Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7052 results about "Ultrasonic generator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

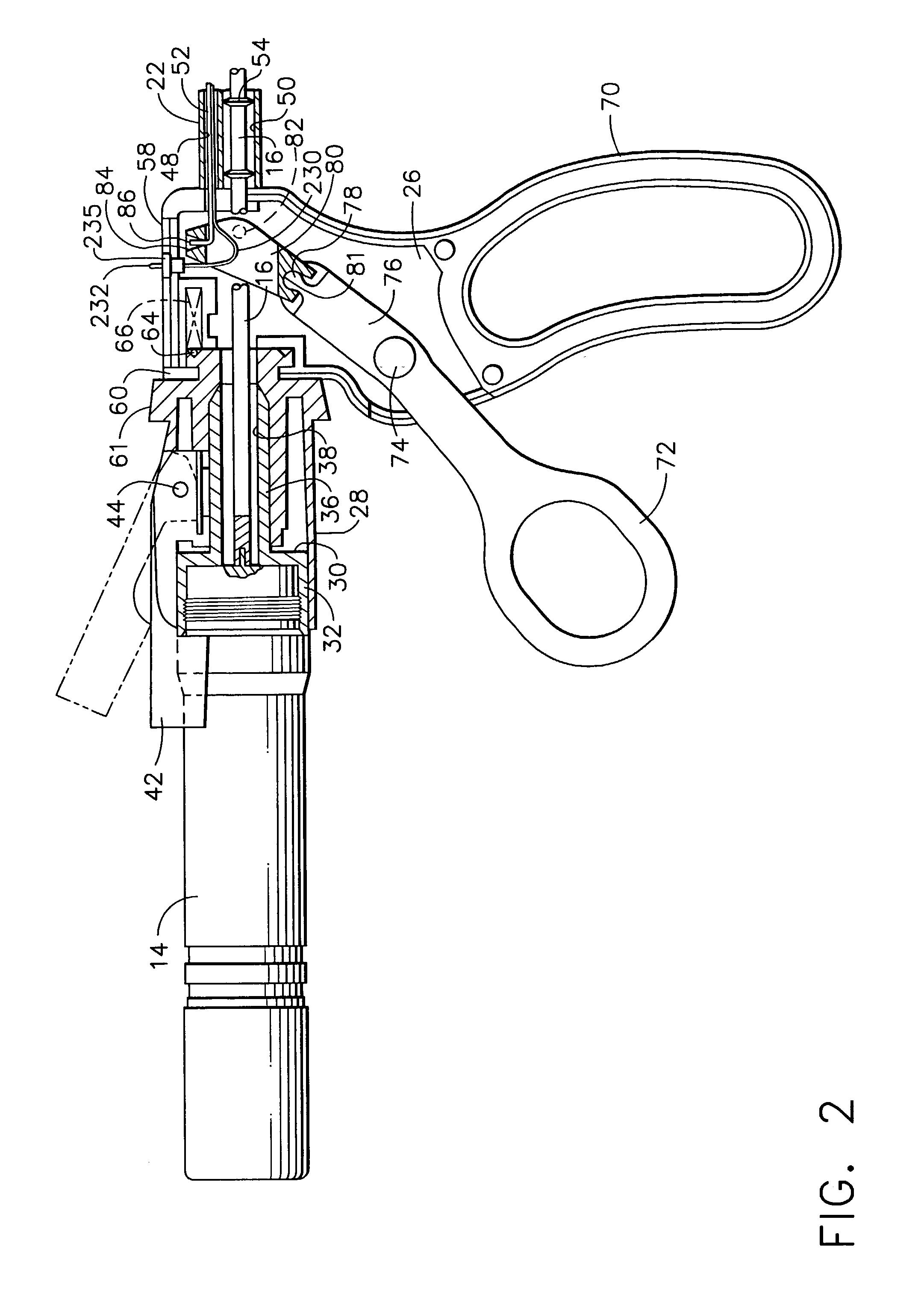

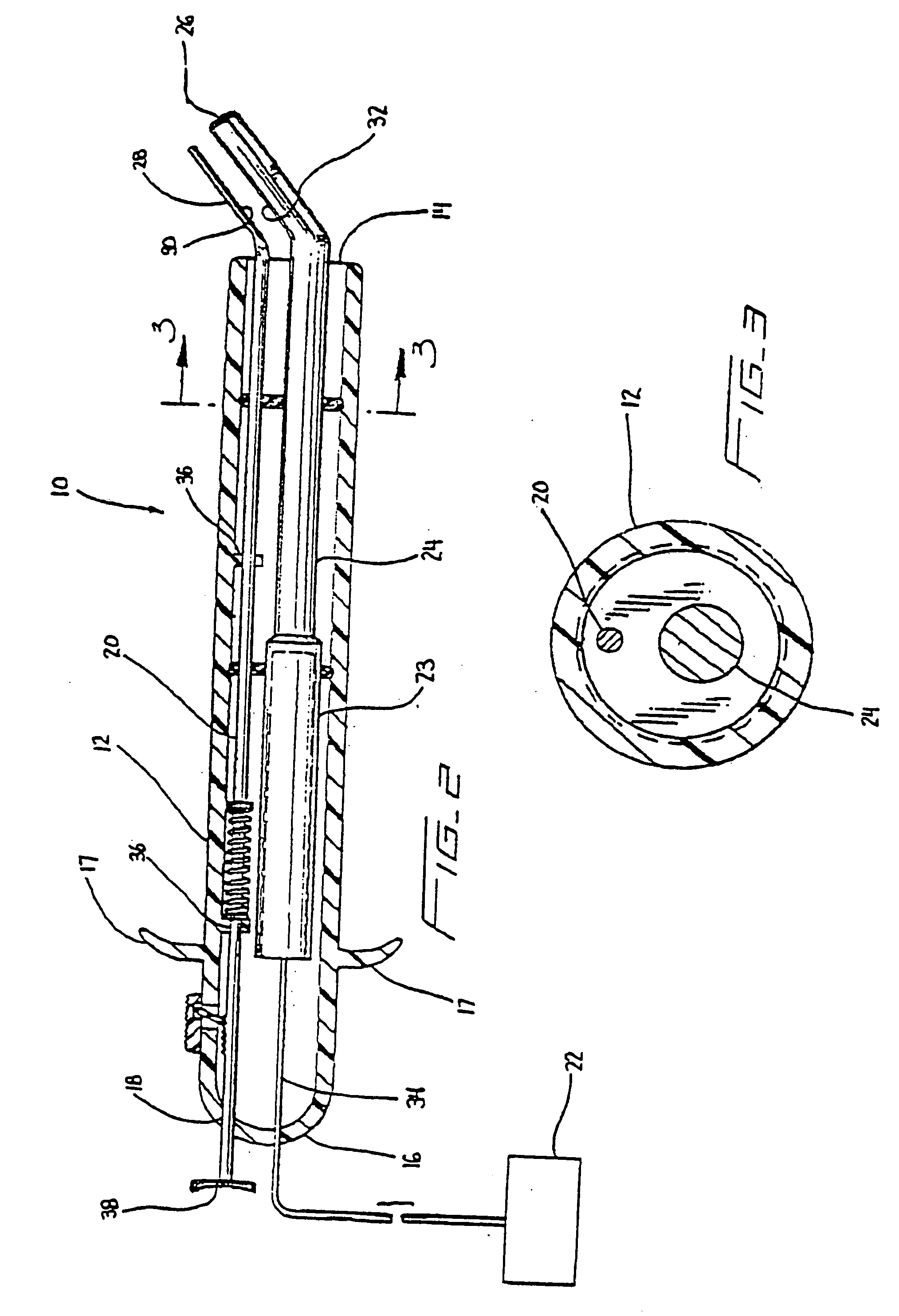

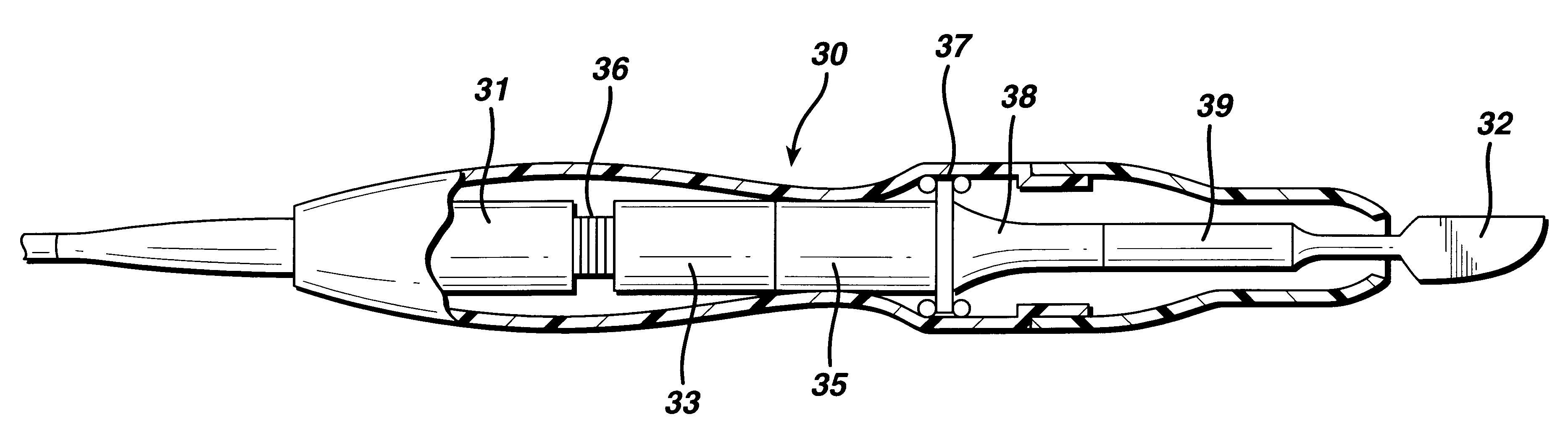

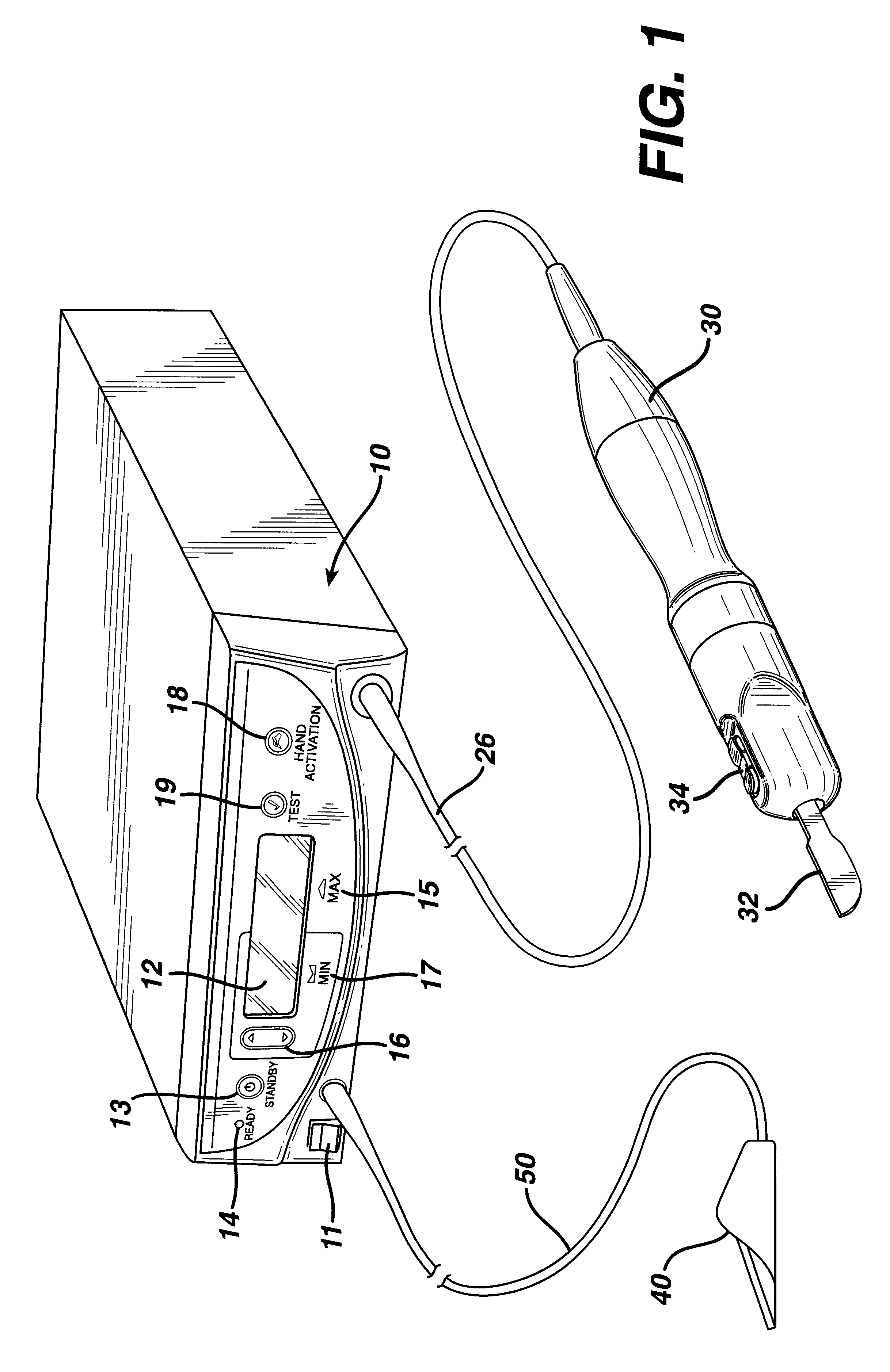

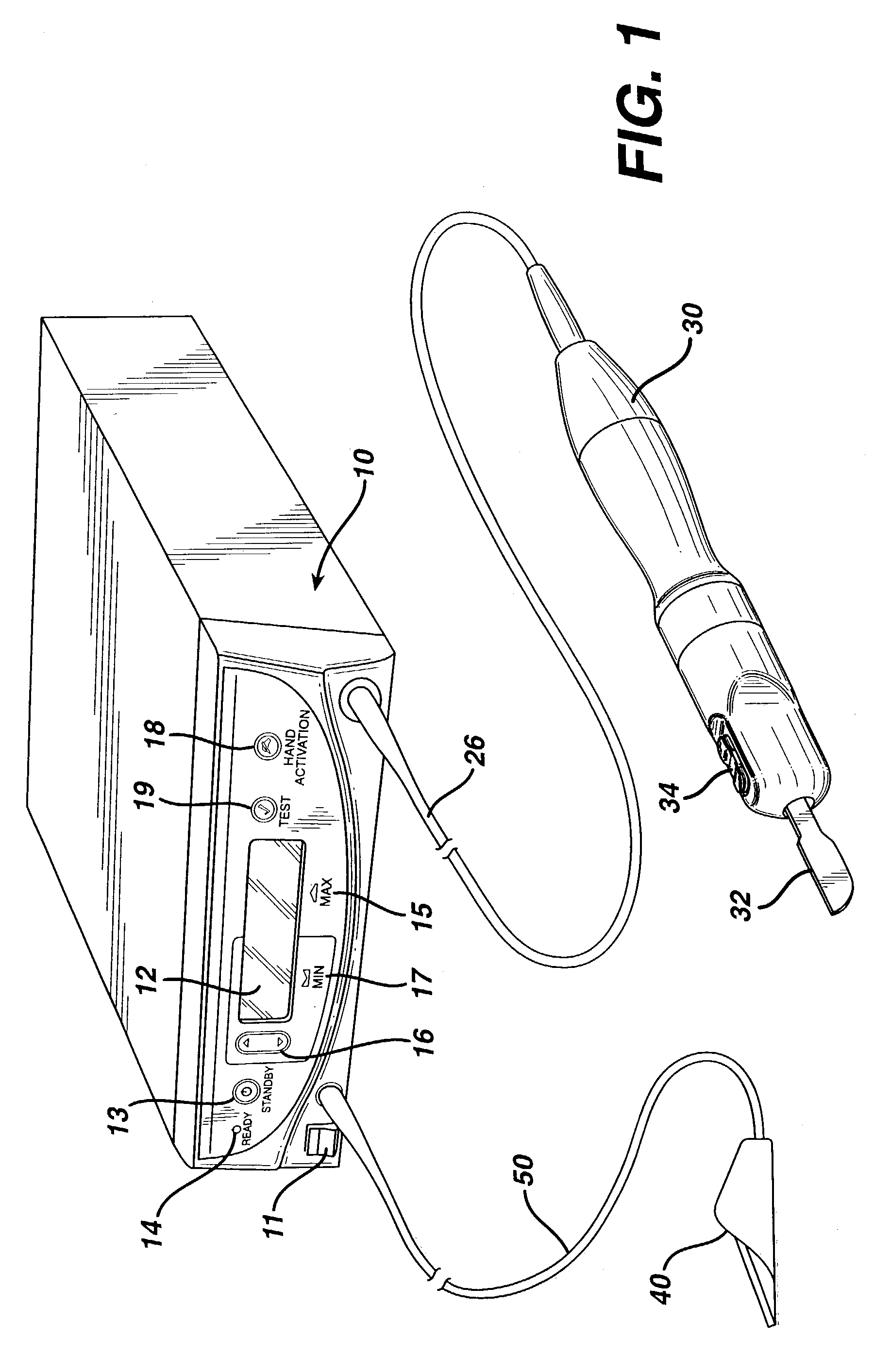

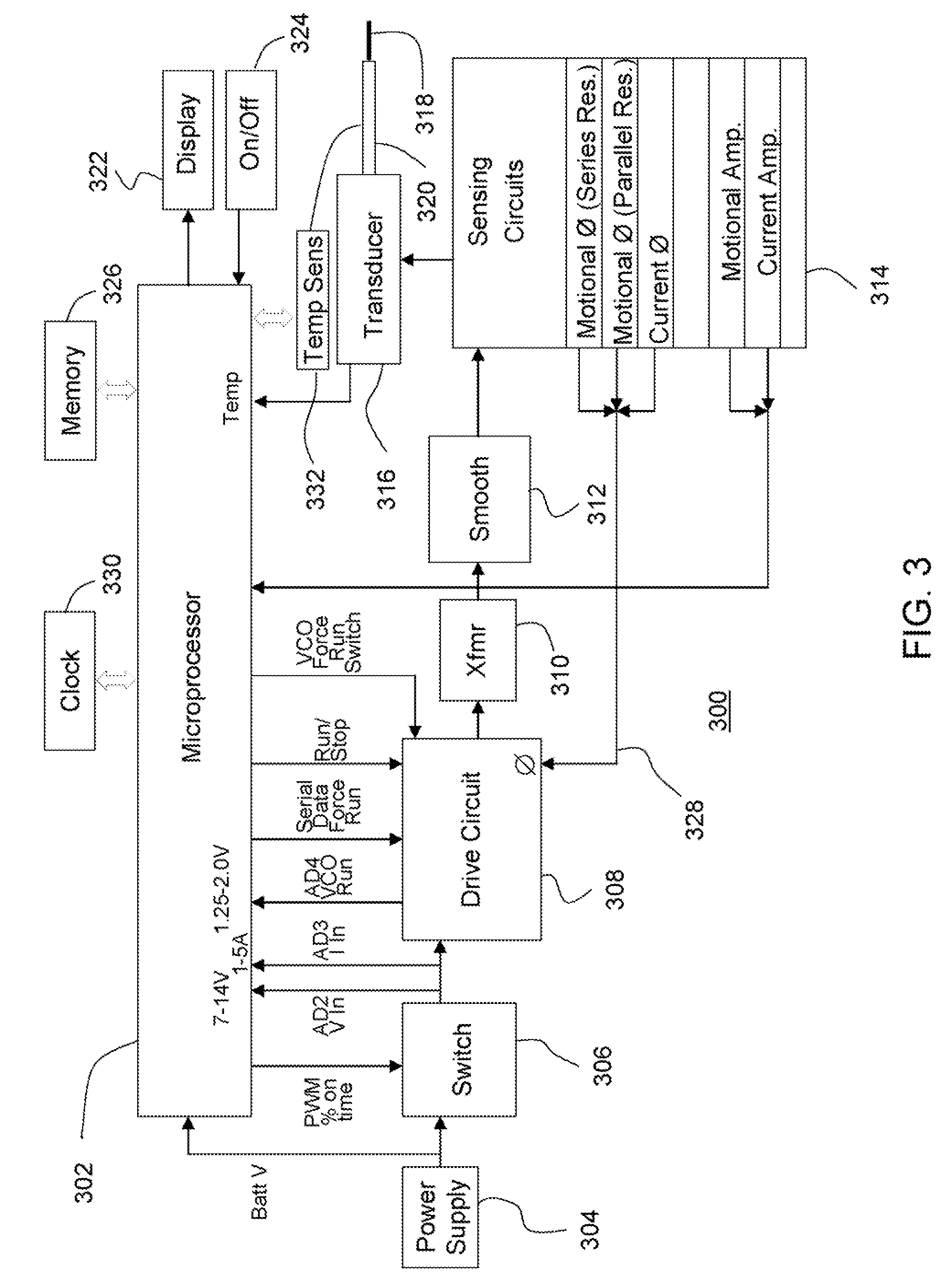

Feedback control in an ultrasonic surgical instrument for improved tissue effects

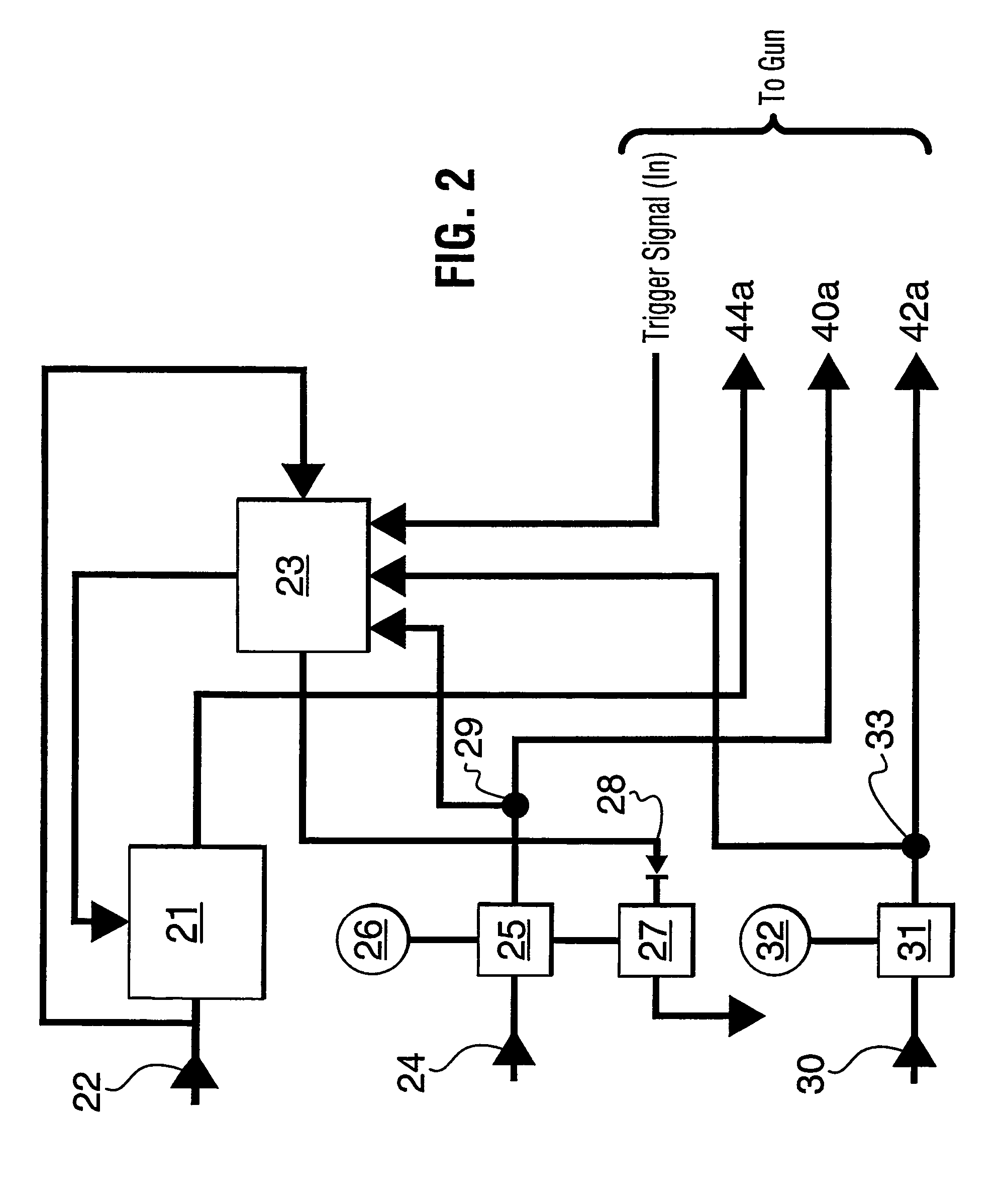

A temperature monitoring device and / or method which control the tissue temperature at the end-effector of a therapeutic ultrasonic cutting and coagulating instrument as the tissue is being heated with ultrasonic vibrations from the end-effector. One or more temperature sensors are located at the end-effector, preferably on a clamping member. The temperature sensors measure the temperature of the tissue engaged by the end-effector either directly or indirectly. An alternate method and apparatus provides an electrical tissue impedance measure in combination with an ultrasonic cutting and coagulating instrument to provide active feedback control of an ultrasonic generator.

