Magnetic blow-out processing control method for consumable-electrode type pulse arc melting

A pulsed arc, processing control technology, applied in the direction of arc welding equipment, manufacturing tools, welding equipment, etc., can solve the problems of accelerated feeding speed, difficult response, and inability to prevent arc cutoff, so as to achieve the effect of preventing arc cutoff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

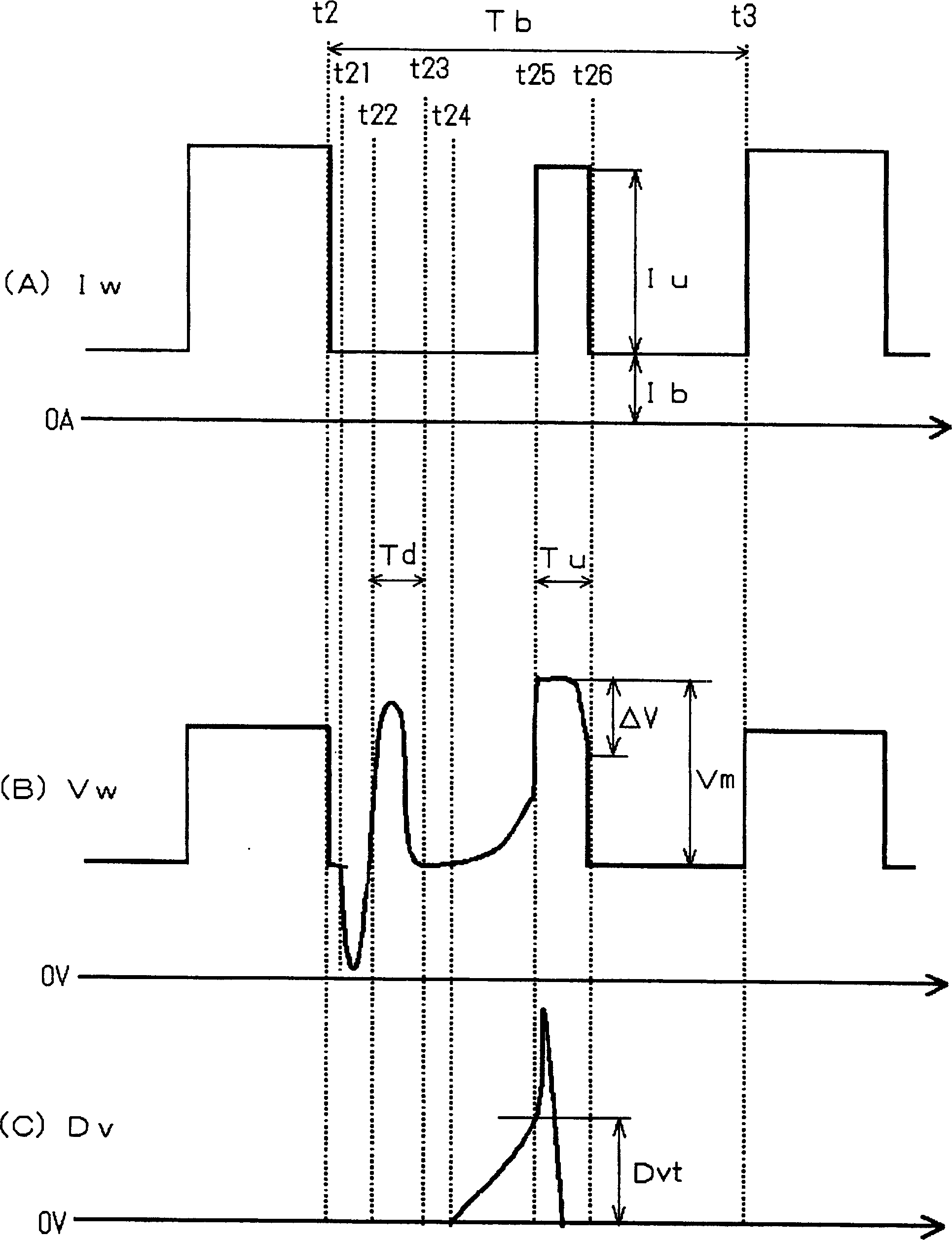

[0029] figure 1 It is a current-voltage waveform diagram showing the magnetic blowing treatment control method according to the embodiment of the present invention. This figure (A) shows the change with time of the welding current Iw, this figure (B) shows the change with time of the welding voltage Vw, and this figure (C) shows the welding voltage when the arc occurs in the basic period Tb immediately before the short circuit occurs The rate of rise of Vw Dv=dVw / dt changes with time. In this figure, the operations other than the basic period Tb from time t2 to t3 are the same as those described above. Figure 6 is the same as when it was used, and its description is omitted here. Hereinafter, the operation in the basic period Tb will be described with reference to this figure.

[0030] ① How to identify the occurrence of magnetic blowing

[0031] As shown in (B) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com