Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

637results about How to "Avoid dangerous accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

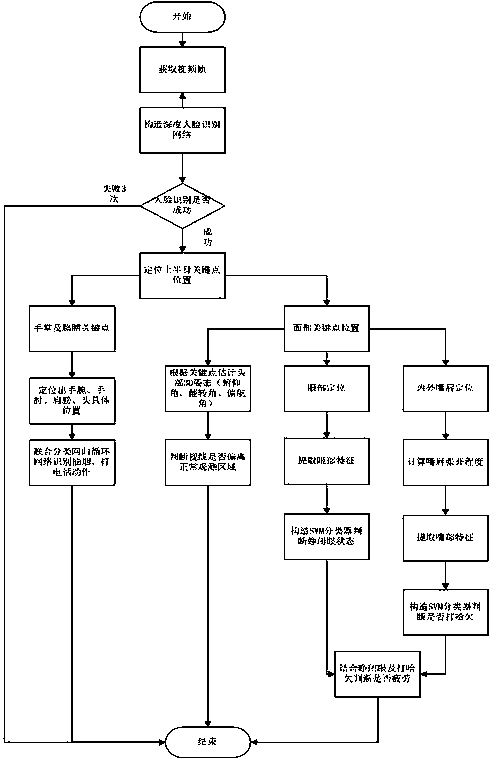

Intelligent control method for vehicle driver fatigue driving

ActiveCN107697069APrevent dangerous accidents from happeningReduce lossesTractorsAlarmsEmbedded systemDriver/operator

The invention relates to the field of vehicle safe driving, in particular to an intelligent control method for fatigue driving. The intelligent control method for vehicle driver fatigue driving comprises the steps that a plurality of key points are set on a driver face, a trunk, and arms and legs for being marked; all the key points are traced through a vehicle-mounted near-infrared image sensor,an action recognition model is trained out through simulation detecting and deep bidirectional LSTM neural network, and a dangerous action is defined based on the action identification model; and thecurrent driver is identified, matching is conducted in the vehicle running process, and if the dangerous action is matched out, an alertor begins to alarm and the driver is reminded of safe driving orresting. According to the intelligent control method for fatigue driving, after setting the key points on the whole body and the face, the model of the key points is established, subsequent judgmenterrors caused by vibrating back and forth of a vehicle in the running process is avoided, then dangerous actions at all levels are matched out through the action identification model, dangerous accidents are avoided, protection for safe travelling of the driver is provided, and loss of life and property is reduced.

Owner:SAIC MOTOR

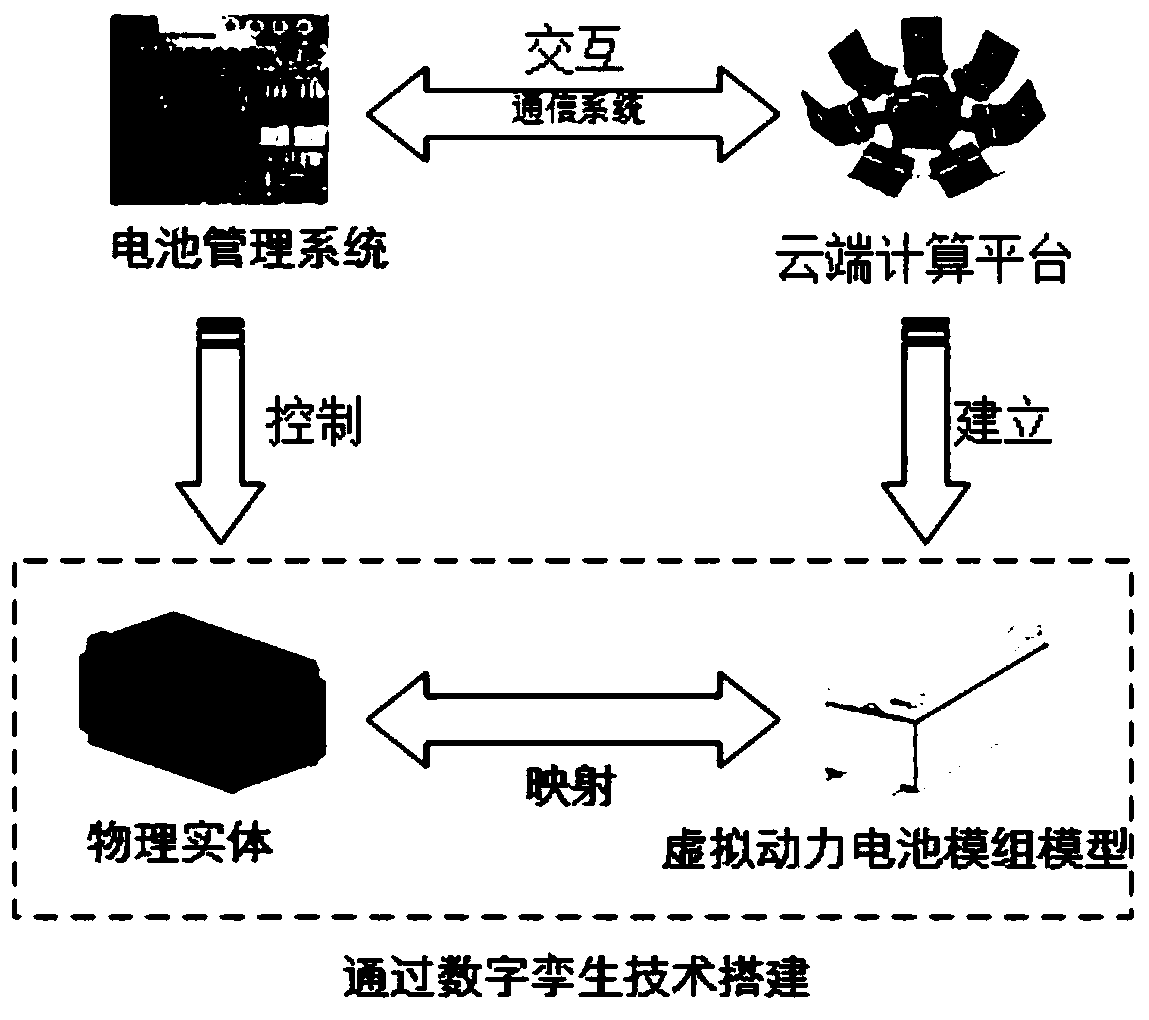

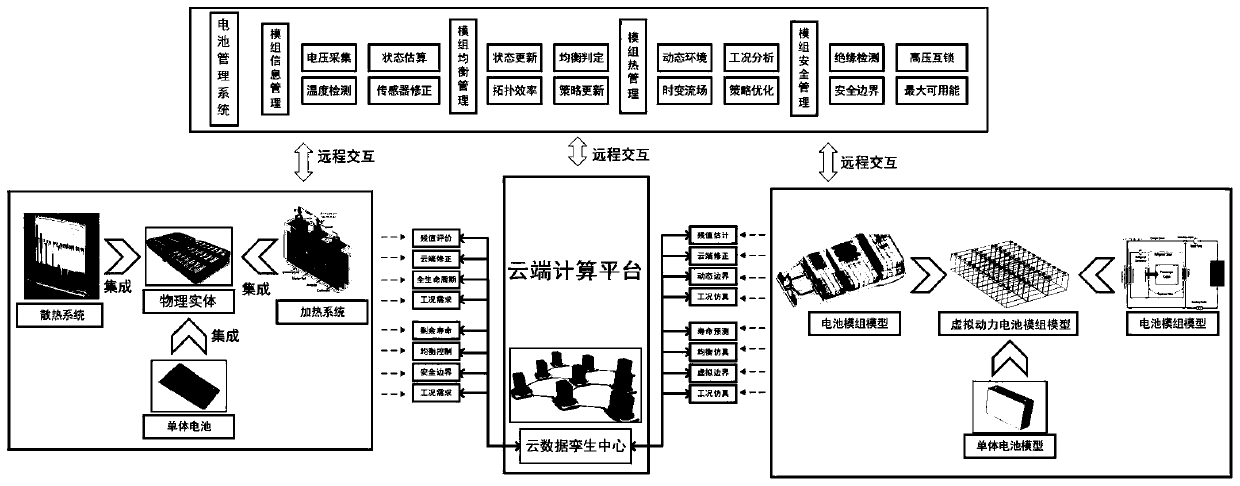

Management method of power battery module based on cloud control technology

ActiveCN110492186AImprove efficiencyImprove work efficiencyCells structural combinationSpecial data processing applicationsOptimal managementCloud computing

The invention relates to a management method of a power battery module based on a cloud control technology. The power battery module is used as a physical entity in an actual working environment, andthe method comprises the following steps: firstly, establishing a digital twined virtual power battery module model matched with a physical entity in a simulation environment of a cloud computing platform based on a digital twinning technology; configuring a simulation working environment of the model; collecting physical data generated by the operation of the physical entity and virtual data generated by the operation of the virtual power battery module model through the cloud computing platform and then performing data analysis and fusion processing; and correcting and updating the virtual power battery module model at the cloud according to the data processing result, and obtaining a corresponding optimal control strategy under the latest model based on the physical entity calibration performance and the current state in combination with an online simulation technology. The cloud computing platform inputs the optimal control strategy into the battery management system based on a cloud control technology so as to automatically control the operation of the physical entity and update feedback in real time, thereby integrally realizing dynamic optimal management.

Owner:BEIHANG UNIV

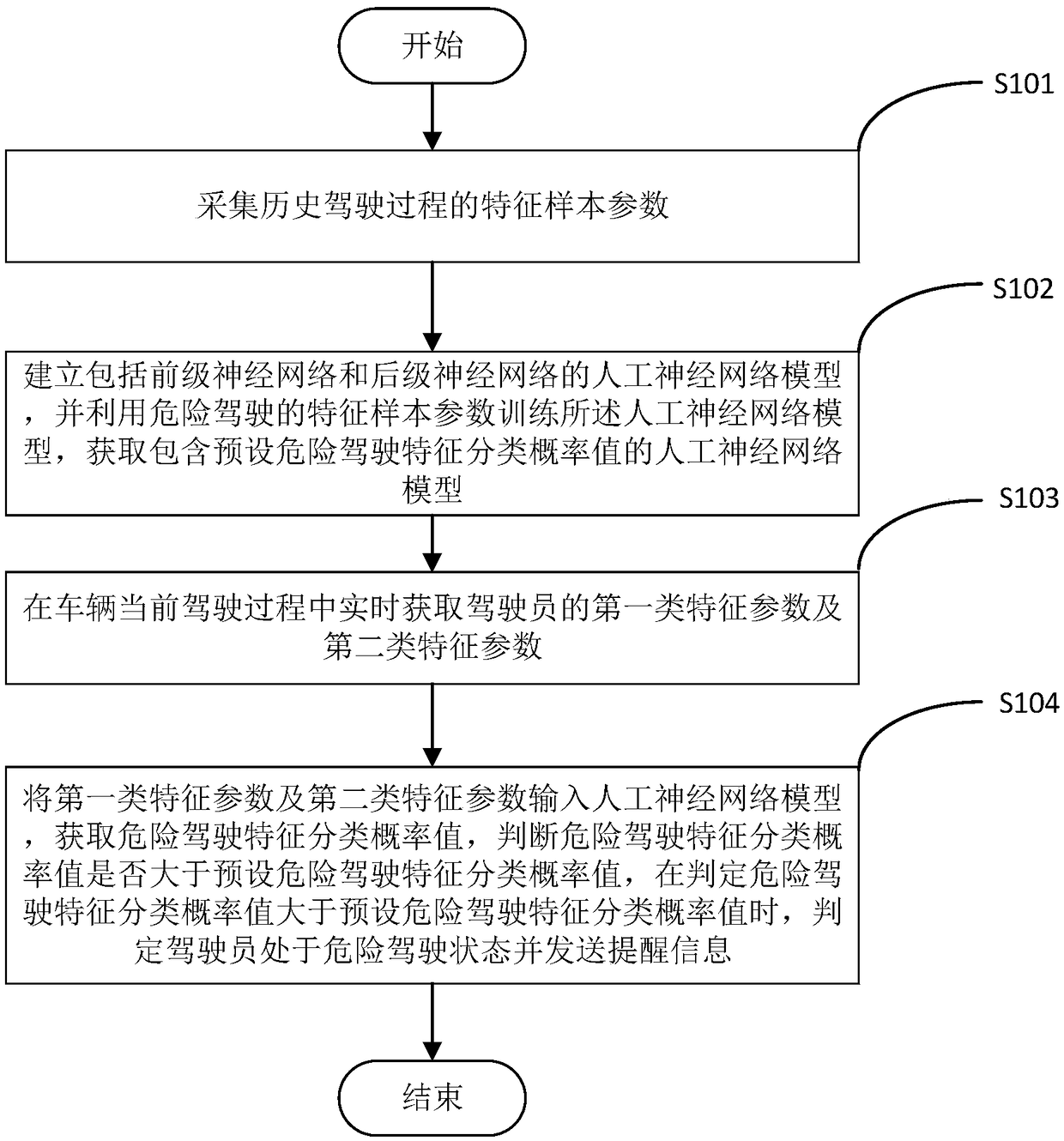

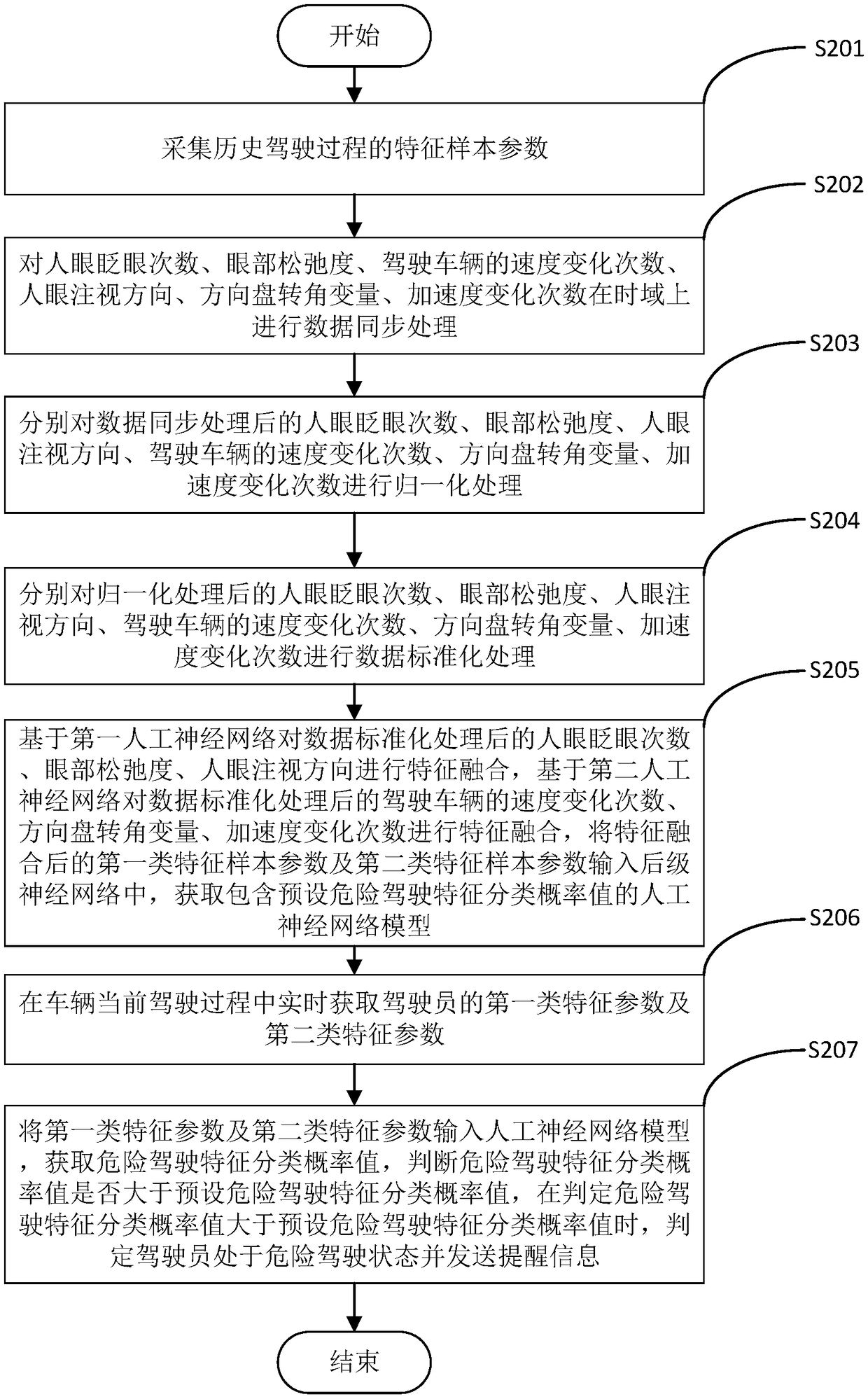

Vehicle safe driving detection method, device and storage medium based on artificial neural network

InactiveCN109460780AReduce false detection rate and missed detection rateImprove accuracy and reliabilityCharacter and pattern recognitionNeural learning methodsDriver/operatorSafe driving

The embodiment of the invention relates to the technical field of automobile electronic control, and discloses a vehicle safe driving detection method based on an artificial neural network, a device and a computer-readable storage medium. In the invention, the method comprises the following steps of: collecting characteristic sample parameters of a historical driving process; Establishing artificial neural network model including front neural network and back neural network, and train artificial neural network model by using characteristic parameters of dangerous driving. The first kind of characteristic parameters and the second kind of characteristic parameters of the driver are obtained in real time during the current driving process of the vehicle. The first and second characteristic parameters are inputted into the artificial neural network model, and the classification probability value of dangerous driving characteristics is obtained. Then the driver is judged to be in dangerousdriving state and the reminder information is sent. The invention provides a vehicle safe driving detection method based on an artificial neural network, a device and a computer-readable storage medium, which can improve reliability and accuracy of dangerous driving evaluation.

Owner:DEEPBLUE TECH SHANGHAI CO LTD

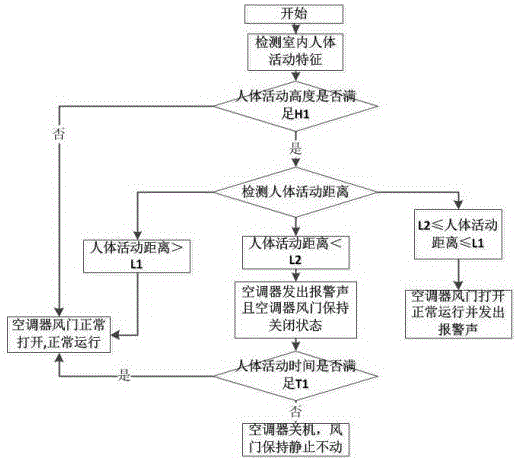

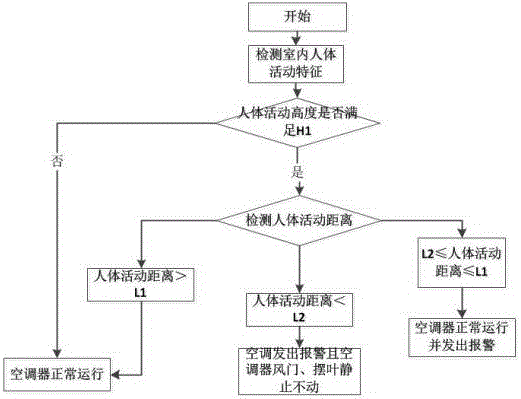

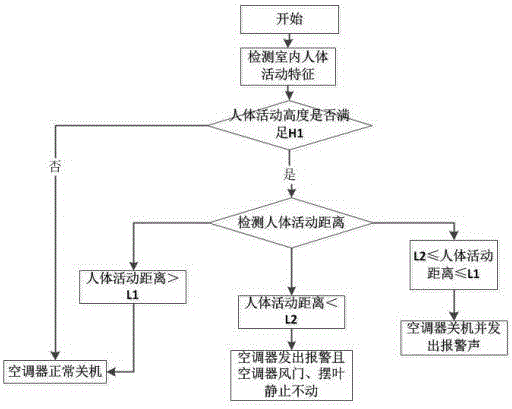

Cabinet air conditioner alarming reminder control method

ActiveCN106408864APrevent penetrationAvoid dangerous accidentsMechanical apparatusSpace heating and ventilation safety systemsAir doorEngineering

The invention relates to a cabinet air conditioner alarming reminder control method, which is characterized by comprising the steps of: in the normal operation of a cabinet air conditioner, step 1, detecting human body activity characteristics by means of a human body activity characteristic sensing device on the cabinet air conditioner; step 2, detecting a human body activity height, namely, stature of a detected object, and jumping to a step 3 if the human body activity height meets H1, otherwise, repeating the step 2; step 3, and detecting a human body activity distance, namely, a straight-line distance between the detected object and the human body activity characteristic sensing device on the cabinet air conditioner, and executing corresponding actions according to the detected human body activity distance. The cabinet air conditioner alarming reminder control method can effectively prevent the occurrence of dangerous accidents caused by children expending hands into an air outlet or approaching an air door during the operation of the cabinet air conditioner.