Owner:ETHICON ENDO SURGERY INC

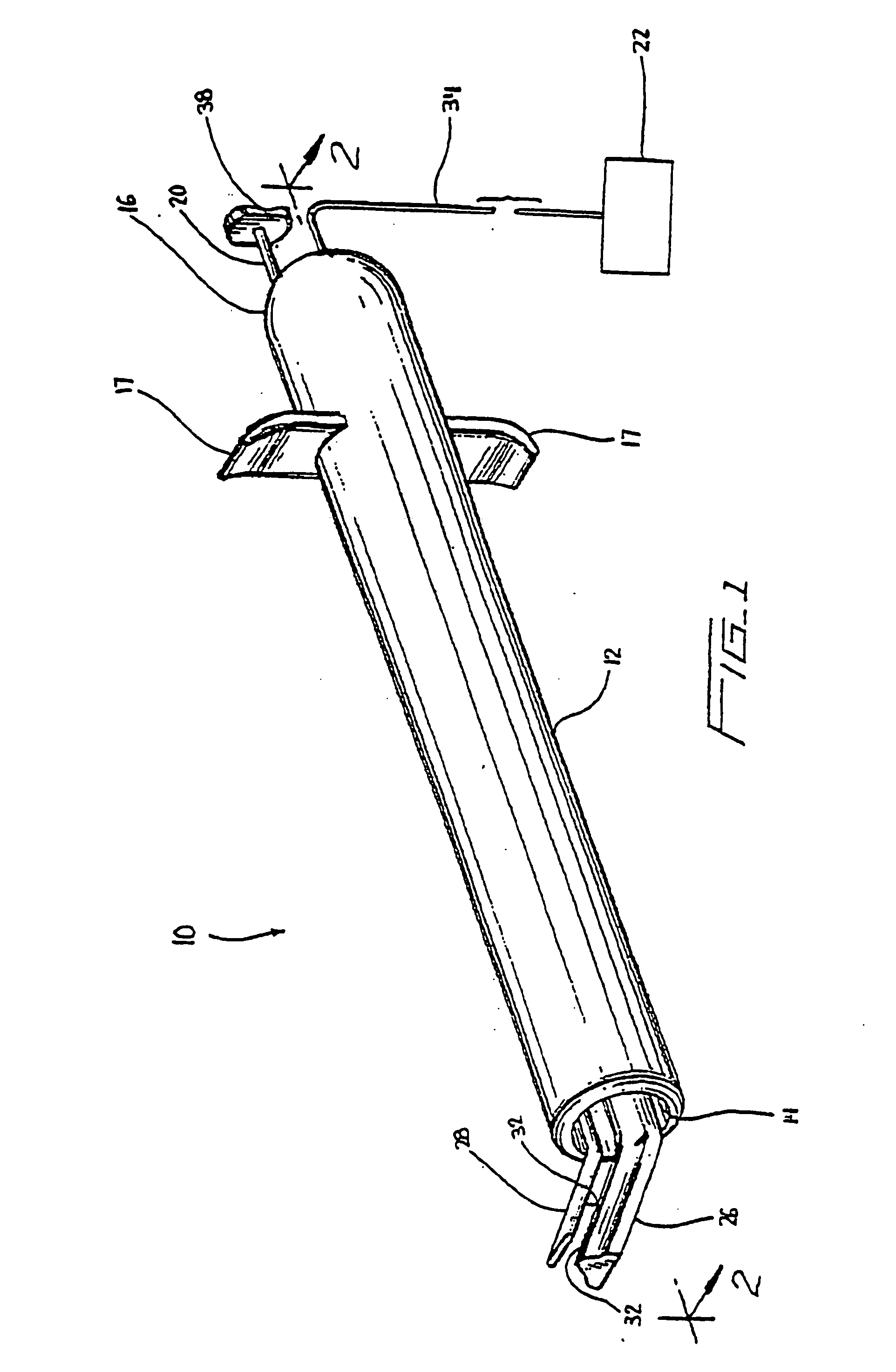

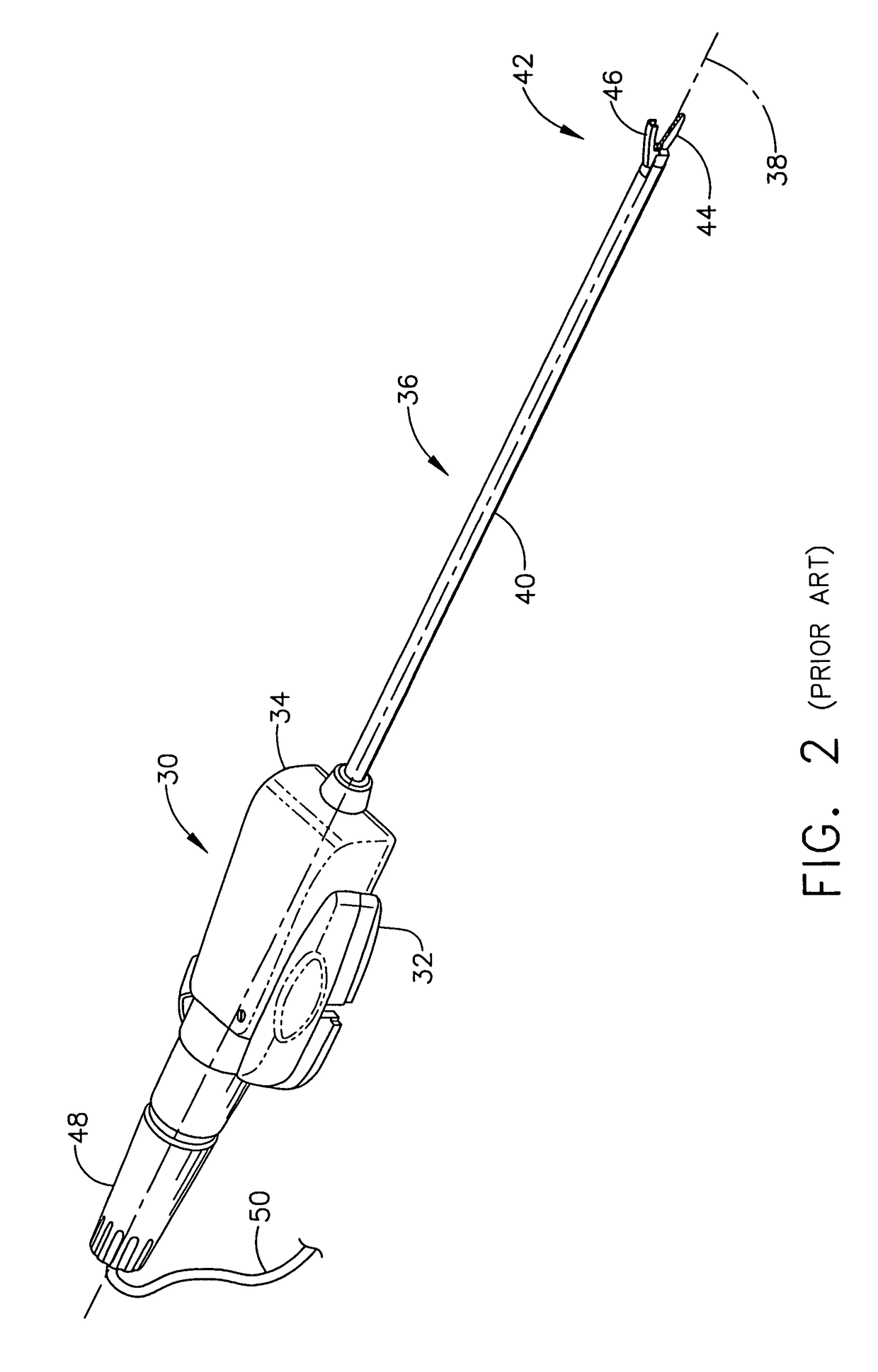

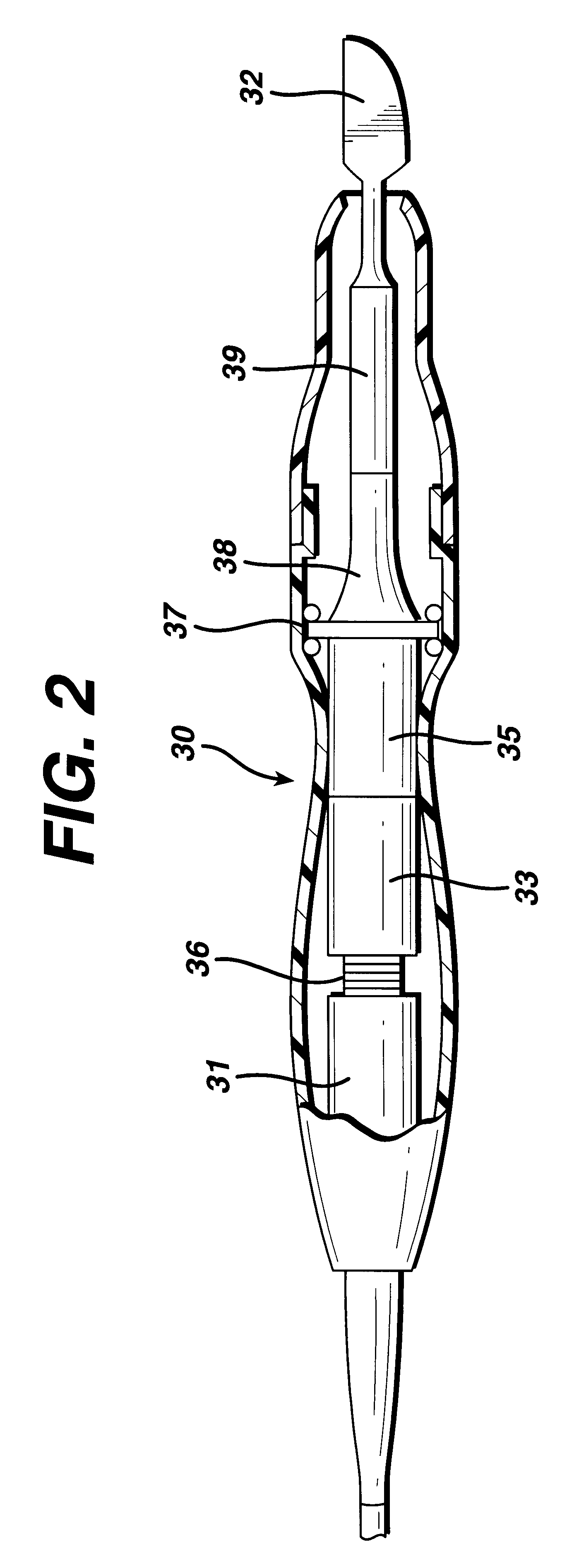

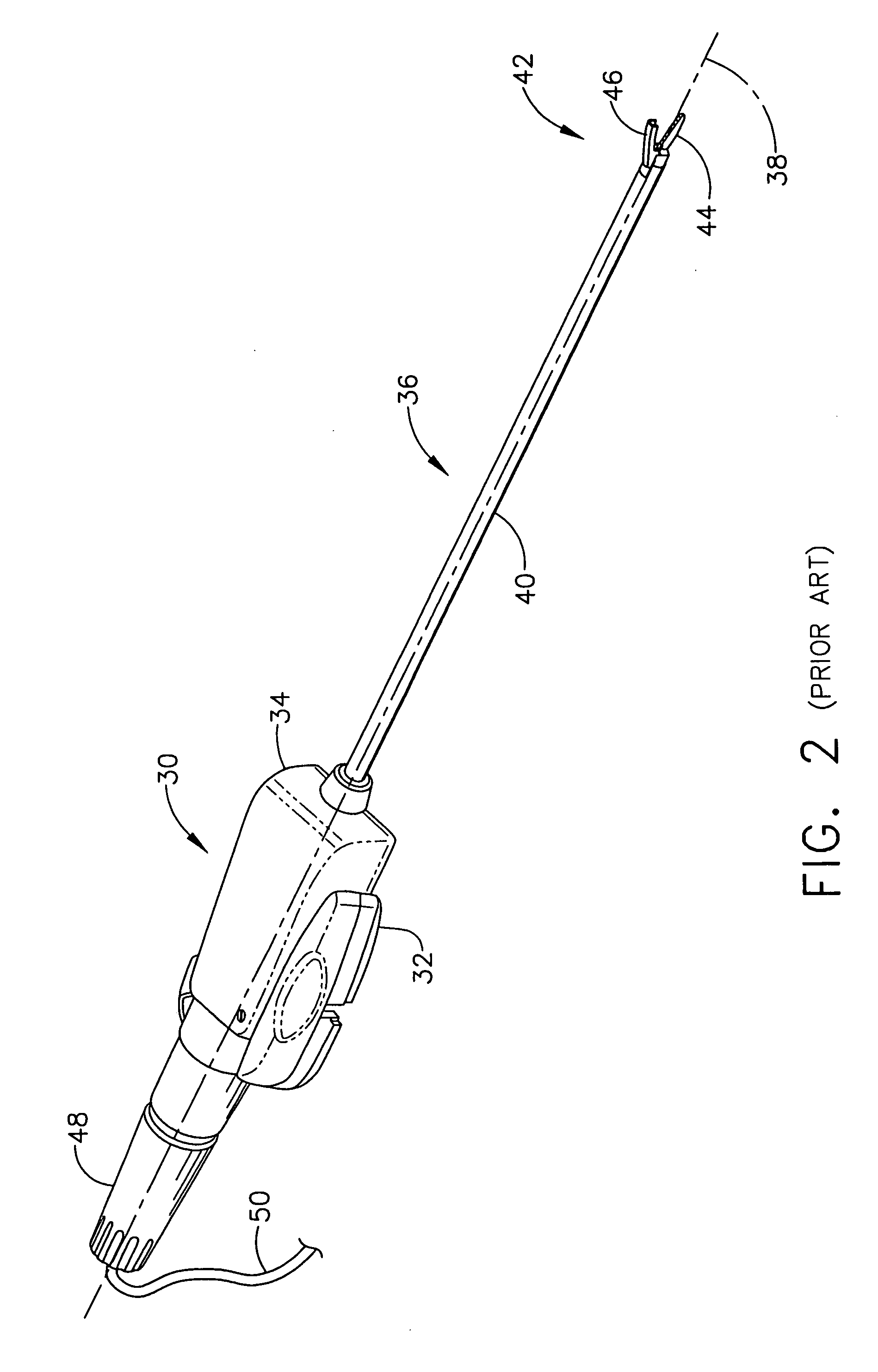

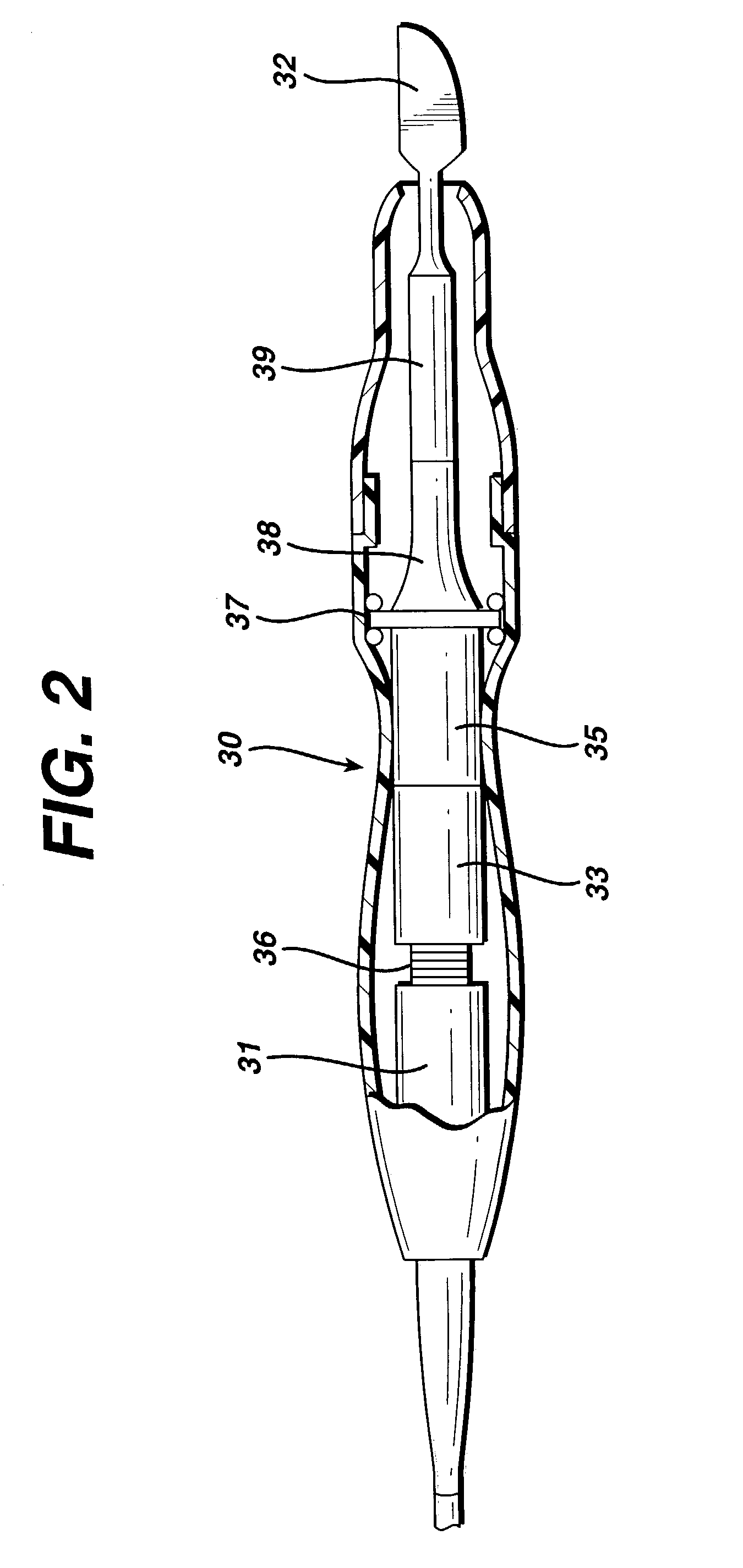

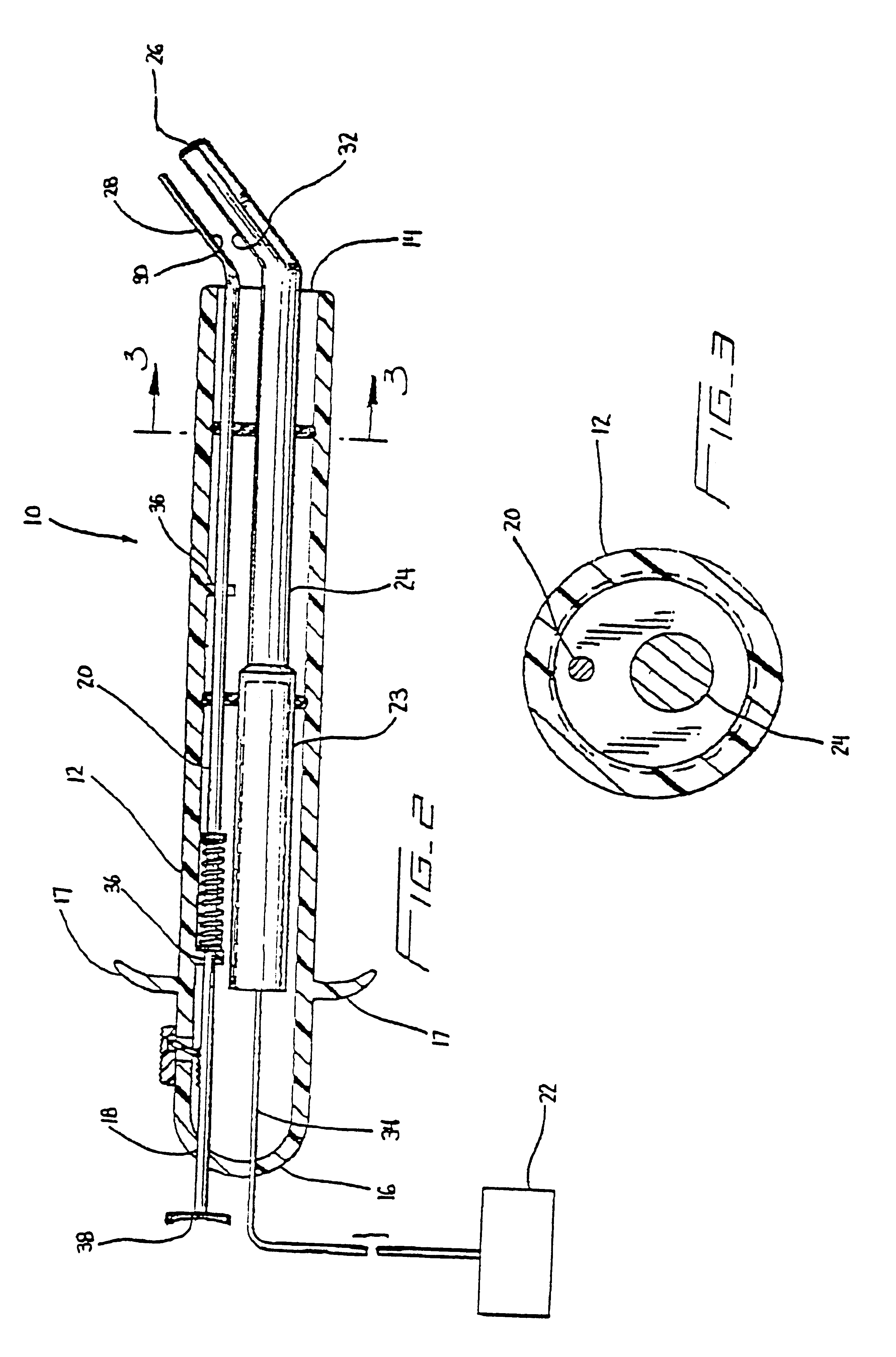

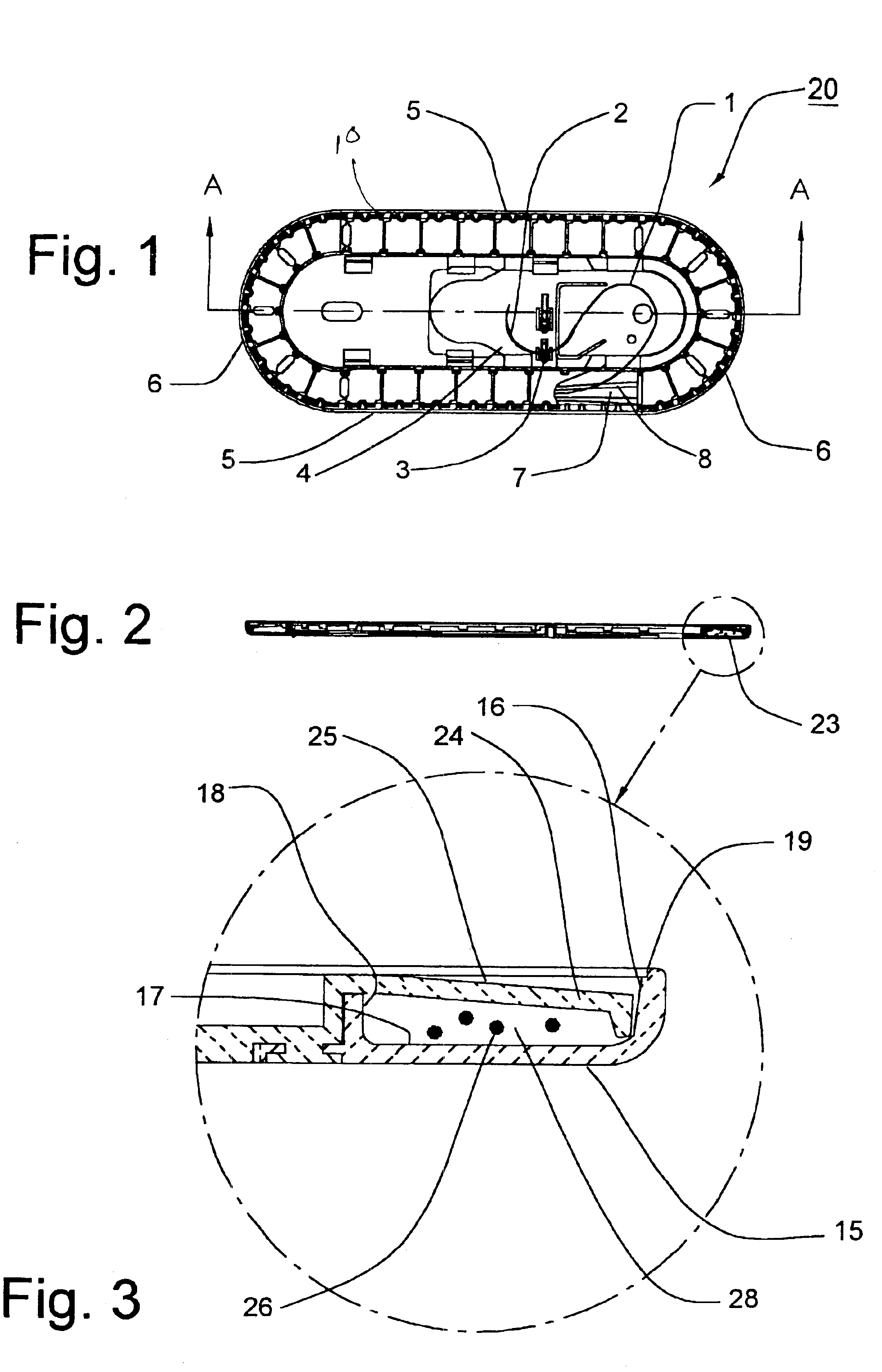

Ultrasonic dissector

InactiveUS20050143769A1Smooth connectionImprove instrument performanceSurgical forcepsEngineeringHigh frequency vibration

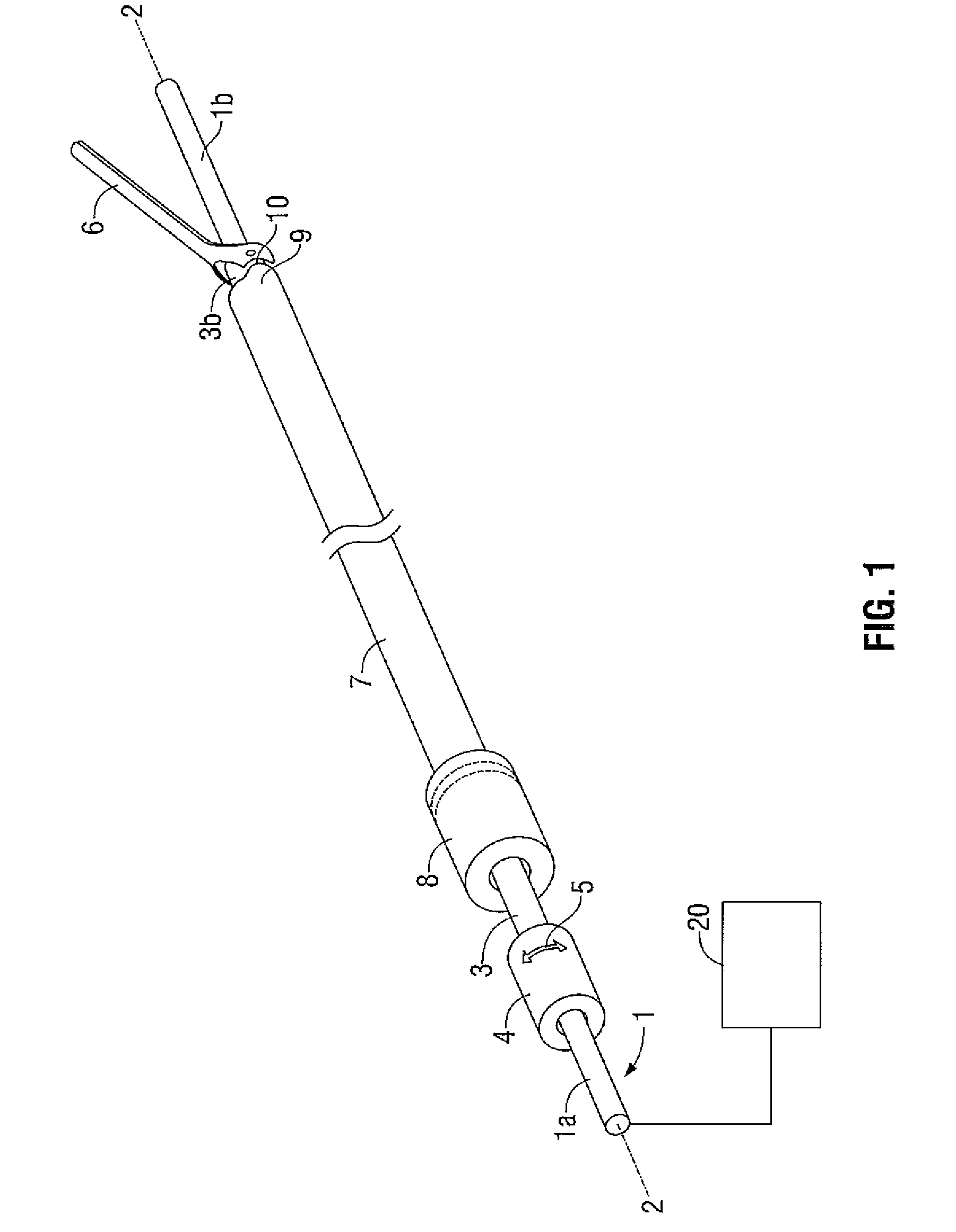

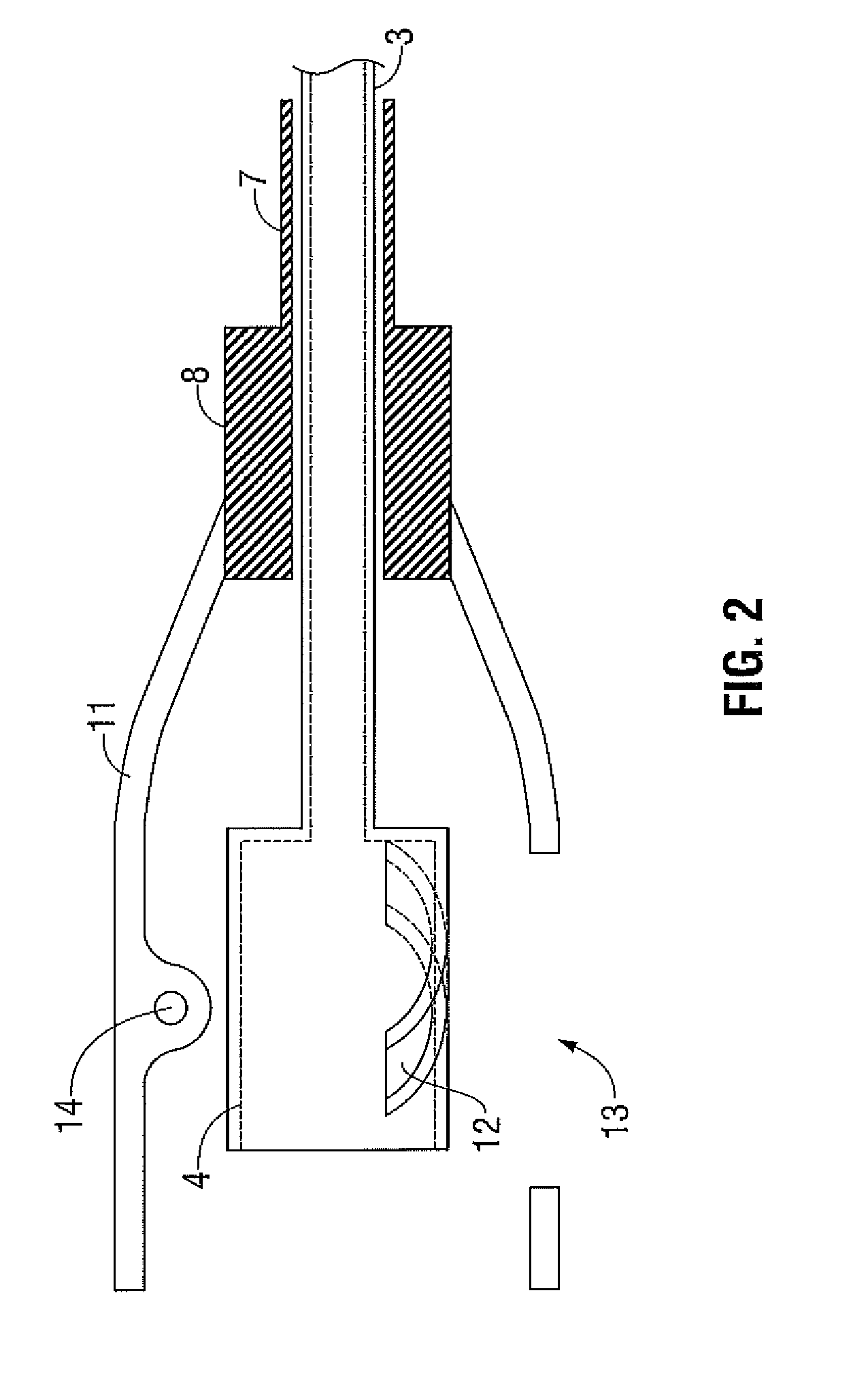

An ultrasonic surgical instrument for dissection and coaguation of tissue is provided. The surgical instrument includes a vibration coupler supported within a housing and operably connected to an ultrasonic generator. An angled blade member is connected to the distal end of the vibration coupler to conduct high frequency vibration from the ultrasonic generator to the blade member. A clamp member is positioned adjacent to the blade member and is movable from a first position to a second approximated position. The clamp member and angled blade member combine to enhance contact between the tissue and the blade member during operation of the instrument to improve the performance of the instrument.

