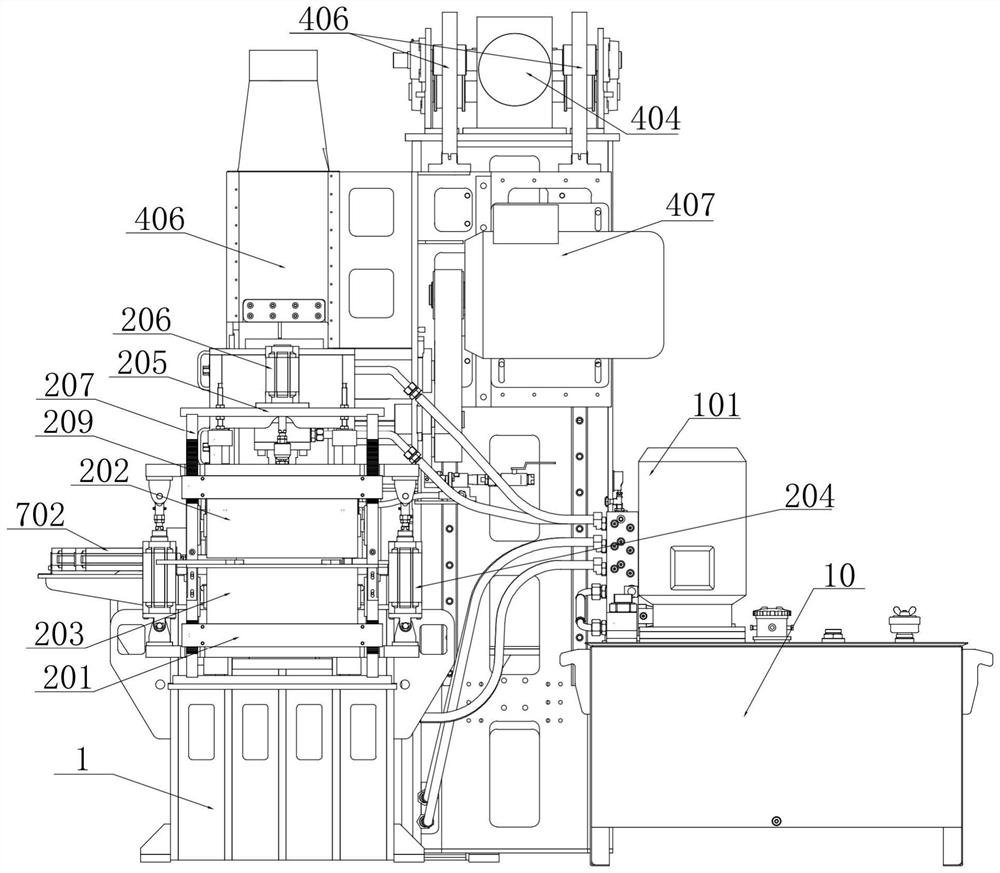

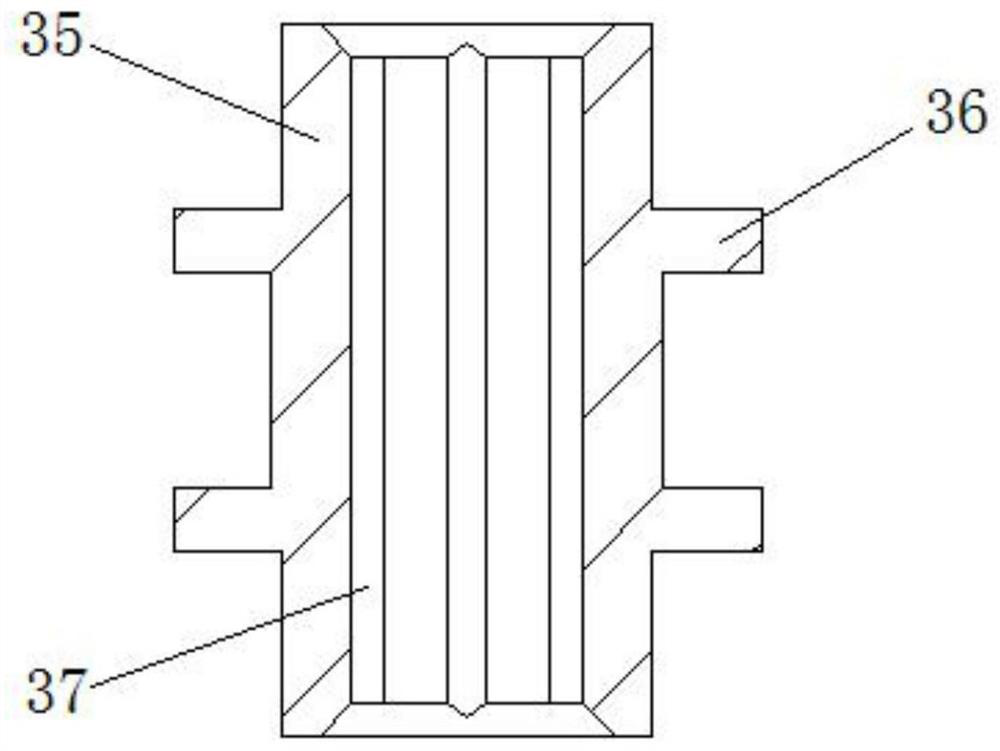

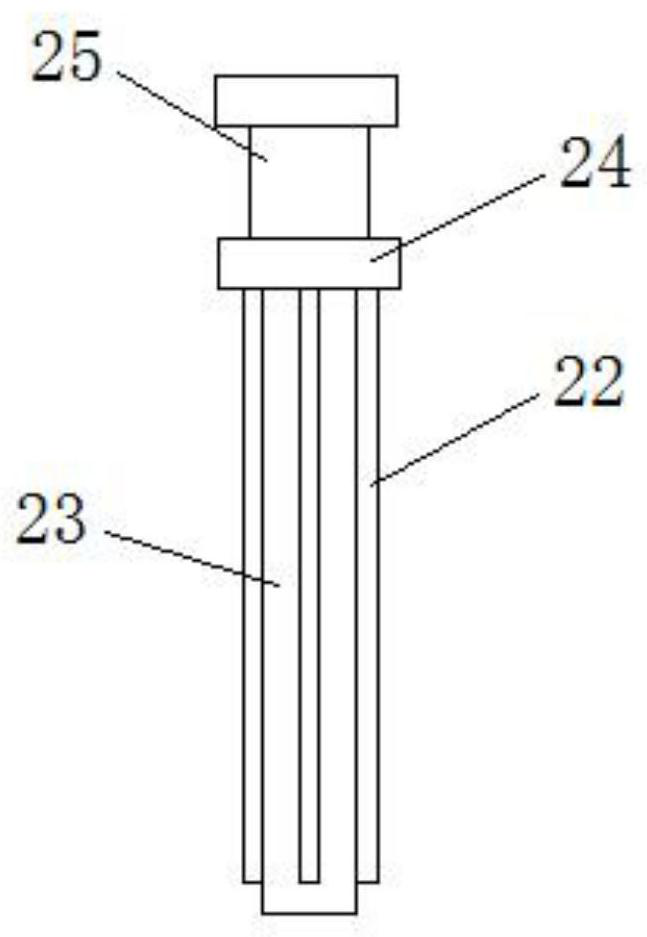

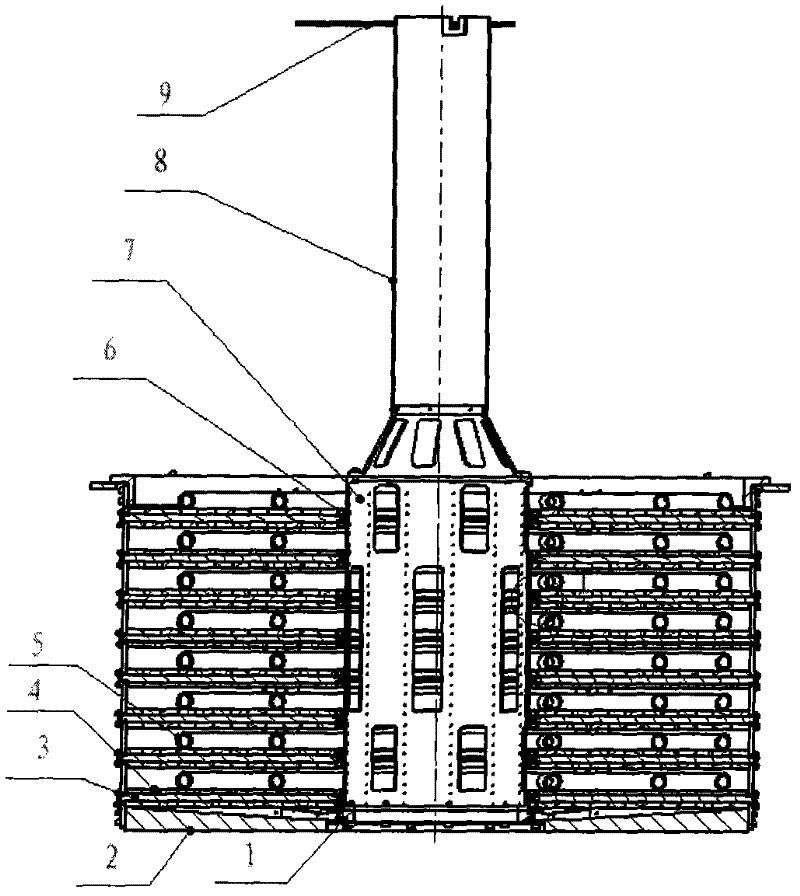

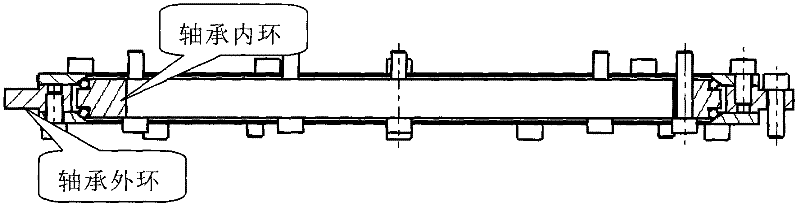

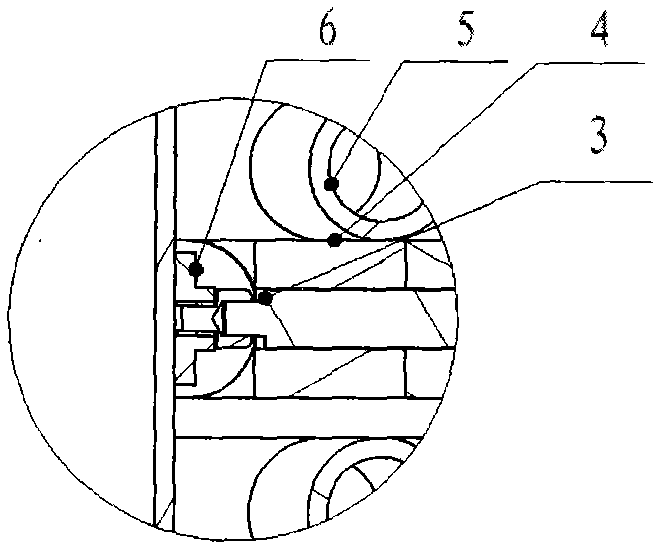

Ultrasonic metallic surface processing device for borer

ActiveCN101480733BEven by forceSatisfy rotation requirementsMechanical vibrations separationBoring/drilling componentsHydraulic circuitEngineering

The invention provides an ultrasonic metal surface processing device for a boring lathe, comprising a boring rod, a hydraulic circuit slip ring, an ultrasonic electric circuit slip ring and a cutter head part, wherein the cutter head part is arranged at one end of the boring rod, and the hydraulic circuit slip ring and the ultrasonic electric circuit slip ring are all arranged on the boring rod; the cutter head part comprises a shell, an ultrasonic generator, a cutter adapter and a cutter head, wherein the cutter head is arranged at the front end of the shell, the ultrasonic generator is arranged inside the shell, the shell is arranged on the cutter adapter by a guide way, and a reactive cylinder is arranged opposite to the cutter head. As for the device, the hydraulic circuit slip ring and the ultrasonic electric circuit slip ring are adopted so as to enable the hydraulic circuit and the electric circuit which are essential to the whole set to satisfy rotation requirements and not tobe affected by the rotation of the boring rod, simultaneously, the reactive cylinder is arranged on the head of the boring rod opposite to the cutter head, which ensures that the boring rod bears a balanced force in the working process and the affection of the flexural torque of the boring rod generated in the working process to the ultrasonic metal surface processing device is avoided.

