Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

172results about "Cooled electrode holders" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

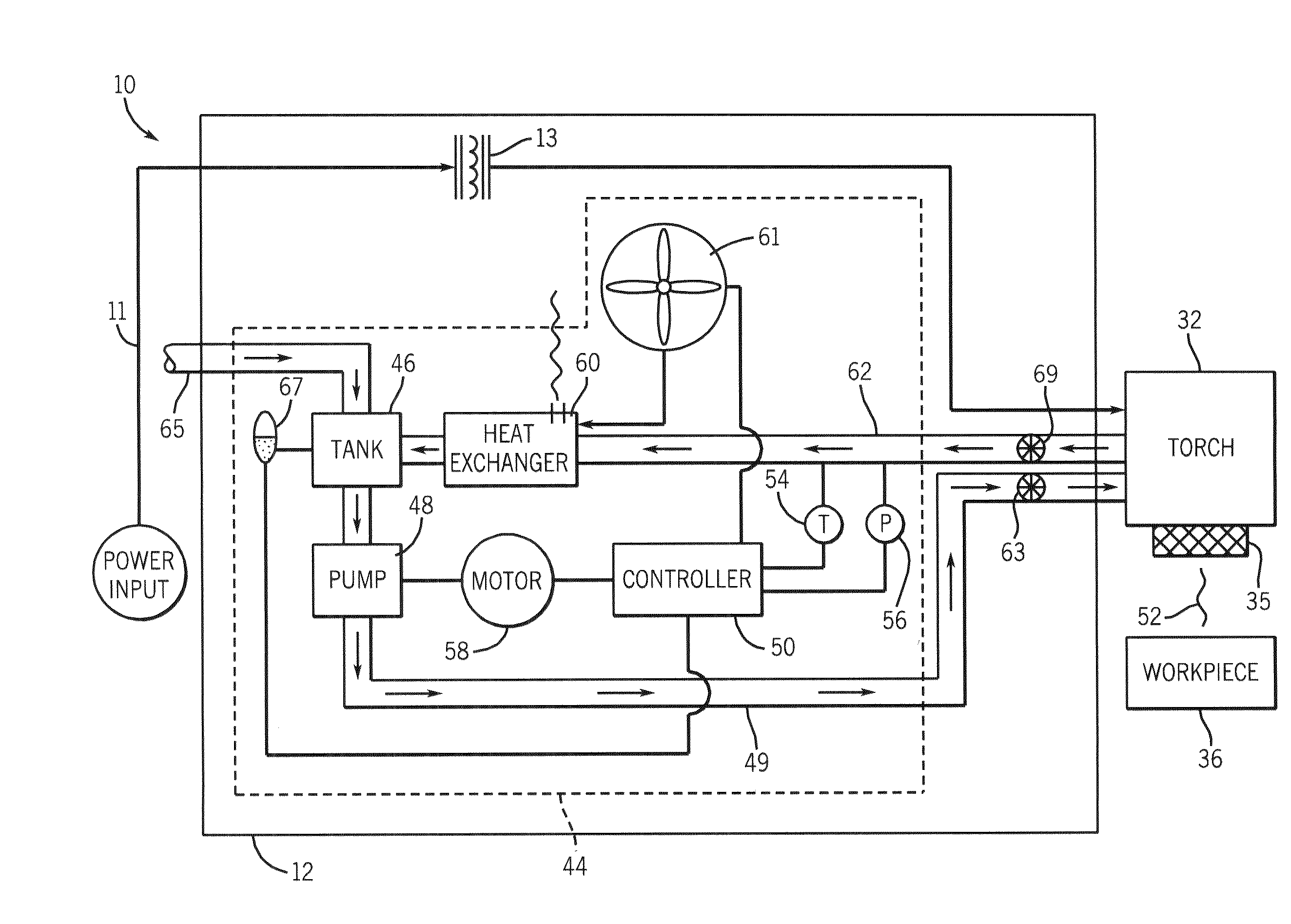

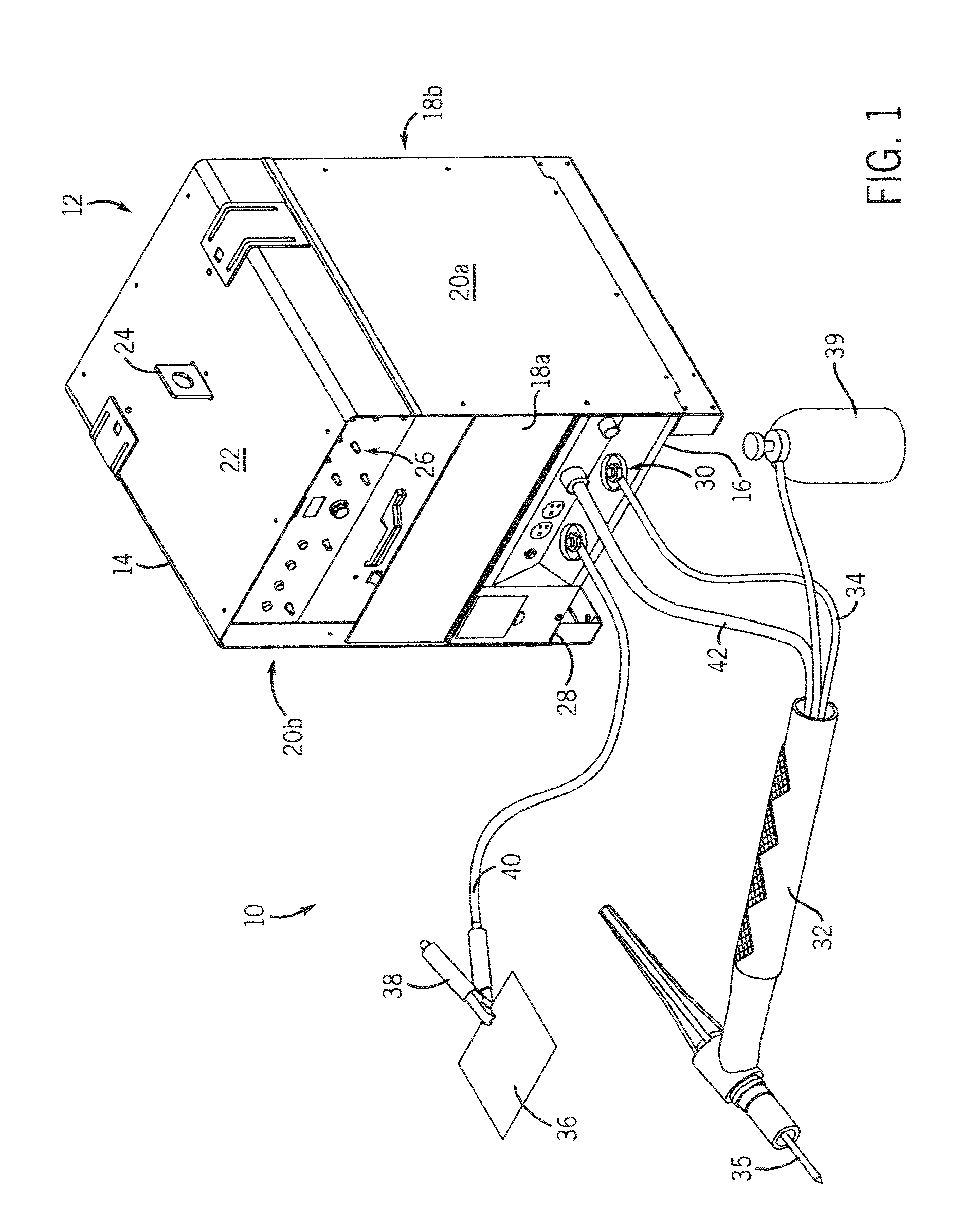

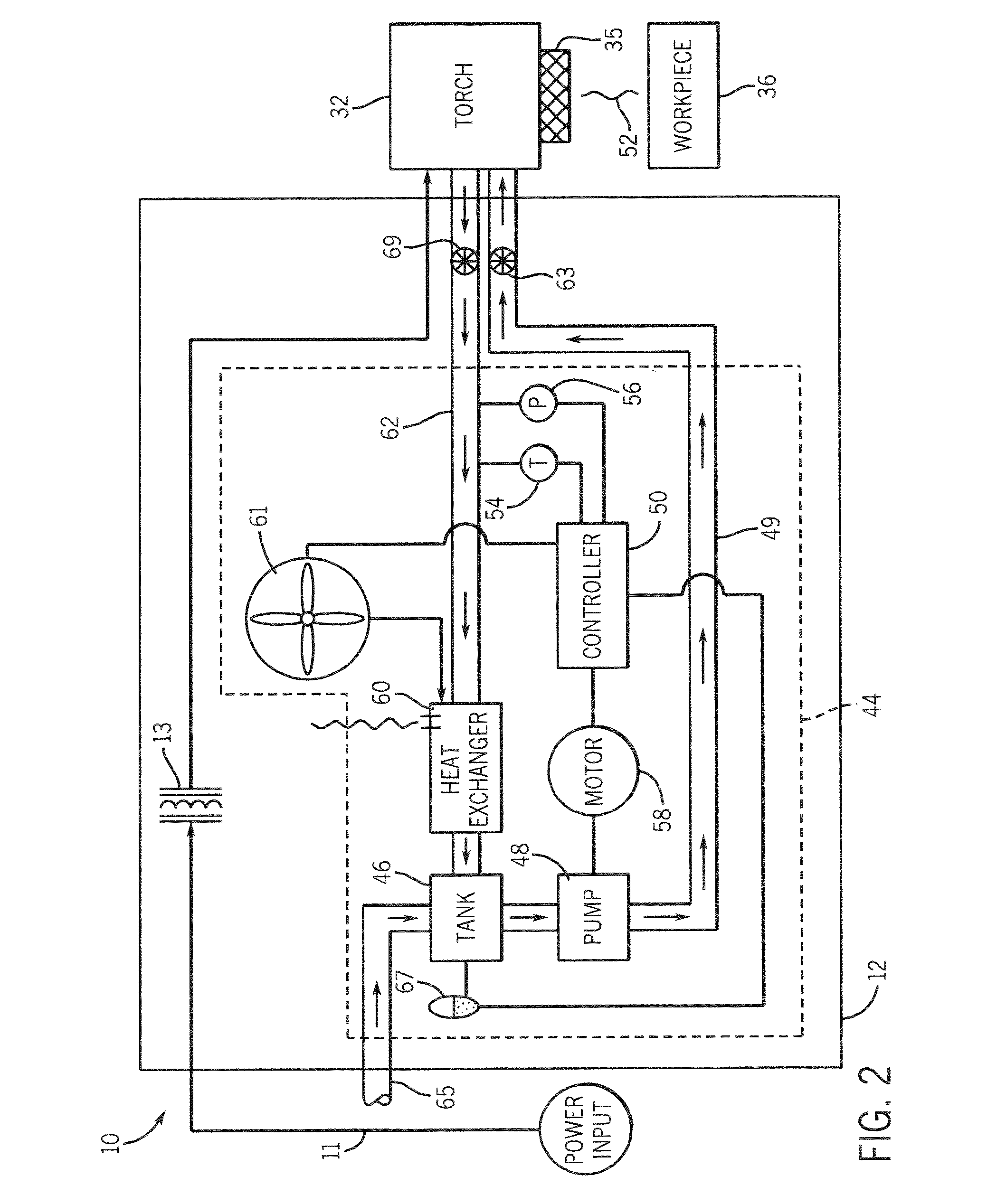

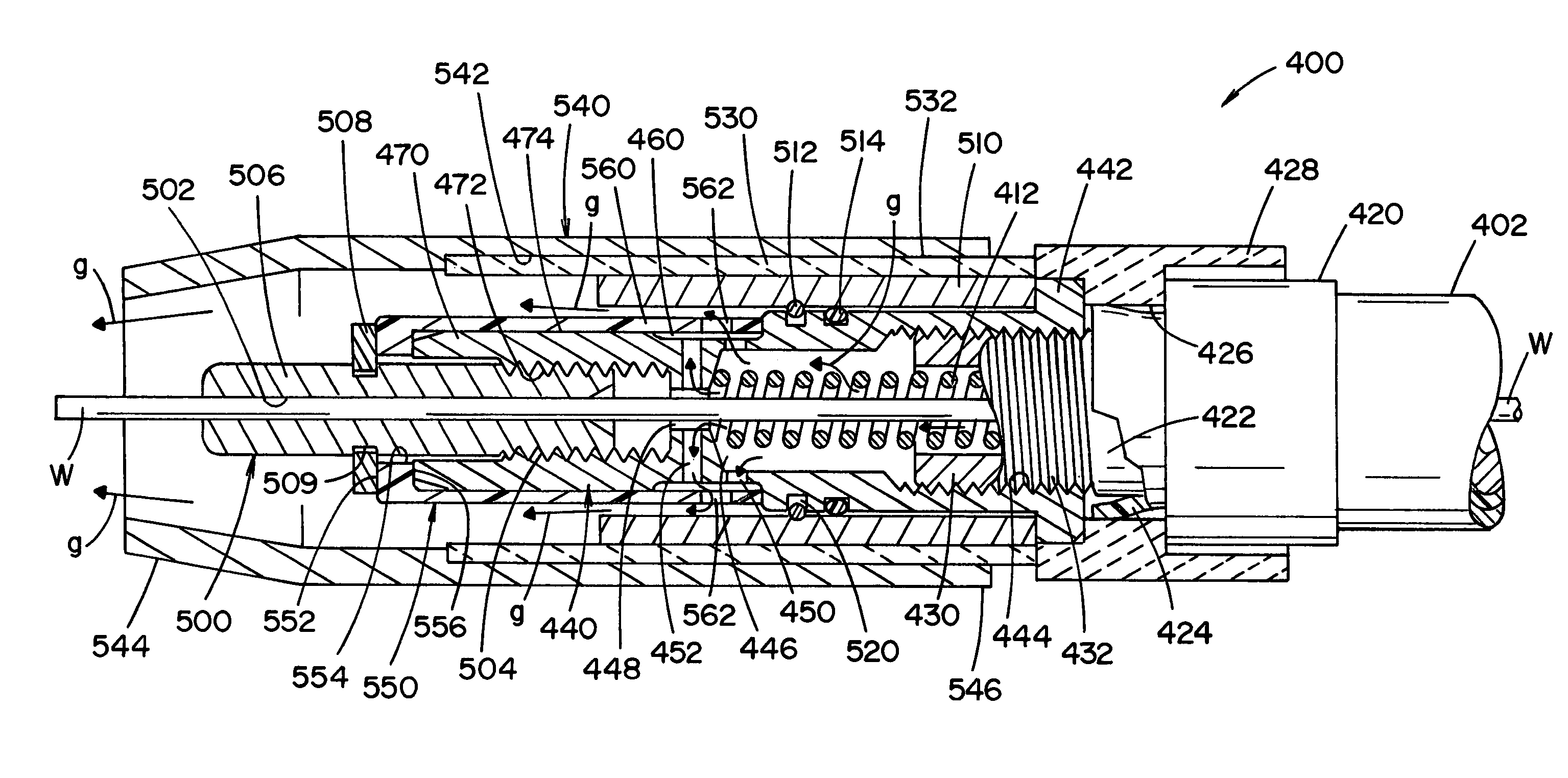

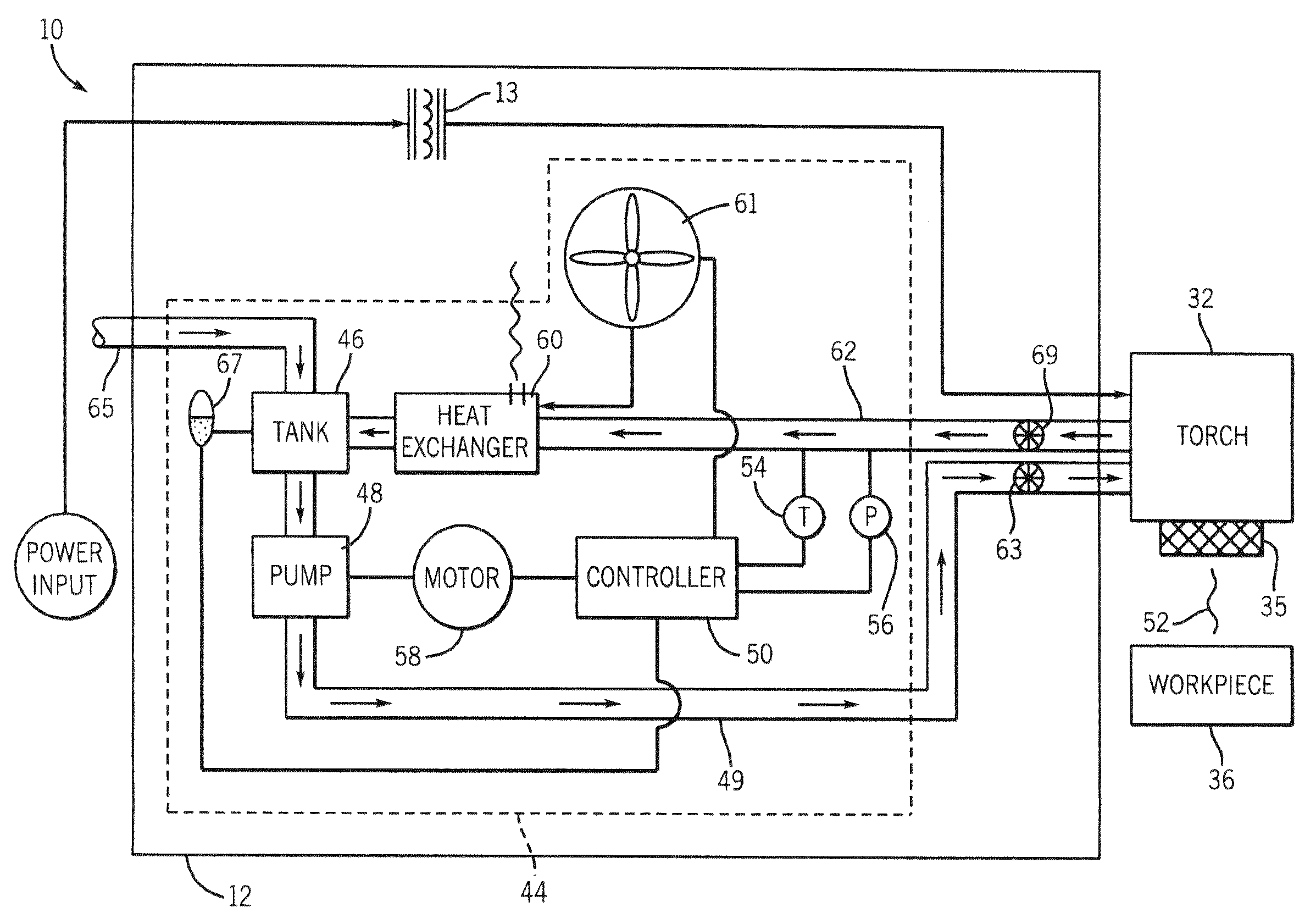

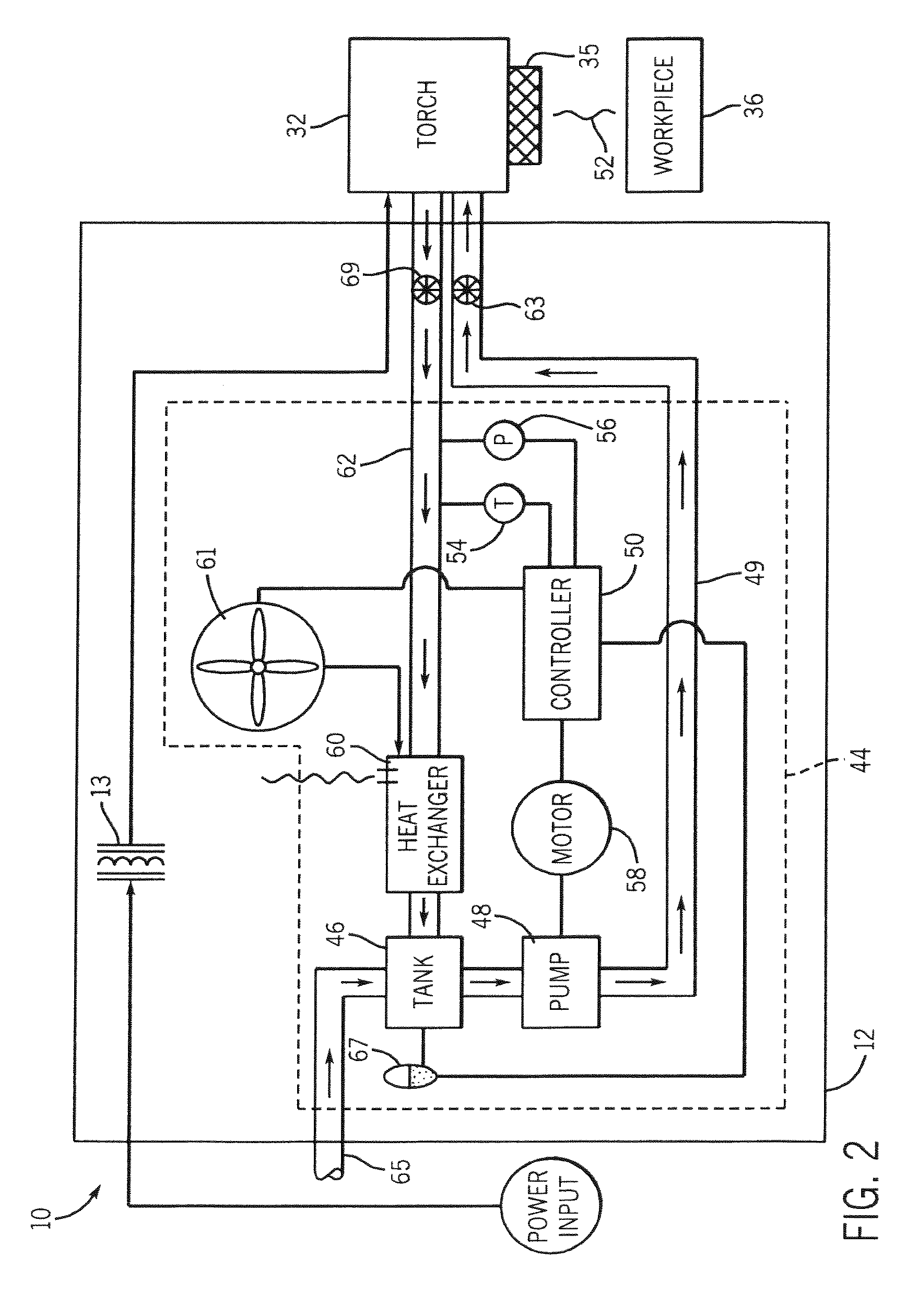

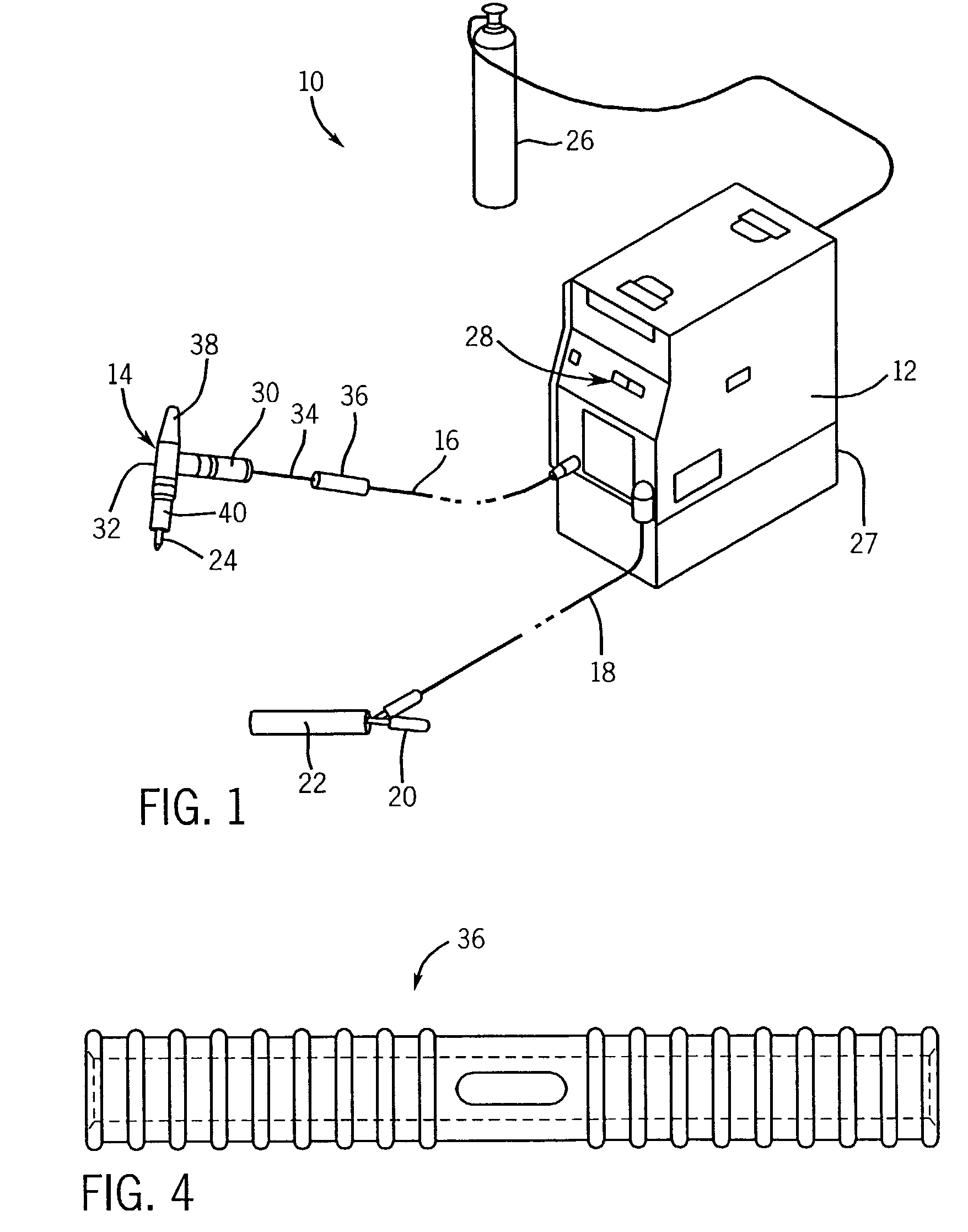

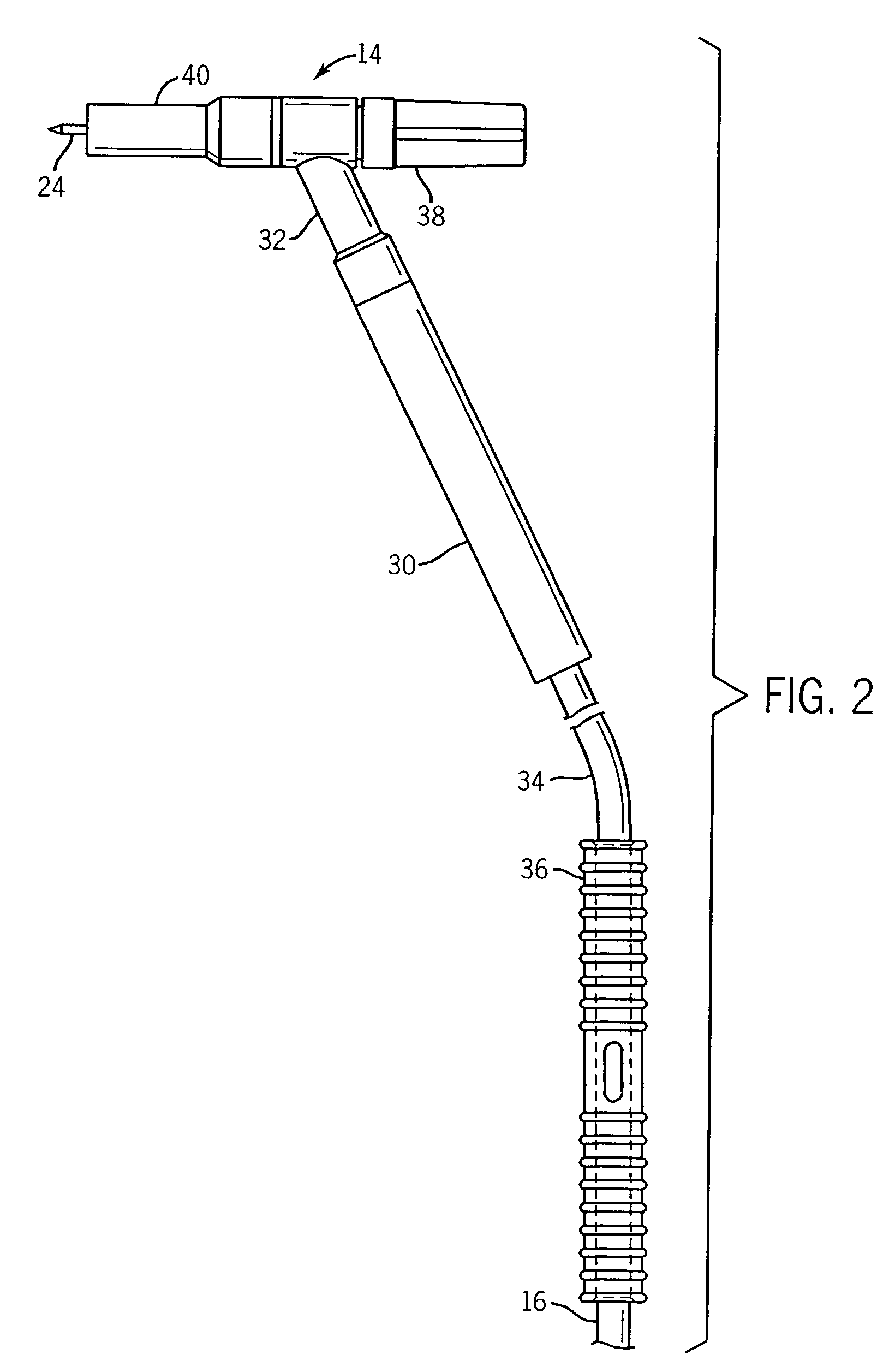

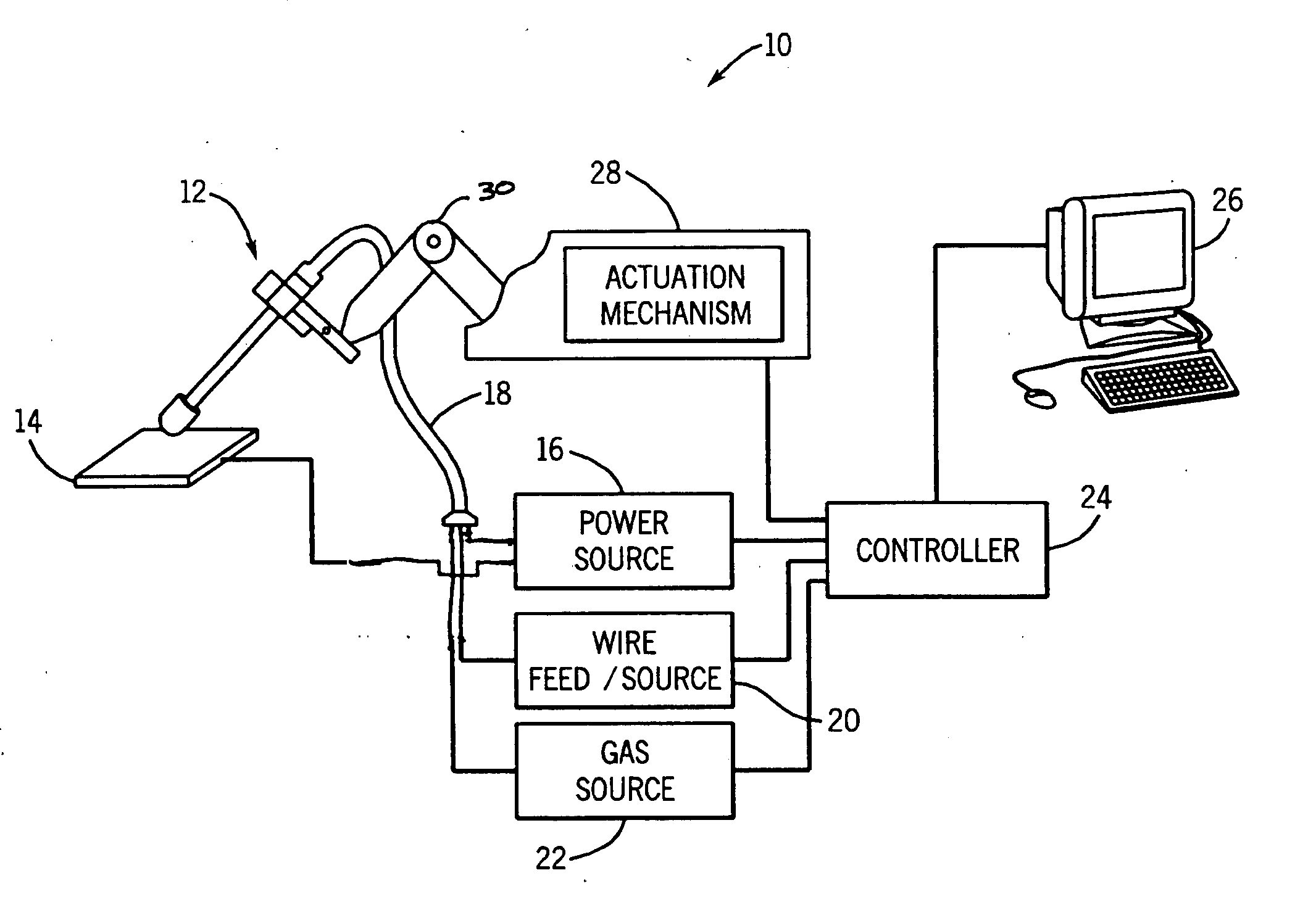

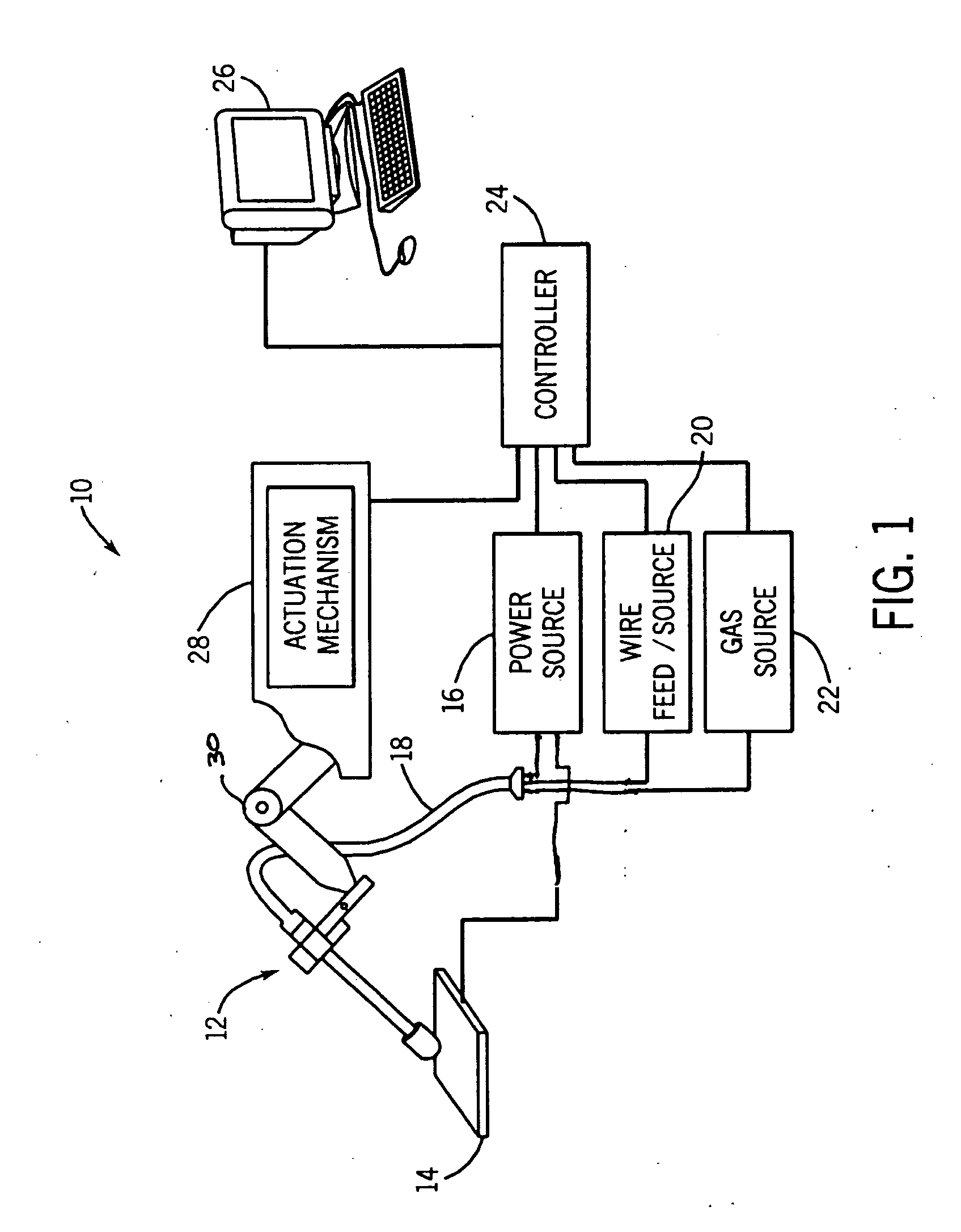

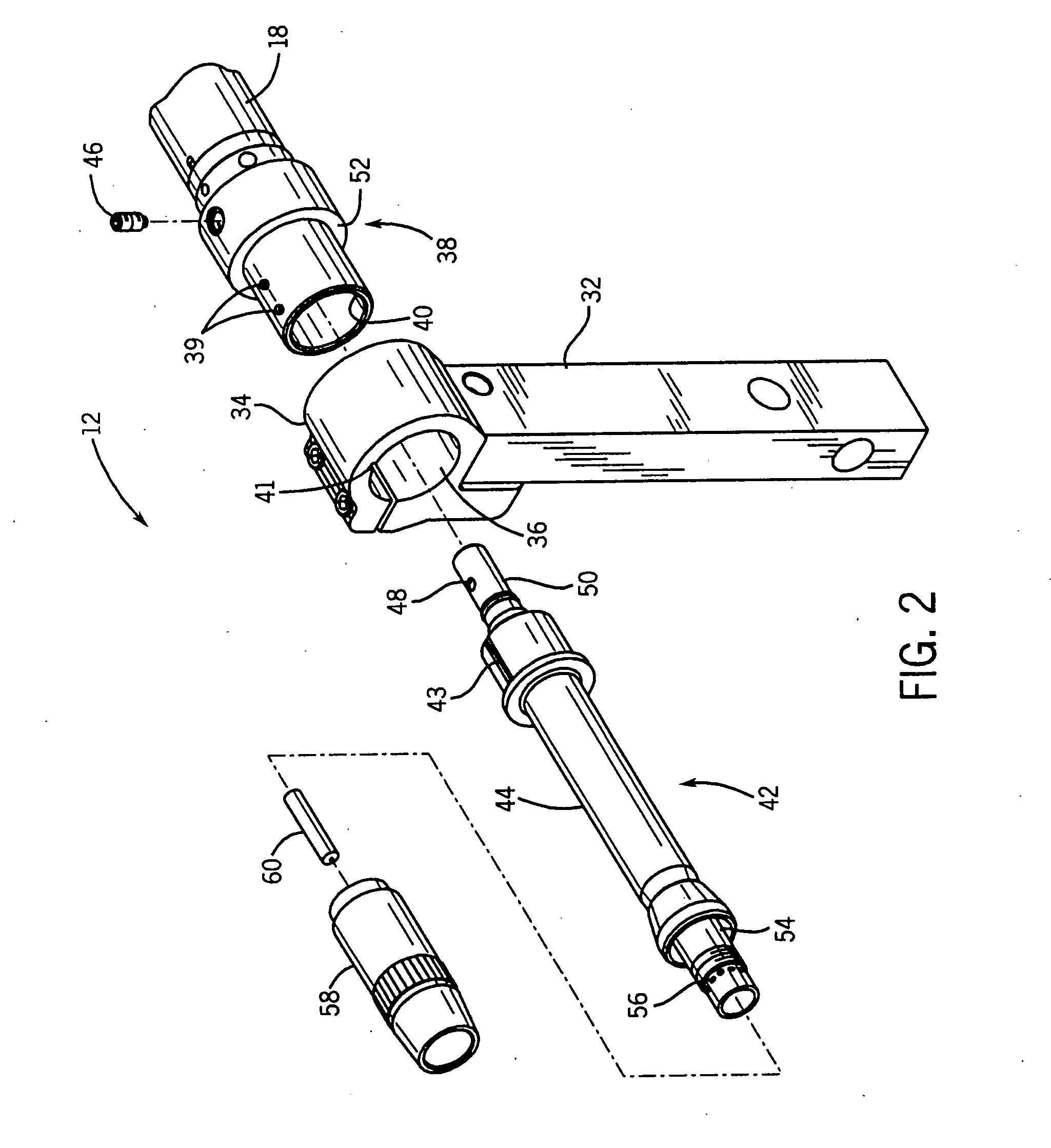

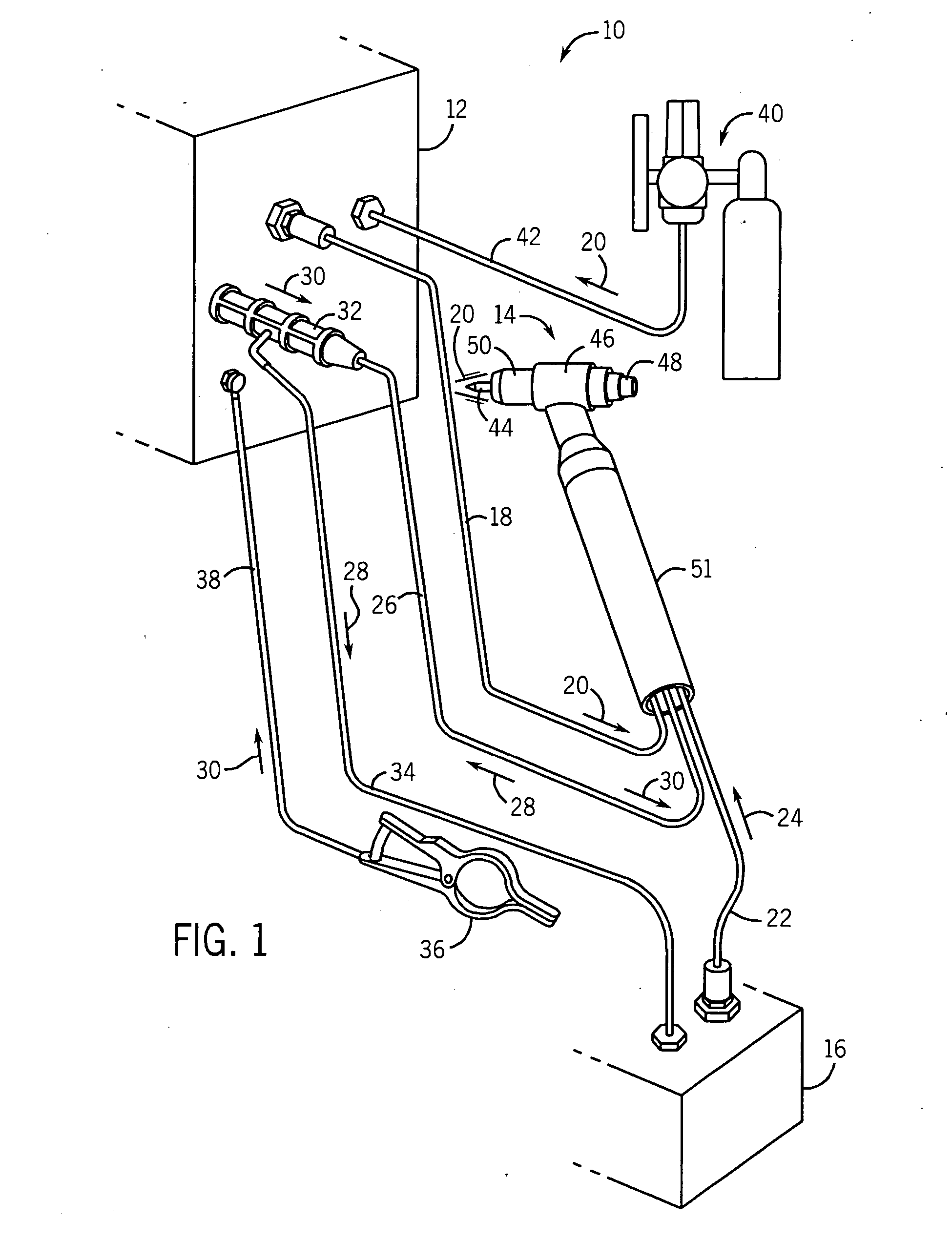

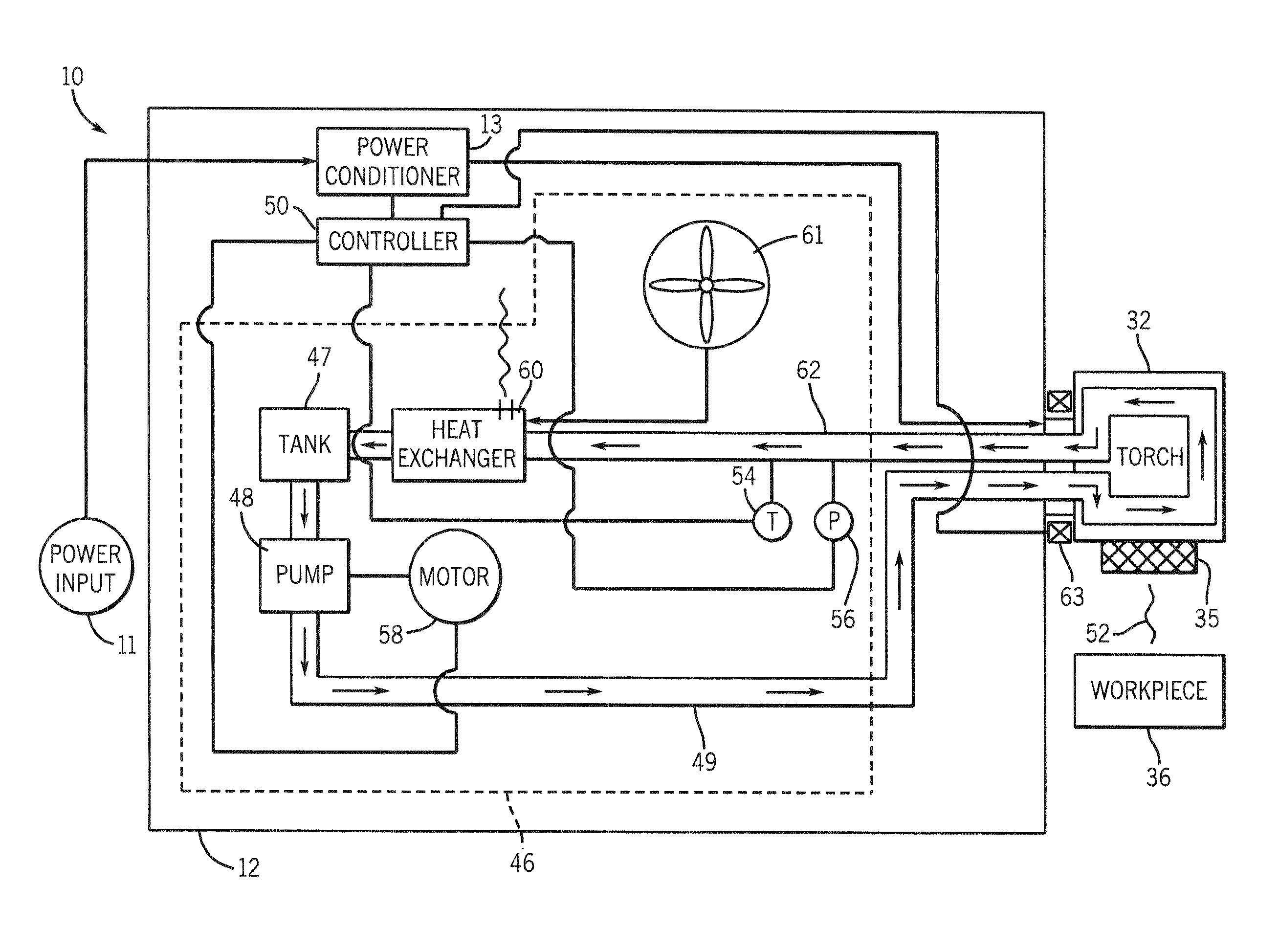

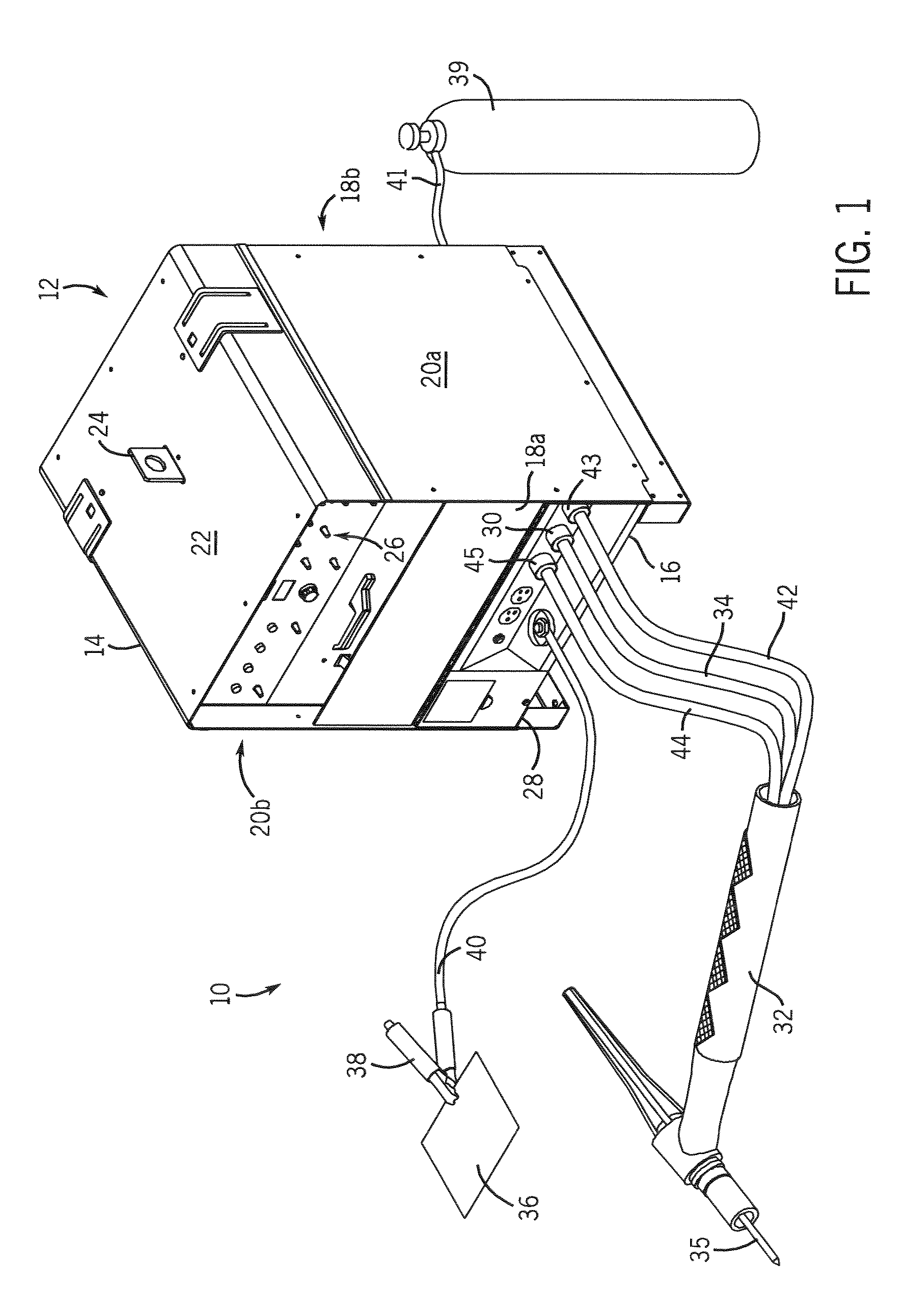

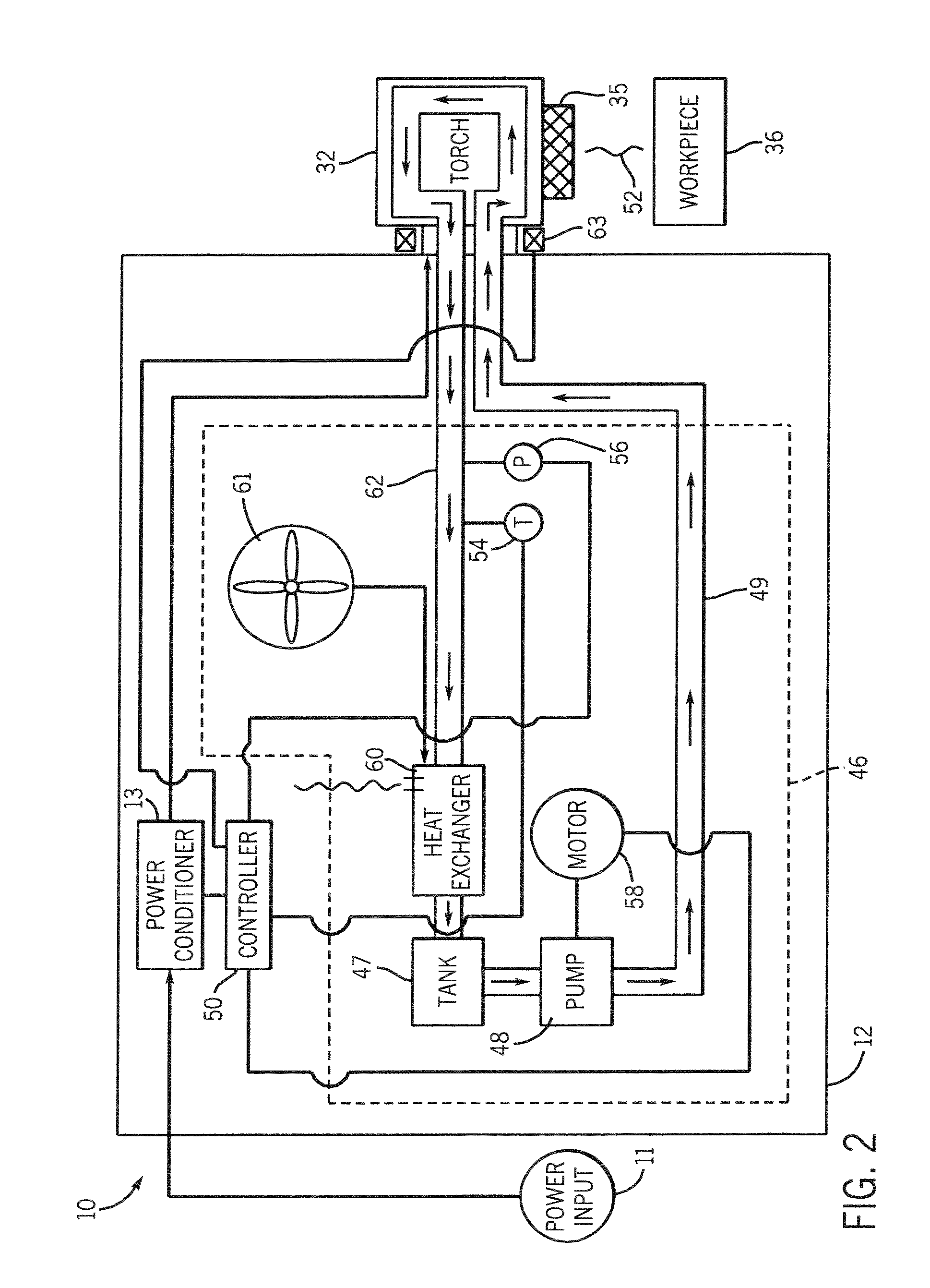

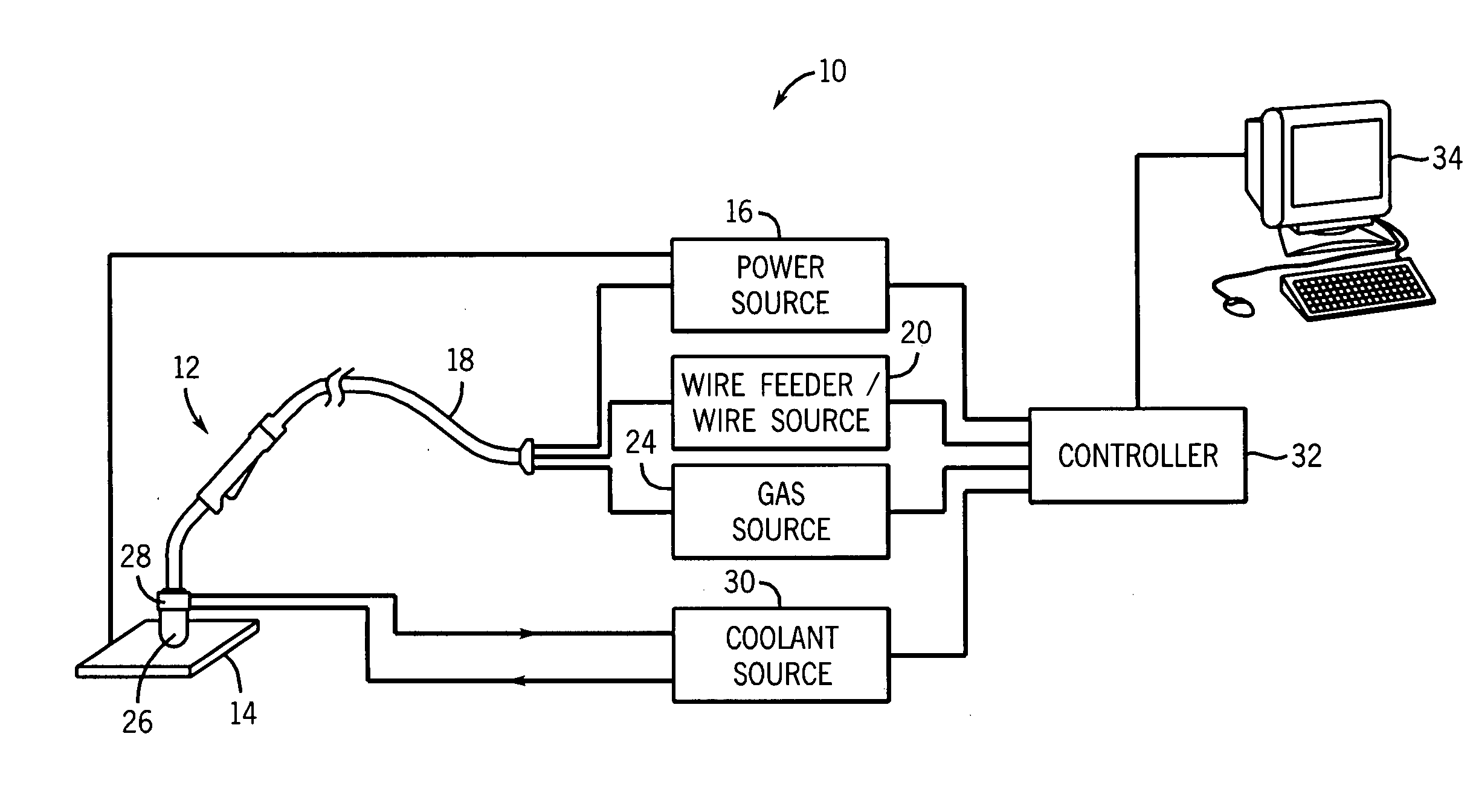

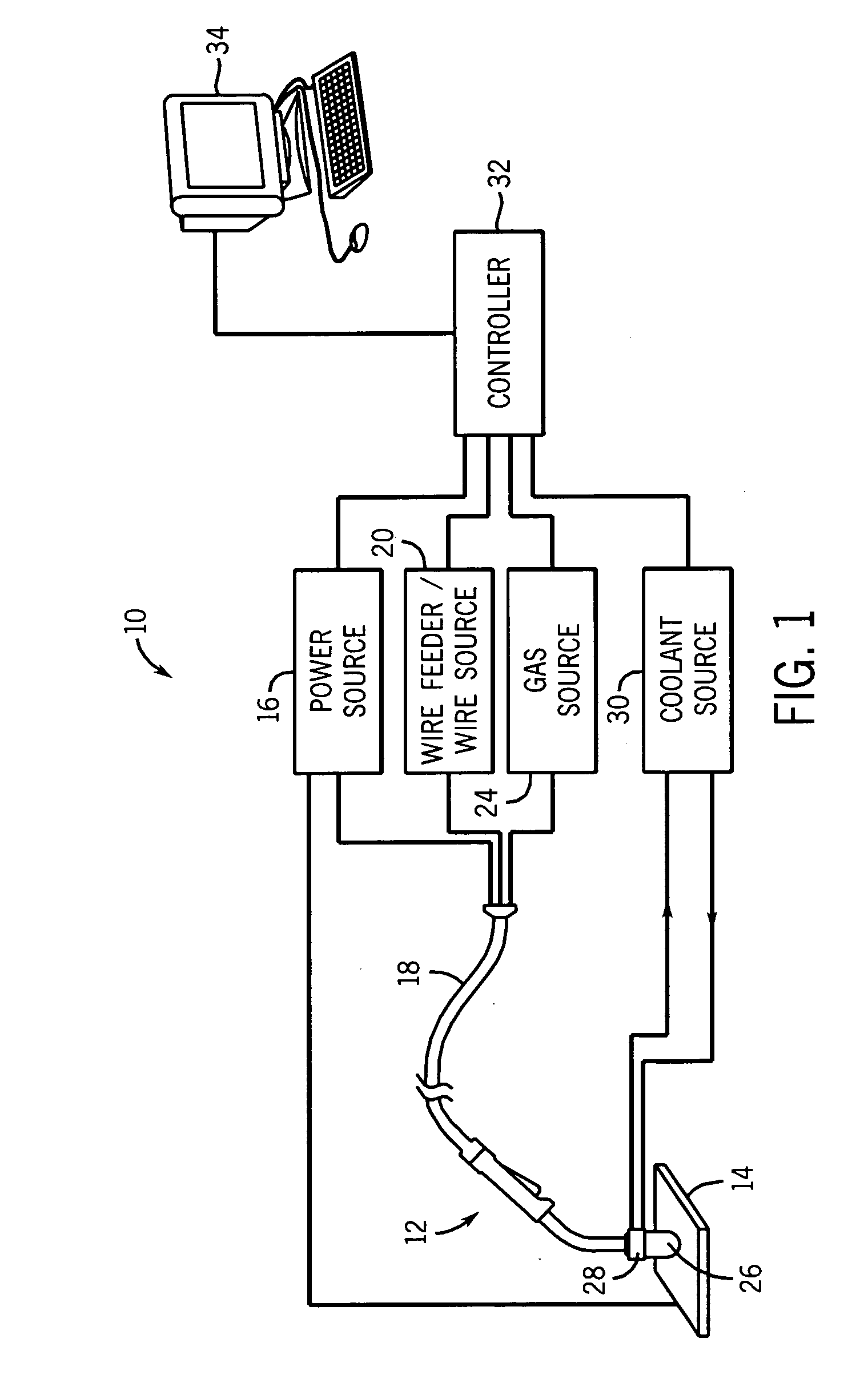

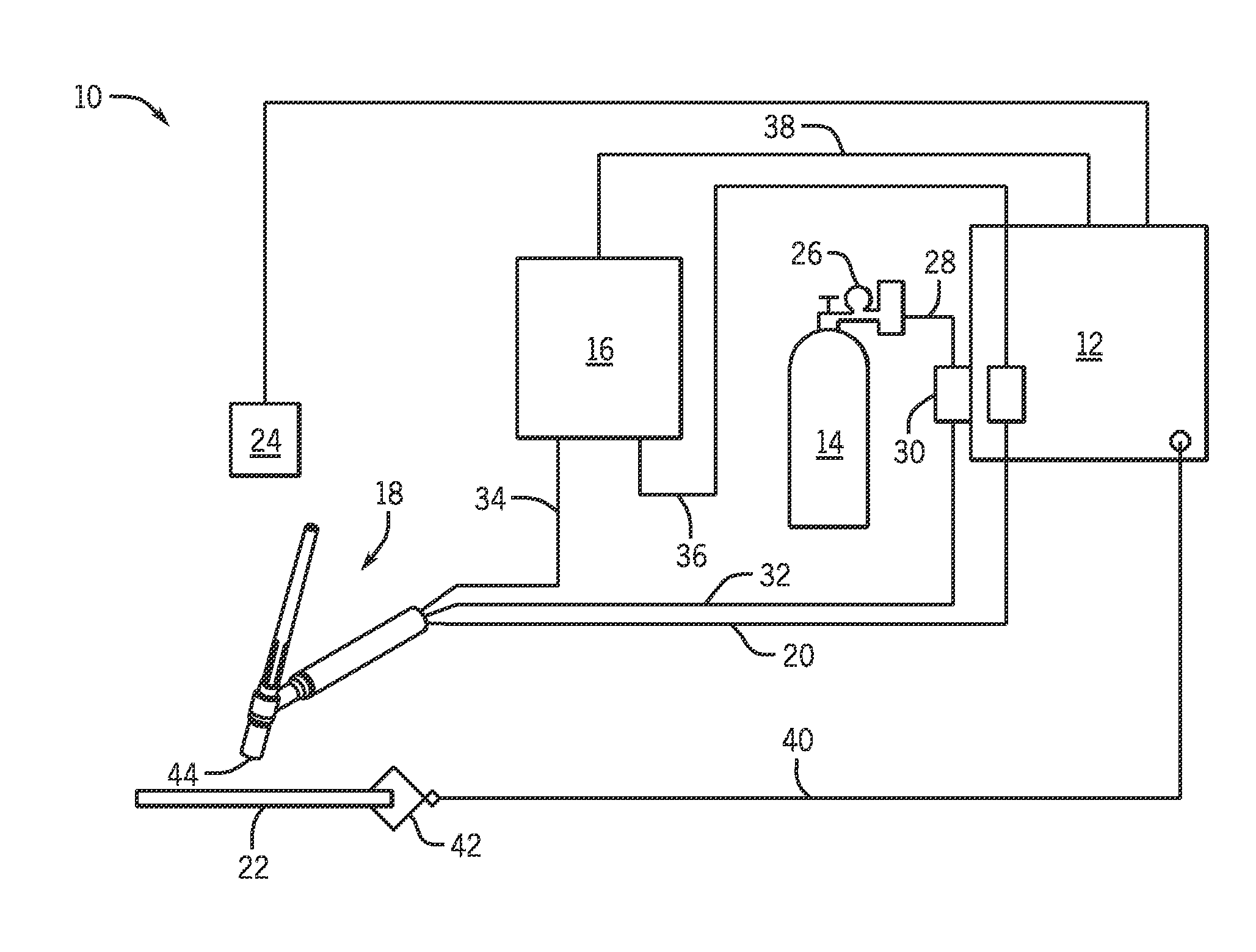

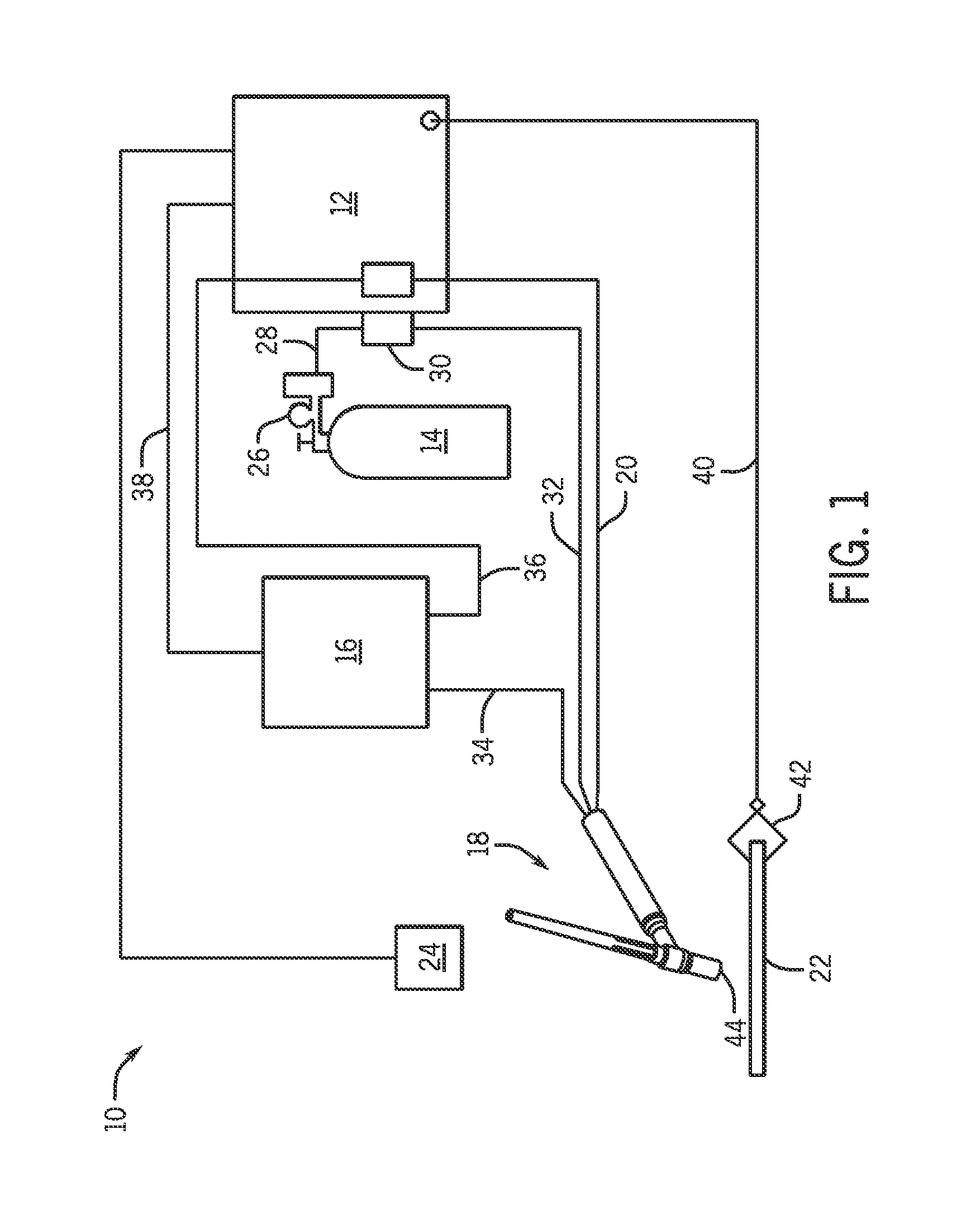

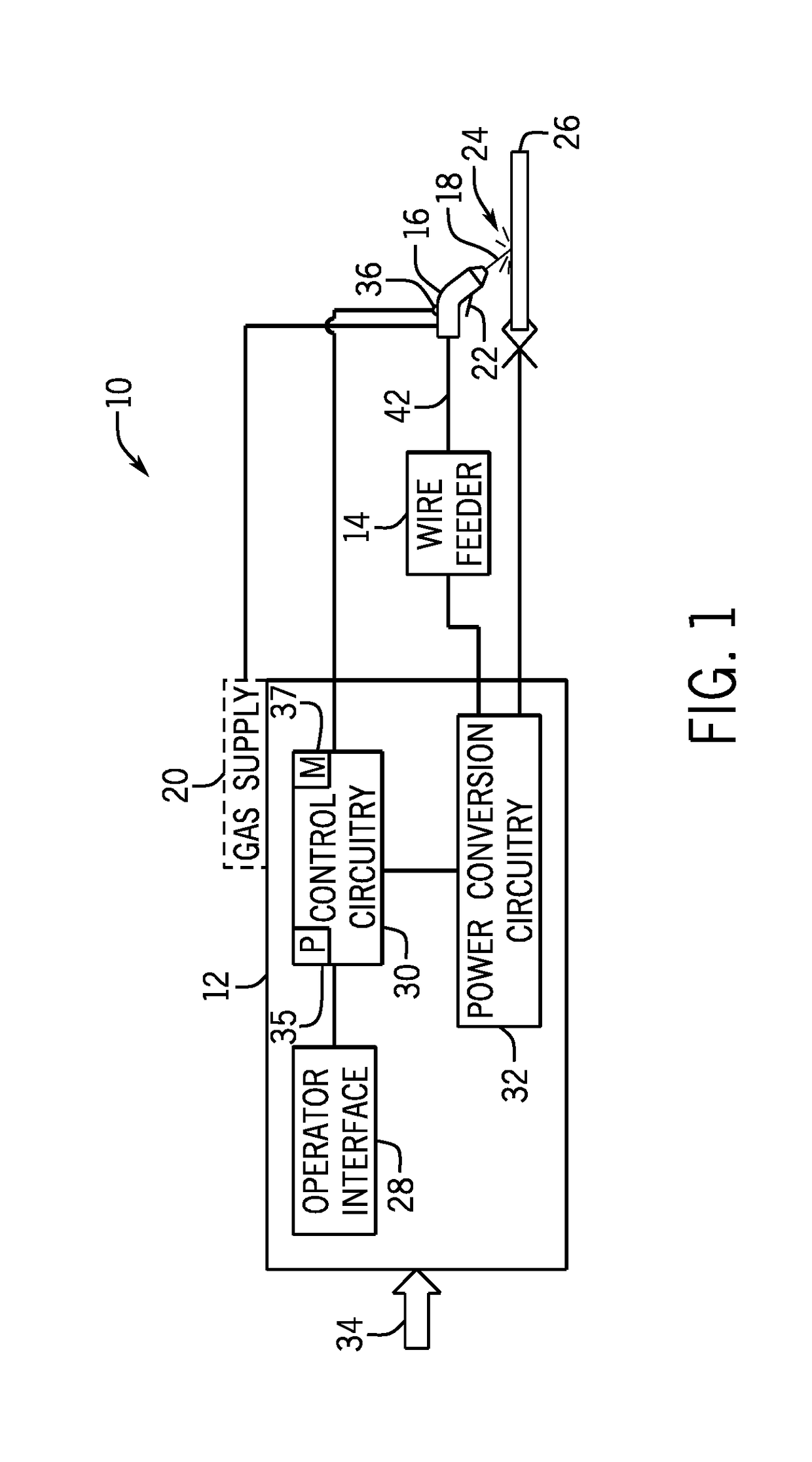

Method and apparatus to adaptively cool a welding-type system

ActiveUS20050016979A1Support devices with shieldingCooled electrode holdersEngineeringBiological activation

A cooling system connected to provide coolant to a welding-type component automatically circulates coolant through the welding component upon activation of the welding component. A controller is configured to regulate the cooling system