Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2534 results about "High frequency vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

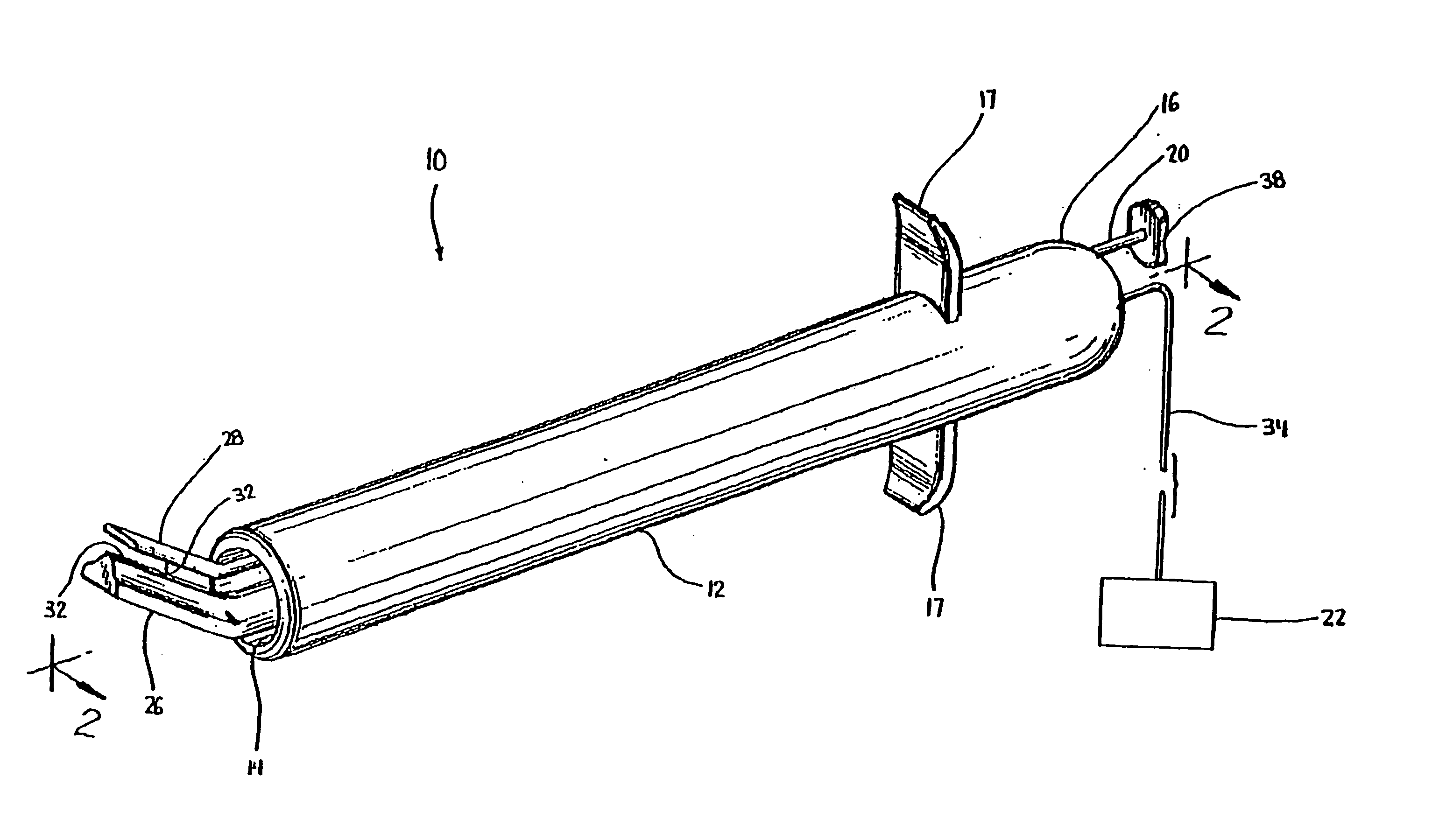

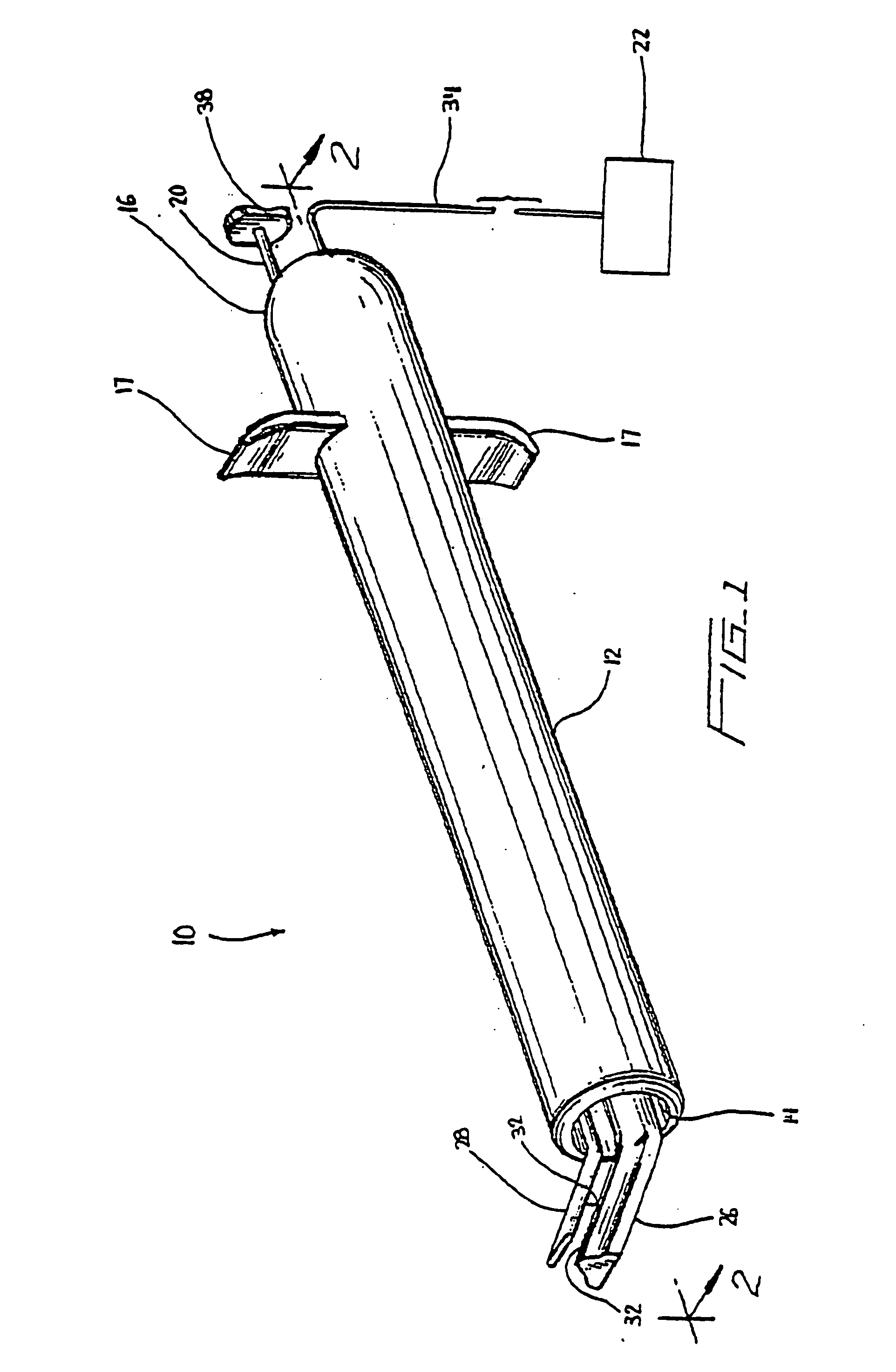

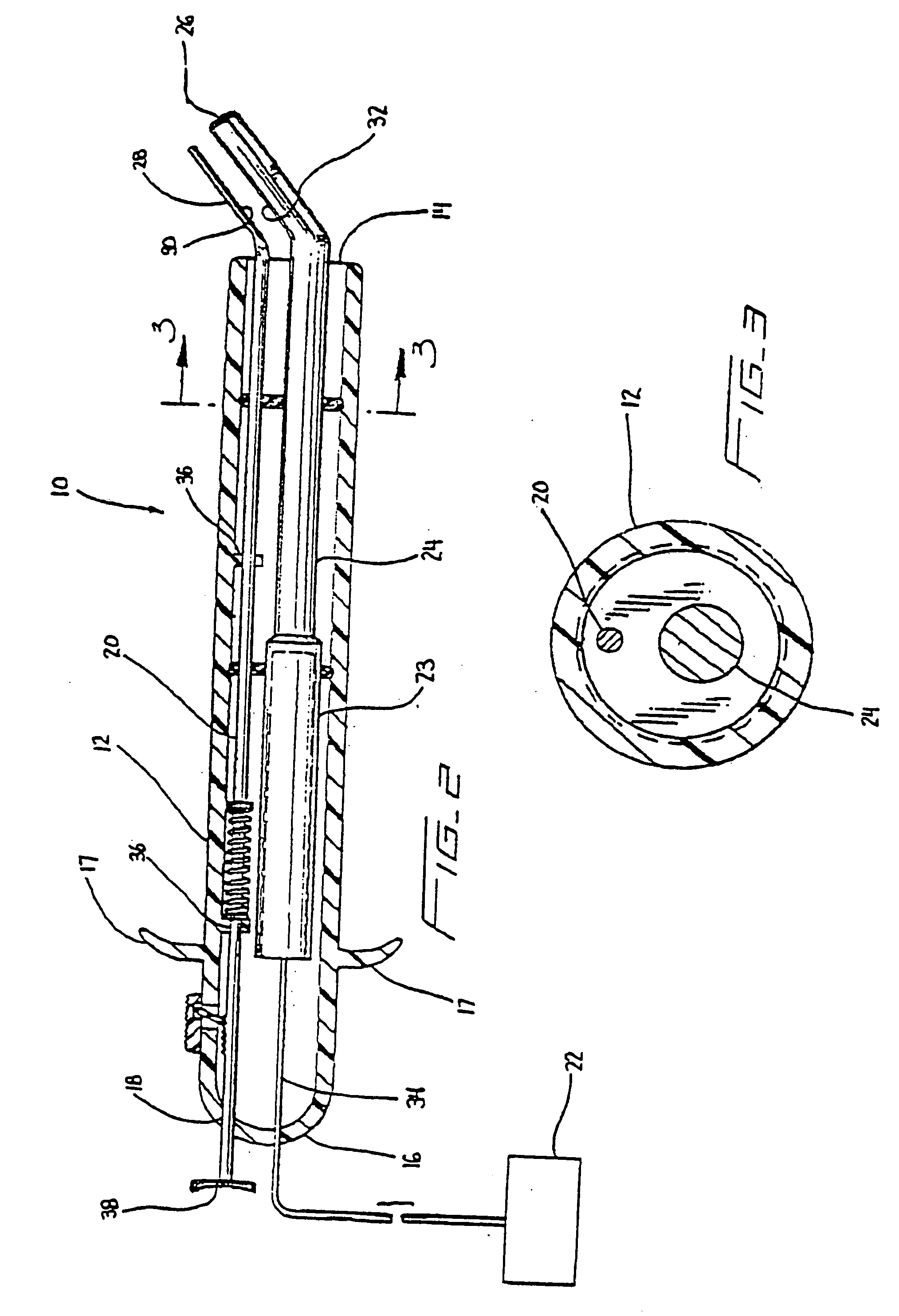

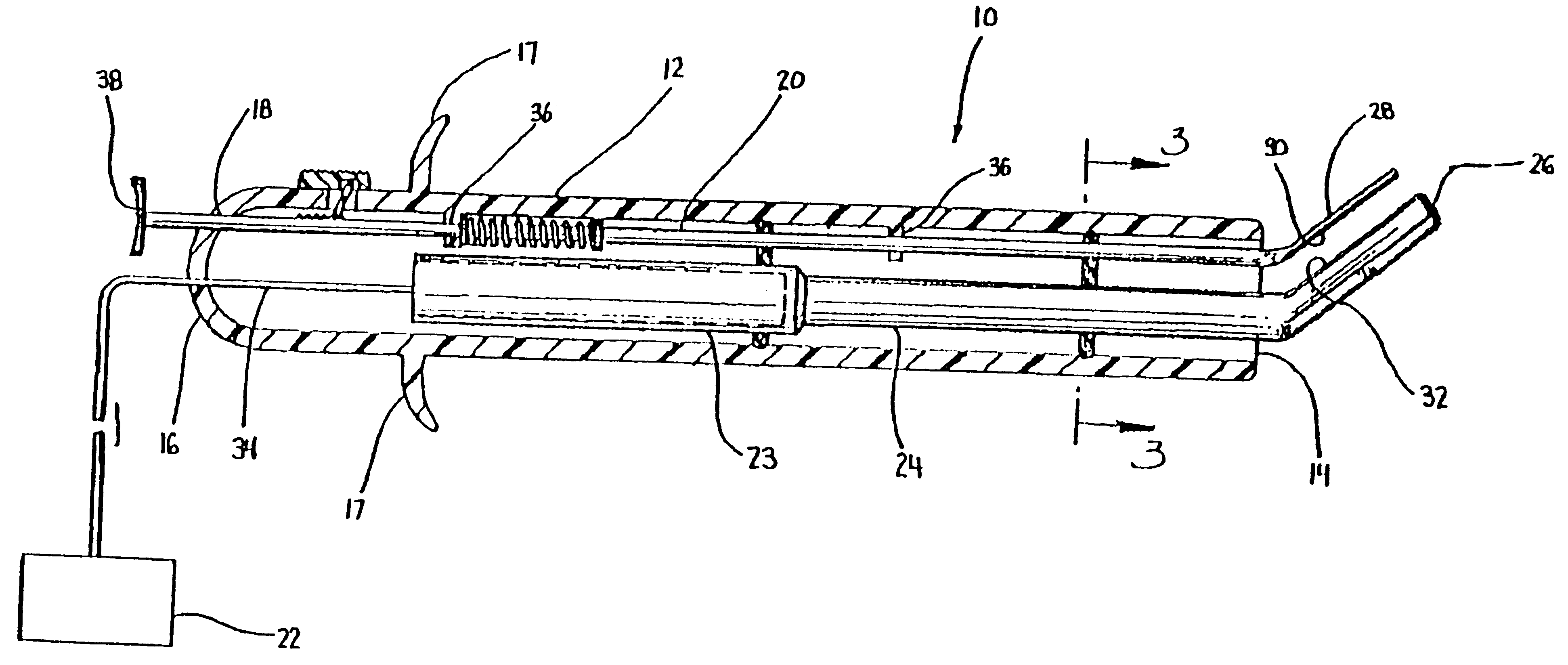

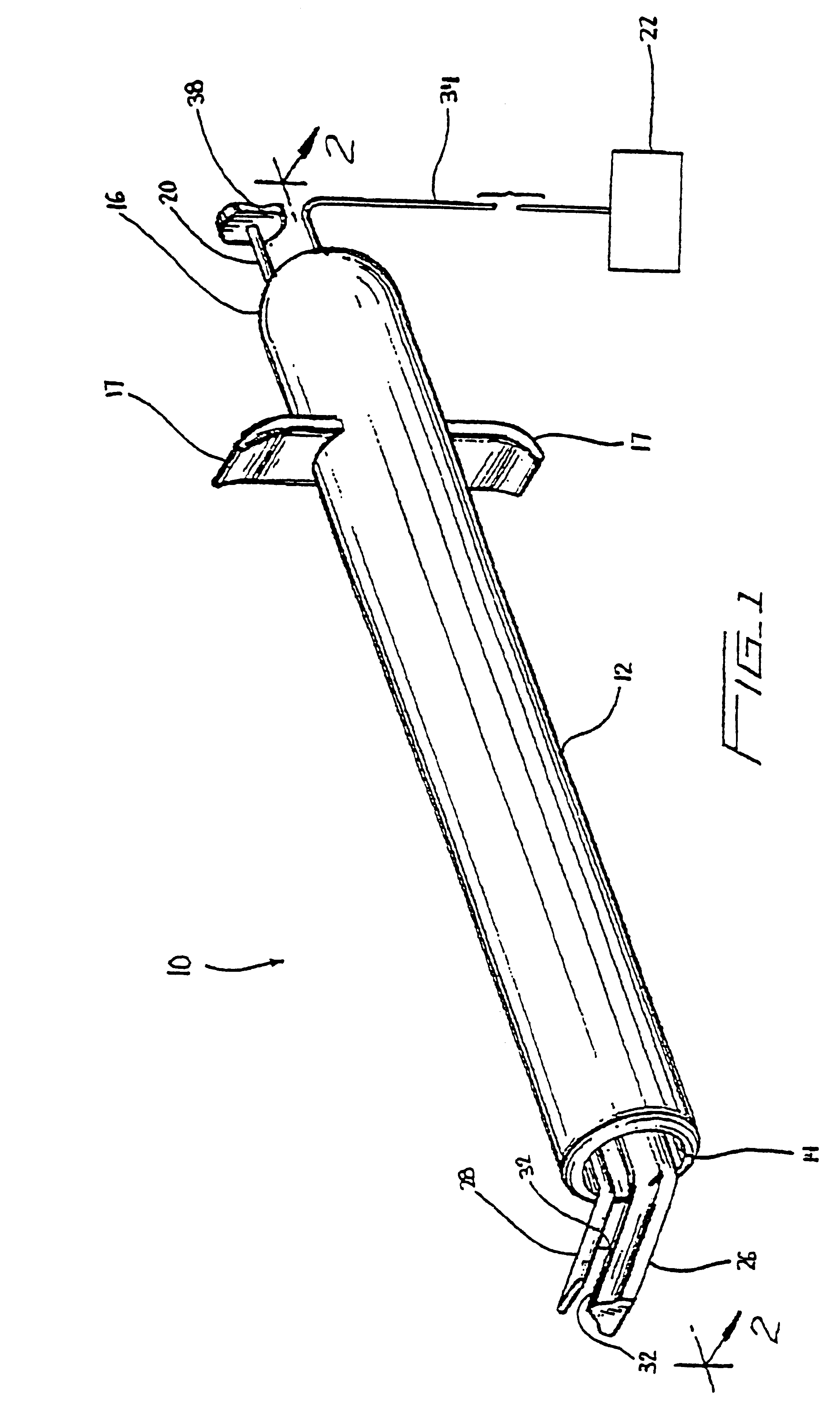

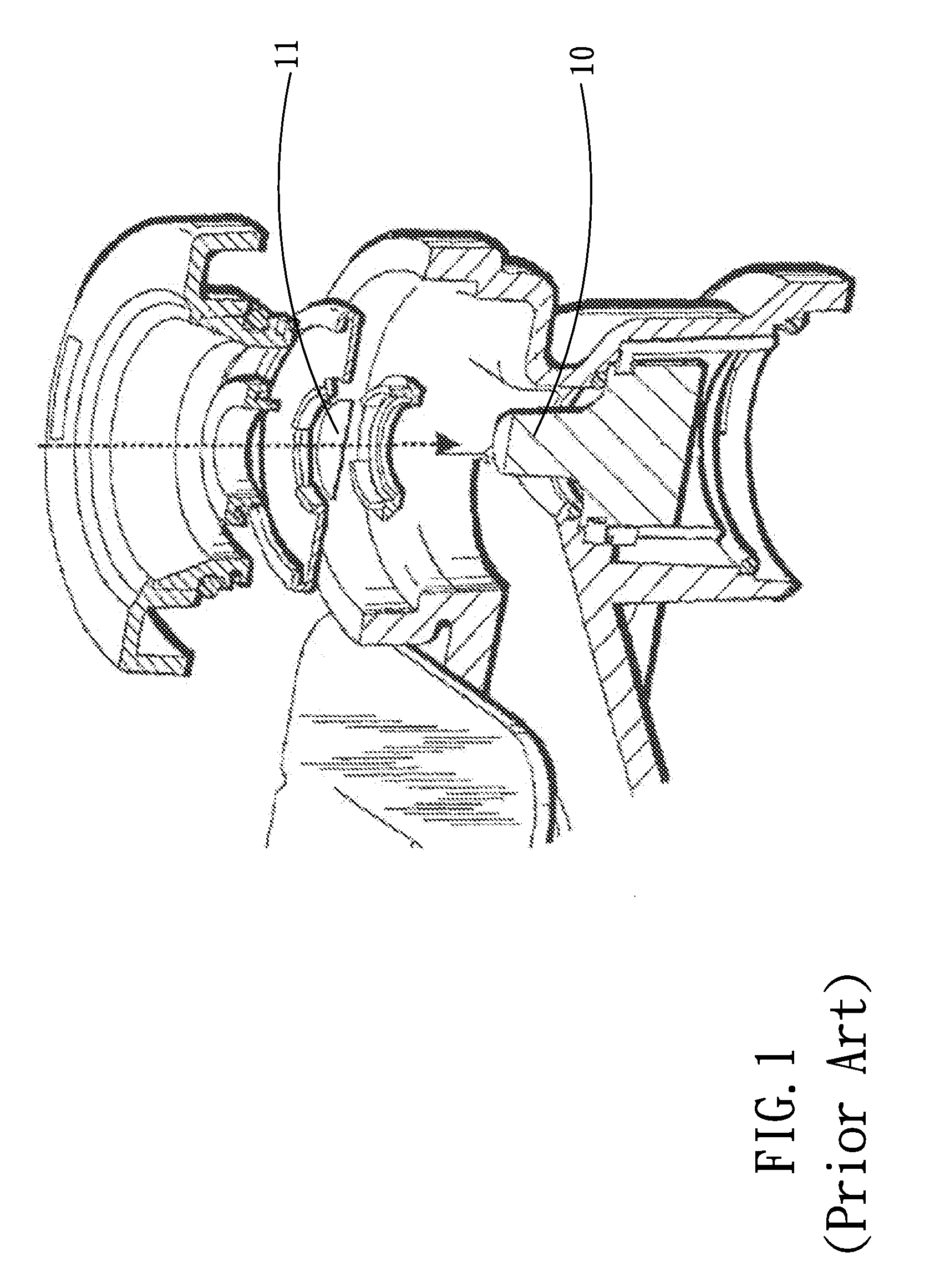

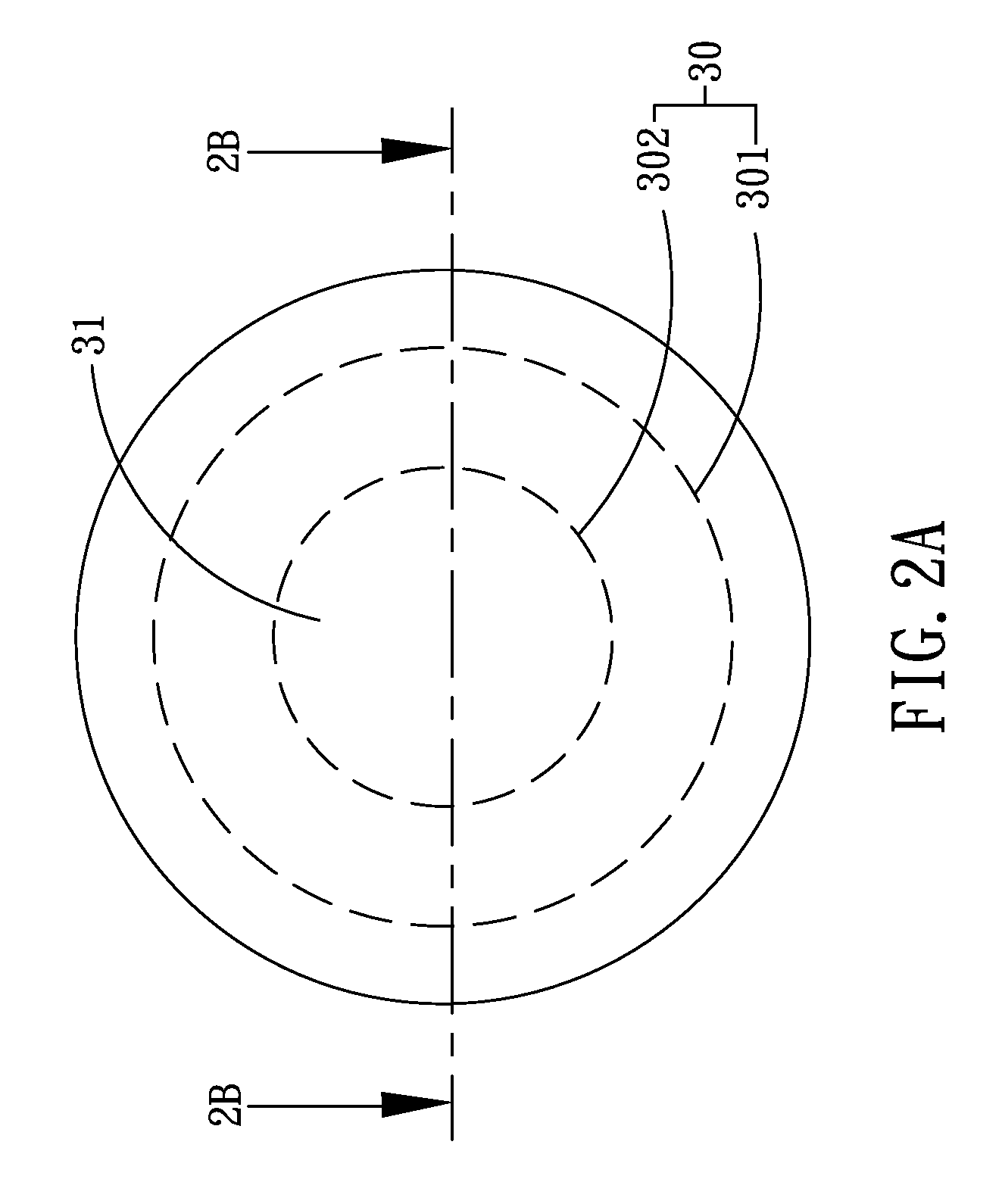

Ultrasonic dissector

InactiveUS20050143769A1Smooth connectionImprove instrument performanceSurgical forcepsEngineeringHigh frequency vibration

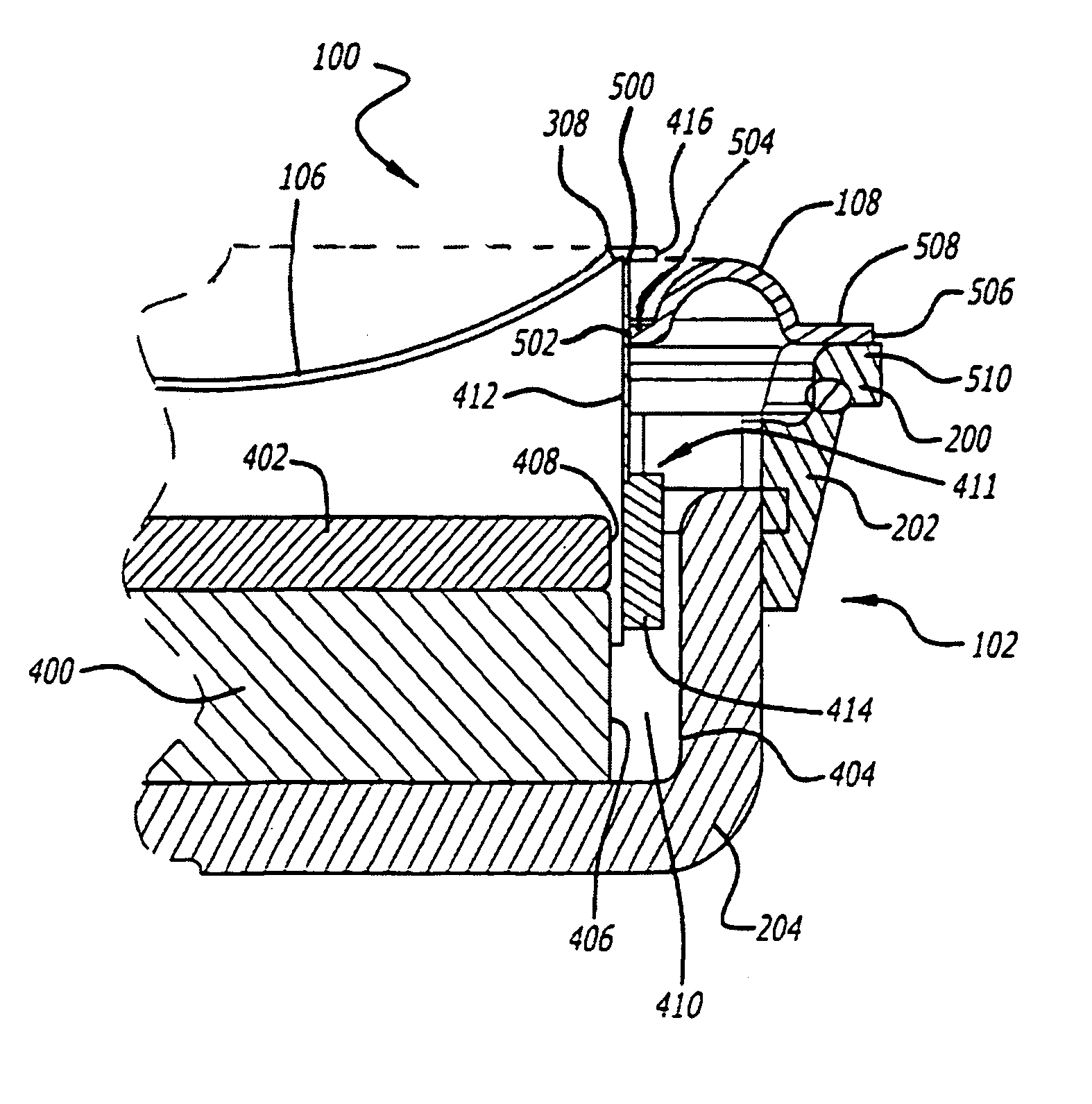

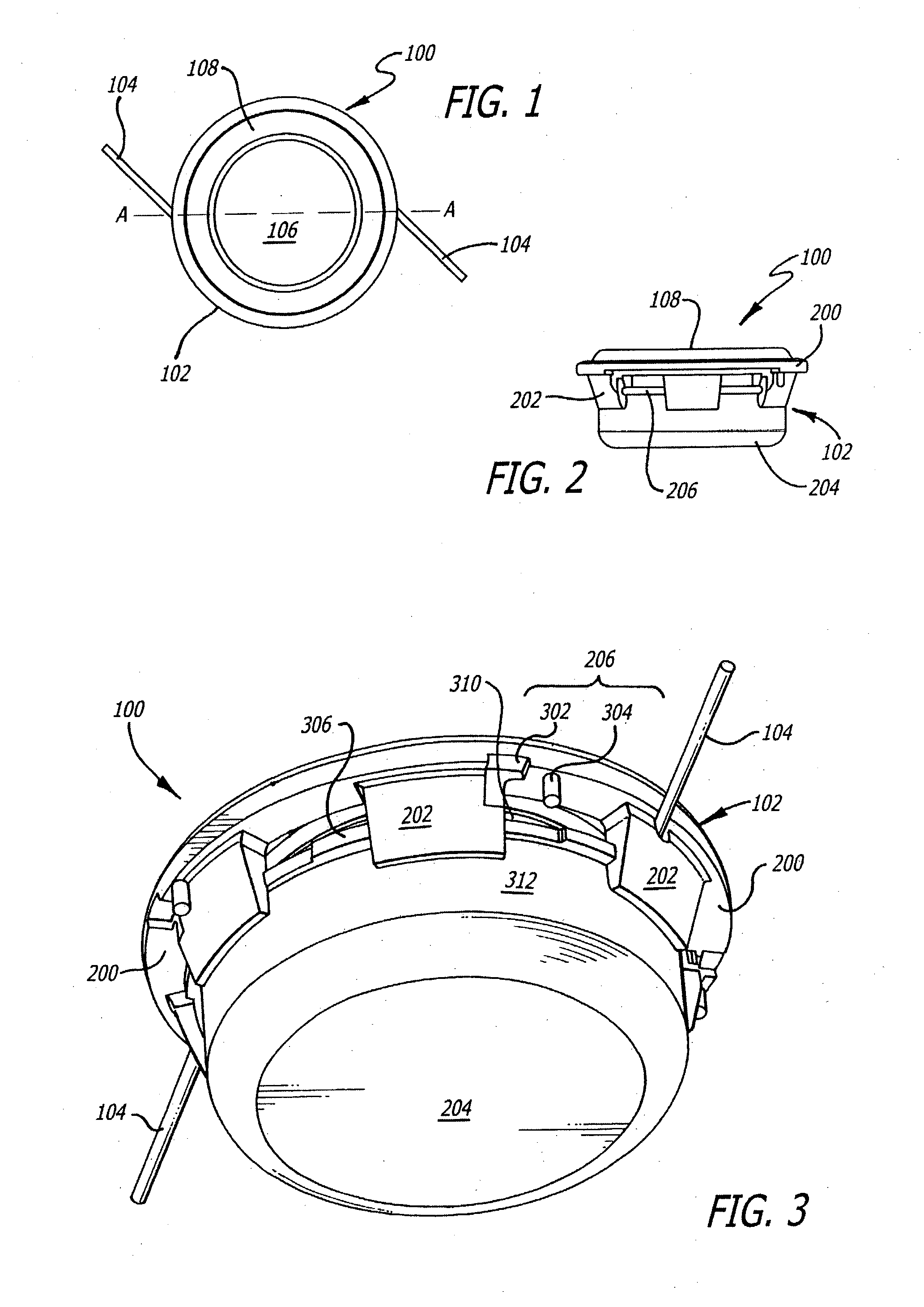

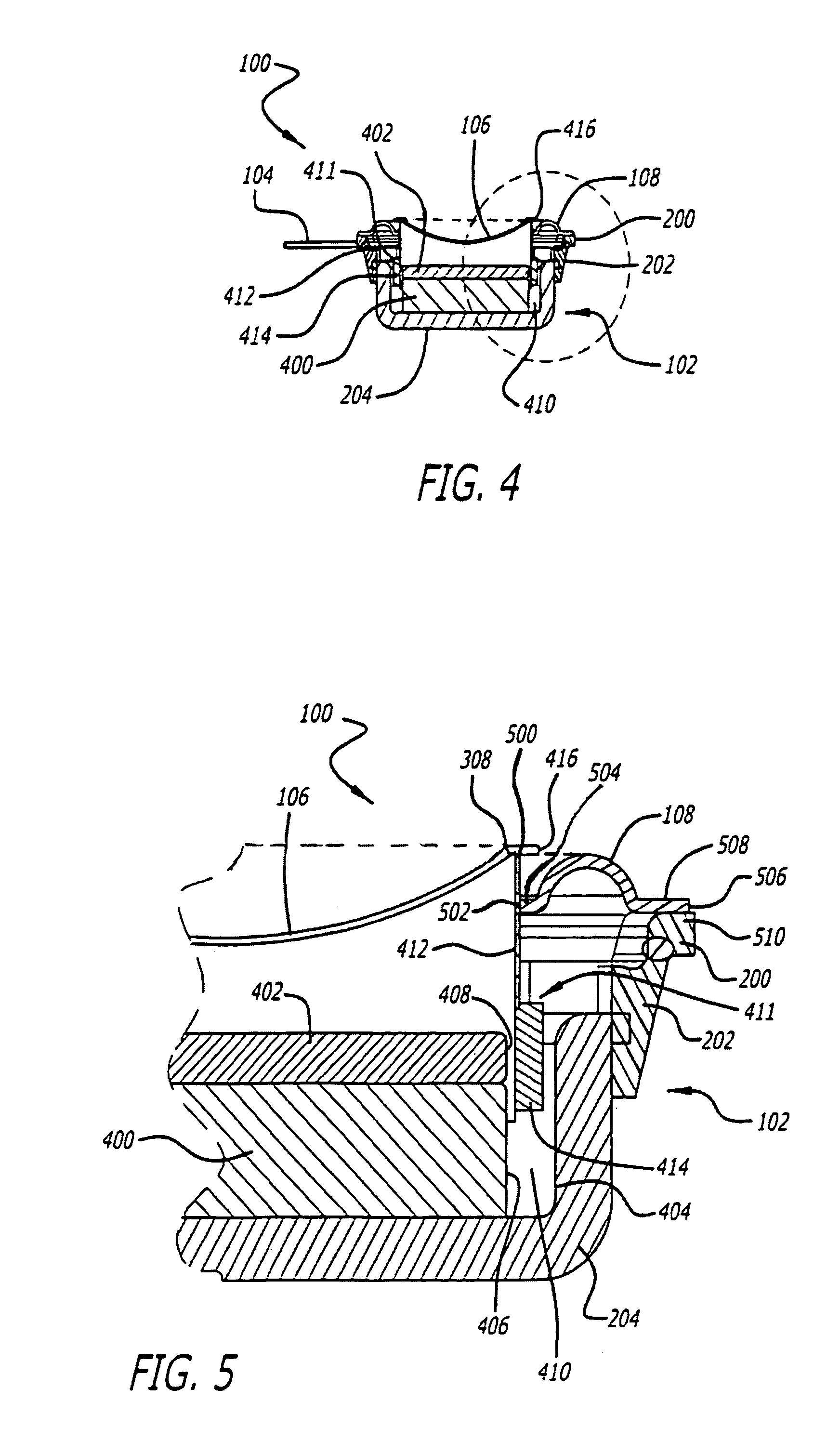

An ultrasonic surgical instrument for dissection and coaguation of tissue is provided. The surgical instrument includes a vibration coupler supported within a housing and operably connected to an ultrasonic generator. An angled blade member is connected to the distal end of the vibration coupler to conduct high frequency vibration from the ultrasonic generator to the blade member. A clamp member is positioned adjacent to the blade member and is movable from a first position to a second approximated position. The clamp member and angled blade member combine to enhance contact between the tissue and the blade member during operation of the instrument to improve the performance of the instrument.