Owner:SHANDONG HUAWIN ELECTRICAL & MECHANICAL TECH

Welding manufacturing process method of large-scale fully welded structure water turbine ball valve

ActiveCN107243704BIncrease the difficulty of assemblyIncrease in sizeWelding apparatusManufacturing technologyWater turbine

The invention discloses a welding manufacturing technology method of a large water turbine ball valve of an all-welded structure. The method represents innovation of an assembly-welding technology method of the large water turbine ball valve of the all-welded structure and is the essential change of the manufacturing method. The technological scheme of coating high-temperature-resistant paint before assembly welding of a shaft sleeve as a welding auxiliary tool, a valve and a valve body single-piece and performing symmetric welding in the vertical welding position during rotating of the valve is applied for the first time, with the adoption of the method, accessibility and operability of welding are greatly improved, welding deformation is effectively controlled, quality of a ball valve welding seam is guaranteed by intermediate flaw detection, critical dimensional stability of the ball valve is guaranteed, and the assembly-welding quality of the large water turbine ball valve of the all-welded structure is remarkably improved accordingly.

Owner:HARBIN ELECTRIC MASCH CO LTD

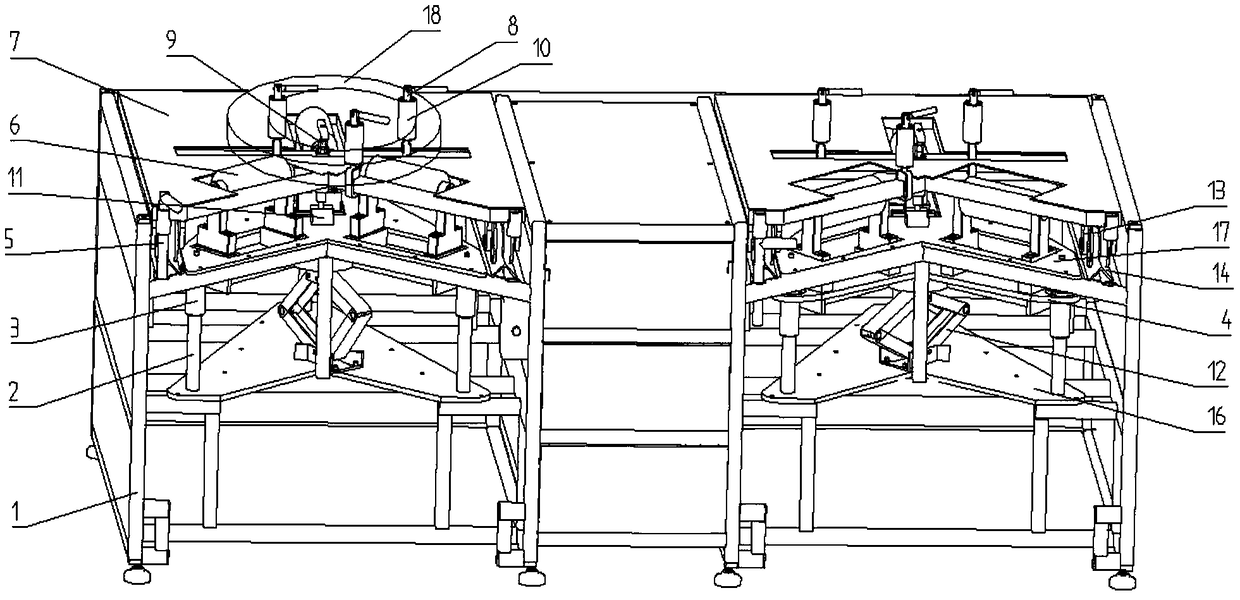

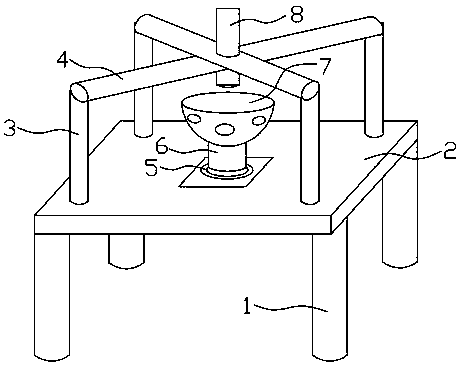

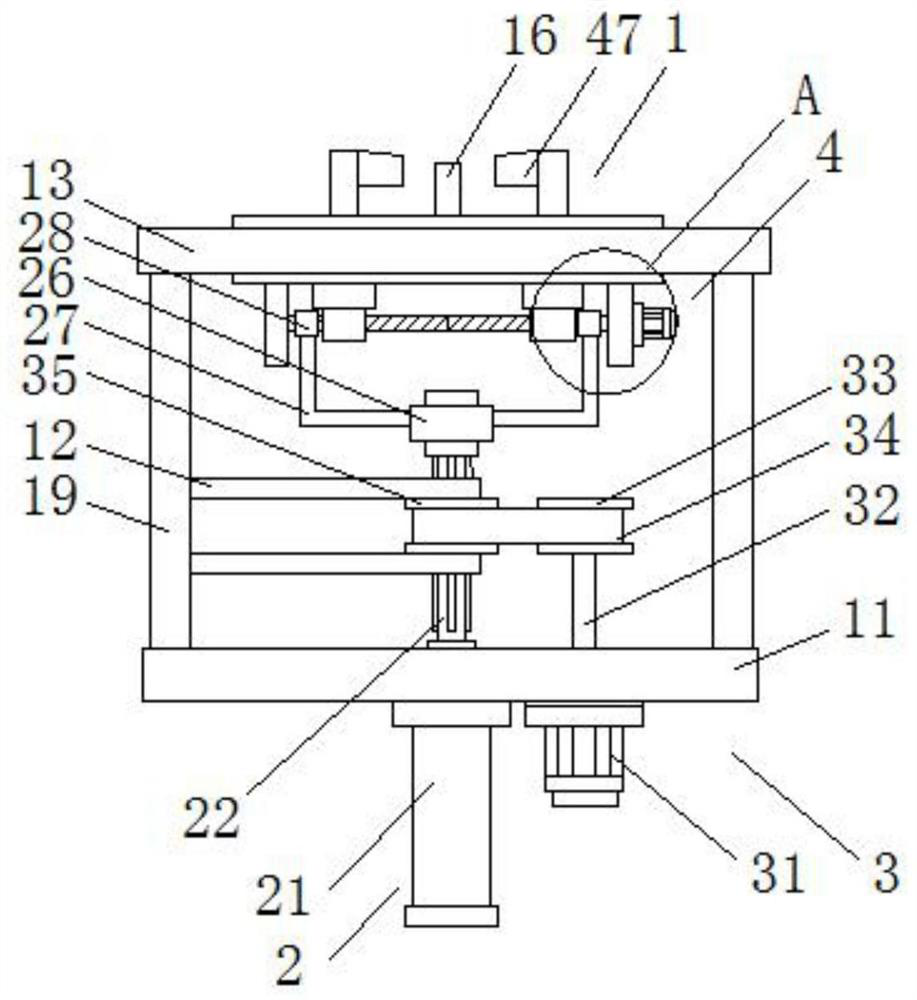

Mold trimming workbench and processing system

InactiveCN108748017AHeight position adjustmentSatisfy rotation requirementsWork benchesAbrasive machine appurtenancesSand blastingMachining system

The invention discloses a mold trimming workbench, and belongs to the field of mold manufacturing. The mold trimming workbench comprises a fixed bracket, wherein the fixed bracket is provided with a lifting bracket and a power device. The mold trimming workbench further comprises a supporting frame. The supporting frame is arranged above the lifting bracket and can be separated from the fixed bracket; and the power device drives the lifting bracket to rises and fall; and the supporting frame is combined with the lifting bracket to enable a workpiece to rotate and lifts without interference with each other. Further, the invention further discloses a mold processing system. The mold processing system comprises the mold trimming workbench, a transfer trolley and sand blasting equipment, so that the traveling operation and waiting time are avoided, and the working efficiency is improved, and meanwhile the comfort and operation efficiency are improved.

Owner:HIMILE MECHANICAL SCI & TECH (SHANDONG) CO LTD

Tamper body structure of vibro-rammer

InactiveCN113846619AMeet vibration requirementsImprove compaction efficiencyRotary piston pumpsRotary piston liquid enginesHydraulic motorGear wheel

The invention discloses a rammer body structure of a vibro-rammer. The rammer body structure comprises a box body, an eccentric mechanism and a driving mechanism, and the eccentric mechanism comprises an eccentric wheel; and the driving mechanism comprises a pump body, a pump cover, a driving gear and a driven gear, the driving gear and the driven gear are arranged in a pump cavity formed by the pump body and the pump cover, an inlet and an outlet are correspondingly formed in the box body and the pump body, the two ends of a wheel shaft of the driving gear are rotationally connected with the pump cover correspondingly, the shaft end of the driven gear extends out of the pump cover and is connected with one end of a wheel shaft of the eccentric wheel, the other end of the wheel shaft of the eccentric wheel is rotatably connected with the box body, and the two ends of a wheel shaft of the driven gear are rotatably connected with the pump cover correspondingly. A hydraulic motor is not needed on the outer side of the box body, the structure is simple, driving is convenient, the rammer body cost and the maintenance cost are reduced while the rammer body vibration requirement is met, driving is not prone to failing, hydraulic oil leakage is prevented, and the service life of the vibro-rammer is prolonged.