Owner:WHITE JEFFREY S +3

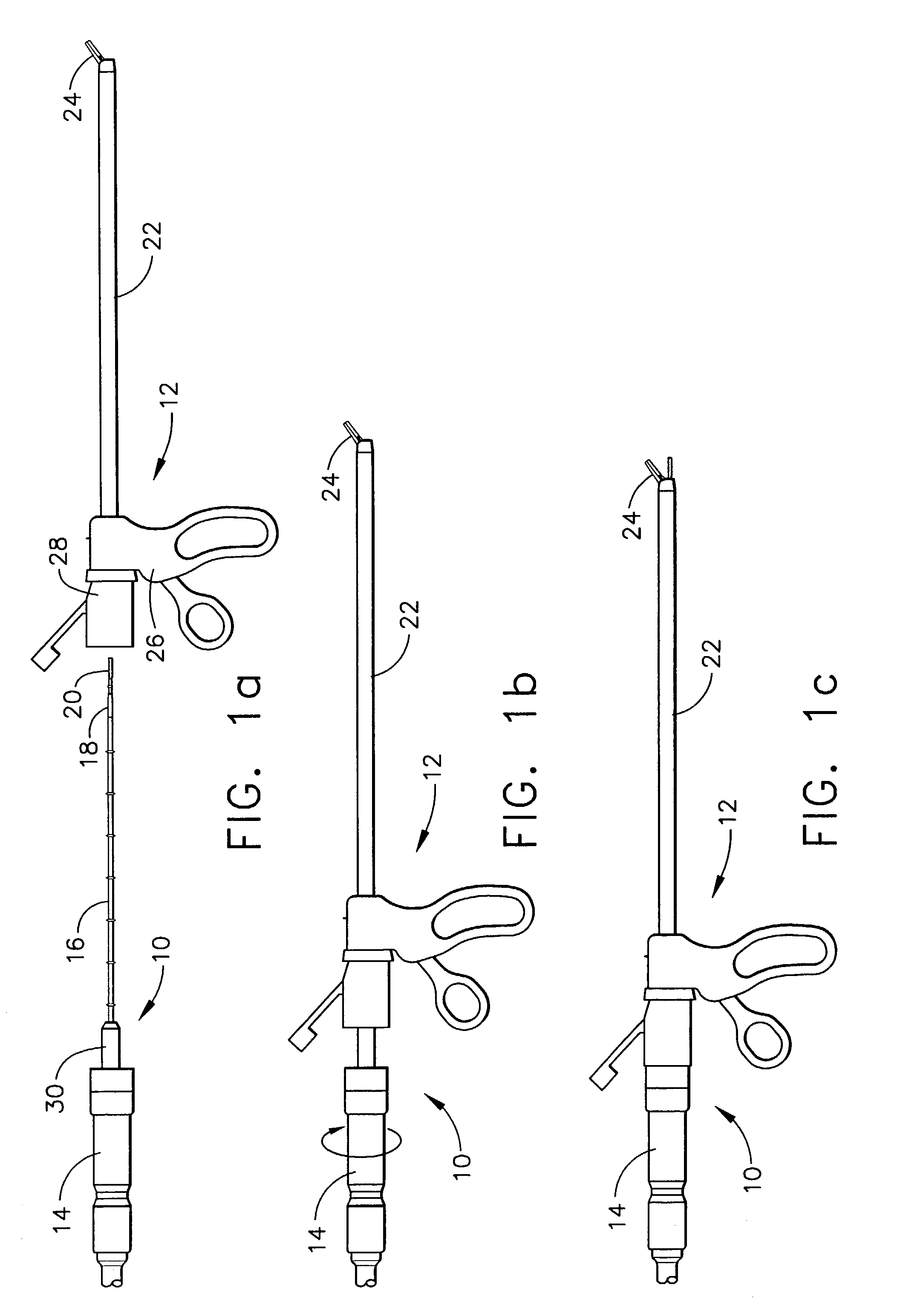

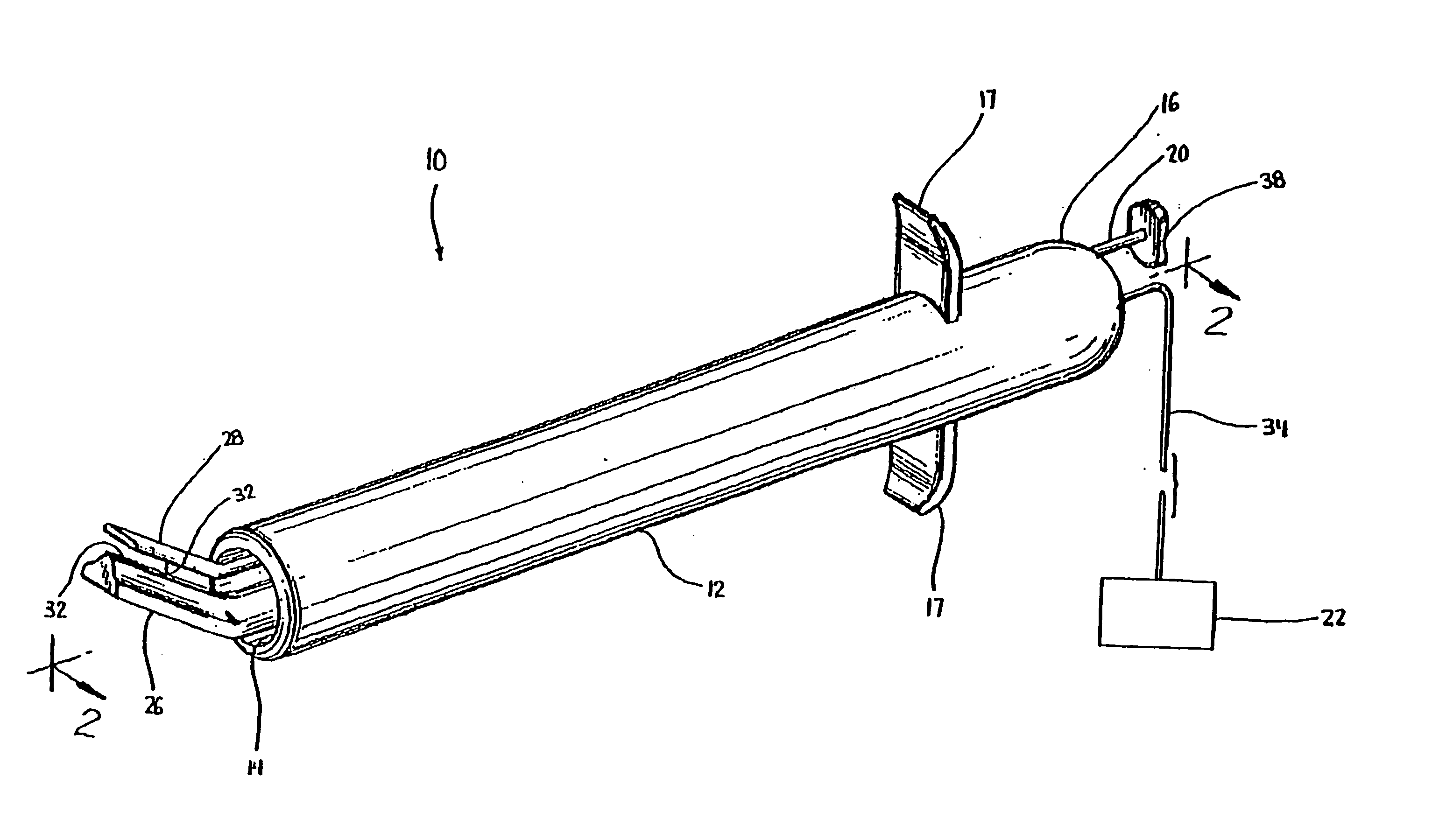

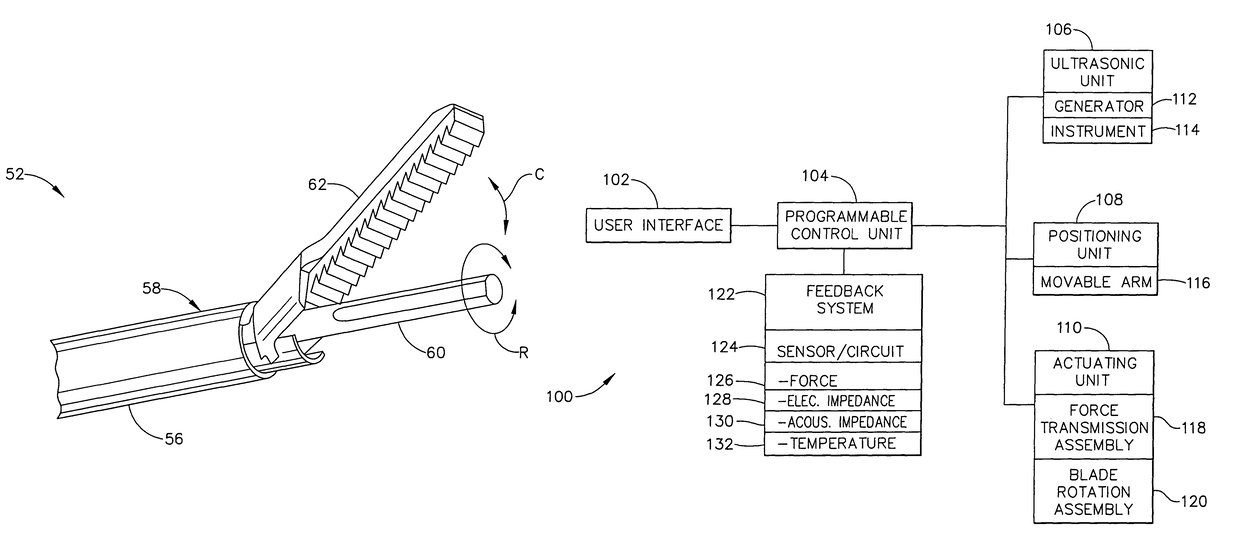

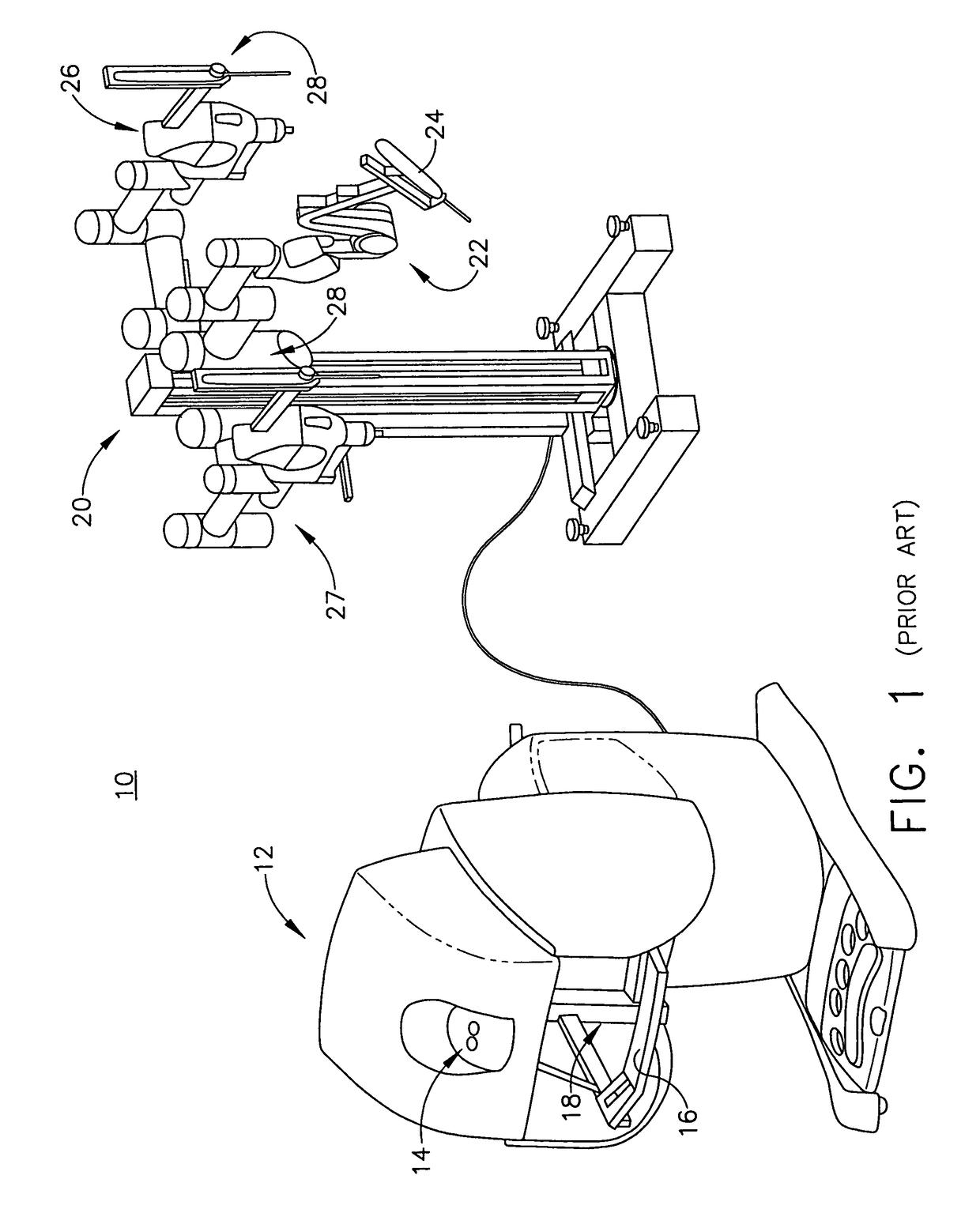

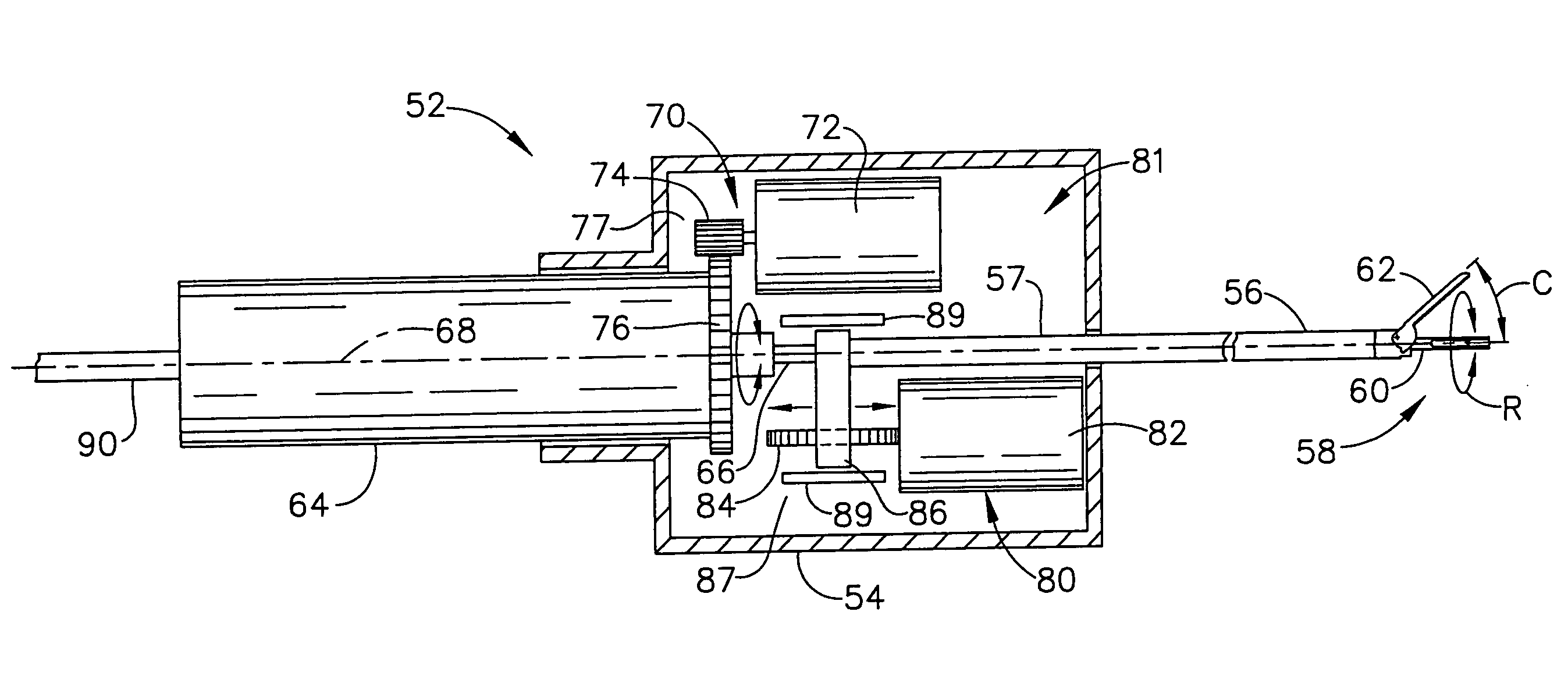

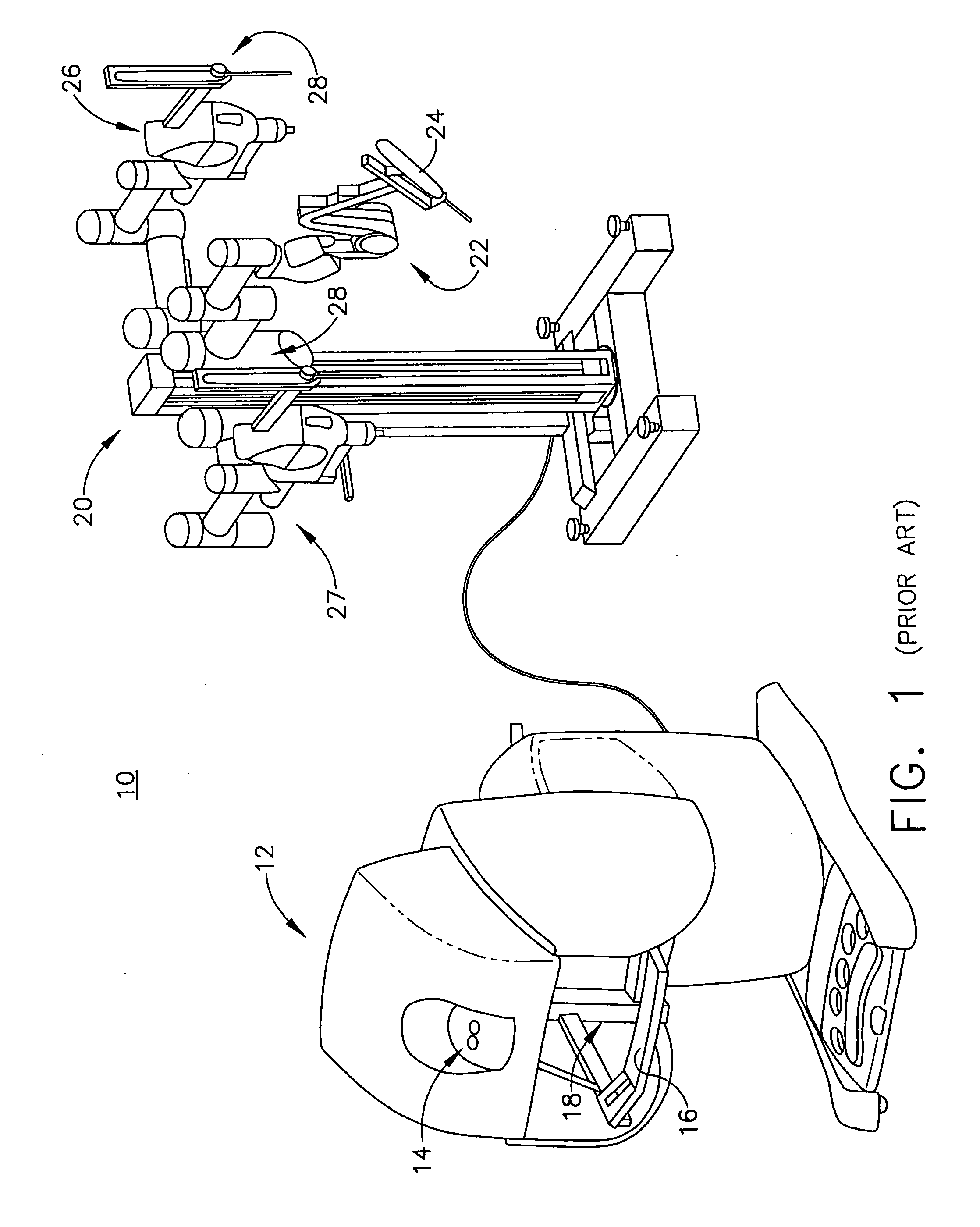

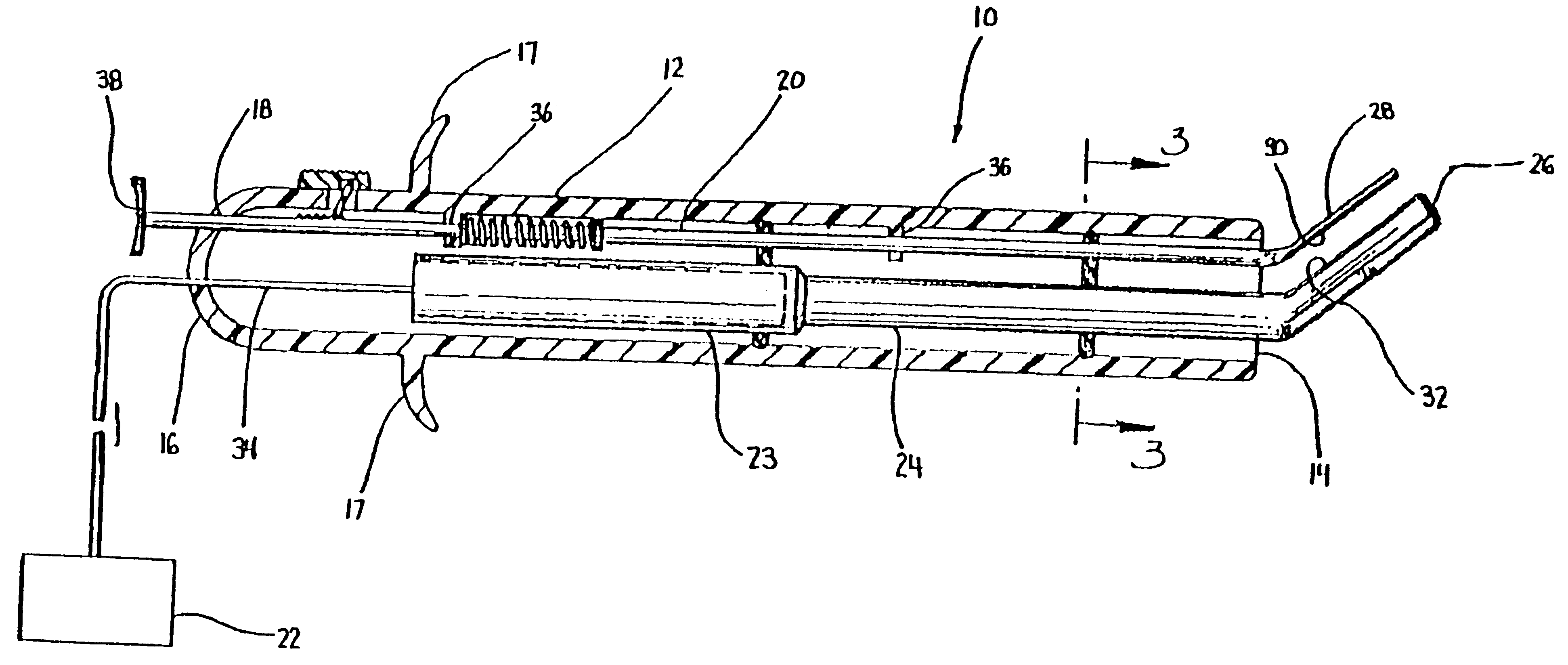

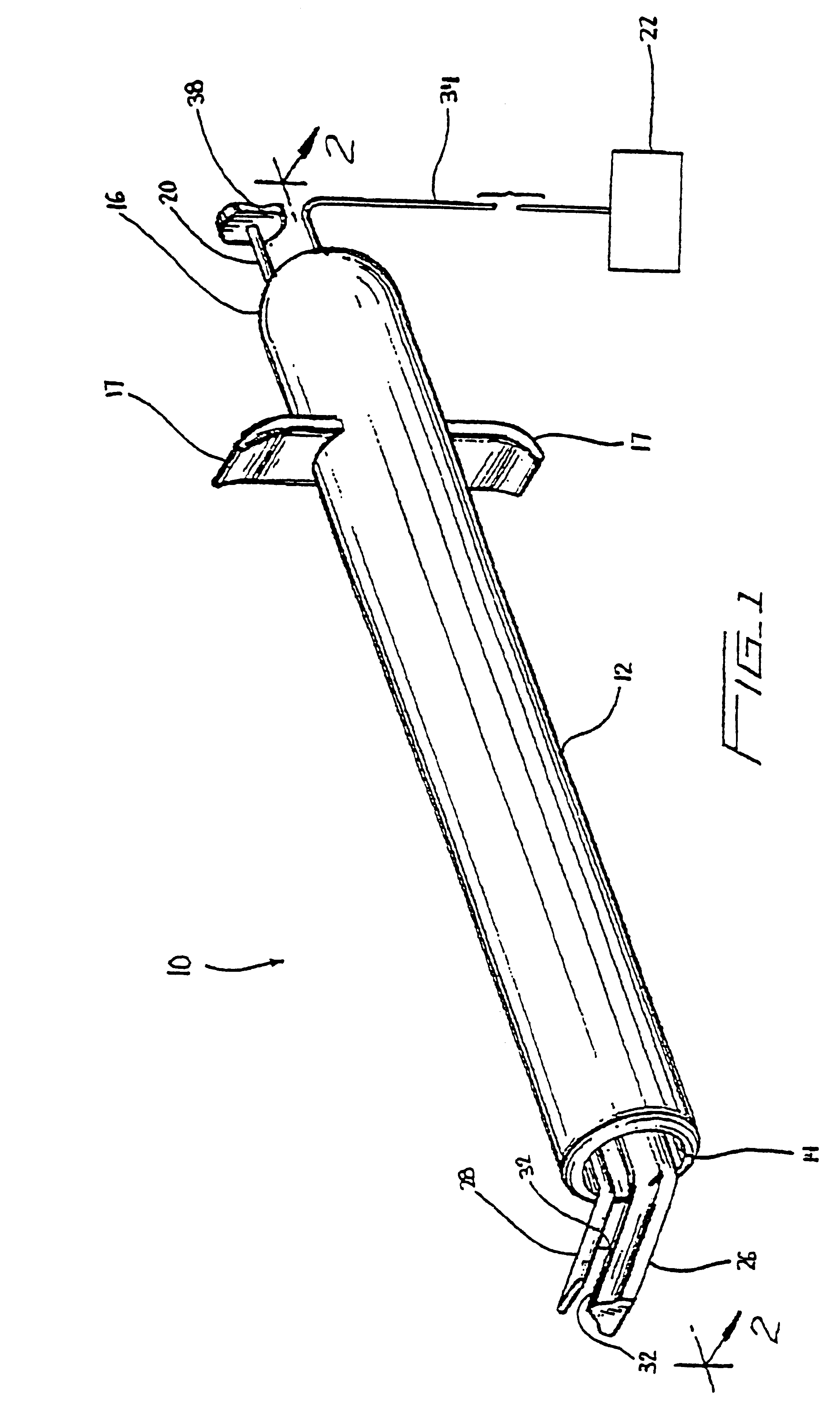

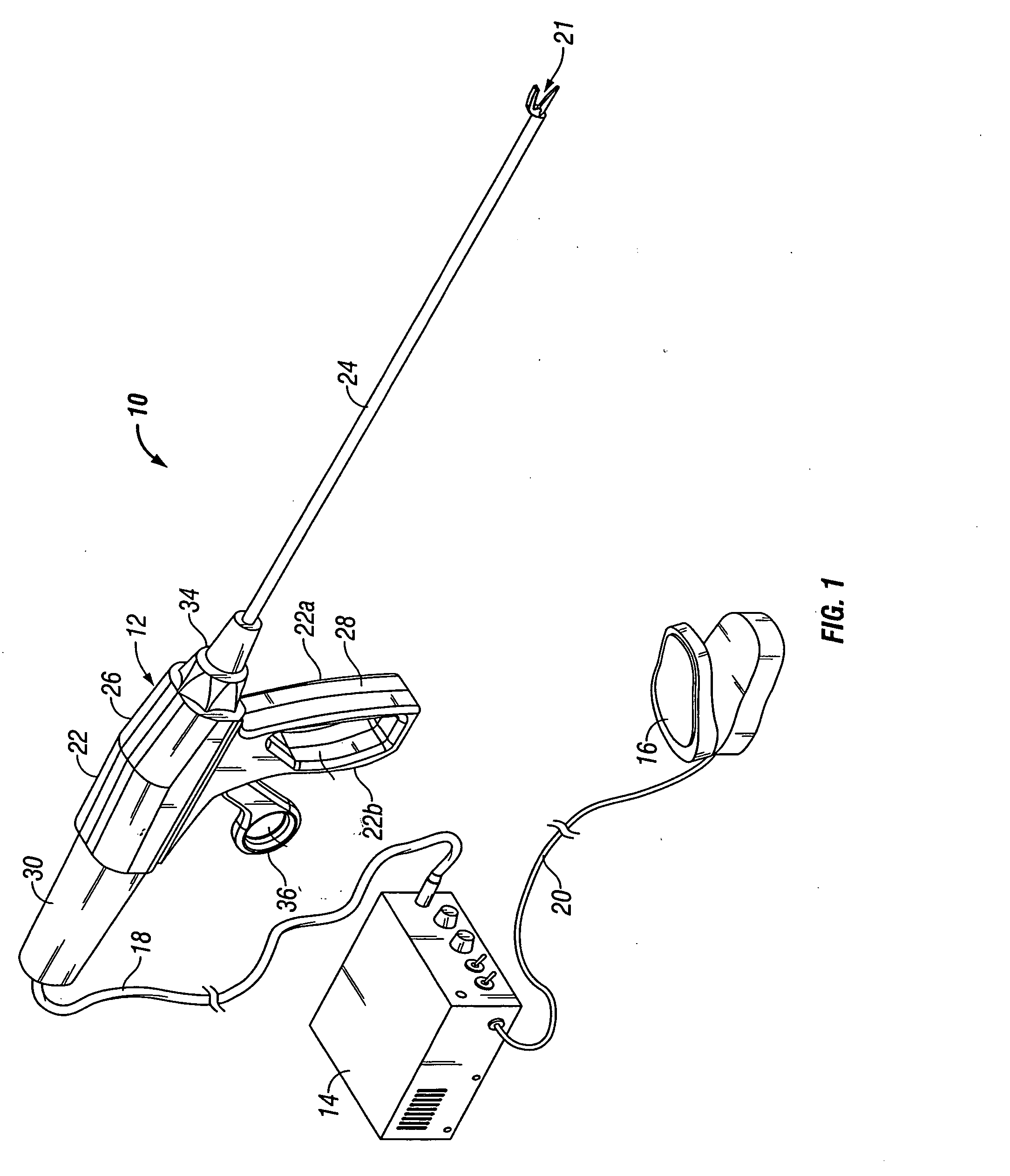

Ultrasonic surgical system and method

An ultrasonic surgical system has an ultrasonic unit including an instrument operatively connected to an ultrasonic generator, wherein the instrument has an ultrasonic end effector on the distal end of a shaft. The system further includes a positioning unit including a movable arm adapted for releasably holding the instrument, whereby an operator may direct the positioning unit to position the end effector at a surgical site inside a body cavity of a patient for performing a plurality of surgical tasks. The system further includes a control unit operatively connected to the ultrasonic and positioning units, wherein the control unit is programmable with a surgical subroutine for performing the surgical tasks. The system further includes a user interface operatively connected to the control unit for initiating an operative cycle of the surgical subroutine such that the surgical tasks are automatically performed during the operative cycle.

Owner:CILAG GMBH INT

Method for detecting transverse mode vibrations in an ultrasonic hand piece/blade

InactiveUS6588277B2Low costRecuperation increasedVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesResonanceEngineering

A method for detecting transverse mode vibrations in an ultrasonic hand piece / blade for determining the existence of unwanted vibration in the hand piece / blade. A tracking filter centered at the drive frequency of the generator, is used to monitor the drive frequency of the ultrasonic generator and attenuate the drive signal when it exceeds a predetermined level. The tracking filter has a wide pass band. Alternatively, a tracking filter having a pass band which is divided into several regions is used to avoid other longitudinal resonances, such as a resonance at a second harmonic, or other spectral features that would otherwise detract from the tracking accuracy of the filter.

Owner:ETHICON ENDO SURGERY INC

Ultrasonic surgical system and method

ActiveUS20070239028A1Automatically performUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsSurgical operationSurgical site

An ultrasonic surgical system has an ultrasonic unit including an instrument operatively connected to an ultrasonic generator, wherein the instrument has an ultrasonic end effector on the distal end of a shaft. The system further includes a positioning unit including a movable arm adapted for releasably holding the instrument, whereby an operator may direct the positioning unit to position the end effector at a surgical site inside a body cavity of a patient for performing a plurality of surgical tasks. The system further includes a control unit operatively connected to the ultrasonic and positioning units, wherein the control unit is programmable with a surgical subroutine for performing the surgical tasks. The system further includes a user interface operatively connected to the control unit for initiating an operative cycle of the surgical subroutine such that the surgical tasks are automatically performed during the operative cycle.

Owner:CILAG GMBH INT

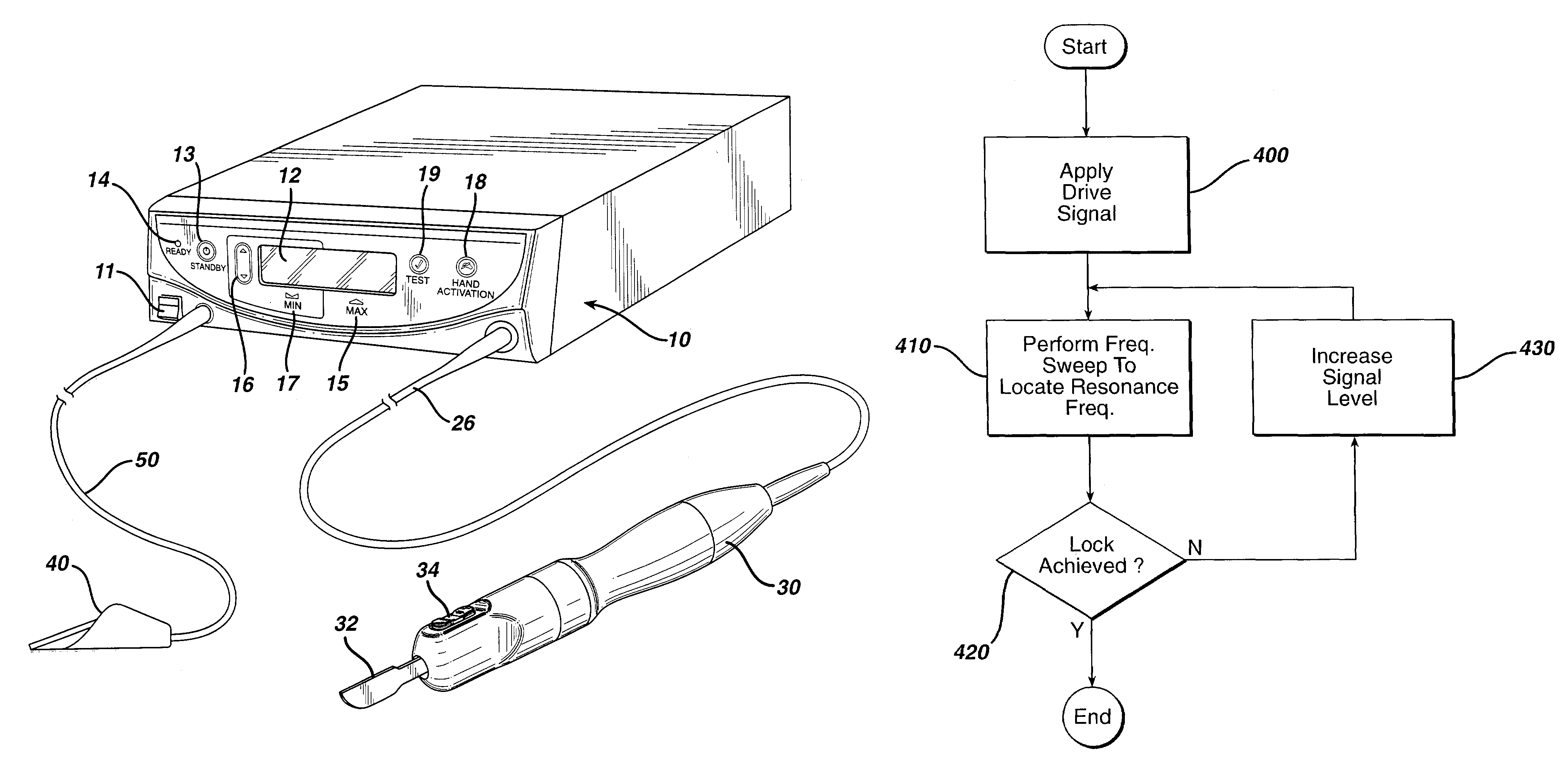

Method for driving an ultrasonic system to improve acquisition of blade resonance frequency at startup

InactiveUS7179271B2Increase load capacityImprove abilitiesSurgeryElectrical measurementsDriving currentResonance

The ability of an ultrasonic system to sweep and lock onto a resonance frequency of a blade subjected to a heavy load at startup is improved by applying a high drive voltage or a high drive current while systematically increasing the level of the applied signal. Increasing the drive signal to the hand piece results in an improved and more pronounced “impedance spectrum.” That is, under load, the increased drive signal causes the maximum phase margin to become higher and the minimum / maximum impedance magnitude to become more pronounced. Increasing the excitation drive signal to the hand piece / blade at startup significantly alleviates the limiting factors associated with ultrasonic generators, which results in an increase of the maximum load capability at startup.

Owner:ETHICON ENDO SURGERY INC

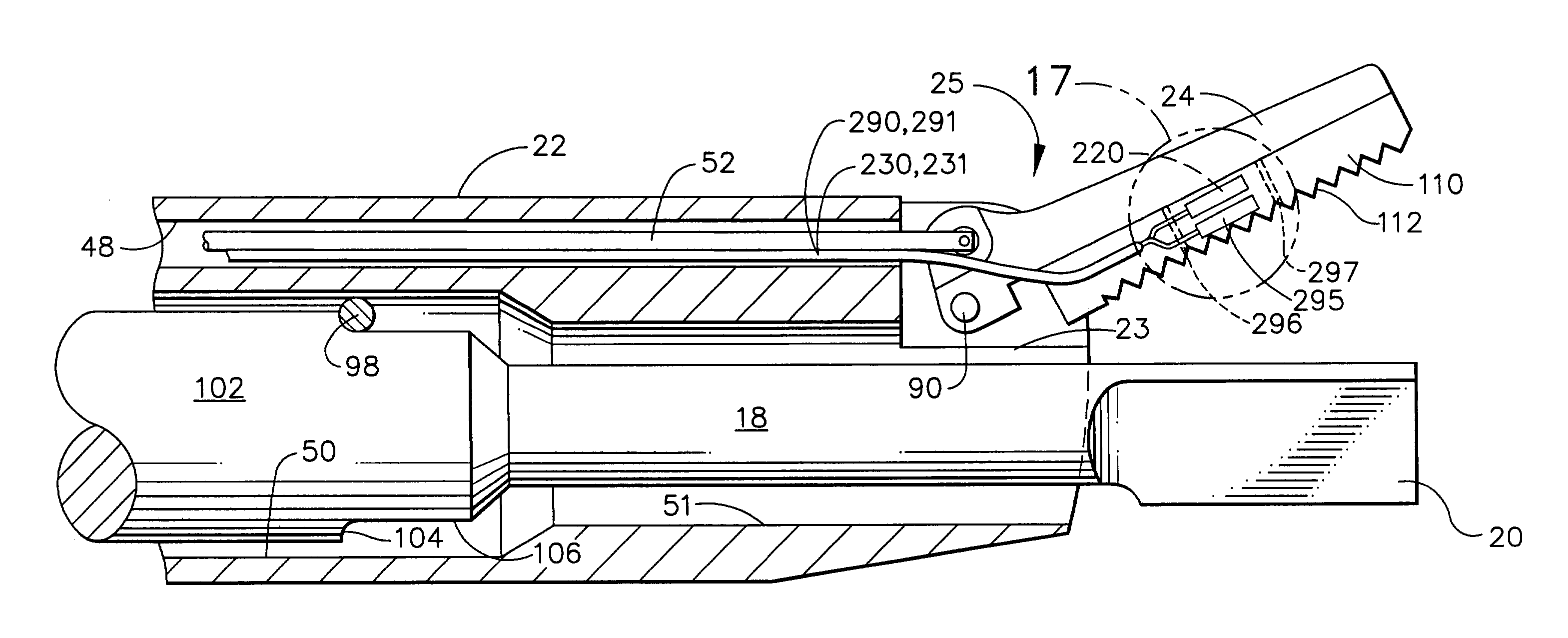

Ultrasonic dissector

InactiveUS6869439B2Smooth connectionImprove instrument performanceSurgical forcepsEngineeringSurgical department

An ultrasonic surgical instrument for dissection and coagulation of tissue is provided. The surgical instrument includes a vibration coupler supported within a housing and operably connected to an ultrasonic generator. An angled blade member is connected to the distal end of the vibration coupler to conduct high frequency vibration from the ultrasonic generator to the blade member. A clamp member is positioned adjacent to the blade member and is movable from a first position to a second approximated position. The clamp member and angled blade member combine to enhance contact between the tissue and the blade member during operation of the instrument to improve the performance of the instrument.

Owner:UNITED STATES SURGICAL CORP +1

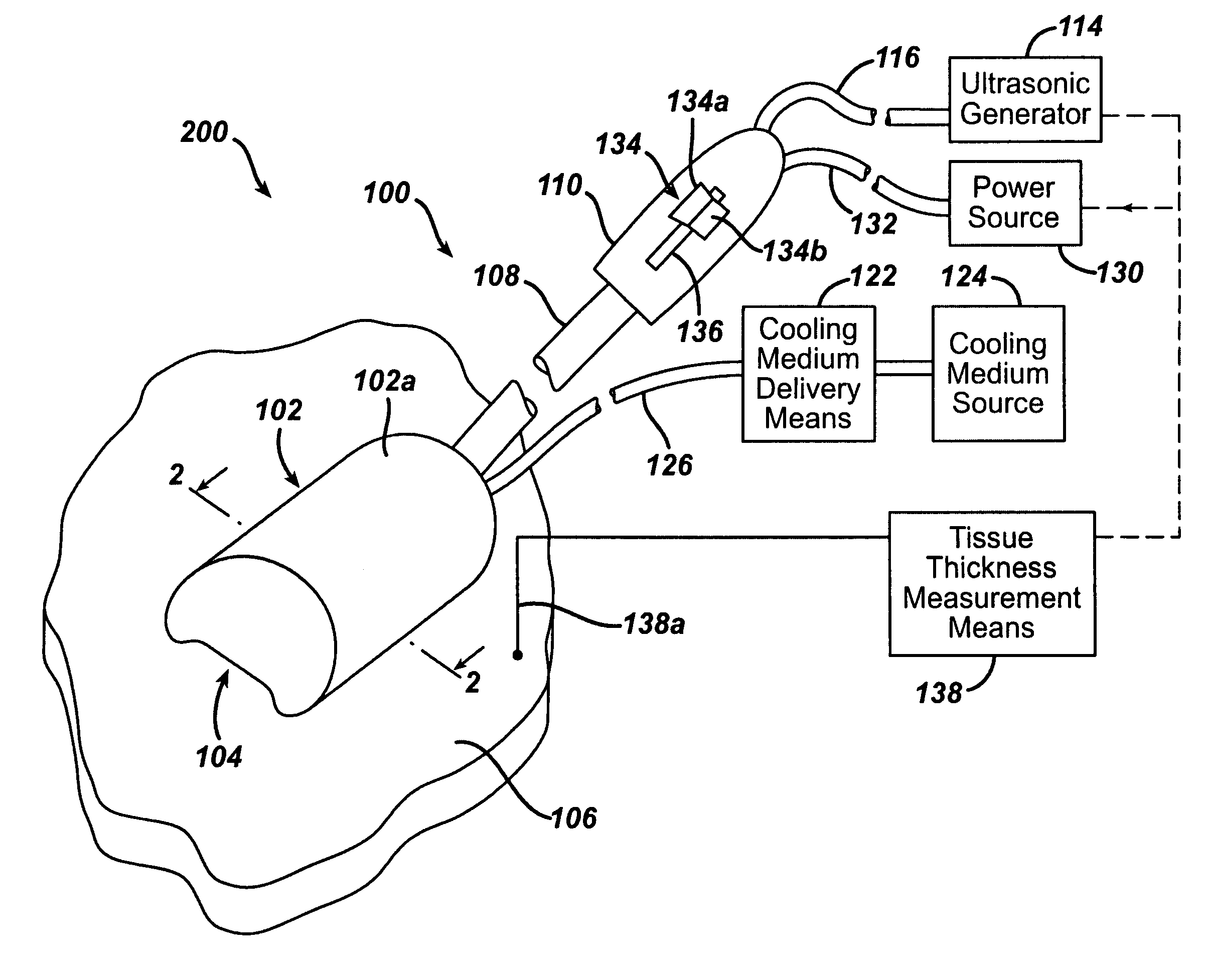

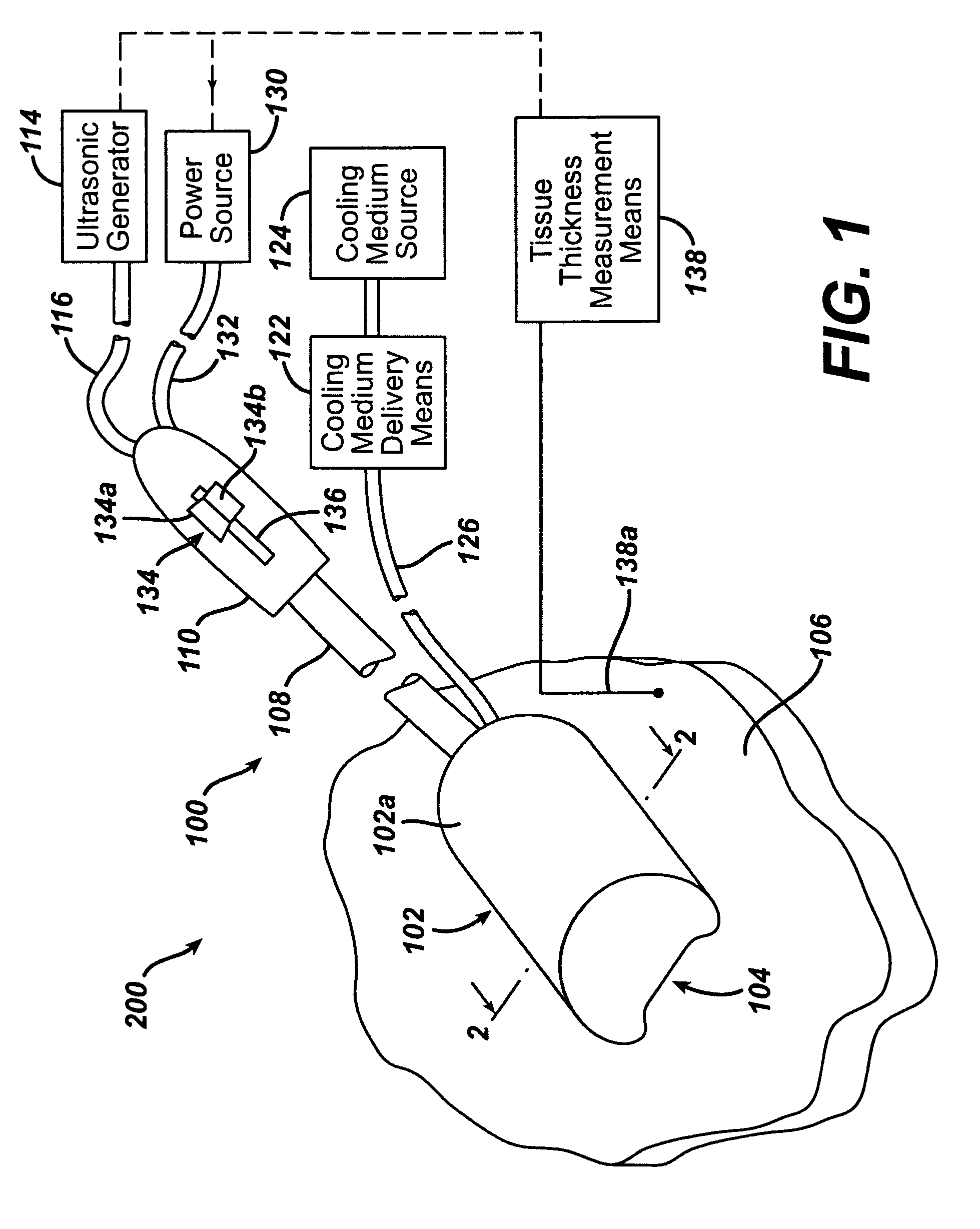

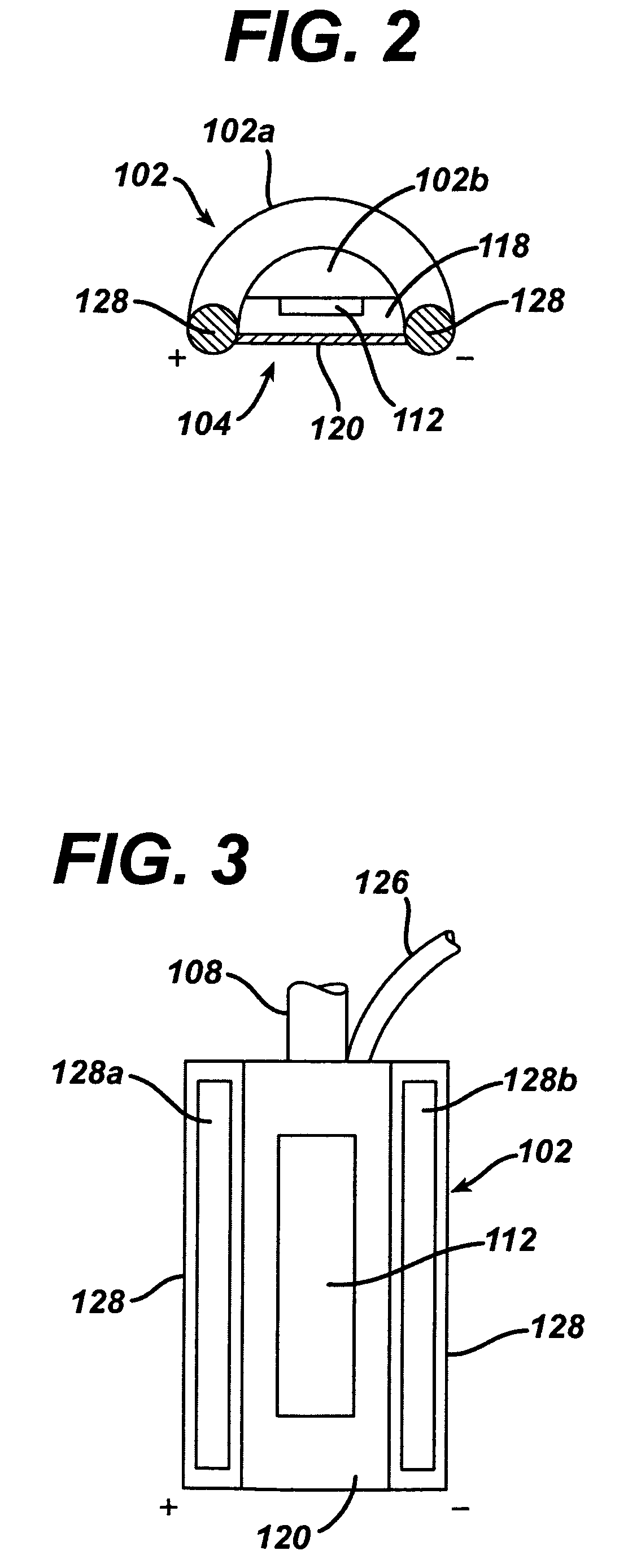

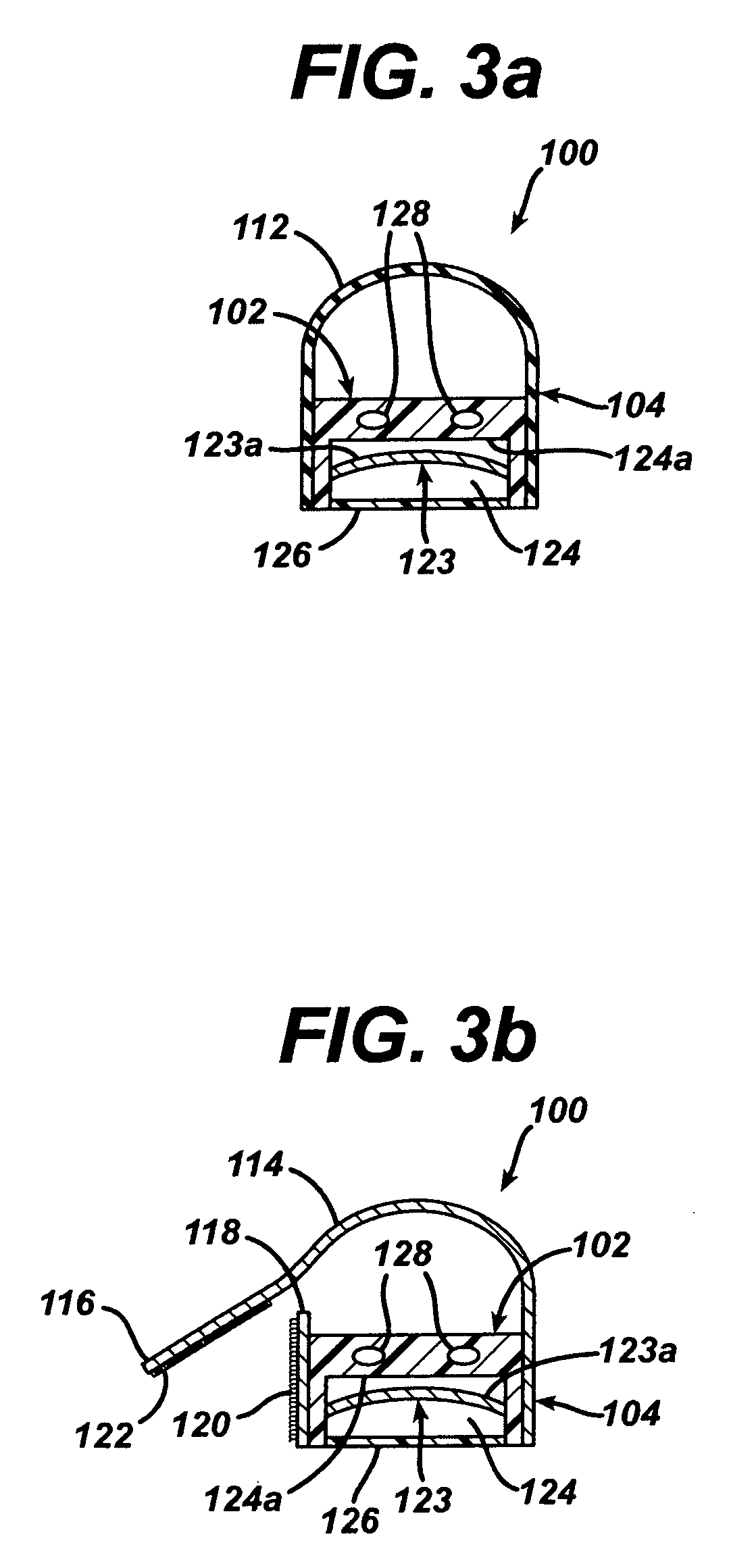

Multi-modality ablation device

ActiveUS7074218B2Minimum activation timeEffects damageUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyRadio frequencyUltrasound energy

An instrument for ablation of tissue. The instrument including: a body having at least one surface for contacting a tissue surface, the at least one surface being substantially planar; an ultrasonic transducer disposed in the body for generating ultrasonic energy and directing at least a portion of the ultrasonic energy to the tissue surface, the ultrasonic transducer being operatively connected to an ultrasonic generator; at least one radio-frequency electrode disposed on the at least one surface for directing radio frequency energy to the tissue surface, the at least one radio-frequency electrode being operatively connected to a power source; and one or more switches for selectively coupling at least one of the ultrasonic transducer to the ultrasonic generator and the at least one radio-frequency electrode to the power source.