Owner:WHITE JEFFREY S +3

Ultrasonic dissector

InactiveUS6869439B2Smooth connectionImprove instrument performanceSurgical forcepsEngineeringSurgical department

An ultrasonic surgical instrument for dissection and coagulation of tissue is provided. The surgical instrument includes a vibration coupler supported within a housing and operably connected to an ultrasonic generator. An angled blade member is connected to the distal end of the vibration coupler to conduct high frequency vibration from the ultrasonic generator to the blade member. A clamp member is positioned adjacent to the blade member and is movable from a first position to a second approximated position. The clamp member and angled blade member combine to enhance contact between the tissue and the blade member during operation of the instrument to improve the performance of the instrument.

Owner:UNITED STATES SURGICAL CORP +1

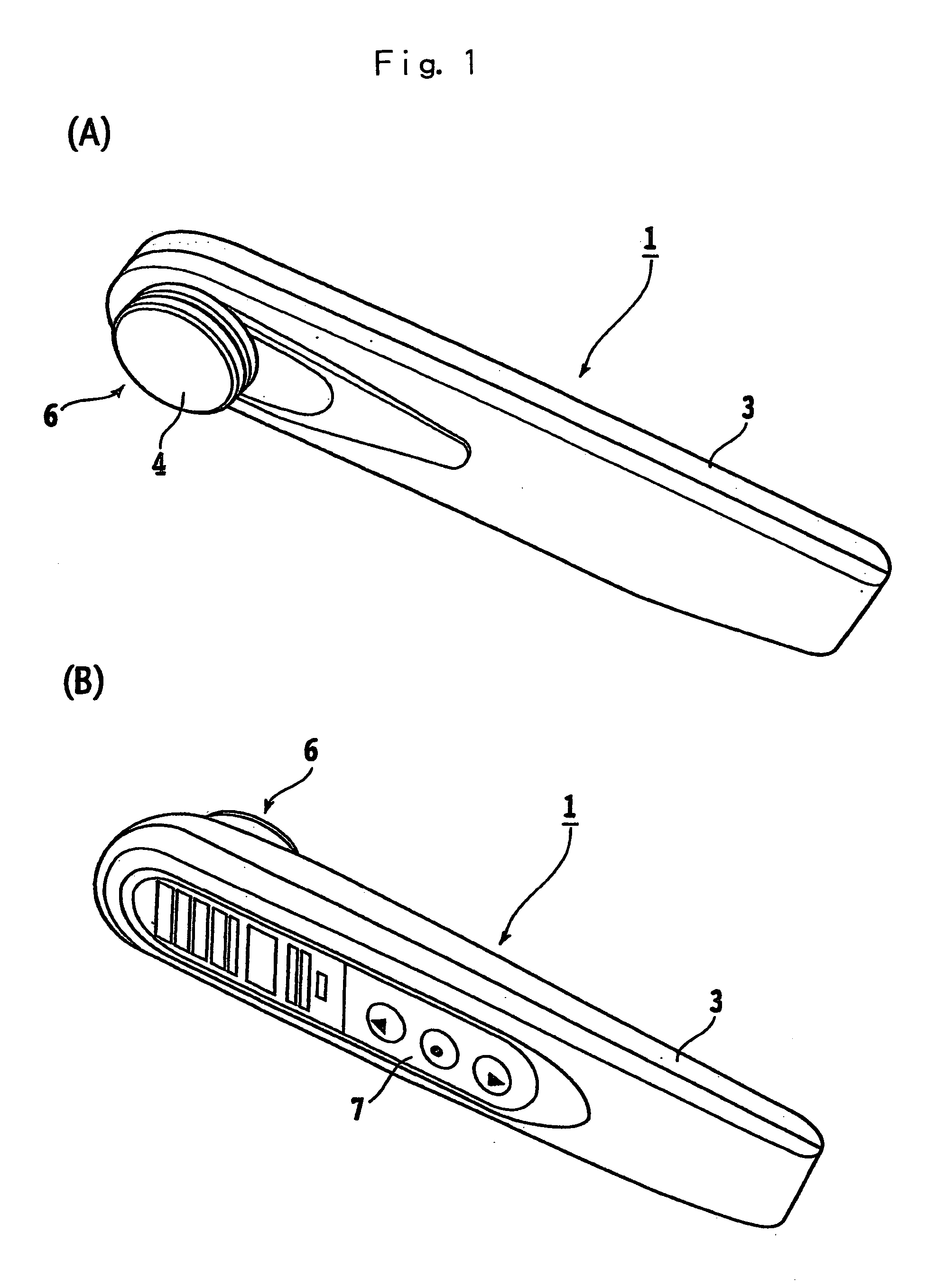

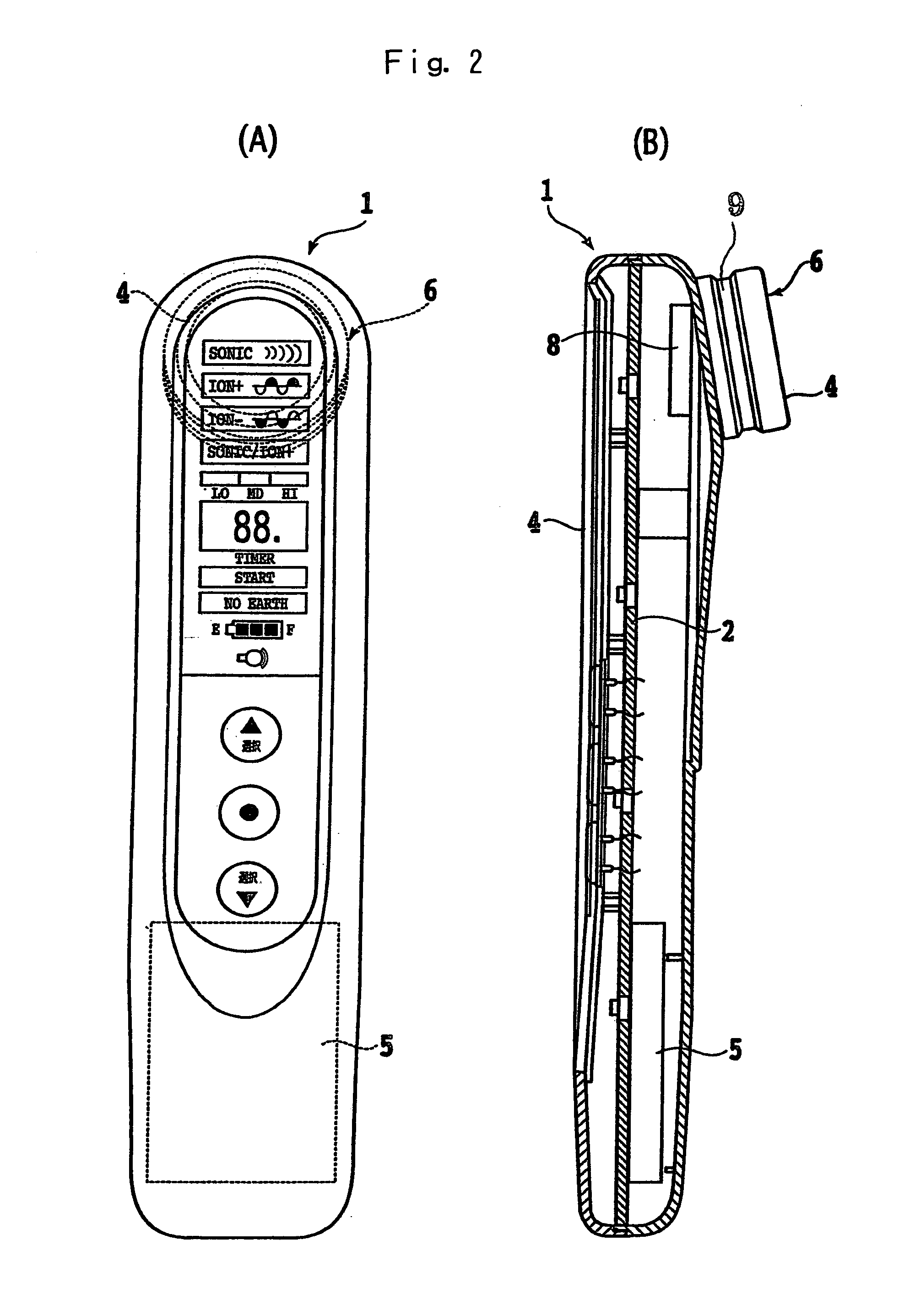

Skin beautification cosmetic system using iontophoresis device, ultrasonic facial stimulator, and cosmetic additive

InactiveUS20050191252A1Skin safeImprove responseCosmetic preparationsElectrotherapyAging skinsCosmetic component

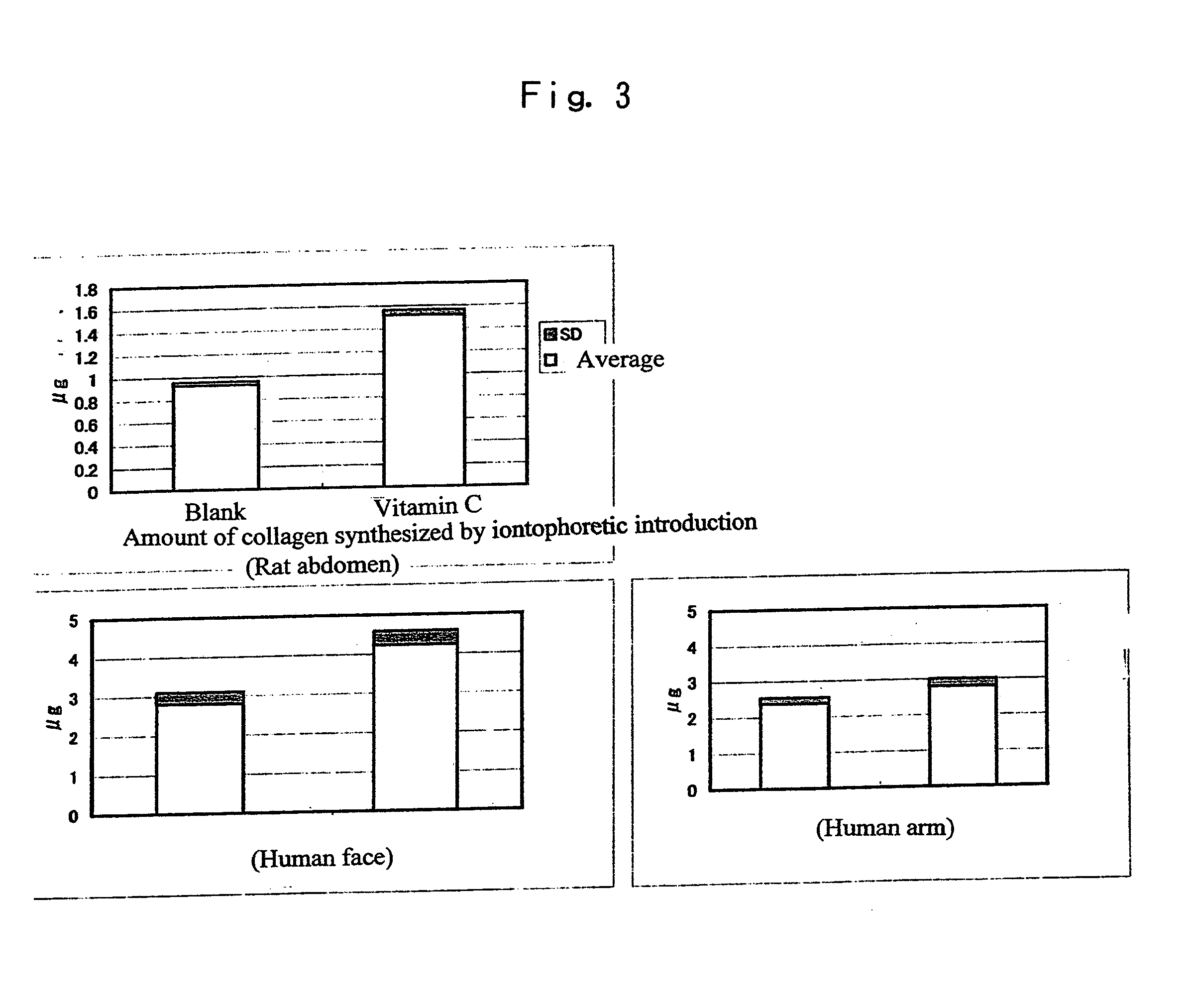

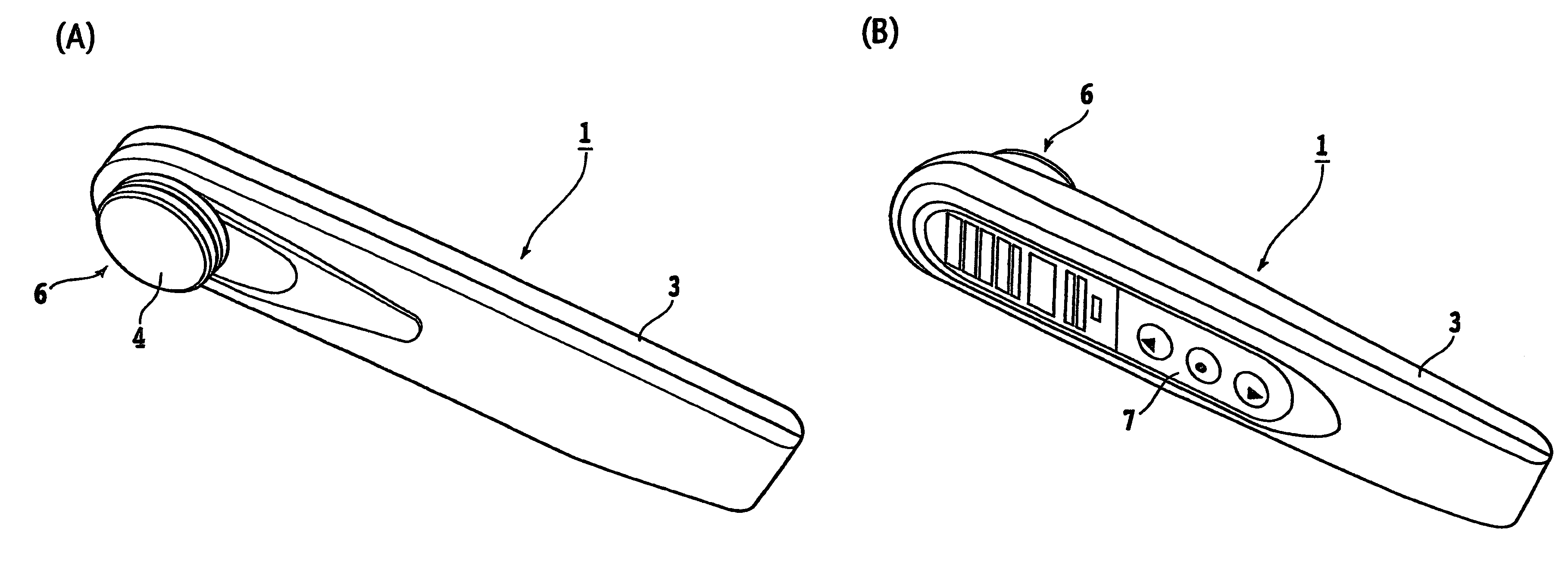

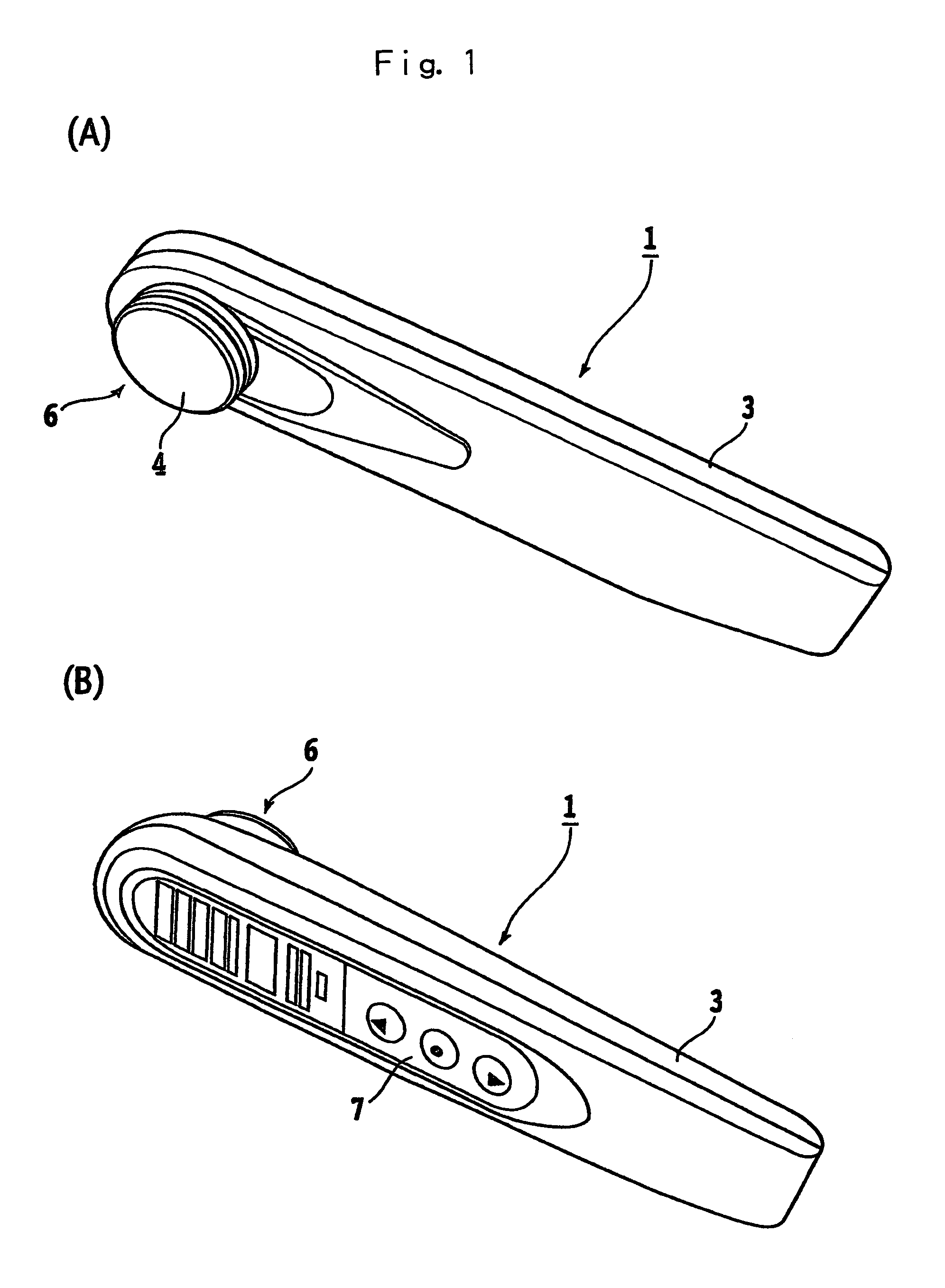

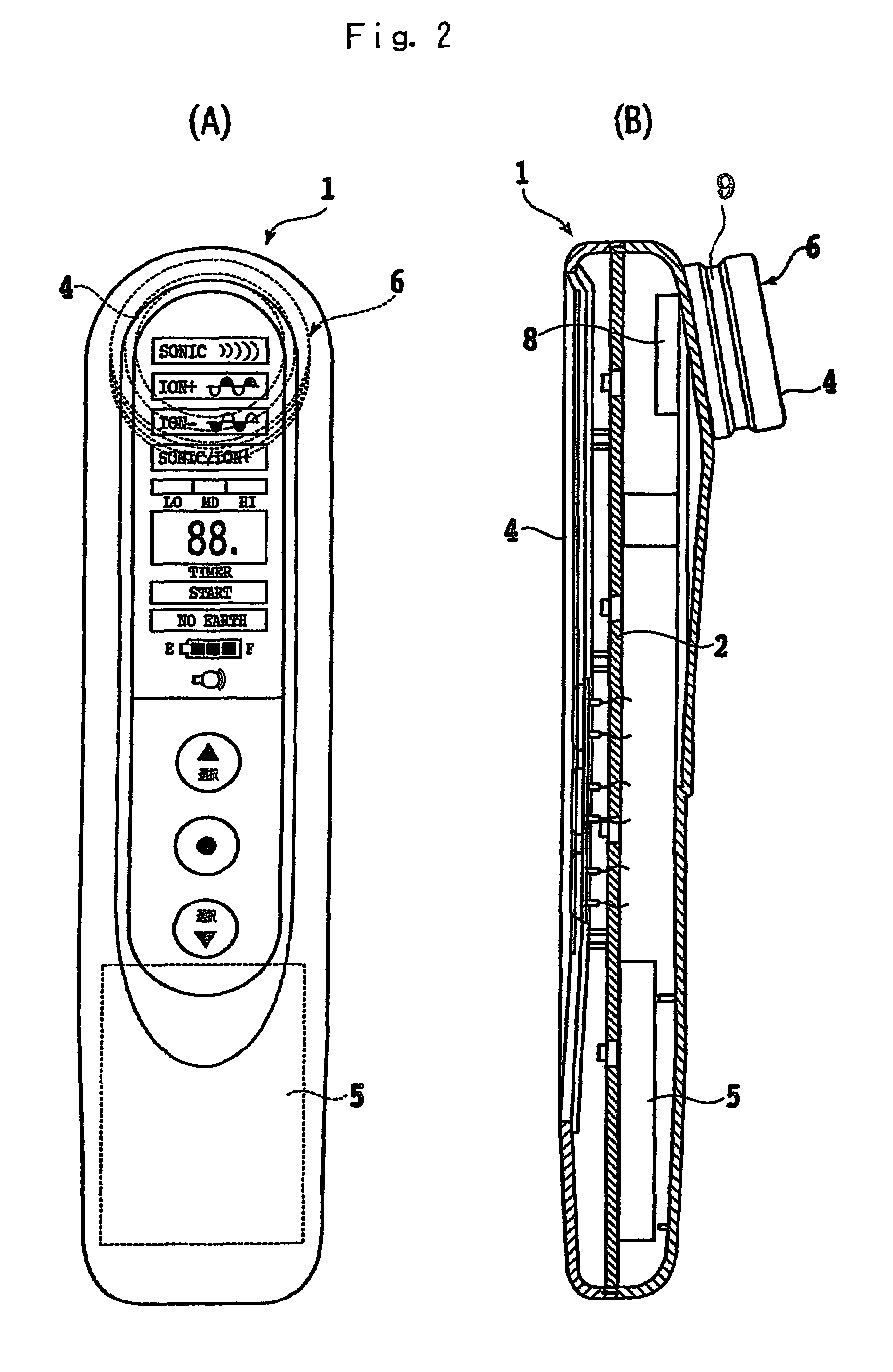

A skin beautification cosmetic system comprising an iontophoresis device, an infrared (including far infrared) generator, an ultrasonic vibrator, and a cosmetic composition is disclosed. The system ensures effective action of moisturizing and whitening cosmetics without causing any problem in the skin. By specifying the type of cosmetic to be used, the system can ensure a more effective beautification action, can improve dry skin and aging skin which adversely affect the female skin, and can decompose and remove melanin. Moisturizing and / or whitening cosmetic components such as hydrophilic gel and ultrafine gel are applied to the face or skin or impregnated in a skin contact member section, following which iontophoresis high frequency vibration is applied to the face or skin for a prescribed period of time using an ultrasonic vibrator 3 with built-in high ionization iontophoresis device 2 and infrared generator 9.

Owner:JAPAN NATURAL LAB

Skin beautification cosmetic system using iontophoresis device, ultrasonic facial stimulator, and cosmetic additive

InactiveUS7427273B2Good effectPromote blood circulationCosmetic preparationsElectrotherapyAging skinsCosmetic component

A skin beautification cosmetic system comprising an iontophoresis device, an infrared (including far infrared) generator, an ultrasonic vibrator, and a cosmetic composition is disclosed. The system ensures effective action of moisturizing and whitening cosmetics without causing any problem in the skin. By specifying the type of cosmetic to be used, the system can ensure a more effective beautification action, can improve dry skin and aging skin which adversely affect the female skin, and can decompose and remove melanin. Moisturizing and / or whitening cosmetic components such as hydrophilic gel and ultrafine gel are applied to the face or skin or impregnated in a skin contact member section, following which iontophoresis high frequency vibration is applied to the face or skin for a prescribed period of time using an ultrasonic vibrator 3 with built-in high ionization iontophoresis device 2 and infrared generator 9.