Owner:AUX AIR CONDITIONING LTD BY SHARE LTD

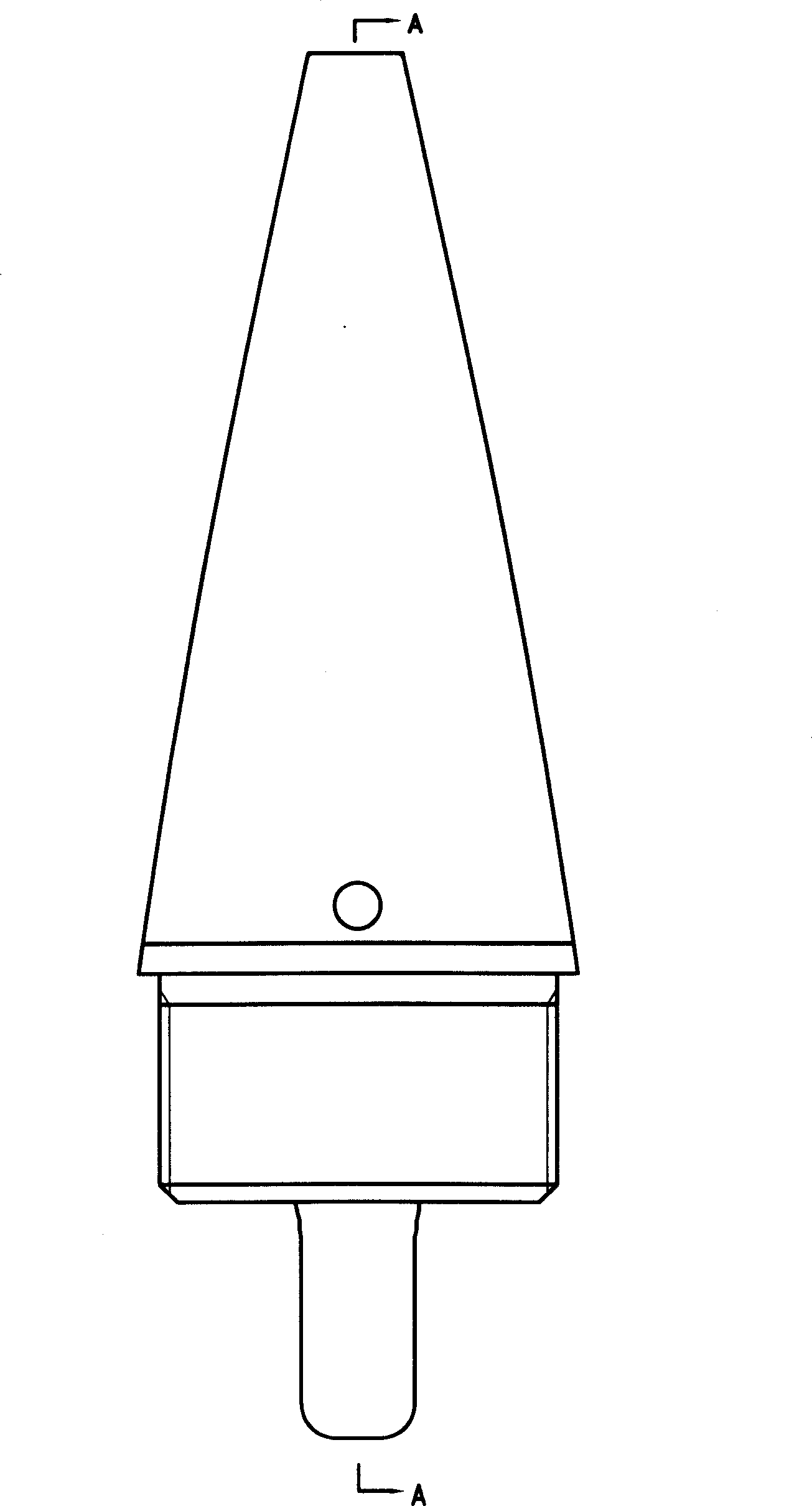

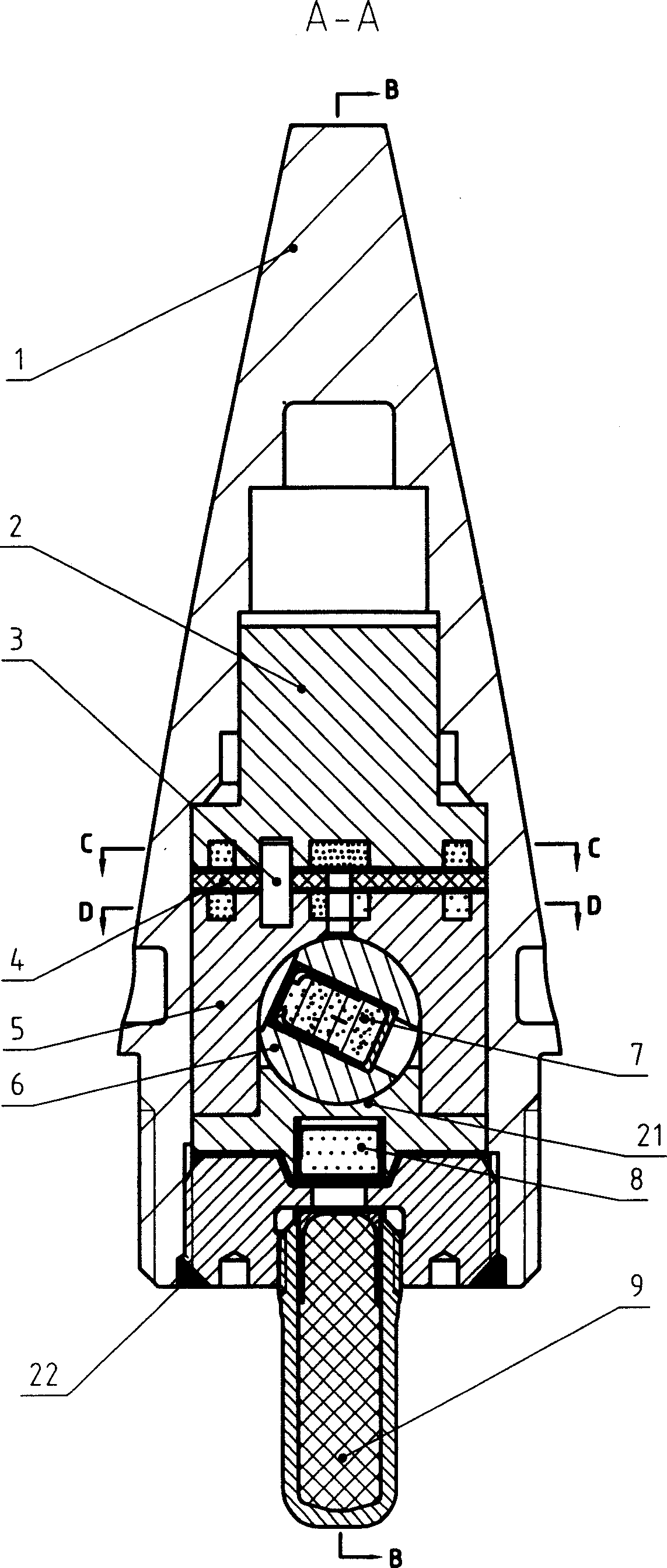

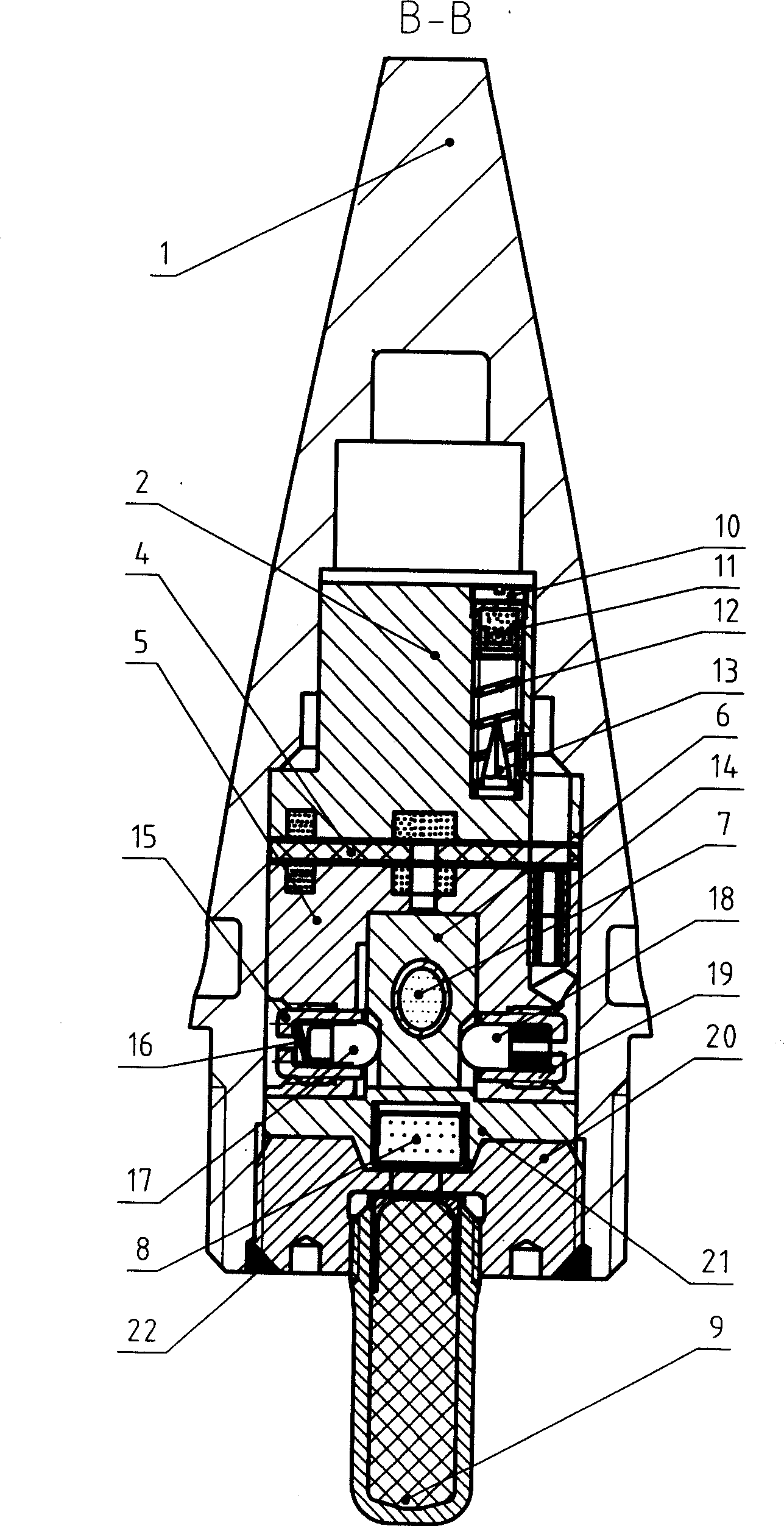

Full insurance type artificial rain bullet detonator

A full-insurance rain bomb fuze relates to an artificial hail-suppressing rain bomb fuze for antiaircraft guns. The present invention mainly includes a fuze body, an upper drug tray, a lower drug tray, a rotary body, a bracket, a pressure screw, and a detonator tube. There is a 134-136° circular groove on the bottom surface of the medicine tray and the top surface of the medicine tray respectively. The gunpowder column is installed on the side, and the gyratory body is installed in the medicine feeding tray. The left and right sides of the medicine feeding tray and the gyratory body are respectively equipped with centrifugal safety screw plugs, centrifugal springs, centrifugal pins and safety pins, and gunpowder safety screw plugs. The dimensions of the booster tube have also been improved. The invention has the advantages of small fragments, sufficient explosion, safe use, good delay reliability and more complete detonation.

Owner:CHANGAN AUTOMOBILE (GRP) CO LTD

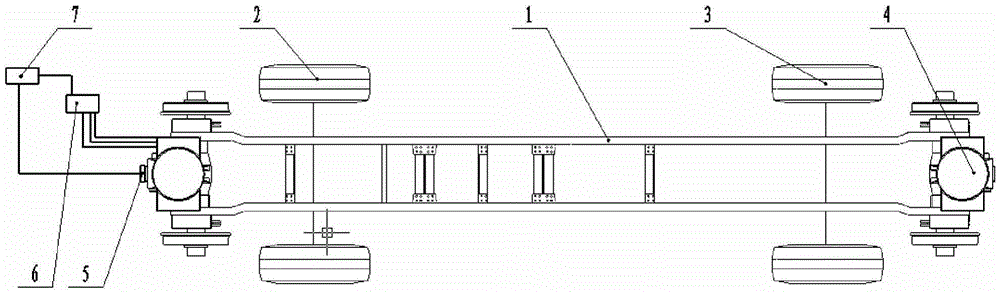

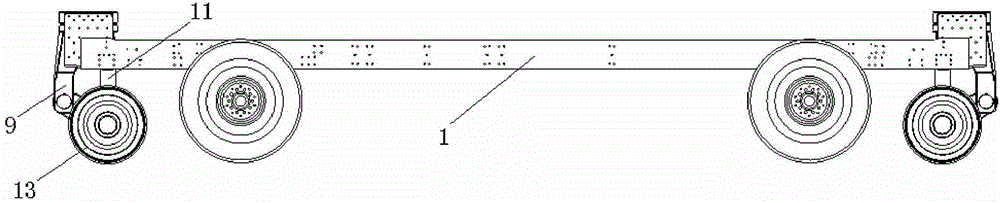

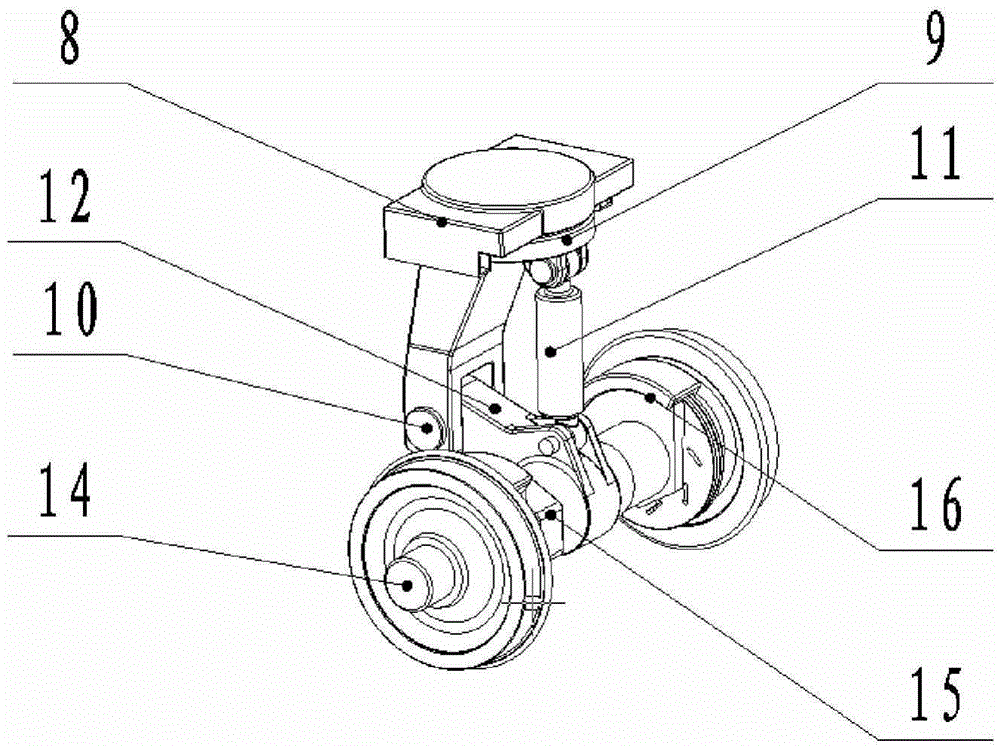

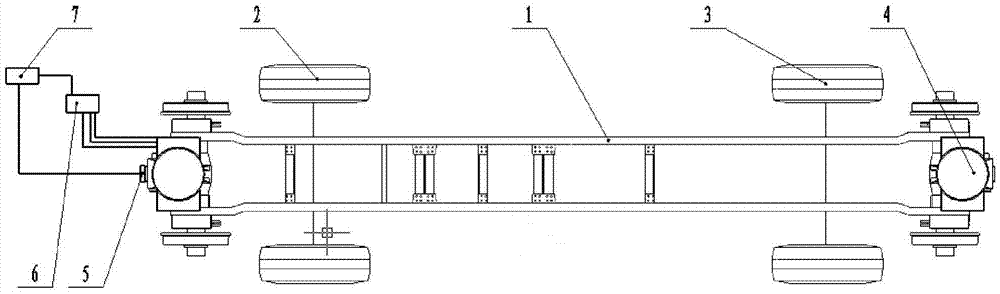

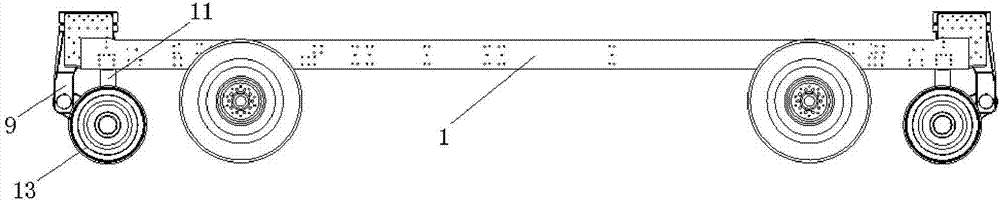

A dual-purpose multifunctional emergency rescue fire truck with two-way driving rail

ActiveCN103935285BWith swivel characteristicsMeet urgent and fast requirementsRail and road vehiclesItem transportation vehiclesVehicle frameEmergency rescue

The invention relates to the field of rescuing fire fighting trucks, in particular to a bidirectional-traveling road-rail dual-purpose multifunctional emergency rescuing fire fighting truck. The bidirectional-traveling road-rail dual-purpose multifunctional emergency rescuing fire fighting truck comprises a truck frame and road traveling bridges connected to the truck frame, and further comprises rail traveling systems, each rail traveling system comprises an upper rotation base, a lower rotation base and a swinging arm, the upper rotation bases are fixedly connected with the truck frame, the lower rotation bases are connected with the upper rotation bases in a rotatable mode, and one ends of the swinging arms are hinged to lower landing legs of the lower rotation bases. According to the bidirectional-traveling road-rail dual-purpose multifunctional emergency rescuing fire fighting truck, wheel pairs have the rotation characteristic, compared with the conditions that in the prior art wheel pairs are pressed through a rail to carry out steering, and reverse braking is achieved through a driving system, a braking mode of the bidirectional-traveling road-rail dual-purpose multifunctional emergency rescuing fire fighting truck is not limited by the 40-Km / h truck speed any more, the speed is one time higher than that of a conventional road-rail truck, and the emergent and rapid requirements during fire rescuing can be met.

Owner:四川川消消防车辆制造有限公司

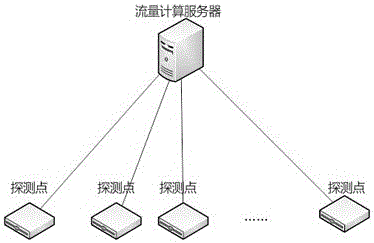

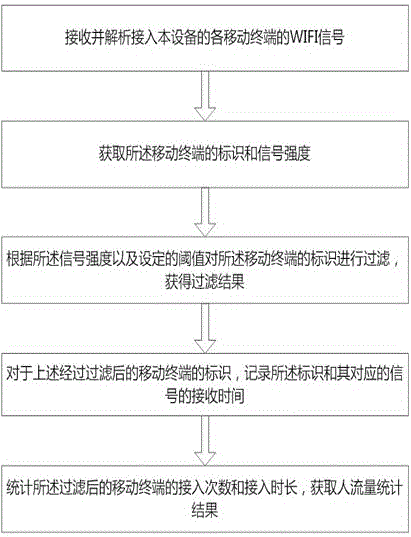

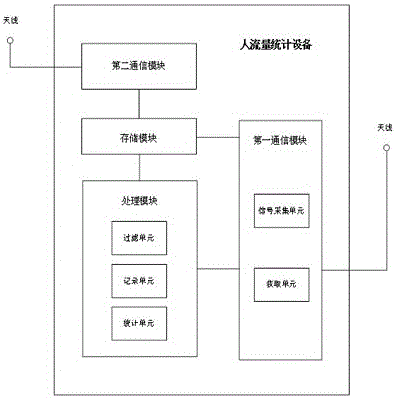

Human traffic statistics method and equipment

PendingCN106210144AAvoid dangerous accidentsReduce the burden onData processing applicationsNetwork traffic/resource managementTraffic volumeTraffic capacity

The invention provides a human traffic statistics method and equipment. The method is applied to the human traffic statistics equipment. The human traffic statistics equipment can be taken as a wireless access point to provide an access to a mobile terminal. The human traffic statistics equipment comprises a first communication module, a second communication module, a processing module and a storage module. The method comprises the following steps of collecting a WIFI signal of each mobile terminal connected to the equipment; obtaining an identification and signal strength of the mobile terminal; and counting the access frequency and the access duration of the mobile terminal to obtain a human traffic statistic result. According to the human traffic statistics method and equipment, the real-time monitoring and display can be carried out on the human traffic of the entire scenic area and branch scenic spots, and the tourist amount in each branch scenic spot can be effectively controlled to prevent a dangerous accident caused by the excessive human traffic; and meanwhile, the human traffic statistics is executed in the human traffic statistics equipment in the branch scenic spots, so that the computational burden of a total server of the scenic spot can be relieved.

Owner:北京易游华成科技有限公司

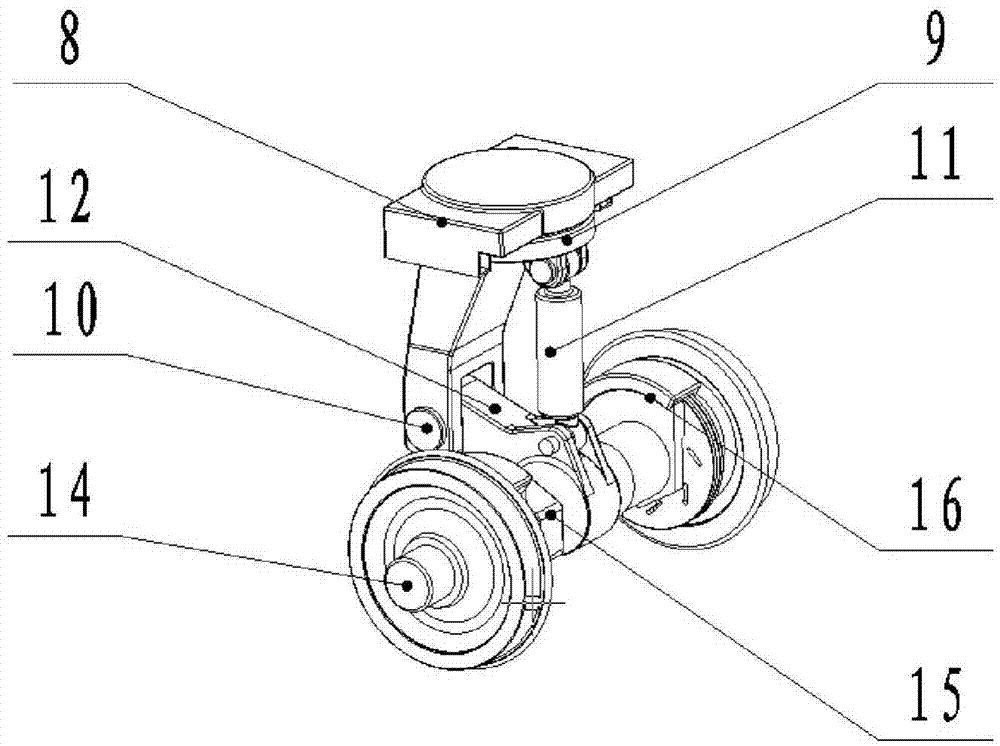

Bidirectional-traveling road-rail dual-purpose multifunctional emergency rescuing fire fighting truck

ActiveCN103935285AWith swivel characteristicsMeet urgent and fast requirementsRail and road vehiclesItem transportation vehiclesVehicle frameEmergency rescue

The invention relates to the field of rescuing fire fighting trucks, in particular to a bidirectional-traveling road-rail dual-purpose multifunctional emergency rescuing fire fighting truck. The bidirectional-traveling road-rail dual-purpose multifunctional emergency rescuing fire fighting truck comprises a truck frame and road traveling bridges connected to the truck frame, and further comprises rail traveling systems, each rail traveling system comprises an upper rotation base, a lower rotation base and a swinging arm, the upper rotation bases are fixedly connected with the truck frame, the lower rotation bases are connected with the upper rotation bases in a rotatable mode, and one ends of the swinging arms are hinged to lower landing legs of the lower rotation bases. According to the bidirectional-traveling road-rail dual-purpose multifunctional emergency rescuing fire fighting truck, wheel pairs have the rotation characteristic, compared with the conditions that in the prior art wheel pairs are pressed through a rail to carry out steering, and reverse braking is achieved through a driving system, a braking mode of the bidirectional-traveling road-rail dual-purpose multifunctional emergency rescuing fire fighting truck is not limited by the 40-Km / h truck speed any more, the speed is one time higher than that of a conventional road-rail truck, and the emergent and rapid requirements during fire rescuing can be met.

