Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

88 results about "Arc blow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Arc blow is the, usually unwanted, deflection of the arc during arc welding. There are two types of arc blow commonly known in the electric welding industry: magnetic and thermal.

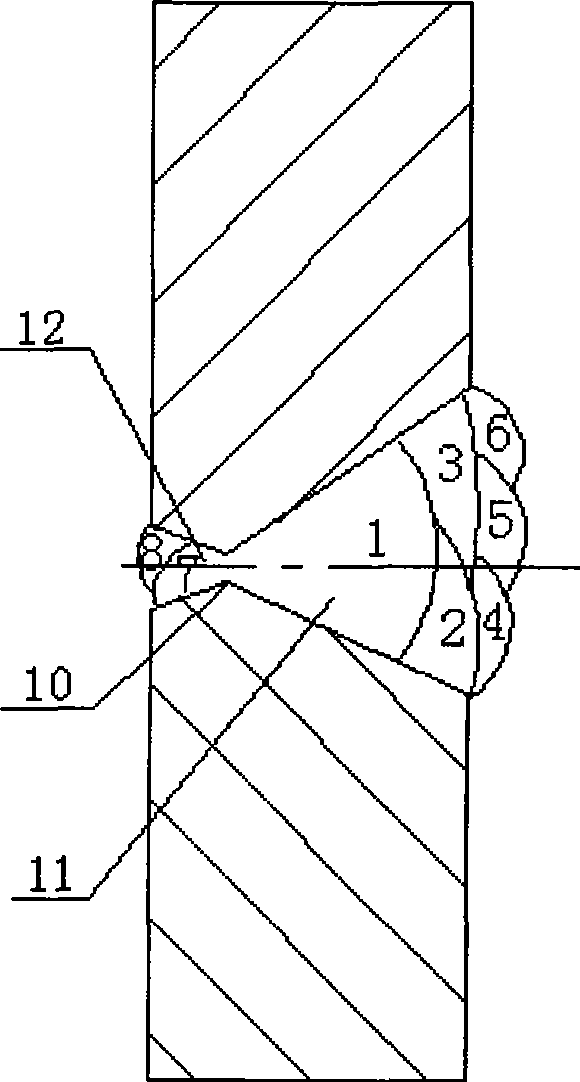

Welding process of large-sized liquefied natural gas storage tank

InactiveCN101412136AEasy to shapeReduce Rooting WorkloadArc welding apparatusDomestic vesselsNatural gas storageEngineering

The invention relates to a method for welding a large liquified natural gas storage tank. The method uses alternating rectangular wave current for welding with a welding parameter of between 8.156 and 24.32 KJ / cm and the interlayer temperature of energy input of between 18.9 and 24.32 KJ / cm of 300 DEG C, and selects low carbon type nickel-based welding wire. The method overcomes the problem of arc blow in welding, not only can avoid impact on 9 percent Ni steel during carbon gouging, but also can save welding materials and manpower so as to accelerate construction process and improve welding efficiency. Welding with the process can improve the cold temperature flexibility of a macrograin area of a welding zone, avoid generation of brittle tissue of a fusion area, avoid generation of cold and heat crack in welding, has excellent quality of weld joint, and effectively ensure the cold temperature flexibility of 9 percent Ni steel welding joints. The method well control the quality of the weld joint, and ensures the overall quality of the natural gas storage tank.

