Environment-friendly casting crude sand screening device based on part casting process

A technology of casting technology and screening device, which is applied in the direction of manufacturing tools, casting molding equipment, cleaning/processing machinery of casting mold materials, etc., and can solve the problem that the screen holes are easy to be blocked, the screen holes cannot be automatically cleared, and the dust purification cannot be realized automatically and other issues to achieve the effect of improving the screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

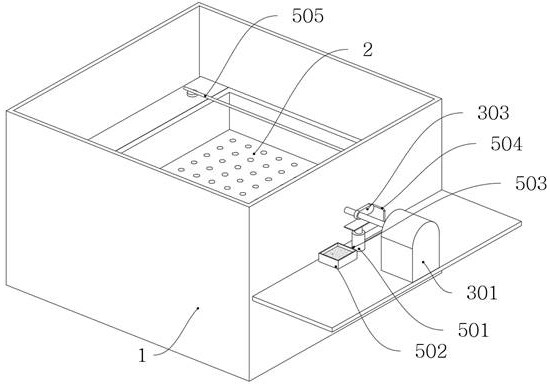

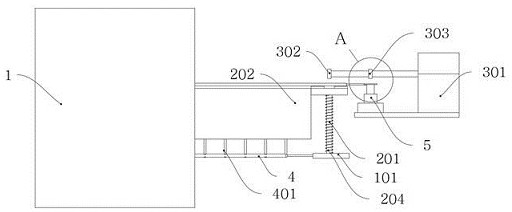

[0056] as attached figure 1 to attach Figure 8 Shown:

[0057] The invention provides an environment-friendly foundry raw sand screening device based on the part casting process, including a box body 1;

[0058] The box body 1 is a rectangular box-like structure;

[0059] Box 1 includes:

[0060] There are two connecting plates 101, and the two connecting plates 101 are symmetrically welded on the inner wall of the box body 1, and the two connecting plates 101 are rectangular plate structures;

[0061] A screening structure 2, the screening structure 2 is installed on the box body 1;

[0062] The driving structure 3, the driving structure 3 is installed on the box body 1;

[0063] The frame 4 is installed on the box body 1 .

[0064] Reference as figure 2 , filter structure 2 includes:

[0065] There are four sliding rods 201, and the four sliding rods 201 are all welded on the connecting plate 101, and the four sliding rods 201 are all stepped shaft-shaped structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com