Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3013 results about "Friction welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

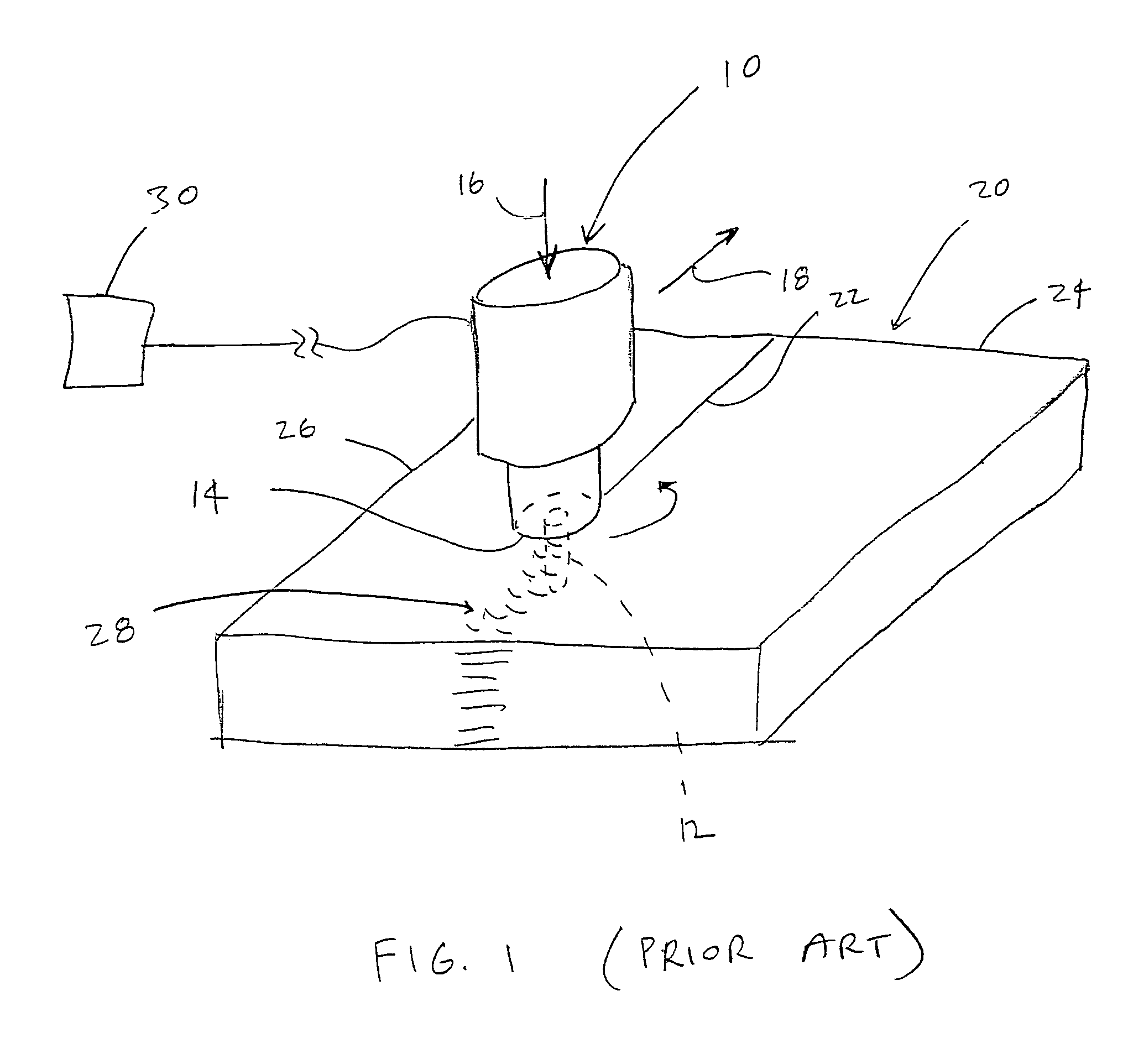

Friction welding (FRW) is a solid-state welding process that generates heat through mechanical friction between workpieces in relative motion to one another, with the addition of a lateral force called "upset" to plastically displace and fuse the materials. Because no melting occurs, friction welding is not a fusion welding process in the traditional sense, but more of a forge welding technique. Friction welding is used with metals and thermoplastics in a wide variety of aviation and automotive applications.

Method and apparatus for in-process sensing of manufacturing quality

InactiveUS6857553B1Low costShorten the timeAnalysing solids using sonic/ultrasonic/infrasonic wavesResonant frequencyFriction weldingAcoustics

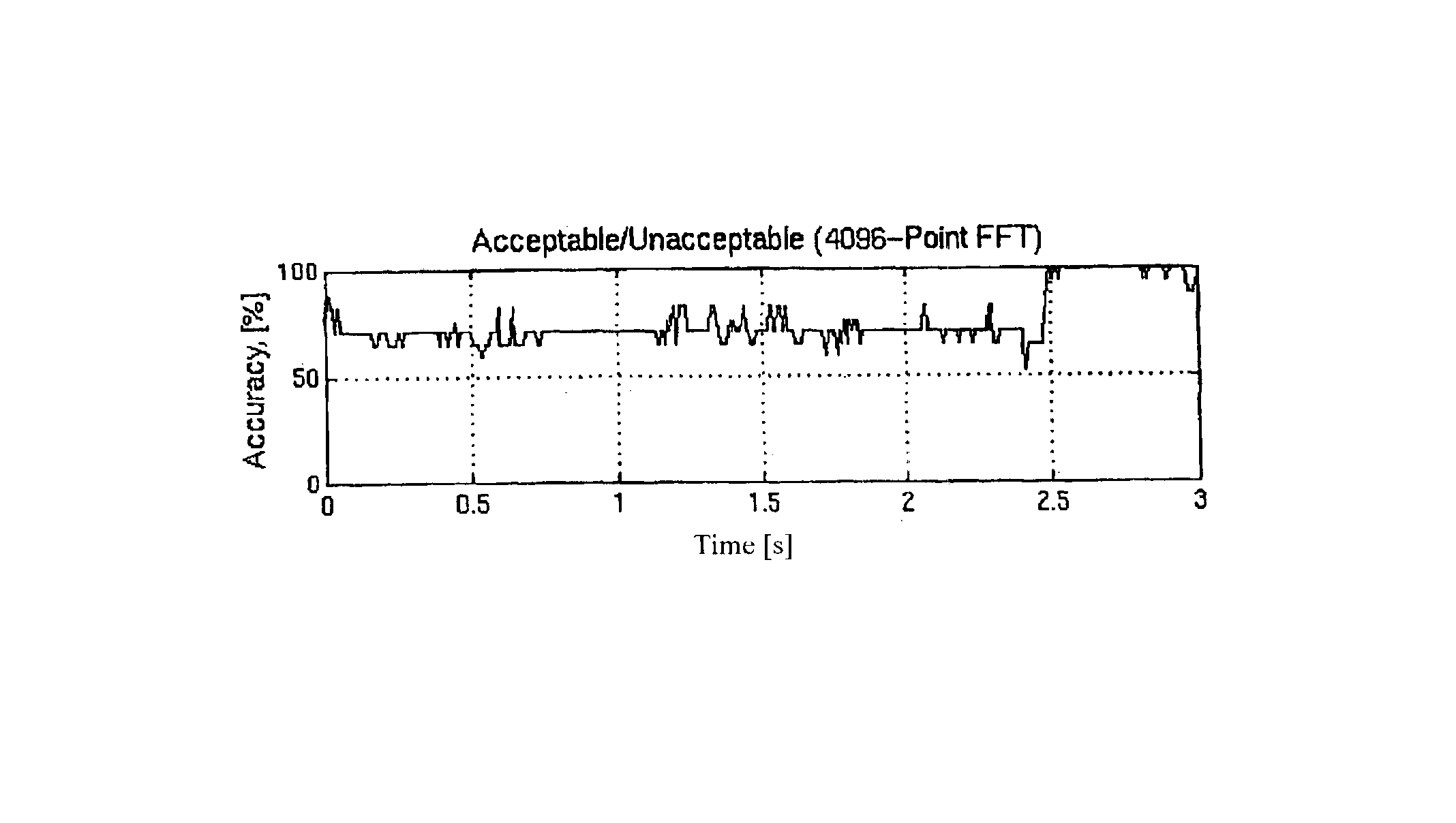

A method for determining the quality of an examined weld joint comprising the steps of providing acoustical data from the examined weld joint, and performing a neural network operation on the acoustical data determine the quality of the examined weld joint produced by a friction weld process. The neural network may be trained by the steps of providing acoustical data and observable data from at least one test weld joint, and training the neural network based on the acoustical data and observable data to form a trained neural network so that the trained neural network is capable of determining the quality of a examined weld joint based on acoustical data from the examined weld joint. In addition, an apparatus having a housing, acoustical sensors mounted therein, and means for mounting the housing on a friction weld device so that the acoustical sensors do not contact the weld joint. The apparatus may sample the acoustical data necessary for the neural network to determine the quality of a weld joint.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

Friction plunge riveting

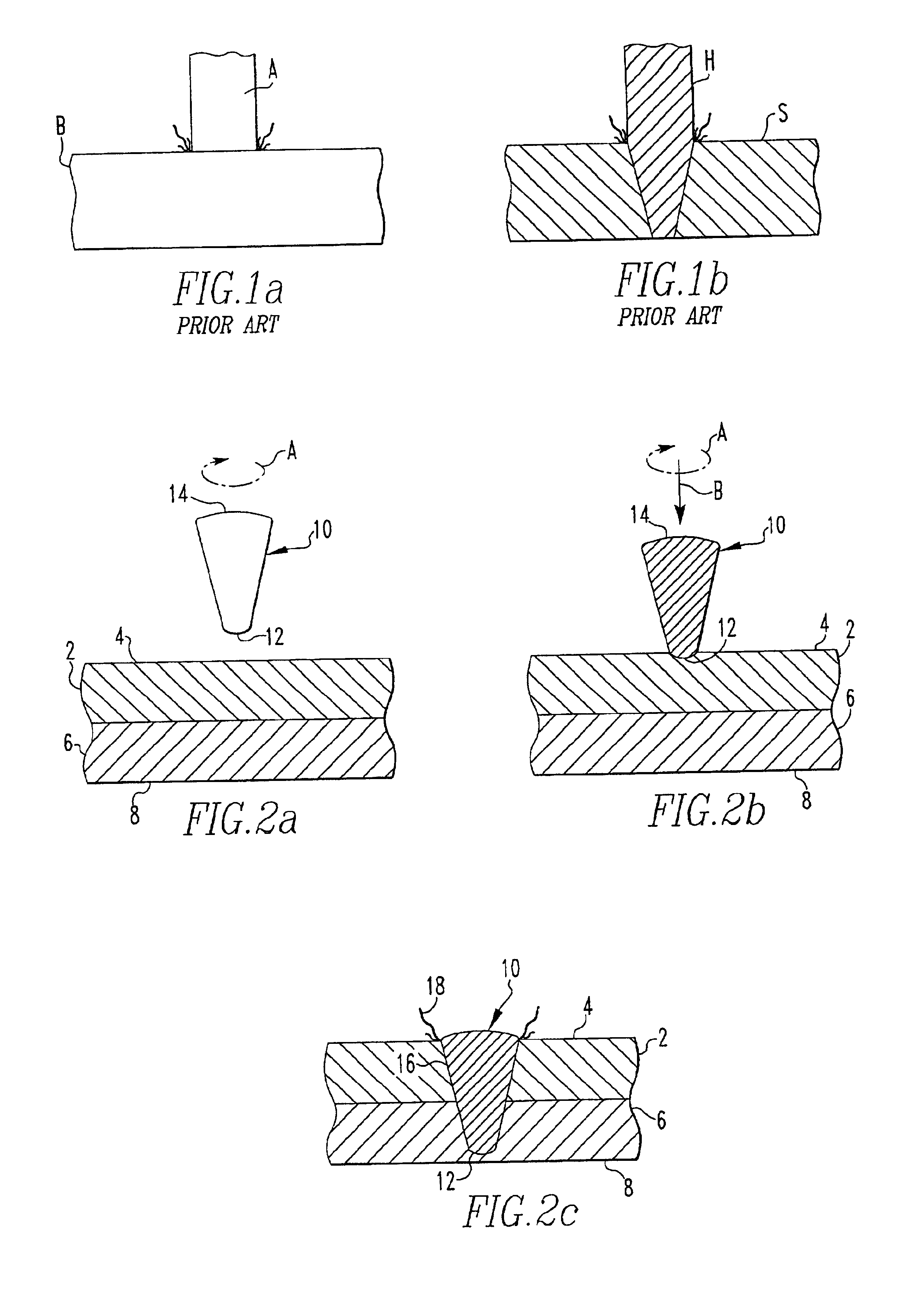

InactiveUS20020125297A1Welding/cutting auxillary devicesAuxillary welding devicesFriction weldingHardness

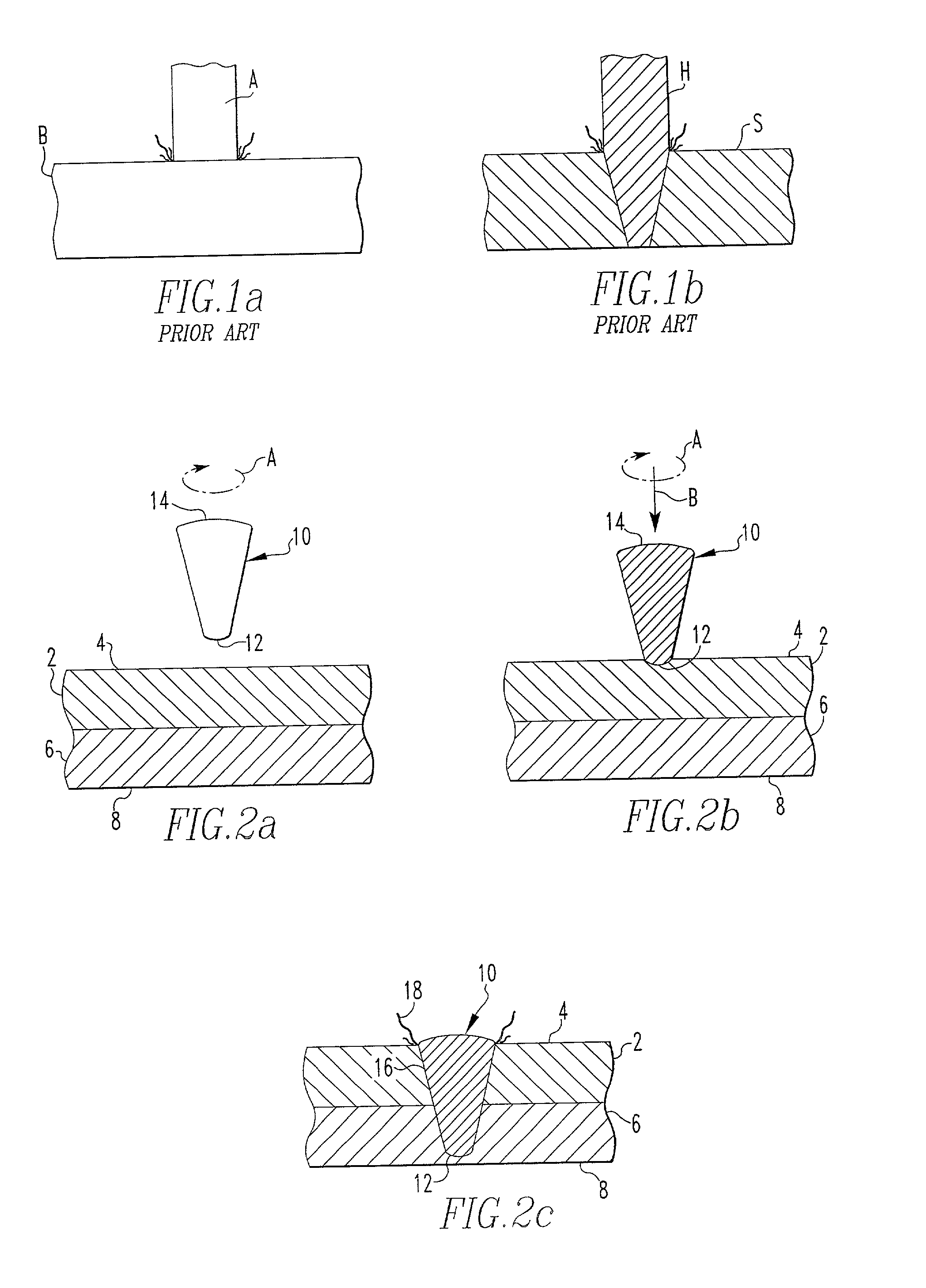

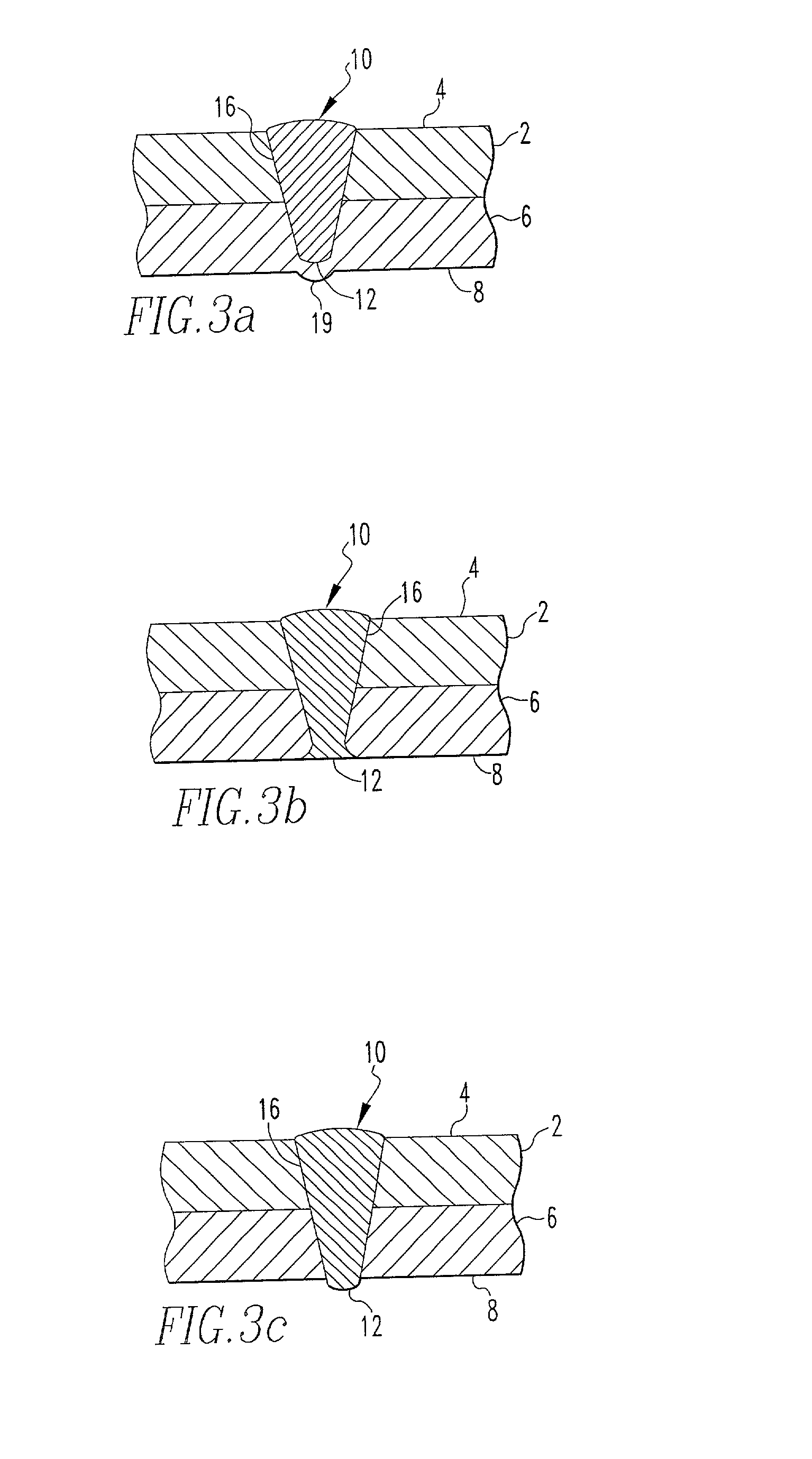

A method of joining a pair of metal components with a rivet having a hardness that is substantially similar to at least one of the metal components. The metal components are stack upon each other and the rivet is rotated and simultaneously plunged in the metal components under pressure to friction weld and metallurgically bond the rivet to the metal components.

Owner:ARCONIC INC

Friction welding metal components

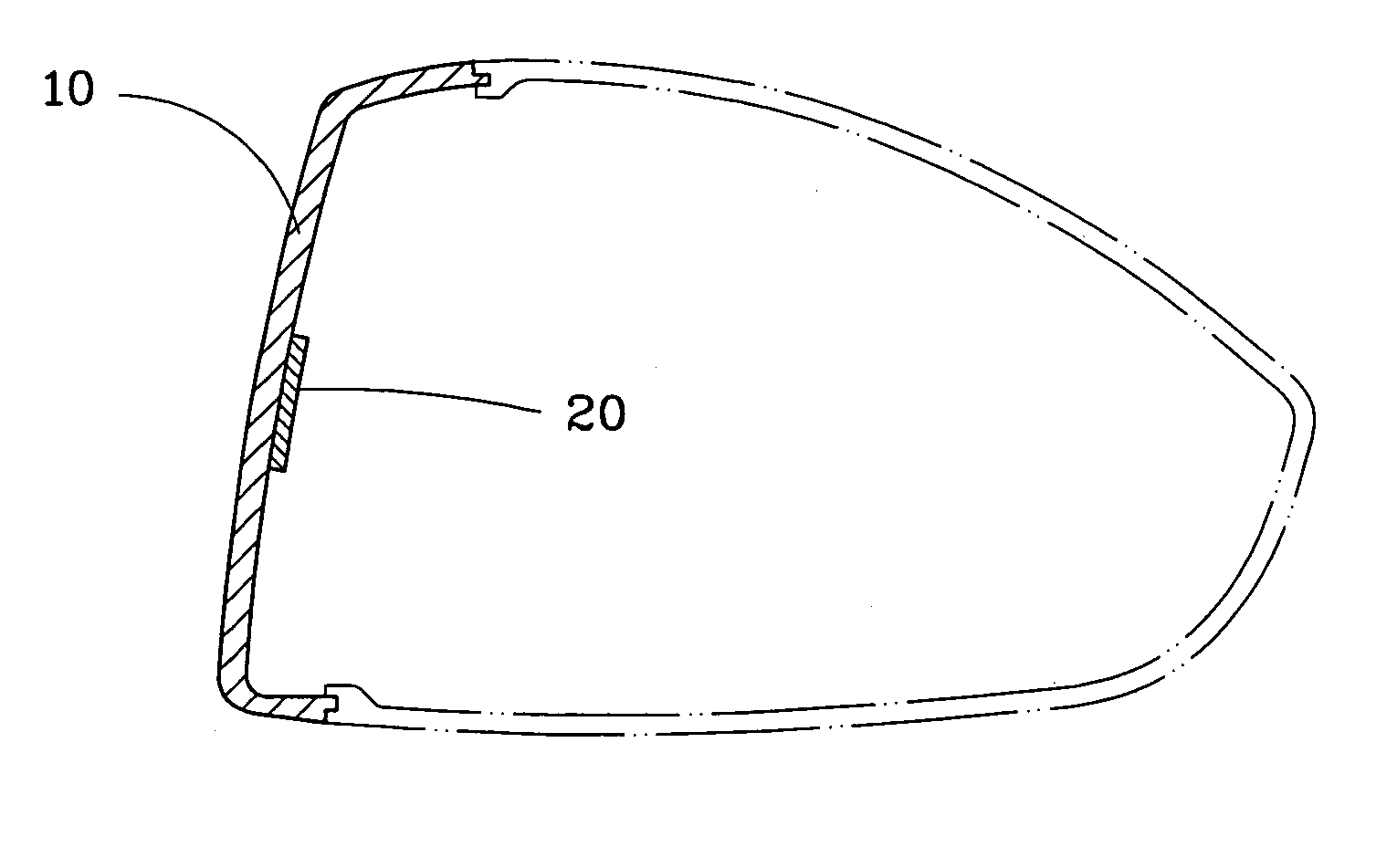

InactiveUS6328261B1Additions can be avoidedPrevent skinFuselage framesWingsFriction weldingButt welding

A method of forming a structural airframe component for an aircraft and an airframe structural component The method includes placing at least two components (1,2) in abutting relationship with each other and joining them together by friction stir butt welding (3), and the structural airframe component comprises a component manufactured according to the method of the invention.

Owner:AIRBUS OPERATIONS LTD

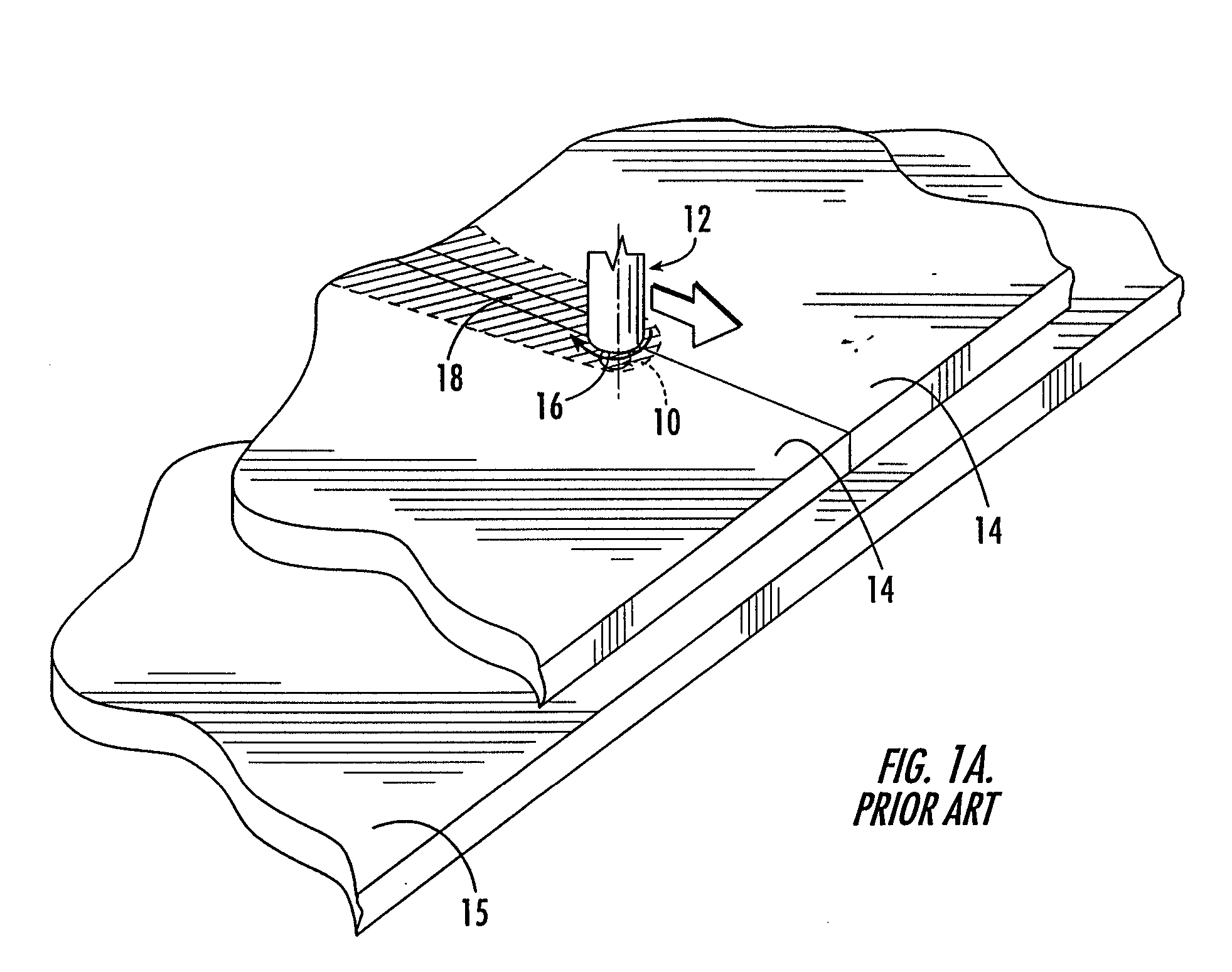

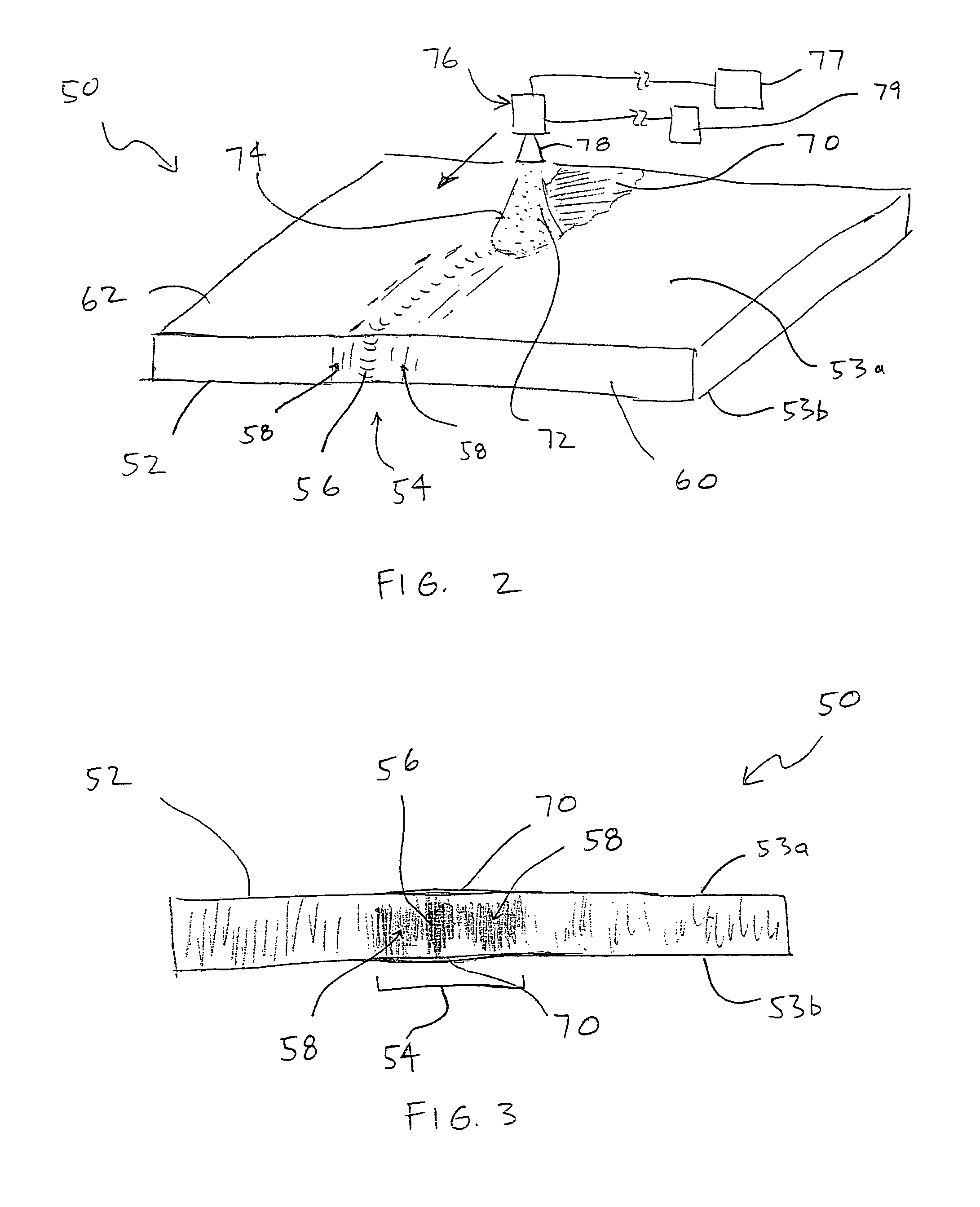

Fabricating low distortion lap weld construction

InactiveUS6247633B1Welding/cutting auxillary devicesAuxillary welding devicesFriction weldingLow distortion