Owner:山东北国宏峰机电科技有限公司

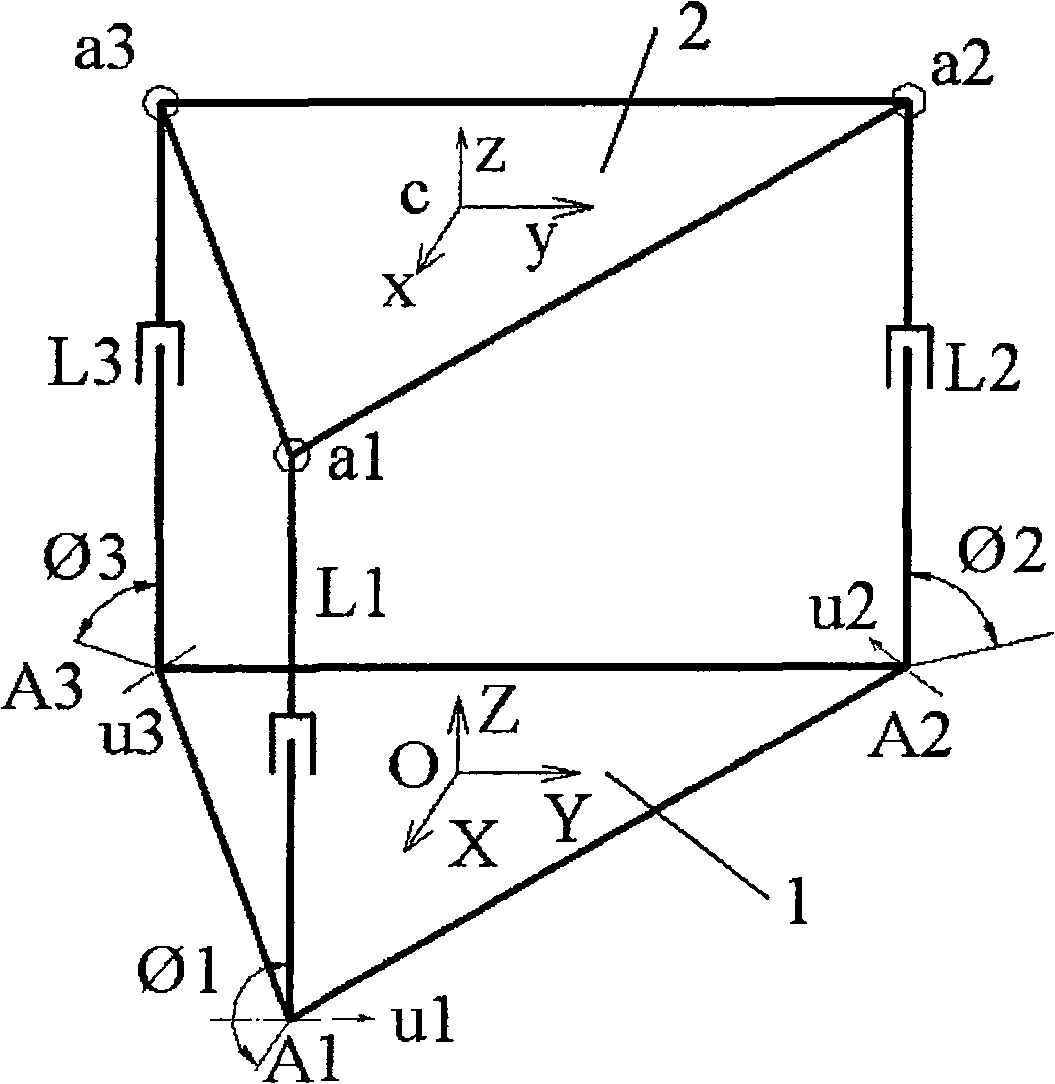

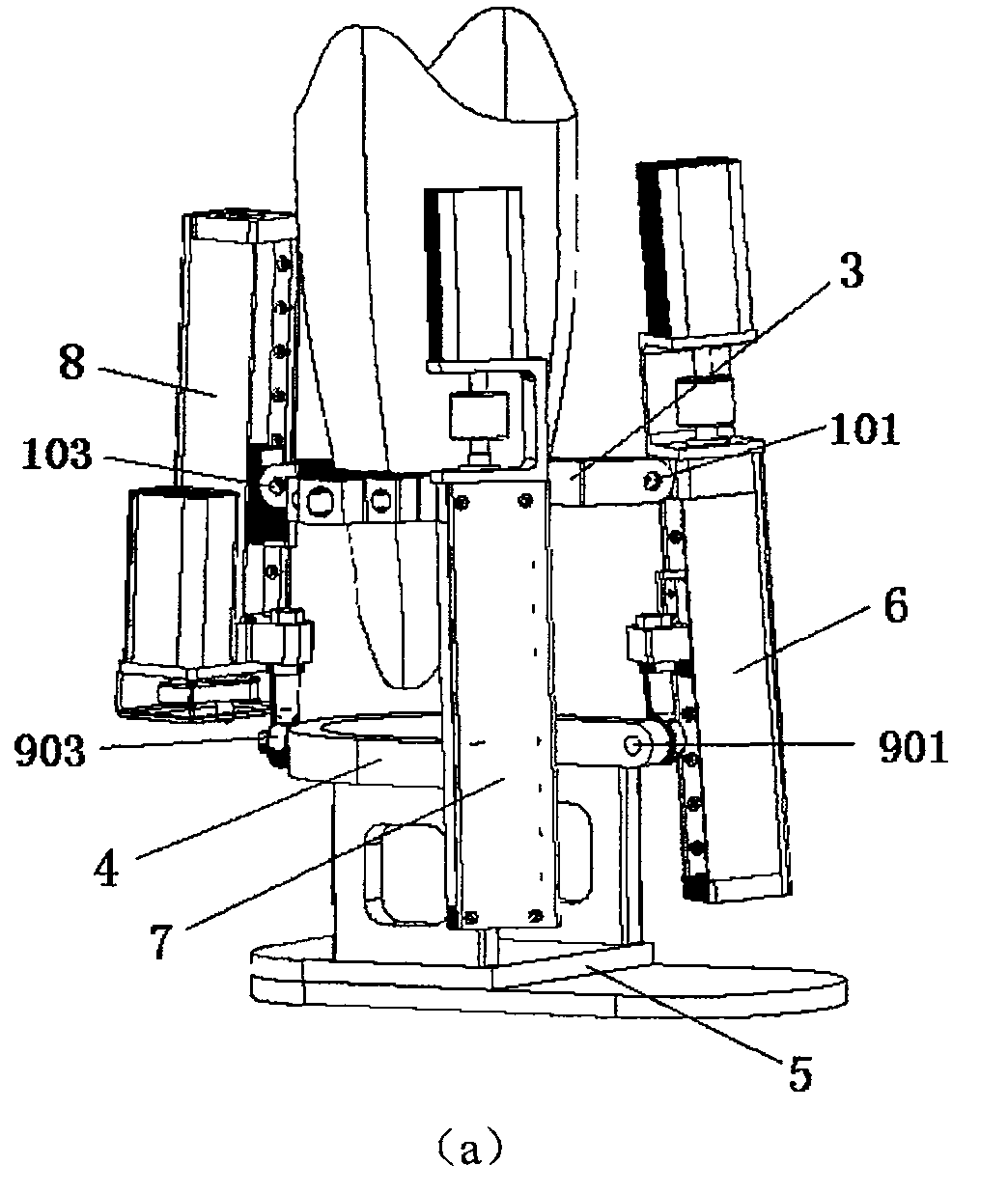

Parallel type multi-freedom artificial limb exoskeleton ankle joint

InactiveCN100558323CIncrease stiffnessAvoid accumulating errorsChiropractic devicesWalking aidsRehabilitation engineeringFoot supports

A parallel multi -free resignation exoskeleton and ankle joint in the field of rehabilitation engineering technology, including: foot support board, imitation human leg jacket, upper platform, lower platform, first active branch chain guide rod, second active branch chain guide guideThe rod and the third active branched chain guide rod, of which: one end of the first active branch chain guide rod is connected to the upper platform activity, the other end is connected to the lower platform activity, and the second active branch chain guide rod is connected to the upper platform activity.The other end is connected to the lower platform activity. One end of the third active chain guide rod is connected to the upper platform activity, and the other end is connected to the lower platform activity.The coat is fixed with the upper platform.The invention agency is rigid, the structure is simple, and the stability is good; the requirements of the human ankle and flexibility are met.

