Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Realize high frequency vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

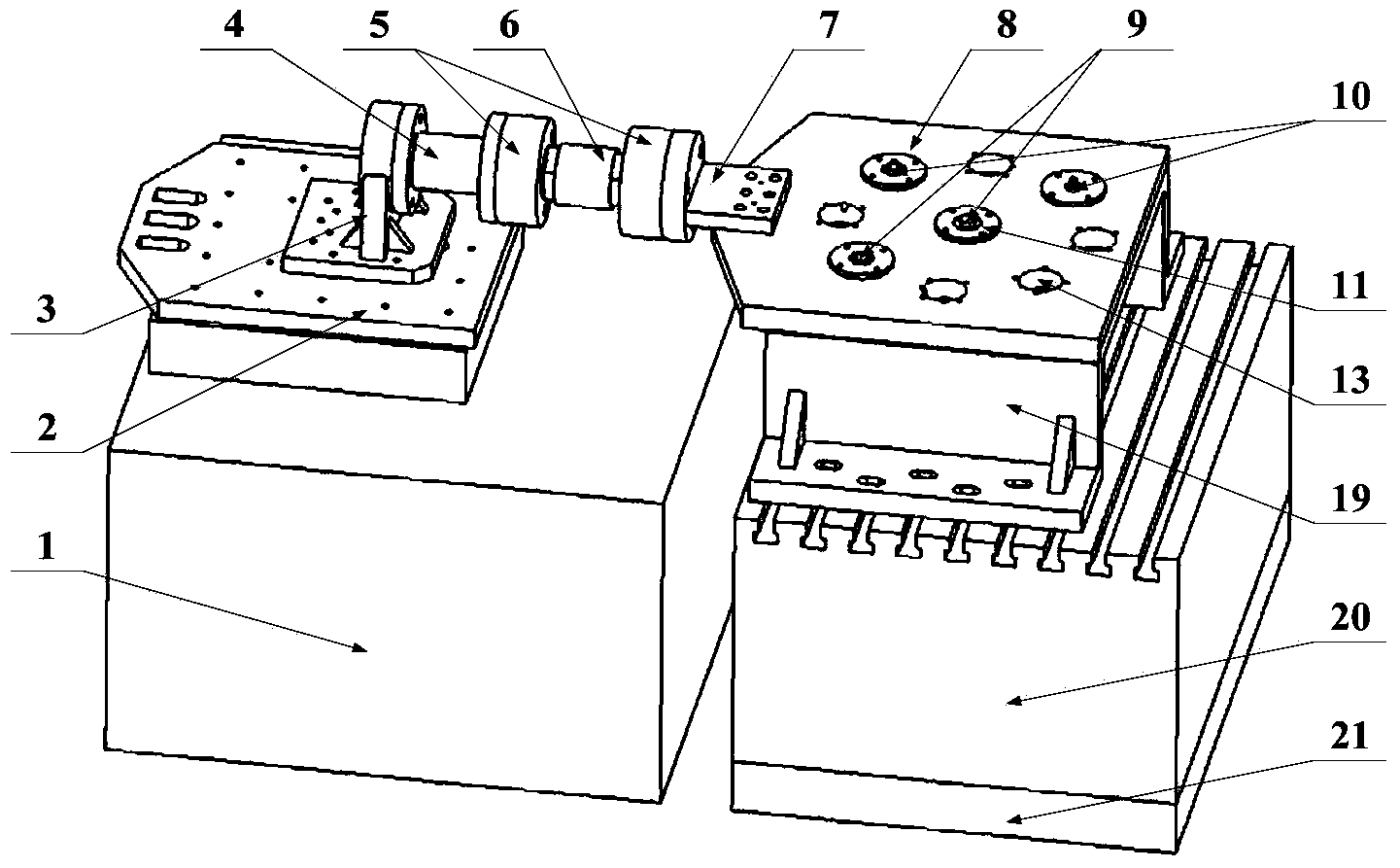

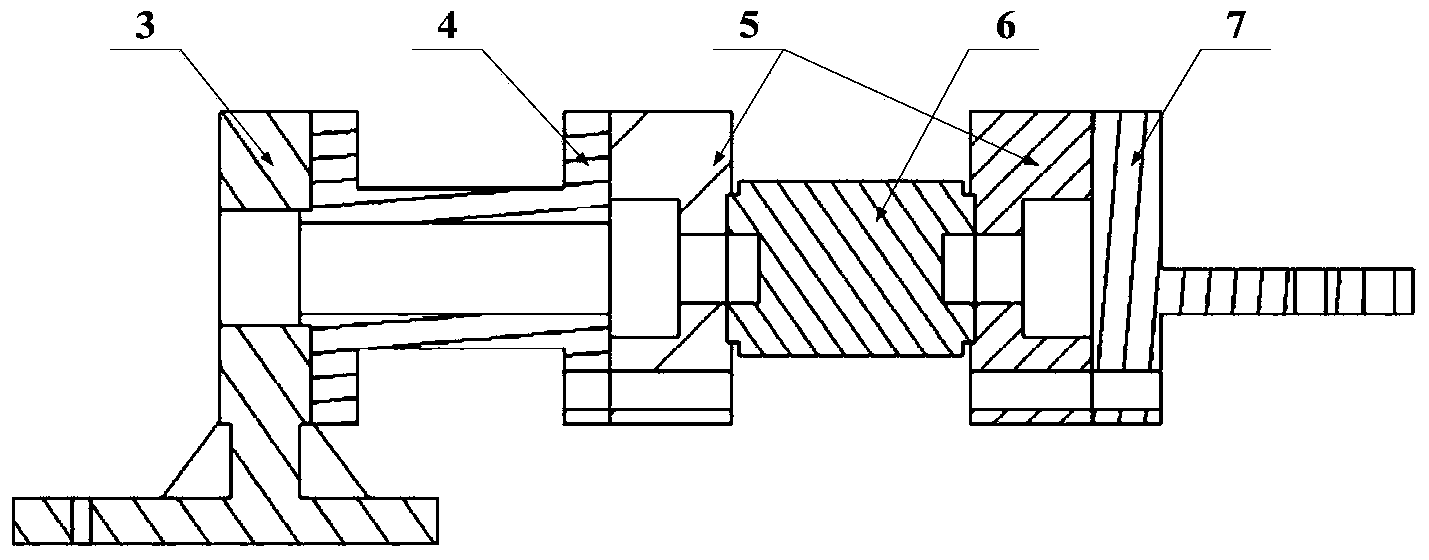

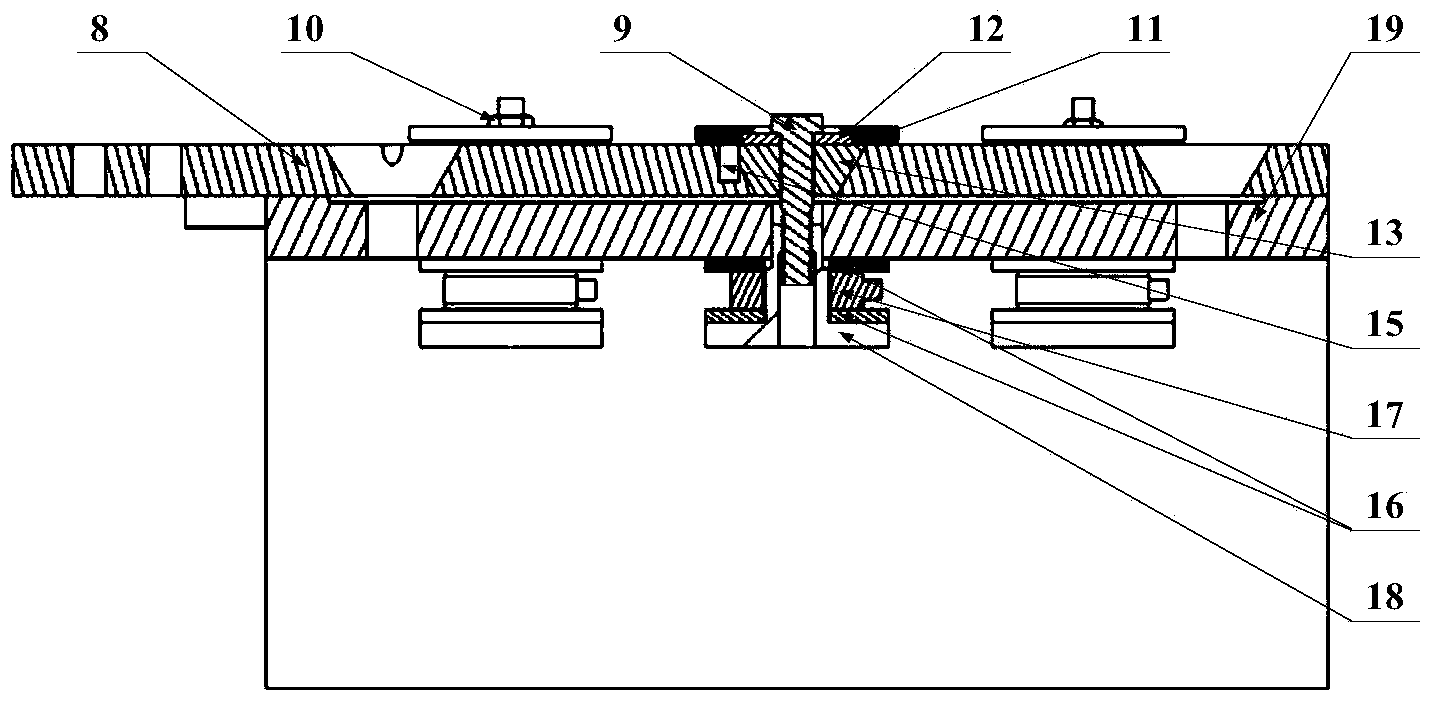

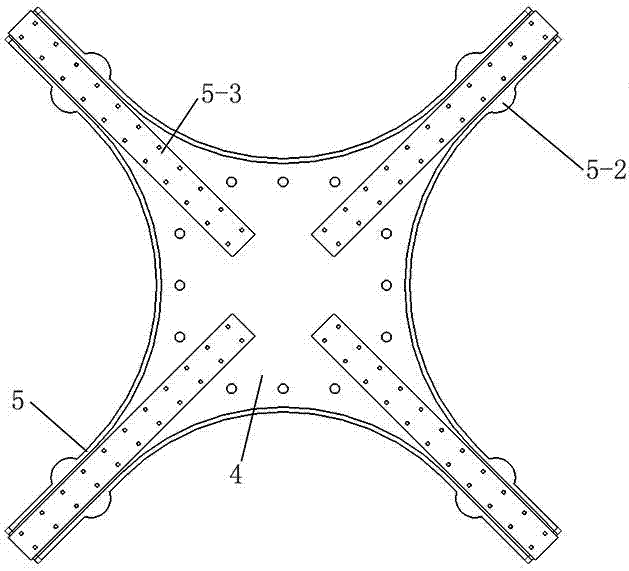

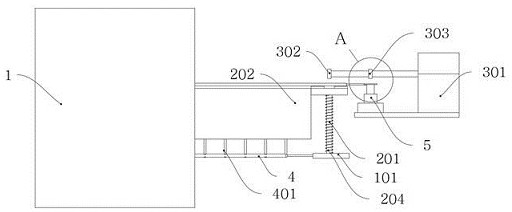

Threaded fastener transverse vibration test device and method

ActiveCN103954419ARealize high frequency vibrationRealize stepless amplitude modulationVibration testingEngineeringEngineering technician

The invention discloses a threaded fastener transverse vibration test device and method. The device comprises a transverse vibration platform, a transmission system, a clamp system, an installation base and a measuring device; one end of the transmission system is fixed to the vibration platform through a bolt, and the other end of the transmission system is fixed to a movable plate in the clamp system; a fixed base of the clamp system is fastened to the installation base through a T-shaped groove; the transmission system is provided with a pull pressure sensor, and the clamp system is provided with a gasket type force sensor. The device and method can simulate high-frequency vibration, achieve electrodeless amplitude modulation, monitor changes of transverse shear force and axial pre-tightening force of a threaded fastener in a vibration process in real time, and test the anti-loose characteristic of single bolts and bolt sets (distributed in a linear, rectangular and circular mode) with different specifications. The device and method provide a basis platform and data support for engineering technicians to analyze anti-loose performance of various threaded fasteners and assess effectiveness of various anti-loose methods.

Owner:XI AN JIAOTONG UNIV +1

Laser vibration displacement sensor and measuring method thereof

ActiveCN104236464ATo achieve an organic combinationRealize high frequency vibrationUsing optical meansHigh frequency vibrationSignal modulation

The invention provides a laser vibration displacement sensor and a measuring method of the laser vibration displacement sensor. A laser device emits laser, the laser is projected to a vibration object through a collimation system, perpendicularly scattered light returns to the laser device through the collimation system, and then a self-mixing interference system is formed. A detector measures the output power of the laser device and enables high-frequency vibration measurement of the vibration object to be achieved through signal modulation. The light enters a focusing system through diagonal scattering of the vibration object, positions of focusing light spots are obtained on the scattering detector in order to form a laser triangulation structure, the absolute distance of the object can be obtained in an inversion mode through the positions of the light spots on the scattering detector, and low-frequency displacement change of the vibration object can be measured. According to the laser vibration displacement sensor and the measuring method of the laser vibration displacement sensor, organic combination of the laser triangulation and the laser self-mixing technology is achieved under the situation that systematic complexity is not increased, and the functions of measuring high-frequency vibration and low-frequency displacement change are achieved.