Owner:SHANGHAI INSTALLATION ENG GRP

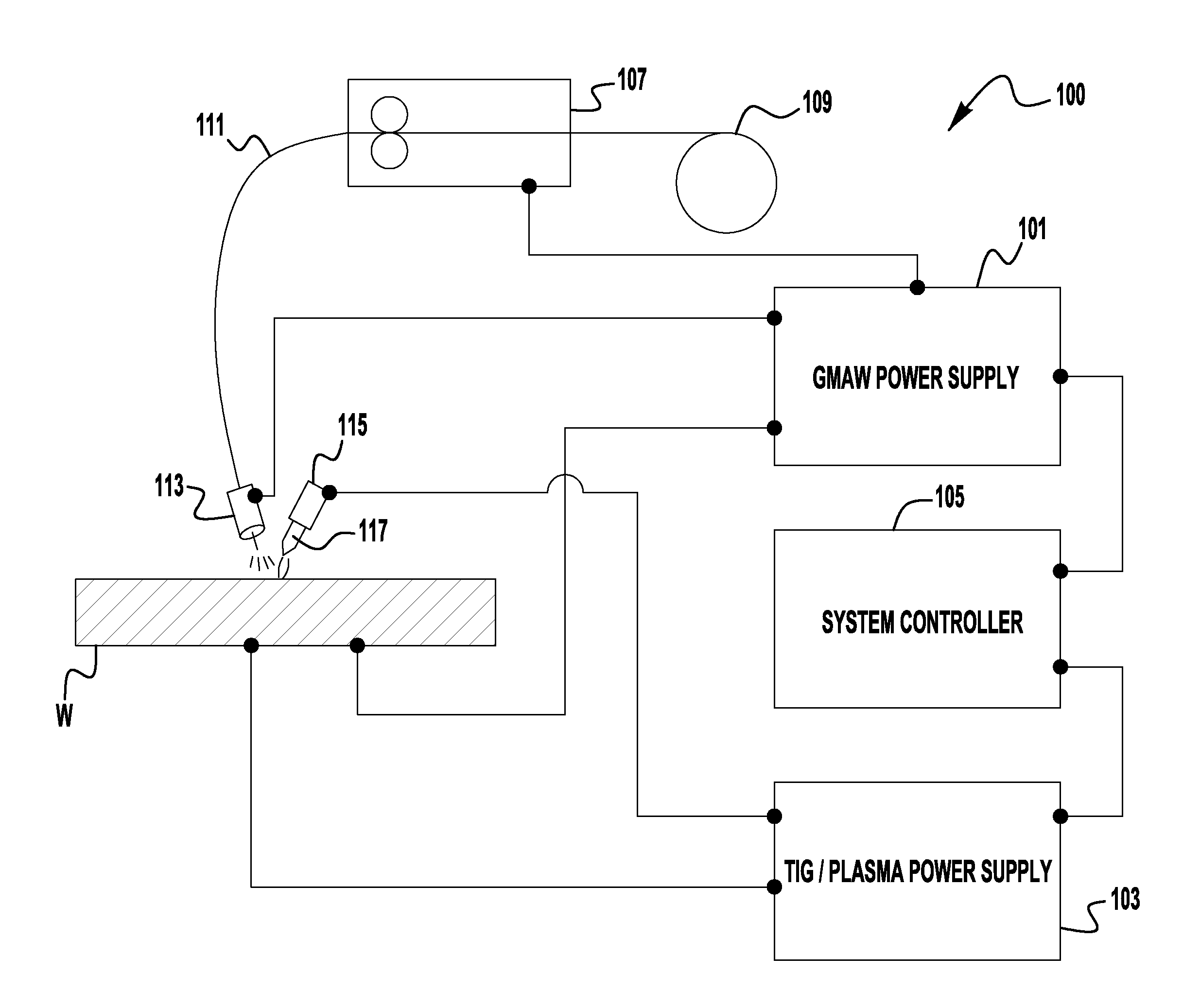

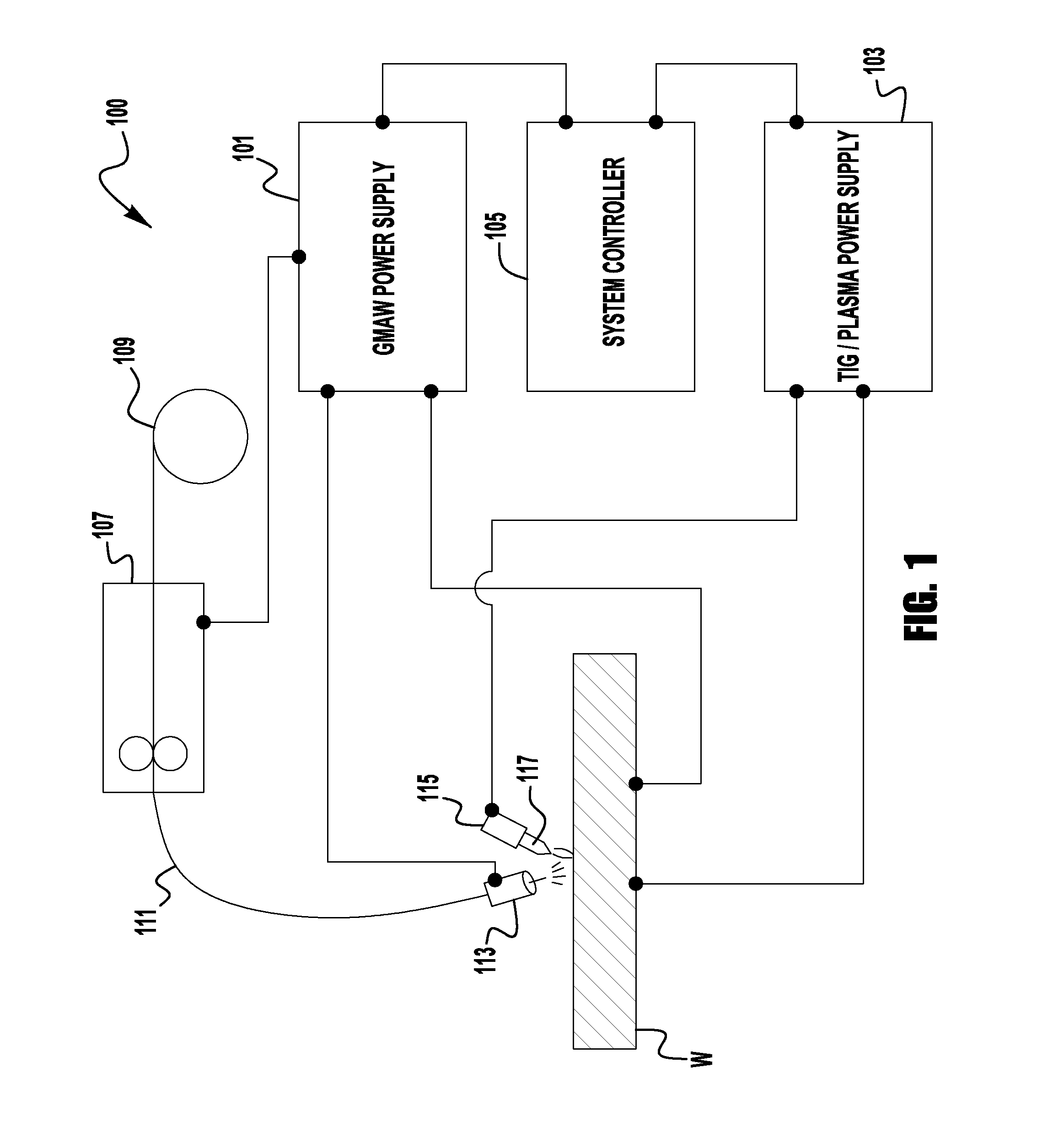

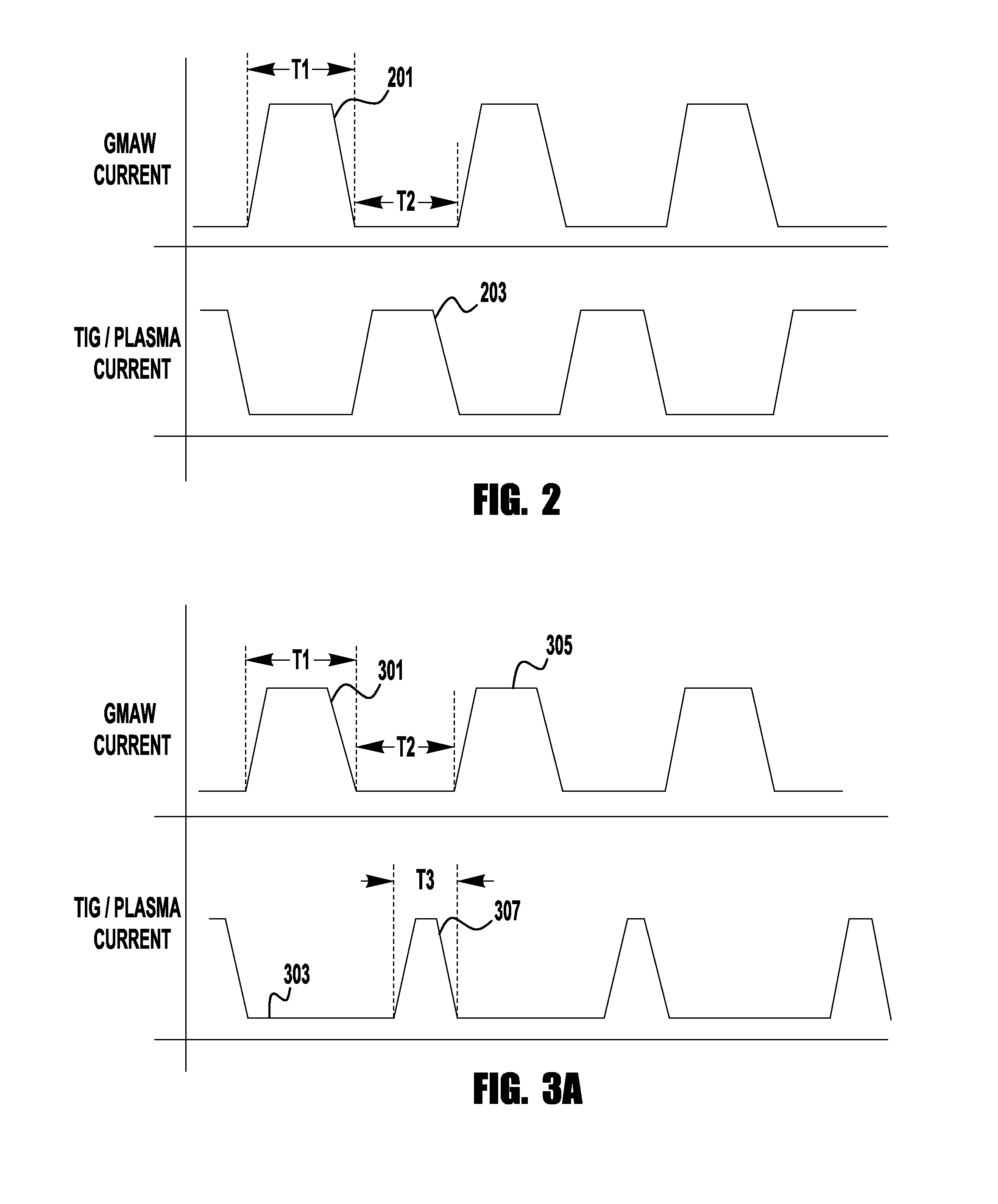

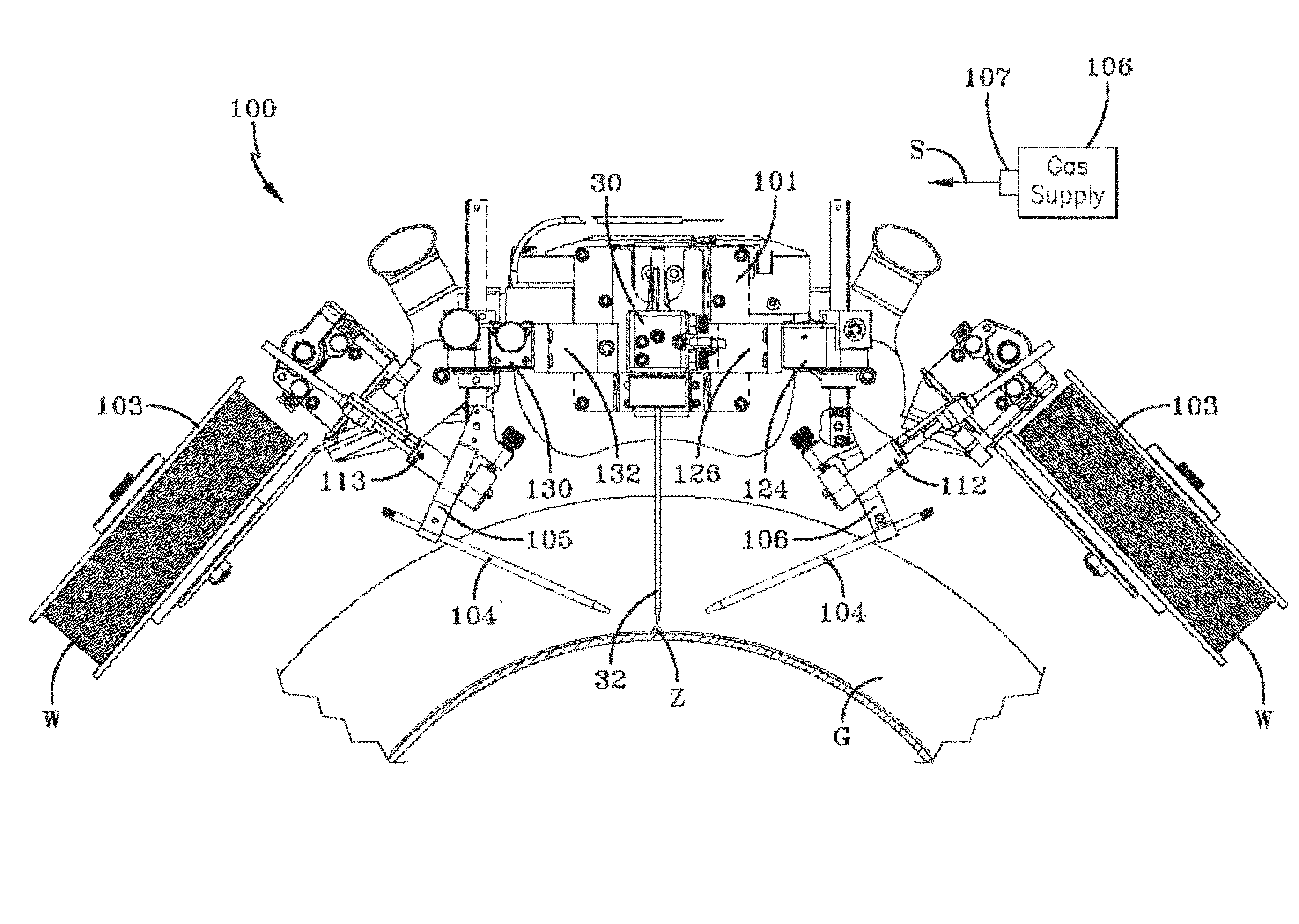

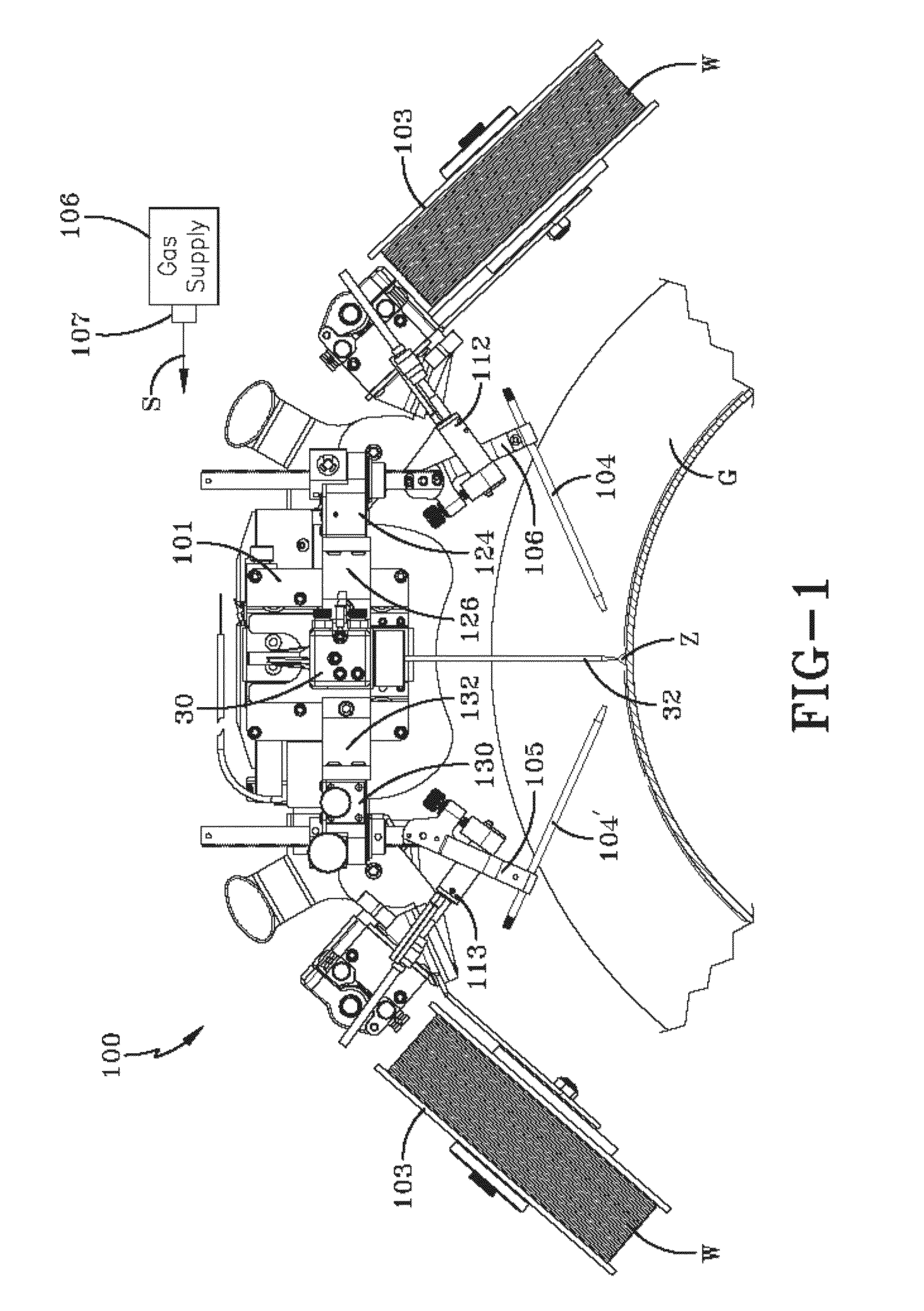

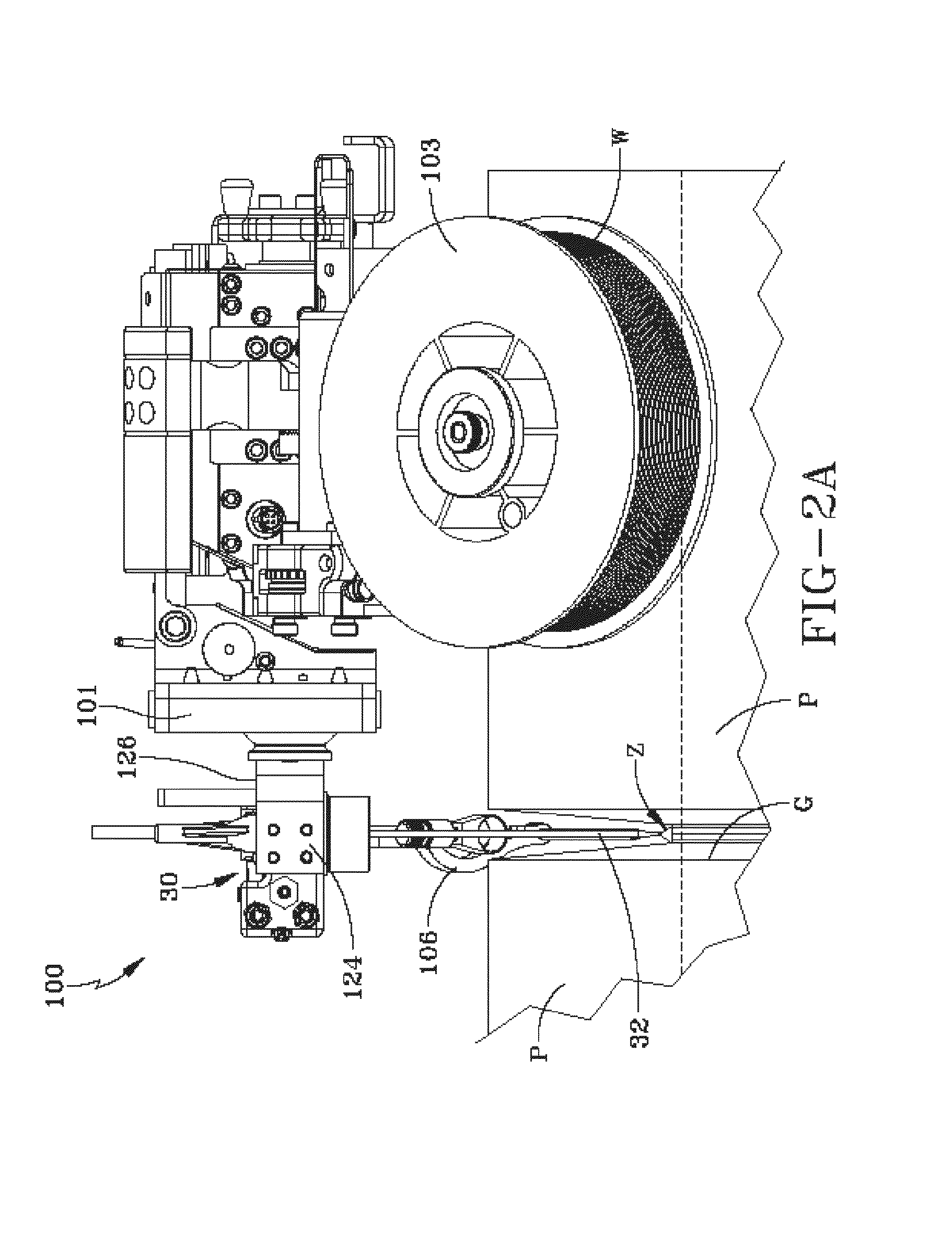

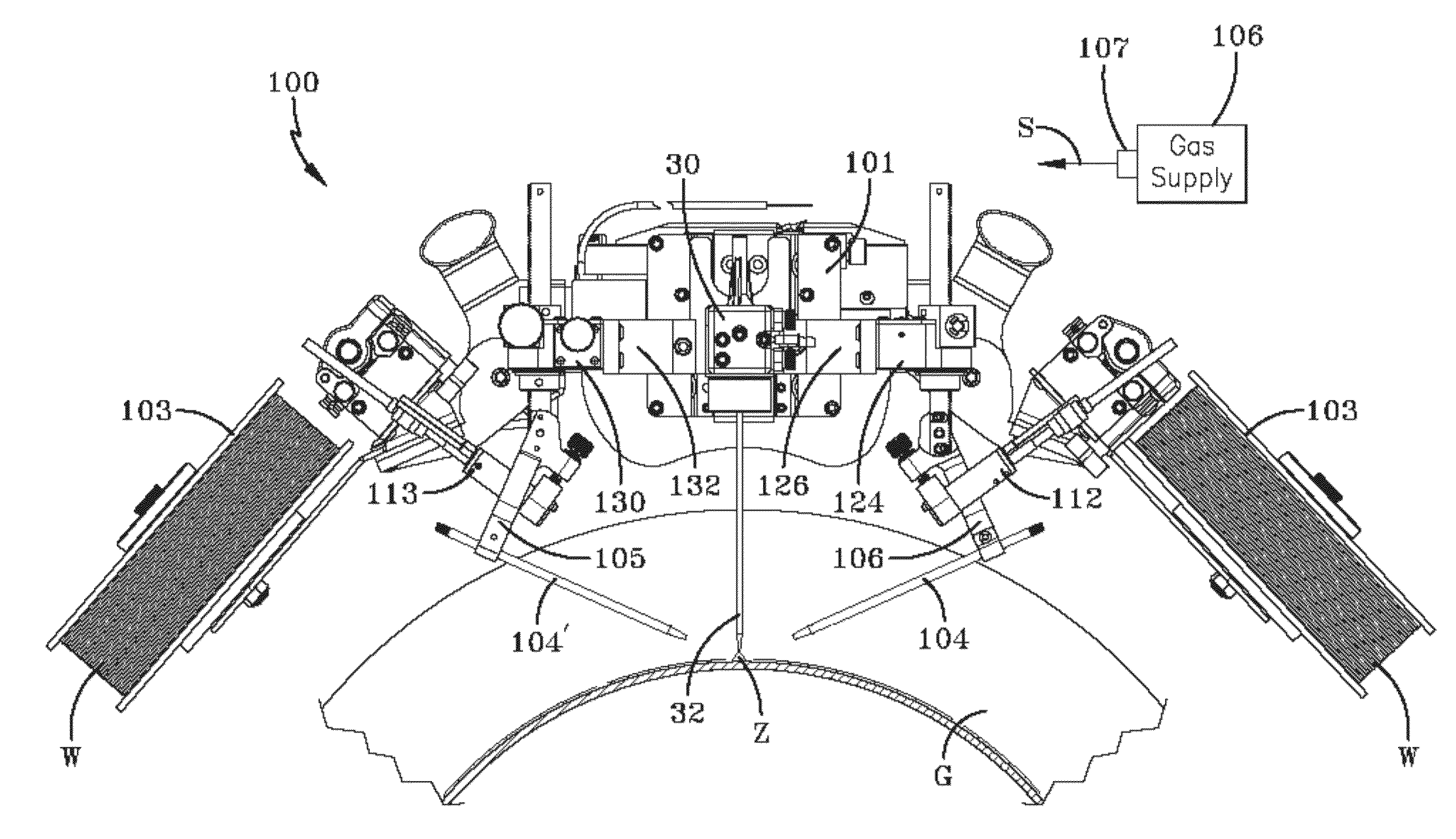

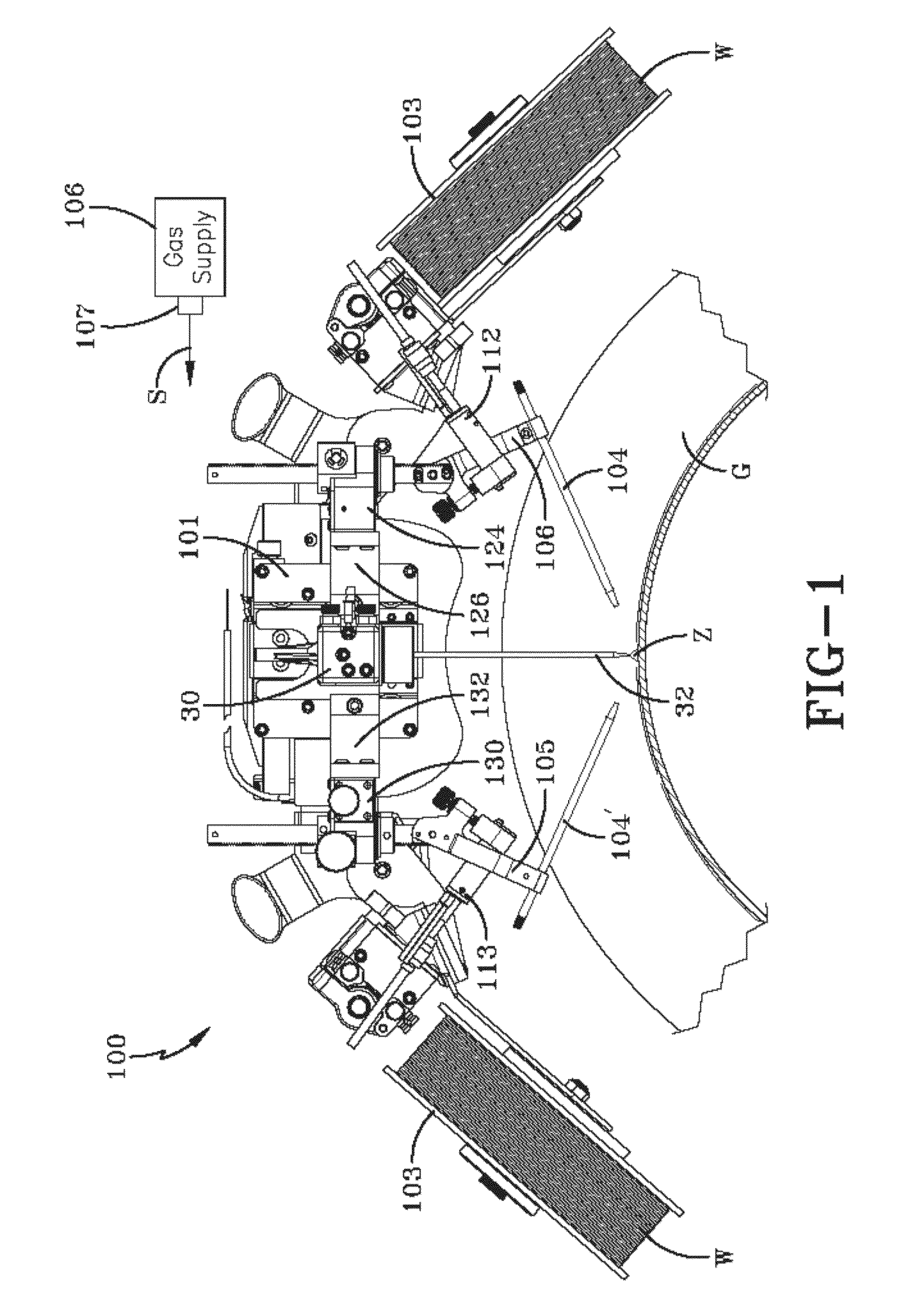

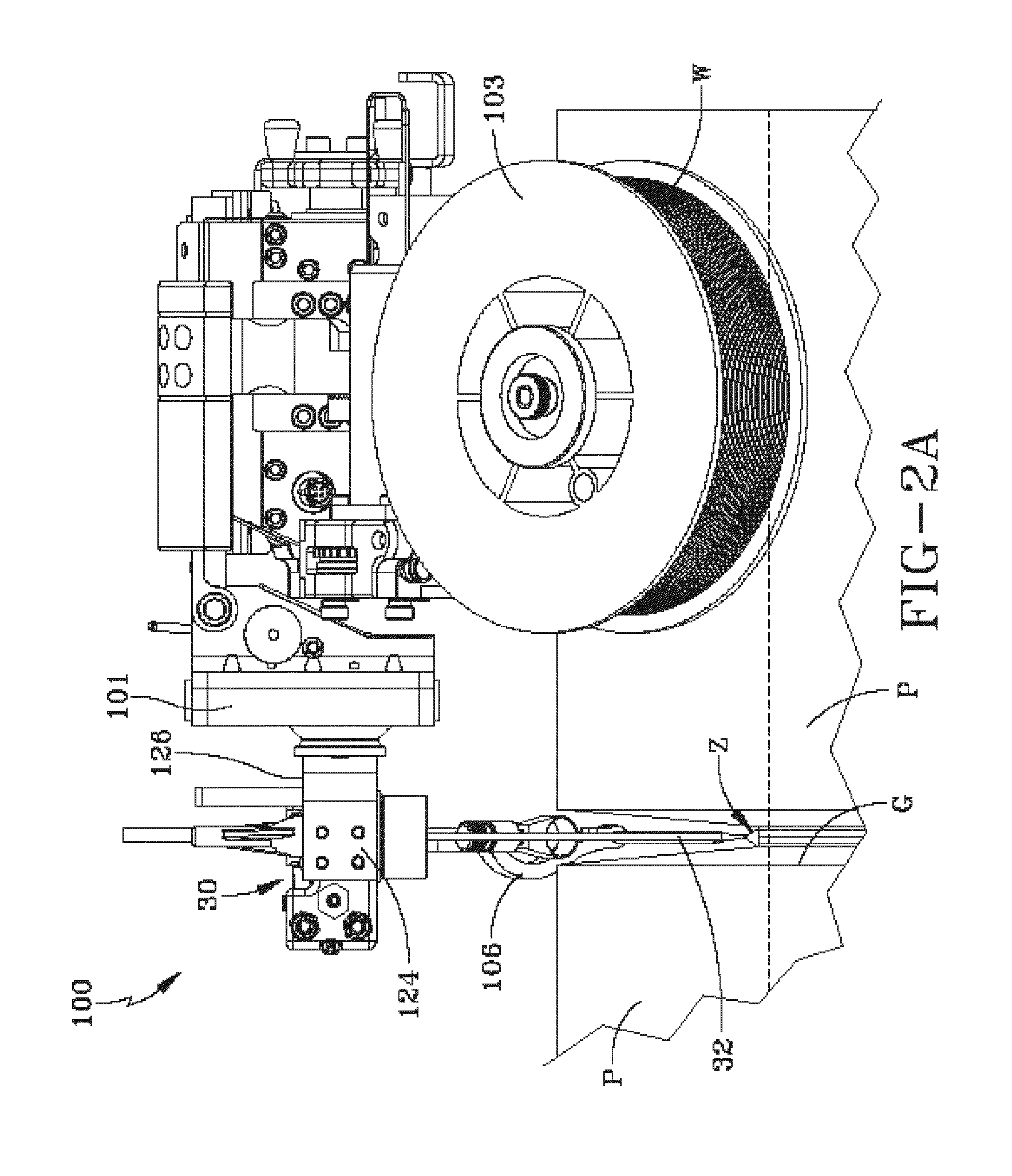

Synchronized hybrid gas metal arc welding with TIG/plasma welding

A system and method is provided in which each of a GMAW power supply and a TIG / plasma power supply are utilized in a common weld joint, where the waveforms from each of the power supplies are pulsed waveform which are pulsed out of phase which each other. Such a system minimizes arc interference and arc blow while at the same time increasing travel speed and throughput of a welding operation.

Owner:LINCOLN GLOBAL INC

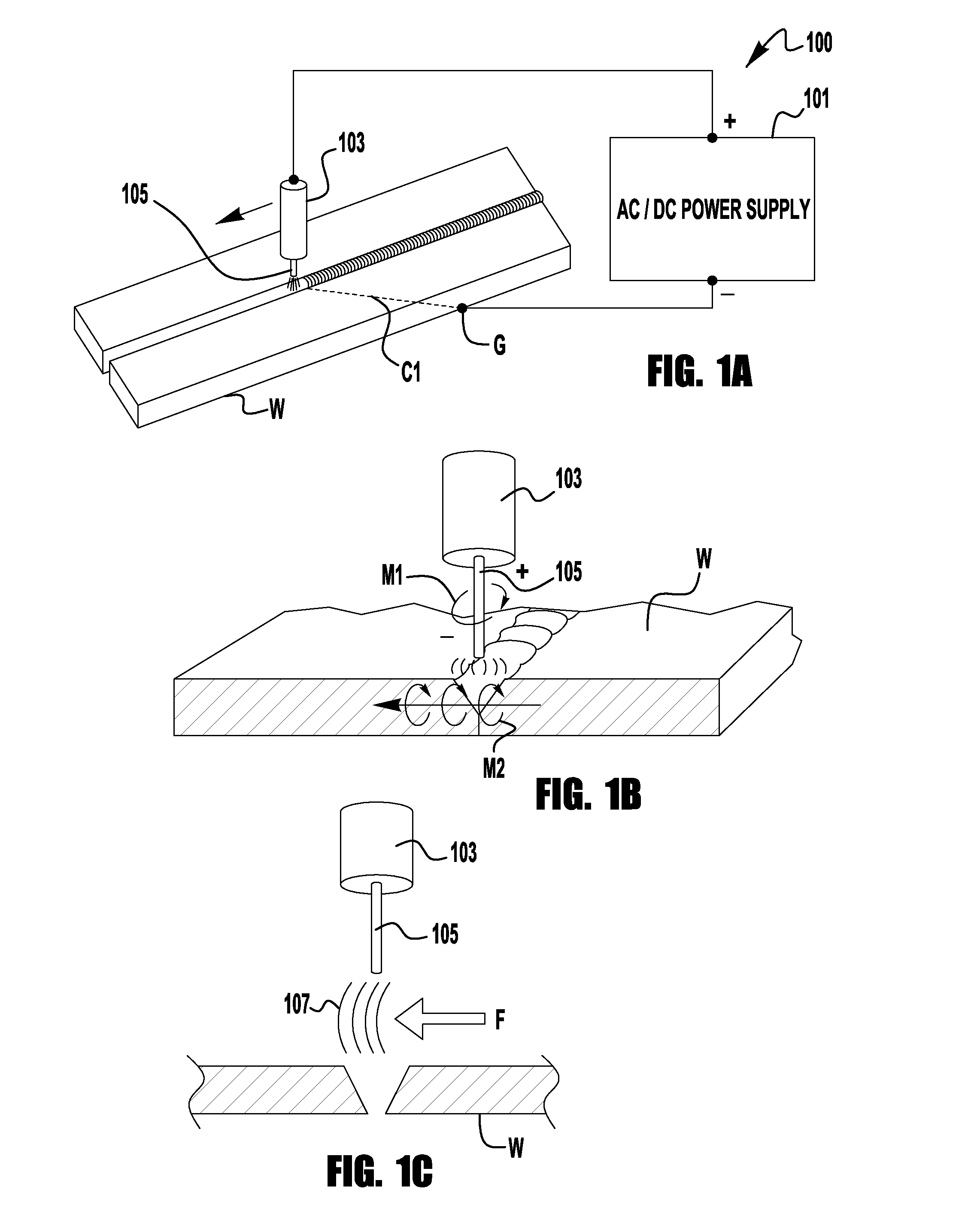

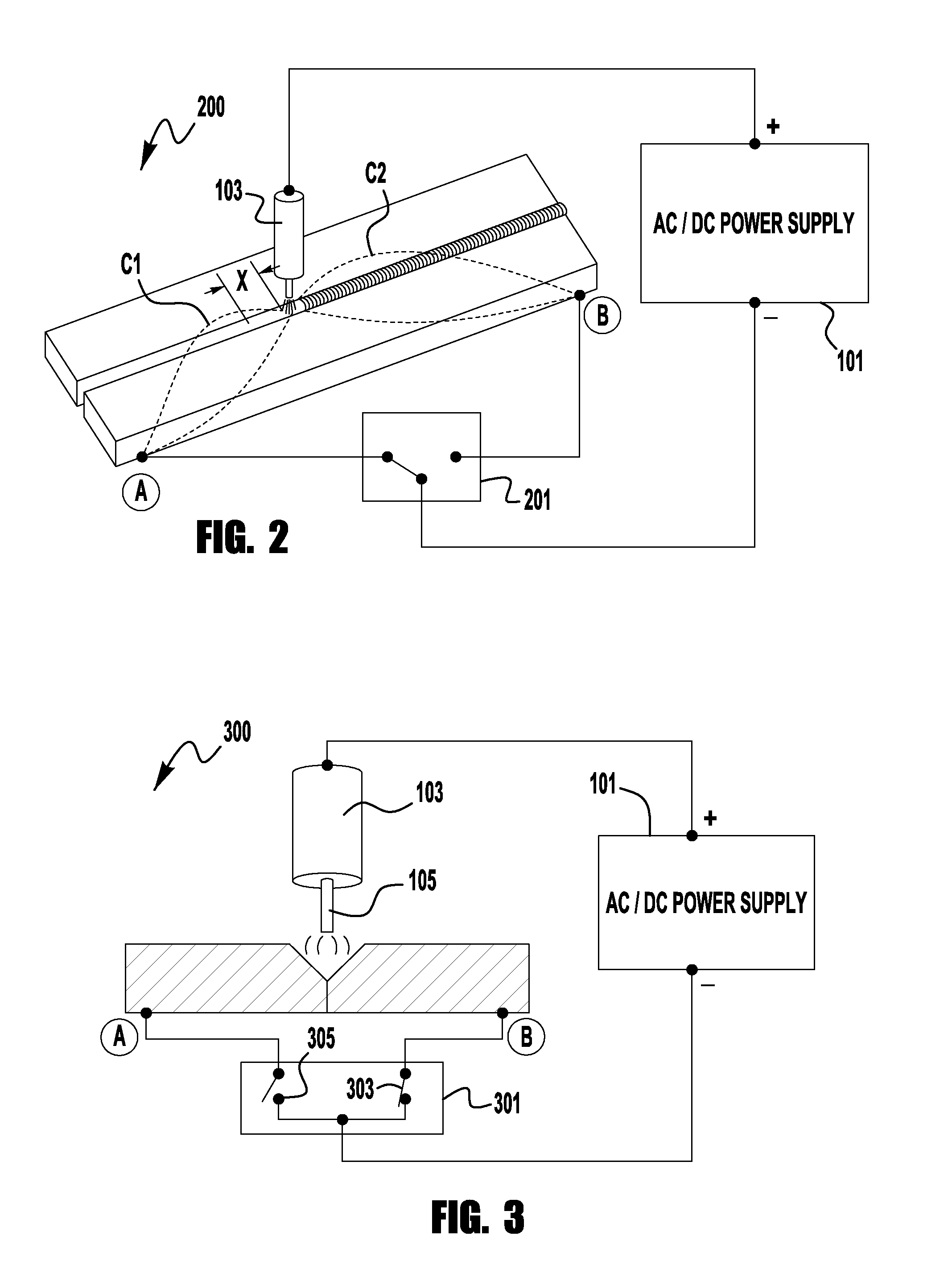

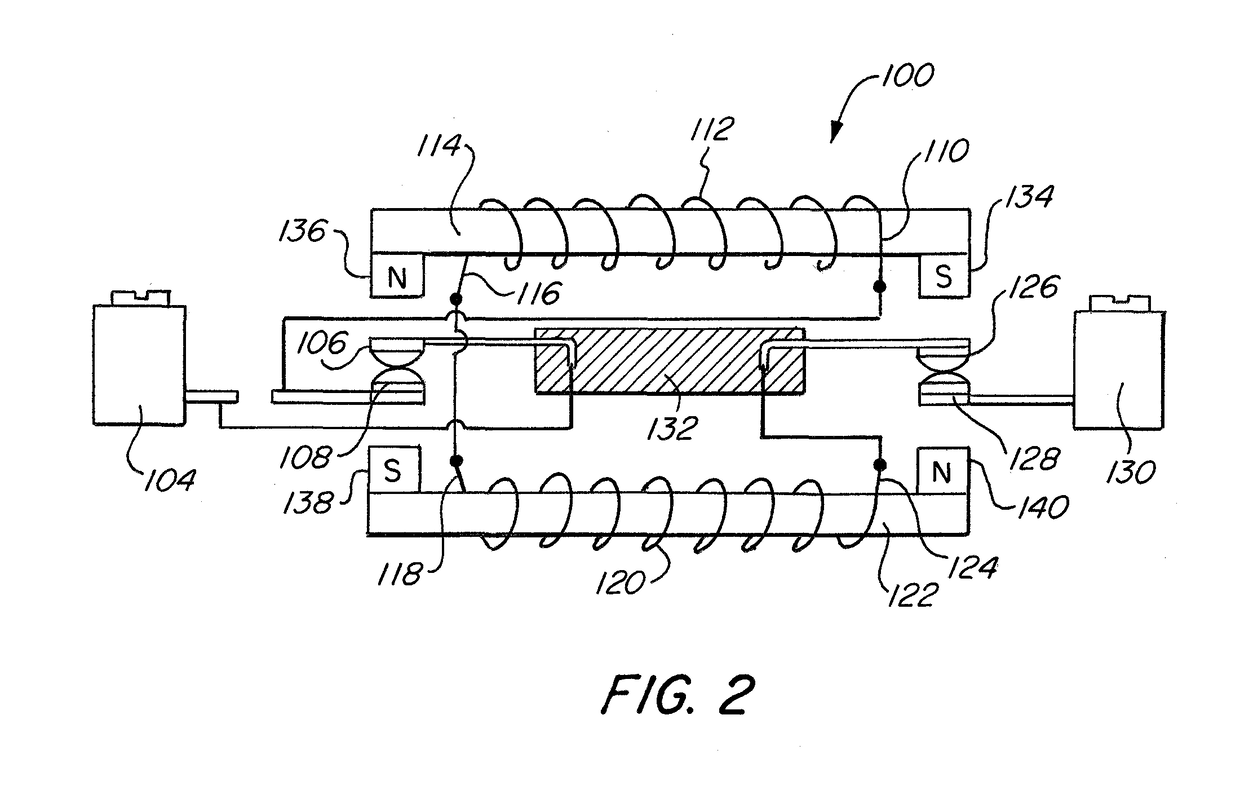

Work current switching to eliminate arc blow

A system and method of welding is provided where welding power supply has a first output electrically coupled to a welding electrode and a second output electrically coupled to a switching mechanism. The welding power supply provides a welding current through either of the first and second outputs to weld at least one work piece. The switching mechanism has at least a first and second switch position, where the first switch position is coupled to a first position on the at least one work piece and the second switch position is coupled to a second position on the at least one work piece, which is remote from the first position. During welding the switching mechanism switches between the first and second switch positions to change a current path for the welding current during through the at least one work piece.