such that upon activation of the welding-type component coolant is caused to at least flow through the welding-type component and circulate after deactivation of the welding torch until a temperature of the coolant falls below a certain value or a specified time period has expired.

Owner:ILLINOIS TOOL WORKS INC

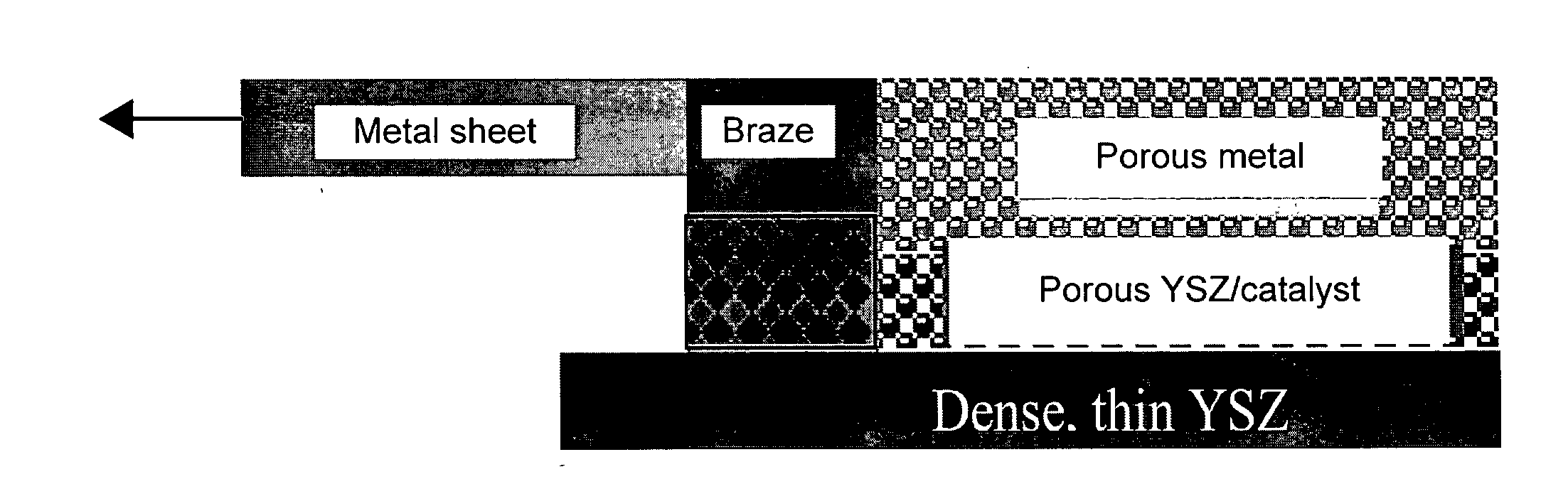

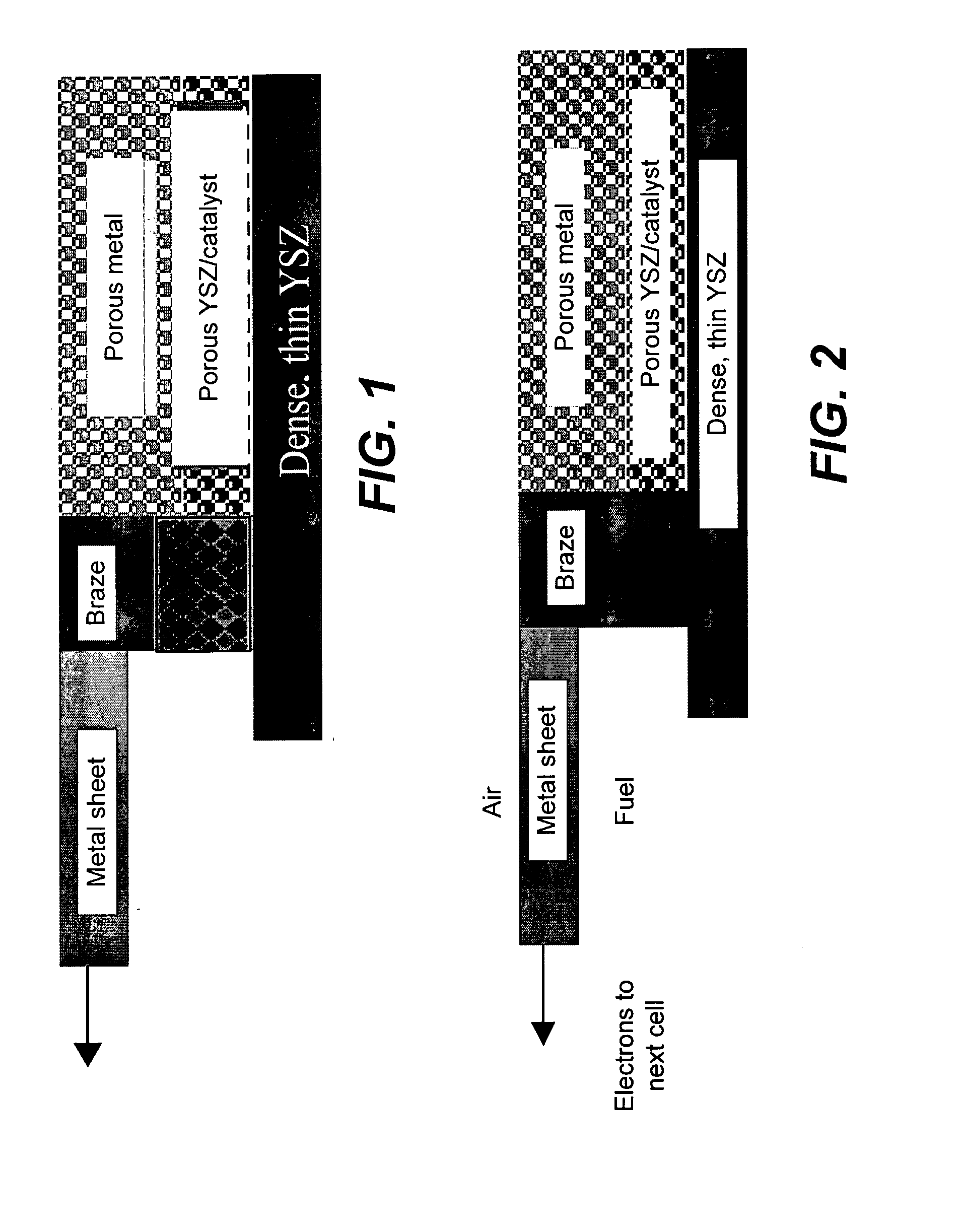

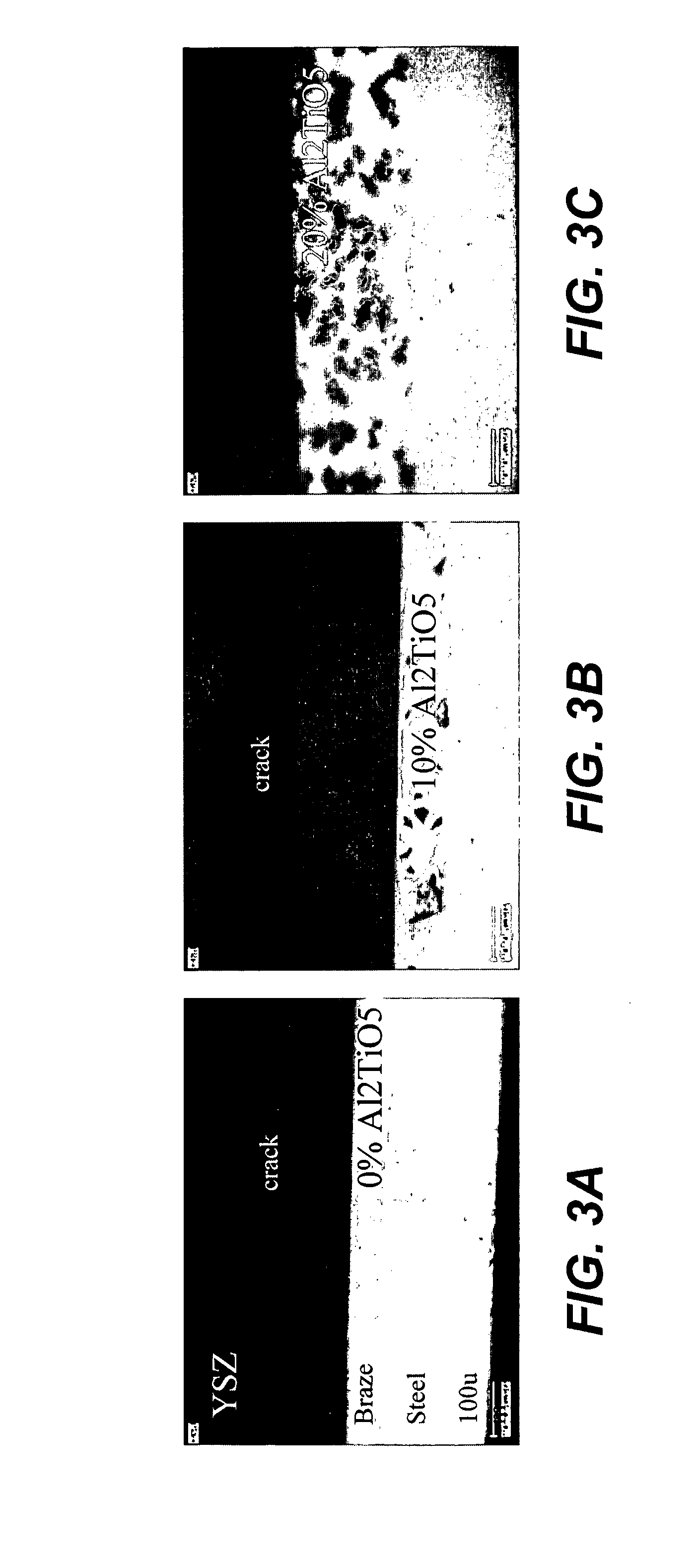

Braze System With Matched Coefficients Of Thermal Expansion

InactiveUS20080131723A1Reduce thermal stressPromote wettingExhaust apparatusFinal product manufactureParticulatesBraze alloy

A CTE modified braze composition that can be utilized to manufacture a strong, gastight joint where at least one of the joining members comprises a ceramic (e.g., a ceramic or a cermet). The braze composition is formulated so as to reduce the thermal stress that results from the mismatch of thermal expansion coefficients between a ceramic joining member and the braze or other joining members. The braze composition comprises a braze alloy in powder, paste or bulk form mixed with one or more particulate or fibrous fillers that exhibit a low (i.e., no more than 6 ppm / K) or negative coefficient of thermal expansion. The braze composition can be used to join members, at least one of which comprises ceramic, and to a composite member produced by joining the two or more members.