Owner:NINGBO SUNNY INTELLIGENT TECH CO LTD +1

Frequency-boosting piezoelectric-electromagnetic composite power generation apparatus under vortex street excitation

ActiveCN107769612ARealize high frequency vibrationImprove power densityPiezoelectric/electrostriction/magnetostriction machinesDynamo-electric machinesEngineeringHigh pressure

The invention discloses a frequency-boosting piezoelectric-electromagnetic composite power generation apparatus under vortex street excitation, and aims to overcome the limitations of narrow energy harvesting frequency band, only realization of efficient energy harvesting in resonance frequency, and low energy density of the current linear pneumatic piezoelectric power generator. The frequency-boosting piezoelectric-electromagnetic composite power generation apparatus comprises a rectangular container cavity, a vortex street excitation apparatus, a limiting shaft and a rectangular coil; the vortex street excitation apparatus and the limiting shaft are mounted in the rectangular container cavity; and the rectangular coil is glued at the back end of the interior of the rectangular containercavity. The vortex street excitation apparatus performs high-frequency vibration under excitation of a low-frequency high-pressure gas, and a magnet at the tail end cuts the rectangular coil to realize electromagnetic power generation; and meanwhile, the vortex street excitation apparatus is in collision with the limiting shaft in the movement process, so that cantilever beam deformation is causedto realize piezoelectric power generation. By virtue of a cylindrical turbulent flow effect, the vibration frequency of the piezoelectric element and the magnet can be improved, and by combination ofpiezoelectric power generation and electromagnetic power generation, the energy harvesting bandwidth of the power generation apparatus is expanded, and energy density is improved, so that the frequency-boosting piezoelectric-electromagnetic composite power generation apparatus has wide application prospect in the field of the pneumatic technology.

Owner:CHANGCHUN UNIV OF TECH

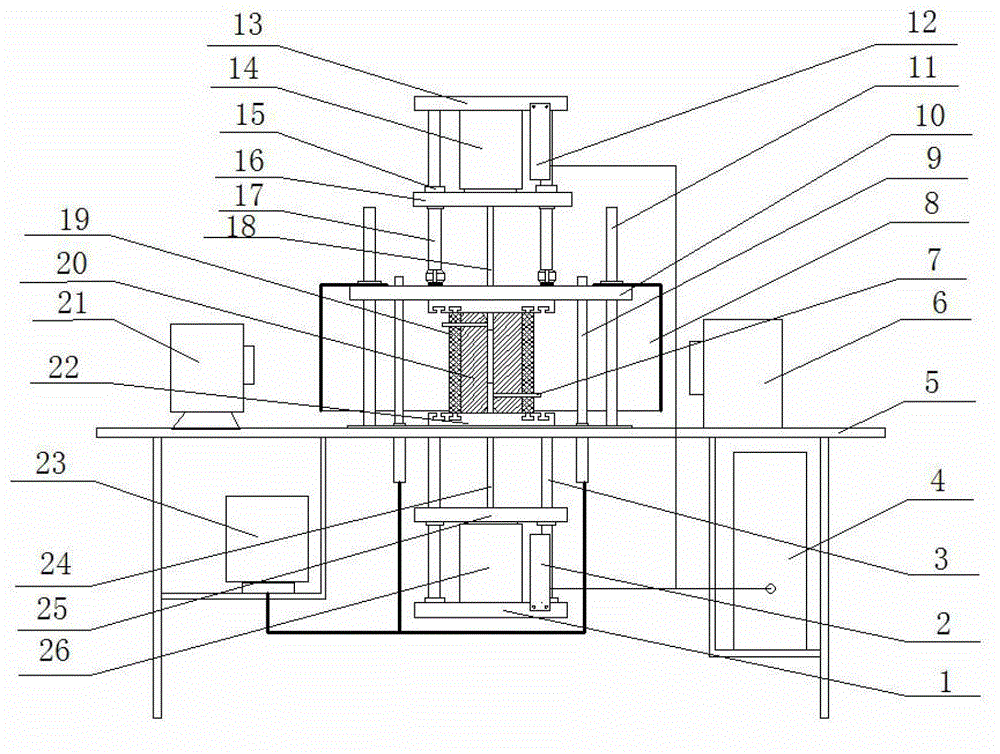

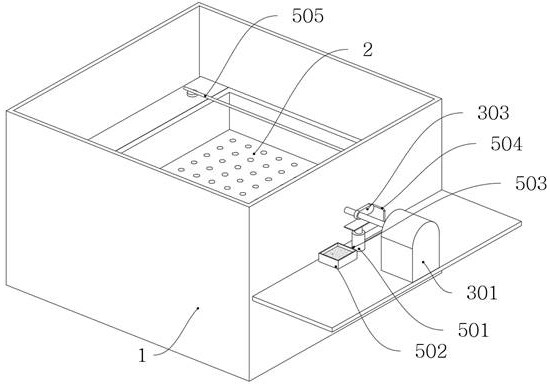

Plastic vibration processing and sample molding integration test equipment and method

The invention discloses plastic vibration processing and sample molding integration test equipment and a method. The equipment comprises a hydraulic power system, a vibration power driving system, a test platform, a piston assembly, a central mould, a visualization device, a controlling system and the like. The equipment and the method combine vibration field quantity with mould sample molding, combine cutting, pressing, vibration and sample processing molding function into a whole, are different from rheological property research limited by polymer of a traditional rheometer, avoid form change of plastic mixture structures when materials in a test cavity are taken out, monitor a microstructure online directly or directly mold and obtain detecting samples. The plastic vibration processing and sample molding integration test equipment and the method can not only achieve the rheological property test of moving state and steady state of the polymer, but also be used for microstructure form research of a plurality of polymer systems under multi-element field quantity and influence rule research between processing performance and technological conditions. The plastic vibration processing and sample molding integration test equipment and the method can be widely applied to industries of material, chemistry, pharmacy, coating, food, building and the like.

Owner:ZHEJIANG UNIV +1

Bottom driving whole hydraulic plate-inserting machine

InactiveCN1932166ARealize high frequency vibrationImprove intubation efficiencySoil preservationPressure generationGear wheel

The present invention discloses a bottom-driving type full-hydraulic plate-inserting machine. It includes the following several portions: shell body, vibration tank, truss, static pressure generation mechanism, core shaft, revolving motor, double-chain gear shaft and planetary reduction device. Said invention also provides its working principle and concrete operation method.