Owner:ETHICON INC

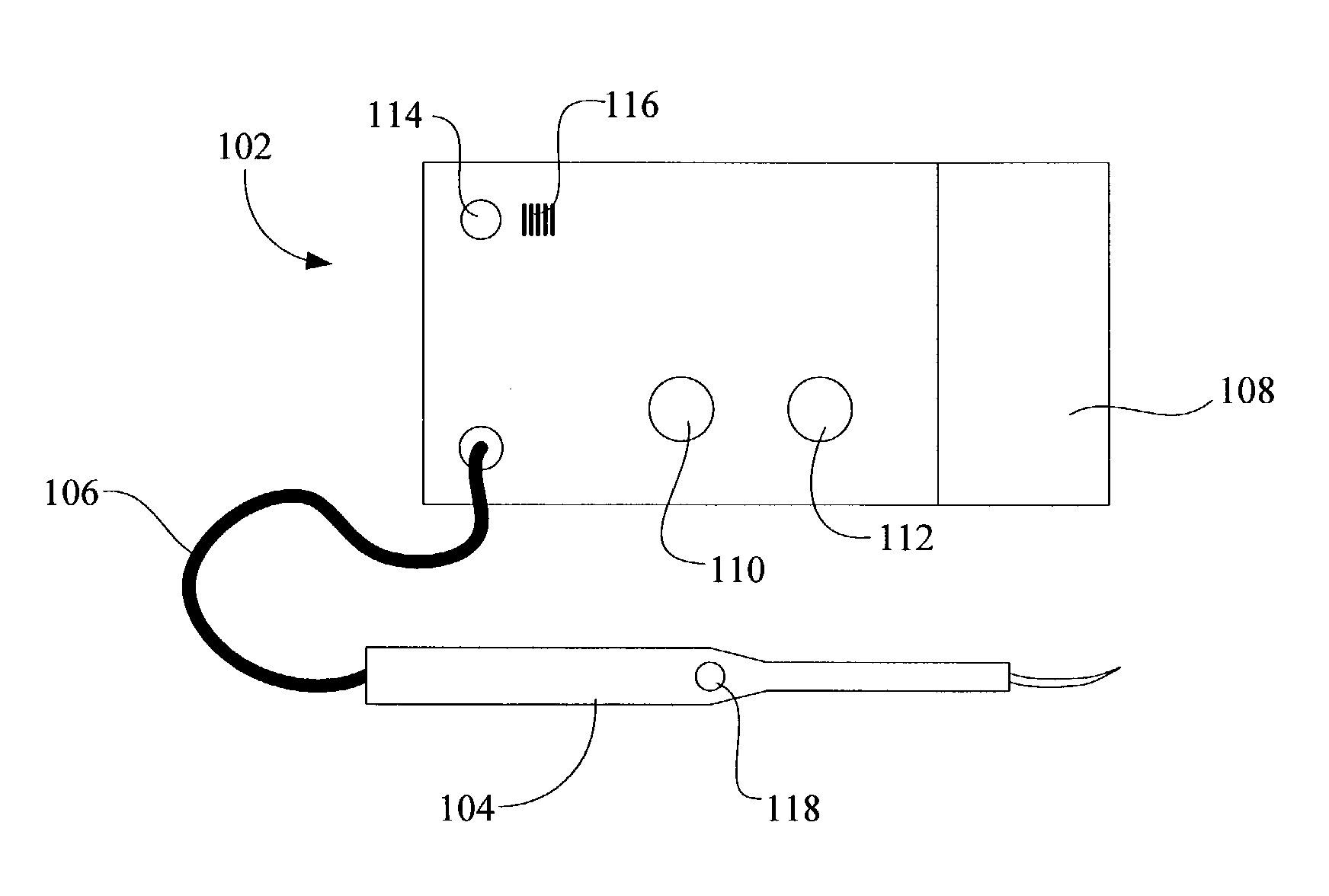

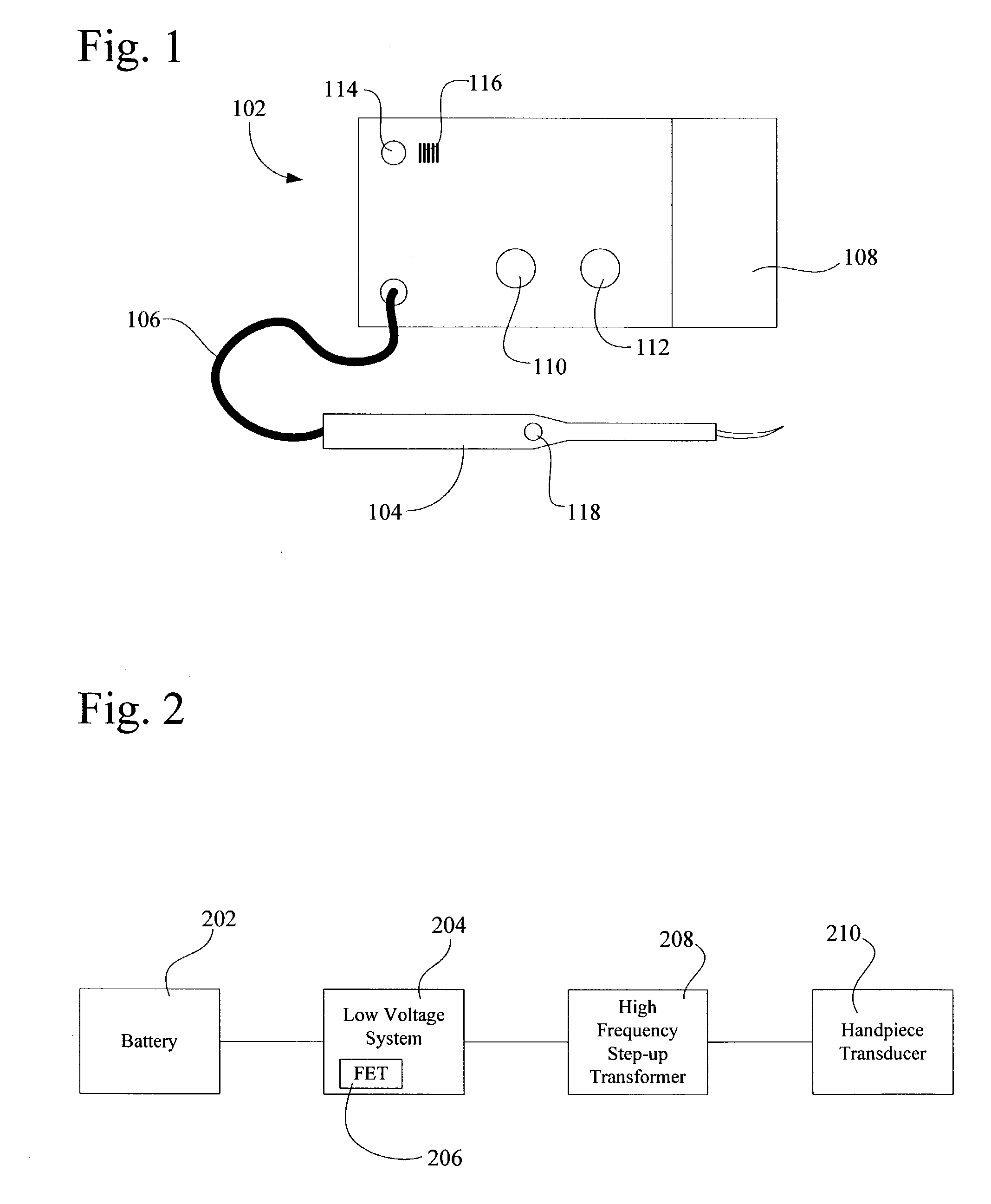

Portable ultrasonic scalpel/cautery device

A portable ultrasonic scalpel / cautery device is disclosed. According to one embodiment of the present invention, the ultrasonic surgical instrument includes a low voltage battery-powered ultrasonic generator and a handheld ultrasonic surgical instrument. The battery-powered ultrasonic generator generates an ultrasonic signal having a frequency of about 55 kHz.

Owner:SONTRA MEDICAL

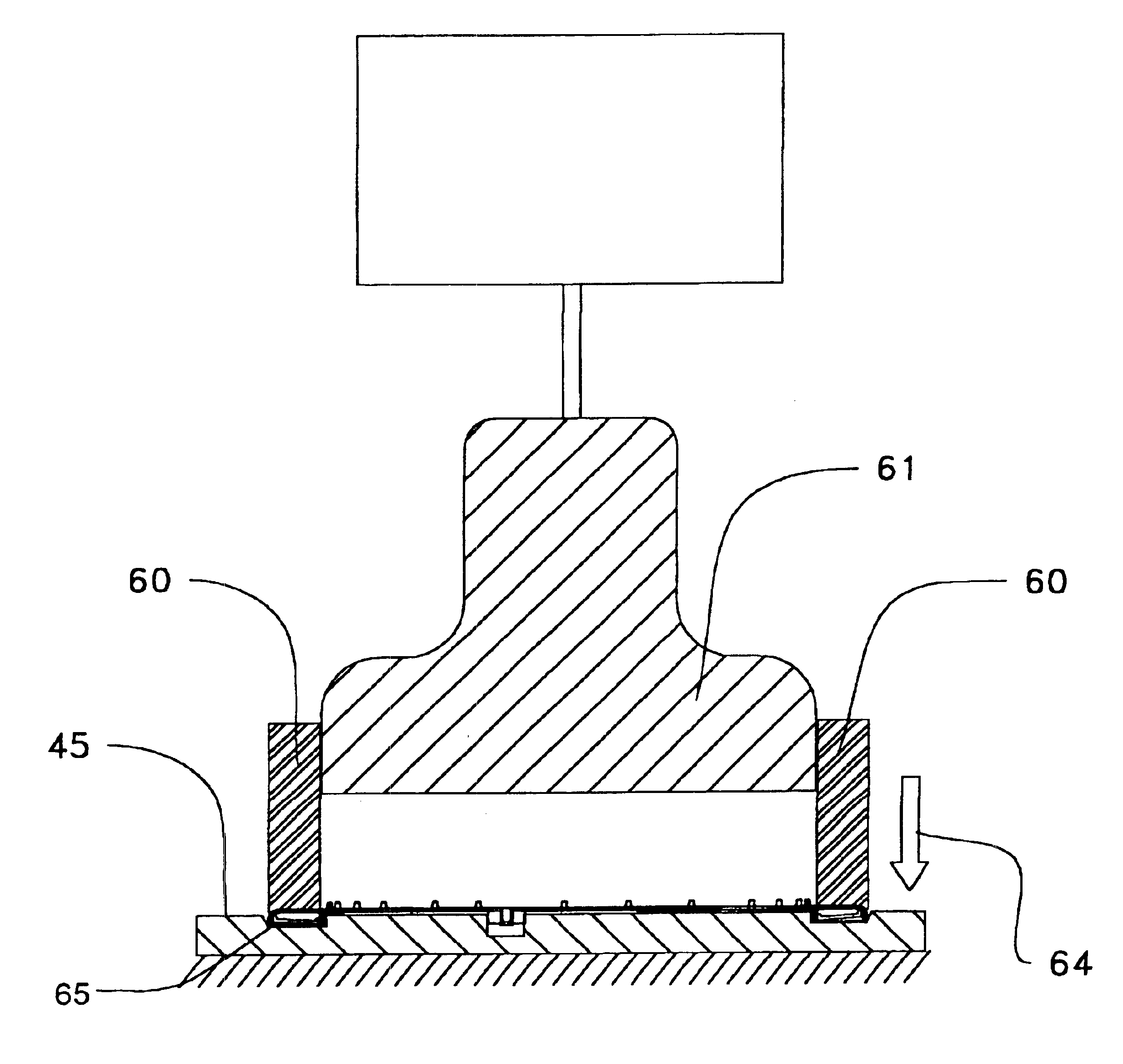

Method for assembling a package for sutures

InactiveUS6915623B2Not slowing downReduce manufacturing costSuture equipmentsSurgical needlesCounterboreUltrasonic generator

A novel method and apparatus for riveting a two-piece suture tray package. A two-piece suture tray assembly is provided having a top member and a bottom member. The top member has a top and a bottom, and plurality of rivet members extending down from the bottom of the top member. The rivet members have free ends. The bottom member has a top and a flat bottom surface, and a plurality of rivet receiving openings extending therethrough. A counterbore surrounds each rivet receiving opening in the flat bottom surface. An ultrasonic riveting apparatus is provided having a clamp member with a cavity, and an ultrasonic horn member having a flat bottom moveably mounted in the cavity. The assembly is mounted in the riveting apparatus and engaged by the clamp member. The flat bottom of the horn member engages the free ends of the rivet members, and when energized by an ultrasonic generator, causes the free ends of the rivet members to deform into the counterbores, such that the free ends are flat and in alignment with the bottom surface of the bottom member.

Owner:ETHICON INC

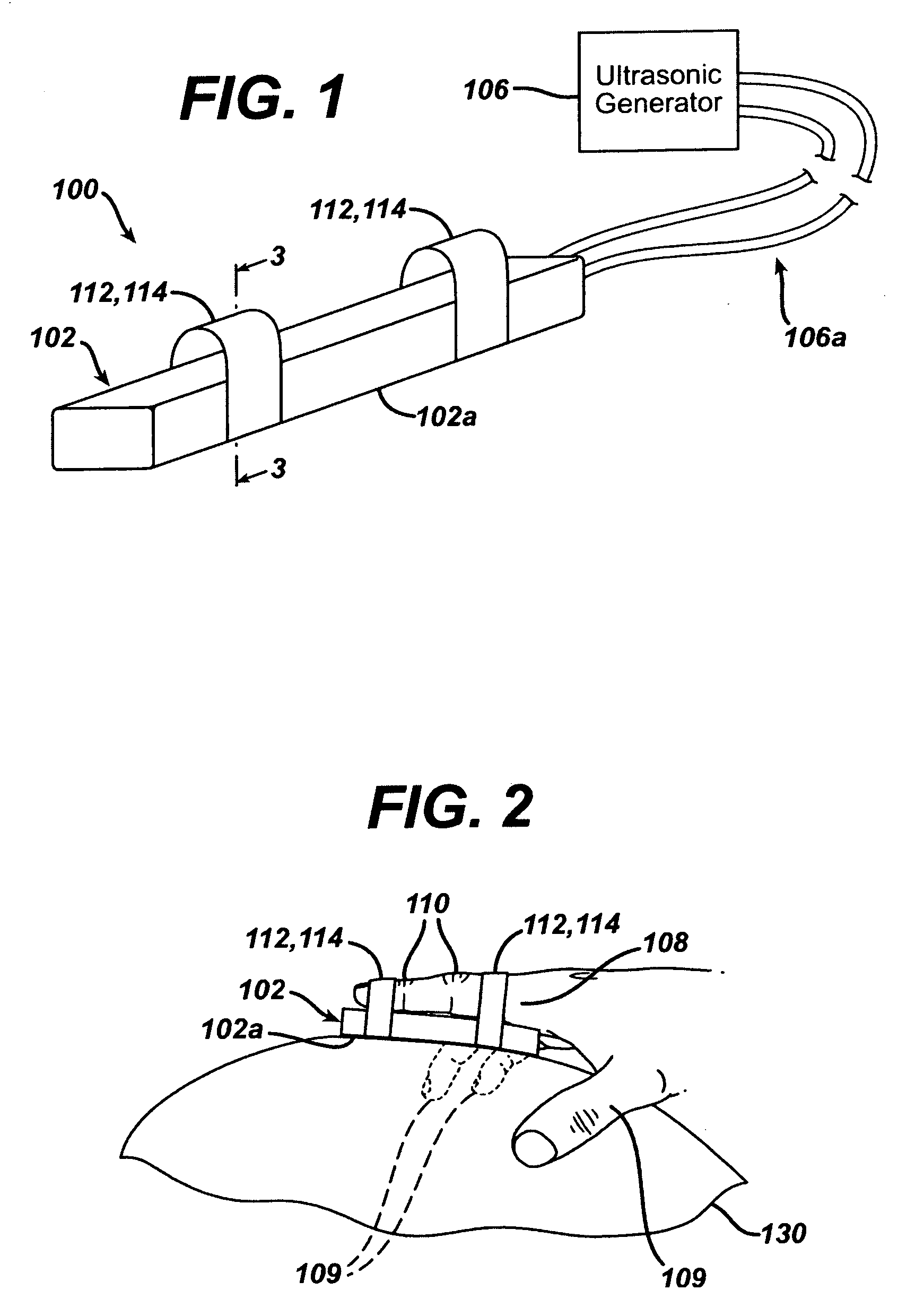

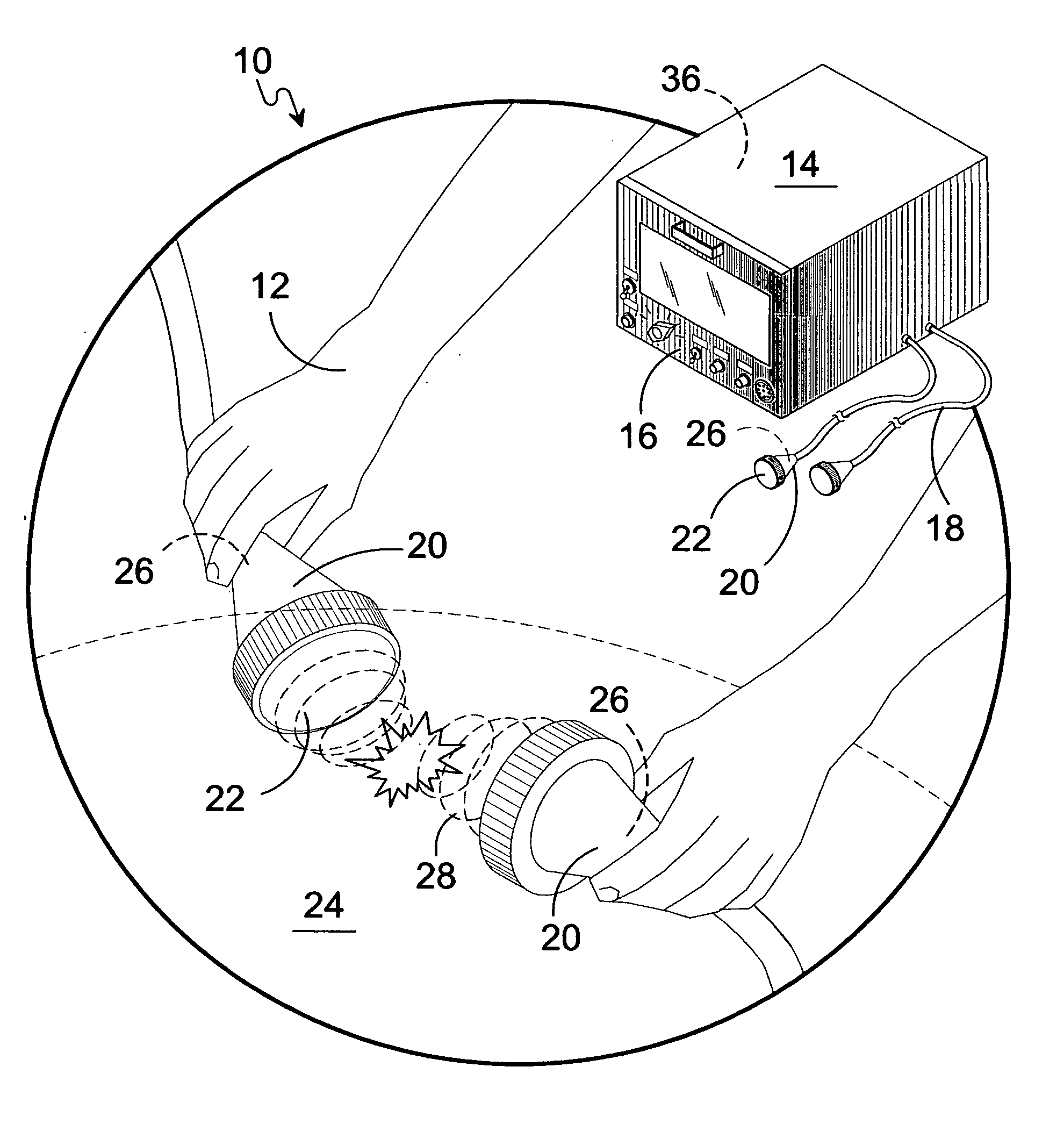

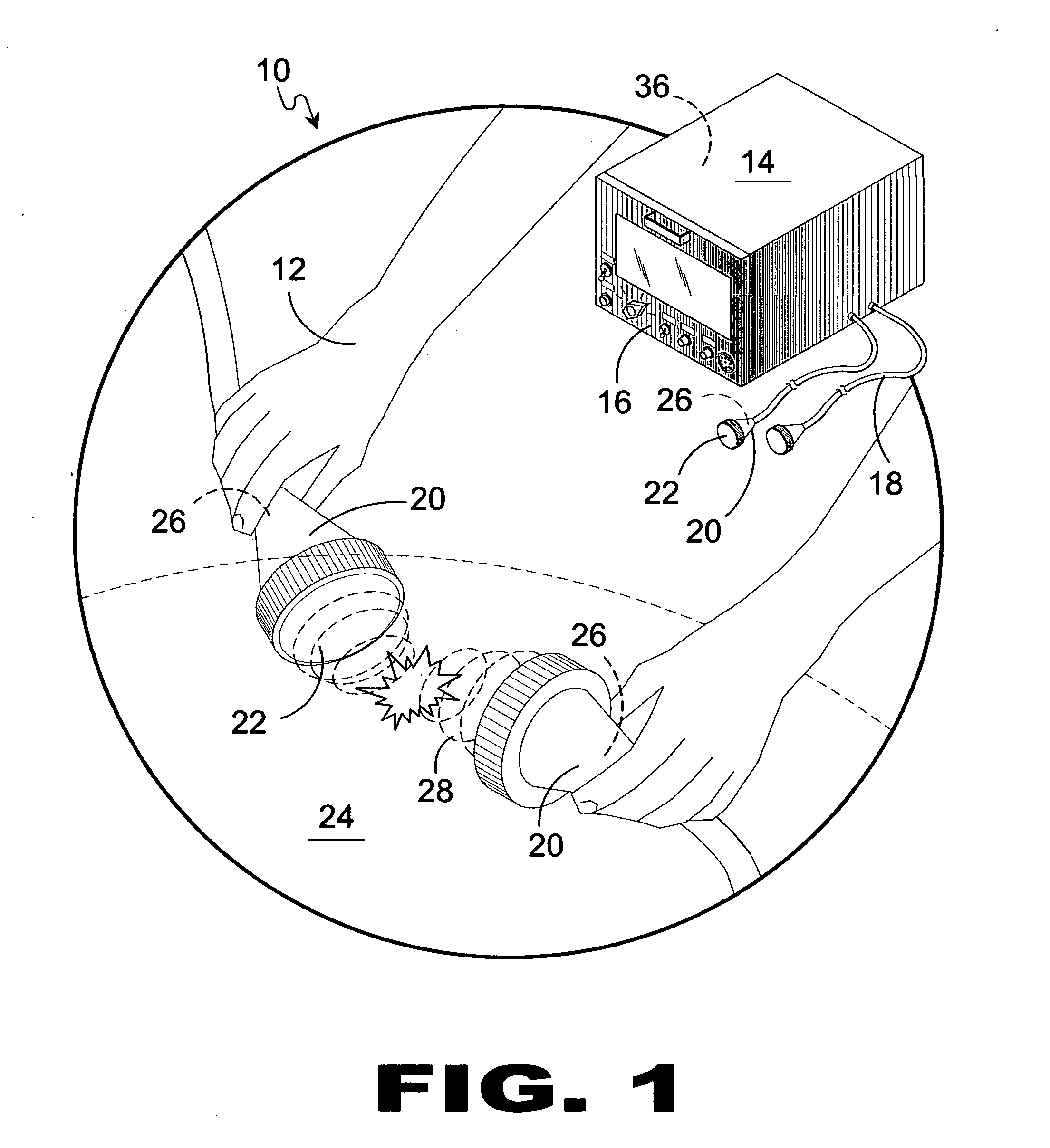

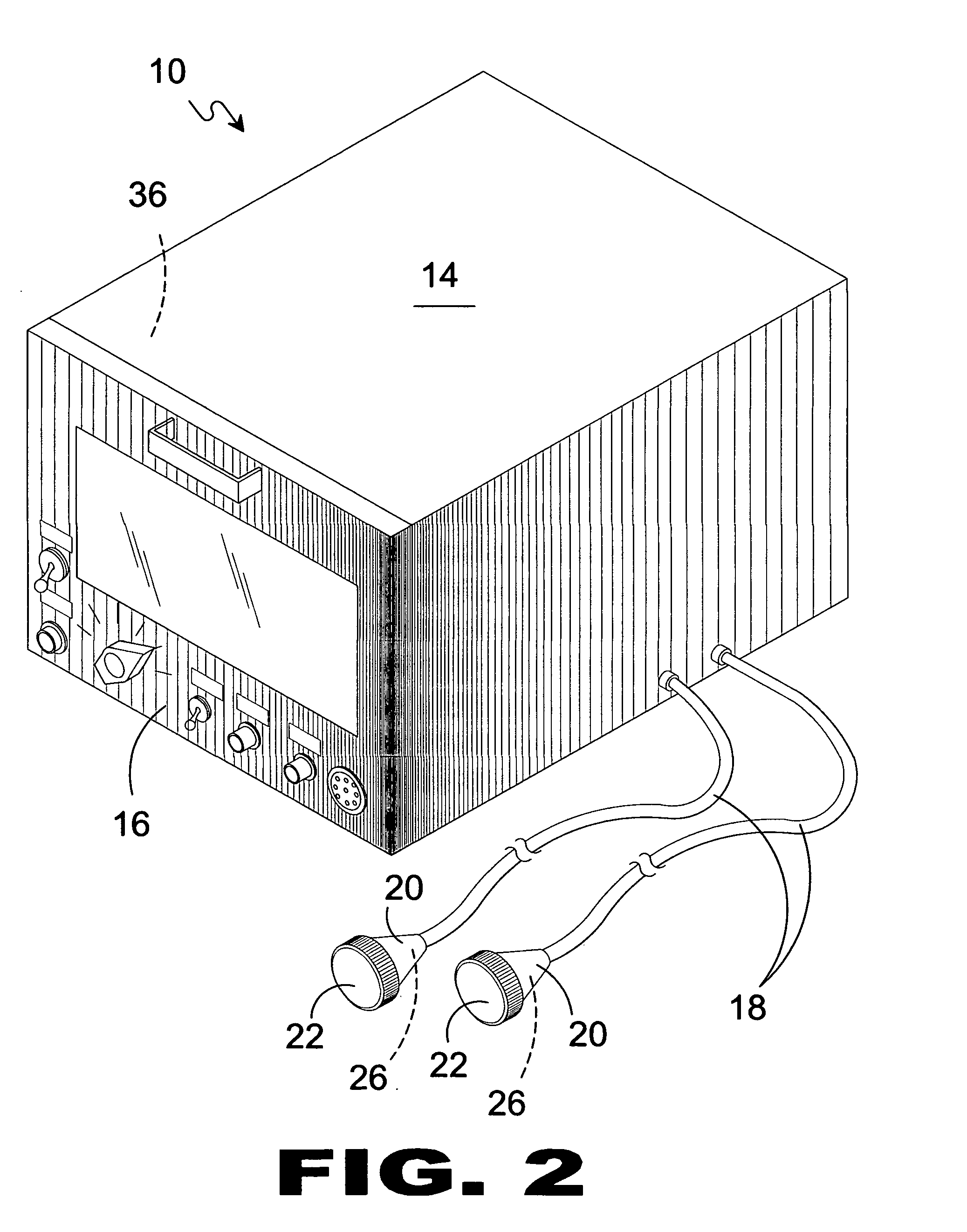

Ultrasonic finger probe

An ultrasonic finger probe including: a body having an ultrasonic transducer disposed therein, the ultrasonic transducer being operatively connected to an ultrasonic generator; and a securing device for securing the body to one or more fingers of an operator.

Owner:ETHICON INC

Ultrasonic probe deflection sensor

An ultrasonic surgical instrument having a deflection detection circuit is disclosed. The instrument includes an ultrasonic probe configured to conduct electricity and positioned a predetermined distance from one or more tubes. The ultrasonic probe is adapted to be operatively connected to an ultrasonic generator for vibration. The instrument also includes a deflection detection circuit having a secondary power source and an indicator, the power source is configured to supply electrical current to the tube, the probe, and the indicator, wherein the circuit is configured to close in response to the probe contacting the tube when the probe is deflected toward the tube thereby activating the indicator.

Owner:TYCO HEALTHCARE GRP LP

Low energy or minimum disturbance method for measuring frequency response functions of ultrasonic surgical devices in determining optimum operating point

ActiveUS8207651B2Ultrasound therapyPiezoelectric/electrostriction/magnetostriction machinesOperating pointEngineering

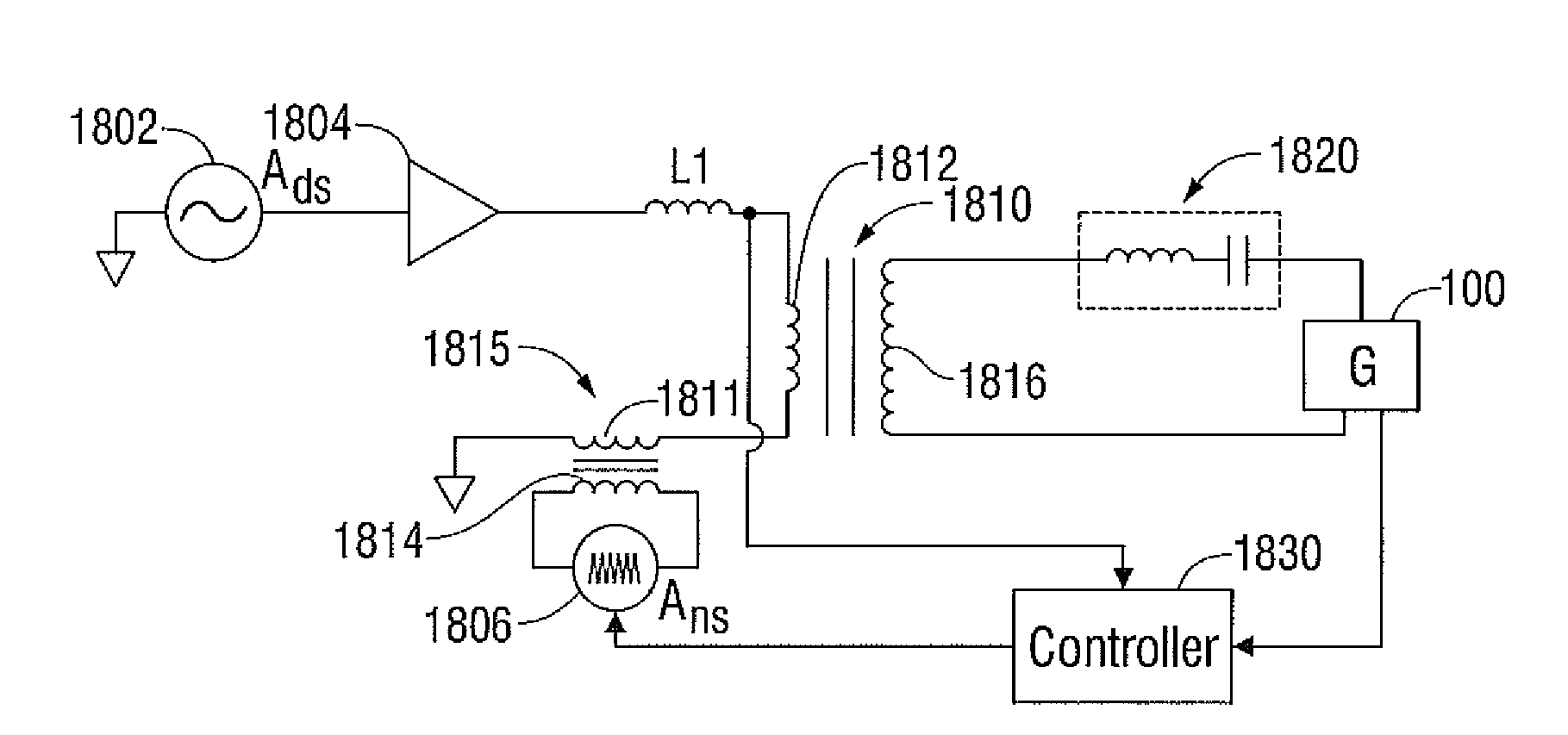

An ultrasonic system is provided that includes an ultrasonic device having an elongated member configured to impart ultrasonic energy to tissue and a resonator configured to impart a frequency to the elongated member. The system also includes an ultrasonic generator configured to supply power to the resonator of the ultrasonic device. The ultrasonic generator has a drive signal generator configured to provide a drive signal, a noise signal generator configure to provide a noise signal, and a controller. The controller receives an output signal from the ultrasonic device and the noise signal from the noise signal generator, calculates a transfer function based on the output signal and the noise signal, and adjusts the drive signal generator based on the calculated transfer function.