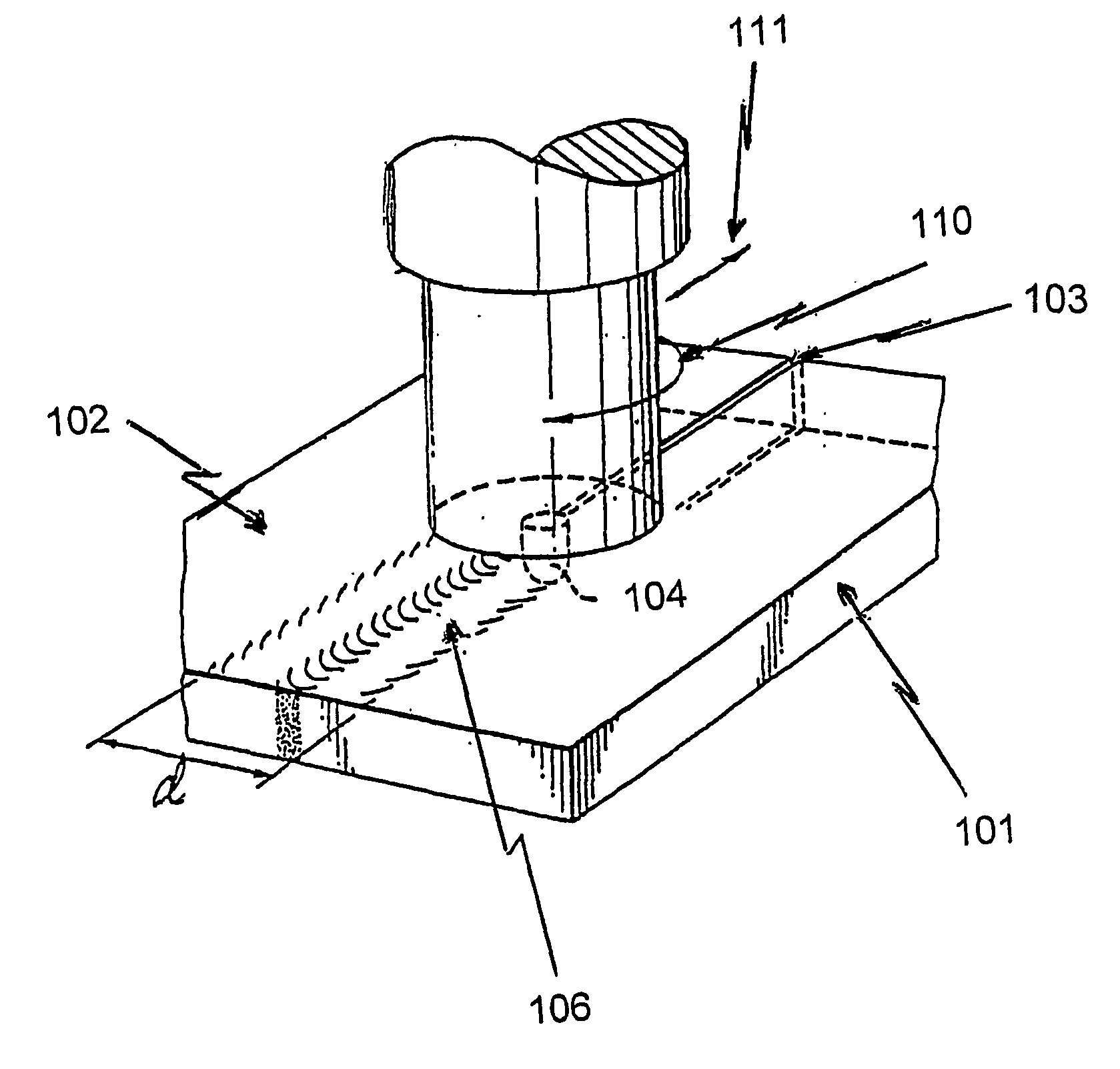

A method of making a low distortion frame construction, the construction having joint regions formed by first and second overlapping members defining a lapped interface, the joint regions being comprised of material that can be converted to a solid state deformable plastic condition by friction heat, comprising: (a) providing a stir friction welding tool having (i) a rotatable thermally conductive body presenting a shoulder to engage the joint region for storing friction-generated heat, and (ii) a friction generating pin rotatable with said body about a pin axis and selectively extendable from the shoulder to progressively penetrate the overlapping members as the joint region in contact with the pin becomes plastic; (b) placing the tool shoulder against the joint region with the pin axis transverse to the lapped interface and spinning the body while progressively extending the pin at a rotational speed effective to generate friction heat that converts the adjacent material of the joint to a plastic condition allowing the spinning of the probe to stir such plastically converted material; and (c) controlling the depth of penetration of the spinning probe while translating the tool across the joint region to perfect a friction stirred welded zone that extends through the interface and between the overlapping members to provide a welded joint that is exceptionally strong in shear.