Owner:四川川消消防车辆制造有限公司

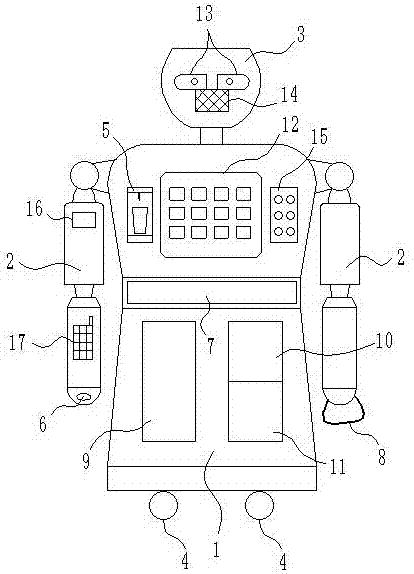

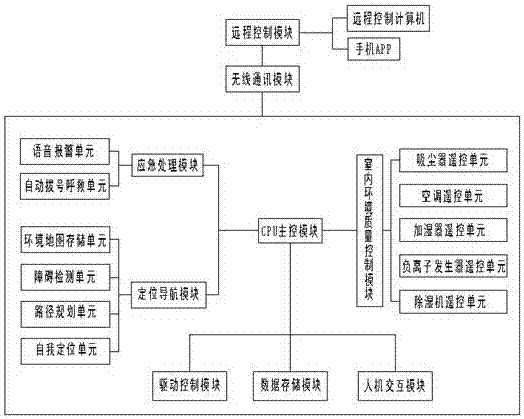

Intelligent nursing robot

InactiveCN107139184AReal-time monitoring of environmental qualitySolve the problem of not using current household appliancesManipulatorDrive wheelSimulation

The invention discloses an intelligent nursing robot. The intelligent nursing robot mainly comprises a robot body, robot arms located on the two sides of the robot body, a robot head located on the upper portion of the robot body and drive wheels located on the lower portion of the robot body; and the intelligent nursing robot furthermore comprises a drinking device, a lighting device, a rest device, a traction device, a conventional health inspection device, a motor drive device, a power source device, a display screen, omnidirectional cameras, voice frequency input / output equipment, an indoor environment quality monitoring sensor, an alarm device and a telephone communication device, and the robot body is internally provided with a CPU main-control module, a drive control module, a man-machine interaction module, an indoor environment control module, a positioning and navigation module, a data storage module and an emergency processing module. The intelligent nursing robot is comprehensive in function and high in intelligent degree, and great convenience is provided for modern households.

Owner:唐建芳

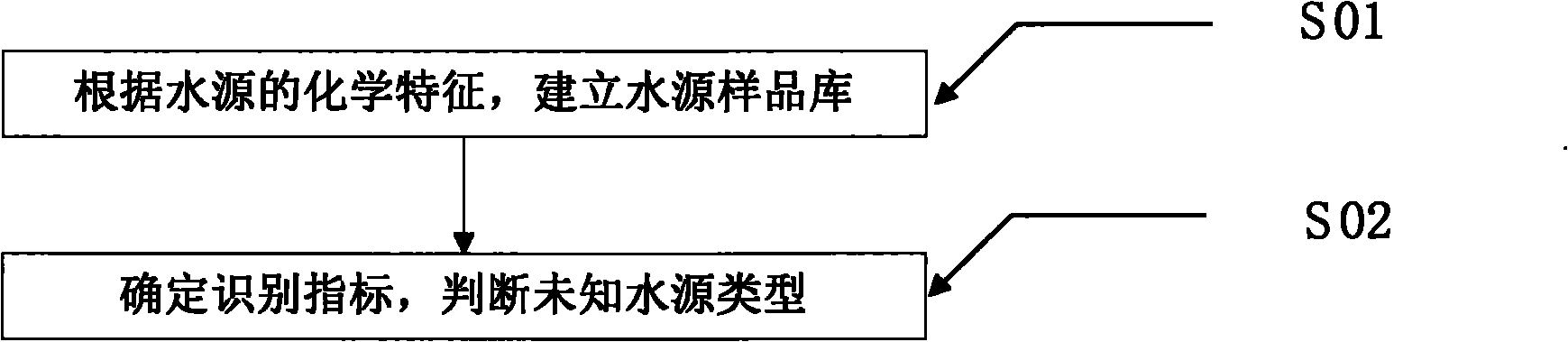

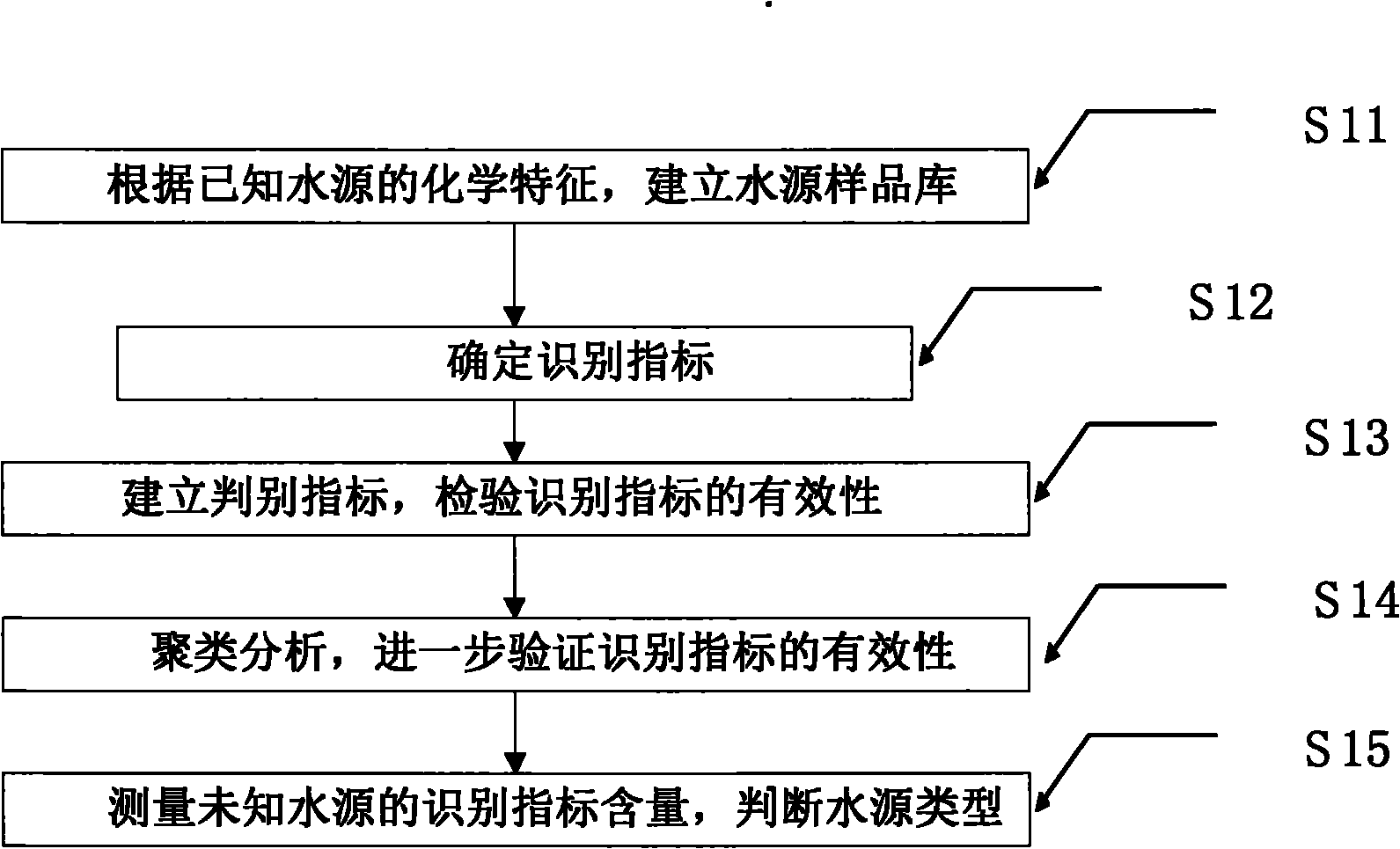

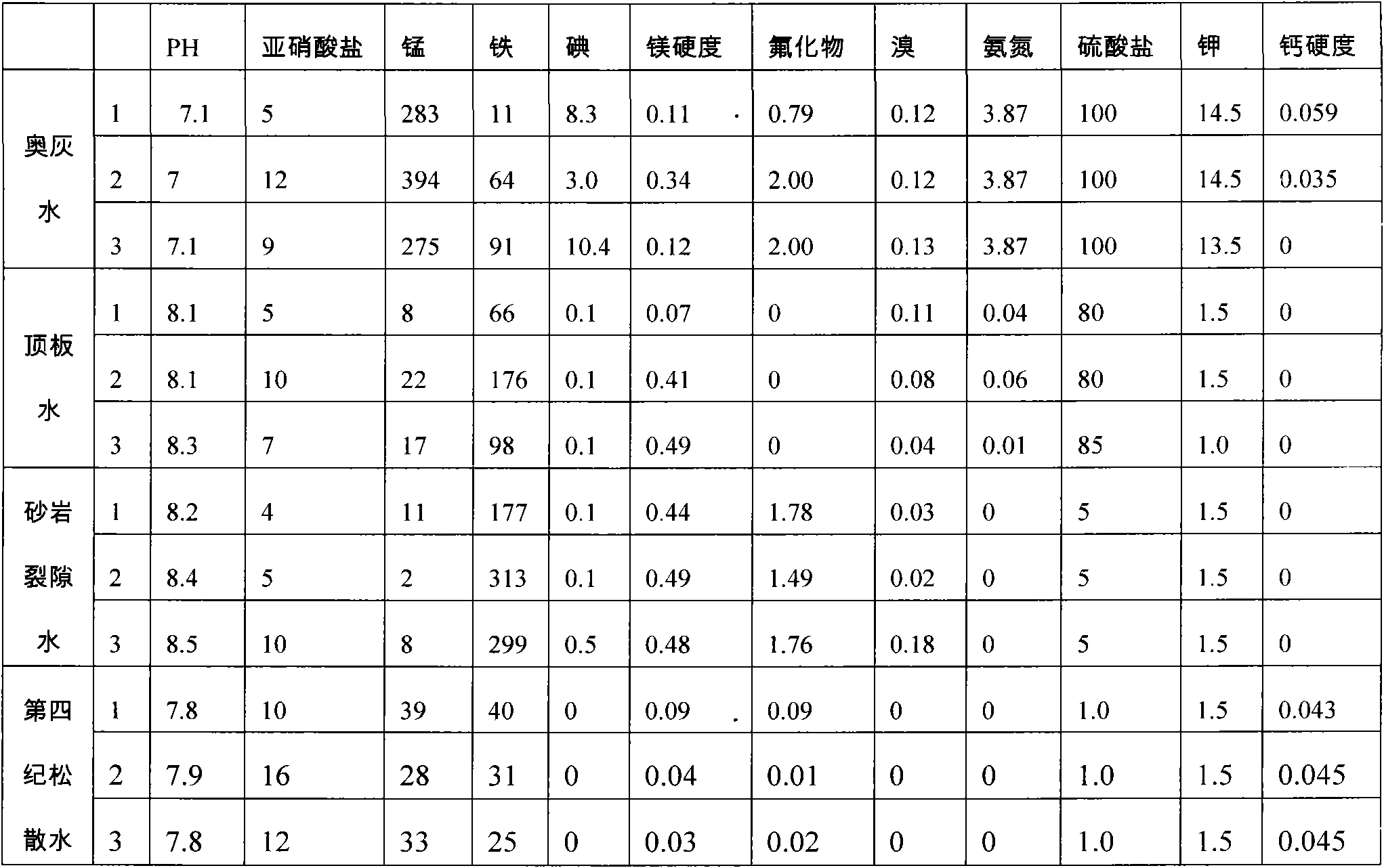

Method and equipment for identifying mining water source

InactiveCN101923084AQuick measurementAccurate identificationTesting waterChemical compositionWater source

The invention discloses a method and equipment for identifying a mining water source. The method comprises the following steps of: establishing a water source sample warehouse according to the chemical characteristic of a known water source; and determining identification indexes, and judging the type of an unknown water source. Correspondingly, the invention also discloses equipment for identifying the water source. Through the method and the equipment, chemical components of underground water in mine water-bearing strata are measured simply and quickly, and the unknown water burst source can be judged accurately in real time so as to prevent water hazards in coal mine from occurring, avoid economic loss and casualties which are caused by water burst accidents and guarantee the safety production of the coal mine.

Owner:BEIJING HUAAN AOTE TECH

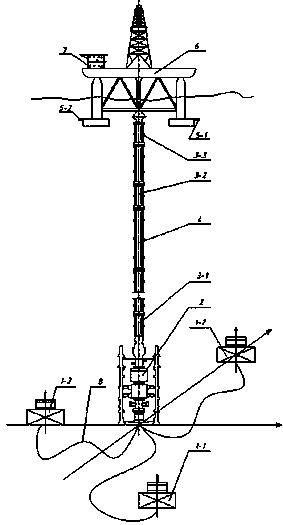

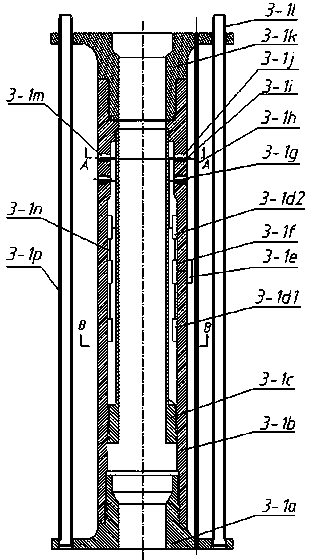

Deepwater drilling riser state monitoring system and working method thereof

InactiveCN103485761AAdjust the status in timeAvoid breakingConstructionsOcean bottomInformation processing

The invention discloses a technique for monitoring riser states in real time during deepwater oil development, belongs to the field of marine oil development, and relates to a deepwater drilling riser state monitoring system and a working method thereof. A riser provided with an information acquisition nipple comprises a riser body and the information acquisition nipples mounted on the riser body. Pressure sensors used for measuring water pressure values, electronic compasses used for measuring geographic orientation values and temperature sensors used for measuring water temperature are arranged in each information acquisition nipple, stress strain gauge devices for monitoring variation of stresses and a CPU (central processing unit) processing module for information processing are attached to the inner wall of each nipple, and signal transmission modules can transmit information outwards. Sea bed base stations and signal collectors can receive and transmit signals from the signal collection nipples as well as transmit the signals to a signal collection processing and controlling center. The riser provided with the signal collection nipples can effectively monitor self states during drilling, and capability of the riser for dealing with deepwater complex environments is improved.

Owner:SOUTHWEST PETROLEUM UNIV

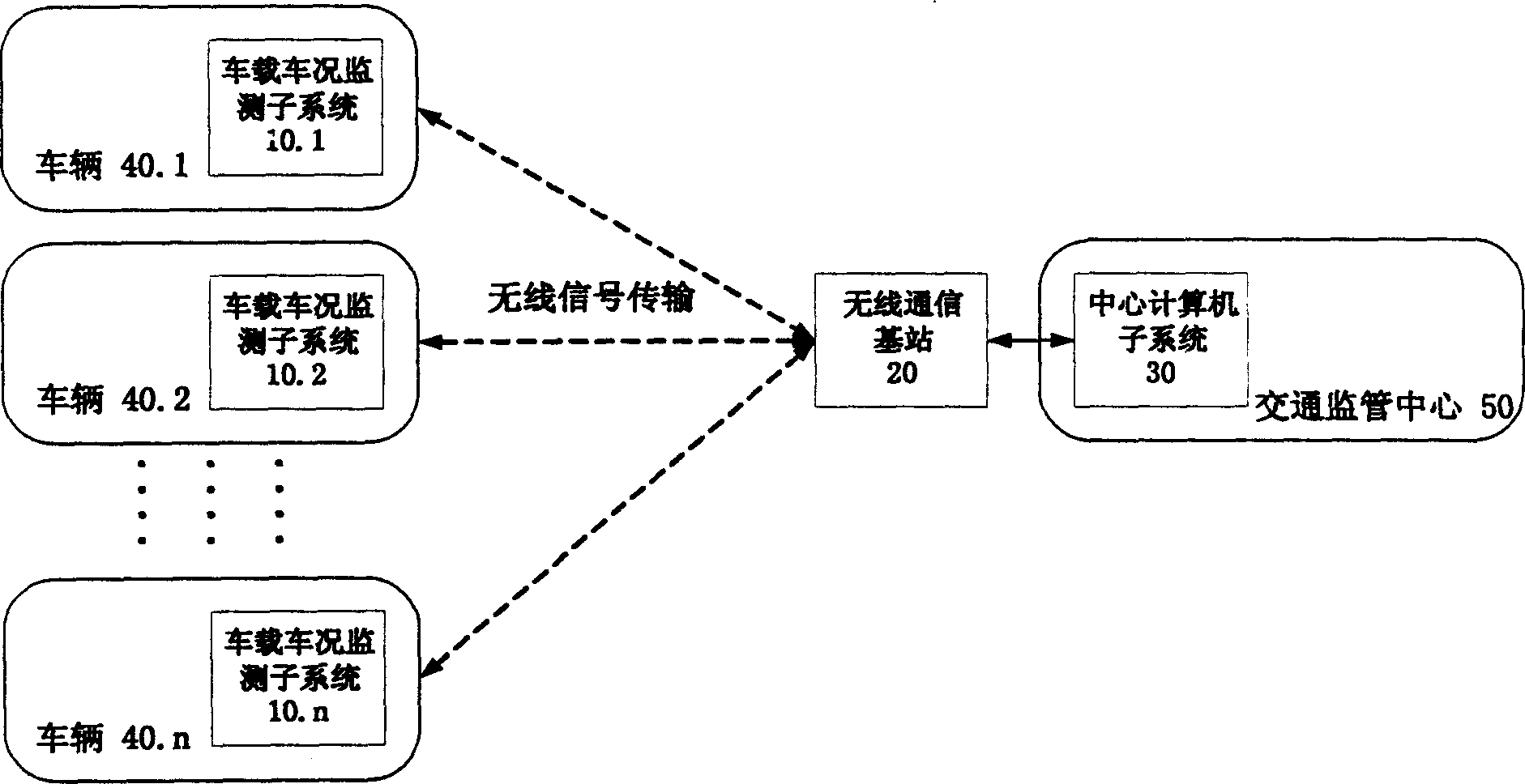

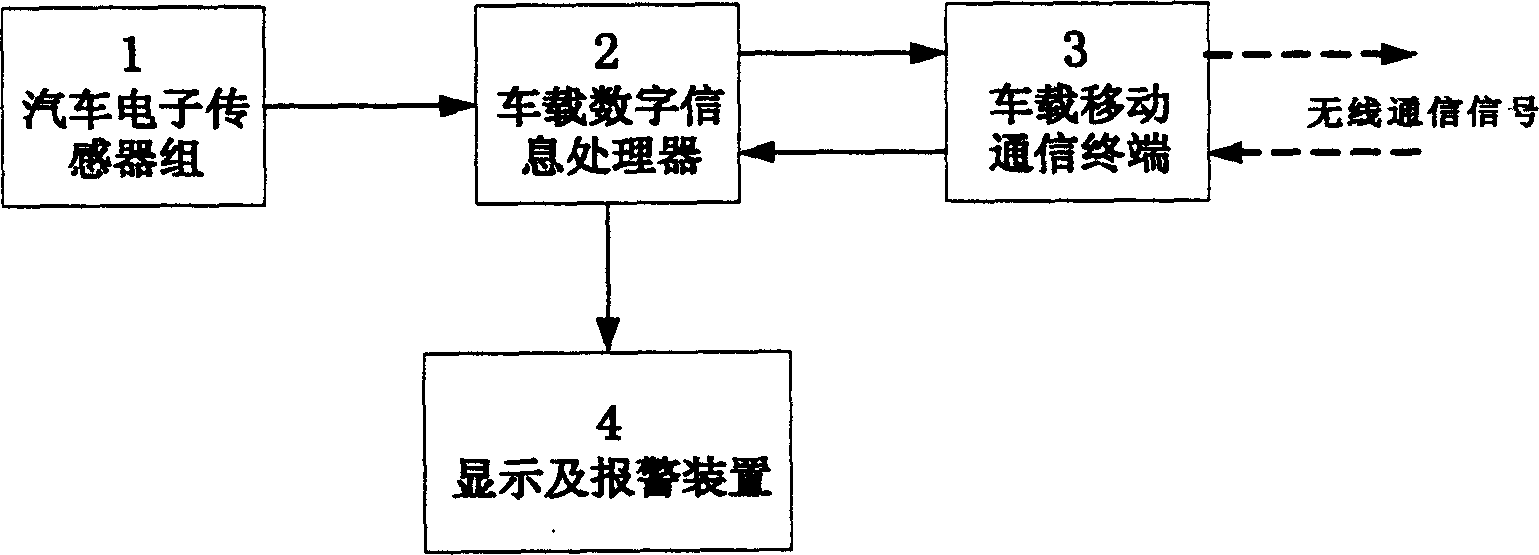

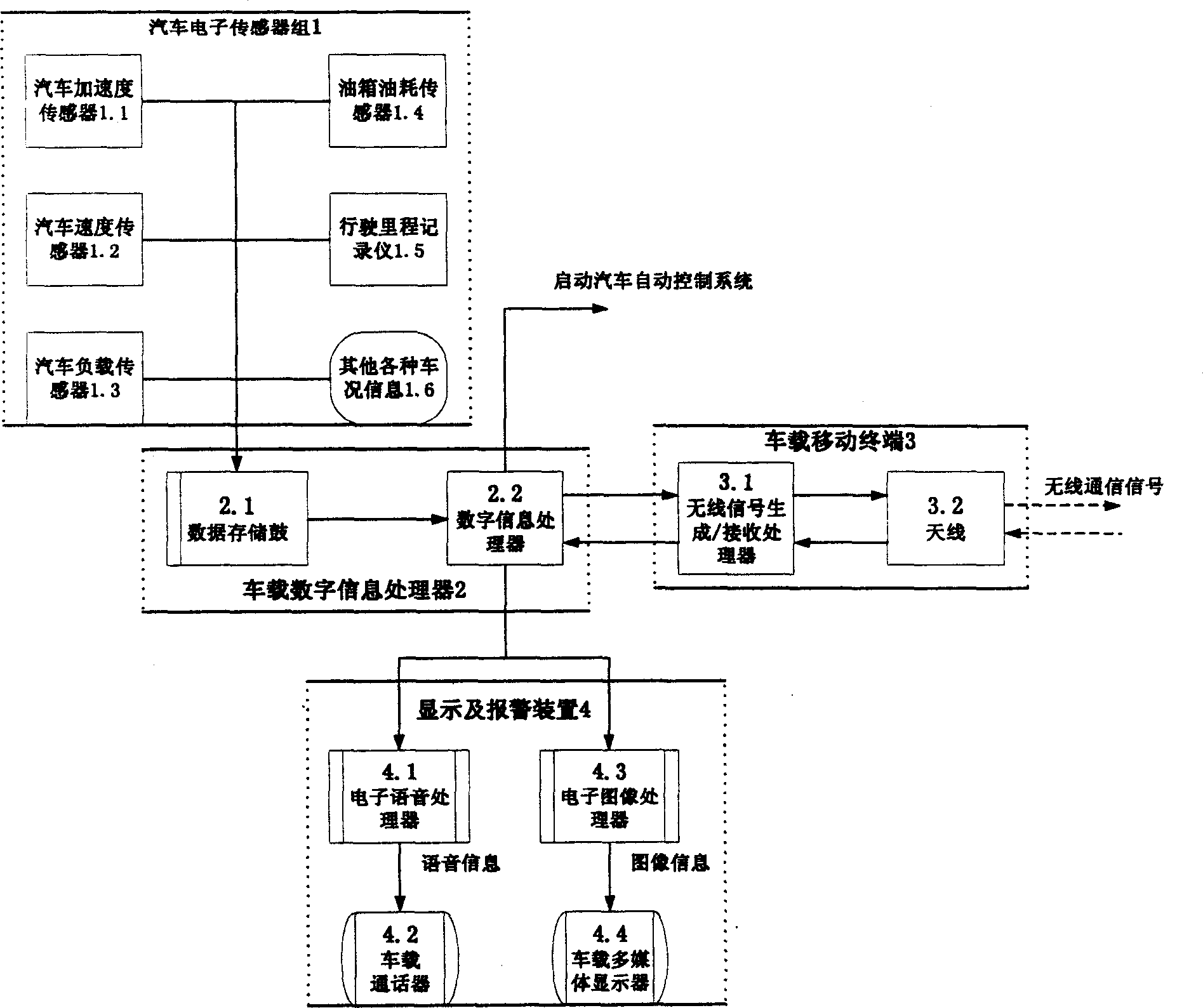

Intelligent vehicle condition monitor system based on mobile communication

InactiveCN1588415ANetworkingFully automatedSpecial data processing applicationsData informationEngineering

The invention discloses an intelligent car state supervising system based on mobile communication. The system includes car borne state supervising subsystem and the center computer subsystem in the traffic monitor. The car borne state supervising subsystem exchanges data information with the center computer subsystem through the base station of the wireless communication network, and forms a traffic monitoring and managing network. The car borne state monitoring subsystem includes a vehicle electron sensor group, car borne digital information processor, car borne mobile communication terminal and displaying and alarming device. The center computer subsystem includes a car identification incriminator, digital information processing computer, storing and recording device, peccancy and deficiency judger and alarm and order information generator. The invention can provide state information to the cit traffic managing department of any car automatically, thus it is convenient to the monitor and management of car state, upgrades the supervising efficiency of traffic state.