Owner:JAPAN NATURAL LAB

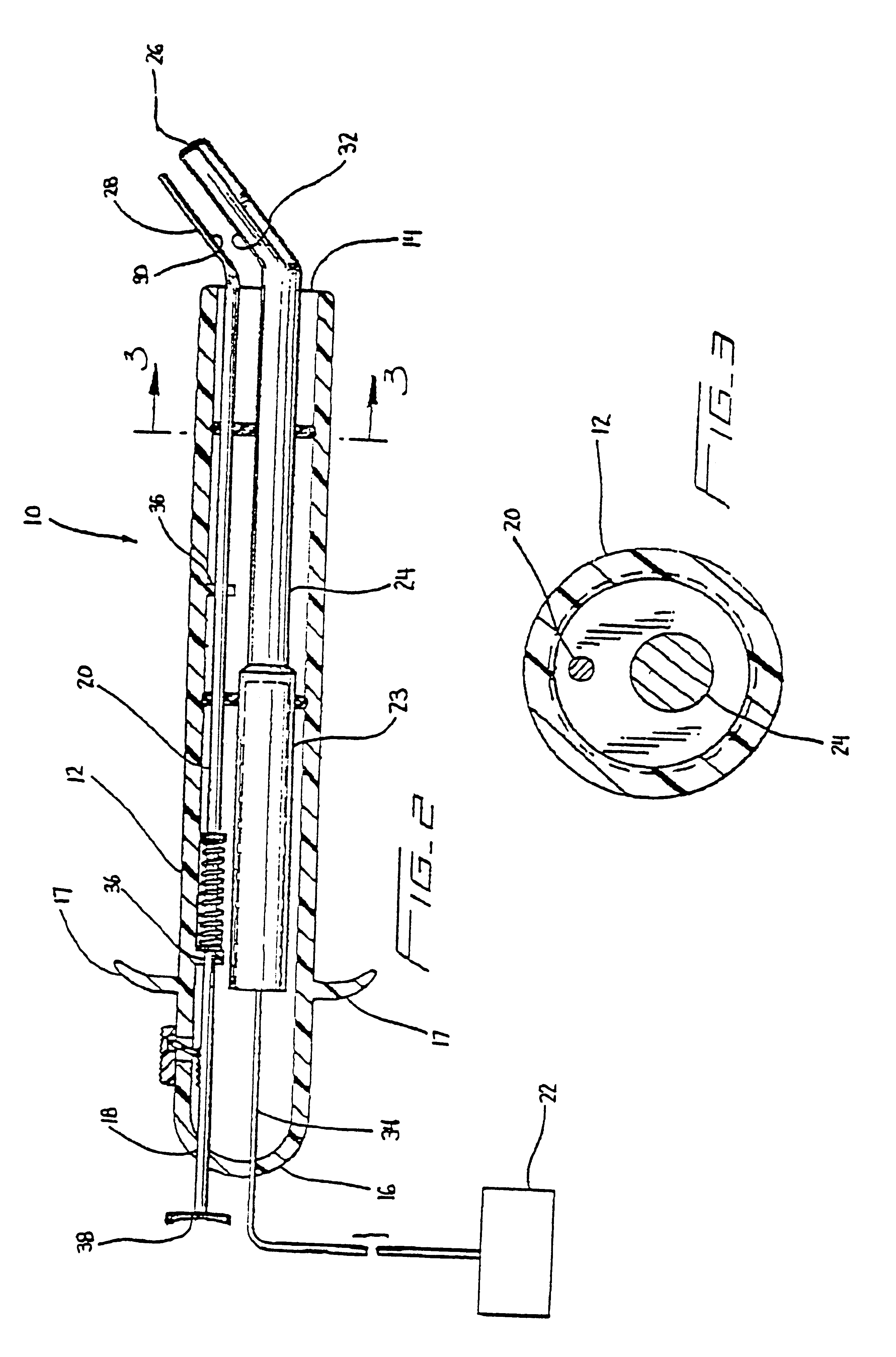

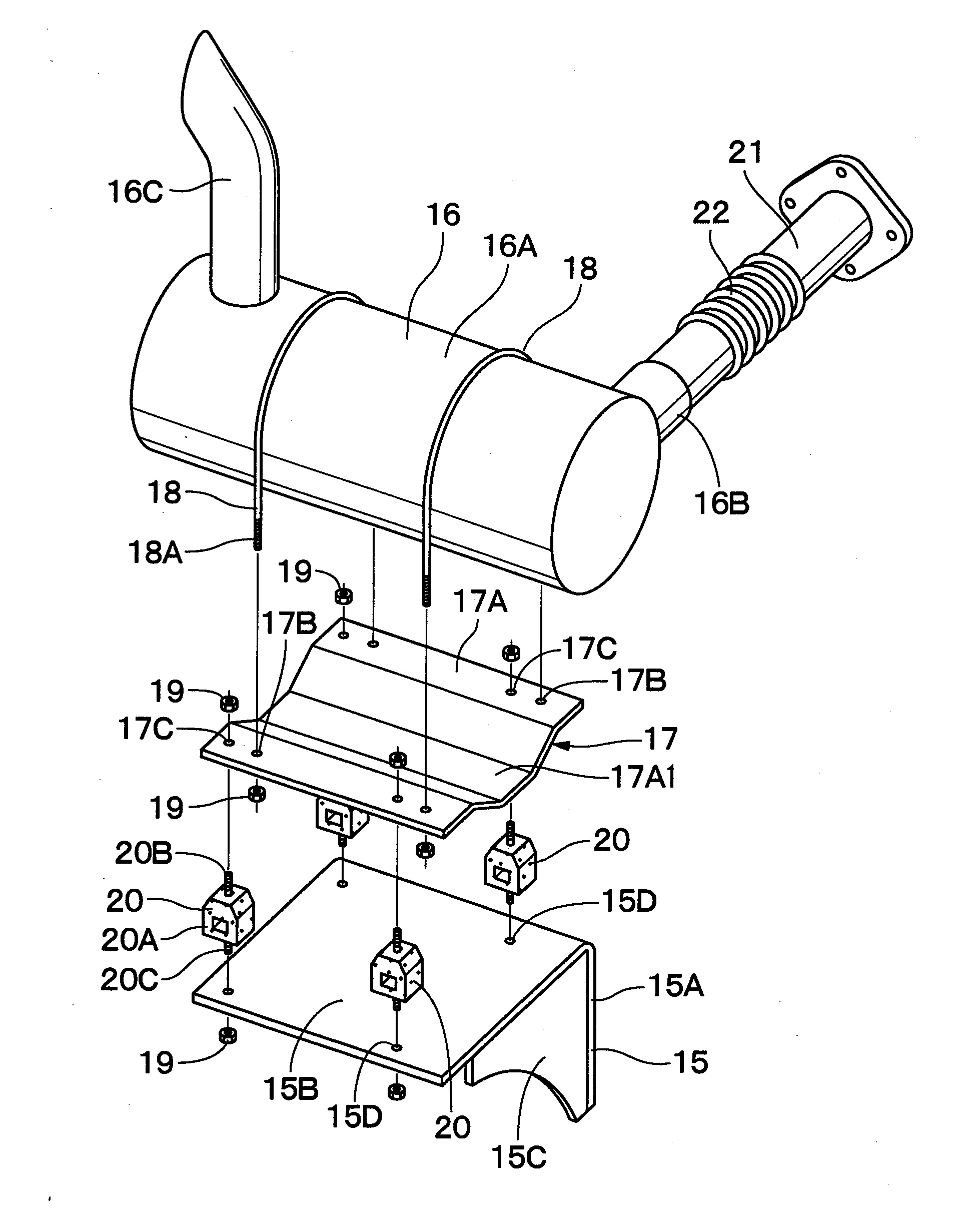

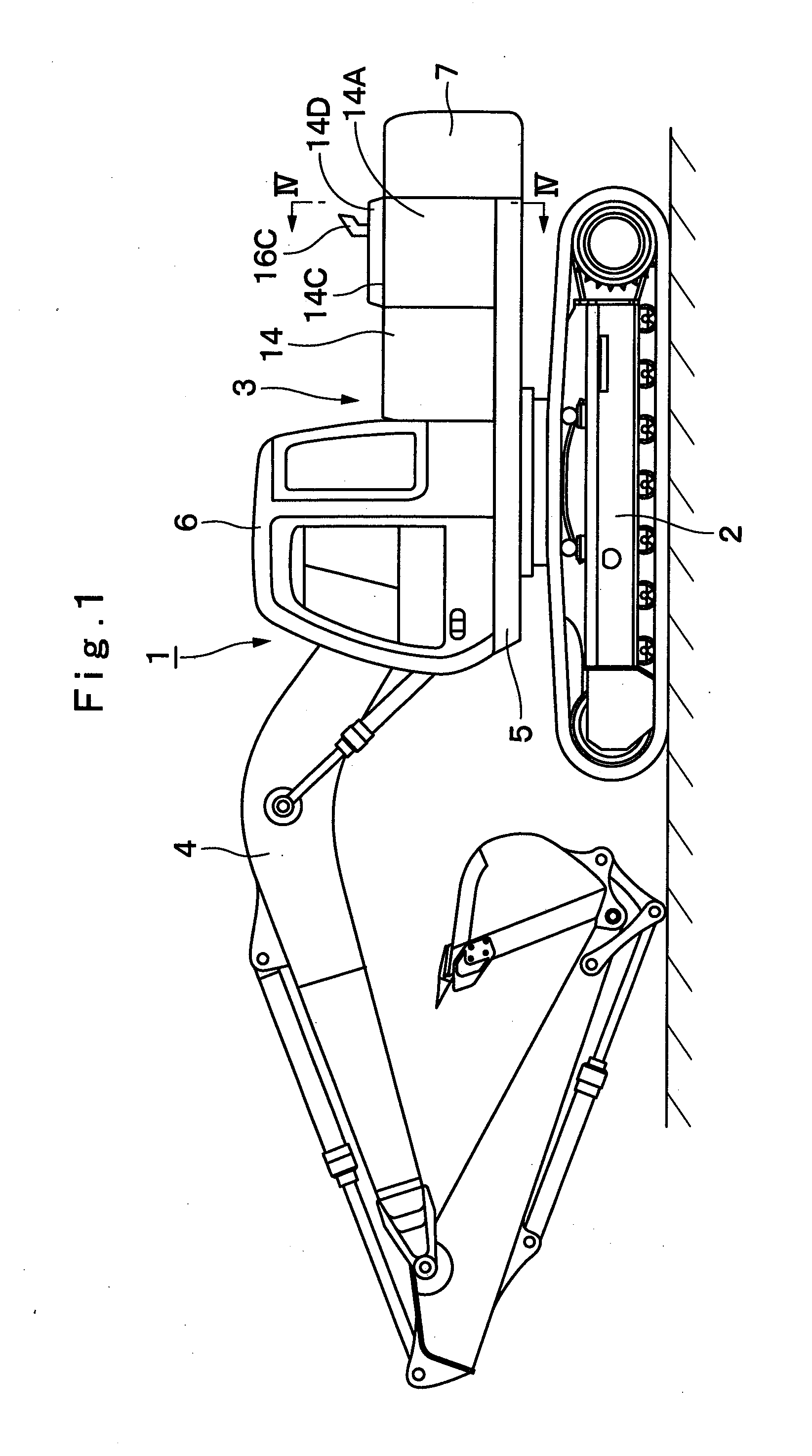

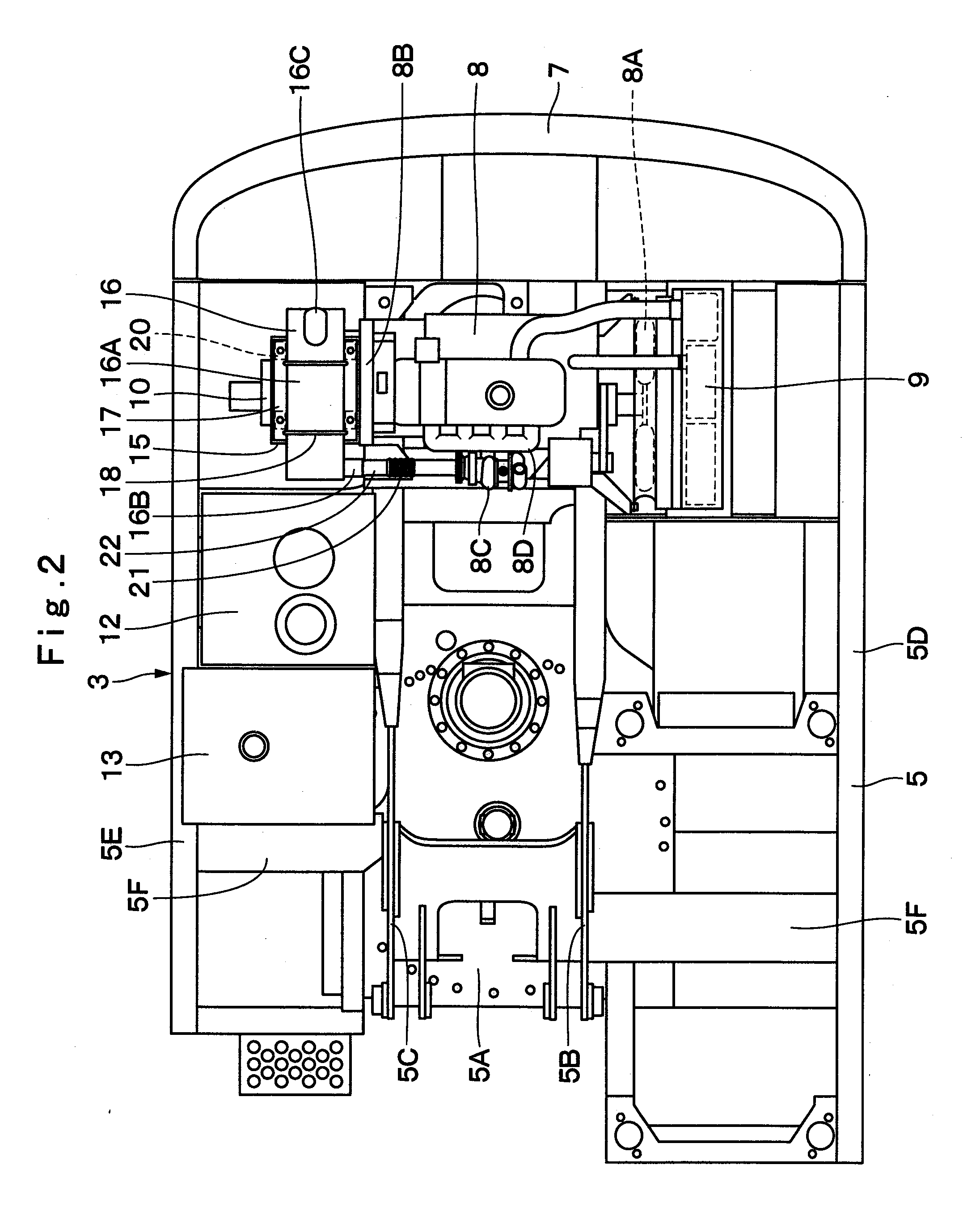

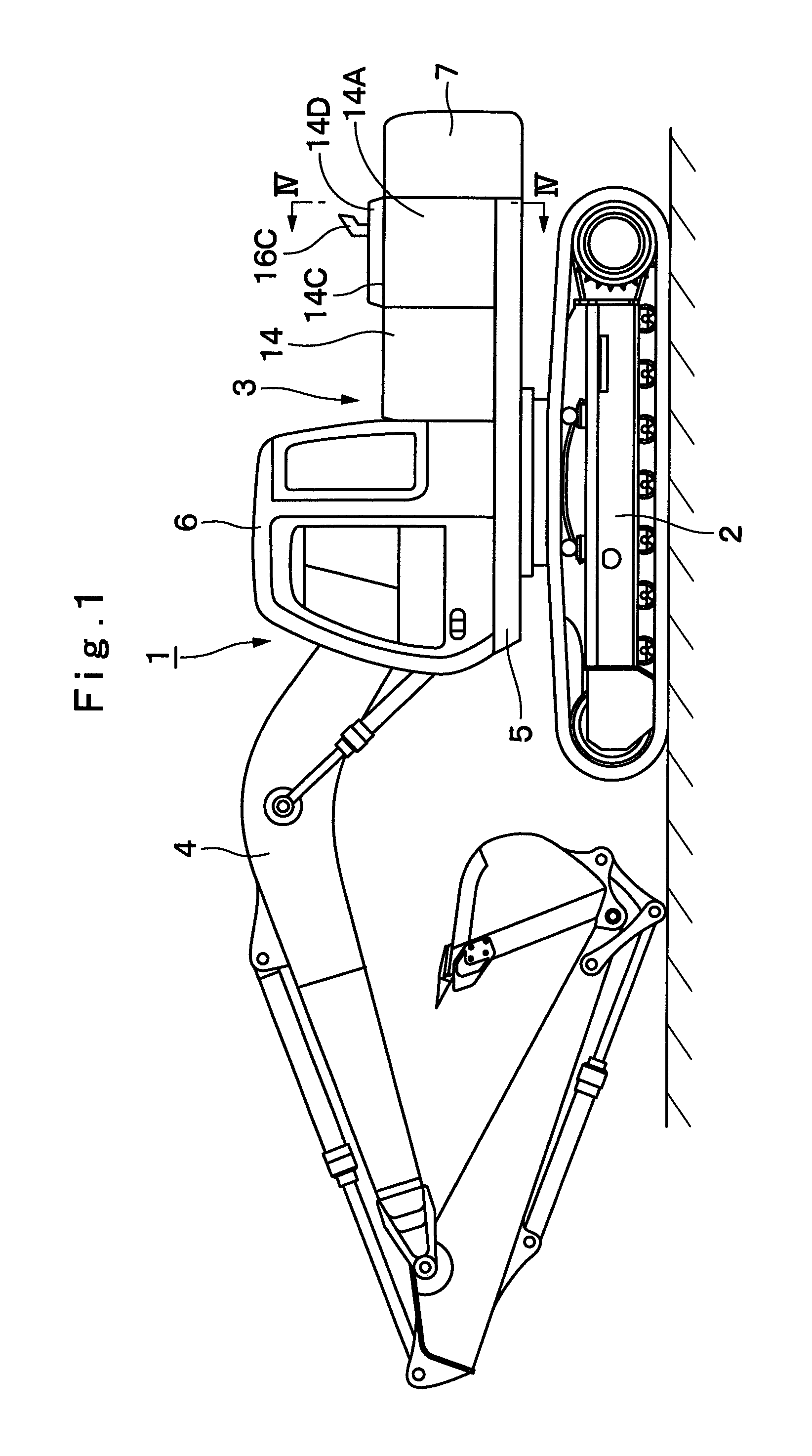

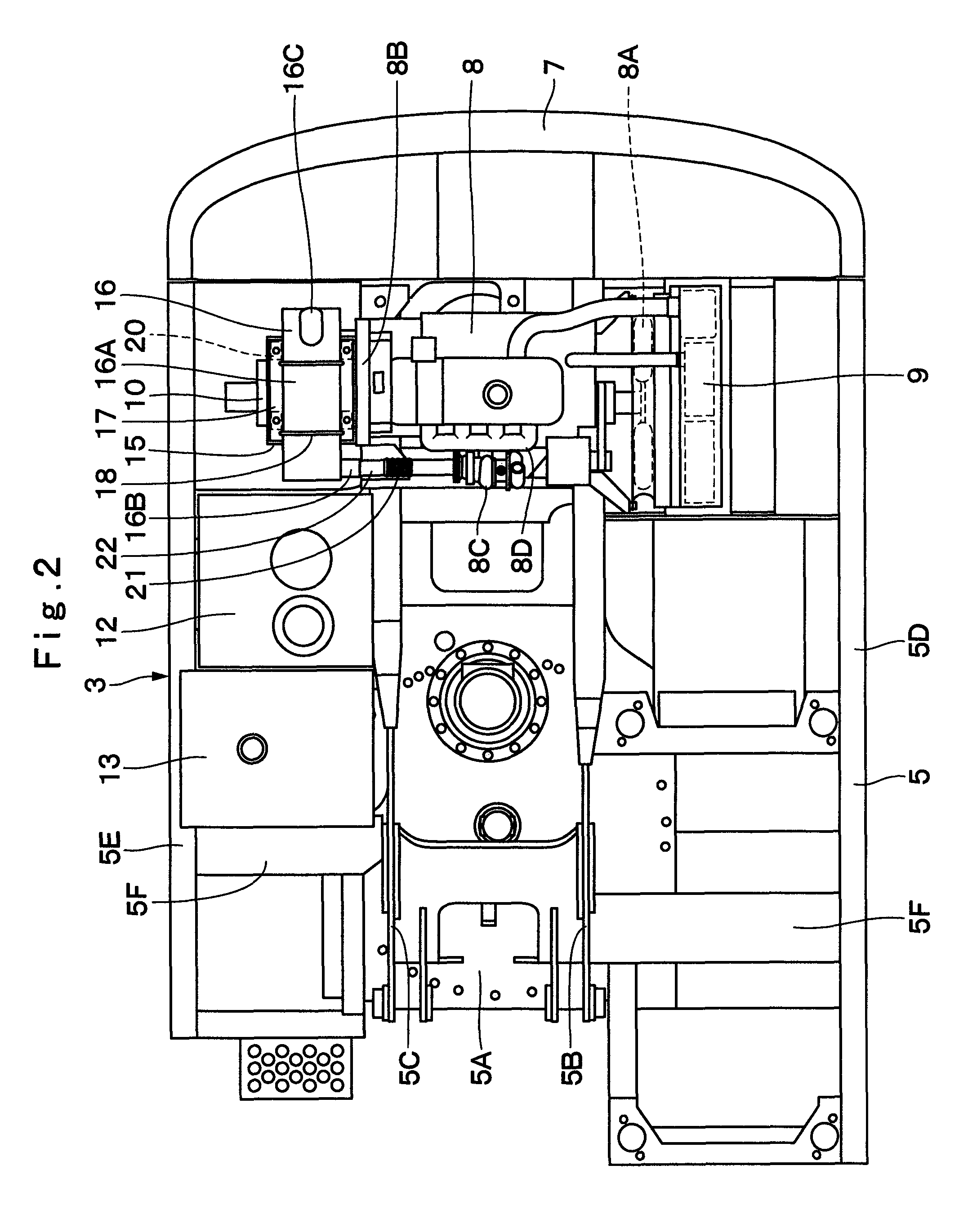

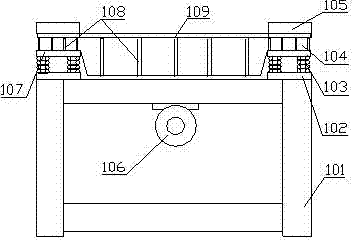

Construction machine

InactiveUS20100275588A1Tend can be blockingProtection from vibrationExhaust apparatusSilencing apparatusHigh frequency vibrationMechanical engineering

An engine (8) is mounted to a vehicle body by means of vibration isolating mounts (8E), and a support member (15) is mounted to the engine (8). Vibration isolating members (20) are provided between this support member (15) and a mounting bracket (17) mounted to an exhaust gas treatment device (16). Accordingly, even in cases where the engine (8) has generated high-frequency vibrations, these vibrations can be damped by the vibration isolating mounts (8E) and the vibration isolating members (20). In consequence, treatment members constituting the exhaust gas treatment device (16) , such as a catalyst, a filter, and a sensor, can be protected from the vibrations of the engine (8). In addition, as the exhaust gas treatment device (16) is provided with the mounting bracket (17), the vibration isolating members (20) can be reliably mounted to the exhaust gas treatment device (16) by means of the mounting bracket (17).

Owner:NIHON KENKI CO LTD

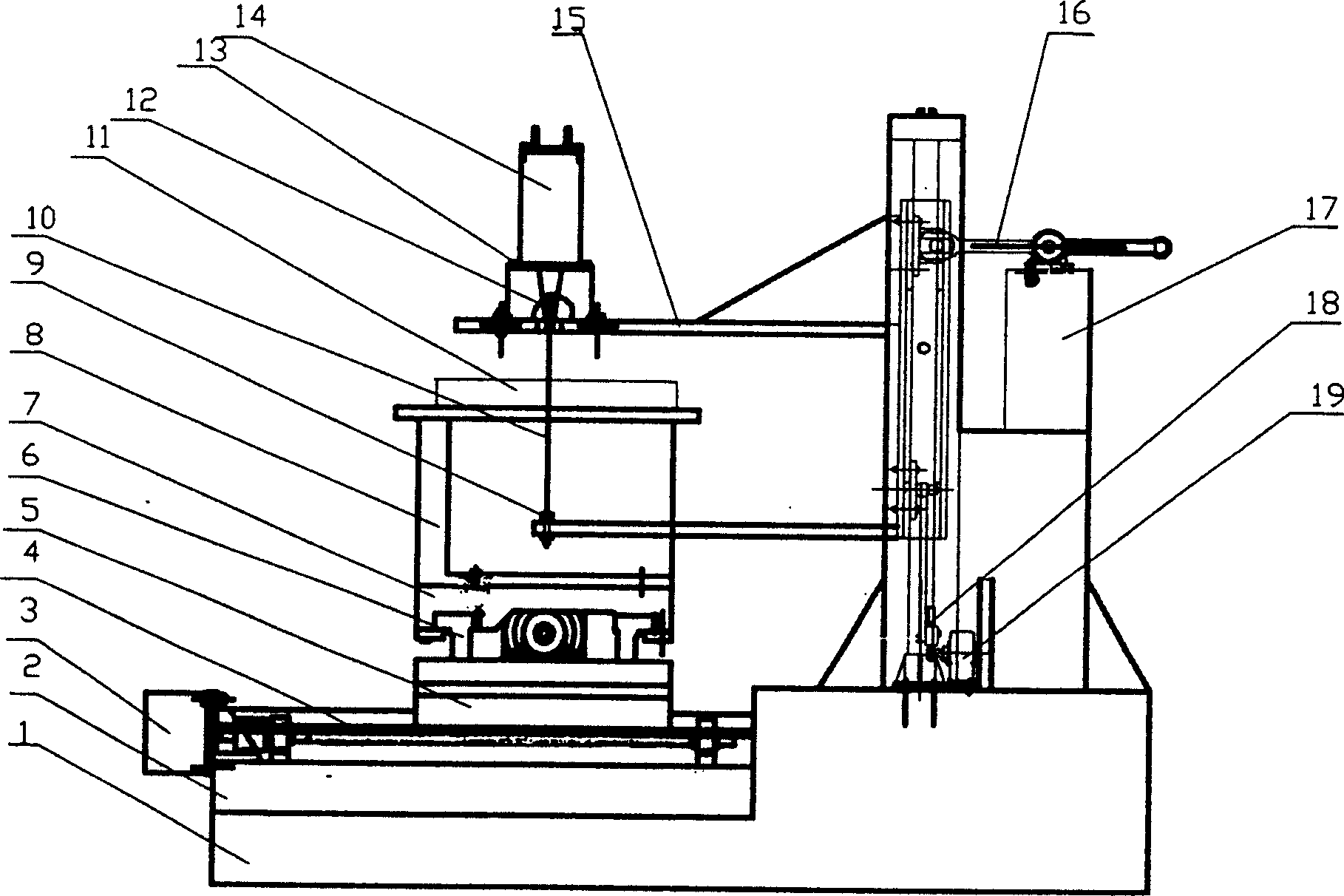

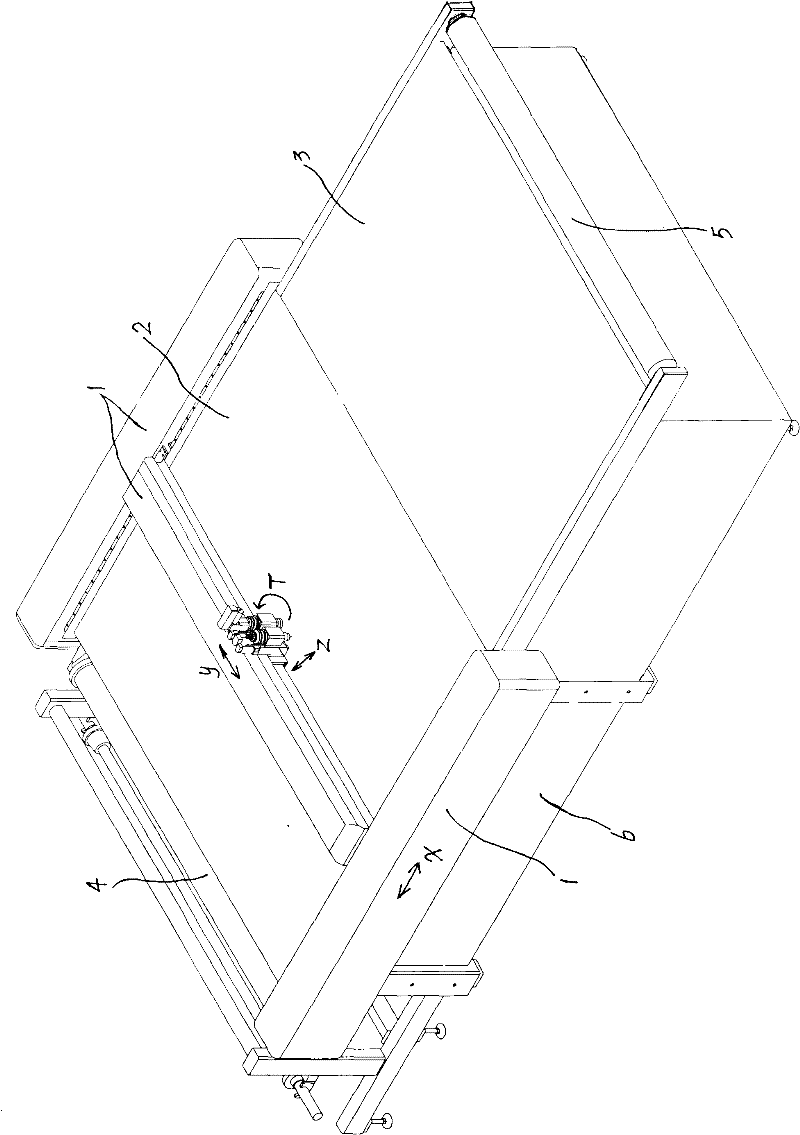

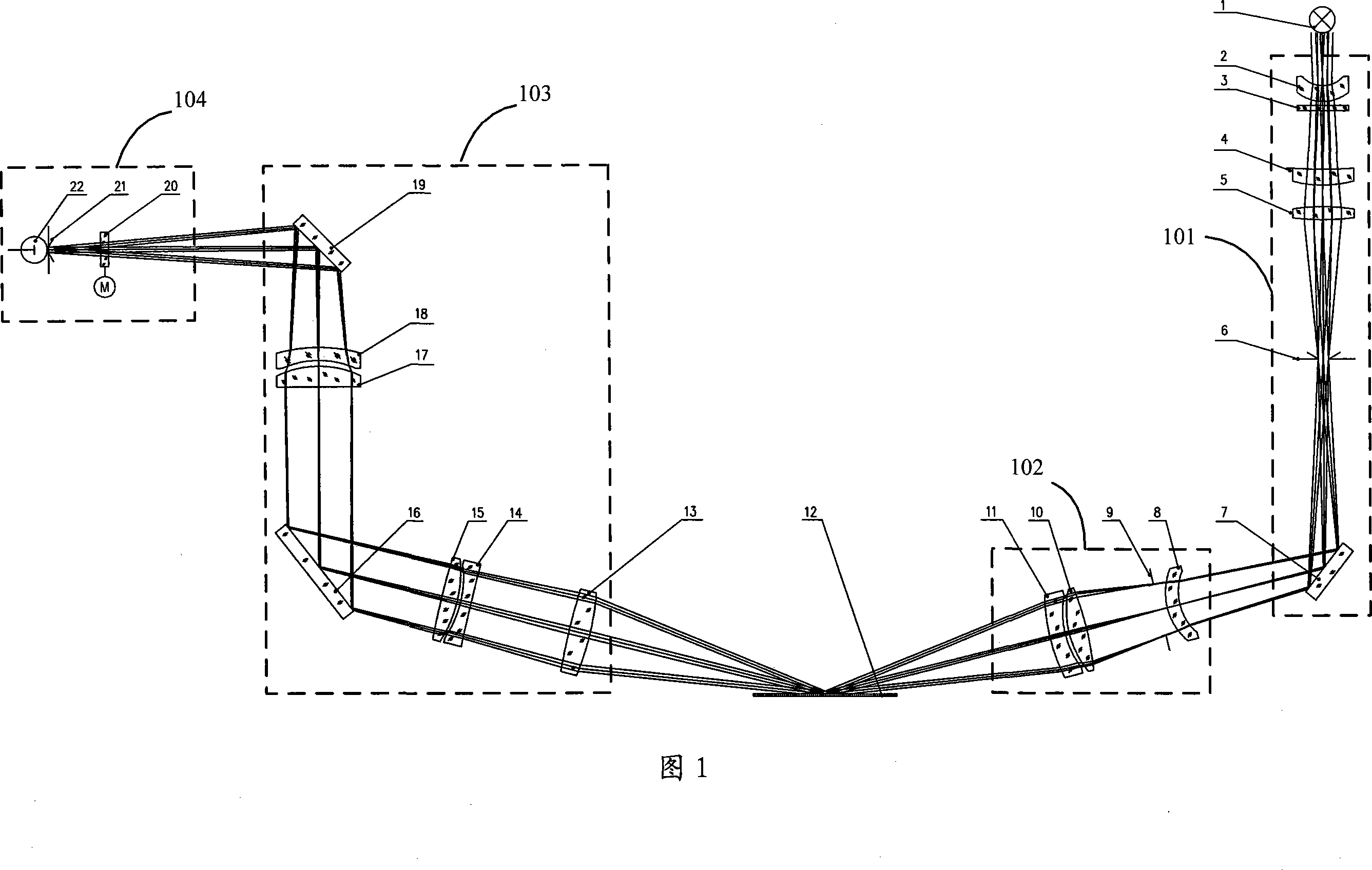

Ultrasonic wire cutting saw for hard-fragile material processing

InactiveCN1488480ASimple structureIncrease productivityStone-like material working toolsWire cuttingEngineering

The invention is a kind of supersonic wave tangent line saw for hard and crisp material, which comprises the bed, longitudinal working slide flat, transversal work slide flat, piece bracket, diamond line saw, supersonic wave vibrating device, saw reciprocating motion mechanism and electricity control device, the supersonic vibrating device is fixed on the upper arm of the C type work bracket through screw, the electrical signal is transformed into mechanical vibration, and enlarges the amplitude through a pole, the diamond saw vibrates as wave, it generates reciprocating motion through cranked rod, C type work bracket, slide flat seat. The saw is in linear high frequency vibration state and reciprocating motion; the invention is simple and has a high productivity.