Owner:COVIDIEN LP

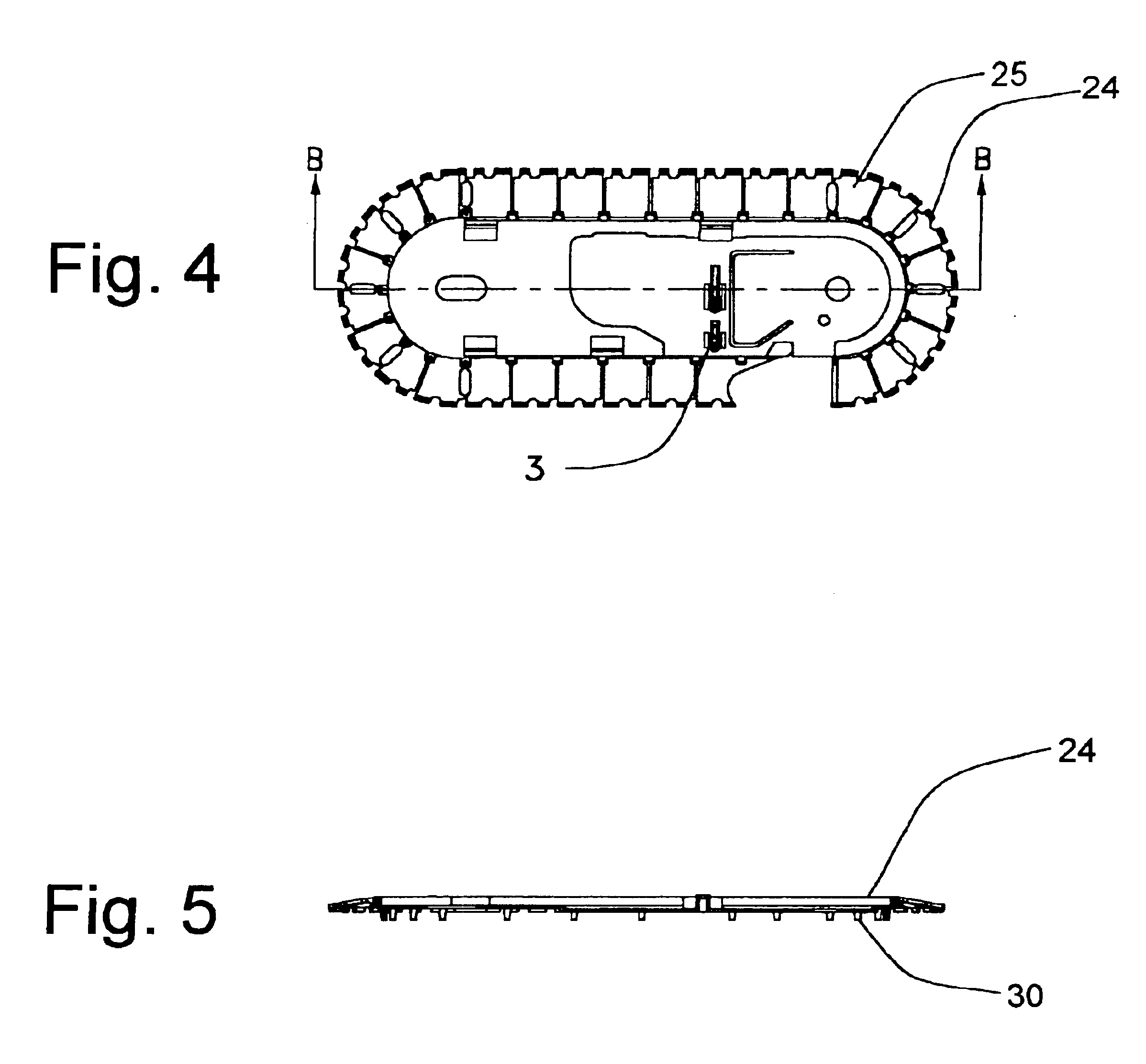

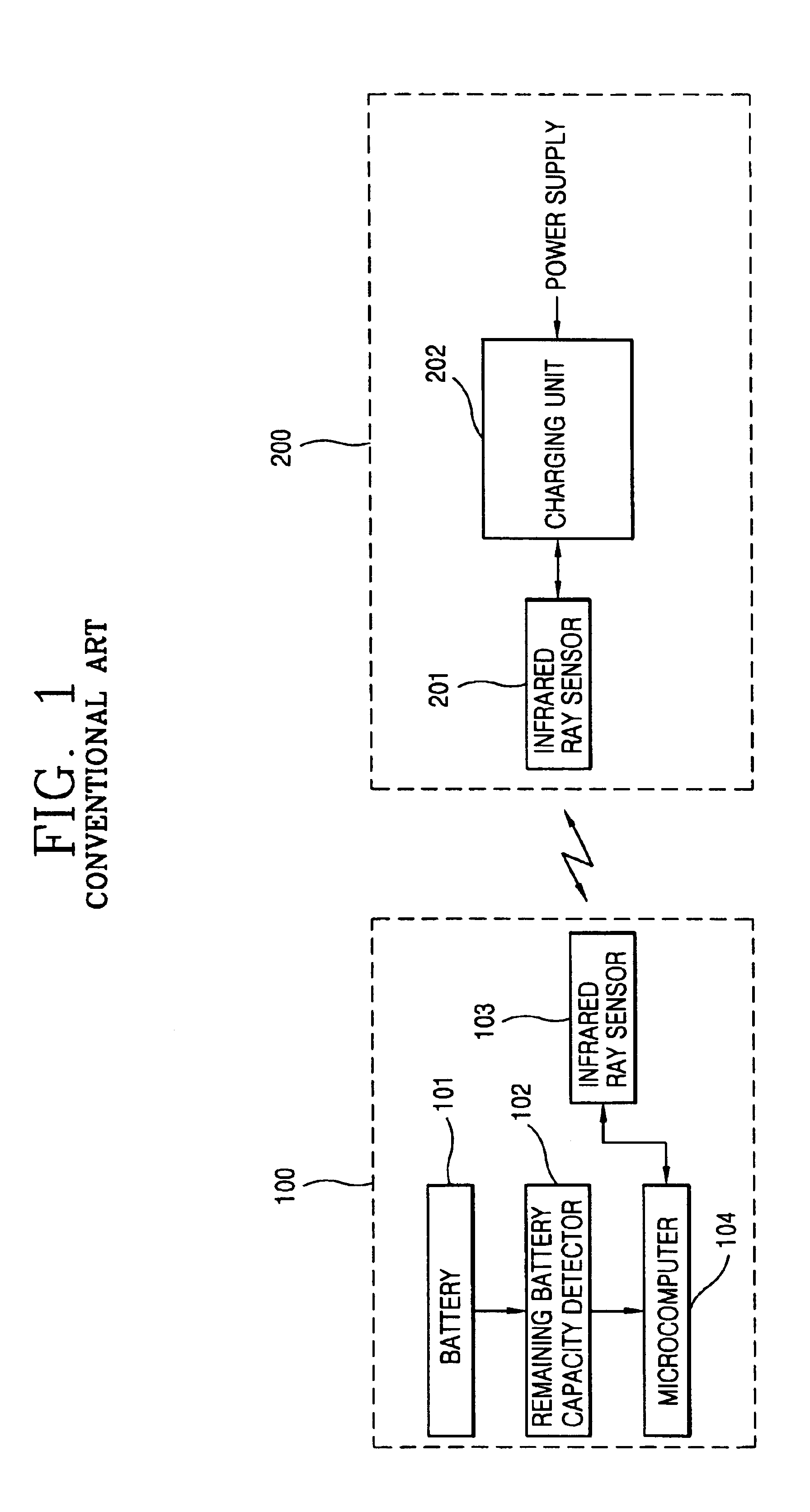

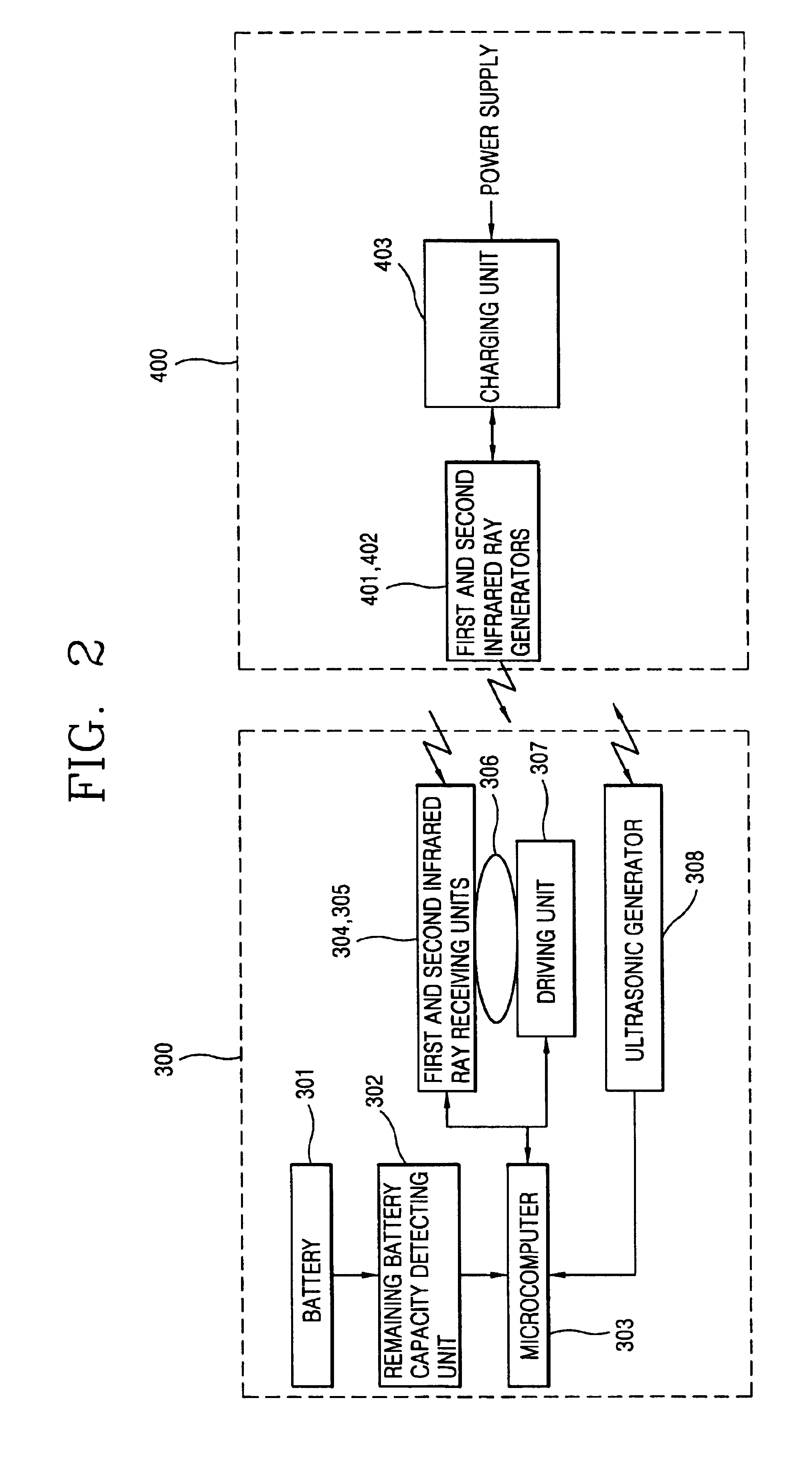

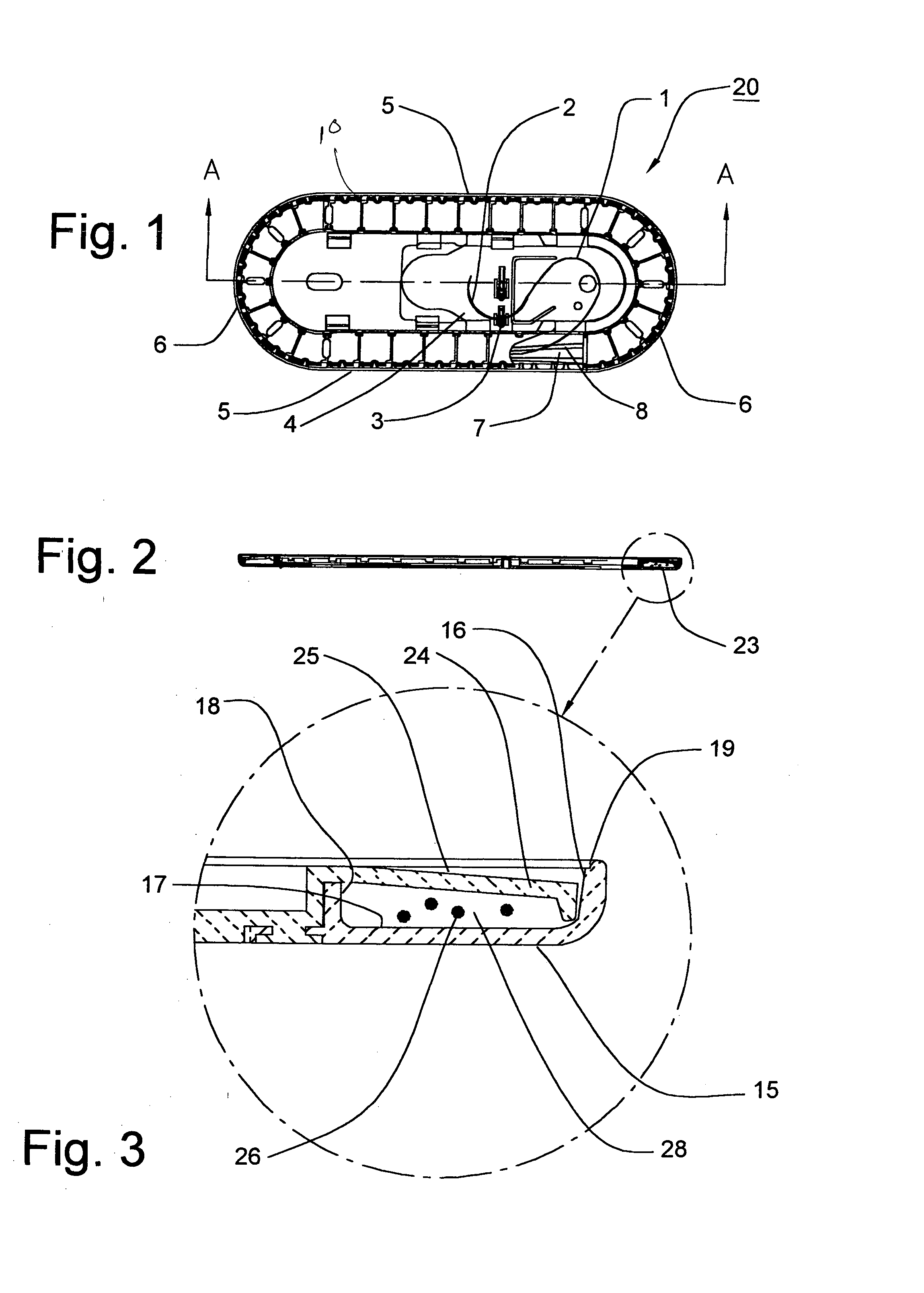

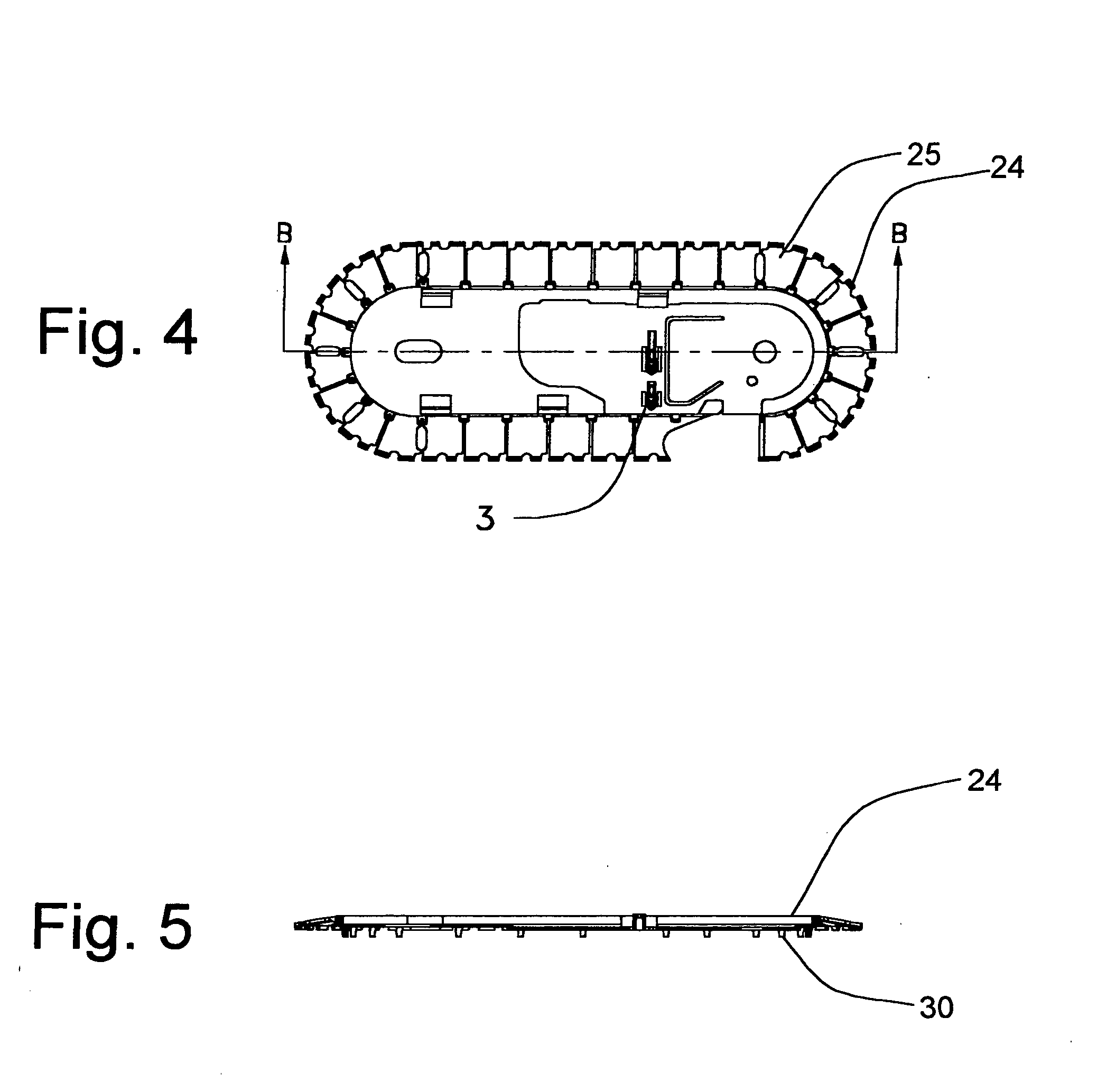

Automatic charging system and method of robot cleaner

ActiveUS6859010B2Accurately and quickly moveAccurately and quickly connectBatteries circuit arrangementsCleaning equipmentInfraredMicrocomputer

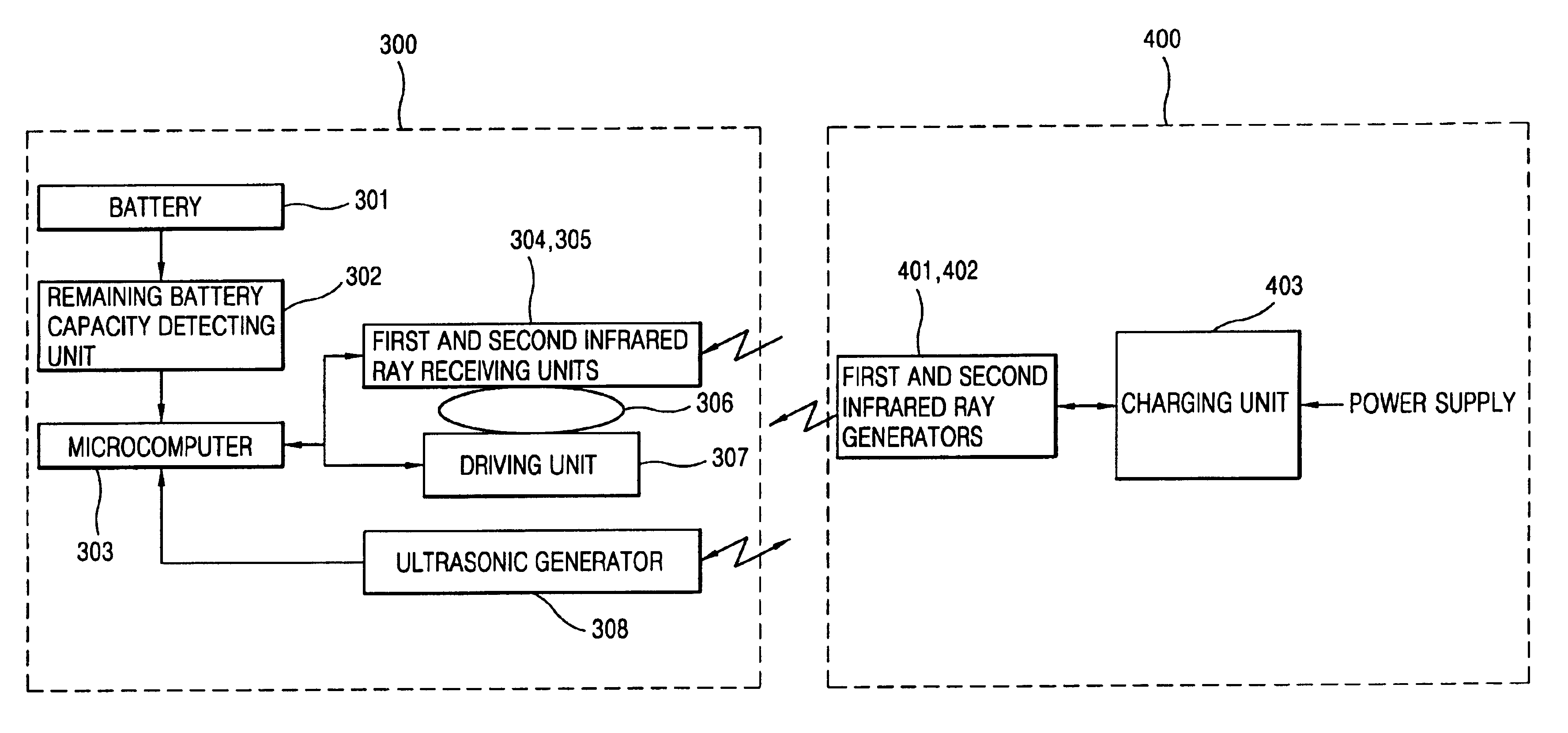

An automatic charging system of a robot cleaner includes: a rotating plate installed at a robot cleaner; an infrared ray receiving unit mounted at the rotating plate and receiving an infrared signal generated from a power supply unit while being rotated; a microcomputer for moving the robot cleaner to the power supply unit on the basis of the received infrared signal; and an ultrasonic generator for generating a stop signal when the robot cleaner nears to the power supply unit. A robot cleaner can be accurately and quickly moved to a power supply unit for a rapid charging operation, and a cost for implementing the robot cleaner can be reduced.

Owner:LG ELECTRONICS INC

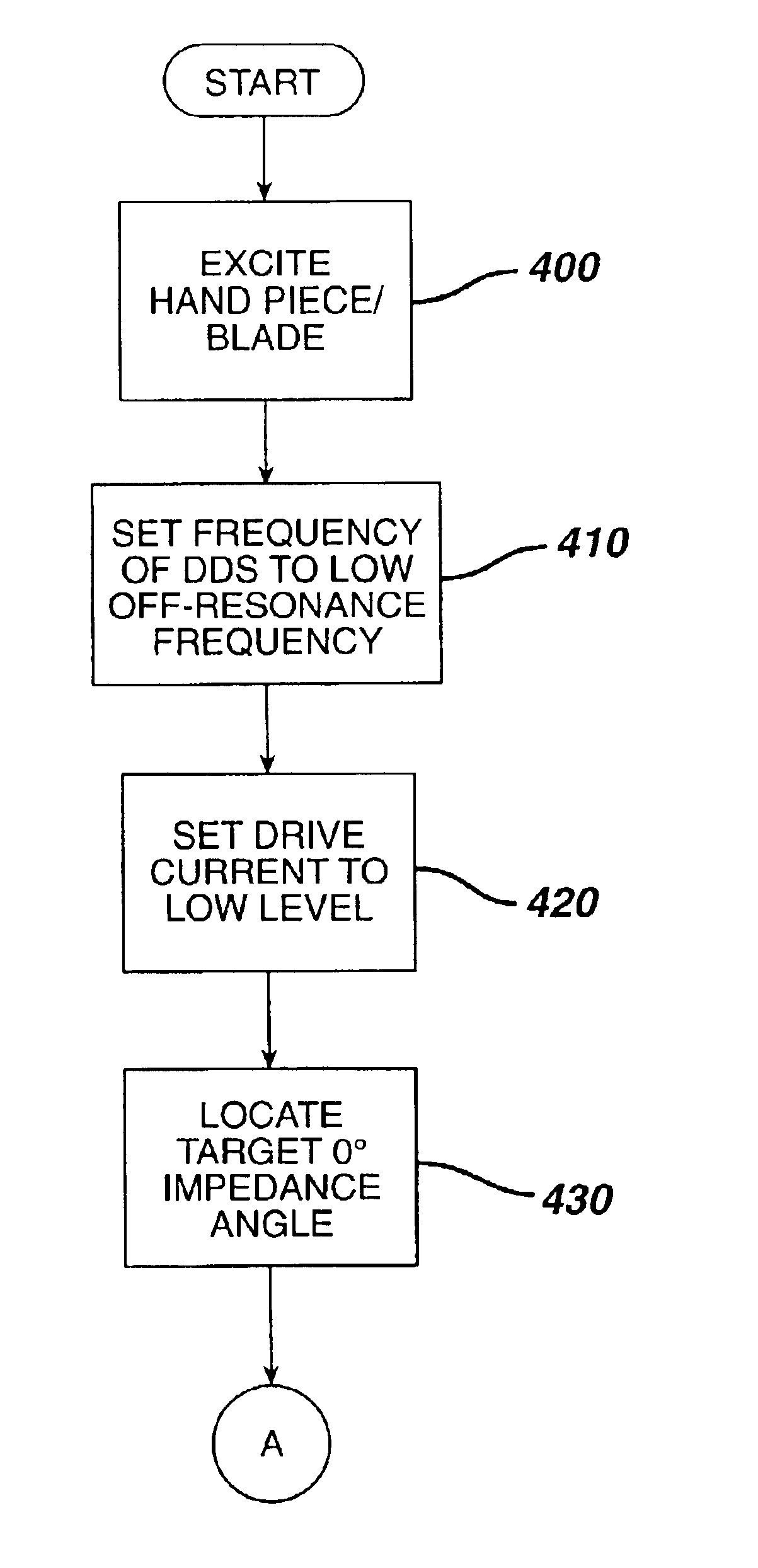

Method for improving the start up of an ultrasonic system under zero load conditions

InactiveUS6898536B2Easy to startIncrease flexibilityNoise figure or signal-to-noise ratio measurementSurgical instrument detailsDriving currentPower flow

The start up performance of an ultrasonic system under zero load conditions is improved by setting a phase set point in a frequency control loop such that, at start up under zero load conditions, the phase set point intersects a point on a phase-frequency response curve which has a low positive slope. This intersection point on the phase-frequency response curve changes as the load is increased and the system Q is decreased. The controller “seeks” a target 0° impedance phase angle. The frequency of the ultrasonic generator is set to an off-resonance frequency which is lower than the resonance of any known hand piece / blade combination. In order for the drive voltage to not exceed the physical limit of the system, the drive current is set to a low level. The drive frequency is then smoothly increased in steps until the target 0° impedance phase delta is located.