Owner:HUAZHONG UNIV OF SCI & TECH

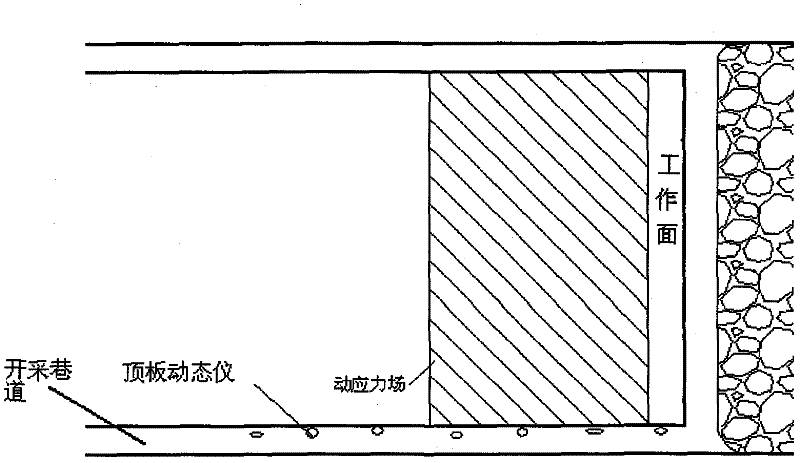

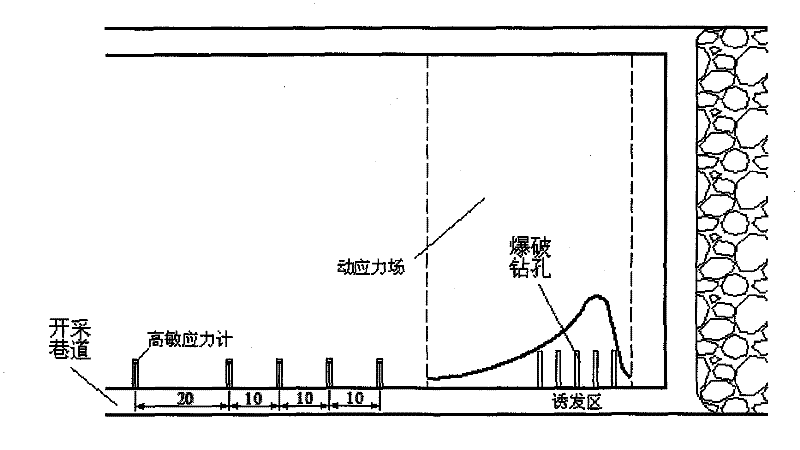

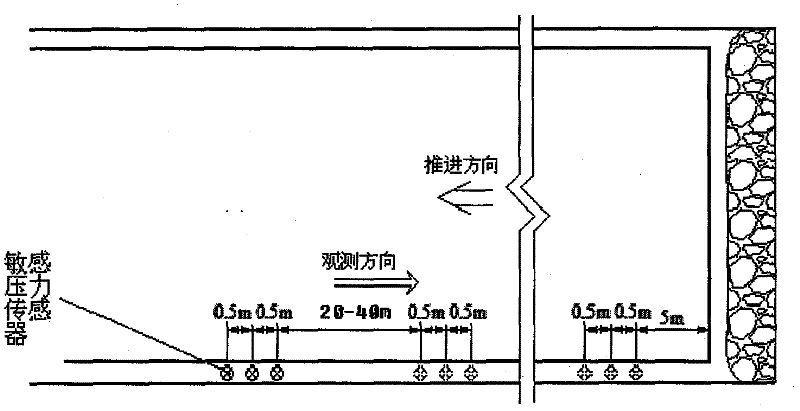

Comprehensive early-warning observation method for coal mine rock burst

The invention discloses a comprehensive early-warning observation method for coal mine rock burst. The method includes the steps: firstly, obtaining the range of a high stress field of a rock burst coal bed; secondly, manually intervening and observing the disturbance range; and finally, performing all-dimensional dynamic monitoring. Comprehensive monitoring is realized by closely associating overburden rock movement damage of a mining face with the size and distribution of the stress field, so that the risk of rock burst is forecast, warning measures are timely taken, and rock burst accidents are avoided.

Owner:SHANDONG UNIV OF SCI & TECH

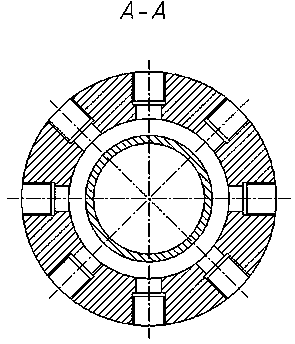

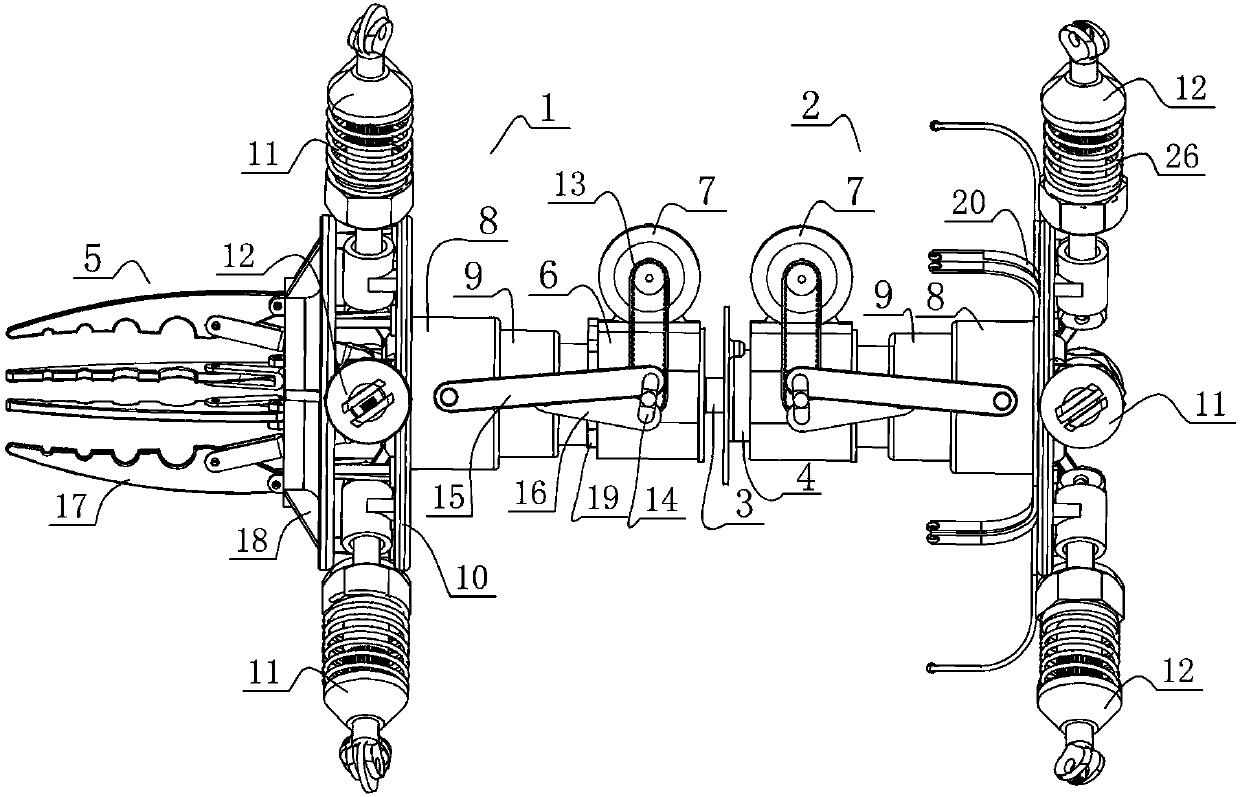

Device capable of walking freely in pipeline

The invention relates to a device capable of walking freely in a pipeline. The device comprises a front walking mechanism and a rear walking mechanism. The front walking mechanism and the rear walking mechanism are the same in structure. The front walking mechanism and the rear walking mechanism are respectively composed of a servo motor, an outer sleeve, an inner sleeve, a walking telescopic arm and a fixed telescopic arm. Each outer sleeve is placed on the periphery of the corresponding inner sleeve. The walking telescopic arms and the fixed telescopic arms are selectively connected with the ends of the inner sleeves and the ends of the outer sleeves. Each servo motor drives the corresponding inner sleeve and the corresponding outer sleeve to make intermittent relative movement through a transmission mechanism. The front walking mechanism and the rear walking mechanism are connected through an electric push rod, and a walking motor used for driving the electric push rod to be telescopic is arranged in the rear walking mechanism. According to the device, the walking telescopic arms and the fixed telescopic arms make selective contact with the inner wall of the pipeline, due to the fact that the electric push rod is driven by the walking motor, the entire device can be driven to walk freely inside the pipeline, the device can replace manual work to conduct maintaining, overhauling and dredging operations of pipelines and pipe networks, the labor of workers is lightened, and dangerous accidents are avoided.

Owner:BINZHOU UNIV

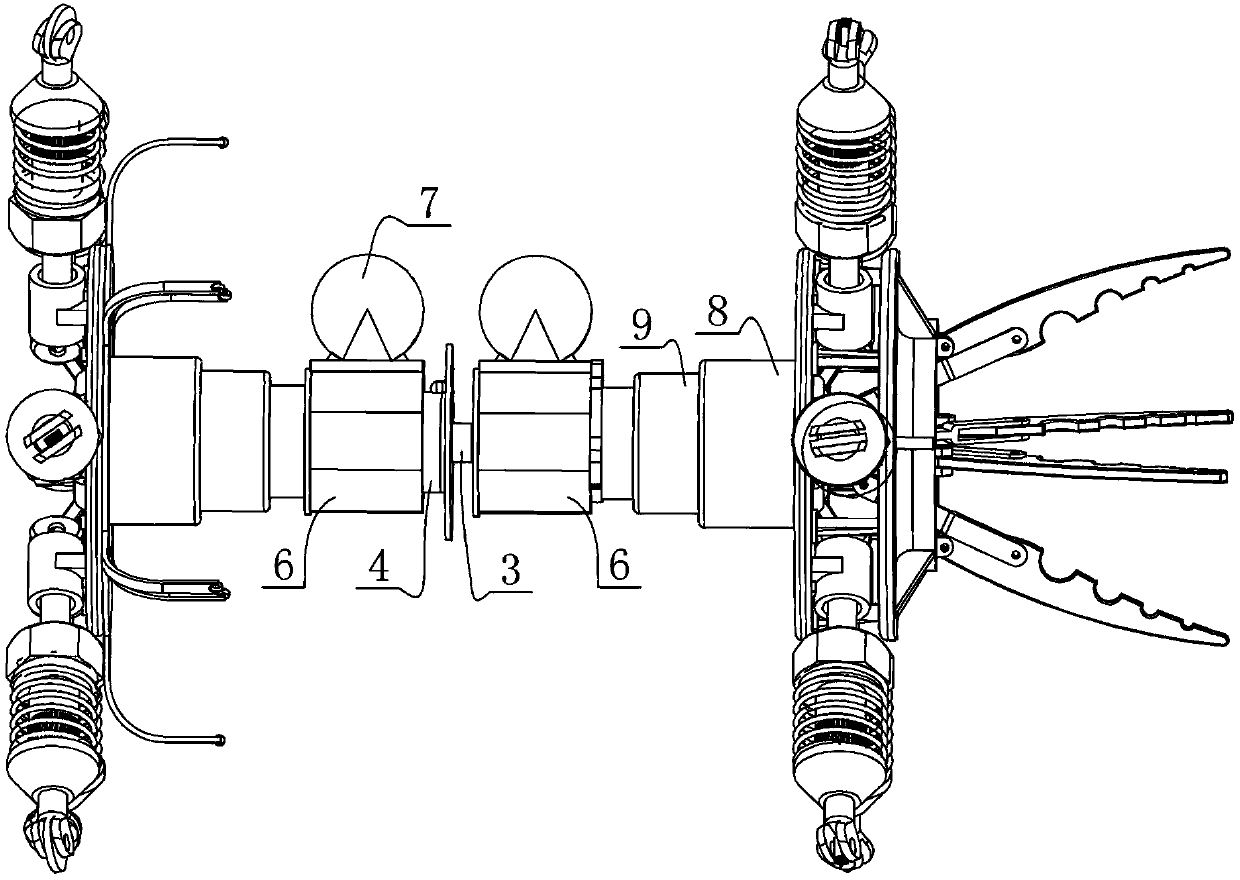

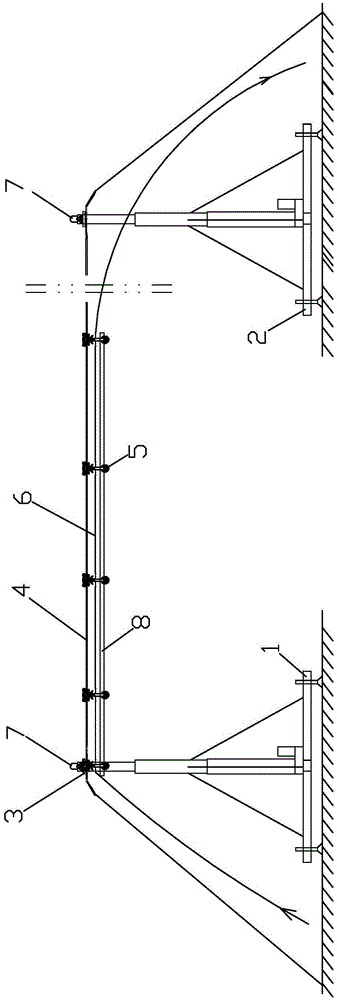

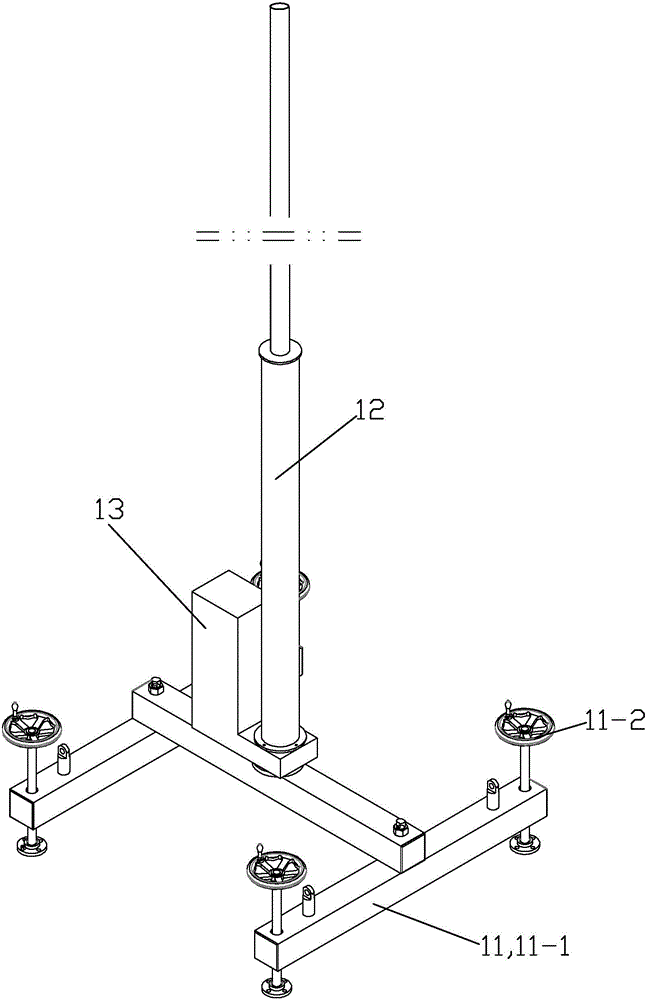

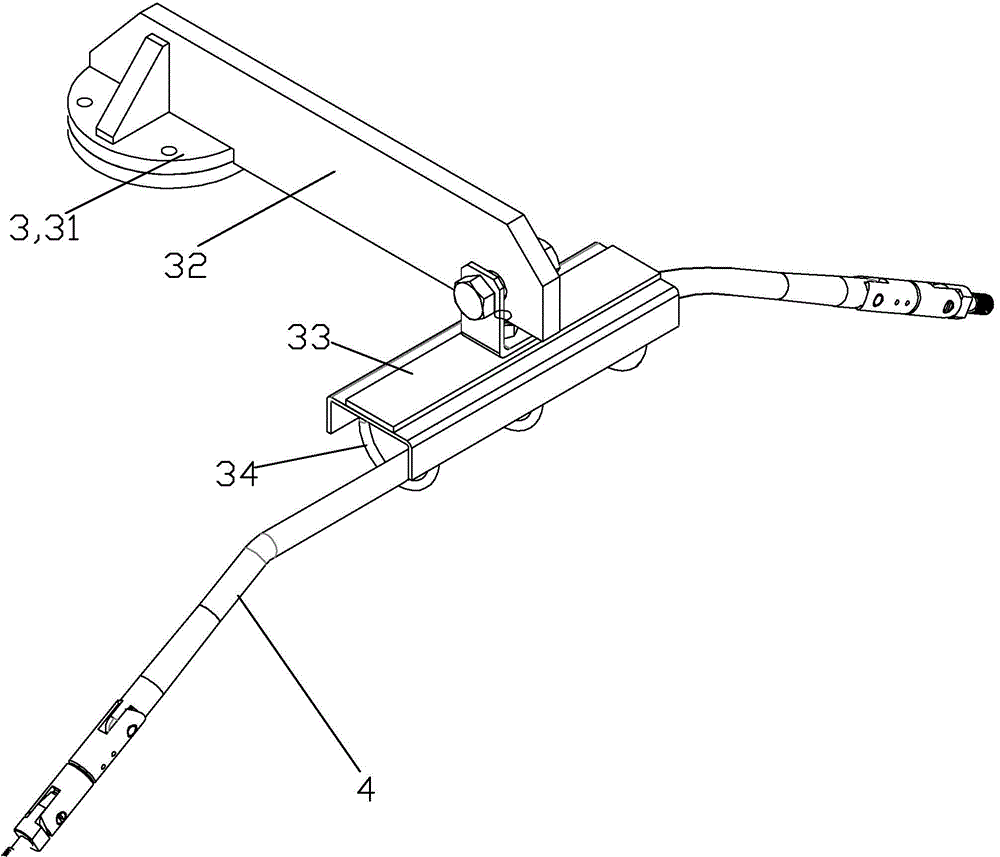

10KV bypass cable overhead laying street crossing apparatus

ActiveCN104868398AEasy to carryShorten the erection timeApparatus for overhead lines/cablesStreet crossingPulley

The invention provides a 10KV bypass cable overhead laying street crossing apparatus. The apparatus comprises a first supporting component, a second supporting component, two rod importing stands, a supporting rope, several mobile pulleys, a mobile pulley connection hauling rope and two infrared range finding alarms, wherein the first supporting component and the second supporting component have the same structure. The first supporting component comprises a pedestal, lifting rods and a driver. The two rod importing stands are arranged on upper ends of the two lifting rods. The supporting rope passes through the two rod importing stands and is used for supporting each mobile pulley. Each mobile pulley is used for supporting the bypass cable needing to carry out street crossing to carry out street crossing and can slide left and right replying on the supporting rope under traction of the mobile pulley connection hauling rope. The two infrared range finding alarms are fixedly installed on top ends of the two lifting rods respectively and installation directions are opposite. The structure of the apparatus is simple, the cost is low. The apparatus is portable and is convenient to use. Applicability is good. Repairing efficiency of a power supply department can be increased and working safety is guaranteed.