Owner:LINCOLN GLOBAL INC

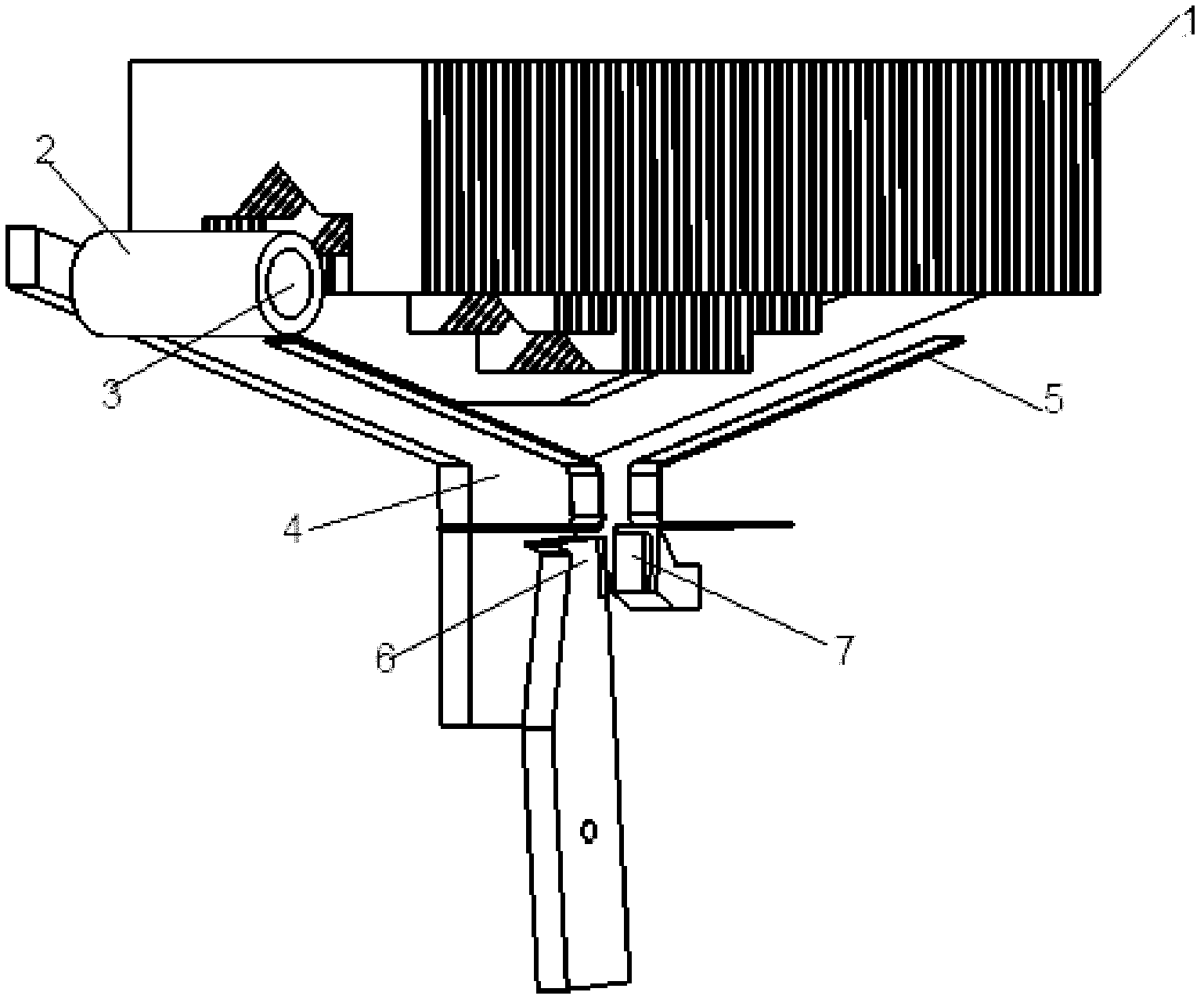

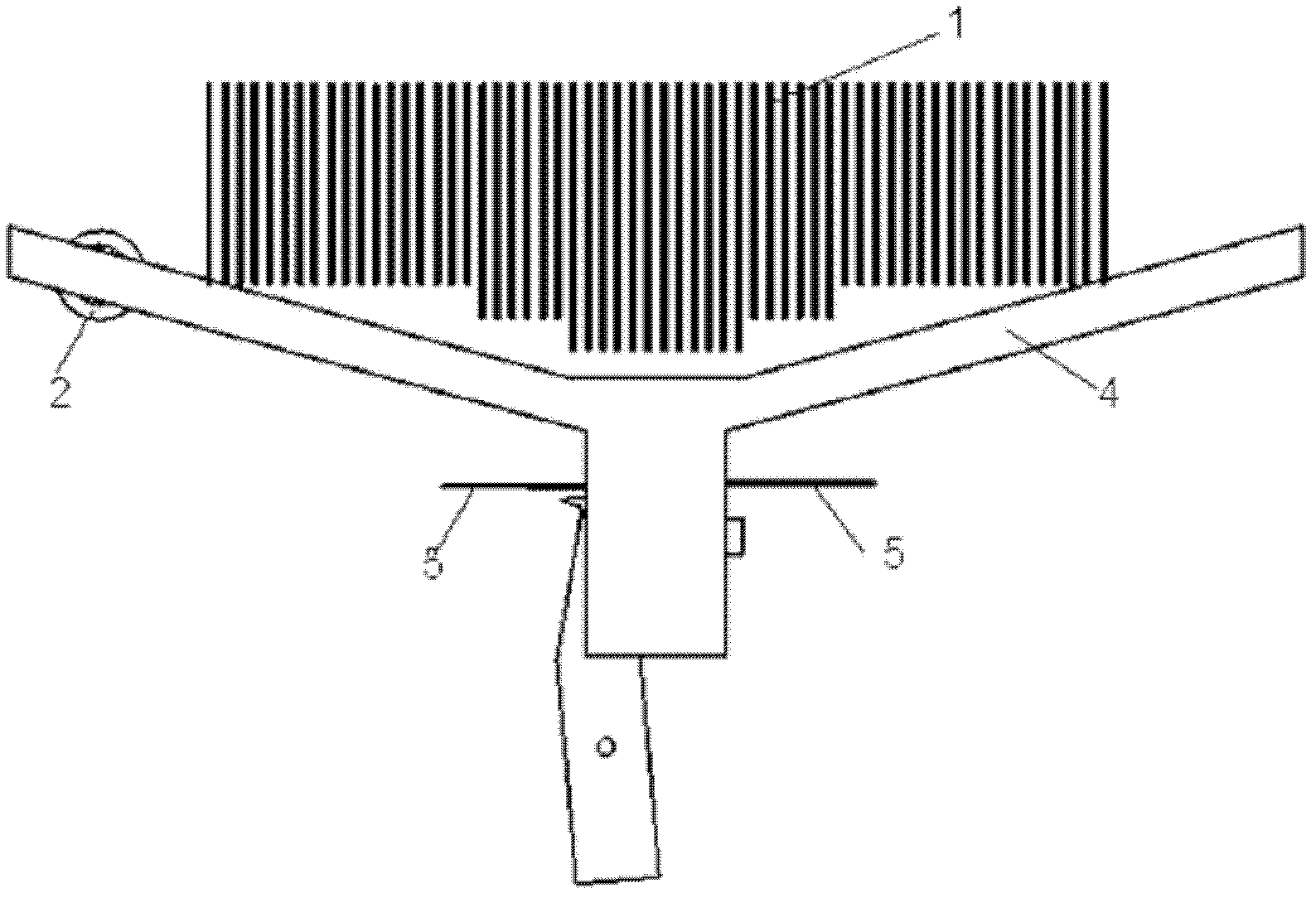

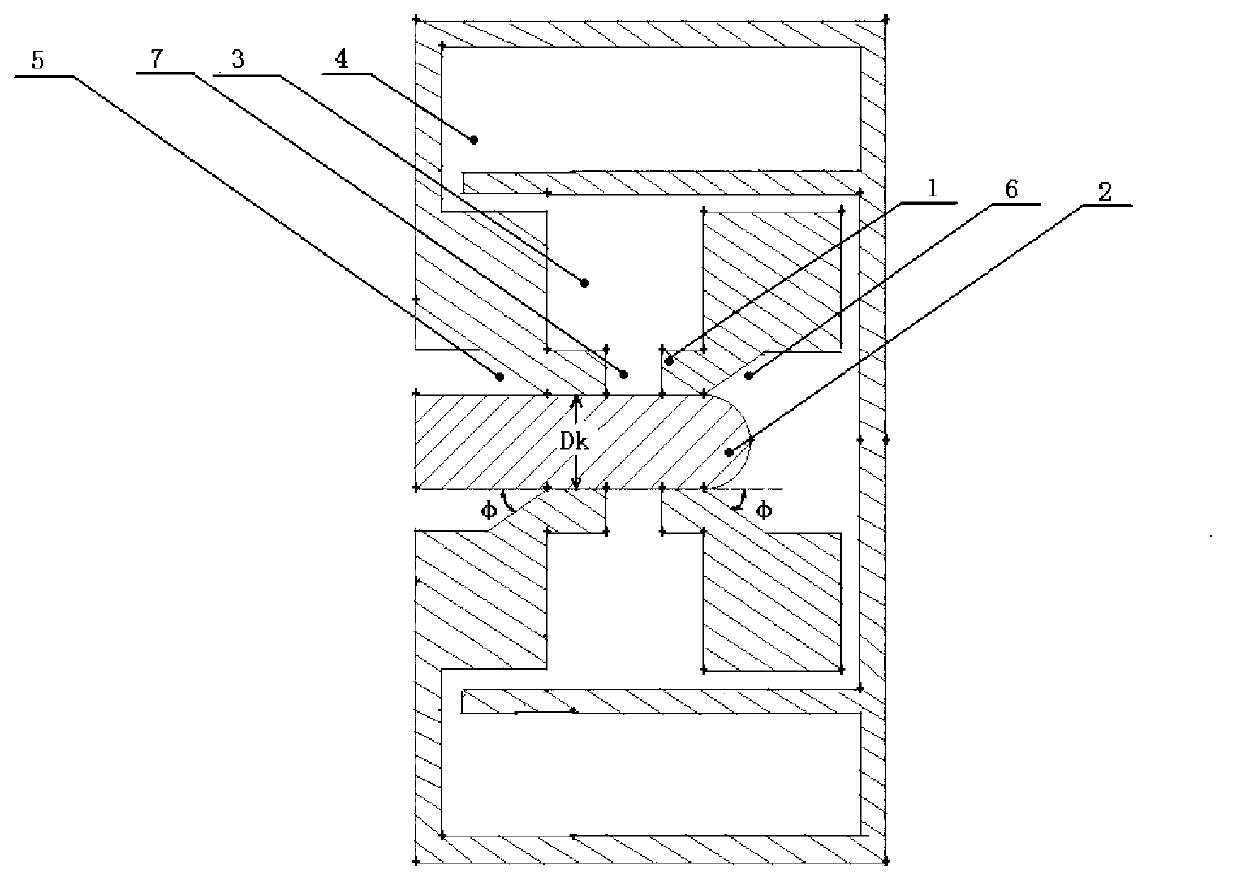

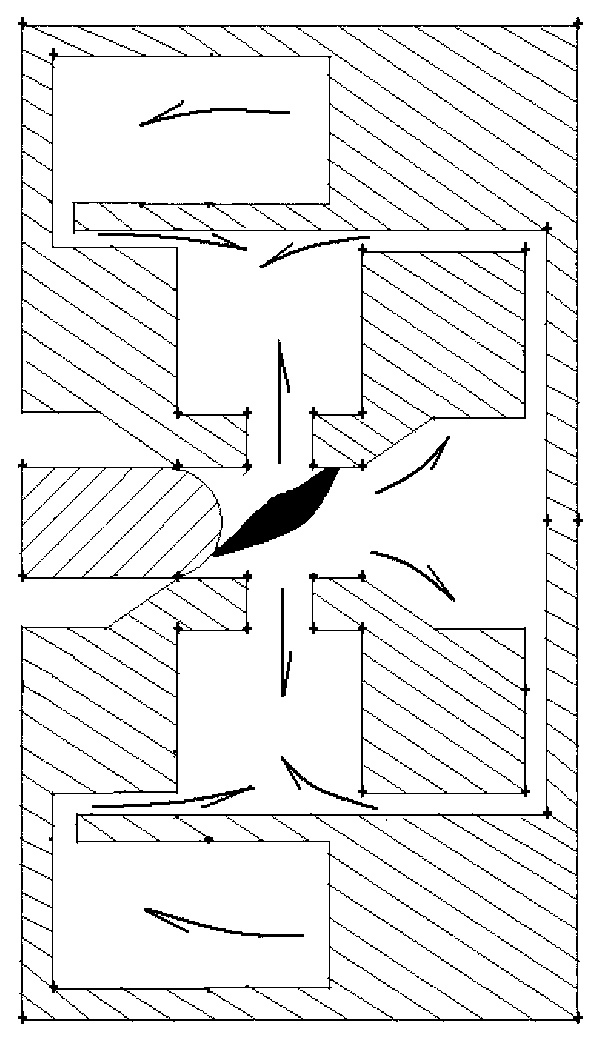

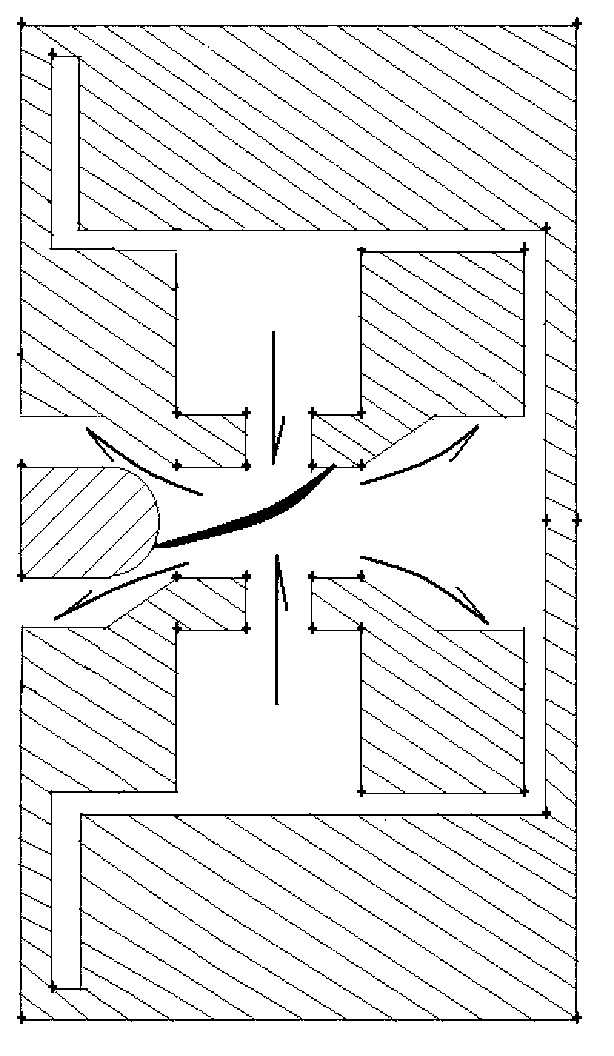

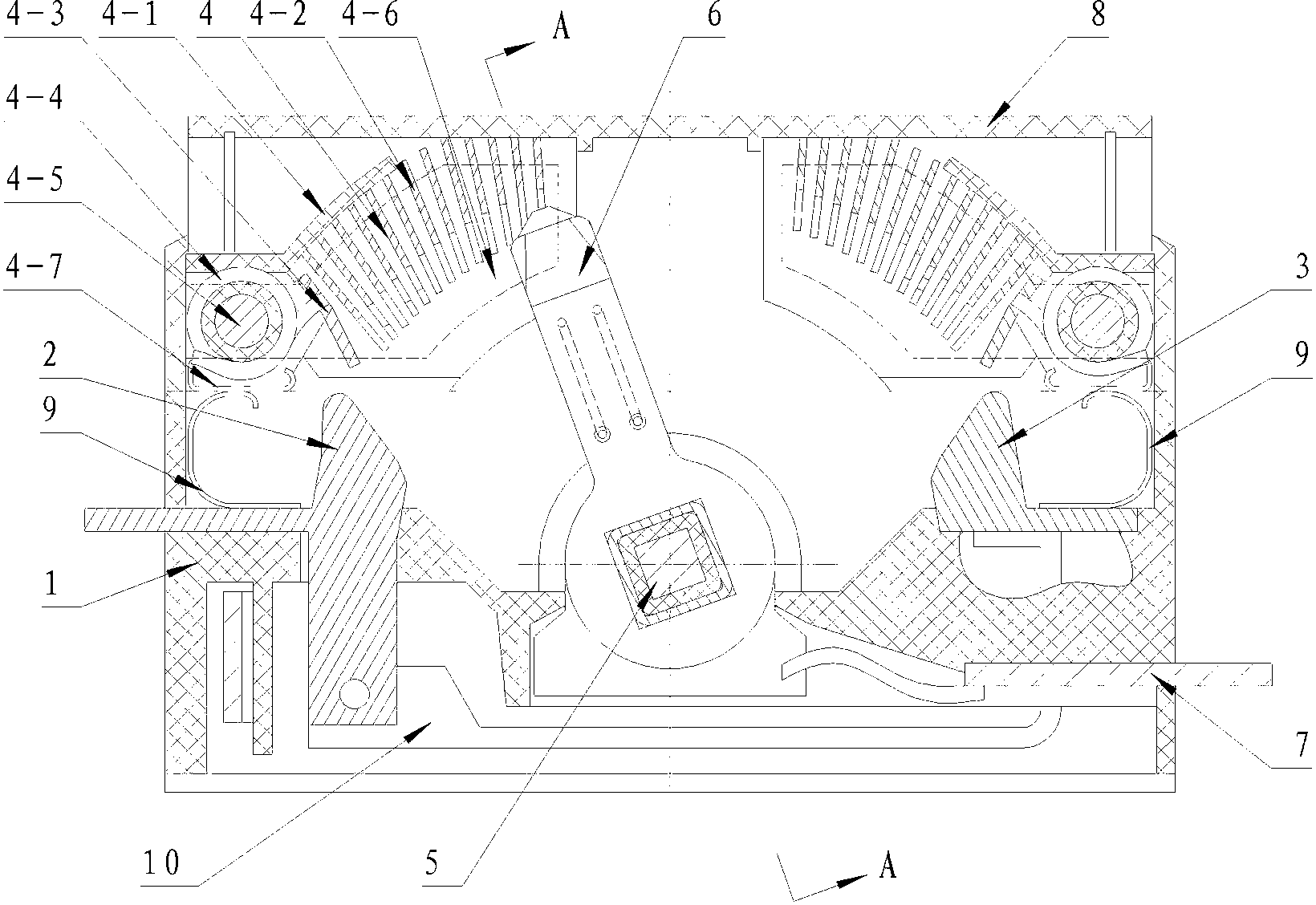

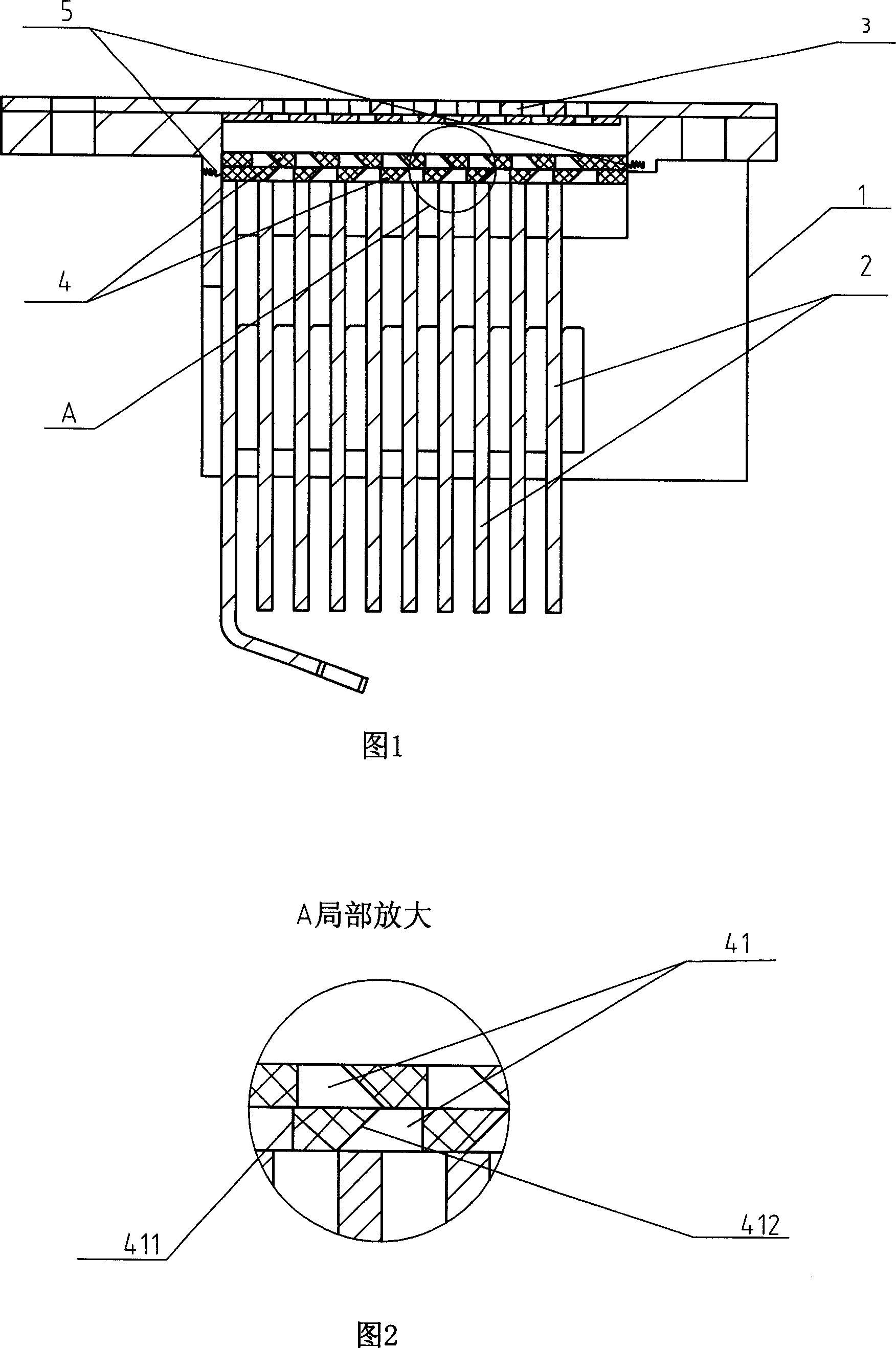

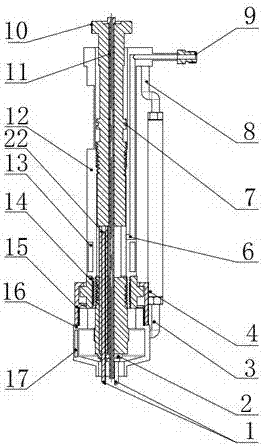

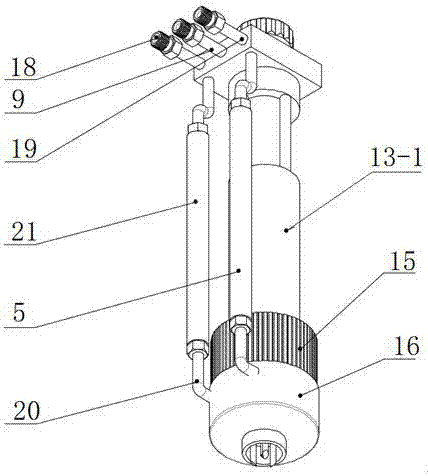

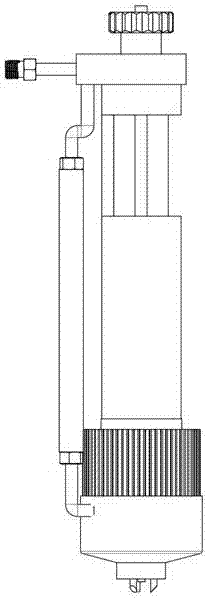

Low current electric arc magnetic blow-out device and arc-blowing method of medium-pressure direct current breaker

InactiveCN102592908AEnhanced magnetic fieldOptimize space layoutCircuit-breaking switch detailsCircuit breakerMedium pressure

The invention discloses a low current electric arc magnetic blow-out device and an arc-blowing method of a medium-pressure direct current breaker. According to the device, a V-shaped arc extinguish chamber grid sheet is adopted, a magnet exciting coil is arranged on the side surface of an arc extinguish chamber shell, which is parallel to the grid sheet, the magnet exciting coil is externally connected with a low current detecting and judging system, and a piece of Y-shaped magnetism enhancing armature iron is arranged at each of the two sides of the arc extinguish chamber shell, which correspond to the regions of movable and fixed contacts and an arc running channel. According to the magnetic blow-out device, the magnetic fields of the regions of the contacts and the arc running channel are effectively enhanced, thereby playing obvious effects on the facts that lower current electric arcs in the contact region can fast enter the grid sheet, the electric arcs can be broken successfully, and the fault probability of the device can be reduced. In addition, the device is compact in structure, can reasonably utilize optimizable breaker spatial layout and results in the reduction of the volume.

Owner:XI AN JIAOTONG UNIV +1

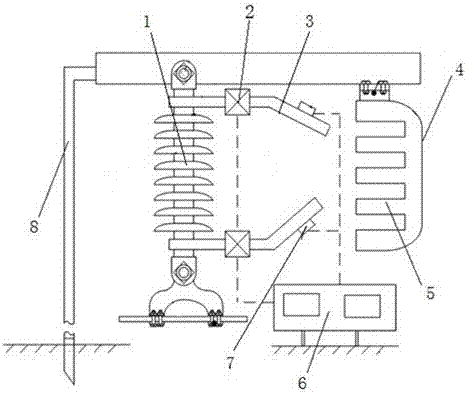

Alternating current electric transmission line lightning flashover restriction method and device

InactiveCN104600567AImprove reliabilityImprove application levelSpark gap detailsInstallation of lighting conductorsBreakdown strengthCombustion

The invention relates to an alternating current electric transmission line lightning flashover restriction method and device. The method includes the steps of current steering, voltage limiting and arc blowing-out. The current steering includes the steps of providing a current discharge channel for power frequency short-circuit current through a parallel gap, wherein the parallel gap is mounted on both ends of an insulator, the breakdown strength of the parallel gap is lower than that of the insulator, and lightning current flows through the parallel gap rather than passing through the insulator when the parallel gap is broken down by lightning. The voltage limiting includes the steps of connecting a non-linear energy absorbing assembly in series with the parallel gap and limiting over-voltage at both ends of the insulator to prevent the insulator from being damaged by lightning flashover, wherein the non-linear energy absorbing assembly is used for absorbing lightning current energy on the basis of current steering. The arc blowing-out includes the steps of treating continuous combustion caused by arc produced in the parallel gap when the power frequency short-circuit current continues to flow through the parallel gap after lightning current passes to prevent tripping of a circuit breaker. The alternating current electric transmission line lightning flashover restriction device is composed of the parallel gap, electrodes, the non-linear energy absorbing assembly and a special-shaped connecting unit which are assembled and connected with one another and is simple in structure, light in weight and small in size.

Owner:STATE GRID CORP OF CHINA +2

Cleaning environment-friendly type copper-base contact material for low-voltage electrical apparatus and its contact preparing method

ActiveCN1767105AImprove antioxidant capacityImprove electrical lifeContactsHazardous substanceLow voltage

The invention relates to a low-voltage electrical apparatus used cleanliness environment-friendly type copper touching bar material and the method for preparing the touching point. The material forming (by weight ratio) is that the first phase conducting core is copper allowance, the second phase anti-analyzing material is pure rear-earth oxide or mixed rear-earth oxide 0.1%-0.5%, the third phase blending agent is anti-oxidant and arc blow-out function alloy elements 0-5úÑ.