Owner:沈阳工业学院

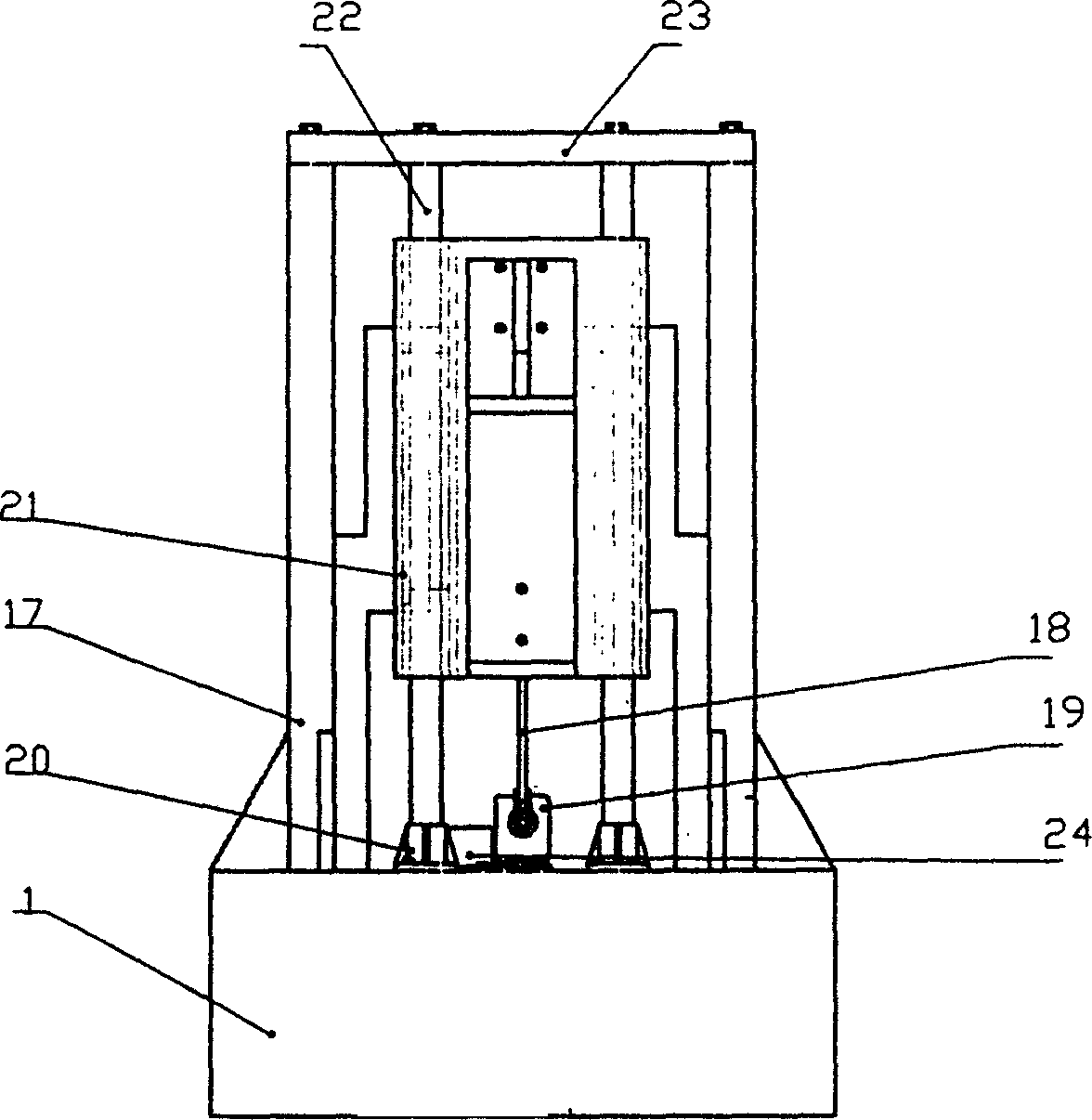

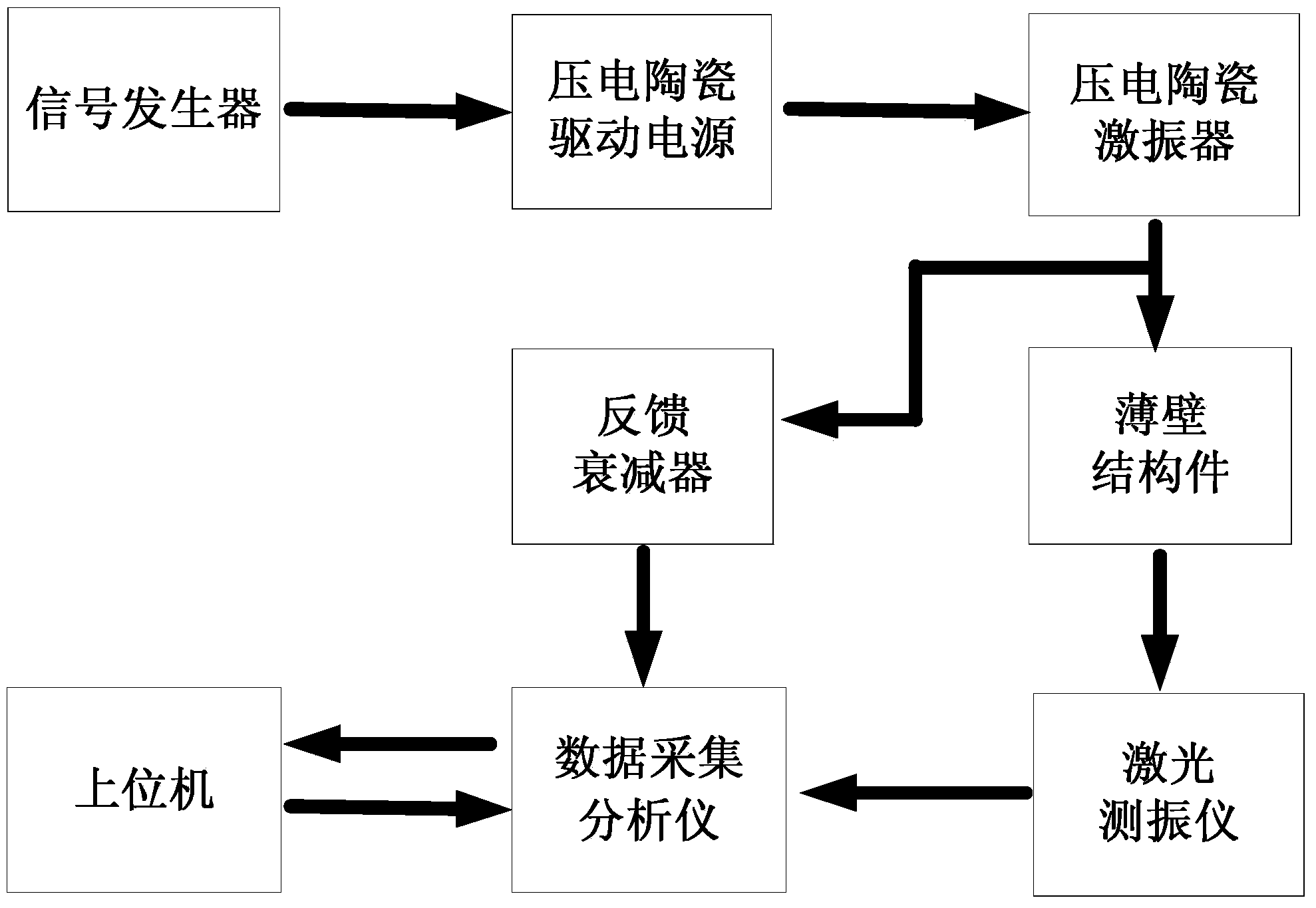

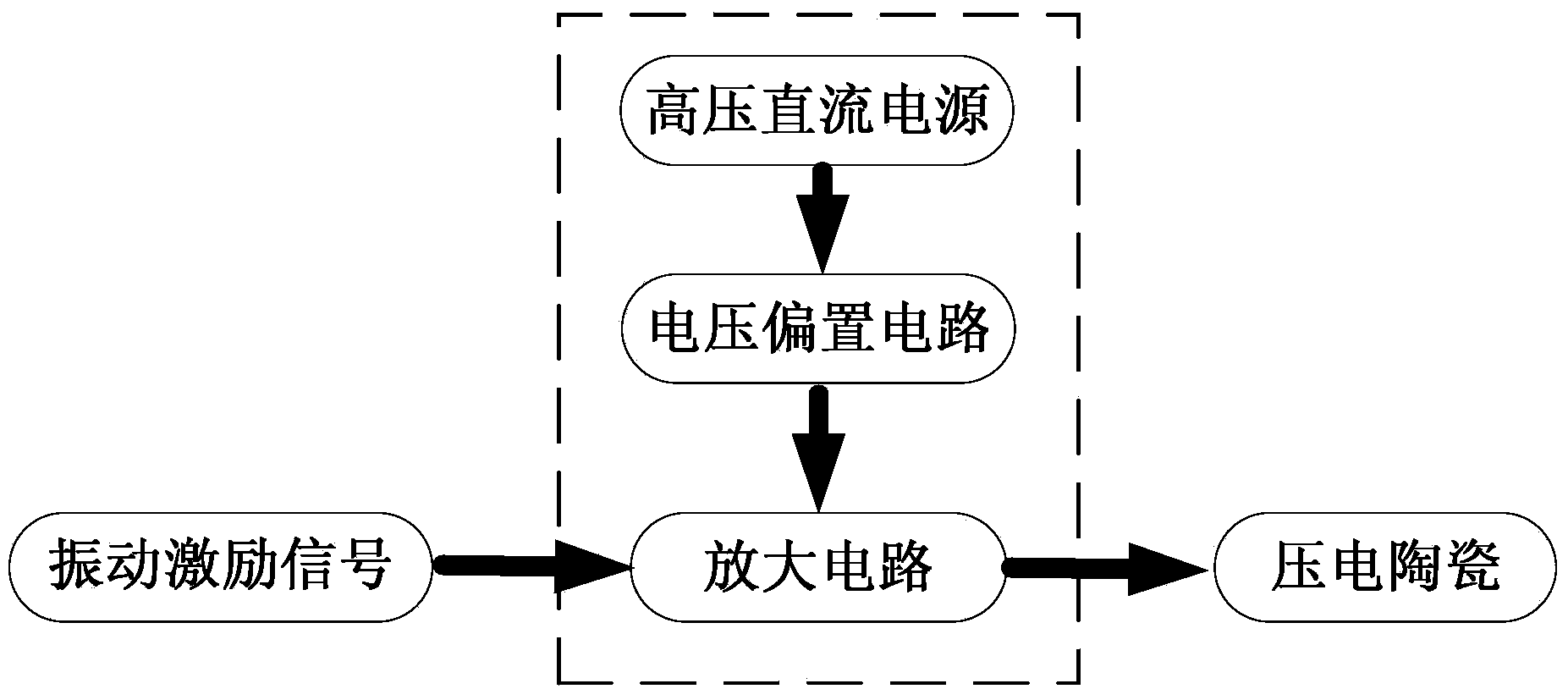

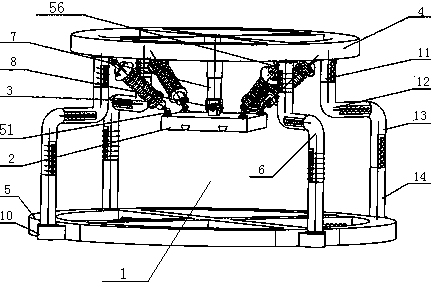

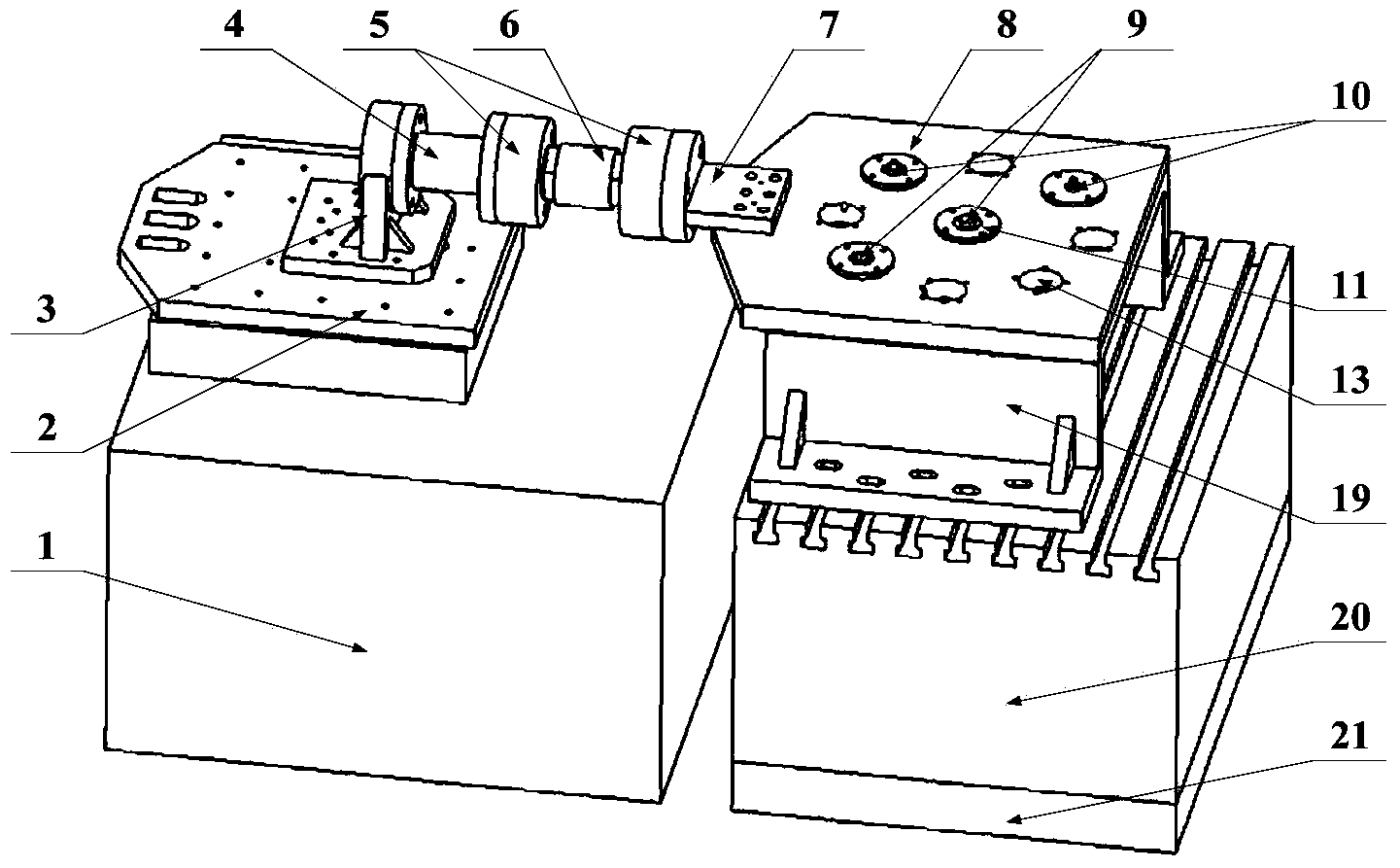

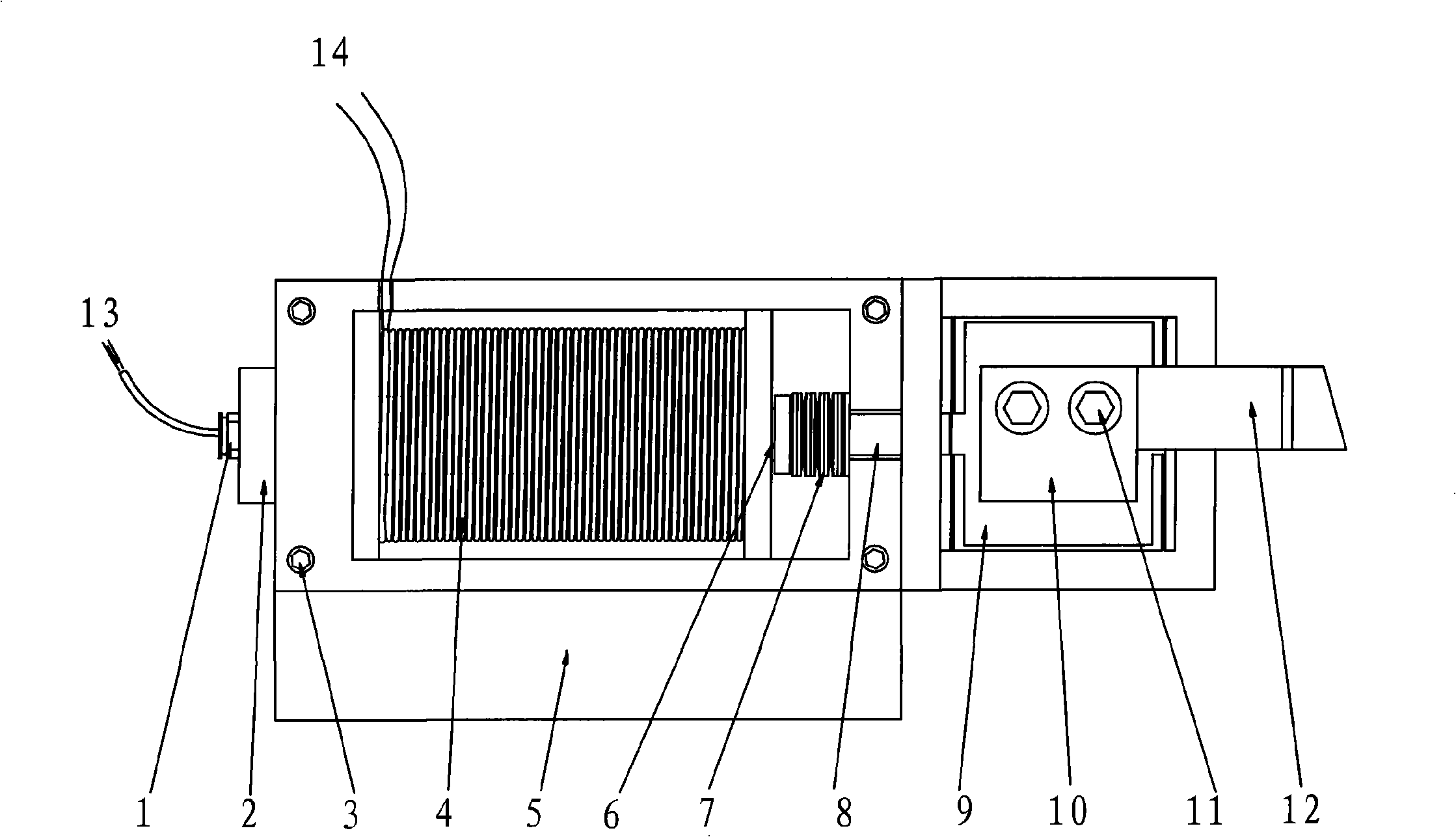

Thin-walled structure part vibration test device and method based on piezoelectric ceramic vibration exciter

ActiveCN103528782AEfficient collectionMeet the modal testSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansDiagnostic Radiology ModalityModal testing

The invention belongs to the technical field of vibration test, in particular to a thin-walled structure part vibration test device and a method based on a piezoelectric ceramic vibration exciter. The device comprises a signal generator, a piezoelectric ceramic drive power supply, a piezoelectric ceramic vibration exciter, a feedback attenuator, a laser vibration meter, a data acquisition analyzer and an upper computer. The method comprises the steps of performing modality test on a thin-walled structure part, determining a linear relationship between excitation voltage and critical excitation frequency of the signal generator and calibrating an excitation force of the piezoelectric ceramic vibration exciter based on a cantilever theory. According to the device and the method, an excitation signal can be effectively acquired; the magnitude of the excitation force when the piezoelectric ceramic vibration exciter excites the structure part is defined; the stable designated excitation force and the linear excitation signal of the excitation frequency can be generated; influencing factors of non-linear piezoelectric ceramic excitation are effectively eliminated; the piezoelectric ceramic vibration exciter is adopted to realize high-frequency vibration excitation; additional mass is low; and the device is convenient to use.

Owner:NORTHEASTERN UNIV

Parallel mechanism based multidimensional vibration platform

ActiveCN104154170AAchieving Nonlinear StiffnessSolve the problem of isolating low frequencySpringsShock absorbersEngineeringUltra low frequency

The invention discloses a parallel mechanism based multidimensional vibration platform. Standard zero stiffness of a vibration isolation platform at the equilibrium position and nonlinear stiffness nearby the equilibrium position can be realized by setting certain structural parameters, and the problem about difficulty in isolating low-frequency or ultra-low-frequency vibration for a traditional linear vibration isolation system; stiffness and damping can be easily and conveniently adjusted, vibration isolation of broad frequency domains are satisfied, and good engineering applicability is achieved; the multidimensional vibration platform is high in bearing stiffness, low in movement stiffness, small in static deflection, low in dynamic inherent frequency and good in vibration isolation effect; inherent contradictions restricting the traditional vibration isolation system, namely the contradictions of low-frequency vibration transmissibility and high-frequency vibration attenuation, can be solved by flexible adjustment of the stiffness and damping; the height and the static equilibrium position of the entire platform can be changed by adjusting a shock absorber spring base in height, and the multidimensional vibration platform is applicable to vibration isolation of objects of different weight.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

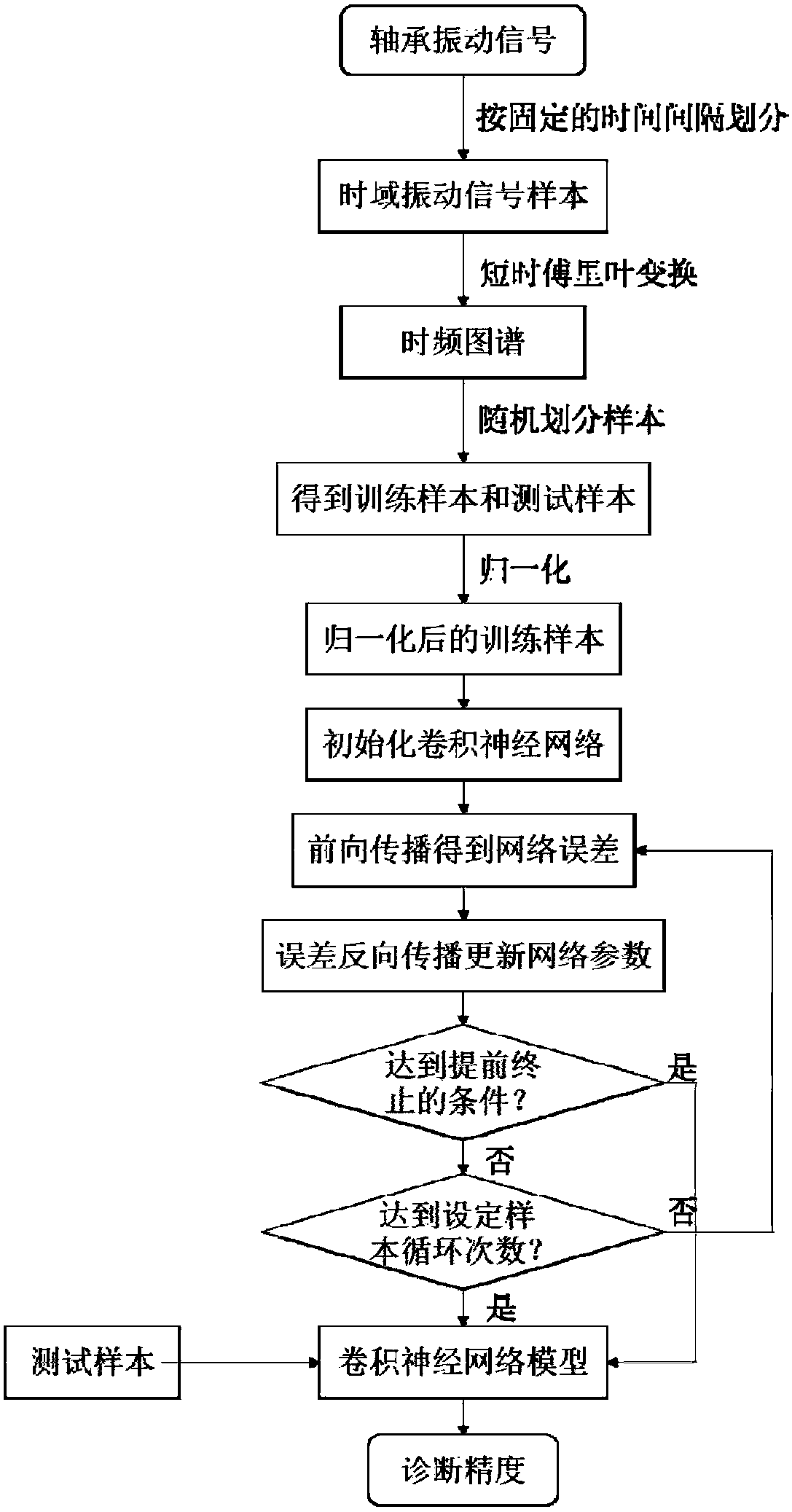

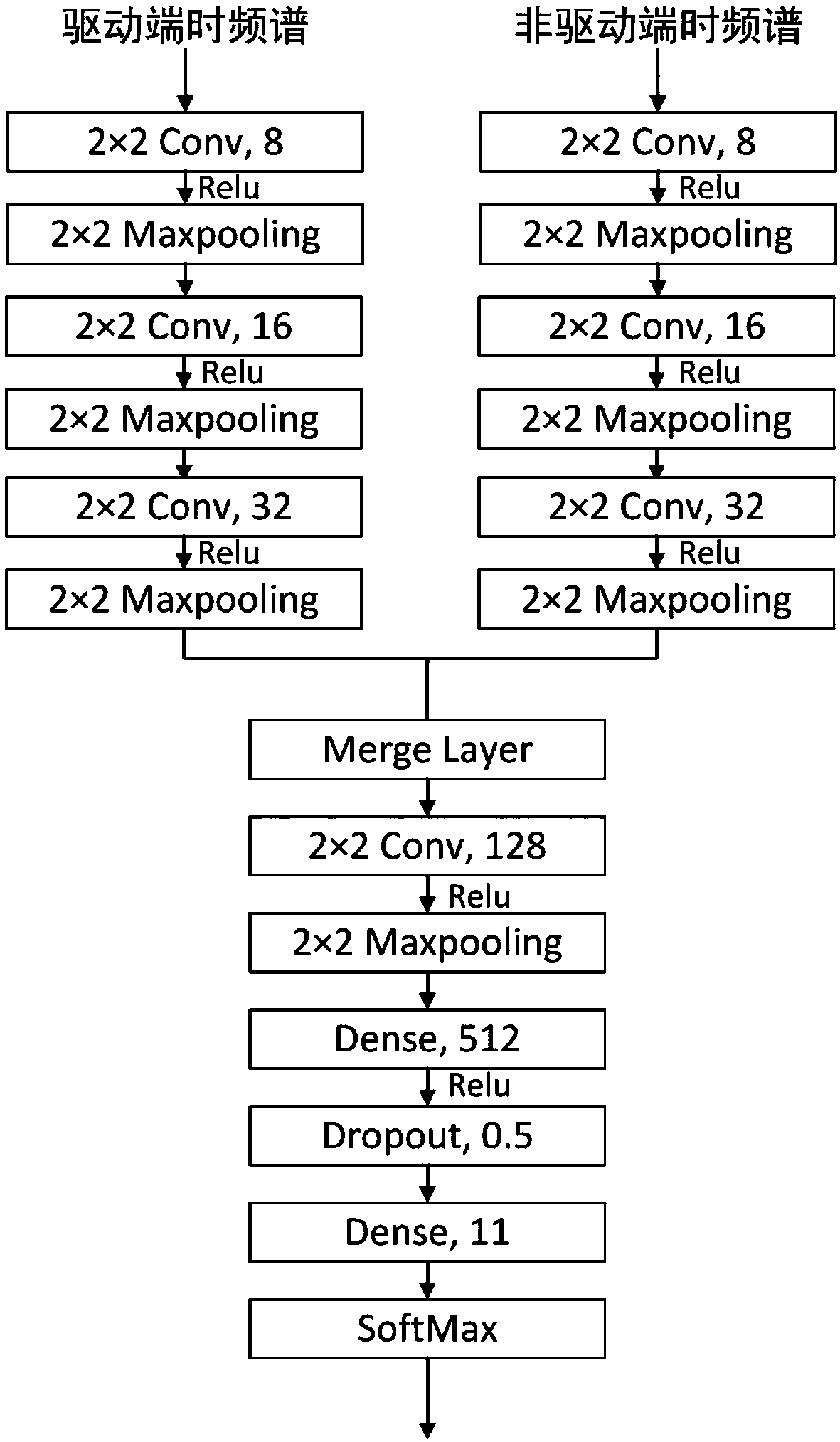

Wind turbine generator bearing fault diagnosis method for multi-channel deep convolutional neural network

ActiveCN107560849AImprove scalabilityAvoid subjectivityMachine bearings testingNeural architecturesExtensibilityVibration acceleration

The invention relates to a wind turbine generator bearing fault diagnosis method for a multi-channel deep convolutional neural network. The method comprises the steps of: simultaneously acquiring high-frequency vibration acceleration signals of a drive end and a non-drive end of a test bearing in various states by using a vibration acceleration sensor; analyzing the acquired vibration signals by using a time frequency analysis technology to obtain corresponding time frequency spectra; establishing a deep convolutional neural network diagnosis model, and training the diagnosis model by using the time frequency spectra and the states of the bearing as a training sample; evaluating the diagnosis model, and applying the diagnosis model to a bearing to be monitored. The method can realize automatic feature learning, avoids feature engineering, effectively utilizes multi-channel vibration signals, and has good universality and extensibility.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

High-speed precision cutting machine

The invention relates to a high-speed precision cutting machine which is mainly suitable for cutting flexible materials, including paper, fabric, leather, composite materials and the like. The high-speed precision cutting machine is characterized in that the high-speed precision cutting machine is further provided with a high-frequency vibration device mounted in a machine head, a linear sliding block mounted on a cross beam and a one-way floating device mounted on a framework; and two motors are respectively arranged on the machine head, a material pressing mechanism comprises a knife seat, a pressing pad, a spring and a seal ring, a transmission mechanism is a steel strip structure with an open hole and flanged edges, a balancing block, an eccentric crankshaft, a knife bar and a bearingare arranged in a mounting seat of the high-frequency vibration device, the linear sliding block comprises a steel ball rolling path and a steel ball retainer, and a guide column, a pressure plate, aY-direction connecting plate and an X-direction connecting plate are arranged on the one-way floating device. The structural design is more compact and reasonable, the volume is small, the mounting is more convenient and the cost is lower; and simultaneously, the high-speed precision cutting machine is convenient and reliable to use and wide in range of applications, and can precisely cut all flexible materials at high speed.

Owner:HANGZHOU ECHO SCI TECH

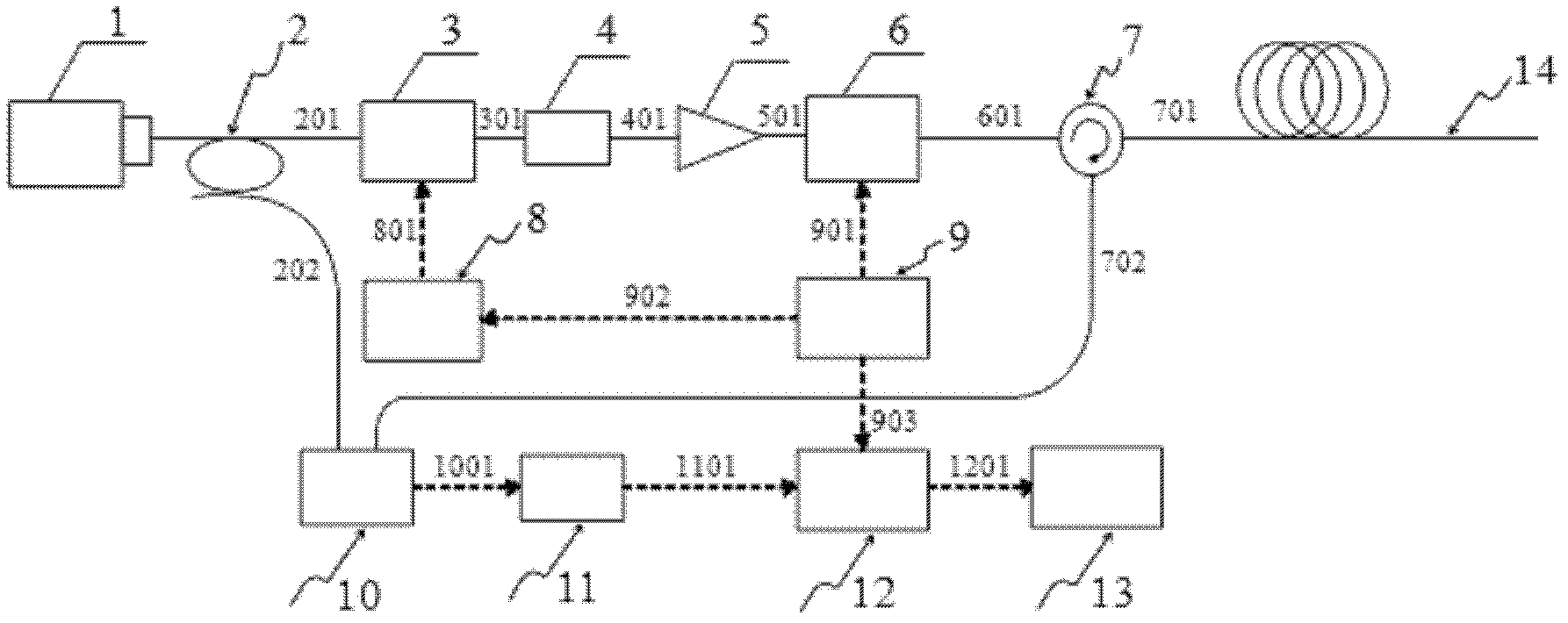

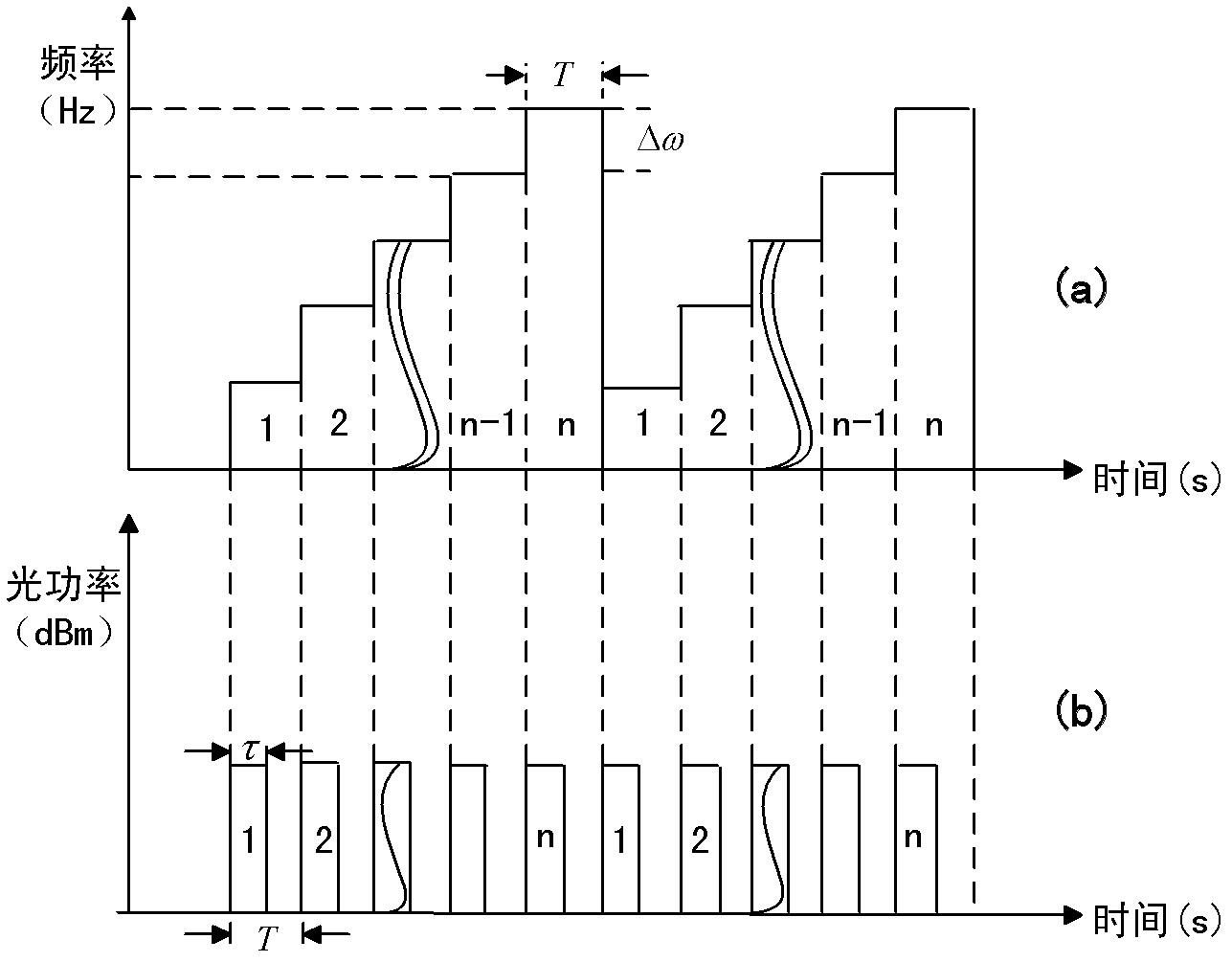

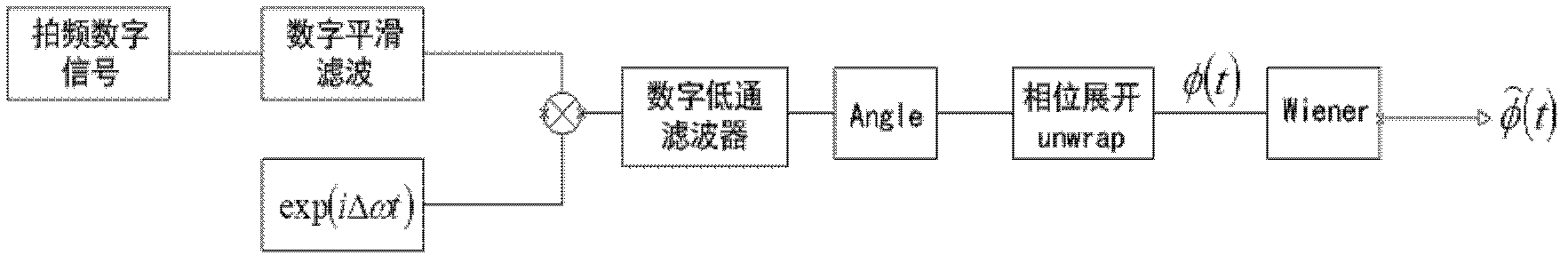

Optical frequency division multiplexing phase-sensitive optical time domain reflectometer

