Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1514 results about "Weld zone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weld Zone. Zone comprising the weld line and the heat-affected areas on either side of the weld line caused by the friction welding and subsequent heat-treatment processes.

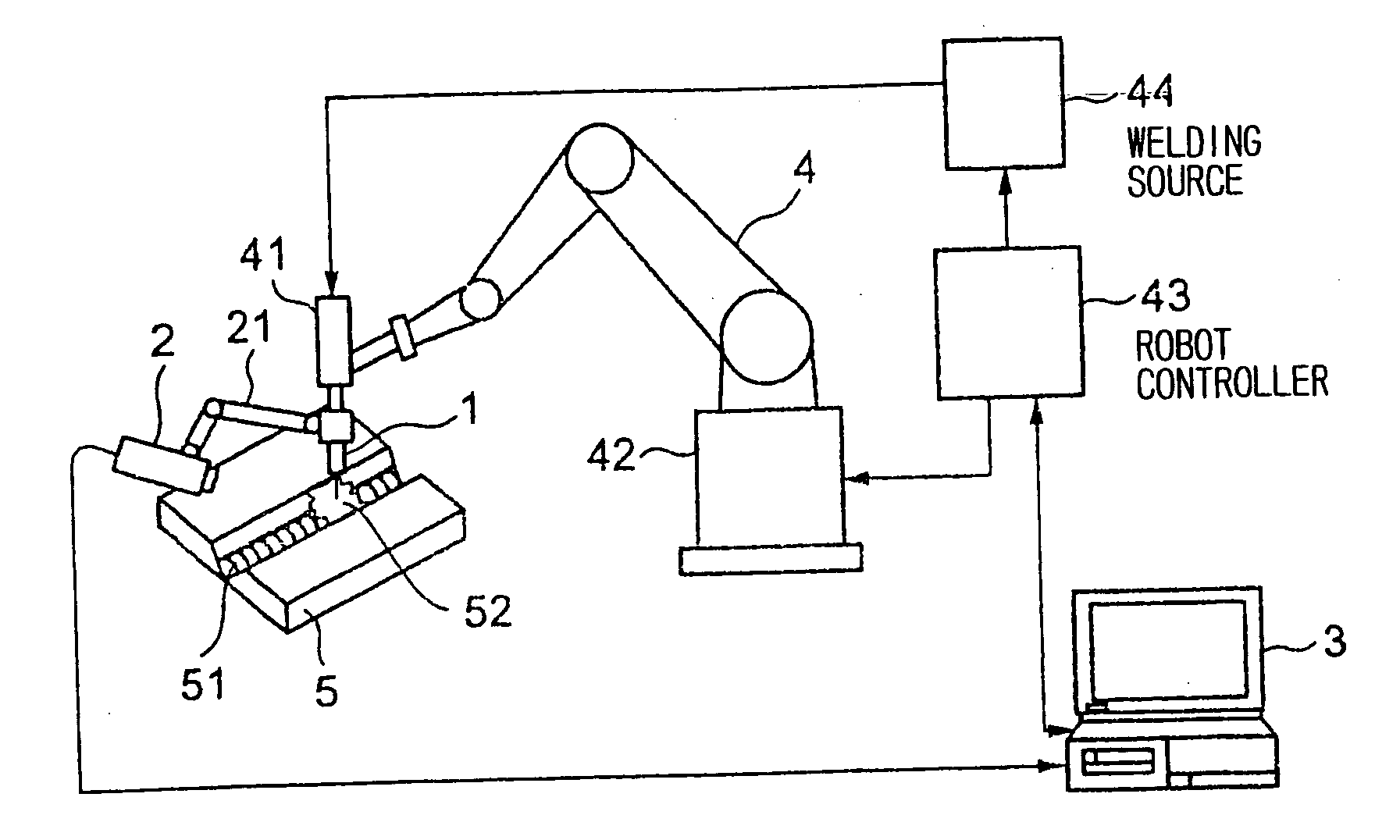

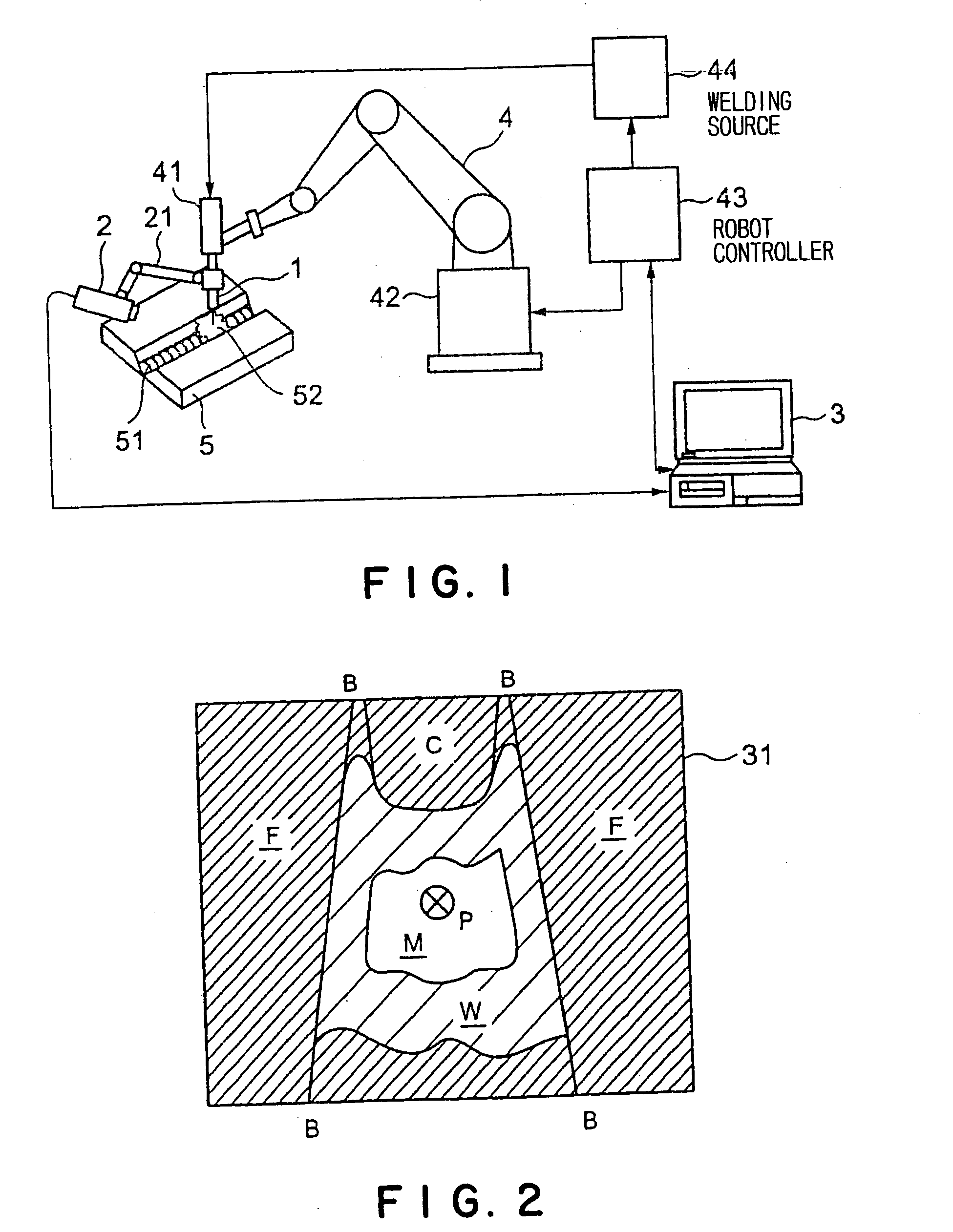

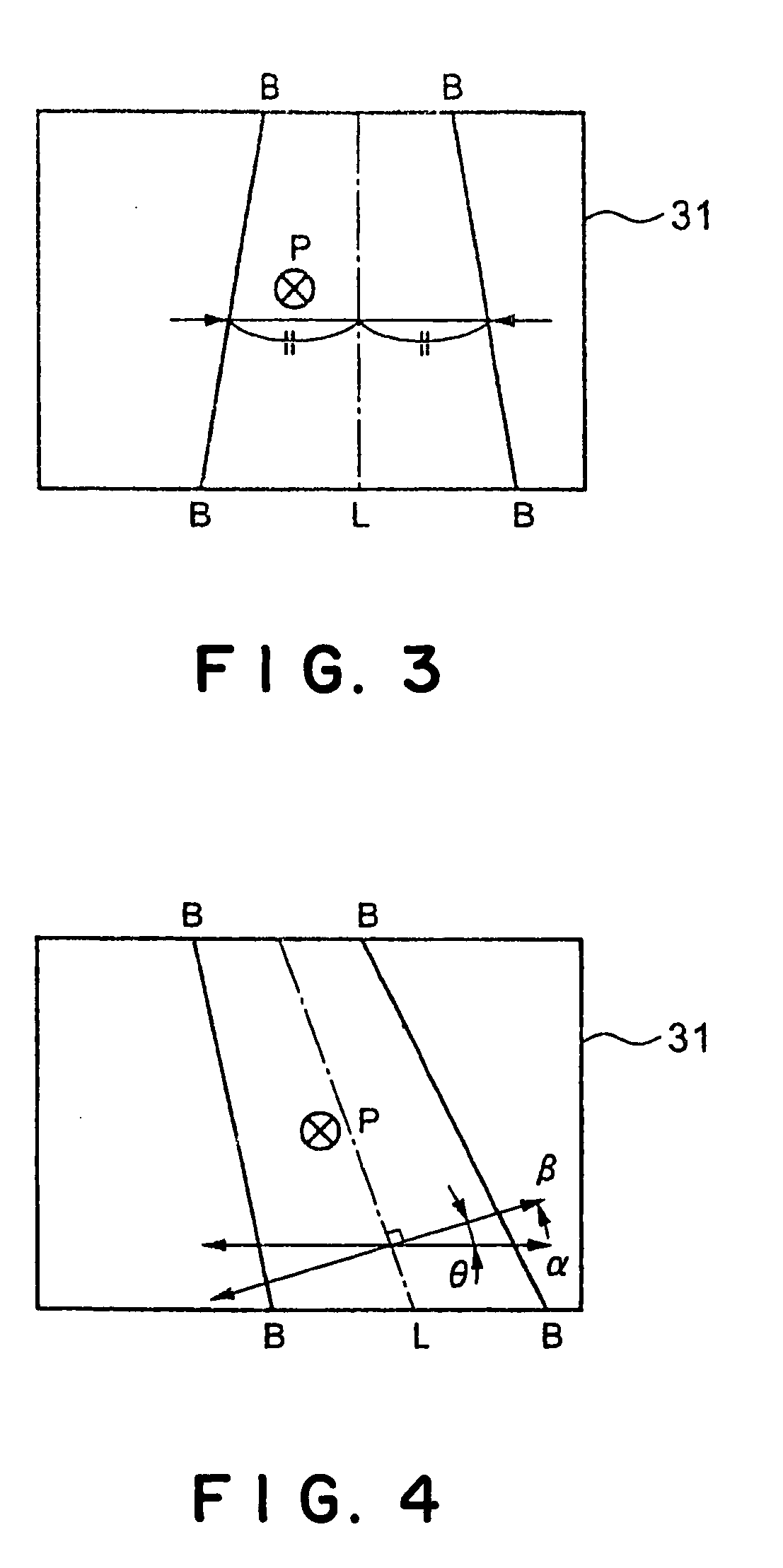

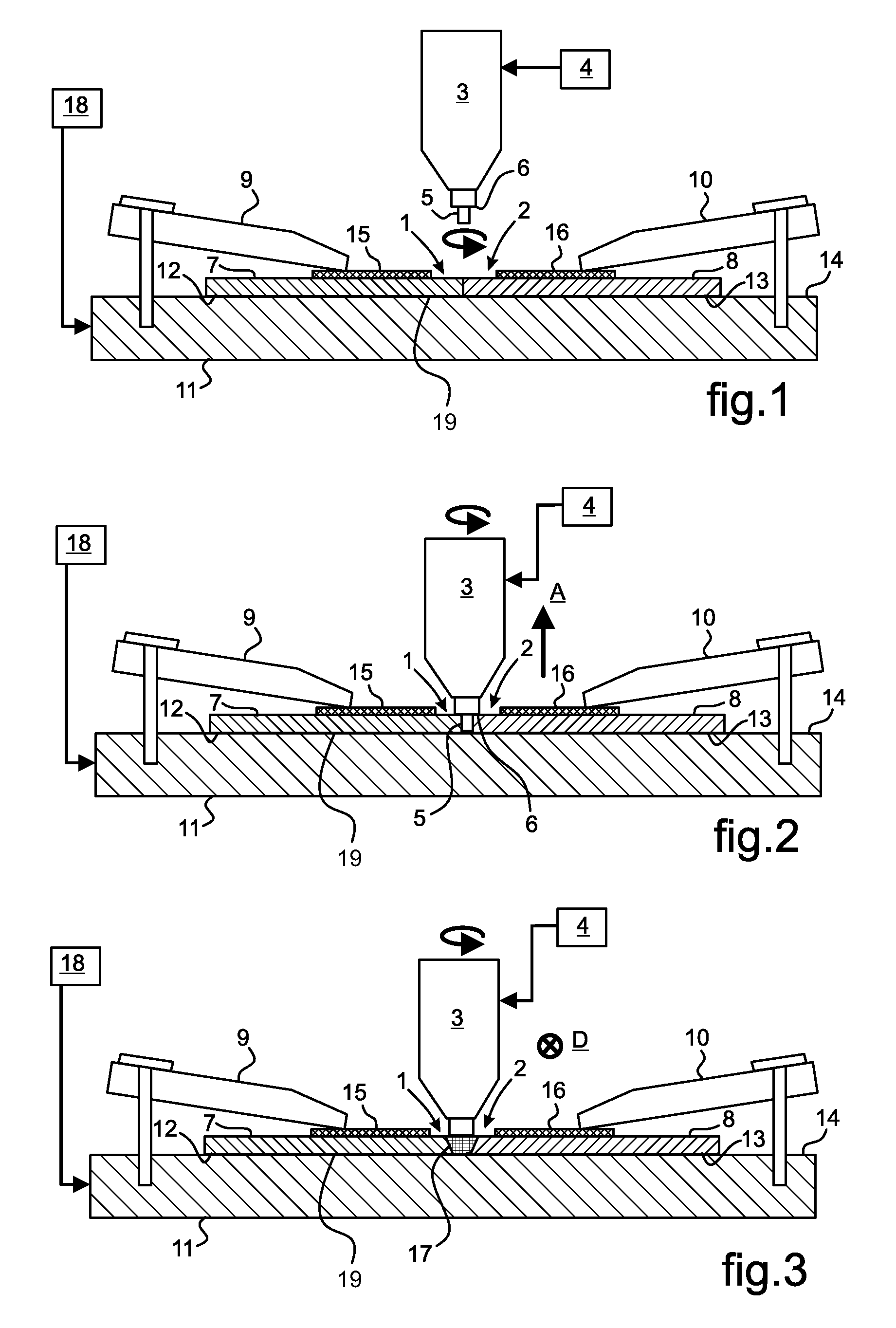

Automatic groove copy welder and welding method

InactiveUS20050103766A1Accurate control operationAccurately carry-outArc welding apparatusEngineeringCcd camera

An automatic groove-tracing welding system is capable of carrying out a welding operation, particularly, a welding operation involving weaving, without requiring monitoring even if conditions of a groove is different from design conditions of the groove. An image processor 3 receives an image signal representing an image of a weld zone 52 including the tip of a welding wire from a camera head 2 provided with a CCD camera, processes the image of the weld zone 52 to determine the position of a groove, calculates the positional relation of the groove with a welding torch 1, and sends a position correction for correcting the position of the welding torch 1 so that the welding path of the tip of the welding torch 1 may coincide with a predetermined middle part in the groove to a robot controller 43 for controlling a welding robot. When the automatic groove-tracing welding system performs a welding operation involving weaving, the image processor 3 receives a weaving phase signal representing phases of weaving from the robot controller 43, calculates the positional relation between the groove and the welding torch on the basis of the phase of weaving, and sends a weaving width correction signal to the robot controller 43.

