Ultrasonic metallic surface processing device for borer

A metal surface and processing device technology, which is applied to metal processing equipment, parts of boring machines/drilling machines, fluids using vibration, etc., can solve problems such as unsuitable boring machines, and achieve force balance and avoid impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

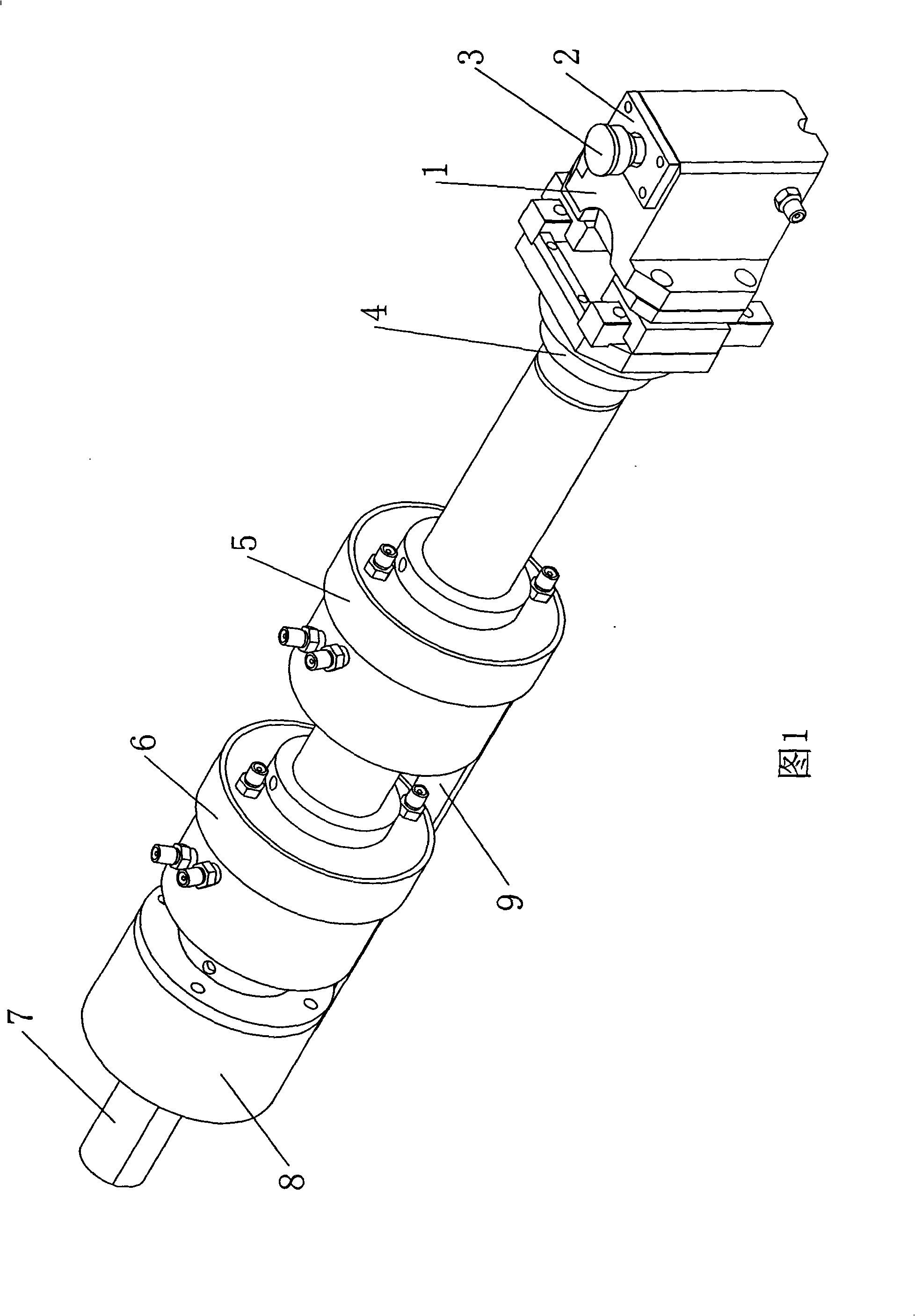

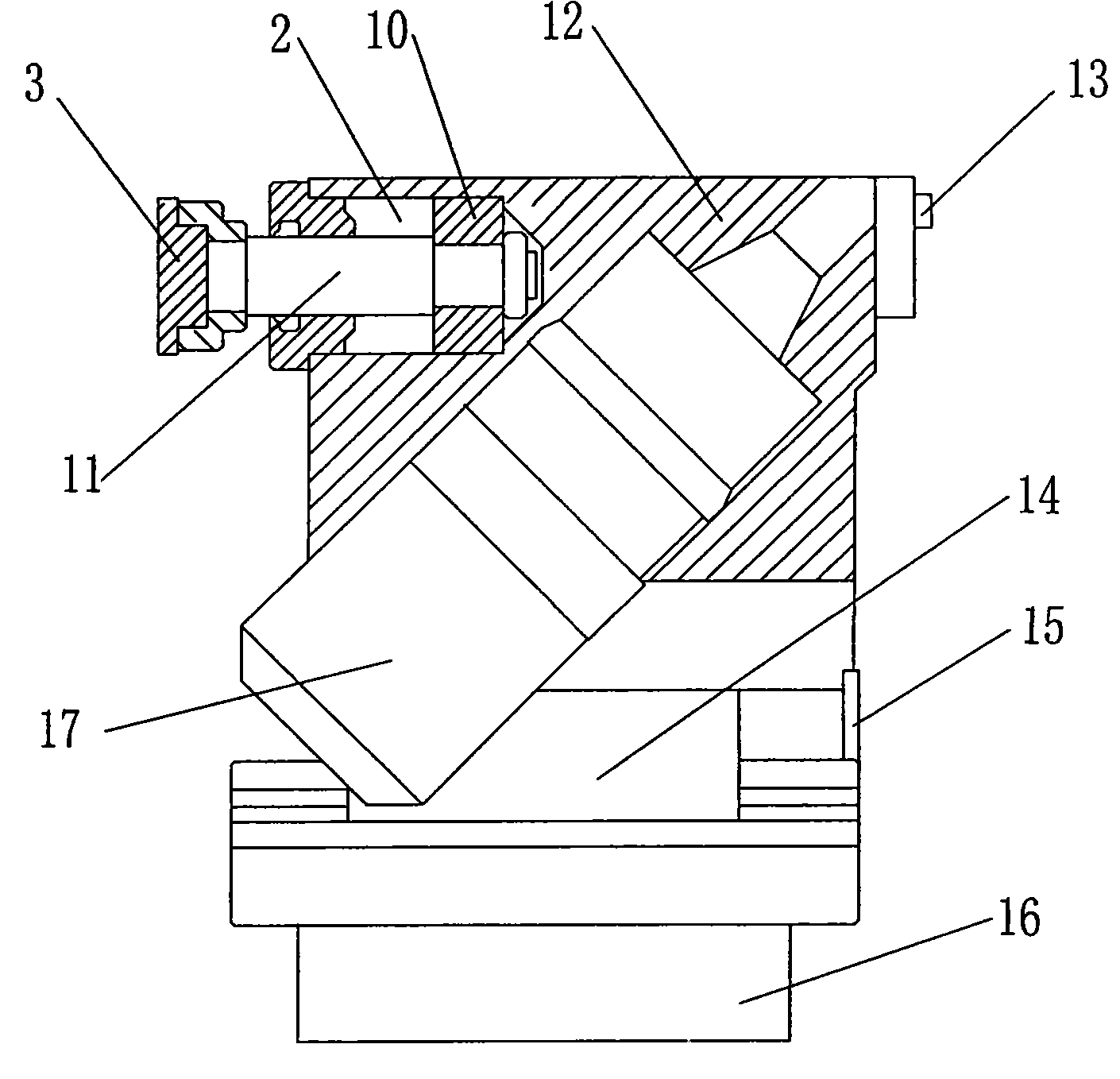

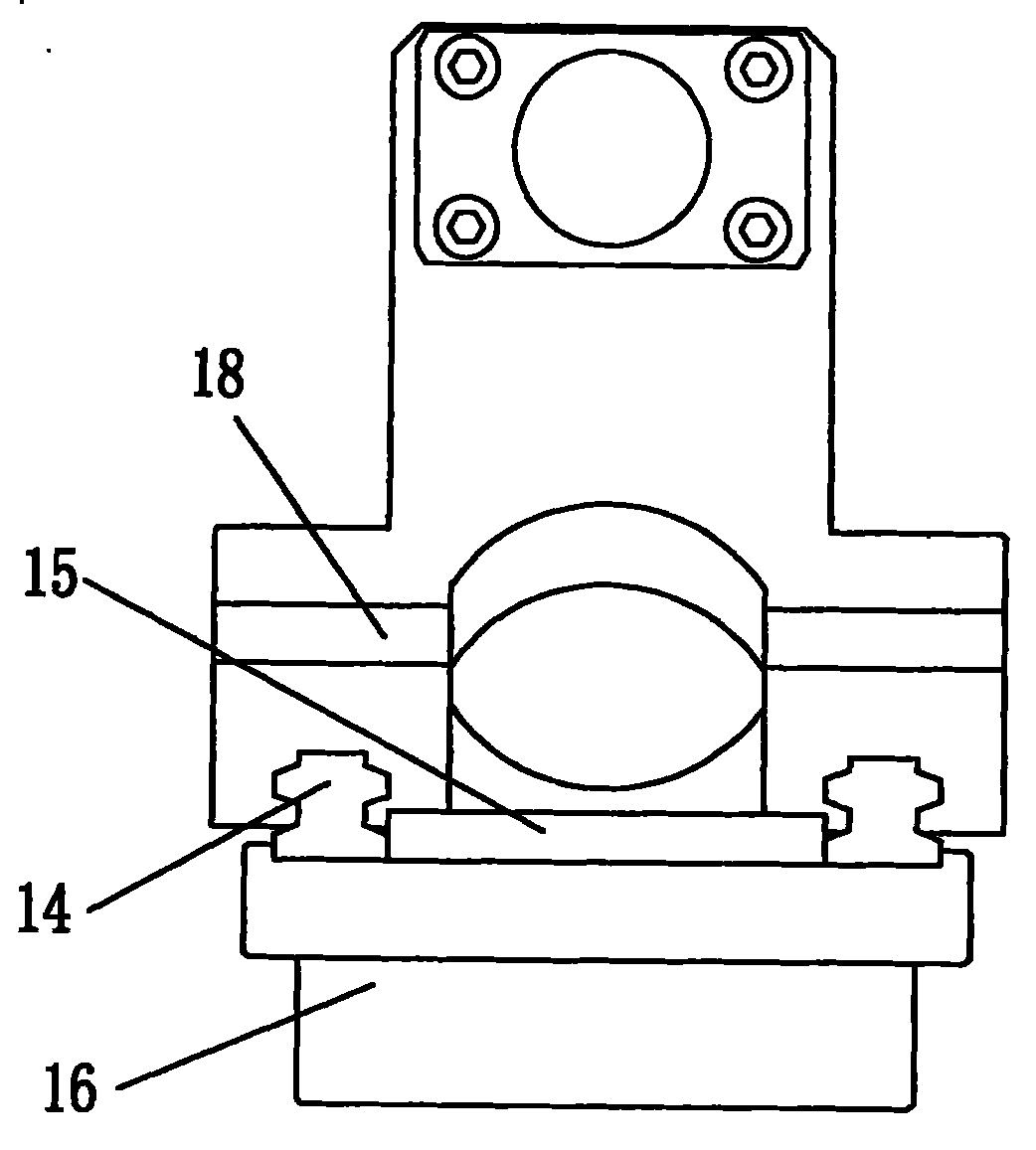

[0021] Such as figure 1 As shown, the ultrasonic metal surface processing device for a boring machine of the present invention includes a boring bar 7 , a hydraulic oil circuit slip ring 5 , a lubricating oil circuit slip ring 6 , an ultrasonic circuit slip ring 8 and a cutter head part 1 . The cutter head part 1 is installed on one end of the boring bar 7 through threaded connection, and locked and positioned by the lock nut 4 . The hydraulic oil circuit slip ring 5, the lubricating oil circuit slip ring 6 and the ultrasonic circuit slip ring 8 are all set on the boring bar 7, and all three are connected to the fixing plate 9. After the boring bar 7 is installed on the main shaft of the boring machine, the connection is fixed The plate 9 is fixed on the body of the boring machine, the hydraulic oil circuit slip ring 5 provides hydraulic oil for each oil cylinder, and the lubricating oil circuit slip ring 6 provides lubrication and cooling medium for the cutter head part 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com