Owner:CHANGZHOU POWER SUPPLY OF JIANGSU ELECTRIC POWER +3

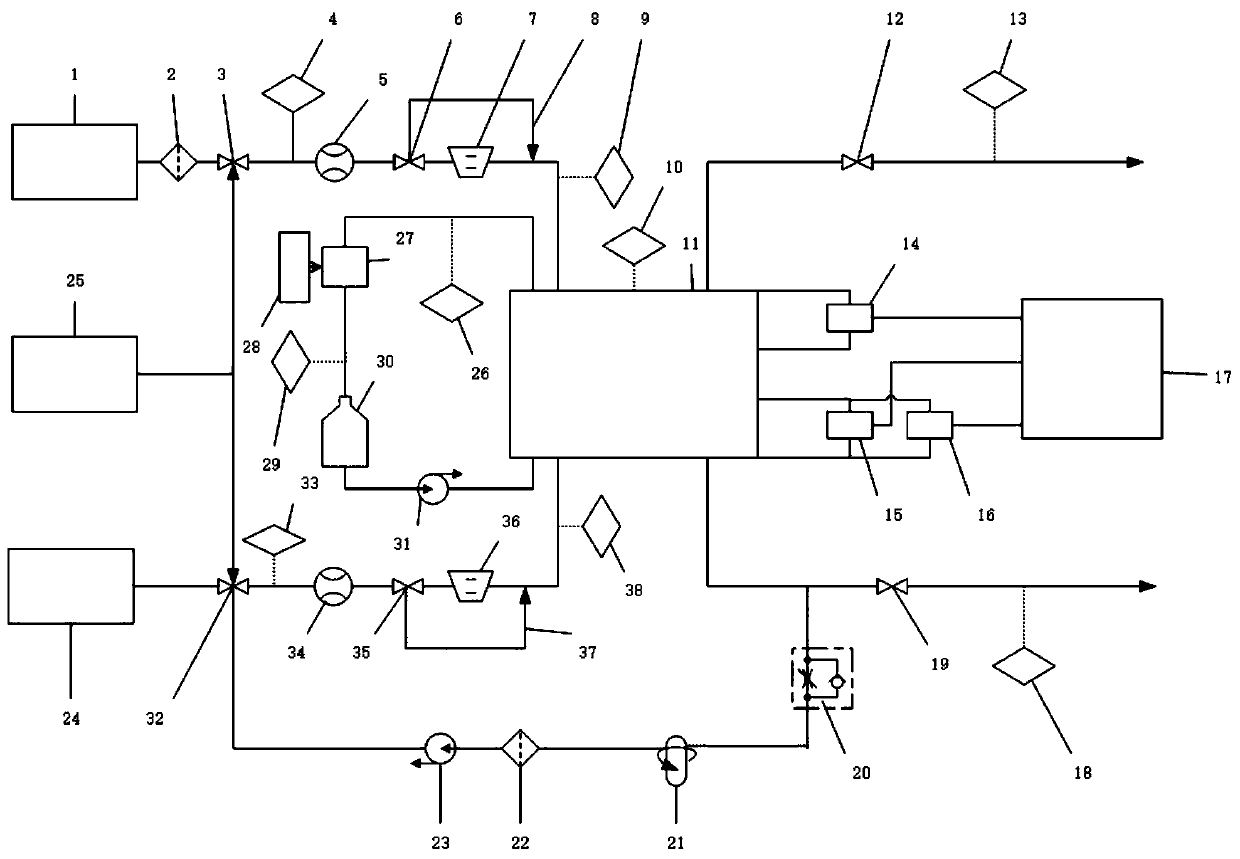

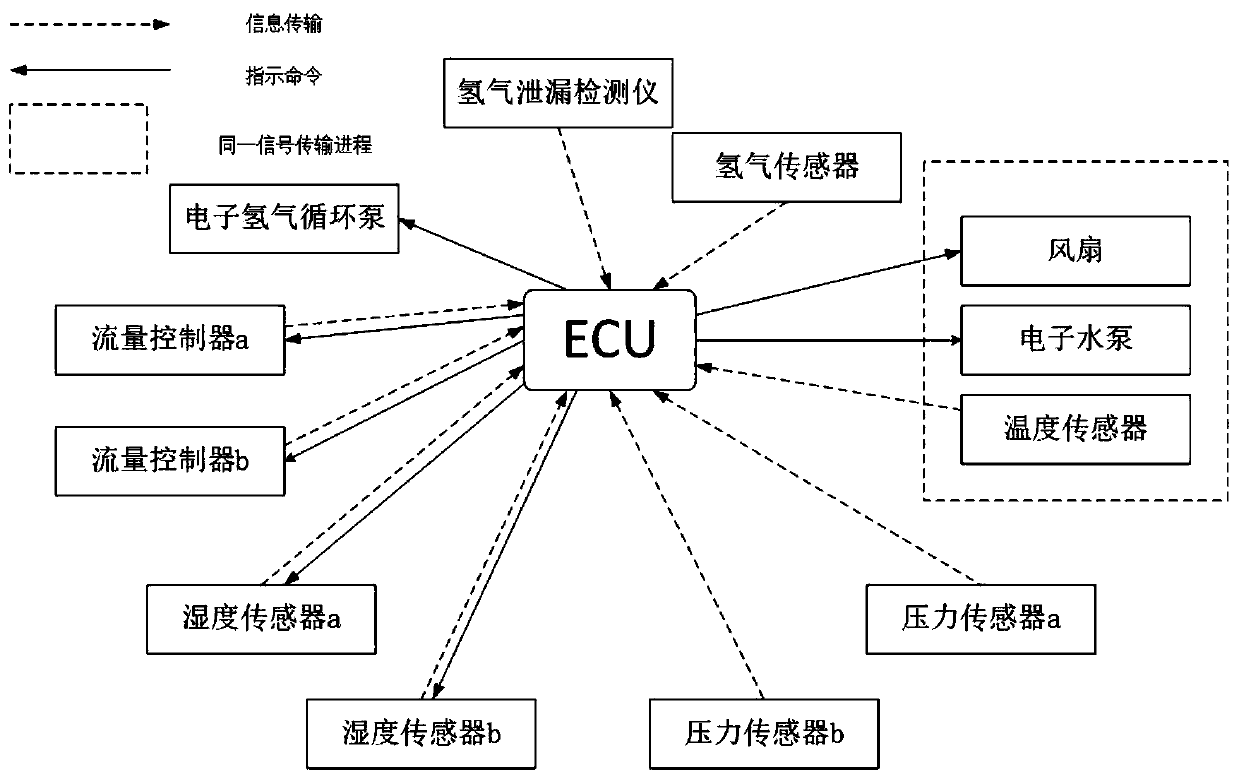

Hydrogen fuel cell stack durability test system and method

ActiveCN111082093AAchieve recyclingLow costFuel cell heat exchangeMeasurement devicesWater storage tankHydrogen fuel cell

The invention belongs to the technical field of fuel cells, and discloses a hydrogen fuel cell stack durability test system and method. An input pipeline and an output pipeline of a cooling water storage tank are respectively communicated with a fuel cell stack; the middle of the input pipeline of the cooling water storage tank is communicated with a conductivity measuring instrument, a radiator and the like; a hydrogen tail gas exhaust pipeline is sequentially communicated with a hydrogen recovery pipeline, a back pressure valve and a hydrogen sensor; a cathode tail gas exhaust pipeline is connected with a tail gas analyzer to realize collection and measurement of concerned cathode tail gas components in the durability testing process; and the stack is connected with an electrochemical workstation to realize the detection of the electrochemical performance of the stack in the durability testing process. According to the invention, the durability of the stack can be comprehensively tested; hydrogen tail gas recovery is realized, and the cost is saved; an alarm can be given in time to prevent dangerous accidents; detection of the electric conductivity, the cathode tail gas components and the like of stack cooling circulating water is realized, and the influence of hydrogen-oxygen interface formation on the stack durability during starting and stopping is eliminated.

Owner:WUHAN UNIV OF TECH

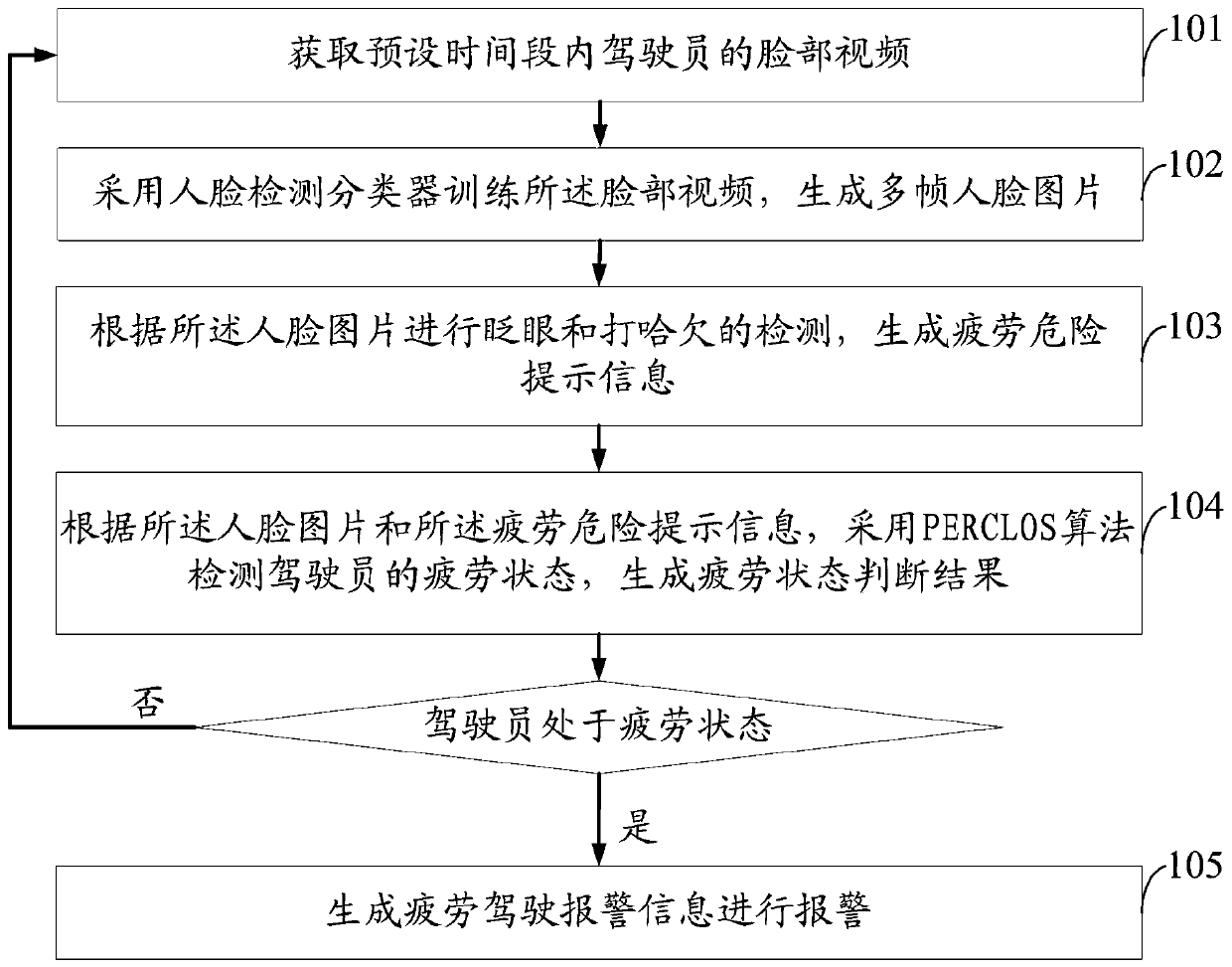

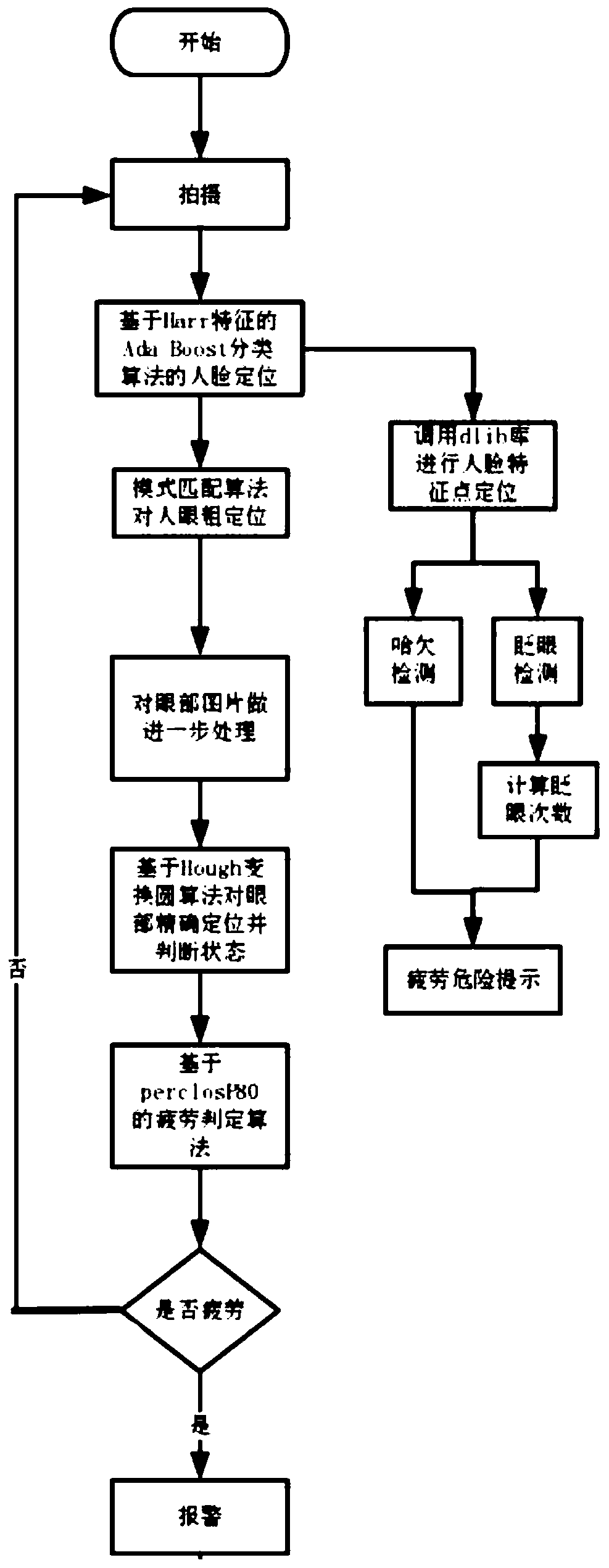

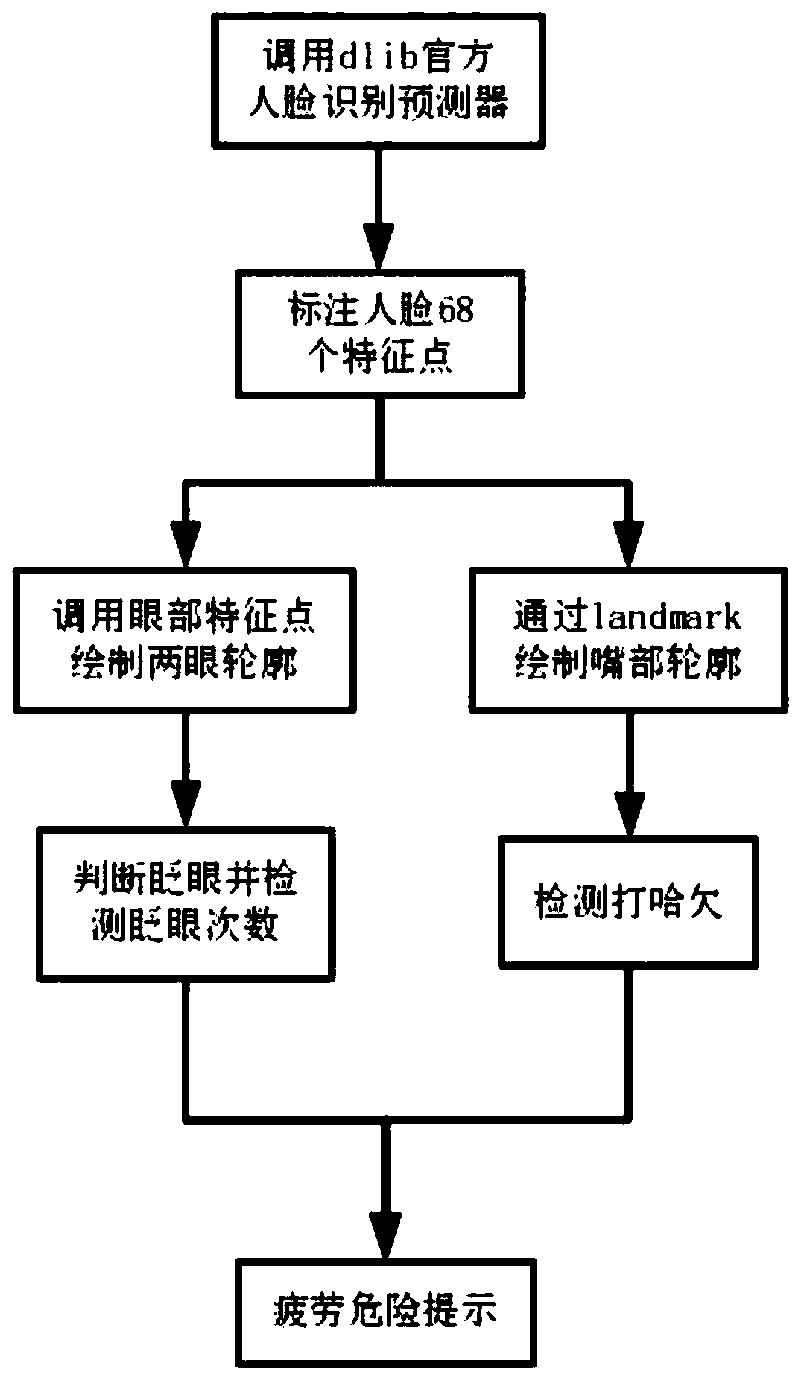

Driver fatigue detection method and system based on computer vision

PendingCN109934199APrevent dangerous accidents from happeningReduce accident rateCharacter and pattern recognitionDriver/operatorComputer based

The invention discloses a driver fatigue detection method and system based on computer vision. The method comprises: firstly, a camera is called to collect a driver face video; Then, the face is positioned through an AdaBoost classifier algorithm of the Harr-like feature; then, blinking and yawing detection are carried out by utilizing the Landmark to prompt fatigue; and finally, positioning humaneyes through picture preprocessing, judging fatigue according to a PERCLOS algorithm criterion, and carrying out early warning. According to the method, fatigue early warning is carried out on the driver by combining a PERCLOS human eye detection algorithm and a human face key point extraction algorithm, non-contact performance and real-time performance are achieved, interference on normal driving of the driver is avoided, and fatigue detection is more accurate, more efficient and faster.

Owner:YANGZHOU UNIV

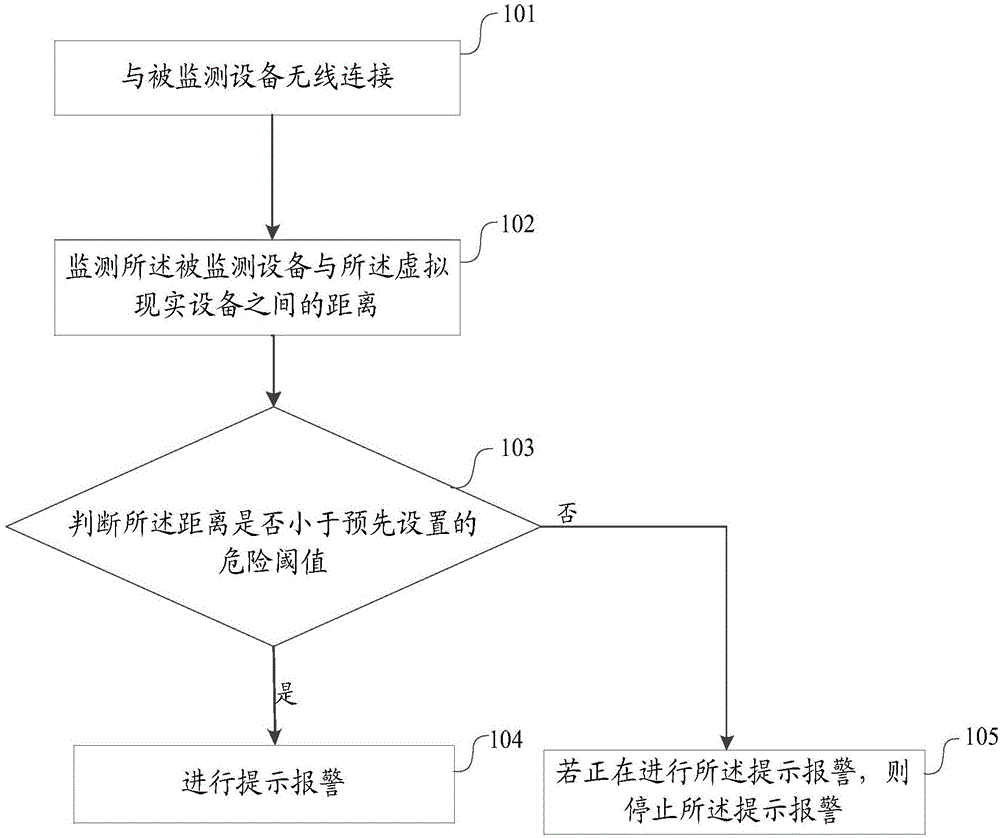

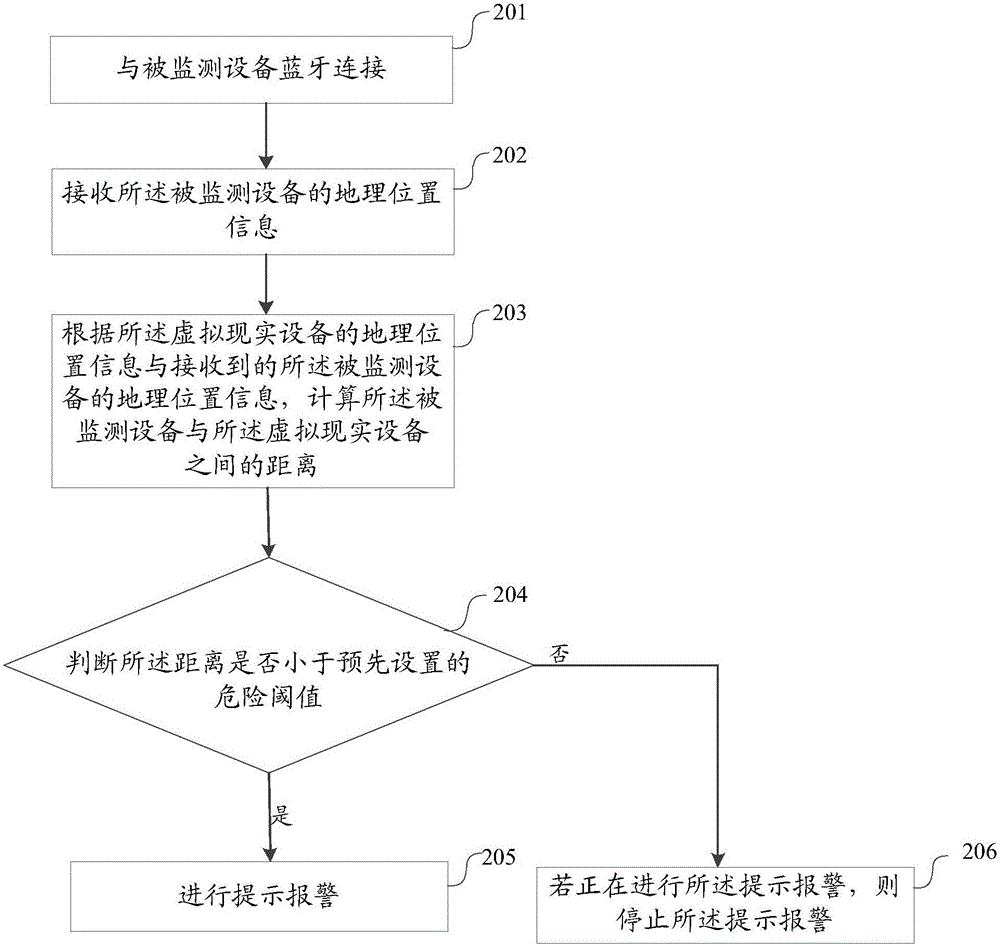

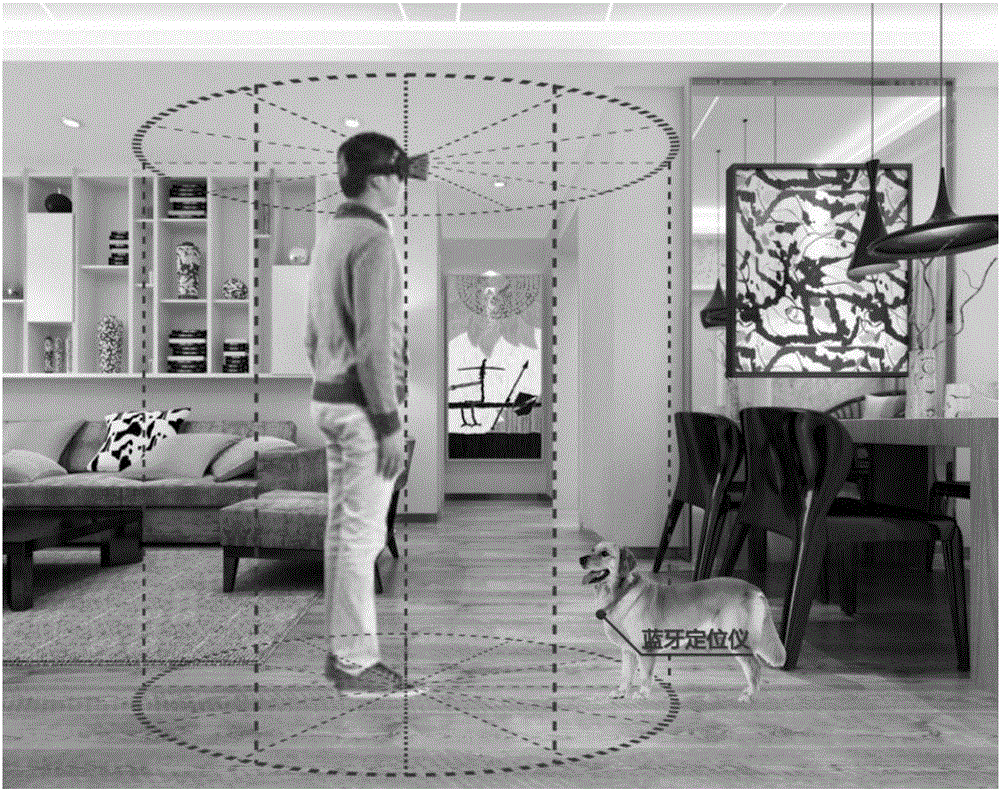

Security monitoring method, device and system and virtual reality equipment

InactiveCN106530620AAvoid dangerous accidentsImprove user experienceInput/output for user-computer interactionAlarmsRisk thresholdVirtual reality