Owner:KAWASAKI HEAVY IND LTD

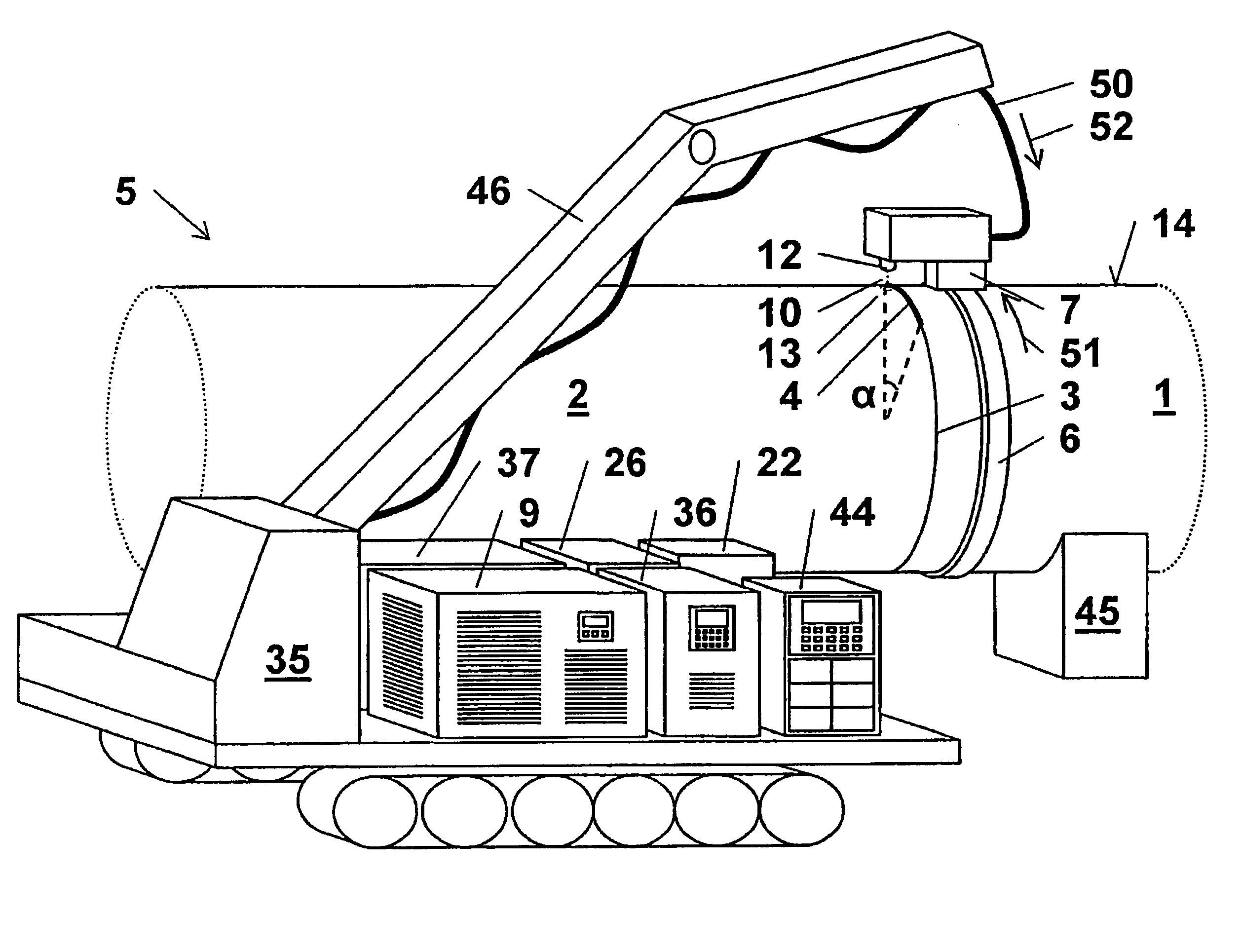

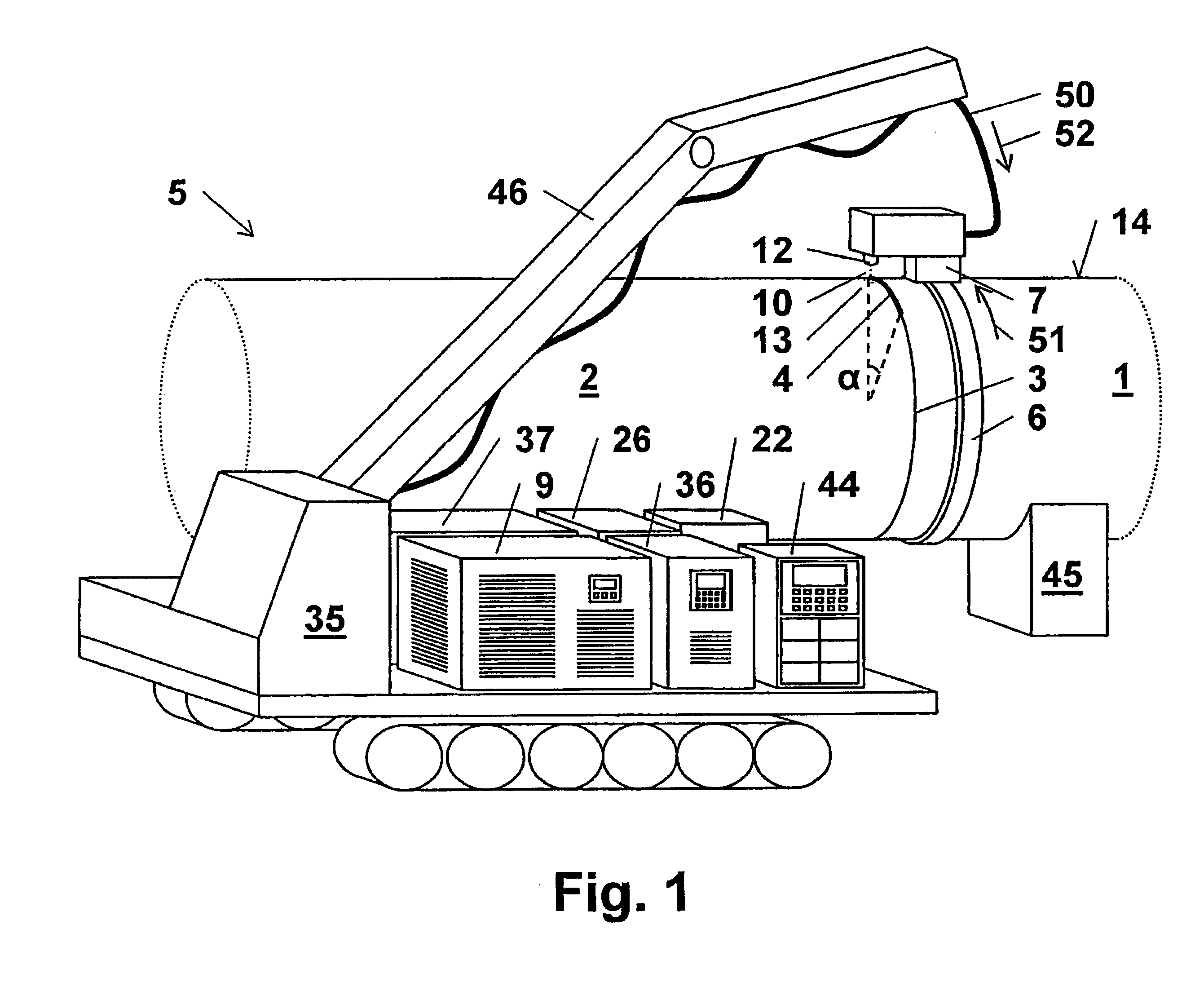

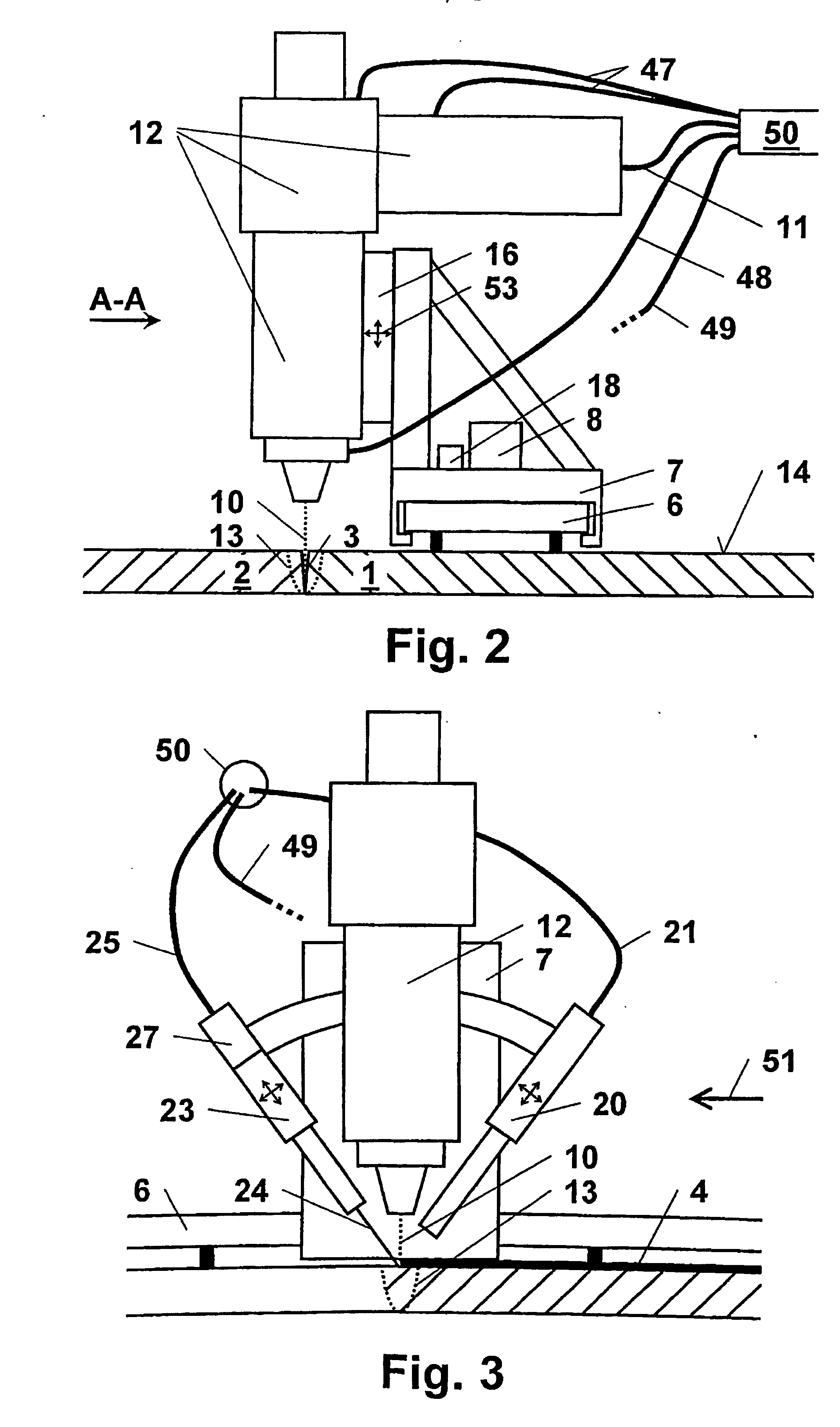

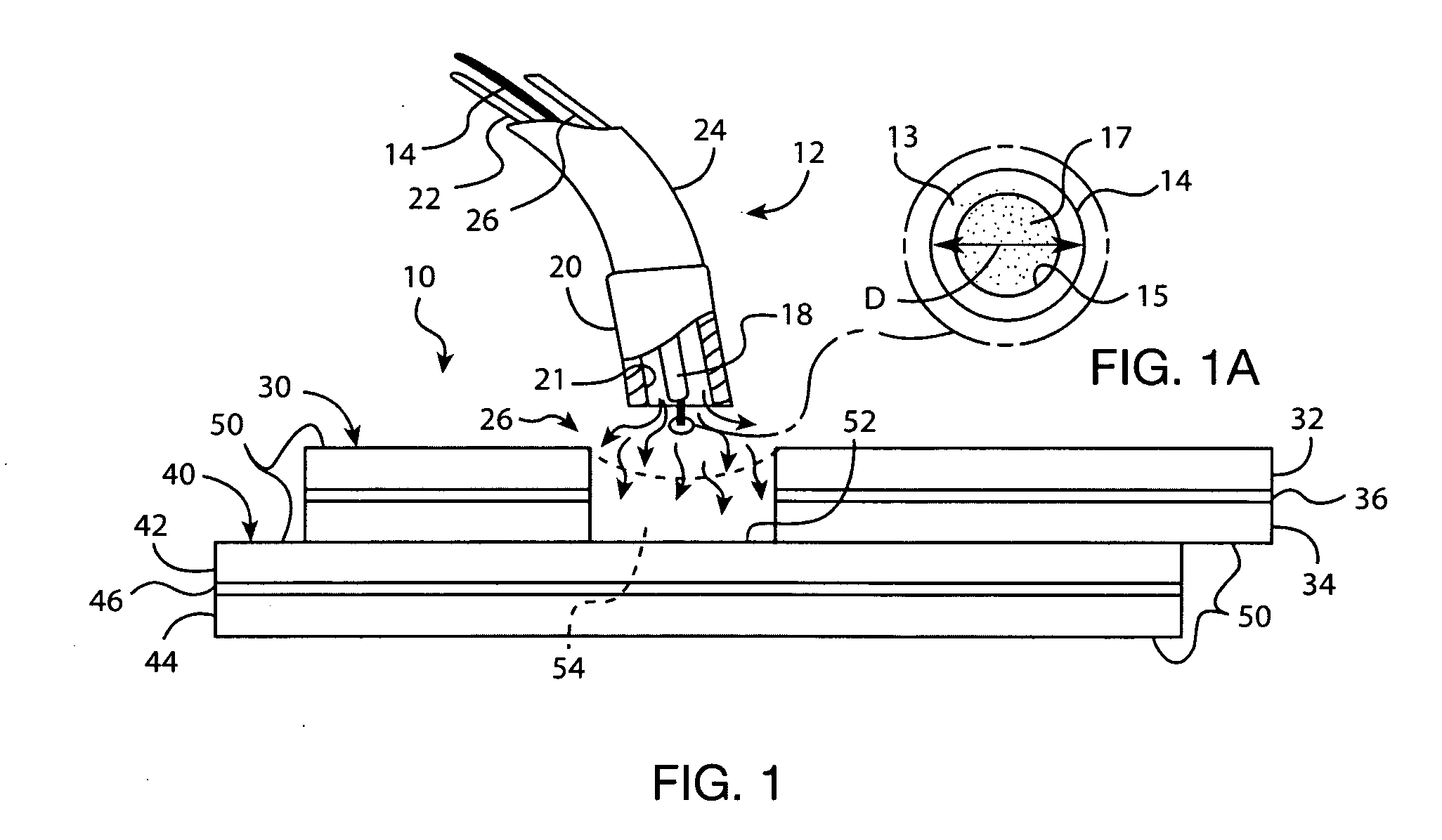

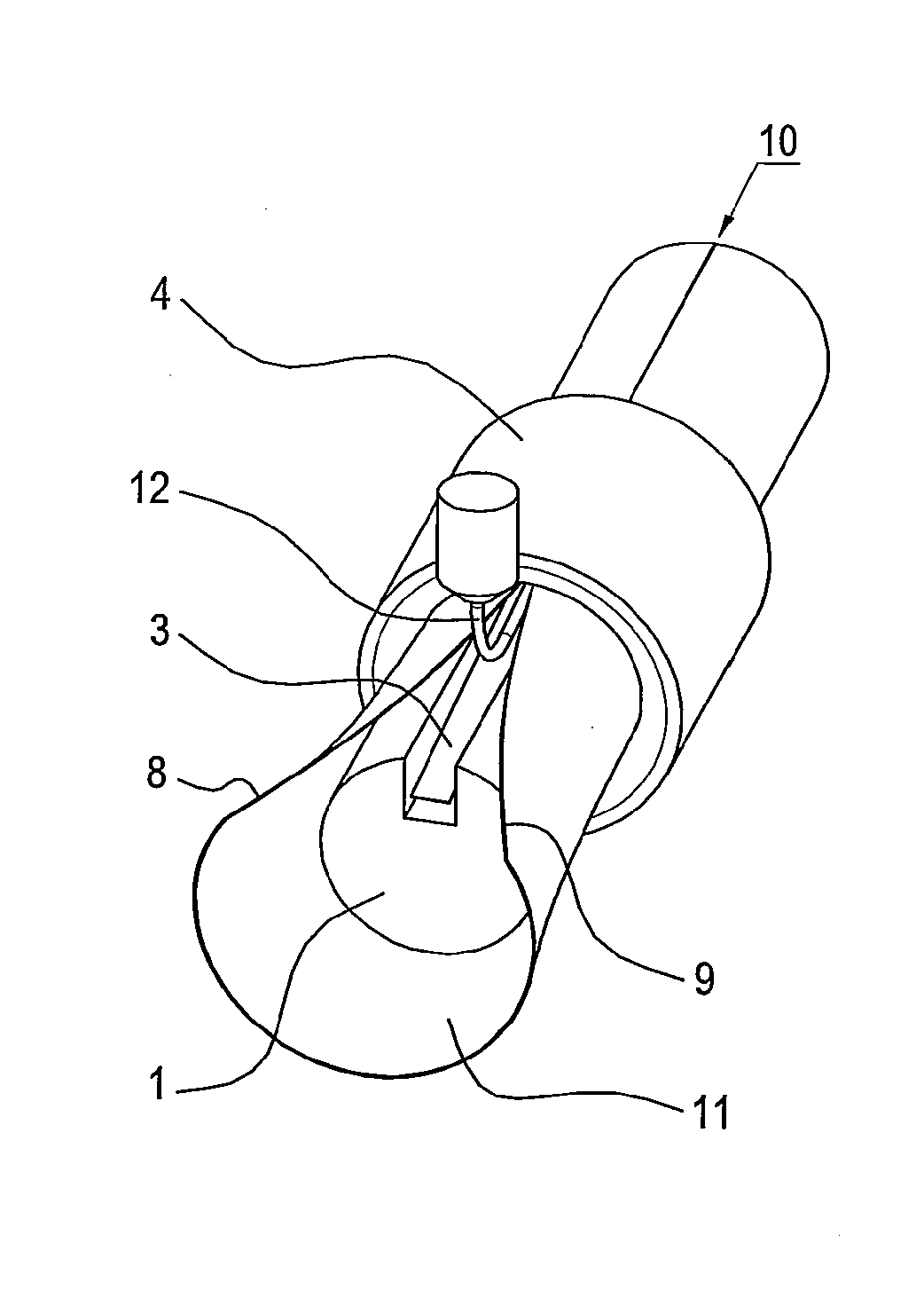

Orbital welding device for pipeline construction

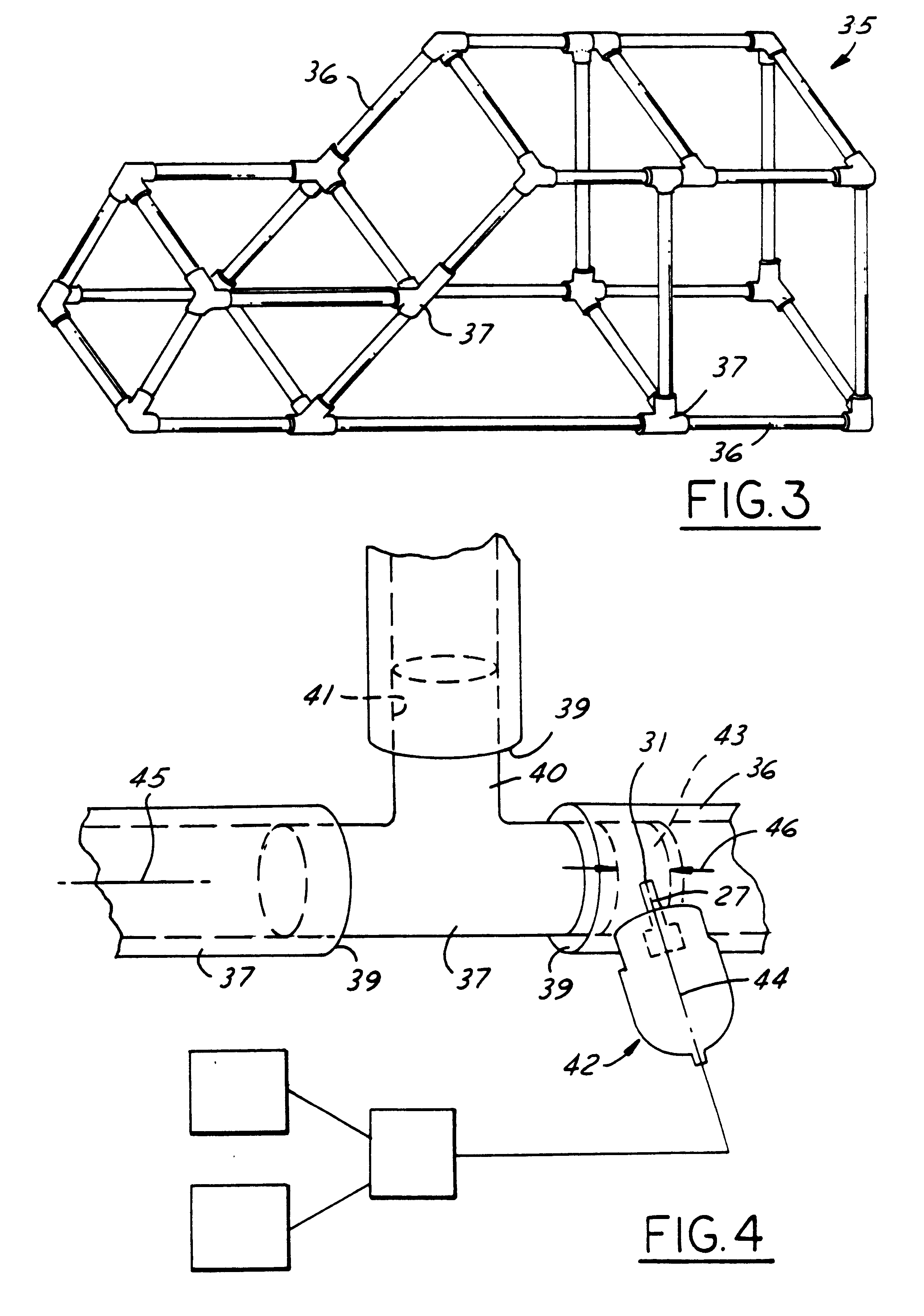

InactiveUS20070119829A1Increase production speedArc welding apparatusLaser beam welding apparatusLight guideBeam source

The invention relates to an orbital welding device for mobile use in order to join a first pipe (1) and a second pipe end (2) along a circumferential joint (3) by at least one weld seam (4), particularly for producing a pipeline (5) to be placed on land. The inventive device includes a guide ring (6), which can be oriented toward the first pipe end (1) and the circumferential joint (3), and an orbital carriage (7) that can be motor-displaced along the guide ring (6) via an advancing device (8). On the orbital carriage (7), a laser welding head (12) for directing a laser beam (10) into a laser welding zone (13) is mounted in a manner that enables it to be oriented toward the circumferential joint (3) whereby enabling the production of the weld seam (4) along the circumferential joint (3) by displacing the orbital carriage (7). The laser beam (10) is produced by a high-power fiber laser beam source (9) located, in particular, on a mobile transport vehicle (35) while being situated at a distance from the orbital carriage (7), is guided by light guide (11) passing through a tube bundle (50) to the orbital carriage (7) and then supplied to the welding head (12). A significant advantage of the invention resides in the fact that the joining of two pipe ends by only one single welding process during a short period of time is made possible in the field with autonomous operation.

Owner:VIETZ

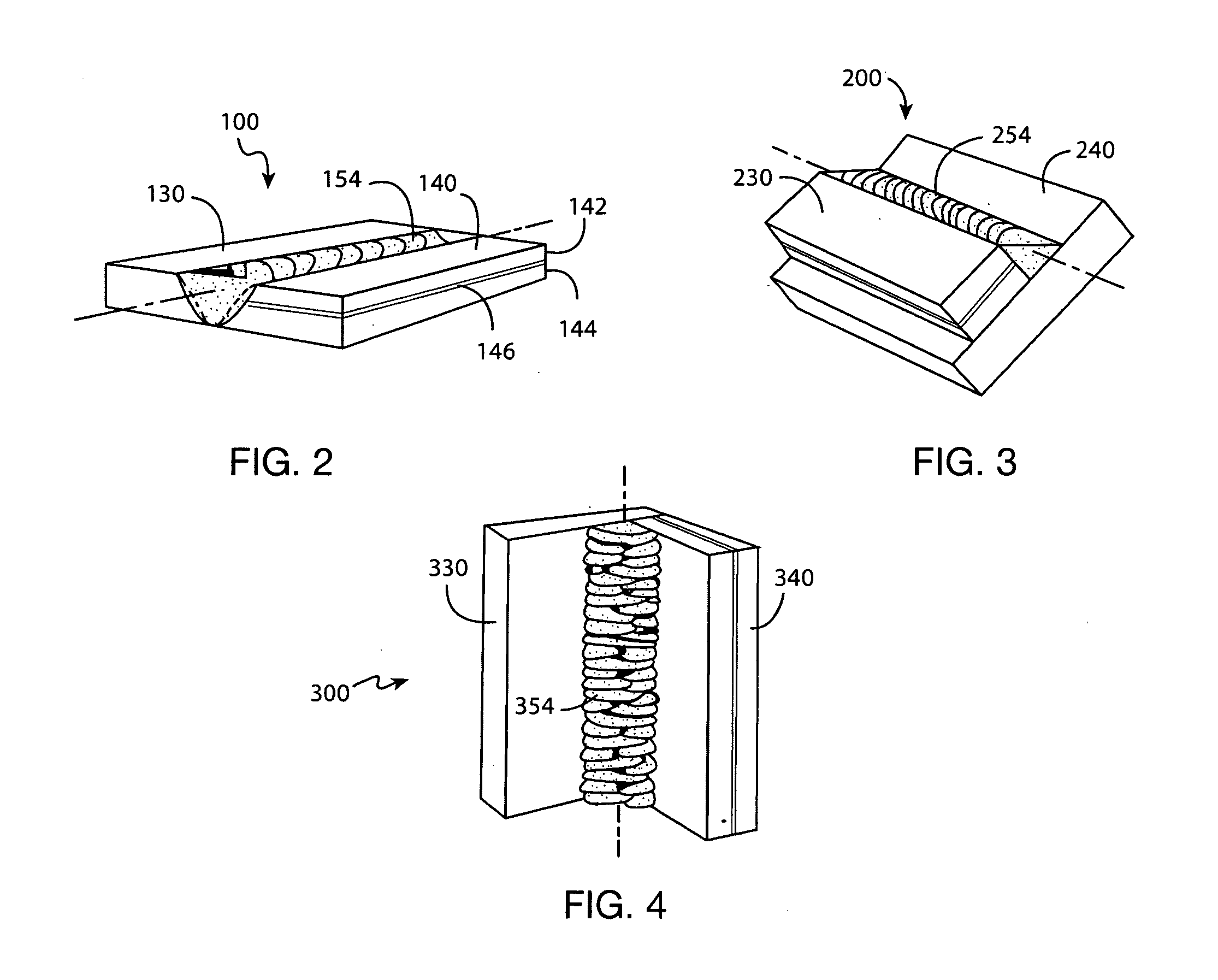

Fabricating low distortion lap weld construction

InactiveUS6247633B1Welding/cutting auxillary devicesAuxillary welding devicesFriction weldingLow distortion

A method of making a low distortion frame construction, the construction having joint regions formed by first and second overlapping members defining a lapped interface, the joint regions being comprised of material that can be converted to a solid state deformable plastic condition by friction heat, comprising: (a) providing a stir friction welding tool having (i) a rotatable thermally conductive body presenting a shoulder to engage the joint region for storing friction-generated heat, and (ii) a friction generating pin rotatable with said body about a pin axis and selectively extendable from the shoulder to progressively penetrate the overlapping members as the joint region in contact with the pin becomes plastic; (b) placing the tool shoulder against the joint region with the pin axis transverse to the lapped interface and spinning the body while progressively extending the pin at a rotational speed effective to generate friction heat that converts the adjacent material of the joint to a plastic condition allowing the spinning of the probe to stir such plastically converted material; and (c) controlling the depth of penetration of the spinning probe while translating the tool across the joint region to perfect a friction stirred welded zone that extends through the interface and between the overlapping members to provide a welded joint that is exceptionally strong in shear.