Owner:FORD GLOBAL TECH LLC +1

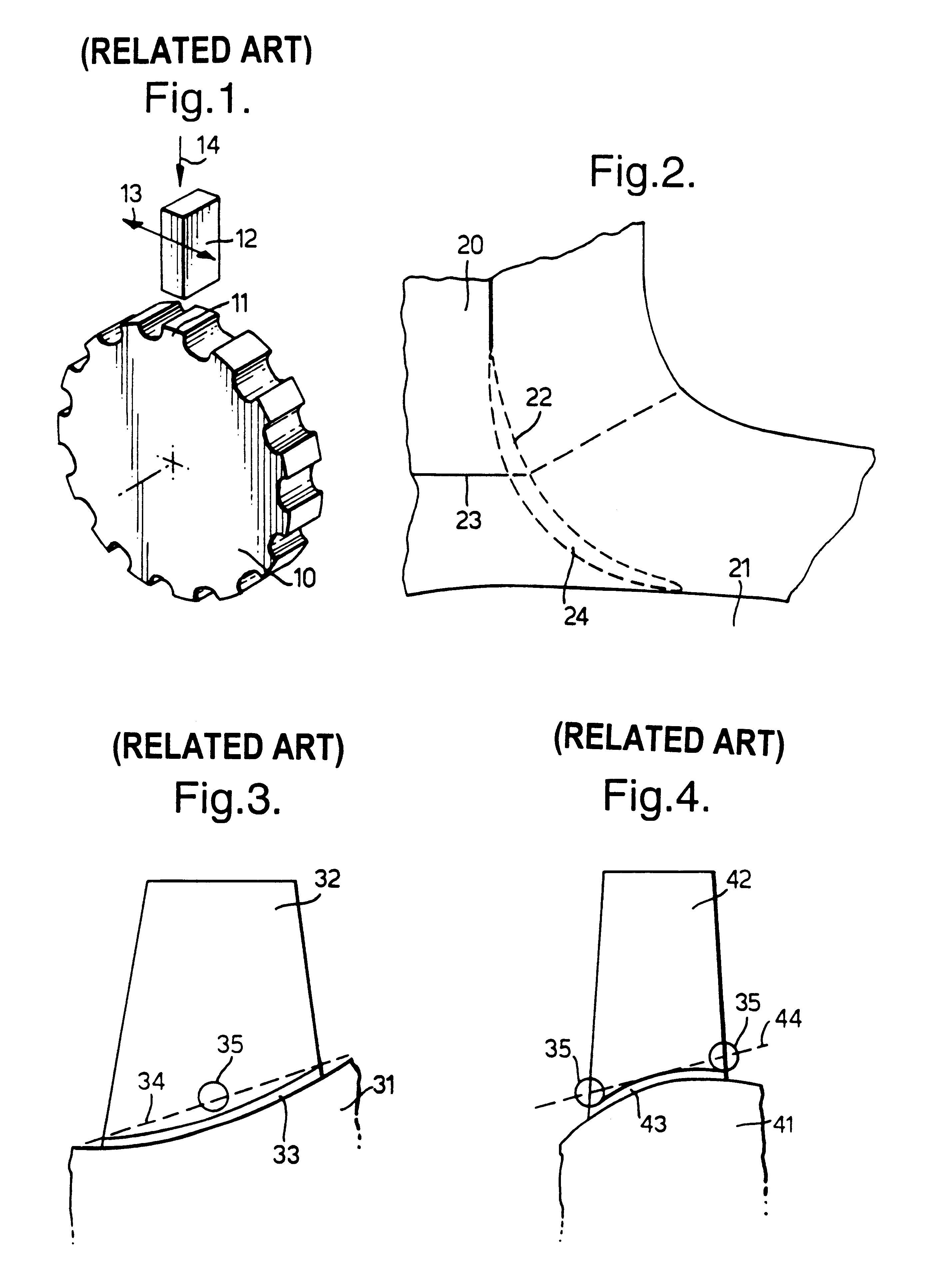

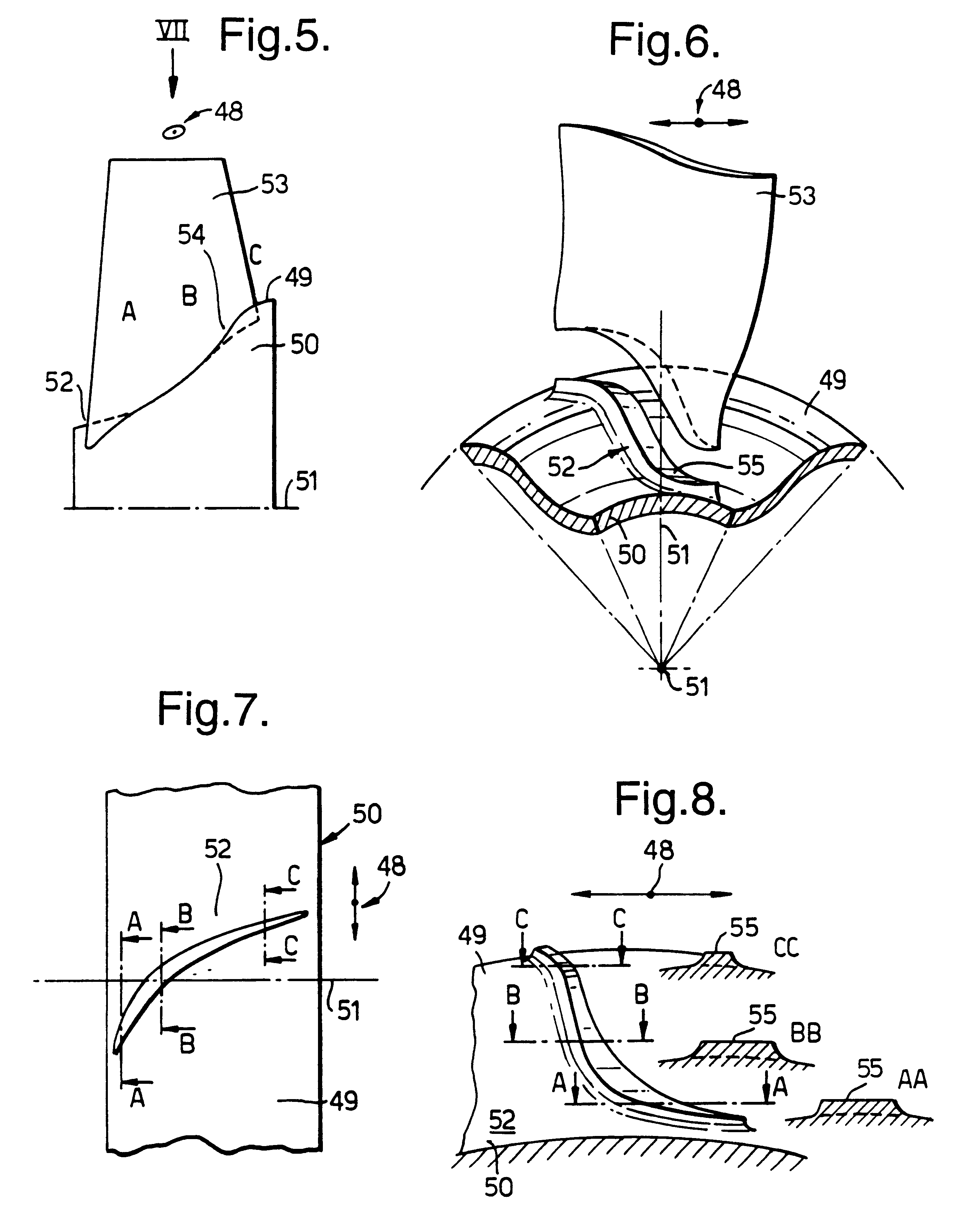

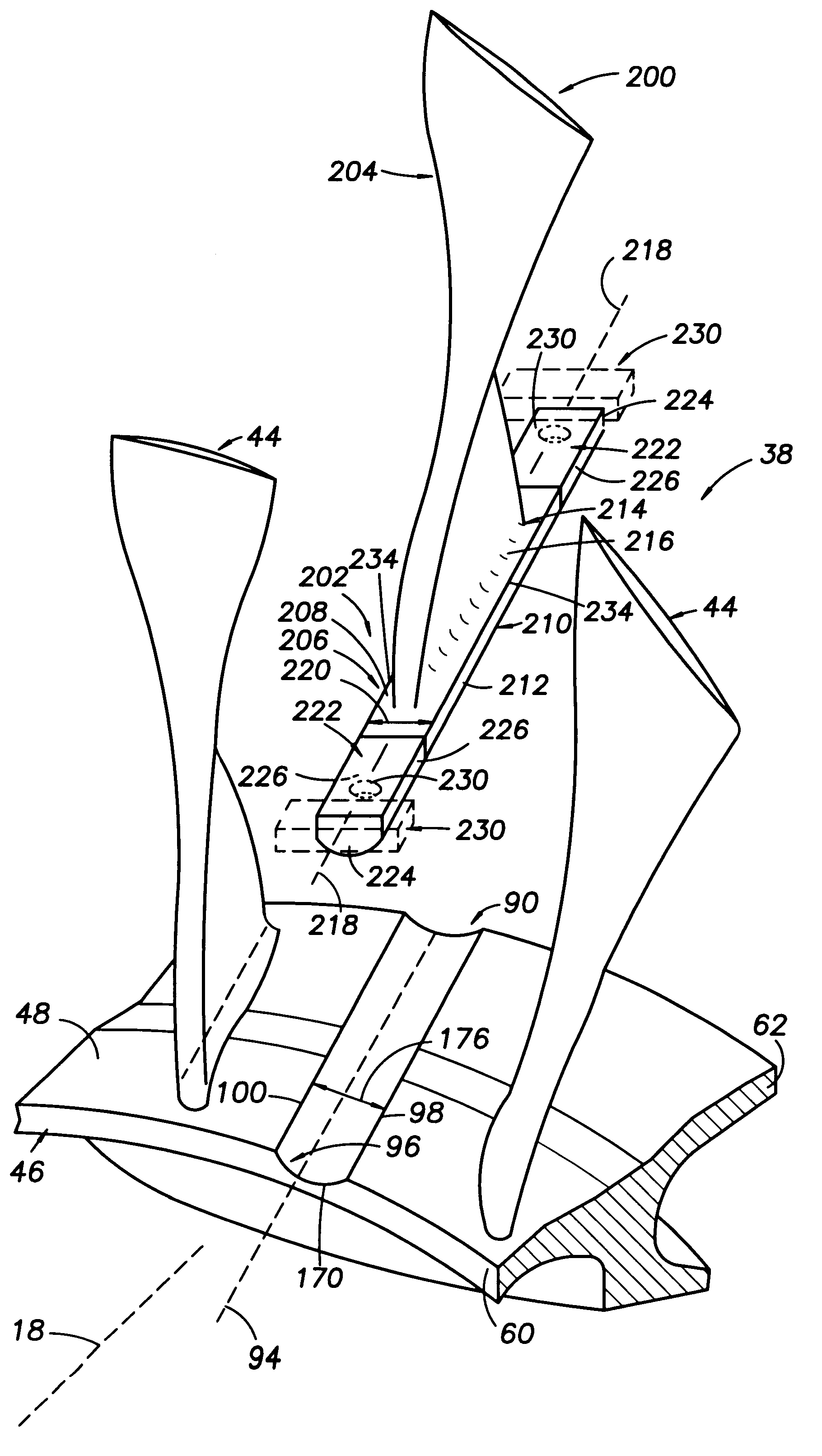

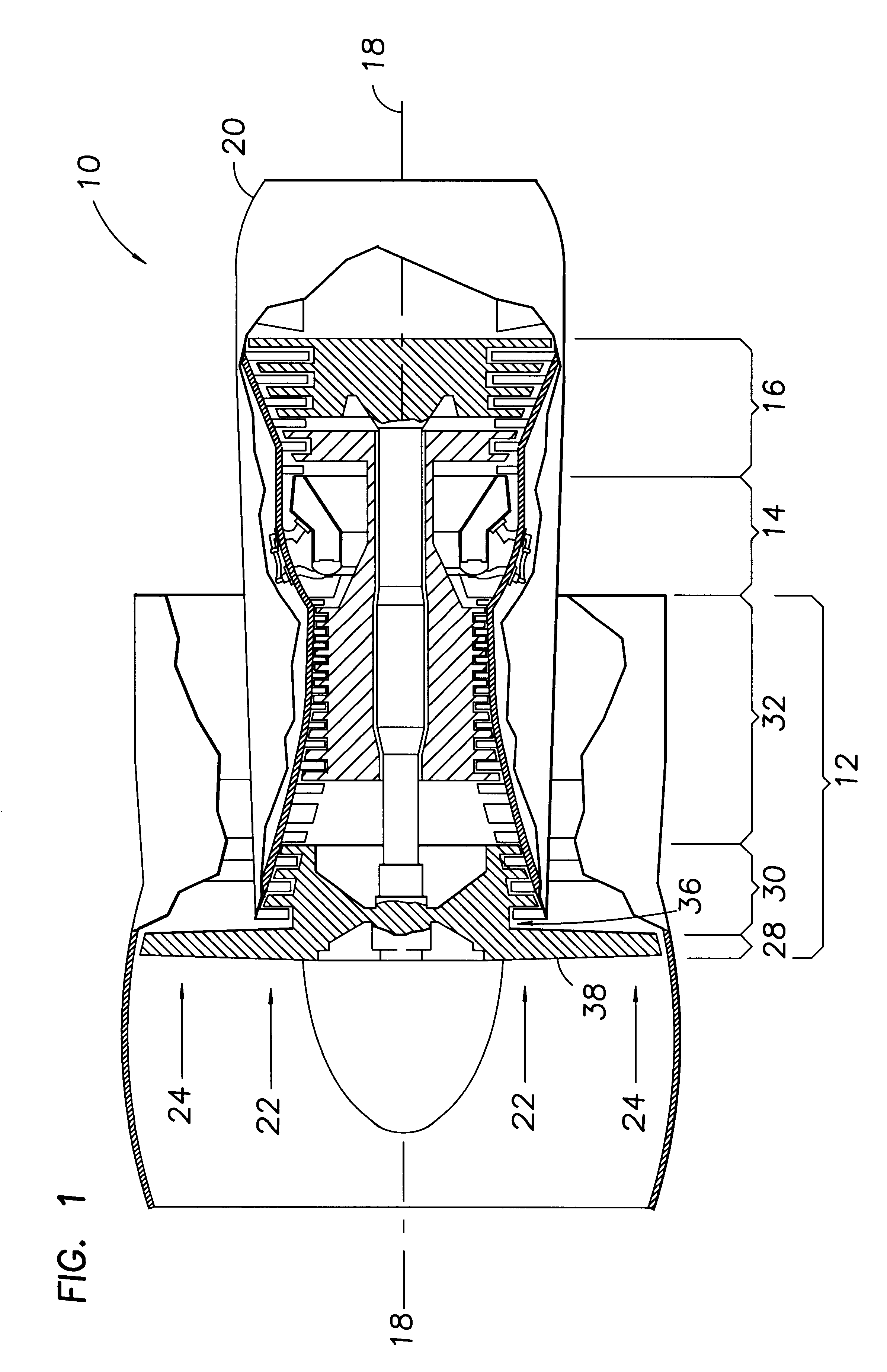

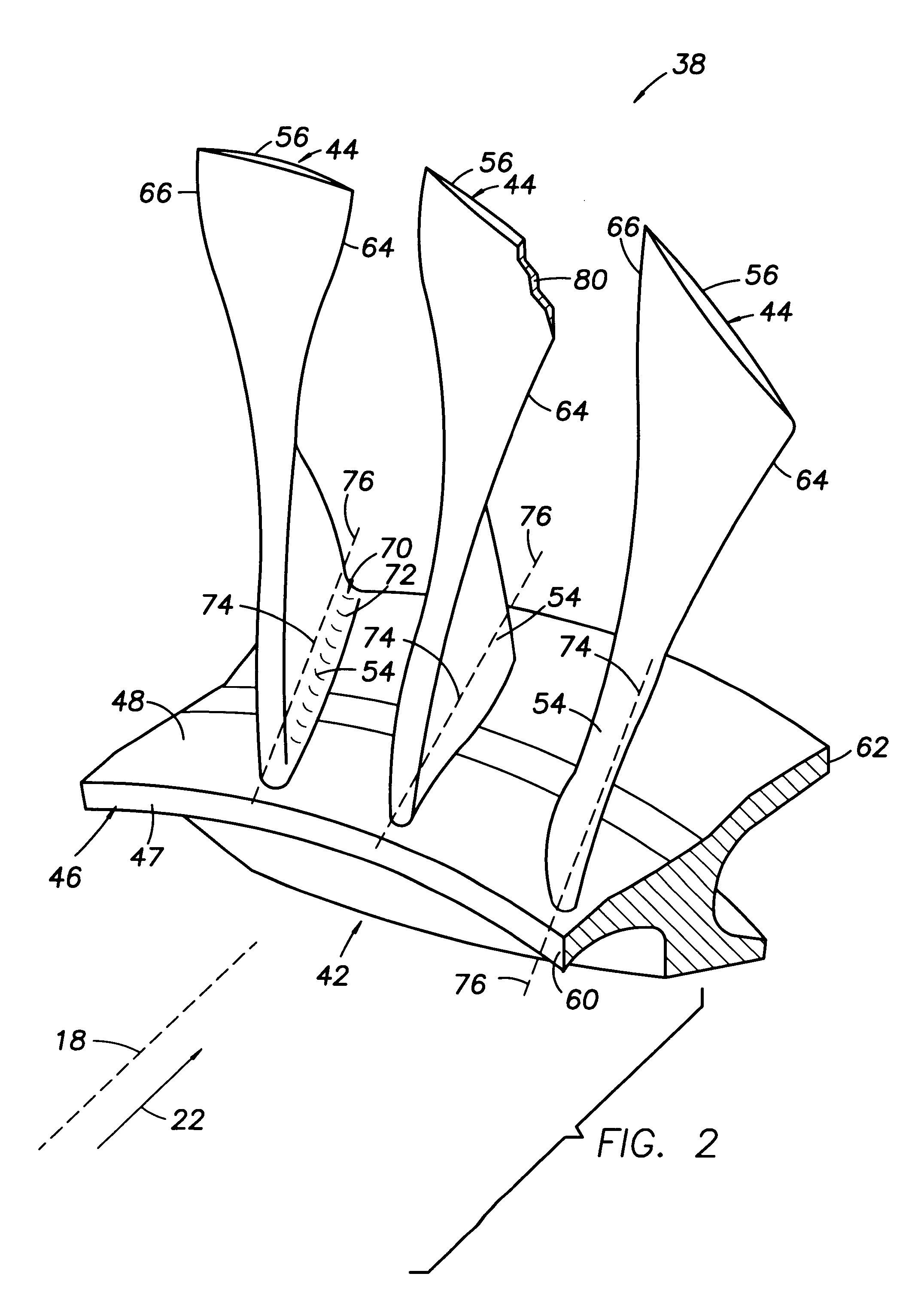

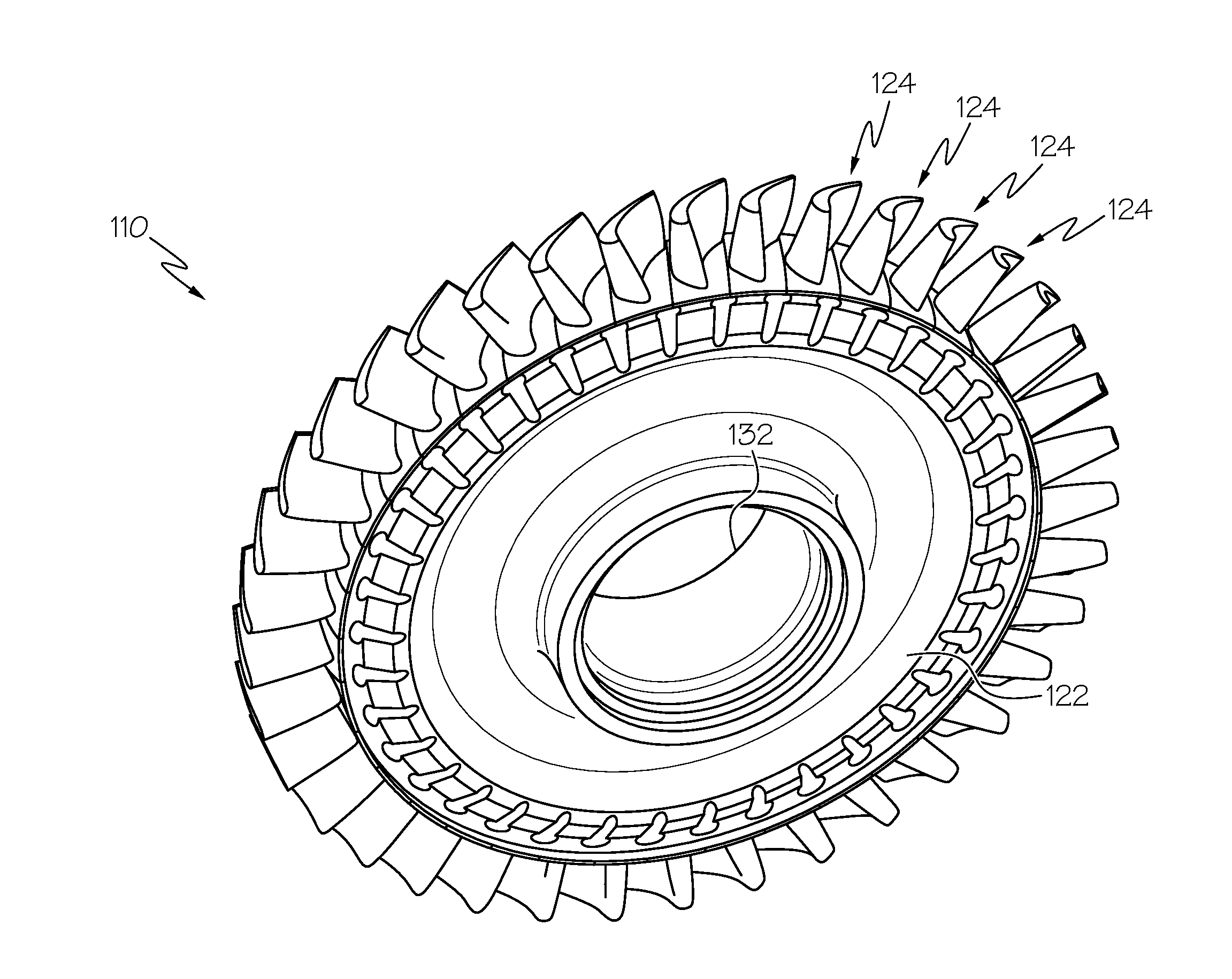

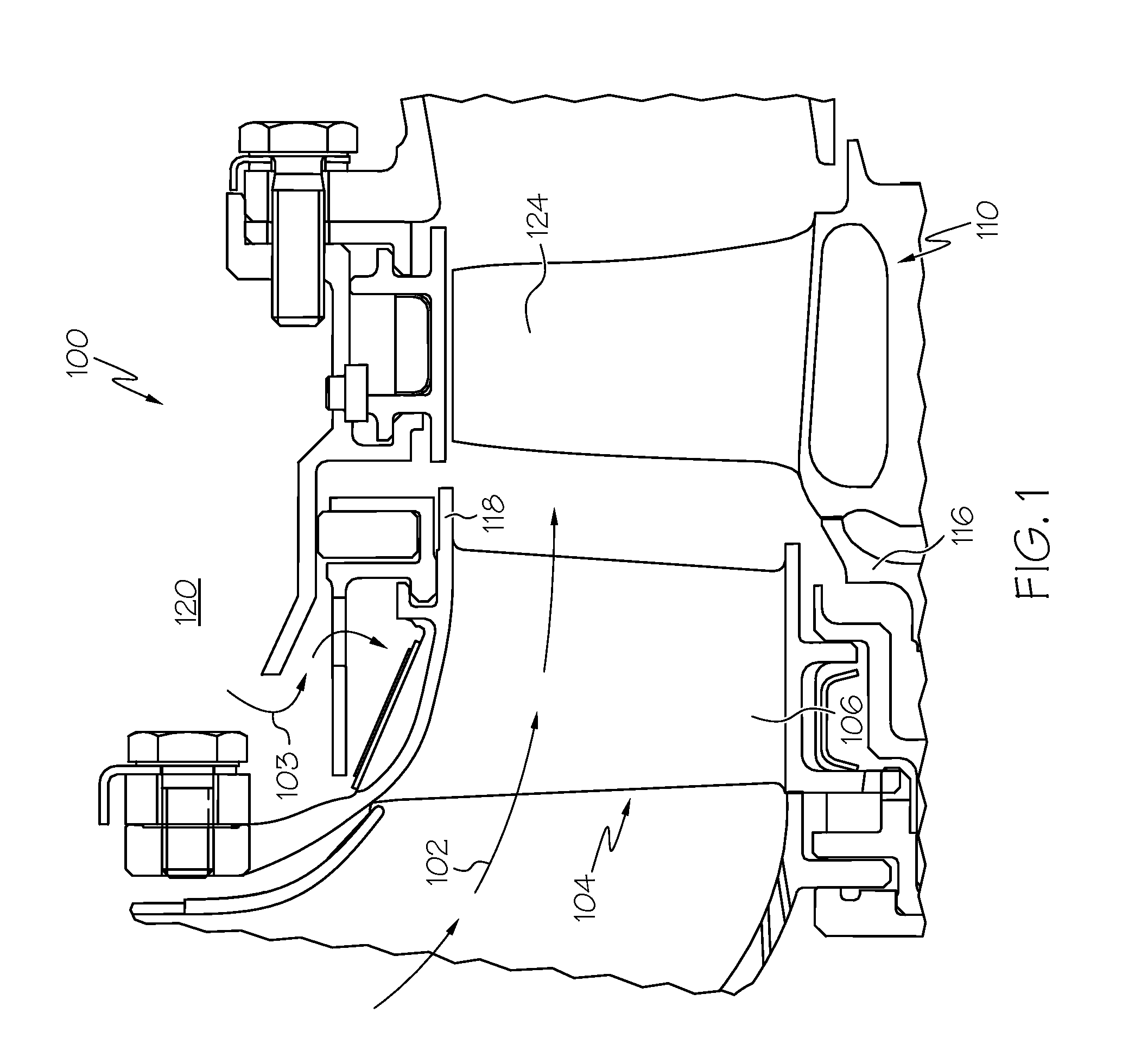

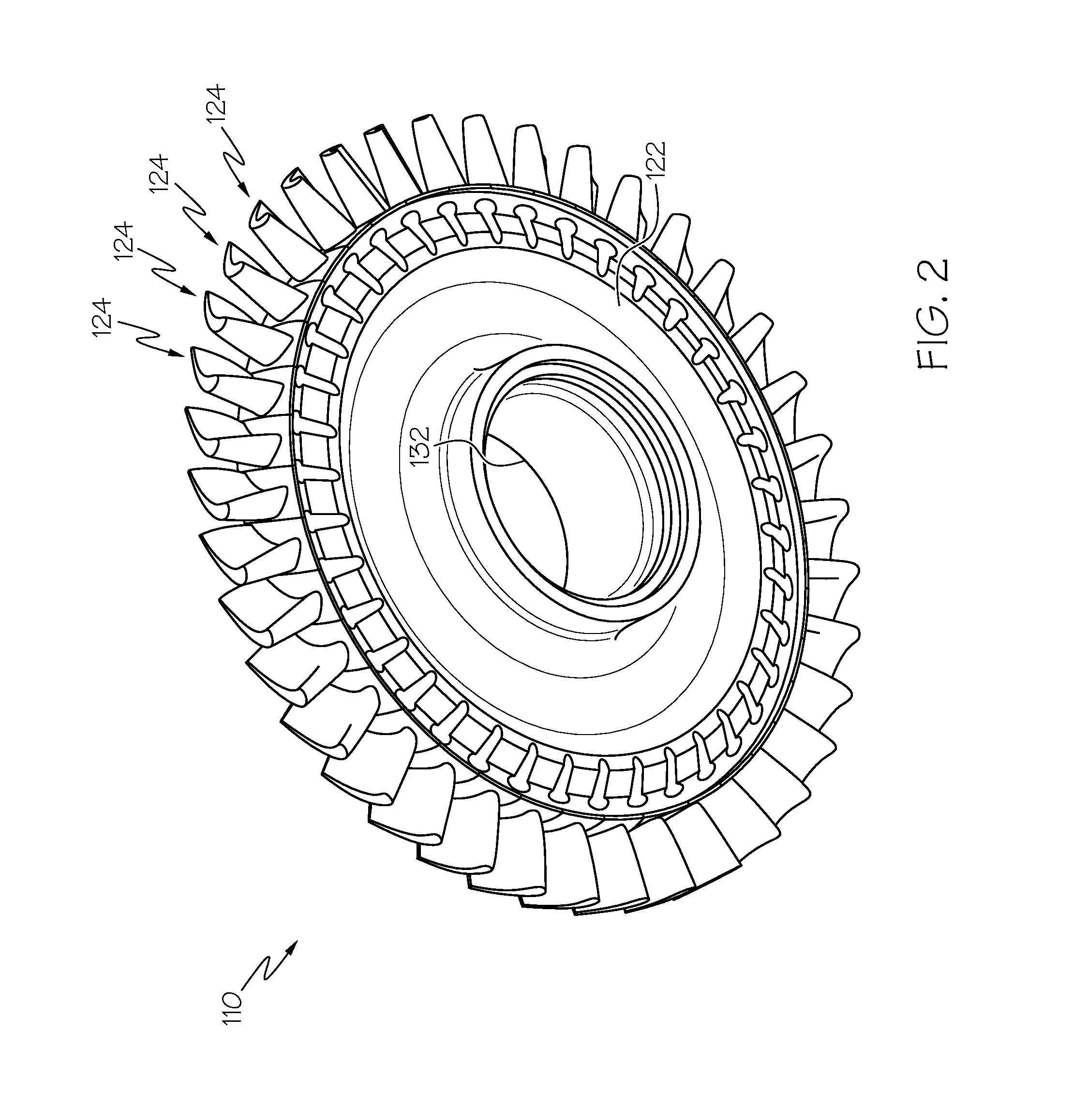

Disk for a blisk rotary stage of a gas turbine engine

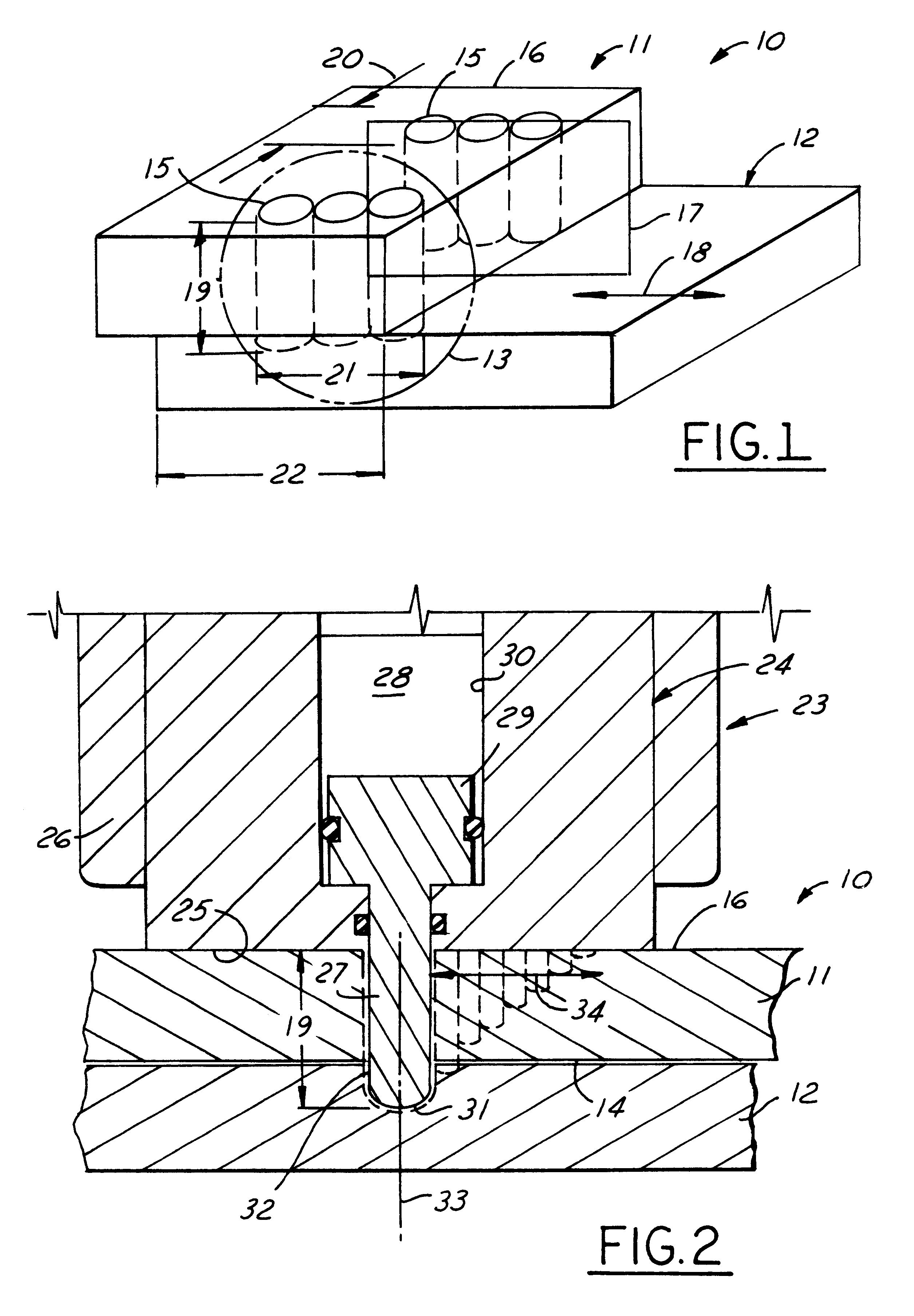

A disk for a BLISK rotary stage of a gas turbine engine includes a stub on the tapered circumferential surface of a turbine disk, the stub defining a weld joint surface on the radially outermost face of the stub. The weld joint surface follows the annulus curvature in axial and circumferential directions while remaining flat in a third direction. A blade is applied radially to the stub and linear friction welding of the blade to the stub is effected by oscillating the blade in said third direction while applying a welding force inwardly along the blade.

Owner:ROLLS ROYCE PLC

Method for the manufacture or repair of a blisk by linear friction welding

A method of making a BLISK by linear friction welding, comprises providing a stub on the circumferential surface of a turbine disk and defining a weld joint surface on the radially outermost face of the stub. The weld joint surface follows the annulus curvature in axial and circumferential directions while remaining flat in a third direction. A blade is applied radially to the stub and linear friction welding of the blade to the stub is effected by oscillating the blade in said third direction while applying a welding force inwardly along the blade.

Owner:ROLLS ROYCE PLC

Method and apparatus for friction stir welding

InactiveUS20030201307A1Effective supportEasy to adaptWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

Owner:THE BOEING CO

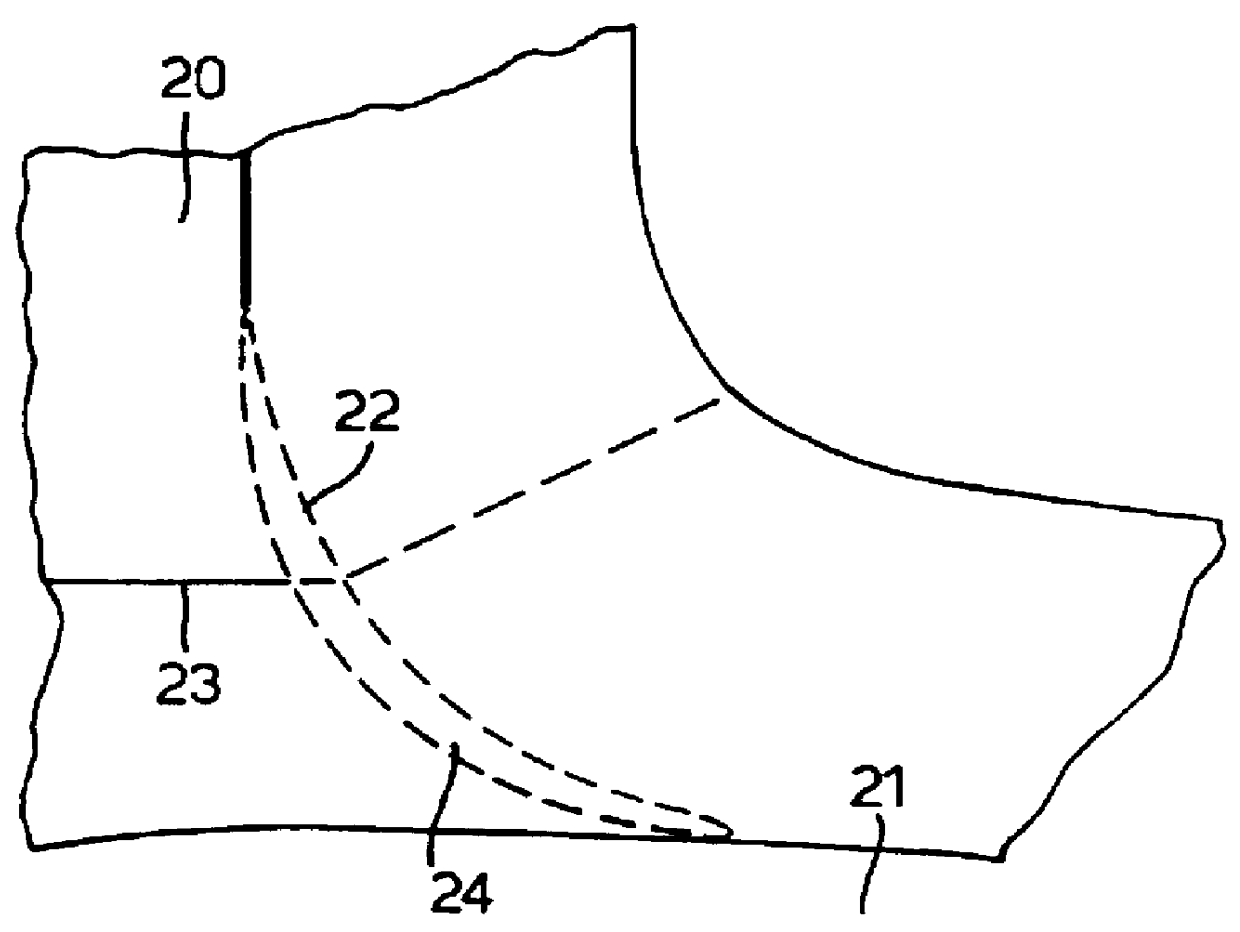

Method for linear friction welding and product made by such method

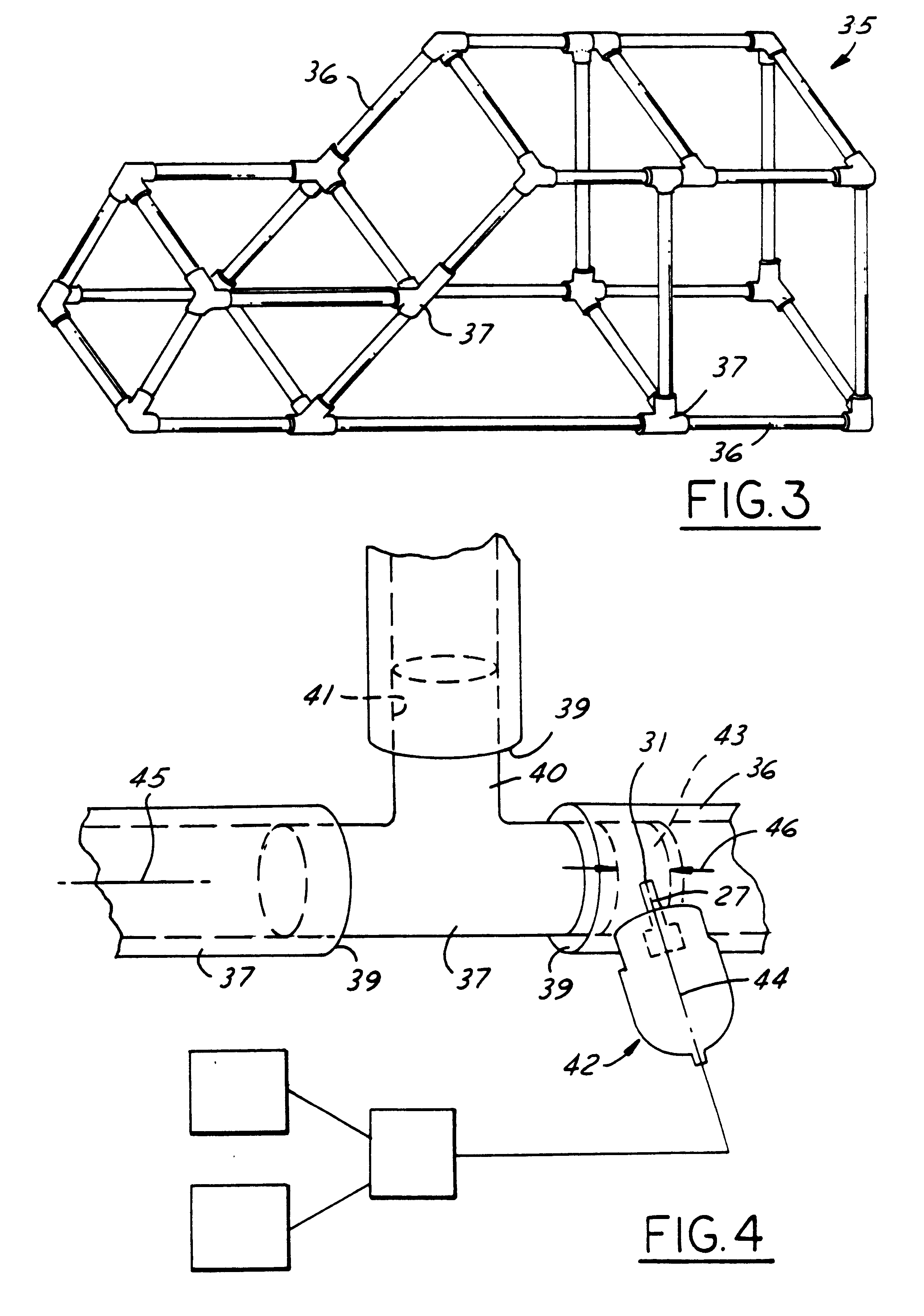

A process for joining a base for an airfoil to a disk for an integrally bladed rotor stage in a gas turbine engine includes providing a disk having a radially outer rim with a slot defined therein by a recessed surface, and further includes providing a base having a longitudinally extending root portion facing opposite a longitudinally extending support portion for supporting the airfoil. The root portion has a root surface and the support portion has an outer surface. The process further includes bringing the root surface of the root portion into contact with the recessed surface bounding the slot, applying pressure and relative movement between the base and the rim to achieve during welding, substantial contiguity between the root surface and the recessed surface over the area of the recessed surface, resulting in a substantially continuous linear friction weld between the base and the rim.

Owner:UNITED TECH CORP

Friction plunge riveting

InactiveUS6769595B2Welding/cutting auxillary devicesAuxillary welding devicesFriction weldingMaterials science

A method of joining a pair of metal components with a rivet having a hardness that is substantially similar to at least one of the metal components. The metal components are stack upon each other and the rivet is rotated and simultaneously plunged in the metal components under pressure to friction weld and metallurgically bond the rivet to the metal components.

Owner:ARCONIC INC

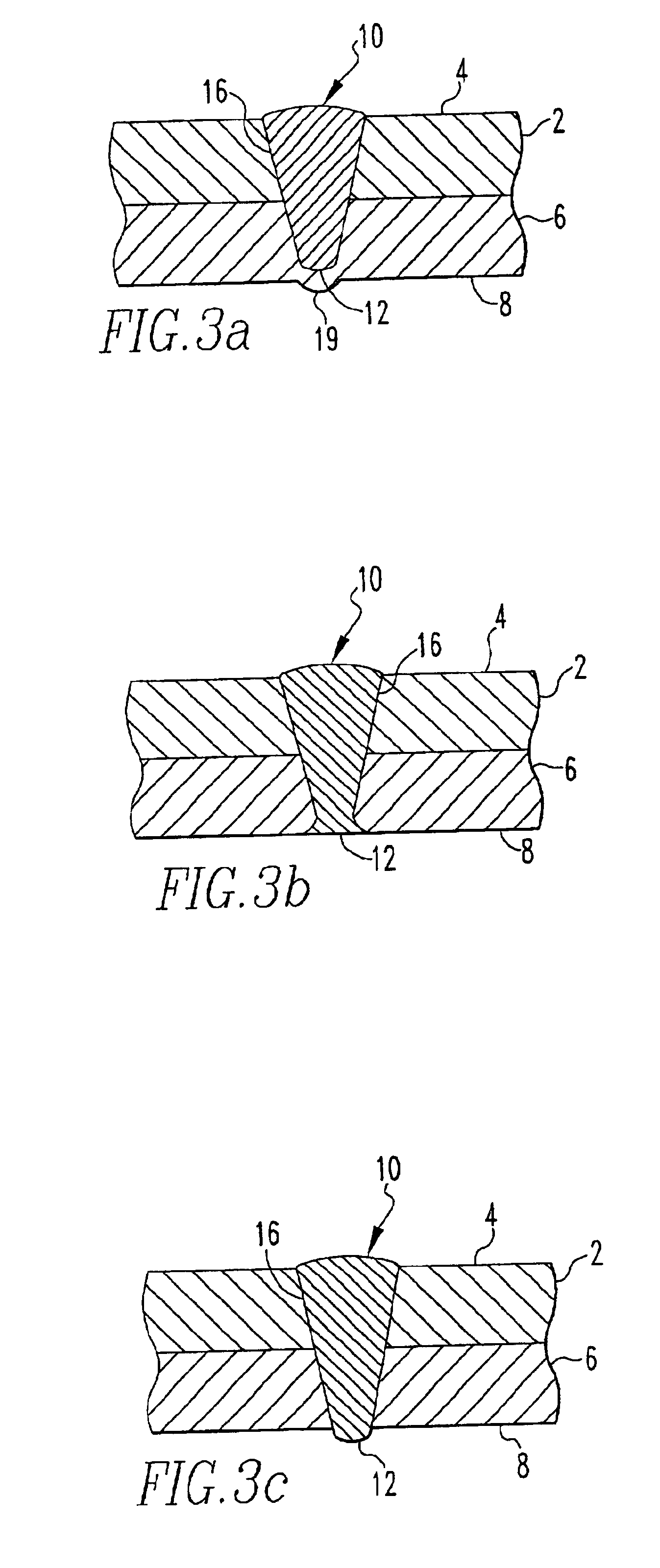

Heat Exchanger

ActiveUS20090308582A1Prevent materialAvoid introducingOther heat production devicesGeothermal energy generationFriction weldingPlate heat exchanger

A heat exchanger and a method for fabricating the heat exchanger are disclosed. The heat exchanger comprises a heat exchanger core that is formed from a plurality of stacked aluminum panels that are joined together via friction stir welding. Each panel in the core is formed from at least two aluminum extrusions that are joined to one another via friction stir welding.