Owner:JIANGSU MASLECH MEDICAL TECH

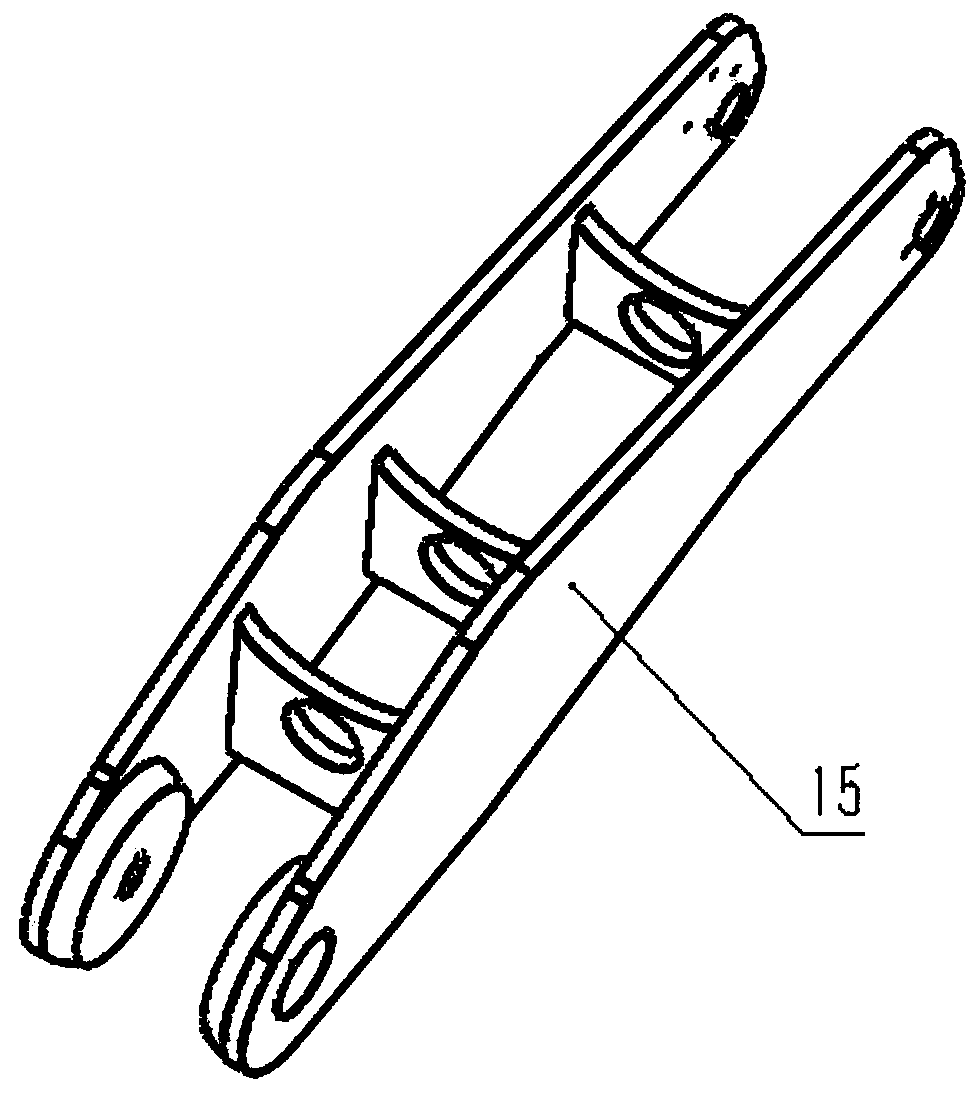

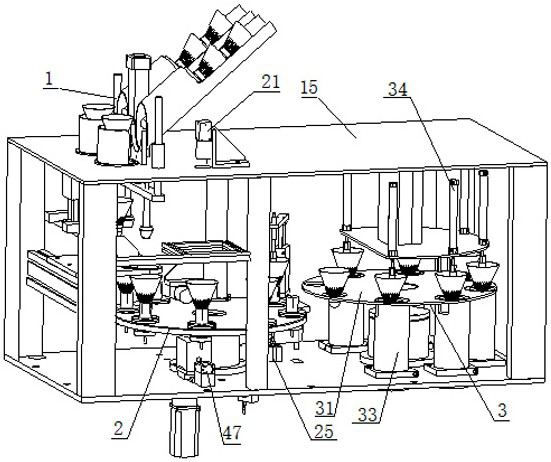

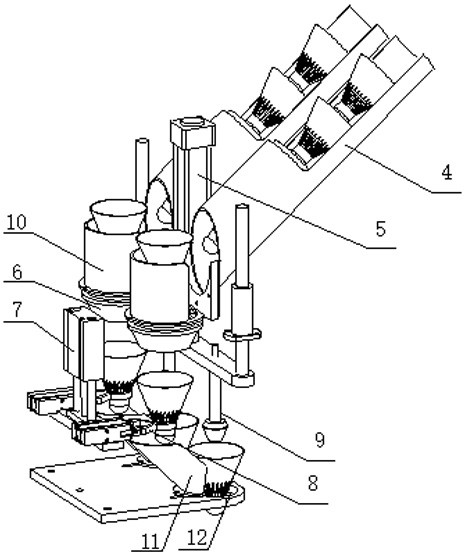

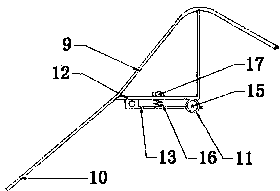

Rotating device for ampoule bottles

The invention discloses a bottle rotating device used for an ampoule. The device comprises a bottle rotating base, a synchronous pulley, a bottle rotating small shaft, a bottle rotating upper shaft, a swing central shaft and a friction wheel. The swing central shaft which is linked with a swing mechanism is arranged on the bottle rotating base. The bottle rotating small shaft is arranged in a hole, which is arranged on the bottle rotating base. The bottom end of the bottle rotating small shaft is connected with the synchronous pulley, and the upper end is connected with the bottle rotating upper shaft. The friction wheel is arranged on the top end of the bottle rotating upper shaft. The bottle rotating upper shaft is a connecting rod, which is provided with a flexible part. The invention has the advantages of simple and compact structure, convenient installation and low cost. The invention is the bottle rotating device used for the ampoule, which leads to the result that the friction wheel clings to the ampoule tightly and gives the ampoule proper pressure when the invention is working.