Owner:FORD GLOBAL TECH LLC +1

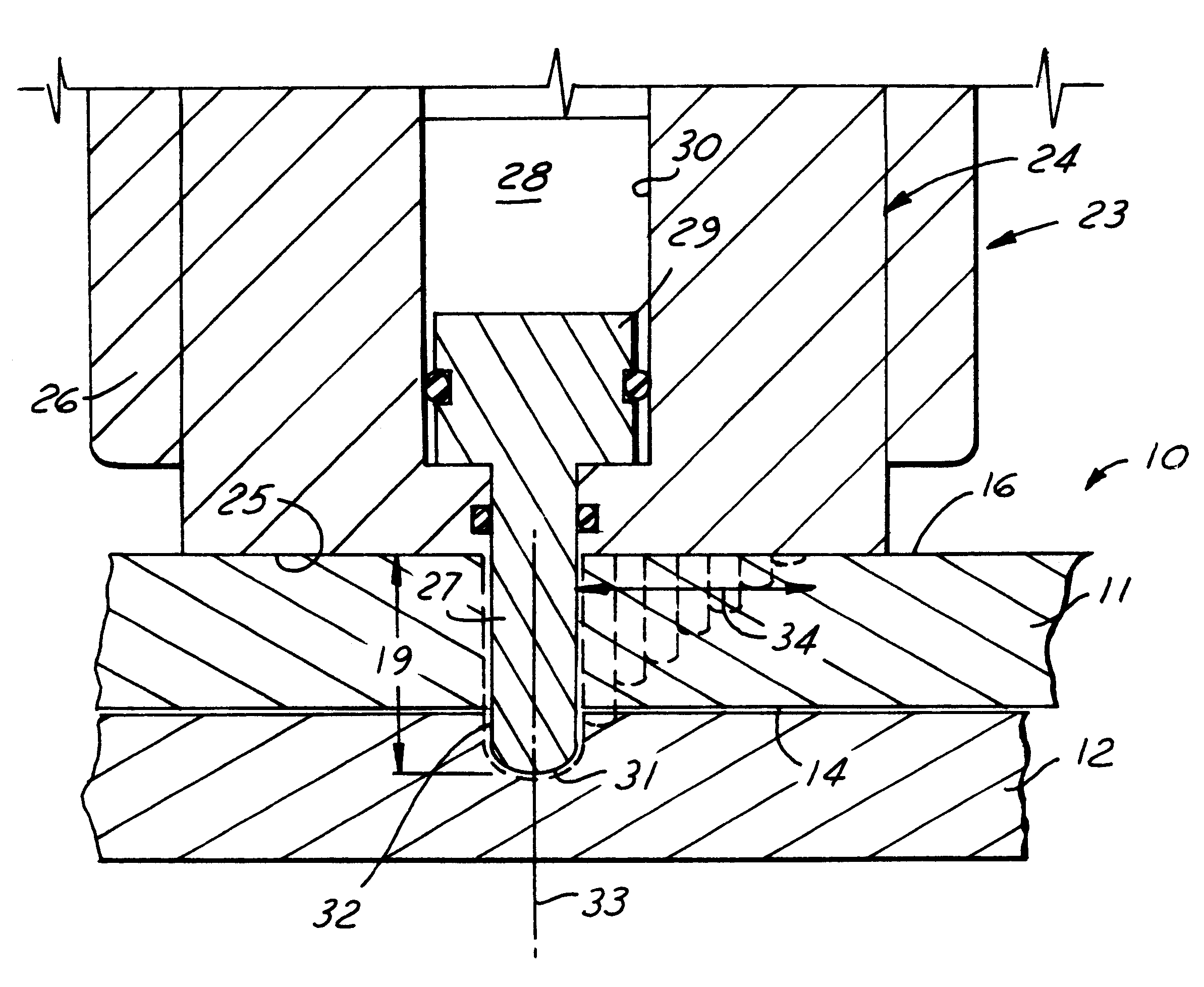

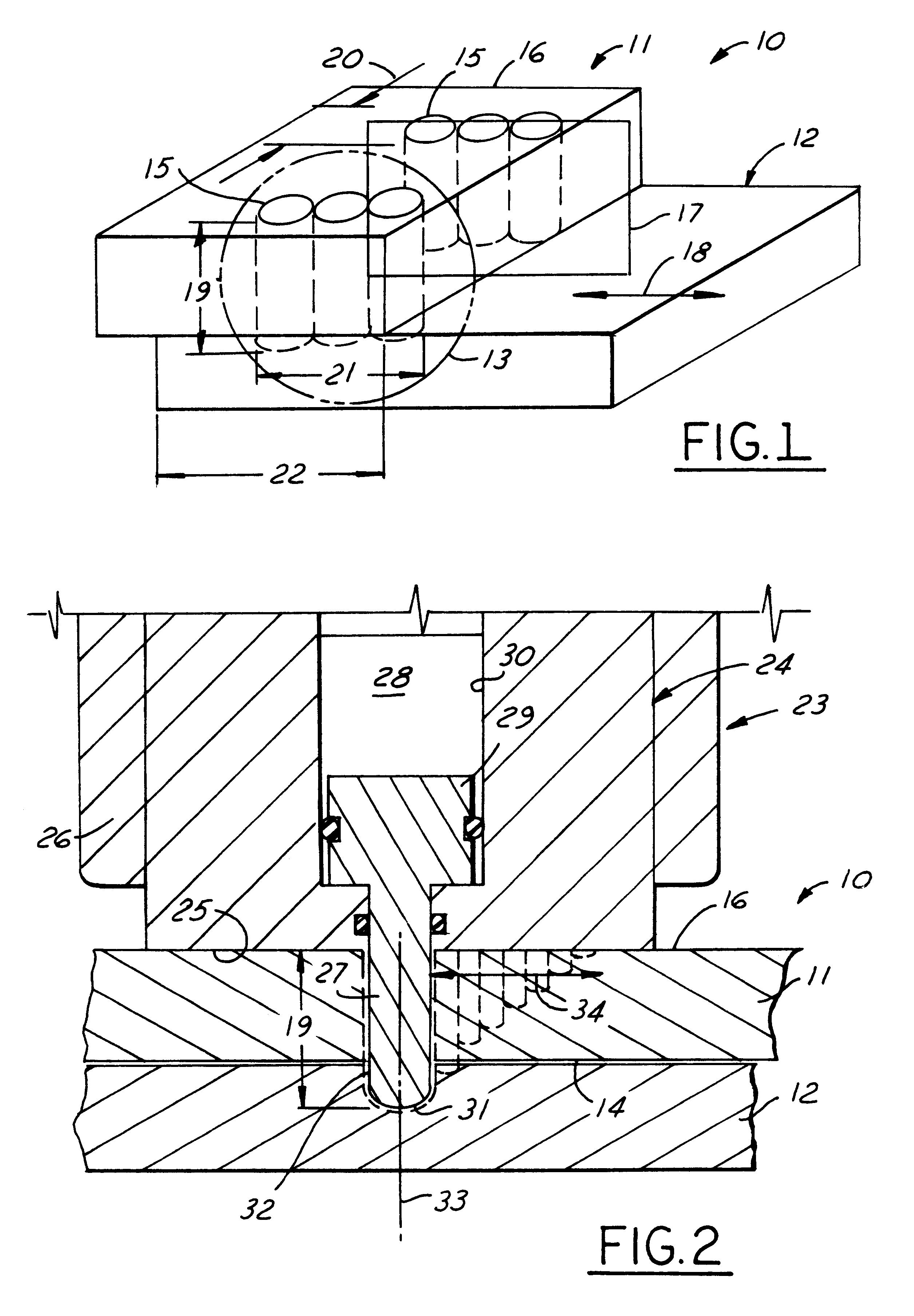

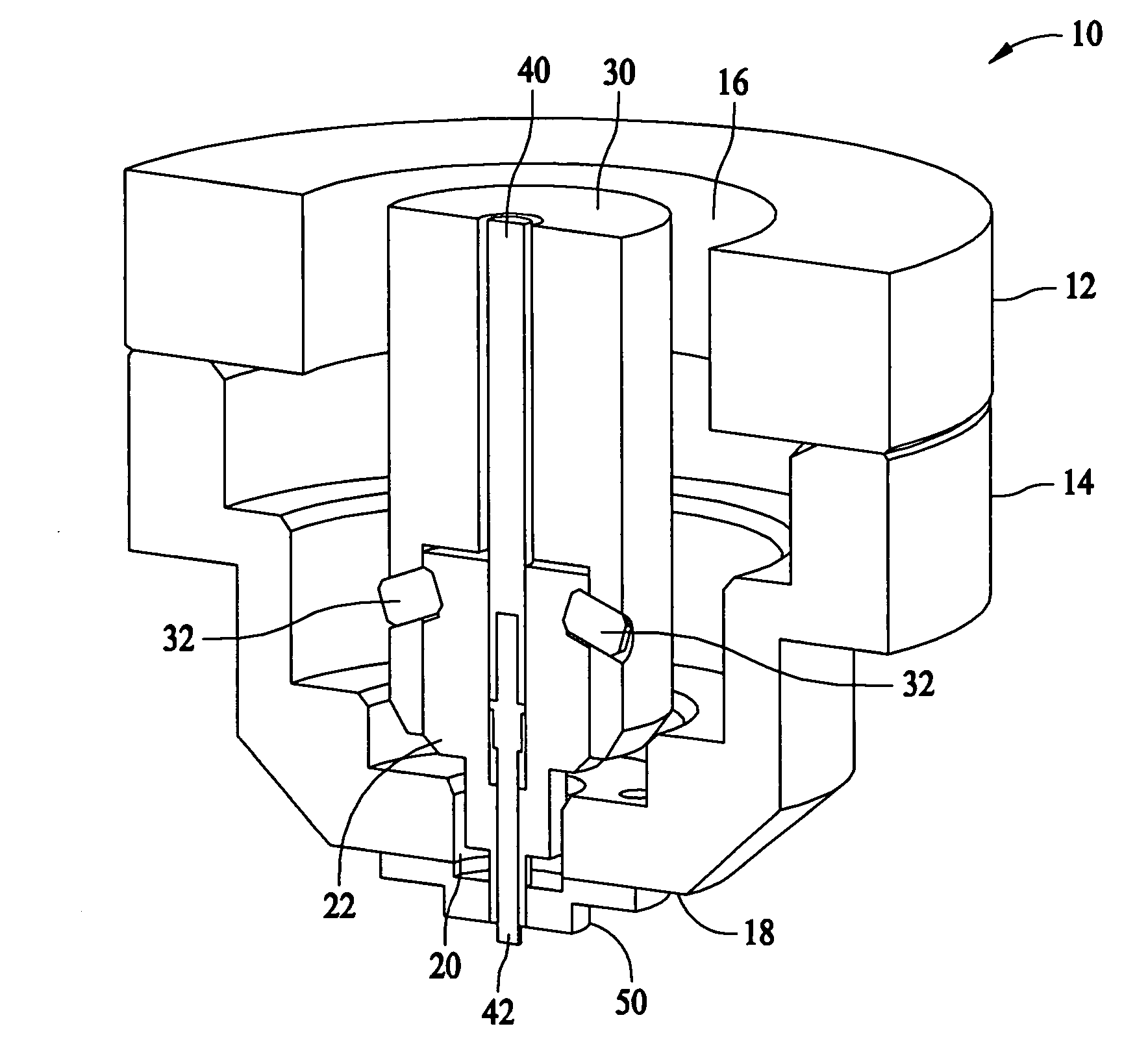

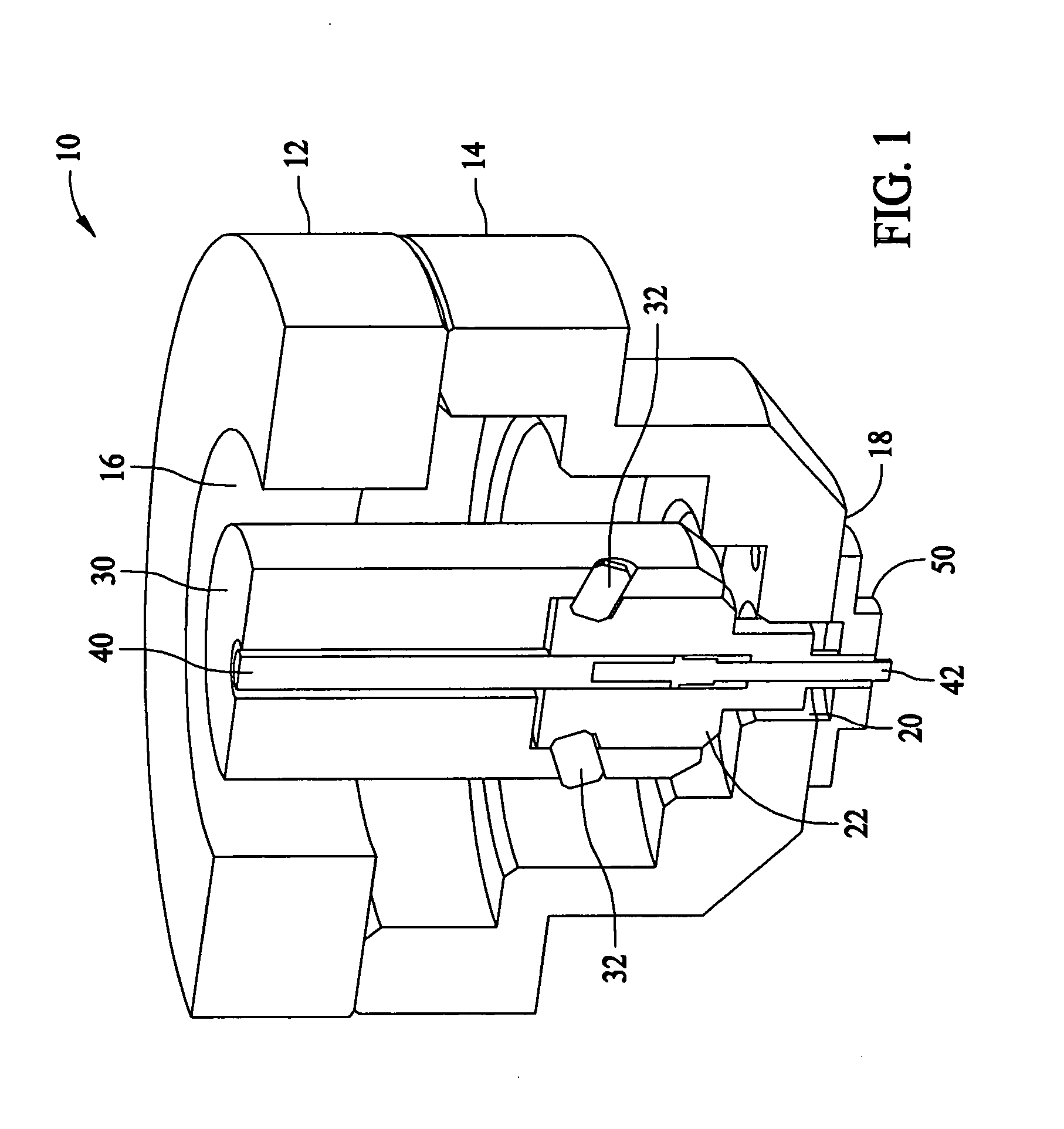

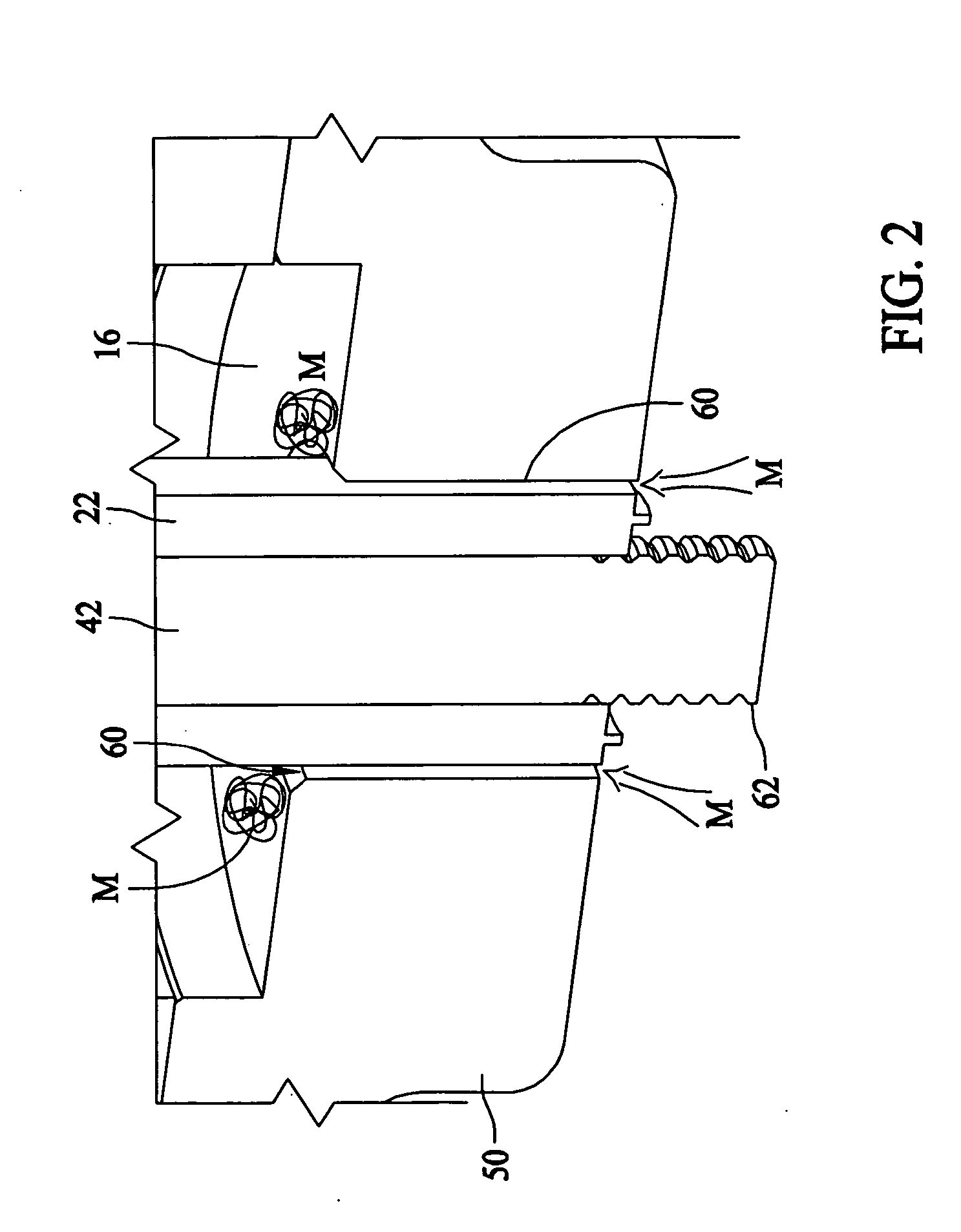

Methods and apparatus for retractable pin friction stir welding and spot welding

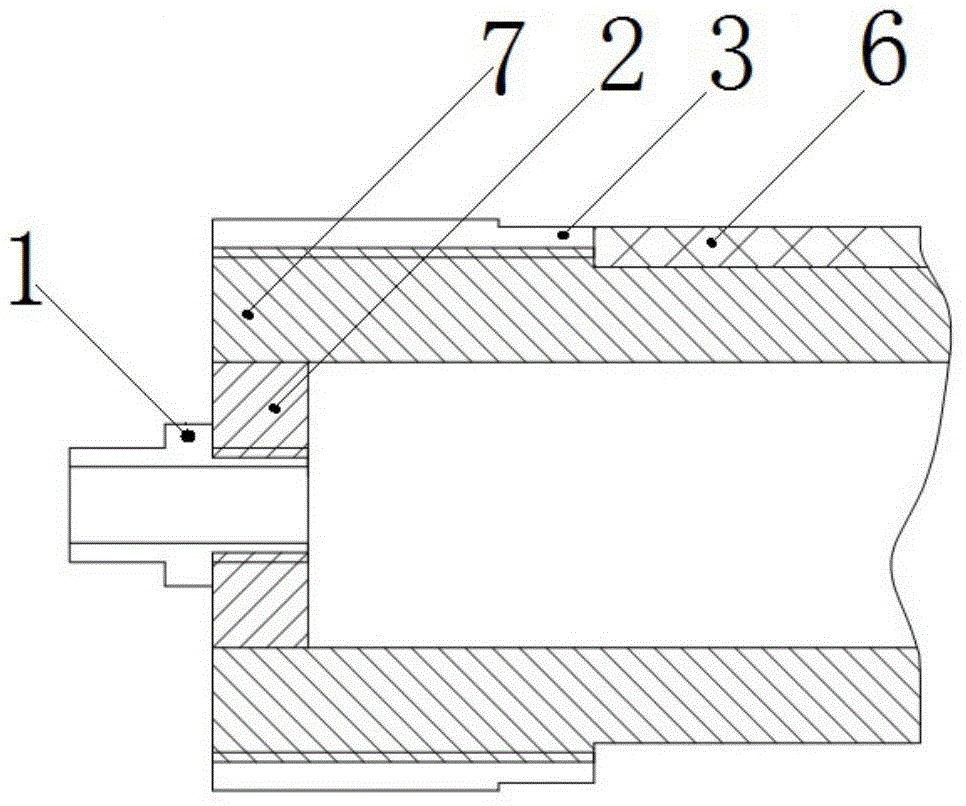

ActiveUS20070152015A1Welding/cutting auxillary devicesAuxillary welding devicesEngineeringSpot welding

An apparatus for friction stir welding is described that includes a stationary assembly having a bore therethrough, the bore having an inner diameter, and a rotational assembly having a welding end. At least the welding end of the rotational assembly extends through the bore. A portion of the rotational assembly is adjacent the inner diameter of the bore. At least one of the adjacent portion of the rotational assembly and the inner diameter of the stationary assembly are configured such that rotation of the rotational assembly will cause plasticized material from a welding process that has entered an area between the adjacent portion and the inner diameter to move towards a welding zone located proximate the welding end.

Owner:THE BOEING CO

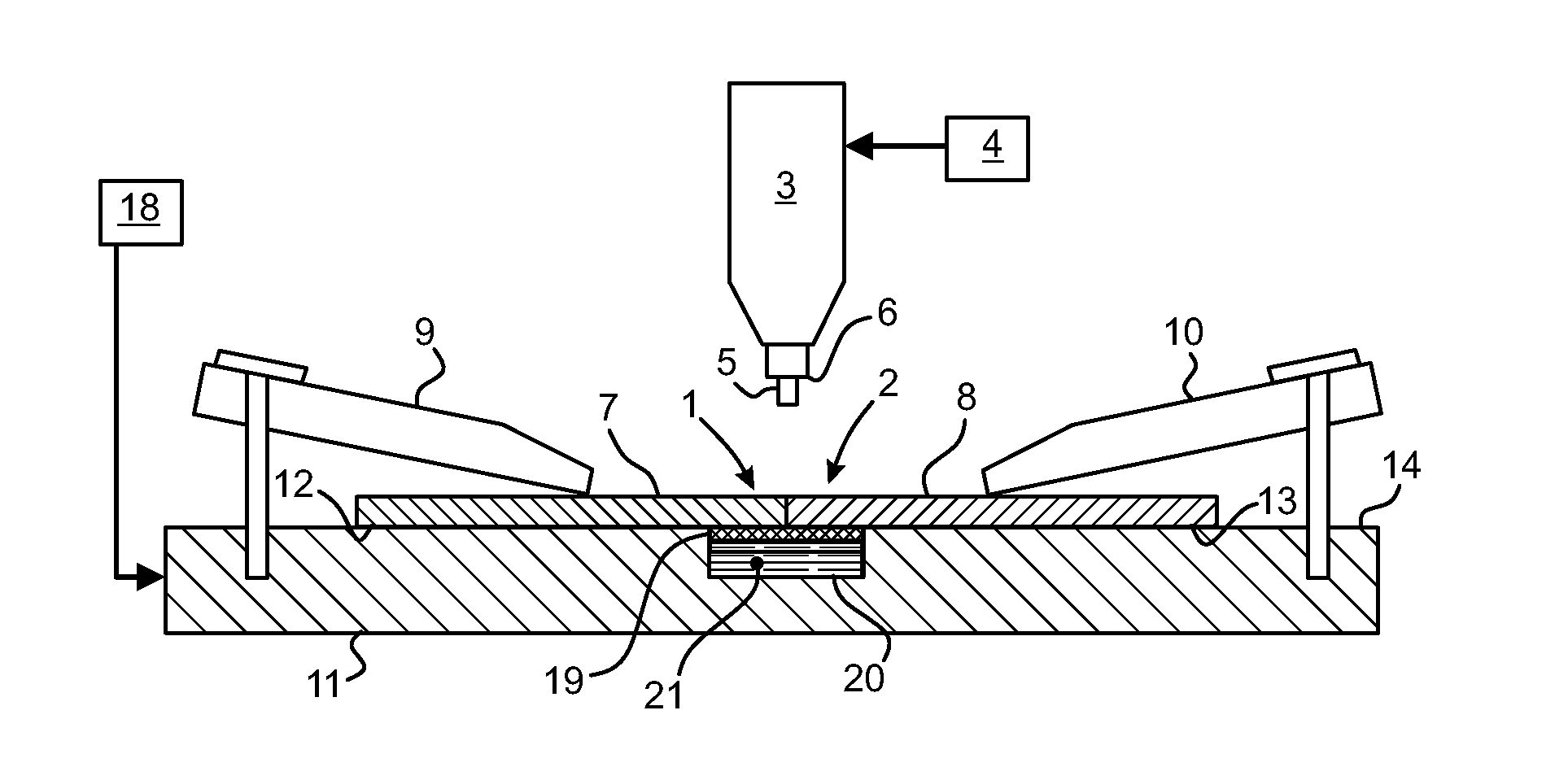

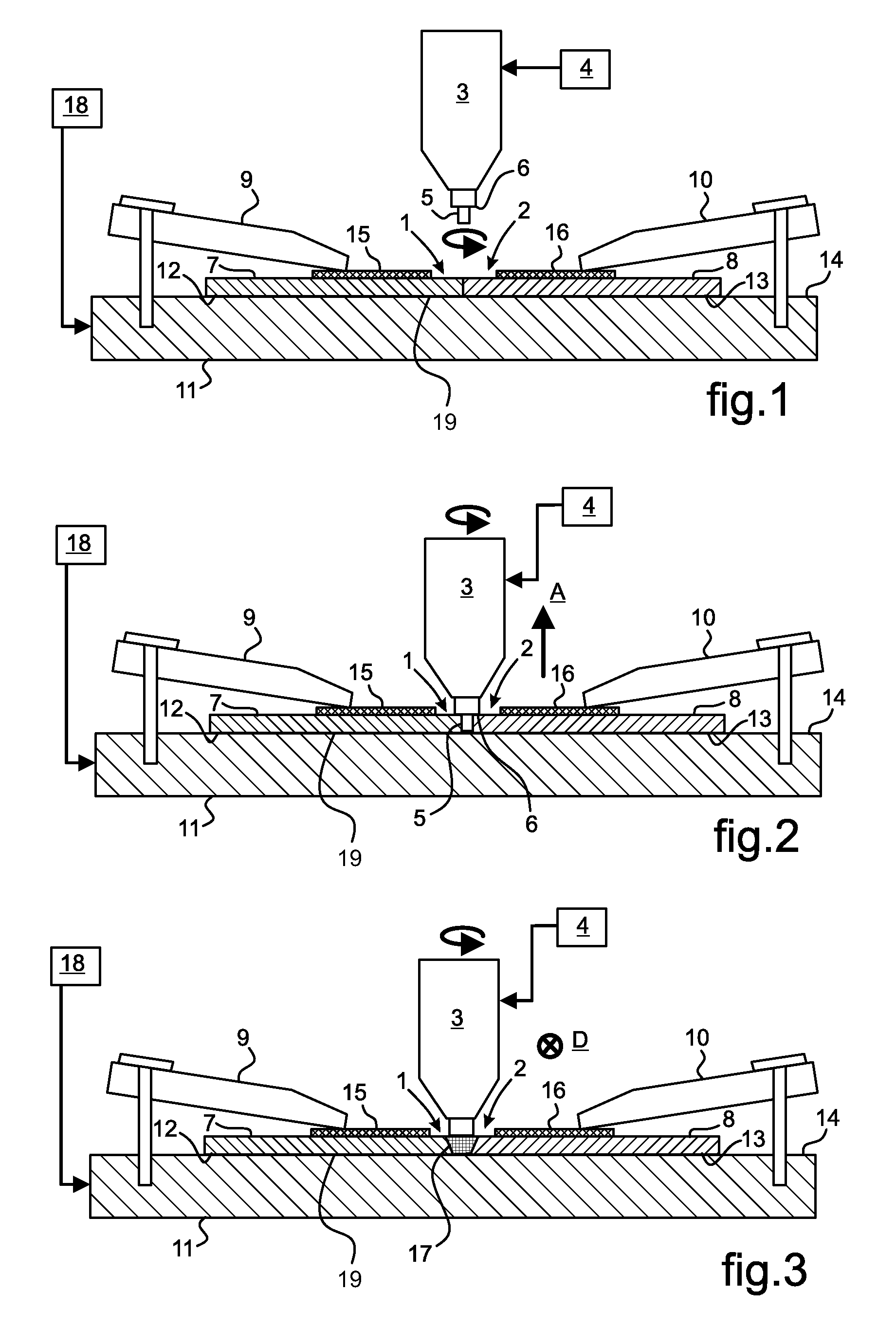

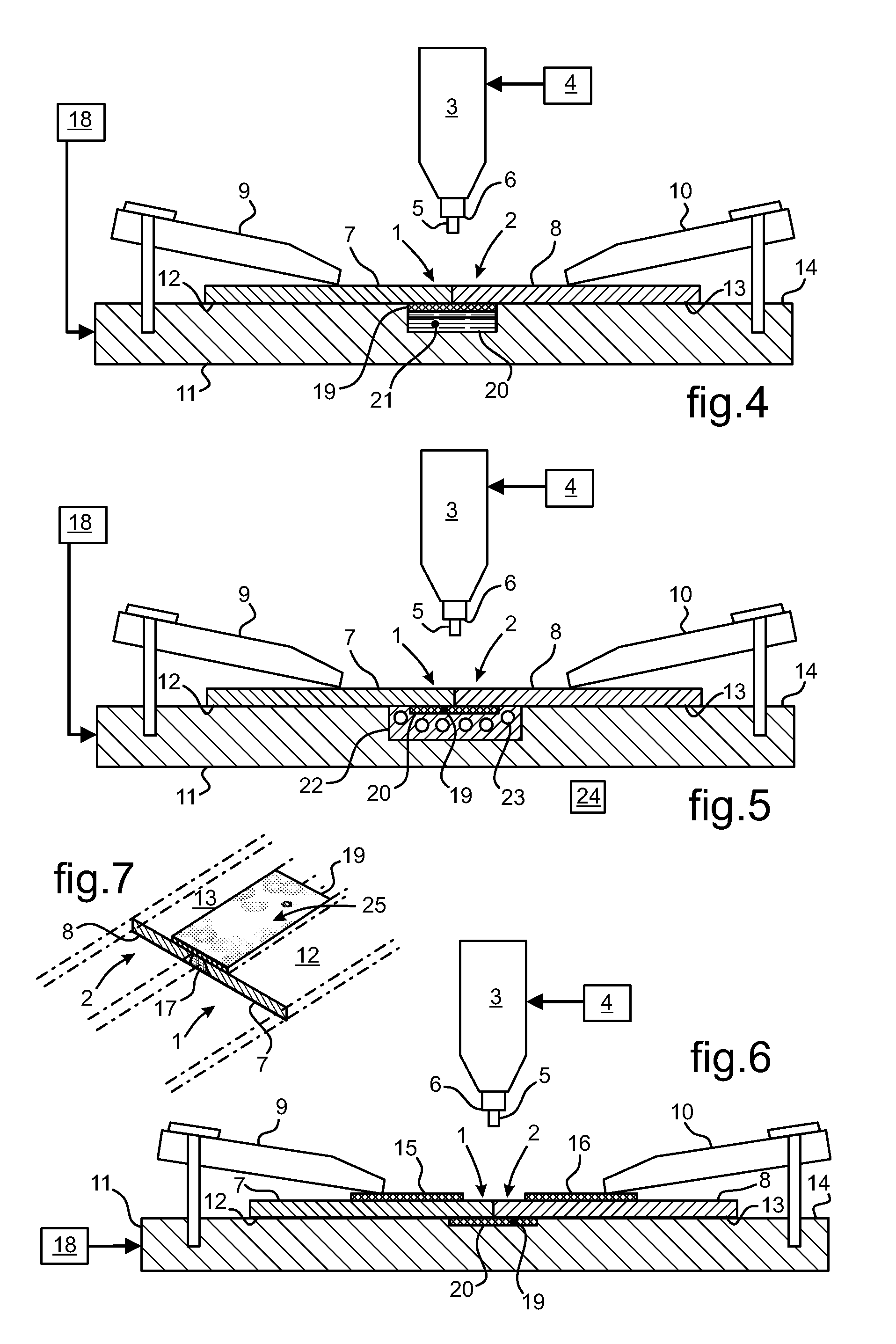

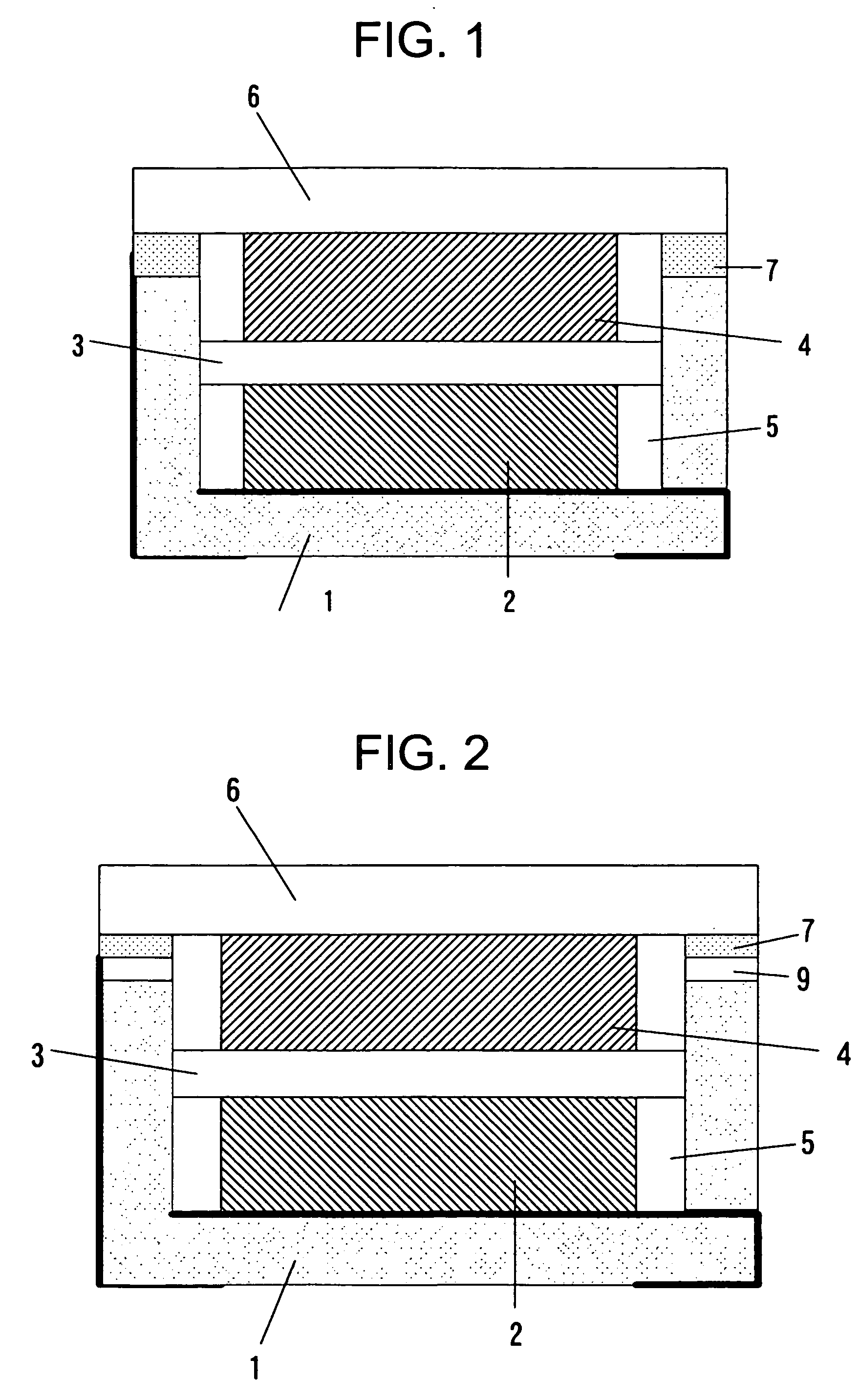

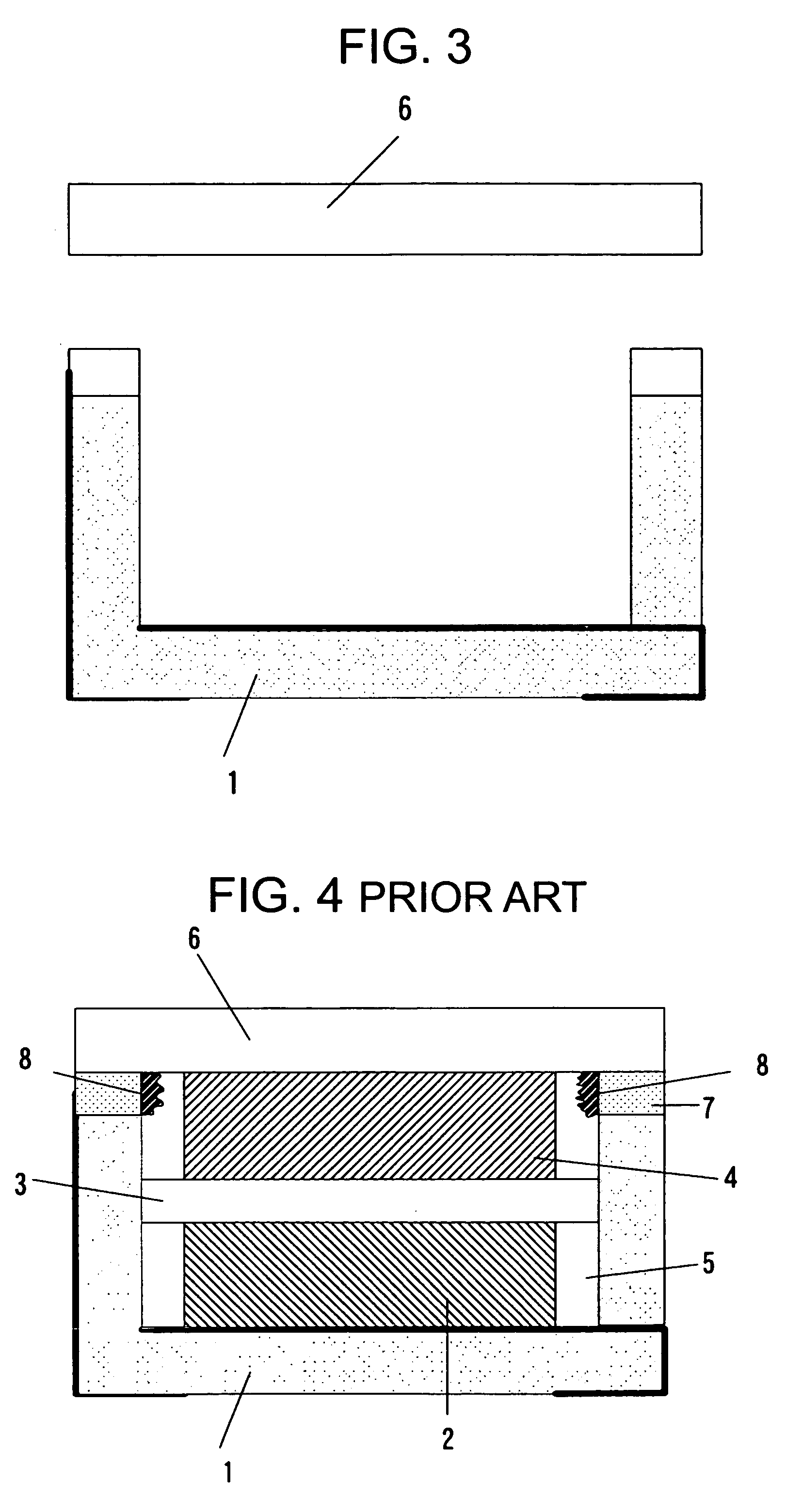

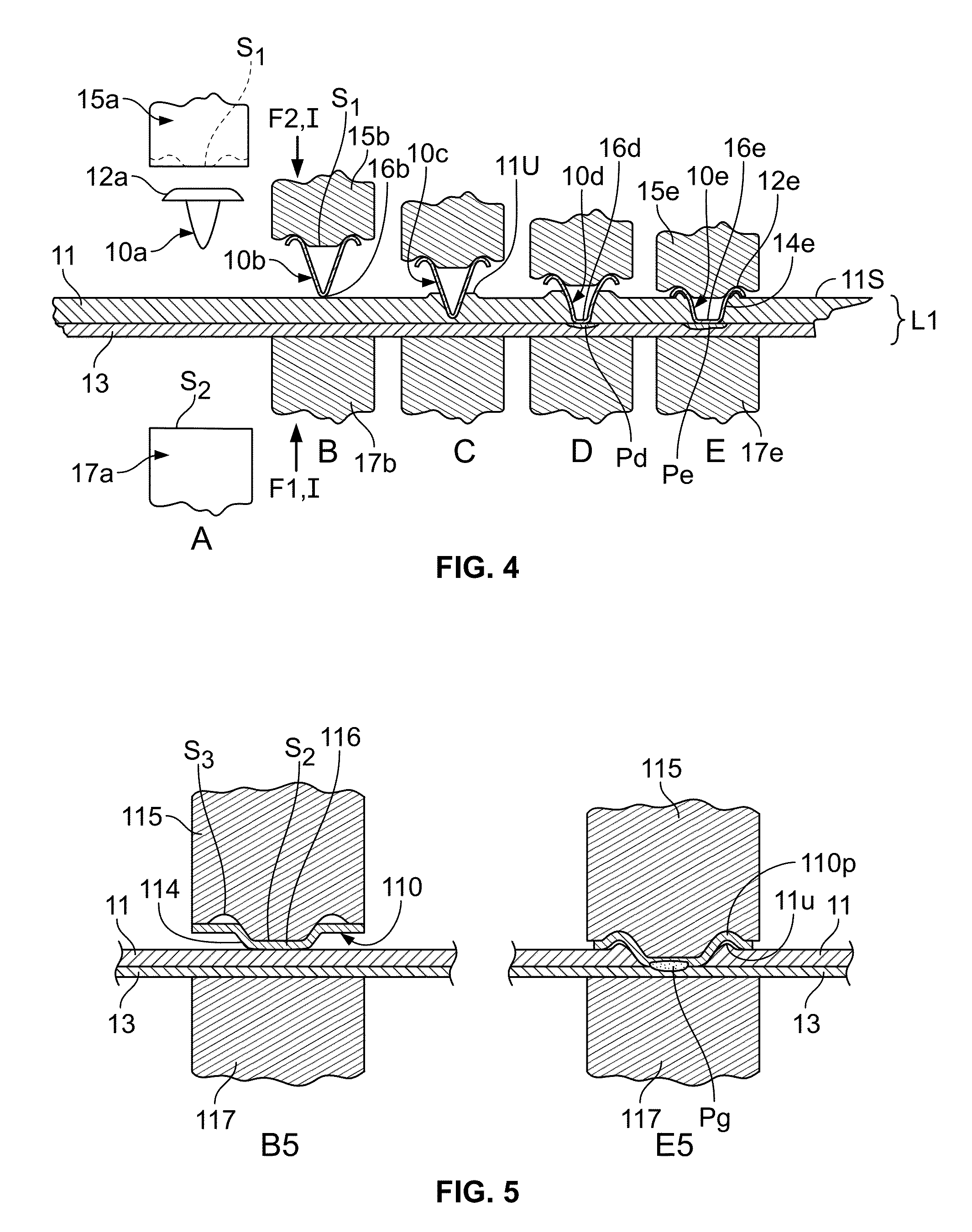

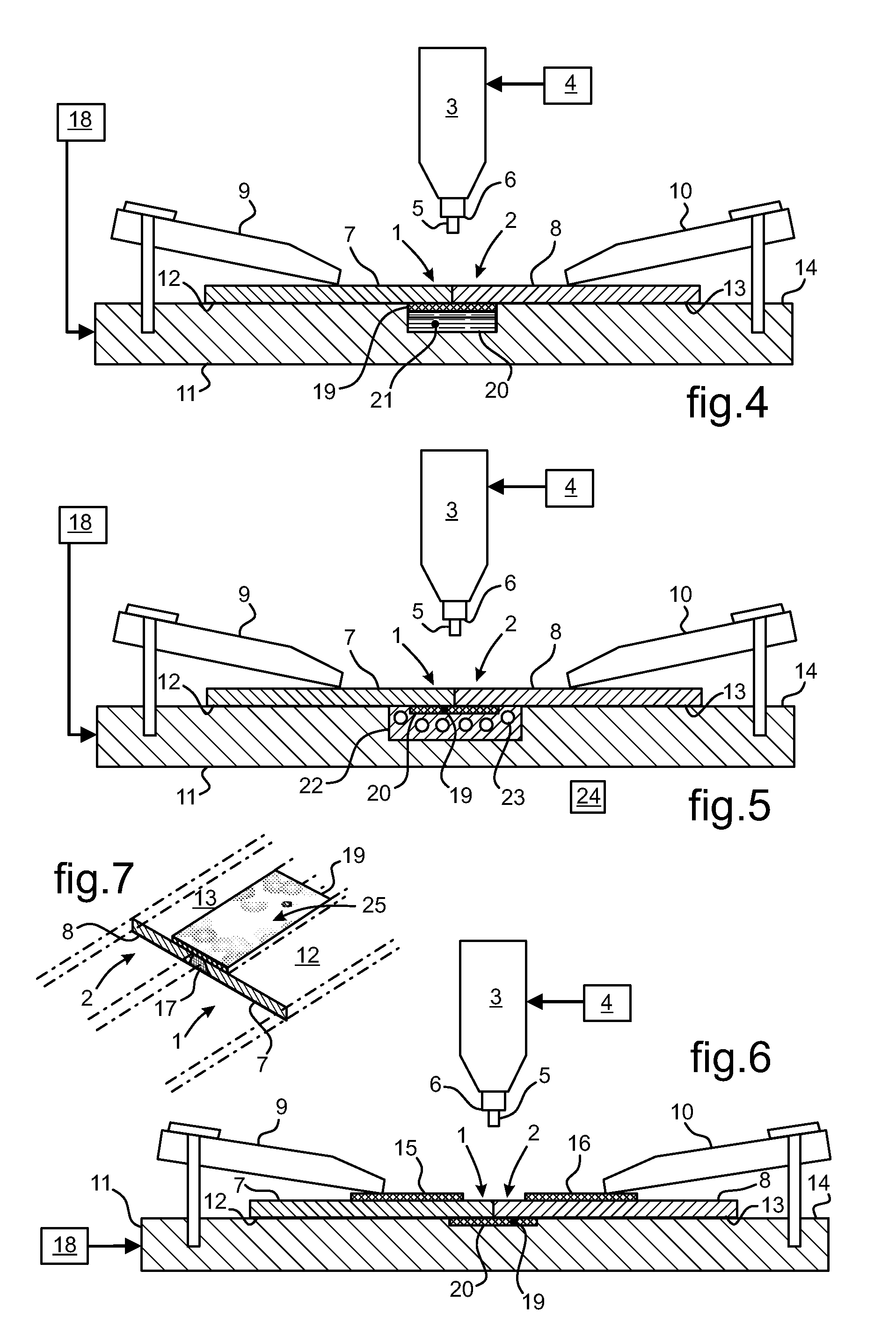

Method of assembling metal parts by friction welding, with the welding temperature being controlled using thermally conductive elements

InactiveUS8393519B2Optimize rateHigh performance mechanical characteristicWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingEngineering

The invention provides a method of assembling together two thin plane parts (1, 2) by friction welding. A main sheet (19) made of a material having high thermal conductivity is held against the parts (1, 2) for assembly. The main sheet (19) picks up the heat induced by the friction of a welding pin (5) against the parts (1, 2) for the purpose of forming the weld bead (17), and it dissipates this heat by radiation. Temperature regulation of the welding operation is obtained by the main sheet (19), ensuring that no localized excess heating occurs in the welding zone. The main sheet (19) is based on copper and presents a thickness that is less than the thickness of the parts (1, 2).