Owner:RGT UNIV OF CALIFORNIA

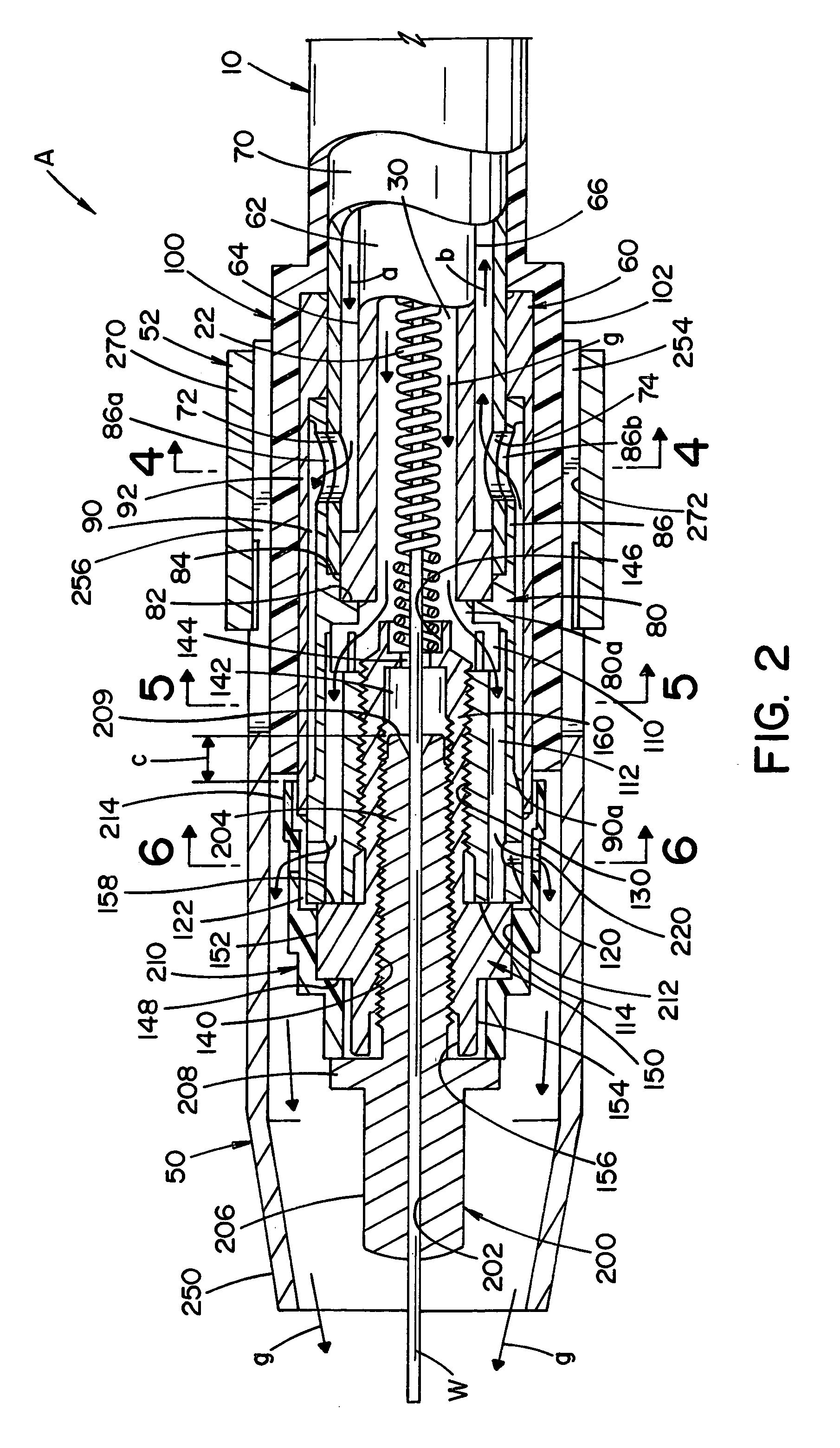

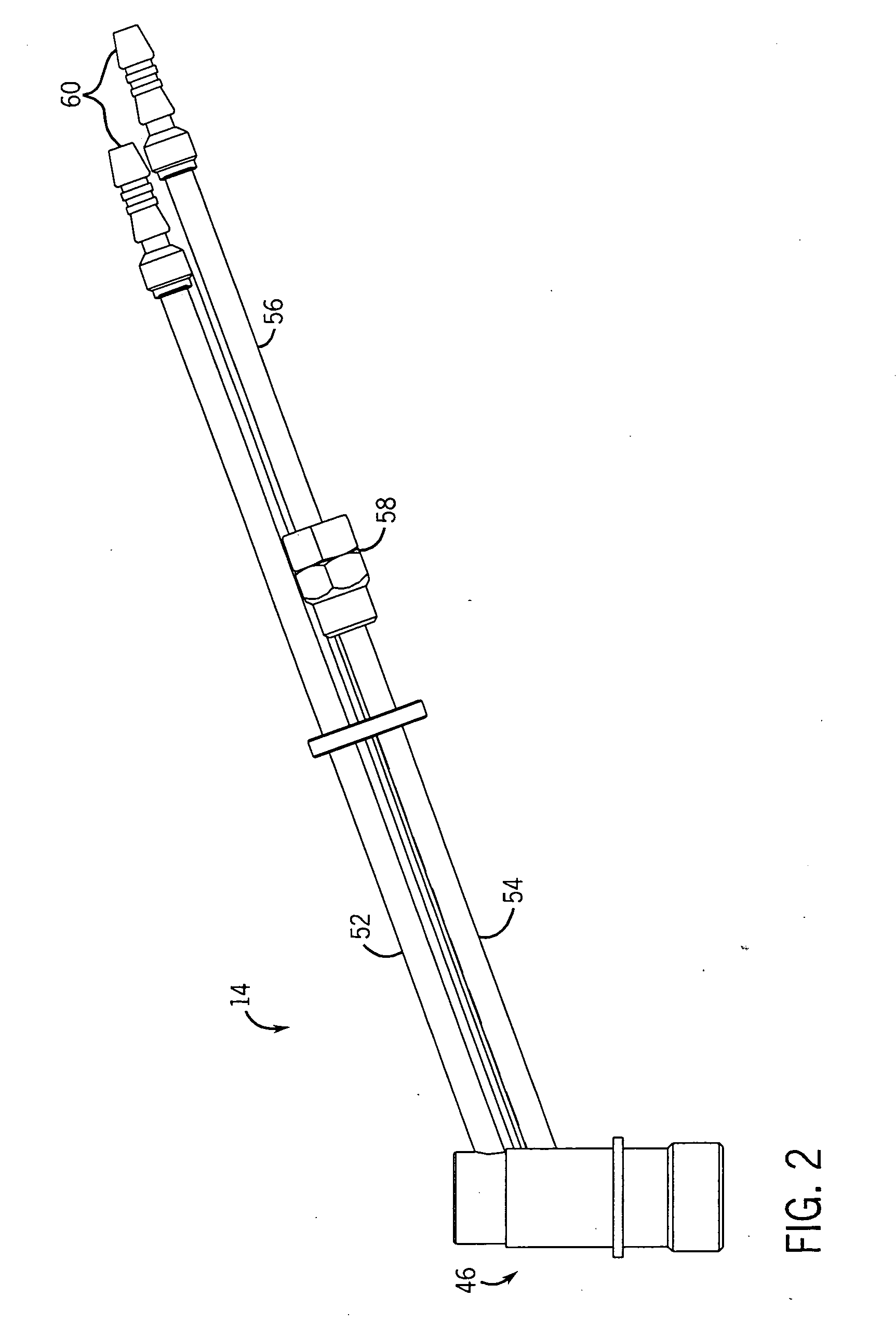

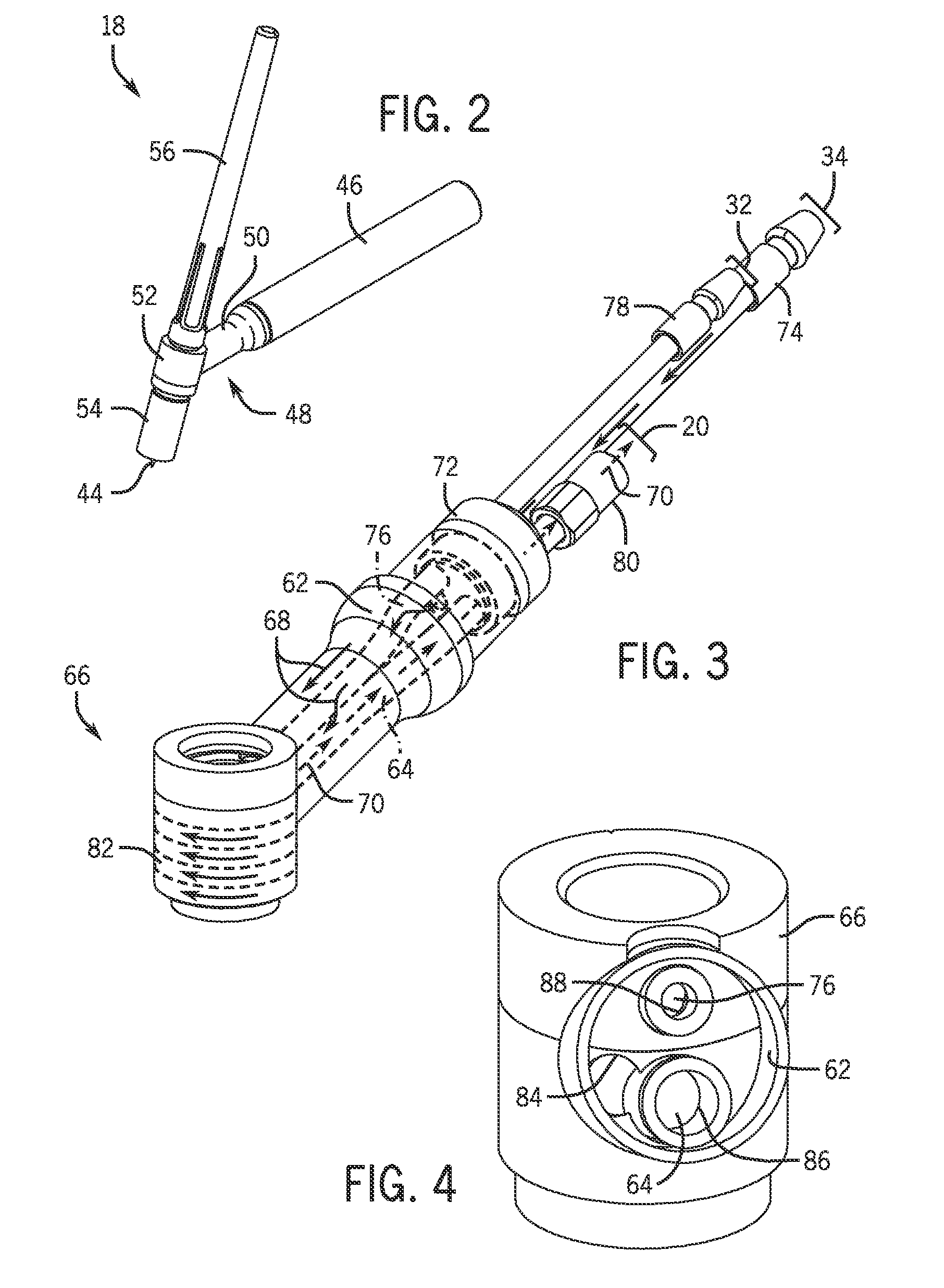

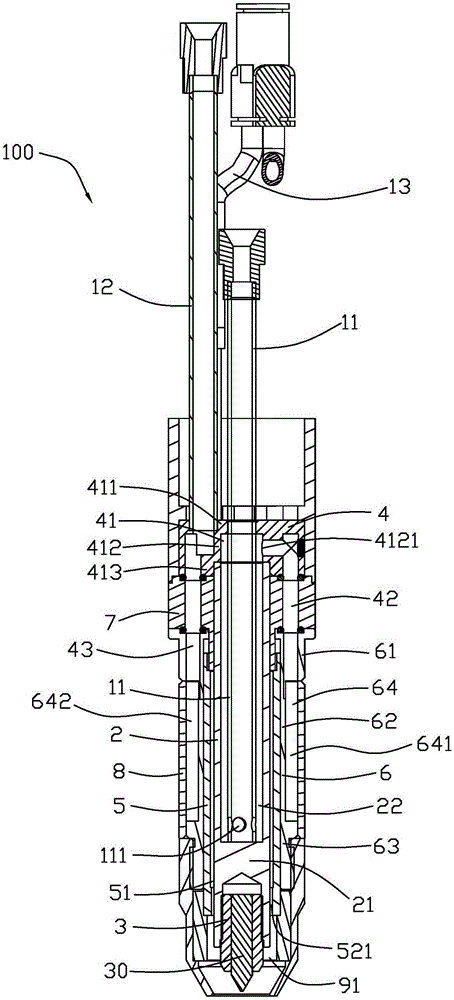

Electric arc torch with cooling conduit

ActiveUS20160074973A1Well formedWelding/cutting auxillary devicesCooled electrode holdersTorchEngineering

An electric arc torch includes a torch base, and a cooling conduit having a conduit wall forming a central axial bore and having a plurality of longitudinal cooling channels spaced circumferentially around the bore. The cooling channels extend through the conduit wall from a first end portion to a second end portion of the conduit. The cooling channels include both a plurality of cooling liquid distribution channels and a plurality of cooling liquid return channels alternately arranged within the conduit wall. The conduit includes a circumferential cooling liquid manifold in fluid communication with each of the cooling liquid distribution channels, a circumferential return manifold in fluid communication with each of the cooling liquid return channels, and a circumferential recirculation manifold in fluid communication with each of the cooling liquid distribution and return channels such that the cooling liquid distribution and return channels are in fluid communication through the circumferential recirculation manifold.