Owner:浙江帕特尼触头有限公司

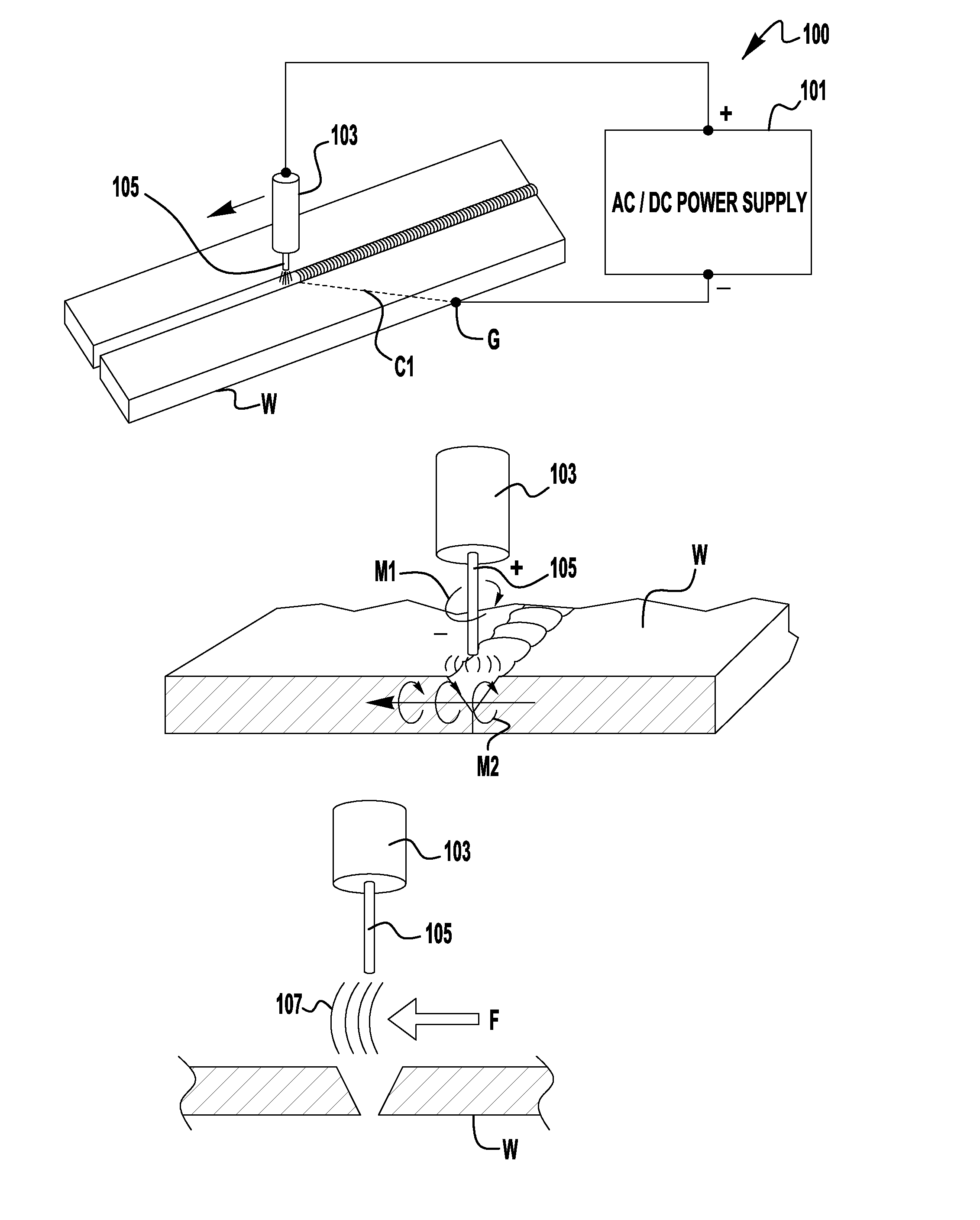

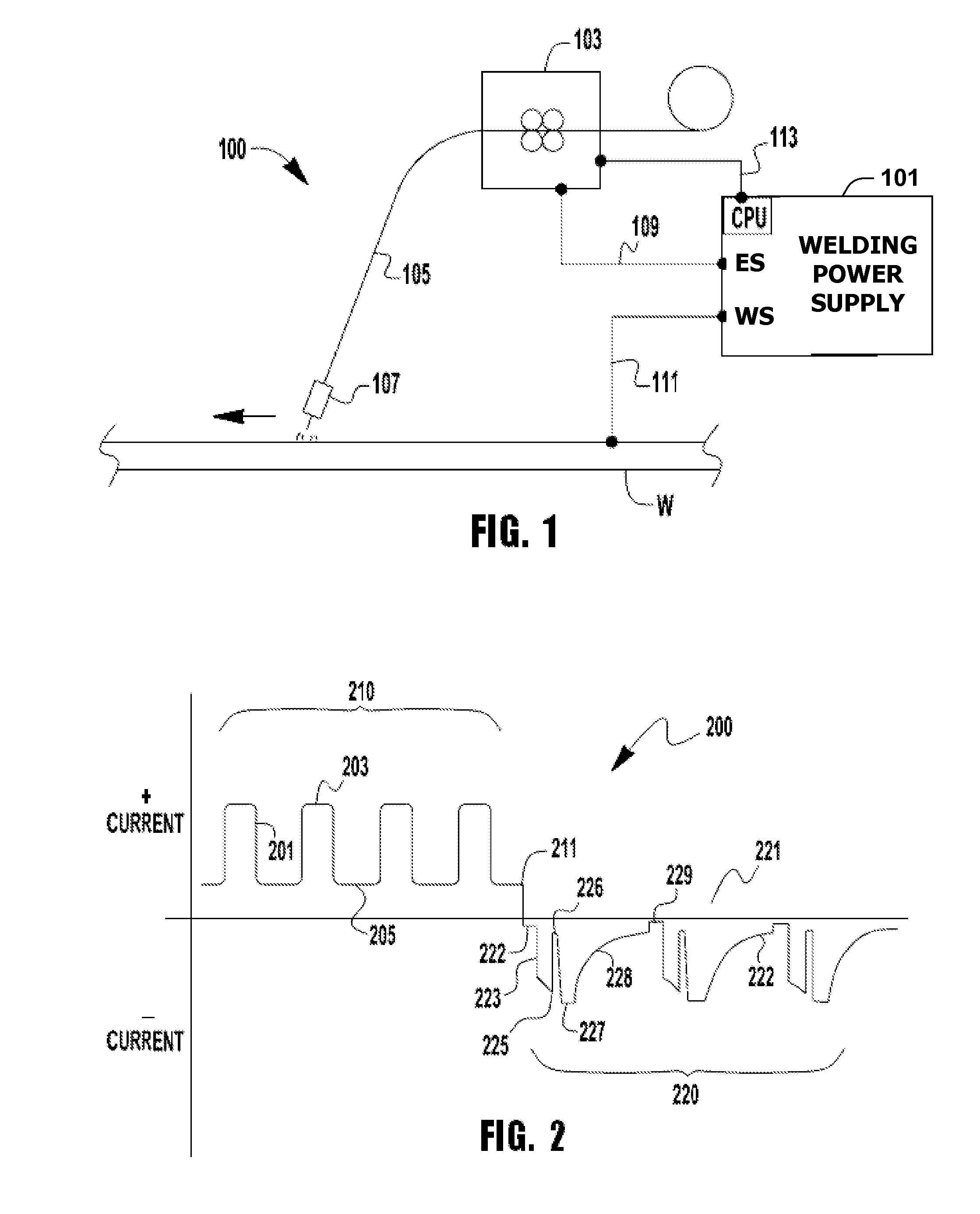

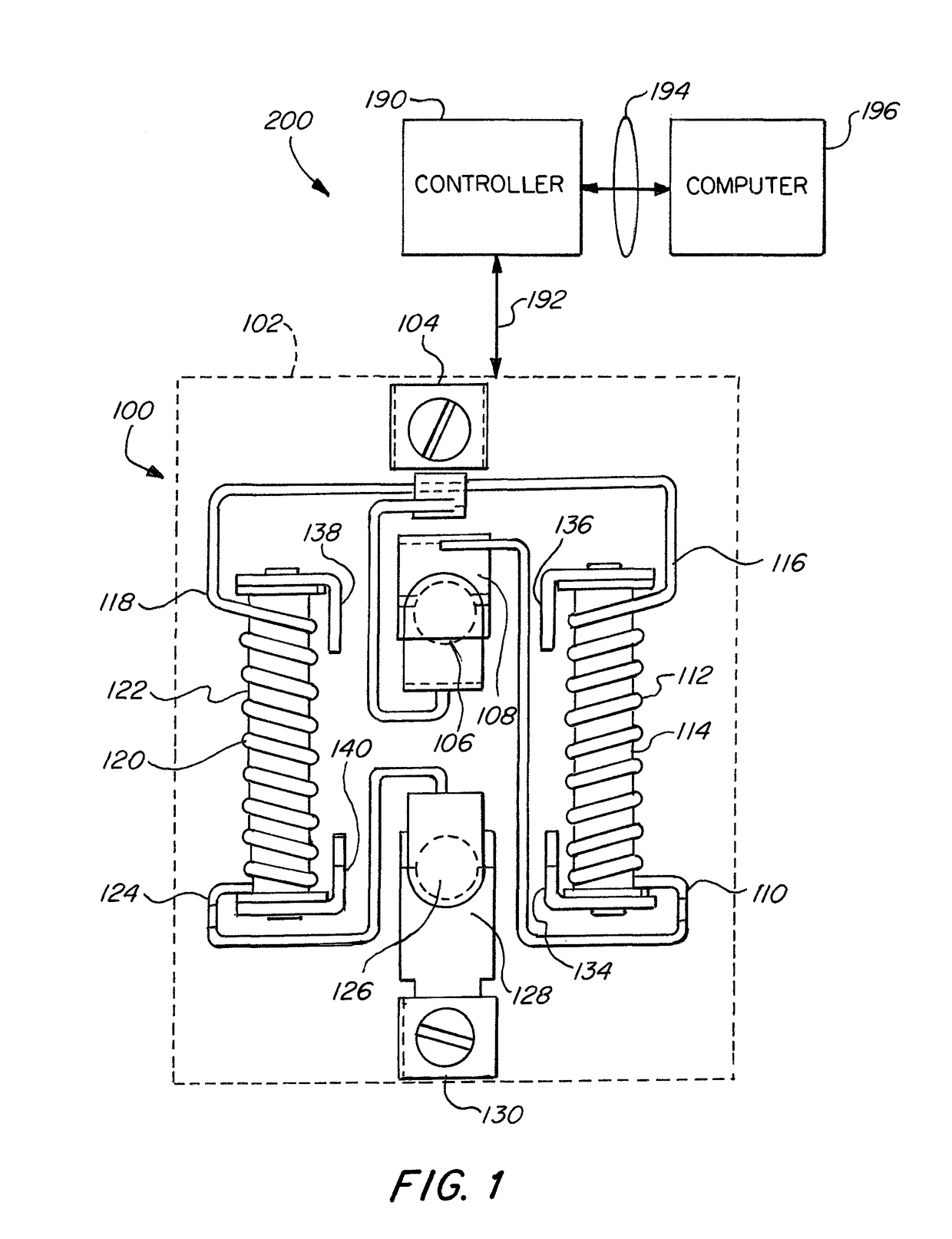

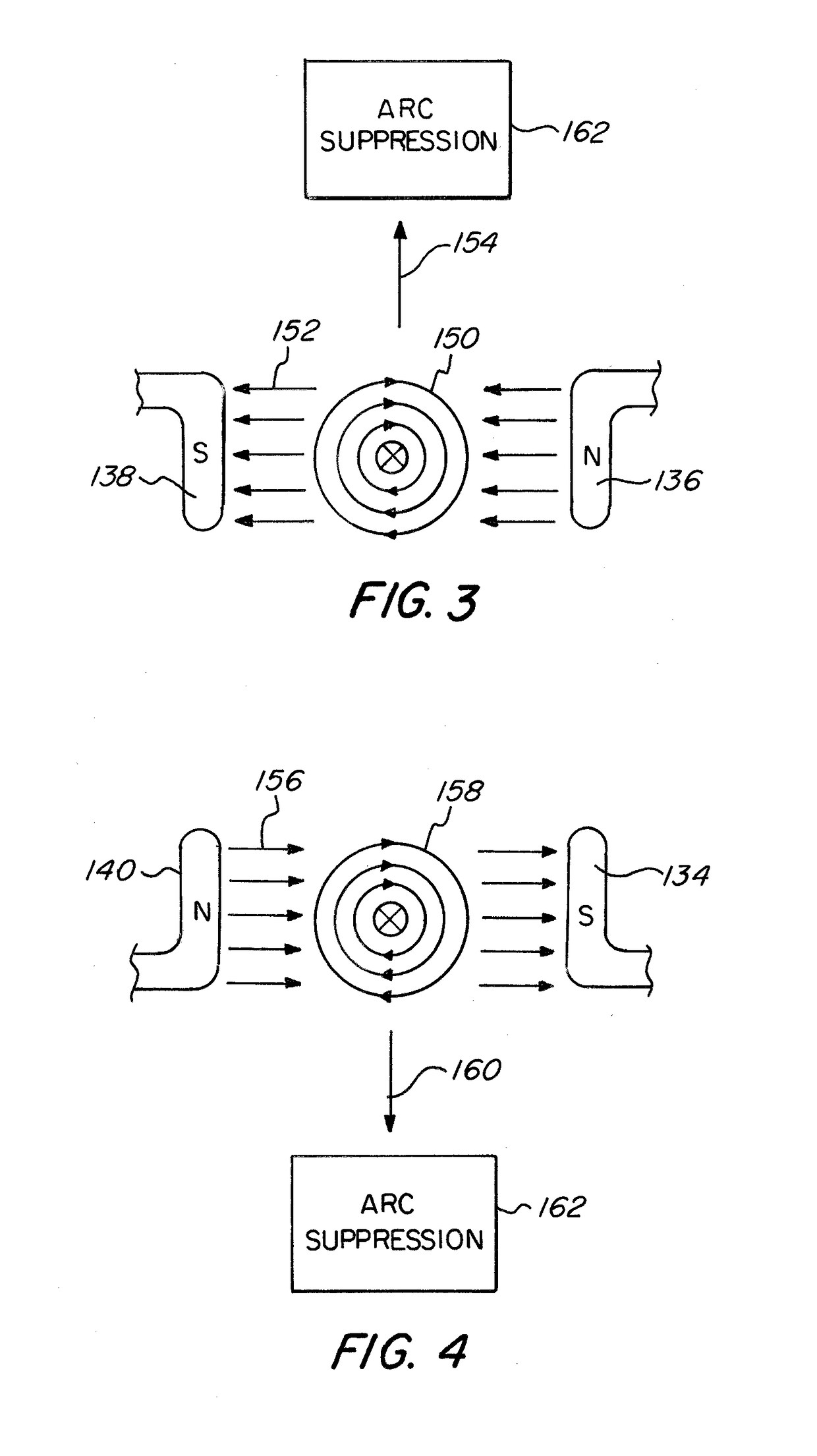

System and method for oscillating waveforms to reduce magnetic arc blow

InactiveUS20160067808A1Increase heat inputReduce magnetic fieldArc welding apparatusWelding/cutting media/materialsPower flowArc blow

The invention described herein generally pertains to a system and method related to reducing magnetic arc blow by adjusting a current welding waveform that is used to create an arc between a workpiece and an electrode. The invention can provide a welder system that includes a component that detects an amount of magnetic field related to arc blow, wherein a controller can adjust the current welding waveform to reduce the amount of magnetic field related to arc blow. In an embodiment, the welder system can utilize the current welding waveform with a first waveform portion that delivers a first amount of energy to the workpiece and a second waveform portion that delivers a second amount of energy to the workpiece. A controller of the welder system can be configured to adjust the first waveform portion or the second waveform portion to equalize, within a tolerance, the first amount of energy and the second amount of energy.

Owner:LINCOLN GLOBAL INC

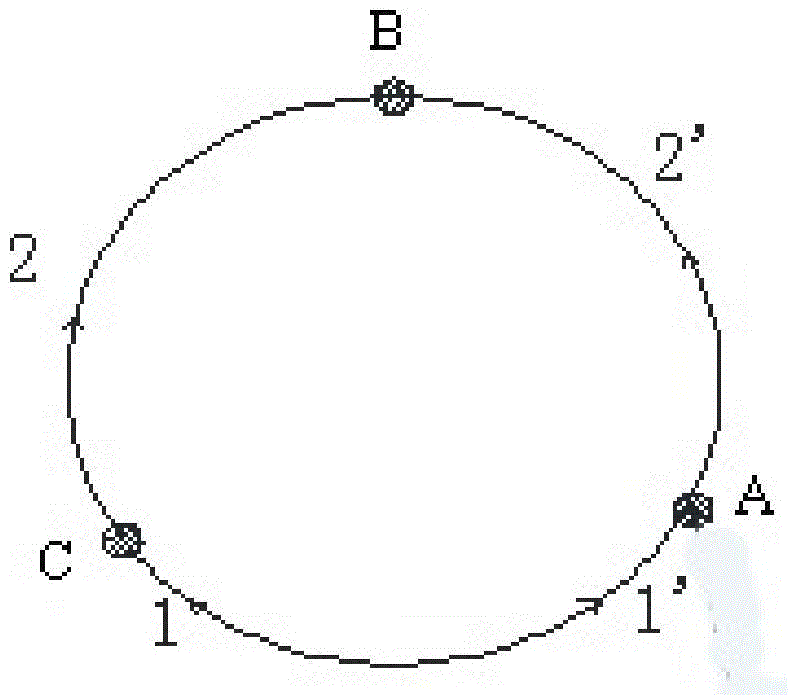

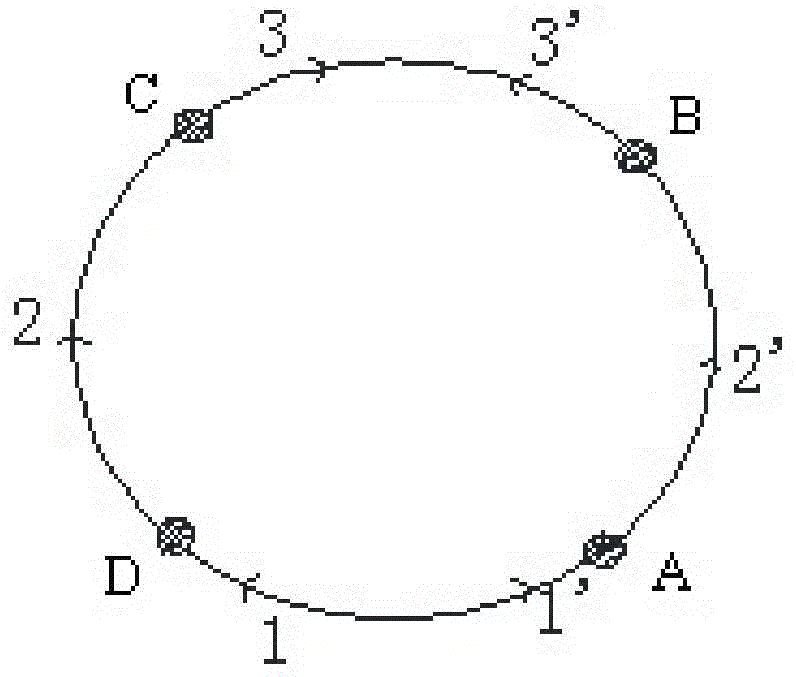

System and method for delivering negative polarity current to release gas from a welding puddle

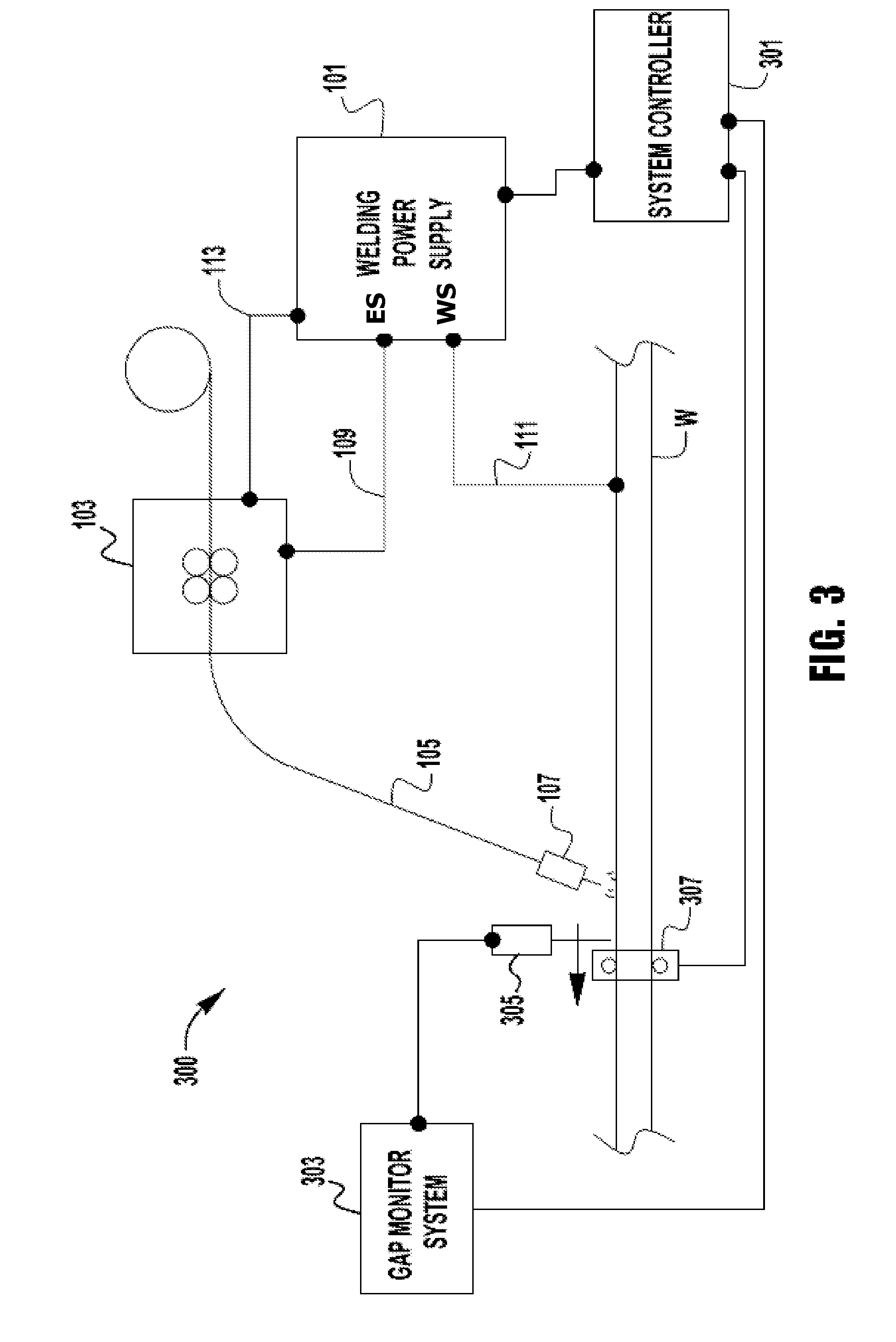

InactiveUS20160082538A1Reduce porosityArc welding apparatusWelding/cutting media/materialsPorosityElectrical connection

The invention described herein generally pertains to a system and method related to reducing magnetic arc blow and steering the arc with two or more ground connections on the workpiece. The invention employs an AC switch component that is configured to activate one of the two or more ground connections to complete an electrical connection via the arc between the electrode and the workpiece. The activated ground connection can be used to counteract a buildup of magnetic field due to arc blow. Moreover, AC switch component can be configured to manipulate a direction of an arc based on activated a ground connection. In addition, AC switch component can oscillate between two or more ground connections to agitate a puddle formed by an electrode to release gas from the puddle and reduce porosity of a resulting weld.

Owner:LINCOLN GLOBAL INC

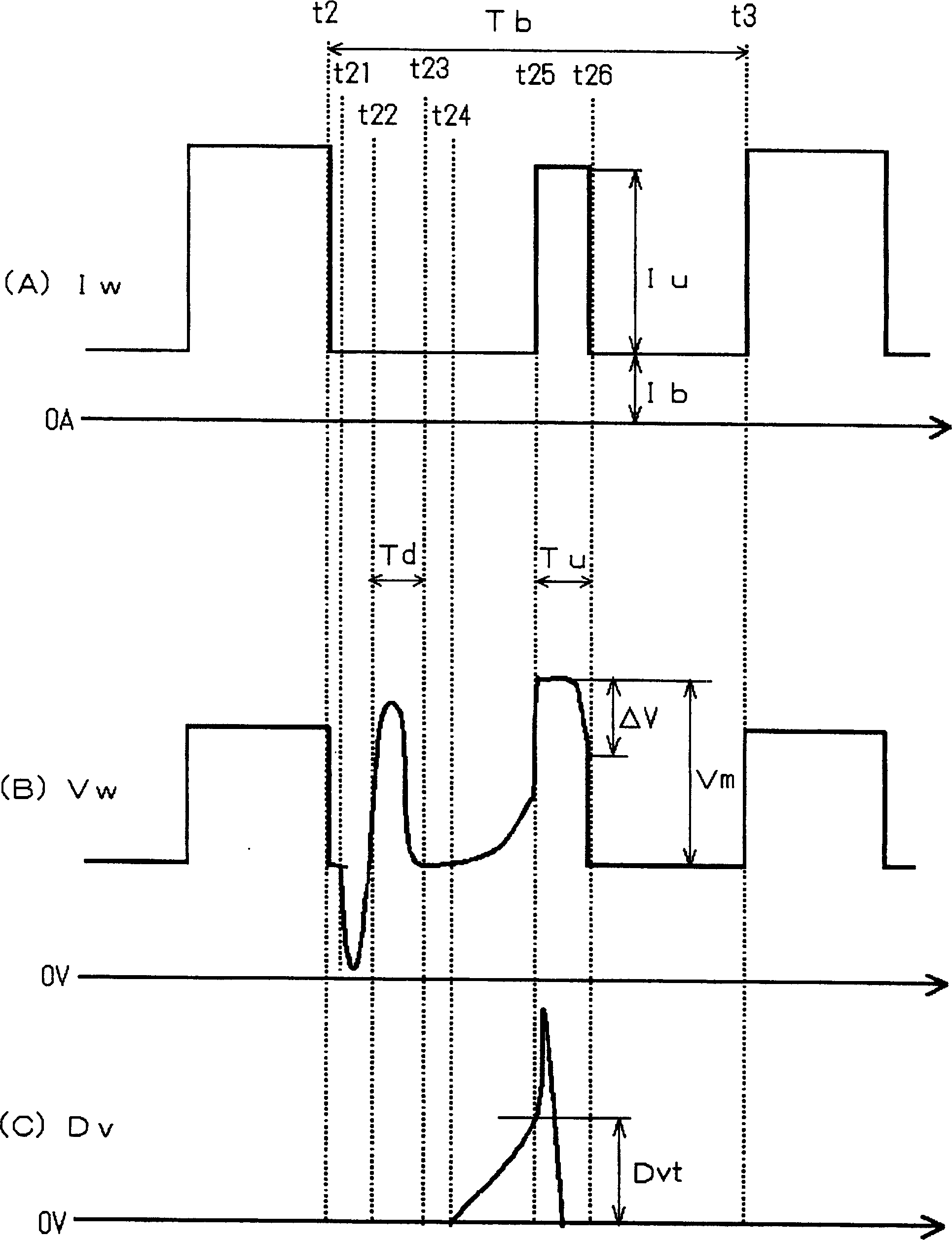

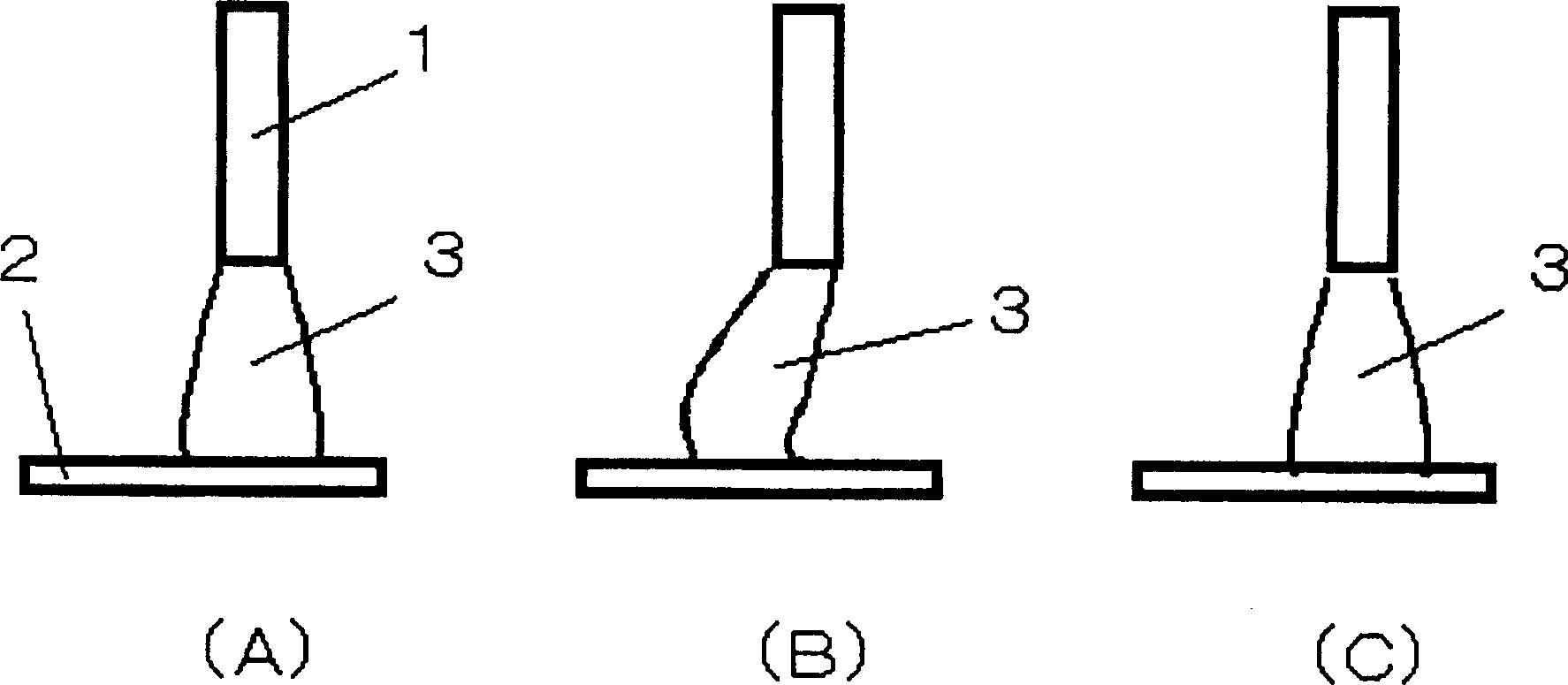

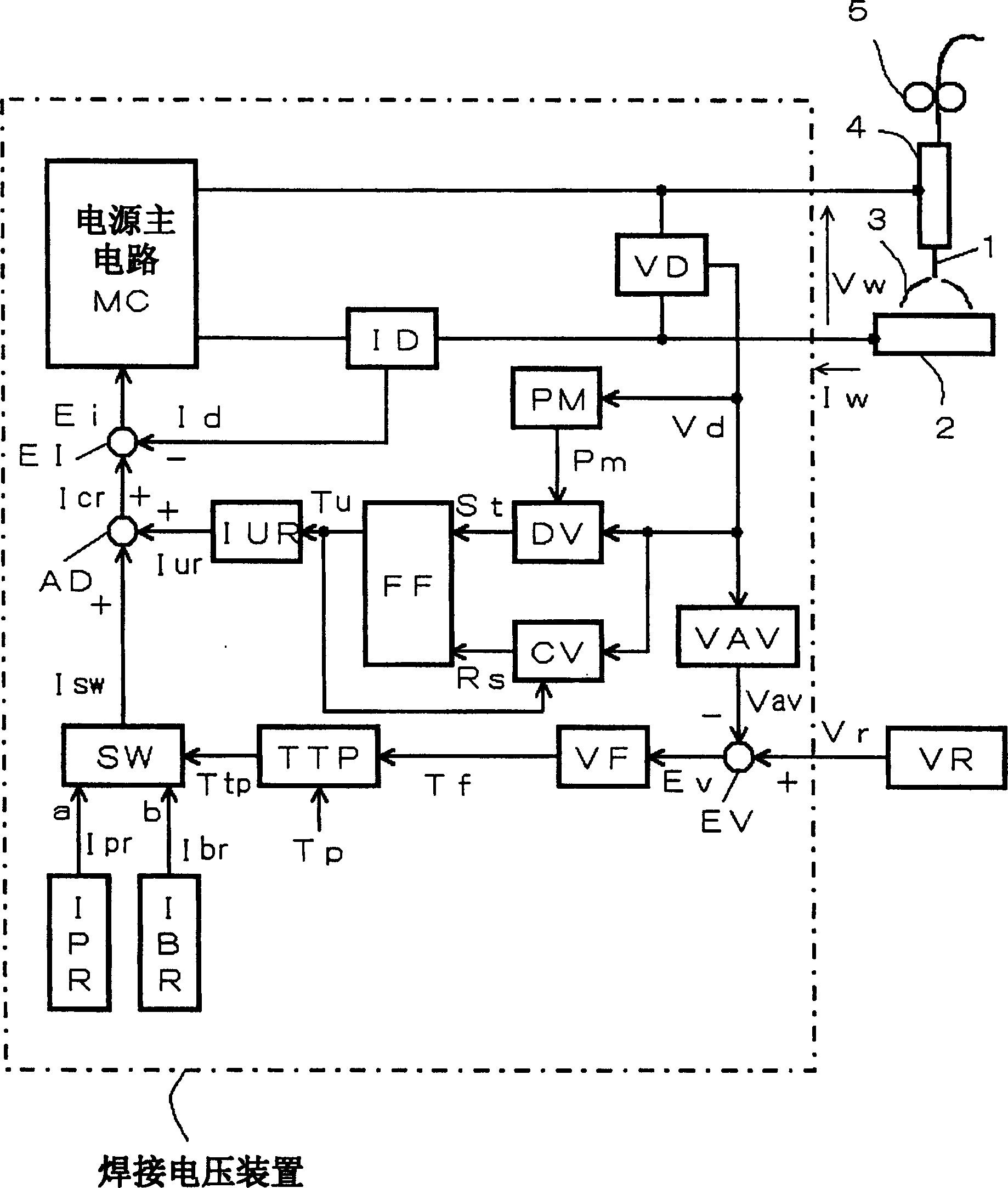

Magnetic blow-out processing control method for consumable-electrode type pulse arc melting

ActiveCN1526506AAvoid truncationNot affected by the arc stateArc welding apparatusEngineeringPeak current

In the consumable-electrode pulse arc welding where the energization of a peak current Ip and a base current Ib are alternately repeated, the arc break caused by the magnetic arc blow is suppressed in a short time in the following way. When an arc is generated during an energization period Tb of the base current and the rising rate Dv of a welding voltage Vw becomes a predetermined reference rising rate Dvt or more with no short circuit being generated just before the voltage Vw becomes so, a judgement (t25) that the magnetic arc blow occurs is made to rapidly increase the base current to 200 A or more. Next, when the welding voltage Vw is decreased during the period of the magnetic arc blow, a judgement (t26) that the magnetic arc blow is ceased is made to return the base current Ib+Iu to the normal value Ib.

Owner:DAIHEN CORP

Stainless steel welding electrode special for end socket and preparation method of stainless steel welding electrode

InactiveCN107900559AGood fluidity of slagArc stabilizationWelding/cutting media/materialsSoldering mediaElectrolysisSlag

The invention discloses a stainless steel welding electrode special for an end socket and a preparation method of the stainless steel welding electrode. The stainless steel welding electrode special for the end socket is composed of a core wire and a coating wrapping the surface of the core wire. The core wire is a stainless steel core with few Si, S and P, and the weight of the coating is 30%-45%of the weight of the adopted core wire. The coating comprises, by weight percent, components including 5.0%-9.0% of marble, 10.0%-15.0% of dolomite, 2.0%-5.0% of cryolite, 0%-2.0% of fluorite, 30.0%-50.0% of natural rutile, 1.0%-3.0% of sodium potassium titanate, 2.0%-5.0% of compound mica, 4.0%-5.0% of feldspar powder, 6.0%-10.0% of micro-carbon ferro chrome, 3.0%-4.0% of electrolytic manganese,3.0%-4.0% of ferroferric oxide, 2.0%-5.0% of ferrotitanium and 0.8%-1.0% of CMC. The stainless steel welding electrode is good in slag flowability during welding, stable in electric arc, moderate inelectric arc blowing force, uniform in slag covering, small in spattering and good in deslagging and all-position operability.