InactiveCN102645268AHigh sensitivityImprove dynamic rangeSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansLine widthLow-pass filter

The invention discloses an optical frequency division multiplexing phase-sensitive optical time domain reflectometer which comprises a narrow line width laser, an optical fiber coupler, a phase modulator, a scrambler, an erbium-doped optical fiber amplifier, an acoustic optical modulator, an optical fiber circulator, a signal generator module, a trigger source, a double balance detector, a low pass filter, a data acquisition card, a computer and a long-distance sensing optical fiber. According to the optical frequency division multiplexing phase-sensitive optical time domain reflectometer, the fundamental contradictions between the measuring distance and sampling rate in a distributed sensing system can be solved, and remoter or higher-frequency vibration is detected; and moreover, due to amplitude and phase information, the characteristics of a vibration source are judged at the first time, and the early warning can be provided immediately.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

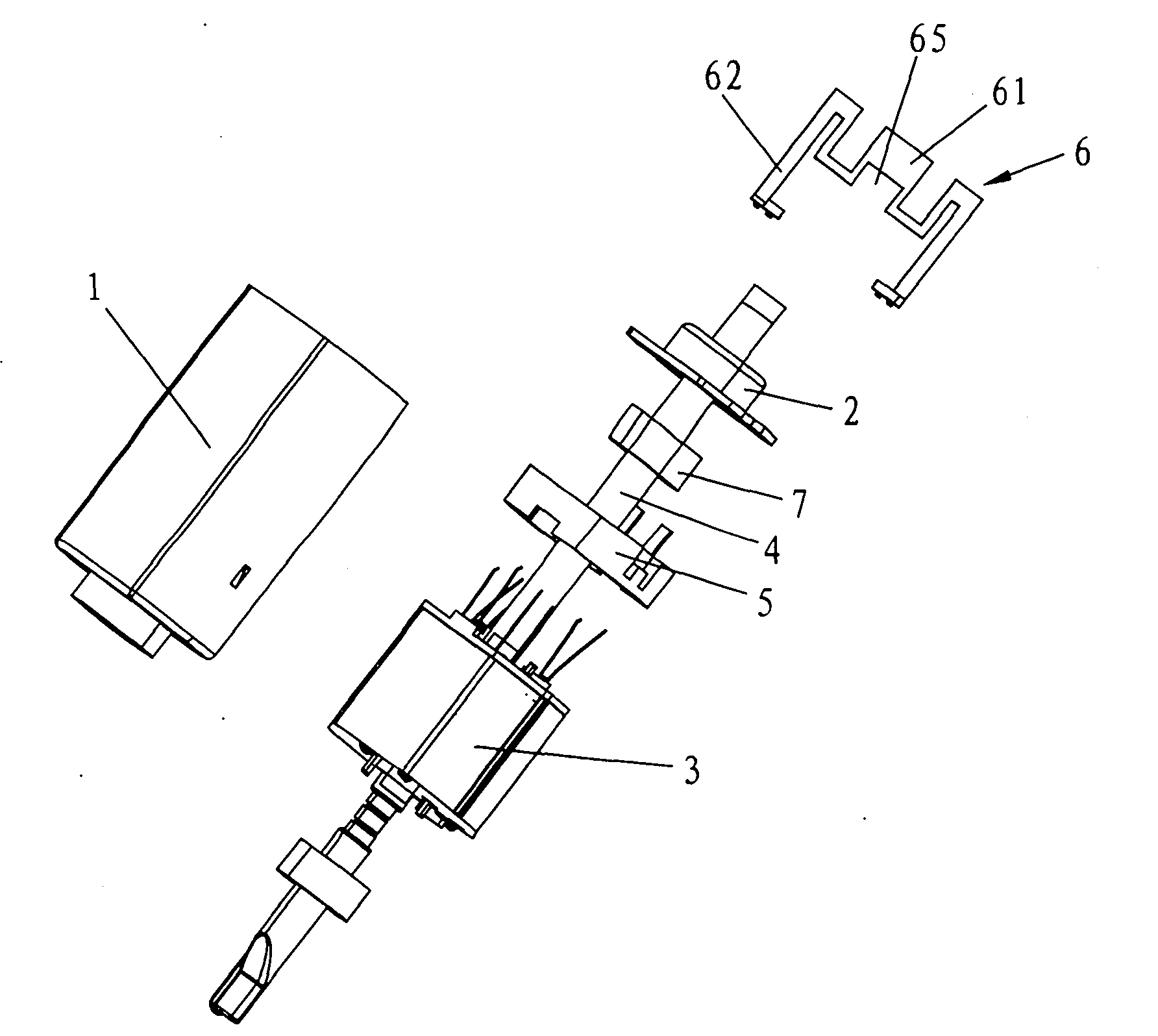

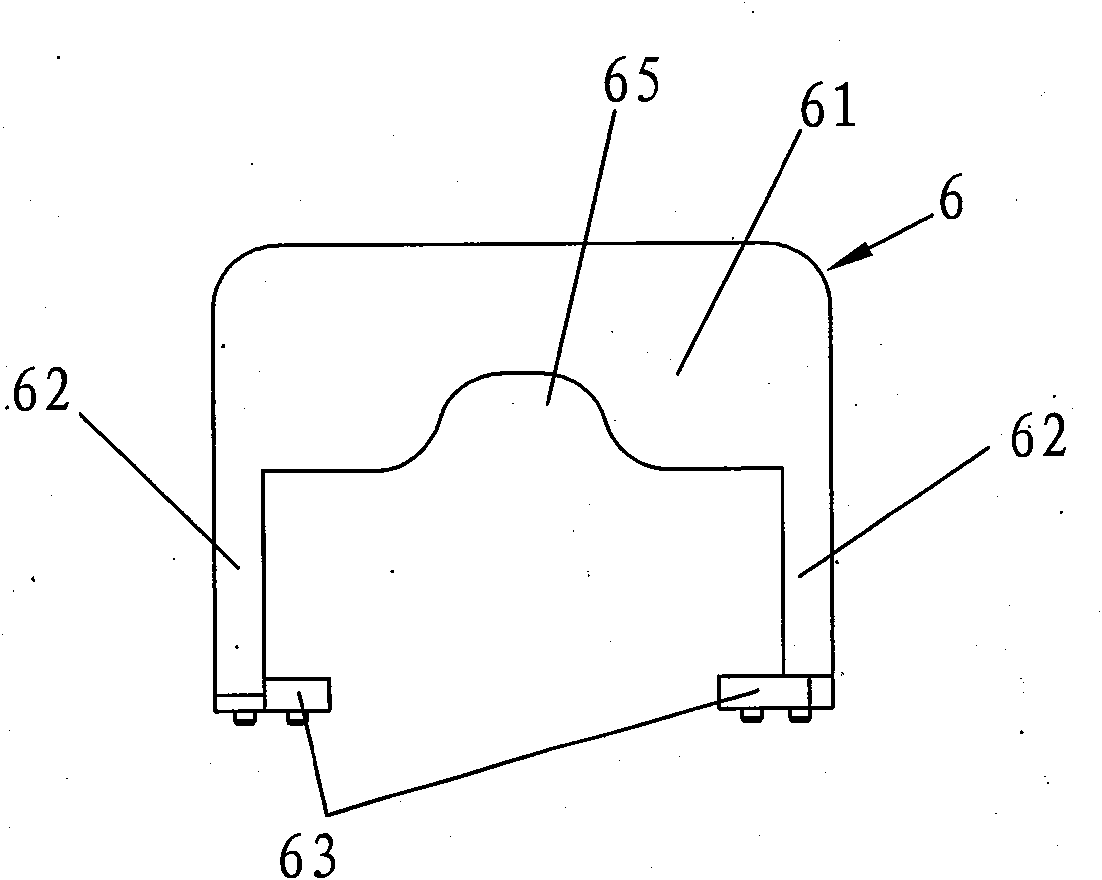

High-frequency vibration motor for electric toothbrush

ActiveCN102111032AReduce in quantityReasonable structureMechanical energy handlingTooth cleaningVibration amplitudeReciprocating motion

The invention relates to the technical field of electric toothbrushes, in particular to a high-frequency vibration motor for an electric toothbrush. The high-frequency vibration motor for the electric toothbrush comprises a shell and a rear cover, wherein a stator, a rotating shaft and an adjusting pad are arranged in the shell; the output end of the rotating shaft is connected with the rear cover through a spring piece; the spring piece comprises a spring piece main body and an elastic arm; the motor generates power to drive the rotating shaft to rotate reciprocally so as to drive the springpiece connected with the rotating shaft to twist to generate torsional deformation; when the frequency of the motor generating reciprocating movement is close to or reaches the torsional resonant frequency of the spring piece, the torsional vibration amplitude of the spring piece reaches the maximum so that the swinging amplitude of the motor reaches the maximum; because of the influence of the reluctance force of the motor per se, the vibration amplitude of an overall system reaches a balanced state, and the spring piece and the motor generate movement under the balanced condition. The high-frequency vibration motor for the electric toothbrush is easy to manufacture and position, along with reasonable structure, less elements, simple machining process, low cost and long service life.

Owner:DONGGUAN LEBOND ELECTRONICS TECH CO LTD

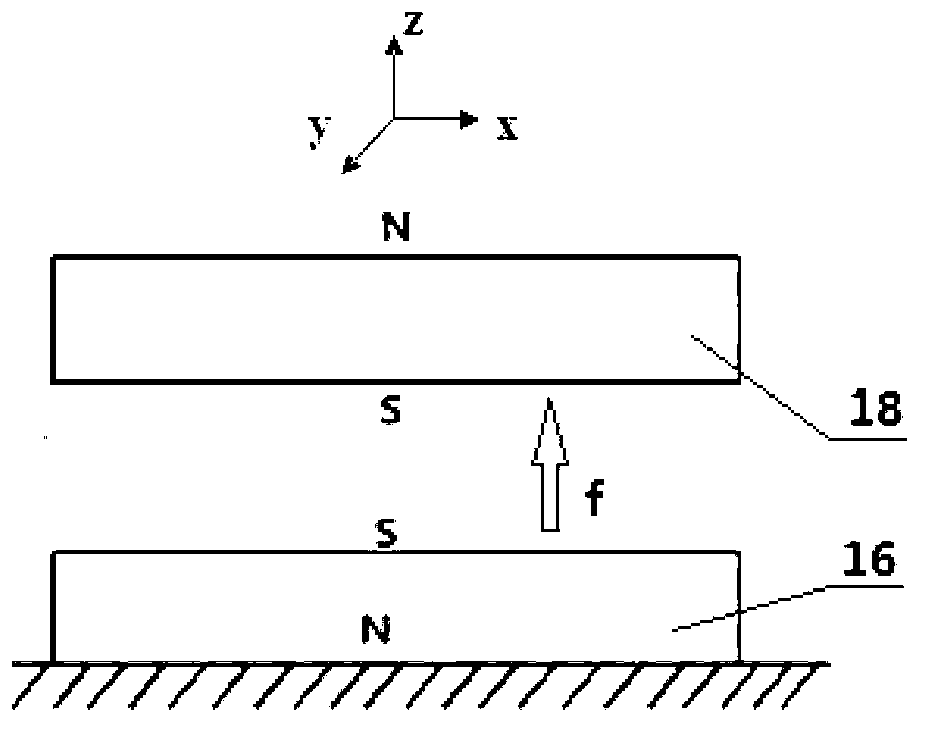

Stiffness-adjustable magnetic vibration isolator with quasi zero stiffness

ActiveCN106402262AImprove carrying capacityEnsure stabilityNon-rotating vibration suppressionNoise controlInternal pressure

The invention belongs to the technical field of vibration and noise control and relates to a relatively-high-applicability passive isolation technology for ultralow-frequency vibration. In order to effectively solve the problem between the low-frequency vibration transmissibility and the high-frequency vibration attenuation rate of the vibration isolator, the invention provides the stiffness-adjustable magnetic vibration isolator with quasi zero stiffness, which adopts rectangular permanent magnets generating negative stiffness and an elastic capsule providing positive stiffness; and when a load is changed, the working position of the elastic capsule is controlled unchanged, the positive stiffness of the elastic capsule is changed because the pressure inside the elastic capsule is changed, and then, the negative stiffness is matched with the positive stiffness through regulating the distance among the rectangular magnets, so that the stiffness-adjustable magnetic vibration isolator with quasi zero stiffness is adaptable to vibration isolation objects with different weights. The stiffness-adjustable magnetic vibration isolator with quasi zero stiffness is simple in structure, convenient to mount, adjustable in bearing capacity, excellent in vibration isolation property, compact in structure, light in weight and suitable for popularization and application.

Owner:NAVAL UNIV OF ENG PLA

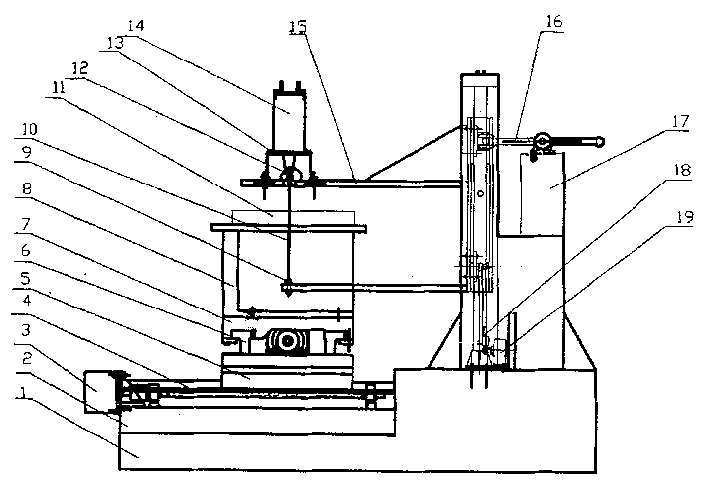

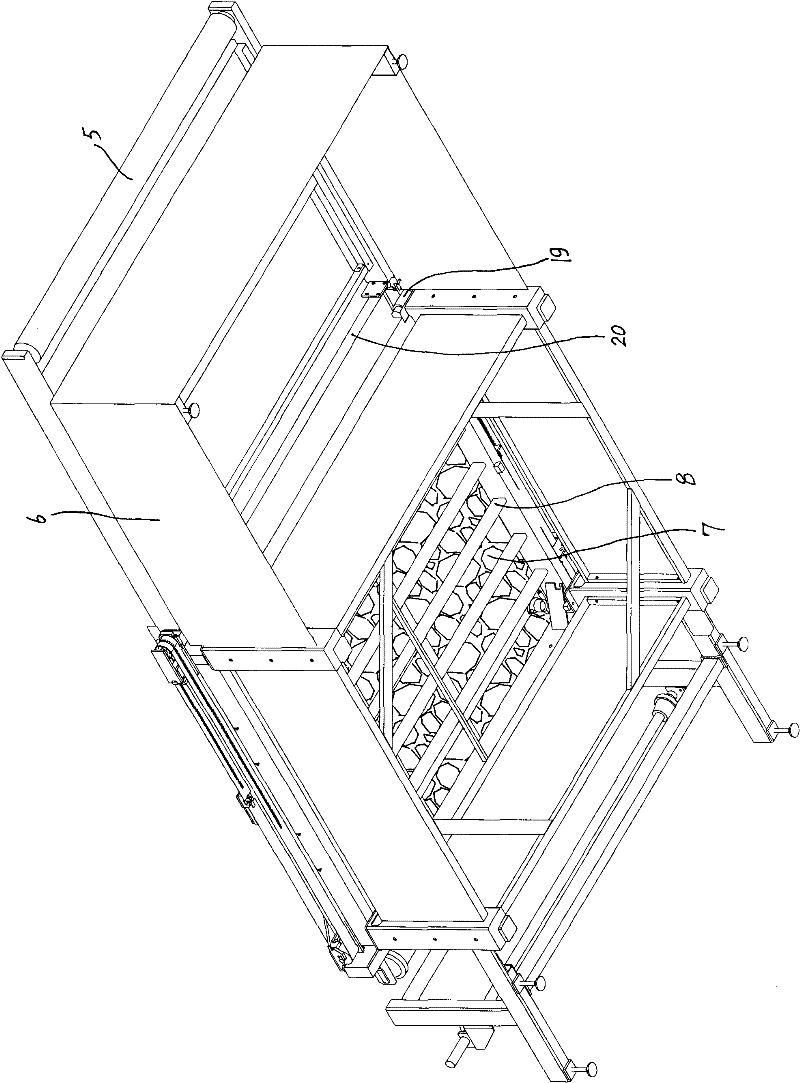

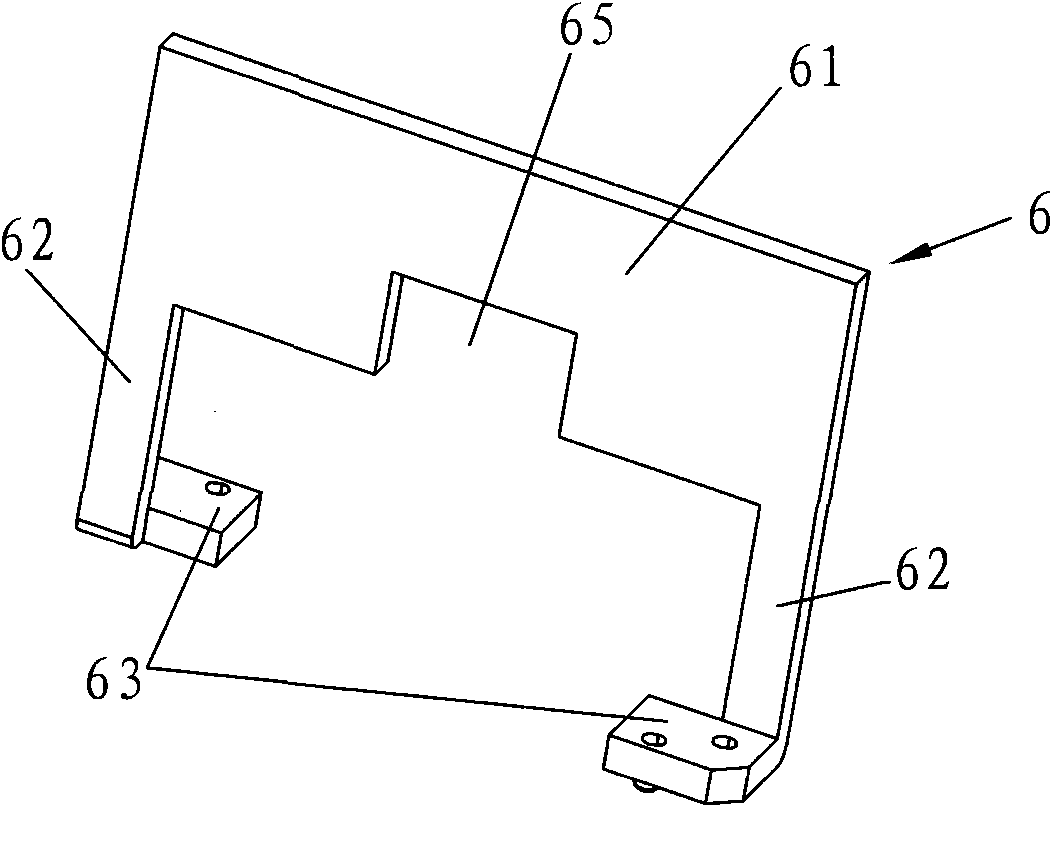

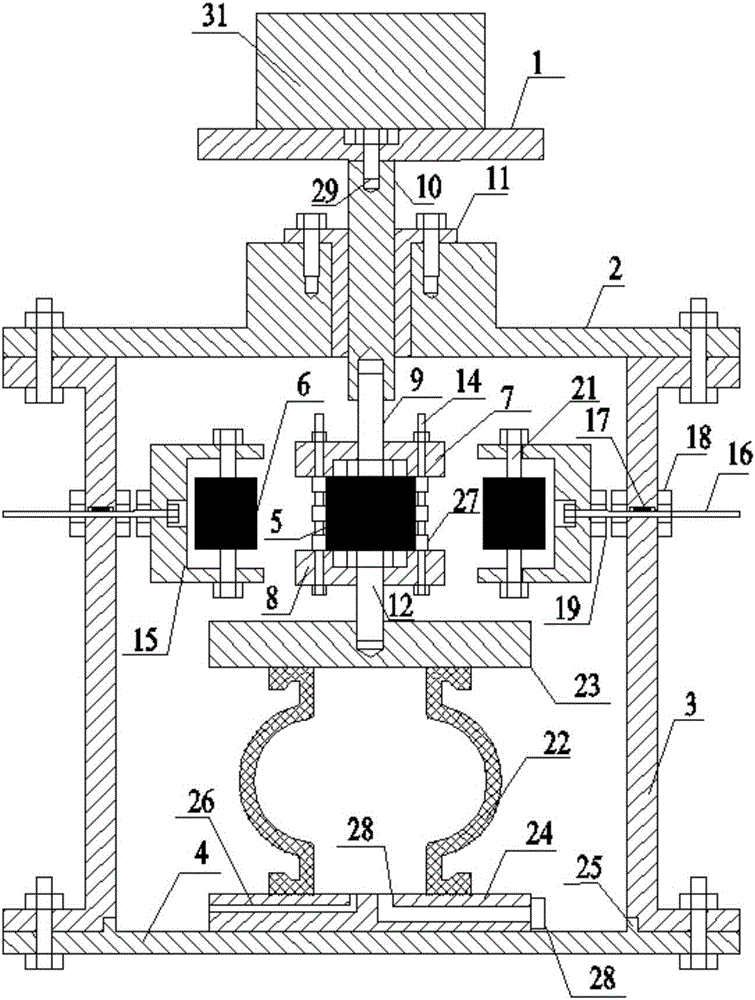

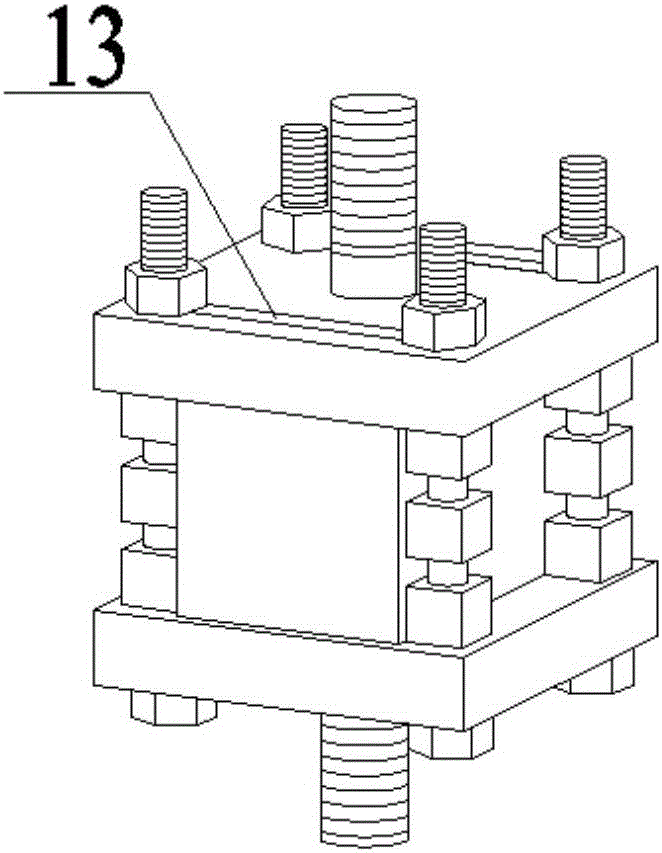

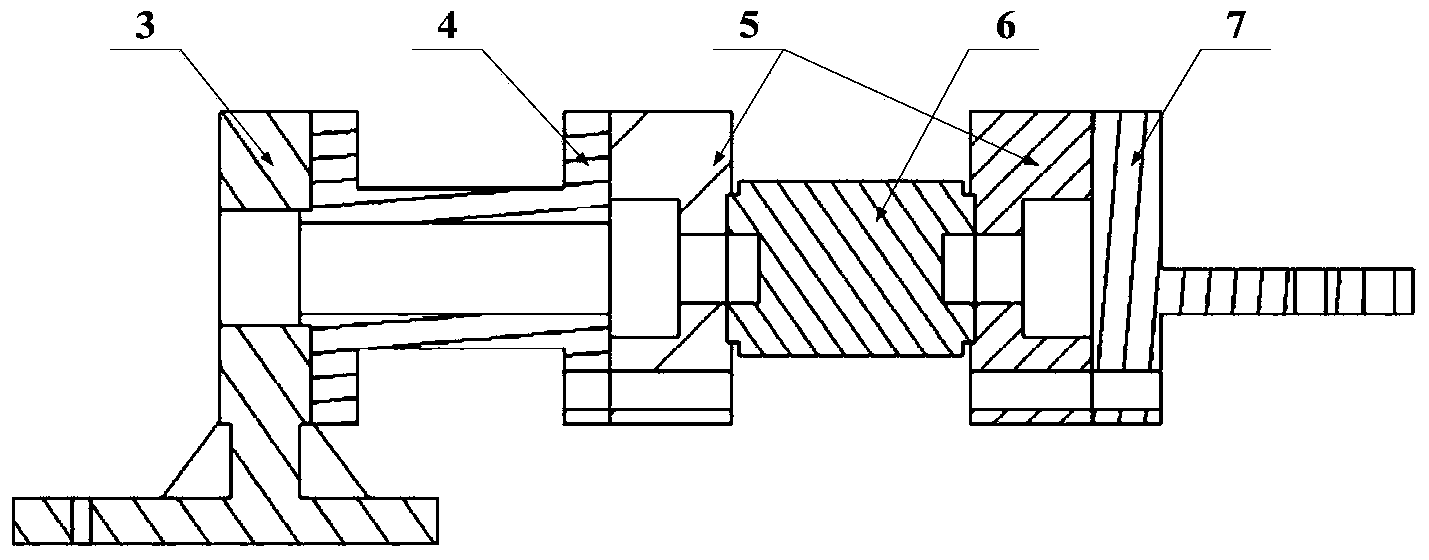

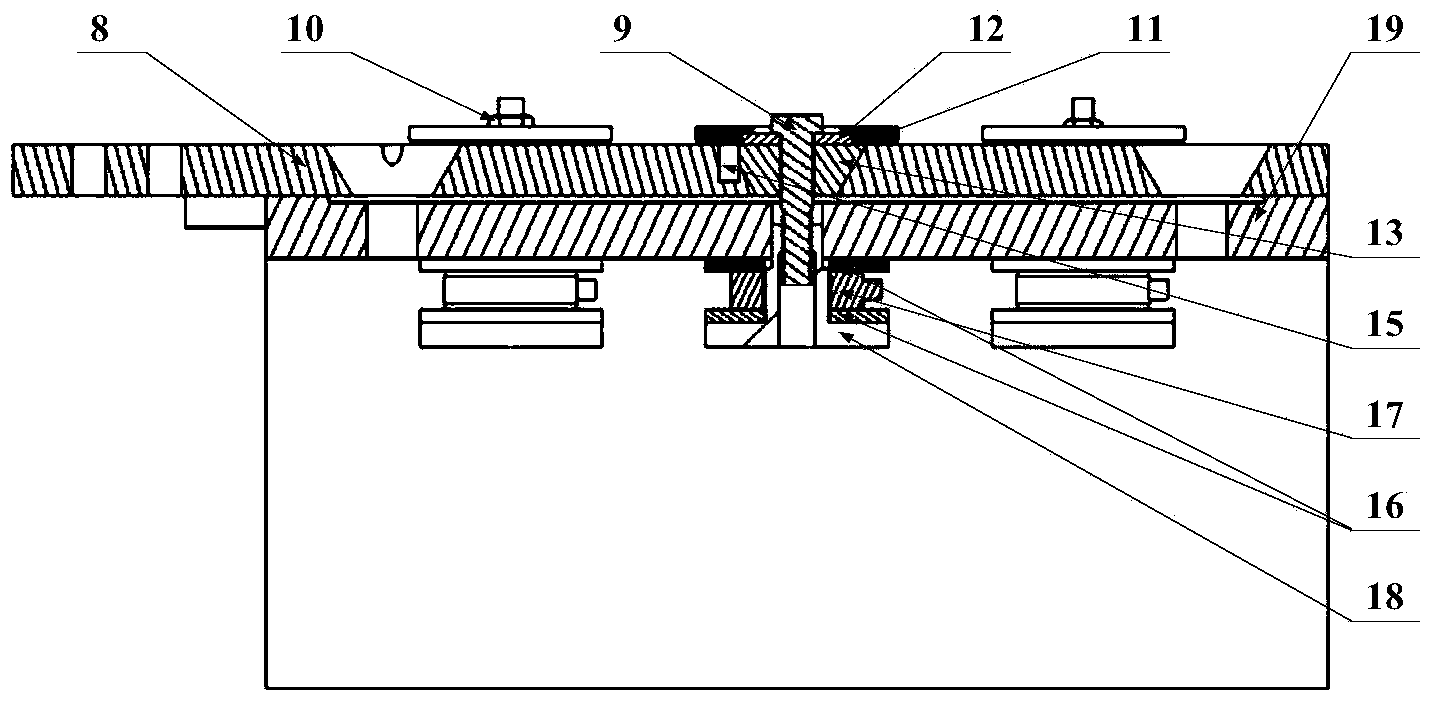

Threaded fastener transverse vibration test device and method

ActiveCN103954419ARealize high frequency vibrationRealize stepless amplitude modulationVibration testingEngineeringEngineering technician

The invention discloses a threaded fastener transverse vibration test device and method. The device comprises a transverse vibration platform, a transmission system, a clamp system, an installation base and a measuring device; one end of the transmission system is fixed to the vibration platform through a bolt, and the other end of the transmission system is fixed to a movable plate in the clamp system; a fixed base of the clamp system is fastened to the installation base through a T-shaped groove; the transmission system is provided with a pull pressure sensor, and the clamp system is provided with a gasket type force sensor. The device and method can simulate high-frequency vibration, achieve electrodeless amplitude modulation, monitor changes of transverse shear force and axial pre-tightening force of a threaded fastener in a vibration process in real time, and test the anti-loose characteristic of single bolts and bolt sets (distributed in a linear, rectangular and circular mode) with different specifications. The device and method provide a basis platform and data support for engineering technicians to analyze anti-loose performance of various threaded fasteners and assess effectiveness of various anti-loose methods.

Owner:XI AN JIAOTONG UNIV +1

Vibration sensor and audio equipment

PendingCN108513241AGood vibration responseImprove effects applied to the audio domainSubsonic/sonic/ultrasonic wave measurementUsing electrical meansMems microphoneEngineering

The invention discloses a vibration sensor and audio equipment. The vibration sensor comprises a shell which is provided with an accommodating cavity with an opening; a circuit board component that isfixedly connected with the shell and blocks the opening; an MEMS microphone that is arranged on one surface of the circuit board component, positioned in the accommodating cavity, and electrically connected with the circuit board component; a first vibration film that is arranged on the inner wall surface of the accommodating cavity; a mass block that is fit with the surface of the first vibration film, wherein when a vibration signal or a pressure signal is input from one side, far away from the accommodating cavity, of the shell, the first vibration film and the mass block vibrate, so as todrive the air pressure in the accommodating cavity to change. The technical scheme provided by the invention aims at enabling the vibration sensor to have good vibration response to high frequency vibration and low frequency vibration, and thus the effect of the vibration sensor applied to the audio field is enhanced.

