A stepless automatic adjusting device for die roll gap of vertical ring die straw briquetting machine

A straw briquetting machine, automatic adjustment technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of high labor intensity, affecting work efficiency, time-consuming, etc., to achieve effective adjustment and ensure forming extrusion pressure, reducing the effect of excessive wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

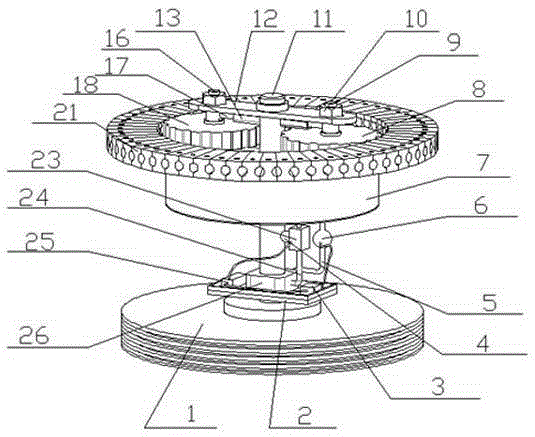

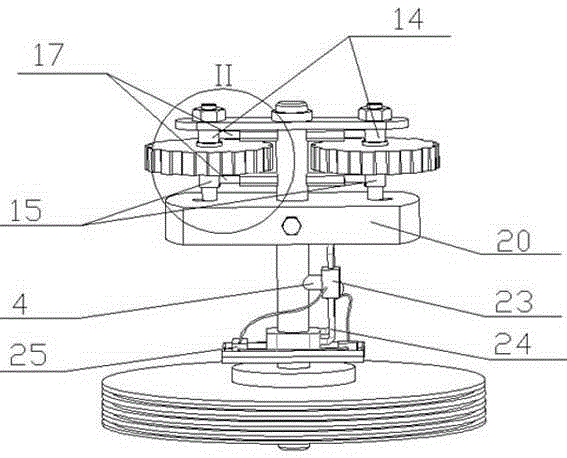

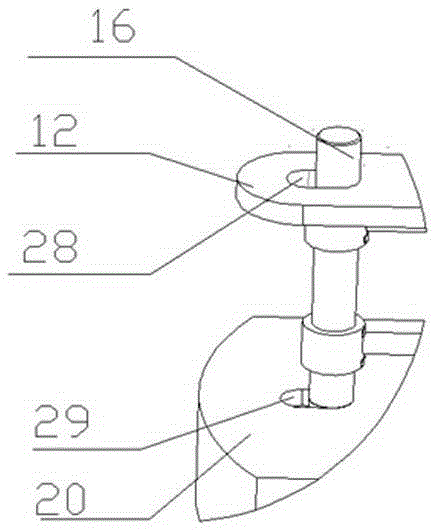

[0021] Such as Figures 1 to 7 As shown, a vertical ring die straw briquetting machine die roller gap stepless automatic adjustment device includes an upper platen 12, a grinding disc 20, an eccentric shaft A16, an eccentric shaft B9, a pressing roller A18, a pressing roller B8, and a vertical main shaft 11 , PLC25, intermediate relay 3, solenoid valve 23, small hydraulic pump 6, oil tank 26, branch oil pipe A24, branch oil pipe B5 and tray 2, the left and right sides of described upper platen 12 are respectively provided with upper chute 28, and described grinding disc The left and right sides of 20 are respectively provided with sliding grooves 29, the upper ends of the eccentric shaft A16 and the eccentric shaft B9 pass through the upper sliding grooves 28 respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com