Owner:ETHICON ENDO SURGERY INC

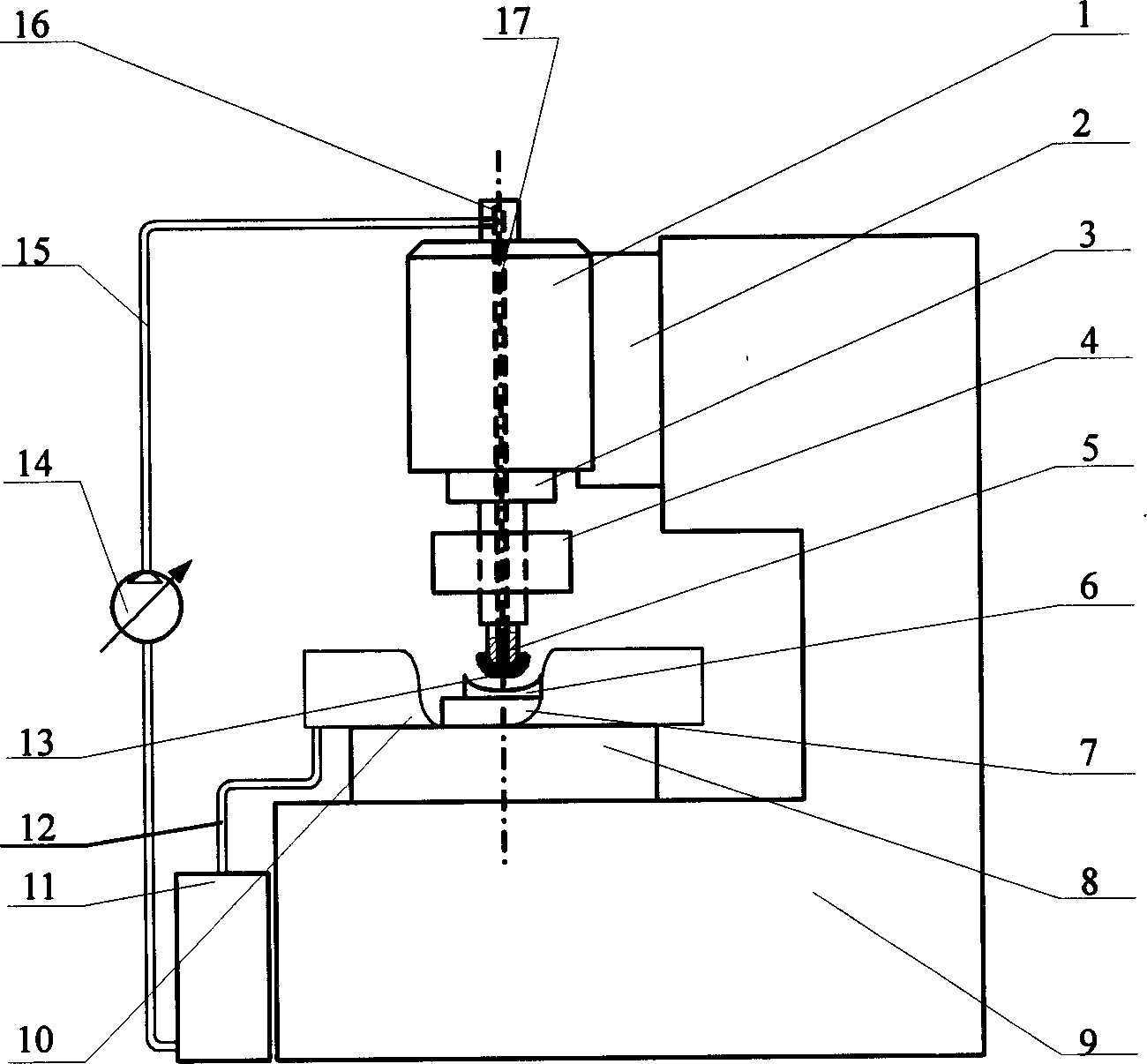

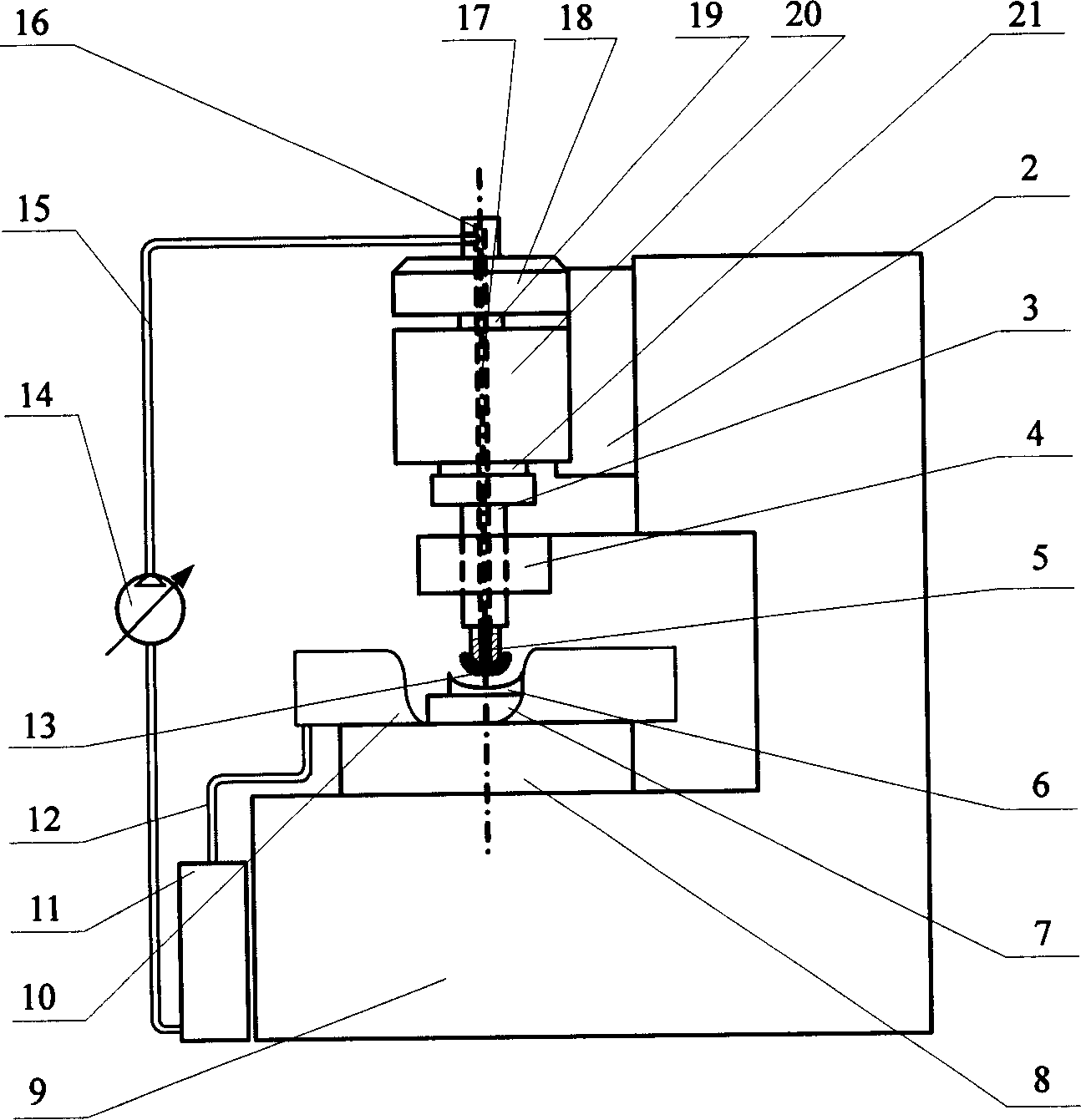

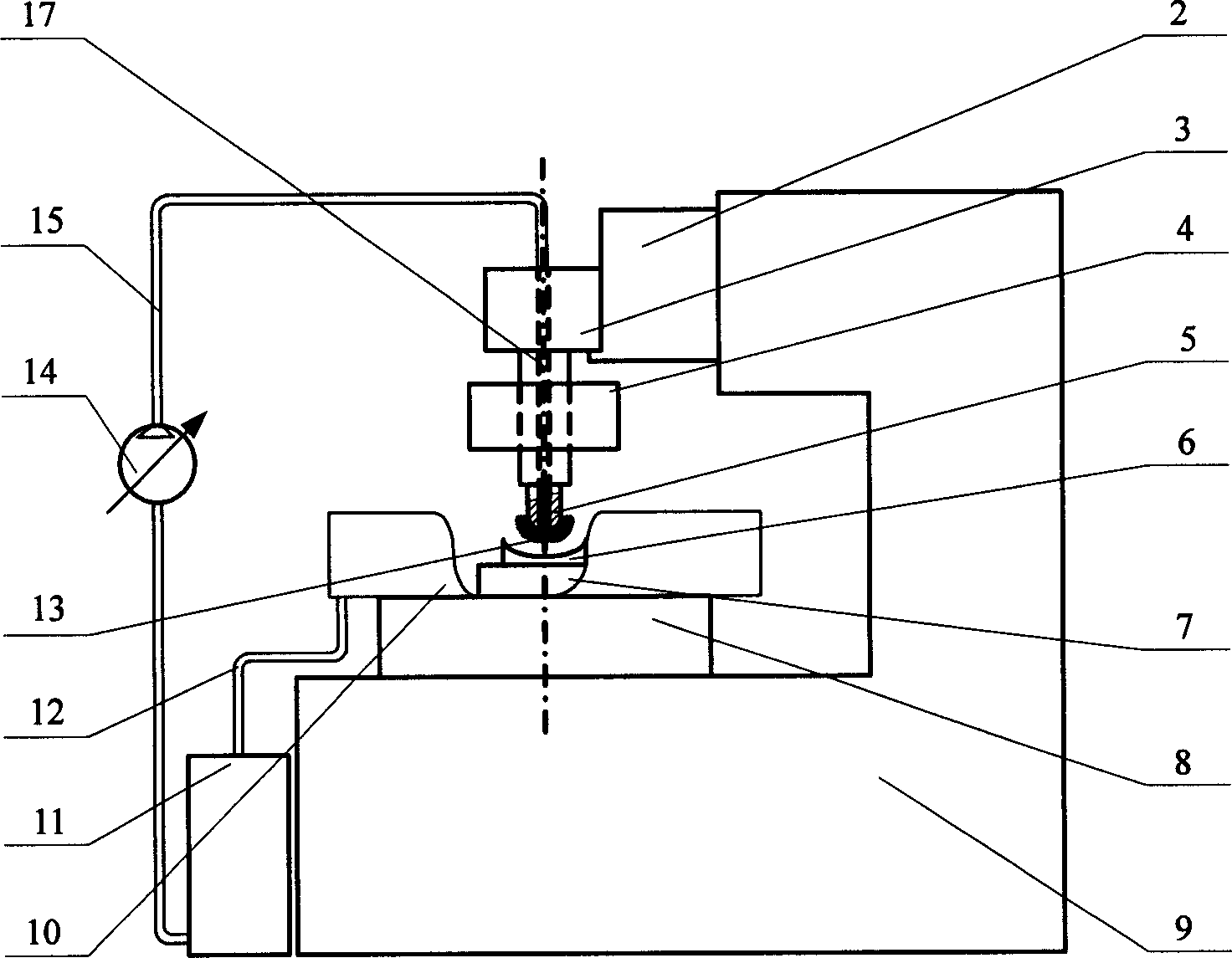

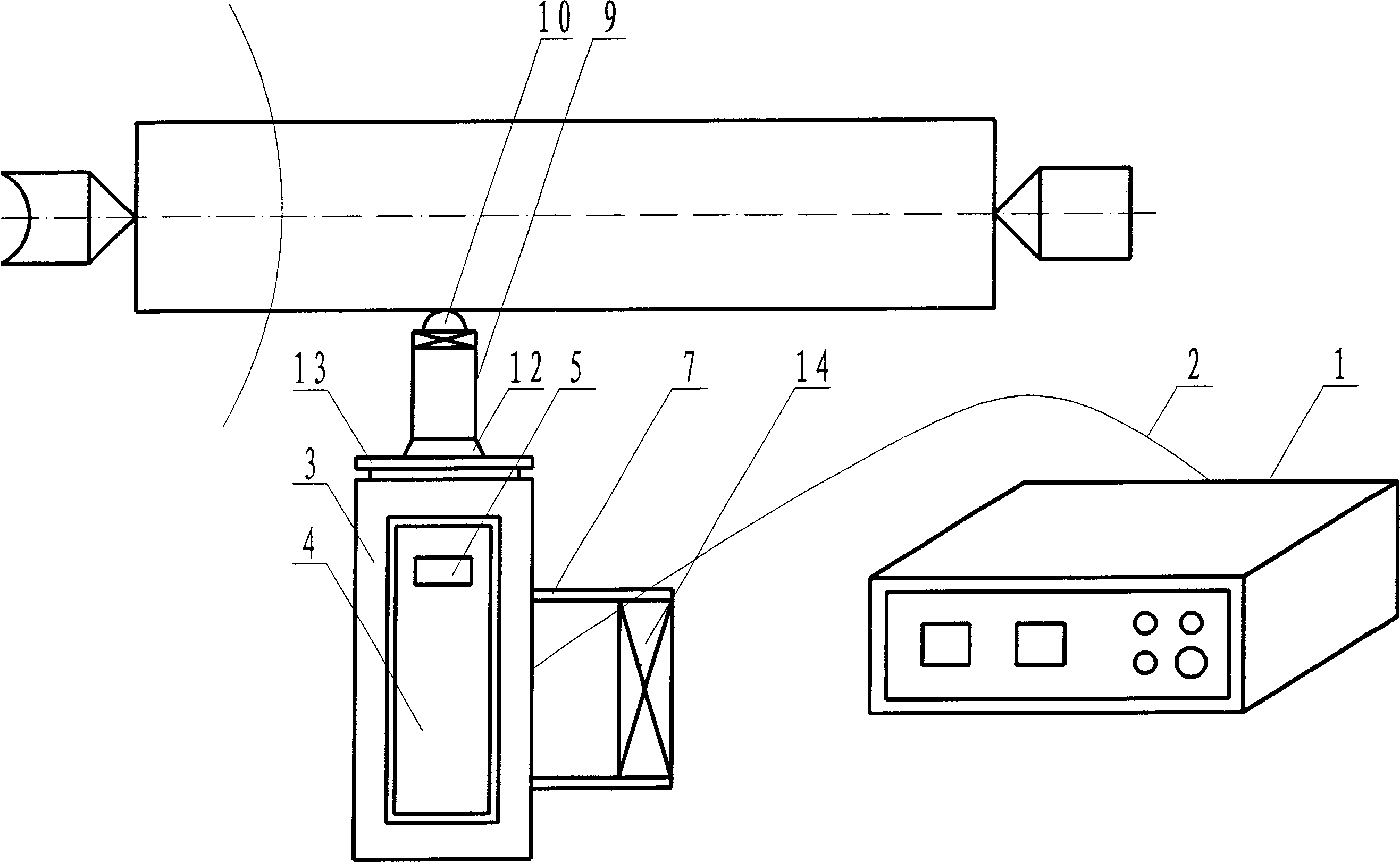

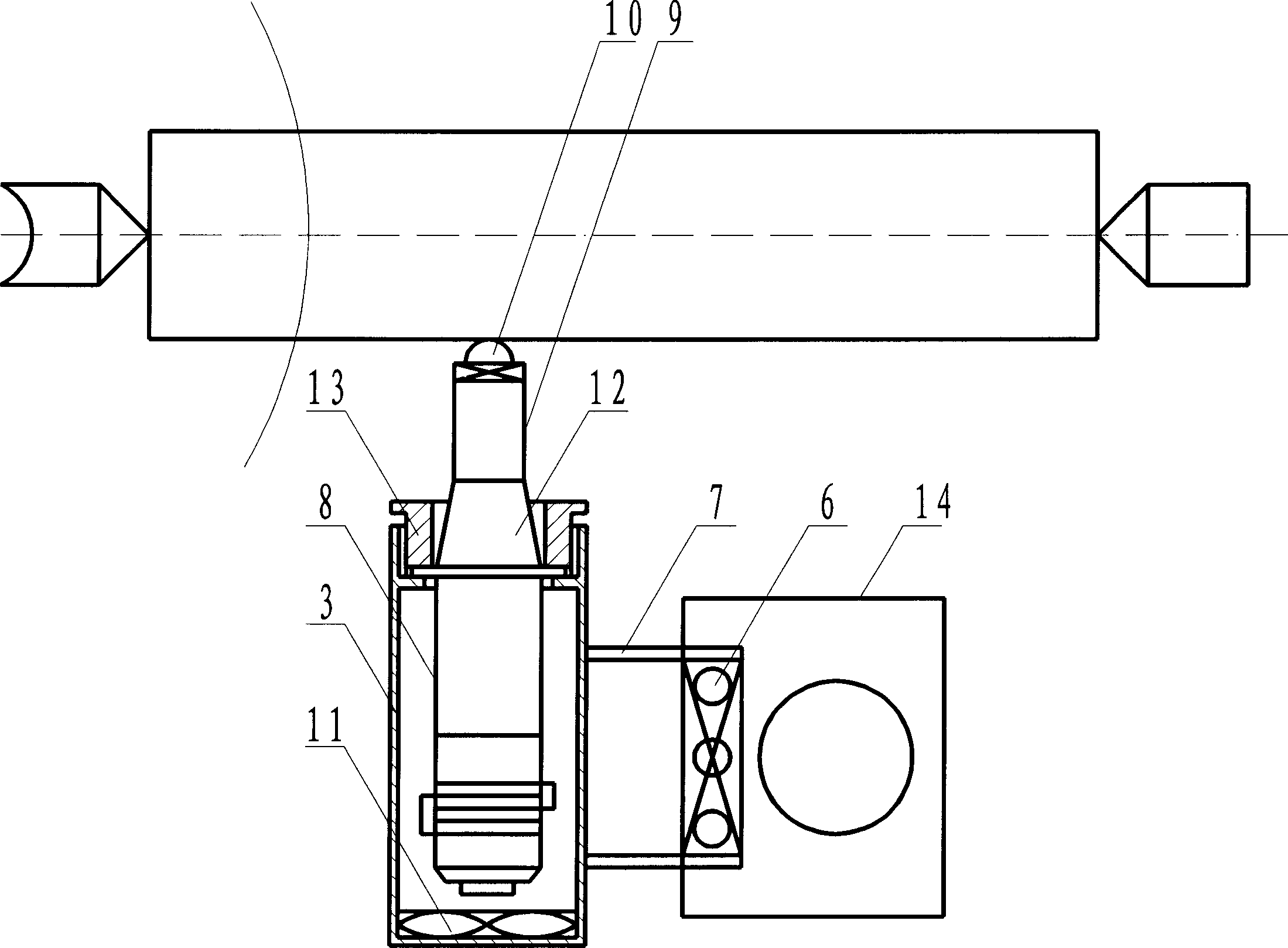

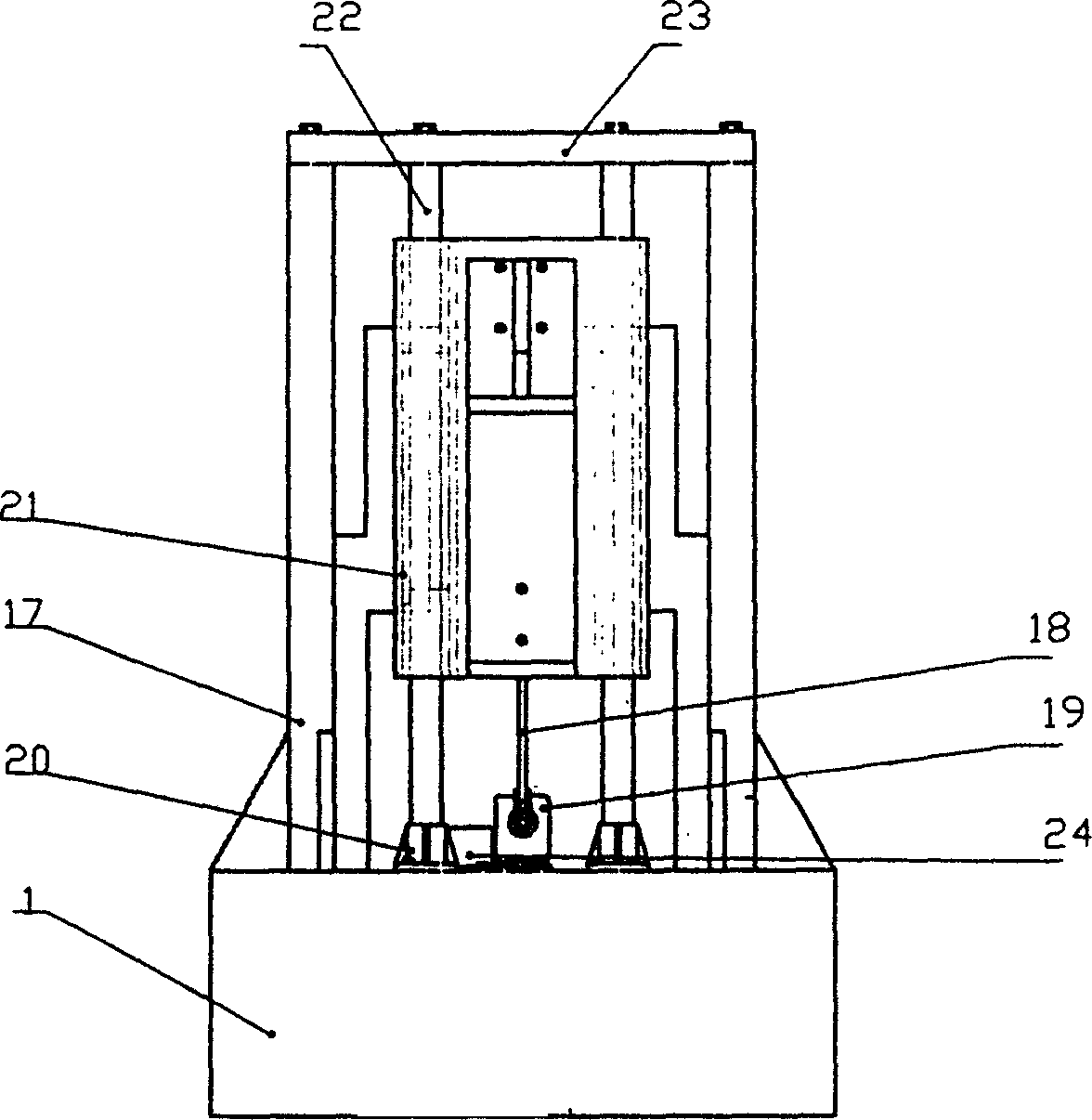

Ultrasonic magnetic rheological composite polishing method and polisher thereof

InactiveCN1613605AAchieve recyclingStable Polishing PropertiesOptical surface grinding machinesUltrasonic vibrationEngineering

An ultrasonic-magnetorheologic polishing method features that the mixture of abrasive material and magnetorheologic liquid is filled in a small-diameter rotary hollow polishing head and a magnetic field is applied to it to make the magnetorheologic liquid become flexible polishing liquid on the polishing head while the ultrasonic vibration is applied to it for higher polishing effect. Its apparatus is composed of polishing head, ultrasonic generator, and electromagnet.

Owner:HARBIN INST OF TECH

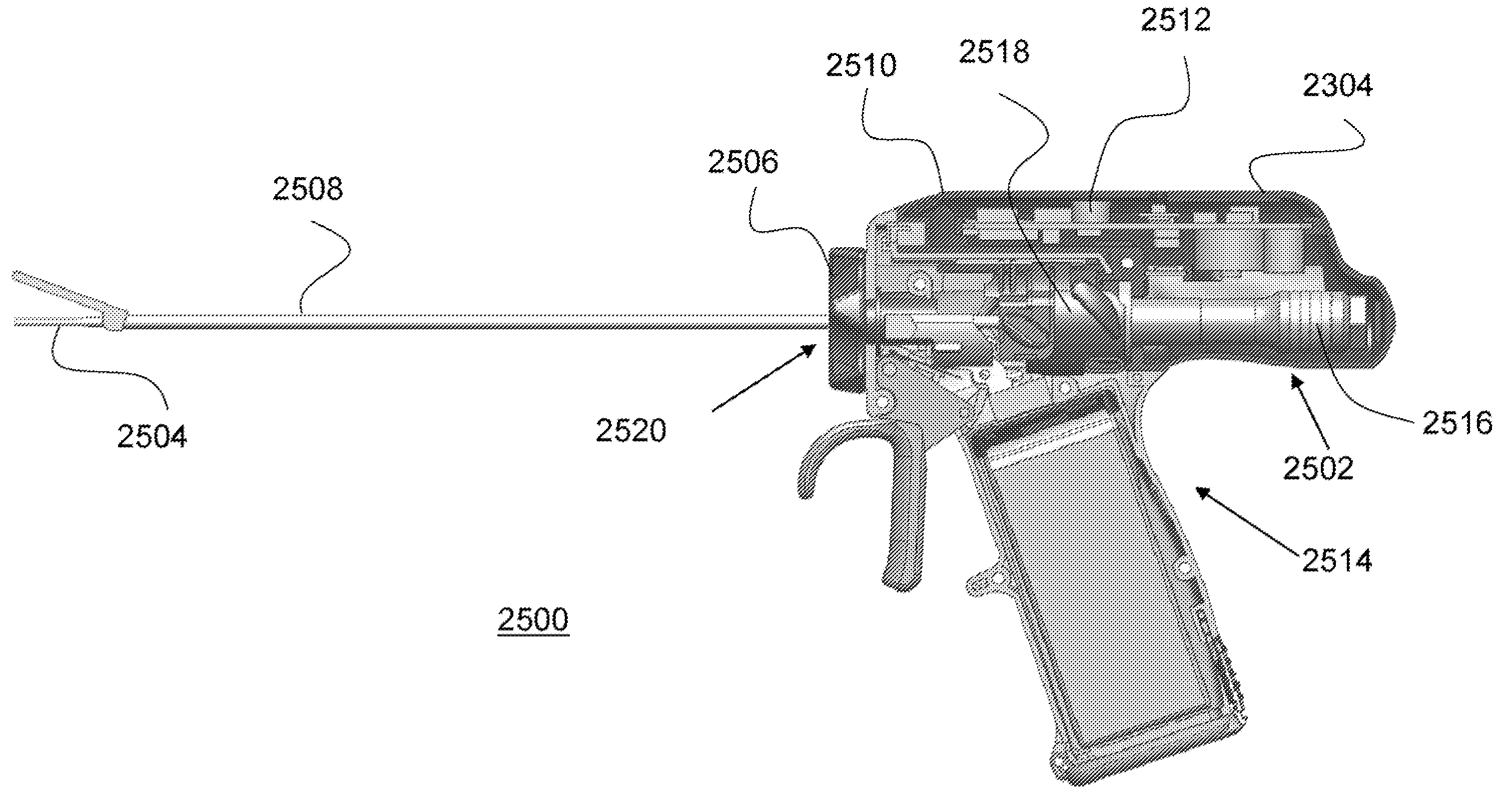

Cordless Hand-Held Ultrasonic Cautery Cutting Device

ActiveUS20090143804A1Alter functionAlter performanceUltrasound therapySurgical instruments for heatingHand heldWaveguide

An ultrasonic assembly that is removably connectable to an ultrasonic waveguide of an ultrasonic surgical handle includes a cordless ultrasonic-movement-generation assembly having an ultrasonic generator and an ultrasonic transducer electrically coupled to the generator and having an output couple, a shell housing therein the ultrasonic-movement-generation assembly and having a securing connection shaped to removably connect to the ultrasonic surgical handle. The output couple is operable to impart ultrasonic movement to the ultrasonic waveguide when the securing connection is connected to the ultrasonic surgical handle and the waveguide is connected to the output couple.

Owner:COVIDIEN AG

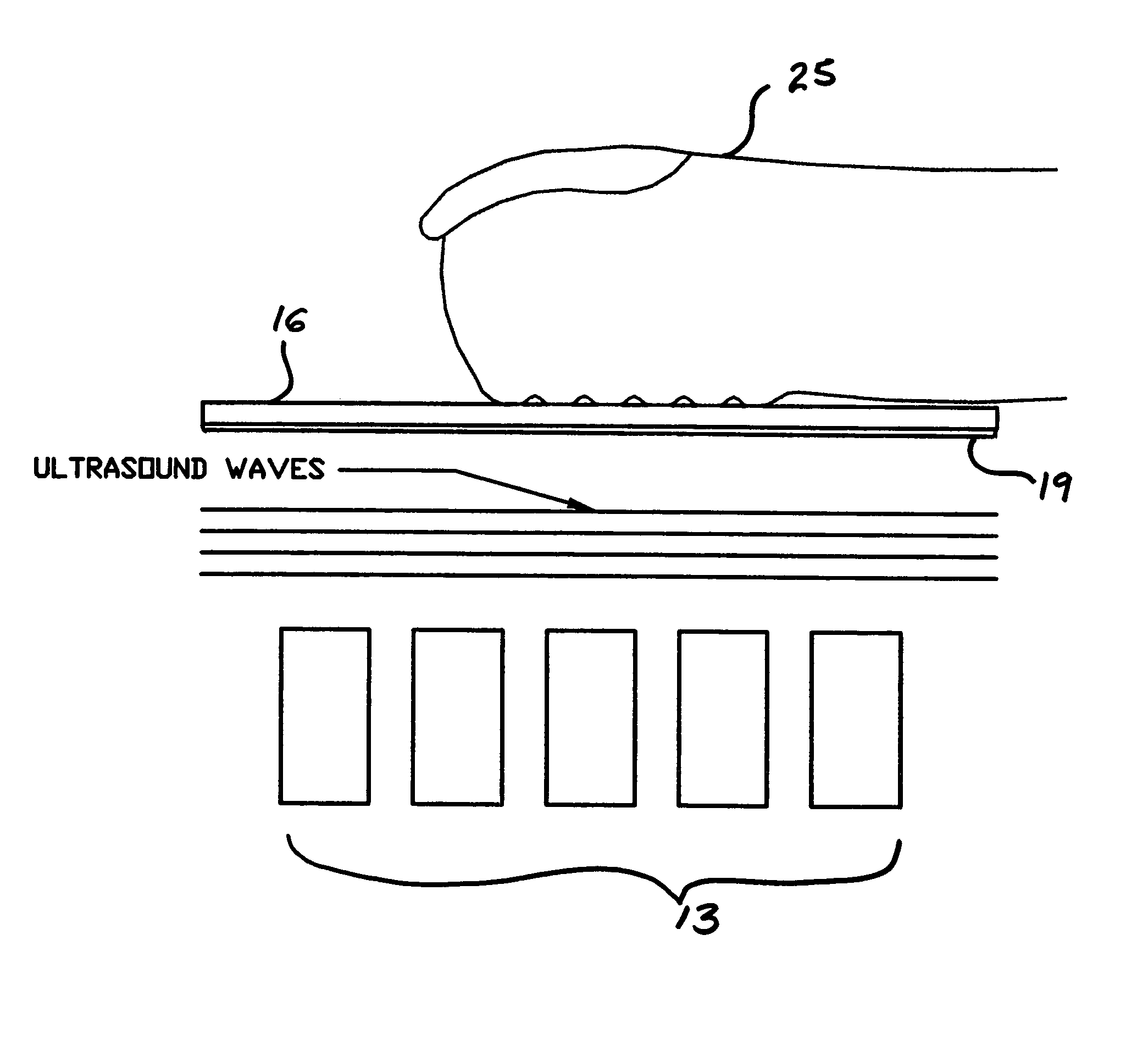

Ultrasonic fingerprint scanning utilizing a plane wave

ActiveUS7739912B2Easy accessEnhance the imageUltrasonic/sonic/infrasonic diagnosticsAnalysing solids using sonic/ultrasonic/infrasonic wavesPlane waveUltrasonic generator

Owner:QUALCOMM INC

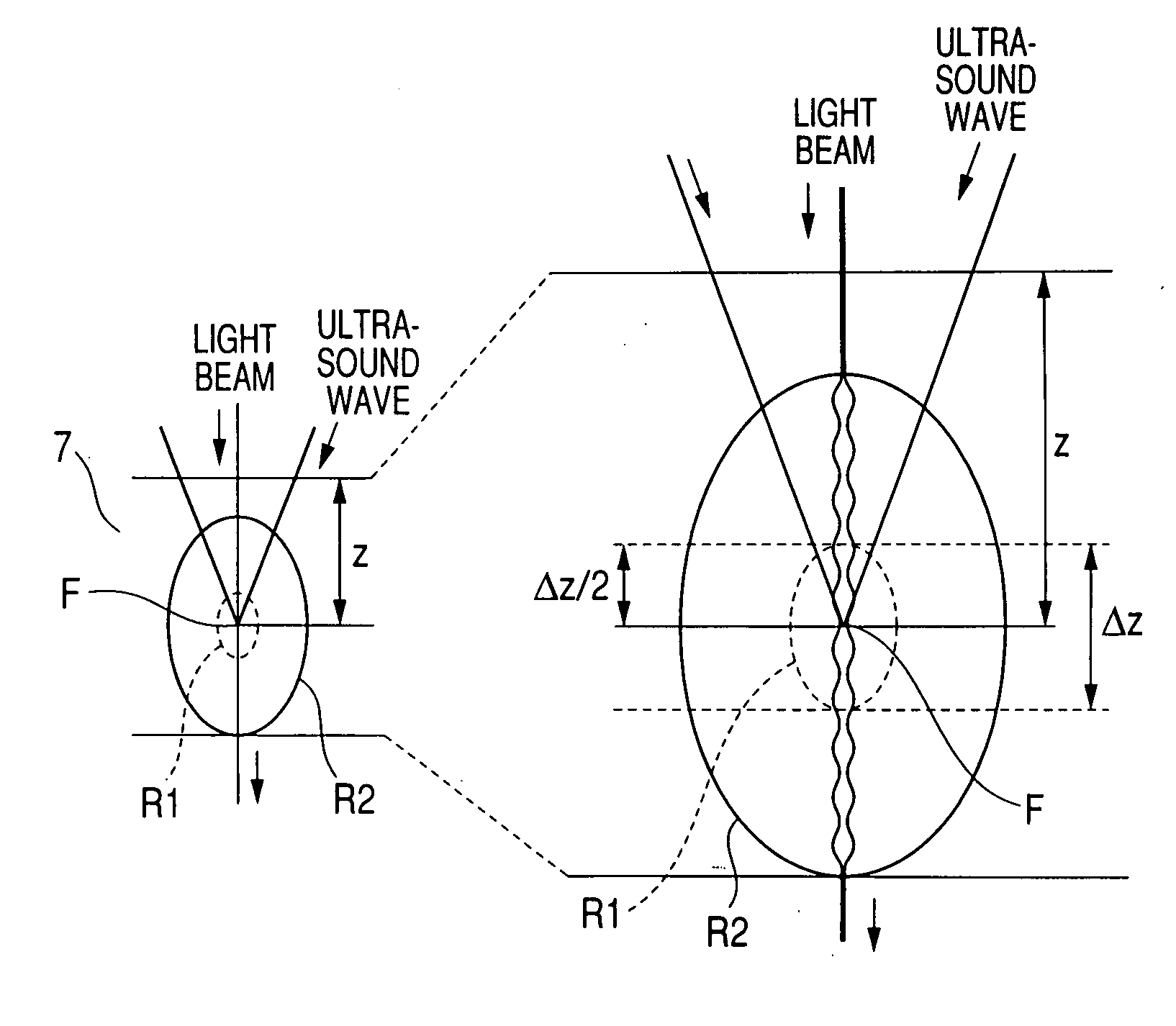

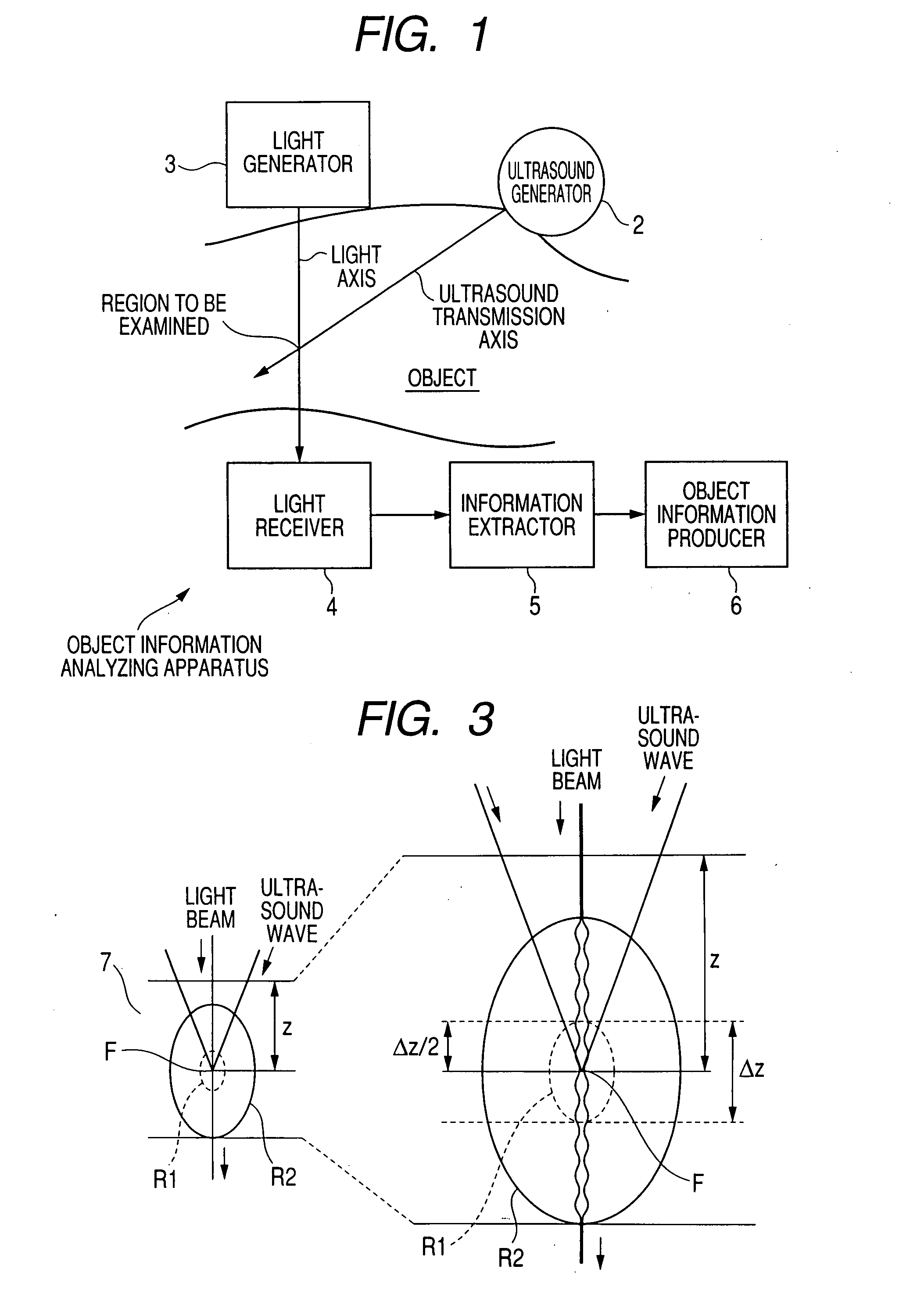

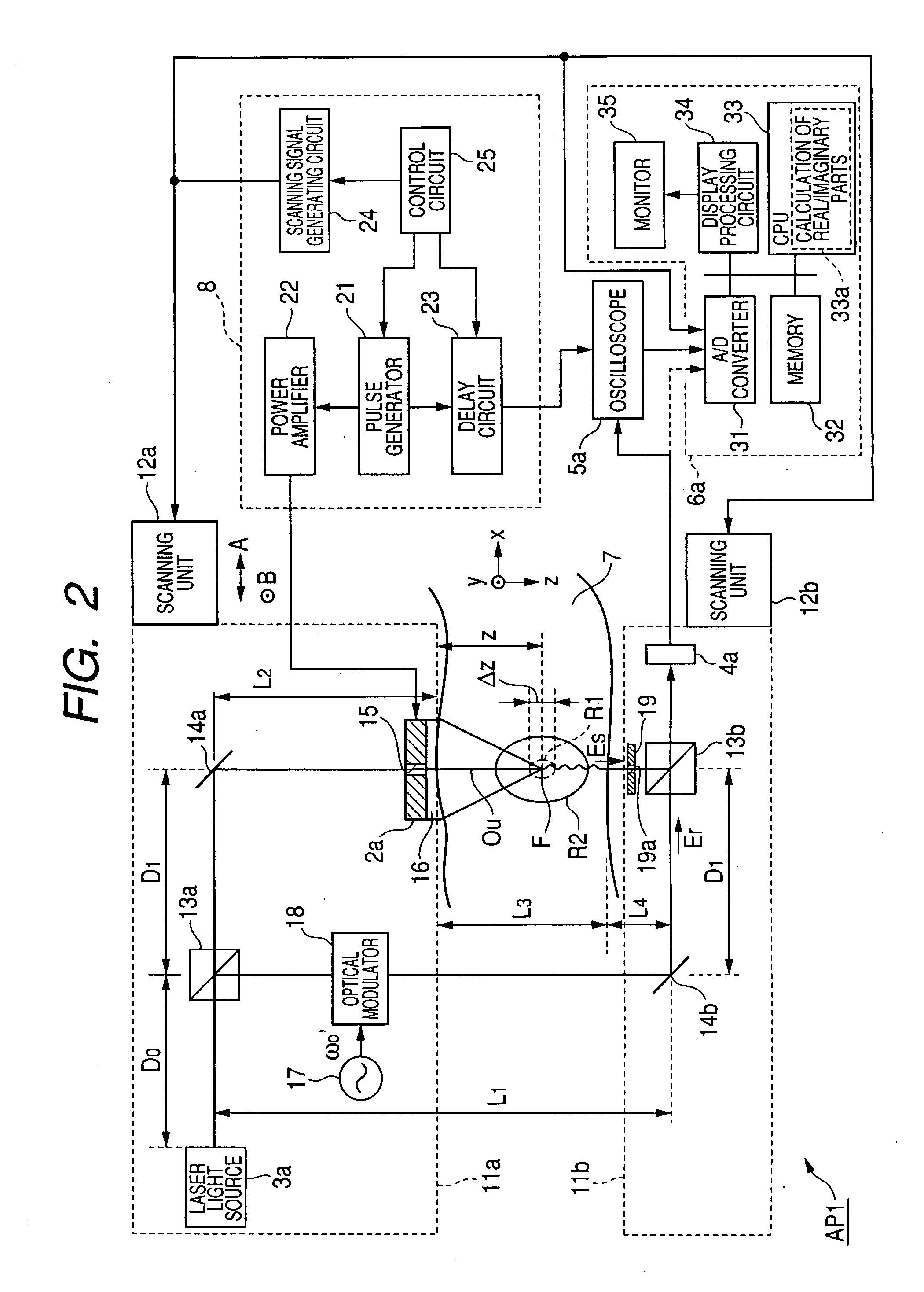

Method and apparatus for analyzing characteristic information of object with the use of mutual interaction between ultrasound wave and light

InactiveUS20070187632A1Easy to getHigh resolutionDiagnostics using lightDiagnostics using spectroscopyUltrasonic generatorPhysics

An apparatus analyzes information indicative of a characteristic of a region to be examined an object. The apparatus comprises an ultrasound generator generating an ultrasound wave toward the region within the object and a light generator generating light toward the region. The ultrasound sound generated is transmitted toward the region. The apparatus further comprises a light receiver, information acquiring unit, and information producer. The light receiver receives light coming from the region and outputting an electric signal corresponding to the received light. The information acquiring unit acquires information indicative of scattering of the light at the region by using either the signal outputted from the light receiver or the light coming from the region. The information producer produces the information indicative of the characteristic of the region based on the scattering information acquired by the information acquiring unit.

Owner:OLYMPUS MEDICAL SYST CORP

Ultrasonic metal surface processing device

ActiveCN1690231AIncrease productivityReduce investmentMechanical vibrations separationElectricityTransducer

The invention provides a ultrasonic working device for metallic surface, which comprises ultrasonic generator and ultrasonic working device linked together by cable conductor. The ultrasonic generator is existing device, and ultrasonic working device comprises shell which is equipped with spring connected to checkout gear for pressure one side and to briquette the other side besides with checkout gear for pressure and display for pressure, checkout gear for pressure, display for pressure, briquette, spring, piezoelectric ceramic transducer equipped in the shell and connected tight to one end of the half-wavelength complex varying amplitude pole by screw, half-wavelength complex varying amplitude pole whose outlet connected tight to tool caput by screw, tool caput and draught fan equipped on other end of the shell. Producing with the device for metallic surface can reduce the processing cost rapidly and effectively, simplify the productive technology, and advance the productive efficiency, as a result, it takes on a nice extendable and applicable value.