Owner:EUROCOPTER

Electrochemical cell

InactiveUS20060035143A1Prevent oxidationInhibition capacityHybrid capacitor electrodesFinal product manufactureOrganic solventInternal resistance

In a conventional electrochemical cell, since a welding between a container and a sealing plate is performed in the atmospheric air, a weld zone is oxidized and a corrosion resistance decreases. For this reason, impurities are eluted from the weld zone into an electrolyte, and this causes an internal resistance increase and a capacity decrease of the electrochemical cell. Further, there is a possibility that an organic solvent in the electrolyte is oxidized by the welding. According to the invention, in order to solve the above problems, the seal welding between the container and the sealing plate of the electrochemical cell is performed under an inert atmosphere.

Owner:SEIKO INSTR INC

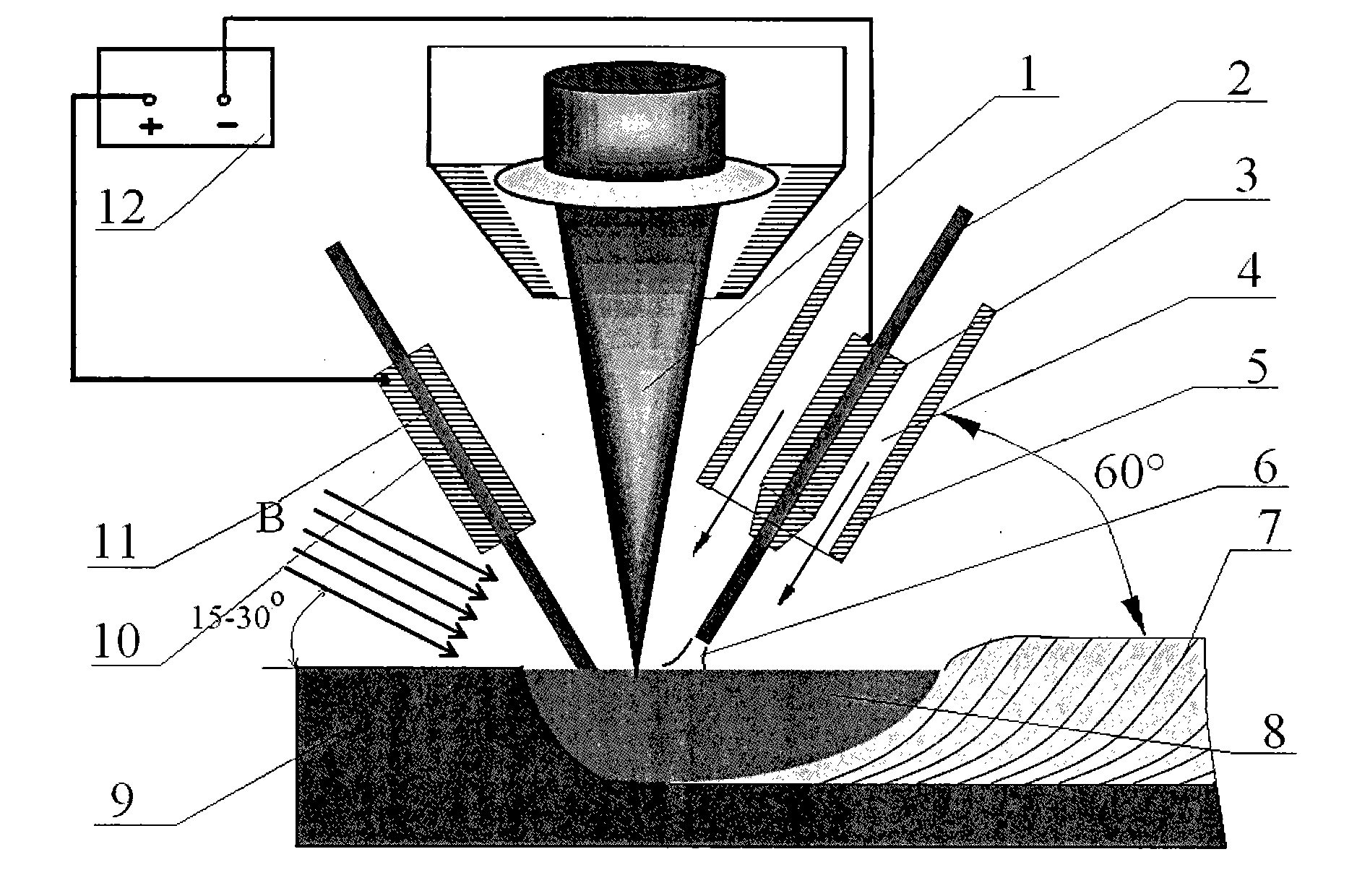

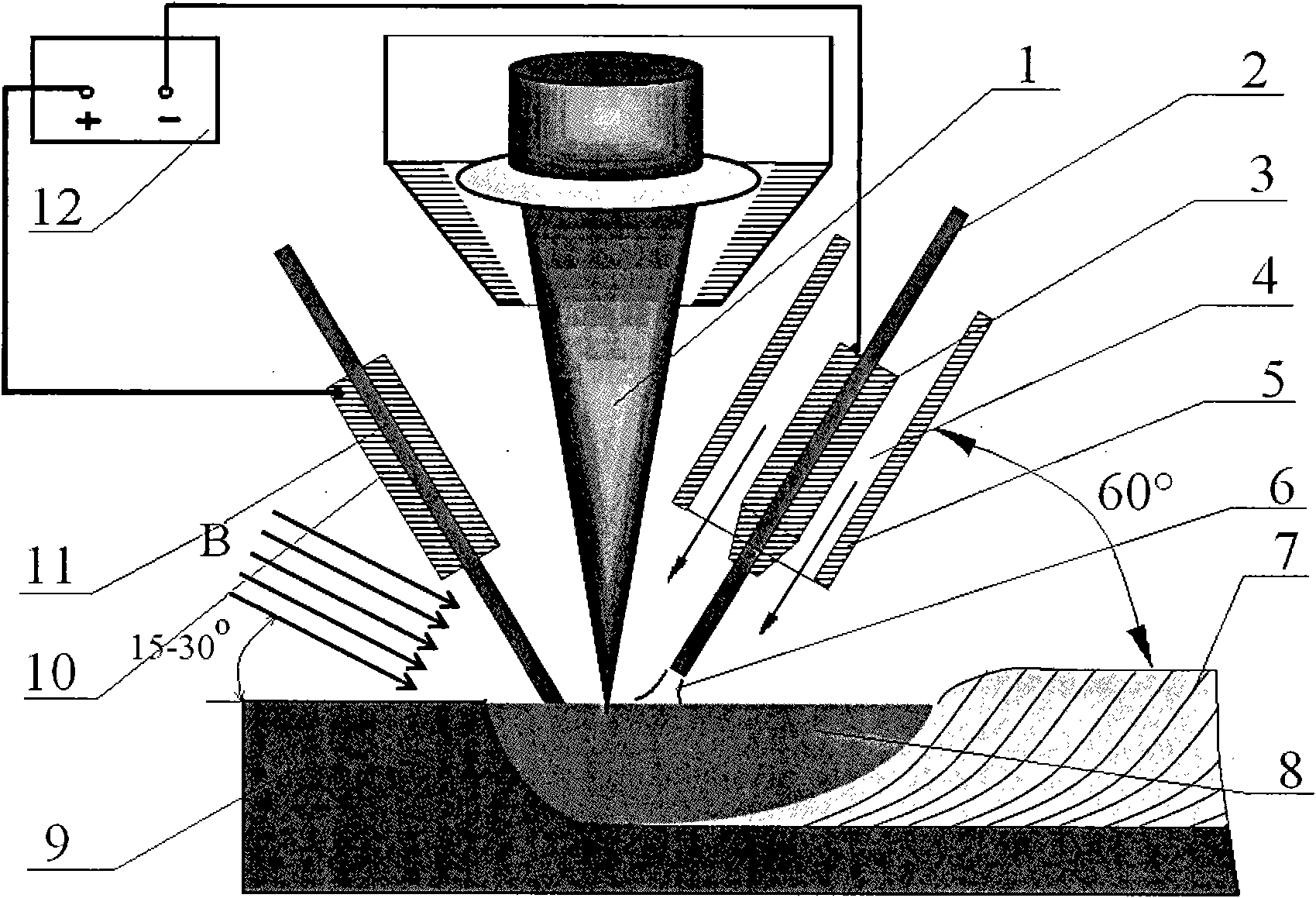

Electromagnetic current coupling field assisted hybrid melting-brazing method for laser-TIG arc and equipment

InactiveCN101862913AImprove connection qualityInhibition formationSoldering apparatusWelding apparatusMetallic materialsWelding defect

The invention discloses an electromagnetic current coupling field assisted hybrid melting-brazing method for a laser-TIG arc and equipment. In addition to the use of the welding zone, an alternating magnetic field is added to control properties of plasma formed through ionization of laser, arc and a raw material metal, thereby improving the laser utilization rate. Under the electric field assisted comprehensive effect, the weld melting depth is increased, and the assistant effect on the melting bath of the liquid-state brazing filler metal for laser-arc melting-brazing is realized through electromagnetic stirring and excitation and enhancement, thereby promoting the orderly flow of the liquid-state brazing filler metal and the rupture, wetting, spreading and proliferation of the liquid-state brazing filler metal on the surface of the high metal material, improving the full mixing of the liquid-state brazing filler metal and the base metal formed by melting the low-melting-point metal material, improving the uniformity of the components of the brazed weld, stabilizing the welding process, reducing welding defects, increasing the welding speed, improving the weld formation, optimizing the structure and performance of the brazed weld, and improving the quality of the brazed joint. Moreover, the equipment has the advantages of simple structure, flexible application, low cost, good effect and easy realization.

Owner:CHONGQING UNIV

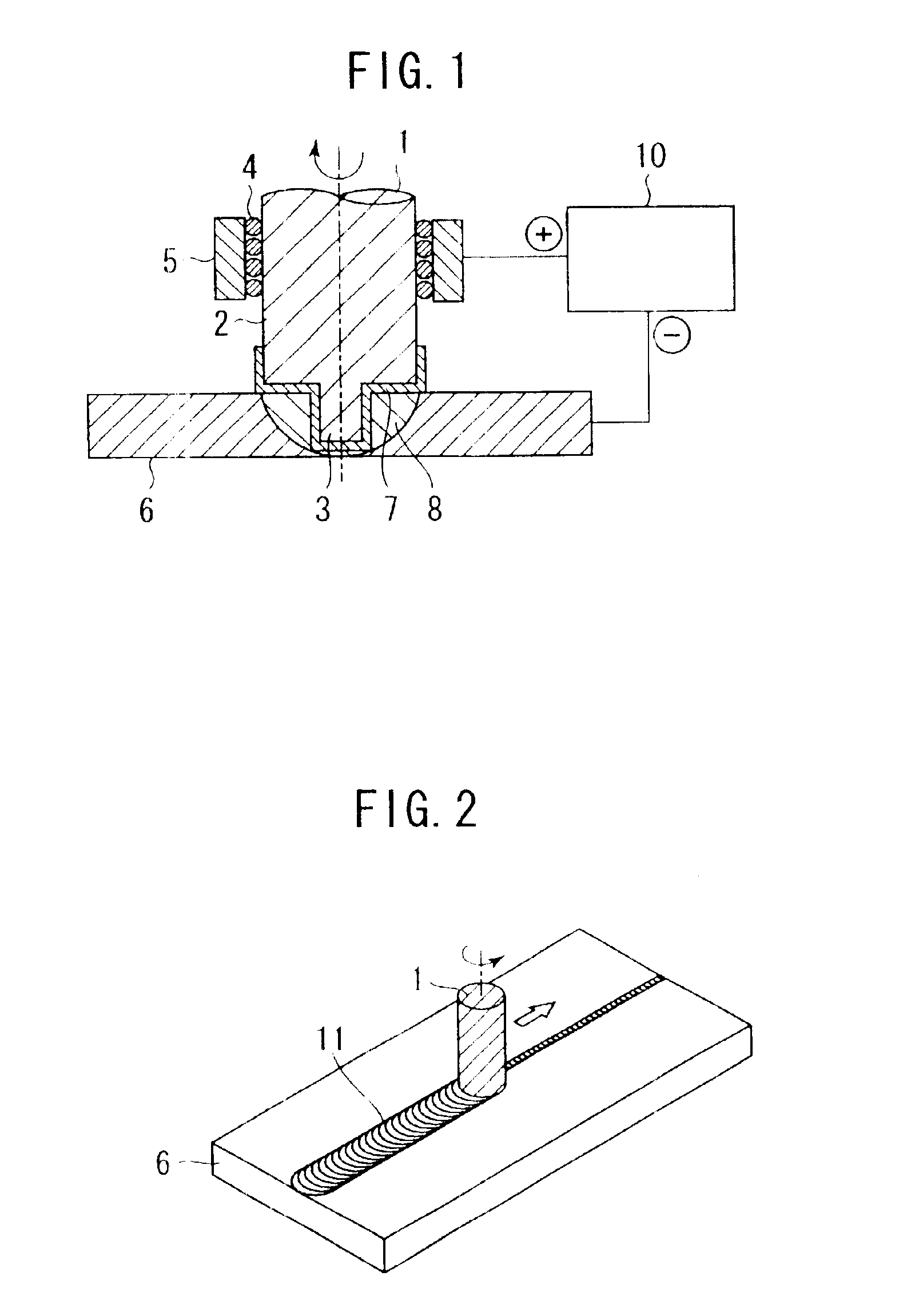

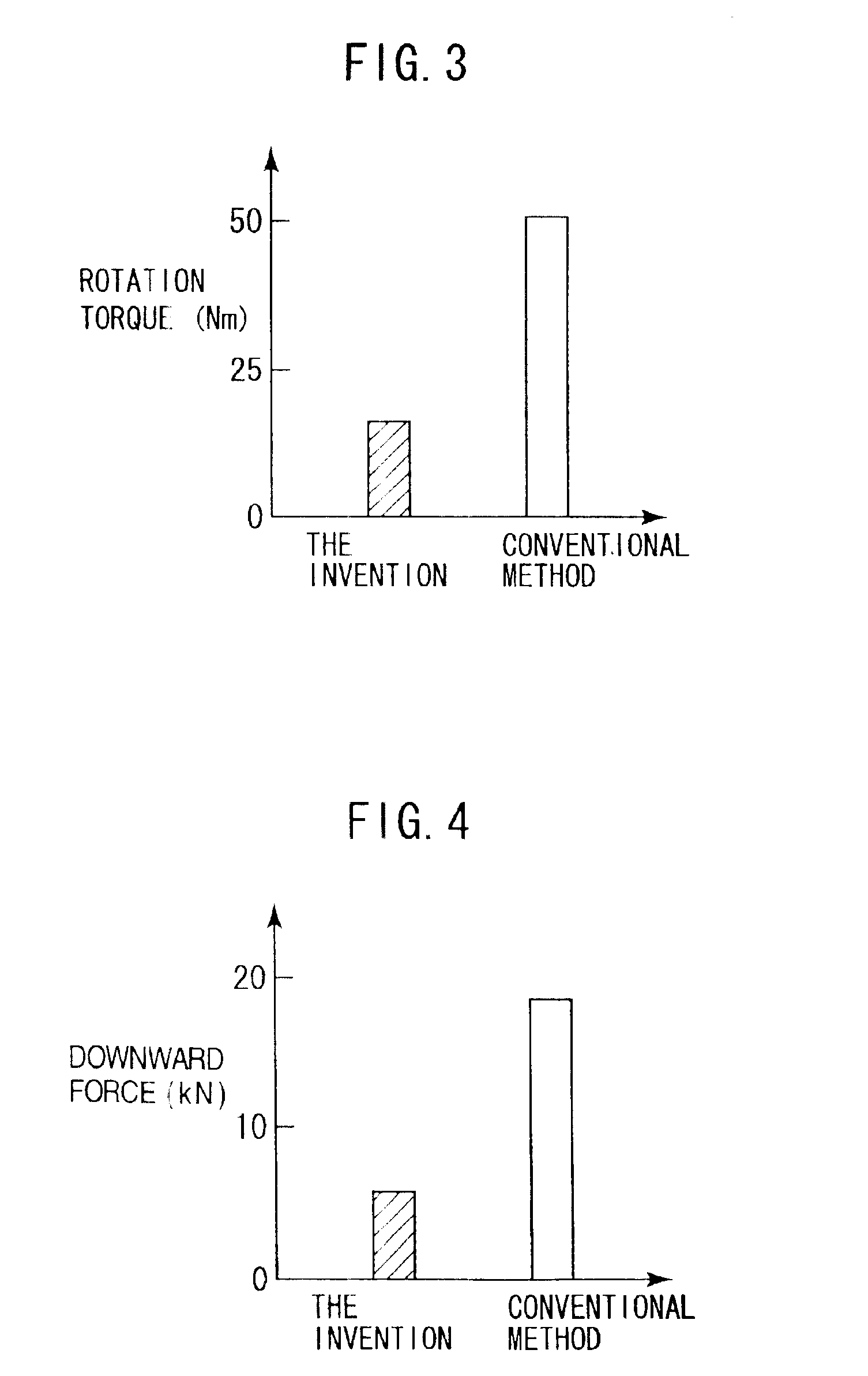

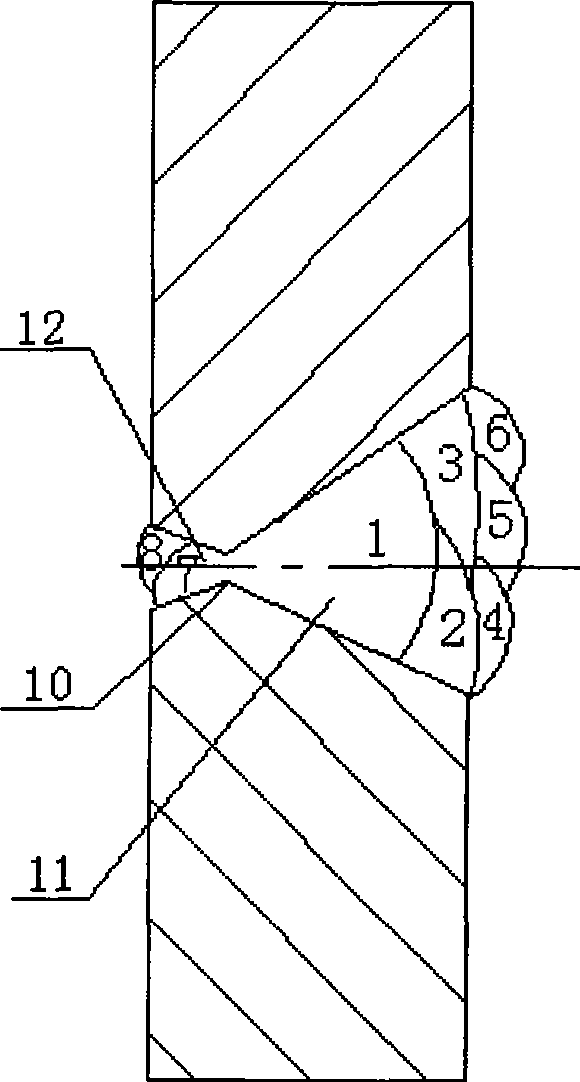

Friction stir welding method

InactiveUS6866181B2Suppress generation of friction forceHeat resistantElectric discharge heatingWelding/cutting auxillary devicesElectrical resistance and conductanceFriction welding

There is provided a method capable of decreasing a friction force in friction stir welding, in which a welding tool is used. In a method of friction stir welding workpieces together by rotating and pressingly plugging a welding tool, formed from a harder material than the workpieces, into a weld zone of the workpieces and moving the welding tool relatively in a welding direction, a power supply device allows a current to flow between the welding tool 1 and the workpieces to cause resistance heating of the welding tool. Combined use of resistance heating makes it possible to decrease a friction force. Preferably, a conductive ceramic is coated on surfaces of the welding tool to cause resistance heating.

Owner:HITACHI LTD

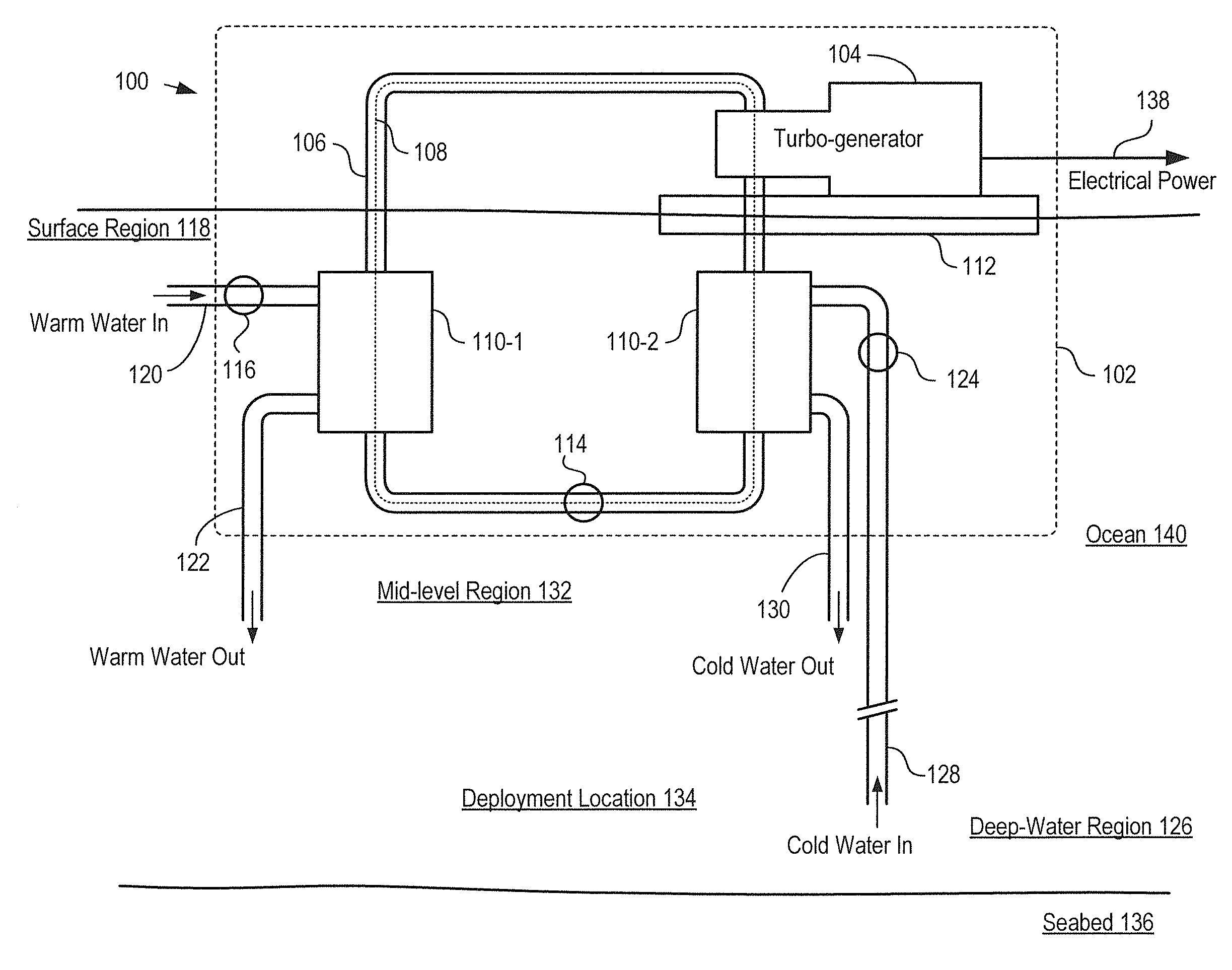

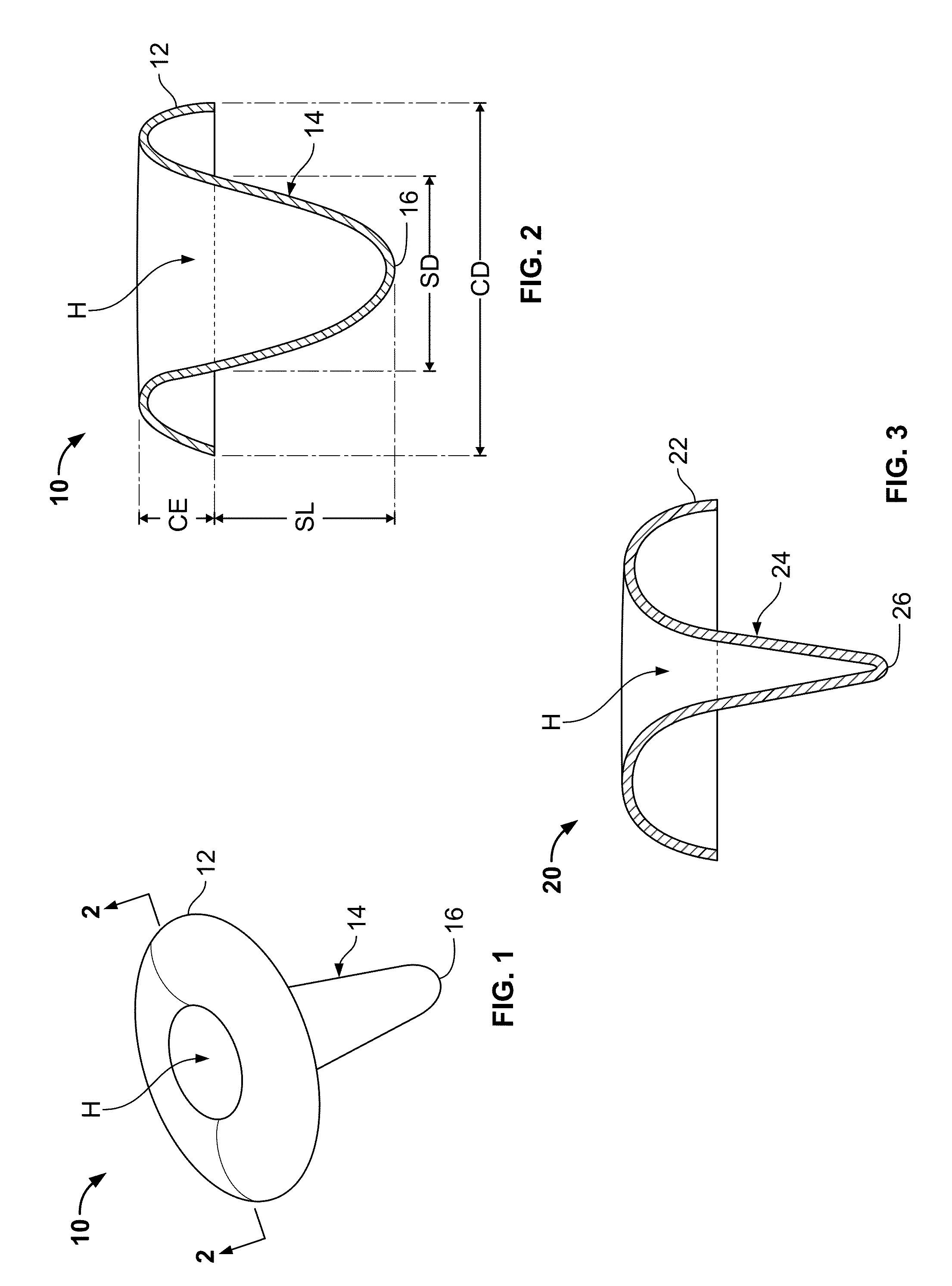

Friction-stir Weld-tool and Method

ActiveUS20110000952A1Welding/cutting auxillary devicesAuxillary welding devicesShell and tube heat exchangerEngineering

A method for joining a tube and tube plate for use in a tube-and-shell heat exchanger is disclosed. The method enables a joint between the tube and tube plate that is substantially hermetic and substantially corrosion-resistant. The method comprises providing an anvil inside the tube, wherein the anvil supports the tube wall during a friction-stir welding process used to join the tube and tube plate. The anvil facilitates formation of a reliable weld region and enables faster friction-stir welding.