Owner:上海德倍佳机械有限公司

Construction machine convenient to use and used for paint filtering

InactiveCN112675588AIncrease usageImprove feed structureStationary filtering element filtersMoving filtering element filtersReciprocating motionStructural engineering

The invention provides a construction machine convenient to use and used for paint filtering, belonging to the technical field of construction machines. The invention solves the problems that the contact efficiency of paint and a filter box cannot be improved through structural improvement and consequently filtering effect cannot be improved; that vibration type filtering cannot be realized through structural improvement; and that residues cannot be avoided through structural improvement. The construction machine convenient to use and used for paint filtering comprises a box body, wherein a feeding structure is mounted on the box body. One scraping plate is welded on every two elastic telescopic rods, and the scraping plates are in elastic contact with the top end surface of a filter box, so residues on the filter box can be scraped when cylindrical pipes drive the scraping plates to do reciprocating motion; and due to the fact that two shifting blocks are symmetrically welded to a rotating shaft and make contact with protrusions, when the rotating shaft rotates, high-frequency vibration of the filter box can be achieved, and then filtering efficiency is improved.

Owner:温州竺陌机械科技有限公司

Support type cement component high-frequency vibration table

ActiveCN106625989AEffectively fixedMeet different usage needsCeramic shaping apparatusMechanical engineeringHigh frequency vibration

Owner:高唐县鼎力建筑机械有限公司

Deformable wing based on intelligent driving device

The invention discloses a deformable wing based on an intelligent driving device. A framework of the deformable wing comprises a wing leading edge, a middle partition plate, a rear partition plate andan empennage which are sequentially arranged from front to back. A front shape memory alloy driving device between the wing leading edge and the middle partition plate forms a lower surface I of thewing, and the skin I covering the wing leading edge and the middle partition plate forms an upper surface I of the wing; a rear shape memory alloy driving device between the middle partition plate andthe rear partition plate forms the lower surface II of the wing, and the skin II covering the middle partition plate and the rear partition plate forms an upper surface II of the wing; the upper surfaces and the lower surfaces of the wings are in smooth transition; the deformable wing upper surface and the deformable wing lower surface are intersected at the rear edge of the empennage; and the upper surface and the lower surface of the empennage are provided with an upper piezoelectric intelligent driving device and a lower piezoelectric intelligent driving device respectively. The deformablewing has the advantages of compact structure, few driving elements, high driving capacity and continuous deformable wing surface, and can be popularized and applied to the structural design of wing camber deformation.

Owner:中国空气动力研究与发展中心设备设计及测试技术研究所

Vibrating table for cement component

PendingCN107020681AImprove the vibration effectIncreased vibration effect weakening phenomenonCeramic shaping apparatusElectric machineryEngineering

The invention discloses a vibrating table for a cement component. The vibrating table comprises a vibrator and a drive motor for driving the vibrator as well as a fixed plate and a vibrating plate, which are mutually independent, wherein the vibrating plate is used for placing a to-be-vibrated cement component; the vibrator is arranged on the bottom surface of the vibrating plate; an extending bracket is arranged at the side end of the vibrating plate; a spring blocking slot is formed in the bottom surface of the extending bracket; the extending bracket at the side end of the spring blocking slot is equipped with a limiting convex base; a bearing plate is mounted on a fixed plate below the spring blocking slot; a spring blocking slot II which corresponds to the spring blocking slot is formed in the bearing plate; springs are inserted and connected in the spring blocking slot and the spring blocking slot II; a limiting blocking plate is mounted on the bearing plate at the side end of the spring blocking slot II; a limiting blocking slot is formed in the limiting blocking plate; and the limiting blocking slot is formed in the side end of a limiting convex base and is used for placing the extending bracket, so that the vibrating plate performs limited shaking or motion in the limiting blocking slot. The vibrating table effectively solves the problems that the vibrating table is not good in vibrating effect, and cannot meet use of various models, realizes high-frequency vibration and increases compactness of the cement component.

Owner:高唐县鼎力建筑机械有限公司

High-frequency micro-moving electrode precision clamp

InactiveCN109128400AHigh-precision clamping and replacementRealize automatic replacementElectrical-based auxillary apparatusBiomedical engineeringHigh frequency vibration

The invention provides a high-frequency micro-moving electrode precision clamp. The high-frequency micro-moving electrode precision clamp comprises a supporting piece, an electrode clamp arranged on the supporting piece, the electrode clamp is provided with a through hole for an electrode to penetrate through, an elastic fixing piece is arranged corresponding to the through hole and is used for fixing the electrode, the elastic fixing part is used for pushing a lever through an air cylinder, the lever is capable of enabling the elastic fixing piece to deform so as to clamp the electrode. According to the high-frequency micro-moving electrode precision clamp, a fixed handle electrode is utilized, the efficient and high-precision clamping and replacing of the electrode are achieved, and high-frequency vibration during electrode machining is achieved.

Owner:科锐精密工业(深圳)有限公司

Seeder for crop planting

InactiveCN108934297ARealize high frequency vibrationRealize adjustable distance sowingPlantingFurrow making/coveringSeederDrive wheel

The invention discloses a seeder for crop planting. The seeder for crop planting comprises an installation shell; a driving motor is mounted in the installation shell; a driving wheel is mounted on the bottom of the installation shell; the part, located at one side of the driving motor, of the installation shell is internally provided with a material storage box; the bottom of the material storagebox is provided with a blanking pipeline; the bottom of the blanking pipeline is provided with a discharge outlet; an ultrasonic vibration plate is arranged at the discharge outlet; the part, locatedat one side of the ultrasonic vibration plate, of the installation shell is internally provided with an ultrasonic generator; the part, located at the discharge outlet, of the bottom of the installation shell is provided with an opener and a covering device; the discharge outlet is arranged between the opener and the covering device; the surface of the installation shell is provided with a PLC controller; and the surface of the PLC controller is provided with a timer. Through arrangement of the opener, the covering device, the material storage box, the timer, the PLC controller, the ultrasonic generator and the ultrasonic vibration plate, the seeder provided by the invention overcomes the problems that conventional seeders cannot adjust fixed-spacing seeding and have low work efficiency.

Owner:徐州佳联农业发展有限公司

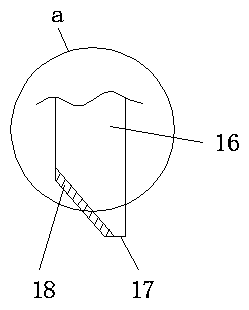

Buffering variable frequency impact type multifunctional electric tool

InactiveCN102756358ARaise the natural frequencyRealize high frequency vibrationPortable power-driven toolsDrive shaftPower tool

The invention discloses a buffering variable frequency impact type multifunctional electric tool comprising a housing (13) and a handle (1), wherein the handle (1) is mounted on one side at the upper end of the housing (13); an in-handle transmission shaft (2) is mounted in the handle (1); one end of the in-handle transmission shaft (2) is connected with a crankshaft (4); the crankshaft (4) is mounted at the upper end of the housing (13) through a bearing (6); a plug hammer (7) is arranged in the middle section of the housing (13); the top of the plug hammer (7) is connected with the middle of the crankshaft (4) through a connecting rod (5); a double-spring oscillator is mounted at the lower section of the housing (13); and the lower end of the oscillator (8) of the double-spring oscillator is connected with a tool piece (16). According to the multifunctional electric tool, the problem that a handheld external power tool cannot perform a high-frequency vibration impacting function is solved; the weight is light; the structure is durable; and functions of hammering, shoveling, riveting, matting, cutting, carving, chiseling and the like can be realized.