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

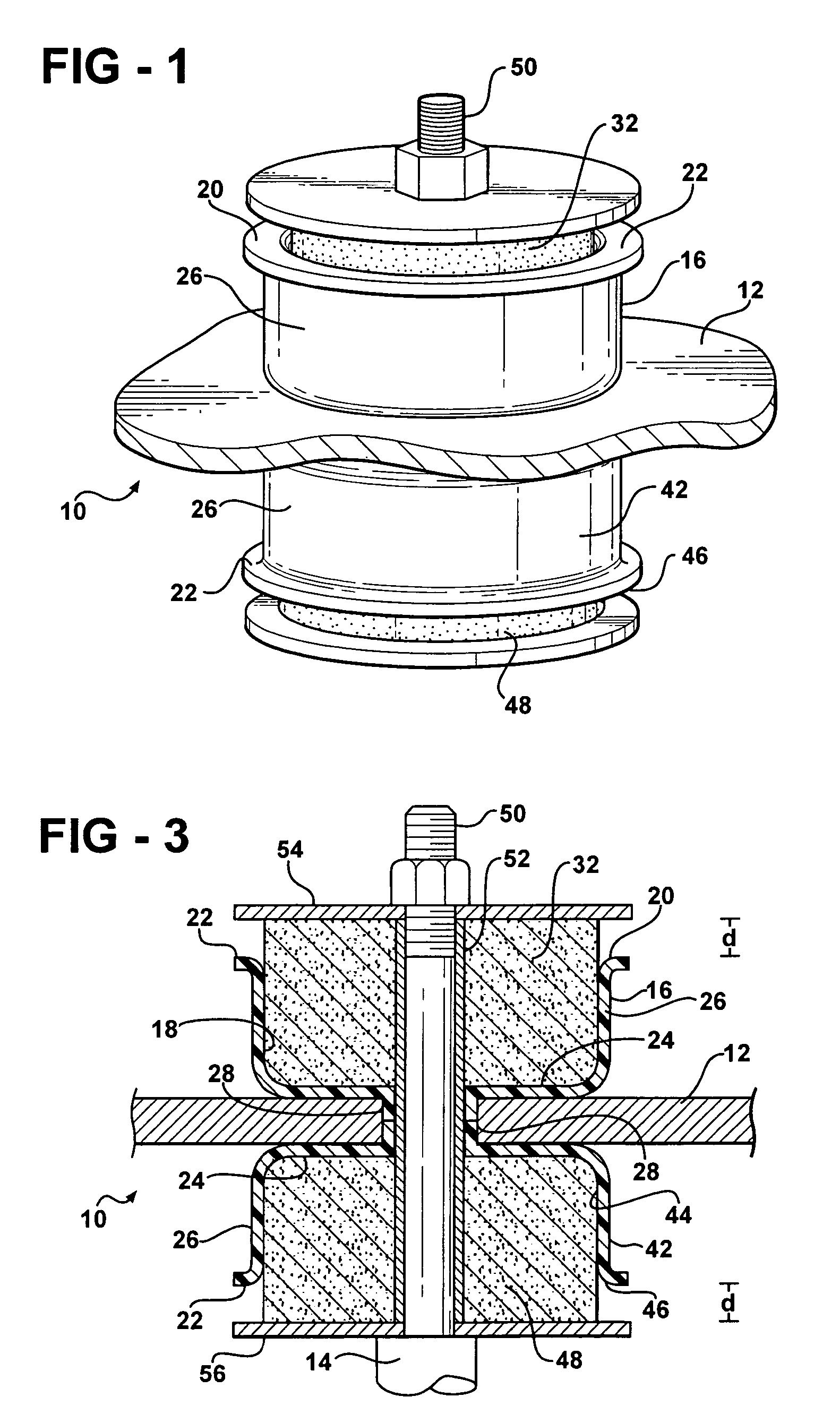

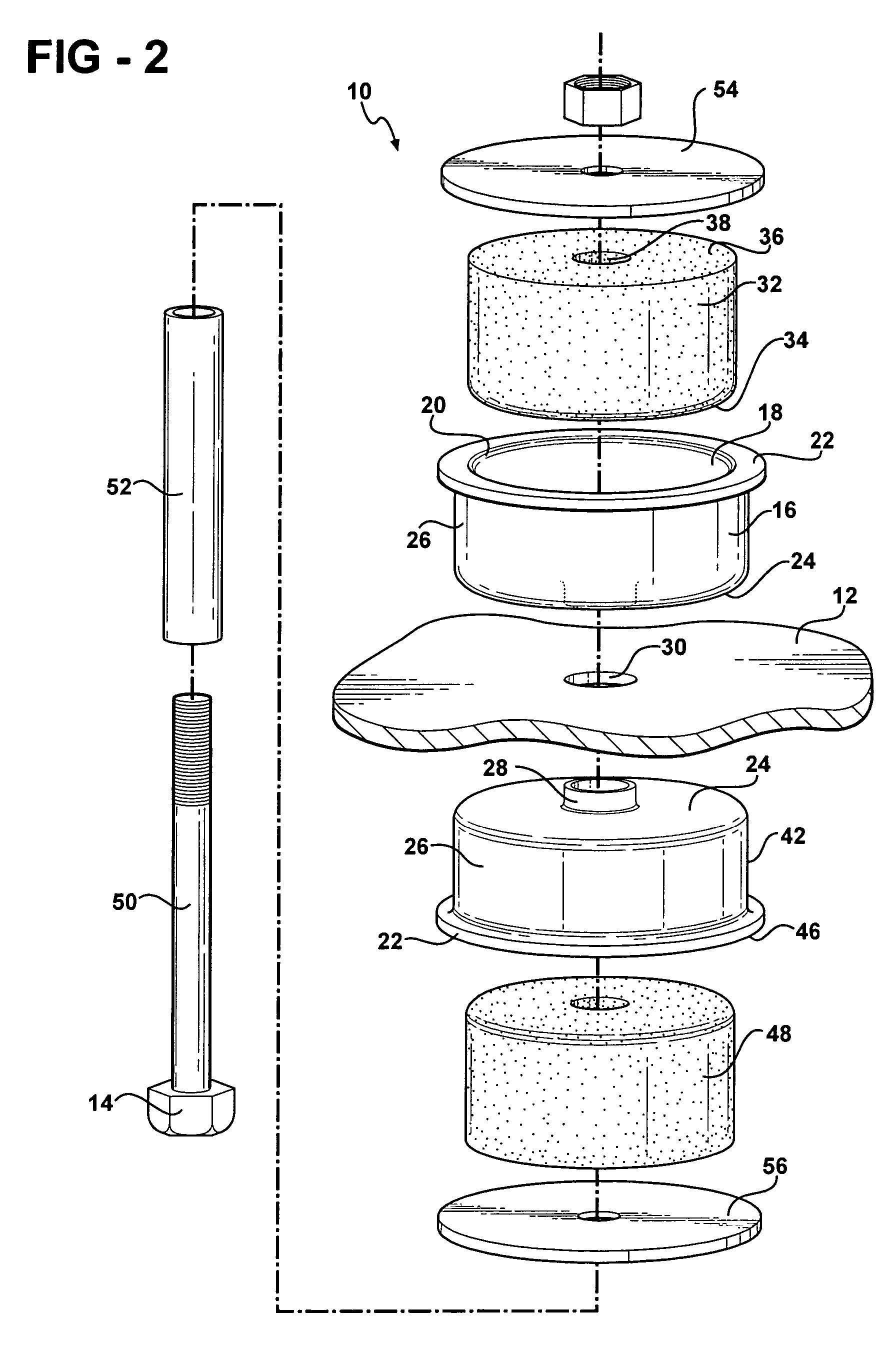

Mount assembly

InactiveUS7070157B2Vehicle body-frame connectionsMultiple spring combinationsPolyurethane elastomerHigh frequency vibration

A mount assembly for use in an automotive suspension system, body mount, cradle mount, or other like device. The mount assembly includes a polyurethane elastomer carrier mounted to a frame and having a peripheral outer rim. A microcellular polyurethane insulator is coupled to the frame and extends beyond the peripheral outer rim. The polyurethane elastomer of the carrier has a first modulus of elasticity. The microcellular polyurethane of the insulator has a second modulus of elasticity that is less than the first modulus of elasticity of the carrier such that the mount assembly can provide two distinct rates of elasticity, or stiffness, for adequately isolating both low amplitude, high frequency vibrations and high amplitude, low frequency impacts.

Owner:BASF CORP

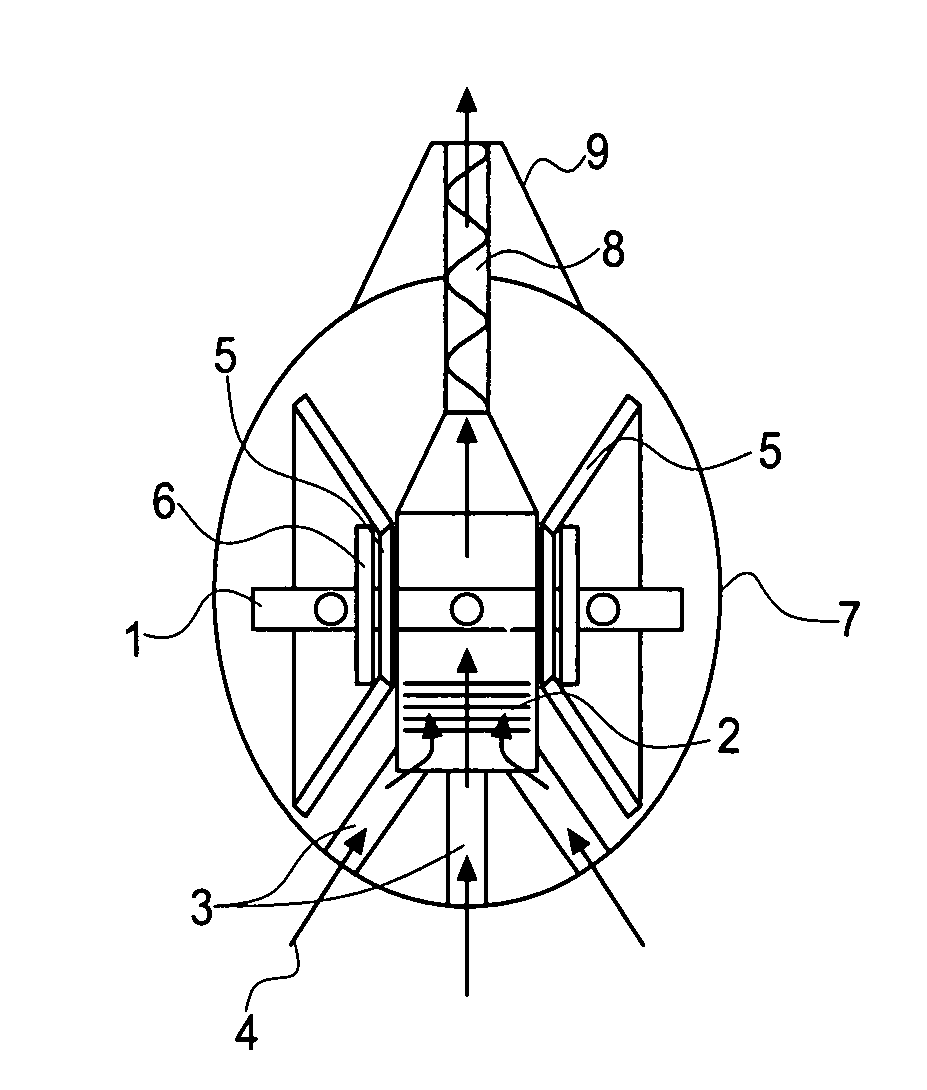

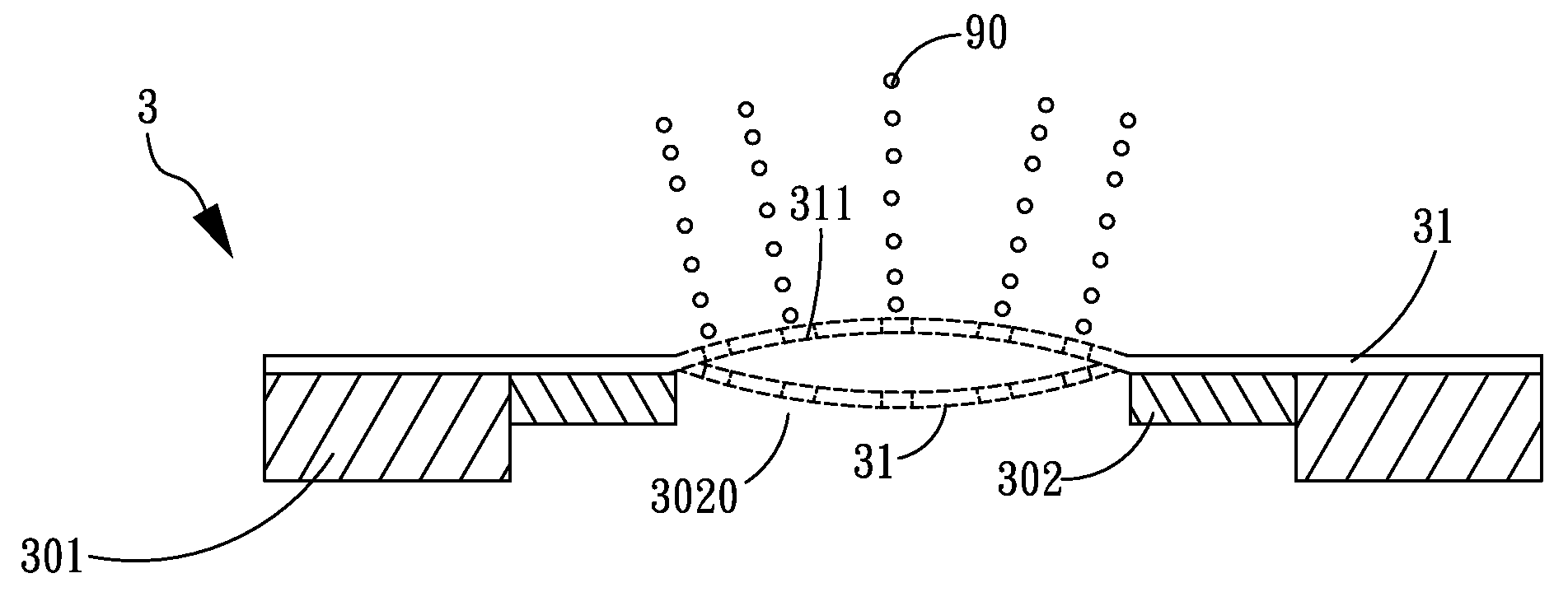

Dry powder inhaler with aeroelastic dispersion mechanism

InactiveUS20070209661A1Optimal drug deliveryImprove efficiencyRespiratorsLiquid surface applicatorsMedicineInhalation

The present invention comprises a dry powder inhaler (DPI) that uses a patient's inhalation flow to concentrate energy in an aeroelastic element for deaggregation and dispersion of a powder dose. The result is a DPI that delivers a dose independent of inspiratory abilities of the patient, solving a major problem of conventional DPIs. Increased tension on the aeroelastic element causes higher frequency vibrations and improved powder dispersion. The tension of the aeroelastic element can be modified prior to dispensing the DPI to the patient, allowing for individualization for single patients or groups of patients. In addition, the DPI has features that increase the turbulence of the airflow as it passes through the device, further increasing the dispersion and deaggregation of the powder. The DPI can hold a single dose or multiple doses. The powder doses can be dispensed directly onto the aeroelastic element, or may be in adjacent blister packaging.

Owner:STC UNM

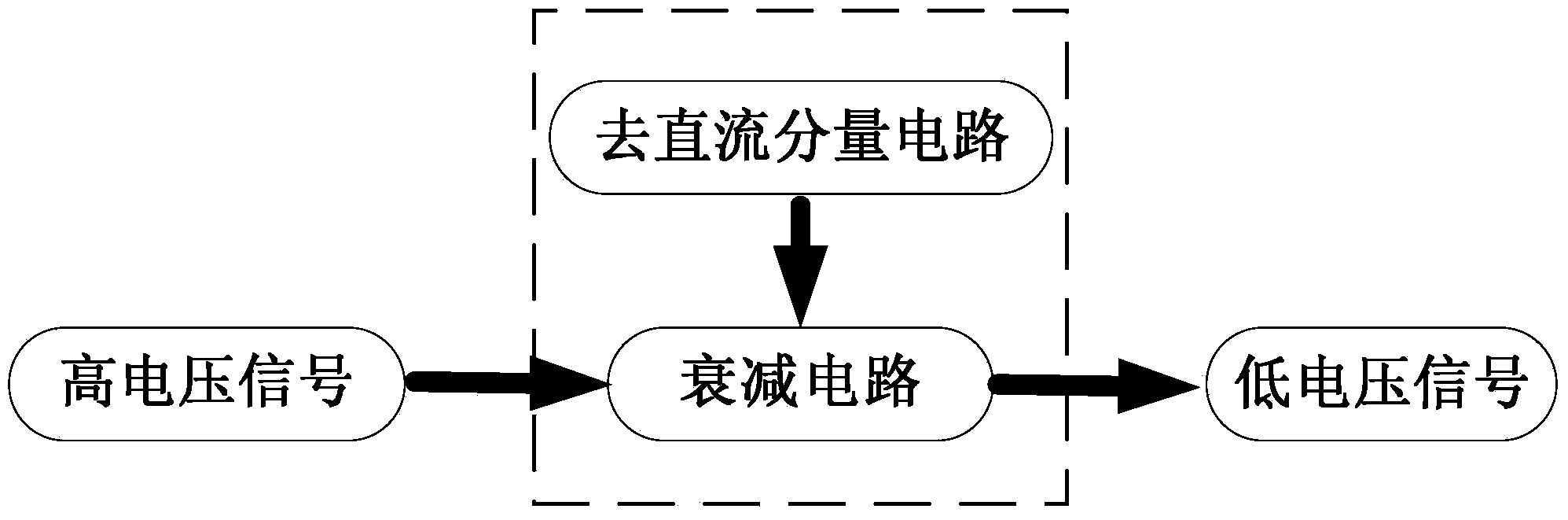

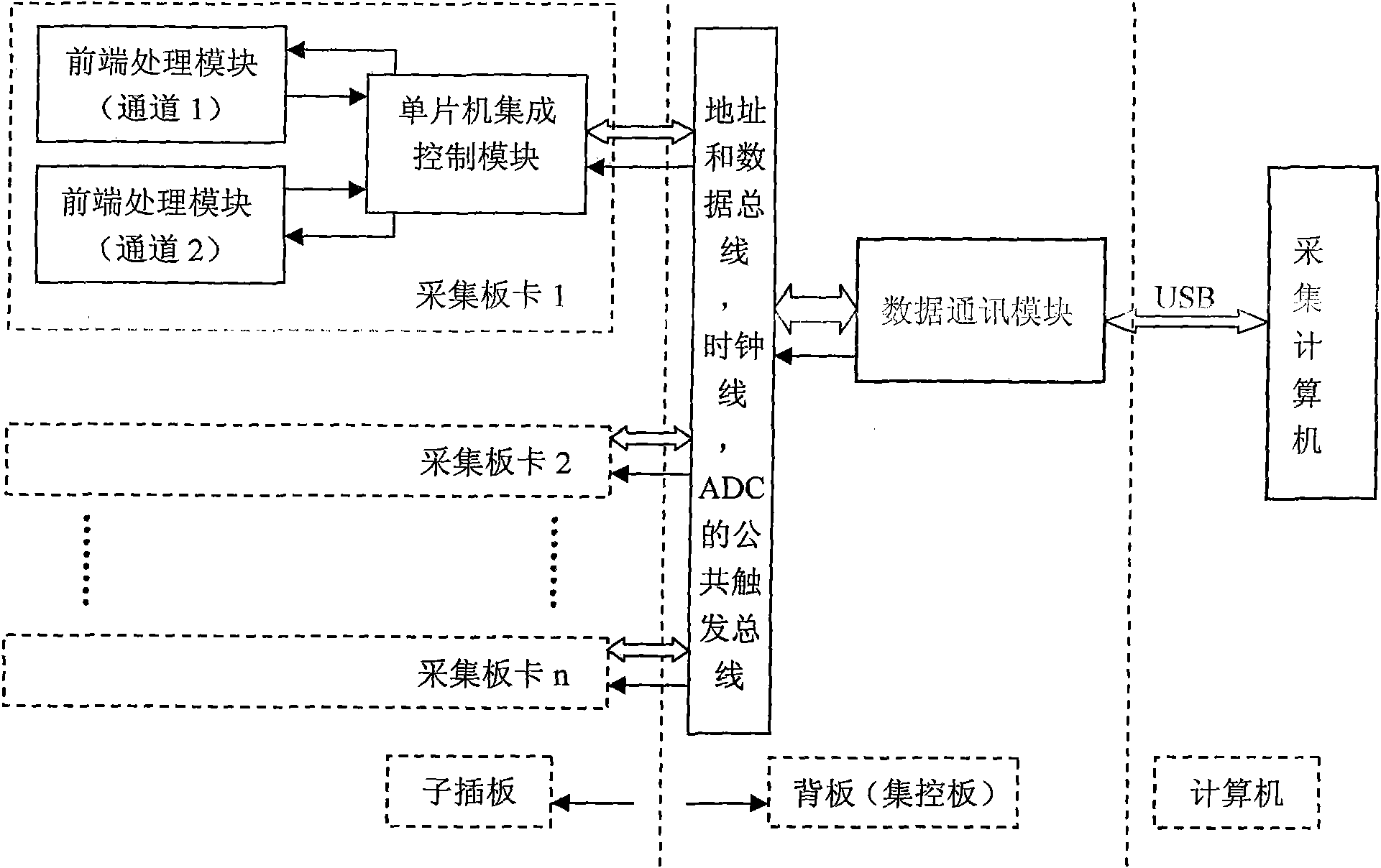

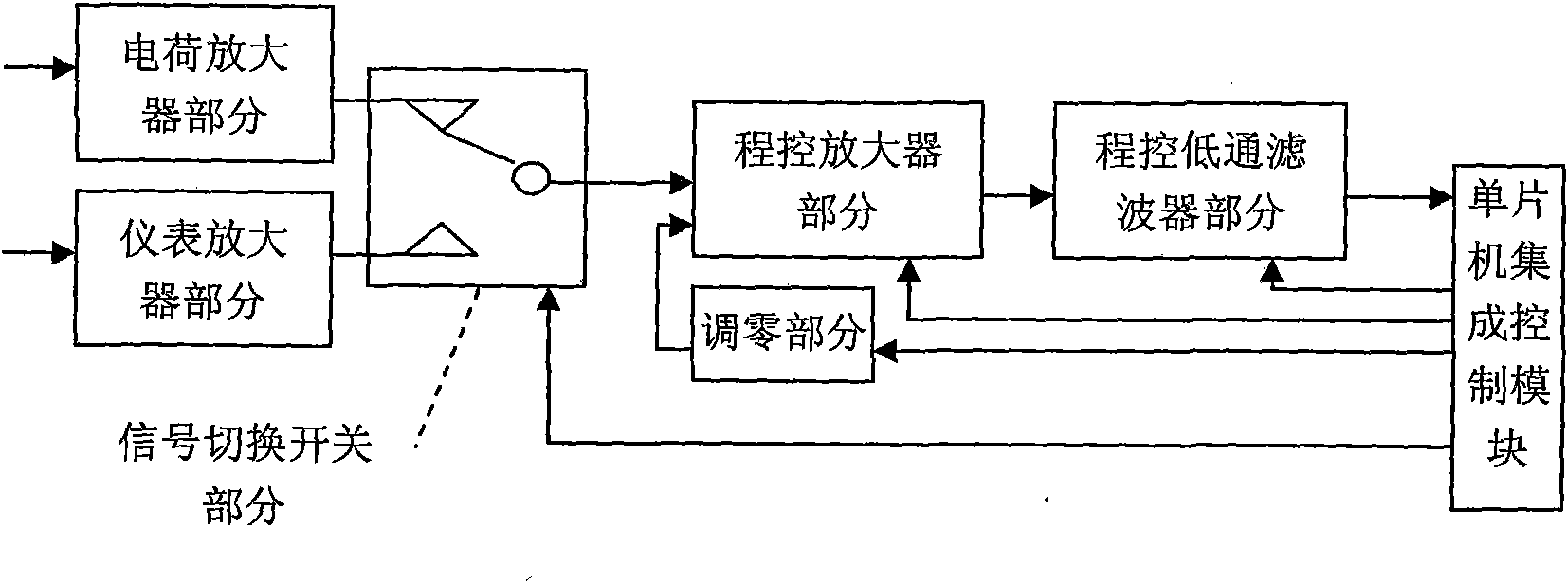

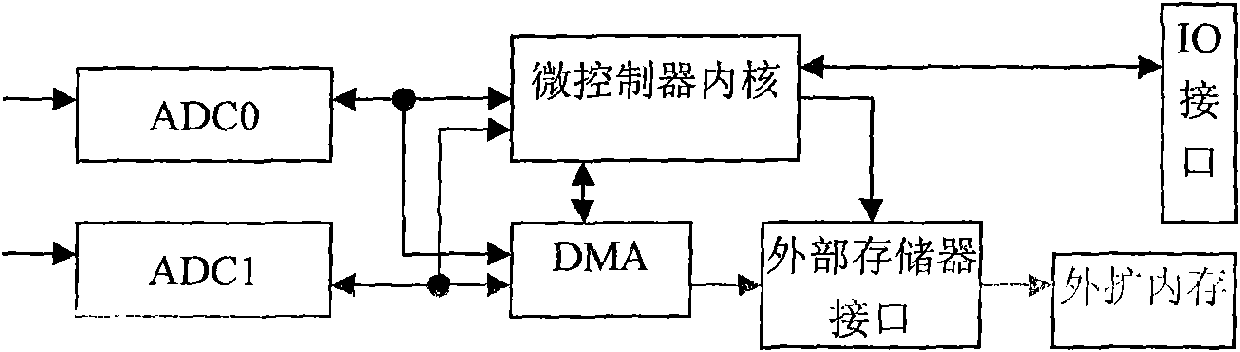

Multi-channel synchronous vibration data collecting system

InactiveCN101566845AMeet collection requirementsSimple designComputer controlSimulator controlMicrocontrollerData synchronization

The invention discloses a multi-channel synchronous vibration data collecting system which comprises signal front-end processing modules, a singlechip integration control module, a data communication module and a collection computer; two signal front-end processing modules and one singlechip integration control module form a collecting card; a plurality of the collecting cards are inserted and connected on a shared address, data, clock and triggering bus; one end of the data communication module is also inserted and connected on the shared address, data, clock and triggering bus while the other end thereof is connected with the collecting computer by a USB communication wire; the collecting system can completely meet vibration signal collecting requirement and simultaneously has multiple sampling channels and the function of collecting synchronous signals; the collecting system also has program control function, can meet the need of different sensor types, has high collecting speed, small volume and two collecting functions of common real-time collection and transient collection, can not only be applied to low-frequency vibration test, but also suitable for high-frequency vibration tests such as crash, explosion and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

Full range loudspeaker

InactiveUS7167573B2Improve performancePrecise alignmentFrequency/directions obtaining arrangementsDiaphragm mounting/tensioningEngineeringLoudspeaker

An edge-driven diaphragm loudspeaker driver is configured such that the suspension system of the driver is connected to the voice coil rather than to the diaphragm. Thus, the diaphragm in the loudspeaker is free of suspension systems connected to or extending from the diaphragm. By attaching the surround suspension to the voice coil rather than to the diaphragm, the diaphragm is isolated from the influence of spurious high frequency vibrations in the suspension system, thereby increasing the performance of the loudspeaker at high frequencies. The loudspeaker driver configuration also provides for a longer excursion range for the voice coil / diaphragm assembly, which allows for the driver components to be more accurately aligned during manufacturing, thereby enabling the loudspeaker driver to operate as a full range unit by producing low output frequencies.

Owner:HARMAN INT IND INC

Three-degree-of-freedom ultralow frequency vibration absorber

ActiveCN103307195AReduce vibrationLower natural frequencyNon-rotating vibration suppressionVibration attenuationThree degrees of freedom

The invention provides a three-degree-of-freedom ultralow frequency vibration absorber which has a compact structure and belongs to the field of accurate vibration attenuation. The vibration absorber respectively utilizes the principle that the positive and negative rigidities are connected in parallel in three degrees of freedom to realize ultralow frequency vibration attenuation, greatly reduces the rigidity of the system on the premise of ensuring the bearing capacity of the system, and realizes the ultralow inherent frequency. The three-degree-of-freedom ultralow frequency vibration absorber adopts the manner that the magnetic positive rigidity and the magnetic negative rigidity are connected in parallel in the z direction and the manner that a flat spring and the magnetic negative rigidity are connected in parallel in the x direction and y direction, so that the integral structure is more compact, the ultralow inherent frequency is provided, excellent vibration attenuation effect is provided for medium-high frequency vibration interference, the low frequency vibration and the ultralow frequency vibration are effectively restrained, and the three-degree-of-freedom ultralow frequency vibration absorber is applicable to the accurate processing equipment and measuring equipment sensitive to vibrations.

Owner:HUAZHONG UNIV OF SCI & TECH

Electrostatic force microscope and measurement method thereof

InactiveCN101493397AImprove spatial resolutionAccurately measure resultsSurface/boundary effectVibration exciterImage resolution

The invention provides an electrostatic microscope and a measurement method. The electrostatic microscope consists of a scan head, a low frequency voltage signal generator, a high frequency voltage signal generator, a low frequency vibration signal detector, a high frequency vibration signal detector and a controller; and the scan head comprises a probe, a probe location inductor, a piezoelectric vibration exciter and a piezoelectric scanner. Based on an existing electrostatic force microscope, a higher order eigenvibration mode of the probe is adopted to measure electrostatic force. As interaction of the probe and the sample is different in different vibration modes, the corresponding performance is different in aspects such as resolution, sensitivity, stability and the like. The electrostatic microscope can help significantly improve spatial resolution of the electrostatic force microscope in atmospheric environment.