Owner:LOCKHEED MARTIN CORP

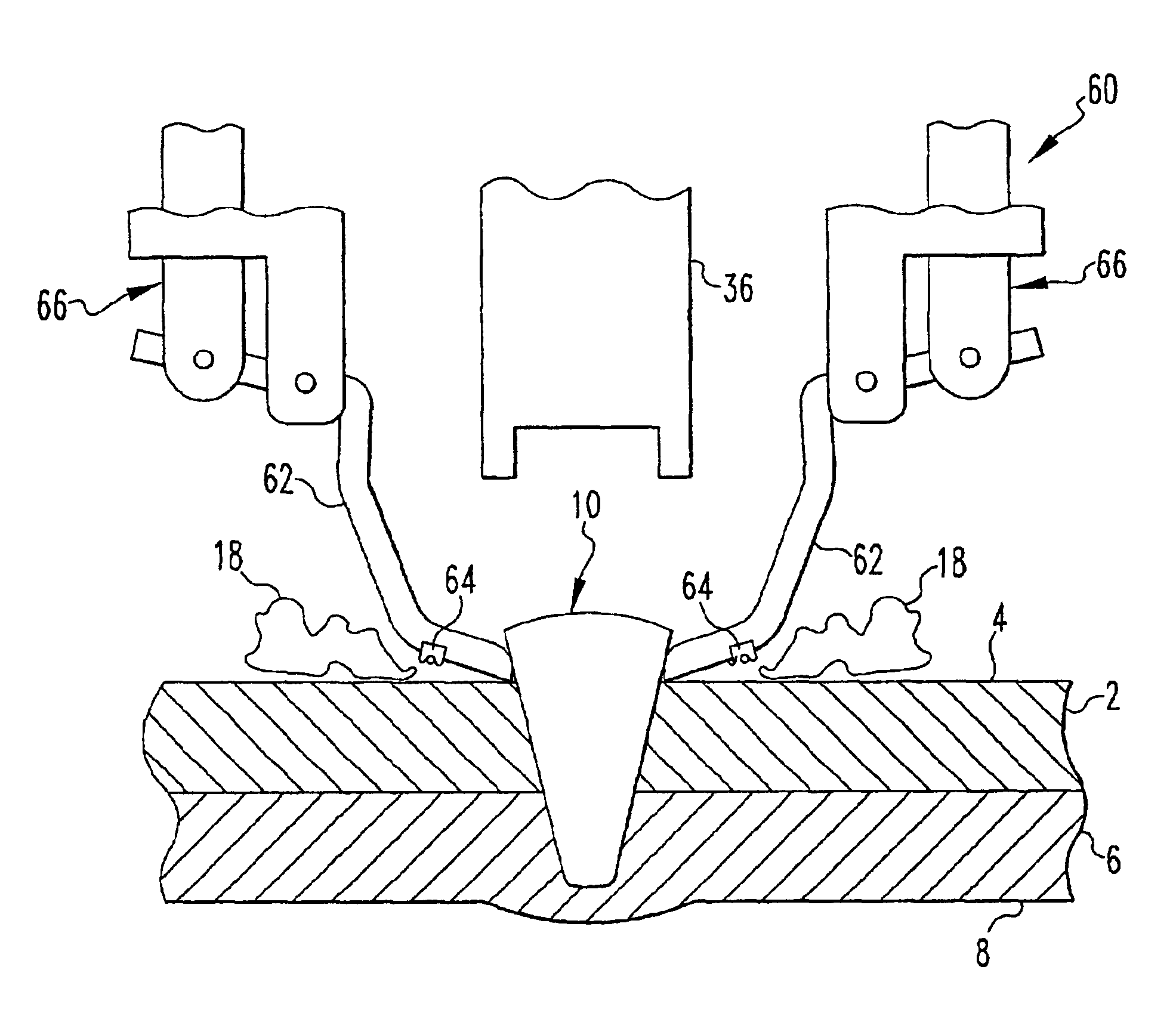

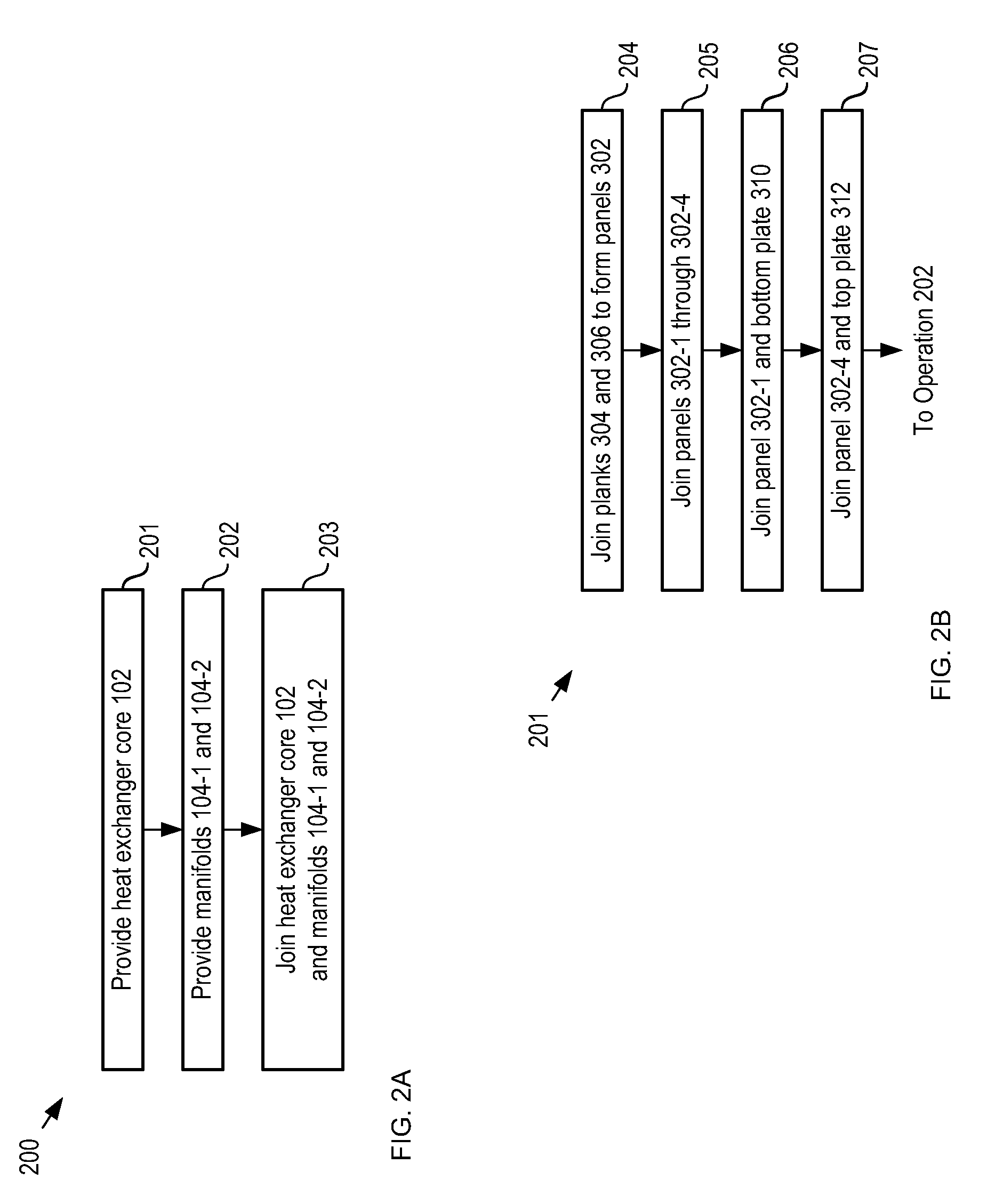

Joining of structural members by friction plug welding

InactiveUS20030201306A1Cost effectiveEfficiently joinedWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

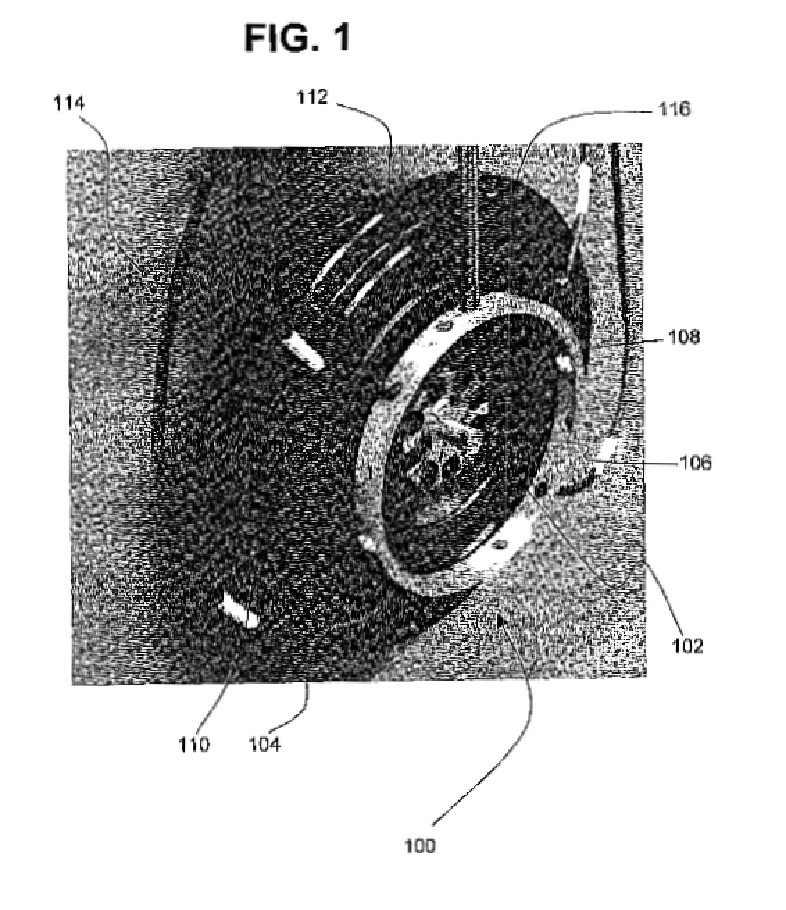

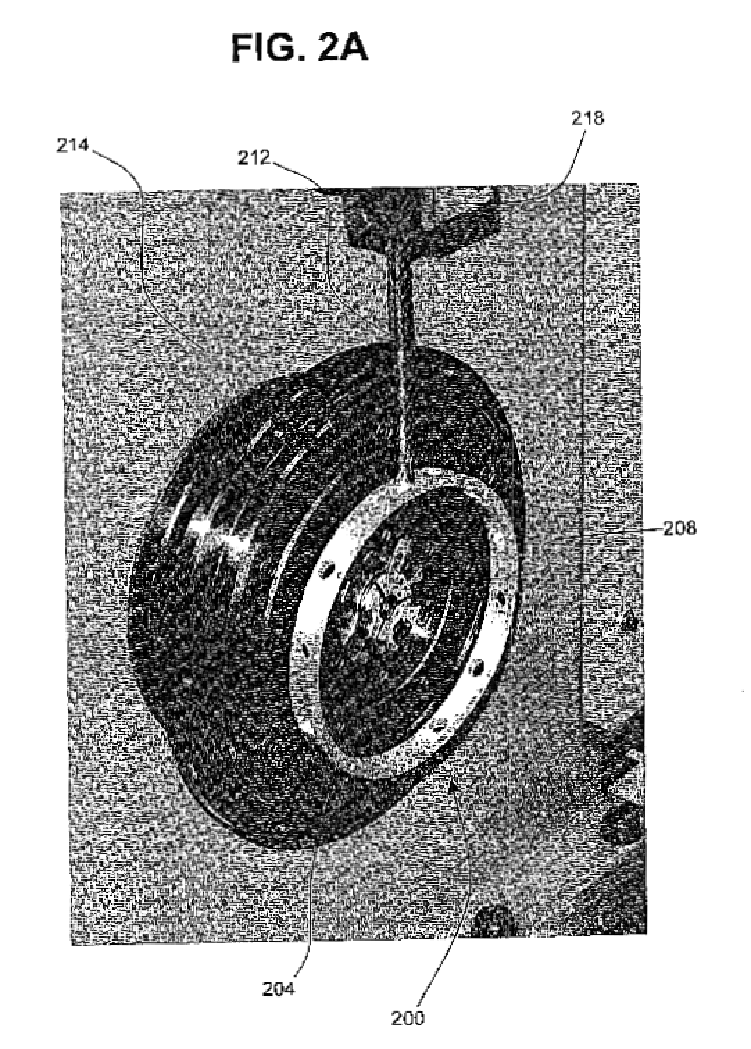

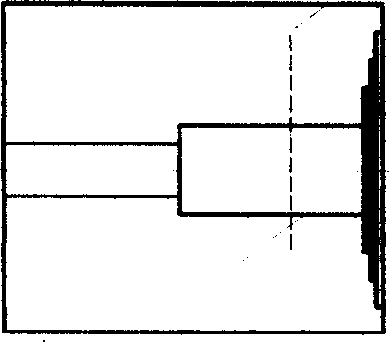

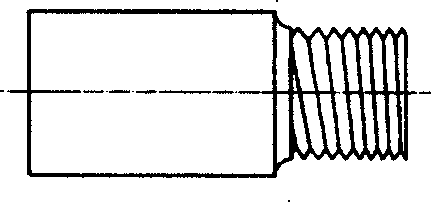

Abstract of the Disclosure The method of manufacturing a structural assembly includes positioning a first structural member at least partially adjacent a second structural member to define an interface therebetween and inserting a rotating plug into the first and second structural members at the interface to thereby join the first structural member to the second structural member. The resulting friction plug weld provides a relatively strong joint between the structural members, requires less forming and machining time, and is compatible with single-sided tooling. Additionally, the friction plug weld is compatible with other joining methods, such as friction stir welding.

Owner:THE BOEING CO

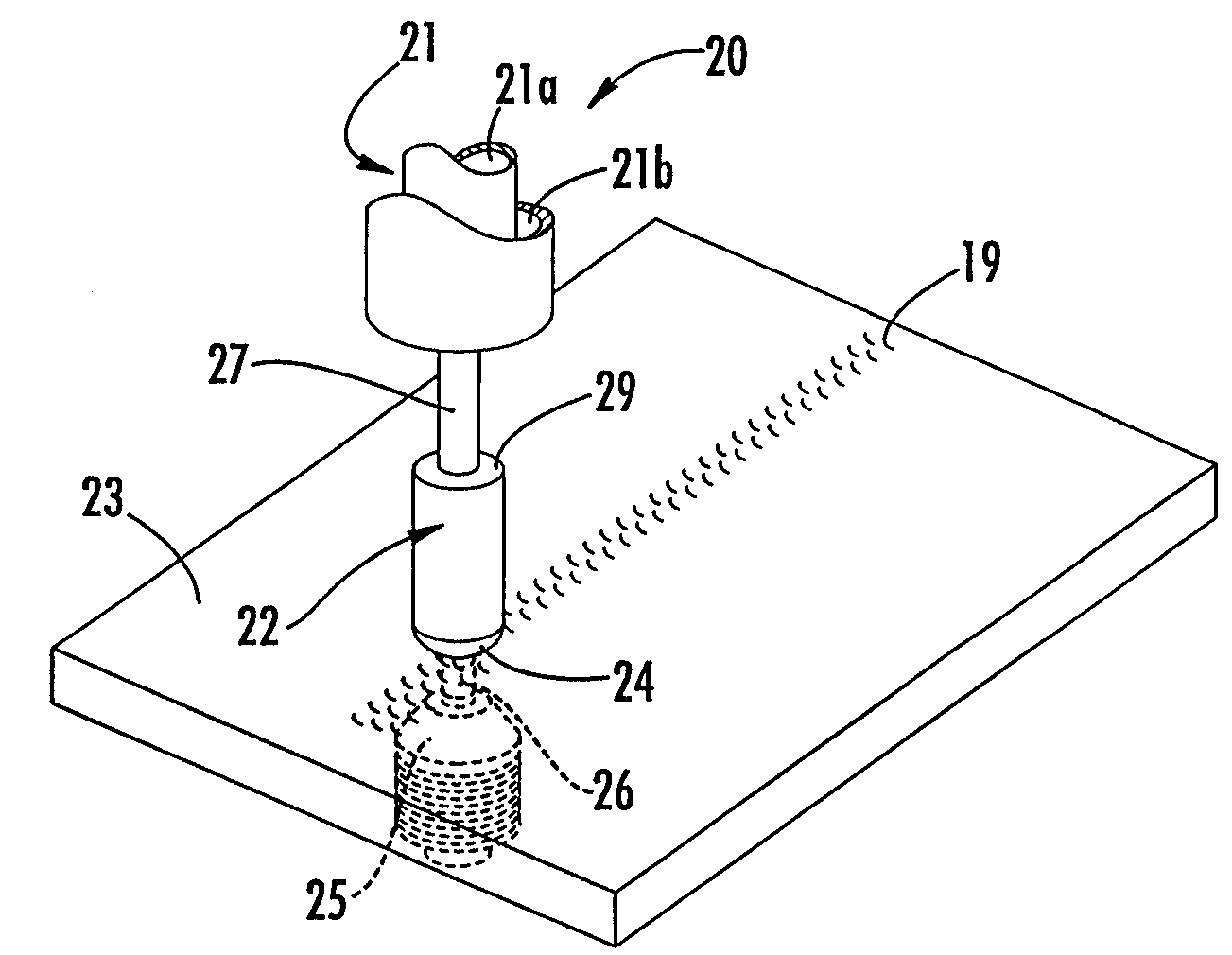

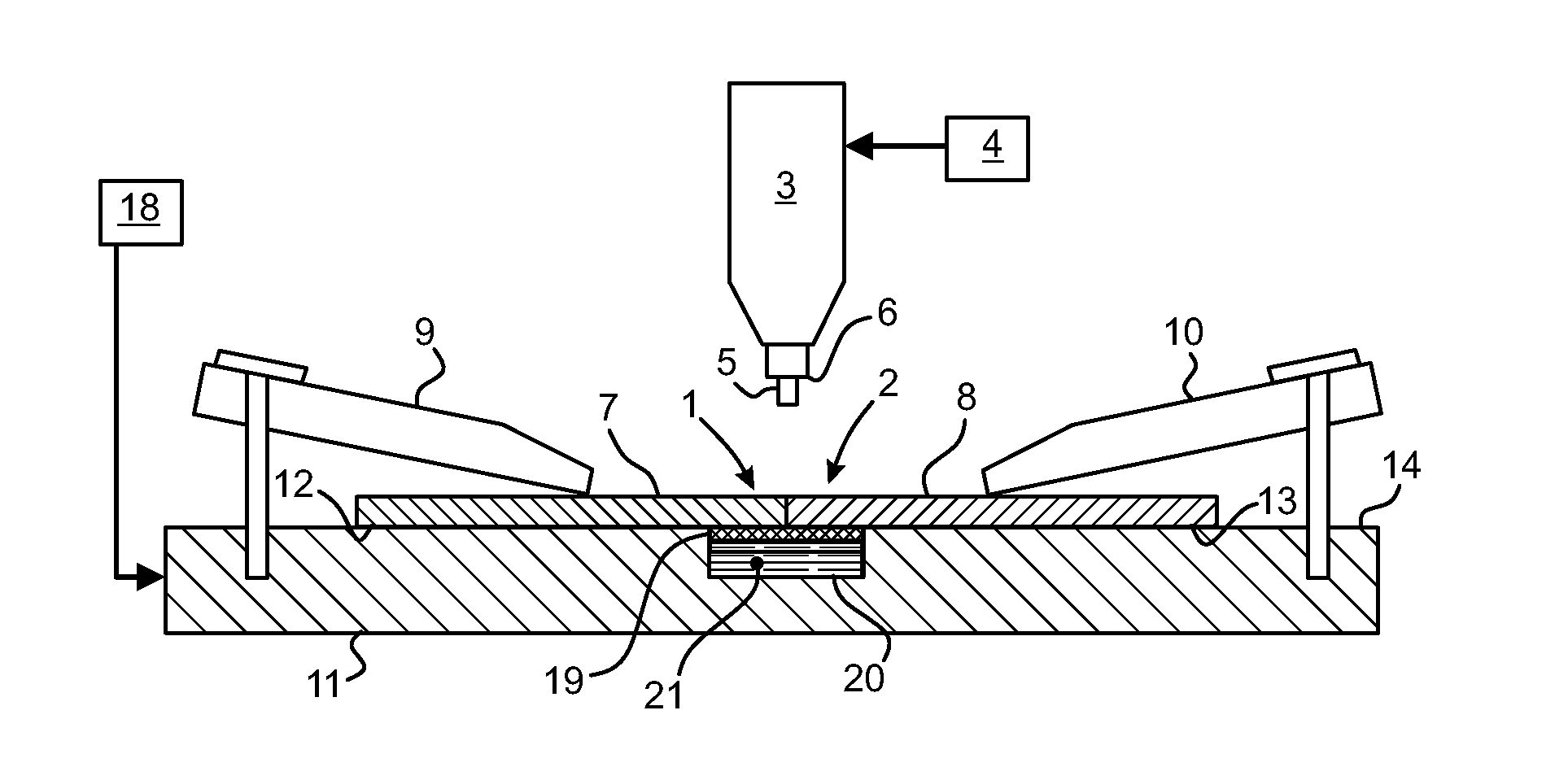

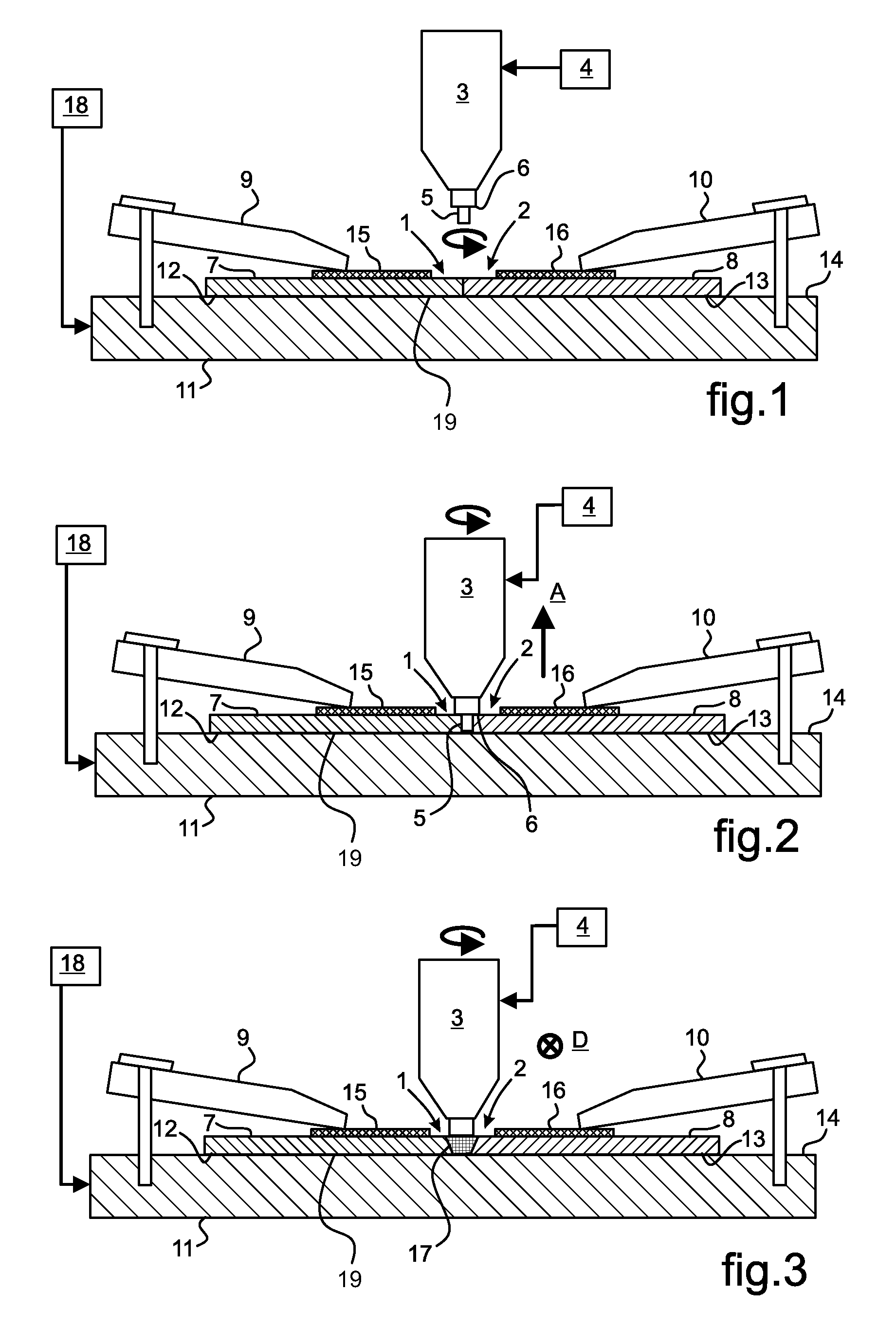

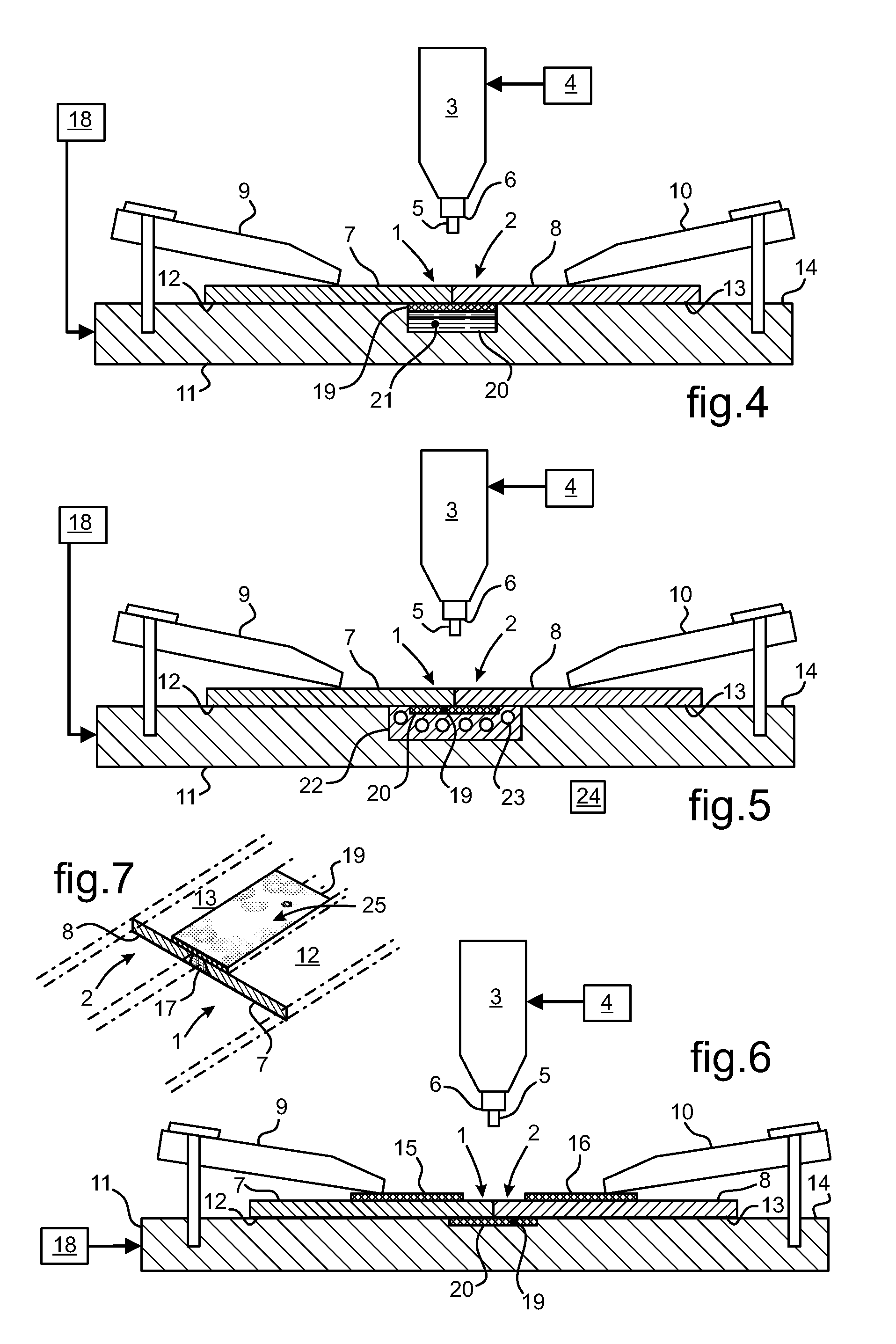

Method of assembling metal parts by friction welding, with the welding temperature being controlled using thermally conductive elements

InactiveUS8393519B2Optimize rateHigh performance mechanical characteristicWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

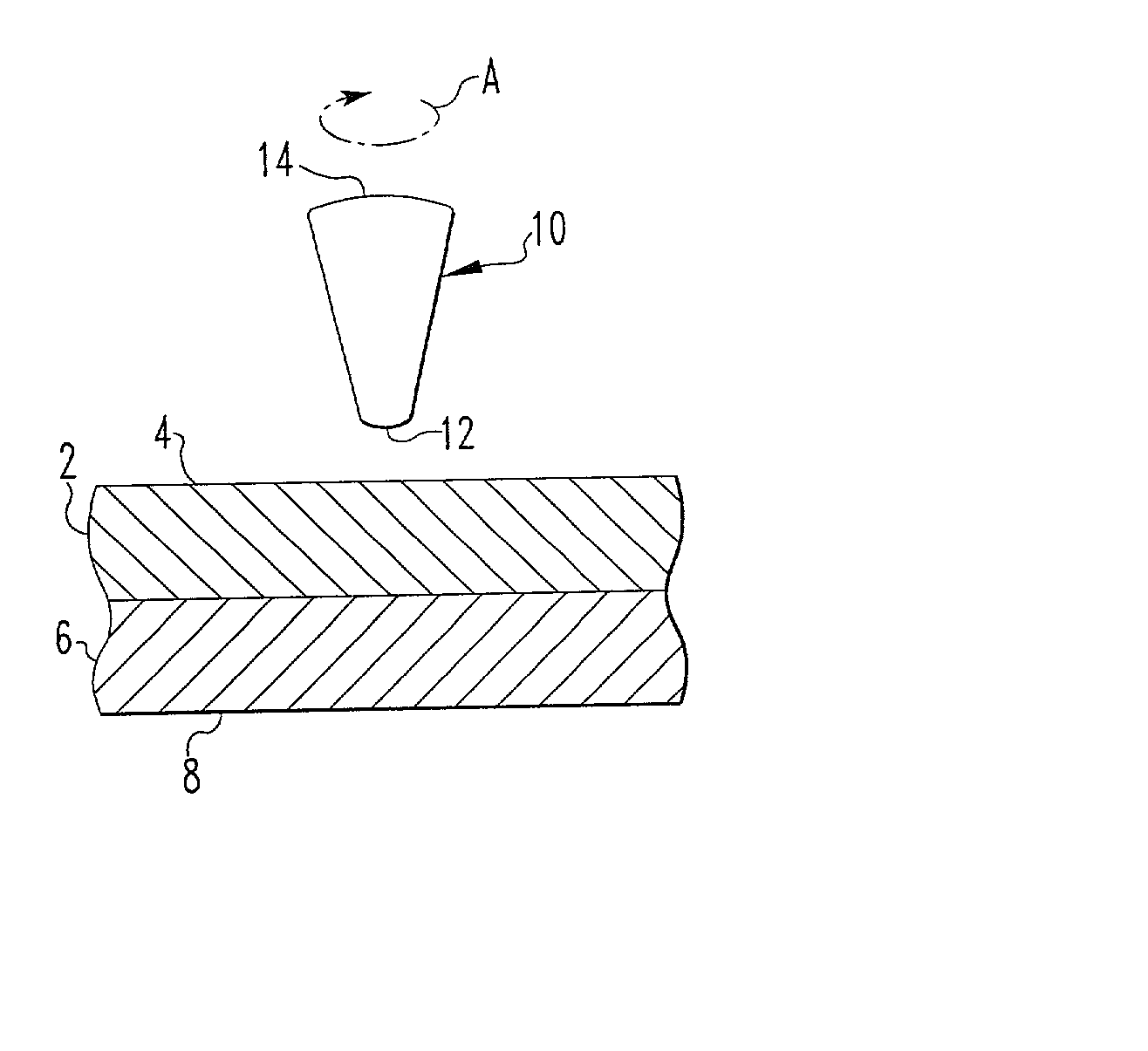

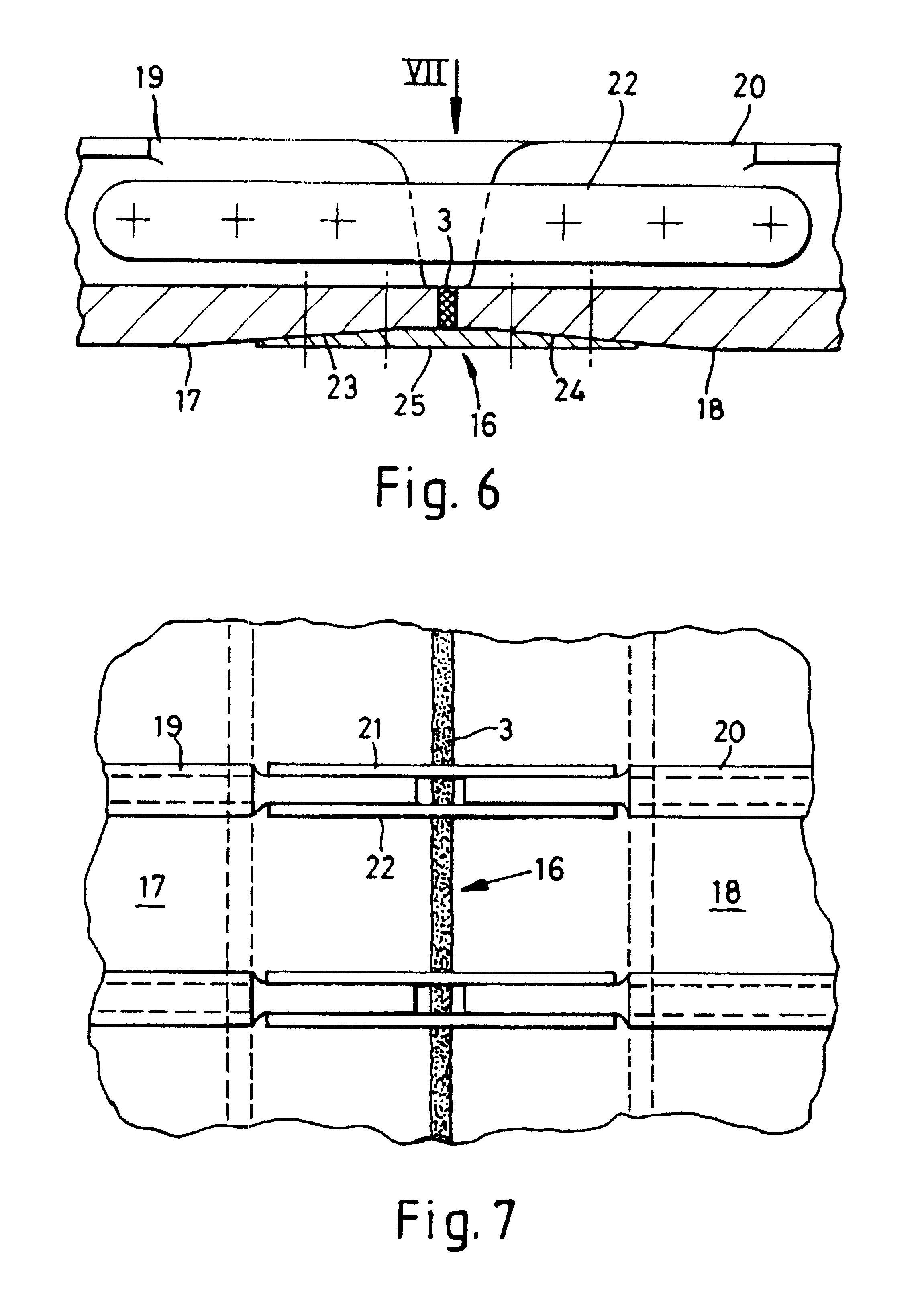

The invention provides a method of assembling together two thin plane parts (1, 2) by friction welding. A main sheet (19) made of a material having high thermal conductivity is held against the parts (1, 2) for assembly. The main sheet (19) picks up the heat induced by the friction of a welding pin (5) against the parts (1, 2) for the purpose of forming the weld bead (17), and it dissipates this heat by radiation. Temperature regulation of the welding operation is obtained by the main sheet (19), ensuring that no localized excess heating occurs in the welding zone. The main sheet (19) is based on copper and presents a thickness that is less than the thickness of the parts (1, 2).