Owner:GUIZHOU ACAD OF SCI

Automatic screening machine for kitchen wastes

ActiveCN102825004BRealize high frequency vibrationWith self-cleaning functionSievingScreeningEngineeringBottle

The invention relates to an automatic screening machine for kitchen wastes screening treatment. The automatic screening machine for kitchen wastes comprises an underframe and a screen shoe, wherein the screen shoe is installed on the underframe through a damper spring; a vibration motor is also fixedly arranged on the screen shoe; a first screen surface is fixedly installed on the screen shoe, and is formed by a plurality of round rods or round tubes which are distributed in parallel side by side; a gap is left between two adjacent round rods or round tubes; the first screen surface is downwards inclined from the right to the left; an organic matter outlet is formed on the underframe, and is positioned right below the first screen surface; and one organic matter outlet is also formed at the left end of the underframe, and is positioned below the left end of the first screen surface. The machine can screen plastic bags, glass bottles and other inorganic matters out from the kitchen wastes, and screen is not blocked.

Owner:BEIJING GOLDENWAY BIO TECH

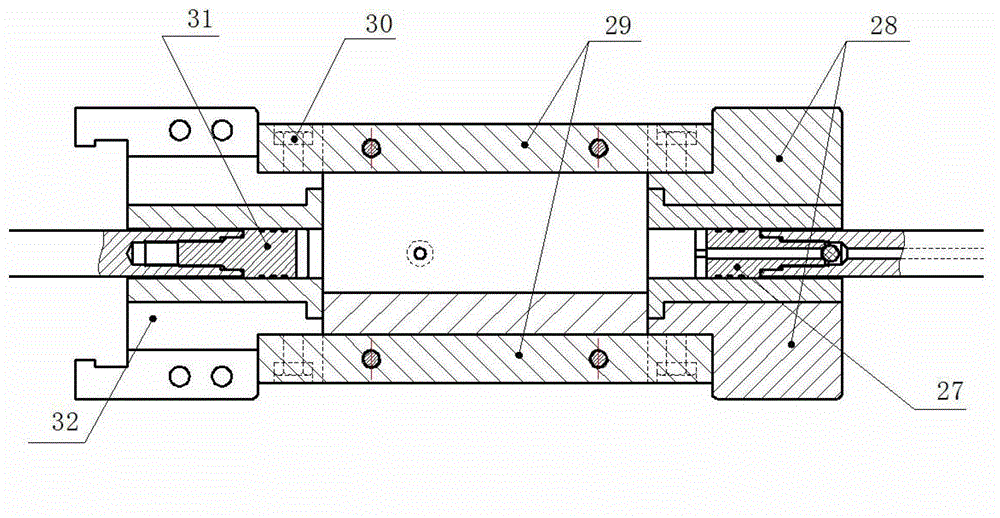

A high frequency hydraulic exciter

ActiveCN111828439BHigh frequency of axial movementRealize high frequency vibrationFluid-pressure actuator componentsConvertersReciprocating motion

The invention provides a high-frequency hydraulic vibration exciter. Hydraulic vibrator consists of valve body, valve core, safety cover, drive shaft and electromechanical converter. There is a convex shoulder on the valve core, and there are 2 groups of 8 axial oil grooves uniformly distributed on it. The axial oil groove is periodic and the 2 groups on the valve body have a total of 8 radial oil holes. Periodic on-off of oil holes. Two groups of radial oil holes on the valve body, one group communicates with the high pressure oil passage, and the other group communicates with the low pressure oil passage. When the valve core rotates under the drive of the electromechanical converter and the transmission shaft, the pressure on the left and right end faces of the valve core shoulder passes through the radial oil holes on the valve body and the axial oil groove on the valve core to alternate high and low pressure, thereby driving the valve core shaft. To reciprocate, to achieve high-frequency vibration. The main feature of the invention is that the axial movement frequency of the valve core is high, the movement frequency is automatically controlled by the electromechanical converter, and the structure is compact. The present invention can be used as an executive element in occasions with high requirements on working frequency, such as hydraulic vibration.

Owner:ZHEJIANG UNIV CITY COLLEGE

High-frequency hydraulic vibration exciter

ActiveCN111828439AHigh frequency of axial movementRealize high frequency vibrationFluid-pressure actuator componentsConvertersReciprocating motion

The invention provides a high-frequency hydraulic vibration exciter. The high-frequency hydraulic vibration exciter consists of a valve body, a valve core, safety covers, a transmission shaft and an electromechanical converter, wherein the valve core is provided with a shoulder; eight axial oil grooves in two groups are uniformly distributed and machined on the shoulder; eight radial oil holes intwo groups are formed in the valve body, when the high-frequency hydraulic vibration exciter works, the axial oil grooves and the radial oil holes are periodically connected and disconnected; in the two groups of radial oil holes in the valve body, one group of radial oil holes communicate with a high-pressure oil passage, and the other group of radial oil holes communicate with a lower-pressure oil passage; and when the valve core rotates under the driving of the electromechanical converter and the transmission shaft, the pressure on the left end face and right end face of the shoulder of thevalve core alternates between high pressure and low pressure through the radial oil holes in the valve body and the axial oil grooves in the valve core, so that the valve core is driven to axially reciprocate to realize the high-frequency vibration. The high-frequency hydraulic vibration exciter is mainly characterized in that the axial movement frequency of the valve core is high, the movement frequency is automatically controlled by the electromechanical converter, and the structure is compact; and the high-frequency hydraulic vibration exciter can be used as an actuating element for occasions with high requirements on working frequency such as the hydraulic vibration.

Owner:ZHEJIANG UNIV CITY COLLEGE

A high-frequency vibrating table for a bracket type cement component

ActiveCN106625989BEffectively fixedMeet different usage needsCeramic shaping apparatusEngineeringHigh frequency vibration

Owner:高唐县鼎力建筑机械有限公司

Efficient novel rotary drying device for mica pearlescent pigment processing

ActiveCN114396774AAvoid wastingReduced optical performanceDrying solid materials with heatGranular material dryingCrystallographyPhysical chemistry

The invention relates to the technical field of pearlescent pigment processing, and discloses an efficient novel rotary drying device for mica pearlescent pigment processing, which comprises a mounting frame, a metal roller capable of drying various pigments is rotatably mounted in the mounting frame, and an electromagnetic assembly capable of heating the metal roller is further arranged on the mounting frame. A revolution assembly and a rotation assembly which can drive the metal roller, the scattering drying cylinder and the pearlescent pigment drying cylinder to rotate are arranged in the mounting frame and the metal roller correspondingly, and a vibration assembly which can slow down the discharging speed of the mica pearlescent pigment is arranged in the kidney-shaped pipe. Compared with a traditional air blowing drying mode, the drying efficiency is improved, pigment scattering and waste are avoided, in addition, the length of a pigment drying channel is increased, the mutual extrusion influence between the pigments is relieved, the scratch influence on the surface of the mica pearlescent pigment is relieved, and the optical effect of the pigment is improved.