The invention discloses a security monitoring method. The method is applied to virtual reality equipment, and comprises the steps of wirelessly connecting the virtual reality equipment with monitored equipment; monitoring the distance between the monitored equipment and the virtual reality equipment; judging whether the distance is smaller than a preset risk threshold; and if so, performing prompt alarm. The position information of the monitored equipment can be received by wirelessly connecting the monitored equipment with the virtual reality equipment, and prompt alarm can be performed when the distance is smaller than the preset risk threshold by monitoring the distance between the monitored equipment and the virtual reality equipment, so that when a user uses the virtual reality equipment and a child or a pet carrying the monitored equipment intrudes into the set risk threshold range, the user is prompted, the risk is prevented, and the user experience is improved. Moreover, the invention further provides a security monitoring device and system and virtual reality equipment, which also have the above advantages.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

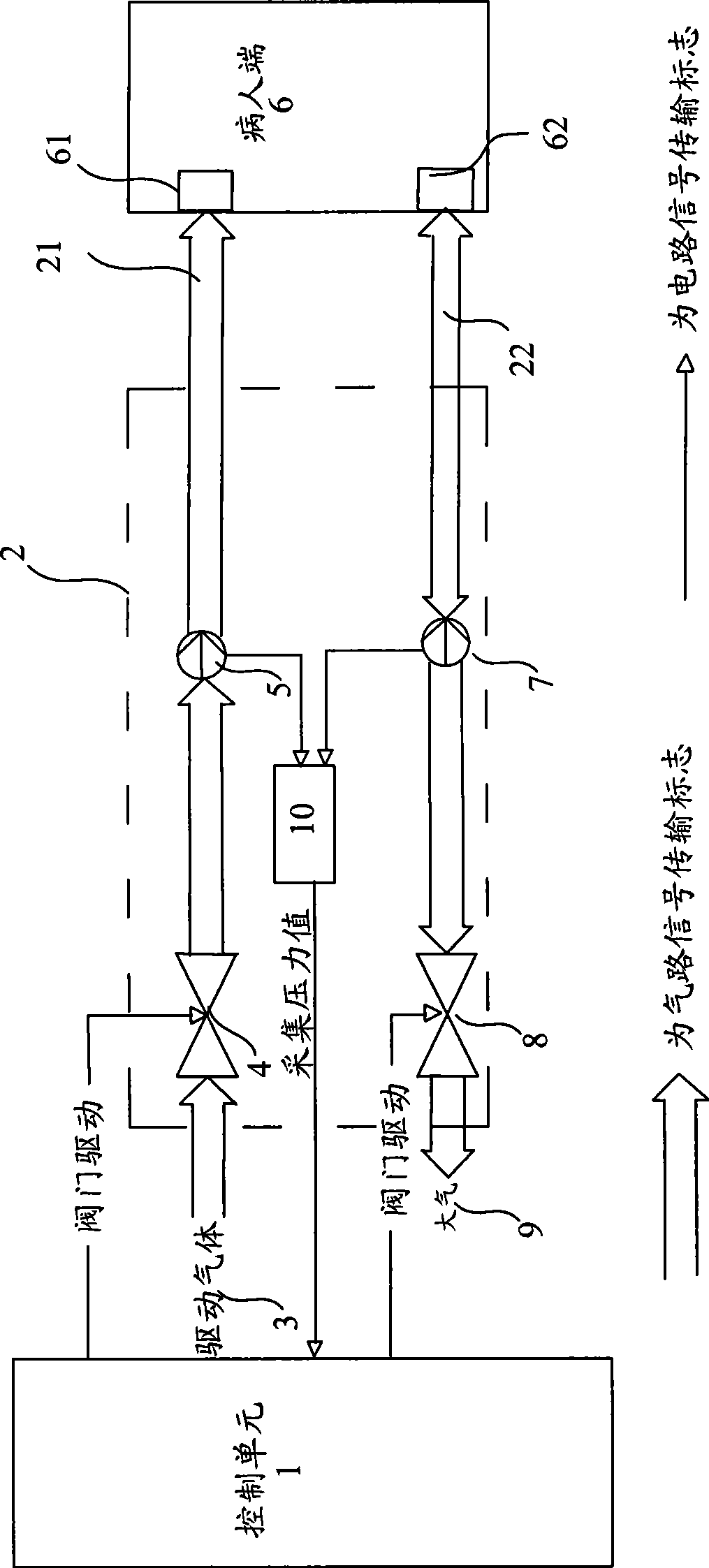

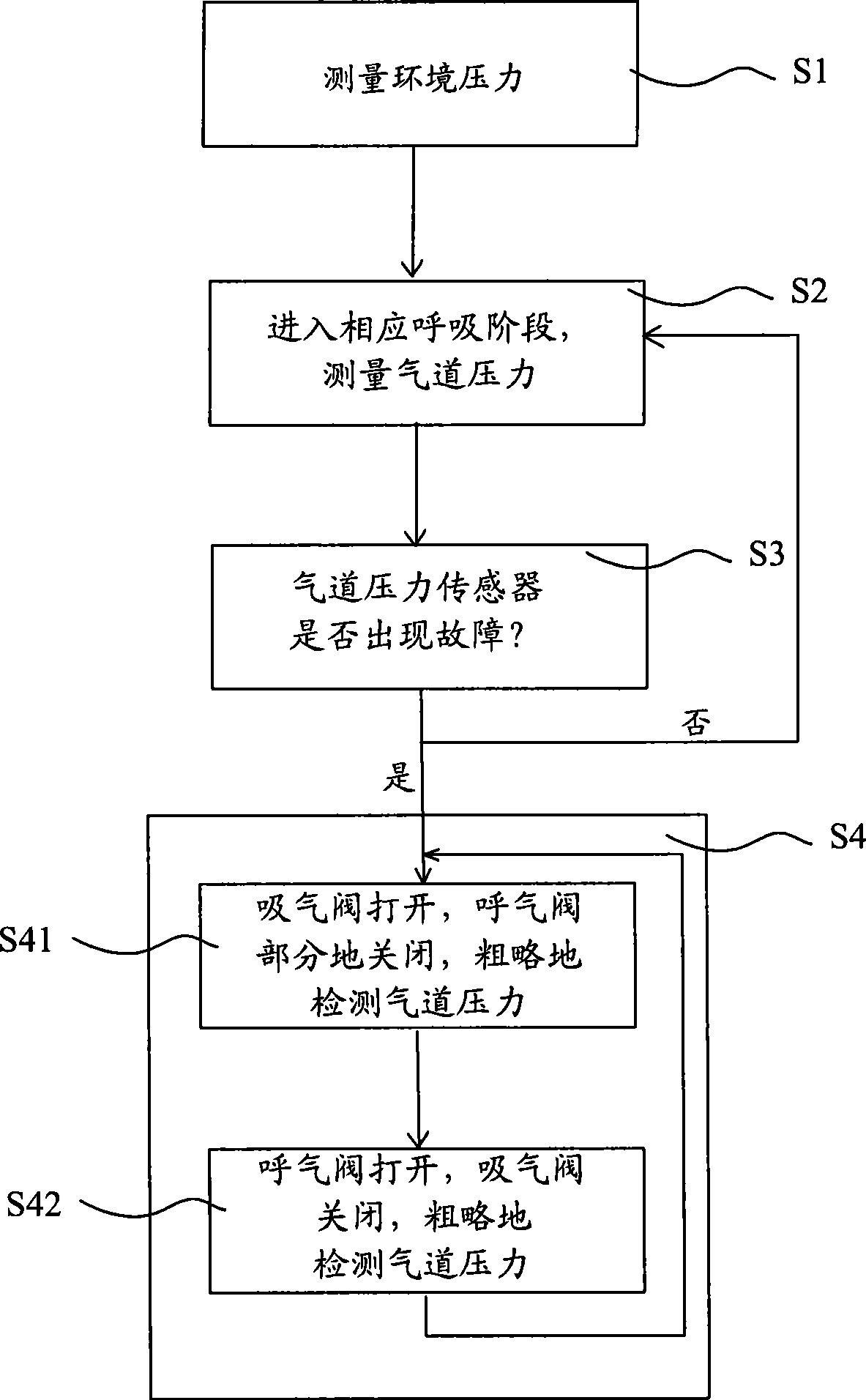

Gas path system and operation method thereof as well as breathing apparatus and anesthesia apparatus using the system

InactiveCN101468219AProtection securityImprove practicalityRespiratorsMedical devicesContinuous useEngineering

The present invention discloses an air course system which is used for medical devices of breathing machine, anesthesia device, etc. and a using method thereof. The air course system comprises the following components: a breathing loop (2) which comprises an air sucking branch line (21) and an air exhaling branch line (22); a control unit (1) which is connected with the breathing loop (2) and controls the opening and closing of air sucking branch line and air exhaling branch line; an air course pressure sensor (7) which is installed in the breathing loop (2) for measuring the pressure of air course, wherein the breathing loop (2) is also provided with an environment pressure sensor (5). The environment pressure sensor (5) is used for detecting the environment pressure in condition of normal use. The environment pressure (5) is used for measuring the air course pressure roughly when the air course pressure sensor (7) is generated with a failure. The air course system according to the invention and the using method thereof guarantee the normal continuous using of breathing system when the air course pressure sensor has a failure and can not detect the air course pressure thereby ensuring the safety of patient.

Owner:BEIJING AEONMED

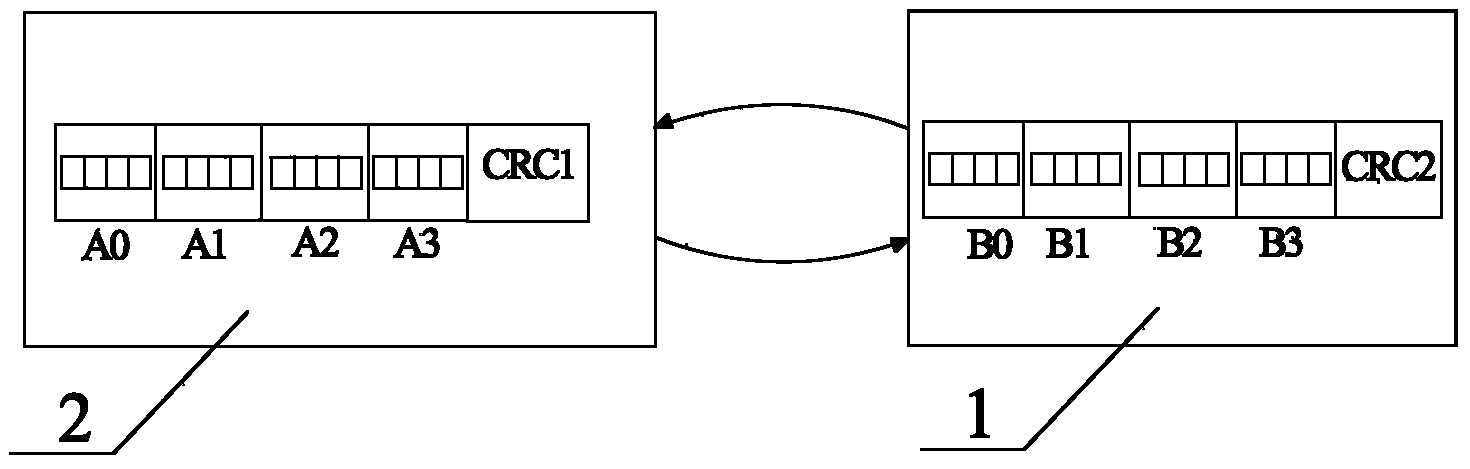

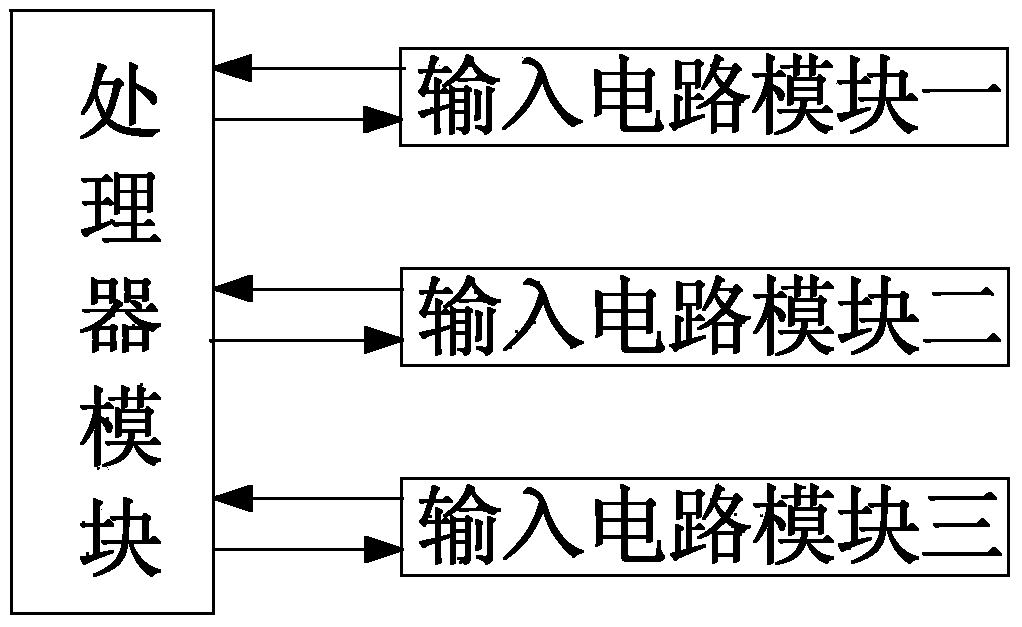

Signal collecting method based on safe input system and system of signal collecting method

ActiveCN103760801AGuaranteed accuracyAssurance controlProgramme controlComputer controlEngineeringExcitation signal

The invention discloses a signal collecting method based on a safe input system and the system of the signal collecting method. In a rail transportation system, input signals are collected through an input circuit module and output to a processor module. As a plurality of input signal modules are arranged, in order to avoid aliasing of the signals, the return checking end of the input circuit module is used for comparing return checking signals and stimulus signals, the input signals and the stimulus signals generated by the processor module are superimposed to generate the return check signals, and whether the input signals are correct is judged. The input signals and the corresponding stimulus signals respectively have two code bits at least, each code bit at least has two code distances, aliasing of the signals of adjacent channels is avoided by increasing the code distances of the code bits, correctness of the collected signals is guaranteed, and mistaken collection of the signals is avoided. It is guaranteed that in the rail transportation system, the signals are accurately controlled and a train is normally scheduled when the train operates, and normal operation of the train is guaranteed.

Owner:浙江众合科技股份有限公司

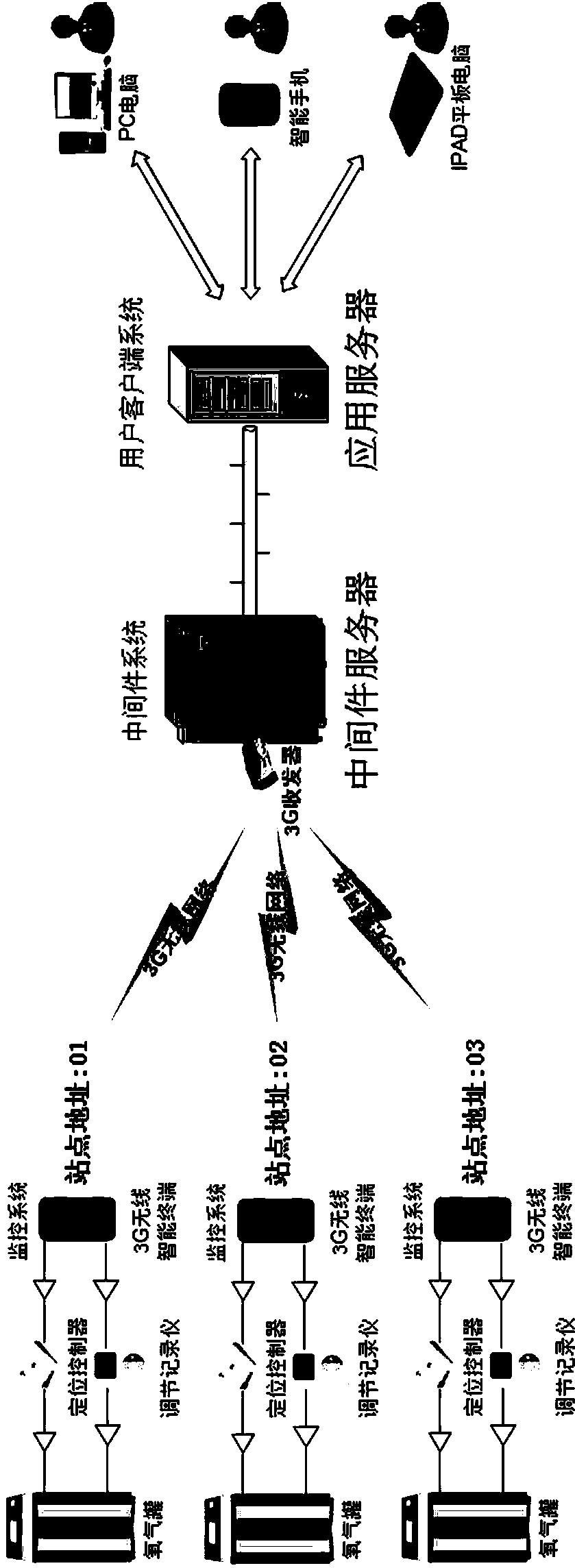

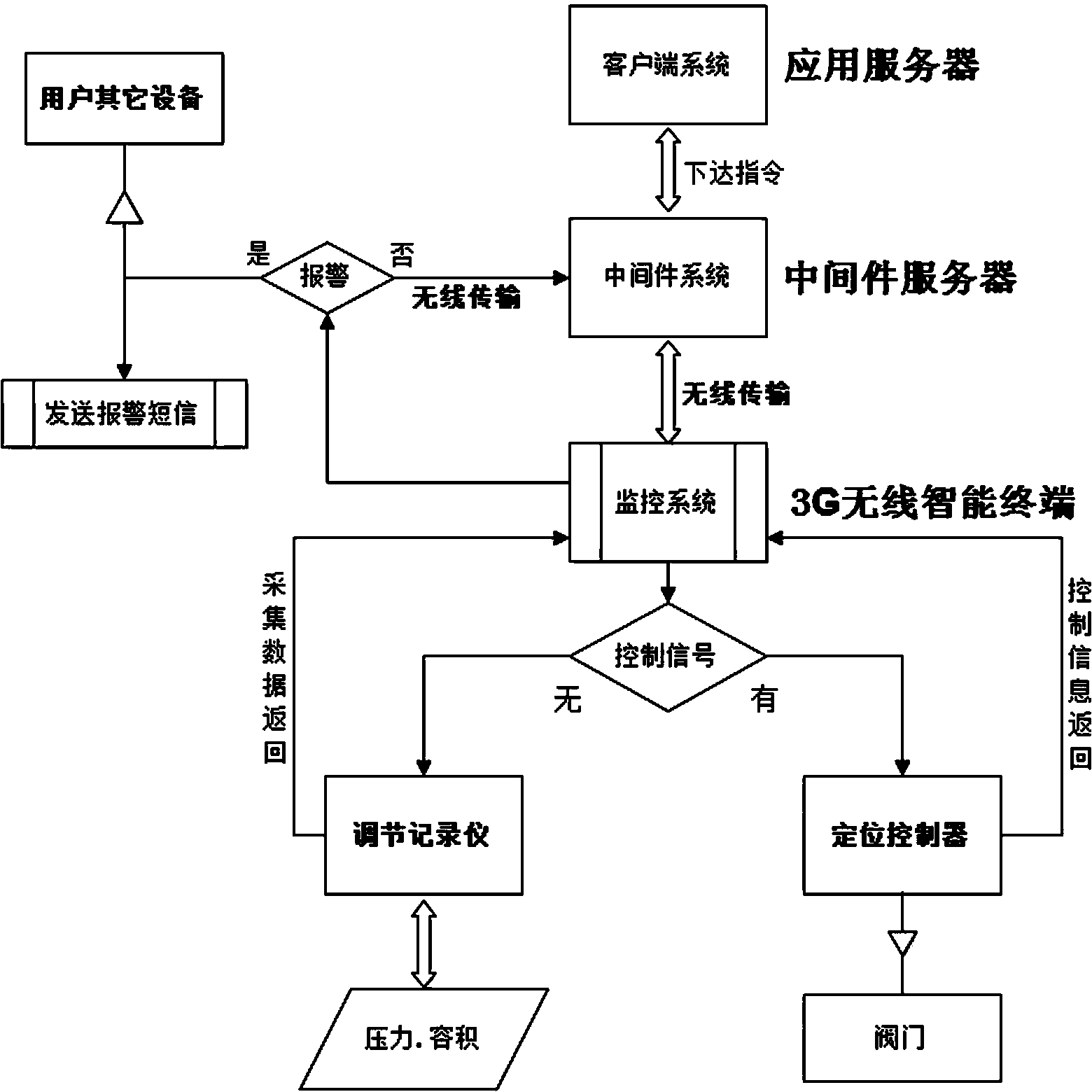

Wireless intelligent terminal based remote wireless monitoring method for oxygen stations

ActiveCN104077909ALow costShort implementation periodTransmission systemsContainer filling methodsApplication serverMonitoring system

The invention discloses a wireless intelligent terminal based remote wireless monitoring method for oxygen stations. The remote wireless monitoring method is realized by adopting an intelligent terminal based remote wireless monitoring system for the oxygen stations; the system comprises a client, an application server and a middleware server, as well as a plurality of intelligent terminals, adjusting recording meters and positioning controllers which are distributed on the oxygen stations, wherein the client is connected with the application server through the Internet; the application server is connected with the middleware server through the Internet; the middleware server is wireless connection with the intelligent terminals of the oxygen stations respectively; the intelligent terminals of the oxygen stations are connected with the adjusting recording meters and the positioning controllers through connecting wires respectively. The remote wireless monitoring method aims at cost reduction, efficiency increase, environmental protection and energy conservation, and is more complete in functions, more humanized and more diversified.