Owner:LOCKHEED MARTIN CORP

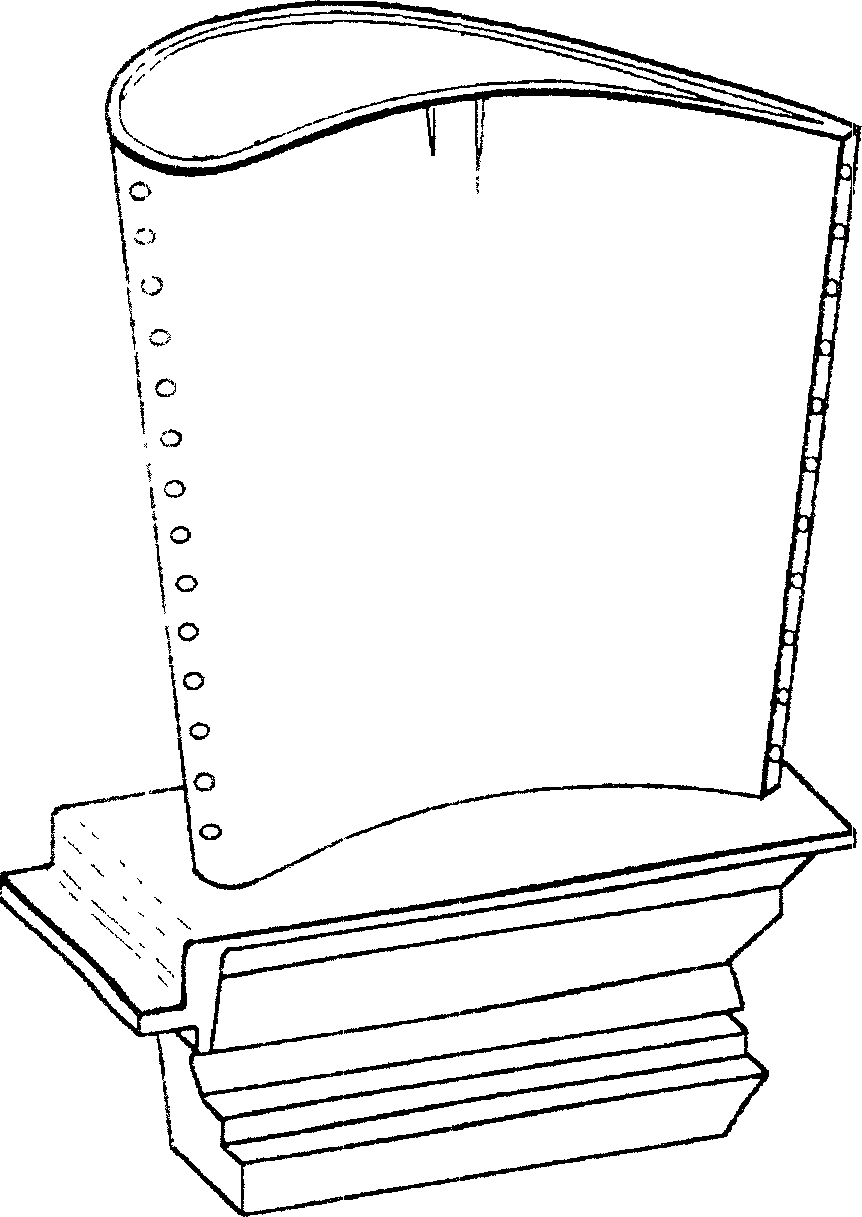

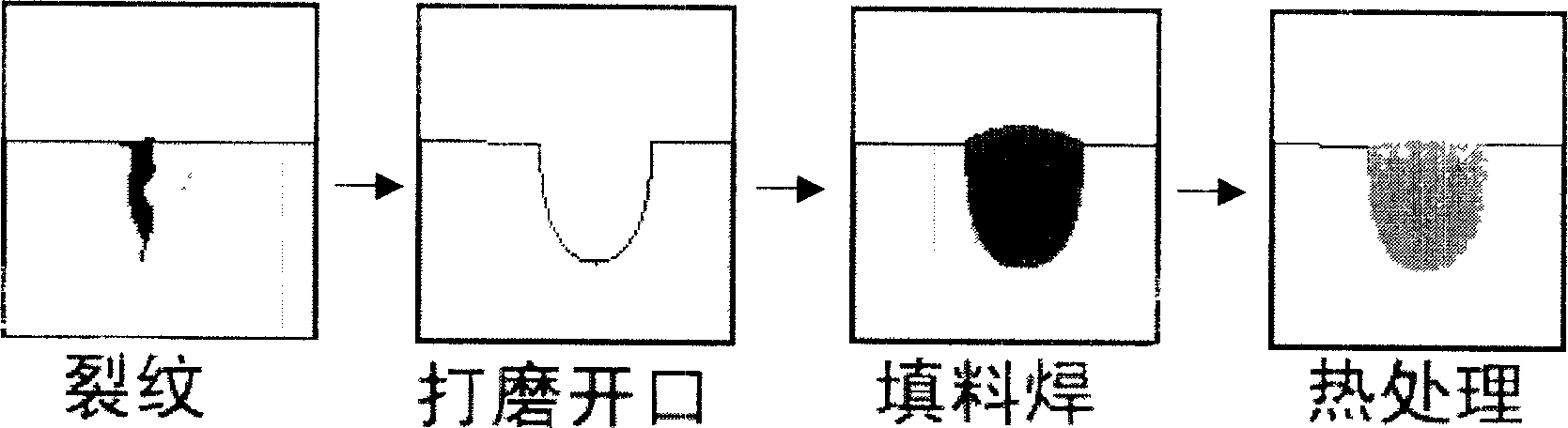

Crack repair process for high-pressure turbine blade tip in gas turbine

The present invention belongs to the metal surface crack repairing method, meaning the tip crack repairing method of a gas-turbine engine high-pressure turbine blade. The method comprises polishing apertures for complete crack removal based on the crack conditions of the gas-turbine engine high-pressure turbine blade tip, carrying out surfacing welding in the repair welding zone using low-heat input welding technology and implementing heat treatment process to the repaired blade. The present invention has the virtues of simple process, needing no vacuum or preheating, small damage to blade base materials, realizing loss-free repair to the high-pressure turbine blade tip cracks and reducing repair cost. The invention can be used to repair both the gas-turbine engine high-pressure turbine blade tip cracks and steam turbine, smoke turbine and other turbine mechanisms high-pressure or low-pressure blade tip cracks. And the aircraft engine high-pressure turbine blade repaired with the method has passes 368h long-term bench trial check.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

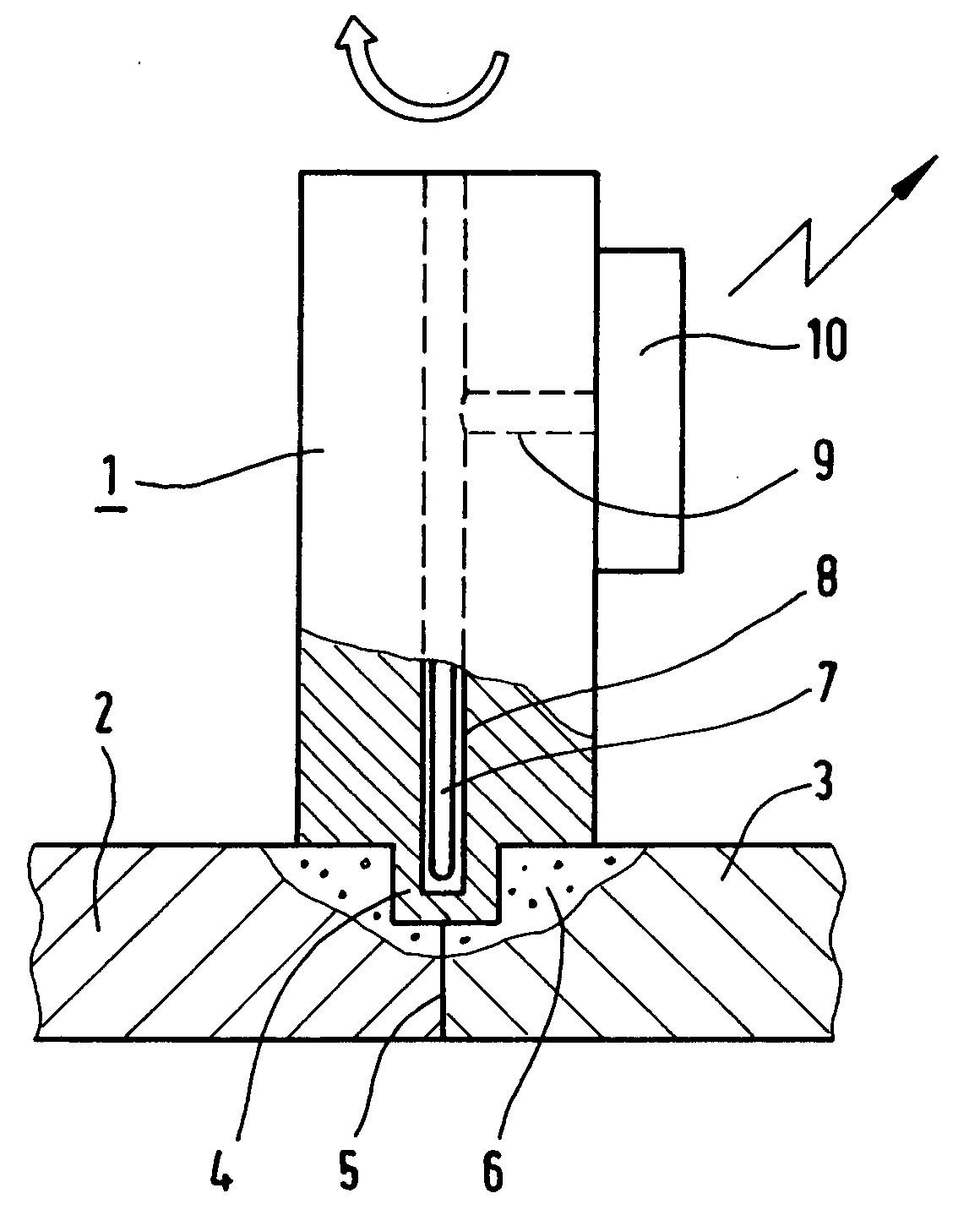

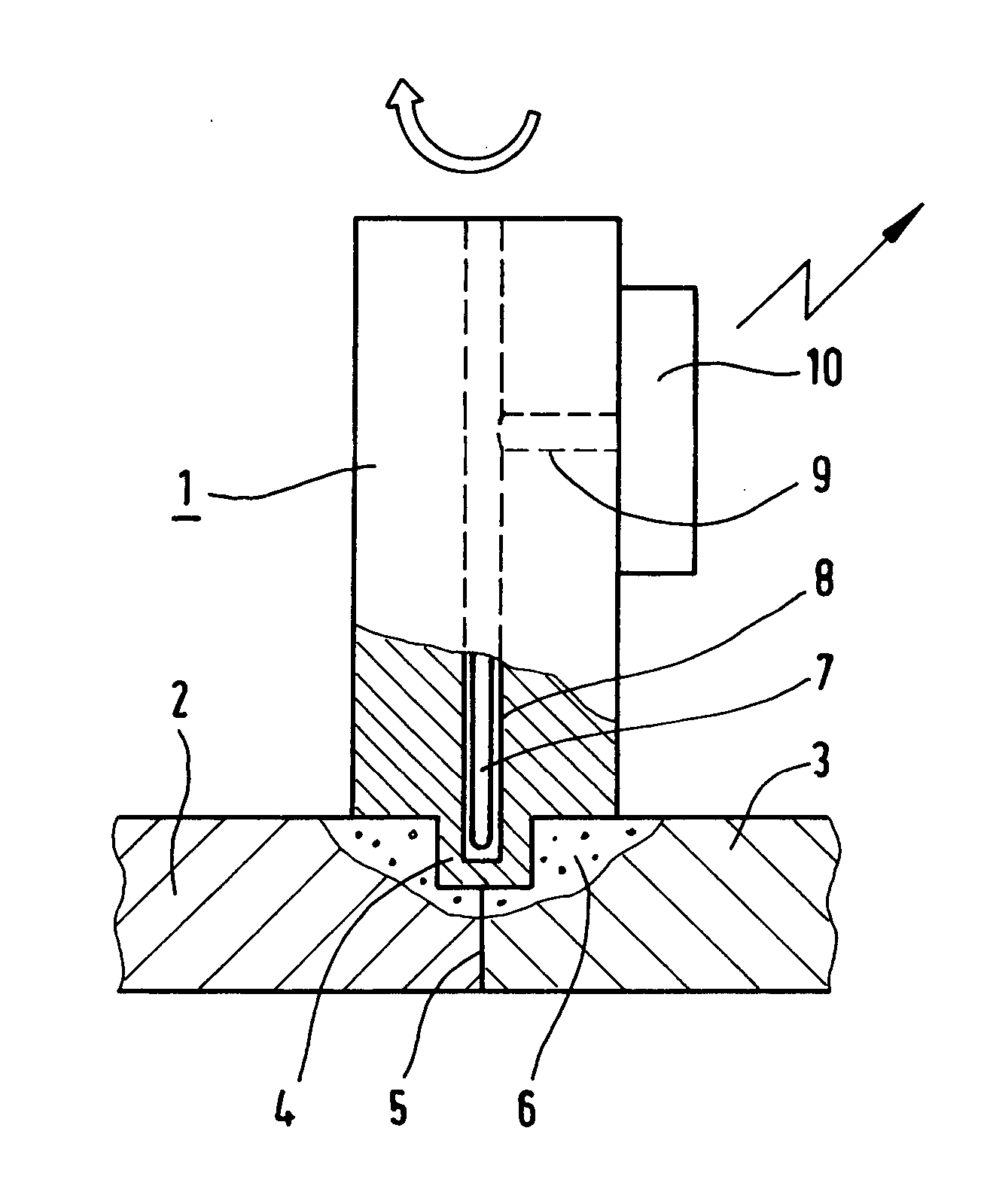

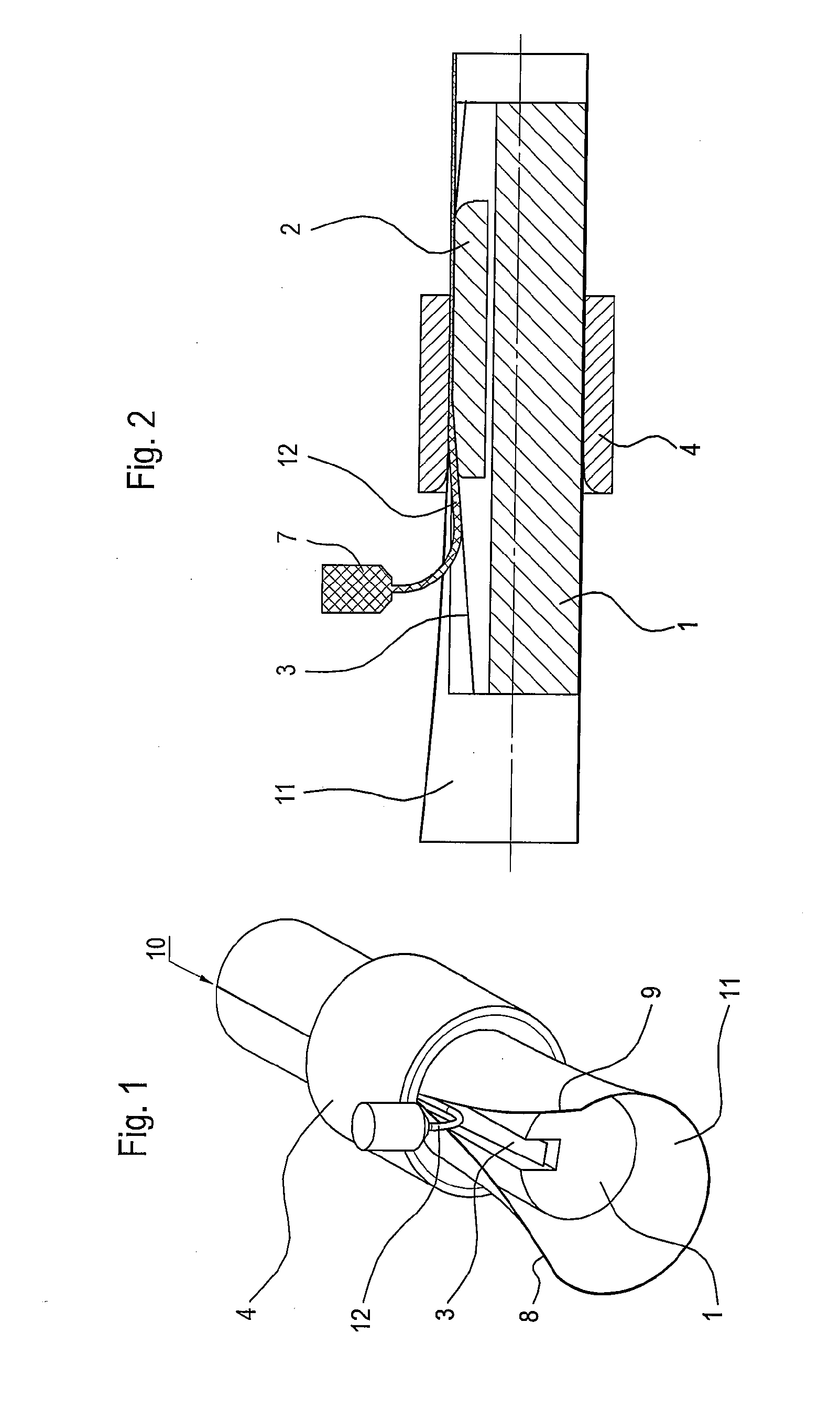

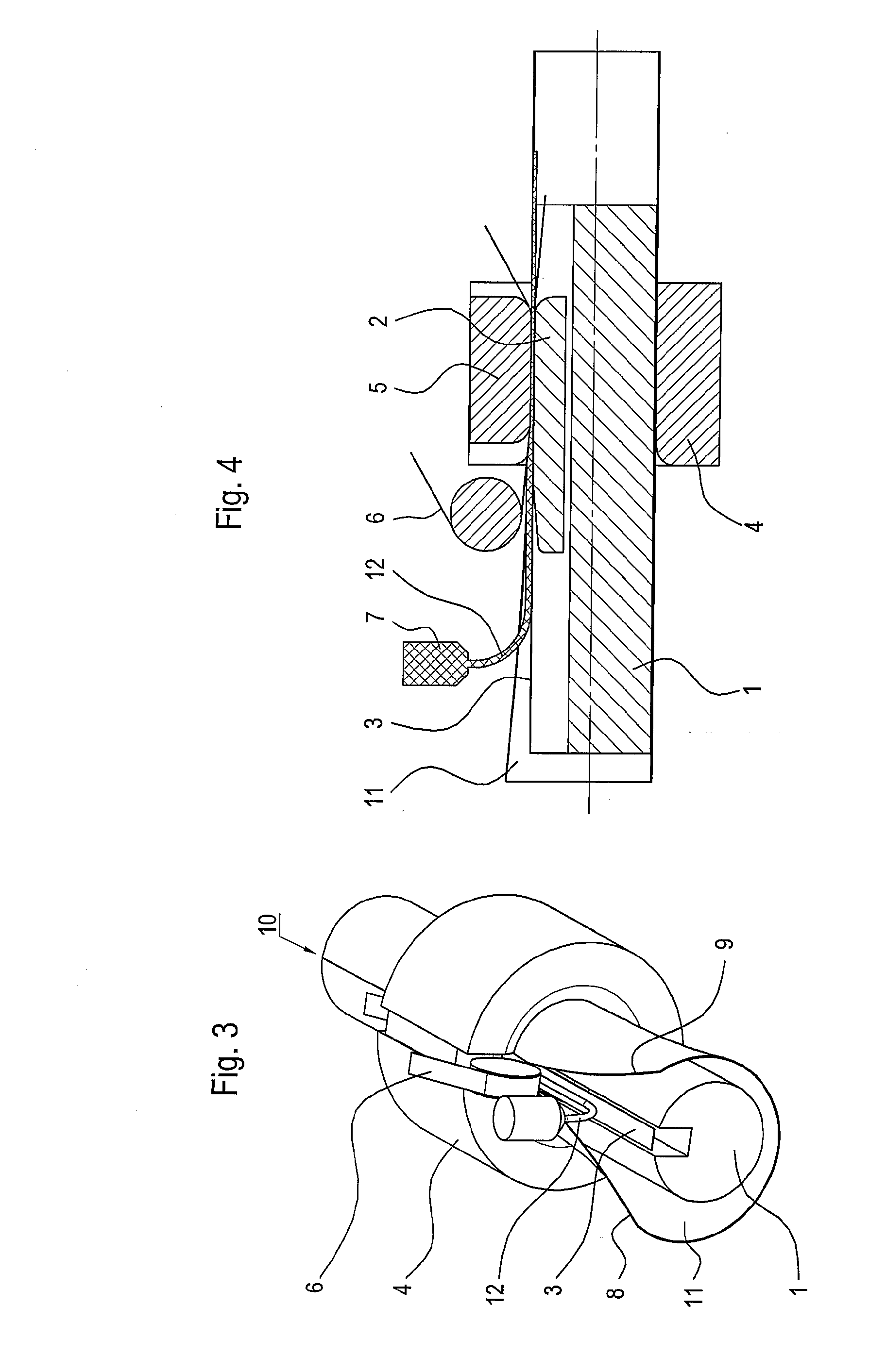

Friction stir tool for friction welding

InactiveUS20050001009A1Automatic control devicesPrecision positioning equipmentFriction weldingMeasurement point

The object of the invention is to create a friction welding tool for friction welding that can be controlled with respect to measuring accuracy based upon the temperature in the weld zone. This object is attained in accordance with the invention by determining the temperature values of the weld zone (6) by means of a temperature sensor (7), which is arranged with its measuring point in the pin (4) of the stir welding tool (1).

Owner:EADS DEUT GMBH

Hybrid welding method and hybrid welding equipment for laser electromagnetic pulse

ActiveCN103737176AImprove adoption efficiencyReduce welding defectsLaser beam welding apparatusStructural deformationMetallic materials

The invention discloses a hybrid welding method and hybrid welding equipment for laser electromagnetic pulse. The method can be used for laser seam welding and laser spot welding technology, a pulsed high magnetic field is applied to a welding region during the process of laser welding on a workpiece with the effect of laser beams so as to mutually react with an induced plasma, a welding pool and a stress strain field through welding and complete welding task. The equipment comprises a laser device, an electromagnetic pulse generator, a numerical control system, an optical transmission system and a laser electromagnetic pulse combined machining head. The combined machining head is used for integrating the laser beams with the pulsed high magnetic field and adjusting the distance between an electromagnetic conversion device and the workpiece; the combined machining head is arranged on a machine tool. The structural deformation can be reduced, the welding quality and machining efficiency are improved, and insurmountable technical problems when a metallic material structure is manufactured through existing single welding technology are solved.

Owner:武汉飞能达激光技术有限公司

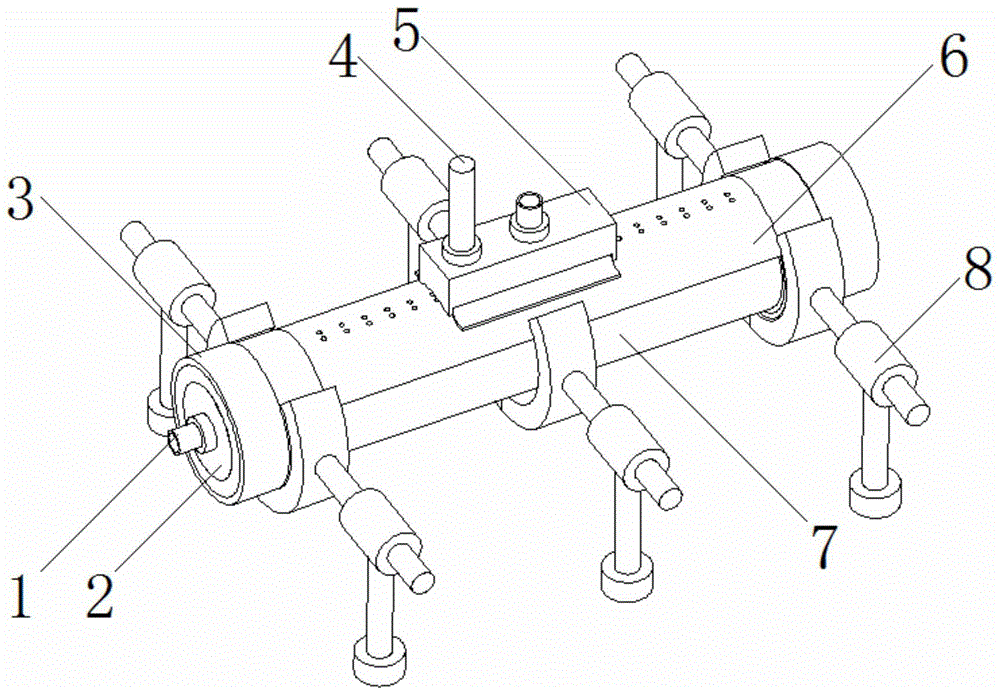

Joint welding clamp of titanium alloy straight pipe and joint welding method

InactiveCN103978290AAvoid partial collapseEliminate influence of welding qualityWelding/cutting auxillary devicesAuxillary welding devicesCopperTitanium alloy

The invention discloses a joint welding clamp of a titanium alloy straight pipe and a joint welding method. The joint welding quality and precision of the titanium alloy straight pipe can be guaranteed by adopting auxiliary supporting and clamping inside the titanium alloy straight pipe and protecting a welding influenced region by inert gas. The method comprises the steps of sealing places where copper sleeves are matched with the titanium alloy straight pipe by sealing tapes at the two ends of a gas feeding pipe, feeding protective gas to a weld joint by two exhaust holes in the feeding pipe, and forming an integral part for supporting a welding region in an auxiliary way by fixedly connecting an arc-shaped copper block, with two exhaust holes, on the gas feeding pipe through super glue; taking out the gas feeding pipe and the arc-shaped copper block from the titanium alloy straight pipe after the completion of welding due to the fact that the radian of the arc-shaped copper block is smaller than a semicircle, performing gas protection on the welding joint outside the titanium alloy straight pipe by a protective cover, fixing a welding gun on the protective cover by a clamp ring, and driving the welding gun to move by moving the protective cover; clamping the titanium alloy straight pipe by adopting an arc-shaped clamp, in order to guarantee the welding continuity..