Owner:LINCOLN GLOBAL INC

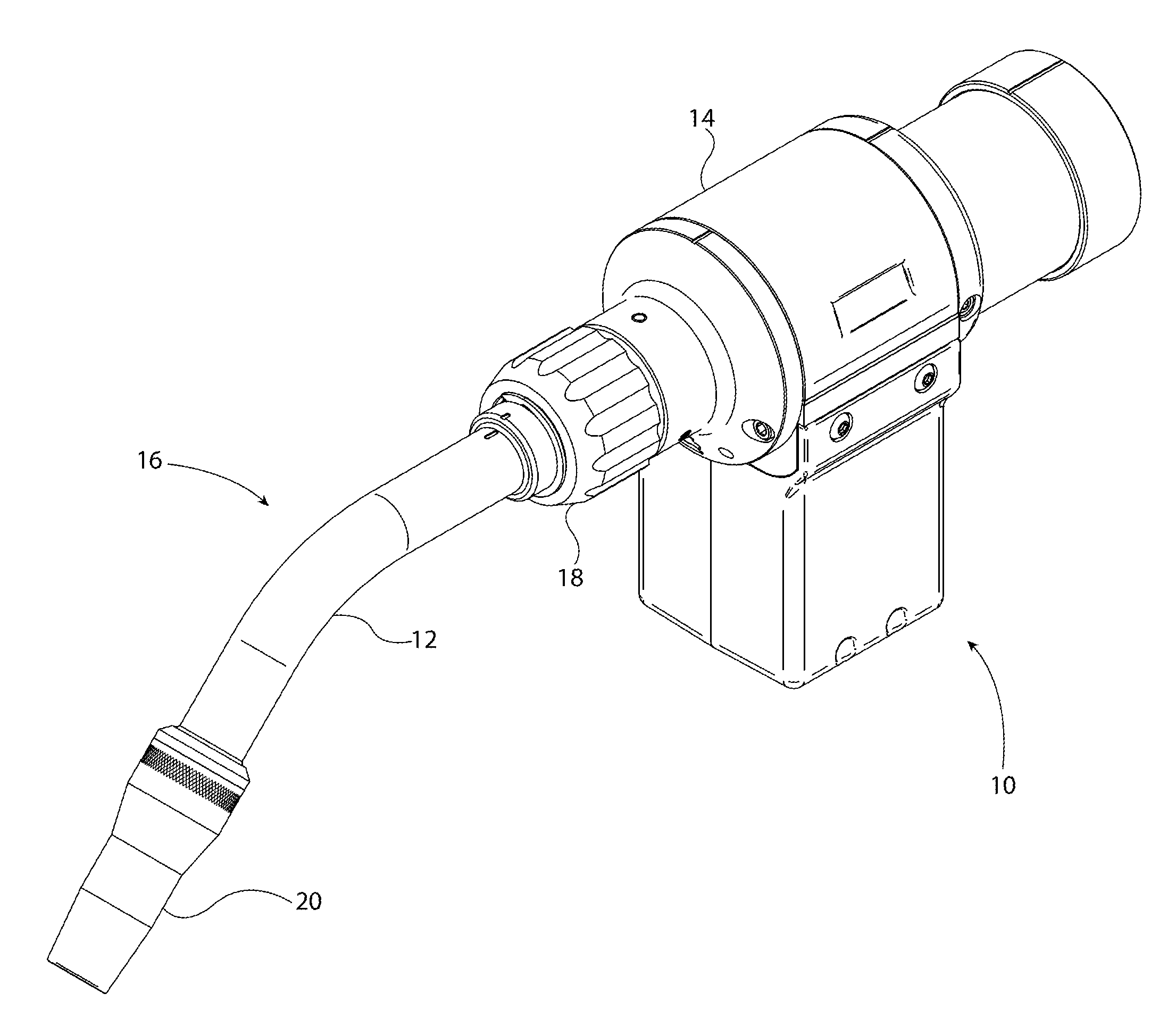

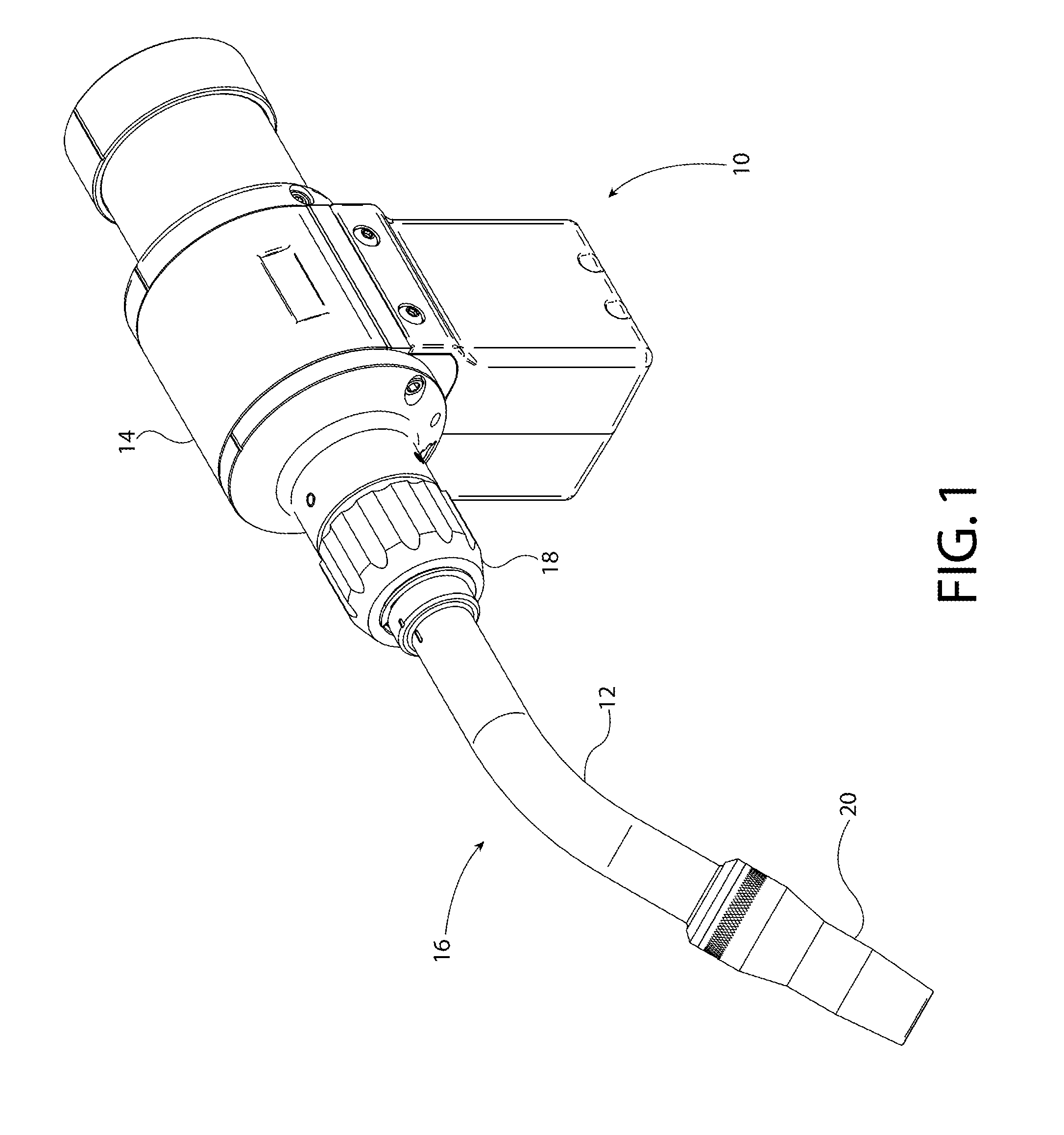

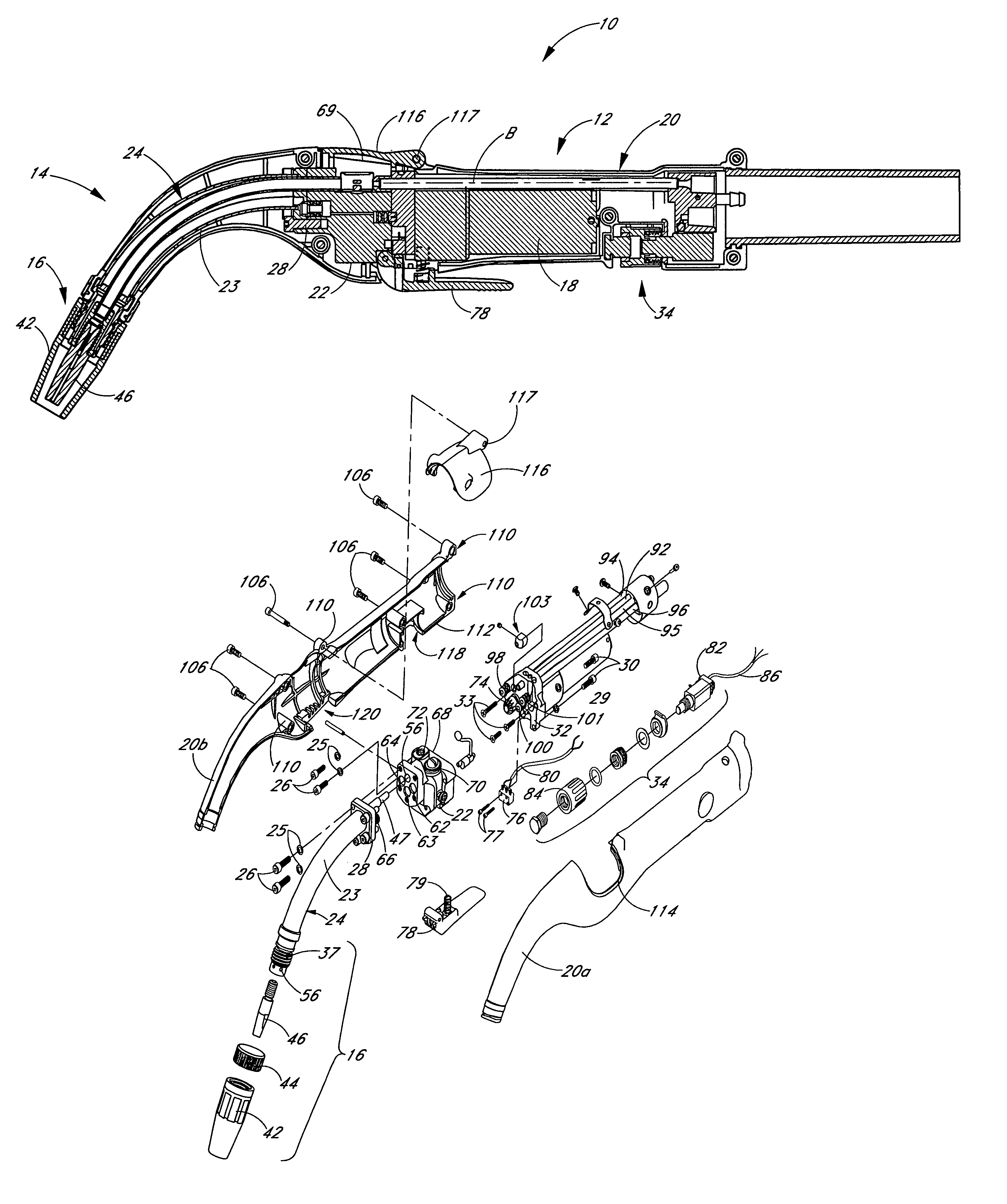

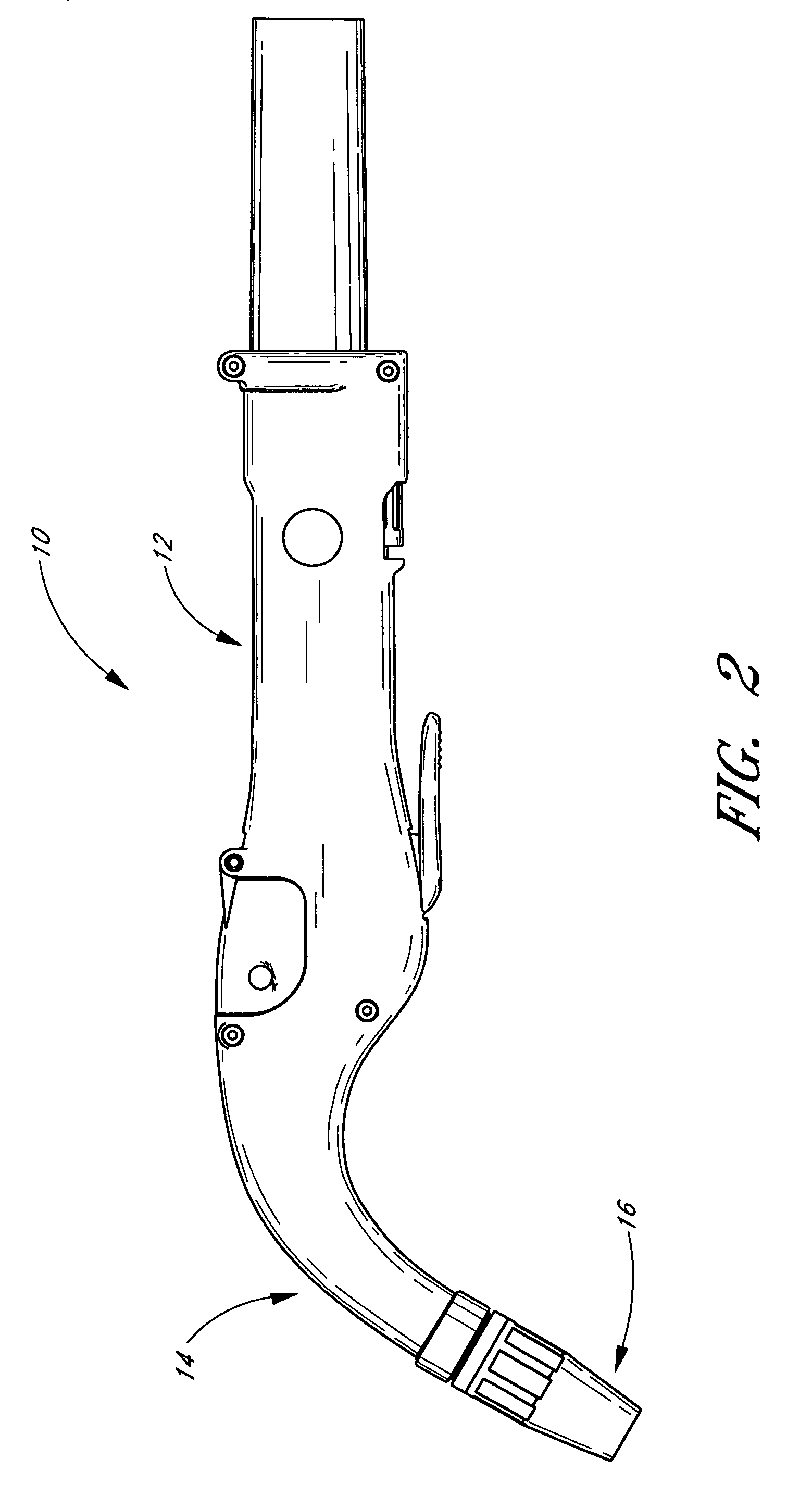

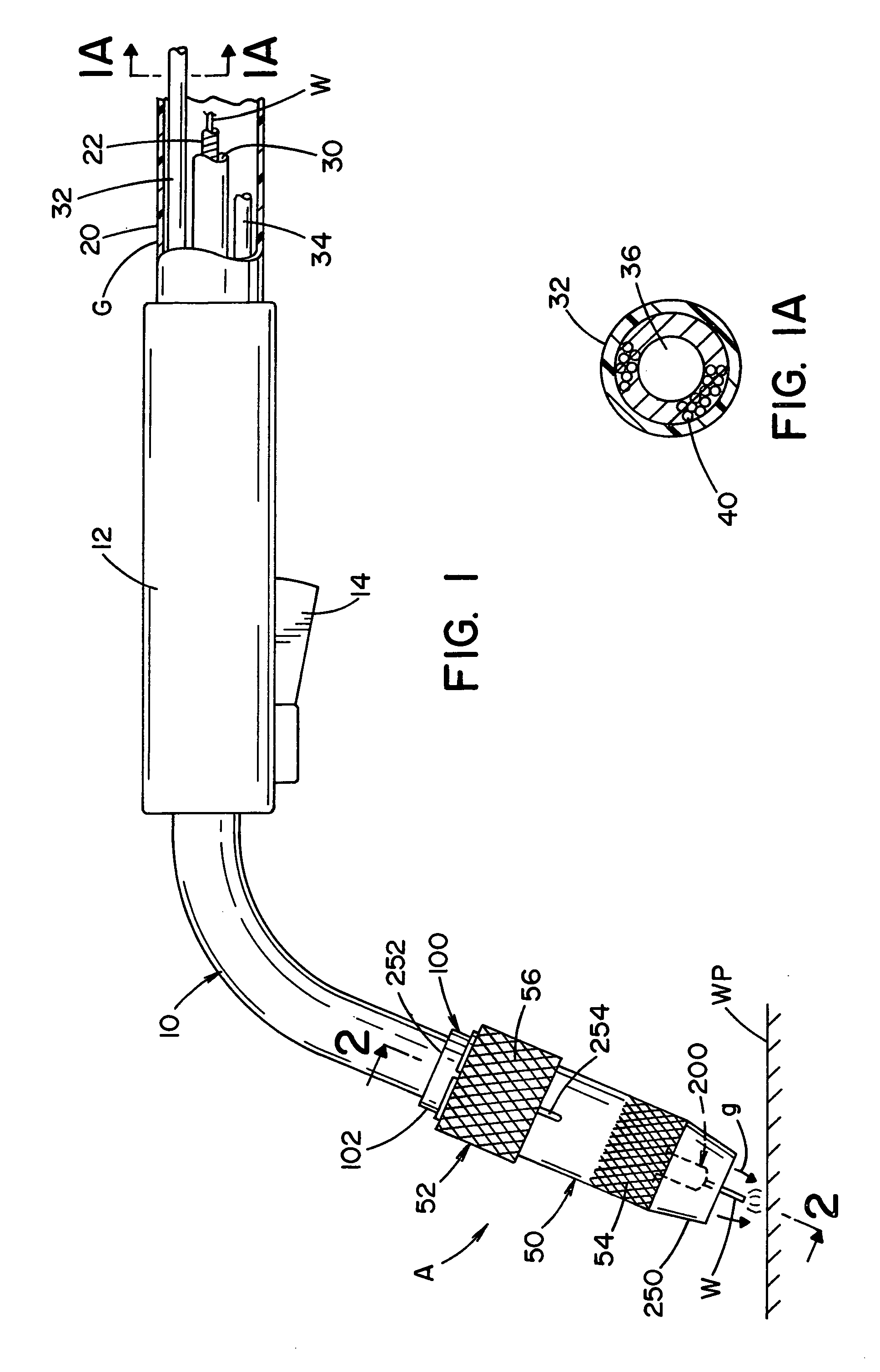

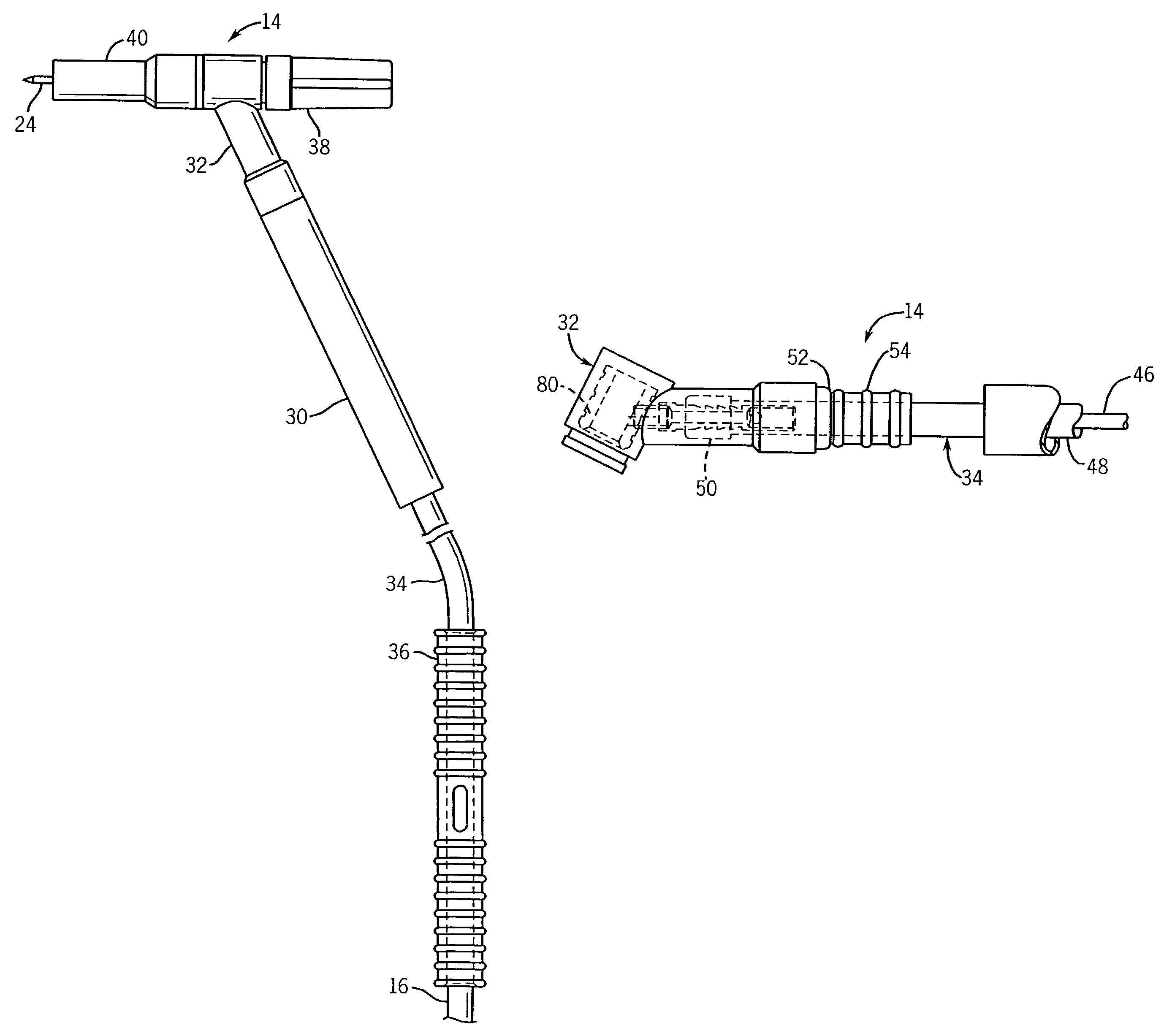

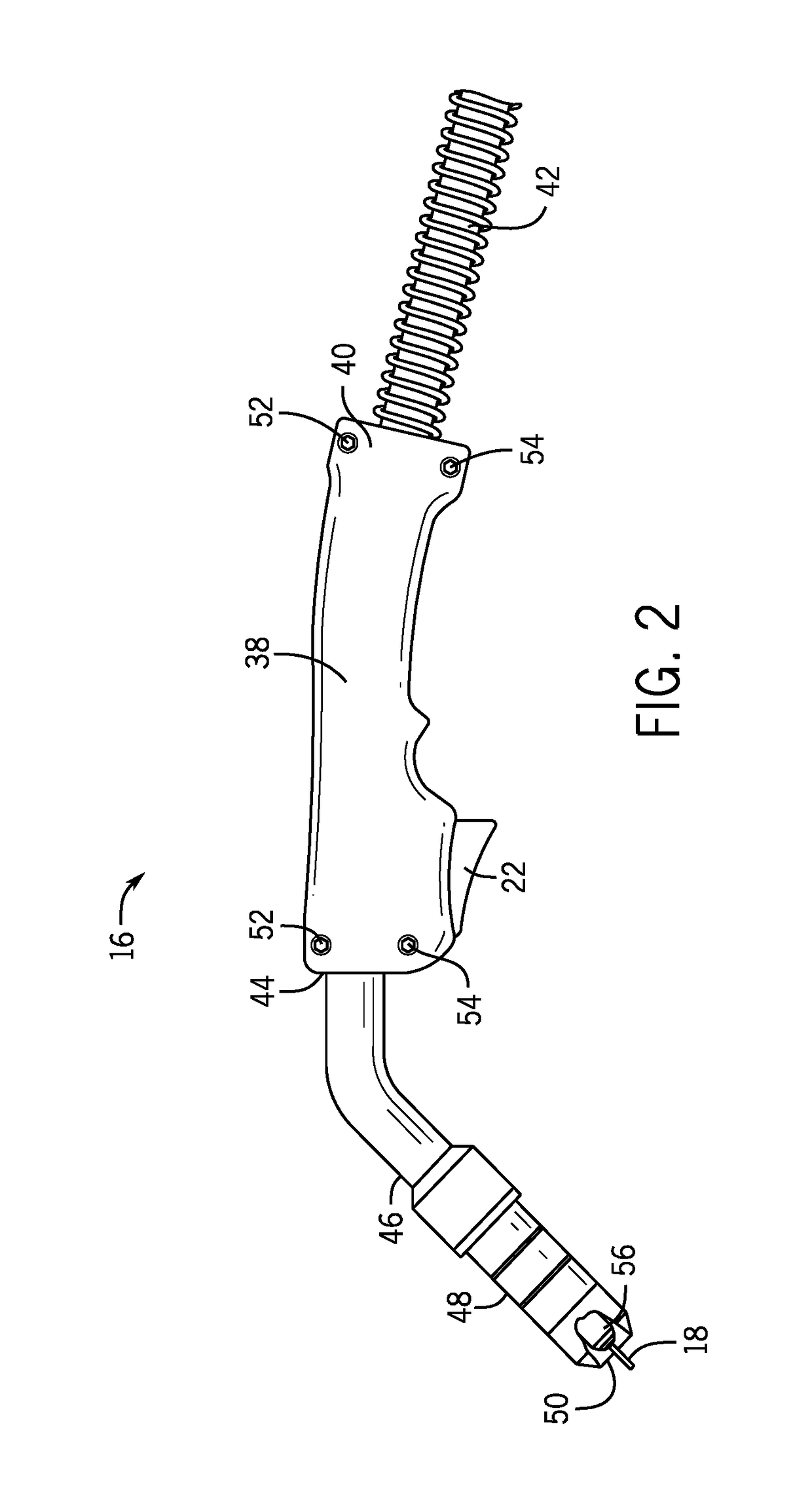

Welding gun

An in-line welding gun includes a mounting block, a wire feed mechanism and a torch barrel. A motor is positioned behind the mounting block along a longitudinal axis of the gun. The torch barrel curves away from the longitudinal axis. The motor and the torch barrel are surrounded by a substantially rigid shell comprising a tubular portion and a torch portion.