Owner:TRUKING TECH LTD

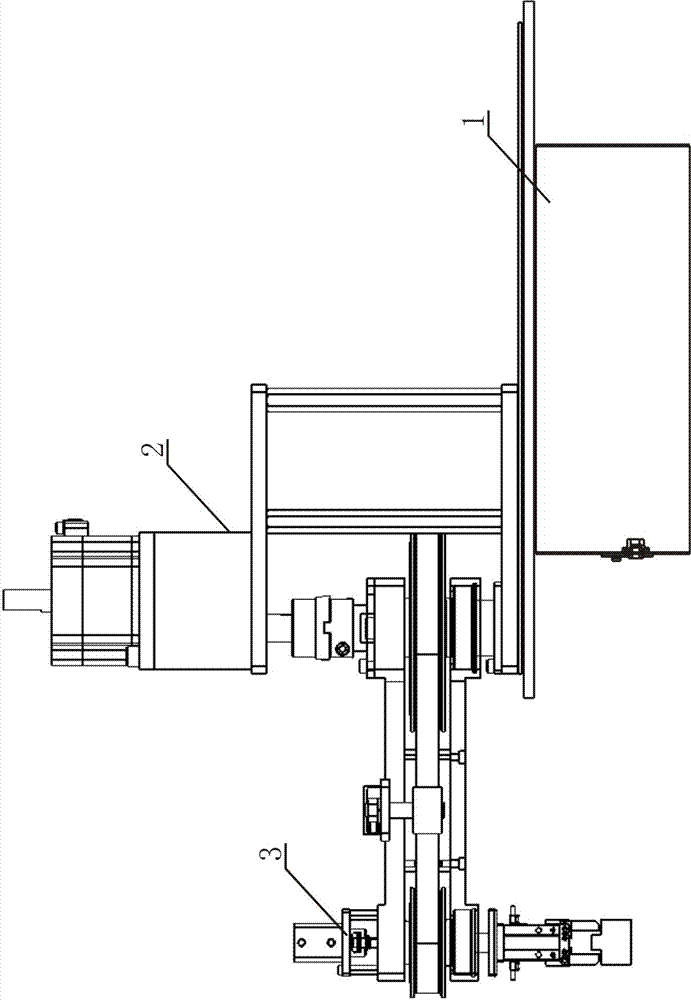

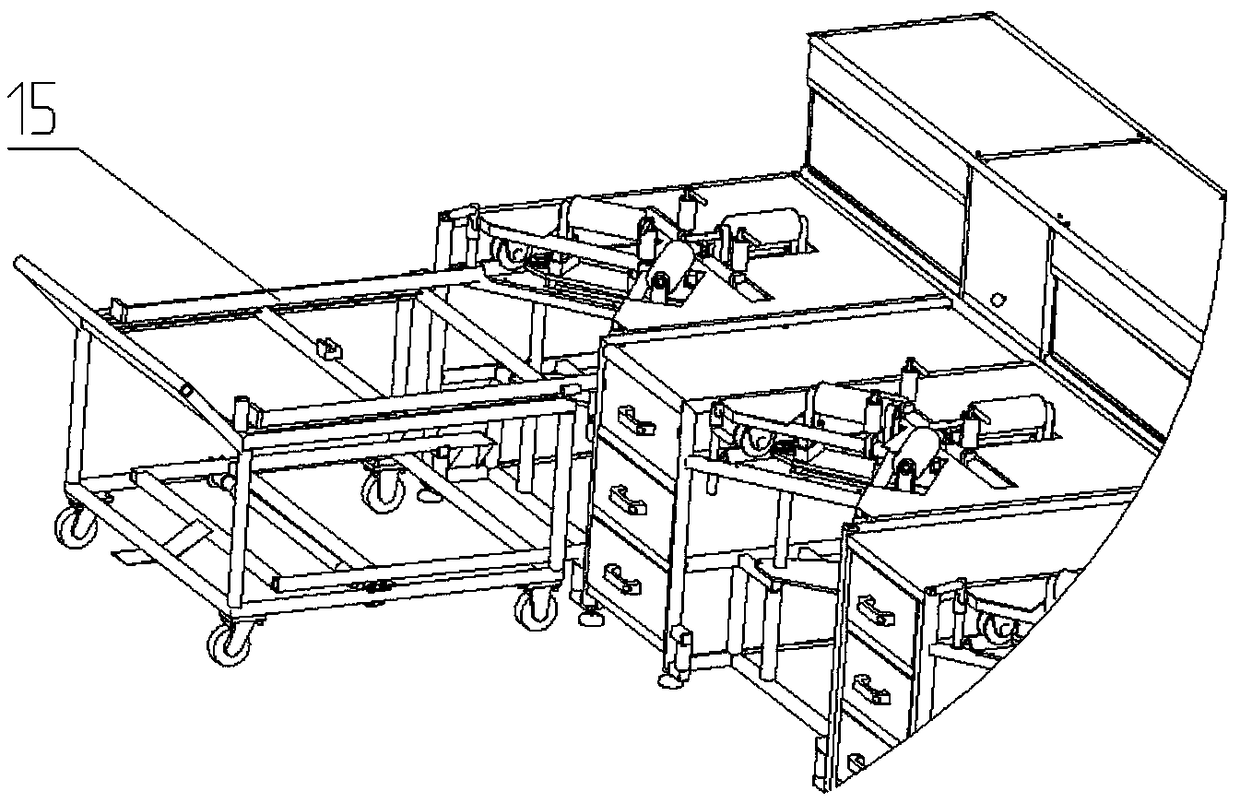

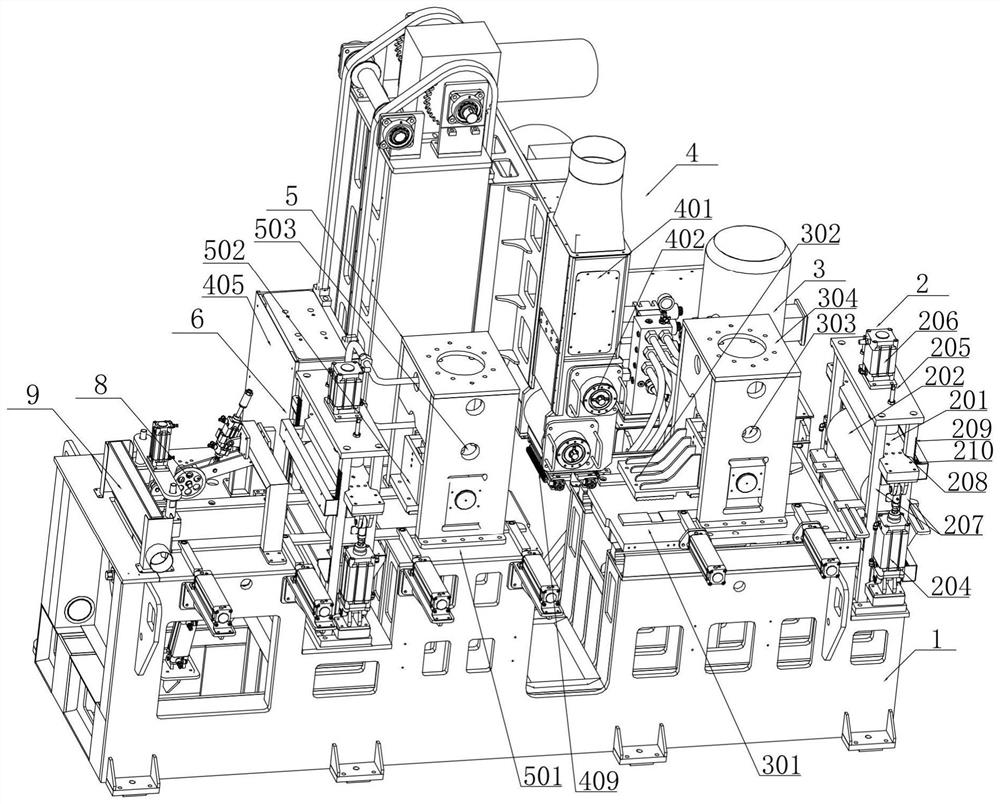

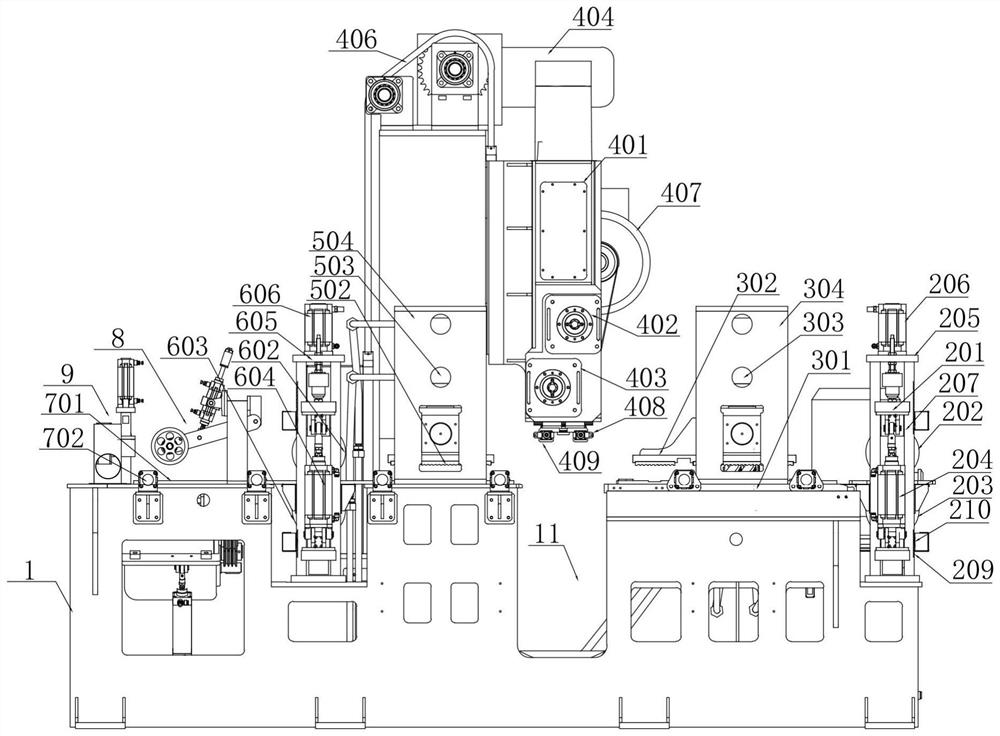

Plate comb tooth lengthening all-in-one machine

PendingCN114434572AAvoid uneven situationsReduce axial forceWood veneer joiningGlue gunsEngineeringMechanical engineering

The invention discloses an all-in-one machine for combing and lengthening plates. The all-in-one machine comprises a rack, a feeding mechanism arranged on the rack, a front pressing-down moving assembly, a combing-tooth glue spraying assembly, a rear pressing-down fixing assembly and a discharging mechanism. The front downward-pressing moving assembly comprises a moving platform and a front downward-pressing plate, the front downward-pressing plate moves up and down under the action of a front downward-pressing power mechanism, and the moving platform moves front and back under the action of a platform power mechanism; the comb tooth glue spraying assembly comprises a comb tooth head, a front comb tooth cutter group, a rear comb tooth cutter group and a glue spraying mechanism; the rear downward pressing fixing assembly comprises a fixing platform and a rear downward pressing plate, and the rear downward pressing plate moves up and down under the action of a rear downward pressing power mechanism. The device is simple and compact in structure and convenient to operate, conveying of a middle conveying line is omitted, the occupied space is small, comb teeth, glue spraying and lengthening are the same standard, the lengthening quality of plates is guaranteed, the cost of plate raw materials is reduced, the machining efficiency of products is greatly improved, and the labor intensity of workers is reduced.

Owner:烟台博海木工机械有限公司

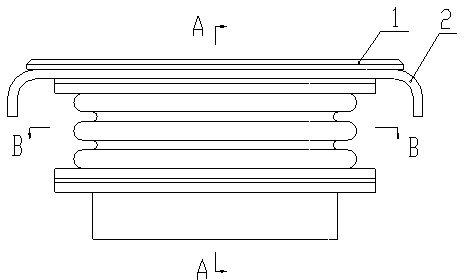

Sliding type ventilating duct for locomotive traction motor

The invention discloses a sliding type ventilating duct for a locomotive traction motor, comprising a wearing plate, an upper bending plate, a rubber air duct body, an upper securing plate, a lower securing plate and a round spring, wherein the upper bending plate is arranged below the wearing plate; the upper securing plate is arranged below the upper bending plate; the rubber air duct body is of waveform; the upper end and the lower end of the rubber air duct body are respectively and fixedly together with the upper securing plate and the lower securing plate; the wearing plate, the upper bending plate and the rubber air duct body are fixed through bolts; the round spring is arranged in the rubber air duct body; and the elastic deformation direction of the round spring is consistent with the waveform deformation direction of the rubber air duct body. The sliding type ventilating duct for the locomotive traction motor, provided by the invention, is compact in whole structure, small in occupied space, attractive and order in whole as well as smaller in wind resistance and easier to meet the requirement of ventilation quantity of the traction motor due to the adoption of a short air duct; and when a locomotive passes by a small curve, the reliability of the air duct is improved, the rotating requirement of a steering frame and a frame is met, and the requirement for the ventilation quantity of the traction motor is ensured.

Owner:CRRC ZIYANG CO LTD

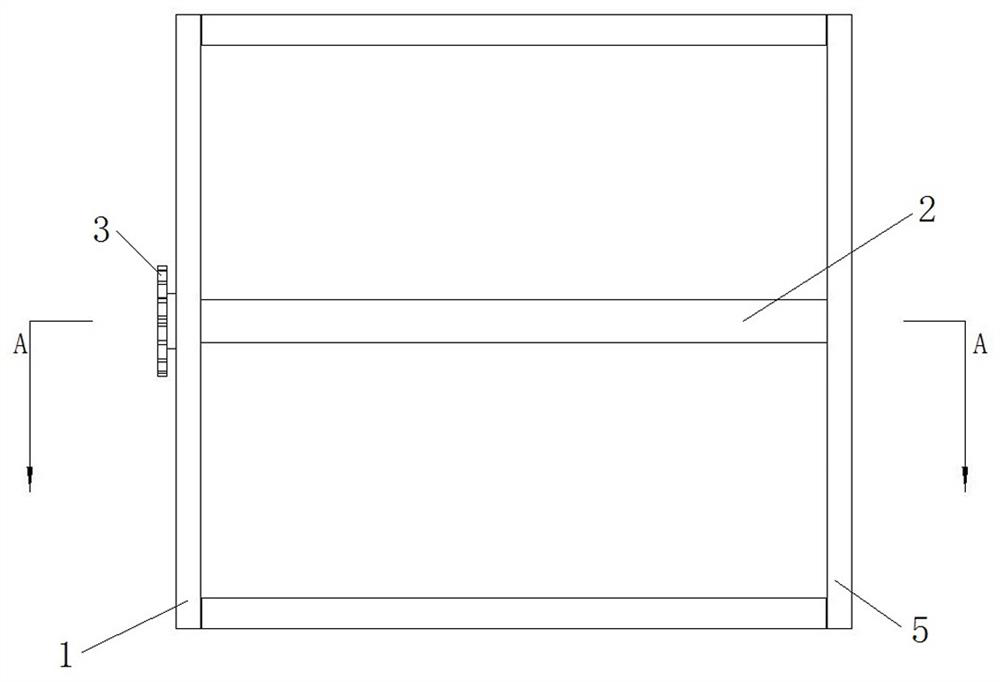

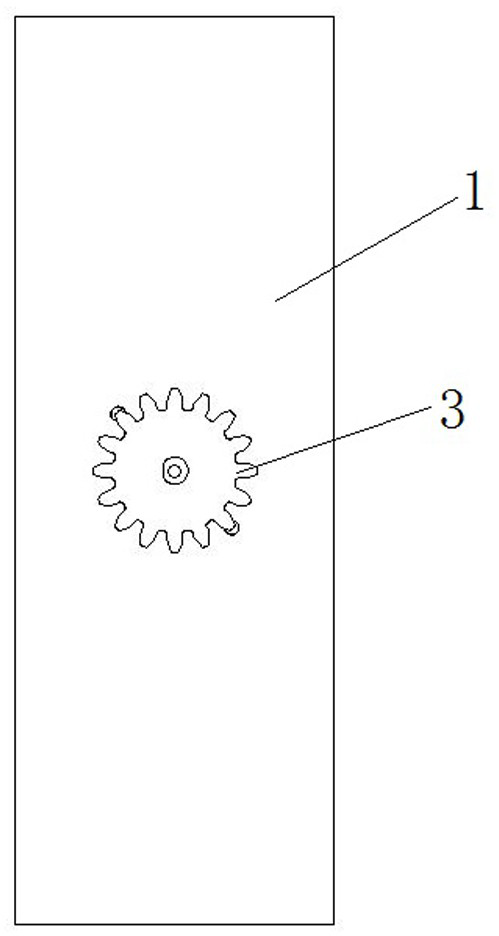

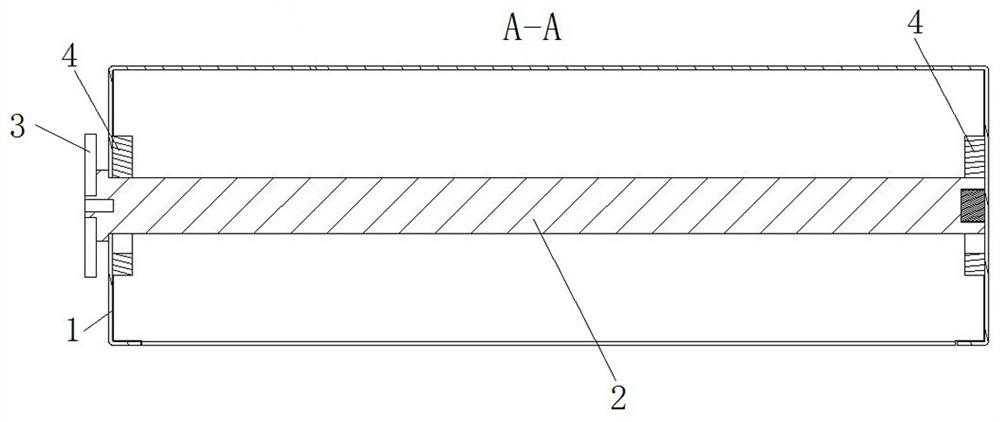

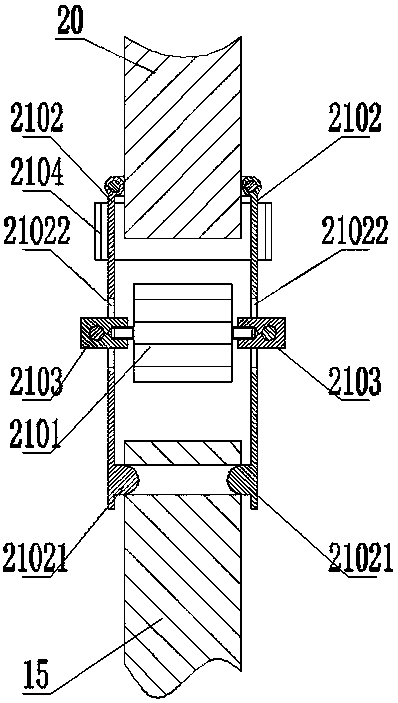

Rotating shaft installation structure and cabinet using the rotating shaft installation structure