Owner:NORTHWESTERN POLYTECHNICAL UNIV +1

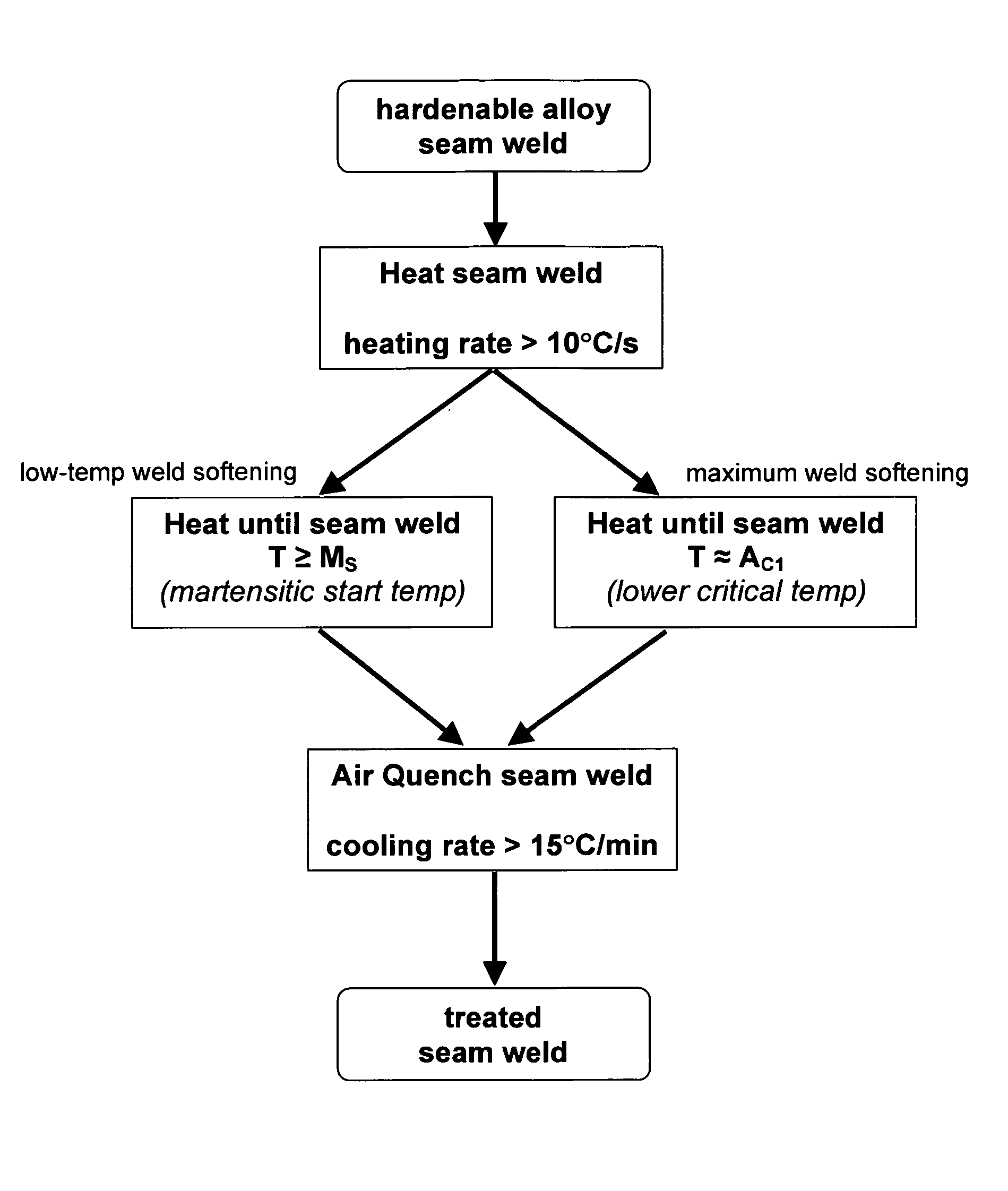

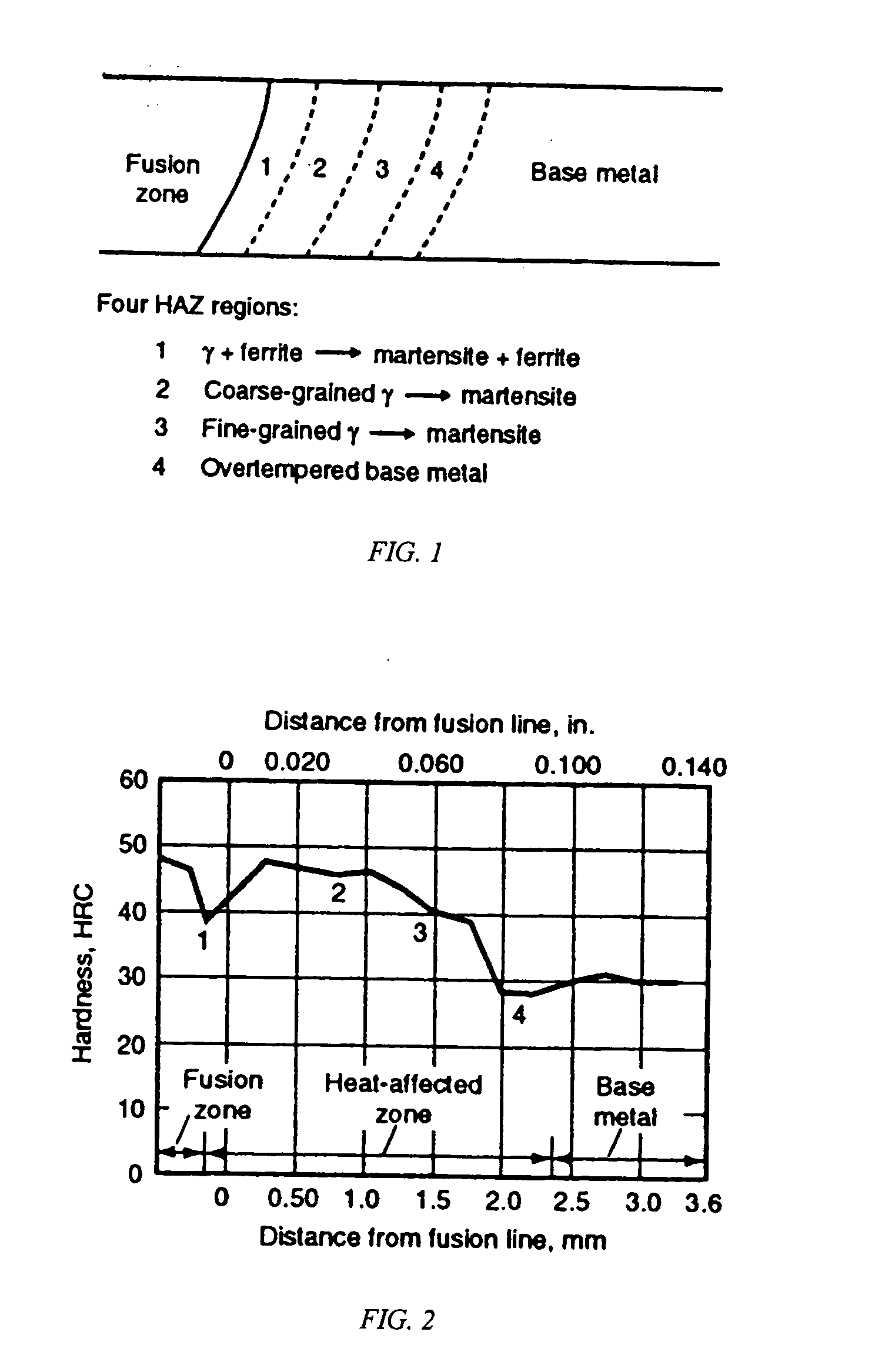

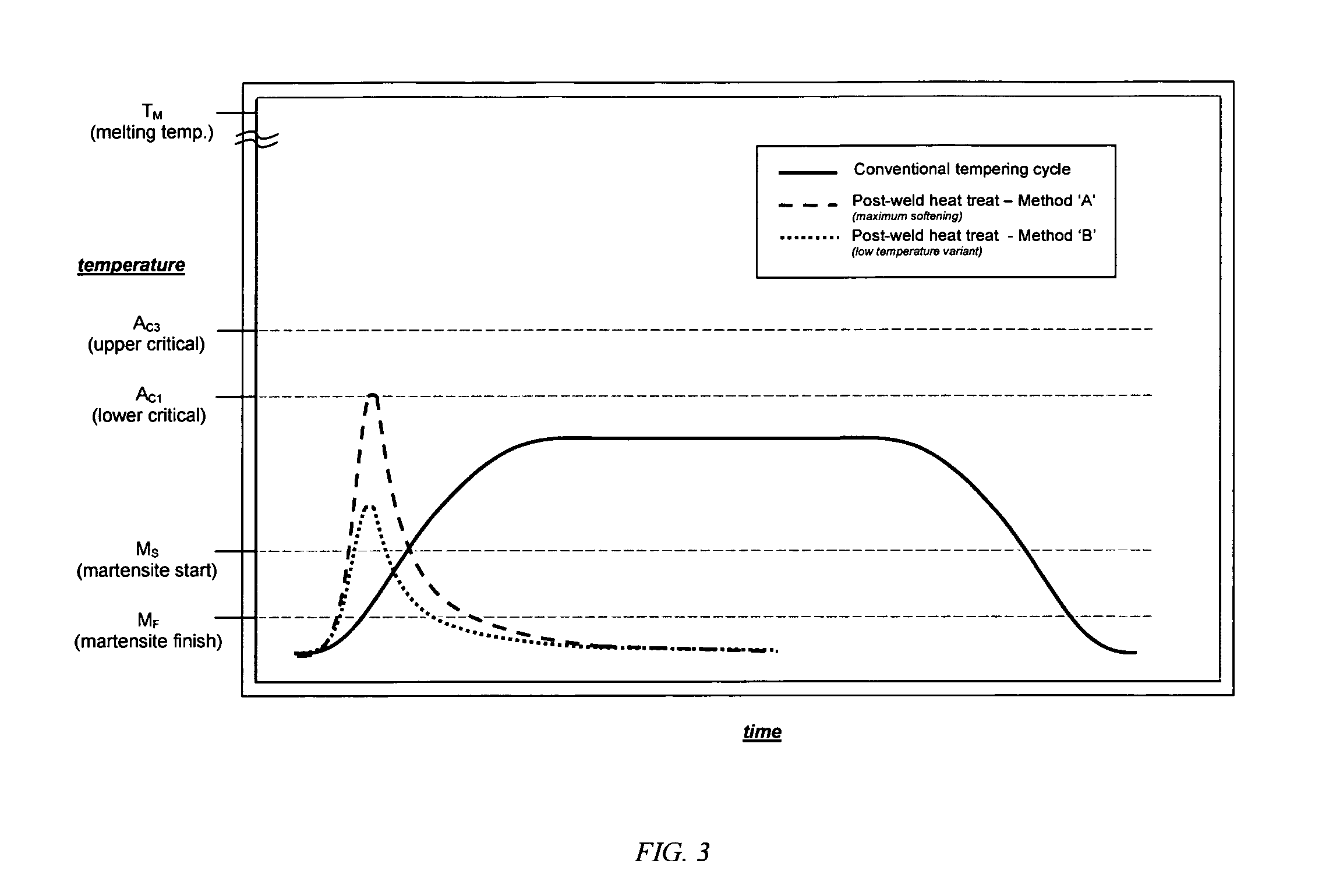

Method for improving the performance of seam-welded joints using post-weld heat treatment

InactiveUS20080115863A1Simple methodImprove mechanical propertiesIncreasing energy efficiencyFurnace typesHardnessAlloy

The present invention provides a method for heat-treating seam-welded constructions of hardenable steel and ferrous alloys with reduced weld-zone hardness and improved weld-zone ductility and toughness. This method consists of heating the seam weld rapidly with a secondary heat source to a temperature greater than the martensitic start temperature but not greater than the lower critical temperature, followed by immediately allowing the seam weld to air-cool. The rapid tempering of this invention is particularly suited to the production of high strength hardenable alloy seam-welded pipe and tubing and other structures.

Owner:CODD DANIEL SHAWN

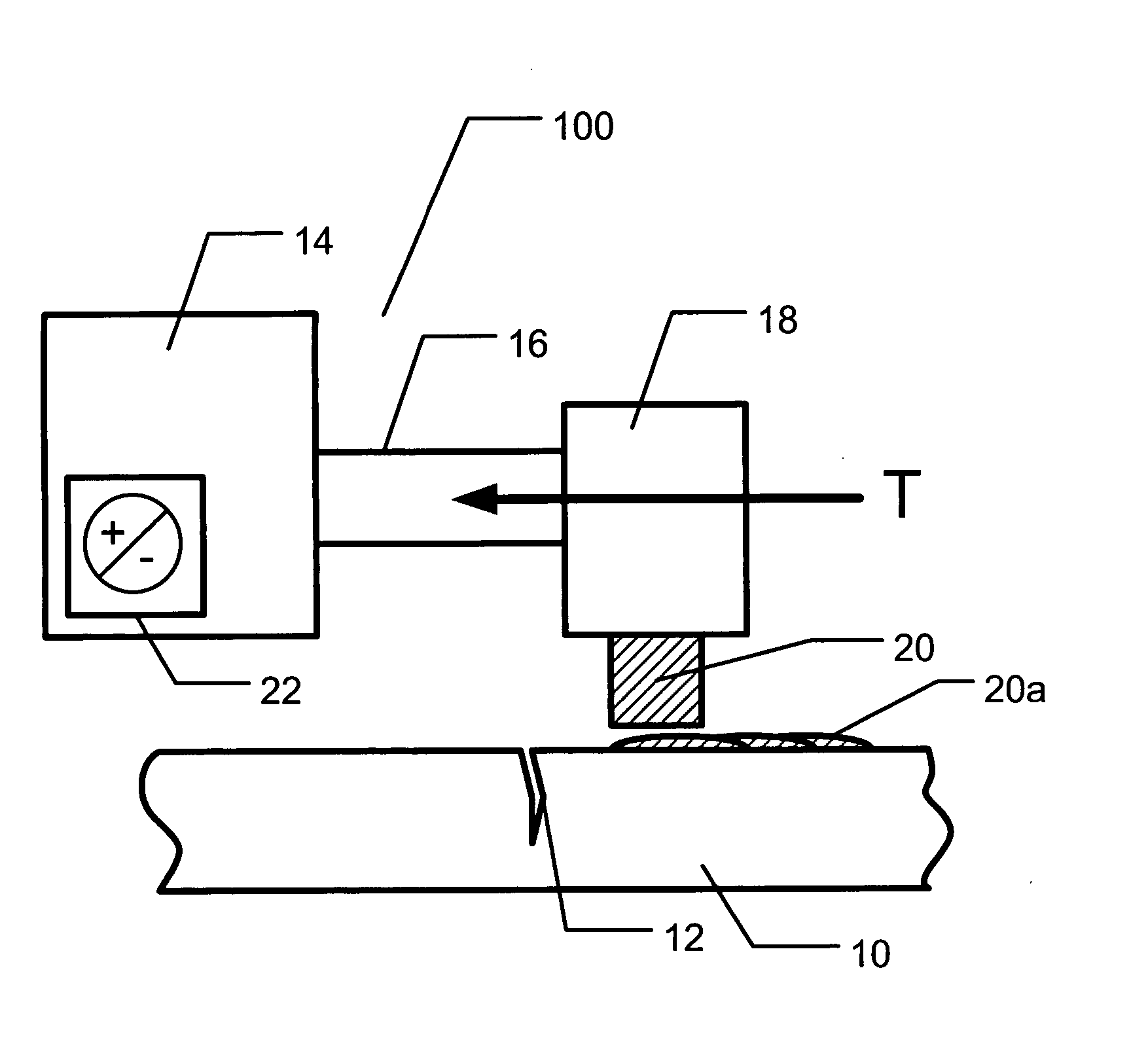

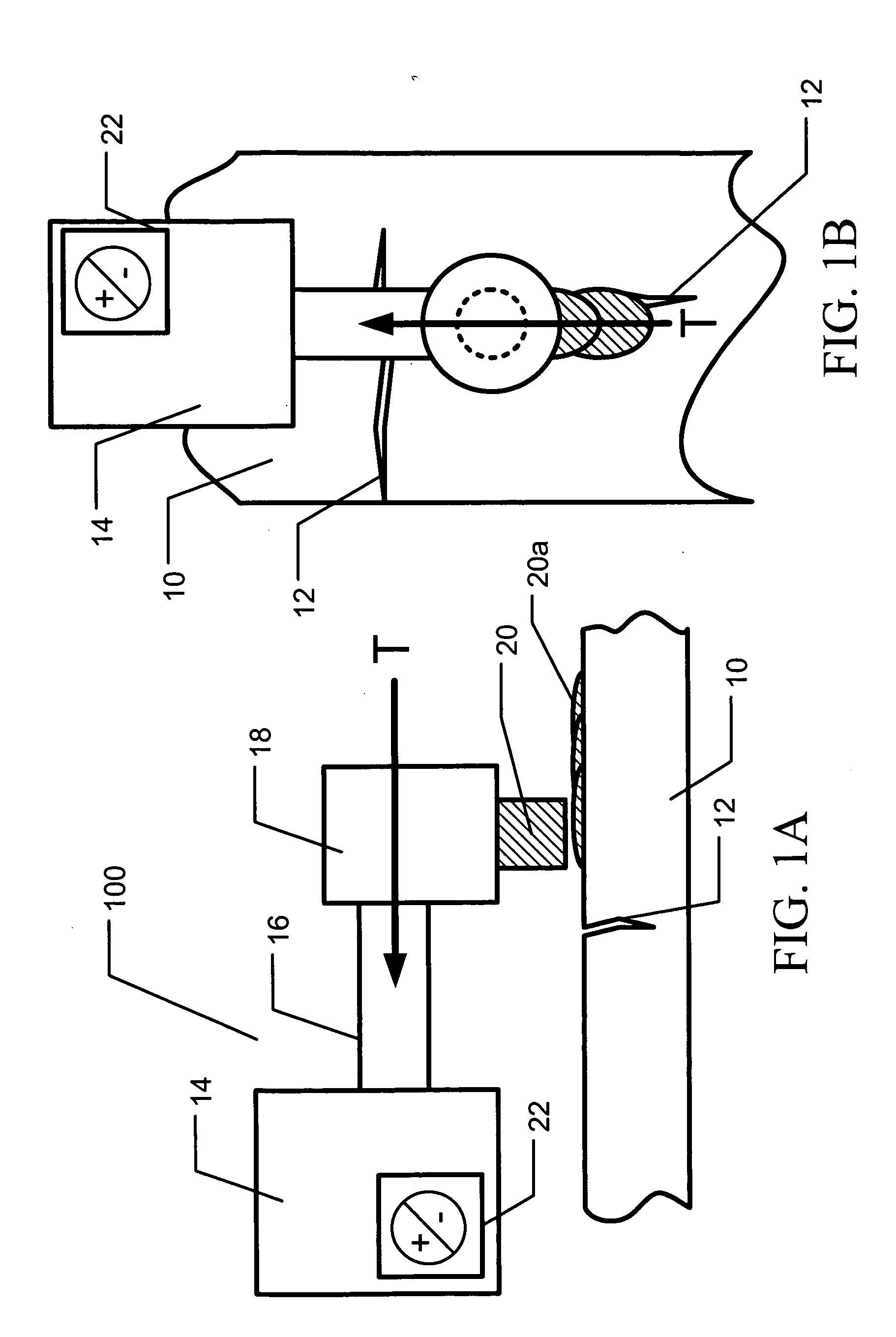

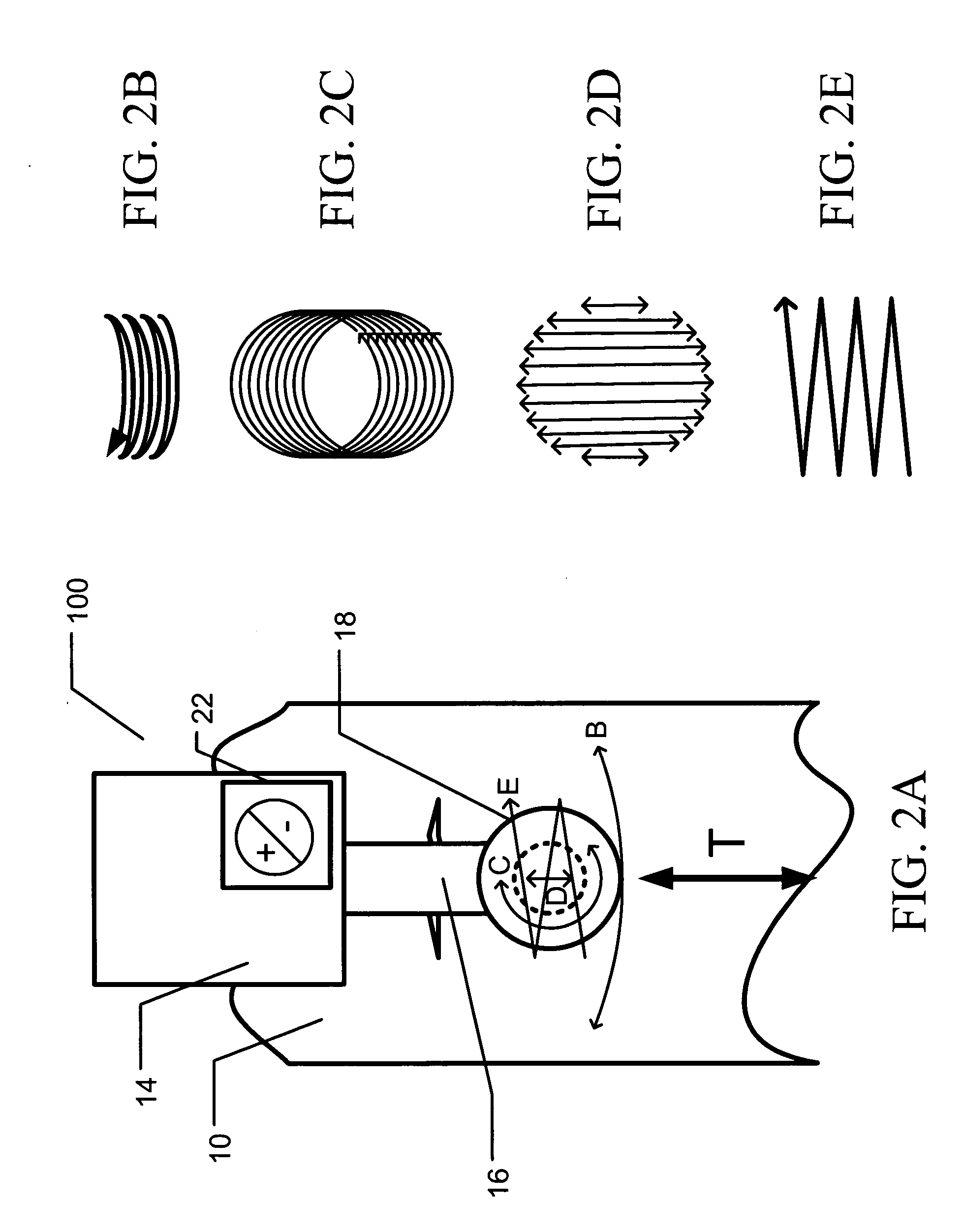

Apparatus and method for electrofriction welding

ActiveUS20050150871A1Heat generationArc welding apparatusResistance welding apparatusFriction weldingElectrical resistance and conductance

An apparatus and method arranged to use a combination of at least electrical resistance heating and mechanical friction heating to case a base material and / or a consumable material to reach a combination of temperature and pressure sufficient to cause welding. The method and apparatus configured for the simultaneous or substantially simultaneous application of both electrical resistance heating and friction heating to achieve welding is referred to as an electrofriction process, method or apparatus. This combination of resistance and friction heating allows the heating to be more localized within a relatively small weld zone, thereby improving the efficiency of the overall process and allowing the size, weight and strength and / or the cost of the application equipment and / or associated fixtures and power supplies to be reduced while enhancing its capability for operation in confined spaces and providing satisfactory welding performance.

Owner:GENERAL ELECTRIC CO

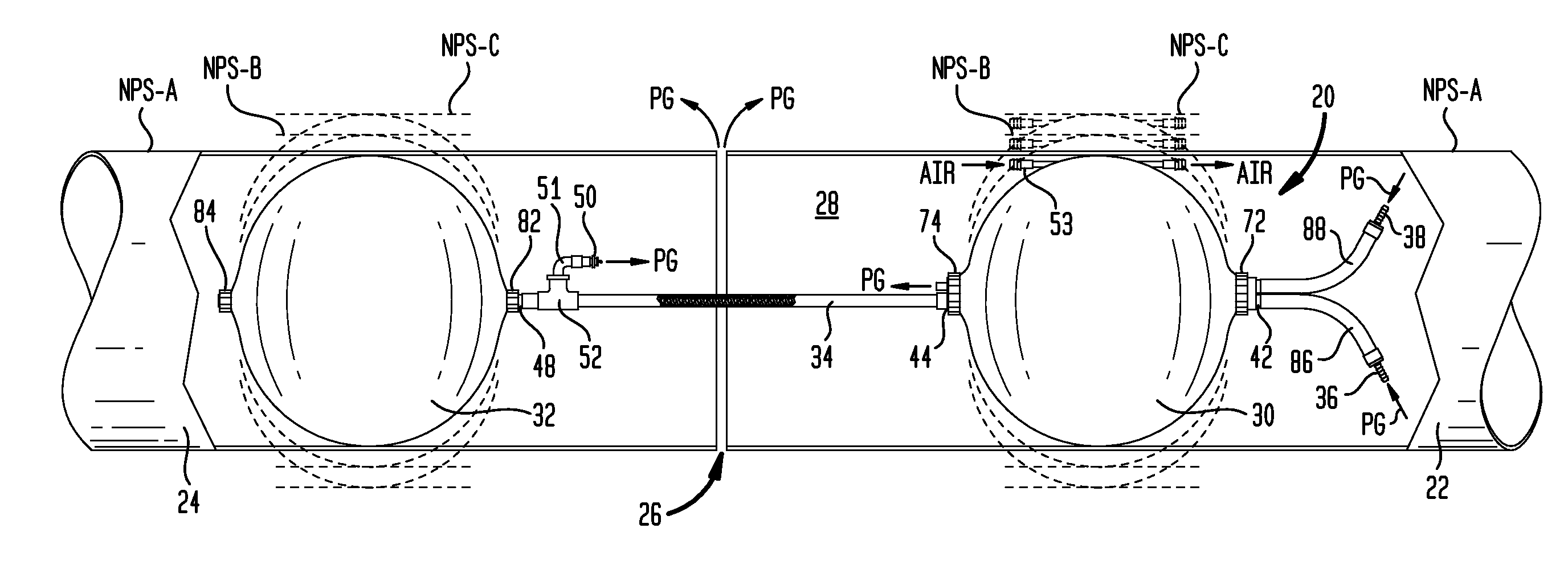

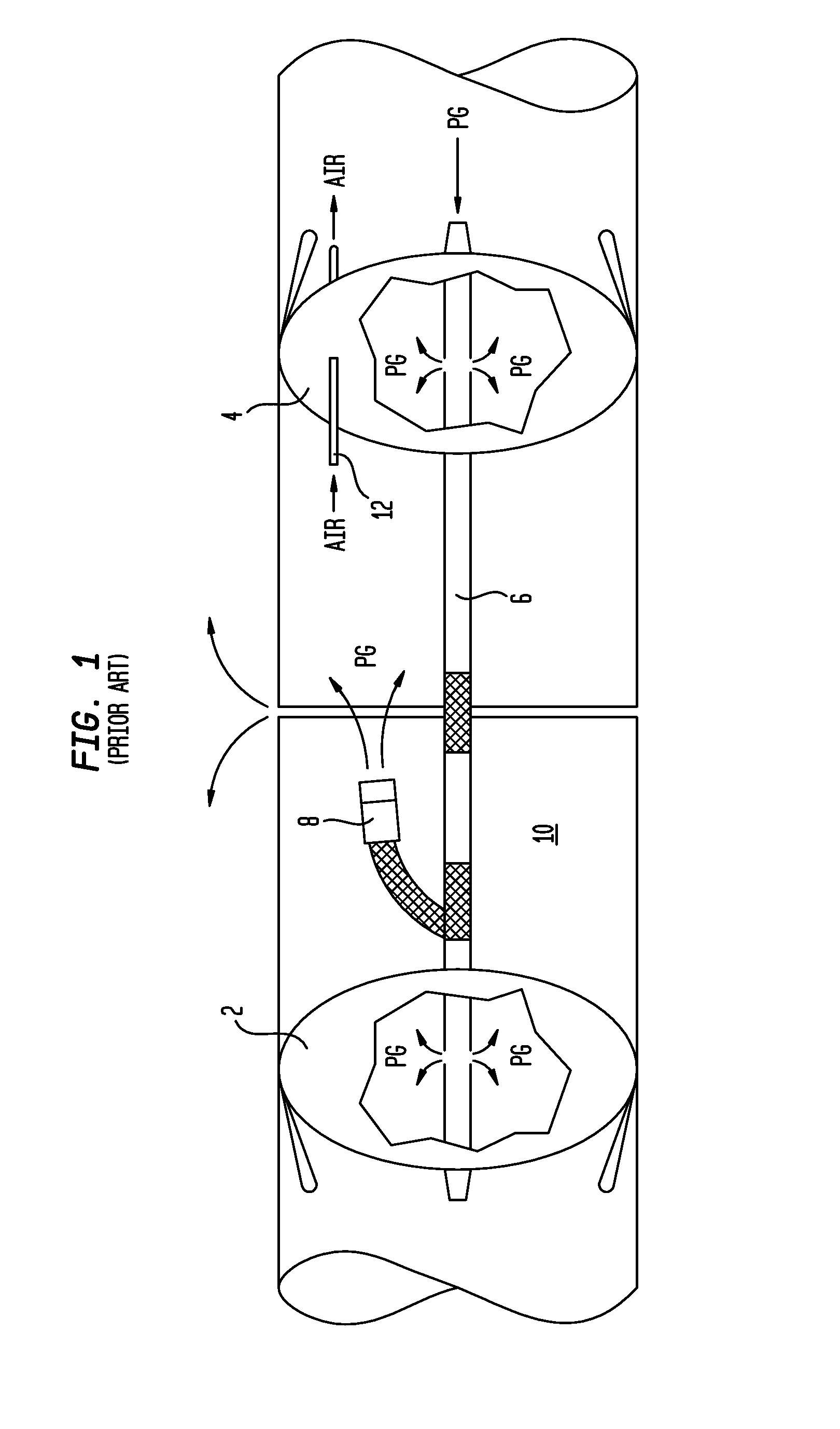

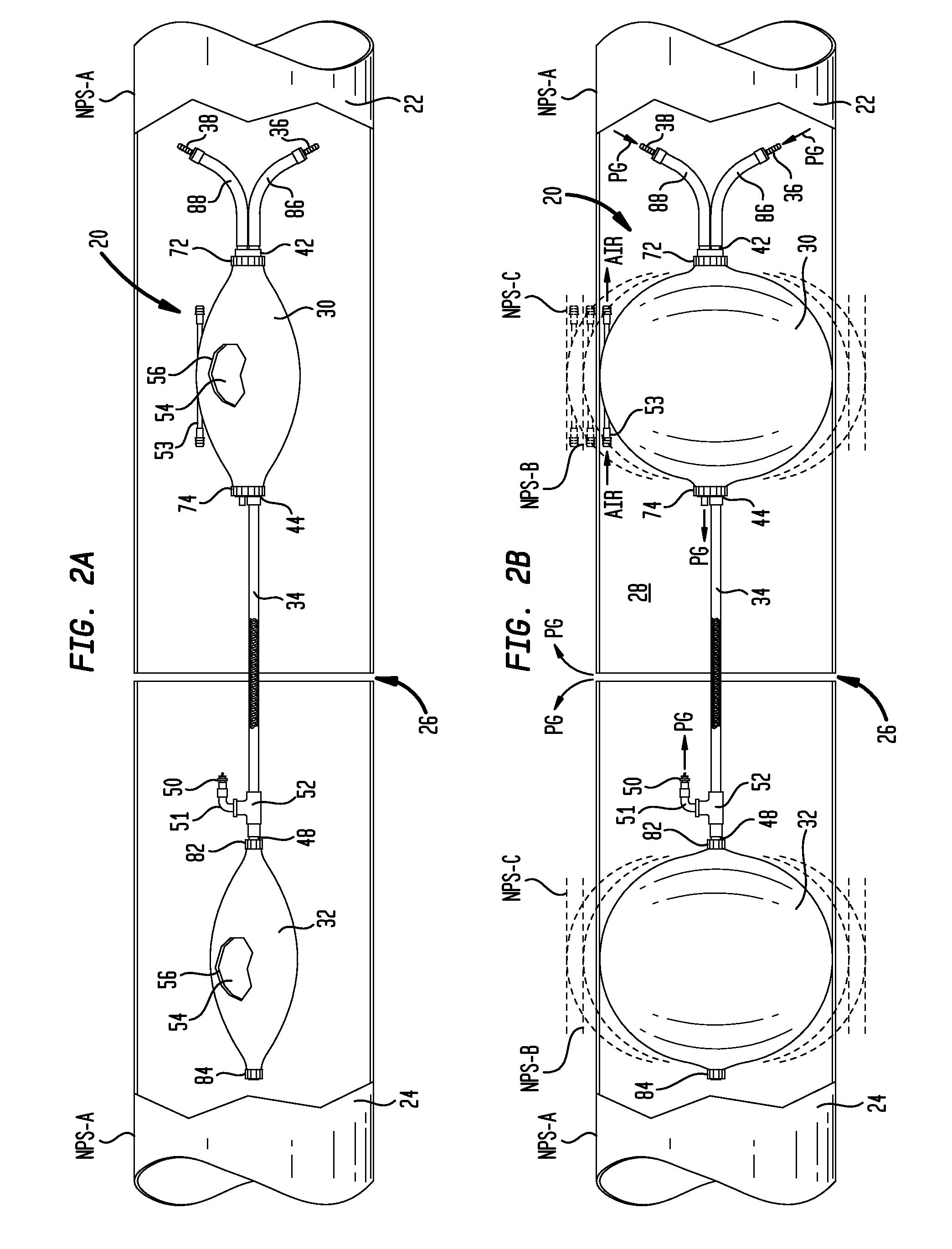

Inflatable Purge Dam Apparatus

ActiveUS20130284297A1Resistant to oxygen leakageMaintaining fluid separationShielding gas supply/evacuation devicesPipe elementsEngineeringAirbag deployment

An inflatable purge dam apparatus for use with pipes of different nominal pipe size (NPS) includes first and second inflatable purge bladders, and an intermediate bridge conduit. In a first aspect, the purge bladders each comprise an expandable inner purge gas retaining liner and a heat-resistant stretchable outer protective cover. The protective covers comprise a heat-resistant stretchable material that is constructed to undergo variable stretching to increase the size of the purge bladders as they are inflated with purge gas to a desired sealing pressure, thereby allowing the purge bladders to form an effective weld zone seal in pipes of different NPS. In a second aspect, an air vent conduit extends between first and second ports located proximate to a longitudinal centerline of the first purge bladder. The air vent conduit provides a vent pathway for venting air from the weld zone through the first purge bladder.