Owner:KENSRUE MILO M

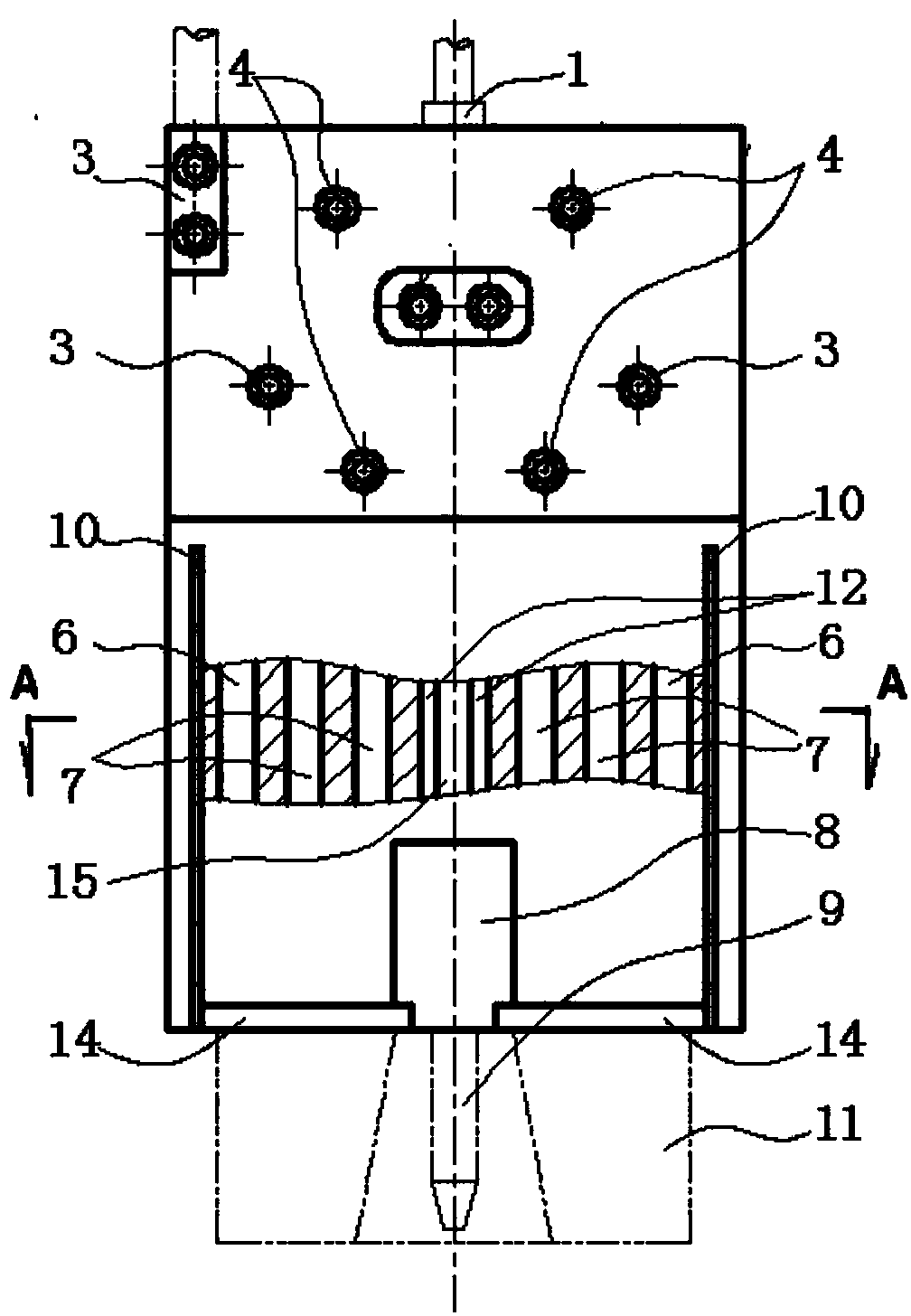

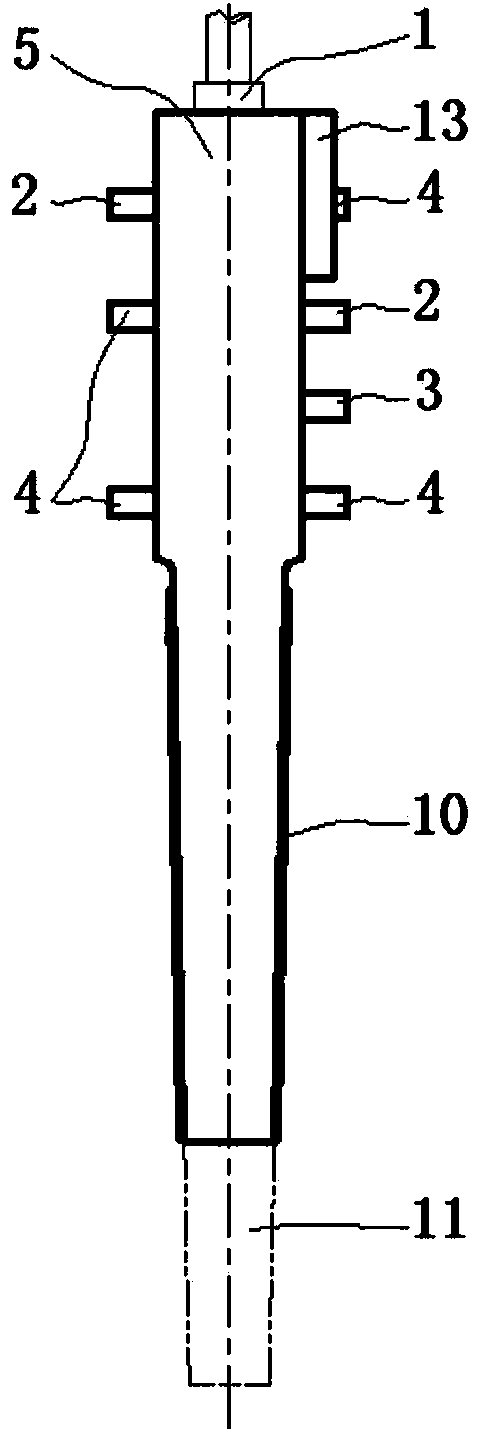

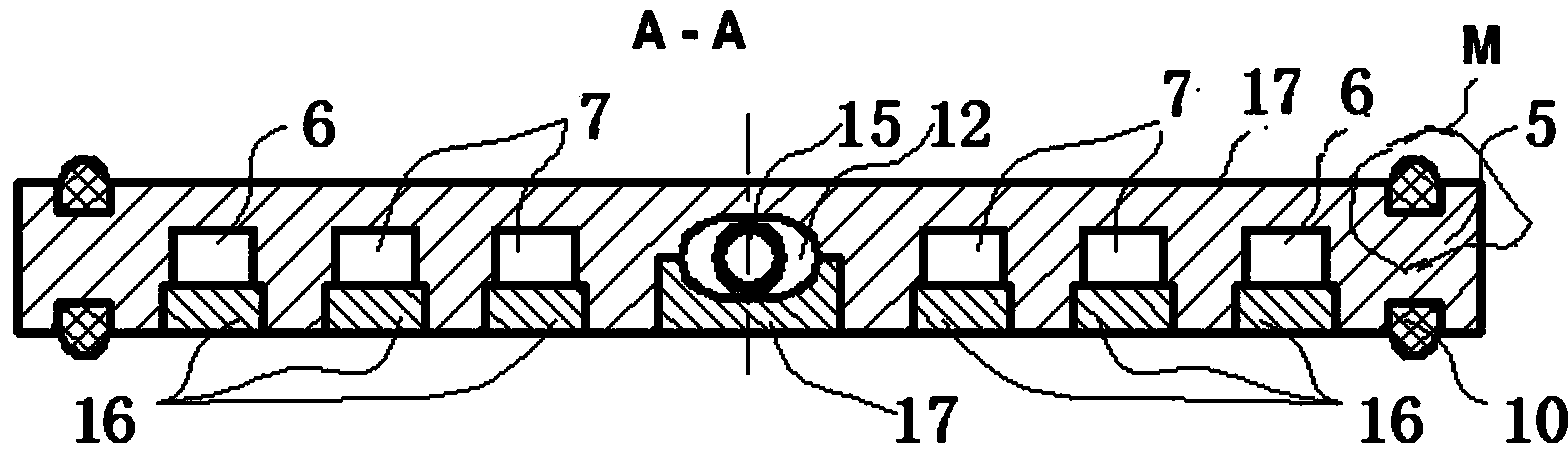

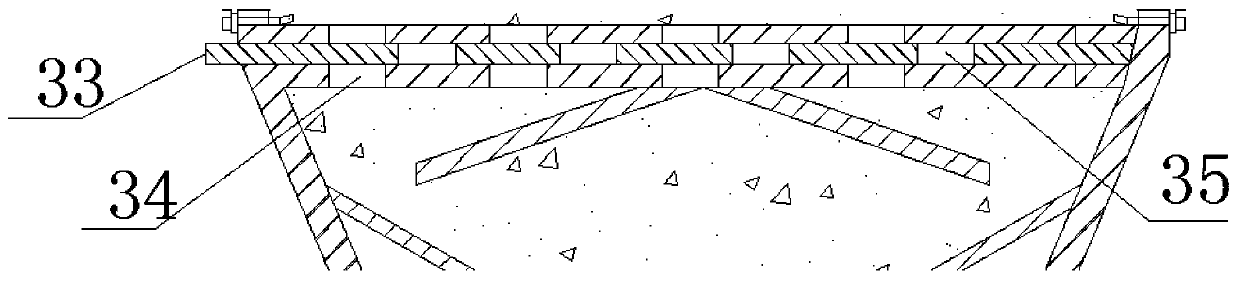

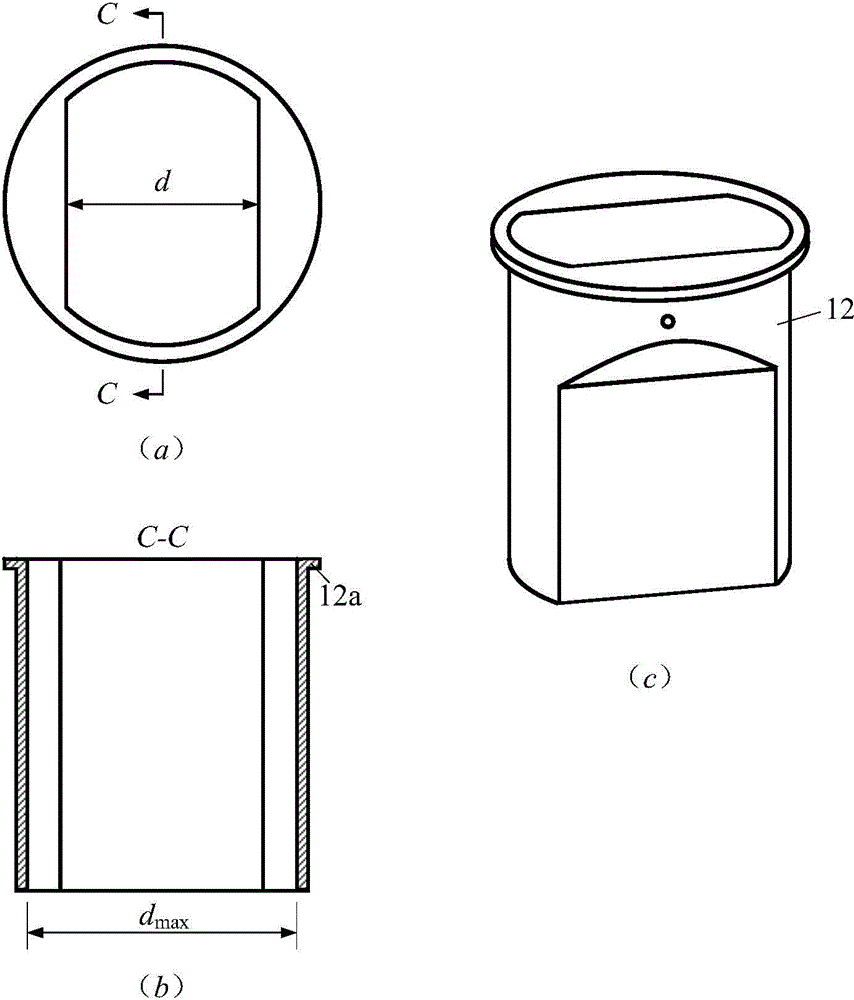

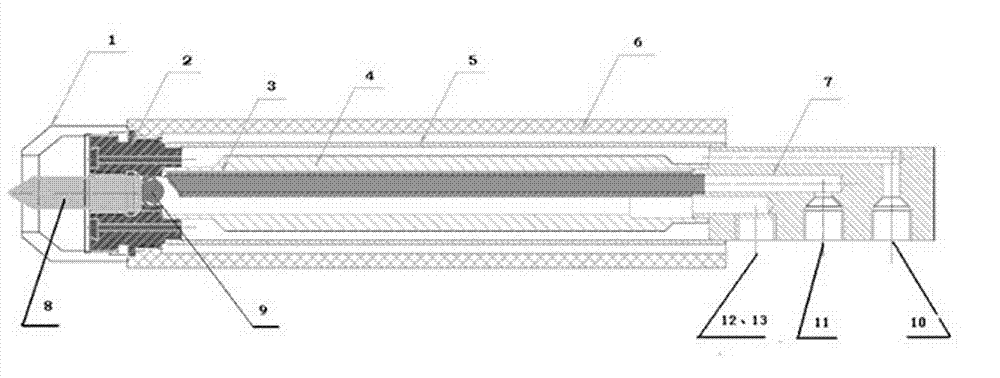

Automatic multifunctional narrow-clearance/super-narrow-clearance gas protection welding gun and manufacturing method thereof

ActiveCN104384683ASmall filling areaUniform fusion with high reliabilityCooled electrode holdersElectrode accessoriesCeramic coatingPipe

The invention relates to an automatic multifunctional narrow-clearance / super-narrow-clearance gas protection welding gun and a manufacturing method thereof. The welding gun comprises a plate-type welding gun body; a guide wire channel, a circulating water cooling runner and a secondary protection gas runner are integrated in the welding gun body, a primary protection gas inlet sea, a secondary protection gas inlet seat, a water inlet pipe seat, a water return pipe seat and a welding cable are fixed on the upper part of the welding gun body, the lower part of the welding gun body is fixedly connected with a gas distribution device, and the gas distribution device is fixed on the lower part of the plate-type welding gun body through the body / a spray nozzle connecting component. The method comprises the steps of preparing raw materials, machining relevant parts, embedding and soldering a runner groove cover plate, embedding a ceramic strip, spraying ceramic coating on external parts, etc. The automatic multifunctional narrow-clearance / super-narrow-clearance gas protection welding gun has the advantages of high integration, high-speed guide wire, stability and reliability in electrical conduction and gas conduction, high efficiency in heat radiation, reliability in insulation, long service life, easiness in machining, low cost, good rigidness, integration of single-wire single gun and double-wire double gun, high working efficiency, safety and reliability.

Owner:武汉纳瑞格智能设备有限公司

Torch for arc welding gun

InactiveUS8552341B2Heat deteriorationInsulate from heatNon-shielding electrode holdersCooled electrode holdersShielding gasFlange

A welding torch comprising: a main cylindrical conductive assembly with a front diffuser section having a plurality of circumferentially spaced shielding gas diffuser orifices for directing shielding gas radially outwardly from the assembly, a forwardly facing threaded bore extending through a cylindrical support nose and an elongated wire passageway coaxial with the threaded bore and opening at the rear end of the assembly. An insulated, cylindrical protective sleeve fitted around both the support nose and the diffuser orifices where the sleeve has a front clearance opening and circumferentially spaced openings communicated with the diffuser orifices and a contact tip having a central wire guide bore with a diameter only slightly larger than the diameter of the welding wire, a threaded rear body, a front extension passing through the front clearance opening and a radially extending flange between the rear body and the front extension to hold the protective sleeve around the nose when the body is screwed into the threaded bore of the main assembly.

Owner:LINCOLN GLOBAL INC

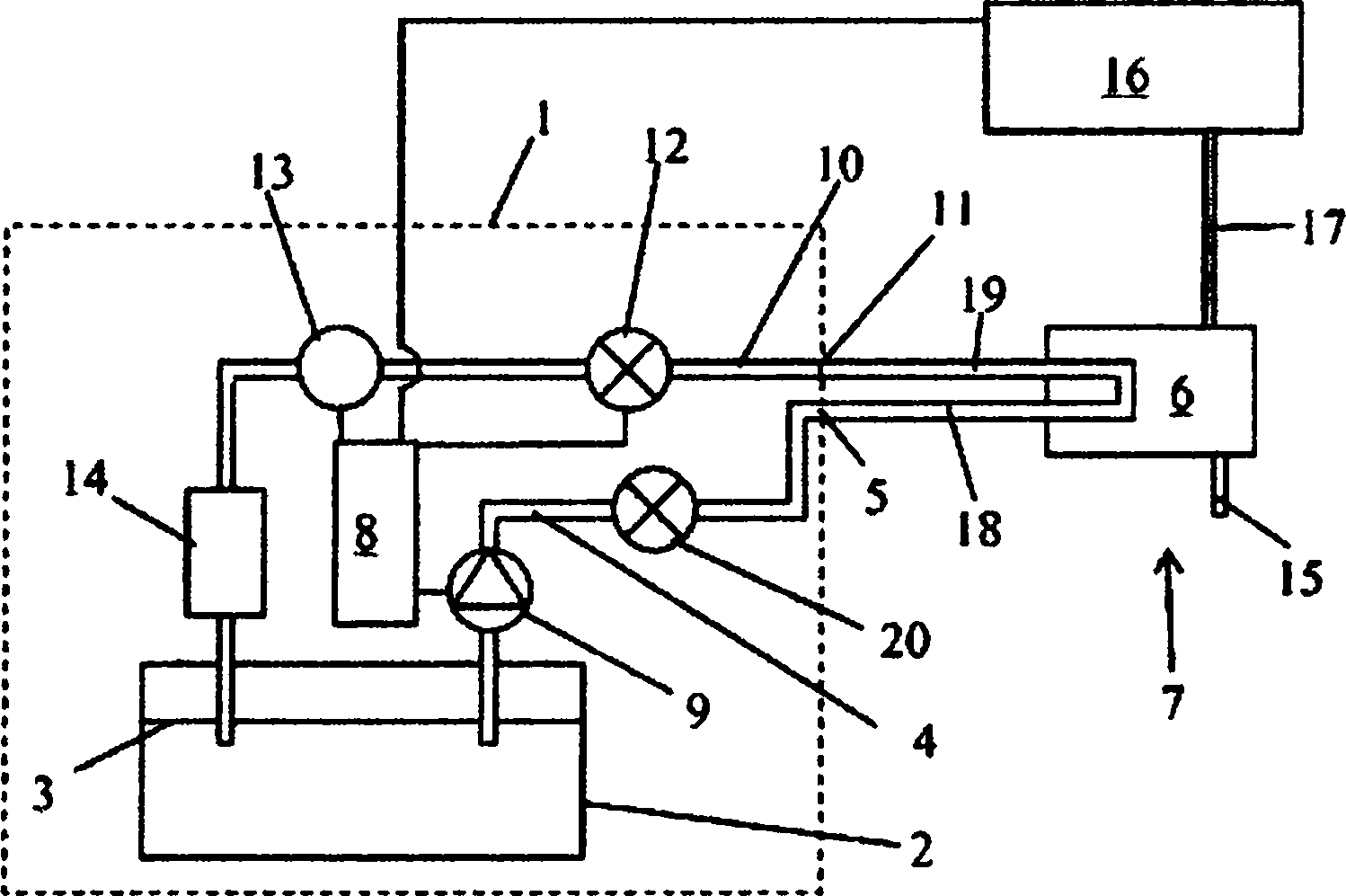

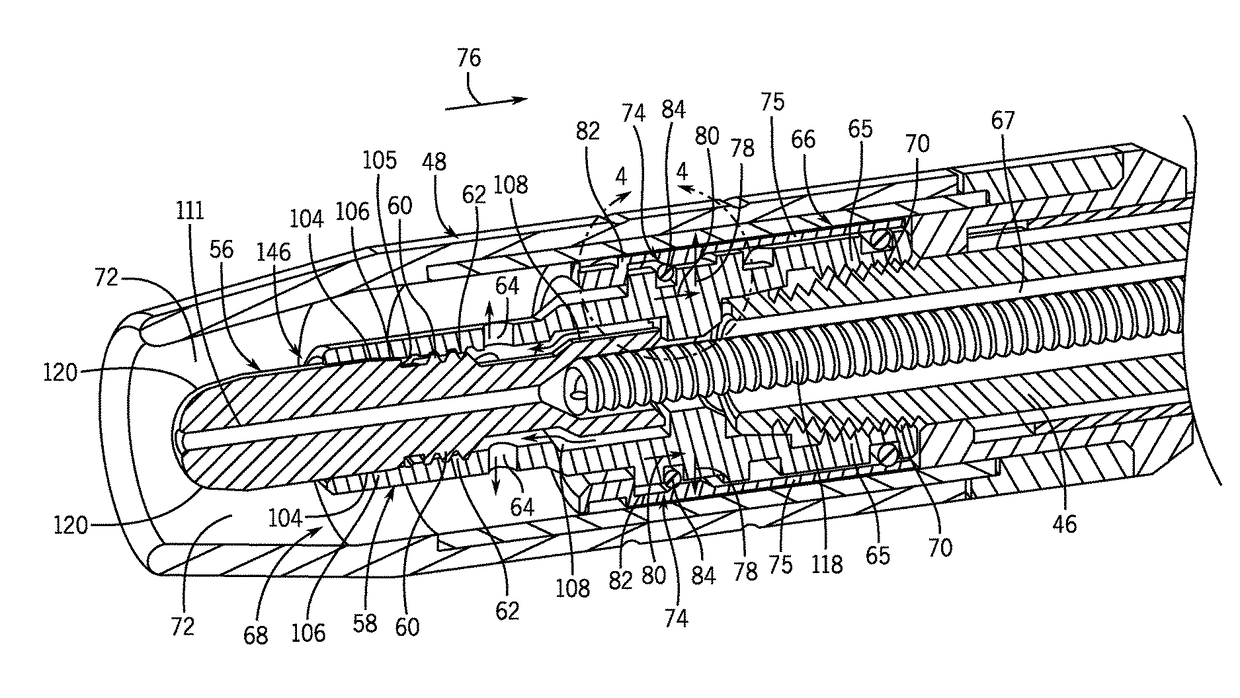

Method and apparatus to adaptively cool a welding-type system

InactiveUS20050016978A1Support devices with shieldingCooled electrode holdersNuclear engineeringBiological activation

A cooling system connected to provide coolant to a welding-type component automatically circulates coolant through the welding component upon activation of the welding component. A controller is configured to regulate the cooling system such that upon activation of the welding-type component coolant is caused to at least flow through the welding-type component and circulate after deactivation of the welding torch until a temperature of the coolant falls below a certain value or a specified time period has expired. The cooling system is constructed to be integrally disposed within a power source housing.

Owner:ILLINOIS TOOL WORKS INC

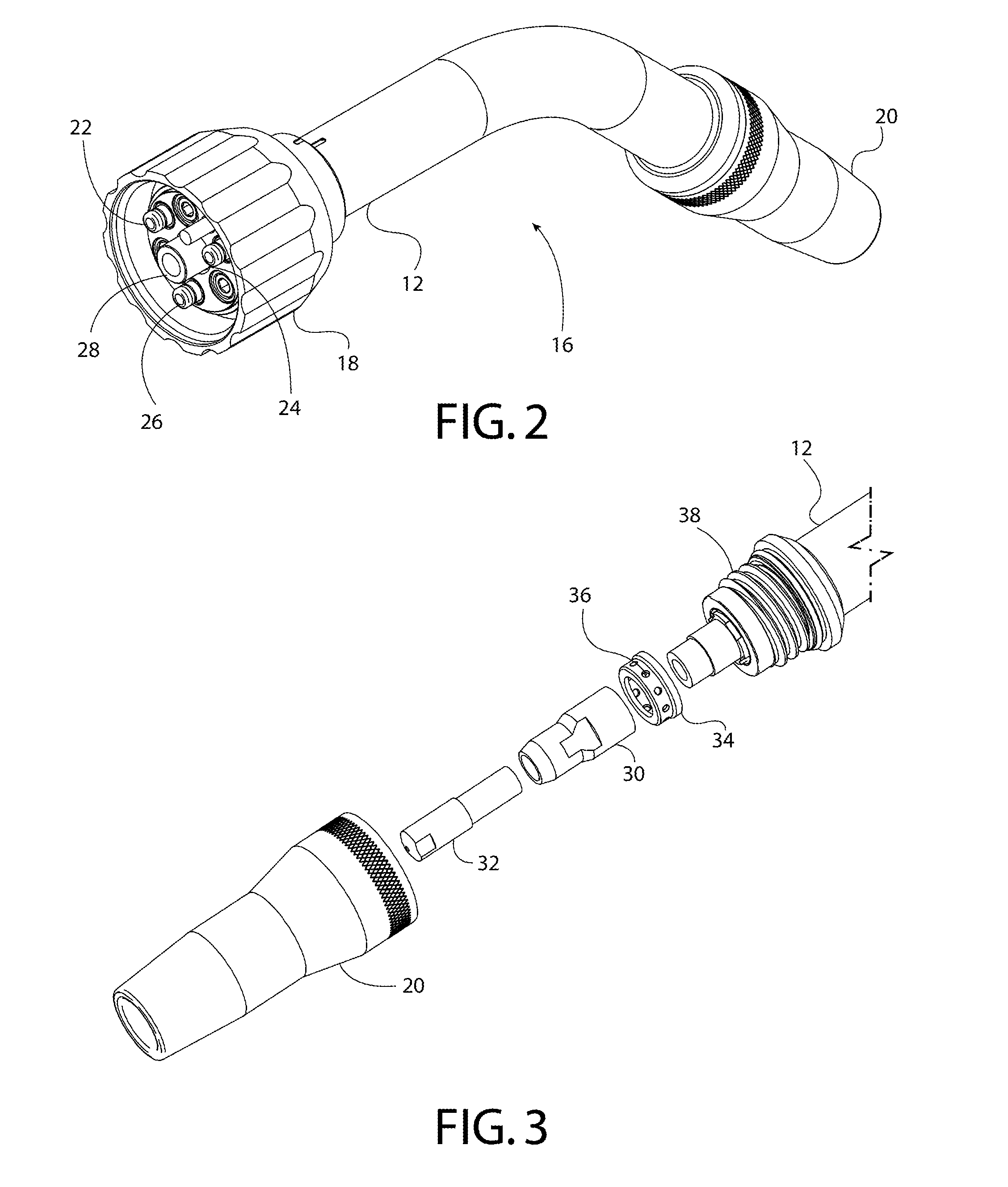

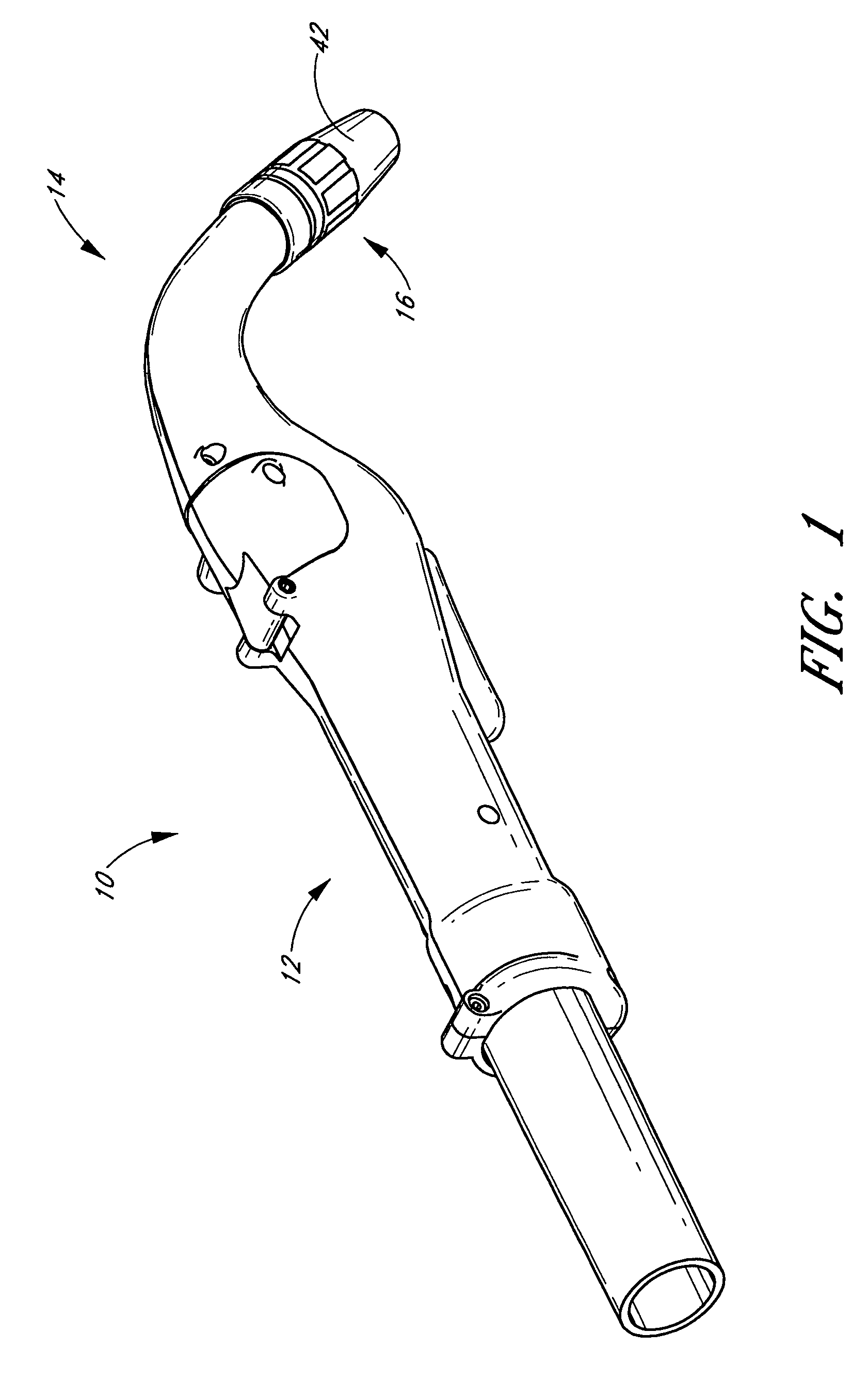

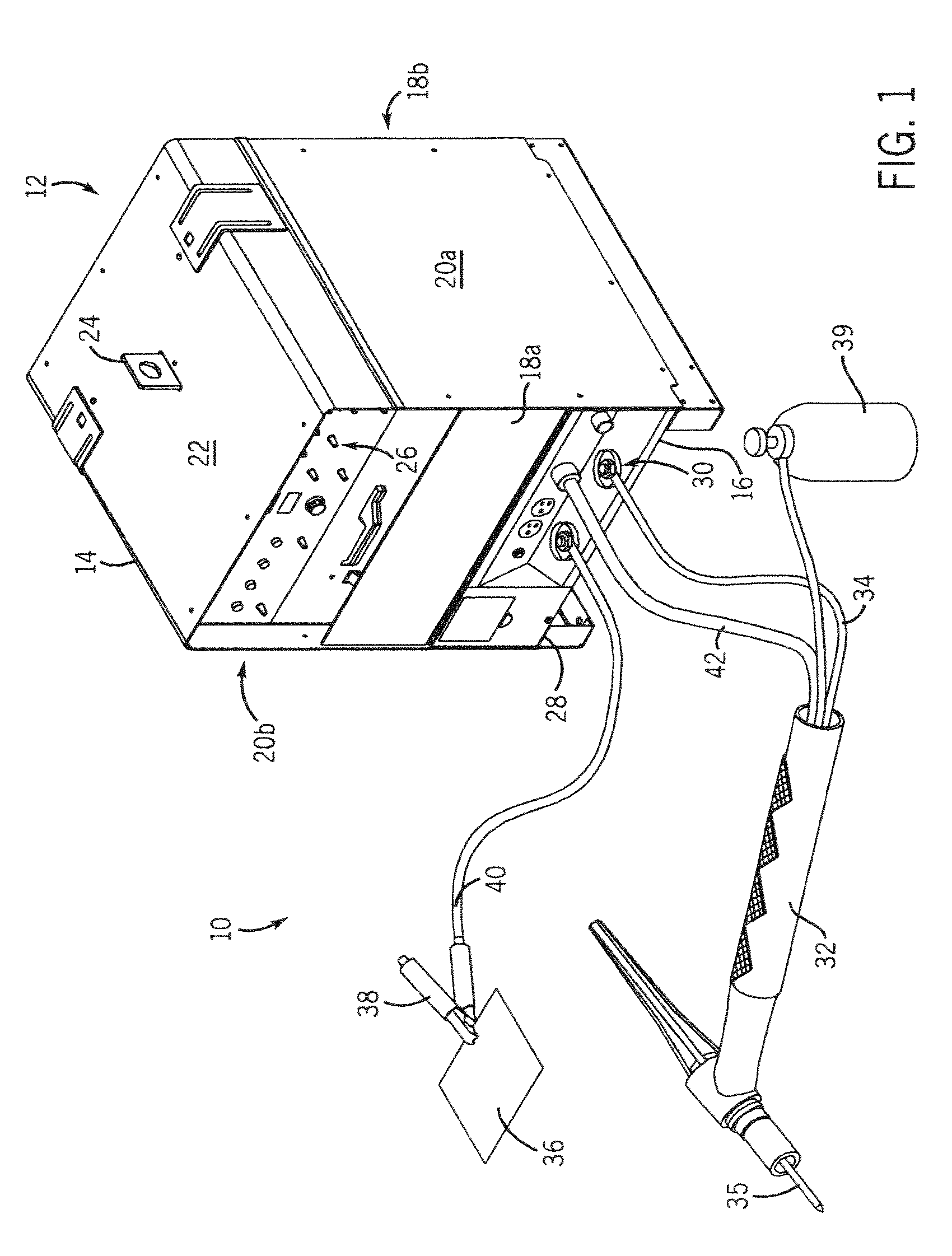

Welding torch having removable handle and method of operating same

InactiveUS7105766B2Avoid arcingElectric discharge heatingCooled electrode holdersElectricityEngineering

A welding torch having a torch body that is adapted to receive a welding electrode. A collet and collet body, or other mechanism, may be used to secure the electrode to the torch body. The welding torch has a handle that is securable to the torch body, but which may be selectively removed from the torch body. The welding torch may be operated with the handle removed. The welding torch is adapted to prevent arcing from the torch body to a surrounding surface when the handle is removed. The welding torch also may have a cable that is adapted to convey gas and electricity that is affixed to the torch body. The torch body may have an electrical connector disposed within the torch body for connection to the cable operable to convey gas and electricity. The cable and torch may also be adapted to provide cooling water to the torch body. The torch body may also be flexible.