ActiveCN108135100BAchieve axial positioningSatisfy rotation requirementsCasings/cabinets/drawers detailsSubstation/switching arrangement casingsClassical mechanicsAxial force

The invention relates to a rotating shaft installation structure and a cabinet using the rotating shaft installation structure, in order to solve the problem of complicated disassembly and assembly of the rotating shaft which does not require high transmission precision in the prior art. The rotating shaft installation structure includes a frame and a rotating shaft mounted on the frame. An axial stop structure is arranged between the frame and the rotating shaft, and a magnetic adsorption for axial positioning of the rotating shaft is realized by cooperating with the axial stop structure. structure. The magnetic adsorption structure can adsorb the rotating shaft on the frame, so as to ensure that the rotating shaft will not detach from the frame along the axial and radial directions of the rotating shaft, and at the same time meet the rotation requirements of the rotating shaft. For the rotating shaft that does not require high transmission accuracy and bears small radial and axial forces, when disassembling, it is only necessary to disconnect the disconnection and use the adsorption effect of the magnetic adsorption structure to disconnect the frame and the rotating shaft. Open and connect, the disassembly process is simple and convenient, which can reflect the advantages of its quick disassembly.

Owner:XJ ELECTRIC +2

Convenient type amyda sincnsis dissecting device

InactiveCN108353985ASatisfy rotation requirementsReduce maintenance difficultySlaughtering animals fettering apparatusPoultry/fish slaughtering/stunningFlavorFiltration

Owner:金华市鸿讯机械工程技术有限公司

An underwater redundant hydraulic mechanical arm and its working method

ActiveCN110630596BLarge working spaceCompact structureServomotor componentsAccumulator installationsEngineeringHydraulic manipulator

The invention relates to an underwater redundant hydraulic mechanical arm and a work method of the underwater redundant hydraulic mechanical arm and belongs to the technical field of underwater mechanical robots. The underwater redundant hydraulic mechanical arm adopts a chain type series structure and comprises a rotating arm, a big arm, a middle arm, a forearm A, a forearm B, a wrist arm, a gripper, a hydraulic system and an STM32 control panel. The rotating arm, the big arm, the middle arm, the forearm A, the forearm B, the wrist arm and the gripper are sequentially connected. The hydraulicsystem provides power for the whole mechanical arm. The STM 32 control panel is used for controlling the mechanical arm to act. The rotating arm is installed on an underwater moving platform to support the whole hydraulic mechanical arm and achieves fixation and rotation of the whole mechanical arm. The big arm and the middle arm achieve pitching within a large range of the mechanical arm. The forearm A achieves transverse swinging of the mechanical arm. The forearm B achieves pitching within a small range of the mechanical arm. The wrist arm achieves transverse swinging and rotation of the gripper. The gripper achieves the clamping function. The underwater redundant hydraulic mechanical arm is compact and reasonable in structure, large in effective operation space, capable of expanding the freedom degree and suitable for different water depths.

Owner:SHANDONG UNIV

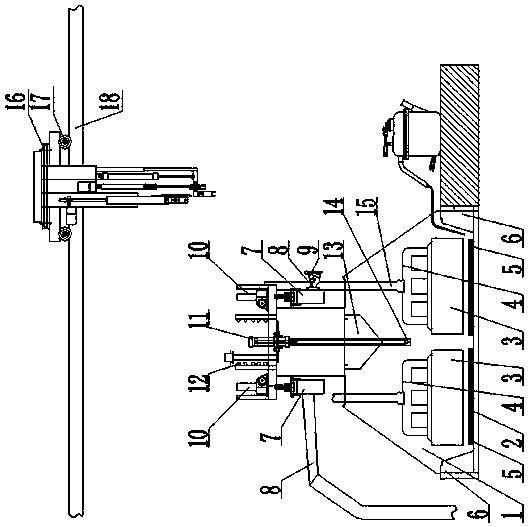

Aluminum electrolysis simulation practical training operating system and operating method thereof

PendingCN111508328AEasy to useImprove the stability of useEducational modelsEngineeringMaterials science

The invention relates to the technical field of practical training teaching aids in universities and colleges, in particular to an aluminum electrolysis simulation practical training operating systemand an operating method thereof. The device comprises an aluminum electrolysis cell, an anode replacing device and an aluminum ladle aluminum discharging device, a cathode carbon block is arranged inthe aluminum electrolysis cell; the cathode carbon block is connected to the bottom of the aluminum electrolysis cell; an aluminum electrolysis cell ledge, an anode carbon block, an anode steel claw,a bus and an anode conducting rod are arranged in the aluminum electrolysis cell, the anode steel claw is connected to the top end of the anode carbon block, the anode conducting rod is connected to the top end of the anode steel claw and connected between the small closing clamp and the bus, and the lower end of the crust breaking discharging driving air cylinder is connected with a crust breaking discharging mechanism; according to the aluminum electrolysis cell, the structure is simplified, and the skill training requirements of students are highlighted. The operation process is carried outat normal temperature, harmful gas and dust pollution is avoided in the operation process, teaching can be carried out conveniently and visually, the learning effect is remarkably improved, and the teaching quality is improved.