Owner:SUN YAT SEN UNIV

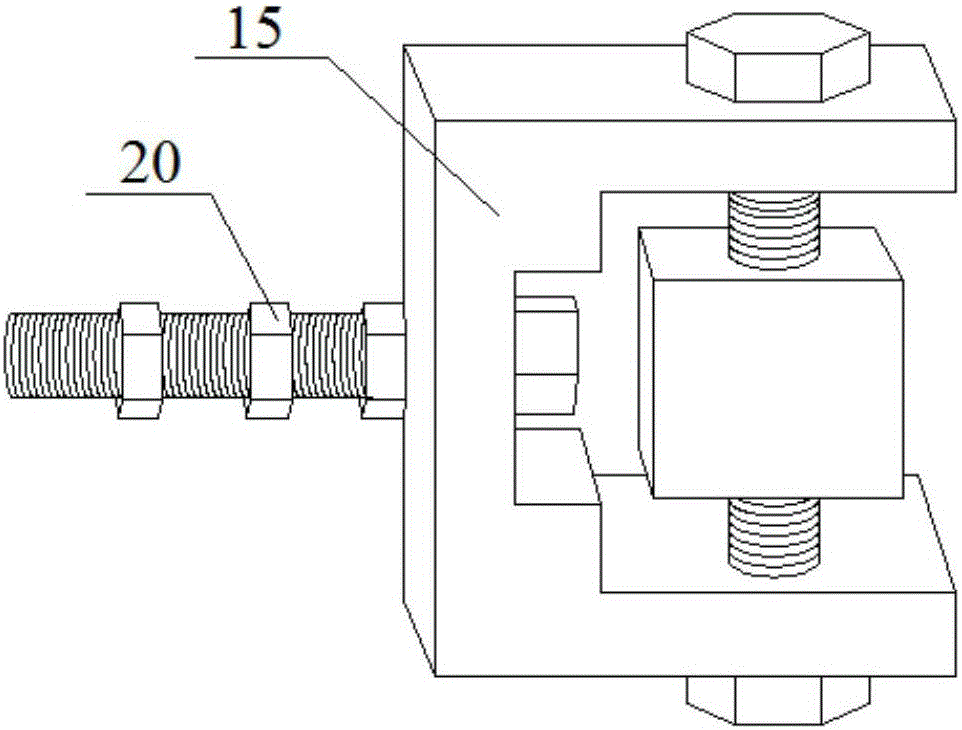

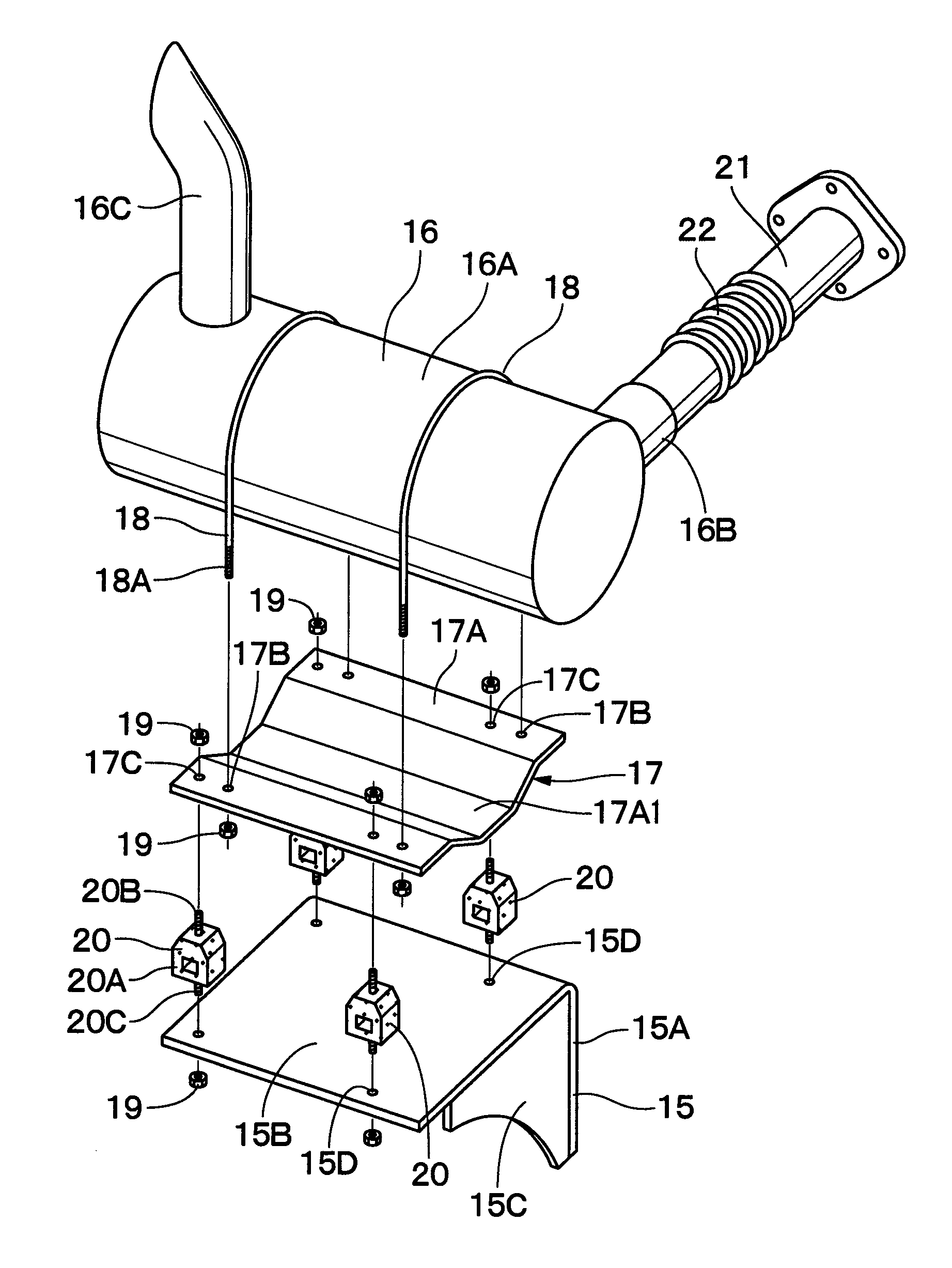

Exhaust gas treatment device for construction machine

InactiveUS8418448B2Protection from vibrationExhaust apparatusSilencing apparatusEngineeringMechanical engineering

An engine (8) is mounted to a vehicle body by means of vibration isolating mounts (8E), and a support member (15) is mounted to the engine (8). Vibration isolating members (20) are provided between this support member (15) and a mounting bracket (17) mounted to an exhaust gas treatment device (16). Accordingly, even in cases where the engine (8) has generated high-frequency vibrations, these vibrations can be damped by the vibration isolating mounts (8E) and the vibration isolating members (20). In consequence, treatment members constituting the exhaust gas treatment device (16), such as a catalyst, a filter, and a sensor, can be protected from the vibrations of the engine (8). In addition, as the exhaust gas treatment device (16) is provided with the mounting bracket (17), the vibration isolating members (20) can be reliably mounted to the exhaust gas treatment device (16) by means of the mounting bracket (17).

Owner:NIHON KENKI CO LTD

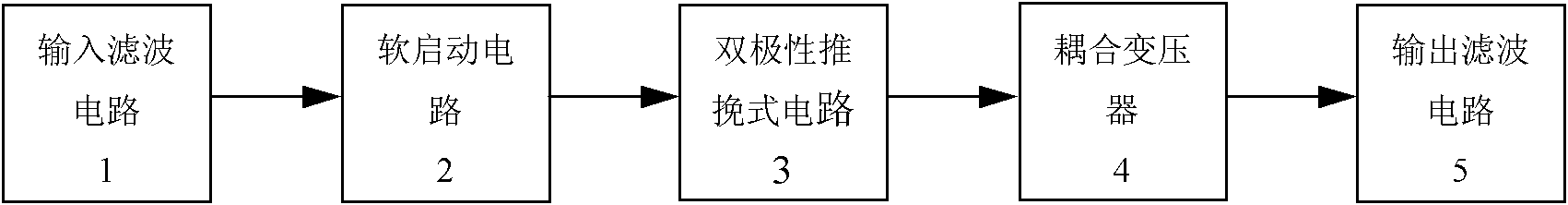

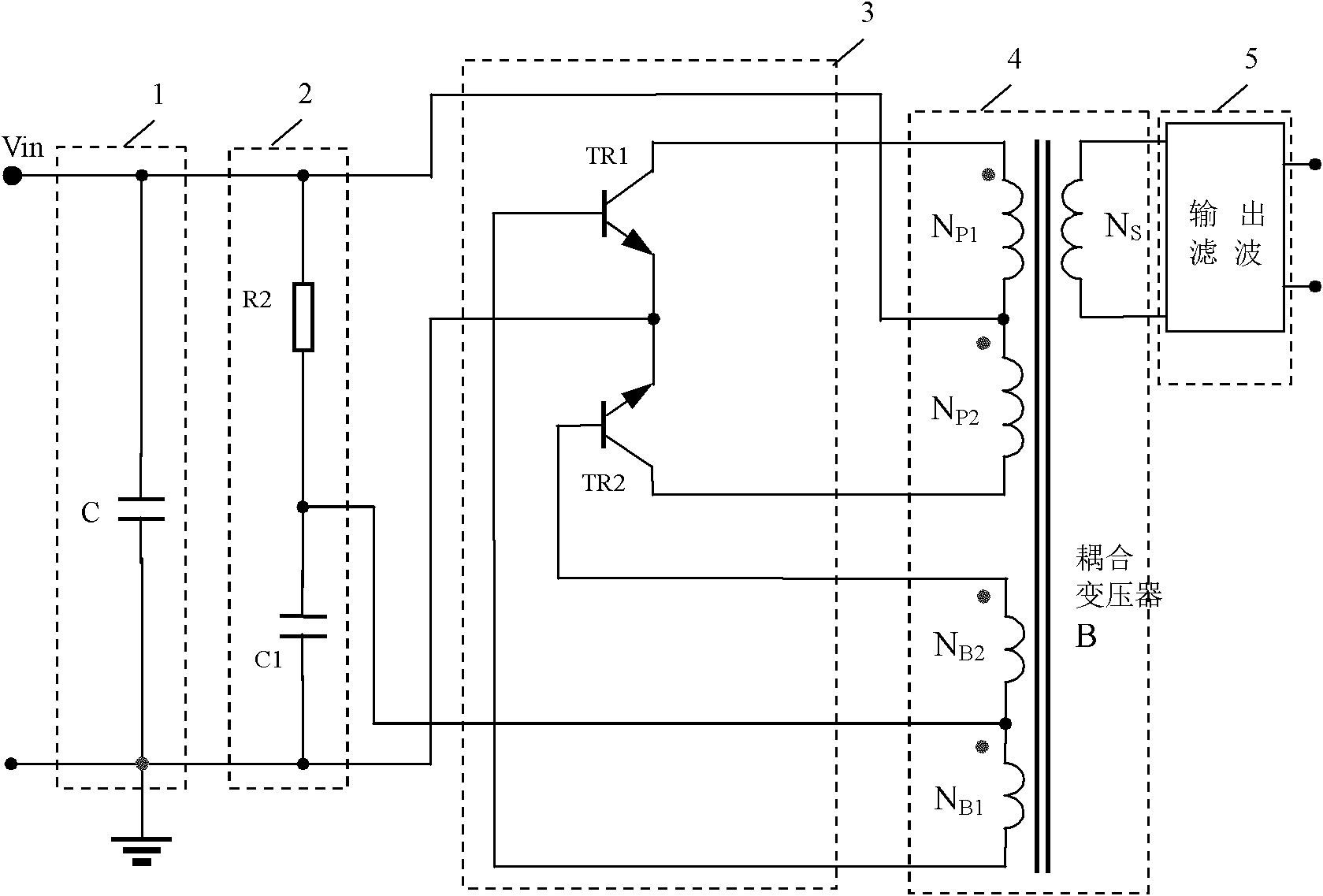

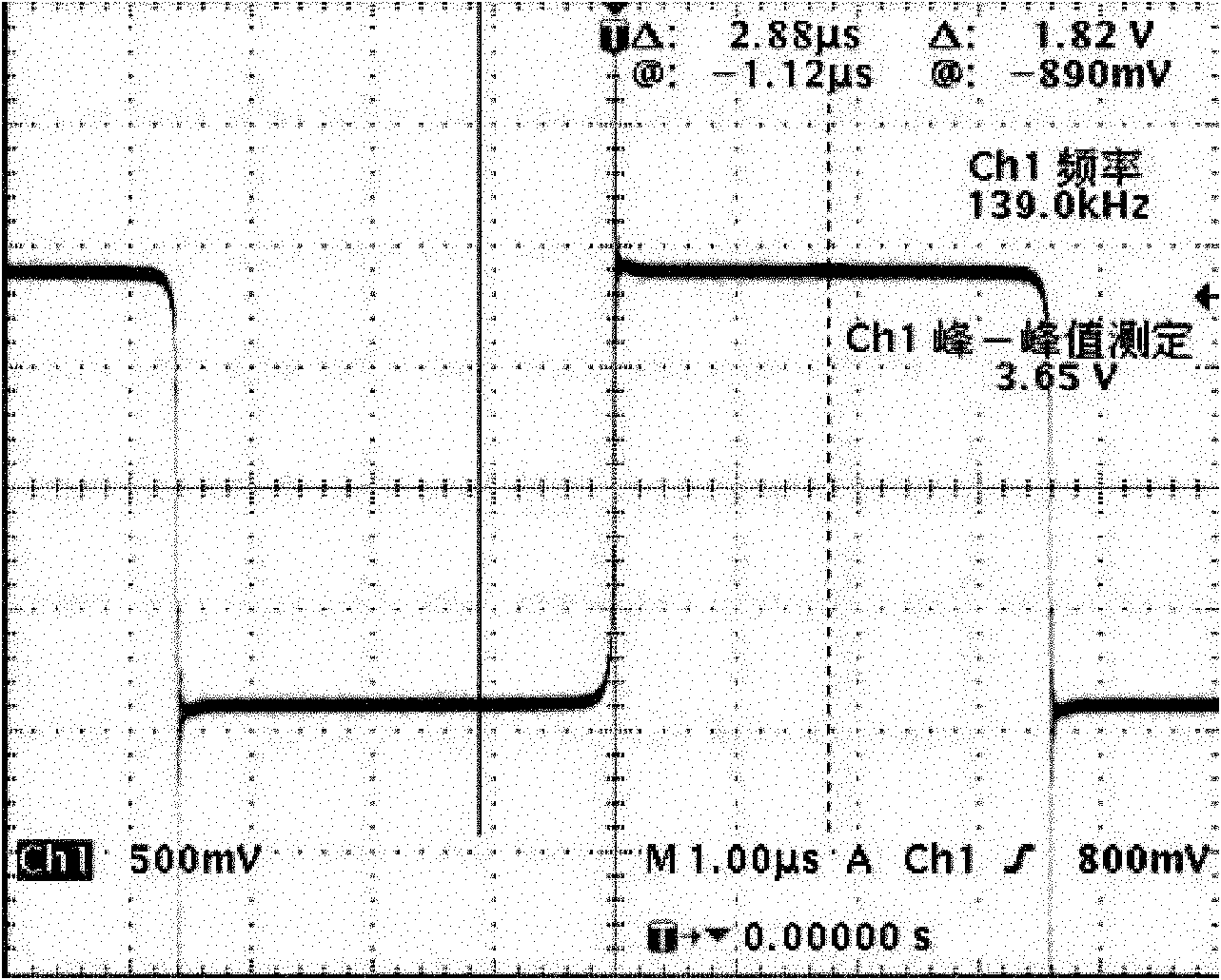

Self-exited push-pull converter

The invention discloses a self-exited push-pull converter, comprising an input soft starting circuit, a bipolar push-pull circuit, a coupling transformer and an output filter circuit, wherein the input soft starting circuit, the bipolar push-pull circuit, the coupling transformer and the output filter circuit are connected in order; the bipolar push-pull circuit comprises two triodes and a high frequency self-exited suppression circuit, wherein the two triodes are in push-pull connection; the emitters of the two triodes are grounded; the bases of the two triodes are respectively connected with two ends of a feedback winding of the coupling transformer; the collectors of the two triodes are connected with two ends of a primary winding of the coupling transformer; the high frequency self-exited suppression circuit is used for removing sine vibration generated due to high characteristic frequency when the triodes are electrified; and the high frequency self-exited suppression circuit is connected in the bipolar push-pull circuit. The self-exited push-pull converter can effectively control high frequency vibration.

Owner:MORNSUN GUANGZHOU SCI & TECH

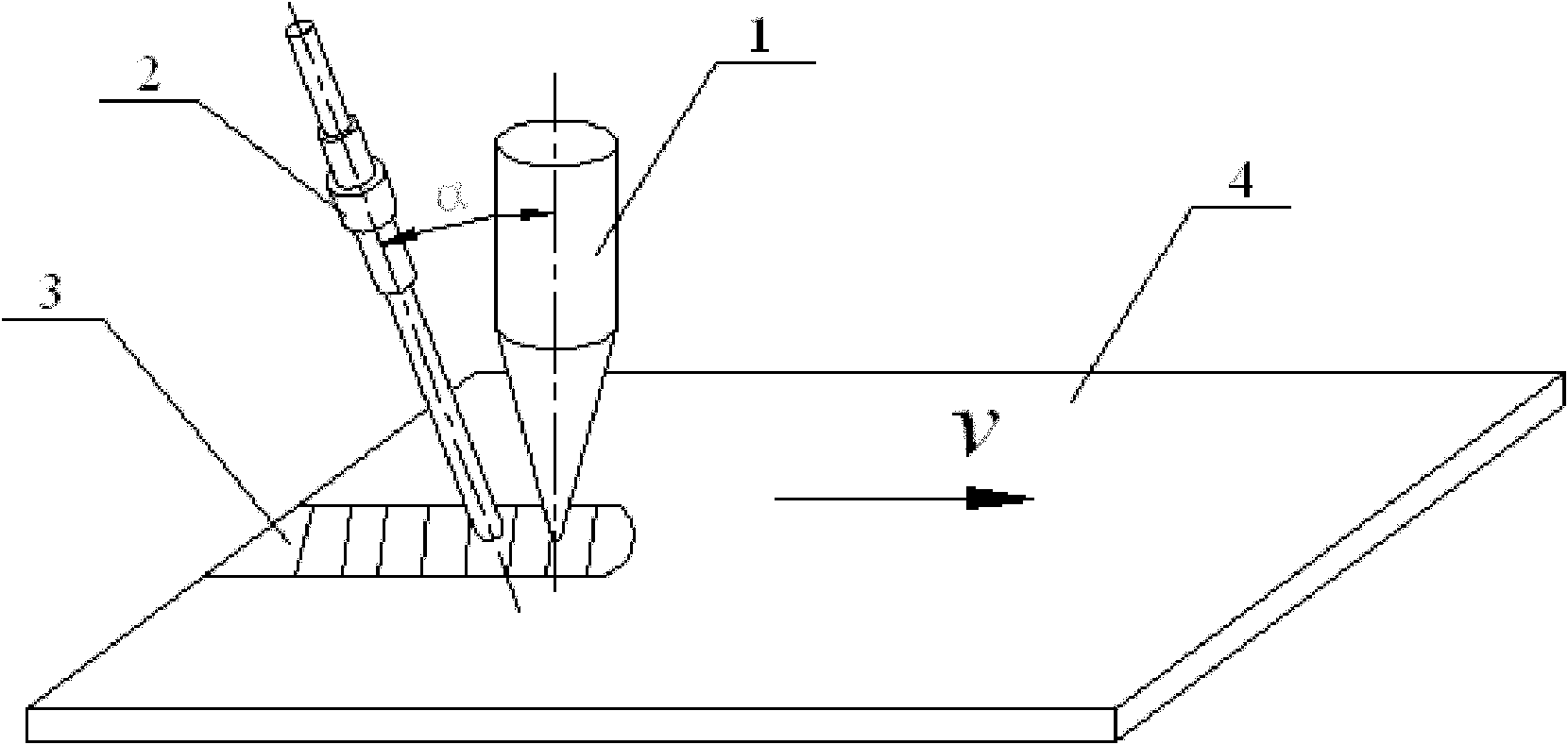

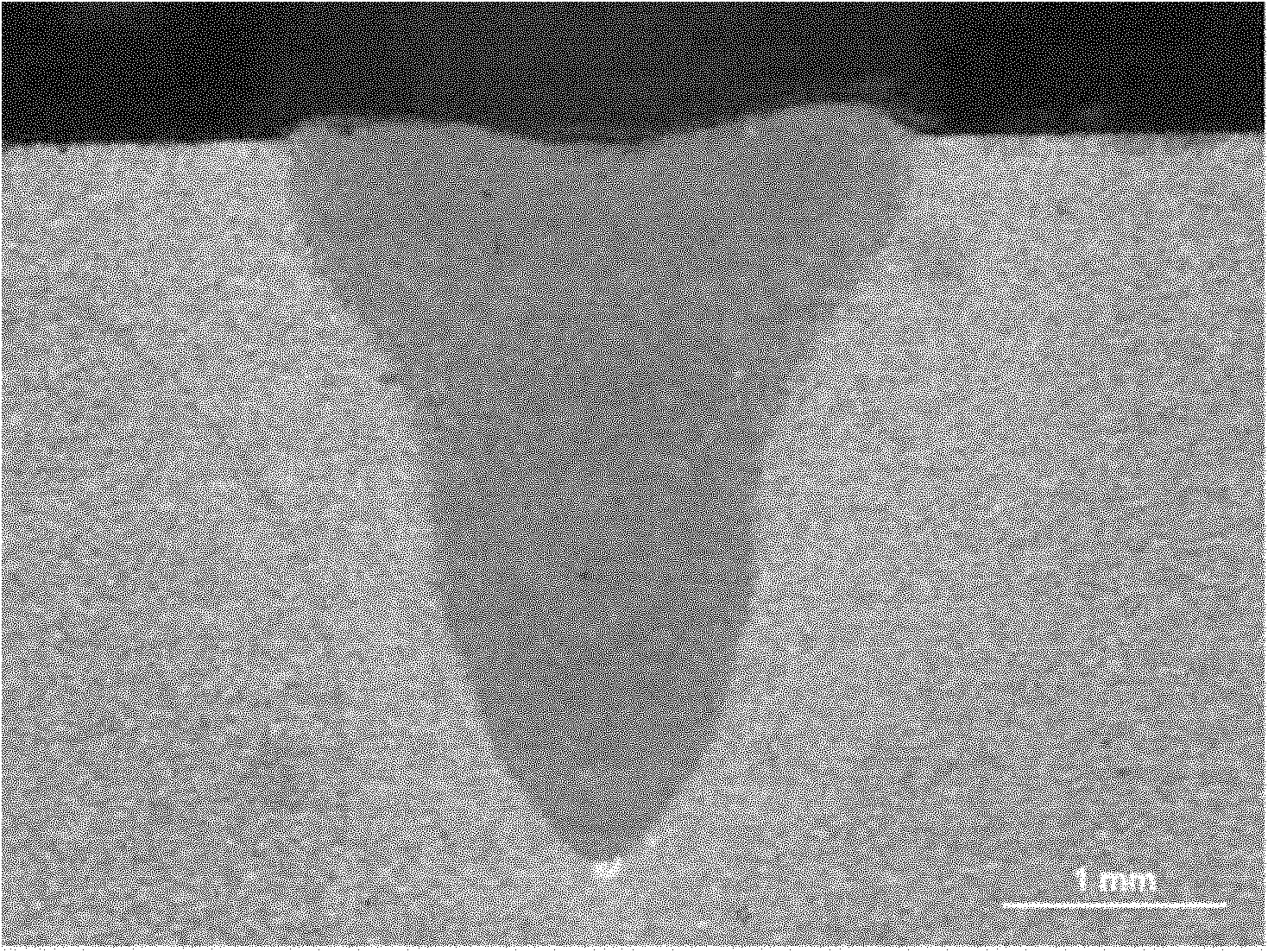

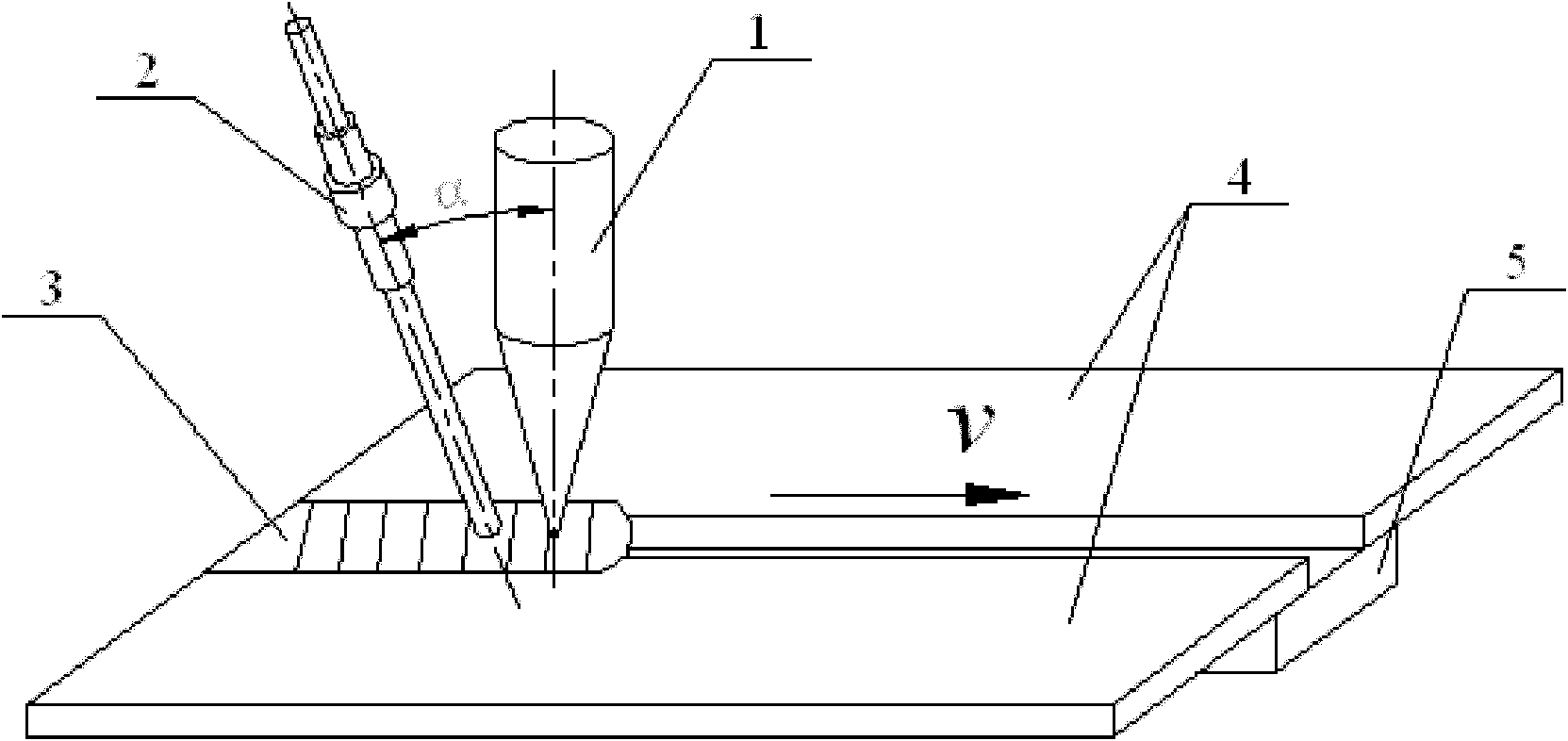

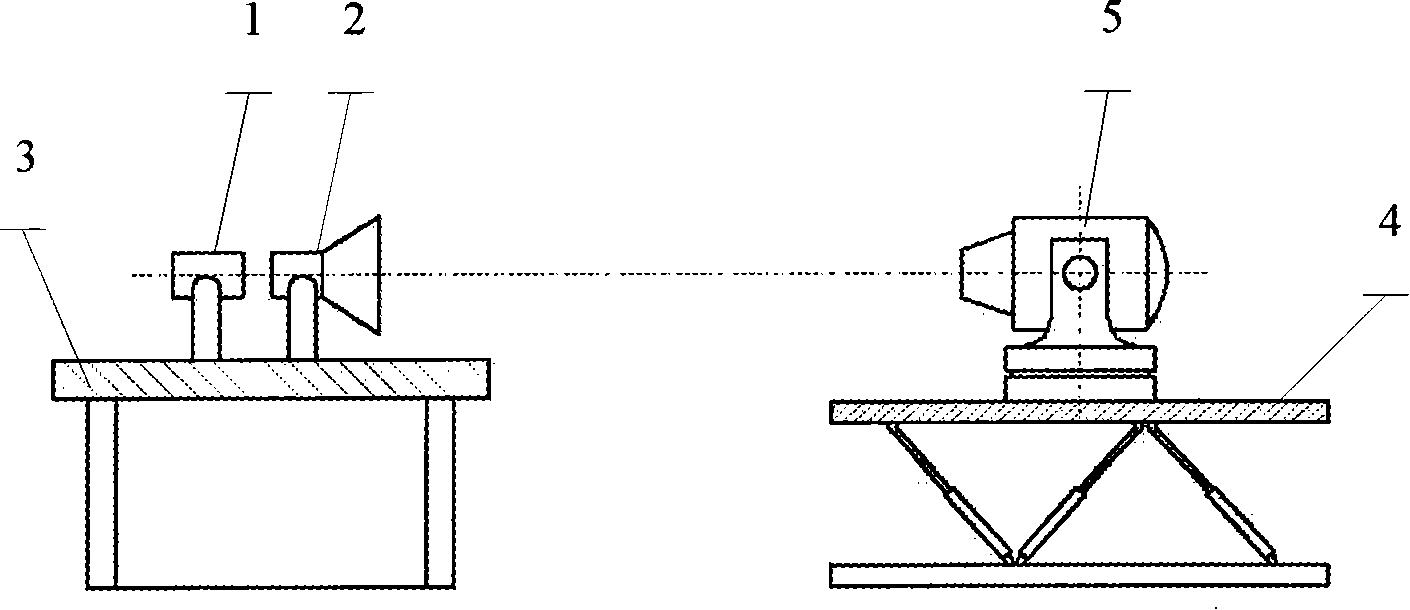

Non-contact-type ultrasonic-assisted laser welding method

InactiveCN102059453AGrain refinementImprove mechanical propertiesLaser beam welding apparatusCavitationLiquid metal

The invention relates to a non-contact-type ultrasonic-assisted laser welding method belonging to the field of material processing engineering and aiming at solving the technical problems of easy air hole and hot crack generation, joint softening, and the like occurring in the laser welding of metal, such as titanium alloys, aluminum alloys, and the like in the prior art. The invention adopts non-contact-type ultrasonic-assisted laser welding of titanium alloys or aluminum alloys, the generated cavitation action and the breaking theory of ultrasonic waves in a molten pool can be used for thinning grains of a welding line and further improving the mechanical performance of the welding line; the high-frequency vibration of the ultrasonic waves can generate a certain stirring action in the molten pool, and moreover, the ultrasonic waves per se have cavitation action, and thus, the full overflow of gases in the liquid metals and the reduction or avoidance of the generation of air holes are benefited. Compared with contact-type ultrasonic-assisted welding, the method has a wide use range because an ultrasonic tool head is not in contact with a workpiece, is convenient to realize omnidirectional automatic flexible welding and improves the efficiency.

Owner:HARBIN INST OF TECH

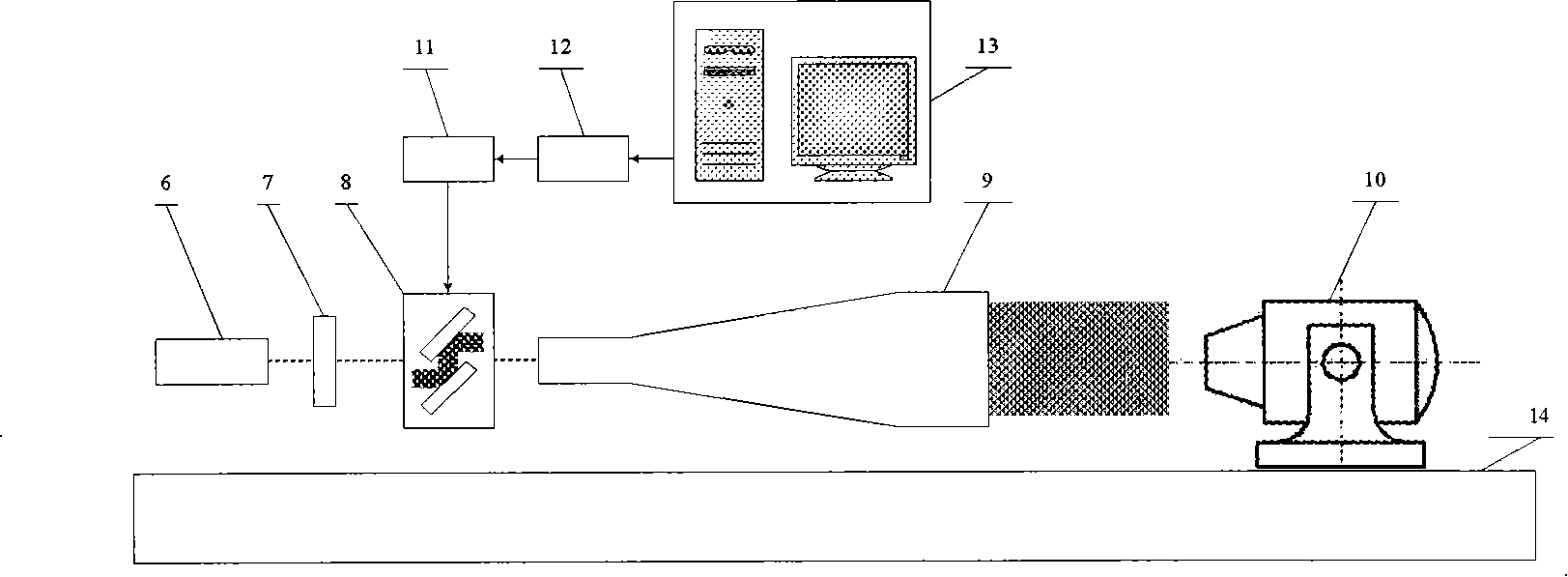

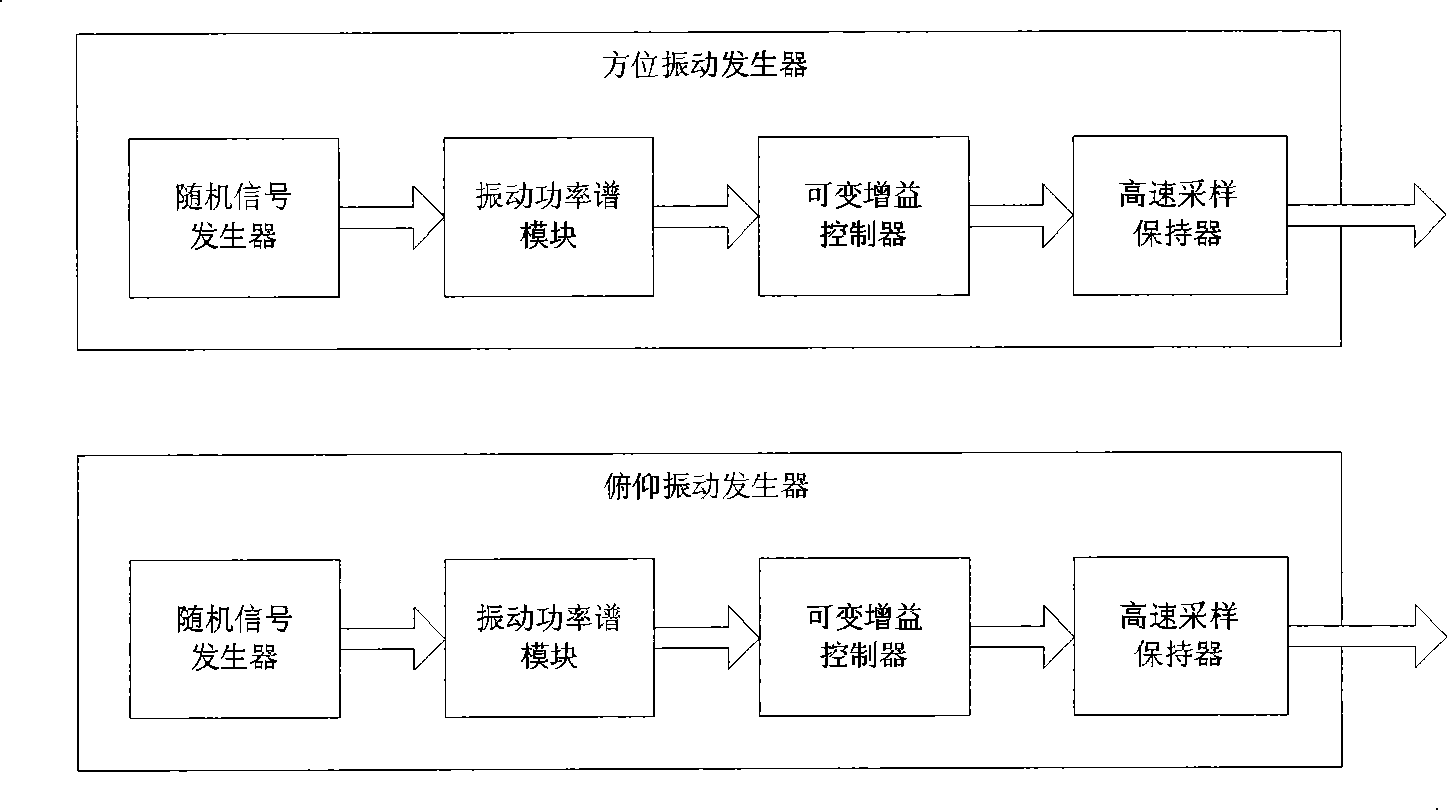

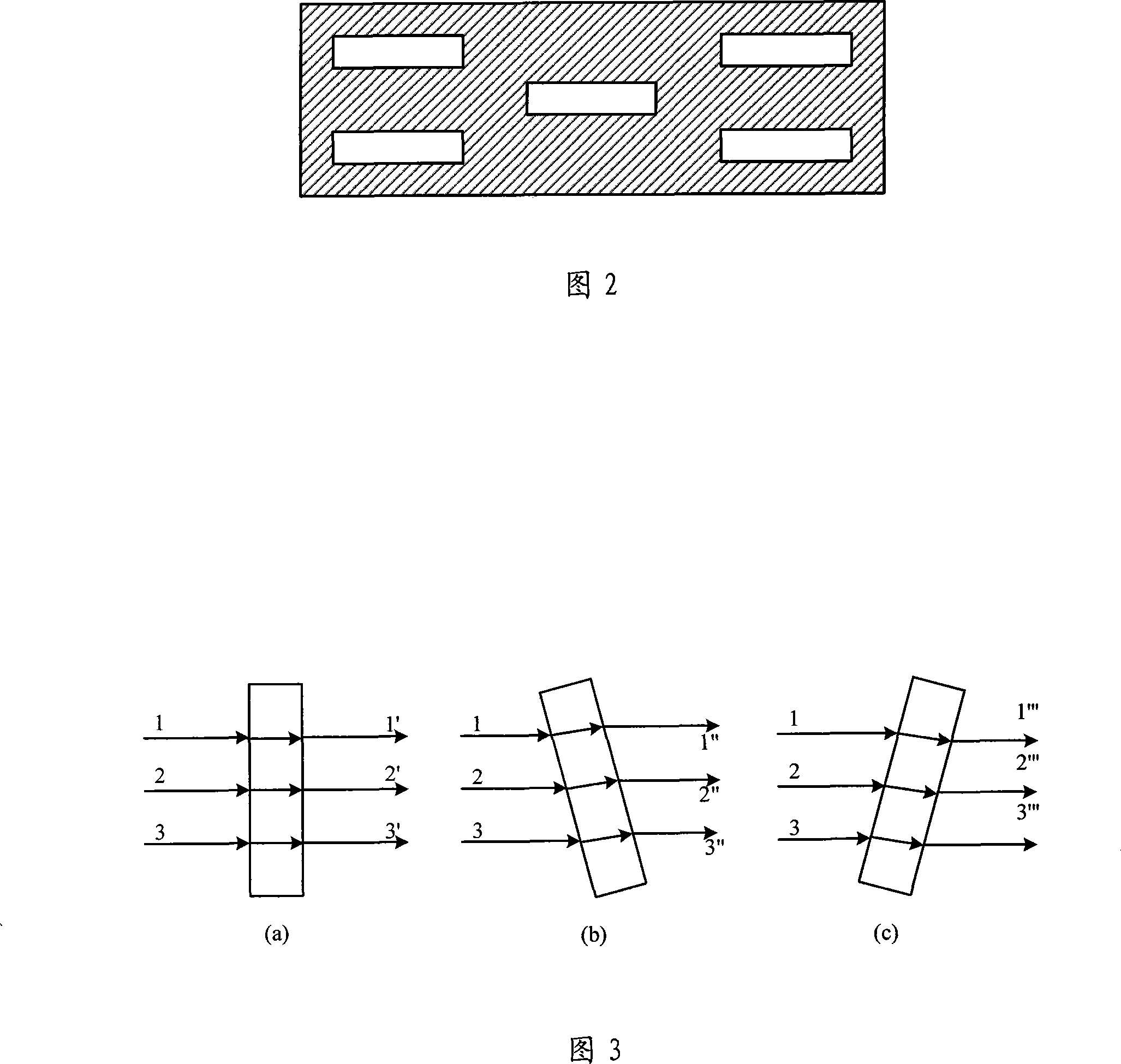

Optical profiletype simulate vibration movement platform device for space laser communication

