Rotary telescopic combined oil cylinder

A combination of oil cylinder and rotary cylinder technology, applied in mechanical equipment, fluid pressure actuators, etc., can solve the problems of small rotational resistance torque, increased linear movement distance of rack, output torque limitation, etc., to achieve compact layout and wide application range The effect of widening and reducing the weight of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

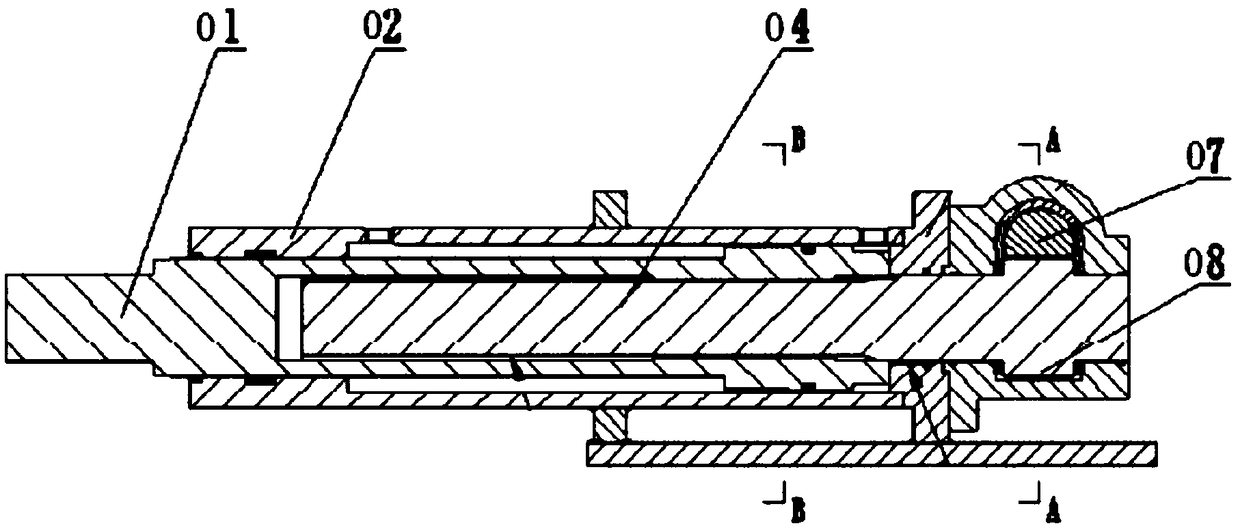

[0032] refer to Figure 4 and Figure 5 , the rotary telescopic combination oil cylinder of this embodiment includes a telescopic cylinder 101 and a rotary cylinder 102;

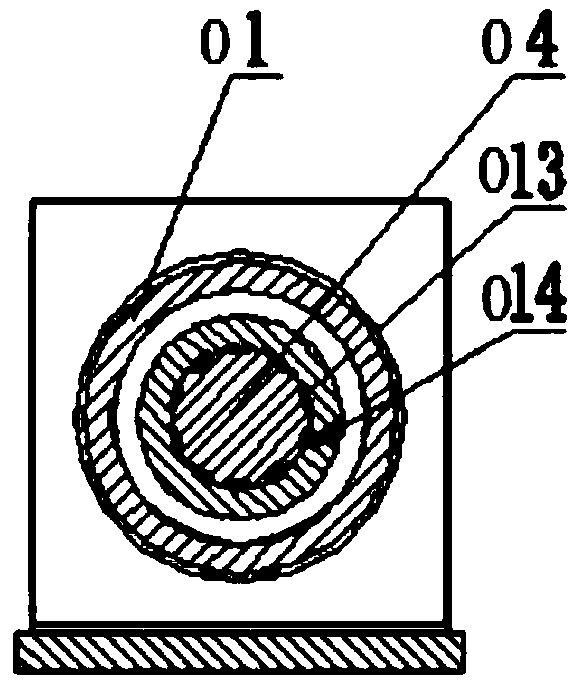

[0033] The telescopic cylinder 101 comprises a first cylinder and a telescopic piston rod 5; in the first cylinder, a rod cavity and a rodless cavity are respectively arranged on both sides of the piston of the telescopic piston rod; The first oil port 11 and the second oil port 12 of the rodless cavity;

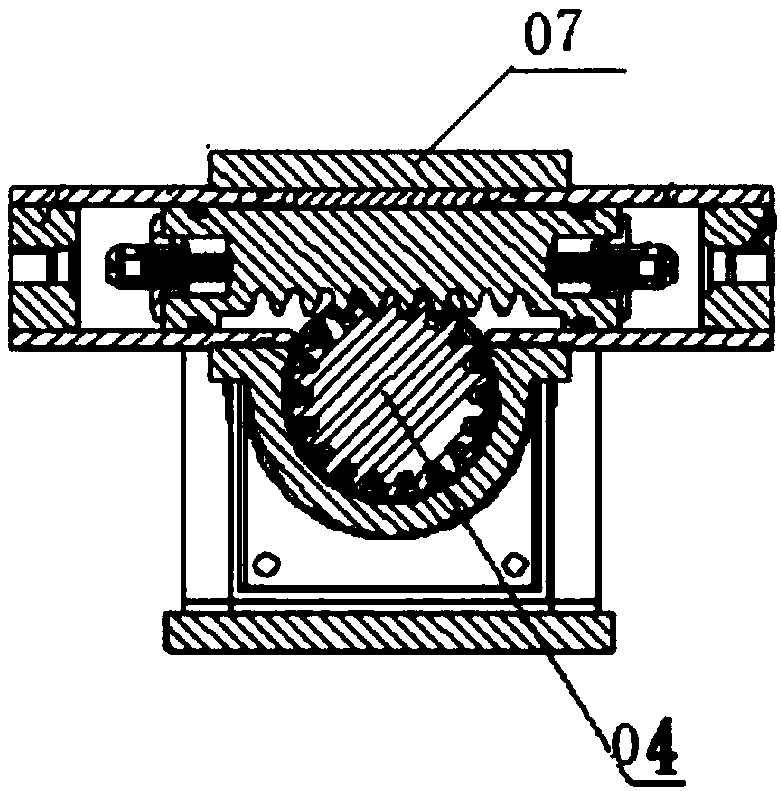

[0034] The rotary cylinder 102 includes a second cylinder, a screw piston 7 and a rotary transmission rod 8; one end of the rotary transmission rod 8 is mounted on the cylinder bottom 9 of the rotary cylinder, and the other end penetrates into the inside of the first cylinder; the outer periphery of the screw piston 7 passes through the screw The sleeve 4 is screwed to the inner circumference of the second cylinder, the inner circumference of the screw piston 7 is screwed to the outer circumference of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com