Owner:ILLINOIS TOOL WORKS INC

Welding torch with enhanced cooling

InactiveUS20060226132A1Improve cooling effectGood curative effectCooled electrode holdersEngineeringBiomedical engineering

In accordance with one embodiment, the present invention relates to a welding torch. The welding torch includes a first hollow member through which wire electrode is routed and that has a plurality of protrusions that extend from an inner surface thereof. Advantageously, these protrusions of the exemplary welding torch increase the surface area of the first hollow member, and increasing the surface area improves the ability of the welding torch to dissipate heat to the surrounding environment, for instance.

Owner:ILLINOIS TOOL WORKS INC

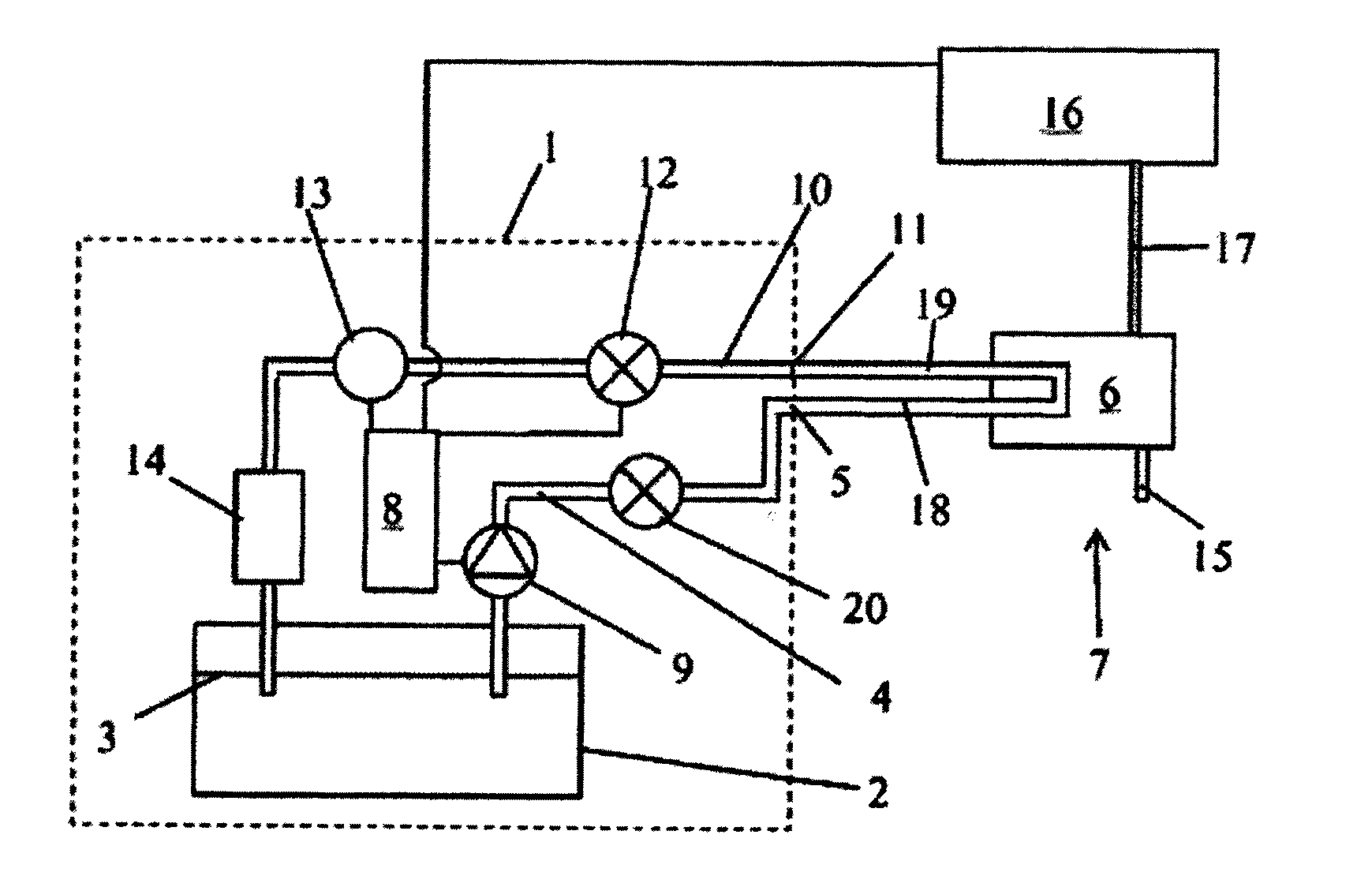

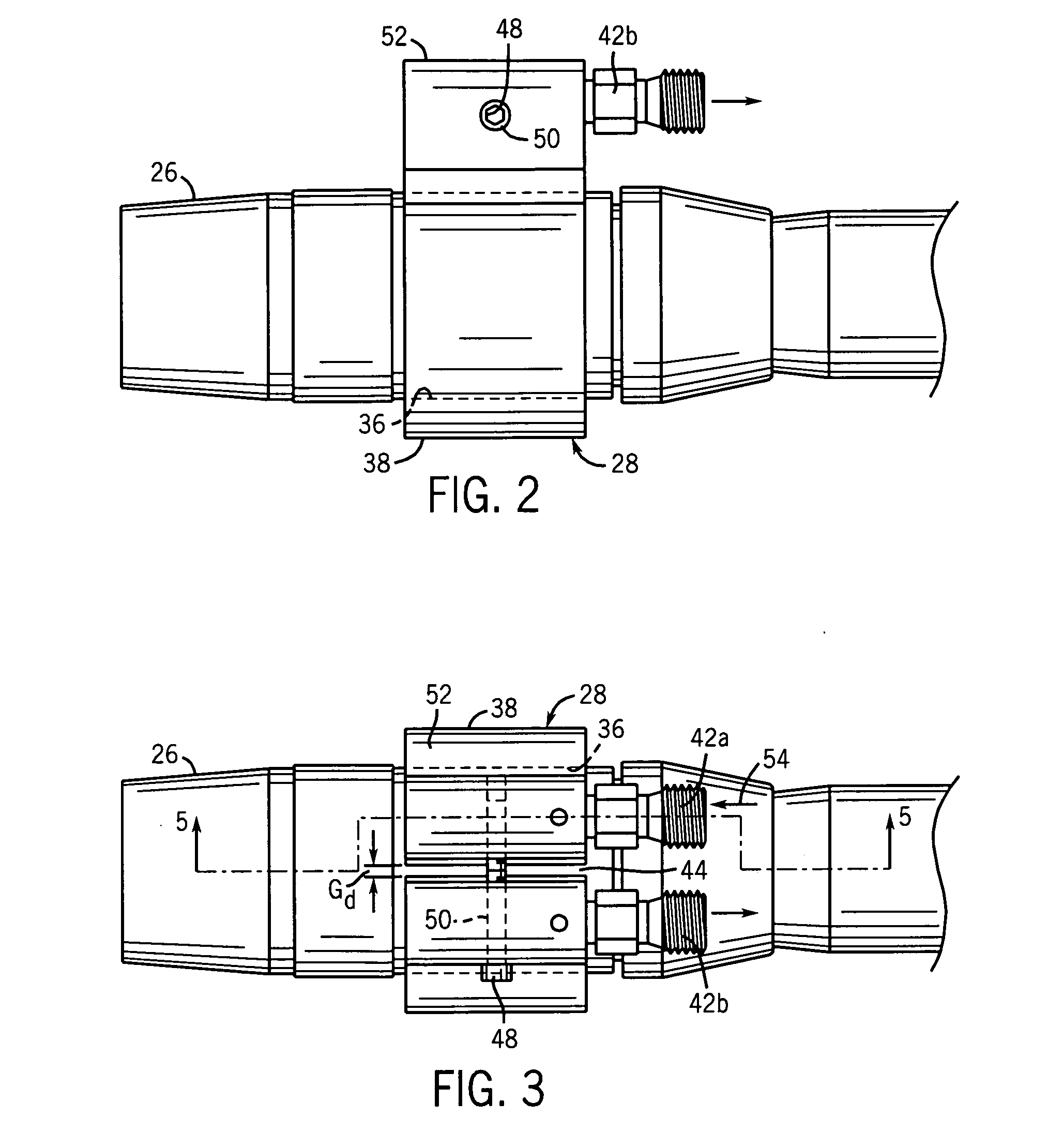

System for cooling a liquid-cooled welding device

A liquid-cooled welding device comprising a torch head body having a helical cooling fin extending along a length of the torch head body. A sleeve may be disposed around the torch head body to define a flow channel over the torch head body. The sleeve may have a liquid inlet and a liquid outlet to enable liquid to flow into and out of the flow channel. The liquid outlet may be located adjacent to the liquid inlet. The liquid-cooled welding device may have a baffle disposed within the sleeve between the liquid inlet and the liquid outlet to direct liquid to flow along the length of the torch head body to enable the helical cooling fin transfer heat to the liquid.

Owner:ILLINOIS TOOL WORKS INC

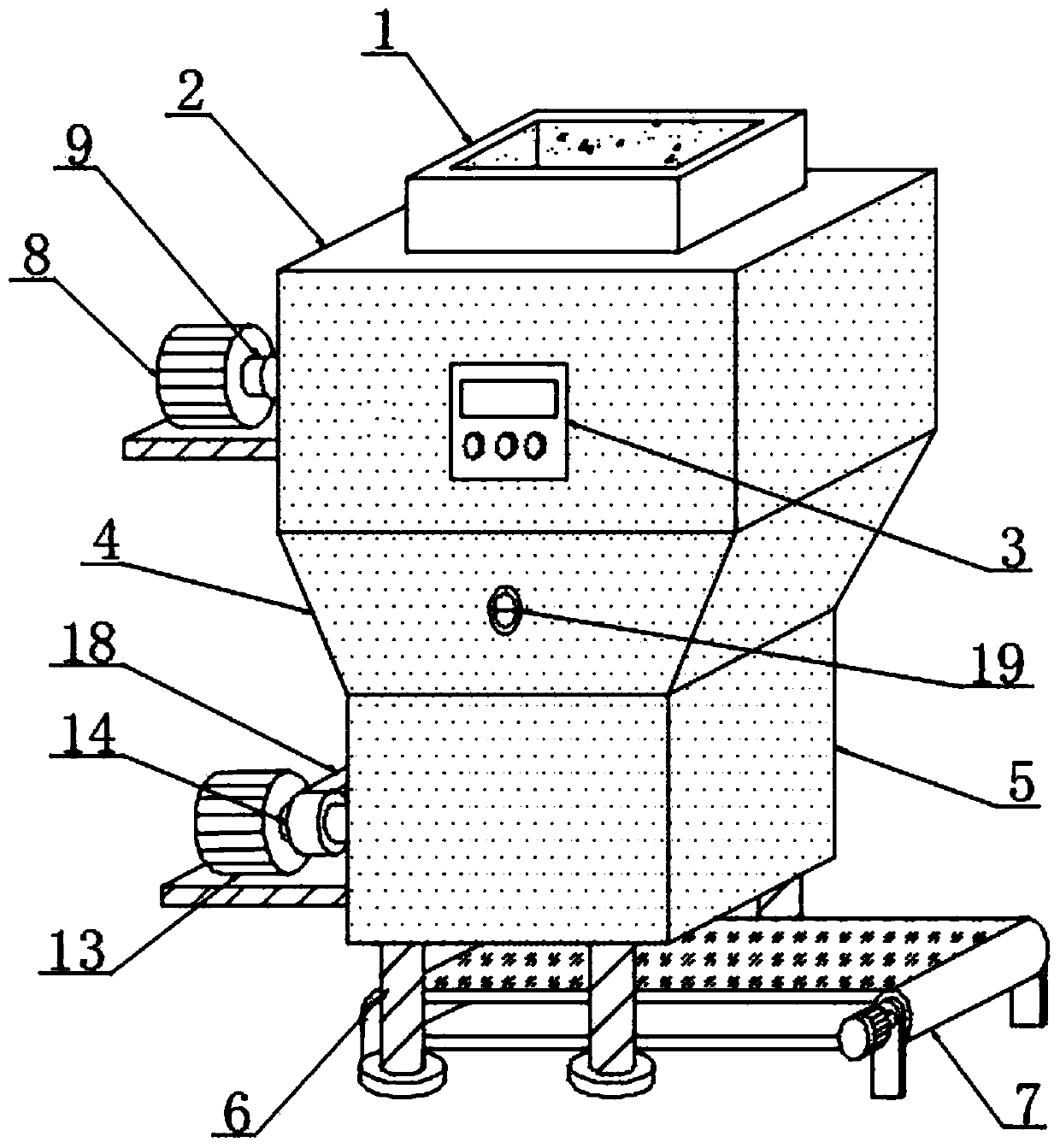

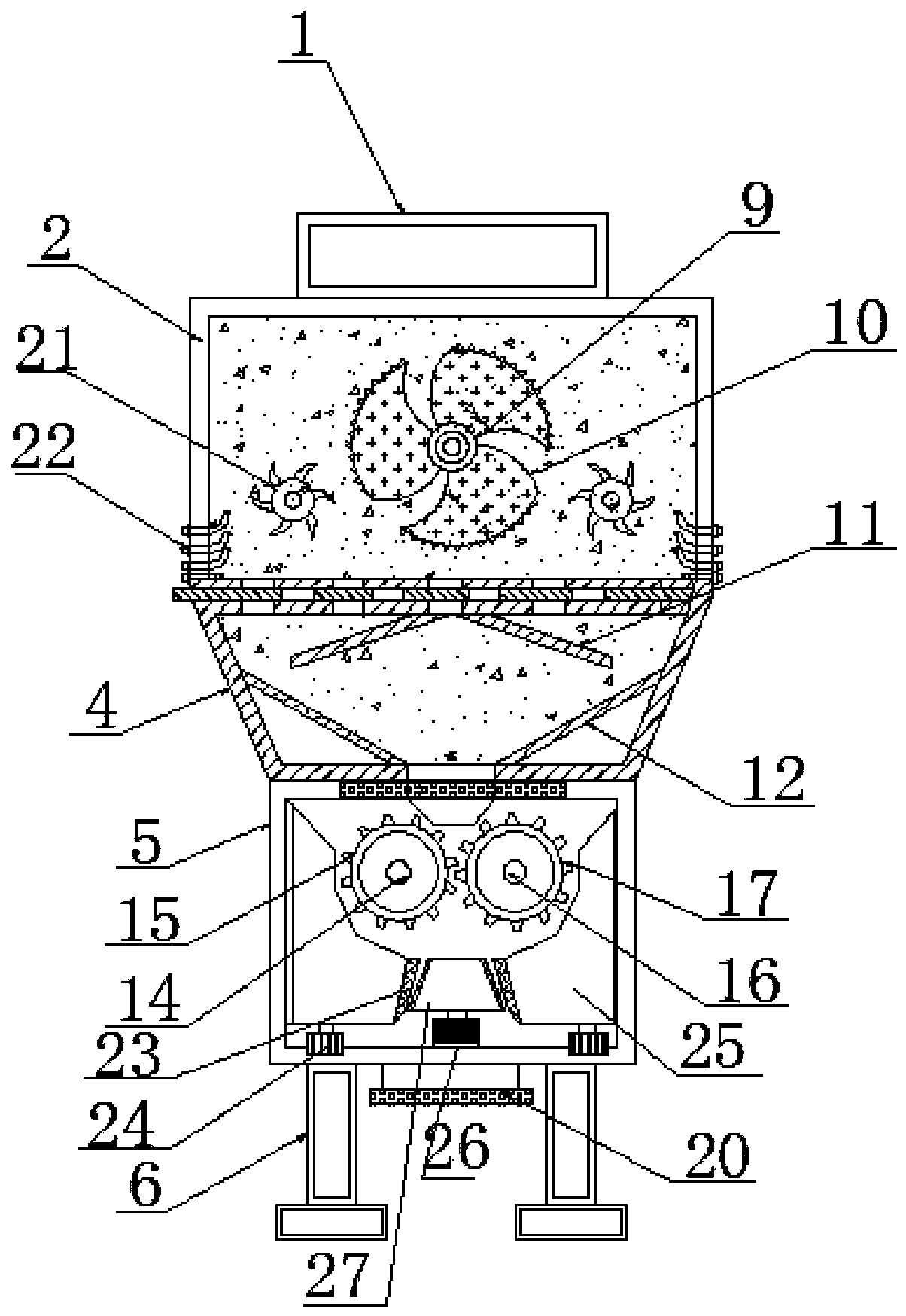

Temperature control type raw material grinding and crushing device for processing concentrated feed for aquatic products

ActiveCN109833951ARealize crushing workRealize the drying workFeeding-stuffWeld torches cleaningTemperature controlAquatic product

The invention discloses a temperature control type raw material grinding and crushing device for processing concentrated feed for aquatic products. An opening and closing control assembly is arrangedbetween a crushing box and a drying box so as to control discharging of materials in the crushing box, and the crushing box is internally provided with a flying stirring assembly enabling the to-be-crushed materials to move upwards, so that the materials can fly to the crushing assembly to be crushed; and the grinding assembly comprises a primary rough grinding assembly and a secondary fine grinding assembly, the primary rough grinding assembly is used for primary coarse grinding of the materials, the secondary fine grinding assembly is used for secondary fine grinding of the materials, the temperature of the inside of the drying box can be monitored in real time through the temperature sensors arranged at the same time, the temperature can be conveniently adjusted according to the humidity of the raw materials, and the grinding treatment of the feed raw materials is realized through the arranged grinding box; and a conveying machine is arranged, so that the automatic conveying work ofthe materials after grinding can be realized, the labor is saved, and the working efficiency is improved.

Owner:惠安先锋机械有限公司

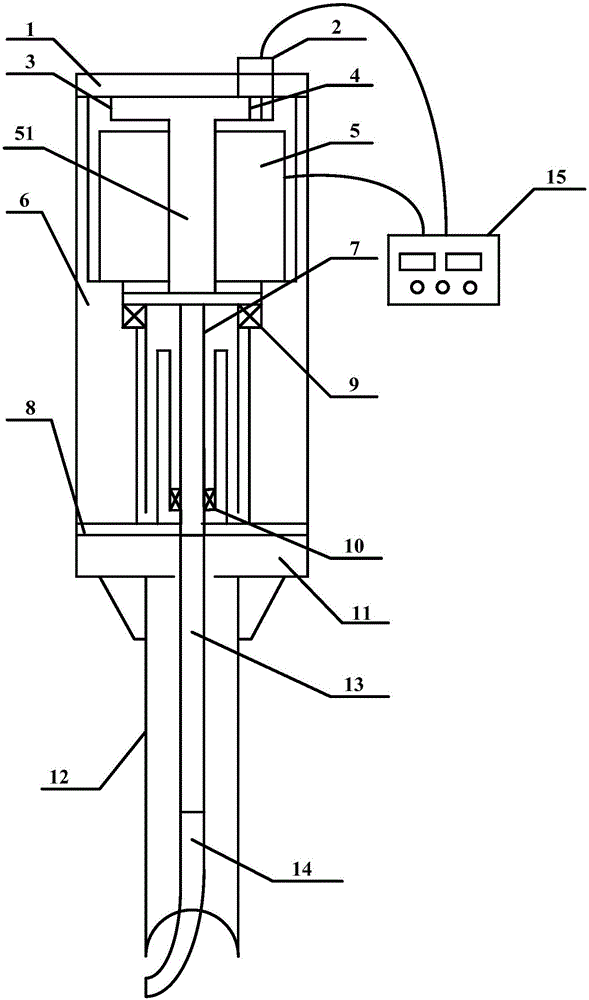

Rotary swing type welding torch and welding method

InactiveCN106180994AEasy to set upIncrease heat inputCooled electrode holdersElectrode accessoriesEngineeringWelding torch

The invention provides a rotary swing type welding torch. The rotary swing type welding torch comprises a current contact nozzle, a rotary swing driving mechanism and a control device, wherein the control device is connected with the rotary swing driving mechanism so as to control the rotary swing driving mechanism to move, and the movement output end of the rotary swing driving mechanism is connected with the current contact nozzle so as to adjust the position of the current contact nozzle and / or enable the current contact nozzle to make rotary swing movement according to preset swing parameters. According to the rotary swing type welding torch, two operating modes of swing and rotation can be realized, so that heat input to the side wall of a groove can be increased by virtue of electric arc swing, and the problem of poor fusion of the side wall and the bottom of the groove during narrow gap welding of large-thickness plates is solved. The invention further provides a welding method.

Owner:HARBIN INST OF TECH AT WEIHAI

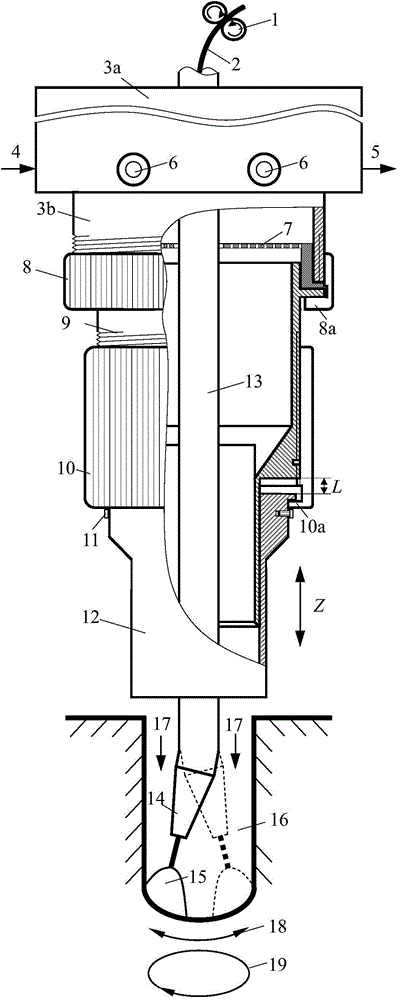

Telescopic nozzle device for narrow gap welding and adjusting method of telescopic nozzle device

ActiveCN103600160APrevent getting involvedNovel adjustment methodShielding gas supply/evacuation devicesCooled electrode holdersWeld seamEngineering

The invention discloses a telescopic nozzle device for narrow gap welding and an adjusting method of the telescopic nozzle device. The nozzle device sequentially comprises a nozzle holder, an air sifter cover, a locking nut, a gas calm sleeve, a telescopic adjusting nut and a movable nozzle sleeve from top to bottom, one end of the gas calm sleeve is fixedly connected with the nozzle holder through the locking nut, the other end of the gas calm sleeve is in transmission connection with the telescopic adjusting nut through a thread pair, the movable nozzle sleeve can vertically move along the axial direction of a nozzle under driving of the telescopic adjusting nut, so that the extending length of the movable nozzle sleeve is changed, and the overall axial length of the nozzle is telescopically adjusted. The telescopic nozzle device is compact in structure, convenient to telescopically adjust and wide in effective gas protection range, an inner cavity of the nozzle is fine in gas tightness, and gas protection can be provided for welding seams with different depths in narrow gap grooves.

Owner:JIANGSU UNIV OF SCI & TECH

Efficient water-cooling argon arc welding gun

The invention provides an efficient water-cooling argon arc welding gun. The efficient water-cooling argon arc welding gun is composed of a handle, a gun head body, a gun head body protecting sleeve, a rear cap, a tungsten electrode rod, a tungsten electrode clamp, an inner heat insulation sleeve, an outer heat insulation sleeve, an outer connection sleeve, a spray nozzle connection ring and a ceramic spray nozzle, wherein the middle of the handle is provided with a gas inlet pipe, a water inlet pipe and a water outlet pipe; the right end of the handle is connected with a machine head body outer sleeve covering the exterior of the gun head body; the lower end of the gas inlet pipe is connected with a gas inlet hole in the side face of the upper end of the gun head body; the gas inlet hole communicates with a vertical through hole in the center of the gun head body; the tungsten electrode clamp is arranged in the middle of the vertical through hole; the tungsten electrode rod penetrates a middle hole of the tungsten electrode clamp; an annular groove is machined in the middle of the outer circle of the gun head body; the exterior of the annular groove is closely sleeved with the inner circle of the inner heat insulation sleeve, and the annular groove is closed into a water-cooling sleeve; the water inlet pipe and the water outlet pipe communicate with the water-cooling sleeve; the outer heat insulation sleeve is arranged outside the inner heat insulation sleeve; the exterior of the outer heat insulation sleeve and the inner circle at the upper end of the ceramic spray nozzle are connected together in a sleeving manner; the outer connection sleeve is arranged at the lower end of the gun head body protecting sleeve; the spray nozzle connection ring is connected to the lower end of the outer connection sleeve and connected with the outer circle at the upper end of the ceramic spray nozzle in a thread screwing manner; and the rear cap is arranged at the top end of the gun head body.

Owner:济南尼克焊接技术有限公司

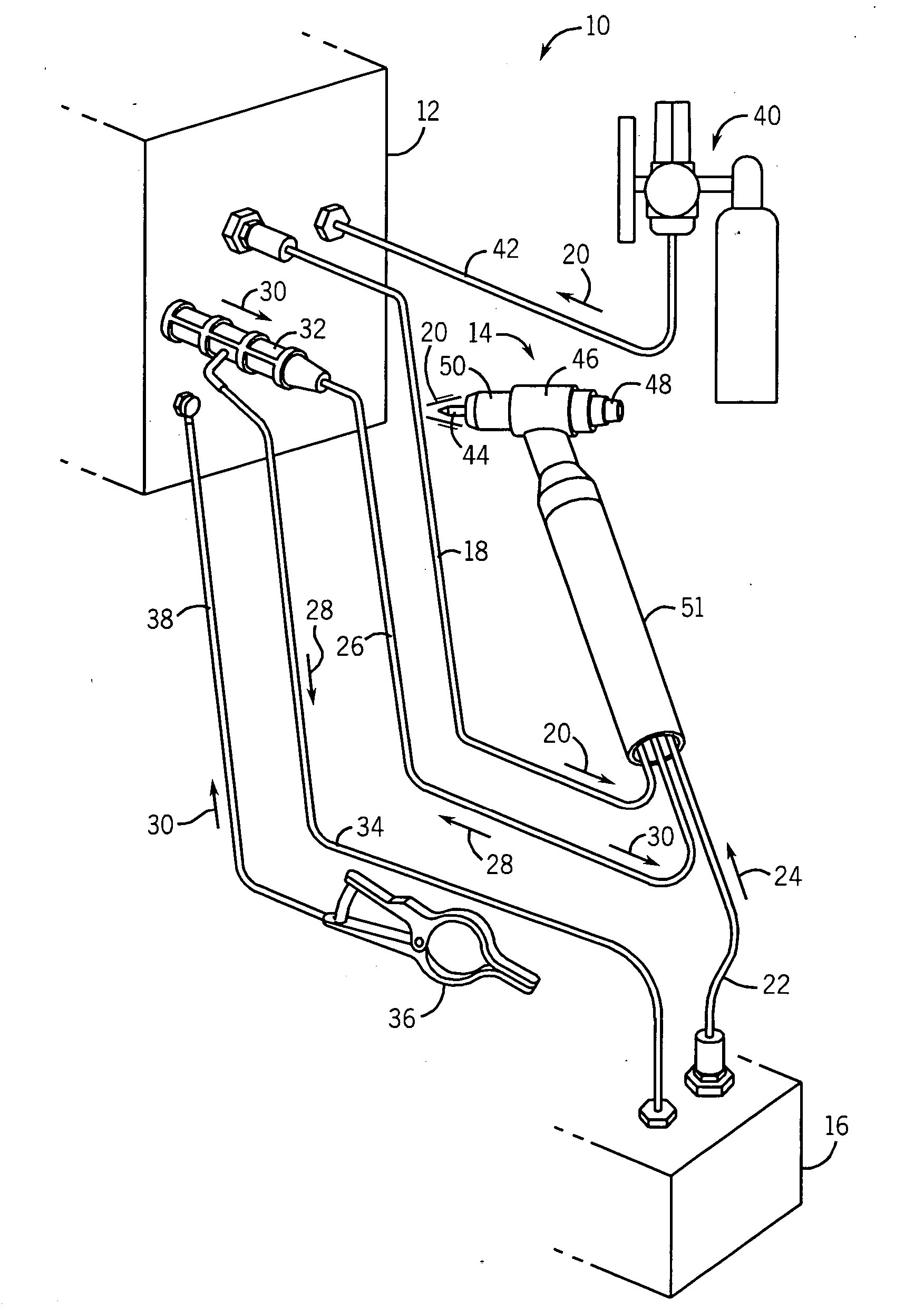

Torch connection detection system and method

ActiveUS20050205542A1Avoid loopsCooled electrode holdersWelding coupling meansCoolant flowEngineering

Owner:ILLINOIS TOOL WORKS INC

Cooling device for welding device

Owner:ESAB AB

Removable nozzle-cooling mechanism

InactiveUS20070215587A1Easy to adjustPromote circulationCooled electrode holdersEngineeringCooling fluid

A removable cooling collar is provided for cooling the nozzle of a welding nozzle. This collar includes first and second parts in fluid communication with a chamber that extends circumferentially within a hollow structure. Cooling fluid circulating through the chamber facilitates dissipation and / or extraction of heat in the nozzle, in turn reducing the likelihood of weld splatter adhesion on the nozzle.

Owner:ILLINOIS TOOL WORKS INC

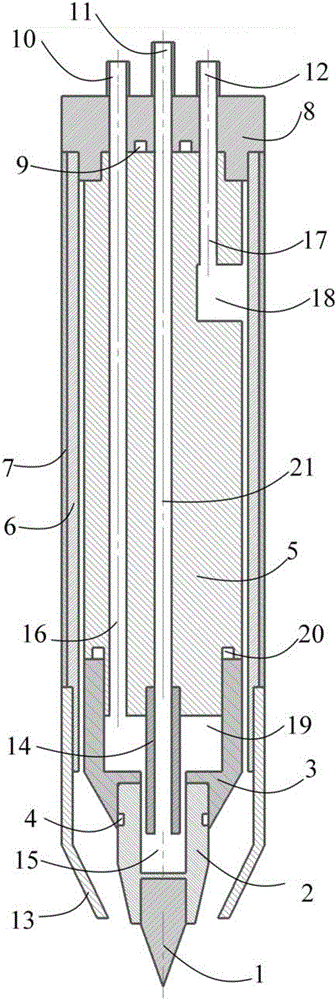

Water-cooling TIG welding gun with copper-coated tungsten electrode on basis of cathode compression effect

ActiveCN105983774AStrong compressionStrong penetrating powerCooled electrode holdersElectrode accessoriesShielding gasEngineering

The invention relates to an argon tungsten-arc welding gun and discloses a water-cooling TIG welding gun with a copper-coated tungsten electrode on the basis of cathode compression effect. The water-cooling TIG welding gun comprises a center column with the upper part connected to a tail cover and the lower part connected to an electrode base, the lower part of the electrode base is connected to a porous electrode sleeve provided with an electrode tip internal hole chamber, and a tungsten electrode tip is installed at the lower end of the porous electrode sleeve in an embedded mode; a sleeve is arranged outside the center column, and a gap air channel is formed between the sleeve and the center column; the lower part of the sleeve is connected to a shielding gas hood; the tail cover is provided with a water outlet pipe, a water inlet pipe and an air inlet pipe, and a water return hole, a water inlet hole, a ventilation hole and a gas stilling chamber communicating with the gap air channel are correspondingly formed inside the gun body; a water spray nozzle communicating with the water inlet hole is connected to the bottom of the center column; a cooling water channel and a shielding gas channel are separated by an upper sealing ring and a lower sealing ring. According to the water-cooling TIG welding gun, cooling liquid is directly guided into the tungsten electrode for strongly cooling the tungsten electrode, the area of a cathode zone can be compressed, arc columns can be compressed more strongly, the penetrating power of arcs can be improved, and the welding arcs can have better penetrability.