Owner:TIANJIN BRIDGE WELDING MATERIALS GROUP +3

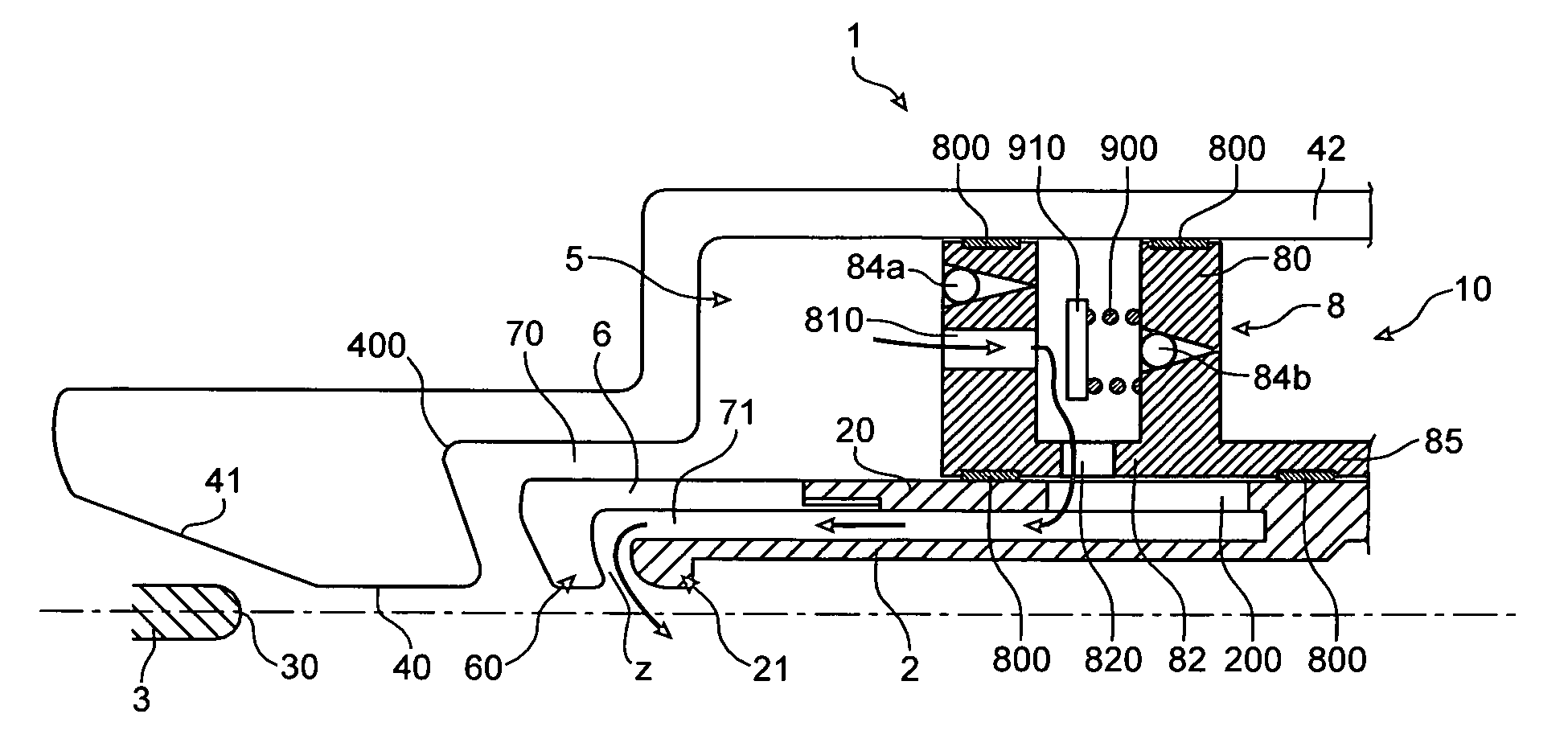

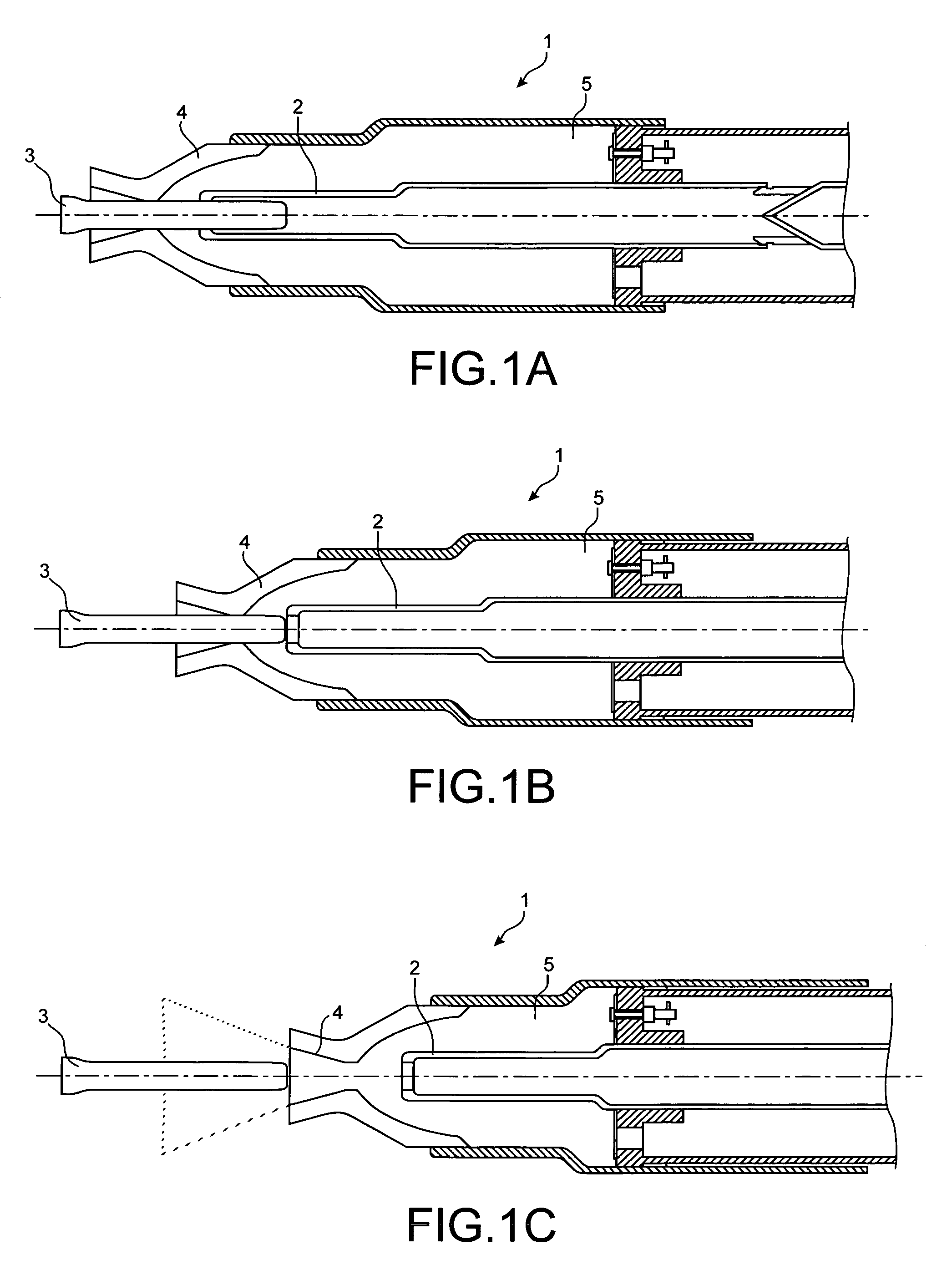

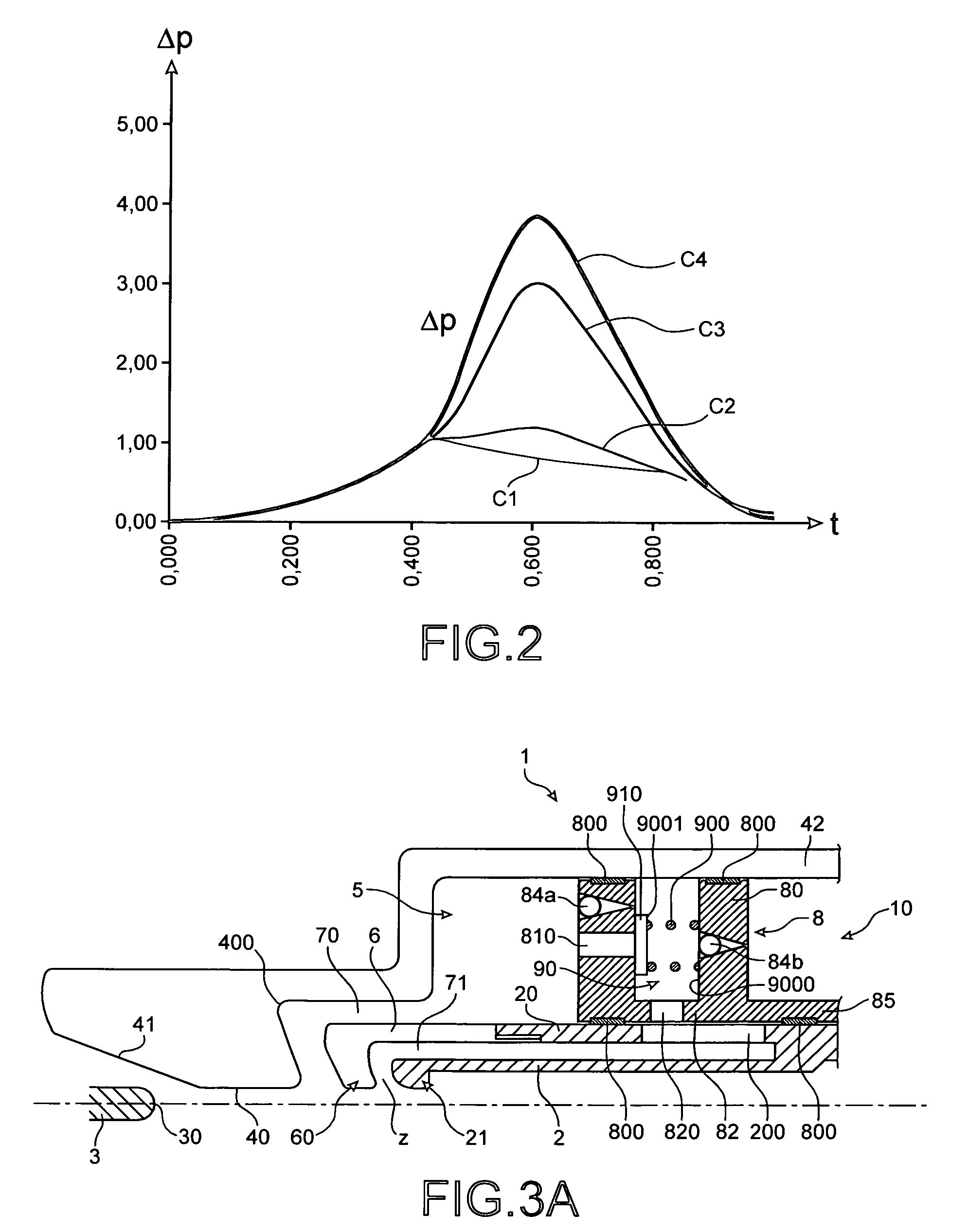

Interrupting chamber for high-voltage circuit breaker with improved arc blow-out

Owner:ALSTOM TECH LTD

Self-energy sulfur hexafluoride (SF6) circuit breaker double nozzle type arc extinguishing chamber and arc extinguishing method thereof

InactiveCN103000444AIncrease pressureAccelerated recovery of strengthHigh-tension/heavy-dress switchesAir-break switchesSulfur hexafluorideEngineering

The invention provides a sulfur hexafluoride (SF6) circuit breaker double nozzle type arc extinguishing chamber and an arc extinguishing method thereof. The arc extinguishing chamber mainly comprises a movable arc contactor, a static arc contactor, an expansion chamber, an air compression chamber, a double contraction expanded nozzle and an auxiliary nozzle and is characterized in that by means of the structure of the double contraction expanded nozzle, horizontal and longitudinal arc blowing modes are integrated so that arc blowing air current can rapidly disperse electric arc energy, and the recovery strength of arced media is rapidly improved to break high short-circuit current.

Owner:BEIHANG UNIV

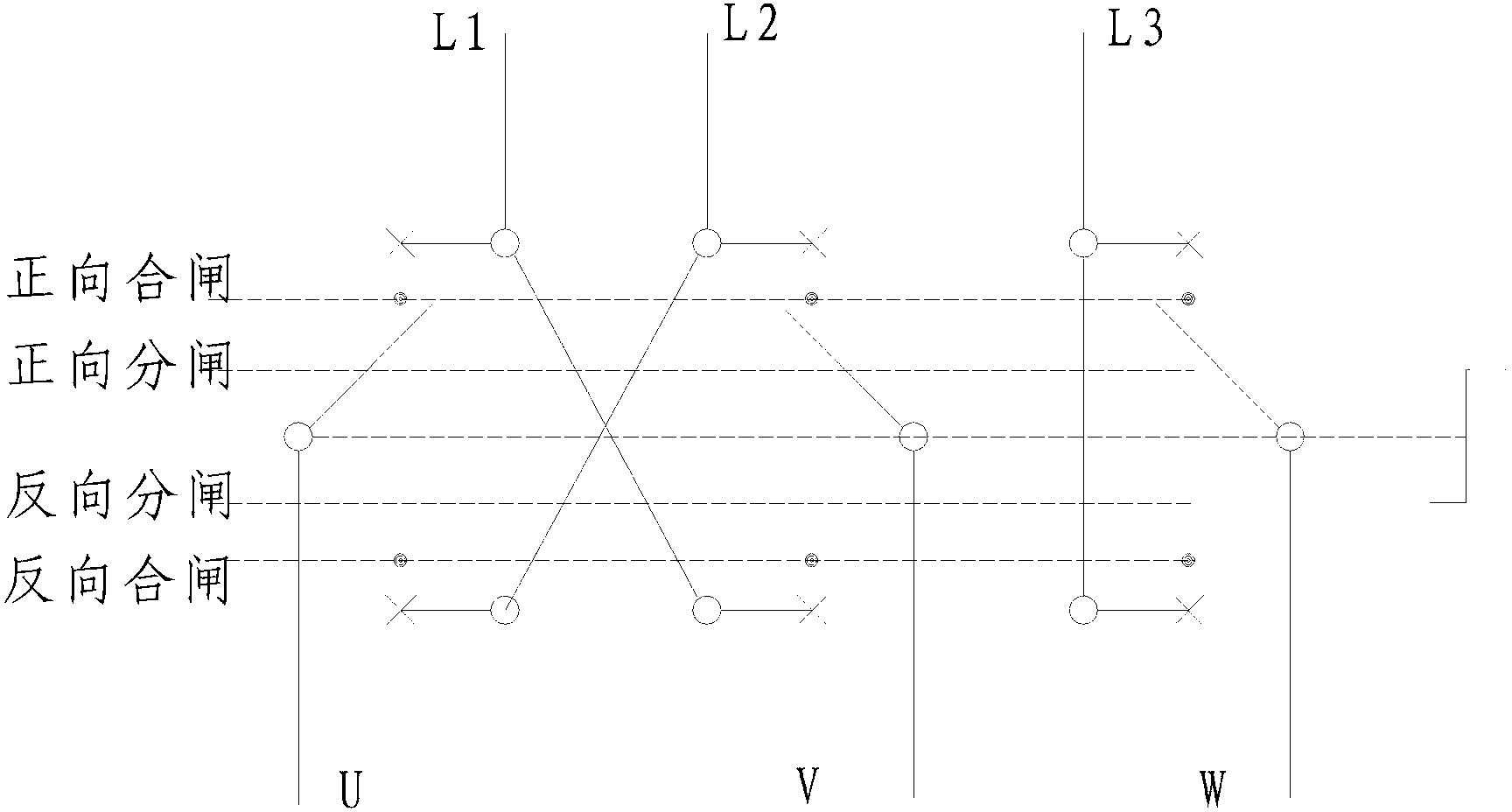

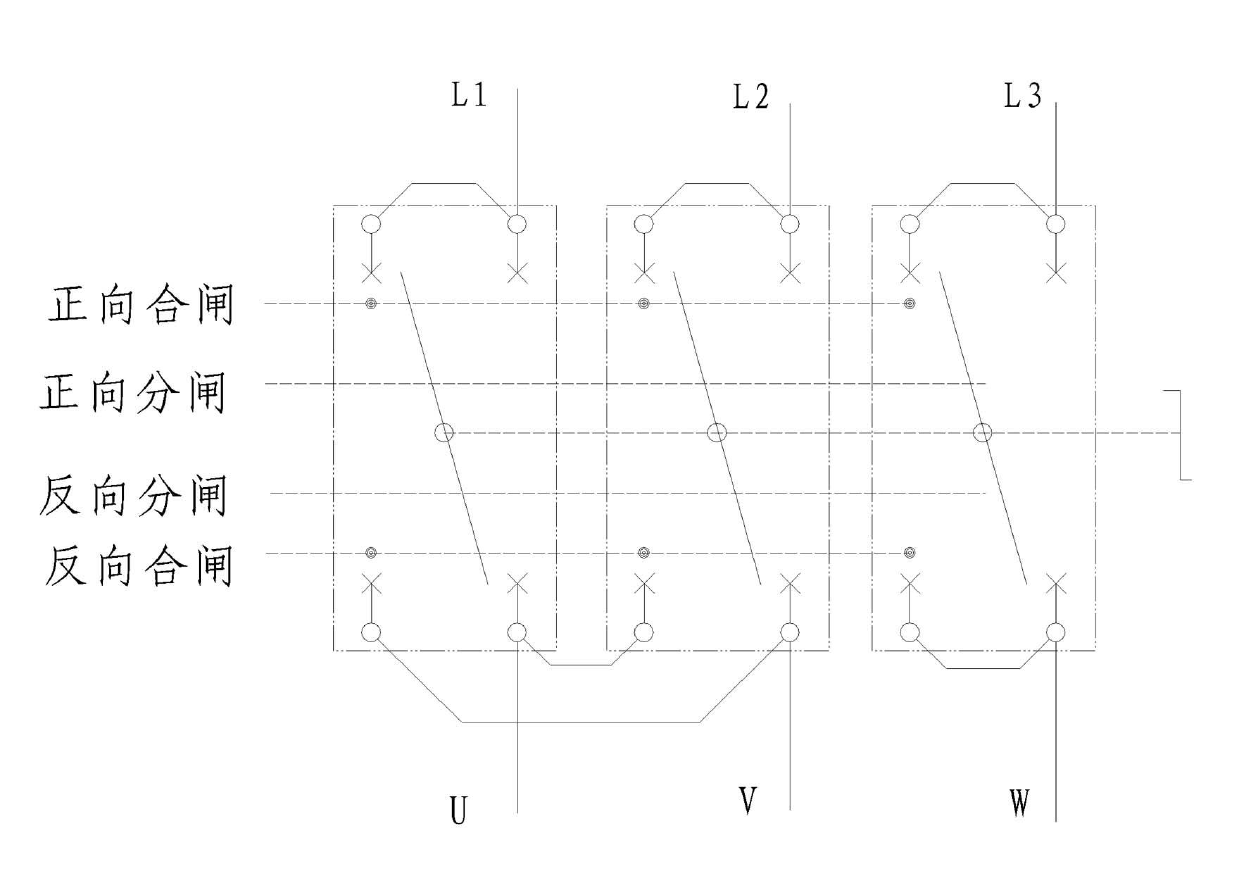

Mining kilovolt-level double-pole single-breakpoint air isolation reversing switch

InactiveCN102709083AContact tightening forceReduce contact resistanceElectric switchesQuenchingElectrical element

The invention discloses a mining kilovolt-level double-pole single-breakpoint air isolation reversing switch, and relates to an electrical element. A double-pole single-breakpoint moving contact and grid type magnetic quenching devices are adopted. Working current switching-on / off capability reaches more than 630A. The grid type magnetic quenching devices are fixed in a transverse isolation groove of an upper cover. The transverse isolation groove of the upper cover and a corresponding transverse isolation groove of an upper cavity of an insulating seat form a closed space in which the grid type magnetic quenching devices are positioned. Each grid type magnetic quenching device comprises a cover, arc quenching grids, a run-on plate, a magnetic blowout coil, a concentrating flux core and a concentrating flux plate. The arc root of an opening arc is shifted downwards to the run-on plates under the action of an electric field, the blowout coils generate an excitation field through arc current, the excitation field generates an arc blowing magnetic field on the two concentrating flux plates through the concentrating flux cores, and the opening arc is struck into the arc quenching grids under the action of the arc blowing magnetic field to be quenched.

Owner:XUZHOU ZHIXIN ELECTRICAL TECH

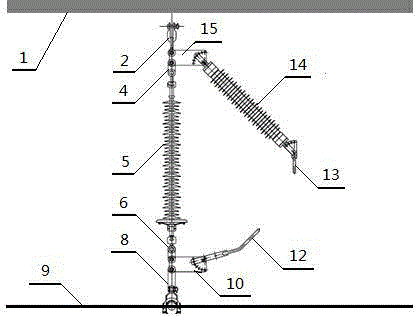

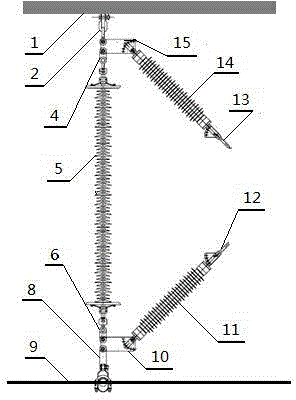

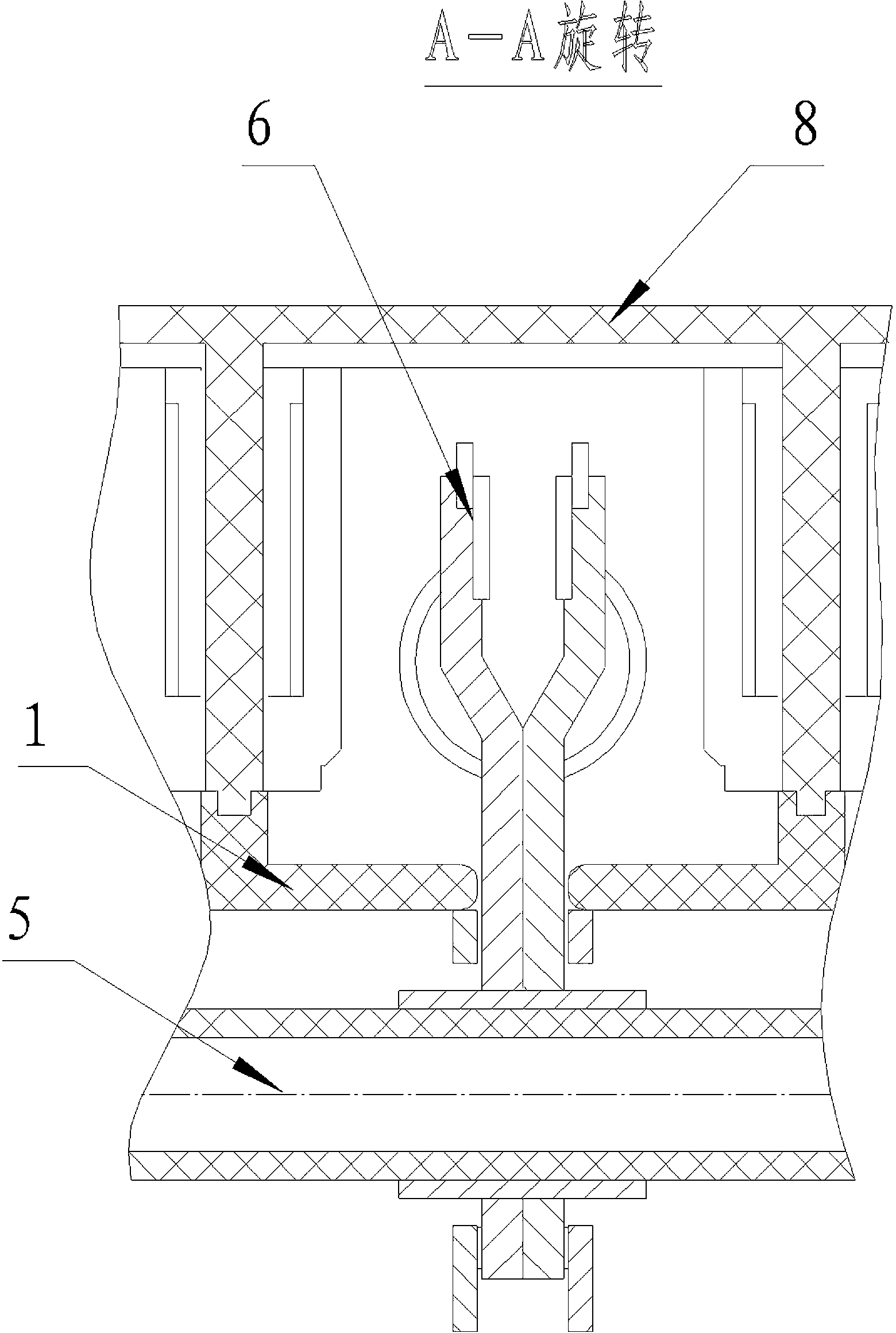

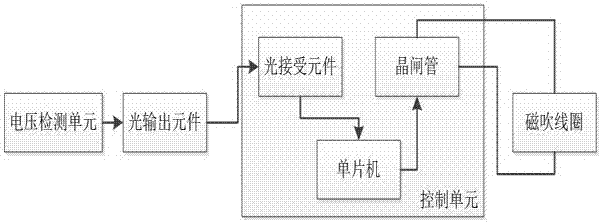

Lightning-protection trip automatic arc blow-out parallel gap system for power distribution network

ActiveCN107481823AOvercoming the Defects in Lightning Protection MeasuresNo trippingSpark gap detailsInsulatorsElectrical connectionControl cell

The invention irons out the defects of conventional line lightning protection measures, and provides a new lightning-protection trip automatic arc blow-out parallel gap system for a power distribution network. The system comprises a voltage detection unit, a control unit, two metal electrodes, and an automatic arc blow-out unit. The two metal electrodes are respectively electrically connected with two ends of an insulator, and a voltage detection unit is disposed on the metal electrodes. A signal output end of the voltage detection unit is connected with a signal input end of the control unit, and a signal output end of the control unit is connected with the automatic arc blow-out unit. The system is wide in application range, can adjust the distance of parallel gaps of different power distribution lines, and can achieve the flexible adjustment of the lines with different relay protection parameters. Arc extinguishing energy comes from lightning, and there is no need to obtain additional energy from a line or in other modes. Finally, the system can flexibly adjust the switching time of a coil according to the size of different lightning overvoltages, and guarantees no tripping while releasing the lightning overvoltage.

Owner:ZHANJIANG POWER SUPPLY BUREAU OF GUANGDONG POWER GRID CO LTD

Air pressure arc-extinguishing device of the breaker

ActiveCN101009183AReliable structure and actionSimple structureElectric switchesCircuit-breaking switch detailsSection planeLow voltage

The invention belongs to low voltage electric equipment, it relates to breaker gas pressure arc-control device which is used in low voltage breaker. The device includes shell and arc blow-out gate which is mounted in the cavity of shell, metallic cover plate with vent hole is set on top of the shell; twp layers of porous metal plates which are inarching with each other are set between the metallic cover plate and arc blow-out gate, elastic cell which can make porous metal plates move horizontally is set between the edge of two layers of porous metal plates and side wall of the shell; the shape of elevation profile of porous metal plates is right-angle trapezium, that is via hole possesses a vertical side wall and a inclined side wall, the inclined side wall of via hole of upper layer porous metal plate and the inclined side wall of lower layer porous metal plate are in different side, and the position of via hole of upper and lower layer of porous metal plates is cross with each other. The invention is simple, and action is reliable, it can regulate and control the air pressure of arc-chute automatically.

Owner:JIANGSU DAQO KFINE ELECTRIC

Kilovolt-level double-pole double-breakpoint air type isolation change-over switch for mines

InactiveCN102683093AContact tightening forceReduce contact resistanceHigh-tension/heavy-dress switchesAir-break switchesBreaking capacityElectrical element

The invention discloses a kilovolt-level double-pole double-breakpoint air type isolation change-over switch for mines and relates to an electric element. A double-pole double-breakpoint movable contact and a magnetic blow grid arc-extinction device are utilized, and make-break capacity of working current can reach more than 630 A. Casings of the arc-extinction device are installed at the upper end and the lower end of an insulation seat respectively and serve as an upper cover and a lower cover of a switch casing, a sealing space is defined by the casings and the insulation seat, and the magnetic blow grid arc-extinction device is arranged in the sealed space. The magnetic blow grid arc-extinction device comprises the casings, arc-extinction grids, an arc striking plate, a magnetic blow coil, a magnetism conduction iron core and magnetism conduction plates. Under the effect of an electric field, the arc root of a brake-separating arc moves to the arc striking plate with the same electric potential as the arc root, the magnetic blow coil connected with the arc striking plate generates excitation through arc current, and the excitation generates an arc blowing magnetic field between two magnetism conduction plates through the magnetism conduction iron core. Under the effect of the arc blowing magnetic field, the brake-separating arc is introduced into arc-extinction areas of the arc-extinction grids to be extinguished.