Owner:EUROCOPTER

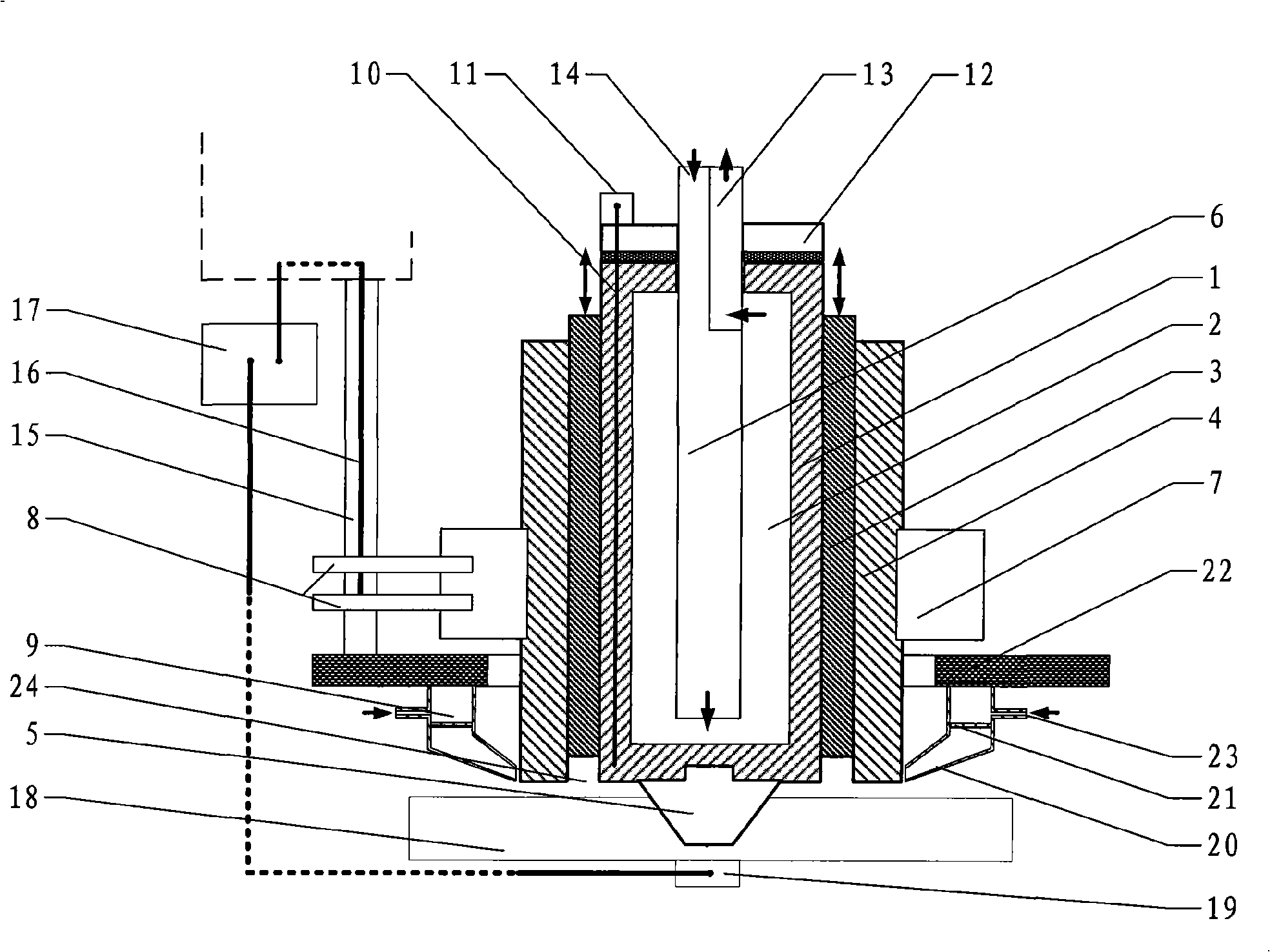

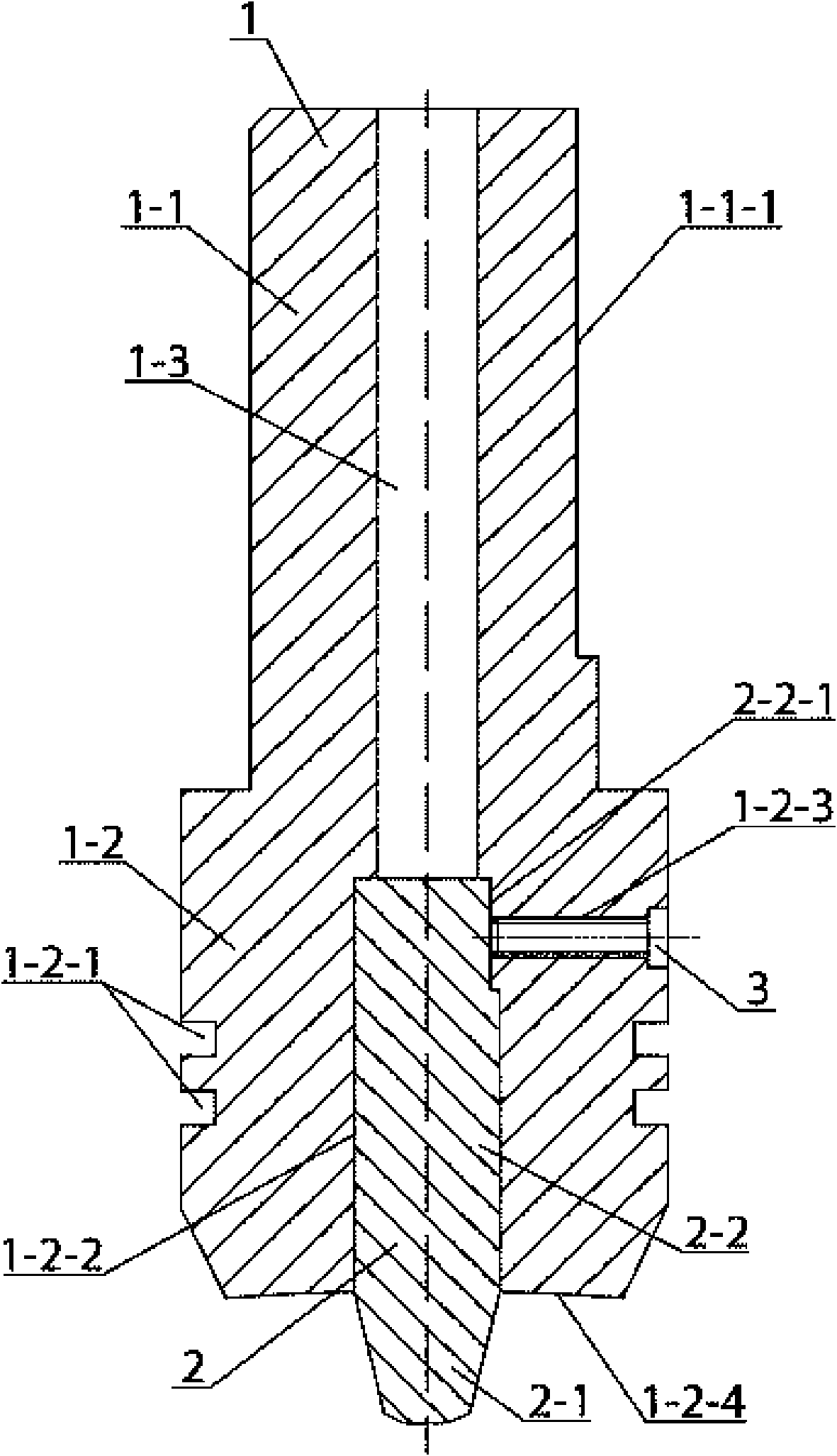

Integrated pin tool for friction stir welding and composite method of resistance-friction stir welding thereof

InactiveCN101537538AReduce wearExtended service lifeEngine sealsWelding/cutting media/materialsElectrical resistance and conductanceFriction welding

The invention discloses an integrated pin tool used for friction stir welding and a composite method of resistance-friction stir welding thereof. The pin tool comprises a pin tool body arranged on a friction welder and a tool pin arranged at the lower part of the tool pin body which is connected with the welder in a clamping and insulating manner; the pin tool also comprises a forced cooling system, a current carrying system, a gas shielding system, a temperature sensing and detecting system, a sealing and insulation system, an inner shaft shoulder and the tool pin, and is an integrated pin tool which has the functions of gas shielding, forced circulation cooling of internal liquid medium, automatic temperature sensing and detection, tool pin changing and composite non-keyhole resistance-friction stir welding. The invention overcomes the difficulty of friction stir welding of the high melting point metal and meets the harsh technical requirements of the friction stir welding of the low melting point metal, improves the quality of welding joints, prolongs the service life of the pin tool and realizes the friction stir welding of high melting point metal and low melting point light alloy, with low cost, high efficiency and excellent quality.

Owner:CHONGQING UNIV

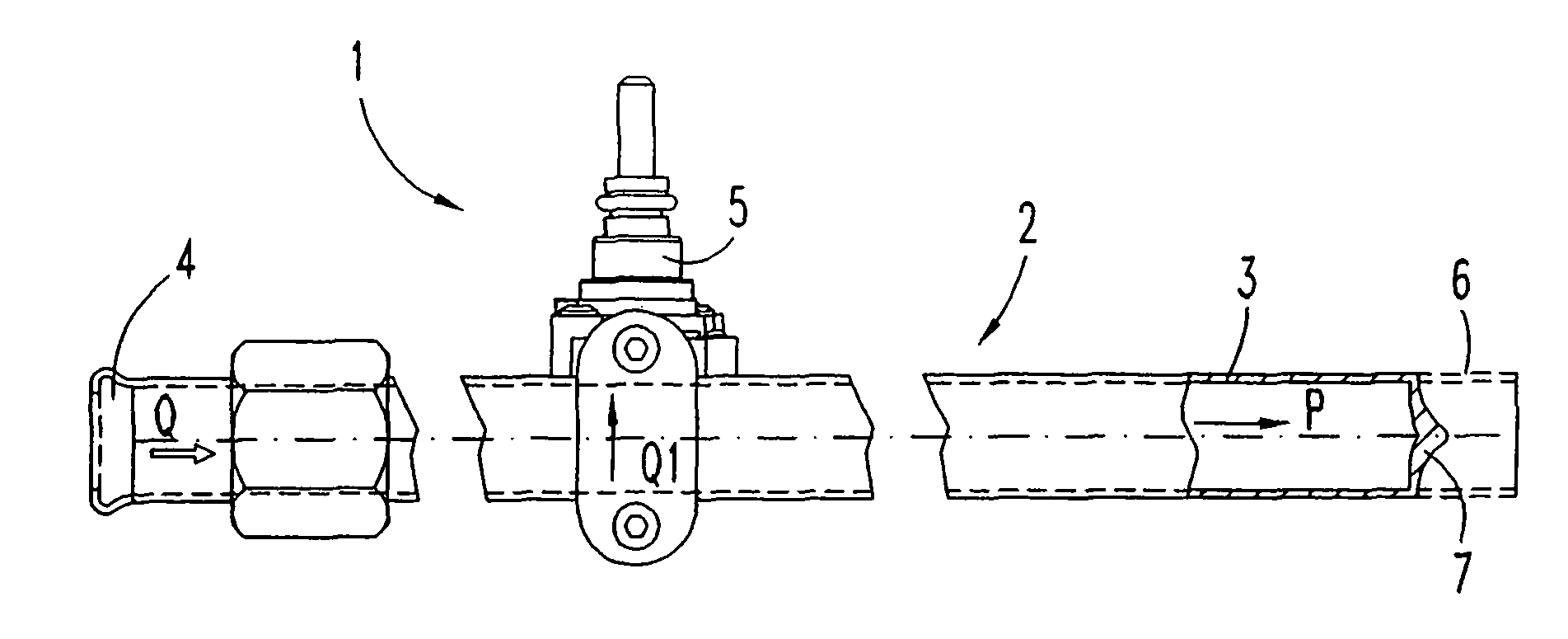

Gas manifold for a cooking range, with a pipe closure

InactiveUS7861706B2Guaranteed tightnessDomestic stoves or rangesStoves/ranges topsFriction weldingEngineering

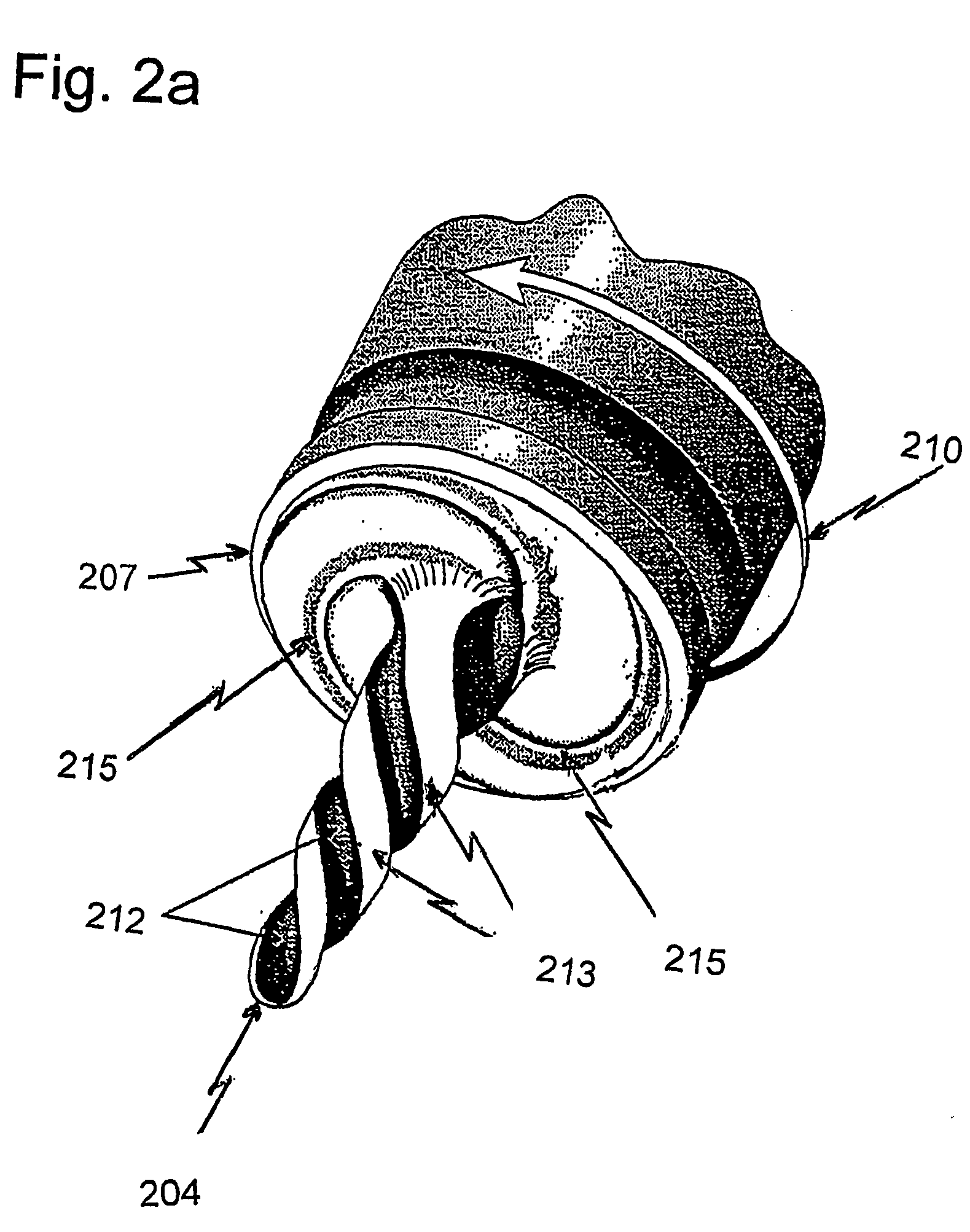

The gas manifold (1) adapted for installation on a cooking range includes a conduit (2) for distribution of a flow (Q) at a pressure “P”, with a number of regulating taps (5) fixed to the conduit (2). The conduit is made from a metal pipe (3) with a thin cylindrical wall To and the pipe end (6) is sealed without cracks by means of friction welding with no addition of material, with a sealing wall (7) formed by means of a thickening in the form of a tip (7a) in the axial direction of an enlargement or height “H” greater than the original thickness To of the pipe. For making the gastight closure a rotary tool (8) is used that includes at least two rotary rollers (9) for the compaction of the metallic mass between two counterposed centripetal forces (Fr), in combination with an axial stretching force (Fa).

Owner:COPRECITEC

Electric conduction-stirring friction composite heat power supply welding method and equipment

ActiveCN101323054AOvercoming a lack of energy inputBreak through limitationsResistance welding apparatusNon-electric welding apparatusEngineeringWeld seam

The invention discloses a conducting-stirring friction hybrid heat source welding method and a piece of equipment, wherein, in stirring friction welding, a stir head and a workpiece are simultaneously insulated from the main body of a welding machine, the clamp of a fixed workpiece and a worktable, current is galvanized in the weld seam direction of the workpiece, the current and the weld seam through which the current flows produce resistance heat with the contact resistance of a friction stirring welding area, and the resistance heat together with stirring friction heat forms the hybrid heat source of the stirring friction welding. The method and the equipment of the invention have the following remarkable effects: 1. the limitation of the stirring friction welding on welding materials is broken through, leading the stirring friction welding to be used for welding such structural materials as black ferrous metals, superalloy, and the like; 2. the service life of the stir head can be improved; and 3. welding speed and welding quality can be further improved, thus improving the mechanical property of a welding joint. The method and the equipment of the invention can be used for the stirring friction welding, the preheating before welding, and the postweld heat treatment of such structural materials as carbon steel, stainless steel, and superalloy, etc.

Owner:罗键

Method of adjusting coefficient of restitution of face of golf club head

InactiveUS20080064523A1Reduce manufacturing costReduce coefficient of restitutionGolf clubsRacket sportsFriction weldingCoefficient of restitution

The present invention provides a method of adjusting a coefficient of restitution (COR) of the face of a golf club head. A metallic assistant device is fixed on a center of a back of the face by friction welding or brazing. The metallic assistant may increases the central thickness of the face that may reduce the COR of the face.

Owner:CHEN ARCHER C C

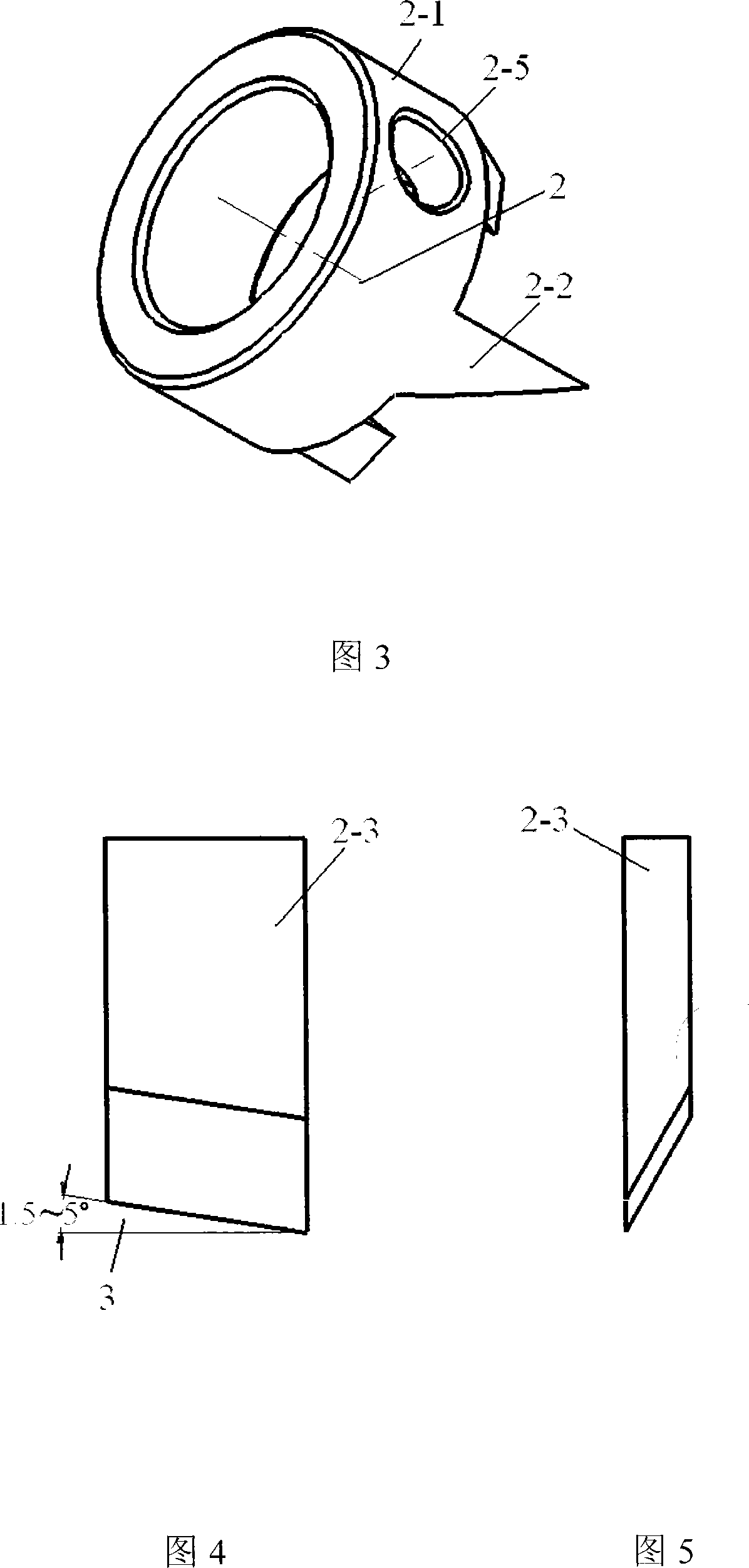

Combined edging stirring friction welding agitator head

InactiveCN101176945AEfficient removalQuality improvementNon-electric welding apparatusFriction weldingSet screw

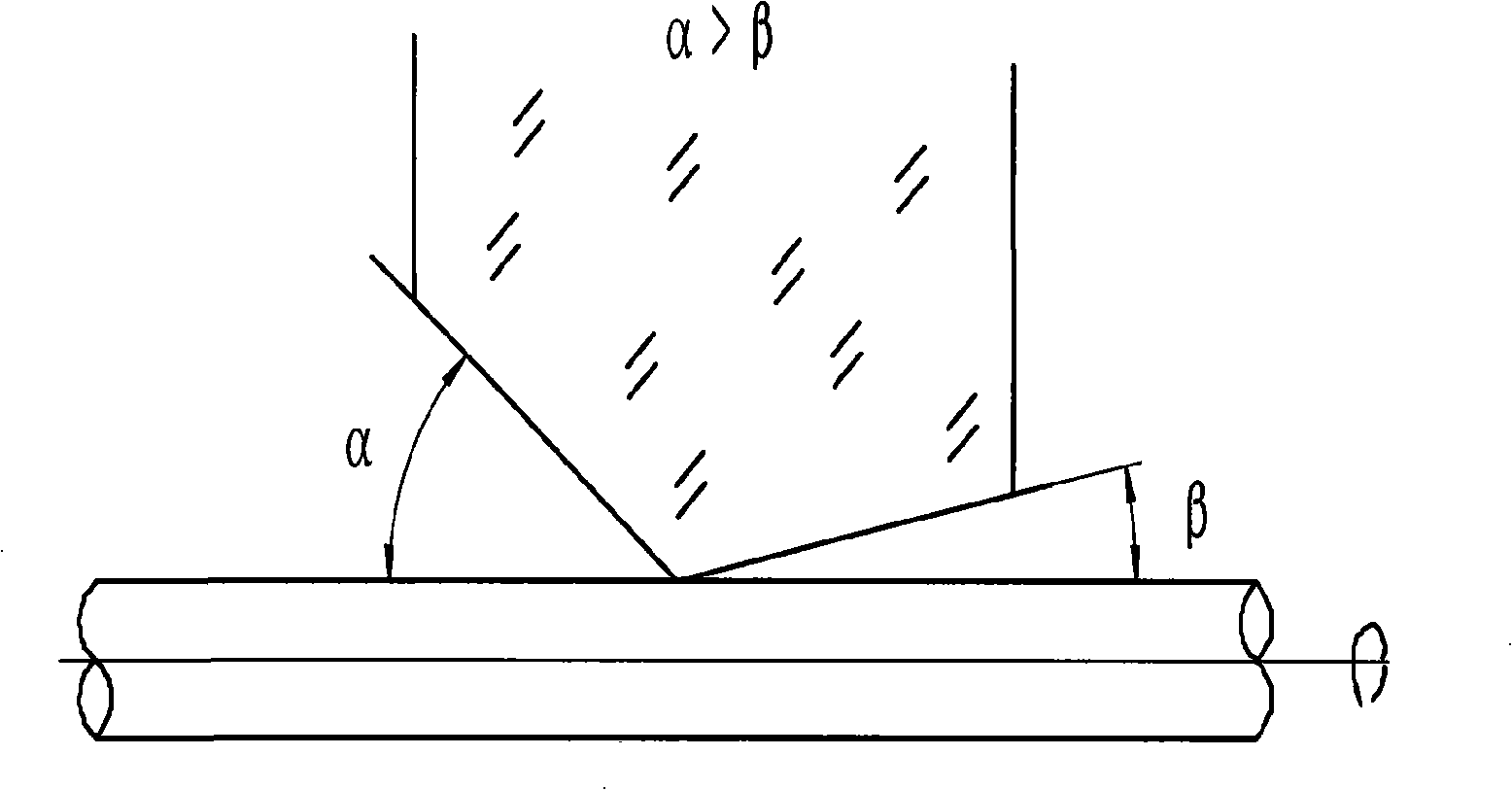

The invention relates to a combined type deburring stirring-friction welding stirrer head used for stirring-friction welding. The stirrer head is a combined type structure, comprising a stirrer head base and a cutter body. The stirrer head base comprises a clamping handle, a support shoulder, a shaft shoulder and a stirring pin. The cutter body comprises an installation ring, a blade holder, a tool blade, a tightly fixed bolt and a thread through-hole; the cutter body is sleeve-jointed with the shaft shoulder of the stirrer head and is fixed through the tightly fixed bolt. One surface of the blade holder is inclined with an inclination angle of 30 to 85 degree corresponding to the axial direction of the stirrer head, and the other surface is flat. The tool blade is embedded on the inclined surface, the lower end face of which is a cutting edge. An inclination angle matched with the friction welding drift angle is formed on surface of the cutting edge. The invention has the advantages of efficiently eliminating the burr of the friction welding, achieving high-quality stirring friction welding joint with flat and smooth surface, enabling to be used as ordinary ones.