Owner:RICHWAY TECH

Environment-friendly casting crude sand screening device based on part casting process

The invention provides an environment-friendly casting crude sand screening device based on a part casting process, relates to the technical field of casting auxiliary equipment, and solves the problem that high-frequency auxiliary vibration screening cannot be realized while vibration screening is performed through structural improvement. And automatic blockage clearing of the sieve pores cannot be realized while screening is carried out. The environment-friendly casting crude sand screening device based on the part casting technology comprises a box body. The box body is of a rectangular box-shaped structure. Through the arrangement of the frame, the auxiliary rods are welded to the frame in the rectangular array shape, the auxiliary rods welded in the rectangular array shape are aligned to the screen holes formed in the rectangular array shape, and when the screening frame moves downwards, the auxiliary rods penetrate through the screen holes, and therefore sand clamped in the screen holes can be cleaned.

Owner:河北金栋机械有限公司

Paperboard cutter for carton packaging box

The paperboard cutter comprises a cutting board, the cutting board is installed on the lower end face of a shell in an up-down sliding mode, the side of the shell is fixed to a platform through a stand column, the platform is provided with a cutting groove corresponding to the cutting board in an up-down mode, and a hydraulic rod is installed on the shell; the output end of the hydraulic rod is connected with the upper end face of the cutting board through a connecting rod and a vertical rod, the sliding groove formed in the lower end face of the connecting rod is slidably connected with the top end of the vertical rod, and the bottom end of the vertical rod is fixedly connected with the cutting board. According to the paperboard cutter of the carton packaging box, the vibration mechanism is used for enabling the cutting board to move vertically up and down and to be in a left-right high-frequency moving state at the same time, so that a water mist spraying effect generated by the same power source is matched, a paperboard is cut more efficiently, the loss of the cutting board is effectively reduced, and the cutting efficiency is improved.

Owner:曾大兵

Carbon nanofiber high-strength spunlace non-woven fabric production equipment

ActiveCN112501793ARealize high frequency vibrationRealize impurity removalMechanical cleaningPressure cleaningCarbon fibersCarbon nanofiber

The invention discloses carbon nanofiber high-strength spunlace non-woven fabric production equipment. The carbon nanofiber high-strength spunlace non-woven fabric production equipment comprises a bottom plate and a vibration assembly; supporting legs are arranged on one side of the surface of the bottom plate, spunlace devices are arranged on the supporting legs, supporting plates are symmetrically arranged on the other side of the surface of the bottom plate, guide rollers are rotatably connected to the supporting plates, a support is arranged on the edge of the surface of the bottom plate,a frame plate is arranged on the support, a collecting assembly is arranged on the frame plate, and an adjusting assembly is arranged on the surface of the bottom plate; and the vibration assembly comprises a mounting frame, two Z-shaped rods, a mounting shaft, a roller and a worm wheel, the mounting frame is arranged on the adjusting assembly, the two Z-shaped rods are symmetrically arranged androtationally connected to the two sides of the mounting frame correspondingly, and the two ends of the mounting shaft are fixedly connected with the opposite ends of the Z-shaped rods on the two sidescorrespondingly. According to the carbon nanofiber high-strength spunlace non-woven fabric production equipment, in the fiber web conveying process, dust removal of a fiber web can be achieved, impurities attached to the fiber web are removed, the product quality is improved, and practicability is high.

Owner:常熟市森拓非织造布有限公司

A kind of nano carbon fiber high-strength spunlace non-woven production equipment

ActiveCN112501793BRealize high frequency vibrationRealize impurity removalMechanical cleaningPressure cleaningCarbon fibersStructural engineering

The invention discloses a nano-carbon fiber high-strength spunlace non-woven production equipment, comprising a bottom plate and a vibration component; A support plate is provided, a guide roller is rotatably connected to the support plate, a bracket is arranged on the surface edge of the bottom plate, a rack plate is arranged on the bracket, a collection component is arranged on the rack plate, and an adjustment component is arranged on the surface of the bottom plate; the vibration component: including Installation frame, Z-shaped rod, installation shaft, roller and worm gear. The installation frame is arranged on the adjustment assembly. Two Z-shaped rods are symmetrically arranged, and the two Z-shaped rods are rotatably connected to both sides of the installation frame. The installation shaft The two ends are fixedly connected to the opposite ends of the Z-shaped rods on both sides respectively. The production equipment of the nano carbon fiber high-strength spunlace non-woven fabric can realize the dust removal of the fiber web, remove the impurities attached to the fiber web, and improve the Product quality and practicability.