Owner:XUZHOU ZHIXIN ELECTRICAL TECH

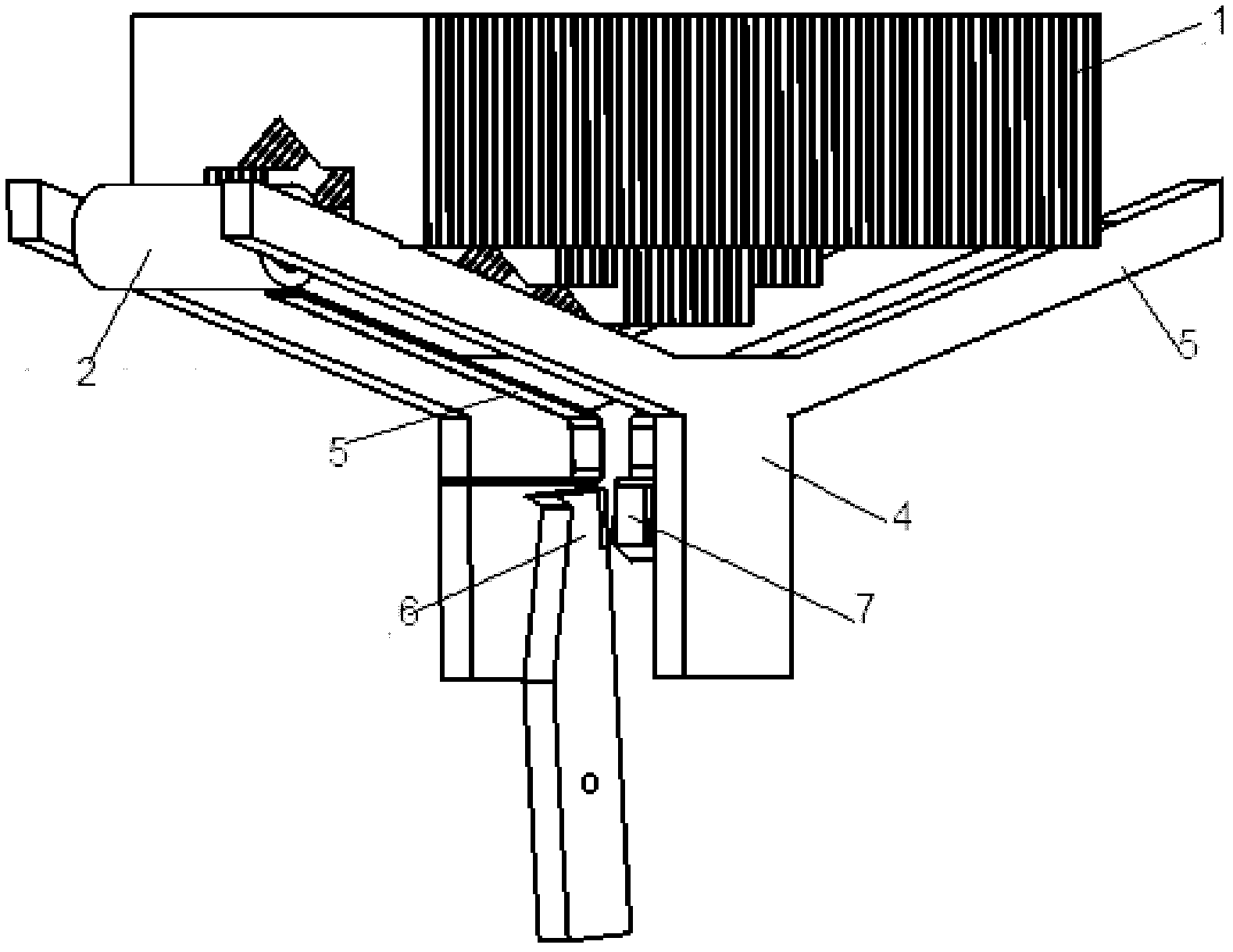

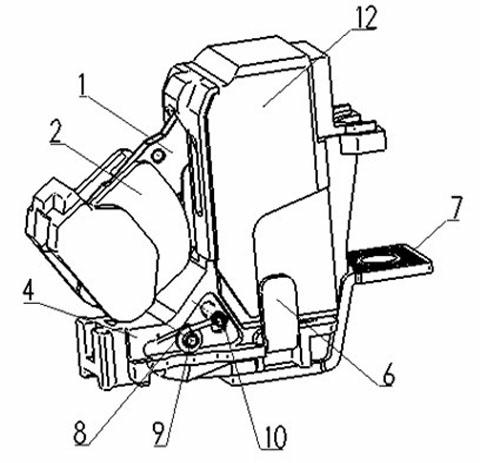

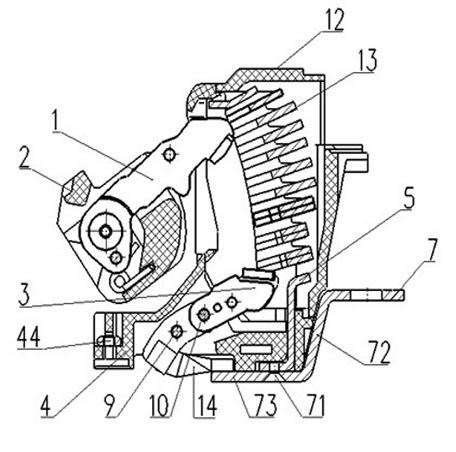

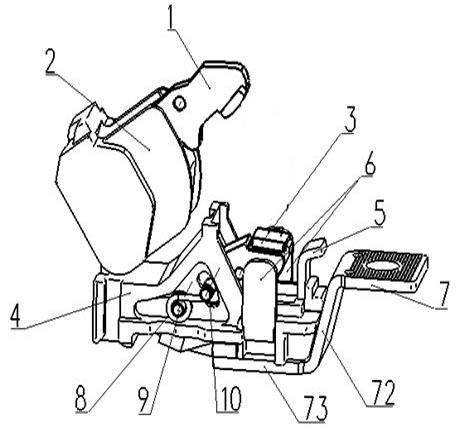

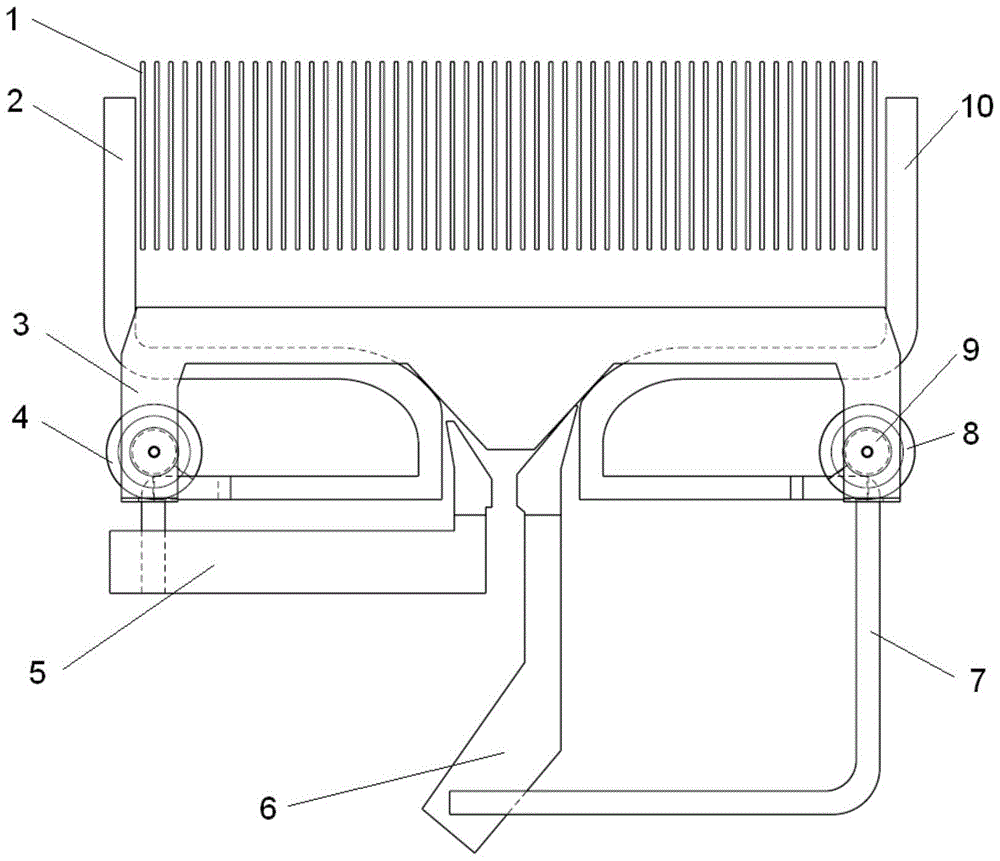

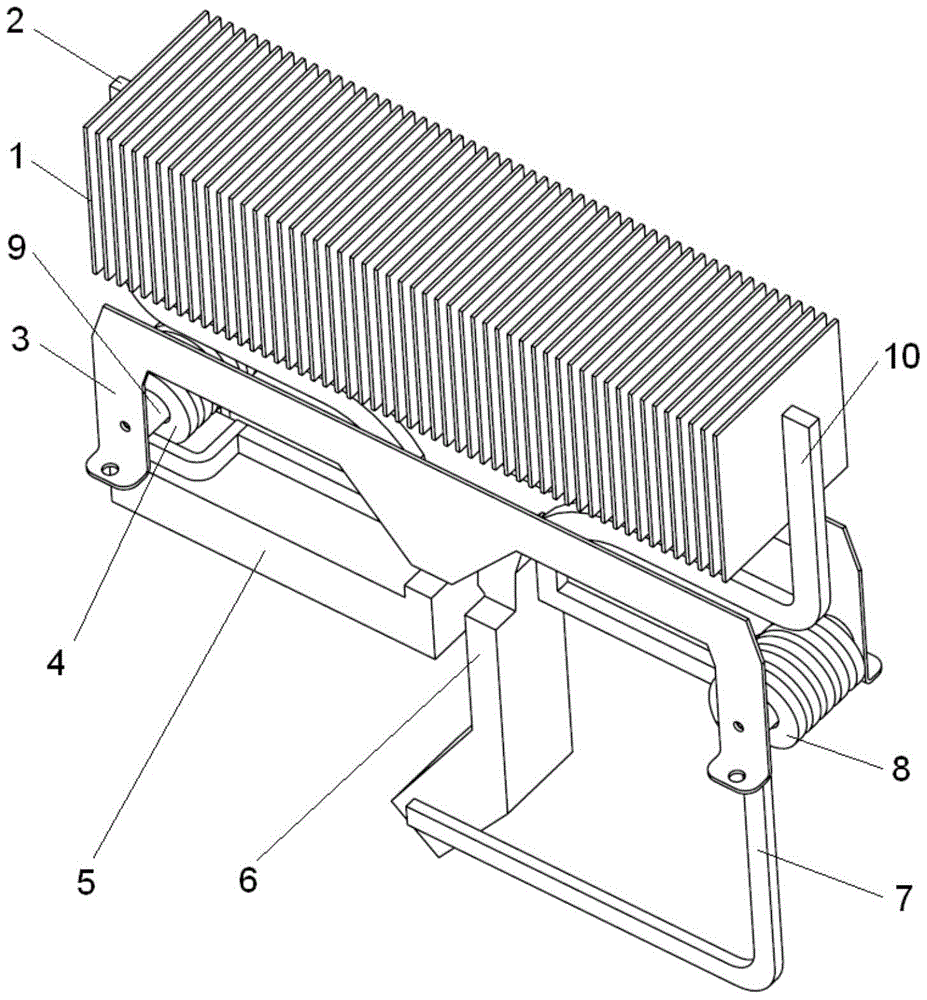

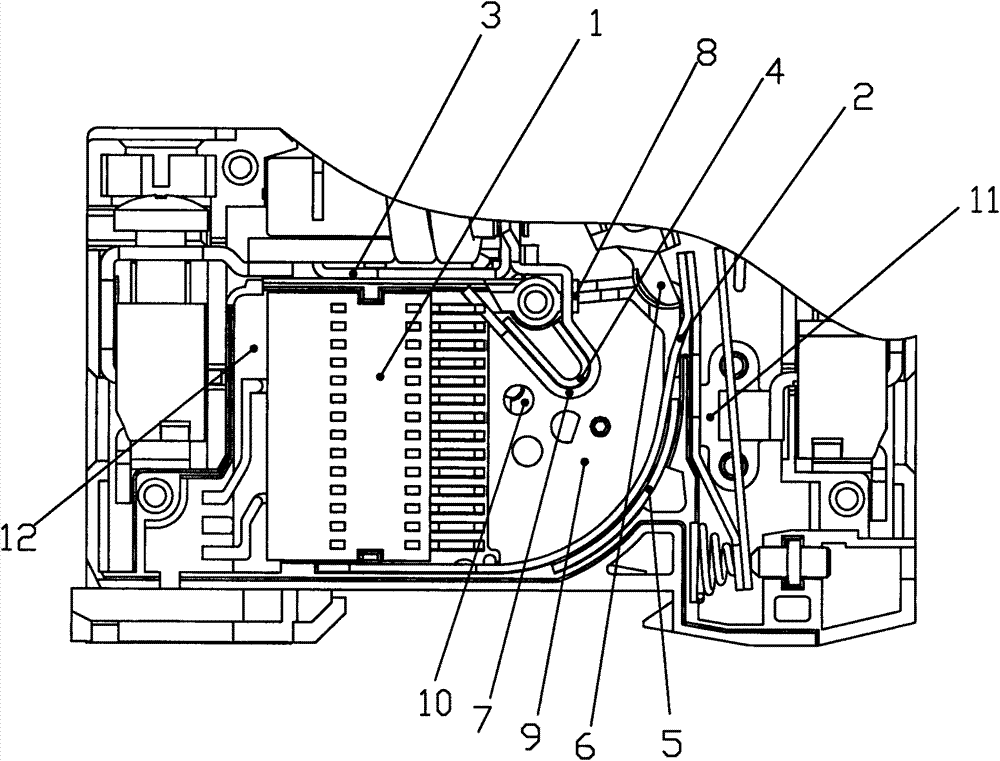

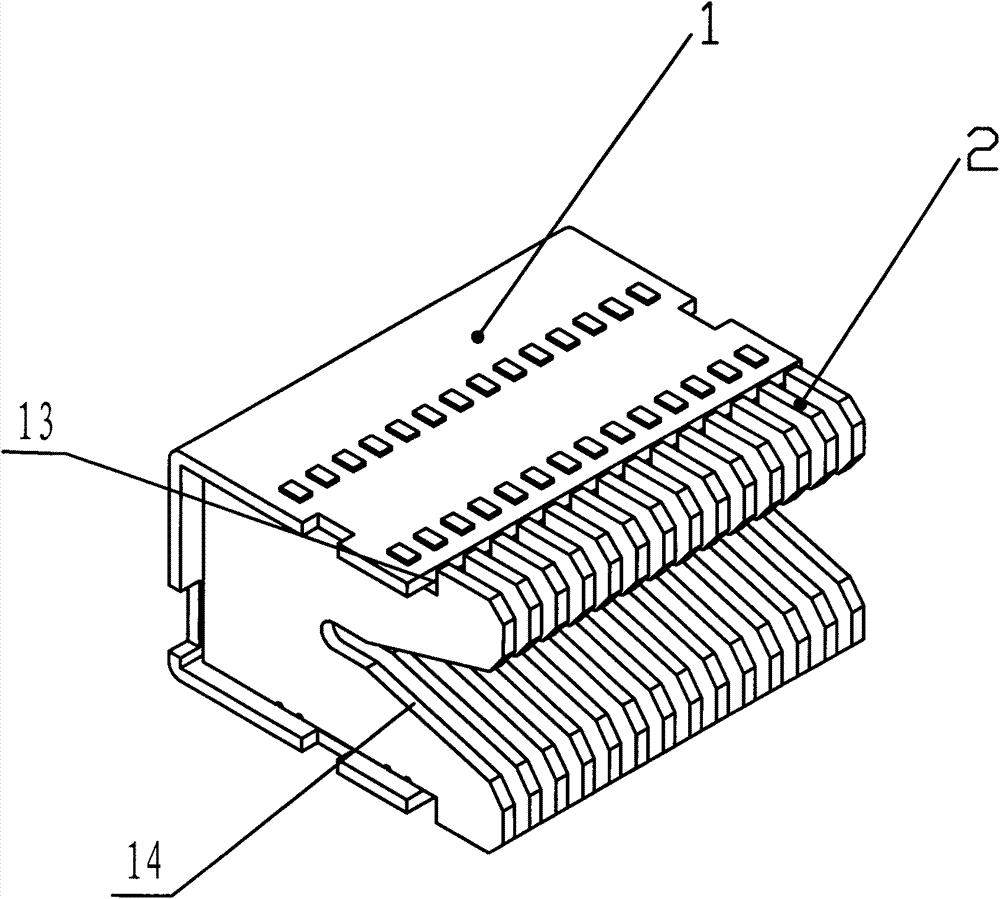

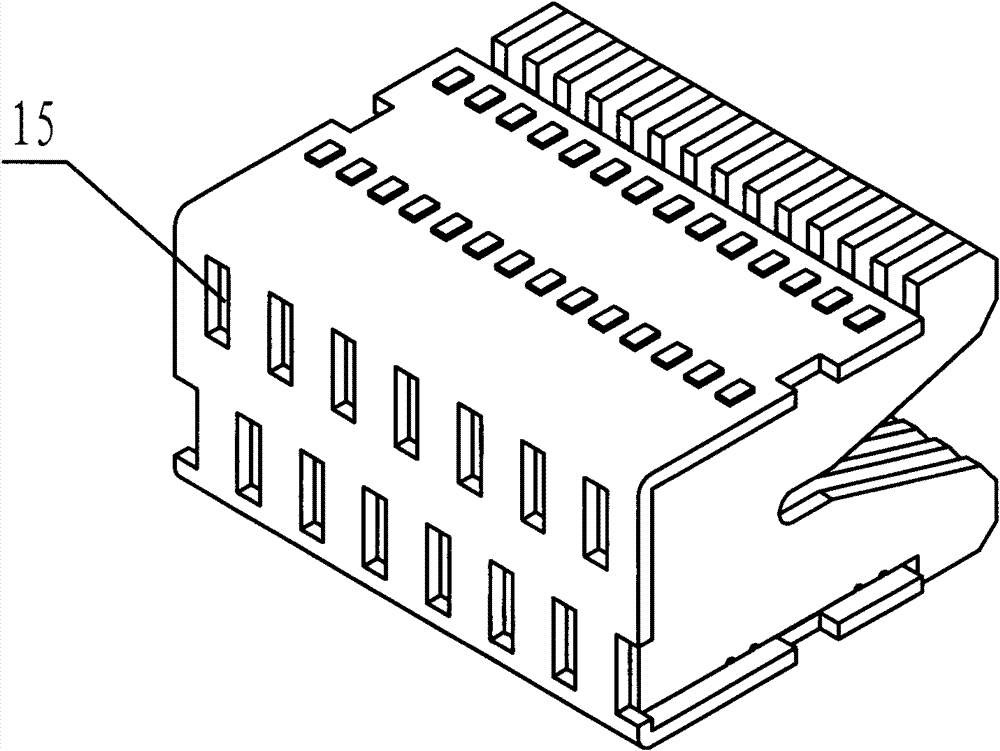

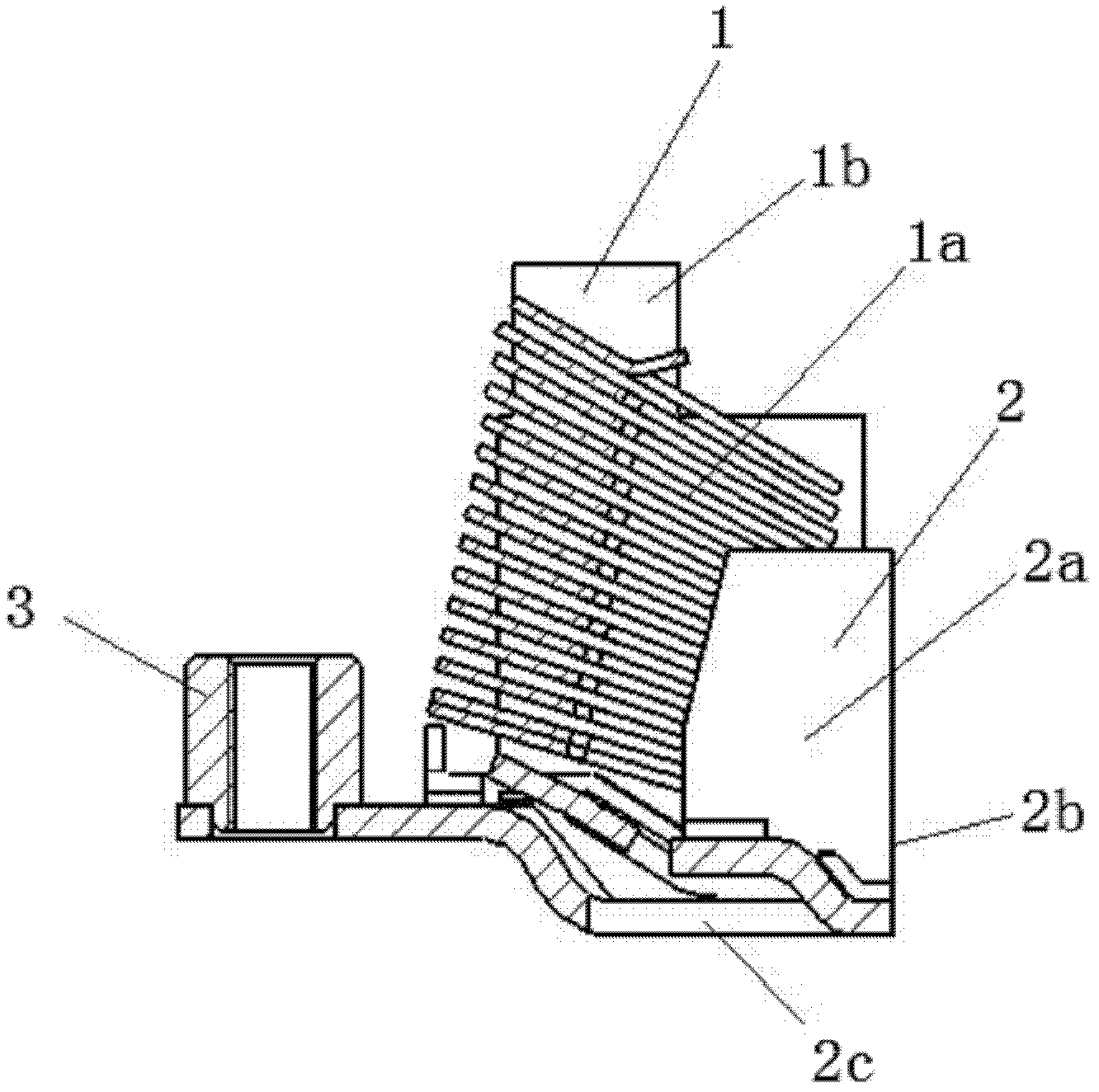

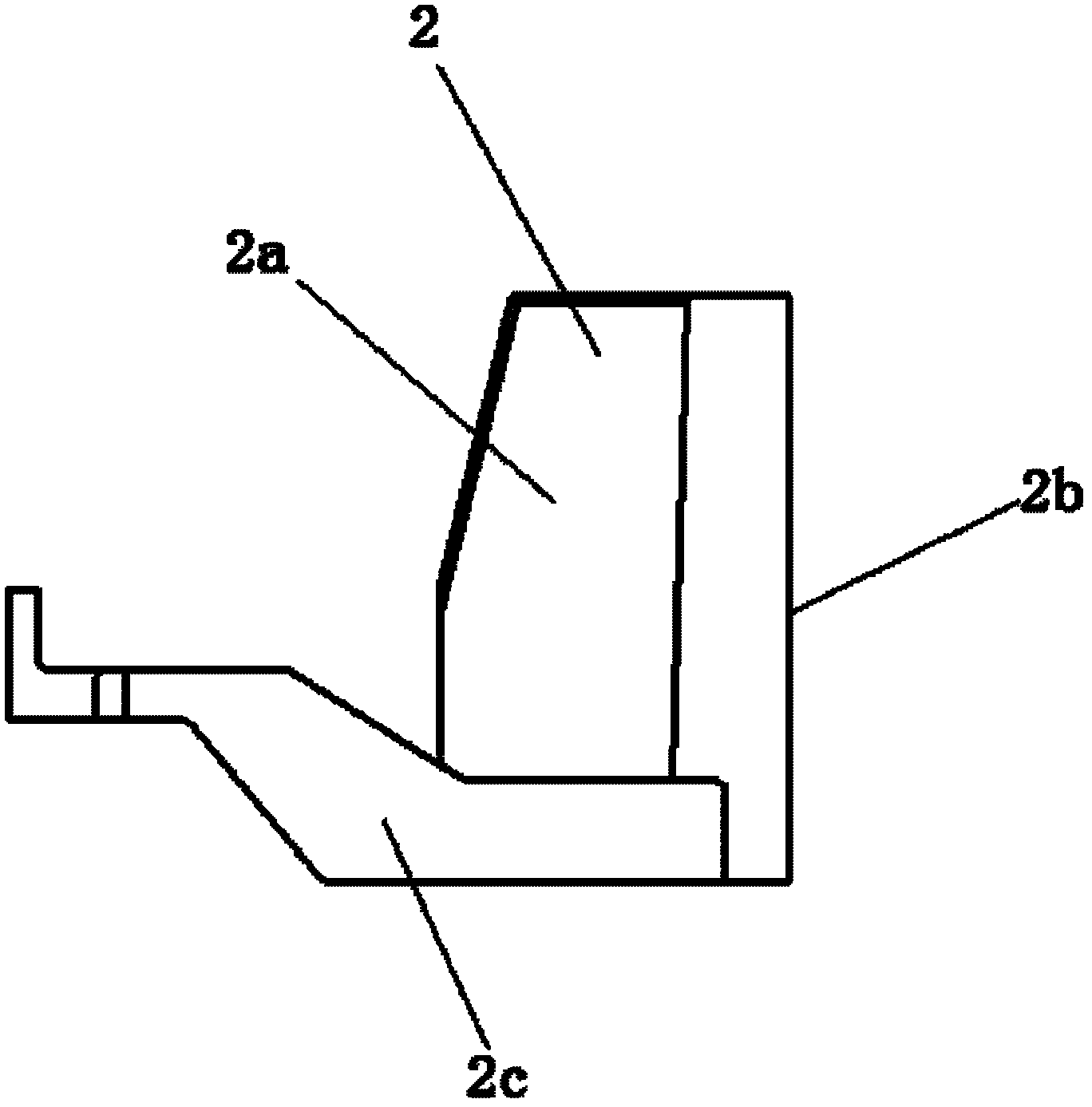

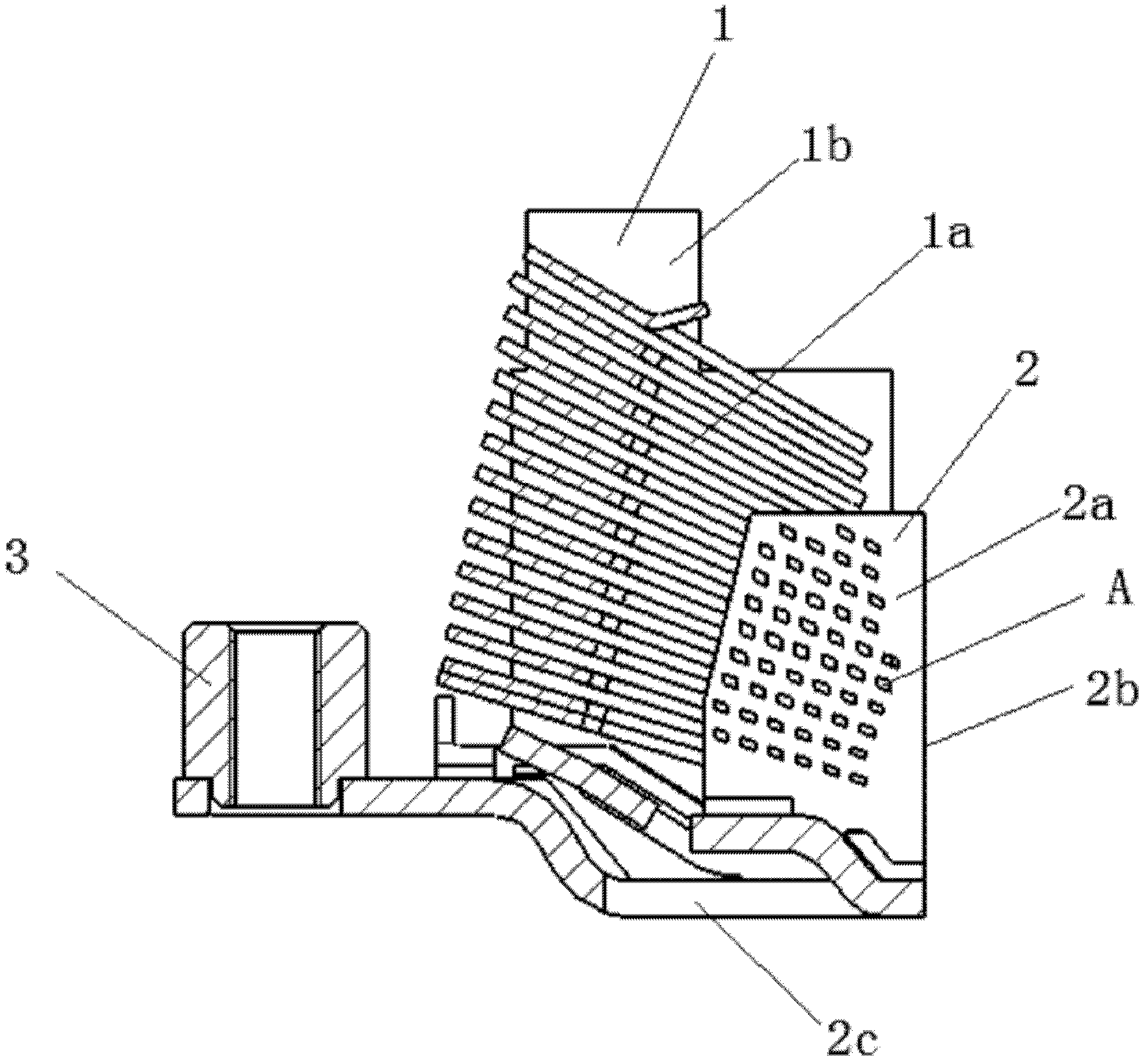

Arc blowing device for low-voltage circuit breaker

InactiveCN102427009ASpeed up repulsionSpeed up entryCircuit-breaking switch detailsEngineeringArc extinction

The invention discloses an arc blowing device for a low-voltage circuit breaker. A bracket is arranged at the lower part of an arc extinguishing chamber; a connecting end at the front end of a static contact can be pivotally connected with the bracket; two first grooves are respectively arranged at the left side and the right side of the rear part of the bracket; magnetism-increasing parts are arranged on the first grooves; the bottom surfaces of the magnetism-increasing parts are fixedly arranged in the first grooves; the side surfaces of the magnetism-increasing parts upwards extend to the outer part of the arc extinguishing chamber; contact ends of a movable contact and the static contact are positioned between the side surfaces of the two magnetism-increasing parts or at the positions close to the front ends of the two magnetism-increasing parts; a connecting plate is arranged at the rear part of the bracket; a magnetic conducting part is arranged between the static contact and the intermediate section of the connecting plate and is also positioned below an arc extinguishing grid plate; the upper section of the magnetic conduction part extends into the arc extinguishing chamber and is parallel to the arc extinguishing grid plate at a clearance; the contact end of the static contact is inclined; the magnetism-increasing parts can be used for enhancing an arc blowing magnetic field and increasing the repelling-open speed of the static contact; and the magnetic conducting part can be used for centralizing a magnetic filed generated by the connecting plate at the electric arc to the part, so that the stay time of the electric arc at the contact is effectively reduced and the entrance of the electric arc into the arc extinguishing device is accelerated.