Owner:BEIJING AVIATION MFG ENG INST CHINA AVIATION NO 1 GRP

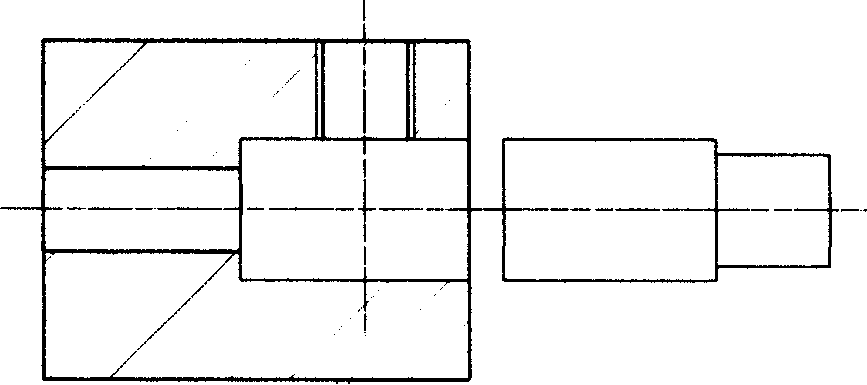

Combination type stirring friction welding tool

InactiveCN101209512AReturn to normal structureRecovery functionNon-electric welding apparatusFriction weldingEngineering

The invention provides a combination-typed mixing friction welding tool. The invention is characterized in that the tool consists of a shaft shoulder and a mixing needle; the shaft shoulder and the mixing needle with different structure design and different material can be exchanged with each other, and a whole welding tool can be formed after assembly. The combination design of the invention can provide greater flexibility for the preparation of the mixing friction welding tool, and provides the possibility for the replacement of the damageable part of the mixing needle. The mixing friction welding tool design of the invention can be applied to the working condition, in which the mixing needles are easy to be broken and abraded.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Aluminum coating for the corrosion protection of welds

ActiveUS7066375B2Improve corrosion resistanceSoldering apparatusPretreated surfacesFriction weldingHeat-affected zone

A method for coating and an associated assembly including such a coating are provided. The assembly includes a workpiece defining a weld portion, such as a friction weld joint and a heat affected zone. A coating is disposed on the weld portion to at least partially cover the weld portion, thereby providing enhanced corrosion resistance to the workpiece.

Owner:THE BOEING CO

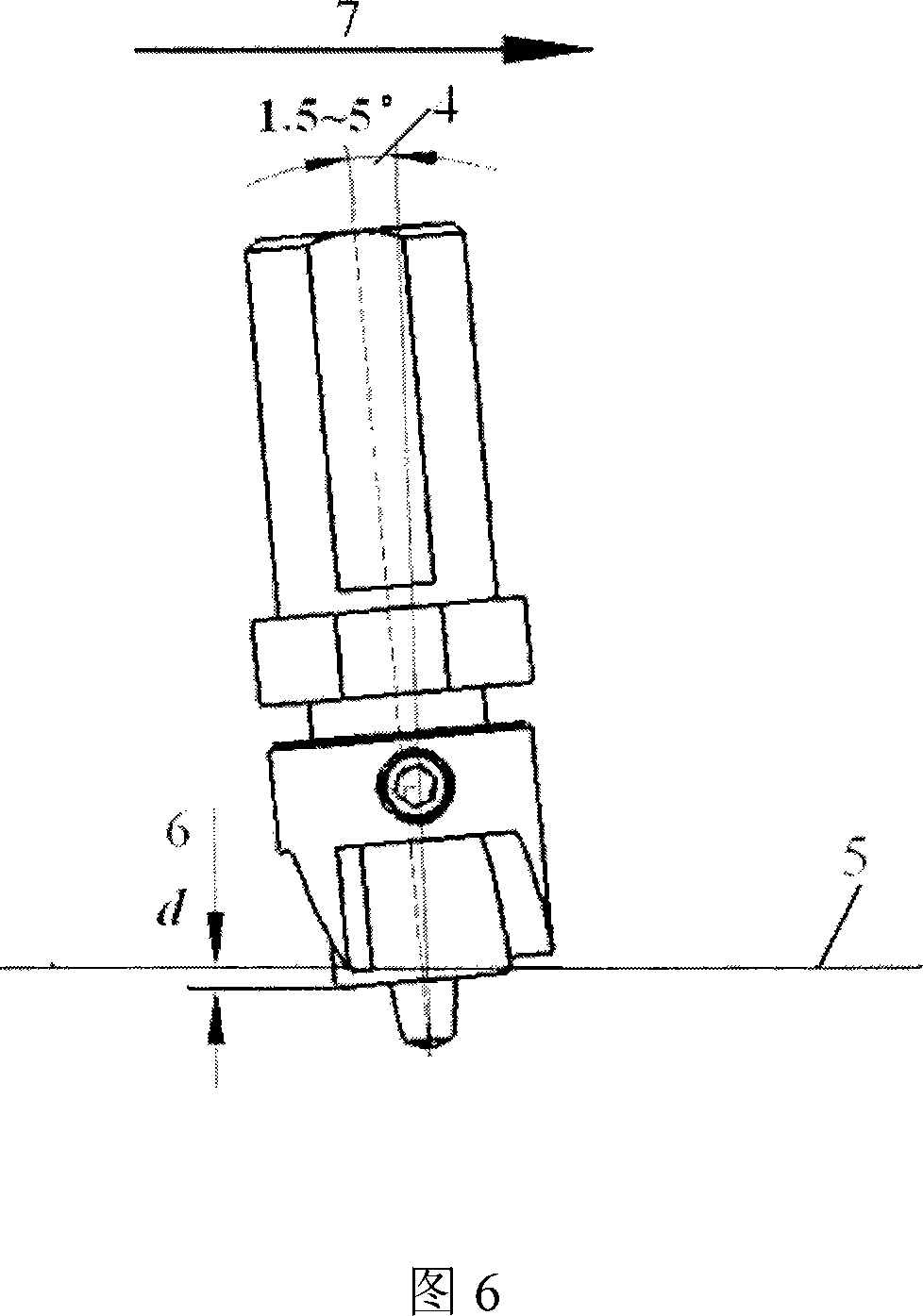

Fill type stirring friction plug repair welding method and welding tool thereof

InactiveCN101670483AReduce distortionAvoid intensityNon-electric welding apparatusFriction weldingEngineering

The invention discloses a fill type stirring friction plug repair welding method and a welding tool thereof, and relates to a stirring friction plug repair welding method and a welding tool thereof. The invention adopts fusion welding or friction plug welding for repair welding and causes the welding joints to reduce strength and have poor mechanical performance. The method comprises the followingsteps: (1) the material of a stirring pin is same as that of the part which repairs welding; (2) a conical preset hole is opened; (3) the size of the stirring pin is determined; (4) positioning is carried out; and (5) welding of the stirring friction plug is repaired. The welding tool is characterized in that the side wall of a clamping hole of a lower cylinder is provided with a thread through hole; a stirring body consists of the stirring pin and a stirring pin seat which are combined into a whole from top to bottom; the outer surface of the stirring pin seat is provided with a stirring pinclamping surface; the stirring pin is a cone; the stirring body is arranged in the clamping hole on the lower cylinder; the stirring pin clamping surface aligns to the thread through hole; and the stirring pin is exposed at the outside of the lower end surface of the lower cylinder. The invention is used for repair welding of the weld defects of stirring friction welding and keyholes.

Owner:HARBIN INST OF TECH

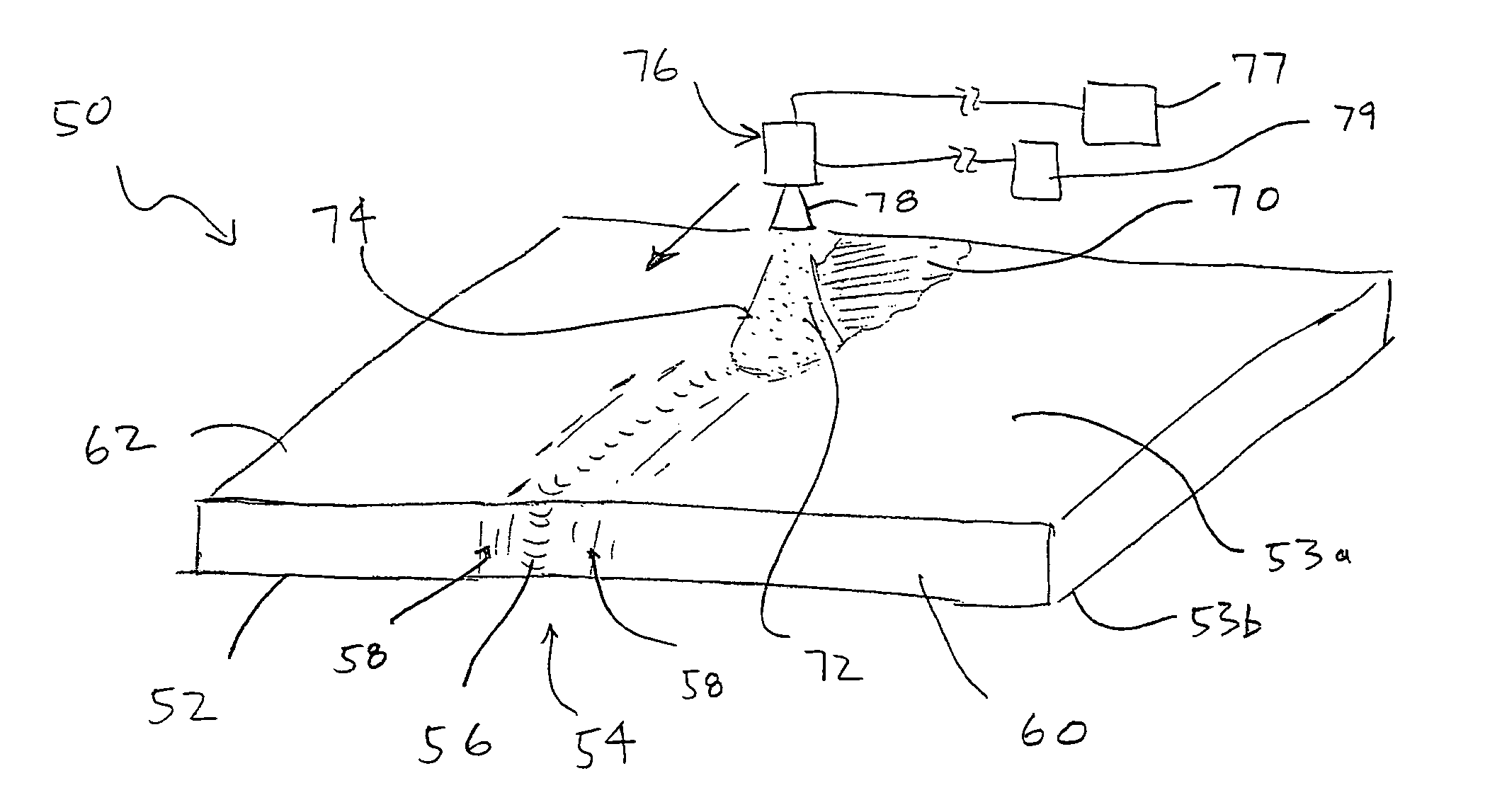

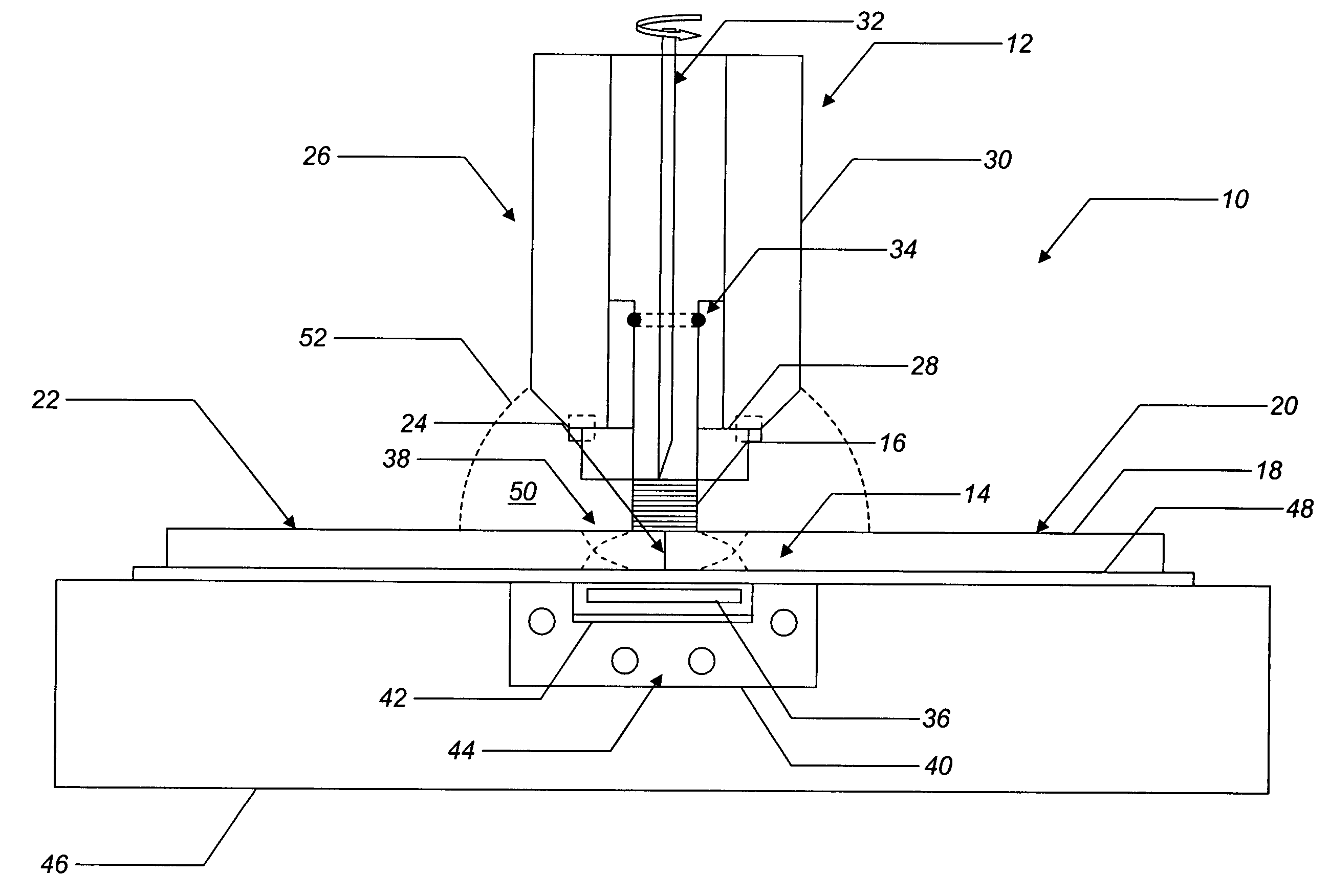

Friction stir welding apparatus and associated thermal management systems and methods

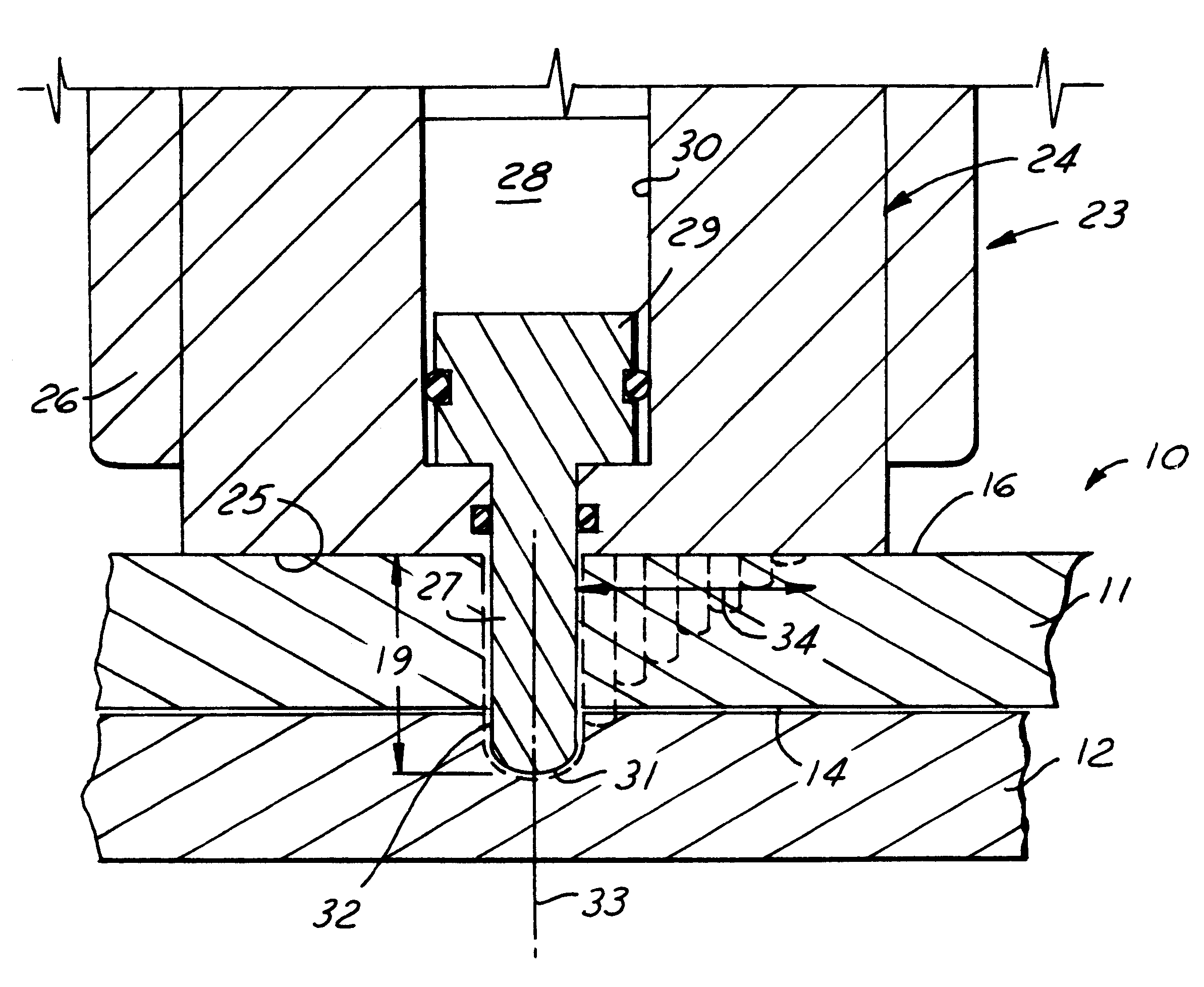

ActiveUS7121448B2Improve integrityQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

The present invention provides a friction stir welding apparatus and associated thermal management systems and methods for joining one or more similar or dissimilar materials forming a workpiece along a joint to be welded. The friction stir welding apparatus includes a pin tool apparatus selectively disposed adjacent to and in direct contact with a first surface of the workpiece along the joint to be welded and a heating member disposed adjacent to a second surface of the workpiece along the joint to be welded, the heating member operable for controllably heating at least a portion of the workpiece adjacent to the joint to be welded. The friction stir welding apparatus also includes an annular spindle having an interior portion and an axis, the interior portion of the annular spindle at least partially defining one or more cooling channels, the one or more cooling channels operable for containing a cooling fluid. The friction stir welding apparatus further includes a shoulder disposed adjacent to the annular spindle and substantially aligned with the axis of the annular spindle and a pin tool disposed adjacent to the shoulder and substantially aligned with the axis of the annular spindle. The cooling fluid is operable for cooling at least one of the shoulder and the pin tool.

Owner:GENERAL ELECTRIC CO

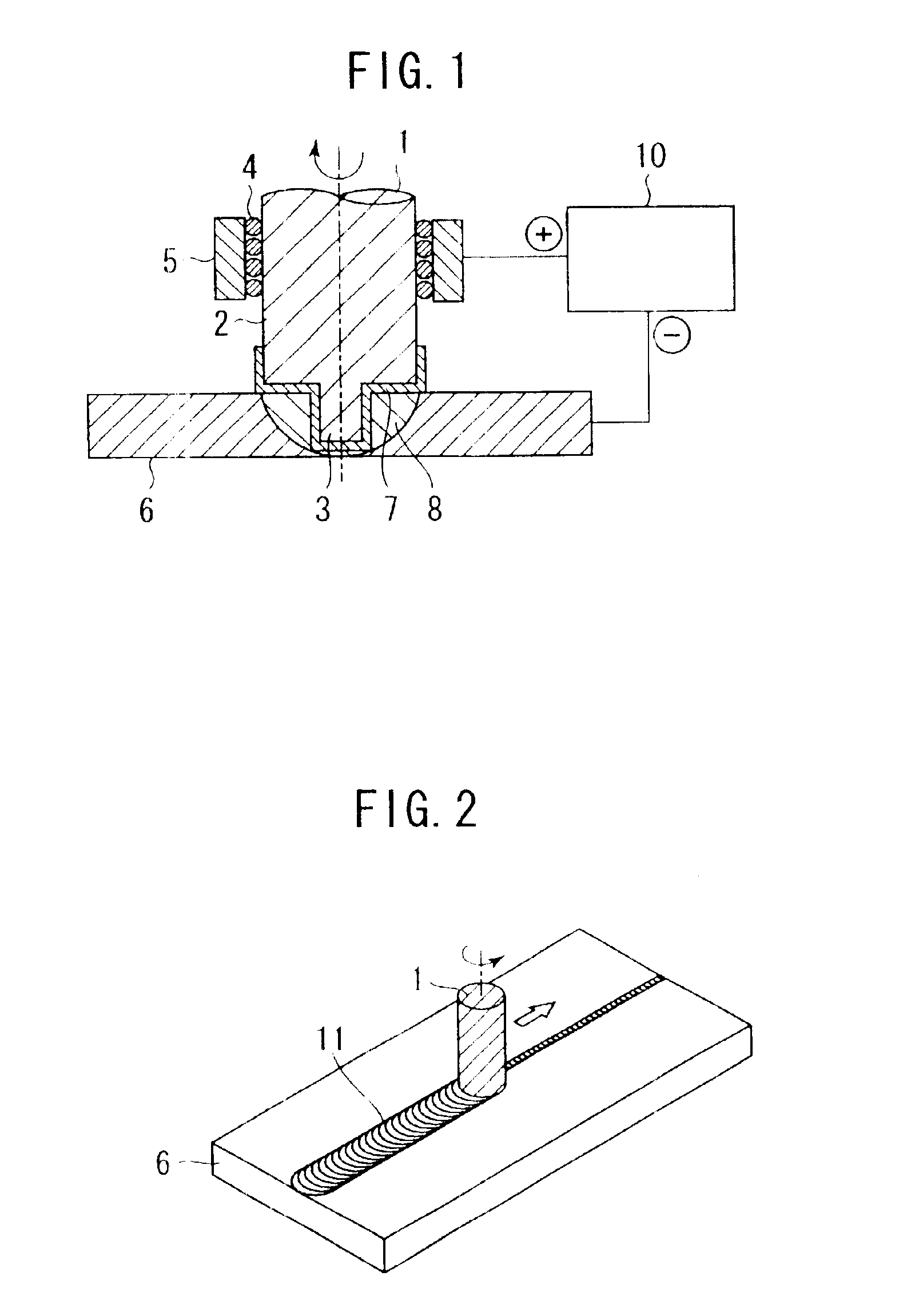

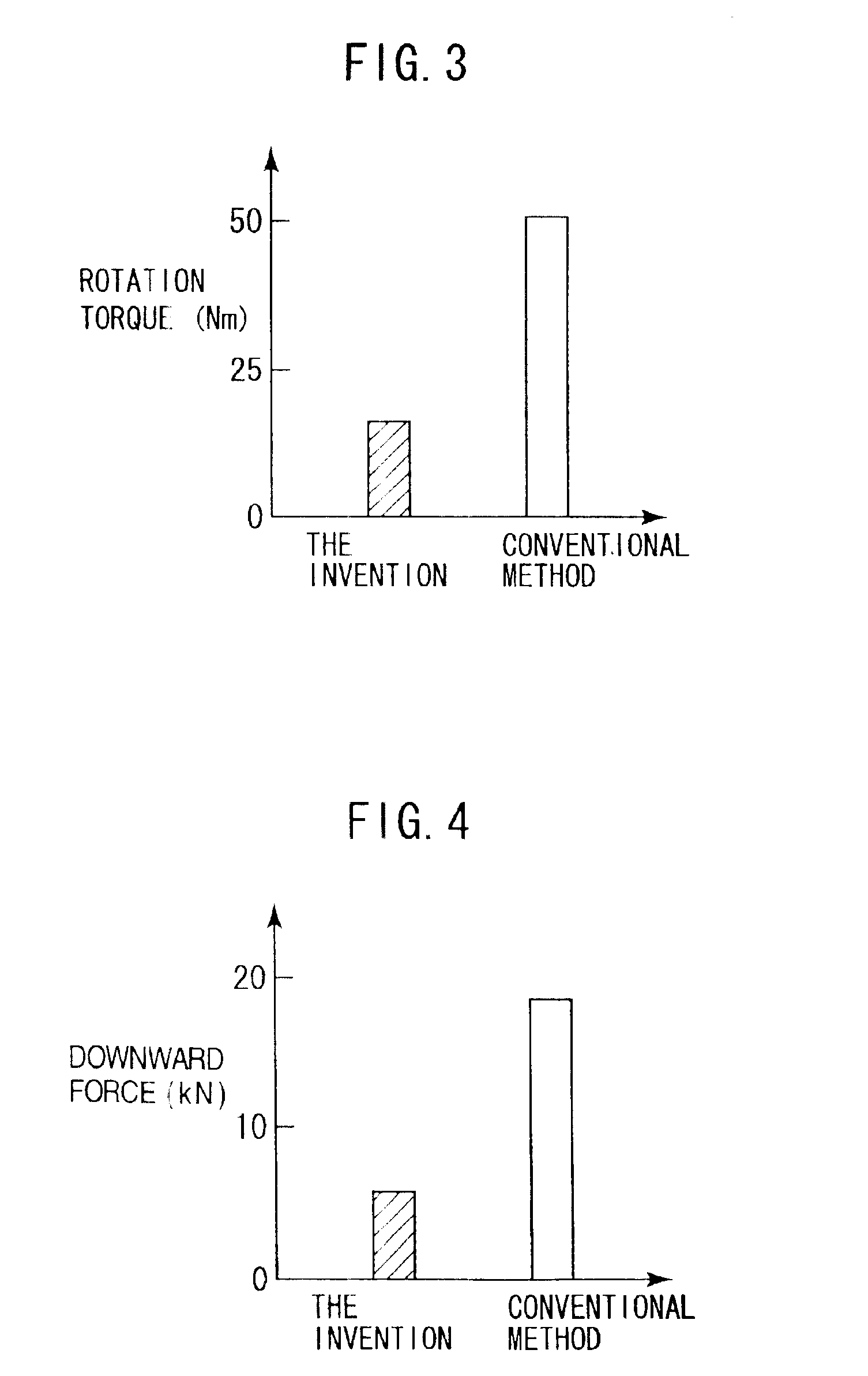

Friction stir welding method

InactiveUS6866181B2Suppress generation of friction forceHeat resistantElectric discharge heatingWelding/cutting auxillary devicesElectrical resistance and conductanceFriction welding

There is provided a method capable of decreasing a friction force in friction stir welding, in which a welding tool is used. In a method of friction stir welding workpieces together by rotating and pressingly plugging a welding tool, formed from a harder material than the workpieces, into a weld zone of the workpieces and moving the welding tool relatively in a welding direction, a power supply device allows a current to flow between the welding tool 1 and the workpieces to cause resistance heating of the welding tool. Combined use of resistance heating makes it possible to decrease a friction force. Preferably, a conductive ceramic is coated on surfaces of the welding tool to cause resistance heating.