Owner:TIANJIN UNIV

Tungsten inert gas welding torch with improved liquid cooling

ActiveUS20120152927A1Wave amplification devicesCooled electrode holdersThermal insulationLiquid cooling system

Systems and methods for improved liquid cooling of a tungsten inert gas (TIG) welding torch are provided. The improved welding torch may feature conduits for conveying coolant from a cooling system to a collar, which holds a tungsten electrode of the welding torch, and back. A coolant return conduit may be disposed in a coolant supply conduit to improve thermal insulation of an outer surface of the welding torch. Some embodiments may feature a helical channel formed in the collar for conveying coolant around the electrode multiple times before returning the coolant through the return conduit.

Owner:ILLINOIS TOOL WORKS INC

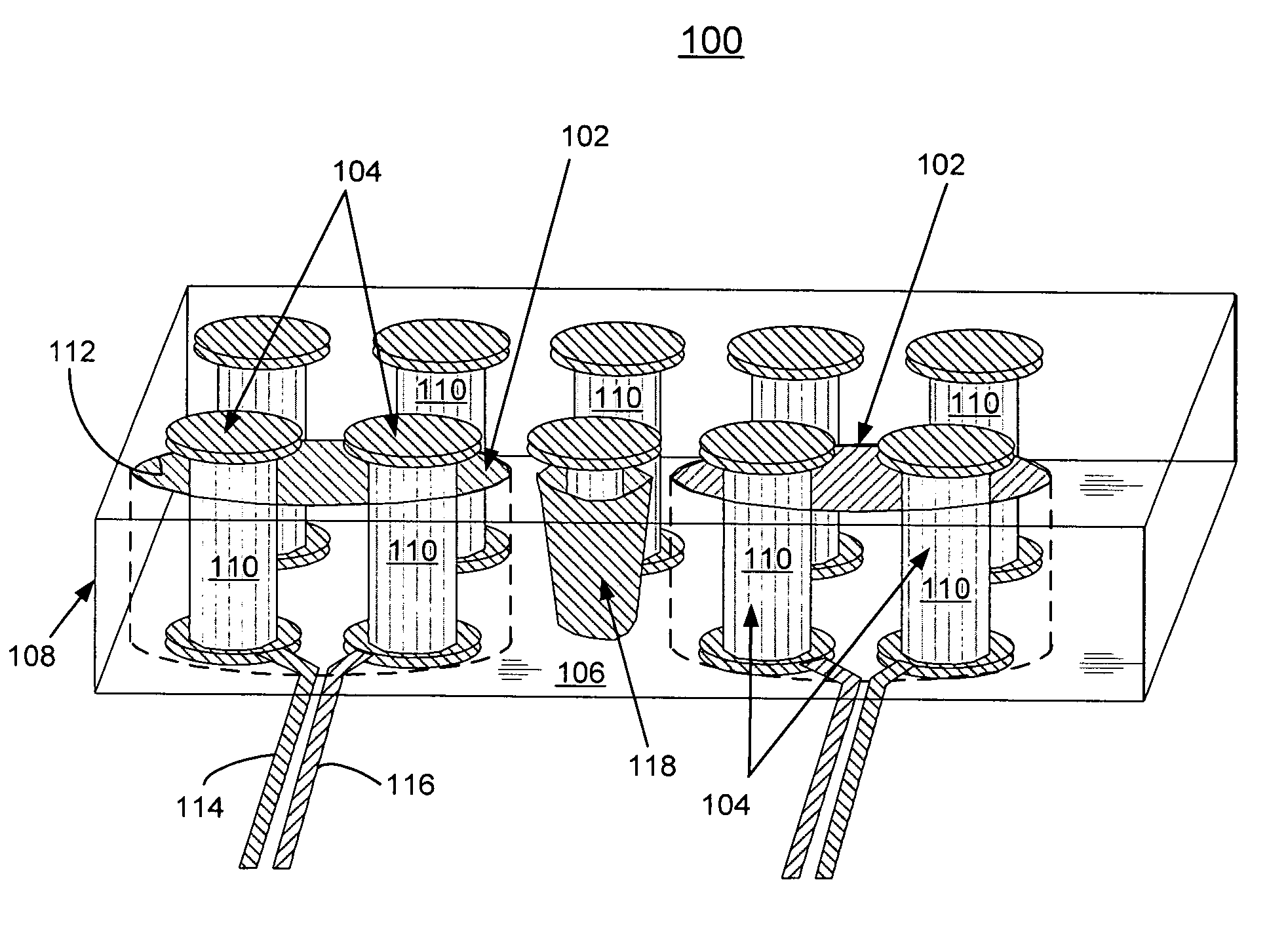

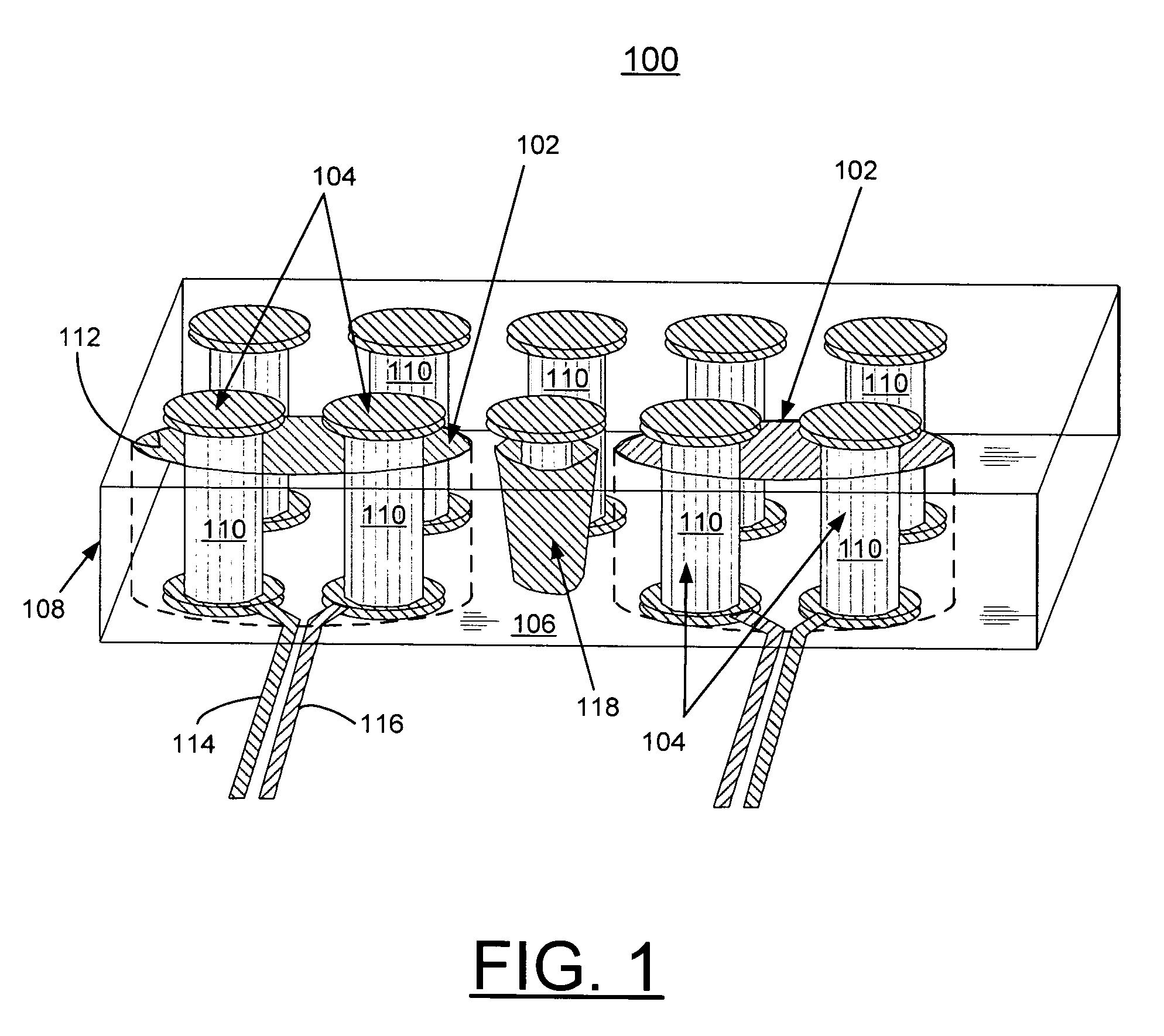

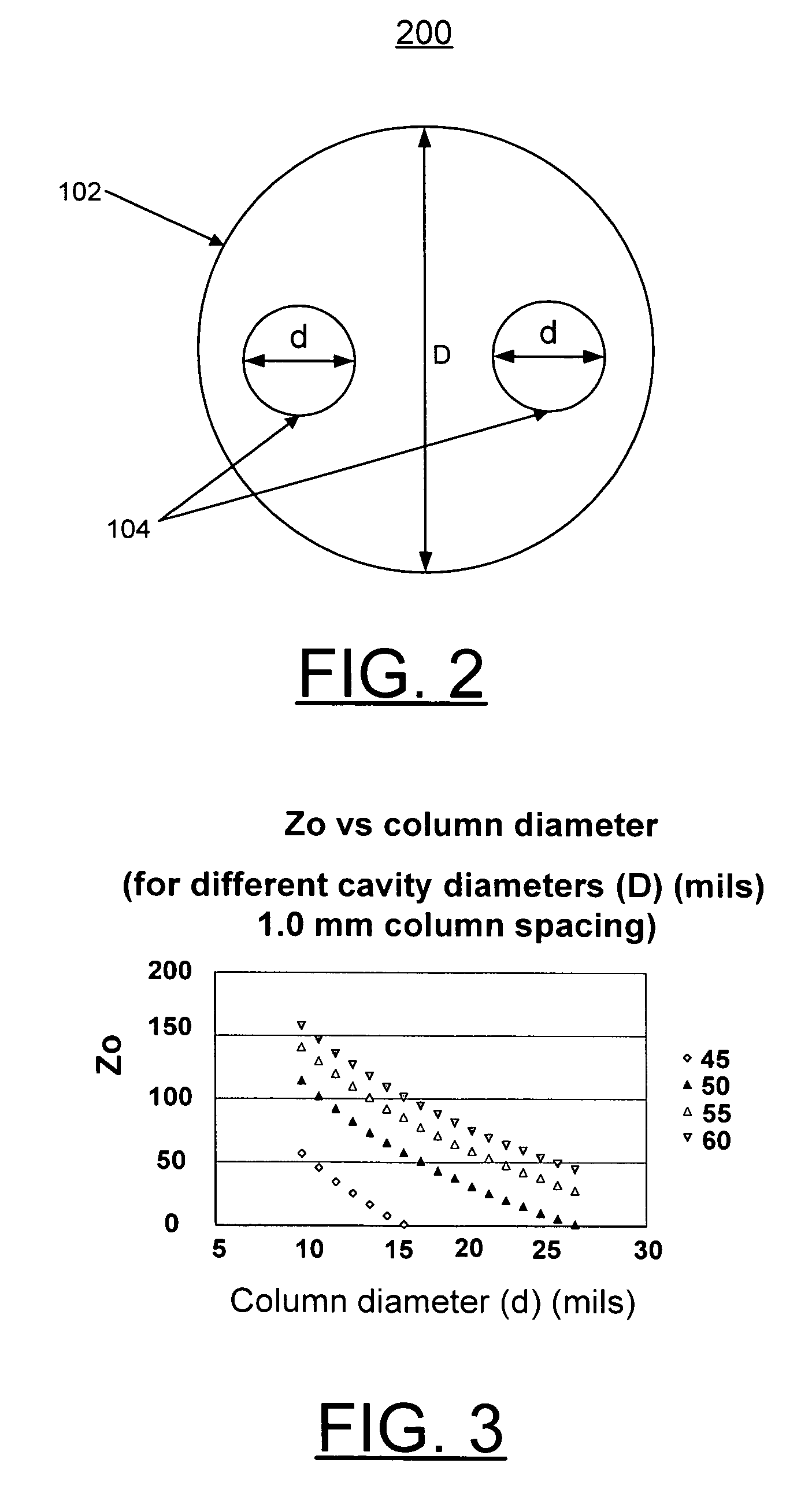

Method and structures for implementing impedance-controlled coupled noise suppressor for differential interface solder column array

InactiveUS7036710B1Noise minimizationCross-talk/noise/interference reductionPrinted circuit aspectsElectricityPower flow

A method and structures are provided for implementing an impedance-controlled coupled noise suppressor for a differential interface solder column array used to join a substrate to a circuit card. The impedance-controlled coupled noise suppressor structure includes a plurality of elongated through openings that are arranged in a predefined pattern with one or more of the through openings receiving a differential signal pair of solder columns. The elongated through openings have electrically conductive sidewalls and are electrically connected together. The predefined pattern of the elongated, electrically conductive through openings corresponds to a layout of solder columns. The solder columns are attached at opposite ends to a substrate and a circuit card. An electrical connection is provided between the impedance-controlled coupled noise suppressor structure and an image return current path of the circuit card.

Owner:IBM CORP

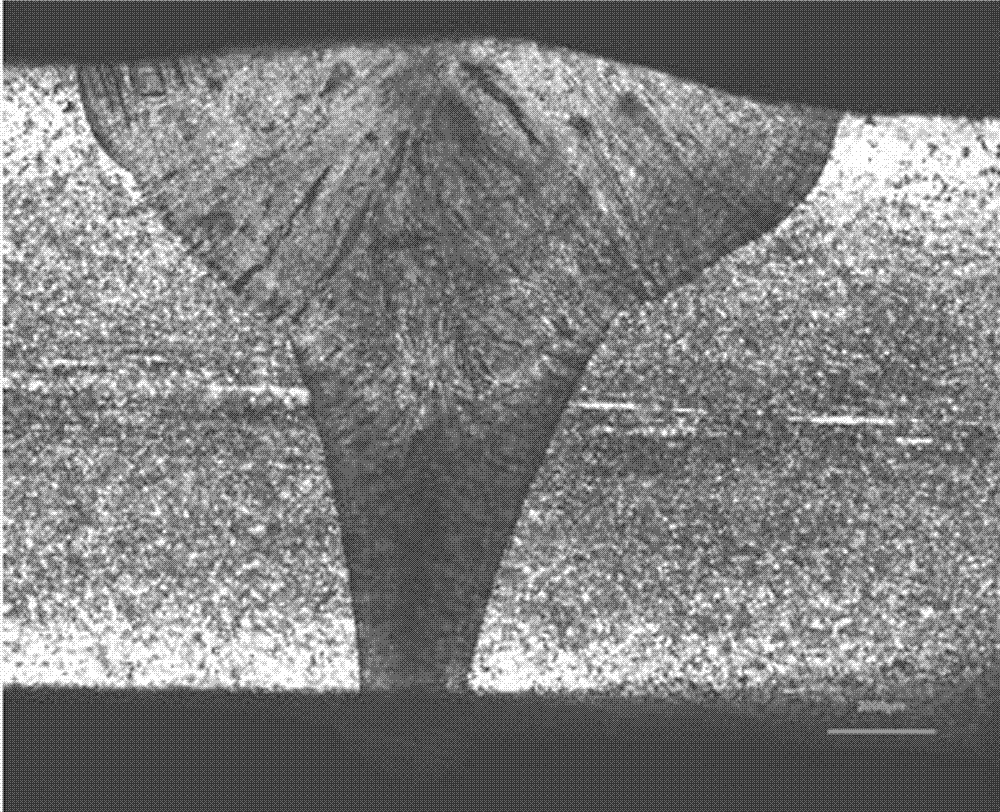

Welding gun of high-energy tungsten electrode inert gas welding and process thereof

InactiveCN104191075AIncrease electron densityIncrease energy densityCooled electrode holdersWelding/cutting media/materialsHigh energyWater flow

The invention discloses a welding gun of high-energy tungsten electrode inert gas welding. The welding gun comprises an outer insulation pipe, a tungsten electrode base in threaded connection with one end of the outer insulation pipe, and a ceramic nozzle in threaded connection with the tungsten electrode base, wherein a tungsten electrode is arranged in the ceramic nozzle, and is mounted on the tungsten electrode base; the other end of the outer insulation pipe is connected with a joint end; the welding gun further comprises a water cooling system; the water cooling system comprises a water way; one end of the water way is a water inlet end of the joint end, and the other end of the water way is a water outlet end of the joint end; and a sealing valve for controlling a water flow of cooling water is arranged between the water way and the tungsten electrode. According to the invention, the indirect cooling of the tungsten electrode in a traditional welding gun is changed to direct water cooling of the tungsten electrode, and the current density on the section of the tungsten electrode is increased through the change of cooling modes, so that the strong and concentrated electric arc force field and temperature field can be obtained through the self-magnetic shrinkage effect generated by electric arc, and the melting capacity of the electric arc is largely improved finally.

Owner:AOTAI ELECTRIC +1

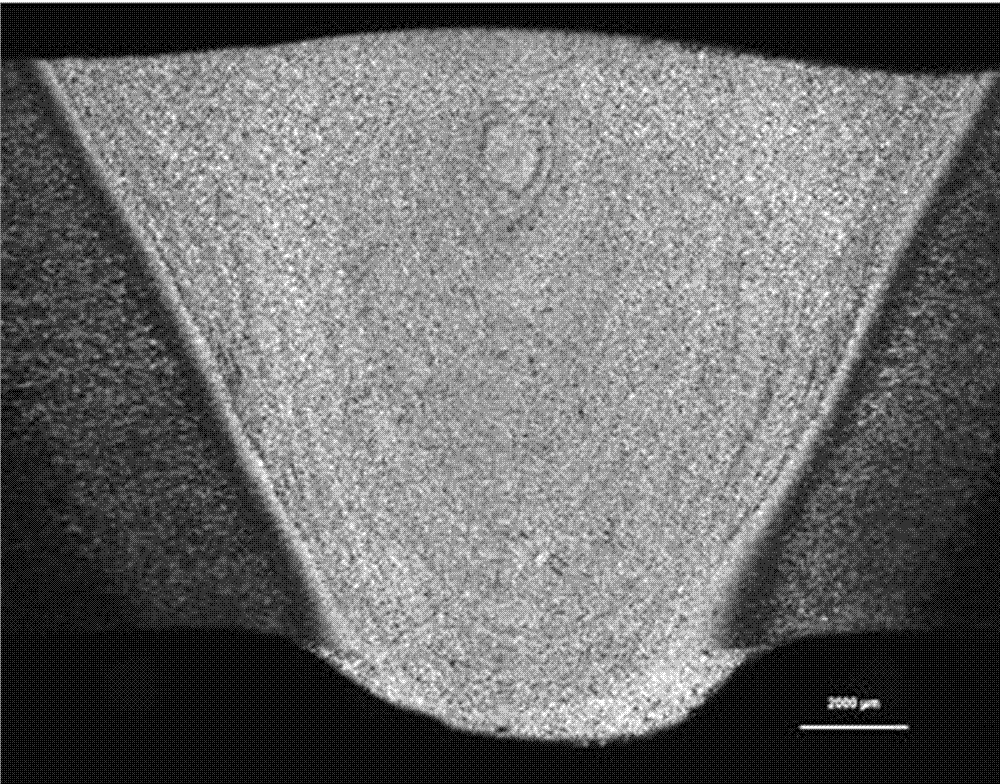

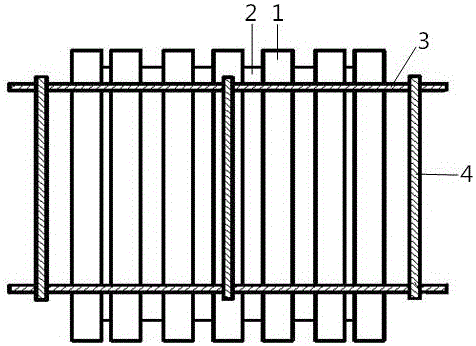

Welding method for nickel-based membrane type wall tube panel

ActiveCN106238866AAvoid deformationGuaranteed dimensional accuracy requirementsCooled electrode holdersEngineeringWeld line

The invention discloses a welding method for a nickel-based membrane type wall tube panel. The welding method includes the following steps that a tube panel is formed by nickel-based tubes (1) and nickel-based flat steel (2), and an anti-deformation tool (3) is arranged at each of the two ends of the tube panel; during welding, a specific welding sequence, a specific welding mode and specific welding line energy are adopted; and it is always kept that flowing cooling water exists in the tube panel in the welding process. The nickel-based tube panel is welded through the welding method, deformation and heat cracks, generated in the welding process, of the nickel-based tube panel can be effectively avoided, therefore, the dimensional precision requirement of the nickel-based tube panel is guaranteed, the repair amount of the nickel-based tube panel is reduced, the production period of the nickel-based tube panel is shortened, and the quality of the nickel-based tube panel is improved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

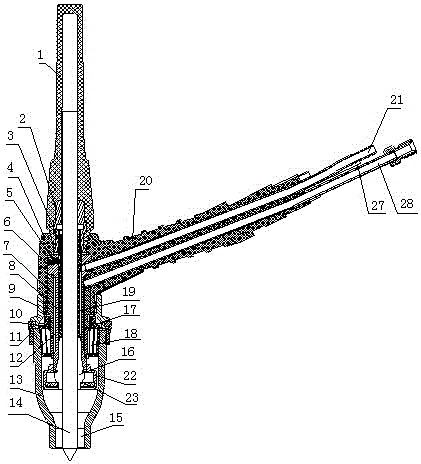

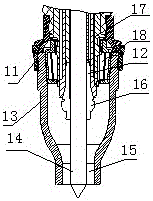

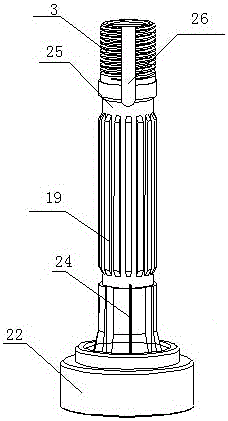

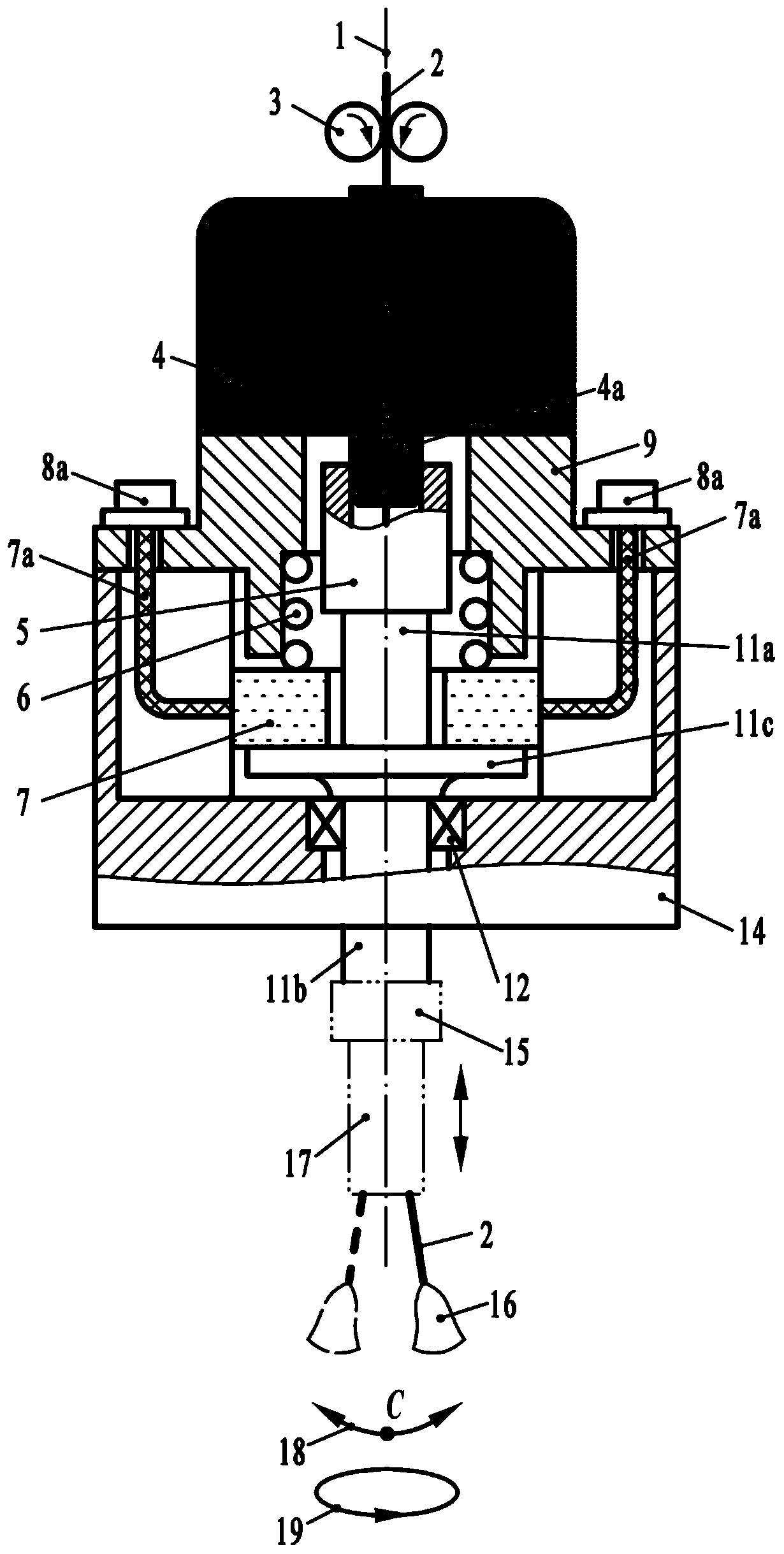

Rocking/rotating arc gas metal arc welding torch and a using method thereof

ActiveCN111390358ASimplified welding torch structureAchieve direct targetingElectrode holder supportersCooled electrode holdersShielding gasCooling effect

The invention discloses a rocking / rotating arc gas metal arc welding torch and a using method thereof. The rocking / rotating arc gas metal arc welding torch comprises a hollow shaft motor, wherein a lower extending shaft is fixedly connected with an upper extending shaft of a feed disc penetrating through an electric brush mechanism in a motor base through a coupler, and a lower extending shaft ofthe feed disc is connected with an eccentric or bent conducting rod mechanism after penetrating through a supporting bearing arranged in an electric brush base; a motor base of the hollow shaft motoris fixedly connected with the electric brush base through connecting screws, and welding shielding gas and welding torch cooling effects are provided through inner holes of the connecting screws and abuilt-in gas circuit and a built-in cooling water circuit of the electric brush base; and when no additional sensing device is arranged on the upper extending shaft of the motor, the arc rocking / rotating frequency and the arc rocking midpoint are identified / detected through pre-calibration or a built-in photoelectric encoder of the servo motor, and the length of the conducting rod mechanism is adjusted through a blending or telescopic adjusting method. The welding torch is simple and compact in structure, high in transmission positioning precision, good in process adaptability, high in practicability, suitable for rocking arc and rotating arc gas shielded welding and capable of being used for submerged-arc welding in an expanded mode.