Owner:LANZHOU RESOURCES & ENVIRONMENT VOC TECH COLLEGE +1

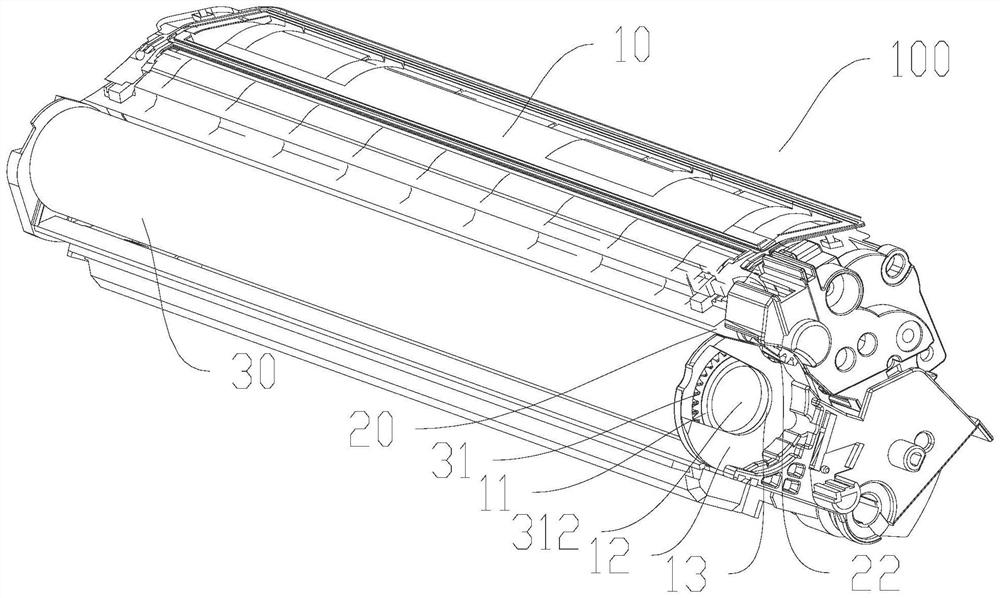

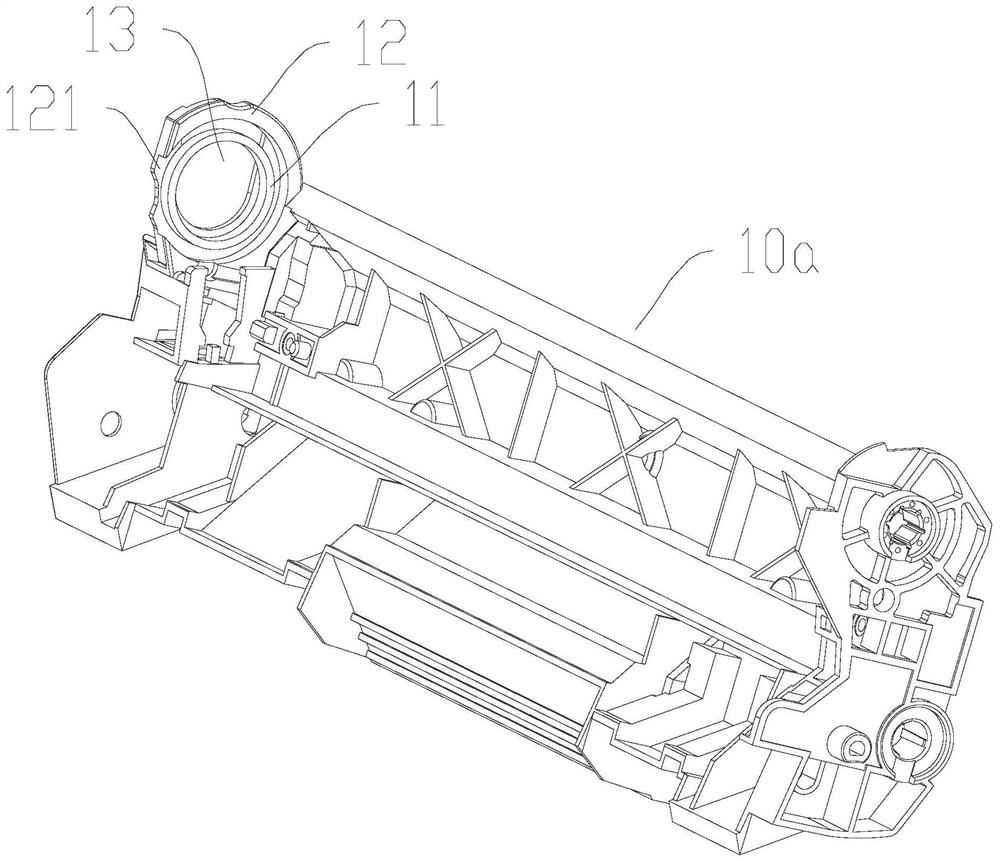

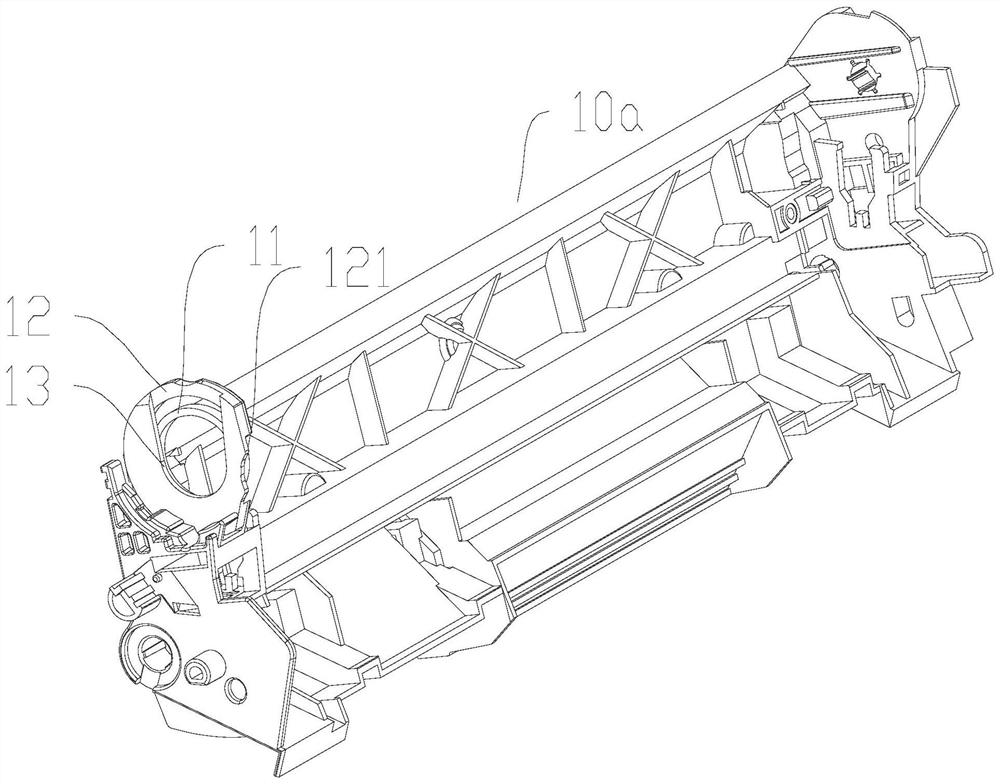

Processing box

PendingCN114545753APlay a positioning roleAvoid link breakageElectrography/magnetographyPhysicsMechanical engineering

The invention provides a processing box. The processing box comprises a processing box body, a developing element and a photosensitive element, the developing element is rotationally mounted in the processing box body through two ends in the length direction, and one end is in meshing transmission with a driving transmission part of the imaging device; the photosensitive element is rotatably mounted in the processing box body through two ends in the length direction and is parallel to the developing element, and one end of the photosensitive element is in meshing transmission with one end of the developing element; the photosensitive element and the driving transmission part are arranged on the same side of the developing element; and a positioning counter bore is concavely formed in the end surface of one end of the photosensitive element and is matched and connected with the cylindrical head shaft hole of the driving transmission part. According to the processing box provided by the invention, special and complex end face arrangement of the photosensitive element is avoided in structural arrangement, the material cost, the processing cost and the like are reduced, and the end face of the photosensitive element can be prevented from being fractured while the driving force of an imaging device is stably received by the processing box.

Owner:ZHUHAI JIALIANXIN IMAGING PROD

Centrifugal pump shell processing jig

ActiveCN110900230BAdjustable support sizeEasy to operateWork clamping meansPositioning apparatusFixed frameEngineering

The invention discloses a jig for processing a centrifugal pump shell, which comprises a fixed frame, a pressing mechanism, a rotating mechanism and a clamping mechanism. Connection, the pressing mechanism is connected with the clamping mechanism, the fixed frame includes the bottom plate, the supporting plate, the fixing plate, the chute, the threaded hole, the positioning rod, the rectangular frame, the rotating tray and the connecting plate, the fixture of the centrifugal pump shell, the pressing mechanism , the rotation mechanism and the clamping mechanism are combined in turn, the setting of the connecting sleeve can meet the rotation requirements of the second rotating shaft, the setting of the limit slide bar and the linear groove can meet the sliding requirements of the collar when the central rotating shaft rotates, so that Each mechanism can operate independently, and each operating mechanism does not need to load the weight of other driving equipment. The coordination effect of each mechanism is good, and the space utilization rate is high. The pump body is fixed by fixing the flange, and the specific clamping model is avoided to effectively fix the pump body. disadvantages.

Owner:哈尔滨凯泉泵业有限公司

Cast steel ball hinged support

ActiveCN101403242BSatisfy rotation requirementsThe force mode is no longer singleBuilding constructionsHorizontal forcePull force

The invention discloses a novel cast-steel spherical hinge support, which comprises a base fixedly connected with a column-shaped supporting body with the top being a spherical crown body which is embedded in a provided groove on the lower end surface of a rolling body, the shape of the inner surface of the provided groove corresponds to that of the spherical crown body, the inner side wall of the provided groove is connected with a baffle ring in a screw way, and the baffle ring is arranged outside the column at the lower part of the spherical crown body. The support can not only meet the rolling demands of the nodes, but also can bear horizontal force and the vertical pull force as well as pressure, thus being mainly used for large-span space structure bearing complicated forces and heavy shaped steel structure.