Owner:HITACHI LTD

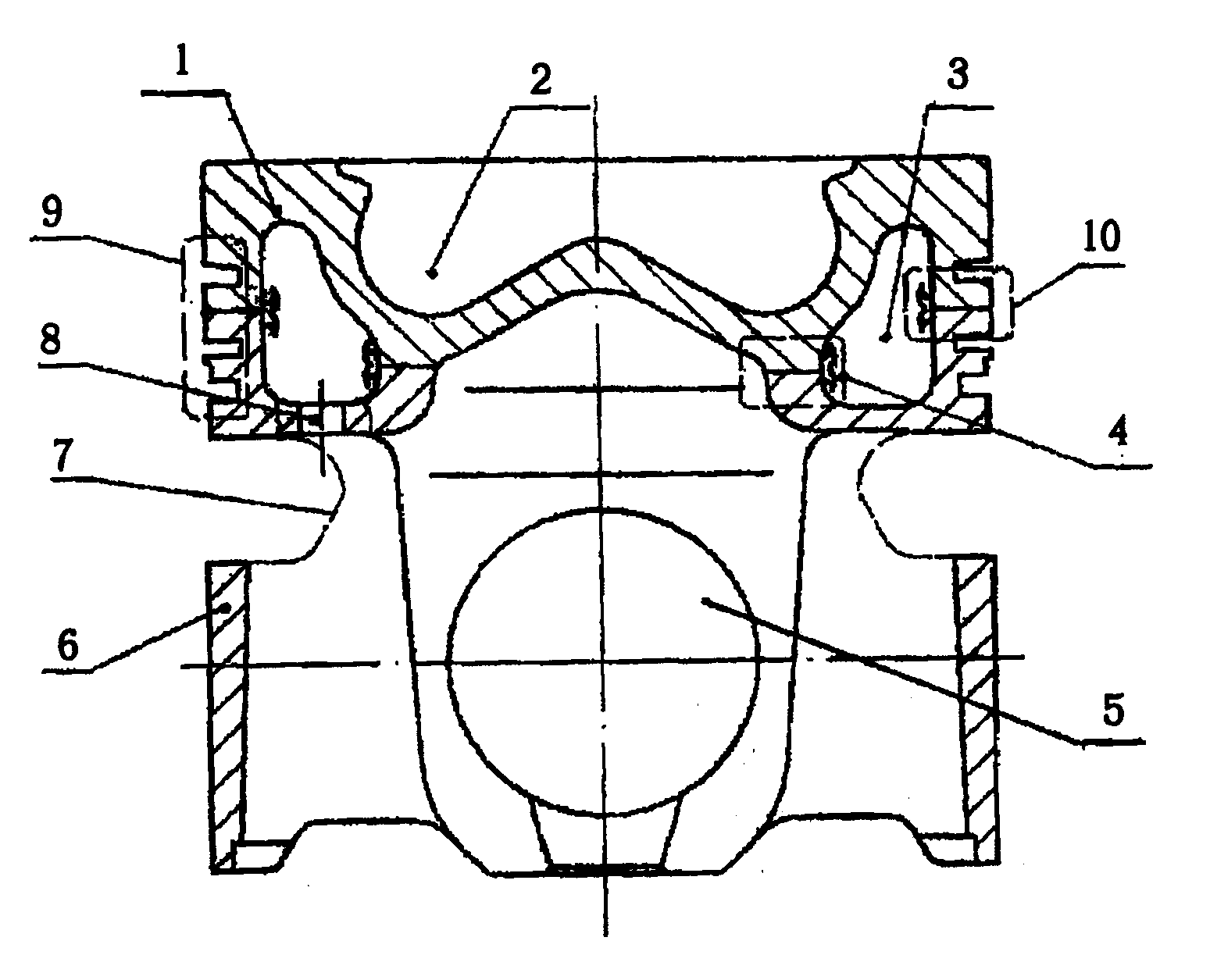

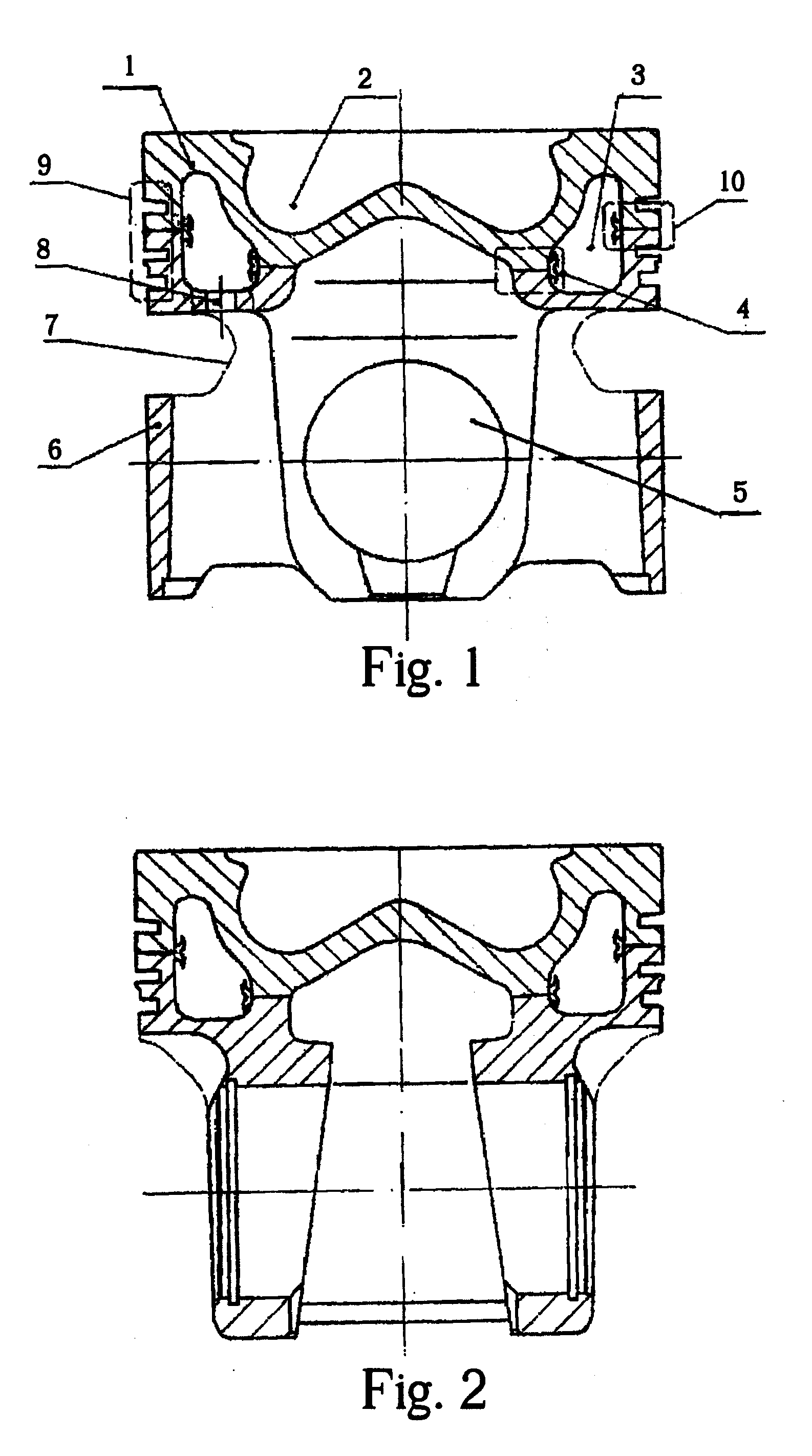

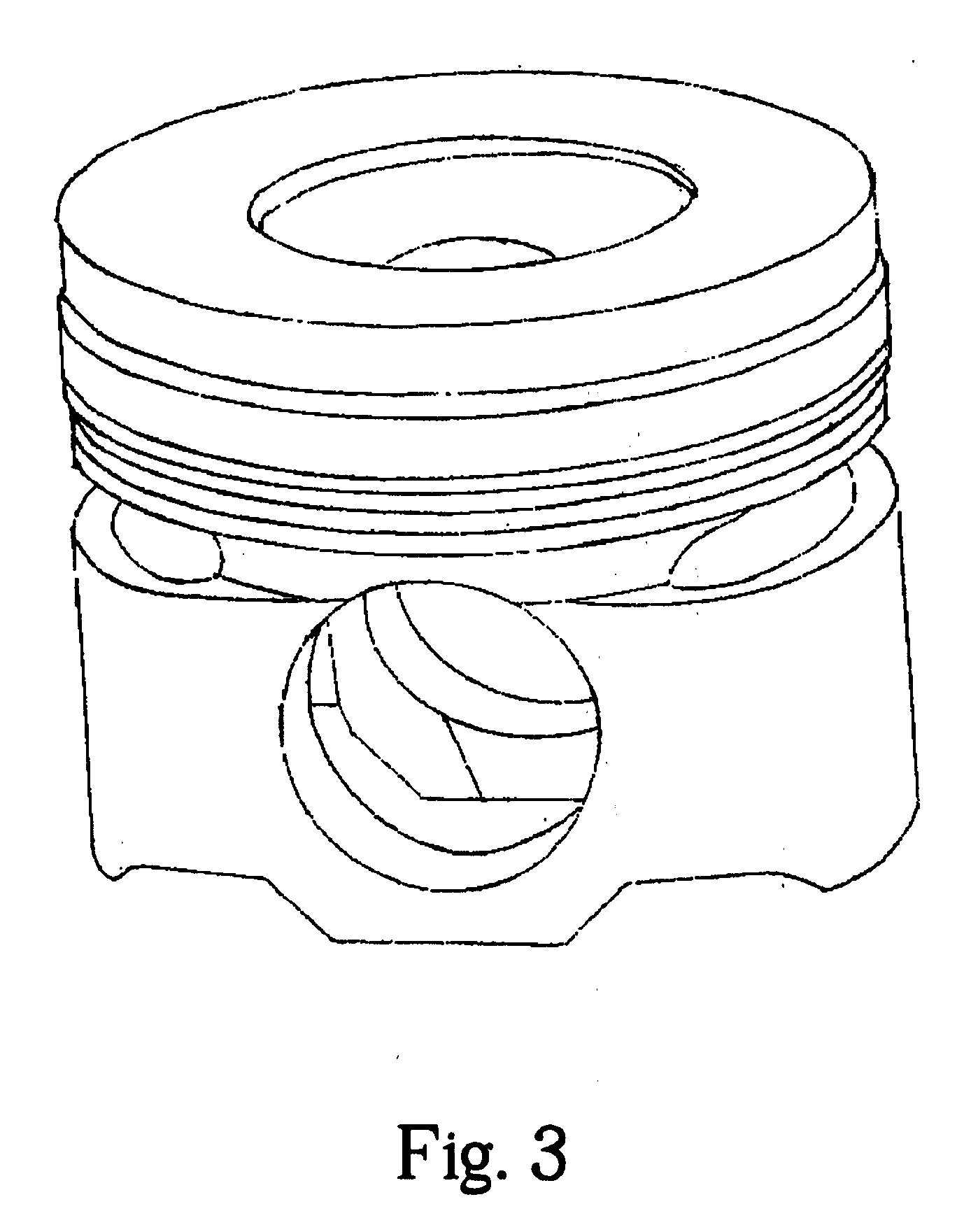

Welding Forged Steel Single Piece Piston and Its Manufacturing Methods

InactiveUS20070079775A1Simple manufacturing processImprove structural strengthAir coolingMachines/enginesFriction weldingCombustion chamber

The present invention has provided a welding forged steel single piece piston and its manufacturing methods. A semi-finished head and a semi-finished skirt are forged respectively; the semi-finished head and semi-finished skirt are heat-treated respectively; rough machining is carried out respectively to the semi-finished head and the semi-finished skirt, and a face of weld between the two adjacent ring grooves is higher than the one under the combustion chamber; the head and the skirt are welded together through friction welding; an annular groove, a combustion chamber, a ring groove, a pinhole, an outer annulus and oil inlet / outlet holes are manufactured respectively; and the surface of the piston is phosphorized and graphitized. Compared with one-piece forged piston, it has better processing technology, because the head and skirt are forged respectively and then welded together. Over-all structural rigidity of the piston has been increased, and distortion of the ring groove in high temperature is slight because the cooling oil recess is sealed through welding. As the annular groove is located on the upper part of skirt, the weight of body of the piston is lowered and this kind of structure can accelerate engine oil returning on, decrease the clearance between the piston and the cylinder and reduce the engine oil consumption.

Owner:SHANDONG BINZHOU BOHAI PISTON

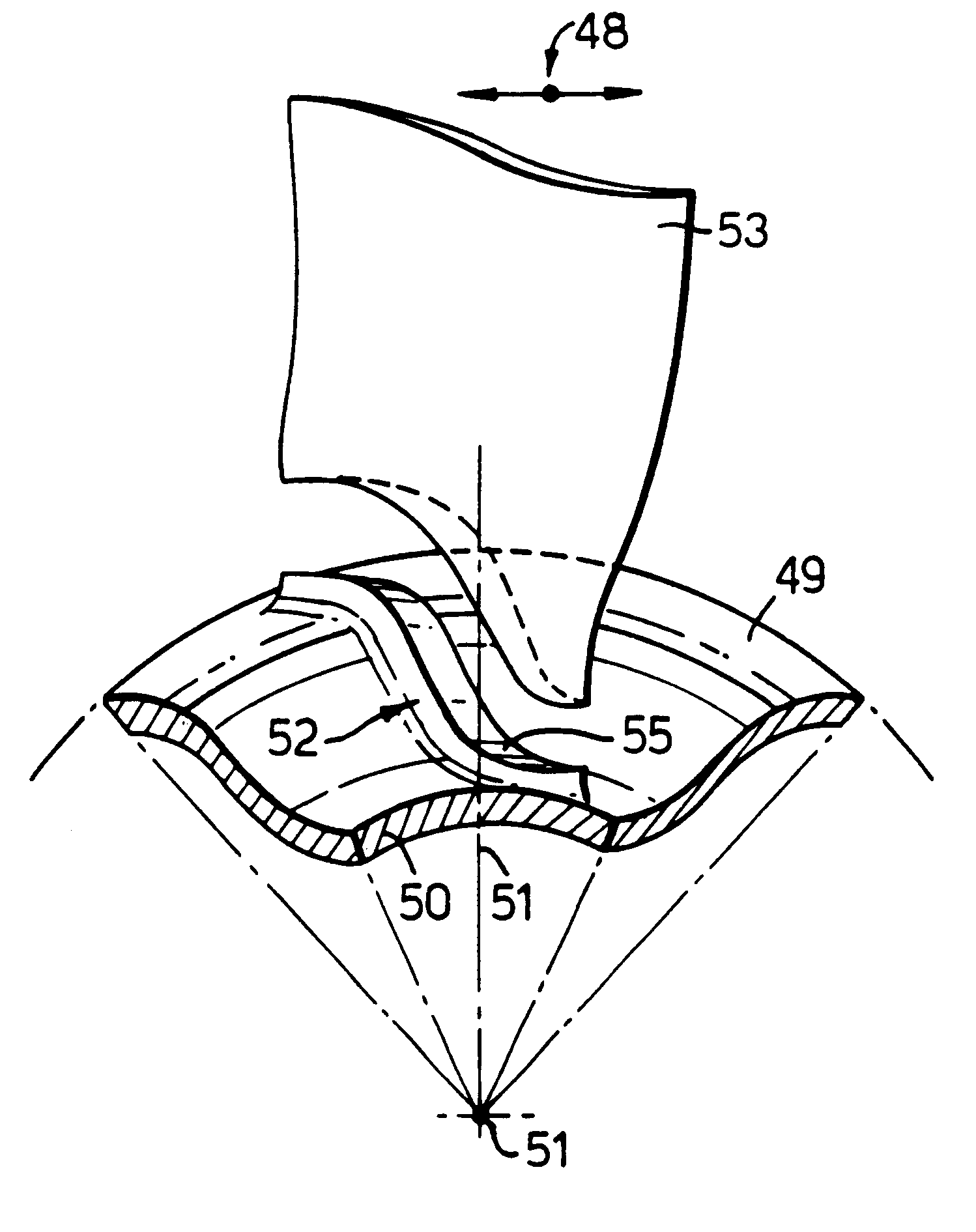

Hybrid bonded turbine rotors and methods for manufacturing the same

Hybrid bonded turbine rotors and methods for manufacturing the same are provided. A method for manufacturing a hybrid bonded turbine rotor comprises the steps of providing turbine disk having a rim portion comprising a live rim of circumferentially continuous material and a plurality of live rim notches in an outer periphery of the turbine disk alternating with a plurality of raised blade attachment surfaces defining the outer periphery; providing a plurality of turbine blades, each of which comprising an airfoil portion and a shank portion, the shank portion having a base surface; metallurgically bonding a compliant alloy material layer to either or both of the raised blade attachments surfaces of the turbine disk and the base surfaces of the blade shanks; and linear friction welding the plurality of blades to the turbine disk so as to form a bond plane between the raised blade attachments surfaces of the turbine disk and the base surfaces of the blade shanks, the compliant alloy material layer being disposed at the bond plane.

Owner:HONEYWELL INT INC

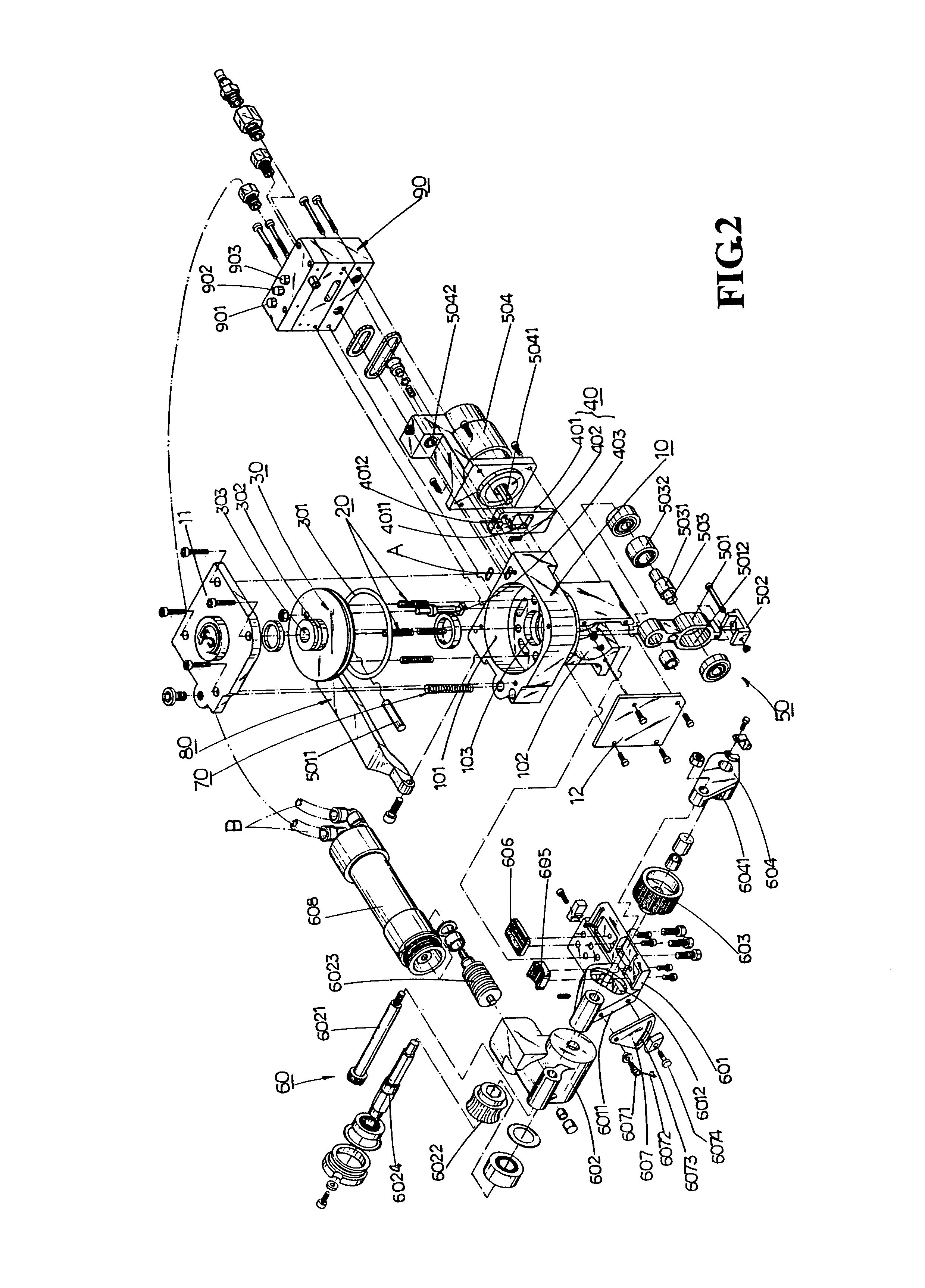

Structure portable strapping machine

InactiveUS7073431B1Easy and convenient and rapid and safe strapping operationEfficient cuttingWelding/cutting auxillary devicesLaminationFriction weldingEngineering

An improved structure portable strapping machine in which a band is articulated via a strap pulling device, a swinging device, and a cutting device and then bound tight by a friction welding means to facilitate strapping objects of various shapes and dimensions that are difficult to ship. As such, utilization of the improved structure portable strapping machine of the present invention is easy, convenient, rapid, reliable, and safe.

Owner:CHEN YU FU

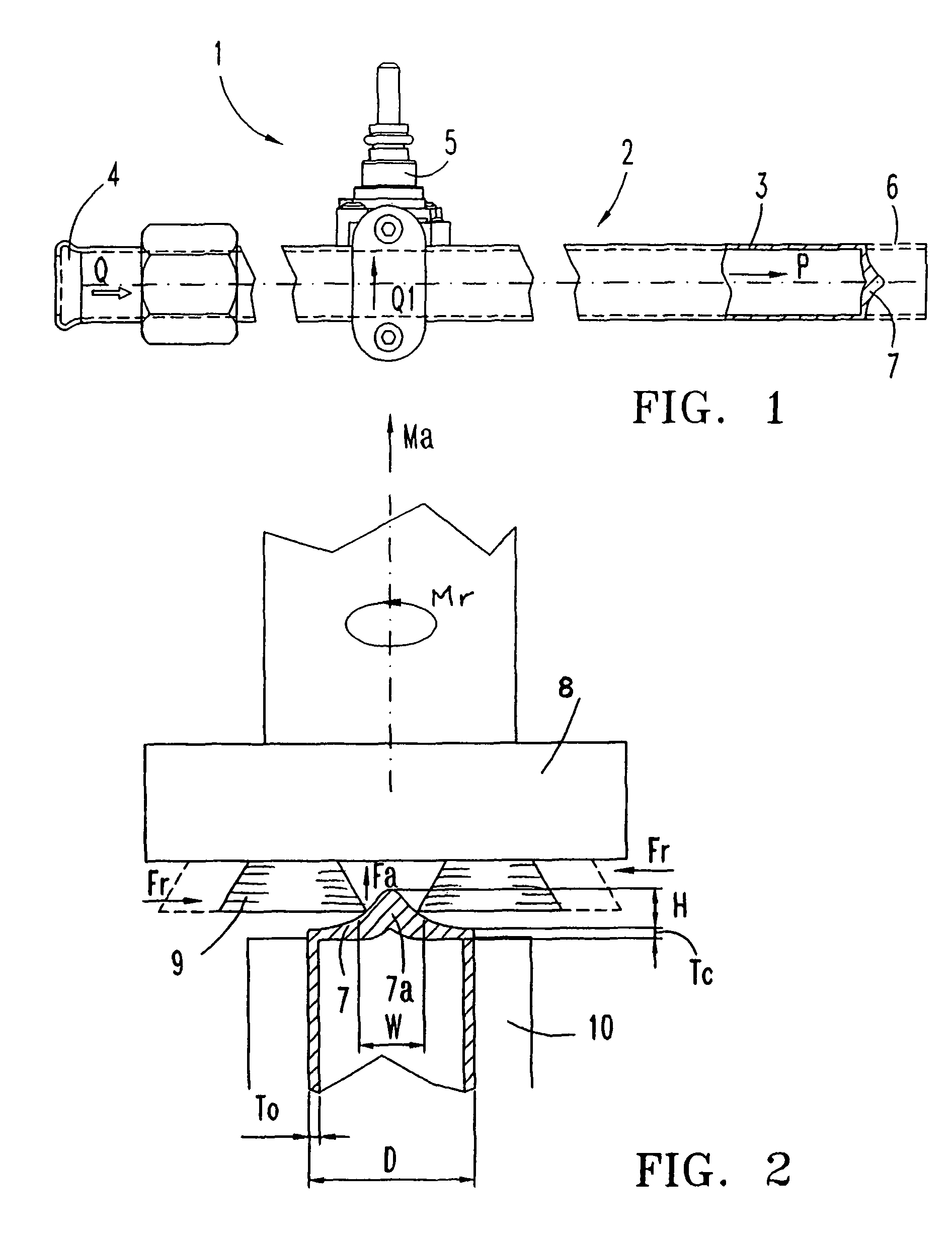

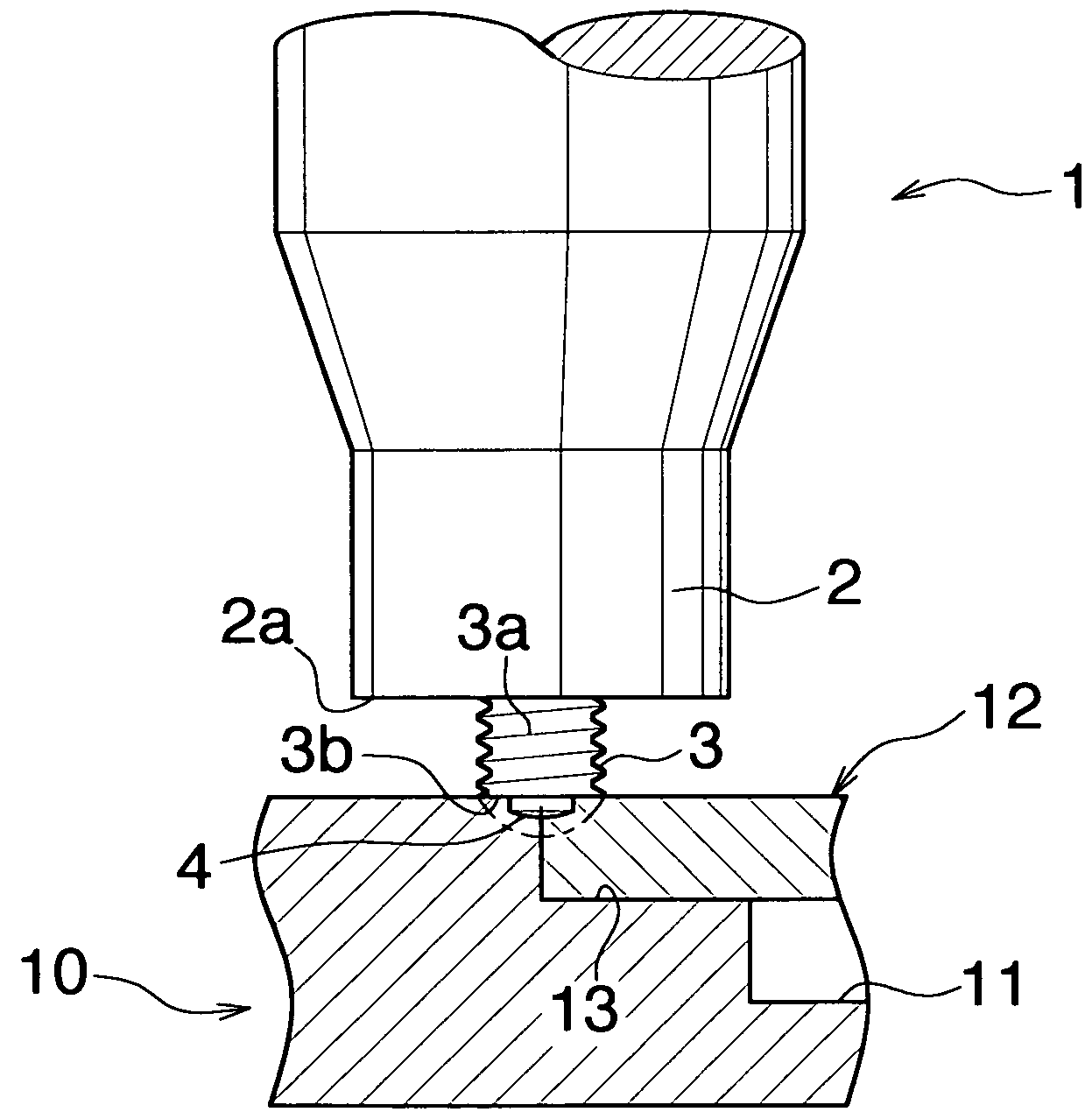

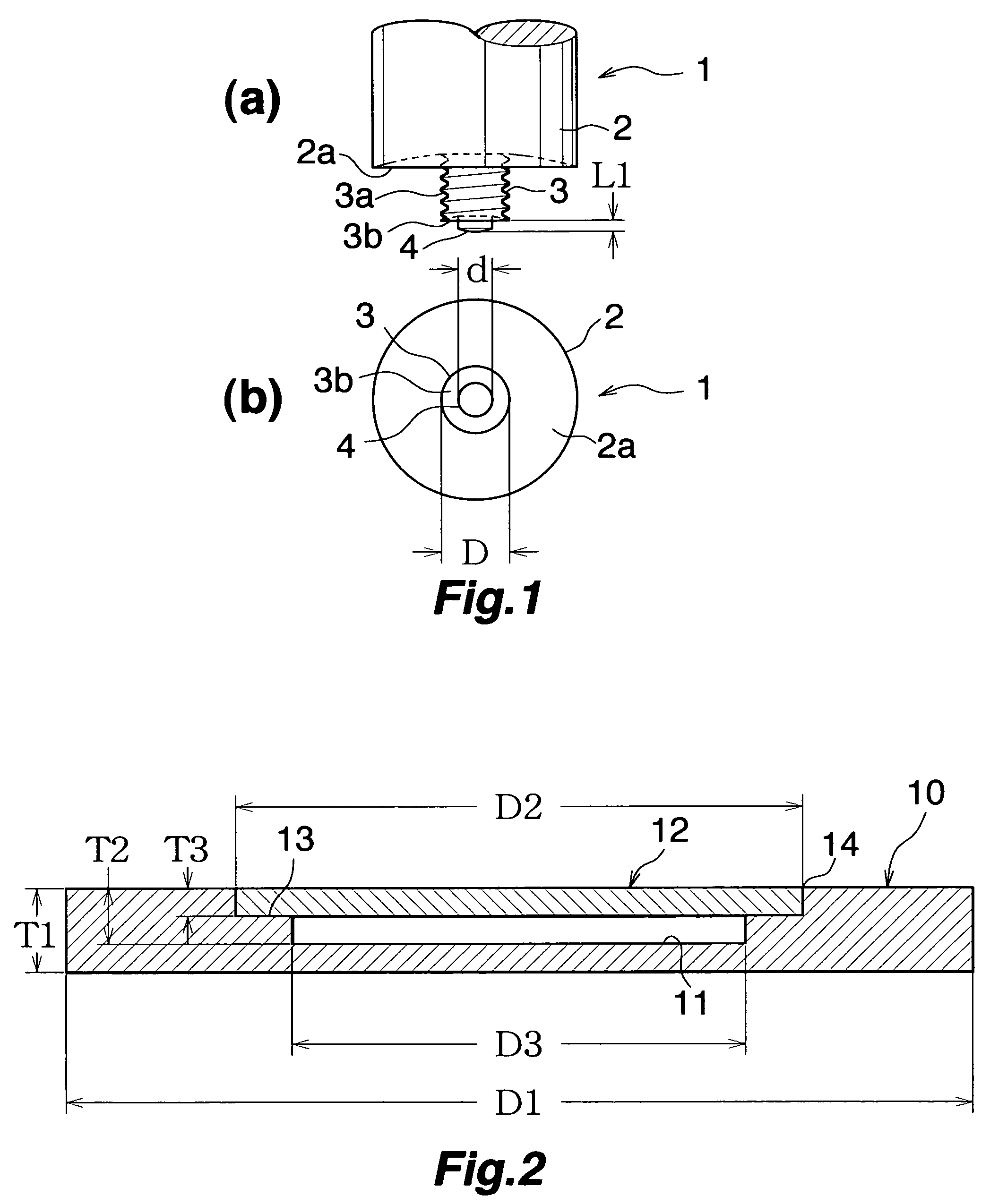

Friction Stir Welding Tool And Friction Stir Welding Method

InactiveUS20090072007A1Improve work efficiencyReduce facility costsWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