Owner:常熟市森拓非织造布有限公司

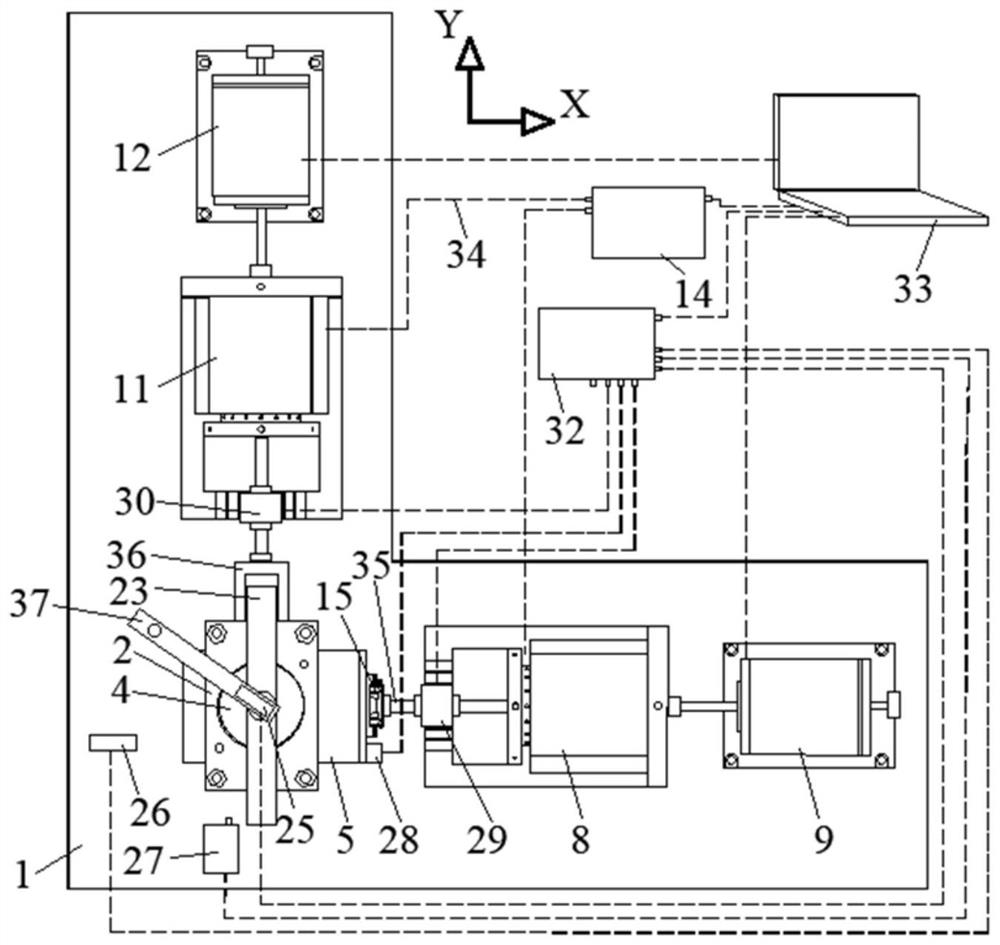

A soil-structure contact surface shear test device capable of bidirectional high-frequency vibration

ActiveCN112858043BAvoid direct contactAchieving static shearMaterial strength using steady shearing forcesClassical mechanicsElectric machinery

The invention relates to a soil-structure contact surface shear test device capable of realizing two-way high-frequency vibration, comprising a test unit, a loading unit and a measurement and control unit, the test unit including a test bench, and an upper shear box fixing mechanism arranged on the test bench , the upper shear box set on the upper shear box fixing mechanism, the double slide rail motion platform set on the test bench, the tray set on the double slide rail motion platform, and the tray set on the pallet and located below the upper shear box The structural panel, the loading unit includes an X-direction voice coil motor loading mechanism adapted to the tray, a Y-direction voice coil motor loading mechanism and a Z-direction loading mechanism adapted to the upper shear box. Compared with the prior art, the present invention realizes joint loading of two-way high-frequency vibration and static shearing of the contact surface, synchronous acquisition of multiple response quantities, avoids friction between the upper shear box and the structural panel during the shearing process, and realizes high Stable application of vertical pressure during high-frequency vibration.

Owner:TONGJI UNIV

Excitation device

InactiveCN100548511CSimple structureImprove cooling effectMechanical vibrations separationFatigue damageBobbin

The vibration excitation device disclosed by the present invention includes a base, a coil skeleton, an AC coil, a DC coil, an inner sleeve, a spring and an outer sleeve from the inside to the outside of the coaxial line device, and the center hole of the coil skeleton is placed on the positioning boss of the base and fastened to the base, a giant magnetostrictive rod and a positioning block are built in the center hole of the coil frame, one end of the positioning block is in contact with the giant magnetostrictive rod, and the other end is placed in the center positioning concave hole of the inner sleeve . When working, the workpiece is fixed on the base of the excitation device or the bottom surface of the inner sleeve, and the giant magnetostrictive rod is in the mixed magnetic field generated by the AC coil and the DC coil. The telescopic rod produces telescopic deformation along the axial direction, and pushes the positioning block and the inner sleeve to reciprocate and vibrate at high frequency along the axial direction. The vibration excitation device of the present invention has simple structure and good heat dissipation, and high-frequency vibration can be conveniently realized by changing the frequency of the AC power supply, and the vibration frequency can reach 1000-3000 Hz, which can effectively prevent fatigue damage of workpieces.

Owner:ZHEJIANG UNIV

Water disturbing device based on ultrasonic wave

PendingCN107899492ARealize high frequency vibrationDisturb water quickly and evenlyShaking/oscillating/vibrating mixersTransportation and packagingEngineeringUltrasonic generator

The invention discloses a water disturbing device based on ultrasonic wave. The water disturbing device based on the ultrasonic wave comprises an outer frame part and a water disturbing part, whereinthe outer frame part comprises an outer box frame, a foam floating body, an upper-layer separating plate and a lower-layer separating plate; and the water disturbing part comprises an ultrasonic transducer, a flange plate, an amplitude-changing pole, a water disturbing rod and an ultrasonic generator. The water disturbing device based on the ultrasonic wave is simple and easy to use and can rapidly and uniformly disturb water and mix water preparation, so that the water disturbing device based on the ultrasonic wave has a good market application prospect.

Owner:SUZHOU UNIV OF SCI & TECH

A kind of lateral vibration test device and test method of threaded fastener

ActiveCN103954419BRealize high frequency vibrationRealize stepless amplitude modulationVibration testingEngineeringEngineering technician

Owner:XI AN JIAOTONG UNIV +1

Sandwich type frictional welding tool and method of metal welding part

PendingCN108608110AImprove reliabilityHigh strengthNon-electric welding apparatusFriction weldingEngineering

A sandwich type frictional welding tool of a metal welding part comprises an upper clamp for clamping an upper metal part, an intermediate layer for clamping an intermediate metal part, and a lower clamp for clamping a lower metal part. The sandwich type frictional welding tool is characterized by further comprising a rotating impacting assembly which is in driving connection with an outer drivingdevice, and a pressure assembly which is mounted on the upper clamp and is used for compressing the upper metal part, the intermediate metal part and the lower metal part; the rotating impacting assembly is mounted in the outer circumference of the intermediate clamp and rotates at high speed to impact the intermediate clamp, and the intermediate clamp is pushed to vibrate in the horizontal direction. According to the sandwich type frictional welding tool, the friction welding intensity of metals can be improved; gaps are avoided; the thickness ratio of the metal layers can be accurately controlled; the welding costs a little time, and the welding efficiency is high; the welding reliability and quality can be improved. The invention also provides a sandwich type frictional welding methodof the metal welding part.

Owner:ZHUZHOU JIABANG REFRACTORY METAL

Soil-structure contact surface shear test device capable of realizing bidirectional high-frequency vibration

ActiveCN112858043ASolve the technical problem that high-frequency vibration combined with static shearing cannot be realizedAvoid direct contactMaterial strength using steady shearing forcesClassical mechanicsElectric machinery

The invention relates to a soil-structure contact surface shear test device capable of realizing bidirectional high-frequency vibration. The device comprises a test unit, a loading unit and a measurement and control unit, the test unit comprises a test bench, an upper shear box fixing mechanism arranged on the test bench, an upper shear box arranged on the upper shear box fixing mechanism, a double-slide-rail motion platform arranged on the test bench, a tray arranged on the double-slide-rail motion platform and a structural panel arranged on the tray and located below the upper shear box. The loading unit comprises an X-direction voice coil motor loading mechanism, a Y-direction voice coil motor loading mechanism and a Z-direction loading mechanism; the X-direction voice coil motor loading mechanism and the Y-direction voice coil motor loading mechanism are respectively matched with the tray; and the Z-direction loading mechanism is matched with the upper shear box. Compared with the prior art, combined loading of bidirectional high-frequency vibration and static shearing of the contact surface and synchronous acquisition of multiple response quantities are realized, friction between the upper shearing box and the structural panel in the shearing process is avoided, and stable application of vertical pressure in the high-frequency vibration process is realized.