Owner:CHONGQING IRON & STEEL GRP ELECTRONIC CO LTD

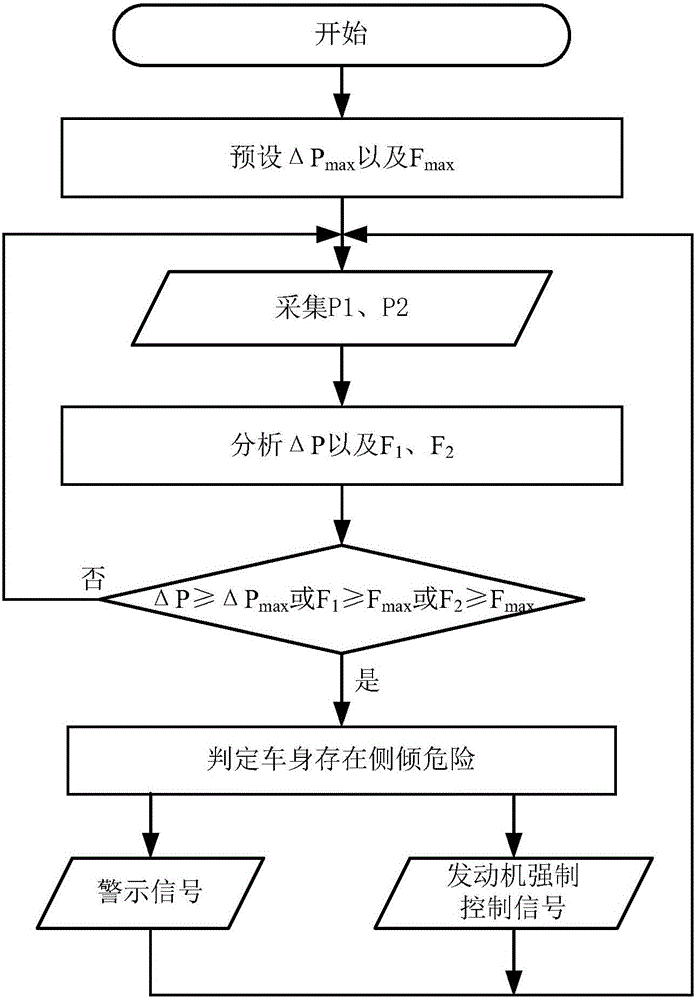

Passenger-car rollover early-warning method based on tire pressure monitoring

InactiveCN105856980ALittle monitoring dataAvoid driving fastTyre measurementsSignalling/lighting devicesRolloverTire pressure

A passenger car rollover warning method based on tire pressure monitoring. First, the tire pressure P1 and P2 of the tires on both sides of the front axle of the car are collected in real time; a maximum absolute value ΔP of the tire pressure difference between the two sides is preset. max And the maximum rate of change of tire pressure F max ;Real-time monitoring and statistics of the tire pressure of the tires on both sides, and analyze the real-time absolute value of the pressure difference ΔP=|P1‑P2|, and the change rate F of the tire pressure of the tires on both sides 1 = dp / dt, F 2 =dp / dt; judgment ΔP≥ΔP max , F 1 ≥F max and F 2 ≥F max , when ΔP≥ΔP max or F 1 ≥F max or F 2 ≥F max Then it is determined that there is a danger of the vehicle body rolling, and at the same time a warning signal and an engine compulsory control signal are output.

Owner:JIANGXI KAMA BONLUCK BUSINESS BUS

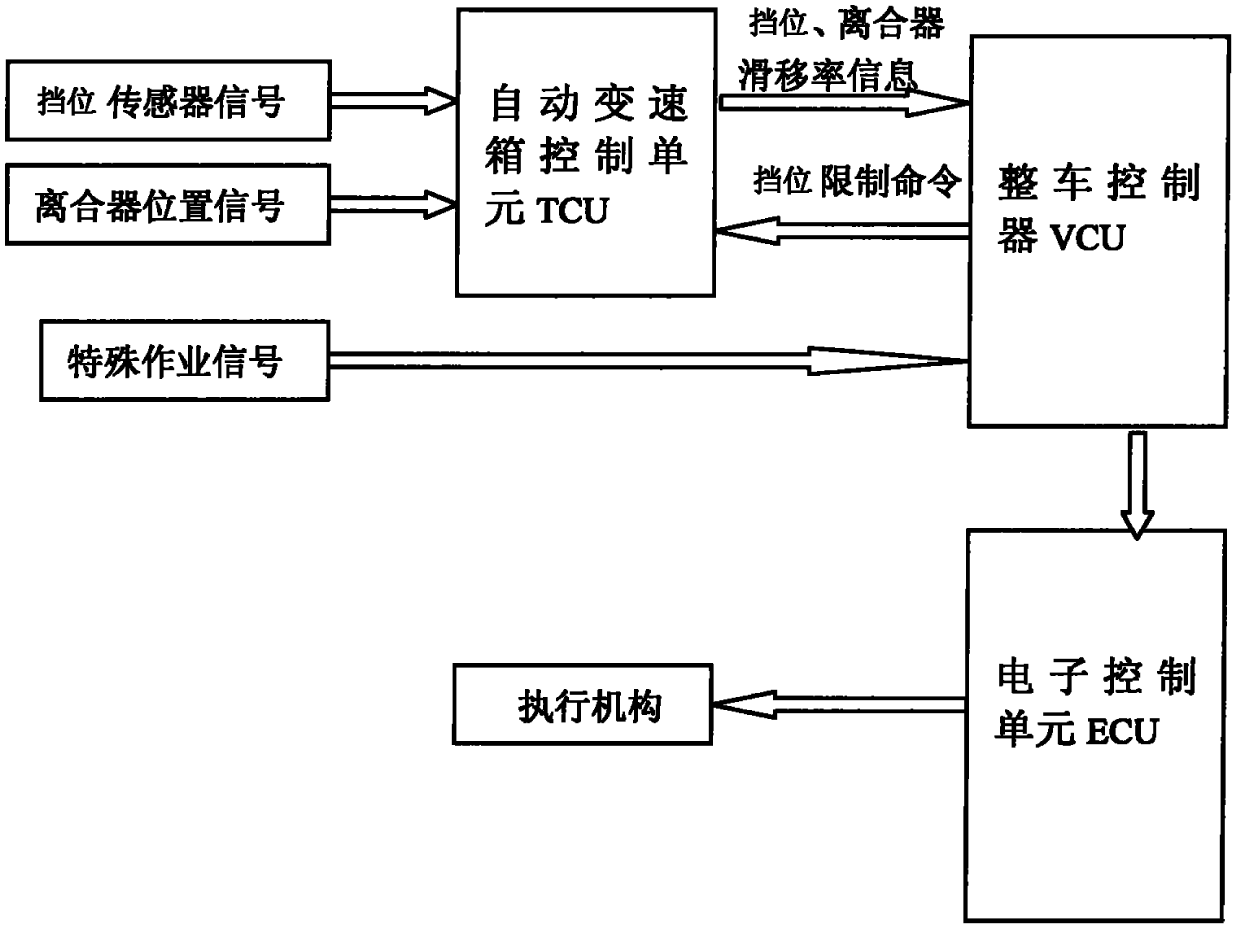

A method for controlling the speed limit of amt vehicles

The invention discloses a control method for speed limit of an AMT (Automatic Mechanical Transmission) type vehicle. The control method comprises the following steps that: a. an automatic TCU (Transmission Control Unit) receives a current gear signal, an engine revolution speed signal and a clutch slip ratio signal detected by a sensor, and transmits the signals and a determined driving chain combination state signal to a VCU (Vehicle Control Unit); b. the VCU calculates a maximum gear allowed to be switched and a maximum limit value of the engine revolution speed, real time transmits a command signal to an ECU (Electronic Control Unit) and detects whether the current gear is higher than the allowed maximum gear; c. the VCU transmits a gear-switching request command and reduces the current gear to be the allowed maximum gear; d. the ECU regulating a rail pressure and a fuel injection quantity according to the maximum limit value of the engine revolution speed so as to regulating the engine revolution speed to be lower than the maximum limit value; and e. a vehicle regularly runs. The invention has the beneficial effects of largely reducing the labor strength when effectively improving the safety of a driver.

Owner:SINO TRUK JINAN POWER

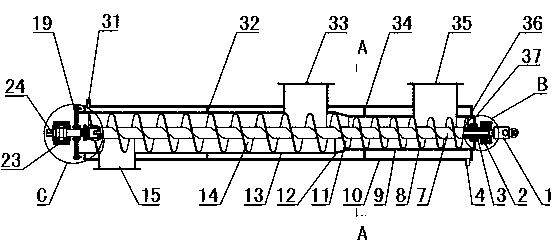

Semi coke waste heat recovery type spiral conveyer

ActiveCN104355071AAvoid dangerous accidentsTo achieve the purpose of full material deliveryStationary tubular conduit assembliesPackagingEngineeringCircular surface

The invention discloses a semi coke waste heat recovery type spiral conveyer, and belongs to the field of semi coke processing equipment. An inner cylinder body includes two or more inner cylinder body sections, a feeding port is communicated with the upper side at the conveying starting end of each inner cylinder body section, and a discharging port (15) is communicated with the lower side at the tail end of the last inner cylinder body section; the volume defined by a pitch screw blade of the N+1th inner cylinder body section, the external circular surface of a spiral base tube (7) and the internal circular surface of the N+1th inner cylinder body section is (N+1) / N plus or minus 1 / 5N times of the volume defined by a pitch screw blade inside the Nth inner cylinder body section, the external circular surface of the spiral base tube (7) and the internal circular surface of the Nth inner cylinder body section, wherein the N is an integer not smaller than 1 and not greater than 5. According to the invention, the fact that after semi coke inside the inner cylinder body section on the front side enters the inner cylinder body section on the rear side, semi coke at the feeding port of the inner cylinder body section on the rear side enters the inner cylinder body section on the rear side, and all the inner cylinder body sections are filled with material exactly is guaranteed, so that filled conveying is realized, and danger of gas leakage can be effectively avoided.

Owner:SHANDONG UNIV OF TECH

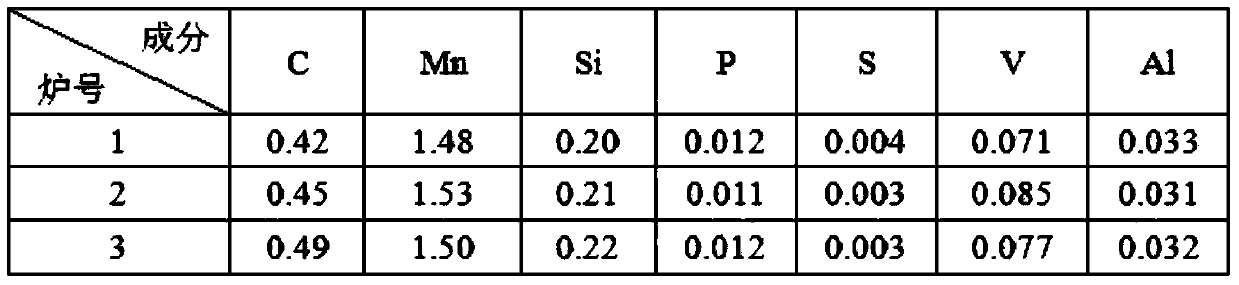

High-strength steel for metallurgical saw blades and heat treatment method thereof

InactiveCN104178691AAppropriate strengthAppropriate hardnessFurnace typesProcess efficiency improvementEnvironmental resistanceImpurity

The invention relates to a high-strength steel for metallurgical saw blades and a heat treatment method thereof, belonging to the technical field of medium-carbon low-alloy steel. The steel for metallurgical saw blades comprises the following chemical components: 0.30-0.60% of C, 0.15-0.30% of Si, 1.35-1.9% of Mn, at most 0.02% of P, at most 0.005% of S, 0.07-0.19% of V, 0.025-0.055% of Al, and the balance of Fe and inevitable impurities. The heat treatment method comprises the following steps: smelting, carrying out continuous casting, carrying out hot rolling to obtain a plate, quenching the plate, and carrying out tempering heat treatment to obtain the steel for metallurgical saw blades. By utilizing the off-line or on-line quenching+tempering heat treatment technique and using water as the quenching medium, the method has the characteristics of low cost, favorable hardenability, high efficiency, uniform hardness and the like, and is beneficial to environmental protection; and by matching with the appropriate chemical component design, the method can ensure the requirements for high hardness and high toughness, simplifies the production technique of the saw blade, shortens the production process and lowers the energy consumption.

Owner:SHOUGANG CORPORATION

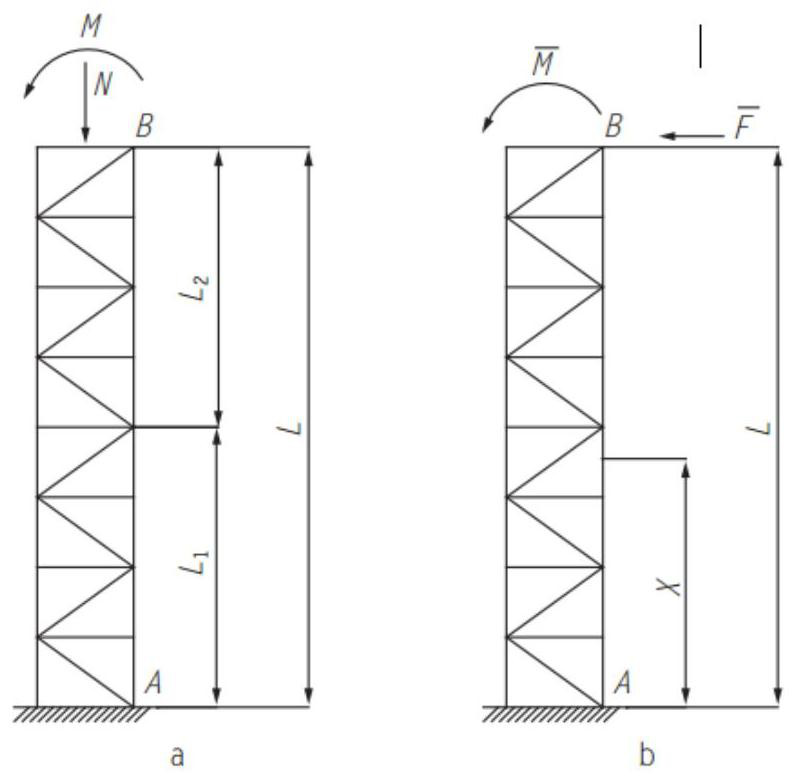

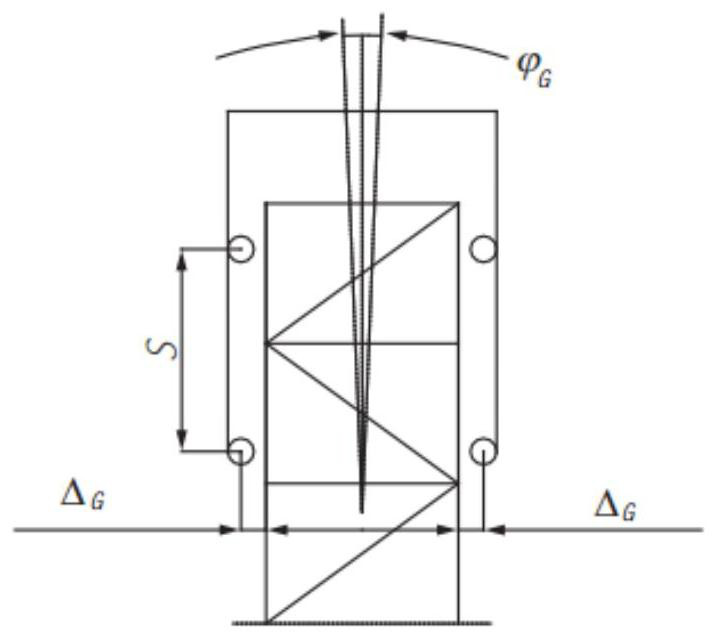

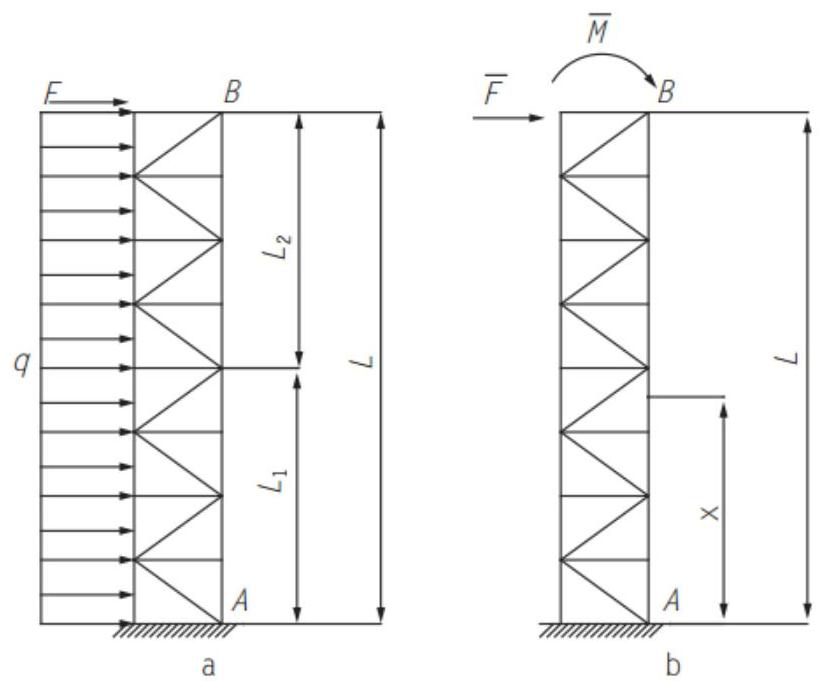

Safety monitoring method and system for tower crane jacking system

ActiveCN111891951AImprove securityExtended service lifeTotal factory controlCranesSystem safetyDynamic monitoring

The invention belongs to the technical field of tower crane control information processing and discloses a safety monitoring method and system for a tower crane jacking system. Inclination state analysis and numerical simulation of the jacking system under a wind load, jacking sleeve frame numerical simulation modeling and analysis under multiple loads, jacking sleeve frame contact equilibrium dynamic detection and regulation thereof, and reliability assessment and a fault diagnosis method of the tower crane hydraulic jacking system are included. According to the safety monitoring method and system, sleeve frame contact equilibrium state detection technology of the tower crane jacking system under variable loads is analyzed, and real-time monitoring and early warning of an equipment operation state can be achieved. Dynamic characteristics analysis and operation stability enhancement technology of the tower crane jacking hydraulic system is analyzed, dangerous accidents can be avoided,and the service life of a tower crane can be prolonged. Reliability assessment and fault diagnosis technology of the tower crane jacking system is analyzed, and operation safety of the tower crane inan installation / disassembly link can be ensured effectively. Through the safety monitoring method and system, the stress condition analysis and dynamic monitoring problems of the sleeve frame under the operation condition of a jacking mechanism are solved.

Owner:丽水市特种设备检测院

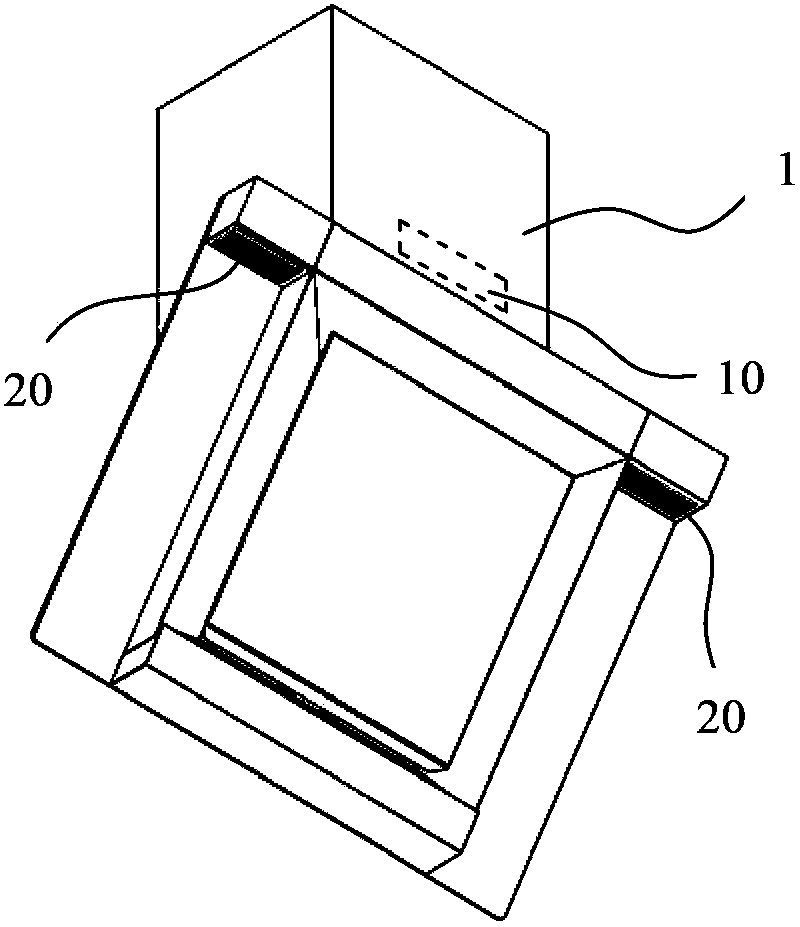

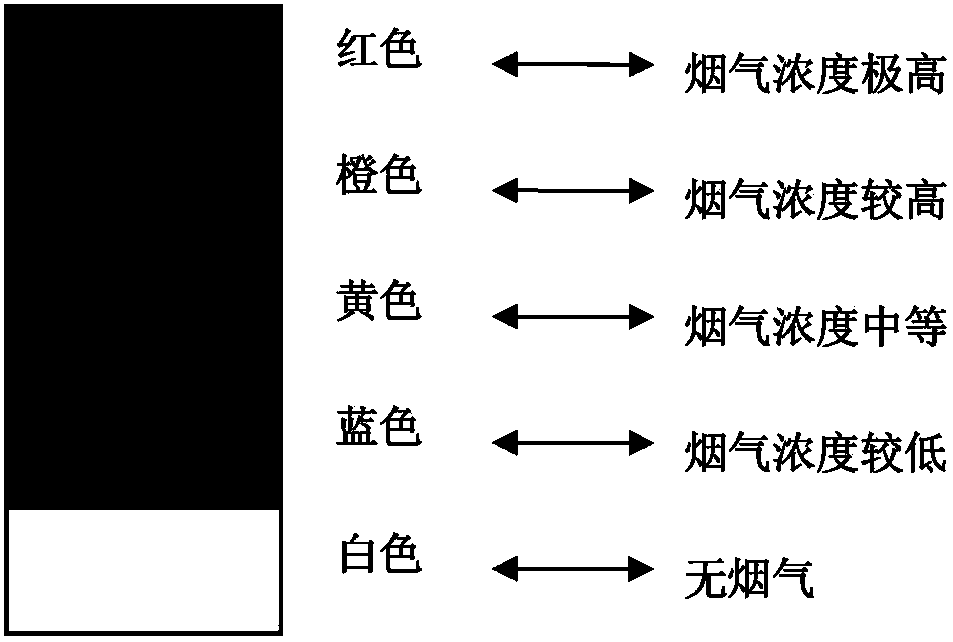

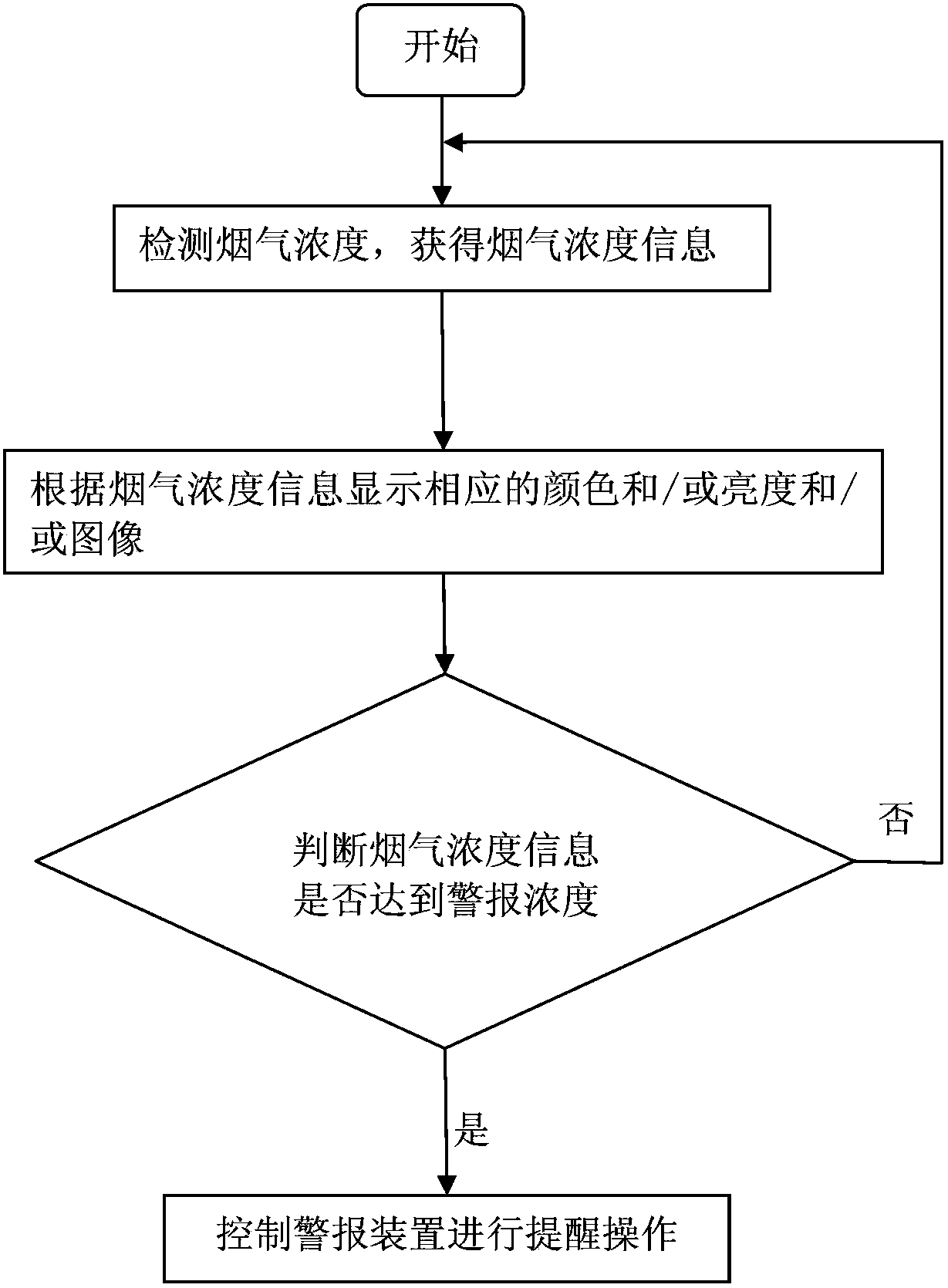

Smoke exhaust ventilator and control method thereof

InactiveCN103900131AAvoid dangerous accidentsDomestic stoves or rangesLighting and heating apparatusProcess engineeringGas concentration