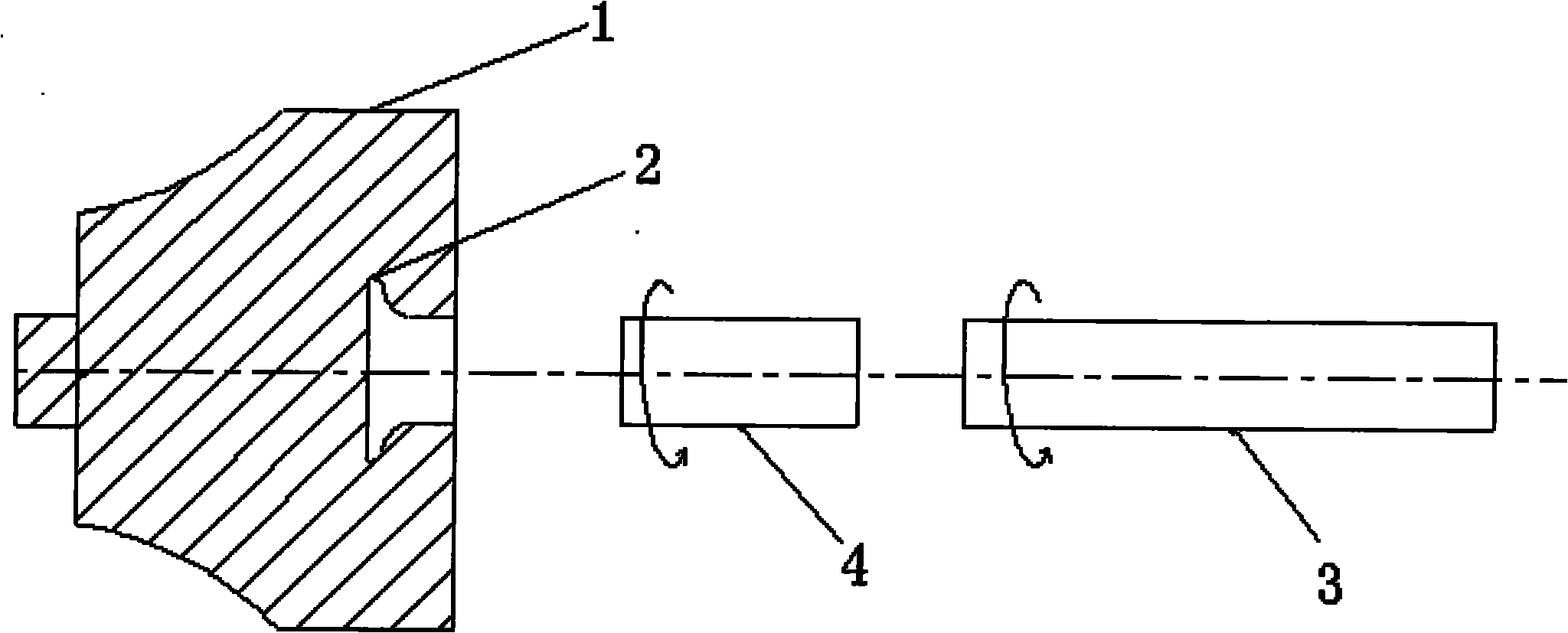

A friction stir welding tool 1 includes a rotor 2 to be attached to a rotation-drive section and a probe 3 concentrically provided on a distal end surface of the rotor 2. A provisional joining projection 4 is concentrically provided on a distal end surface of the probe 3. A relation 0.3 D≦d≦0.8 D is satisfied, where D represents a diameter (mm) of the distal end surface of the probe 3, and d represents a diameter (mm) of the contour of a transverse cross section of the provisional joining projection 4. The provisional joining projection 4 has a length of 0.3 to 2 mm. This friction stir welding tool can improve the work efficiency of friction stir welding and can carry out friction stir welding which is excellent in welding quality after main friction stir welding.

Owner:SHOWA DENKO KK +1

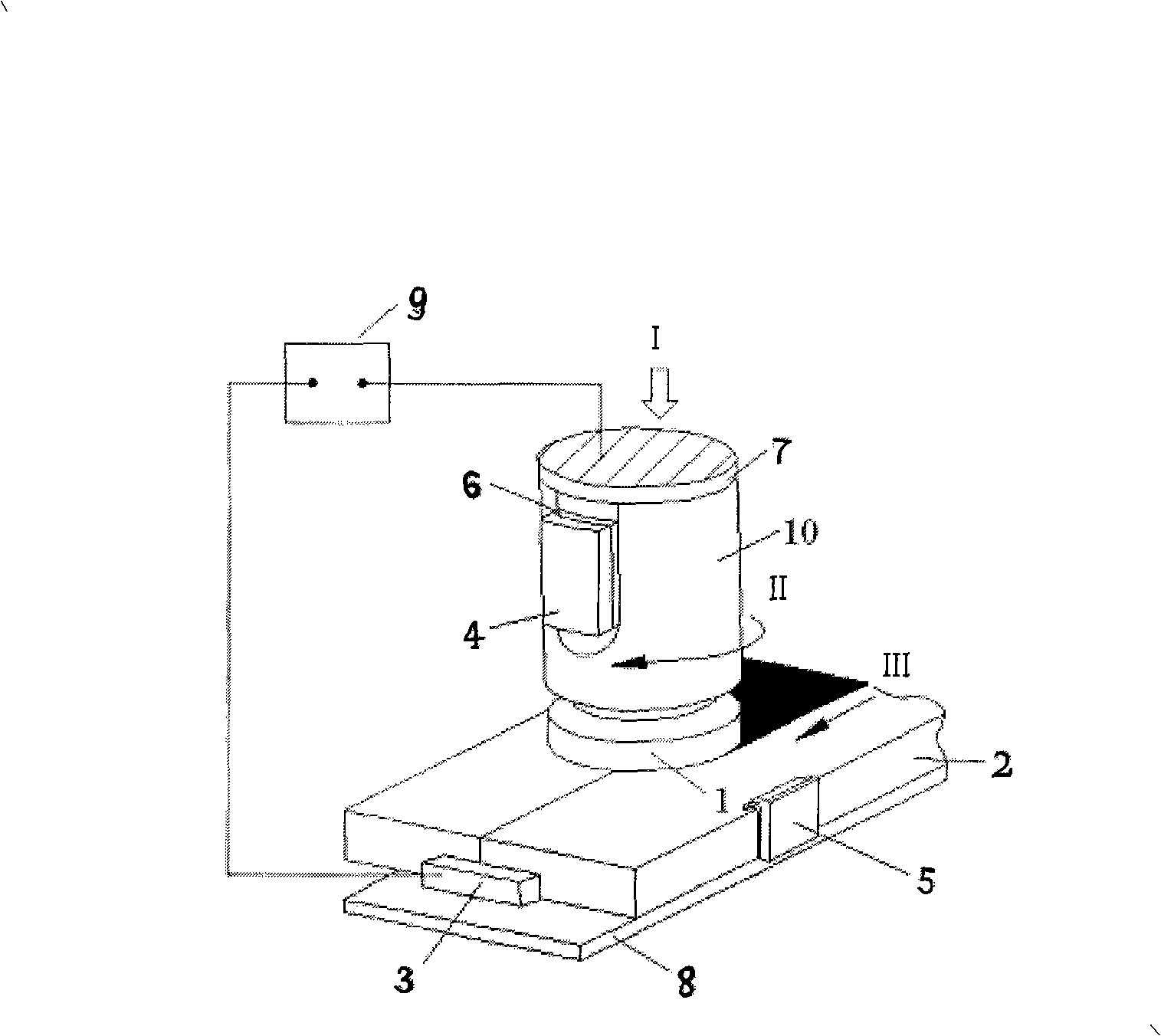

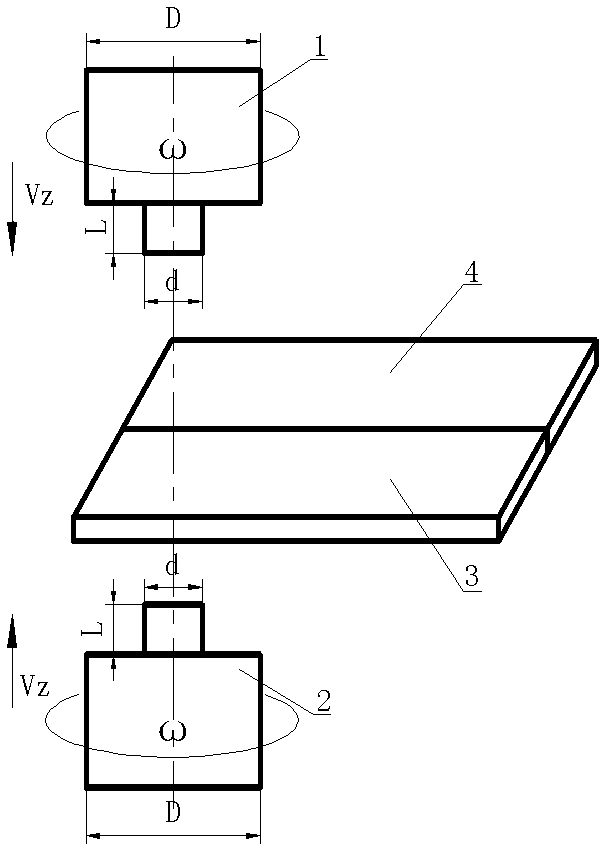

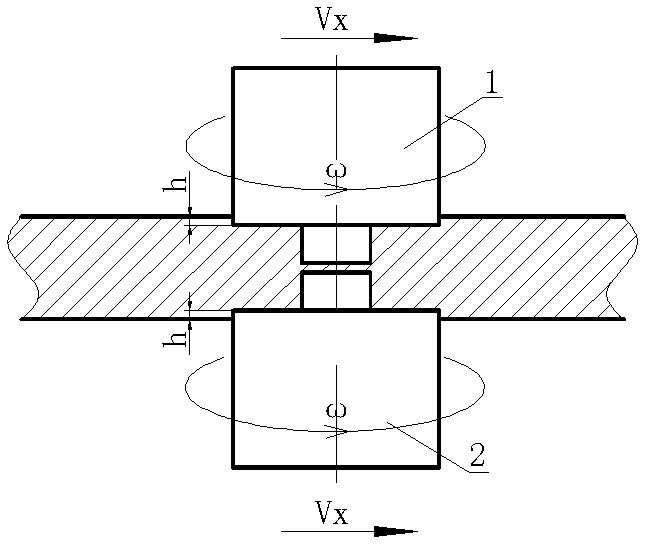

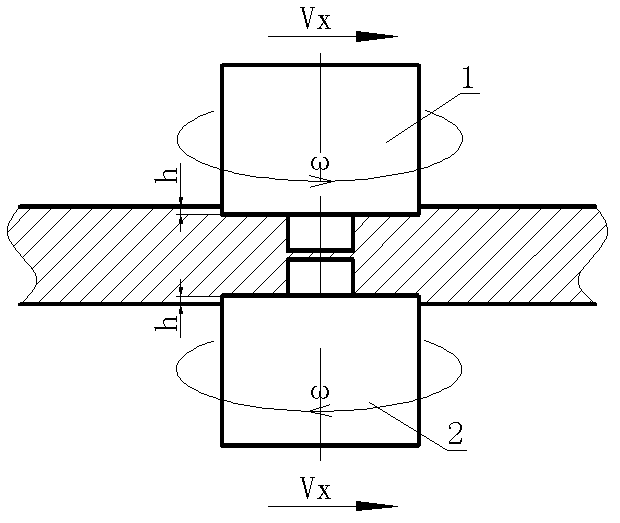

Double-side symmetric friction stir welding method

InactiveCN102601516ARemove asymmetryReduce card loading requirementsNon-electric welding apparatusFriction weldingRotation velocity

The invention relates to a friction stir welding method, in particular to a double-side symmetric friction stir welding method, which solves the technical problems of asymmetric structure and mechanical properties, root defects, difficulty in clamping, easiness in breakage of a self-sustaining friction stir welding stirring pin, and low welding efficiency and joint property of a single-side friction stir welding joint. The method includes: firstly, fixing workpieces to be welded onto a worktable and positioning the workpieces on the same horizontal plane; secondly, plunging two stirring heads into the two workpieces respectively at the same rotation speed omega in the same or opposite rotation directions to reach preset positions; and thirdly, welding the workpieces to be welded by the aid of the two stirring heads at the same welding speed. By means of adjusting the rotation directions of an upper shaft shoulder and a lower shaft shoulder, flow of materials can be improved, functional asymmetry of heat engines on two sides of the cross section of a joint is eliminated, the mechanical property of the joint is improved, the two stirring heads are used for acting on the upper surfaces and the lower surfaces of the workpieces to be welded respectively to avoid the root defects, and the two stirring heads simultaneously generate heat so that welding efficiency can be remarkably improved.

Owner:HARBIN INST OF TECH

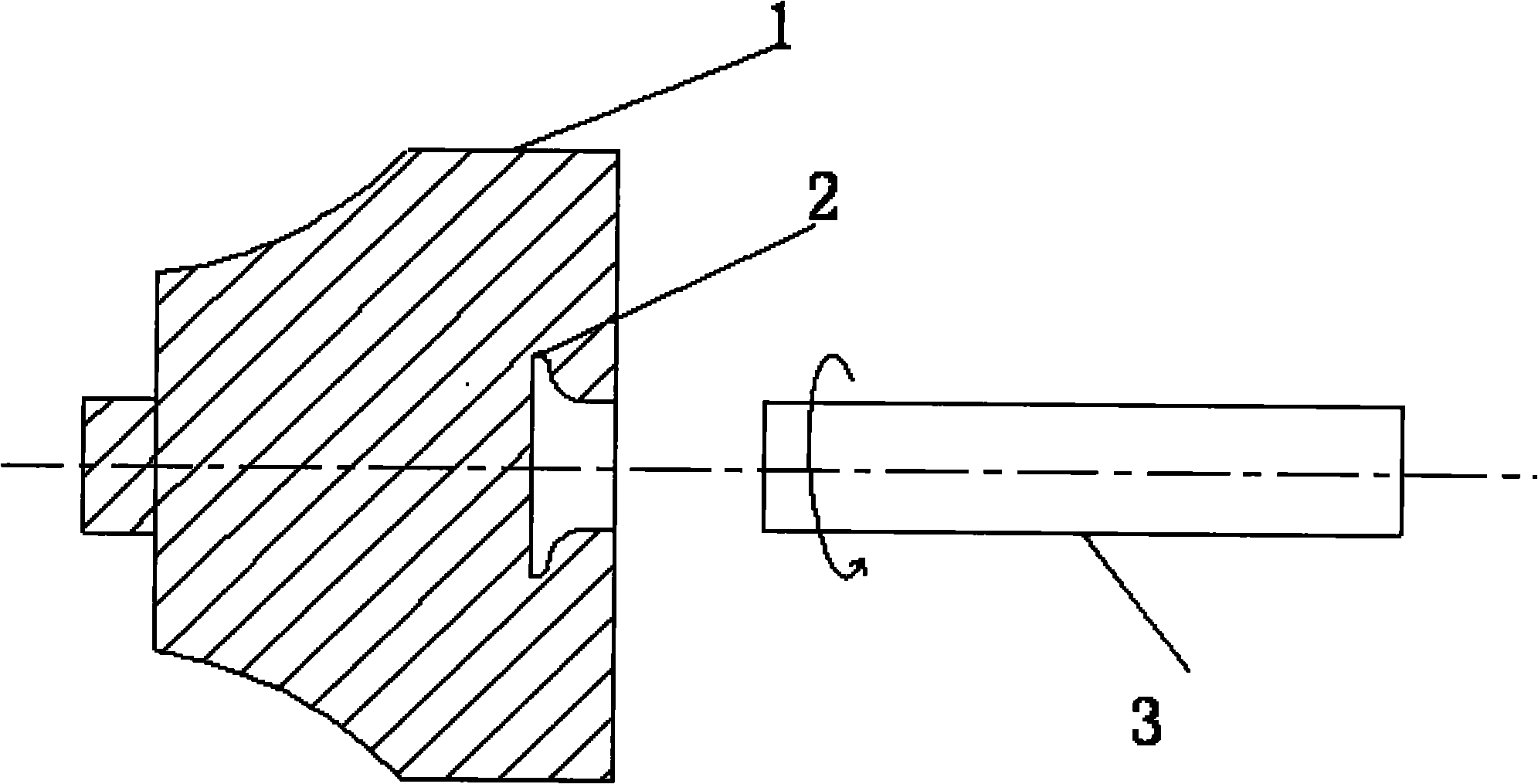

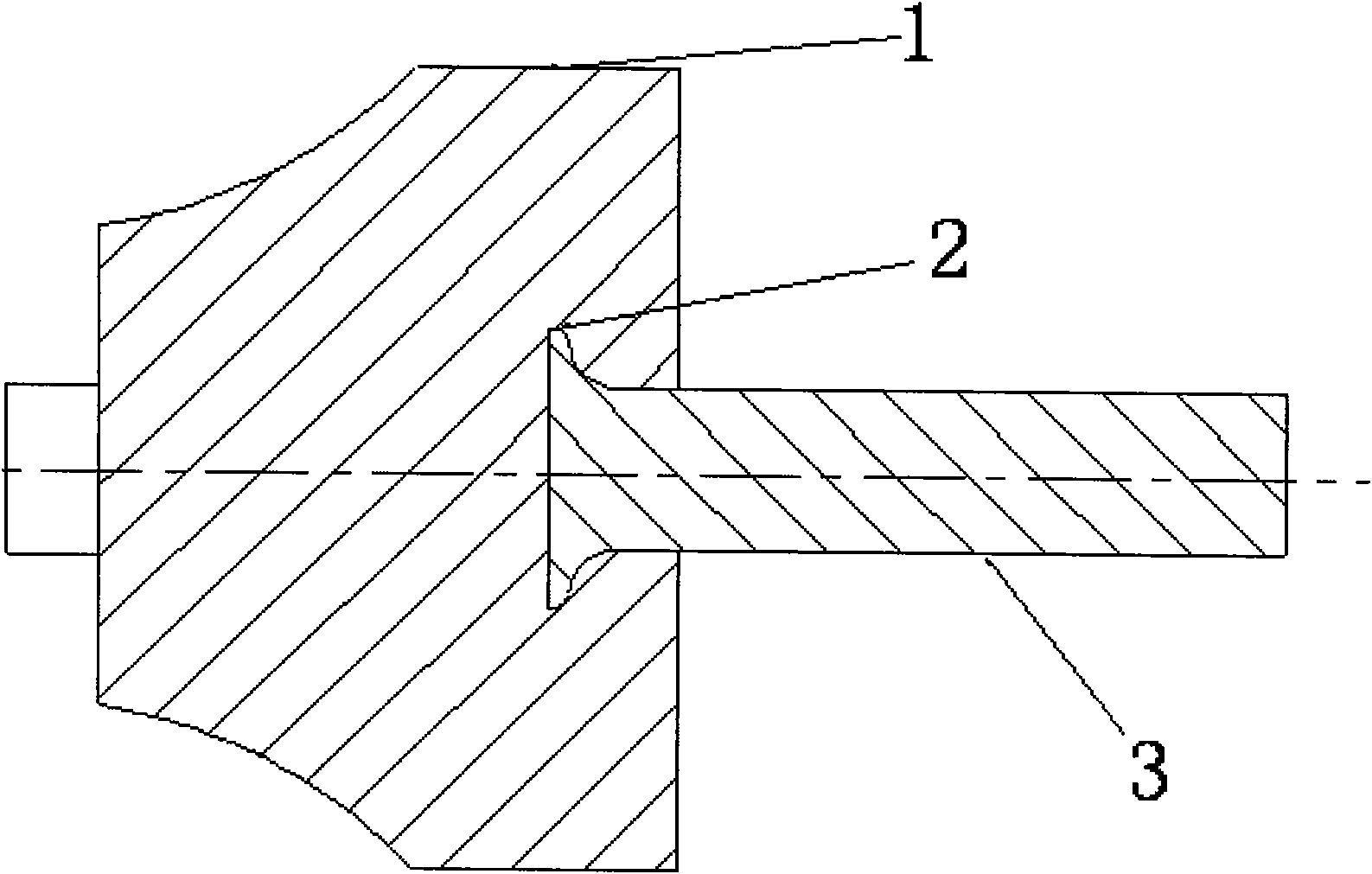

Friction welding method of titanium-aluminum alloy turbine and 42CrMo quenched and tempered steel shaft

InactiveCN101844271AHigh tensile strength at room temperatureAchieve associativityNon-electric welding apparatusFriction weldingDual effect

The invention discloses a friction welding method of a titanium-aluminum alloy turbine and a 42CrMo quenched and tempered steel shaft, which aims to solve the technical problem that when the titanium-aluminum alloy turbine rotor and the quenched and tempered steel shaft are connected by the current method, the tensile strength of a joint is low. The invention has the technical scheme that an embedded groove in a shape of a solid of revolution is processed at one side of the titanium-aluminum alloy turbine; in the welding process, the welding end surface of the turbine shaft has friction with the welding surface of the embedded groove of the titanium-aluminum alloy turbine; and by controlling the friction shortening amount, the casting fins formed at the turbine shaft side are fully filled into the embedded groove. Thus dual effects of metallurgical bonding and mechanical connection of the welding surface are achieved, and the tensile strength of the joint of connecting pieces at room temperature is increased from 390MPa in the background art to 480-537MPa.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

FSW tool

InactiveUS20040195291A1Welding/cutting auxillary devicesAuxillary welding devicesBiomedical engineeringFriction stir welding

The invention resides in a friction stir welding tool comprising a shaft (532) and a tapered probe (504), said probe having a plurality of helically pitched surfaces (512) extending in the direction from the proximal end (530) of the probe to a distal end (531) of the probe, such that the diameter of the probe, in every longitudinal cross-section of the probe (504), diminishes continously from the proximal end (530) to the distal end (531) of the probe.

Owner:ANDERSSON CLAES GORAN +1

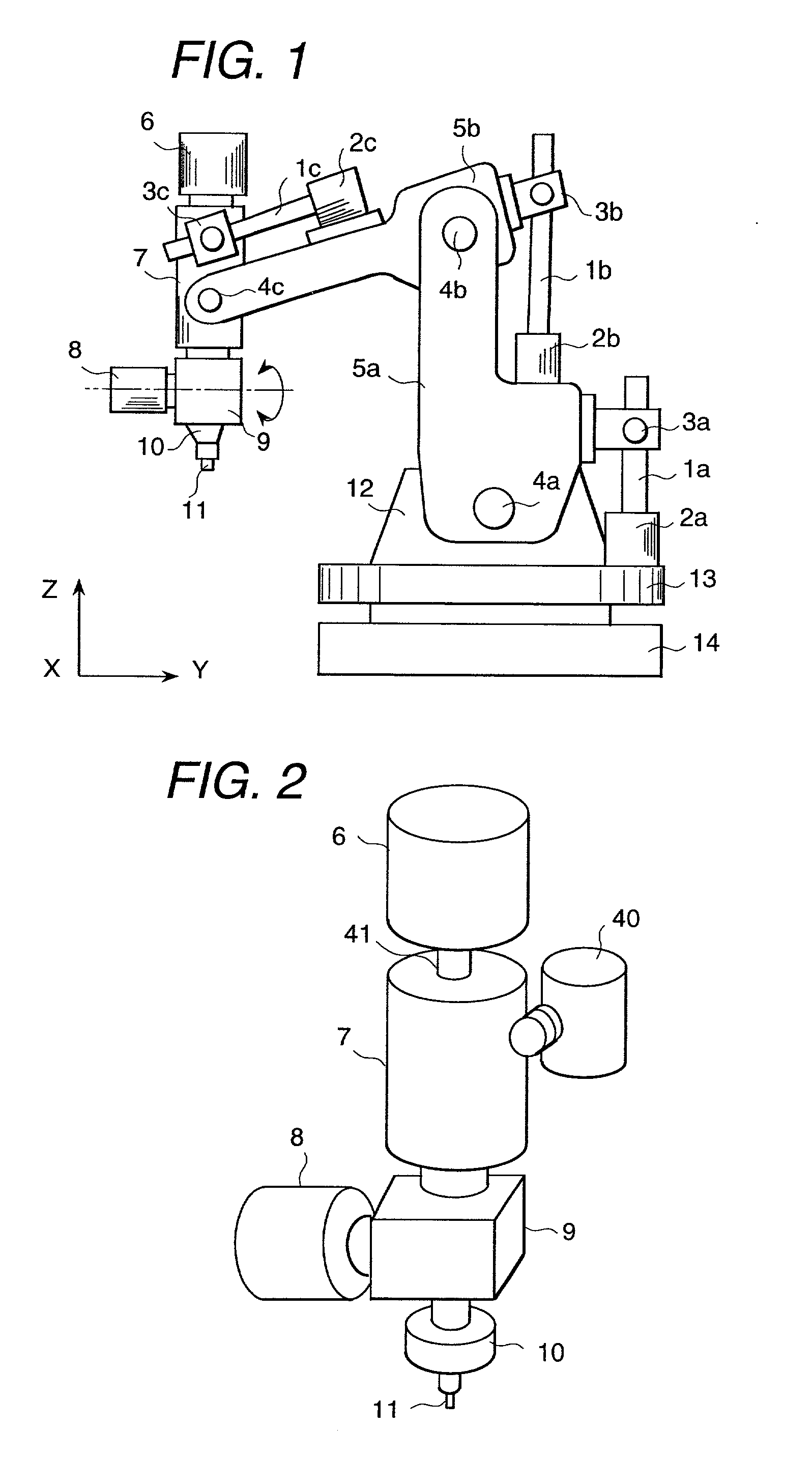

Friction stir welding method and apparatus, and welded structure

InactiveUS20020145031A1Welding/cutting auxillary devicesAuxillary welding devicesRotational axisGeometric relations

It is an object of the present invention to provide a friction stir welding method and apparatus capable of maintaining a rotating tool and workpieces at a substantially constant geometrical relation for arbitrary curved surfaces having a three-dimensional shape, as well as a welded structure obtained thereby. The present invention resides in a friction stir welding method comprising joining workpieces while setting rotational angles of two rotational axes of a rotating tool which the two rotational axes are rotatable in intersecting directions or perpendicularly intersecting directions independently of rotation of the rotating tool, detecting a normal line direction with respect to joint surfaces of the workpieces and a tangential direction of a joint line, and joining the workpieces in three-dimensional directions while setting, on the basis of the detected normal line direction and tangential direction, an angle relative to a normal line direction, as well as a tangential direction, at a tip end of the rotating tool, and also resides in a friction stir welding apparatus using the said method.

Owner:HITACHI LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com