Owner:JIANGSU PHONO ELECTRIC

Arrangement for double break contact with electro-magnetic arc-blow

ActiveUS10236136B1Rapid inhibitionMinimizes formation of arcContact engagementsCircuit-breaking switch contactsHigh voltageArc blow

A high voltage switch system including a circuit interrupter having a first set of contacts in series with a first coil, which are in series with a second coil and a second set of contacts, the first coil wound around a first core and the second coil wound around a second coil such that upon an arc forming between the contacts of the first and second contacts, the arcs are motivated in opposite directions to be extinguished.

Owner:CARLING TECH

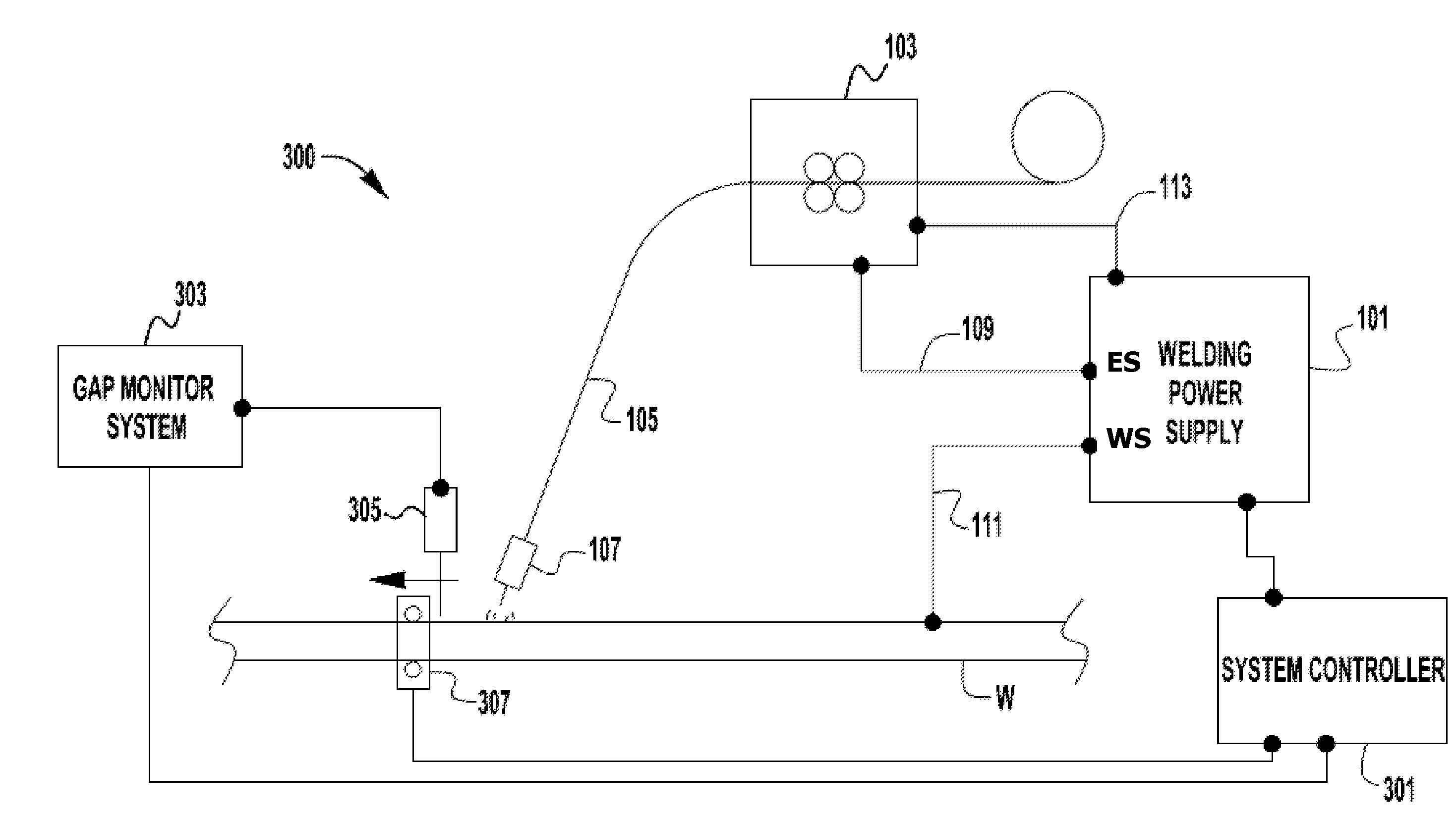

System and method for ground switching

The invention described herein generally pertains to a system and method related to reducing magnetic arc blow and steering the arc with two or more ground connections on the workpiece. The invention employs an AC switch component that is configured to activate one of the two or more ground connections to complete an electrical connection via the arc between the electrode and the workpiece. The activated ground connection can be used to counteract a buildup of magnetic field due to arc blow. Moreover, AC switch component can be configured to manipulate a direction of an arc based on activated a ground connection. In addition, AC switch component can oscillate between two or more ground connections to agitate a puddle formed by an electrode to release gas from the puddle and reduce porosity of a resulting weld.

Owner:LINCOLN GLOBAL INC

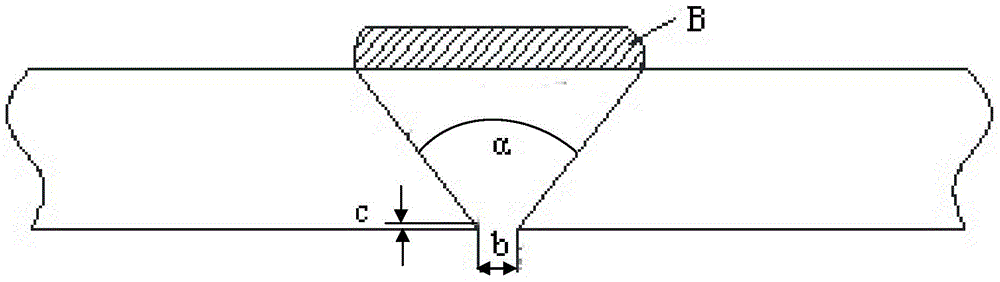

Titanium pipe welding process of seawater lift pump system

InactiveCN104084672AAvoid absorptionAvoid it happening againArc welding apparatusWelding/soldering/cutting articlesSocial benefitsTitanium

The invention relates to a titanium pipe welding process of a seawater lift pump system. The titanium pipe welding process comprises the following steps of step 1, selecting the closed welding environment; step 2, cleaning welds of a titanium pipe and welding wires to be utilized through the acetone before the titanium pipe is assembled; step 3, performing the equal wall thickness V-shaped groove abutting joint on the titanium pipe, performing alignment on a pipeline and adopting a grinding or machining mode during groove machining, wherein the angle of a groove is 50 to 70 degrees, a root gap is 2 to 4 mm, and the blunt edge is 0 to 1 mm; step 4, implementing back side protection and drag covert protection after the assembly is achieved, wherein the 99.999% high-purity canned argon gas is selected to serve as the protection gas and the pressure is not less than 25 bar; step 5, performing welding in a two-person piecewise symmetric welding mode; step 6, performing arc blow-out and performing continuous protection through the protection gas until the surface temperature drops to below 100 DEG C. According to the titanium pipe welding process of the seawater lift pump system, the welding quality of the titanium pipe can meet the use requirements of the seawater lift pump system, the welding process is stable, the control is convenient, the practicability is high, and the large economic and social benefits can be produced.

Owner:CSSC GUANGZHOU WENCHONG DOCKYARD CO LTD

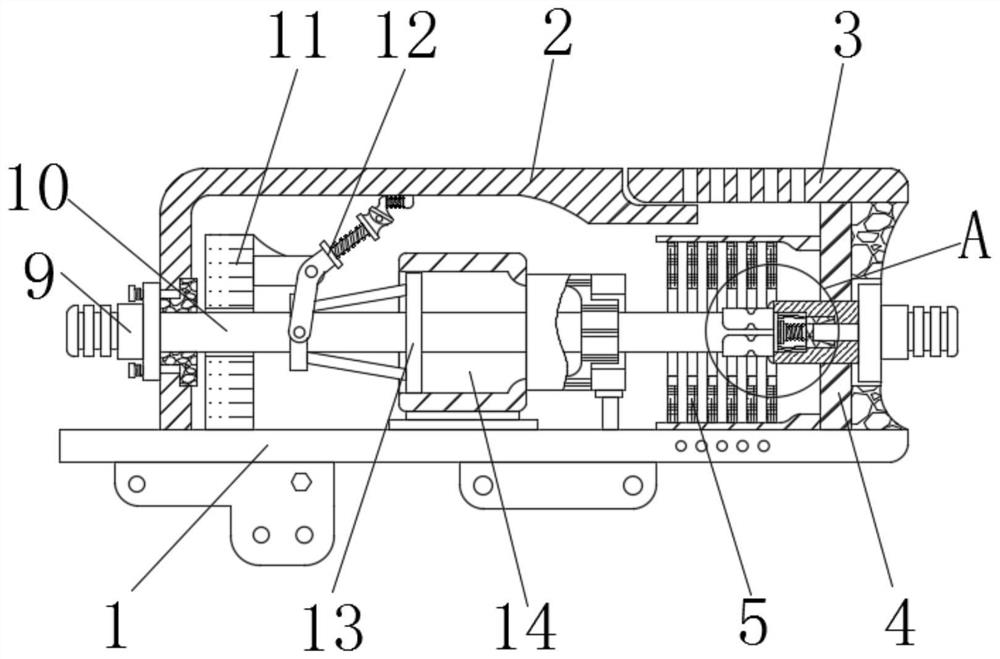

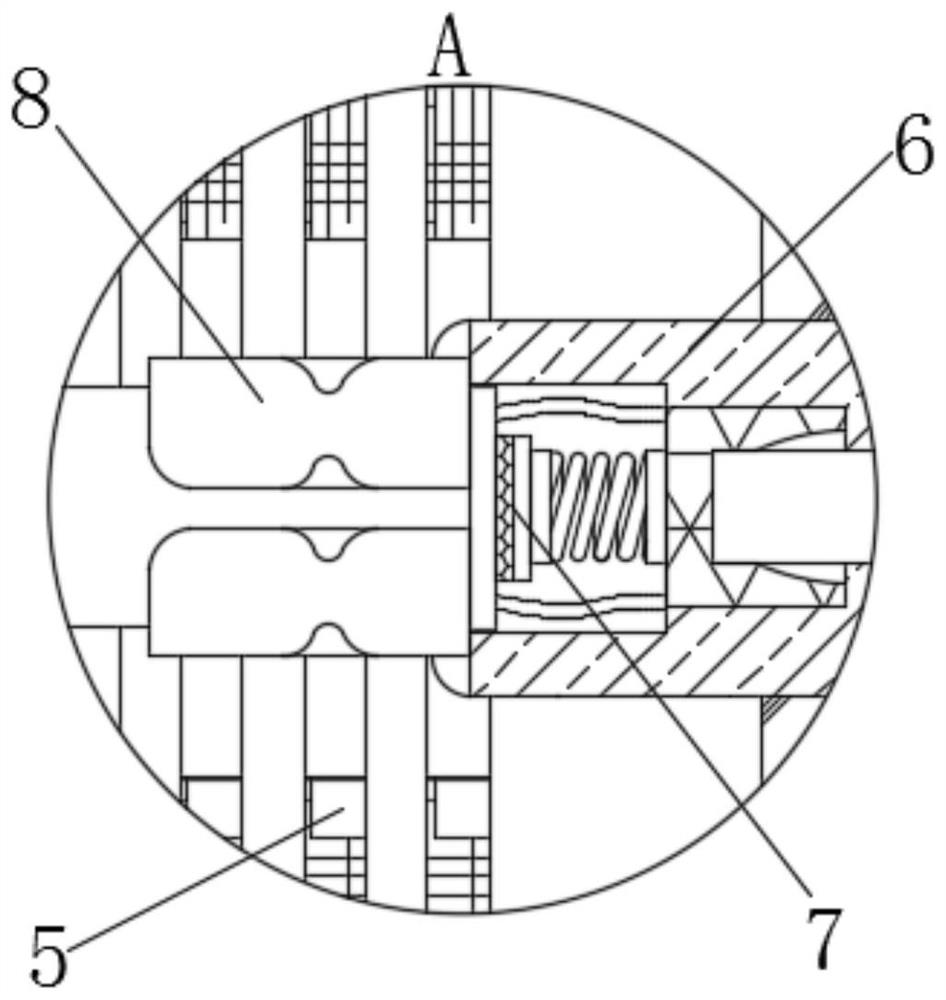

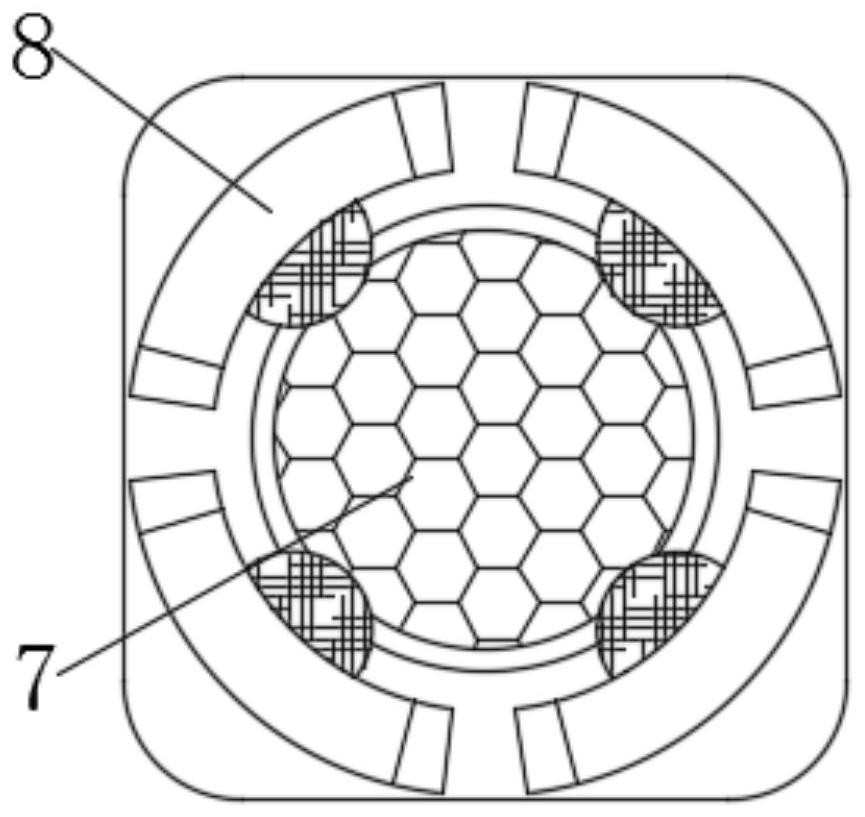

Arc blowing and extinguishing device of switch circuit breaker

InactiveCN112908752AAvoid accidentsImprove reliabilityElectric switchesActive componentElectric power equipment

The invention relates to the technical field of power equipment, and discloses an arc blowing and extinguishing device of a switch circuit breaker, which comprises a mounting seat. A sliding seat is arranged above the left side of the mounting seat, a fixed seat is arranged above the right side of the mounting seat, an insulating layer is arranged at the right part of the inner side of the fixed seat, and an arc chute is fixedly connected to the left side of the insulating layer. A static contact penetrates through the middle of the insulating layer, a limiting plate is arranged in the static contact, a contact piece is arranged on the left side of the limiting static contact, a binding post is arranged at the left end of the sliding seat, a movable contact pin is fixedly connected to the right end of the binding post, and a fixing frame is arranged outside the movable contact pin. According to the arc blowing and extinguishing device of the switch circuit breaker, airflow generated in the arc blowing device passes through the gap between the movable contact pin and the supporting frame, is excited by the electromagnetic coil and then longitudinally blows over the circuit breaking position, compared with a traditional circuit breaker, the arc blowing mechanism is not an active component, the reliability of equipment is greatly improved, and meanwhile the arc extinguishing effect can be effectively improved by longitudinally blowing air to the arc extinguishing gate.

Owner:南京众川家具有限公司

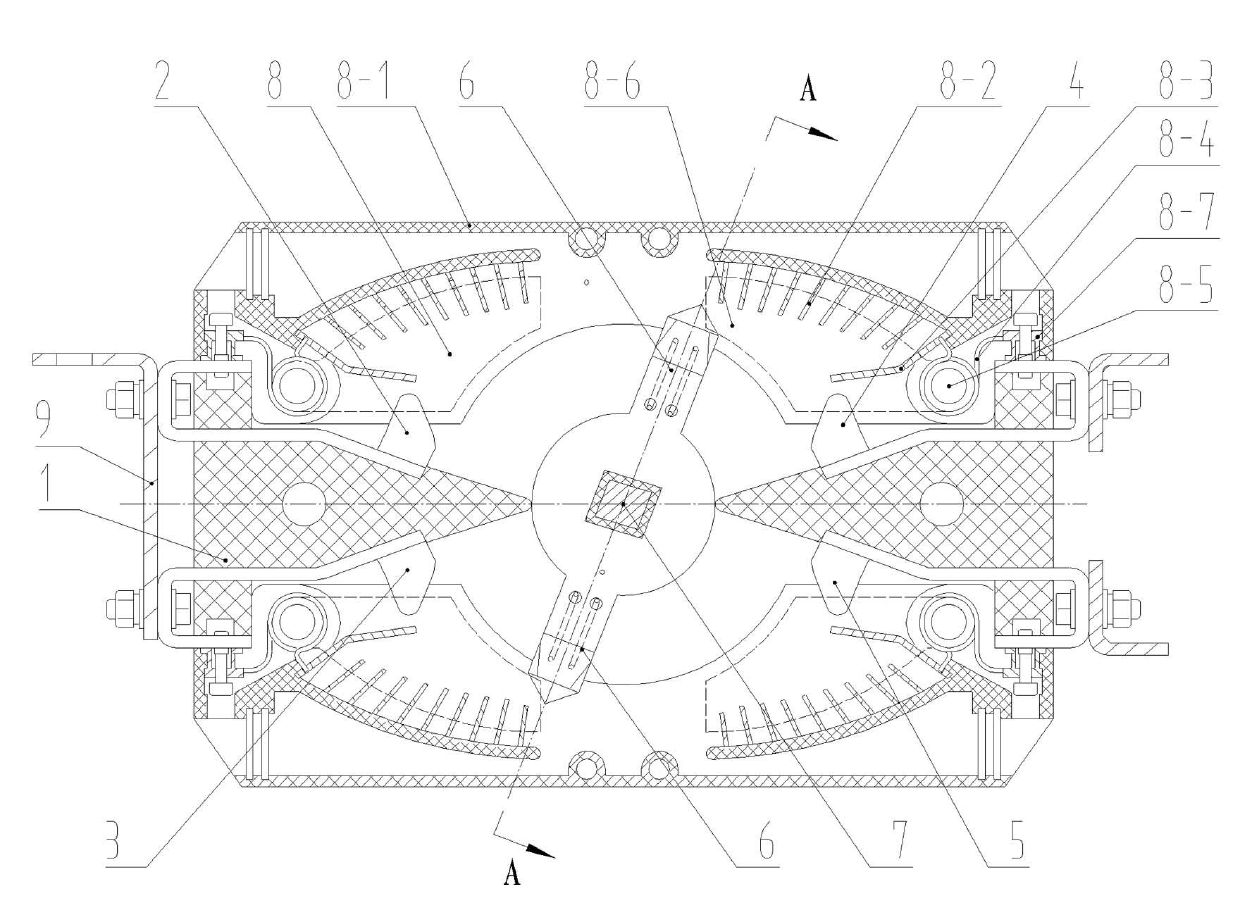

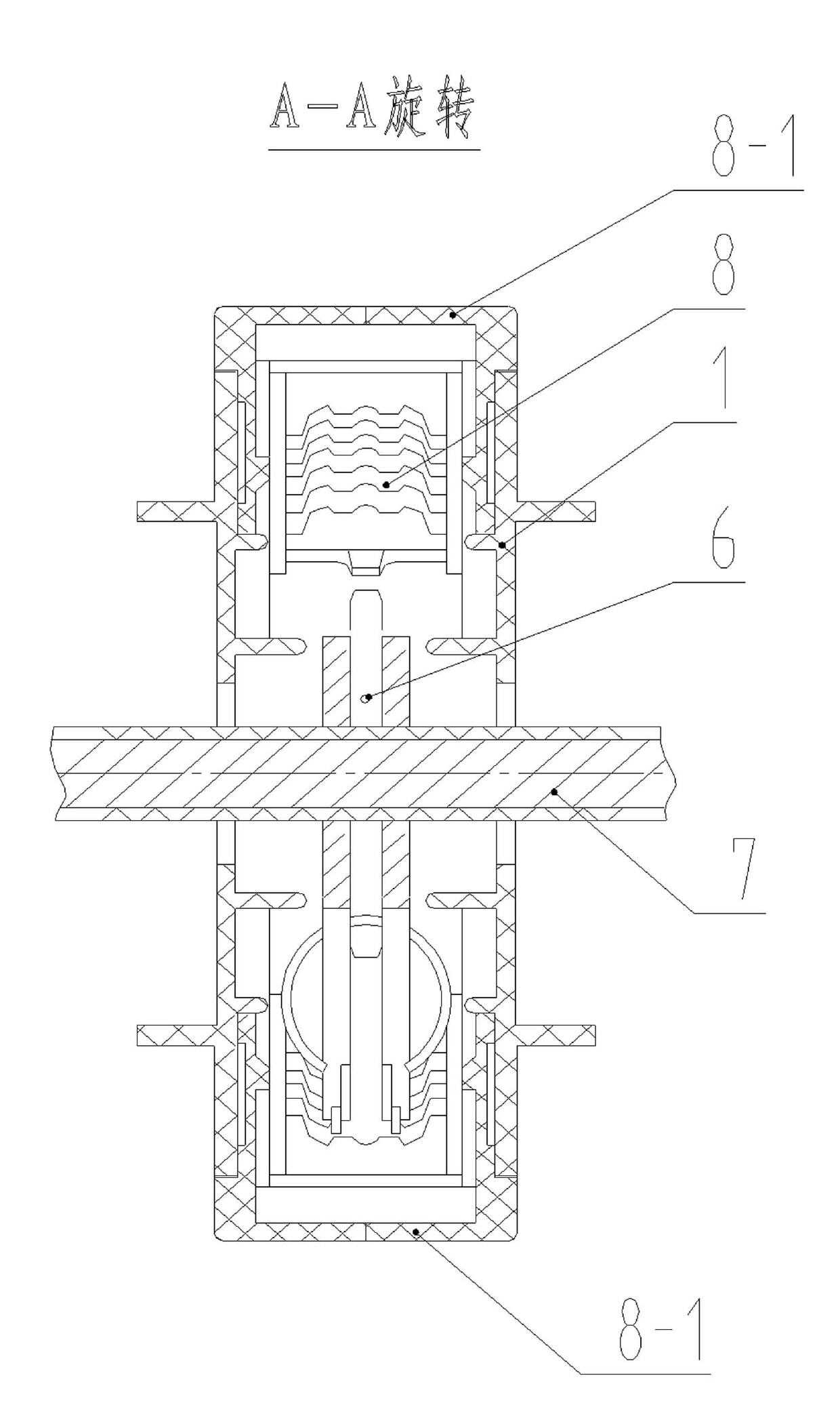

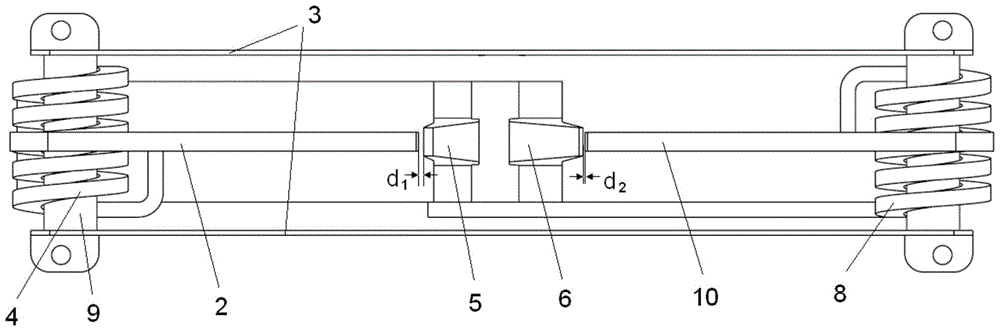

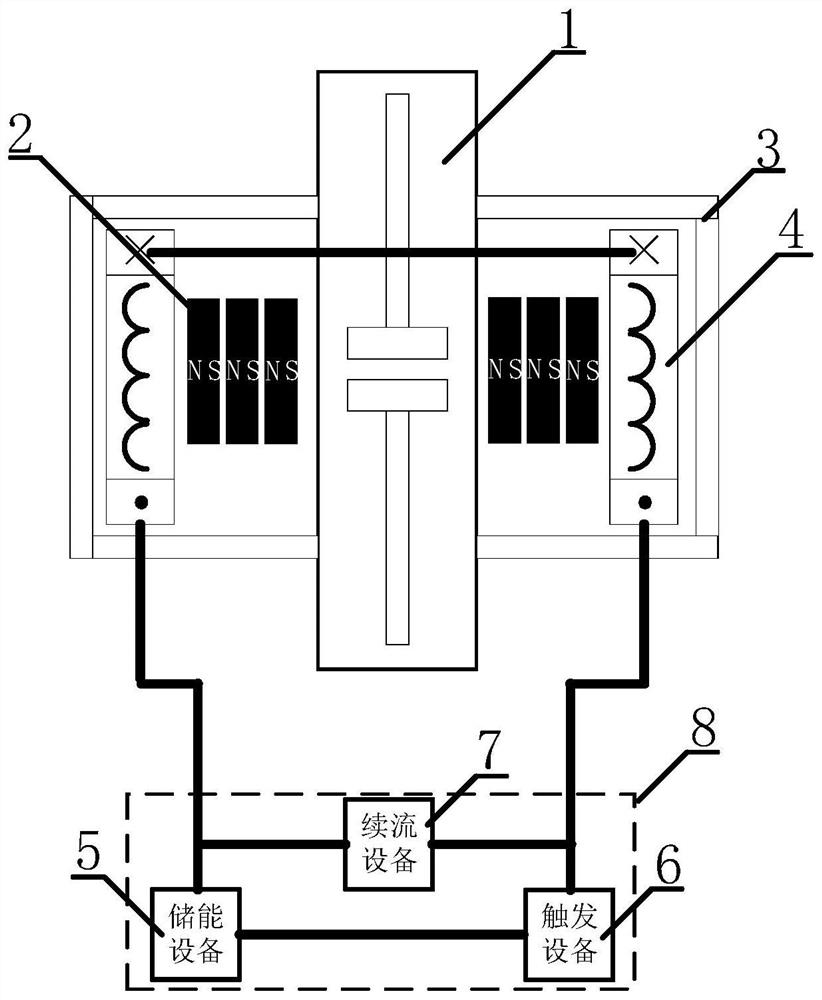

A DC circuit breaker magnetic blowing device

ActiveCN104124118BMove quicklyImprove breaking capacityElectric switchesCircuit-breaking switch detailsDc circuit breakerBreaking capacity

The invention relates to a magnetic blowing device for a DC circuit breaker, which includes a static end arc striking angle, a magnet plate, a static end magnetic blowing coil, a static contact, a moving contact, a wire, a moving end magnetic blowing coil, an iron core, and a moving end arc angle. An iron core is coaxially placed in the magnetic blowing coil at the static end, and its two ends are respectively connected with the arc striking angle and the static contact at the static end; an iron core is placed coaxially in the magnetic blowing coil at the moving end, and its two ends are connected with the The end arc angle and the connection with the moving contact through the wire; the two ends of the magnet plate are closely matched with the same side end faces of the two iron cores; the axial end faces of the static end magnetic blowing coil and the moving end magnetic blowing coil do not exceed the iron core same-side end face. Advantages: 1. The direction of the arc blowing magnetic field can automatically change with the change of the main circuit current, so the safety and reliability are high; 2. The arc blowing magnetic field is concentrated in the fracture area of the dynamic and static contacts and the area near the arc strike angle, which is effective It is conducive to the rapid movement of the arc root, thereby driving the arc to quickly enter the arc extinguishing chamber, and improving the breaking capacity of the circuit breaker.