Owner:TONGJI UNIV

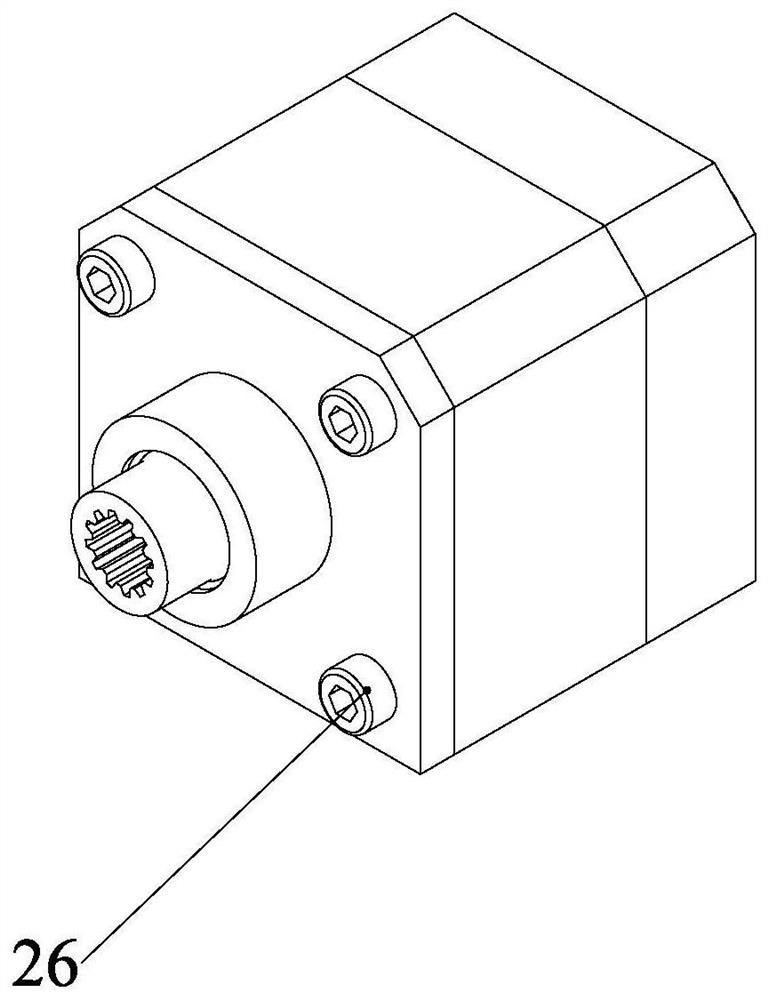

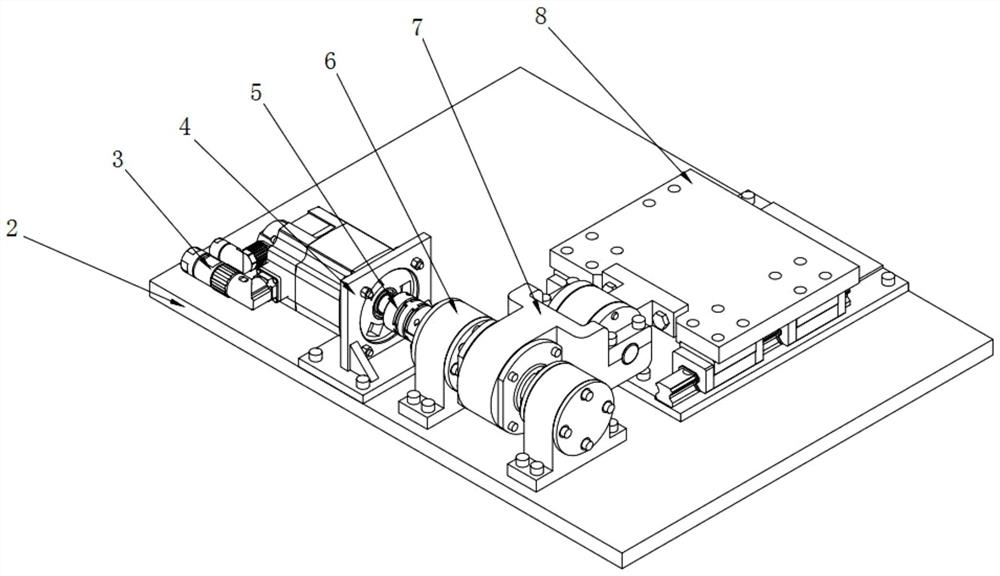

Vibration platform cutting auxiliary device for multi-wire saw

ActiveCN113681738ARealize high frequency vibrationSmooth vibrationWorking accessoriesFine working devicesDrive shaftCoupling

The invention relates to a vibration platform cutting auxiliary device for a multi-wire saw. The vibration platform cutting auxiliary device comprises a bottom plate, a motor, a motor stand, a coupler, two bearing seats, a vibrating component and a sliding platform, wherein an output shaft of the motor is connected with a drive shaft of the vibrating component through the coupler; the drive shaft is connected with an eccentric sleeve through a key and drives the eccentric sleeve to rotate; the vibrating component is sleeved on the outer surface of the eccentric sleeve; a guide rail mounting plate is fixed to a base, and guide rails are symmetrically arranged at the two sides of the guide rail mounting plate; a sliding block is fixedly installed at the bottom of a workbench, so that the workbench can reciprocate along the guide rails; and a T-shaped connector is fixedly connected with the workbench. According to the device, a cut workpiece can vibrate at high frequency in the tangential direction, and therefore the purpose of improving the workpiece machining quality and the working efficiency is achieved.

Owner:唐山晶玉科技股份有限公司

A vibrating platform cutting auxiliary device for multi-wire cutting machine

ActiveCN113681738BRealize high frequency vibrationSmooth vibrationWorking accessoriesFine working devicesDrive shaftCoupling

Owner:唐山晶玉科技股份有限公司

Electromagnetic vibrator

InactiveCN112403872ARealize high frequency vibrationReduce noiseMechanical vibrations separationEngineeringSilicon rubber

The invention relates to the technical field of electromagnetic control, in particular to an electromagnetic vibrator which is compact and reasonable in structure and low in generated noise. The electromagnetic vibrator comprises a base, a guide column is installed on the base and sleeved with a movable iron core, a power supply connecting wire is arranged on the side face of the movable iron core, and a coil and an electromagnet are arranged in the movable iron core; and a pressure spring for pressing the movable iron core is arranged on the guide column, a mounting groove is formed in the middle of the base, a fixed iron block is arranged in the mounting groove, a gap is reserved between the end surface of the fixed iron block and the movable iron core, and a silicon rubber case surrounding the movable iron core is arranged on the base.

Owner:WUXI RICH INTELLIGENT EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com