Owner:AQUASOL CORP LLC +1

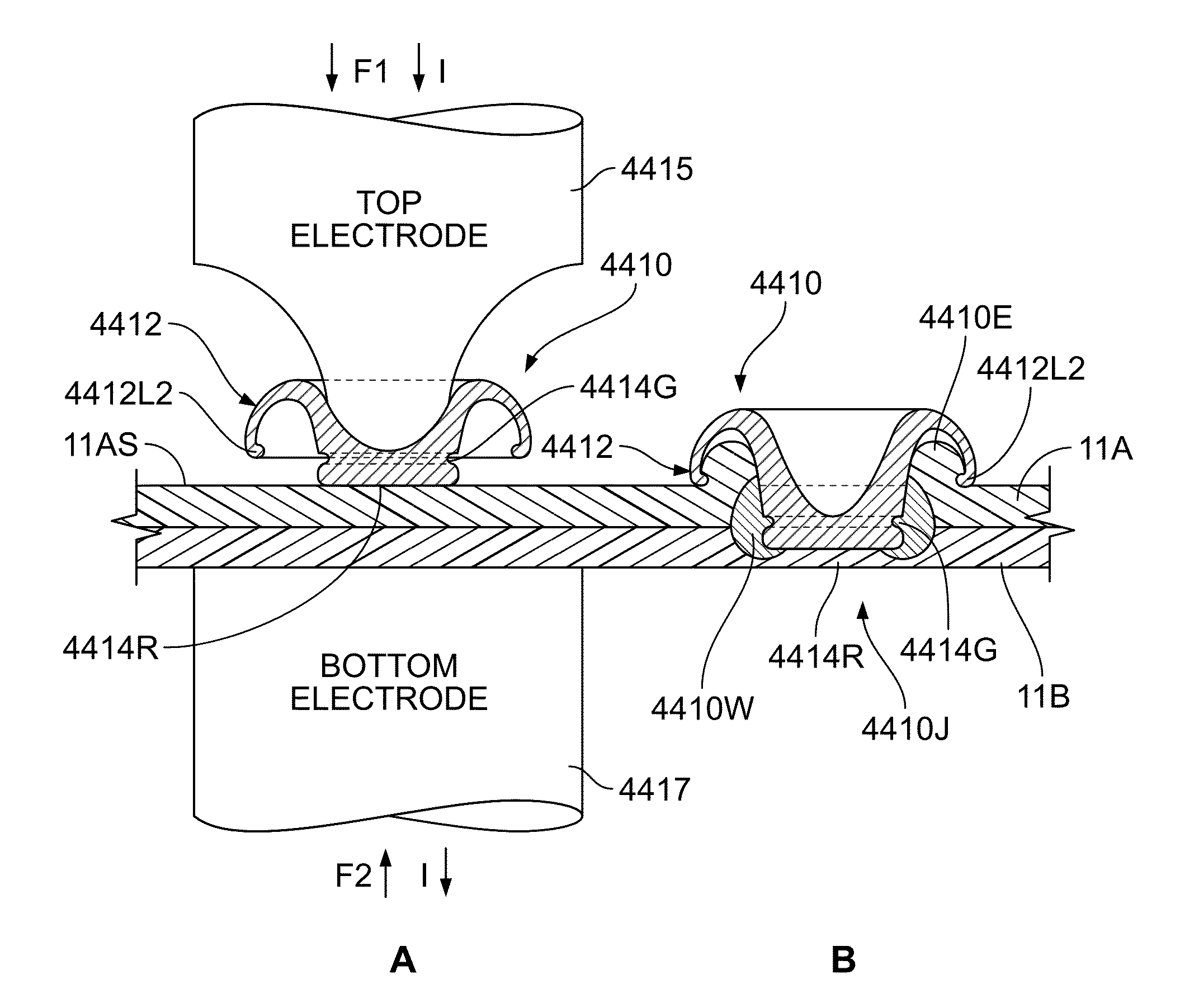

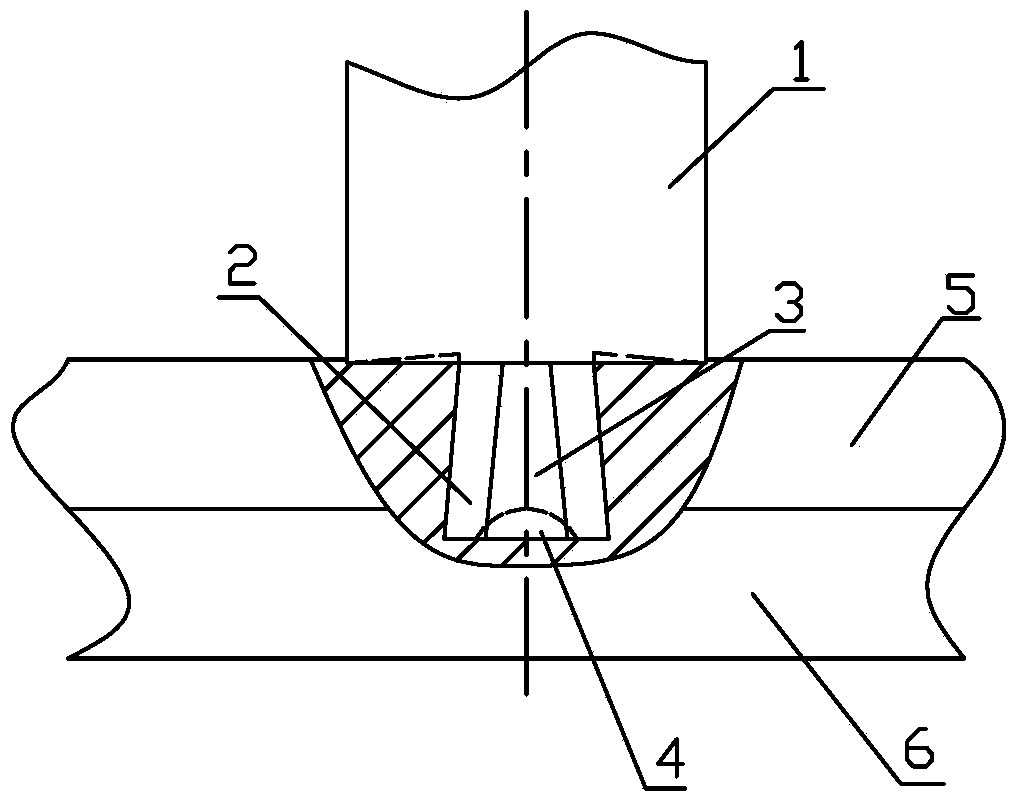

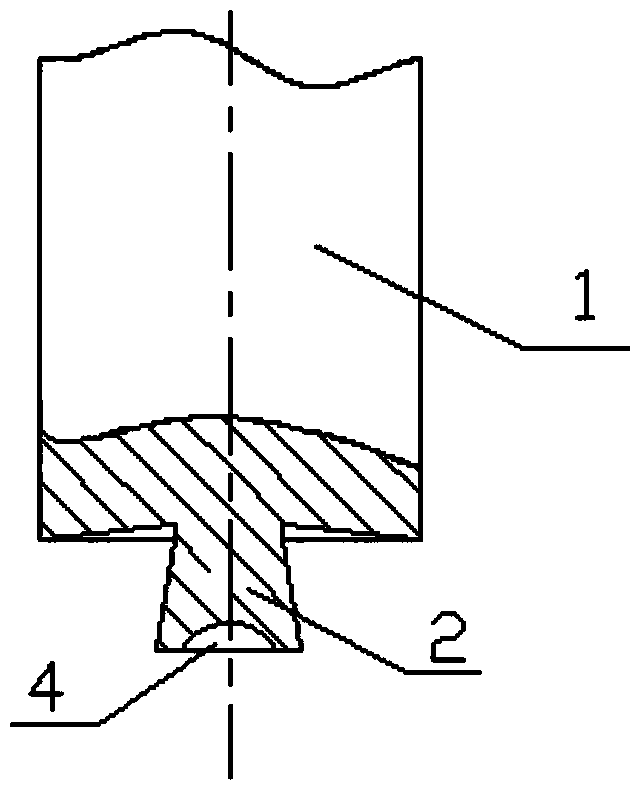

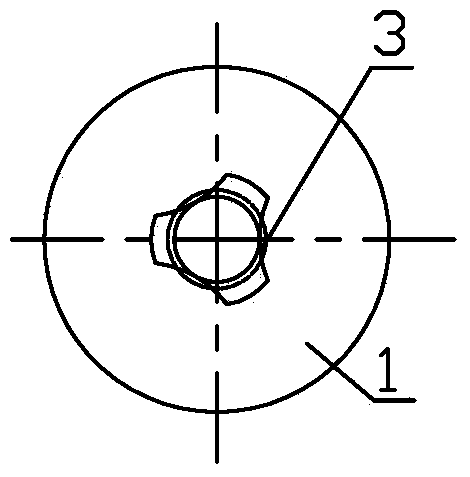

Resistance welding fastener, apparatus and methods for joining similar and dissimilar materials

ActiveUS20160167158A1Improve the immunitySheet joiningWelding/cutting media/materialsConductive materialsAlloy

An apparatus and method for fastening layers of non-ferrous alloys, like aluminum, magnesium and copper utilizes a steel fastener and a spot welding machine. The fastener and metals are stacked and the heat from the welder's electric current softens the lower melting point aluminum allowing the fastener to penetrate the aluminum. A weld zone between the fastener and the various layers creates an internal weld. The fastener has a rough shaft that is coated by the molten weld zone and is hard to withdraw on solidification. Layers of non-conductive materials like plastics and ceramics may also be affixed to a conductive layer using a fastener made from a compatible material that extends through a pilot hole and welds to or penetrates a conductive layer. The fastener may have projections that initially reduce contact area with the stack.

Owner:HOWMET AEROSPACE INC

Friction stir welding tool for overlap joint

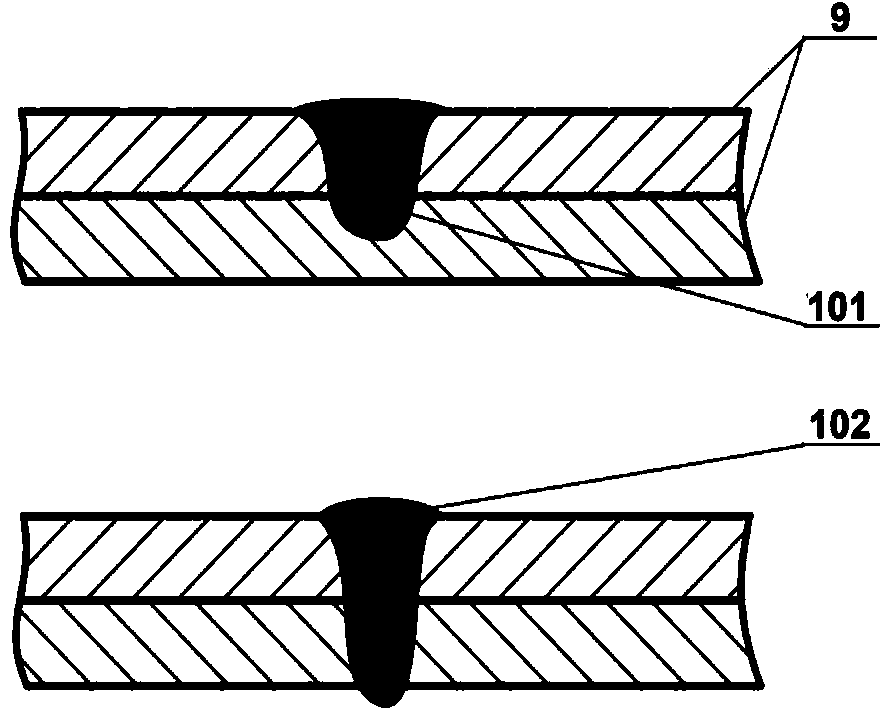

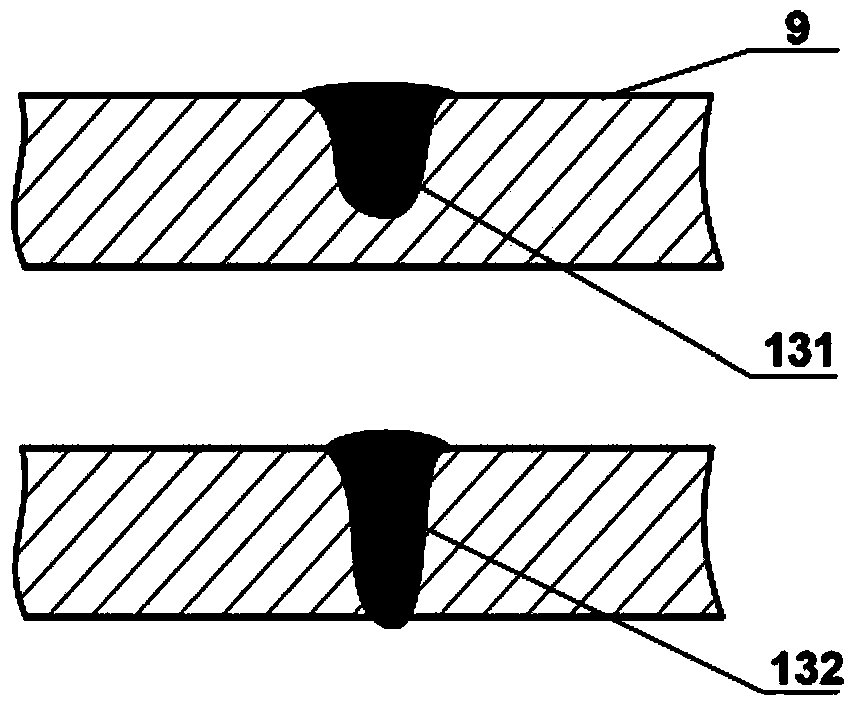

InactiveCN103521912AStrengthening Strength CoefficientReduce vertical movementNon-electric welding apparatusWeld zoneFriction stir welding

The invention discloses a friction stir welding tool for an overlap joint. The friction stir welding tool is composed of a shaft shoulder and a stirring needle. The stirring needle is shaped like a frustum, the small bottom of the frustum is connected with the shaft shoulder, the end face of the large bottom of the frustum is provided with a round concave hole, and the outer surface of the frustum is provided with three arc-shaped grooves distributed in the circumferential direction. Meanwhile, the invention further discloses the stirring needle and the structures and the sizes of all parts of the shaft shoulder. When a stirring tool designed through the friction stir welding tool is adopted for carrying out friction stir overlap welding, the stirring needle of the frustum shape generates oblique upward thrust on plasticized metal around the overlap face, so that the perpendicular motion of the plasticized metal is reduced, and the perpendicular moving tendency of the overlap face is reduced. Moreover, as the concave hole and the grooves in the side face are formed in the bottom of the stirring needle, material flow in weld zones is improved, the overlap face is broken completely, and the weld metal can be mixed fully. Accordingly, the size of the hook-like defect in a weld joint obtained through welding of the tool is greatly reduced, and the strength coefficient of the joint is remarkably improved.

Owner:TIANJIN UNIV

Welded metal laminate structure and method for welding a metal laminate structure

An improved method for welding a laminated metal structure is presented herein. In one embodiment, the method includes: placing the laminated structure against a second work piece, feeding a consumable metal cored wire electrode to the weld zone, feeding a stream of shielding gas to the weld zone, and melting the consumable metal cored wire electrode. If the weld joint is a plug weld, the method also includes forming a plug hole in one of the work pieces, melting the consumable metal cored wire electrode along the circumference of the plug hole, and thereafter progressively spiraling the welding gun inwards towards the center of the plug hole to fill it with the melted electrode. The method may also include determining if melting the electrode is causing sputtering, and delaying spiraling the welding gun inwards until the sputtering subsides. A welded laminate metal structure is also provided herein.

Owner:MATERIAL SCIENCES CORPORATION

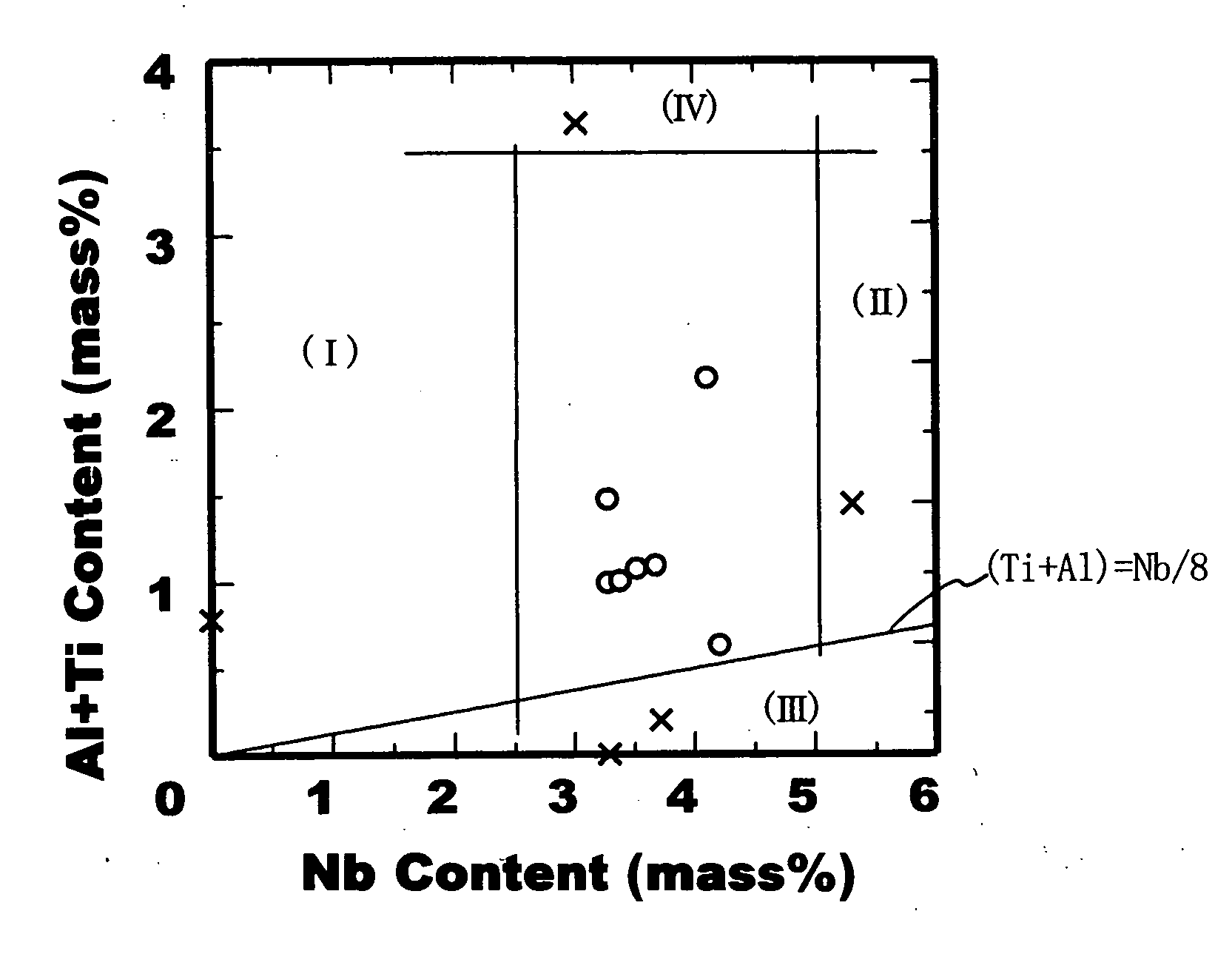

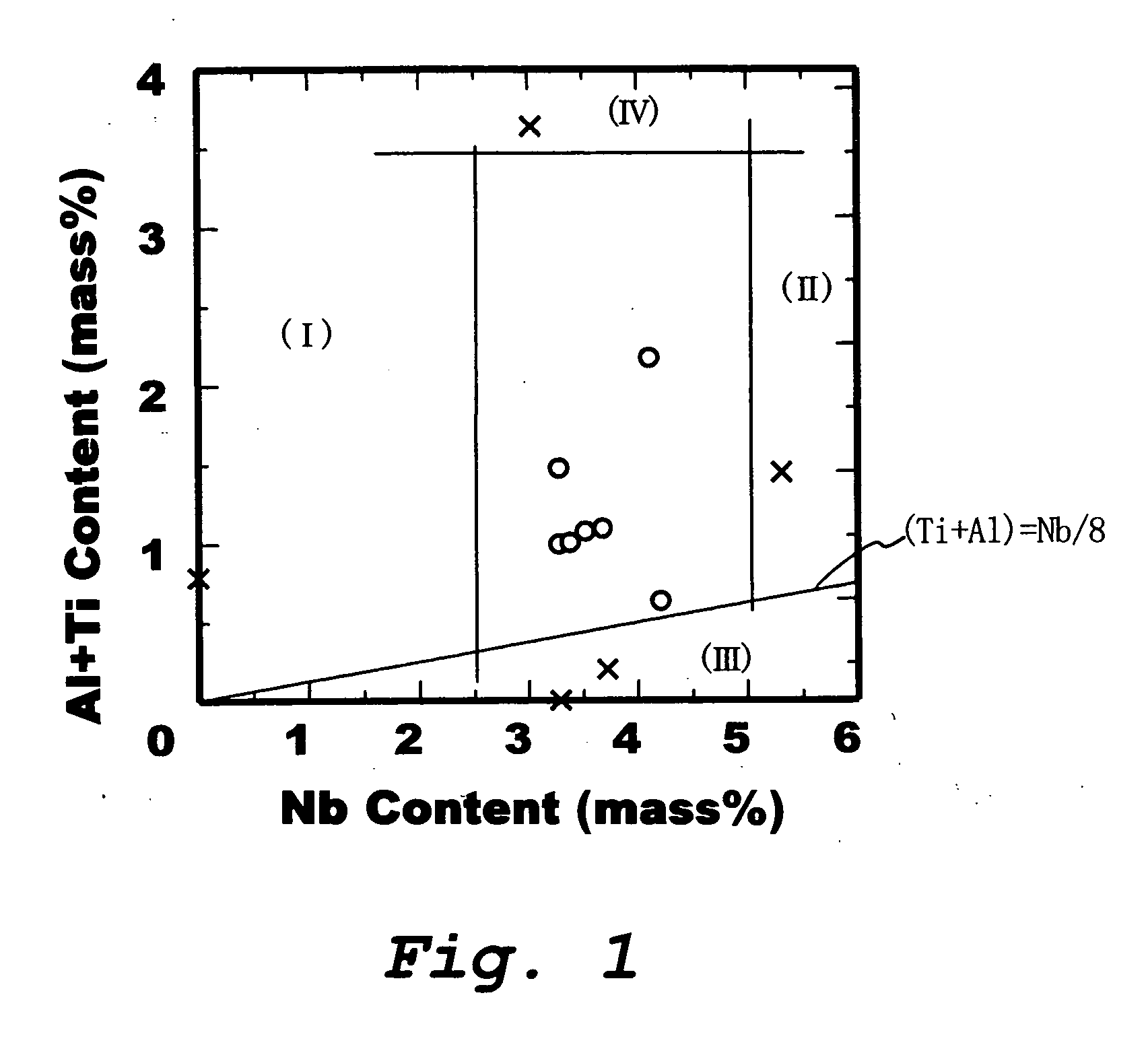

Welded joint made of an austenitic steel

InactiveUS20060191606A1High strengthIncrease resistanceArc welding apparatusMachines/enginesChemical compositionHigh pressure hydrogen

A weld joint having a base material and a weld metal both of an austenitic steel, wherein the weld metal has a chemical composition, in mass %, that C: 0.04% or less, Si: 1.0% or less, Mn: 3% or less, P: 0.02% or less, S: 0.005% or less, Cr: 15 to 25%, Ni: 30% or more, Mo: 10% or less, Nb: 2.5 to 5%, Al: 3.0% or less, Ti: 0.5% or less, and the balance: Fe and inevitable impurities, the contents of Al and Ti satisfying the following: (Ti+Al)>Nb / 8. The weld joint is a high strength austenitic steel weld joint which exhibits excellent toughness at a low temperature and excellent resistance to hydrogen embrittlement, which are required for a piping and a vessel for high pressure hydrogen, particularly also in a welded zone.

Owner:NIPPON STEEL CORP

Method of assembling metal parts by friction welding, with the welding temperature being controlled using thermally conductive elements

InactiveUS20100243714A1Simple and easy to performHeat dissipationWelding/cutting auxillary devicesAuxillary welding devicesFriction weldingCopper

The invention provides a method of assembling together two thin plane parts (1, 2) by friction welding. A main sheet (19) made of a material having high thermal conductivity is held against the parts (1, 2) for assembly. The main sheet (19) picks up the heat induced by the friction of a welding pin (5) against the parts (1, 2) for the purpose of forming the weld bead (17), and it dissipates this heat by radiation. Temperature regulation of the welding operation is obtained by the main sheet (19), ensuring that no localized excess heating occurs in the welding zone. The main sheet (19) is based on copper and presents a thickness that is less than the thickness of the parts (1, 2).

Owner:EUROCOPTER

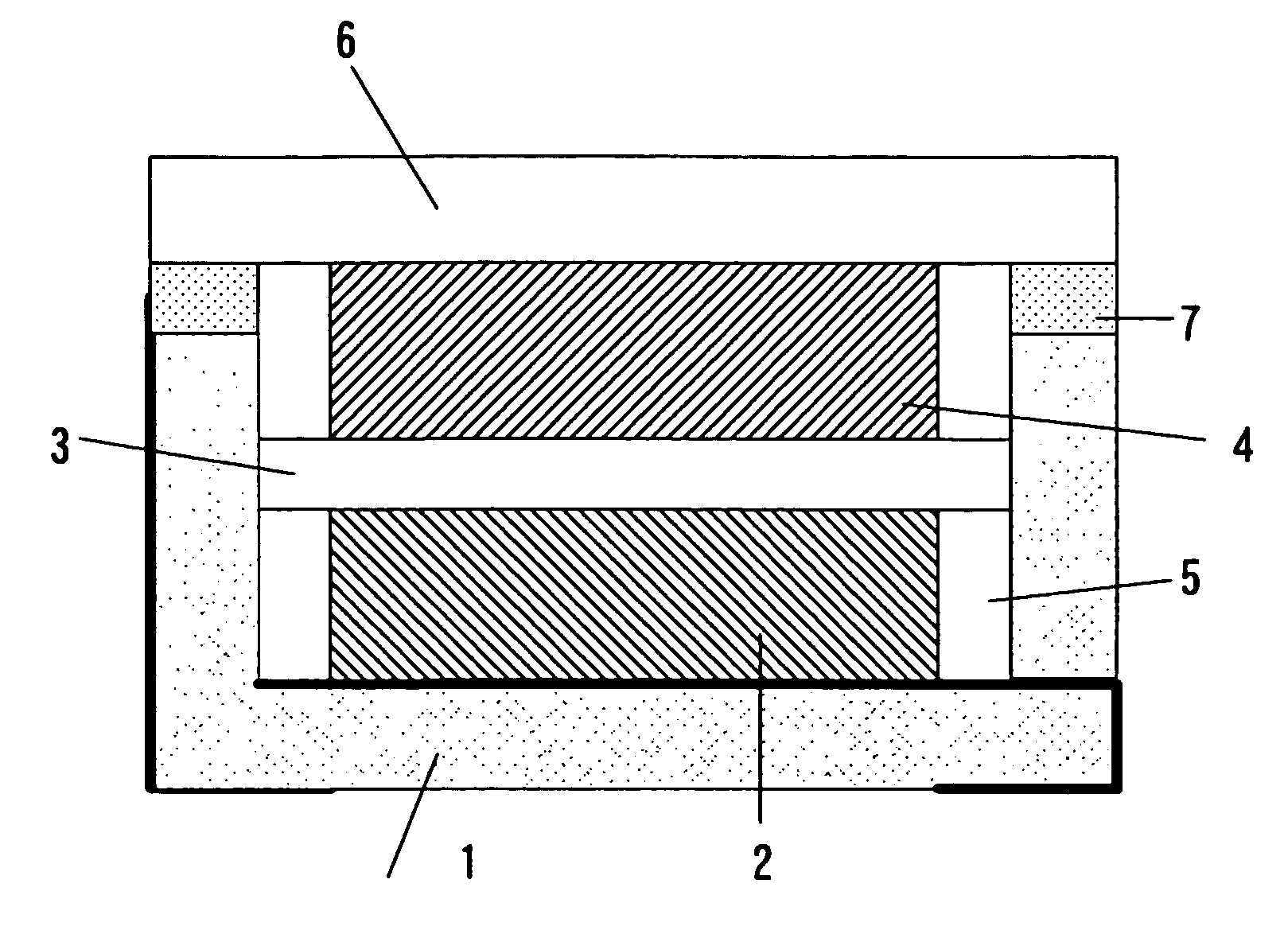

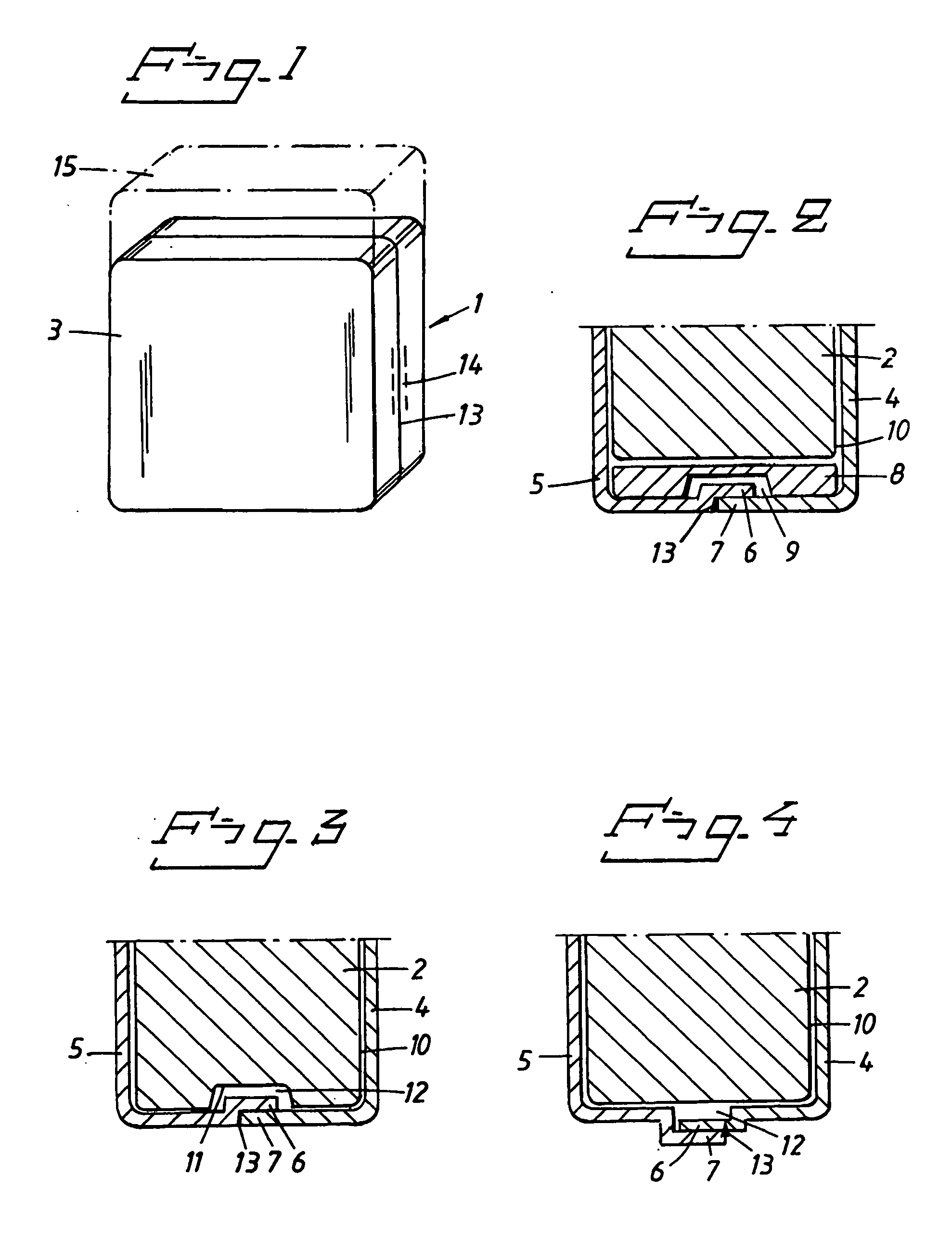

Battery and a battery encapsulation

InactiveUS20050019653A1Increase the use of spaceElectrotherapyCell component detailsEngineeringElectrical and Electronics engineering

A battery unit comprising a battery (2), and a battery encapsulation (3), comprising first and second encapsulation parts (4, 5) joined by a weld along a weld zone (14), the battery (2) being located in the encapsulation (3). The battery (2) comprises a recess (11) extending along the weld zone (14), such that a heat insulating space (12) is formed between the battery (2) and the encapsulation (3) along the weld zone (14).