InactiveCN101178336AMeet the tracking accuracy test requirementsImprove dynamic rangeVibration testingEngineeringOptical table

The invention relates to a libration simulator for a space laser communicating platform and is provided with a laser emission unit (6), an optical power adjusting unit (7), a beam servounit (8), a beam extending unit (9), a communicating optical transmitter and receiver (10) for the tested laser, a beam servo drive unit (11), a DA transfer card (12), a power spectrum generating unit (13) and an optical table (14). The invention can simulate on low frequency agitation and high frequency libration and can effectively inspect and verify the APT tracing precision of a space laser communicating system. A simulative bandwidth can reach to 100Hz, the maximum simulative extent of low frequency can reach to 20mrad, and the controlling precision of high frequency extent can reach to Mu rad magnitude. The invention has broader dynamic range, can librate randomly according to the wide spectrum of a power spectrum simulative platform, can also simulate the movement of a relative angle and sinusoidal excitation, and can detect on the dynamic lag error of the APT system, realize two-dimensional libration simulation, realize optical power adjusting and big caliber parallel beam emission and meet the test requirement for the tracing precision of the space laser communicating APT.

Owner:CHANGCHUN UNIV OF SCI & TECH

Medical liquid droplet apparatus

InactiveUS20090242663A1Avoid failureGuaranteed functionMovable spraying apparatusSpray nozzlesEngineeringPolymer thin films

The present invention provides a medical liquid droplet apparatus, which comprises a driving base and a polymeric film. The driving base is capable of providing a vibrating energy. The polymeric film, having a plurality of tiny openings formed thereon, is disposed on the driving base for receiving the vibrating energy so as to generating liquid droplet. By means of the present invention, the embrittled problem due to the high frequency vibration occurred in the conventional nebulizing film or malfunction due to the chemical eroding of the conventional vibrating film can be avoided.

Owner:QUATEK

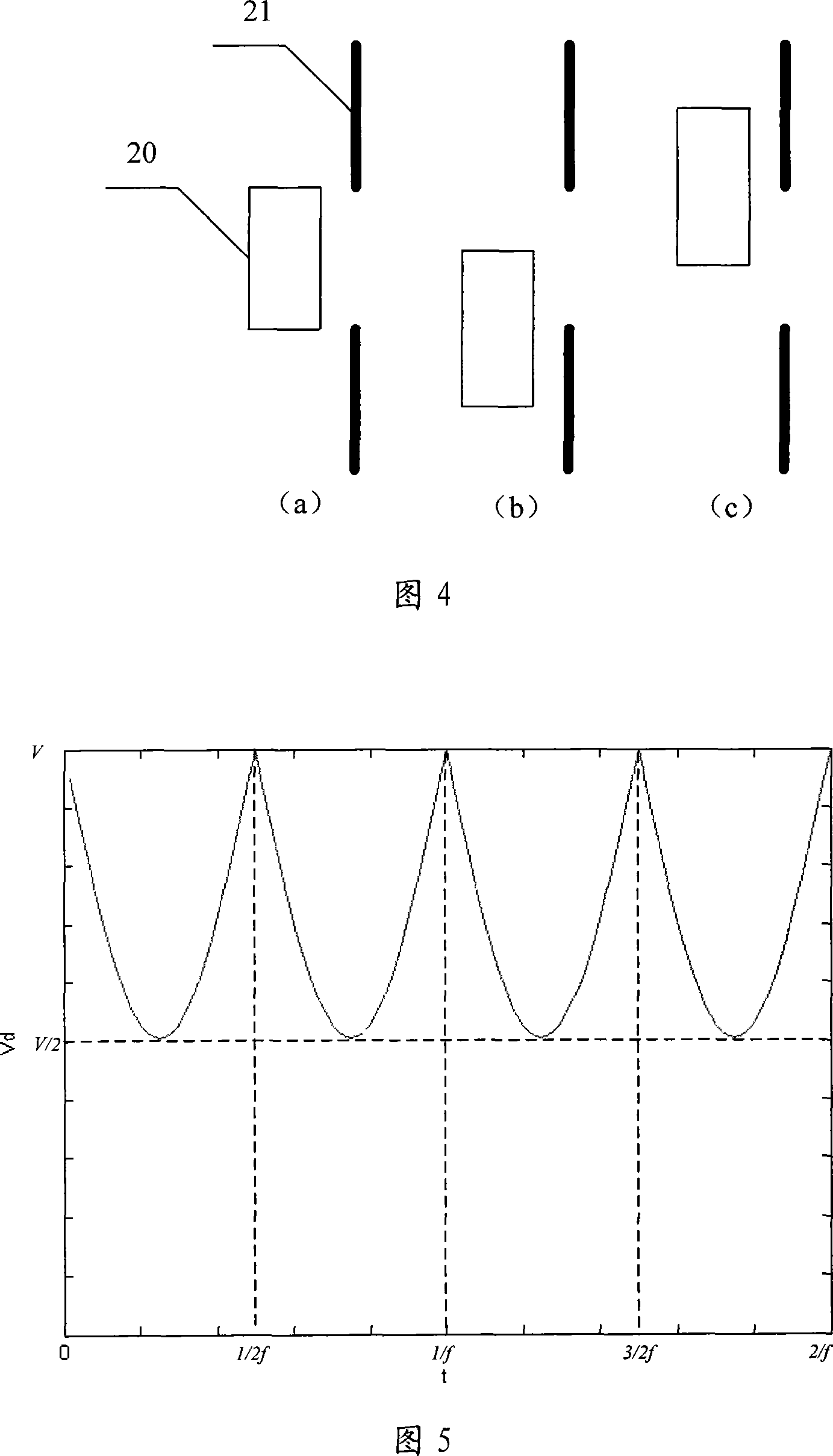

Device for automatically focusing and leveling

ActiveCN101201546ASmall sizeEasy to achieve high frequency vibrationPhotomechanical exposure apparatusMicrolithography exposure apparatusElectricityFlat glass

The invention provides an automatic focusing and leveling device and is applied in a photoetching machine to measure the height value and lean degree of the surface of a silicon chip to be measured relative to the focal plane of a projection objective lens, therefore, the focusing and leveling of the silicon chip can be realized. The automatic focusing and leveling device is provided with an optical module and a control module, both of which are connected with each other through electricity, wherein, the optical module adopts a plate glass and gets rid of limitation of mechanical size, therefore, the invention can realize high-frequency vibration more easily and is easy to be regulated.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

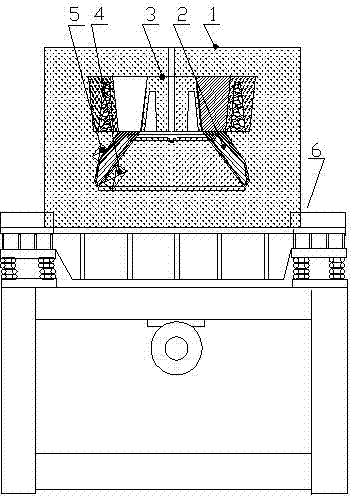

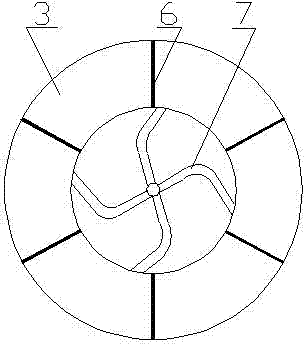

High-frequency vibration casting mold of conical sand maker breaking wall and casting process

ActiveCN102962399AImprove wear resistanceHigh densityFoundry mouldsFoundry coresHigh densityCasting mold

The invention relates to a high-frequency vibration casting mold of a conical sand maker breaking wall and a casting process capable of achieving the effect of no shrinkage cavity and effectively improving the cast density during casting feeding of the conical sand maker breaking wall. The high-frequency vibration casting mold is characterized in that a sand box is located on a high-frequency vibration platform; and the height of a breaking wall forming mold cavity in the sand box is smaller than the height of a casting riser or the volume of the forming mold cavity is smaller than the volume of the casting riser. The casting process comprises the following steps: casting high chromium cast iron into the breaking wall forming mold cavity and the casting riser, then carrying out high-frequency vibration on the high-frequency vibration platform, and cooling to obtain the high chromium cast iron breaking wall with a high density. The high-frequency vibration casting mold and the casting process have the advantages that firstly, the wear resistance of the high chromium cast iron breaking wall is effectively improved, and the sand making cost is greatly reduced; secondly, the feeding effect is good, the cast is high in density, and the occurrence of damage phenomenon is avoided; and thirdly, the wear resistance, the shock resistance and the service life are increased by nearly 5 times, and unexpected technical effects are achieved.

Owner:ZHEJIANG SHUANGJIN MACHINERY HLDG

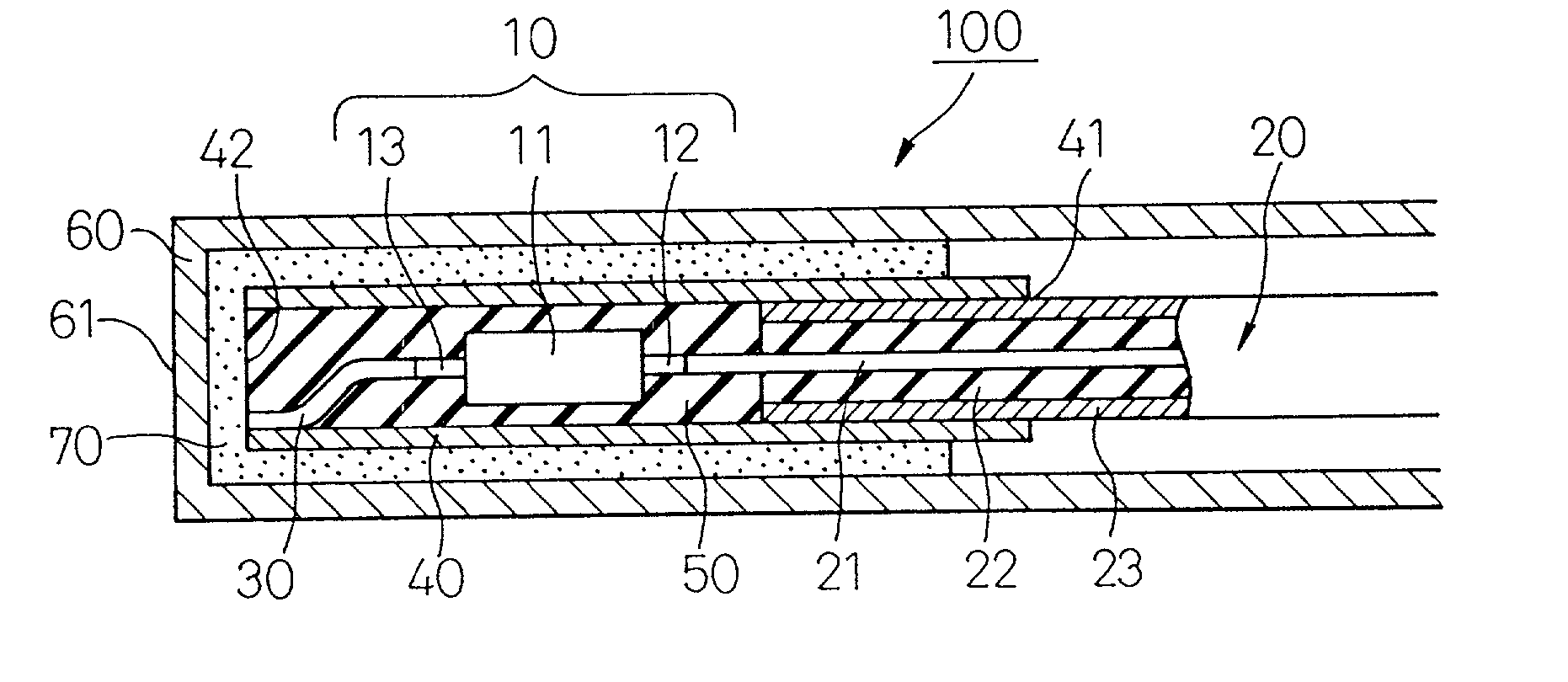

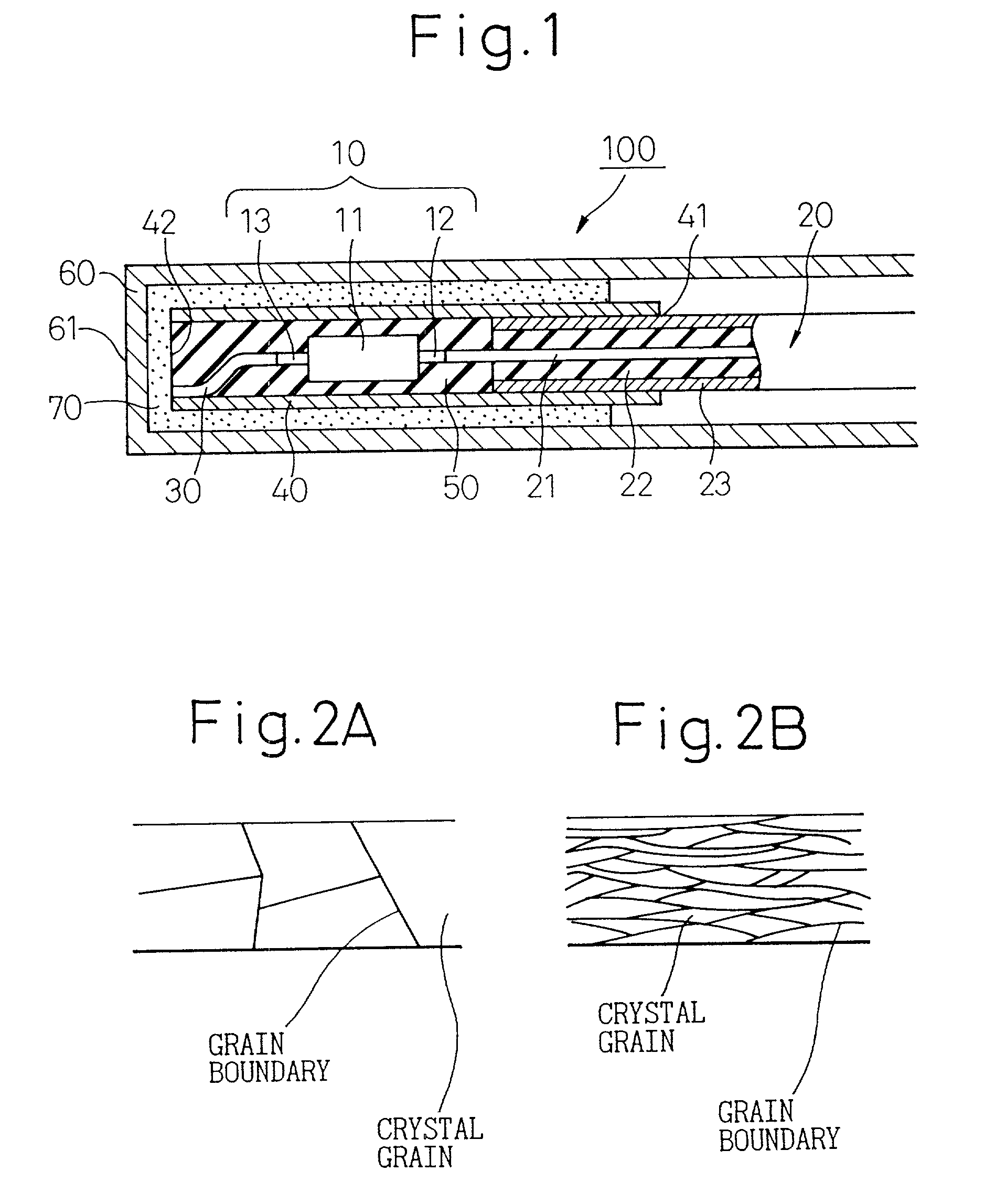

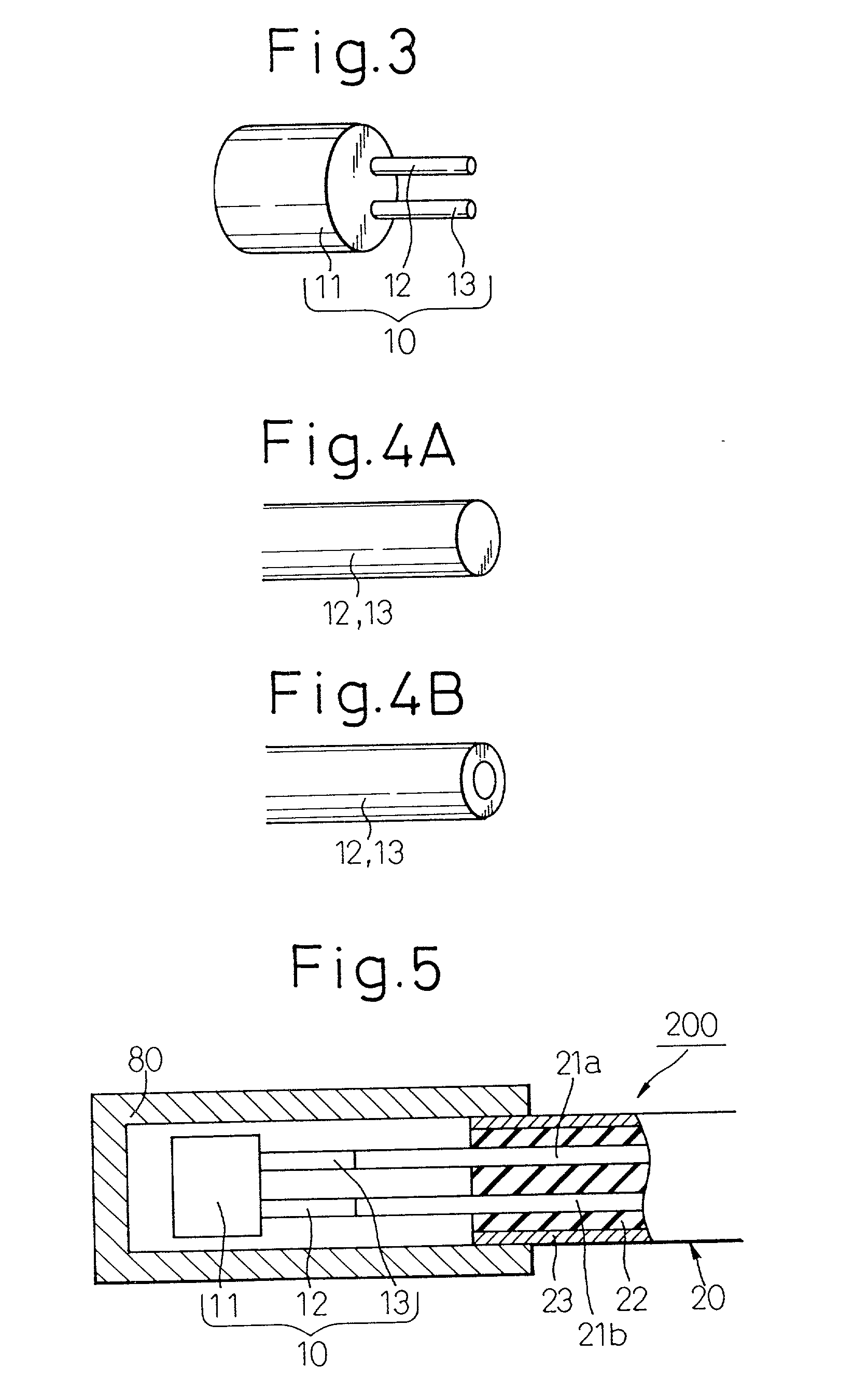

Thermostor-type temperature sensor

InactiveUS20020084884A1Improve usabilityAvoid breakingThermometers using electric/magnetic elementsNegative temperature coefficient thermistorsAdhesiveEngineering

The present invention provides a thermistor-type temperature sensor equipped with a thermistor element having a thermistor section and electrode wires for acquiring thermistor signals that prevent breakage of electrode wires caused by high-frequency vibrations. Thermistor element (10) is equipped with thermistor section (11) and electrode wires (12) and (13) made of a dispersion-strengthened material having for its main component platinum or platinum alloy, and is insulated and held in cylindrical metal case (40) having opening (42) on one end by means of insulating powder (50). A bottomed, cylindrical metal protective tube (60) houses metal case (40) so that its bottom (61) covers opening (42). Heat-resistant adhesive (70) is juxtaposed in a gap between metal case (40) and protective tube (60) so as to seal opening (42) to prevent insulting powder (50) from spilling into this gap from opening (42).

Owner:DENSO CORP

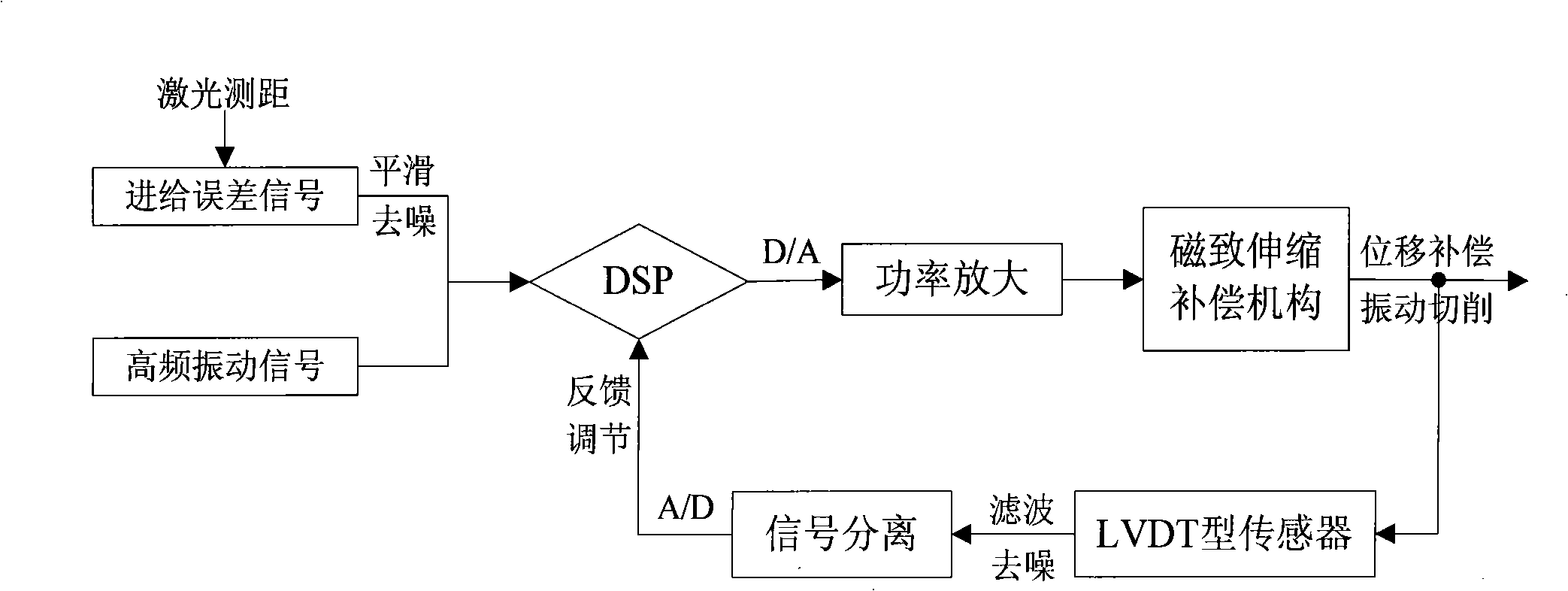

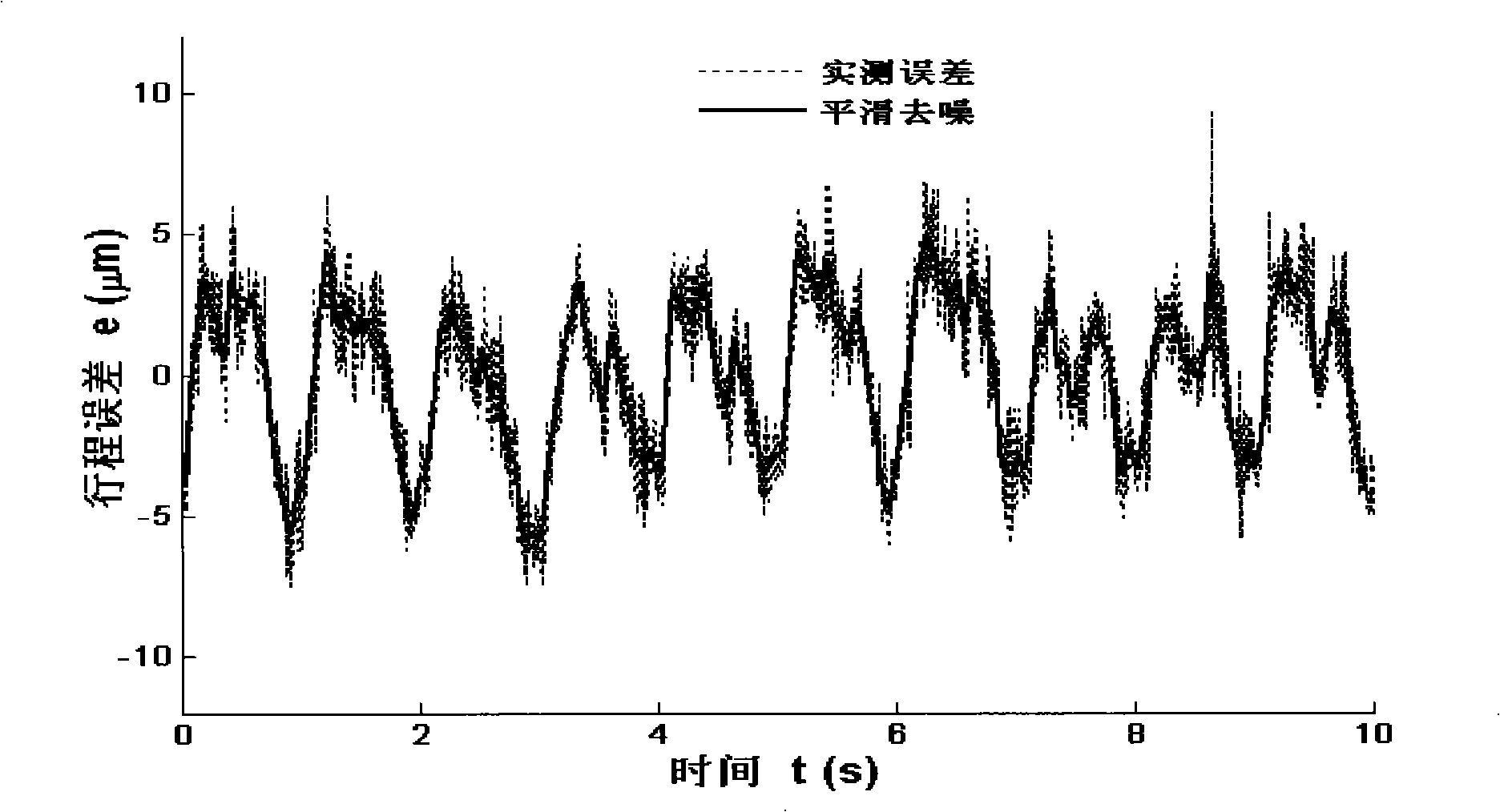

Compensation process capable of increasing machine precision of numerical-controlled lathe and magnetic striction compensation mechanism

ActiveCN101337330AHigh compensation accuracyAvoid breakingAutomatic control devicesMeasurement/indication equipmentsNumerical controlClosed loop

The invention discloses a compensation method for enhancing the machining accuracy of a numerical control machine tool and a magnetostrictive compensation mechanism, in particular to a method for compensating the accuracy of the numerical control machine tool through combined feed and a modularized accuracy compensation mechanism. The method comprises the following steps: aiming to the machine tool, because of a geometrical error formed by a plurality of factors such as manufacture, abrasion, etc., feed errors in a full-stroke range are measured by a dual-frequency laser interferometer; the modularized compensation mechanism is driven to produce the corresponding displacement compensation quantity through power amplification after an error signal is pretreated; the micro-displacement feed is performed in cooperation with the macro displacement feed, so as to correct the accuracy of the machine tool. High-frequency vibration signals are superposed as a drive compensation mechanism for driving the voltage to perform vibration cutting, thereby effectively inhibiting a flutter phenomenon caused by friction during cutting, and enhancing the machining accuracy. An LVDT inductive displacement transducer is mounted at the tail end of an elastic micro-displacement mechanism for position feedback regulation; furthermore, the closed-loop control is formed through real-time control operation in a DSP chip to realize precise positioning.

Owner:JIANGSU HAIJIAN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com