Owner:中国船舶重工集团公司第七一二研究所

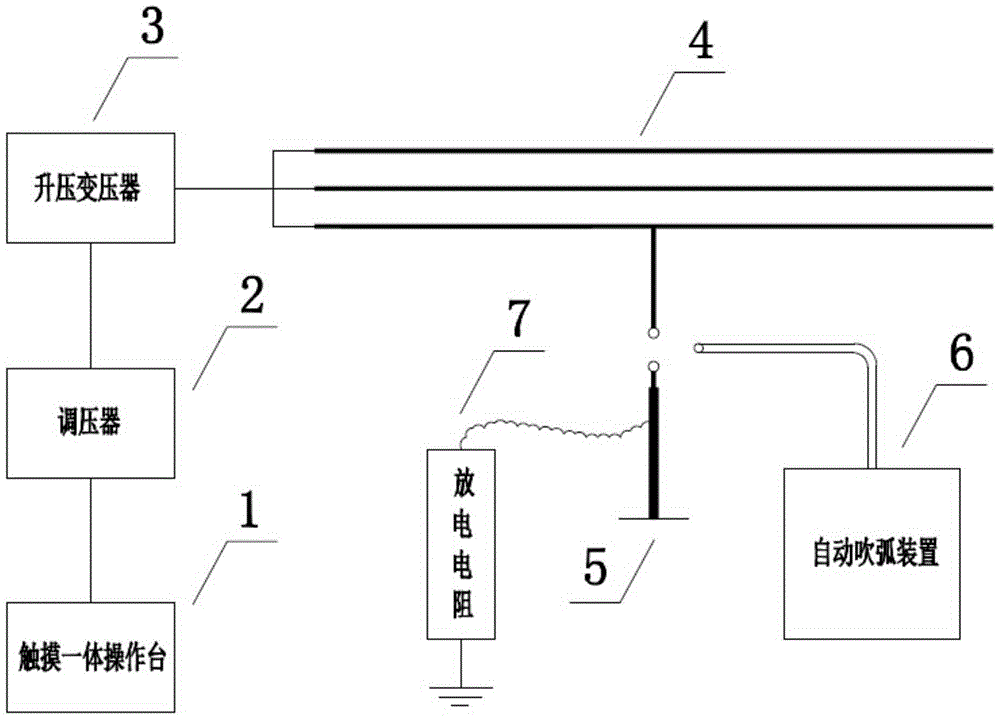

High-voltage discharge demonstration system and method

The invention relates to a high-voltage discharge demonstration system and method. The system comprises a touch integrated operation table, a voltage regulator, a boosting transformer, a simulation high-voltage wire, an arcing device, an arc blowing device and a grounded resistor; the voltage regulator is connected with the touch integrated operation table; the voltage regulator is connected with the voltage regulator; the simulation high-voltage wire is connected with the boosting transformer, and a discharge ball is arranged in the middle of a single phase of the simulation high-voltage wire; the arcing device comprises a push rod and a small ball arranged at the top end of the push rod, and the push rod is connected with the touch integrated operation table; the arc blowing device is connected with the touch integrated operation table; and the grounded resistor is connected with the small ball. By means of the method of the high-voltage discharge demonstration system, the high-voltage discharge phenomenon can be truly restored, and a student can personally experience the significance of the high-voltage safety distance; meanwhile, arcs are formed through the arcing device, and the injuries of high-temperature burns of the arcs can be visually observed. The system and the method are visual in effect, simple in device, novel in method and good in teaching treatment effect.

Owner:STATE GRID CORP OF CHINA +2

Lightning protection device

PendingCN111200238AArc thinningTo achieve the purpose of arc extinguishingSpark gap detailsOvervoltage arrestors using spark gapsElectric power systemGear wheel

The invention discloses a lightning protection device, which comprises a rotary arc extinguishing electrode, wherein the rotary arc extinguishing electrode comprises a ceramic shell; a transition electrode is fixedly inserted into the top of a rotary connecting rod; the rotary connecting rod is located in the ceramic shell and is fixedly sleeved with a rotary matching gear; the rotary matching gear is movably matched with telescopic racks arranged on the two sides; fixing plates extruding an air bag on the two sides are communicated with an air leakage ring through hollow connecting rods; theair leakage ring is communicated with an air passage of the rotary connecting rod through a passage formed inside; an arc blowing channel is formed in the transition electrode; a plurality of arc blowing holes are respectively formed in two ends of the transition electrode; and a pair of bimetal isolation sheets are fixedly mounted in the air passage of the rotary connecting rod. According to thelightning protection device, rapid extinguishing of electric arcs is achieved in a mixed arc extinguishing mode, the safety of an electric power system is guaranteed, manual intervention and an external power source are not needed, and the device is energy-saving, environmentally friendly, intelligent, practical and suitable for being widely popularized in the electric power system.

Owner:安徽英驰电气科技有限公司

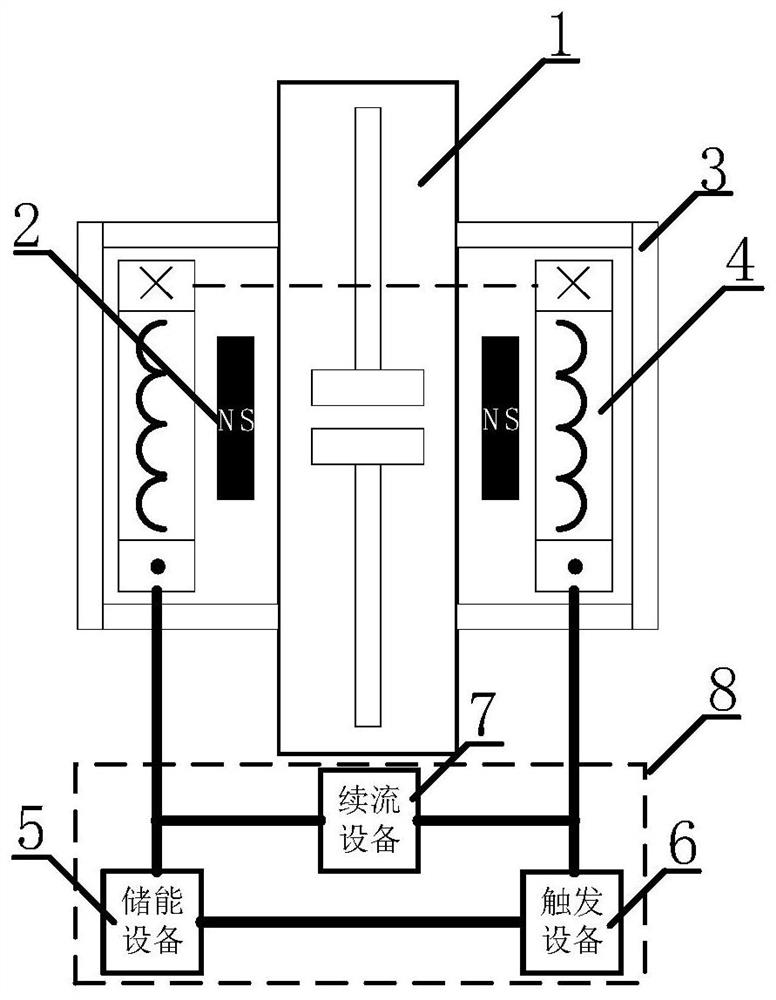

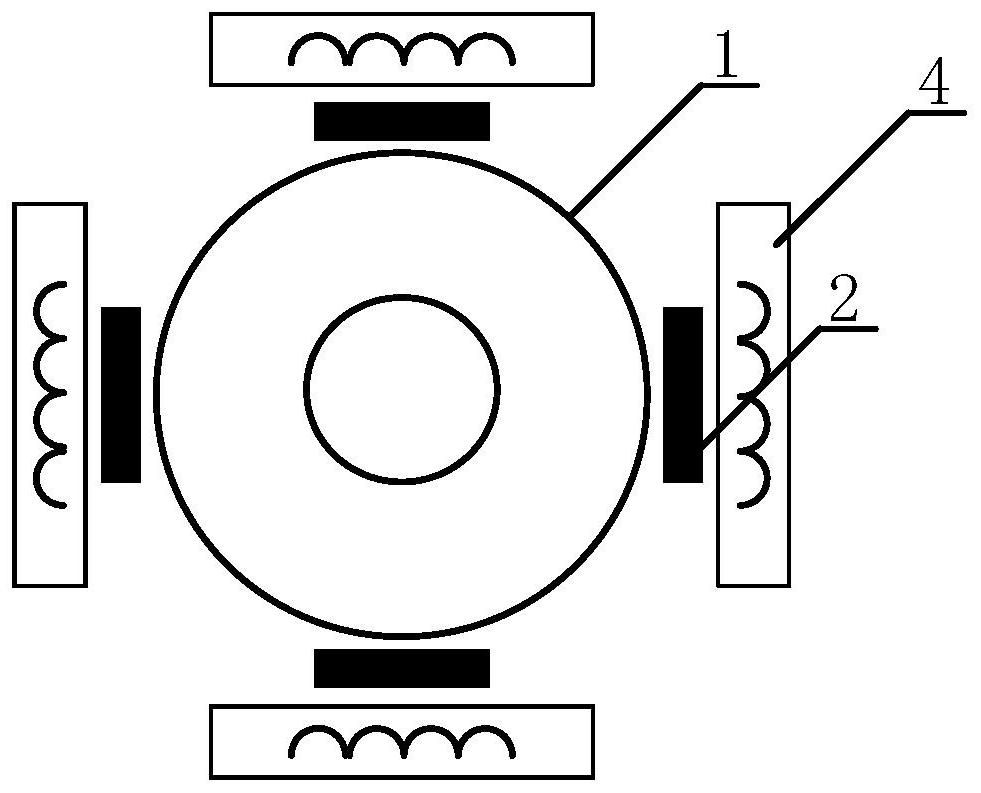

Device for increasing switching arc voltage and control method thereof

ActiveCN112420443AMove quicklyElongated lengthHigh-tension/heavy-dress switchesAir-break switchesArc extinctionElectrical current

The invention provides a device for increasing switching arc voltage and a control method thereof. The device comprises a vacuum arc-extinguishing chamber, permanent magnets, arc-blowing coils and anarc-blowing loop, a switch fracture is arranged in the vacuum arc-extinguishing chamber, the switch fracture comprises a moving contact and a static contact, and an arc voltage is generated when the moving contact and the static contact are separated; the permanent magnets are symmetrically arranged on two sides of the vacuum arc-extinguishing chamber; the arc blowing coils are symmetrically arranged on the two sides of the vacuum arc-extinguishing chamber, are arranged on the outer sides of the permanent magnets and are connected in series; and the arc blowing loop is connected with the arc blowing coils in parallel, and provides currents for the arc blowing coils during working so as to improve the arc voltage.

Owner:NR ELECTRIC CO LTD +1

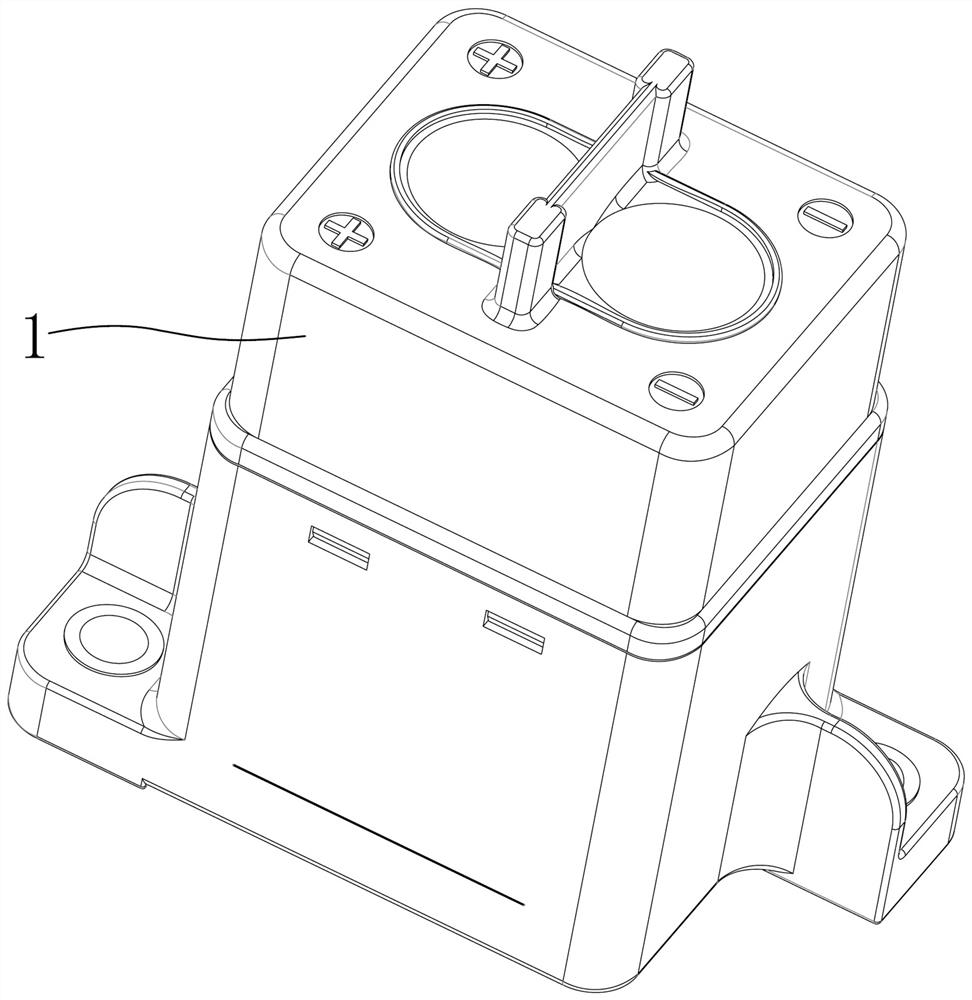

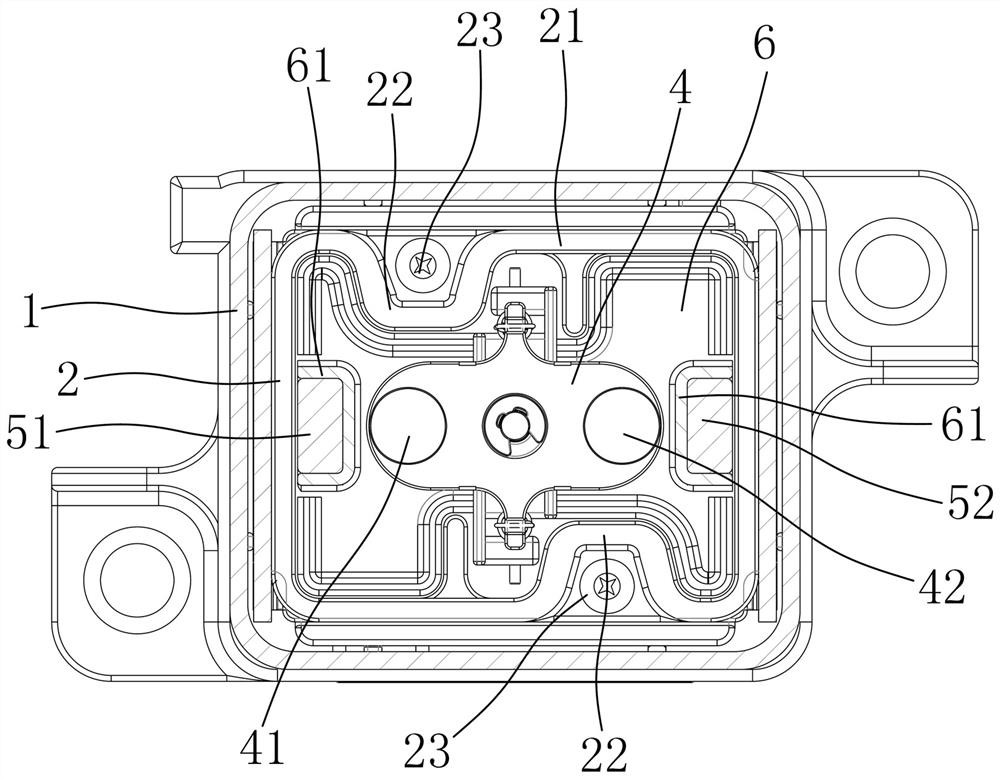

High-efficiency arc extinguishing relay

PendingCN111755285AImprove arc extinguishing effectElectromagnetic relay detailsEngineeringStructural engineering

The invention aims to provide the high-efficiency arc extinguishing relay which is better in arc extinguishing effect and enables an electric arc not to be liable to rebound to a movable contact and astatic contact after the arc hits the inner wall of an insulating cover. In order to achieve the purpose, the invention adopts the following technical scheme that the relay comprises an outer shell,wherein an insulating cover and a yoke plate are arranged in the outer shell; the insulating cover and the yoke plate form a cavity for accommodating a moving contact and a static contact; the movingcontacts comprise a left moving contact and a right moving contact which are fixed at the left end and the right end of the moving reed; the static contacts comprise a left static contact corresponding to the left moving contact and a right static contact corresponding to the right moving contact, and magnetic steel used for arc blowing of electric arcs generated by breaking of the moving contactand the static contact is arranged in the cavity.

Owner:ZHEJIANG YINGLUOHUA NEW ENERGY TECH CO LTD

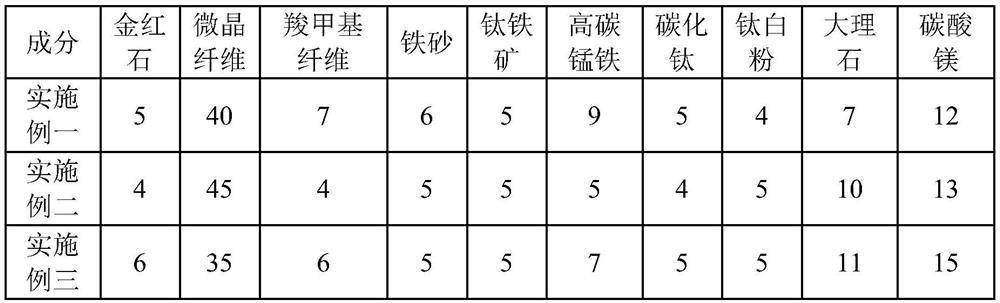

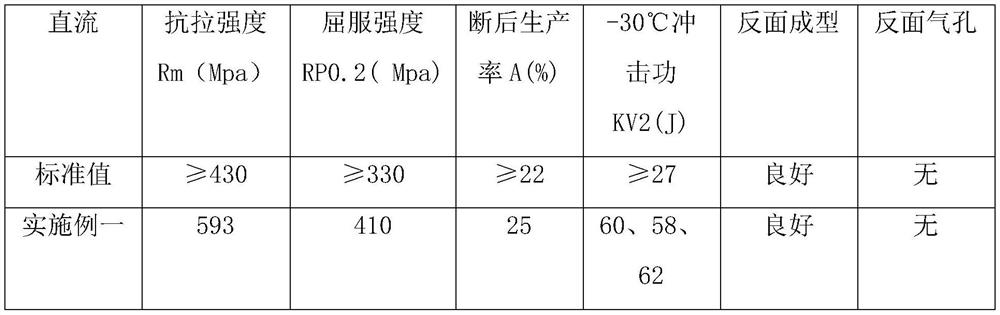

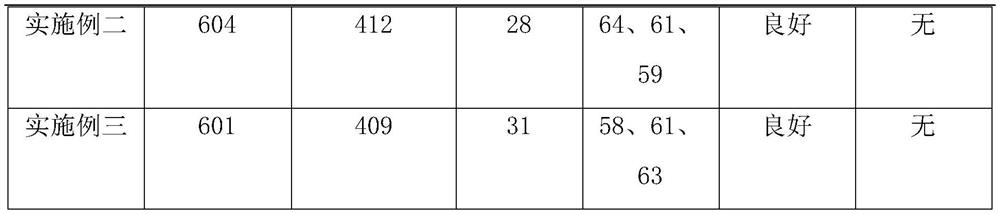

Alternating-current and direct-current dual-purpose high-blowing-force cellulose welding rod

ActiveCN112958939AIncrease arc blowing forceGuaranteed mechanical propertiesWelding/cutting media/materialsSoldering mediaCelluloseFiber

The invention provides an alternating-current and direct-current dual-purpose high-blowing-force cellulose welding rod which comprises a welding core and a coating, and the coating comprises the following components in parts by weight, 2-9 parts of rutile, 30-55 parts of microcrystalline fibers, 3-9 parts of carboxymethyl fibers, 3-9 parts of iron sand, 3-9 parts of ilmenite, 3-12 parts of high-carbon ferromanganese, 2-7 parts of titanium carbide, 2-7 parts of titanium dioxide, 5-15 parts of marble and 10-17 parts of magnesium carbonate. The cellulose welding rod can meet the outdoor operation welding requirements of large long-distance pipelines, petroleum pipelines and the like, slag removal is easy, welding bead forming is attractive, welding arc blowing force and single-face welding double-face forming are guaranteed, the mechanical property of welding seams is excellent, the cellulose welding rod can be used for welding of the large long-distance pipelines, the petroleum pipelines and the like, and the welding quality can be guaranteed.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

Hot wire TIG welding gun with three tungsten electrodes

InactiveCN107414263ANon-stop deliveryIncrease costCooled electrode holdersElectrode accessoriesAutomatic controlFeeding tube

The invention belongs to the field of automatic control of welding, mainly relates to a TIG welding gun, and discloses a hot wire TIG welding gun with three tungsten electrodes. The hot wire TIG welding gun aims to solve the problem that arc power of traditional TIG welding is limited due to the limited current loading capacity. The hot wire TIG welding gun comprises a hollow gun body, one side of the gun body is provided with a gun head, the other side of the gun body is provided with a gun tail, a conductive nozzle is arranged at the gun head, a wire feeding tube and the multiple tungsten electrodes are arranged in the gun body, one end of the wire feeding tube and one ends of the tungsten electrodes extend from the inner part of the gun body to the outside of the conductive nozzle, the central axis of the wire feeding tube is parallel to the central axes of the tungsten electrodes, and the tungsten electrodes are uniformly distributed in the circumferential direction of the wire feeding tube. According to the hot wire TIG welding gun, the technological problems such as arc blow and hot wire feeding position fluctuation generated during welding by a TIG welding device adopting external resistors to heat and preheat welding wires are effectively solved.

Owner:JIANGSU ASWEMET PRECISION TECH CO LTD

Arc extinguishing device of circuit breaker

InactiveCN103500692AShorten exercise timeRaise split arcCircuit-breaking switch detailsRight-hand ruleEngineering

The invention discloses an arc extinguishing device of a circuit breaker, and relates to the technical field of the circuit breaker. The arc extinguishing device is arranged in a circuit breaker casing, and comprises an arc extinguishing cover. The device is characterized in that the arc extinguishing cover is made of a three-surface enclosure vulcanized paper sheet with enlarged integral size, the interior of the arc extinguishing cover is provided with 14 arc striking plates which are used for separating electric arcs from cooling the electric arcs, the wire inlet end of the arc extinguishing device also comprises a connecting plate, the connecting plate is a triangular loop meeting a right hand rule, and each arc striking plate is provided with a Y-shaped opening with enlarged size to facilitate the electric arcs to enter. The arc extinguishing device has the advantages that the capability of separating the electric arcs from cooling the electric arcs is improved, the connecting plate at the wire inlet end adopts the triangular loop design meeting the right hand rule, a strong arc blowing magnetic field is always formed for alternating current, the electric arcs are forced to quickly enter an arc extinguishing chamber, the movement time of the electric arcs is shortened, and the arc extinguishing effect is greatly improved; the structure is simple, the economy is good, and the opening capability of the circuit breaker is obviously improved.

Owner:CNC ELECTRIC GRP

Arc-extinguishing device of breaker

InactiveCN102522276AImprove job stabilitySolve burstCircuit-breaking switch detailsArc extinctionArc blow

The invention discloses an arc-extinguishing device of a breaker. The arc-extinguishing device comprises an arc extinguish chamber device and an arc insulating device. The arc insulating device includes two flash barriers; and the arc extinguish chamber device includes a plurality of arc-extinguishing grid plates that are arranged between the two flash barriers at a uniform interval. Besides, the arc-extinguishing device is characterized in that air dispersion holes that are in a latticed shape are opened on each of the flash barriers. According to the invention, local air pressures inside the arc-extinguishing device can be effectively reduced when a breaker is broken; and an arc blow-out effect can be enhanced. When the provided arc-extinguishing device is applied to a breaker, working stability of the breaker can be effectively improved and cost can be saved.

Owner:FORETECH ELEC APP JIANGSU CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com