Owner:ST JUDE MEDICAL

Welding asset tracking with heartbeat monitoring

PendingUS20210053136A1Input/output for user-computer interactionPosition fixationAsset trackingReliability engineering

Apparatus and methods for welding asset tracking with heartbeat monitoring are disclosed. In some examples, a welding asset tracking system may comprise an asset tracking network of tags, hubs, and / or gateways retained by welding assets within a welding area. The welding asset tracking system may generate heartbeat signals that certain welding assets may require for normal operation, so as to ensure the welding assets are used in appropriate welding contexts and / or welding areas. In some examples, information obtained from the asset tracking network may be used to determine whether one or more heartbeat signals should be discontinued.

Owner:ILLINOIS TOOL WORKS INC

Welding process of large-sized liquefied natural gas storage tank

InactiveCN101412136AEasy to shapeReduce Rooting WorkloadArc welding apparatusDomestic vesselsNatural gas storageEngineering

The invention relates to a method for welding a large liquified natural gas storage tank. The method uses alternating rectangular wave current for welding with a welding parameter of between 8.156 and 24.32 KJ / cm and the interlayer temperature of energy input of between 18.9 and 24.32 KJ / cm of 300 DEG C, and selects low carbon type nickel-based welding wire. The method overcomes the problem of arc blow in welding, not only can avoid impact on 9 percent Ni steel during carbon gouging, but also can save welding materials and manpower so as to accelerate construction process and improve welding efficiency. Welding with the process can improve the cold temperature flexibility of a macrograin area of a welding zone, avoid generation of brittle tissue of a fusion area, avoid generation of cold and heat crack in welding, has excellent quality of weld joint, and effectively ensure the cold temperature flexibility of 9 percent Ni steel welding joints. The method well control the quality of the weld joint, and ensures the overall quality of the natural gas storage tank.

Owner:SHANGHAI INSTALLATION ENG GRP

Surface treating method for metal workpieces

InactiveCN101205616APrevent fadingAvoid the effects of stainingAnodisationMetallic material coating processesAnodic oxidationMetal

The invention provides a surface treatment method for a metal workpiece, which includes the following steps: the metal workpiece is provided, and the metal workpiece is provided with a welding zone which is formed during welding; the surface of the metal workpiece is conducted with anodic oxidation treatment to form an anode oxidation film on the surface of the metal workpiece; the metal workpiece is immersed in activate fluid to conduct activating treatment to the welding zone; the surface of the metal workpiece is washed by water; the metal workpiece is dipped in dyeing liquor for dyeing treatment; the surface of the workpiece is washed by water; the surface of the workpiece is dipped in hole sealing solution for hole sealing treatment.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

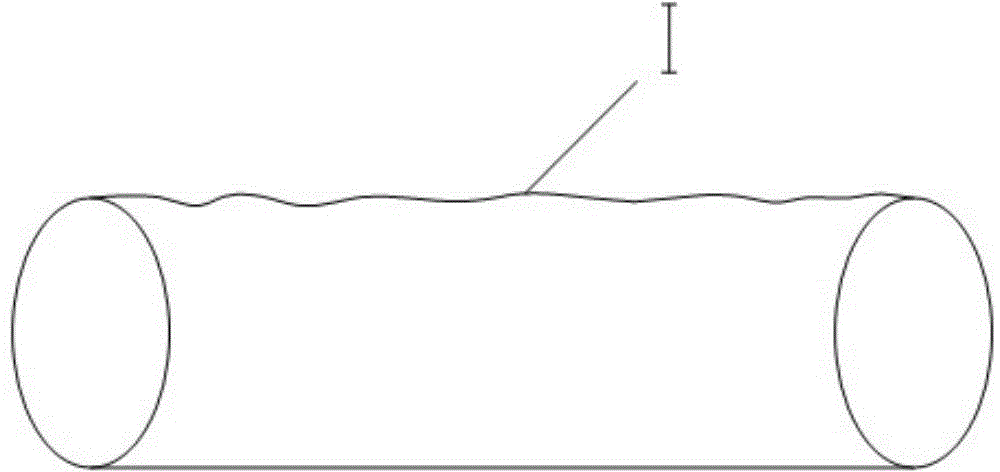

Metal foil tube and method and apparatus for production thereof

InactiveUS20060150388A1Even out shapeEven out surface roughnessWelding with roller electrodesElectrographic process apparatusThin metalMetallurgy

The present invention provides a metal foil tube with a thickness of 10 to 100 μm and a method and apparatus of production of the metal foil tube enabling even an extremely thin metal foil to be reliably finished into a tube, that is, a metal foil tube comprised of a metal foil sheet W with a thickness t of 10 to 100 μm joined by welding, the method of production of the metal foil tube shaping the metal foil sheet W to form an overlap part G, then welding the facing sides and finishing the weld zone part flat.

Owner:INADA KOKI +6

Welding method and silver based metal for hard-alloy heavy type cutting tools

InactiveCN101342626ALow melting pointEasy to breedOther manufacturing equipments/toolsWelding/cutting media/materialsAlloyEngineering

The invention discloses a welding method of heavy type hard-alloy cutting tool and silver based solder thereof. The welding method and the silver based solder can effectively avoid the welding crack during welding process, and consequently assure the welding quality of the heavy cutting tool. The welding method comprises the following procedures: surface treatment of the welding area, removal of oil, purities and rust-spotting, and enabling the welding surface to have the certain roughness; coating the welding flux and the silver based solder on the welding surface of hard-holly blade and steel substrate, putting the welding material into a vacuum heating furnace, and counterweighing the welding material with a metal block; filling inert gas into the vacuum heating furnace and heating up to 600 to 640 DEG C and insulating; decreasing to 280 to 300 DEG C and insulating, and finally decreasing to the room temperature for completing the welding process. The composition of the silver based solder in weight percentage is as follows: 40 to 50 percent of Argentum, 20 to 30 percent of Copper, 18 to 25 percent of Zinc, 1 to 3 percent of Stannum, 1 to 3 percent of Nickel and impurities.

Owner:王朝

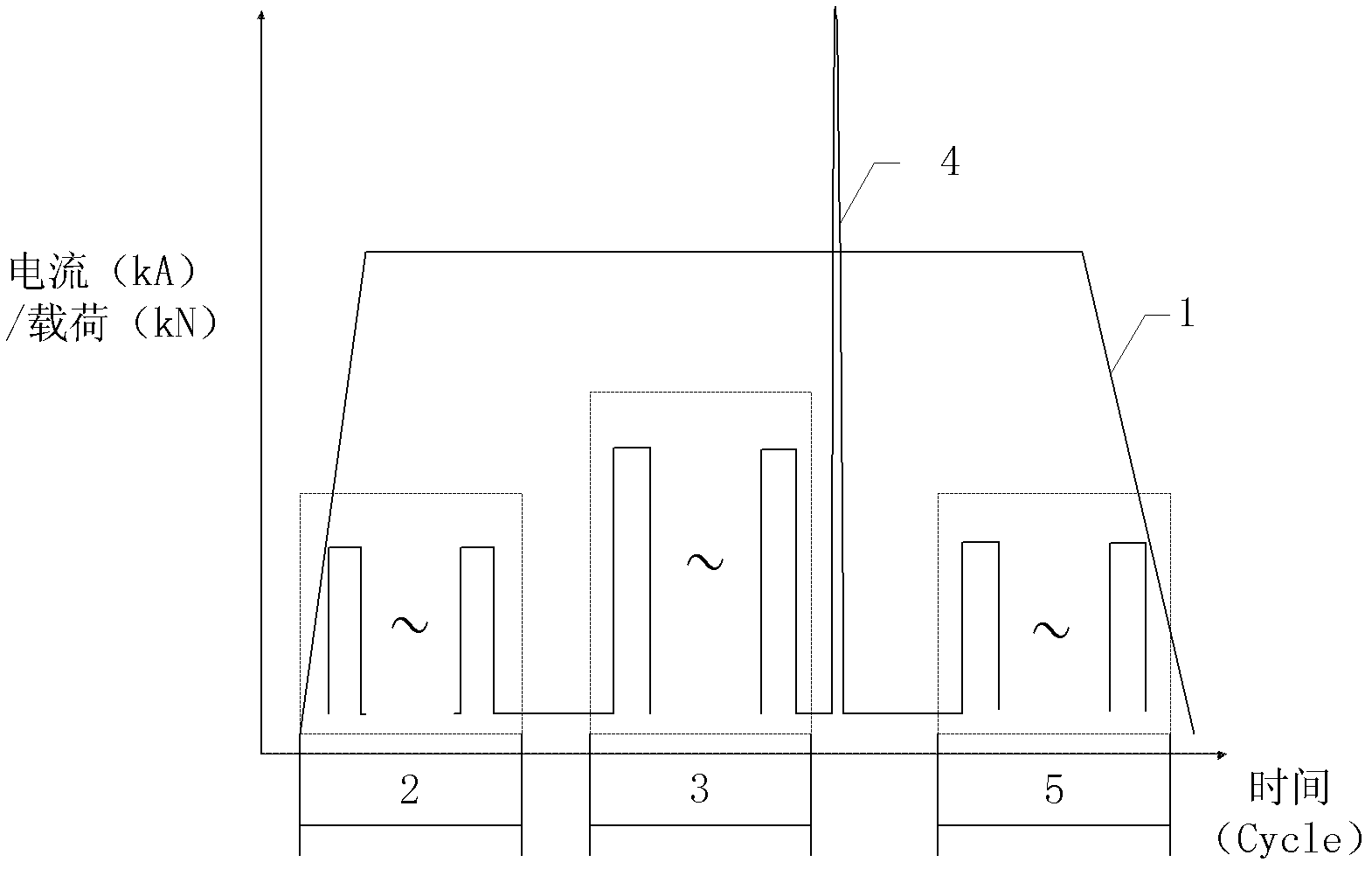

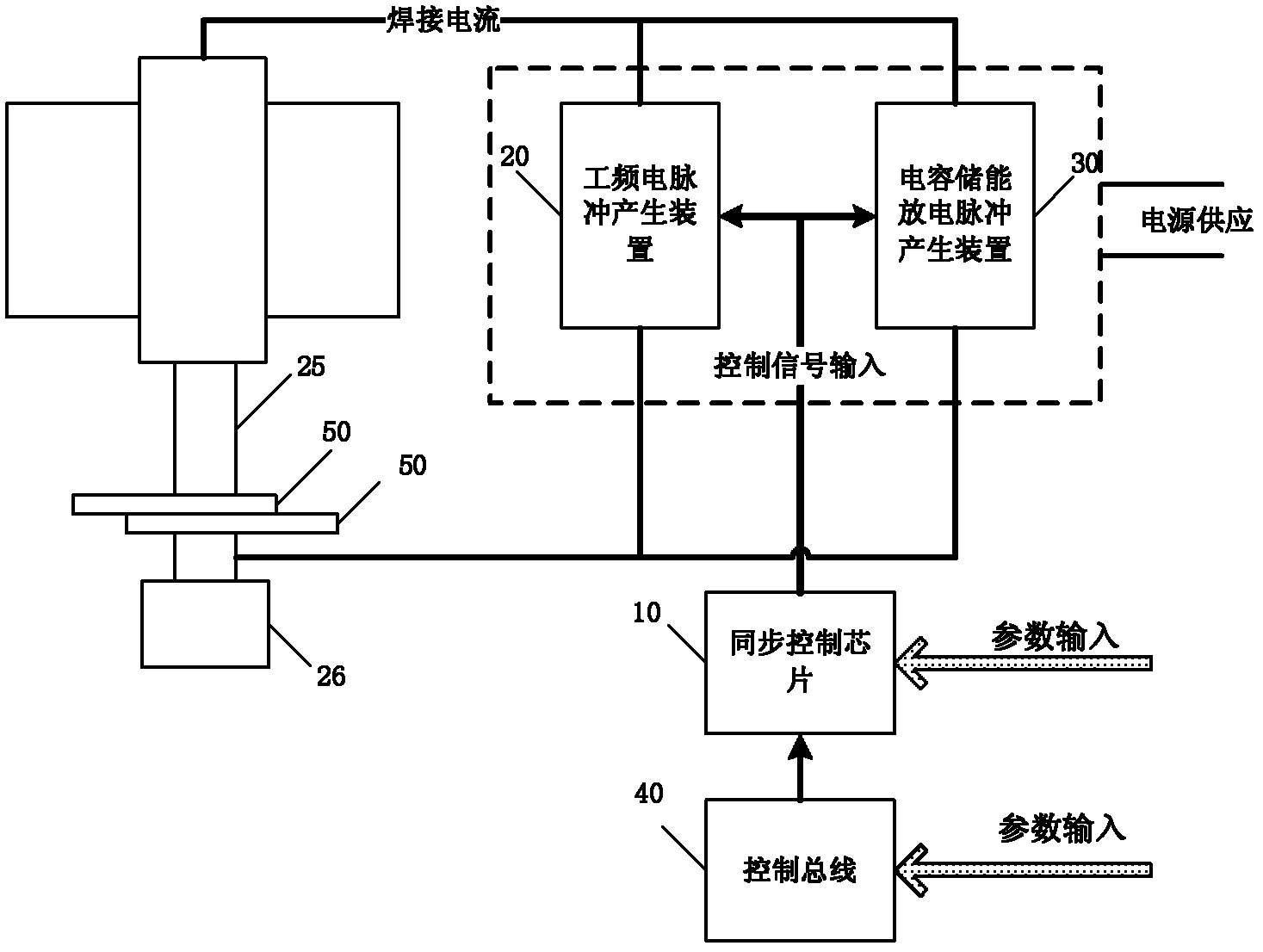

Composite pulsation spot welding process and system

The invention discloses resistance spot welding process and a system, and relates to composite pulsation spot welding process and a system. By the aid of the composite pulsation spot welding process and the system, power-frequency spot welding current of traditional resistance spot welding process and condenser discharge pulses are combined. The condenser discharge pulses with high-current peak values and short discharge time are released in a weld nugget solidification stage after supply of the power-frequency welding current is finished and before supply of power-frequency temper current starts. The composite pulsation spot welding process is realized in the composite pulsation spot welding system, wherein the composite pulsation spot welding system comprises a power-frequency pulse portion, a condenser discharge portion and a synchronous system. By the aid of the composite pulsation spot welding process and the system, welding zone textures can be remarkably improved, crystal grains are refined, anisotropy is weakened, welding cracks are reduced, components are homogenized, and accordingly mechanical performances of resistance spot welding are enhanced.

Owner:SHANGHAI JIAO TONG UNIV

Process and device for the internal welding of plastic tubes

ActiveUS20100000674A1Facilitating and improving conditionIncrease temperatureBox making operationsPaper-makingMolten statePlastic packaging

The invention relates to a process for manufacturing plastic packaging in tubular form, which process comprises a wrapping step during which a laminate (11) is wrapped, an abutting step during which the edges (8, 9) of the laminate (11) are butted together and a fastening step during which said edges (8, 9) of the laminate (11) are welded together, characterized in that a bead (12) of plastic in the molten state is extruded and deposited on the internal face of the packaging so as to cover at least the weld zone (10) defined between the edges. The energy needed to produce the weld (10) comes from the plastic bead (12).The invention also relates to packaging obtained from the aforementioned process and to a device for implementing said process.

Owner:AISAPACK HLDG SA

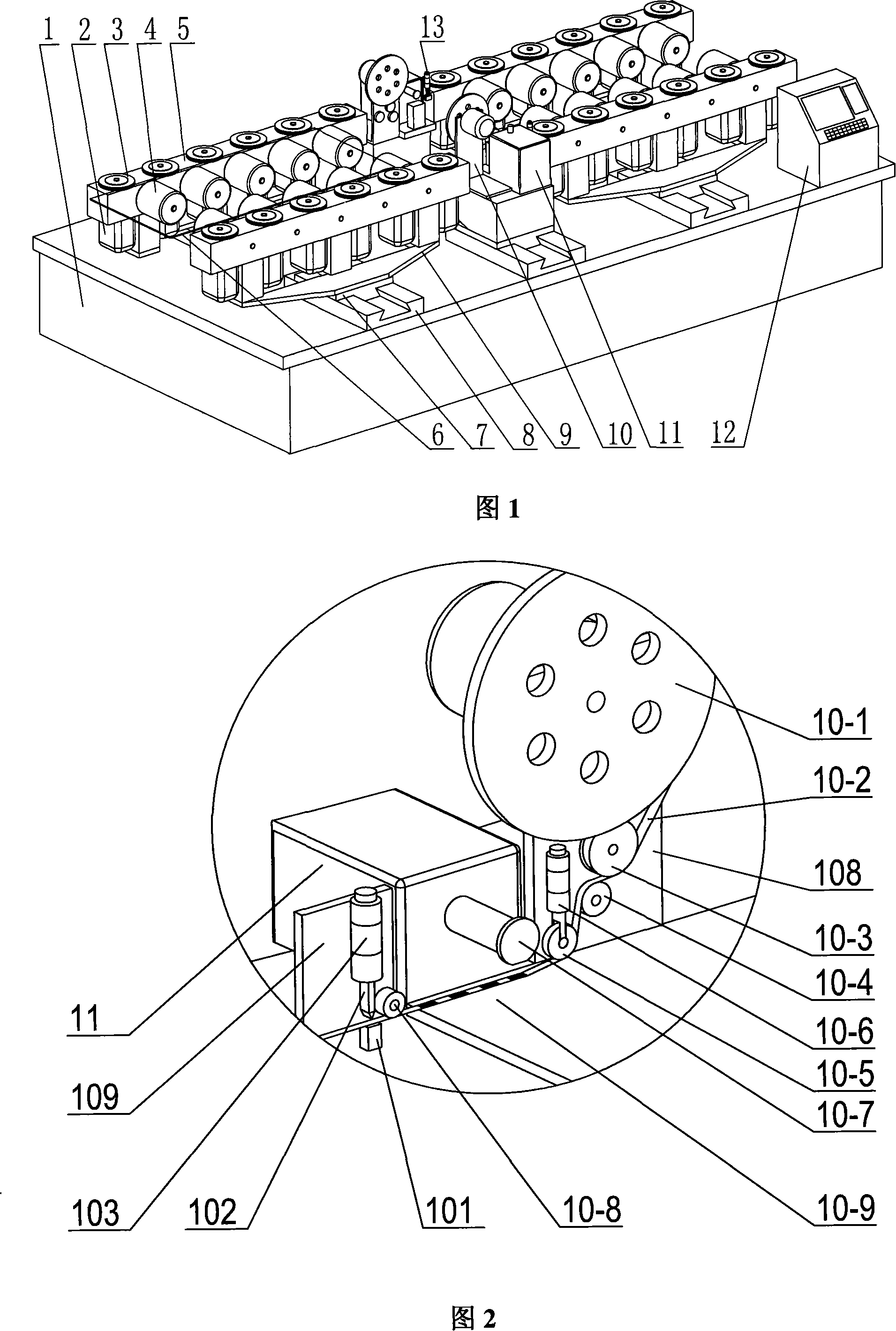

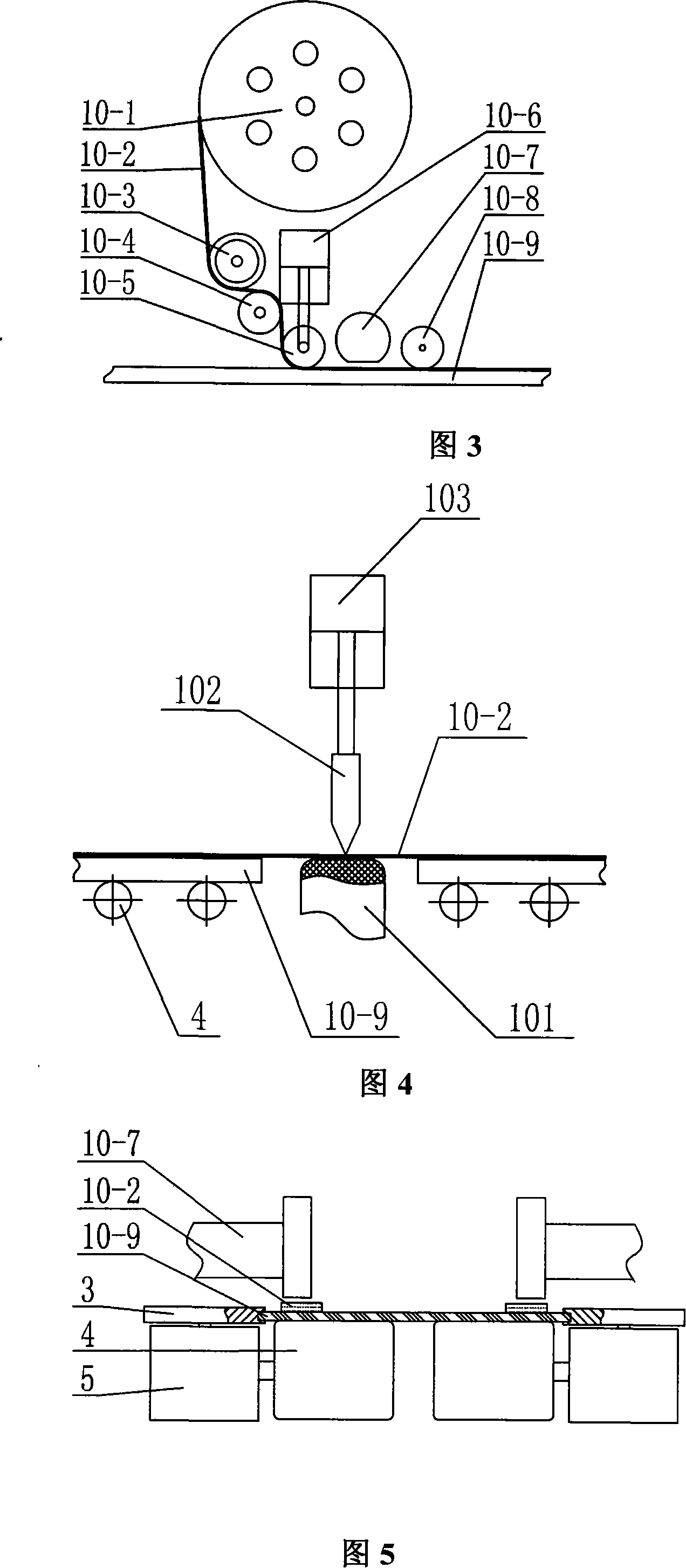

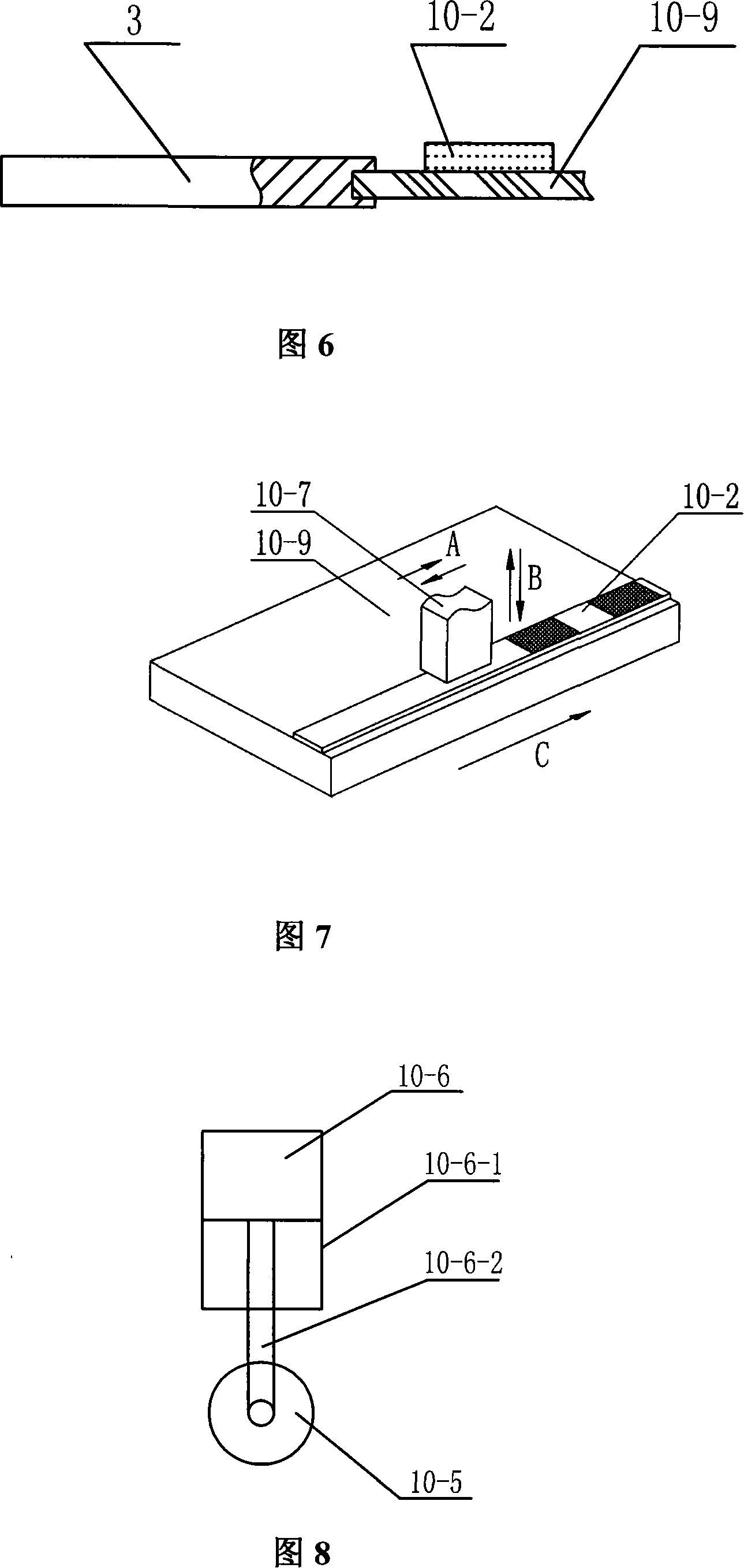

Ultrasonic soldering equipment for solar cell electrode

InactiveCN101110458ASatisfy the pressure line requirementsImprove efficiencyFinal product manufactureSemiconductor devicesElectrical batteryEngineering

The present invention discloses an automatic ultrasonic wave welding equipment for welding amorphous silicon solar cell electrode, which aims to improve current ultrasonic wave metal spot welding machine and add a mechanical wire pressing and take-up device and method to replace manual wire pressing and laying and is technically characterized in that a working table is composed of a feeding zone, a welding zone and a discharging zone. An electrode wire 10-2 is coiled on an uncoiling wheel 10-1 of the electrode wire pressing device 10. A guide wheel 10-3 and an extension-resistant tightening pulley 10-4 are arranged on a front slab bracket 108 below the uncoiling wheel 10-1. A corresponding ultrasonic wave welding head 10-7 is mounted between a coiling wheel 10-5 and a flattening wheel 10-8. The present invention is suitable for automatic welding of thin film solar cell electrode with glass or flexible material as substrate, thus ensuring high precision, nice appearance and equal distance between welding spots, improving welding efficiency and eliminating rosin joint.

Owner:李毅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com