Owner:SHANDONG HUAWIN ELECTRICAL & MECHANICAL TECH

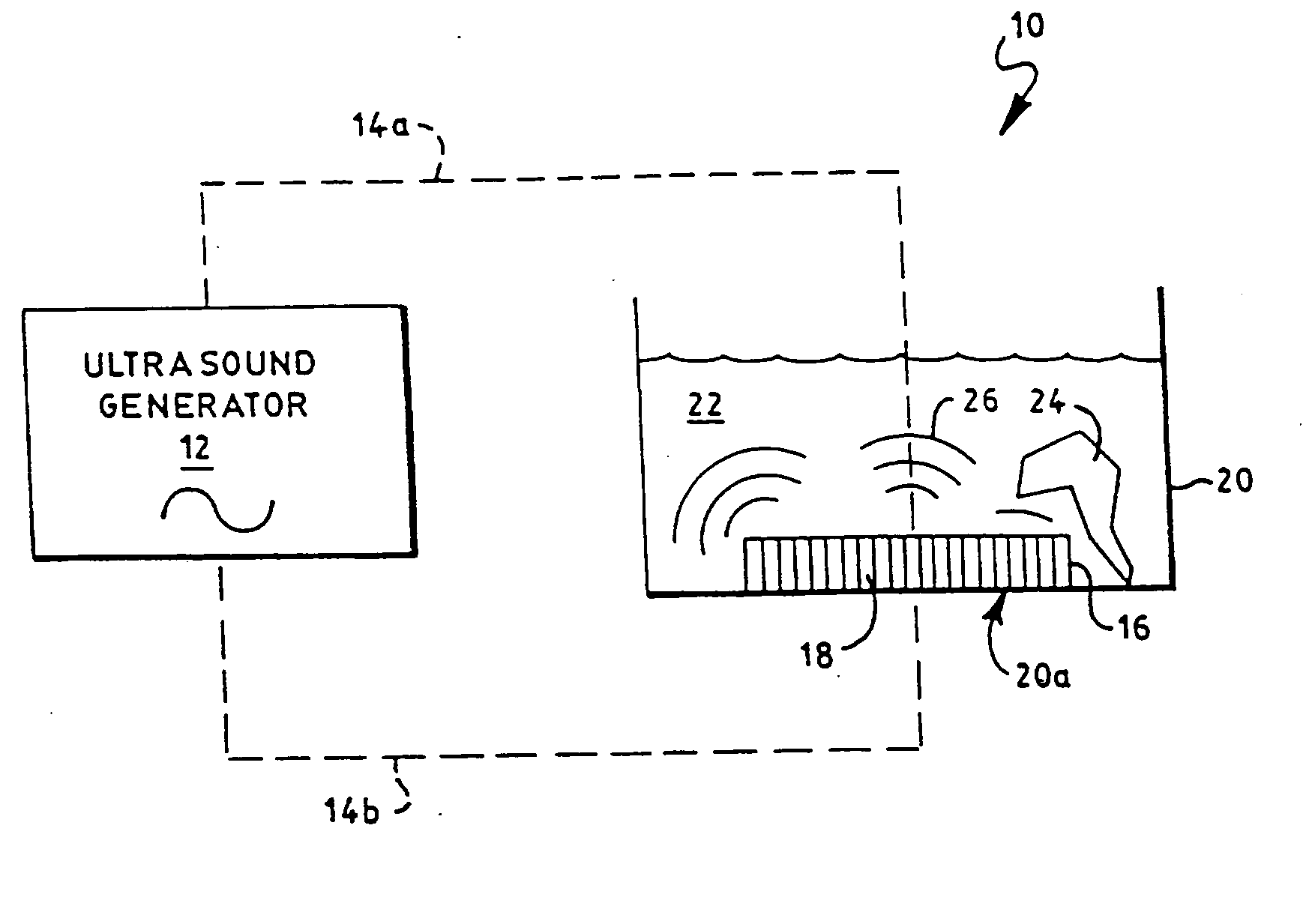

Apparatus, circuitry, signals and methods for cleaning and/or processing with sound

InactiveUS20050017599A1Improve cleanlinessSimple processPiezoelectric/electrostriction/magnetostriction machinesMechanical vibrations separationCavitationResonance

The invention utilizes a multiple frequency ultrasound generator driving a multiple frequency harmonic transducer array to improve cleaning and processing effects while eliminating damage to parts being cleaned. An AC switch and circuitry to modify the output of an ultrasound generator in combination with techniques such as random AM and FM signals are used to produce ultrasound waves that have no single frequency components which eliminates exciting parts being cleaned into resonance. Generator signals that increase cavitation efficiency and that have successive time periods with predominately stable cavitation and predominantly transient cavitation further improve the performance of the cleaning or processing systems.

Owner:PUSKAS WILLIAM L

Skin and adipose tissue treatment by nonfocalized opposing side shock waves

The present invention is a device for the destruction of adipose tissue comprising two or more ultrasound generators positioned on opposing sides of the treatment area each generating a non-focused wave that converge forming a interferential clash zone with the treatment area therein. Ultrasound generators are contained within a handpiece housing. Furthermore the present invention provides an optional housing having a source of vacuum for encompassing a treatment area whereby the treatment area is drawn bell-shaped into the housing whereupon a pair of shock wave generators are energized to produce cavitational areas within the treatment area and a third interferential energized area between the cavitational areas.

Owner:DEL GIGLIO ANTONIO

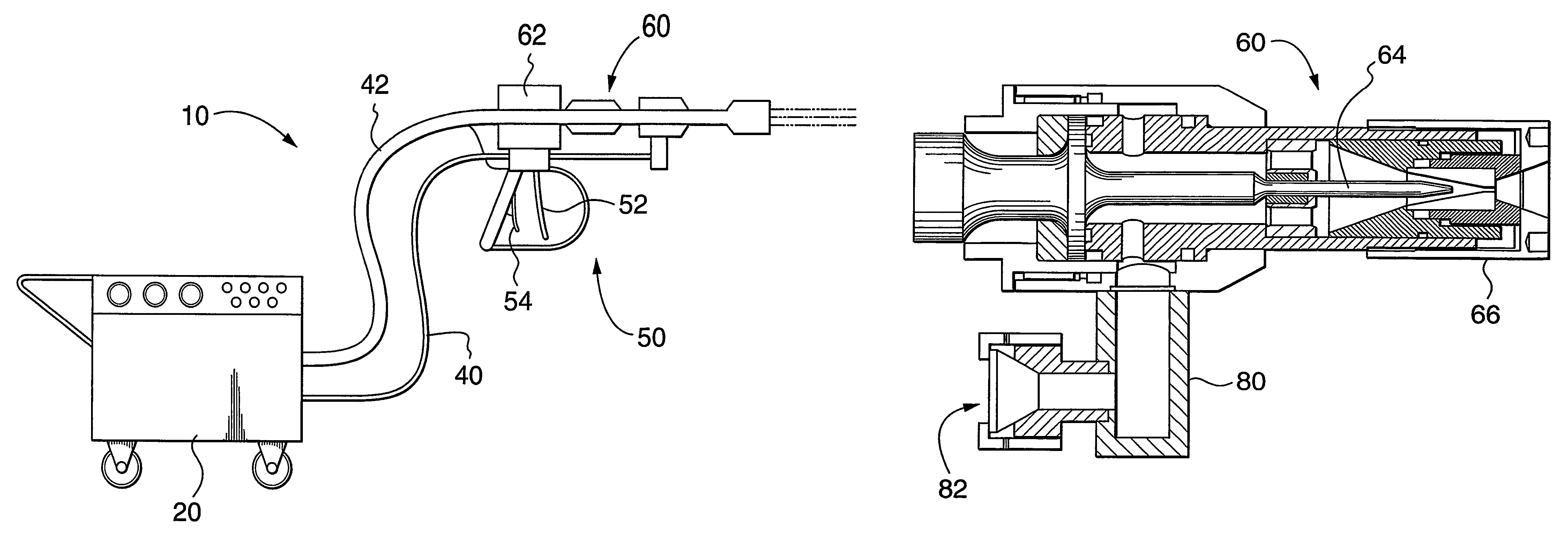

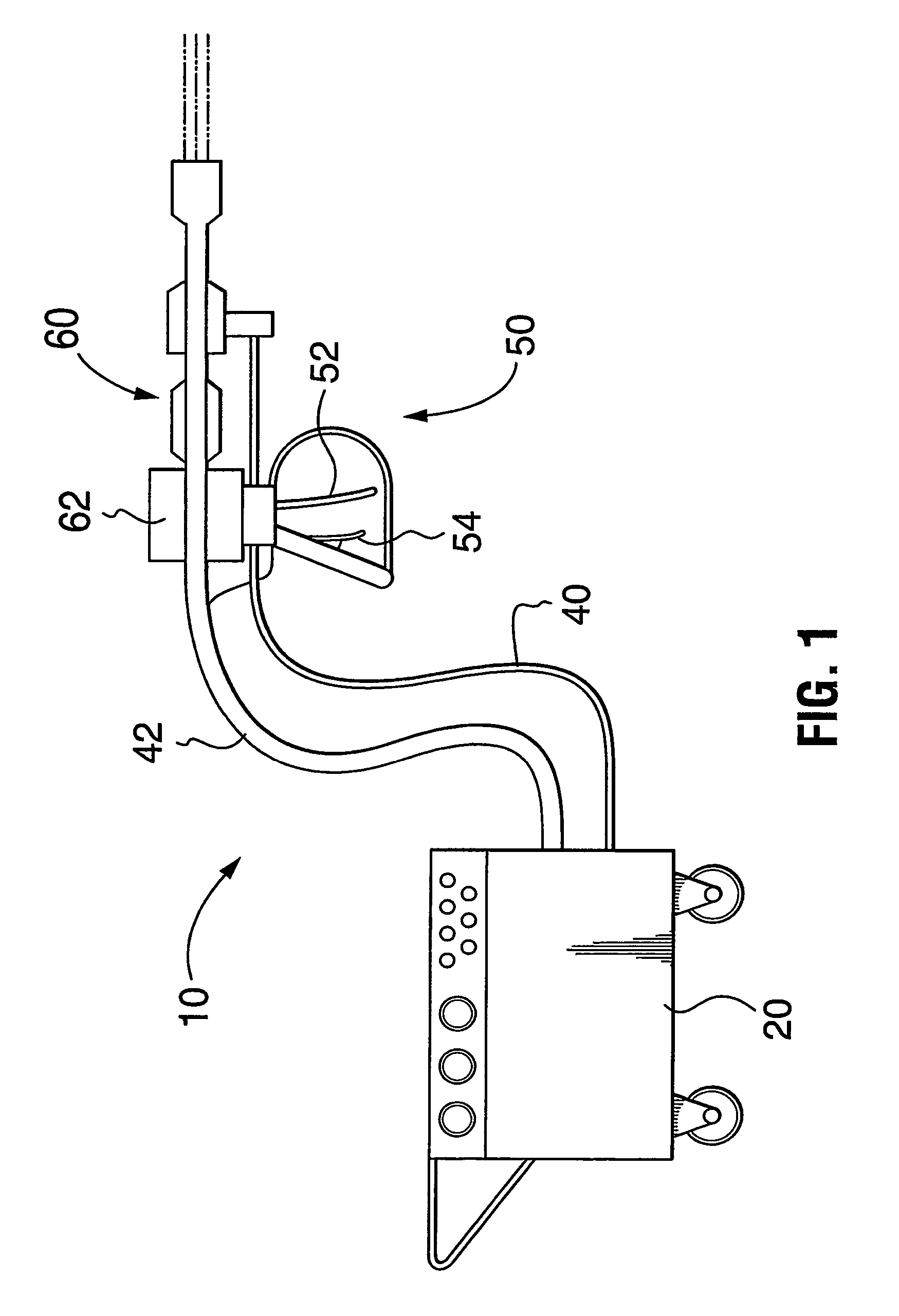

Ultrasonic waterjet apparatus

ActiveUS7594614B2Reduce cleaningReduce pressureLiquid surface applicatorsPiezoelectric/electrostriction/magnetostriction machinesSonic nozzleUltrasonic nozzle

An ultrasonic waterjet apparatus (10) has a mobile generator module (20) and a high-pressure water hose (40) for delivering high-pressure water from the mobile generator module (20) to a hand-held gun (50) with a trigger and an ultrasonic nozzle (60). An ultrasonic generator in the mobile generator module (20) transmits high-frequency electrical pulses to a piezoelectric or magnetostrictive transducer (62) which vibrates to modulate a high-pressure waterjet flowing through the nozzle (60). The waterjet exiting the ultrasonic nozzle (60) is pulsed into mini slugs of water, each of which imparts a waterhammer pressure on a target surface. The ultrasonic waterjet apparatus (10) may be used to cut and de-burr materials, to clean and de-coat surfaces, and to break rocks. The ultrasonic waterjet apparatus (10) performs these tasks with much greater efficiency than conventional continuous-flow waterjet systems because of the repetitive waterhammer effect. A nozzle with multiple exit orifices or a rotating nozzle (76) may be provided in lieu of a nozzle with a single exit orifice to render cleaning and de-coating large surfaces more efficient. A water dump valve (27) and controlling solenoid are located in the mobile generator module (20) rather than the gun (50) to make the gun lighter and more ergonomic.

Owner:PRATT & WHITNEY MILLTARY AFTERMARKET SERVICES

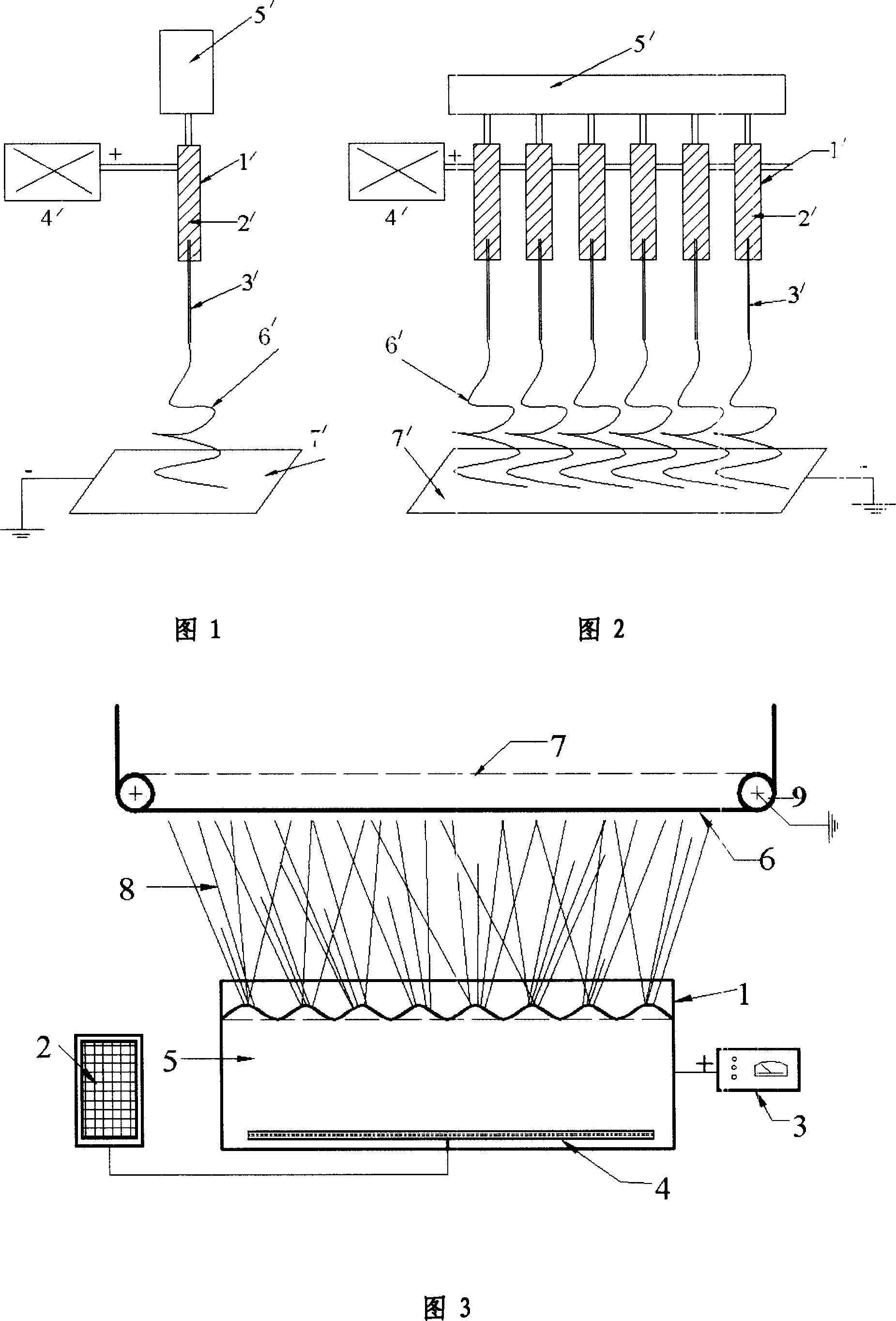

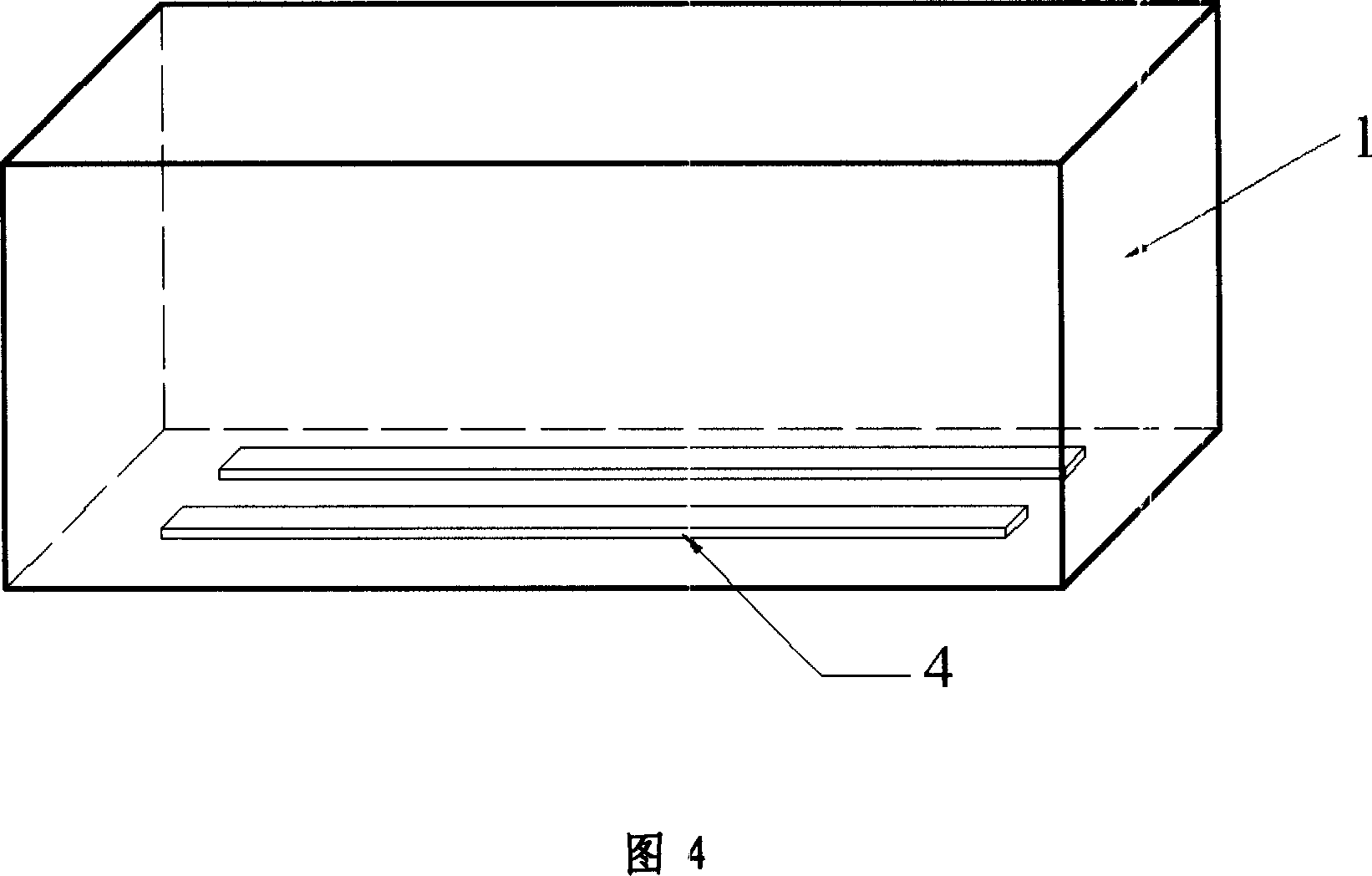

Vibrating electrostatic spinning device for nano fiber

InactiveCN1986913ANo frequent replacementNo need for frequent cleaningFilament/thread formingFiberElectrospinning

The vibrating electrostatic spinning set for nanometer fiber includes one container for holding spinning solution or melt, one high voltage electrostatic generator, one ultrasonic generator, and one piezoelectric sensor. The container is one cubic liquid storage tank with upper opening; and the piezoelectric sensor is set in the bottom of the tank and connected with the ultrasonic generator outside the tank. Over the liquid storage tank, there are one nanometer fiber conveyer and one nanometer fiber receiver, the conveyer includes guide roll, earthed electrode and conducting plate connected to the earthed electrode to form the negative pole; one electrostatic field is formed between the negative pole and the solution or melt inside the tank connected through electric plate to the high voltage electrostatic generator; and the receiver is one receiving screen. The present invention is used for producing nanometer fiber and has high production efficiency.

Owner:DONGHUA UNIV

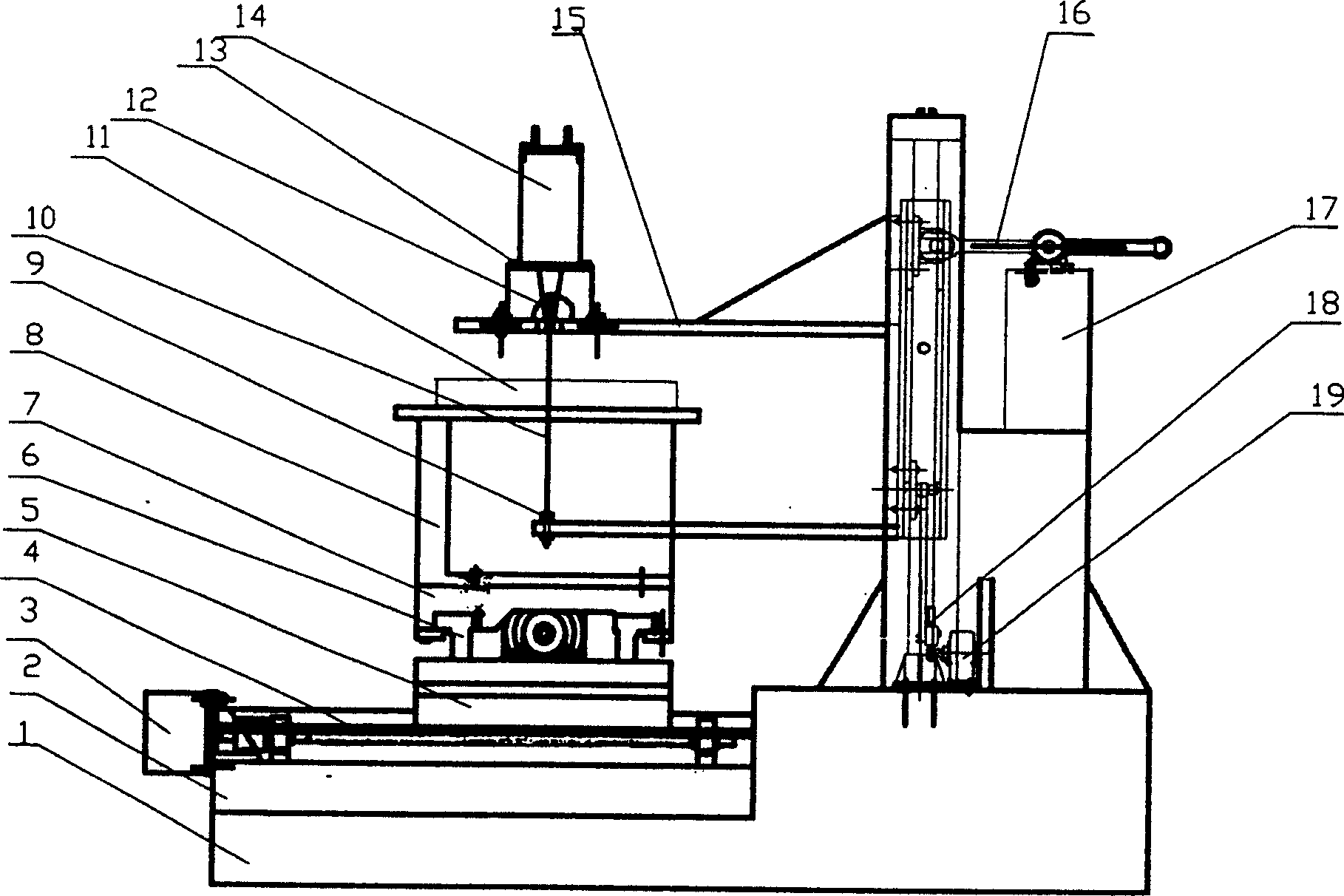

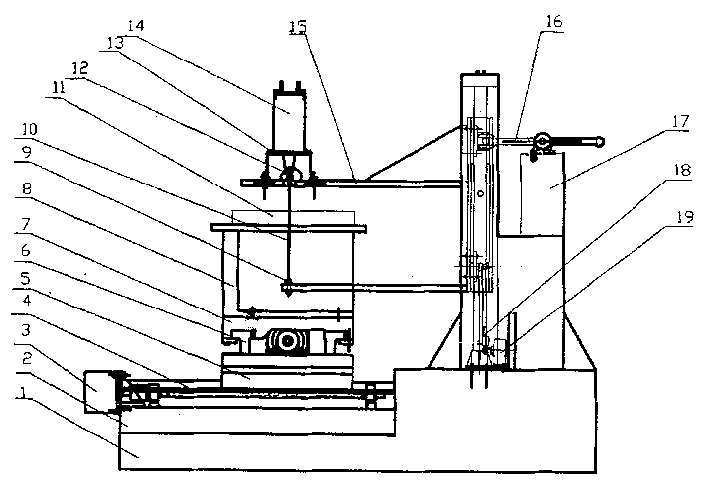

Ultrasonic wire cutting saw for hard-fragile material processing

InactiveCN1488480ASimple structureIncrease productivityStone-like material working toolsWire cuttingEngineering

The invention is a kind of supersonic wave tangent line saw for hard and crisp material, which comprises the bed, longitudinal working slide flat, transversal work slide flat, piece bracket, diamond line saw, supersonic wave vibrating device, saw reciprocating motion mechanism and electricity control device, the supersonic vibrating device is fixed on the upper arm of the C type work bracket through screw, the electrical signal is transformed into mechanical vibration, and enlarges the amplitude through a pole, the diamond saw vibrates as wave, it generates reciprocating motion through cranked rod, C type work bracket, slide flat seat. The saw is in linear high frequency vibration state and reciprocating motion; the invention is simple and has a high productivity.

Owner:沈阳工业学院

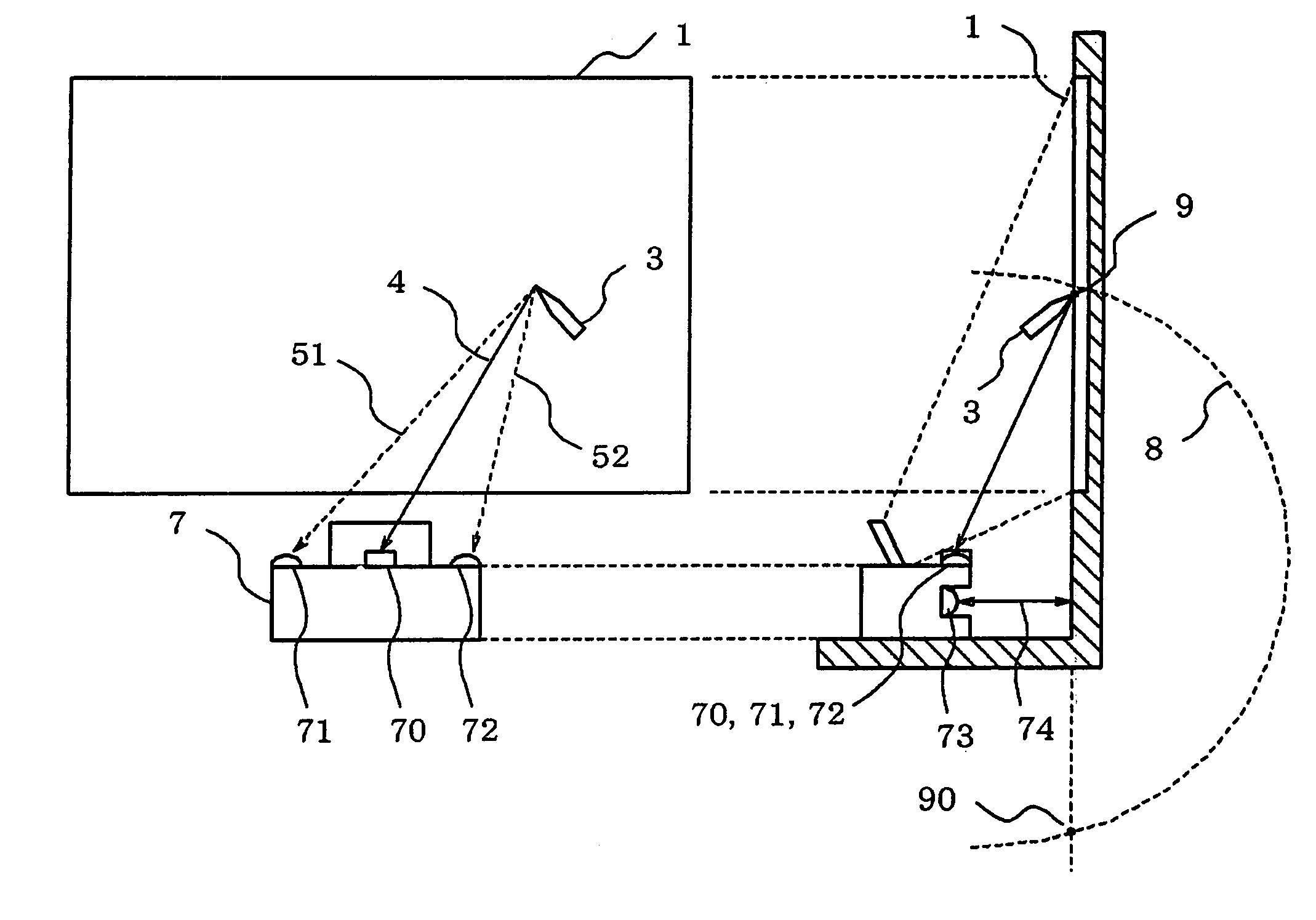

Projector and projector accessory

ActiveUS7185987B2Input/output for user-computer interactionTelevision system detailsPhotovoltaic detectorsPhotodetector

A projector for enlarging and projecting the display image on a light valve onto a screen is provided with: an infrared photodetector for photodetecting infrared light that is emitted by an electronic pen that is manipulated on the screen and that is provided with an infrared light emission device and ultrasonic generator; at least two ultrasonic receivers for detecting ultrasonic waves that are emitted by the electronic pen; means for measuring the distance to a screen; and means for supplying coordinate data in which the position of the electronic pen on the screen, which has been calculated based on output of the infrared photodetector, output of the ultrasonic generator, and output of the means for measuring the distance to the screen, has been normalized by the length of a side of a projected rectangular image that has been enlarged and projected.