Owner:BSH ELECTRICAL APPLIANCES JIANGSU

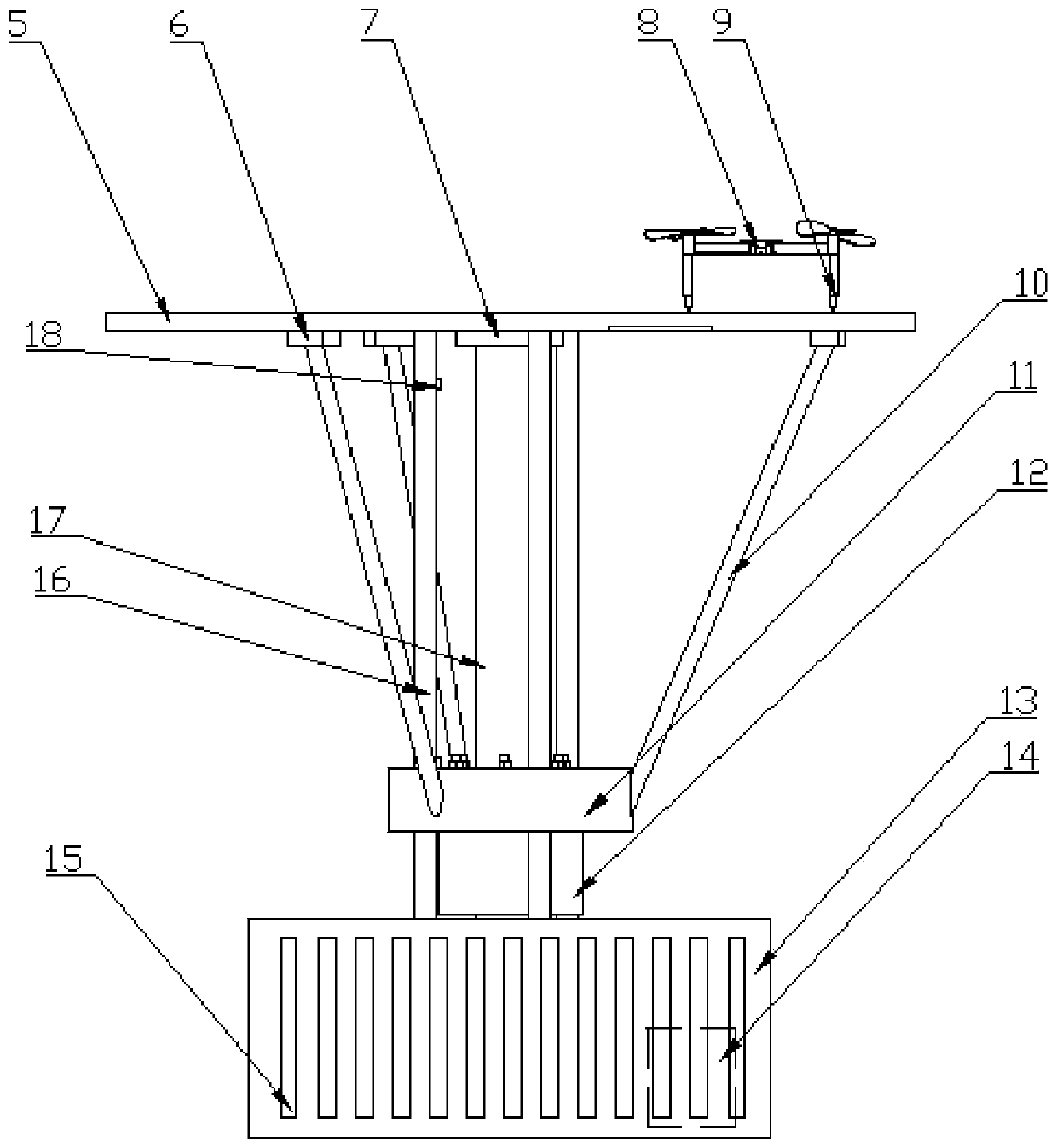

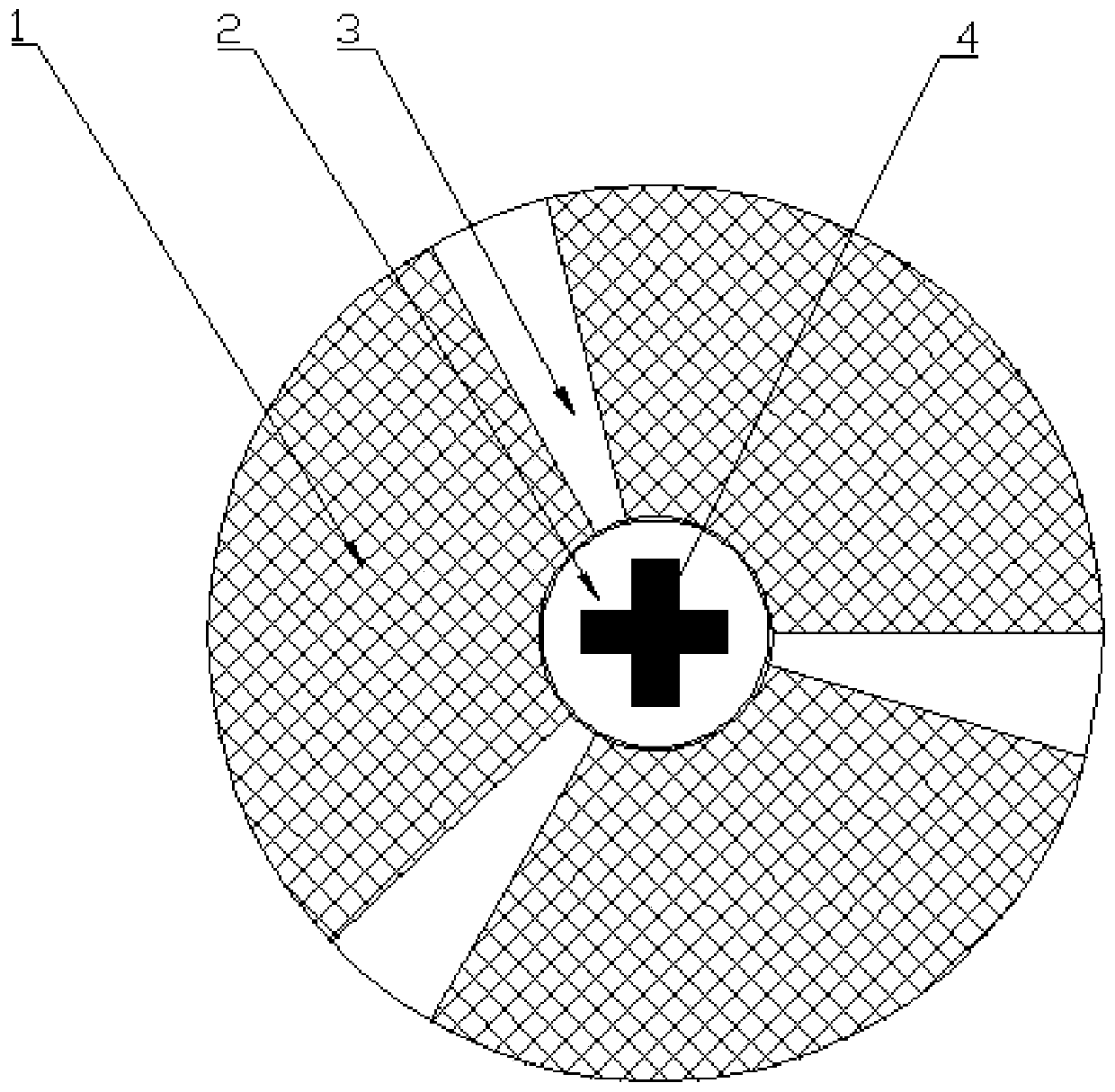

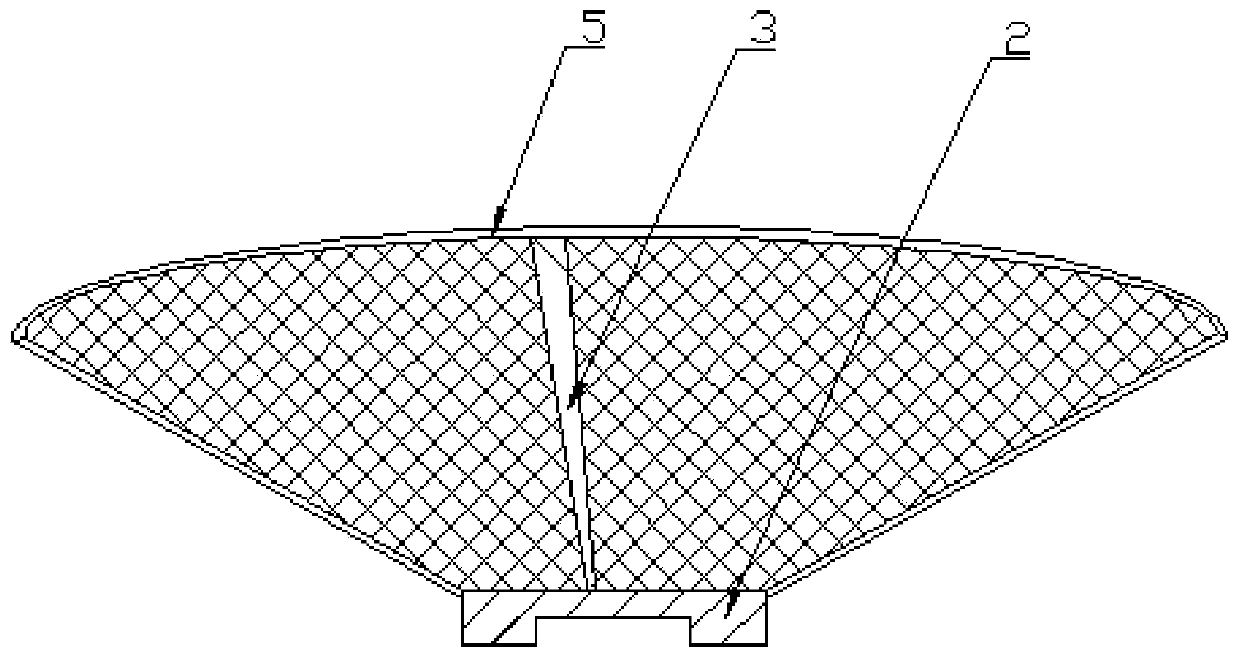

Umbrella-like automatic centering and charging device for unmanned aerial vehicle

PendingCN110729778ARealize chargingSolve the problem of not being able to reach the designated location for chargingBatteries circuit arrangementsPhotovoltaicsUncrewed vehicleStress sensors

The invention discloses an umbrella-like automatic centering and charging device for an unmanned aerial vehicle. The device comprises an unmanned aerial vehicle take-off and landing supporting frame (9), a parking apron charging structure and a main controller.; the unmanned aerial vehicle take-off and landing supporting frame (9) is provided with four supporting legs; the bottom end of each supporting leg is connected with a universal wheel; a positioning device (8) is arranged at the bottom of the unmanned aerial vehicle; the parking apron charging structure comprises a parking apron (5), acentral charging platform (2) and a charging device; the parking apron (5) is divided into three fan-shaped plates; a pressure sensor is arranged on the surface of the parking apron (5); and the pressure sensor is connected with the main controller; the central charging platform (2) is connected with the charging device; the central charging platform (2) is of a columnar structure; the three fan-shaped plates are hinged and fixed to the central charging platform (2); and the fan-shaped plates of the parking apron can be unfolded into a plane or folded into an umbrella-shaped structure with anupward opening through a telescopic mechanism, so that the unmanned aerial vehicle can be centered and charged. The umbrella-like automatic centering and charging device is compact in structure, is capable of effectively collecting, centering and charging unmanned aerial vehicles and has high working efficiency.

Owner:SHENYANG AEROSPACE UNIVERSITY

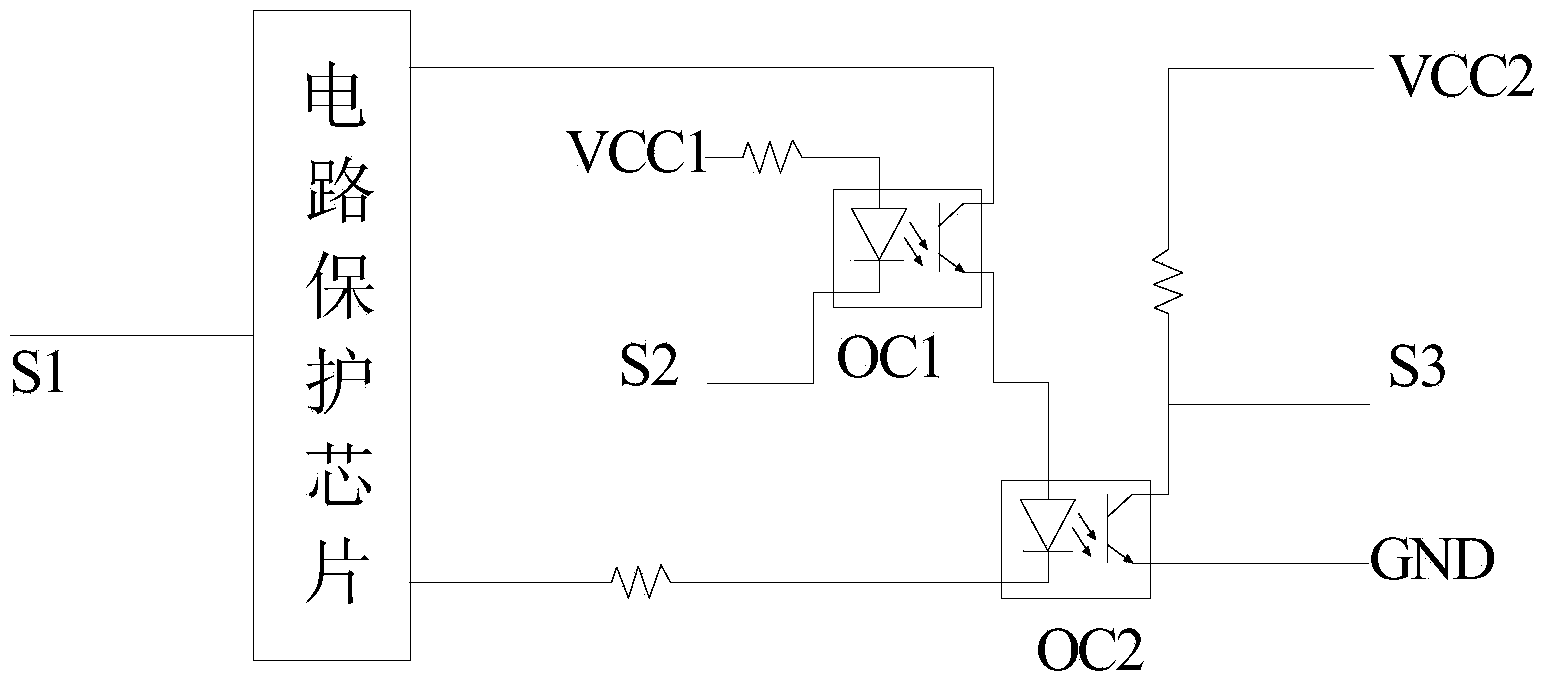

Intelligent construction safety power consumption system and method

The invention discloses an intelligent construction safety power consumption system and method. The intelligent construction safety power consumption system comprises a primary power distribution box and a secondary power distribution box subordinate to the primary power distribution box. The secondary power distribution box is electrically connected with various kinds of electric equipment. A tail-end circuit of the primary power distribution box, a tail-end circuit of the secondary power distribution box and tail-end circuits of the electric equipment are each provided with a power consumption information collection circuit. When an intelligent control terminal transmits power consumption information, information of the corresponding equipment is sent synchronously; due to the fact that an access control system, a power consumption protection device and an illumination circuit voltage monitoring device are arranged, construction power consumption safety is ensured. According to the intelligent construction safety power consumption system and method, the intelligent power consumption management is comprehensively achieved, active management is carried out, the monitoring loophole caused by manual passive management is overcome, and the accident rate is decreased.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD QUZHOU POWER SUPPLY CO +3

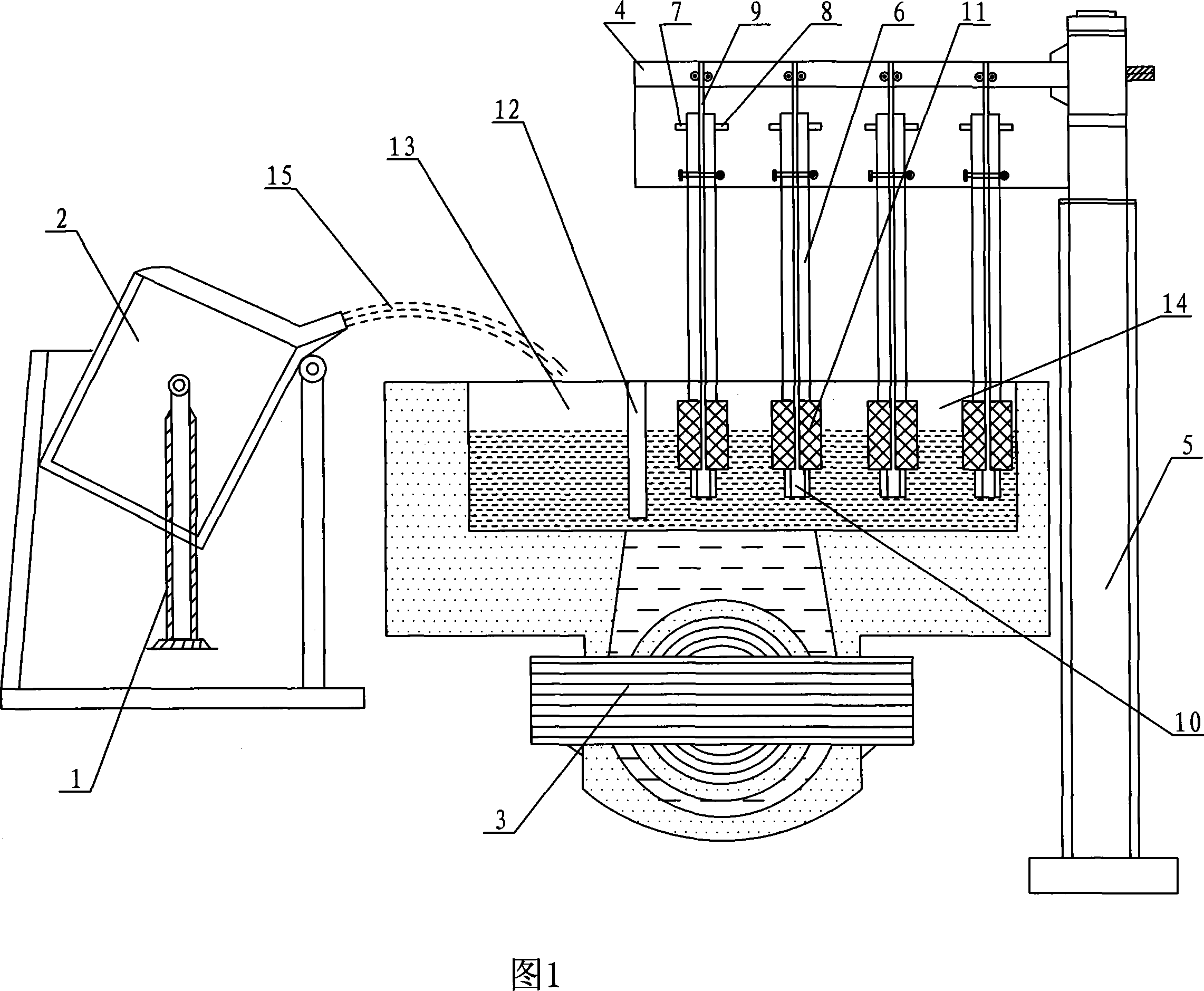

Upper-drawing casting device for the silicon bronze bar blank

The invention discloses an up-drawing casting device for silicon bronze bar billet, comprising a smelter positioned on the landing control device. A side face of the smelter is provided with a power frequency furnace with an iron core, the upper surface of the power frequency furnace with an iron core is provided with a plurality of drawing devices which are positioned on a rolling crane. The drawing devices are provided with a crystallizer, the upper end of which is provided with a water inlet port and a water outlet port respectively. The dummy bars of the drawing devices are arranged through and in the crystallizer. The lower end of the crystallizer is provided with a graphite mould. The outside of the connection of the graphite mould and the crystallizer is provided with graphite protecting jacket. The invention has the advantages that the casting temperature of the up-drawing casting device for silicon bronze bar billet is low, the drawing speed is fast, the productivity effect is high, the grain of silicon bronze bar billet produced by the invention is uniformity and the production safety is good, thereby avoiding the dangerous accidents in operation.

Owner:GAOXIN ZHANGTONG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com