Starch noodle manufacturing apparatus

A technology for making a device and vermicelli, which is applied in the fields of food forming, food science, application, etc., can solve the problems of increased production cost, large labor participation, and high labor intensity, and achieves a system that improves uniformity, improves processing quality, and is simple and convenient to operate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

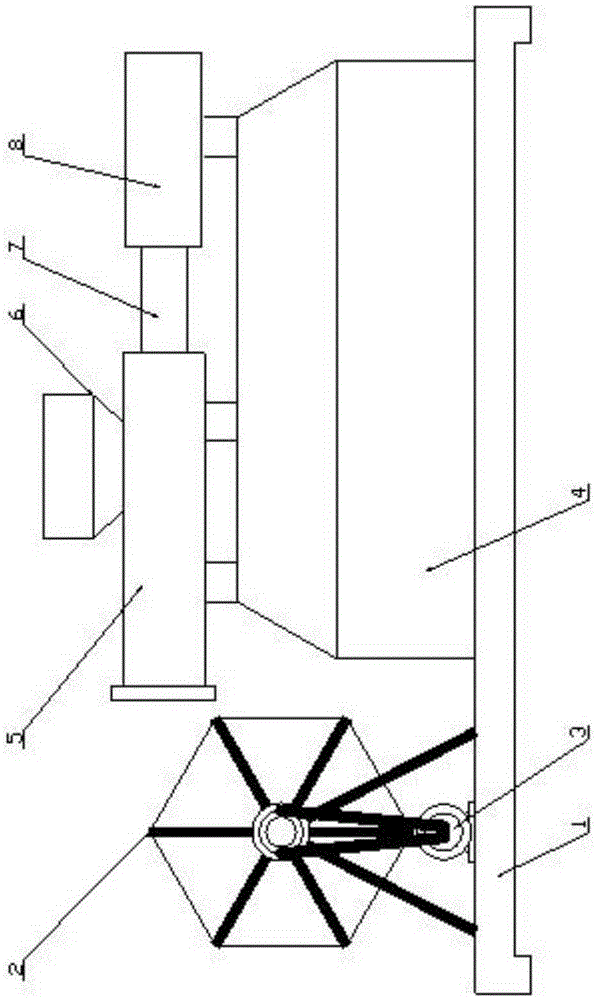

[0013] A device for making vermicelli, comprising a base 1, a winding wheel frame 2, a motor 3, a control box 4, a powder outlet cylinder 5, a material inlet 6, a hydraulic rod 7, and a hydraulic cylinder 8.

[0014] Such as figure 1 As shown, one end of the upper part of the base 1 is provided with a winding wheel frame 2, and the other end is provided with a control box 4. The bottom of the winding wheel frame 2 is provided with a power mechanism, and is connected with the power mechanism. Power mechanism, comprises motor 3, pulley, belt, described motor 3, one end of its main shaft cooperates and connects with the main shaft around wheel frame 2 by belt pulley, belt, and described control box 4, its top one end is provided with powder outlet cylinder 5 , the other end is provided with a hydraulic mechanism, the powder outlet cylinder 5 is provided with a material inlet 6 at one end of its upper part, and the powder outlet cylinder 5 is provided with an end cover with throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com