Owner:JIANGSU UNIV OF SCI & TECH

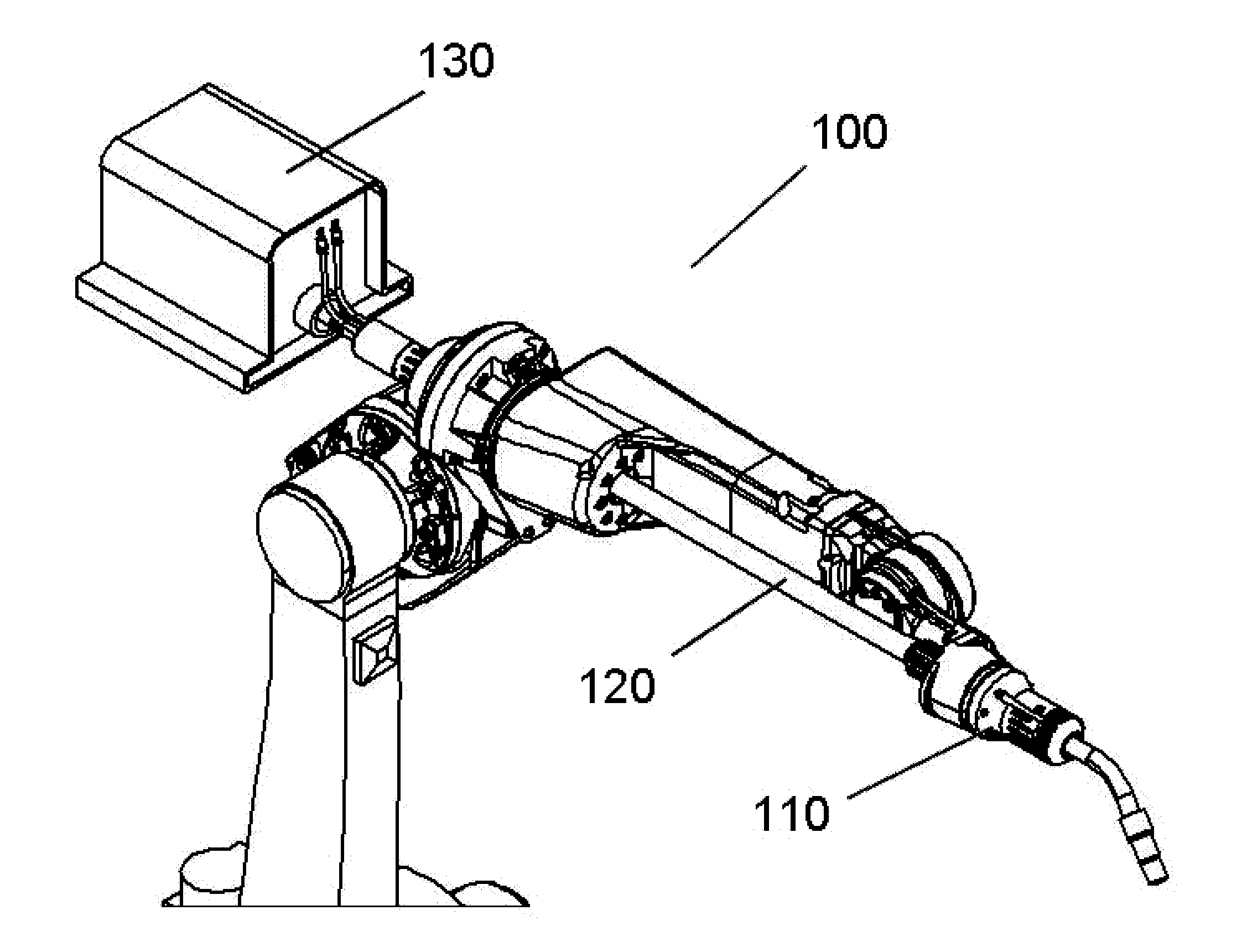

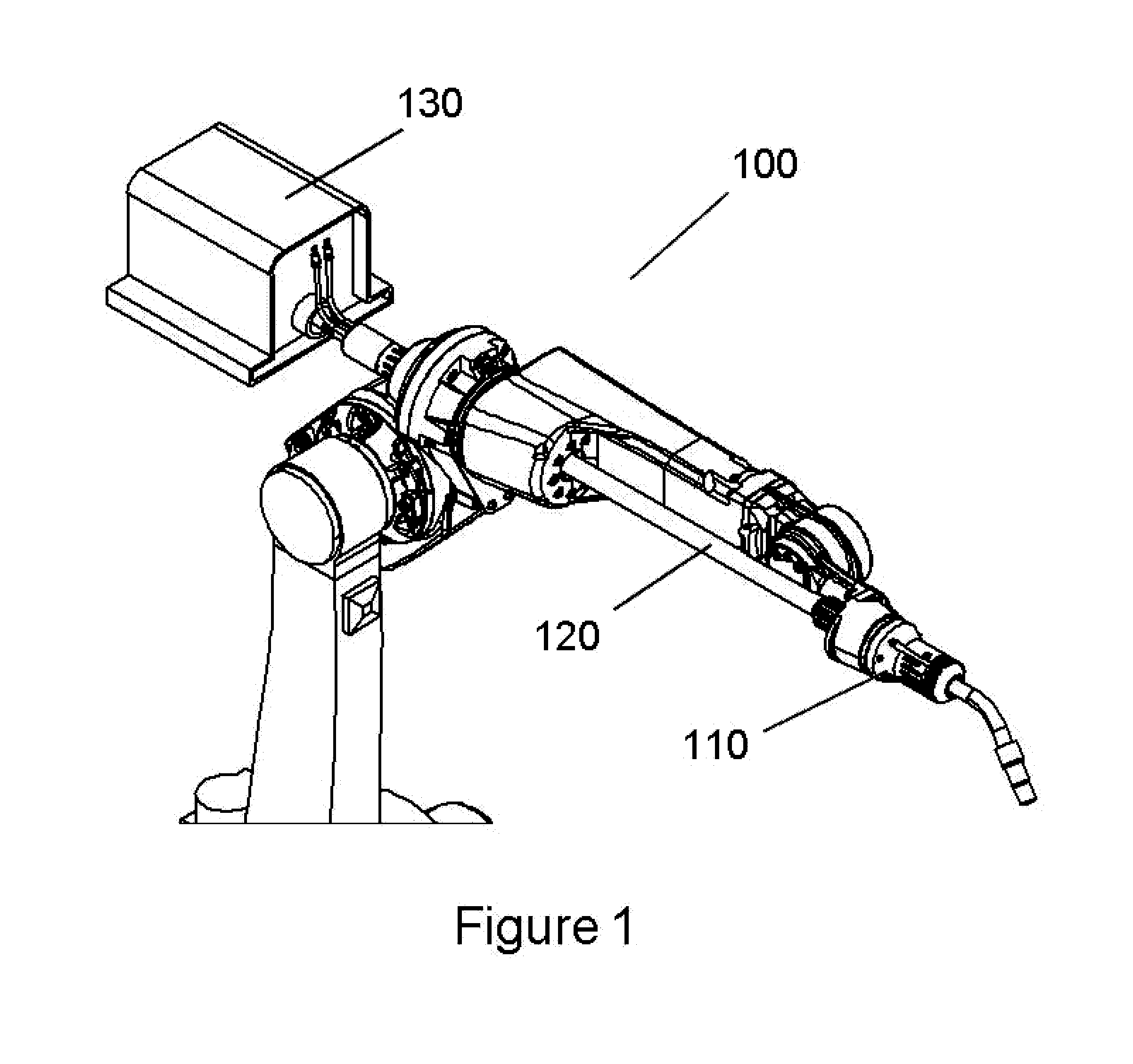

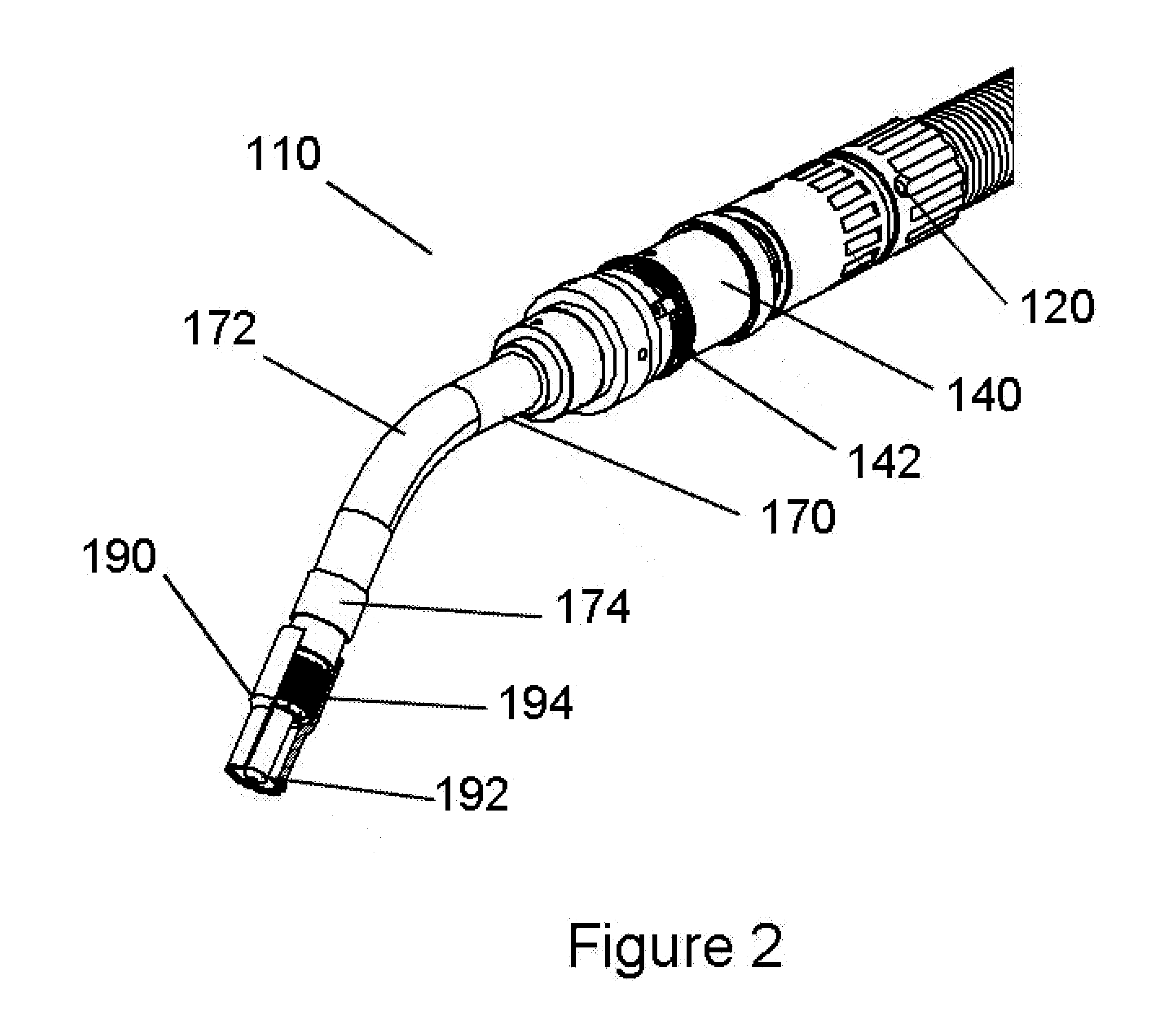

Rotary Welding Torch

ActiveUS20110198332A1Electrode holder supportersCooled electrode holdersElectrical currentWelding process

A rotary robotic welding torch that enables the welding process in a robotic unit. The rotary welding torch allows for clockwise and counterclockwise rotation during the welding process, while being supplied with an uninterrupted supply of inert gas and electrical current. The rotary robotic welding torch may also be supplied with an uninterrupted supply of coolant and / or electrode / filler wire during the welding process.

Owner:CENKO ARBEN

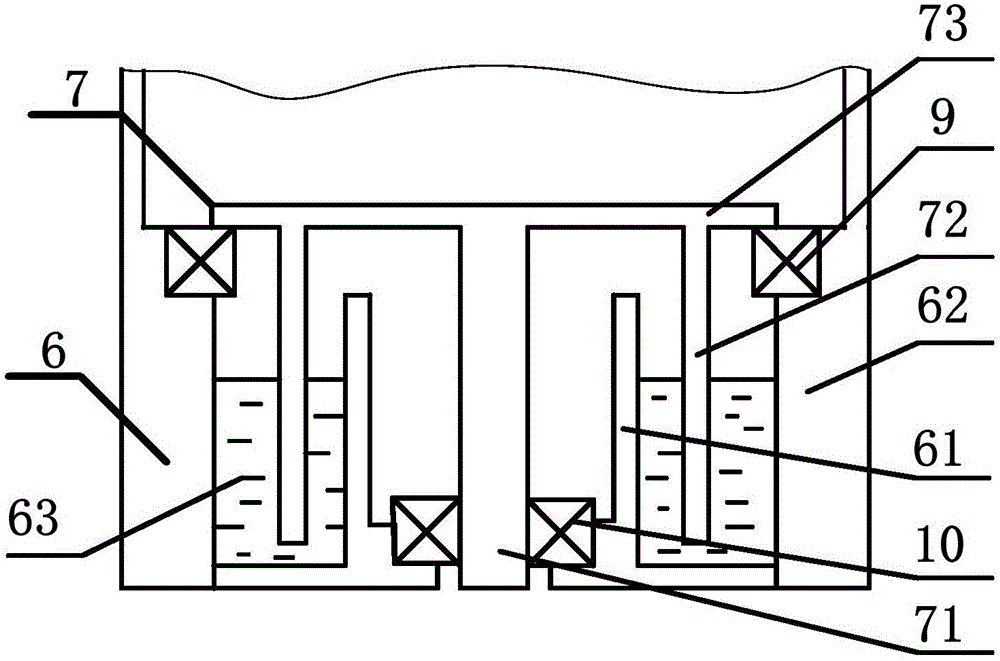

Oscillating-arc narrow-gap MIG/MAG (Metal Inert Gas/Metal Active Gas) welding torch

ActiveCN103658942AImprove the heating effectSolve non-fusion problemsCooled electrode holdersElectrode accessoriesSpray nozzleEngineering

The invention relates to an oscillating-arc narrow-gap MIG / MAG (Metal Inert Gas / Metal Active Gas) welding torch to solve the problem that side walls are not fused during narrow-gap welding. A motor gear is fixedly arranged on an output shaft of a motor. A transition gear is synchronously engaged with the motor gear and an oscillating gear. Two ends of a conductive plate are respectively connected with a welding gun connector and a conductive shaft. The conductive shaft is arranged in a center hole of the oscillating gear and is fixedly connected with the oscillating gear. A conductive shaft sleeve and the conductive shaft form a cavity. The cavity is communicated with two water holes formed in the conductive shaft. Two water pipes respectively communicate a water inlet and a water outlet with the two water holes in the conductive shaft. The upper end of a bent conductive rod is connected onto the conductive shaft through a thread and the lower end of the bent conductive rod penetrates through an external narrow-gap spray nozzle. The axis of a bending head at the lower part of the bent conductive rod and the axis of the conductive shaft form an included angle of 5-15 degrees. A contact tip is connected onto the bending head through a thread. A spray nozzle height adjusting part is installed on the shell of the welding gun. The external narrow-gap spray nozzle is fixedly arranged below the spray height adjusting part. The oscillating-arc narrow-gap MIG / MAG welding torch is used for narrow-gap welding.

Owner:HARBIN INST OF TECH

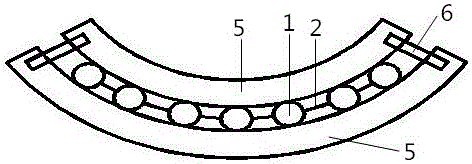

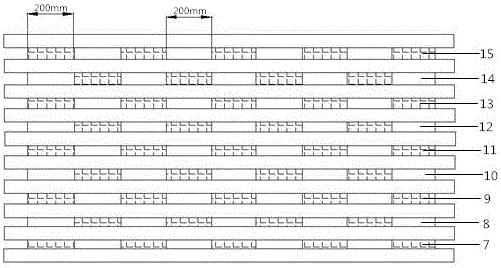

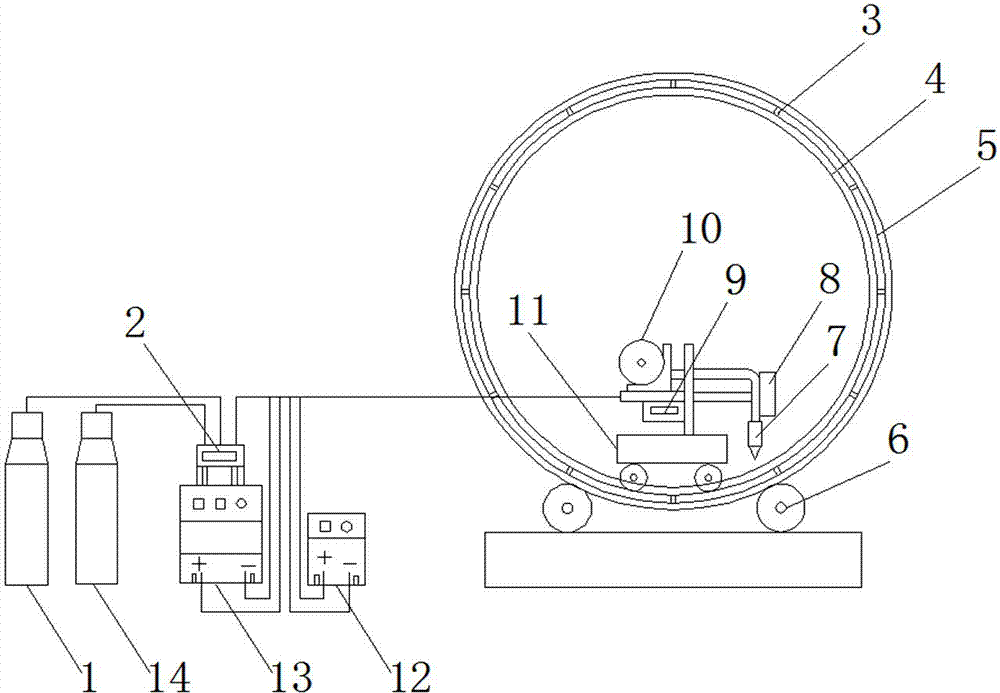

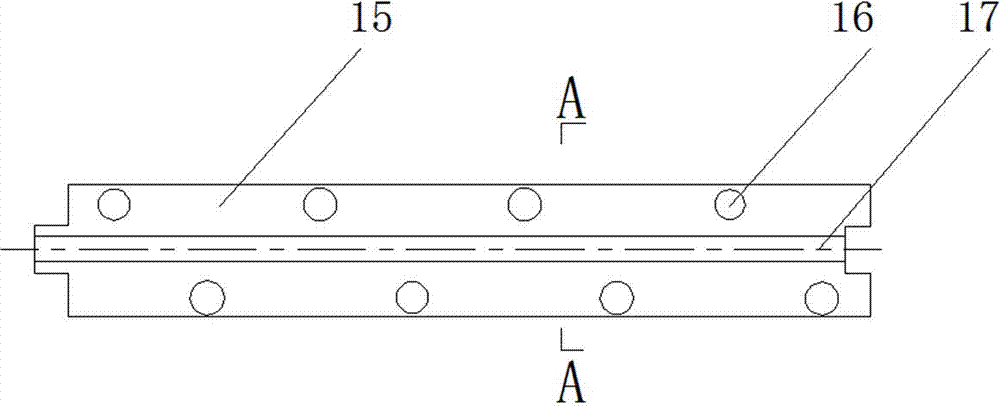

Automatic inner cylindrical circular seam welding machine with flexible rail

InactiveCN104741735AImprove welding qualityReduce rework costsWelding/cutting auxillary devicesCooled electrode holdersWelding power supplySeam welding

The invention discloses an automatic inner cylindrical circular seam welding machine with a flexible rail. The automatic inner cylindrical circular seam welding machine comprises a main welder body, a gas supply mechanism, a cooling mechanism, and a rolling mechanism; the main welder body comprises a weld gun, wherein the weld gun is connected with a wire feeder, and the bottom part of the wire feeder is provided with a welding oscillator; the gas supply mechanism comprises a welding power source connected with the main welder body; the rolling mechanism comprises a speed regulating roller frame, and the cylinder body is located on the speed regulating roller frame; a flexible rail is arranged around the annular seam in the cylinder body, and the flexible rail comprises a rail base layer, and a rail located in the center of the rail base layer; the rail is convexly arranged on the surface of the rail base layer, both sides of the rail are respectively provided with a line of holes, and two lines of holes are aligned at intervals. The automatic inner cylindrical circular seam welding machine is added with a walking trolley, the welding oscillator and a water cold weld gun, and paves rail in the cylinder body, thus the full automatic welding of the circular seam in a pressure container is realized; the automatic inner cylindrical circular seam welding machine can apply welding to multiple circular seams at the same time, and also can eliminate the adverse influence of axial movement of the cylinder in rotating process on welding.

Owner:NANTONG UNION MACHINERY ELECTRONTCS TECH CO LTD

Contact tip, gas diffuser, and nozzle for welding torch

PendingUS20170282278A1Maximizes performance of wearEasy to replaceSupport devices with shieldingCooled electrode holdersWelding torchNozzle

In certain embodiments, a welding contact tip includes a first axial end portion having a welding wire outlet of an internal bore of the welding contact tip. The welding contact tip also includes a threaded middle portion adjacent the first axial end portion. The threaded middle portion includes external threads configured to mate with internal threads of a gas diffuser of a welding torch. The first axial end portion includes a tapered outer surface adjacent the threaded middle portion. In other embodiments, a welding torch assembly includes a gas diffuser having an outer circumferential groove having an outer surface with first and second walls that extend radially outward from first and second opposite axial sides of the outer surface, a nozzle having an inner circumferential rib with a tapered inner surface, and a compressible member disposed within the outer circumferential groove of the gas diffuser and the inner circumferential rib of the nozzle.

Owner:ILLINOIS TOOL WORKS INC

Gas-cooled welding gun for an arc welding device

InactiveUS20130313241A1Increase surface areaIncrease heat absorptionCooled electrode holdersElectricityCarbon Dioxide / Helium

A gas-cooled welding gun for an arc welding device, comprising an electrically conductive current contact tube disposed concentrically within an electrically conductive outer tube and separated therefrom by an intermediate space. The current contact tube includes a wire guiding channel for a welding wire. A plurality of spacers is disposed at intervals in the intermediate space between the current contact tube and outer tube,. electrically insulating these components from each other. A shielding gas is provided in the intermediate space to cool the system and openings in the spacers allow the gas to flow therethrough. Structures are provided on the current contact tube which increase the overall surface area thereof. Regions of the surface of the current contact tube not covered by spacers are exposed toward the intermediate space and therefore to the shielding gas.

Owner:DINSE GMBH +1

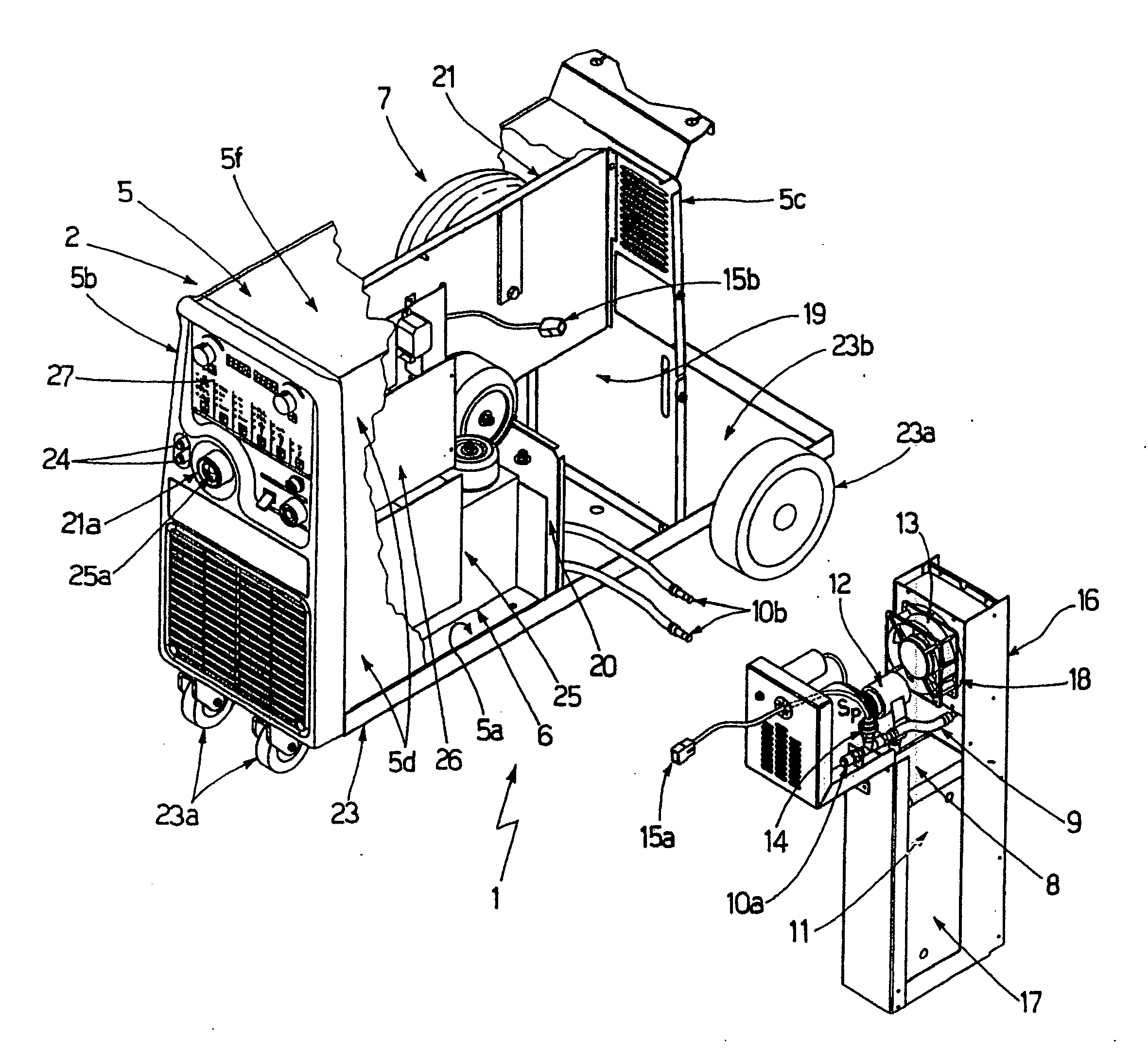

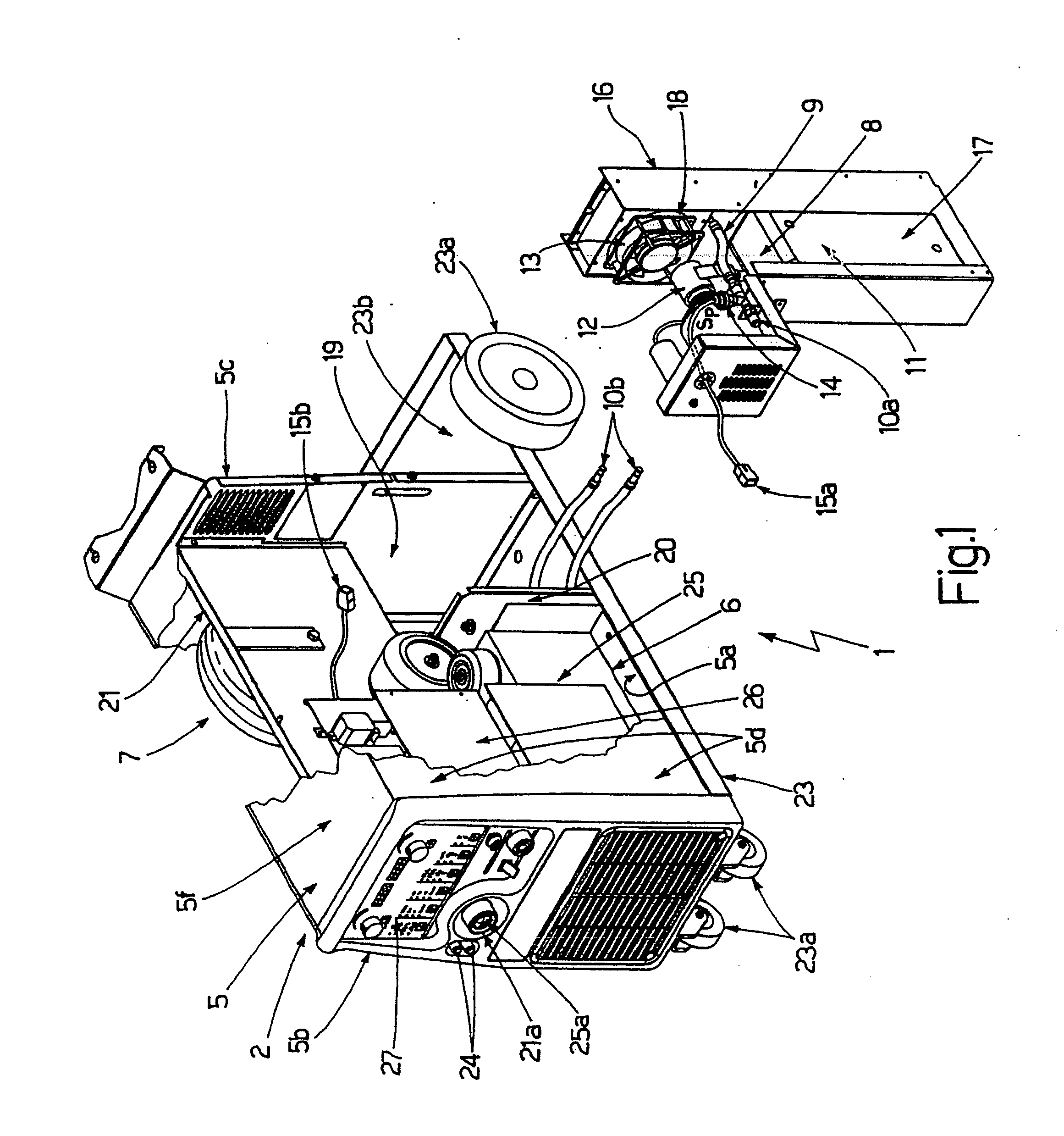

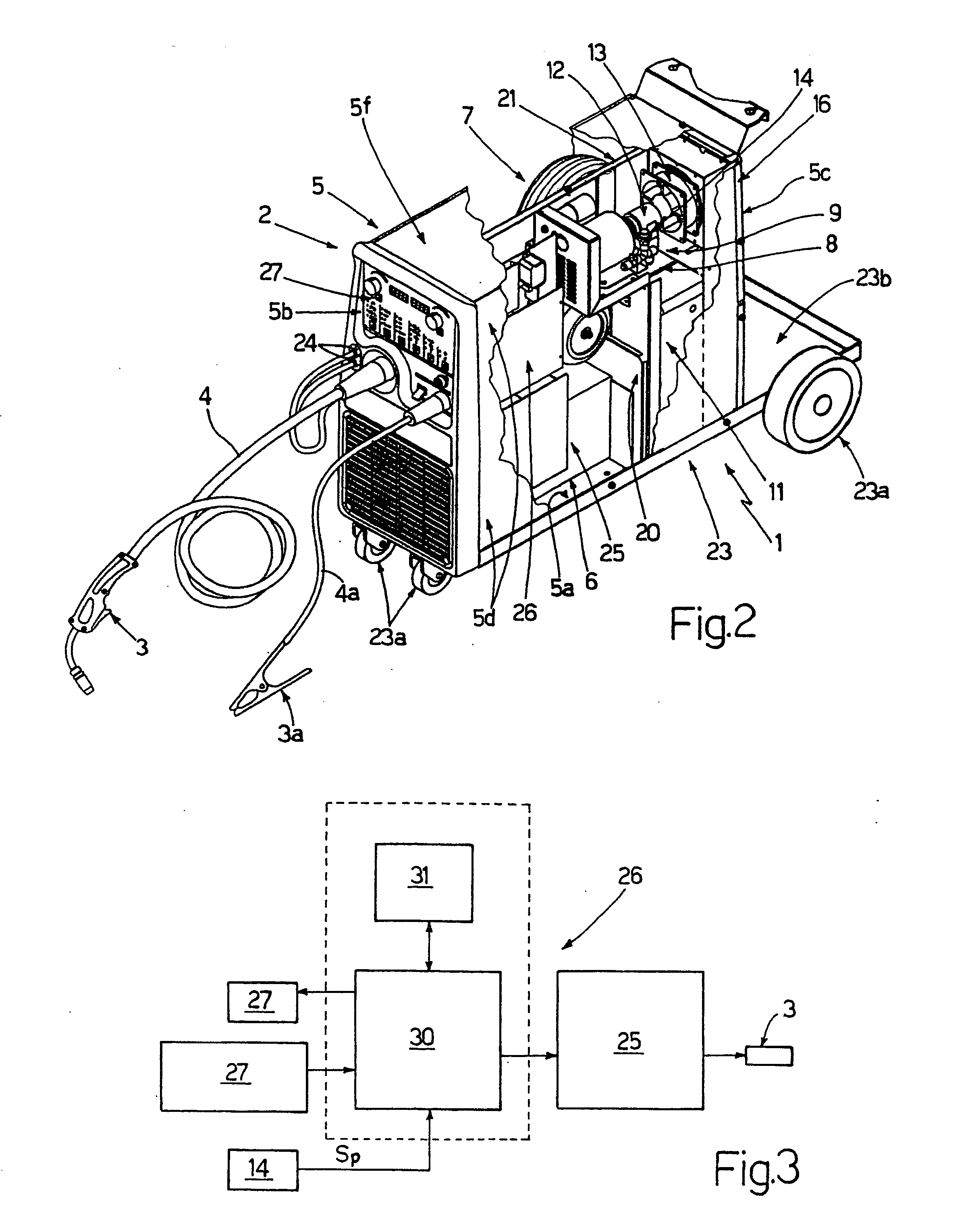

Welding machine and relative operating method

ActiveUS20060043081A1Eliminating respective drawbackWelding/cutting auxillary devicesCooled electrode holdersElectric cablesPhysics

A welding machine having a welding unit for generating a welding voltage / current, and at least one welding tool connectable to the welding unit by a cable and supplied by the cable with welding voltage / current; the welding unit has a closed protective casing, and a cooling unit for cooling the welding tool and / or cable on command; and the welding machine also has a modular unit containing the cooling unit and insertable stably and in easily removable manner inside the casing which is closed for protection of the welding unit, so as to be easily extracted and detached from the casing.

Owner:ITW WELDING PRODS ITAL

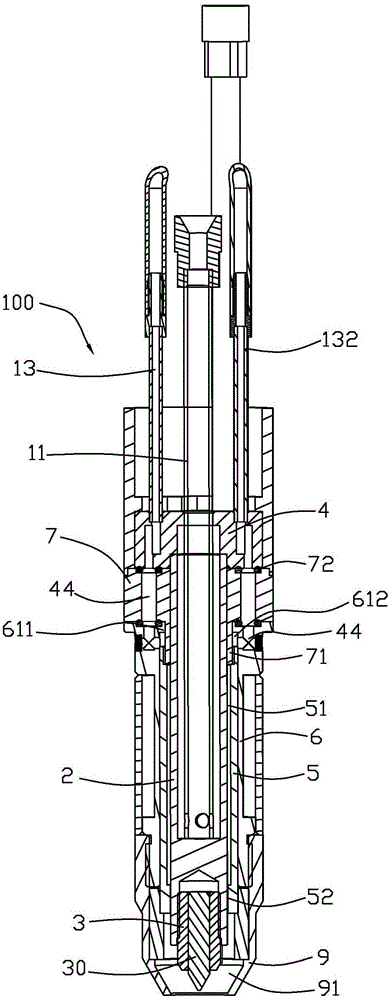

TIG welding gun

ActiveCN105171209AHigh duty cycleImprove welding qualityCooled electrode holdersElectrode accessoriesEngineeringWater cooling

The invention provides a TIG welding gun. The TIG welding gun comprises a water electric pipe positioned in the axis position, a core rod arranged at the outer periphery of the water electric pipe, a tungsten electrode clamp fixed at one end of the core rod, an electric conducting connection base fixed at the other end of the core rod and connected with the water electric pipe, a water cooling jacket arranged at the outer side of the core rod, an insulation block fixedly connected between the water cooling jacket and the electric conducting connection base in the axial direction, a shell fixed at the outer periphery of the water cooling jacket, and a water outlet pipe fixed on the electric conducting connection base. An isolation part is arranged in the core rod near the tungsten electrode clamp. The water electric pipe extends to the position of the isolation part, and is provided with a first water outlet hole penetrating through in the radial direction. A first water cavity communicated with the first water outlet hole is formed between the core rod and the water electric pipe. The electric conducting connection base is provided with a first water inlet communicated with the first water cavity. A second water cavity is formed between the water cooling jacket and the shell. The electric conducting connection base and the insulation block are formed with a first communication hole for communicating the first water inlet with the second water cavity and a second communication hole for communicating the second water cavity with the water outlet pipe.

Owner:HUAHENG WELDING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com