Owner:SHARP NEC DISPLAY SOLUTIONS LTD

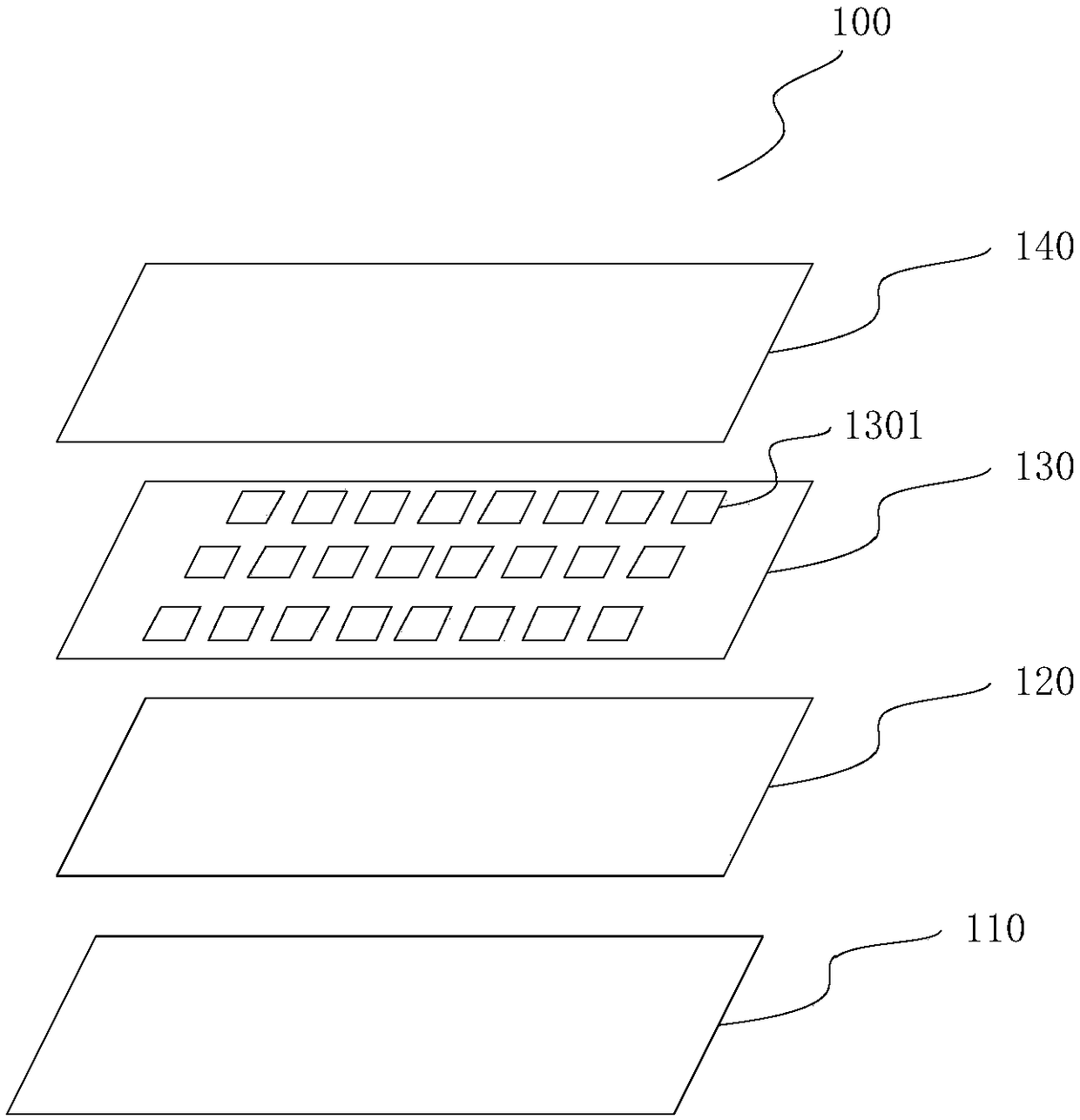

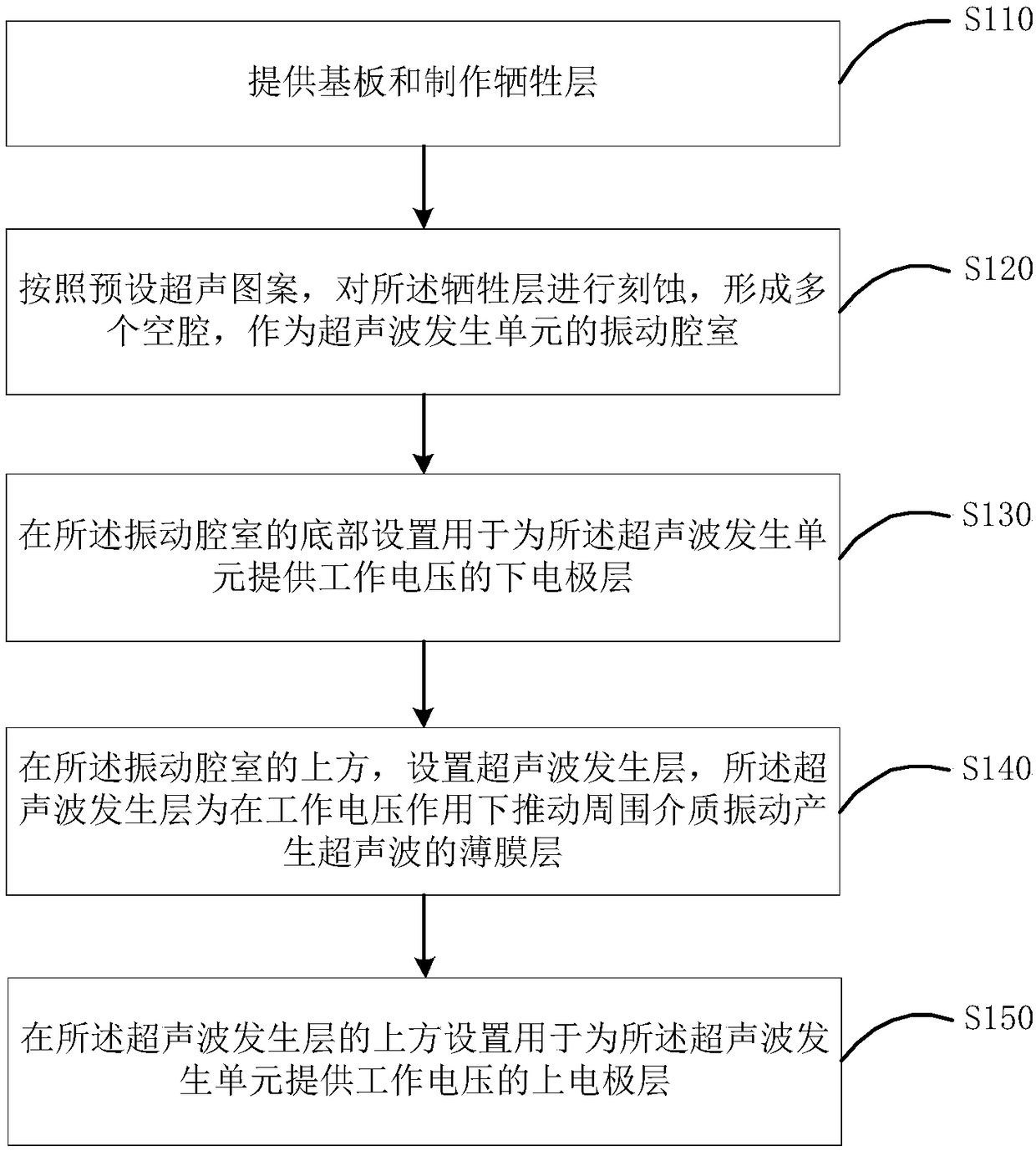

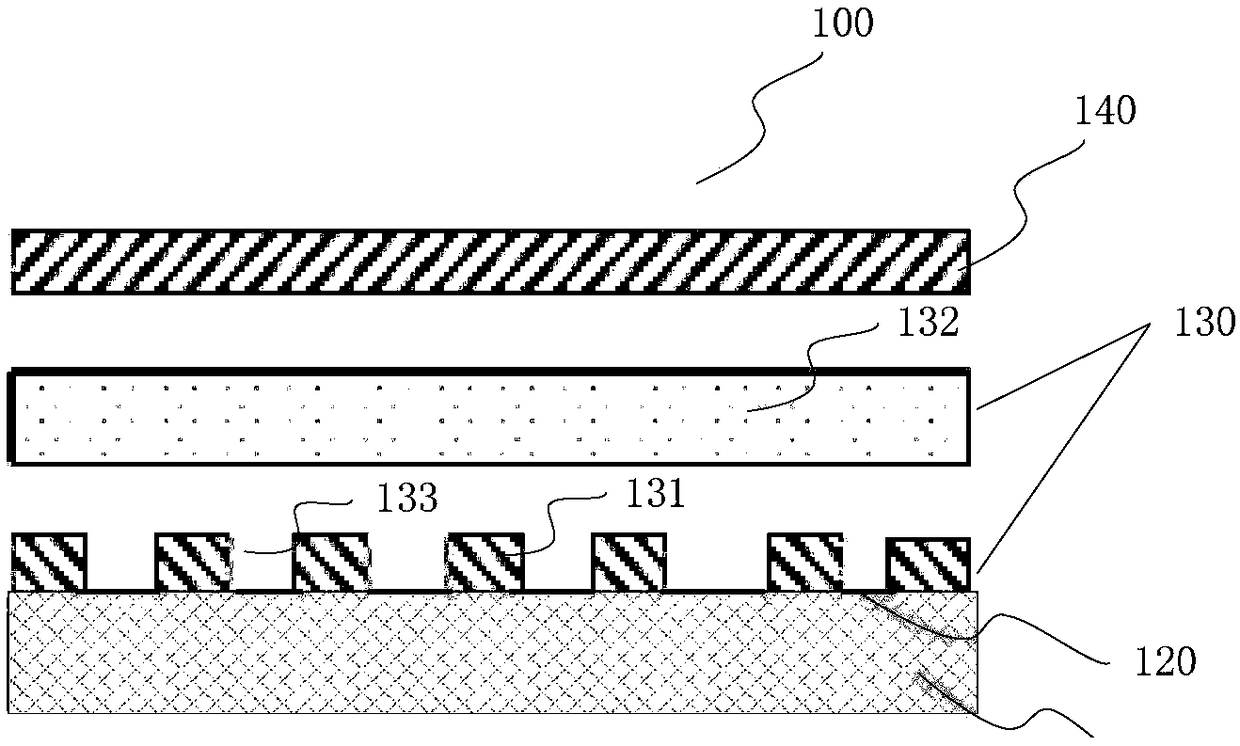

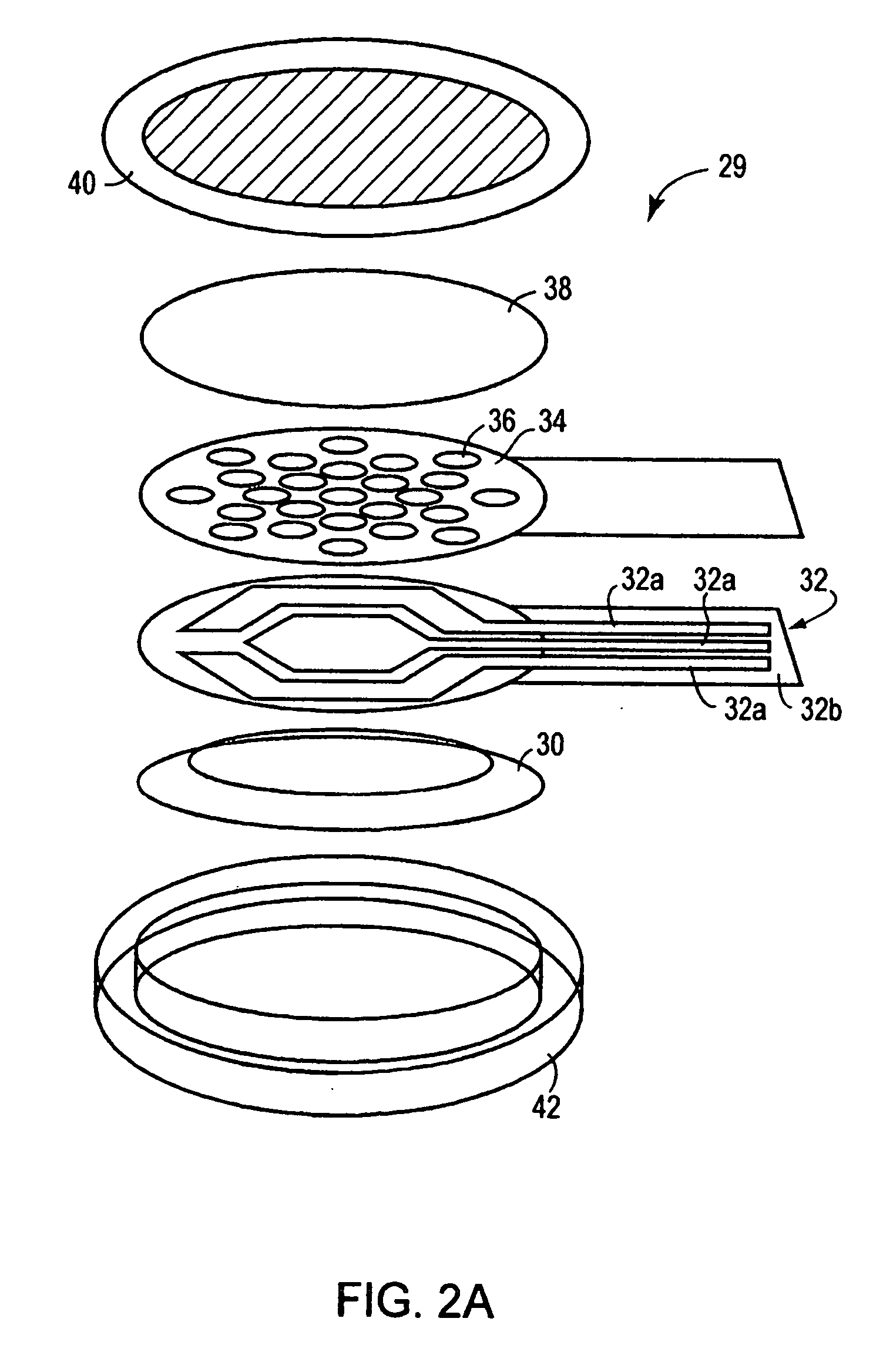

Screen sounding device, sounding display screen, manufacturing method thereof, and screen sounding system

InactiveCN109068245AEasy to collect voiceGood display functionMicrophonesTransducer detailsEngineeringSounds device

The invention provides an ultrasonic generator, a screen sounding device, a sounding display screen, a manufacturing method thereof and a screen sounding system. The screen sounding device comprises asubstrate, a lower electrode layer, an ultrasonic generating unit array and an upper electrode layer arranged in order from bottom to top, wherein the substrate is used for providing support for thescreen sounding device; the lower electrode layer is disposed on the upper surface of the substrate and includes a lower electrode for supplying the working voltage of each ultrasonic generating unitin the ultrasonic generating unit array. The ultrasonic generating unit array is arranged above the low electrode layer and includes a plurality of ultrasonic generating unit arranged according to a preset ultrasonic pattern; the upper electrode lay is disposed above thet ultrasonic generating cell array and includes an upper electrode for supplying an operating voltage of each ultrasonic generating unit in the ultrasonic generating unit array. Thus, the space occupation of the sound producing device is reduced, the sound producing device is convenient to be integrated with the display panel,and directional sound producing can be realized.

Owner:BOE TECH GRP CO LTD

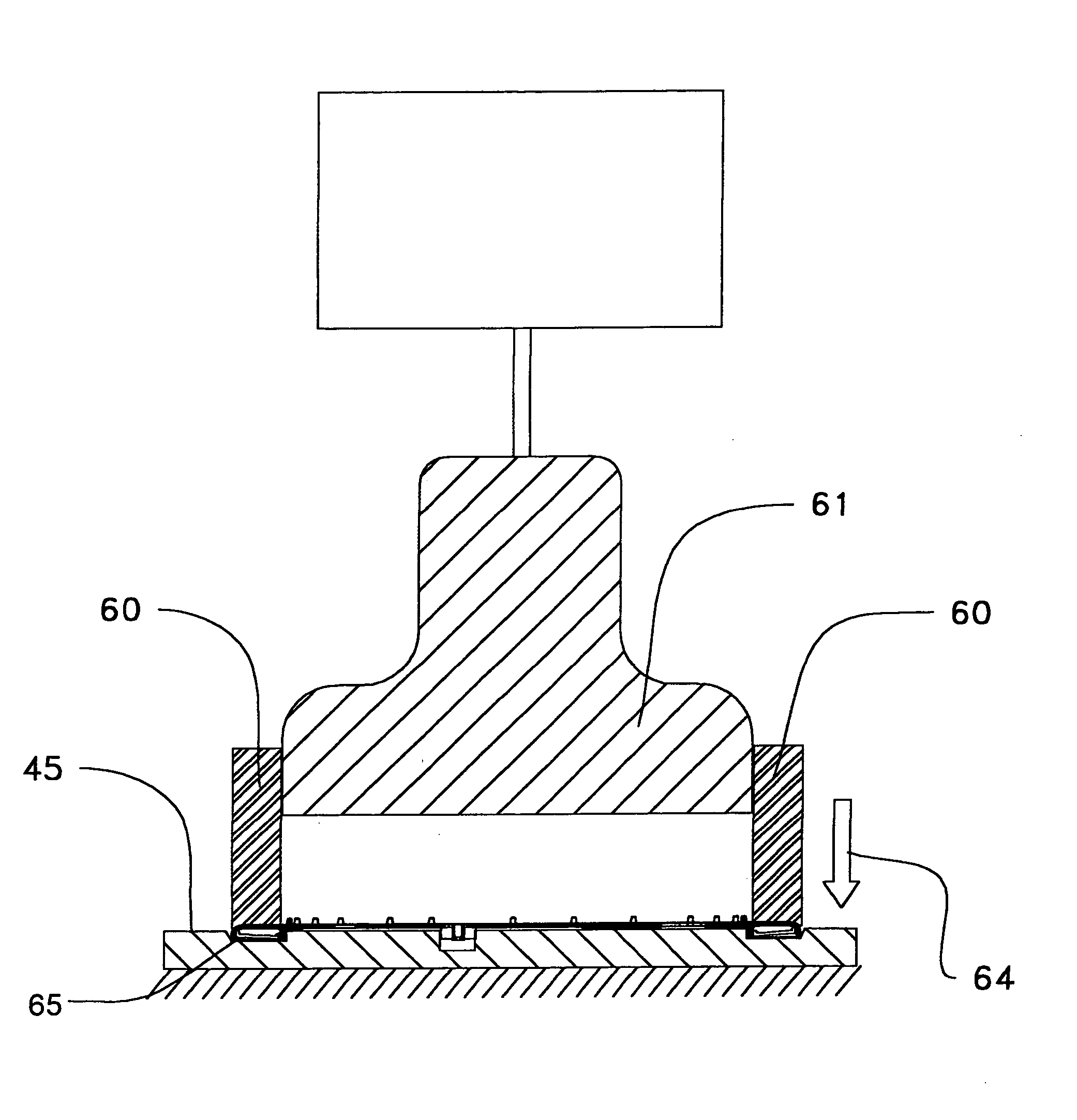

Method for assembling a package for sutures

InactiveUS20050034431A1Quick applicationReduce manufacturing costSuture equipmentsSurgical needlesEngineeringCounterbore

A novel method and apparatus for riveting a two-piece suture tray package. A two-piece suture tray assembly is provided having a top member and a bottom member. The top member has a top and a bottom, and plurality of rivet members extending down from the bottom of the top member. The rivet members have free ends. The bottom member has a top and a flat bottom surface, and a plurality of rivet receiving openings extending therethrough. A counterbore surrounds each rivet receiving opening in the flat bottom surface. An ultrasonic riveting apparatus is provided having a clamp member with a cavity, and an ultrasonic horn member having a flat bottom moveably mounted in the cavity The assembly is mounted in the riveting apparatus and engaged by the clamp member. The flat bottom of the horn member engages the free ends of the rivet members, and when energized by an ultrasonic generator, causes the free ends of the rivet members to deform into the counterbores, such that the free ends are flat and in alignment with the bottom surface of the bottom member.

Owner:ETHICON INC

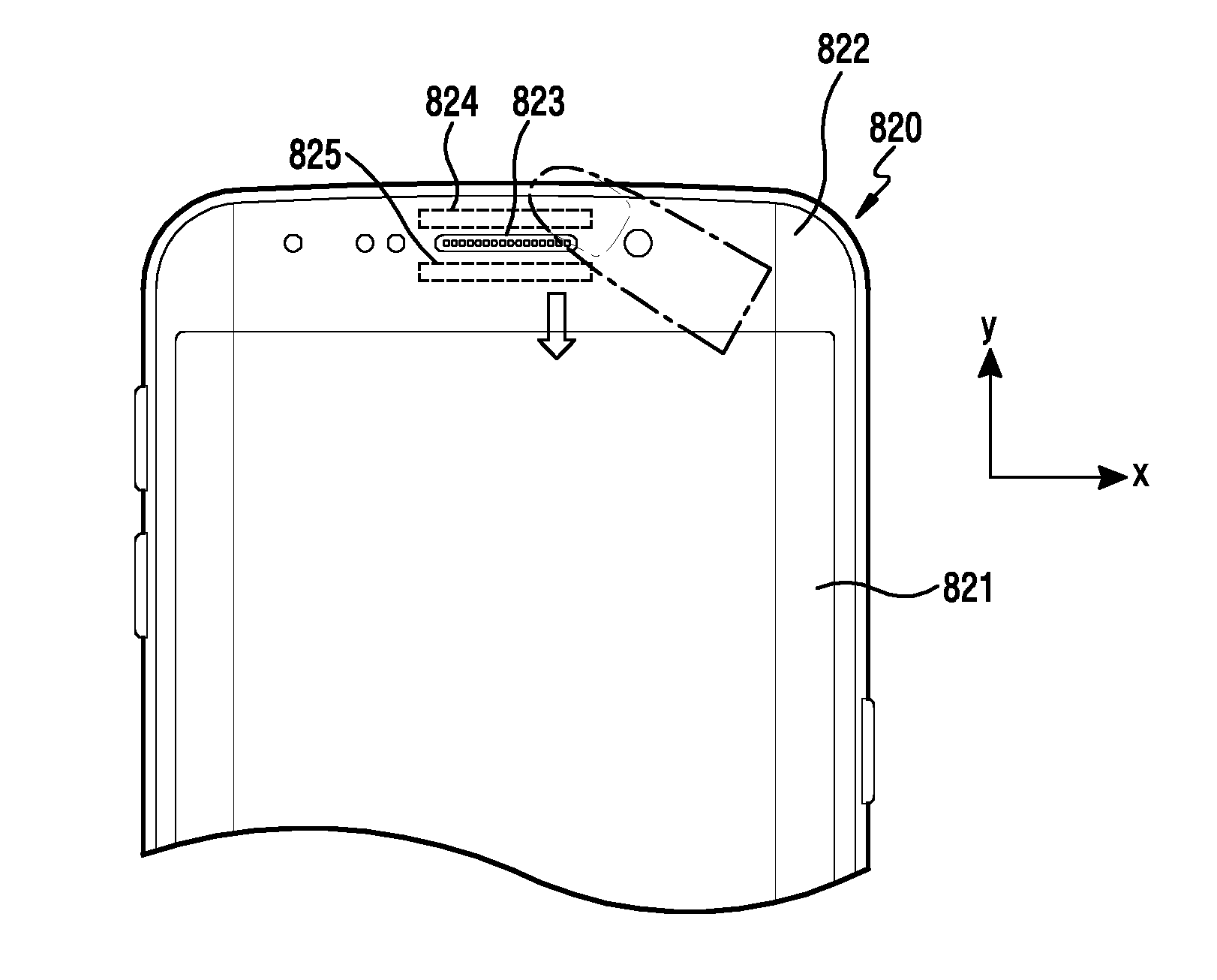

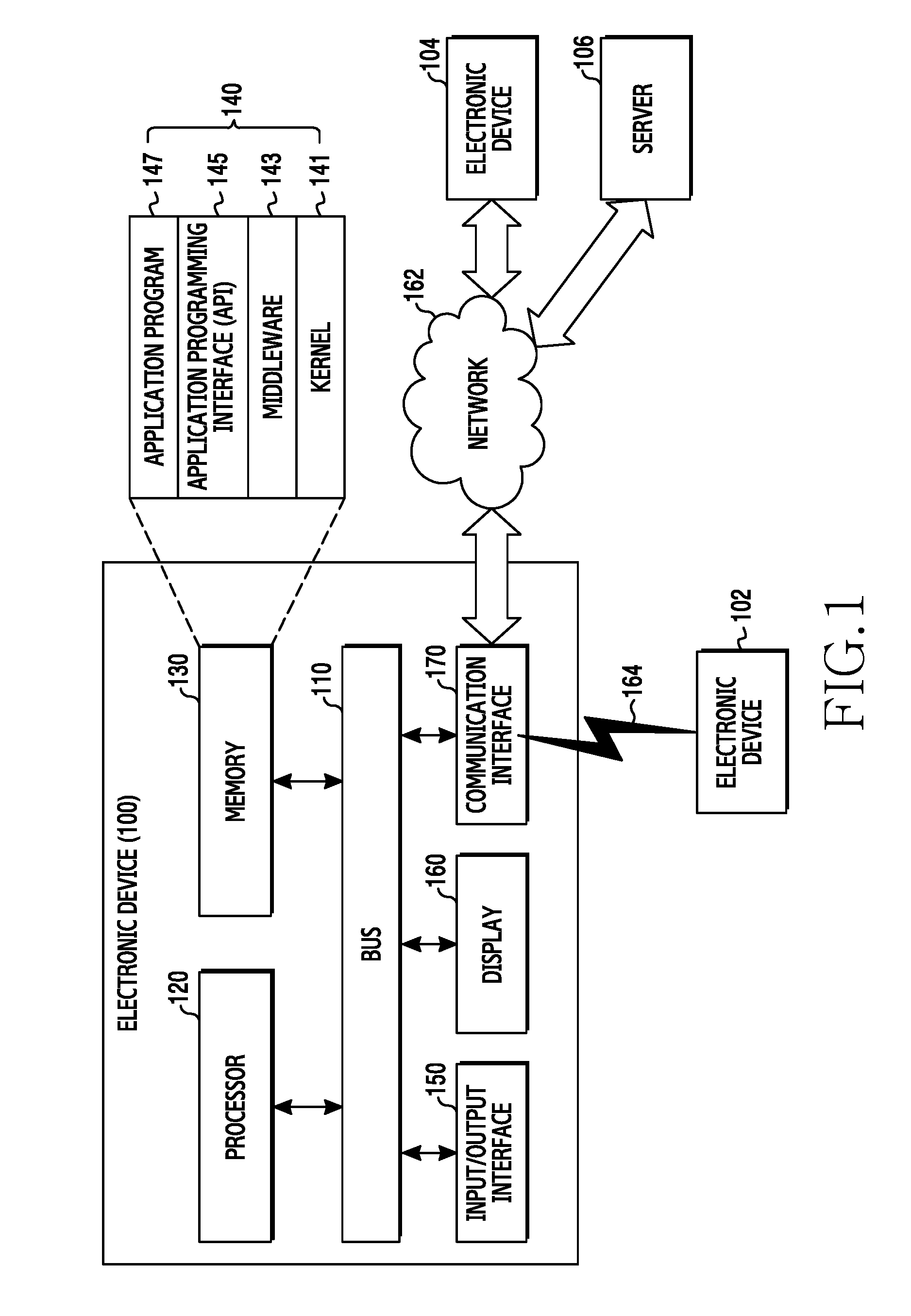

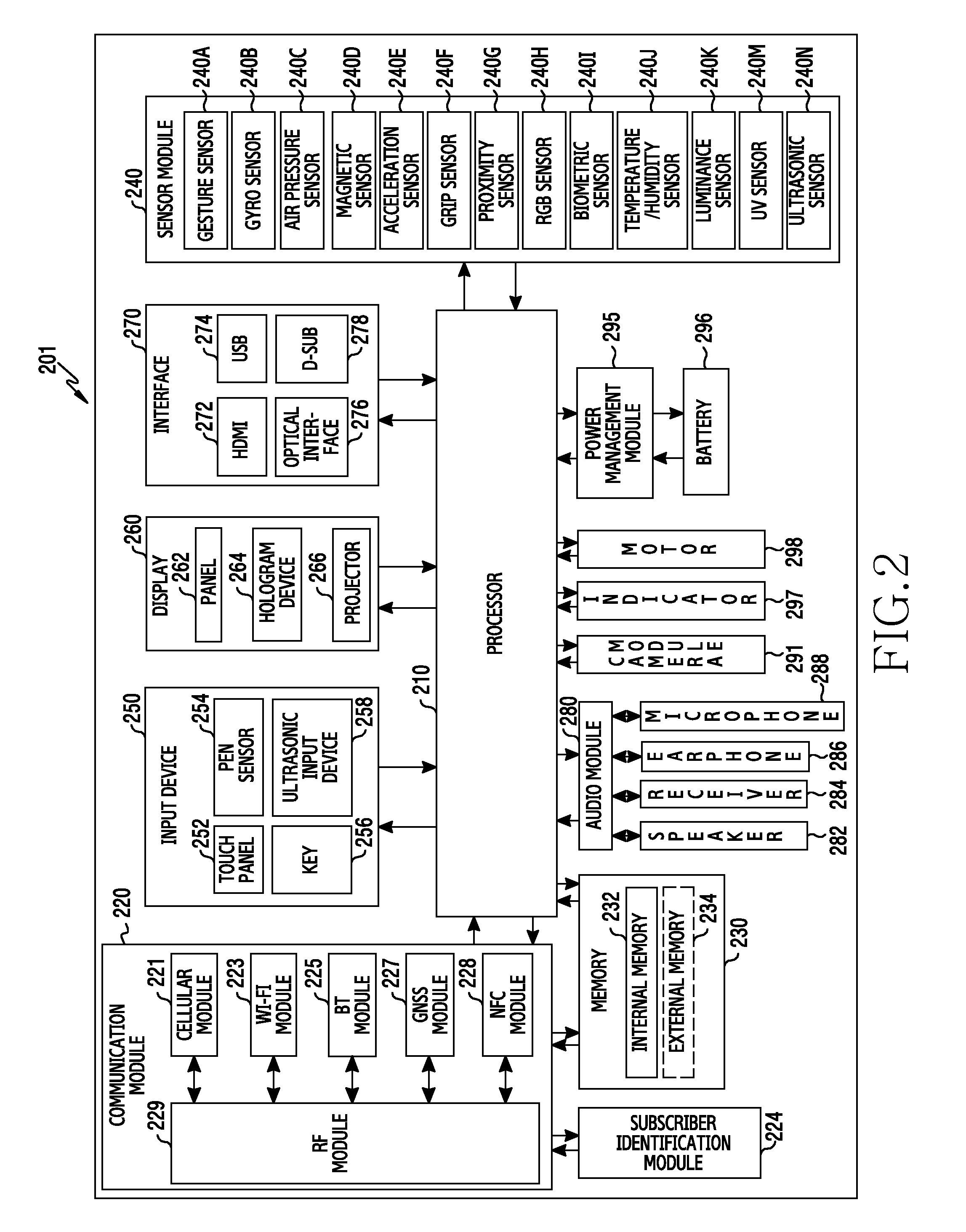

Method of recognizing surrounding environment and electronic device for the same

An electronic device is provided. The electronic device includes a housing, at least one ultrasonic wave generator and at least one ultrasonic sensor operatively disposed on the housing, and a processor electrically connected to the at least one ultrasonic wave generator and the at least one ultrasonic sensor and configured to emit ultrasonic waves from at least one surface of the housing using the at least one ultrasonic wave generator, receive reflected waves reflected from at least one object through the at least one ultrasonic sensor, and determine a proximity between the electronic device and the object based on at least a difference between a first time, at which the ultrasonic waves are emitted, and a second time, at which the reflected waves are received.

Owner:SAMSUNG ELECTRONICS CO LTD

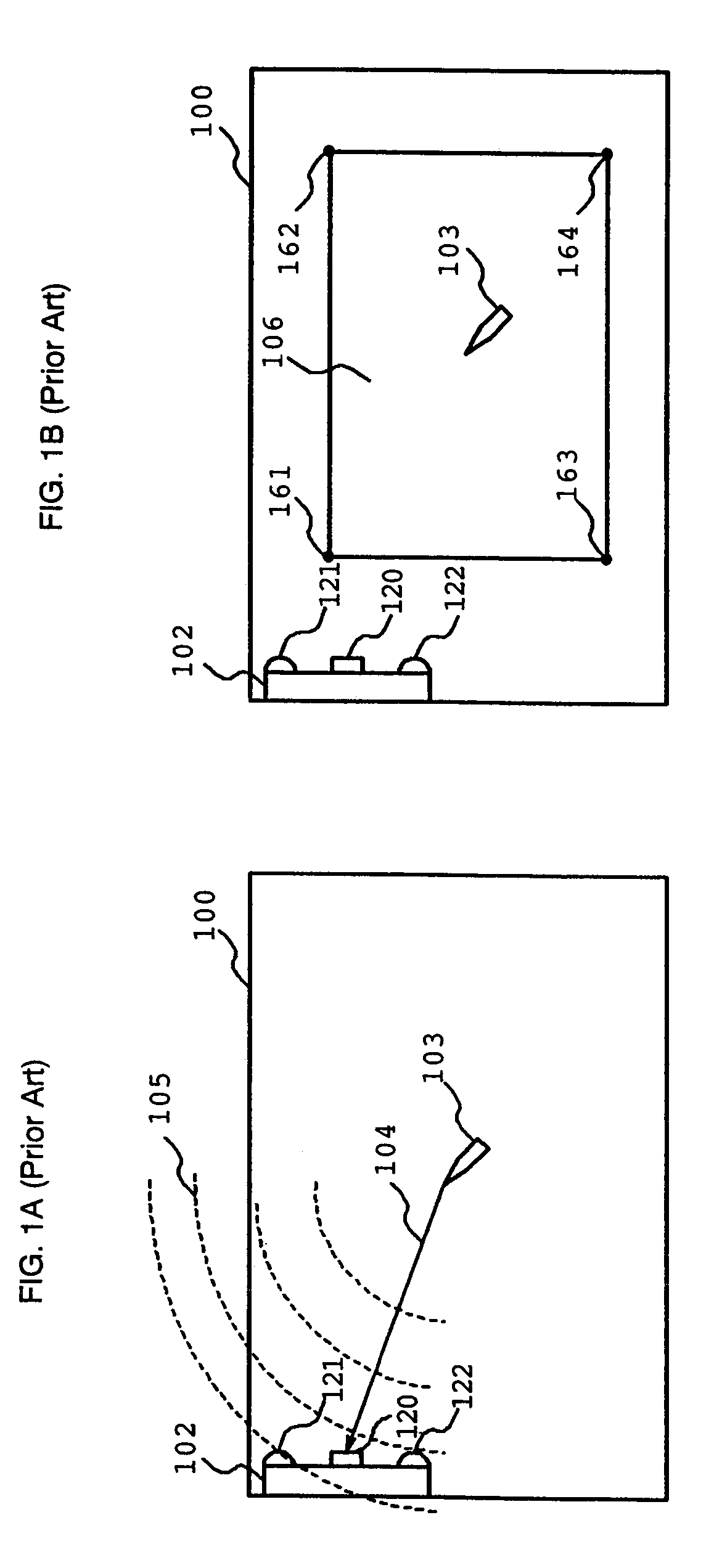

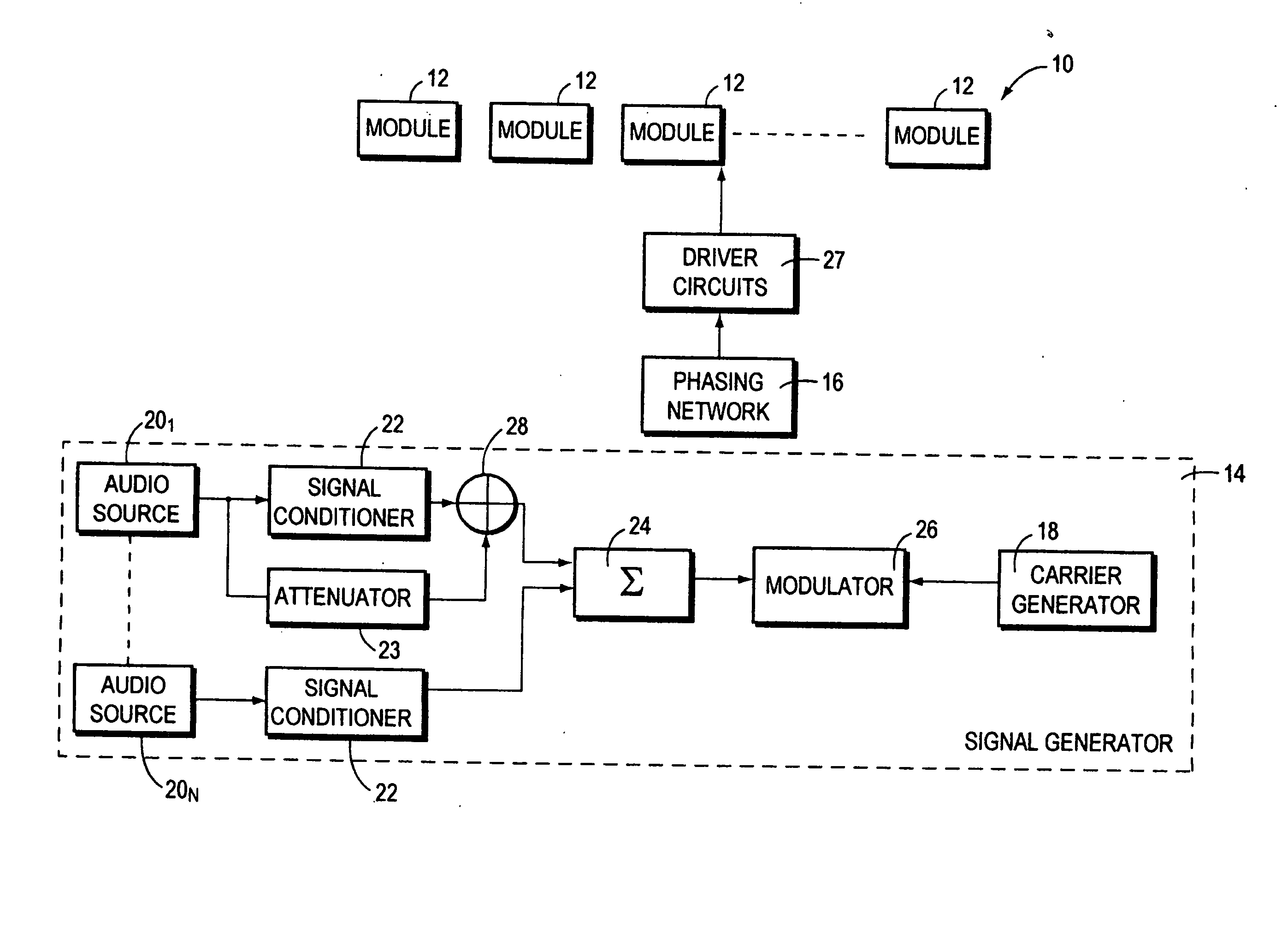

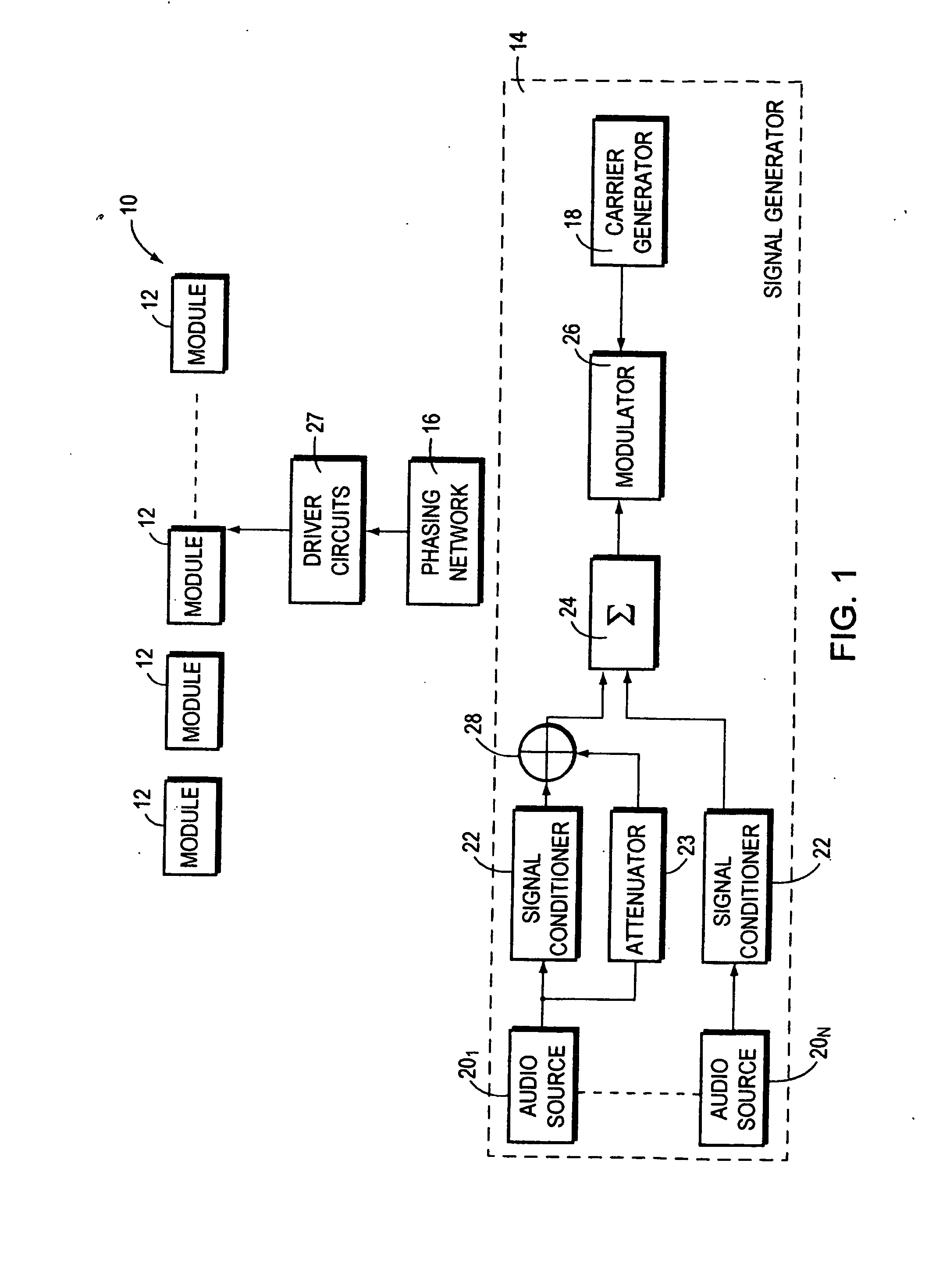

Parametric audio system

InactiveUS20050248233A1Reduce distortion problemsEnhanced harmonic effectUltrasonic/sonic/infrasonic diagnosticsPiezoelectric/electrostriction/magnetostriction machinesCarrier signalUltrasonic generator

Ultrasonic signals are used to transmit sounds from a modulated ultrasonic generator to other locations from which the sounds appear to emanate. In particular, an ultrasonic carrier is modulated with an audio signal and demodulated on passage through the atmosphere. The carrier frequencies are substantially higher than those of prior systems, e.g., at least 60 kHz, and the modulation products thus have frequencies which are well above the audible range of humans; as a result, these signals are likely harmless to individuals who are within the ultrasonic fields of the system. The signals may be steered to moving locations, and various measures are taken to minimize distortion and maximize efficiency.

Owner:MASSACHUSETTS INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com