Owner:TIANJIN UNIV

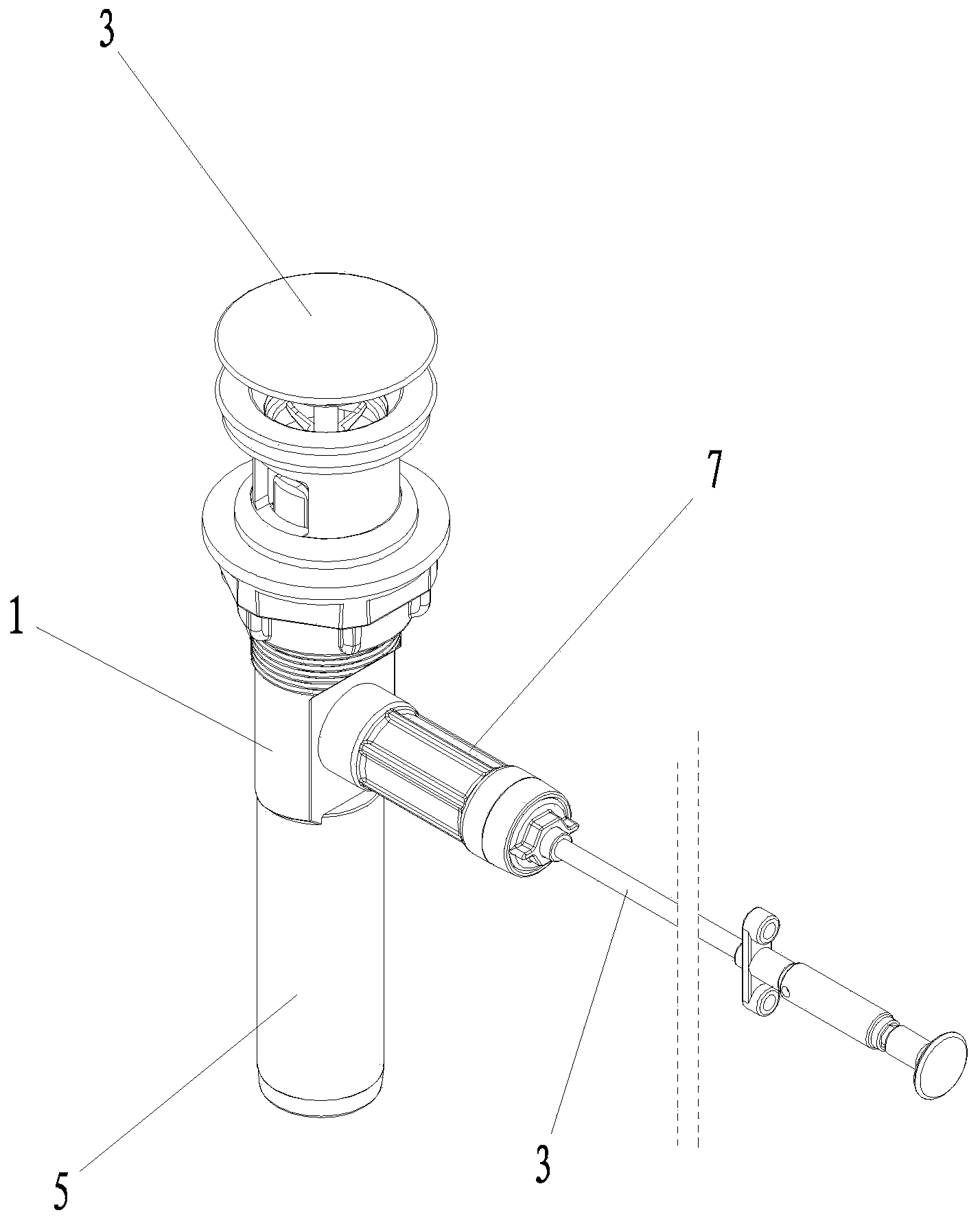

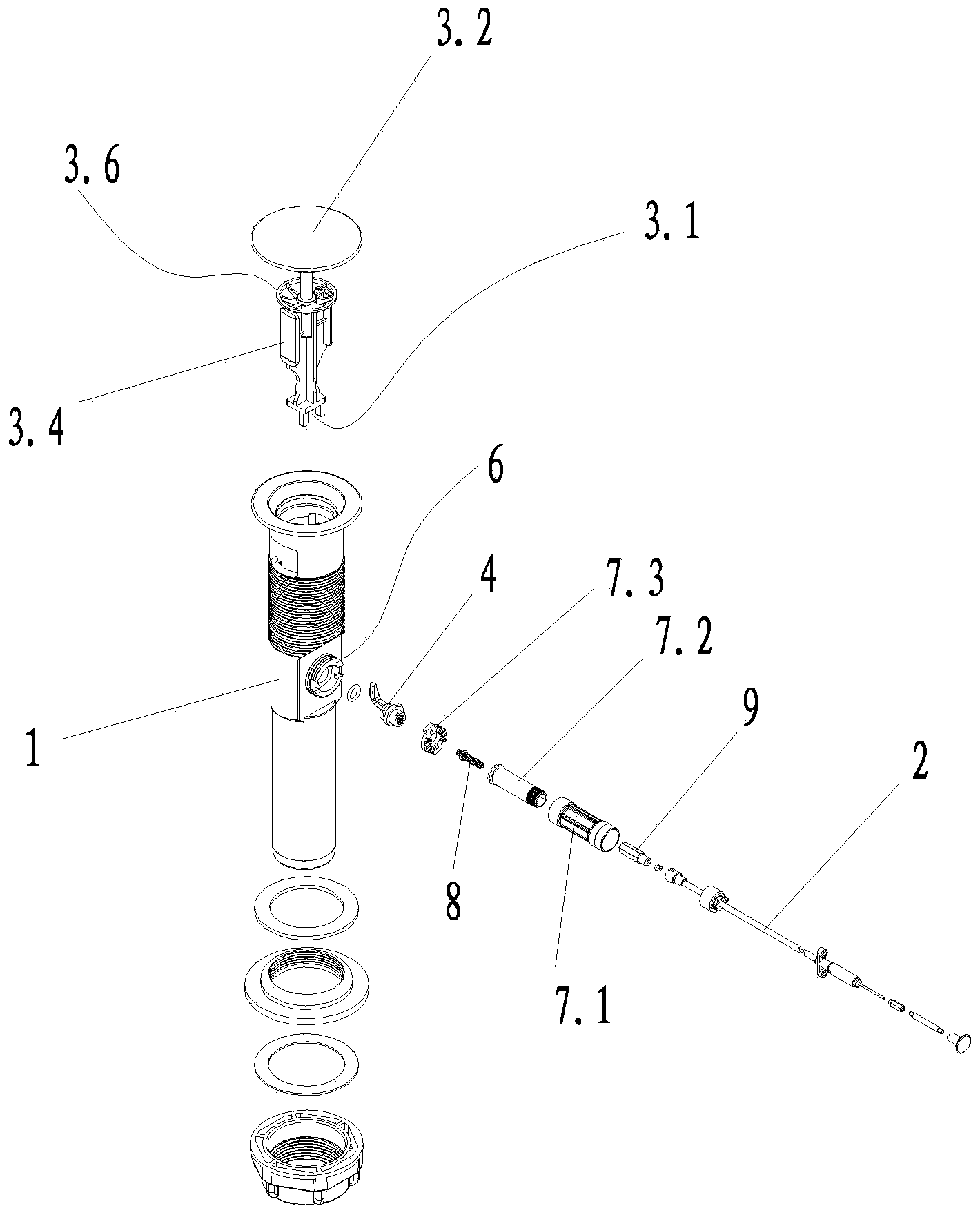

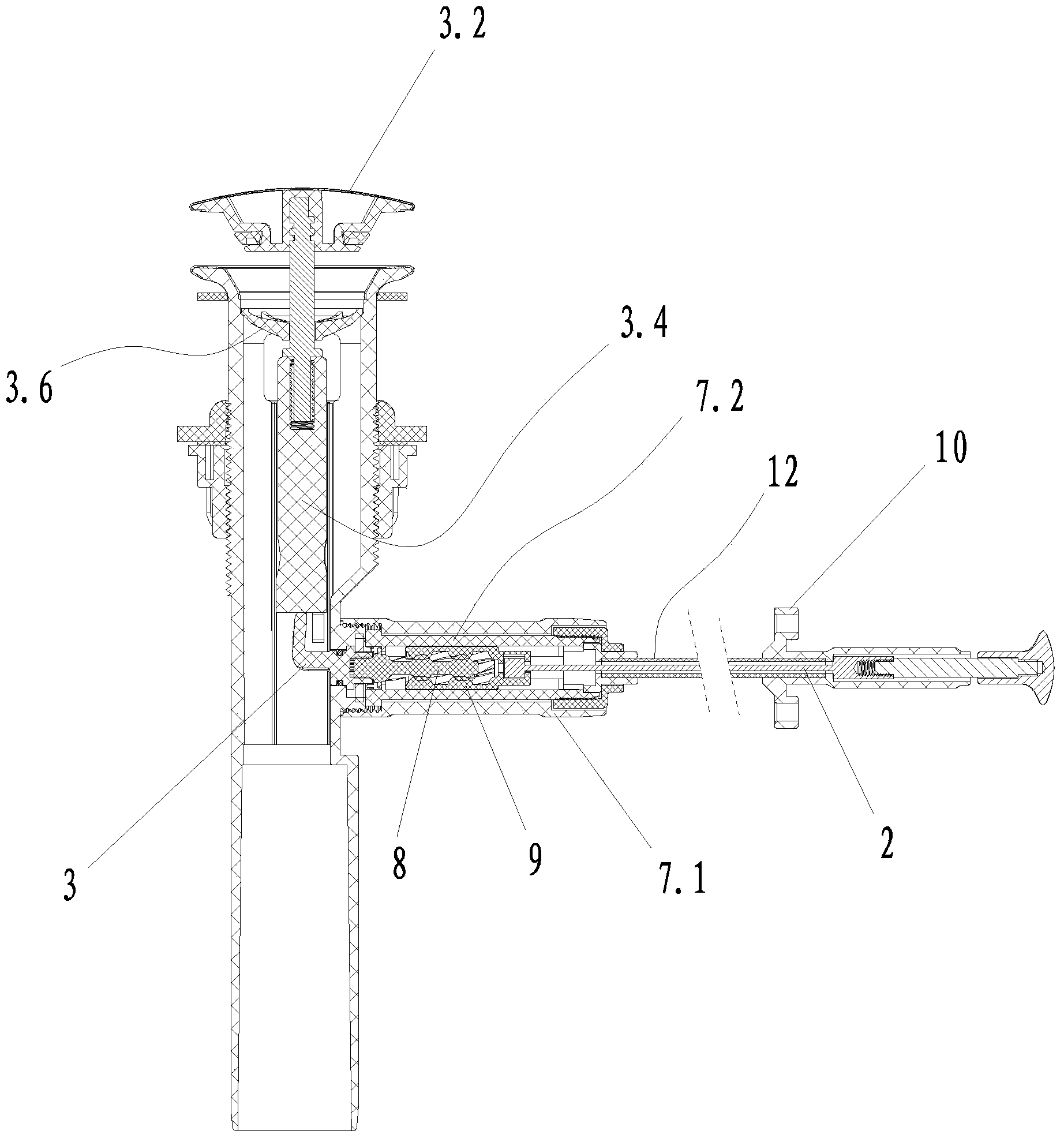

Dehydrator

InactiveCN103711183AStrong controllabilityPull simpleDomestic plumbingControllabilityMechanical engineering

The invention relates to a dehydrator which comprises a dehydration main body and a pull wire, wherein a water plug and a lever for driving the water plug are arranged in the dehydration main body; the lower end of the dehydration is provided with a connecting pipe connected with an outside sewer; the side wall of the dehydration main body is provided with a mounting port; the mounting port is connected with a support member; the tail of the lever extends to the outside of the mounting port and is connected with the pull wire through a helical structure; and the lever, helical structure and pull wire are assembled and fixed by the support member. The flexible pull wire can be properly deformed to adapt to water basins with different sizes, thereby providing the applicability of the dehydrator; the pull wire implements control on the rise and fall of the water plug through the helical structure so as to implement the start and stop of the dehydrator, and the dehydrator can implement drainage or water accumulation without extending the hand into the basin; the helical casing and helical rod are matched to linearly control the rotating angle of the lever, thereby controlling the opening or closing size of the water plug according to needs and controlling the drainage discharge, so the controllability is high; and the pull wire is simple to pull and push and easy to operate.

Owner:ZHEJIANG DELIFU TECH CO LTD

Mounting frame for a laser measuring instrument

ActiveCN103277639BCompact designLow costSurveying instrumentsUsing optical meansLaser transmitterLaser ranging

Owner:STATE GRID CORP OF CHINA +1

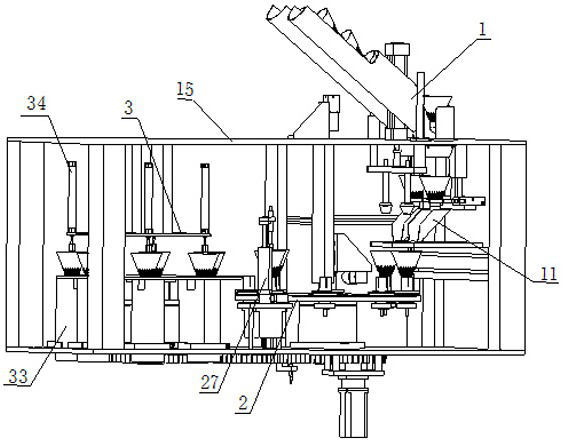

Badminton testing machine

ActiveCN111054645BRealize automatic loadingRealize automatic sorting and sortingSortingComputer hardwareEngineering

The invention discloses a badminton testing machine, which comprises a frame body, a controller and a ball-up mechanism, a detection mechanism and a ball-down mechanism which are signal-connected with the controller. The detection mechanism includes a rotating disk, a rotating station, an upper camera, a side camera and a light source. The rotating station is evenly distributed on the rotating disk. The rotating station can keep rotating relative to the rotating disk. The upper camera and the side camera correspond to the detection position at the same time. The top and side of the rotary station, the upper and lower ball mechanisms correspond to the rotary station respectively. Its structure realizes the automatic loading of badminton, detection and automatic sorting after detection, which greatly improves the detection efficiency and quality of detection, with high sorting accuracy and good stability, and can be used in conjunction with various automatic badminton production equipment .

Owner:林先明

Direction line winding mechanism for telescope

The invention relates to a direction line winding mechanism for a telescope, which is of a structure capable of independently assembling and running and is provided with a bearing capable of rotating, the outer race of the bearing is connected with a fixed base frame set, the inner race of the bearing is connected with a rotary barrel and can be driven to synchronously rotate together with a direction shaft of the telescope by a connecting pipe and a cross-shaped slide ring, and the fixed base frame set is fixed on a base of equipment to ensure that the inner race and the outer race of the bearing oppositely rotate well. The direction line winding mechanism ensures function realization on the telescope, simultaneously meets the rotation requirement on the telescope and improves the adaption of the telescope.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

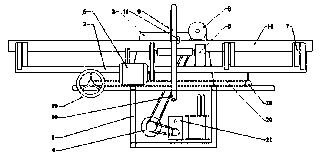

Novel bar grinder

InactiveCN104440431AExtended service lifeDurableRevolution surface grinding machinesGrinding work supportsEngineeringBar pressing

The invention discloses a novel bar grinder which comprises a base, a support, a grinding wheel stand, a motor, an adjustable-speed motor, a driving wheel, a riding wheel, a grinding wheel and a roll bar pressing handle, wherein the support of the bar grinder is mounted above the base, and the adjustable-speed motor, the driving wheel and the riding wheel are mounted on the support; the adjustable-speed motor drives the driving wheel; the grinding wheel stand is mounted above the base, and the grinding wheel is mounted on the grinding wheel stand; the motor drives the grinding wheel, and one end of the roll bar pressing handle is hinged to the grinding wheel stand; a handle and a roll bar pressing code used for pressing a roll bar are arranged on the roll bar pressing handle. The novel bar grinder can remove solid grapefruits on the roll bar and has the advantages of being high in speed, durable, practical and low in cost.

Owner:吴四新

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com